MV-65ST

SERVICE MANUAL

Ver 1.0 2004.03

Copyrights

This product incorporates copyright protection

technology that is protected by method claims

of certain U.S. patents, other intellectual

property rights owned by Macrovision

Corporation, and other rights owners. Use of

this copyright protection technology must be

authorized by Macrovision Corporation, and is

intended for home and other limited viewing

uses only unless otherwise authorized by

Macrovision Corporation. Reverse engineering

or disassembly is prohibited.

Manufactured under license from Dolby

Laboratories. “Dolby”, “Pro Logic”, and the

double-D symbol are trademarks of Dolby

Laboratories. Confidential unpublished works.

Copyright 1998-1999 Dolby Laboratories. All

rights reserved.

“DTS,” “DTS Digital Surround” and “DTS

Digital Out” are trademarks of Digital Theater

Systems, Inc.

System

Laser Semiconductor laser

Signal format system NTSC/PAL

Audio characteristics

Frequency response 20 Hz to 20 kHz

Signal to noise ratio 90dB (A)

Harmonic distortion 0.03 %

Dynamic range 90dB

Wow and flutter below measurable limits

General

Outputs Audio output

Inputs Audio input

Power requirements 12 V DC

Dimensions Approx. 188 × 99 × 241 mm

Mass Approx. 2.3 kg

Operating temperature 0 ˚C to 45 ˚C

Canadian Model

Model Name Using Similar Mechanism NEW

SPECIFICATIONS

Supplied accessories Mounting straps (4)

(±0.001% W PEAK)

Monitor

System Liquid crystal color display

Video output

Optical output

Headphones output

Video input

DC 12V input

1

/2× 4 × 9 1/2 in)

(7

(w/h/d)

(5 lb 1 oz)

(32 ˚F to 113 ˚F)

Display Manual flipdown panel

Drive system TFT-LCD active matrix

Picture size 6.5 inches wide screen

Picture segment 280,800 (w 1200 × h 234)

Design and specifications are subject to change

without notice.

US Model

AEP Model

UK Model

E Model

AC power adaptor (1)

(including AC power cord

(1))

Power cord for the cigar

lighter socket (1)

Antenna for FM

transmission (1)

(US, Canadian, Mexican only)

Card remote commander

RM-X137 (including

lithium battery (1))

Carrying bag (1)

Operating Instructions (1)

system

(16:9)

dots

9-877-614-01 Sony Corporation

2004C05-1 e Vehicle Company

© 2004.03 Published by Sony Engineering Corporation

PORTABLE DVD PLAYER

MV-65ST

About discs this player can

play

This player can play the following discs:

• DVD

• DVD-R

• DVD-RW

• Video CD

• Audio CD

• CD-R/CD-RW

Disc type Label on the disc

DVD Videos

Video CDs

Audio CDs

MP3 files/

JPEG files

“DVD VIDEO,” “DVD-R” and “DVD-RW” are

trademarks.

W

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

This label is located on the bottom of the

chassis.

CAUTION INVISIBLE

VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

This label is located on the drive unit’s internal

chassis.

On power sources

• Use house current or car battery (12 V DC).

• For use in your house, use the AC power

adaptor supplied with the player. Do not use

any other AC power adaptor since it may

cause the player to malfunction.

Polarity of

the plug

LASER RADIATION WHEN OPEN

DO NOT STARE INTO BEAM OR

Notes on CD-Rs (recordable CDs)/

CD-RWs (rewritable CDs)

• Some CD-Rs/CD-RWs (depending on the

equipment used for its recording or the

condition of the disc) may not play on this

player.

• You cannot play a CD-R/CD-RW that is not

finalized*.

• You cannot play a CD-R/CD-RW that is

recorded in Multi Session.

• You can play MP3/JPEG files recorded on

CD-ROMs, CD-Rs, and CD-RWs.

* A process necessary for a recorded CD-R/CD-R

disc to be played on the audio CD player.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

SECTION 1

SERVICING NOTES

MV-65ST

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL

Location of Controls ....................................................... 4

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Base (Monitor) Assy ....................................................... 8

3-3. Cabinet (Front) Assy ....................................................... 8

3-4. Monitor Assy ................................................................... 9

3-5. Hinge ............................................................................... 10

3-6. MONITOR Board ........................................................... 10

3-7. Liquid Crystal Display Panel (LCD1)............................ 11

3-8. DVD MD Assy ................................................................ 11

3-9. SERVO Board, Mechanism Deck................................... 12

3-10. TD-S-Top-Cover ............................................................. 12

3-11. Loading Mechanism Assy............................................... 13

3-12. Traverse Mechanism Assy .............................................. 13

4. TEST MODE.............................................................. 14

5. ELECTRICAL ADJUSTMENTS......................... 15

6. DIAGRAMS

6-1. Block Diagram – AUDIO Section – ............................... 18

6-2. Block Diagram – VIDEO, PANEL Section –................ 19

6-3. Block Diagram – POWER Section –.............................. 20

6-4. Note for Printed Wiring Boards

and Schematic Diagrams ................................................ 21

6-5. Printed Wiring Board

– MONITOR Board (Side A) – ...................................... 22

6-6. Printed Wiring Board

– MONITOR Board (Side B) – ...................................... 23

6-7. Schematic Diagram – MONITOR Board (1/4) – ........... 24

6-8. Schematic Diagram – MONITOR Board (2/4) – ........... 25

6-9. Schematic Diagram – MONITOR Board (3/4) – ........... 26

6-10. Schematic Diagram – MONITOR Board (4/4) – ........... 27

6-11. Printed Wiring Board – KEY Board –............................ 28

6-12. Schematic Diagram – KEY Board – .............................. 29

6-13. Schematic Diagram – POWER Section (1/2) –.............. 30

6-14. Schematic Diagram – POWER Section (2/2) –.............. 31

6-15. Printed Wiring Board – POWER Board (Side A) – ....... 32

6-16. Printed Wiring Board – POWER Board (Side B) – ....... 33

6-17. Printed Wiring Board – AMP Section – ......................... 34

7. EXPLODED VIEWS

7-1. Overall Section................................................................ 46

7-2. Cabinet (Front) Section................................................... 47

7-3. Base (Monitor) Section ................................................... 48

7-4. Monitor Section............................................................... 49

7-5. Cabinet (Lower) Section-1.............................................. 50

7-6. Cabinet (Lower) Section-2.............................................. 51

7-7. Mechanism Deck Section-1 ............................................ 52

7-8. Mechanism Deck Section-2 ............................................ 53

7-9. Mechanism Deck Section-3 ............................................ 54

8. ELECTRICAL PARTS LIST ............................ 55

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

For E model NTSC type and PAL type.

The type of an NTSC system and the type of a P AL system exist in

E model.

Please refer to the following figure about how to recognize.

– BACK VIEW –

NTSC: NTSC TYPE

PAL: PAL TYPE

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

3

MV-65ST

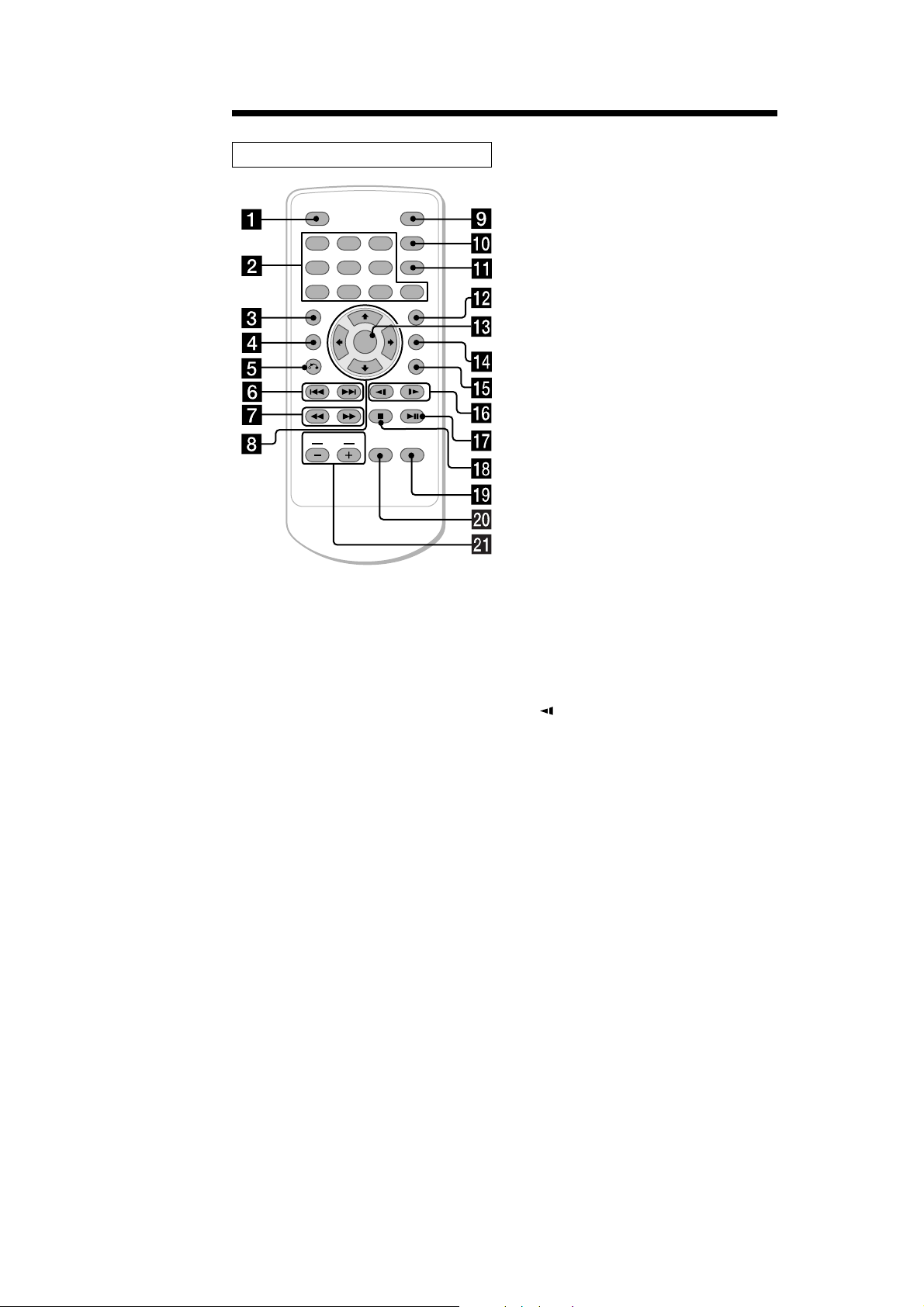

Location of controls

MV-65ST

6

SECTION 2

GENERAL

D

IS

C

I

N

R

E

E

S

T

This section is extracted from

instruction manual.

9

0

qa

qs

qd

7

8

Refer to the pages listed for details.

1 Monitor

2 VOL −/+ buttons

To turn up or down the volume or to select

the item during menu operation.

3 Disc slot

4 DISC IN light

When a disc is in the player, the DISC IN

light glows orange.

5 POWER (on/off) button

To turn on/off the player.

6 u (play/pause) button

7 x (stop) button

8 . (previous)/> (next) buttons

9 Receptor for the card remote

commander

q; Reverse button

To switch images upside down and

reverse the output of the audio channels.

qf

qg

qa Speakers (left/right)

qs MENU button

To make various display settings and FM

transmitter setting.

qd HEADPHONES jacks

To connect the headphones. 2 sets of

headphones can be connected.

qf Z (eject) button

Available to eject a disc from the player

even when the player is turned off.

qg RESET button

Note

Even when the player is turned off by pressing

(POWER), you can eject a disc from the player,

though you cannot insert a disc.

4

Card remote commander RM-X137

ENTER

INPUT

POWER

SEARCH

CLEAR

SUBTITLE

ANGLE

AUDIO

SETUP

DISPLAY

123

456

7 890

TOP MENU

MENU

VOL

The corresponding buttons of the card

remote commander control the same

functions as those on the player.

Instructions in this manual describe how to use

the player by mainly using the card remote

commander.

Tip

Refer to “Replacing the lithium battery of the card

remote commander” for details on how to replace

the battery.

MV-65ST

Refer to the pages listed for details.

1 DISPLAY button

To display the time information of the disc.

2 Number buttons (0 to 9)

3 TOP MENU button

To display the top menu of a recorded

DVD.

4 MENU button

To display the recorded DVD menu, or to

turn on/off the PBC (Playback control)

menu of a Video CD.

5 O (return) button

6 ./> (previous/next) buttons

7 m (fast reverse)/

M (fast forward) buttons

8 M/,/m/< buttons

9 POWER (on/off) button

To turn on/off the player.

q; SEARCH button

To specify a desired point on a disc by

chapter, title, or track.

qa CLEAR button

qs SUBTITLE button

To change the subtitle language while

playing a DVD.

qd ENTER button

To enter a setting.

qf ANGLE button

To select the multiple angles of view while

playing a DVD.

qg AUDIO button

To change the audio output/audio

language.

qh

(slow reverse)/y (slow forward)

buttons

qj u (play/pause) button

qk x (stop) button

ql SETUP buttons

Used to perform menu operations.

w; INPUT button

To select the input source.

wa VOL (−/+) buttons

To turn up or down the volume.

5

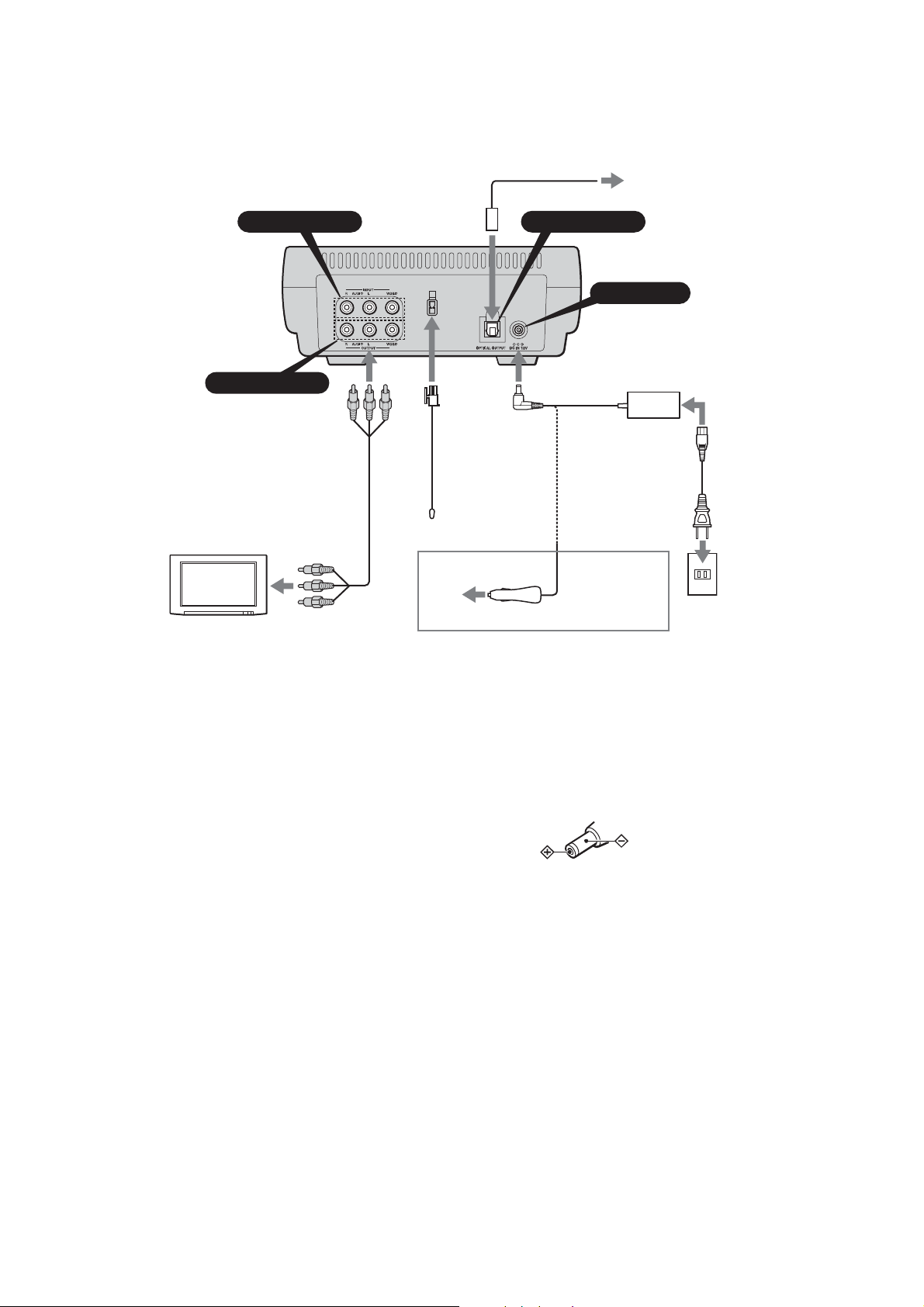

MV-65ST

This player is supplied with two types of

power cable. When you use the player in the

car, connect the player to the cigar lighter

socket; when using at home, connect it to the

AC outlet.

AUDIO/VIDEO INPUT OPTICAL OUTPUT

Two headphones

connectors

(at the side)

AUDIO/VIDEO OUTPUT

Audio/video

cable

(not supplied)

TV, etc.

Antenna for FM

transmission

(supplied)

(US, Canadian

Mexican only)

Optical cable

(not supplied)

AC power

adaptor

(supplied)

*

Power cord for the

cigar lighter socket

DC IN 12V

AC power cord

(supplied)

(supplied)

When using the

player in the car

To a digital

amplifier, etc.

To audio/video

input connectors

On AUDIO/VIDEO OUTPUT

connectors

Yo u can connect a TV to the AUDIO/VIDEO

OUTPUT connectors to output the contents

being played back on the player. Connect the

yellow plugs of the audio/video cable to the

video connectors on both the TV and the

player and connect the white plugs and the red

plugs to the white (left audio) connectors and

red (right audio) connectors respectively.

On AUDIO/VIDEO INPUT connectors

Yo u can connect a VTR, etc. to the AUDIO/

VIDEO INPUT connectors to input the

contents being played back on the device. You

can connect the device in the same way as

described on “On AUDIO/VIDEO OUTPUT

connectors” above.

To the cigar lighter socket

Notes

• When connecting the other device to the player,

be sure to connect the player to the power

source after all other connections are completed.

• If an obstacle such as cigar ash is caught inside

the cigar lighter socket, the contact between the

power cord plug and the socket becomes

incomplete and the plug may get extremely hot

during use. To avoid this, check the socket and

clean it if necessary before connecting the power

cord.

* Polarity of the plug

To a

wall

outlet

6

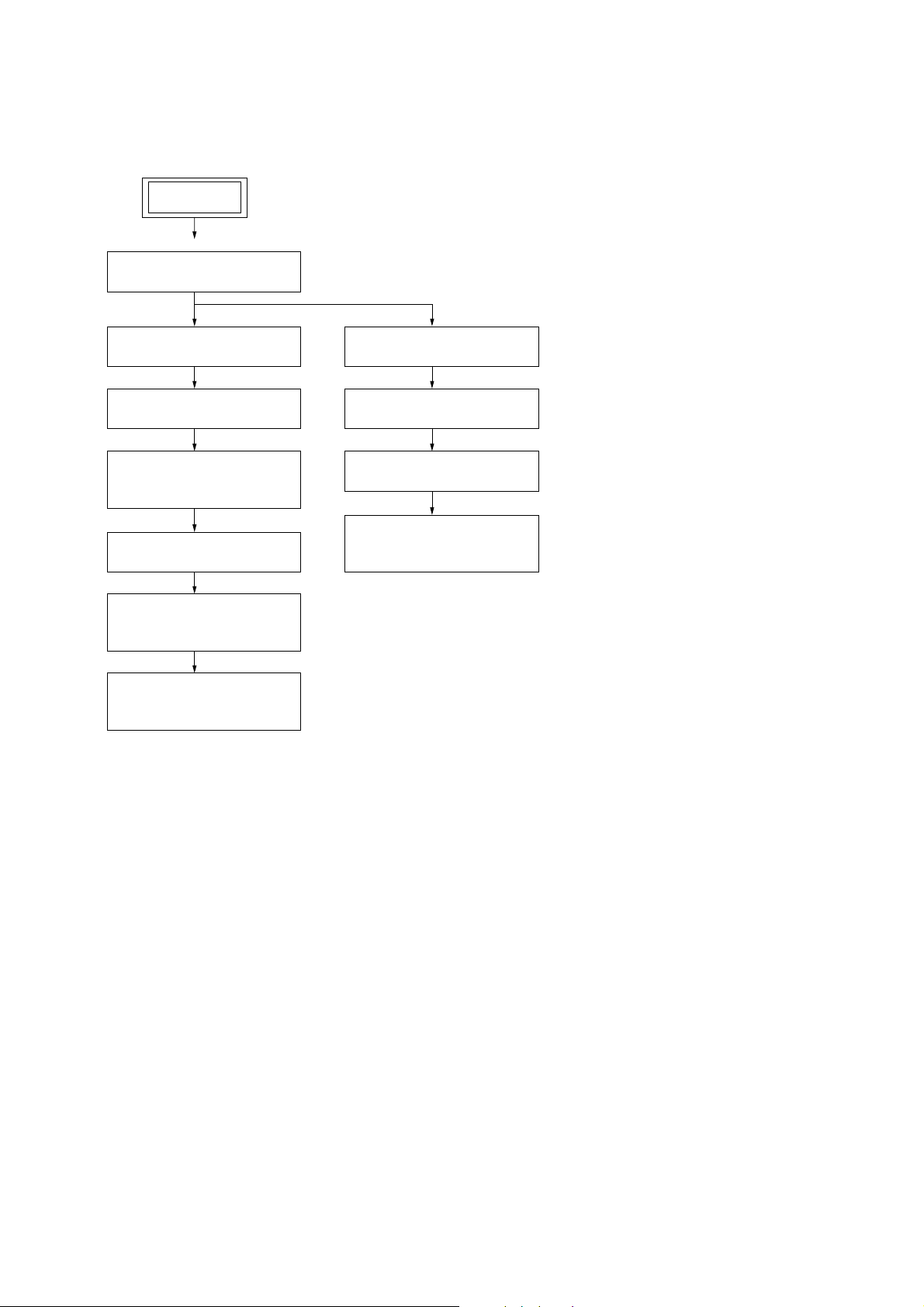

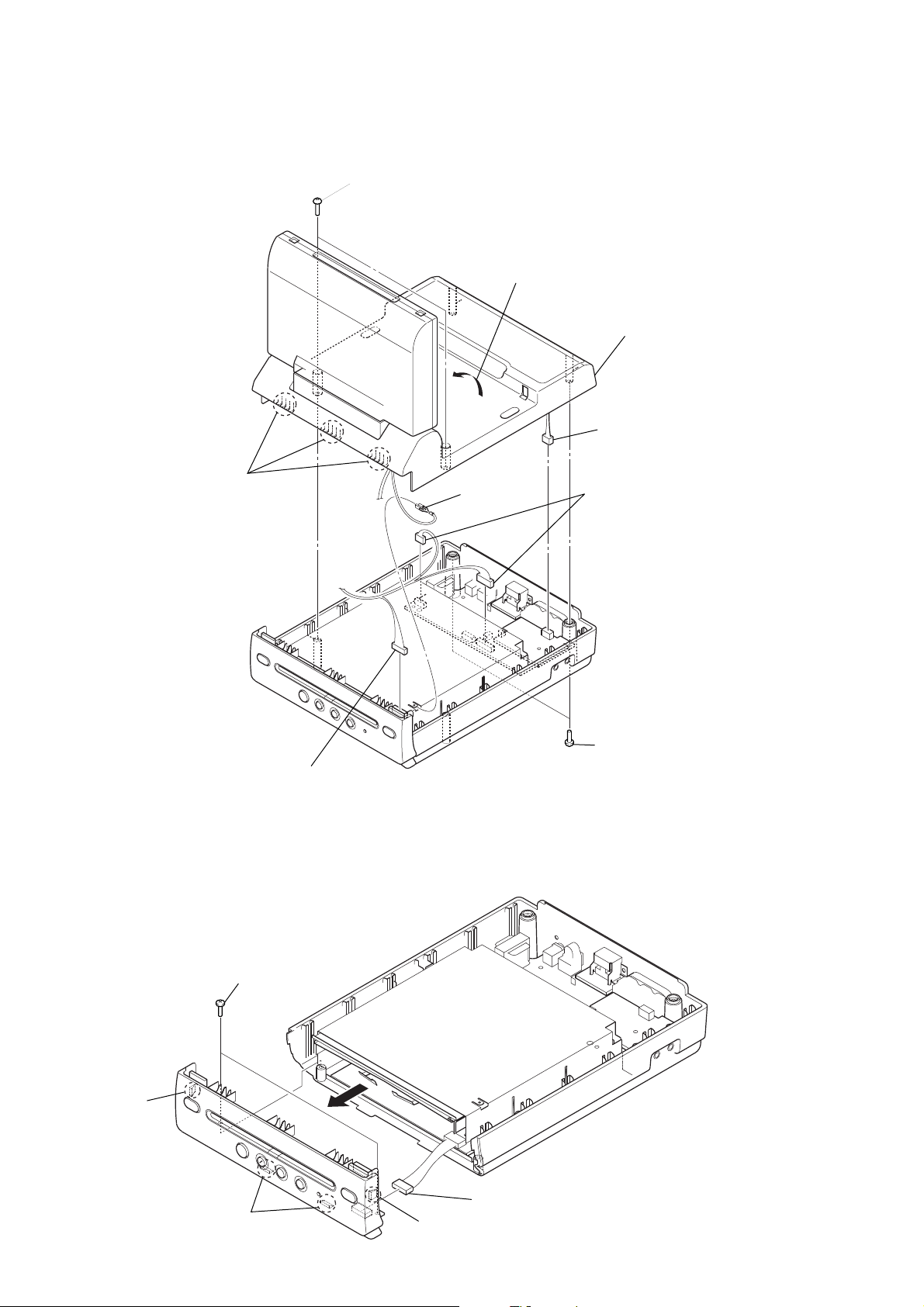

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. BASE (MONITOR) ASSY

(Page 8)

MV-65ST

SECTION 3

DISASSEMBLY

3-3. CABINET (FRONT) ASSY

(Page 8)

3-8. DVD MD ASSY

(Page 11)

3-9. SERVO BOARD,

MECHANISM DECK

(Page 12)

3-10. TD-S-TOP-COVER

(Page 12)

3-11. LOADING MECHANISM

ASSY

(Page 13)

3-12. TRAVERSE MECHANISM

ASSY

(Page 13)

3-4. MONITOR ASSY

(Page 9)

3-5. HINGE

(Page 10)

3-6. MONITOR BOARD

(Page 10)

3-7. LIQUID CRYSTAL

DISPLAY PANEL (LCD1)

(Page 11)

7

MV-65ST

y

Note: Follow the disassembly procedure in the numerical order given.

3-2. BASE (MONITOR) ASSY

3

two screws

(BVTP3

4

three claws

×

12)

5

2

terminal

Open the monitor

6

6

two connectors

(CN901, CN902)

7

base (monitor) ass

connector

(CN371)

6

3-3. CABINET (FRONT) ASSY

1

two screws

(BTP2.6 × 8)

2

claw

connector

(CN701)

3

1

two screws

(BVTP3

×

12)

4

2

two claws

2

claw

connector

(CN702)

8

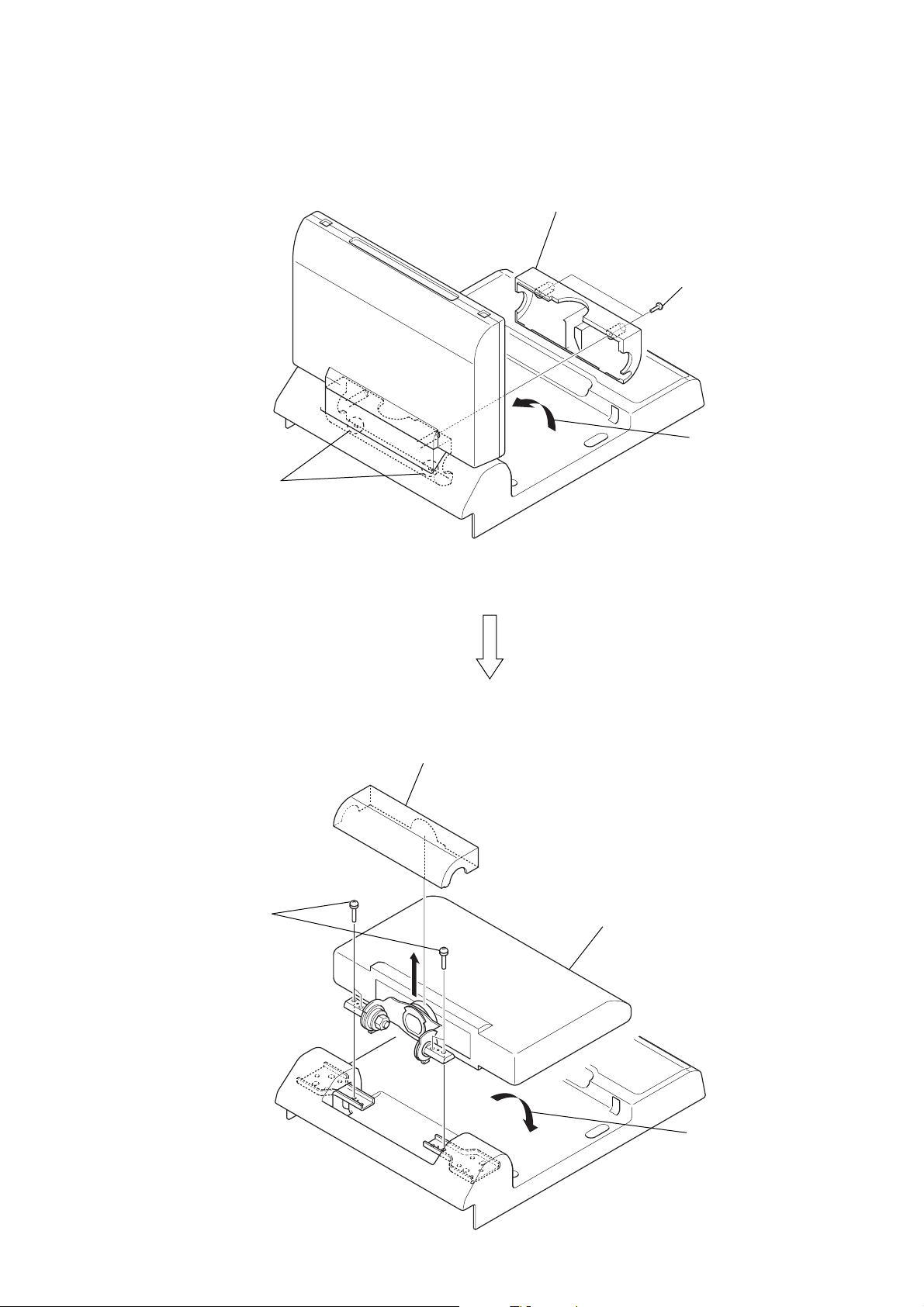

3-4. MONITOR ASSY

3

two claws

4

front cover (hinge)

2

two screws

(P2 × 8)

1

Open the monitor.

MV-65ST

7

four screws

(PS3

×

10)

6

rear cover (hinge)

8

monitor assy

5

Close the monitor.

9

MV-65ST

s

s

3-5. HINGE

three connectors

4

(CN904, CN905, CN906)

3

rear case (LCD)

2

four claws

5

two screws

(P2 × 8)

9

LCD bracket

hinge

2

five claws

2

four claw

3-6. MONITOR BOARD

2

connector

(CN850)

6

8

six screws

(B2.6 × 4)

4

two screws

(B2 × 5)

3

four screw

(P2 × 8)

1

q;

hinge

7

It is half rotation about a hinge.

two screws

(B2 × 5)

10

1

LCD flexible board

(CN801)

5

MONITOR board

MV-65ST

s

)

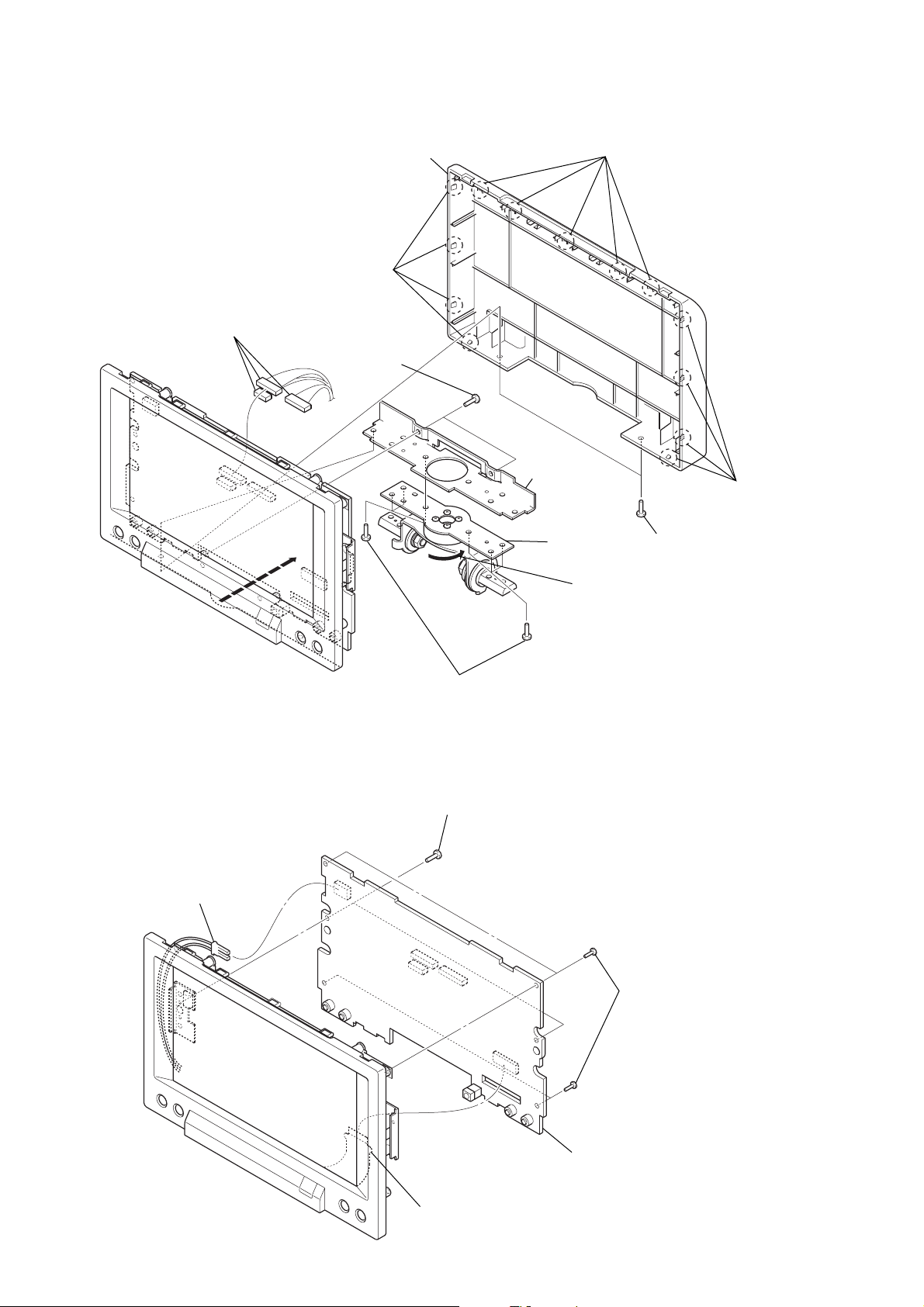

3-7. LIQUID CRYSTAL DISPLAY PANEL (LCD1)

6

two retainers (LCD)

2

bracket (LCD)

1

8

sheet (insulating)

9

liquid crystal display panel (LCD1)

two screws

(BTP2 × 6)

5

four screws

(BTP2 × 6)

6

two retainers (LCD)

7

insulating sheet (B)

3

4

bracket (LCD)

two screw

(BTP2 × 6)

3-8. DVD MD ASSY

2

top case (shield)

3

5

1

three screws

(B2.6

two screws

(BVTP3

DVD MD assy

×

×

12)

6)

q;

front case (LCD) assy

1

three screws

(B2.6

×

6)

4

three screws

(CN302, CN303, CN903

3

two screws

(BVTP3

×

12)

11

MV-65ST

)

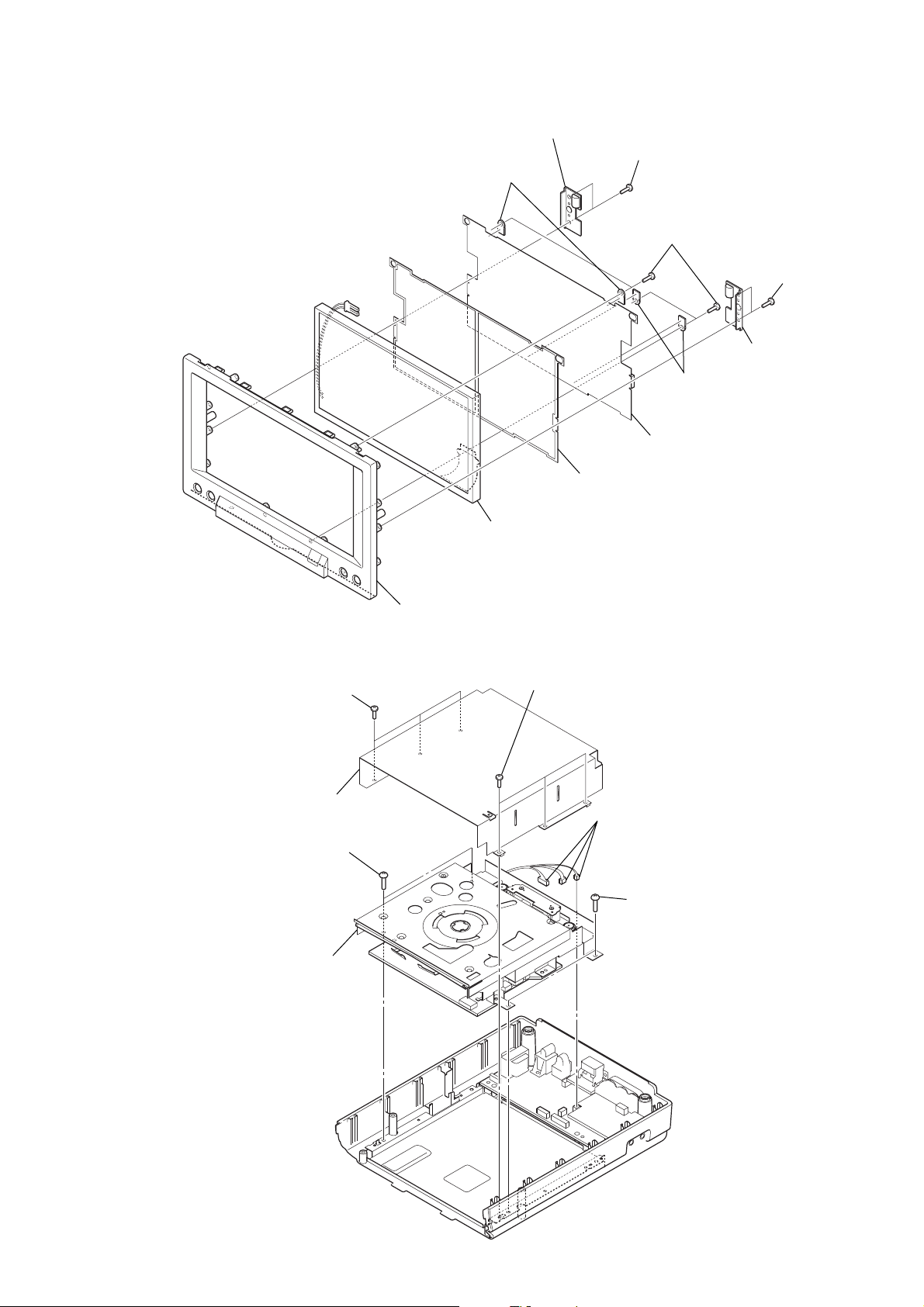

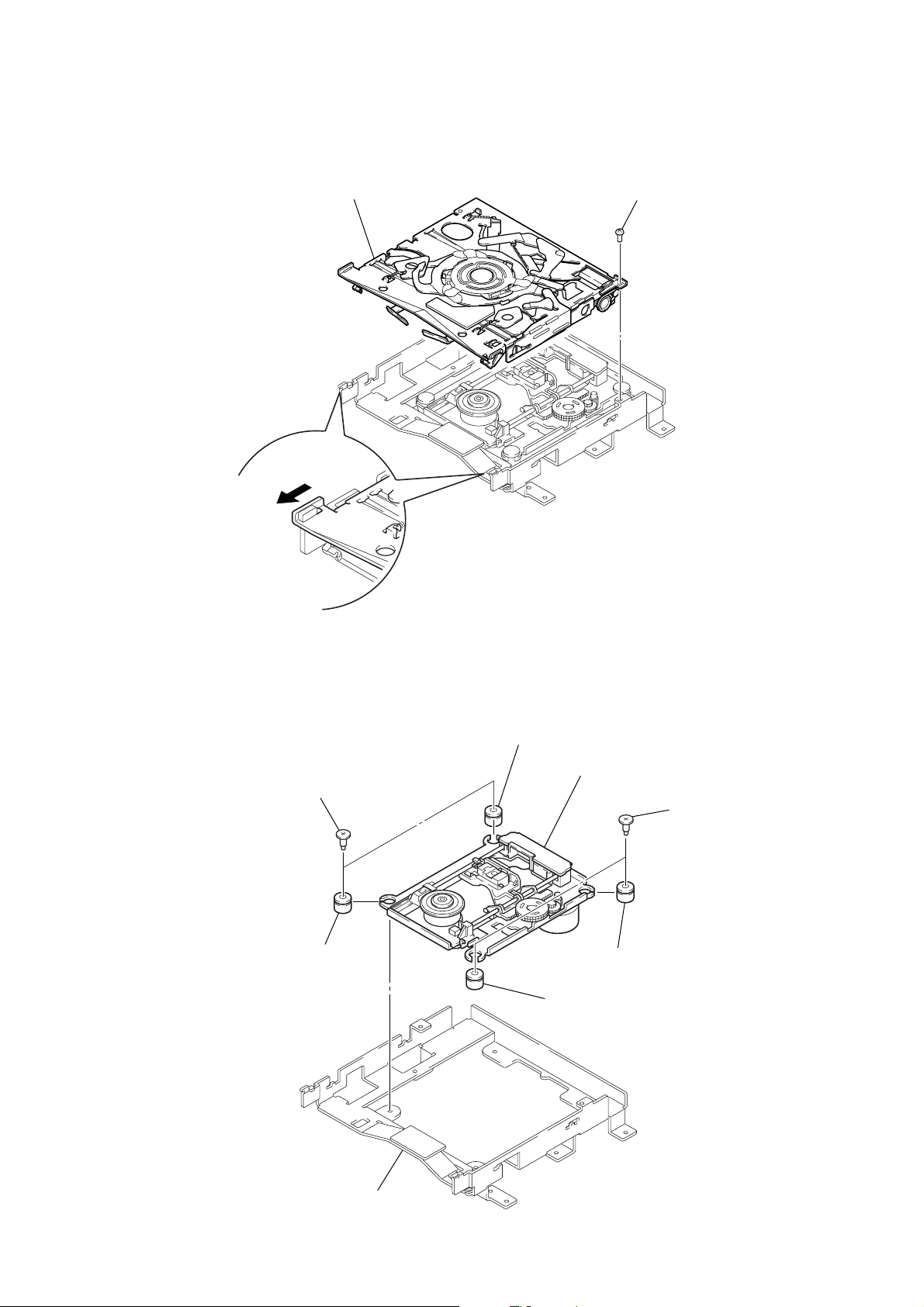

3-9. SERVO BOARD, MECHANISM DECK

6

mechanism deck

2

wire (flat type)

(CN401)

1

FFC-0.5-24 core L70

(CN301)

5

SERVO board

3

two screws

(B2.6

3-10. TD-S-TOP-COVER

2

Slide the TD-S-top-cover

in the direction of arrow

then disengage the claw and .

Hold up the TD-S-top-cover

in the direction of arrow

then disengage the claw and .

×

6)

4

three connectors

(J401, J402, J403

3

two screws

×

6)

(B2.6

1

A

B

claw

,

a

b

,

c

d

a

B

screw

(PTT2

claw

×

4)

b

A

d

claw

12

claw

c

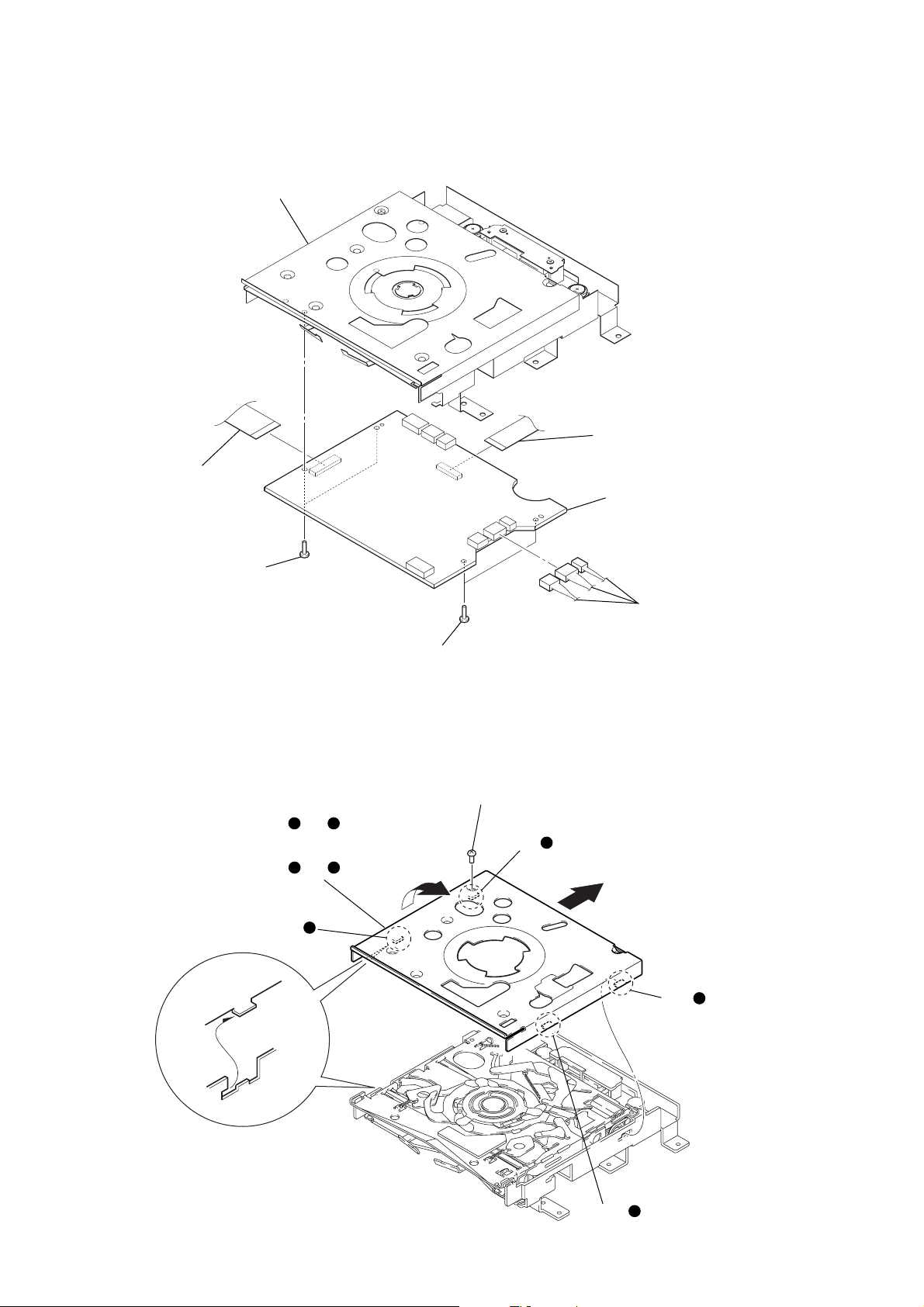

3-11. LOADING MECHANISM ASSY

)

s

2

loading mechanism assy

1

screw

(PTT2

MV-65ST

×

4

3-12. TREVERSE MECHANISM ASSY

1

two SCW-dampers

4

damper idle

7

damper idle

5

8

traverse mechanism assy

6

damper idle

damper idle

2

two SCW-damper

3

AS-main-base

13

MV-65ST

SECTION 4

TEST MODE

Note: This set is able to setting the adjustment data, reset to factory de-

fault and initialize the EEPROM (IC402 on the MONITOR board)

in the test mode.

ENTER THE TEST MODE

Procedure:

1. Press the [POWER] button to turn the power on.

2. While pressing the [VOL --] and . buttons, press the [RE-

SET] button.

3. The set is enter the test mode and display as bellow figure.

Display

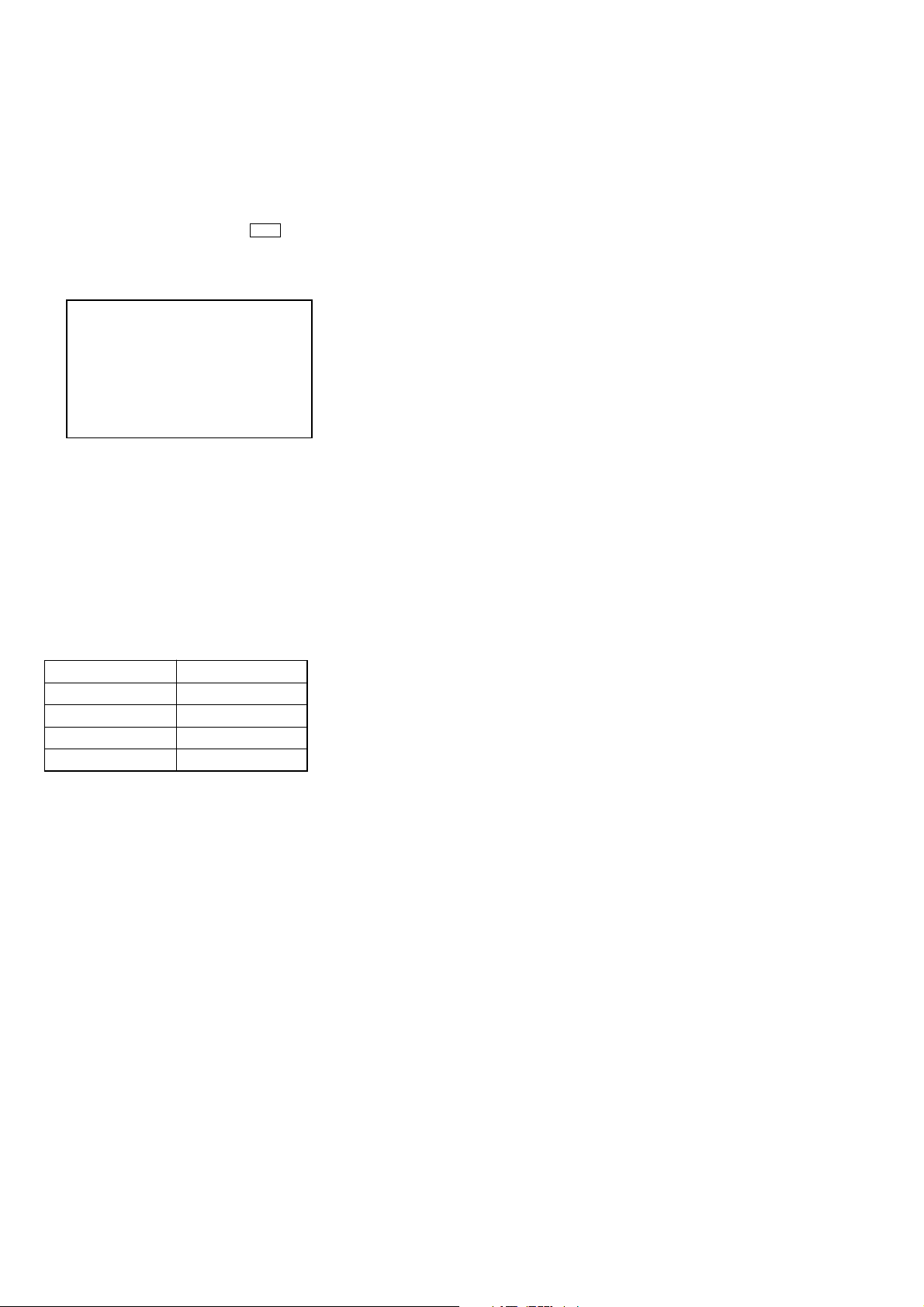

MV-65ST TEST MODE MENU

1. NTSC/PAL SELECT

2. FOR FACTORY

3. LCD SETTING

4. FM TRANSMITTER

5. HEAT PROTECTION

6. LOAD DEFAULT

7. SOFT RESET(EXIT)

Ver.20XX-XX-XX

Note: If initial data is not written to the EEPROM (IC402 on the MONI-

TOR board) or data is clobbered, the set is not able to display normally screen.

BATCH WRITING OF THE INITIAL DATA TO

EEPROM

In the test mode, by pressing the [VOL --] button at two seconds,

batch writing is possible of the initial data to EEPOM (IC402 on

the MONITOR board).

3. LCD SETTING

This mode is not used in servicing.

4. FM TRANSMITTER

In this mode, switch the frequency range of FM transmitter as

follow.

1) USA (88.3 to 89.9 MHz)

2) Japan (76.5 to 79.5 MHz)

3) Transmitter off

5. HEAT PROTECTION

This mode is not used in servicing.

6. LOAD DEFAULT

This mode is not used in servicing.

7. SOFT RESET (EXIT)

Releasing the test mode.

OPERATION OF THE TEST MODE

All operations are performed using the bellow buttons.

Button Function

MENU Select the item

REVERSE Enter

VOL + Up the data value

VOL − Down the data value

RELEASING THE TEST MODE

In the test mode menu screen, press the [MENU] button to select

“7. SOFT RESET (EXIT)”, and press the [REVERSE] button to

release the test mode.

OPERATING THE EACH ITEM

1. NTSC/PAL SELECT

In this mode, switch the signal format system to NTSC or P AL.

2. FOR FACTORY

In this mode, change the data of adjustment data.

Enter this mode, it displays each adjustment item as follow.

1) Com Gain

2) Y Gain

3) Black Limit

4) White Limit

5) R-Sub BRT

6) B-Sub BRT

7) R-Sub CONT

8) B-Sub CONT

9) Gamma 1

10) Gamma 2

11) VCO Free Run

12) PLL/V Pos

13) H Pos

14

SECTION 5

r

r

r

r

r

r

ELECTRICAL ADJUSTMENTS

MV-65ST

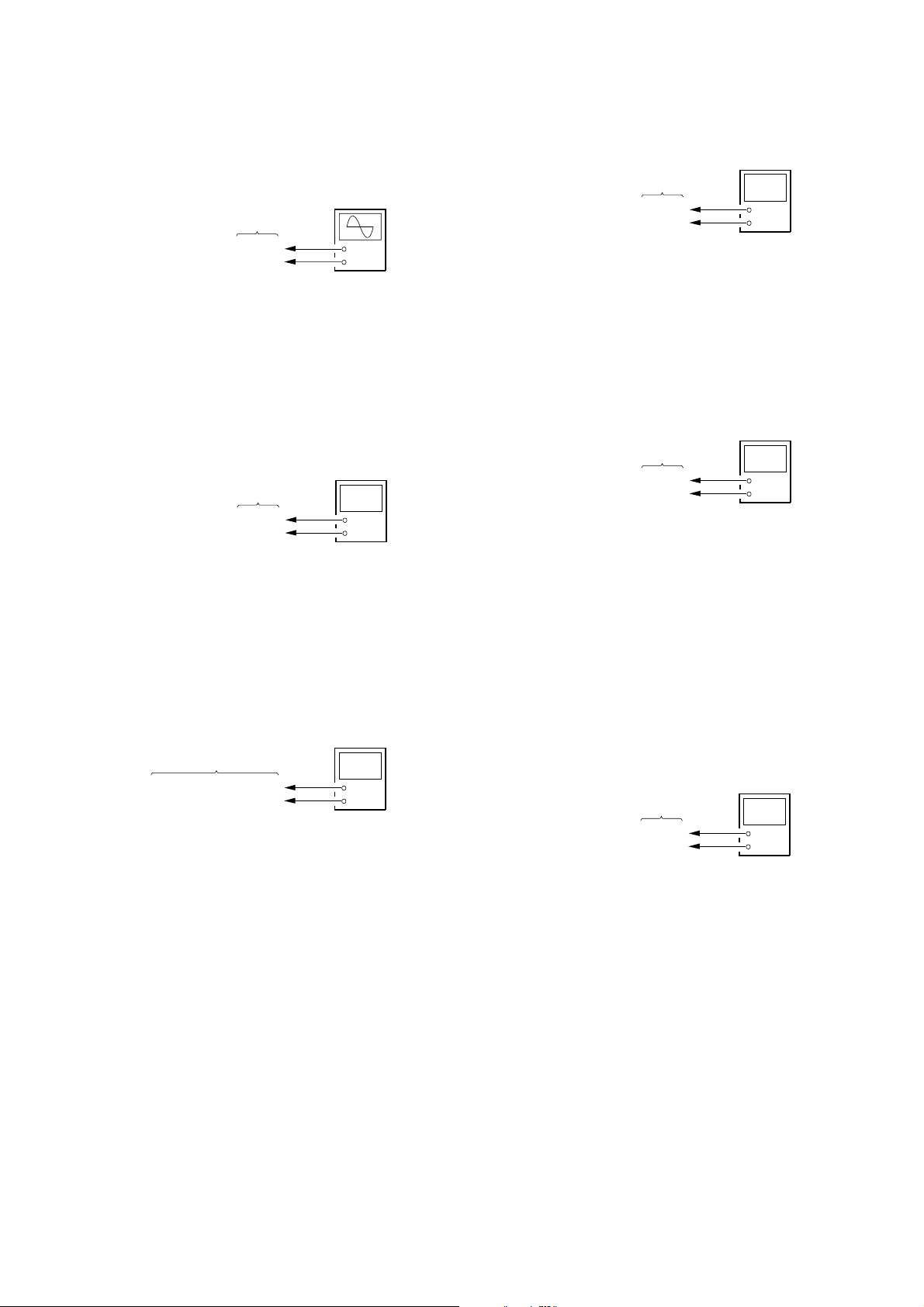

1. DC/DC CONVERTER ADJUSTMENT

1-1. Frequency Adjustment

Setting:

oscilloscope

or

frequency counte

MONITOR board

TP802

TP804

Procedure:

1. Connect an oscilloscope or frequency counter to the TP802

and TP804 on the MONITOR board.

2. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

3. Adjust the RV801 on the MONITOR board so that the value

of oscilloscope or frequency counter becomes 243 kHz ±3 kHz.

1-2. 5V V oltage Adjustment

Setting:

MONITOR board

TP807

TP804

Procedure:

1. Connect a digital voltmeter to the TP804 and TP807 on the

MONITOR board.

2. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

3. Adjust the RV803 on the MONITOR board so that the value

of digital voltmeter becomes 5.05 V ±0.03 V .

1-3. Other V oltages Check

Setting:

MONITOR board

TP805/TP806/TP808

TP804

Procedure:

− Vdd V oltage Check −

1. Connect a digital voltmeter to the TP804 and TP808 on the

MONITOR board.

2. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

3. Check that the value of digital voltmeter is 3.45 V ±0.2 V .

− Vgh V oltage Check −

4. Connect the digital voltmeter to the TP804 and TP806 on the

MONITOR board.

5. Check that the value of digital voltmeter is 17.5 V ±1.5 V .

− Vss V oltage Check −

6. Connect the digital voltmeter to the TP804 and TP805 on the

MONITOR board.

7. Check that the value of digital voltmeter is –12.0 V ±1.5 V.

+

–

digital voltmete

+

–

digital voltmete

+

–

2. PLL ADJUSTMENT

Setting:

digital voltmete

MONITOR board

TP601

TP602

+

–

Procedure:

1. Connect a digital voltmeter to the TP601 and TP602 on the

MONITOR board.

2. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

3. Adjust the RV601 on the MONITOR board so that the value

of digital voltmeter becomes 2.5 V ±0.15 V .

3. INVERTER HIGH VOLTAGE CHECK

Setting:

digital voltmete

MONITOR board

TP853

TP854

+

–

Procedure:

− High Voltage Check −

1. Connect a digital voltmeter (for withstand high voltage) to the

TP853 and TP854 on the MONITOR board.

2. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

(DIMMER: off)

3. Check that the value of digital voltmeter is 550 V ±150 V (rms).

− Frequency Check −

4. Connect an oscilloscope (use a probe for withstand high voltage) to the TP853 and TP854 on the MONITOR board.

5. Check that the frequency of oscilloscope is 66 kHz ±2.5 kHz.

4. OSD DOT CLOCK CHECK

Setting:

frequency counte

MONITOR board

TP403

TP405

Procedure:

1. Connect a frequency counter (high impedance) to the TP403

and TP405 on the MONITOR board.

2. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

3. Check that the value of frequency counter is 6.5 MHz ±0.2

MHz.

+

–

15

MV-65ST

r

r

e

V

V

+

–

oscilloscope

MONITOR board

TP811

TP513

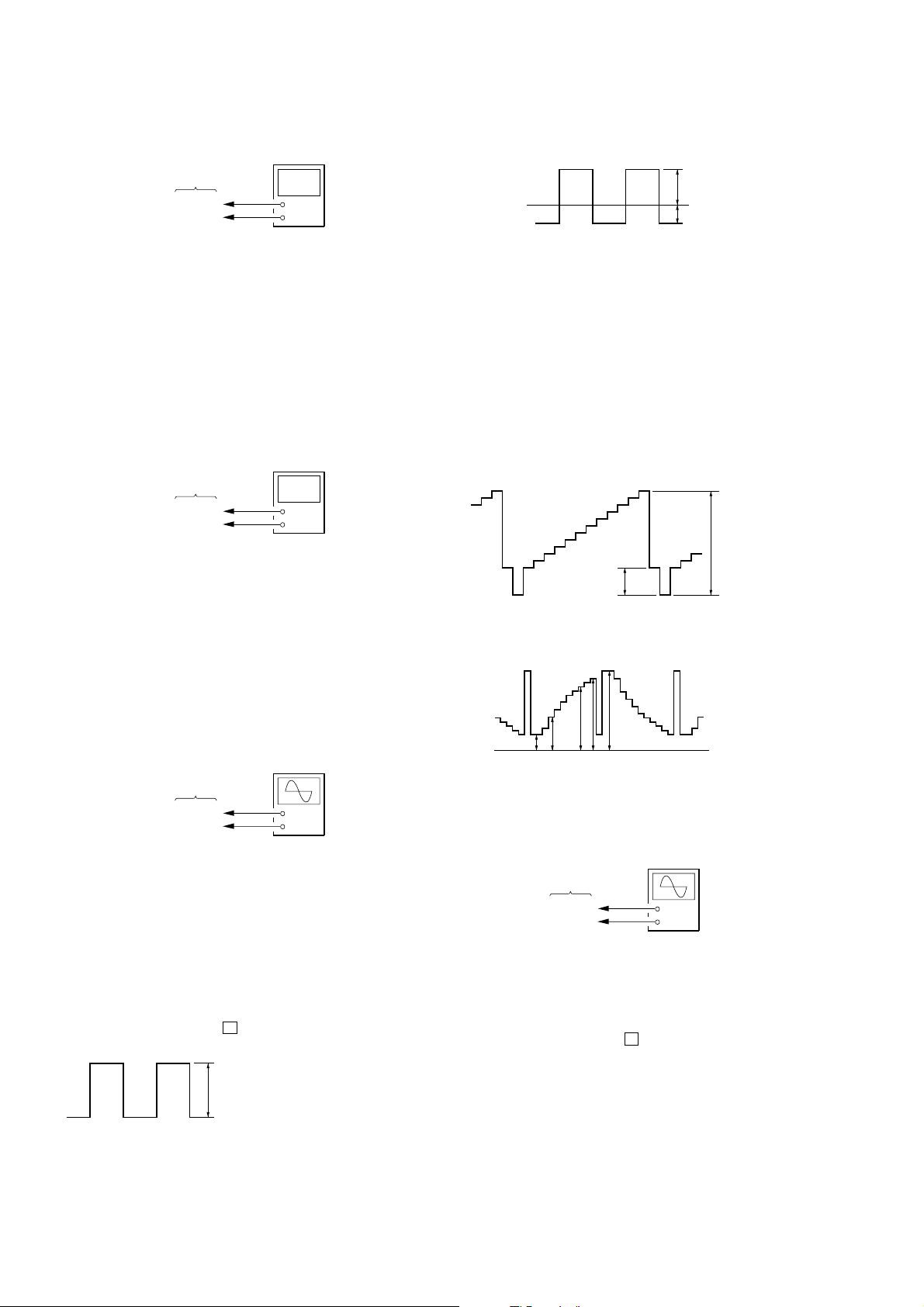

5. NTSC SUB CARRIER CHECK

Setting:

frequency counte

MONITOR board

TP510

TP513

+

–

Procedure:

1. Connect a frequency counter (high impedance) to the TP510

and TP513 on the MONITOR board.

2. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

3. Set the signal format system to NTSC. (refer to “4. TEST

MODE”)

4. Check that the value of frequency counter is 3.579545 MHz

±100 Hz.

6. PAL SUB CARRIER CHECK

Setting:

frequency counte

MONITOR board

TP510

TP513

Procedure:

1. Connect a frequency counter (high impedance) to the TP510

and TP513 on the MONITOR board.

2. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

3. Set the signal format system to PAL. (refer to “4. TEST

MODE”)

4. Check that the value of frequency counter is 4.433619 MHz

±100 Hz.

+

–

− Waveform Position Set-up Adjustment −

7. Adjust the RV802 on the MONITOR boar d so that A value of

waveform becomes −2.1 V ±0.1 V.

4.9 V ± 0.1 V

0 V

A

: – 2.1 V ± 0.1

8. VIDEO ADJUSTMENT

Note: Perform the following adjustment items in test mode.

Common Setting:

1. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

2. Enter the test mode, and enter the “2. FOR FA CTORY” mode.

(refer to “4. TEST MODE”)

3. Set the signal format system to NTSC. (refer to “4. TEST

MODE”)

4. Input 10 steps signal (NTSC, without burst) to the VIDEO

INPUT jack (J301 on the POWER board) from pattern generator.

Waveform of input signal

1 Vp-p

0.286 V

fig. 8-1

Waveform of output signal

(TP810, TP811, TP812)

7. V-COM ADJUSTMENT

Setting:

oscilloscop

MONITOR board

TP819

TP828

Procedure:

− Voltage Set-up Adjustment −

1. Connect an oscilloscope to the TP819 and TP828 on the MONITOR board.

2. Check that the voltage between TP951 (−) and TP952 (+) is

14.4 V. Press the [POWER] button to turn the power on.

3. Enter the test mode, and enter the “2. FOR FA CTORY” mode.

(refer to “4. TEST MODE”)

4. Press the [MENU] button to display “Com Gain”, and press the

[REVERSE] button.

5. Adjust by pressing the [+]/ − buttons so that the voltage of

oscilloscope becomes 7.0 Vp-p ±0.1 V.

7.0 Vp-p ± 0.1

6. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

+

–

0 V

AB CDE

fig. 8-2

1 Contrast Level of Luminance Signal

Setting:

Procedure:

1. Connect an oscilloscope to the TP513 and TP811 on the MONITOR board.

2. Press the [MENU] button to display “Y Gain”, and press the

[REVERSE] button.

3. Adjust by pressing the [+]/

− buttons so that the D value of

waveform (fig. 8-2) becomes 3.4 V ±0.1 V.

4. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

16

MV-65ST

r

2 Back Limiter Level

Procedure:

1. In the “1 Contrast Level of Luminance Signal” status, press

the [MENU] utton to display “Black Limit”, and press the [RE-

VERSE] button.

2. Adjust by pressing the [+]/ − buttons so that the A value of

waveform (fig. 8-2) becomes 1.0 V ±0.1 V.

3. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

3 White Limiter Level

Procedure:

1. In the “2 Black Limiter Level” status, press the [MENU] but-

ton to display “White Limit”, and press the [REVERSE] but-

ton.

2. Adjust by pressing the [+]/ − buttons so that the E value of

waveform (fig. 8-2) becomes 3.9 V ±0.1 V.

3. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

4 R-sub Bright

Procedure:

1. In the “3 White Limiter Level” status, connect the oscillo-

scope to the TP513 and TP810 on the MONITOR board.

2. Press the [MENU] button to display “R-Sub BRT”, and press

the [REVERSE] button.

3. Adjust by pressing the [+]/ − buttons so that the A value of

waveform (fig. 8-2) becomes 1.0 V ±0.1 V.

4. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

5 B-sub Bright

Procedure:

1. In the “4 R-sub Bright” status, connect the oscilloscope to

the TP513 and TP812 on the MONITOR board.

2. Press the [MENU] button to display “B-Sub BRT”, and press

the [REVERSE] button.

3. Adjust by pressing the [+]/

− buttons so that the A value of

waveform (fig. 8-2) becomes 1.0 V ±0.1 V.

4. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

6 R-ch Sub Contrast

Procedure:

1. In the “5 B-sub Bright” status, connect the oscilloscope to

the TP513 and TP810 on the MONITOR board.

2. Press the [MENU] button to display “R-Sub CONT”, and press

the [REVERSE] button.

3. Adjust by pressing the [+]/ − buttons so that the D value of

waveform (fig. 8-2) becomes 3.4 V ±0.1 V.

4. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

7 B-ch Sub Contrast

Procedure:

1. In the “6 R-ch Sub Contrast” status, connect the oscilloscope

to the TP513 and TP812 on the MONITOR board.

2. Press the [MENU] button to display “B-Sub CONT”, and press

the [REVERSE] button.

3. Adjust by pressing the [+]/ − buttons so that the D value of

waveform (fig. 8-2) becomes 3.4 V ±0.1 V.

4. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

8 Gamma 1

Procedure:

1. In the “7 B-ch Sub Contrast” status, connect the oscilloscope

to the TP513 and TP811 on the MONITOR board.

2. Press the [MENU] button to display “Gamma 1”, and press the

[REVERSE] button.

3. Adjust by pressing the [+]/ − buttons so that the B value of

waveform (fig. 8-2) becomes 2.0 V ±0.1 V.

4. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

9 Gamma 2

Procedure:

1. In the “8 Gamma 1” status, press the [MENU] button to dis-

play “Gamma 2”, and press the [REVERSE] button.

2. Adjust by pressing the [+]/ − buttons so that the C value of

waveform (fig. 8-2) becomes 3.2 V ±0.1 V.

3. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

q; VCO Free Run

Setting:

frequency counte

MONITOR board

TP506

TP513

+

–

Procedure:

1. In the “9 Gamma 2” status, connect a frequency counter to

the TP506 and TP513 on the MONITOR board.

2. Press the [MENU] button to display “VCO Free Run”, and press

the [REVERSE] button.

3. Adjust by pressing the [+]/

− buttons so that the value of fre-

quency counter becomes 15.734 kHz ±50 Hz.

4. Confirm that the displayed screen is normally display.

5. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

qa Vertical Position

Procedure:

1. In the “q; VCO Free Run” status, input the monoscope signal

to the VIDEO INPUT jack (J301 on the POWER board).

2. Press the [MENU] button to display “PLL/V Pos”, and press

the [REVERSE] button.

3. Adjust by pressing the [+]/ − buttons so that the vertical posi-

tion of screen on the monitor becomes the most suitable.

4. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

qs Horizontal Position

Procedure:

1. In the “qa Vertical Position” status, press the [MENU] button

to display “H Pos”, and press the [REVERSE] button.

2. Adjust by pressing the [+]/ − buttons so that the horizontal

position of screen on the monitor becomes the most suitable.

3. Press the [REVERSE] button and write the date to EEPROM

(IC402 on the MONITOR board).

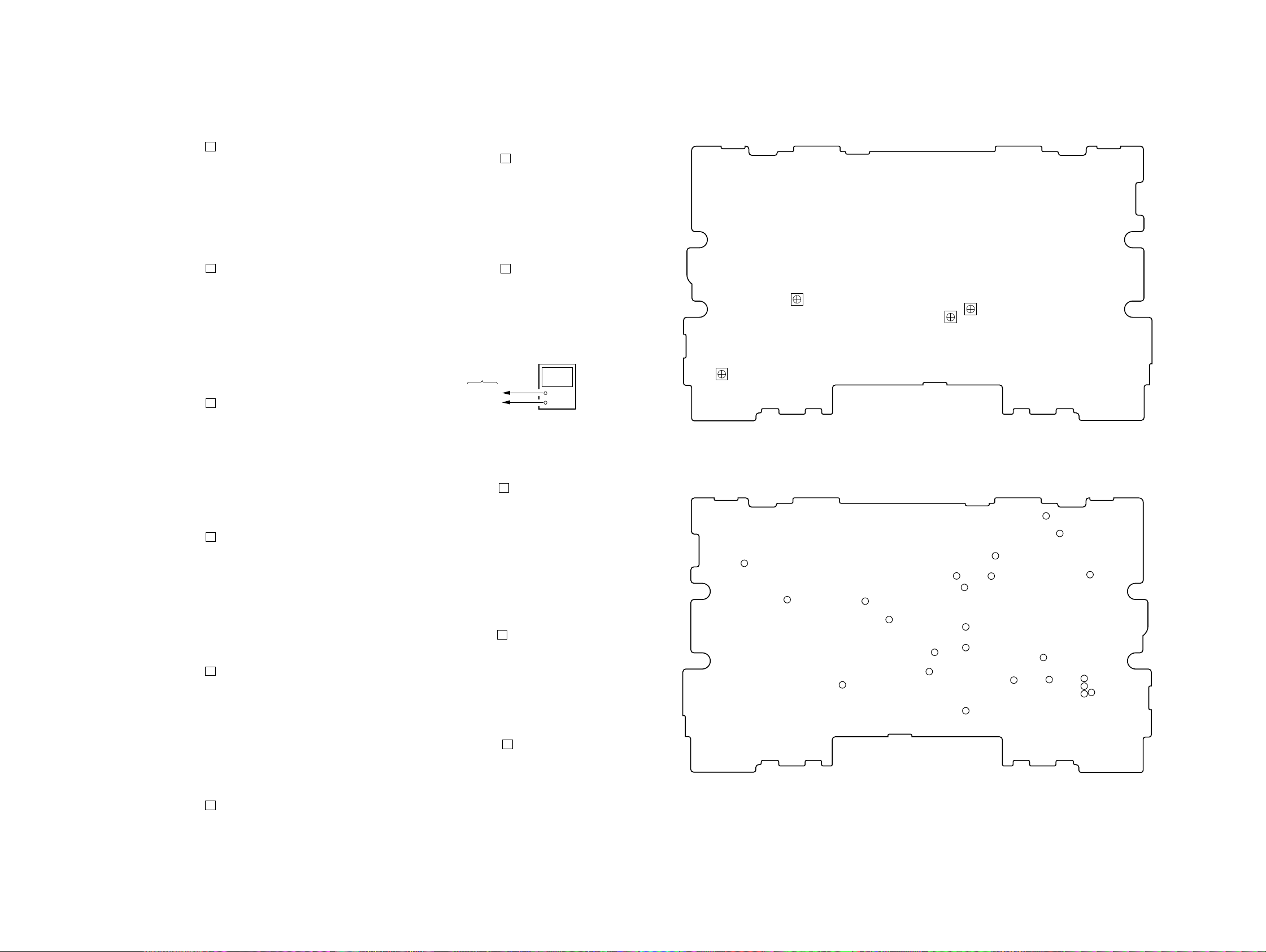

Adjustment Location:

– MONITOR BOARD (SIDE A) –

RV601

RV802

– MONITOR BOARD (SIDE B) –

TP853

TP854

TP802

TP952 (+)

TP951 (

−

)

TP808

TP807

RV803

TP954

TP953

RV801

TP804

TP805

TP806

TP403

TP602

TP405

TP601

TP819

TP513

TP510

TP810

TP811

TP812

TP506

TP828

1717

MV-65ST

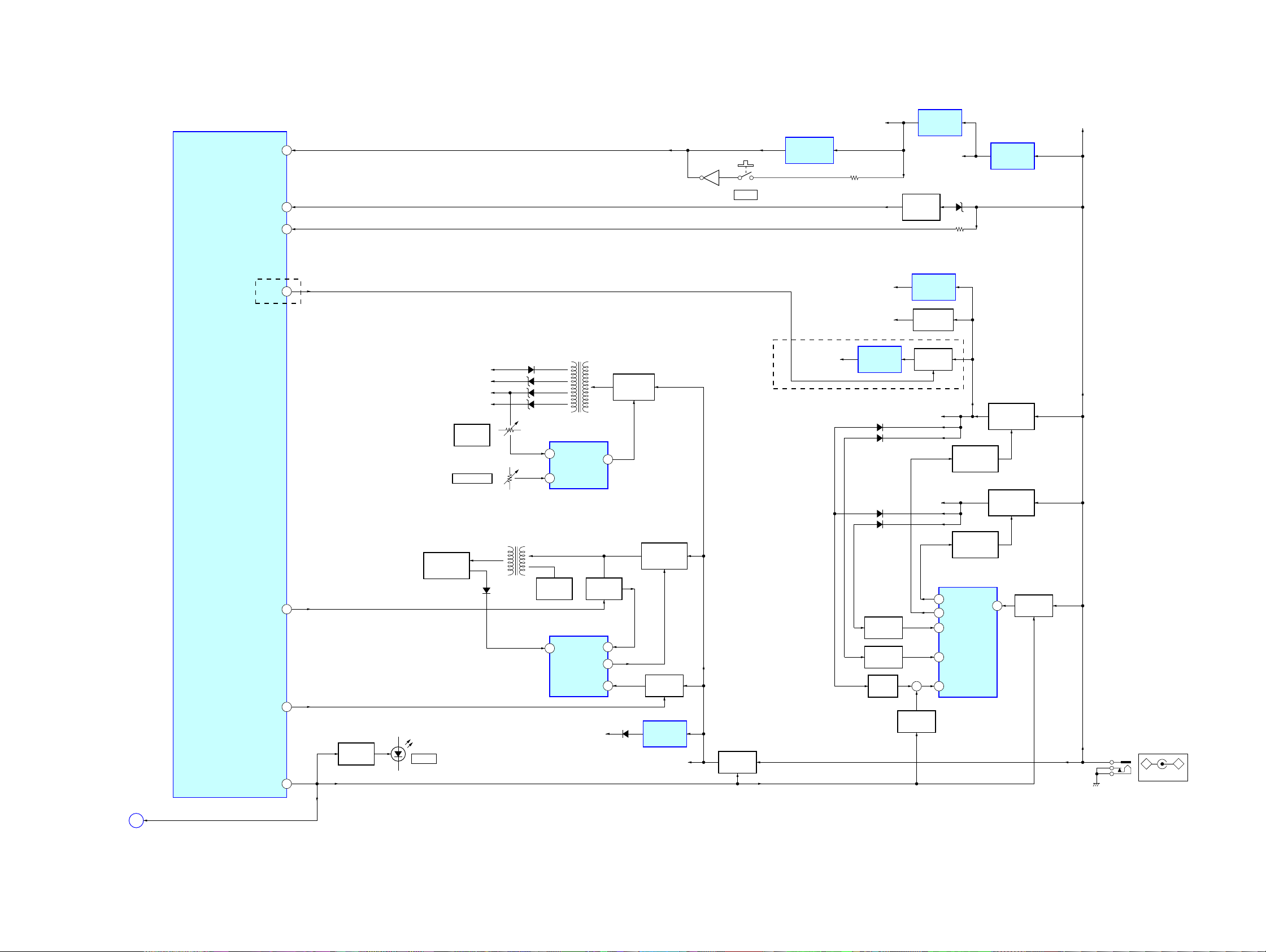

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM – AUDIO Section –

J301 (1/2)

VIDEO

R-CH

DIFFERENTIAL

R-CH

AMP

IC301

INPUT

OPTICAL

OUTPUT

L

AUDIO

R

OPTICAL

TRANSCEIVER

DVD MECHANISM

DECK BLOCK

AUDIO-DL

AUDIO-DR

J302

SPDIF

CVBS

VIDEO/AUDIO SELECT

IC302

3 VIN1

8 LIN1

1

7 LIN2

VOUT2

VIN2

SW22SW1

9

CVBS

J301 (2/2)

VIDEO

BUFFER AMP

IC305

R-CH

MUTING

Q102

R-CH

(US, Canadian, Mexican)

15

11LOUT2

14VOUT1

10LOUT1

R-CH

22

1

LIN

RIN

14 13

MPX ADJ

XIN

X301

7.6MHz

L

R

5

XOUT

OUTPUT

AUDIO

BUFFER AMP

Q305, 306

FM STEREO

TRANSMITTER

IC306

A

VTIN

9

PD

7

17

LEVEL SHIFT

Q307 – 310

(Page 19)

RF OUT

DATA16CLK15CE

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: DVD (VIDEO)

: DVD (AUDIO)

: DIGITAL OUT

: INPUT (VIDEO)

: INPUT (AUDIO)

CN304

TRANSMIT

11

ATT

18

BPF

FL301

XMD

XMC

+8V

+5V

+3.3V

VFD-CS

TEMP

B+8V

B+5V

U-COM +3.3V

ELECTRICAL VOLUME

IC303

8

LIN1

LOUT1

CLK4DATA

5

FM-DATA

FM-CLK

FM-CE

L/R INVERSE

IC304

1

11 IN4

Q301

IN1

3 IN2

8 IN3

CONT1

5

13

L/R INVERSE

SWITCH

D309

7

R-CH

OUT1

10OUT4

CONT3

CONT212CONT4

6

Q302

D303

2

4OUT2

9OUT3

R-CH

(US, Canadian, Mexican)

BUFFER

Q201

MUTING

Q171

MUTING

SWITCH

Q315

POWER ON

MUTING

Q316, 317

R-CH

MUTING

CONTROL

Q313, 314

POWER AMP

IC371

STANDBY

SWITCH

Q371, 372

R-CH

POWER ON

SP1

(L)

SP2

(R)

J371

2

HEADPHONE

J372

1

(Page 20)

B

UD

(Page 19)

C

15

16

DA (IN)-BE

17

18

33

CK-BE

CS-BE

DA (OUT)-BE

TEMP

FM-CE

FM-CLK

FM-DATA

6

63

SW1

7

S-SDA

S-SCL

SYSTEM CONTROLLER

IC401 (1/3)

54

U/D

4

3

FM-DATA

5

FM-CE

FM-CLK

53

AMUTE

64

H/P DET

1818

6-2. BLOCK DIAGRAM – VIDEO, PANNEL Section –

TRAP

IC501

BUFFER

Q501

PAL/NTSC SWITCH

(Page 18)

X502

X501

4.43MHz

3.58MHz

63

64

VXO-PAL

VXO-NTSC

CVBS

A

SYNC

SEPARATOR

Q502, 503

YIN

52

57

46

CTRAPOUT

CIN

CSYNCIN

CSYNCOUT

V-SDA48V-SCK47HSYNCLOCK

HDOUT

VDOUT

39

SYNC DET

Q505, 506

53

RGB DECODER

34

32

31

54

35

Q504

CTRAPIN

VDIN

MV-65ST

LIQUID CRYSTAL

DISPLAY MODULE

LCD1

V COM AMP

IC802

28

VCOMOUT

26

R-OUT

21

G-OUT

19

B-OUT

14

R-IN2

15

G-IN2

16

B-IN2

17

YS

BLAK36POL

18

BLAK

HD

POL

VD

R

G

B

OSD DRIVER

IC405

16

VR

17 VG

18 VB

15 BLK

20 HSYNCN

19 YSYNCN

3

DATA

OSC OUT

SCLK2CSN

DATA

1

CLK

7

OSC

8OSC IN

PHASE

COMPARATOR

IC602

RV601

CS

PLL

Q601

HD

VD

BLAK

POL

33

36 VCO1

37 VCO0

2 HSYNCIN

5 VDBIN

8 BLACK

14 POL

46 NP

LCD CONTROLLER

PD

QHSEL31JUST13UD

CPHSEL

4

3

V COM BIAS

Q803 – 807

IC601

LTBOX

12

STV1

20

26STV2

23STH1

24STH2

29CPH1

27CPH2

25CPH3

16CPV

19OEV1

18OEV2

17OEV3

21OEH

28L/R

RV802

V-COM

R

G

B

Q603

VCOM

VCOM

RED

GREEN

BLUE

STV1

STV2

STH1

STH2

CPH1

CPH2

CPH3

CPV

OEV1

OEV2

OEV3

OEH

L/R

UD

VHG

VDD1

VCC

VEE

VHG +17V

VDD +3.3V

VCC +5V

VB

VSS –13V

51

52

V-SCK

V-SDA

8

LED DRIVE

Q953, 954

D703

DISC IN

DISC_LED

21

SYNC-DET

KEY IN

27

S401 – 404

UD

(Page 18)

C

CS

CLK

DATA

57

59

61

SDA13SCL

14

6

SCL

SDA

58

SIDE2

SIDE1

ZOOM

X1

41 40

X401

4.19MHz

JUST

43

VD

SYSTEM CONTROLLER

IC401 (2/3)

KEY DVD

28

S701 – 704

S706

Z

29

KEY EJ

KEY PW

30

D403

D402

S705

POWER

20

19

OSD DATA

WAKE UP

SWITCH

Q401, 403

22

OSD CSN

OSD SCLK

44

KEY HALT

SIRCS BUFFER

REMOTE CONTROL

RECEIVER

23

N/P

REM HALT45REM IN

47

Q460

IC404

5

EEPROM

IC402

55

LR

X2

• SIGNAL PATH

: DVD (VIDEO)

: DVD (AUDIO)

1919

MV-65ST

6-3. BLOCK DIAGRAM – POWER Section –

SYSTEM CONTROLLER

IC401 (3/3)

RESET

PW-IN

PW DET

FM-ON

DIMMER

TFT ON

PW-ON

36

46

32

(US, Canadian, Mexican)

49

60

56

2

LED DRIVE

Q955, 956

BACK LIGHT

D702

POWER

VSS –13V

VGH +17V

VCC +5V

VDD +3.3V

RV803

5V

VOLTAGE

(DC/DC CONVERTER)

RV801

FREQUENCY

(DC/DC CONVERTER)

UNIT

INVERTER

TRANSFORMER

T850

D852, 853

D801

D802

D803

D804

POWER CONTROL

3

1IN+

2RT

OSC

Q857, 858

POWER CONTROL

1IN+

1

DC/DC

CONVERTER

T801

IC801

IC850

VCC +7.5V

71OUT

DIMMER

Q860, 861

162IN+

11

C2

12VCC

DC/DC

CONVERTER

Q801, 802

D950

SWITCHING

REGULATOR

Q855, 856, 859

B+ SWITCH

Q853, 854

+8V

REGULATOR

IC950

VCC

Q402

S707

RESET

B+ SWITCH

Q951, 952

RESET SIGNAL

GENERATOR

IC403

FM +5V

(US, Canadian, Mexican)

U-COM +3.3V

E-VOL +5V

IC305 B+

REGULATOR

IC307

D905

D908, 909

D904

D906, 907

DEAD TIME

DEAD TIME

LATCH

+5V

Q913

Q914

Q911

REGULATOR

BATTERY

DETECT

Q404

REGULATOR

REGULATOR

Q303, 304

B+ SWITCH

Q311, 312

+

SWITCHING

Q912

+3.3V

IC952

PANEL +5V

+5V

IC308

B+8V

B+5V

POWER CONTROL

OUT2

12

7 OUT1

11 DT2

6 DT1

15 SCP

D404

REGULATOR

CONTROL

Q902, 903

REGULATOR

CONTROL

Q905, 906

IC901

VCC

+5V

REGULATOR

IC951

SWITCHING

REGULATOR

Q901

SWITCHING

REGULATOR

Q904

B+ SWITCH

9

Q907, 908

BATT

J901

–

DC IN 12V

+

(Page 18)

B

POWER ON

2020

Loading...

Loading...