Sony Md Walkman MZ-R37 Service Manual

– 1 –

MICROFILM

MZ-R37

SERVICE MANUAL

PORTABLE MINIDISC RECORDER

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Tourist Model

Model Name Using Similar Mechanism MZ-R55

MiniDisc Mechanism Type MT-MZR37-161

Optical Pick-up Type KMS-280A

US and foreign patents licensed from Dolby Laboratories

Licensing Corporation.

System

Audio playing system

MiniDisc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 780 nm

Emission duration: continuous

Laser output: less than 44.6 µW

(This output is the value measured at a

distance of 200 mm from the lens surface on

the optical pick-up block with 7 mm

aperture.)

Recording and playback time

Maximum 74 minutes (MDW-74, stereo

recording)

Maximum 148 minutes (MDW-74, monaural

recording)

Revolutions

400 rpm to 900 rpm (CLV)

Error correction

Advanced Cross Interleave Reed Solomon

Code (ACIRC)

Sampling frequency

44.1 kHz

Sampling rate converter

Input: 32 kHz / 44.1 kHz / 48 kHz

Coding

Adaptive TRansform Acoustic Coding (ATRAC)

Modulation system

EFM (Eight to Fourteen Modulation)

Number of channels

2 stereo channels

1 monaural channel

Frequency response

20 to 20,000 Hz ± 3 dB

Wow and Flutter

Below measurable limit

Inputs

MIC (PLUG IN POWER): stereo mini-jack,

0.35–1.38 mV

(OPTICAL) LINE IN: stereo mini-jack with

optical (digital) in

• Line in: 69–194 mV

• Optical (digital) in: wave length 660 nm

Outputs

PHONES/REMOTE: stereo mini-jack,

maximum output level 5 mW + 5 mW, load

impedance 16 ohm

LINE OUT: stereo mini-jack, 194 mV, load

impedance 10 kilohm or greater

General

Power requirements

Sony AC Power Adaptor (supplied)

connected at the DC IN 4.5 V jack:

120 V AC, 60 Hz (US, Canadian model)

220–230 V AC, 50/60 Hz (AEP model)

230–240 V AC, 50 Hz (UK model)

240 V AC, 50 Hz (Australian and New Zealand model)

Two nickel-cadmium rechar geable batteries

NC-AA (supplied)

Two LR6 (size AA) alkaline batteries (not supplied)

– Continued on next page –

Ver 1.3 1999. 11

With SUPPLEMENT-1

(9-926-952-81)

With SUPPLEMENT-2

(9-926-952-82)

– 2 –

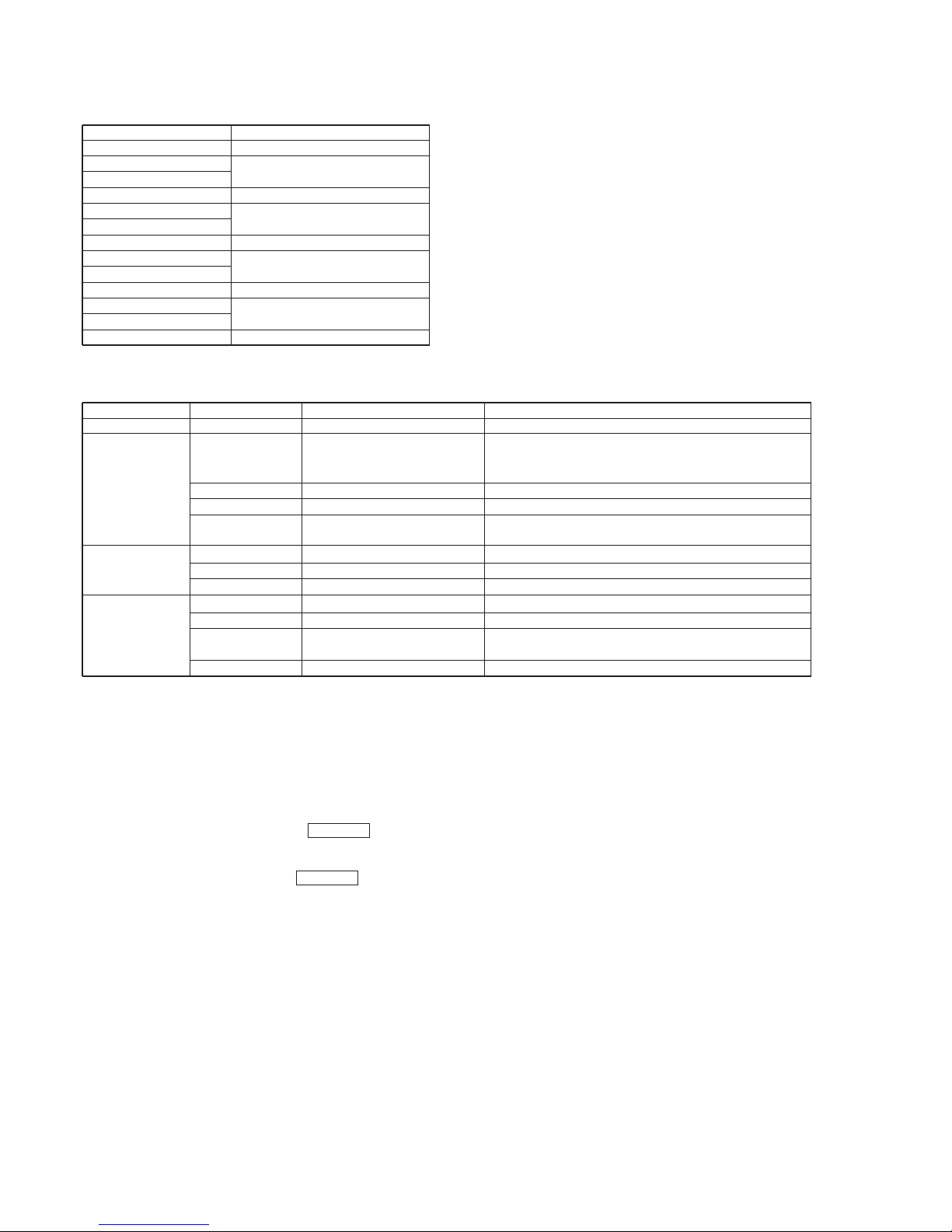

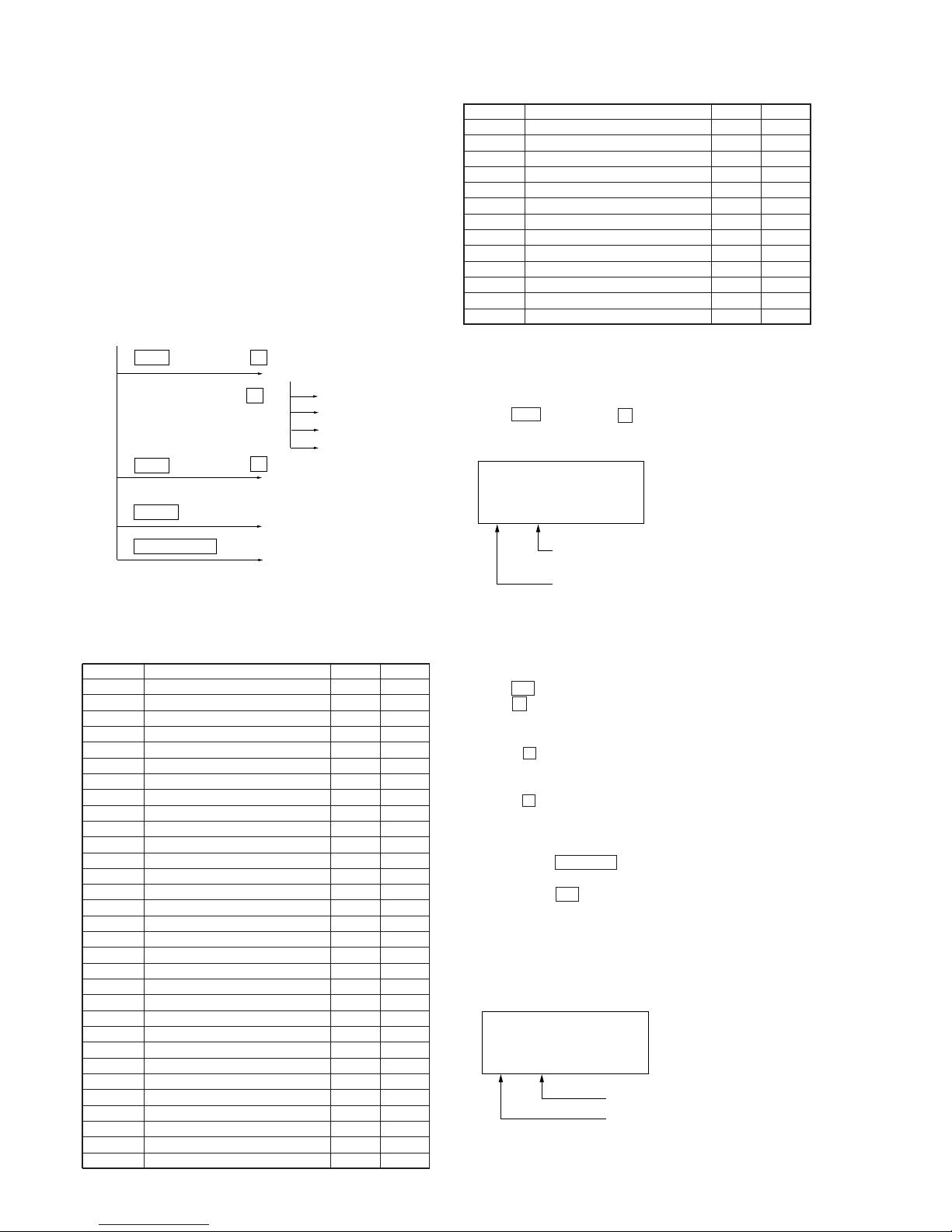

Battery operation time

1)

Batteries Recording

2)

Playback

Two NC-AA Approx. Approx.

nickel-cadmium

3 hours 5 hours

rechargeable batteries

Two LR6 (size AA) ––––

3)

Approx.

Sony alkaline dry batteries 13 hours

1)

The battery life may be shorter due to

operating conditions and the temperature

of the location.

2)

When you record, use fully charged

rechargeable batteries.

3)

Recording time may differ according to the

alkaline batteries.

Dimensions

Approx. 116.8 × 18.5 × 86.1 mm (w/h/d)

(4 5/8 × 3/4 × 3 1/2 in.)

Mass

Approx. 160 g (5.6 oz) the recorder only

Approx. 220 g (7.8 oz) incl. a recordable MD,

and two NC-AA nickel-cadmium

rechargeable batteries

Supplied accessories

Optical cable (1) (MC-918)

AC power adaptor (1) (AC-MZR37)

Headphones with a remote control (1) (SZR-S17)

NC-AA nickel-cadmium rechargeable batteries (2)

Rechargeable battery carrying case (1)

Design and specifications are subject to change without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Precautions for Laser Diode Emission Check

When checking the emission of the laser diode during adjustments, never view directly downwards as this may lead to

blindness.

Precautions for Using Optical Pick-up (KMS-280A)

As the laser diode inside the optical pick-up damages by static

electricity easily, solder the laser tap of the Optical pick-up

flexible board when handling. Also take the necessary measures

to prevent damages by static electricity. Handle the Optical pickup flexible board with care as it breaks easily.

Laser tap

Optical Pick-up flexible board

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

IN NO EVENT SHALL SELLER BE

LIABLE FOR ANY DIRECT,

INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY NATURE, OR

LOSSES OR EXPENSES RESULTING

FROM ANY DEFECTIVE PRODUCT

OR THE USE OF ANY PRODUCT.

“MD WALKMAN” is a trademark of Sony

Corporation.

This MiniDisc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER

PRODUCT label is located on

the bottom exterior.

– 3 –

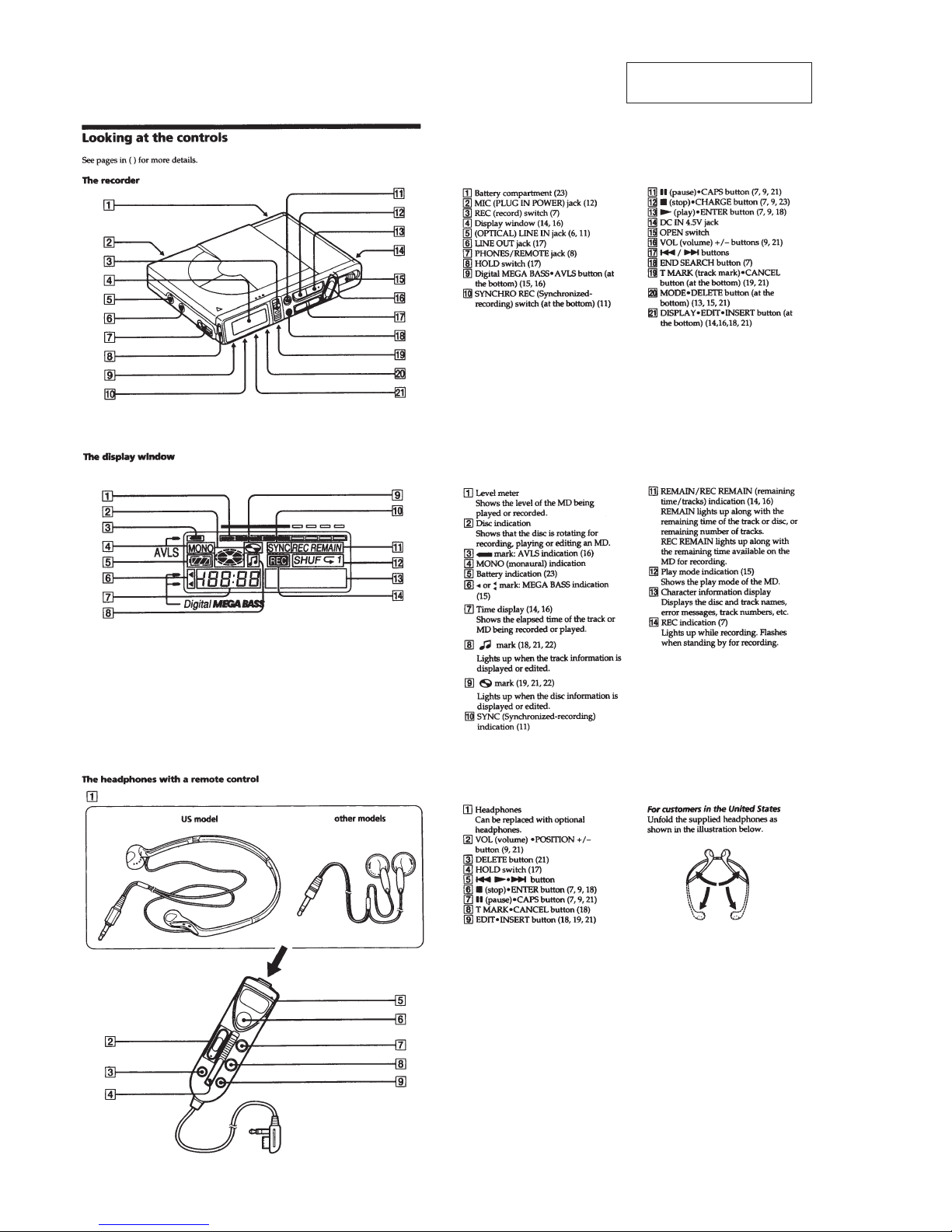

1. GENERAL

Looking at the controls ...................................................... 4

2. SELF-DIAGNOSTIC

2-1. General ............................................................................... 5

2-2. Test Mode Setting .............................................................. 5

2-3. Operation in Test Mode Setting ......................................... 5

2-4. Releasing the Test Mode .................................................... 5

2-5. Self-Diagnostic Mode ........................................................ 5

2-6. Clearing the Error Indication Code

and T otal Recording Time .................................................. 6

3. DISASSEMBLY

3-1. Panel, Bottom..................................................................... 7

3-2. Panel (SV) Assy, Front ....................................................... 7

3-3. LCD Module ...................................................................... 8

3-4. Connector ........................................................................... 8

3-5. Main Board ........................................................................ 9

3-6. Panel (SV) Assy, Upper ..................................................... 9

3-7. Cabinet (SV) Assy ........................................................... 10

3-8. OP Block Assy ................................................................. 10

3-9. Holder Assy...................................................................... 11

TABLE OF CONTENTS

4. TEST MODE

4-1. General ............................................................................. 12

4-2. Test Mode Setting ............................................................ 12

4-3. Test Mode Structure......................................................... 12

4-4. Manual Mode ................................................................... 12

4-5. Overall Adjustment Mode (Assy Mode).......................... 15

4-6. Hybrid Mode, Key Check Mode...................................... 16

5. ELECTRICAL ADJUSTMENTS........................... 17

6. DIAGRAMS

6-1. IC Pin Descriptions .......................................................... 20

6-2. Block Diagram – Servo Section –.................................... 25

6-3. Block Diagram – Audio Section – ................................... 27

6-4. Block Diagram – System Control Section – .................... 29

6-5. Printed Wiring Board ....................................................... 31

6-6. Schematic Diagram – Main Section (1/3) –..................... 35

6-7. Schematic Diagram – Main Section (2/3) –..................... 38

6-8. Schematic Diagram – Main Section (3/3) –..................... 41

7. EXPLODED VIEWS

7-1. Panel Section.................................................................... 49

7-2. Cabinet (SV) Assy Section .............................................. 50

7-3. Mechanism Deck Section ................................................ 51

8. ELECTRICAL PARTS LIST................................... 52

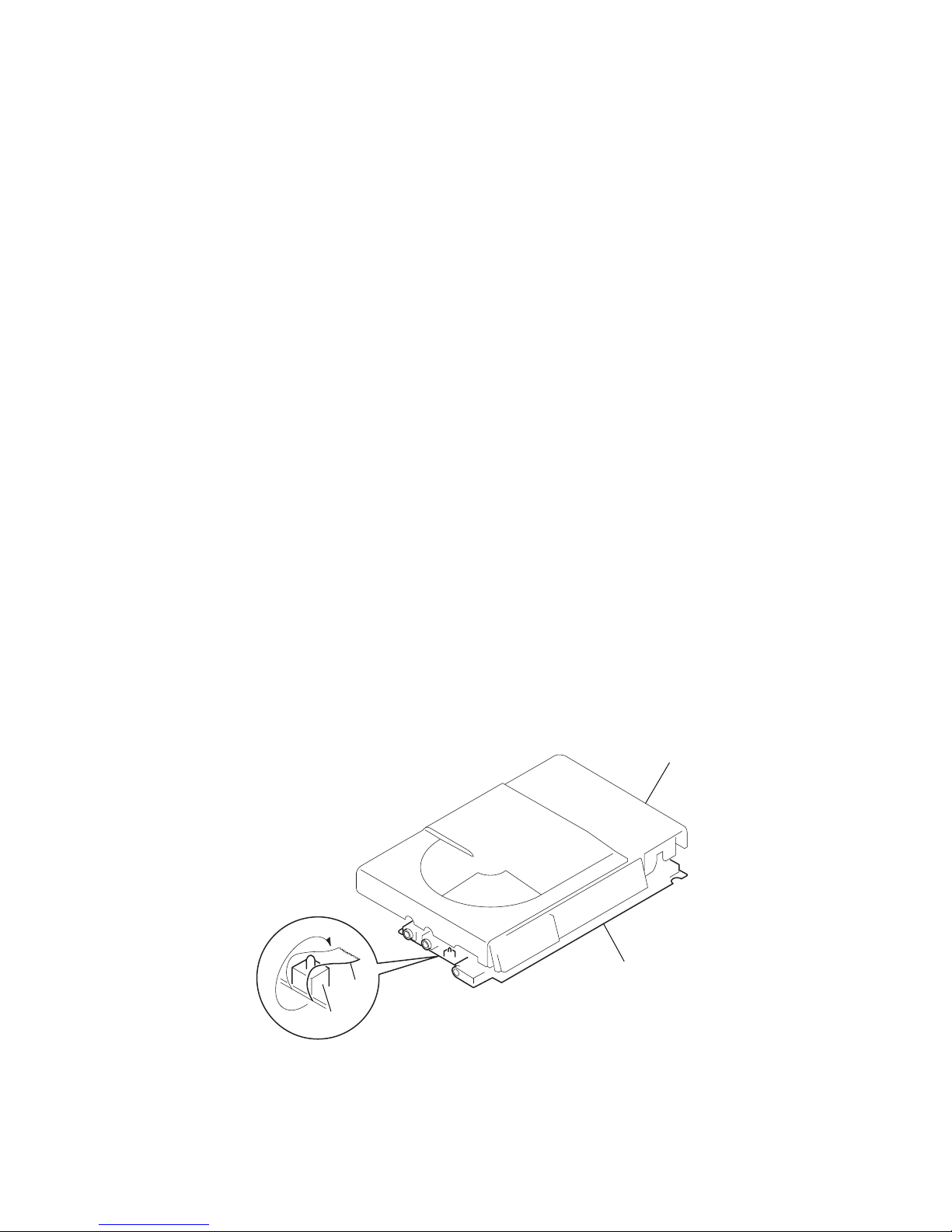

SERVICING NOTE

1) When repairing this device with the power on, if you remove

the main board or open the upper panel assy, this device stops

working.

In this case, you can work without the device stopping by

fastening the hook of the OPEN1 switch (S801) with tape.

2) This set is designed to perform automatic adjustment for each

adjustment and write its value to EEPROM. Therefore, when

EEPROM (IC803) has been replaced in service, be sure to perform automatic adjustment and write resultant values to the new

EEPROM.

Refer to page 12 for details.

panel assy, uppe

r

MAIN board

tape

S801

– 4 –

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 5 –

SECTION 2

SELF-DIAGNOSTIC

2-1. GENERAL

This set uses the self-diagnostic system in which if an error occurs

in playback/recording mode, the error is detected by the model

control and power control blocks of the microprocessor and information on the cause is stored as history in EEPROM.

By viewing this history in test mode, it helps you to analyze a fault

and determine its location.

2-2. TEST MODE SETTING

There are two different methods to set the test mode:

1 Short BP801 (TEST) on the main board with a solder bridge

(connect pin @§ of IC801 to the ground). Then, turn on the

power.

2 In the normal mode, use the keys on the unit to perform the

following operations:

Press and hold down ( and press the keys below in this turn:

+ n + n =n = n + n = n + n

= n P n P

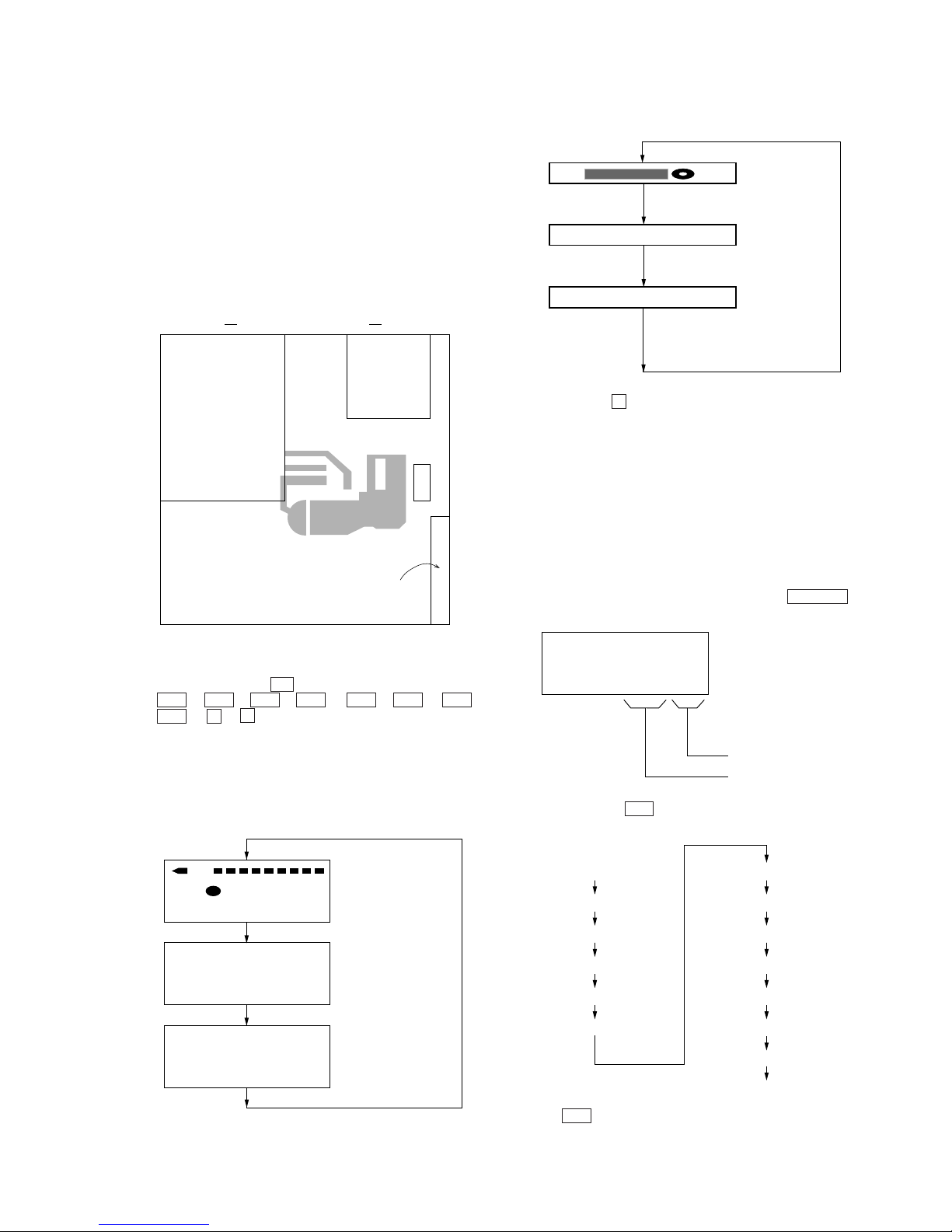

2-3. OPERATION IN TEST MODE SETTING

When the test mode is set, the LCD shows repeated cycles of the

following display:

1) Unit LCD

2) Remote controller LCD

• Holding down P allows the current display to be maintained

while it being depressed.

2-4. RELEASING THE TEST MODE

For test mode set with the method 1:

Turn off the power and open the solder bridge on BP801 on the

main board.

For test mode set with the method 2:

Turn off the power.

2-5. SELF-DIAGNOSTIC MODE

1. Go into the test mode.

2. With the unit LCD indicators all flashing, press DISPLAY key

to go into the self-diagnostic mode.

3. Then, eac h time ) ke y is pressed, the reference information

display changes as given below.

• Press = key to go back to the previous display.

C401

X801

26

25

IC801

IC301

BP801

(TEST)

MAIN BOARD (SIDE B)

All ON

All OFF

Microprocessor

version

display

Vr. 1.00

188:88 pppppp

ı

1st ‚ XX

1st 1 ‚‚

1st 2 ‚‚

1st ‚ XX

N ‚ XX

N 1 ‚‚

N 2 ‚‚

N-1 ‚ XX

N-1 1 ‚‚

N-1 2 ‚‚

N-2 ‚ XX

N-2 1 ‚‚

N-2 2 ‚‚

R XXXX

(return)

888

ı

Vr. 1.‚‚

All ON

All OFF

Microprocessor

version

display

Error indication code

History code

1st0 00

– 6 –

• Description of History Codes

History code number Description

1st 0 The first error

1st 1

1st 2

00 indicated

N 0 The last error

N1

N2

00 indicated

N-1 0 One error before the last.

N-1 1

N-1 2

00 indicated

N-2 0 Two errors before the last.

N-2 1

N-2 2

00 indicated

R Total recording time *1)

*1) Total recording time

Total recording time is recorded in minutes as an index for load to

the OP . It is recorded in he xadecimal format and up to 65,535 min.

(about 886 discs of 74-minute disc) can be counted. It returns to

“0000h” when recorder goes beyond this limit.

Example :REC 000A n Approx. 10 min.

REC 00A0 n Approx. 160 min.

REC 0A00 n Approx. 2,560 min.

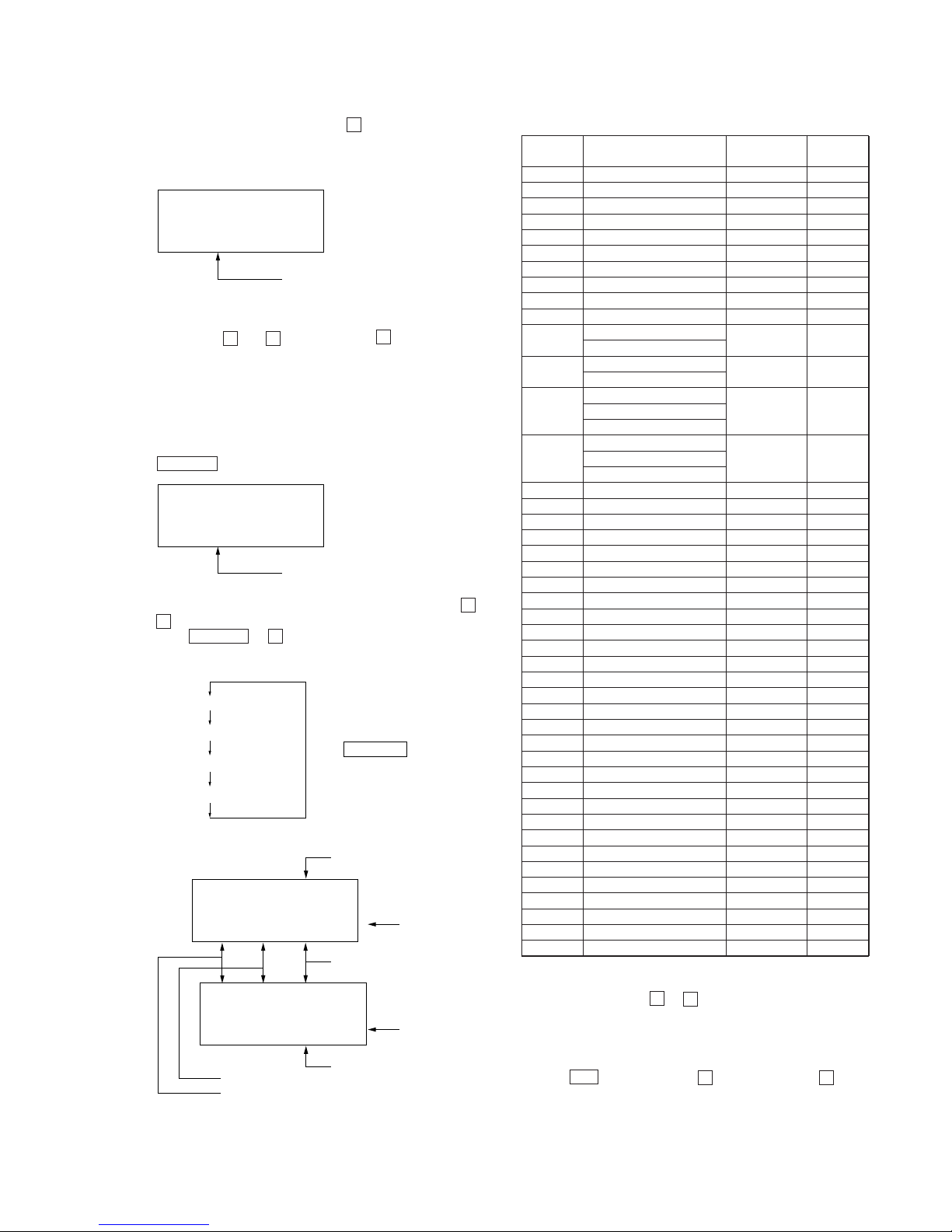

• Description of Error Indication Codes

Problem Indication code Meaning of code Description

No error 00

Abnormal stop

during recording

Abnormal disc RPM.

01 Servo error Focus out of alignment.

Attempt to access an abnormal address.

02 ADIP read error Unable to read the ADIP address.

03 Shock detected during write Jumped by 1.5 tracks or more due to shock during write.

Shock detected during

04

laser down

Shock detected when laser was moving down.

Abnormal stop

during playback

11 No focus applied Focus could not be applied.

12 CRC error Unable to read the address.

15 FG error Abnormal rotation of disc.

Abnormal stop of

recording/playback

caused by power

system

21 Lower voltage due to overload Power voltage reduced due to overload.

22 Momentary interruption Momentary interruption detected.

23

Lower power voltage in motor Power voltage for motor continuously reduced to less than

system 1V.

24 Low power voltage in DSP

2-6. CLEARING THE ERROR INDICATION CODE

AND TOT AL RECORDING TIME

After repair, reset the error indication code.

Reset the total recording time when you have replaced the OP.

1. Go into the self-diagnostic mode. (See page 5.)

2. To reset the error indication code, slide REC c key when

the code is displayed.

(All data including 1st, N , N-1 and N-2 are reset.)

3. T o reset the total recording time, slide REC c key when the

time is displayed.

– 7 –

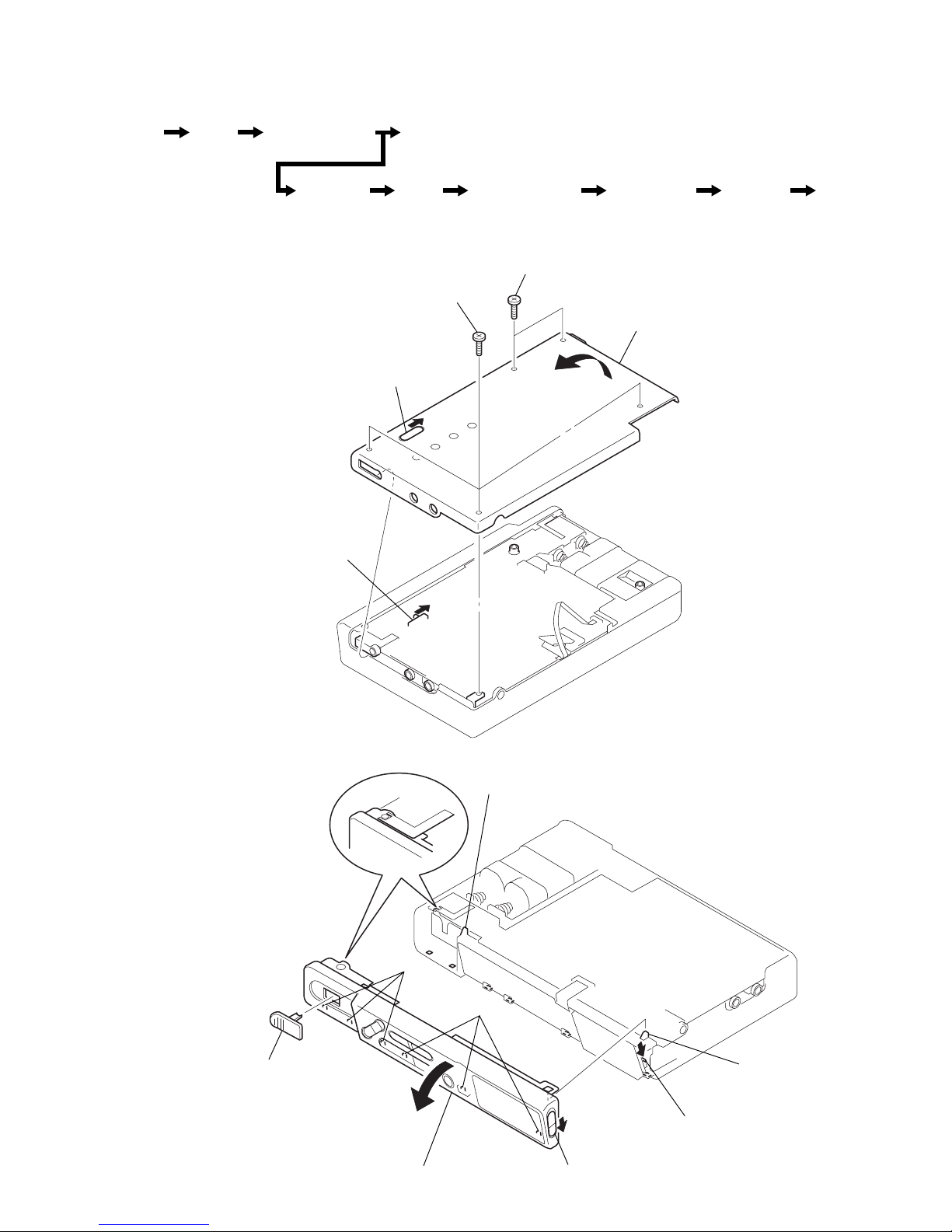

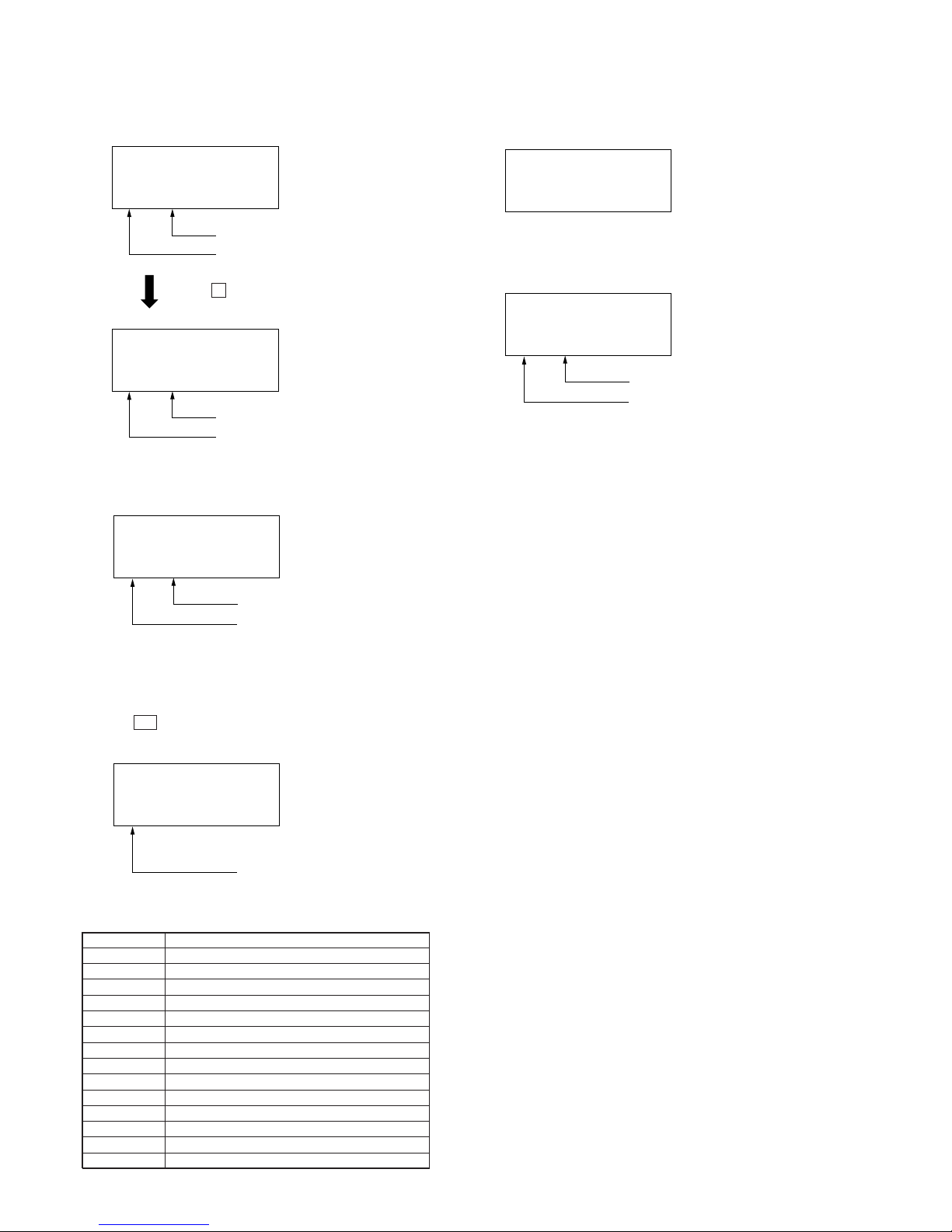

Note : This set can be disassemble according to the following sequence.

SECTION 3

DISASSEMBLY

3-1. PANEL, BOTTOM

3-2. PANEL (SV) ASSY, FRONT

Note : Follow the disassembly procedure in the numerical order given.

Set Panel,

Bottom

Panel (SV) Assy,

Front

Panel (SV) Assy,

Upper

LCD Module

Connector Main

Board

Cabinet (SV)

Ass

y

OP Block

Ass

y

Holder

Ass

y

1

1.7x4.5, tapping

2

1.7x4.5, tapping

3

panel, bottom

knob

switch

1

knob (OPEN)

2

claw

5

panel (SV) assy, front

3

claw

4

claws

claws

knob

switch

– 8 –

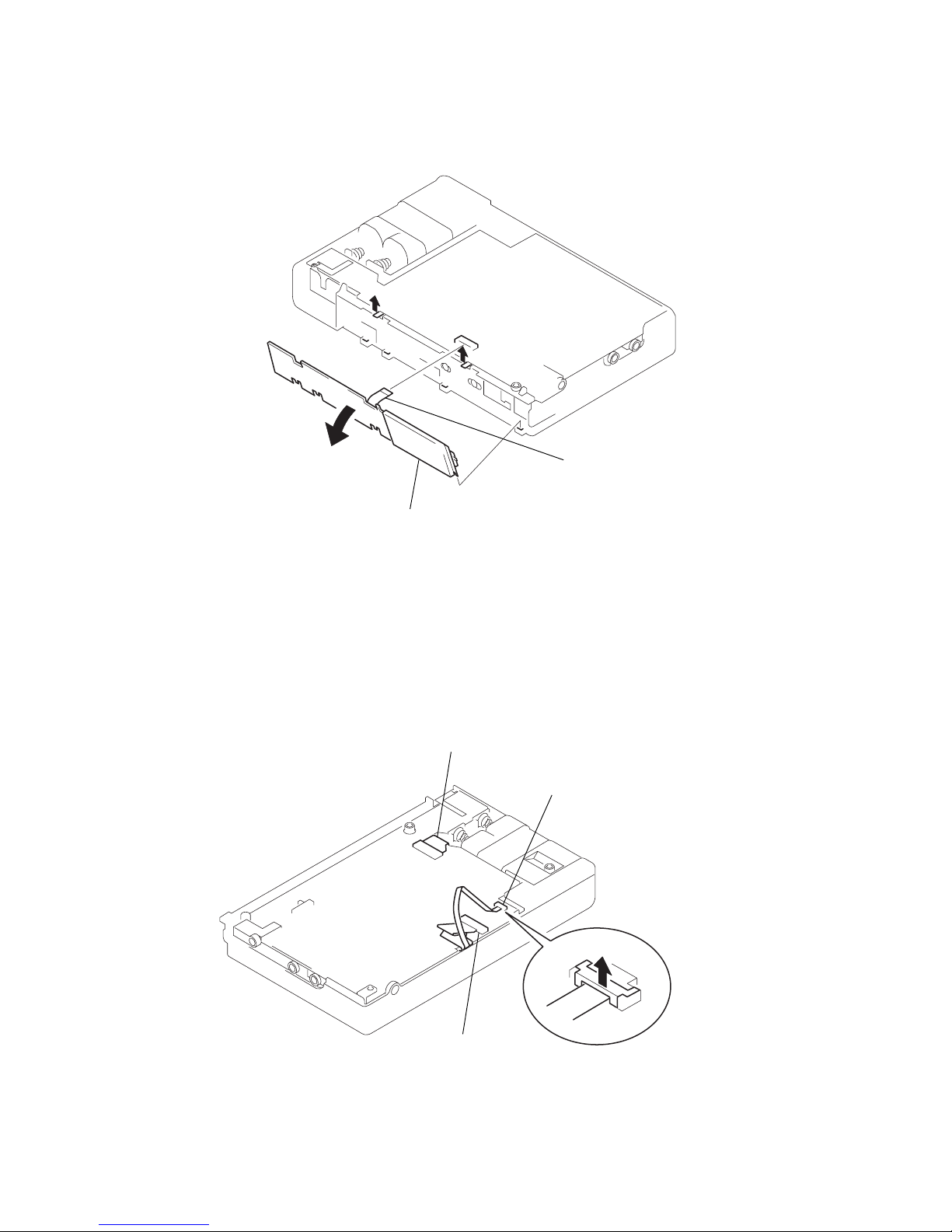

3-3. LCD MODULE

3-4. CONNECTOR

5

LCD module

1

CN801

2

4

3

1

CN601

2

CN702

3

CN701

– 9 –

3-5. MAIN BOARD

3-6. PANEL (SV) ASSY, UPPER

1

1.7x4.5, tapping

claws

2

1.7x4.5, tapping

3

4

MAIN board

4

claw

3

bearing (stopper

)

1

M1.4, precision

8

panel (SV) assy, upper

6

boss

5

claw

2

7

– 10 –

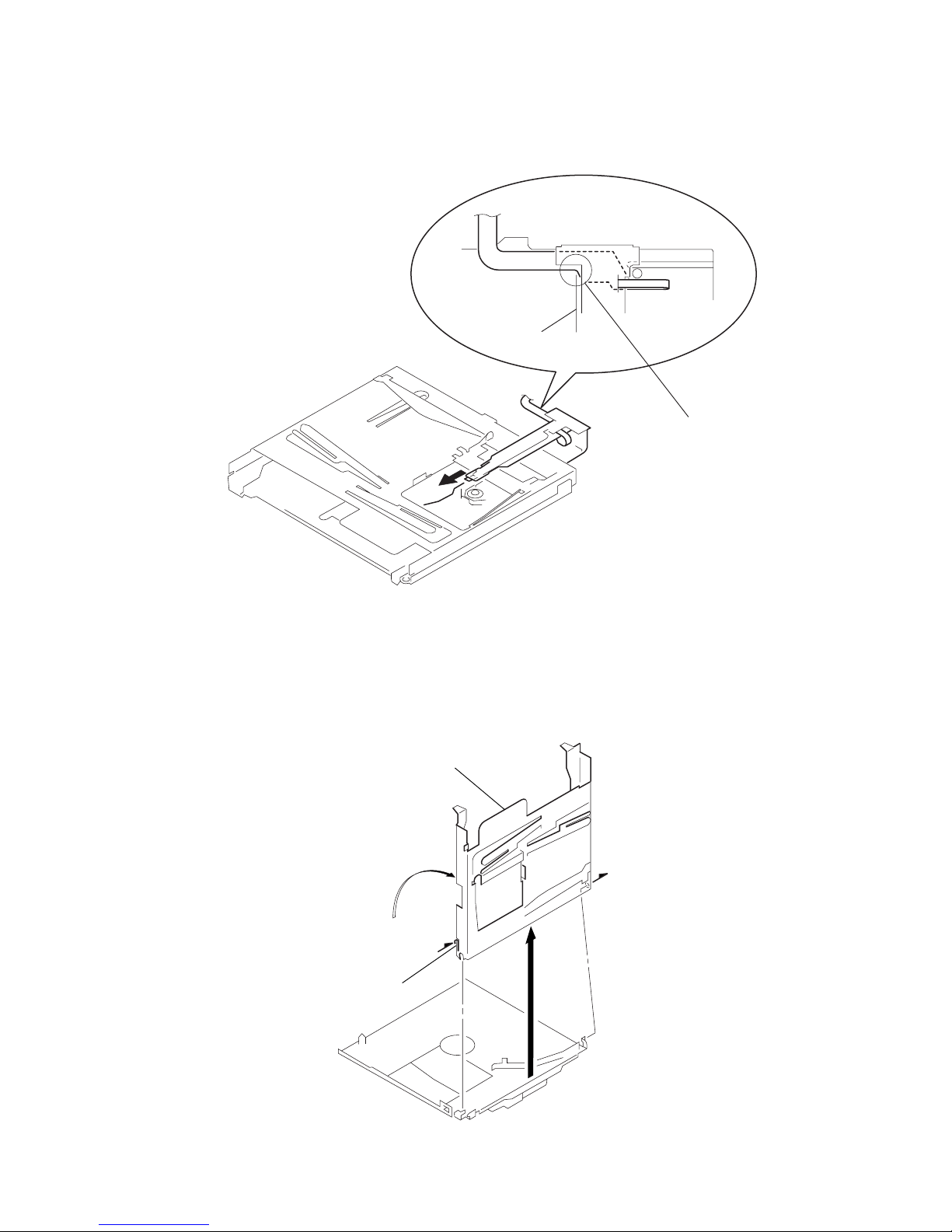

3-7. CABINET (SV) ASSY

3-8. OP BLOCK ASSY

1

MD, step

2

MD, step

4

cabinet (SV) ass

y

3

mechanism block assy

1

M1.4x3.0 locking

3

shaft, mai

n

4

flexible board

adhesive sheet

OP block assy

2

M1.4x3.0

– 11 –

3-9. HOLDER ASSY

• Location of the Flexible Board

• Be careful to avoid contact

of the lens with the chassis

when installing the OP block

assy.

Align this portion of the

flexible board with the

marked line on the holder.

marked line

1

claw

4

holder assy

2

3

• Notes for Installation of the OP Block Assy

– 12 –

SECTION 4

TEST MODE

4-1. GENERAL

This set provides the Overall adjustment mode (Assy mode) that

allows CD and MO disk to be automatically adjusted when in the

test mode. In this Assy mode, the system discriminates between

CD and MO disk and then automatically perform adjustments for

them in sequence. If a fault is found, the system displays its location. Also, the Serv o mode allows each indi vidual adjustment to be

automatically adjusted.

4-2. TEST MODE SETTING

See page 5.

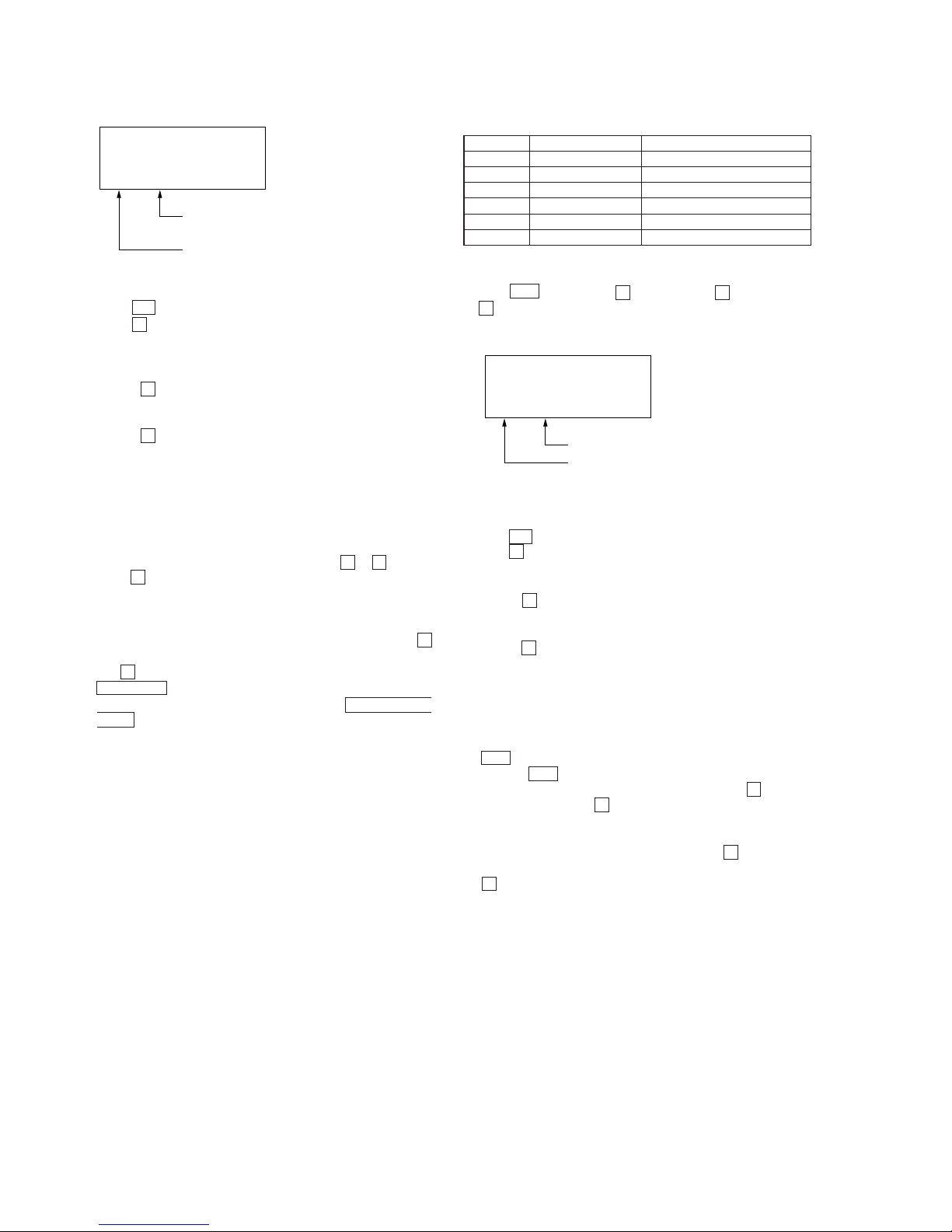

4-3. TEST MODE STRUCTURE

Test mode

4-4. MANUAL MODE

(1) Servo Mode

• How to Transfer in the Servo Mode:

Mode No. Test Description Check Write

000 Servo mode

010 Offset correction value indication

011 VC offset correction

012 Focus bias correction

013 FE offset correction

014 ABCD offset correction

015 All servo ON

016 Temperature indication

020 Laser power adjustment

021 Laser CD/MO read adjustment ® (08)

022 Laser MO write adjustment ® (4C)

023 Sled normal ® (45)

024 Sled intermittent ® (65)

025 Sled access ® (30)

030 MO test adjustment

031 MO focus search adjustment

032 MO read EF balance adjustment ® (0F)

033 MO read ABCD level ® (07)

034 MO write EF balance adjustment ® (10)

035 MO write ABCD level ® (18)

036 Laser MO read adjustment ® (08)

037 MO focus gain ® (30)

038 MO tracking gain ® (30)

039 MO focus bias ®® (0B)

040 Low reflection CD test adjustment

041

Low reflection CD focus search adjustment

042

Low reflection CD EF balance adjustment

® (10)

043 Low reflection CD ABCD level ® (06)

044 Laser low reflection CD read ® (08)

045 Low reflection CD focus gain ® (30)

046 Low reflection CD tracking gain ® (30)

Mode No. Test Description Check Write

047 Low reflection CD focus bias ®® (00)

050 CD test adjustment

051 CD focus search adjustment

052 CD EF balance adjustment ® (10)

053 CD ABCD level adjustment ® (15)

054 Laser CD read ® (08)

055 CD focus gain ® (30)

056 CD tracking gain ® (30)

057 CD focus bias ®® (00)

060 Recording test

061 32 cluster full recording

062 Recording shock

063 32 cluster full playback

Check : Mode to display error rate and cluster.

Write : Mode to permit adjustment (Default value given in paren

theses).

1. Go into the test mode.

2. Press + or VOLUME + key to set the servo mode.

Unit LCD display

3. Press the keys below to change the mode No.

( : Increases the one place.

p : Sets the one place to 0.

This key brings the ten place to 0 if the one place is

0.

VOLUME + :Increases the ten place by 10 if the one place is 0.

Increases the adjustment value if the one place

is non-zero.

VOLUME – : Decreases the ten place by 10 if the one place is 0.

Decreases the adjustment value if the one place is

non-zero.

Note) Press the REC c key is the mode “33” to shift to the

mode “34”.

Press the ( key is the mode “34” to shift to the mode

“35”.

• How to Adjust in Servo Mode:

1. When the servo mode is set to the appropriate mode for each

adjustment, the lower two digits of the mode No. and the value

stored in EEPROM are displayed and flashing.

Manual Mode

Servo Mode

Audio Mode

Mechanism Mode

Power Mode

or VOLUME key

VOLUME key

Overall Adjustment Mode

or VOLUME key

Hybrid Mode (ALL Mode)

+

–

+

=

+

EDIT/ENTER key

MODE key

Key Check Mode

(Assy Mode)

Adjustment value

(The data can be changed/written when flashing.

)

Mode No.

(The lower two digits are indicated.

Three digits are indicated on the

remote controller LCD.)

XX XX SERVO

Adjustment value (flashing

)

Mode No. (lower two digits

)

XX XX SERVO

– 13 –

(2) Audio Mode

• How to Transfer in the Audio Mode

Mode No. Test Description Write

Change

Description

100 Audio mode

110 Audio playback

111 L/R=1 kHz 0 dB Playback VOL HP output

112 L=1 kHz 0 dB Playback VOL HP output

113 R=1 kHz 0 dB Playback VOL HP output

114 L/R – ∞ dB Playback VOL HP output

115

L/R=1 kHz 0 dB & EVR max

Playback VOL HP output

116

L/R=1 kHz 0 dB & AVLS on

Playback VOL HP output

117 INFI ZERO & BEEP Playback VOL HP output

120 Audio recording test

121 LINE manual recording

Recording VOL HP output

*1) MIC manual recording

122

DEMP LINE manual recording

Recording VOL HP output

*1) DEMP MIC manual recording

123 LINE automatic recording

*1) OPT automatic recording HP VOL HP output

MIC automatic recording

124

DEMP LINE automatic recording

*1)

DEMP OPT automatic recording

HP VOL HP output

DEMP MIC automatic recording

130 DIGITAL A GC ADJ1

131 MIC UP SR ® (30)

132 MIC DOWN SR ® (FA)

133 MIC THD0 ® (D0)

134 MIC GAIN ® (00)

135 MIC A TT A CK ® (A0)

136 MIC RECOVER ® (F8)

137 MIC THD2 ® (F0)

138 MIC GAIN2 ® (D0)

139 MIC RTIME ® (01)

140 DIGITAL A GC ADJ2

141 LINE UP SR ® (17)

142 LINE DOWN SR ® (FF)

143 LINE THD0 ® (D0)

144 LINE GAIN ® (0C)

145 LINE A TT A CK ® (33)

146 LINE RECOVER ® (FB)

147 LINE THD2 ® (E4)

148 LINE GAIN2 ® (5F)

149 LINE RTIME ® (04)

150 DIGITAL A GC ADJ3

151 MAN UP SR ® (C0)

152 MAN DOWN SR ® (40)

153 AUTO THD3 ® (51)

154 AUTO LMT UP SR ® (FF)

155 AUTO LMT DOWN SR ® (E0)

156 MAN THD3 ® (51)

157 MANU LMT UP SR ® (FF)

158 MANU LMT DOWN SR ® (A0)

159 THD1 ® (1A)

*1) The port is detected and the input is automatically selected.

Contents changed : Contents to be changed when VOLUME

+ or – key is pressed.

Write : Mode to permit adjustment

(Default value given in parentheses)

1. Go into the test mode.

2. Press + key or VOLUME + key and VOLUME + key in

this turn to set the audio mode.

2. To perform automatic adjustment for an adjustment item with

the mode number 030 to 047, press P key.

If the result of adjustment is OK, the adjustment value changes

from flashing to steady on and it is automatically written to

EEPROM.

3. To perform manual adjustment, change the adjustment v alue with

VOLUME + or – key, and press P key to write it to

EEPROM.

Note) Normally, automatic adjustment should be performed. Do

not execute manual adjustment.

• System Gain Mode

1. This mode allows the system gain to be freely adjusted. Press

DISPLAY key to enter this mode.

2. Increase or decrease the adjustment value with V OLUME + or

– key.

3. Press DISPLAY or p key to return to the normal mode.

4. For the error rate display enabled:

Note) In normal service, do not adjust the system gain mode.

Adjustment value

(flashing to steady on

)

32 OF SERVO

Adjustment value (flashing

)

32 OF S-GAIN

Adjustment value (flashing)

Mode No. (lower two digits)

39 OA 000a4F

39 OA 000b4F

Cluster value

Indicate of block error rate

ATT error value

Block error value

Indicate of AT error rate

Normal Mode

System gain Mode

AT error rate

Press DISPLAY key

Block error rate

– 14 –

3. Press the keys below to change the mode number.

( : Increases the one place.

p : Sets the one place to 0.

This key brings the ten place to 0 if the one place

is 0.

VOLUME + : Increases the ten place by 10 if the one place is 0.

Increases the adjustment value if the one place is

non-zero.

VOLUME – : Decreases the ten place by 10 if the one place is 0.

Decreases the adjustment value if the one place is

non-zero.

• How to Adjust in the Audio Mode

1. When the audio mode is set to the appropriate mode for each

adjustment, the lower tow digits of the mode No. and the value

stored in EEPROM are displayed and flashing.

2. Change the adjustment value with VOLUME + or – key and

press P key to write the new value to EEPROM.

• How to Check in the Audio Mode

The audio mode allows the checks below to be performed:

1. For the mode numbers of 111 to 113, 115 and 116, pressing P

key will activ ate a beep. But for the mode number of 117, pressing P key will not activate a beep. (No beep sounds when

c HOLD switch is put on.)

2. For the mode numbers of 121 to 124, pressing Digital MEGA

BASS key will display the DBB mode for the adjustment v alue.

1 : Mode 1

2 : Mode 2

13 : OFF

(This will not be accepted when the LINE OUT jack is plugged.

The display will be 13 : OFF when LINE OUT jack is plugged

in Modes 1 and 2.)

Unit LCD display (3) Mechanism Mode

• How to Transfer the Mode in the Mechanism Mode:

Mode No. Test Description Operation

200 FUNCTION Stepper control

210 MECHA test Initial position return

211 HEAD adjustment Operation variation changing (19)

212 REC position Recording head descent

220 RESUME Resume

221 RESUME CLEAR Resume clear/initialization

( ) : Default value

1. Go into the test mode.

2. Press + or V OLUME + and VOLUME + and VOLUME

+ in this turn to set the mechanism mode.

Unit LCD display

3. Press the keys below to change the mode No.

( : Increases the one place.

p : Sets the one place to 0.

This key brings the ten place to 0 if the one place is

0.

VOLUME + : Increases the ten place by 10 if the one place is 0.

Increases the adjustment value if the one place

is non-zero.

VOLUME – : Decreases the ten place by 10 if the one place is 0.

Decreases the adjustment value if the one place is

non-zero.

• How to Check in the Mechanism Mode

The mechanism mode allows the checks below to be performed:

1. For the mode numbers of 200, 210 to 212, 220 and 221, pressing

= key will move the optical pickup to the inner radius.

Pressing + key will move the pickup to the outer radius.

2. For the mode numbers of 211 and 212, pressing P key will

start aging. Pressing p key will stop aging.

• Mode No. 211 ... Sled aging with stepper at playback position.

• Mode No. 212 ... Sled aging with stepper at recording position.

3. With the mode number 210 selected, pressing P k ey will start

aging with steeper at between home and recording positions.

p key will stop aging.

Adjustment value

(The data can be changed/written when flashing.

)

Mode No.

(Lower two digits are displayed.)

XX XX AUDIO

Adjustment value

Mode No.

(Lower two digits are displayed.

)

XX XX MECHA

– 15 –

1. Go into the test mode.

2. Press + key or VOLUME + and VOLUME + and VOLUME + and VOLUME + in this turn to set the power mode.

3. Press the keys below to change the mode No.

( :Increases the one place.

p : Sets the one place to 0.

This key brings the ten place to 0 if the one place is

0.

VOLUME + : Increases the ten place by 10 if the one place is 0.

Increases the adjustment value if the one place

is non-zero.

VOLUME – : Decreases the ten place by 10 if the one place is 0.

Decreases the adjustment value if the one place is

non-zero.

Note) With the mode number 310 selected, pressing ( key will

transfer to the mode number (311) for the currently operating power.

With the mode number 300 selected, pressing P key will

set the sleep mode. Pressing p key will release it.

• How to Check in the Power Mode

1. For the mode numbers of 311, the voltage of the currently

operating power is displayed.

4-5. O VERALL ADJUSTMENT MODE (ASSY MODE)

• How to Adjust in Assy Mode

1. Go into the test mode.

2. Press = or VOLUME – key.

3. Insert the test CD (TDYS-1) or an available SONY CD.

4. Press ( key . The system discr iminates between CD and MO

and performs automatic adjustment for CD.

• CD Automatic Adjustment

Mode No. Adjustment Description

052 CD EF balance adjustment

053 CD ABCD level adjustment

055 CD focus gain

056 CD tracking gain

057 CD focus bias

5. If the result of automatic adjustment is OK, the following display appears:

6. If the result of automatic adjustment is NG, the following display appears:

Adjustment value

Mode No.

(Lower two digits are displayed.

)

XX XX POWER

XX ASSY-M

Mode No. under adjustment.

51 CD-RUN

CD-OK

MD-OK

(CD)

(MD)

XX XX MD-OK

Result of adjustment

NG mode No. (lower two digits

)

XX XX CD-NG

(4) Power Mode

Mode No. Test Description Indication value Remark

300 POWER test

310 POWER SUPPLY

311 DC IN +B voltage value

320 CHG TEST

321 Charging start

322 BATT under CHGMNT

voltage value

323 BATT under +B CHGMNT

voltage value

– 16 –

* For the mode numbers of 039 and 057, if the focus bias value is

NG, the following display is repeated:

While P key is being depressed

* For the mode numbers of 039 and 061, if the At error rate is NG,

the following display is repeated:

7. If NG, set the servo mode. Perform automatic adjustment for

the items not accepted (see the servo mode).

8. Insert a MO disk.

9. Press ( key . The system discriminates between CD and MO

and performs automatic adjustment for the MO disk.

• MO Automatic Adjustment

Mode No. Adjustment Description

032 MO read EF balance adjustment

033 MO read ABCD level

034 MO write EF balance adjustment

035 MO write ABCD level

037 MO focus gain

038 MO tracking gain

061 32 cluster full recording

062 Recording shock

063 32 cluster full playback

039 MO focus bias

042 Low refrection CD EF balance adjustment

043 Low refrection CD ABCD level

044 Laser low reflection CD read

046 Low refrection CD tracking gain

10. If the result of automatic adjustment is OK, the following display appears:

11. If the result of automatic adjustment is NG, the following display appears:

12. If NG, set the servo mode. Perform automatic adjustment for

the items not accepted (see the servo mode).

4-6. HYBRID MODE, KEY CHECK MODE

These modes are not used in normal service.

Focus bias value

Mode No.

Error code (01 to 04)

Meaning of focus bias

55 30

77 01

At error value

Mode No. (lower two digits

)

39 03

Mode No. (lower two digits)

61

00

Result of adjustment

NG Mode No. (lower two digits

)

82 00

– 17 –

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTIONS FOR ADJUSTMENT

1) Perform all adjustments in the order given in the test mode.

After adjusting, exit the test mode.

2) Use the following tools and measuring instruments.

• Test CD TDYS-1

(Part No. : 4-963-646-01)

• Recorded MO disk PTDM-1

(Part No. : J-2501-054-A)

• Laser power meter LPM-8001

(Part No. : J-2501-046-A)

• Oscilloscope (Frequency band above 40 MHz. Perform the

calibration of probe first before measuring.)

• Digital voltmeter

3) Unless specified othewise, supply DC 4.5V from the DC IN 4.5V

jack.

4) Swtich, knob positions

HOLD switch .............. OFF

AVLS switch ................ NORM

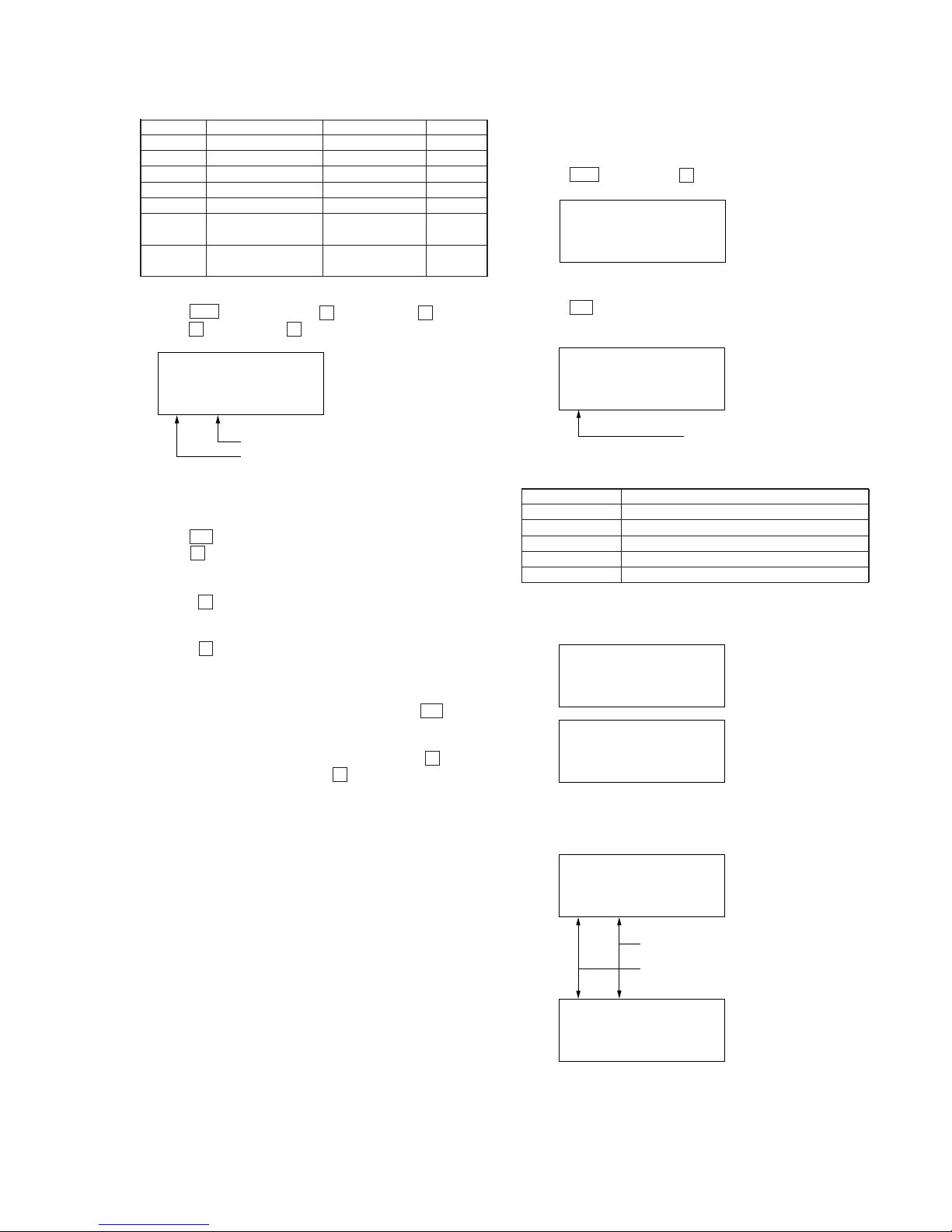

LASER POWER CHECK

Connection :

Adjustment Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ( key, and set the laser power adjustment mode

(Mode : 020) using the VOLUME + or – key.

3. Press the = key and move the optical pick-up to the inner

most circumference.

4. Open the cover and set the laser power meter on the objective

lens of the optical pick-up.

5. Press the ( key, and set the laser CD/MO read adjustment

mode (Mode : 021).

6. Check that the laser power meter reading is 0.85 ± 0.085 mW.

7. Check that the voltage between AP5117 (VCC) and AP574

(LDI0) at this time is below 40 mV.

8. Press the ( key, and set the laser MO write adjustment

mode (Mode : 022).

9. Check that the laser power meter reading is 6.8 ± 0.68 mW.

10. Press the P key to finalize the adjustment data.

11. Check that the voltage between AP5117 (VCC) and AP574

(LDI0) at this time is below 80 mV.

12. Press the p key.

13. Exit the test mode.

Adjustment Location : See page 19.

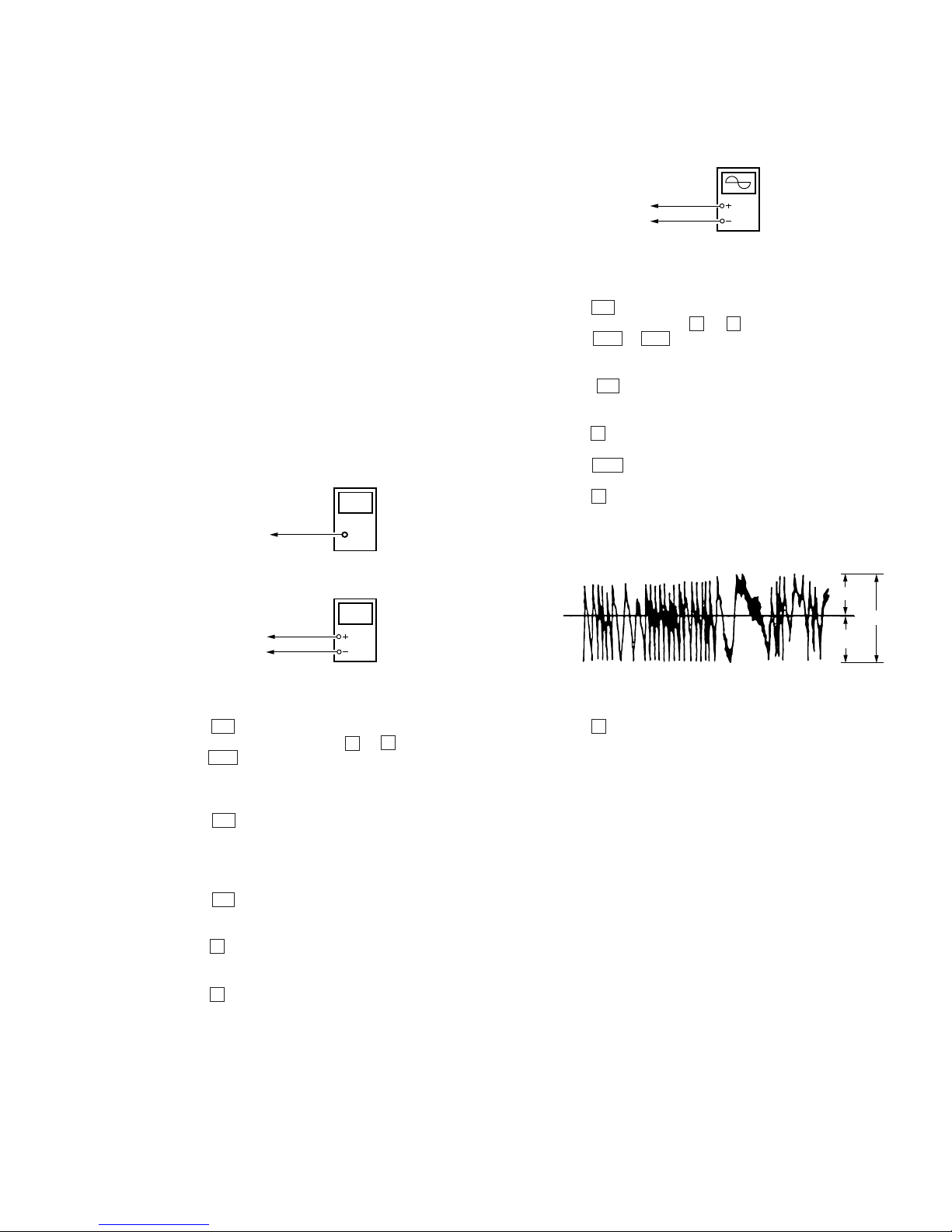

MO TRA VERSE ADJUSTMENT

Connection :

Adjustment Method :

1. Set the servo mode of the test mode (Mode : 000).

2. Press the ( key , and set the MO test adjustment mode (Mode

: 030) using the VOLUME + or – key.

3. Press the = or + key and move the optical pick-up to

the center circumference.

4. Insert any MO disk available on the market.

5. When the ( key is pressed, the MO read EF balance adjustment mode (Mode : 032) will be set after MO focus search

adjustment mode (Mode : 031).

6. Press the P key to perform automatic adjustment, and check

that the traverse waveform is symmetrical at the top and bottom.

7. Slide the REC key and set the MO write EF balance adjust

ment mode (Mode : 034).

8. Press the P key to perform automatic adjustment, and check

that the traverse wav eform is symmetrical at the top and bottom.

9. Check that the traverse level at this time is above 1.0 Vp-p.

10. Press the p key.

11. Exit the test mode.

Note) Using a recorded disk in this adjustment will erase the data.

Adjustment Location : See page 19.

digital voltmete

r

MAIN board

AP5117 (VCC)

AP574 (LDI0)

laser

power meter

Optical pick-up

objective lens

oscilloscop

e

MAIN board

SP526 (TE)

AP503 (VC)

A

B

C

Specification : A = B, C 1.0 Vp-p

0 V

(Traverse waveform)

>

=

Loading...

Loading...