立体声耳机

Stereo Headphones

产品信息

Product Information

產品資訊

MDR-EX1000

©2010

索尼公司

Sony Corporation Printed in Japan

日本印刷

4-257-842-14(1)

简介

多年以来,Sony与专业制作录音室的专业人员携手共进,通过他们的反

馈,制作出各种达到其高期望值的卓越耳机。在他们的期望中,最为重要

的元素之一为高精度声音。为了让使用者在室外环境中也能欣赏高精度声

音,我们出品的各种耳机经历了在功能和性能方面追求完美的进化历程。

为了兼顾高精度声音以及适合在室外使用和携带,这些耳机中使用了

Sony长久以来积累的各种技术以及Sony自己研发的尖端技术。本手册将对

这些技术组件进行说明。

2 (CS)

1.为了获取高音质

丰富的低音和广阔的高音:

16 mm的大口径动态型驱动单元

在封闭型入耳式耳机中,采用了业内最大的直径为16 mm的大口径动态驱

动单元。这样,只需一个动态驱动单元即可实现宽广的动态范围以及播放

音域跨度宽广的声音,在保持清晰高精度声音的同时,在低音到高音的范

围内做到令人难以置信的平衡。

驱动单元尺寸比较

9 mm驱动单元

13.5 mm驱动单元

16 mm驱动单元

3 (CS)

抑制不需要的振动和提供高分辨率的声音播放:

液晶高分子膜片

作为驱动单元的膜片材料,需要具备质轻、高刚性和高内损这些似乎相互

矛盾的特点。刚性对于在宽带宽上将输入信号精确转换成声音非常关键,

但同时也需要具备高内损的特点以便抑制膜片本身产生不必要的振动。

一段时间以来,液晶高分子被认为是一种可以使这两个特点良好结合并实

现平衡的材料。但是,由于薄膜拉伸度低和难以成形而造成无法满足耳机

应用所需的薄度、以及由于无法合成和缺乏获得足够耐热性的制作工艺,

所以无法用其制作耳机膜片。

为了解决这个问题,成功研制出的高拉伸度液晶

高分子可以用于采用高分子漆面的铸型薄膜,从

而在宽带宽上兼顾了刚性和高内损度,同时也提

供了足以承受创建薄型膜片的强度。简而言之,

用于制作可还原高精度声音的理想膜片材料诞生

了。

液晶高分子膜液晶高分子膜

4 (CS)

提高磁通量密度和实现高灵敏度播放:

440 kJ/m3高磁力钕磁

为了提高声音分辨率,采用了440 kJ/m3高磁力钕磁,这是最节能的通用

工业产品。可以再现清晰的中音、高音和强劲低音。

这种称为“横磁场压制方法”的制作工艺,进一步增强了钕磁的磁力。通

过这种制作工艺,可将磁粉粒子的方向从磁化粒子的磁场的N极到S极平行

排列,从而进一步增强磁力。

纵磁场 横磁场

5 (CS)

兼顾高音质和小型化:

与驱动单元一体化的外壳

为了使外壳小而薄,采用了驱动单元和外壳一体化的结构。除了可以消除

组件之间的狭小缝隙造成的漏气现象以外,还可以抑制不必要的振动和实

现低音频率的平滑响应。

6 (CS)

耳机组件分解图

调节器

主要平衡中音和低音。

驱动寄存器

主要平衡中

音和低音。

440 kJ/m3

钕磁

液晶高分子膜片

前外壳

耳塞

后外壳

后寄存器

主要平衡中音和

低音。

镁合金外壳

框架

磁极片

前寄存器

主要平衡低音。

均衡器

主要平衡中音和

高音。

7 (CS)

手动调节各组件的音质:

Sony原创的声学调谐器

除了在制作过程中对各组件进行的精密测量以外,也可将声阻材料手动调

节为常数。为了达到理想的音质,只有通过严格的声音控制标准的产品才

能出厂。通过精密控制的声学调谐组件和Sony原创的声学调谐器,可进行

反复的精细调谐,从而确保实现前所未有的高精度音质控制。

抑制音乐信号的传送损失:

高级7N-OFC绞合导线

用于传送信号的导线采用超高纯度(99.99999 %)的

7N OFC(无氧铜)。抑制导线中的信号损失,并最

大限度减轻声音衰减。

8 (CS)

隔音的基本原理:

噪音隔离耳塞

耳塞内部的氨基甲酸酯释压泡沫可根据内耳的凹凸不平,使耳道受力均

匀。因此,可增强隔音效果,同时耳塞的贴合舒适度也超过以往。

噪音隔离耳塞的横切面

低密度硅

高密度硅

氨基甲酸酯释压泡沫

9 (CS)

2.为了佩戴舒适

大口径驱动单元实现良好的贴合度:

封闭型垂直入耳式

采用了直径16 mm的大口径驱动单元,将驱动单元以封闭型垂直入耳式与

外耳道呈直角放入。另外,为了确保对耳机贴合度造成影响的外壳厚度达

到最小,采用了高强度的镁合金作为外壳。这样可比使用普通树脂材料制

作的外壳厚度减少30%以上。

10 (CS)

镁的物理特性

比重

强度系数

上漆前的镁合金外壳

镁 铝 铁 ABS

1.82

154

2.7 7.86 1.03

1.7 66 34

11 (CS)

根据每个人的耳形实现高度稳定贴合:

采用TEKNOROTE™的灵活耳挂

对于耳挂组件TEKNOROTE™,采用了可以自由折叠并维持形状

的塑料材质。此材料可根据每个人的耳朵改变耳挂形状,

因此可以实现出色的贴合稳定性。另外,因为TEKNOROTE™更

轻且更难以折断,因此其可实现舒适且安全的贴合度。

* TEKNOROTE是Mitsui Chemicals, Inc.的商标。

12 (CS)

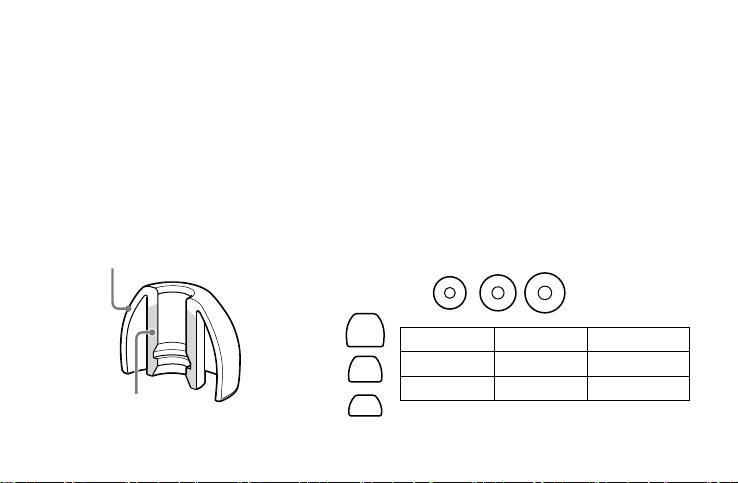

可根据耳朵大小选择:

7混合硅胶耳塞

新研制的混合硅胶耳塞结合了两种硬度的硅。这种新型设计可通过使内核

坚韧而保持发出声音的耳塞顶端的形状,并防止由于耳塞顶端受到挤压而

导致音质下降。外部组件柔软,可改善与外耳道的贴合度。总之,耳塞的

封闭性得到增强,即使长时间使用也可保持更舒适的贴合度。附送了7种

耳塞以满足不同的耳形状。

混合硅胶耳塞的横切面

低硬度硅

高硬度硅

高

高度

低

耳塞尺寸

小 直径 大

–

S(橙色) M(绿色) L(浅蓝色)

SS(红色) MS(黄色)

ML(蓝色) LL(紫色)

–

13 (CS)

3.其他特点

可拆卸式导线

附送的导线为可拆卸式,分别为

0.6 m和1.2 m。用户可根据需要选择导

线长度。

14 (CS)

享受高品质感受和便携性:

真皮携带盒

方便的携带盒采用真皮制成。您一定会期待这款随岁月流失

而日益萌生的奇妙温馨的真皮触感。

15 (CS)

Introduction

Over many years, Sony has joined together with people who work in professional production studios,

and using their feedback has crafted superior headphones that meet their high expectations. One of the

most important elements among those expectations is accurate sound. In order to allow the wearer to

enjoy that sound in an outdoor environment, these headphones have passed through a development

stage that pursued perfection in functionality and performance. To provide accurate sound and a fit

designed for outdoor usage and portability without compromise, they are packed with technology that

Sony has accumulated to date as well as Sony’s own cutting edge technology. This pamphlet explains

these technological components.

2 (GB)

1. For high sound quality

Rich bass and expansive treble:

Large caliber 16 mm diameter dynamic-type driver unit

In the closed-body-type in-ear headphones, a large caliber dynamic driver unit that is the largest in the

industry at 16 mm diameter was used. It enables a wide dynamic range available only with a dynamic

driver unit and playback of a broad range of sound, providing a clear and accurate sound with

incredible balance from the bass to treble range.

Driver unit size comparison

9 mm driver unit 13.5 mm driver unit 16 mm driver unit

3 (GB)

Suppressing unwanted vibrations and providing high resolution sound playback:

Liquid Crystal Polymer film diaphragm

For the driver unit diaphragm material, lightness and consideration to the seemingly contradictory

features of highly rigidity vs. high internal loss is essential. Though rigidity is key in accurately

converting input signals over a wide bandwidth into sound, a high level of internal loss is also required

to suppress unnecessary vibration of the diaphragm itself.

Liquid Crystal Polymer has already been identified for some time as a material that can provide a

balanced combination of these two characteristics in high order. However, previously it could not be

used to create diaphragms for headphones due to the inability of compositions and manufacturing

methods to obtain sufficient heat resistance and the inability to achieve the thinness required for usage

in headphones, caused by a low degree of film elongation and the difficulty of formation.

To solve this problem, a highly stretchable Liquid Crystal Polymer

was successfully developed for use as a casting film using polymer

varnish. This made it possible to enable both rigidity and a high level

of internal loss over a wide bandwidth, while also providing the level

of strength required to stand up to the process of creating a thin film.

In short, a material for creating the perfect diaphragm for

reproducing accurate sound was born.

Liquid Crystal Polymer filmLiquid Crystal Polymer film

4 (GB)

Loading...

Loading...