Page 1

M-530V/535V/630V/635VK

SERVICE MANUAL

Ver 1.0 1999. 02

Photo : M-530V

SPECIFICATIONS

US Model

Canadian Model

M-530V/535V/630V/635VK

AEP Model

E Model

M-530V/535V/630V

Chinese Model

M-630V

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MZ-530V-99

Tape

y (normal position type)

Recording system

2-track 1-channel monaural

Speaker

Approx. 3.6 cm (1 7/16 in.) dia.

Tape speed

2.4 cm/s (15/16 ips), 1.2 cm/s (15/32 ips)

Frequency range

250 - 4,000 Hz (with TAPE SPEED switch at 2.4 cm/s)

Input (M-635VK/630V only)

Microphone input jack (minijack/PLUG IN POWER)

sensitivity 0.24 mV for 3 kilohms or lower impedance microphone

Output

Earphone jack (minijack) for 8 - 300 ohms earphone

Power output (at 10% harmonic distortion)

250 mW

Power requirements

3 V DC batteries size AA (R6) × 2/External DC 3 V power sources

Dimensions (w/h/d)

Approx. 62.2 × 121.5 × 24.3 mm (2 1/2 × 4 7/8 × 31/32 in.) incl. projecting

parts and controls

Mass

Approx. 125 g (4.5 oz.)

Supplied accessories

AC power adaptor AC-E351 (1) (M-635VK only)

Battery charge adaptor BCA-35E (1) (M-635VK only)

Rechargeable batteries NC-AA, 1.2 V, 600 mAh, Ni-Cd (2) (M-635VK

only)

Microcassette tape MC-30 (1) (M-630V/535V/530V for Europe only)

Batteries R6P (SR) (2) (M-630V for Europe only)

Carrying case (1) (M-630V for Europe only)

Design and specifications are subject to change without notice.

MICROFILM

– 1 –

MICROCASSETTE

-CORDER

TM

Page 2

TABLE OF CONTENTS

1. GENERAL ....................................................................3

2. DISASSEMBLY

2-1. Lid Assy, Cassette ...............................................................4

2-2. Lid, Battery Case ................................................................ 5

2-3. Cabinet (Rear) Assy ............................................................ 5

2-4. Main Board ......................................................................... 6

2-5. Mechanism Deck................................................................. 6

2-6. LED Unit............................................................................. 7

2-7. Head, Ceramic..................................................................... 7

3. MECHANICAL ADJUSTMENTS..............................8

4. ELECTRICAL ADJUSTMENTS ...............................8

5. DIAGRAMS

5-1. Block Diagram .................................................................. 11

5-2. Printed Wiring Board ........................................................ 13

5-3. Schematic Diagram ........................................................... 15

6. EXPLODED VIEWS

6-1. Cabinet Section ................................................................. 17

6-2. Mechanism Deck Section.................................................. 19

7. ELECTRICAL PARTS LIST.....................................20

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PAR TS WHOSE

P ART NUMBERS APPEAR AS SHOWN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

Page 3

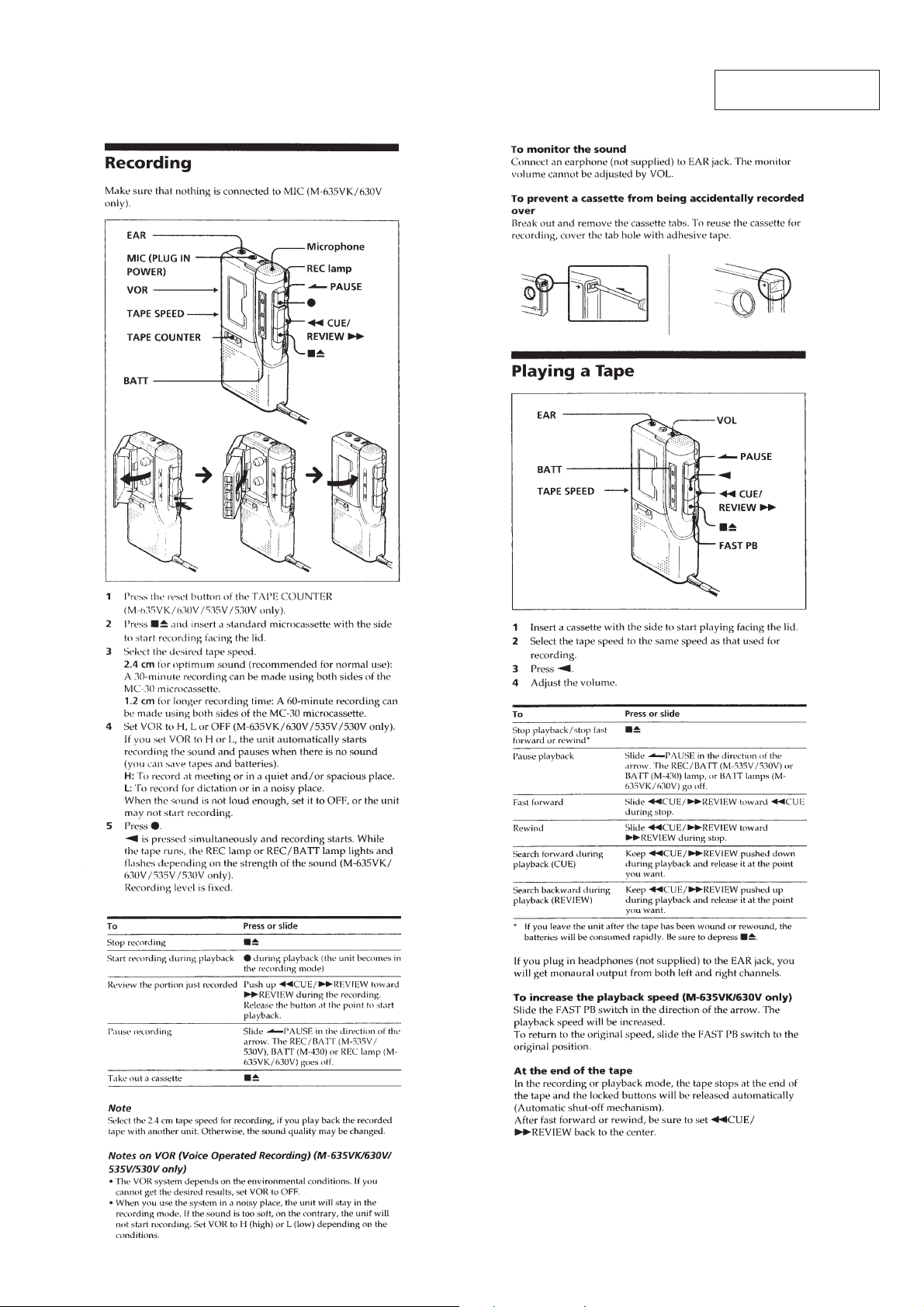

SECTION 1

GENERAL

This section is extracted

from instruction manual.

– 3 –

Page 4

SECTION 2

DISASSEMBLY

• The equipment can be removed using the following procedure.

Set Lid assy,

cassette

Cabinet (rear)

assy

Main

board

Mechanism

deck

Head,

ceramic

Lid,

battery case

Note : Follow the disassembly procedure in the n umerical order given.

2-1. LID ASSY, CASSETTE

top view

4

lid assy,

cassette

3

cabinet (front)

precision screwdriver

or equivalent

2

Stop the lid assy, cassette

halfway.

1

LED

unit

precision screwdriver

or equivalent

7

6

8

Note :When removing the cassette lid, put cloth on the end of a

screwdriver or use a polyacetal driver to avoid damage to

the cabinet.

9

lid assy, cassette

5

– 4 –

Page 5

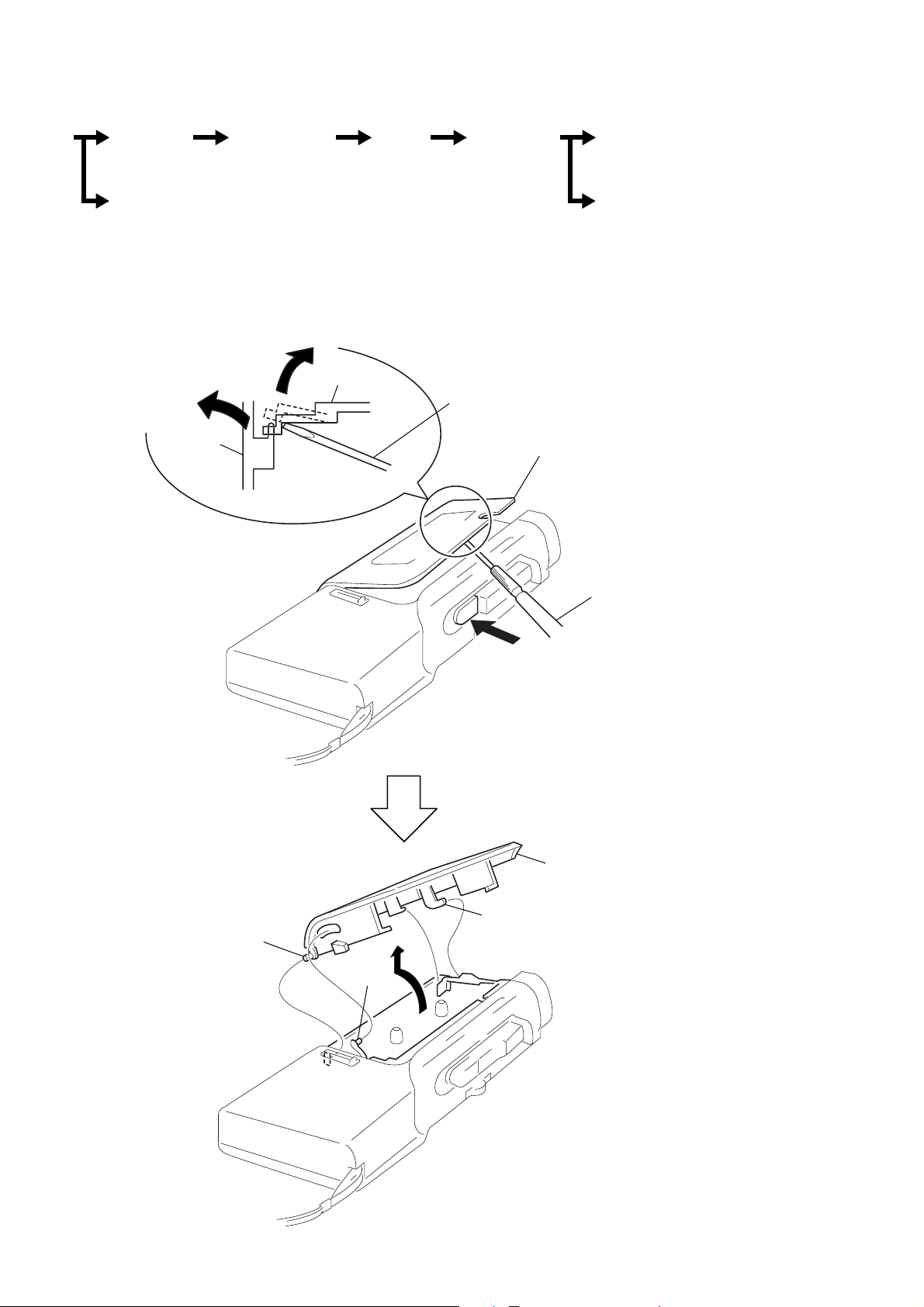

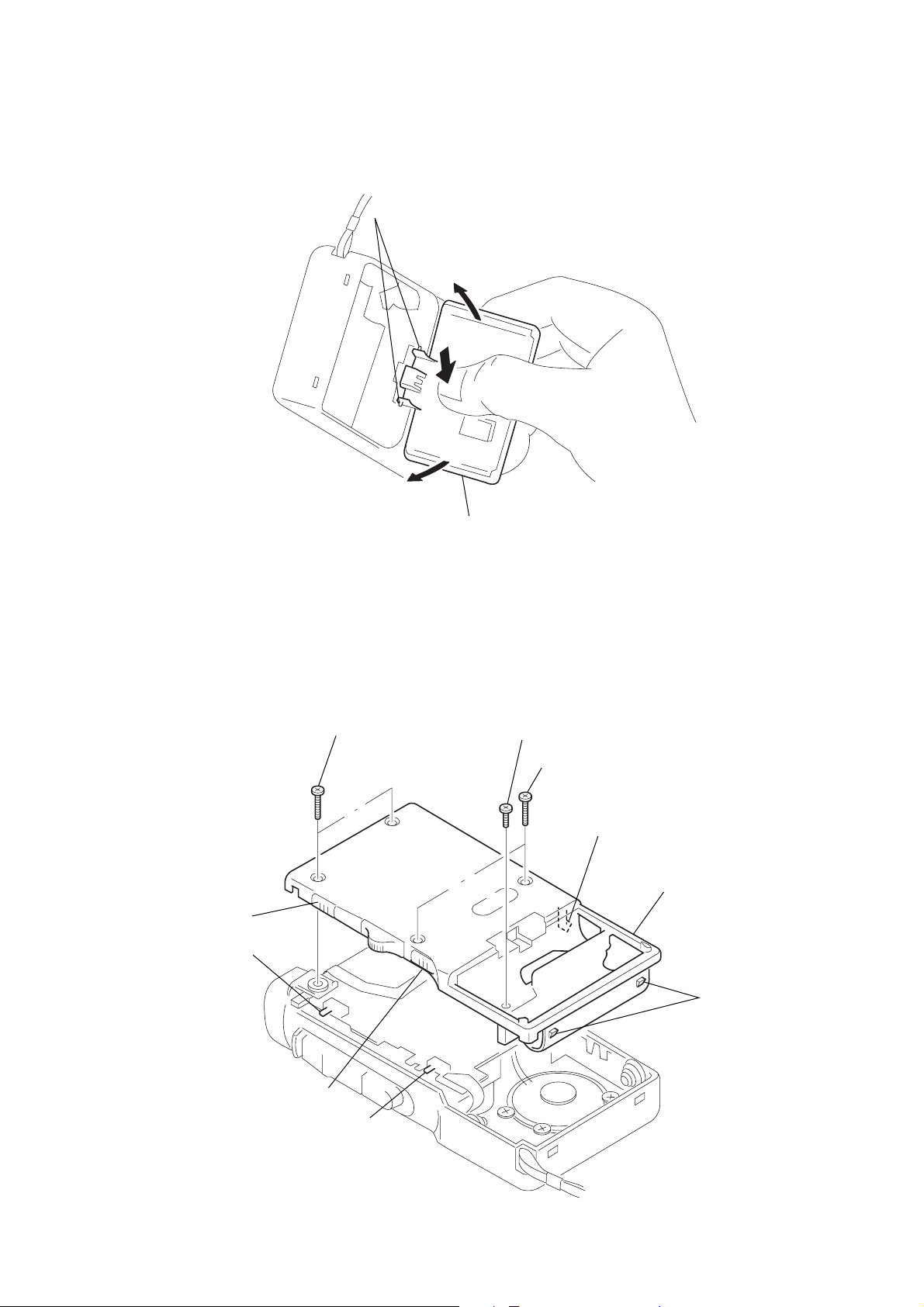

2-2. LID, BATTERY CASE

3

claws

2

2

1

5

lid, battery case

2-3. CABINET (REAR) ASSY

Note : When installing, fit the knobs and switches .

1

screw (1.7x16)

knob

switch

3

screw (B1.7x5), tapping

2

screw (1.7x16)

5

claw

6

cabinet (rear) assy

4

claws

knob

switch

– 5 –

Page 6

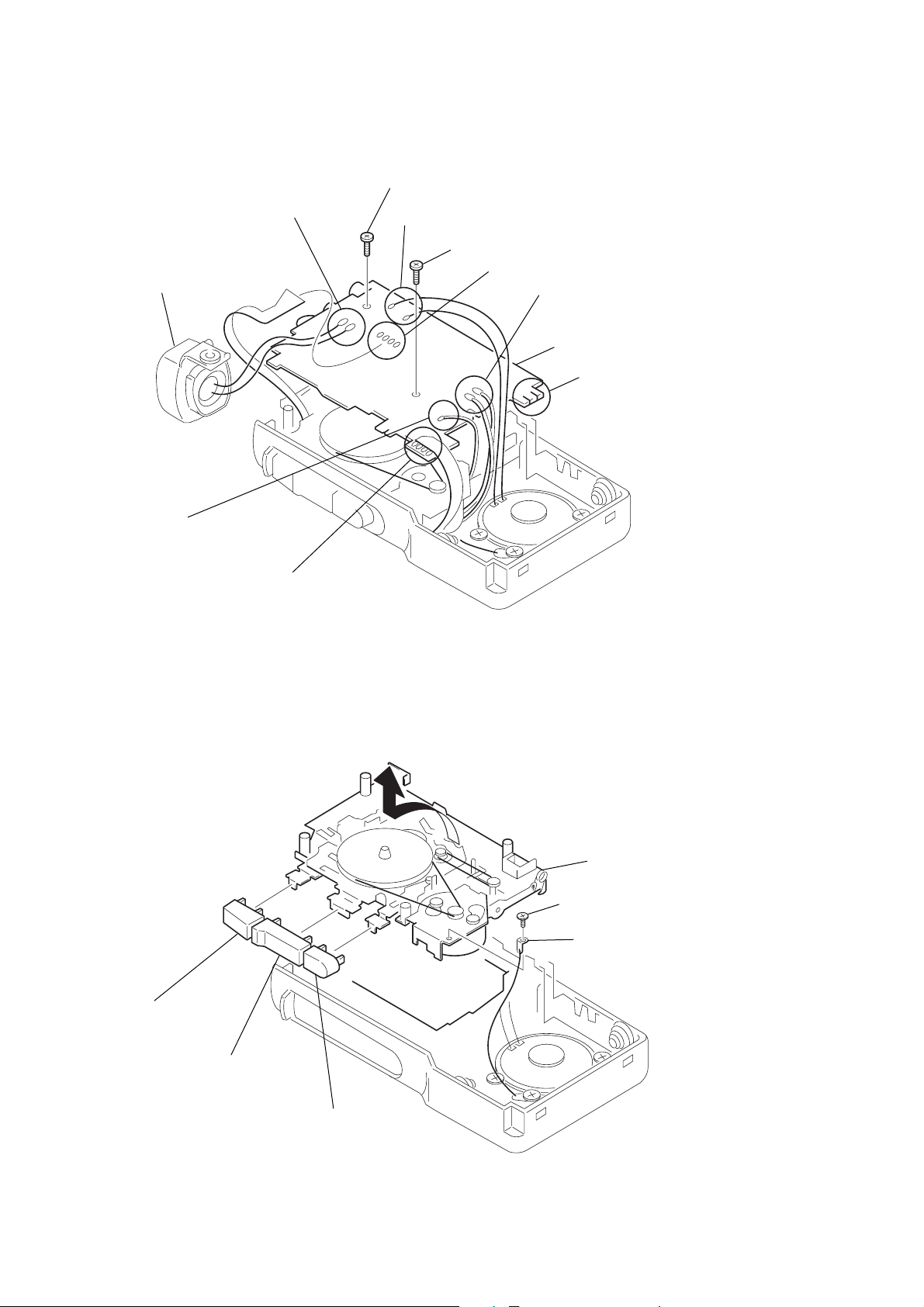

2-4. MAIN BOARD

8

mic assy

7

Unsolder.

1

Unsolder the 2 places.

9

(M1.4x3.0), locking

2

Unsolder the 2 places.

0

(M1.4x3.0), locking

3

Unsolder the 4 places.

4

Unsolder the 2 places.

!¡

MAIN board

5

Unsolder the 2 places.

2-5. MACHANISM DECK

2

button (REC)

6

Unsolder the 4 places.

(M-630V/635VK only)

1

7

mechanism deck

(MZ-530V-99)

5

(1.7x2.0), special head

6

lug, 2

button (PLAY)

3

4

button (STOP)

– 6 –

Page 7

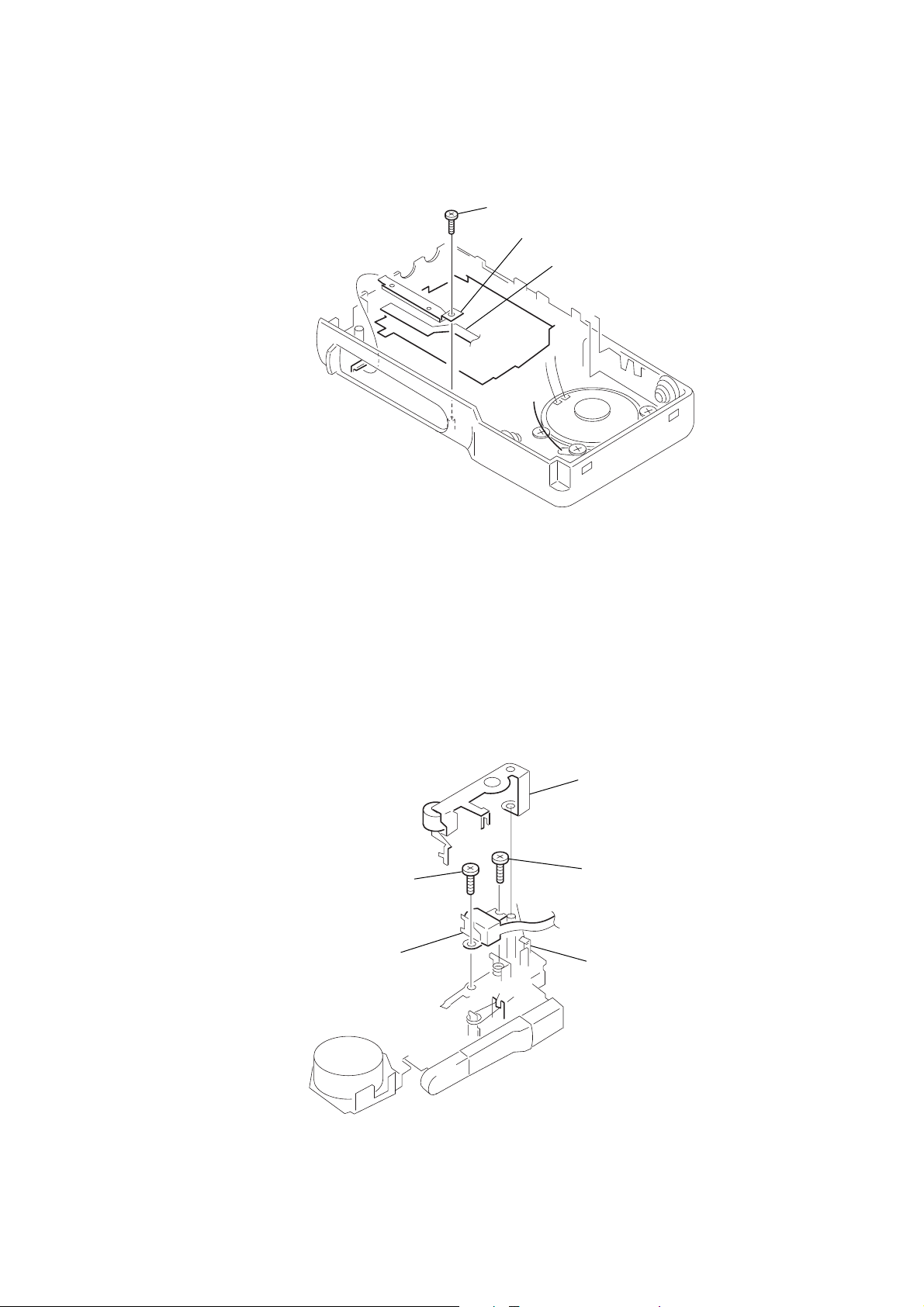

2-6. LED UNIT

1

(1.7), tapping

2

bracket (LED)

3

LED unit

2-7. HEAD, CERAMIC

4

M1.4, special head

5

head, ceramic

2

arm (pinch roller) assy

3

M1.4, special head

1

claw

– 7 –

Page 8

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback/erase head pinch roller

rubber belts capstan

2. Demagnetize the record/playback/erase head with a head

demagnetizer. (Do not bring the head demagnetizer close to the

erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Power supply voltage : 3 Vdc

TAPE SPEED switch : 2.4cm

Torque Measurement

Mode Torque Meter Meter Reading

Forward CQ-103M

Fast Forward CQ-201M

Rewind CQ-201M

T ape Tension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403M

5 – 13 g • cm

(0.07 – 0.180 oz • inch)

more than 30 g • cm

(more than 0.42 oz • inch)

more than 30 g • cm

(more than 0.42 oz • inch)

more than 20 g

(more than 0.28 oz)

Test T ape

Type Signal Used for

S-2-A030 3 kHz, – 20 dB

WS-24 2.4

WS-12

3 kHz, – 10 dB Tape Speed Adjustment

Head Azimuth Adjustment

T ape Speed

(cm/s)

2.4

1.2

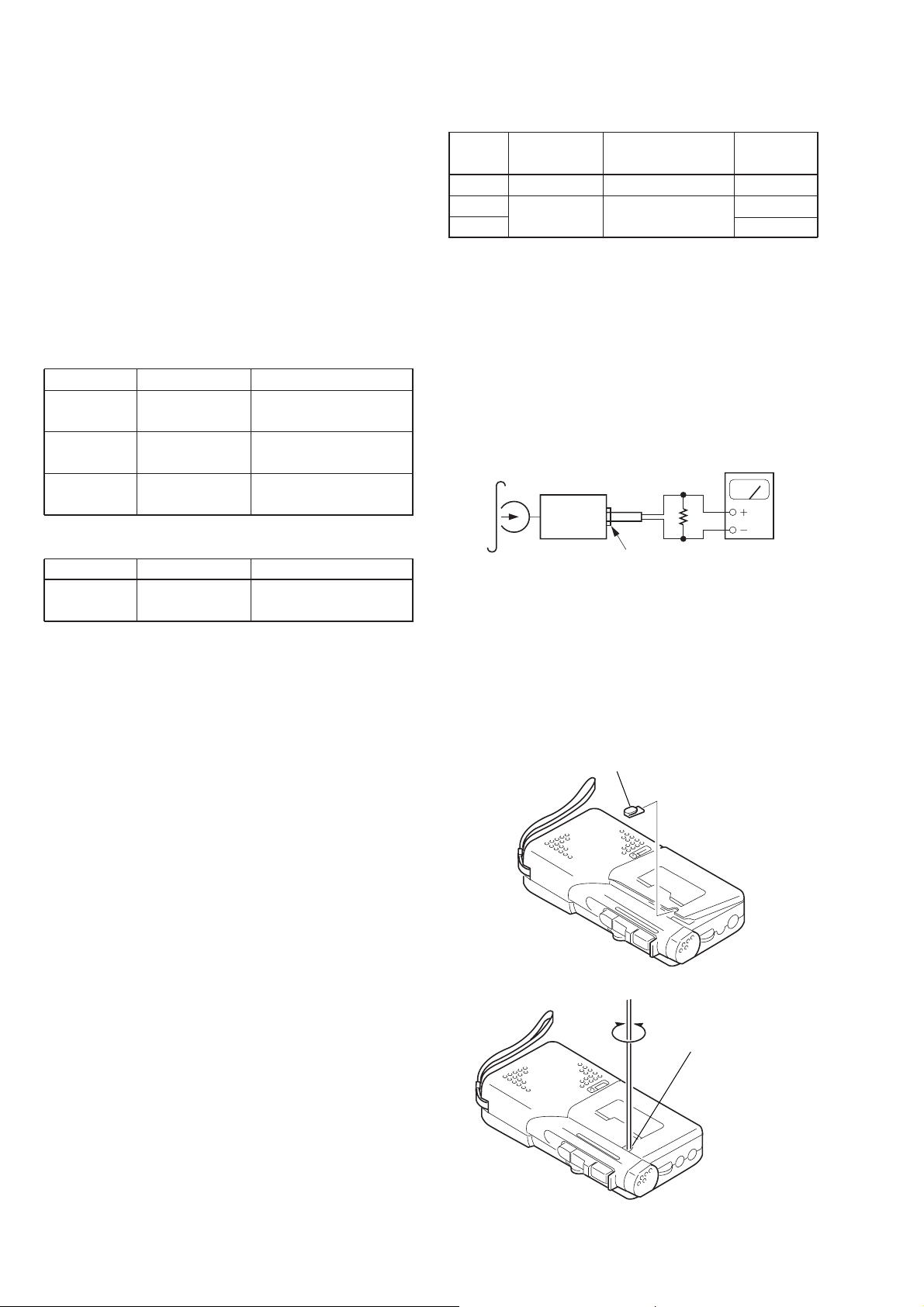

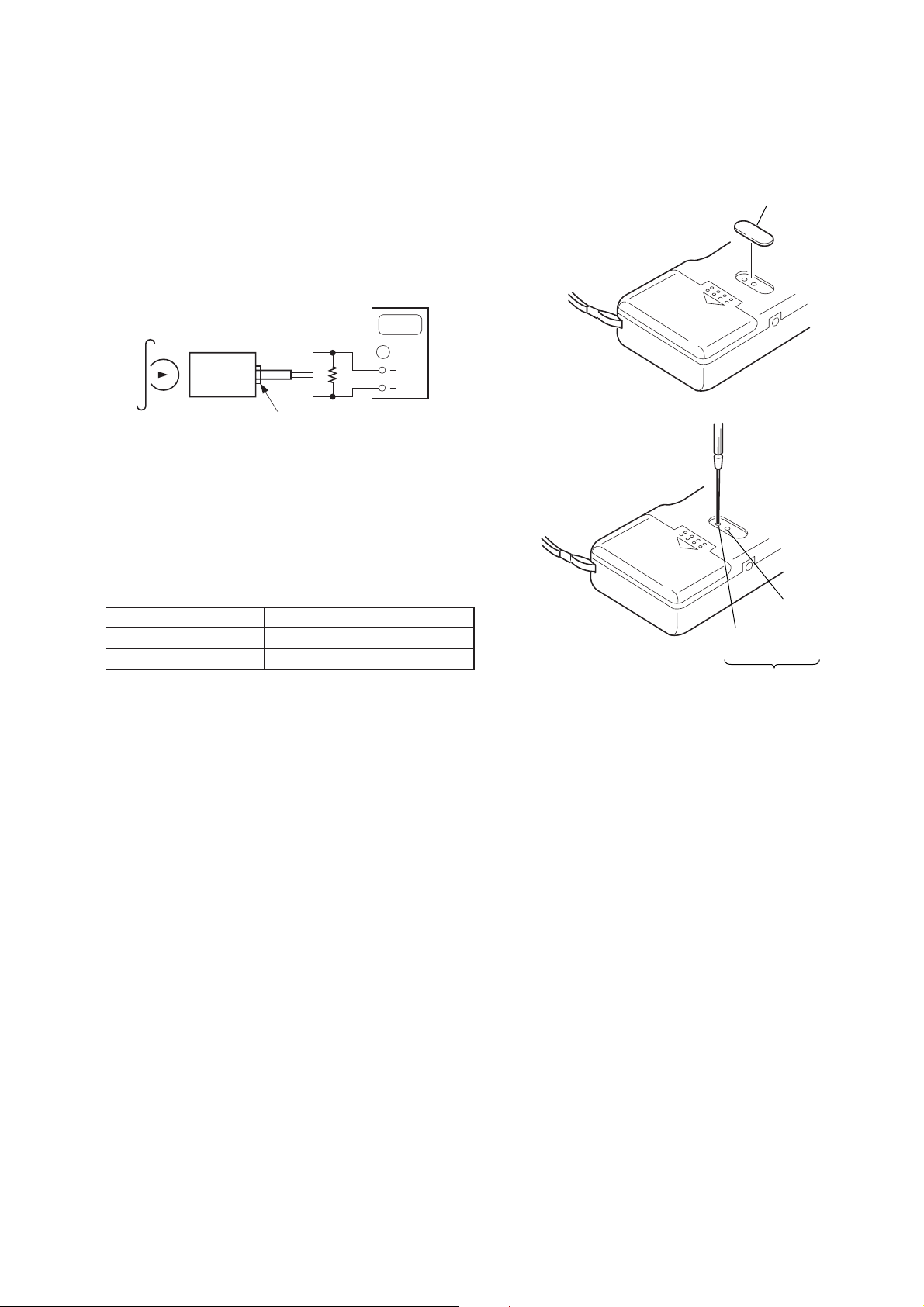

Record/Playback/Erase Head Azimuth Adjustment

Setting:

VOL control : mechanical mid

TAPE SPEED switch : 2.4cm/s

VOR switch : OFF

Procedure:

1. Mode : Playback

test tape

S-2-A030

(3 kHz, –20 dB) level meter

16

Ω

set

EAR jack (J101)

2. Turn the adjustment screw to obtain the maximum reading on

level meter.

Note: Several peaks may appear, but the maximum.

Adjustment Location :

First remove the cover (AZ).

Remove the

cover (AZ).

head azimuth

adjustment screw

– 8 –

Page 9

Tape Speed Adjustment

RV601

1.2cm/s

RV602

2.4cm/s

speed adjustable resistors

Setting:

VOL control : mechanical mid

VOR switch : OFF

Procedure:

• Reform 2.4 cm/s speed adjustment before 1.2 cm/s speed

adjustment mode : playback

Adjustment Location :

First remove the plate, blind.

Remove the

plate, blind.

test tape

WS-24: tape speed 2.4cm/s

WS-12: tape speed 1.2cm/s

(3 kHz, –10 dB)

set

EAR jack (J101)

digital frequency

counter

16

Ω

0000

1. Tape Speed : 2.4 cm/s

Playback WS-24 (tape center part) and adjust RV602 so that

reading on the digital frequency counter becomes 3,000 Hz.

2. Tape Speed : 1.2 cm/s

Playback WS-12 (tape center part) and adjust RV601 so that

reading on the digital frequency counter becomes 3,000 Hz.

Specification Value:

Tape Speed Frequency counter

2.4 cm/s 2,880 to 3,120 Hz

1.2 cm/s 2,850 to 3,150 Hz

Frequency difference between the beginning and the end of the tape

should be within ±0.5%.

2.4 cm/s (15 Hz)

1.2 cm/s (15 Hz)

– 9 –

Page 10

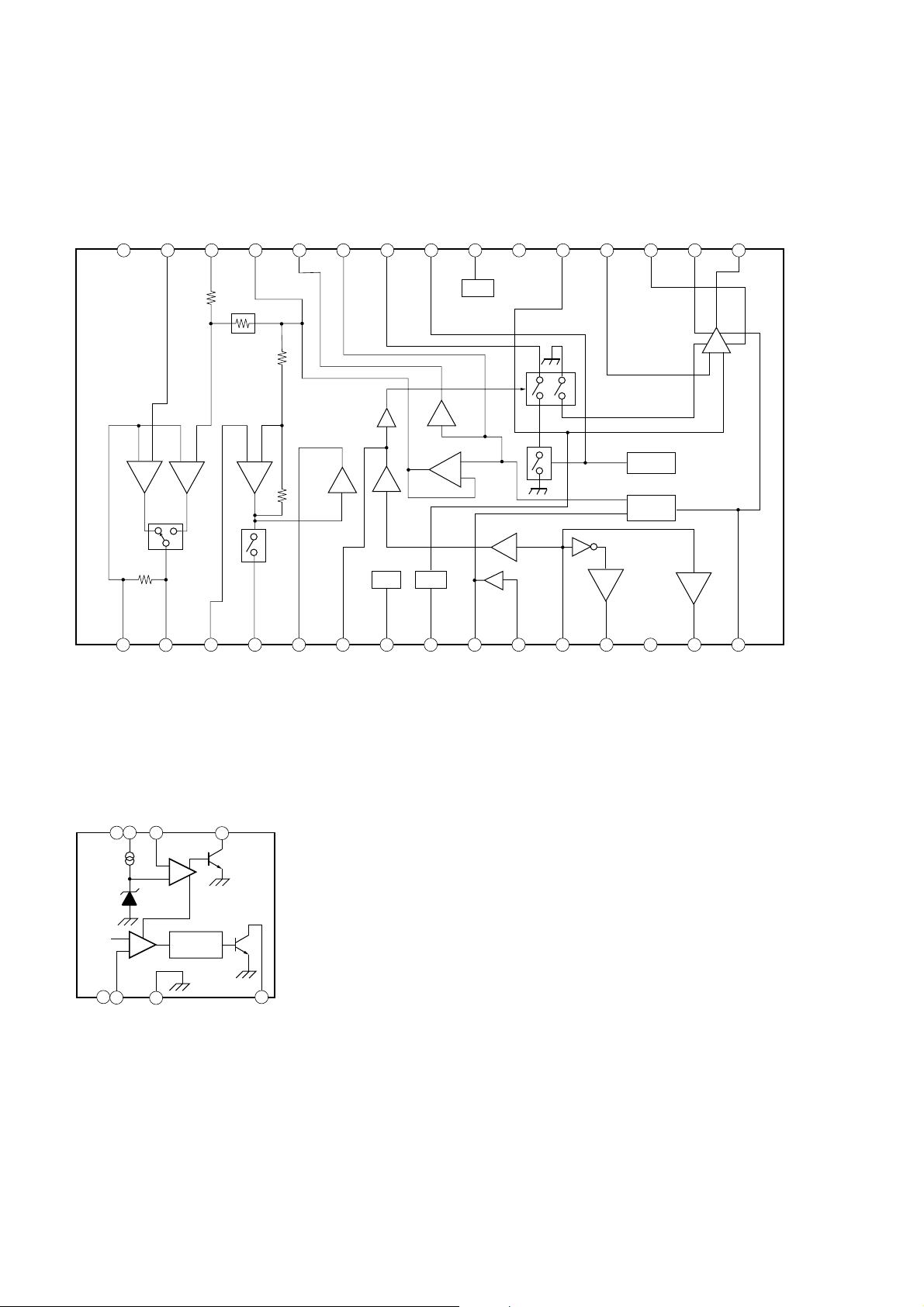

• IC Block Diagrams

IC101 LA4168ML

PRE GND

30

EQ IN

MIC IN

Vref OUT

MIC VCC

SECTION 5

DIAGRAMS

R, F OUT

LED DRIVE

R/P SW

PAUSE

P/R MUTE

212223242526272829

GVN CONT

GVN Vref

Vs

GVN GND

GVN OUT

181920

17

16

1

PRE NF

300k

SPEED

8

GNV SPEED UP

PAUSE

MIC

VCC

+

–

Vref

9

AUT STOP CONT

10

AUT STOP IN

11

PWR IN

1

12

PWR OUT1

R/P

R, F

POWER

13

PWR GND

2

14

PWR OUT2

GVN

15

Vcc

2.2k

30k

2k

+

–

EQ

2

PRE OUT

+

–

MIC

3

REG IN

+

4

–

20k

REC

REG OUT

5

ALC CONT

ALC

6

VOX CONT

VOX

VOX

7

VOX DELAY

IC501 MM1251BFBE (M-630V/635VK only)

NC

VCC

VREF

VS

7

8

6

–

+

+

VOLTAGE UP

–

1

2

3

CT

NC

GND

HYS

5

CIRCUIT

4

OUT

– 10 –

Page 11

J102

MIC

MIC901

MIC

(PLUG IN POWER)

MIC

530V/535V

630V/635VK

ALC CONTROL

Q101

HRPE901

REC/PB/ERASE

HEAD

REC/PB

SWITCH

Q102

REC/PB

SWITCH

Q110, 111

VOR

SWITCH

Q104

REC LED

SWITCH

Q106, 108

REC LED

DRIVE

Q107

NF CONTROL

Q103, 105

REC/PB

SWITCH

Q112

PB

REC

S101-3

(REC/PB)

(REC/PB)

(ERASE)

1.2cm 2.4cm

S602-2

TAPE SPEED

S101-1

(REC/PB)

PB

REC

26 15

21

27

5

4

1

29

28

2

REC/PB AMP

IC101 (1/2)

+

–

+

–

+

–

+

–

MIC IN

MIC

EQ

PRE NF

ALC CONT

REC OUT

VREF OUT

EQ IN

MIC VCC

MUTE

R.F

VCC

3

REC IN

630V/635VK

PRE OUT

7

VOX

VOX DELAY

B+

(3V)

ALC

MIC

VCC

S101-4

(REC/PB)

PB

REC

OFF

ON

PB

REC

OFF

L

H

S103

VOR

RV101

VOL

S603

FAST PB

S602-1

TAPE SPEED

S601

PAUSE

D102

REC

REC/BATT

(630V/635VK)

(530V/535V)

530V/535V

RV601

TAPE

SPEED

1.2cm

RV602

TAPE

SPEED

2.4cm

FAST PB

SWITCH

Q601

1.2cm 2.4cm

20

24

19

11 14

PWR IN PWR OUT2

12

16

22

PWR OUT1

GVM OUT

GVM VREF

GVM CONT

POWER AMP

IC101 (2/2)

LED DRIVE

23

P/R SW

P/R

PAUSE

D504

630/635VK

REC LED

SWITCH

Q109

BATT LED

SWITCH

Q501

PAUSE

Q113

B+

(+3V)

BATT LED

SWITCH

Q502

M

B+

(+3V)

B+

(+3V)

M901

MOTOR

5

3

4

OUT

HYS

6

VS

7

VCC

GND

BATTERY LOW DET

IC501

630V/635VK

S101-2

(REC/PB)

J101

EAR

+

SP901

SPEAKER

04

LED UNIT

BATT

B+

DRY BATTERY

SIZE "AA"

(IED DESIGNATION R6)

2PCS, 3V

DC IN 3V

CN101

OFF

ON

S102

(POWER)

Signal path

: PB

: REC

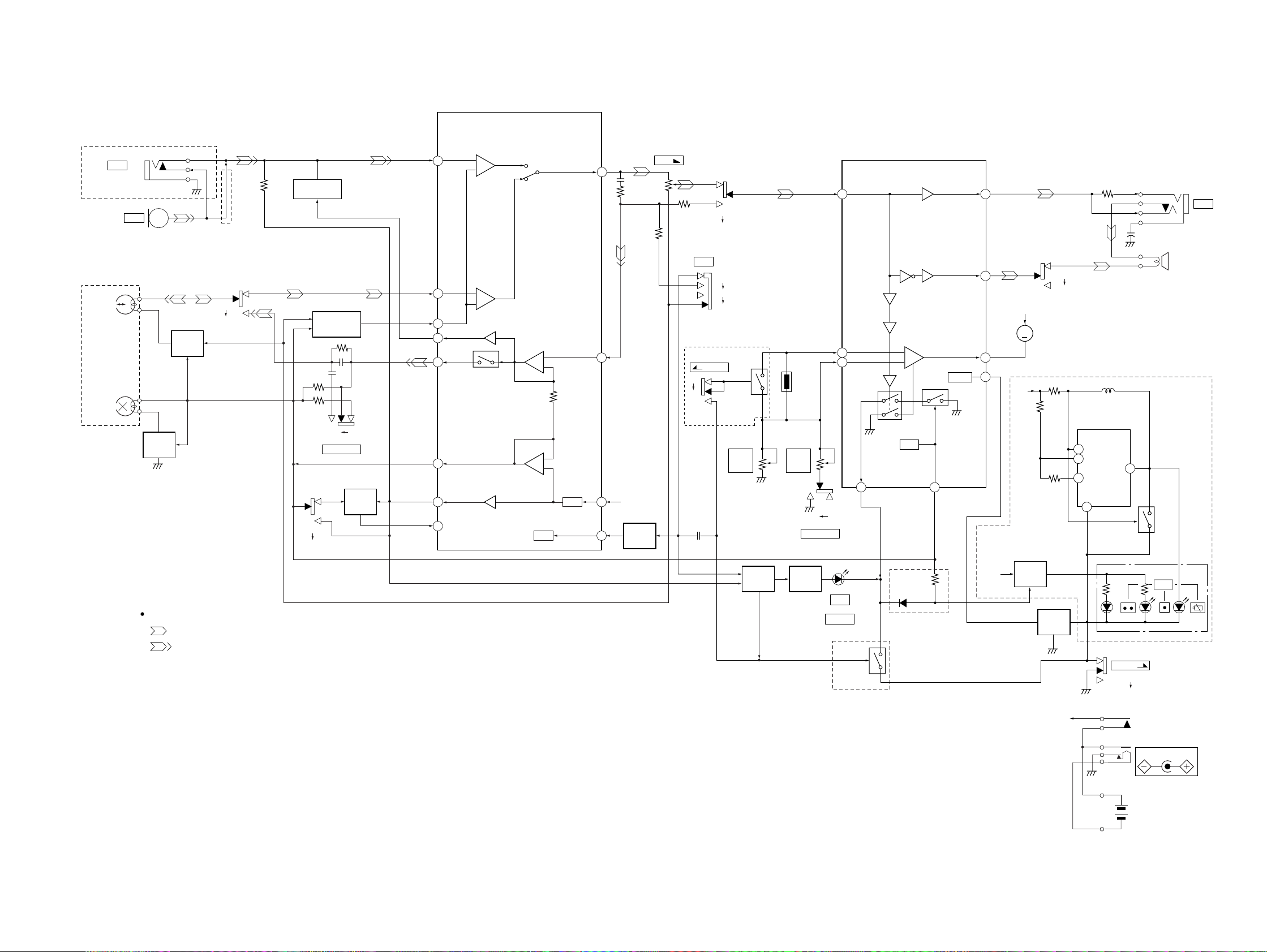

5-1. BLOCK DIAGRAM

M-530V/535V/630V/635VK

– 11 – – 12 –

Page 12

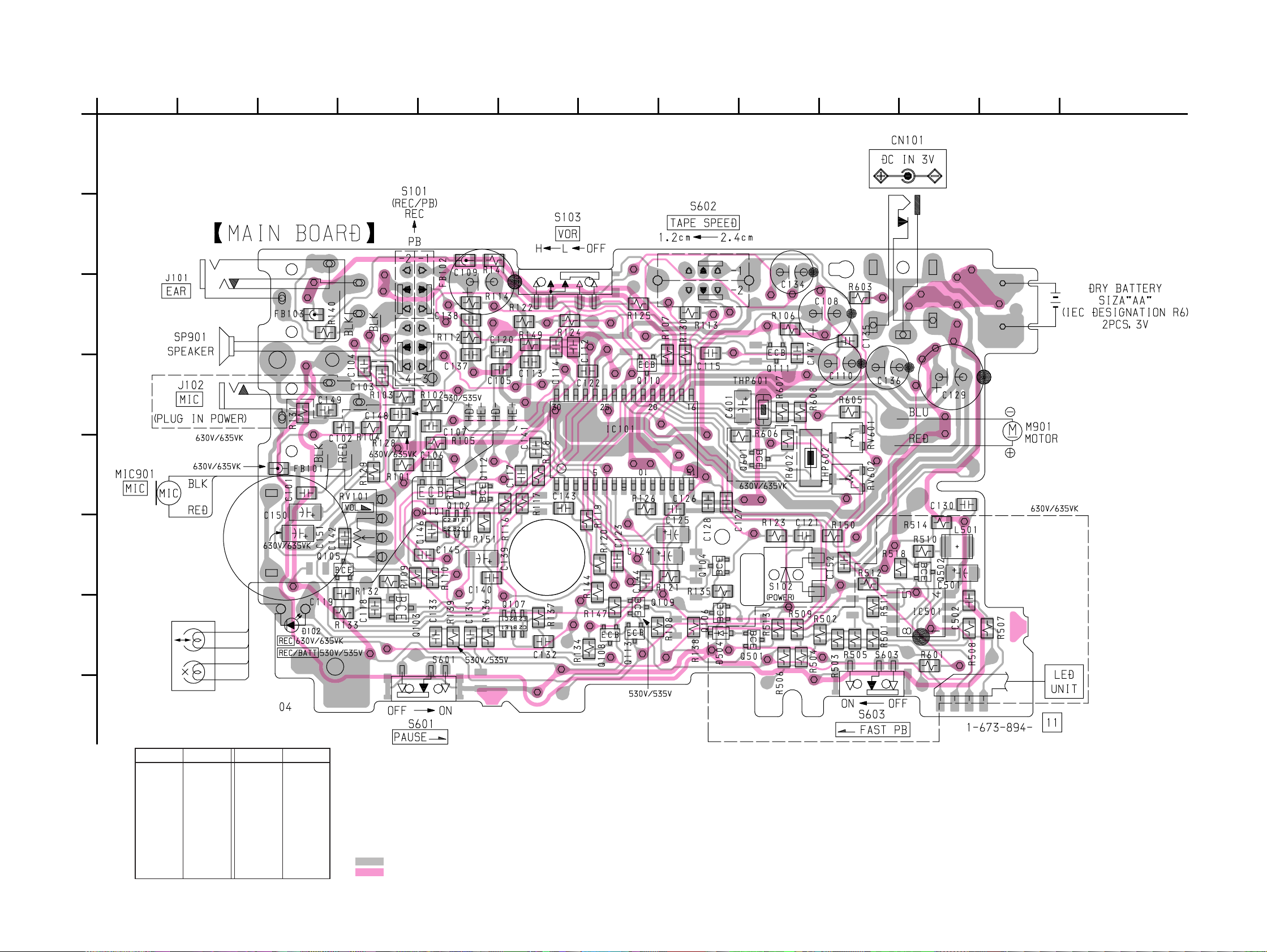

M-530V/535V/630V/635VK

5-2. PRINTED WIRING BOARD

A

B

C

D

1

2345678910111213

E

F

G

H

HRPE901

REC/PB/ERASE

HEAD

HD+

(REC/PB)

(ERASE)

• Semiconductor Location

Ref. No. Location

D102 G-3

(D504) G-8

IC101 D-7

(IC501) G-11

Q101 E-4

Q102 E-5

Q103 G-4

Q104 F-8

Q105 F-3

( ) : 630V/635VK only

< > : 530V/535V only

HD–

HE+

HE–

Ref. No. Location

Q106 G-8

Q107 G-5

Q108 G-7

<Q109> G-7

Q110 C-7

Q111 C-9

Q112 E-5

Q113 G-7

(Q501) G-8

(Q502) F-11

(Q601) E-8

Note:

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

• : Pattern of the rear side.

– 13 – – 14 –

Page 13

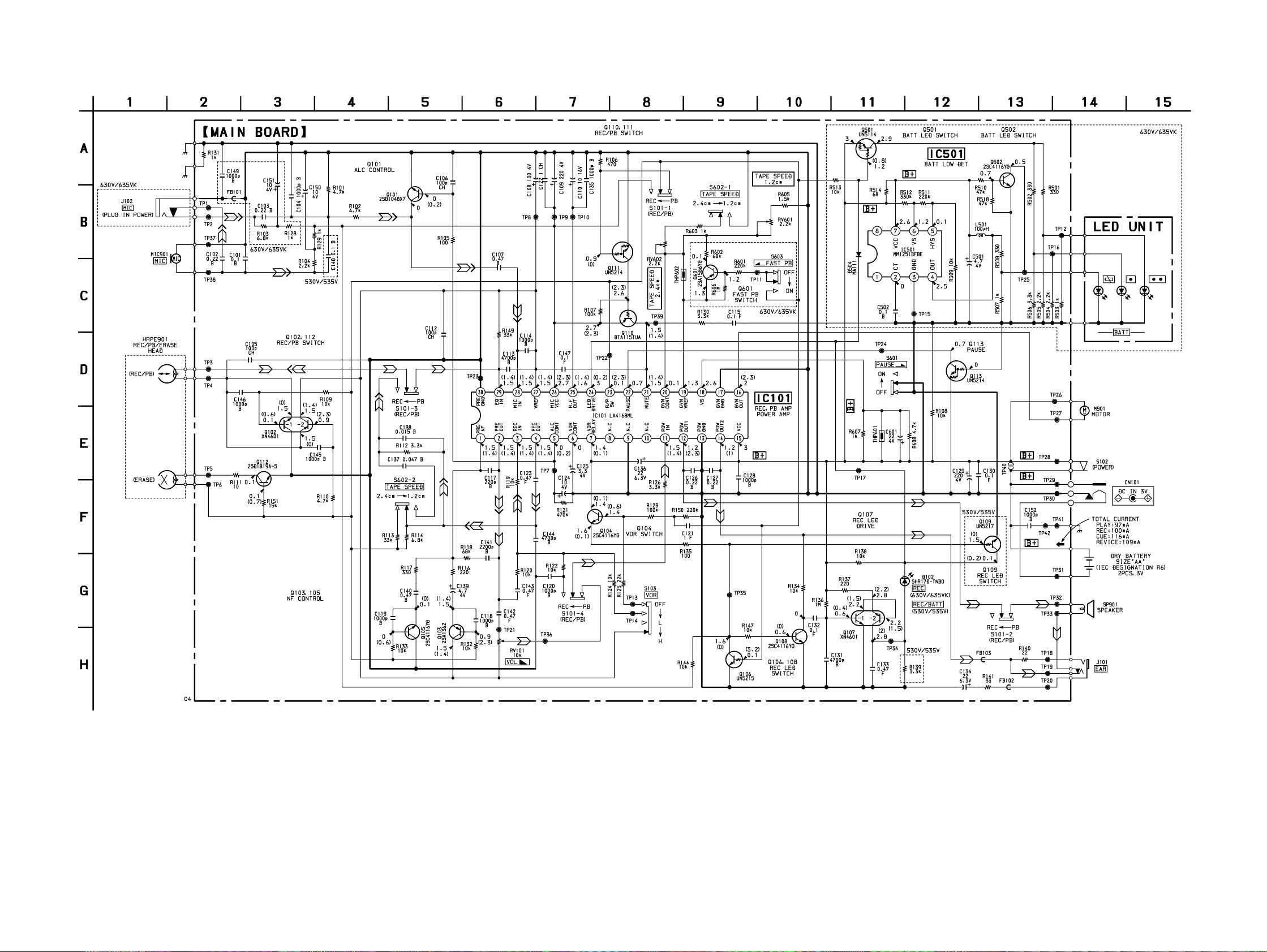

5-3. SCHEMATIC DIAGRAM • Refer to page 10 for IC Block Diagrams.

M-530V/535V/630V/635VK

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• C : panel designation.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 3 V and fed with regulated dc power

supply from battery terminal.

4

W or less unless otherwise

• Voltage is dc with respect to ground under no-signal

condition.

no mark : PB

( ) : REC

• Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage var iations may be noted due to normal production tolerances.

• Signal path.

E : PB

a : REC

– 15 – – 16 –

Page 14

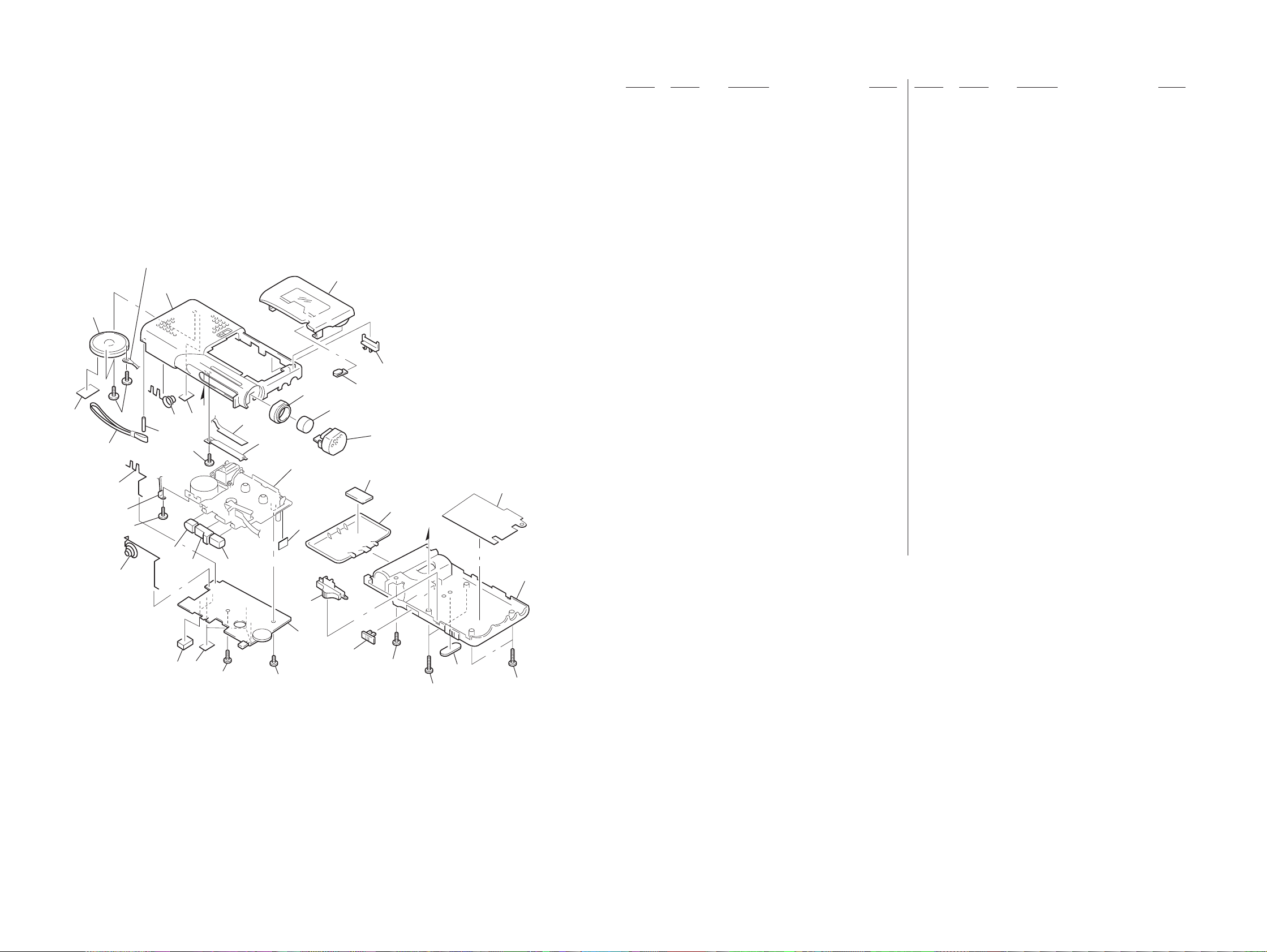

SECTION 6

EXPLODED VIEWS

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

6-1. CABINET SECTION

not supplied

11

SP901

33

9

10

26

25

8

32

31

7

4

24

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

N

Parts Color Cabinet’s Color

N

12

29

14

A

3

27

28

MZ-530V-99

13

MIC901

15

16

18

34

6

5

• Accessories and packing materials are

given in the last of this parts list.

• Abbreviation

CND : Canadian model

EE : East European model

CH : Chinese model

E : Indication of country of origin

1E : No indication of country of origin

17

A

1 A-3021-217-A MAIN BOARD, COMPLETE (630V/635VK)

1 A-3021-219-A MAIN BOARD, COMPLETE (530V/535V)

2 3-704-197-31 SCREW (M1.4X3.0), LOCKING

3 3-831-441-99 SPACER, KNOB

4 3-034-687-01 TERMINAL (-), BATTERY

5 3-031-376-11 BUTTON (REC) (BLACK) (530V/535V)

5 3-031-376-21 BUTTON (REC) (SILVER) (630V/635VK)

6 3-031-375-01 BUTTON (PLAY) (BLACK) (530V/535V)

6 3-031-375-11 BUTTON (PLAY) (SILVER) (630V/635VK)

7 3-031-374-01 BUTTON (STOP) (BLACK) (530V/535V)

7 3-031-374-11 BUTTON (STOP) (SILVER) (630V/635VK)

8 3-034-686-01 TERMINAL (+), BATTERY

9 3-034-792-01 SCREW (2X2.5), TAPPING (B)

10 3-010-503-01 SPRING (B), BATTERY COIL

11 3-032-409-01 CABINET (FRONT) (SILVER) (530V:1E)

11 3-032-409-11 CABINET (FRONT) (SILVER) (530V :EXCEPT 1E)

11 3-032-409-61 CABINET (FRONT) (BLACK) (535V:1E)

11 3-032-409-71 CABINET (FRONT) (BLACK) (535V:EXCEPT 1E)

11 X-3377-234-1 CABINET (FRONT) SUB ASSY (BLACK)

(630V:AEP)

11 X-3377-236-1 CABINET (FRONT) SUB ASSY (SILVER)

(630V:1E)

11 X-3377-238-1 CABINET (FRONT) SUB ASSY (SILVER) (635VK)

11 X-3377-252-1 CABINET (FRONT) SUB ASSY (SILVER)

(630V:EXCEPT 1E)

12 X-3377-233-1 LID ASSY, CASSETTE (BLACK) (630V:AEP)

12 X-3377-239-1 LID ASSY, CASSETTE (BLACK) (535V)

12 X-3377-251-1 LID ASSY, CASSETTE (SILVER) (630V/635VK)

12 X-3377-253-1 LID ASSY, CASSETTE (SILVER) (530V)

* 13 3-033-185-01 COVER (AZ) (BLACK) (535V/630V:AEP)

* 13 3-033-185-11 COVER (AZ) (SILVER) (530V/630V/635VK)

14 3-031-382-01 CUSHION (MIC)

15 3-031-372-01 CASE, MICROPHONE

* 16 3-914-930-01 CUSHION (BATTERY CASE LID)

17 3-037-004-01 PLATE, SHIELD

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

18 3-031-371-01 LID, BATTERY CASE (BLACK) (535V/630V :AEP)

18 3-031-371-11 LID, BATTERY CASE (SILVER)

(530V/630V/635VK)

19 X-3377-318-1 CABINET (REAR) ASSY (SILVER) (530V)

19 X-3377-321-1 CABINET (REAR) ASSY (SILVER)

(630V/635VK)

19 X-3377-322-1 CABINET (REAR) ASSY (BLACK) (630V:AEP)

19 X-3377-323-1 CABINET (REAR) ASSY (BLACK) (535V)

20 3-035-255-01 SCREW (1.7X16) (BLACK)

(535V:1E/630V:AEP)

20 3-035-255-11 SCREW (1.7X16) (SILVER) (530V/

535V:EXCEPT 1E/630V/635VK)

21 3-358-363-41 PLATE, BLIND (BLACK) (535V/630V:AEP)

21 3-358-363-61 PLATE, BLIND (SILVER) (530V/630V/635V)

22 3-318-203-71 SCREW (B1.7X5), TAPPING (BLACK)

(535V/630V:AEP)

22 3-318-203-72 SCREW (B1.7X5), TAPPING (SILVER)

(530V/630V/635VK)

23 3-031-381-01 KNOB (FR) (BLACK) (535V/630V:AEP)

23 3-031-381-11 KNOB (FR) (SILVER) (530V/630V/635VK)

24 3-318-382-31 SCREW (1.7), TAPPING (630V/635VK)

25 3-328-319-01 STRAP, HAND

26 3-669-481-07 PIN (DIA.1X10), PARALLEL

27 1-468-399-11 LED UNIT (630V/635VK)

28 3-031-395-01 BRACKET (LED) (630V/635VK)

29 3-033-358-01 KNOB (VOR) (LIGHT GRAY) (530V/630V/635VK)

29 3-033-358-11 KNOB (VOR) (DARK GRAY) (535V/630V:AEP)

30 3-033-357-01 KNOB (F-PB) (LIGHT GRAY) (630V/635VK)

31 3-891-132-00 SCREW (M1.7X2.0), SPECIAL HEAD

32 7-623-505-01 LUG, 2

33 3-037-193-01 CUSHION (SP)

34 3-036-882-01 SPACER (JACK)

35 3-037-146-01 CUSHION (A)

MIC901 1-542-386-11 MICROPHONE, ELECTRET CONDENSER (MIC)

SP901 1-505-838-11 SPEAKER (3.6cm)

19

35

23

1

30

3

2

2

22

20

21

20

– 17 – – 18 –

Page 15

6-2. MECHANISM DECK SECTION

(MZ-530V-99)

69

70

71

72

73

74

57

75

76

77

78

64

62

65

68

61

63

60

66

67

55

54

59

56

53

57

52

52

58

51

HRPE901

86

M901

88

80

87

82

89

81

79

83

84

85

51 3-028-965-01 SPRING (PINCH ARM), TORSION

52 3-703-816-31 SCREW (M1.4), SPECIAL HEAD

53 3-703-816-73 SCREW (M1.4), SPECIAL HEAD

54 3-028-960-01 SPRING (AZIMUTH), COMPRESSION

55 3-028-909-01 GUIDE (N), TAPE

* 56 3-029-640-01 LEVER (PLAY.OW)

57 3-331-007-21 WASHER

58 3-350-989-01 WASHER

59 3-028-961-01 SPRING (BUTTON), COMPRESSION

60 3-028-924-01 LEVER (PLAY)

61 X-3376-235-1 ARM (PINCH ROLLER) ASSY

62 3-028-929-01 LEVER (SW)

63 3-028-940-01 LEVER (SRS)

64 3-028-938-01 LEVER (SLIDE)

65 3-578-224-00 WASHER

66 X-3376-227-1 LEVER (F/R) ASSY

67 X-3376-228-1 LEVER (TU) ASSY

68 3-029-634-01 BEARING

69 X-3376-231-1 FLYWHEEL ASSY

70 3-377-420-11 BELT (FLYWHEEL)

71 X-3376-224-1 LEVER (REC) ASSY

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

72 3-029-641-01 SPRING, TORSION

73 3-028-957-01 SPRING (CAM GEAR), TENSION

74 3-028-966-01 GEAR (S-OFF-OW), CAM

75 X-3376-230-1 LIMITER ASSY

76 3-028-955-01 SPRING (LOCK), TENSION

77 X-3377-535-1 LEVER (LOCK) ASSY

78 4-992-239-01 WASHER (A)

* 79 3-028-967-01 LEVER (PAUSE RELEASE)

80 3-028-954-01 SPRING (SW LEVER), TENSION

81 3-321-483-11 RING, RETAINING

82 3-028-928-01 LEVER (EJECT)

83 3-028-964-01 SPRING (SLIDER), TORSION

84 4-926-562-01 WASHER, STOPPER

85 3-028-927-01 LEVER (STOP)

86 3-028-917-01 SPRING (GROUND), COMPRESSION

87 1-548-579-41 COUNTER, TAPE (SMALL TYPE)

88 X-3376-223-1 CHASSIS (COMP) ASSY

89 3-343-948-01 BELT (COUNTER,TAPE)

HRPE9011-500-593-11 HEAD, CERAMIC (REC/PB/ERASE)

M901 1-698-533-11 MOTOR, DC (CAPSTAN/REEL)

(including PULLEY)

– 19 –

Page 16

SECTION 7

MAIN

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-3021-217-A MAIN BOARD, COMPLETE (630V/635VK)

A-3021-219-A MAIN BOARD, COMPLETE (530V/535V)

*********************

< CAPACITOR >

ELECTRICAL PARTS LIST

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

When indicating parts by reference

number, please include the board.

• Abbreviation

CND : Canadian model

EE : East European model

CH : Chinese model

E : Indication of country of origin

1E : No indication of country of origin

C142 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C143 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C144 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C145 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C146 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

The components identified by

mark ! or dotted line with mark.

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

When indicating parts by reference

number, please include the board.

C101 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C102 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C103 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

(630V/635VK)

C104 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C105 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C106 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C107 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C108 1-124-433-00 ELECT 100uF 20% 4V

C109 1-124-434-00 ELECT 220uF 20% 4V

C110 1-104-396-11 ELECT 10uF 20% 16V

C112 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C113 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C114 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C115 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C117 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C118 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C119 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C120 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C121 1-164-346-11 CERAMIC CHIP 1uF 16V

C122 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C123 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C124 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C125 1-135-180-21 TANTALUM CHIP 3.3uF 20% 6.3V

C126 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C127 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C128 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C129 1-104-402-11 ELECT 220uF 20% 4V

C130 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C131 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C132 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C147 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C148 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

(530V/535V)

C149 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

(630V/635VK)

C150 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C151 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C152 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C501 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

(630V/635VK)

C502 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

(630V/635VK)

C601 1-104-847-11 TANTAL. CHIP 22uF 20% 4V

< JACK >

CN101 1-580-372-41 JACK, DC (POLARITY UNIFIED TYPE)

(DC IN 3V)

< DIODE >

D102 8-719-062-18 LED SHR17D-TNBO (REC/BATT) (530V/535V)

D102 8-719-062-18 LED SHR17D-TNBO (REC) (630V/635VK)

D504 8-719-404-50 DIODE MA111-TX (630V/635VK)

< FERRITE BEAD >

FB101 1-414-235-22 INDUCTOR, FERRITE BEAD (630V/635VK)

FB102 1-414-235-22 INDUCTOR, FERRITE BEAD

FB103 1-414-235-22 INDUCTOR, FERRITE BEAD

< IC >

IC101 8-759-492-49 IC LA4168ML-TE-L

IC501 8-759-399-49 IC MM1251BFBE (630V/635VK)

C133 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C134 1-126-153-11 ELECT 22uF 20% 6.3V

C135 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C136 1-126-153-11 ELECT 22uF 20% 6.3V

C137 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C138 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C139 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

C140 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C141 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

< JACK >

J101 1-785-791-11 JACK (EAR)

J102 1-785-790-11 JACK (MIC (PLUG IN POWER)) (630V/635VK)

< COIL >

L501 1-412-032-11 INDUCTOR CHIP 100uH (630V/635VK)

– 20 –

Page 17

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

< TRANSISTOR >

Q101 8-729-800-37 TRANSISTOR 2SD1048-X7

Q102 8-729-402-84 TRANSISTOR XN4601

Q103 8-729-230-72 TRANSISTOR 2SA1362YG

Q104 8-729-230-63 TRANSISTOR 2SC4116-YG

Q105 8-729-230-63 TRANSISTOR 2SC4116-YG

Q106 8-729-420-50 TRANSISTOR UN5215

Q107 8-729-402-84 TRANSISTOR XN4601

Q108 8-729-230-63 TRANSISTOR 2SC4116-YG

Q109 8-729-422-48 TRANSISTOR UN5217 (530V/535V)

Q110 8-729-028-78 TRANSISTOR DTA115TUA-T106

Q111 8-729-402-93 TRANSISTOR UN5214-TX

Q112 8-729-402-33 TRANSISTOR 2SD1819A-S

Q113 8-729-402-93 TRANSISTOR UN5214-TX

Q501 8-729-402-96 TRANSISTOR UN5114 (630V/635VK)

Q502 8-729-230-63 TRANSISTOR 2SC4116-YG (630V/635VK)

Q601 8-729-230-60 TRANSISTOR 2SA1586-YG (630V/635VK)

< RESISTOR >

R101 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R102 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R103 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

(630V/635VK)

R104 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R105 1-216-025-00 RES,CHIP 100 5% 1/10W

R106 1-216-041-11 METAL CHIP 470 5% 1/10W

R107 1-216-097-00 RES,CHIP 100K 5% 1/10W

R108 1-216-073-00 METAL CHIP 10K 5% 1/10W

R109 1-216-073-00 METAL CHIP 10K 5% 1/10W

R110 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R111 1-216-001-00 METAL CHIP 10 5% 1/10W

R112 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R113 1-216-085-00 METAL CHIP 33K 5% 1/10W

R114 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R116 1-216-033-00 METAL CHIP 220 5% 1/10W

R134 1-216-073-00 METAL CHIP 10K 5% 1/10W

R135 1-216-025-00 RES,CHIP 100 5% 1/10W

R136 1-216-121-00 RES,CHIP 1M 5% 1/10W

R137 1-216-033-00 METAL CHIP 220 5% 1/10W

R138 1-216-073-00 METAL CHIP 10K 5% 1/10W

R139 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

(530V/535V)

R140 1-216-009-00 RES,CHIP 22 5% 1/10W

R141 1-216-013-00 METAL CHIP 33 5% 1/10W

R144 1-216-073-00 METAL CHIP 10K 5% 1/10W

R147 1-216-073-00 METAL CHIP 10K 5% 1/10W

R149 1-216-085-00 METAL CHIP 33K 5% 1/10W

R150 1-216-105-00 RES,CHIP 220K 5% 1/10W

R151 1-216-077-00 METAL CHIP 15K 5% 1/10W

R501 1-216-037-00 METAL CHIP 330 5% 1/10W

(630V/635VK)

R502 1-216-037-00 METAL CHIP 330 5% 1/10W

(630V/635VK)

R503 1-216-049-11 RES,CHIP 1K 5% 1/10W

(630V/635VK)

R504 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

(630V/635VK)

R505 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

(630V/635VK)

R506 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

(630V/635VK)

R507 1-216-049-11 RES,CHIP 1K 5% 1/10W

(630V/635VK)

R508 1-216-037-00 METAL CHIP 330 5% 1/10W

(630V/635VK)

R509 1-216-073-00 METAL CHIP 10K 5% 1/10W

(630V/635VK)

R510 1-216-089-00 RES,CHIP 47K 5% 1/10W

(630V/635VK)

R511 1-216-105-00 RES,CHIP 220K 5% 1/10W

(630V/635VK)

R512 1-216-109-00 METAL CHIP 330K 5% 1/10W

(630V/635VK)

R117 1-216-037-00 METAL CHIP 330 5% 1/10W

R118 1-216-093-00 RES,CHIP 68K 5% 1/10W

R119 1-216-073-00 METAL CHIP 10K 5% 1/10W

R120 1-216-073-00 METAL CHIP 10K 5% 1/10W

R121 1-216-113-00 METAL CHIP 470K 5% 1/10W

R122 1-216-073-00 METAL CHIP 10K 5% 1/10W

R123 1-216-097-00 RES,CHIP 100K 5% 1/10W

R124 1-216-073-00 METAL CHIP 10K 5% 1/10W

R125 1-216-081-00 METAL CHIP 22K 5% 1/10W

R126 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R128 1-216-049-11 RES,CHIP 1K 5% 1/10W

(630V/635VK)

R129 1-216-049-11 RES,CHIP 1K 5% 1/10W

R130 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R131 1-216-049-11 RES,CHIP 1K 5% 1/10W

R132 1-216-073-00 METAL CHIP 10K 5% 1/10W

R133 1-216-073-00 METAL CHIP 10K 5% 1/10W

R513 1-216-073-00 METAL CHIP 10K 5% 1/10W

(630V/635VK)

R514 1-216-021-00 METAL CHIP 68 5% 1/10W

(630V/635VK)

R518 1-216-089-00 RES,CHIP 47K 5% 1/10W

(630V/635VK)

R601 1-216-105-00 RES,CHIP 220K 5% 1/10W

(630V/635VK)

R602 1-216-093-00 RES,CHIP 68K 5% 1/10W

(630V/635VK)

R603 1-216-049-11 RES,CHIP 1K 5% 1/10W

R605 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R606 1-216-121-00 RES,CHIP 1M 5% 1/10W

(630V/635VK)

R607 1-216-049-11 RES,CHIP 1K 5% 1/10W

R608 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

– 21 –

Page 18

M-530V/535V/630V/635VK

MAIN

Ref. No. Part No. Description Remark

< VARIABLE RESISTOR >

RV101 1-237-731-21 RES, VAR, CARBON 10K (VOL)

RV601 1-223-584-11 RES, ADJ, CARBON 2.2K

RV602 1-223-584-11 RES, ADJ, CARBON 2.2K

< SWITCH >

S101 1-572-964-11 SWITCH, SLIDE (REC/PB)

S102 1-572-688-11 SWITCH, PUSH (1 KEY) (POWER)

S103 1-692-605-31 SWITCH, SLIDE (VOR)

S601 1-572-922-11 SWITCH, SLIDE (PAUSE)

S602 1-692-298-11 SWITCH, SLIDE (TAPE SPEED)

S603 1-572-922-11 SWITCH, SLIDE (FAST PB) (630V/635VK)

< THERMISTOR (POSITIVE) >

THP601 1-810-552-11 THERMISTOR, POSITIVE

THP602 1-803-117-11 THERMISTOR, POSITIVE

*************************************************************

MISCELLANEOUS

***************

27 1-468-399-11 LED UNIT (630V/635VK)

87 1-548-579-41 COUNTER, TAPE (SMALL TYPE)

HRPE9011-500-593-11 HEAD, CERAMIC (REC/PB/ERASE)

M901 1-698-533-11 MOTOR, DC (CAPSTAN/REEL)

(including PULLEY)

MIC901 1-542-386-11 MICROPHONE, ELECTRET CONDENSER (MIC)

Ref. No. Part No. Description Remark

ACCESSORIES & PACKING MATERIALS

********************************

! 1-528-405-31 ADAPTOR, BATTER Y CHARGE (BCA-35E) (635VK)

! 1-693-073-21 ADAPTOR, AC (AC-E351) (635VK)

3-035-588-01 POUCH, CARRYING (630V:AEP,EE)

3-865-285-11 MANUAL, INSTRUCTION (ENGLISH,FRENCH)

(530V:US,CND/535V:EXCEPT E,1E)

3-865-285-61 MANUAL, INSTRUCTION (SPANISH,ITALIAN)

(535V:AEP)

3-865-285-71 MANUAL, INSTRUCTION (ENGLISH)

(630V:US,CND/635VK)

3-865-285-81 MANUAL, INSTRUCTION (FRENCH) (530V:AEP/

630V:CND,AEP/635VK:CND)

3-865-285-91 MANUAL, INSTRUCTION (ENGLISH,SPANISH,

PORTUGUESE,ITALIAN) (530V:AEP,E/

535V:E/630V:AEP,E)

3-866-171-11 MANUAL, INSTRUCTION (GERMAN,DUTCH,

SWEDISH,FINNISH) (530V:AEP/

630V:AEP)

3-866-171-21 MANUAL, INSTRUCTION (ENGLISH,

SIMPLIFIED CHINESE,HUNGARIAN,

RUSSIAN) (EE,CH)

3-866-171-31 MANUAL, INSTRUCTION

(TRADITIONAL CHINESE,KOREAN,

POLISH,CZECH) (EE)

3-866-171-41 MANUAL, INSTRUCTION (ENGLISH,

TRADITIONAL CHINESE) (1E)

SP901 1-505-838-11 SPEAKER (3.6cm)

*************************************************************

9-926-961-11

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

Sony Corporation

Personal A&V Products Company

– 22 –

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

99B0484-1

Printed in Japan C1999. 2

Published by Quality Engineering Dept.

(Shinagawa)

Page 19

M-530V/535V/630V/635VK

SERVICE MANUAL

Ver 1.1 1999. 05

Photo : M-530V

SPECIFICATIONS

US Model

Canadian Model

M-530V/535V/630V/635VK

AEP Model

E Model

Chinese Model

M-530V/535V/630V

Tourist Model

M-530V

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MZ-530V-99

Tape

y (normal position type)

Recording system

2-track 1-channel monaural

Speaker

Approx. 3.6 cm (1 7/16 in.) dia.

Tape speed

2.4 cm/s (15/16 ips), 1.2 cm/s (15/32 ips)

Frequency range

250 - 4,000 Hz (with TAPE SPEED switch at 2.4 cm/s)

Input (M-635VK/630V only)

Microphone input jack (minijack/PLUG IN POWER)

sensitivity 0.24 mV for 3 kilohms or lower impedance microphone

Output

Earphone jack (minijack) for 8 - 300 ohms earphone

Power output (at 10% harmonic distortion)

250 mW

Power requirements

3 V DC batteries size AA (R6) × 2/External DC 3 V power sources

Dimensions (w/h/d)

Approx. 62.2 × 121.5 × 24.3 mm (2 1/2 × 4 7/8 × 31/32 in.) incl. projecting

parts and controls

Mass

Approx. 125 g (4.5 oz.)

Supplied accessories

AC power adaptor AC-E351 (1) (M-635VK only)

Battery charge adaptor BCA-35E (1) (M-635VK only)

Rechargeable batteries NC-AA, 1.2 V, 600 mAh, Ni-Cd (2) (M-635VK

only)

Microcassette tape MC-30 (1) (M-630V/535V/530V for Europe only)

Batteries R6P (SR) (2) (M-530V for Tourist and M-630V for Europe only)

Carrying case (1) (M-530V for Tourist and M-630V for Europe only)

Design and specifications are subject to change without notice.

MICROFILM

– 1 –

MICROCASSETTE

-CORDER

TM

Page 20

TABLE OF CONTENTS

1. GENERAL ....................................................................3

2. DISASSEMBLY

2-1. Lid Assy, Cassette ............................................................... 4

2-2. Lid, Battery Case ................................................................ 5

2-3. Cabinet (Rear) Assy ............................................................ 5

2-4. Main Board ......................................................................... 6

2-5. Mechanism Deck................................................................. 6

2-6. LED Unit............................................................................. 7

2-7. Head, Ceramic (HRPE901)................................................. 7

3. MECHANICAL ADJUSTMENTS..............................8

4. ELECTRICAL ADJUSTMENTS ...............................8

5. DIAGRAMS

5-1. Block Diagram .................................................................. 11

5-2. Printed Wiring Board ........................................................ 13

5-3. Schematic Diagram ........................................................... 15

6. EXPLODED VIEWS

6-1. Cabinet Section ................................................................. 17

6-2. Mechanism Deck Section.................................................. 19

7. ELECTRICAL PARTS LIST.....................................20

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PAR TS WHOSE

P ART NUMBERS APPEAR AS SHOWN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

Page 21

SECTION 1

GENERAL

This section is extracted

from instruction manual.

– 3 –

Page 22

SECTION 2

DISASSEMBLY

• The equipment can be removed using the following procedure.

Set Lid assy,

cassette

Cabinet (rear)

assy

Main

board

Mechanism

deck

Head,

ceramic (HRPE901)

Lid,

battery case

Note : Follow the disassembly procedure in the n umerical order given.

2-1. LID ASSY, CASSETTE

top view

4

lid assy,

cassette

3

cabinet (front)

precision screwdriver

or equivalent

2

Stop the lid assy, cassette

halfway.

1

LED

unit

precision screwdriver

or equivalent

7

6

8

Note :When removing the cassette lid, put cloth on the end of a

screwdriver or use a polyacetal driver to avoid damage to

the cabinet.

9

lid assy, cassette

5

– 4 –

Page 23

2-2. LID, BATTERY CASE

3

claws

2

2

1

4

lid, battery case

2-3. CABINET (REAR) ASSY

Note : When installing, fit the knobs and switches .

1

screw (1.7x16)

knob

switch

3

screw (B1.7x5), tapping

2

screw (1.7x16)

5

claw

6

cabinet (rear) assy

4

claws

knob

switch

– 5 –

Page 24

2-4. MAIN BOARD

8

mic assy

7

Unsolder.

1

Unsolder the 2 places.

9

(M1.4x3.0), locking

2

Unsolder the 2 places.

0

(M1.4x3.0), locking

3

Unsolder the 4 places.

4

Unsolder the 2 places.

!¡

MAIN board

5

Unsolder the 2 places.

2-5. MACHANISM DECK

•

How to apply the belts

flywheel assy

belt (counter, tape)

M901

6

Unsolder the 4 places.

(M-630V/635VK only)

belt (flywheel)

1

7

mechanism deck

(MZ-530V-99)

5

(1.7x2.0), special head

6

lug, 2

2

button (REC)

3

button (PLAY)

4

button (STOP)

– 6 –

Page 25

2-6. LED UNIT

1

(1.7), tapping

2

bracket (LED)

3

LED unit

2-7. HEAD, CERAMIC (HRPE901)

4

M1.4, special head

5

head, ceramic

(HRPE901)

2

arm (pinch roller) assy

3

M1.4, special head

1

claw

– 7 –

Page 26

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback/erase head pinch roller

rubber belts capstan

2. Demagnetize the record/playback/erase head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Power supply voltage : 3 Vdc

TAPE SPEED switch : 2.4cm

Torque Measurement

Mode Torque Meter Meter Reading

Forward CQ-103M

Fast Forward CQ-201M

Rewind CQ-201M

T ape Tension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403M

5 – 13 g • cm

(0.07 – 0.180 oz • inch)

more than 30 g • cm

(more than 0.42 oz • inch)

more than 30 g • cm

(more than 0.42 oz • inch)

more than 20 g

(more than 0.28 oz)

Test T ape

Type Signal Used for

S-2-A030 3 kHz, – 20 dB

WS-24 2.4

WS-12

3 kHz, – 10 dB Tape Speed Adjustment

Head Azimuth Adjustment

T ape Speed

(cm/s)

2.4

1.2

Record/Playback/Erase Head Azimuth Adjustment

Setting:

VOL control : mechanical mid

TAPE SPEED switch : 2.4cm/s

VOR switch : OFF

Procedure:

1. Mode : Playback

test tape

S-2-A030

(3 kHz, –20 dB) level meter

16

Ω

set

EAR jack (J101)

2. Turn the adjustment screw to obtain the maximum reading on

level meter.

Note: Several peaks may appear, but the maximum.

Adjustment Location :

First remove the cover (AZ).

Remove the

cover (AZ).

head azimuth

adjustment screw

– 8 –

Page 27

Tape Speed Adjustment

RV601

2.4cm/s

RV602

1.2cm/s

speed adjustable resistors

Setting:

VOL control : mechanical mid

VOR switch : OFF

Procedure:

• Reform 1.2 cm/s speed adjustment before 2.4 cm/s speed

adjustment mode : playback

Adjustment Location :

First remove the plate, blind.

Remove the

plate, blind.

test tape

WS-24: tape speed 2.4cm/s

WS-12: tape speed 1.2cm/s

(3 kHz, –10 dB)

set

EAR jack (J101)

digital frequency

counter

16

Ω

0000

1. Tape Speed : 2.4 cm/s

Playback WS-24 (tape center part) and adjust RV601 so that

reading on the digital frequency counter becomes 3,000 Hz.

2. Tape Speed : 1.2 cm/s

Playback WS-12 (tape center part) and adjust RV602 so that

reading on the digital frequency counter becomes 3,000 Hz.

Specification Value:

Tape Speed Frequency counter

2.4 cm/s 2,880 to 3,120 Hz

1.2 cm/s 2,850 to 3,150 Hz

Frequency difference between the beginning and the end of the tape

should be within ±0.5%.

2.4 cm/s (15 Hz)

1.2 cm/s (15 Hz)

– 9 –

Page 28

• IC Block Diagrams

IC101 LA4168ML

PRE GND

30

EQ IN

MIC IN

Vref OUT

MIC VCC

SECTION 5

DIAGRAMS

R, F OUT

LED DRIVE

R/P SW

PAUSE

P/R MUTE

212223242526272829

GVN CONT

GVN Vref

Vs

GVN GND

GVN OUT

181920

17

16

1

PRE NF

300k

SPEED

8

GNV SPEED UP

PAUSE

MIC

VCC

+

–

Vref

9

AUT STOP CONT

10

AUT STOP IN

11

PWR IN

1

12

PWR OUT1

R/P

R, F

POWER

13

PWR GND

2

14

PWR OUT2

GVN

15

Vcc

2.2k

30k

2k

+

–

EQ

2

PRE OUT

+

–

MIC

3

REG IN

+

4

–

20k

REC

REG OUT

5

ALC CONT

ALC

6

VOX CONT

VOX

VOX

7

VOX DELAY

IC501 MM1251BFBE (M-630V/635VK only)

NC

VCC

VREF

VS

7

8

6

–

+

+

VOLTAGE UP

–

1

2

3

CT

NC

GND

HYS

5

CIRCUIT

4

OUT

– 10 –

Page 29

J102

MIC

MIC901

MIC

(PLUG IN POWER)

530V/535V

630V/635VK

ALC CONTROL

Q101

HRPE901

REC/PB/ERASE

HEAD

REC/PB

SWITCH

Q102

REC/PB

SWITCH

Q110, 111

VOR

SWITCH

Q104

REC LED

SWITCH

Q106, 108

REC LED

DRIVE

Q107

NF CONTROL

Q103, 105

REC/PB

SWITCH

Q112

PB

REC

S101-3

(REC/PB)

(REC/PB)

(ERASE)

1.2cm 2.4cm

S602-2

TAPE SPEED

S101-1

(REC/PB)

PB

REC

26 15

21

27

5

4

1

29

28

2

REC/PB AMP

IC101 (1/2)

+

–

+

–

+

–

+

–

MIC IN

MIC

EQ

PRE NF

ALC CONT

REC OUT

VREF OUT

EQ IN

MIC VCC

MUTE

R.F

VCC

3

REC IN

630V/635VK

PRE OUT

7

VOX

VOX DELAY

B+

(3V)

ALC

MIC

VCC

S101-4

(REC/PB)

PB

REC

OFF

ON

PB

REC

OFF

L

H

S103

VOR

RV101

VOL

S603

FAST PB

S602-1

TAPE SPEED

S601

PAUSE

D102

REC

REC/BATT

(630V/635VK)

(530V/535V)

530V/535V

RV601

TAPE

SPEED

2.4cm

RV602

TAPE

SPEED

1.2cm

FAST PB

SWITCH

Q601

1.2cm 2.4cm

20

24

19

11 14

PWR IN PWR OUT2

12

16

22

PWR OUT1

GVM OUT

GVM VREF

GVM CONT

POWER AMP

IC101 (2/2)

LED DRIVE

23

P/R SW

P/R

PAUSE

D504

630/635VK

REC LED

SWITCH

Q109

BATT LED

SWITCH

Q501

PAUSE

Q113

B+

(+3V)

BATT LED

SWITCH

Q502

M

B+

(+3V)

B+

(+3V)

M901

MOTOR

5

3

4

OUT

HYS

6

VS

7

VCC

GND

BATTERY LOW DET

IC501

630V/635VK

S101-2

(REC/PB)

J101

EAR

+

SP901

SPEAKER

04

LED UNIT

BATT

B+

DRY BATTERY

SIZE "AA"

(IED DESIGNATION R6)

2PCS, 3V

DC IN 3V

CN101

OFF

ON

S102

(POWER)

Signal path

: PB

: REC

5-1. BLOCK DIAGRAM

M-530V/535V/630V/635VK

– 11 – – 12 –

Page 30

M-530V/535V/630V/635VK

5-2. PRINTED WIRING BOARD

A

B

C

D

1

2345678910111213

E

F

G

H

HRPE901

REC/PB/ERASE

HEAD

HD+

(REC/PB)

(ERASE)

• Semiconductor Location

Ref. No. Location

D102 G-3

(D504) G-8

IC101 D-7

(IC501) G-11

Q101 E-4

Q102 E-5

Q103 G-4

Q104 F-8

Q105 F-3

( ) : 630V/635VK only

< > : 530V/535V only

HD–

HE+

HE–

Ref. No. Location

Q106 G-8

Q107 G-5

Q108 G-7

<Q109> G-7

Q110 C-7

Q111 C-9

Q112 E-5

Q113 G-7

(Q501) G-8

(Q502) F-11

(Q601) E-8

Note:

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

• : Pattern of the rear side.

– 13 – – 14 –

Page 31

5-3. SCHEMATIC DIAGRAM • Refer to page 10 for IC Block Diagrams.

M-530V/535V/630V/635VK

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• C : panel designation.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 3 V and fed with regulated dc power

supply from battery terminal.

4

W or less unless otherwise

• Voltage is dc with respect to ground under no-signal

condition.

no mark : PB

( ) : REC

• Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage var iations may be noted due to normal production tolerances.

• Signal path.

E : PB

a : REC

– 15 – – 16 –

Page 32

SECTION 6

EXPLODED VIEWS

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

6-1. CABINET SECTION

not supplied

11

SP901

33

9

10

26

25

8

32

31

7

4

24

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

N

Parts Color Cabinet’s Color

N

12

29

14

A

3

27

28

MZ-530V-99

13

MIC901

15

16

18

34

6

5

• Accessories and packing materials are

given in the last of this parts list.

• Abbreviation

CND : Canadian model

EE : East European model

CH : Chinese model

E : Indication of country of origin

1E : No indication of country of origin

JE : T ourist model

17

A

1 A-3021-217-A MAIN BOARD, COMPLETE (630V/635VK)

1 A-3021-219-A MAIN BOARD, COMPLETE (530V/535V)

2 3-704-197-31 SCREW (M1.4X3.0), LOCKING

3 3-831-441-99 SPACER, KNOB

4 3-034-687-01 TERMINAL (-), BATTERY

5 3-031-376-11 BUTTON (REC) (BLACK) (530V/535V)

5 3-031-376-21 BUTTON (REC) (SILVER) (630V/635VK)

6 3-031-375-01 BUTTON (PLAY) (BLACK) (530V/535V)

6 3-031-375-11 BUTTON (PLAY) (SILVER) (630V/635VK)

7 3-031-374-01 BUTTON (STOP) (BLACK) (530V/535V)

7 3-031-374-11 BUTTON (STOP) (SILVER) (630V/635VK)

8 3-034-686-01 TERMINAL (+), BATTERY

9 3-034-792-01 SCREW (2X2.5), TAPPING (B)

10 3-010-503-01 SPRING (B), BATTERY COIL

11 3-032-409-01 CABINET (FRONT) (SILVER) (530V:1E)

11 3-032-409-11 CABINET (FRONT) (SILVER) (530V :EXCEPT 1E)

11 3-032-409-61 CABINET (FRONT) (BLACK) (535V:1E)

11 3-032-409-71 CABINET (FRONT) (BLACK) (535V:EXCEPT 1E)

11 X-3377-234-1 CABINET (FRONT) SUB ASSY (BLACK)

(630V:AEP)

11 X-3377-236-1 CABINET (FRONT) SUB ASSY (SILVER)

(630V:1E)

11 X-3377-238-1 CABINET (FRONT) SUB ASSY (SILVER) (635VK)

11 X-3377-252-1 CABINET (FRONT) SUB ASSY (SILVER)

(630V:EXCEPT 1E)

12 X-3377-233-1 LID ASSY, CASSETTE (BLACK) (630V:AEP)

12 X-3377-239-1 LID ASSY, CASSETTE (BLACK) (535V)

12 X-3377-251-1 LID ASSY, CASSETTE (SILVER) (630V/635VK)

12 X-3377-253-1 LID ASSY, CASSETTE (SILVER) (530V)

* 13 3-033-185-01 COVER (AZ) (BLACK) (535V/630V:AEP)

* 13 3-033-185-11 COVER (AZ) (SILVER) (530V/630V/635VK)

14 3-031-382-01 CUSHION (MIC)

15 3-031-372-01 CASE, MICROPHONE

* 16 3-914-930-01 CUSHION (BATTERY CASE LID)

17 3-037-004-01 PLATE, SHIELD

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

18 3-031-371-01 LID, BATTERY CASE (BLACK) (535V/630V :AEP)

18 3-031-371-11 LID, BATTERY CASE (SILVER)

(530V/630V/635VK)

19 X-3377-318-1 CABINET (REAR) ASSY (SILVER)

(530V:EXCEPT JE)

19 X-3377-320-1 CABINET (REAR) ASSY (SILVER) (530V:JE)

19 X-3377-321-1 CABINET (REAR) ASSY (SILVER)

(630V/635VK)

19 X-3377-322-1 CABINET (REAR) ASSY (BLACK) (630V:AEP)

19 X-3377-323-1 CABINET (REAR) ASSY (BLACK) (535V)

20 3-035-255-01 SCREW (1.7X16) (BLACK)

(535V:1E/630V:AEP)

20 3-035-255-11 SCREW (1.7X16) (SILVER) (530V/

535V:EXCEPT 1E/630V/635VK)

21 3-358-363-41 PLATE, BLIND (BLACK) (535V/630V:AEP)

21 3-358-363-61 PLATE, BLIND (SILVER) (530V/630V/635V)

22 3-318-203-71 SCREW (B1.7X5), TAPPING (BLACK)

(535V/630V:AEP)

22 3-318-203-72 SCREW (B1.7X5), TAPPING (SILVER)

(530V/630V/635VK)

23 3-031-381-01 KNOB (FR) (BLACK) (535V/630V:AEP)

23 3-031-381-11 KNOB (FR) (SILVER) (530V/630V/635VK)

24 3-318-382-31 SCREW (1.7), TAPPING (630V/635VK)

25 3-328-319-01 STRAP, HAND

26 3-669-481-07 PIN (DIA.1X10), PARALLEL

27 1-468-399-11 LED UNIT (630V/635VK)

28 3-031-395-01 BRACKET (LED) (630V/635VK)

29 3-033-358-01 KNOB (VOR) (LIGHT GRAY) (530V/630V/635VK)

29 3-033-358-11 KNOB (VOR) (DARK GRAY) (535V/630V:AEP)

30 3-033-357-01 KNOB (F-PB) (LIGHT GRAY) (630V/635VK)

31 3-891-132-00 SCREW (M1.7X2.0), SPECIAL HEAD

32 7-623-505-01 LUG, 2

33 3-037-193-01 CUSHION (SP)

34 3-036-882-01 SPACER (JACK)

35 3-037-146-01 CUSHION (A)

MIC901 1-542-386-11 MICROPHONE, ELECTRET CONDENSER (MIC)

SP901 1-505-838-11 SPEAKER (3.6cm)

19

35

23

1

30

3

2

2

22

20

21

20

– 17 – – 18 –

Page 33

6-2. MECHANISM DECK SECTION

(MZ-530V-99)

69

70

71

72

73

74

57

75

76

77

78

64

62

65

68

61

63

60

66

67

55

54

59

56

53

57

52

52

58

51

HRPE901

86

M901

88

80

87

82

89

81

79

83

84

85

51 3-028-965-01 SPRING (PINCH ARM), TORSION

52 3-703-816-31 SCREW (M1.4), SPECIAL HEAD

53 3-703-816-73 SCREW (M1.4), SPECIAL HEAD

54 3-028-960-01 SPRING (AZIMUTH), COMPRESSION

55 3-028-909-01 GUIDE (N), TAPE

* 56 3-029-640-01 LEVER (PLAY.OW)

57 3-331-007-21 WASHER

58 3-350-989-01 WASHER

59 3-028-961-01 SPRING (BUTTON), COMPRESSION

60 3-028-924-01 LEVER (PLAY)

61 X-3376-235-1 ARM (PINCH ROLLER) ASSY

62 3-028-929-01 LEVER (SW)

63 3-028-940-01 LEVER (SRS)

64 3-028-938-01 LEVER (SLIDE)

65 3-578-224-00 WASHER

66 X-3376-227-1 LEVER (F/R) ASSY

67 X-3376-228-1 LEVER (TU) ASSY

68 3-029-634-01 BEARING

69 X-3376-231-1 FLYWHEEL ASSY

70 3-377-420-11 BELT (FLYWHEEL)

71 X-3376-224-1 LEVER (REC) ASSY

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

72 3-029-641-01 SPRING, TORSION

73 3-028-957-01 SPRING (CAM GEAR), TENSION

74 3-028-966-01 GEAR (S-OFF-OW), CAM

75 X-3376-230-1 LIMITER ASSY

76 3-028-955-01 SPRING (LOCK), TENSION

77 X-3377-535-1 LEVER (LOCK) ASSY

78 4-992-239-01 WASHER (A)

* 79 3-028-967-01 LEVER (PAUSE RELEASE)

80 3-028-954-01 SPRING (SW LEVER), TENSION

81 3-321-483-11 RING, RETAINING

82 3-028-928-01 LEVER (EJECT)

83 3-028-964-01 SPRING (SLIDER), TORSION

84 4-926-562-01 WASHER, STOPPER

85 3-028-927-01 LEVER (STOP)

86 3-028-917-01 SPRING (GROUND), COMPRESSION

87 1-548-579-41 COUNTER, TAPE (SMALL TYPE)

88 X-3376-223-1 CHASSIS (COMP) ASSY

89 3-343-948-01 BELT (COUNTER,TAPE)

HRPE9011-500-593-11 HEAD, CERAMIC (REC/PB/ERASE)

M901 1-698-533-11 MOTOR, DC (CAPSTAN/REEL)

(including PULLEY)

– 19 –

Page 34

SECTION 7

MAIN

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-3021-217-A MAIN BOARD, COMPLETE (630V/635VK)

A-3021-219-A MAIN BOARD, COMPLETE (530V/535V)

*********************

< CAPACITOR >

ELECTRICAL PARTS LIST

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

When indicating parts by reference

number, please include the board.

• Abbreviation

CND : Canadian model

EE : East European model

CH : Chinese model

E : Indication of country of origin

1E : No indication of country of origin

JE : Tourist model

C142 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C143 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C144 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C145 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C146 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

The components identified by

mark ! or dotted line with mark.

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

When indicating parts by reference

number, please include the board.

C101 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C102 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C103 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

(630V/635VK)

C104 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C105 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C106 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C107 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C108 1-124-433-00 ELECT 100uF 20% 4V

C109 1-124-434-00 ELECT 220uF 20% 4V

C110 1-104-396-11 ELECT 10uF 20% 16V

C112 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C113 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C114 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C115 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C117 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C118 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C119 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C120 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C121 1-164-346-11 CERAMIC CHIP 1uF 16V

C122 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C123 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C124 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C125 1-135-180-21 TANTALUM CHIP 3.3uF 20% 6.3V

C126 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C127 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C128 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C129 1-104-402-11 ELECT 220uF 20% 4V

C130 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C131 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C132 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C147 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C148 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

(530V/535V)

C149 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

(630V/635VK)

C150 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C151 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C152 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C501 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

(630V/635VK)

C502 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

(630V/635VK)

C601 1-104-847-11 TANTAL. CHIP 22uF 20% 4V

< JACK >

CN101 1-580-372-41 JACK, DC (POLARITY UNIFIED TYPE)

(DC IN 3V)

< DIODE >

D102 8-719-062-18 LED SHR17D-TNBO (REC/BATT) (530V/535V)

D102 8-719-062-18 LED SHR17D-TNBO (REC) (630V/635VK)

D504 8-719-404-50 DIODE MA111-TX (630V/635VK)

< FERRITE BEAD >

FB101 1-414-235-22 INDUCTOR, FERRITE BEAD (630V/635VK)

FB102 1-414-235-22 INDUCTOR, FERRITE BEAD

FB103 1-414-235-22 INDUCTOR, FERRITE BEAD

< IC >

IC101 8-759-492-49 IC LA4168ML-TE-L

IC501 8-759-399-49 IC MM1251BFBE (630V/635VK)

C133 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C134 1-126-153-11 ELECT 22uF 20% 6.3V

C135 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C136 1-126-153-11 ELECT 22uF 20% 6.3V

C137 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C138 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C139 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

C140 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C141 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

< JACK >

J101 1-785-791-11 JACK (EAR)

J102 1-785-790-11 JACK (MIC (PLUG IN POWER)) (630V/635VK)

< COIL >

L501 1-412-032-11 INDUCTOR CHIP 100uH (630V/635VK)

– 20 –

Page 35

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

< TRANSISTOR >

Q101 8-729-800-37 TRANSISTOR 2SD1048-X7

Q102 8-729-402-84 TRANSISTOR XN4601

Q103 8-729-230-72 TRANSISTOR 2SA1362YG

Q104 8-729-230-63 TRANSISTOR 2SC4116-YG

Q105 8-729-230-63 TRANSISTOR 2SC4116-YG

Q106 8-729-420-50 TRANSISTOR UN5215

Q107 8-729-402-84 TRANSISTOR XN4601

Q108 8-729-230-63 TRANSISTOR 2SC4116-YG

Q109 8-729-422-48 TRANSISTOR UN5217 (530V/535V)

Q110 8-729-028-78 TRANSISTOR DTA115TUA-T106

Q111 8-729-402-93 TRANSISTOR UN5214-TX

Q112 8-729-402-33 TRANSISTOR 2SD1819A-S

Q113 8-729-402-93 TRANSISTOR UN5214-TX

Q501 8-729-402-96 TRANSISTOR UN5114 (630V/635VK)

Q502 8-729-230-63 TRANSISTOR 2SC4116-YG (630V/635VK)

Q601 8-729-230-60 TRANSISTOR 2SA1586-YG (630V/635VK)

< RESISTOR >

R101 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R102 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R103 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

(630V/635VK)

R104 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R105 1-216-025-00 RES,CHIP 100 5% 1/10W

R106 1-216-041-11 METAL CHIP 470 5% 1/10W

R107 1-216-097-00 RES,CHIP 100K 5% 1/10W

R108 1-216-073-00 METAL CHIP 10K 5% 1/10W

R109 1-216-073-00 METAL CHIP 10K 5% 1/10W

R110 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R111 1-216-001-00 METAL CHIP 10 5% 1/10W

R112 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R113 1-216-085-00 METAL CHIP 33K 5% 1/10W

R114 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R116 1-216-033-00 METAL CHIP 220 5% 1/10W

R134 1-216-073-00 METAL CHIP 10K 5% 1/10W

R135 1-216-025-00 RES,CHIP 100 5% 1/10W

R136 1-216-121-00 RES,CHIP 1M 5% 1/10W

R137 1-216-033-00 METAL CHIP 220 5% 1/10W

R138 1-216-073-00 METAL CHIP 10K 5% 1/10W

R139 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

(530V/535V)

R140 1-216-009-00 RES,CHIP 22 5% 1/10W

R141 1-216-013-00 METAL CHIP 33 5% 1/10W

R144 1-216-073-00 METAL CHIP 10K 5% 1/10W

R147 1-216-073-00 METAL CHIP 10K 5% 1/10W

R149 1-216-085-00 METAL CHIP 33K 5% 1/10W

R150 1-216-105-00 RES,CHIP 220K 5% 1/10W

R151 1-216-077-00 METAL CHIP 15K 5% 1/10W

R501 1-216-037-00 METAL CHIP 330 5% 1/10W

(630V/635VK)

R502 1-216-037-00 METAL CHIP 330 5% 1/10W

(630V/635VK)

R503 1-216-049-11 RES,CHIP 1K 5% 1/10W

(630V/635VK)

R504 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

(630V/635VK)

R505 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

(630V/635VK)

R506 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

(630V/635VK)

R507 1-216-049-11 RES,CHIP 1K 5% 1/10W

(630V/635VK)

R508 1-216-037-00 METAL CHIP 330 5% 1/10W

(630V/635VK)

R509 1-216-073-00 METAL CHIP 10K 5% 1/10W

(630V/635VK)

R510 1-216-089-00 RES,CHIP 47K 5% 1/10W

(630V/635VK)

R511 1-216-105-00 RES,CHIP 220K 5% 1/10W

(630V/635VK)

R512 1-216-109-00 METAL CHIP 330K 5% 1/10W

(630V/635VK)

R117 1-216-037-00 METAL CHIP 330 5% 1/10W

R118 1-216-093-00 RES,CHIP 68K 5% 1/10W

R119 1-216-073-00 METAL CHIP 10K 5% 1/10W

R120 1-216-073-00 METAL CHIP 10K 5% 1/10W

R121 1-216-113-00 METAL CHIP 470K 5% 1/10W

R122 1-216-073-00 METAL CHIP 10K 5% 1/10W

R123 1-216-097-00 RES,CHIP 100K 5% 1/10W

R124 1-216-073-00 METAL CHIP 10K 5% 1/10W

R125 1-216-081-00 METAL CHIP 22K 5% 1/10W

R126 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R128 1-216-049-11 RES,CHIP 1K 5% 1/10W

(630V/635VK)

R129 1-216-049-11 RES,CHIP 1K 5% 1/10W

R130 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R131 1-216-049-11 RES,CHIP 1K 5% 1/10W

R132 1-216-073-00 METAL CHIP 10K 5% 1/10W

R133 1-216-073-00 METAL CHIP 10K 5% 1/10W

R513 1-216-073-00 METAL CHIP 10K 5% 1/10W

(630V/635VK)

R514 1-216-021-00 METAL CHIP 68 5% 1/10W

(630V/635VK)

R518 1-216-089-00 RES,CHIP 47K 5% 1/10W

(630V/635VK)

R601 1-216-105-00 RES,CHIP 220K 5% 1/10W

(630V/635VK)

R602 1-216-093-00 RES,CHIP 68K 5% 1/10W

(630V/635VK)

R603 1-216-049-11 RES,CHIP 1K 5% 1/10W

R605 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R606 1-216-121-00 RES,CHIP 1M 5% 1/10W

(630V/635VK)

R607 1-216-049-11 RES,CHIP 1K 5% 1/10W

R608 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

– 21 –

Page 36

M-530V/535V/630V/635VK

MAIN

Ref. No. Part No. Description Remark

< VARIABLE RESISTOR >

RV101 1-237-731-21 RES, VAR, CARBON 10K (VOL)

RV601 1-223-584-11 RES, ADJ, CARBON 2.2K

RV602 1-223-584-11 RES, ADJ, CARBON 2.2K

< SWITCH >

S101 1-572-964-11 SWITCH, SLIDE (REC/PB)

S102 1-572-688-11 SWITCH, PUSH (1 KEY) (POWER)

S103 1-692-605-31 SWITCH, SLIDE (VOR)

S601 1-572-922-11 SWITCH, SLIDE (PAUSE)

S602 1-692-298-11 SWITCH, SLIDE (TAPE SPEED)

S603 1-572-922-11 SWITCH, SLIDE (FAST PB) (630V/635VK)

< THERMISTOR (POSITIVE) >

THP601 1-810-552-11 THERMISTOR, POSITIVE

THP602 1-803-117-11 THERMISTOR, POSITIVE

*************************************************************

MISCELLANEOUS

***************

27 1-468-399-11 LED UNIT (630V/635VK)

87 1-548-579-41 COUNTER, TAPE (SMALL TYPE)

HRPE9011-500-593-11 HEAD, CERAMIC (REC/PB/ERASE)

M901 1-698-533-11 MOTOR, DC (CAPSTAN/REEL)

(including PULLEY)

MIC901 1-542-386-11 MICROPHONE, ELECTRET CONDENSER (MIC)

Ref. No. Part No. Description Remark

ACCESSORIES & PACKING MATERIALS

********************************

! 1-528-405-31 ADAPTOR, BATTER Y CHARGE (BCA-35E) (635VK)

! 1-693-073-21 ADAPTOR, AC (AC-E351) (635VK)

3-035-588-01 POUCH, CARRYING (530V:JE/630V:AEP,EE)

3-865-285-11 MANUAL, INSTRUCTION (ENGLISH,FRENCH)

(530V:US,CND/535V:EXCEPT E,1E)

3-865-285-61 MANUAL, INSTRUCTION (SPANISH,ITALIAN)

(535V:AEP)

3-865-285-71 MANUAL, INSTRUCTION (ENGLISH)

(630V:US,CND/635VK)

3-865-285-81 MANUAL, INSTRUCTION (FRENCH) (530V:AEP/

630V:CND,AEP/635VK:CND)

3-865-285-91 MANUAL, INSTRUCTION (ENGLISH,SPANISH,

PORTUGUESE,ITALIAN) (530V:AEP,E/

535V:E/630V:AEP,E)

3-866-171-01 MANUAL, INSTRUCTION (JAPANESE) (530V:JE)

3-866-171-11 MANUAL, INSTRUCTION (GERMAN,DUTCH,

SWEDISH,FINNISH) (530V:AEP/

630V:AEP)

3-866-171-21 MANUAL, INSTRUCTION (ENGLISH,

SIMPLIFIED CHINESE,HUNGARIAN,

RUSSIAN) (EE,CH,JE)

3-866-171-31 MANUAL, INSTRUCTION

(TRADITIONAL CHINESE,KOREAN,

POLISH,CZECH) (EE,JE)

3-866-171-41 MANUAL, INSTRUCTION (ENGLISH,

TRADITIONAL CHINESE) (1E)

SP901 1-505-838-11 SPEAKER (3.6cm)

*************************************************************

9-926-961-12

Sony Corporation

Personal Audio Company

– 22 –

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

Published by General Engineering Dept.

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

99E0410-1

Printed in Japan C1999. 5

Page 37

M-530V/535V/630V/635VK

US Model

Canadian Model

M-530V/535V/630V/635VK

SERVICE MANUAL

Ver 1.2 1999. 09

SUPPLEMENT-1

File this supplement with the service manual.

Subject : • Change of Main Board

• Corrections

Printed wiring board and schematic diagram of new type, and changed parts list

are described in this Supplement-1.

Refer to original service manual (9-926-961-12) previously issued for the other

information.

When performing service and inspection, check the suffix of the part number of

the main board.

– MAIN BOARD (CONDUCTOR SIDE) –

AEP Model

E Model

Chinese Model

M-530V/535V/630V

Tourist Model

M-530V

(ECN-MTA00149)

MAIN Board Part No.

Former type : 1-673-894-11

New type : 1-673-894-12

– 2 –

Page 38

M-530V/535V/630V/635VK

1. PRINTED WIRING BOARD

A

B

C

D

E

1

2345678910111213

TP20

TP19

TP33

TP2

TP37

TP18

TP38

TP32

TP1

TP9

TP3

TP4

TP5

TP6

TP7

TP23

TP14

TP13

TP8

TP39

TP10

TP28

TP27

TP26

TP30

TP29

TP40

F

G

H

HRPE901

REC/PB/ERASE

HEAD

HD+

(REC/PB)

(ERASE)

• Semiconductor Location

Ref. No. Location

D102 G-3

D103 C-3

(D504) G-8

IC101 D-7

(IC501) G-11

Q101 E-5

Q102 F-5

Q103 G-4

Q104 F-8

Q105 F-4

( ) : 630V/635VK only

< > : 530V/535V only

HD–

HE+

HE–

TP34

Ref. No. Location

Q106 G-8

Q107 G-6

Q108 G-7

<Q109> G-7

Q110 D-7

Q111 C-9

Q112 E-5

Q113 G-7

(Q501) G-9

(Q502) F-11

(Q601) E-9

TP21

TP36

TP22

TP17

TP15

TP24

Note:

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

• Pattern of the rear side is omitted.

TP35

TP16

TP12

TP25

TP11

– 3 – – 4 –

Page 39

2. SCHEMATIC DIAGRAM

M-530V/535V/630V/635VK

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• C : panel designation.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 3 V and fed with regulated dc power

supply from battery terminal.

4

W or less unless otherwise

• Voltage is dc with respect to ground under no-signal

condition.

no mark : PB

( ) : REC

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

E : PB

a : REC

– 5 – – 6 –

Page 40

3. ELECTRICAL PARTS LIST

MAIN

MAIN

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-3021-217-A MAIN BOARD, COMPLETE (630V/635VK)

A-3021-219-A MAIN BOARD, COMPLETE (530V/535V)

*********************

4-935-749-11 SPACER (S)

< CAPACITOR >

C101 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C102 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C103 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C104 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C105 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C106 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C107 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C108 1-124-433-00 ELECT 100uF 20% 4V

C109 1-124-434-00 ELECT 220uF 20% 4V

C110 1-104-396-11 ELECT 10uF 20% 16V

C112 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C113 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C115 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C117 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C118 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C119 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C120 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C121 1-164-346-11 CERAMIC CHIP 1uF 16V

C122 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C123 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C124 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C125 1-135-180-21 TANTALUM CHIP 3.3uF 20% 6.3V

C126 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C127 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C128 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C129 1-124-434-00 ELECT 220uF 20% 4V

C130 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C131 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C132 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C133 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C134 1-126-153-11 ELECT 22uF 20% 6.3V

C135 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C136 1-126-153-11 ELECT 22uF 20% 6.3V

C137 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C138 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

When indicating parts by reference

number, please include the board.

• Abbreviation

CND : Canadian model

EE : East European model

CH : Chinese model

E : Indication of country of origin

1E : No indication of country of origin

JE : Tourist model

C140 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C141 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C142 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C143 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C144 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C145 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C146 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C147 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C148 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

(630V/635VK)

C149 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

(630V/635VK)

C150 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C151 1-135-201-11 TANTALUM CHIP 10uF 20% 4V