Page 1

8mm Video MECHANICAL ADJUSTMENT MANUAL

Ver 1.0 2000. 12

IX

M2000 MECHANISM

Please use this manual with the service manual of the respective models.

MECHANISM DECK

Page 2

TABLE OF CONTENTS

1. Preparations for Check, Adjustment and

Replacement of Mechanism Block

1-1. Service Jigs and Tools ························································ 3

1-2. Mode Selector II Operating Procedure·······························5

2. Periodic Inspection and Maintenance

2-1. Rotary Drum Cleaning ······················································· 9

2-2. Tape Path System Cleaning ················································ 9

2-3. Periodic Inspection List····················································10

2-4. Appling Oil and Grease ···················································· 10

3. Before Replacement, Check or Adjustment

3-1. Phase Adjustment ····························································· 11

3-2. Cassette compartment assembly·······································12

4. Check, Adjustment and Replacement

4-1. Drum Assembly ································································ 14

4-2. HCL Arm Assembly, Loading Motor Assembly ·············· 15

4-3. Drum Base Assembly, Drum Earth ·································· 16

4-4. Guide Rail T2, Capstan Motor ········································· 17

4-5. Blind Plate, Lock Guide ··················································· 18

4-6. Reel Table (T) Assembly, T Soft Assembly ····················· 19

4-7. S Ratchet RE Plate, Cassette Guide S ······························ 20

4-8. R Drive Gear Assembly, LS Cam Plate···························· 21

4-9. LS Cam Plate Position Adjustment ·································· 22

4-10. LS Chassis Block Assembly············································· 23

4-11. TG7 Arm Block Assembly, Pinch Arm Assembly ··········· 24

4-12. Guide Base (T) Block Assembly,

Guide Base (S) Block Assembly ······································ 25

4-13. TG1 Arm, Reel Tab le (S) Assembly, Push Switch (3Key) · 26

4-14. Hall Element (H001, H002 (T/S Reel)),

Photo Transistor (Q001, Q002 (Tape Top/Tape End)),

LED (D001 (Tape LED))·················································· 27

4-15. LS Guide Roller, Guide Lock Plate (T),

Pinch Pusher Assembly, Eject Arm···································· 28

4-16. Rotary Switch, Cam Relay Gear,

Change Gear Assembly, Timing Belt ······························· 29

4-17. Guide Gear Assembly, Guide Gear T Assembly,

Cam Relay Gear 1, Guide Lock Plate (S) ························ 30

4-18. LD Gear 4, Cam Gear 1, HC Drive Arm ·························· 31

4-19. M Slide Plate Assembly, LS Arm Assembly,

Cam Gear 2, GL Arm Assembly ······································ 32

5. Adjustment

5-1. Check and Adjustment of TG1 Back-tension Position····· 33

5-2. Check and Adjustment of FWD/RVS Back-tension·········34

5-3. Capstan Motor Azimuth Position Adjustment·················· 35

5-4. Tape Path Adjustment ······················································· 36

6. Exploded Views

6-1. Cassette Compartment Assy, Drum Assy ························· 40

6-2. LS Chassis Block Assembly············································· 41

6-3. Mechanical Chassis Block Assembly-1 ··························· 42

6-4. Mechanical Chassis Block Assembly-2 ··························· 43

7. Printed Wiring Boards and

Schematic Diagrams .............................................. 44

— 2 —

Page 3

1. Preparations for Check, Adjustment and Replacement of Mechanism Block

Before Replacement, Check or Adjustment

• Refer to the “DISASSEMBLY” section of the SER VICE MANU AL of the respectiv e models for details of removing cabinets and printed

wiring boards.

• When checking a mechanism ir making any adjustment to the mechanism or r eplacing mechanical parts, be sure to use the Mode Selector

II and select the appropriate status of the mechanical deck such that the mechanical status is suitable for the desired work. Refer to section

“1-2. Mode Selector II Operating Procedure” for details on how to enter the mode shown in a rectangle [ ] mode in the sequent sections

of this manual.

* Assemble and adjust the parts in the [USE] mode if any mode is not specified in this manual.

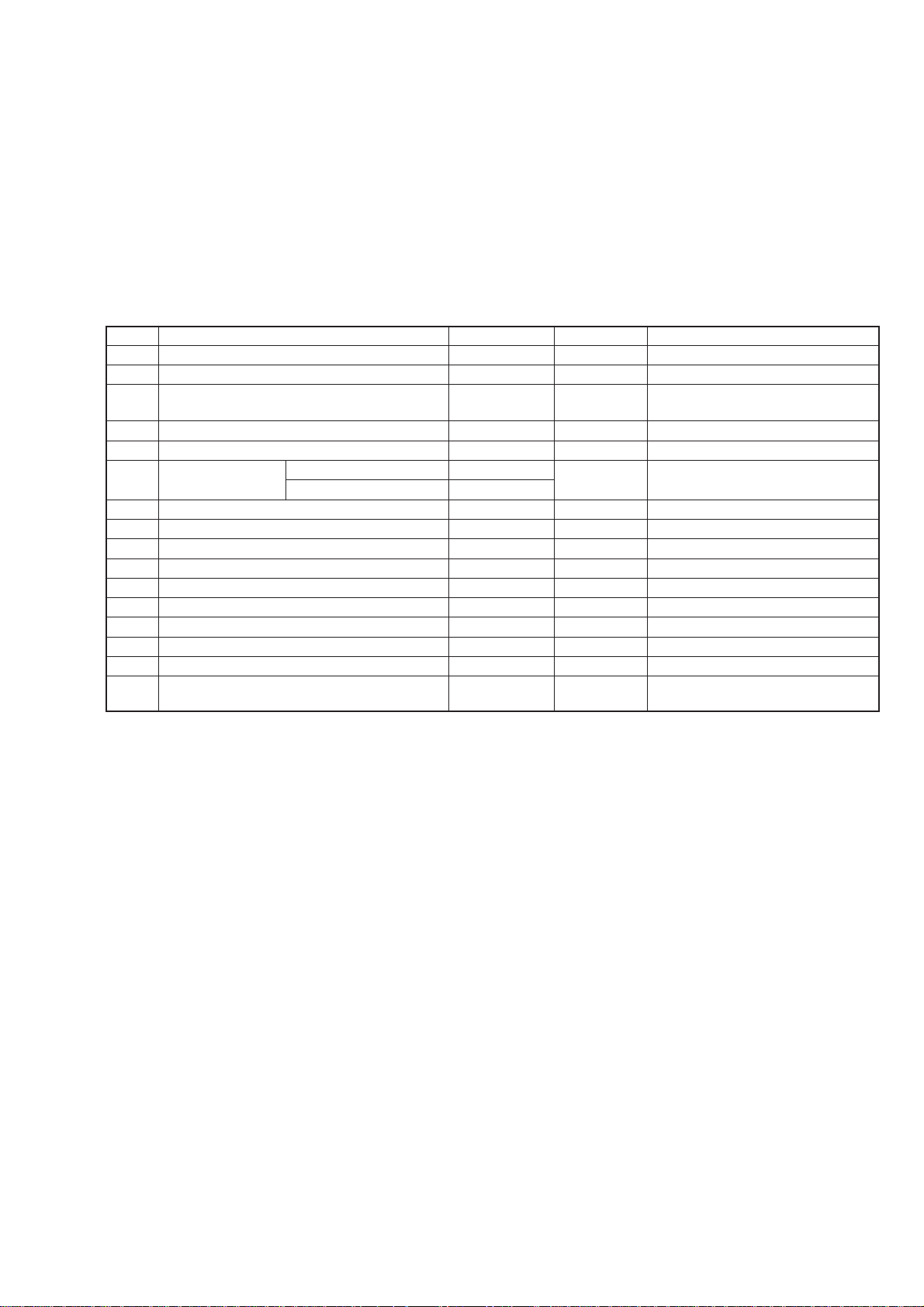

1-1. Service Jigs and Tools

Ref. No.

J-1

Cleaning fluid

J-2

Wiping cloth

Super-fine applicator

J-3

(made by Nippon Applicator (P752D))

J-4

Head eraser

J-5

Mirror (small oval type)

J-6

Alignment tape

J-7

FWD/RVS take-up torque cassette

J-8

Tape path screwdriver

J-9

Adjustment remote commander (

J-10

MD process table

J-11

Floil grease

J-12

Torque screwdriver

J-13

Mode Selector II

J-14

Mode Selector II conversion board

J-15

Mode Selector II ROM, Ver 1.6

J-16

Thickness gauge

Other required equipment:

• Oscilloscope

• Analog tester (20 kΩ)

Name

NTSC : WR5-1NP

PAL : WR5-1CP

RM-95 upgrated

Part code

Y-2031-001-0

7-741-900-53

commercially available

J-6080-840-A

8-967-995-02

8-967-995-07

J-6080-824-A

J-6082-026-A

)

J-6082-053-B

J-6082-166-A

7-662-001-39

J-9049-330-A

J-6082-282-B

J-6082-516-A

J-6082-314-E

9-911-053-00

Note: If the micro processor IC in the adjustment remote commander is

Jig inscription

Tape path

GD-2038

GD-2086

not the new micro processor (UPD7503G-C56-12), the pages cannot

be switched. In this case, replace with the new micro processor (8759-148-35).

Tape path

For tracking adjustment

For tape guide adjustment

Tape path (for setting the path mode)(Note)

For capstan azimuth adjustment,

LS cam plate position adjustment

Used for

— 3 —

Page 4

J-1 J-2 J-3 J-4 J-5

J-6 J-7 J-8 J-9 J-10

J-11 J-12 J-13 J-14 J-15

J-16

Fig. 1-1.

— 4 —

Page 5

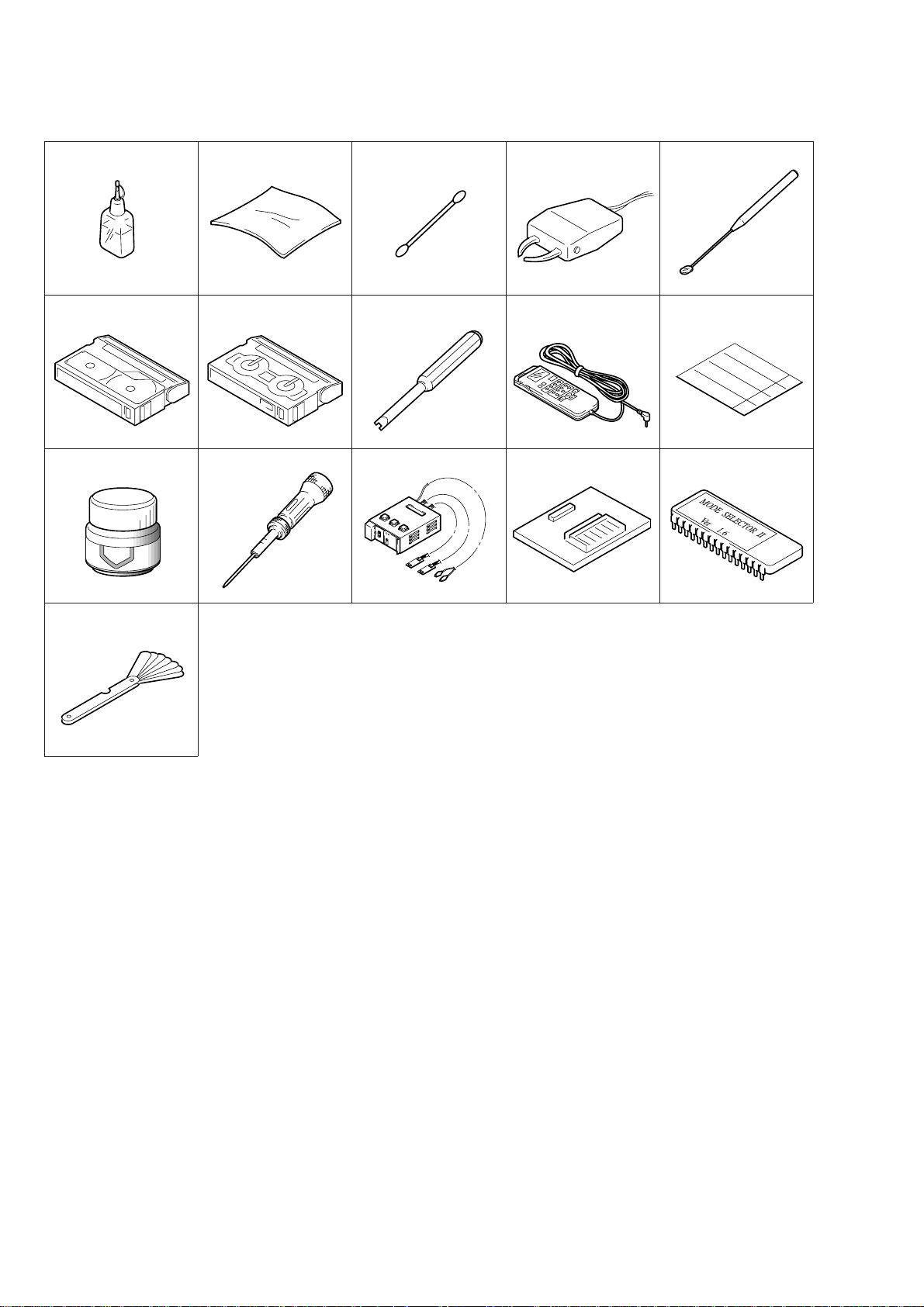

1-2. Mode Selector II Operating Procedure

1-2-1. Introduction

The Mode Selector II is a mechanism drive tool that assists

maintenance work of the various mechanism decks. It has the

following functions.

1. Manual Test

In this mode, the motor of the mechanism deck is powered only

during the period while the switch is turned on manually. Using the

Manual Test, the operator can freely control the motor of the

mechanism deck.

2. Step Test

In this mode, the motor of the mechanism deck is kept turned on

until the mechanical status is changed from the present mechanical

status that is obtained from the sensor information. The Step T est is

used to confirm a series of movements of the mechanism deck.

LCD display screen

Selector button

Mode Selector II

(Ref. No. J-13)

RVS

FF

SEL

3. Auto Test

The Mode Selector II stores the status transition table in its memory

as data indicating the respective modes of the mechanism deck.

The status transition table can be used to confirm whether a

mechanism deck is operating normally or has abnormality from a

series of movements of a mechanism deck. If an abnormal status

transition is detected during operation, the “NG” indication appears

and the mechanism stops moving.

Mode Selector II (J-6082-282-B) connection diagram

M2000 mechanism

Connector (black) 6-pin

(not used in M2000 mechanism)

External battery is

connected here as

a power supply

Relay board

(already connected)

Mode selector ll

Alligator clip

Fig. 1-2.

Alligator clip

(not used in M2000 mechanism)

Mode selector ll

conversion board (M)

(Ref. No. J-14)

Relay board

Battery such as NP-55, NP-77

(power supply)

Connector (white) 6-pin

Fig. 1-3.

— 5 —

Page 6

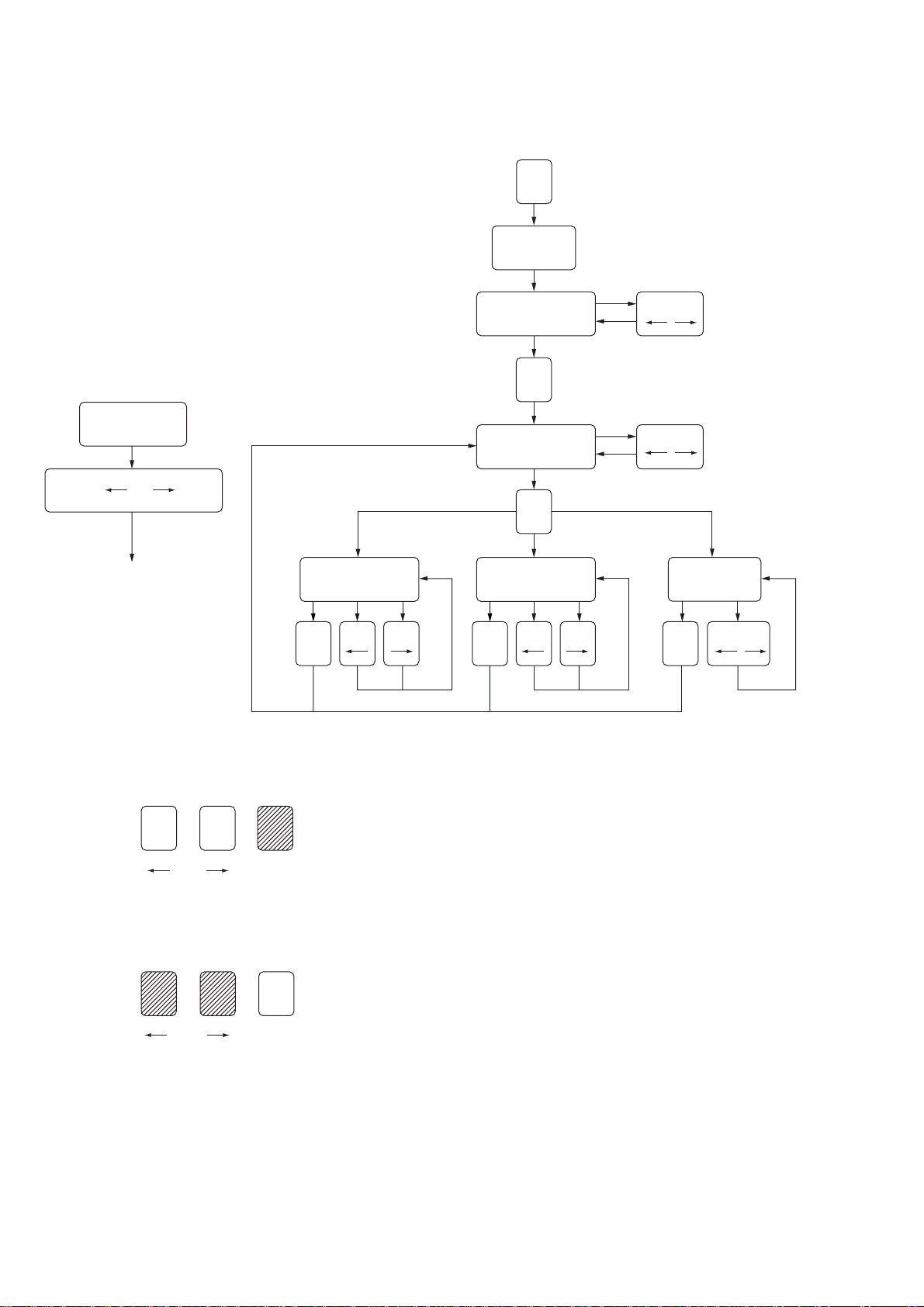

1-2-2. Operation

1. Operation Flow Chart

Note: The ROM in the Mode Selector II supports the M2000 mechanism.

From any status

Press RVS and FF for

2 sec. simultaneously

Main power is

turned off

MANUAL TEST

SEL

POWER ON

MECHA SELECT

SEL

MODE SELECT

SEL

STEP TEST

RVS, FF

RVS, FF

AUT O TEST

2. Mode Selector II Power On

Turn on the main power of the Mode Selector II as follows.

Press the SEL button.

RVS FF SEL

3. Mode Selector II Power Off

Turn off the main power of the Mode Selector II as follows.

Press the RVS and FF buttons at the same time for 2 seconds or

longer while the power is on.

RVS FF SEL

RVS, FFSELRVS FFSELRVS FFSEL

— 6 —

Page 7

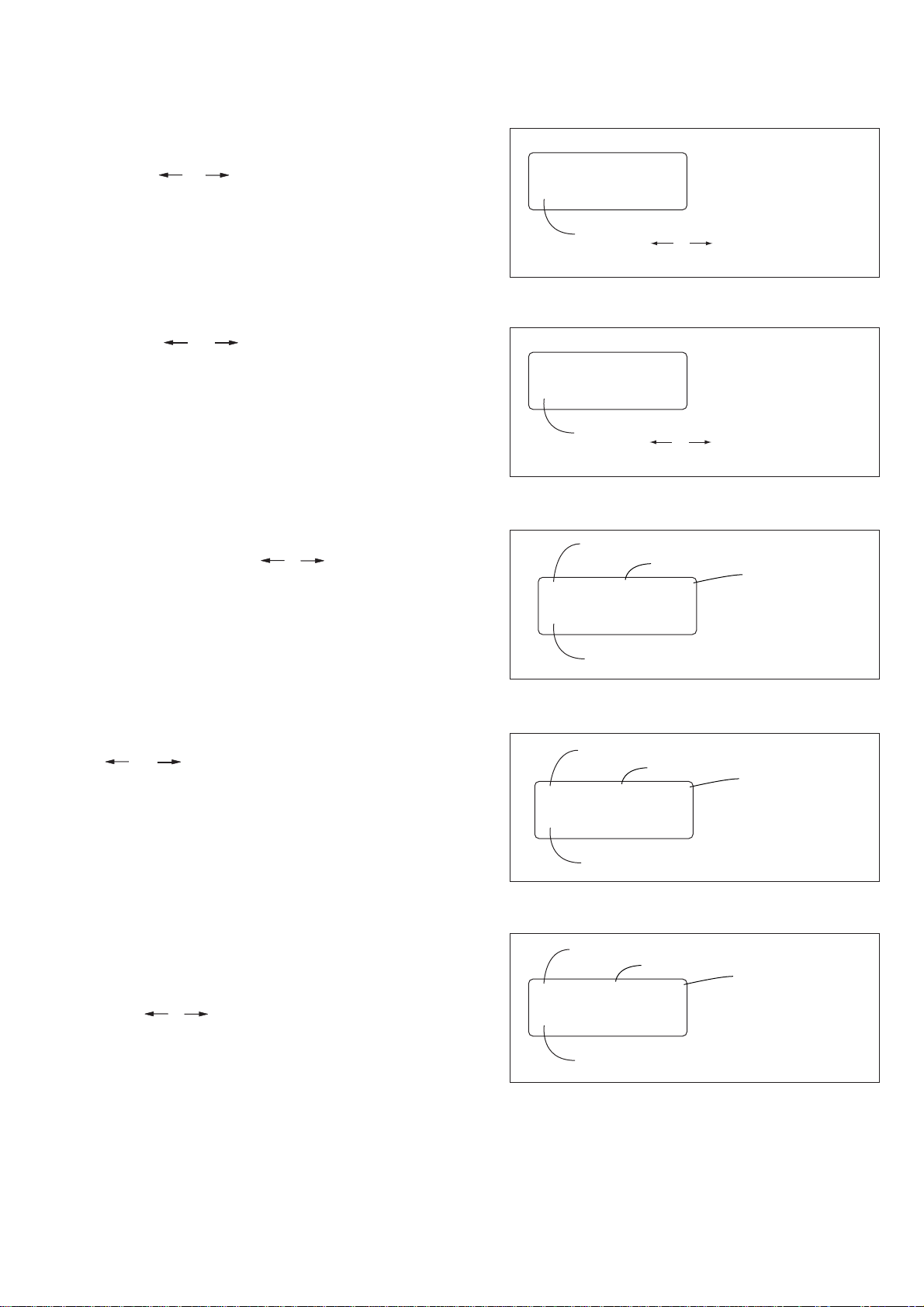

4. Mecha Select

)

)

)

When the main power is turned on, the MECHA SELECT display

appears on the LCD screen. Select the desired mechanism name

using the R VS and FF buttons. Selection is complete when the SEL

button is pressed. (Fig. A shows the B mechanism.)

5. Test Type Select

Using the RVS and FF buttons, select a desired test type from the

three types of “MANUAL”, “STEP” and “AUTO”. Selection is

complete when the SEL button is pressed.

6. Manual Test

In this test, the motor of the mechanism deck is turned on only

during the period while the R VS or FF button is pressed manually.

MECHA SELECT

B

Pressing the RVS or FF button

changes the mechanism name.

Fig. a

TEST TYPE SELECT

MANUAL

Pressing the RVS or FF button cycles

among MANUAL, STEP, AUTO in this order.

Fig. b

Mechanism name

Present mode

Motor ON/OFF

B MANUAL OFF

STATUS

7. Step Test

In this test, the direction of motor movement is determined by the

RVS and FF buttons. The motor of the mechanism deck is kept

turned on until the mechanical status is changed from the present

mechanical status that is obtained from the sensor information.

8. Auto Test

In this test, the mechanism deck is tested as to whether it performs

a series of movements correctly in accordance with the operation

sequence that is memorized earlier for each type of deck, by checking

the output signals from sensors with the stored memory. Turning

on the RVS or FF button performs the same operation.

Present status of sensor appears. (example: EJ

Fig. c

Mechanism name

Present mode

Motor ON/OFF

B STEP OFF

STATUS

Present status of sensor appears. (example: EJ

Fig. d

Mechanism name

Present mode

Motor ON/OFF

B AUTO OFF

STATUS

Present status of sensor appears. (example: EJ

Fig. e

— 7 —

Page 8

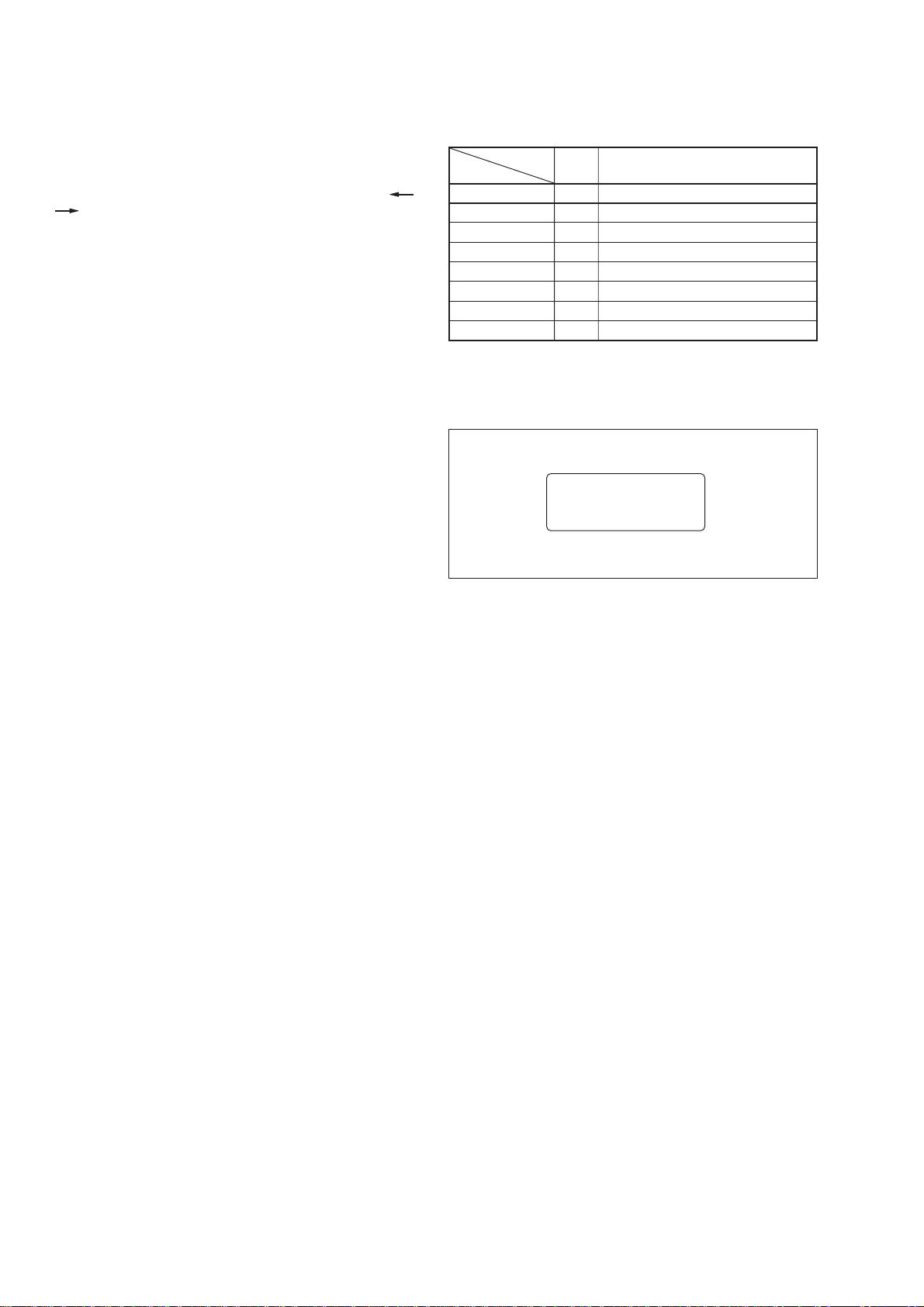

1-2-3. Mechanism Status (Position) Transition Table Using Mode Selector II

After selecting a mechanism deck, select either the MANUAL or

STEP test (not AUTO) using the Mode Selector II. The desired

mechanism status (position) can be specified by pressing the RVS

or FF button. (The selected status appears on STATUS.)

EJyUSEyLOADySTOPyTURNyRPyREW

1-2-4. Battery Alarm Indication

When the level of the battery used to supply power to this system

decreases, this display appears asynchronously . When this happens,

all operations are disabled and the battery must be replaced.

MD name

Code

ABC

100

110

010

011

001

000

101

0 is common and short.

[

1 is common and open.

M2000 Mechanism

1

EJ

2

USE

3

LOAD

4

STOP

5

TURN

6

RP

7

REW

BATT DOWN

CHANGE PLEASE

Fig. f

]

— 8 —

Page 9

2. Periodic Inspection and Maintenance

r

• Be sure to perform the following maintenance and inspection so

that the machine delivers its full performance and functions, and

to protect the machine and tape. Also, perform the following

maintenance items after completing the repair work, regardless

of the number of hours the machine has been operated by the

user.

2-1. Rotary Drum Cleaning

1) Press a wiping cloth (Ref. No. J-2) moistened with cleaning

fluid (Ref. No. J-1) lightly against the rotary drum. Rotate the

upper drum with a super-fine applicator slo wly in the counterclockwise direction to clean the rotary drum.

Caution: Never rotate the rotary drum by turning on the main power of

the motor or rotate it in the clockwise direction. Never move the

cloth vertically against the head tip, as this will surely damage

the video head; the video head must not be cleaned by any other

different methods.

TG5

T-reel

TG6

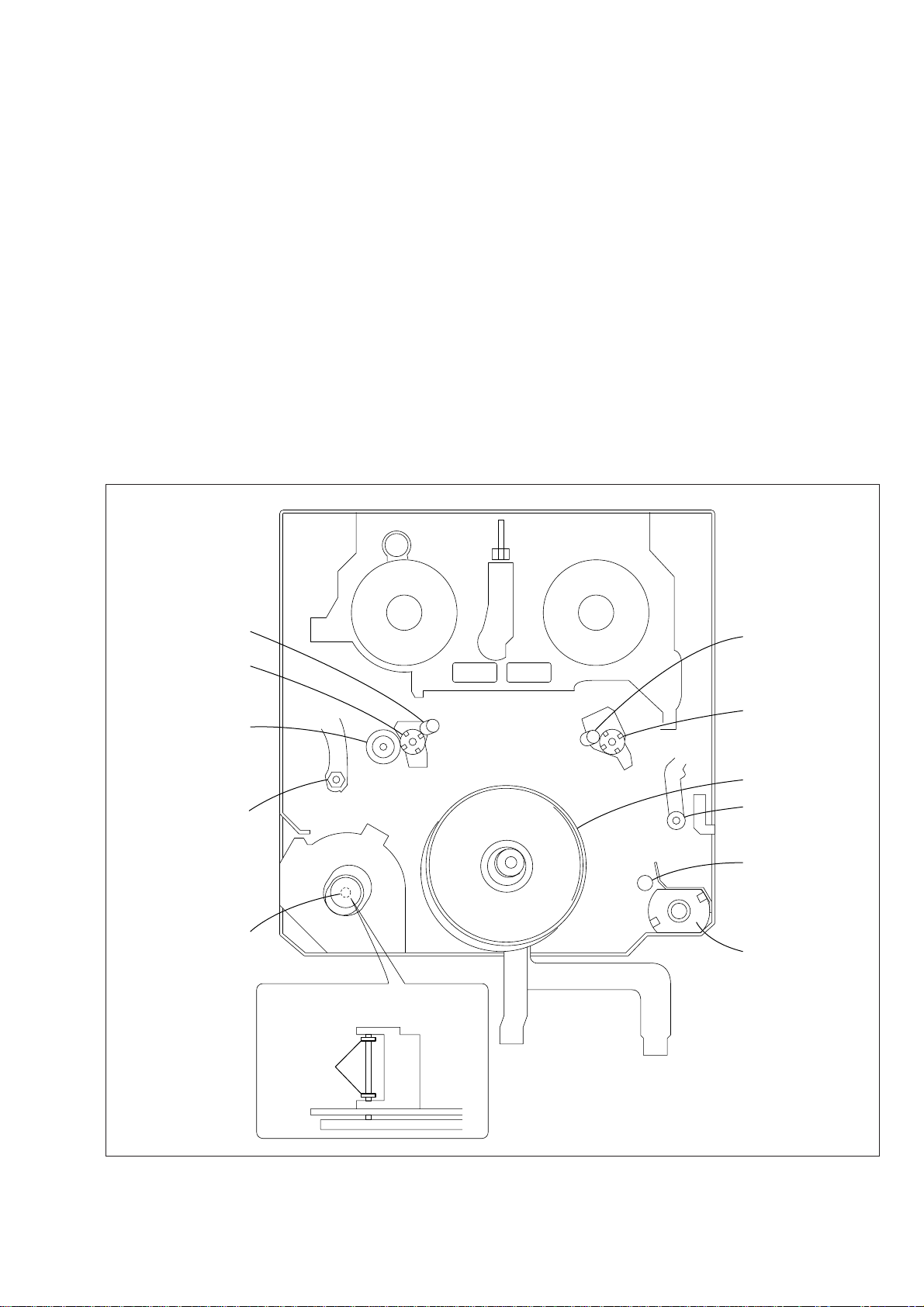

2-2. Tape Path System Cleaning

(Refer to Fig. 2-1.)

1) Set the EJECT state. Clean the tape running path (TG1, 2, 3,

4, 5, 6 and 7, pinch roller and capstan shaft) and lower drum

with a super-fine applicator (Ref. No. J-3) moistened with

cleaning fluid.

Note 1: Be careful not to allow oil or grease of the various link mechanisms

Note 2: Once the super-fine applicator has been moistened with alcohol,

Note 3: When cleaning the capstan shaft, be carefull not to move the oil

to get on the super-fine applicator (Ref. No. J-3).

do not use it to clean other mechanical parts such as the tape guide.

However, the pinch roller is cleaned with alcohol.

seal. If the oil seal is moved, oil will leak.

S-reel

TG4

Pinch roller

TG7

Capstan shaft

TG3

Drum

TG1

TG2

Loading moto

Capstan shaft cleaning

Oil seal

Fig. 2-1

— 9 —

Page 10

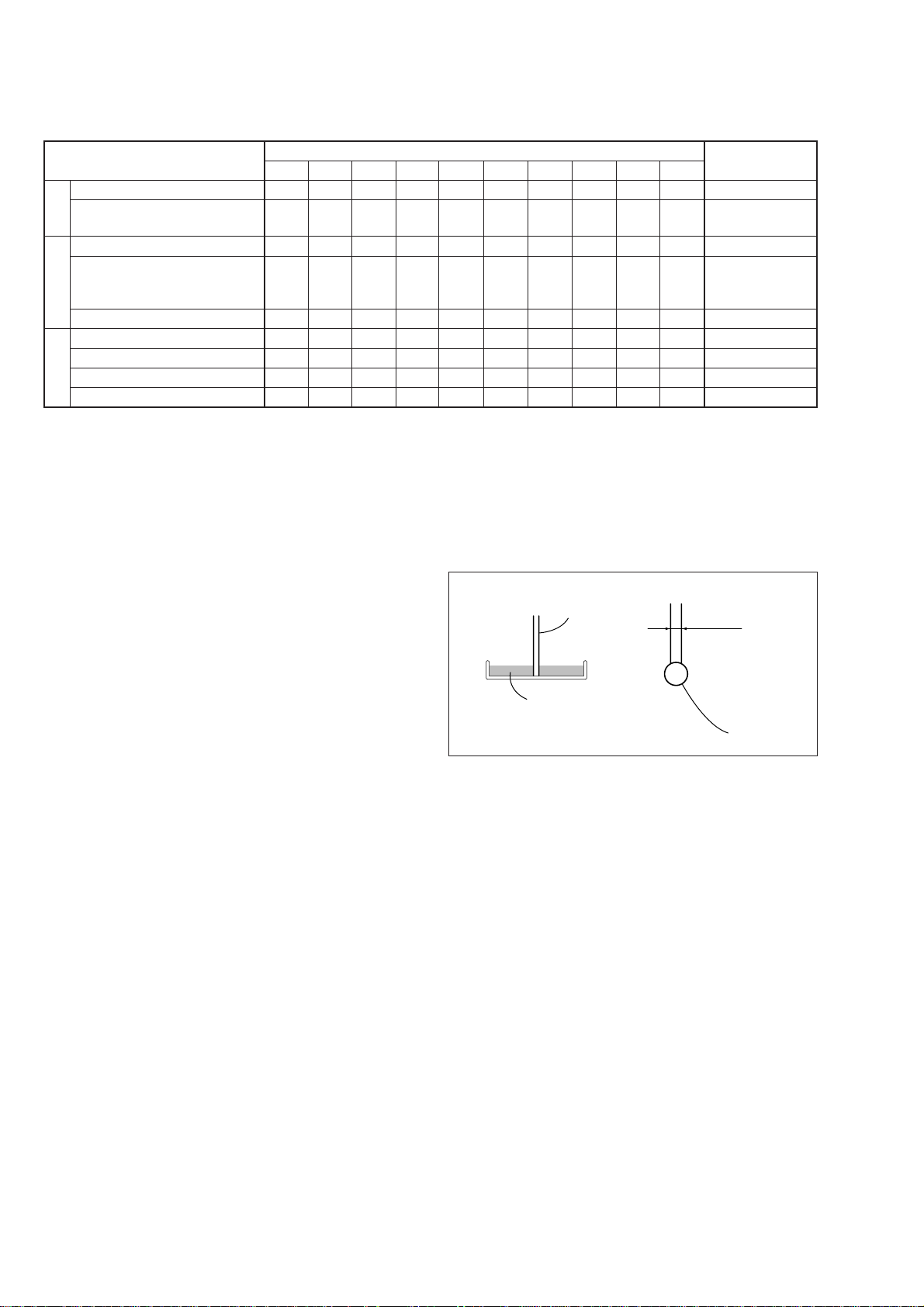

2-3. Periodic Inspection List

r

Maintenance and inspection item

Tape running surface cleaning

Rotary drum cleaning and

degaussing

Timing belt

Capstan shaft

Drive

mechanism

Loading motor

Abnormal sound

Back-tension measurement

Brake system

check

Performance

FWD/RVS torque measurement

Note: When the machine is overhauled, replace the parts referring to the

above list.

500

a

a

—

—

—

✩

—

—

—

1000

a

a

✩

✩

✩

✩

✩

✩

✩

1500

a

a

—

—

—

✩

—

—

—

2-4. Appling Oil and Grease

When replacing or assembling the parts, use oil and grease while

referring to the following.

On Oil

• Be sure to use the specified grease only. (If oil of different viscosity

is used, it can cause various troubles.)

Oil: Part No. 7-661-018-18

(Mitsubishi diamond oil hydro fluid NT-68)

• The oil used for bearings must not contain any dust or other

materials, otherwise excessive abrasion and seizure of the bearing

could occur.

• A drop of oil means the amount of oil as shown in the illustration

in the right, which is the amount that is attracted to the top of a

rod of 2 mm diameter.

Operating hours (H)

2000

2500

3000

a

a

a

a

a

a

✩

—

✩

✩

—

✩

✩

—

✩

✩

✩

✩

✩

—

✩

✩

—

✩

✩

—

✩

3500

4000

a

a

a

a

—

✩

—

✩

—

✩

✩

✩

—

✩

—

✩

—

✩

Metal rod of

1 mm diameter

Fill the oil of

about 2 mm depth

4500

a

a

—

—

—

✩

—

—

—

5000

a

a

Remarks

Be careful not to attach oil

Be careful not to attach oil

✩

Never attach oil to the

✩

tape running path during

periodic inspection.

✩

✩

✩

✩

✩

a: Cleaning, ✩: Check

1 mm diamete

Oil

On Grease

• Be sure to use the specified grease only. (If oil of different viscosity

is used, it can cause various troubles.)

Floil grease: Part No. 7-662-001-39

• Be sure to use grease into which dust is not mixed.

• The amount of grease is 1 to 1.5 mm diameter in length.

Fig. 2-2

— 10 —

Page 11

3. Before Replacement, Check or Adjustment

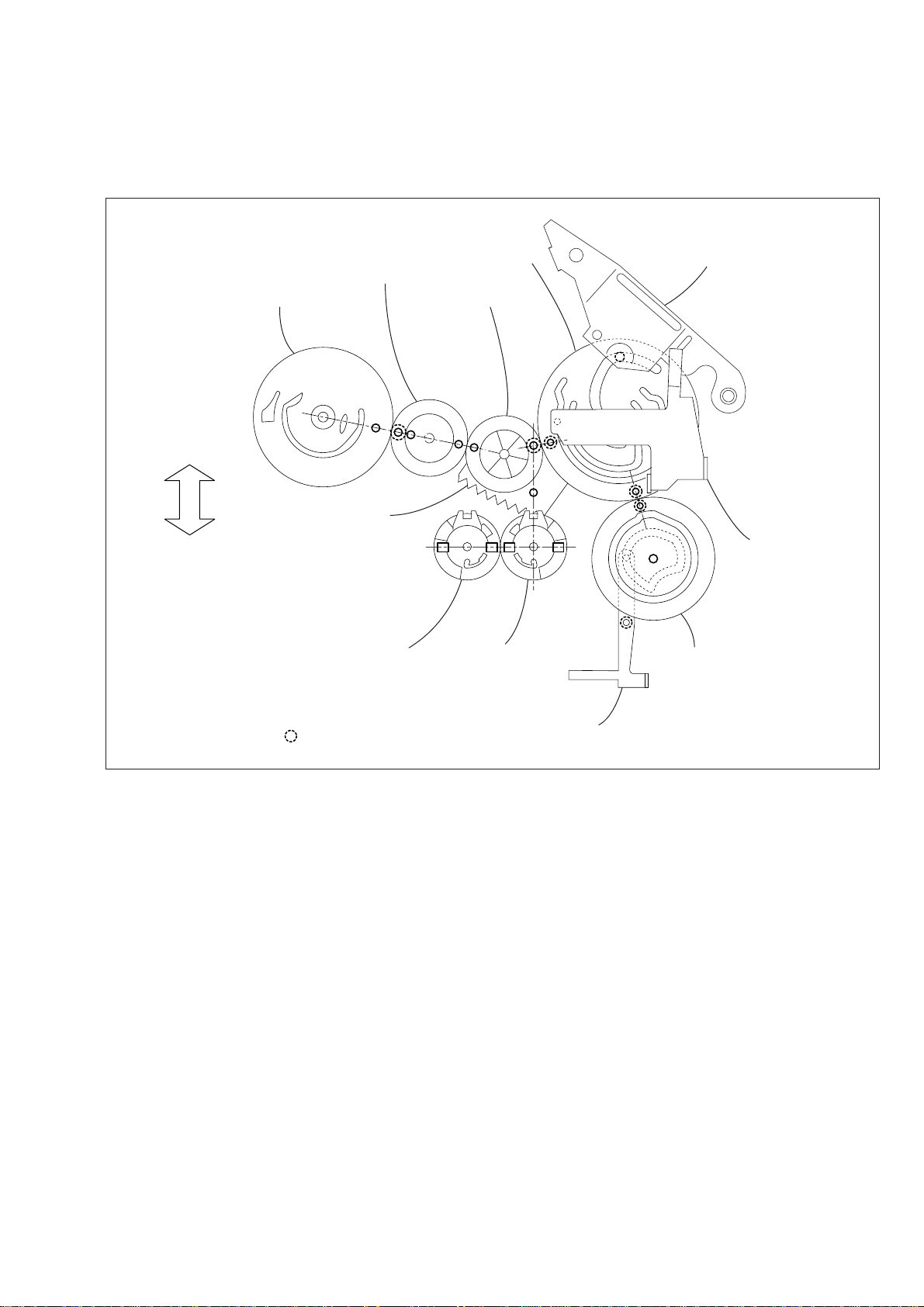

3-1. Phase Adjustment

The phase adjustment of this mechanism block has been adjusted

by using the in-phase markings shown in the following figure.

When replacing or assembling the parts, check the phase.

Cam gear (2) LS arm assembly

Cam relay gear (2)

Rotary switch

Front side

Cam relay gear (1)

Drum side

GL arm assembly

Guide gear

(S) assembly

Hole of mechanism chassis

Guide gear

(T) assembly

Fig. 3-1.

HC drive arm

Cam gear (1)

M slide plate

assembly

— 11 —

Page 12

3-2. Cassette compartment assembly

1. Removal procedure

1) Set the [EJ] mode to move up the cassette compartment

assembly 0.

2) Remove the capstan flexible board and flexible wiring board

(FP-300) 1 from the holders X, Y and Z in the directions

of the arrows A, B and C.

3) Push the damper assembly 3 in the directions of the arrows

D and E and remove it from the notch of the LS chassis block

assembly .

4) Remove the two screws (camera pan2 main M1.4 × 1.6) 4.

5) With the cassette compartment assembly 0 half opened , move

the face plate in the direction of the arrow F and remove it

from the grooves 6 and 7 on the LS chassis block assembly .

6) Remove the cassette holder (S) 8 and cassette holder (T) 9

of the cassette compartment assembly 0 from the groove on

the LS chassis block assembly.

2. Attachment procedure

1) Set the [USE] mode.

2) Insert the cassette holder (S) 8 of the cassette compartment

assembly 0 and cassette holder (T) 9 into the grooves on

both sides of the LS chassis block assembly.

3) While moving down the cassette compartment assembly 0,

lift up the face plate in the direction of the arrow F and keep

this status. Then, insert the face plate in the grooves 6 and 7

on the LS chassis block assembly.

4) Tighten the two screws (camera pan2 main M1.4×1.6) 4.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

5) Move the damper arm of the damper assembly 3 to the 4

o’clock position and insert the damper assembly into the hole

on the LS chassis block assembly and the dowel of the cassette

holder (T) 9.

6) Align the damper assembly 3 with the notch of the LS chassis

block assembly and rotate the damper assembly 3 in the

opposite direction to the arrow E to fix it.

— 12 —

Page 13

Damper

assembly

E

Cassette holder (T)

1

FP-300 flexible board,

Capstan flexible board

Remove the flexible board in the

direction of the arrow

C

Z

Capstan flexible board

A B C

FP-300 flexible board

B

X

Y

D

Push

2

Remove the damper assembly in the direction

of the arrow

3

Damper assembly

.

A

E

.

Move the damper arm

to the 4 o'clock position.

Insert into these holes

and attach.

Damper arm

*

Be careful not to

deform here.

Cassette holder (T)

While pressing

toward the inside

9

7

0

Cassette compartment

assembly

8

Cassette holder (S)

While pressing

toward the inside

4

(camera pan 2 main M1.4

6

*

Be careful not to

deform here.

T wo screws

×

1.6)

Face plate

F

5

Remove the cassette

compartment assembly

in the direction of the

arrow

F

.

Fig. 3-2.

— 13 —

When attaching it, coat the hatched portion with grease.

Page 14

4. Check, Adjustment and Replacement

Note: For removal procedure of the cabinets, printed wiring boards and other parts, refer to “DISASSEMBLY” of the Service Manual of the respective

models.

4-1. Drum Assembly

1. Removal procedure

1) Remove the three screws (drum fitting M1.4 × 2.5) 1 fixing

the drum and remove the drum.

Drum (rear view)

Hole (reference hole B)

Hole (reference hole A)

2. Attachment procedure

1) Align the two reference holes A and B on the rear of the drum

with the reference pins A and B of the drum base assembly.

2) Attach the drum with the three screws (drum fitting M1.4 ×

2.5) 1 in the order of A, B and C.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

3) Clean the drum while referring to 2-1.

4) Adjust the tape path. (Refer to “4. Tape Path Adjustment”.)

Note: Do not touch the outside circumference.

Drum

Reference pin A

1

Three screws

(drum fitting M1.4

×

2.5)

B

Reference pin B

Drum base assembly

C

A

Fig. 4-1.

— 14 —

Page 15

4-2. HCL Arm Assembly, Loading Motor Assembly

1. Removal procedure

1) Hook the HC arm spring in the direction of the arrow B.

2) Remove the HCL arm assembly 2 from the loading motor

assembly 4.

3) Remove the screw (M1.4 × 2.5) 3.

4) Remove the three claws of the loading motor assembly 4 from

the mechanism chassis assembly in the direction of the arrow

A.

Hook the HC arm spring on the notch

of the loading motor assembly.

B

2. Attachment procedure

1) Coat the worm shaft and gear of the loading motor assembly

4 with grease.

2) Insert the three claws of the loading motor assembly 4 into

the groove on the mechanism chassis assembly.

3) Attach the screw (M1.4 × 2.5) 3.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

4) Check the position of the HCL arm assembly 2 and the HC

drive arm. Then attach the HCL arm assembly 2 to the loading

motor assembly 4.

5) Hook the HC arm spring 1 on the notch of the loading motor

assembly 4.

6) Clean the drum assembly. (Refer to section 2-1.)

2

HCL arm

assembly

Drive pin

3

Screw

×

(M1.4

A polarity exists.

The marked side has

a red line.

4

assembly

2.5)

Loading motor

Remove the loading motor

assembly in the direction

of the arrow

A

.

A

1

Pull and hook the HC arm spring in

the direction of the arrow

When attaching it, coat the hatched

portion with grease.

Drive pin

HC drive arm

B

.

Loading motor

assembly

(rear view)

Three

claws

Mechanical chassis assembly

Cover

sheet

Loading motor

assembly

Fig. 4-2.

— 15 —

Page 16

4-3. Drum Base Assembly, Drum Earth

1. Removal procedure

1) Remove the capstan flexible board and flexible wiring board

(FP-300) from the holders X, Y and Z in the direction of the

arrow .

2) Remove the drum assembly. (Refer to section 4-1.)

3) Remove the screw (M1.4 × 2.5) 2.

4) Remove the claw D of the guide rail T2 3 from the hole E

of the drum base assembly in the direction of the arrow F.

5) Remove the three screws (M1.4 × 2.5) 4.

6) Remove the drum base assembly 5 in the direction of the arro w .

7) Remove the screw (screw assy PW M1.7 × 2.6) 6.

8) Remove the drum earth 7 and earth spacer 8.

Guide rail

(T2)

Remove the guide rail

(T2) in the direction

of the arrow

F

.

F

Claw

Drum base assembly

D

2. Attachment procedure

1) Attach the ground spacer 8 and drum ground 7 with the scre w

(screw assy PW M1.7 × 2.6) 6.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

2) Align the drum base assembly 5 with the reference pin and

tighten the three screws (M1.4 × 2.5) 4 in the order of G, H

and I.

3) Insert the claw D of the guide rail T23 into the hole E of the

drum base assembly 5 and tighten the screw (M1.4 × 2.5) 2.

Tightening torque: 0.078 ± 0.01 N•m (0.8 kgf•cm)

4) Remove the drum assembly. (Refer to 4-1.)

5) Attach the flexible wiring board (FP-300) 1 and capstan

flexible board to the drum base assembly.

6) Clean the tape running path. (Refer to 2-2.)

hole

H

E

G

I

4

Three screws

(M1.4

5

Drum base

assembly

×

2.5)

3

Guide

rail (T2)

2

Screw

(M1.4

×

2.5)

Remove the flexible board in the

direction of the arrow

C

Z

Capstan flexible board

1

FP-300 flexible board,

Capstan flexible board

A B C

FP-300 flexible board

B

X

Y

A

Two dowels

.

6

Screw

(screw assy PW

M1.7

×

2.6)

7

Drum

ground

8

Ground

spacer

Claw

D

Fig. 4-3.

— 16 —

Page 17

4-4. Guide Rail T2, Capstan Motor

1. Removal procedure

1) Remove the capstan flexible board and flexible wiring board

(FP-300) 1 from the holders X, Y and Z in the directions

of the arrows A, B and C.

2) Remove the screw (M1.4 × 2.5) 2.

3) Remove the claw of the guide rail T2 3 from the hole on the

drum base assembly in the direction of the arrow D.

4) Remove the six solderings 4.

5) Remove the FP-228 flexible wiring board (2P) (DEW sensor)

5.

6) Remove the two screws (camera pan2 main M1.4 × 1.6) 6

and the screw (SANG camera pan2 main M1.4 × 4.5) 7.

7) Remove the capstan motor 8.

8) Remove the capstan spring 9 (be careful not to dr op the capstan

spring) and timing belt 0.

Attachment position of

FP-228 flexible board

Approx.0.5mm

6

T wo screws

(camera pan 2 main

M1.4 × 1.6)

7

Screw

(SANG camera pan

2 main M1.4 × 4.5)

5

FP-228 flexible

board (2P)

(DEW sensor)

8

Capstan motor

3

Guide rail (T2)

2. Attachment procedure

1) Hook the timing belt 0 on the gear of the capstan motor 8,

attach the capstan motor while aligning it with the reference

boss of the mechanism chassis assembly.

2) Attach the screw (SANG camera pan2 M1.4 × 4.5) 7 and

capstan spring 9. (temporally attachment)

3) Attach the two screws (camera pan2 M1.4 × 1.6) 6.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

4) Attach the six solderings 4 to the FP-228 flexible wiring board

5 (2P) (DEW sensor) and the FP-299 flexible wiring board

(4P).

5) Insert the guide rail T2 3 into the hole on the drum base

assembly and tighten the screw (M1.4 × 2.5) 2.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

6) Attach the capstan flexible board and the flexible wiring board

(FP-300) 1 to the holders X, Y and Z.

7) Adjust the height of the capstan motor using the thickness gauge

(Ref. No. J-16). (Refer to 5-3.)

Note: Be careful not to touch the center of the capstan motor 0 shaft and

the FP-228 flexible wiring board (DEW sensor) with soldering iron

or other tool.

2

Screw

(M1.4 × 2.5)

Remove the Guide rail (T2)

in the direction of the

D

.

Guide rail

(T2)

D

Drum base

assembly

4

Remove the

six solderings

FP-299 flexible

board (4P)

arrow

1

FP-300 flexible board,

Capstan flexible board

Remove the flexible board in the

direction of the arrow A B C.

FP-300 flexible board

C

Z

Capstan flexible board

B

X

Y

9

Capstan spring

A

Fig. 4-4.

— 17 —

0

Timing belt

Note: Any foreign materials must not be attached

to the capstan motor.

Page 18

4-5. Blind Plate, Lock Guide

1. Removal procedure

1) Remove the diode D001 (tape LED) 1 from the notch of the

plate 4.

2) Remove the flexible wiring board 2 (FP-301) from T-shaped

portion of the blind plate 4 in the direction of the arrow A.

3) Remove the screw (camera pan2 main M1.4 × 1.6) 3.

4) Release the hook on the notches G, D, E and F of the blind

plate 4 in the direction of the arrow B.

5) Remove the reel release lever 5 in the direction of the arrow

C.

3

Screw

(camera pan 2 main M1.4 × 1.6)

4

Remove the blind plate in the

direction of the arrow B.

Notch

G

A

2. Attachment procedure

1) Attach the reel release lever 5 to the blind plate 4.

2) Hang the notches G, D, E and F of the blind plate 4 on

the hook.

3) Attach the screw (camera pan2 main M1.4 × 1.6) 3.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

4) Attach the flexible wiring board (FP-301) 2 to the T-shaped

portion of the blind plate 4.

5) Attach the diode (tape LED) 1 to the notch of the blind plate

4.

C

5

Remove the reel release

lever in the direction of

the arrow C.

Claw

Notch

D

Notch

B

E

2

Remove the FP-301 flexible

board in the direction of

the arrow A.

Fig. 4-5.

Notch

F

1

D001

Diode (tape LED)

— 18 —

Page 19

4-6. Reel Table (T) Assembly, T Soft Assembly

1. Removal procedure

1) Remove the blind plate. (Refer to 4-5.)

2) Open the claw of the reel table T assembly 1 in the directions

of the arrows B and C and remove the reel table T assembly.

3) Remove the T soft assembly 2 in the direction of the arrow

A.

4) Remove the T ratchet spring 3.

5) Remove the T ratchet arm 4 in the direction of the arro w D.

Open the claw of the reel table T

in the directions of the arrows

B

and C.

B

C

2. Attachment procedure

1) Insert the T ratchet arm 4 into the groove on the LS chassis

block assembly to attach it.

2) Attach the T ratchet spring 3 to the notch of the T ratchet arm

4 and LS chassis block assembly.

3) Insert the T soft assembly into the groove on the LS chassis

block assembly.

4) Check the location of the reel table T assembly and attach the

LS chassis block assembly to the shaft.

5) Attach the blind plate. (Refer to 4-5.)

Check the location of the reel

1

Reel table (T)

assembly

A

table (T) assembly.

The reel table (T)

assembly is at a

slant.

4

Remove the T ratchet arm in

the direction of the arrow D.

D

Fig. 4-6.

2

Remove the T soft assembly in the

direction of the arrow A.

3

T ratchet

spring

When attaching it, coat the hatched

portion with grease.

— 19 —

Page 20

4-7. S Ratchet RE Plate, Cassette Guide S

1. Removal procedure

1) Remove the blind plate. (Refer to 4-5.)

2) Remove the RE return plate spring 1.

3) Remove the S ratchet spring 2.

4) Remove the S ratchet arm 3 in the direction of the arrow A.

Note: Do not reuse the S ratchet arm.

5) Remove the S ratchet RE plate.

6) Remove the screw (camera tapping M1.4 × 2)5.

7) Remove the cassette guide S 6 in the direction of the arrow

B.

Remove the S ratchet arm in the

direction of the arrow

Do not reuse

the S ratchet arm.

Fixed here.

S ratchet spring

Remove the S ratchet (RE) plate in the

direction of the arrow

A

A

B

.

dowel

B

.

3

S ratchet arm

2. Attachment procedure

1) Attach the cassette guide S 6 to the notch of the LS chassis

block assembly with the screw (camera tapping M1.4 × 2).

2) Attach the S ratchet RE plate 4 to the shaft of the LS chassis

block assembly.

3) Attach the S ratchet arm 3 to the shaft of the LS chassis block

assembly. At this time, the dowel of the S ratchet RE plate 4

must be inserted into the U-shaped notch of the S ratchet arm

3.

4) Hook the S ratchet spring 2 on the notch of the S ratchet arm

and attach it to the notch of the LS chassis block assembly.

5) Attach the RE return plate spring 1 to the notch of the LS

chassis block assembly.

6) Attach the blind plate. (Refer to 4-5.)

2

S ratchet

spring

B

6

Remove the cassette

guide (S) in the direction

of the arrow

B

.

4

S ratchet

(RE) plate

Fig. 4-7.

1

RE return plate spring

5

Screw

(camera tapping M1.4

×

2)

— 20 —

Page 21

4-8. R Drive Gear Assembly, LS Cam Plate

1. Removal procedure

1) Remove the blind plate. (Refer to 4-5.)

2) Remove the lumiler cut washer (0.98 × 3 × 0.13) 1.

3) Remove the R drive gear assembly 2.

4) Remove the HLC cut (1.8 × 4 × 0.5) 3 and the two screws

(precision type3 +P1.7 × 1.8) 4.

5) Remove the LS cam plate 5.

5

LS cam plate

1

Lumiler (W)

cut (0.98 × 3 × 0.13)

Do not bend the claw.

2

R drive gear

assembly

2. Attachment procedure

1) Attach the R drive gear assembly 2 with the lumiler cut washer

(0.98 × 3 × 0.13) 1.

2) Align the LS cam plate 5 with the two dowels of the LS chassis

block assembly, temporarily fix the LS cam plate 5 with the

two screws (precision type3 +P1.7 × 1.8), then attach it with

the HLC cut (1.8 × 4 × 0.5) 3.

3) Adjust the position of the LS cam plate. (Refer to 4-9.)

4

T wo screws

(precision type3 +P1.7 × 1.8)

3

HLC cut (1.8 × 4 × 0.5)

When attaching it, coat

the hatched portion

with grease.

Fig. 4-8.

— 21 —

Two dowel

When attaching it, coat the hatched

portion with grease.

Page 22

4-9. LS Cam Plate Position Adjustment

s

1. Adjustment Pr ocedure

1) Perform loading of the LS chassis block assembly 1 until the

tip of the guide base (S) assembly reaches the drum base

assembly.

2) Loosen the two screws (precision type3 +P1.7 × 1.8) 2 of the

LS cam plate and slide the LS chassis block assembly to the

drum side so as to remove play.

3) Insert the thickness gauge 0.6 mm (Ref. No. J-16) between the

LS cam plate and the LS chassis block assembly . Push the LS

cam plate in the direction opposite to the drum to remove play .

4) Fix the two screws (precision type3 +P1.7 × 1.8) 2.

Tightening torque: 0.108 ± 0.01 N•m (1.1 kgf•cm)

Two screws

(precision type3 +P1.7

×

1.8)

Thickness

gauge

t =0.6mm

Two dowels

LS cam plate

Fig. 4-9.

Guide base (S)

block assembly

1

LS chassis

block assembly

Push the LS chassi

2

block assembly

to remove play.

— 22 —

Page 23

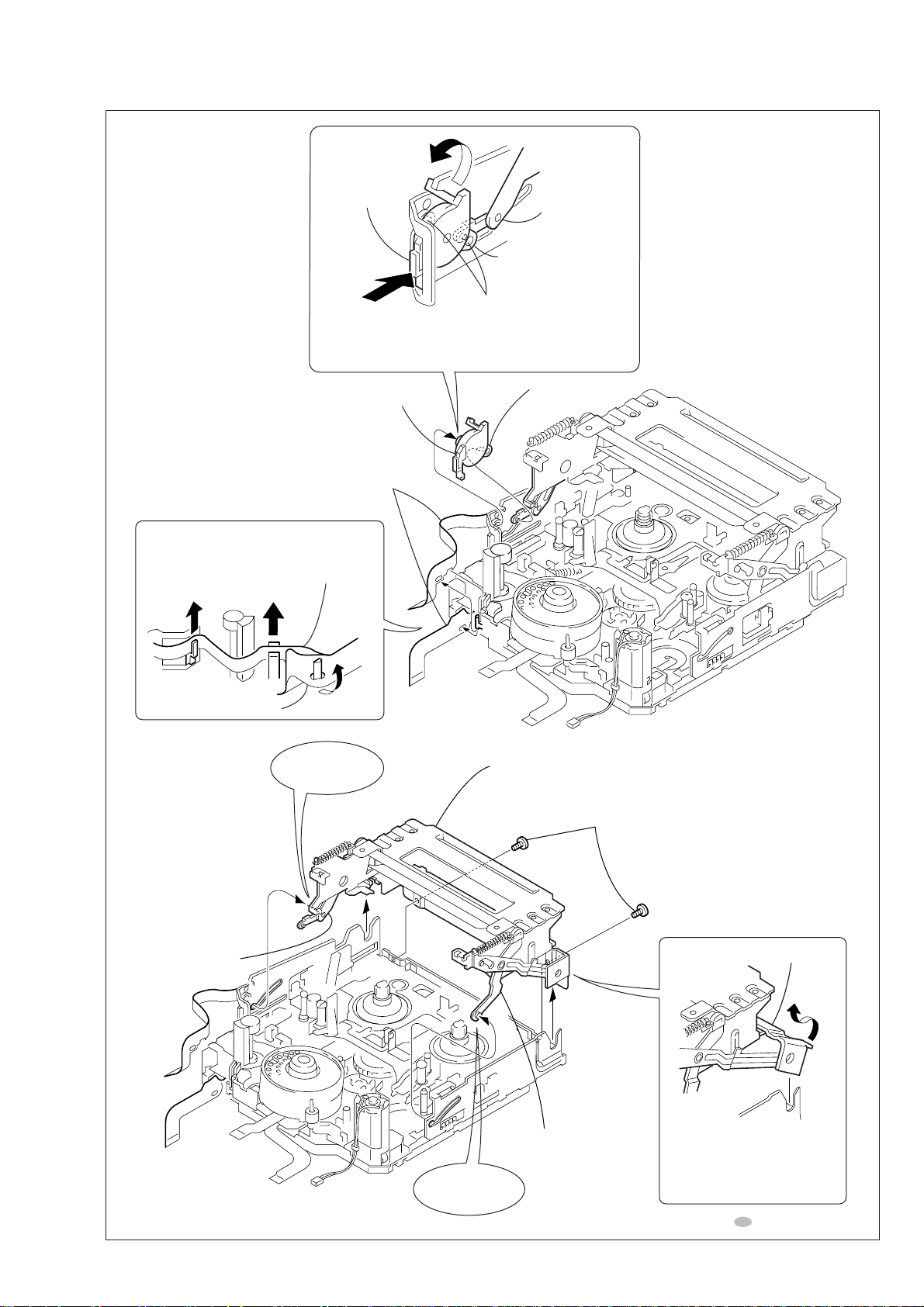

4-10.LS Chassis Block Assembly

1. Removal procedure

1) Move the LS chassis block assembly between [USE] and

[LOAD].

2) Remove the blind plate. (Refer to 4-5.)

3) Remove the R drive gear assembly. (Refer to 4-8.)

4) Remove the HCL cut (1.8 × 4 × 0.5) 1.

5) Remove the three screws (M1.4 × 2.5) 2.

6) Remove the LS chassis block assembly 3 in the direction of

the arrow A.

When attaching it, coat the hatched

portion with grease.

5

TG7 arm block

assembly

4

Slot of LS chassis

(at two locations)

2. Attachment procedure

1) Insert the LS guide roller and LS guide T2 pin of the mechanical

chassis block assembly into the slot of the LS chassis block

assembly 4.

2) Insert the pin of the LS arm assembly into the cam groove on

the LS cam plate, face the TG7 driv e pin 5 in the direction of

the arrow B, and insert it to the two slot of the mechanical

chassis. Then, tighten the three screws (M1.4 × 2.5) 2 in the

order of C, D and E.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

3) Attach the HCL cut (1.8 × 4 × 0.5) 1 to the pin of the LS arm

assembly .

4) Attach the R drive gear assembly. (Refer to 4-8.)

5) Attach the blind plate. (Refer to 4-5.)

6) Clean the tape running path. (Refer to 2-2.)

Note: Each arm must move smoothly.

C

2

Three screws

D

E

(M1.4

LS cam plate

Cam groove

×

2.5)

1

HCL cut

(1.8

×

4 × 0.5)

3

Remove the LS chassis

block assembly in the

A

direction of the arrow

A

.

LS guide

T2 shaft

B

LS guide roller

Do not

bend here.

6 to 8mm

Fig. 4-10.

When attaching it, coat the

hatched portion

with grease.

Pin

LS arm assembly

Mechanical chassis block assembly

— 23 —

Page 24

4-11.TG7 Arm Block Assembly, Pinch Arm Assembly

1. Removal procedure

1) Remove the LS chassis block assembly. (Refer to 4-10.)

2) Remove the screw (camera pan2 M1.4 × 1.6) 1.

3) Remove the TG7 retainer 2 in the direction of the arrow.

4) Remove the TG7 arm block assembly 6 and TG7 arm spring

7.

5) Remove the pinch roller arm assembly 3.

6) Remove the P lim arm roller 4 and pinch arm load spring 5.

6

TG7 arm block

assembly

7

TG7 arm spring

PRECAUTION DURING

INSTALLATION

Rising metal

sheet

2. Attachment procedure

1) Attach the P lim arm roller 4 to the pinch roller arm assembly

3.

2) Insert one end of the pinch arm load spring 5 into the hole on

the rising metal sheet of the LS chassis block assembly, and

hook the other end of the spring on the position setting

protrusion of the LS-057 board.

3) Attach the pinch roller arm assembly 3 to the shaft of the LS

chassis block assembly, and hook the pinc h arm load spring 5

on the rising metal sheet of the pinch roller assembly 3.

4) Hook the TG7 arm spring 7 on the shaft of the LS chassis

block assembly while the hook side of the spring is facing

downward.

5) When attaching the TG7 arm block assembly 6 to the shaft of

the LS chassis block assembly , hook the hook side of the TG7

arm spring 7 on the rising metal sheet of the LS chassis block

assembly and hook the top side of the spring to the notch of the

TG7 arm block assembly 6.

6) Attach the TG7 retainer 2 with the screw (camera pan2 M1.4

× 1.6) 1.

7) Remove the LS chassis block assembly. (Refer to 4-10.)

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

8) Clean the tape running path. (Refer to 2-2.)

1

Screw

(camera pan2 M1.4 × 1.6)

2

Remove the TG7 retainer in the

direction of the arrow.

3

Pinch arm assembly

Pinch arm assembly

(rear view)

Temporarily fix the pinch arm load

spring to the rising metal sheet

of the LS chassis.

After attaching the pinch arm

assembly, release the temporarily

fixed pinch arm load spring.

Pinch arm road spring

TG7

retainer

LS chassis block

assembly

TG7 arm block

assembly

P lim

arm roller

TG7 arm

spring

Pinch arm

assembly

Rising metal

sheet

LS chassis block

assembly

4

P lim arm roller

Be careful not to drop.

5

Pinch arm road spring

Location where grease is coated

Inside the top edge of the metal

When attaching it, coat the hatched

portion with grease.

Fig. 4-11.

— 24 —

Page 25

4-12.Guide Base (T) Block Assembly, Guide Base (S) Block Assembly

1. Removal procedure

1) Remove the LS chassis block assembly. (Refer to 4-10.)

2) Align the claw of the guide base (T) block assembly 1 with

the notch of the guide arm T and remove the guide base (T)

block assembly.

3) Remove the screw (M1.4 × 2.5) 2 and remove the guide rail

(T) 3.

4) Align the claw of the guide base (S) block assembly 4 with

the notch of the guide arm S and remove the guide base (S)

block assembly.

5) Remove the screw (M1.4 × 2.5) 5 and remove the guide rail

(S) 6.

Two rising

metal sheets

2. Attachment procedure

1) Align the holes on the guide rail (S) 6 with the protrusions (at

two locations) of the LS chassis block assembly and attach the

guide rail (S) 6 with the screw (M1.4 × 2.5) 5.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

2) Attach the guide base (S) block assembly 4 while aligning it

with the groove on the guide arm S.

3) Align the holes on the guide rail (T) 3 with the protrusions (at

two locations) of the LS chassis block assembly and attach the

guide rail (T) 3 with the screw (M1.4 × 2.5) 2.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

4) Attach the guide base (T) block assembly 1 while aligning it

with the groove on the guide arm T.

Note: Do not forget to hook the plate spring.

5) Withdraw the joint portion of the guide arm S and the guide

arm T in the directions of the arrows A and B.

6) Attach the LS chassis block assembly to the mechanical chassis.

(Refer to 4-10.)

7) Clean the tape running path. (Refer to 2-2.)

Note: Be careful of the shape of the guide base T/S block assembly.

Guide base (T) block assembly = Guide base (small)

Guide base (S) block assembly = Guide base (large)

2

Screw

(M1.4

3

×

2.5)

Guide rail (T)

Two dowels

5

Screw

(M1.4

×

2.5)

1

Guide base (T)

block assembly

4

Guide base (S)

block assembly

While aligning the direction of the claw,

remove the guide base (T) block assembly.

When attaching the guide base (T) block

assembly, be careful of the shape.

Guide base

(large)

Guide base

(small)

B

6

Guide rail (S)

Two rising

metal sheets

Do not bend the spring.

LS chassis block

assembly

A

Guide arm SGuide arm T

Fig. 4-12.

— 25 —

Page 26

4-13.TG1 Arm, Reel Table (S) Assembly, Push Switch (3Key)

1. Removal procedure

1) Remove the TG1 arm spring 1.

Note: Take note of the position where the spring has been hooked.

2) Remove the TG1 arm 2.

3) Open the claw of the reel table (S) assembly 4 in the directions

of the arrows B and C and remove the reel table S assembly.

4) Remove the RVS arm spring 5.

5) Rotate the S ratchet arm 3 in the direction of the arrow A

and remove the BT band assembly 6.

6) Remove the lock guide 7.

7) Remove the four solderings of the LS-057 board.

8) Remove the two claws 9 of the cassette guide T qs from the

notch of the LS chassis.

9) Remove the push switch (3key) qa by releasing the two claws

of the cassette guide T qs.

B

2. Attachment procedure

1) Attach the push switch (3key) qa to the cassette guide T qs

with the two claws 0.

2) Attach the cassette guide T qs to the notch of the LS chassis

block assembly with the two claws 9.

3) Solder the cassette guide T qs to the LS-057 board at the four

locations.

4) Attach the lock guide 7.

5) Attach the BT band assembly 6.

6) Check the location of the reel table S 4. Then, rotate the S

ratchet arm 3 in the direction of the arrow A and insert the

band of the BT band assembly 6 into the groove on the side.

7) Attach the BT band assembly to the TG1 arm 2 and attach it

to the mechanism chassis block assembly.

8) Check the shape of the hook of the TG1 arm spring 1. Hook

one end of the spring on the TG1 arm 2. Then, hook the other

end of the spring on the same location of the LS chassis block

assembly where you have taken note when the spring is

removed.

9) Attach the RVS arm spring.

10) Check the TG1 back-tension. (Refer to 5-1.)

Note: The BT band assembly 5 must be completely inserted into

the groove on the side of the reel table (S) 4.

4

Reel table (S)

assembly

Check the location of

the reel table (S) assembly.

Open the claw of the reel

table S in the directions

of the arrows

7

Lock guide

qs

Cassette guide T

8

Remove the four

solderings

B

and C.

0

Two

claws

C

qa

Push switch

(3key) (REC proof)

2

TG1 arm

9

Two

claws

When attaching it, insert it

under the LS chassis assembly.

6

BT band assembly

Never coat grease, never attach any

foreign materials nor bend the assembly.

Fit here.

Reel table

5

RVS arm spring

1

TG1 arm spring

Double-hook side

(S) assembly

TG1 arm

Reel table (S)

assembly is at

right angles.

Thin

BT band

assembly

RVS arm

spring

Double-hook side

TG1 arm

spring

Fig. 4-13.

— 26 —

A

Mechanism status before

removing the parts.

3

Rotate the S ratchet arm

in the direction of the arrow

When attaching it, coat the hatched

portion with grease.

A

.

Page 27

4-14.Hall Element (H001, H002 (T/S Reel)),

Photo Transistor (Q001, Q002 (Tape Top/Tape End), D001 (Tape LED)),

LED (D001 (Tape LED))

1. Removal procedure

1) Remove the LS chassis block assembly. (Refer to 4-10.)

2) Remove the LS grease cover.

3) Remove the two solderings and remove Q001 (tape top).

4) Remove the two solderings and remove Q002 (tape end).

5) Remove the two solderings and remove D001 (tape LED).

6) Remove the four solderings respectively from H001 (T reel)

and H002 (S reel) and remove the H001 and H002.

T reel sensor (H001)

Drum side

H001

Hall element (T reel)

A polarity exists.

The protrusion faces

inside unit.

Q001

Photo transistor

(tape top)

Remove the two

solderings

Push out hook

2. Attachment procedure

1) Solder H001 (T reel) and H002 (S reel) respectively at the four

locations.

2) Solder Q002 (tape end) at the two locations.

3) Solder Q001 (tape top) at the two locations.

4) Solder D001 (tape LED) at the two locations.

5) Attach the LS grease cover.

6) Attach the LS chassis block assembly to the mechanical chassis.

(Refer to 4-10.)

Note: Be careful of the plarities of the Hall element (H001, H002), Photo-

transistor (Q001, Q002) and LED (D001).

Tape LED (D001)

S reel sensor (H002)

Drum side

D001

Diode (tape LED)

A polarity exists.

The protrusion faces

inside unit.

Drum side

H002

Hall element (S reel)

FP-300 flexible board

LS-057 board

FP-301 flexible board

Outside the edge of the shaft

LS chassis assembly (rear view)

Fig. 4-14.

LS chassis

assembly

Q002

Photo transistor

(tape end)

FP-302 flexible board

TG1 arm metal

Three

claws

Inside the top edge of the metal

LS grease cover

— 27 —

Page 28

4-15.LS Guide Roller, Guide Lock Plate (T), Pinch Pusher Assembly, Eject Arm

1. Removal procedure

1) Remove the LS chassis block assembly. (Refer to 4-10.)

2) Remove the LS guide roller 1.

3) Remove the P pressure plate spring 2.

4) Remove the HLW cut (0.98 × 3 × 0.25) 3.

5) Remove the pitch pressure plate assembly 4 in the direction

of the arrow A.

6) Remove the relay gear 5.

7) Remove the screw (camera pan2 M1.4 × 1.6) 6.

8) Remove the guide lock plate (T) 7 in the direction of the arro w

B.

9) Remove the eject arm spring 8 and HLW cut (0.98 × 3 ×

0.25) 9.

Note: Do not reuse the HLW cut.

10) Remove the eject arm 0.

Notch C

3

HLW cut

×

A

3 × 0.25)

.

(0.98

4

Remove the pinch pressure

plate assembly in the direction

of the arrow

Pinch the rotary switch.

A

2. Attachment procedure

1) Attach the eject arm spring 8 to the eject arm 0.

2) Hook one end of the eject arm spring 8 on the protrusion of

the main chassis block assembly and attach the eject arm to the

shaft.

3) Attach the HLW cut (0.98 × 3 × 0.25) 9.

Do not reuse the HLW cut.

4) Attach the guide lock plate T 7 while aligning it with the

notches C and D.

5) Attach the screw (camera pan2 M1.4 × 1.6) 6.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

6) Attach the relay gear 5.

7) Attach the pinch pusher plate 4 with the HL W cut (0.98 × 3 ×

0.25) 3.

8) Attach the P pressure plate spring 2.

Insert the concave side of the LS guide roller 1 into the shaft

to attach the LS guide roller.

Note: Insert the roller completely.

9) Attach the LS chassis block assembly to the mechanical chassis.

(Refer to 4-10.)

Notch

D

B

6

Screw

(camera pan 2 main M1.4

7

Remove the guide lock

plate (T) in the direction

of the arrow

Coat inside with grease too.

9

HLW cut (Do not reuse)

(0.98

0

Eject arm

×

3 × 0.25)

B

.

×

1.6)

Coat inside with grease too.

2

P pressure

plate spring

Fig. 4-15.

5

Relay gear

8

Eject arm spring

Concave side

1

LS guide roller

When attaching it, coat the hatched

portion with grease.

— 28 —

Page 29

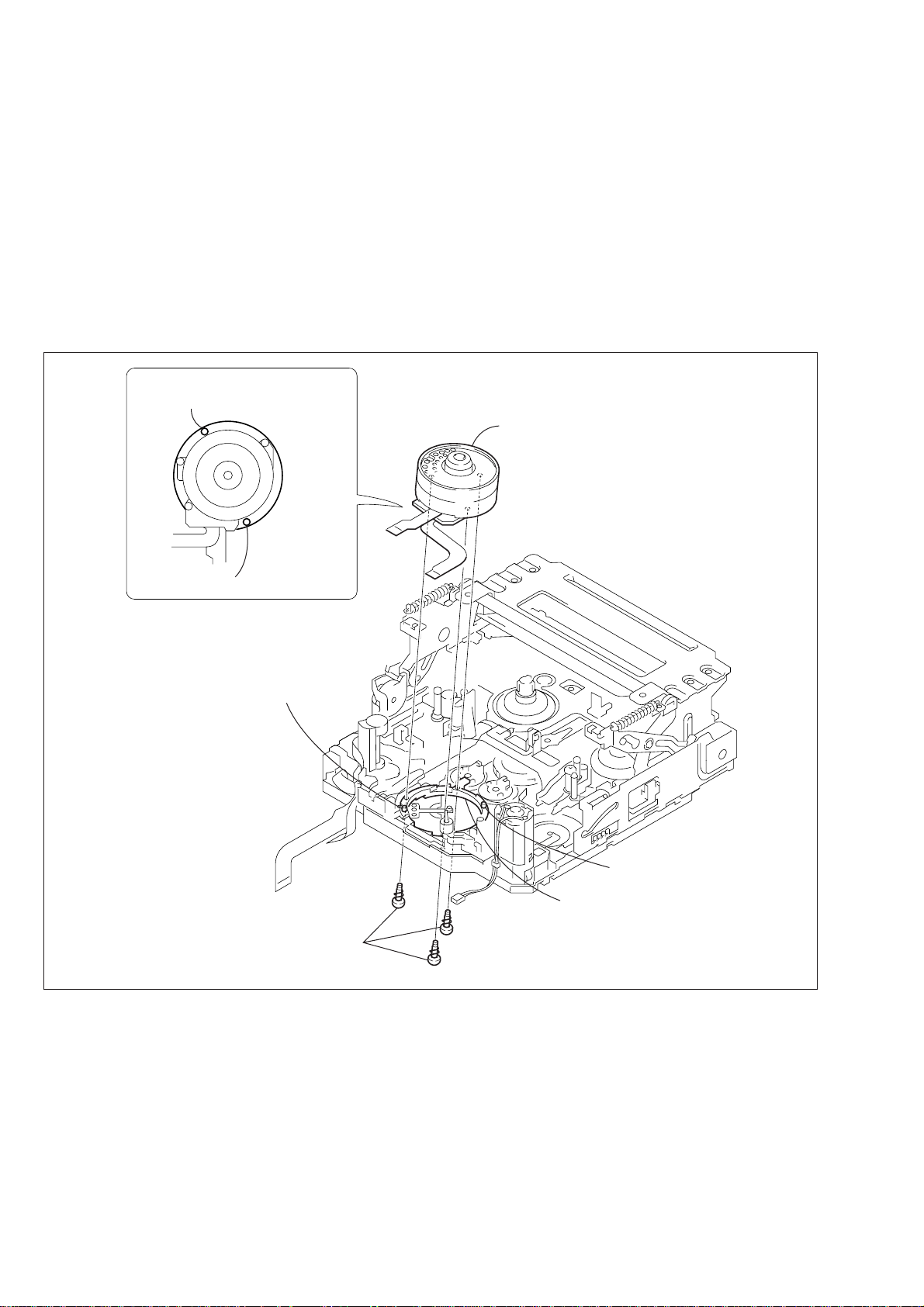

4-16.Rotary Switch, Cam Relay Gear, Change Gear Assembly, Timing Belt

Before replacing the timing belt, remove the guide rail T2 and capstan motor. (Refer to 4-4.)

1. Removal procedure

1) Remove the LS chassis block assembly. (Refer to 4-10.)

2) Remove the guide lock plate (T), pinch pressure assembly and

eject arm. (Refer to 4-15.)

3) Remove the cam relay gear 1.

4) Remove the timing belt 2.

5) Remove the HLW cut (0.98 × 3 × 0.25) 3 and change gear

assembly 4.

6) Remove the four solderings 5 and remove the FP-299 fle xible

wiring board 6.

7) Push up the dowel of the rotary switch 7 from the bottom of

the mechanism chassis assembly and remove the rotary switch

in the direction of the arrow.

7

Remove the rotary switch

in the direction of the arrow.

Clearance must exist between

the claw of the rotary switch and

the belt.

2. Attachment procedure

1) Insert the dowel of the rotary switch 7 into the hole on the

mechanism chassis assembly and attach the rotary switch

clockwise.

2) Align the FP-299 flexible wiring board 6 with the reference

hole on the mechanism chassis and solder the flexible wiring

board to the rotary switch 7 (at four locations).

3) Attach the change gear assembly 4 with the HLC cut (0.98 ×

3 × 0.25)3.

4) Attach the timing belt 2.

Note: There must be a clearance between the rotary switch 7 and

timing belt 2.

5) Attach the cam relay gear 1.

The in-phase markings of the rotary switch 7, cam relay gear

(2) and cam relay gear (1) must be aligned.

6) Attach the guide lock plate (T), pinch pressure assembly and

eject arm. (Refer to 4-15.)

7) Attach the LS chassis block assembly to the mechanical chassis.

(Refer to 4-10.)

8) Clean the shaft of the capstan motor. (Refer to 2-2.)

Attachment direction

The ribs must be facing upward.

Dowel

1

Cam relay gear (2)

3

HLW cut

(0.98 × 3 × 0.25)

Belt must be completely

free from twist or stain

when it is installed

5

Remove the

four solderings

Bend here at right angles.

6

FP-299 flexible

board

Align the holes.

4

Change gear

assembly

SETTING THE GEAR POSITION

Hole of mechanism chassis

2

Timing

belt

Rotary switch

Cam relay gear (2)

Cam relay gear (1)

Cam relay

gear (1)

Fig. 4-16.

— 29 —

When attaching it, coat the hatched

portion with grease.

Page 30

4-17.Guide Gear Assembly , Guide Gear T Assembly , Cam Relay Gear 1,

Guide Lock Plate (S)

1. Removal procedure

1) Remove the LS chassis block assembly. (Refer to 4-10.)

2) Remove the screw (camera pan2 main M1.4 × 1.6) 1.

3) Remove the guide lock plate (S) 2 in the direction of the arro w

A.

4) Remove the two stop rings (E type 1.2) 3.

5) Remove the guide gear (S) assembly 4 and guide gear (T)

assembly 5.

6) Remove the HLW cut (0.98 × 3 × 0.25) 6.

7) Remove the cam relay gear (1) 7.

SETTING THE GEAR POSITION

Cam relay gear (2) Cam relay gear (1)

5

Guide gear

(T) assembly

2. Attachment procedure

1) Attach the cam relay gear (1) 7 with the HL W cut (0.98 × 3 ×

0.25) 6.

Note: The in-phase markings of the cam relay gear (1) 7, cam gear

(2) and cam relay gear must be aligned.

2) Attach the guide gear (T) assembly 5 and guide gear (S)

assembly 4 to the shaft in this order and adjust the positions.

Then, attach them with the two stop rings (E type 1.2) 3.

Note1:The in-phase markings of the GL arm assembly, guide gear

(S) 4 and guide gear (T) 5 must be aligned.

Note2:The guide gear assembly (S/T) has a different shape

respectively. Pay attention to the shapes.

3) Fit the guide lock plate (S) 2 in the groove on the shaft and

insert the portion B into the notch. Then, attach the plate with

the screw (camera pan2 main M1.4 × 1.6) 1.

Tightening torque: 0.078 ± 0.01 N•m (0.8 ± 0.1 kgf•cm)

4) Attach the LS chassis block assembly to the mechanical chassis.

(Refer to 4-10.)

2

1

Screw

(camera pan 2 main

×

1.6)

M1.4

6

HLW cut

×

(0.98

3 × 0.25)

Remove the guide lock plate (S)

in the direction of the arrow

A

A

.

GL arm

assembly

Rotary switch

Guide gear

(T) assembly

Hole of mechanism chassis

When attaching it, coat the hatched

portion with grease.

Pay attention

to the shapes.

Guide gear

(S) assembly

Cam

gear (2)

3

Two stop ring

(E type1.2)

B

7

Cam relay gear (1)

The pattern-printed side

must be facing upward.

4

Guide gear (S) assembly

Cam gear (2)

GL arm

assembly

Fig. 4-17.

— 30 —

Page 31

4-18.LD Gear 4, Cam Gear 1, HC Drive Arm

Remove in advance the HCL arm assembly and loading motor assembly beforehand. (Refer to 4-2.)

1. Removal procedure

1) Remove the LS chassis block assembly. (Refer to 4-10.)

2) Remove the guide lock plate (S). (Refer to 4-17.)

3) Remove the cover sheet 1 and LD gear (4) 2.

4) Remove the T1 limiter arm 3 and cam gear (1) 4.

5) Remove the HC drive arm 5 in the direction of the arrow.

SETTING THE GEAR POSITION

LS arm assembly

M slide plate

Cam gear (2)

Cam relay

gear (1)

assembly

2. Attachment procedure

1) Attach the HC drive arm 5 under the drive base assembly.

2) Attach the cam gear (1) 4.

3) Attach the LD gear (4) 2 with the cover sheet 1.

4) Attach the guide plate (S).

5) Attach the LS chassis block assembly to the mechanical chassis.

6) Clean the tape running path. (Refer to 2-2.)

Cover sheet

Loading motor

assembly

The dowel of the HC drive arm 5 must be inserted into the

groove on the lower side of the cam gear (1) 4.

The in-phase markings of the cam gear (1) 4, cam gear (2)

and cam relay gear (1) must be aligned.

(Refer to 4-10.)

3

1

Cover

sheet

4

Cam

gear (1)

T1 limitter

arm

Cam relay

gear (2)

Coat more than half round

of the grooves on both the

inner and outer sides of

the cam with grease.

HC drive arm

Hole of mechanism chassis

When attaching it, coat the hatched

portion with grease.

Cam gear (1)

2

LD gear (4)

Attachment direction

The larger gear must be

facing upward.

Fig. 4-18.

T1 limitter

arm

5

Remove the HC

drive arm in the

direction of the

arrow.

Cam relay

gear (1)

Cam gear (2)

— 31 —

Page 32

4-19.M Slide Plate Assembly, LS Arm Assembly, Cam Gear 2, GL Arm Assembly

y

1. Removal procedure

1) Remove the LS chassis block assembly. (Refer to 4-10.)

2) Remove the guide lock plate (S) (Refer to 4-17.)

3) Remove the relay gear 1.

4) Remove the M slide plate assembly 2 in the direction of the

arrow A.

5) Remove the LS arm assembly 3 and LS arm roller 4.

6) Remove the cam gear (2) 5.

7) Remove the GL arm assembly 6 from the lower side of the

cam relay gear (1) in the direction of the arrow B.

Note: After removing the GL arm assembly, f ix the guide gear (S/T)

assembly.

SETTING THE GEAR POSITION

Hole of mechanism

chassis

Rotary switch

Cam relay

gear (2)

Cam gear (2)

Cam relay

gear (1)

LS arm assembly

M slide plate

assembly

2. Attachment procedure

1) Attach the GL arm assembly 6 to the shaft so that the GL arm

assembly 6 is positioned under the cam relay gear (1) .

Note: The in-phase markings of the guide gear (S/T) assembly and

GL arm assembly 6 must be aligned.

2) While aligning the cam gear (2) 5 with the dowel of the GL

arm assembly, attach the cam gear (2) 5.

Note: The in-phase markings of the cam relay gear (1), cam gear (1)

and cam gear (2) 5 must be aligned.

3) Attach the LS arm roller 4 to the LS arm assembly 3. While

aligning them with the cam groove on the cam gear (2) 5,

attach them.

4) Attach the M slide plate assembly 2.

5) Attach the relay gear 1.

6) Attach the guide lock plate (S). (Refer to 4-17.)

7) Attach the LS chassis block assembly to the mechaical chassis.

(Refer to 4-10.)

Note: Check that the in-phase marking of each gear is aligned.

2

1

Relay gear

A

Remove the M slide

plate assembly in the

direction of the arrow

3

assembl

A

.

LS arm

GL arm

assembly

Guide gear

(T) assembly

Guide gear

(T) assembly

Guide gear

(S) assembly

Guide gear

(S) assembly

Cam gear (1)

B

4

LS arm roller

Be careful not

Coat the cam groove

with grease.

5

Cam gear (2)

6

Remove the GL arm

assembly in the direction

of the arrow

When attaching it, coat the hatched

portion with grease.

to drop.

B

.

Cam relay gear (1)

Cam gear (1)

Fig. 4-19.

— 32 —

Page 33

5. Adjustment

5-1. Check and Adjustment of TG1 Back-tension Position

1. Check Procedure

1) Assemble the mechanism deck into the main unit.

2) Thread a normal tape and let the machine enter the PB (or REC)

mode.

3) Check that the distance between the upper flange of the TG1

guide and the side surface of the LS chassis block is 12.0 ± 0.4

mm (range of fluctuation: 0.5 mm or less).

S reel

Drum

Loading motor

Right

Left

Left Right

BT band

Rising metal sheet

TG1

12.0

±

0.4 mm

(range of fluctuation:

0.5 mm or less).

2. Adjustment Procedure

1) Remove the cassette compartment and the blind plate.

2) Adjust the position of the TG1 guide by changing the tilt of the

rising metal sheet of the LS chassis block assembly.

Fig. 5-1.

— 33 —

Page 34

5-2. Check and Adjustment of FWD/RVS Back-tension

1. Check Procedure

1) Install the mechanism deck in the main unit and set the take-up

torque cassette (Ref. No. J-7).

2) Check the FWD/RVS take-up torque.

Check the FWD torque in the PLAY state.

Specified value: 7 to 12 gf•cm

Check the RVS torque in the RVS state.

Specified value: 19.5 to 29.5 gf•cm

2. Adjustment Procedure

1) If the value of the FWD torque is larger than the specifica tions,

change the position where the TG1 arm spring is hooked in the

direction of the arrow A. If the value of the FWD torque is

smaller than the specifications, change the position in the

direction of the arrow B.

Reel table

(T) assembly

TG1 arm

BT band

assembly

RVS arm

spring

A

TG1 arm

spring

B

Fig. 5-2.

— 34 —

Page 35

5-3. Capstan Motor Azimuth Position Adjustment

Capstan

motor

1

Capstan azimuth adjustment screw

(SANG camera pan 2 M1.4

×

4.5)

2

Thickness gauge

t = 0.75 mm

FP-300 flexible

board

Mechanism

chassis

Protrusion of the mechanism chassis

1. Check Procedure

1) Insert the thickness gauge (Ref. No. J-16) of 0.75 mm between

the protrusion of the mechanism chassis and the capstan motor,

and check the azimuth position.

2. Adjustment Procedure

1) Loosen the capstan azimuth adjustment screw (SANG camera

pan 2 M1.4 × 4.5), and insert the thickness gauge (0.75

mm)(Ref. No. J-16) between the protrusion of the mechanism

chassis and the capstan motor.

2) Slowly tighten the capstan azimuth adjustment screw until it

slightly contacts the thickness gauge, and remove the thickness

gauge.

Fig. 5-3.

— 35 —

Page 36

5-4. Tape Path Adjustment

Purpose: Adjust the linearity of the head.

If the adjustment is not correct:

Noise appears on the top and bottom of the screen

when playing back the tape that is recorded by other

recorders.

5-4-1. Adjustment Preparation

1) Clean the tape running surface (tape guides, drum, capstan shaft,

pinch roller).

2) Connect the adjustment remote commander to the remote

terminal.

3) Set the adjustment remote commander to the P A TH mode (track

shift mode)* and release the auto tracking.

4) Connect an oscilloscope as follows:

CH1: Test connector’ PB RF terminal

External trigger: Test connector’ RF SWP terminal

5) Playback the tracking alignment tape WR5-1NP (NTSC), WR51CP (PAL) (Ref. No. J-6).

6) Confirm that the RF wav eform on scope is flat both at entrance

side and exit side.

If the RF waveform is not flat, perform the adjustment by

referring to section 4-2.)

7) After the adjustment is completed, release the PATH mode

(track shift mode)*.

Entrance side

Exit side

Normal

Entrance side is defective

Exit side is defective

Fig. 5-4.

TG3 TG4 TG5

TG2

TG1

S reel

* Setting and releasing the track shift mode

TG6

Capstan shaft

TG7

Drum

Pinch roller

T reel

Fig. 5-5.

In case of the DCR-TRV230

Setting

1. Select page: 0, address: 01 and set data: 01.

2. Select page: F , address: 22 and set data: 88, and press the P A USE

button.

3. Select page: 2, address: 2E and set data: 02. (Note)

— 36 —

Releasing

1. Select page: 0, address: 01 and set data: 01.

2. Select page: F, address: 22 and set data: 80, and press the P A USE

button.

3. Select page: 2, address: 2E and set data: 00.

4. Select page: 0, address: 01 and set data: 00. (Note)

Note: In case of the Digital8 only, set the data of page: 2, address: 2E.

Page 37

5-4-2. Tracking Adjustment (Refer to Fig. 5-6.)

e

Tape slack

2

Capstan

1

No.6 guide

(TG6)

3

No.7 guide

(TG7)

4

TG7 nut

1) Playback the tracking alignment tape WR5-1NP (NTSC), WR51CP (PAL) (Ref. No. J-6).

2) Adjust the No.3 guide until the envelope at the entrance side

waveform becomes flat.

3) Adjust the No.6 guide until the envelope at the exit side

waveform becomes flat.

✩ The TG-3/6 zenith adjustment screws do not need to be adjusted.

No.6 guide

(TG6)

No.3 guid

(TG3)

5-4-3. No.7 Guide (TG7) Adjustment

(Refer to Fig. 5-7.)

1) Playback the tape and set the REV mode.

2) Confirm that tape slack does not occur in between the No.6

guide (TG6) 1 and capstan 2. If any tape slack occurs, rotate

the TG7 nut 4 of the No.7 guide (TG7) 3 to remove the tape

slack.

3) Playback the tape again and confirm that tape slack does not

occur between the capstan 2 and No.7 guide (TG7) 3. If the

tape slack occurs exceeding the specifications (specifications:

0.5 mm or less), rotate the TG7 nut 4 to make the tape slack

below the specifications (0.5 mm). When the tape slack between

the No.6 guide (TG6) 1 and capstan 2 is 0.3 mm or less in

the REV mode, it means that the adjustment is completed.

Guide zenith adjustment screw

Fig. 5-6.

Fig. 5-7.

— 37 —

Page 38

5-4-4. CUE and REV Waveform Check

A

A

(Refer to Fig. 5-8)

1) Playback the tracking alignment tape WR5-1NP (NTSC), WR51CP (PAL)(Ref. No. J-6) and enter the REV mode.

Confirm on an oscilloscope that the pitches between the peaks

of the RF waveform are equally spaced for 5 seconds or more.

If pitches between peaks of the RF waveform are not equal,

perform sections “5-4-2 Tracking Adjustment” and “5-4-3 No.

7 Guide (TG7) Adjustment”.

2) Enter the UCE mode. Confirm on an oscilloscope that the

pitches between the peaks of the RF waveform are equally

spaced for 5 seconds or more.

If pitches between peaks of the RF waveform are not equal,

perform section “5-4-2 Tracking Adjustment”.

abcd

5-4-5. Check upon Completion of Adjustment

5-4-5-1. Tracking Check

1) Playback the tracking alignment tape in the PATH mode.

Compare the amplitude of the RF waveform in the AUTO

tracking mode and with that in the PATH mode. Confirm that

the amplitude of the RF waveform decreases to about 3/4 when

the tracking alignment tape is switched from the A UTO tracking

mode to the PATH mode. (Refer to Fig. 5-9)

2) During step 1, confirm that the minimum amplitude (E MIN) is

65% or more of the maximum amplitude (E MAX) of the RF

waveform. (Refer to Fig. 5-10)

3) Confirm that the RF waveform does not fluctuate too

excessively.(Refer to Fig. 5-11)

3/4 A

Fig. 5-9.

Fig. 5-8.

Fig. 5-10.

A

C 1/6

Fig. 5-11.

E

MIN

E

MAX

E

MIN

MAX

65 (%)

E

C

C

— 38 —

Page 39

5-4-5-2. Rise-up Check (Refer to Fig. 5-12)

5-4-5-3. Tape Run Check (Refer to Fig. 5-13)

1) Playback the tracking alignment tape WR5-1NP (NTSC), WR51CP (PAL)(Ref. No. J-6).

2) Turn OFF the Track Shift mode.

3) Eject the cassette tape once. Then insert the cassette tape for

loading again.

4) Confirm that the RF waveform rises up to the flat envelope

within 3 seconds after the machine enters the PLAY mode.

Check also that the tape slack does not occur at around the

pinch roller.

5) Run the tape in the CUE/REV and the FF/REW mode. Then

playback the tracking alignment tape and confirm the RF

waveform rises up to the flat envelope within 3 seconds after

the machine enters the PLAY mode. Check also that the tape

slack does not occur at around the pinch roller.

6) Repeat the above steps 3) to 5) once again for re-check.

Capstan

No.7 guide

(TG7)

No.6 guide

(TG6)

1) Playback the thin video tape such as P6-120MP (NTSC), P690MP (PAL). Confirm that tape does not float and the major

tape curl of more than 0.3 mm does not occur at the top flange

of the No. 3 guide (TG3), at the top flange of the No. 6 guide

(TG6) and at both the top and bottom flanges of the No. 7

guide (TG7).

2) Confirm that tape does not float and the major tape curl of

more than 0.3 mm does not occur at the flanges of the respective

guide when the FF button is pressed during PLAY mode to

enter the CUE mode and when the REW button is pressed

during PLAY mode to enter the REV mode.

No.1 guide

(TG1)

No.7 guide

(TG7)

Pinch roller

No.6 guide

(TG6)

Drum

No.3 guide

(TG3)

Tape slack

Capstan

Fig. 5-13.

Fig. 5-12.

— 39 —

Page 40

6. Exploded Views

6-1. Cassette Compartment Assy, Drum Assy

702

701

705

701

703

M901 (Note)

LS chassis block

assembly

(See page 41)

706

707

704

708

709

Note: Type name and part code number

of the M901 drum differ depending

on models. Refer to Service Manual

of the respective models.

Mechanical chassis block

assembly

(See page 42 to 43)

710

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

701 3-065-932-01 PAN (2 MAIN M1.4X1.6), CAMERA

702 3-065-895-01 LEVER, REEL RELEASE

703 3-065-896-01 PLATE, BLIND

704 X-3951-298-1 CASSETTE COMPARTMENT ASSY

705 X-3951-302-1 DAMPER ASSY

706 X-3951-297-1 GEAR ASSY, R DRIVE

707 3-065-840-01 CUT (0.98X3X0.13), LUMILER (W)

708 3-065-935-01 HLC CUT (1.8X4X0.5)

709 3-947-503-01 SCREW (M1.4)

710 X-3951-299-1 SCREW ASSY, DRUM FITTING

M901 — Note — DRUM

— 40 —

Page 41

6-2. LS Chassis Block Assembly

755

Q001

LS-057

not supplied

FP-301

not supplied

FP-300

not supplied

757

756

S002

not supplied

H001

FP-302

not supplied

759

758

D001

H002

762

Q002

760

S001

752

774

761

763

765

764

772

766

775

777

776

779

778

767

768

769

770

771

781

780

773

not

supplied

754

753

752

783

751

782

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

751 3-065-822-01 RAIL (S), GUIDE

752 3-947-503-01 SCREW (M1.4)

753 A-7096-416-A BASE (S) BLOCK ASSY, GUIDE

754 A-7096-415-A BASE (T) BLOCK ASSY, GUIDE

755 A-7096-426-A CHASSIS ASSY, LS

756 3-065-802-01 SPRING, TG7 ARM

757 A-7096-414-A ARM BLOCK ASSY, TG7

758 3-065-801-01 RETAINER, TG7

759 3-065-932-01 PAN (2 MAIN M1.4X1.6), CAMERA

760 X-3951-303-1 ARM ASSY, PINCH

771 3-065-830-01 SPRING, S RATCHET

772 X-3951-288-1 TABLE (T) ASSY, REEL

773 3-065-819-01 SPRING, TG1 ARM

774 3-065-821-01 RAIL (T), GUIDE

775 X-3951-289-1 TABLE (S) ASSY, REEL

776 3-065-833-01 GUIDE, LOCK

777 3-065-831-01 PLATE (SPR), RE RETURN

778 X-3951-304-1 ARM ASSY, TG1

779 3-065-835-01 GUIDE (S), CASSETTE

780 3-065-820-01 SPRING, RVS ARM

761 3-065-823-01 ARM, T RATCHET

762 3-065-794-01 ROAD (SPR), PINCH ARM

763 3-065-792-01 ROLLER, P LIM ARM

764 3-065-834-01 GUIDE (T), CASSETTE

765 3-065-824-01 SPRING, T RATCHET

766 A-7096-417-A SOFT ASSY, T

767 7-627-852-38 SCREW,PRECISION +P1.7X1.8 TYPE3

768 3-065-832-01 PLATE, LS CAM

769 3-065-828-01 ARM, S RATCHET

770 3-065-829-01 PLATE, S RATCHET (RE)

781 X-3951-296-1 BAND (ASSY), BT

782 3-065-836-01 COVER, LS GREASE

783 3-067-167-01 SCREW (M1.4X2), CAMERA TAPPING

D001 8-719-988-42 DIODE GL453 (TAPE LED)

H001 8-719-033-37 ELEMENT, HALL HW-105C (T REEL)

H002 8-719-033-37 ELEMENT, HALL HW-105C (S REEL)

Q001 8-729-907-25 PHOTO TRANSISTOR PT4850F (TAPE TOP)

Q002 8-729-907-25 PHOTO TRANSISTOR PT4850F (TAPE END)

S001 1-692-614-11 SWITCH, PUSH (3 KEY) (REC PROOF)

— 41 —

Page 42

6-3. Mechanical Chassis Block Assembly-1

802

M902

809

805

804

806

811

810

807

802

808

815

814

813

812

820

816

805

818

815

824

817

815

821

822

823

819

not

supplied

802

M903

803

Mechanical chassis

block assembly-2

(See page 43)

801

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

801 A-7096-422-A BASE ASSY, DRUM

802 3-947-503-01 SCREW (M1.4)

803 3-065-928-01 SPACER, GROUND

804 3-065-927-01 GROUND, DRUM

805 3-065-932-01 PAN (2 MAIN M1.4X1.6), CAMERA

806 3-067-154-01 SPRING, CAPSTAN

807 3-065-931-01 RAIL (T2), GUIDE

808 X-3947-398-1 SCREW ASSY, M1.7 PW

809 3-065-933-01 PAN (2 MAIN 1.4X4.5), CAMERA

810 1-677-049-11 FP-228 FLEXIBLE BOARD (DEW SENSOR)

811 1-680-434-11 FP-299 FLEXIBLE BOARD

812 3-065-877-01 PLATE (T), GUIDE LOCK

813 X-3951-301-1 PLATE ASSY, PINCH PRESSURE

814 3-065-881-01 SPRING, P PRESSURE PLATE

815 3-065-934-01 HLW CUT 0.98X3X0.25

816 1-786-096-11 SWITCH, ROTARY

817 3-065-898-01 SPRING, EJECT ARM

818 3-065-870-01 ROLLER, LS GUIDE

819 A-7096-421-A ARM ASSY, HCL

820 3-065-918-01 GEAR (2), CAM RELAY

821 A-7096-419-A GEAR ASSY, CHANGE

822 3-065-902-01 BELT, TIMING

823 3-065-905-01 GEAR, RELAY

824 3-065-882-01 ARM, EJECT

M902 8-835-701-01 MOTOR, DC SCE13A/C-NP (CAPSTAN)

M903 A-7096-420-A MOTOR ASSY, LD (LOADING)

— 42 —

Page 43

7. Printed Wiring Boards and Schematic Diagrams

6-4. Mechanical Chassis Block Assembly-2

860

861

858

853

852

851

859

855

857

854

856

862

863

867

866

865

864

FP-302

FLEXIBLE

Q002

TAPE END

FP-301

FLEXIBLE

D001

TAPE LED

LS-057 BOARD

2

1

2

1

H002

S REEL

SENSOR

H001

T REEL

SENSOR

FP-300

FLEXIBLE

Q001

TAPE TOP

TAPE TOP (C)

1

2

TAPE END (C)

3

TAPE LED (K)

TAPE LED (A)

4

GND

5

6

S REEL (-)

7

S REEL (+)

3

4

ME/MP

S001

S002

C.C. LOCK

REC PROOF

Hi8 MP

3

4

SENSOR (Vcc)

8

T REEL (+)

9

T REEL (-)

10

HALL COM

11

ME/MP

12

13

REC PROOF

14

Hi8 MP

15

C LOCK SW

TO

MECHA

CONTROL

BLOCK

868

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

851 3-065-920-01 ARM, HC DRIVE

852 3-065-913-01 GEAR (4), LD

853 3-065-914-01 SHEET, COVER

854 3-065-917-01 GEAR (1), CAM RELAY

855 3-065-934-01 HLW CUT 0.98X3X0.25