Sony KV-XS29N90, KV-XS29N93 Service manual

SERVICE MANUAL

BG-3S

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-XS29N90 RM-914 TAIWAN SCC-P13J-A KV-XS29N93 RM-914 TAIWAN SCC-P13H-A

MODEL COMMANDER DEST. CHASSIS NO.

TRINITRON

®

COLOR TV

KV-XS29N90/XS29N93

RM-914

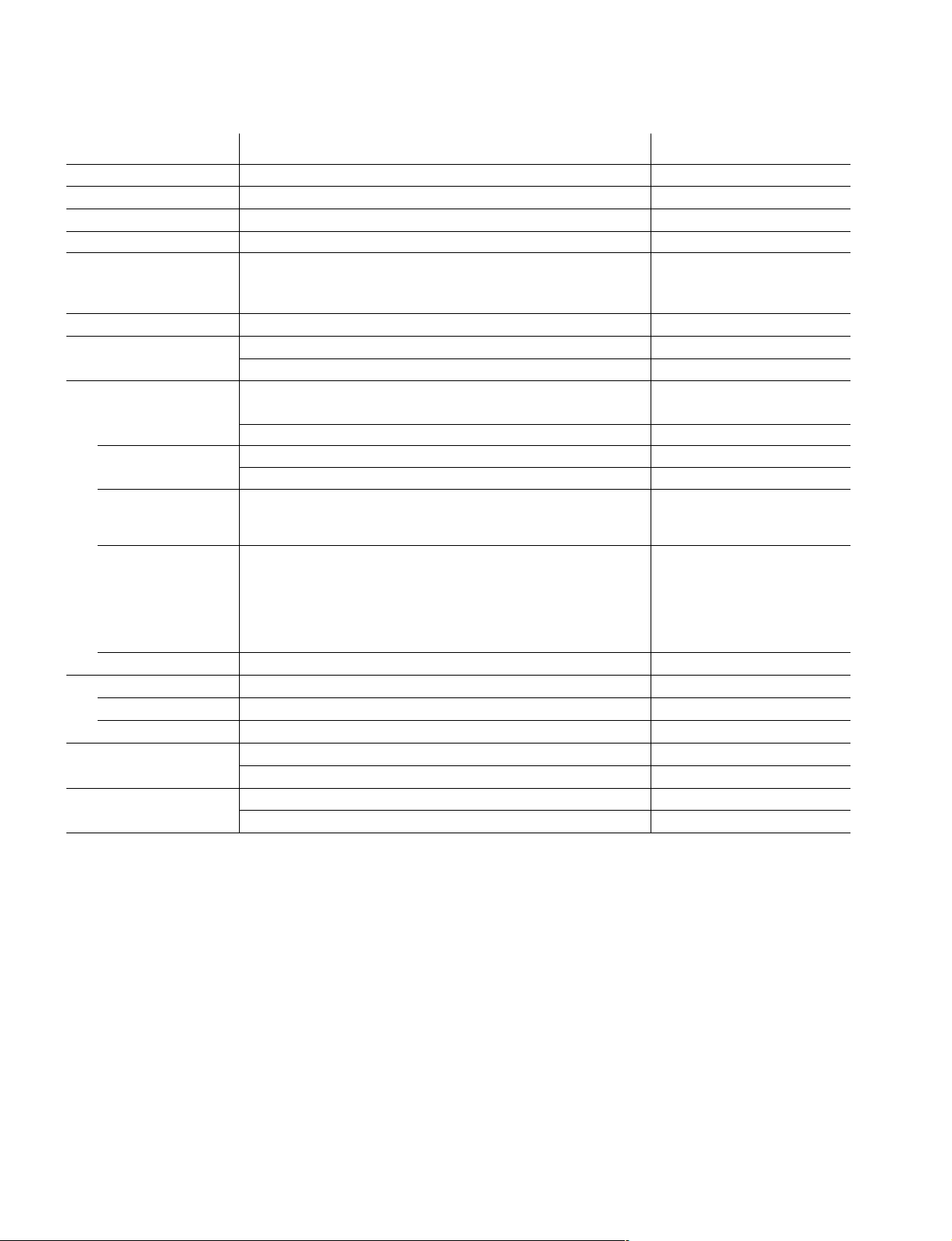

Power requirements 110 V AC, 60 Hz

Power consumption (W) Indicated on the rear of the TV

Television system M

Color system PAL*, PAL 60*, SECAM*, NTSC4.43*, NTSC3.58 * AV IN ONLY

Channel coverage

M VHF: 2 to 13 / UHF: 14 to 69 /

˘ (Antenna) 75-ohm external terminal

Audio output 8W + 8W KV-XS29N90

Number of terminal

(Video) Input: 3 Output: 1 Phono jacks; 1 VP-P, 75 ohms KV-XS29N90

(Audio) Input: 3 Output: 1 Phono jacks; 500 mVrms KV-XS29N90

(S Video) Input: 2 Y : 1 Vp-p, 75 ohms,

(Component Video) Input: 1 Phono jacks; KV-XS29N93

2 (Headphone) Output: 1 Minijack

Picture tube 29 inch

Tube size (mm) 724 Measured diagonally

Screen size (mm) 679 Measured diagonally

Dimensions (w/h/d, mm) 794 × 573 × 517 KV-XS29N90

Mass (kg) 51 KV-XS29N90

SPECIFICATIONS

CATV: 1 to 125

6W + 6W+ 15W KV-XS29N93

Input: 4 Output: 1 Phono jacks; 1 VP-P, 75 ohms KV-XS29N93

Input: 4 Output: 1 Phono jacks; 500 mVrms KV-XS29N93

unbalanced, sync negative

C : 0.286 Vp-p, 75 ohms

Y : 1 Vp-p, 75 ohms,

sync negative

B :0.7 Vp-p, 75 ohms

C

C

R :0.7 Vp-p, 75 ohms

Audio: 500 mVrms

794 × 589 × 517 KV-XS29N93

54 KV-XS29N93

Design and specifications are subject to change without notice.

Note

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMA TIC DIA GRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

TABLE OF CONTENTS

KV-XS29N90/XS29N93

RM-914

Section Title Page

SELF DIAGNOSIS FUNCTION................................ 4

1. GENERAL........................................................................ 8

2. DISASSEMBLY

2-1. 3D Speaker Box Removal ....................................... 24

2-2. Rear Cover Removal................................................ 24

2-3. Speaker Removal ..................................................... 24

2-4. Chassis Assy Removal ............................................. 24

2-5. F Bracket Removal .................................................. 25

2-6. Service Position ....................................................... 25

2-7. Replacement of Parts ............................................... 25

2-7-1. Replacement of Control Button ..................................... 25

2-7-2. Replacement of Light Guide .......................................... 25

2-8. D3 Board Removal .................................................. 26

2-9. Terminal Bracket Removal ...................................... 26

2-10. B5 and B7 Boards Removal .................................... 26

2-11. H5 Board Removal .................................................. 26

2-12. A and B3 Boards Removal ...................................... 27

2-13. Picture Tube Removal.............................................. 27

3. SET-UP ADJUSTMENTS

3-1. Beam Landing.......................................................... 29

3-2. Convergence............................................................. 30

3-3. Focus Adjustment .................................................... 32

3-4. G2 (Screen) and White Balance Adjustments......... 33

Section Title Page

5. DIAGRAMS

5-1. Block Diagram ......................................................... 45

5-2. Frame Schematic Diagram ...................................... 49

5-3 Circuit Boards Location .......................................... 53

5-4. Schematic Diagrams and Printed Wiring Boards ... 54

(1) Schematic Diagram of A (1/2) Board...................... 55

(2) Schematic Diagram of A (2/2) Board...................... 59

(3) Schematic Diagram of B3 Board ............................ 67

(4) Schematic Diagram of C Board .............................. 71

(5) Schematic Diagrams of F, H5 and J4 Boards ......... 75

(6) Schematic Diagrams of B5 and VM Boards.......... 81

(7) Schematic Diagrams of B7 and D3 Boards ............ 87

5-5. Semiconductors ............................................................... 90

6. EXPLODED VIEWS

6-1. Speaker Bracket ...................................................... 93

6-2. Chassis .................................................................... 94

6-3. Picture Tube ............................................................ 95

6-4. 3D Speaker.............................................................. 96

7. ELECTRICAL PARTS LIST...................................... 97

4. CIRCUIT ADJUSTMENT

4-1. Adjustments with Commander ................................ 34

4-2. Adjustment Method ................................................. 35

4-3. Picture Quality Adjustments .................................... 40

4-4. A Board Adjustment After IC003 (Memory)

Replacement............................................................. 40

4-5. Picture Distortion Adjustment................................. 41

– 3 –

KV-XS29N90/XS29N93

RM-914

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically

begin to flash.

The number of times the lamp flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER

lamp flash indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom cannot

be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past

problems and how often these problems occur.

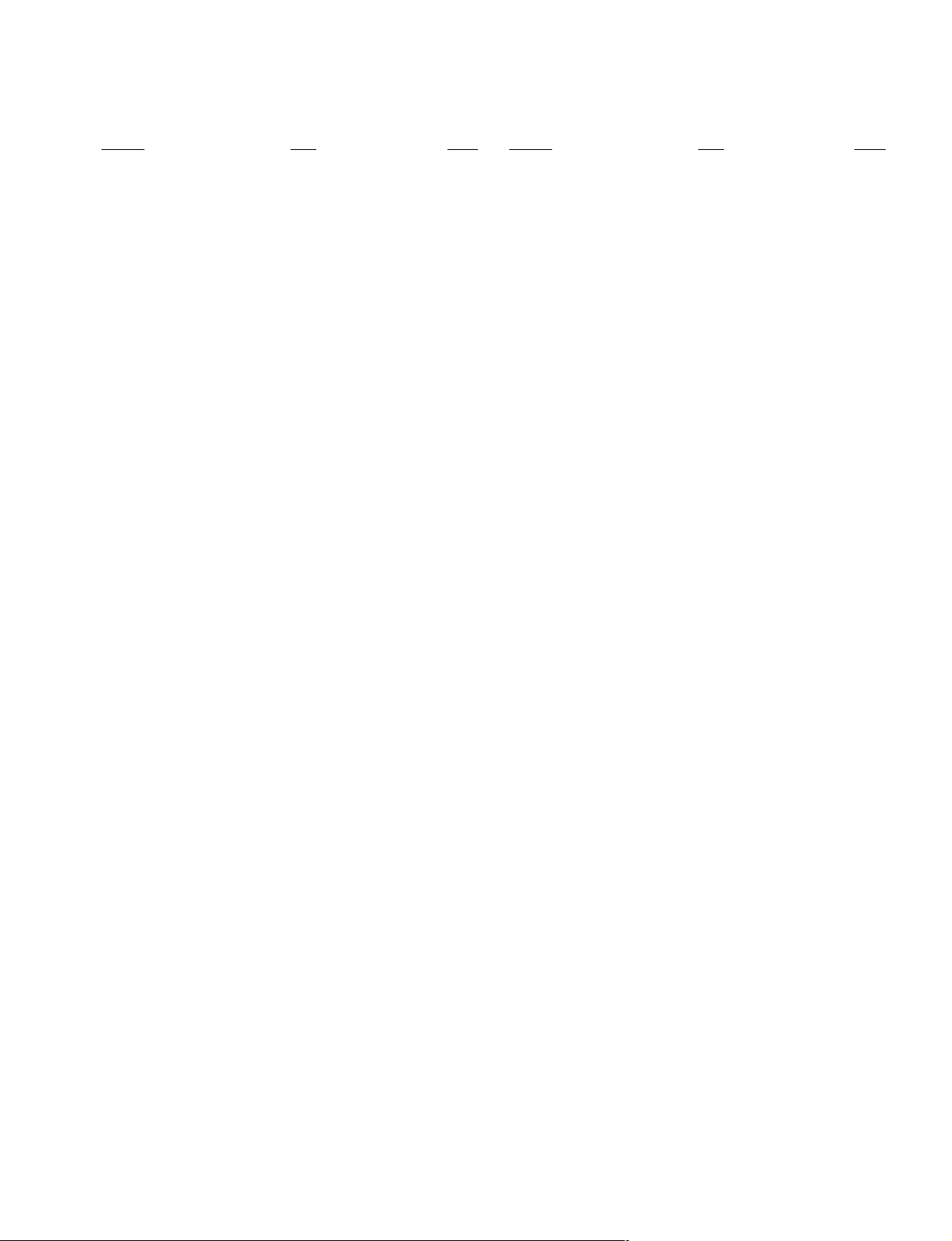

1. DIAGNOSTIC TEST INDICAT ORS

When an errors occurs, the STANDBY/TIMER lamp will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occured if the screen displays a “0”.

Diagnostic

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP) or

overvoltage

(OVP)

• Vertical deflection

stopped

• Horizontal

deflection

overdrive

• White balance

failure (no

PICTURE)

• Micro reset

No. of times

STANDBY/TIMER

lamp flashes

Does not light

2 times

5 times

—

Self-diagnostic

display/Diagnostic

result

—

002:000 or

002:001~255

003:001~255

004:001~255

at the same time

005:000 or

005:001~225

101:00 or

101:001~225

Probable

Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out F4601

(F)

• H.OUT Q511 is shorted. (A

board)

• IC701 is shorted. (C board)

• -13V is not supplied. (A

board)

• IC 503 faulty (A board)

• G2 is improperly adjusted.

(Note 2)

• CRT problem.

• Video OUT IC701 is faulty.

(C board)

• IC301 is faulty. (A board)

• No connection A board to C

board.

• Discharge CRT (C Board)

• Static discharge

• External noise

Detected

Symptoms

• Power does not come on.

• No power is supplied to the

TV.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is

shorted.

• Has entered standby state

after horizontal raster.

• Vertical deflection pulse is

stopped.

• Power line is shorted or

power supply is stopped.

• No raster is generated.

• CRT cathode current

detection reference pulse

output is small.

• Power is shut down shortly,

after this return back to

normal.

• Detect Micro latch up.

Note 1: If a + B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously.

The symptom that is diagnosed first by the microcontroller is displayed on the screen.

Note 2: Refer to screen (G2) Adjustment in section 3-4 of this manual.

– 4 –

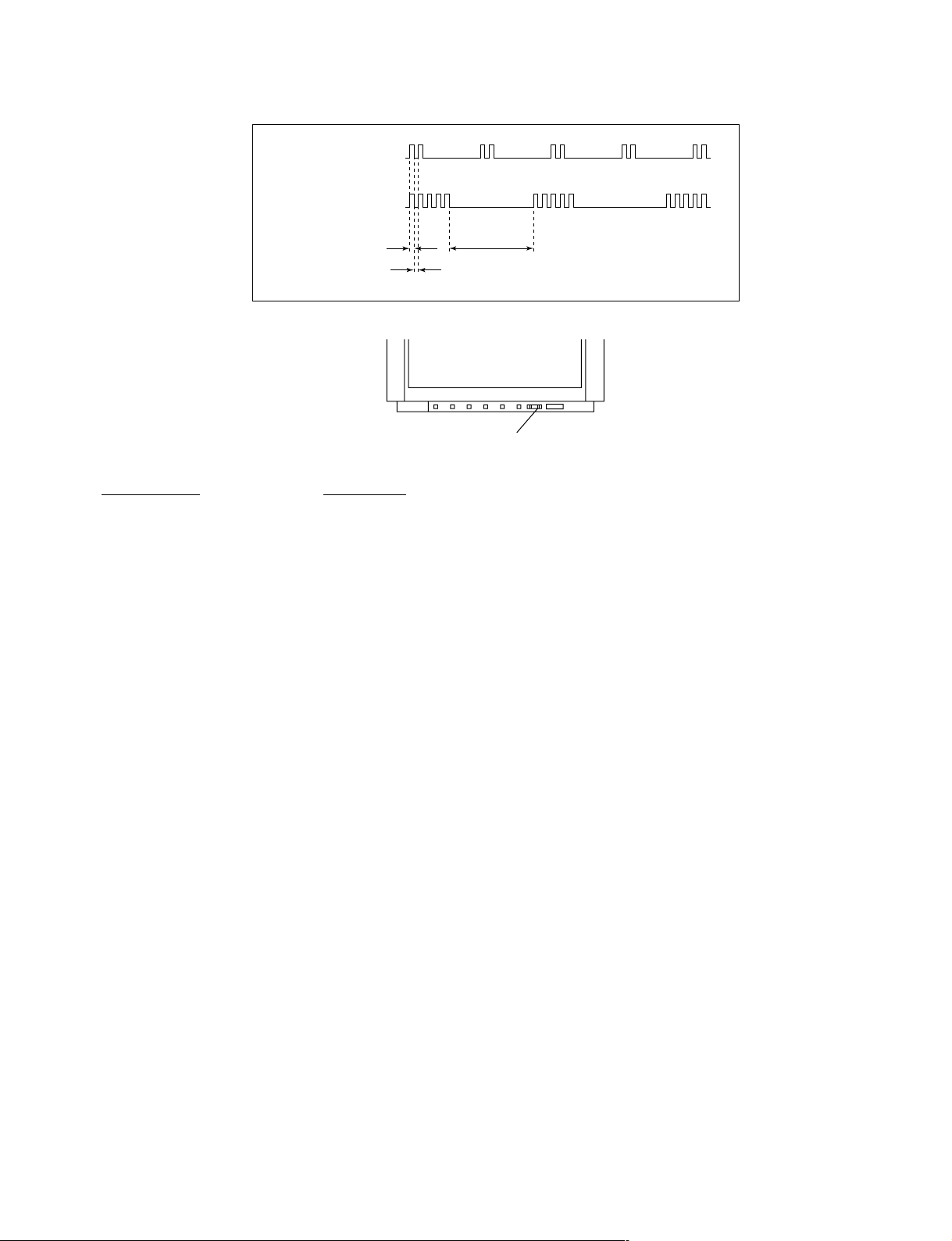

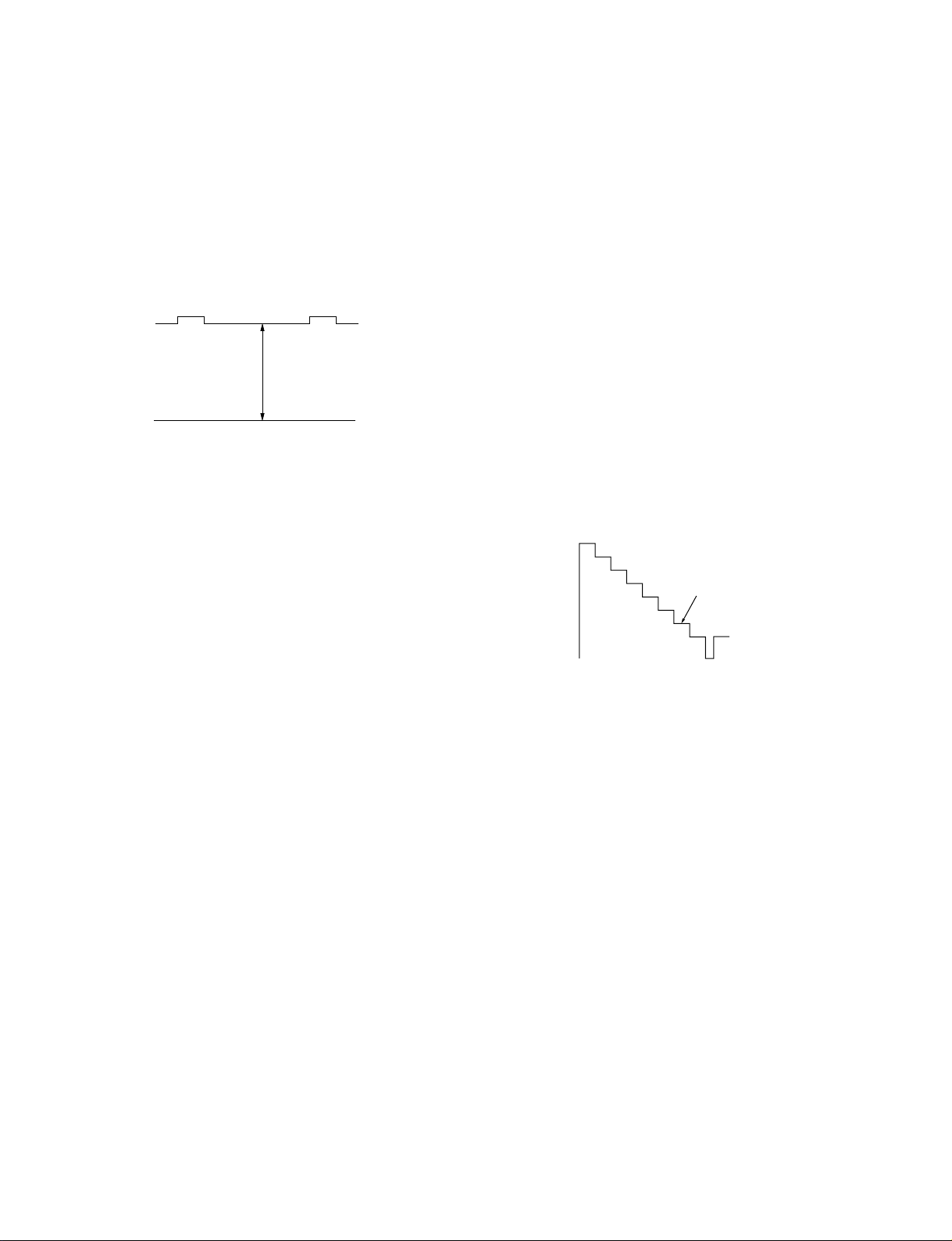

2. DISPLA Y OF STANDBY/TIMER LIGHT FLASH COUNT

2 times

5 times

KV-XS29N90/XS29N93

RM-914

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

STANDBY/SLEEP lamp

Diagnostic Item Flash Count*

+B overcurrent/overvoltage 2 times

Vertical deflection stopped

White balance failure 5 times

* One flash count is not used for self-diagnostic.

3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp

from flashing.

– 5 –

KV-XS29N90/XS29N93

RM-914

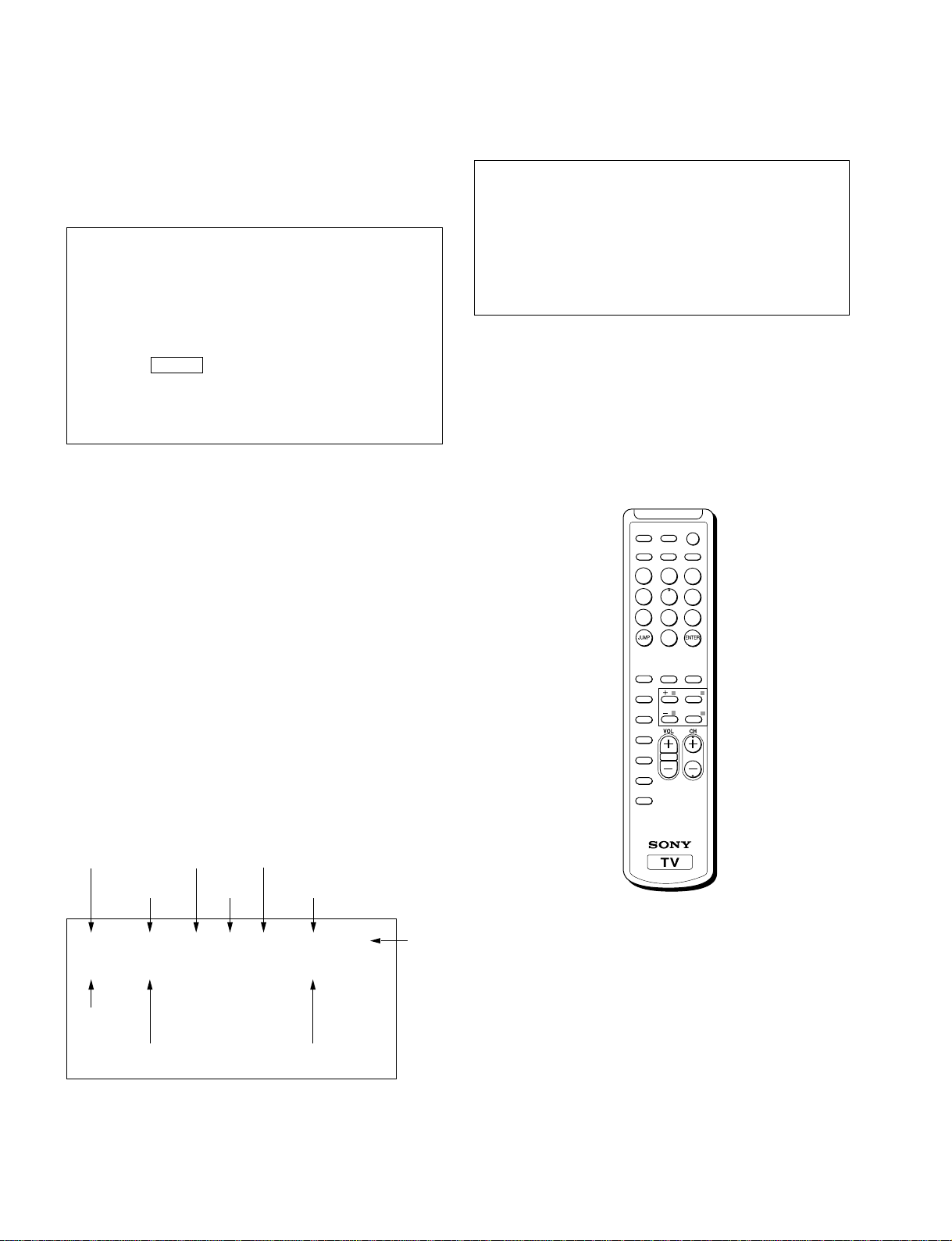

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it

is possible to bring up past occurances of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

[Screendisplay] / channel [5] / Sound volume [-] / Power ON

˘

Note that this differs from entering the service mode (mode volume [+]).

Self-Diagnosis screen display

SELF DIAGNOSTIC

002 : 000

003 : 000

004 : 000

005 : 001

101 : 000

Numeral "0" means that no fault has been detected.

Numeral "1" means a fault has been detected.

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to “0”, press buttons on the remote commander sequentially as shown below when the diagnostic

screen is being displayed.

Channel [8] / 0

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

– 6 –

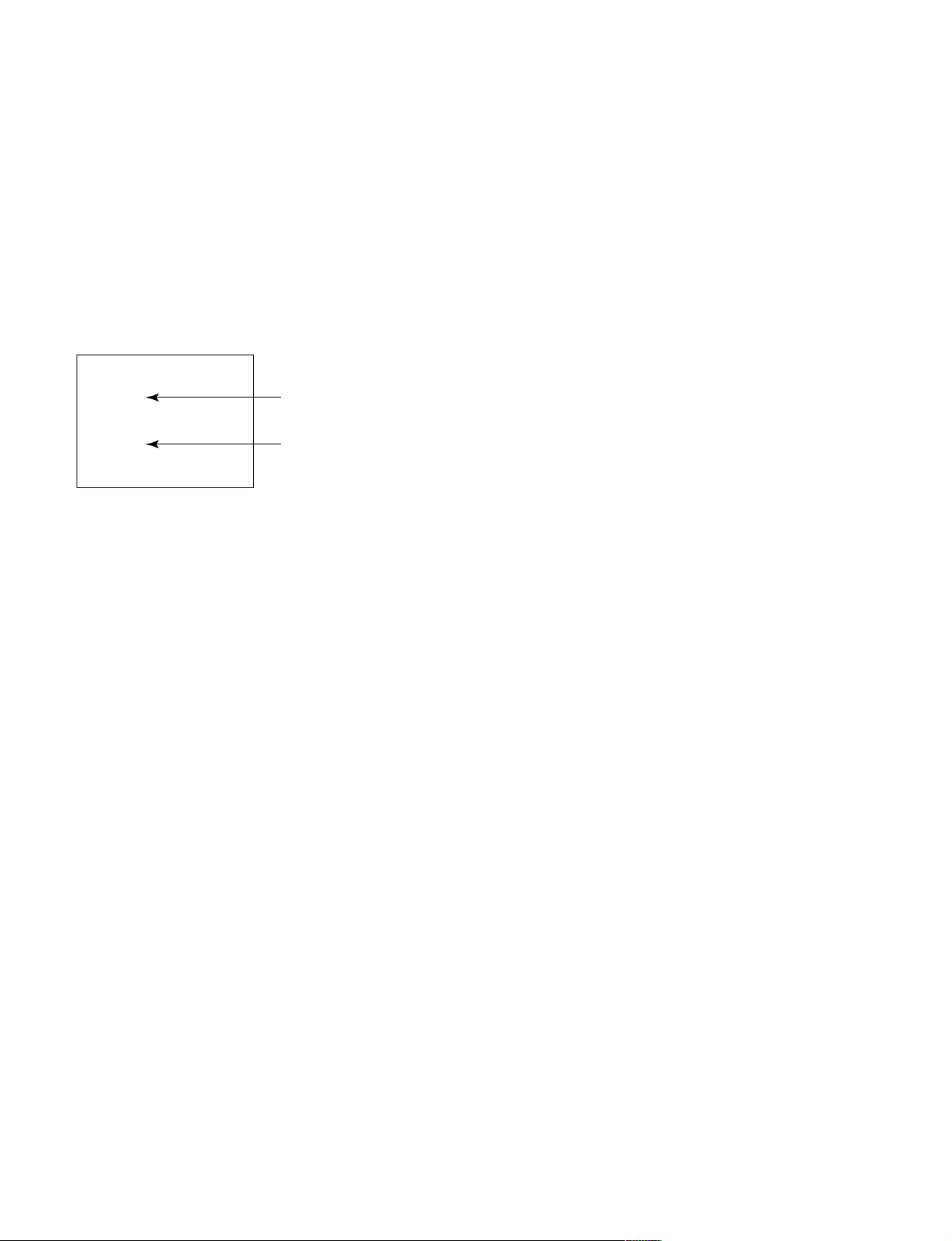

6. SELF-DIAGNOSTIC CIRCUIT

KV-XS29N90/XS29N93

RM-914

FROM

CRT

FROM

[+B] Q604 C

[V] Q509/507

IC301

Y/CHROMA JUNGLE

IK-IN

MP/

18 51

PROTECT

SDA

4635

IC001

SYSTEM

IO-8DAT

O-LED

IO-SDAT

MEMORY

B-DAT

54521

IC003

[+BovercurrentªOCPº] Occurs when an overcurrent on the +B(135) line is detected by Q604. If Q604 go to ON

and the voltage to pin 18 of IC301 should go down when V.SYNC is more than seven

verticals in a period, the unit will automatically turn off.

[Verticaldeflectionstopped] Occurs when an absence of the vertical deflection pulse is detected by Q509 and IC001

shut down the power supply.

[Verticaldeflectionovercurrent] Occurs when an overcurrent on V drive line is detected by Q507. Power supply will be

shut down when detect this by IC001.

[Whitebalancefailure] If the RGB levels* do not balance or become low level within 5 seconds, this error will be

detected by IC301. TV will stay on, but there will be no picture.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects IK.)

– 7 –

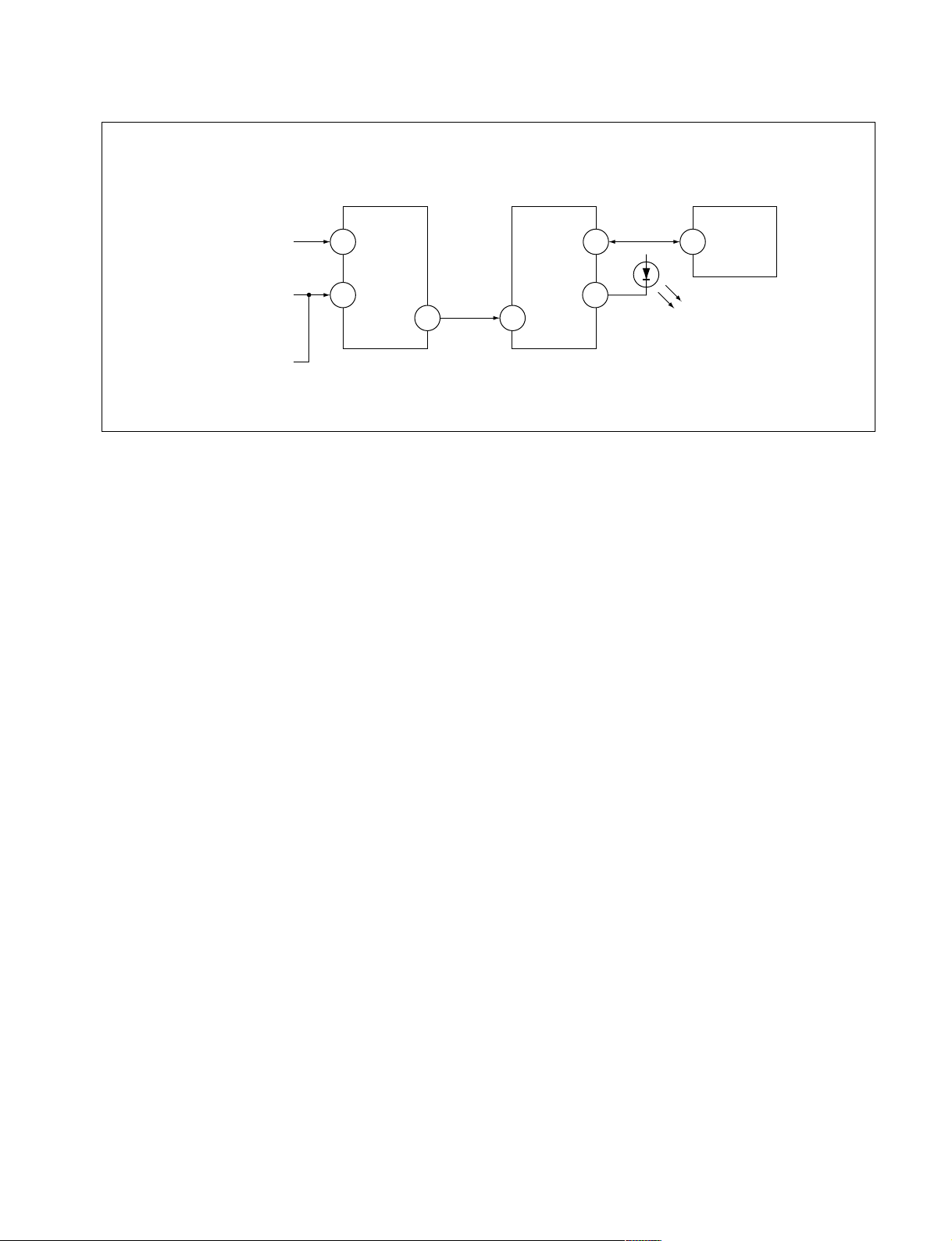

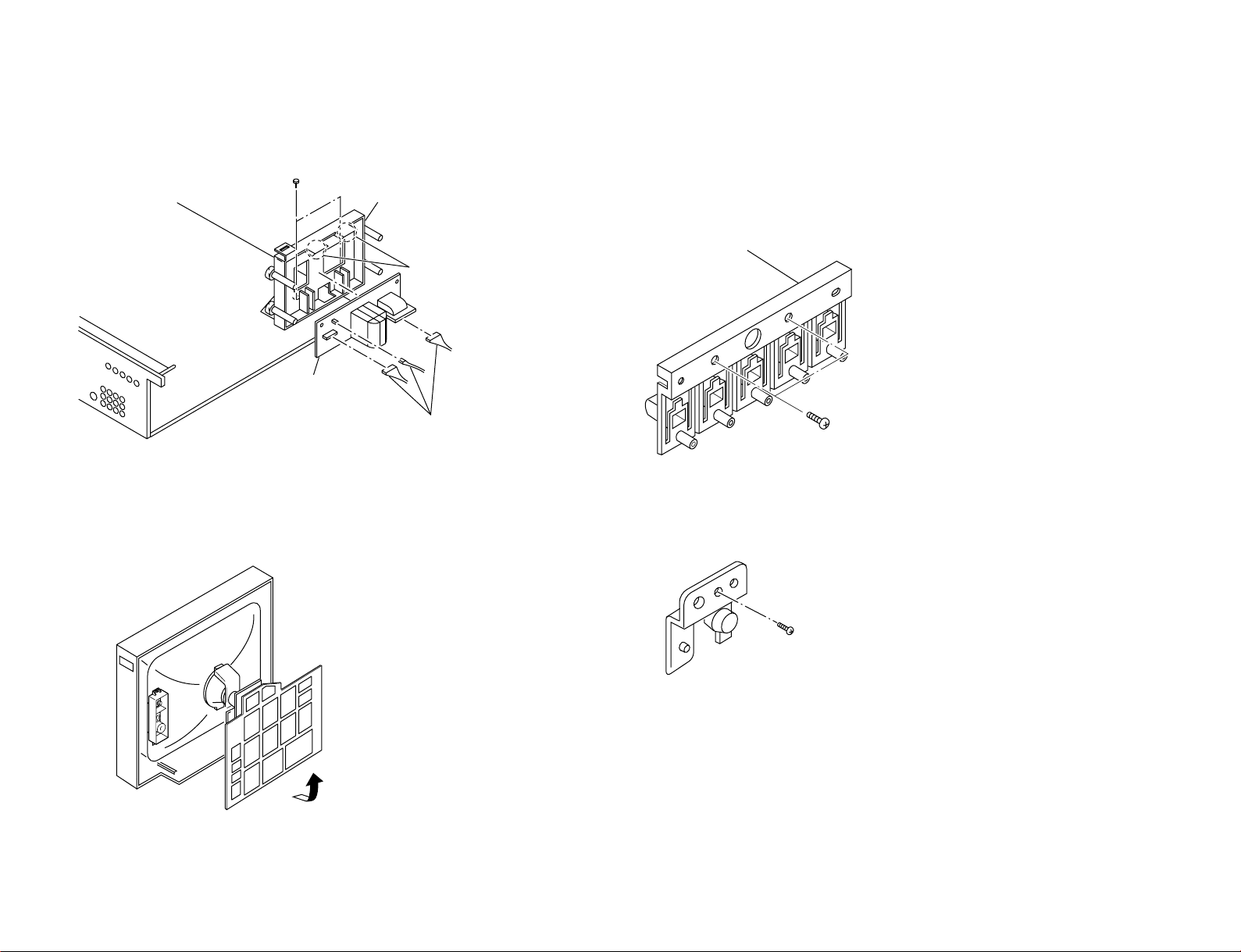

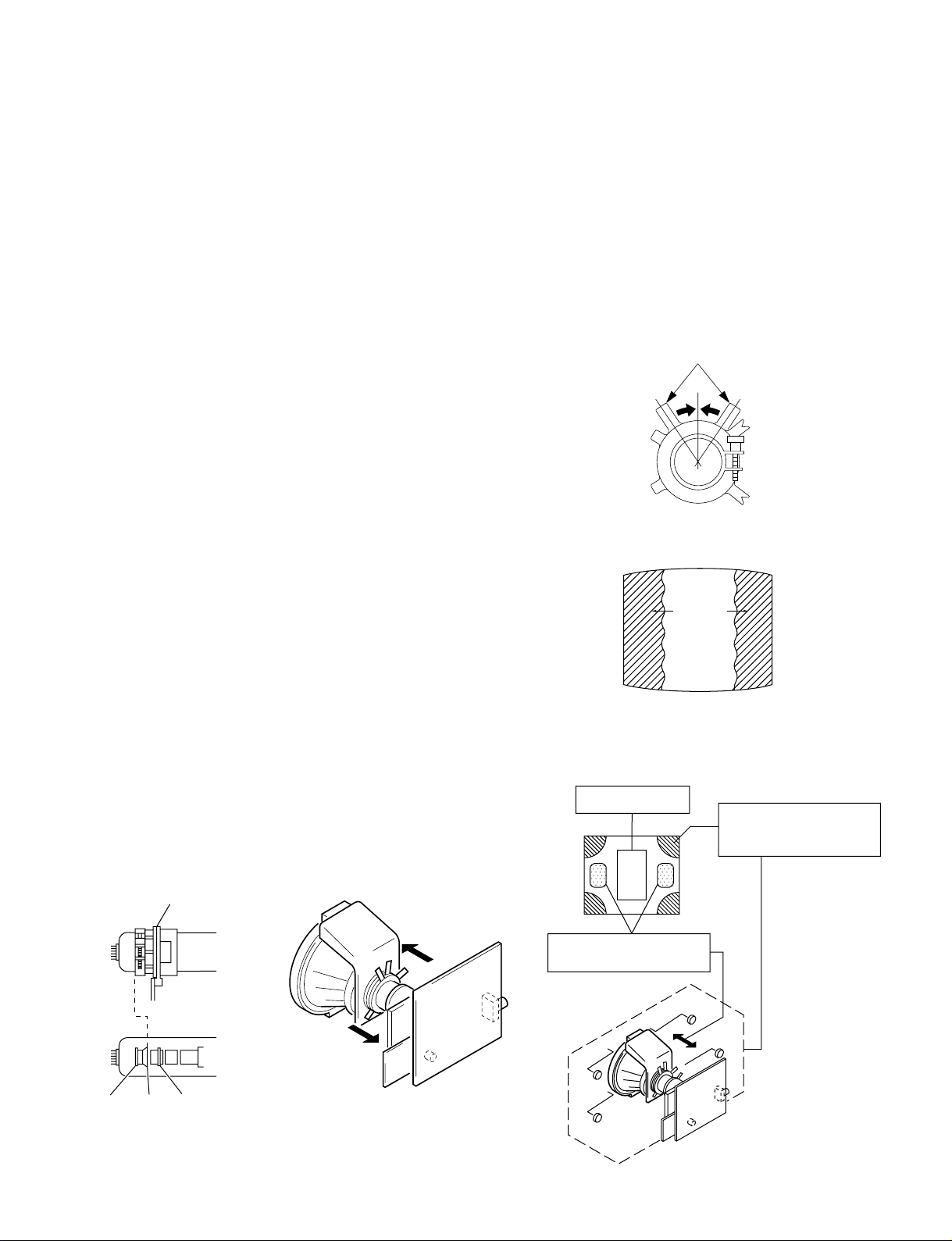

SECTION 2

1 Two screws (Washer head)

(+P 4 × 16)

3 Four screws

(+BVTP 4 × 16)

2 Two screws

(+BVTP 3 × 12)

2 Bracket, speaker

1 Chassis assy

1 Eight screws

(+BVTP 4 × 16)

2 Rear cover

4 One screw

(+BVTP 4 × 16)

3 Three screws

(+BVTP 4 × 16)

1 3D Speaker box assy

Black wire

Red wire

DISASSEMBLY

KV-XS29N90/XS29N93

RM-914

2-1. 3D SPEAKER BOX REMOVAL

– 24 –

2-2. REAR COVER REMOVAL

2-3. SPEAKER REMOVAL

2-4. CHASSIS ASSY REMOVAL

Multi button

Two screws

One screw

(+BVTP 3 × 12)

2-5. F BRACKET REMOVAL

2 Two screws

(+BVTP 3 × 12)

3 F Board bracket

5 Two claws

1 Three connectors

6 F board

– 25 –

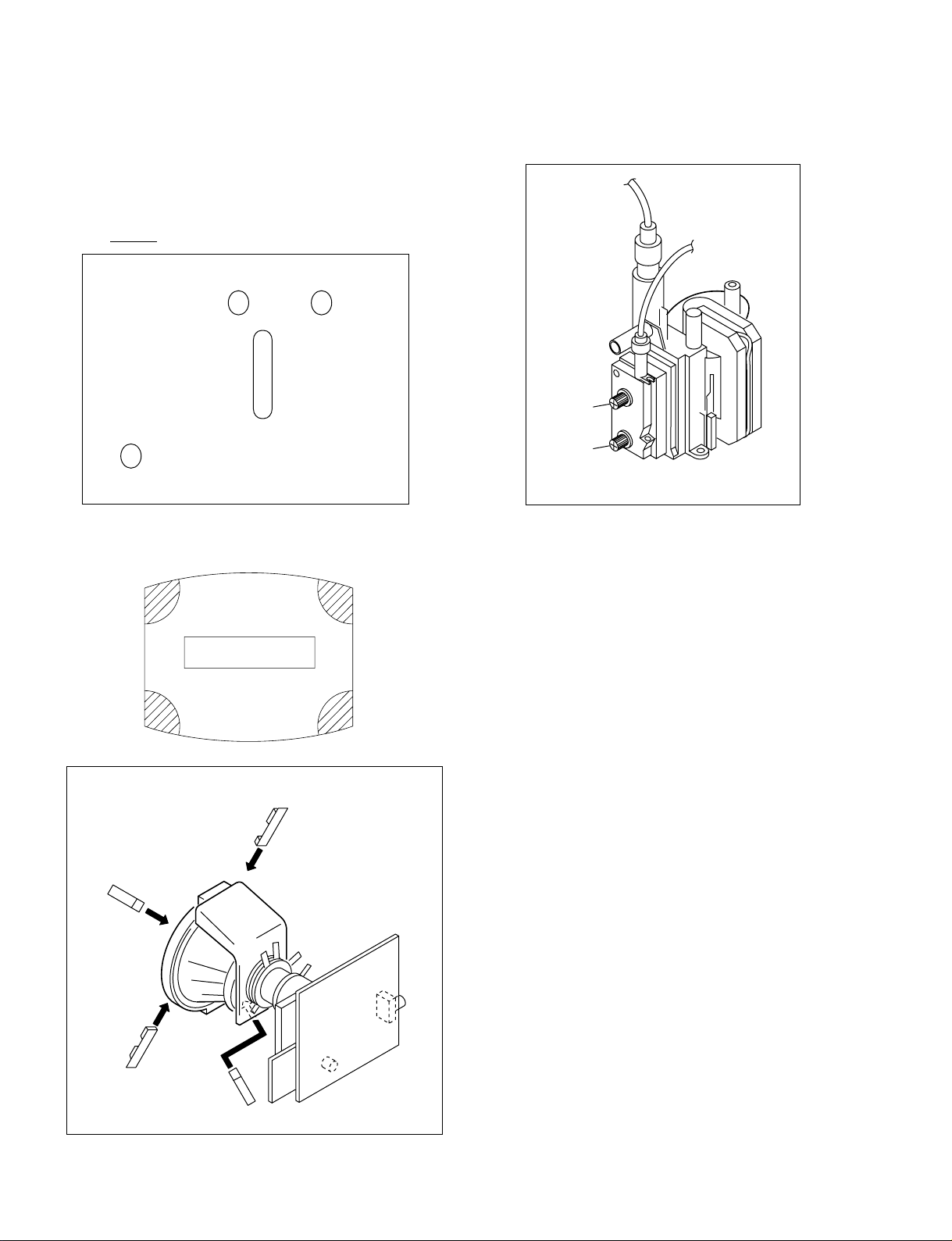

2-7. REPLACEMENT OF PARTS

For replacement of the Control Button and Light Guide, unscrew them, exchange

with the new parts, and fix them with screws (+BVTP) respectively.

2-7-1. REPLACEMENT OF CONTROL BUTTON

2-6. SERVICE POSITION

(Note: Remove F Bracket first.)

2-7-2. REPLACEMENT OF LIGHT GUIDE

KV-XS29N90/XS29N93

RM-914

KV-XS29N90/XS29N93

One screw

(+BVTP 3 × 12)

Two screws

(+BVTP 3

×

12)

Two screws

(+BVTP 3

×

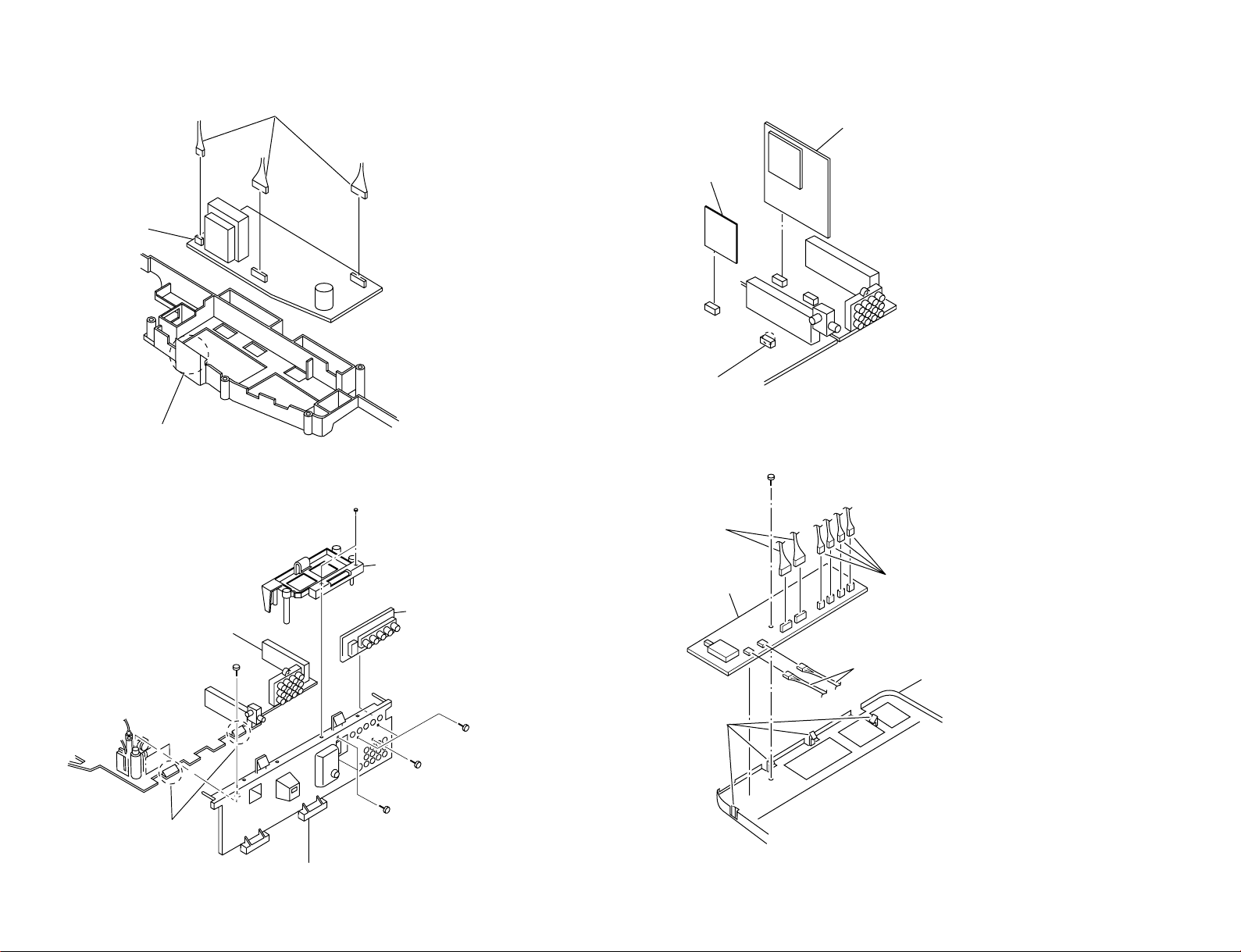

12)

2 Two claws

3 Terminal bracket

3 Two screws

(+BVTP 3

×

12)

PWB holder

J4 Board

(KV-XS29N93 only)

7

5

6

1 Three connectors

2 One claw

3 D3 board

B7 board

B5 board

1 One claw

3 Two connectors

6 One screw (+BVTP 3

× 12 with washer)

1 Two connectors

4 Four claws

5 H5 Board

2 Four connectors

2-8. D3 BOARD REMOVAL

– 26 –

2-9. TERMINAL BRACKET REMOVAL

2-10. B5 and B7 BOARDS REMOVAL

RM-914

2-11. H5 BOARD REMOVAL

4 B3 Board

5 A Board

1 Two screws

(+BVTAP 3

× 12)

2 Two screws

(+BVTAP 3

× 12)

2-12. A AND B3 BOARDS REMOVAL

!¡ Cushion

!º Picture Tube

9 Two screws

(Tapping)

9 Two screws

(Tapping)

!¢ Earth Assy,

Coating

!∞ Tension

spring

6 Deflection

yoke

4 C Board

1 Coil Demagnetic

!• Four DGC Clips

!¶ Holder, Degause coil

5 VM Board

3 Cushion (50 × 550)

DGC

3 Cushion (50 × 550)

DGC

!§ Chassis Assy

7 Anode cap

8 Speaker Bracket Assy (L)

!™ Speaker Bracket Assy (R)

2 Two screws

(washer head)

(+P 4 × 16)

!ª Two screws

(+BVTP 3 × 12)

@º Four screws

(+BVTP 4 × 16)

2 Two screws

(washer head)

(+P 4 × 16)

!· Two screws

(+BVTP 4 × 16)

@º Four screws

(+BVTP 4 × 16)

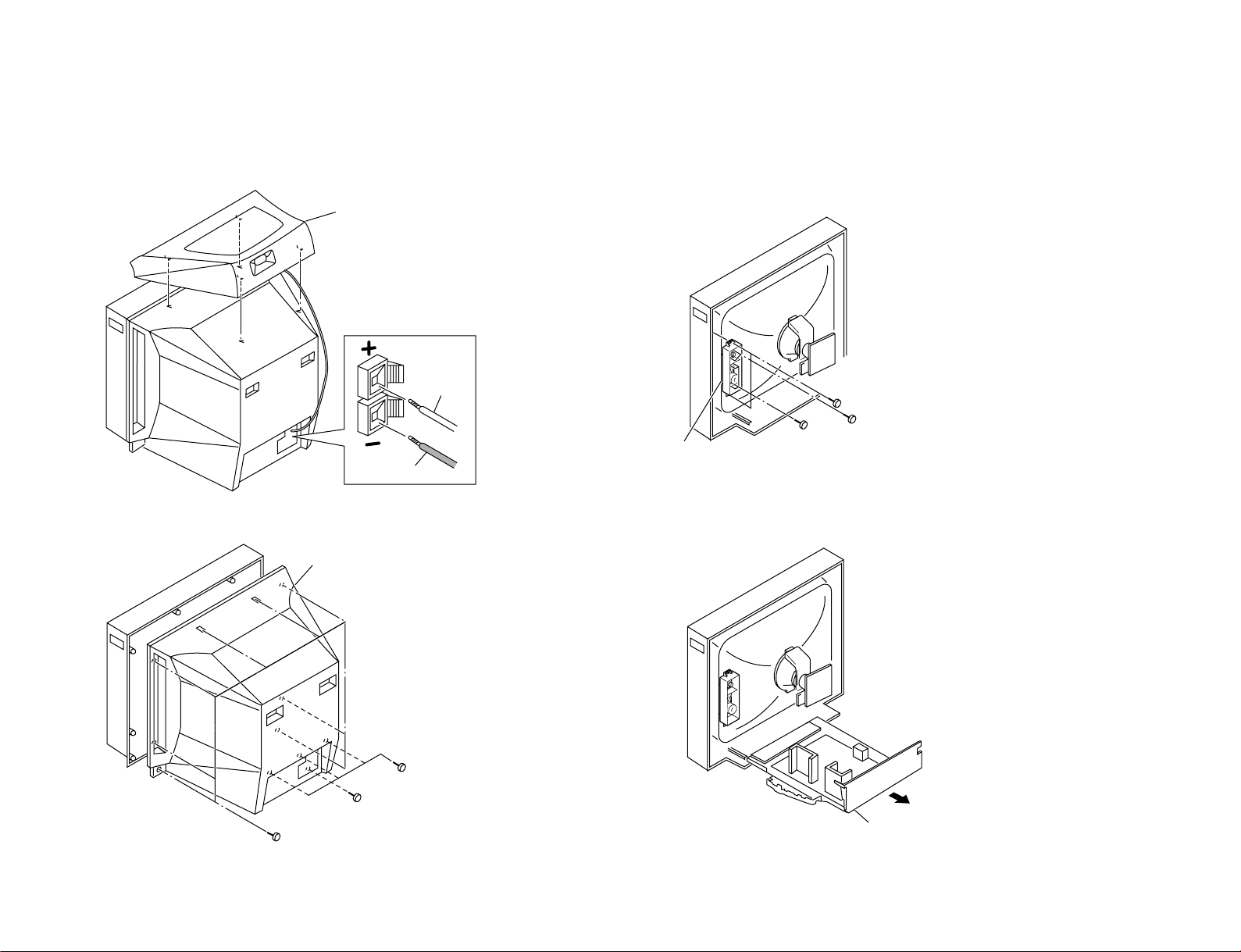

2-13. PICTURE TUBE REMOV AL

– 27 –

KV-XS29N90/XS29N93

RM-914

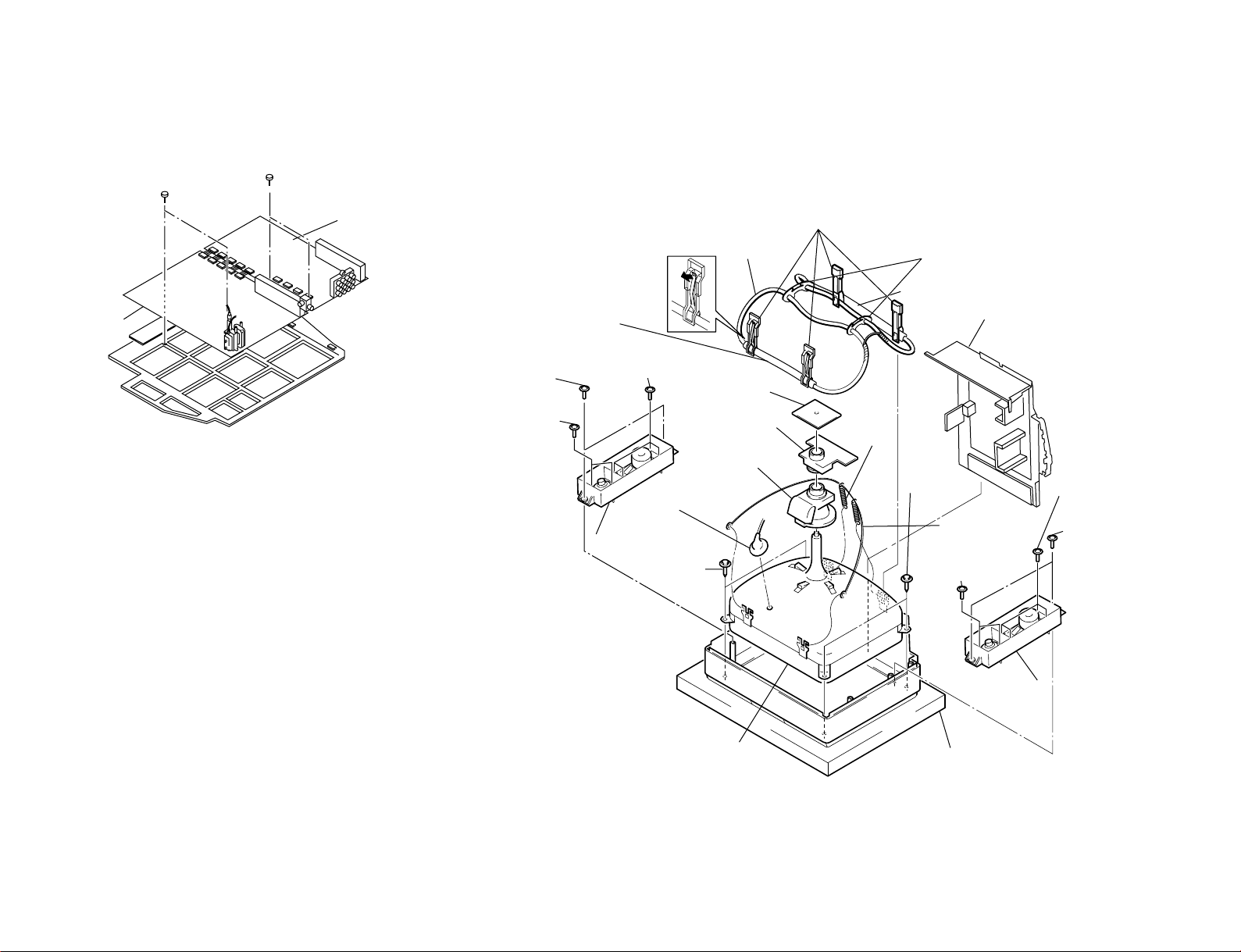

•REMOVAL OF ANODE-CAP

Anode button

a

a

b

b

c

NOTE : After removing the anode, short circuit the anode of the picture tube and

the anode cap to the metal chassis, CRT shield or carbon paint on the

CRT.

•REMOVING PROCEDURES

1 Turn up one side of the rubber cap in the direction indicated by the arrow a.

KV-XS29N90/XS29N93

RM-914

– 28 –

2 Using a thumb pull up the rubber cap firmly in the direction indicated by the arrow b.

3 When one side of the rubber cap is separated from the anode button, the anode-cap

can be removed by turning up the rubber cap and pulling it up in the direction of the

arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with sharp shaped objects.

2 Do not press the rubber too hard so as not to damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage the rubber.

SECTION 3

Neck assy

G2G1 G3

Behind the G2 edge

SET-UP ADJUSTMENTS

KV-XS29N90/XS29N93

RM-914

• The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

• These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Controls and switches should be set as follows unless otherwise noted:

PICTURE control........................................................... normal

BRIGHTNESS control................................................... normal

................................................................................................................................................................................................................................

Preparation :

• In order to reduce the influence of geomagnetism on the set's

picture tube, face it east or west.

• Switch on the set's power and degauss with the degausser.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

4. White Balance

Note : Test Equipment Required.

1. Color-bar/Pattern Generator

2. Degausser

3. Oscilloscope

Purity control

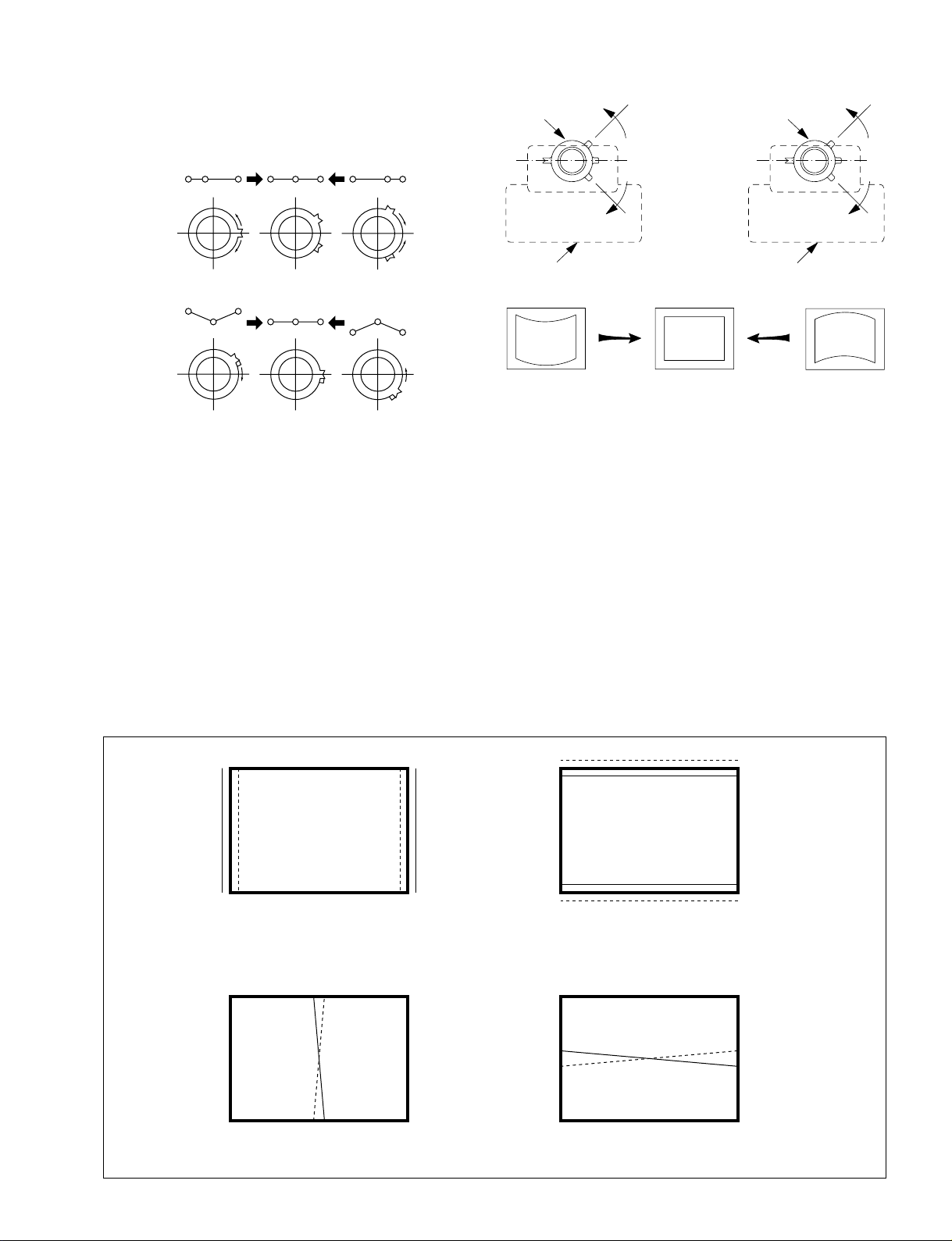

3-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck assy as shown in Fig3-2.

3. Set the pattern generator raster signal to a green raster.

4. Move the deflection yoke to the rear and adjust with the purity

control so that the green is at the center and the blue and the red

take up equally sized areas on each side.

(See Figures 3-1 through 3-4.)

5. Move the deflection yoke forward and adjust so that the entire

screen is green. (See Figure 3-2.)

6. Switch the raster signal to blue, then to red and verify the

condition.

7. When the position of the deflection yoke has been decided,

fasten the deflection yoke with the screws and DY spacers.

8. If the beam does not land correctly in all the corners, use a

magnet to adjust it.

(See Figure 3-5.)

}

normal

Red

Purity control

corrects this area.

b

a

Fig. 3-3

Blue

Green

Fig. 3-4

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

Fig. 3-1

Fig. 3-2

– 29 –

c

Deflection yoke positioning

corrects these areas.

a

d

d

Fig. 3-5

b

c

KV-XS29N90/XS29N93

RM-914

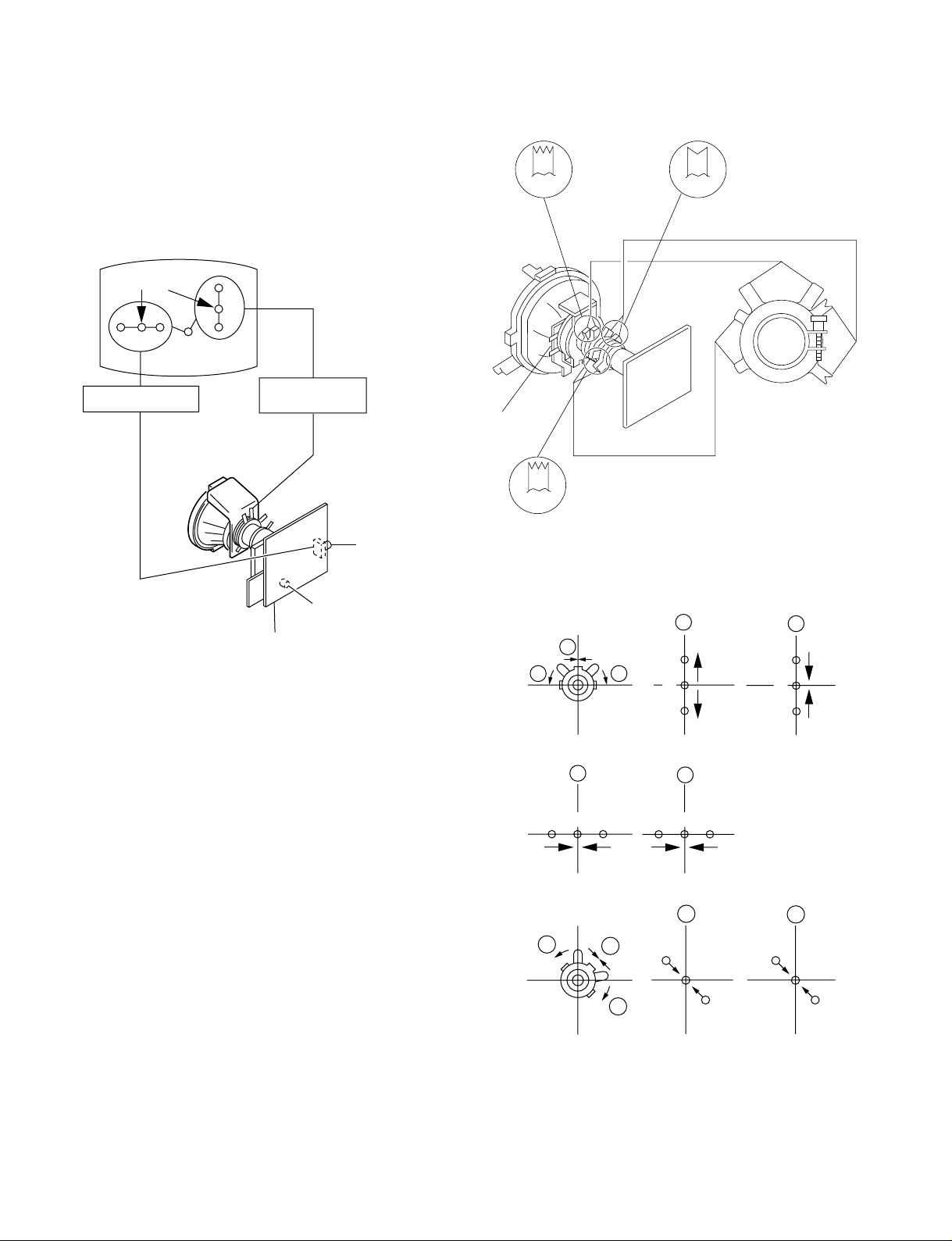

3-2. CONVERGENCE

Preparation :

• Before starting this adjustment, adjust the focus, horizontal size

and vertical size.

• Minimize the brightness setting.

• Provide dot pattern.

(1) Horizontal and Vertical Static Convergence

BMCPurity

BMC (Hexapole)

Purity

Center dot

R G B

H. STAT VR

R

G

B

V. STAT

Magnet

RV702

H. STAT

RV701

SCREEN (G2)

C Board

1. (Moving horizontally), adjust the H.STAT control so that the

red, green and blue dots are on top of each other at the center of

the screen.

2. (Moving vertically), adjust the V.STAT magnet so that the red,

green and blue dots are on top of each other at the center of the

screen.

3. If the H.STAT variable resistor cannot bring the red, green and

blue dots together at the center of the screen, adjust the

horizontal convergence with the H.STAT variable resistor and

the V.STAT magnet in the manner given below.

(In this case, the H.STAT variable resistor and the V.STAT

magnet influence each other, so be sure to perform adjustments

while tracking.)

DY pocket

V.STAT

1 V. STAT

b b

2 H. STAT VR

R

3

b

V.STAT

a

a

a

G

B

B

G

R

b

R

G

B

a

b

B

G

R

b

a

R

G

b

B

B

G

R

– 30 –

Blue

Red

VM board

Blue

Red

VM board

Neck assy Neck assy

4 BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or aligned, then

use the BMC magnet to adjust in the manner described below.

RG B R G B R GB

KV-XS29N90/XS29N93

RM-914

RB

G

RG

GB

RB

5 Y separation axis correction magnet adjustment.

1. Receive the cross-hatch signal and adjust [PICTURE] to [MIN]

and [BRIGHTNESS] to [STANDARD] .

2. Adjust the Y separation axis correction magnet on the neck

assembly so that the horizontal lines at the top and bottom of

the screen are straight.

(2) Dynamic Convergence Adjustment

Preparation:

• Before starting this adjustment, adjust the horizontal static

convergence and the vertical static convergence

Note

1. The Red and Blue magnets should be equally far from the

horizontal center line.

2. Do not separate the Red and Blue magnets too far. (Less than

8 mm)

RB

B

R

TLH TLV

RB

R

B

YCH XCV

– 31 –

KV-XS29N90/XS29N93

RM-914

TLV Rotate TLV-2 VOL (29”, 34”) on DY

Rotate TLV VOL (25”) on DY

XCV Rotate XCV Adj core on DY

YCH Rotate YCH VOL on DY

TLH Insert TLH Correction Plate to DY Pocket (Left or

Right)

ON DY:

YCH

TLV1

XCV

TLV2

3-3. FOCUS ADJUSTMENT

Adjust FOCUS control on the flyback transformer for the best

focus.

Focus

Screen

FLYBA CK TRANSFORMER (T503)

(3) Screen-corner Convergence

ba

a-d : screen-corner

misconvergence

cd

Fix a Permalloy assy corresponding to the misconverged

areas.

a

b

d

Permalloy assembly

c

– 32 –

KV-XS29N90/XS29N93

RM-914

3-4. G2 (SCREEN) AND WHITE BALANCE

ADJUSTMENTS

1. G2 (SCREEN) ADJUSTMENT

1) Set the PICTURE to normal.

2) Put to VIDEO input mode without signals.

3) Connect R, G and B of the C board cathode to the oscilloscope.

4) Adjust BRIGHTNESS to obtain the cathode voltage to the value

below.

5) Adjust G2 (screen) on the FBT until picture shows the point

before cut off.

Cathode setting voltage:

180V ±2(VDC)...29"

0 V

2. WHITE BALANCE ADJUSTMENT

1) Set to Service Mode (Refer Section 4-1: ADJUSTMENTS

WITH COMMANDER).

2) Input white raster signal.

3) Set the PICTURE to minimum.

4) Select GCT (WHB 4) and BCT (WHB 5) with [1] and [4], and

adjust the level with

5) Set the PICTURE to maximum.

6) Select GDR (WHB 1) and BDR (WHB 2) with [1] and [4], and

adjust the level with

7) Write into the memory by pressing

3. SUB BRIGHT ADJUSTMENT

1) Set to service mode.

2) Input a staircase signal of black to white from the pattern

generator.

3) BRIGHTNESS ....50%.

PICTURE ............MINIMUM

4) Select SBR (WHB7) with [1] and [4], and adjust SBR (WHB7)

level with

dimly lit.

[3] and [6] so that the second stripe from the right is

[3] and [6] for the best white balance.

[3] and [6] for the best white balance.

[MUTING] then [0].

White

second from the right

Black

– 33 –

KV-XS29N90/XS29N93

RM-914

4-1. ADJUSTMENTS WITH COMMANDER

Service adjustments are made with the RM-914 that come with

this unit.

a. ENTERING SERVICE MODE

With the unit on standby

↓

[DISPLAY]

↓

5

↓

VOL (+)

↓

[POWER]

This operation sequence puts the unit into service mode.

b. METHOD OF CANCELLATION FROM SERVICE

MODE

Set the standby condition (Press [POWER] button on the commander),

then press [POWER] button again, hereupon it becomes TV mode.

c. METHOD OF WRITE INTO MEMORY

1) Set to Service Mode.

2) Press [1] (UP) and [4] (DOWN), select an item of adjustment.

3) Press [MUTING] button and it will indicate WRITE on the screen.

4) Press [0] button to write into memory.

d. MEMORY WRITE CONFIRMATION METHOD

1) After adjustment, pull out the plug from AC outlet, and then

plug into AC outlet again.

2) Turn the power switch ON and set to Service Mode.

3) Call the adjusted items again to confirm adjustments were made.

The screen display is :

SECTION 4

CIRCUIT ADJUSTMENTS

1, 4 Select the adjustment item.

↓

3, 6 Raise/lower the data value.

↓

[MUTING] Writes.

↓

- Executes the writing.

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

5, - Service data initialization (Be sure not to use

2, - Write 50Hz adjustment data to 60Hz, or vice

usually.)

versa.

MTS

1

4

7

SOUND

MODE

PIC MODE

WAKE UP

SLEEP

CABLE

AUTO

PROGRAM

ADD/ERASE

DISPLAYMUTING

VIDEO

2

5

8

0

SURROUND

POWER

TV

3

6

9

FAVORITE

MENU

RETURN

Device Name

GEO

024S

Suffix No

(OEM Code)

Software version

Item Name

Item No

00

1.0C

Marking of virgin NVM

Data

HPS 1C SERVICE

Mode

p

59 7F 000A0

Total Power-On time (hours)

50

RM-914

PAL, SECAM : 50

NTSC : 60

– 34 –

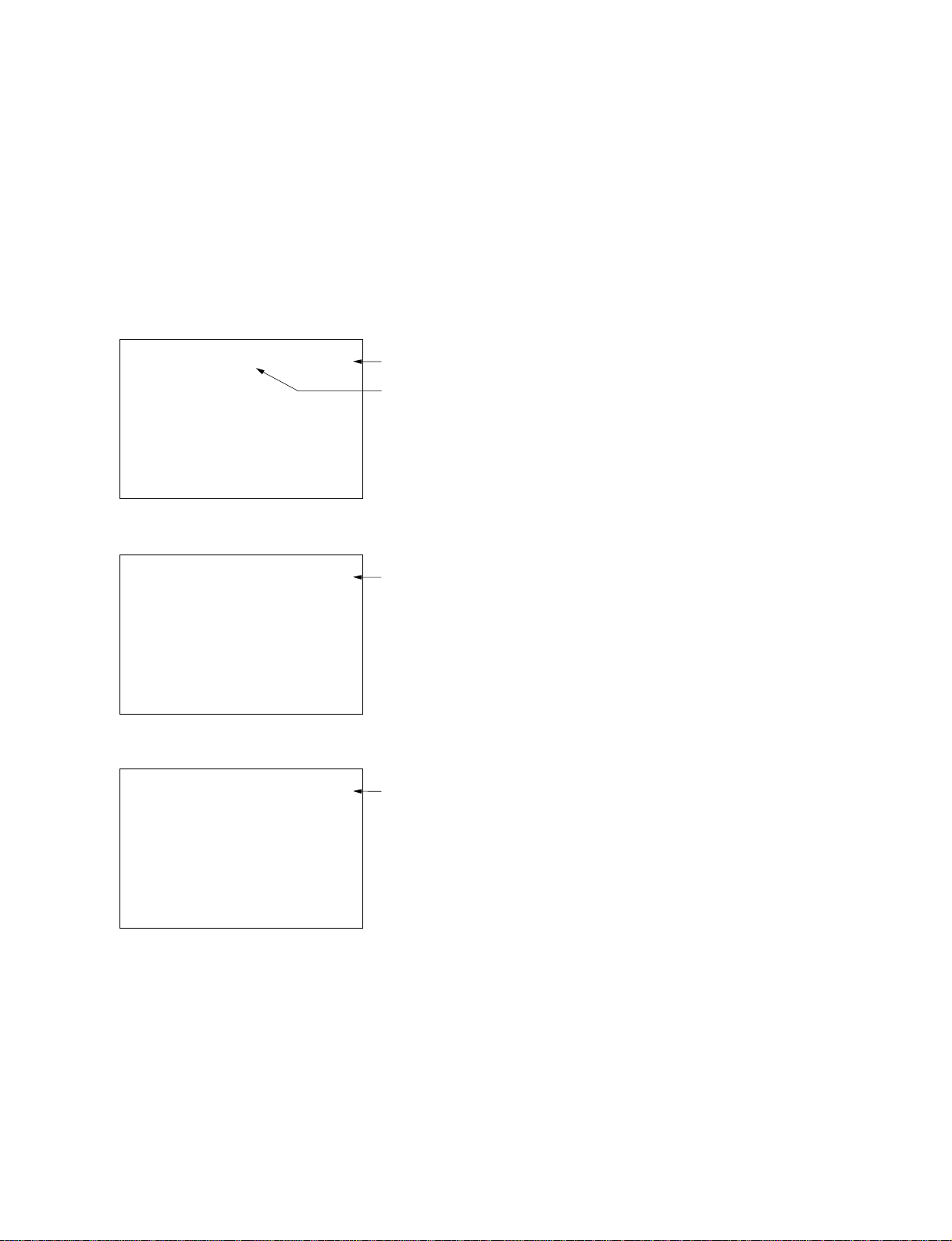

4-2. ADJUSTMENT METHOD

Item Number 00 of device GEO

This explanation uses H-Position as an example.

1. Select “GEO 00 HPS” with the 1 and 4 buttons.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is 1F for P AL reception.)

4. Write with the

WRITE.)

5. Execute the writing with the - button. (The WRITE

display will be changed to red color while excuting, and back

to SERVICE.)

[MUTING] button. (The display changes to

KV-XS29N90/XS29N93

Use the same method for all Items. Use 1 and 4 to select the

adjustment item, use 3 and 6 to adjust, write with

then execute the write with -.

Note : 1. In

[WRITE], the data for all items are written into memory

together.

2. For adjustment items that have different standard data

between 50Hz or 60Hz, be sure to use the respective

input signal after adjustment.

[MUTING],

RM-914

GEO 00

024S 1.0C

GEO 00

024S 1.0C

GEO 00

024S 1.0C

1F SERVICE 50HPS

7F 0 000A59

1F WRITE 50HPS

7F 0 000A59

Written with [MUTING]

1F SERVICE 50HPS

7F 0 000A59

GREEN

Adjusted with [3]

and [6] buttons.

GREEN

RED

The WRITE display

then the display

returns to a green

SERVICE.

Write executed with [0]

– 35 –

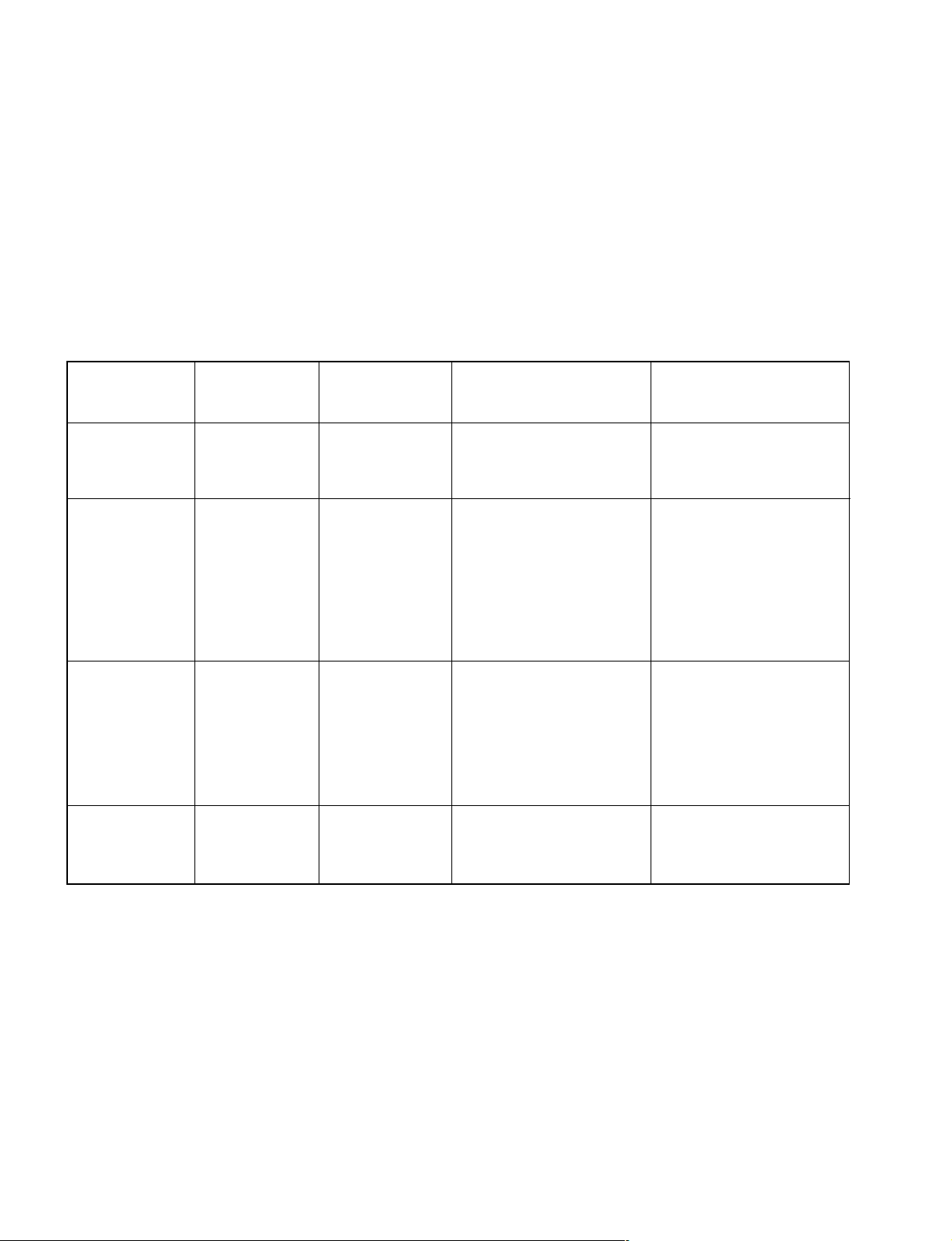

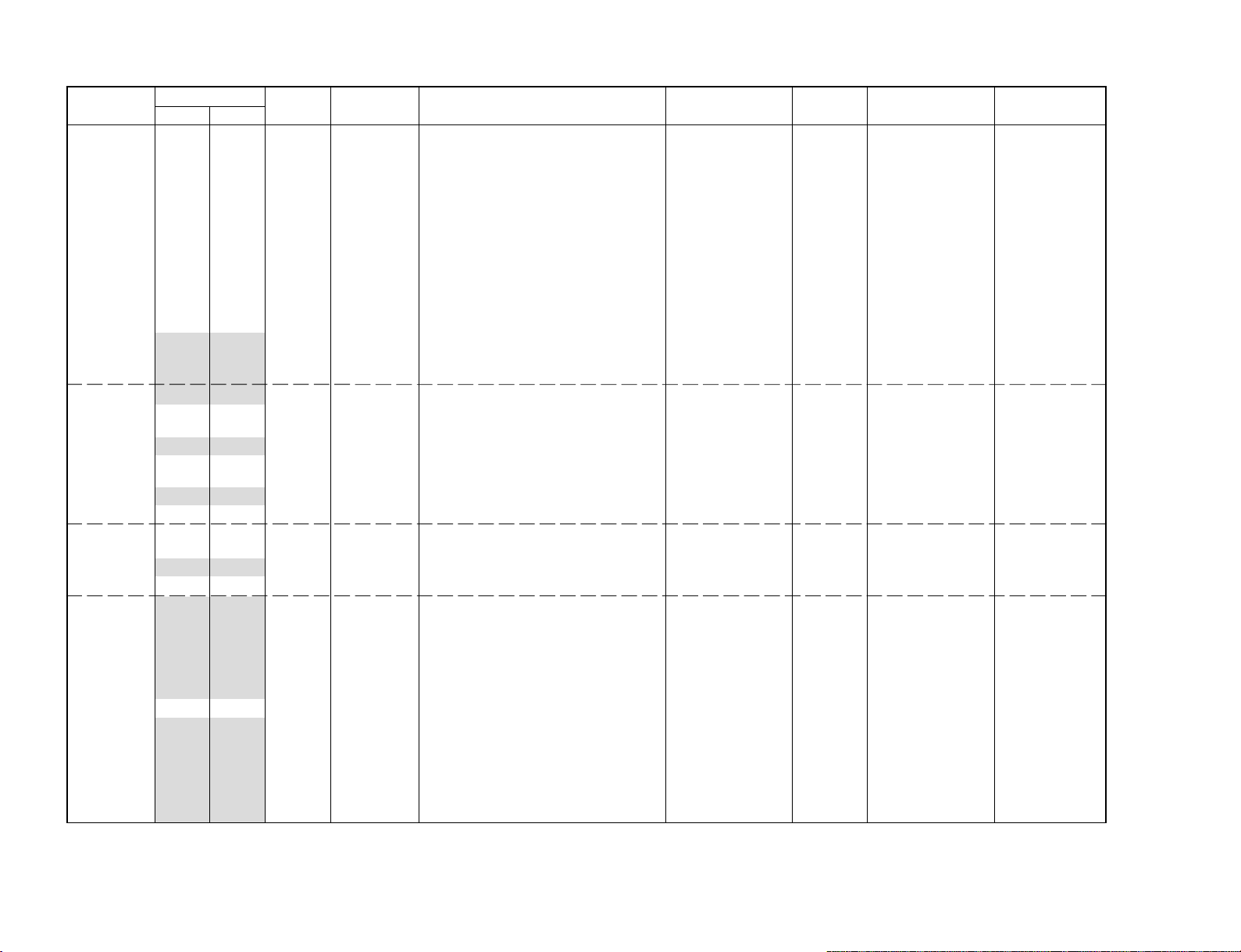

Adjustment Item Table

Device Functionality Note Data Range Function Note for Register Slava RAM Address

Name No Name Different Data No. (bit) Address (bit)

GEO 0 HPS 7 3F H Position 50/60Hz 12 (7-2) CXA2130S(88H) 9A (7-2)

WHB 0 RDR 1F 3F R Drive DYNAMIC/others 09 (7-2) CXA2130S(88H) A7 (7-2)

– 36 –

SAJ 0 PMX 36 3F Picture Maximum Data 03 (7-2) CXA2130S(88H) 105

VP 0 EHT 5 0F EHT Comp 50/60HLC 15 (3-0) CXA2130S(88H) 9D (3-0)

1 HSZ 1F 3F H Size 50/60Hz 11 (7-2) 99 (7-2)

2 PAP 1F 3F Pin Amp 50/60Hz 13 (7-2) 9B (7-2)

3 TLT 7 0F Trapezium 50/60Hz 15 (7-4) 9D (7-4)

4 VPS 1F 3F V Position 50/60Hz 0F (7-2) 97 (7-2)

5 VSZ 1F 3F V Size 50/60Hz 0E (7-2) 96 (7-2)

6 SCO 7 0F S Correction 50/60Hz 10 (7-4) 98 (7-4)

7 VLN 7 0F V Linearity 50/60Hz 10 (3-0) 98 (3-0)

8 BOW 7 0F AFC Bow 50/60Hz 16 (7-4) 9E (7-4)

9 AGL 7 0F AFC Angle 50/60Hz 16 (3-0) 9E (3-0)

10 UPN 1F 3F Upper Pin 50/60Hz 14 (7-2) 9C (7-2)

11 LPN 2F 3F Lower Pin 50/60Hz 18 (7-2) A0 (7-2)

12 HBL 1 1 H Blanking on/off 18 (1) ID (1)

13 LBL 0F 0F Left H Blanking 50/60Hz 17 (7-4) 9F (7-4)

14 RBL 2 0F Right H Blanking 50/60Hz 17 (3-0) 9F (3-0)

1 GDR 1F 3F G Drive DYNAMIC/others 0A (7-2) A8 (7-2)

2 BDR 1F 3F B Drive DYNAMIC/others 0B (7-2) A9 (7-2)

3 RCT 7 0F R Cutoff SECAM/others 07 (3-0) AB (3-0)

4 GCT 7 0F G Cutoff SECAM/others 08 (7-4) AC (7-4)

5 BCT 7 0F B Cutoff SECAM/others 08 (3-0) AC (3-0)

6 BMN 15 1F Brightness Minimum Data 06 (7-2) 106

7 SBR 1F 3F Sub Brightness Control 06 (7-2) 107

1 SHU 8 0F Sub Hue Control TV/Video 05 (7-2) 108

2 SSH 8 0F Sub Sharpness Control TV/Video 07 (7-4) 109

3 SCL 1F 3F Sub Color Control NTSC/others 04 (7-2) 10A

1 GMA 2 03

2 YDL 0D 0F Y Delay

3 SST 1 03 SECAM ID Start Position 1B (1-0) 73 (1-0)

4 SSP 1 03 SECAM ID Stop Position 1B (3-2) 73 (3-2)

5 SLV 2 03 SECAM ID Level 1C (1-0) 74 (1-0)

6 SBF 22 3F SECAM BELL fO 1C (7-2) 74 (7-2)

7 DYC 1 1 Dynamic Color on/off 0A (1) 62 (1)

8 ABL 1 1 ABL Mode Switching (except STANDARD mode) 09 (1) 61 (1)

9 VTH 1 1 ABL Detection Vth Switching 09 (0) 61 (0)

10 SFO 1 1 FO Switching for Sharpness NTSC/others 05 (1) 34A (1)

11 DCX 1 1 DC Trans. Ratio Switching 06 (1) 5E (1)

12 SHT 1 1 Pre-/Overshoot ratio Switch NTSC/others 06 (0) 34B (0)

Gamma Correction (separated in STANDARD mode

)

PAL/SECAM/NTSC/DVD

NTSC/others 0B (1-0) 359 (1-0)

0C (3-0) 35C (3-0)

KV-XS29N90/XS29N93

RM-914

Adjustment Item Table

Device Functionality Note Data Range Function Note for Register Slava RAM Address

Name No Name Different Data No. (bit) Address (bit)

VP 13 HDW 0 1 H Drive Pulse Width Switch 00 (6) 58 (6)

AP 0 BCS 2 3 Bass Center Shift #4 (3-0) TDA7315(80H) 34C (1-0)

– 37 –

MSP 0 WST 15 FF W/G Stereo Threshold MSP3415D(84H) 165

14 AFC 1 03 AFC Gain Control TV/Video/Text 0F (1-0) A5 (1-0)

15 HOS 7 0F H Oscillation 0C (7-4) 64 (7-4)

16 HSS 0 1 Slice Level of H Sync Sep. 0D (1) 65 (1)

17 VSS 0 1 Slice Level of V Sync Sep. 0D (0) 65 (0)

18 HMS 1 1 Macro Vision C/m off/on 50/60Hz 0E (0) 96 (0)

19 YUV 0 1 YUV Switch Control 01 (0) 59 (0)

20 CDV 1 3

21 RON 1 1 R ON not memorized 01 (3) 59 (3)

22 GON 1 1 G ON not memorized 01 (2) 59 (2)

23 BON 1 1 B ON not memorized 01 (1) 59 (1)

24 PON 1 1 P ON not memorized 00 (7) 58 (7)

25 BLK 0 1 BLK Off 12 (0) 6A (0)

26 VMC 0 1 VM Off 13 (0) 6B (0)

1 TCS 1 3 Treble Center Shift #5 (3-0) 34D (1-0)

2 TRF 2 3 RF T reble Offset #5 (3-0) 356 (1-0)

1 WBT EC FF W/G Bilingual Threshold 166

2 WLL 5 FF W/G Monaural Threshold 167

3 WAC 1 0F W/G Agreement Count 168

4 WDL 30 FF W/G Search Delay 169

5 NDL 20 FF NICAM Search Delay 16A

6 SDL 10 FF Stereo status Read Delay 16B

7 AGC 1 1 AGC Switch Auto/Constant 00BB (7) 116 (7)

8 REL 28 3F AGC Gain at Constant Mode 00BB (6-1) 116 (6-1)

9 CRM 0 1 Carrier muting on/off 00BB (9) 115 (9)

10 ACO 1 1 Audio Clock out on/off 0083 (5) 11A (5)

11 FP 1B 7F FM Prescale for non-M system 000E (14-8) 321

12 FPM 32 7F FM Prescale for M system 000E (14-8) 322

13 FH 36 7F FM Prescale for HDEV 000E (14-8) 323

14 FHM 65 7F FM Prescale for HDEV and M 000E (14-8) 324

15 WGP 1C 7F W/G Prescale 000E (14-8) 325

16 NIP 7F 7F NICAM Prescale 0010 (14-8) 14F

17 ERR 50 FF Auto FM switch Threshold 0021 (10-3) 174

18 VOL 6D FF Loud Speaker gain 7000h to 7ff0h 0000 (11-4) 352

CD mode for Video and RF under no signal

Video only 0D (5-4) 357 (5-4)

KV-XS29N90/XS29N93

RM-914

Loading...

Loading...