SONY KV-XR34M81, KV-XR34N90 Service Manual

REVISION HISTORY

BX1

CHASSIS

MODEL

KV-XR34M81

KV-XR34N90

NO. SUFFIX DATE SUPPL. / CORR DESCRIPTION

1 -01 2003/12 -- 1st. Issue

PA RT NO. : 9-872-426-01

SERVICE MANUAL BX1

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-XR34M81

KV-XR34N90

RM-W103 Saudi ArabiaSCC-V10L-A

RM-W150 Taiwan SCC-V05F-A

MODEL COMMANDER DEST. CHASSIS NO.

RM-W103 RM-W150

TRINITRON

®

COLOR TV

KV-XR34M81/XR34N90

RM-W103 RM-W150

TABLE OF CONTENTS

Section Title Page

SELF DIAGNOSIS FUNCTION ................................ 3

1. DISASSEMBLY

1-1. Rear Cover Removal ................................................. 6

1-2. Speaker Removal ...................................................... 6

1-3. Chassis Assy Removal .............................................. 6

1-4. Service Position ........................................................ 6

1-5. Terminal Bracket and J1 Board Removal................. 6

1-6. F Board Removal ...................................................... 6

1-7. H3 Board Removal .................................................... 7

1-8. DL Board Removal ................................................... 7

1-9. A Board Removal ...................................................... 7

1-10.Picture Tube Removal ............................................... 8

2. SET-UP ADJUSTMENTS

2-1. Beam Landing ........................................................... 9

2-2. Convergence ............................................................ 10

2-3. Focus Adjustment .................................................... 12

2-4. G2 (SCREEN) Adjustments ................................... 12

2-5. White Balance Adjustment ..................................... 12

2-6. Sub Bright Adjustment ........................................... 12

3. CIRCUIT ADJUSTMENTS

3-1. Adjustment With Commander ................................ 13

3-2. Adjustment Method ................................................ 14

3-3. Picture Quality Adjustment .................................... 28

3-4. Deflection Adjustment ............................................ 29

3-5. Picture Distortion Adjustment ................................ 30

Section Title Page

4. DIAGRAMS

4-1. Block Diagram ........................................................ 32

4-2. Circuit Boards Location .......................................... 33

4-3. Schematic Diagram Information ............................ 33

4-3-1. C Board Schematic Diagram ....................... 34

4-3-2. A Board — Processor (Block A) ................. 35

4-3-3. A Board — Audio (Block B) ....................... 37

4-3-4. A Board — Power Supply (Block C) .......... 39

4-3-5. A Board — Tuner (Block D) ....................... 41

4-3-6. A Board — Jack (Block E) .......................... 43

4-3-7. A Board — Heat Sink (Block F) ................. 45

4-3-8. H3 Board Schematic Diagram ..................... 46

4-3-9. F and VM Board Schematic Diagram ......... 48

4-3-10. DL and J1 Board Schematic Diagram ....... 50

4-4. Voltage Measurement and Waveforms ................... 53

4-5. Printed Wiring Boards and Parts Location ............. 57

4-6. Semiconductors ....................................................... 62

5. EXPLODED VIEWS

5-1. Picture Tube and Speaker ....................................... 64

5-2. Chassis ..................................................................... 65

6. ELECTRICAL PARTS LIST.................................... 66

OPERATING INSTRUCTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD,

OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

SELF DIAGNOSIS FUNCTION

The units in this manual contain a self diagnosis function. If an error occurs, the STANDBY (1) indicator will automatically

begin to flash. The number of times the STANDBY (1) indicator flasher translates to a probable source of the problem. If

an error symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored

in memory to reveal past problems and how often these problems occur.

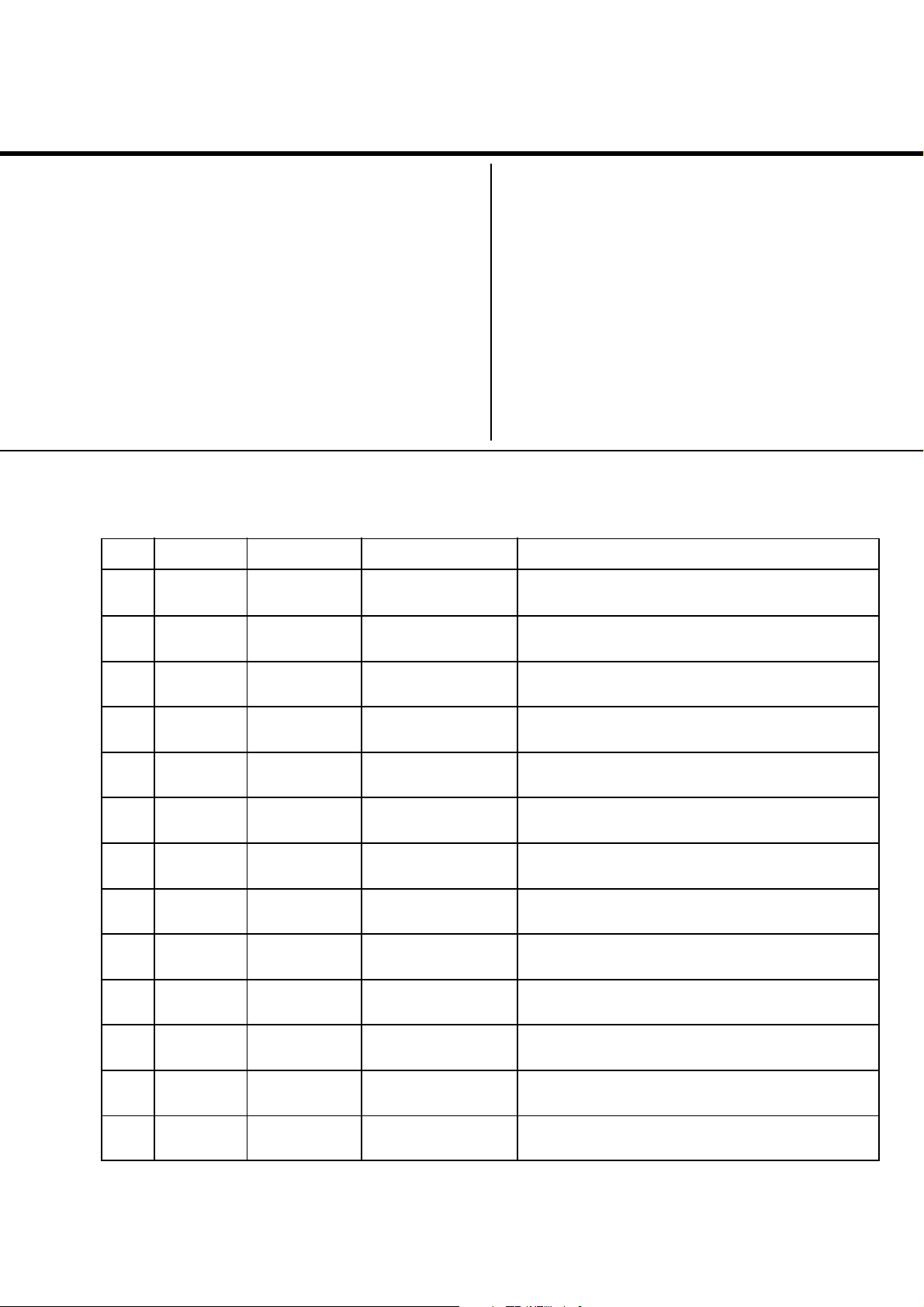

1. DIAGNOSIS TEST INDICATORS

When an errors occurs, the STANDBY/(1) indicator will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the indicator will identify the first of the problem areas.

Result for all of the following diagnosis items are displayed on screen. No error has occured if the screen displays a "0".

Diagnosis

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP)*

• I-Port

• IK (AKB)

No. of times

STANDBY/TIMER

lamp flashes

Does not light

2 times

4 times

5 times

Self-diagnostic

display/Diagnosis

result

—

2:0

2:1 ~ 255

4:0

4:1 ~ 255

5:0

5:1 ~ 255

Probable

Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out (F4601)

(A Board)

• H.OUT (Q511) is shorted.

(A board)

• IC751 is shorted.

(C/CV Board)

• +13V is not supplied.

(A Board)

• IC503 voltage list is faulty.

(A Board)

• Video OUT (IC751) is faulty.

(C Board)

• IC001 is faulty. (A Board)

• Screen (G2) is improperly

adjusted.

Detected

Symptoms

• Power does not come on.

• No power is supplied to the

TV.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is

shorted.

• Has entered standby state

after horizontal raster.

• Vertical deflection pulse is

stopped.

• Power line is shorted or

power supply is stopped.

• No raster is generated.

• CRT cathode current

detection reference pulse

output is small.

• HV Protect

Note 1: If a + B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously.

The symptom that is diagnosed first by the microcontroller is displayed on the screen.

Note 2: Refer to screen (G2) Adjustment in section 2-4 of this manual.

8 times

8:0

8:1 ~ 255

• IC604 faulty.

• IC607 faulty.

• No power supply to CRT

ANODE.

• No RASTER is generated.

– 3 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

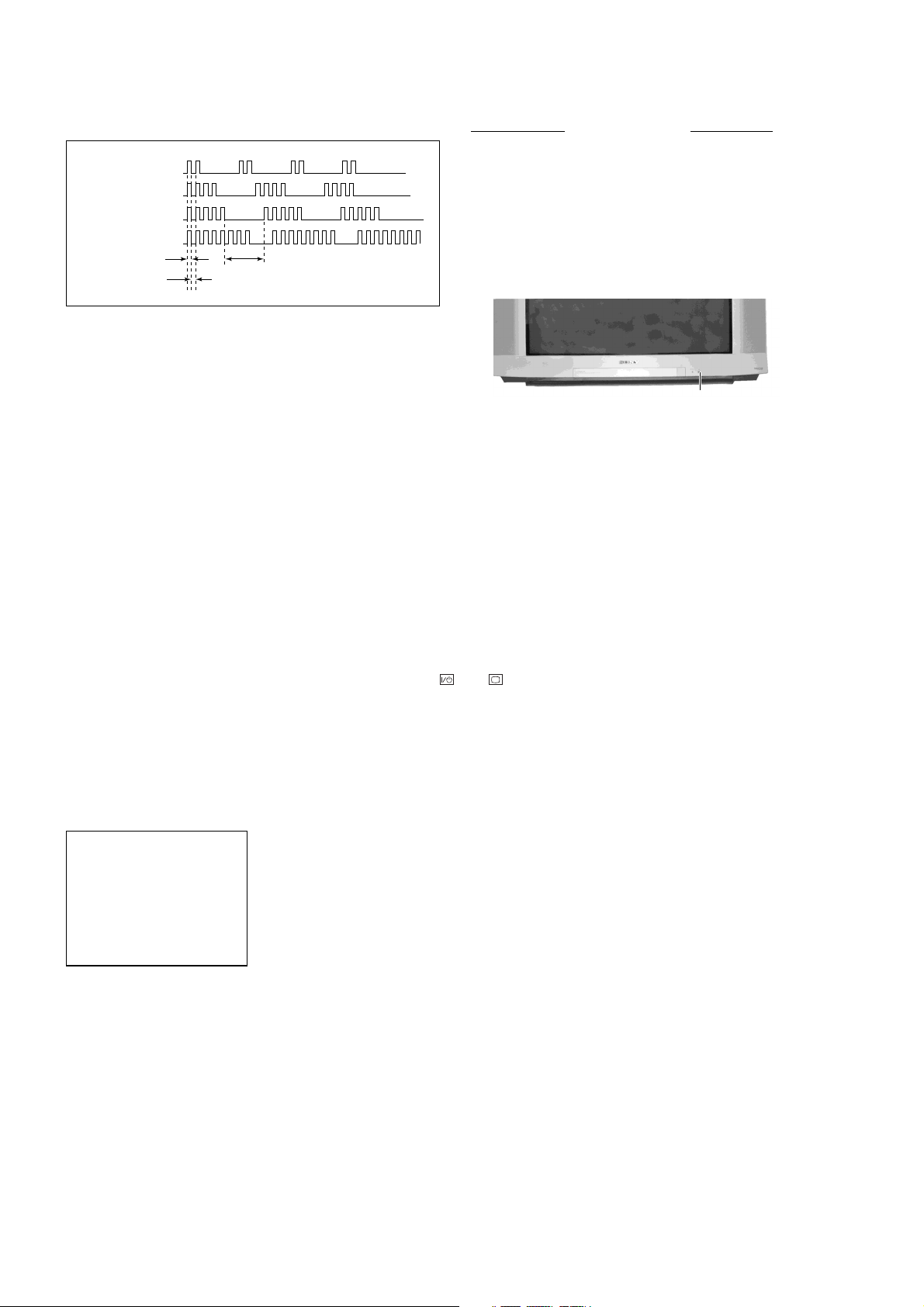

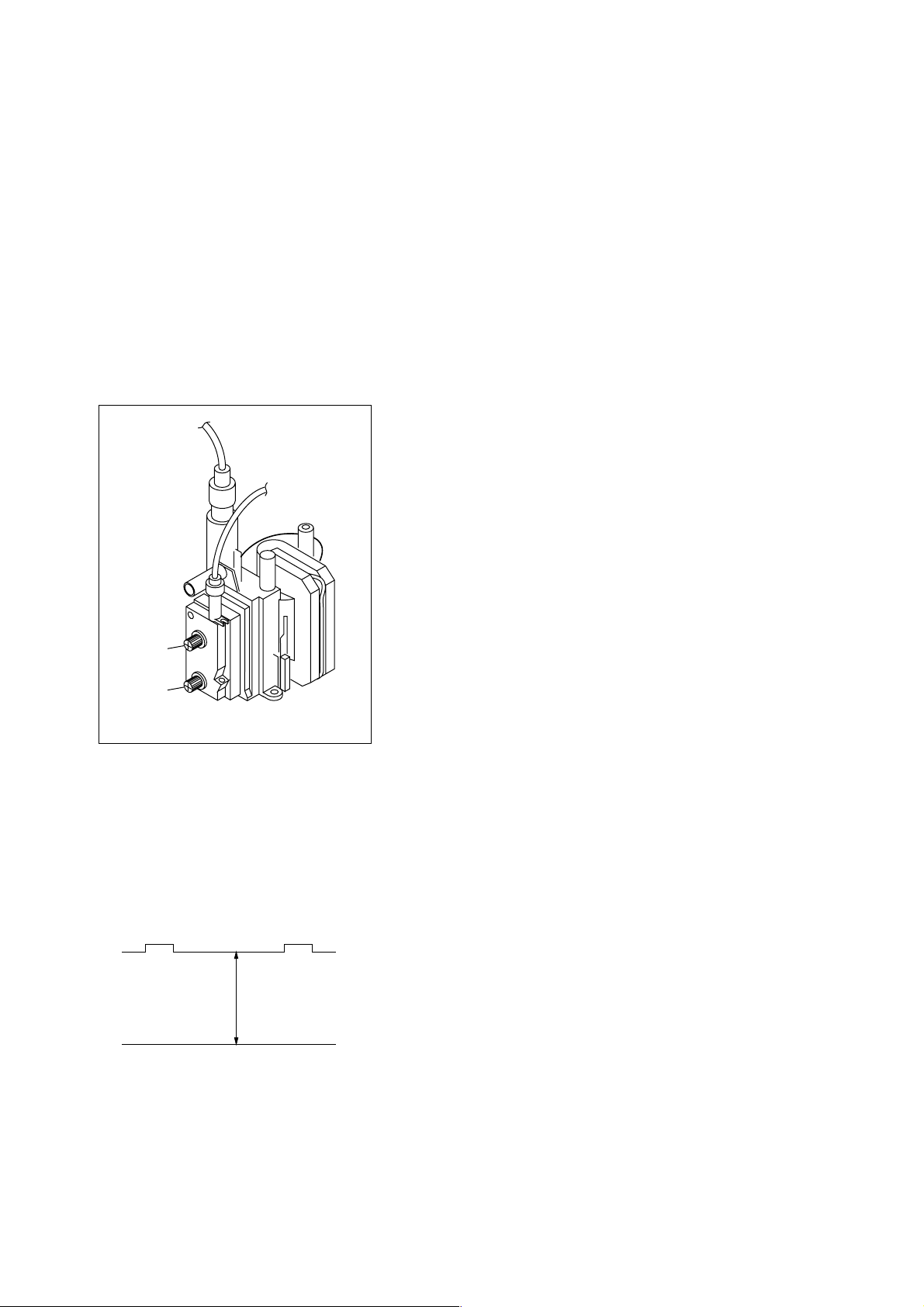

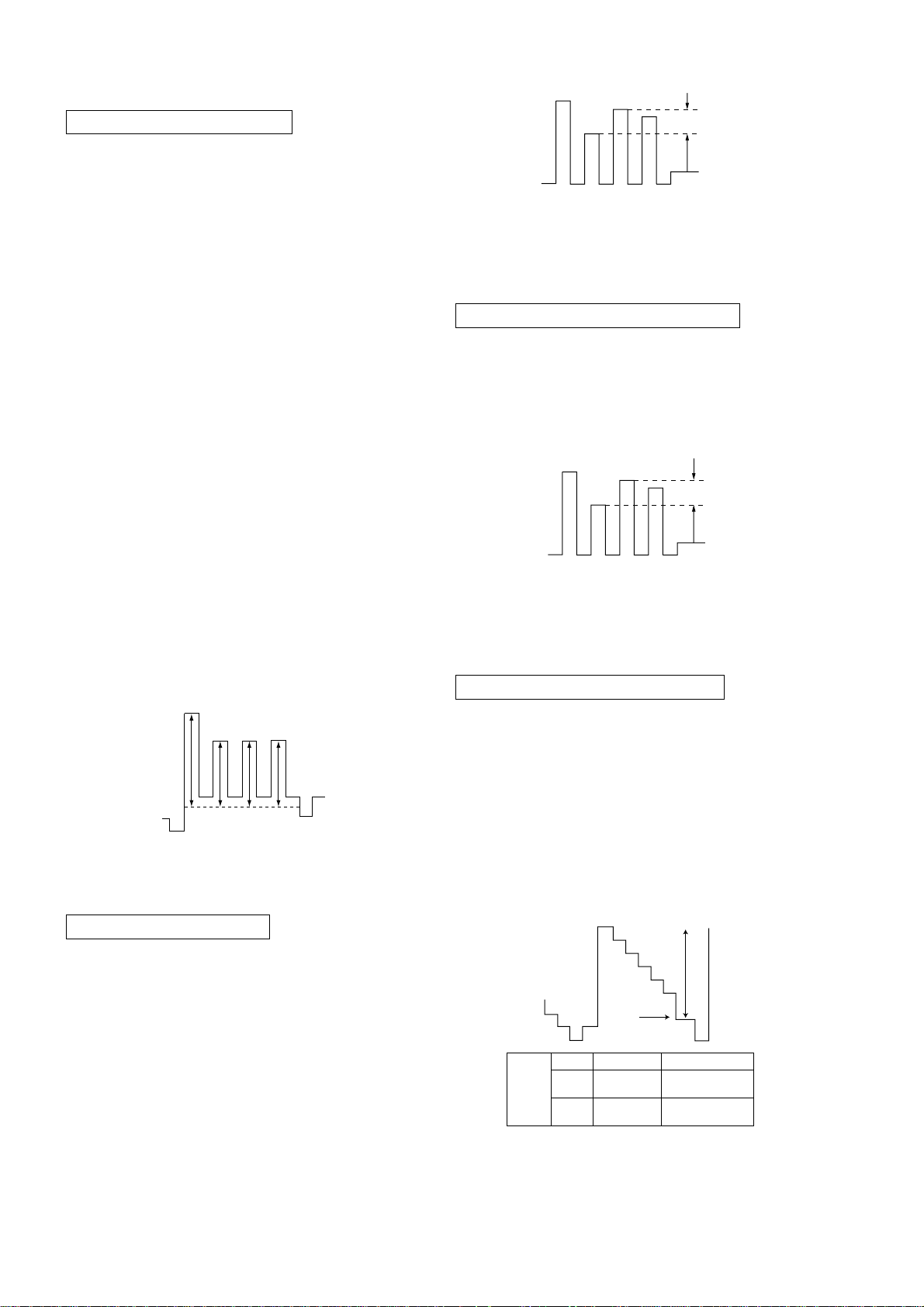

2. DISPLAY OF STANDBY/(1) indicator FLASH

COUNT

Lamp ON 300ms

Lamp OFF 300ms

Lamp OFF 3 sec

3. STOPPING THE STANDBY/(1) indicator FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/(1) lamp

from flashing.

Diagnosis Item Flash Count*

+B overcurrent 2 times

I-Prot 4 times

IK (AKB) 5 times

HV Protect 8 times

* One flash count is not used for self-diagnosis.

FLASH RED n Please refer diagnosis item.

FLASH GREEN n OK

STANDBY indicator

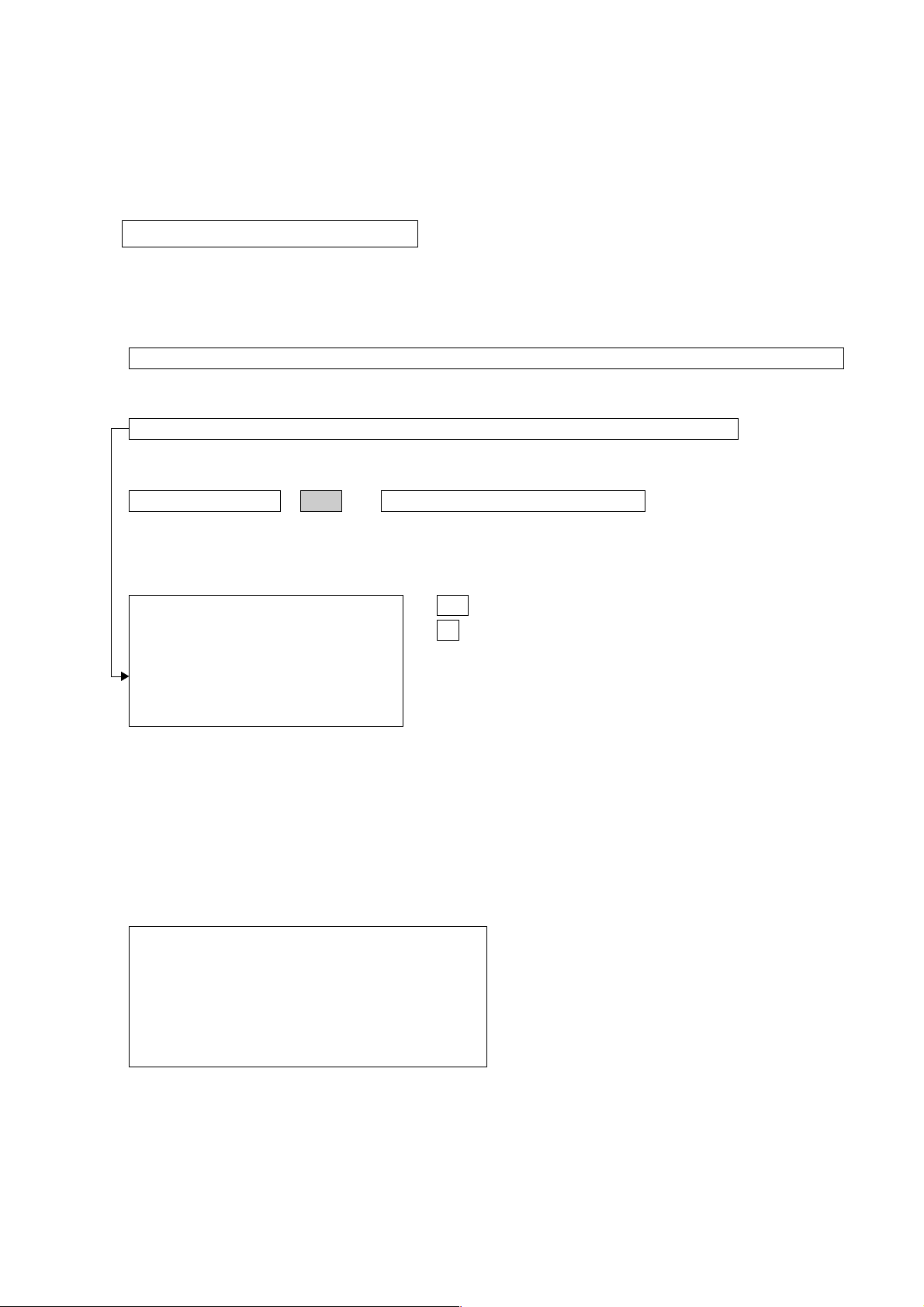

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as "power sometimes shuts off" or "screen sometimes goes out" that cannot be confirmed,

it is possible to bring up past occurrence of failure on the screen for confirmation.

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

[display] / channel [5] / volume [-] / Power

/ TV

˘

Note that this differs from entering the service mode (volume [+]).

Self-Diagnostic screen display

SELF DIAGNOSTIC

2 : 0

3 : N/A

4 : 0

5 : 1

8 : 0

101 : N/A

Numeral "0" means that no fault was detected.

Numeral "1" means the number of a fault occurrence (1~255).

– 4 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnosis results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to "0".

Unless the result display is cleared to "0", the self-diagnosis function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to "0", press buttons on the remote commander sequentially when the self-diagnostic screen is

displayed, as shown below:

Channel [8] / "0"

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

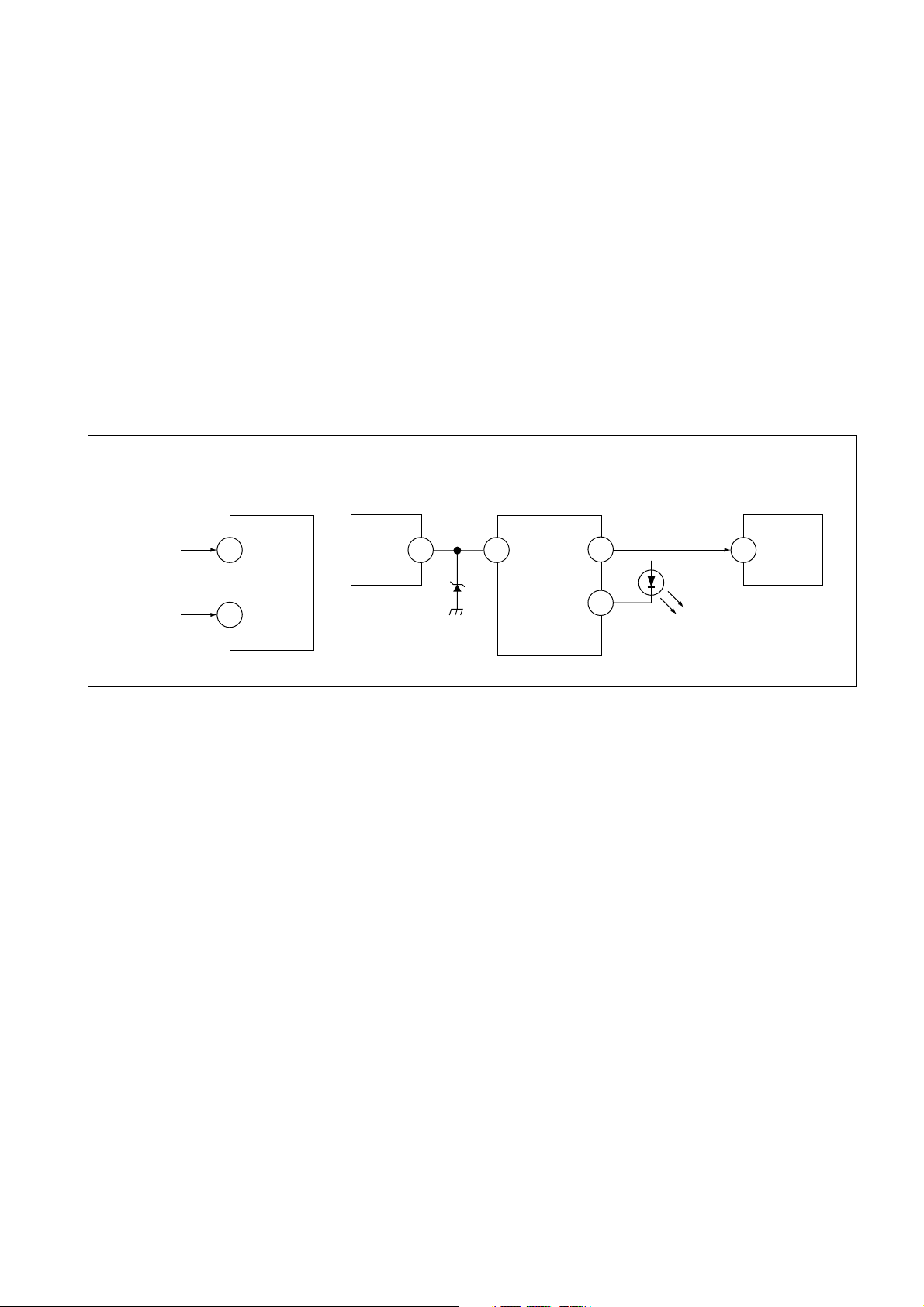

6. SELF-DIAGNOSIS CIRCUIT

FROM

C BOARD

IC751 PIN 5

A BOARD

FROM

Q511

COLLECTOR

A BOARD

IC001

Y/CHROMA JUNGLE

IK

97

EHTO

A BOARD

IC503

V.OUT

F.B-PLS

A BOARD

IC001

SYSTEM

SDA1

3 11645

V.GUARD

RED LED

20

7

DISPLAY

A BOARD

IC003

MEMORY

5

SDA

[+B overcurrent OCP ] Occurs when an overcurrent on the +B (135V) line is detected by pin 97 of IC001

(A Board). If the voltage of pin 97 of IC001 (A Board) is less than 1V when V.SYNC is

more than HV, the unit will automatically go to standby.

[I-Port] Occurs when an absence of the vertical deflection pulse is detected by pin 116 of

IC001 (A Board).

[IK $AKB%] If the RGB levels* do not balance within 15 sec after the power is turned on, this error

will be detected by IC001 (A Board). TV will stay on, and indicalor will start to Blink 5

times.

[HV Protect] Occurs when IC001 internal HV protect detects an abnormal. H-Pulse (frequency) due

to unproper power supply to IC001. TV cuts off high voltage power of anode CRT. No

picture will be detected eg IC607, IC604 go faulty.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects 1K)

– 5 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

SECTION 1

DISASSEMBLY

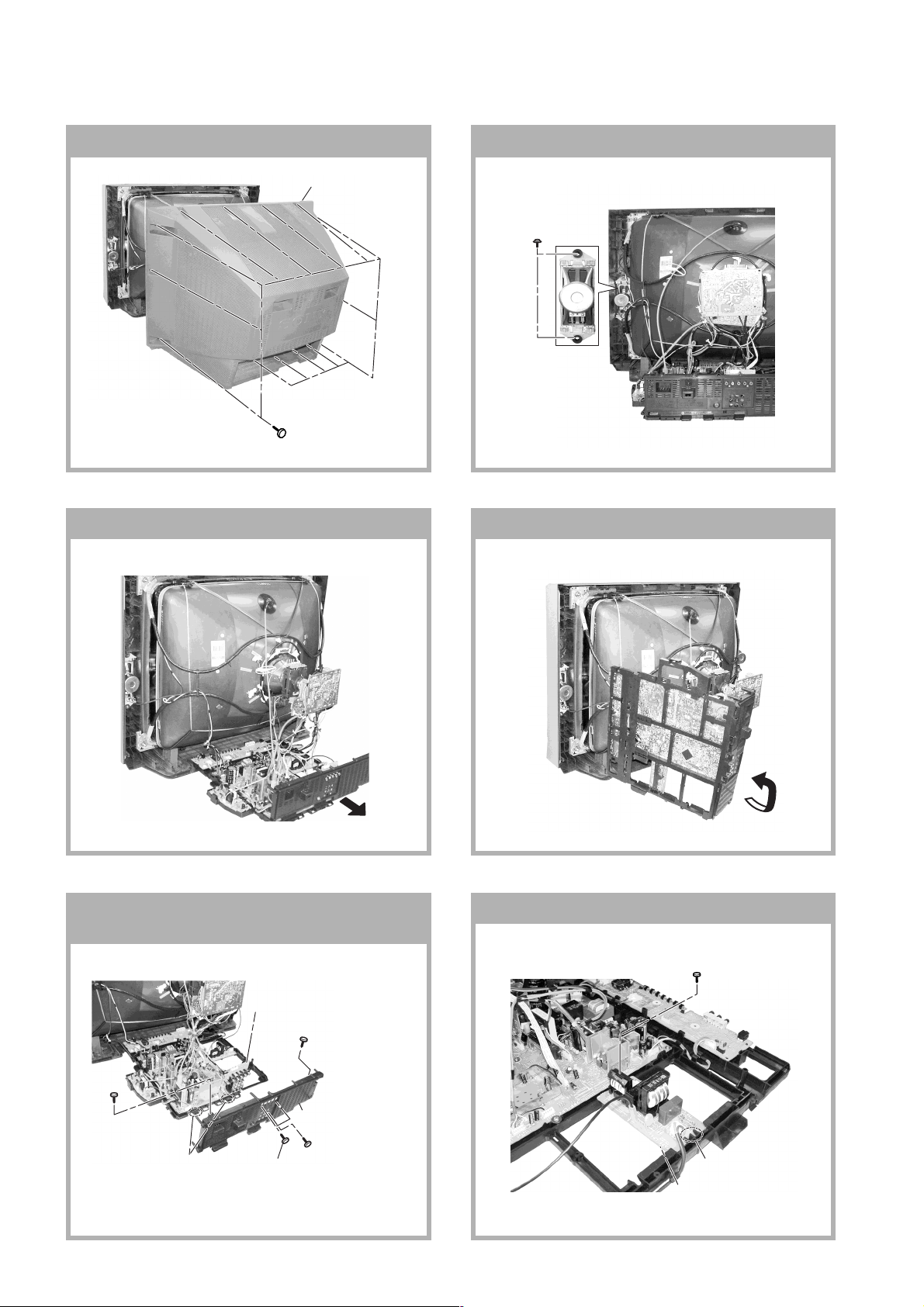

1-1. REAR COVER REMOVAL

2 Rear cover

1 Fourteen screws

(+BVTP 4 × 16)

1-2. SPEAKER REMOVAL

1 Two screws

(Washer Head)

(+P4 × 16)

1-3. CHASSIS ASSY REMOVAL 1-4. SERVICE POSITION

1-5. TERMINAL BRACKET AND J1 BOARD

REMOVAL

7 J1 Board

2 One screws

(+BVTP 3 × 12)

1 One screws

(+BVTP 3 × 12)

6 Two hooks

5 Terminal bracket

3 One screws

(+BVTP 4 × 16)

4 Two screws

(+BVTP 3 × 12)

1-6. F BOARD REMOVAL

1 One screws

(+BVTP 3 × 12)

2 Two hooks

3 F Board

– 6 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

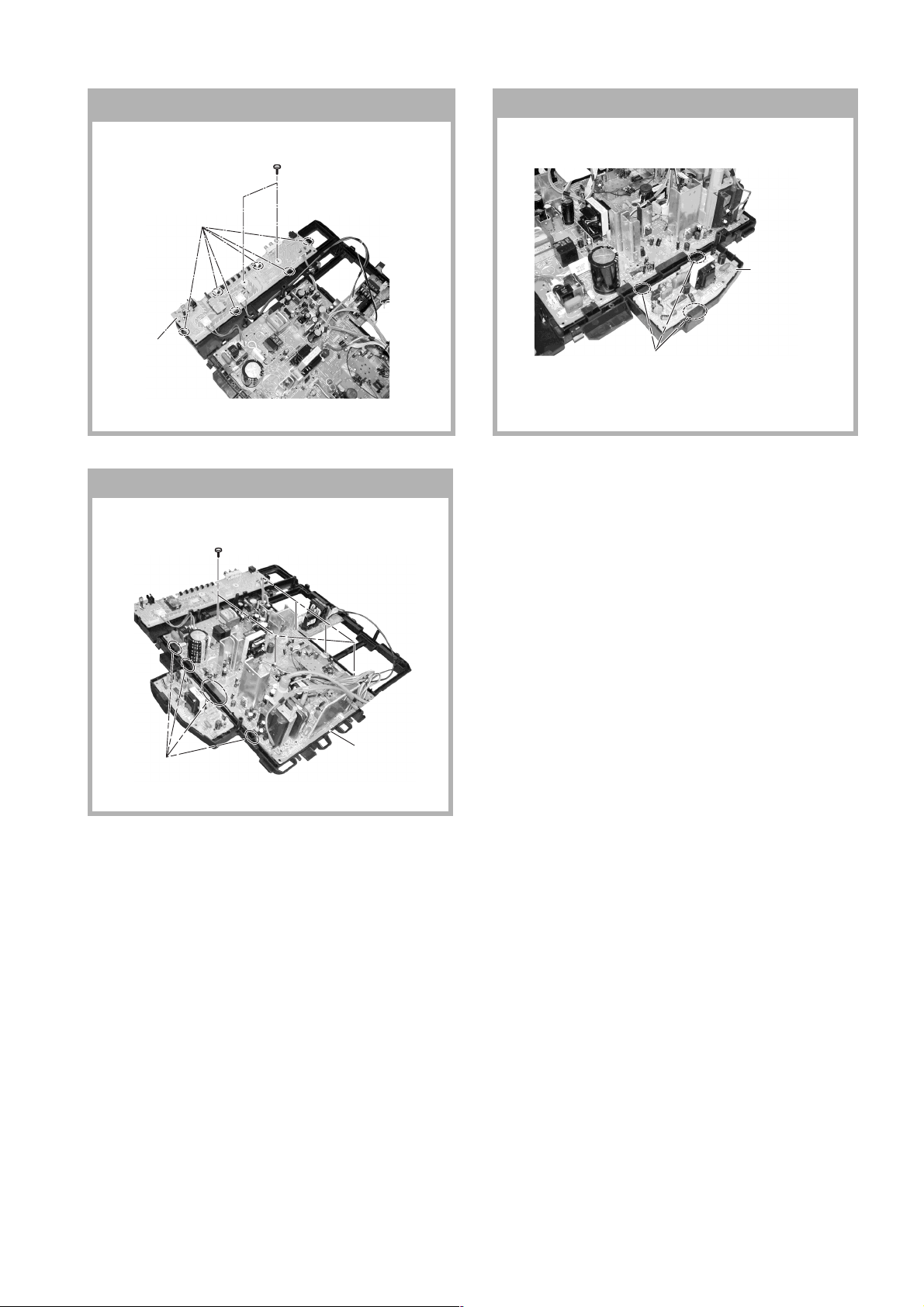

1-7. H3 BOARD REMOVAL

1 Two screws (washer head)

(+BVTP 3 × 12)

2 Six Hooks

H3 Board

3

1-9. A BOARD REMOVAL

1 Six screws (washer head)

(+BVTP 3 × 12)

1-8. DL BOARD REMOVAL

7 DL Board

6 Three hooks

2 Four Hooks

3 A Board

– 7 –

KV-XR34M81/XR34N90

c

RM-W103 RM-W150

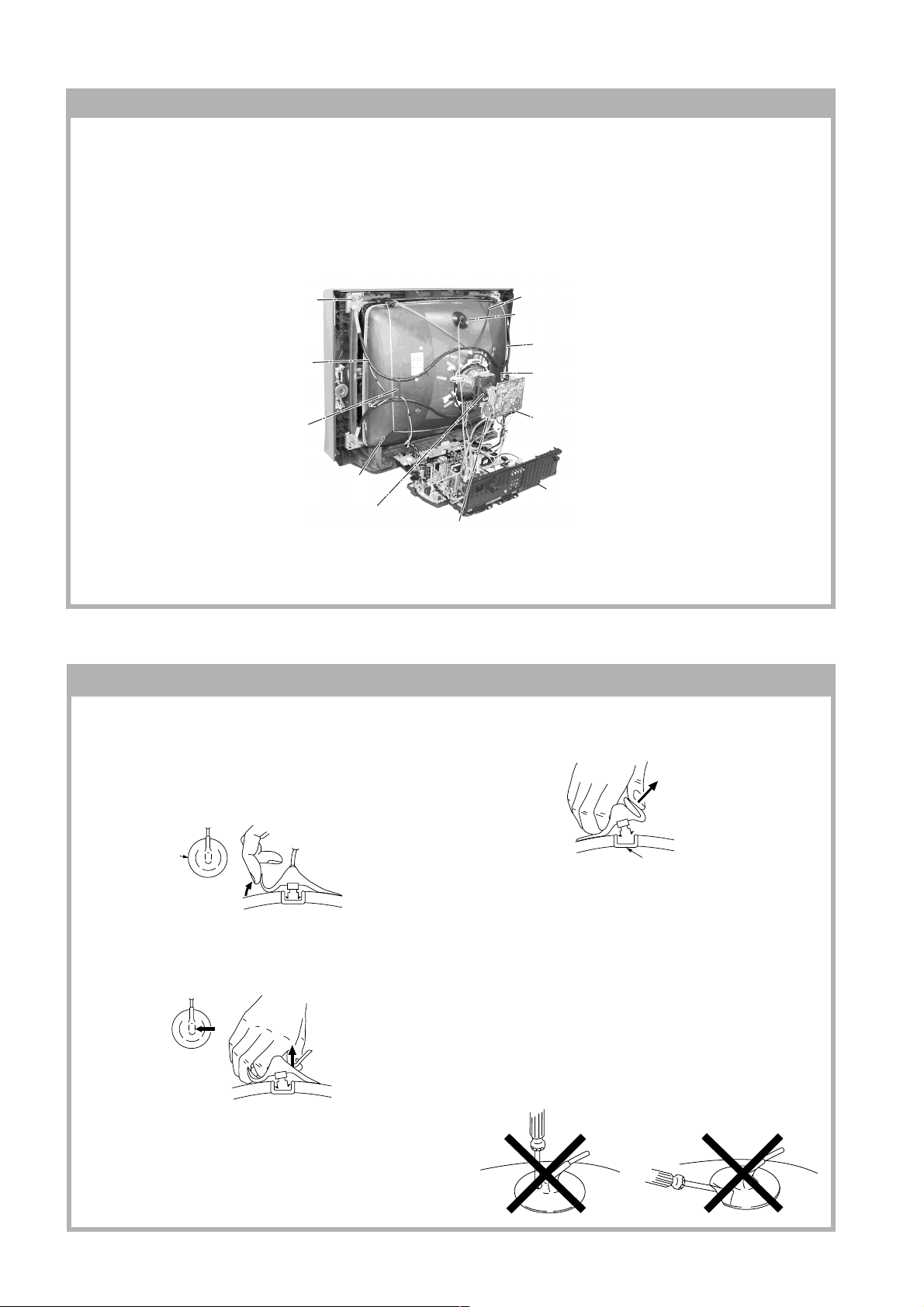

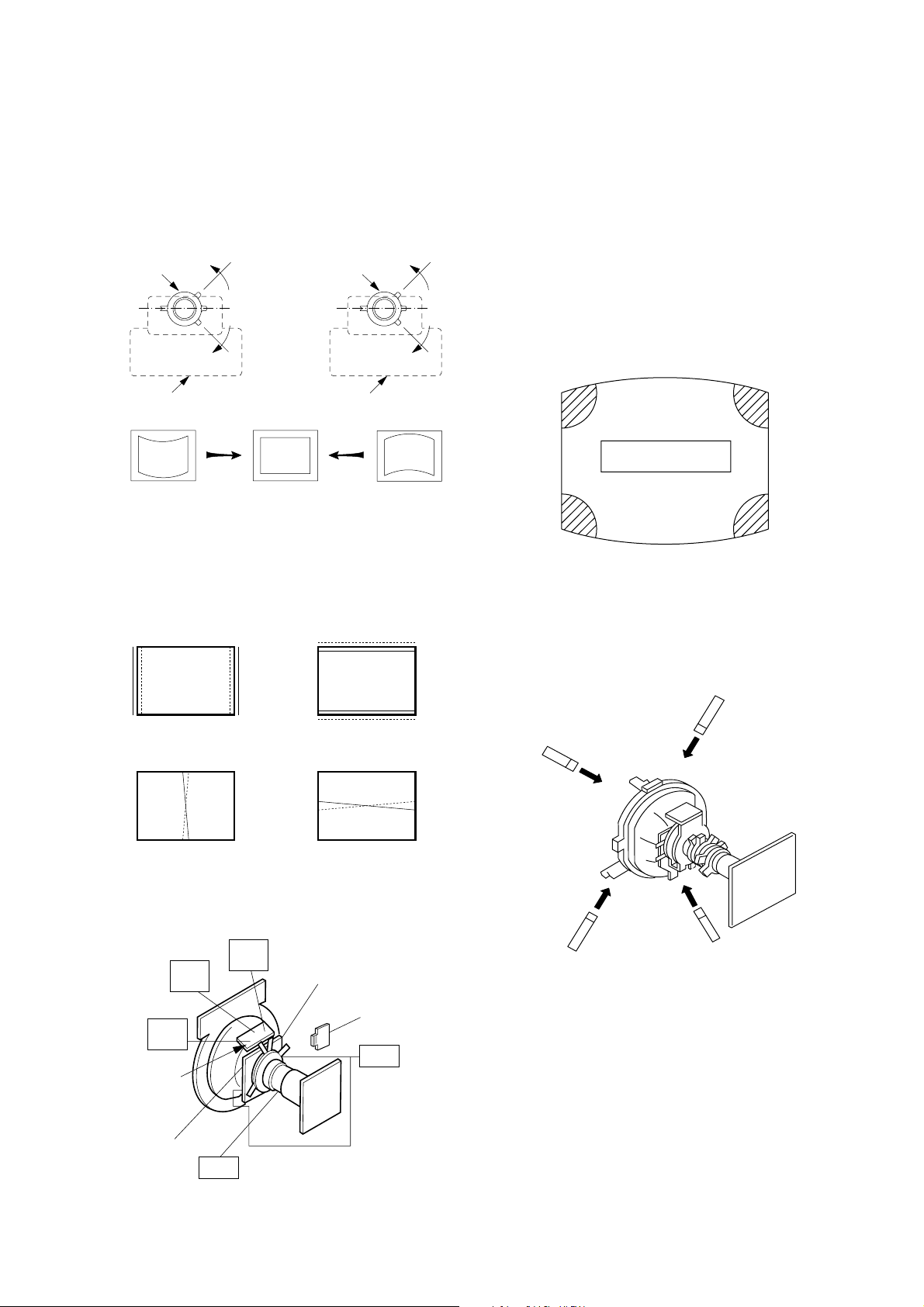

1-10. PICTURE TUBE REMOVAL

Note:

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom

right and left.

1) Place the TV set with the CRT face down on a cushion jig

2) Remove the rear cover.

3) Unplug all interconnecting leads from the Deflection Yoke,Neck assy, Degaussing Coil and CRT grounding strap.

qf Nut, Special, CRT (x4)

qd Degaussing Coil

qs Holder, DGC(x2)

Removal

9 Spring Tension Removal (x2)

8 Loosen the Deflection Yoke

fixing screw and remove

7 VM Board Removal

qa Band, DGC Removal

4 Anode Cap Removal

0 Earth Coating Assy

6 Loosen the Neck Assembly

fixing screw and removal

5 C Board Removal

9 Chassis Assy Removal

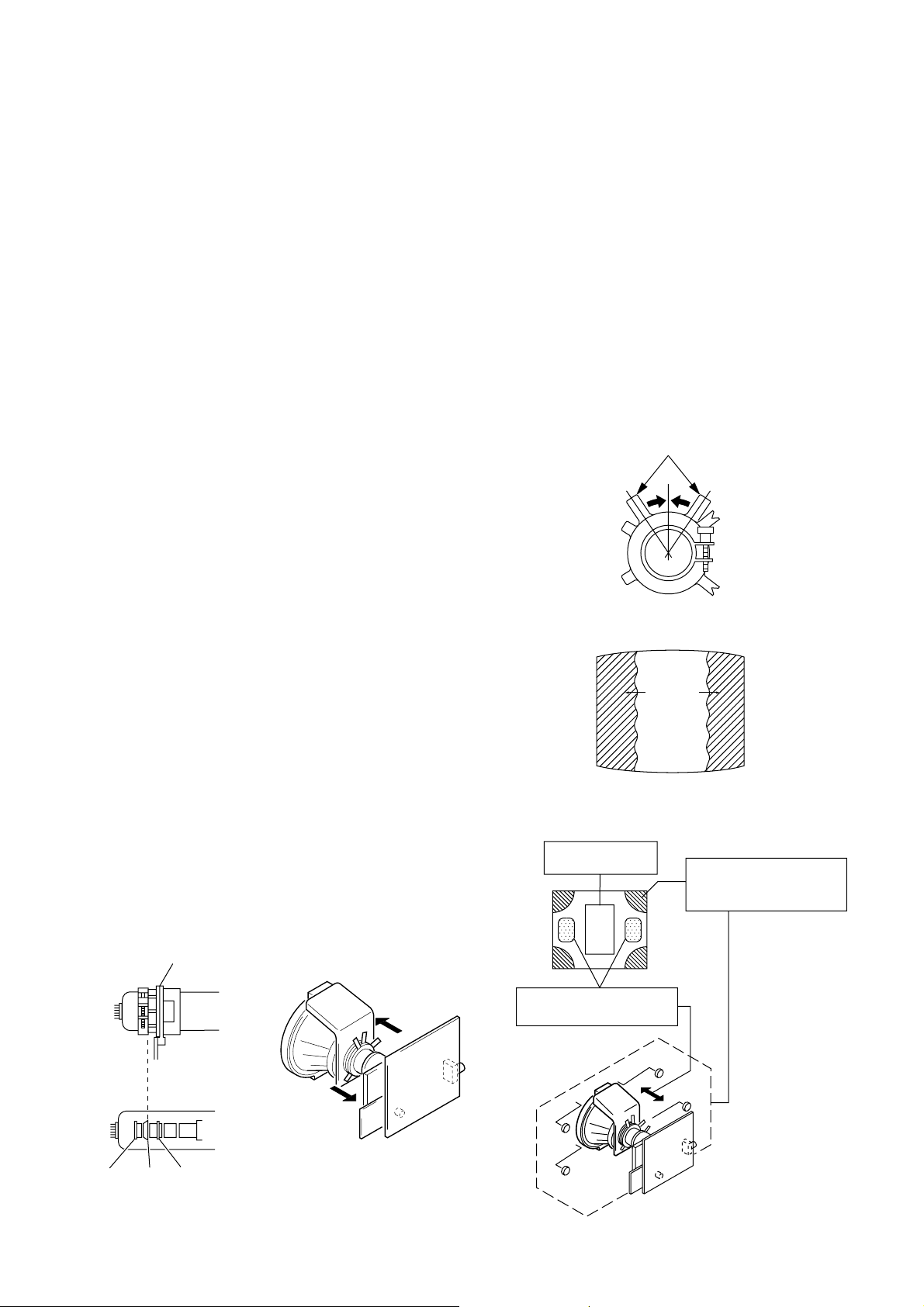

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

b

b

2 Using a thumb pull up the rubber cap firmly in the direc-

tion indicated by the arrow b.

anode button

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be removed by

turning up the rubber cap and pulling it up in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

– 8 –

SECTION 2

SET-UP ADJUSTMENTS

KV-XR34M81/XR34N90

RM-W103 RM-W150

The following adjustments should be made when a

complete realignment is required or a new picture tube is

installed.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

Set the controls as follows unless otherwise noted:

VIDEO MODE: .................................................... Standard

4. Screen(G2)

5. White Balance

PICTURE CONTROL:......................................... Normal

BRIGHTNESS CONTROL: ................................. Normal

Note : Test Equipment Required.

1. Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

5. Oscilloscope

................................................................................................................................................................................................................................

Preparation :

• In order to reduce the influence of geomagnetism on

the set's picture tube, face it east or west.

Purity control

• Switch on the set's power and degauss with the

degausser.

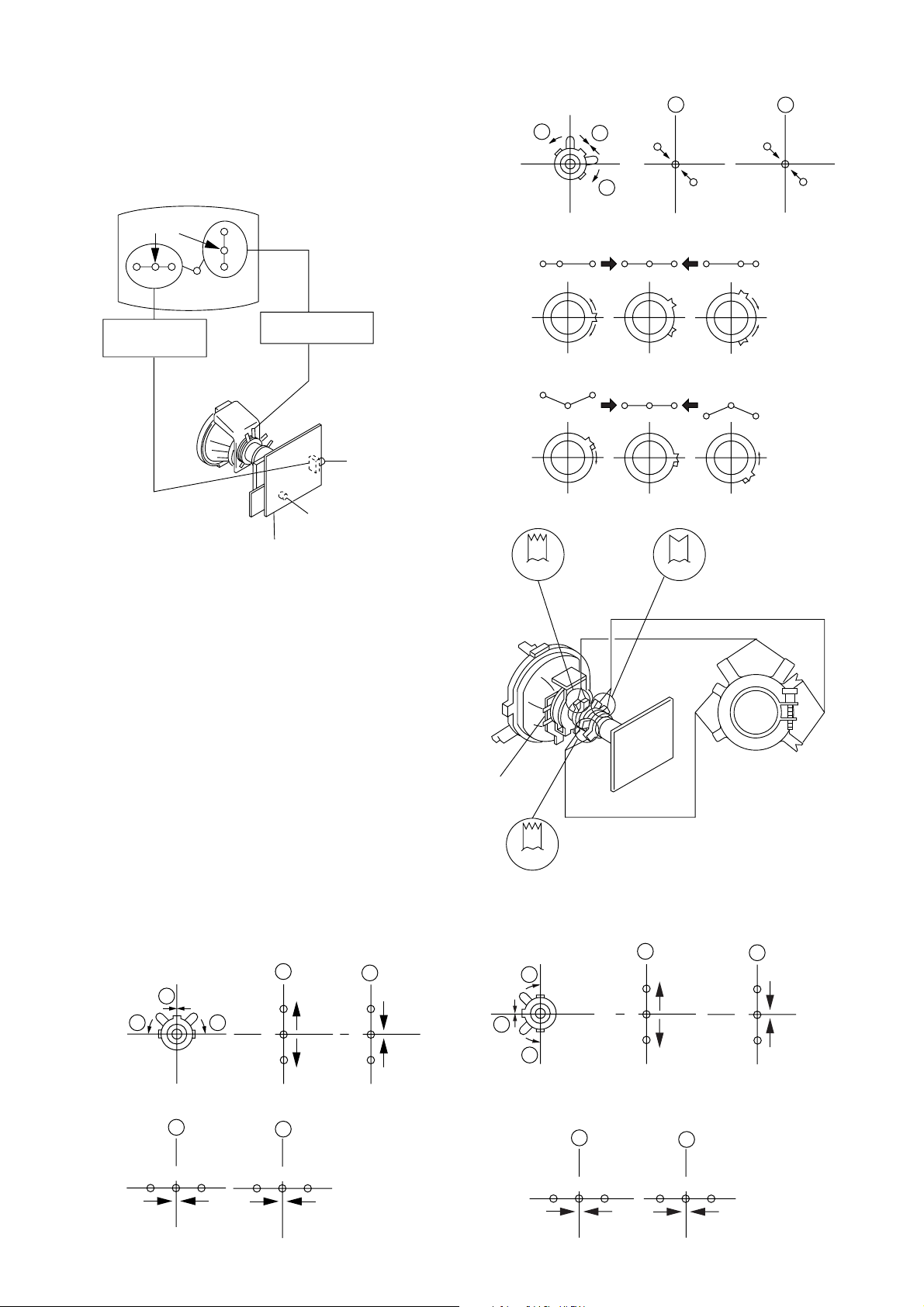

2-1. BEAM LANDING

PICTURE MODE: DYNAMIC

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck assy as shown in Fig 2-1.

}

normal

Fig. 2-3

3. Set the pattern generator raster signal to a green

raster.

4. Move the deflection yoke to the rear and adjust with

purity control so that the green is at the center and the

Blue

Red

blue and the red take up equally sized areas on each

side. (Figures 2-1 through 2-4.)

Green

5. Move the deflection yoke forward and adjust so that the

entire screen is green. (Figure 2-2.)

6. Switch the raster signal to blue, then to red and verify

the condition.

Fig. 2-4

7. When the position of the deflection yoke have been

decided, fasten the deflection yoke with the screws and

DY spacers.

8. If the beam does not land correctly in all the corners,

use a magnet to adjust it.

(Figure 2-5.)

Purity control

corrects this area.

b

a

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

Neck assy

Align the edge of

the neck assy with

the edge of the G2 grid.

G2G1 G3

Fig. 2-1

Fig. 2-2

– 9 –

c

Deflection yoke positioning

corrects these areas.

a

d

d

Fig. 2-5

b

c

KV-XR34M81/XR34N90

RM-W103 RM-W150

2-2. CONVERGENCE

• Before starting this adjustment, adjust the focus,

horizontal size and vertical size.

• Receive dot/hatch signal

• Pic mode: Soft

Center dot

R G B

H. STAT VR

R

G

B

V. STAT

Magnet

RV705

H. STAT

RV1800

SCREEN (G2)

C Board

(1) Horizontal and Vertical Static Convergence

1. (Moving vertically), adjust the V.STAT magnet so that

the red, green and blue dots are on top of each other

at the centre of the screen.

2. (Moving horizontally), adjust the H.STAT VR control so

that the red, green and blue dots are on top of each

other at the center of the screen.

3. If the H.STAT variable resistor cannot bring the red,

green and blue dots together at the center of the

screen, adjust the horizontal convergence with the

H.STAT variable resistor and the V.STAT magnet in the

manner given below.

(In this case,the H.STAT variable resistor and the

V.STAT magnet influence each other so be sure to

perform adjustments while tracking).

4. BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or

aligned, then use the BMC magnet to adjust in the

manner described below.

1 V. STAT

a

b b

a

B

G

R

b

B

G

R

3 H. STAT.

b

a

b

a

R

G

B

B

G

3 BMC (Hexapole) magnet.

RG B R G B R GB

RB

G

Purity

DY pocket

V.STAT

5. Operation of V.STAT magnet

If the V.STAT magnet is moved in the "a" and "b" arrows,

the red, green and blue dots moves as shown below.

b

a

b

RG

V.STAT

B

G

R

BMC

BMC (Hexapole)

Purity

a

GB

RB

b

B

G

R

b

R

2 H. STAT VR

a

RGGBB

6. Moved RV705 H.STAT.

b

R

the red, green an blue dots move as shown below.

a

RGGBB

b

R

– 10 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

7. Y separation axis correction magnet adjustment.

1. Receive the cross-hatch signal and adjust

[PICTURE] to [MIN] and [BRIGHTNESS] to

[STANDARD] .

2. Adjust the Y separation axis correction magnet

on the neck assembly so that the horizontal lines

at the top and bottom of the screen are straight.

Neck assy Neck assy

VM1 board VM1 board

Blue

Red Blue

Red

(2) Dynamic Convergence Adjustment

Preparation:

Before starting this adjustment, adjust the horizontal and

the vertical static convergence

TLV Rotate TLV-2 VOL (29", 34") on DY

XCV Rotate XCV Adj core on DY

YCH Rotate YCH VOL on DY

TLH Insert TLH Correction Plate to DY Pocket

(Left or Right)

(3) Screen-corner Convergence

If you are unable to adjust the corner convergence

properly, this can be corrected with the use Piece A(90)

Conv. Correct.

ba

a-d : screen-corner

misconvergence

cd

1. Affix the Piece A(90) Conv. Correct corresponding to

the misconverged areas.

RB

ON DY:

B

R

TLH TLV

RB

R

B

YCH XCV

(VR1)

(VR2)

YCH

(VR3)

TLV

TLV

DY pocket

TLH Plate

XCV

Fix a Permalloy assy

corresponding to the

misconverged areas

a

d

b

c

a to d : permalloy assembly

DY pocket

XCV

– 11 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

2-3. FOCUS ADJUSTMENT

FOCUS adjustment should be completed before W/B

adjustment.

(Except 34")

1. Receive digital monoscope pattern.

2. Set "Picture Mode" to "DYNAMIC".

3. a) Adjust focus VR so that the center of screen

becomes just focus(29", 34").

b) Adjust focus VR so that the lion teeth

becomes just focus(25").

4. Change the receiving signal to white pattern and blue

back.

5. Confirm Magenta ring is not noticeable. Incase

Magenta ring is obvious, adjust FOCUS VR to balance

between MAGENTA RING and FOCUS.

2-5. WHITE BALANCE ADJUSTMENT

1. Set to Service Mode (Refer Section 3-1:

ADJUSTMENTS WITH COMMANDER).

2. Input white raster signal.

3. Set Picture to DYNAMIC.

i. Set PICT 006 WTS to 00h (all models except AR2

series).

ii. For AR2 set OPTB 006 OPB 6 to 00.

4. Select WHBL 002"RDRV" and the value to 37

5. Select WHBL 003"GDRV" and 004 "BDRV"and adjust

the data for the best white balance in highlight

condition.

6. Adjust WHBL 000 "BKOR" and 001 "BKOG"and adjust

the data for best white balance cut-off condition.

7. Write into the memory by pressing [MUTING] then

8. Write offset data for other mode.

After adjustment, please reset:

i. OPTM 006 – OPB 6 to original data (AR2 series).

ii. PICT 006 – WTS to original data (All models except

AR2 series)

Adjust Offset Offset

18000 t 12363 t 9300

BKOR –2 –3

BKOG +1 +2

RDRV 0 0

GDRV –3 –8

BDRV –8 –18

-.

Focus

Screen

FLYBACK TRANSFORMER (T503)

2-4. G2 (SCREEN) ADJUSTMENTS

1. Set the PICTURE to Normal.

2. Put the VIDEO input mode without signals

3. Connect R,G,B of the C board cathode to the

oscilloscope.

4. Adjust cathode voltage to the value below.

5. Adjust G2 (screen) on the FBT until picture shows the

point before cut off.

Cathode setting voltage:

170 V ± 2 (VDC)

2-6. SUB BRIGHT ADJUSTMENT

1) Set to service mode.

2) Brightness set to 50%, Picture: Minimum.

3) Select WHBL SBRT with 1 and 4, and adjust 'SBRT'

data with 3 and 6 so that the third stripe from right

dimly lit.

4) Write into the memory by pressing [MUTING] then -.

5. Models cut-off: 0 IRE (25" and 34")

10 IRE (29")

Slightly Glimmer: 10 IRE (25" and 34")

20 IRE (29")

– 12 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

SECTION 3

CIRCUIT ADJUSTMENTS

3-1. ADJUSTMENTS WITH COMMANDER

Service adjustments to this model can be performed using the supplied remote commander RM-W103 / RM-W150.

a. ENTERING SERVICE MODE

With the unit on standby

t [DISPLAY] t 5 t [VOL $+% ] t [POWER]

This operation sequence puts the unit into service mode.

This screen display is:

category in decimal item name in decimal NG service command frequency video input name

GEOM 006 HSIZ 031 x SERVICE 60 S VIDEO 1

release ID version in binary for factory color system (decimal?)

SUS01 0.69U 0001 1111 FF FF NTSC3 65535

111 11 11 1 7 11 FG xy 111 000000 000000

S : for Sony

A : Aiwa

U S : US/Latin/Taiwan

E U : Europe

G A : General Area

J P : Japan

item no. service data NVM field channel no./

software service data reserved power on time

Status Byte Status Byte

Flash DCXO #1 SSD #2 SSD

VDSP_C Flag

CO_LOCKED

VDSP

Detected Stereo Type (Direct Value from CZ_ Stereo_Mode)

111 Needed for Nicam DCXO aligment Purpose

xy Value of x = 0 - Unknown, 1 - BTSC, 2 - A2, 3 - NICAM,

4 - KOREAN, 5 - Japan, 6 - AV Stereo

Value of y = 0 - Mono, 1 - Stereo, 2 - Bilingual, 4 - SAP/Single

0 1 : serial no. of the M/P release

for each destination

b. METHOD OF CANCELLATION FROM SERVICE MODE

Set the standby condition (Press [POWER] button on the commander), then press [POWER] button again, hereupon it

becomes TV mode.

c. METHOD OF WRITE INTO MEMORY

1. Set to Service Mode.

2. Press

3. Change item by pressing

1 (UP) and 4 (DOWN), to select the adjustment item.

3, 6.

4. Press [MUTING] button to indicate WRITE on the screen.

5. Press

- button to write into memory.

1, 4 Select the adjustment item.

r

3, 6 Raise/lower the data value.

r

[MUTING] Writes.

r

- Executes the writing.

d. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, pull out the plug from AC outlet, and then plug into AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confirm adjustments were made.

– 13 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

e. OTHER FUNCTION VIA REMOTE COMMANDER

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

Display, - Service data initialization (Be sure not to use usually.)

2, 5 Select Device or Category (Up, Down)

3-2. ADJUSTMENT METHOD

Item Number 000 HPOS

This explanation uses H POSITION as an example.

1. Select "000 HPOS" with the

2. Raise/lower the data with the

3. Select the optimum state. (The standard is IF for PAL reception.)

4. Write with the [MUTING] button. (The display changes to WRITE.)

5. Execute the writing with the

SERVICE.)

Example on screen display :-

1 and 4 buttons, or 2 and 5.

3 and 6 buttons.

- button. (The WRITE display will be changed to red color while excuting, and back to

GEO 00

637S

1.0C

1F 60HPOS

7F 0 000A59

SERVICE

GREEN

Adjusted with 3

and 6 buttons.

GEO 00

637S 1.0C

1F WRITE

7F 0 000A59

60HPOS

GREEN

Write with [MUTING]

GEO 00

637S

1.0C

Write executed with

WRITE

1F 60HPOS

7F 0 000A59

RED

The WRITE display

then the display

returns to green

SERVICE.

Use the same method for all Items. Use

[MUTING], then execute the write with

Note : 1. In [WRITE], the data for all items are written into memory together.

2. For adjustment items that have different standard data between 50Hz or 60Hz, be sure to use the respective

input signal after adjustment.

1 and 4 to select the adjustment item, use 3 and 6 to adjust, write with

-.

– 14 –

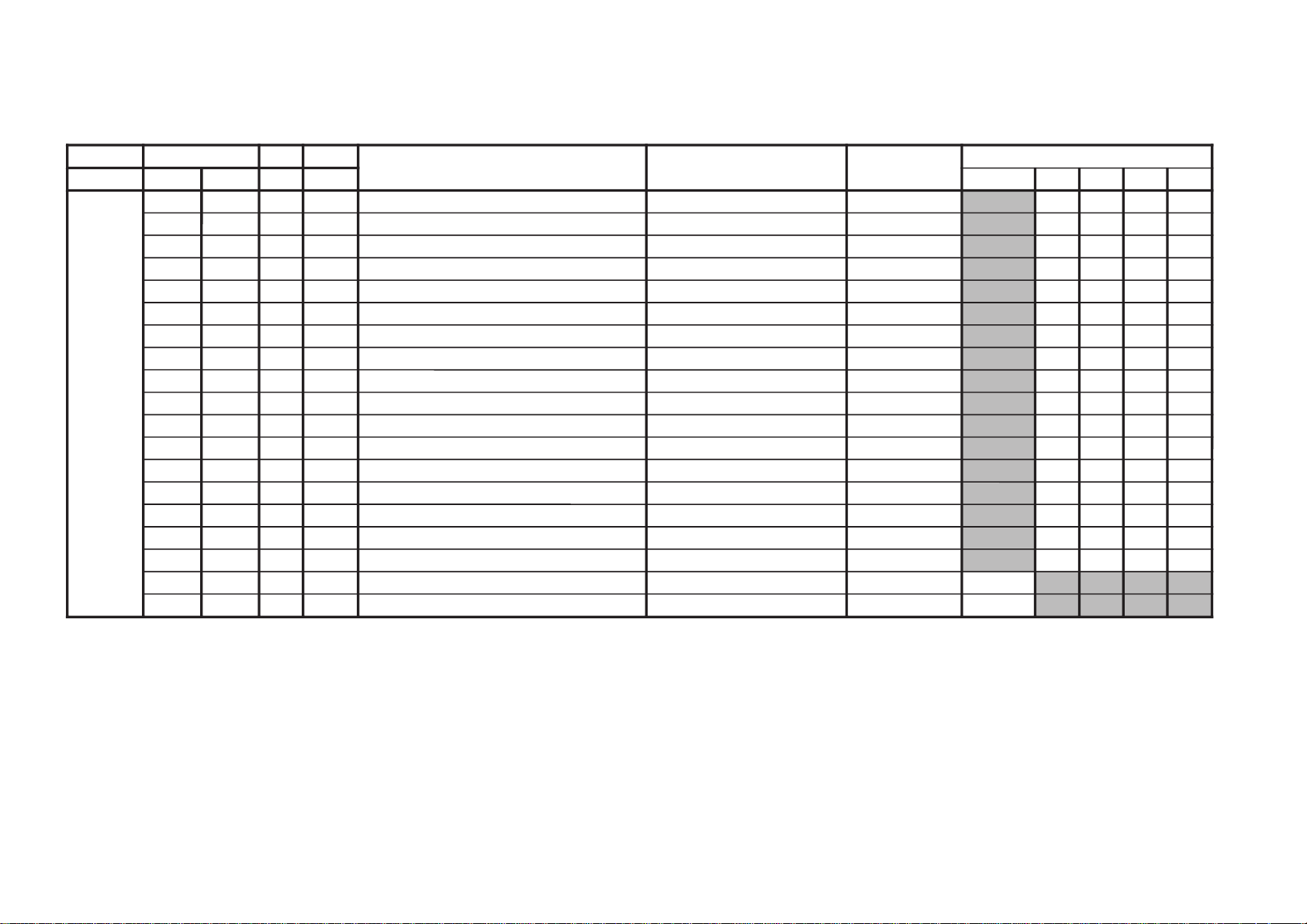

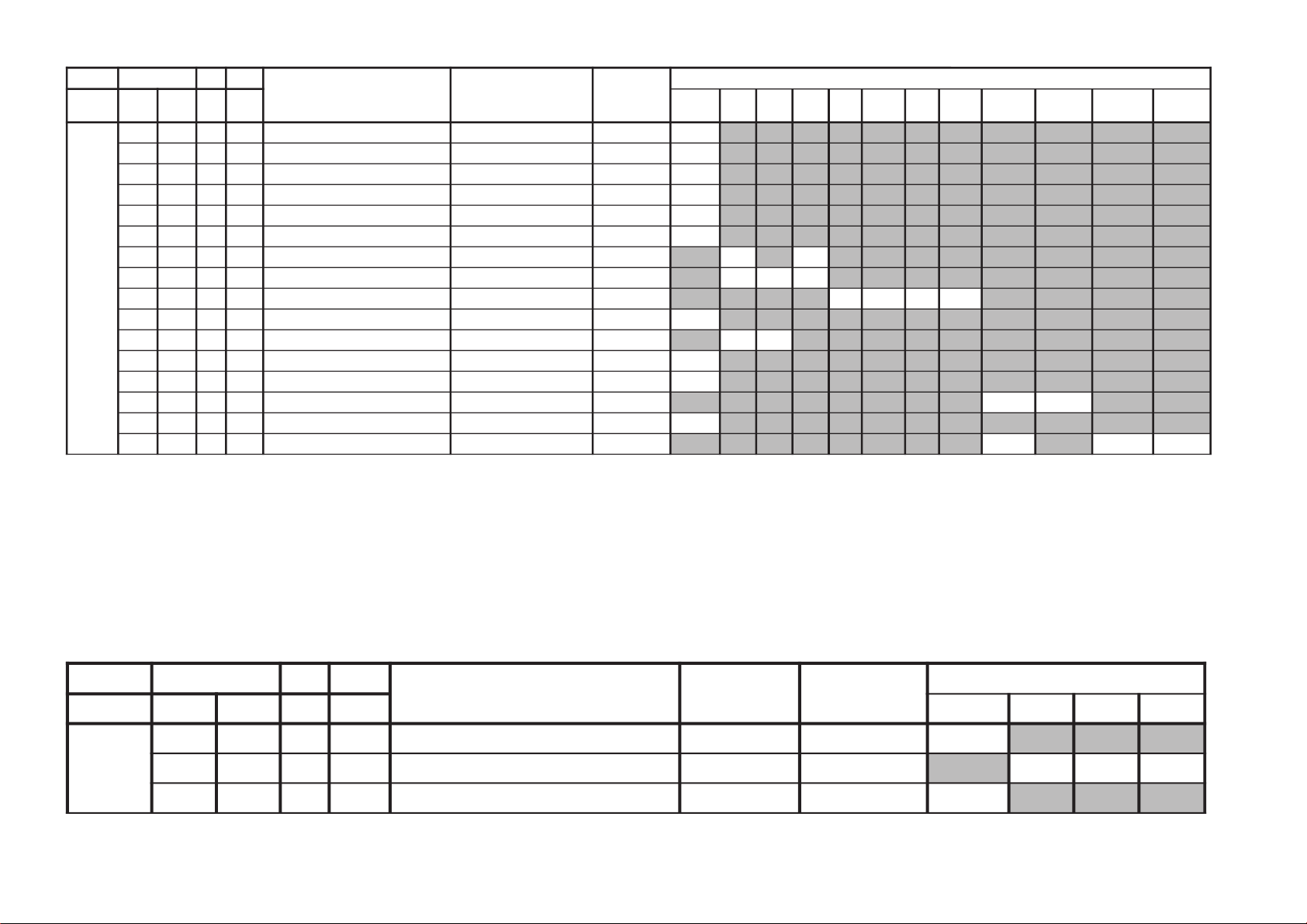

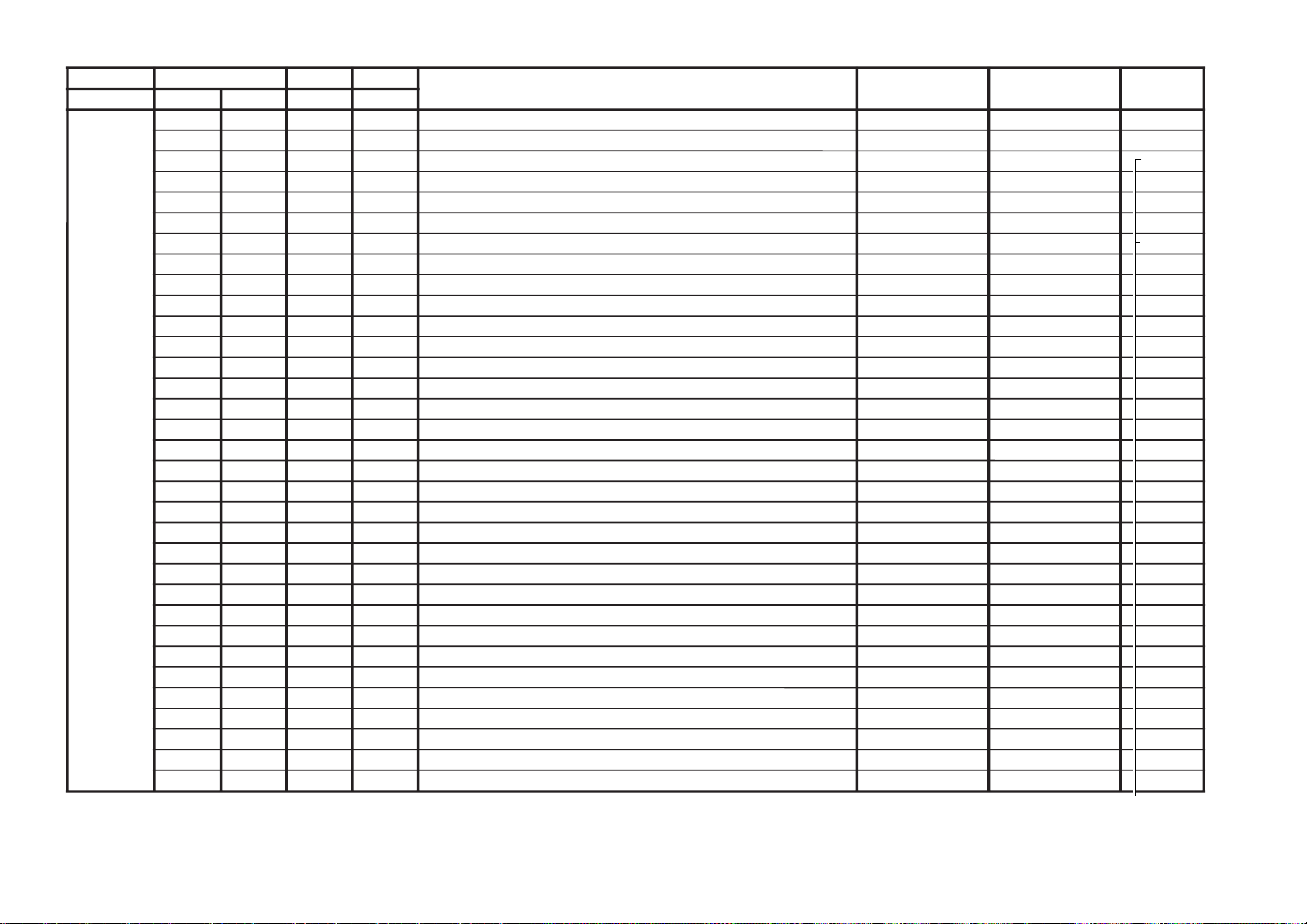

Adjustment Item Table

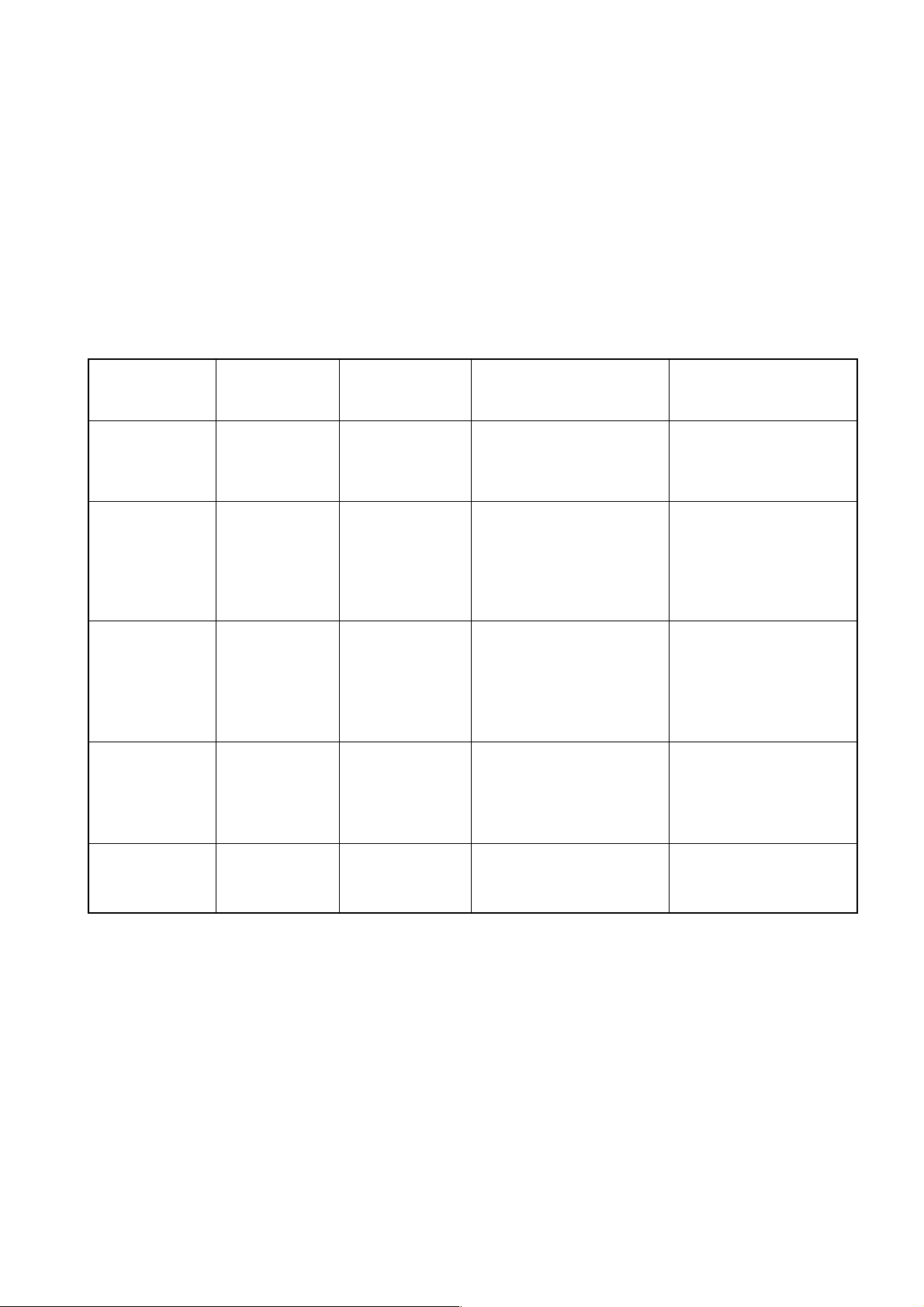

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD )sserddAevalS(nommoC050605w06w

MOEG000SOPH130360)SH(tfihSlatnoziroH )BGRNPJ+(06w/05w/06/05rossecorP-VT

13131313

100RAPH130360margolellaraPlatnoziroH06w/05w/06/05)hA8(

13131313

200WOBH130360woBlatnoziroH06w/05w/06/05

13131313

300NILV130360ytiraeniLlacitreV06w/05w/06/05

13131313

400RCSV130360llorcSlacitreV06w/05w/06/05

13131313

500ZISH130360)WE(htdiWWE )BGRNPJ+(06w/05w/06/05

13131313

600WPWE130360)WP(htdiW/alobaraPWE06w/05w/06/05

13131313

700POCU710360alobaraPrenroCreppUWE06w/05w/06/05

71717171

800POCL710360alobaraPrenroCrewoLWE06w/05w/06/05

71717171

900ZTWE130360muizeparTWE06w/05w/06/05

13131313

010PLSV130360)SV(epolSlacitreV06w/05w/06/05

13131313

11013ZISV510360edutilpmAlacitreV06w/05w/06/05

51515151

210ROCS410360)CS(noitcerroC-S06w/05w/06/05

41414141

310SOPV130360)HSV(tfihSlacitreV06w/05w/06/05

13131313

410LBH000100edoMgniknalBBGR06w/05w/06/05

10101010

510FBW700510)FBW(gniknalBediWfognimiT06w/05w/06/05

80508050

610RBW700510)RBW(gniknalBediWfognimiT06w/05w/06/05

90019001

710LBS000100gniknalBecivreSenon00

810YPOC000100aeraMVNzH06/05llaotatadOEGehtypoCenon00

– 15 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

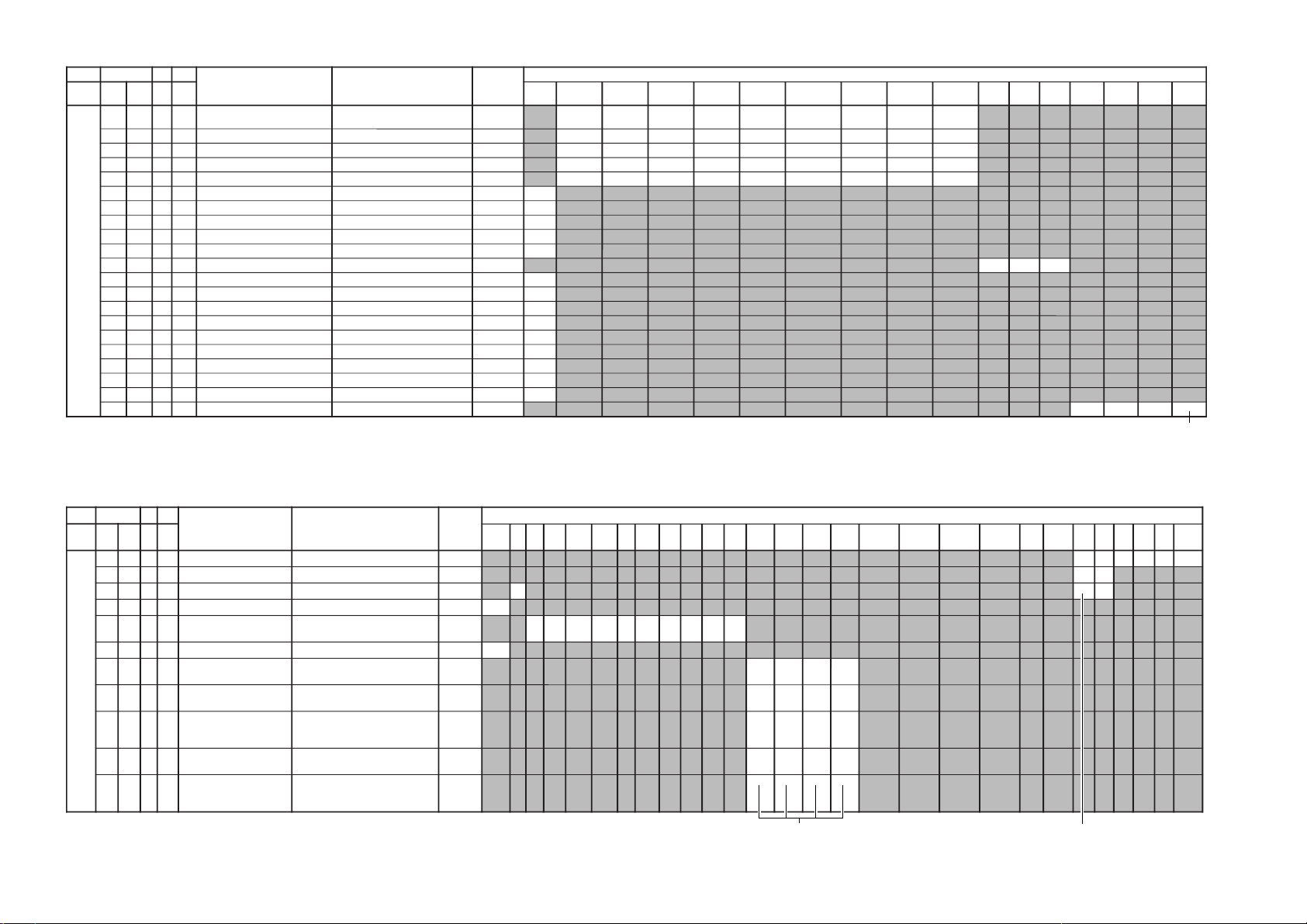

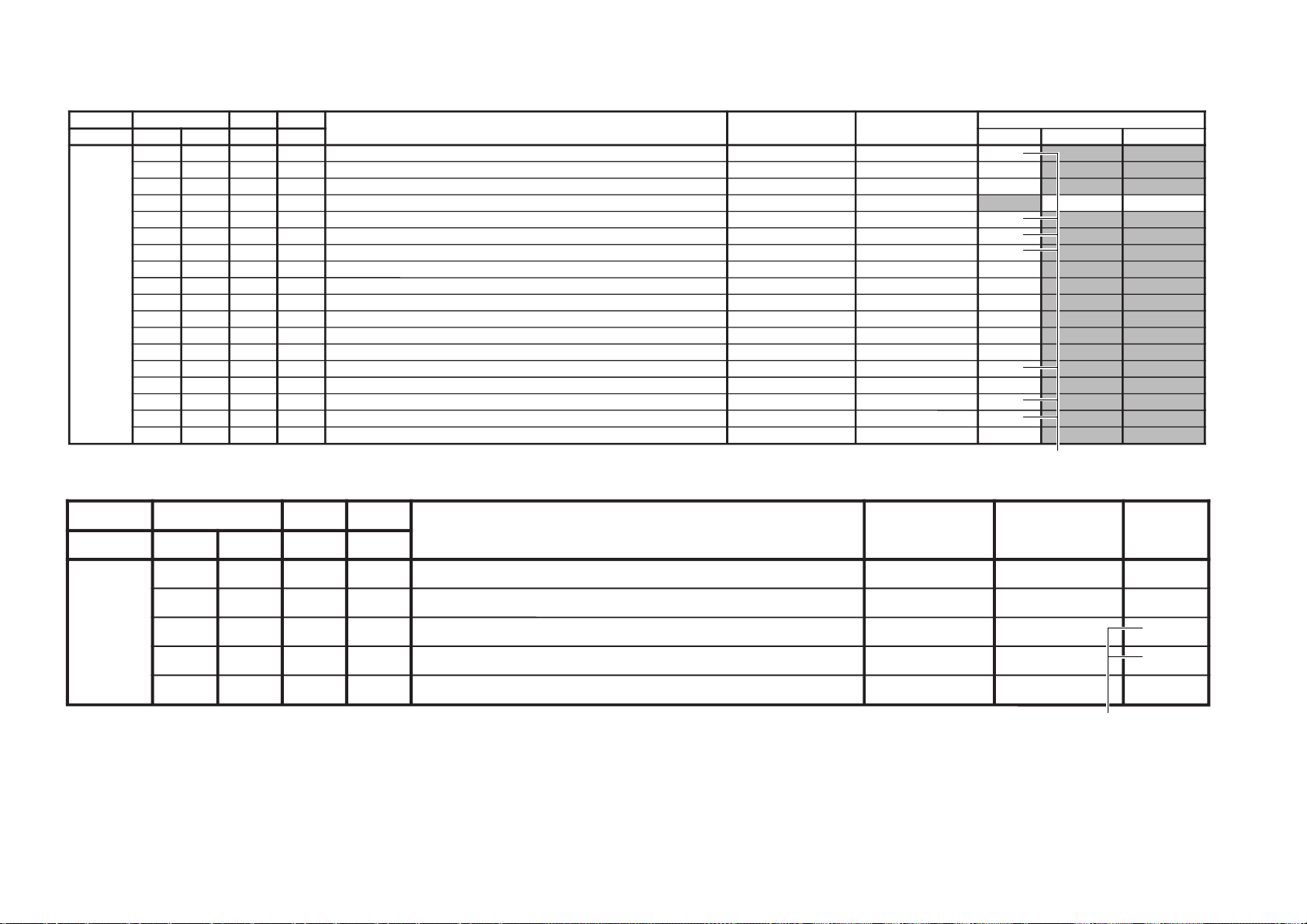

KV-XR34M81/XR34N90

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD

)sserddAevalS(nommoCpmeTloC

)rehtoHGIH(

pmeTloC

)rehtoWOL(

pmeTloC

)rehtoMRON(

pmeTloC

)VUYHGIH(

pmeTloC

)VUYWOL(

pmeTloC

)VUYLAMRON(

pmeTloC

)BGRHGIH(

pmeTloC

)BGRWOL(

pmeTloC

)BGRMRON(

srehtOBGRVUYedomciP

0

edomciP

1

edomciP

2

edomciP

3

LBHW

000ROKB

130360Btesffo,)00=BFO(RtesffOleveLkcalB

)10=BFO(

)srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

rossecorP-VT

131313131313131313

100GOKB130360GtesffOleveLkcalB )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc)hA8(

020202020202020202

200VRDR730360RtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc)HA8(orP-VT

737373737373737373

300VRDG730360GtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

542473542473542473

400VRDB730360BtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

840403840403840403

500GPL000100teserPniaGBGR enon

00

600RGP130721)RGP(RniaGteserP enon05

700GGP130721)GGP(GniaGteserP enon05

800BGP130721)BGP(BniaGteserP enon05

900FONG000510tesffOniaGteserP enonpoolCCC01

010TRBS130360ssenthgirB-buS VUY/BGR/srehtO

838383

110ORBS000300)ciPtnegilletnI(tesffOssenthgirB-buS enon00

210LGE000100metsySCCCnipooLniaGelbanE enon00

310LGS000300metsySCCCnitnerruChgiHfonoitceleS enon00

410BKA000100noitazilibatStnerruCkcalB enon00

510SBC000100gnitimiLtnerruCmaeBfoecneuqeSlortnoC enon00

610BBGR000300gniknalBBGR enon00

710GBLB000100tuptuOneerG&eulBfogniknalB enon00

810BFO000100eulBtesffOleveLkcalB enon10

910RBSN000510tesffOssenthgirBdradnatSnoN enon00

020PBW000300)woL:3,2,lamroN:1,hgiH:0(gnitteSpmeTroloC edoMerutciP

00102000/10

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD

)sserddAevalS(nommoCVUYlap05

)VT(

lap05

)oediV(

maces05

)VT(

maces05

)oediV(

VT06oediV06VUY05VUY06BGR05BGR06edomciP

0

edomciP

1

edomciP

2

edomciP

3

ocE*cimanyD

)npJ(dts

ocE*cimanyD

)npJ(hcum

ocE*dradnatS

)npJ(dts

ocE*dradnatS

)npJ(hcum

dtsocE

)npJ(

hcumocE

)npJ(

VToediVVT

ediW

oediV

ediW

MVA

)npJ(

ediWVA

)npJ(

JDAS000XAMP360360mumixaMerutciP )BGRNPJ+(>ediW/lamroN</)ediW/lamroN(*)oediV/VT( rossecorP-VT

448344830000

100EUHS700510euH-buS oediV/VT

2090

200PHSS510360ssenprahS-buS )BGRNPJ+(VUY/oediV/VT

62

52/8103

300OHSS000300)ciPtnegilletnI(tesffOssenprahS-buS enon30

400LOCS130360roloC-buS /)oediv(maces05/)vt(maces05/)oediv(lap05/)vt(lap05

BGR06/BGR05/VUY06/VUY05/oediv06/VT06

92039203923392330000

500OOCS000300)ciPtnegilletnI(tesffOroloC-buS enon10

600CIP130721;)dilavni(001>,)dilav(001-0:AG[lortnoCerutciP

])dilavni(6tiberongi;)dilav(36-0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

36/00175/0957/74001/36

700LOC130721;)dilavni(001>,)dilav(001-0:AG[lortnoCroloC

])dilavni(6tiberongi;)dilav(36-0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

63/7513/0582/5483/05

800TRB130721,)dilav(001-0:AG[lortnoCssenthgirB

tiberongi;)dilav(36-0:srehtO;)dilavni(001>

])dilavni(6

)ataDteseRresU=lanosreP:AG(ledoMerutciP

13/8413/0513/0513/05

900EUH130721;)dilavni(001>,)dilav(001-0:AG[lortnoCeuH

])dilavni(6tiberongi;)dilav(36-0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

13/0513/0513/0513/05

010PHS130721,)dilav(001-0:AG[lortnoCssenprahS

tiberongi;)dilav(36-0:srehtO;)dilavni(001>

])dilavni(6

)ataDteseRresU=lanosreP:AG(ledoMerutciP

73/0653/5582/5413/05

RM-W103 RM-W150

– 16 –

XR34M81/XR34N90

XR34M81/XR34N90

XR34M81/XR34N90

– 17 –

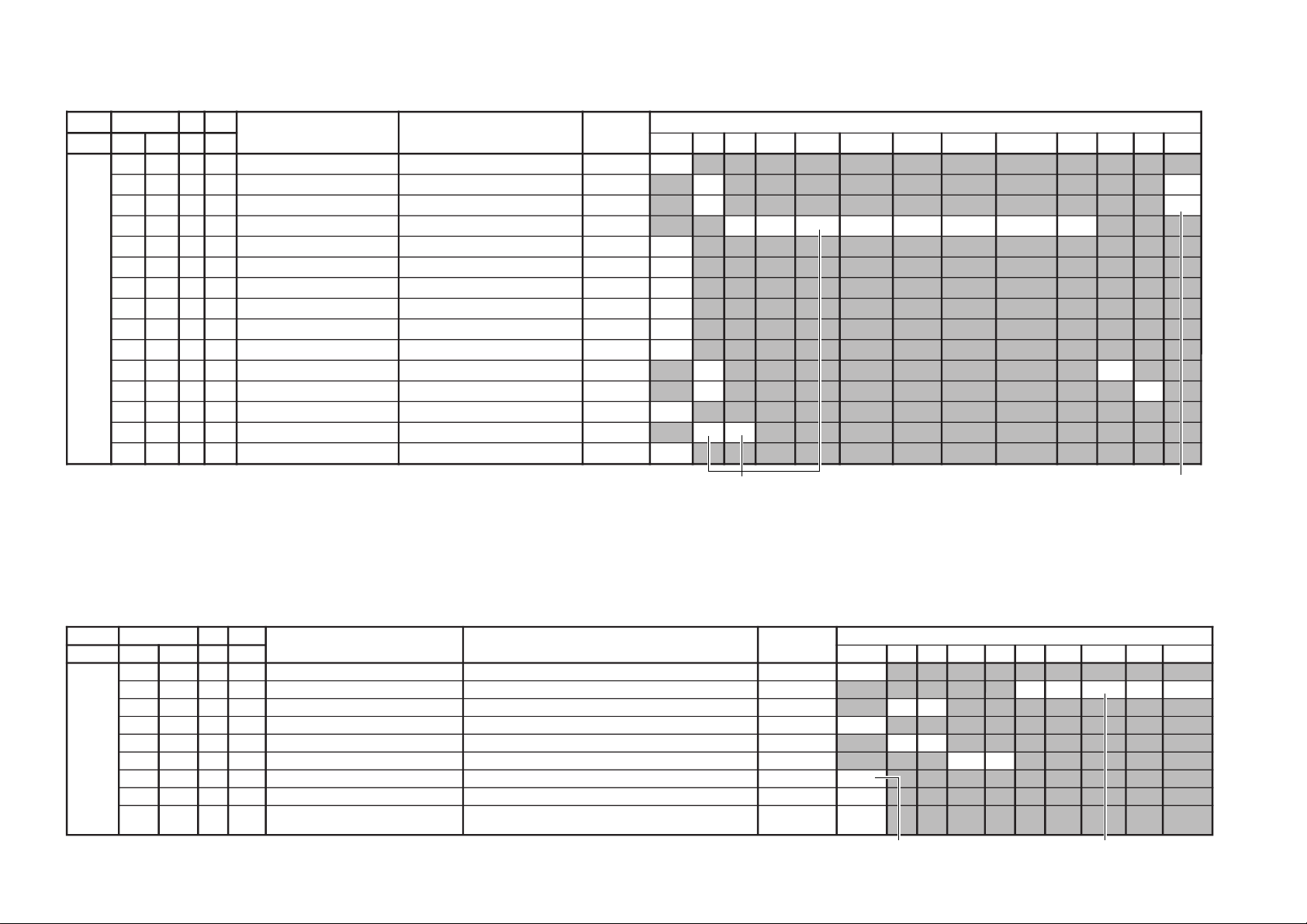

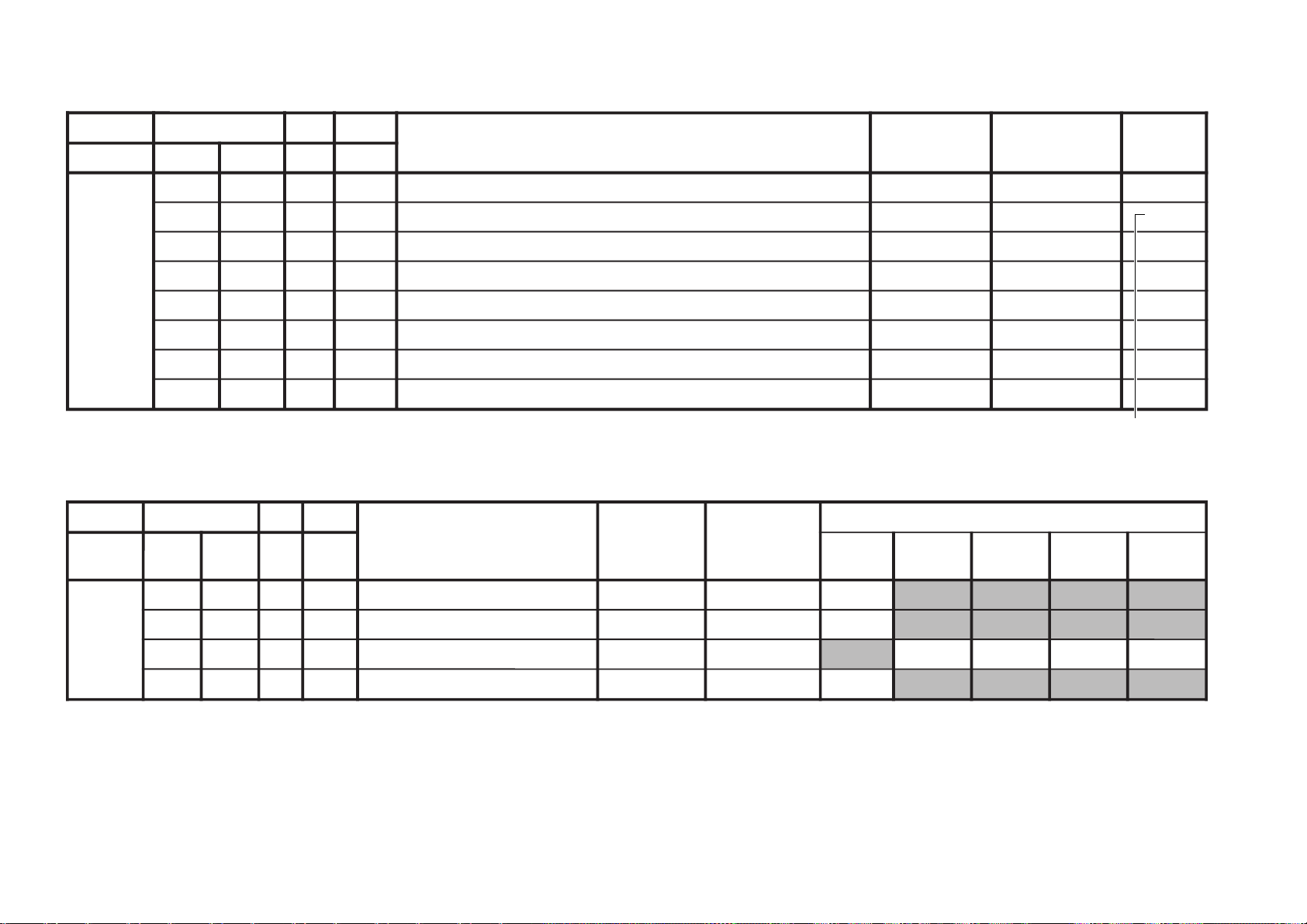

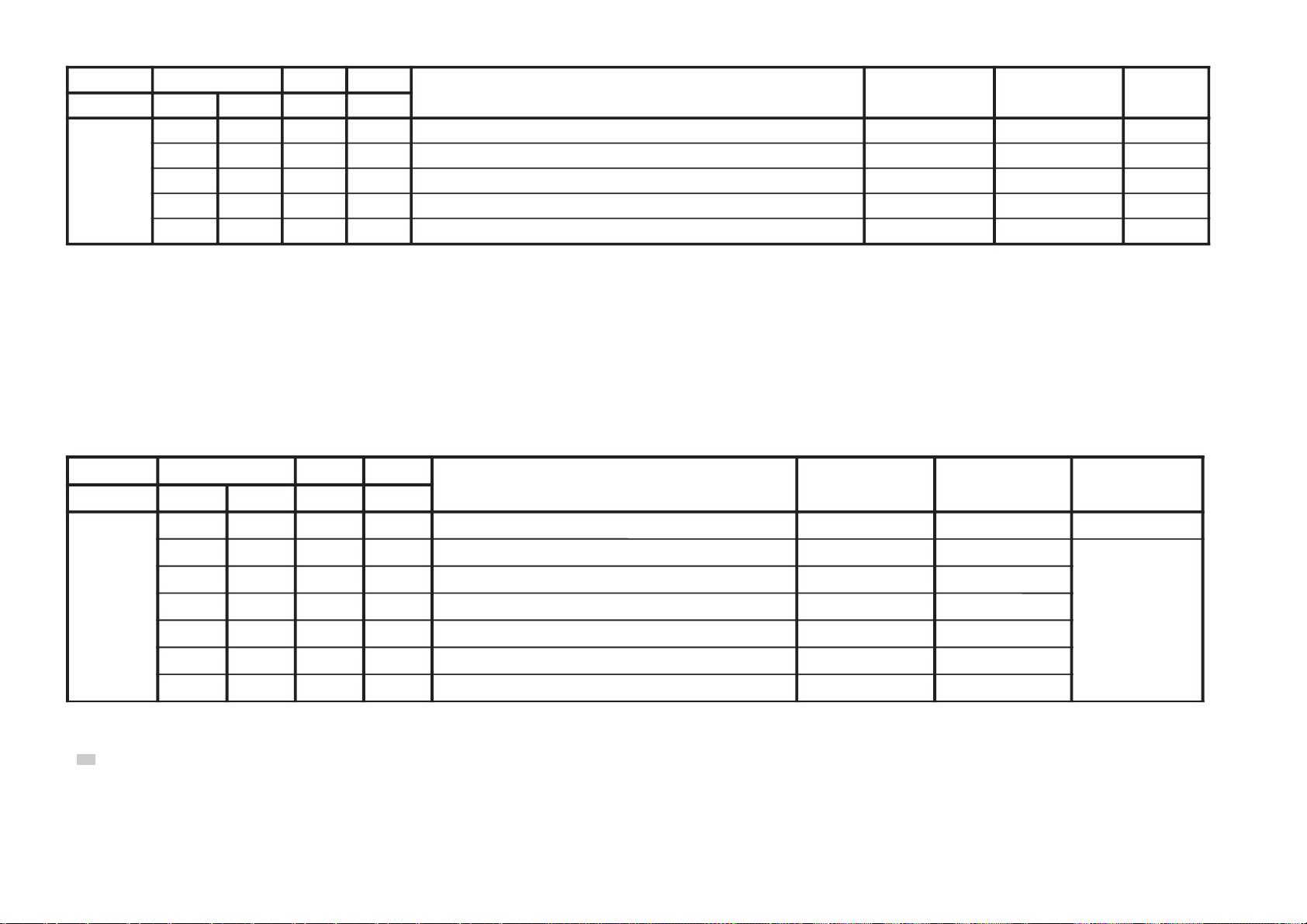

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD )sserddAevalS(nommoCsrehtOVUY)VT(LAP)VT(CSTN)VT(MACES)oediV(LAP)oediV(CSTN)oediV(MACESTUPNI-SMACESCSTNVT

CY000QRFP000300yaleDdnaycneuqerFretneCgnikaeP rossecorP-VT00

100APR####300toohSrevO&erPoitaR rehto/VT

20

20/00

200OPR200300skaePevitageN&evitisoPfooitaR rehto/VT

20

10/00

300YLDY210510yaleD-Y TUPNI-S/VUY+)OEDIV/VT(*)MACES/CSTN/LAP(

010160/016011906001

400TAMC000300xirtaM)ASU/napaJ(CSTNroMACES-LAP )BGRNPJ(00

500LCA100100gnitimiLroloCcitamotuA 10

600BC000100ycneuqerFretneCssapdnaBamorhC )xif0:oediV*(VThtiwylnodilav00

700OBS100300tesffOkcalBMACES 10

800ESHC100300ytivitisneStnedICSTN/LAP 30

900OLC000100retliF)lleB(ehcolCfoycneuqerFretneC 00

010PRTC000100edoMparTamorhC srehto/MACES

00

10

110SPB000100eniLyaleDdnab-esaBamorhCfossapyB srehto/CSTN

00

10

210OCF000100nOroloCdecroF 00

310TNIT130360lortnoCtniTdnaB-esaB srehto/VUY

13/2313/23

410VUT000100slangiSVUnolortnoCtniT 00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD )sserddAevalS(nommoC0506srehtOVUYVToediVtxeteleTpi-VTlangisoN

CNYS000SYS000100tupnICNYSYnonoitazinorhcnyS 00

100OF000300tnatsnoCemiT1esahP )FR(langisoNrogninuTotuA/txeteleT/oediV/FFOPIVT/NOPIVT

303000/100000

200DIV000100edoMtnedIoediV 06/05

0000

300LSF000100cnySlacitreVrofleveLgnicilSdecroF 00

400LSS000100rotarapeScnySleveLgnicilS 06/05

0000

500DIVS100700noitacifitnedIoediVrofnoitceleSecruoS srehtO/VUY

0000

600FROF000300ycneuqerFdleiFdecroF 10/30

700KVM000100gniyeKnoisiVorcaM 10

800TCFA

000300,611niP:SU,AG(lortnoChctiwsgnimiTCFA

821NIP:NPJ,OREU

30

XR34M81/XR34N90

XR34M81/XR34N90

XR34M81/XR34N90

XR34M81/XR34N90

KV-XR34M81/XR34N90

RM-W103 RM-W150

KV-XR34M81/XR34N90

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD )sserddAevalS(nommoCVUYVToediV

WS0002VC000100noitceleSlangiStupnI2SBVC 00

100OVS10030084@niPISBVC/OVS/OVFIfonoitcnuFVUY/oediV/VT

201010

200LFD000100noitcetorPhsalF 10

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD

)sserddAevalS(nommoCsrehtOBGReviLVT

)nyD(

VT

)srehtO(

oediV

)nyD(

oediV

)srehtO(

pmeTroloC

)HGIH(

pmeTroloC

)srehtO(

roloC

)WOL(pmeT

pmeTroloC

)LAMRON(

TCIP000LDAC700510leveLevirDedohtaC 50

100AFC000300edoMretliFbmoC 00

200COS200300leveLgnippilCtfoS )hA8(20

300LWP100100hctiwSgnitimiLetihWkaeP 10

400LTHW600510gnitimiLetihWkaeP 40

500MAG100100ammaG 10

600STW100300hctertSetihWdnalortnoCammaGsrehtO/eviL

10

10

700RFT000100langiSecnanimuLfooitaRrefsnarTCD )BGRNPJ+(srehtO/eviL

100010

800ROC300300gniroC )srehto/anyD(*)oediV/VT(

10200010

900OROC000100)ciPtnegilletnI(tesffOgniroC 10

010SKB300300hctertSkcalBsrehto/BGR

2020

110SAA100100hctertSkcalBehtffohctiwSotaerAkcalB 10

210KSD000100lortnoCnikScimanyD 00

310SLB000100hctertSeulB )SREHTO/HGIH(pmetloc

0000

410SLBN000100tiucriChctertSeulBnoitarepO 00

510RRN000100noitcudeRdeRnoN )LAMRON/WOL/HGIH(pmetloc

10

1010

RM-W103 RM-W150

– 18 –

– 19 –

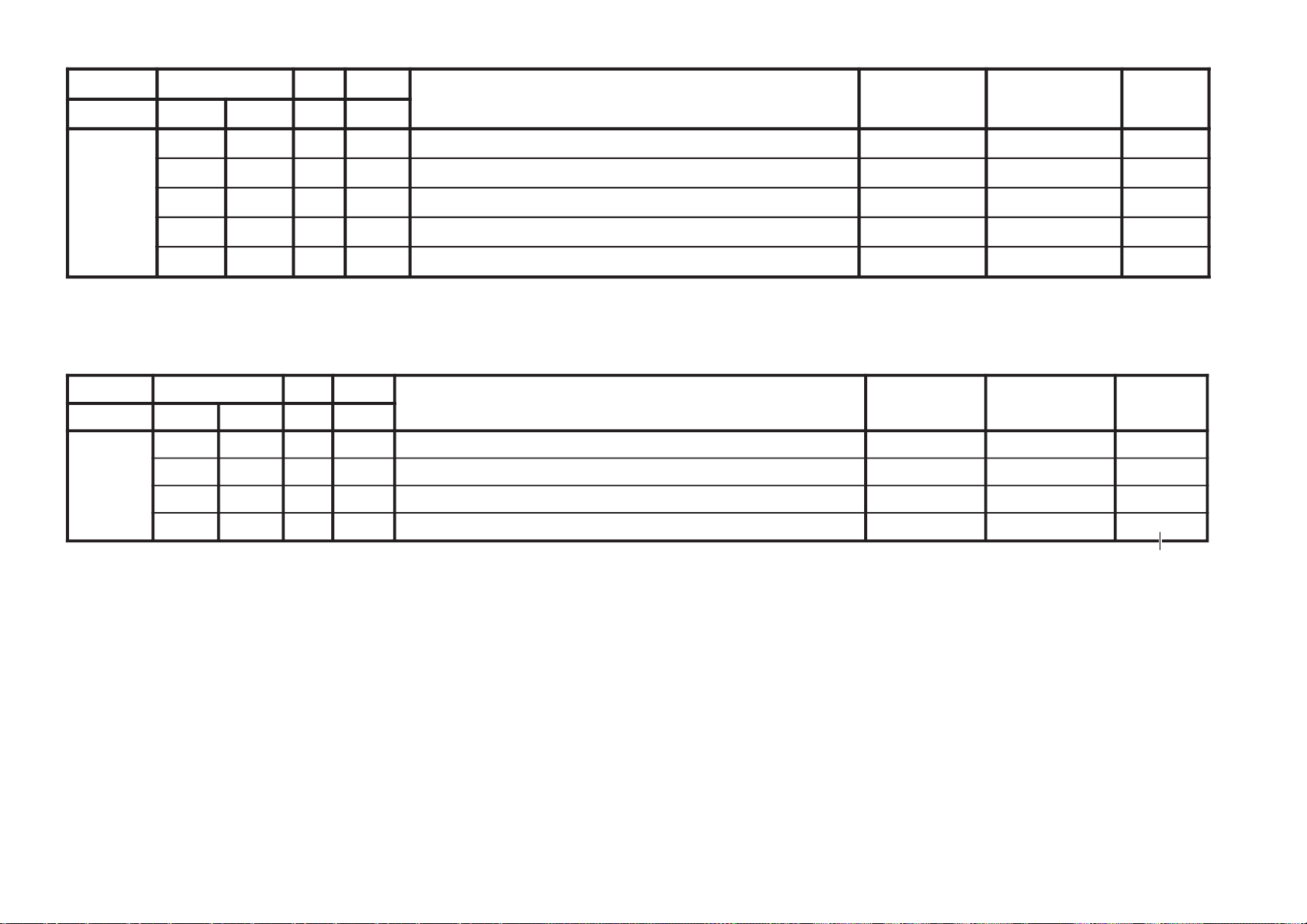

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD )sserddAevalS(

FIV000DFIO630360rotaludomeDFItesffO rossecorP-VT63

100TCGA130360revo-ekaTCGA )hA8(13/42

200MTS000100edoMgninuThcraeS 10

300DG000100langiS1SBVCnoyaleDpuorG 00

400SCGA100300deepSCGAFI 10

500IFF000100LLPFIretliFtsaF 00

600PMAO300300)metsyS'L&Lylno(edutilpmAlangiStuptuOoediV 30

700IAV000100)metsyS'L&Lylno(noitcerroCedutilpmAlangiStuptuOImetsyS 00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD

)sserddAevalS(nommoCedomciP

0

edomciP

1

edomciP

2

edomciP

3

MV000DBGR300700tuptuOMVottuptuOBGRfoyaleDenonrossecorP-VT50

100AMV300300tuptuOMVfoedutilpmAenon)hA8(30

200PAMV200300)FFO:3,2,woL:1,hgiH:0(gnittesMVedoMerutciP

00001000

300OMMV300300edoMMV 10

XR34M81/XR34N90

KV-XR34M81/XR34N90

RM-W103 RM-W150

KV-XR34M81/XR34N90

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD )sserddAevalS(

MEDS000SWMF000300rotaludomeDMFrofnoitceleSwodniW rossecorP-VT20

100SSQ100100)ledoMAGtpecxe(edoMreifilpmA)SSQ(dnuoStilpSisauQ )hA8(10

200BPB000100retliFssapdnaBdnuoSfossapyB 00

300OLMA000100dnuoSMAroflangiStuptuOoiduA 00

400CVPH000100lortnoCemuloVenohPdaeH 00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD )sserddAevalS(

TXT000VXT930360spilihProfnoitisoPlacitreVtxeteleT redoceDtxeT00/93

100DHT500721tfihSegdEevitcAcnys-HtxeteleT )h06(00/50

200RBT400510ssenthgirBBGRtxeteleT 00/51

300BCL####)XETSAFrofgnittes(elbane:1elbasid-OBCLtxeteleT 00/00

RM-W103 RM-W150

– 20 –

XR34M81/XR34N90

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD nommoC)oruE(L-VTVToediVffOWOW/SRSdnuorrusurToeretsIonomI

PSDS000MVA200700edoMLVA DSS20

100VVA500510leveLecnerefeRLVA )h0B(90

200LBB000510ruotnoCEBB 00

300HBB000510ssecorPEBB

00

400WLBB000510tesffOruotnoCEBB

60

500FOVS000510tesffOemuloVedoMtceffE/dnuorruS onomI/oeretsI/dnuorrusurT/)WOW/SRS(ffO

4011406040

600FOVI000700tesffOevitisoPemuloVretsaM 60

700FOVE000700tesffOevitageNemuloVretsaM 60

800DAL000130tsujdAleveLredoceD 50

900MAL000130tsujdAleveLonoM 50

010NAL000130tsujdAleveLmaciN 22

110SAL000130tsujdAleveLPAS 80

210AAL000130tsujdAleveLCDA

000000

310FES300700tceffEoeretS/onoMelbidercnI oediV/Lnon-VT/L-VTI)oruEnoN(oediV/vT

5030

410L1A000552tfeLemuloV1XUA onomI/oeretsI00

510R1A000552thgiRemuloV1XUA 00

610SAB800510tesffOssaBniaM 31

710ERT800510tesffOelberTniaM 41

8101QE800510tesffO)zH001(dnaBlennahCniaMrezilauqE 11

9102QE800510tesffO)zH003(dnaBlennahCniaMrezilauqE 00

0203QE800510tesffO)zH0001(dnaBlennahCniaMrezilauqE 90

1204QE800510tesffO)zH0003(dnaBlennahCniaMrezilauqE 00

2205QE800510tesffO)zH0008(dnaBlennahCniaMrezilauqE 21

320TCFB500700lortnoCEBBdnaBUD,EBD 00

420NECS100510lortnoCretneCD3SRS 40

520APSS000510lortnoCecapSD3SRS 10

620WHBB000510edomWOWnitesffossecorpEBB 00

720ERTS200700edomdnuorrusroftesffOelberT 10

820THBB000510edomVTnitesffOEBB 00

920AWD000000AWD 00

030ERTT200700edoMVTnitesffOelberT 30

– 21 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

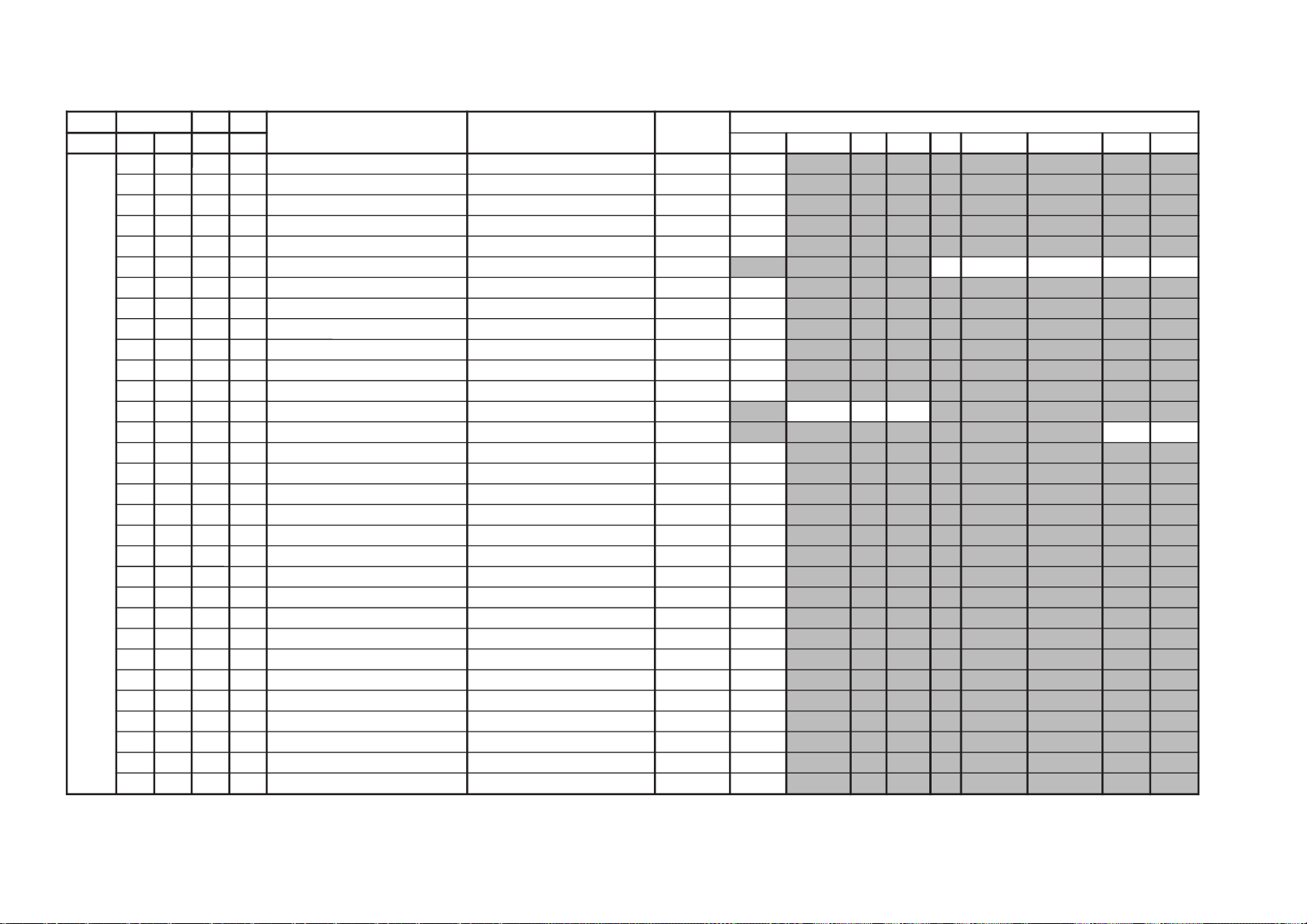

KV-XR34M81/XR34N90

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

nommoC

yrogetaC.oNemaNceDceD

CEDS000UTPM300510)CSTB(noitcetedtolipXPMrofdlohserhTreppU DSS20

100LTPM900510)CSTB(noitcetedtolipXPMrofdlohserhTrewoL )h0B(50

200UTPS300510noitcetedreirracPASrofdlohserhTreppU 50/80

300LTPS600510noitcetedreirracPASrofdlohserhTrewoL 51

400HT1C0001301CSfonoitcetedrofdlohserhTlamroN 00

500PA1C0001301CSfonoitcetedrofdlohserhTmargorPotuA 00

600HTPS000130PASfoetumotuarofdlohserhTesioN 50/00

700YHPS400510PASfoetumotuarofezissiseretsyH 30

800HTMF000130dradnats2AMFni2CSfoetumotuarofdlohserhTesioN 81

900YHMF400510dradnats2AMFni2CSfoetumotuarofezissiseretsyH 70

010HTTB000130reirracoeretsCSTBfoetumotuarofdlohserhTesioN 00

110YHTB400510oeretsCSTBfoetumotuarofezissiseretsyH 30

210HTJE000130reirracbusMFJAIEfoetumotuarofdlohserhTesioN 00

310YHJE400510reirracbusMFJAIEfoetumotuarofezissiseretsyH 40

410YLNO000100tuptuoCEDnoMACINdetalerylnoecudorpeR 00

510MAXE000100)PEDD(LdradnatsnietumotuafoesacniecruoskcabllaF 00

610TMIN000100)PEDD(etarrorretibnodnepednoitcnufetumotuaMACIN 00

710ELIN001552)PEDD(timilrorrerewolMACIN 05

810EUIN002552)PEDD(timilrorrereppuMACIN 002

910DMPE100300)PEDD(gnimmargorPysaECEDMED 10

020SDTS910130sedomSSSdnaDSArofdexelpitlumstiB 31

120AMVO100100noitpadanoitaludomrevoMF 00

220WBLF000300htdiwdnabretlifrotaludomedMA/MF 10/30

320DMDI000300edomSSSnideepstnediMF 00

420LAPF000100gnidocedCSTBrofycneuqefeniL 00

520TMVO100200lanimonotevitalerdlohserhtlevelnoitaludomrevO 30

620IXCD000100retrevnIlortnoCgnilacSOXCDMACIN 00

720GXCD000700niaGlortnoCgnilacSOXCDMACIN 00

820LLCD110510)L(timiLlortnoCgnilacSOXCDMACIN 00

920HLCD000130)H(timiLlortnoCgnilacSOXCDMACIN 00

030UEDI100300DTS2AnaeporuErofgnittesDOMDI 00

130RKDI100300DTSMnaeroKrofgnittesDOMDI 00

230PJDI100300DTSJAIErofgnittesDOMDI 00

RM-W103 RM-W150

– 22 –

XR34M81/XR34N90

– 23 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD nommoC0506

MTPO000THSA600700)nim5*atad(remitffotuhsotuA 70/00

100BDSO000510ssenthgirbDSO h06orciM/RMM51

200HDSO500510noitisoPlatnoziroHDSO h06orciM/RMM60

300VDSO730360noitisoPlacitreVDSO 06/05h06orciM/RMM

5403

400ETUM000100)delbane=1(hctiwSetuMlangiSoN 10/00

500LUFR510510)hf0nehwelbasiD(dekcolnUretfaretnuoCegnahClangiSFR 10/40

600KLFR510510)hf0nehwelbasiD(dekcoLretfaretnuoCegnahClangiSFR 40/00

700LUVA510510)hF0nehwelbasiD(dekcolnUretfaretnuoCegnahClangiSVA 40

800KLVA510510)hF0nehwelbasiD(dekcoLretfaretnuoCegnahClangiSVA 00

900GNAL000300noitidnocgnippihsegaugnalDSO 00

010TXTH000100wsrotarepescnyS )A8(rossecorP-VT00

110SSMC000100wscnyS )A8(rossecorP-VT10

210OXCD060592eulaVOXCD PSD/h06orciM/RFS07

310LBXE000510esioNetihWetanimilEotremiTgniknalBdednetxE 40/80

410SYST000300 )ledoMAG(]K/D:3,M:2,I:1,G/B:0[teseRtseTtaMVNnisySVTeziromeM 00

510UOVT100100 )ledomORUE(langistuohtiwetuM:1,ffoetumsyawlA:0noitidnocetumtuoVT 10/00

610LBL100100.noitidnoClangiSontAgnitcudeRssenthgirB 10/00

710ORPH100100noitatoRerutciProftesffoarapH 40

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

nommoC

yrogetaC.oNemaNceDceD

SUPO000FFOS000100)noCAhtiwybdnats:1,noCAhtiwyromemtsalwollof:0(ffoyatS 00

100RBCC000510ssenthgirBDSOCC h06orciM/RMM00

200HCPS100721noitidnoCgnippihSretfarebmuNlennahC 70/00

300ACPS100100)nOelbaC=1(noitidnoCgnippihSretfanoitceleSelbaC 10/00

400YRTC000100noitcelesgnippihsyrtnuoCPIHCV 00

XR34M81/XR34N90

XR34M81/XR34N90

KV-XR34M81/XR34N90

RM-W103 RM-W150

– 24 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

nommoC

yrogetaC.oNemaNceDceD

WAPO000XMEB040480)48ot0(repeeB"remiTpUekaW"foemulovmumixaM )hOB(DSS00

100TARB600010)%001ot%0()01ot0(oitaremuloVretsaMotpeeB )hOB(DSS00

200RUDB200030)petssm05ni(noitarudrepeeB )hOB(DSS00

300QEFB300700)7-0(ycneuqerfrepeeB )hOB(DSS00

400TRCT100100ledomTRCnortinirT enon)A8(rossecorP-VT00

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

nommoC

yrogetaC.oNemaN

ceDceD

BTPO

000LLAI

000100

)MVNnideziromemton(hctiwSetirWdradnatS

00

1001BPO

000552

)detalermetsyS(1noitpO

referesaelP

atadnoitpoot

72~52egap

2002BPO

000552

)detalerlangiSoediV(2noitpO

3003BPO

000552

)detalergnidoceDoeretS(3noitpO

4004BPO

000552

)suoenallecsiM(4noitpO

5005BPO

000552

)suoenallecsiM(5noitpO

6006BPO

000552

)detaleregaugnaLDSO(6noitpO

KV-XR34M81/XR34N90

RM-W103 RM-W150

NOTE

•

• Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and for each mode.

• Note for Different Data Those are the standard data values written on the microprocessor. Therefore, the data values of the modes and stored respectively in the memory.

In case of a device replacement, adjustment by rewriting the data value is necessary for some items.

shaded items are no data.

ITEM INFORMATION

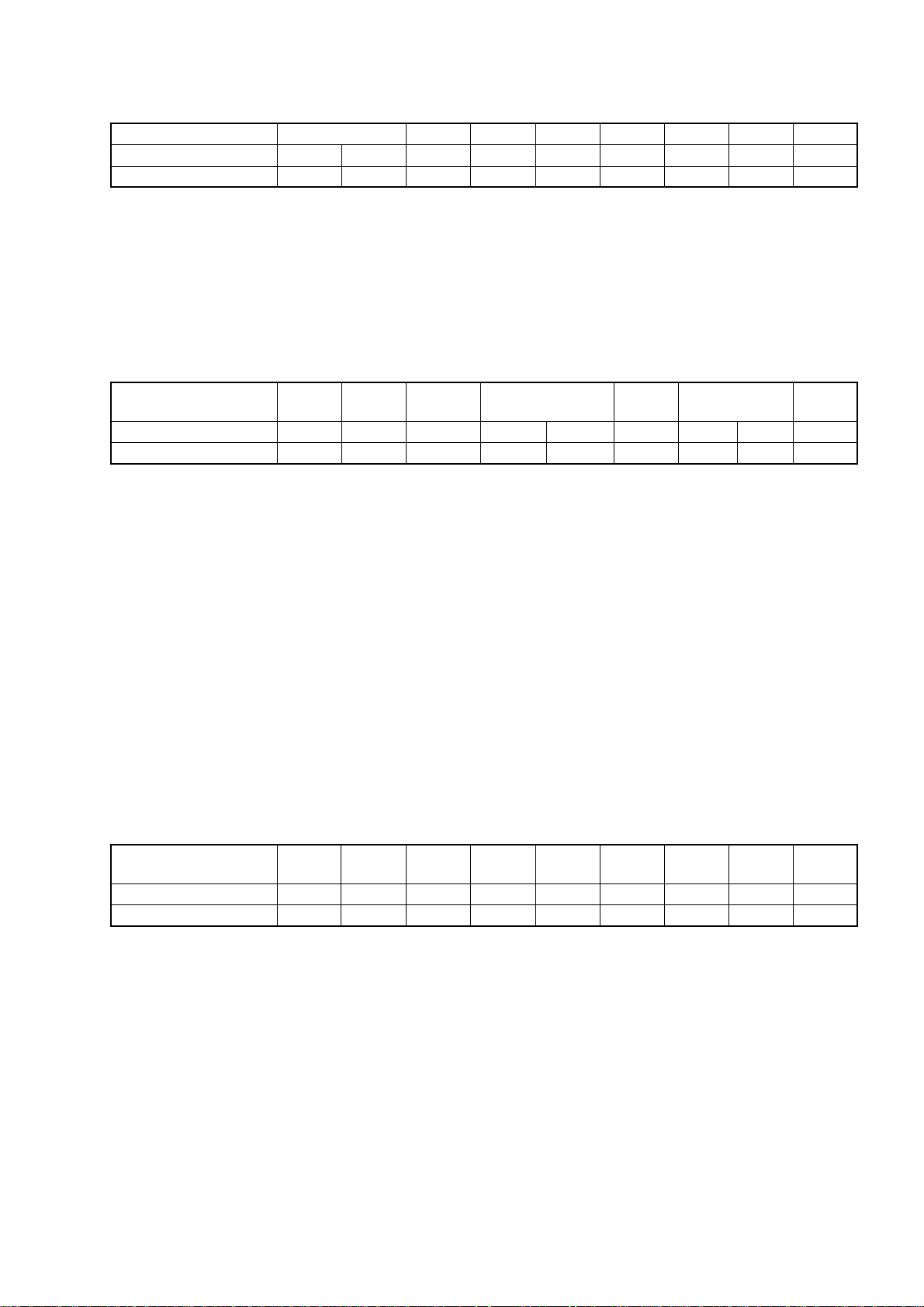

No. OPB1

Item

KV-XR34M81

KV-XR34N90

SPEED SEARCH (Time of speed search) 00 = disabled (original cycle speed)

TV System Selection 0 = disabled, 1 = enabled

No. OPB2

Item

KV-XR34M81

KV-XR34N90

Speed Search

0

1

D1(JPN)

0

0

1

1

AV Multi/

PAM(GA)

0

0

M/N(US)

0

1

Component

1

1

KV-XR34M81/XR34N90

RM-W103 RM-W150

L’

0

0

1

1

M

1

0

01 = 4 time speed from the original

10 = 6 time speed from the original

11 = 8 time speed from the original

B/G

1

0

SECAM

1

1

1

0

I

1

0

Color DecordingComposite (SCART)

D/K

1

0

0

0

0

1

DEC

79

224

DEC

60

57

No. OPB3

Item

KV-XR34M81

KV-XR34N90

D1 (D1 Terminal) 0 = not available, 1 = available

AV Multi/ (AV Multi Terminal) - JP 0 = not available, 1 = available

PAM Portable Audio Mode - GA 0 = not available, 1 = available

Component (Component [YCbCr] Terminals) 0 = not available, 1 = available

Composite (No. of Composite Terminals) 00 = no composite terminal

(Euro:no Scart) BX1L:No Video

(SCART) (No. of SCART Terminals) 01 = 1 composite terminal

(Euro:1 Scart) BX1L:2 Video in

10 = 2 composite terminals

(Euro:2 Scart) BX1L:3 Video in

11 = 3 composite terminals

(Euro:no terminal) BX1L:4 Video in

SECAM (SECAM Color System) 0 = not available, 1 = available

Color decoding (Color Crystal Selection) 00 = PAL/NTSC/SECAM (Multi)

01 = NTSC (3.58MHz)

10 = PAL/NTSC/SECAM (4.43MHz)

11 = PAL/NTSC (Tri-Norma)

HDEV

0

0

NICAM

ST

0

0

NICAM

BI

0

0

A2 ST

0

0

Thai

Bilingual

0

0

JP/US

ST

0

1

Korean

ST

0

0

MONO

DEC

0

0

0

4

HDEV (High Deviation Mode) 0 = disabled, 1 = enabled

NICAM ST (NICAM Stereo) 0 = disabled, 1 = enabled

NICAM BI (NICAM Stereo) 0 = disabled, 1 = enabled

A2 ST/BI (A2 [West German]

Stereo/Bilingual) 0 = disabled, 1 = enabled

Thai Bilingual (A2 [Thai] Bilingual)

or Force SAP if JP/US ST is act 0 = disabled, 1 = enabled

JP/US ST (JP/US Stereo) 0 = disabled, 1 = enabled

Korean ST (Korean Stereo) 0 = disabled, 1 = enabled

MONO (Monaural Model) 0 = Stereo (SSD) Model

1 = Monuaral Model

– 25 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

No. OPB4

Item

KV-XR34M81

KV-XR34N90

No. OPB5

Item

KV-XR34M81

KV-XR34N90

Firmware/

SMAT

1

1

Firmware (SSD Firmware Downloading) 0 = disabled, 1 = enabled

SMAT Surround Matrix 0 = Active, 1 = Passive

1 spk Models 1 Speaker Models 0 = 2 or 3 Speaker Models,

VM (Velocity Modulation) 0 = disabled, 1 = enabled

Equalizer (5-band Equalizer Model) 0 = Bass/Treble Model, 1 = Equalizer Model

Surround (US/GA Surround Selection) 0 = Off/Simulated/Surround

V-Chip (V-Chip Model) 0 = Channel Block Model (no rating)

TOP (Forced TOP) 0 = Auto Mode (TOP/FLOF), 1 = Forced TOP

TEXT (Teletext Model) 0 = Non-Teletext Model, 1 = Teletext Model

Full

Surround

0

0

1 spk

Models

0

0

No

Surround

0

0

Forced

VM

1

1

60

0

1

Equalizer

ASD

1

1

0

0

Surround

0

0

Tilt

1

1

V-Chip

0

0

1 = 1 speaker Models

1 = Off/Simulated/WOW/TruSurround (US)

1 = Off/Simulated/SRS (3D) Surround (GA)

1 = Parental Control Model (rating)

IP Plus

1

1

To p

0

0

IP

1

1

Te xt

1

0

Wide

1

1

DEC

177

176

DEC

15

47

Full Surround (Full Surround option) 0 = Normal Surround Model

1 = Full Surround Model

(Off/simulated/surround/

SRS/WOW/TruSurround)

No Surround (No Surround Model) 0 = Surround Model, 1 = Non-Surround Model

Forced 60 (Forced 60Hz in no signal) 0 = 50Hz, 1 = 60Hz

ASD (Automatic Standard Detection) 0 = disabled, 1 = enabled

Tilt (Tilt Correction/PIC Rotation) 0 = disabled, 1 = enabled

IP Plus (Intelligent Picture Plus) 0 = disabled, 1 = enabled

IP (Intelligent Picture) 0 = disabled, 1 = enabled

Wide (Wide Mode/V-Compressed) 0 = disabled, 1 = enabled

– 26 –

No. OPB6

KV-XR34M81/XR34N90

RM-W103 RM-W150

Item

KV-XR34M81

KV-XR34N90

OSD Language Selection

0

1

1 = Taiwan/Korea/Philippine

1 = Latin (Volume Figure Display)

1 = Comb available

1 = PiP available

1

0

(Wake-up timer enable)

(GA Surround Spec:OFF,

SIMULATED, SRS)

0xx1 = Portuguese

1xxx = Simplified Chinese

xx1x = Thai

xxx1 = Vietnamese

0

1

DEC

0

0

4

202

0

0

Feature 1

0

0

US 1x1x = Complicated Chinese

(GA NTSC) 1xx1 = Korean

GA x1xx = Arabic

GA US

0

1

GA US (US Model Destination) 0 = US/CANADA/Latin

Latin (US Model Latin Destination) 0 = US/CANADA (No Volume Figure Display)

Feature 2 (Temporary for BX1L) 0 = Comb Not available

Feature 1 (Temporary for BX1L) 0 = PiP Not Available

OSD Language Selection 01xx = French

(English always available except JP) US 0x1x = Spanish

Latin

Feature 2

0

1

0000 = Destination ADE

EU 0001 = Destination BL

0010 = Destination KR

0011 = Destination U

– 27 –

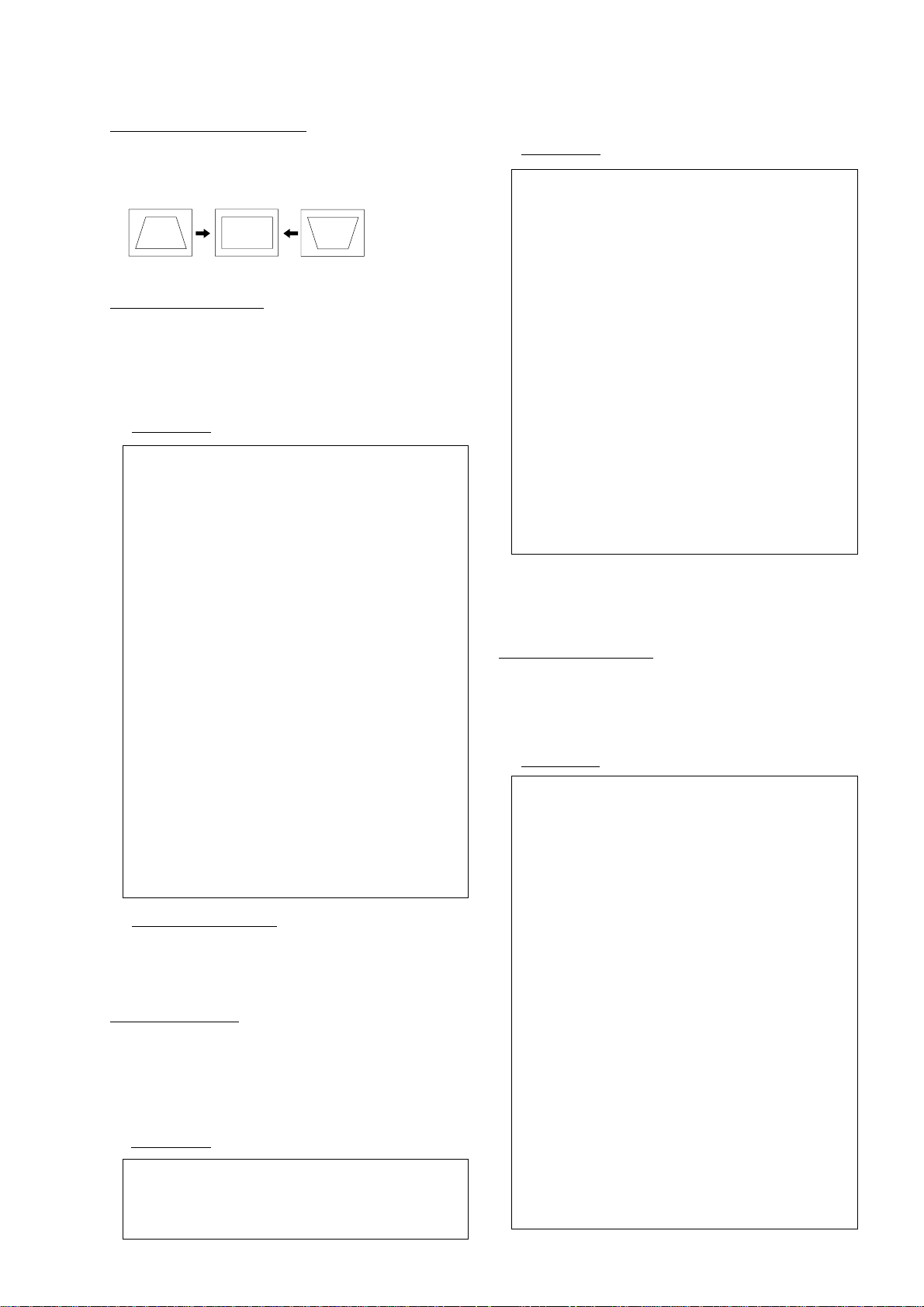

KV-XR34M81/XR34N90

VB1

VB2

VB3

VB4

VB1 = VB2 = VB3 = VB4

80mV

VB1

VB2

VB3

VB4

VB1 = VB2 = VB3 = VB4

80mV

RM-W103 RM-W150

3-3. PICTURE QUALITY ADJUSTMENT

SUB COLOR ADJUSTMENT

1. Select Video.

2. Input PAL 100% Color Bar.

3. Set to following condition:

PICTURE 100%,COLOR 50%, BRIGHTNESS 50%,

HUE Center, SHP 50%.

4. Set the PICT 06 WTS to 00h.

5. Connect an oscilloscope to pin 2 (B OUTPUT) of

CN004 A Board.

6. Set the service mode and select SADJ 04 "SCOL"

1 and 4 of the commander then adjust to

with

VB2=VB3=VB4 with 3 and 6 (For PAL), write the

data as below :

Add 2 steps to SCOL (PAL) - 25" and 29".

Add 6 steps to SCOL (PAL) - 34".

7. Copy "SCOL 50 PAL(Video)"data to "SCOL 50

SECAM(Video)"

8. Copy "SCOL 50 PAL(Video)" and "SCOL 50 SECAM

(Video)" data to "SCOL 50 PAL(TV)" and "SCOL 50

SECAM(TV)" table.

9. Input NTSC 75% Color Bar to TV set and repeat item 3-5.

10. Set the service mode and select SADJ 04 "SCOL"

with 1 and 4 of the commander then adjust to

VB1 = VB4 Write 3 and 6 (for NTSC) and write in

the data as below :

Add 5 steps to SCOL (NTSC) - 25"

Add 3 steps to SCOL (NTSC) - 29".

Add 6 steps to SCOL (NTSC) - 34".

11. Copy "SCOL 60 NTSC(Video)"data to "SCOL 60

NTSC(TV)"

12. Copy "SCOL 50 PAL"data to "SCOL 50 YUV" table

and "SCOL 60 NTSC" data to "SCOL 60 YUV".

13. Set WTS back to original data.

VB1

VB2 VB3

VB2 = VB3 = VB4(For PAL sub color adjustment)

VB1 = VB4(For NTSC sub color adjustment)

(Difference is within 70mV)

VB4

The highest level of VB1, VB2, VB3, VB4 must be

aligned at the same time.

The ideal difference between VB2 and VB3 is within ±

80mV.

Sub Hue Adjustment For YUV input

1. Select YUV input.

2. Input NTSC 3.58 Color Bar Into YUV mode.

3. Connect an oscilloscope to pin 1 (B output) of CN004.

4. Set the service mode and select YC 13 "TINT" with

1

and 4 of the commander then adjust to

VB1=VB2=VB3=VB4 with

5. Then press [MUTING] t

3 and 6.

- to write the data.

The highest level of VB1, VB2, VB3, VB4 must be aligned

at the same time.

The ideal difference between VB2 and VB3 is within ±

80mV.

PMAX/CONTRAST ADJUSTMENT

Picture Mode: Sport (NTSC model)

Picture Mode: Personal (Others)

1. Select Video mode.

2. i)Input PAL Color Bar toTV set. (Other)

ii)Input NTSC 75% Color Bar (NTSC model).

3. Set the following condition:

PICTURE 100%, COLOR 0%,BRIGHTNESS 50%

4. Connect oscilloscope to pin 4 (R Output) of CN004,

5. Set to Service Mode PWL PICT 03 to 00h and WHBL

017 BLBG to 01h.

6. Select SADJ 00 "PMAX" with

commander then adjust VR within spec with

1 and 4 of the

3 and 6.

SUB HUE ADJUSTMENT

1. Select Video.

2. Input NTSC 3.58 Color Bar to TV set.

3. Set to following condition:

4. Connect an oscilloscope to pin 2 (B output) of

5. Set the service mode and select SADJ 01 "SHUE"

6. Then press [MUTING] t

7. Select TV channel with NTSC 3.58 and repeat item 3-6.

8. For single system models with NTSC 4.43 select TV

PICTURE 100%,COLOR 50%, BRIGHTNESS 50%,

HUE Center, SHP 50%.

CN004.

1 and 4 of the commander then adjust to

with

VB1=VB2=VB3=VB4 with

3 and 6.

- to write the data.

channel with 4.43 and repeat 3-6.

VR

Black

NTSC

1.85±0.03Vpp

1.57±0.03Vpp

VR

25"

34"

29"

PA L

2.20±

0.03Vpp

1.90±

0.03Vpp

7. Copy PMAX data to TV models.

8. Select "WIDE" mode for TV & Video mode, Write the

PMAX Data – 6 Steps" (for model with V-Compression

features only).

9. Set the PWL & BLBG back to (PWL: 01h and

BLBG: 00h)

– 28 –

KV-XR34M81/XR34N90

RM-W103 RM-W150

3-4. DEFLECTION ADJUSTMENT

H-TRAPEZOID ADJUSTMENT

1. Receive cross hatch/dot signal

2. Adjust RV1801 on C-Board to make H-Trapezoid

distortion best.

NORMAL MODE (50Hz)

1. Set to Service Mode.

2. Input SPCB Signal (For NTSC models select Video

mode)

3. Using the

mode) Raise/lower data using the

to adjust the following items:Service Item

GEOM: 000 HPOS HORIZONTAL SHIFT (HS)

4. For Korea models only:

a) For GEOM items, copy adjusted 60Hz to 50Hz

b) Add 6 steps to 50Hz "HPOS" item and save data.

c) Add 3 steps to 50Hz "HSIZ" item and save data.

WIDE MODE (50Hz)

(V-Compression Adjustment)

1. Input SPCB signal(For NTSC models select Video

mode)

2. Adjust condition to WIDE MODE : ON.

3. Copy (item from NORMAL MODE (50Hz) adjusted

data for the following items:

Service Item

GEOM: 003 VLIN VERTICAL LINEARITY

1 and 4 buttons select GEOM (service

3 and 6 buttons

001 HPAR HORIZONTAL

PARALLELOGRAM

002 HBOW HORIZONTAL BOW

003 VLIN VERTICAL LINEARITY

004 VSCR VERTICAL SCROLL

005 HSIZ EW WIDTH (EW)

006 EWPW EW PARABOLA/WIDTH

(PW)

007 UCOP EW UPPER CORNER

PARABOLA

008 LCOP EW LOWER CORNER

PARABOLA

009 EWTZ EW TRAPEZIUM

010 VSLP VERTICAL SLOPE (VS)

011 VSIZ VERTICAL AMPLITUDE

012 SCOR S-CORRECTION (SC)

013 VPOS VERTICAL SHIFT (VSH)

014 HBL RGB BLANKING MODE

015 WBF TIMING OF WIDE

BLANKING (WBF)

016 WBR TIMING OF WIDE

BLANKING (WBR)

017 SBL SERVICE BLANKING

018 COPY COPY THE GEO DATA TO

ALL 50/60Hz NVM AREA

005 HSIZ EW WIDTH (EW)

011 VSIZ VERTICAL AMPLITUDE

012 SCOR S-CORRECTION (SC)

4. Raise/lower data using the 3 and 6 buttons, select

and adjust the following item to obtain optimum

image.

Service Item

GEOM: 000 HPOS HORIZONTAL SHIFT (HS)

001 HPAR HORIZONTAL

PARALLELOGRAM

002 HBOW HORIZONTAL BOW

004 VSCR VERTICAL SCROLL

006 EWPW

007 UCOP EW UPPER CORNER

008 LCOP EW LOWER CORNER

009 EWTZ EW TRAPEZIUM

010 VSLP VERTICAL SLOPE (VS)

013 VPOS VERTICAL SHIFT (VSH)

014 HBL RGB BLANKING MODE

015 WBF

016 WBR

017 SBL SERVICE BLANKING

018 COPY COPY THE GEO DATA TO

5. For Korea models only:

a) Copy adjusted 60Hz data to 50Hz

b) Add 6 steps to 50Hz "HPS" item and save data.

NORMAL MODE (60Hz)

1. Input 525/60Hz signal.

2. Using the 1 and 4 buttons select category GEO

(Service Mode.)

3. Raise/ lower data using the 3 and 6 buttons to

obtain optimum image

Service Item

GEOM: 000 HPOS HORIZONTAL SHIFT (HS)

001 HPAR HORIZONTAL

002 HBOW HORIZONTAL BOW

003 VLIN VERTICAL LINEARITY

004 VSCR VERTICAL SCROLL

005 HSIZ EW WIDTH (EW)

006 EWPW EW PARABOLA/WIDTH

007 UCOP EW UPPER CORNER

008 LCOP EW LOWER CORNER

009 EWTZ EW TRAPEZIUM

010 VSLP VERTICAL SLOPE (VS)

011 VSIZ VERTICAL AMPLITUDE

012 SCOR S-CORRECTION (SC)

013 VPOS VERTICAL SHIFT (VSH)

014 HBL RGB BLANKING MODE

015 WBF TIMING OF WIDE

016 WBR TIMING OF WIDE

017 SBL SERVICE BLANKING

018 COPY COPY THE GEO DATA TO

EW PARABOLA/WIDTH (PW)

PARABOLA

PARABOLA

PARALLELOGRAM

TIMING OF WIDE BLANKING

(WBF)

TIMING OF WIDE BLANKING

(WBR)

ALL 50/60Hz NVM AREA

PARALLELOGRAM

(PW)

PARABOLA

PARABOLA

BLANKING (WBF)

BLANKING (WBR)

ALL 50/60Hz NVM AREA

– 29 –

Loading...

Loading...