SONY KV-T25SN81 Service Manual

SERVICE MANUAL

BG-1S

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-T25SN81

RM-870 New Zealand SCC-K37F-A

MODEL COMMANDER DEST. CHASSIS NO.

TRINITRON

®

COLOR TV

KV-T25SN81

RM-870

Power requirements 110-240 V AC, 50/60 Hz

Power consumption (W) Indicated on the rear of the TV

Television system B/G

Color system PAL, PAL 60, NTSC4.43, NTSC3.58(AV IN)

Stereo/Bilingual system NICAM Stereo/Bilingual B/G, A2 Stereo/Bilingual (German) B/G

Teletext Language English, German, Swedish, Italian, French, Spanish

Channel coverage VHF : 1 to 11 / UHF : 21 to 69 / CATV: S01 to S03, S1 to S41

Audio output (speaker) 5W × 2

Inputs Antenna: 75 ohms

Outputs Headphone jack: minijack

Picture tube 25 in.

Tube size (cm) 64 Measured diagonally

Screen size (cm) 60 Measured diagonally

Dimensions (w/h/d, mm) 613 × 542 × 472

Mass (kg) 32

SPECIFICATIONS

Note

VIDEO IN jacks: phono jacks

Video: 1 Vp-p, 75 ohms

Audio: 500 mVrms, high impedance

MONITOR OUT jacks: phono jacks

Video: 1 Vp-p, 75 ohms

Audio: 500 mVrms

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

Design and specifications are subject to change without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMA TIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

KV-T25SN81

TABLE OF CONTENTS

Section Title Page Section Title Page

RM-870

SELF DIAGNOSIS FUNCTION ............................... 4

1. GENERAL.................................................................... 5

2. DISASSEMBLY

2-1. Rear Cover Removal............................................ 11

2-2. A Board Removal ................................................ 11

2-3. F1 Board Removal ............................................... 11

2-4. Service Position ................................................... 11

2-5. Replacement of Parts ........................................... 12

2-6. Demagnetization Coil Removal .......................... 12

2-7. Picture Tube Removal.......................................... 13

3. SET-UP ADJUSTMENTS

3-1. Beam Landing ...................................................... 14

3-2. Convergence......................................................... 15

3-3. Focus Adjustment ................................................ 17

3-4. G2 (Screen) and White Balance Adjustments..... 17

4. CIRCUIT ADJUSTMENTS

4-1. Adjustments with Commander ............................ 18

4-2. Adjustment Method ............................................. 19

4-3. A Board Adjustment after IC003 (Memory)

Replacement......................................................... 22

4-4. Picture Distortion Adjustment............................. 22

5. DIAGRAMS

5-1. Block Diagram ...................................................... 25

5-2. Circuit Boards Location ....................................... 29

5-3. Schematic Diagrams and Printed Wiring Boards. 29

(1) Sc hematic Dia gram of A Board ........................... 33

(2) Schematic Diagrams of A3, F1 and V1 Boards ... 37

(3) Sc hematic Diagrams of C and VM Boards .......... 45

5-4. Semiconductors ..................................................... 48

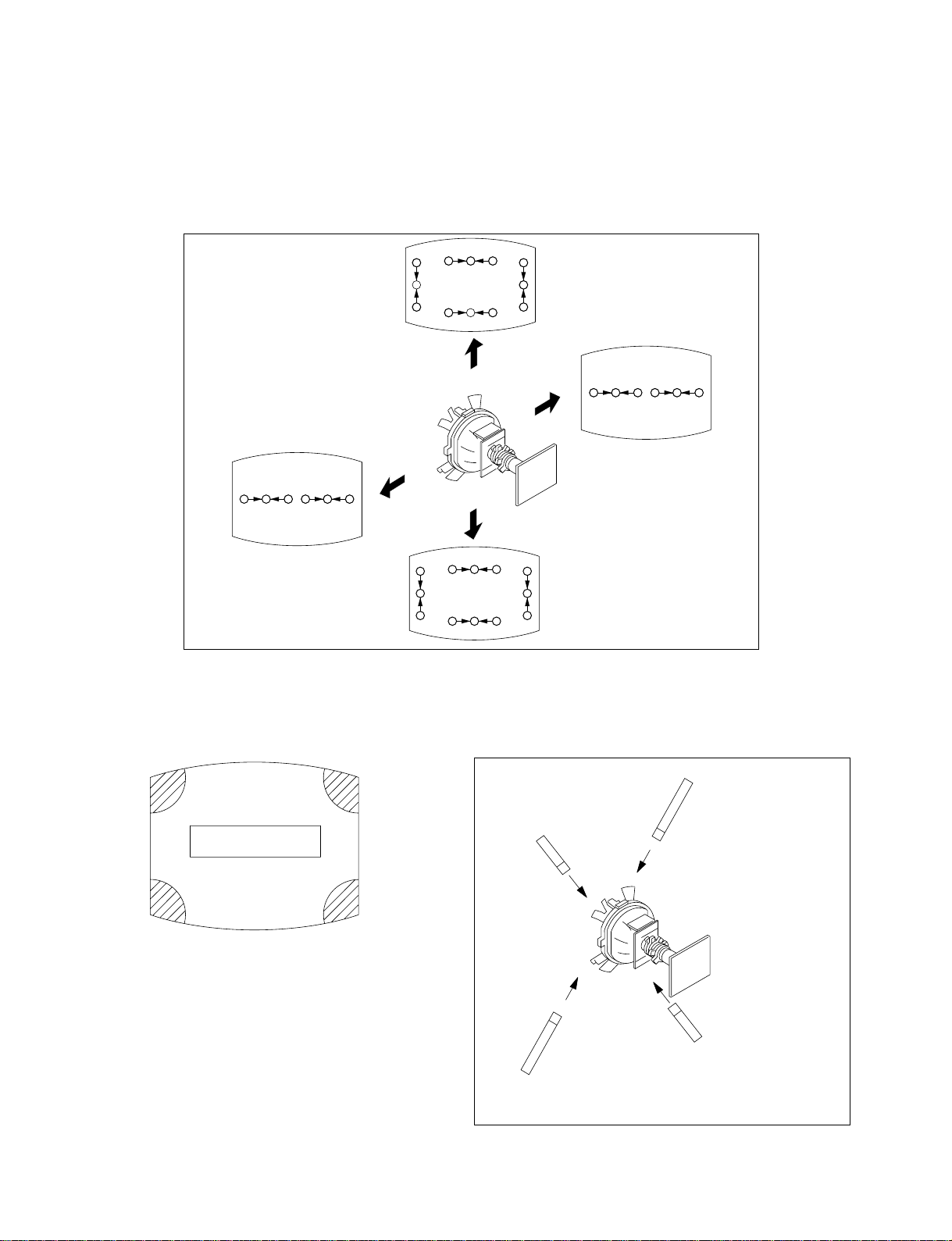

6. EXPLODED VIEW

6-1. Chassis .................................................................. 51

7. ELECTRICAL PARTS LIST ................................... 53

– 3 –

KV-T25SN81

RM-870

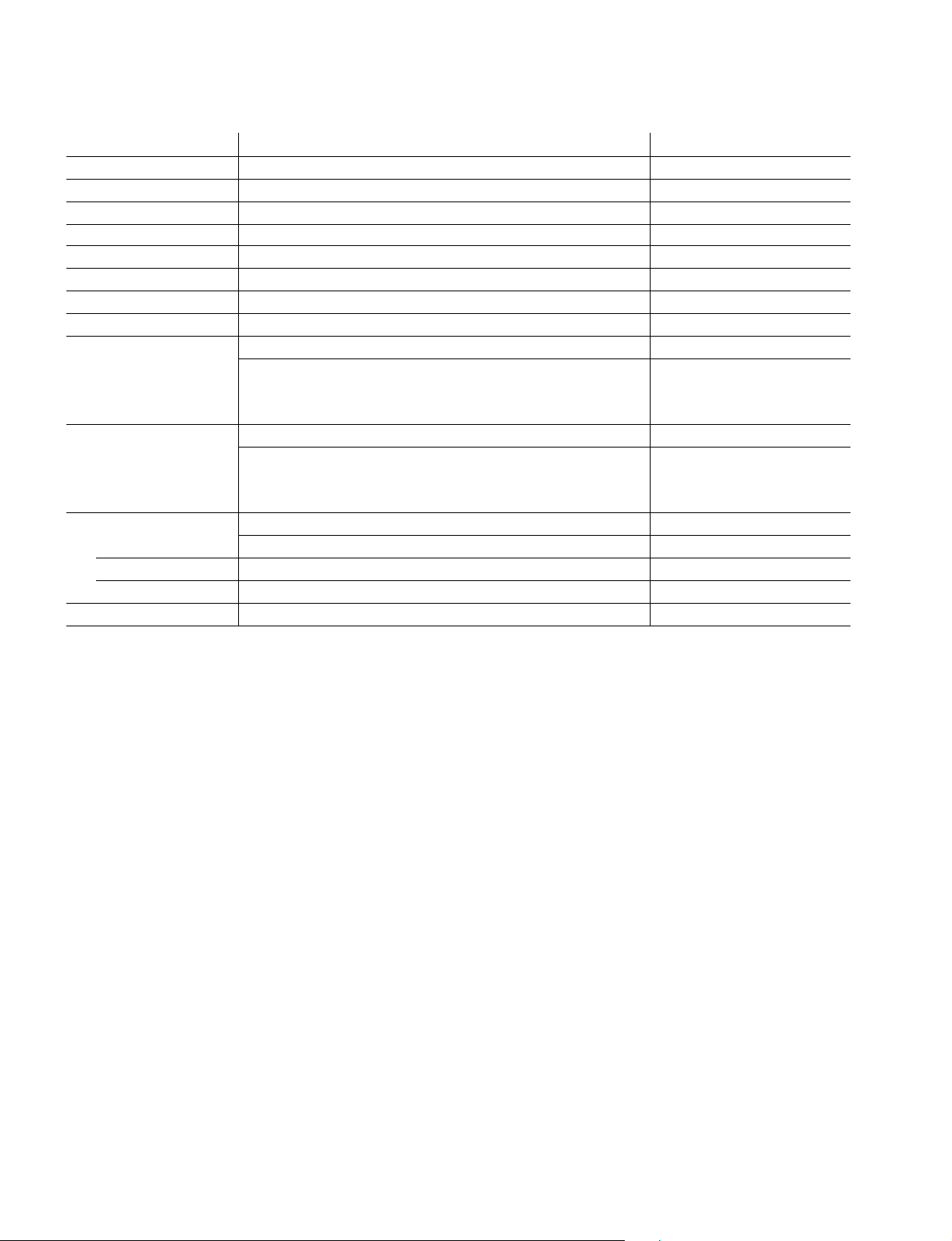

If no acknowledgement is returned from a device which is turned "ON", the device has a problem.

In this case, one of the LED's responding to the problem device will flicker a defined number of times.

Flickering is operated by lighting the LED's for 60ss each time.

The flickering frequency responding to each failed device is shown below.

SELF DIAGNOSIS FUNCTION

NONVOLATILE

Device

Flickering

Frequency

All the devices are checked one after another from the left of the table.

If an error is found, the responding LED will start flickering.

So, if more than 1 device have failed, only the one on the left side will flicker.

MEMORY

1

—

—

Y/C JUNGLE

(IC300)

3

—

—

—

—

TONE

CONTROL

(IC201)

6

– 4 –

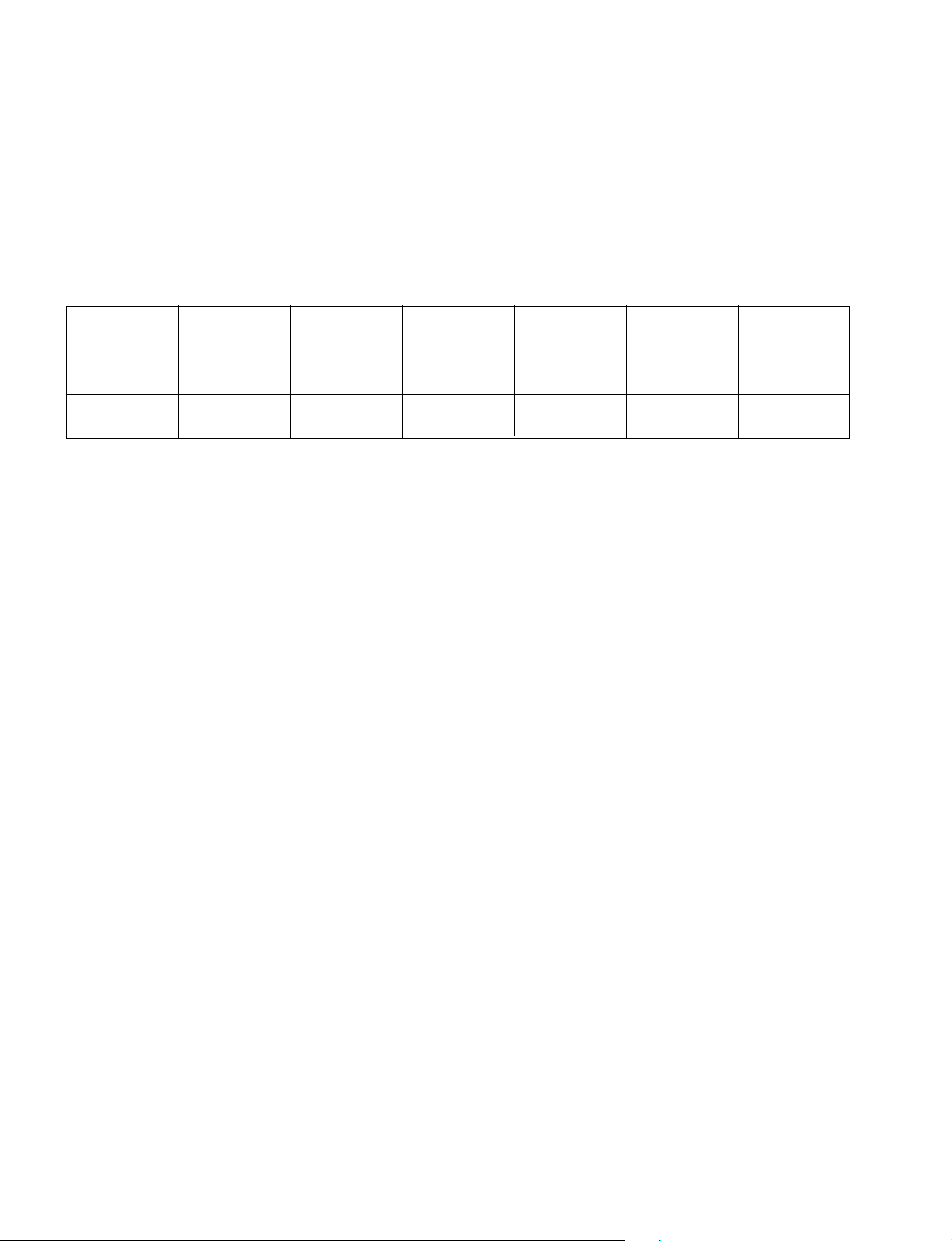

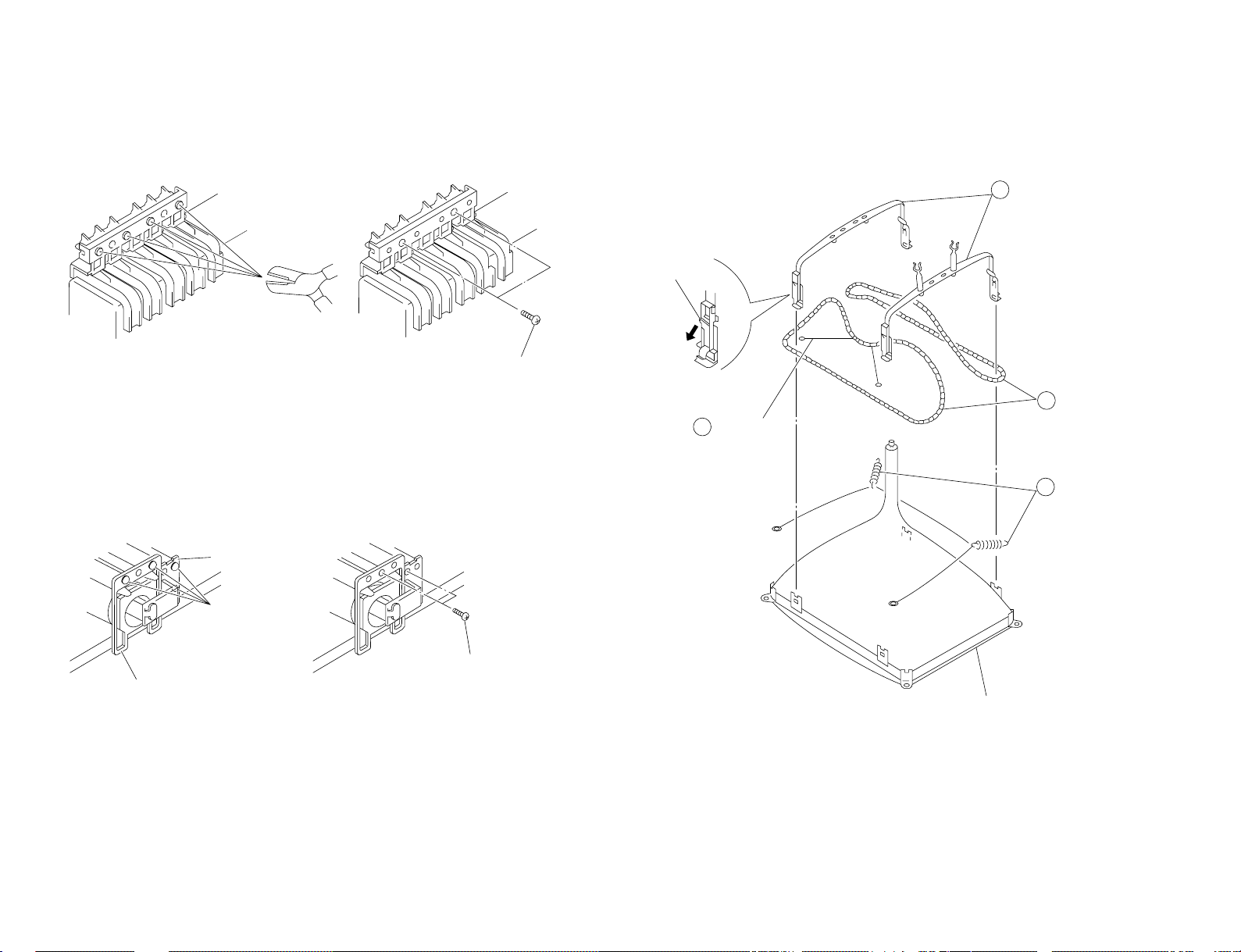

SECTION 2

2

Two screws

(BVTP 4×16)

3

One screw

(BVTP 3×16)

1

Two screws

(BVTP 4×16)

Lever

Lever

A board

A board

F1 board

DISASSEMBLY

2-1. REAR COVER REMOVAL 2-3. F1 BOARD REMOVAL

– 11 –

2-2. A BOARD REMOVAL

2-4. SERVICE POSITION

KV-T25SN81

RM-870

KV-T25SN81

3

Demagnetization coil

4

Tension spring

Picture tube

2

DGC holder

1

DGC band

Remove the claw

Cut

Light guide

Power button

Two screws

(BVTP 3×12)

Two screws

(BVTP 3×12)

2-5. REPLACEMENT OF PARTS

For replacement of the Multi Button, Power Button and Light Guide, cut the welded portions

from them, exchange with the new parts, and fix them with screws (+BVTP) respectively.

2-5-1. REPLACEMENT OF MULTI BUTTON

– 12 –

2-5-2. REPLACEMENT OF POWER BUTTON AND LIGHT GUIDE

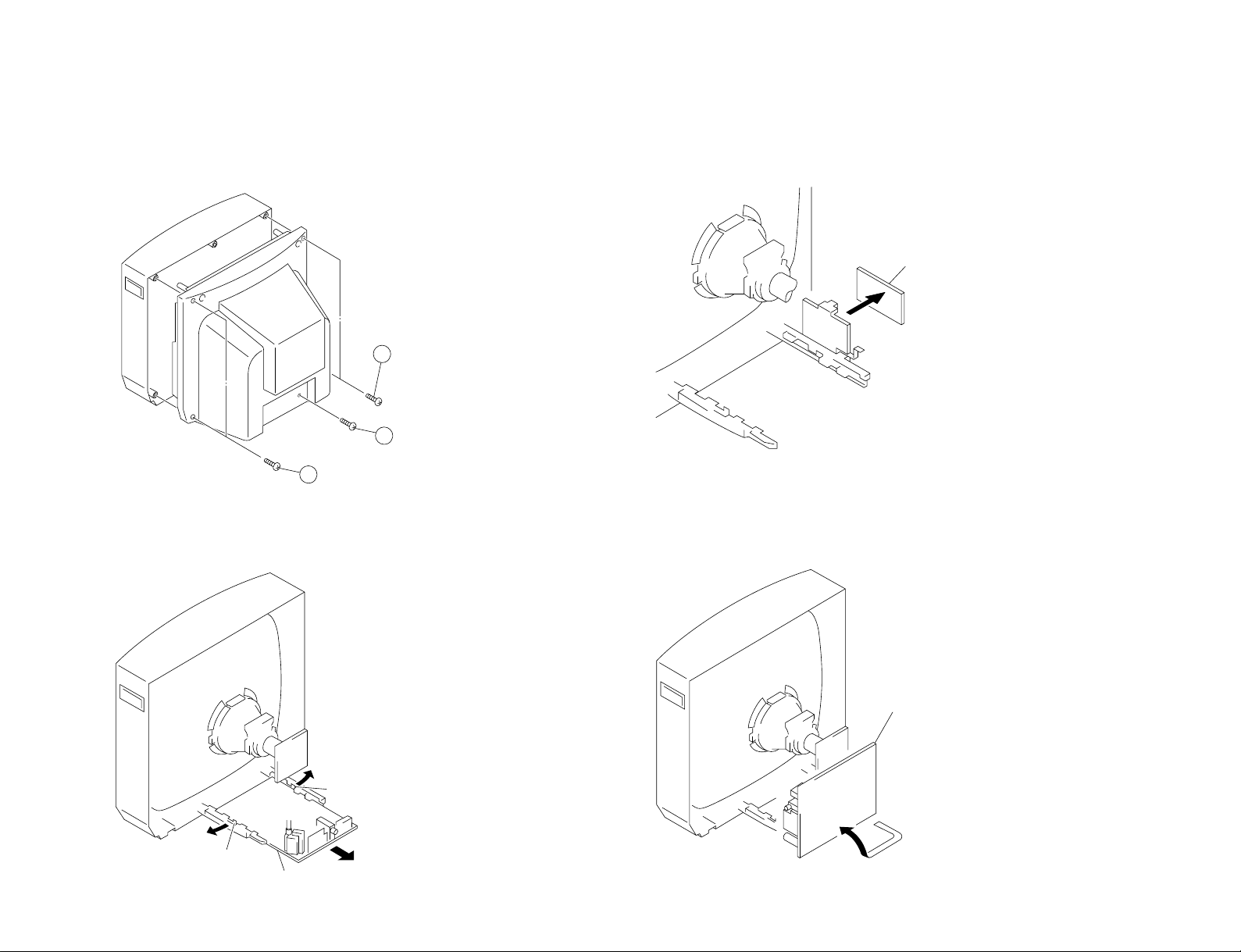

2-6. DEMAGNETIZATION COIL REMOVAL

RM-870

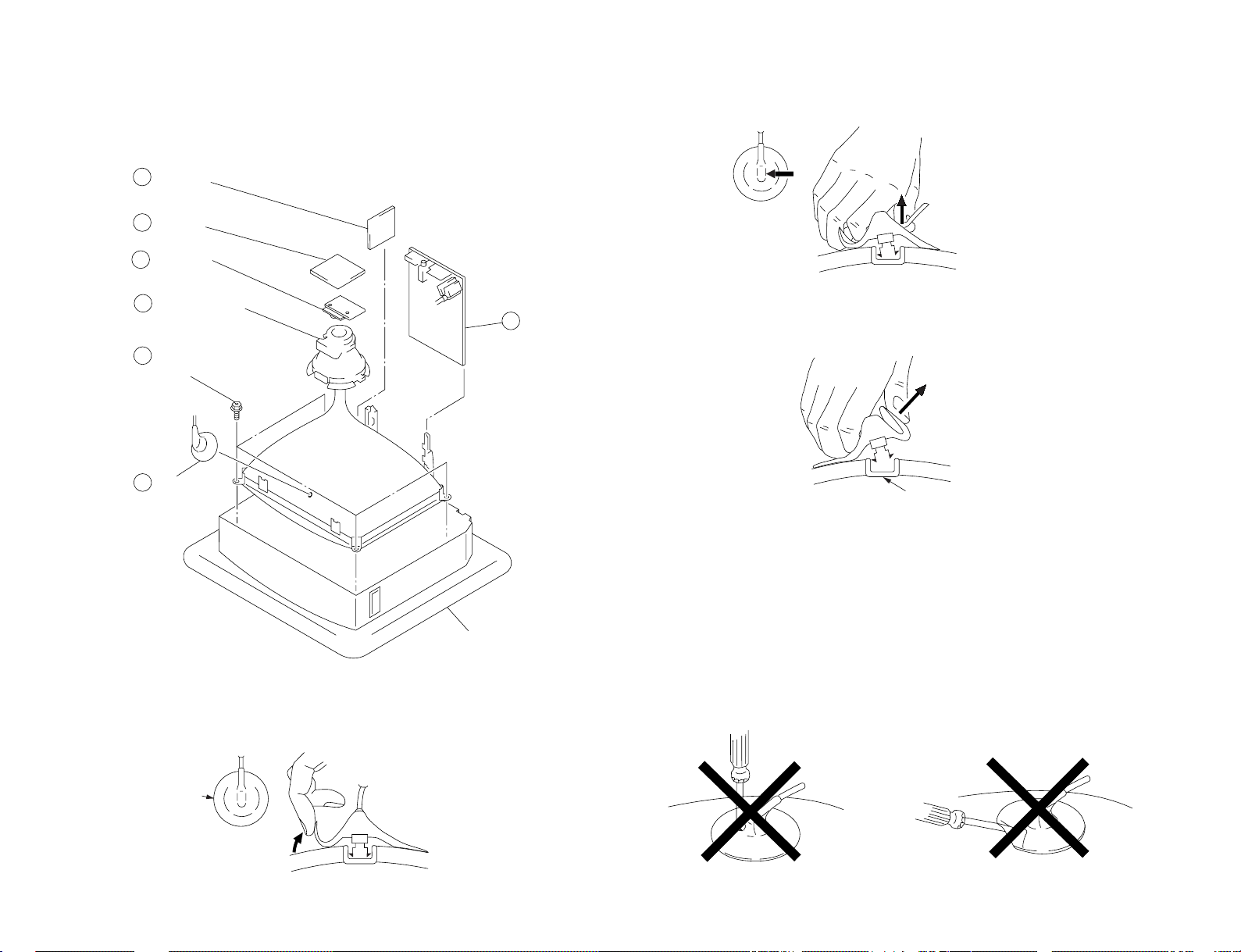

b

b

c

Anode button

a

a

2 A board

5 Deflection yoke

Cushion

6 Four screws

(Tapping screws)

1 Anode cap

4 C board

3 F1 board

7 VM board

– 13 –

2-7. PICTURE TUBE REMOVAL

NOTE : The picture tube for this model are upside-down, and the position for the anode-cap

and tension spring are changed accordingly.

2 Using a thumb press down then pull up the rubber cap firmly in the direction

indicated by the arrow b.

•REMOVAL OF ANODE-CAP

NOTE : After removing the anode, short circuit the anode of the picture tube and the

•REMOVING PROCEDURES

1 Turn up one side of the rubber cap in the direction indicated by the arrow a.

anode cap to the metal chassis, CRT shield or carbon paint on the CRT.

3 When one side of the rubber cap is separated from the anode button, the

anode-cap can be removed by turning up the rubber cap and pulling it up in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with sharp shaped objects.

2 Do not press the rubber too hard so as not to damage the inside of anode-caps.

A metal fitting called the shatter-hook terminal is built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage the rubber.

KV-T25SN81

RM-870

KV-T25SN81

GREEN

BLUE RED

RM-870

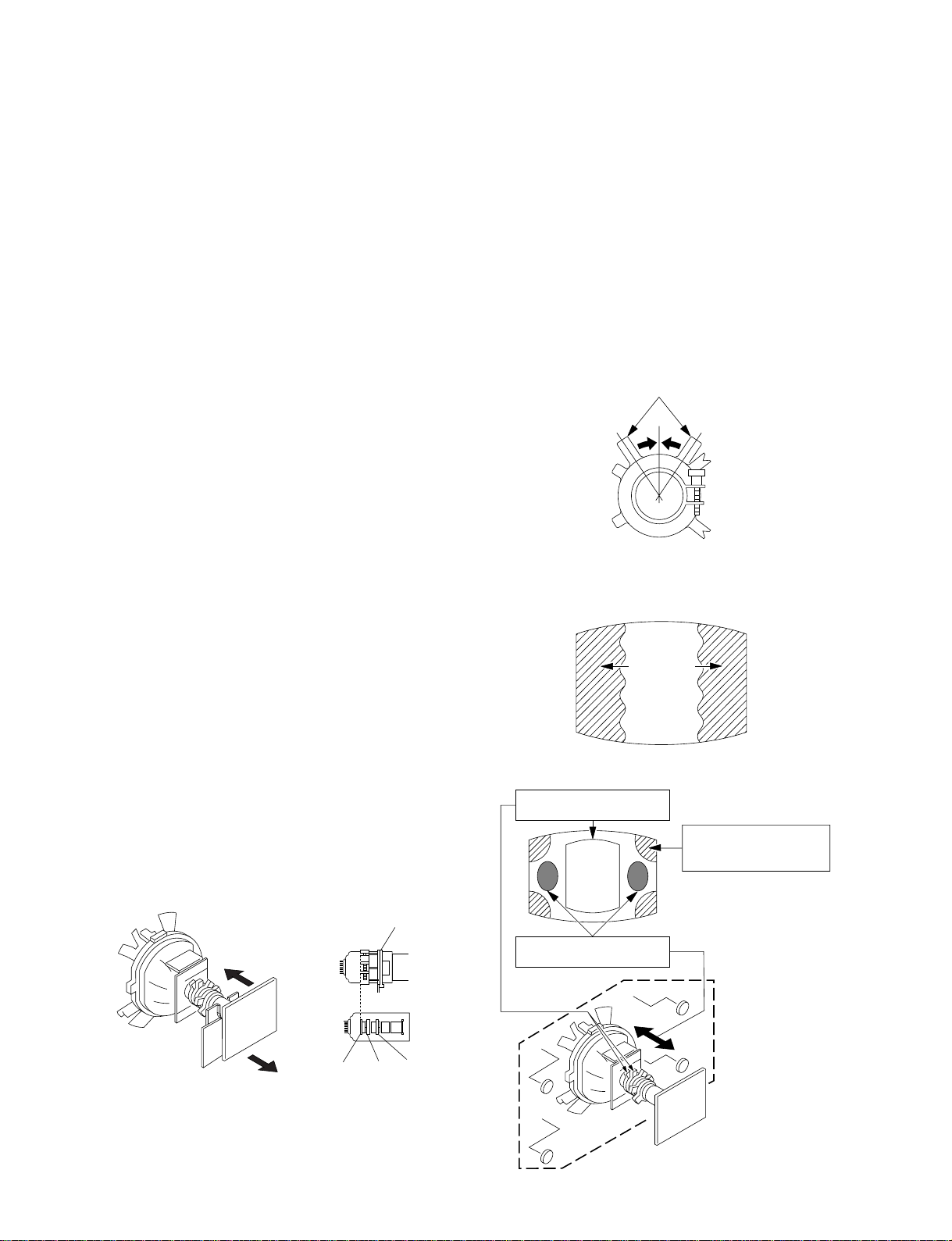

SECTION 3

SET-UP ADJUSTMENTS

• The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

• These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Controls and switch should be set as follows unless otherwise noted:

PICTURE control........................................................... normal

BRIGHTNESS control................................................... normal

................................................................................................................................................................................................................................

Preparation :

• In order to reduce the influence of geomagnetism on the set's

picture tube, face it east or west.

• Switch on the power and degauss with the degausser.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

4. White Balance

Note : Test Equipment Required.

1. Color-bar/Pattern Generator

2. Degausser

3. Oscilloscope

Purity control

3-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck assy as shown in Figure 3-1.

3. Set the pattern generator raster signal to a green raster.

4. Move the deflection yoke to the rear and adjust with the purity

control so that the green is at the center and the blue and the red

take up equally sized areas on each side.

(See Figures 3-1 through 3-3.)

5. Move the deflection yoke forward and adjust so that the entire

screen is green. (See Figure 3-1.)

6. Switch the raster signal to blue, then to red and verify the

condition.

7. When the position of the deflection yoke has been decided,

fasten the deflection yoke with the screw.

8. If the beam does not land correctly in all the corners, use a

magnet to adjust it.

(See Figure 3-4.)

}

normal

Fig. 3-2

Fig. 3-3

Purity control corrects

this area.

a

b

Disk magnets or rotatable

disk magnets correct

these areas (a-d).

Fig. 3-1

Neck assy

G1 G2 G3

– 14 –

c

Deflection yoke positioning

corrects these areas.

b

d

d

Fig. 3-4

a

c

3-2. CONVERGENCE

Preparation :

• Before starting this adjustment, adjust the focus, horizontal size

and vertical size.

• Minimize the brightness setting.

• Provide dot pattern.

(1) Horizontal and Vertical Static Convergence

BMC (Hexapole)

Purity

• Operation of the V.STAT magnet.

If the V-STAT ma gnet is moved in the direction of the a and

b arrows, the red, green and blue dots move as shown below.

1

2

a

bb

a

ab

B

GG

R

R G B

B

R

a

KV-T25SN81

RM-870

V.STAT

1. (Moving vertically), adjust the V.STAT magnet so that the red,

green and blue dots in the center of the screen are separated

from each other.

2. Adjust the BMC (Hexapole) magnet so that the red, green and

blue dots are aligned in a straight line.

3. Adjust the BMC (Hexapole) magnet so that the red, green and

blue dots are balanced (ie. equal distance) on either side of the

green dot.

4. (Moving horizontally), adjust the H.STAT VR magnet so that

the red, green and blue dots converge on top of each other in

the center of the screen.

Center dot

R G B

R

G

B

3

b

b

a

b

a

R

G

b

B G R

B

G

B

• Operation of BMC (Hexapole) Magnet.

To align or balance the red, green and blue dots, adjust the BMC

(Hexapole) magnet as shown below.

RG B

RGB R GB

b

R

C board

V.STAT Magnet

RV 701

SCREEN (G2)

R

B

G

RGB

G

R

• The respective dot positions resulting from moving each magnet

interact, so be sure to perform adjustment while tracking.

Use the V. STAT magnet to adjust the red, green and blue dots

so they coincide at the center of screen (by moving the dots in

the horizontal direction).

– 15 –

B

KV-T25SN81

RM-870

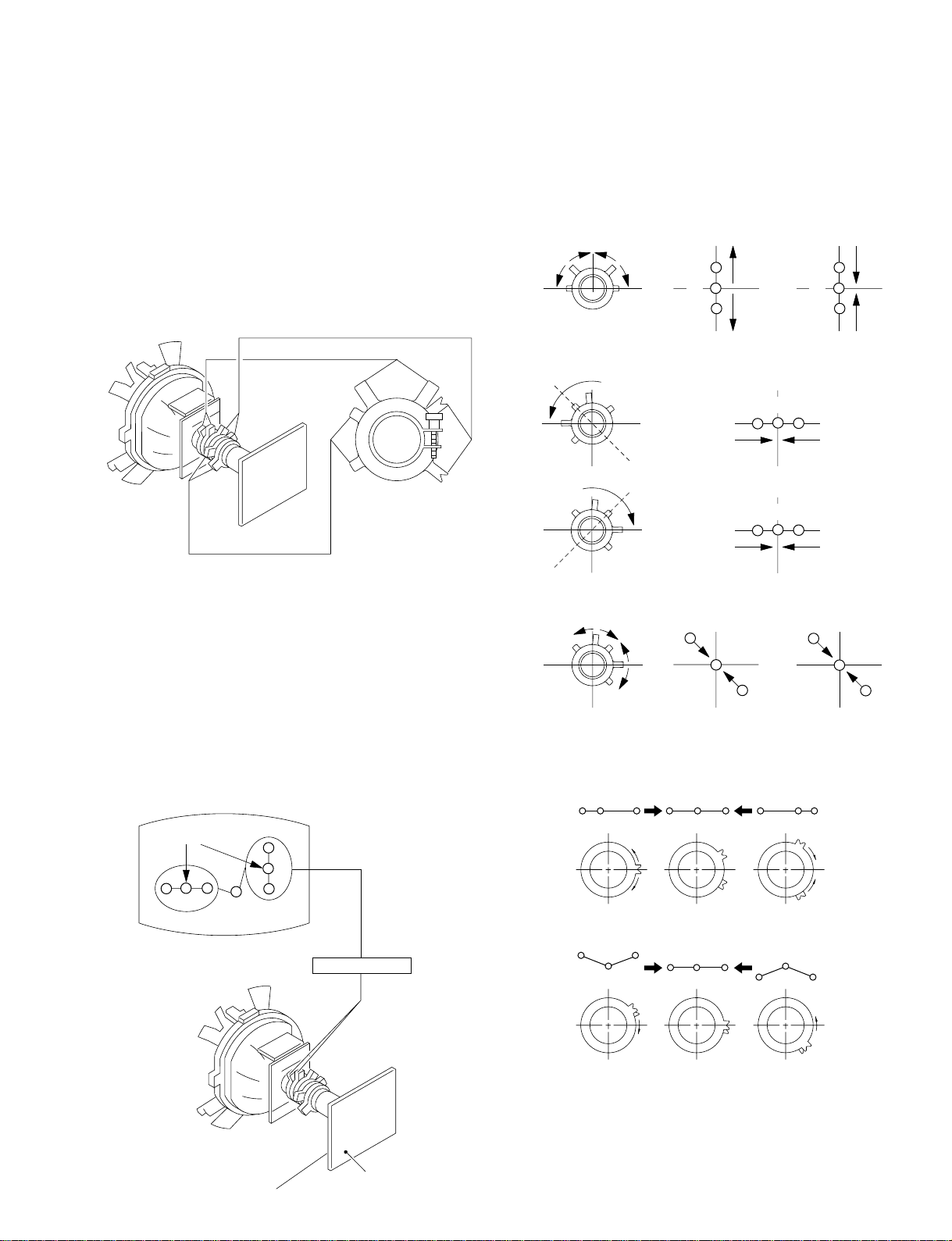

(2) Dynamic Convergence Adjustment

Preparation :

• Before starting this adjustment, adjust the horizontal static

convergence and the vertical static convergence.

1. Slightly loosen the deflection yoke screws.

2. Remove the deflection yoke spacer.

3. Move the deflection yoke as shown in the figure below and

optimize the convergence.

4. Tighten the deflection yoke screws.

5. Install the deflection yoke spacer.

RGB RGB

R

G

RGB

B

B

R

G

R

B

RGB

G

R

RGBRGB

R

B

G

G

RGB

B

(3) Screen-corner Convergence

b

a-d : screen-corner

misconvergence

c

b

Fix a Permalloy assy

a

a

corresponding to the

misconverged areas

d

c

d

Permalloy assembly

– 16 –

Loading...

Loading...