Page 1

REVISION HISTORY

BX1L

CHASSIS

MODEL

KV-SZ252M50

KV-SZ252M61

KV-SZ252M81

KV-SZ252N50

KV-SZ252N60

NO. SUFFIX DATE SUPP / CORR DESCRIPTION

1 -01 2007/04 _ _ 1st Issue

PART NO.: 9-872-963-01

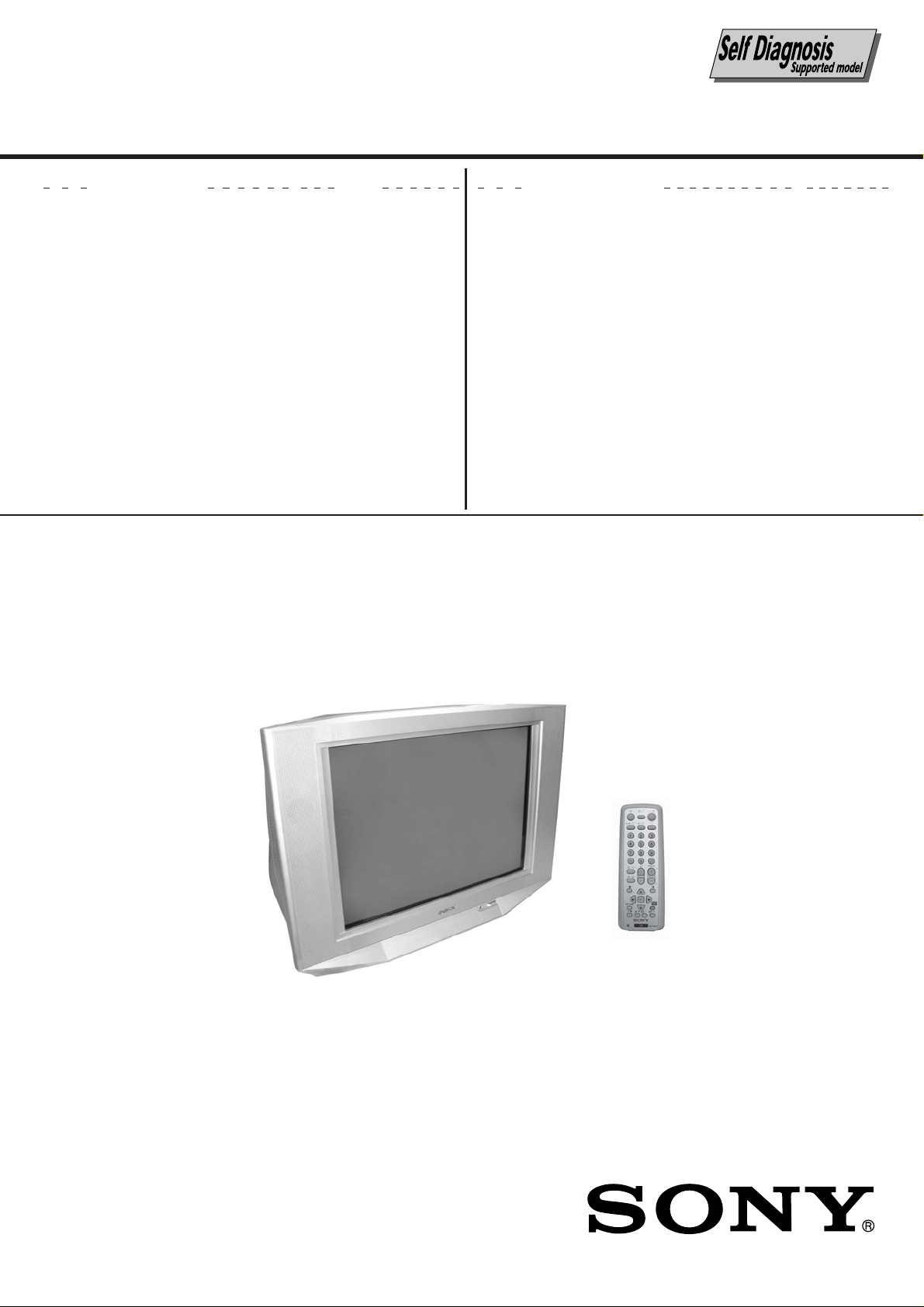

Page 2

SERVICE MANUAL

BX1L

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-SZ252M50 RM-GA002 E SCC-V66P-A

KV-SZ252M61 RM-GA002 GE SCC-V44U-A

KV-SZ252M81 RM-GA002 Middle East SCC-V83H-A

KV-SZ252N50 RM-GA002 Philipines SCC-V80K-A

KV-SZ252N60 RM-GA002 Philipines SCC-V80J-A

MODEL COMMANDER DEST. CHASSIS NO.

RM-GA002

TRINITRON

®

COLOR TV

Page 3

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

TABLE OF CONTENTS

Section Title Page

SELF DIAGNOSTIC FUNCTION ........................................... 3

1. DISASSEMBLY

1-1. Rear Cover Removal..................................................5

1-2. Speaker Removal ....................................................... 5

1-3. Chassis Assy Removal ............................................... 5

1-4. Service Position ......................................................... 5

1-5. A and H2 Board Removal ......................................... 5

1-6. Picture Tube Removal................................................ 6

2. WIRE DRESSING

2-1. Lead Assy, Jumper Wire Dressing at A board...........7

2-2. Lead Assy, Jumper Wire Dressing at A board

(only for Audio 6+6 Non DSP models) .................... 7

2-3. Wire Dressing at A and H2 board ............................. 7

2-4. Dressing of Conn Assy, 4P VH ................................. 8

2-5. Dressing of Conn Assy, 5P YUV ............................... 8

2-6. Dressing of Conn Assy, 4P VM and

Connector Assy, 5P Front In...................................... 8

2-7. Installation and Dressing of Earth Assy Coating ...... 8

2-8. Installation and Dressing of Earth Assy Coating ...... 9

2-9. Insertion of Lead Assy, H Static................................ 9

2-10. Dressing of Conn Assy, 5P Front In .......................... 9

2-11. Dress Lead Assy, Earth and Conn Assy,

5P In with Purse Lock Ø 5 ...................................... 10

2-12. CV Board Connector Assy Wire Dressing.............. 10

2-13. Connector Assy Wire Dressing................................10

2-14. Connector Assy Wire Dressing................................11

2-15. Overall V iew of Rotation Coil Conn Dressing ....... 11

2-16. Overall View of Lead Assy, G2; Lead Assy, Focus

and Rotation Coil Conn Dressing ........................... 11

2-17. Dress Lead Assy, Speaker to Rotation Coil using

Purse Lock Ø 9 ........................................................ 12

2-18. Dressing of PF Board Conn Assy (for models

with PF board only) ................................................. 12

2-19. Cap Assy, High Voltage Installation ........................12

2-20. HV Cap Assy Wire Dressing ................................... 13

2-21. AC Power Cord Wire Dressing ............................... 13

Section Title Page

4. CIRCUIT ADJUSTMENTS

4-1. Adjustment With Commander ................................18

4-2. Adjustment Method ................................................19

4-3. Picture Quality Adjustment .................................... 36

4-3-1. P Max/Contrast Adjustment .........................36

4-3-2. Sub Color Adjustment ..................................36

4-3-3. Sub Hue Adjustment ....................................36

4-4. Geometry Adjustment .............................................37

4-4-1. H-Trapezoid Adjustment ..............................37

4-4-2. Normal Mode 50Hz/60Hz ............................ 37

4-4-3. Wide Mode 50Hz/60Hz

(V Compression Adjustment)................................ 37

5. DIAGRAMS

5-1. Block Diagram ......................................................... 38

5-2. Circuit Boards Location .......................................... 39

5-3. Schematic Diagram Information ............................. 39

5-3-1. A Board — (Block 001)............................... 40

5-3-2. A Board — (Block 002)............................... 42

5-3-3. A Board — (Block 003).............................. 44

5-3-4. A Board — (Block 004)............................... 46

5-3-5. A Board — (Block 005)............................... 48

5-3-6. A Board — (Block 006)............................... 50

5-3-7. A Board — (Block 007)............................... 52

5-3-8 CV Board Schematic Diagram ..................... 53

5-3-9. H2 Board Schematic Diagram...................... 55

5-4. Voltage Measurement and Waveform...................... 57

5-5. Printed Wiring Boards ............................................. 61

5-6. Semiconductors........................................................ 67

6. EXPLODED VIEWS

6-1. Chassis ..................................................................... 69

7. ELECTRICAL PARTS LIST .......................................... 71

OPERATING INSTRUCTIONS

3. SET-UP ADJUSTMENTS

3-1. Beam Landing Adjustment...................................... 14

3-2. Convergence Adjustment.........................................15

3-3. Focus Adjustment .................................................... 17

3-4. G2 (SCREEN) Adjustments ....................................17

3-5. Sub Bright Adjustment ............................................ 17

3-6. White Balance Adjustment...................................... 17

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

Page 4

KV-SZ252M50/M61/M81/N50/N60

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY Indicator will automatically

begin to flash.

The number of times the STANDBY Indicator flashes translates to a probable source of the problem.If an error symptom

cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to

reveal past problems and how often these problems occur.

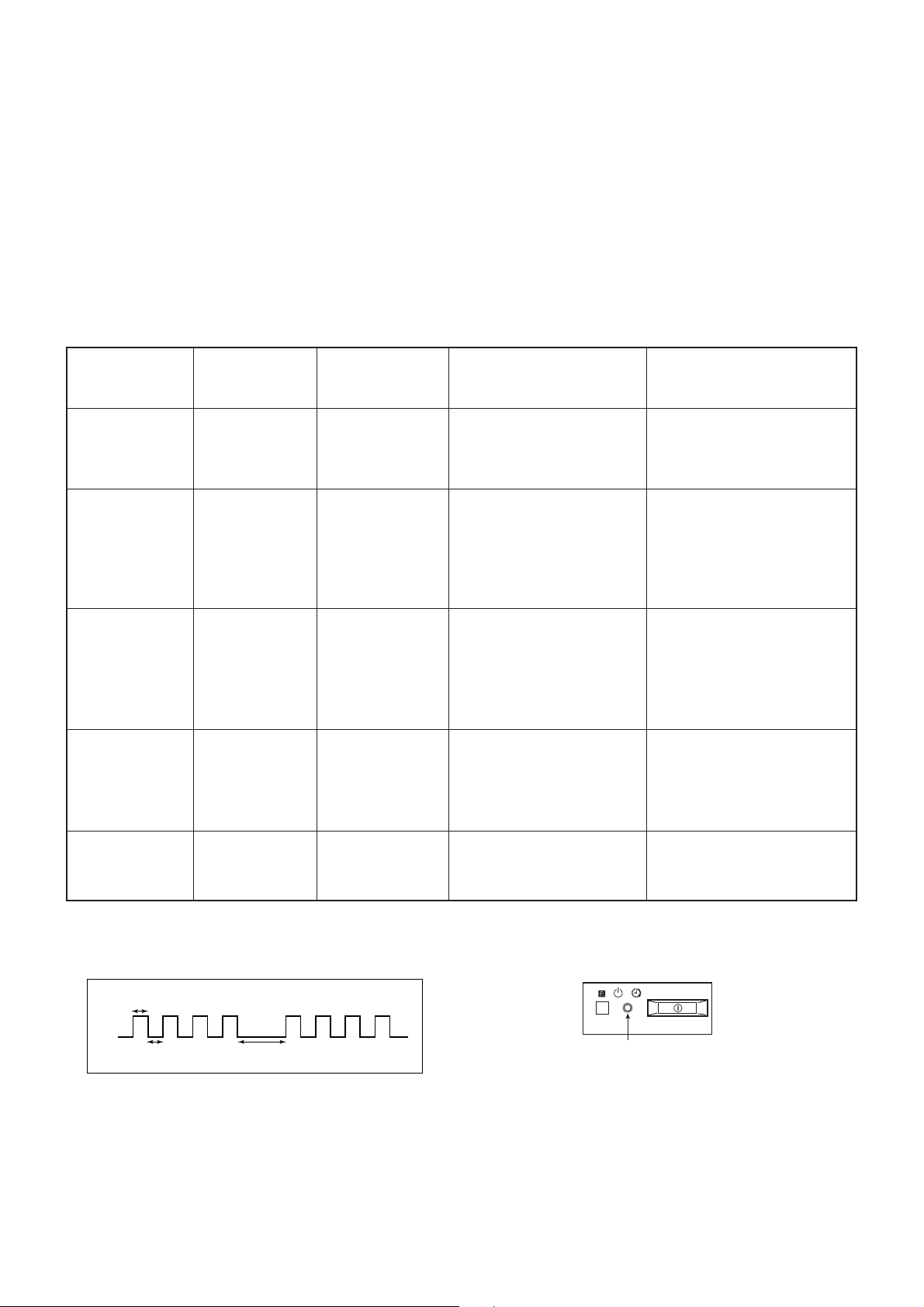

1. DIAGNOSTIC TEST INDICATORS

When an error occurs, the STANDBY Indicator will flash a number of times to indicate the possible cause of the

problem. If there is more than one error, the Indicator will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occured if the screen displays a “0”.

RM-GA002

Diagnosis

Item

Description

• No Power

• +B overcurrent

(OCP)

•Vertical NG.

• IK (AKB)

No. of times

STANDBY

Indicator flashes

Does not light

2 times

4 times

5 times

Diagnostic Result

on screen display

—

2 OCP:0

2 OCP:1 ~ 255

4 VSTOP:0

4 VSTOP:1 ~ 255

5 AKB:0

5 AKB:1 ~ 255

Probable

Cause

Location

•Power cord is not plugged

in.

• Fuse is burned out (F4101)

(H2 Board)

• H.OUT (Q511) is shorted.

(A board)

• IC751 is shorted.

(C/CV Board)

• +13V is not supplied.

(A Board)

• IC503 voltage list is faulty.

(A Board)

• Video OUT (IC751) is faulty.

(CV Board)

• IC001 is faulty. (A Board)

• Screen (G2) is improperly

adjusted.

Detected

Symptoms

•Power does not turn on.

•No power is supplied to the

TV.

•AC power supply is faulty.

•Power does not turn on.

•Load on power line is

shorted.

•Has entered standby state

after horizontal raster.

•Vertical deflection pulse is

stopped.

•Power line is shor ted or

power supply is stopped.

•No raster is generated.

•CRT cathode current

detection reference pulse

output is small.

• Supply Voltage

Protection

8 times

8 SUP:0

8 SUP:1 ~ 255

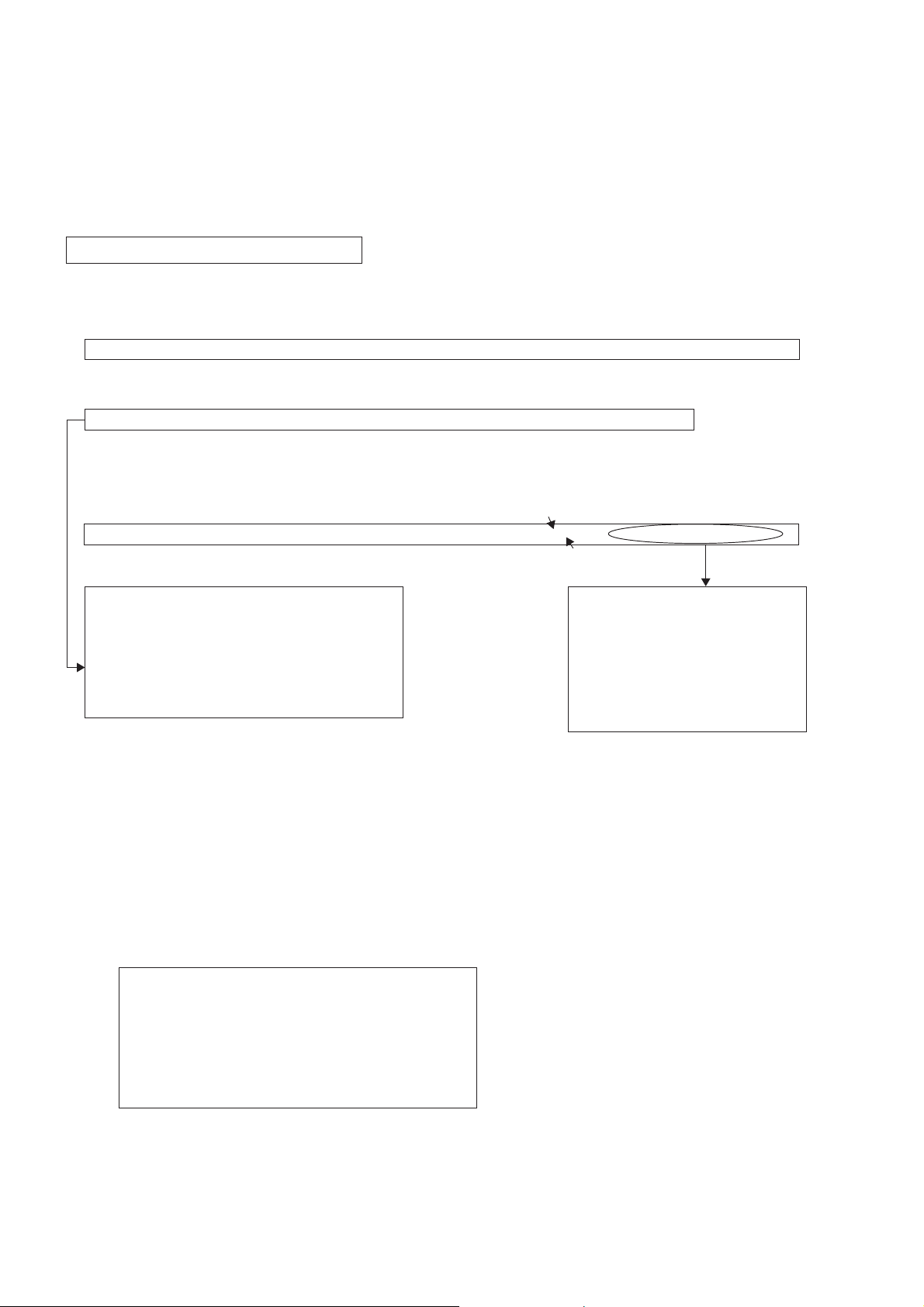

2. STANDBY INDICATOR BLINKING PROCESS

Lamp ON 300ms

Lamp OFF 300ms

The example above represents for 4 times blink

Lamp OFF 3 seconds

• IC604 faulty.

• IC607 faulty.

•No power supply to CRT

ANODE.

•No RASTER is generated.

3. STANDBY INDICATOR ON TV FRONT PANEL

Standby indicator

– 3 –

Page 5

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

4. SELF DIAGNOSTIC SCREEN DISPLAY

SELF DIAGNOSTIC

2 : 000

3 : N/A

4 : 000

5 : 001

8 : 002

101 : N/A

5. HANDLING SELF DIAGNOSTIC SCREEN DISPLAY

No. Description Method

1. Display self diagnostic screen [Display] t [Channel ] t [Volume ] t [Power / TV]

2. Stop standby flash i) Turn off power switch on main.

3. Clear fault result In self diagnostic screen, press [Channel ] t -

4. Quit self diagnostic screen Turn off power switch of remote commander or main unit.

"0" means no fault has been detected.

"1" means a fault has been detected.

"2" means two faults has been detected.

"N/A" means not available for this models.

5

Note: The above must be performed while TV is on standby mode.

ii) Unplug power cord from the outlet.

8

Note: Diagnostic results display on screen is not automatically cleared. Therefore,

clear result after completion of repair.

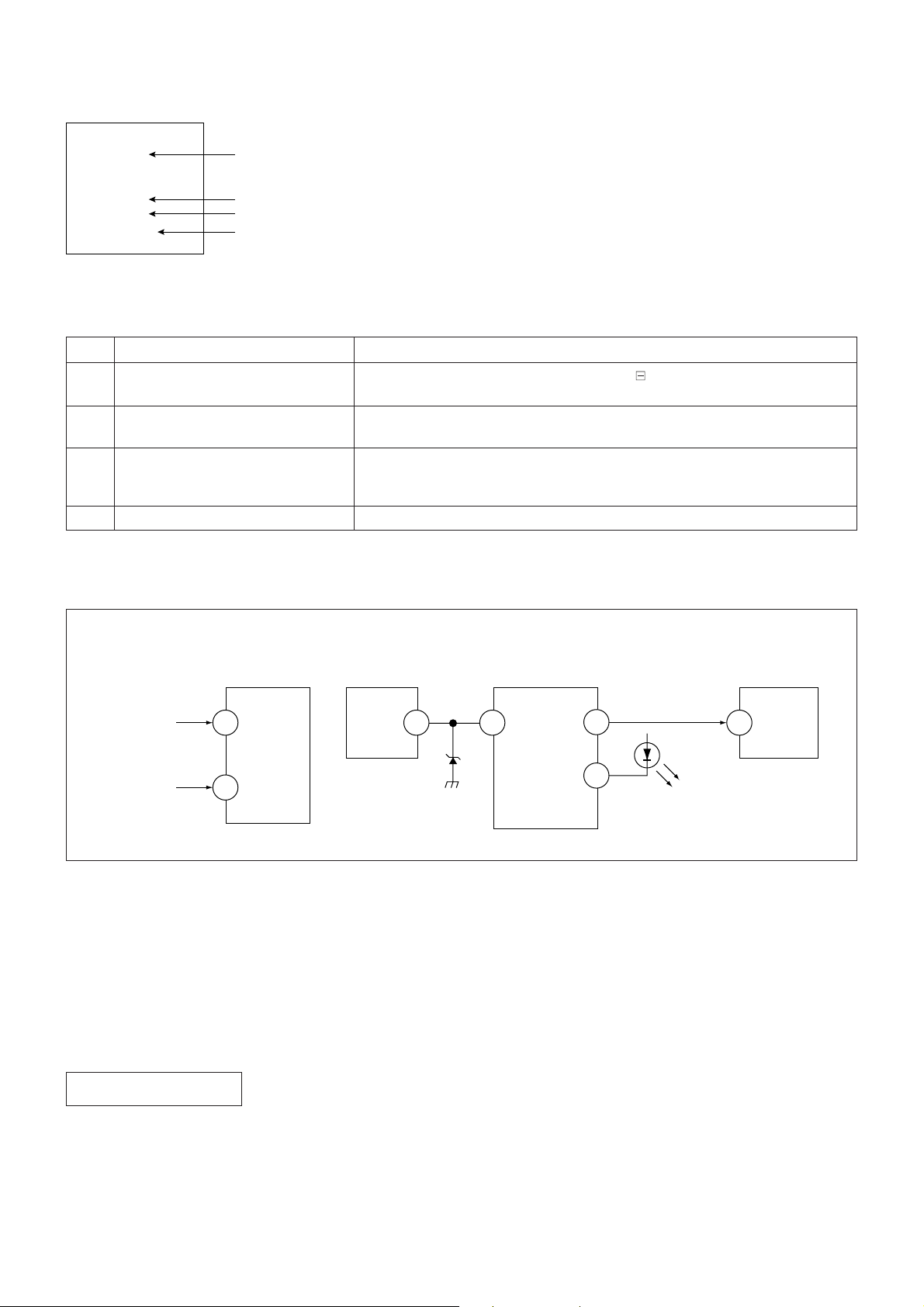

6. SELF-DIAGNOSTIC CIRCUIT

A BOARD

IC003

MEMORY

5

SDA

FROM

CV BOARD

IC751 PIN 5

A BOARD

FROM

Q816

COLLECTOR

A BOARD

IC001

Y/CHROMA JUNGLE

IK

32

EHT0

A BOARD

IC503

V.OUT

F.B-PLS

A BOARD

IC001

SYSTEM

SDA1

3 1384

V.GUARD

RED LED

99

122

DISPLAY

[+B overcurrent $OCP%] Occurs when an overcurrent on the +B(135V) line is detected by pin 32 of IC001 (A board).

If the voltage of pin 32 of IC001 (A board) is more than 4V, the unit will automatically go to

standby.

[V-PROTECT] Occurs when an absence of the vertical deflection pulse is detected by pin 13 of IC001

(A board).

[IK $AKB%] If the RGB levels* do not balance within 15 sec after the power is turned on, this error will be

detected by IC001 (A board). TV will stay on, but there will be 5 times LED blinking.

POWER SUPPLY NG (+5V)

for VIDEO PROCESSOR

Occurs when IC001 internal HV protect detects an abnormal H-Pulse (frequency) due to

improper power supply to IC001. TV cuts off high voltage power of anode CRT. No picture will be

detected. eg: IC602, IC604 go faulty.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects IK.)

– 4 –

Page 6

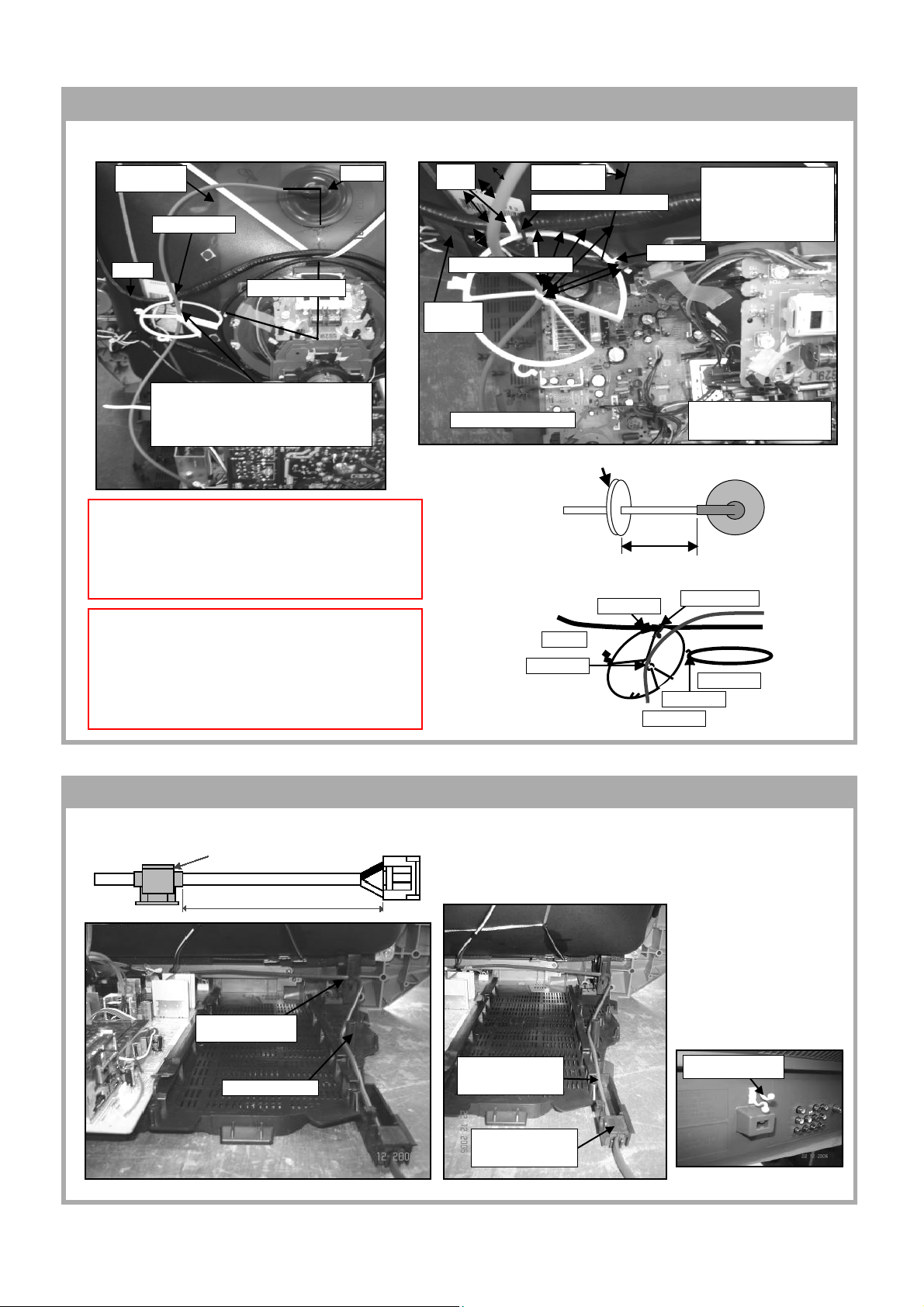

SECTION 1

DISASSEMBLY

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

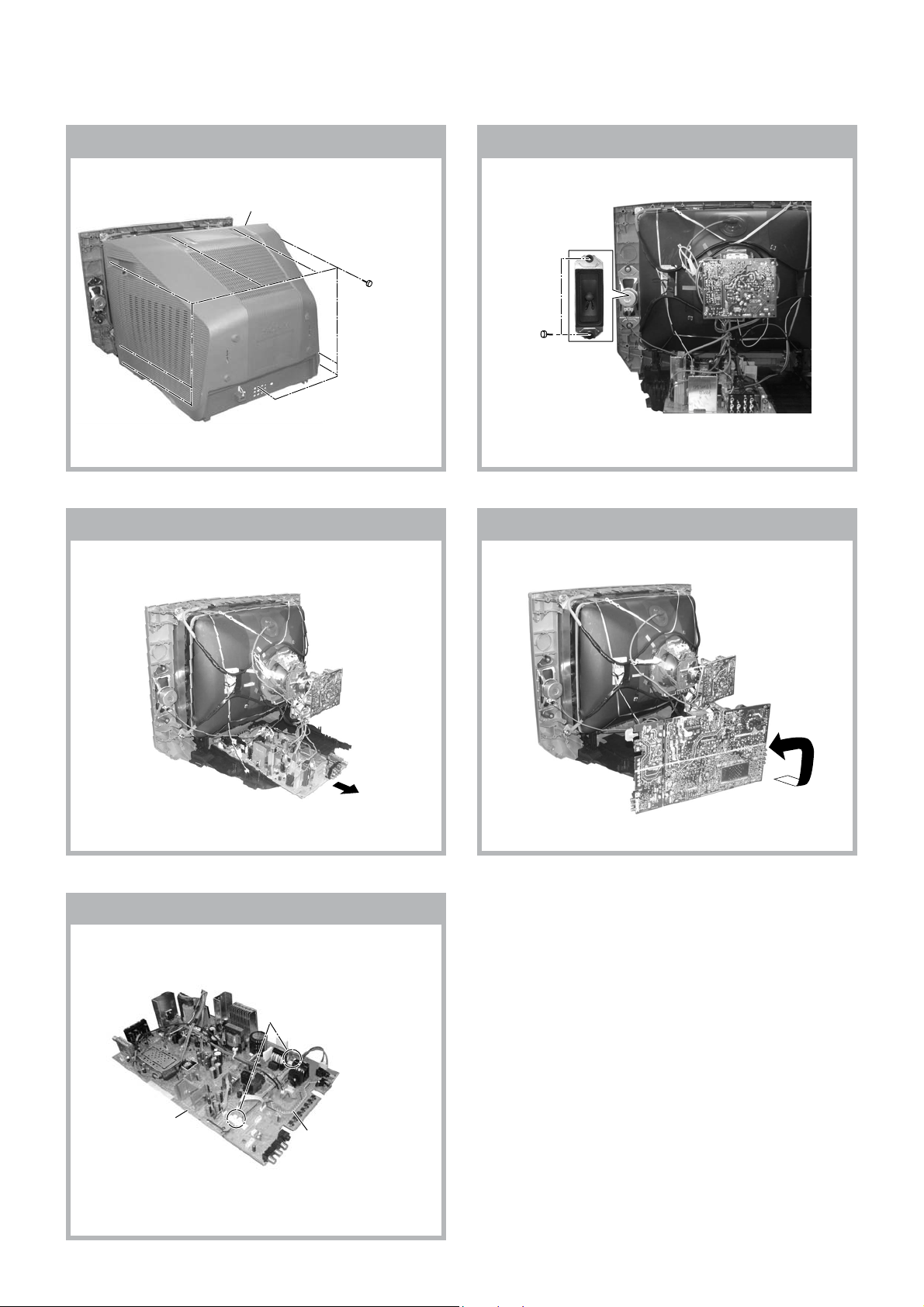

1-1. REAR COVER REMOVAL

2 Rear cover

1 Nine screws

(+BVTP 4 × 16)

1-2. SPEAKER REMOVAL

1 Two screws

(Tapping screw)

(+PWH 4x16)

1-3. CHASSIS ASSY REMOVAL 1-4. SERVICE POSITION

1-5. A AND H2 BOARD REMOVAL

1 Two hooks

3 A Board

2 H2 Board

– 5 –

Page 7

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

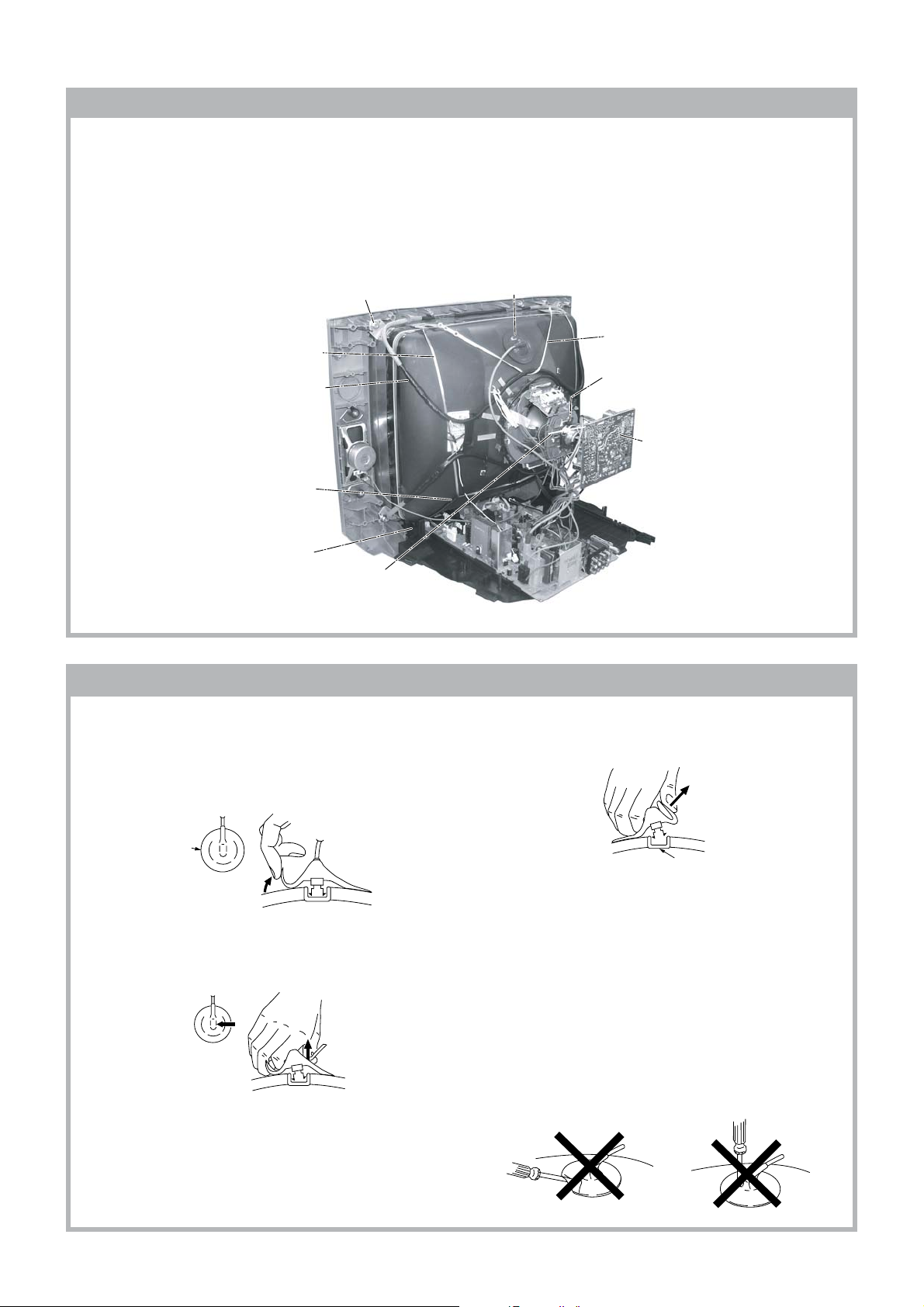

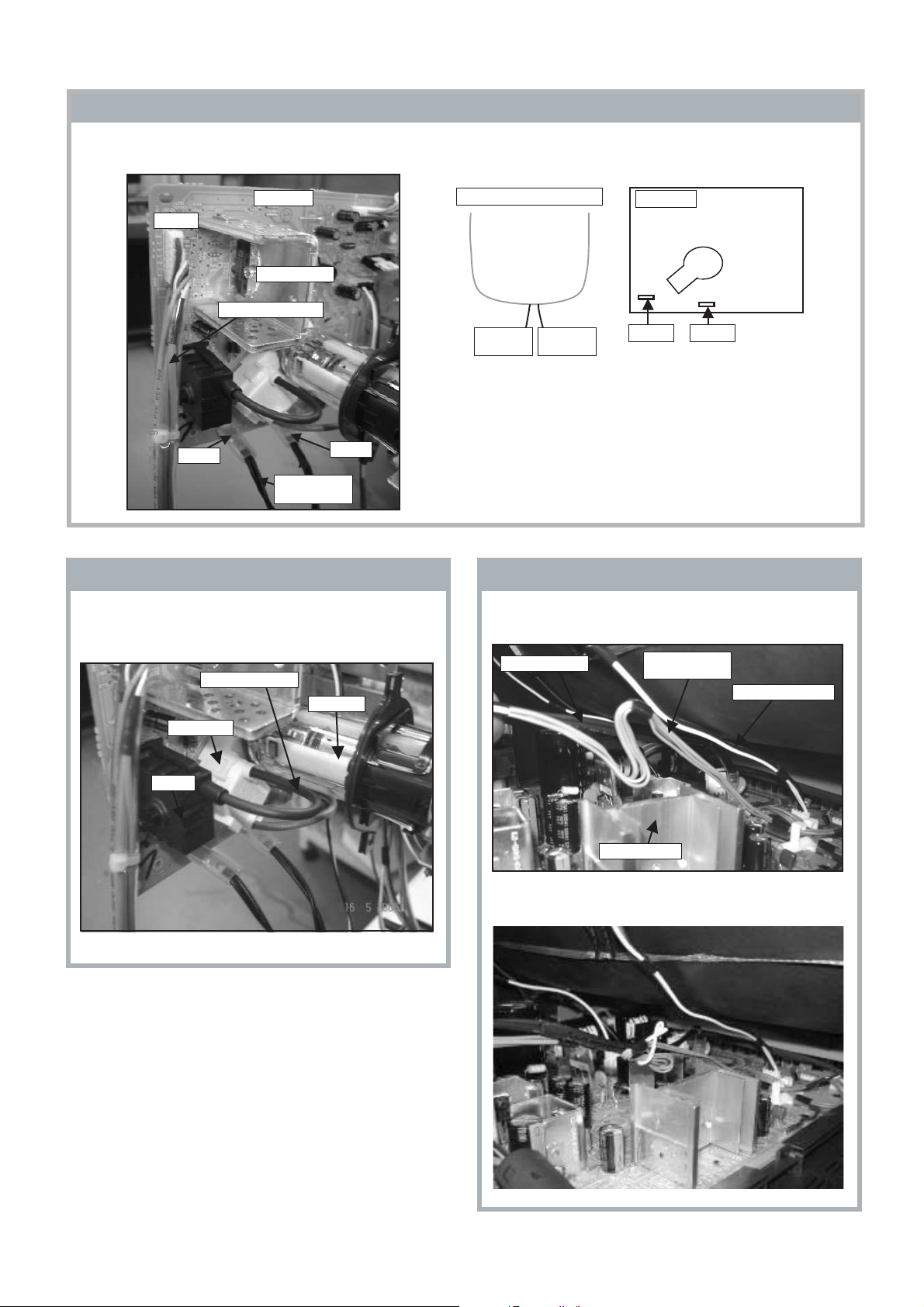

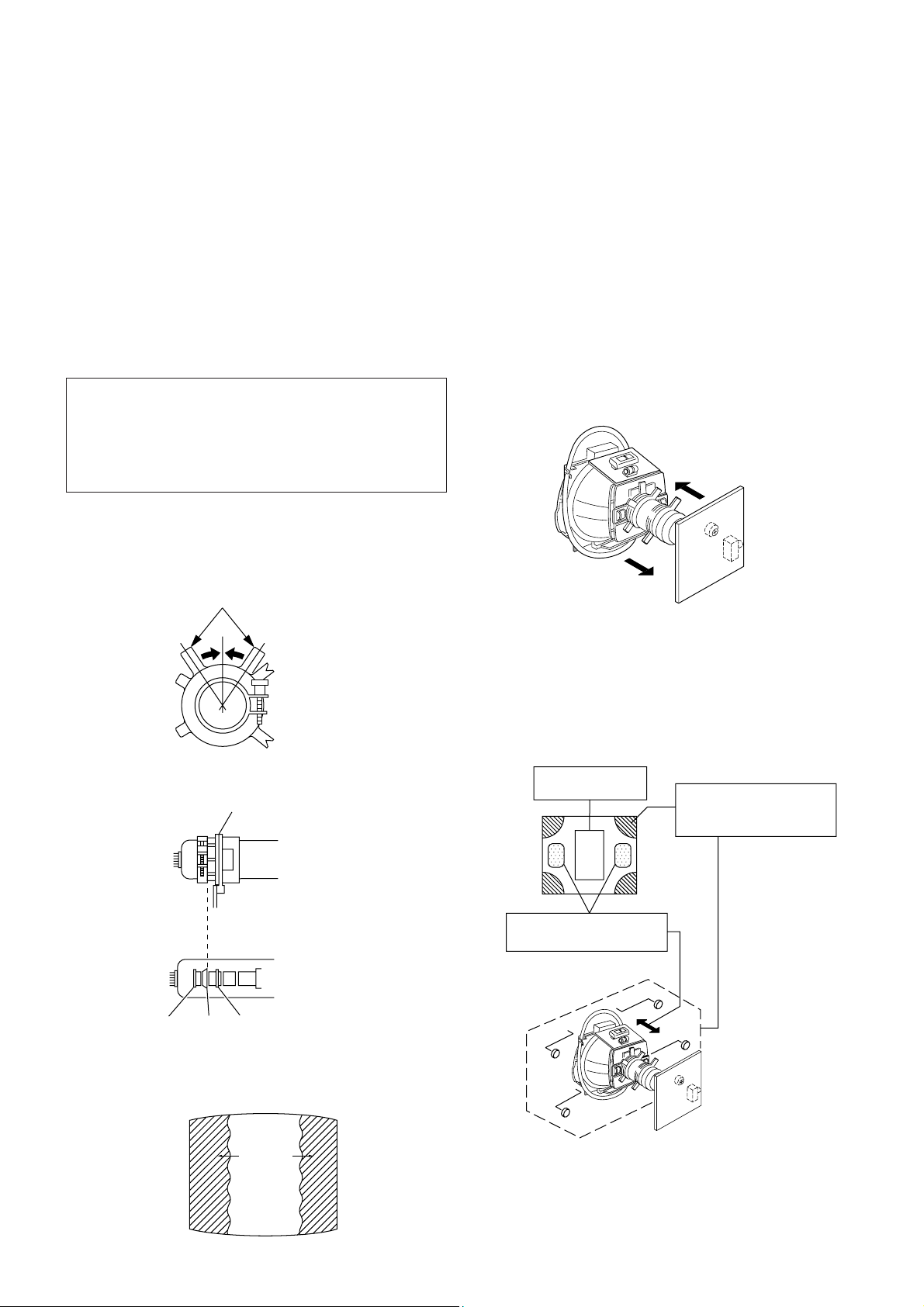

1-6. PICTURE TUBE REMO VAL

Note:

• Please make sure the TV set is not in standing position bef ore removing necessary CRT support located on bottom

right and left.

1) Remove the rear cover.

2) Unplug all interconnecting leads from the Deflection yoke, Neck assy, Degaussing Coil and CRT grounding strap.

Remove Chassis Assy.

3) Place the TV set with the CRT face down on a cushion jig.

qd Screw Tapping

7+ Crown Washer (x4)

0 Earth Coating Assy

9 Degaussing Coil

8 Spring Tension(x2)

Removal

qs Supports CRT (x2)

Removal

qa Loosen the Deflection Yoke

fixing screw and remove

4 Anode Cap Removal

7 Band, DGC Removal

6 Loosen the Neck Assembly

fixing screw and remove

Neck Assy

5 CV Board Removal

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

b

b

2 Using a thumb pull up the rubber cap firmly in the direc-

tion indicated by the arrow b.

c

Anode Button

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be remo ved by

turning up the rubber cap and pulling it up in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

– 6 –

Page 8

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

SECTION 2

WIRE DRESSING

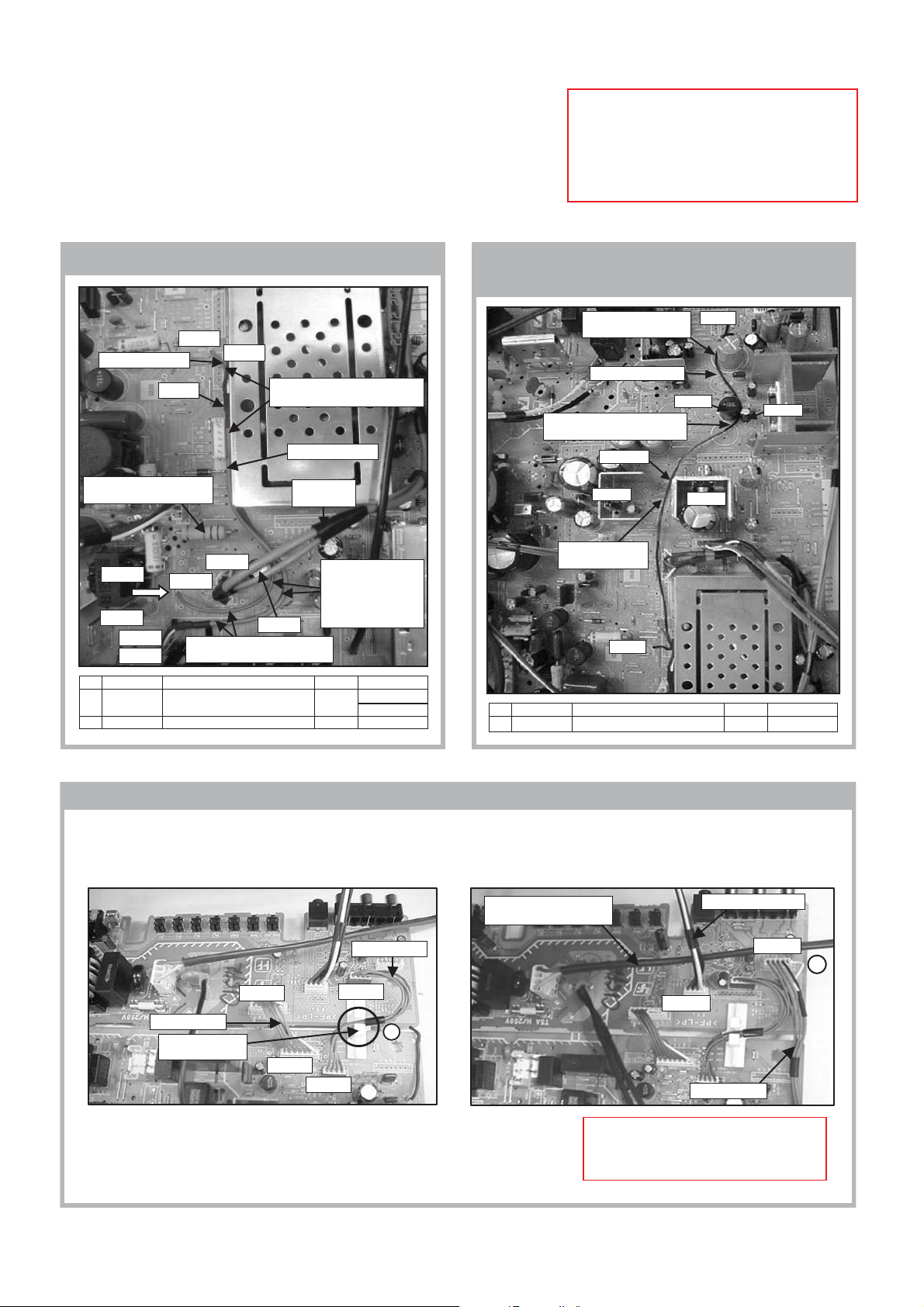

2-1. Lead Assy, Jumper Wire Dressing at A board

W082

P/N 1-923-512-11

W016

Keep Lead Assy, Jumpers

away from R121

W077

Dress both Lead Assy, Jumpers

along edge of shield case

P/N 1-910-026-28

Conn Assy,

5P YUV

CAUTION :

1. Do not ov erpull the wires during dressing

--> avoid disconnection of wires.

2. Make sure wires are kept away from

sharp edges, heatsinks & other

high-temperature parts.

2-2. Lead Assy, Jumper Wire Dressing at A board

(only for Audio 6+6 Non DSP models)

L2601

A002

W075

C211

Dress Lead Assy,

Jumper around C249

P/N 1-910-036-25

Dress Lead Assy, Jumper in

between C211 and L2601

UL Tube

A003

Dress between

T501

C514

W084

W065

No. Part No. Description Block Remark

1 1-910-026-28 Lead Assy, Jumper A(Var)

W077-W065(0)

2 1-923-512-11 WIRE UL1007 AWG24 150MM ORG A(Com) W082-W010(1)

CN905

W010

C903

Dress Lead Assy, Jumper far

away from C514 and T501

Dress both Lead

Assy, Jumpers

around CN905, C903

and below Conn

Assy, 5P YUV

W016-W084(1)

No. Part No. Description Block Remark

2 1-910-036-25 Lead Assy, Jumper A(Var) W075-W085(1)

A003 and A002

W085

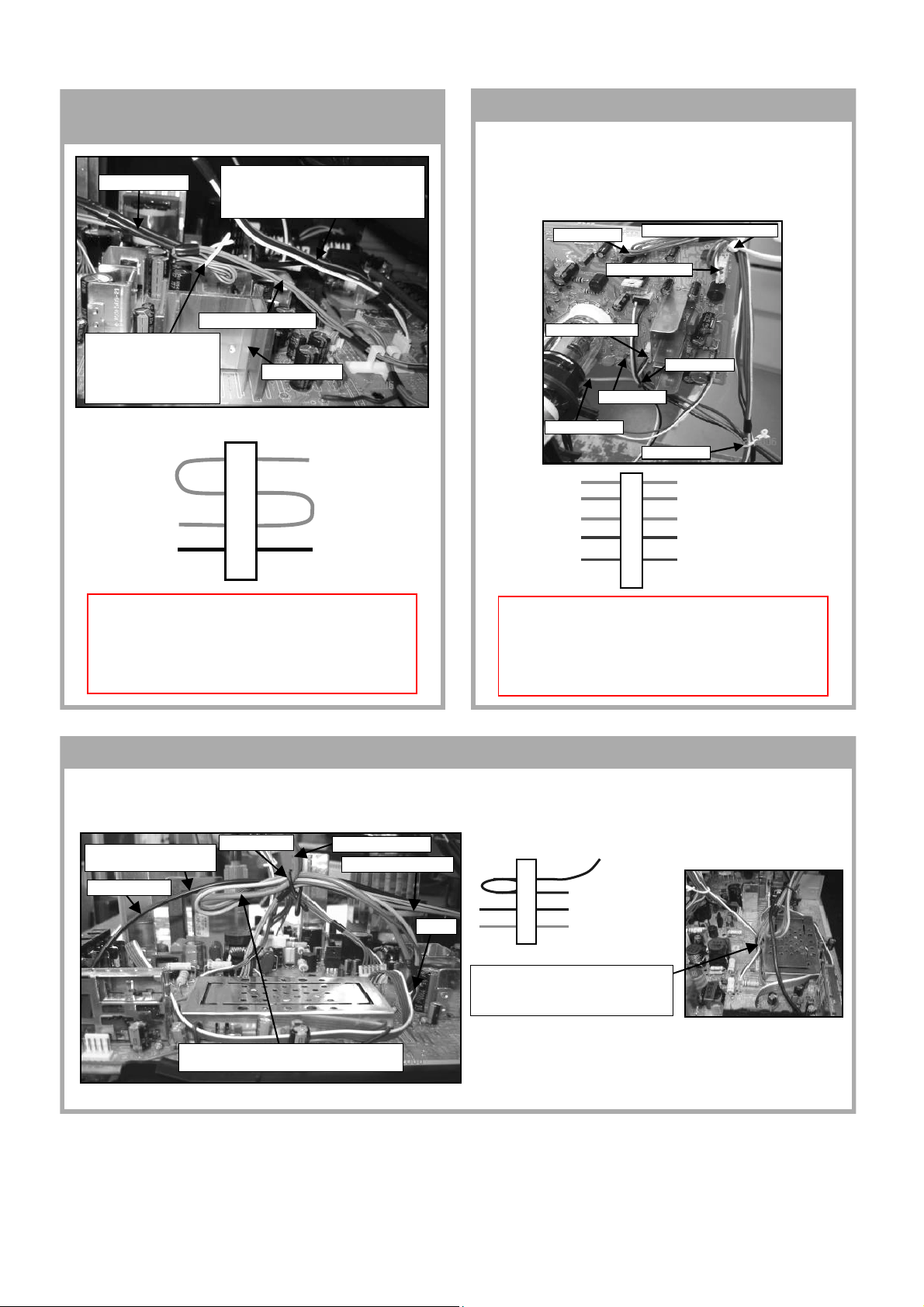

2-3. Wire Dressing at A and H2 board

i) Insert and dress Conn Assy, 4P into hook. ii) Insert Conn Assy, 5P into CN4105.

Make sure AC Power Cord is behind Lead Assy,

Speaker at CN4106.

AC Power Cord is behind

Lear Assy, Speaker

Conn Assy, 4P

CN4110

1

CN2105

Conn Assy, 7P

Insert Conn Assy,

4P into hook

CN4113

CN3102

Lead Assy, Speaker

CN4105

2

CN4106

Conn Assy, 5P

– 7 –

TVSR:

Connector assy must be kept away

from primary area(10mm minimum).

Page 9

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

2-4. Dressing of Conn Assy, 4P VH

Dress Conn Assy, 4P VH into hook as shown.

CN4102

Insert Connector Assy,

4P VH into holder

CN6101

2-5. Dressing of Conn Assy, 5P YUV

Dress Conn Assy, 5P YUV around shield case.

Use pin, wires A019 and A017 to dress Conn Assy,

5P YUV as shown.

Pin, wire A019

CN007

Make sure the UL tape is positioned at

the sharp edge of shield case to prevent

wire from being scratched

Dress Conn Assy, 5P YUV

around shield case

CN9201

Keep wires away

from R121

CN905

Pin, wire A017

Conn Assy, 5P YUV

2-6. Dressing of Conn Assy, 4P VM and

Connector Assy, 5P Front In

Dress Conn Assy, 4P VM behind Conn Assy, 5P Front In

as shown.

Conn Assy, 5P Front In is used to prevent Conn Assy,

4P VM from bending towards T504, R579 and R5032

(high temperature parts).

Dress Conn Assy, 4P VM behind

Conn Assy, 5P Front In

Deflection area

T504

Conn Assy, 4P VM

R5032

CN003

R579

CAUTION:

Keep Conn Assy, 5P Front In away from deflection area

(T504, R5032, etc.) when dressing.

Lead Assy, Earth is

above Conn Assy, 5P

CN9201

Conn Assy, 5P

Front In

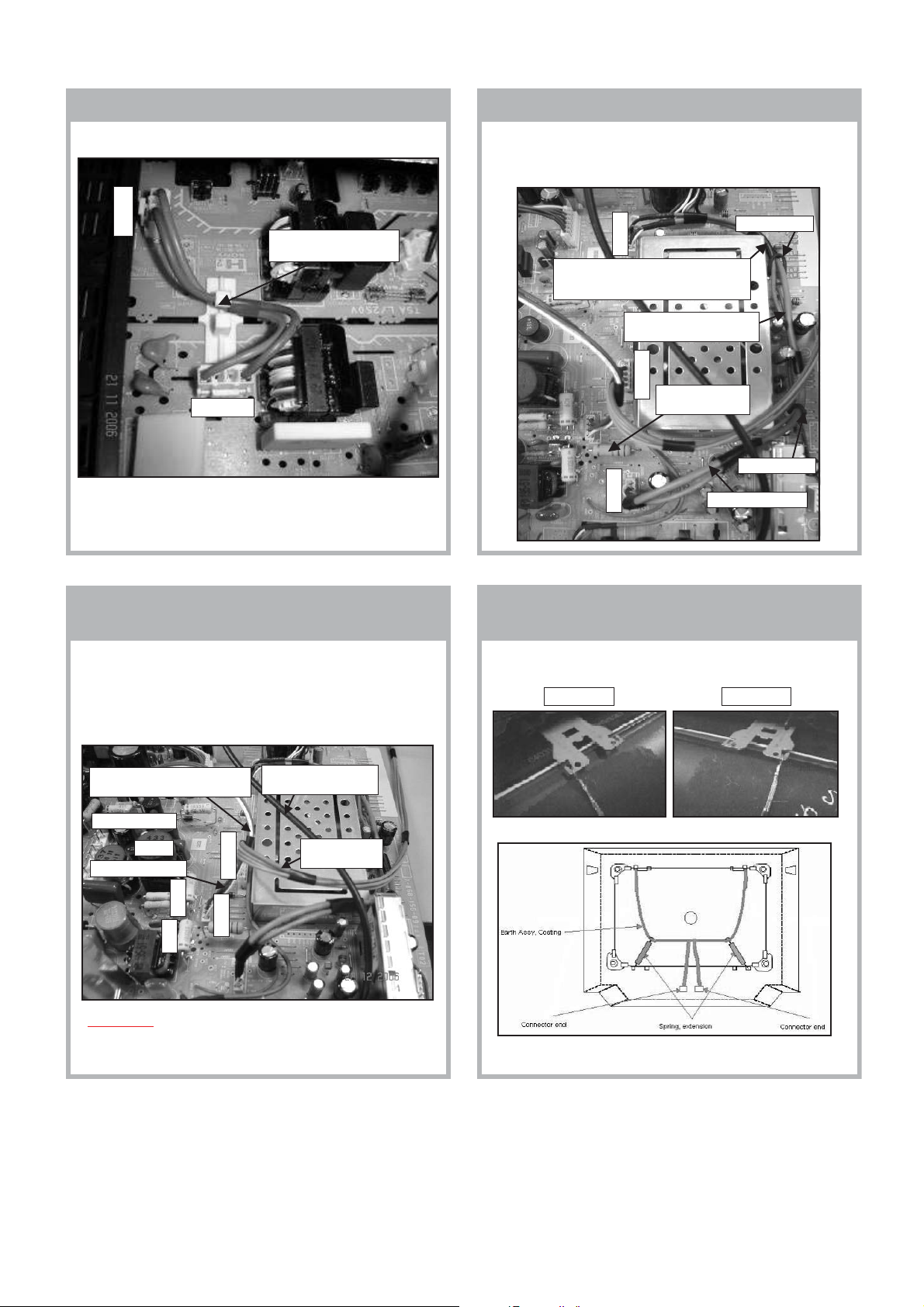

2-7. Installation and Dressing of Earth Assy

Coating

i) Earth Assy, Coating is installed as shown.

Right side Left side

– 8 –

Page 10

2-8. Installation and Dressing of Earth Assy Coating

ii) Insert the 2 Earth Assy, Coating wires to CN705 &

CN707 as shown. Insert Conn Assy, 7P RGB into CN701.

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

CV board

CN701

Heatsink A751

Conn Assy, 7P RGB

CN707

Coating wires

CN705

Earth Assy,

2-9. Insertion of Lead Assy, H Static

Insert Lead Assy, H Static into CRT socket and RV750 as

shown. Make sure the wire is naturally curved, to avoid

touching CRT neck.

Lead Assy, H static

CRT neck

CRT socket

Earth Assy, Coating dressing

BLK+BLK

to CN705

BLK+BLK

to CN707

CV board

CN707 CN705

2-10. Dressing of Conn Assy, 5P Front In

Make a 'S' shaped loop on Conn Assy, 5P Front In

as shown. Keep wires away from heatsink A010.

Lead Assy, Earth

Conn Assy, 5P

Front In

Lead Assy, Speaker

RV750

Heatsink A010

Next, Conn Assy, 5P Front In is dressed together with

Lead Assy,Earth using purse lock Ø 5. Refer to next page.

– 9 –

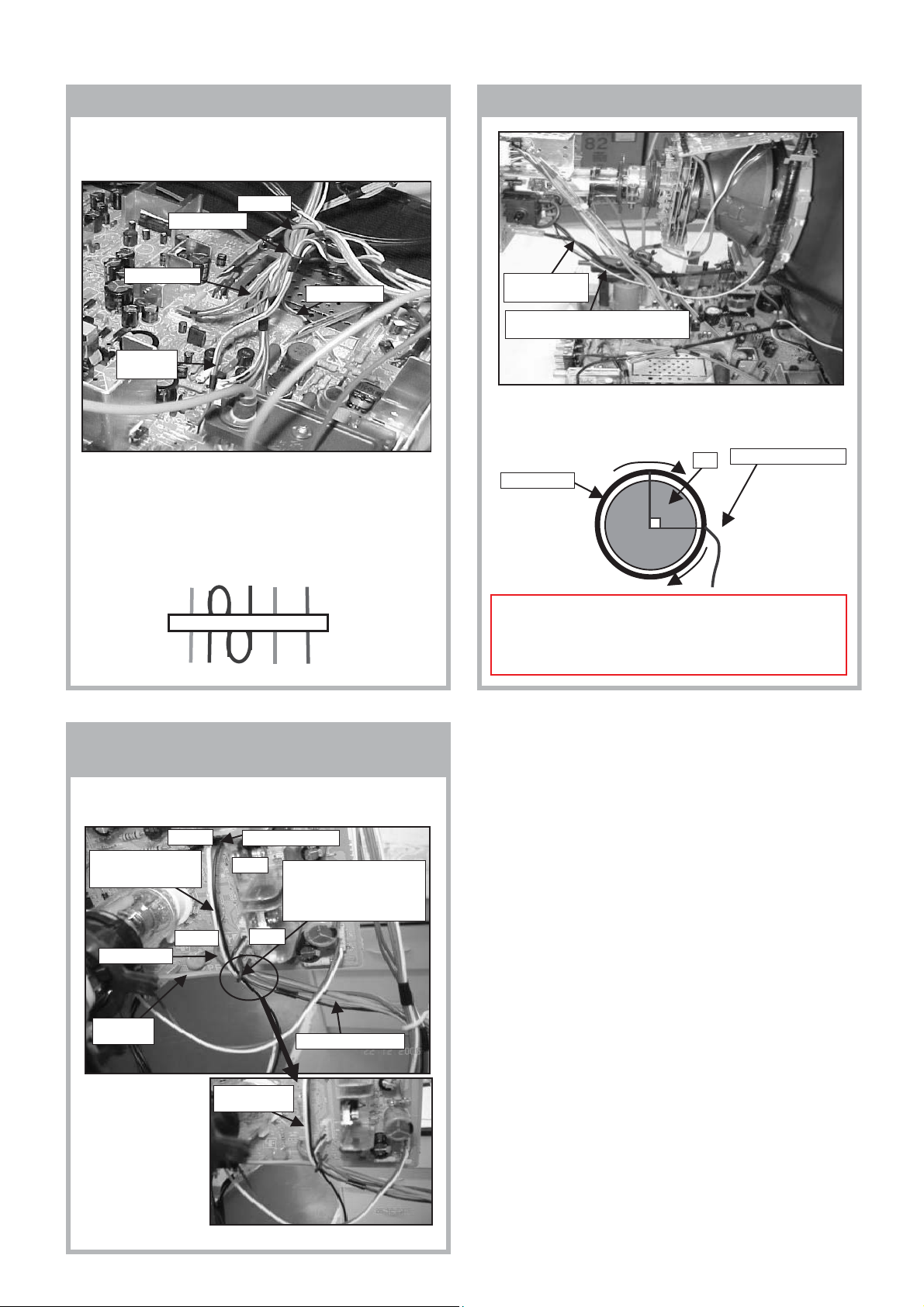

Page 11

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

2-11. Dress Lead Assy, Earth and Conn Assy,

5P In with purse lock

Lead Assy, Earth

Make a 'S' shaped loop on

Conn Assy, 5P Front In

and dress together with

Lead Assy, Earth using

purse lock Ø 5

Note: Dress while chassis is halfway docked into beznet.

together with purse lock. Keep Lead Assy,

Conn Assy, 5P Front In

Ø

5

Lead Assy, Speaker is not dressed

Speaker away from heatsink A010 by

dressing it close to the CRT

Heatsink A010

Conn Assy,

Purse lock Ø 5

5P Front In

Lead Assy, Earth

2-12. CV Board Connector Assy Wire Dressing

i) Dress Conn Assy, 6P and Conn Assy, 4P VM using tie,

cable at alignment hole 'B' on CV board as shown.

ii) Dress Conn Assy, 4P 200V; Conn Assy, 6P; Conn Assy,

4P VM; Lead Assy, G2 and Lead Assy, Focus with purse

lock Ø 5.

Conn Assy, 6P

Conn Assy, 4P 200V

Lead Assy, Focus

Tie, cable at alignment hole 'B'

Conn Assy, 4P VM

Pin, wire A707

Lead Assy, G2

Purse lock Ø 5

Purse lock Ø 5

Conn Assy, 4P VM

Conn Assy, 4P 200V

Conn Assy, 6P

Lead Assy, Focus

Lead Assy, G2

CAUTION:

Prevent tie, cable from touching rear cover or any

enclosures by turning them away from it --> avoid

rattle sound. Also prevent tie, cable's end from

touching solder side of board.

2-13. Connector Assy Wire Dressing

i) Dress Conn Assy, 7P RGB; Conn Assy, 5P Front In and

Lead Assy, Earth using purse lock Ø 9. Keep wires away from

heatsinks and high-temperature parts.

Lead Assy, Earth is behind

Conn Assy, 7P RGB

Lead Assy, Earth

Make loop of Conn Assy, 7P RGB as large as

possible when dressing with purse lock

Purse lock Ø 9

Conn Assy, 7P RGB

Conn Assy, 5P Front In

CN004

CAUTION:

Prevent tie, cable from touching rear cover or any

enclosures by turning them away from it --> avoid

rattle sound. Also prevent tie, cable's end from

touching solder side of board.

Conn Assy, 7P RGB

Lead Assy, Earth

Conn Assy, 5P Front In

Purse lock Ø 9

Keep Conn Assy, 5P Front In wire in an upward

path from CN9201 to where it is dressed with

purse lock Ø 9. This is to keep it away from

deflection area.

– 10 –

Page 12

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

2-14. Connector Assy Wire Dressing

Dress DY Connector; Conn Assy, 4P 200V;

Conn Assy 4P VM and Conn Assy, 6P using purse lock

Ø 9 as shown.

DY Conn

Purse lock Ø 9

Conn Assy, 6P

Conn Assy, 4P

Conn Assy,

4P 200V

Note: Make sure DY connector is inserted securely.

--> prevent it from coming out.

2-15. Overall View of Rotation Coil Conn Dressing

Earth Assy,

Coating wires

Rotation coil conn is dressed outside

and below Earth Assy, Coating wires.

Install Rotation Coil as shown.

1) Coil positioned in clockwise direction.

2) Wire is at 3 o'clock position.

Wire from Roation Coil

DY

Rotation Coil

DY Connector

Conn Assy,

4P VM

Purse lock Ø 9

Conn Assy,

4P 200V

Conn Assy, 6P

2-16. Overall View of Lead Assy, G2; Lead Assy,

Focus and Rotation Coil Conn Dressing

Avoid any stress on Lead Assy, G2; Lead Assy, Focus and

terminal at W7001.

CN1802

Keep wire away

from R781 and

heatsinks A713, A715.

W7001

Lead Assy, G2

Lead Assy,

Focus

Rotation Coil Conn

A715

connector together with Lead

Assy, G2; Lead Assy Focus

and Conn Assy, 4P 200V

A713

Conn Assy, 4P 200V

Dress Rotation Coil

using pin, wire A707

CAUTION:

Prevent wires from touching rear cover or any

enclosures by turning them away from it--> avoid rattle

sound.

Keep wire away

from R781

– 11 –

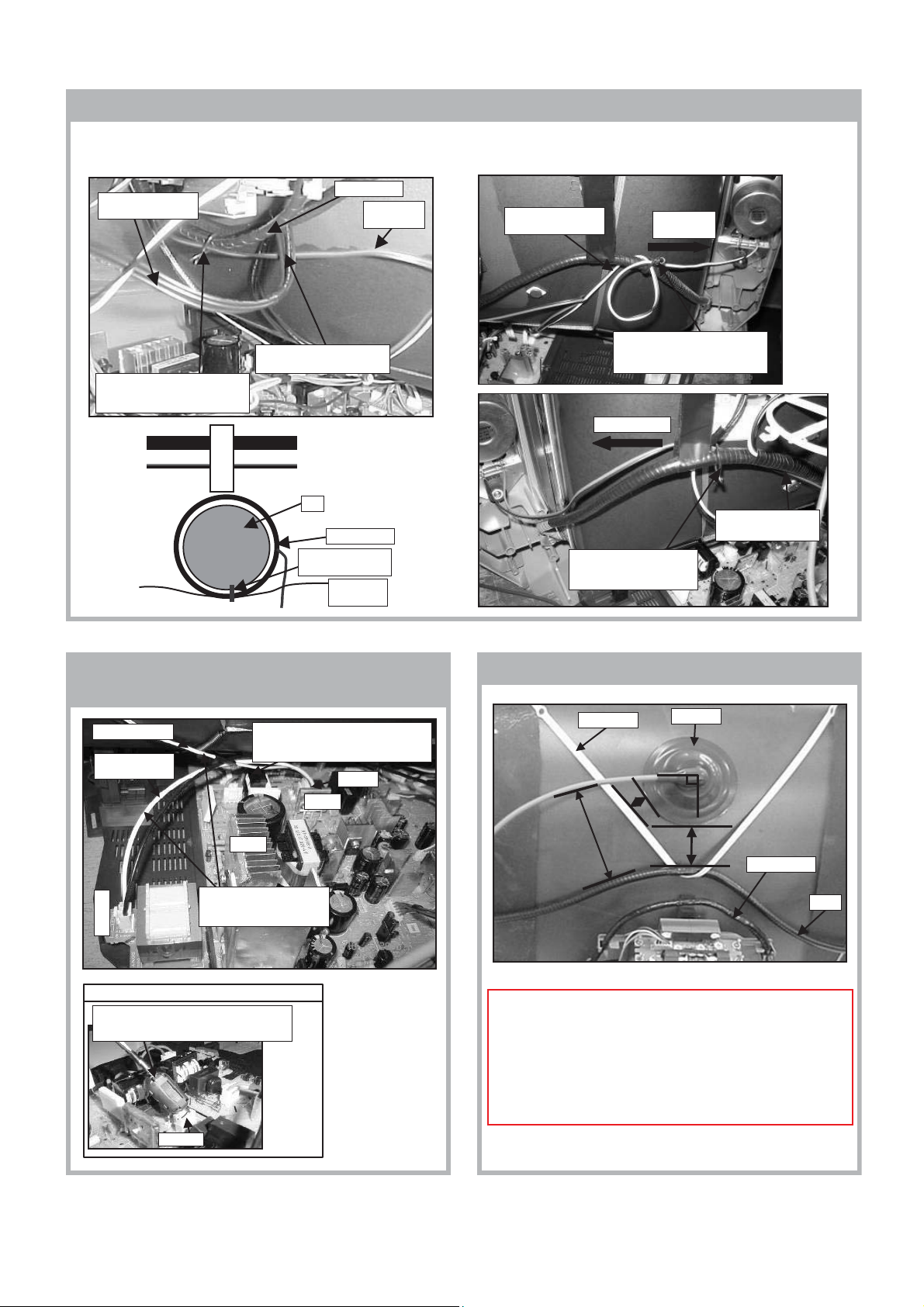

Page 13

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

2-17. Dress Lead Assy, Speaker to Rotation Coil using Purse Lock Ø 9

Dress Lead Assy, Speaker to center position of Rotation Coil using purse lock Ø 9 as shown. Make sure Earth

Assy, Coating wire is above Lead Assy, Speaker. This is to keep Lead Assy, Speaker away from Deflection Yoke.

Earth Assy, Coating

wire

Dress Lead Assy, Speaker to

center position of Rotation Coil

using purse lock Ø 9

Purse lock Ø 9

Rotation coil

Lead Assy,

Earth Assy, Coating wire is

above Lead Assy, Speaker

Rotation Coil

Lead Assy, Speaker

(RED+BLK)

DY

Rotation Coil

Attach purse lock Ø 9

here

Lead Assy,

Speaker

Speaker

Lead Assy, Speaker

goes behind DGC

Dress Lead Assy, Speaker

directly on to DGC using

Pull wire to

the right

Loop Lead Assy, Speaker and

dress directly on to DGC using

purse lock

Pull wire to left

purse lock Ø 9

Ø 9

Lead Assy, Speaker

goes behind DGC

2-18. Dressing of PF Board Conn Assy

(for models with PF board only)

DGC Connector

Connector Assy,

3P VH

heatsinks A007, D604 and

CN6620

Apply to all SZ252 Narrow 220V CISPR models ONLY

Clamp the ferrite core at the end of the DGC

wire as shown. Position it directly above DGC

Connector's housing

DGC Connector is below Conn Assy,

3P VH to keep Conn Assy, 3P VH

away from Heatsink A007 and D604

D604

A007

Keep wires away from

conductive parts

CN605

2-19. Cap Assy, High Voltage Installation

DGC Band

>5mm

Keep distance of

1mm/kV

TVSR Requirement:

1. Keep HV cable away from conductive parts

(distance of 1mm/kV).

2. Keep spacing between edge of anode cap

& conductive parts (distance of 0.5mm/kV).

3. Keep spacing between edge of anode cap &

non-conductive parts (distance of at least 5mm or more).

HV Cap

90º

Keep distance of

0.5mm/kV

Rotation coil

DGC

Housing

– 12 –

Page 14

2-20. HV Cap Assy Wire Dressing

Dress Cap Assy, High Voltage with Holder, HV Cable combi as shown.

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

CRT's carbon

area

purse lock Ø 9.

DGC

10 o'clock position

Dress Holder, HV Cable Combi to Cap Assy,

High Voltage and attach side hook to rotation

coil at 10 o'clock position. Then, attach large

hook to DGC and dress with

purse lock

Ø

9.

HV cap

90º

CAUTION: 1) Make sure the specified position is

being followed.

2) Position the Cap Assy, High Voltage in

the inner ring of the Holder, HV cable

combi (see diagram).

TVSR requirement:

1. Spacing between HV cable and other conductive

part's surface is 1mm/kV or more.

2. Spacing between HV cable's and enclosure with

ventilation or the edge where terminal bracket and

rear cover meet: 10mm or more.

Large

hook

Min. distance = 1mm/kV

P-P taping

of DGC

Min. distance = 1mm/kV

CRT's carbon

area

Dress using Purse lock Ø 9

Holder, HV cable combi

250 ± 5 mm

Large hook

DGC

Inner Ring

Dress Holder, HV Cable

Combi to the right of P-P

taping of DGC. Dress

purse lock

of large hook on Holder,

HV Cable Combi.

Side hook

Keep distance of HV cable

from other wires, conductive

parts and CRT's carbon area

Purse lock Ø 9

Rotation coil

Side hook

Top view

Ø

9 to the right

2-21. AC Power Cord Wire Dressing

Install AC cord holder to AC power cord at specified position as shown.

AC Cord Holder

290 ± 5mm 630 ± 5mm

Hook AC cord into

CRT support's hook

Make sure AC cord is

straight between

Dress behind boss

boss and holder

Attach AC cord onto

holder and insert to

bottom cover

Attach Purse Lock (S)

Ø 8 in to rear cover

– 13 –

Page 15

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

SECTION 3

SET-UP ADJUSTMENTS

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows :

1. Beam Landing

2. Convergence

3. Focus

The controls and switch should be set as follows unless

otherwise noted:

4. G2(SCREEN)

5. White Balance

Picture Control....................................."NORMAL"

Brightness Control..............................."NORMAL"

Note : Test Equipment Required.

1. Pattern Generator 5. Oscilloscope

2. Degausser 6. Landing Checker

3. DC Power Supply 7. XCV Adjuster

4. Digital Multimeter

......................................................................................................................................................................................................................

Preparation :

•Feed in the white pattern signal.

6. Then move the DY forward and adjust so that the entire

screen becomes green.

• Before starting, degauss the entire screen with the

degausser.

• In order to reduce the geomagnetism on the set's picture

tube, face it east or west.

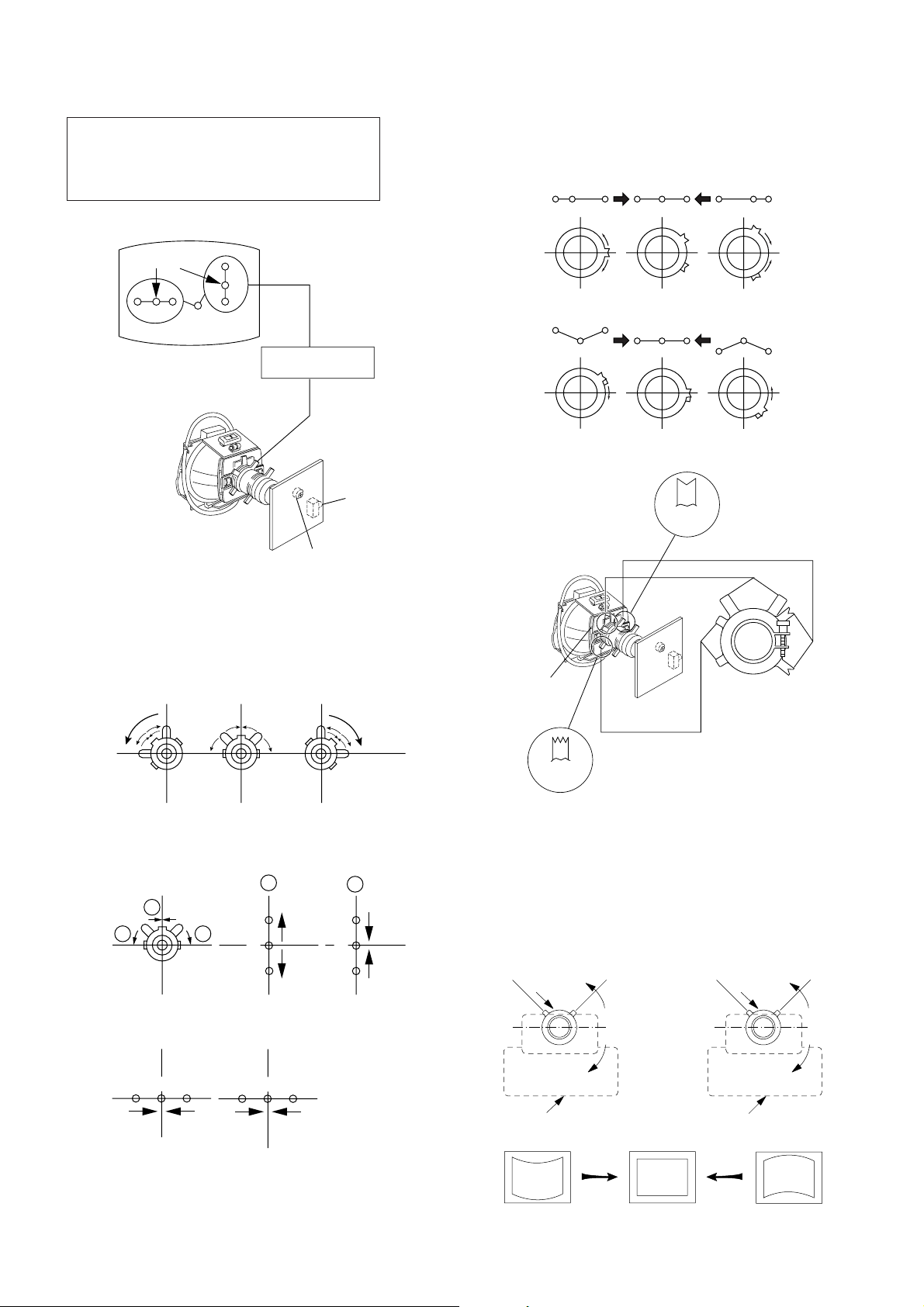

3-1. BEAM LANDING ADJUSTMENT

1. Input a raster signal with the pattern generator.

2. Loose the deflection yoke(DY) mounting screw, and set

the purity control to the center as shown below:-

Purity control

3. Position Neck Assy as shown below:-

Neck assy

Align the edge of

the neck assy with

the edge of the G2 grid.

G2G1 G3

4. Set the raster signal of the pattern generator to green.

5. Move the DY backward and adjust the purity control so

that green is in the center and blue and red are at the

sides evenly.

7. Now switch over raster signal to red then blue and

confirm the condition.

8. When the position of the DY is determined, tighten it with

the DY mounting screw.

9. If the beam does not land correctly in all the corners of

the screen, use magnet disc to correct it.

Purity control

corrects this area.

b

c

Deflection yoke positioning

corrects these areas.

a

a

d

d

Disc magnets or rotatable

disc magnets correct these

areas (a-d).

b

c

Red

Blue

Green

– 14 –

Page 16

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

3-2. CONVERGENCE ADJUSTMENT

Preparation:

• Before starting, perform FOCUS adjustment.

• Picture Mode "CUSTOM"

• Receive dot/cross hatch pattern.

a) Vertical Static Convergence

Center dot

R G B

R

G

B

4 pole magnet

RV750

H. STAT

b) Horizontal Static Convergence

If the blue dots does not converge with the red and

green dots, use the 6 pole magnet to adjust in

the manner described below:-

RG B R G B R GB

RB

G

RG

6 Pole

Magnet

GB

RB

RV1800

G2 (SCREEN)

1. (Moving vertically), adjust the 4 pole magnet to

converge red, green and blue dots in the center of

the screen.

2. Tilt the 4 pole magnet and adjust static convergence

to open or close the 4 pole magnet.

3. When the 4 pole magnet is moved in the direction of

arrow A and B, the red, green and blue dots moves

as shown below:-

A

B B

A

B

G

R

B

B

G

R

Moved RV750 (H.STAT)

6 Pole Magnet

Purity

DY pocket

4 pole Magnet

4 Pole

Magnet

c) Y Separation axis correction magnet adjustment.

1. Receive cross hatch signal.

2. Set Picture to "MINIMUM", Brightness to "STANDARD".

3. Adjust the Y separation axis correction magnet on

the Neck Assembly so that the horizontal lines at

the top and bottom of the screen are straight.

Neck assy Neck assy

RedBlue

RedBlue

RGGRB

B

VM board VM board

– 15 –

Page 17

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

d) Convergence Rough Adjustment

Preparation:

• Before starting this adjustment, adjust the

horizontal and vertical static convergence.

Input cross hatch pattern.

i) TLH

Adjust the horizontal convergence of red and blue

dots by inserting TLH Correction Plate to the DY

pocket(left or right).

ii) YCH

Adjust YCH to balance Y axis.

iii) TLV

Adjust the vertical convergence of red and blue dots.

iv) XCV

Adjust XCV to balance X-axis

B

R

TLH

(VR2)

YCH

RB

YCH

B

R

ON DY :

(VR1)

TLV1 (no need to adjust)

TLV

DY pocket

b1

a1

c1

d1

R

B

a1~d1: Piece A(90), Convergence Correct

or

Permaloy Assy Correction

XCV

(VR3)

TLV2

(XCV)

DY pocket

TLH Plate

e) Screen Corner Convergence

Affix a Piece A(90), Convergence Correct/Permaloy Assy

Correction to the misconverged areas.

ba

a-d : screen-corner

misconvergence

cd

– 16 –

Page 18

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

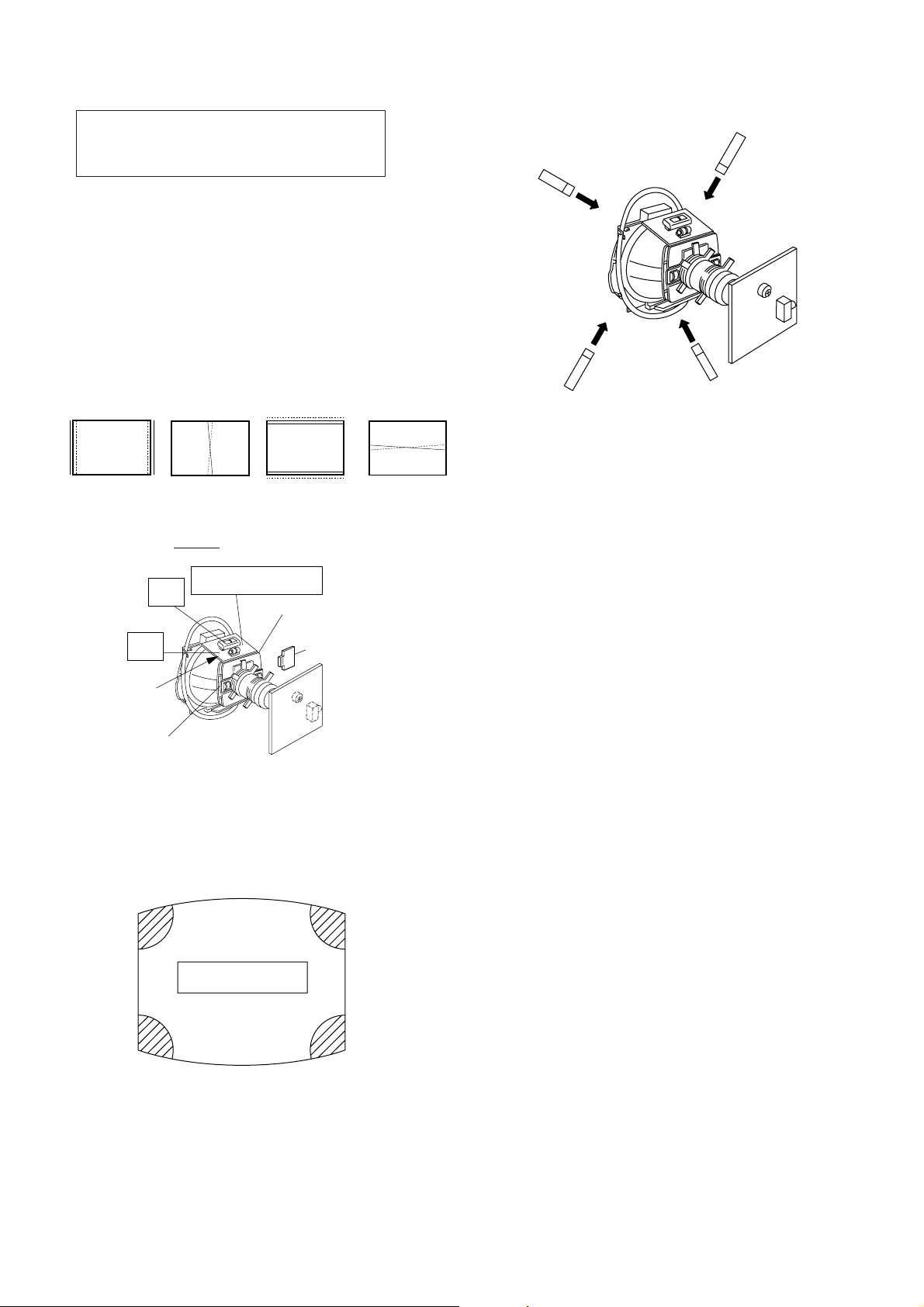

3-3. FOCUS ADJUSTMENT

FOCUS adjustment should be completed before W/B

adjustment.

1. Receive digital monoscope pattern.

2. Set Picture Mode to "VIVID".

3. Adjust focus VR to obtain a just focus at the

center of the screen.

4. Change the receiving signal to white pattern

and blue back.

5. Confirm magenta ring is not noticeable. In case

magenta ring is obvious, then adjust FOCUS VR

to balance magenta ring and FOCUS.

3-5. SUB BRIGHT ADJUSTMENT

1. Set TV to RF mode.

2. Input PAL monoscope to RF mode (OTHER model) and

NTSC monoscope (NTSC model).

3. Set Brightness to 50% and Picture to "MINIMUM" in

"CUSTOM" mode.

4. Select WHBL 010 "SBRT" with 1 and 4 button and

adjust its data using 3 and 6 button so that the Cut Off

level and slightly glimmer is as the specification below:-

TV size Cut Off Slightly Glimmer

25" 10 IRE 20 IRE + 2 steps

29" 10 IRE 20 IRE + 2 steps

34" 10 IRE 20 IRE + 2 steps

28" 10 IRE 20 IRE

32" 10 IRE 20 IRE

5. Write into the memory by pressing [MUTING] t -.

6. Copy the adjusted data WHBL 010 “SBRT” to Video

mode.

7. Once adjustment is completed in RF and Video mode,

carry out adjustment in DVD mode. Repeat step 2 to 3.

Select WHBL 010 “SBRT” and adjust its data as the

specification below:-

Focus

Screen

FLYBA CK TRANSFORMER (T503)

3-4. G2 (SCREEN) ADJUSTMENTS

1. Set the following condition:

- Picture and Brightness to "STANDARD".

- TV to Video mode.

- WHBL 013 "RGBB" to 01.

2. Connect R,G,B of the CV board cathode to

oscilloscope.

3. Adjust Brightness to obtain the cathode value

to the value stated below.

Cathode setting voltage:

175 V ± 2 (VDC)

TV size Cut Off Slightly Glimmer

25" 10 IRE 20 IRE + 2 steps

29" 10 IRE 20 IRE

34" 10 IRE 20 IRE + 2 steps

28" 10 IRE 20 IRE

32" 10 IRE 20 IRE

3-6. WHITE BALANCE ADJUSTMENT

1. Set to Service Mode.

2. Input white raster signal using signal generator.

3. Set the following condition:

Picture "VIVID", PICT 006 "WTS" to 00.

4. At Highlight condition, select WHBL 003 "GDRV"

and 002 "RDRV" with 1 and 4 button of the

remote commander then adjust the data with

3 and 6 button.

5. At Cutoff, select WHBL 000 "BKOR" and 001 "BKOG"

and adjust the data.

6. Perform adjustment at Hightlight and Cutoff condition

until it reaches its target.

7. Write data into memory by pressing [MUTING]t-.

8. Finally set PICT 006 "WTS" back to its original data.

4. Adjust SCREEN VR on the FBT until the scanning line

disappears.

5. Finally set WHBL 16 "RGBB" back to 00.

– 17 –

Page 19

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

SECTION 4

CIRCUIT ADJUSTMENTS

4-1. ADJUSTMENT WITH COMMANDER

Service adjustments to this model can be performed using the supplied remote commander RM-GA002.

a. ENTERING SERVICE MODE

With the unit on standby

t [DISPLAY] t 5 t [VOL $+% ] t [POWER]

This operation sequence puts the unit into service mode.

This screen display is:

Category in decimal Item name in decimal NG Command Frequency Video Input Name

GEOM 006 EWPW 031 x SERVICE 60 S VIDEO 1

Item no. Service data NVM Service Field Channel no./

Release ID Version in binary for factory Color System (decimal)

NT01 3.50M 0001 1111 FF FF NTSC3 65553

Status SID,

Lock, SL

:not locked

(no signal) Status Status BC, Status Status S/N Status Status Display

:locked VW, IVWF HBC BCF LEVEL (0-7) GL Area

111 11 11 1 7 11 ZZ xy 1 1 000000 000000

S: for Sony

A: for AIWA

L: BX1L Full

B: BX1L Basic

D: DVD Combo

N T : Taiwan/Korea/Philippines

G A : General Area

01 : Serial no. of the M / P release for each destination

Software Service data Reserved Power On Time

Status

PTW

ZZ : DCXO Flash Value

xy : Value of x : Value of y

0 - unknown 0 - Mono

1 - BTSC 1 - Stereo

2 - A2 2 - Bilingual

3 - NICAM 4 - SAP/Single

4 - KOREAN

5 - Japan

6 - AV Stereo

b. METHOD OF CANCELLATION FROM SERVICE MODE

Set the standby condition (Press [POWER] button on the commander), then press [POWER] button again, hereupon it becomes

TV mode.

c. METHOD OF WRITE INTO MEMORY

1. Set to Service Mode.

2. Press 1 (UP) and 4 (DOWN), to select the adjustment item.

3. Change item by pressing

3, 6.

4. Press [MUTING] button to indicate WRITE on the screen.

5. Press

- button to write into memory.

1, 4 Select the adjustment item.

r

3, 6 Raise/lower the data value.

r

[MUTING] Writes.

r

- Executes the writing.

d. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, pull out the plug from AC outlet, and then plug into AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confirm adjustments were made.

– 18 –

Page 20

e. OTHER FUNCTION VIA REMOTE COMMANDER

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

[Display], - Service data initialization (Be sure not to use usually.)

2, 5 Select Device or Category (Up, Down)

4-2. ADJUSTMENT METHOD

Item Number 000 HPOS

This explanation uses H POSITION as an example.

1. Select "000 HPOS" with the 1 and 4 buttons, or 2 and 5.

2. Raise/lower the data with the

3. Select the optimum state. (The standard is IF for PAL reception.)

4. Write with the [MUTING] button. (The display changes to WRITE.)

5. Execute the writing with the

SERVICE.)

Example on screen display :-

3 and 6 buttons.

- button. (The WRITE display will be changed to red color while excuting, and back to

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

GEOM

SUS01

GEOM

SUS01

GEOM

SUS01

Use the same method for all Items. Use

then execute the write with

-.

HPOS

000

3.50M FF FF

HPOS

000

3.50M FF FF

HPOS

000

3.50M FF FF

1 and 4 to select the adjustment item, use 3 and 6 to adjust, write with [MUTING],

031

SERVICE

1111

0001

031

WRITE

1111

0001

Write with [MUTING]

031

WRITE

1111

0001

Write executed with -

50

NTSC3 65553

50

NTSC3 65553

50

NTSC3 65553

GREEN

Adjusted with 3

and 6 buttons.

GREEN

RED

The WRITE display

then the display

returns to green

SERVICE.

Note : 1. In [WRITE], the data for all items are written into memory together.

2. For adjustment items that have different standard data between 50Hz or 60Hz, be sure to use the respective input

signal after adjustment.

– 19 –

Page 21

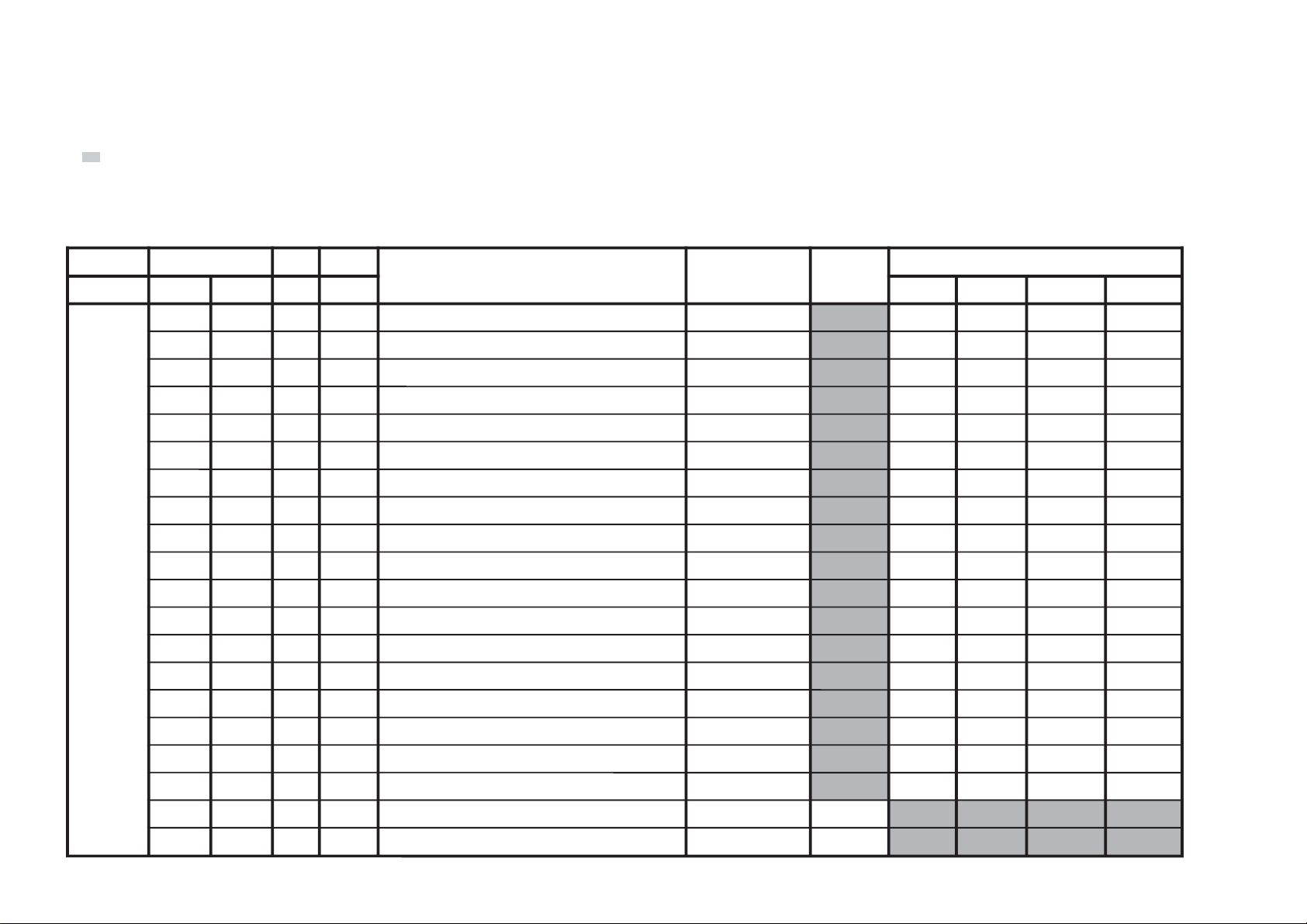

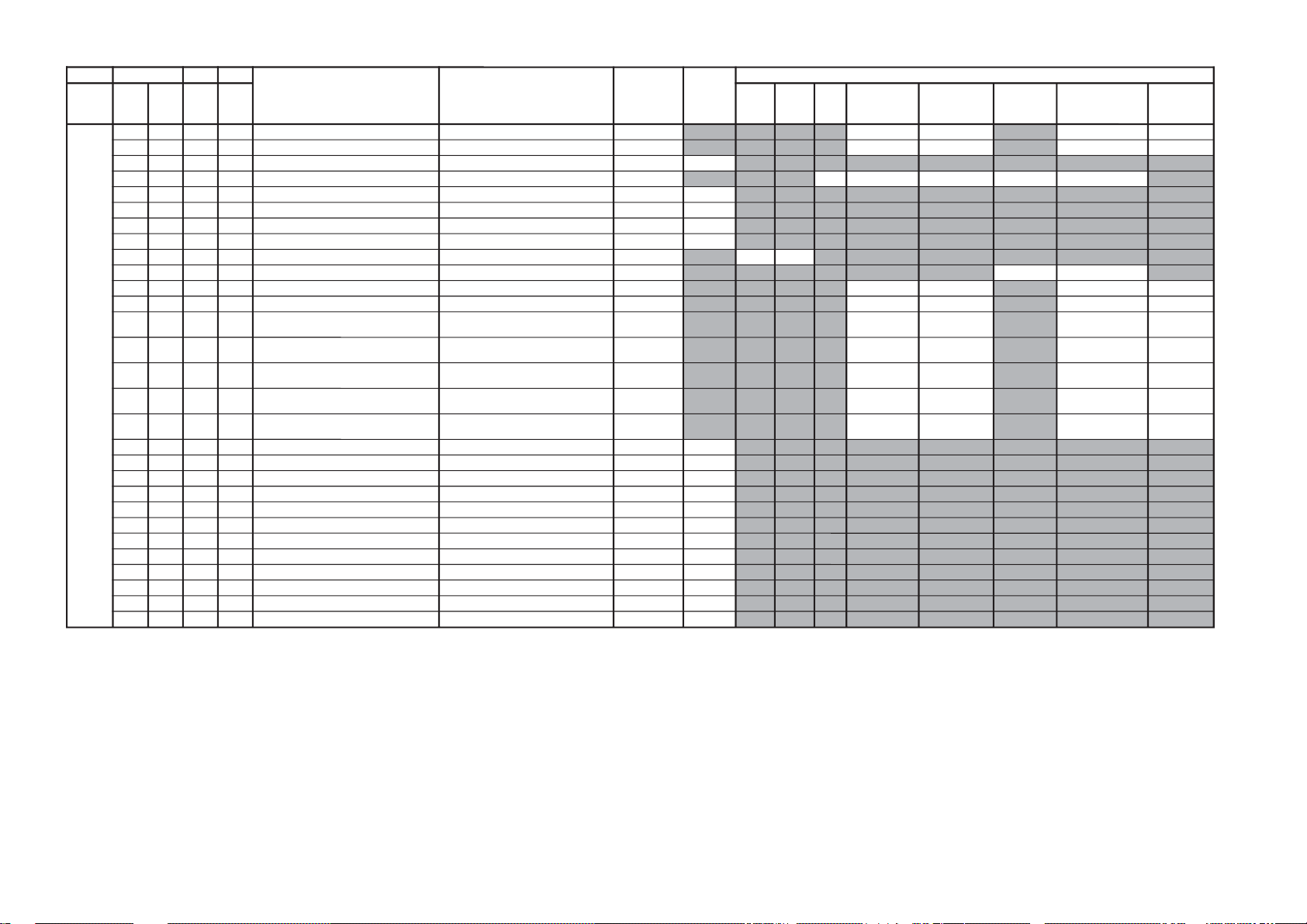

Adjustment Item Table

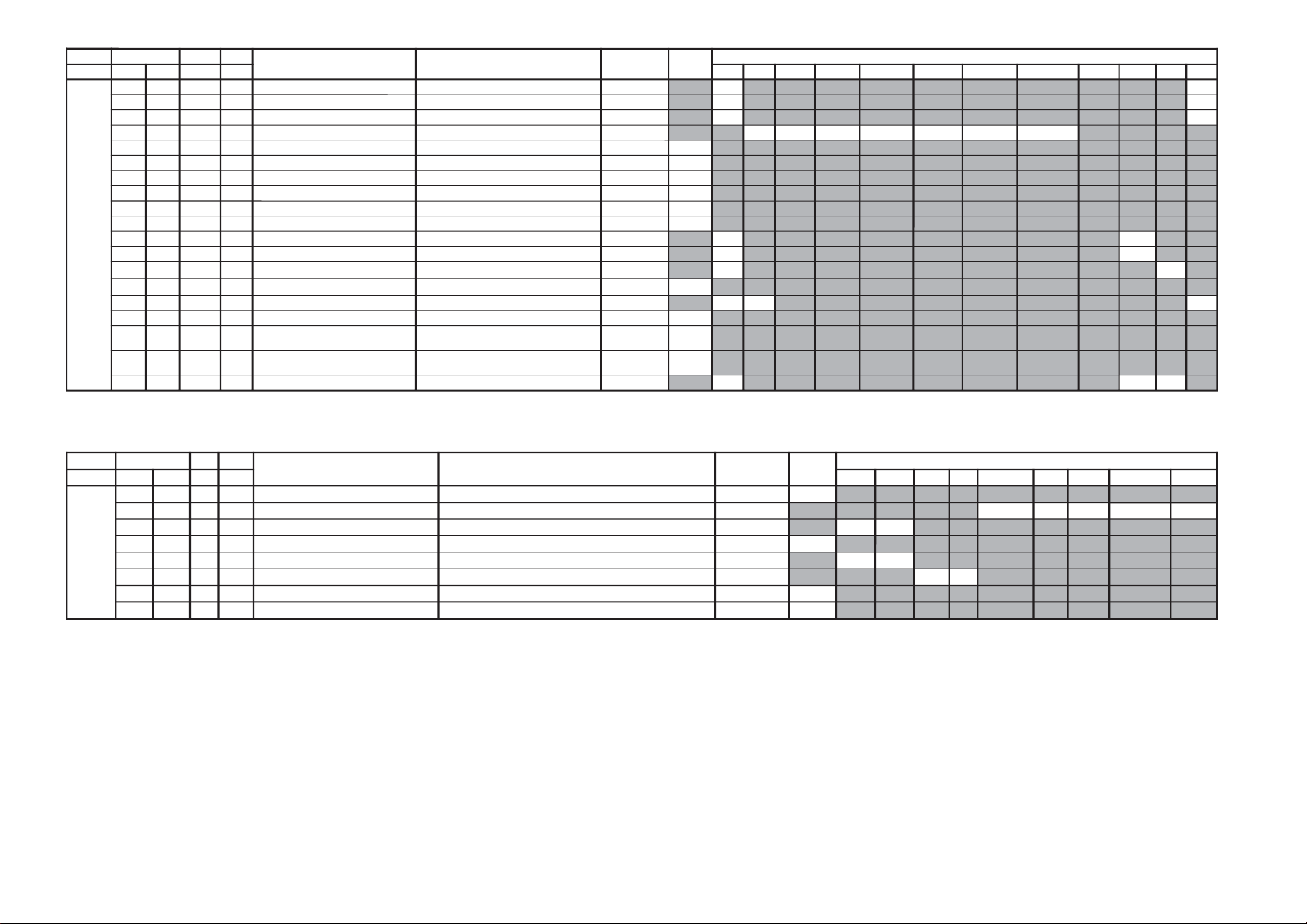

JVTytilanoitcnuF.tinIegnaRnoitcnuFemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 05)3:4(06)3:4(05w)3:4(06w)3:4(

MOEG000SOPH130360)SH(tfihSlatnoziroHrossecorP-VT

62630373

100RAPH130360margolellaraPlatnoziroH

34442454

200WOBH130360woBlatnoziroH

03426282

300NILV130360ytiraeniLlacitreV

93939393

400RCSV130360llorcSlacitreV

13131313

500ZISH130360)WE(htdiWWE

24146474

600WPWE130360)WP(htdiW/alobaraPWE

54749453

700POCU710360alobaraPrenroCreppUWE

04839375

800POCL710360alobaraPrenroCrewoLWE

54748551

900ZTWE130360muizeparTWE

72718113

010PLSV130360)SV(epolSlacitreV

13131313

110ZISV510360edutilpmAlacitreV

12128191

210ROCS410360)CS(noitcerroC-S

73737373

310SOPV130360)HSV(tfihSlacitreV

84940444

410MOZV130360)ZV(mooZlacitreV

00000000

510LBH000100edoMgniknalBBGR

10101010

610FBW700510)FBW(gniknalBediWfognimiT

01300130

710RBW700510)RBW(gniknalBediWfognimiT

11011101

810LBS000100gniknalBecivreS00

910YPOC000100aeraMVNzH06/05llaotatadOEGehtypoCX

NOTE

a) In the initial value (detailed) column, the data after the slash mark ("/") refers to NTSC model data.

No ("/") means data is common for Multi and NTSC model.

b) Item remarked "*", please refer page 32 for the data.

c)

shaded items are no data.

d) Standard data listed on the Adjustment Item Tab le are reference values, therefore it may be different for each model and for each mode.

e) Note for the Different Data those are the standard data values written on the microprocessor. Therefore, the data values of the models are stored respectively in the memory.

In the case of a device replacement, adjustment by rewriting the data value is necessary for some items.

f) Multi ver8.21, NTSC ver8.21N.

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

– 20 –

Page 22

– 21 –

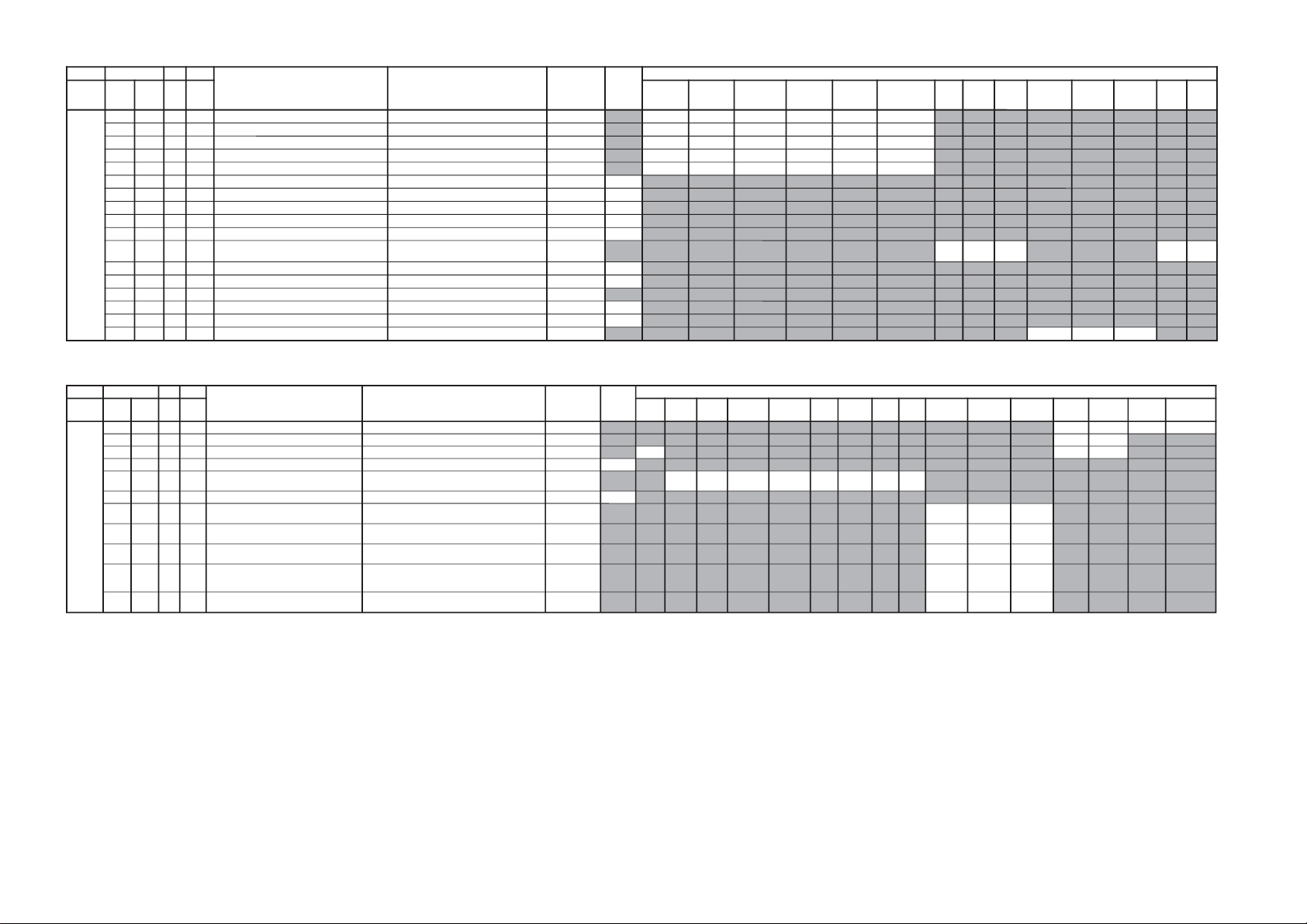

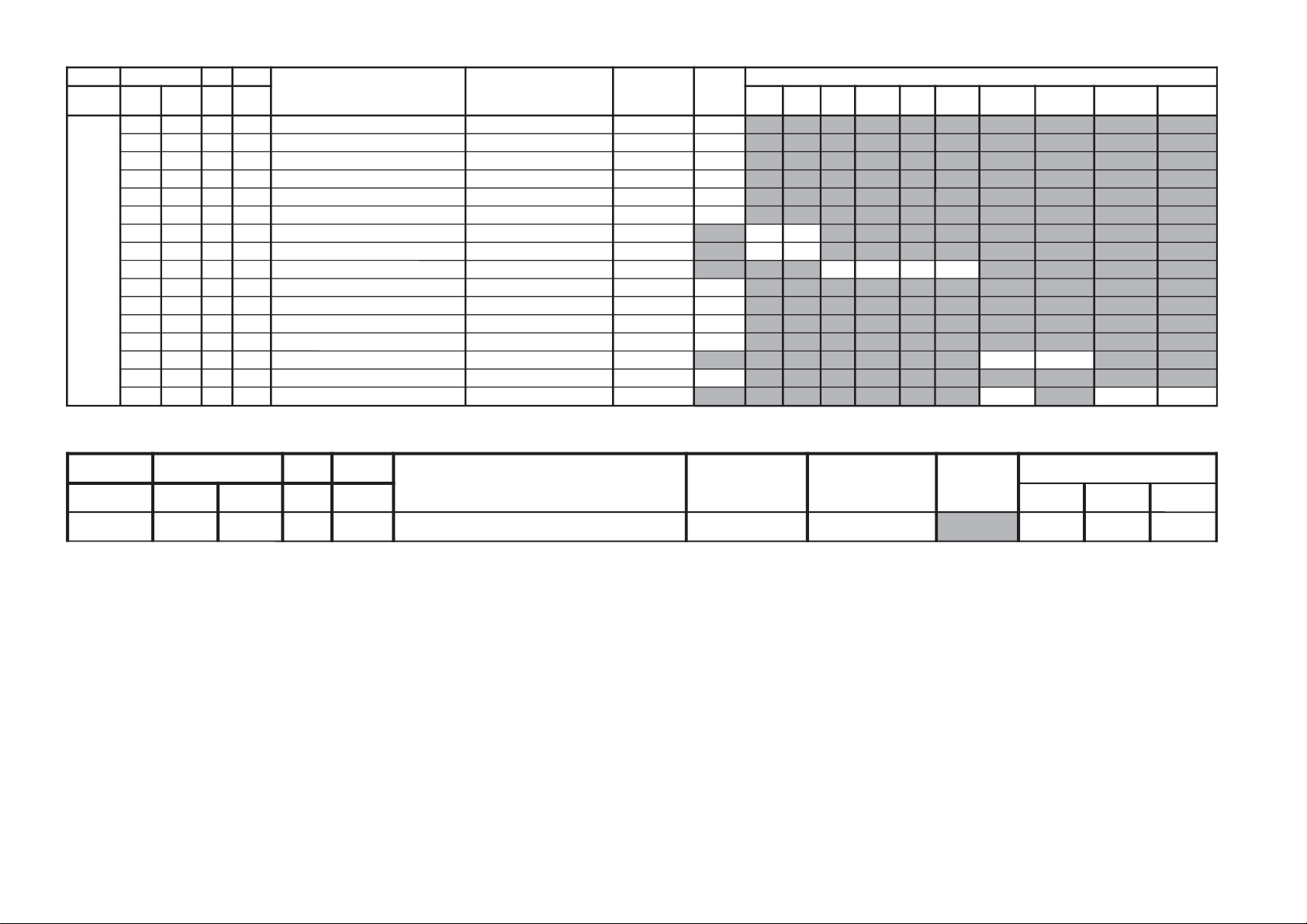

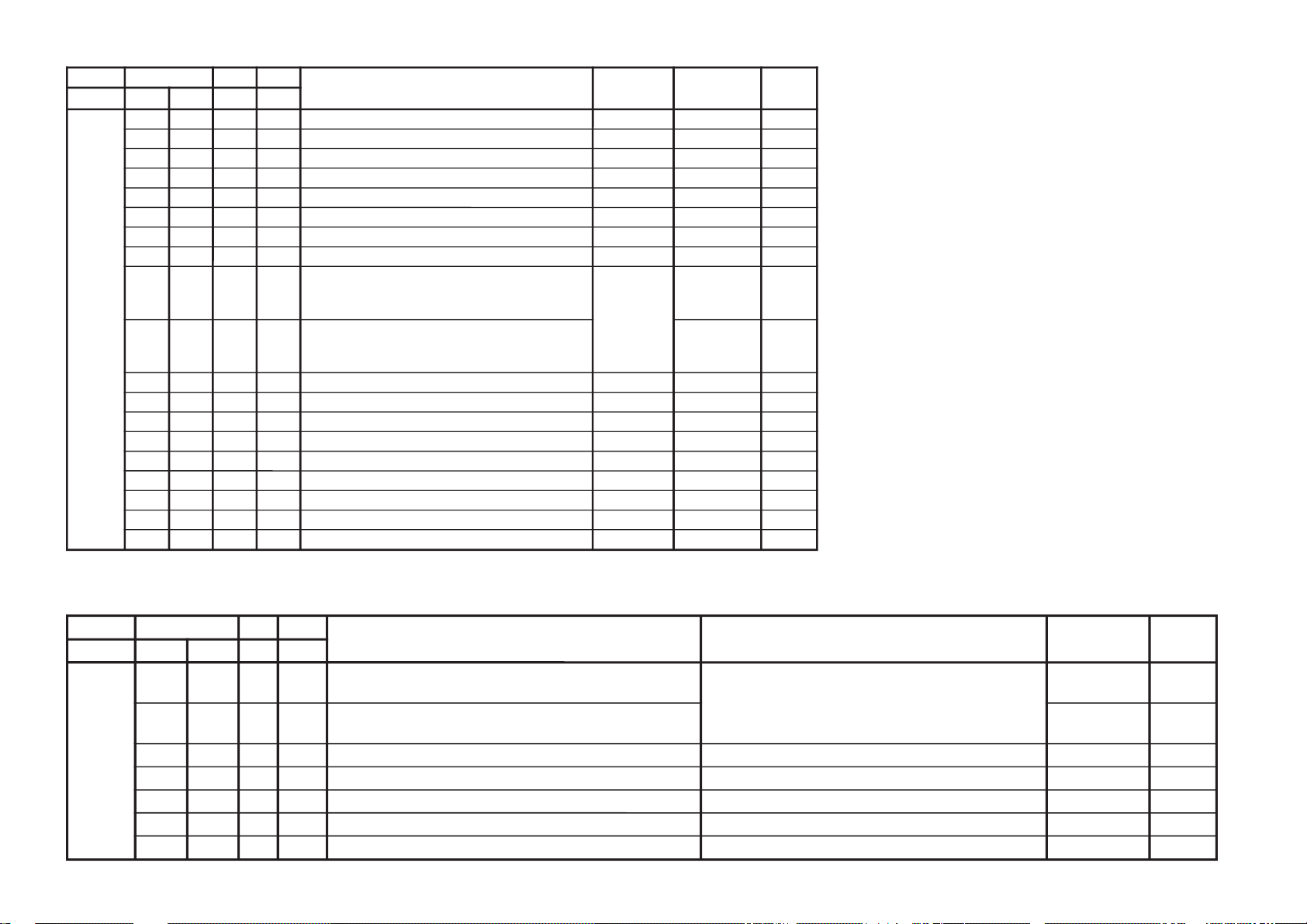

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

pmeTloC

LOOC(

)rehto

pmeTloC

MRAW(

)rehto

pmeTloC

LARTUEN(

)rehto

pmeTloC

)VUYLOOC(

pmeTloC

MRAW(

)VUY

pmeTloC

LARTUEN(

)VUY

VUYlap05

)N(

lap05

)oediV(

0edomciP

diviV/

1edomciP

dtS/

2edomciP

motsuC/

VToediV

LBHW000ROKB130360)10=BFO(BtesffO,)00=BFO(RtesffOleveLkcalB )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetlocrossecorP-VT

131313131313

100GOKB130360GtesffOleveLkcalB )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

020202020202

200VRDR730360RtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetlocrossecorP-VT

737373737373

300VRDG730360GtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

542473542473

400VRDB730360BtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

340403340403

500GPL000100teserPniaGBGR enon00

600RGP130721)RGP(RniaGteserP enon95

700GGP130721)GGP(GniaGteserP enon95

800BGP130721)BGP(BniaGteserP enon95

900FONG000510tesffOniaGteserP enonpoolCCC01

010TRBS

130360ssenthgirB-buS nlaP*/)VT(nlaP*/)oediV(rehtO/VT(srehtO

]ylnosledomSU*[VUY/)oediV(

235333

5333

110ORBS000300)ciPtnegilletnI(tesffOssenthgirB-buS enon00

210SBC000100gnitimiLtnerruCmaeBfoecneuqeSlortnoC enon00

310BBGR000300gniknalBBGR enon

410GBLB000100tuptuOneerG&eulBfogniknalB enon00

510BFO000100eulBtesffOleveLkcalB enon10

610PBW000300)woL:3,2,lamroN:1,hgiH:0(gnitteSpmeTroloC edoMerutciP

001010

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

VUYlap05

)VT(

lap05

)oediV(

maceS05

)VT(

maceS05

)oediV(

cstn06

)VT(

cstn06

)oediV(

VUY05VUY06/0edomciP

diviV

/1edomciP

dradnatS

/2edomciP

motsuC

VToediV

ediWVT

)3:4(

ediWoediV

)3:4(

JDAS000XAMP360360mumixaMerutciP >ediW/lamroN</)ediW/lamroN(*)oediV/VT(rossecorP-VT

84842424

100EUHS700510euH-buS oediV/VT

6011

200PHSS510360ssenprahS-buS VUY/oediV/VT

03

6243

300OHSS000700)ciPtnegilletnI(tesffOssenprahS-buS enon40

400LOCS130360roloC-buS /)oediv(maces05/)vt(maces05/)oediv(lap05/)vt(lap05

BGR06/BGR05/VUY06/VUY05/oediv06/VT06

5373921333131443

500OOCS000300)ciPtnegilletnI(tesffOroloC-buS enon20

600CIP130721;)dilavni(001>;)dilav(001~0:AG[lortnoCerutciP

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

00117001

700LOC130721;)dilavni(001>;)dilav(001~0:AG[lortnoCroloC

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

751405

800TRB130721;)dilavni(001>;)dilav(001~0:AG[lortnoCssenthgirB

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

847405

900EUH130721;)dilavni(001>;)dilav(001~0:AG[lortnoCeuH

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ledomSUhtiw)0-5(hE1#TNITotdneS*(

)ataDteseRresU=lanosreP:AG(ledoMerutciP

058405

010PHS130721;)dilavni(001>;)dilav(001~0:AG[lortnoCssenprahS

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

850505

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

Page 23

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD srehtOVUY)VT(LAP)VT(CSTN)VT(MACES)oediV(LAP)oediV(CSTN)oediV(MACESTUPNI-SMACESCSTNVT

CY000QRFP000300yaleDdnaycneuqerFretneCgnikaeP rehto/VTrossecorP-VT

00

00

100APR100300toohSrevO&erPoitaR rehto/VT

20

20

200OPR200300skaePevitageN&evitisoPfooitaR rehto/VT

20

20

300YLDY210510yaleD-Y TUPNI-S/VUY+)OEDIV/VT(*)MACES/CSTN/LAP(

** * * * * *

400TAMC000300xirtaM)ASU/napaJ(CSTNroMACES-LAP 00

500LCA100100gnitimiLroloCcitamotuA 10

600BC000100ycneuqerFretneCssapdnaBamorhC )xif0:oediV*(VThtiwylnodilav00

700OBS100300tesffOkcalBMACES 10

800ESHC100300ytivitisneStnedICSTN/LAP 20

900OLC000100retliF)lleB(ehcolCfoycneuqerFretneC 00

010PRTC000100edoMparTamorhC srehto/MACES

*

*

110TDQ000100parTamorhCdnoceS srehto/MACES

*

*

210SPB

000100eniLyaleDdnab-esaBamorhCfossapyB

srehto/CSTN

00

*

310OCF

000100nOroloCdecroF 00

410TNIT130360lortnoCtniTdnaB-esaB VT/srehto/VUY

2323

23

510VUT000100slangiSVUnolortnoCtniT 00

610CYWB000100

roloczH85.3rofedomCYtahtdiwdnaB

)CYWB(metsys

00

710BSO000100

amorhcfoeslupyektsrublanretnifohtdiW

)BSO(rotaludomed

00

810CKB000100noitisoPyektsruB

00

1000

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 05)3:4(06)3:4(srehtOVUY)FFO_PI(VToediVtxeteleT)NO_PI(pi-VTlangisoN

CNYS000SYS000100tupnICNYSYnonoitazinorhcnyS 00

100OF000300tnatsnoCemiT1esahP )FR(langisoNrogninuTotuA/txeteleT/oediV/FFOPIVT/NOPIVT

3030100000

200DIV000100edoMtnedIoediV 06/05

0000

300LSF000100cnySlacitreVrofleveLgnicilSdecroF 00

400LSS000100rotarapeScnySleveLgnicilS 06/05

0000

500DIVS100700noitacifitnedIoediVrofnoitceleSecruoS srehtO/VUY

0000

600FROF000300ycneuqerFdleiFdecroF 30

700KVM000100gniyeKnoisiVorcaM 10

(For '*' refer to page 32)

– 22 –

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

Page 24

– 23 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

srehtOdiviVVT

)nyD(

VT

)srehtO(

oediV

)nyD(

oediV

)srehtO(

pmeTroloC

)HGIH(

pmeTroloC

)srehtO(

roloC

)WOL(pmeT

pmeTroloC

)LAMRON(

TCIP000LDAC700510leveLevirDedohtaC 30

100AFC000300edoMretliFbmoC *

200COS200300leveLgnippilCtfoS 00

300LWP100100hctiwSgnitimiLetihWkaeP 10

400LTHW600510gnitimiLetihWkaeP 20

500MAG100100ammaG 10

600STW100300hctertSetihWdnalortnoCammaGsrehtO/eviL

10/*10/*

700RFT000100langiSecnanimuLfooitaRrefsnarTCDsrehtO/eviL

1010

800ROC300300gniroC )srehto/anyD(*)oediV/VT(

10200010

900OROC000300)ciPtnegilletnI(tesffOgniroC 10

010SKB300300hctertSkcalBsrehto/BGR20

110SAA100100hctertSkcalBehtffohctiwSotaerAkcalB 10

210KSD000100lortnoCnikScimanyD 00

310SLB000100hctertSeulB )SREHTO/HGIH(pmetloc

0000

410SLBN000100tiucriChctertSeulBnoitarepO 00

510RRN000100noitcudeRdeRnoN )LAMRON/WOL/HGIH(pmetloc

10

1010

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD VUYVToediV

WS100OVS10030084@niPISBVC/OVS/OVFIfonoitcnuFVUY/oediV/VT

301010

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

Page 25

– 24 –

JVTytilanoitcnuF

laitinI

egnaR

noitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

FIV000DFIO630360rotaludomeDFItesffO rossecorP-VT63

100TCGA130360revo-ekaTCGA 81

200MTS000100edoMgninuThcraeS 10

300DG000100langiS1SBVCnoyaleDpuorG 00

400SCGA100300deepSCGAFI 10

500IFF000100LLPFIretliFtsaF 00

600IANL000100eulavlaitinitibANLpmAFR 00

700TANL591522leveLdlohserhTpmAFR 591

800NSNL400700dlohserhTleveLNSpmAFR 30

900DSNL200700dlohserhTporDleveLNSpmAFR 10

010XENL610360gnimiTporDNSkcehcpmAFR 03

110RTHC840721edoMresUpmAFRtesotgrPotuAretfadlohserhTlennahC 52

210OSUT000100desUrenuTynoS *

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

srehtO/0edomciP

diviV

/1edomciP

dradnatS

/2edomciP

motsuC

VT

MV000DBGR300700tuptuOMVottuptuOBGRfoyaleDenonrossecorP-VT30

100AMV300300tuptuOMVfoedutilpmAenon30

200PAMV200300)FFO:3,2,woL:1,hgiH:0(gnittesMVedoMerutciP

000000

300OMMV300300edoMMV 30

400AMVF

400400)erawtfoSlluF(tuptuOMVfoedutilpmA

srehto/MACES

500OARC000100MVSnogniroCsrehto/VT

00

10

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

(For '*' refer to page 32)

Page 26

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

MEDS000SWMF000300rotaludomeDMFrofnoitceleSwodniW rossecorP-VT20

100SSQ100100 )metsysMitlumAGrofA/N(edoMreifilpmA)SSQ(dnuoStilpSisauQ 10/*

200BPB000100retliFssapdnaBdnuoSfossapyB 00

300OLMA000100dnuoSMAroflangiStuptuOoiduA 00

400CVPH000100lortnoCemuloVenohPdaeH 00

500ACMC000100lennahConoMetavitcA 00

600SBPB000100)SBPB(edomoeretstaretlifssapdnabdnuosfossapyB 10

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

TXT000VXT930360spilihProfnoitisoPlacitreVtxeteleT redoceDtxeT93

100DHT010721tfihSegdEevitcAcnys-HtxeteleT 01

200RBT510130ssenthgirBBGRtxeteleT 81

300QCA000100)1-LAP,0-otuA(noitisiuqcAtxeteleT RFS10

400MRBT300130ssenthgirBedoMxiMtxeteleT 30

(For '*' refer to page 32)

– 25 –

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

Page 27

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD VToediV

ffOdnuorruS

)WOW/SRS(

dnuorruS

)dnuorrusurT(

dnuorruS

)no(oeretsI(

)eivoM/

dnuorruS

)detalumiS(onomI(

)tropS/

dnuorruS

,SRS:rehtO(

)ffO,oeretsI

PSDS000LBB000510ruotnoCEBB rehto/wow/urT>ylnolluF-LIXBDSS

0000

0000

100HBB000510ssecorPEBB rehto/wow/urT>ylnolluF-LIXB

0000

0000

200WLBB000510tesffOruotnoCEBB 40

300FOVS000510tesffOemuloVedoMtceffE/dnuorruS onomI/oeretsI/dnuorrusurT/)WOW/SRS(ffO

6011608060

400DAL000130tsujdAleveLredoceD

50

500MAL000130tsujdAleveLonoM 50

600NAL000130tsujdAleveLmaciN 22

700SAL000130tsujdAleveLPAS 50

800AAL000130tsujdAleveLCDA buSoediV/buSFR/kpSretnec/oediV/FR

0000

900FES300700tceffEoeretS/onoMelbidercnI onomI/oeretsI

5030

010SAB000130)evitageN:1evitisoP:0BSM(tesffOssaBniaM

2222

2222

110ERT000130)evitageN:1evitisoP:0BSM(tesffOelberTniaM

7272

7272

2101QE000130tesffO)zH001(dnaBlennahCniaMrezilauqE

)evitageN:1evitisoP:0BSM(

1010

1010

3102QE000130tesffO)zH003(dnaBlennahCniaMrezilauqE

)evitageN:1evitisoP:0BSM(

8181

8181

4103QE000130tesffO)zH0001(dnaBlennahCniaMrezilauqE

)evitageN:1evitisoP:0BSM(

1010

1010

5104QE000130tesffO)zH0003(dnaBlennahCniaMrezilauqE

)evitageN:1evitisoP:0BSM(

6161

6160

6105QE000130tesffO)zH0008(dnaBlennahCniaMrezilauqE

)evitageN:1evitisoP:0BSM(

1010

1010

710TCFB500700lortnoCEBBdnaBUD,EBD 00

810NECS100510lortnoCretneCD3SRS 40

910APSS000510lortnoCecapSD3SRS 10

020WHBB000510edomWOWnitesffossecorpEBB 00

120ERTS200700edomdnuorrusroftesffOelberT 10

220THBB000510edomVTnitesffOEBB 00

320ERTT200700edomVTnitesffOelberT 30

420SABV000300emulovresunodnepedtesffossaB 10

520ERTV000300emulovresunodnepedtesffoelberT 10

620SABT200700VTroftesffossaB 00

720OLBB000300emuloVresUnodnepedtesffOLBB 00

820OHBB000300emuloVresUnodnepedtesffOHBB 00

– 26 –

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

Page 28

– 27 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaN

ceDceD

CEDS000UTPS300510noitcetedreirracPASrofdlohserhTreppU DSS80

100LTPS600510noitcetedreirracPASrofdlohserhTrewoL 51

200HTPS000130PASfoetumotuarofdlohserhTesioN 00

300YHPS400510PASfoetumotuarofezissiseretsyH 30

400HTMF000130dradnats2AMFni2CSfoetumotuarofdlohserhTesioN 81

500YHMF400510dradnats2AMFni2CSfoetumotuarofezissiseretsyH 70

600ELIN001552)PEDD(timilrorrerewolMACIN 05

700EUIN002552)PEDD(timilrorrereppuMACIN 002

800DMPE

100300

)PEDD(gnimmargorPysaECEDMED

0=DMPEfI

0=SDTSdna

tiB3POdna

CEDS1=1

siyrogetac

dnaelbasiD

yrogetacCKDS

revoekatlliw

10/*

900SDTS

910130

sedomSSSdnaDSArofdexelpitlumstiB

31/*

010AMVO100100noitpadanoitaludomrevoMF 00

110WBLF000300htdiwdnabretlifrotaludomedMA/MF 30

210DMDI000300edomSSSnideepstnediMF 00

310TMVO100200lanimonotevitalerdlohserhtlevelnoitaludomrevO 30

410IXCD000100retrevnIlortnoCgnilacSOXCDMACIN 00/*

510GXCD000700niaGlortnoCgnilacSOXCDMACIN 00/*

610LLCD110510)L(timiLlortnoCgnilacSOXCDMACIN 00

710HLCD000130)H(timiLlortnoCgnilacSOXCDMACIN 00/*

810RKDI100300DTSMnaeroKgnittesDOMDI 00

JVTytilanoitcnuF.tinIegnaRnoitcnuF etoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

CKDS000LLNK000552etyBrewoLdlohserhTrewoLteDesioNnaeroK 0=DMPEfI

0=SDTSdna

CKDSdnaelbasiDsiyrogetacCEDS1=1tiB3POdna

revoekatlliwyrogetac

100HLNK

210552etyBrehgiHdlohserhTrewoLteDesioNnaeroK

200LHNK000552etyBrewoLdlohserhTreppUteDesioNnaeroK

300HHNK020552etyBrehgiHdlohserhTreppUteDesioNnaeroK

400CILK060552tnuoCgniniatniaMDItoliPtsoLnaeroK

500MILK100721reilpitluMtnuoCgniniatniaMDItoliPtsoLnaeroK

600CDSK600552tnuoCtceteDoeretSnaeroK

(For '*' refer to page 32)

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

Page 29

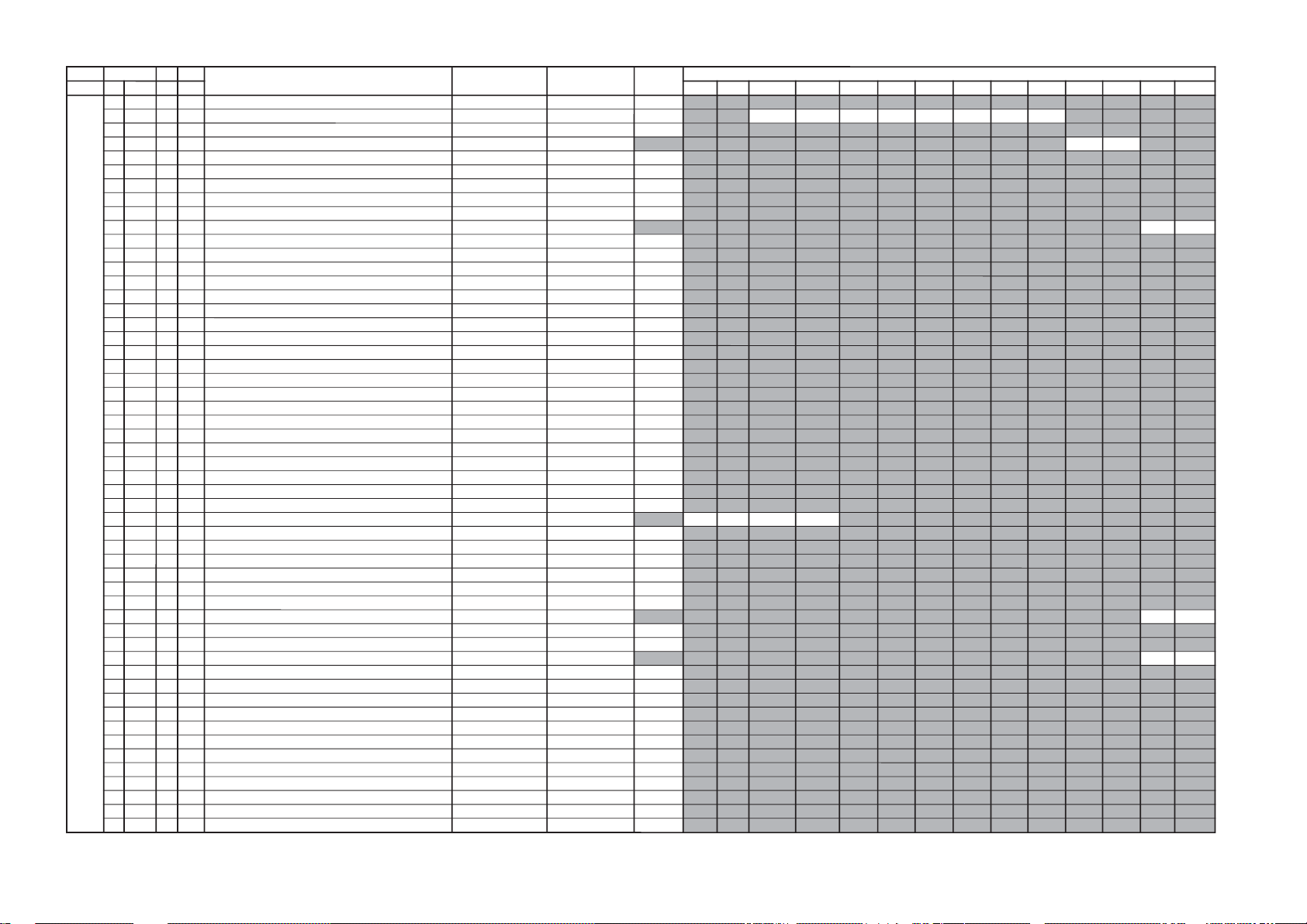

KV-SZ252M50/M61/M81/N50/N60

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaN

ceDceD 05)3.4(06)3:4(ZW05)9:61(ZW06)9:61(N05)9:61(N06)9:61(F05)9:61(F06)9:61(Z05)9:61(Z06)9:61(zH05buSzH06buSVToediV

PIP

000SPH

150552noitisoPerutciPlatnoziroH X8829ADS

100SPV

720552noitisoPerutciPlacitreV

200PFV

800510noitisoPeniFlacitreV

300PFH

510510noitisoPeniFlatnoziroH

)ciPbuS(zH06/05

400PSV

000100noitcudeResioNesluPcnySlacitreV

500LDV

000130yaleDesluPcnySlacitreV

600YLD

100510yaleDyaleS

700VGA

110510eulaVlortnoCniaGcitamotuA

800DPC

000300noitaruDgnipmalC

900LLP

000300tnatsnoCemitLLPtresnI

oediV/VT

010DCY

210510yaleDC/Y

110LIK

000300dlohserhTrellikroloC

210PGB

000100noitisoPetaGtsruB

310MED

100300noitcleSesahpmeeD

410AMC100300hctiwdnaBamorhC

510CFI

200300retliFnoitasnepmoCFI

610EUH

230360lortnoCEUH

710ACS

600130tnemtsujdAreirracbuSroloC

810NOC

000510tnemtsujdAtsartnoC

910TRB

000510tnemtsujdAssenthgirb

020RKP

331552deRleveLkaeP

120GKP

331552neerGleveLkaeP

220BKP

331552eulBleveLkaeP

320YRF

510510YroloCemarF

420TAS

700510tnemtsujdAnoitarutaSroloC

520KPY

300700tnemtsujdAgnikaePY

620OCY

100100elbanEgniroCY

72012P

0007001LDILAPdna2LDILAP

820LAP

000100leveLDILAP

920VOP

000700lacitreVtesffOnoitisoP

030HOP

610130latnoziroHtesffOnoitisoP

130LPC

100300htgneLesluPgnipmalC

230LRS

000300leveLnoitcejeRmaceS

330LIS

700700leveLnoitakifitnedImaceS

430DES

100100redividmaceS

530AFB

100100tnemtsujdAretliflleB

63021P

0003002dna1tnemercnILAP

730SOL

100300deepSgnikcoL

oediV/VT

830LAS

000700leveLecnatpeccAmaceS

930AES

000100ecnatpeccAmaceS

040RSN

000700LLPlatnoziroHroFnoitcudeResioN

oediV/VT

140HLS

000300HdlohserhTleveLgnicilS

240JAI

000300LLPlatnoziroHroFtnemtsujda-I

34005V

000721zH05gninepOnoisserppuSesioNwodniWlacitreV

44006V

230721zH06gninepOnoisserppuSesioNwodniWlacitreV

540SNV

000510zH06gnisolCnoisserppuSesioNwodniWlacitreV

640CSV

000510zH05gnisolCnoisserppuSesioNwodniWlacitreV

740TVS

510510VTLS&ytiraloPVdlohserhTleveLgnicilS

840MFV

000300edoMleehwylFlacitreV

940WFV

000100leehwylFlacitreV

050SVL

000300noitarapes-cnySlacitreVrofssapwoL

150ALC

300300ycnetalgnipmalC

250PCS

400130esluPgnipmalCfotratS

– 28 –

(Not used for this model)

RM-GA002

Page 30

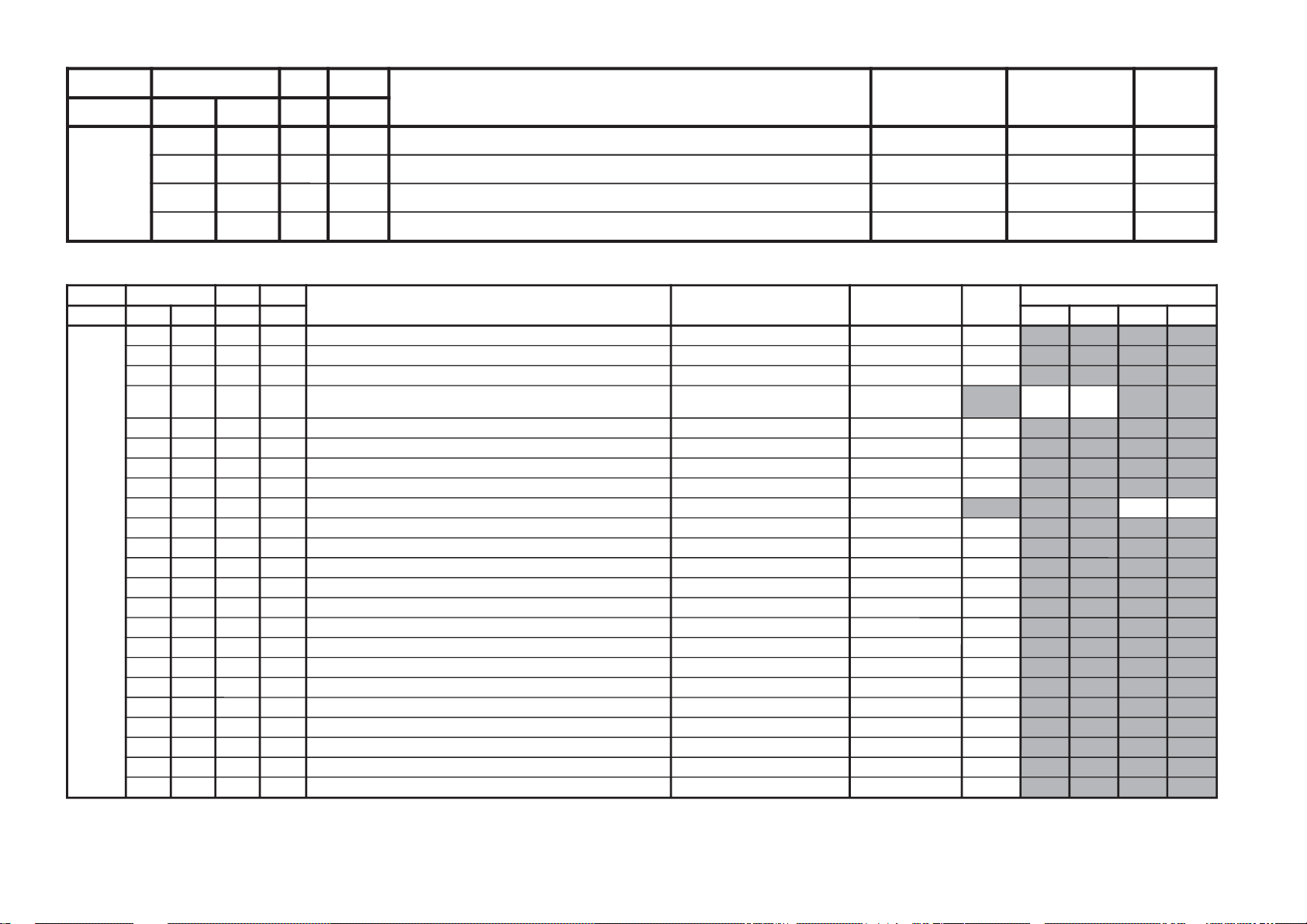

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

VTH000XAMV000360)XAMV+53=XAM(leveLemuloVmumixaM leveLemuloV00

100INIV520130norewoPtaleveLemuloVlaitinI leveLemuloV00

200YBTS000100 )YBTSsyawla=1,sutatsrewoptsalehtwollof=0(sutatSrewoPtsaL rewoPtsaL00

300GRPI100721)sledoMitluMrofylno(norewoPtarebmuNmargorPlaitinI rebmuNmargorP00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 05)3:4(06)3:4(srehtOVUY

MTPO000THSA600700)nim5*atad(remitffotuhsotuA 70/00

100BDSO510130ssenthgirbDSO h06orciM/RMM61

200HDSO800510noitisoPlatnoziroHDSO h06orciM/ATADX80

300VDSO730360noitisoPlacitreVDSO

)06/05(9:61<>06/053:4<

>)lluFlamroN()mooZediW()ediW(

h06orciM/RMM

1623

400ETUM000100)delbane=1(hctiwSetuMlangiSoN 10/00

500LUFR510510)hf0nehwelbasiD(dekcolnUretfaretnuoCegnahClangiSFR 10/40

600KLFR510510)hf0nehwelbasiD(dekcoLretfaretnuoCegnahClangiSFR 40/00

700GNAL000300noitidnocgnippihsegaugnalDSO 00

800TXTH000100wsrotarepescnyS srehto/VUYrossecorP-VT

0000

900SSMC000100wscnyS rossecorP-VT10

010OXCD060721eulaVOXCD PSD/h06orciM/RFS35/*

110CSID821552cedrolocybtsujdaOXCDrofatadOCSIDtegrat 821

210LBXE000510esioNetihWetanimilEotremiTgniknalBdednetxE 40/80

310SYST000300 )ledoMAG(]M:3,K/D:2,I:1,G/B:0[teseRtseTtaMVNnisySVTeziromeM 00

410WSNL100100)ffO:0,otuA:1(noitidnocteseRtseT/gnippihSretsooBlangiS 10

510LBL100100noitidnoclangiSoNtAnoitcudeRssenthgirB 10

610ORPH100100noitatoRerutciProftesffOarapH 50

710LUVA510510)hF0nehwelbasiD(dekcolnUretfaretnuocegnahclangisvA 40

810KLVA510510)hF0nehwelbasiD()dekcolretfaretnuocegnahclangisvA -/00

910MPSC000100 )edompotselbasid:1,edompots:0(ybdnatsniedompotselbasiD 10

020HNES000100)nO:1,ffO:0(m/cdnuosgnilkcarCrecnahnEdnuoS 10

120CSPS100300)semit8:3,semit6:2,semit4:1,elbasid:0(hcraeSDEEPS 10

220OLUM100100)woLevitcA:1,hgiHevitcA:0(noitceleScigoLtroPetuMoiduA 10

– 29 –

(For '*' refer to page 32)

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

Page 31

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

MFPO000TCMF100300dlohserhTreirraCnacSotuAoidaRMF 02

100TSPR300721teserpoidargnirudpetsycneuqerfhcaerofemitgnitiaW 01

200UTPM300510)OIDARMF(noitcetedtolipXPMrofdlohserhTreppU DSS21

300UOCD331552rotaludomedMFmorftesffoCDrofdlohserhTreppU 241/*

400LOCD711552rotaludomedMFmorftesffoCDrofdlohserhTrewoL 611/*

500AMVO100100)OIDARMF(noitpadanoitaludomrevoMF DSS00

600RBMF000130edoMMFgnirudssenthgirBDSO h06orciM/RMM11

700ERTR000700edoMoidaRMFnitesffOelberT DSS20

800SABR200800edoMoidaRMFnitesffOssaB DSS20

900TCGA540360edoMoidaRMFnirevoekatGCA rossecorP-VT*

010WBLF300300htdiwdnabretlifrotaludomedMA/MF DSS10

110SDTS000100

sisahpmeedsu05)71(LESDTS:OFIelbatceleS

)ylnoCSTN/SU(sisahpmeedsu57)81(LESDTS:1

00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD srehtOVUY

SUPO000FFOS000100)noCAhtiwybdnats:1,noCAhtiwyromemtsalwollof:0(ffoyatS 00/-

100HCPS100721noitidnoCgnippihSretfarebmuNlennahC 70/-

200ACPS100100)nOelbaC=1(noitidnoCgnippihSretfanoitceleSelbaC 10/-

300RBCC510130)SUrofylno(ssenthgirBCC 00/-

400PHCC800510)SUrofylno(noitisoPHCC 00/-

500VUO000100)SUrofylno(slangiStupniVUnolortnoCtesffO VUY/srehtO

00/-00/-

6002AFC

000100

)SUrofylno(nOretliFbmoCdecroF enon

00/-

700CYSH000700SUrofylno)DISrokcoL,LS(gninnutrofnoitcelescnySH 00/-

800KLC521552SUrofylno)nim51/sm8:pets1(tesffokcolcSU 00/-

900SKLC521552SUrofylno)nim51/sm8:pets1(ybdnatsnitesffokcolcSU 00/-

(For NTSC model only)

– 30 –

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

(For '*' refer to page 32)

Page 32

– 31 –

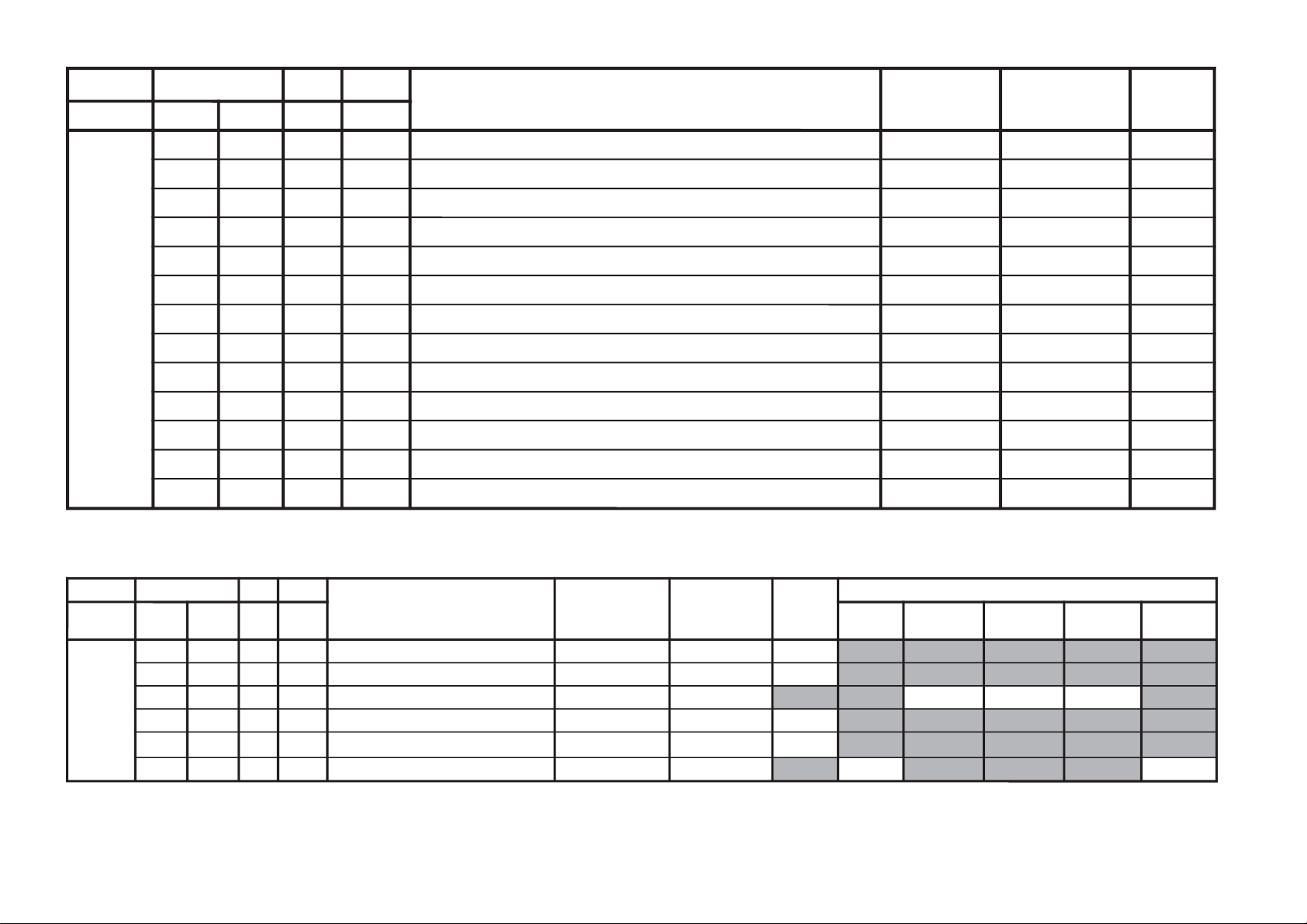

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

BTPO000LLAI000100)MVNnideziromemton(hctiwSetirWdradnatS x

1001BPO000552)detalermetsyS(1noitpO 33egaprefer

2002BPO000552)detalerlangiSoediV(2noitpO 33egaprefer

3003BPO000552)detalergnidoceDoeretS(3noitpO 43egaprefer

4004BPO000552)suoenallecsiM(4noitpO 43egaprefer

5005BPO000552)suoenallecsiM(5noitpO 53egaprefer

6006BPO000552)detaleregaugnaLDSO(6noitpO 53egaprefer

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

Page 33

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

Data Variant depend on models

Category No Name Table Comb No Comb

YC 003 YDLY YUV 10 10

010 CTRP Other 00 01

011 QDT Other 00 01

012 BPS NTSC 01 00

Category No Name Comb No Comb

PICT 001 CFA 00 01

PAL (TV) 10 06

NTSC (TV) 10 03

SECAM (TV) 06 06

PAL (Video) 11 03

NTSC (Video) 09 06

SECAM (Video) 06 03

SECAM 01 01

SECAM 00 00

Category No Name Others Live/Vivid

PICT 006 WTS Comb 01 01

No Comb 01 02

Category No Name Sony Tuner Current Alps Tuner New VA Alps (TEQEXL01A) Panasonic Tuner

VIF 012 TUSO 01 00 02 03

Category No Name Stereo AV Stereo India/ China Vietnam

SDEM 001 QSS 01 00 01 01

Category No Name Stereo AV Stereo

SDEC 008 EPMD 02 01

009 STDS 31 13

014 DCXI 00 00

015 DCXG 03 00

017 DCLH 06 00

Category No Name Stereo AV Stereo Mono

OPTM 010 DCXO 54 53 53

Category No Name Sony Tuner Alps Tuner Pana Tuner

OPFM 003 DCOU 140 144 142

004 DCOL 114 118 116

OPFM 009 AGCT = VIF 01 AGCT (A87F) + Offset

15 2 2

– 32 –

Page 34

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

ITEM INFORMATION

No. OPB1

Item

KV-SZ252M50 000 0111115

KV-SZ252M61 000 0111115

KV-SZ252M81 000 0111115

KV-SZ252N50 000 010008

KV-SZ252N60 000 010008

Reserved Mini Visualizer M B/G I D/K DEC

Jack

00 =

01 =

10 =

11 = 1 =

Mini Jack (US MODEL only) 0 = disabled, 1 = enabled

Visualizer (BX1L FULL only) 0 = disabled, 1 = enabled

TV System Select (M, B/G, I, D/K) 0 = disabled, 1 = enabled

No. OPB2

Item

KV-SZ252M50 001 0110044

KV-SZ252M61 011 01100108

KV-SZ252M81 001 0110044

KV-SZ252N50 001 0110044

KV-SZ252N60 011 01100108

Party Mode FM Radio Component Composite (SCART) SECAM Color Decording DEC

Party Mode Party Mode Function 0 = not available, 1 = available

FM Radio FM Radio Function 0 = not available, 1 = available

Component (Component [YCbCr] Terminals) 0 = not available, 1 = available

Composite (No. of Composite Terminals) 00 = 1 composite terminal

01 = 2 composite terminals

10 = 3 composite terminals

11 = 4 composite terminals

SECAM (SECAM Color System) 0 = disabled, 1 = enabled

Color decoding (Color Crystal Selection) 00 = PAL/NTSC (Multi)

01 = NTSC (3.58MHz)

10 = PAL/NTSC (4.43MHz)

11 = PAL/NTSC (Tri-Norma)

– 33 –

Page 35

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

No. OPB3

Item

KV-SZ252M50 000 000011

KV-SZ252M61 011 10000112

KV-SZ252M81 000 000011

KV-SZ252N50 000 000011

KV-SZ252N60 000 001004

Reserved NICAM NICAM A2 ST Thai US ST JP/Korean MONO DEC

Reserved Not used

NICAM ST (NICAM Stereo) 0 = disabled, 1 = enabled

NICAM BI (NICAM Bilingual) 0 = disabled, 1 = enabled

A2 ST/BI (A2 [West German]

Thai Bilingual (A2 [Thai] Bilingual)

US ST (US Stereo) 0 = disabled, 1 = enabled

Korean ST (Korean Stereo) 0 = disabled, 1 = enabled

MONO (Monaural Model) 0 = Stereo (SSD) Model

ST BI Bilingual ST

Stereo/Bilingual) 0 = disabled, 1 = enabled

or Force SAP if US ST is active 0 = disabled, 1 = enabled

1 = Monaural Model

No. OPB4

Item

KV-SZ252M50 001 0110044

KV-SZ252M61 001 0000133

KV-SZ252M81 001 0110145

KV-SZ252N50 001 0110044

KV-SZ252N60 001 0000032

Initial setup 1 spk VM Surround Top Text DEC

menu Models

Initial Setup menu Skip Initial Setup

"Display this menu next time?" 0 = Not Skip, 1= Skip Initial Setup "Display this menu

(for us models or)

1 spk Models 1 Speaker Models 0 = 2 or 3 Speaker Models, 1 = 1 speaker Models

VM (Velocity Modulation) 0 = disabled, 1 = enabled

Surround (Surround Selection) 000 = Off/Simulated/Surround

001 = Off/Simulated/SRS (3D) Surround

010 = Off/Simulated/WOW/TruSurround

011 = No Surround

100 = Off/Sports/Movie

101 = Off/Sports/Tru Surround

110 = 3.1 Channel Surround Off/Sim/Tru

(US models only)

111 = 5.1 Channel Surround Off/5.1/Sim/Tru

(US models only)

TOP(Forced TOP) 0 = Auto Mode (TOP/FLOF), 1 = Forced TOP

TEXT (Teletext Model) 0 = Non-Teletext Model, 1 = Teletext Model

– 34 –

Page 36

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

No. OPB5

Item

KV-SZ252M50 101 01011171

KV-SZ252M61 100 11011155

KV-SZ252M81 101 01011171

KV-SZ252N50 000 0101111

KV-SZ252N60 000 0101111

Signal MSYS COSMIC_A ASD Tilt Band IP Wide DEC

Booster ASD ASD Edge

Signal Booster Signal Booster feature 0 = disabled, 1 = enabled

MSYS ASD (ASD Improvement for 0 = disabled, 1 = enabled

M System channels)

*Only applicable when ASD = 1

COSMIC ASD Automatic Standard Detection 0 = disabled, 1 = enabled

Using COSMIC (Non-Stereo)

ASD (Automatic Standard Detection) 0 = disabled, 1 = enabled

Tilt (Tilt Correction/PIC Rotation) 0 = disabled, 1 = enabled

Band Edge (VHF-H band Limit Position) 0 = 427.25MHz, 1 = 429.25MHz

IP Plus (Intelligent Picture & 0 = disabled, 1 = enabled

Intelligent Picture Plus)

Wide (Wide Mode/V-Compressed) 0 = disabled, 1 = enabled

No. OPB6

Item

KV-SZ252M50 100 01000136

KV-SZ252M61 000 010008

KV-SZ252M81 100 00100132

KV-SZ252N50 100 01010138

KV-SZ252N60 000 0101010

AV ST Mono 3D OSD 3D Comb PiP OSD Language Selection DEC

AVST Mono

3D OSD (BX1L Full version GA Multi 0 = Normal with 3D Intelligent Picture OSD

3D Comb 3D comb feature 0 = Comb Not available

PiP PiP feature 0 = PiP Not Available

OSD Language Selection US (GA NTSC) 1x1x = Complicated Chinese

(AV Stereo mono Chip model) 0 = mono model

1 = AV stereo model

Destination ONLY) 1 = Disable 3D Intelligent picture OSD

1 = Comb available

1 = PiP available

GA 1xxx = Simplified Chinese

x1xx = Arabic/Russian

x1xx = Arabic/Russian

xx1x = Thai

xxx1 = Persian/Vietnamese

– 35 –

Page 37

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

4-3. PICTURE QUALITY ADJUSTMENT

4-3-1. P MAX / CONTRAST ADJUSTMENT

1. Set TV to Video mode.

2. Set Picture mode to "CUSTOM".

3. Input PAL 100% Color Bar to TV set (OTHER model)

and NTSC 75% Color Bar (NTSC model).

4. Set the following condition:

Picture 100%, Color 0%, Brightness 50%.

5. Connect an oscilloscope to pin 4 (R output) of CN004.

6. Go to service mode and set PICT 003 "PWL" to 00h and

WHBL 014 "BLBG" to 01h.

7. Select SADJ 000 "PMAX" with 1 and 4 button of the

commander then adjust VR with spec with 3 and 6

button until reach the spec below:

VR

Black

PAL

34"

VR

29"

25"

NTCS

1.85 0.03Vpp

1.57 0.03Vpp

1.85 0.03Vpp

8. Copy "SCOL" 50(PAL) video data to "SCOL" 50

(SECAM) video.

9. Then copy "SCOL" 50(PAL) video data and "SCOL"

50(SECAM) video data to "SCOL" 50(PAL) and "SCOL"

50(SECAM) TV table.

10. For NTSC model input NTSC 75% Color Bar to TV and

repeat step no. 4 to 6.

11. Select SADJ 004 "SCOL" with 1 and 4 button of the

commander then adjust using 3 and 6 so that

VB1=VB4 then write in the data as below:

Add 11 steps to SCOL (NTSC) – 25"

Add 11 steps to SCOL (NTSC) – 29"

Add 6 steps to SCOL (NTSC) – 34"

VB1 VB2 VB3

VB1 = VB4 (for NTSC)

(Difference is within 70mV)

VB4

12. Copy "SCOL" 60(NTSC) video data to "SCOL"

60(NTSC) TV .

13. Finally copy "SCOL" 50(PAL) and "SCOL" 60(NTSC)

data to "SCOL" 50(PAL) and 60(NTSC) in DVD mode.

14. Then press [MUTING] t - to write the data.

15. Set PICT 006 "WTS" back to original data.

Add 5 steps to "PMAX" - (25" and 29")

8. Then copy the adjusted PMAX data to TV mode.

9. Select Wide mode to "ON" in TV and Video mode and

write "PMAX" data -6 steps

(for models with V-Compression features only).

10. Press [MUTING] t - to write the data.

11. Set “PWL" and "BLBG" back to initial data.

("PWL" : 01h and "BLBG" : 00h).

12. Finally press [MUTING] t - to write the data.

4-3-2. SUB COLOR ADJUSTMENT

1. Set TV to Video mode.

2. Set Picture mode to "CUSTOM".

3. Input PAL 100% Color Bar to TV.

4. Set the following condition:

Picture 100%, Color 50%, Brightness 50%, Hue 50%

and Sharpness 50%

5. Set PICT 006 "WTS" to 00h.

6. Connect an oscilloscope to pin 2 (B output) of CN004 A

Board.

7. Select SADJ 004 "SCOL" with 1 and 4 button of the

commander then adjust with 3 and 6 so that

VB2=VB3=VB4 (for PAL) then write in the data as below:

Add 11 steps to "SCOL" (PAL) – 25"

Add 11 steps to vSCOL" (PAL) – 29"

Add 6 steps to "SCOL" (PAL) – 34"

VB1

4-3-3.SUB HUE ADJUSTMENT

1. Set TV to Video mode.

2. Input NTSC 3.58 Color Bar to TV set.

3. Set the following condition:

Picture 100%, Color 50%, Brightness 50%, Hue 50%,

Sharpness 50%.

4. Connect oscilloscope to pin 2 (B output) of CN004.

5. Set to service mode and select SADJ 001 "SHUE" or

YC 013 "TINT" with 1 and 4 button then adjust to

VB1=VB2=VB3=VB4 using 3 and 6 button.

6. Press [MUTING] t - to write the data.

7. Select TV channel with NTSC 3.58 and perform step 3

to 6.

8. For single system model with NTSC 4.43, select TV

channel with NTSC 4.43 and perform step 3 to 6.

9. Once adjustment is completed in Video mode, carry out

adjustment in DVD mode. Input NTSC 3.58 Color Bar.

10. Connect oscilloscope to pin 2 (B output) of CN004.

11. Set to service mode and adjust service item YC 013

"TINT" with 1 and 4 button until VB1=VB2=VB3=VB4.

12. Press [MUTING] t - to write the data.

VB3

VB1

VB2

Illustration 1

VB4

80mV

VB2 VB3 VB4

VB2 = VB3 = VB4 (for PAL)

The highest level of VB1, VB2, VB3 and VB4 should

be aligned at the same line.

The ideal difference between VB2 and VB3 is within

– 36 –

+ 80mV.

Page 38

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

4-4. GEOMETRY ADJUSTMENT

4-4-1. H-TRAPEZOID ADJUSTMENT

1. Receive cross hatch/dot signal.

2. Adjust RV1800 on CV Board to make H-Trapezoid

distortion best/to obtain the center illustration shown in

Ta ble 1.

4-4-2. NORMAL MODE 50Hz / 60Hz

1. Input PAL Special Color Bar (SPCB) or PAL Monoscope

(OTHER model) and Video mode or NTSC Monoscope

(NTSC model) signal using a pattern generator.

2. Set Wide Mode to "OFF".

3. Select Category items listed in Table 1.

4. Raise and Lower the data value using 3 and 6 button

to obtain the center illustration.

5. Press [MUTING] t - to save the data into the memory.

6. For Korea models, copy adjusted 60Hz to 50Hz. Add 6

steps to 50Hz "HPOS" and 3 steps to 50Hz "HSIZ" and

save the data.

4-4-3. WIDE MODE 50Hz / 60Hz

(V Compression Adjustment)

1. Input PAL Special Color Bar (SPCB) (OTHER model) or

Monoscope NTSC (NTSC model) signal using a pattern

generator.

2. Set Wide Mode to "ON".

3. Copy NORMAL MODE 50Hz/60Hz adjusted data for the

following items:GEOM: 011 VSIZ, 010 VSLP, 012 SCOR and 003 VLIN

4. Select Category items listed in Table 1 except GEOM:

003 VLIN, 010 VSLP, 011 VSIZ, and 012 SCOR and

adjust the data to obtain the center illustration.

5. Press [MUTING] t - to save the data into the memory.

6. For Korea models, copy adjusted 60Hz to 50Hz. Add 6

steps to 50Hz "HPOS" and save the data.

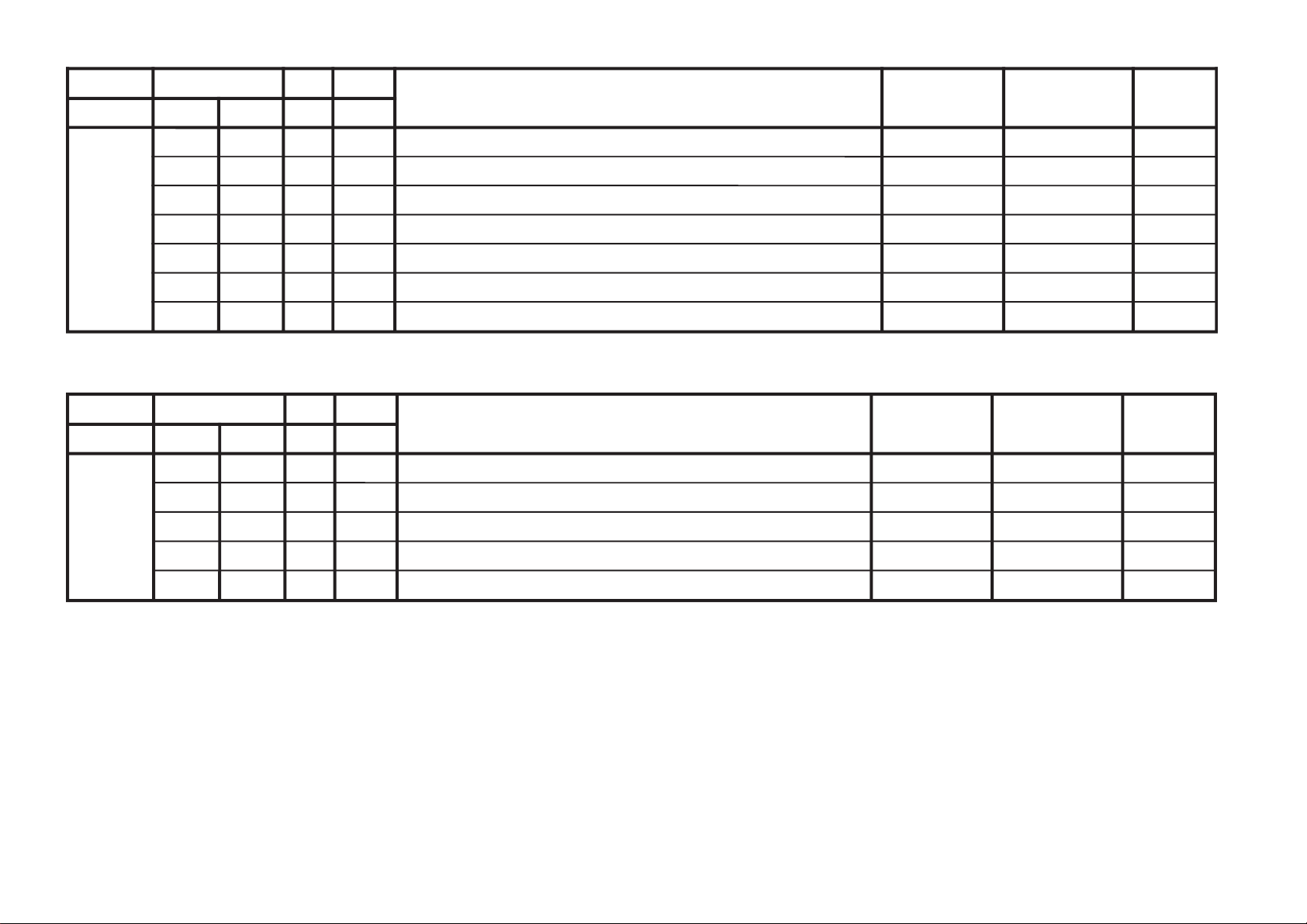

Category Function Illustration

GEOM 000 H Position

(HPOS)

GEOM 001 H Parallelogram

(HPAR)

GEOM 002 H Bow

(HBOW)

GEOM 003 Linearity

(VLIN)

GEOM 005 EW Width

(HSIZ)

Note: Adjust HSIZ

16.6 + -(SPCB) _ 50Hz

14.8 + -(PAL Monoscope) _ 50Hz

15.3 + -(NTSC Monoscope) _ 60Hz

GEOM 006 EW Parabola/Width

(EWPW)

GEOM 007 EW Upper Corner

(UCOP) Parabola

GEOM 008 EW Lower Corner

(LCOP) Parabola

GEOM 009 EW Trapezoid

(EWTZ)

GEOM 011 V-Amplitude

(VSIZ)

Note: Adjust VSIZ

12.6 + -(SPCB) _ 50Hz

11.3 + -(PAL Monoscope) _ 50Hz

11.7 + -(NTSC Monoscope) _ 60Hz

GEOM 012 S-Correction

(SCOR)

GEOM 013 V-Shift

(VPOS)

Tabl e 1

– 37 –

Page 39

VIF

SAW

SIF

SAW

MAIN

Power

Supply

Stdby

Power

TUNER

Y

U

V

24.576MHz

Rear YUV in

Rear AV in

Front AV in

Mon out

* FM Radio Function (STEREO model)

Mon

out

AV1

in

AV2

in

YUV

in

AC in ~

110 ~ 220V

CISPR/

PFC

Relay

LOW B

Stdy 3.3

AUDIO VCC

L

Audio Amp

ATT

NVM

V Def

H Def

DF

DQP

VM

RGB Amp

Rot Amp

LCC Amp

6W

R

6W

L,R

H

P

EW, Hd

L,R

V+, V-

PWM

RGB

SIRCS

KEY

buttons

PLL

I/O Port

I/O Port

VIF & SIF

POWER

Color

Decoder

YUV

Processor

Jungle

RGB

A

D

C

D

A

C

Stereo,

DSP

Micro

Text

CC & V-chip

LED

+B

KV-SZ252M50/M61/M81/N50/N60

5-1. BLOCK DIAGRAM

RM-GA002

– 38 –

DIAGRAMS

SECTION 5

Page 40

5-2. CIRCUIT BOARDS LOCATION

CV Board

KV-SZ252M50/M61/M81/N50/N60

RM-GA002

A Board

5-3. SCHEMATIC DIAGRAM INFORMATION

Note:

• All capacitors are in µF unless otherwise noted.

• All electrolytic capacitors are rated at 50V unless otherwise

noted.

• All resistors are in ohms.

kΩ = 1000Ω, MΩ = 1000kΩ

• Indication of resistance which does not have rating electrical

power is as follows.

Pitch: 5 mm

Rating electrical power 1/4W (CHIP: 1/10W)

• : nonflammable resistor.

• : fusible resistor.

• ¢ : internal component.

•: panel designation or adjustment for repair.

• All variable and adjustable resistors have characteristic curve

B unless otherwise noted.

• Readings are taken with a color-bar signal input.

no mark : Common