SONY KV-SW21M95 Service Manual

SERVICE MANUAL

BX1S

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-SW21M20 RM-GA002 South Africa

KV-SW21M80 RM-GA002 Pakistan

KV-SW21M95 RM-GA002 Russia SCC-V13N-A

MODEL COMMANDER DEST. CHASSIS NO.

(Except KV-SW21M95)

RM-GA002

(KV-SW21M95)

TRINITRON

®

COLOR TV

KV-SW21M20/M80/M95

RM-GA002

TABLE OF CONTENTS

Section Title Page

SELF DIAGNOSTIC FUNCTION................................... 3

1. DISASSEMBLY

1-1. 3D Box Removal.......................................................... 5

1-2. Rear Cover Removal .................................................... 5

1-3. Speaker Removal ......................................................... 5

1-4. Chassis Assy Removal ................................................. 5

1-5. Service Position ........................................................... 5

1-6. Terminal Bracket and J Board Removal ..................... 5

1-7. A Board Removal ........................................................ 6

1-8. Picture Tube Removal.................................................. 6

2. SET-UP ADJUSTMENTS

2-1. Beam Landing Adjustment .......................................... 8

2-2. Convergence Adjustment .............................................8

2-3. Focus Adjustment ...................................................... 10

2-4. G2 (SCREEN) Adjustments ...................................... 10

2-5 White Balance Adjustment ........................................ 10

3. CIRCUIT ADJUSTMENTS

3-1. Adjustment With Commander ................................... 11

3-2. Adjustment Method ................................................... 12

3-3. Picture Quality Adjustments...................................... 28

3-3-1. P MAX/Contrast Adjustment ......................... 28

3-3-2. Sub Color Adjustment .................................... 28

3-3-3. Sub Hue Adjustment ....................................... 28

3-3-4. Sub Bright Adjustment ................................... 28

3-4. Geometry Adjustments .............................................. 28

3-4-1. General Setting ............................................... 28

3-4-2. Pal 50Hz Normal Mode .................................. 29

Section Title Page

4. DIAGRAMS

4-1. Block Diagram ...........................................................30

4-2. Circuit Boards Location ............................................ 31

4-3. Schematic Diagram Information ............................... 31

4-3-1. A Board — (Block 001).................................. 32

4-3-2. A Board — (Block 002).................................. 34

4-3-3. A Board — (Block 003).................................. 36

4-3-4. A Board — (Block 004).................................. 38

4-3-5. A Board — (Block 005).................................. 40

4-3-6. A Board — (Block 006).................................. 42

4-3-7. A Board — (Block 007).................................. 44

4-3-8. C and J Boards Schematic Diagrams ............. 45

4-4. Voltage Measurement and Waveforms ...................... 46

4-5. Printed Wiring Boards ............................................... 49

4-6. Semiconductors .......................................................... 52

5. EXPLODED VIEWS

5-1. Picture Tube and Chassis........................................... 54

5-2 3D Speaker ................................................................. 54

6. ELECTRICAL PARTS LIST......................................... 56

OPERATING INSTRUCTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

KV-SW21M20/M80/M95

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self diagnostic function. If an error occurs, the STANDBY (1) indicator will automatically

begin to flash. The number of times the STANDBY (1) indicator flashes translates to a probable source of the problem. If an

error symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in

memory to reveal past problems and how often these problems occur.

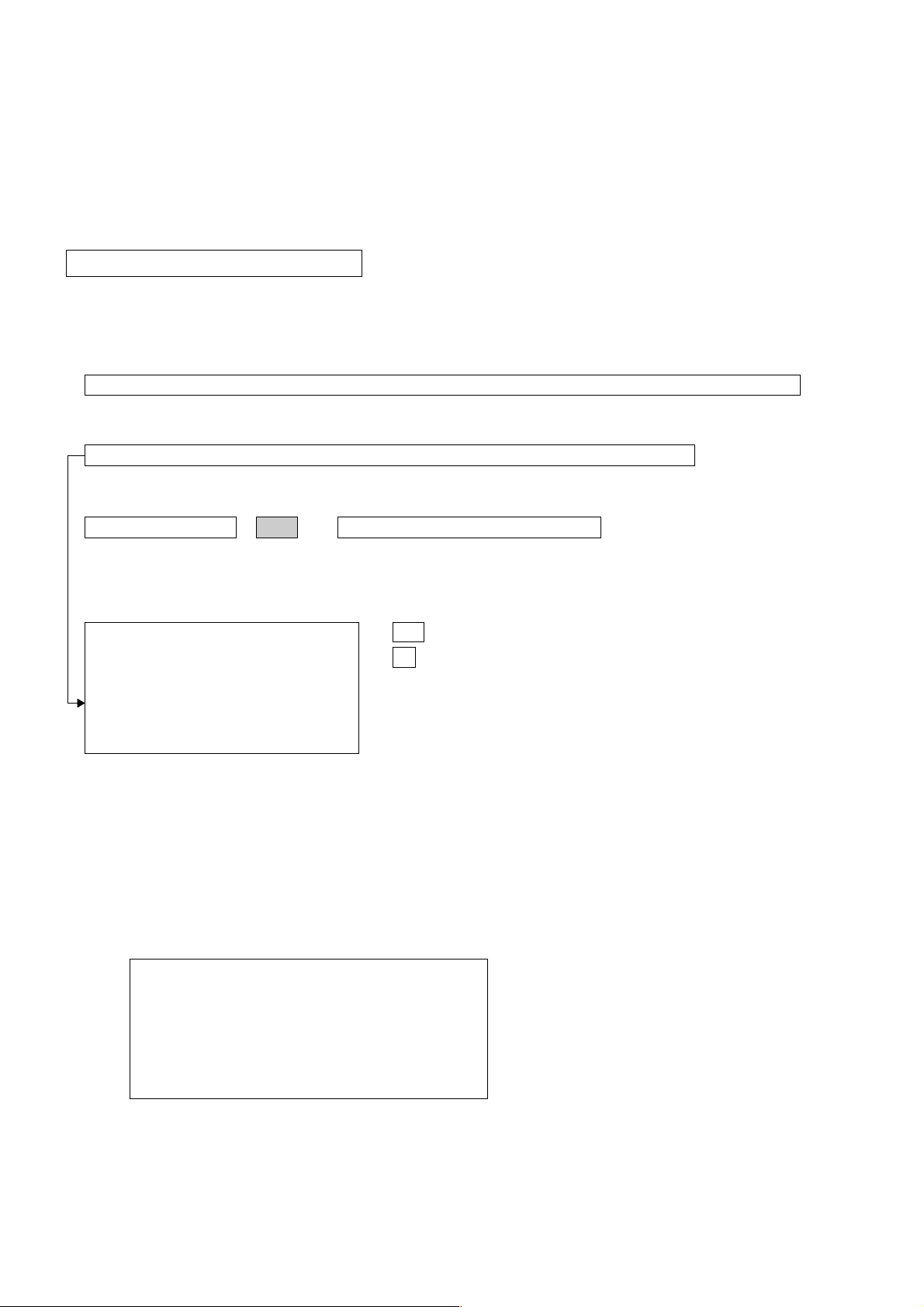

1. DIAGNOSTIC TEST INDICATORS

When an errors occurs, the STANDBY (1) indicator will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the indicator will identify the first of the problem areas.

Result for all of the following diagnosis items are displayed on screen. No error has occurred if the screen displays a "0".

RM-GA002

Diagnosis

Item

Description

No Power

+B overcurrent

(OCP)

V-Protect (OVP)

IK (AKB)

Power supply

NG (+5V) for

Video Processor

No. of timer

STANDBY (1)

indicator flashes

Does not light

2 times

4 times

5 times

8 times

Diagnostic Result

on screen display

–

2:0

or

2:1 ~ 255

4:000

or

4:1 ~ 255

5:0

or

5:1 ~ 255

8:0

or

8:1 ~ 255

Probable Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out (F600)

A board.

• H OUT (Q805) is shorted.

(A board)

IC751 is shorted. (C board)

•

• +13V is not supplied.

(A board)

• IC804 is faulty. (A board)

• Video OUT (IC1545) is

faulty. (A board)

• IC001 is faulty. (A board)

• Screen (G2) is improperly

adjusted.

• IC604 faulty.

• IC602 faulty.

Detected

Symptoms

• Power does not turn on.

• No power is supplied on

TV.

• AC Power supply is faulty.

• Power does not turn on.

• Load on power line is

shorted.

• Has entered standby state

after horizontal raster.

• Vertical deflection pulse is

stopped.

• Power line is shorted or

power supply is shorted.

• No raster is generated.

• CRT Cathode current

detection reference pulse

output is small.

• No power supply to CRT

ANODE.

• No RASTER is generated.

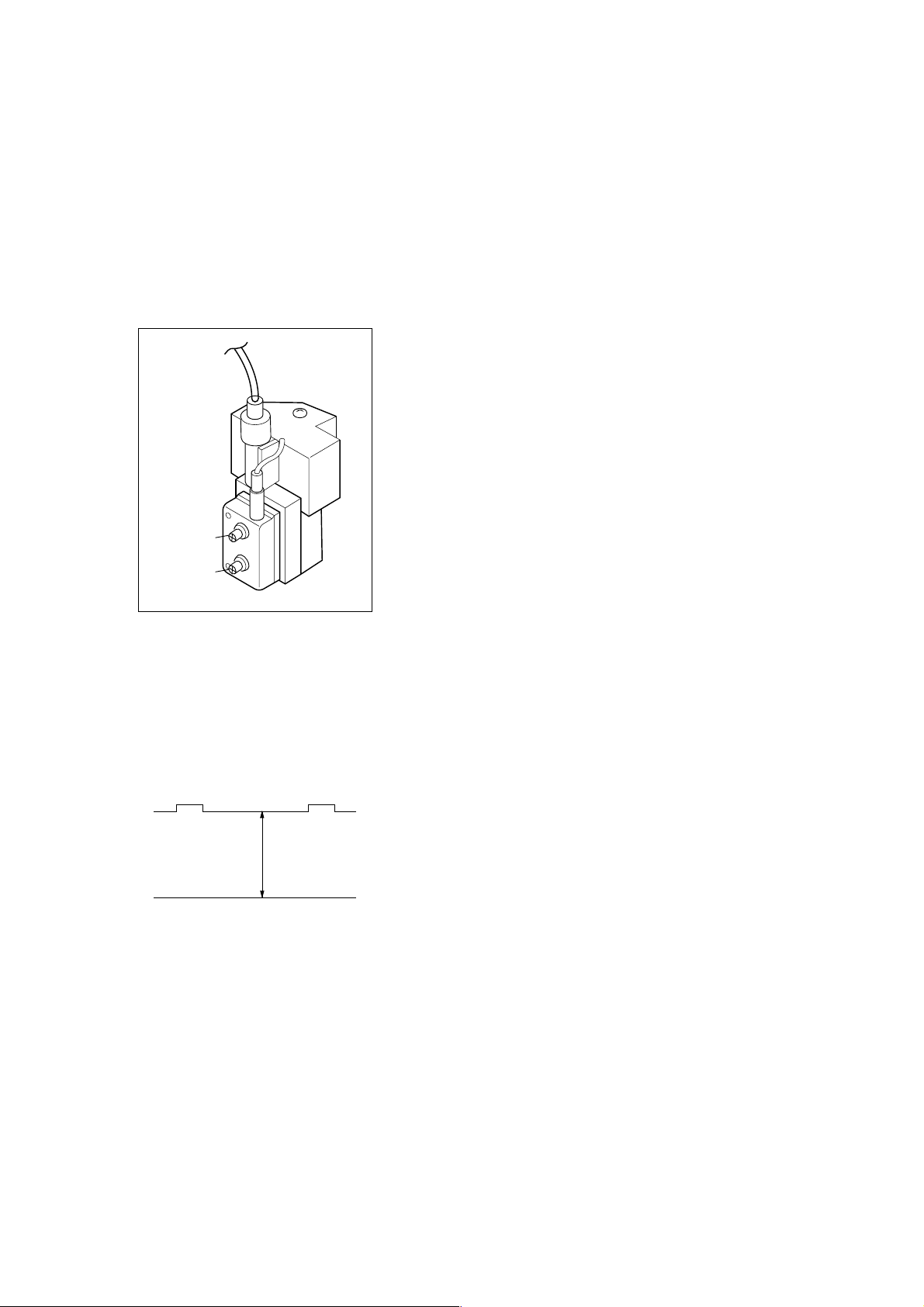

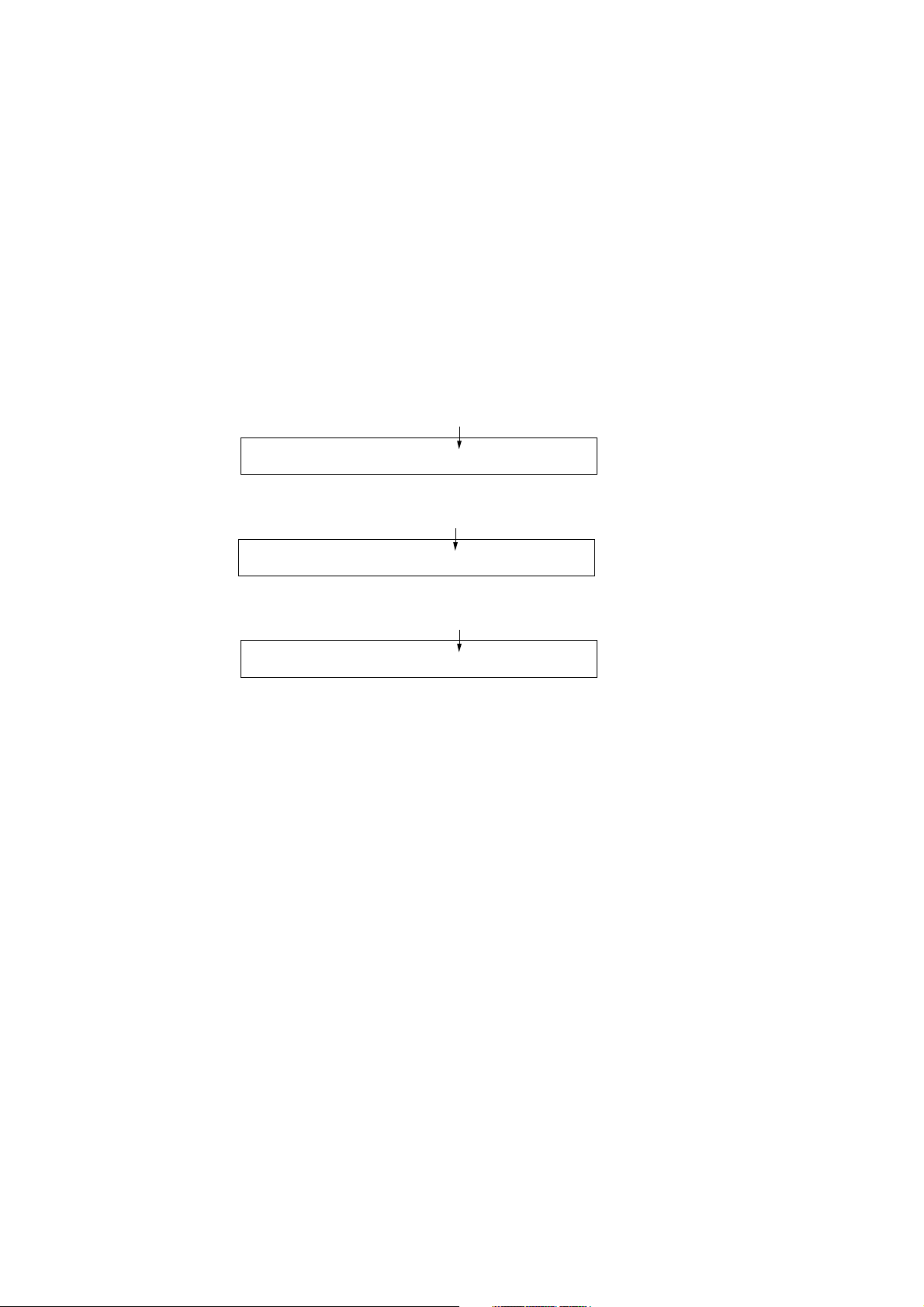

2. STANDBY INDICATOR BLINKING PROCESS

Lamp ON 300ms

Lamp OFF 300ms

The example above represents for 4 times blink

Lamp OFF 3 seconds

3. STANDBY INDICATOR ON TV FRONT PANEL

Standby indicator

– 3 –

KV-SW21M20/M80/M95

RM-GA002

4. SELF DIAGNOSTIC SCREEN DISPLAY

SELF DIAGNOSTIC

2 : 000

3 : 000

4 : 000

5 : 001

8 : 002

101 : N/A

5. HANDLING SELF DIAGNOSTIC SCREEN DISPLAY

No. Description Method

1. Display self diagnostic screen [Display] t [Channel ] t [Volume ] t [Power / TV]

2. Stop standby flash i) Turn off power switch on main.

3. Clear fault result [Channel ] t -

4. Quit self diagnostic screen Turn off power switch of remote commander or main unit.

"0" means no fault has been detected.

"1" means a fault has been detected.

"2" means two faults have been detected.

"N/A" means not available for this models.

5

Note: The above must be performed while TV is on standby mode.

ii) Unplug power cord from the outlet.

8

Note: Diagnostic results display on screen is not automatically cleared. Therefore,

clear result after completion of repair.

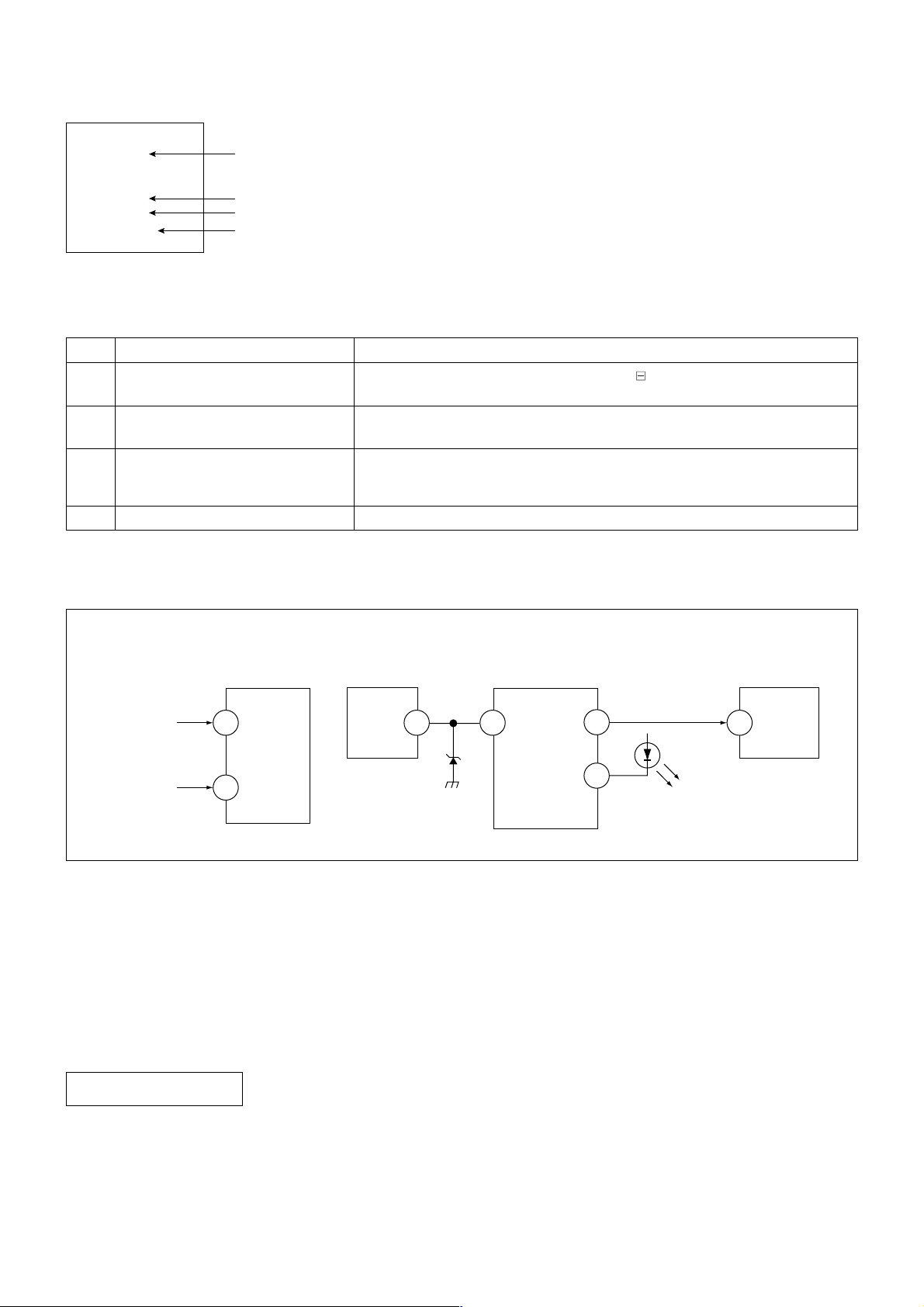

6. SELF-DIAGNOSTIC CIRCUIT

FROM

C BOARD

IC751 PIN 5

A BOARD

FROM

Q816

COLLECTOR

A BOARD

IC001

Y/CHROMA JUNGLE

IK

32

EHTO

A BOARD

IC804

V.OUT

F.B-PLS

A BOARD

IC001

SYSTEM

SDA1

3 1384

V.GUARD

RED LED

99

122

DISPLAY

A BOARD

IC003

MEMORY

5

SDA

[+B overcurrent $OCP%] Occurs when an overcurrent on the +B(135V) line is detected by pin 32 of IC001 (A board).

If the voltage of pin 32 of IC001 (A board) is more than 4V, the unit will automatically go to

standby.

[V-PROTECT] Occurs when an absence of the vertical deflection pulse is detected by pin 13 of IC001

(A board).

[IK $AKB%] If the RGB levels* do not balance within 15 sec after the power is turned on, this error will be

detected by IC001 (A board). TV will stay on, but there will be 5 times LED blinking.

POWER SUPPLY NG (+5V)

for VIDEO PROCESSOR

Occurs when IC001 internal HV protect detects an abnormal H-Pulse (frequency) due to

improper power supply to IC001. TV cuts off high voltage power of anode CRT. No picture will be

detected. eg: IC602, IC604 go faulty.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects IK.)

– 4 –

SECTION 1

DISASSEMBLY

KV-SW21M20/M80/M95

RM-GA002

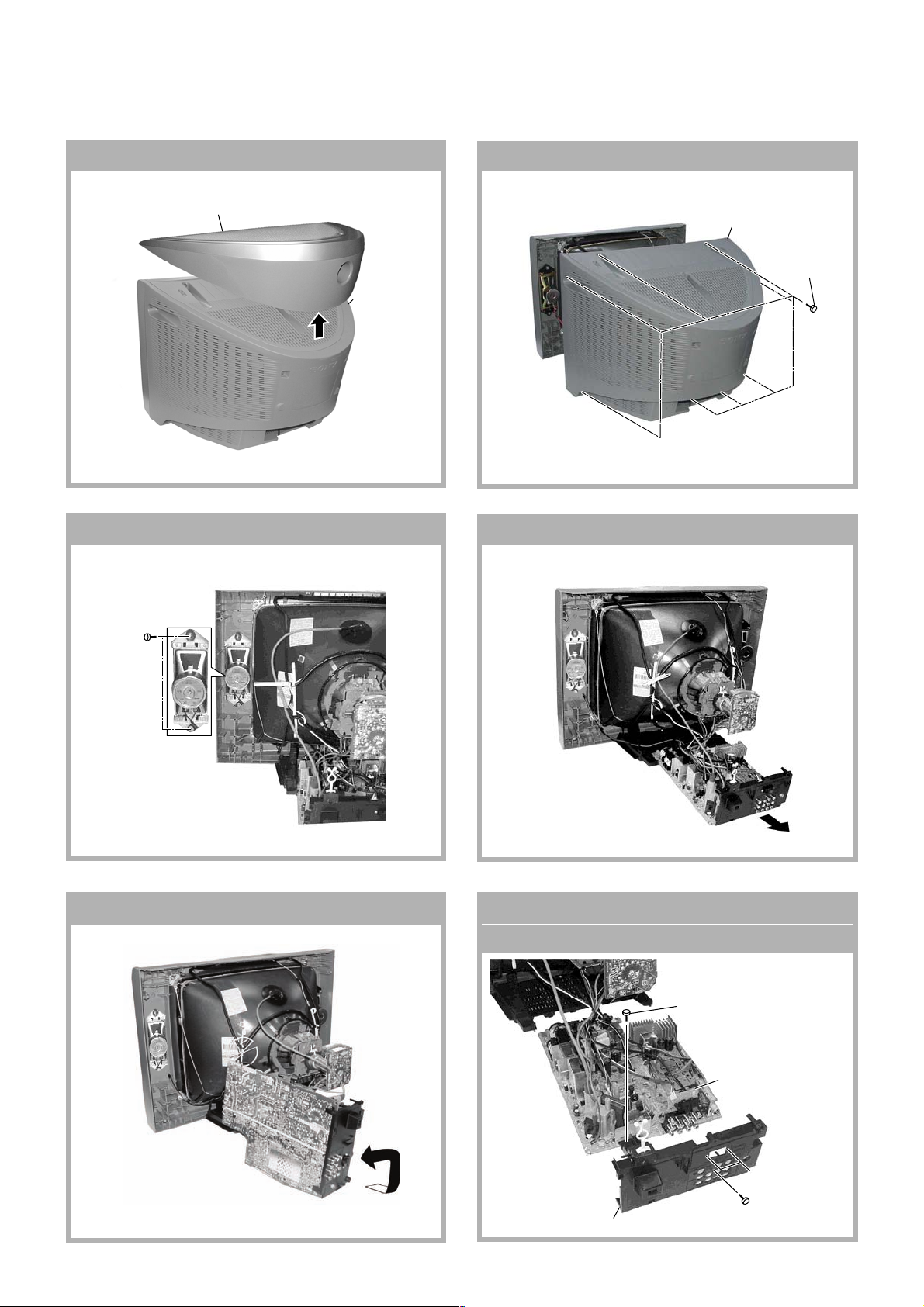

1-1 3D BOX REMOVAL (KV-SW21M95)

1

3D Speaker box assy

2

1-3. SPEAKER REMOVAL

1

Two screws

(Washer Head)

(+P4 x16)

Rear cover

1-2 REAR COVER REMOVAL

1-4. CHASSIS ASSY REMOVAL

2 Rear cover

Eight screws

1

(+BVTP 4

× 16)

1-5. SERVICE POSITION

– 5 –

1-6. TERMINAL BRACKET AND

J BOARD REMOVAL

1

One screw

(+

BVTP 3

5

(

One screw

2

+BVTP

3

Terminal bracket

(

× 12)

J Board

KV-SW21M95

Two screws

4

+BVTP

(

16

×

4

)

)

12

×

3

)

KV-SW21M20/M80/M95

RM-GA002

1-7. A BOARD REMOVAL

A Board

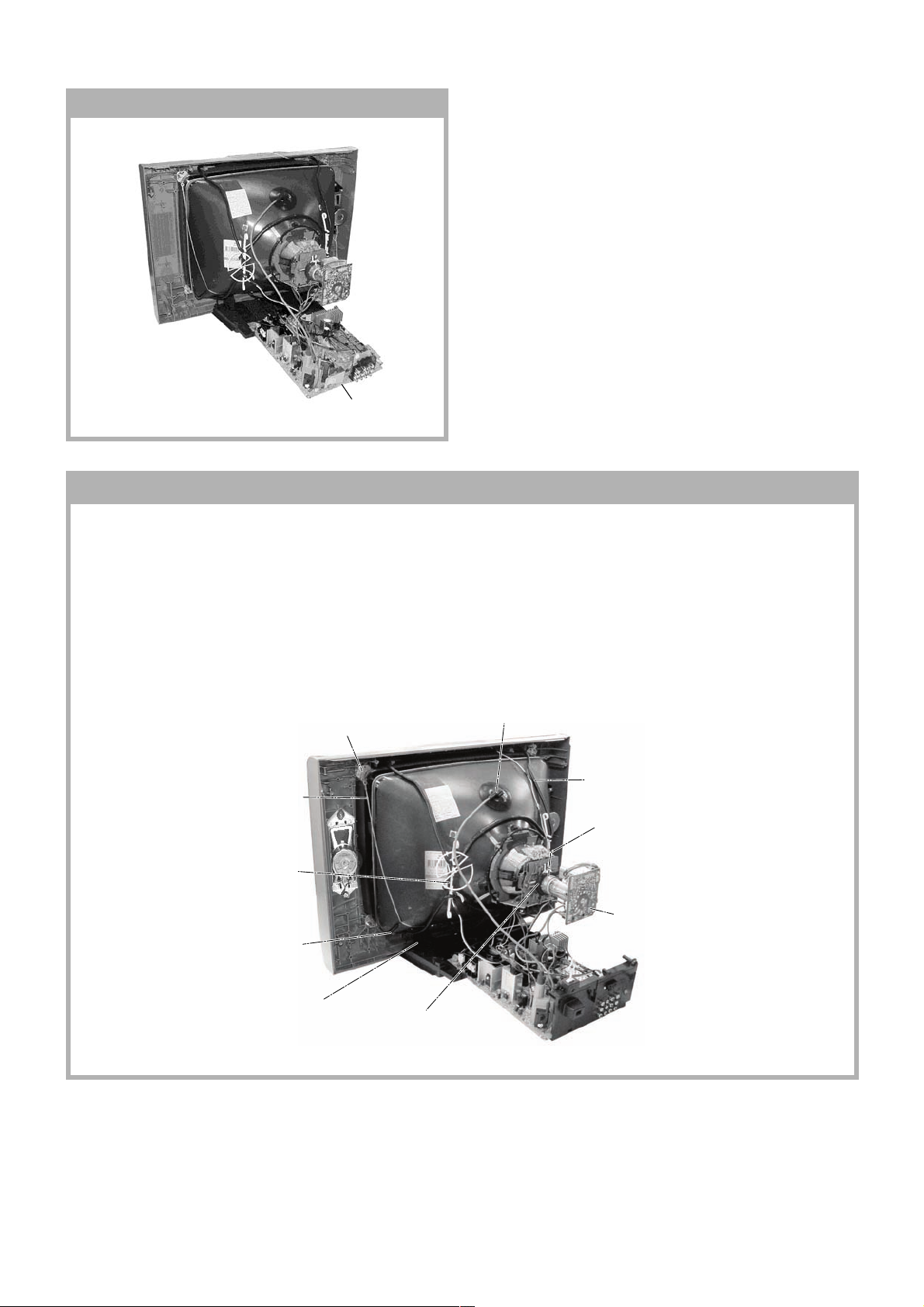

1-8. PICTURE TUBE REMOVAL

Note:

• The picture tube is upside down for (KV-SW21M20(South Africa)) only and the position for the anode cap and tension

springs are changed accordingly.

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom right

and left.

1) Remove the Rear Cover.

2) Unplug all interconnecting leads from the Deflection Yoke, Neck Assy, Degaussing Coils and CRT grounding strap.

Remove Chassis Assy.

3) Place the TV set with the CRT face down on a cushion (jig).

4

Anode Cap Removal

7

Degaussing Coil

6

Loosen the Neck Assembly

fixing screw and remove

Neck Assy & VM board

5

C Board Removal

0

Earth Coating Assy

8

Holder, DGC

Removal (x2)

qd

Screw, Tapping 5 + Crown Washer (x4)

9

Spring Tension

Removal (x2)

qs

Supports, CRT

Removal (x2)

qa

Loosen the Deflection Yoke

fixing screw and remove

– 6 –

KV-SW21M20/M80/M95

RM-GA002

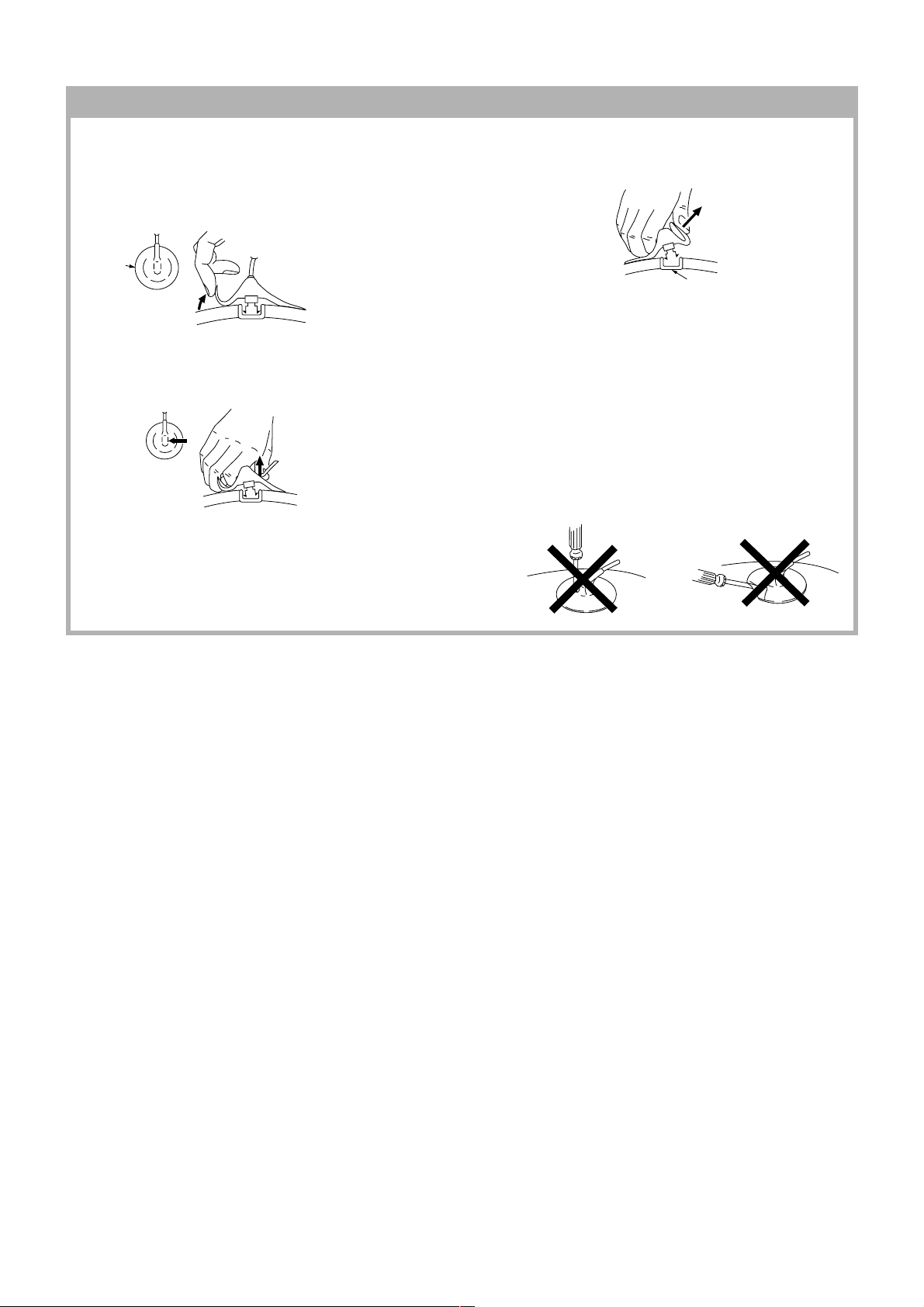

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or

carbon paint on the CRT.

• REMOVING PROCEDURES

A

A

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

B

B

2 Using a thumb pull up the rubber cap firmly in the direction

indicated by the arrow b.

C

Anode Button

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be removed by turning

up the rubber cap and pulling it up in the direction of the

arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with sharp

shaped objects.

2 Do not press the rubber too hard so as not to damage

the inside of anode-cap.

A metal fitting called the shatter-hook terminal is built

into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage the

rubber.

– 7 –

KV-SW21M20/M80/M95

RM-GA002

SECTION 2

SET-UP ADJUSTMENTS

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

The controls and switch should be set as follows unless

otherwise noted:

3. Focus

4. G2 (SCREEN)

5. White Balance

Picture control ......................................................... NORMAL

Brightness control ................................................... NORMAL

Note: Test Equipment Required

1. Pattern Generator

2. Degausser

3. DC Power Supply

5. Oscilloscope

6. Landing Checker

7. XCV Adjuster

4. Digital Multimeter

.................................................................................................................................................................................................................................

Preparation :

• Feed in the white pattern signal.

• Before starting, degauss the entire screen with the

degausser.

• In order to reduce the geomagnetism on the set's

picture tube, face it east or west.

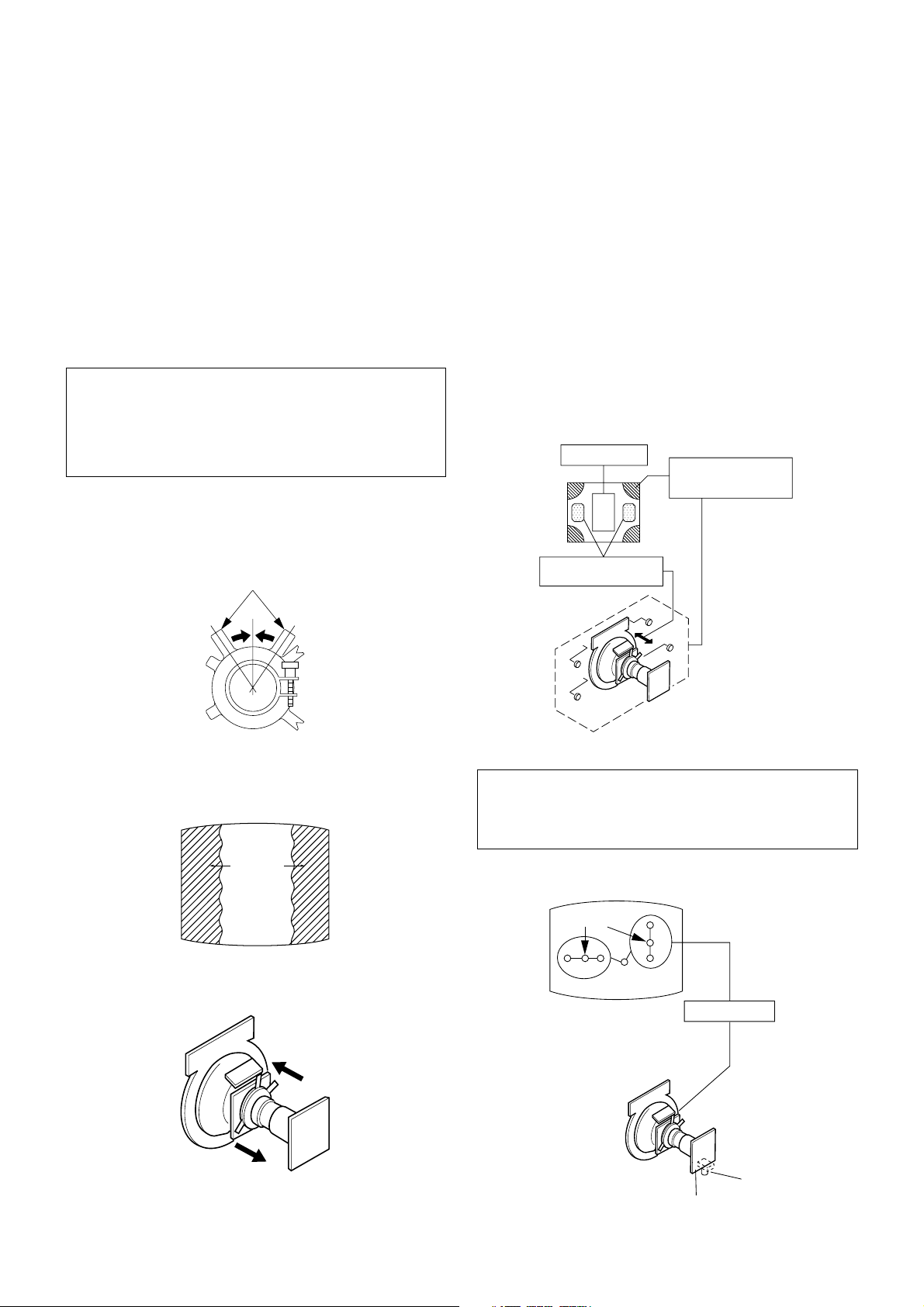

2-1. BEAM LANDING ADJUSTMENT

1. Input a raster signal with the pattern generator.

7. When the position of the DY is determined, tighten it

with the DY mounting screw.

8. If the beam does not land correctly in all corners of the

screen, use magnet disc to correct it.

Purity control

corrects this area.

a

b

d

c

Disc magnets or rotatable

disc magnets correct these

areas (a-d).

2. Loosen the deflection yoke mounting screw, and set the

purity control to the center as shown below.

Purity control

Deflection yoke positioning

corrects these areas.

3. Set the raster signal of the pattern generator to green.

4. Move the deflection yoke (DY) backward and adjust the

purity control so that green is in the center and blue and

red are at the sides evenly.

Blue

Red

Green

5. Then move the DY forward and adjust so that the entire

screen becomes green.

b

c

a

d

2-2. CONVERGENCE ADJUSTMENT

Preparation :

• Before starting, perform FOCUS adjustment.

• Picture mode STANDARD.

• Receive dot/cross hatch pattern.

a) Vertical Static Convergence

Center dot

R G B

R

G

B

4 pole magnet

6. Now switch over raster signal to red then blue and

confirm the condition.

RV750

H. STAT

C/CV Board

– 8 –

KV-SW21M20/M80/M95

ba

cd

a-d : screen-corner

misconvergence

RM-GA002

1. (Moving vertically), adjust the 4 pole magnet to converge

red, green and blue dots in the center of the screen.

2. Tilt the 4 pole magnet and adjust static convergence to

open or close the 4 pole magnet.

3. When the 4 pole magnet is moved in the direction of

arrow A and B, the red, green and blue dots moves as

shown below:

A

B

A

B

G

R

B

B

G

R

Moved RV750 (H.STAT)

RGGRB

B

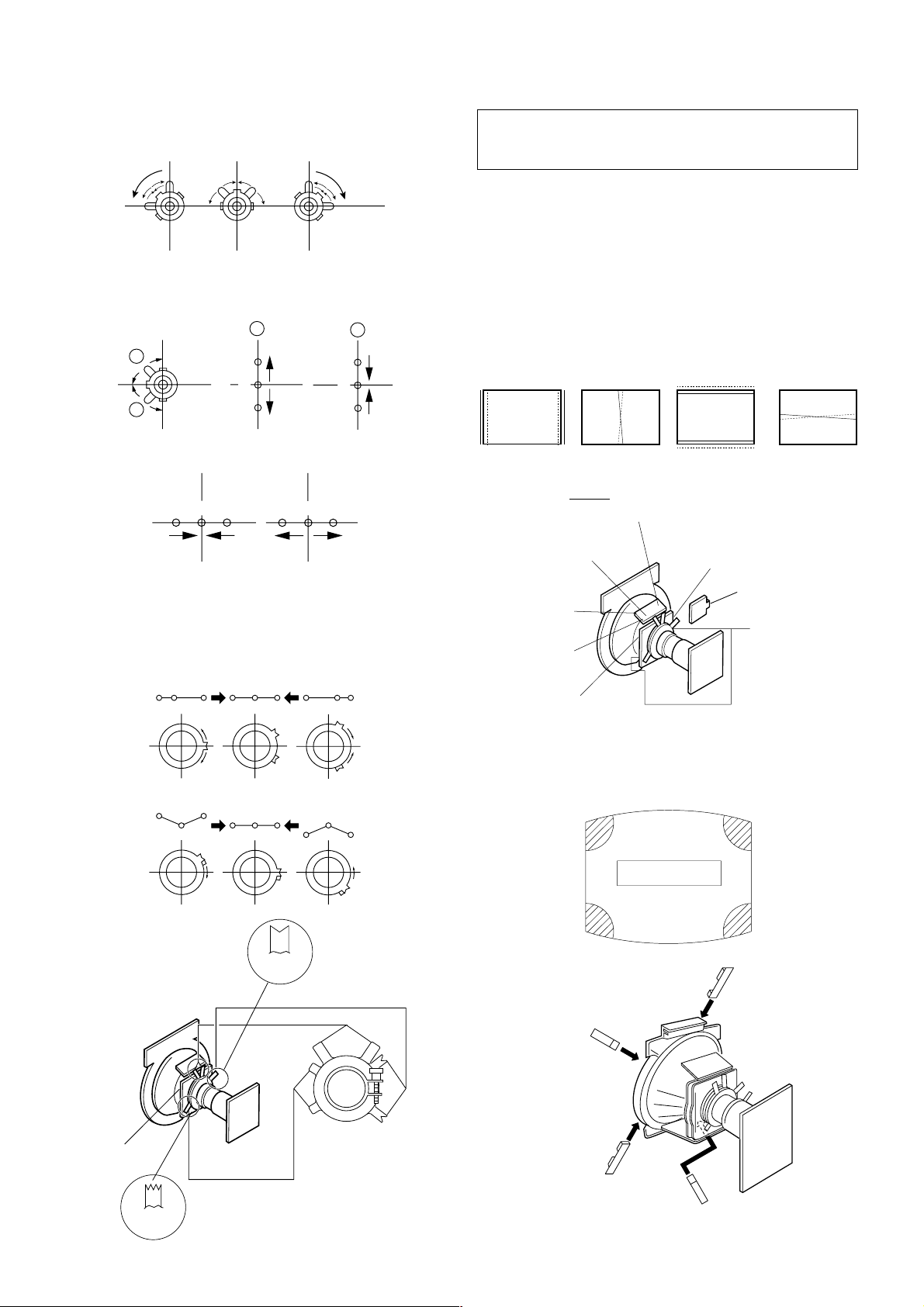

c) Convergence Rough Adjustment

Preparation :

• Before starting this adjustment, adjust the horizontal

and vertical static convergence.

Input cross hatch pattern.

i) TLH

Adjust the horizontal convergence of red and blue dots

by inserting TLH Correction Plate to the DY pocket (left

or right).

ii) YCH

Adjust YCH to balance Y axis.

iii) TLV

Adjust the vertical convergence of red and blue dots.

iv) XCV

Adjust XCV to balance X-axis.

ON DY:

RB

YCH

TLV

B

R

R

B

TLV

B

R

TLH

XCV

b) Horizontal Static Convergence

If the blue dots does not converge with the red and green

dots, use the 6 pole magnet to adjust in the manner

described below.

RG B R G B R GB

RB

G

RG

6 Pole

Magnet

6 Pole Magnet

Purity

GB

RB

YCH

TLV

XCV

DY pocket

DY pocket

TLH Plate

XCV

d) Screen Corner Convergence

Affix a Piece A (90), Convergence Correct/Permaloy Assy

Correction to the misconverged areas.

b1

a1

DY pocket

4 Pole Magnet

4 Pole

Magnet

– 9 –

a1~d1:Piece A (90), Convergence Correct

Permaloy Assy Correction

d1

or

c1

KV-SW21M20/M80/M95

RM-GA002

2-3. FOCUS ADJUSTMENT

FOCUS adjustment should be completed before W/B

adjustment.

1. Receive digital monoscope pattern.

2. Set Picture Mode to "DYNAMIC".

3. Adjust focus VR to obtain a just focus at the center of

the screen.

4. Change the receiving signal to white pattern and blue

back.

5. Confirm magenta ring is not noticeable. In case magenta

ring is obvious, then adjust FOCUS VR to balance

magenta ring and FOCUS.

FOCUS

2-5. WHITE BALANCE ADJUSTMENT

1. Set to Service Mode.

2. Input white raster signal using signal generator.

3. Set the following condition:

Picture "DYNAMIC", PICT 006 "WTS" to 00.

4. At Highlight condition, select WHBL 003 "GDRV" and

004 "BDRV" with 1 and 4 button of the remote

commander then adjust the data with 3 and 6 button.

5. At Cutoff, select WHBL 000 "BKOR" and 001 "BKOG"

and adjust the data.

6. Perform adjustment at Highlight and Cutoff condition

until it reaches its target.

7. Write data into memory by pressing [MUTING] t -.

8. Finally set PICT 006 "WTS" back to its original data.

SCREEN

2-4. G2 (SCREEN) ADJUSTMENT

1. Set the following condition:

– Picture and Brightness to "STANDARD".

– TV to Video mode.

– WHBL 016 "RGBB" to 01

2. Connect R, G, B of the C/CV board cathode to

oscilloscope.

3. Adjust Brightness to obtain the cathode value to the

value stated below.

165 ± 2VDC

4. Adjust SCREEN VR on the FBT until the scanning line

disappears.

5. Finally set WHBL 016 "RGBB" back to 00.

– 10 –

SECTION 3

CIRCUIT ADJUSTMENTS

3-1. ADJUSTMENTS WITH COMMANDER

Service adjustments to this model can be performed using the supplied remote commander RM-GA002.

a. ENTERING SERVICE MODE

With the unit on standby

t [DISPLAY] t 5 t [VOL $+% ] t [POWER]

This operation sequence puts the unit into service mode.

This screen display is:

KV-SW21M20/M80/M95

RM-GA002

category in decimal item name in decimal NG service command frequency video input name

GEOM 006 HSIZ 031 x SERVICE 60 S VIDEO 1

release ID version in binary for factory color system (decimal)

SUS01 0.69U 0001 1111 FF FF NTSC3 65535

111 11 11 1 7 11 FG xy 111 000000 000000

S : for Sony

A : Aiwa

U S : US/Latin/Taiwan

E U : Europe

G A : General Area

J P : Japan

item no. service data NVM field channel no./

software service data reserved power on time

Status Byte Status Byte

Flash DCXO #1 SSD #2 SSD

VDSP_C Flag

CO_LOCKED

VDSP

Detected Stereo Type (Direct Value from CZ_ Stereo_Mode)

111 Needed for Nicam DCXO aligment Purpose

xy Value of x = 0 - Unknown, 1 - BTSC, 2 - A2, 3 - NICAM,

4 - KOREAN, 5 - Japan, 6 - AV Stereo

Value of y = 0 - Mono, 1 - Stereo, 2 - Bilingual, 4 - SAP/Single

0 1 : serial no. of the M/P release

for each destination

b. METHOD OF CANCELLATION FROM SERVICE MODE

Set the standby condition (Press [POWER] button on the commander), then press [POWER] button again, hereupon it becomes

TV mode.

c. METHOD OF WRITE INTO MEMORY

1. Set to Service Mode.

2. Press 1 (UP) and 4 (DOWN), to select the adjustment item.

3. Change item by pressing 3, 6.

4. Press [MUTING] button to indicate WRITE on the screen.

5. Press - button to write into memory.

1, 4 Select the adjustment item.

r

3, 6 Raise/lower the data value.

r

[MUTING] Writes.

r

- Executes the writing.

d. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, pull out the plug from AC outlet, and then plug into AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confirm adjustments were made.

– 11 –

KV-SW21M20/M80/M95

RM-GA002

e. OTHER FUNCTION VIA REMOTE COMMANDER

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

Display, - Service data initialization (Be sure not to use usually.)

2, 5 Select Device or Category

3-2. ADJUSTMENT METHOD

Item Number 000 HPOS

This explanation uses H POSITION as an example.

1. Select "000 HPOS" with the 1 and 4 buttons, or 2 and 5.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is IF for PAL reception.)

4. Write with the [MUTING] button. (The display changes to WRITE.)

5. Execute the writing with the - button. (The WRITE display will be changed to red color while excuting, and back to

SERVICE.)

Example on screen display :-

GREEN

GEOM 000 HPOS 039 SERVICE 50 VIDEO 1

Adjusted with 3 and 6 buttons.

GREEN

GEOM 000 HPOS 039 WRITE 50 VIDEO 1

write with [MUTING].

RED

GEOM 000 HPOS 039 WRITE 50 VIDEO 1

Write executed with -.

The WRITE display

then returns to green

SERVICE

Use the same method for all Items. Use 1 and 4 to select the adjustment item, use 3 and 6 to adjust, write with

[MUTING], then execute the write with -.

Note : 1. In [WRITE], the data for all items are written into memory together.

2. For adjustment items that have different standard data between 50Hz or 60Hz, be sure to use the respective input

signal after adjustment.

– 12 –

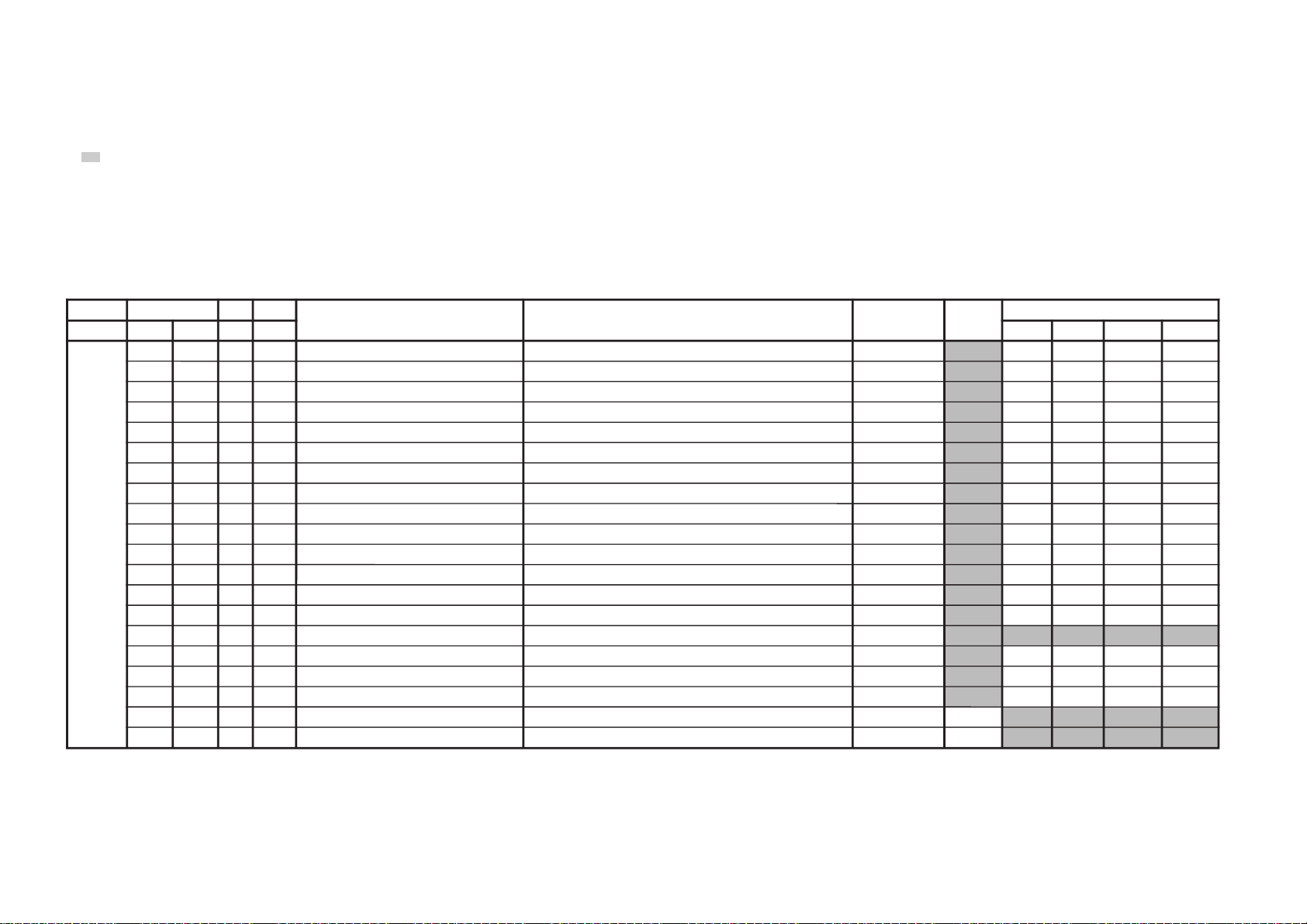

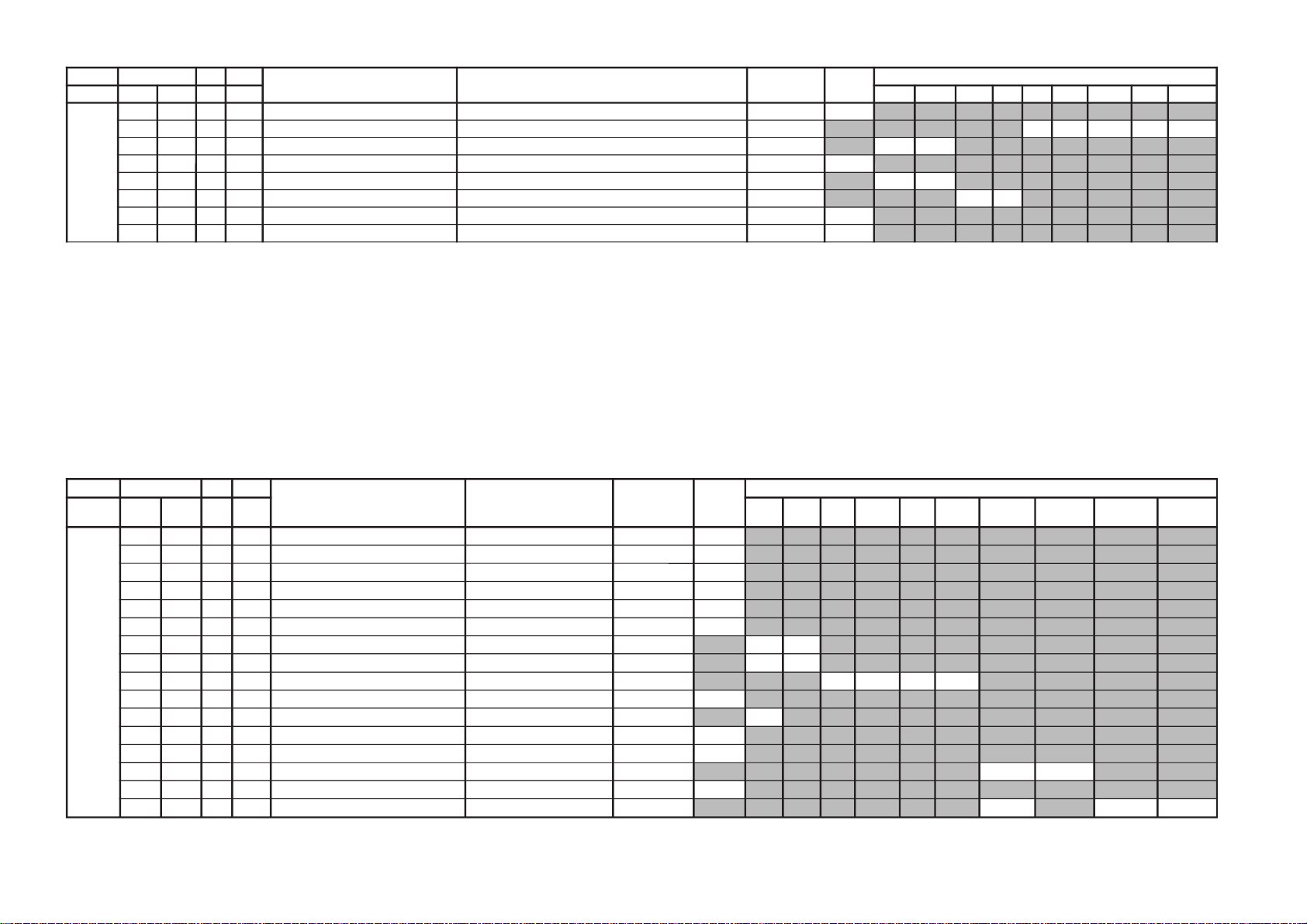

Adjustment Item Tabl e

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 05)3:4(06)3:4(05w)3:4(06w)3:4(

MOEG000SOPH130360)SH(tfihSlatnoziroH >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4< rossecorP-VT

13/0413/5413/2413/24

100RAPH130360margolellaraPlatnoziroH >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

13131313

200WOBH130360woBlatnoziroH >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

13131313

300NILV130360ytiraeniLlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

13131313

400RCSV130360llorcSlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

13131313

500ZISH130360)WE(htdiWWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

13/6213/8213/5213/52

600WPWE130360)WP(htdiW/alobaraPWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

13/42131313

700POCU710360alobaraPrenroCreppUWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

71/1371/1371/1371/13

800POCL710360alobaraPrenroCrewoLWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

71/1371/1371/1371/13

900ZTWE130360muizeparTWE >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4< 13131313

010PLSV130360)SV(epolSlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

13131313

110ZISV510360edutilpmAlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

51/4251/625151

210ROCS410360)CS(noitcerroC-S >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

41/5241/5241/5241/52

310SOPV130360)HSV(tfihSlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

13/9313/821313

410MOZV130360)ZV(mooZlacitreV >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

510LBH000100edoMgniknalBBGR >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

10101010

610FBW700510)FBW(gniknalBediWfognimiT >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

70707070

710RBW700510)RBW(gniknalBediWfognimiT >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4<

01010101

810LBS000100gniknalBecivreS >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4< 00

910YPOC000100aeraMVNzH06/05llaotatadOEGehtypoC >)Z/F/N/ZW(*)06/05(neercS9:61<>06w/05w/06/05neercS3:4< 00/X

NOTE

a) In the initial value (detailed) column, the data after the slash mark ("/") refers to NTSC model data.

No ("/") means data is common for Multi and NTSC model.

b) Item remarked "*" and "**", please refer page 25 for the data.

c)

shaded items are no data.

d) Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and for each mode.

e) Note for the Different Data those are the standard data values written on the microprocessor. Therefore, the data values of the models are stored respectively in the memory.

In the case of a device replacement, adjustment by rewriting the data value is necessary for some items.

f) Multi ver 6.16, NTSC ver 6.16N.

– 13 –

KV-SW21M20/M80/M95

RM-GA002

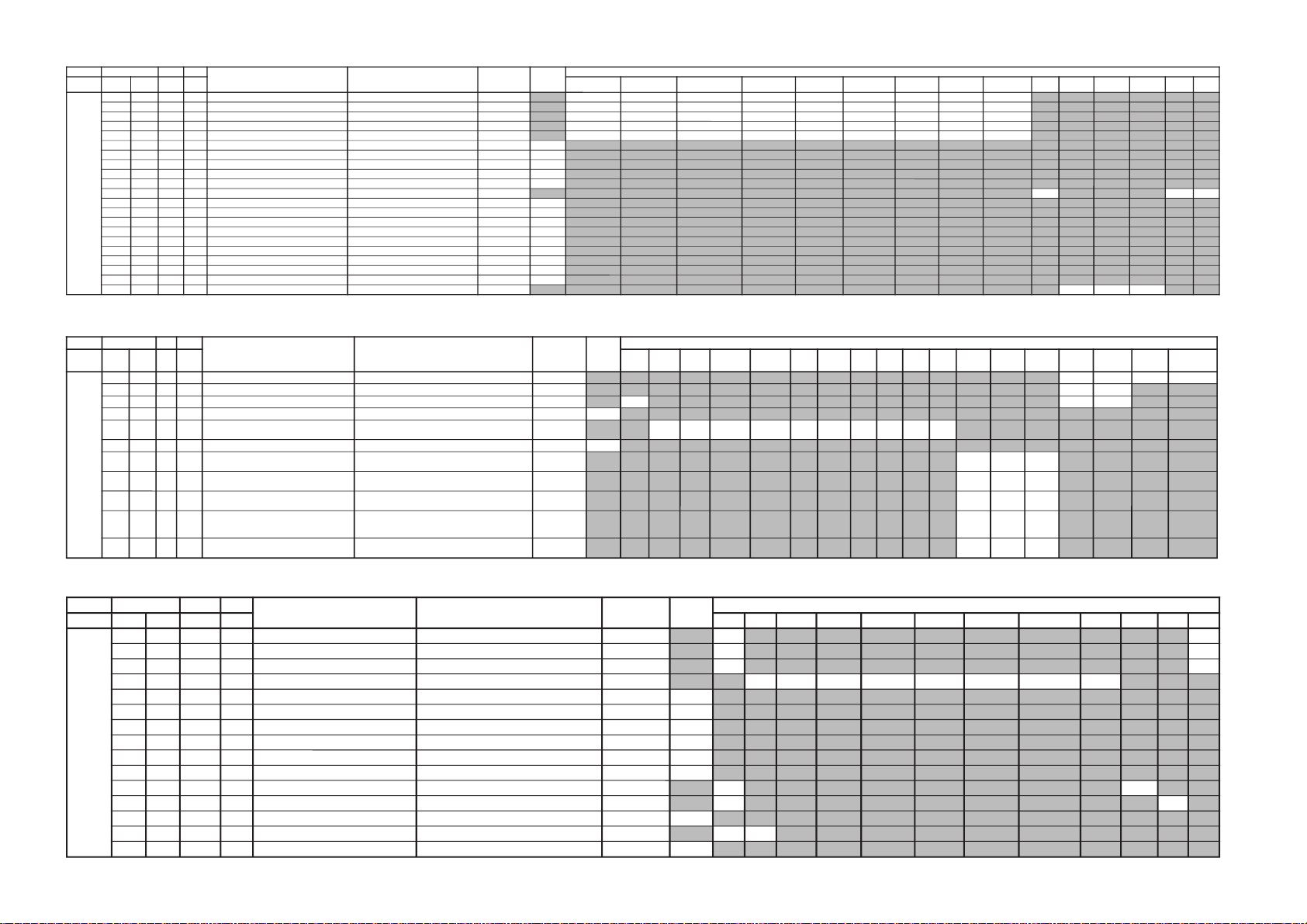

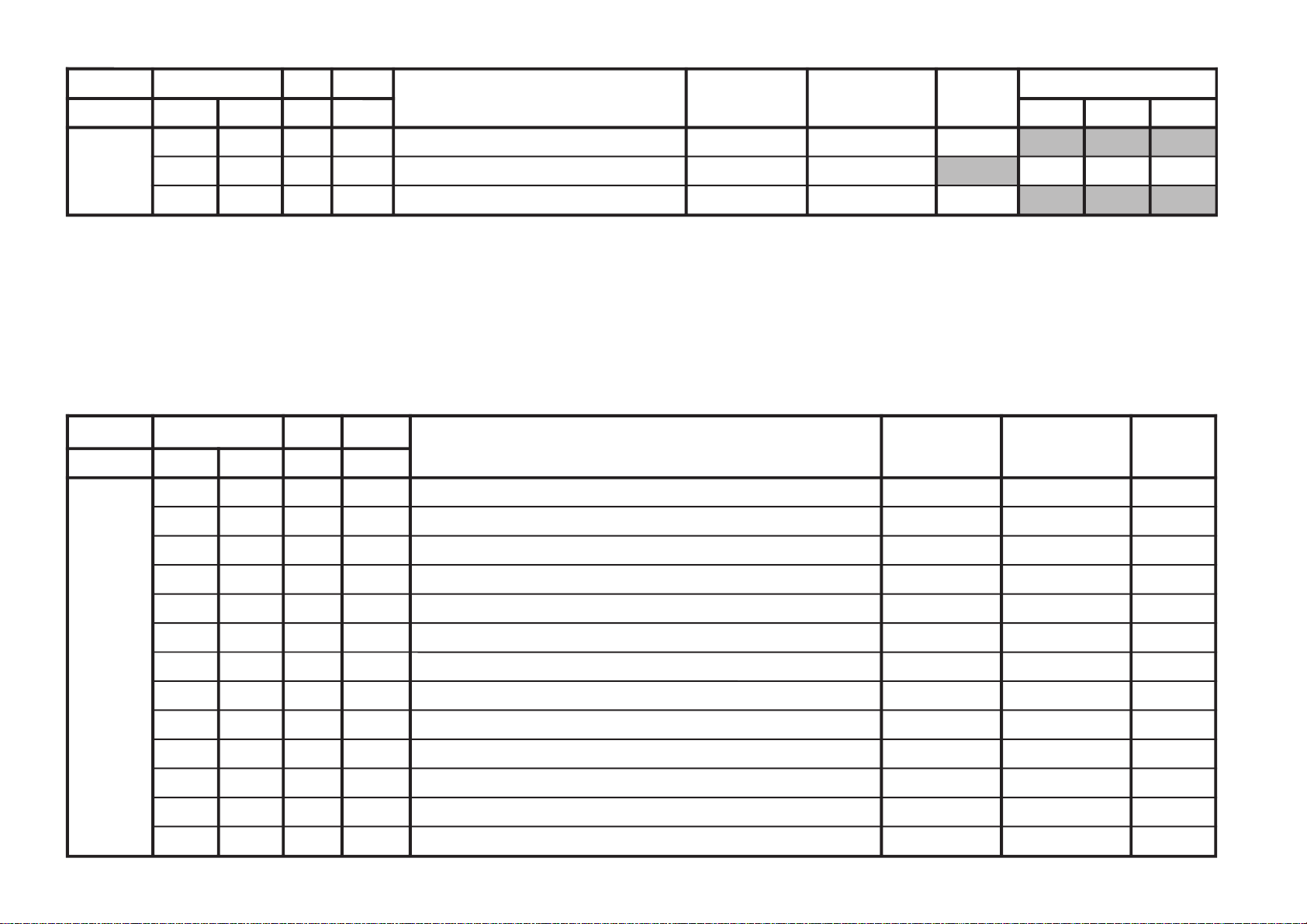

KV-SW21M20/M80/M95

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

VUYlap05

)VT(

lap05

)oediV(

maceS05

)VT(

maceS05

)oediV(

VT0606

)oediV(

VUY05VUY06BGR05BGR06edomciP

0

edomciP

1

edomciP

2

VToediV

ediWVT

)3:4(

ediWoediV

)3:4(

JDAS000XAMP360360mumixaMerutciP >ediW/lamroN</)ediW/lamroN(*)oediV/VT(rossecorP-VT

73737373

100EUHS700510euH-buS oediV/VT

7070

200PHSS510360ssenprahS-buS VUY/oediV/VT

53

84/3353

300OHSS000700)ciPtnegilletnI(tesffOssenprahS-buS enon60

400LOCS130360roloC-buS /)oediv(maces05/)vt(maces05/)oediv(lap05/)vt(lap05

BGR06/BGR05/VUY06/VUY05/oediv06/VT06

00/131300/1313131300/131300/1313

500OOCS000300)ciPtnegilletnI(tesffOroloC-buS enon20

600CIP130721;)dilavni(001>;)dilav(001~0:AG[lortnoCerutciP

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

00108001

700LOC130721;)dilavni(001>;)dilav(001~0:AG[lortnoCroloC

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

69/650505

800TRB130721;)dilavni(001>;)dilav(001~0:AG[lortnoCssenthgirB

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

050505

900EUH130721;)dilavni(001>;)dilav(001~0:AG[lortnoCeuH

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ledomSUhtiw)0-5(hE1#TNITotdneS*(

)ataDteseRresU=lanosreP:AG(ledoMerutciP

050505

010PHS130721;)dilavni(001>;)dilav(001~0:AG[lortnoCssenprahS

])dilavni(6tiberongi;)dilav(36~0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

060505

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD srehtOVUY)VT(LAP)VT(CSTN)VT(MACES)oediV(LAP)oediV(CSTN)oediV(MACESTUPNI-SMACESCSTNVT

CY000QRFP000300yaleDdnaycneuqerFretneCgnikaeP rehto/VTrossecorP-VT

00

00

100APR000300toohSrevO&erPoitaR rehto/VT

20

30/20

200OPR200300skaePevitageN&evitisoPfooitaR rehto/VT

20

10/20

300YLDY210510yaleD-Y TUPNI-S/VUY+)OEDIV/VT(*)MACES/CSTN/LAP(

9080/1150/808011901190

400TAMC000300xirtaM)ASU/napaJ(CSTNroMACES-LAP 00

500LCA100100gnitimiLroloCcitamotuA 10

600BC000100ycneuqerFretneCssapdnaBamorhC )xif0:oediV*(VThtiwylnodilav00/10

700OBS100300tesffOkcalBMACES 00

800ESHC100300ytivitisneStnedICSTN/LAP 20

900OLC000100retliF)lleB(ehcolCfoycneuqerFretneC 00

010PRTC000100edoMparTamorhC srehto/MACES

00

00/10

110SPB000100eniLyaleDdnab-esaBamorhCfossapyB srehto/CSTN

00

10

210OCF000100nOroloCdecroF 00

310TNIT130360lortnoCtniTdnaB-esaB srehto/VUY

1313

410VUT000100slangiSVUnolortnoCtniT 00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC

pmeTloC

)rehtoLOOC(

pmeTloC

)rehtoMRAW(

pmeTloC

)rehtoLARTUEN(

pmeTloC

)VUYLOOC(

pmeTloC

)VUYMRAW(

pmeTloC

)VUYLARTUEN(

pmeTloC

)BGRLOOC(

pmeTloC

)BGRMRAW(

pmeTloC

)BGRLARTUEN(

VUY0edomciP1edomciP2edomciPVToediV

LBHW000ROKB130360)10=BFO(BtesffO,)00=BFO(RtesffOleveLkcalB )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetlocrossecorP-VT

131313131313131313

100GOKB130360GtesffOleveLkcalB )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

131313131313131313

200VRDR730360RtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetlocrossecorP-VT

737373737373737373

300VRDG730360GtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

73/1373/1373/1373/1373/1373/13-/13-/13-/13

400VRDB730360BtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

73/1373/1373/1373/1373/1373/13-/13-/13-/13

500GPL000100teserPniaGBGR enon10

600RGP130721)RGP(RniaGteserP enon04

700GGP130721)GGP(GniaGteserP enon04

800BGP130721)BGP(BniaGteserP enon04

900FONG000510tesffOniaGteserP enonpoolCCC51

010TRBS130360ssenthgirB-buS VUY/BGR/srehtO

13

1313

110ORBS000300)ciPtnegilletnI(tesffOssenthgirB-buS enon00

210LGE000100metsySCCCnipooLniaGelbanE enon00

310LGS000300metsySCCCnitnerruChgiHfonoitceleS enon00

410BKA000100noitazilibatStnerruCkcalB enon00

510SBC000100gnitimiLtnerruCmaeBfoecneuqeSlortnoC enon00

610BBGR000300gniknalBBGR enon00

710GBLB000100tuptuOneerG&eulBfogniknalB enon00

810BFO000100eulBtesffOleveLkcalB enon10

910RBSN000510tesffOssenthgirBdradnatSnoN enon00

020PBW000300)woL:3,2,lamroN:1,hgiH:0(gnitteSpmeTroloC edoMerutciP

001010

RM-GA002

– 14 –

– 15 –

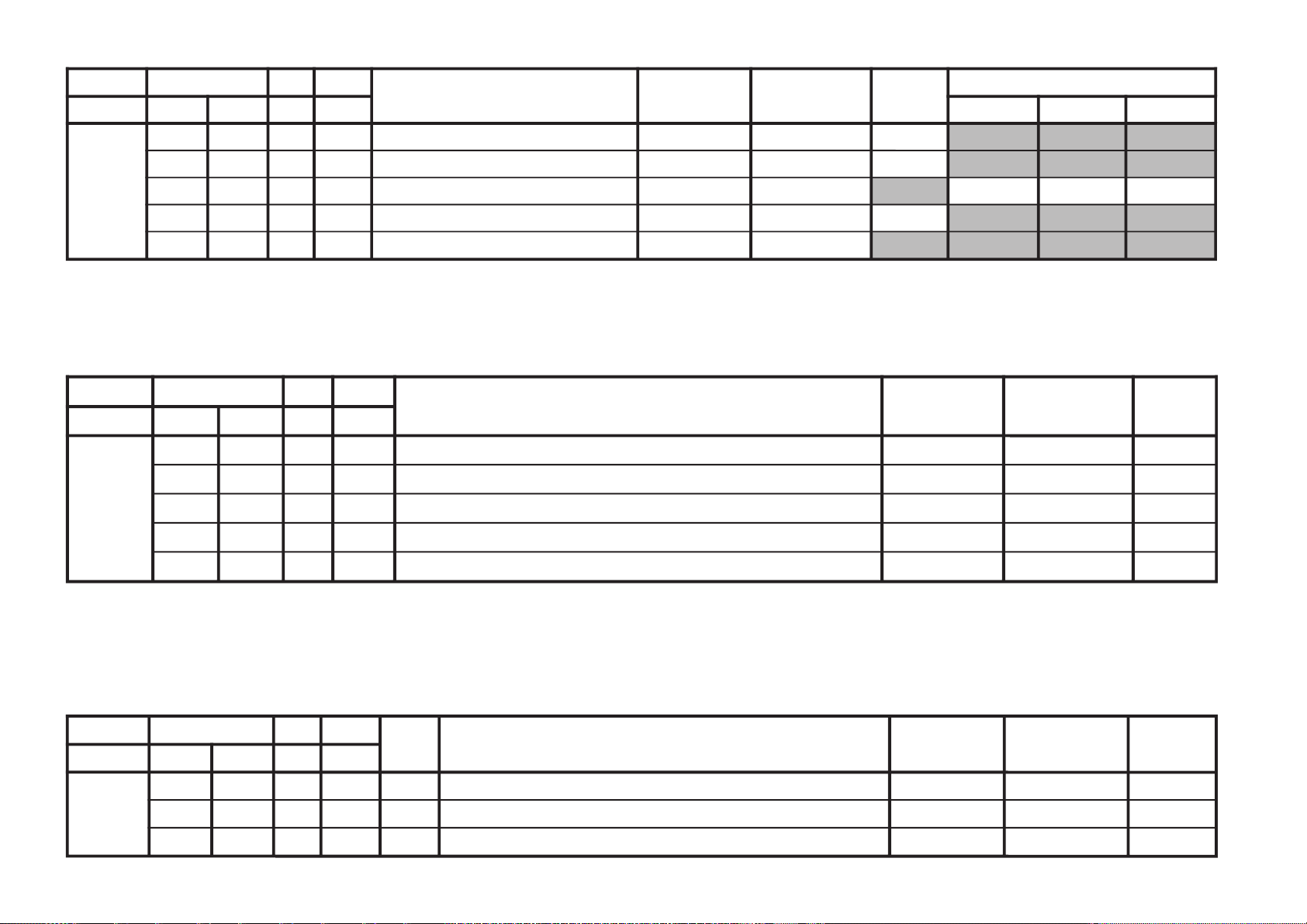

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 05)3:4(06)3:4(srehtOVUYVToediVtxeteleTpi-VTlangisoN

CNYS000SYS000100tupnICNYSYnonoitazinorhcnyS rossecorPVT00

100OF000300tnatsnoCemiT1esahP )FR(langisoNrogninuTotuA/txeteleT/oediV/FFOPIVT/NOPIVT

303000/100000

200DIV000100edoMtnedIoediV 06/05

0000

300LSF000100cnySlacitreVrofleveLgnicilSdecroF 00

400LSS000100rotarapeScnySleveLgnicilS 06/05

0000

500DIVS100700noitacifitnedIoediVrofnoitceleSecruoS srehtO/VUY

0000

600FROF000300ycneuqerFdleiFdecroF 30

700KVM000100gniyeKnoisiVorcaM 10

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

srehtOeviLVT

)nyD(

VT

)srehtO(

oediV

)nyD(

oediV

)srehtO(

pmeTroloC

)HGIH(

pmeTroloC

)srehtO(

roloC

)WOL(pmeT

pmeTroloC

)LAMRON(

TCIP000LDAC700510leveLevirDedohtaC 00

100AFC000300edoMretliFbmoC 00

200COS200300leveLgnippilCtfoS 00

300LWP100100hctiwSgnitimiLetihWkaeP 10

400LTHW600510gnitimiLetihWkaeP 00

500MAG100100ammaG 00

600STW100300hctertSetihWdnalortnoCammaGsrehtO/eviL

2020

700RFT000100langiSecnanimuLfooitaRrefsnarTCDsrehtO/eviL

1010

800ROC300300gniroC )srehto/anyD(*)oediV/VT(

00000000

900OROC000300)ciPtnegilletnI(tesffOgniroC 20

010SKB300300hctertSkcalBsrehto/BGR

20

110SAA100100hctertSkcalBehtffohctiwSotaerAkcalB 10

210KSD000100lortnoCnikScimanyD 00

310SLB000100hctertSeulB )SREHTO/HGIH(pmetloc

0000

410SLBN000100tiucriChctertSeulBnoitarepO 00

510RRN000100noitcudeRdeRnoN )LAMRON/WOL/HGIH(pmetloc

10

1010

KV-SW21M20/M80/M95

RM-GA002

KV-SW21M20/M80/M95

JVTytilanoitcnuF

laitinI

egnaR

noitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

FIV000DFIO630360rotaludomeDFItesffO rossecorP-VT63

100TCGA130360revo-ekaTCGA 13

200MTS000100edoMgninuThcraeS 10

300DG000100langiS1SBVCnoyaleDpuorG 00

400SCGA100300deepSCGAFI 10

500IFF000100LLPFIretliFtsaF 00

600IANL000100eulavlaitinitibANLpmAFR 00

700TANL591522leveLdlohserhTpmAFR 591

800NSNL400700dlohserhTleveLNSpmAFR 30

900DSNL200700dlohserhTporDleveLNSpmAFR 10

010XENL610360gnimiTporDNSkcehcpmAFR 03

110RTHC840721edoMresUpmAFRtesotgrPotuAretfadlohserhTlennahC 52

210OSUT000100desUrenuTynoS 10/00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD VUYoediVVT

WS0002VC000100noitceleSlangiStupnI2SBVC 00

100OVS10030084@niPISBVC/OVS/OVFIfonoitcnuFVUY/oediV/VT

201010

200LFD000100noitcetorPhsalF 10

RM-GA002

– 16 –

– 17 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

MEDS000SWMF000300rotaludomeDMFrofnoitceleSwodniW rossecorP-VT20

100SSQ100100 )metsysMitlumAGrofA/N(edoMreifilpmA)SSQ(dnuoStilpSisauQ *

200BPB000100retliFssapdnaBdnuoSfossapyB 00

300OLMA000100dnuoSMAroflangiStuptuOoiduA 00

400CVPH000100lortnoCemuloVenohPdaeH 00

JVTytilanoitcnuF.tinIegnaRataDnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

TXT000VXT930360XIFspilihProfnoitisoPlacitreVtxeteleT redoceDtxeT00/93

100DHT010721XIFtfihSegdEevitcAcnys-HtxeteleT 00/01

200RBT510130XIFssenthgirBBGRtxeteleT 00/41

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0edomciP1edomciP2edomciP

MV000DBGR300700tuptuOMVottuptuOBGRfoyaleDenonrossecorP-VT40

100AMV300300tuptuOMVfoedutilpmAenon00

200PAMV200300)FFO:3,2,woL:1,hgiH:0(gnittesMVedoMerutciP

001000

300OMMV300300edoMMV 10

400AMVF400400)erawtfoSlluF(tuptuOMVfoedutilpmAsrehto/MACES

KV-SW21M20/M80/M95

RM-GA002

– 18 –

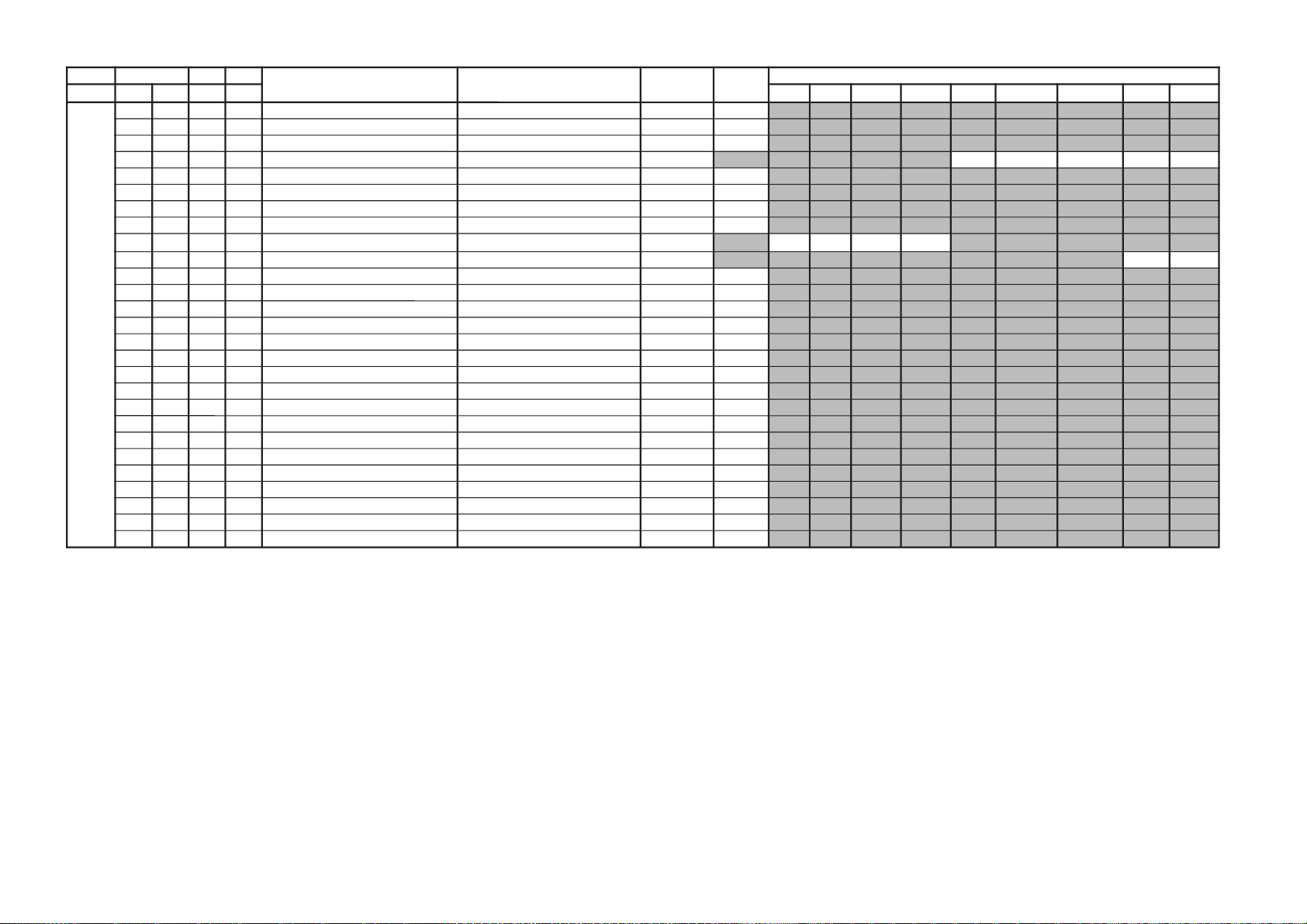

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD VToediVbuSFRbuSoediV

ffOWOW/SRSdnuorrusurToeretsIonomI

PSDS000LBB000510ruotnoCEBB DSS00

100HBB000510ssecorPEBB 00

200WLBB000510tesffOruotnoCEBB 60

300FOVS000510tesffOemuloVedoMtceffE/dnuorruS onomI/oeretsI/dnuorrusurT/)WOW/SRS(ffO

4011406040

400DAL000130tsujdAleveLredoceD 50

500MAL000130tsujdAleveLonoM 50

600NAL000130tsujdAleveLmaciN *

700SAL000130tsujdAleveLPAS 50/80

800AAL000130tsujdAleveLCDA buSoediV/buSFR/kpSretnec/oediV/FR

0000-/00-/00

900FES300700tceffEoeretS/onoMelbidercnI onomI/oeretsI

5030

010SAB000510tesffOssaBniaM *

110ERT000510tesffOelberTniaM *

2101QE000510tesffO)zH001(dnaBlennahCniaMrezilauqE *

3102QE000510tesffO)zH003(dnaBlennahCniaMrezilauqE *

4103QE000510tesffO)zH0001(dnaBlennahCniaMrezilauqE 00

5104QE000510tesffO)zH0003(dnaBlennahCniaMrezilauqE *

6105QE000510tesffO)zH0008(dnaBlennahCniaMrezilauqE *

710TCFB500700lortnoCEBBdnaBUD,EBD 00

810NECS100510lortnoCretneCD3SRS 40

910APSS000510lortnoCecapSD3SRS 10

020WHBB000510edomWOWnitesffossecorpEBB 00

120ERTS200700edomdnuorrusroftesffOelberT 10

220THBB000510edomVTnitesffOEBB 00

320ERTT200700edomVTnitesffOelberT 20

420SABV000300emulovresunodnepedtesffOssaB 00

520ERTV000300emanresunodnepedtesffOelberT 00

620SABT200700VTroftesffOssaB 00

KV-SW21M20/M80/M95

RM-GA002

Loading...

Loading...