REVISION HISTORY

AG3E

CHASSIS

MODEL

KV-DR34M97

NO. SUFFIX DATE SUPP / CORR DESCRIPTION

1 -01 2002/3 -- 1st. Issue

PART NO. : 9-872-294-01

SERVICE MANUAL

AG3E

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-DR34M97 RM-991 Hong Kong SCC-U79B-A

MODEL COMMANDER DEST. CHASSIS NO.

TRINITRON

®

COLOR TV

KV-DR34M97

RM-991

Power requirements 220-240V AC, 50/60 Hz

Power consumption (W) Indicated on the rear of the TV

Television system B/G, I, D/K, M

Color system PAL, PAL 60, SECAM, NTSC3.58, NTSC4.43

Stereo/Bilingual system NICAM Stereo/Bilingual B/G, I;

Channel coverage

B/G VHF: E2 to E2

I UHF: B21 to B68

D/K VHF: C1 to C12, R1 to R12

M VHF: A2 to A13

˘(Antenna) 75-ohm external terminal

Audio output (Speaker) 6W + 6W

3D WOOFER 15W

Number of terminal

DVideo Input: 4 Output: 1 Phone jacks; 1 Vp-p, 75 ohms

≥ Audio Input: 4 Output: 1 Phone jacks; 500 mVrms

Video) Y: 1 Vp-p, 75 ohms

2 (Headphone) Output: 1 Stereo minijack

Picture tube 34 in

Tube size (cm) 86 Measured diagonally

Screen size (cm) 80 Measured diagonally

Dimension (w/h/d,mm) 894 × 690 × 569

Mass (kg) 85

SPECIFICATIONS

A2 Stereo/Bilingual B/G

UHF: E21 to E69

CATV: S01 to S03, S1 to S41

CATV: S01 to S03, S1 to S41

UHF: C13 to C57, R21 to R60

CATV: S01 to S03, S1 to S41, Z1 to Z39

UHF: A14 to A79

CATV: A-8 to A-2, A to W+4, W+6 to W+84

(S Video) Input : 2 Y: 1 Vp-p, 75 ohms

unbalanced, sync negative

C: 0.286 Vp-p, 75 ohms

(Component Input : 1 Phono jacks:

sync negative

B/CB: 0.7 Vp-p, 75 ohms

P

P

R/CR: 0.7 Vp-p, 75 ohms

Audio: 500mVrms

Note

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD,

OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

Design and specifications are subject to change without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

TABLE OF CONTENTS

KV-DR34M97

RM-991

Section Title Page

SELF DIAGNOSTIC FUNCTION .......................................4

1. DISASSEMBLY

1-1. Rear Cover Removal .................................................. 7

1-2. 3D Speaker Box Removal .......................................... 7

1-3. Speaker Removal ........................................................ 7

1-4. Chassis Assy Removal ................................................ 7

1-5. DH Board Removal .................................................... 7

1-6. Service Position .......................................................... 7

1-7 Service Position on TV Stand .................................... 8

1-8. Terminal Bracket Removal ......................................... 8

1-9. B3 and D5 Boards Removal ....................................... 8

1-10. F1 Board Removal ...................................................... 8

1-11. BC1 and P Boards Removal ....................................... 8

1-12. H1 and H2 Boards Removal....................................... 9

1-13. A and D Boards Removal........................................... 9

1-14. Picture Tube Removal ................................................ 9

2. SERVICE JIG .............................................................. 11

3. CIRCUIT BOARDS LOCATION ................................. 11

4. ADVANCE OPERATION

4-1. "RESET" Function ................................................... 12

Section Title Page

7. DIAGRAMS

7-1. Block Diagram ......................................................... 40

7-2. Schematic Diagram .................................................. 49

(1) A Board Schematic Diagrams ............................ 50

(2) B3 Board Schematic Diagram ............................ 54

(3) D Board Schematic Diagram.............................. 56

(4) D5 Board Schematic Diagram ........................... 58

(5) C Board Schematic Diagram .............................. 60

(6) P Board Schematic Diagram .............................. 62

(7) BC1 Board Schematic Diagram ......................... 64

(8) H1 Board Schematic Diagram ........................... 66

(9) H2, DH and J Boards Schematics Diagrams ..... 68

(10)

F1 and VM Boards Schematics Diagrams ..........

7-3. Voltage Measurement and Waveforms..................... 72

7-4. Printed Wiring Boards and Parts Location .............. 86

7-5. Semiconductors ........................................................ 98

8. EXPLODED VIEWS

8-1. Speaker Bracket ...................................................... 101

8-2. 3D Speaker ............................................................. 101

8-3. Chassis .................................................................... 102

8-4. Picture Tube ............................................................ 103

9. ELECTRICAL PARTS LIST ...................................... 104

70

5. SET-UP ADJUSTMENTS

5-1. Beam Landing .......................................................... 13

5-2. Convergence Adjustment ......................................... 14

5-3. Focus Adjustment ..................................................... 16

5-4. Neck Assy Twist Adjustment ................................... 16

5-5. G2 (SCREEN) and White Balance Adjustment ....... 16

6. CIRCUIT ADJUSTMENTS

6-1. Adjustment With Commander ................................. 17

6-2. Adjustment Method .................................................. 17

6-3. Picture Quality Adjustments .................................... 36

6-4. Sub Hue/Col Adjustments ........................................ 36

6-5. Deflection Adjustments ............................................ 37

6-6. A Board Adjustment After IC003 (MEMORY)

Replacement ............................................................. 38

6-7. Picture Distortion Adjustment.................................. 39

OPERATING INSTRUCTIONS

– 3 –

KV-DR34M97

RM-991

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically

begin to flash.

The number of times the lamp flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER

lamp flash indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom cannot

be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past

problems and how often these problems occur.

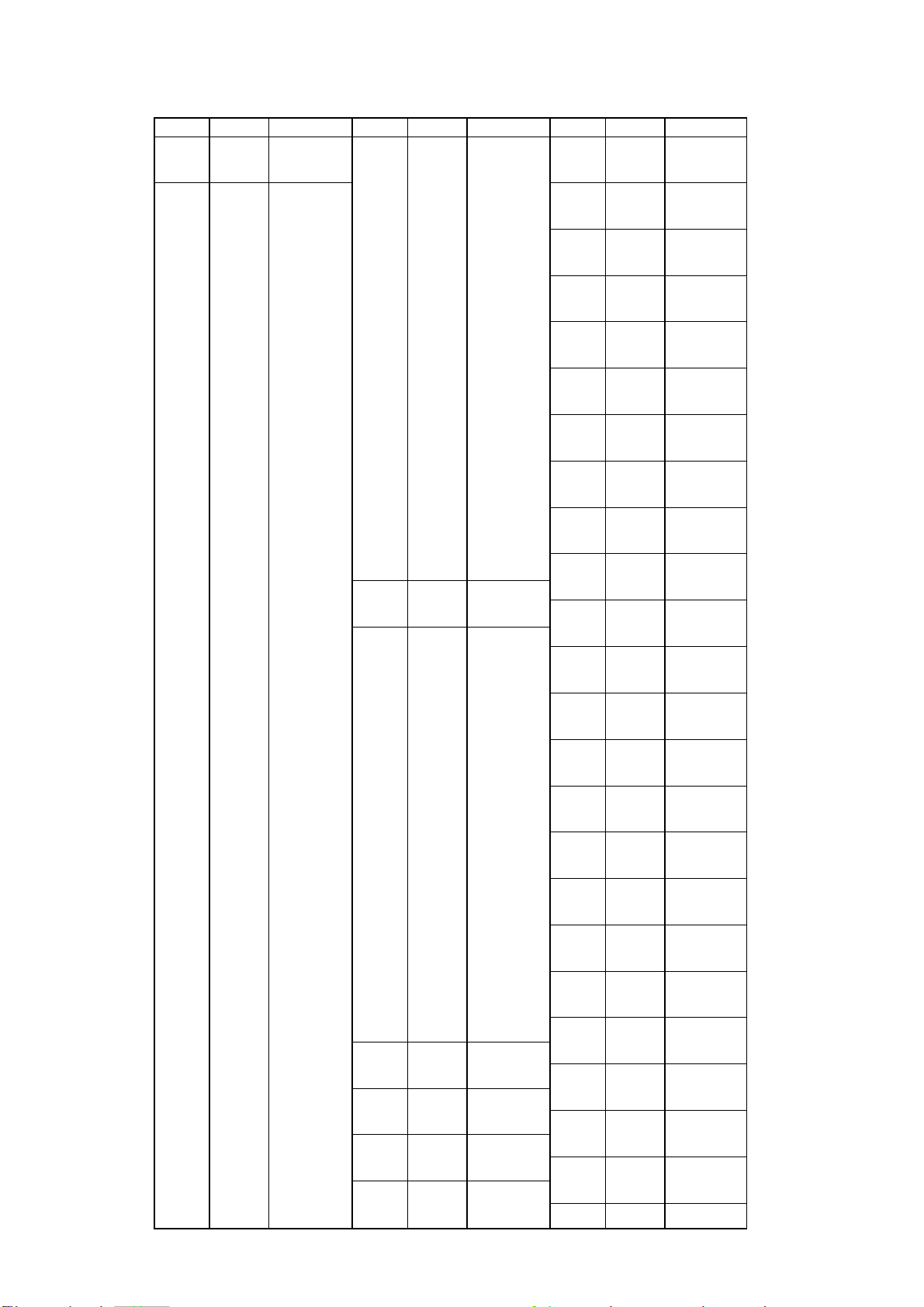

1. DIAGNOSTIC TEST INDICATORS

When an error occurs, the STANDBY/TIMER lamp will flash a number of times to indicate the possible cause of the

problem. If there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occured if the screen displays a “0”.

Diagnostic

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP)

• +B overvoltage

(OVP)

• Vertical deflection

failure

• White balance

failure (no

PICTURE)

• Horizontal

deflection failure

• Micro reset

Note 1: Refer to screen (G2) Adjustment in section 5-5 of this manual.

No. of times

STANDBY/TIMER

lamp flashes

Does not light

2 times

3 times

4 times

5 times

6 times

—

Self-diagnostic

display/Diagnostic

result

—

002:000 or

002:001~255

003:000 or

003:001~255

004:000 or

004:001~255

005:000 or

005:001~255

006:000 or

006:001~225

101:00 or

101:001~225

• Power cord is not plugged

in.

• Fuse is burned out F1601

(F1 Board)

• H.OUT Q6807 is shorted.

• H.IN Q6810 is shorted.

Q6802 shorted.

• PH6602 faulty.

D6644 faulty, R6651 open.

• 10.5V is not supplied.

(D board)

• V.OUT IC6800 faulty

D6816 faulty

D6817 faulty

D6824 faulty

R6852 open

R6851 open (D board)

• G2 is improperly adjusted.

(Note 2)

• CRT problem.

• Video OUT IC9001, 9002,

9003 are faulty. (C board)

• IC8306 (A board) and

IC4301 (A board) are faulty.

• C6831 is open circuit.

PS6606 open, PS6605

open. (D board)

• CRT Discharge (C Board)

• Static discharge

• External noise

Probable

Cause

Location

Detected

Symptoms

• Power does not come on.

• No power is supplied to the

TV.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is

shorted.

• Power does not come on.

• Vertical deflection pulse is

stopped.

• Vertical size is too small.

• Vertical deflection stopped.

• No raster is generated.

• CRT cathode current

detection reference pulse

output is small.

• H pulse output is too high.

• Power is shut down shortly,

after this return back to

normal.

• Detect Micro latch up.

– 4 –

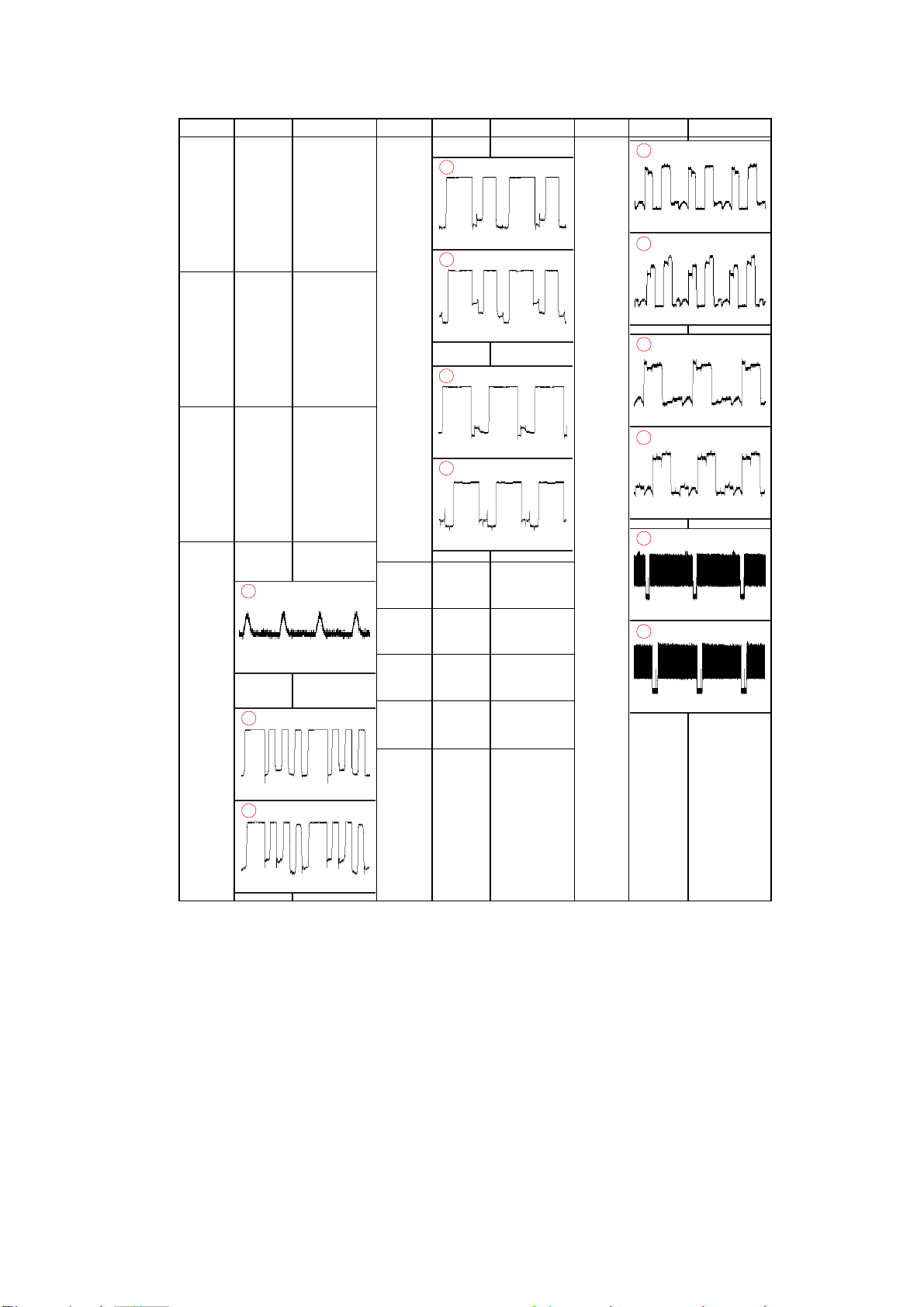

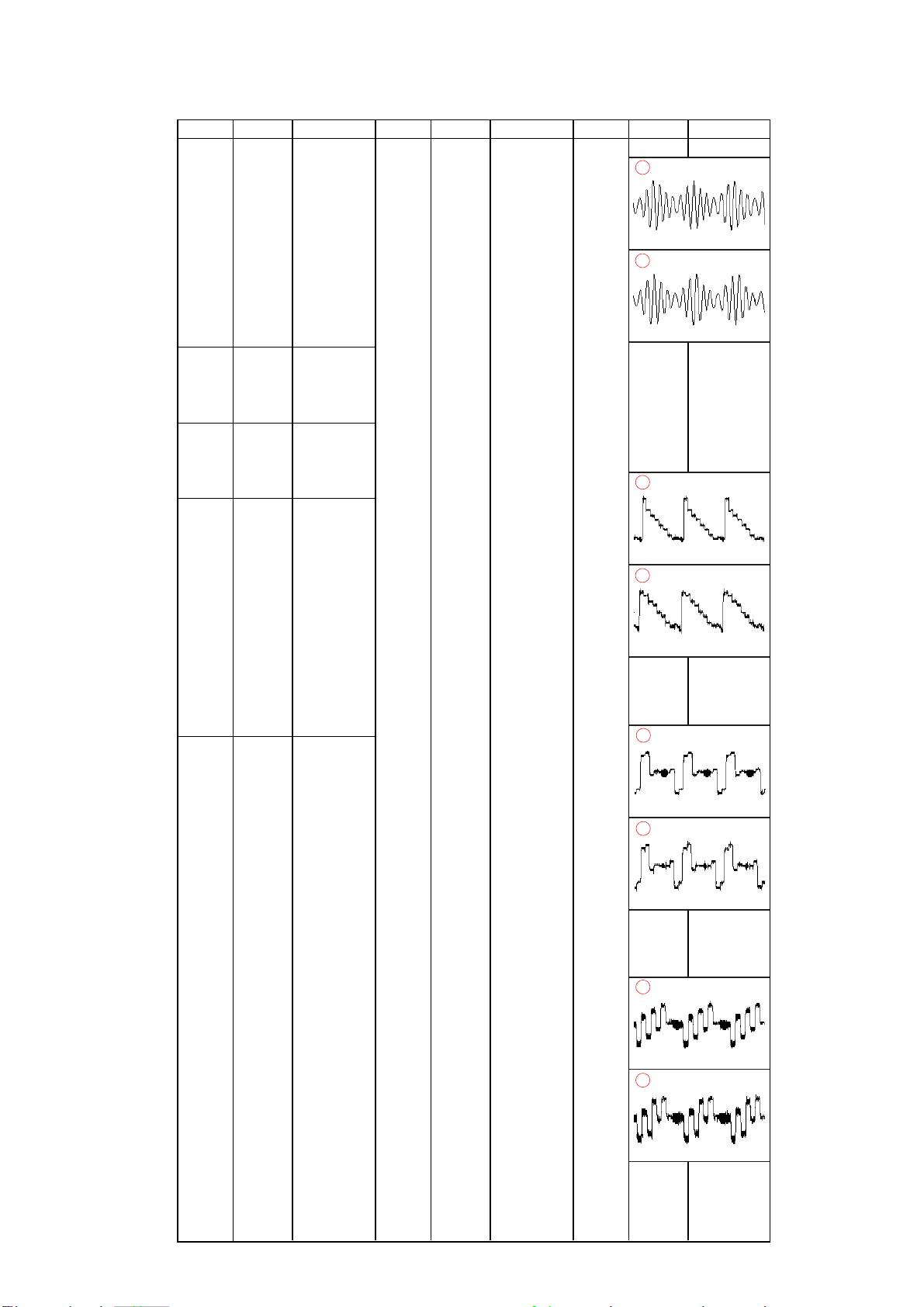

2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

2 times

3 times

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

KV-DR34M97

RM-991

Diagnostic Item Flash Count*

+B overcurrent 2 times

+B overvoltage 3 times

V deflection stop 4 times

White balance failure 5 times

Horizontal Deflection Failure 6 times

4 times

5 times

6 times

* One flash count is not used for self-diagnostic.

STANDBY/SLEEP lamp

3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp

from flashing.

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes off ” that cannot be confirmed, it

is possible to bring up past occurances of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

[Screendisplay] / channel [5] / Sound volume [-] / Power ON

˘

Note that this differs from entering the service mode (mode volume [+]).

Self-Diagnosis screen display

SELF DIAGNOSTIC

002 : 000

003 : 000

004 : 000

005 : 001

006 : 002

101 : 000

Numeral "0" means that no fault has been detected.

Numeral "1" means a fault has been detected.

Numeral "2" means two faults have been detected.

– 5 –

KV-DR34M97

RM-991

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to “0”, press buttons on the remote commander sequentially as shown below when the diagnostic

screen is being displayed.

Channel [8] / 0

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

6. SELF-DIAGNOSTIC CIRCUIT

FROM

CRT (IK)

[H] D6825, D6830

[V] Q6819, R6832

IC4301

RGB JUNGLE

IKIN

34

H PROT

35

V PROT

CXA2150AQ

OVP OCP

SDA

SYSTEM

3

6

IC001

LED 1

54

SDA

IC003

MEMORY

558

[+BovercurrentªOCPº] Occurs when an overcurrent on the +B(135) line is detected by Q6610

and Q6609.

If Q6610 and Q6609 go to ON, the voltage to the pin3 of IC001 go to UP.

The unit will automatically turn off.

[+BovervoltageªOVPº] Occurs when an overvoltage on the +B(135) line is detected by D6635

and Q6611. If Q6611 go to ON, the voltage to pin6 of IC001 go to UP. The

unit will automatically turn off.

[Verticaldeflectionfailure] Occurs when an absence of the vertical deflection pulse is detected by

Q6819 and R6832. Shut down the power supply.

[Whitebalancefailure] If the RGB levels do not balance or become low level within 5 seconds.

This error will be detected by IC4301.

TV will stay on, but there will be no picture.

[HighvoltageprotectorofHorizontalDeflection] Occurs when an overvoltage of horizontal pulse is detected by D6809 and

IC6801.

If the voltage of anode D6830, Q6800 and D6825 goes to High, the

voltage to pin34 of IC4301 go to UP. The unit will automatically turn off.

– 6 –

SECTION 1

DISASSEMBLY

KV-DR34M97

RM-991

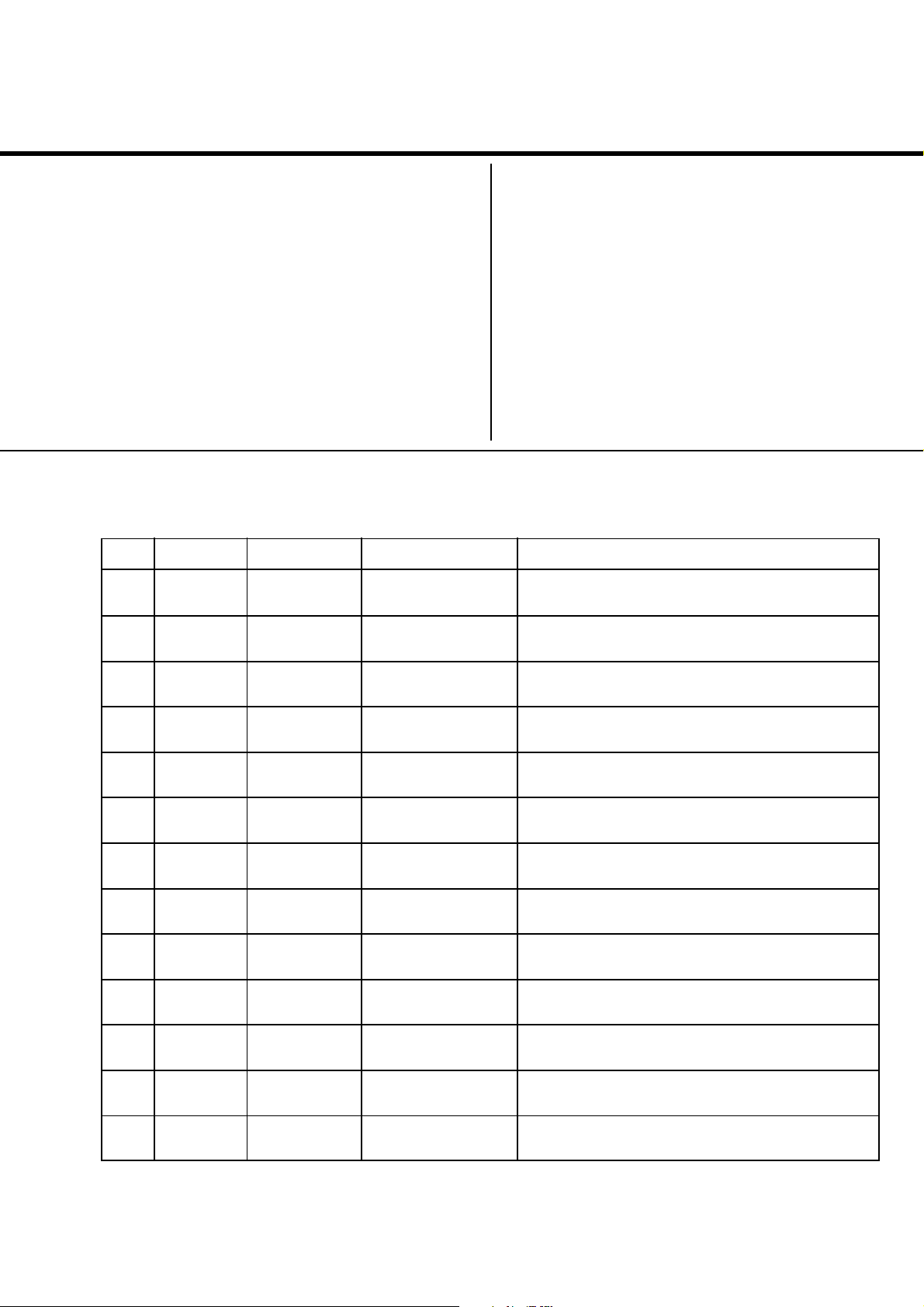

1-1. REAR COVER REMOVAL

2 Rear cover

1 Sixteen screws

(+BVTP 4 × 16)

1-2. 3D SPEAKER BOX REMOVAL

1 Two screws

(TP + TWH 4 × 25)

1-3. SPEAKER REMOVAL 1-4. CHASSIS ASSY REMOVAL

2 3D Speaker

box assy

3 Two screws

(+BVTP 4 × 16)

1-5. DH BOARD REMOVAL

1 Two hooks

1 Two screws

(+BVTP 4 × 16)

2 Two screws

(Washer Head)

(+P4x16)

1-6. SERVICE POSITION

2 DH Board

– 7 –

KV-DR34M97

RM-991

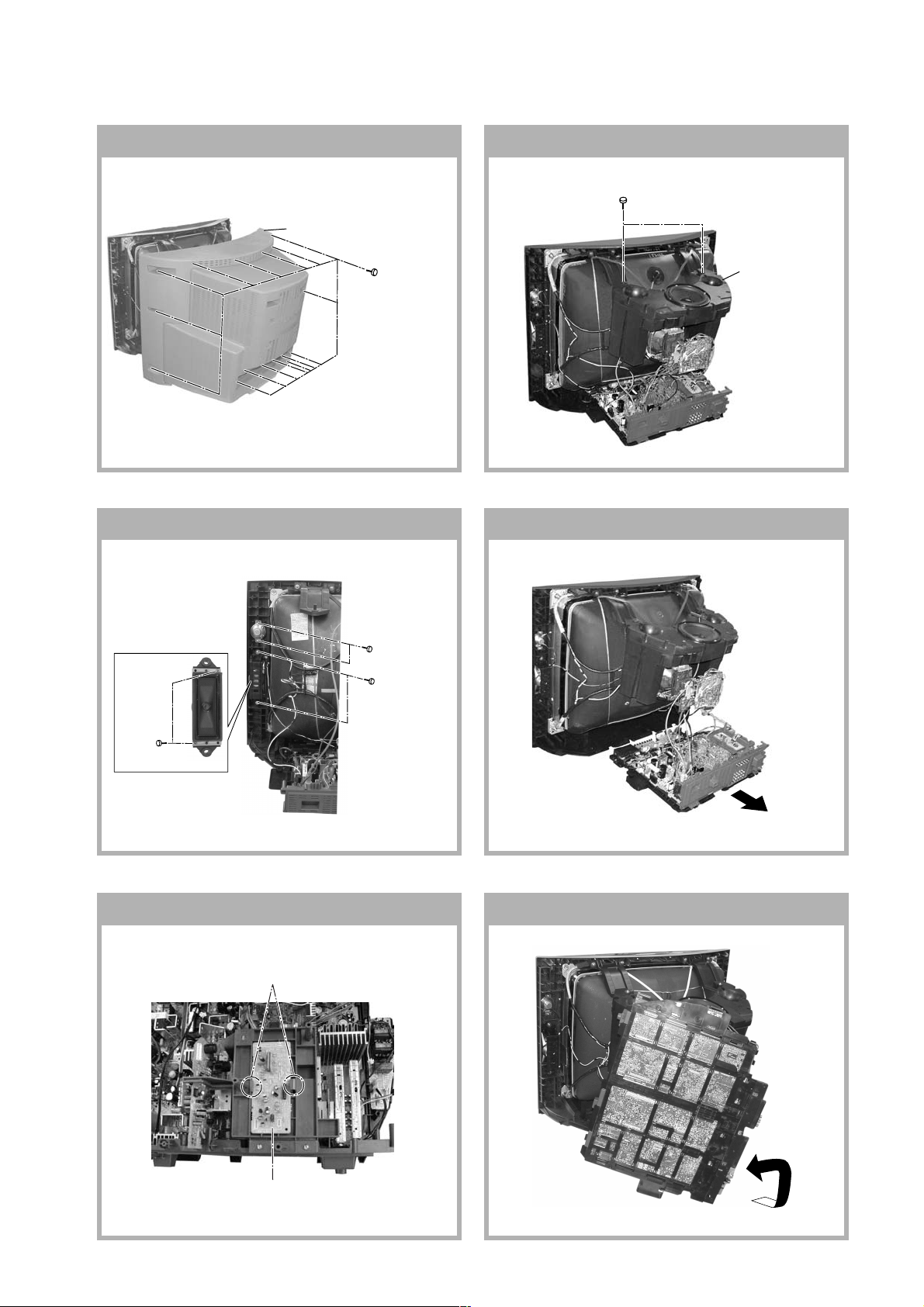

1-7. SERVICE POSITION ON TV STAND

Note: 1) Remove the Rear Cover (refer 1-1)

- unscrew all 16 screws fixed on the Rear Cover. Hold

the top of the TV Cabinet; lift the Rear Cover slightly

upwards to release the Rear Cover foot from the TV

Stand and slide it backwards from the TV Cabinet.

2) Remove the 3D Speaker Box (refer 1-2)

3) Release the Lead Assy Speaker (left side)

4) Lift up the chassis and place it in the Ser vice

Position as shown:-

Caution: 1) In Service Position, make

sure all the TV connections

are connected correctly

before turning on the TV

set.

2) The TV on the TV Stand

without Rear Cover is

unstable. As such be

careful not to push the TV

Place the front of the main

bracket on to the foot of the

TV Cabinet

foward or backward

1-8. TERMINAL BRACKET REMOVAL

Use a non elastic and non

conductive string to tie the

main bracket to the woofer

bracket

Place the Terminal

Bracket edge into the hole

on the TV Stand foot

1-9. B3 AND D5 BOARDS REMOVAL

Note: Access to the B3 board is possible after removal

of the shiledcase. Remove the shiledcase by

removing 2 screws +BVTP 3x16

2 D5 Board

3 One screw

(+BVTP 3 × 12)

4 Two hooks

3 One screw

(+BVTP 3 × 12)

2 Two screws

1 One screw

(+BVTP 4 × 16)

(+BVTP 3 × 12)

5 Terminal bracket

1 Two clips

3 Two clips

1-10. F1 BOARD REMOVAL 1-11 . BC1 AND P BOARDS REMOVAL

4 V2 Board

2 BC1 Board

(not used for this model)

6 P Board

4 B3 Board

1 Two hooks

2 F1 Board

5 One clip

3 Two clips

1 One clip

– 8 –

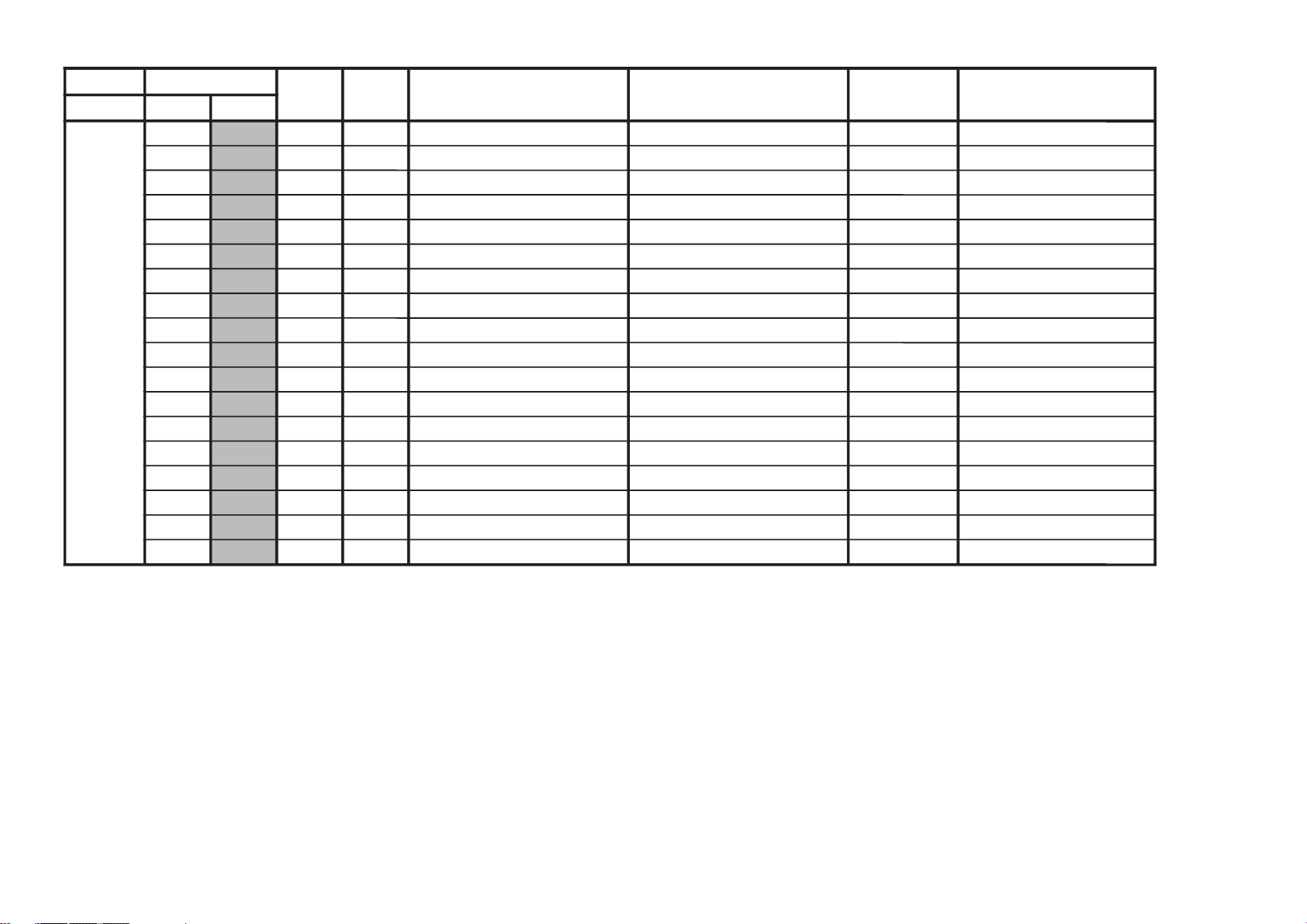

1-12. H1 AND H2 BOARDS REMOVAL 1-13. A AND D BOARDS REMOVAL

2 Three screws

(3 × 12)(+) BVTP

3 Three hooks

4 Cover, H

5 H2 Board

1 Five hooks

2 H1 Board

5 One screw

(3 × 12)(+)(BVTP)

KV-DR34M97

RM-991

3 Four hooks

4 A Board

1 Five connectors

7 D Board

6 Four hooks

5 One screw

(3 × 12)(+)(BVTP)

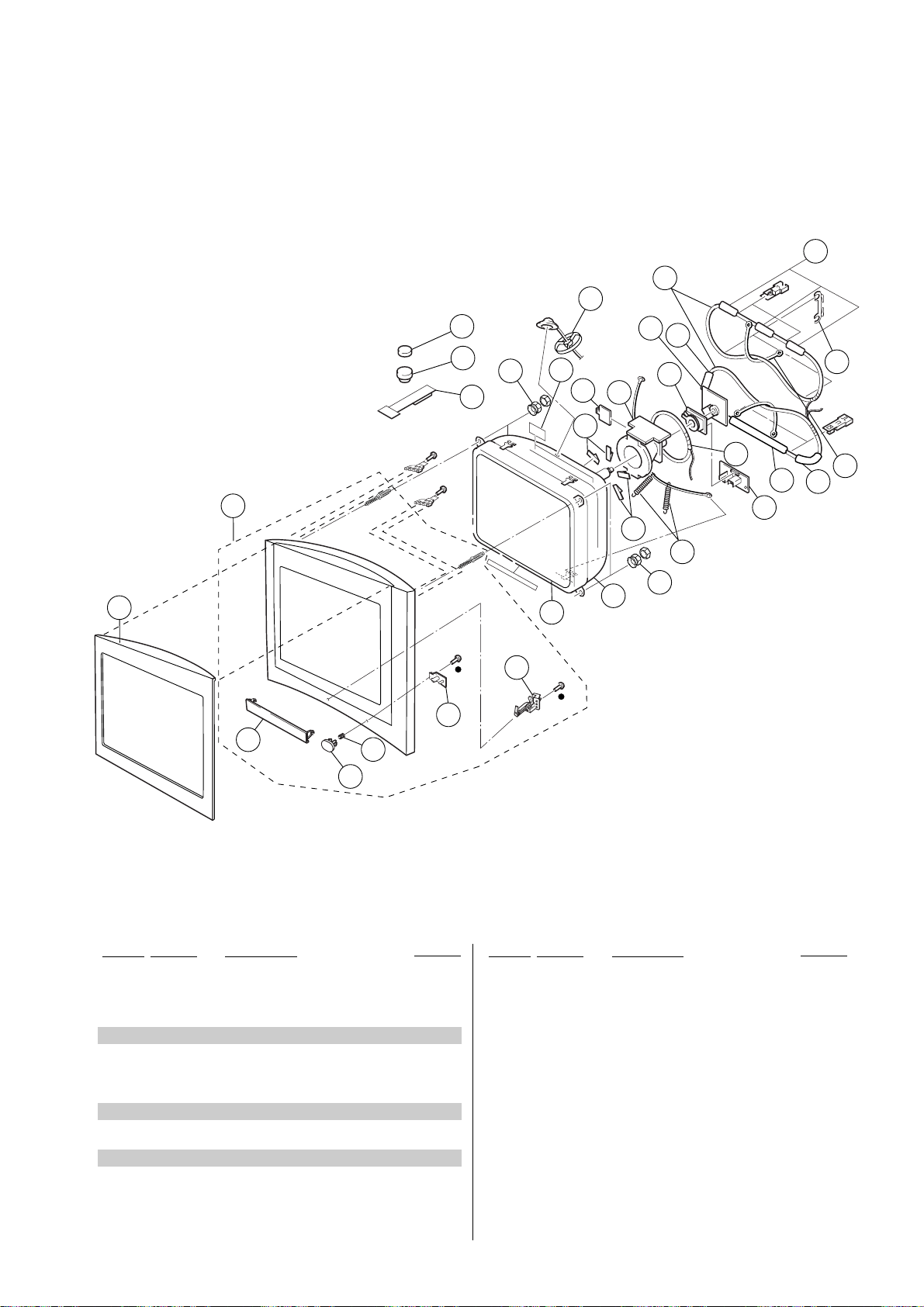

1-14. PICTURE TUBE REMOVAL

Note:

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom

right and left.

• When removing the Nut Locking: first make sure to hold the Nut special CRT with a spanner while opening the Nut

Locking using a torque driver. Then proceed to remove the Nut special CRT using a torque driver.

1)Place the TV set with the CRT face down on a cushion (jig).

2)Removal the Rear Cover.

3)Removal the 3D Box.

4)Unplug all interconnecting leads from the Deflection Yoke, Neck Assy, Degaussing Coils and CRT grounding strap.

+ Nut special CRT (4)

$ Band, DGC(1) Removal (only top-side)

5 Anode Cap Removal

" Bracket Woofer(2) Removal

~ Nut, Locking (4)

% Holder, DGC(2) Removal

& DGC(2) Removal

( Spring Tension(2)

Removal

# Supports, CRT(2) Removal

9 Loosen the Deflection Yoke

fixing screw and remove

) Earth Coating Assy(2) Removal

7 Loosen the Neck Assembly

fixing screw and remove

6 C Board Removal

! Chassis Assy Removal

8 VM Board Removal

– 9 –

KV-DR34M97

RM-991

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

b

b

2 Using a thumb pull up the rubber cap firmly in the direc-

tion indicated by the arrow b.

c

Anode Button

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be removed by

turning up the rubber cap and pulling it up in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

– 10 –

KV-DR34M97

SECTION 2

SERVICE JIG

2-1. JIGS REQUIRED FOR SERVICING

REF NO. DESCRIPTION QUANTITY PART NO. REMARK

J-1 TOOL(20P),SERVICE 1 3-702-763-01 For A to BC1 board extension

1 For A to P board extension

J-2 TOOL(40P),SERVICE 1 3-702-764-01 For A to B3 board extension

J-3 TOOL(50P-A),SERVICE 1 3-702-765-01 For D to D5 board extension

J-4 TOOL(7PX2),SERVICE 1 3-702-775-01 For A to V2 board extension

(not used for this model)

J-1 J-2

RM-991

J-3

J-4

SECTION 3

CIRCUIT BOARDS LOCATION

C Board

H2 Board

D Board

D5 Board

B3 Board

J Board

P Board

A Board

F1 Board

– 11 –

VM Board

BC1 Board

V2 Board (not used for this model)

H1 Board

DH Board

KV-DR34M97

RM-991

SECTION 4

ADVANCE OPERATION

4-1. "RESET" FUNCTION

1. Purpose

If a customer faces some setting problem that cannot be solved, using the "RESET" function some items will be

reset to its original setting (shipping condition)

2. How to Operate

There are 2 ways to access to the "RESET" Function:-

a) By pressing "RESET" button on the Remote Commander.

b) By pressing "MENU" button on the Front Key Input and hold it down for 5 seconds.

3. Subsequent of Operation

Sequential to the resetting operation (either methods being used in No. 2), TV set would shut down once and

automatically turn on again. The power-off duration is expected to be about 500msec. An OSD message,

"RESET" tentatively will be displayed for 10 sec after IK status gets stable.

As a result, some items will be reset to an initial condition (shipment condition) wheareas some other remains at

the last selection by user.

Items that remains at the last selection by user

Program No., PIC rotation, OSD Language,

Fine tuning, TV System, Skip

Reset Items

Video input RF

Volume 30

DRC-MF DRC1250

Picture mode DYNAMIC

Sound mode DYNAMIC

Surround mode OFF

Color system(video) AUTO

Multi picture(PIP) OFF

PIP position Bottom-right

OSD recall OFF

Intelligent volume OFF

ECO mode OFF

Color system(RF) AUTO*

*= only when in RF mode

Antenna sensitivity HIGH*

Stereo mode STEREO/NICAM*

Bilingual mode MAIN*

High-deviation mode AUTO*

Child lock OFF*

Wide mode OFF

Game mode OFF

Teletext mode OFF

Sleep timer OFF

Wake-up timer OFF

Sound muting OFF

3DNR ON

– 12 –

SECTION 5

Purity control

corrects this area.

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

Deflection yoke positioning

corrects these areas.

a

b

b

c

c

d

d

a

SET-UP ADJUSTMENTS

KV-DR34M97

RM-991

• The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

• These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

4. White Balance

Controls and switches should be set as follows unless otherwise

noted:

PICTURE control ........................................................... normal

BRIGHTNESS control ................................................... normal

................................................................................................................................................................................................................................

Note : Test Equipment Required.

1. Color-bar/Pattern Generator

2. Degausser

3. Oscilloscope

Preparation :

• In order to reduce the influence of geomagnetism on the set's

picture tube, face it east or west.

• Switch on the set's power and degauss with the degausser.

5-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck assy as shown in Fig 5-1.

3. Set the pattern generator raster signal to a green raster.

4. Move the deflection yoke to the rear and adjust with the

purity control so that the green is at the center and the blue

and the red take up equally sized areas on each side.

(See Figures 5-1 through 5-3.)

5. Move the deflection yoke forward and adjust so that the

entire screen is green. (See Figure 5-2.)

6. Switch the raster signal to blue, then to red and verify the

condition.

7. When the position of the deflection yoke has been decided,

fasten the deflection yoke with the screws and DY spacers.

8. If the beam does not land correctly in all the corners, use a

magnet to adjust it.

(See Figure 5-4.)

}

normal

Fig. 5-2

Blue

Red

Green

Fig. 5-3

Neck assy

G2G1 G3

Fig. 5-1

Align the edge of

the neck assy with

the edge of the G3 grid.

Fig. 5-4

– 13 –

KV-DR34M97

RM-991

5-2. CONVERGENCE ADJUSTMENT

Preparation :

• Before starting this adjustment, adjust the focus, horizontal

size and vertical size.

• Receive cross hatch/dot pattern and set picture mode to

"STANDARD".

(1) Horizontal and Vertical Static Convergence

1 V. S TAT

a

b b

a

B

G

R

b

B

G

R

Center dot

R G B

H. STAT VR

R

G

B

V. STAT

Magnet

Y magnet

RV702

H. STAT

C Board

2 H. STAT VR

a

RGGBB

b

3

b

R

a

a

R

b

B

b

B

GG

R

1. (Moving horizontally), adjust the H.STAT control so that the

red, green and blue dots are on top of each other at the center

of the screen.

2. (Moving vertically), adjust the V.STAT magnet so that the

red, green and blue dots are on top of each other at the center

of the screen.

3. Adjust Horizontal Trapezoid with “GEO 11 HTR” in Service

Mode to make H-Trapezoid distortion best.

4. If the H.STAT variable resistor cannot bring the red, green

and blue dots together at the center of the screen, adjust the

horizontal convergence with the H.STAT variable resistor and

the V.STAT magnet in the manner given below.

(In this case, the H.STAT variable resistor and the V.STAT

magnet influence each other, so be sure to perform

adjustments while tracking.)

BMC (Hexapole)

Purity

V.STAT

– 14 –

KV-DR34M97

RM-991

4 BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or aligned,

then use the BMC magnet to adjust in the manner described

below.

RG B R G B R GB

RB

G

RG

GB

RB

5 Y separation axis correction magnet adjustment.

1. Receive the cross-hatch signal and adjust [PICTURE] to

[MIN] and [BRIGHTNESS] to [STANDARD] .

2. Adjust the Y separation axis correction magnet on the neck

assembly so that the horizontal lines at the top and bottom of

the screen are straight.

Neck assy Neck assy

Blue

(2) Dynamic Convergence Adjustment

Preparation:

• Before starting this adjustment, adjust the horizontal static

convergence and the vertical static convergence

• Set the PICTURE and BRIGHTNESS to normal.

1. Adjust TLH. (TLH convergence piece)

1 Receive the dot/hatch pattern signal and adjust picture quality

by the menu.

2 Correct horizontal mis-convergence of red and blue of both

sides on the X axis.

When red is outside insert TLH convergence piece to right

side (TLH +) views from DY neck. And when blue is outside,

insert it to left side (TLH –) and take both sides.

R

(B)B(R)

(R)

B

TLH +

R

(B)

TLH -

2. Adjust XCV core.

To able to become balance of XCV on the X axis well.

3. Adjust V-TILT.

Correct the vertical mis-convergence of red and blue of

Red

vertically sides on the Y axis.

4. Adjust YCH.

Adjust horizontal mis-convergence of red and blue of

vertically sides on the Y axis. Mentioned above steps 2 to 4

are adjusting respectively perform minuteness tracking.

VM board

Red

VM board

Blue

Note

1. The Red and Blue magnets should be equally far from the

horizontal center line.

2. Do not separate the Red and Blue magnets too far. (Less than

8 mm)

YCH

TLV2

VM board

TLV1

(3) Screen-corner Convergence

ba

a-d : screen-corner

misconvergence

XCV

BMC magnet

C board

RV9001

– 15 –

cd

KV-DR34M97

RM-991

Fix a Permalloy assy corresponding to the

misconverged areas.

a

d

Permalloy assembly

b

c

5-3. FOCUS ADJUSTMENT

Note

Focus adjustment should be completed before W/B adjustment.

(1) Receive digital monoscope pattern.

(2) Set "A/V CONTROL" to "STANDARD".

(3) Adjust FOCUS VR so that the center of the screen becomes

just focus.

(4) Change the receiving signal to white pattern and blue back.

(5) Confirm MAGENTA RING is not noticeable. In case

MAGENTA RING is obvious, adjust FOCUS VR to balance

between MAGENTA RING and FOCUS adjustment.

5-4. NECK ASSY TWIST ADJUSTMENT

(1) Receive dot/hatch pattern DRC-MF, DRC1250, DYNAMIC.

(2) Turn FOCUS VR fully counter-clockwise.

(3) Confirm the dot shape at the screen center. (Fig. 5-4)

(4) Resume FOCUS VR.

Note

In case of turning NECK ASSY, loosen the screw 3 turns. Do not

move the position.

OK

Turn NECK ASSY clockwise.

Turn NECK ASSY counter clockwise.

Fig. 5-4

5-5. G2 (SCREEN) AND WHITE BALANCE

ADJUSTMENT

1. G2 (SCREEN) ADJUSTMENT

1) Set the PICTURE and BRIGHTNESS to normal.

2) Put to VIDEO input mode without signals.

3) Connect R, G and B of the C board cathode to the

oscilloscope.

4) Adjust BRIGHTNESS to obtain the cathode voltage to the

value below.

5) Whilst watching the picture, adjust the screen VR [RV9002]

located on the C board to the point just before the retrace

lines disappear (to the point before cut-off)

Lead Assy,

Focus

Focus

Screen

(No Function)

FLYBACK TRANSFORMER (T6803)

170 V ± 2 (VDC)

0 V

2. WHITE BALANCE ADJUSTMENT

1) Set to Service Mode (Refer Section 6-1: ADJUSTMENTS

WITH COMMANDER).

2) Input white raster signal.

3) Set the following condition.

PICTURE minimum, BRIGHTNESS 50%

4) Select GCT (WHB 08) and BCT (WHB 09) with 1 and 4,

and adjust the level with 3 and 6 for the best white

balance.

5) Set the PICTURE to maximum.

6) Select GDR (WHB 05) and BDR (WHB 06) with 1 and

4, and adjust the level with 3 and 6 for the best white

balance.

7) Write into the memory by pressing [MUTING] then -.

– 16 –

SECTION 6

29 SERVICE 50VSZ

Adjusted with [3]

and [6] buttons.

GREEN

Write with [MUTING]

Write executed with [0]

GEO 00

59 FFFF0 000A

0

1F WRITE 50VSZ

GREEN

GEO 00

59 0 000A

0

1F WRITE 50VSZ

RED

The WRITE

(red display)

return to SERVICE

(green display)

shows write is

executed.

GEO 00

59 FF 0 000A

0

044Q

0.8M

001 27E

08

1

044Q

0.8M

044Q

0.8M

001 27E

08

1

001 27E

08

1

CIRCUIT ADJUSTMENTS

KV-DR34M97

RM-991

6-1. ADJUSTMENTS WITH COMMANDER

Service adjustments to this model can be performed using the

supplied Remote Commander RM-991.

a. ENTERING SERVICE MODE

With the unit on standby

n

[DISPLAY] n 5 n VOL (+) n [POWER]

The screen display is :

Device

Name

GEO

0

08 1

3D NR

S/N

detection

Item No

00

044Q

Suffix No

(OEM Code)

Item

Name

VSZ 29 SERVICE

0.8M

3D NR

mode

Software version

Total Power-On time (hours)

Data

59 000A

001

H count

of SYNC

detection

27E

V count

of SYNC

detection

Marking of new NVM

Mode

p

FF 0

PAL,SECAM:50

NTSC :60

50

b. CANCELLATION OF SERVICE MODE

Set the standby condition (Press [POWER] button on the commander),

then press [POWER] button again, hereupon it becomes TV mode.

6-2. ADJUSTMENT METHOD

Item Number 00 of device GEO

This explanation uses V-size as an example.

1. Select “GEO 00 VSZ” with the 1 and 4 buttons.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is 1F for PAL

reception.)

4. Press [MUTING] button to indicateWRITE on screen. (The

display from SERVICE (green display) to WRITE (green

display).

5. Execute the writing with the - button. (The WRITE

display changes to red color while executing and then back to

SERVICE (green display).

6. The WRITE execution is completed.

Example on screen display :-

c. METHOD OF WRITE INTO MEMORY

1) Set to Service Mode.

2) Press 1 (UP) and 4 (DOWN), to select the adjustment

item Name.

3) Press 3 or 6 to raise/lower the data value.

4) Press [MUTING] button to indicate WRITE on the screen.

5) Press - button to write into memory.

d. OTHER FUNCTION VIA REMOTE COMMANDER

7, - All the data becomes the values in memory.

8, - All goes to the standard state.

5, - Service data initialization (Be sure not to use

[DISPLAY], - Write 50Hz adjustment data to 60Hz, or vice

2, - Copy and write all data.

Cursor +/– Skip category (device) to category (device)

usually.)

versa.

example : GEO 00 VSZ

e. MEMORY WRITE CONFIRMATION METHOD

↕

DAC 00 HCT

1) After adjustment, pull out the plug from AC outlet, and then

plug into AC outlet again.

2) Turn the power switch ON and set to Service Mode.

3) Call the adjusted items again to confirm adjustments were

made.

Use the same method for all Items.

Note : 1. In [WRITE], the data for all items are written into

memory together.

2. For adjustment items that have different standard data

between 50Hz or 60Hz, be sure to use the respective

input signal after adjustment.

– 17 –

KV-DR34M97

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN CN05CN06CV05CV06

05GORP

CN

06GORP

CN

05GORP

CV

06GORP

CV

OEG00ZSV12F3eziSVCN/CV*06/05QA0512AXC32624262

10SPV72F3noitisopVCN/CV*06/0552227242

20NLV5F0ytiraeniLVCN/CV*06/0570807080

30OCSA0F0noitcerroCSCN/CV*06/0590A090A0

40ZSHE1F3eziSHCN/CV*06/0512B112C1

50SPHF2F3noitisoPH CN/CV*06gorPDVD/05gorPDVD/06/05

A1119101A1A19090

60PAP82F3pmAniPCN/CV*06/05519181B1

70NPU52F3niPrenroCreppUCN/CV*06/0552627282

80NPL32F3niPrenroCrewoLCN/CV*06/0522722282

90GCU03 tnemtsujdAniPrenroCreppUtsoMCN/CV*06/05

10

10

30

10

A0GCL13 tnemtsujdAniPrenroCrewoLtsoMCN/CV*06/05

10

20

00

20

B0PCU23 gnitteSnoitisoPnoitcerroCniPrenroCreppUtsoMCN/CV*06/05

20

20

20

20

C0PCL23 gnitteSnoitisoPnoitcerroCniPrenroCrewoLtsoMCN/CV*06/05

30

20

20

20

D0LOP01 ytiraloPniPrewoL/reppUtsoMCN/CV*06/05

00

00

00

00

E0HPP42F3tnemtsujdAdiozeparTVCN/CV*06/05*RP/4R/FF029112B1

F0LGAA0F0elgnACFACN/CV*06/05D1D11222

01WOB6F0woBCFACN/CV*06/0581819181

11RTHF0F1lortnoCniaGleveLwaSevaWOwaSVCN/CV*06/05*RP/4R/FF00000000

21DPM4F0lortnoCsaiBCDevaWaraPPMCN/CV*06/05*RP/4R/FF70707070

31APME0F0lortnoCniaGevaWaraPPMCN/CV*06/05*RP/4R/FF

50

50

50

50

41PBPF1F3lortnoCniaGleveLwaSevaWaraPtneCHCN/CV*06/05*RP/4R/FF72723252

51ABPF0F1lortnoCniaGevaWaraPtneCHCN/CV*06/05*RP/4R/FFA0B0B0C0

61SBH11 WSFFO/NOklBHCN/CV*06/05*RP/4R/FF

10

10

10

10

71LBH73F3lortnoCnoitisoPklBHtfeL CN/CV*06gorPDVD/05gorPDVD/06/05

91

52

91

52 E1

92 E1

92

81RBHC2F3lortnoCnoitisoPklBHthgiR CN/CV*06gorPDVD/05gorPDVD/06/05

82

92

82

92

D2

E2

D2

E2

91PCP07 gnitteSnoitcerroCnoitrotsiDVHpmAniPCN/CV*06/05*RP/4R/FF

00

00

00

00

A1PCA17 gnitteSnoitcerroCnoitrotsiDVHnoitisoPHCN/CV*06/05*RP/4R/FF

00

00

00

00

B1PCV83 gnitteSnoitcerroCnoitrotsiDVHlacitreVCN/CV*06/05

C0

C0

C0

C0

C1PCH23 gnitteSnoitcerroCnoitrotsiDVHeziSHCN/CV*06/05

70

70

70

70

D1CSU01 FFO/NOedoMpmuJesluPfeRCN/CV*06/05*RP/4R/FF

00

00

10

10

E1SAVF2F3lortnoCtcepsAVCN/CV*06/05

F2

F2

03

03

F1CSVF1F3lortnoCllorcSVCN/CV*06/05

F1

F1

E1

F1

02UBV71 lortnoCnoitisoPpoTklBVCN/CV*06/05*RP/4R/FF

40

90

E0

C0

12LBV71 lortnoCnoitisoPmottoBklBVCN/CV*06/05*RP/4R/FF

00

90

C0 F0

22BKAF0F1gnitteSgnimiTesluPfeRhcBBKACN/CV*06/05

C1

F0

C1

71

32SDV11 wSFFO/NOpmuJesluPFERhcBCN/CV*06/05*RP/4R/FF

00

00

00

00

42TSR01 gnitteSnoitisoPtratSevirDVfOecarteRCN/CV*06/05*RP/4R/FF

00

00

00

00

52YPC01 aeraMVNzH06/05llaotatadOEGehtypoC

Adjustment Item Table

– 18 –

RM-991

– 19 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoC0506CNnOocECNffOocECVnOocECVffOocE

CAD00TCH33F7retneCHzH06/055781AXC

A4A4

10NLH72F3ytiraeniLHzH06/05

9393

20

HDQF1F3esahPFDzH06/05

38

38

30

STHBBFFgnitteSataDtratSdiozeparTHelbaton

9C

40

OTHE0FFgnitteSataDtesffOdiozeparTHelbaton

E0

50

SSNF7FFataDtratSSNelbaton

E7

60

OSN90FFataDtesffOSNelbaton

90

70

CBA0FFlortnoCA/DLBACN/CV*ffo/noOCE

00000000

80YPC01 aeraMVNzH06/05llaotatadCADehtypoC

GVT0ytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaT

emaNeciveDnommoC

nommoCoNemaN

BHW00

SOY7F0langisYrofrellecnaCtesffOCD QA0512AXC70

10

SOUF1F31bCrofrellecnaCtesffOCD F1

20

SOVF1F31rCrofrellecnaCtesffOCD F1

30RBSF1F3lortnoCssenthgirBbuS 91

40

RDR92F3evirDR 92

50RDG42F3evirDG 42

60RDB52F3evirDB 52

70

TCR92F3ffotuCR 92

80TCG01F3ffotuCG 01

90TCB52F3ffotuCB 01

A0

OBS02F3tesffOssethgirBbuS cimanyDtpecxeedoMerutciPC1

B0

ODRF1F3tesffOevirDR cimanyDtpecxeedoMerutciPF1

C0

ODG91F3tesffOevirDG cimanyDtpecxeedoMerutciP91

D0

ODBB1F3tesffOevirDB cimanyDtpecxeedoMerutciPA1

E0

OCRF1F3tesffOffotuCR cimanyDtpecxeedoMerutciPF1

F0

OCG92F3tesffOffotuCG cimanyDtpecxeedoMerutciPA2

01

OCBA1F3tesffOffotuCB cimanyDtpecxeedoMerutciPD1

KV-DR34M97

RM-991

– 20 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN CNnOocECNffOocECVnOocECVffOocE0506cimanyD

-dradnatS

amarD/

-/eniF-iH

tfoS

lanosreP

JAS00

CIPF3F3lortnoCerutciP lanosrePtpecxeedoMerutciPQA0512AXC

B33382

10

TRBF1F3lortnoCssenthgirB lanosrePtpecxeedoMerutciP

32F1B1

20

LOC72F3lortnoCroloC lanosrePtpecxeedoMerutciP

C2F1F1

30

EUHF1F3lortnoCeuH lanosrePtpecxeedoMerutciP

F1F1F1

40

PHS42F3lortnoCssenprahS lanosrePtpecxeedoMerutciP

22F1D1

50

LMV33 leveLMVedoMerutciP

30301030

60

CYD11 ffo/noroloCcimanyDedoMerutciP

10100010

70

SBW00 hctiwSBWedoMerutciP

00000000

80

XAC23 noitacificepSxirtaMroloCzH06/05

1030

90

AMG33 noitcerroCammaGedoMerutciP

20100010

A0

TCD13 lortnoCnoissimsnarTCDedoMerutciP

20201020

B0

LPD13 lortnoCleveLlatsedePotuAedoMerutciP

20200020

C0

MBA03 lortnoCedoMLBAedoMerutciP

10000000

D0

TBA03 lortnoChtVnoitcetedtnerruCLBACN/CV*ffo/noOCE5000C070

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCCNnOocECNffOocECVnOocECVffOocEVT05oediV05DVD05VT06oediV06DVD06

-RPDVD

05GO

-RPDVD

06GO

JASEO

OLC9F0tesffOroloC 06/05gorPDVD/oediV/VT*06/05QA0512AXC

6080

9090

4040

FO

WLC37 N/SfoegnahCehtothtdiWpetSroloC 30

01

OUH9F0tesffOeuH 06/05gorPDVD/oediV/VT*06/05

5030

7060

4050

11

OHS7F1tesffOssenprahS 06/05gorPDVD/oediV/VT*06/05

012190C0F090A1A1

21

WHS17 N/SfoegnahCehtothtdiWpetSssenprahS 10

31

ORB7F0tesffOssenthgirB

CN/CV*ffo/noOCE

70707070

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoC

DVD

GORP

CN05CN06CV05CV06

001CRD

CN

001CRD

CV

021CRD

CN

021CRD

CV

LGJ00

NOP11 ffO/nOtuptuOesluPecnerefeRBKAdnaBGR QA0512AXC10

10

BGR77 noitceleStuptuOBGR 70

20

GGA03 noitceleSedoMgnigA 00

30

TBB33 lortnoCrettimiLmottoBBGR 30

40

LML03 lortnoCrettimiLedutilpmABGR 00

50

BAPF0F0LBAkaeProfleveLCD F0

60

BAS03 gnitteSniagLBAS CN/CV*06gorPDVD/05gorPDVD/06/05

0000000000000000

70

OCS7F0lortnoCerutciPbuS 70

80

2VL5F02BGRrofleveLBGR 50

90

LMG01 FFO/NOnoitcerroClaitnereffiDammaG 0000

KV-DR34M97

RM-991

– 21 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCVT05oediV05DVD05VT06oediV06DVD06cimanyD

-dradnatS

amarD/

-/eniF-iH

tfoS

lanosreP

LGJAO

SYS23 noitceleSdnaBlangiSDVD/oediV/VT*06/05QA0512AXC

102020202020

BO

0FS11 gnitteS0fssenprahSDVD/oediV/VT*06/05

101010101010

CO

1FS33 lortnoCniaGssenprahS0fhgiHDVD/oediV/VT*06/05

303030303030

DO

SDC03 noitarutaSroloChgiHnilortnoCniaGssenprahS 00

EO

FDC01 FFO/NODCPHS 00

FO

ORP33 lortnoCoitaRtoohS-revO/erPDVD/oediV/VT*06/05

303030303030

01

ITL33 tnemevorpmItneisnarTecnanimuLedoMerutciP

30200000

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoC

DVD

GORP

cimanyD

-dradnatS

amarD/

-/eniF-iH

tfoS

lanosreP

anyD

wsb

LGJ11

MTL03 gnitteSedoMITL QA0512AXC00

21

ITC03 tnemevorpmItneisnarTecnanimorhCedoMerutciP

00000000

31

MTC03 gnitteSedoMITC 00

41

LDV33 lortnoCesahPTUOMV 30

51

RCV03 gnitteSleveLgniroCTUOMV 00

61

OFV03 gnitteS0FTUOMV 00

71

MLV03 gnitteSleveLretimiLTUOMV 00

81

CFA13 lortnoCniaGpooLCFA evissergorPDVD/nommoC2010

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCVToediV

CRD00

DOM03

)ylnOnoitaulavEroF(edoMCRD

,i0521decroF-10,lamroN-00

evissergorPelpmiSdecroF-30,evissergorPdecroF-20

KV-DR34M97

RM-991

KV-DR34M97

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCVToediV

PIP00

ORP01 elbanEedoMnacSevissergorPX9849ADS00

10DER01 edoMelbuoDdaeR 00

20

IEF03 tceleSdleiF 00

30

SPH33FFnoitisoPerutciPlatnoziroH 33

40

SPVB1FFnoitisoPerutciPlacitreV B1

50

PFH8F0gninoitisoPeniFlatnoziroH 80

60

PFV0F0gninoitisoPeniFlacitreV 00

70

SID03 dradnatSyalpsiD 00

80

SOH03 eziSlatnoziroH 00

90

SEV03 eziSlacitreV 00

A0

SPF03 dradnatStneraPecroF 00

B0

MZH07 mooZlatnoziroH 00

C0

PSV11 noitcudeResioNesluPcnySlacitreV 10

D0

LDV0F1yaleDesluPcnySlacitreV 00

E0

HRF57 latnoziroHhtdiWemarF 50

F0

VWF23 lacitreVhtdiWemarF 20

01

DRV01 noitcudeR 00

11

KBV01 gniknalBlacitreV 00

21

YLD1F yaleDtceleS 10

31

RCP01 noitcerroCnoitisoP 00

41

MGA33 edoMCGA 30

51

CGA9F eulaVlortnoCniaGcitamotuA 90

61

BVC03 tceleSSBVC 00

71

DPC13 noitaruDGNIPMALC 10

81

TPC13 tratSesluPGNIPMALC 10

91

MUL03 tesffOecnanimuL 00

A1

LLP03 tnatsnocemiTLLPtresnIoediV/VT

0000

B1

DCY8F yaleDC/Y 80

C1

RSN03 llPtesnirofnoitcudeReisoNoediV/VT

2000

D1

PSL01 deepSnoitacifitnedIdradnatS 00

E1

LIK23 dlohserTrelliKroloC 20

F1

PGB11 noitisoPetaGtsruB 10

RM-991

– 22 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCVToediV

PIP02

CES11 levelnoitacifitnedIMACES 10

12

MED13 noitceleSesahpmeeD 10

22

AMC03 htiwdnaBamorhC 00

32

CFI23 retliFnoitasnepmoCFI 20

42

EUH0F1euH 00

52

ACS6F1tnemtsujdAreirracbuSroloC 60

62

NOC0F tnemtsujdAtsartnoC 50

72

RLB0F lennahCdeRleveLgniknalB 00

82

TRB0F tnemtsujdAssenthgirB 00

92

GLB0F lennahCneerGleveLgniknalB 00

A2

RIB01 lennahCdeRnoisrevnIgniknalB 00

B2

BIB01 lennahCeulBnoisrevnIgniknalB 00

C2

BLB0F lennahCeulBleveLgniknalB 00

D2

TNI01 llavretnIhserfeR 00

E2

RKP58FFlennahCdeRleveLkaeP 58

F2

GKP58FFlennahCneerGleveLkaeP 58

03

BKP58FFlennahCeulBleveLkaeP 58

13

YRF9F YroloCemarF 90

23

TUO11 tamroFtuptuO 10

33

URF0F UroloCemarF 00

43

VRF0F VroloCemarF 00

53

TAS7F tnemtsujdAnoitarutaSroloC 70

63

KPY37 tnemtsujdAkaePY 30

73

OCY0F elbanEgniroCY 00

83LAP33 leveLDILAP 30

93VOP07 lacitreVtesffOnoitisoP 00

A3HOP0F1latnoziroHtesffOnoitisoP 00

B3

HSV0F1knirhSlacitreV 00

C3

HSH0F1knirhSH 00

D3

LPC13 htgneLesluPGNIPMALC 10

– 23 –

KV-DR34M97

RM-991

– 24 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCVToediVVT05oediV05DVD05VT06oediV06DVD06

TCY00

TNT02F3CSTNroftnemtsujdAtniToediV/VTQA3612AXC

02F1

10

GNP11 htdiWetaGCSTN/LAP 10

20

INP01 WSytivitisneSCSTN/LAP 00

30LCS5F0lortnoCroloCbuSoediV/VT*06/05

5050

5060

40TCS7F0lortnoCtsartnoCbuSoediV/VT*06/05

7070

7070

50

0FS23 gnignahCycneuqreFretneCssenprahS 20

60

QES33 citsiretcarahCrezilauqEssenprahS 30

70

GHS7F0lortnoCniaGssenprahSDVD/oediV/VT*06/05

406060508050

80LOYF1F3lortnoCleveLtuptuO-Y E1

90

PSB03 gnignahCtnioPtratShctertSkcalB 00

A0LOC01F3lortnoCleveLtuptuOrC/bC 31

B0

RCD03 tnemtsujdAoitaRnoitarotseRCD 00

C0

0FB13 tnemtsujdA0FFQT/FPB 10

D0

QFB23 tnemtsujdAQFQT/FPB 20

E0

WSF11 hctiwSFQT/FPB 10

F0

TDS11 hctiwSparTelbuoDMACES 10

01

FPL11 hctiwSFPLrC/bC/Y 10

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoC

itluM

bmoC

bmoCD3tupnI-SsrehtOoediVDVD

TCY11

LDY6F0tnemtsujdAemiTLD-Y srehto/tupni-S/bmocD3/bmocD2

60606060

21

1OB7F0)etuorniam(tnemtsujdA1tesffObC 70

31

1OR7F0tnemtsujdA1tesffOrC 70

41

FDC07 hctiwSycneuqerFnwoDtnuoCVlangisonrofzH05decrof00

51

MDC03 hctiwSegduJnwoDtnuoCV 00

61

CFA03 hctiwSytivitisneSCFADVD/oediV)/VT(

0000

71

MVM11 ksaMCFA+ksaMnoisivorcaM 10

81

YRS7F0tnemtsujdAkcalBY-RMACES 70

91

YBS1F0tnemtsujdAkcalBY-BMACES 10

A1

LEB23 gnihctiwSFPH/LLEBMACES 20

B1

FLB01 tnemtsujdA0fLLEB 00

C1

IVS01 hctiwSDI-VMACES 00

D1

PGS03 tnemtsujdAnoitisoPetaGMACES 00

E1

DIS11 hctiwSytivitisneSMACESMACEStpecxe10

F1

HIS01 hctiwSnoitibihnIMACES 00

02

PTS01 sulPLAProfputeSleveLkcalBY 00

12

RN311 ffO/nOnoitarepORND3 10

22

6WB11 ffO/nOlangiStsuB-noNzH06rofRND3 10

32

HSW03 noitcudeResioNrofpetSniaGssenprahS 00

42

OCW03

esioNrofpetSleveLtuptuOrC/bC

noitcudeR

00

KV-DR34M97

RM-991

– 25 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

nommoC

yrogetaCoNemaN

NYS00

TAM13 noisrevnoCxirtaMfoepyTtceleS 1512AXC00

10

RFV11 tuptuOcnySymmuDfoycneuqerFtceleS 10

20

CTV33 tnatsnoCemiTnoitarapeScnySVehtsteS 30

30

DWH03 htdiWesluPtuptuOTUO_HLESehtsteS 00

40

LSH01 dohteMnoitarapeScnySehtsteS 00

50

CTH01 tupniNIGYfotnatsnoCemiTnoitarapeScnySHehtsteS 00

60

AMH11 TUOHLEStacnysVnihtiWcnysHddaottonrorehtehWsteS 10

70

CAM11 langiSP525ehtfolangisnoisivorcaMehtgnitanimilErofhctiwS 10

80

LSG13 TUORCLESottuptuOlangiSehtfoetuMroniaGehtstceleS 10

90

GBC7F0lortnoCniaGTUOBCLES 70

A0

GRC7F0lortnoCniaGTUORCLES 70

B0

GY7F0lortnoCniaGTUOYLES 70

C0

RFH13 TUOHLESottuptuOcnySymmuDehtfoycneuqerFehttceleS 10

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCcimanyD

-/dradnatS

amarD

-/eniF-iH

tfoS

wsbanyDwsbamarDwsbtfoS

2PA00

SBB3F0gnitteStsooBssaB 9311WJN30

10

BCB01 ssaB-buStuC/tsooB 00

20

SBS03 gnitteSssaB-buS 00

30

TCB01 elberT-buStuC/tsooB 00

40

STS03 gnitteSelberT-buS 00

50

LGA03 gnitteSleveLCGA 00

60

WSB01 hctiwStsooBssaB 00

70

SAB41F1lortnoCedomdnuoSssaB FFO/NOSBBhtiwlanosreptubedoM.S

410101211010

80

ERT61F1lortnoCedomdnuoSelberT FFO/NOSBBhtiwlanosreptubedoM.S

616101616101

90

EBB84FFlortnoCedomdnuoSEBB FFO/NOSBBhtiwlanosreptubedoM.S

84A30084A300

KV-DR34M97

RM-991

KV-DR34M97

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

nommoC

yrogetaCoNemaN

PSM00

TSW51FFdlohserhToeretSG/W D5143PSM51

10

TBWCEFFdlohserhTlaugniliBG/W CE

20

LLW5FFdlohserhTlaruanoMG/W 50

30

CAW1F0tnuoCtnemeergAG/W 10

40

LDW03FFyaleDhcraeSG/W 03

50

LDN02FFyaleDhcraeSMACIN 02

60

LDS01FFyaleDdaeRsutatSoeretS 01

70

CGA11 tnatsnoC/otuAhctiwSCGA 10

80

LER82F3edoMtnatsnoCtaniaGCGA 82

90

MRC01 ffO/nOgnituMreirraC 00

A0

OCA11 ffO/nOtuOkcolCoiduA 10

B0

PFB1F7metsySM-noNrofelacserPMF B1

C0

MPF23F7metsysMrofelacserPMF 23

D0

HF63F7VEDHrofelacserpMF 63

E0

MHF56F7MdnaVEDHrofelacserpMF 56

F0

PGWC1F7elacserPG/W C1

01

PINF7F7elacserPMACIN F7

11

RRE05FFdlohserhThctiwSMFotuA 05

RM-991

– 26 –

– 27 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCVToediVcimanyD

-dradnatS

amarD/

-/eniF-iH

tfoS

lanosreP

ITLA1

WLN77 reifilpmAytiraeniL-noNfohtdiWpetS 70

B1

DGVF1F3ammaGelbairaVedoMerutciP

22F1F1F1

C1

WGV07 ammaGelbairaVfohtdiWpetS 00

D1

DKPF3F3edutilpmAgnikaePedoMerutciP

F303E003

E1

WKP8F0edutilpmAgnikaePfohtdiWpetS 80

F1

DPS0F3noitcerroCssenpeetSedoMerutciP

00000000

02

DRCB1F3leveLgniroCedoMerutciP

61610061

12

WRC9F0leveLgniroCfohtdiWpetS 60

22

ORC6F0edoMoediVroftesffOleveLgniroC 10

32

DWLF1F3noitcerroChtdiWeniL F1

42

MNS07 noitidnoCN/SelbailernUrednUedoMN/S 00

52

CNS3F0retnuoCegarevAoitaRN/SoediV/VT

3030

62

CMF2F0retnuoCgnihctaMedoMerutaeF 20

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCcimanyD

-dradnatS

amarD/

-/eniF-iH

tfoS

lanosreP

ITL00

HDL11 noitceleStnemgesmargotsiH8719ADT10

10

SFC11 noitceleSretliFruotnoC 10

20

BLW01 hctiwSwodniWxobretteL 00

30

CDV11 gniroCtnednepeDoediVedoMerutciP

10101010

40

MED01 edoMnoitartsnomeD 00

50

PDC470yaleDecnanimuL 40

60

PSO01 gnikaePtramSelurrevO 00

70

OPW01 ffOhctertStnioPetihW 00

80

KSD01 hctiwSenoTnikSedoMerutciP

00000000

90

KSA01 noitceleSelgnAenoTnikS 00

A0

KSW01 noitceleShtdiWenoTnikS 00

B0

KSS01 noitceleSeziSenoTnikS 00

C0

RGD11 hctiwStnemecnahnEneerGedoMerutciP

10100010

D0

TGD77 hctiwStnemecnahnEneerGfodlohserhT 70

E0

RGG01 niaGtnemecnahnEneerG 00

F0

RGW01 htdiWtnemecnahnEneerG 00

01

RGS01 eziStnemecnahnEneerG 00

11

LBD01 hctiwShctertSeulB 00

21

LBG01 noitceleSniaGhctertSeulB 00

31

LBS01 noitceleSeziShctertSeulB 00

41

SDC11 ssenprahStnednepeDroloCedoMerutciP

10100010

51

TSC77 ssenprahStnednepeDroloCfodlohserhT 70

61

ITC11 tnemevorpmItneisnarTroloCedoMerutciP

10100000

71

NOB01 noitasnepmoCtesffOkcalBedoMerutciP

00000000

81

DTB0F3htcertSkcalBevitpadAedoMerutciP

00000000

91

DLN51F3reifilpmAytiraeniL-noNedoMerutciP

51510051

KV-DR34M97

RM-991

KV-DR34M97

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCVToediV0edomRN1edomRN2edomRN3edomRNcimanyD

-dradnatS

amarD/

-/eniF-iH

tfoS

lanosreP

MC300

MRN03 edoMnoitarepOnoitcudeResioN 38046DPU00

10

OCYE0F0noitceleStuptuOlangiSC/Y D0

20

CYS13 noitceleSkcolCmetsyS 10

30

DTS03 noitceleSnoitarepOdradnatS-noN/dradnatS 00

40

SSM03 noitceleSnoitarepOeniL-retnI/emarF-retnI 00

50

LIK33 noitceleSnoitarepOrelliK-noN/relliK 30

60

SCE13 noitceleStupnIcnyS-ClanretxE 10

70

PPC23 noitceleShtdiWesluPpmulC&leveLtupnICDA 00

80

PDH57 tnemtsujdAesahPlatnoziroH 50

90

LDC47 tnemtsujdAyaleDlangiS-C 40

A0

CYD2F0tnemtsujdAleveLgniroCnoitceleDYD)3-0(edoMRN

20202040

B0

GYDA0F0tnemtsujAniaGnoitceleDYD)3-0(edoMRN

A0A0A0A0

C0

CCD5F0tnemtsujdAleveLgniroCnoitceteDCD)3-0(edoMRN

50303050

D0

GCD5F0tnemtsujdAniaGnoitceteDCD)3-0(edoMRN

50A0A050

E0

RNY1F0puteSretliFraeniL-noNRNY 10

F0

RNC1F0puteSretliFraeniL-noNRNC 10

01

CSW13 tnemtsujdAgniroCnitceteDesioN 10

11

HTV13 dradnatS-noNcnyS-HrofnoitceleSsiseretsyHoediV/VT

1010

21

RTV13 dradnatS-noNcnyS-HrofnoitceleSytivitisneSoediV/VT

1010

31

RDL23 dradnatS-noNcnyS-emarFrofnoitceleSytivitisneSoediV/VT

2010

41

PAV37 noitcerroCepahSlacitreVroftnemtsujdAniaGedoMerutciP

30000000

51

IAVC0F1noitcerroCepahSlacitreVroftnemtsujdAgnihsinaVedoMerutciP

C0000000

61

FPY33 FPBgnikaeP-YrofnoitceleSycneuqerFretneCedoMerutciP

30303030

71

GPY8F0FPBgnikaeP-YroftnemtsujdAniaGedoMerutciP

80808080

81

ESVA0F0puteSretliFbmoCeniL A0

91

NCC01 hctiwSretliFtilpSlangiS-C 00

A1

SOC01 noitcudeReisoNtahctiwSylaeDlangiS-C 00

B1

CDS01 hctiwSytivitisneSnoitceteDCD 00

C1

YDS11 hctiwSytivitisneSleveL-rewoLnoitceteDYD 10

D1

CHY03 noitceleSgniroCleveL-rehgiHlangiS-YedoMerutciP

00000000

E1

GHY01 hctiwSniaGreveL-rehgiHlangiS-YedoMerutciP

00000000

F1

THS0F0stiBtseTretnuoCV/H&noitceteDdradnatS-noN 00

02

KLC8F0stiBtseTkcolC 80

12

LLPD0F0puteSretliFLLP D0

22

FRK3F0tnemtsujdAecnerefeRnoitceteDrelliK 30

32

LSHC0F0tnemtsujdAleveLecilScnyS-H C0

42

LSV8F0tnemtsujdAleveLecilScnyS-V 80

52

SPB4F0tnemtsujdAnoitisoPtratSetaGtsruBlanretnI 40

62

WPBA0F0tnemtsujdAhtdiWetaGtsruBlanretnI A0

72

CDA33 noitceleSyaleDkcolCCDA 30

82

DPA11 hctiwSnwoD-rewoPCDA 10

92

DPS23 hctiwSnwoD-rewoPyromeM 00

RM-991

– 28 –

– 29 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCGORPDVD0506VToediV

MC200

NUF33 noitcnuF N96A09CT30

10

MCY03 rotarapeSC/Y 00

20

RNC03 KRNC 00

30

MIL03 timiLRNC 00

40

FPC01 FPL-C 00

50

PLS01 FPL-CleS 00

60

OFY01 ofP-Y oediV/VT

0000

70

GPY13 niaGQE-Y oediV/VT

0020

80

LPY13 timiLC.N/QE-Y oediV/VT

0000

90

PLC01 pilC.sdP 00

A0

FPY11 FPL-Y oediV/VT

0000

B0

GEV37 niaGhpmE-V 30

C0

NEV37 L.NhpmE-V 30

D0

CEV23 eroChpmE-V 20

KV-DR34M97

RM-991

KV-DR34M97

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoC

DVD

GORP

0506VToediV

,0RN

CSTN

,0RN

srehto

,1RN

CSTN

,1RN

srehto

,2RN

CSTN

,2RN

srehto

,3RN

CSTN

,3RN

srehto

RN300

CHWF2F3)44=CSTN,74=LAP(gnitteSrediviDLLP06/05F09AO9CT

F2C2

10

QIN0010ytiraloPtupnIV/U 10

20

WLCE1F3htdiWesluPpmalCD/A06/05

D0D0

30

PLC05FFesahPesluPpmalCD/A06/05

0505

40

WBYA8FFhtdiWgniknalBHY06/05

A8A8

50

LBY00F0tnemtsujdAleveLgniknalBY 00

60

OBY0010ffO/nOgniknalBHYlanretnI 00

70

TUM0010gnituMtuptuOlangiS 00

80

SBY82F7tnioPtratSgniknalBHY06/05

8282

90

WBCA8FFhtdiWgniknalBHV/U06/05

A8A8

A0

SBC82F7tnioPtratSgniknalBHV/U06/05

8282

B0

OBC0010ffO/nOgniknalBHV/UlanretnI 00

C0

LBV00F0tnemtsujdAleveLgniknalBHV 00

D0

LBU00F0tnemtsujdAleveLgniknalBHU 00

E0

LDC0070yaleDtuptuOV/U06/05

0000

F0

LDY0070yaleDtuptuOY06/05

0000

01

IVP0010ytiraloPtupnIDV 00

11

IHP0010ytiraloPtupnIDH 00

21

WDH01F3htdiWesluPDH 01

31

OVP1010ytiraloPtuptuODV 00

41

OHP1010ytiraloPtuptuODH 00

51

TSHB1FFnoitisoPtratSesluPtuODH 03

61

LDV00F0noitisoPtratSesluPtuODV 00

71

WDV30F0htdiWesluPtuODV 30

81

EDN00F0tnioPnoitceteDesioN 00

91

PVN20F0eniLtceteDesioN 20

A1

SDN2030ytivitisneSnoitceteDesioN 30

B1

FOH0010)0=NO(ffO/nOesluPecnerefeRH 00

C1

WDN90F0htdiWetaGtceteDesioN 90

D1

SOU0070leveLtesffOU 40

E1

TOP0030lortnoC1/0troPtuptuO06/05

0000

F1

FVU0010ytiraloPgarFVU 00

02

CPA0010ytiralopkcehCPA 00

12

PAD0010)1=NO(evaSrewoPCAD 00

22

VLY80F0leveLRNYsrehto/CSTN*3/2/1/0RN

0000D0D0E0E08080

32

TSY0010nO/ffOnoitceteDdradnatSY 00

42

TNY1010noitceteDdradnatSCSTNY 10

52

LPY1010noitceteDdradnatSLAPY 10

62

VMY0010)0=NO(retliFnoitceteDgnivoMY 00

RM-991

– 30 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoC0506

,0RN

CSTN

,0RN

srehto

,1RN

CSTN

,1RN

srehto

,2RN

CSTN

,2RN

srehto

,3RN

CSTN

,3RN

srehto

RN372

RCY80F1leveLgniroCnoitceteDgnivoMYsrehto/CSTN*3/2/1/0RN

00007070A0A00000

82

SOV0070leveLtesffOV 40

92

GMY1030niaGnoitceteDgnivoMYsrehto/CSTN*3/2/1/0RN

0000000000000000

A2

GEY1010)1=NO(nOnoitceteDgnivoMY 10

B2

LEY60F0ytivitisneSnoitceteDgnivoMegdEYsrehto/CSTN*3/2/1/0RN

3030303030304040

C2

MLY60F7leveLtimiLkcaBdeeFRNYsrehto/CSTN*3/2/1/0RN

0000404080803030

D2

VLCA0F0leveLRNCsrehto/CSTN*3/2/1/0RN

00009090B0B08080

E2

TNC1010NDTSYotRNCetaleR 10

F2

LPC1010PDTSYotRNCetaleR 10

03

GMC1030niaGnoitceteDgnivoMCsrehto/CSTN*3/2/1/0RN

0000000000000000

13

RCC30F1leveLnoitceteDgnivoMCsrehto/CSTN*3/2/1/0RN

00006060C0C00000

23

MLC60F7leveLtimiLkcaBdeeFRNCsrehto/CSTN*3/2/1/0RN

0000505050504040

33

SVN41FFeniLtratSlacitreVRN06/05

4141

43

SHN01F7noitisoPtratSlatnoziroHRN06/05

0101

53

EVN09FF)d001+:tesffo(eniLdnelacitreVRN06/05

4F4F

63

EHNE4F7noitisoPdnelatnoziroHRN06/05

8787

73

GNY1030niaGgniroCY06/05

1010

83

ROC0010)0=gniroC(hguorhT/gniroC06/05

0000

93

FPL0010)0=nO(ffO/nOFPL 10

A3

TLY60F0leveLtimiLgniroCY06/05

6060

B3

CNY80F0leveLtesffOgniroCYsrehto/CSTN*3/2/1/0RN

8080C0C0E0E08080

C3

OCY1010)1=nO(ffOgniroCY06/05

0000

– 31 –

KV-DR34M97

RM-991

KV-DR34M97

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoC

DVD

GORP

TXT00

HXTA2FFspiliihProfnoitisoPlatnoziroHtxeteleT 4625AASA2

10

VXT72F3spilihProfnoitisoPlacitreVtxeteleT 72

20

DHT00F7tfihSegdEevitcAcnyS-HtxeteleT 00

30

DVT00F7tfihSegdEevitcAcnyS-VtxeteleT 00

40

LPH1010noitarugifnoCytiraloPcnyS-HtxeteleT 10

50

LPV0010noitarugifnoCytiraloPcnyS-VtxeteleT 00

60

LPF1010noitarugifnoCytiraloPdleiFtxeteleT 10

70

DMF0030edoMecroFPOT/txetsaFtxeteleT 00

80

RBT80F0ssenthgirBBGRtxeteleT 80

90

PON10F0noitarugifnoCelbaTnoitpOlanoitaNtxeteleT 10

A0

HCT1030noitarugifnoCteSretcarahCdetsiwTtxeteleT 10

RM-991

– 32 –

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoCGORPDVD

MPO00HSO21F3noitisoPHDSOoediV/VT690057PXC21E0

101WF0F31#puteSwodniWdleiFNEVE/DDODSO 00

202WF3F32#puteSwodniWdleiFNEVE/DDODSO 30

30

MOC030noitceleSnoitarepObmoC 00

40

CPA11 hctiwSCPA 10

50

YST030metsySVTotuAhtiWgnihcraeSrednUnoitceleSmetsySVT 00

60

TUM01 etuMlangiSoN 00

70

MFA11 hctiwSMFotuA 10

80OVT37 noitatoRerutciPotnoitcerroCelgnA-V 30

90LBD01 noitcnuFkcabeulBelbasiD 00

A0

OSS13 noitceleShcraeSHCdeepS 10

B0PRT0F3tupnihcaerofnoitcudeResioNGEPJ/GEPM 00

C0HCSF7F7noitidnoCgnippihSrofnoitceleSHC ylnOCSTNF7

D0ACS11 noitidnoCgnippihSrofnoitceleSriA/elbaC ylnOCSTN10

E0NSV11 edoMoediVninoitcudeResioNelbanE 10

F0QSP01 cepSnoitceteDscriSsounitnoCrofqeSrewoP 00

01ROP01 TCYmorFnoitceteDteseRnOrewoP 00

11CURF0F0dekcolnUretfaretnuoCegnahClangiSFR hF0ottesfielbasidF0

21CLRF0F0dekcolretfaretnuoCegnahClangiSFR hF0ottesfielbasidF0

31BBL01 ytisnetnIkcaBeulBrewoL 00

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTemaNeciveD

)deliated(eulaVlaitinI

yrogetaCoNemaN nommoC

DVD

GORP

BPO001PO7EFF)43egaprefer(1stiBlanoitpO stiB-noitpOFF

102PO71FF)43egaprefer(2stiBlanoitpO 49

203PO00FF)43egaprefer(3stiBlanoitpO 00

– 33 –

KV-DR34M97

RM-991

KV-DR34M97

RM-991

Abbreviation

VC = V-Compressed Mode NC = Non-compressed Mode ECO = Eco Mode

Sur = Surround NR = Noise Reduction FF = Flicker Free

R4 = Real 4 PR = Progressive

NOTE

shaded items are fixed data.

•

no data.

•

• Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and

for each mode.

• Note for Different Data: The data indicated in the initial colomn are the standard data values written on the microproces-

sor. Therefore, the data values of the modes are stored respectively in the memory. In case of a device replacement,

adjustment by rewriting the data value is necessary for some items.

OPTION NOTE

COM Comb Operation Selection 00 = Auto

01 = No comb,

02 = Forced 2D comb,

03 = Forced 3D comb,

TSY TV System Selection for Auto TV System 00 = B/G, 01 = I, 10 = D/K, 11 = M

SSO Speed CH Search Selection 00 = normal, 01 = 4 times, 10 = 6 times, 11 = 8 times

TRP MPEG/JPEG Noise Reduction

Input

OP1 Items

Item

KV-DR34M97

AV Input 00 = no AV Input, 01 = 1 AV Input, 10 = 3 AV Input, 11 = 4 AV Input

OP2 Items

Item

KV-DR34M97 11

PiP Models PiP models 0 = No PiP, 1 = PiP

Korean Stereo* Korean Stereo 0 = disabled, 1 = enabled

Video NTSC3.58* Video Color System 0 = Multi System, 1 = Single System (NTSC3.58)

A-TVsys Auto TV System in Auto Program 0 = Disabled, 1 = enabled

US ST* USA Stereo 0 = disabled, 1 = enabled

OSD Language (Multi) 000 = English only 100 = English & Chinese

OSD Language (NTSC) 000 = English only 010 = English & Taiwanese

TOP

0

PiP Models

1

NICAM

1

Korean Stereo

0

010 = English & Arabic 110 = English, Chinese & Arabic

001 = English & Thai 101 = English, Chinese & Thai

011 = English, Arabic & Thai 111 = English, Chinese, Arabic & Thai

001 = English & Korean 011 = English, Taiwanese & Korean

HDEV

1

Vid NTSC3.58

0

Thai Bil.

0

A-TV sys

1

Sleep Mode

1

US ST

0

DVD Input

1

Chinese

1

AV Input

Arabic Thai

DVDVideo 4Video 3Video 2Video 1TV––

HEX

11

6F

HEX

97

OP3 Items

Item

KV-DR34M97

Forced 50/60* Forced to 50/60Hz during no signal condition 0 = 60Hz, 1 = 50Hz

Initial Menu Activate initial setup or not 0 = Not active 1 = Active

*APPLICABLE FOR NTSC MODELS ONLY

N/A

0

N/A

0

N/A

0

N/A

0

N/A

0

N/A

0

Initial menu

1

– 34 –

Forced 50/60

0

HEX

02

NOTE

No. Modes Details Entry Conditions

1.

50NC/60NC

2.

50VC/60VC

3.

ECO ON/OFF NC

4.

ECO ON/OFF VC

5.

50/60 DVD

6.

Multi Comb

7.

3D Comb

8.

S-Input

9.

NR0

10.

NR3

11.

NR1

12.

NR2

Signal 50/60Hz Non-Compressed

mode.

Signal 50/60Hz V-Compressed

mode.

Eco modeON/OFF

Non-Compressed mode.

ECO mode ON/OFF

V-Compressed mode.

Signal 50/60Hz Digital Video Disk

Multi Comb Filter

3 Dimensional Comb Filter

S-Video Input

Input 50Hz(PAL)/60Hz(NTSC), wide mode OFF (TV/

video mode)

Input 50Hz(PAL)/60Hz(NTSC), wide mode ON (TV/

Video mode)

ECO mode ON/OFF, wide mode OFF

ECO mode ON/OFF, wide mode ON

Input 50Hz(PAL)/60Hz(NTSC), DVD

Input PAL, NTSC 3.58, Service mode category OPM 03

COM 01 (Multi Model only)

Input NTSC 3.58 only, Service mode category OPM 03

COM 02 (NTSC model only)

Connect S-Video Cable, video mode

3D NR mode OFF

3D NR mode ON and signal level is poor.

3D NR mode ON and signal level is bad.

3D NR mode ON and signal level is worst.

KV-DR34M97

RM-991

– 35 –

KV-DR34M97

VB1 VB2 VB3 VB4

RM-991

6-3. PICTURE QUALITY ADJUSTMENTS

Adjustment condition

1. Set to service mode.

2. Set picture mode to HI-FINE.

3. Set the following condition.

ECO MODE : OFF

WIDE MODE : OFF

DRC-MF : DRC1250

3D-NR : ON

Input signal : Video Color Bar

RF Color Bar

MEASUREMENT POINT

A board CN4301

1 R-OUT

5 B-OUT

CAUTION

After Adjustment, these adjustment parameters must be

recovered to the original condition.

Original Condition

SAJ 00 PIC 28 HI-FINE

50 TV 50 VIDEO 60 TV 60 VIDEO

0E CLO 06 08 09 09

1O HUO 05 03 07 06

(ii) NTSC (RF MODE)

Input signal : NTSC Color Bar (75%) to Video

Condition: SAJ 00 PIC 3F

SAJ 02 COL 00

JGL 01 RGB 04

Adjusting parameter :

YCT 04 SCT

VR

VR2

GND

VR1 - VR2 = ∆VR = 2.35 ± 0.07 (Vp-p) (PAL)

(∆VR = 1.85 ± 0.07 (Vp-p)-For NTSC)

6-4. SUB HUE/COL ADJUSTMENT

6-4(1). SUB HUE/SUB COL (VIDEO MODE)

Input signal : NTSC Color bar (75%)

Picture : HI-FINE mode

Condition : SAJ 00 PIC 3F

SAJ 02 COL 1F

SAJ 10 HUO 05

SAJ 0E CLO 04

Adjusting parameter:

YCT 03 SCL

YCT 00 TNT

6-3(1). DRIVE ADJUSTMENT (VIDEO MODE)

(i) SUB CONTRAST (PAL)

Input signal : PAL Color bar (100%) to Video

Picture : HI-FINE mode

Condition : SAJ 00 PIC 3F

SAJ 02 COL 00

JGL 01 RGB 04

Adjusting parameter:

YCT 04 SCT

(ii) SUB CONTRAST (NTSC)

Input signal : NTSC Color Bar (75%) to Video

Picture : HI-FINE mode

Condition: SAJ 00 PIC 3F

02 COL 00

JGL 01 RGB 04

Adjusting parameter :

YCT 04 SCT

6-3(2). DRIVE ADJUSTMENT (RF MODE)

(i) SUB CONTRAST (PAL)

Input signal : PAL Color bar (100%) to Video

Condition : SAJ 00 PIC 3F

SAJ 02 COL 00

JGL 01 RGB 04

Adjusting parameter:

YCT 04 SCT

6-4(2). SUB HUE/SUB COL (NTSC RF MODE)

Input signal : NTSC Color bar (75%)

Condition : SAJ 00 PIC 3F

SAJ 02 COL 1F

SAJ 10 HUO 05

SAJ 0E CLO 04

Adjusting parameter:

YCT 03 SCL

YCT 00 TNT

NTSC

VB1 = VB4 ± 70 mV

VB2 = VB3 ± 70 mV

6-4(3). SUB COLOR ADJUSTMENT (PAL RF MODE)

(Except NTSC models)

Input signal : RF PAL Color bar (100%)

Picture : HI-FINE mode

Condition : SAJ 00 PIC 3F

SAJ 02 COL 1F

SAJ 0E CLO 04

SAJ 10 HUO 05

JGL 01 RGB 07

Adjusting parameter:

YCT 03 SCL

VB4

PAL

VB1 VB2 VB3 VB4

VB2 = VB3 = VB4

– 36 –

KV-DR34M97

RM-991

6-4(4). SUB COLOR ADJUSTMENT (PAL VIDEO MODE)

Input signal : PAL Color bar (100%)

Picture : HI-FINE mode

Condition : SAJ 00 PIC 3F

SAJ 02 COL 1F

SAJ 0E CLO 04

SAJ 10 HUO 05

JGL 01 RGB 07

Adjustment parameter:

YCT 03 SCL

6-5. DEFLECTION ADJUSTMENTS

FOR DRC 1250 (50Hz) MODE

1. Set to Service Mode.

2. Input a PAL cross hatch/dot signal.

3. Set the following condition.

Picture Mode to [DYNAMIC], Picture Rotation to [+/–0] and

Eco Mode to OFF.

4. Set to DRC-MF1250 mode.

5. Using the [1] and [4] button, select category GEO (Service

Mode).

6. Select and adjust the following items to obtain optimum

image. Raise/lower the data using the [3] and [6] buttons.

Service Item

GEO : 00 VSZ V SIZE

01 VPS V POSITION

02 VLN V LINEARITY

03 SCO S CORRECTION

04 HSZ H SIZE

06 PAP PIN AMP

07 UPN UPPER CORNER PIN

08 LPN LOWER CORNER PIN

CORRECTION POSITION

SETTING

09 UCG MOST UPPER CORNER

PIN ADJUSTMENT

0E PPH V TRAPEZOID ADJUSTMENT

0F AGL AFC ANGLE

10 BOW AFC BOW

11 HTR V SAW0 WAVE SAW LEVEL

GAIN CONTROL

12 MPD MP PARA WAVE DC

BIAS CONTROL

14 PBP H CENT PARA WAVE SAW

LEVEL GAIN CONTROL

15 PBA H CENT PARA WAVE GAIN

CONTROL

DAC : 00 HCT H CENTER

01 HLN H LINEARITY

7. Write into the memory by pressing [MUTING] then [0] on

the remote commander.

FOR WIDE MODE, DRC1250 (50Hz)

8. Adjust condition change to WIDE MODE : ON.

9. COPY (item FOR DRC 1250 (50Hz) MODE and adjust

data for the following items.

Service Item

GEO : 00 VSZ V SIZE

01 VPS V POSITION

04 HSZ H SIZE

12 MPD MP PARA WAVE DC BIAS

CONTROL

14 PBP H CENT PARA WAVE SAW

LEVEL GAIN CONTROL

10. Adjust V Blanking the following items.

Service Item

GEO : 1E VAS V ASPECT

1F VSC V SCROLL

FOR DRC 1250 (60Hz) MODE

11. Input 525/60Hz signal.

12. Set to DRC-MF : 1250

13. COPY (item for DRC 1250 (50Hz) mode and adjust data

for the following items.

Service Item

GEO : 12 MDP MP PARA WAVE DC BIAS

CONTROL

14 PBP H CENT PARA WAVE SAW

LEVEL GAIN CONTROL

14. Adjust the following items.

Service Item

GEO : 00 VSZ V SIZE

01 VPS V POSITION

02 VLN V LINEARITY

03 SCO S CORRECTION

04 HSZ H SIZE

05 HPS H POSITION

06 PAP PIN AMP

07 UPN UPPER CORNER PIN

08 LPN LOWER CORNER PIN

09 UCG MOST UPPER CORNER

PIN ADJUSTMENT

0E PPH V TRAPEZOID ADJUSTMENT

0F AGL AFC ANGLE

10 BOW AFC BOW

11 HTR V SAWO WAVE SAW LEVEL

GAIN CONTROL

15 PBA H CENT PARA WAVE GAIN

CONTROL

– 37 –

KV-DR34M97

RM-991

FOR WIDE MODE, DRC 1250 (60Hz)

15. Set to WIDE MODE : ON

16. Copy the DRC 1250 (60Hz) MODE and adjust the

following items to obtain optimum image.

Raise/lower the data with the [3] and [6] buttons.

GEO 00 VSZ V SIZE

01 VPS V POSITION

04 HSZ H SIZE

12 MPD MP PARA WAVE DC

BIAS CONTROL

14 PBP H CENT PARA WAVE SAW

LEVEL GAIN CONTROL

17. Adjust V Blanking for the following items.

GEO 1E VAS V ASPECT

1F VSC V SCROLL

18. Adjust the following items.

Service Item

GEO : 02 VLN V LINEARITY

03 SCO S CORRECTION

05 HPS H POSITION

06 PAP PIN AMP

07 UPN UPPER CORNER PIN

08 LPN LOWER CORNER PIN

09 UCG MOST UPPER CORNER

PIN ADJUSTMENT

0E PPH V TRAPEZOID ADJUSTMENT

0F AGL AFC ANGLE

10 BOW AFC BOW

11 HTR V SAWO WAVE SAW LEVEL

GAIN CONTROL

15 PBA H CENT PARA WAVE GAIN

CONTROL

19. Input a NTSC cross hatch/dot signal and repeat all above

steps.

6-6. A BOARD ADJUSTMENT AFTER IC003

(MEMORY) REPLACEMENT

1. Enter to Service Mode.

2. Press commander buttons 5 and - (Data Initialize), and

2 and - (Data Copy) to initialize the data.

3. Call each item number and check if the respective screen

shows the normal picture.

In cases where items are not well adjusted, rectify the items

with fine adjustment.

Write the data per each item number ([MUTING] +-).

4. Select item numbers “OPB00” (OP1), “OPB01” (OP2) and

respectively set the bit per model with command buttons 3

and 6.

5. Press commander buttons 8 and - (Test Normal) to return

to the data that was set on the shipment from the factory.

(This will also cancel Service Mode.)

– 38 –

KV-DR34M97

RM-991

6-7. PICTURE DISTORTION ADJUSTMENT (1)

Item Number 00 – 0B

GEO 0 VSZ (V SIZE)

GEO 1 VPS (V POSITION)

GEO 2 VLN (V LINEARITY)

GEO 3 SCO (VERTICAL S-Correction)

GEO 4 HSZ (H SIZE)

PICTURE DISTORTION ADJUSTMENT (2)

V SAWO WAVE SAW LEVEL GAIN CONTROL (GEO 11 HTR)

GEO 5 HPS (H POSITION)

GEO 6 PAP (PIN AMP)

GEO 07 UPN (UPPER CORNER PIN)

GEO 08 LPN (LOWER CORNER PIN)

GEO 9 TRZ (TRAPEZIUM)

GEO 0A AGL (AFC.ANGLE)

GEO 0B BOW (AFC.BOW)

– 39 –

7-1. BLOCK DIAGRAM

V-DVD

H-DVD

>

>

>>>

VU

Y

}

DVD PROGRESSIVE

VU

Y

>>>

J8301

423

1

Video In 1

V1

L1

R1

Video In 2

V2

L2

R2

Video In 3

V3

L3

R3

Q8361

BUFFER

COMPONENT I/F

SELVOUT

23

22

SELHOUT

3

Y

2

Cb

1

Cr

Q8362

BUFFER

IC3001

SELCBOUT

SELCROUT

EXTCLK/XTAL

CRYSTAL

Q8363

BUFFER

SELYOUT

20

X3001

BUFFER

Q8302

BUFFER

Q8365

SECTION 7

DIAGRAMS

27

26

25

Y-BUFFER

U-BUFFER

V-BUFFER

MAIN COLOR DECORDER

C3

39

41

CVBS/Y3

46

FSC OUT

10

SCP

19

Y1

18

Cb1

17

Cr1

COUT2

47

36

NT/PAL

3

Y1

5

C1

7

S-1

1

V1

2

LV1

4

RV1

8

V2

9

LV2

11

RV2

30

V5

15

V3

16

LV3

18

RV3

59

LV6

61

RV6

Q3015

Q3018

Q3023

IC8306

CVBS OUT(2VPpp)

Y OUT

Cb OUT

Cr OUT

CVBS/Y2

C2

43

44

IC8302

AV SW

LOUT2