SONY KV-DA34M61, KV-DA34M81 Service Manual

REVISION HISTORY

CX1

CHASSIS

MODEL

KV-DA34M61

KV-DA34M81

KV-DA34M81

NO. SUFFIX DATE SUPP / CORR DESCRIPTION

1 -01 2004/9 _ _ 1st Issue

PART NO. : 9-872-468-01

SERVICE MANUAL CX1

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-DA34M61 RM-W105 GE SCC-V25A-A

KV-DA34M81 RM-W105 Middle East SCC-V24A-A

KV-DA34M81 RM-W105 Saudi Arabia SCC-V22B-A

MODEL COMMANDER DEST. CHASSIS NO.

RM-W105

TRINITRON

®

COLOR TV

KV-DA34M61/M81

RM-W105

TABLE OF CONTENTS

Section Title Page

SELF DIAGNOSTIC FUNCTION..............................3

1. DISASSEMBLY

1-1. Rear Cover Removal................................................. 6

1-2. Speaker Removal ...................................................... 6

1-3. Chassis Assy Removal .............................................. 6

1.4. Service Position ........................................................ 6

1-5. Terminal Bracket Removal ....................................... 6

1-6. J Board Removal....................................................... 6

1-7. F1 Board Removal .................................................... 7

1-8. DL Board Removal ................................................... 7

1-9. BH1, BP and BC Boards Removal ........................... 7

1-10.H1 and H2 Boards Removal..................................... 7

1-11.A and D Boards Removal ......................................... 7

1-12.Picture Tube Removal............................................... 8

2. SERVICE JIG.......................................................... 10

3. CIRCUIT BOARDS LOCATION ............................. 10

4. ADVANCE OPERATION

4-1. "RESET" Function.................................................. 11

Section Title Page

7. DIAGRAMS

7-1. Block Diagram ........................................................ 65

7-2. Schematic Diagram Information ............................ 66

7-2-1. BC board Schematic Diagram ................... 67

7-2-2. BH1 board (Block 001) .............................69

7-2-3. BH1 board (Block 002).............................. 71

7-2-4. F1 board Schematic Diagram......................73

7-2-5. H1 board Schematic Diagram .................... 74

7-2-6. H2 board Schematic Diagram .................... 76

7-2-7. A Board (Block 001) .................................. 77

7-2-8. A Board (Block 002) .................................. 79

7-2-9. A Board (Block 003) .................................. 81

7-2-10.A Board (Block 004) .................................. 83

7-2-11. C board Schematic Diagram ...................... 84

7-2-12.D board (Block 001)................................... 86

7-2-13.D board (Block 002)................................... 88

7-2-14.DL board Schematic Diagram.................... 89

7-2-15.VM board (Block 001) ............................... 91

7-2-16.VM board (Block 002) ............................... 93

7-2-17.J board Schematic Diagram ....................... 94

7-3. Voltage Measurement and Waveform..................... 95

7-4. Printed Wiring Boards .......................................... 107

7-5. Semiconductors..................................................... 120

5. SET-UP ADJUSTMENTS

5-1. Beam Landing ......................................................... 12

5-2. Convergence Adjustment........................................ 13

5-3. Focus Adjustment.................................................... 15

5-4. Neck Assy Twist Adjustment.................................. 15

5-5. G2 (SCREEN) and White Balance Adjustment ..... 15

6. CIRCUIT ADJUSTMENTS

6-1. Adjustment With Commander ................................ 16

6-2. Adjustment Method ................................................ 17

6-3. Picture Quality Adjustments................................... 62

6-4. Sub Hue/Col Adjustment ........................................ 62

6-5. Deflection Adjustments .......................................... 62

6-6. A Board Adjustment After IC003 (MEMORY)

Replacement............................................................ 63

6-7. Picture Distortion Adjustment ................................ 64

8. EXPLODED VIEWS

8-1. Speaker Bracket .................................................... 122

8-2. Chassis................................................................... 124

9. ELECTRICAL PARTS LIST.................................. 125

OPERATING INSTRUCTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD,

OR CARBON P AINTED ON THE CRT, AFTER REMOVING THE

ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

KV-DA34M61/M81

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY (1) indicator will

automatically begin to flash.

The number of times the STANDBY (1) flashes translates to a probable source of the problem. If an error symptom

cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to

reveal past problems and how often these problems occur.

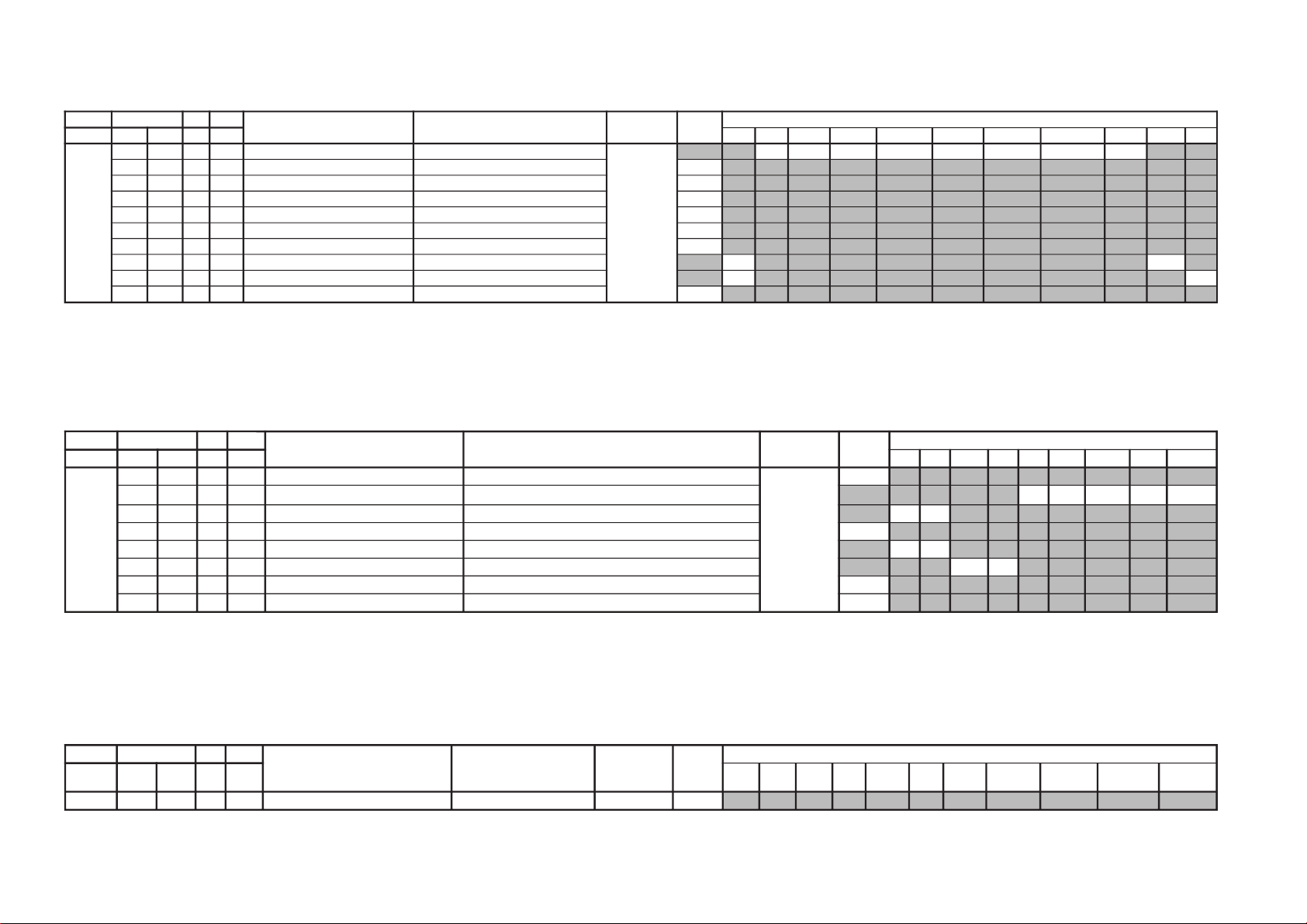

1. DIAGNOSTIC TEST INDICATORS

When an error occurs, the STANDBY (1 ) indicator will flash a number of times to indicate the possible cause of the

problem. If there is more than one error, the indicator will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occured if the screen displays a

“0”.

RM-W105

Diagnostic

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP)

• Horizontal

deflection failure

• +B overvoltage

(OVP)

• Vertical deflection

failure

• White balance

failure (no

PICTURE)

• 5V/9V Failure

• Micro reset

No. of times

STANDBY (1)

indicator flashes

Does not light

2 times

3 times

4 times

5 times

8 times

—

Self-diagnostic

display/Diagnostic

result

—

002:000 or

002:001~255

003:000 or

003:001~255

004:000 or

004:001~255

005:000 or

005:001~255

008:000 or

008:001~225

101:00 or

101:001~225

Probable

Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out F1601

(F1 Board)

• H.OUT Q6802 is shor ted.

• C6831 is open circuit.

PS6606 open, PS6605

open.(D board)

• PH6602 faulty.

D6644 faulty, R6651 open.

• 10.5V is not supplied.

(D board)

• V.OUT IC6800 faulty

D6816 faulty

D6817 faulty

D6824 faulty

R6852 open

R6851 open (D board)

• G2 is improperly adjusted.

• CRT problem.

• Video OUT IC9001, 9002,

9003 are faulty. (C board)

• IC4301 (CXA2170Q)

(A board) is faulty.

• 5V Regulator (IC2601)

faulty.

• 9V Regulator (IC2600)

faulty.

• CRT Discharge (C Board)

• Static discharge

• External noise

Detected

Symptoms

• Power does not come on.

• No power is supplied to the

TV.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is

shorted.

• H pulse output is too high.

• Power does not come on.

• Vertical deflection pulse is

stopped.

• Vertical size is too small.

• Vertical deflection stopped.

• No raster is generated.

• CRT cathode current

detection reference pulse

output is small.

• TV Blank

• No Raster

• Power is shut down shortly,

after this return back to

normal.

• Detect Micro latch up.

– 3 –

KV-DA34M61/M81

RM-W105

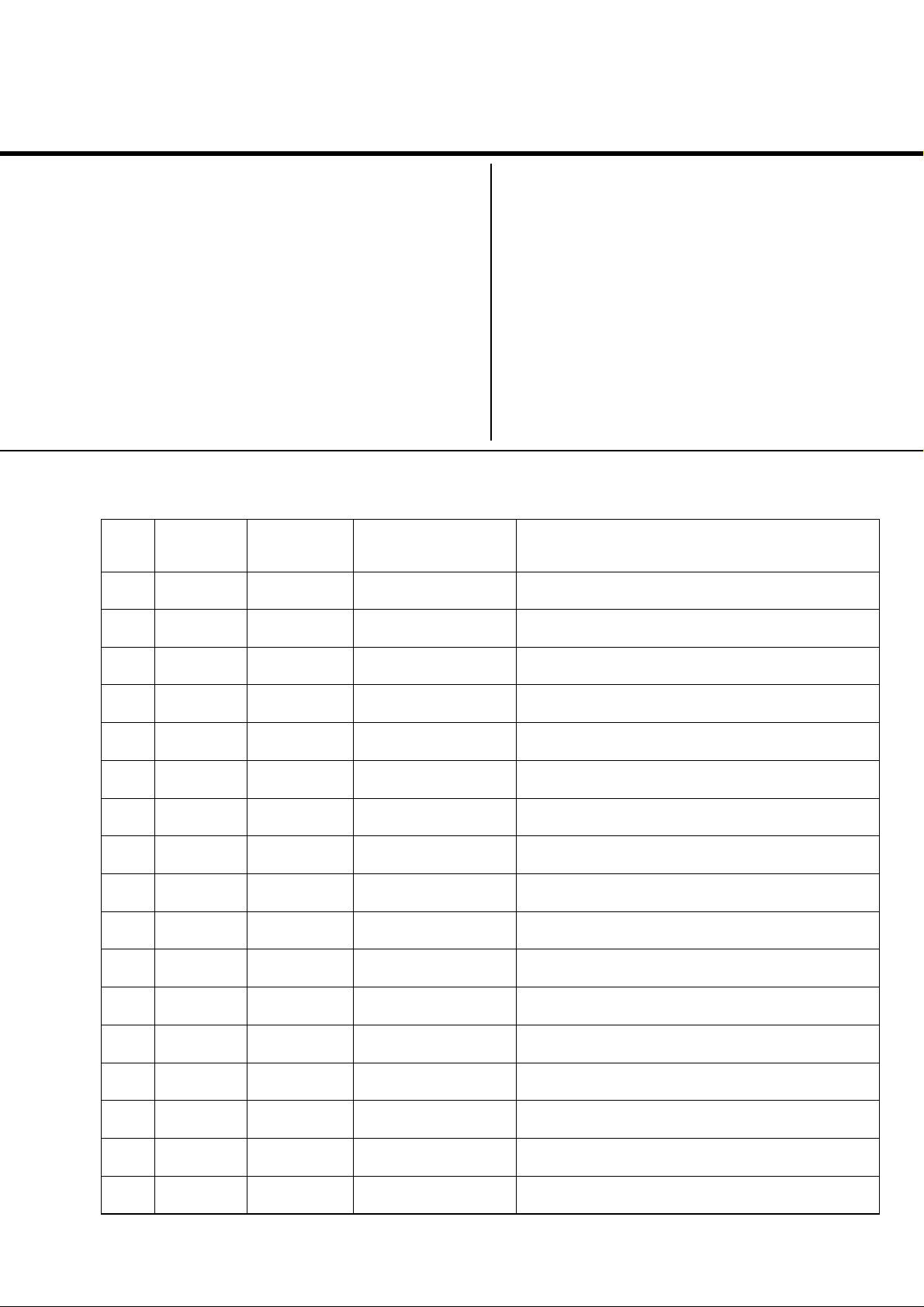

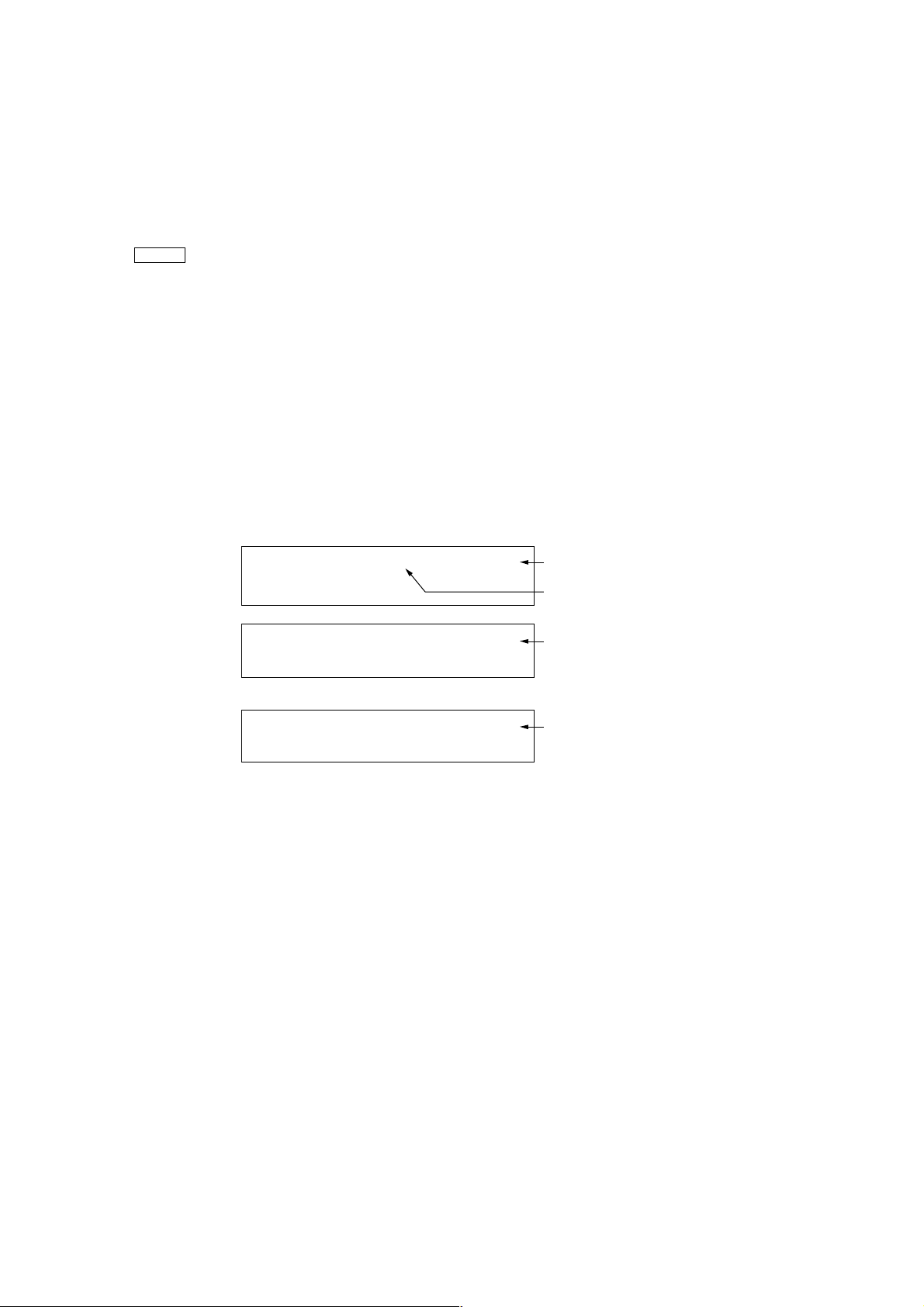

2. DISPLAY OF STANDBY (1) indicator FLASH COUNT

2 times

3 times

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

Diagnostic Item Flash Count*

+B overcurrent,Horizontal Deflection F ailure 2 times

+B overvoltage 3 times

V deflection stop 4 times

White balance failure 5 times

5V/9V Failure 8 times

4 times

5 times

8 times

* One flash count is not used for self-diagnostic.

STANDBY (1) indicator

3. ST OPPING THE STANDBY (1) indicator FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY (1)

indicator from flashing.

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as "power sometimes shuts off" or "screen sometimes goes off" that cannot be

confirmed, it is possible to bring up past occurence of failure on the screen for confirmation.

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

[display] / channel

5 / volume [-] / Power / TV

˘

Note that this differs from entering the service mode (volume [+]).

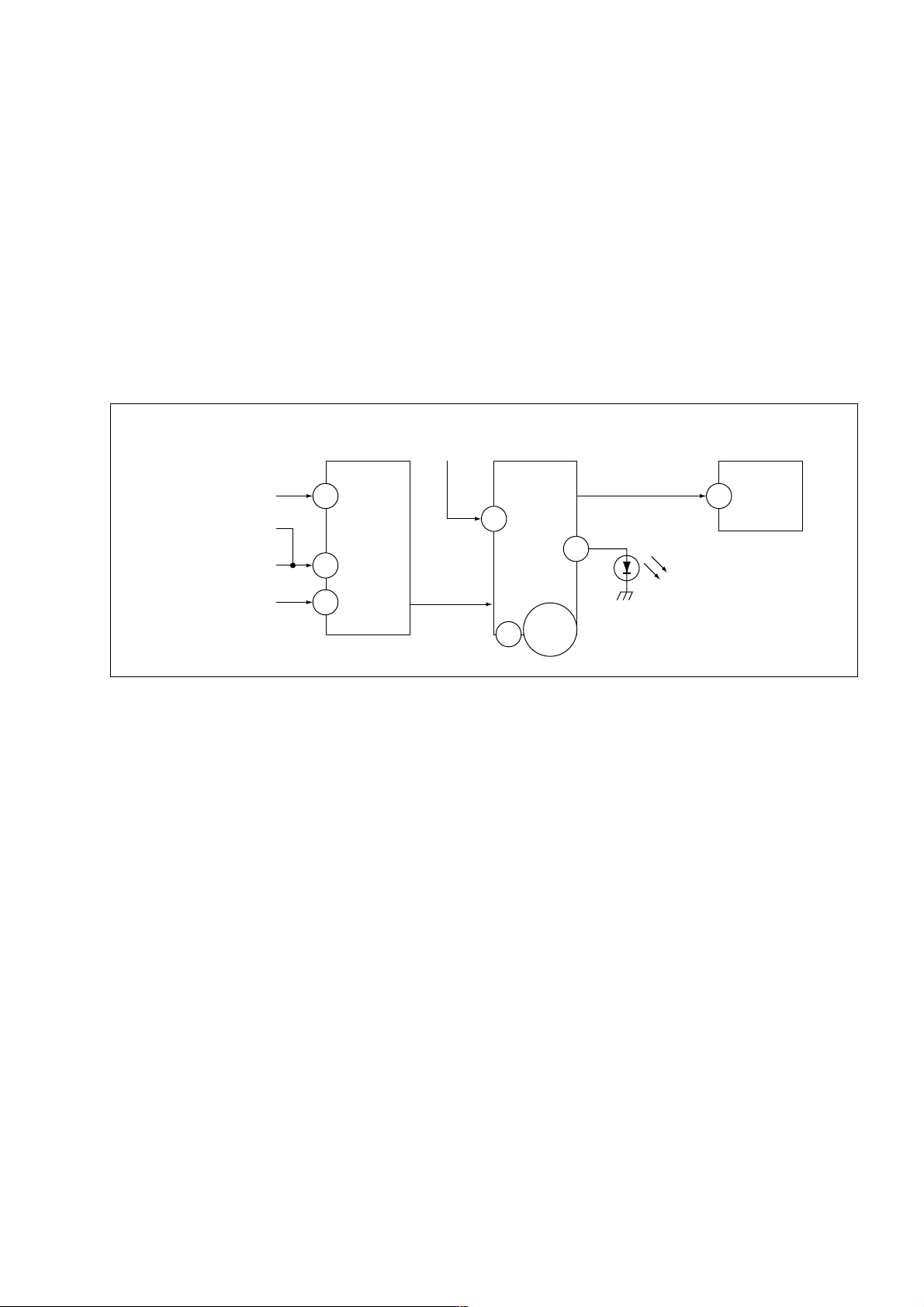

Self-Diagnostic screen display

SELF DIAGNOSTIC

002 : 000

003 : 000

004 : 000

005 : 001

008 : 002

101 : 000

Numeral "0" means that no fault has been detected.

Numeral "1" means a fault has been detected.

Numeral "2" means two faults have been detected.

– 4 –

KV-DA34M61/M81

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic

screen during repairs. When you have completed the repairs, clear the result display to "0".

Unless the result display is cleared to "0", the self-diagnostic function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to "0", press buttons on the remote commander sequentially when the self-diagnostic screen

is displayed as shown below:

Channel 8 / "0"

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

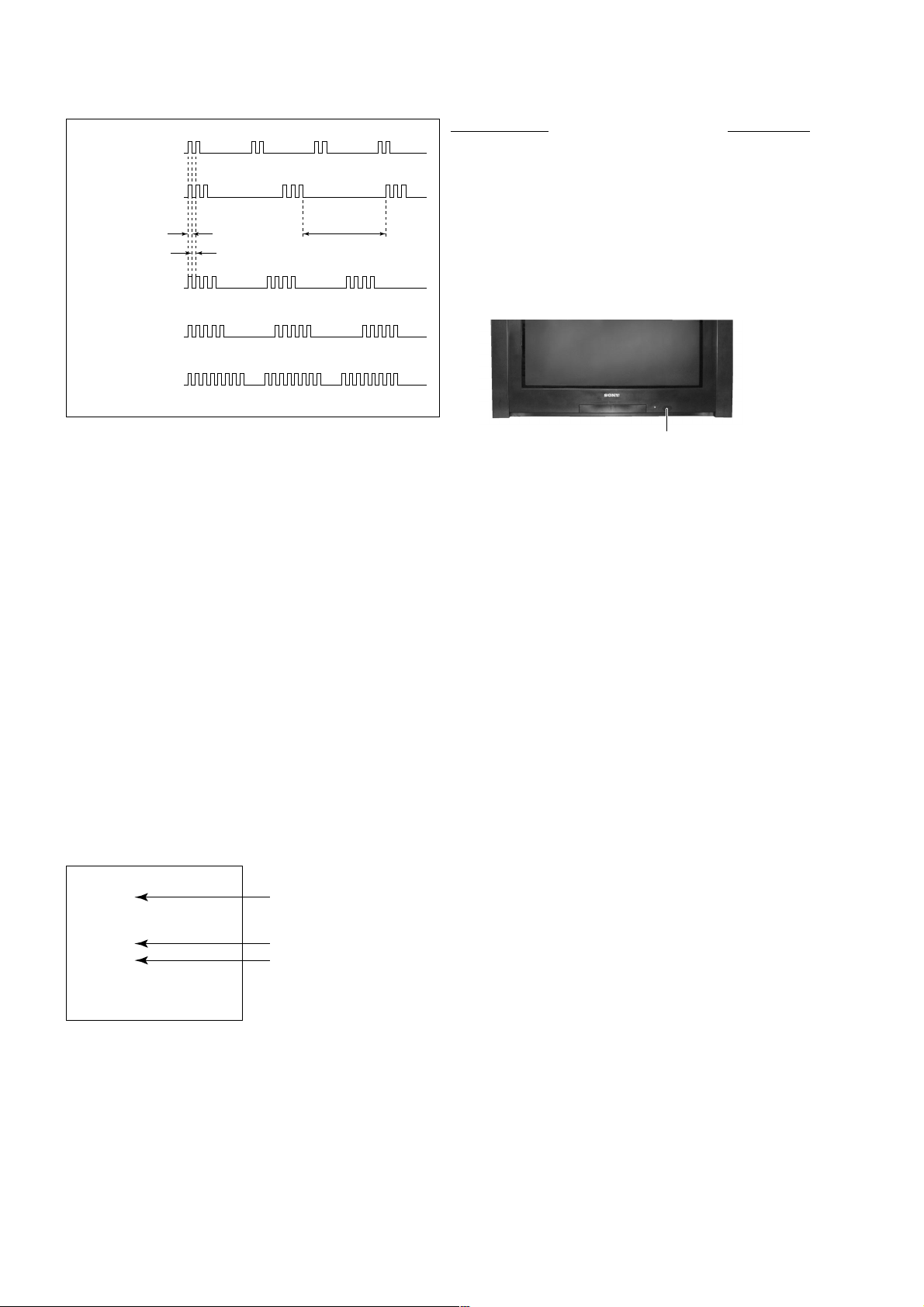

6. SELF-DIAGNOSTIC CIRCUIT

RM-W105

FROM

CRT (IK)

[OCP] Q6804, D6821

[H] D6808, D6809

[V] Q6808, R6910

IC4301

RGB JUNGLE

IK_IN

57

H PROT

56

V PROT

CXA2170AQ

OVP

SDA

IC001

SYSTEM

6

RED LED

5V

9V

14,47,82

84

IC004

MEMORY

SDA

7

524

[+B overcurrent OCP ] Occurs when an overcurrent on the +B(135) line is detected by

Q6804.

If Q6804 go to ON, the voltage to the pin57 of IC4301 go to "HIGH".

The unit will automatically turn off.

[High voltage protector of Horizontal Deflection] Occurs when an overvoltage of horizontal pulse is detected by

D6809.

If the voltage of anode D6809, Q6814 and D6808 goes to "High", the

voltage to pin57 of IC4301 go to "HIGH". The unit will automatically

turn off.

[+B overvoltage OVP ] Occurs when an overvoltage on the +B(135) line is detected by

D6635 and Q6611. If Q6611 go to ON, the voltage to pin6 of IC001

go to "HIGH". The unit will automatically turn off.

[Vertical deflection failure] Occurs when an absence of the vertical deflection pulse is detected

by Q6808 and R6910. Shut down the power supply.

[White balance failure] If the RGB levels do not balance or become low level within 5

seconds. This error will be detected by IC4301.

TV will stay on, but there will be no picture.

[Micro Fails to Start-up] Occurs when 5V/9V is not supplied to micon (IC001). No Raster will

be detected or No Picture.

– 5 –

KV-DA34M61/M81

RM-W105

SECTION 1

DISASSEMBLY

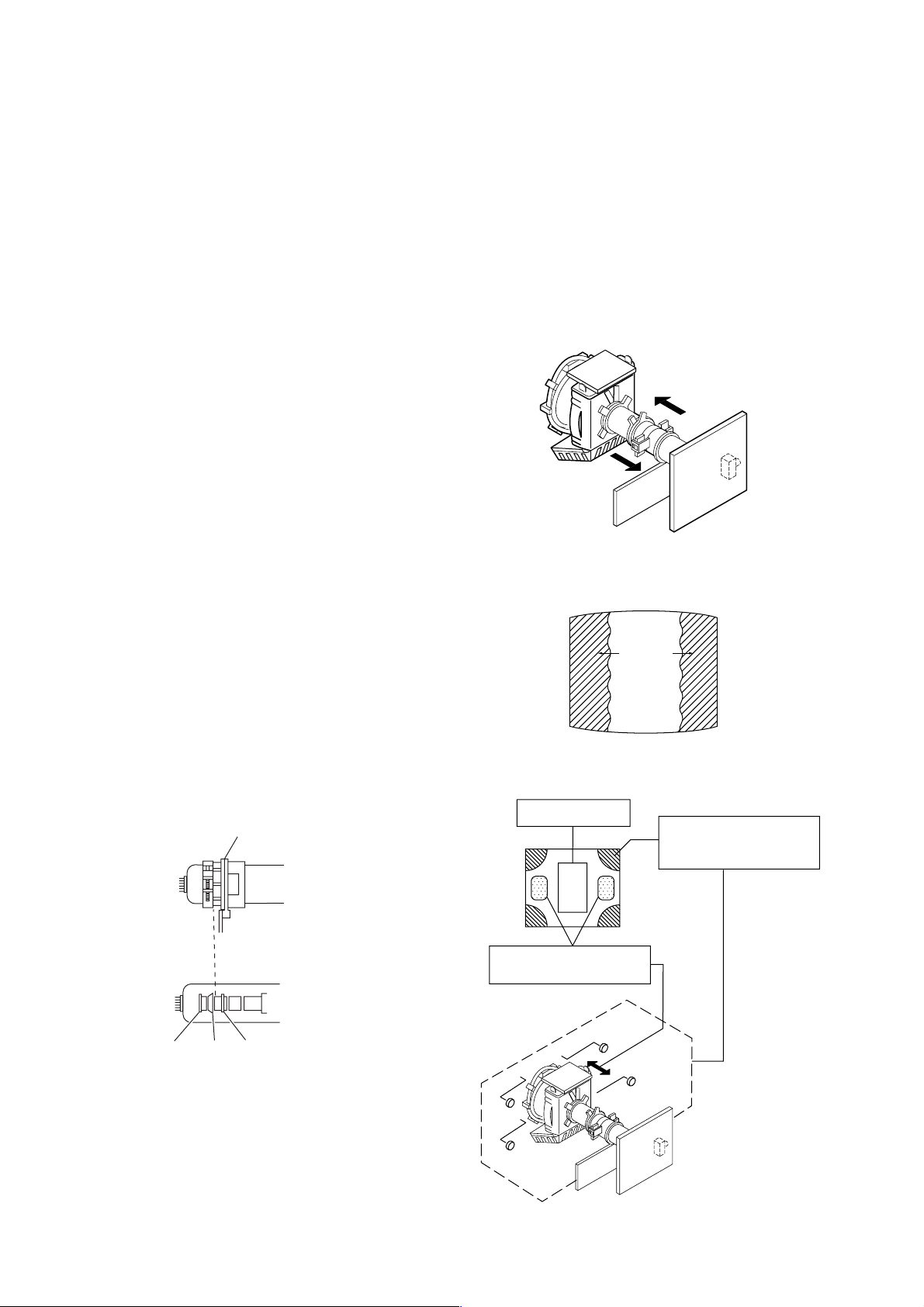

1-1. REAR COVER REMOVAL

2 Rear cover

1 Fourteen screws

(+BVTP 4 × 16)

1-2. SPEAKER REMOVAL

1 Two screws

(+BVTP 4 × 16)

2 Two screws

(Washer Head)

(+P4 × 16)

1-3. CHASSIS ASSY REMOVAL 1-4. SERVICE POSITION

1-5. TERMINAL BRACKET REMOVAL 1-6. J BOARD REMOVAL

5 Three Hooks

2 One Screw

(+BVTP 3 × 12)

1 One screw

(+BVTP 3 × 12)

4 Terminal Bracket

3 One screw

(+BVTP 4 × 16)

1 Five screws

(+BVTP 3 × 12)

– 6 –

2 J Board

KV-DA34M61/M81

RM-W105

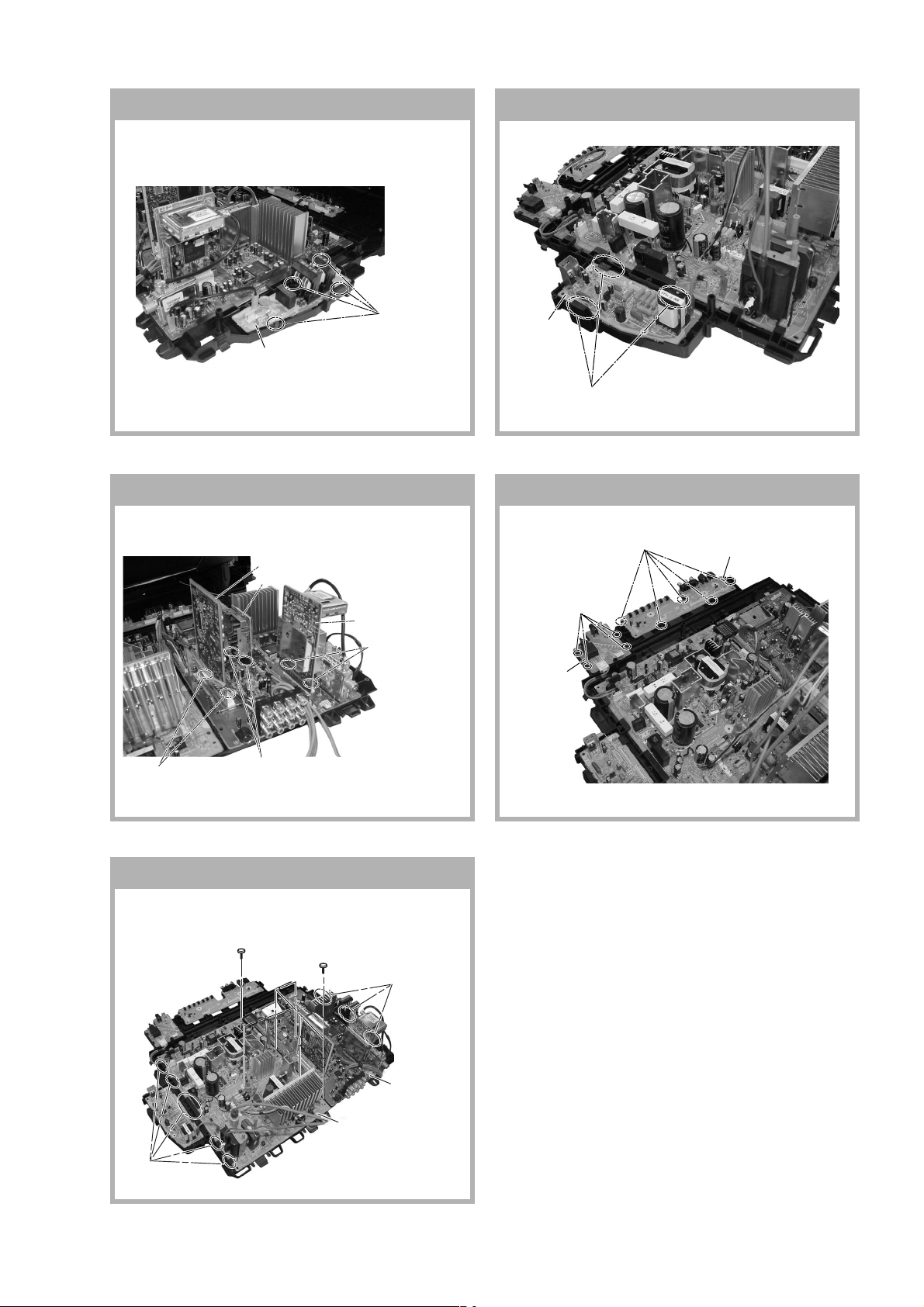

1-7. F1 BOARD REMOVAL

1 Four Hook

2 F1 Board

1-8. DL BOARD REMOVAL

2

DL Board

1 Three Hooks

1-9. BH1, BP AND BC BOARDS REMOVAL 1-10. H1 AND H2 BOARDS REMOVAL

2 BH1 Board

4 BC Board

6 BP Board

(Not used for these models)

5 Two

Hooks

1 Five Hooks

3 Four

Hooks

4 H2 Board

2 H1 Board

1 Two Hooks

3 Two Hooks

1-11. A AND D BOARDS REMOVAL

3 One screw

(washer head)

(+P 3 × 12)

2 Five Hooks

1 Five screws

(+BVTP 3 × 12)

5 Three Hooks

4 D Board

6 A Board

– 7 –

KV-DA34M61/M81

RM-W105

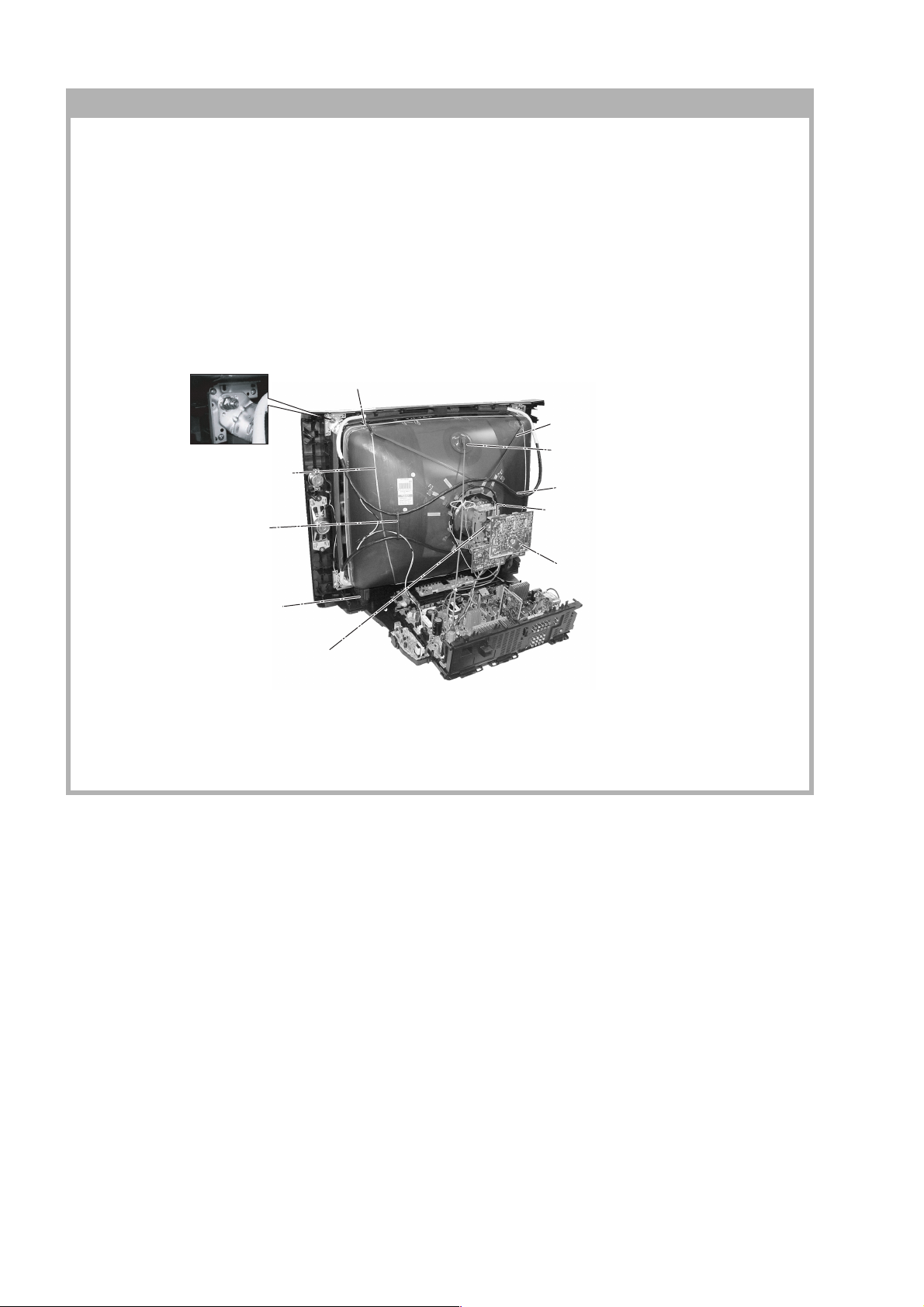

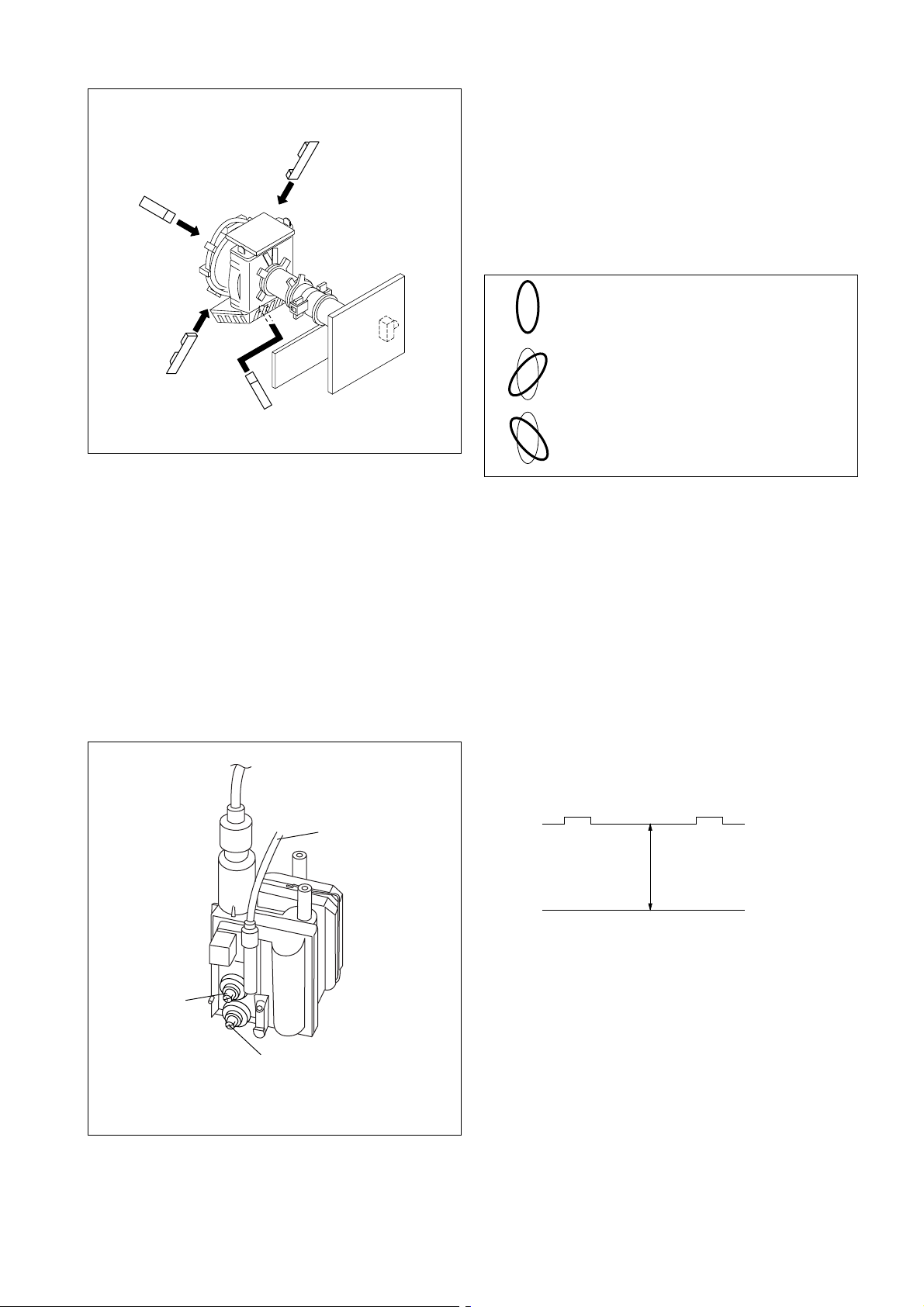

1-12. PICTURE TUBE REMOV AL

Note:

• Please make sure the TV set is not in standing position before removing necessary CRT support located on

bottom right and left.

• When removing the Nut Locking: first make sure to hold the Nut special CR T with a spanner while opening the Nut

Locking using a torque driver. Then proceed to remove the Nut special CRT using a torque driver.

1)Removal the Rear Cover.

2)Unplug all interconnecting leads from the Deflection Yoke, Neck Assy, Degaussing Coils and CRT grounding strap.

Remove Chassis Assy.

3)Place the TV set with the CRT face down on a cushion (jig).

qf Screw, Tapping 7 +

Crown Washer

9 Earth Coating Assy

5 Holder, DGC

Removal (x2)

8 Spring Tension(4)

Removal

6 Band, DGC Removal

4 Anode Cap Removal

7 Degaussing Coil

qa Loosen the Neck Assembly

fixing screw and remove Neck Assy &

VM board

qd Support CRT

Removal (x2)

qs Loosen the Deflection Yoke

fixing screw and remove

q; C Board Removal

– 8 –

KV-DA34M61/M81

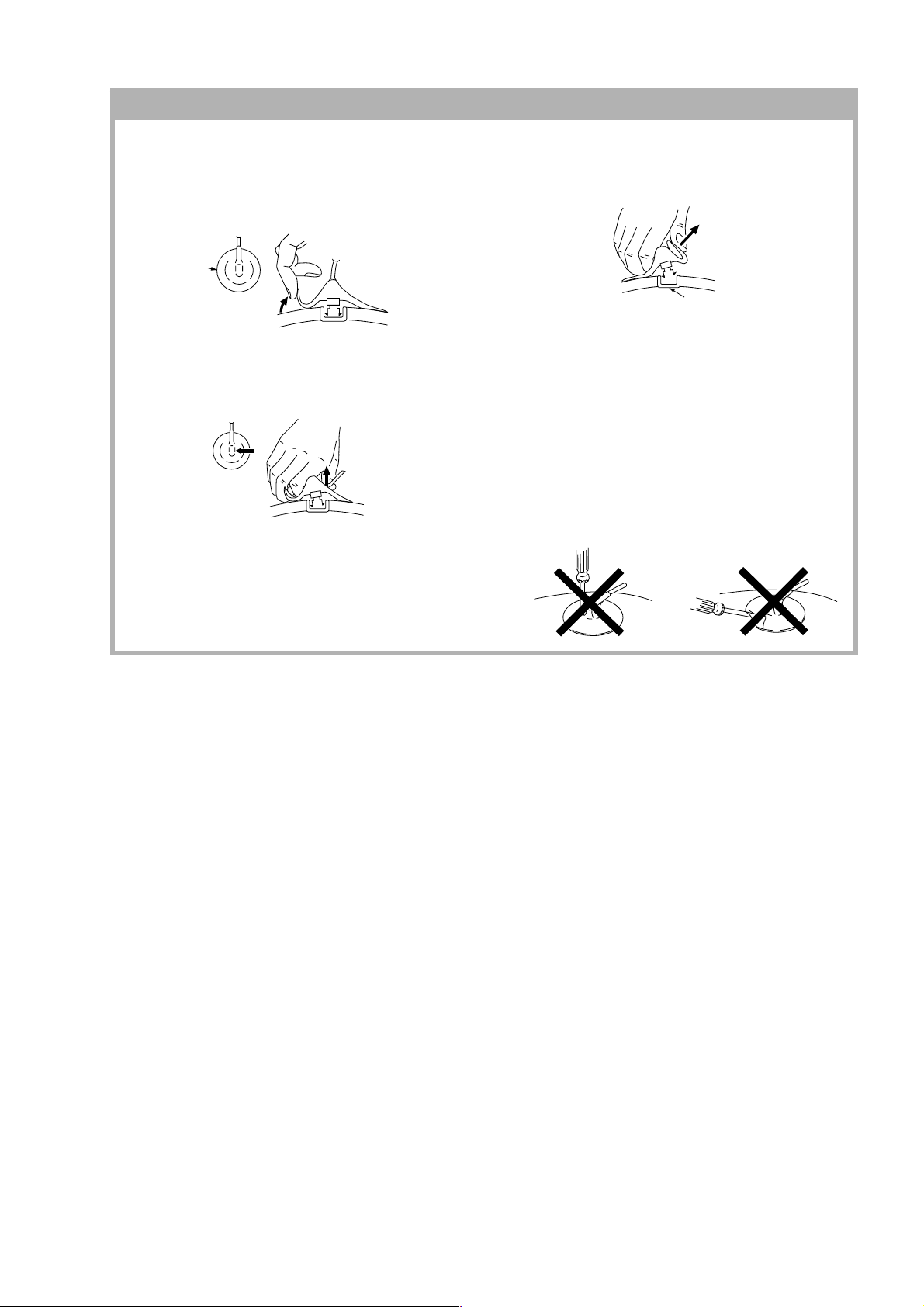

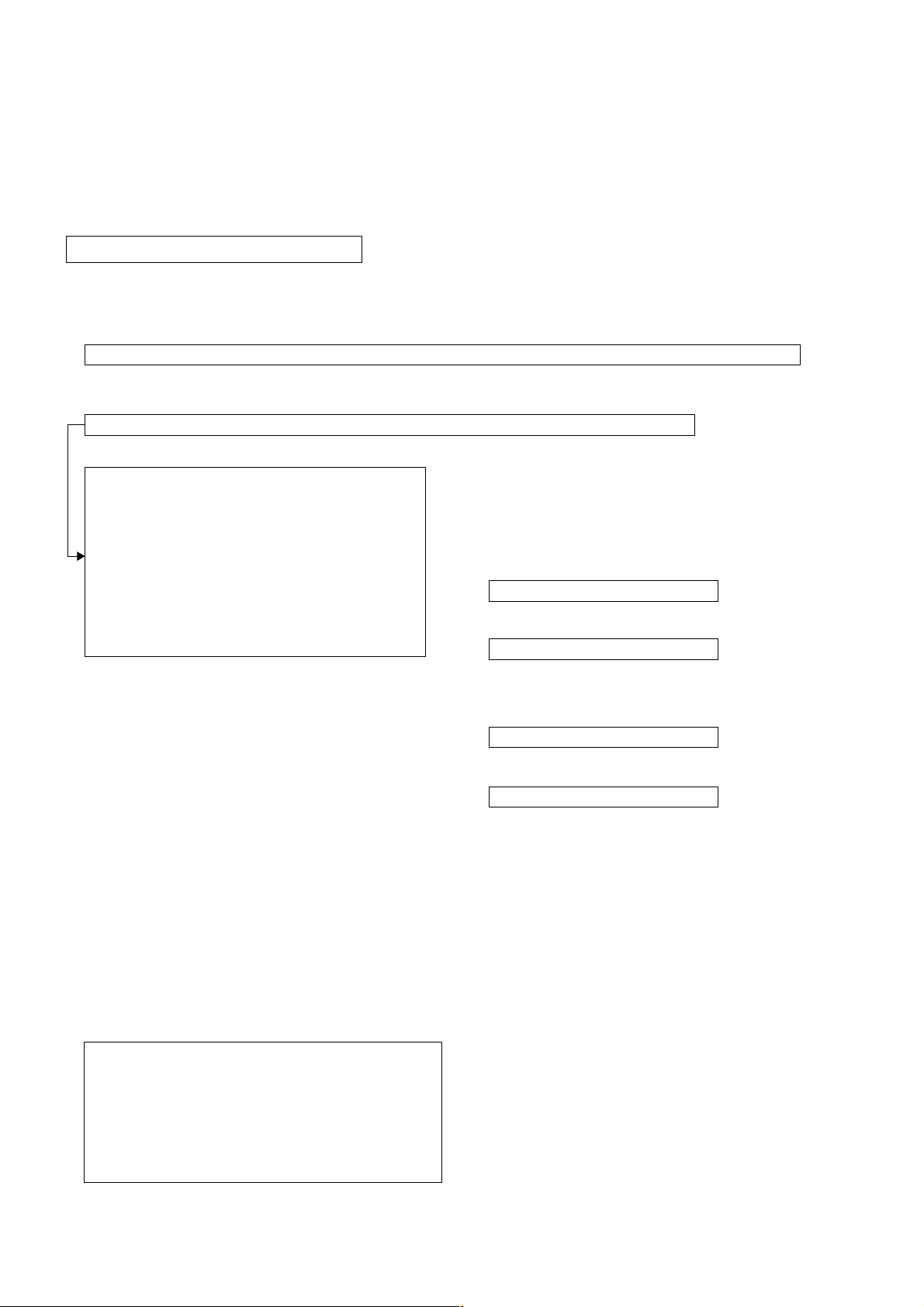

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

c

a

RM-W105

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

b

b

2 Using a thumb pull up the rubber cap firmly in the direc-

tion indicated by the arrow b.

Anode Button

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be remo ved by

turning up the rubber cap and pulling it up in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

– 9 –

KV-DA34M61/M81

RM-W105

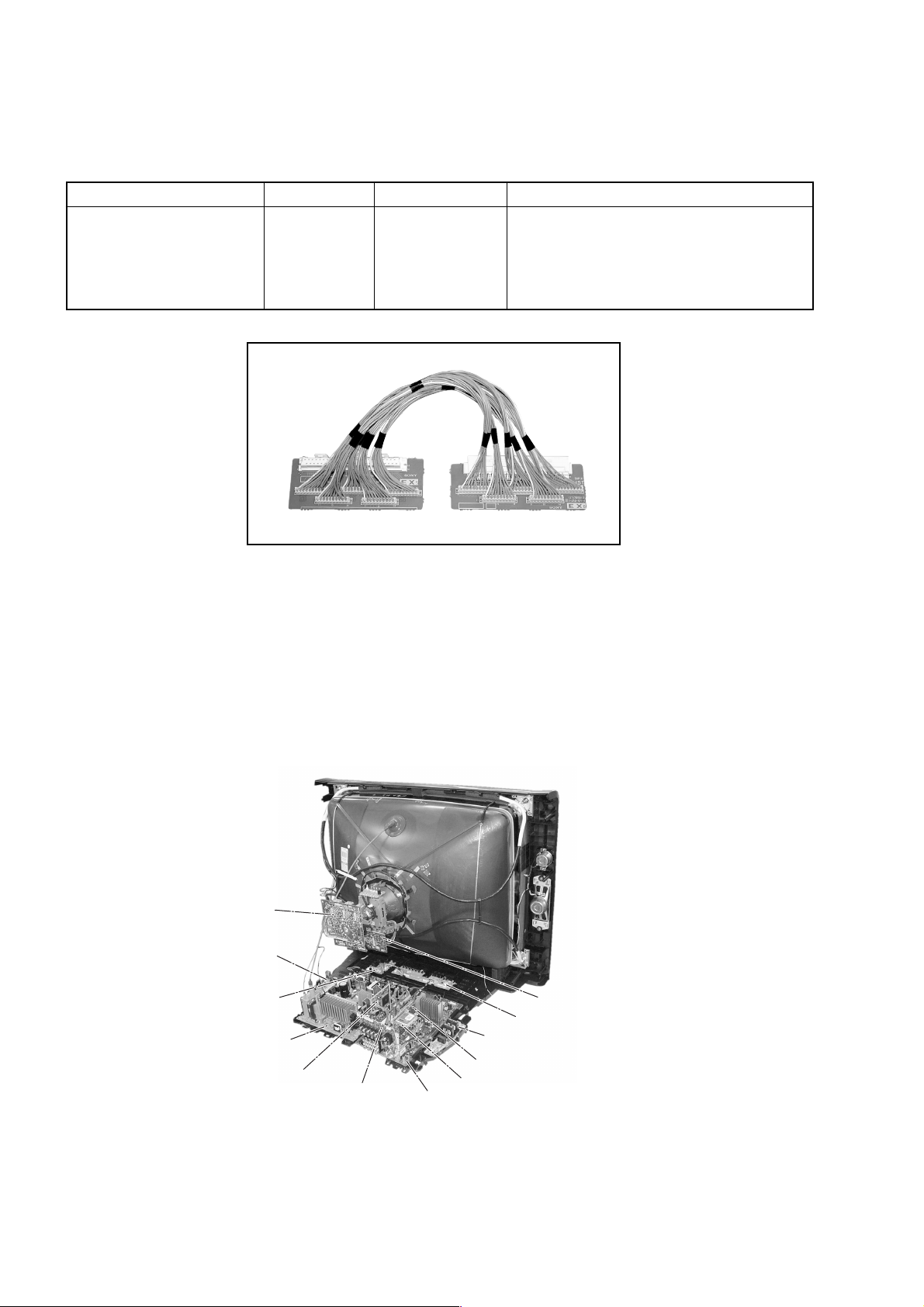

2-1. JIGS REQUIRED FOR SERVICING

DESCRIPTION QUANTITY PART NO. REMARK

TOOL(7P,8P),SERVICE 1 J-2509-400-D For A to BC board extension

TOOL(30P),SERVICE 1 J-2509-400-E For A to BP board extension

TOOL(50P-A),SERVICE 1 3-702-765-01 For A to BH1 board extension

SECTION 2

SERVICE JIG

(not used for these models)

SAMPLE

C Board

DL Board

H2 Board

D Board

BH1 Board

SECTION 3

CIRCUIT BOARDS LOCATION

VM Board

H1 Board

F1 Board

BC Board

J Board

A Board

BP Board (not used for these models)

– 10 –

KV-DA34M61/M81

SECTION 4

ADVANCE OPERATION

4-1. "RESET" FUNCTION

1. Purpose

If a customer faces some setting problem that cannot be solved, using the "RESET" function some items

will be reset to its original setting (shipping condition)

2. How to Operate

There are 2 ways to access to the "RESET" Function:-

a) By pressing "RESET" button on the Remote Commander.

b) By pressing "MENU" button on the Front Key Input and hold it down for 5 seconds.

(Note : only available for KV-DAXXNXX and KV-DAXXKXX.)

3. Sequence of Operation

RM-W105

Sequential to the resetting operation, TV set would shut down once and automatically turn on again.

The power-off duration is expected to be about 500msec. Initial Setup Menu is displayed.

As a result, some items will be reset to an initial condition (shipment condition) where else some other

remains at the last selection by user.

Items that remains at the last selection by user

Program No., Picture Position (includes Picture Rotation and

Picture V-Position), OSD Language, Fine Tuning,

TV System, Skip, Program label, Program Sorting, Video

label, Program block (NTSC model)

Reset Items

Category Default Category Default

Video input RF user last setting

Volume 25

DRC-MF DRC1050

Picture mode DYNAMIC

3D Intelligent Picture ON

Sound mode DYNAMIC

Intelligent volume OFF

Surround OFF

Wide Mode 4:3

Auto Wide ON

Twin OFF

Program Index OFF

*Program Block Reset to particular channel to

unblock

WEGA Theatre Setup

Direct Input Video 1

Speaker Main

Game Mode OFF (Video) *Not available in RF

mode

Color System Reset to Auto at the CH, others

keep user setting

ECO Mode OFF

Wide Mode Wide Zoom

Auto Wide ON

4:3 Default Wide Zoom

V Center 00

V Size 00

Picture Mode RF user last setting

Mute OFF

OSD Display Setting OFF

Main Volume 25

Center-in Volume 25

(Remote Button)

Center Speaker Main or Center in (No menu display)

(Under WEGA Main or Center in (selected only

Theatre Setup Menu) when WTM turns on)

Initial Setup Menu Reactive / ON

Twin size Center

*= Reset only during watching time

- For multi model only

- Not reset for NTSC model

– 11 –

KV-DA34M61/M81

RM-W105

SECTION 5

SET-UP ADJUSTMENTS

• The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

• These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

4. White Balance

Controls and switches should be set as follows unless otherwise

noted:

PICTURE control........................................................... normal

BRIGHTNESS control................................................... normal

................................................................................................................................................................................................................................

Note : Test Equipment Required.

1. Color-bar/Pattern Generator

2. Degausser

3. Oscilloscope

Preparation :

• In order to reduce the influence of geomagnetism on the set's

picture tube, face it east or west.

• Switch on the set's power and degauss with the degausser.

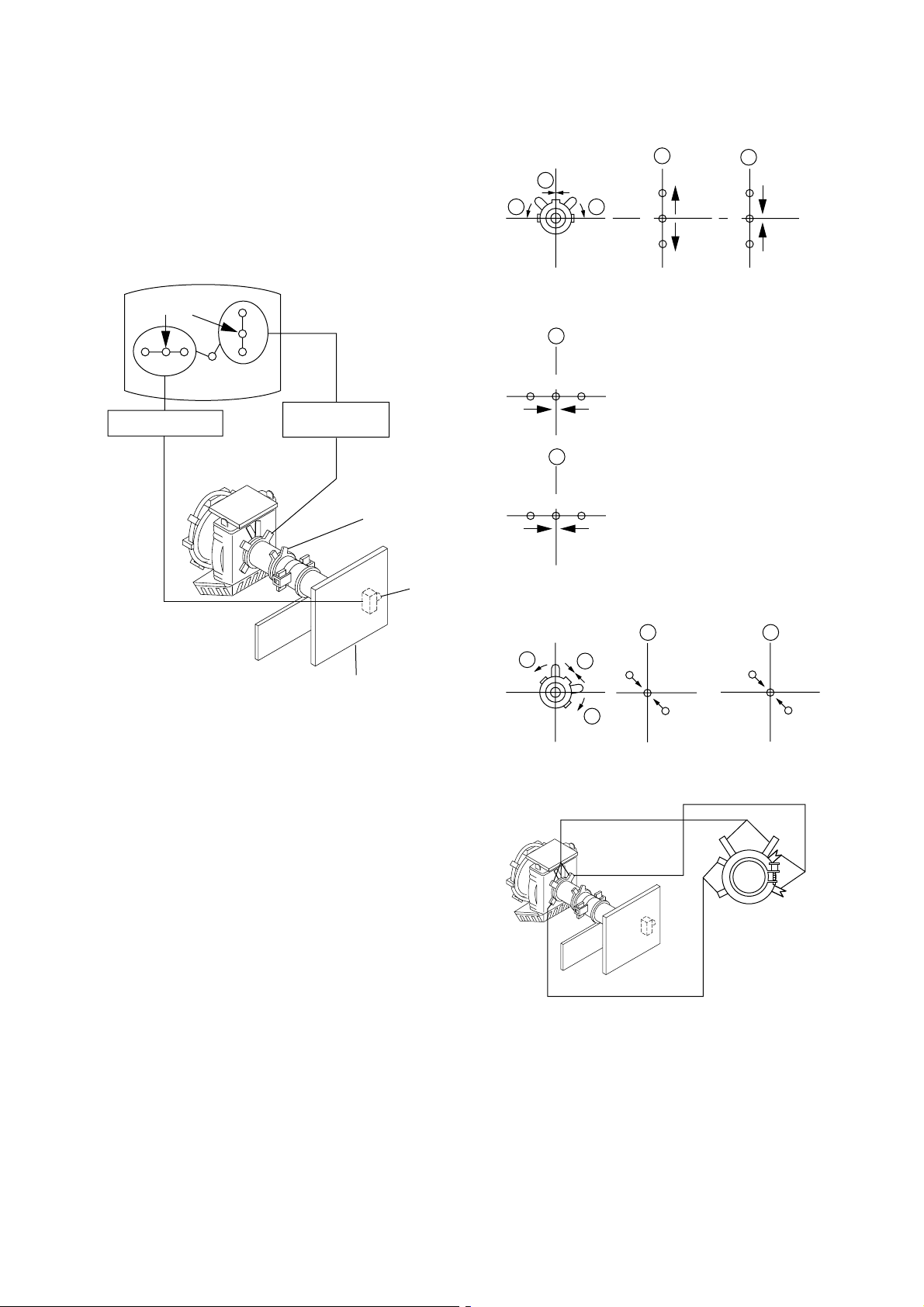

5-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Picture mode : Dynamic

2. Position neck assy as shown in Fig 5-1.

3. Set the pattern generator raster signal to a green raster.

4. Move the deflection yoke to the rear and adjust with the

purity control so that the green is at the center and the blue

and the red take up equally sized areas on each side.

(See Figures 5-1 through 5-3.)

5. Move the deflection yoke forward and adjust so that the

entire screen is green. (See Figure 5-2.)

6. Switch the raster signal to blue, then to red and verify the

condition.

7. When the position of the deflection yoke has been decided,

fasten the deflection yoke with the screws and DY spacers.

8. If the beam does not land correctly in all the corners, use a

magnet to adjust it.

(See Figure 5-4.)

Fig. 5-2

Blue

Red

Green

Fig. 5-3

Neck assy

Align the edge of

the neck assy with

the edge of the G3 grid.

G2G1 G3

Fig. 5-1

Purity control

corrects this area.

b

c

Deflection yoke positioning

corrects these areas.

a

d

a

d

b

Fig. 5-4

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

c

– 12 –

5-2. CONVERGENCE ADJUSTMENT

Preparation :

• Before starting this adjustment, adjust the focus, horizontal

size and vertical size.

• Receive cross hatch/dot pattern and set picture mode to

"STANDARD".

(1) Horizontal and Vertical Static Convergence

1 V. STAT

b b

KV-DA34M61/M81

RM-W105

a

a

B

G

R

b

B

G

R

Center dot

R G B

H. STAT VR

R

G

B

V. STAT

Magnet

Y magnet

RV702

H. STAT

C Board

1. (Moving horizontally), adjust the H.STAT control so that the

red, green and blue dots are on top of each other at the center

of the screen.

2. (Moving vertically), adjust the V.STAT magnet so that the

red, green and blue dots are on top of each other at the center

of the screen.

3. Adjust Horizontal Trapezoid with “DEF1 005 HTPZ” in

Service Mode to make H-Trapezoid distortion best.

4. If the H.STAT variable resistor cannot bring the red, green

and blue dots together at the center of the screen, adjust the

horizontal convergence with the H.STAT variable resistor and

the V.STAT magnet in the manner given below.

(In this case, the H.STAT variable resistor and the V.STAT

magnet influence each other, so be sure to perform

adjustments while tracking.)

2 H. STAT VR

a

RGGBB

b

3

b

R

a

a

R

b

Purity

B

BMC (Hexapole)

V.STAT

b

B

GG

R

– 13 –

KV-DA34M61/M81

RM-W105

4 BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or aligned,

then use the BMC magnet to adjust in the manner described

below.

RG B R G B R GB

RB

G

RG

GB

RB

5 Y separation axis correction magnet adjustment.

1. Receive the cross-hatch signal and adjust [PICTURE] to

[MIN] and [BRIGHTNESS] to [STANDARD].

2. Adjust the Y separation axis correction magnet on the neck

assembly so that the horizontal lines at the top and bottom of

the screen are straight.

Neck assy

Blue

Red

Neck assy

Blue

Red

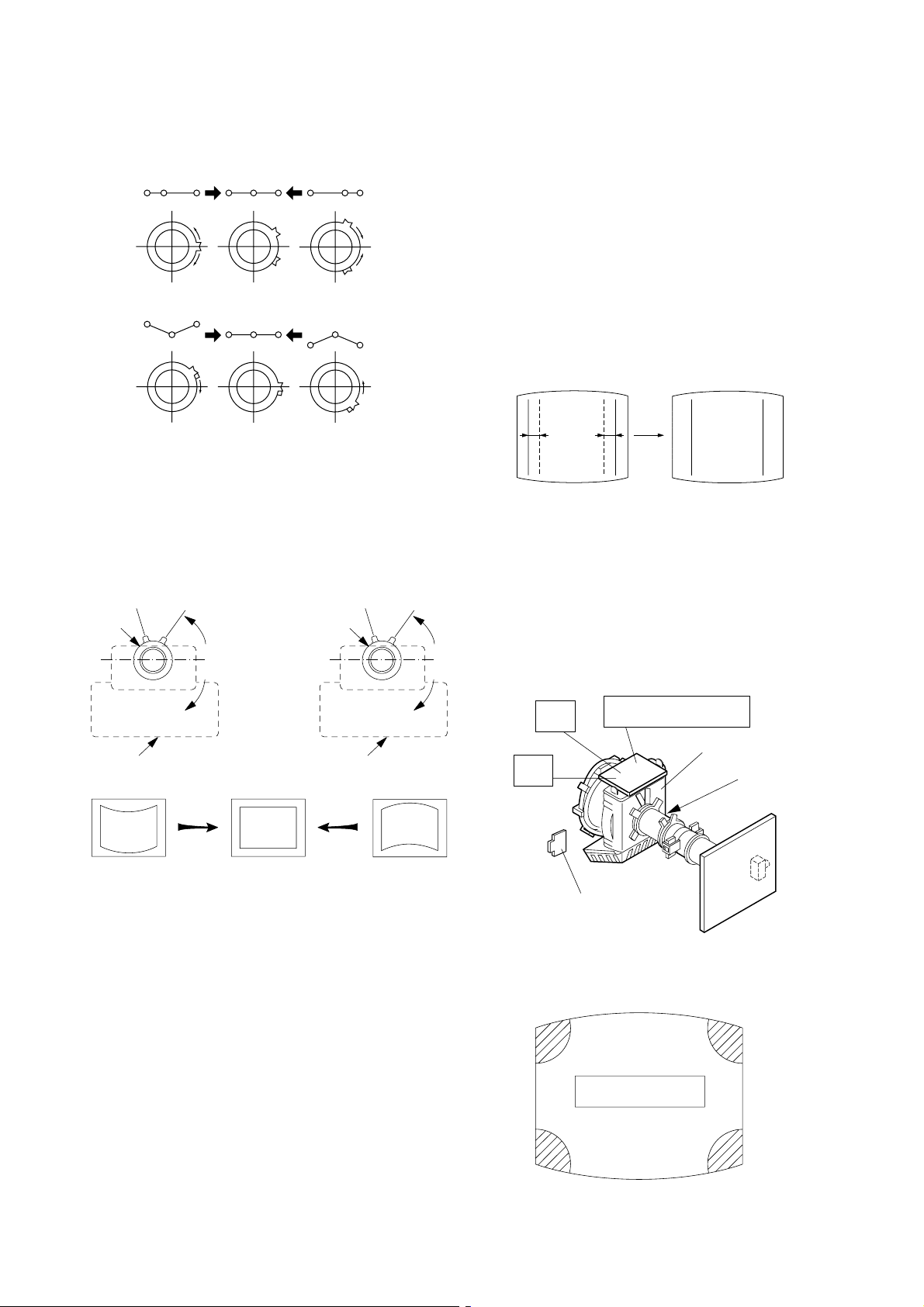

(2) Dynamic Convergence Adjustment

Preparation:

• Before starting this adjustment, adjust the horizontal static

convergence and the vertical static convergence.

• Set the PICTURE and BRIGHTNESS to normal.

1. Adjust TLH. (TLH convergence piece)

1 Receive the dot/hatch pattern signal and adjust picture quality

by the menu.

2 Correct horizontal mis-convergence of red and blue of both

sides on the X axis.

When red is outside insert TLH convergence piece to right

side (TLH +) views from DY neck. And when blue is outside,

insert it to left side (TLH –) and take both sides.

R

(B)B(R)

(R)

B

TLH +

R

(B)

TLH -

2. Adjust XCV core.

To able to become balance of XCV on the X axis well.

3. Adjust TL V.

Correct the vertical mis-convergence of red and blue of

vertically sides on the Y axis.

4. Adjust YCH.

Adjust horizontal mis-convergence of red and blue of

vertically sides on the Y axis. Mentioned above steps 2 to 4

are adjusting respectively perform minuteness tracking.

Note

1. The Red and Blue magnets should be equally far from the

horizontal center line.

2. Do not separate the Red and Blue magnets too far.

(Less than 8 mm)

(VR2)

YCH

(VR3)

TLV2

TLH Plate

(VR1)

TLV1 (no need to adjust)

(3) Screen-corner Convergence

ba

a-d : screen-corner

misconvergence

cd

DY pocket

(XCV)

– 14 –

KV-DA34M61/M81

RM-W105

Fix a Permalloy assy corresponding to the

misconverged areas.

a

d

Permalloy assembly

b

c

5-3. FOCUS ADJUSTMENT

Note

Focus adjustment should be completed before W/B adjustment.

1. Receive digital monoscope pattern.

2. Set Picture mode to "STANDARD".

3. Adjust FOCUS VR so that the center of the screen becomes

just focus.

4. Change the receiving signal to white pattern and blue back.

5. Confirm MAGENTA RING is not noticeable. In case

MAGENTA RING is obvious, adjust FOCUS VR to balance

between MAGENTA RING and FOCUS adjustment.

5-4. NECK ASSY TWIST ADJUSTMENT

1. Receive dot/hatch pattern DRC-MF, DRC1250, DYNAMIC.

2. Turn FOCUS VR fully counter-clockwise.

3. Confirm the dot shape at the screen center. (Fig. 5-4)

4. Resume FOCUS VR.

Note

In case of turning NECK ASSY, loosen the screw 3 turns. Do not

move the position.

OK

Turn NECK ASSY clockwise.

Turn NECK ASSY counter clockwise.

Fig. 5-4

5-5. G2 (SCREEN) AND WHITE BALANCE

ADJUSTMENT

1. G2 (SCREEN) ADJUSTMENT

1. Set the PICTURE and BRIGHTNESS to normal.

2. Put to any signal mode.

3. Connect R, G and B of the C board cathode to the

oscilloscope.

4. Adjust BRIGHTNESS to obtain the cathode voltage to the

value below.

5. Whilst watching the picture, adjust the screen VR [RV9002]

located on the Flyback Transformer to the point just before

the retrace lines disappear (to the point before cut-off).

Lead Assy,

Focus

Focus

G2

FL YB A CK TRANSFORMER (T6803)

170v ± 2 (VDC)

0 V

2. WHITE BALANCE ADJUSTMENT

(Highlight Condition)

1. Set Picture to Dynamic mode.

2. Go to Service mode and adjust SADJ "COL" from 60 to 00.

3. Fix WHBL "RDRV" to 41.

4. Fix WHBL "RCUT" to 31.

5. Adjust "GDRV" and "BDRV" for highlight.

6. Adjust "GCUT" and "BCUT" for cut-off.

(Cut-off Condition)

1. Set Picture to Dynamic mode.

2. Adjust SADJ "COL" from 00 to 100.

3. Adjust "CBOF" and "CROF" for cut-off.

Once the above adjustments have been set, change back the

SADJ "COL" data to 60 (original condition).

– 15 –

KV-DA34M61/M81

RM-W105

SECTION 6

CIRCUIT ADJUSTMENTS

6-1. ADJUSTMENTS WITH COMMANDER

Service adjustments to this model can be performed using the supplied remote commander RM-W105.

a. ENTERING SERVICE MODE

With the unit on standby

t [DISPLAY] t 5 t [VOL $+% ] t [POWER]

This operation sequence puts the unit into service mode.

The screen display is as below:

Category in decimal Item name in decimal NG Command Frequency Video Input Name

WHBL 000 BKOR 000 x SERVICE 50 S VIDEO 1

Item no. Service data NVM Service Field Channel no./

Release ID Version in binary for factory Color System (decimal)

CGA01 0.16M 0000 0000 FF FF NTSC3 00100

S_ _ : for Sony

A_ _ : for AIWA

L_ _ : BX1L Full

B_ _ : BX1L Basic

D_ _ : DVD Combo

C_ _ : CX1

Z_ _ :Sound Special

_ _ _01 : Serial no. of the M/P release for each destination

_ _ _10 ~: use for FY04

_ _ _SB : Sub Hercules

Software Service data Reserved Power On Time

For BP Board version; and PF Engine Version;

Category and release ID will be different. The rest

are the same.

BP Board version

item no. item

Category in decimal name

SUBP 000 10XH

software

release ID version

CBP00 0.06

PF Engine version

item no. item

Category in decimal name

9090 000

software

release ID version

PF0018M

b. METHOD OF CANCELLATION FROM SERVICE MODE

Set the standby condition (Press [POWER] button on the commander), then press [POWER] button again, hereupon it becomes TV

mode.

c. METHOD OF WRITE INTO MEMORY

1. Set to Service Mode.

2. Press 1 (UP) and 4 (DOWN), to select the adjustment item.

3. Change item by pressing 3, 6.

4. Press [MUTING] button to indicate WRITE on the screen.

5. Press - button to write into memory.

1, 4 Select the adjustment item.

r

3, 6 Raise/lower the data value.

r

[MUTING] Writes.

r

- Executes the writing.

– 16 –

KV-DA34M61/M81

d. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, pull out the plug from AC outlet, and then plug into AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confirm adjustments were made.

e. OTHER FUNCTION VIA REMOTE COMMANDER

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

Display , - Service data initialization (Be sure not to use usually.)

2, 5 Select Device or Category

6-2. ADJUSTMENT METHOD

Item Number 000 BKOR

This explanation uses Black Level Offset as an example.

1. Select "000 BKOR" with the 1 and 4 buttons, or 2 and 5.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is IF for PAL reception.)

4. Write with the [MUTING] button. (The display changes to WRITE.)

5. Execute the writing with the - button. (The WRITE display will be changed to red color while excuting, and back to

SERVICE.)

Example on screen display :-

RM-W105

WHBL 000

CGA01

WHBL 000

CGA01

WHBL 000

CGA01

0.16M

0.16M

0.16M

Write with [MUTING]

Write executed with

000 50BKOR

SERVICE

0000 FF FF PAL 001220000

000 50BKOR

0000 FF FF PAL 001220000

000 50BKOR

0000 FF FF PAL 001220000

WRITE

WRITE

GREEN

Adjusted with 3

and 6 buttons.

GREEN

RED

The WRITE display

then the display

returns to green

SERVICE.

Use the same method for all Items. Use 1 and 4 to select the adjustment item, use 3 and 6 to adjust, write with

[MUTING], then execute the write with -.

Note : 1. In [WRITE], the data for all items are written into memor y together.

2. For adjustment items that have different standard data between 50Hz or 60Hz, be sure to use the respective

input signal after adjustment.

– 17 –

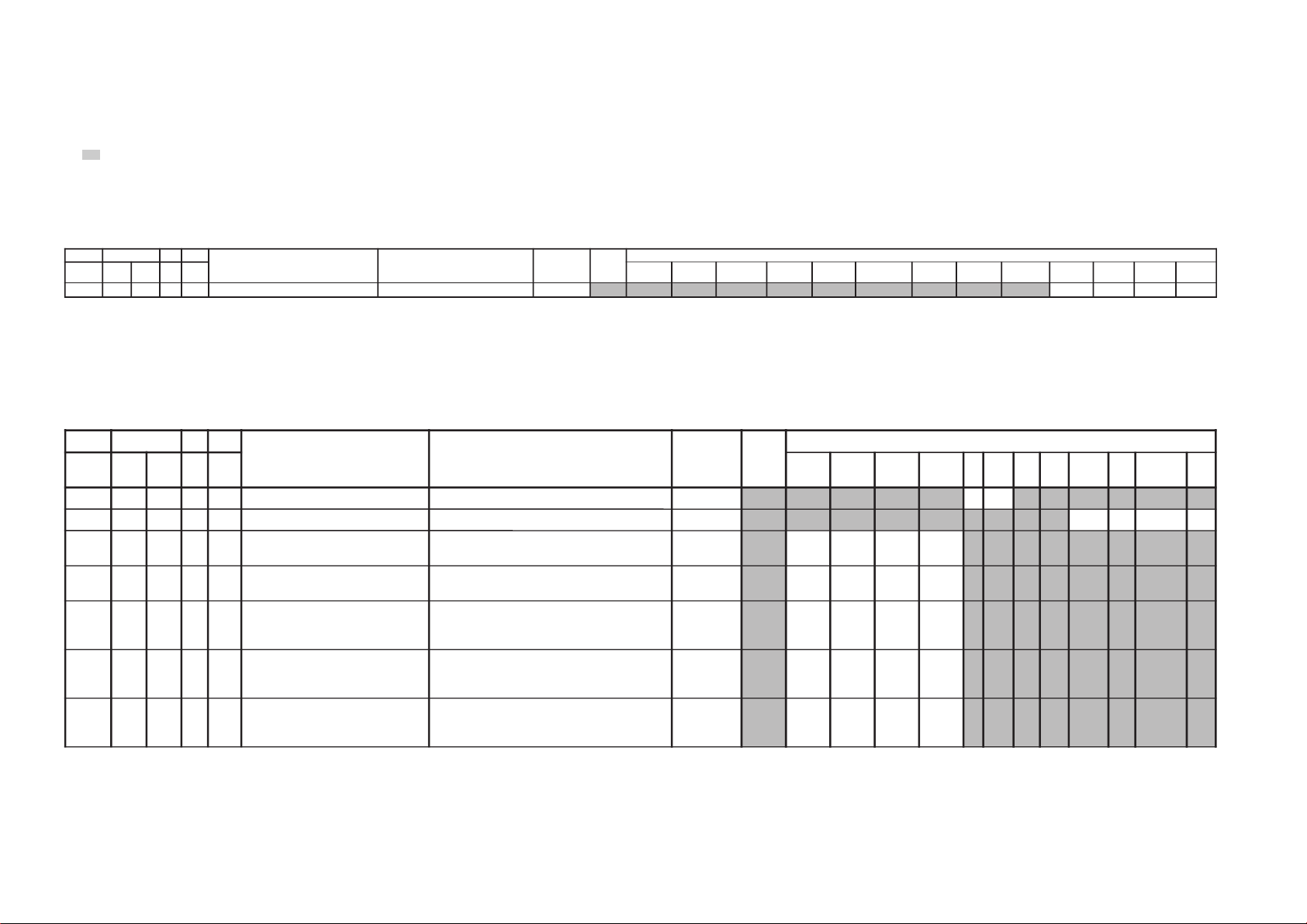

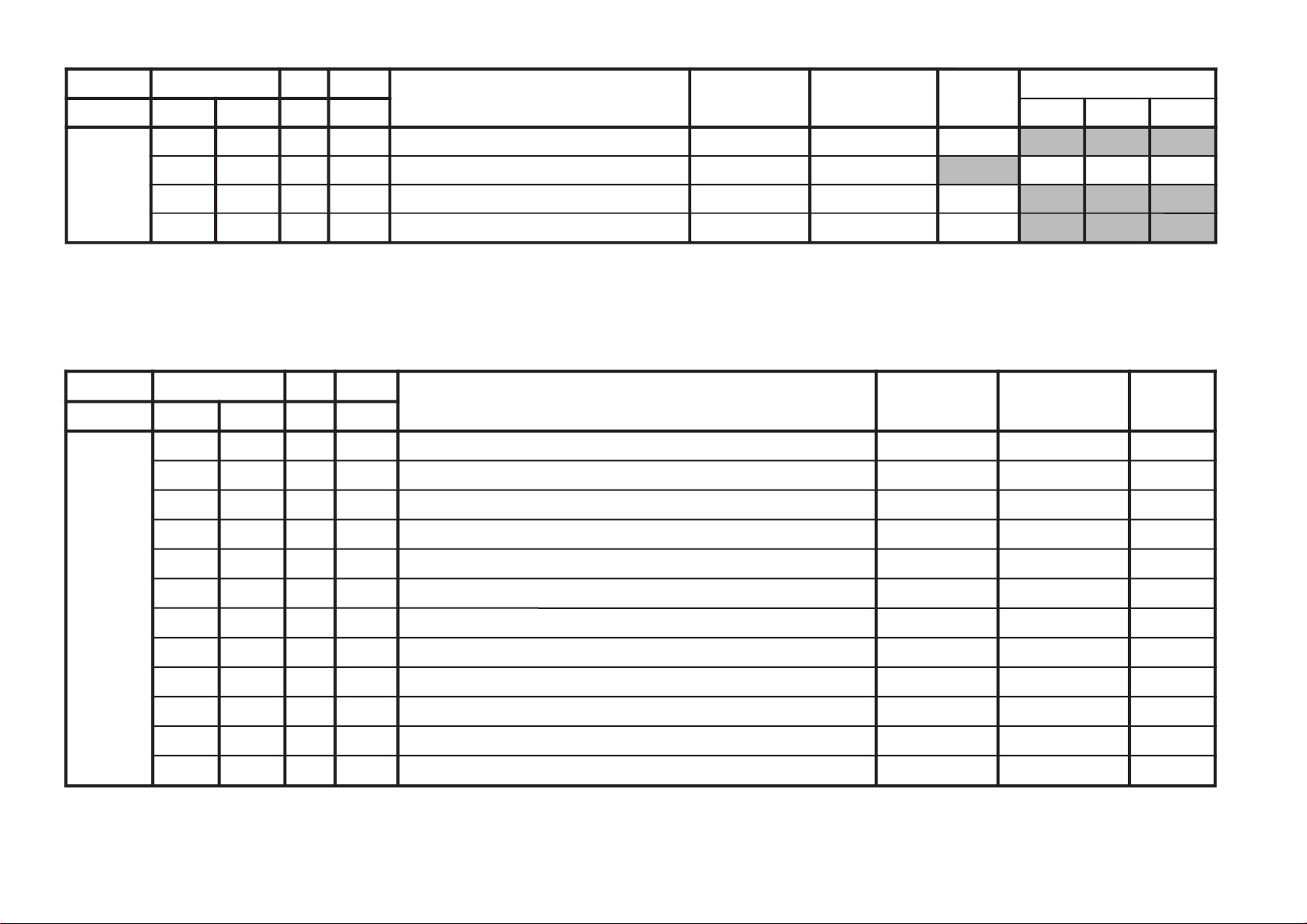

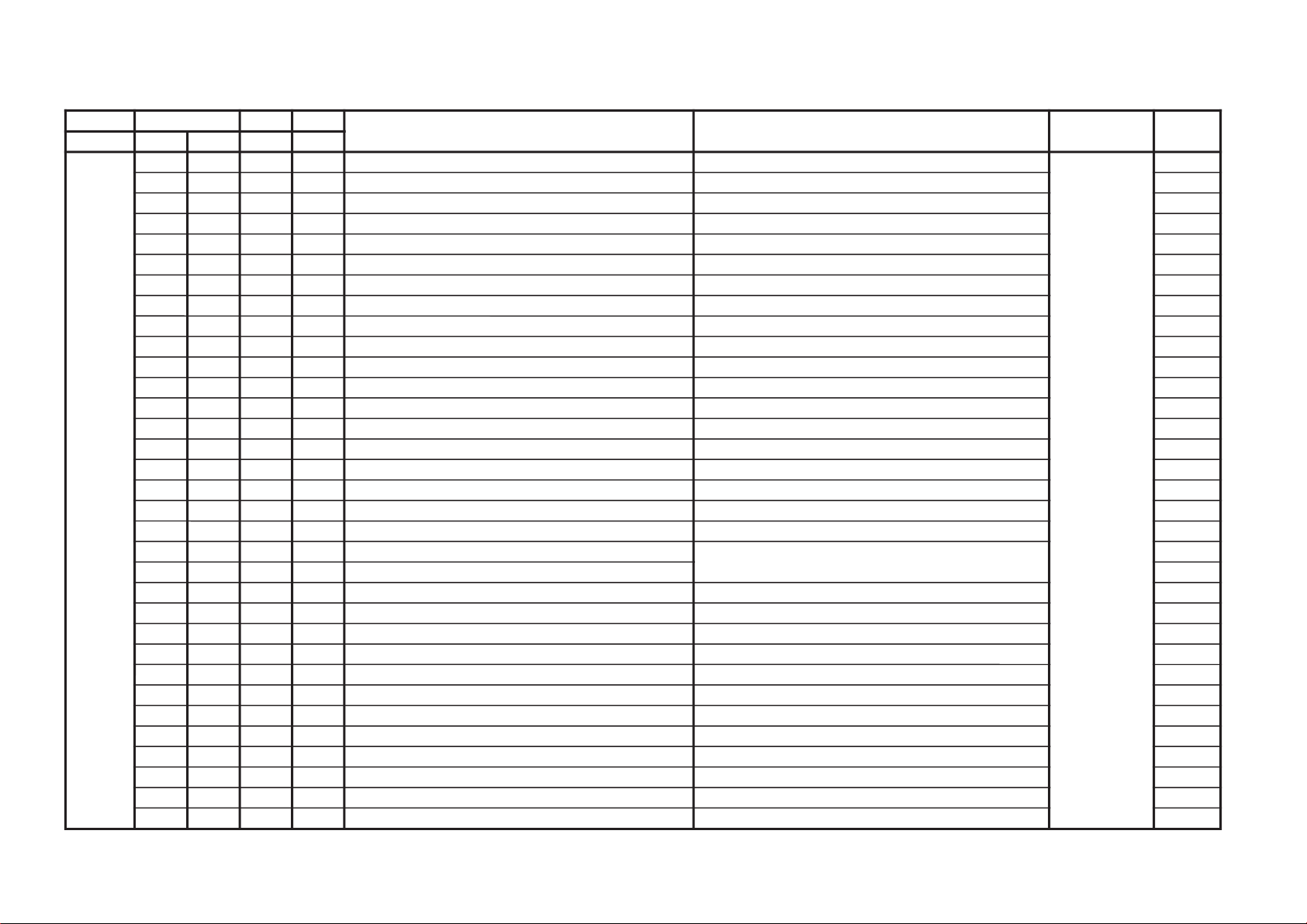

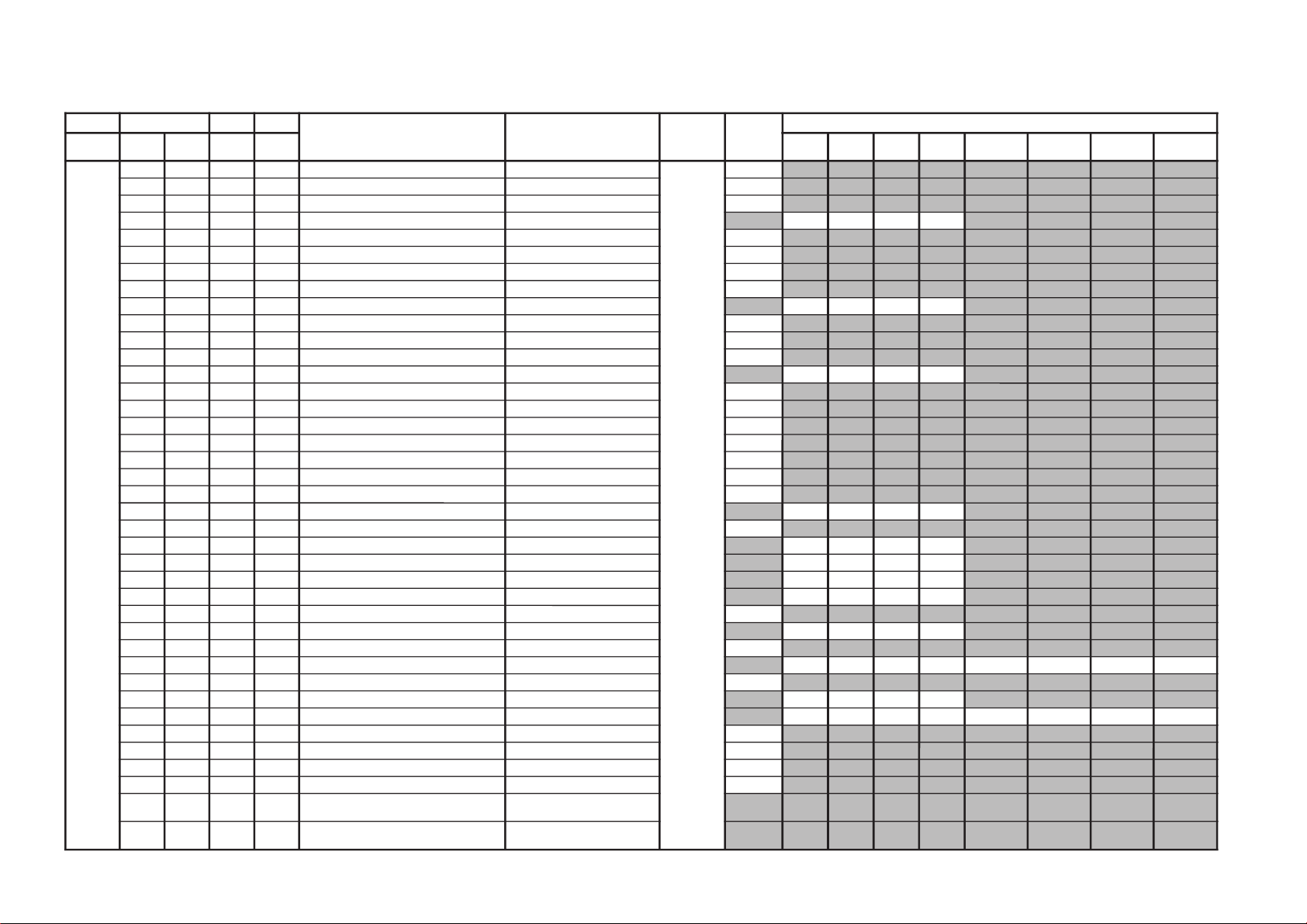

Adjustment Item Table (Main Micon)

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

pmeTloC

)rehtoHGIH(

pmeTloC

)rehtoWOL(

pmeTloC

)rehtoMRON(

pmeTloC

)VUYHGIH(

pmeTloC

)VUYWOL(

pmeTloC

)VUYLAMRON(

pmeTloC

)BGRHGIH(

pmeTloC

)BGRWOL(

pmeTloC

)BGRMRON(

0edomciP1edomciP2edomciP3edomciP

LBHW000PBW

000300)woL:3,2,lamroN:1,hgiH:0(gnitteSpmeTroloC

edoMerutciP

00102010

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

edomciP

0

edomciP

1

edomciP

2

edomciP

3

VToediVVT

ediW

oediV

ediW

lamroN

)3:4(

DHxednI/niwT

paP/

rehtO

JDAS000EUHS700510euH-buS oediV/VT

2090

100FOIP000700)%57(ocE*02/)atad-02(*erutciP(tesffOerutciP REHTO/ITLUM/LAMRON/SMenignEFP

45 7 0

200CIP130721;)dilavni(001>,)dilav(001-0:AG[lortnoCerutciP

])dilavni(6tiberongi;)dilav(36-0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

001080605

300LOC130721;)dilavni(001>,)dilav(001-0:AG[lortnoCroloC

])dilavni(6tiberongi;)dilav(36-0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

06060505

400TRB130721,)dilav(001-0:AG[lortnoCssenthgirB

tiberongi;)dilav(36-0:srehtO;)dilavni(001>

])dilavni(6

)ataDteseRresU=lanosreP:AG(ledoMerutciP

34050505

500EUH130721;)dilavni(001>,)dilav(001-0:AG[lortnoCeuH

otdneS*(])dilavni(6tiberongi;)dilav(36-0:srehtO

)ledomSUhtiw)0-5(hE1#TNIT

)ataDteseRresU=lanosreP:AG(ledoMerutciP

05050505

600PHS130721,)dilav(001-0:AG[lortnoCssenprahS

tiberongi;)dilav(36-0:srehtO;)dilavni(001>

])dilavni(6

)ataDteseRresU=lanosreP:AG(ledoMerutciP

05050505

NOTE

a) In the initial value (detailed) colomn, the data after the slash mark ("/") refers to NTSC model data.

No("/") means data is common for Multi and NTSC model.

b) Item remarked "*" and "**", please refer page xx~xx for the data.

c)

shaded items are no data.

d) Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and for each mode.

e) Note for the Different Data those are the standard data values written on the microprocessor. Therefore, the data values of the models are stored respectively in the memory.

In the case of a device replacement, adjustment by rewriting the data value is necessary for some items.

f) Multi ver0.22.

– 18 –

KV-DA34M61/M81

RM-W105

– 19 –

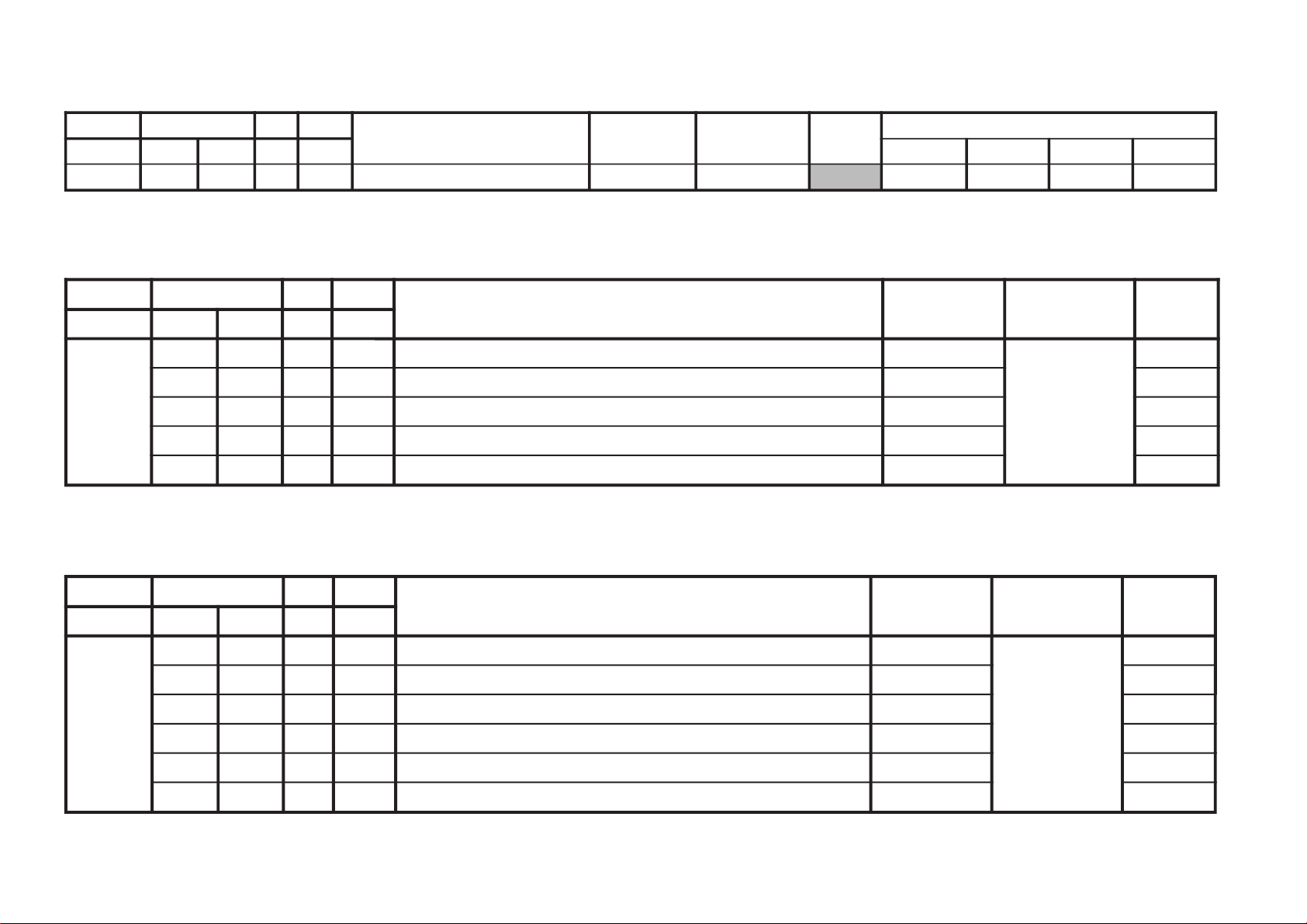

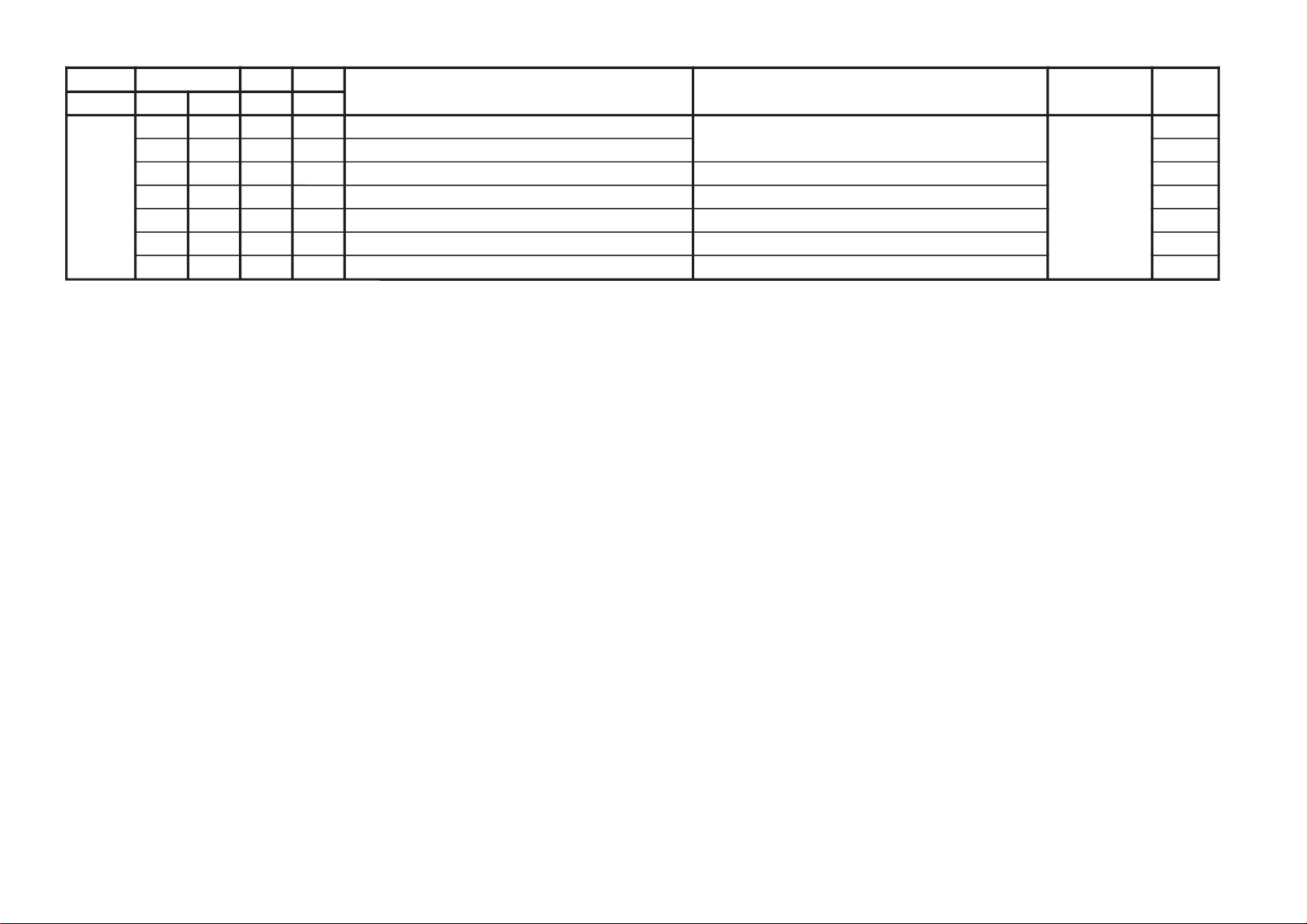

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD srehtOVUY)VT(LAP)VT(CSTN)VT(MACES)oediV(LAP)oediV(CSTN)oediV(MACESTUPNI-SMACESCSTN

CY000YLDY210510yaleD-Y TUPNI-S/VUY+)OEDIV/VT(*)MACES/CSTN/LAP(

0011606001116001

100TAMC000300xirtaM)ASU/napaJ(CSTNroMACES-LAP 00

200LCA100100gnitimiLroloCcitamotuA 10

300BC000100ycneuqerFretneCssapdnaBamorhC )xif0:oediV*(VThtiwylnodilav00

400OBS100300tesffOkcalBMACES 10

500ESHC100300ytivitisneStnedICSTN/LAP 30

600OLC000100retliF)lleB(ehcolCfoycneuqerFretneC 00

700PRTC000100edoMparTamorhC srehto/MACES

00

10

800SPB000100eniLyaleDdnab-esaBamorhCfossapyB srehto/CSTN

00

10

900OCF000100nOroloCdecroF 00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0506srehtOVUYVToediVtxeteleTpi-VTlangiSoN

CNYS000SYS000100tupnICNYSYnonoitazinorhcnyS 00

100OF

000300tnatsnoCemiT1esahP

)FR(langisoNrogninuTotuA/txeteleT/oediV/FFOPIVT/NOPIVT

3030100000

200DIV000100edoMtnedIoediV 06/05

0000

300LSF000100cnySlacitreVrofleveLgnicilSdecroF 00

400LSS000100rotarapeScnySleveLgnicilS 06/05

0000

500DIVS100700noitacifitnedIoediVrofnoitceleSecruoS srehtO/VUY

0000

600FROF200300ycneuqerFdleiFdecroF 20

700KVM000100gniyeKnoisiVorcaM 10

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

srehtOBGReviLVT

)nyD(

VT

)srehtO(

oediV

)nyD(

oediV

)srehtO(

pmeTroloC

)HGIH(

pmeTroloC

)srehtO(

roloC

)WOL(pmeT

pmeTroloC

)LAMRON(

TCIP100AFC000300edoMretliFbmoC 00

KV-DA34M61/M81

RM-W105

KV-DA34M61/M81

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD VUYVToediV

WS0002VC000100noitceleSlangiStupnI2SBVC 00

100OVS10030084@niPISBVC/OVS/OVFIfonoitcnuFVUY/oediV/VT

201010

200LFD000100noitcetorPhsalF 10

300FTNI000100langisecafretniVUYfoytiraloP/edutilpmA 00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

FIV000DFIO630360rotaludomeDFItesffO rossecorP-VT63

100TCGA130360revo-ekaTCGA 72

200MTS000100edoMgninuThcraeS 10

300DG000100langiS1SBVCnoyaleDpuorG 00

400SCGA100300deepSCGAFI 10

500IFF000100LLPFIretliFtsaF 00

600IANL100100eulavlaitinitibANLpmAFR 00

700TANL591552leveLdlohserhTpmAFR 591

800NSNL400700dlohserhTleveLNSpmAFR 40

900DSNL200700dlohserhTporDleveLNSpmAFR 10

010XENL610360gnimiTporDNSkcehcpmAFR 03

110RTHC840721edoMresUpmAFRtesotgrPotuAretfadlohserhTlennahC 52

RM-W105

– 20 –

– 21 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0edomciP1edomciP2edomciP3edomciP

MV000PAMV200300)FFO:3,2,woL:1,hgiH:0(gnittesMVedoMerutciP

00000000

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

MEDS000SWMF000300rotaludomeDMFrofnoitceleSwodniW rossecorP-VT20

100SSQ100100 )metsysMitlumAGrofA/N(edoMreifilpmA)SSQ(dnuoStilpSisauQ *

200BPB000100retliFssapdnaBdnuoSfossapyB 00

300OLMA000100dnuoSMAroflangiStuptuOoiduA 00

400CVPH000100lortnoCemuloVenohPdaeH 00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

TXT000VXT930360spilihProfnoitisoPlacitreVtxeteleT redoceDtxeT93

100DHT010721tfihSegdEevitcAcnys-HtxeteleT 11

200RBT820130)edomllufrof(ssenthgirBBGRtxeteleT 82

300MRBT310130)edomXIMrof(ssenthgirBBGRtxeteleT 31

400BCL000100)XETSAFrofgnittes(elbane:1elbasid:0BCLtxeteleT 00

500DTSN000100)elbasid:1,elbane:0(langiSdradnatSnoNfoM/C 00

KV-DA34M61/M81

(only for model with teletext function)

RM-W105

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD )oruE(L-VTVToediVffOWOW/SRSdnuorrusurToeretsIonomI

PSDS000MVA200700edoMLVA DSS20

100VVA500510leveLecnerefeRLVA 90

200LBB000510ruotnoCEBB 20

300HBB000510ssecorPEBB

60

400WLBB000510tesffOruotnoCEBB

60

500FOVS000510tesffOemuloVedoMtceffE/dnuorruS onomI/oeretsI/dnuorrusurT/)WOW/SRS(ffO

4011406040

600FOVI000700tesffOevitisoPemuloVretsaM 60

700FOVE000700tesffOevitageNemuloVretsaM 60

800DAL000130tsujdAleveLredoceD 40

900MAL000130tsujdAleveLonoM 40

010NAL000130tsujdAleveLmaciN 22

110SAL000130tsujdAleveLPAS 80

210AAL000130tsujdAleveLCDA oediV/Lnon-VT/L-VTI)oruEnoN(oediV/vT

717100

310FES300700tceffEoeretS/onoMelbidercnI onomI/oeretsI

5030

410L1A000552tfeLemuloV1XUA 00

510R1A000552thgiRemuloV1XUA 00

610SAB000510tesffOssaBniaM 02

710ERT000510tesffOelberTniaM 22

8101QE000510tesffO)zH001(dnaBlennahCniaMrezilauqE 20

9102QE000510tesffO)zH003(dnaBlennahCniaMrezilauqE 22

0203QE000510tesffO)zH0001(dnaBlennahCniaMrezilauqE 00

1204QE000510tesffO)zH0003(dnaBlennahCniaMrezilauqE 81

2205QE000510tesffO)zH0008(dnaBlennahCniaMrezilauqE 10

320TCFB500700lortnoCEBBdnaBUD,EBD 50

420NECS100510lortnoCretneCD3SRS 40

520APSS000510lortnoCecapSD3SRS 10

620WHBB000510edomWOWnitesffossecorpEBB 00

720ERTS200700edomdnuorrusroftesffOelberT 10

820THBB000510edomVTnitesffOEBB 00

920AWD000000???AWD 00

030ERTT200700edoMVTnitesffOelberT 30

1301QEC800510)zH001(ataDdnaBrezilauqEnI-retneC 60

2302QEC800510)zH003(ataDdnaBrezilauqEnI-retneC 90

3303QEC800510)zH0001(ataDdnaBrezilauqEnI-retneC 01

4304QEC800510)zH0003(ataDdnaBrezilauqEnI-retneC 01

5305QEC800510)zH0008(ataDdnaBrezilauqEnI-retneC 70

– 22 –

KV-DA34M61/M81

RM-W105

JVTytilanoitcnuF.tinIegnaRnoitcnuF etoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

CEDS000UTPM300510)CSTB(noitcetedtolipXPMrofdlohserhTreppU DSS20

100LTPM900510)CSTB(noitcetedtolipXPMrofdlohserhTrewoL 50

200UTPS300510noitcetedreirracPASrofdlohserhTreppU 80

300LTPS600510noitcetedreirracPASrofdlohserhTrewoL 51

400HT1C0001301CSfonoitcetedrofdlohserhTlamroN 00

500PA1C0001301CSfonoitcetedrofdlohserhTmargorPotuA 00

600HTPS000130PASfoetumotuarofdlohserhTesioN 00

700YHPS400510PASfoetumotuarofezissiseretsyH 30

800HTMF000130dradnats2AMFni2CSfoetumotuarofdlohserhTesioN 81

900YHMF400510dradnats2AMFni2CSfoetumotuarofezissiseretsyH 70

010HTTB000130reirracoeretsCSTBfoetumotuarofdlohserhTesioN 00

110YHTB400510oeretsCSTBfoetumotuarofezissiseretsyH 30

210HTJE000130reirracbusMFJAIEfoetumotuarofdlohserhTesioN 00

310YHJE400510reirracbusMFJAIEfoetumotuarofezissiseretsyH 40

410YLNO000100tuptuoCEDnoMACINdetalerylnoecudorpeR 00

510MAXE000100)PEDD(LdradnatsnietumotuafoesacniecruoskcabllaF 00

610TMIN000100)PEDD(etarrorretibnodnepednoitcnufetumotuaMACIN 00

710ELIN001552)PEDD(timilrorrerewolMACIN 05

810EUIN002552)PEDD(timilrorrereppuMACIN 002

910DMPE100300)PEDD(gnimmargorPysaECEDMED

1=1tiB3POdna0=SDTSdna0=DMPEfI

revoekatlliwyrogetacCKDSdnaelbasiDsiyrogetacCEDS

*

020SDTS910130sedomSSSdnaDSArofdexelpitlumstiB *

120AMVO100100noitpadanoitaludomrevoMF 00

220WBLF000300htdiwdnabretlifrotaludomedMA/MF 30

320DMDI000300edomSSSnideepstnediMF 00

420LAPF000100gnidocedCSTBrofycneuqefeniL 00

520TMVO100200lanimonotevitalerdlohserhtlevelnoitaludomrevO 30

620IXCD000100retrevnIlortnoCgnilacSOXCDMACIN *

720GXCD000700niaGlortnoCgnilacSOXCDMACIN *

820LLCD110510)L(timiLlortnoCgnilacSOXCDMACIN 00

920HLCD000130)H(timiLlortnoCgnilacSOXCDMACIN *

030UEDI100300DTS2AnaeporuErofgnittesDOMDI 00

130RKDI100300DTSMnaeroKrofgnittesDOMDI 00

230PJDI100300DTSJAIErofgnittesDOMDI 00

– 23 –

KV-DA34M61/M81

RM-W105

JVTytilanoitcnuF.tinIegnaRnoitcnuF etoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

CKDS000LLNK000552etyBrewoLdlohserhTrewoLteDesioNnaeroK

1=1tiB3POdna0=SDTSdna0=DMPEfI

revoekatlliwyrogetacCKDSdnaelbasiDsiyrogetacCEDS

100HLNK210552etyBrehgiHdlohserhTrewoLteDesioNnaeroK

200LHNK000552etyBrewoLdlohserhTreppUteDesioNnaeroK

300HHNK020552etyBrehgiHdlohserhTreppUteDesioNnaeroK

400CILK060552tnuocgniniatniamDItoliPtsoLnaeroK

500MILK100721reilpitlumtnuocgniniatniamDItoliPtsoLnaeroK

600CDSK600552tnuoCtceteDoeretSnaeroK

(only applicable fo Korea model)

– 24 –

KV-DA34M61/M81

RM-W105

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTeciveD

emaN

nommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

0RN1RN2RN3RN0CSTN1CSTN1RN-FR-FR

1CSTN

-VT

LAP

-VT

CSTN

OEDIV

LAP-

-OEDIV

CSTN

-S

LAP

-S

CSTN

RN3

000SCY

000300EDOMSCY bmoCD300

100CER

000100CED-C:CER 10

200TED3000700TEDD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

7070707070707070

300ROC3000100RROCRND3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

1000000010000000

400FOB

000100NOTSRUB 10

500NYS

000100NOCNYS 00

600CFA000300NIAGCFA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

3030303030303030

700GEH000300NIAGAHNEH 00

800RNC2000510MILRNCD2&KRNC-D2

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0040509000004000

900CNY000700MILCN-Y;RELLECNACESIONY

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0030507010104030

010RNY2000510NIAGRNYD2;KRNYD2

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0000008010102040

110LNY2000300MILRNYD2

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0020003020203020

210KLB000300PXEKLB 00

310RNC3000700MILRNCD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0000307000000000

410KNC3000300KRNCD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0000000000000000

510GNC3000700NIAGRNCD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0020207000004000

610RNY3000700MILRNYD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0030606000001000

710KNY3000300KRNYD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0010000000001000

810GNY3000700NIAGRNYD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0020606000001000

910YLDY000821YALEDTUPTUOY

/LAP-DIV/CSTN-VT/LAP-VT

CSTN-S/LAP-S/CSTN-DIV

307060505151

020ACI000100OTUAPMALCTNI 00

120MCI000100LAUNAMPMALCTNI 00

220HNEC000100AHNEC 10

320KCI000100YEKPMALCTUPNI 10

420KGB000100YEKETAGTSRUB 10

520LSS000100FPLPESCNYS 00

– 25 –

KV-DA34M61/M81

RM-W105

KV-DA34M61/M81

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTeciveD

emaN

nommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

0RN1RN2RN3RN0CSTN1CSTN1RN-FR-FR

1CSTN

-VT

LAP

-VT

CSTN

OEDIV

LAP-

-OEDIV

CSTN

-S

LAP

-S

CSTN

lamroN

)3:4(

DHxednI/niwT

paP/

rehtO

RN3

620RCEV000300EROCAHNEV

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

bmoCD3

0010300000101010

720GEV000300NIAGAHNEV

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0000100000102010

820NEV000300LNAHNEV

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

0000100000102010

9201PMA0007001PMADH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

6060606060606060

030VGDH000130VNIAGDH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

8181818181818181

1302PMA0007002PMADH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

6060606060606060

2301GDH0001301NIAGDH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

3131313131313131

3303PMA0007003PMADH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5050505010105010

4302GDH0001302NIAGDH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

4040404010104010

530PLSC000510PLSSCA&PLSMCA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5141015101010101

630PLSY000510PLSSYA&PLSMYA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5151400141414141

730SMCA000510TESFMCA&TESEMCA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5101015151510151

830SSCA000510TESFSCA&TESESCA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5101015101010101

930SMYA000510TESFMYA&TESEMYA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5111015151511151

040SSYA000510TESFSYA&TESESYA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5111015101014101

140LSCB000510PLSSCB&PLSMCB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

51

01015151510151

240LSYB000510PLSSYBPLSMYB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5101015131310131

340SMCB000510TESFMCB&TESEMCB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5101015101010101

440SSCB000510TESFSCB&TESESCB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5101015101010101

540SMYB000510TESFMYBTESEMYB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5151015151515151

640SSYB000510TESFSYBTESESYB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5151015101015101

740UMCB000100PUMCB

10

840MCEC000700PMCEC

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

7040704040407040

940MCSC000510PMCSC

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5101510000005100

050VH1F000510REV1F&REH1F

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

5080505050508050

150FERM000510FERM

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

2070404060607060

250YEDC000300EYEDC

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

2030202000003020

350YEDY000300EYEDY

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

2030202000003020

450SAMH000700TUOKSAM-H

00

550SAMV000130TUOKSAM-V

00

RM-W105

– 26 –

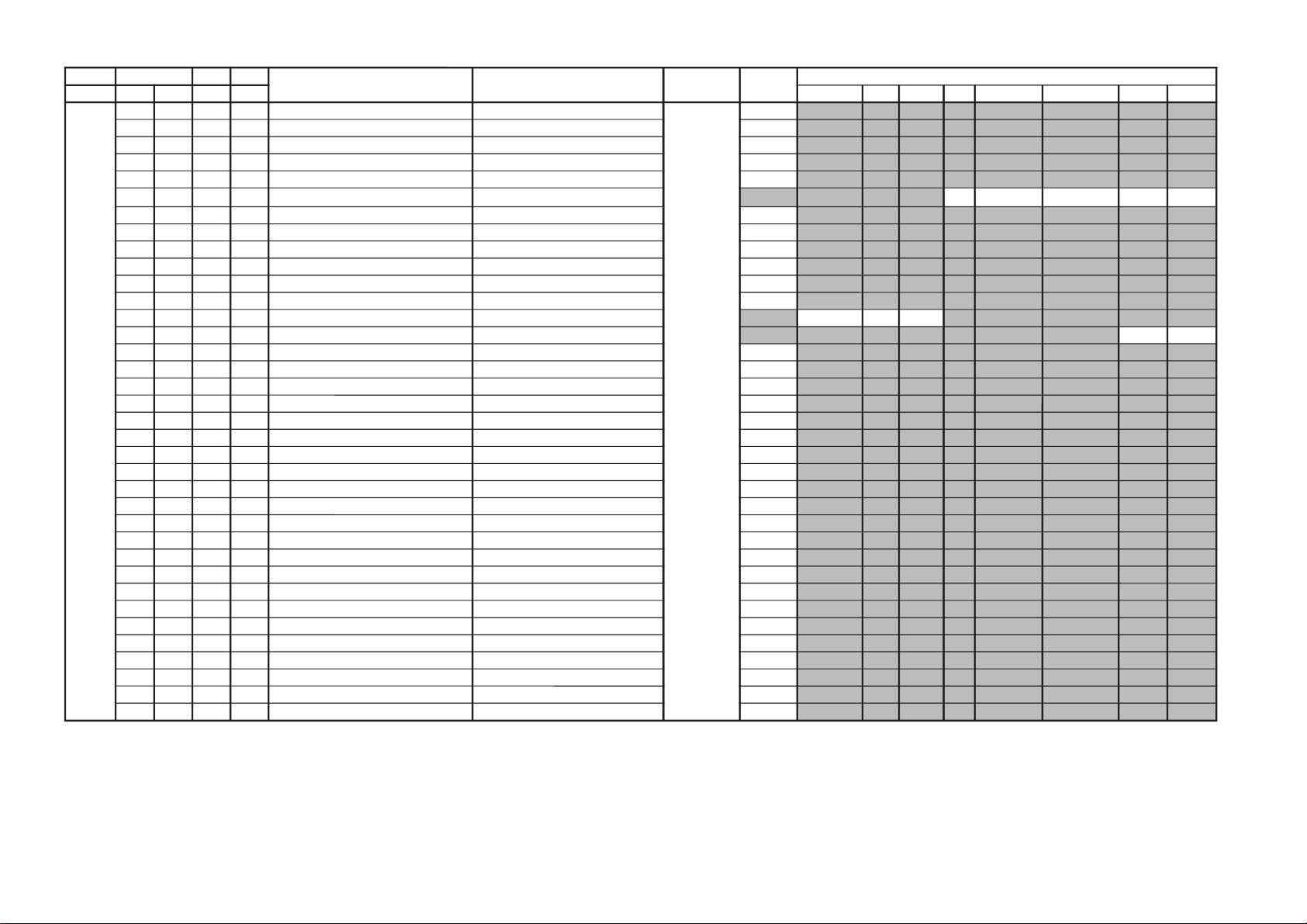

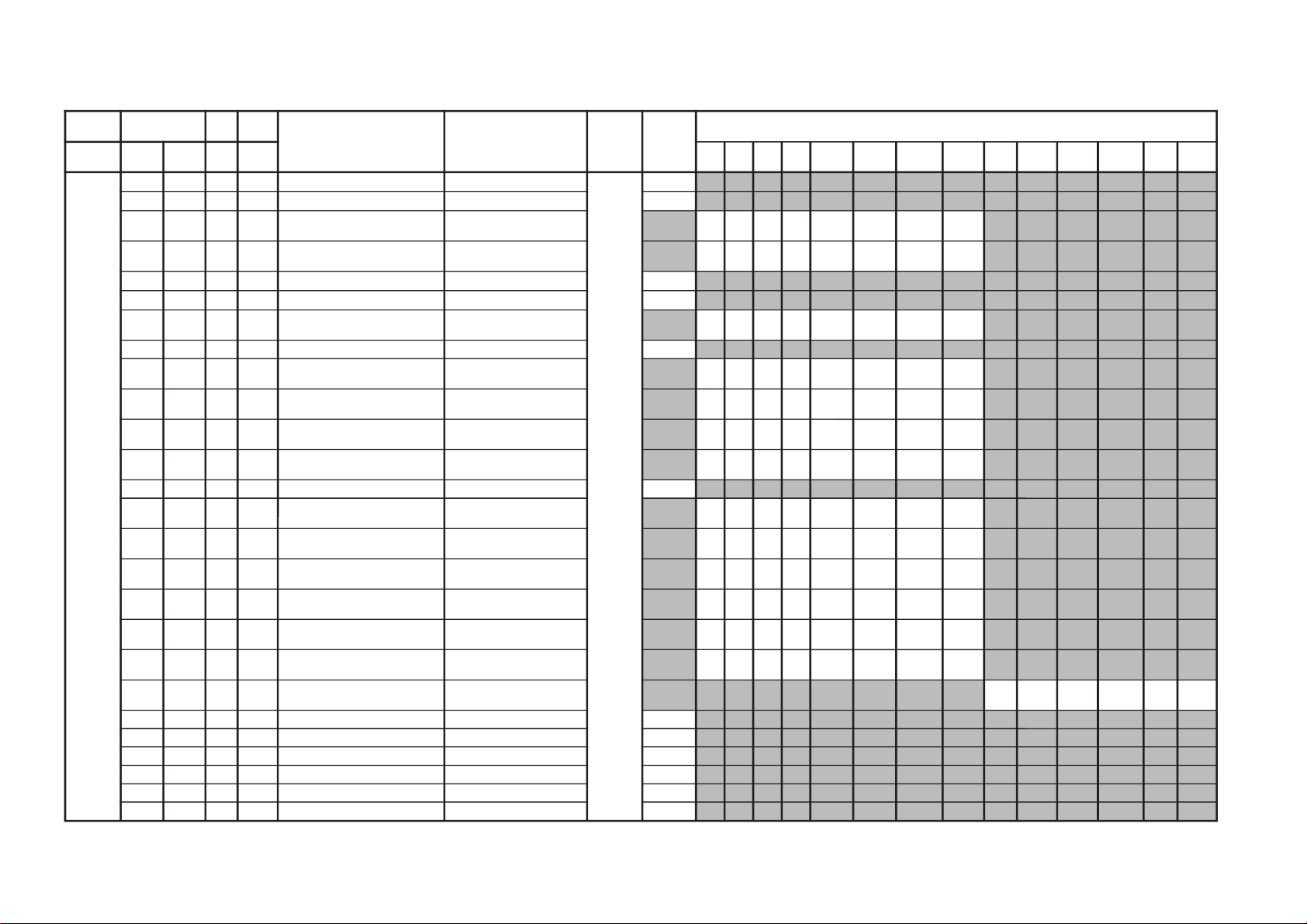

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTeciveD

emaN

nommoC

)deliateD(eulaVlaitinI

yrogetaCoNemaNceDceD

ciP

0edom

ciP

1edom

ciP

2edom

ciP

3edom

FRtpecxE

0edomciP

FRtpecxE

1edomciP

FRtpecxE

2edomciP

FRtpecxE

3edomciP

ITL000HDL100100noitceleStnemgesmargotsiH 8719ADT10

100SFC100100noitceleSretliFruotnoC 10

200BLW000100hctiwSwodniWxobretteL 00

300CDV100100gniroCtnednepeDoediVedoMerutciP

10101010

400MED000100edoMnoitartsnomeD 00

500PDC400700yaleDecnanimuL 40

600PSO000100gnikaePtramSelurrevO 00

700OPW000100ffOhctertStnioPetihW 00

800KSD000100hctiwSenoTnikSedoMerutciP

00000000

900KSA000100noitceleSelgnAenoTnikS 00

010KSW000100noitceleShtdiWenoTnikS 00

110KSS000100noitceleSeziSenoTnikS 00

210RGD100100hctiwStnemecnahnEneerGedoMerutciP

10100010

310TGD700700hctiwStnemecnahnEneerGfodlohserhT 70

410RGG000100niaGtnemecnahnEneerG 00

510RGW000100htdiWtnemecnahnEneerG 00

610RGS000100eziStnemecnahnEneerG 00

710LBD000100hctiwShctertSeulB 00

810LBG000100noitceleSniaGhctertSeulB 00

910LBS000100noitceleSeziShctertSeulB 00

020SDC100100ssenprahStnednepeDroloCedoMerutciP

10100010

120TSC700700ssenprahStnednepeDroloCfodlohserhT 70

220ITC100100tnemevorpmItneisnarTroloCedoMerutciP

10100010

320NOB000100noitasnepmoCtesffOkcalBedoMerutciP

00000000

420DTB000360htcertSkcalBevitpadAedoMerutciP

00000000

520DLN120360reifilpmAytiraeniL-noNedoMerutciP

12120012

620WLN700700reifilpmAytiraeniL-noNfohtdiWpetS 70

720DGV130360ammaGelbairaVedoMerutciP

53535353

820WGV000700ammaGelbairaVfohtdiWpetS 00

920DKP040360edutilpmAgnikaeP)srehtO/VT(*edoMerutciP

0403410404034104

030WKP800510edutilpmAgnikaePfohtdiWpetS 80

130DPS000360noitcerroCssenpeetSedoMerutciP

00000000

230DRC050360leveLgniroC)srehtO/VT(*edoMerutciP

5454005405050005

330WRC900510leveLgniroCfohtdiWpetS 60

430ORC600510edoMoediVroftesffOleveLgniroC 60

530DWL130360noitcerroChtdiWeniL 13

630MNS000700noitidnocN/SelbailernurednuedoMN/S 00

730CNS300510retnuoCegarevAoitaRN/S

noelbaliavAtoNmetIecivreS

)E3GAmorfdeipoC(VTlautca

830CMF200510retnuoCgnihctaMedoMerutaeF

noelbaliavAtoNmetIecivreS

)E3GAmorfdeipoC(VTlautca

– 27 –

KV-DA34M61/M81

RM-W105

– 28 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

DEFP000DEFP000100edoMecivreSenignEFPenignEFP00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0506

PBUS000HXDI500510noitisoplatnozirohDSOxednIataDtimsnarTossaciPbuSossaciPbuS50

100VXDI740360noitisoplacitrevDSOxednI)06/05(ataDtimsnarTossaciPbuSossaciPbuS7474

200BXDI130130ssenthgirbDSOxcednIataDtimsnarTossaciPbuSossaciPbuS13

(only applicable for 2 tuners models)

KV-DA34M61/M81

RM-W105

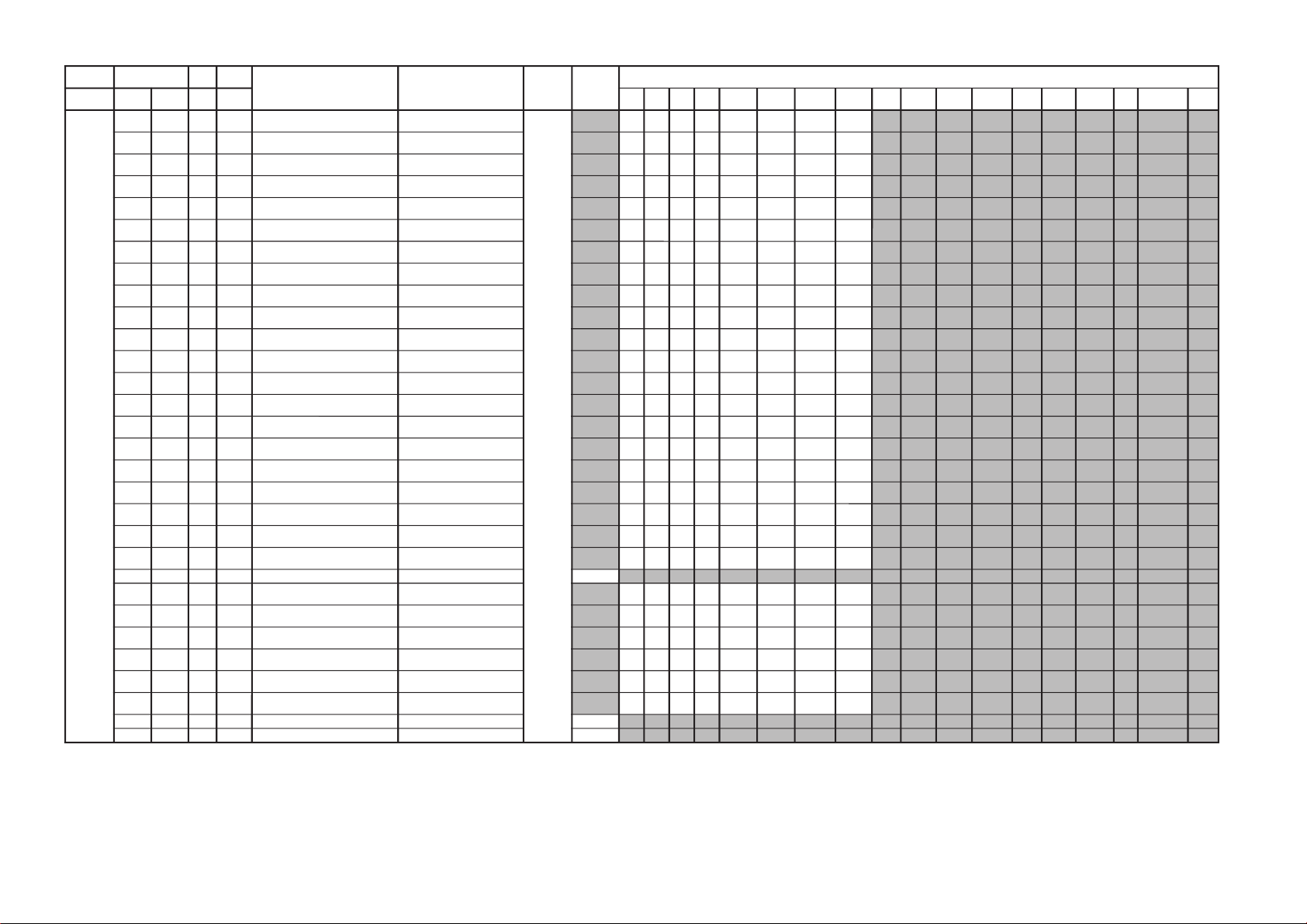

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0506VUYVToediVlangiSoN

SOCS000SYS100100tupnICNYSYnonoitazinorcnyS -VTbuS

rossecorP

00

100OF000300tnatsnoCemiT1esahP )FR(langisoNrogninuTotuA/VT

003000

200DIV100100edoMtnedIoediV 06/05

0000

300LSF000100cnySlacitreVrofleveLgnicilSdecroF 00

400LSS000100rotarapeScnySleveLgnicilS 06/05

0000

500DIVS000700noitacifitnedIoediVrofnoitceleSecruoS VUY/oediV/VT

000000

600FROF300300ycneuqerFdleiFdecroF 20

700OVS00030084@niPISBVC/OVS/OVFIfonoitcnuF VUY/oediV/VT

000000

800EXDV

000100dnareifilpmaFInoisivneewtebgnilpuocfolortnoC

tiucricnoitasinorhcnys

00

900XDV

000100dnareifilpmaFInoisivneewtebgnilpuoC

tiucricnoitasinorhcnys

00

010YLDY210510tnemtsujdayaled-Y 21

110DFIO630360rotaludomeDFItesffO 63

210TCGA130360revo-ekaTCGA 13

310MTS100100edoMgninuThcraeS 10

410DG000100langiS1SBVCnoyaleDpuorG 00

510SCGA100300deepSCGAFI 10

610IFF000100LLPFIretliFtsaF 00

710SSMC000100tiucrictnedioedivehtroflangistupnicnysfonoitceleS 00

810PMAO300300edutilpmAlangiStuptuOoediV 00

910IAV000100noitcerroCedutilpmAlangiStuptuOImetsyS 00

020SWMF200300rotaludomeDMFrofnoitceleSwodniW 20

120SSQ

000100edoMreifilpmA)SSQ(dnuoStilpSisauQ

)ledoMAGtpecxe(

00

220BPB000100retliFssapdnaBdnuoSfossapyB 00

3202BPB0001002retliFssapdnaBdnuoSfossapyB 00

420TPS000100edomkcirtecnamrofrepcnyS 00

520D2E000100nipMEEDUAnolangistuptuooiduafonoitceleS 00

620CVPH000100lortnoCemuloVenohPdaeH 00

720GSD000100stuptuooiduaotstupnioiduamorfniaG 00

820DSV100100elbasidnacslacitreV 00

920ESHC100300ytivitisneStnedICSTN/LAP 20

– 29 –

(only applicable for 2 tuners models)

KV-DA34M61/M81

RM-W105

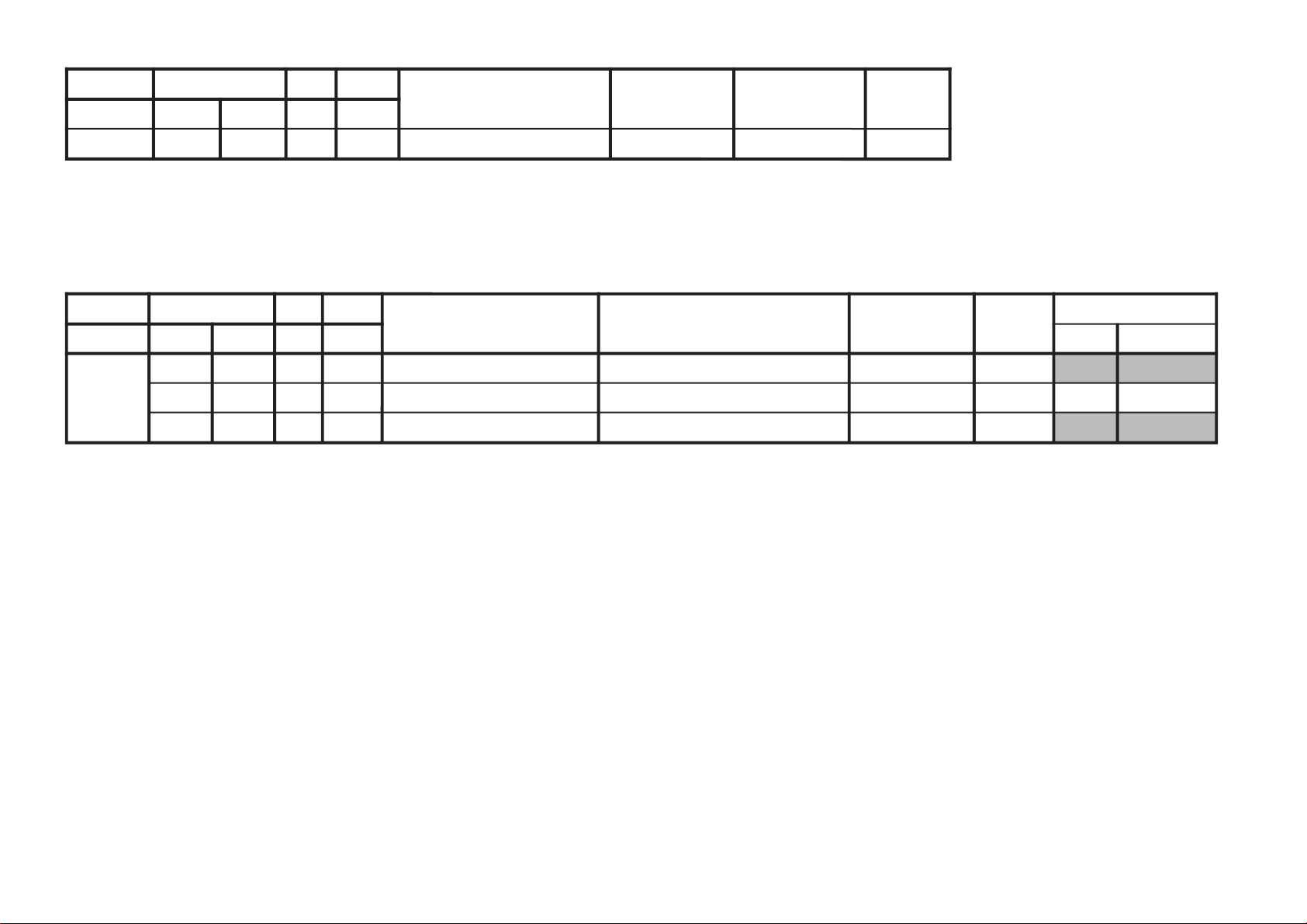

Loading...

Loading...