Page 1

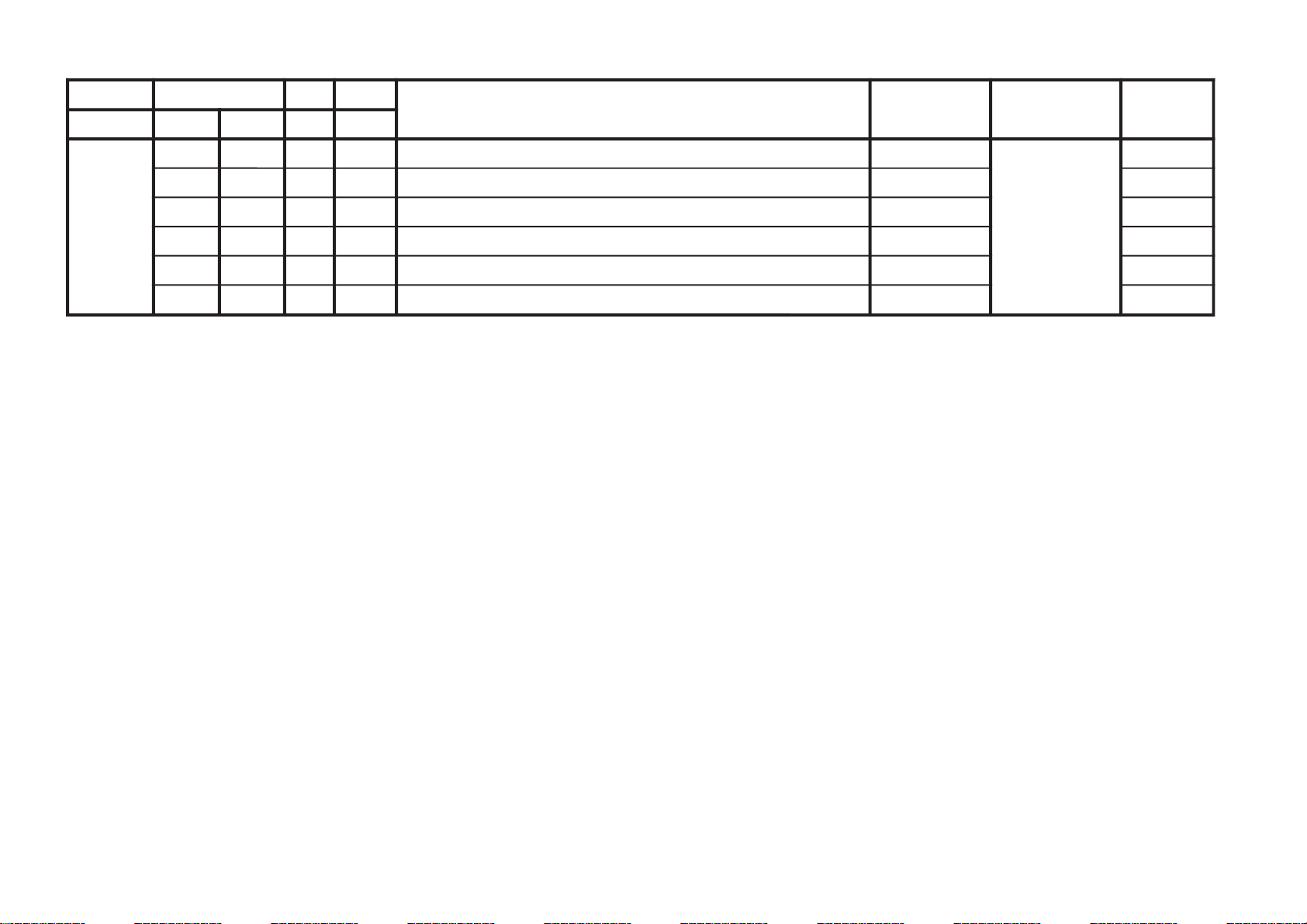

REVISION HISTORY

CX1

CHASSIS

MODEL

KV-DA322M64

KV-DA322M66

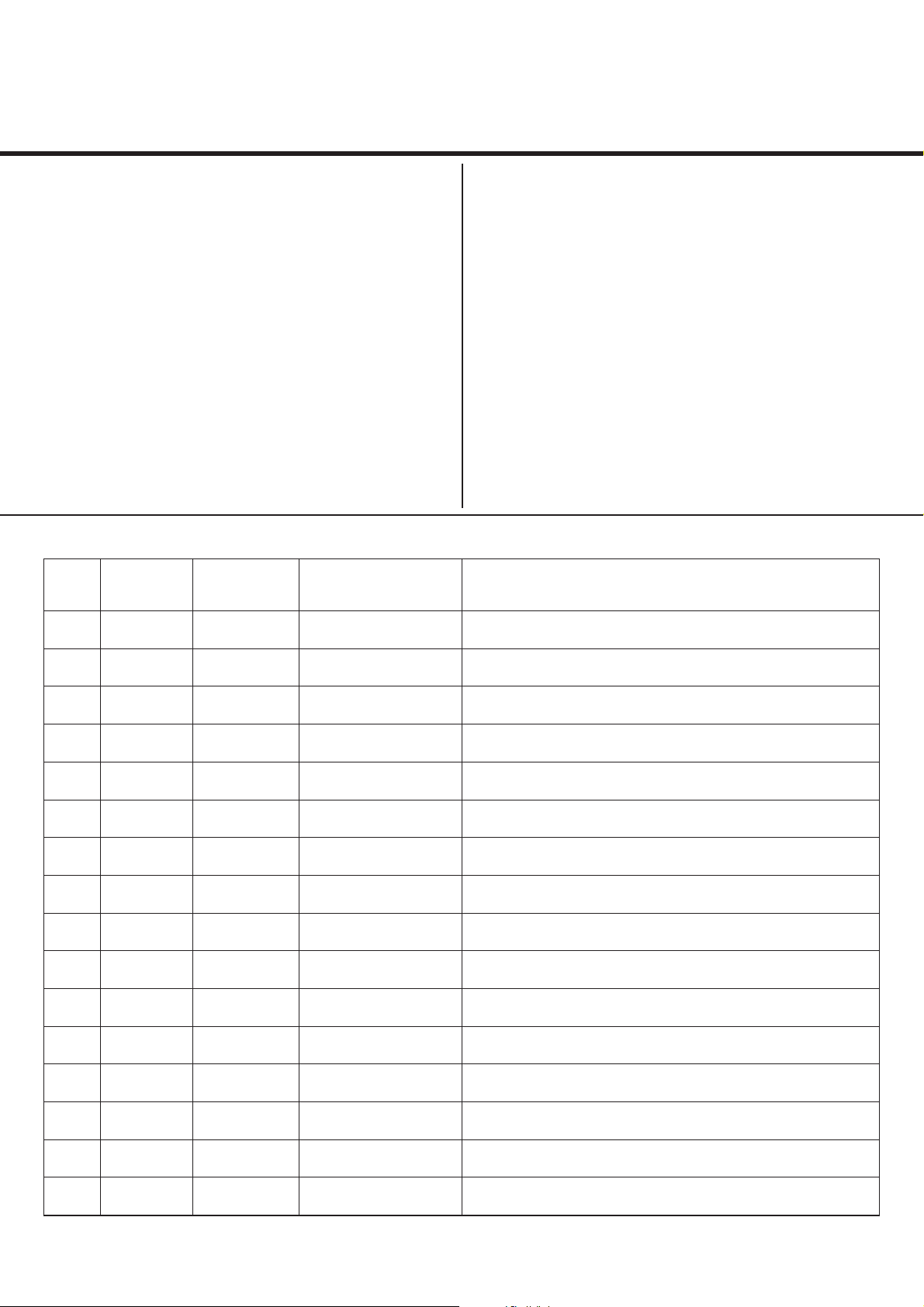

NO. SUFFIX DATE SUPP / CORR DESCRIPTION

1 -01 2005/9 _ _ 1st Issue

PA RT NO.: 9-872-850-02

2 -02 2005/12 CORR-1 Correction on Deflection Adjustment (Page 157)

Page 2

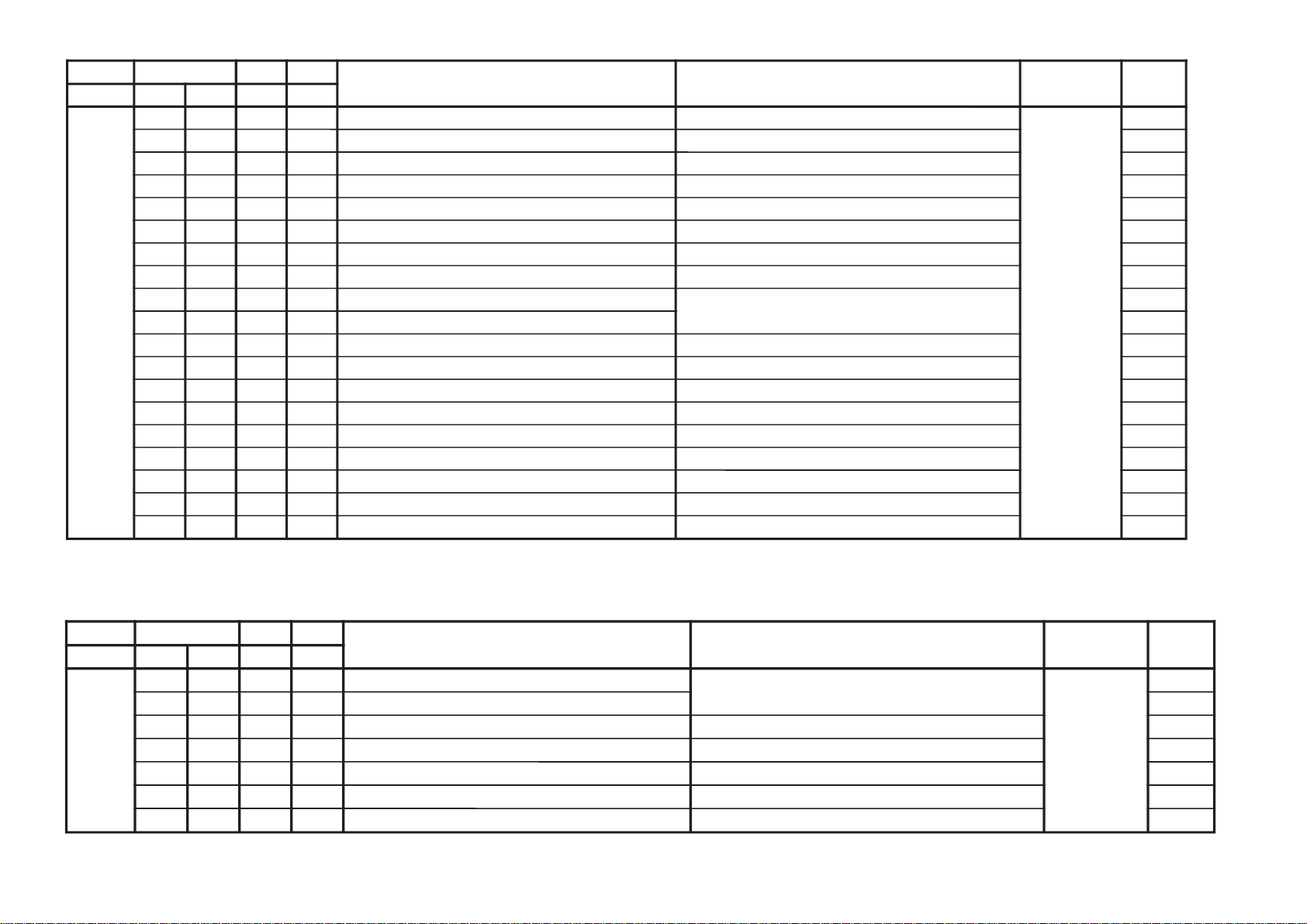

SERVICE MANUAL

CX1

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-DA322M64 RM-GA001 Thailand SCC-V27D-A

KV-DA322M66 RM-GA001 GE SCC-V25D-A

MODEL COMMANDER DEST. CHASSIS NO.

RM-GA001

TRINITRON

®

COLOR TV

Page 3

KV-DA322M64/M66

RM-GA001

TABLE OF CONTENTS

Section Title Page

SELF DIAGNOSTIC FUNCTION................................... 3

1. DISASSEMBLY

1-1. Rear Cover Removal.................................................. 5

1-2. Speaker Removal........................................................5

1-3. Chassis Assy Removal................................................5

1-4. Service Position..........................................................5

1-5. Terminal Bracket Removal......................................... 5

1-6. J1 Board Removal.......................................................5

1-7. BH1, BP1 and BC1 Boards Removal..........................6

1-8. F1 Board Removal......................................................6

1-9. WL Board Removal....................................................6

1-10. DL Board Removal.....................................................6

1-11. H2 and H3 Boards Removal....................................... 6

1-12. A and D Boards Removal...........................................6

1-13. Picture Tube Removal................................................ 7

2. SERVICE JIG

2-1. Jigs Required for Servicing........................................ 8

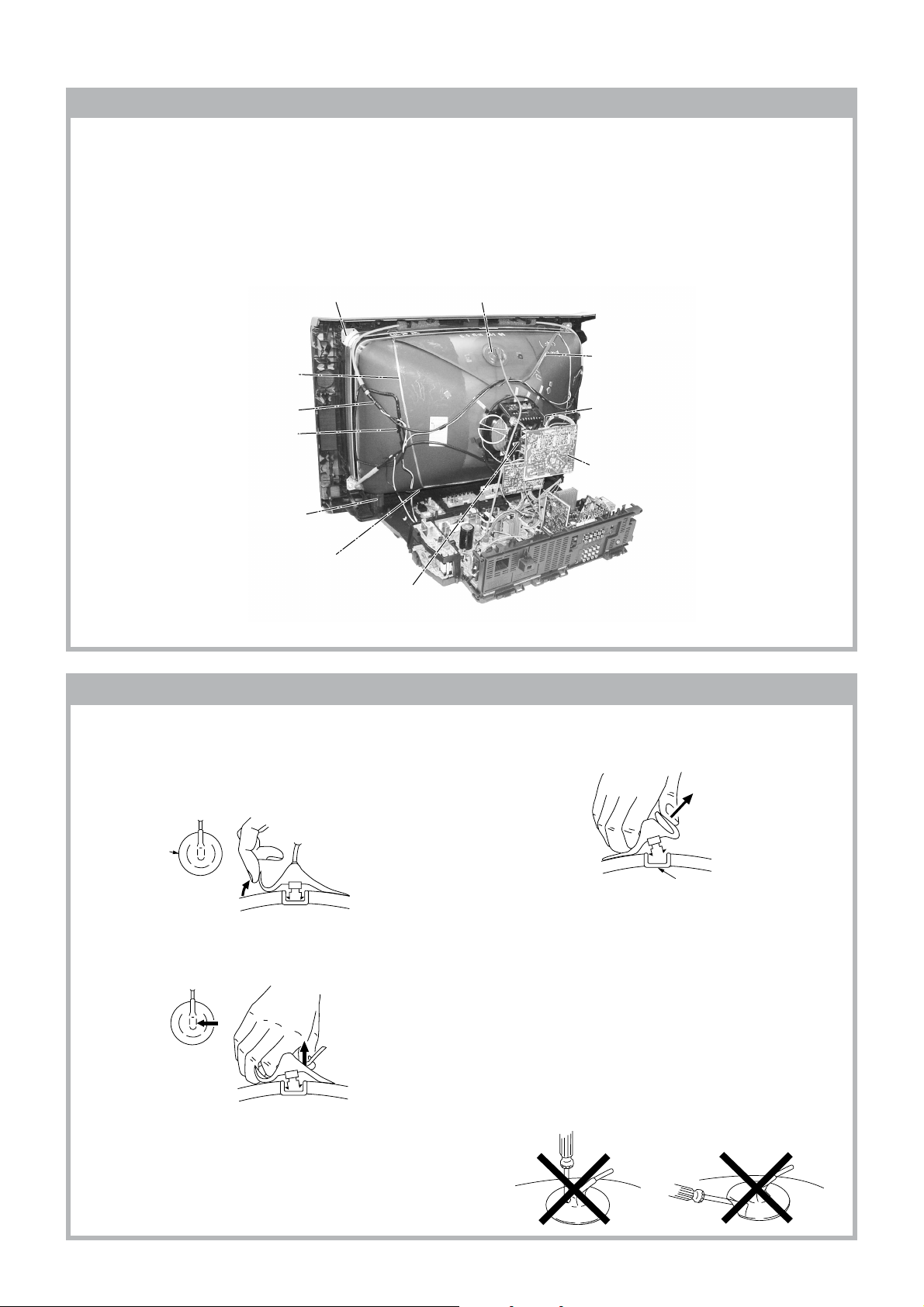

3. CIRCUIT BOARDS LOCATION ........................................ 8

4. ADVANCE OPERATION

4-1. "RESET" Function.................................................... 9

Section Title Page

7. DIAGRAMS

7-1. Block Diagram......................................................... 65

7-2. Schematic Diagram Information...............................66

7-2-1. A Board – (Block 001)...................................67

7-2-2. A Board – (Block 002)...................................69

7-2-3. A Board – (Block 003)...................................71

7-2-4. A Board – (Block 004)...................................73

7-2-5. BC1 Board Schematic Diagram.....................74

7-2-6. BH1 Board – (Block 001).............................. 76

7-2-7. BH1 Board – (Block 002)............................. 78

7-2-8. BP1 Board Schematic Diagram..................... 80

7-2-9. C Board Schematic Diagram........................ 82

7-2-10. D Board – (Block 001)................................ 84

7-2-11. D Board – (Block 002)................................ 86

7-2-12. DL Board Schematic Diagram .................... 87

7-2-13. H2 Board Schematic Diagram .....................89

7-2-14. F1 Board Schematic Diagram ..................... 90

7-2-15. H3 Board Schematic Diagram..................... 91

7-2-16. VM1 Board Schematic Diagram.................. 93

7-2-17. J1 Board Schematic Diagram.......................95

7-2-18. WL Board Schematic Diagram.................. 97

7-3. Voltage Measurement and Waveform..................... 98

7-4. Printed Wiring Boards............................................ 110

7-5. Semiconductors...................................................... 122

5. SET-UP ADJUSTMENTS

5-1. Beam Landing Adjustment....................................... 10

5-2. Convergence Adjustment.......................................... 11

5-3. Focus Adjustment..................................................... 13

5-4. G2 (SCREEN) Adjustments......................................13

5-5. Sub Brightness Adjustment.......................................13

5-6. White Balance Adjustment........................................13

6. CIRCUIT ADJUSTMENTS

6-1. Adjustments With Commander..................................15

6-2. Adjustment Method.................................................. 16

6-3. Picture Quality Adjustments.....................................61

6-4. Sub Hue/Col Adjustment.........................................61

6-5. Deflection Adjustments............................................ 62

6-6. A1 Board Adjustment After IC003

(Memory) Replacement............................................63

6-7. Picture Distortion Adjustments.................................64

8. EXPLODED VIEWS

8-1. Picture Tube and Speaker Bracket.......................... 124

8-2. Chassis....................................................................125

9. ELECTRICAL PARTS LIST ........................................... 126

OPERATING INSTRUCTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

Page 4

KV-DA322M64/M66

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically

begin to flash.

The number of times the lamp flashes translates to a probable source of the problem. If an error symptom cannot be

reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past

problems and how often these problems occur.

1. DIAGNOSTIC TEST INDICATORS

When an error occurs, the STANDBY/TIMER lamp will flash a number of times to indicate the possible cause of the

problem. If there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occured if the screen displays a “0”.

RM-GA001

Diagnostic

Item

Description

•Power does not

turn on

• +B overcurrent

(OCP)

• Horizontal

deflection failure

• +B overvoltage

(OVP)

•Vertical deflection

failure

• White balance

failure (no

PICTURE)

• 5V/9V failure

• Micro reset

No. of times

STANDBY/TIMER

lamp flashes

Does not light

2 times

3 times

4 times

5 times

8 times

—

Self-diagnostic

display/Diagnostic

result

—

002:000 or

002:001~255

003:000 or

003:001~255

004:000 or

004:001~255

005:000 or

005:001~255

008:000 or

008:001~225

101:00 or

101:001~225

Probable

Cause

Location

•Power cord is not plugged

in.

• Fuse is burned out F1601

(F1 Board)

• H.OUT Q6802 is shorted.

• PH6602 faulty.

D6644 faulty

• 11V is not supplied.

(D board)

•V.OUT IC6801 faulty

D6827 faulty

D6817 faulty

• G2 is improperly adjusted.

•CRT problem.

• Video OUT IC9001, 9002,

9003 are faulty. (C board)

• IC4301 CXA2170Q (A

board) are faulty.

• 5V regulator (IC2601) faulty.

• 9V regulator (IC2600) faulty.

•CRT Discharge (C Board)

• Static discharge

• External noise

Detected

Symptoms

•Power does not turn on.

• No power is supplied to the

TV.

•AC power supply is faulty.

•Power does not turn on.

• Load on power line is

shorted.

•H pulse output is too high.

•Power does not come on.

•Vertical deflection pulse is

stopped.

•Vertical size is too small.

•Vertical deflection stopped.

• No raster is generated.

•CRT cathode current

detection reference pulse

output is small.

• TV Blank

• No Raster

•Power is shut down shortly,

after this return back to

normal.

• Detect Micro latch up.

2. STANDBY INDICATOR BLINKING PROCESS

Lamp ON 300ms

Lamp OFF 300ms

The example above represents for 4 times blink

Lamp OFF 3 seconds

3. STANDBY INDICATOR ON TV FRONT PANEL

Standby indicator

– 3 –

Page 5

KV-DA322M64/M66

RM-GA001

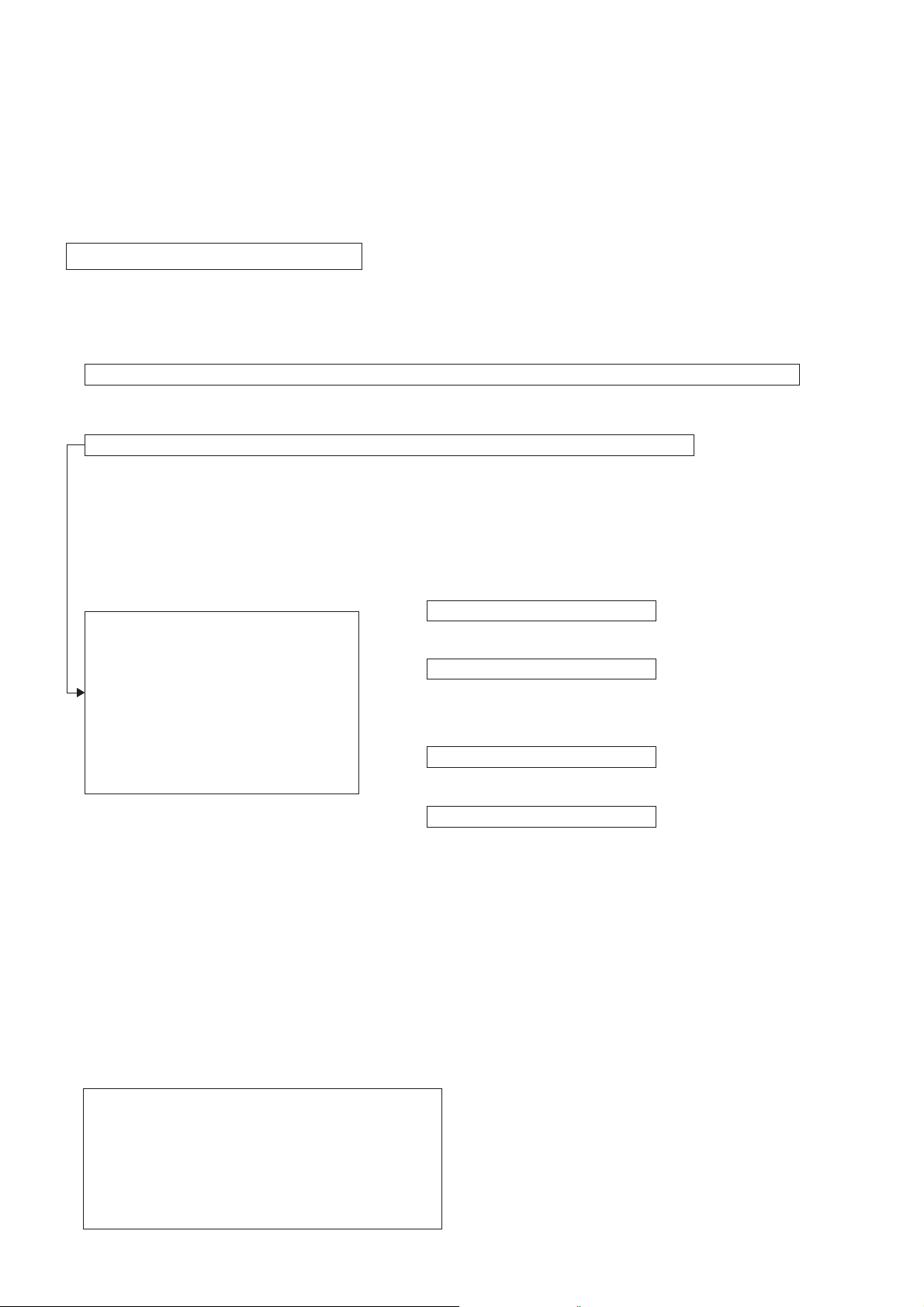

4. SELF DIAGNOSTIC SCREEN DISPLAY

SELF DIAGNOSTIC

2 : 000

3 : N/A

4 : 000

5 : 001

8 : 002

101 : N/A

5. HANDLING SELF DIAGNOSTIC SCREEN DISPLAY

No. Description Method

1. Display self diagnostic screen [Display] t [Channel ] t [Volume ] t [Power / TV]

2. Stop standby flash i) Turn off power switch on main.

3. Clear fault result In self diagnostic screen, press [Channel ] t -

4. Quit self diagnostic screen Turn off power switch of remote commander or main unit.

"0" means no fault has been detected.

"1" means a fault has been detected.

"2" means two faults has been detected.

"N/A" means not available for this models.

5

Note: The above must be performed while TV is on standby mode.

ii) Unplug power cord from the outlet.

8

Note: Diagnostic results display on screen is not automatically cleared. Therefore,

clear result after completion of repair.

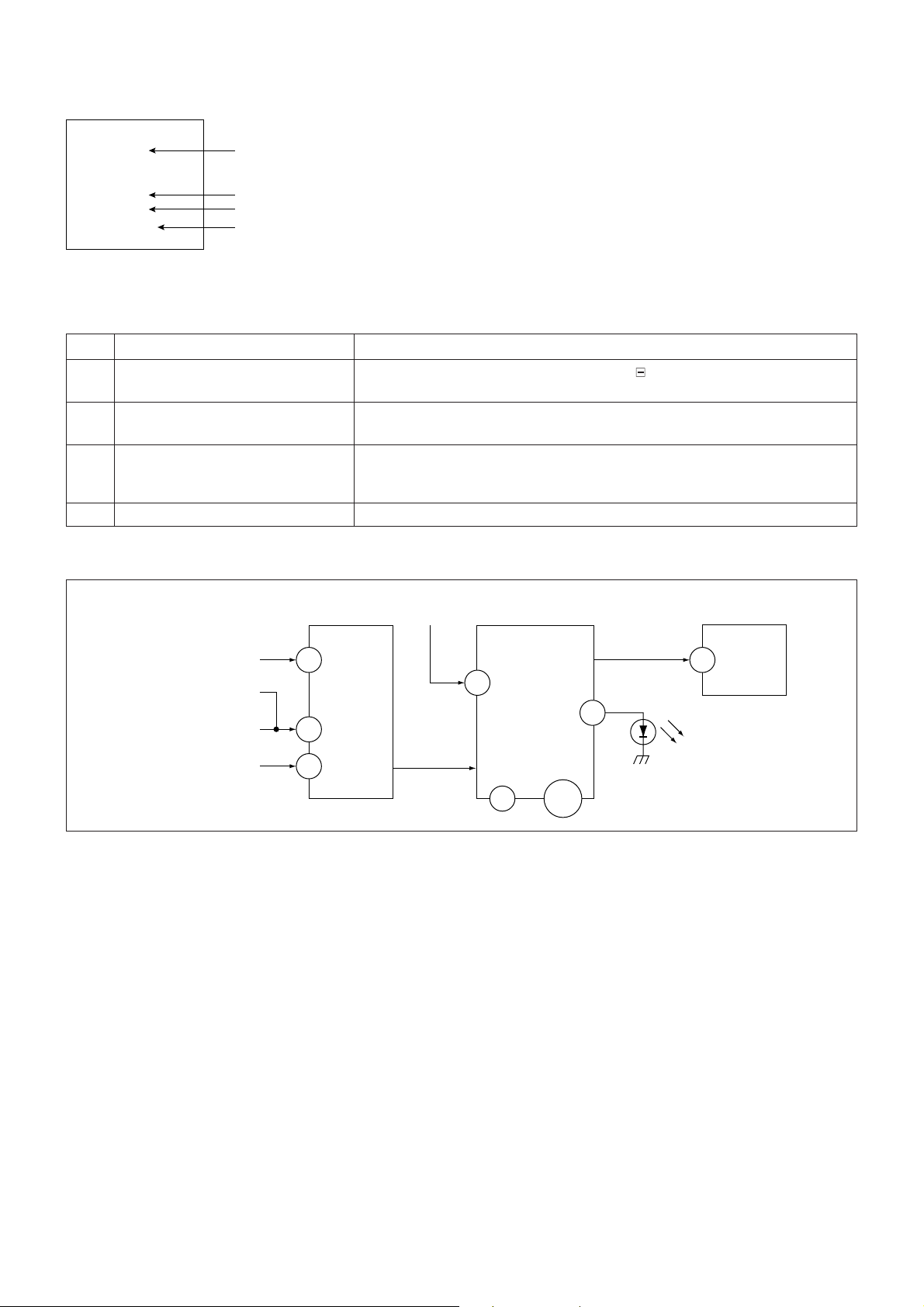

6. SELF-DIAGNOSTIC CIRCUIT

FROM

CRT (IK)

[OCP] Q6804, D6821

[H] D6808, D6809

[V] Q6808

IC4301

RGB JUNGLE

IK_IN

57

H PROT

56

V PROT

CXA2170AQ

OVP

SDA

SYSTEM

2

9V

IC001

84

RED LED

5V

14,47,

82

IC004

MEMORY

SDA

7

524

[+B overcurrent OCP ] Occurs when an overcurrent on the +B(135) line is detected by Q6804.

[High voltage protector of Horizontal Deflection] If Q6804 go to ON, the voltage to the pin57 of IC4301 go to "HIGH".

The unit will automatically turn off.

Occurs when an overvoltage of horizontal pulse is detected by D6809.

If the voltage of anode D6809, Q6814 and D6808 goes to High, the voltage

to pin57 of IC4301 go to "HIGH".

The unit will automatically turn off.

[+B overvoltage OVP ] Occurs when an overvoltage on the +B(135) line is detected by D6635 and

Q6606. If Q6606 go to ON, the voltage to pin2 of IC001 go to "HIGH". The

unit will automatically turn off.

[Vertical deflection failure] Occurs when an absence of the vertical deflection pulse is detected by

Q6808. Shut down the power supply.

[White balance failure] If the RGB levels do not balance or become low level within 5 seconds. This

error will be detected by IC4301.

TV will stay on, but there will be no picture.

[5V/9V failure] Occurs when 5V/9V is not supplied to Micon (IC001).

No raster will be detected or no picture.

– 4 –

Page 6

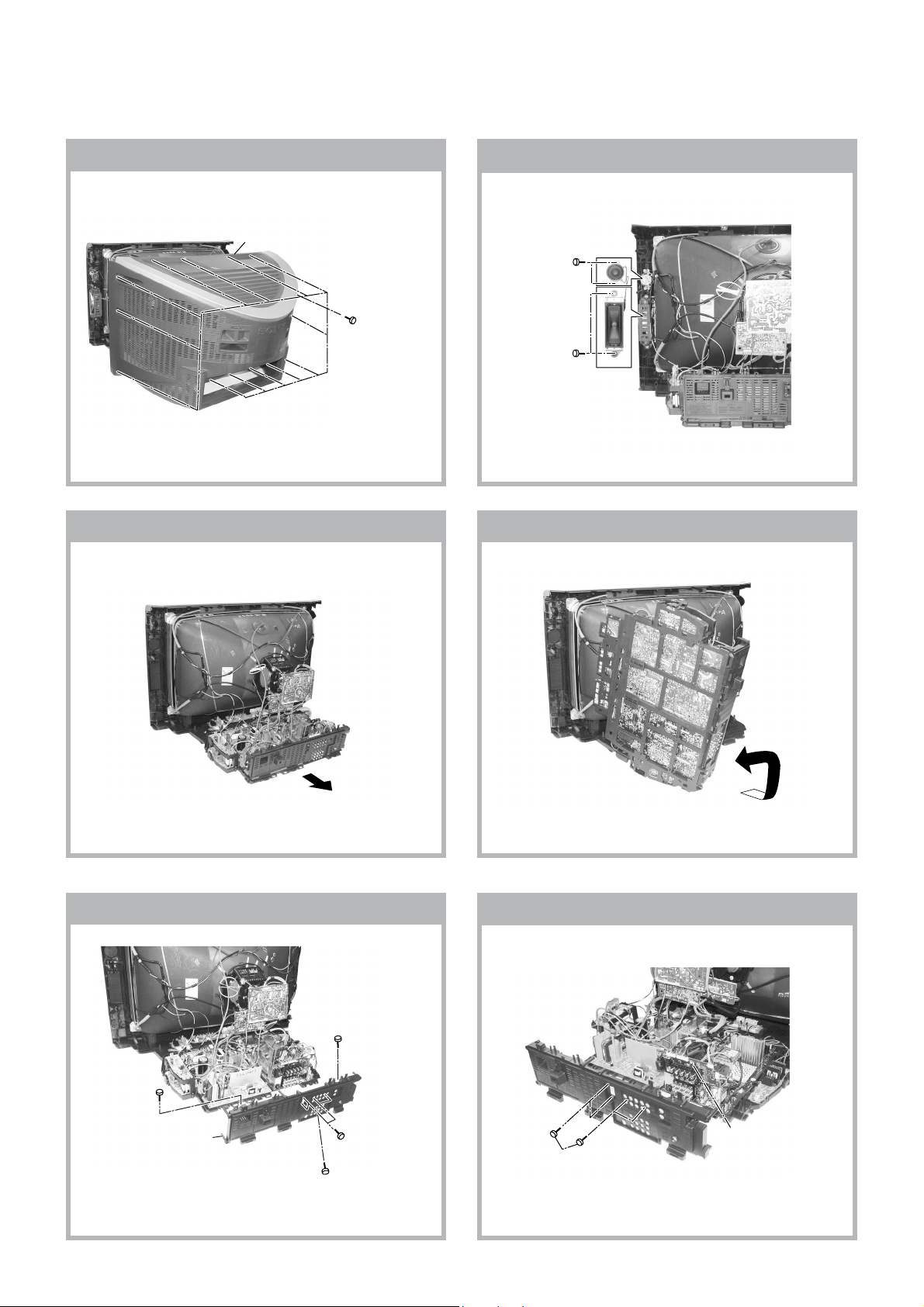

SECTION 1

DISASSEMBLY

KV-DA322M64/M66

RM-GA001

1-1. REAR COVER REMOVAL

2 Rear cover

1 Fourteen screws

(+BVTP 4 × 16

TYPE2 IT-3)

1-2. SPEAKER REMOVAL

1 Two screws

(+BVTP 4 × 16

TYPE2 IT-3)

2 Two screws

TAPPING SCREW

(+PWH 4X16)

1-3. CHASSIS ASSY REMOVAL 1-4. SERVICE POSITION

1-5. TERMINAL BRACKET REMOVAL

5 One screw

(+BVTP 3 × 12)

4 One screw

(+BVTP 3 × 12)

3 Terminal bracket

2 Four screws

(+BVTP 3 × 12

TYPE2 IT-3)

1 One screw

(+BVTP 4 × 16

TYPE2 IT-3)

1-6. J1 BOARD REMOVAL

1 J1 Board

2 Four screws

(+BVTP 3 × 12 TYPE2 IT-3)

– 5 –

Page 7

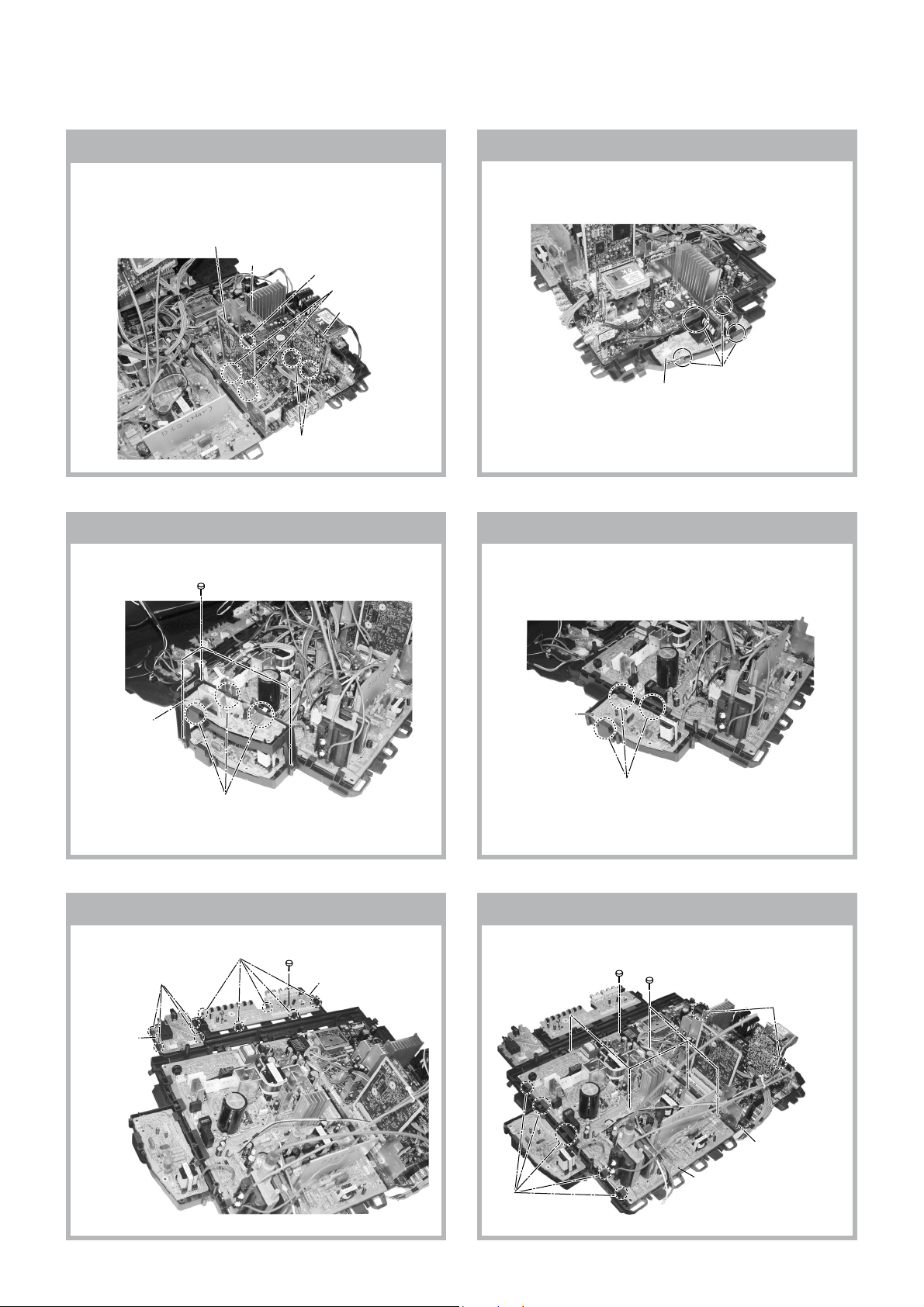

KV-DA322M64/M66

RM-GA001

1-7. BH1, BP1 AND BC1 BOARDS REMOVAL

1-8. F1 BOARD REMOVAL

Note: Access to the BH1 board is possible after

removal of the shiledcase. Remove the

shiledcase by removing 2 screws +BVTP 3x12

Type2 IT-3

5 BH1 Board

4 BC Board

6 Two clips

3 Two clips

2 BP1 Board

2 F1 Board

1 Two clips

1-9. WL BOARD REMOVAL 1-10. DL BOARD REMOVAL

2 Three screws

+BVTP 3X12 TYPE2 IT-3

1 Four hooks

2 WL Board

1 Three clip

2 DL Board

1 Three clip

1-11. H2 AND H3 BOARDS REMOVAL 1-12. A AND D BOARDS REMOVAL

5 One screw

(Washer Head)

(3 × 12)(+)(BVTAP)

2 Five screws

(3 × 12)(+) BVTAP

4 H2 Board

3 Four hooks

1 Five hooks

3 One screw

(3X12)(+)BVTAP

2 H3 Board

3 Two hooks

7 D Board

– 6 –

4 A Board

6 Five hooks

Page 8

KV-DA322M64/M66

1-13. PICTURE TUBE REMOVAL

Note:

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom right

and left.

1) Remove the Rear Cover.

2) Unplug all interconnecting leads from the Deflection yoke, Neck assy, Degaussing Coil and CRT grounding strap. Remove

Chassis Assy.

3) Place the TV set with the CRT face down on a cushion jig.

RM-GA001

qf Screw Tapping 7 +

Crown Washer (L40) (X4)

qa Earth Coating Assy

0 Degaussing Coil

9 Holder, DGC

Removal (x2)

qs Supports, CRT

Removal (x2)

8 Spring Tension(2)

Removal

qd Loosen the Deflection Yoke

fixing screw and remove

4 Anode Cap Removal

7 Band, DGC Removal

6 Loosen the Neck Assembly

fixing screw and remove

Neck Assy & VM1 board

5 C Board Removal

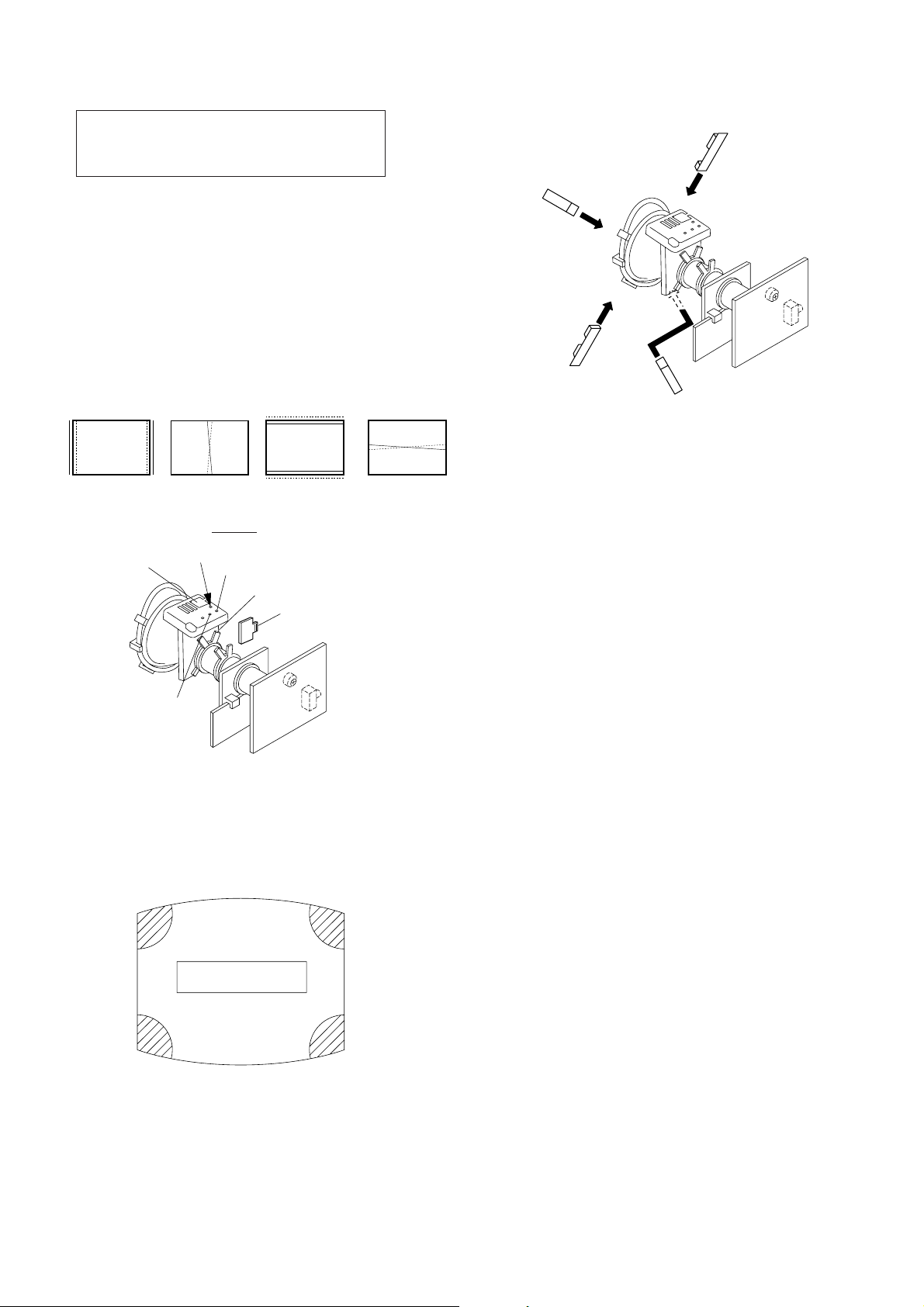

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield

or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

b

b

2 Using a thumb pull up the rubber cap firmly in the direction

indicated by the arrow b.

c

anode button

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be removed by turning

up the rubber cap and pulling it up in the direction of the

arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with sharp

shaped objects.

2 Do not press the rubber too hard so as not to damage

the inside of anode-cap.

A metal fitting called the shatter-hook terminal is built

into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage the

rubber.

– 7 –

Page 9

KV-DA322M64/M66

RM-GA001

2-1. JIGS REQUIRED FOR SERVICING

DESCRIPTION QUANTITY PART NO. REMARK

TOOL(50P-A),SERVICE 1 3-702-765-01 For A to BH1 board extension

SECTION 2

SERVICE JIG

SAMPLE

WL Board

DL Board

SECTION 3

CIRCUIT BOARDS LOCATION

C Board

H2 Board

BH1 Board

A Board

J1 Board

D Board

BP1 Board

H3 Board

VM1 Board

BC1 Board

F1 Board

– 8 –

Page 10

KV-DA322M64/M66

SECTION 4

ADVANCE OPERATION

4-1. "RESET" FUNCTION

1. Purpose

If a customer faces some setting problem that cannot be solved, using the "RESET" function some items will be

reset to its original setting or factory setting (shipping condition)

2. How to Operate

The following is to show on how to access to the "RESET" Function:-

User selection = press 'WEGA GATE' t selectt 'SETTING' t go to 'SETUP' page t select 'FACTORY

SETTINGS' t select 'YES'

3. Subsequent of Operation

RM-GA001

Sequential to the resetting operation, TV set would shut down once and automatically turn on again. The power-off

duration is expected to be about 500msec. Initial Setup Menu is displayed.

As a result, some items will be reset to their initial conditions (shipment condition) wheareas some others remain

at the last user selection.

Items that remain at the last user selection

Program No., PICTURE POSITION (included PICTURE

ROTATION and PICTURE V-POSITION), OSD Language, Fine

tuning,TV System, Skip, Program label, Program sorting, Video

label.

Reset Items

Category Default Category Default

Video input RF user last setting

Main Volume 25

DRC-MF DRC1250

Picture mode VIVID

3D Intelligent Picture ON

Sound mode DYNAMIC

Intelligent volume OFF

Surround OFF

Wide mode 4.3

Auto wide ON

Twin OFF

Program Index OFF

* Program Block Reset particular displayed

channel to unblock

WEGA Theatre Setup

Direct Input HD/DVD 1

Speaker Main

Game mode OFF (Video) *Not available in RF

mode

*Color System RF = Reset to Auto at the particular/displayed Video

= MI Reset to Auto CH, others keep user setting

Eco mode OFF

Wide mode Wide zoom

Auto wide ON

4.3 Default Wide zoom

V Center 00

V Size 00

Mute OFF

OSD Display status OFF

Center-in volume 25

Initial setup menu Reactivate/ON

Twin size Center

*= Will reset only if watched/displayed during RESET operation

- For Multi model only

– 9 –

Page 11

KV-DA322M64/M66

RM-GA001

SECTION 5

SET-UP ADJUSTMENTS

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows :

1. Beam Landing

2. Convergence

3. Focus

The controls and switch should be set as follows unless

otherwise noted:

4. G2(SCREEN)

5. White Balance

Picture Control....................................."NORMAL"

Brightness Control..............................."NORMAL"

Note : Test Equipment Required.

1. Pattern Generator 5. Oscilloscope

2. Degausser 6. Landing Checker

3. DC Power Supply 7. XCV Adjuster

4. Digital Multimeter

......................................................................................................................................................................................................................

Preparation :

•Feed in the white pattern signal.

6. Then move the DY forward and adjust so that the entire

screen becomes green.

• Before starting, degauss the entire screen with the

degausser.

• In order to reduce the geomagnetism on the set's picture

tube, face it east or west.

5-1. BEAM LANDING ADJUSTMENT

1. Input a raster signal with the pattern generator.

2. Loose the deflection yoke(DY) mounting screw, and set

the purity control to the center as shown below:-

Purity control

3. Position Neck Assy as shown below:-

Neck assy

(For 34")

Neck assy

(For 29" and 32")

Align the edge of

the neck assy with

the edge of the G2 grid.

G2G1 G3

4. Set the raster signal of the pattern generator to green.

5. Move the DY backward and adjust the purity control so

that green is in the center and blue and red are at the

sides evenly.

7. Now switch over raster signal to red then blue and

confirm the condition.

8. When the position of the DY is determined, tighten it with

the DY mounting screw.

9. If the beam does not land correctly in all the corners of

the screen, use magnet disc to correct it.

Purity control

corrects this area.

b

c

Deflection yoke positioning

corrects these areas.

a

d

a

d

b

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

c

Red

Blue

Green

– 10 –

Page 12

KV-DA322M64/M66

RM-GA001

5-2. CONVERGENCE ADJUSTMENT

Preparation:

• Before starting, perform FOCUS adjustment.

• Receive dot/cross hatch pattern.

• Picture Mode "CUSTOM" (PIC 90%, BRT 50%,

COL 50%, HUE 50%, SHP 50%).

a) Vertical Static Convergence

Center dot

R G B

R

G

B

4 pole

magnet

Y magnet

RV9001

4-pole

b) Horizontal Static Convergence

If the blue dots does not converge with the red and

green dots, use the 6 pole magnet to adjust in

the manner described below:-

RG B R G B R GB

RB

G

RG

6 Pole

Magnet

GB

RB

6 Pole Magnet

Purity

C Board

1. (Moving vertically), adjust the 4 pole magnet to converge

red, green and blue dots in the center of

the screen.

2. Tilt the 4 pole magnet and adjust static convergence

to open or close the 4 pole magnet.

3. When the 4 pole magnet is moved in the direction of

arrow A and B, the red, green and blue dots moves

as shown below:-

a

A

B

B

B

G

R

b

B

G

R

Moved RV9001 (H.STAT)

DY pocket

4 Pole Magnet

4 Pole

Magnet

c) Y Separation axis correction magnet adjustment.

1. Receive cross hatch signal.

2. Set Picture to "MINIMUM", Brightness to

"STANDARD".

3. Adjust the Y separation axis correction magnet on

the Neck Assembly so that the horizontal lines at

the top and bottom of the screen are straight.

Blue

Neck assy Neck assy

Red

Red

Blue

RGGRB

Red

B

VM1 Board VM1 Board

Blue

– 11 –

Page 13

KV-DA322M64/M66

RM-GA001

d) Convergence Rough Adjustment

Preparation:

• Before starting this adjustment, adjust the

horizontal and vertical static convergence.

Input cross hatch pattern.

i) TLH

Adjust the horizontal convergence of red and blue

dots by inserting TLH Correction Plate to the DY

pocket(left or right).

ii) YCH

Adjust YCH to balance Y axis.

iii) TLV

Adjust the vertical convergence of red and blue dots.

iv) XCV

Adjust XCV to balance X-axis

B

R

TLH

RB

YCH

ON DY:

B

R

TLV

Fix a Permaloy Assy Correction

to the misconverged

a

d

Permalloy assembly

R

B

a to d: Piece B(120), Convergence Correct

or

b

c

Permaloy Assy Correction

XCV

H-TRAP

XCV

YCH

TLV

DY pocket

TLH Plate

e) Screen Corner Convergence

Affix a Piece B(120), Convergence Correct/Permaloy

Assy

Correction to the misconverged areas.

.

ba

a-d : screen-corner

misconvergence

cd

– 12 –

Page 14

KV-DA322M64/M66

RM-GA001

5-3. FOCUS ADJUSTMENT

FOCUS adjustment should be completed before White

Balance adjustment.

1. Receive digital monoscope pattern.

2. Set Picture Mode to "STANDARD".

3. Adjust focus VR so that the center of the screen

becomes just focus.

4. Change the receiving signal to white pattern

and blue back.

5. Confirm magenta ring is not noticeable. In case

magenta ring is obvious, then adjust FOCUS VR

to balance magenta ring and FOCUS.

Lead Assy,

Focus

5-5. SUB BRIGHTNESS ADJUSTMENT

1. Set TV to RF Mode.

2. Input PAL monoscope to RF mode (OTHER model) and

NTSC monoscope (NTSC model).

3. Set the following condition:

i) Set "PICTURE MODE" to "CUSTOM" and adjust

PICTURE to 0% and BRIGHTNESS to 50%.

ii) Receive RF PAL monoscope signal

(RF NTSC monoscope: NTSC models)

iii) Adjust Sub BRT (service item COLR 008 SBRT)

to make 10 IRE Slightly glimmer.

iv) Apply the offset steps according to TV size as in Sub

Brightness offset table

Preset constant

Inch R/G B/G

34" 0.745 0.905

32" 0.775 0.915

29" 0.790 0.903

Sub Brightness offset

Inch Offset

34" Adjusted + 3 Steps

32" Adjusted + 3 Steps

29" Adjusted + 6 Steps

Focus

G2 Adjustment

FLYBACK TRANSFORMER (T6805)

5-4. G2 (SCREEN) ADJUSTMENTS

1. Set the following condition:

- Picture and Brightness to "STANDARD".

- TV to Video mode.

- WHBL 16 "RGBB" to 01.

2. Connect R,G,B of the C board cathode to

oscilloscope.

3. Adjust Brightness to obtain the cathode value

to the value stated below.

Cathode setting voltage:

170 V ± 2 (VDC)

4. Adjust SCREEN VR on the FBT until the scanning line

disappears.

5. Finally set WHBL 016 "RGBB" back to 00.

5-6. WHITE BALANCE ADJUSTMENT

1. Set to Service Mode.

2. Input white raster signal using signal generator.

3. Set the following condition:

i) Receive 100 IRE PAL white signal.

ii) Set to "VIVID" mode.

SADJ 003 COL 60 ➔ 00

iii) Adjust White Balance

COLR 003 GDRV

004 BDRV

006 GCUT

007 BCUT

4) i) Receive PAL ALL White signal (10 uit)

ii) Set to "VIVID" mode

SADJ 003 COL 00 ➔ 100

iii) Adjust color offset

MCP 010 CBOF

011 CROF

– 13 –

Page 15

KV-DA322M64/M66

oNemaNtiB

CRD

golanAIVD

CY/VC/SB/FRi084-PMOCp675/p084p027i0801rehtOCRDp084p027i0801AGV

01FOBC2-7detsujdA4-detsujdA4-detsujdA2+detsujdA2+detsujdA432383230434

11FORC2-7detsujdA5-detsujdA3-detsujdA3+detsujdA3+detsujdA738334838484

oNemaNtiB

BGR/CSTA/latigiD

SM

niwT

CRDp084p027i0801

01FOBC2-73+detsujdA1+detsujdA6-detsujdA5+detsujdA043+detsujdA

11FORC2-77+detsujdA7+detsujdA0+detsujdA31+detsujdA842-detsujdA

RM-GA001

iv) Apply the offset steps according signal as in Ta b le below : White Balance Offset

– 14 –

Page 16

SECTION 6

CIRCUIT ADJUSTMENTS

6-1. ADJUSTMENTS WITH COMMANDER

Service adjustments to this model can be performed using the supplied remote commander RM-GA001.

a. ENTERING SERVICE MODE

With the unit on standby

t [DISPLAY] t 5 t [VOL $+% ] t [POWER]

This operation sequence puts the unit into service mode.

This screen display is:

item no. service data NVM service field channel no./

category in decimal item name in decimal NG command frequency video input name

WHBL 000 WBP 000 x SERVICE 50 S VIDEO 1

KV-DA322M64/M66

RM-GA001

release ID version in binary for factory color system (decimal)

CGA01 0.16M 0000 0000 FF FF NTSC3 00100

S_ _ : for SONY

A_ _ : for AIWA

L_ _ : BX1L Full

B_ _ : BX1L Basic

D_ _ : DVD Combo

C_ _ : CX1

Z_ _ : Sound special

_ _ _01 : Serial no. of the M/P release for each

_ _ _10 ~: use for FY04 BX1

_ _SB : Sub Hercules

software service data reserved power on time

For BP1 Board Version; and PF Engine Version;

Category and release ID will be different.

The rest are the same.

destination

BP1 Board Version

category in decimal name

SUBP 000 IDXH

release ID version

CBP01 0.06

PF Engine Version

category in decimal name

9090 000 UOF

release ID version

PF 0018M

item no. item

software

item no. item

software

b. METHOD OF CANCELLATION FROM SERVICE MODE

Set the standby condition (Press [POWER] button on the commander), then press [POWER] button again, hereupon it becomes

TV mode.

c. METHOD OF WRITE INTO MEMORY

1. Set to Service Mode.

2. Press 1 (UP) and 4 (DOWN), to select the adjustment item.

3. Change item by pressing 3, 6.

4. Press [MUTING] button to indicate WRITE on the screen.

5. Press - button to write into memory.

1, 4 Select the adjustment item.

r

3, 6 Raise/lower the data value.

r

[MUTING] Writes.

r

- Executes the writing.

– 15 –

Page 17

KV-DA322M64/M66

RM-GA001

d. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, pull out the plug from AC outlet, and then plug into AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confirm adjustments were made.

e. OTHER FUNCTION VIA REMOTE COMMANDER

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

Display, - Service data initialization (Be sure not to use usually.)

2, 5 Select Device or Category

6-2. ADJUSTMENT METHOD

Item Number 000 HPOS

This explanation uses H POSITION as an example.

1. Select "000 HPOS" with the 1 and 4 buttons, or 2 and 5.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is IF for PAL reception.)

4. Write with the [MUTING] button. (The display changes to WRITE.)

5. Execute the writing with the - button. (The WRITE display will be changed to red color while executing, and back to

SERVICE.)

Example on screen display :-

GREEN

WHBL 000 WBP 000 SERVICE 50 VIDEO 1

Adjusted with [3] and [6] buttons.

GREEN

WHBL 000 WBP 000 WRITE 50 VIDEO 1

write with [MUTING].

RED

WHBL 000 WBP 000 WRITE 50 VIDEO 1

Write executed with [0].

The WRITE display

then returns to green

SERVICE

Use the same method for all Items. Use 1 and 4 to select the adjustment item, use 3 and 6 to adjust, write with

[MUTING], then execute the write with -.

Note : 1. In [WRITE], the data for all items are written into memory together.

2. For adjustment items that have different standard data between 50Hz or 60Hz, be sure to use the respective input

signal after adjustment.

– 16 –

Page 18

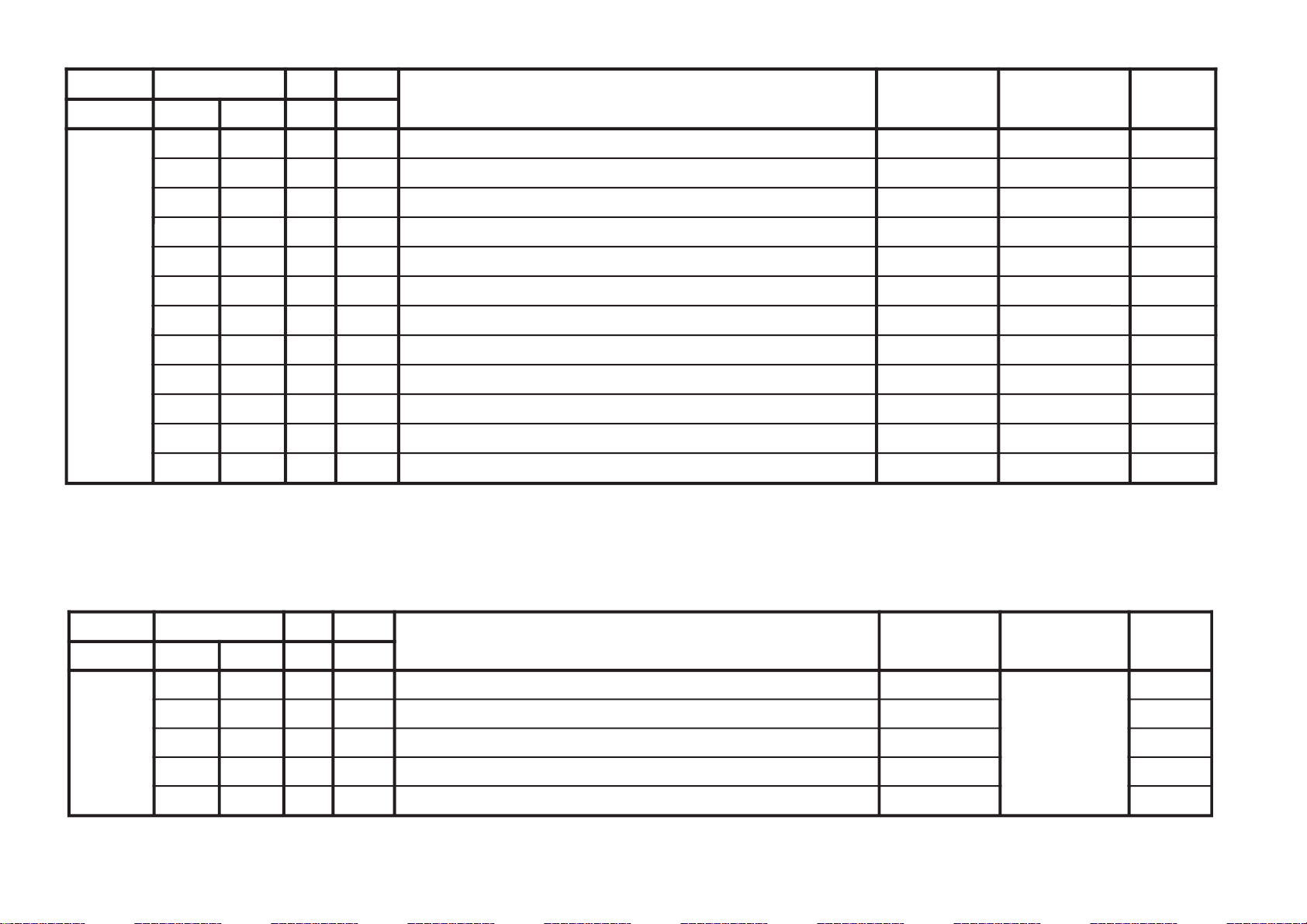

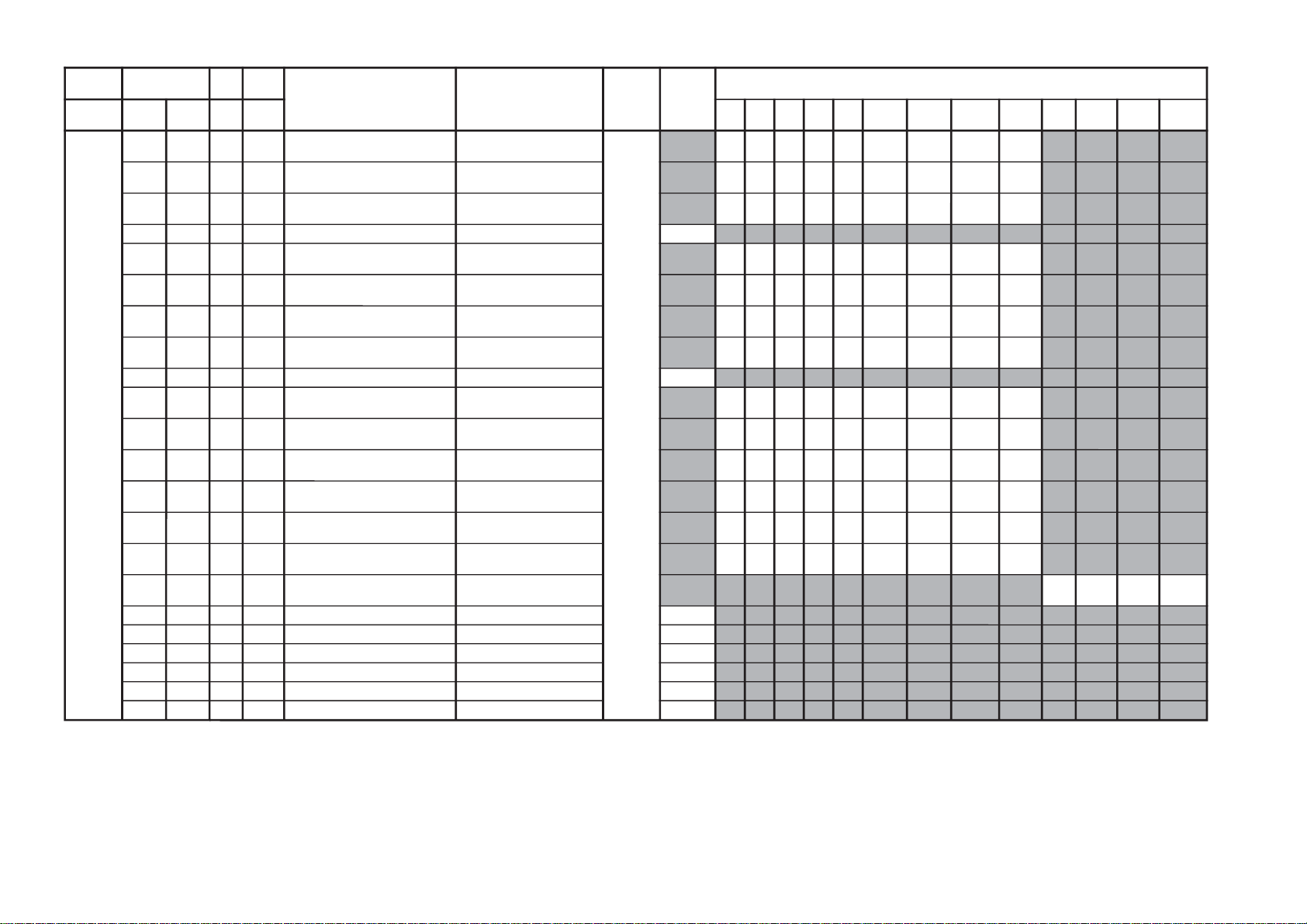

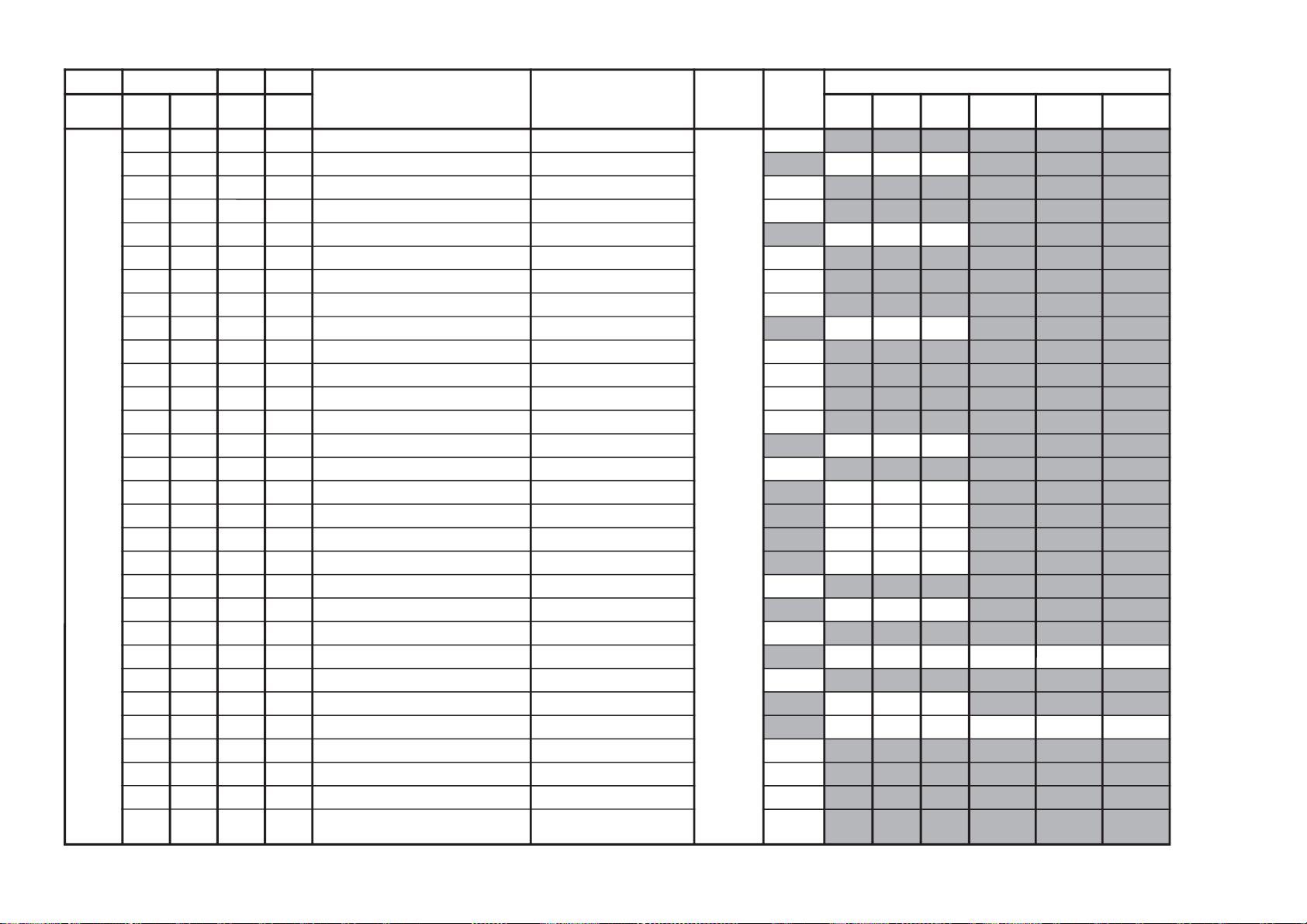

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD srehtOVUY)VT(LAP)VT(CSTN)VT(MACES)oediV(LAP)oediV(CSTN)oediV(MACESTUPNI-SMACESCSTN

CY000YLDY210510yaleD-Y TUPNI-S/VUY+)OEDIV/VT(*)MACES/CSTN/LAP(cimsoC

0011606001* 6001

100TAMC000300xirtaM)ASU/napaJ(CSTNroMACES-LAP 00

200LCA100100gnitimiLroloCcitamotuA 10

300BC000100ycneuqerFretneCssapdnaBamorhC )xif0:oediV*(VThtiwylnodilav00

400OBS100300tesffOkcalBMACES 10

500ESHC100300ytivitisneStnedICSTN/LAP 30

600OLC000100retliF)lleB(ehcolCfoycneuqerFretneC 00

700PRTC000100edoMparTamorhC srehto/MACES

00

10

800SPB000100eniLyaleDdnab-esaBamorhCfossapyB srehto/CSTN

00

*

900OCF000100nOroloCdecroF 00

Adjustment Item Ta ble (Main Micon)

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

pmeTloC

)rehtoHGIH(

pmeTloC

)rehtoWOL(

pmeTloC

)rehtoMRON(

pmeTloC

)VUYHGIH(

pmeTloC

)VUYWOL(

pmeTloC

)VUYLAMRON(

pmeTloC

)BGRHGIH(

pmeTloC

)BGRWOL(

pmeTloC

)BGRMRON(

0edomciP1edomciP2edomciP

LBHW000PBW000300)woL:3,2,lamroN:1,hgiH:0(gnitteSpmeTroloC edoMerutciPcimsoC

001010

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

edomciP

0

edomciP

1

edomciP

2

VToediVlamroN

)3:4(

DHxednI/niwT

paP/

rehtO

JDAS000EUHS700510euH-buS oediV/VT

4080

100FOIP000700)%57(ocE*02/)atad-02(*erutciP(tesffOerutciP REHTO/ITLUM/LAMRON/SMenignEFP

** * *

200CIP130721

0[lortnoCerutciP

-

])CSTN(36-0,)ITLUM(001

)ataDteseRresU=lanosreP:AG(ledoMerutciP

0010705

300LOC130721])CSTN(36-0,)ITLUM(001-0[lortnoCroloC )ataDteseRresU=lanosreP:AG(ledoMerutciP

060605

400TRB130721])CSTN(36-0,)ITLUM(001-0[lortnoCssenthgirB )ataDteseRresU=lanosreP:AG(ledoMerutciP

050505

500EUH130721])CSTN(36-0,)ITLUM(001-0[lortnoCeuH )ataDteseRresU=lanosreP:AG(ledoMerutciP

050505

600PHS130721]])CSTN(36-0,)ITLUM(001-0[lortnoCssenprahS )ataDteseRresU=lanosreP:AG(ledoMerutciP

050505

NOTE

a) In the initial value (detailed) colomn, the data after the slash mark ("/") refers to NTSC model data.

No ("/") means data is common for Multi and NTSC model.

b) Item remarked "*" and "**", please refer page 32 for the data.

c)

shaded items are no data.

d) Standard data listed on the Adjustment Item Tab le are reference values, therefore it may be different for each model and for each mode.

e) Note for the Different Data those are the standard data values written on the microprocessor. Therefore, the data values of the models are stored respectively in the memory.

In the case of a device replacement, adjustment by rewriting the data value is necessary for some items.

f) Multi ver1.07.

– 17 –

KV-DA322M64/M66

RM-GA001

Page 19

– 18 –

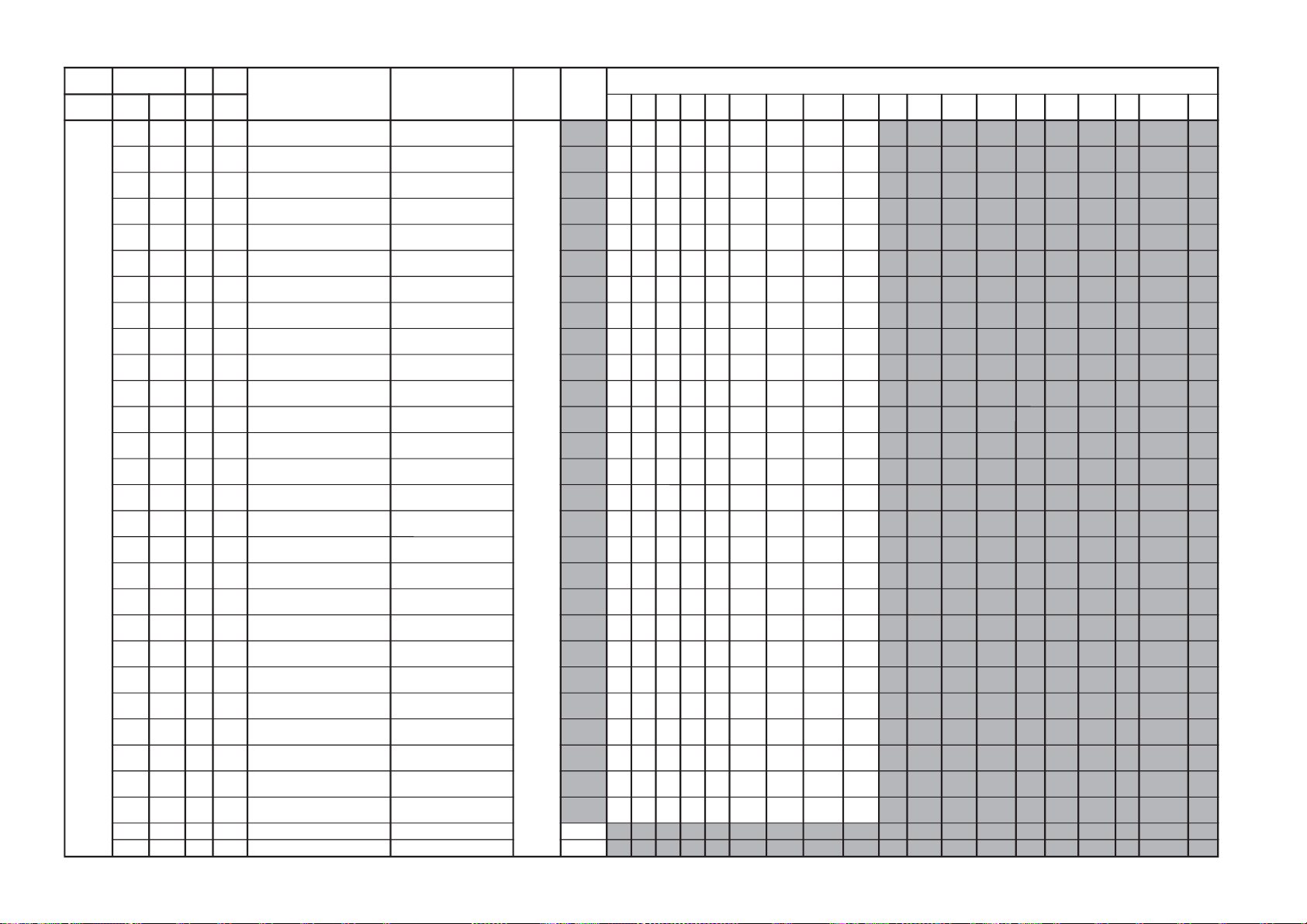

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0506srehtOVUYVToediVtxeteleTpi-VTlangiSoN

CNYS000SYS000100tupnICNYSYnonoitazinorhcnyS cimsoC00

100OF

000300tnatsnoCemiT1esahP

)FR(langisoNrogninuTotuA/txeteleT/oediV/FFOPIVT/NOPIVT

3030100000

200DIV000100edoMtnedIoediV 06/05

0000

300LSF000100cnySlacitreVrofleveLgnicilSdecroF 00

400LSS000100rotarapeScnySleveLgnicilS 06/05

0000

500DIVS100700noitacifitnedIoediVrofnoitceleSecruoS srehtO/VUY

0000

600FROF200300ycneuqerFdleiFdecroF 20

700KVM000100gniyeKnoisiVorcaM 10

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

srehtOBGReviLVT

)nyD(

VT

)srehtO(

oediV

)nyD(

oediV

)srehtO(

pmeTroloC

)HGIH(

pmeTroloC

)srehtO(

roloC

)WOL(pmeT

pmeTroloC

)LAMRON(

TCIP000AFC000300edoMretliFbmoC cimsoC00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD VUYVToediV

WS0002VC000100noitceleSlangiStupnI2SBVC cimsoC00

100OVS10030084@niPISBVC/OVS/OVFIfonoitcnuFVUY/oediV/VT

201010

200LFD000100noitcetorPhsalF 10

300FTNI000100langisecafretniVUYfoytiraloP/edutilpmA 00

KV-DA322M64/M66

RM-GA001

Page 20

– 19 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

MEDS000SWMF000300rotaludomeDMFrofnoitceleSwodniW cimsoC20

100SSQ100100 )metsysMitlumAGrofA/N(edoMreifilpmA)SSQ(dnuoStilpSisauQ *

200BPB000100retliFssapdnaBdnuoSfossapyB 00

300OLMA000100dnuoSMAroflangiStuptuOoiduA 00

400CVPH000100lortnoCemuloVenohPdaeH 00

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

FIV000DFIO630360rotaludomeDFItesffO cimsoC63

100TCGA130360revo-ekaTCGA 72

200MTS000100edoMgninuThcraeS 10

300DG000100langiS1SBVCnoyaleDpuorG 00

400SCGA100300deepSCGAFI 10

500IFF000100LLPFIretliFtsaF 00

600IANL100100eulavlaitinitibANLpmAFR 00

700TANL591552leveLdlohserhTpmAFR 591

800NSNL400700dlohserhTleveLNSpmAFR 40

900DSNL200700dlohserhTporDleveLNSpmAFR 10

010XENL610360gnimiTporDNSkcehcpmAFR 03

110RTHC840721edoMresUpmAFRtesotgrPotuAretfadlohserhTlennahC 52

Note: For remark "*", refer to page 32.

KV-DA322M64/M66

RM-GA001

Page 21

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

TXT000VXT930360spilihProfnoitisoPlacitreVtxeteleT ossaciP93

100DHT010721tfihSegdEevitcAcnys-HtxeteleT 11

200RBT820130)edomllufrof(ssenthgirBBGRtxeteleT 82

300MRBT310130)edomXIMrof(ssenthgirBBGRtxeteleT 31

400DTSN000100)edomXIMotog:1,TXTlecnac:0(langiSdradnatSnoNfoM/C 00

500QCA000100)1-LAP,0-otuA(noitisiuqcAtxeteleT 00

(only for model with teletext function)

– 20 –

KV-DA322M64/M66

RM-GA001

Page 22

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD )oruE(L-VTVToediVffOWOW/SRSdnuorrusurToeretsIonomI

PSDS000LBB000510ruotnoCEBB dnuoS

PSD

*

100HBB000510ssecorPEBB *

200WLBB000510tesffOruotnoCEBB *

300FOVS000510tesffOemuloVedoMtceffE/dnuorruS onomI/oeretsI/dnuorrusurT/)WOW/SRS(ffO

4090406040

400DAL000130tsujdAleveLredoceD 40

500MAL000130tsujdAleveLonoM 40

600NAL000130tsujdAleveLmaciN *

700SAL000130tsujdAleveLPAS 80

800AAL000130tsujdAleveLCDA oediV/Lnon-VT/L-VTI)oruEnoN(oediV/vT

717100

900FES300700tceffEoeretS/onoMelbidercnI onomI/oeretsI

5030

010SAB000510tesffOssaBniaM *

110ERT000510tesffOelberTniaM *

2101QE000510tesffO)zH001(dnaBlennahCniaMrezilauqE *

3102QE000510tesffO)zH003(dnaBlennahCniaMrezilauqE *

4103QE000510tesffO)zH0001(dnaBlennahCniaMrezilauqE *

5104QE000510tesffO)zH0003(dnaBlennahCniaMrezilauqE *

6105QE000510tesffO)zH0008(dnaBlennahCniaMrezilauqE *

710TCFB500700lortnoCEBBdnaBUD,EBD 50

810NECS100510lortnoCretneCD3SRS 40

910APSS000510lortnoCecapSD3SRS 10

020WHBB000510edomWOWnitesffossecorpEBB *

120ERTS200700edomdnuorrusroftesffOelberT 10

220THBB000510edomVTnitesffOEBB 00

320ERTT200700edoMVTnitesffOelberT 30

4201QEC800510)zH001(ataDdnaBrezilauqEnI-retneC 60

5202QEC800510)zH003(ataDdnaBrezilauqEnI-retneC 90

6203QEC800510)zH0001(ataDdnaBrezilauqEnI-retneC 01

7204QEC800510)zH0003(ataDdnaBrezilauqEnI-retneC 01

8205QEC800510)zH0008(ataDdnaBrezilauqEnI-retneC 70

– 21 –

KV-DA322M64/M66

RM-GA001

Page 23

– 22 –

JVTytilanoitcnuF.tinIegnaRnoitcnuF etoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

CEDS000UTPS300510noitcetedreirracPASrofdlohserhTreppU dnuoS

PSD

80

100LTPS600510noitcetedreirracPASrofdlohserhTrewoL 51

200HTPS000130PASfoetumotuarofdlohserhTesioN 00

300YHPS400510PASfoetumotuarofezissiseretsyH 30

400HTMF000130dradnats2AMFni2CSfoetumotuarofdlohserhTesioN 81

500YHMF400510dradnats2AMFni2CSfoetumotuarofezissiseretsyH 70

600ELIN001552)PEDD(timilrorrerewolMACIN 05

700EUIN002552)PEDD(timilrorrereppuMACIN 002

800DMPE100300)PEDD(gnimmargorPysaECEDMED

1=1tiB3POdna0=SDTSdna0=DMPEfI

revoekatlliwyrogetacCKDSdnaelbasiDsiyrogetacCEDS

*

900SDTS910130sedomSSSdnaDSArofdexelpitlumstiB *

010AMVO100100noitpadanoitaludomrevoMF 00

110WBLF000300htdiwdnabretlifrotaludomedMA/MF 30

210DMDI000300edomSSSnideepstnediMF 00

310TMVO100200lanimonotevitalerdlohserhtlevelnoitaludomrevO 30

410IXCD000100retrevnIlortnoCgnilacSOXCDMACIN *

510GXCD000700niaGlortnoCgnilacSOXCDMACIN *

610LLCD110510)L(timiLlortnoCgnilacSOXCDMACIN 00

710HLCD000130)H(timiLlortnoCgnilacSOXCDMACIN *

810RKDI100300DTSMnaeroKrofgnittesDOMDI 00

JVTytilanoitcnuF.tinIegnaRnoitcnuF etoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

CKDS000LLNK000552etyBrewoLdlohserhTrewoLteDesioNnaeroK

1=1tiB3POdna0=SDTSdna0=DMPEfI

revoekatlliwyrogetacCKDSdnaelbasiDsiyrogetacCEDS

100HLNK210552etyBrehgiHdlohserhTrewoLteDesioNnaeroK

200LHNK000552etyBrewoLdlohserhTreppUteDesioNnaeroK

300HHNK020552etyBrehgiHdlohserhTreppUteDesioNnaeroK

400CILK060552tnuocgniniatniamDItoliPtsoLnaeroK

500MILK100721reilpitlumtnuocgniniatniamDItoliPtsoLnaeroK

600CDSK600552tnuoCtceteDoeretSnaeroK

Note: For remark "*", refer to page 30~31.

(only applicable for Korea model)

KV-DA322M64/M66

RM-GA001

Page 24

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTeciveD

emaN

nommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

0RN1RN2RN3RN4RN0CSTN1CSTN1RN-FR-FR

1CSTN

-VT

LAP

-VT

CSTN

OEDIV

LAP-

-OEDIV

CSTN

RN3

000TED3000700TEDD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

bmoCD3

707070707070707070

100ROC3000100RROCRND3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

100000000010000000

200CFA000300NIAGCFA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

303030303030303030

300GEH000300NIAGAHNEH 00

400RNC2000510MILRNCD2&KRNC-D2

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

003050509020003000

500CNY000700MILCN-Y;RELLECNACESIONY

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

003030507020103030

600RNY2000510NIAGRNYD2;KRNYD2

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

000020008010102000

700LNY2000300MILRNYD2

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

002030003020203030

800KLB000300PXEKLB 10

900RNC3000700MILRNCD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

000030307000000000

010KNC3000300KRNCD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

000000000000000000

110GNC3000700NIAGRNCD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

002020207000004000

210RNY3000700MILRNYD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

003030606000001000

310KNY3000300KRNYD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

001020000000001030

410GNY3000700NIAGRNYD3

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

002050606000001000

510YLDY000821YALEDTUPTUOY

/LAP-DIV/CSTN-VT/LAP-VT

CSTN-S/LAP-S/CSTN-DIV

30706040

610ACI000100OTUAPMALCTNI 10

710MCI000100LAUNAMPMALCTNI 00

810HNEC000100AHNEC 10

910KCI000100YEKPMALCTUPNI 10

020KGB000100YEKETAGTSRUB 10

120LSS000100FPLPESCNYS 00

– 23 –

KV-DA322M64/M66

RM-GA001

Page 25

KV-DA322M64/M66

JVTytilanoitcnuF

.tinIegnaRnoitcnuFetoN&elbaTeciveD

emaN

nommoC )deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD

0RN1RN2RN3RN4RN0CSTN1CSTN1RN-FR-FR

1CSTN

-VT

LAP

-VT

CSTN

OEDIV

LAP-

-OEDIV

CSTN

-S

LAP

-S

CSTN

lamroN

)3:4(

DHxednI/niwT

paP/

rehtO

RN3

220RCEV000300EROCAHNEV

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

bmoCD3

001010300000101010

320GEV000300NIAGAHNEV

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

000010100000100010

420NEV000300LNAHNEV

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

000010100000100010

5201PMA0007001PMADH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

606060606060606060

620VGDH000130VNIAGDH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

818181818181818181

7202PMA0007002PMADH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

606060606060606060

8201GDH0001301NIAGDH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

313131313131313131

9203PMA0007003PMADH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

505050505050105050

0302GDH0001302NIAGDH

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

404040404040104040

130PLSC000510PLSSCA&PLSMCA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

514101015101010101

230PLSY000510PLSSYA&PLSMYA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

515101400141414141

330SMCA000510TESFMCA&TESEMCA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

510101015151510151

430SSCA000510TESFSCA&TESESCA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

510101015151010101

530SMYA000510TESFMYA&TESEMYA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

511101015151511151

630SSYA000510TESFSYA&TESESYA

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

511141015111014101

730LSCB000510PLSSCB&PLSMCB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

51

0101015141510151

830LSYB000510PLSSYBPLSMYB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

510101015141310121

930SMCB000510TESFMCB&TESEMCB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

510101015151010101

040SSCB000510TESFSCB&TESESCB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

510101015151010101

140SMYB000510TESFMYBTESEMYB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

515101015151515151

240SSYB000510TESFSYBTESESYB

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

515101015151015101

340MCEC000700PMCEC

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

704070704040407040

440MCSC000510PMCSC

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

510151510000005100

540VH1F000510REV1F&REH1F

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

508050505050508050

640FERM000510FERM

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

207040404010607060

740YEDC000300EYEDC

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

203020202020003000

840YEDY000300EYEDY

/1tN/0TN/3RN/2RN/1RN/0RN

1CSTN-FR/1RN-FR

203020202020003000

940SAMH000700TUOKSAM-H

00

050SAMV000130TUOKSAM-V

00

RM-GA001

– 24 –

Page 26

GVTytilanoitcnuF

laitinIegnaRnoitcnuFetoN&elbaTeciveD

emaN

nommoC

)deliateD(eulaVlaitinI

yrogetaCoNemaNceDceD

ciP

0edom

ciP

1edom

ciP

2edom

FRtpecxE

0edomciP

FRtpecxE

1edomciP

FRtpecxE

2edomciP

ITL000SFC100100noitceleSretliFruotnoC 10

100CDV100100gniroCtnednepeDoediVedoMerutciP

101010

200MED000100edoMnoitartsnomeD 00

300PDC400700yaleDecnanimuL 40

400KSD000100hctiwSenoTnikSedoMerutciP

000000

500KSA000100noitceleSelgnAenoTnikS 00

600KSW000100noitceleShtdiWenoTnikS 00

700KSS000100noitceleSeziSenoTnikS 00

800RGD100100hctiwStnemecnahnEneerGedoMerutciP

101000

900TGD700700hctiwStnemecnahnEneerGfodlohserhT 70

010RGG000100niaGtnemecnahnEneerG 00

110RGW000100htdiWtnemecnahnEneerG 00

210RGS000100eziStnemecnahnEneerG 00

310SDC100100ssenprahStnednepeDroloCedoMerutciP

101000

410TSC700700ssenprahStnednepeDroloCfodlohserhT 70

510ITC100100tnemevorpmItneisnarTroloCedoMerutciP

101000

610NOB000100noitasnepmoCtesffOkcalBedoMerutciP

000000

710DTB000360htcertSkcalBevitpadAedoMerutciP

000000

810DLN120360reifilpmAytiraeniL-noNedoMerutciP

121200

910WLN700700reifilpmAytiraeniL-noNfohtdiWpetS 70

020DGV130360ammaGelbairaVedoMerutciP

***

120WGV000700ammaGelbairaVfohtdiWpetS 00

220DKP040360edutilpmAgnikaeP)srehtO/VT(*edoMerutciP

*0341 ***

320WKP800510edutilpmAgnikaePfohtdiWpetS 80

320DPS000360noitcerroCssenpeetSedoMerutciP

000000

520DRC050360leveLgniroC)srehtO/VT(*edoMerutciP

*0300* 8100

620WRC900510leveLgniroCfohtdiWpetS 60

720ORC600510edoMoediVroftesffOleveLgniroC 60

820DWL130360noitcerroChtdiWeniL 13

920ITLE100100

ITLelbasiD/elbanE

]noitpo1XC-tsoP[lortnoc

10

– 25 –

KV-DA322M64/M66

RM-GA001

Page 27

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

DEFP000DEFP000100edoMecivreSenignEFPenignEFP

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0506

PBUS000HXDI500510noitisoplatnozirohDSOxednIataDtimsnarTossaciPbuSossaciPbuS50

100VXDI740360noitisoplacitrevDSOxednI)06/05(ataDtimsnarTossaciPbuS7474

200BXDI130130ssenthgirbDSOxcednIataDtimsnarTossaciPbuS13

(only applicable for 2 tuners models)

– 26 –

KV-DA322M64/M66

RM-GA001

Page 28

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD 0506VUYVToediVlangiSoN

SOCS000SYS100100tupnICNYSYnonoitazinorcnyS cimsoCbuS00

100OF000300tnatsnoCemiT1esahP )FR(langisoNrogninuTotuA/VT

003000

200DIV100100edoMtnedIoediV 06/05

0000

300LSF000100cnySlacitreVrofleveLgnicilSdecroF 00

400LSS000100rotarapeScnySleveLgnicilS 06/05

0000

500DIVS000700noitacifitnedIoediVrofnoitceleSecruoS VUY/oediV/VT

000000

600FROF300300ycneuqerFdleiFdecroF 20

700OVS00030084@niPISBVC/OVS/OVFIfonoitcnuF VUY/oediV/VT

000000

800EXDV

000100dnareifilpmaFInoisivneewtebgnilpuocfolortnoC

tiucricnoitasinorhcnys

00

900XDV

000100dnareifilpmaFInoisivneewtebgnilpuoC

tiucricnoitasinorhcnys

00

010YLDY210510tnemtsujdayaled-Y 00

110DFIO630360rotaludomeDFItesffO 63

210TCGA130360revo-ekaTCGA 13

310MTS100100edoMgninuThcraeS 10

410DG000100langiS1SBVCnoyaleDpuorG 00

510SCGA100300deepSCGAFI 10

610IFF000100LLPFIretliFtsaF 00

710SSMC000100tiucrictnedioedivehtroflangistupnicnysfonoitceleS 00

810PMAO300300edutilpmAlangiStuptuOoediV 00

910IAV000100noitcerroCedutilpmAlangiStuptuOImetsyS 00

020SWMF200300rotaludomeDMFrofnoitceleSwodniW 20

120SSQ

000100edoMreifilpmA)SSQ(dnuoStilpSisauQ

)ledoMAGtpecxe(

10

220BPB000100retliFssapdnaBdnuoSfossapyB 00

3202BPB0001002retliFssapdnaBdnuoSfossapyB 00

420TPS000100edomkcirtecnamrofrepcnyS 00

520D2E000100nipMEEDUAnolangistuptuooiduafonoitceleS 00

620CVPH000100lortnoCemuloVenohPdaeH 00

720GSD000100stuptuooiduaotstupnioiduamorfniaG 00

820DSV100100elbasidnacslacitreV 00

920ESHC100300ytivitisneStnedICSTN/LAP 30

– 27 –

(only applicable for 2 tuners models)

KV-DA322M64/M66

RM-GA001

Page 29

– 28 –

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

VTH100XAMV000360)XAMV+53=XAM(leveLemuloVmumixaM leveLemuloV00

200INIV520130norewoptaleveLemuloVlaitinI leveLemuloV52

300YBTS000100 )YBTSsyawla=1,sutatsrewoptsalehtwollof=0(sutatSrewoPtsaL rewoPtsaL00

400GRPI100721)sledomitluMrofylno(norewoptarebmuNmargorPlaitinI

ot0:lageL(rebmuNmargorP

)1otteserlliw,001>fi,99

10

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

MTPO000THSA600700)nim5*atad(remitffotuhsotuA 00

100ETUM000100)delbane=1(hctiwSetuMlangiSoN 00

200LUFR510510)hf0nehwelbasiD(dekcolnUretfaretnuoCegnahClangiSFR 40

300KLFR510510)hf0nehwelbasiD(dekcoLretfaretnuoCegnahClangiSFR 00

400GNAL000300noitidnocgnippihsegaugnalDSO *

500TXTH000100wsrotarapescnyS cimsoC00

600SSMC000100wscnyS cimsoC10

700OXCD060592eulaVOXCD ossaciP*

800CSID821552cedrolocybtsujdaOXCDrofatadOCSIDtegraT 431

900LBXE000510esioNetihWetanimilEotremiTgniknalBdednetxE 01

010SYST000300 )ledoMAG(]M:3,K/D:2,I:1,G/B:0[teseRtseTtaMVNnisySVTeziromeM *

110LBL100100noitidnoclangiSoNtAnoitcudeRssenthgirB 10

210P32100100otuA:1,FFOecroF:0edoMnwoDlluP3/2 enignEFP10

310WSNL100100)ffO:0,otuA:1(noitidnocteseRtseT/gnippihSretsooBlangiS 10

410MTSD000100)elbasid:1,elbane:0(ybdnatSniedompotselbasiD 00

510MPSC000100)elbasid:1,elbane:0(yromeMtsaLrekaepSretneCelbanE 00

610WSRN100200)HGIH-2,woL-1,FFO-0(noitidnoCgnippihSretfagnitteSRN *

Note: For remark "*", refer to page 30~31.

KV-DA322M64/M66

RM-GA001

Page 30

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC)deliateD(eulaVlaitinI

yrogetaC.oNemaNceDceD srehtOVUY

SUPO000FFOS000100)noCAhtiwybdnats:1,noCAhtiwyromemtsalwollof:0(ffoyatS

100RBCC510130ssenthgirBDSOCC

200HCPS100721noitidnoCgnippihSretfarebmuNlennahC

300ACPS100100)nOelbaC=1(noitidnoCgnippihSretfanoitceleSelbaC

400VUO000100)SUrofylno(slangiStupnIVUnolortnoCtesffO VUY/srehtOcimsoC

5002AFC000100)SUrofylno(nOretliFbmoCdecroF enoncimsoC

(only applicable for NTSC models)

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoCsrehtOMACESCSTN

yrogetaC.oNemaNceDceD

PVPO000SBPB000100)SBPB(edomoeretstaretlifssapdnabdnuosfossapyB cimsoC00

100CYWB000100)CYMB(metsysroloczHM85.3rofedomCYtahtdiwdnaB 00

200BSO000100)BSO(rotaludomedamorhcfoeslupyektsrublanretnifohtdiW 00

300VUYT000100)VUYTXT(noitcelestuptuoCC/TXT 10

400DCL000100)DCL(edoMDCL 10

500CKB000100noitisoPyeKtsruB )LAP(SREHTO/MACES/CSTN

001000

JVTytilanoitcnuF.tinIegnaRnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD

BTPO000LLAI000100)MVNnideziromemton(hctiwSetirWdradnatS X

1001BPO000552)detalerlangiSoediV(1noitpO

tibnoitporoF(

otreferatad

)43~33segap

2002BPO000552)detalergnidoceDoeretS(2noitpO

3003BPO000552)suoenallecsiM(3noitpO

4004BPO000552)suoenallecsiM(4noitpO

5005BPO000552)detaleregnaugnaLDSO(5noitpO

– 29 –

KV-DA322M64/M66

RM-GA001

Page 31

KV-DA322M64/M66

RM-GA001

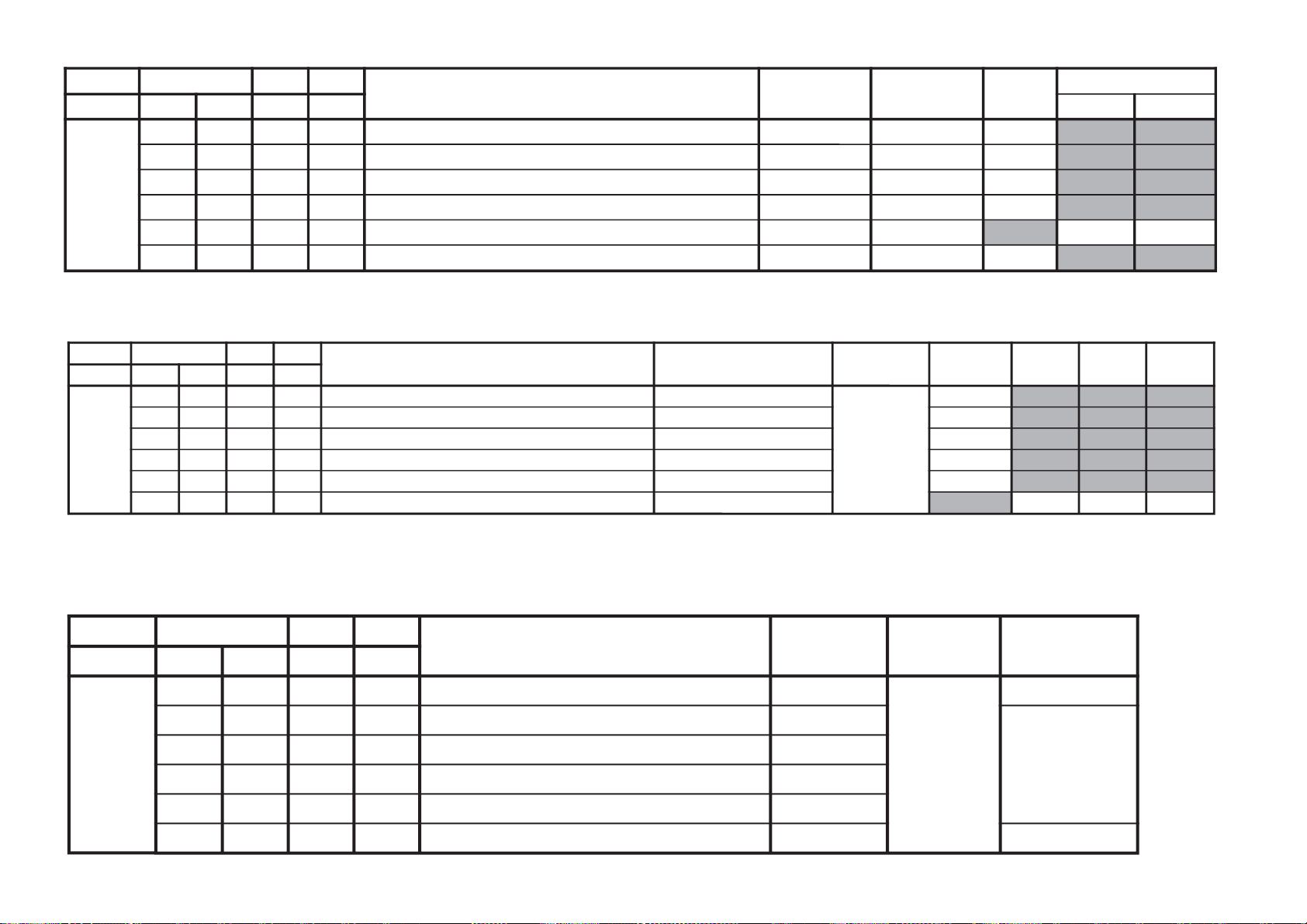

Data Variant depend on models

Category No Name 10+10 10+10 10+10 10+10 10+10

SDSP 000 BBL 02 02 02 02 02

001 BBH 06 06 06 06 06

002 BBLW 04 04040404

010 BAS 21 20 20 22 21

011 TRE 23 22 22 23 22

012 EQ1 02 02 02 03 03

013 EQ2 19 22 21 19 22

014 EQ3 00 00 00 00 00

015 EQ4 17 18 17 18 19

016 EQ5 01 01 02 00 00

020 BBHW 00 00 00 00 00

Category No Name Stereo AV Stereo

SDEC 008 EPMD 02 01

DB29 DB34 DA322 DB29 DB34

non-China non-China China China

009 STDS 31 13

014 DCXI 00 00

015 DCXG 03 00

017 DCLH 06 00

Category No Name Other county China

OPTM 004 LANG 00 01

Category No Name Stereo AV Stereo

OPTM 007 DCXO 53 48

Category No Name Other county China HK

OPTM 010 TSYS 00 02 01

Category No Name DA322/DB29M98 DB29/34

OPTM 016 NRSW 00 01

Category No Name AV Stereo China / India Stereo

SDEM 001 QSS 01 01 01

Category No Name NVM Address Others China

YC 000 YDLY (NTSC-Video) 11 08

– 30 –

Page 32

Category No Name Others China

YC 008 BSP 01 00

LT I 020 VGD 25 27

25 27

25 27

022 PKD 40 55

35 40

30 40

20 20

025 CRD 35 *

**

Category No Name Others HK

SDSP 006 LAN 22 17

Category No Name Others (29"/34") Others (32")

LT I 025 CRD 25 22

KV-DA322M64/M66

RM-GA001

Category No Name China 34" China 29"

LT I 025 CRD 20 40

20 30

yrogetaC.oNemaNelbaT

)3:4(lamroN402040

DH

JDAS200FOIP

PAP/xednI/niwT707070

rehtO002000

yrogetaC.oNemaN

"92anihC"43anihCsrehtO

550605

JDAS600PHS

"92anihC"43anihCsrehtO

353505

)ced("43)ced("23)ced("92

50

0edoMciP

1edoMciP

eziS

5050

– 31 –

Page 33

KV-DA322M64/M66

RM-GA001

ITEM INFORMATION

No. OPB1

Item

KV-DA322M64 0010110044

KV-DA322M66 01101100108

WSS RF HD Front

WSS RF (Wide Screen Signaling in RF mode) 0 = disabled, 1 = enabled

HD Front (HD at front input) 0 = disabled, 1 = enabled

Component (Component [YCbCr] Terminals) 0 = 1 Component terminal

Composite (No. of Composite Terminals) 0 = 3 Composite terminals

NR (Noise Reduction) 0 = NR disabled,

SECAM (SECAM Color System) 0 = disabled,

Color decording (Color Crystal Selection) 00 = PAL/NTSC/SECAM (Multi)

Component

NR Composite SECAM Color decoding

1 = 2 Component terminals

1 = 4 Composite terminals

1 = enabled (Note: 3D Comb must be off when NR is

set to ON

1 = enabled (valid only if Color Decording = 00 or 10)

01 = NTSC (3.58MHz)

10 = PAL/NTSC/SECAM (4.43MHz)

11 = Reserved (Tri-Norma)

DEC

No. OPB2

Item

KV-DA322M64 0101000080

KV-DA322M66 0101000080

No. OPB3

Item

KV-DA322M64 01111100124

KV-DA322M66 01101101109

REV NICAM REV A2 Thai US ST Korean REV Dec

Bilingual ST

NICAM (NICAM Stereo) 0 = disabled, 1 = enabled

A2 (A2 [West German] Stereo/Bilingual) 0 = disabled, 1 = enabled

Thai Bilingual (A2 [Thai] Bilingual) 0 = disabled, 1 = enabled

Forced SAP (Force SAP mode only if US

ST is active) 0 = disabled, 1 = enabled

US ST (US Stereo) 0 = disabled, 1 = enabled

Korean ST (Korean Stereo) 0 = disabled, 1 = enabled

SPEED SEARCH VM Band Edge 3D Comb PAP TOP TEXT DEC

SPEED SEARCH(Cycle of speed search) 00 = disabled (original cycle speed)

01 = 4 time speed from the original

10 = 6 time speed from the original

11 = 8 time speed from the original

VM (Velocity Modulation) 0 = disabled, 1 = enabled

Band Edge (VHF-H Band Limit Position) 0 = 427.25MHz 1 = 429.25MHz

3D Comb (3D Comb functions) 0 = No 3D Comb, 1 = 3D Comb available

PA P(PAP 2 tuner functions) 0 = No PAP, 1 = PAP available

TOP(Forced Top) 0 = Auto Mode(TOP/FLOF), 1 = Forced Top

TEXT (Teletext Model) 0 = Non-Teletext Model

1 = Teletext Model

– 32 –

Page 34

KV-DA322M64/M66

RM-GA001

No. OPB4

Item

KV-DA322M64 0101011187

KV-DA322M66 0001011123

Simple Surround (Surround selection) 0 = Tru Surround Model/WOW/Simulated/Off

MSYS ASD ASD Improvement for Msystem 0 = disabled, 1 = enabled

COSMIC ASD Automatic Standard Detection 0 = disabled, 1 = enabled

ASD (Automatic Standard Detection) 0 = disabled, 1 = enabled

Signal Booster *only for Multi models 0 = disabled, 1 = enabled

WEGA Theatre (Wega Theatre with/without Center 0x = No WEGA Theatre function & No Center SP

Wide (16:9 model) 0 = 4:3, 1= 16:9

Full MSYS COSMIC ASD Signal WEGA Wide DEC

Surround ASD ASD Booster Theatre

1 = (On/simulated/Off)

channels *(only applicable when ASD = 1)

using COSMIC

*for AV Stereo or Mono models

Speaker option) 10 = WEGA Theatre function available with no Center SP

11 = WEGA Theatre function available with Center

SP (original)

No. OPB5

Item

KV-DA322M64 0000111014

KV-DA322M66 0000111014

REV China REV RUSS OSD Languange Selection DEC

China (China model option) 0 = Non China Model

*only for Multi models 1 = China (SSV) models

Russian (Russian OSD option) 0 = Non Russian Model, 1 = Russian Model

*only for Multi models

OSD Language Selection US 1x1x = Complicated Chinese

(GA NTSC) 1xx1 = Korean

GA 1xxx = Simplified Chinese

x1xx = Arabic

xx1x = Thai

xxx1 = Vietnamese (only Vietnam Model)

Russian xxx1 = Russian (Only Russian Model, option

"Russian" = 1)

– 33 –

Page 35

KV-DA322M64/M66

yrogetaCoNemaN

diviV

FRSBCY/VCpmoC

I06_084I06_084I05_675I06_084I06_084I05_675I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801

CSTNLAPLAPCSTNLAPLAP

AMUL0FORB 333033300 111133

1MMAG 555555555555555

6KLB 666666666777777

yrogetaCoNemaN

dradnatS

FRSBCY/VCpmoC

I06_084I06_084I05_675I06_084I06_084I05_675I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801

CSTNLAPLAPCSTNLAPLAP

AMUL0FORB 555533333441100

1MMAG 444444444555555

6KLB 333333333445555

yrogetaCoNemaN

motsuC

FRSBCY/VCpmoC

I06_084I06_084I05_675I06_084I06_084I05_675I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801

CSTNLAPLAPCSTNLAPLAP

AMUL0FORB 333333333000000

1MMAG 000000000000000

6KLB 000000000000000

Adjustment Item Ta ble (PF Engine)

a) Version PF0.208/M

– 34 –

RM-GA001

Page 36

– 35 –

yrogetaCoNemaN

dradnatS

IVD SM

niwT

tamroFllA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_080106_AGVxednIlluFpupoPreyalPeivoM

AMUL0FORB3344 1111111111 5

1MMAG44555555555555 4

6KLB33445555555555 3

yrogetaCoNemaN0AMMAG1AMMAG2AMMAG3AMMAG4AMMAG5AMMAG6AMMAG7AMMAG

AMUL2SMAG3131313131313131

3MAGR02345678

4MAGG02345678

5MAGB02345678

yrogetaCoNemaN0KLB1KLB2KLB3KLB4KLB5KLB6KLB7KLB

AMUL7DEPA02312112

8RTCD0501010150101

9MLBA01100011

yrogetaCoNemaN

diviV

IVD SM

niwT

tamroFllA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_080106_AGVxednIlluFpupoPreyalPeivoM

AMUL0FORB00111133311111 0

1MMAG 55555555555555 5

6KLB 66777777755555 6

KV-DA322M64/M66

RM-GA001

Page 37

– 36 –

yrogetaCoNemaN

motsuC

IVD SM

niwT

tamroFllA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_080106_AGVxednIlluFpupoPreyalPeivoM

AMUL0FORB 33000000000000 3

1MMAG 00000000000000 0

6KLB 00000000000000 0

yrogetaCoNemaN

diviV

cteBGR/CSTA/latigiD itluMVA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801i084p084

AMUL0FORB001111330 1

1MMAG 5555555555

6KLB 6677777767

yrogetaCoNemaN

motsuC

cteBGR/CSTA/latigiD itluMVA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801i084p084

AMUL0FORB 3300000030

1MMAG 0000000000

6KLB 0000000000

yrogetaCoNemaN

dradnatS

cteBGR/CSTA/latigiD itluMVA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801i084p084

AMUL0FORB3344 111134

1MMAG4455555545

6KLB3344555534

KV-DA322M64/M66

RM-GA001

Page 38

– 37 –

yrogetaCoNemaN

dradnatS

FRSBCY/VCpmoC

I06_084

CSTN

I06_084

LAP

I05_675

LAP

I06_084

CSTN

I06_084

LAP

I05_675

LAP

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801

RLOC0FOLC113 311333445555

1FOUH221111133333333

32TSRG 000000000000000

yrogetaCoNemaN

motsuC

FRSBCY/VCpmoC

I06_084

CSTN

I06_084

LAP

I05_675

LAP

I06_084

CSTN

I06_084

LAP

I05_675

LAP

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801

RLOC0FOLC 333333553333333

1FOUH221111133333333

32TSRG 000000000000000

yrogetaCoNemaN0TSRG1TSRG2TSRG3TSRG

RLOC42BSRG0123

52RSRG0123

yrogetaCoNemaN

diviV

FRSBCY/VCpmoC

I06_084

CSTN

I06_084

LAP

I05_675

LAP

I06_084

CSTN

I06_084

LAP

I05_675

LAP

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801

RLOC0FOLC 555567766557777

1FOUH221100033333333

32TSRG 000000000000000

KV-DA322M64/M66

RM-GA001

Page 39

– 38 –

yrogetaCoNemaN

dradnatS

IVD SM

niwT

tamroFllA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_080106_AGVxednIlluFpupoPreyalPeivoM

RLOC0FOLC33445555544444 4

1FOUH 33333333333333 4

32TSRG 00000000000000 0

yrogetaCoNemaN

motsuC

IVD SM

niwT

tamroFllA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_080106_AGVxednIlluFpupoPreyalPeivoM

RLOC0FOLC 53333333333333 3

1FOUH 33333333333333 4

32TSRG 00000000000000 0

yrogetaCoNemaN

diviV

IVD SM

niwT

tamroFllA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_080106_AGVxednIlluFpupoPreyalPeivoM

RLOC0FOLC 66557777777777 6

1FOUH 33333333333333 3

32TSRG 00000000000000 0

yrogetaCoNemaN

diviV

cteBGR/CSTA/latigiD itluMVA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801i084p084

RLOC0FOLC 6655777765

1FOUH 3333333333

32TSRG 0000000000

KV-DA322M64/M66

RM-GA001

Page 40

– 39 –

yrogetaCoNemaN

dradnatS

cteBGR/CSTA/latigiD itluMVA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801i084p084

RLOC0FOLC3344555534

1FOUH 3333333333

32TSRG 0000000000

yrogetaCoNemaN

motsuC

cteBGR/CSTA/latigiD itluMVA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801i084p084

RLOC0FOLC 3333333353

1FOUH 3333333333

32TSRG 0000000000

yrogetaCoNemaN

RLOC2VRDR14

3VRDG24

4VRDB84

5TUCR14

6TUCG62

7TUCB44

8TRBS32

9LOCD1

KV-DA322M64/M66

RM-GA001

Page 41

– 40 –

yrogetaCoNemaN

diviVdradnatSmotsuC

DS

CSTN

rehtO05DH06DHSMniwT

DS

CSTN

rehtO05DH06DHSMniwT

DS

CSTN

rehtO05DH06DHSMniwT

RLOC81SIXA2013102013102 0 1 310

yrogetaCoNemaNLOOCMRAWLOOCDIM

RLOC01WSBW000

11FOBS222

21FODR131313

31FODG339213

41FODB835213

51FOCR121313

61FOCG528213

71FOCB823213

yrogetaCoNemaN0S1XA1S1XA2S1XA3S1XA

RLOC91RY-R414169

02BY-R515199

12RY-G4899

22BY-G4477

yrogetaCoNemaN1edoM2edoM3edoM

RLOC62HWPH110

KV-DA322M64/M66

RM-GA001

Page 42

– 41 –

yrogetaCoNemaN

diviV

FRSBCY/VCpmoC

I06_084I06_084I05_675I06_084I06_084I05_675I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801

CSTNLAPLAPCSTNLAPLAP

YLTC0MSYS 111111111113322

1LMVU 222222322333333

2RCMV 222222 111000000

3MLMV 333333300000000

40FMV 222222222222222

5LDMV212121212121212121515151515151

6FOHS 33333330000 1100

70FHS 111111111111111

8VORP 333333333333333

9VL1F 000000000223300

01VLTL 222222222333333

11DMTL 111111111111111

21VLTC 000000000000000

31EDIM 3333665 1111727291911212

51OPHS 000000000000000

KV-DA322M64/M66

RM-GA001

Page 43

– 42 –

yrogetaCoNemaN

dradnatS

FRSBCY/VCpmoC

I06_084I06_084I05_675I06_084I06_084I05_675I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801

CSTNLAPLAPCSTNLAPLAP

YLTC0MSYS 111111111113322

1LMVU 222222322333333

2RCMV 2222222 11000000

3MLMV 333333300000000

40FMV 222222222222222

5LDMV212121212121212121515151515151

6FOHS 111111100000000

70FHS 111111111111111

8VORP 333333333333333

9VL1F 000000000 110000

01VLTL 0000000000000 11

11DMTL 111111111111111

21VLTC 000000000000000

31EDIM 2222555 0101626291911212

51OPHS 000000000000000

yrogetaCoNemaN

diviVdradnatSmotsuC

WOLDIMHGIHWOLDIMHGIHWOLDIMHGIH

YTLC41VLMV47514501455

KV-DA322M64/M66

RM-GA001

Page 44

– 43 –

yrogetaCoNemaN

motsuC

FRSBCY/VCpmoC

I06_084I06_084I05_675I06_084I06_084I05_675I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801

CSTNLAPLAPCSTNLAPLAP

YLTC0MSYS 111111111113322

1LMVU 222222322333333

2RCMV 2222222 11000000

3MLMV 333333300000000

40FMV 222222222222222

5LDMV212121212121212121515151515151

6FOHS 000000000000000

70FHS 111111111111111

8VORP 333333333333333

9VL1F 000000000000000

01VLTL 000000000000000

11DMTL 111111111111111

21VLTC 000000000000000

31EDIM 000099988 424261618181

51OPHS 000000000000000

KV-DA322M64/M66

RM-GA001

Page 45

– 44 –

yrogetaCoNemaN

diviV

IVD SMniwT

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_080106_AGVxednIlluFpupoPreyalPeivoMtamroFllA

YLTC0MSYS11223322333333 2

1LMVU 33333333322222 2

2RCMV11000000000000 0

3MLMV 00000000000000 0

40FMV 22222222222222 0

5LDMV212151515151515151515151515121

6FOHS 00001100000000 1

70FHS 11111111111111 1

8VORP 33333333333333 3

9VL1F 00223300000000 0

01VLTL 22333333300000 2

11DMTL 11111111111111 1

21VLTC 00000000000000 0

31EDIM111172729191121291323232323272

51OPHS 00000000000000 0

KV-DA322M64/M66

RM-GA001

Page 46

– 45 –

yrogetaCoNemaN

motsuC

IVD SMniwT

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_080106_AGVxednIlluFpupoPreyalPeivoMtamroFllA

YLTC0MSYS11223322333333 2

1LMVU 33333333322222 2

2RCMV11000000000000 0

3MLMV 00000000000000 0

40FMV 22222222222222 0

5LDMV212151515151515151515151515121

6FOHS 00000000000000 0

70FHS 11111111111111 1

8VORP 33333333333333 3

9VL1F 00000000000000 0

01VLTL 00000000000000 0

11DMTL 11111111111111 1

21VLTC 00000000000000 0

31EDIM8842426161818161020202020242

51OPHS 00000000000000 0

yrogetaCoNemaN

dradnatS

IVD SMniwT

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_080106_AGVxednIlluFpupoPreyalPeivoMtamroFllA

YLTC0MSYS11223322333333 2

1LMVU 33333333322222 2

2RCMV11000000000000 0

3MLMV 00000000000000 0

40FMV 22222222222222 0

5LDMV212151515151515151515151515121

6FOHS 00000000000000 0

70FHS 11111111111111 1

8VORP 33333333333333 3

9VL1F00110000000000 0

01VLTL 000000 11100000 0

11DMTL 11111111111111 1

21VLTC 00000000000000 0

31EDIM010162628181818181222222222262

51OPHS 00000000000000 0

KV-DA322M64/M66

RM-GA001

Page 47

– 46 –

yrogetaCoNemaN

dradnatS

cteBGR/CSTA/latigiD itluMVA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801i084p084

YLTC0MSYS 1111332222

1LMVU 2233333333

2RCMV11000000 10

3MLMV 0000000000

40FMV 2222222222

5LDMV21215151515151512151

6FOHS 0000000000

70FHS 1111111111

8VORP 3333333333

9VL1F001100000 1

01VLTL 0000001100

11DMTL 1111111111

21VLTC 0000000000

31EDIM01016262818181810162

51OPHS 0000000000

yrogetaCoNemaN

diviV

cteBGR/CSTA/latigiD itluMVA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801i084p084

YLTC0MSYS 1111332222

1LMVU 2233333333

2RCMV11000000 10

3MLMV 0000000000

40FMV 2222222222

5LDMV21215151515151512151

6FOHS 0000 110000

70FHS 1111111111

8VORP 3333333333

9VL1F 0022330000

01VLTL 2233333323

11DMTL 1111111111

21VLTC 0000000000

31EDIM11117272919112121172

51OPHS 0000000000

KV-DA322M64/M66

RM-GA001

Page 48

– 47 –

yrogetaCoNemaN

motsuC

cteBGR/CSTA/latigiD itluMVA

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801i084p084

YLTC0MSYS 1111332222

1LMVU 2233333333

2RCMV11000000 10

3MLMV 0000000000

40FMV 2222222222

5LDMV21215151515151512101

6FOHS 0000000000

70FHS 1111111111

8VORP 3333333333

9VL1F 0000000000

01VLTL 0000000000

11DMTL 1111111111

21VLTC 0000000000

31EDIM88424261618181842

51OPHS 0000000000

yrogetaCoNemaN

WOLHGIH

85.3CSTNREHTO85.3CSTNREHTO

YLTC61RNHS050101

71RNLV0558

81RNCV0222

KV-DA322M64/M66

RM-GA001

Page 49

– 48 –

yrogetaCoNemaN012 3456789 011121314151

EDIM1YLHM 3333 131113110121

2CLHM 3333333333330333

3YLVM 0000000000000000

4CLVM 0000000000000000

5RYHM 000 1022100011011

6LYHM 1111111111111111

7EYHM 2227055700274666

8OYHM 1111100 111101111

9RCHM 222222222222 1111

01LCHM 1111111111111111

11ECHM 0235000500007777

21OCHM 1111100111100111

31RYVM 0002 122211111111

41LYVM 1111111111110000

51EYVM 00250 11500340034

61RCVM 222222222222 1111

71LCVM 1111111111110000

81ECVM 0003000300000023

yrogetaCoNemaN

eniF-iH

FRCY/VC/SBtnenopmoCIVD)BGR(itluMVA/CSTA

VCRD0SERO821821821821821

1TCNO821821821821821

yrogetaCoNemaN

diviV dradnatS

FRCY/VC/SBtnenopmoCIVD)BGR(itluMVA/CSTAFRCY/VC/SBtnenopmoCIVD)BGR(itluMVA/CSTA

VCRD0SERO821821821821821821821821821821

1TCNO821821821821821821821821821821

KV-DA322M64/M66

RM-GA001

Page 50

yrogetaCoNemaN61718191021222324252627282920313

EDIM1YLHM 22200000 11110100

2CLHM 0000000000000300

3YLVM 0000000000000000

4CLVM 0000000000000000

5RYHM00110 10 0 11110 111

6LYHM 11110 100 11111111

7EYHM 2224070002477052

8OYHM011111110000 1111

9RCHM 1111111122221111

01LCHM 1111010011111111

11ECHM 0224070000257052

21OCHM 1111111111111111

31RYVM 220212 1111110122

41LYVM 1111111111111011

51EYVM0124071202247052

61RCVM 1112222222222122

71LCVM00111111111110 11

81ECVM 002307120 1237052

yrogetaCoNemaN

WOLHGIH

85.3CSTNREHTO85.3CSTNREHTO

EDIM911RNM 1111

022RNM 1111

123RNM 1111

– 49 –

KV-DA322M64/M66

RM-GA001

Page 51

yrogetaCoNemaN23334353637383930414243444546474

EDIM1YLHM 1111000011000000

2CLHM 3333000033000000

3YLVM 0000000000000000

4CLVM 0000000000000000

5RYHM 11110000 11000000

6LYHM112 2 111111110000

7EYHM4727247725770000

8OYHM 11110000 11000000

9RCHM 000000 11220 10000

01LCHM 000000 1111110000

11ECHM 0000004400440000

21OCHM 000000 1111110000

31RYVM00110000 11000000

41LYVM0111001111110000

51EYVM 0375004403440000

61RCVM 0000001122 110000

71LCVM 0000001111110000

81ECVM 0000004400440000

– 50 –

KV-DA322M64/M66

RM-GA001

Page 52

– 51 –

yrogetaCoNemaN84940515253545556575859506162636

EDIM1YLHM 0000000000000000

2CLHM 0000000000000000

3YLVM 0000000000000000

4CLVM 0000000000000000

5RYHM 0000000000000000

6LYHM0111100000000000

7EYHM0247700000000000

8OYHM 0000000000000000

9RCHM 000 1100000000000

01LCHM 000 1100000000000

11ECHM 0004400000000000

21OCHM 000 1100000000000

31RYVM 0000000000000000

41LYVM 000 1100000000000

51EYVM 0004400000000000

61RCVM 000 1100000000000

71LCVM 0001100000000000

81ECVM 0004400000000000

yrogetaCoNemaN)lamroN(elgniSNIWTezeerFxednIetirovaFSM

2DIM0 LOCB041446

yrogetaCoNemaN

pmocVrehtO

zH05zH06zH001zH021zH05zH06zH001zH021

1DIM

2PVDM00515100 5151

yrogetaCoNemaNelgniSrehtO

1DIM

0DCYD00

yrogetaCoNemaN)CSTA(SM,)lamroN(elgniSezeerF/niwT2-SMXEDNI

1DIM1DSYD1111

KV-DA322M64/M66

RM-GA001

Page 53

– 52 –

yrogetaCoNemaN

IVD/)rPbPY(itluMVA/pmoC )CSTA(SM/CSTA/BGR/)BGR(itluMVA

2-SM

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801rehtOI06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801rehtO

3DIM

0HPHM1-031212212-1-42222222

yrogetaCoNemaN

FRSB/VC

CY IVD)rPbPY(itluMVA/pmoC

zH05zH06zH05zH06zH05zH06I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801rehtO

3DIM

1HPHS01-01-01- 000000 0 00

yrogetaCoNemaN

)CSTA(SM/CSTA/BGR/)BGR(itluMVA

2-SM

I06_084I05_675P06_084P05_675P06_027P05_027I06_0801I05_0801rehtO

3DIM

1HPHS 000000 0 000

yrogetaCoNemaN

PCM0FOCT0

1NOP1

2NOR1

3NOG1

4NOB1

5OBKA0

yrogetaCoNemaN

PCM6LBGR0

7TMLY0

8BKLB1

yrogetaCoNemaN

FRSB/VCCY

zH05zH06zH05zH06zH05zH06

3DIM

0HPHM01-1-1-1-1-

yrogetaCoNemaN

2DIM1 SYSM1

KV-DA322M64/M66

RM-GA001

Page 54

– 53 –

yrogetaCoNemaN

WSV0CTV1

1PESH1

yrogetaCoNemaN

01234567

RNNS0PHS763727251 6500

11FY7 3222 1100

2ITL7 00000000

3ITC7 00000000

4LMV7 11111100

5CMV7 222 11100

6LOC7 66663300

7TRB70101963200

8DDIM72818181815100

9ARVS40235120115 0000

01BRVS40235120115 0000

yrogetaCoNemaNrehtO

llamS

)lamroN(ciP

PCM51TLBA0 4

yrogetaCoNemaN

CRDgolanAIVDBGR/CSTA/latigiDSMniwTtxeteleT

CY/VC/SB/FRi084-pmoCp675/p084p027i0801rehtOCRDp084p027i0801AGVCRDp084p027i0801

PCM9FOY77777777777777777 7

01FOBC731313231313238323040423832304040406

11FORC631313231313833483848483348384842304

21CIPS898999 21 9999 2199997 7

31LOCS433313030303131303030313130303036283

41EUHS139292929292929292929292929292929213

KV-DA322M64/M66

RM-GA001

Page 55

– 54 –

yrogetaCoNemaN

PDSO0LVEL5

1VLFF0

yrogetaCoNemaN

SDSO0SOPH32

1ZISH56

yrogetaCoNemaN

lluF

lamroN

zH05

lluF

lamroN

zH06

lluF

lamroN

zH001

lluF

lamroN

zH021

ediW

mooZ

zH05

ediW

mooZ

zH06

ediW

mooZ

zH001

ediW

mooZ

zH021

mooZ

zH05

mooZ

zH06

mooZ

zH001

mooZ

zH021

xednI

zH05

xednI

zH06

etirovaF

zH05

etirovaF

zH06

niwT

zH05

niwT

zH06

I0801DH

zH05

I0801DH

zH06