Sony KV-AR25M81A Service Manual

REVISION HISTORY

BG3R

CHASSIS

MODEL

KV-AR25M81A

NO. SUFFIX DATE SUPP / CORR DESCRIPTION

1 -01 2002/11 -- 1st. Issue

PA RT NO. : 9-872-347-01

SERVICE MANUAL BG3R

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-AR25M81A RM-952 Pakistan

MODEL COMMANDER DEST. CHASSIS NO.

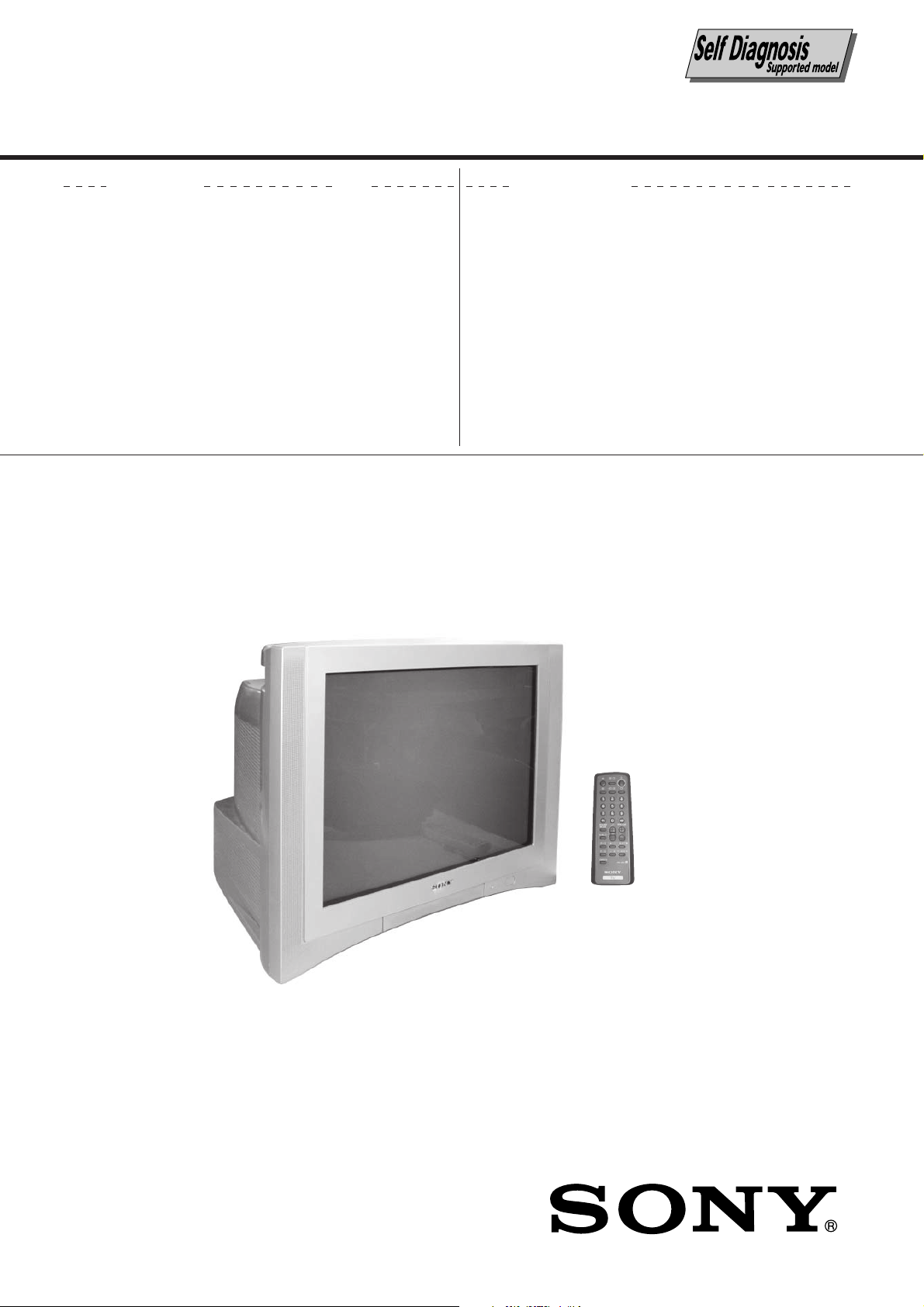

TRINITRON

®

COLOR TV

KV-AR25M81A

RM-952

Power requirements 110-240 V AC, 50/60 Hz

Power consumption (W) Indicated on the rear of the TV

Television system B/G, I, D/K, M

Color system PAL, PAL 60, SECAM, NTSC3.58, NTSC4.43

Teletext language English, Arabic, French

Channel coverage

B/G VHF: E2 to E12

I UHF: B21 to B68

D/K VHF: C1 to C12, R1 to R12

M VHF: A2 to A13

˘(Antenna) 75-ohm external terminal

Audio output (Speaker) 5W + 5W

Number of terminal

DVideo Input: 3* Output: 1 Phono jacks; 1 Vp-p, 75 ohms * Two input lines available

≥ Audio Input: 3* Output: 1 Phono jacks; 500 mVrms * Two input lines available

(S Video) Input : 1 Y: 1 Vp-p, 75 ohms,

(Component Input : 1 Phono jacks:

Video) Y: 1 Vp-p, 75 ohms,

2 (Headphone) Output: 1 Stereo minijack

Picture tube 25 in.

Tube size (cm) 64 Measured diagonally

Screen size (cm) 60 Measured diagonally

Dimension (w/h/d,mm) 650 × 517 × 496

Mass (kg) 39

SPECIFICATIONS

UHF: E21 to E69

CATV: S01 to S03, S1 to S41

CATV: S01 to S03, S1 to S41

UHF: C13 to C57, R21 to R60

CATV: S01 to S03, S1 to S41, Z1 to Z39

UHF: A14 to A79

CATV: A-8 to A-2, A to W+4, W+6 to W+84

unbalanced, sync negative

C: 0.286 Vp-p, 75 ohms

sync negative

CB: 0.7 Vp-p, 75 ohms

R: 0.7 Vp-p, 75 ohms

C

Audio: 500mVrms

Note

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

Design and specifications are subject to change without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

TABLE OF CONTENTS

KV-AR25M81A

RM-952

Section Title Page

SELF DIAGNOSTIC FUNCTION ........................................4

1. DISASSEMBLY

1-1. Rear Cover Removal ................................................... 7

1-2. Speaker Block Assy Removal ..................................... 7

1-3. Chassis Assy Removal ................................................ 7

1-4. Service Position .......................................................... 7

1-5. Terminal Bracket and J Board Removal .................... 7

1-6. V1 Board Removal ..................................................... 7

1-7. H1 and H2 Boards Removal ....................................... 8

1-8. A and B9 Boards Removal ......................................... 8

1-9. Picture Tube Removal................................................. 8

2. SET-UP ADJUSTMENTS

2-1. Beam Landing ........................................................... 10

2-2. Convergence .............................................................. 11

2-3. Focus Adjustment ..................................................... 13

2-4. G2 (SCREEN) and White Balance Adjustment ....... 14

3. CIRCUIT ADJUSTMENTS

3-1. Adjustment With Commander .................................. 15

3-2. Adjustment Method .................................................. 15

3-3. Picture Quality Adjustments..................................... 21

3-4. Deflection Adjustments ............................................ 21

3-5. H-Trapezoid Adjustment .......................................... 22

3-6. A Board Adjustment After IC003 (MEMORY)

Replacement .............................................................. 22

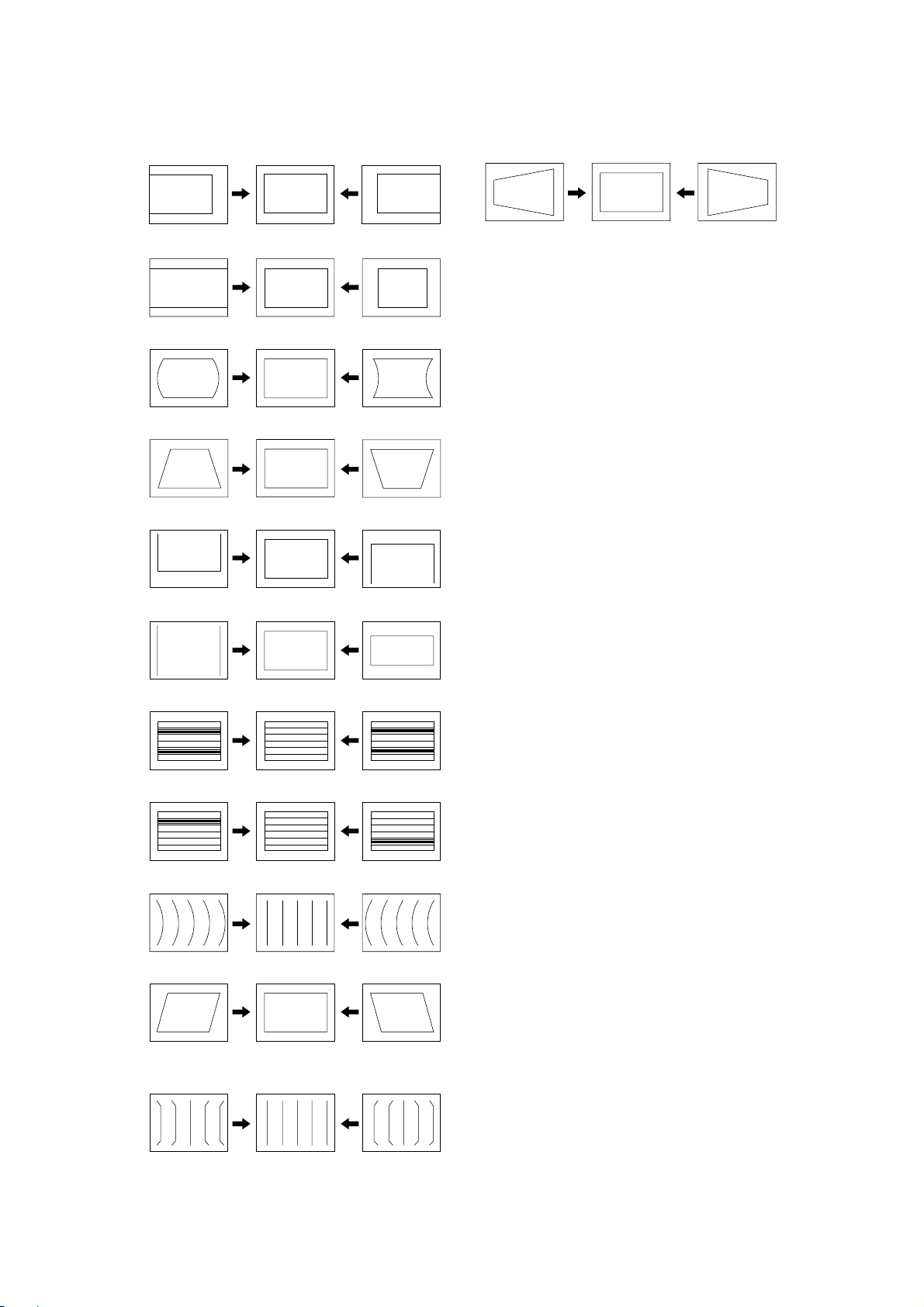

3-7. Picture Distortion Adjustment .................................. 23

Section Title Page

4. DIAGRAMS

4-1. Block Diagram .......................................................... 24

4-2. Circuit Board Location ............................................. 26

4-3. Schematic Diagram ................................................... 27

(1) A Board Schematic Diagram .............................. 28

(2) B9 Board Schematic Diagram ............................ 32

(3) V1 Board Schematic Diagram ............................ 34

(4) C6 Board Schematic Diagram ............................ 36

(5) H1 Board Schematic Diagram ............................ 38

(6) H2 Board Schematic Diagram ............................ 40

(7) J Board Schematic Diagram ............................... 41

(8) VM1 Board Schematic Diagram ........................ 42

4-4. Voltage List and Waveforms ..................................... 43

4-5. Printed Wiring Boards and Parts Location ............... 47

4-6. Semiconductors ......................................................... 52

5. EXPLODED VIEWS

5-1. Speaker Block ........................................................... 54

5-2. Chassis ...................................................................... 55

5-3. Picture Tube .............................................................. 56

6. ELECTRICAL PARTS LIST ......................................... 57

INSTRUCTION MANUAL

– 3 –

KV-AR25M81A

RM-952

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically

begin to flash.

The number of times the lamp flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER

lamp flash indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom cannot

be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past

problems and how often these problems occur.

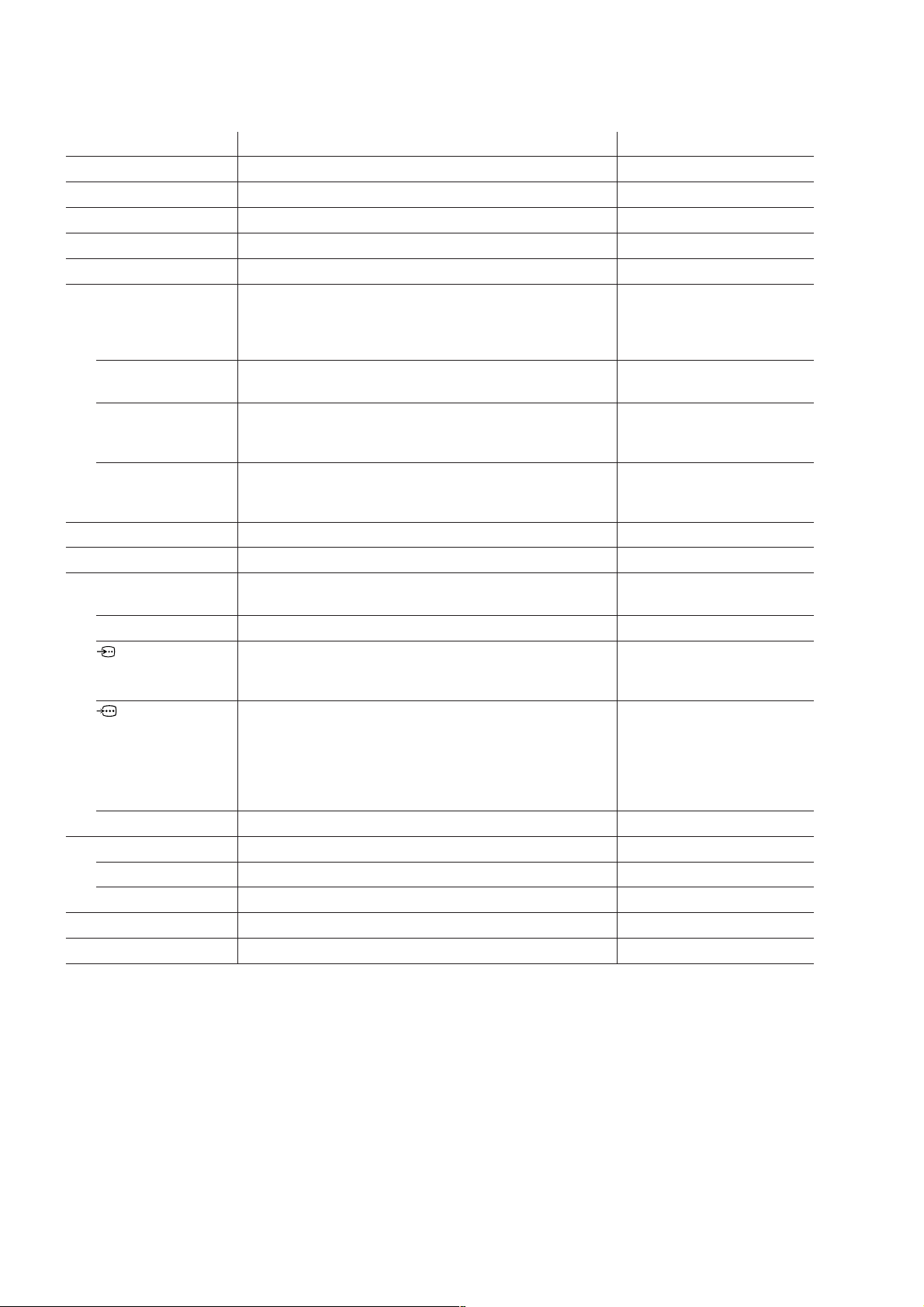

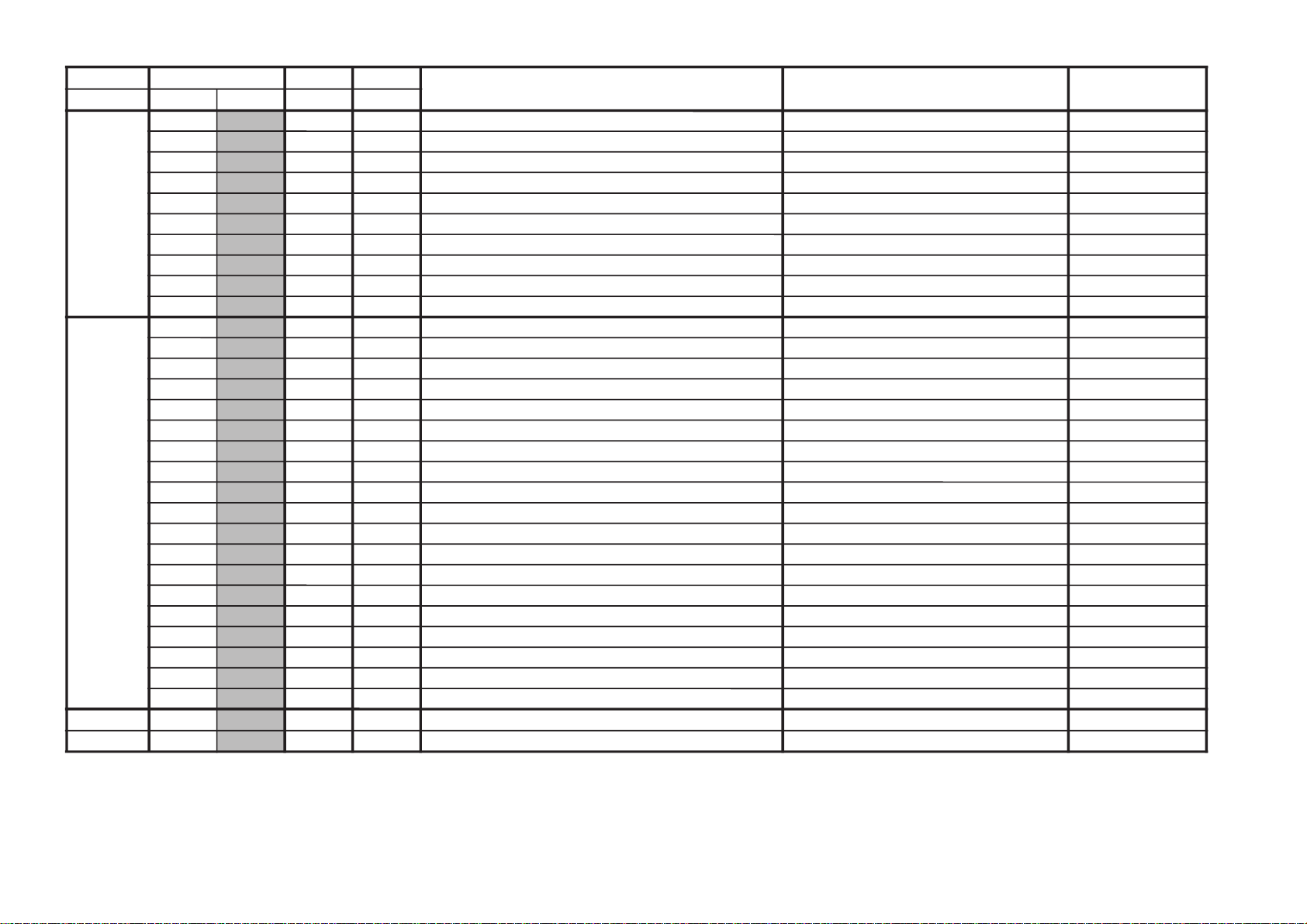

1. DIAGNOSTIC TEST INDICATORS

When an errors occurs, the STANDBY/TIMER lamp will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occured if the screen displays a “0”.

Diagnostic

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP) or

overvoltage

(OVP)

• Vertical deflection

stopped

• Horizontal

deflection

overdrive

• White balance

failure (no

PICTURE)

No. of times

STANDBY/TIMER

lamp flashes

Does not light

2 times

5 times

Self-diagnostic

display/Diagnostic

result

—

002:000 or

002:001~255

003:001~255

004:001~255

at the same time

005:000 or

005:001~225

Probable

Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out F4601

(F)

• H.OUT Q511 is shorted.

(A board)

• Q701, Q702, Q703 is

shorted (C6 board)

• -13V is not supplied.

(A board)

• IC 503 faulty (A board)

• G2 is improperly adjusted.

(Note 2)

• CRT problem.

• R(Q703), G(Q702) or

B(Q701) out is faulty

(C6 board)

• IC301 is faulty. (A board)

• No connection A board to

C6 board.

Detected

Symptoms

• Power does not come on.

• No power is supplied to the

TV.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is

shorted.

• Has entered standby state

after horizontal raster.

• Vertical deflection pulse is

stopped.

• Power line is shorted or

power supply is stopped.

• No raster is generated.

• CRT cathode current

detection reference pulse

output is small.

• Micro reset

Note 1: If a + B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously.

The symptom that is diagnosed first by the microcontroller is displayed on the screen.

Note 2: Refer to screen (G2) Adjustment in section 2-4 of this manual.

* R(Q703), G(Q702) or B(Q701) out is faulty (C6 board).

—

101:00 or

101:001~225

• Discharge CRT (C6 Board)

• Static discharge

• External noise

• Power is shut down shortly,

after this return back to

normal.

• Detect Micro latch up.

– 4 –

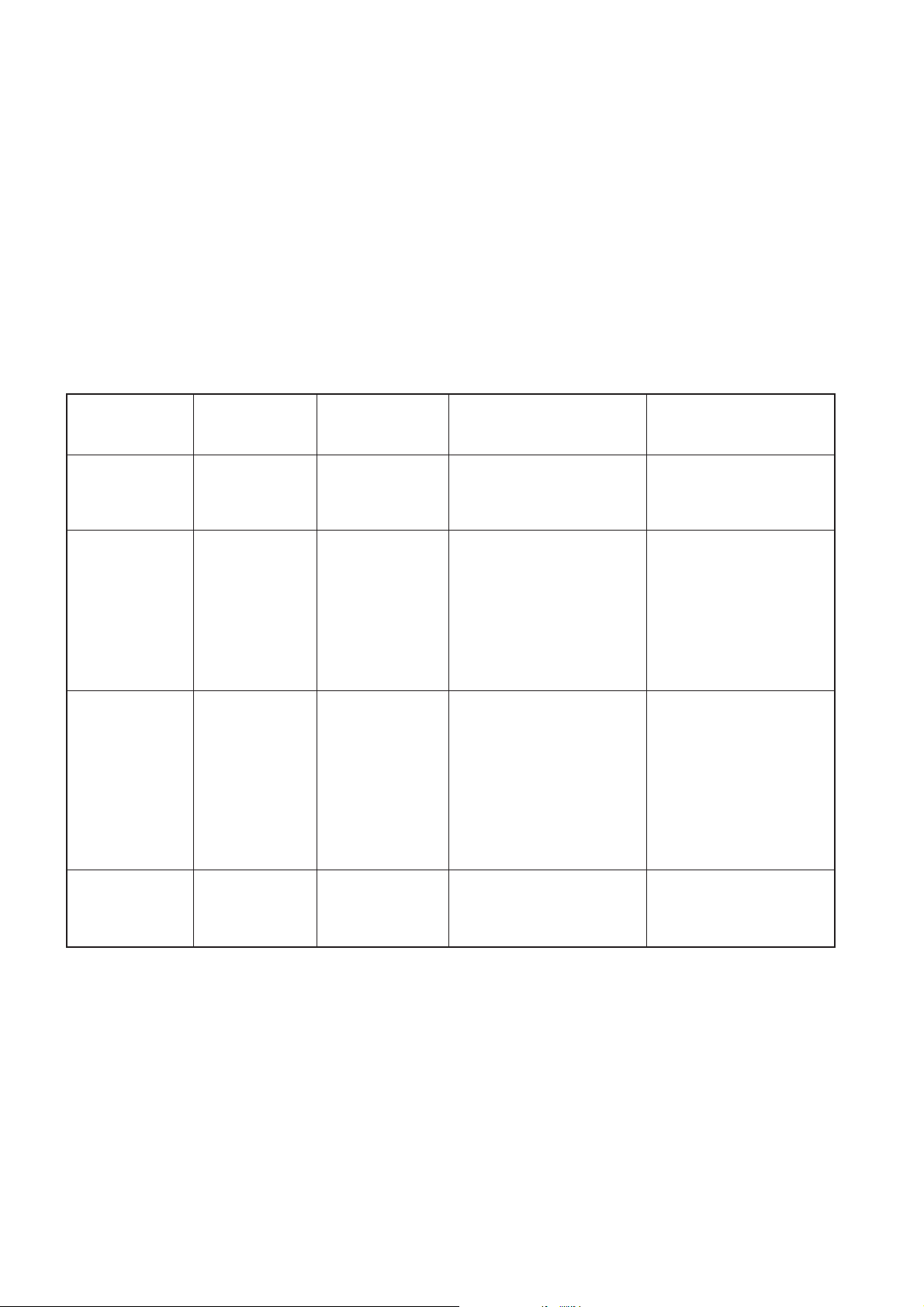

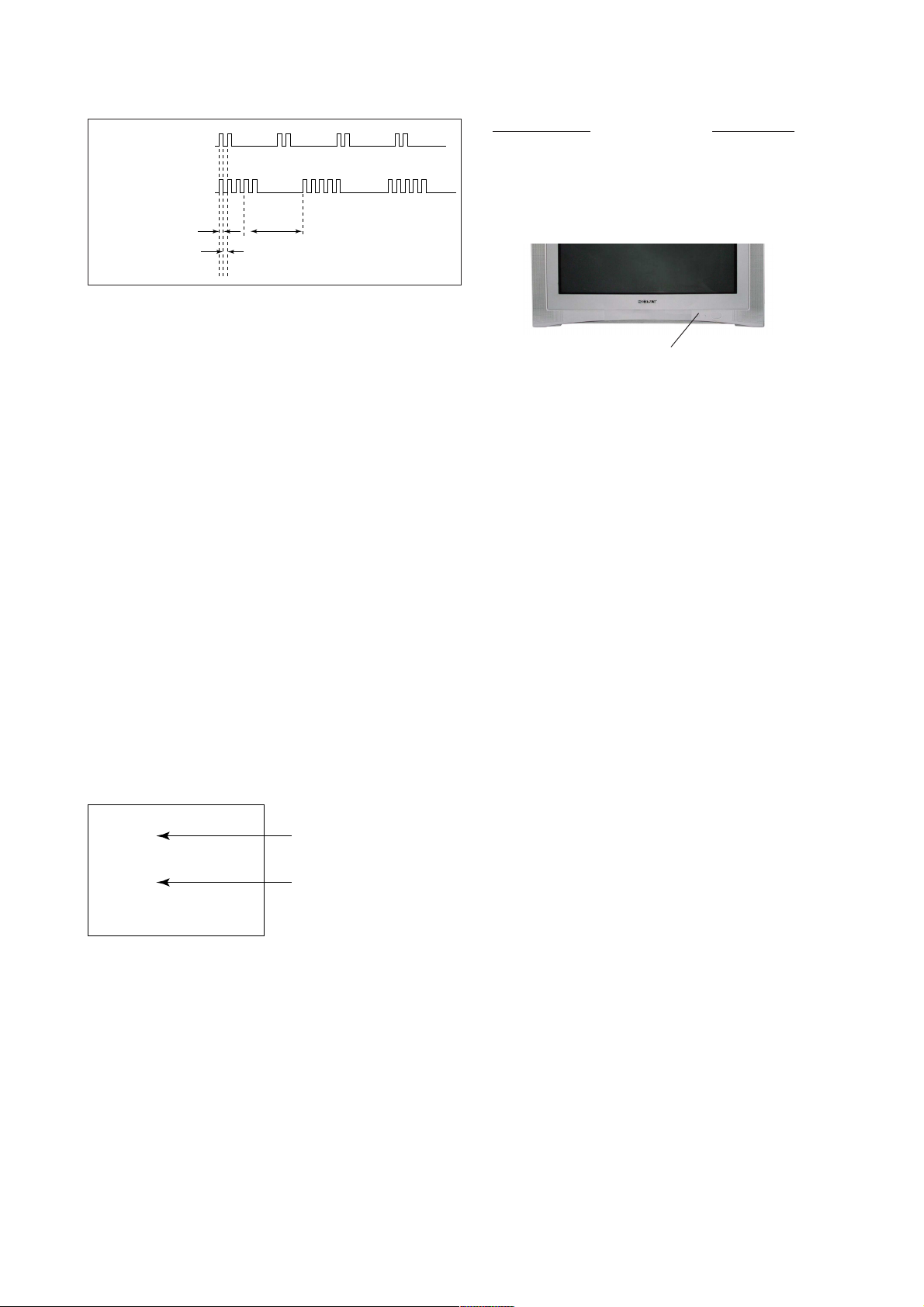

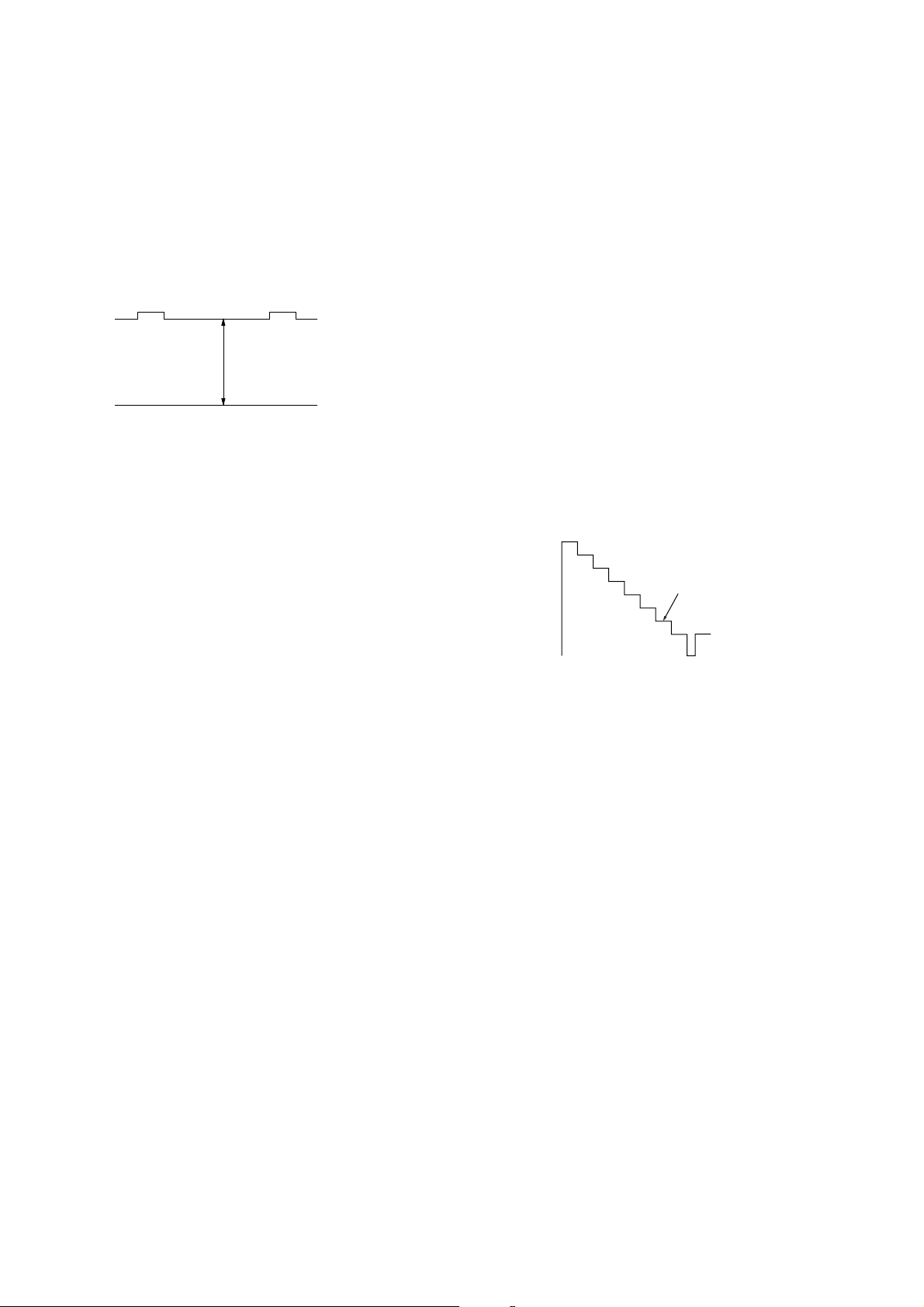

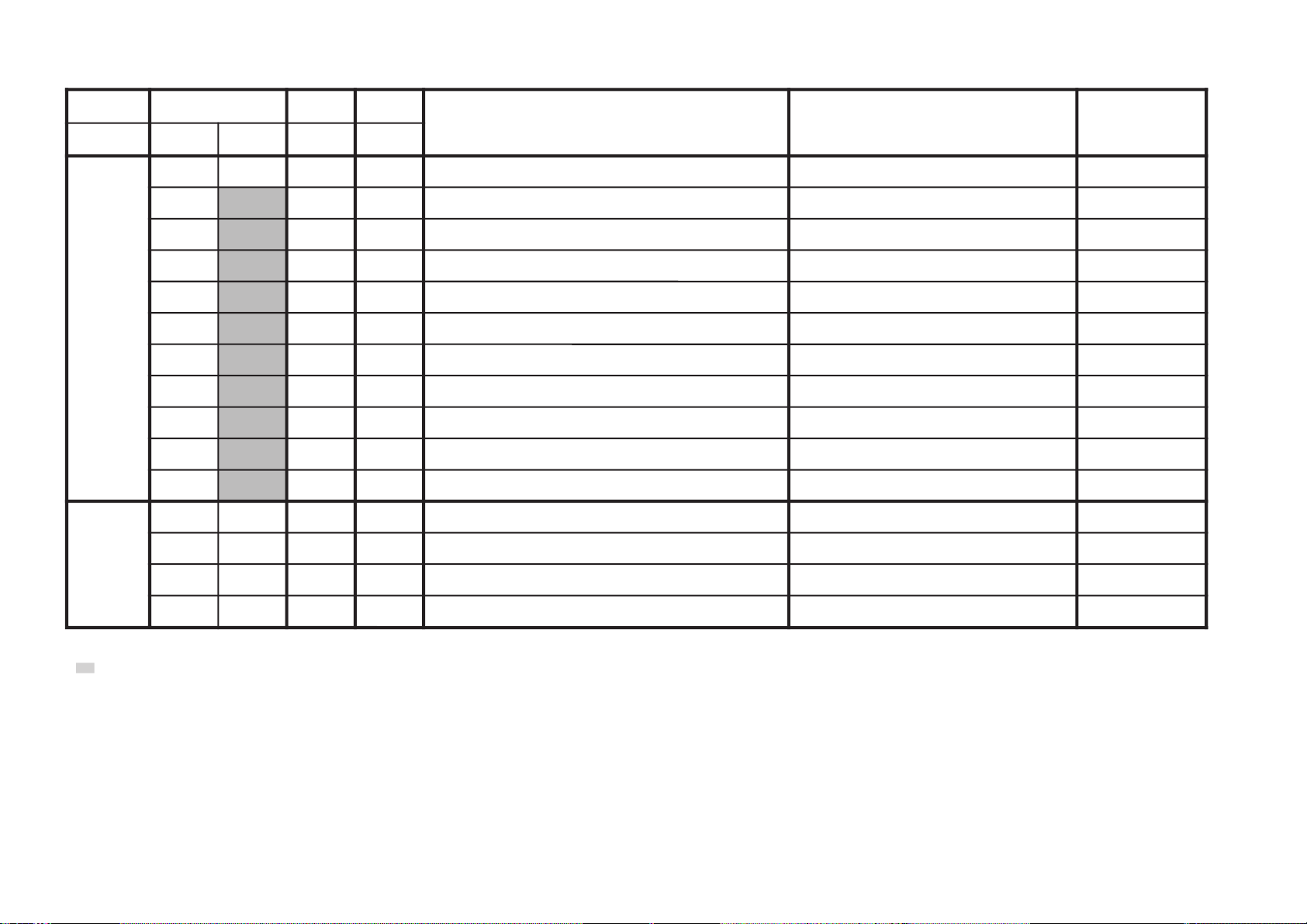

2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

KV-AR25M81A

RM-952

2 times

+B overcurrent/overvoltage 2 times

Vertical deflection stopped

Diagnostic Item Flash Count*

5 times

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

White balance failure 5 times

* One flash count is not used for self-diagnostic.

STANDBY/SLEEP lamp

3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp

from flashing.

4. SELF-DIAGNOSTIC SCREEN DIPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it

is possible to bring up past occurances of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

[Screendisplay] / channel [5] / Sound volume [-] / Power ON

˘

Note that this differs from entering the service mode (mode volume [+]).

Self-Diagnosis screen display

SELF DIAGNOSTIC

002 : 000

003 : 000

004 : 000

005 : 001

101 : 000

Numeral "0" means that no fault has been detected.

Numeral "1" means a fault has been detected.

– 5 –

KV-AR25M81A

RM-952

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to “0”, press buttons on the remote commander sequentially as shown below when the diagnostic

screen is being displayed.

Channel [8] / 0

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

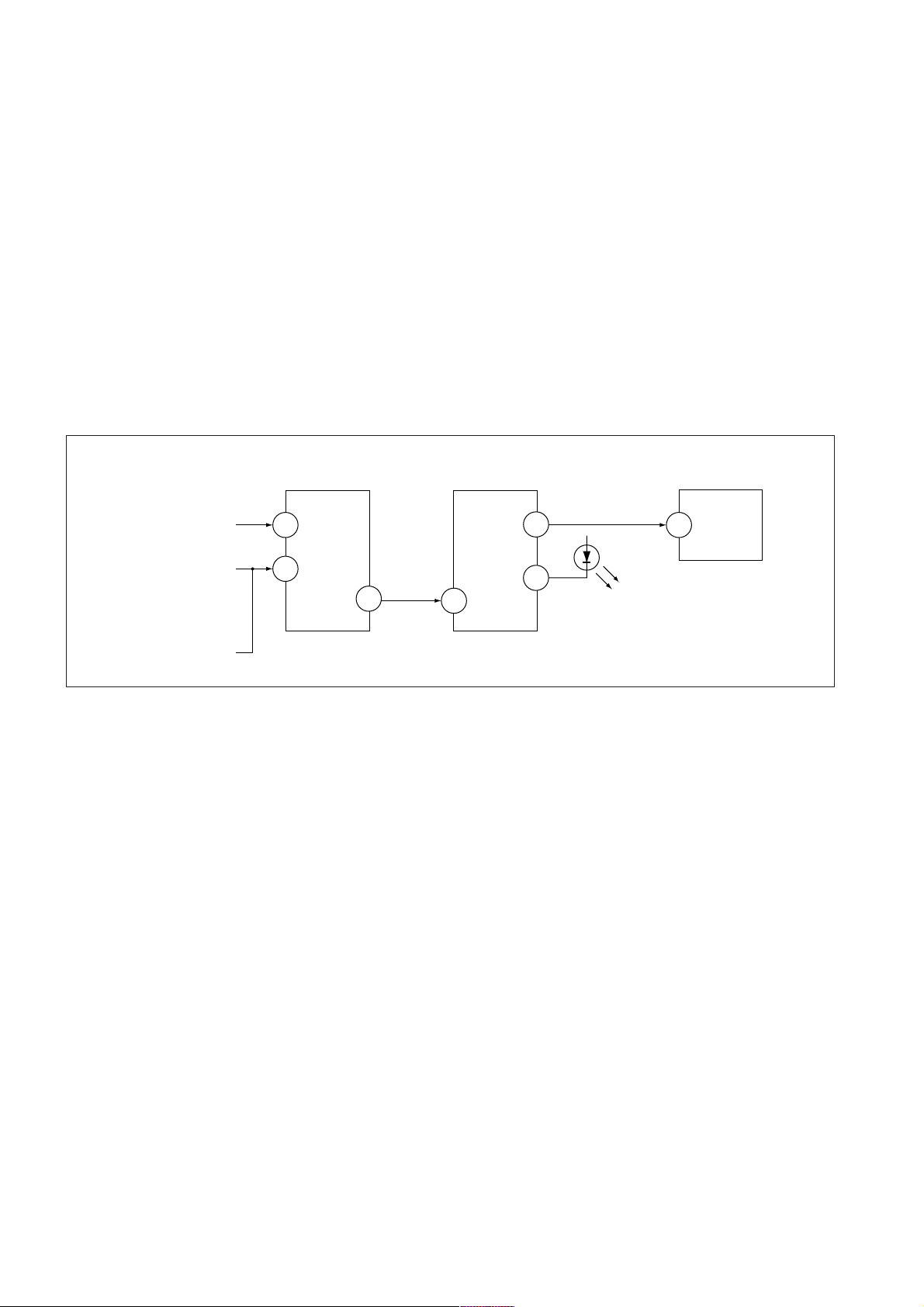

6. SELF-DIANOSTIC CIRCUIT

FROM

CRT

FROM

[+B] Q604 C6

[V] Q509/507

IC301

Y/CHROMA JUNGLE

IK-IN

MP/

18

PROTECT

35

SDA

IC001

SYSTEM

IO-8DAT B-DAT

O-LED

46

IO-SDAT

45

51

IC003

MEMORY

521

[+BovercurrentªOCPº] Occurs when an overcurrent on the +B(135) line is detected by Q604. If Q604 go to ON

and the voltage to pin 18 of IC301 should go down when V.SYNC is more than seven

verticals in a period, the unit will automatically turn off.

[Verticaldeflectionstopped] Occurs when an absence of the vertical deflection pulse is detected by Q509 and IC001

shut down the power supply.

[Verticaldeflectionovercurrent] Occurs when an overcurrent on V drive line is detected by Q507. Power supply will be

shut down when detect this by IC001.

[Whitebalancefailure] If the RGB levels* do not balance or become low level within 5 seconds, this error will be

detected by IC301. TV will stay on, but there will be no picture.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects IK.)

– 6 –

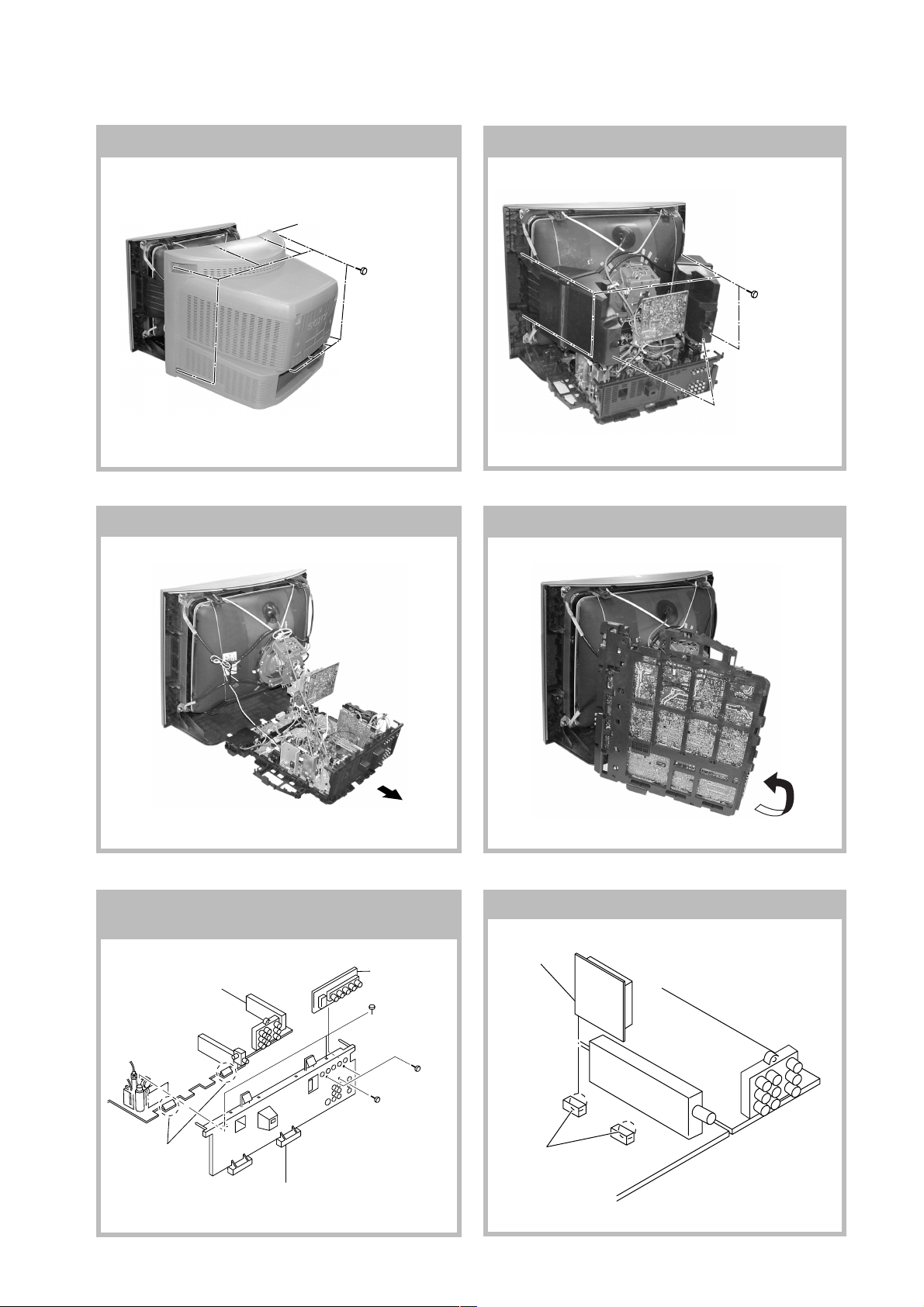

SECTION 1

DISASSEMBLY

KV-AR25M81A

RM-952

1-1. REAR COVER REMOVAL

2 Rear cover

1-3. CHASSIS ASSY REMOVAL

1 Nine screws

(+BVTP 4 × 16)

1-2. SPEAKER BLOCK ASSY REMOVAL

1 Four screws

(Washer head)

(+P 4×16 )

2 Speaker Block Assy

1-4. SERVICE POSITION

1-5. TERMINAL BRACKET AND J BOARD

REMOVAL

3 J Board

4 Two screw

(+BVTP 3 × 12)

2 Two screws

(+BVTP 3 × 12)

1 One screw

(+BVTP 4 × 16)

6 Two Hooks

5 Terminal bracket

1-6. V1 BOARD REMOVAL

2 V1 Board

1 Two claws

– 7 –

KV-AR25M81A

RM-952

1-8. A AND B9 BOARDS REMOVAL1-7. H1 AND H2 BOARDS REMOVAL

3 Two screws

(Washer head)

(+BVTAP 3 x 12)

(Washer head)

(+BVTAP 3 x 12)

4 B9 Board

6 H2 Board

5 Cover, H

4 Two hooks

1 Two screws

(Washer head)

(+BVTP 3 x 12)

3 Four hooks

3 H1 Board

1 One screw

(Washer head)

(+BVTAP 3 x 12)

5 A Board

2 One screw

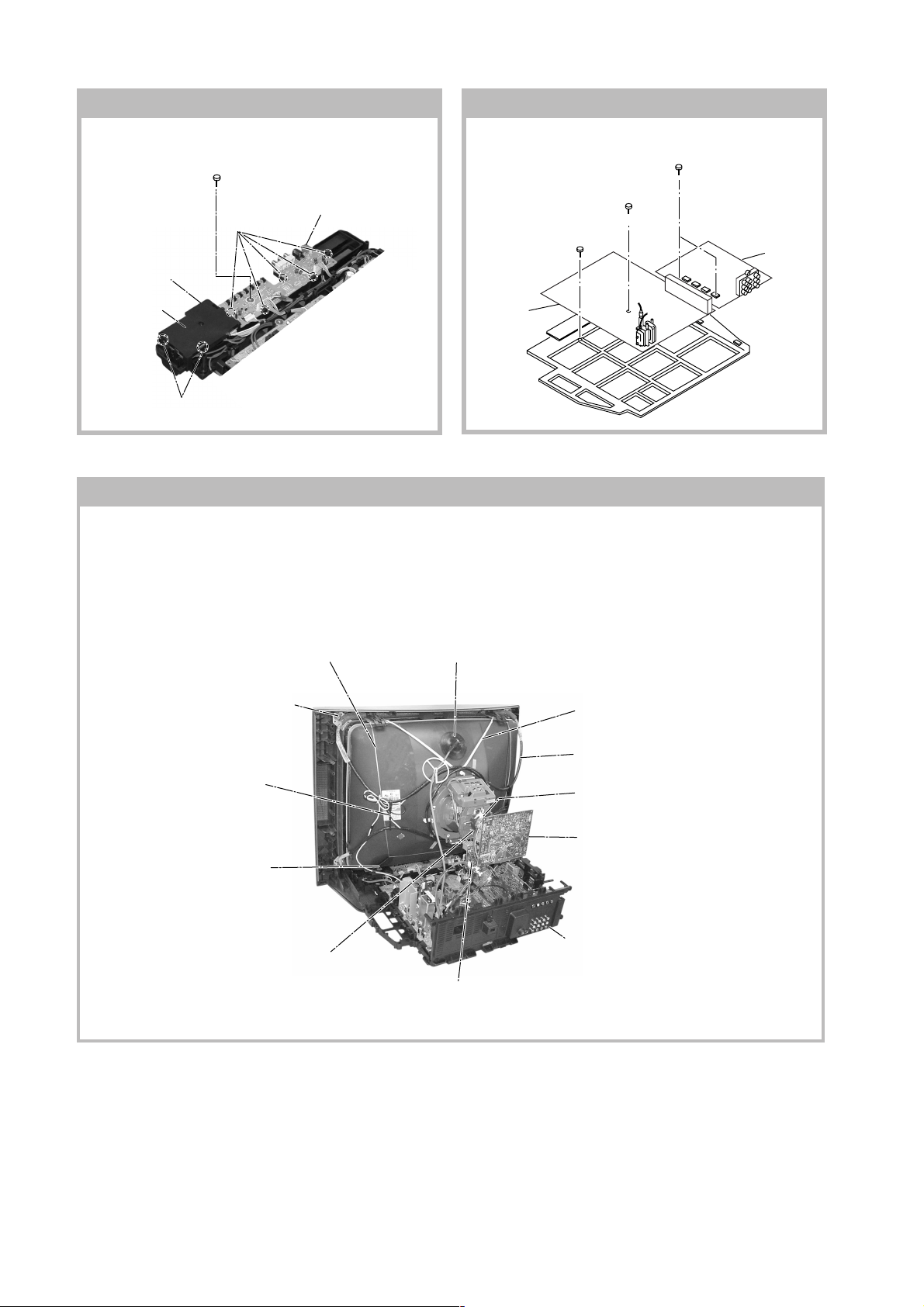

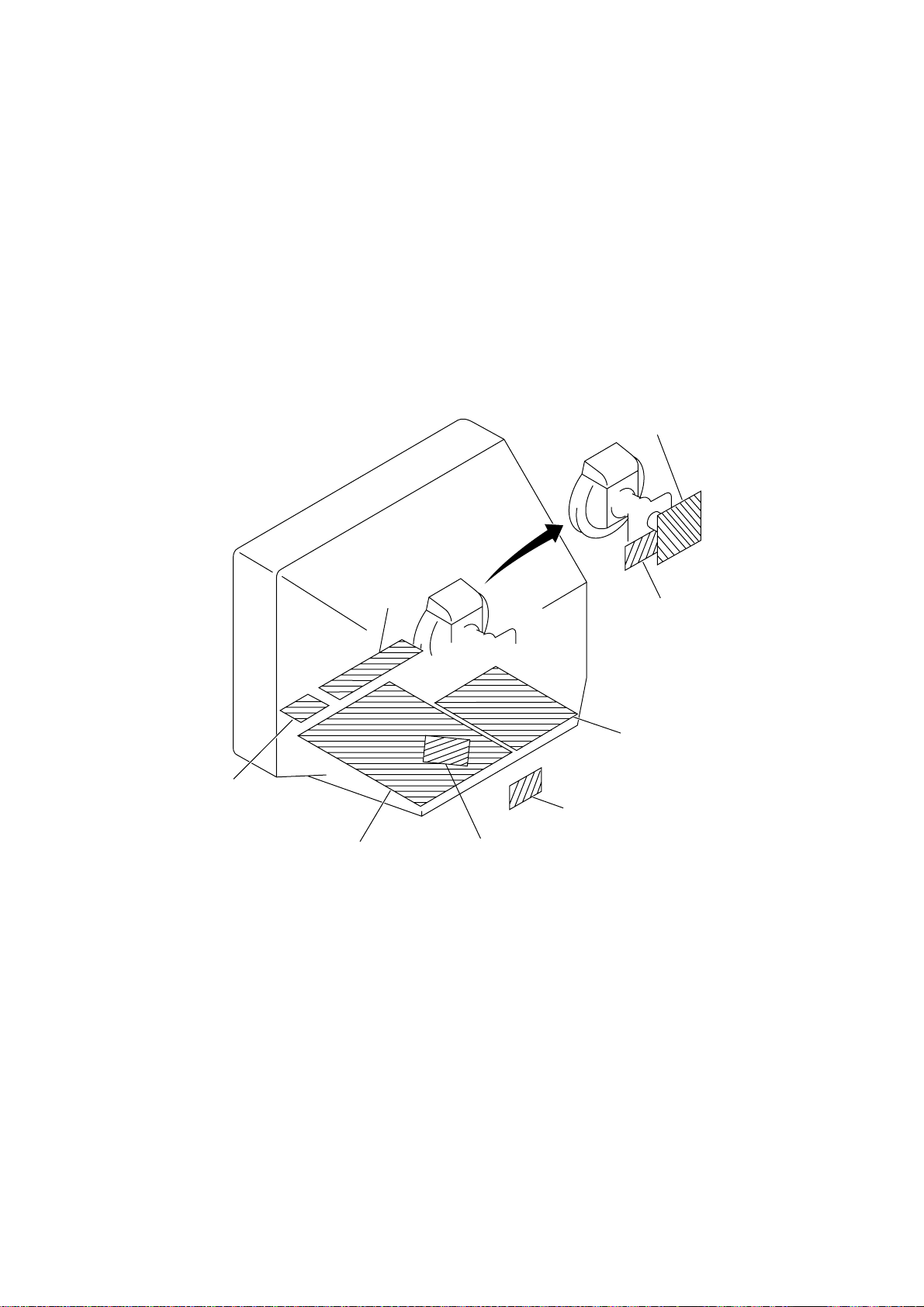

1-9. PICTURE TUBE REMOVAL

Note:

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom

right and left.

1) Place the TV set with the CRT face down on a cushion jig.

2) Removal the rear cover.

3) Removal the Speaker Block Assy.

qf Earth Coating Assy

!∞ Nut, locking

!¡ Holder, DGC(2)

Removal

q; Spring Tension(2)

Removal

8 Loosen the Neck Assembly

fixing screw and removal

4 Anode Cap Removal

!£ Band, DGC Removal

qs Degaussing Coil

6 Loosen the Neck Assembly

fixing screw and removal

5 C6 Board Removal

9 Chassis Assy Removal

7 VM1 Board Removal

– 8 –

KV-AR25M81A

c

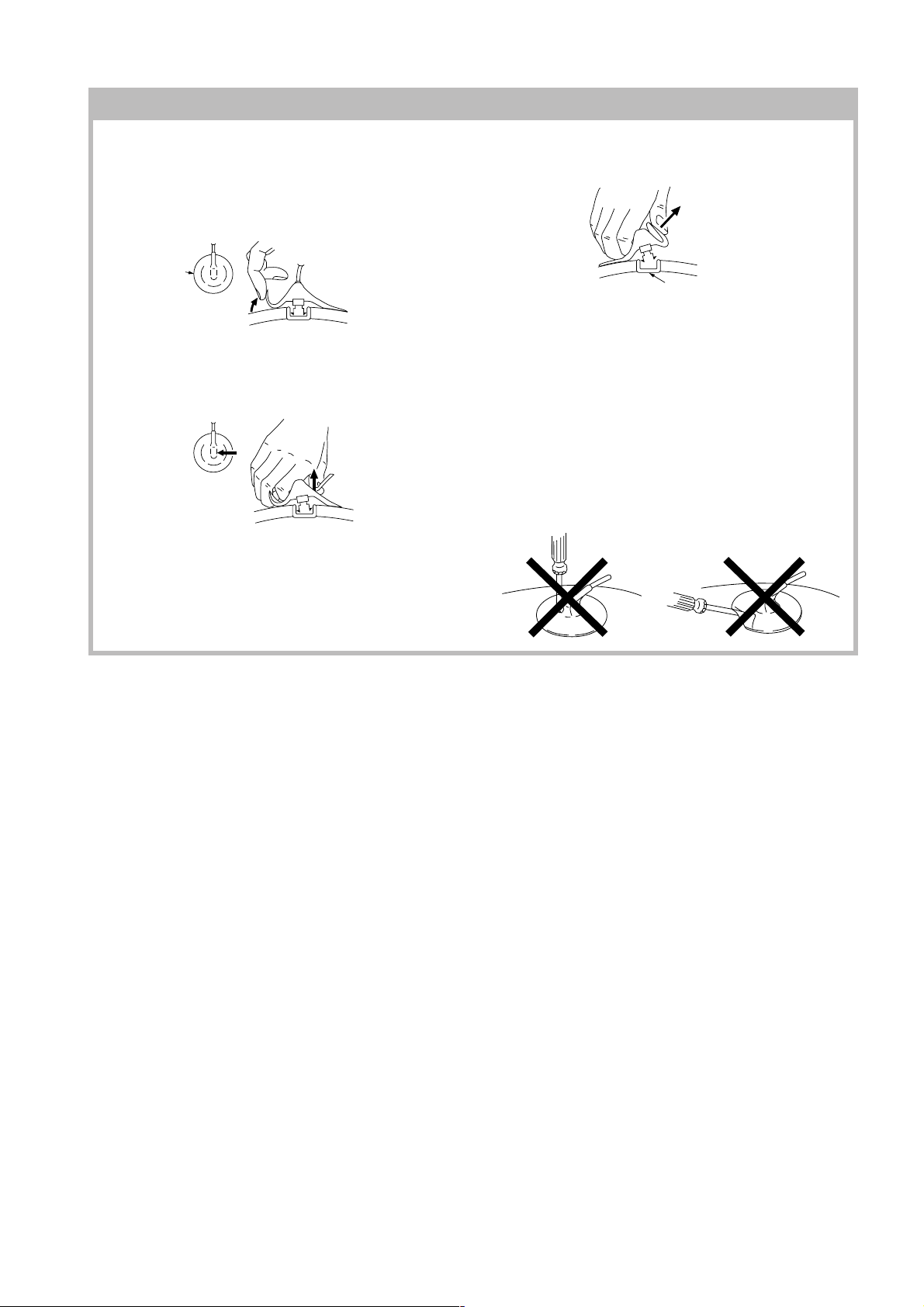

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

b

b

2 Using a thumb pull up the rubber cap firmly in the direc-

tion indicated by the arrow b.

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be removed by

turning up the rubber cap and pulling it up in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

anode button

RM-952

– 9 –

KV-AR25M81A

RM-952

SECTION 2

SET-UP ADJUSTMENTS

• The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

• These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

4. White Balance

Controls and switches should be set as follows unless otherwise noted:

PICTURE control ........................................................... normal

BRIGHTNESS control ................................................... normal

Note : Test Equipment Required.

1. Pattern Generator

2. Degausser

3. Oscilloscope

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

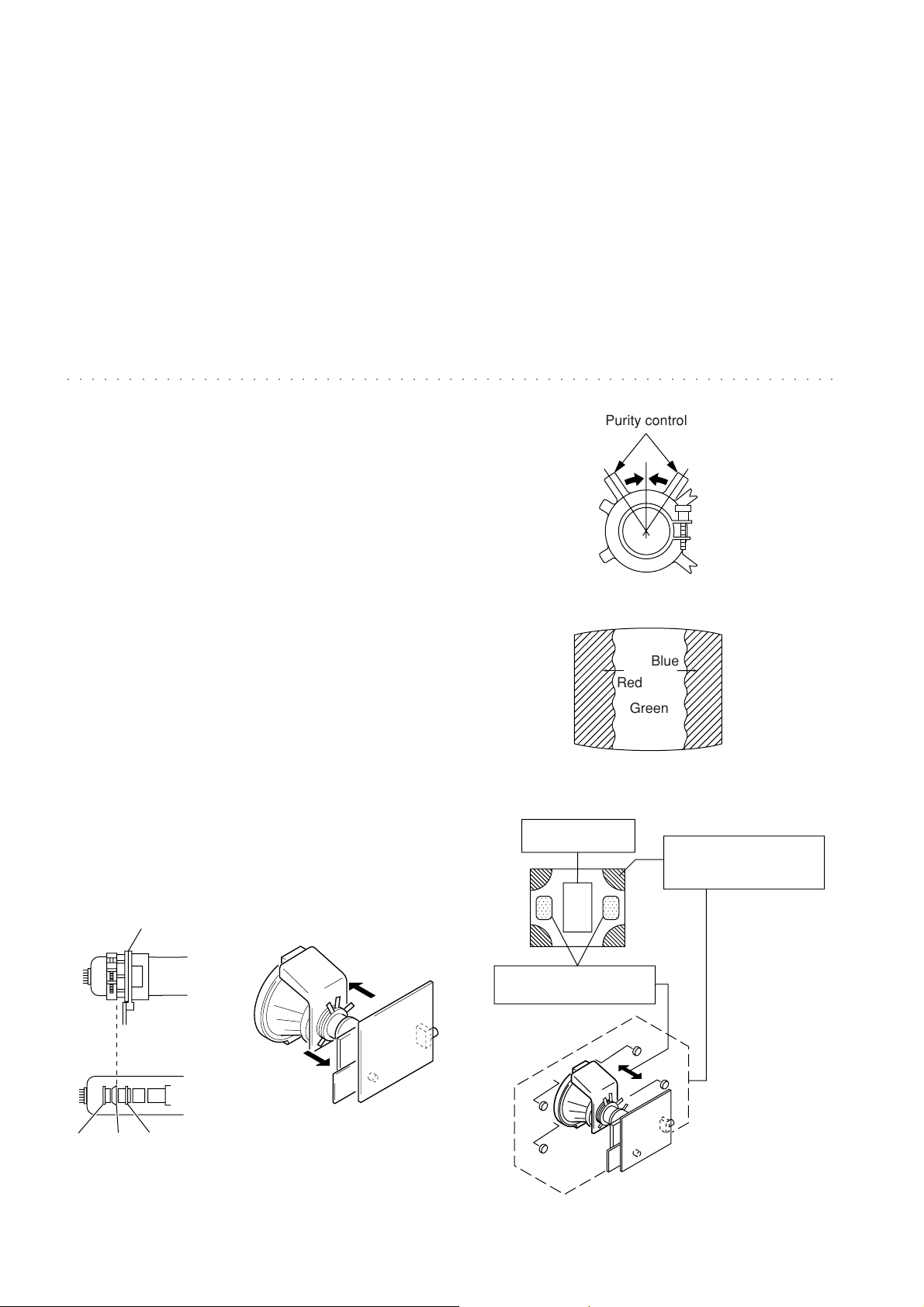

Preparation :

• In order to reduce the influence of geomagnetism on the set's

Purity control

picture tube, face it east or west.

• Switch on the set's power and degauss with the degausser.

2-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck assy as shown in Fig2-2.

}

normal

Fig. 2-3

3. Set the pattern generator raster signal to a green raster.

4. Move the deflection yoke to the rear and adjust with the

purity control so that the green is at the center and the blue

and the red take up equally sized areas on each side.

(See Figures 2-1 through 2-4.)

5. Move the deflection yoke forward and adjust so that the

Blue

Red

Green

entire screen is green. (See Figure 2-2.)

6. Switch the raster signal to blue, then to red and verify the

condition.

7. When the position of the deflection yoke has been decided,

Fig. 2-4

fasten the deflection yoke with the screws and DY spacers.

8. If the beam does not land correctly in all the corners, use a

magnet to adjust it.

(See Figure 2-5.)

Purity control

corrects this area.

b

a

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

Neck assy

Align the edge of

the neck assy with

the edge of the G2 grid.

G2G1 G3

Fig. 2-1

Fig. 2-2

– 10 –

c

Deflection yoke positioning

corrects these areas.

a

d

d

Fig. 2-5

b

c

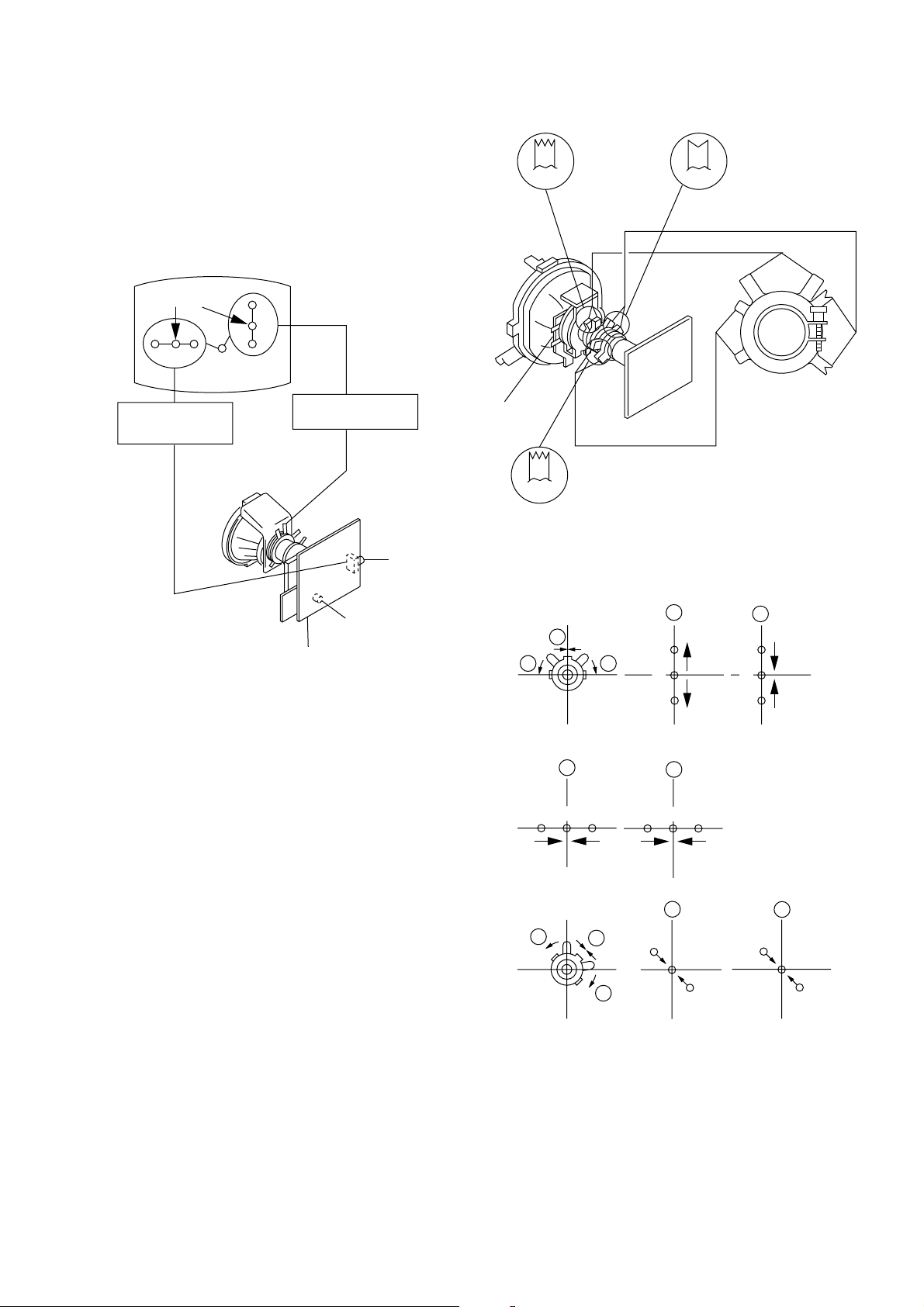

2-2. CONVERGENCE

Purity

BMC

BMC (Hexapole)

Purity

DY pocket

V.STAT

V.STAT

Preparation :

• Before starting this adjustment, adjust the focus, horizontal size

and vertical size.

• Receive dot/hatch signal.

• Pic mode: Personal (Pic 90%, Brightness 50%, Colour 50 %,

Hue 50%, Sharpness 50%).

(1) Horizontal and Vertical Static Convergence

KV-AR25M81A

RM-952

Center dot

RGB

H. STAT VR

R

G

B

V. STST

Magnet

RV702

H. STAT

RV701

SCREEN (G2)

C6 Board

1. (Moving horizontally), adjust the H.STAT control so that the

red, green and blue dots are on top of each other at the center of

the screen.

2. (Moving vertically), adjust the V.STAT magnet so that the red,

green and blue dots are on top of each other at the center of the

screen.

3. If the H.STAT variable resistor cannot bring the red, green and

blue dots together at the center of the screen, adjust the

horizontal convergence with the H.STAT variable resistor and

the V.STAT magnet in the manner given below.

(In this case, the H.STAT variable resistor and the V.STAT

magnet influence each other, so be sure to perform adjustments

while tracking.)

1 V. S TAT

a

b b

2 H. STAT VR

a

RGGBB

3

a

B

G

R

b

R

a

b

B

G

R

b

– 11 –

b

a

R

b

G

B

B

G

R

KV-AR25M81A

RM-952

4 BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or aligned, then

use the BMC magnet to adjust in the manner described below.

RG B R G B R GB

RB

G

RG

GB

RB

5 Y separation axis correction magnet adjustment.

1. Receive the cross-hatch signal and adjust [PICTURE] to [MIN]

and [BRIGHTNESS] to [STANDARD] .

Neck assy Neck assy

Blue

Red Blue

VM1 board VM1 board

Note

1. The Red and Blue magnets should be equally far from the

horizontal center line.

2. Do not separate the Red and Blue magnets too far.

(Less than 8 mm)

Red

2. Adjust the Y separation axis correction magnet on the neck

assembly so that the horizontal lines at the top and bottom of

the screen are straight.

(2) Dynamic Convergence Adjustment

Preparation:

• Before starting this adjustment, adjust the horizontal static

convergence and the vertical static convergence

RB

TLH TLV

B

R

RB

R

B

YCH XCV

– 12 –

KV-AR25M81A

RM-952

TLV Rotate TLV-2 VOL (29”, 34”) on DY

Rotate TLV VOL (25”)

XCV Rotate XCV Adj core on DY

YCH Rotate YCH VOL on DY

TLH Insert TLH Correction Plate to DY Pocket

(Left or Right)

ON DY:

YCH

TLV1

XCV

TLV2

(3) Screen-corner Convergence

ba

a-d : screen-corner

misconvergence

2-3. FOCUS ADJUSTMENT

FOCUS adjustment should be completed before W/B adjustment.

Focus

Screen

FLYBACK TRANSFORMER (T503)

1. Receive digital monoscope pattern.

2. Set "Picture Mode" to "DYNAMIC".

3. Adjust focus VR so that the lion teeth becomes just focus.

4. Change the receiving signal to white pattern blue back.

5. Confirm Magenta ring is not noticable. Incase magneta ring is

obvious, adjust FOCUS VR to take balance of MAGENTA

RING and FOCUS.

cd

Fix a Permalloy assy corresponding to the misconverged

areas.

a

d

Permalloy assembly

b

c

– 13 –

KV-AR25M81A

RM-952

2-4. G2 (SCREEN) AND WHITE BALANCE

ADJUSTMENTS

1. G2 (SCREEN) ADJUSTMENT

1) Set the PICTURE to normal.

2) Put to VIDEO input mode without signals.

3) Connect R, G and B of the C6 board cathode to the

oscilloscope.

4) Adjust BRIGHTNESS to obtain the cathode voltage to the

value below.

5) Adjust G2 (screen) on the FBT until picture shows the point

before cut off.

Cathode setting voltage:

180 V ± 2 (VDC)

0 V

2. WHITE BALANCE ADJUSTMENT

1) Set to Service Mode (Refer Section 3-1: ADJUSTMENTS

WITH COMMANDER).

2) Input white raster signal.

3) Set the PICTURE to minimum.

4) Select WHB 04 "GCT" and WHB 05 "BCT" with [1] and

[4], and adjust the level with [3] and [6] for the best

white balance.

5) Set the PICTURE to maximum.

6) Select WHB 01 "GDR" and WHB 02 "BDR" with [1] and [4],

and adjust the level with [3] and [6] for the best white

balance.

7) Write into the memory by pressing [MUTING] then [0].

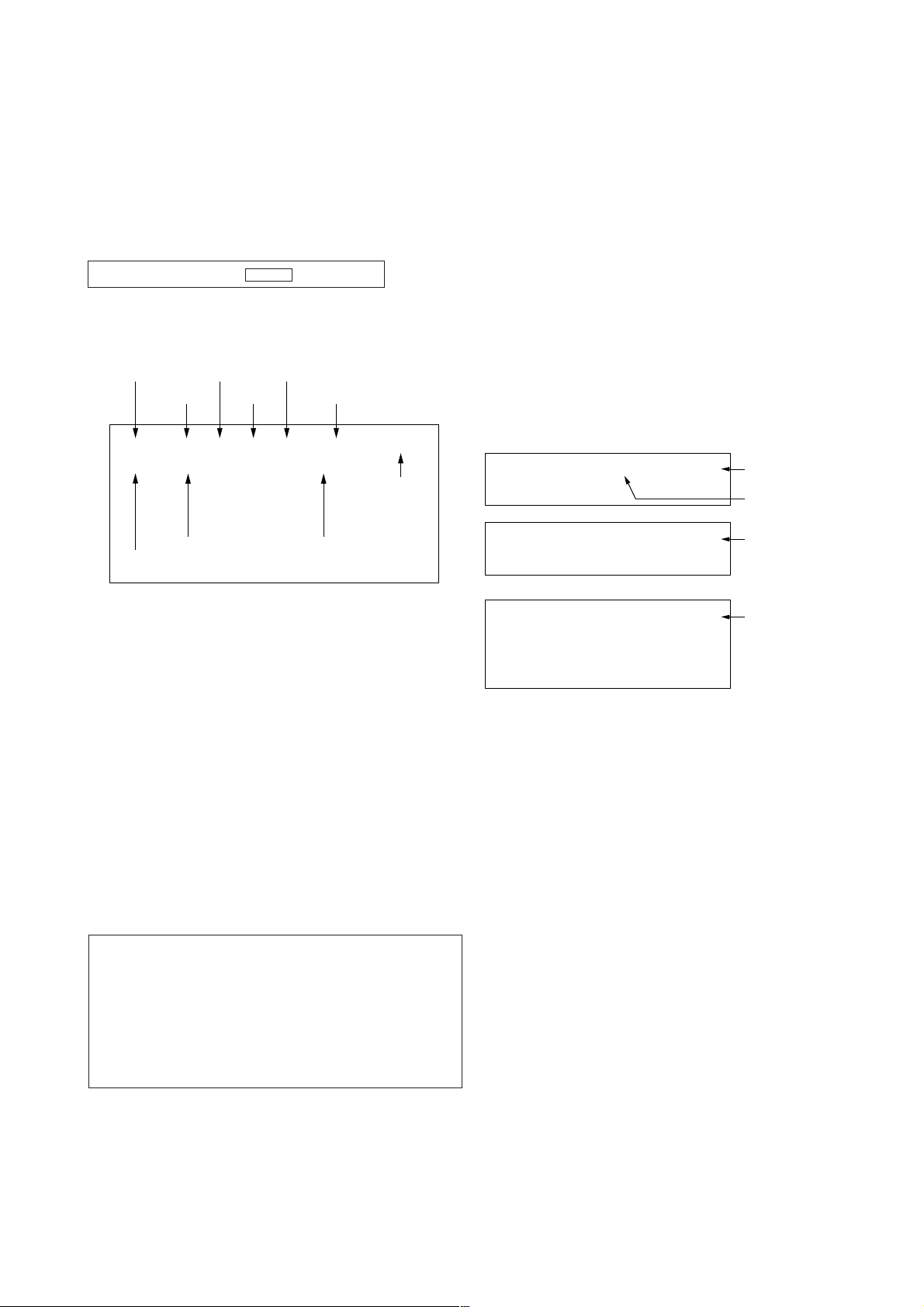

3. SUB BRIGHT ADJUSTMENT

1) Set to service mode.

2) Input a staircase signal of black to white from the pattern

generator.

3) BRIGHTNESS ....50%.

PICTURE ............MINIMUM

4) Select WHB 07 "SBR" with [1] and [4], and adjust WHB 07

"SBR" level with [3] and [6] so that the second stripe from the

right is dimly lit.

White

second from the right

Black

– 14 –

SECTION 3

1F 50HPS SERVICE

GEO 00

7F 0 000A59

0.3A

1F WRITE 50HPS

GEO 00

7F 0 000A59

0.3A

1F 50HPS WRITE

GEO 00

7F 0 000A59

0.3A

GREEN

Write with [MUTING]

Write executed with -

GREEN

RED

The WRITE display

then the display

returns to green

SERVICE.

Adjusted with 3

and 6 buttons.

638S

638S

638S

CIRCUIT ADJUSTMENTS

KV-AR25M81A

RM-952

3-1. ADJUSTMENTS WITH COMMANDER

Service adjustments to this model can be performed using the

supplied Remote Commander RM-952.

a. ENTERING SERVICE MODE

With the unit on standby

n

[DISPLAY] n 5 n VOL (+) n [POWER]

This operation sequence puts the unit into service mode.

The screen display is :

Device

Name

Software version Total Power-On time (hours)

Suffix No

(OEM Code)

b. METHOD OF CANCELLATION FROM SERVICE

MODE

Set the standby condition (Press [POWER] button on the commander),

then press [POWER] button again, hereupon it becomes TV mode.

Item No

00

0.3A

Item

Name

Data Mode

HPS SERVICE 501C pGEO

59 7F 000A0638S

Marking of new NVM

PAL,SECAM:50

NTSC :60

3-2. ADJUSTMENT METHOD

Item Number 00 of device GEO

This explanation uses H-Position as an example.

1. Select “GEO 00 HPS” with the 1 and 4 buttons.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is 1F for PAL

reception.)

4. Write with the [MUTING] button. (The display changes to

WRITE.)

5. Execute the writing with the - button. (The WRITE

display will be changed to red color while excuting, and

back to SERVICE.)

Example on screen display :-

c. METHOD OF WRITE INTO MEMORY

1) Set to Service Mode.

2) Press [1] (UP) and [4] (DOWN), to select the adjustment.

4) Press [MUTING] button to indicate WRITE on the screen.

5) Press [0] button to write into memory.

d. MEMORY WRITE CONFIRMATION METHOD

1) After adjustment, pull out the plug from AC outlet, and then

2) Turn the power switch ON and set to Service Mode.

3) Call the adjusted items again to confirm adjustments were made.

[MUTING], - Write 50Hz adjustment data to 60Hz, or vice

plug into AC outlet again.

1, 4 Select the adjustment item.

↓

3, 6 Raise/lower the data value.

↓

[MUTING] Writes.

↓

- Executes the writing.

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

5, - Service data initialization (Be sure not to use

usually.)

2, - Copy and write all data.

versa.

– 15 –

Use the same method for all Items. Use 1 and 4 to select the

adjustment item, use 3 and 6 to adjust, write with [MUTING],

then execute the write with -.

Note : 1. In [WRITE], the data for all items are written into

memory together.

2. For adjustment items that have different standard data

between 50Hz or 60Hz, be sure to use the respective

input signal after adjustment.

KV-AR25M81A

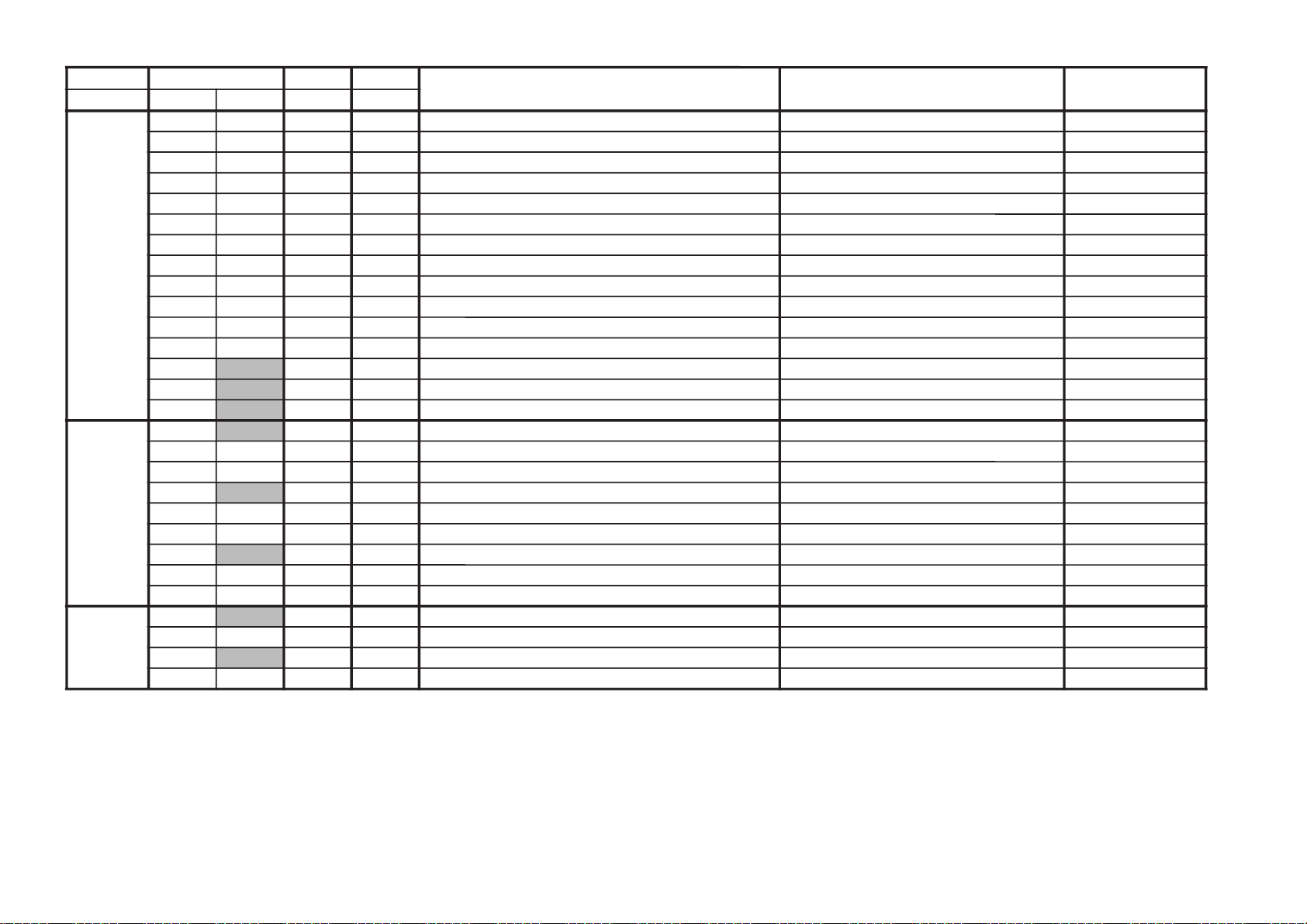

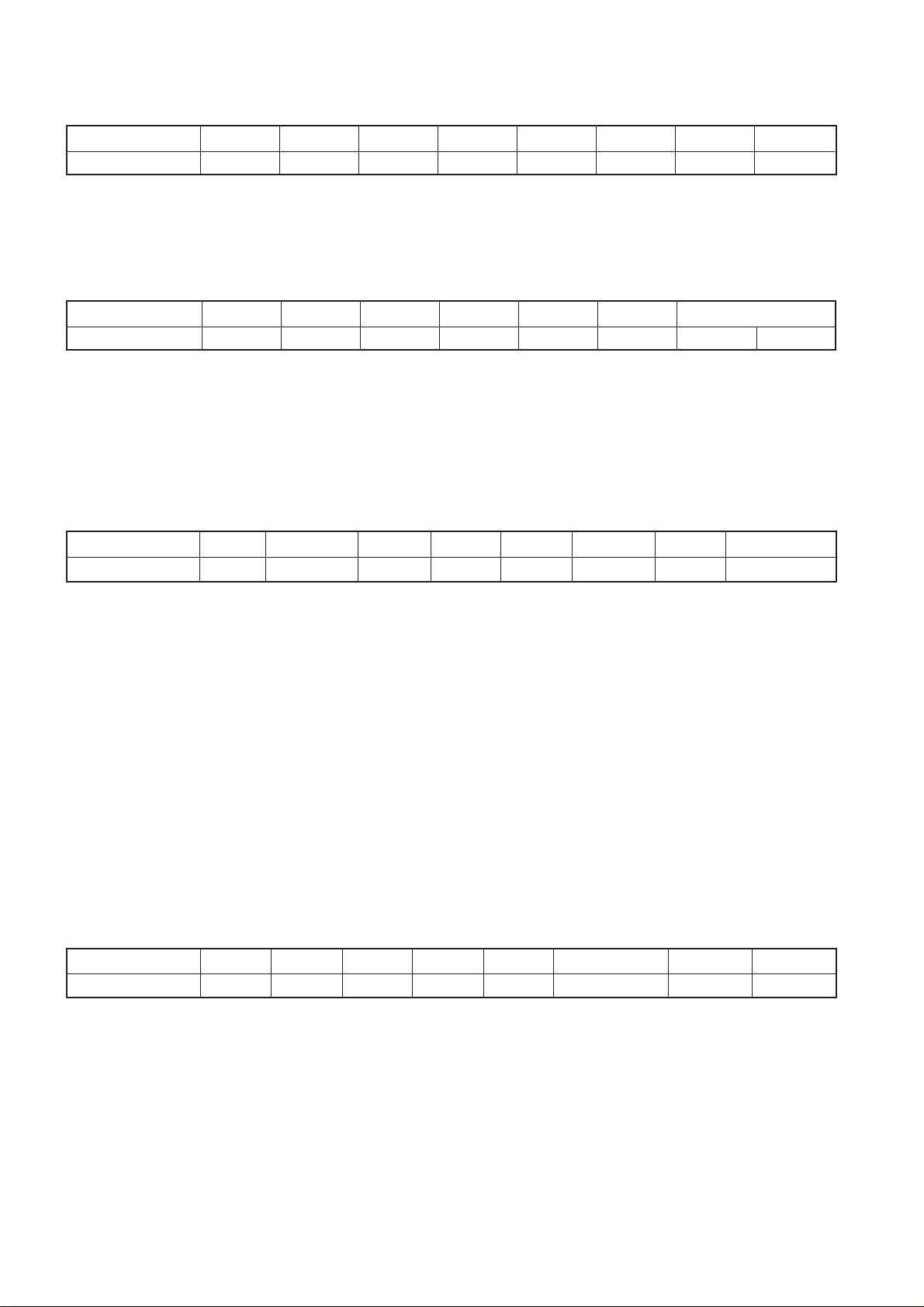

GVTytilanoitcnuF.tinIegnaR

noitcnuFetoN&elbaTeulaVlaitinI

)deliated(

yrogetaCoNemaN

OEG00SPH7F3noitisoPH )06/05(ediW/)06/05(lamroN)61/E1()61/E1(

10ZSHF1F3eziSH )06/05(ediW/)06/05(lamroNF1

20PAPF1F3pmAniP )06/05(ediW/)06/05(lamroNF1

30TLT7F0muizeparT )06/05(ediW/)06/05(lamroN70

40SPVF1F3noitisoPV )06/05(ediW/)06/05(lamroNF1

50ZSVF1F3eziSV )06/05(ediW/)06/05(lamroNF1

60OCS7F0noitcerroCS )06/05(ediW/)06/05(lamroN70

70NLV7F0ytiraeniLV )06/05(ediW/)06/05(lamroN70

80WOB7F0woBCFA )06/05(ediW/)06/05(lamroN70

90LGA7F0elgnACFA )06/05(ediW/)06/05(lamroN70

A0NPUF1F3niPreppU )06/05(ediW/)06/05(lamroNF1

B0NPLF1F3niPrewoL )06/05(ediW/)06/05(lamroNF1

C0

LBH01 ffo/nogniknalBH 10

D0

LBL2F0gniknalBHtfeL )06/05(ediW/)06/05(lamroN)F0/F0(/)F0/F0(

E0

LBRB0F0gniknalBHthgiR )06/05(ediW/)06/05(lamroN)00/00(/)00/00(

BHW00

RDR52F3evirDR srehto/CIMANYDA2/52

10RDG52F3evirDG srehto/CIMANYDF1

20RDB52F3evirDB srehto/CIMANYDF1

30

TCRA0F0ffotuCR srehto/MACES70

40TCG7F0ffotuCG srehto/MACES70

50TCB7F0ffotuCB srehto/MACES70

60

NMB51F1ataDmuminiMssenthgirB 51

70RBSF1F3lortnoCssenthgirBbuS 52

80BPA23 3#CNProfWSltCthgirBbuS 20

JAS00

XMP33F3ataDmumixaMerutciP ediW/ediW-noNE2/33

10UHS8F0lortnoCeuHbuS oediV-VT80

20

HSS3F0lortnoCssenprahSbuS oediV-VT90/50

30LCSF1F3lortnoCroloCbuS )srehto/CSTN(ediW/)srehto/CSTN(F1

RM-952

– 16 –

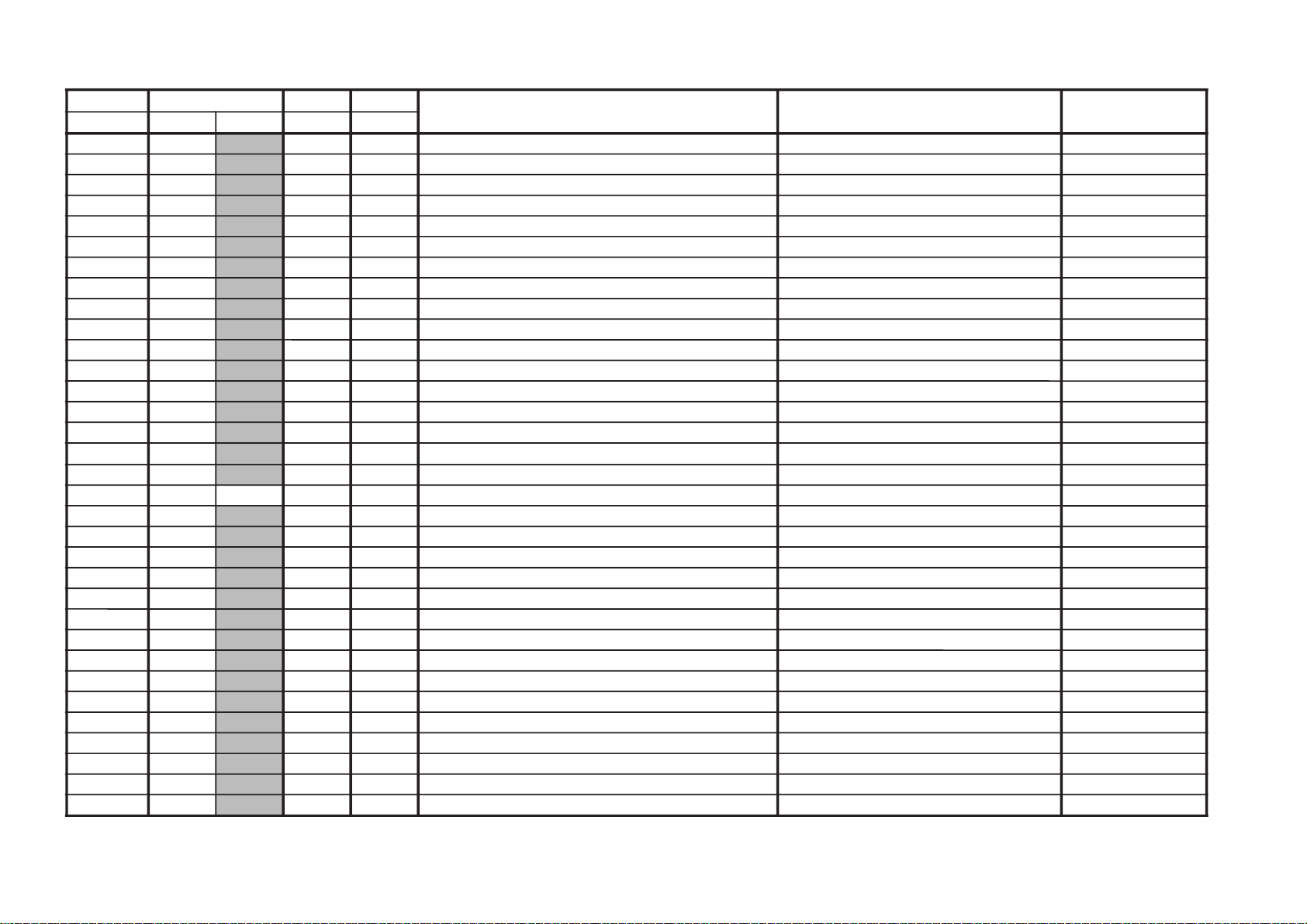

GVTytilanoitcnuF.tinIegnaR

noitcnuFetoN&elbaTeulaVlaitinI

)deliated(

yrogetaCoNemaN

PV00

THE4F0pmoCTHEzH06/05)20/20(/)20/20(

10

AMG230noitcerroCammaG 4ApaMMVNrefeR)10/10(/)20/20(

20

GPA01 3#CNProfWSltCammaG 00

30 LDY6F0yaleDY DVD/CSTN/MACES/LAP80/80/90/60

40

TSS130noitisoPtratSDIMACES LAP/MACES10/10

50

PSS130noitisoPpotSDIMACES LAP/MACES10/10

60

MLR03 timiLBGR 20

70

VLS230leveLDIMACES LAP/MACES20/20

80

FBS22F30fLLEBMACES LAP/MACES22/22

90

CYD11 ffo/noroloCcimanyD 10

A0

LBA11 gnihctiwSedoMLBA 0syawlADRADNATS10

B0

HTV11 gnihctiwShtVnoitceteDLBA 10

C0

0FS11 ssenprahSrofgnihctiwS0F srehto/CSTN10/10

D0

XCD11 gnihctiwSoitaRsnarTCD 10

E0

THS11 hctiwSoitartoohsrevO/-erP srehto/CSTN10/10

F0

WDH01 hctiwShtdiWesluPevirDH 00

01

CFA130lortnoCniaGCFA txeT/oediV/VT10/00/10

11SOH7F0noitallicsOH 70

21

SSH01 .peScnySHfoleveLecilS 00

31

SSV01 .peScnySVfoleveLecilS 00

41

SMH11 no/ffom/CnoisiVorcaMzH06/05)10/10(/)10/10(

51

VUY01 lortnoChctiwSVUY 10

61

VDC13 oediVrofedomDC ylnooediV10

71

NOR11NOR deziromemton10

81

NOG11NOG deziromemton10

91

NOB11NOB deziromemton10

A1

NOP11NOP deziromemton10

B1

NXA11 WSSIXA )anyDylnO(srehto/CSTN)10/10(/)10/10(

C1

LSR01 LESBGR 00

D1

WBV13 WKLBV 00

E1

PFR01PFER 00

F1

PMJ01pmuJ 00

02

CMV23 ffOMV 30

– 17 –

KV-AR25M81A

RM-952

KV-AR25M81A

GVTytilanoitcnuF.tinIegnaR

noitcnuFetoN&elbaTeulaVlaitinI

)deliated(

yrogetaCoNemaN

PA00

FNI5F3ffodnuorrusnehWnoitaunettAtupnI 50

10

SNIA0F3)YLNO-GX(nodnuorrusnehWnoitaunettAtupnI A0

20

FES0F0)YLNO-AX(lortnoCtceffEdnuorruS 00

30

1HP33 noitceleSretsiger1esahP 30

40

2HP03 )YLNO-GX(noitceleSretsigeR2esahP 00

50

3HP03 )YLNO-GX(noitceleSretsigeR3esahP 00

60

4HP03 )YLNO-GX(noitceleSretsigeR4esahP 00

70

SCB23 tfihSretneCssaB 10

80

SCT23 tfihSretneCelberT 20

90

FRT23 tesffOelberTFR 20

PSM00

TSW51FFdlohserhToeretSG/W 51

10

TBWAEFFdlohserhTlaugniliBG/W CE

20

LLW5FFdlohserhTlaruanoMG/W 50

30

CAW0F0tnuoCtnemeergAG/W 10

40

LDW03FFyaleDhcraeSG/W 03

50

LDN02FFyaleDhcraeSMACIN 02

60

LDS01FFyaleDdaeRsutatsoeretS 01

70

CGA11 tnatsnoC/otuAhctiwSCGA 10

80

LER82F3edoMtnatsnoCtAniaGCGA 82

90

MRC01 ffo/nognitumreirraC 00

A0

OCA11 ffo/notuokcolCoiduA 10

B0

PFB1F7metsysM-nonrofelacserPMF B1

C0

MPF23F7metsysMrofelacserPMF 23

D0

HF63F7VEDHrofelacserPMF 63

E0

MHF56F7MdnaVEDHrofelacserPMF 56

F0

PGWA2F7elacserPG/W C1

01

PIND6F7elacserPMACIN F7

11

RRE05FFdlohserhThctiwsMFotuA 05

21

LOVD6FFh0ff7oth0007niaGrekaepS D6

TXT00

HXT03 noitisoPlatnoziroHtxeteleT 00

10

VXT03 noitisoPlacitreVtxeteleT 00

RM-952

– 18 –

GVTytilanoitcnuF.tinIegnaR

noitcnuFetoN&elbaTeulaVlaitinI

)deliated(

yrogetaCoNemaN

MPO00HSOA0F3noitisoPHDSO csiM-noitpOF0

10

MOC130noitceleSbmoC 20

20

CPA11 hctiwSCPA 10

30

YST030sySVTotuAtasySVT 00

40

TUM01 etuMlangiSoN 00

50

MFA01 hctiwSMFotuA 10

60

BFR03 lortnoCFPB-C 00

70

OVT07 tesffoelgnA-VottliT 20

80

LBD01 noitcnuFkcabeulBelbasiD 00

90

HCS1F7noitidnoCgnippihSrofnoitceleSHC ylnosledoMCSTN00

A0

ACS11 noitidnocgnippihsrofnoitcelesriA/elbaC ylnosledoMCSTN00

PSM001POFFFF)wolebees(1stiBlanoitpO stiB-noitpOFE

102PO26FF)wolebees(2stiBlanoitpO 66

203PO1BFF)wolebees(3stiBlanoitpO 1B

304PO20FF)wolebees(4stiBlanoitpO 20

– 19 –

NOTE

•

• Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and for each mode.

• Note for Different Data Those are the standard data values written on the microprocessor. Therefore, the data values of the modes and stored respectively in the memory.

shaded items are fixed data.

In case of a device replacement, adjustment by rewriting the data value is necessary for some items.

KV-AR25M81A

RM-952

KV-AR25M81A

RM-952

ITEM INFORMATION

No. OPB0 OP1

Item

KV-AR25M81A

NOTE: When Bit 7, 6 & 5 = 000, Only PAL color system is selected.

No. OPB1 OP2

Item

KV-AR25M81A 01

XTAL 4.43

1

XTAL 3.58

1

SECAM

1

2nd Lang

1

B/G

1

I

1

D/K

1

M

1

When Bit 7 is selected, Auto, PAL & NTSC 4.43 Color system is enable

When Option is single color system, Color system cannot be changed & “AUTO” will not be displayed.

TOP

0

NICAM

0

HDEV

0

Thai Bil.

0

Dis Fav.

0

DVD Input

1

AV Input

AV Input 00 = no AV Input 01 = 1 AV Input

10 / 11 = 2 AV Input

DVD Input Effective only when “AV Input” is set to 2 AV Input

Dis Fav. Disable Favorite Channel (Only Effective For 21” & 14” Models Only)

No. OPB2 OP3

Item

KV-AR25M81A

Pic Rot

2199 Curve

Pic Rot

1

*1

*1

2199 Curve

*1

0

Auto PIC Auto Picture Improvement 0 = inactive, 1 = active

A-TVsys Auto TV System in Auto Program0 = disabled, 1 = enabled

US ST USA Stereo 0 = disabled, 1 = enabled

AV Mono

*1

11 Key Front Key Selection 0 = 7 key model, 1 = 11 key model

Color SW

*2&*1

Note:*1 - For XA21/XG25 Models Only

*2

- For XA34/29/25 Models Only

No. OPB3 *OP4

Item

KV-AR25M81A

(unused)

0

(unused)0(unused)0(unused)0(unused)

*

*1

Auto PIC

1

A-TVsys

0

US ST

0

AV Mono

0

*1

11 Key

0

Colour SW

2&*1

1

Picture Rotation Feature Switch 0 = disabled, 1 = enabled

2199 Volume Curve Selection 0 = Others, 1= 2199 Volume Curve.

AV Mono models, 0 = Stereo, 1 = Mono (No Balance & Surround selection).

Color Data Selection in Dynamic Mode 0 = 65 (No PIP), 1 = 57 (PIP)

Vid NTSC3.58

0

0

AP_XG

*1

(unused)

1

0

AP_XG

*1

Note:*1 - For XA-21 / XG25 Models Only

To select the XG AP (board B6) ) 0: No; 1 = Yes

– 20 –

KV-AR25M81A

RM-952

3-3. PICTURE QUALITY ADJUSTMENTS

SUB COLOR ADJUSTMENT SCL

1. Select Video.

2. Input PAL Color Bar.

3. Set to following condition PICTURE 100%, BRIGHTNESS

50%, Color 50%.

4. Connect an oscilloscope to pin 1 (BOUT) of CN305, A Board.

5. Set the service mode and select SAJ 3 ‘SCL’ with 1 and 4 of

the commander then adjust the VB2=VB3=VB4 3 and 6.

6. Add 6 steps and save the data.

7. Input NTSC Color Bar.

8. Repeat item 4 to 6.

9. Select "WIDE" mode, write the "SAME DATA- 3 STEPS" for

both PAL and NTSC Color Bar input.

VB1

VB2 VB3

VB2 = VB3 = VB4

VB4

VB2 = VB3 = VB4 (FOR PAL SUB COLOR ADJUSTMENT)

(Difference is within 70mV)

SUB HUE ADJUSTMENT (SHU)

1. Select Video.

2. Input NTSC3.58 Color Bar

3. Set to following condition PICTURE 100%, BRIGHTNESS

50%, Color 50%.

4. Connect an oscilloscope to pin 1 (BOUT) of CN305, A Board.

5. Set the service mode and select SAJ 01 ‘SHU’ with 1 and 4

of the commander then adjust the VB1=VB2=VB3=VB4 3

and 6.

6. Press

7. Adjust SAJ 01 "SHU" as step 2 to 5 when receiving TV mode.

The highest level of VB1,VB2,VB3,VB4 must be aligned at the

same line. Ideal difference level between VB2 and VB3 should be

within ± 110mV.

[MUTING] → - of the commander to write the data.

VB1

VB3

VB4

VB2

VB1 = VB2 = VB3 = VB4

≤ 110mV

3-4. DEFLECTION ADJUSTMENTS

NORMAL MODE (50Hz)

1. Set to Service Mode.

2. Using the 1 and 4 buttons select category GEO (Service

Mode).

3. Select and adjust the following items to obtain obtimum image.

Raise/lower the data with the 3 and 6 buttons.

Service Item

GEO : 00 HPS H POSITION

01 HSZ H SIZE

02 PAP PIN AMP

03 TLT TILT

04 VPS V POSITION

05 VSZ V SIZE

06 SCO S CORRECTION

07 VLN V LINEARITY

08 BOW AFC BOW

09 AGL AFC ANGLE

0A UPN UPPER CORNER PIN

0B LPN LOWER CORNER PIN

WIDE MODE (50Hz)

4. Input a PAL color-bar.

5. Adjust condition change to WIDE MODE : ON.

6. Using the 1 and 4 button, select category GEO

(Service Mode).

7. Copy (item from normal mode (50Hz)) adjusted data for

the following item:

Service Item

GEO : 01 HSZ H POSITION

05 VSZ V POSITION

06 SCO S CORRECTION

07 VLN V LINEARITY

8. Raise/lower data using 3 and 6 buttons, select and

adjust the following items to obtain optimum image.

Service Item

GEO : 00 HPS H POSITION

02 PAP PIN AMP

03 TLT TILT

04 VPS V POSITION

08 BOW AFC BOW

09 AGL AFC ANGLE

0A UPN UPPER CORNER PIN

0B LPN LOWER CORNER PIN

9. After confirm WIDE MODE : ON – OFF.

10. Repeat same steps for NTSC input signal.

– 21 –

KV-AR25M81A

RM-952

NORMAL MODE (60Hz)

11. Input 525/60 Hz signal.

12. Using the 1 and 4 buttons select category GEO (Service

Mode).

13. Select and adjust the following items to obtain obtimum image.

Raise/lower the data with the 3 and 6 buttons.

Service Item

GEO : 00 HPS H POSITION

01 HSZ H SIZE

02 PAP PIN AMP

03 TLT TILT

04 VPS V POSITION

05 VSZ V SIZE

06 SCO S CORRECTION

07 VLN V LINEARITY

08 BOW AFC BOW

09 AGL AFC ANGLE

0A UPN UPPER CORNER PIN

0B LPN LOWER CORNER PIN

WIDE MODE (60Hz)

14. Input NTSC Color Bar

15. Adjust condition change to WIDE MODE: ON.

16. Using the 1 and 4 button select category GEO (Service

Mode).

17. Copy (item from NORMAL MODE (60Hz)) adjusted data for

the following items:

Service Item

GEO : 01 HSZ H SIZE

05 VSZ V SIZE

06 SCO S CORRECTION

07 VLN V LINEARITY

3-5. H-TRAPEZOID ADJUSTMENT

1. Receive cross hatch/dot signal.

2. Adjust RV1801 on C6 board to make H-Trapezoid distortion

best.

3-6. A BOARD ADJUSTMENT AFTER IC003

(MEMORY) REPLACEMENT

1. Enter to Service Mode.

2. Press commander buttons 5 and - (Data Initialize), and

2 and - (Data Copy) to initialize the data.

3. Call each item number and check if the respective screen

shows the normal picture.

In cases where items are not well adjusted, rectify the fine

adjustment.

Write the data per each item number (

4. Select item numbers “OPB00” (OP1), “OPB01” (OP2), "OPB

02" (OP3) and "OPB 03" (OP4) respectively set the bit per

model with command buttons 3 and 6.

5. Press commander buttons 8 and - (Test Normal) to return

to the data that was set on the shipment from the factory.

(This will also cancel Service Mode.)

[MUTING] → -).

18. Raise/lower the data with the 3 and 6 buttons. Select and

adjust the following items to obtain optimum image.

Service Item

GEO : 00 HPS H POSITION

02 PAP PIN AMP

03 TLT TILT

04 VPS V POSITION

08 BOW AFC BOW

09 AGL AFC ANGLE

0A UPN UPPER CORNER PIN

0B LPN LOWER CORNER PIN

19. After confirm WIDE MODE : ON – OFF.

– 22 –

KV-AR25M81A

RM-952

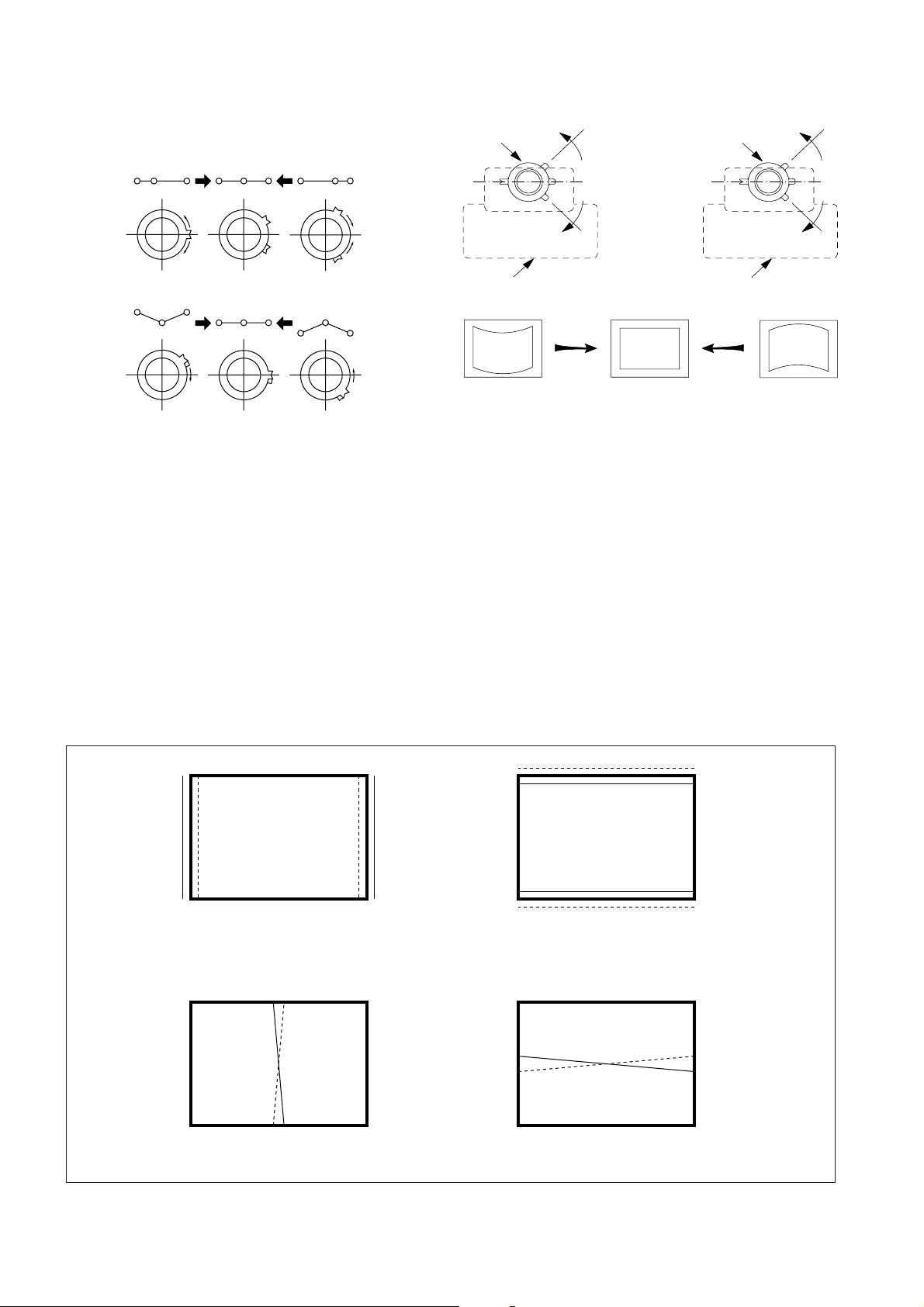

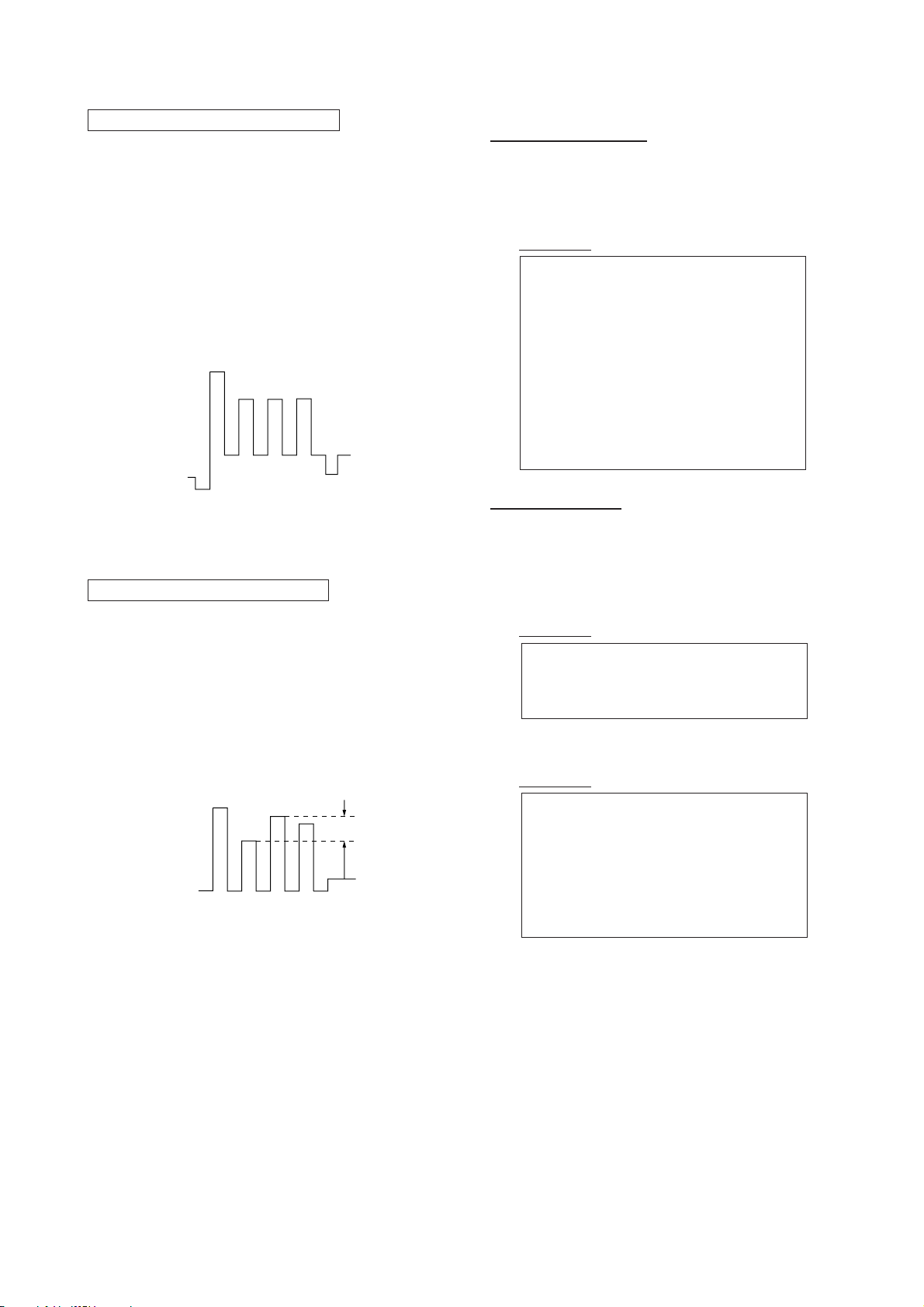

3-7. PICTURE DISTORTION ADJUSTMENT (1)

Item Number 00 – 0B

GEO 0 HPS (H POSITION)

GEO 1 HSZ ( H SIZE)

GEO 2 PAP (PIN AMP)

GEO 3 TLT (TRAPEZIUM)

GEO 4 VPS (V POSITION)

PICTURE DISTORTION ADJUSTMENT (2)

H-TRAPEZOID (ROTATE RVI801)

GEO 5

GEO 6

GEO 7

GEO 8

GEO 9

VSZ (V SIZE)

SCO (VERTICAL S-Correction)

VLN (V LINEARITY)

BOW (AFC. BOW)

AGL (AFC. ANGLE)

GEO 0A

GEO 0B

UPN (UPPER CORNER PIN)

LPN (LOWER CORNER PIN)

– 23 –

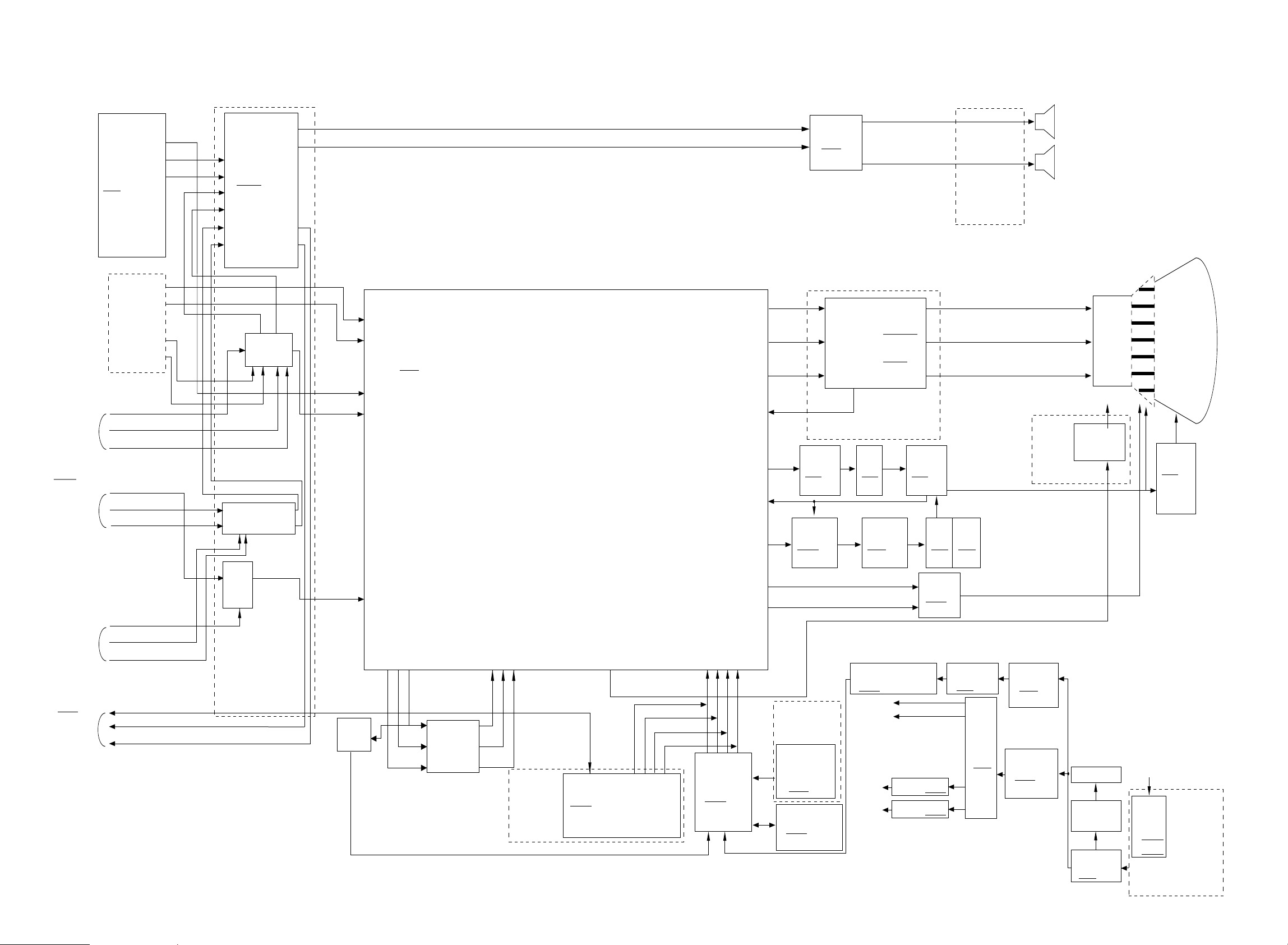

4-1. BLOCK DIAGRAM

SECTION 4

DIAGRAMS

KV-AR25M81A

RM-952

KV-AR25M81A

RM-952

MAIN. TUVIF

<slave: 90H>

TU101

BTF-LG433

<slave:C0H>

VIDEO IN 1

JACK BLOCK

J7402

PIN 9P

VIDEO IN 2

V3 Y in

VIDEO IN 3

(FRONT)

J3903 3P

MONITOR

OUT

J

(DVD

TERMINAL)

V1 Y in

V1 L in

V1 R in

V2 Y in

V2 L in

V2 R in

V3 L in

V3 R in

V out 2

L out 2

R out 2

TV V in

TV L in

TV R in

V

U

L

R

AUDIO

PROSESSOR

IC7203

TDA7429S

<slave: 90H>

R out

L out

IC7501

SWITCH

TV Y in

V I Y in

AUDIO MIXER

IC7204 UPC4558G2

Q7310

CASIO

MIXER

V 2 Y in

B9

(CISPR, AC fuse, A/V Input,

DVD Switch, Monitor Out)

PNC

& ADC

40

41

YC JUNGLE

IC301

CXA2159S

46

<slave:88H>

43

4

A

(System Controller, Y/C Jungle, Deflection, Tuvif, Front Amp, Power Supply)

41 40 39 34 33 32

V out

Y out

U out

Additional

Color Matrix

Y in

V in

U in

TELETEXT

V1

SYSTEM DECODER with

IC801

SAA5261

<slave:88H>

17

VM out

u

com

BLK

28 29 30 31

B G R BLK

SYSTEM

u

com

IC001

CXP86461

R out

24

G out

25

B out

26

IK in

23

H. DRIVE

21

H. PULSE

20

E/W

13

VD+

15

VD-

16

H2

RECEIVER

SIRCS

SBX3081-21

IC3901

MEMORY

I2L

AUDIO OUT

IC201

TA8223K

RED OUT

GREEN OUT

BLUE OUT

(Video Amp, Rotation Circuit)

C6

H-DRIVE

Q506

2SC2785

PIN-CONT

IC502

NJM2903M

(Receiver Power

SW LED)

IC003

M24C08

VIDEO AUP

Q701-712

IC1800

LA6510

HDT

T501

H-OUT

Q511

2SD2578

PIN-OUT

Q505

PMT

T505

IRF614

V-OUT

IC503

TDA8172

5V REG & RESET

IC002 MM1319AFBE

+B

Audio Front Vcc

9V REC IC603

+9V

5V REC IC604

+5V

H1

(Front AV IN, Key SW)

CRT SOCKET

HLT

T504

STB TRANS

T604

SRT

T603

11V

7V

SP ASSY

R out

G out

B out

VM1

(Velocity

Modulation)

STB SW TR

Q605

2SK2845

POWER

IC601

STR-F6656

DY

Y25RSA-Y

NECK ASSY

VM DRIVE

Q5902/5906

DGC

THP

THP600

LINE FILTER

T601

CRT

A60LPN70X

FBT

T503

NX-4009

AC CORD

LINE

FILTER

T7601

T7602

B9

(CISPR, AC fuse, A/V Input,

DVD Switch, Monitor Out)

– 25 –– 24 –

KV-AR25M81A

RM-952

4-2. CIRCUIT BOARDS LOCATION

C6

H2

A

H1

VM1

B9

J

V1

– 26 –

4-3. SCHEMATIC DIAGRAM

Note:

• All capacitors are in µF unless otherwise noted.

• All electrolytic capacitors are rated at 50V unless otherwise

noted.

• All resistors are in ohms.

kΩ = 1000Ω, MΩ = 1000kΩ

• Indication of resistance which does not have rating electrical

power is as follows.

Pitch: 5 mm

Rating electrical power 1/4W (CHIP: 1/10W)

• : nonflammable resistor.

• ¢ : internal component.

• : panel designation or adjustment for rrepair.

• All variable and adjustable resistors have characteristic curve

B unless otherwise noted.

• Readings are taken with a color-bar signal input.

no mark : COMMON

(): PAL

[ ] : NTSC 3.58

• Readings are taken with a 10 MΩ digital multimeter.

• Voltage are dc with respect to ground unless otherwise

noted.

• Voltage variations may be noted due to normal production tolerances.

• All voltage are in Volt.

• ✽ : Cannot be measured.

• Circled numbers are waveform references.

• : B +bus.

• : B –bus.

• ÷ : signal path.

KV-AR25M81A

RM-952

Reference information

RESISTOR : RN METAL FILM

COIL : LF-8L MICRO INDUCTOR

CAPACITOR : TA TANTALUM

Note: The component identified by shading and

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: RW NONFLAMMABLE WIREWOUND

: ✽ ADJUSTMENT RESISTOR

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

mark ! are critical for safety. Replace only

with part number specified.

– 27 –

Loading...

Loading...