Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

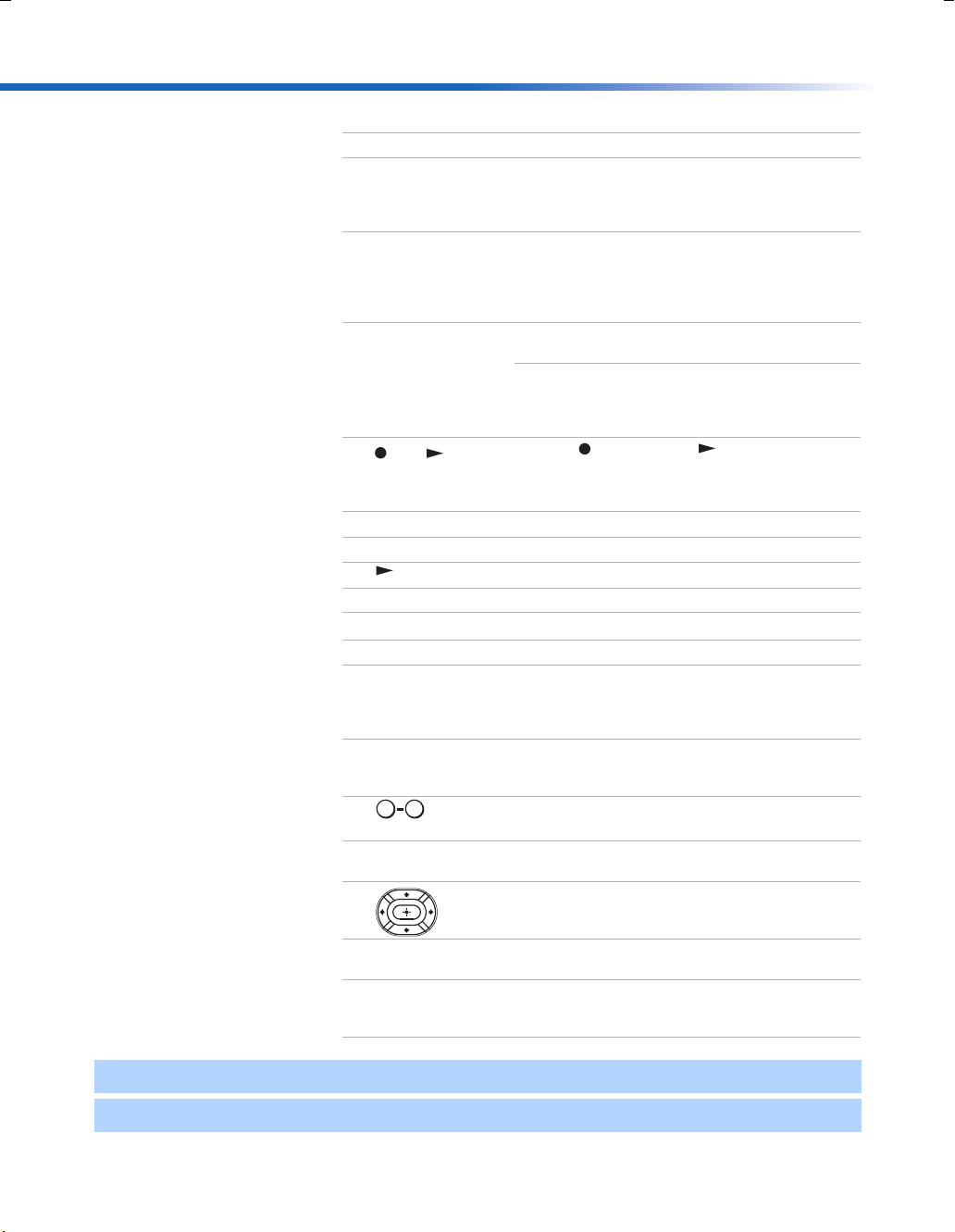

KV-34FV310

KV-38FV310

RM-Y181 BRAZIL SCC-S63F-A

RM-Y181 BRAZIL SCC-S63G-A

BA-5D

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 9/2003

REVISION DATE REVISION TYPE SUBJECT

9/2003 No revisions or updates are applicable at this time.

TRINITRON® COLOR TELEVISION

9-965-954-01

Page 2

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-34FV310

KV-38FV310

RM-Y181 BRAZIL SCC-S63F-A

RM-Y181 BRAZIL SCC-S63G-A

BA-5D

CHASSIS

9-965-954-01

KV-38FV310 RM-Y181

TRINITRON® COLOR TELEVISION

Page 3

TABLE OF CONTENTS

SECTION TITLE PAG E

Specifi cations ............................................................................................................................................. 4

Warning and Cautions ................................................................................................................................ 5

Safety Check-Out ....................................................................................................................................... 6

Self-Diagnostic Function............................................................................................................................. 7

SECTION 1: DISASSEMBLY........................................................................................................................... 10

1-1. Rear Cover Removal........................................................................................................................ 10

1-2. Chassis Assembly Removal ............................................................................................................. 10

1-3. Service Position Removal ................................................................................................................ 10

1-4. Picture Tube Removal .......................................................................................................................11

Anode Cap Removal Procedure........................................................................................................11

SECTION 2: SET-UP ADJUSTMENTS............................................................................................................ 12

2-1. Beam Landing .................................................................................................................................. 12

2-2. Convergence.................................................................................................................................... 13

2-3. Focus ............................................................................................................................................... 14

SECTION 3: SAFETY RELATED ADJUSTMENTS......................................................................................... 16

3-1.

X

RV8002 Confi rmation Method (HV Hold-Down Confi rmation) and Readjustments.................... 16

KV-34FV310/38FV310

SECTION 4: CIRCUIT ADJUSTMENTS.......................................................................................................... 17

4-1. Setting the Service Adjustment Mode .............................................................................................. 17

4-2. Memory Write Confi rmation Method ................................................................................................ 17

4-3. Remote Adjustment Buttons and Indicators ..................................................................................... 17

4-4. Service Data Lists ............................................................................................................................ 18

4-5. ID Map Table.................................................................................................................................... 25

4-6. A Board Adjustments........................................................................................................................ 26

SECTION 5: DIAGRAMS................................................................................................................................. 29

5-1. Circuit Boards Location .................................................................................................................... 29

5-2. Printed Wiring Board and Schematic Diagram Information.............................................................. 29

5-3. Block Diagram .................................................................................................................................. 30

5-4. Schematics and Supporting Information .......................................................................................... 33

A Board Schematic Diagram............................................................................................................ 33

HU Board Schematic Diagram ......................................................................................................... 39

HW Board Schematic Diagram ........................................................................................................ 42

HZ Board Schematic Diagram ......................................................................................................... 43

P Board Schematic Diagram............................................................................................................ 44

GW Board Schematic Diagram ........................................................................................................ 47

BS Board Schematic Diagram ......................................................................................................... 50

V Board Schematic Diagram............................................................................................................ 53

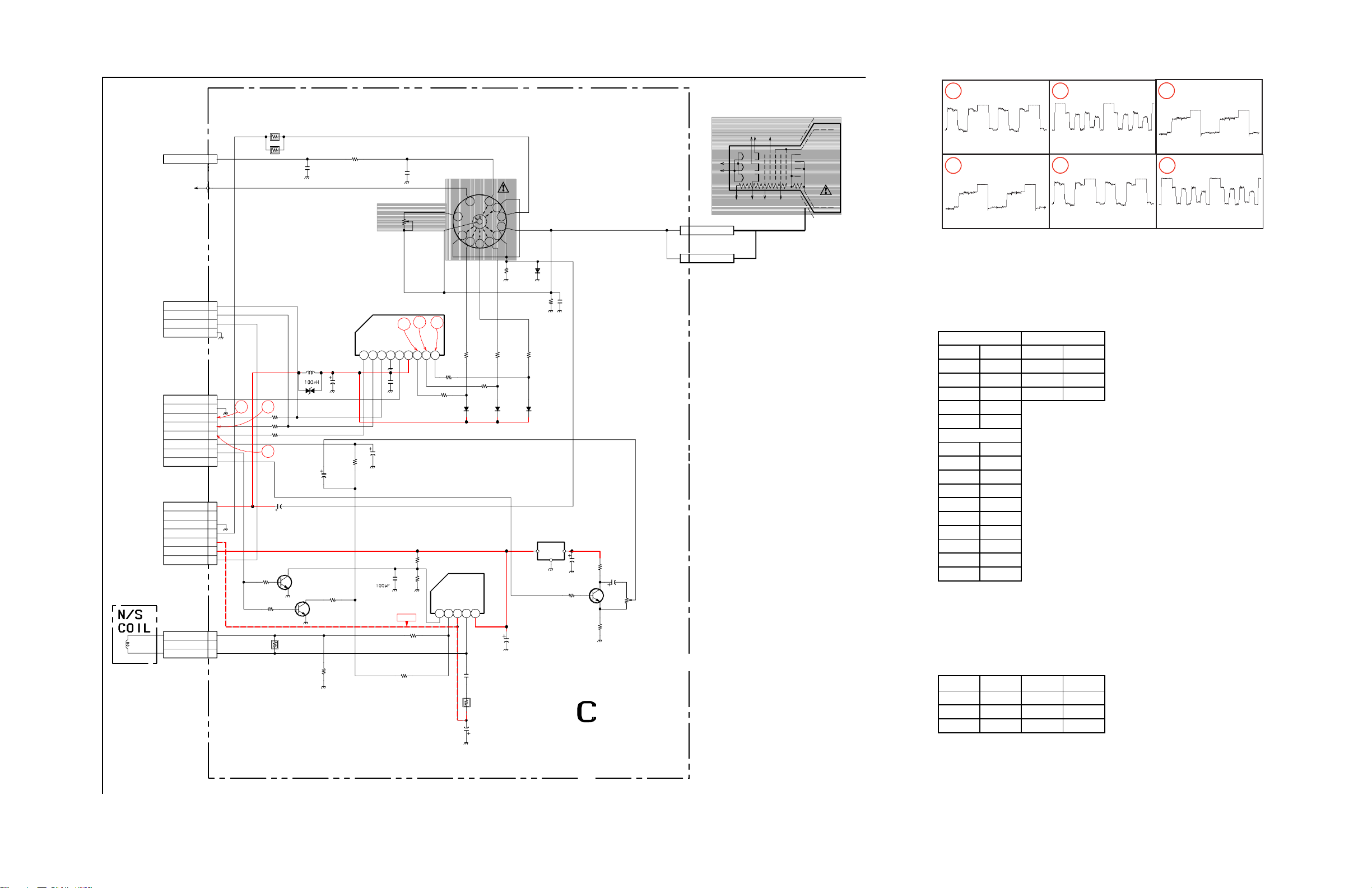

C Board Schematic Diagram............................................................................................................ 56

D Board Schematic Diagram............................................................................................................ 59

5-5. Semiconductors ............................................................................................................................... 62

SECTION 6: EXPLODED VIEWS.................................................................................................................... 63

6-1. Chassis (KV-34FV310 Only) ............................................................................................................ 63

6-2. Picture Tube (KV-34FV310 Only)..................................................................................................... 64

6-3. Chassis (KV-38FV310 Only) ............................................................................................................ 65

6-4. Picture Tube (KV-38FV310 Only)..................................................................................................... 66

SECTION 7: ELECTRICAL PARTS LIST........................................................................................................ 67

— 3 —

Page 4

SPECIFICATIONS

KV-34FV310 KV-38FV310

Power requirements 120-220V, 50/60Hz 120-220V, 50/60Hz

Number of Inputs/Outputs

Video

1)

33

S Video

2)

22

Y, PB, P

R

3)

22

Audio

4)

33

Audio Out

5)

11

Monitor Out 11

7.5 W X 2, 7.5 W X 2,

Speaker output (W) 15 Wsubwoofer 15 Wsubwoofer

Power Consumption (W)

In use (Max) 235 W 235 W

In Standby 1W 1W

Dimensions(W x H x D)

mm 898 x 682 x 584 mm 1020 x 760 x 640 mm

in

35

3

/8 x 26

7/8

x 23

40

1/4

x 30 x 25

1/4

Mass

kg 79 kg 103.4 kg

lbs

174 lbs. 4 oz. 228 lbs.

KV-34FV310/38FV310

Television system

American TV standard, NTSC

Channel coverage

VHF: 2-13/ UHF: 14-69/ CATV: 1-125

Picture tube

FD Trinitron® tube

Visible screen size

32 inch picture measured diagonally (KV-34FV310)

36 inch picture measured diagonally (KV-38FV310)

Actual screen size

34 inch measured diagonally (KV-34FV310)

38 inch measured diagonally (KV-38FV310)

Antenna

75-ohm external antenna terminal for VHF/UHF

Supplied Accessories

Size AA (R6) batteries (2)

Remote Control RM-Y181 (1)

Optional Accessories

TV Stand: SU-32F1 for (KV-34FV310)

SU-36F1 for (KV-38FV310)

Design and specifi cations are subject to change without notice.

— 4 —

1)

1 Vp-p 75 ohms unbalanced, sync negative

2)

Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3)

Y: 1.0 Vp-p, 75 ohms, sync negative;

PB: 0.7 Vp-p, 75 ohms

PR: Vp-p, 75 ohms

4)

500 mVrms (100% modulation), Impedance: 47 kilohms

)

More than 408 mVrms at the maximum volume setting (variable)

5

More than 408 mVrms (fi x)

TruSurround is a trademark of

SRS Labs, Inc. SRS and the SRS

symbol are registered trademarks of

™

TruSurround

by SRS

SRS Labs, Inc. in the United States

®

and in select foreign countries. SRS

and TruSurround are incorporated

under license from SRS Labs, Inc. and are protected under United

States Patent Nos. 4,748,669 and 4,841,572 with numerous

additional issued and pending foreign patents. Purchase of this

product does not convey the right to sell recordings made with the

TruSurround technology.

(• ) SRS (SOUND RETRIEVAL SYSTEM)

The ( • ) SRS (SOUND RETRIEVAL SYSTEM) is

manufactured by Sony Corporation under license

from SRS Labs, Inc. It is covered by U.S. Patent No.

4,748,669. Other U.S. and foreign patents pending.

The word ‘SRS’ and the SRS symbol ( • ) are

registered trademarks of SRS Labs, Inc.

BBE and BBE symbol are trademarks of BBE Sound,

Inc. and are licensed by BBE Sound, Inc. under U.S.

Patent No. 4,638,258 and 4,482,866.

Page 5

KV-34FV310/38FV310

WARNING AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT, after

removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the ac power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe

operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

— 5 —

Page 6

SAFETY CHECK-OUT

g

KV-34FV310/38FV310

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if

sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

Leakage Test

The AC leakage from any exposed metal part to earth ground and from

all exposed metal parts to any exposed metal part having a return to

chassis, must not exceed 0.5 mA (500 microamperes). Leakage current

can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75 V,

so analog meters must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples of passive

VOMs that are suitable. Nearly all battery-operated digital multimeters

that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground. If the retaining

screw is to be used as your earth ground, verify that it is at ground by

measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure B).

To Exposed Metal

Parts on Set

AC Outlet Box

0.15 µF

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

kΩ

1.5

Earth Ground

AC Voltmeter

(0.75 V)

Ohmmeter

Cold-water Pipe

— 6 —

Page 7

KV-34FV310/38FV310

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY/TIMER LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. If the screen displays a “0”, an error has occurred.

Diagnostic Item

Power does not turn on Does not light

+B overcurrent (OCP)* 2 times

+B overvoltage (OVP) 3 times

V-Stop 4 times

IK (AKB) 5 times

Zero Cross 9 times

9V Check 10 times

No. of times

STANDBY / TIMER

lamp flashes

Probable Cause Location Detected Symptoms

• Power cord is not plugged in.

• Fuse is burned out (F601).

(GW Board)

• H.OUT (Q502) is shorted. (A Board)

• IC702 is shorted. (C Board)

• IC501 is faulty. (A Board)

• If a high is supplied to pin 2 of IC501.

(A Board)

• +12V is not supplied. (A Board)

• IC561 is faulty. (A Board)

• Video OUT (IC561) is faulty. (A Board)

• IC702 is faulty. (C Board)

• Screen (G2) is improperly adjusted. **

• No zero cross pulses on pin 45

IC1001. (A Board)

• Relay failed (RY600) • Power does not come on.

• Power does not come on.

• No power is supplied to the TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line shorted.

• Has entered standby mode.

• Has entered standby state after

horizontal raster.

• Vertical deflection pulse is stopped.

• Power line is shorted or power

supply is stopped.

• No raster is generated.

• CRT Cathode current detection

reference pulse output is small.

• Power does not come on.

* If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously. The symptom that is diagnosed first

by the microcontroller is displayed on the screen.

** Refer to Screen (G2) Adjustments in Section 2-4 of this manual

Display of Standby/Timer LED Flash Count

2 times

3 times

4 times

5 times

9 times

10 times

LED ON 0.3 sec.

LED OFF 0.3 sec.

LED OFF

3 sec.

Diagnostic Item Flash Count*

+B Overcurrent 2 times

+B Overvoltage 3 times

V-STOP 4 times

IK (AKB) 5 times

Zero Cross 9 times

9V 10 times

*One fl ash count is not used for self-diagnostic.

— 7 —

Page 8

KV-34FV310/38FV310

Stopping the Standby/Timer LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER LAMP from fl ashing.

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up past

occurrences of failure on the screen for confi rmation.

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

DISPLAY

Channel

Sound volume - Power ON.

5

SELF DIAGNOSIS

2: +B OCP 0

3: +B OVP 0

4: VSTOP 0

Numeral “0” means that no fault was detected.

Numeral “1” means a fault was detected one time only.

5: AKB 1

9: ZCD 0

10: 9VON 0

101: WDT 0

Serial: xxxxxxx

Model: xxxxxxx

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

8

ENTERChannel

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

Self-Diagnostic Circuit

FROM

C BOARD

IC702 PIN 5

A BOARD

FROM

Q530

A BOARD

IC301

Y/CHROMA JUNGLE

IK-AKBIN

36

33

VM-OUT

HP(PROT)

31

SDA

TO V BOARD

Q904

BASE

A BOARD

Q651

61

A BOARD

IC561

V. OUT

REF

3

FROM

A BOARD

Q003

COLLECTOR

FROM

A BOARD

Q6006

COLLECTOR

— 8 —

A BOARD

IC001

SYSTEM

IO-BDAT

48

I-OCP

O-TIMER-LED

27

45

ZERO CROSS

26

60

33

38

I_9V CK

9V

A BOARD

IC003

MEMORY

5

BDA

DISPLAY

Page 9

KV-34FV310/38FV310

+B overcurrent (OCP)

Occurs when an overcurrent on the +B (135V) line is detected by pin 48 of IC001 (A Board). If the voltage of pin 48 of IC001 (A Board) is less than 1V

when V.SYNC is more than seven verticals in a period, the unit will automatically turn off.

+B over voltage (OVP)

Occurs when a high is felt onpin 2 of IC501 (A Board).

V-STOP

Occurs when an absence of the vertical defl ection pulse is detected by pin 31 of IC301 (A Board). Power supply will shut down when waveform interval

exceeds 2 seconds.

IK (AKB)

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC301 (A Board). TV will stay on, but

there will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

Zero Cross

Check Q691 collector (GK Board) 7.5V STBY goes to 0V when the set is turned on.

9V Check

Check Q691 collector (GK Board) 7.5V STBY goes to 0V when the set is turned on.

— 9 —

Page 10

1-1. REAR COVER REMOVAL

4 Screws

+BVTP 4 x 16

KV-34FV310/38FV310

SECTION 1: DISASSEMBLY

4 Screws

+BVTP 4 x 16

Rear Cover

4 Screws

+BVTP 4 x 16

7 Screws

+BVTP 4 x 16

1-3. SERVICE POSITION REMOVAL

C Board

A Board

V Board

1-2. CHASSIS ASSEMBLY REMOVAL

Chassis Assembly

GW Board

D Board

— 10 —

Page 11

1-4. PICTURE TUBE REMOVAL

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

KV-34FV310/38FV310

Coated

Earth

Ground

Strap

1

2

10

1. Discharge the anode of the CRT and remove the anode cap.

2. Unplug all interconnecting leads from the defl ection yoke,

neck assembly, degaussing coils and CRT grounding strap.

3

8

6

3. Remove the C Board from the CRT.

4. Remove the chassis assembly.

5. Loosen the neck assembly fi xing screw and remove.

5

6. Loosen the defl ection yoke fi xing screw and remove.

7. Place the set with the CRT face down on a cushion and

remove the degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring tension devices.

10. Unscrew the four CRT fi xing screws [located on each CRT

corner] and remove the CRT [Take care not to handle the

9

4

CRT by the neck].

7

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to

remove the anode cap. After removing the anode cap, short circuit to either the metal chassis, CRT shield, or carbon painted on the CRT.

NOTE: After removing the anode cap, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield or carbon

painted on the CRT.

REMOVAL PROCEDURES

a

Turn up one side of the rubber cap in

the direction indicated by arrow a .

b

Use your thumb to pull the rubber

cap fi rmly in the direction indicated

by arrow b .

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the anode

cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too

hard. A material fi tting called a shatter-hook terminal is built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

Anode Button

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow c .

c

— 11 —

Page 12

SECTION 2: SET-UP ADJUSTMENTS

KV-34FV310/38FV310

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power supply

voltage unless otherwise noted.

The controls and switch should be set as follows unless otherwise

noted:

PICTURE CONTROL: normal

BRIGHTNESS CONTROL: normal

2-1. BEAM LANDING

Preparation:

• Input a white pattern signal.

• Face the picture tube in an East or West direction to reduce the

infl uence of geomagnetism.

NOTE: Do not use the hand degausser; it magnetizes the CRT .

ADJUSTMENT PROCEDURE

1. Input white pattern from pattern generator.

2. Loosen the defl ection yoke mounting screw, and set the purity control

to the center as shown below:

Purity Control

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)/White Balance

Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

5. Oscilloscope

6. CRT Analyzer

6. Switch over the raster signal to red and blue and confi rm the

condition.

7. When the position of the defl ection yoke is determined, tighten it with

the defl ection yoke mounting screw.

8. When landing at the corner is not right, adjust by using the disk

magnets.

3. Input green pattern from pattern generator.

4. Move the defl ection yoke backward, and adjust with the purity control

so that green is in the center and red and blue are even on both sides.

Blue Red

Green

5. Move the defl ection yoke forward, and adjust so that the entire screen

becomes green.

— 12 —

Disk magnets

or rotatable disk

magnets correct

these areas (a-d)

b

d

Purity control

corrects this area

ba

cd

Deflection yoke positioning

corrects these areas

a

c

Page 13

KV-34FV310/38FV310

2-2. CONVERGENCE

Preparation:

• Perform FOCUS, V. LIN and V. SIZE adjustments.

• Set BRIGHTNESS control to minimum.

• Input dot pattern.

Center dot

RV701 V.STAT

R G B

R

G

B

V.STAT magnet

OPERATION OF BMC (HEXPOLE) MAGNET

The respective dot positions resulting from moving each magnet interact,

so perform adjustment while tracking.

1 Use the V.STAT tabs to adjust the red, green, and blue dots so they

line up at the center of the screen (move the dots in a horizontal

direction).

RG B

RGB RGB

RGB

RGB

RGB

Y SEPARATION AXIS CORRECTION MAGNET

ADJUSTMENT

VERTICAL AND HORIZONTAL STATIC

CONVERGENCE

1. Adjust V. STAT magnet to converge red, green and blue dots in the

center of the screen (Vertical movement).

Tilt the V. STAT magnet and adjust static convergence to open or

close the V. STAT magnet.

2. When the V. STAT magnet is moved in the direction of arrow a and b,

red, green, and blue dots move as shown below:

1

a

b

2

a

a

B

b

G

R

B

G

R

a

RG B

b

1. Input cross-hatch pattern, adjust PICTURE to minimum and

BRIGHTNESS to normal.

2. Adjust the defl ection yoke upright so it touches the CRT.

3. Adjust so that the Y separation axis correction magnet on the neck

assembly is symmetrical from top to bottom (open state).

V. STAT

BMC MAGNET

PURITY

4. Return the defl ection yoke to its original position.

a

G

BG R

B

B

b

b

G

R

b

3

b

a

R

b

— 13 —

Page 14

KV-34FV310/38FV310

DYNAMIC CONVERGENCE ADJUSTMENT

Before starting, perform Vertical and Horizontal Static Convergence

Adjustment.

1. Slightly loosen defl ection yoke screw.

2. Remove defl ection yoke spacers.

3. Move the defl ection yoke for best convergence as shown below:

BGR

R

B

G

G

R

B

B

G

R

RGB

RGB

G

B

BGR RGB

R

G

B

R

RGB

BGR

4. Tighten the defl ection yoke screw.

5. Install the defl ection yoke spacers.

TLH PLATE ADJUSTMENT

1. Adjust XCV core to balance X axis.

2. Adjust YCH VR to balance Y axis.

3. Adjust vertical red and blue convergence with V.TILT (TLV VR.)

Perform adjustments while tracking items 1 and 2.

4. Adjust Y MAGNET to correct V.BOW Geometry Distortion.

5. Adjust H-TRP to correct H.Trapezoid Geometry Distortion.

After adjusting items 4 and 5, confi rm overall geometry again.

SCREEN-CORNER CONVERGENCE

1. Affi x a permalloy assembly corresponding to the misconverged areas:

b

a

ba

a-d: screen-corner

misconvergence

cd

c

d

2-3. FOCUS

Preparation:

• Input crosshatch pattern.

• Adjust Picture Quality to standard, Picture and Brightness to 50%, and

Other to standard.

• Adjust the Horizontal Convergence of red and blue dots by tilting the

TLH plate on the defl ection yoke.

C Board

V Board

TLH Plate

Y Magnet

1. Input monoscope signal.

2. Set user controls to normal.

3. Set video mode to STANDARD.

4. Set the PICTURE to maximum.

5. Adjust at 325 Mark for best center/corner focus balance.

6. Receive an entire white signal. Make sure Magenta Ring is at an

RV701

V. STAT

XCV

H-TRP

TLV

YCH

acceptable level.

Screen (G2)

35 MARK

CENTER

CIRCLE

Focus

325 MARK

35

325

B R

(R)(B)

R B

(B)(R)

TLH+

TLH-

— 14 —

Page 15

KV-34FV310/38FV310

Adj. NO. Disp. Item All Models

VID_ADJ 0 RDRV Red Drive 41

VID_ADJ 1 GDRV Green Drive 32

VID_ADJ 2 BDRV Blue Drive 29

VID_ADJ 3 RCUT Red Cut-off 31

VID_ADJ 4 GCUT Green Cut-off 14

VID_ADJ 5 BCUT Blue Cut-off 17

VP2 4 SBRT Sub Bright 16

2-4. SCREEN (G2)

1. Input dot pattern from the pattern generator.

2. Set the user controls to NORMAL.

3. Attach the G2-Jig to the C Board.

4. Adjust RCUT, GCUT, BCUT, and SBRT in service mode with an

oscilloscope so that voltages on the red, green, and blue cathodes

are 170 ± 4.0Vdc.

5. Observe the screen and adjust SCREEN (G2) VR to obtain the

faintly visible background of dot signal.

6. Push the TEST + JUMP (+ Channel) to cut off the signal. The screen

should be bright or dark. Brightness of raster must be increased

when adjusting.

7. Adjust screen VR until the screen is slightly cut off, or scarcely lights

up. A signal cannot be seen when the brightness of the raster is high.

8. Push the JUMP again to release the cut off.

.

170 + 4.0 Vdc

GND

170Vdc

pedestal

2-5. WHITE BALANCE ADJUSTMENTS

1. Set program palette to STANDARD and push RESET.

2. Input an entire white signal.

3. Set to Service Adjustment Mode.

4. Set the PICTURE and BRIGHT to minimum.

5. Adjust with SBRT if necessary.

6. Set RCUT to “14”.

7. Select GCUT and BCUT with

8. Adjust by pressing

9. Set the PICTURE and BRIGHT to maximum.

10. Select GDRV and BDRV with and .

11. Adjust with 3 and 6 for the best white balance.

12. Write into the memory by pressing

13. Repeat steps 1-12 for GDR4, BDR4, GCU4 and BCU4 using

Video 4 input.

1

and

3

and 5 .

4

for the best white balance.

5

3

then

.

* Use values from Sub Contrast Adjustments

White balance should be adjusted after Sub Contrast because

RDRV is also used in Sub Contrast Adjustment. (See page 26)

— 15 —

Page 16

SECTION 3: SAFETY RELATED ADJUSTMENTS

KV-34FV310/38FV310

3-1. X RV8002 CONFIRMATION METHOD

(HV HOLD-DOWN CONFIRMATION) AND

READJUSTMENTS

Always perform the following adjustments when replacing the following

components marked with a

Part Replaced (Y) Adjustment (X)

D BOARD: HV HOLD DOWN

D8022, IC8001, IC8004, IC8005, RV8002

IC8104, R8014, R8015, R8016,

R8017, R8019, R8021, R8046,

R8052, R8072, R8078, R8079,

R8082, R8091, R8095

GW BOARD:

IC601

Y

mark on the schematic diagram:

PREPARATION BEFORE CONFIRMATION

Equipment: HV meter, DVM, Analog Current meter.

Condition: AC input voltage: 130 (+

Set condition: Reset condition.

Signal Input: All black video signal for Cut off, All white signal for High

light.

2) VAC.

HV PROTECTOR CHECK-HIGH LIGHT

CONDITION

1. Short across C8002, C8021, C8301, C8012 and C8015.

2. Open pin 10 (ABL) of IC301 (YCJ).

3. Set video to white fi eld. Set HV current load to iabl = 3.04 ± 0.05mA

for 34/38” by adjusting picture and brightness to maximum condition.

4. Adjust VR jig to obtain 34.25 ± 0.2kV for 34/38”.

5. Remove short from C8002 and confi rm that hold down activates.

6 Short C8002 again and confi rm that HV recovers.

7 Then readjust precision VR jig to obtain 32.0 ± 0.2kV for 34/38”.

8. Remove shorts from C8002, C8021 and C8301.

9. Confi rm that hold down does not

10.Remove shorts from C8012, C8015.

activate.

HV PROTECTOR CHECK-CUT OFF

CONDITION

1. Remove D board and carefully lift as necessary to gain access to the

bottom of the board. Open ABL pin 1 on RHT (T8001) and connect

analog current meter.

2. Make Cut Off condition. Input all black video signal and set picture

and brightness to min., ABL current should be approximately 0.16 ±

0.05mA for 34/38”.

3. Short across C8002, C8021 and C8301.

4. Turn off the set and install precision VR jig (initially set to 100K) to IC

8005 pin 1 and GND (C8076 -). Restore power and adjust to obtain

36.0 ± 0.2kV for 34/38”.

5. Remove short from C8002 and confi rm that hold down activates.

6. Short C8002 again and confi rm that HV recovers.

7. Then readjust precision VR jig to obtain 32.5 ± 0.2kV for 34/38”.

8. Remove short from C8002, C8021 and C8301.

9. Confi rm that hold down does not

.

activate

— 16 —

Page 17

SECTION 4: CIRCUIT ADJUSTMENTS

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y181) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

KV-34FV310/38FV310

4-1. SETTING THE SERVICE ADJUSTMENT

MODE

1. Standby mode (Power off).

2. Press the following buttons on the remote commander within a

second of each other:

DISPLAY

Channel 5 Sound Volume + Power

SERVICE ADJUSTMENT MODE ON

Item

order

0

TV

Item

data

7

SERVICE

Disp.

(Item)

VP

HSIZ

Mode

1. The CRT displays the item being adjusted.

1

2. Press

3. Press

4. Press

or 2 on the Remote Commander to select the item.

3

or 6 on the Remote Commander to change the data.

MUTING

then

ENTER

to write into memory.

SERVICE ADJUSTMENT MODE MEMORY

Item

order

0

TV

Item

data

7

SERVICE

1. Press 8 then

Item

Disp.

order

(Item)

Disp.

(Item)

VP

HSIZ

ENTER

on the Remote Commander to initialize.

Item

data

4-2. MEMORY WRITE CONFIRMATION

METHOD

1. After adjustment, pull out the plug from the AC outlet, then replace

the plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confi rm they were adjusted.

4-3. REMOTE ADJUSTMENT BUTTONS AND

INDICATORS

MUTING

(Enter into

memory)

1

Disp. (Item up)

2

(Device Item Up)

4

Disp. (Item down)

8

(Initialize)

VOLUME (+)

(Service Mode)

POWER

(Service Mode)

DISPLAY

(Service Mode)

3

Item

(Data up)

6

Item

(Data down)

5

(Device item

down)

ENTER

(Enter into

memory)

0

(Remove from

memory)

VP

HSIZ

7

TV

WRITE

0

Carry out Step 1 when adjusting

ID’s 0-7 and when replacing and

adjusting IC003.

2. Press

MUTING

then

ENTER

to write into memory.

3. DO NOT turn off set until SERVICE appears.

RM-Y181

— 17 —

Page 18

4-4. SERVICE DATA LISTS

KV-34FV310/38FV310

Service

Group

VERSION Fix 0 VER Microprocessor version information =

Service

Group

VP1

Fix/

Var

Fix/

Var

Var 0 HSIZ H SIZE (11/ 2-7)

Var 1 HPOS HPOS (12 / 2-7)

Var 2 VBOW AFC BOW (16 / 4-7)

Var 3 VANG AFC ANGLE (16 / 0-3)

Var 4 VTRP TRAPEZIUM (20 / 3-7)

Var 5 HTRP H. TRAPEZOID (15 / 4-7)

Var 6 TROT TILT ROTATION (0-63)

Var 7 PAMP PIN AMP (13 / 2-7)

Var 8 UPIN UP-CPIN (14 / 2-7)

Var 9 LPIN LO-CPIN (1C / 2-7)

Var 10 VSIZ V SIZE (0E / 2-7)

Var 11 VPOS V POSITION (0E / 2-7)

Var 12 VLIN V LINEARITY (10 / 0-3)

Var 13 SCOR S CORRECTION (10 / 4-7)

Fix 14 VZOM 16:9 CRT Z Mode on/off 0

Var 15 EHT Vertical High-Voltage Compensation 0

Fix 16 ASP Aspect Ratio control (4:3 Mode) 47

Fix 17 ASP1 Aspect Ratio control (16:9 Mode) 47

Fix 18 SCRL 16:9 CRT Z Mode Trans. Scroll 31

Fix 19 HBLK Horizontal Blanking on/off 1

Fix 20 LBLK Left Blanking Adjustment 12

Fix 21 RBLK Right Blanking Adjustment 6

Fix 22 HDW Horizontal Drive Pulse Width 1

Fix 23 EWDC "Parabola" EW, D.C. Adjustment 0

Fix 24 LVLN Lower Screen BTM Vertical Line Adj. 0

Fix 25 UVLN Upper Screen BTM Vertical Line Adj. 0

Fix 26 INTL INTERLACE 0

Fix 27 HOSC Horizontal VCO Oscillation Freq. 7

Fix 28 VSS Vertical Sync Slice Level 0

Fix 29 HSS Horizontal Sync Slice Level 0

Fix 30 HMSK For Macro Vision 0

Fix 31 VTMS Select Signal VTIM Pin 0

Fix 32 TCMD

Fix 33 VCMD

Fix 34 AFC AFC Loop Gain Switching 0

Fix 35 FIFR Field Frequency 1

Fix 36 VBLK VBLKW 0

Fix 37 HTSW H-Trap Switch : NEW 0

Name Description

No.

No. DescriptionName

Vertical Count Down Mode Switching (for

TV)

Vertical Count Down Mode Switching (for

Video)

Common

Init

Data

Common

Init

Data

1

3

— 18 —

Page 19

SERVICE DATA LISTS

KV-34FV310/38FV310

Service

Group

VP2

Fix/

Var

Fix 0 REFP REFP 0

Fix 1 JPSW Jump SW =

Var 2 SHUE Sub HUE adjustment

Var 3 SCOL Sub COLOR adjustment

Var 4 SBRT Sub BRIGHTNESS adjustment

Fix 5 SBRO Sub BRIGHTNESS adjustment for YUV 3

Fix 6 AXPL Axis PAL 0

Fix 7 AXNT Axis NTSC 1

Fix 8 CBPF Chroma BPF on/off 1

Fix 9 CTRP Y TRAP FILTER on/off 1

Fix 10 COFF Color On/off =

Fix 11 KOFF Set Color Killer 0

Fix 12 SSHR Sub SHARPNESS for RF 4

Fix 13 SSHV Sub SHARPNESS for Video 4

Fix 14 SHP4 Sub SHARPNESS for YUV 4

Fix 15 TSPF SHARPNESS Circuit Fo (for TV) 2

Fix 16 VSPF SHARPNESS Circuit Fo (for Video) 3

Fix 17 PREL Pre-Shoot/ Over-Shoot 1

Fix 18 ABLM ABL Mode Switch 1

Fix 19 VTH ABL CD VHT Switching =

Fix 20 YDEC

Fix 21 YDYS

Fix 22 NCOL No Color ID 1

Fix 23 FSC FSC Out on/off 0

Fix 24 KID Killer ID Control on/off 0

Fix 25 SHOF Offset for sharpness 0

Y Delay Time Control (Video4, SVideo1,

SVideo2)

Y Delay Time Control (RF, Video1,

Video2, Video3)

DescriptionNo. Name

Common

Init

Data

0

0

Service

Group

VID_ADJUSTMENT

Fix/

No. Name Description

Var

Fix 0 RDRV R DRIVE (0A / 7-2) 41

Var 1 GDRV G DRIVE (0B / 7-2)

Var 2 BDRV B DRIVE (0C / 7-2)

Fix 3 RCUT R CUT OFF ( 07 / 7-2) 31

Var 4 GCUT G CUT OFF (08 / 7-2)

Var 5 BCUT B CUT OFF (09 / 7-2)

Var 6 SCON Sub Contrast adjustment

Fix 7 CHUE Sub HUE adjustment for TV 18

Var 8 HUE4 Sub HUE adjustment for YUV

Fix 9 CCOL Sub COLOR adjustment for TV 14 18 23

Var 10 COL4 Sub COLOR adjustment for YUV

Var 11 UOFS YUV U offset

Var 12 VOFS YUV V offset

Fix 13 RON R ON (01 / 3) =

Fix 14 GON G ON (01 / 2) =

Fix 15 BON B ON (01 / 1) =

Var 16 HUEV Sub HUE adjustment for Video

Var 17 COLV Sub COLOR adjustment for Video 7 7 7

Common NTSC PAL-M PAL-N

Init Init Init Init

Data Data Data Data

— 19 —

Page 20

SERVICE DATA LISTS

KV-34FV310/38FV310

Service

Group

ENCODER

Service

Group

COL_TMP

Fix/

No.

Var

Fix 0 RDR4 R DRIVE (0A / 7-2) 41

Var 1 GDR4 G DRIVE (0B / 7-2)

Var 2 BDR4 B DRIVE (0C / 7-2)

Fix 3 RCU4 R CUT OFF ( 07 / 7-2) 31

Var 4 GCU4 G CUT OFF (08 / 7-2)

Var 5 BCU4 B CUT OFF (09 / 7-2)

Fix 6 CON4 Sub Contrast adjustment 12

Fix 7 EHUE Sub HUE adjustment for TV 28

Fix 8 ECOL Sub COLOR adjustment for TV 31

Fix 9 HPO4 HPOS (12 / 2-7)

Fix 10 CDL4 Encoder CDL 3D Register 6

Fix 11 YNR4 Encoder YNRL 3D Register 1

Fix 12 CNR4 Encoder CNRL 3D Register 1

Fix 13 NRM4 Encoder VAPG 3D Register 3

Fix 14 VAP4 Encoder NRMD 3D Register 3

Var 15 ESHU Sub HUE adjustment for Video 10

Var 16 ESCO Sub COLOR adjustment for Video 9

Fix 17 HCN4 Encoder HCNT 3D Register 0

Fix 18 YPGE Encoder YPGE 3D Register 9

Fix/

Var

Fix 0 GDOF G DRIVE Offset 4

Fix 1 BDOF B DRIVE Offset 15

Fix 2 GCOF G CUT Offset 5

Fix 3 BCOF B CUT Offset 12

Fix 4 DCOL Dynamic Color =

Name Description

Name

DescriptionNo.

Common

Init

Data

Common

Init

Data

Same as HPOS + 1

Service

Group

PIC_IMP

Fix/

No.

Var

Fix 0 BLAD Black area detect (01 / 6-7) 0

Fix 1 SRTS SRT level (01 / 4-5) 3

Fix 2 YNR YNR(01 / 2) 1

Fix 3 GIRE Gamma correction(01 / 0-1) 3

Fix 4 DAC1 DAC1(02 / 7) 0

Fix 5 DAC2 DAC2(02 / 6) 0

Fix 6 VMGA VM on 1226 (02/5-4) 0

Fix 7 GCUR Gamma curve(02 / 2) 1

Fix 8 BLKC Black Compensation (02 / 1) 1

Fix 9 TEST TEST(03 / 6-7) 3

Fix 10 RS RS (03 / 3-5) 0

Fix 11 RTCH RTC(03 / 0-2) 3

Fix 12 RTCL RTC(03 / 0-2) 3

Fix 13 RTCO RTC(03 / 0-2) 0

Fix 14 APAH APAC 0

Fix 15 APAL APAC 1

Fix 16 APAO APAC 1

Fix 17 SRTH SRT bit for Dynablack = High 1

Fix 18 SRTL SRT bit for Dynablack = Low 1

Fix 19 SRTO SRT bit for Dynablack = Off 0

Fix 20 SHPH Sharpness level for Dynablack = High 57

Fix 21 SHPL Sharpness level for Dynablack = Low 52

Fix 22 SHPO Sharpness level for Dynablack = Off 0

DescriptionName

Common

Data

Init

— 20 —

Page 21

SERVICE DATA LISTS

KV-34FV310/38FV310

Service

Group

PALETTE

Service

Group

3L_COMB

Fix/

Var

Fix 0 VPIC User picture setting 0:min, 63: max 63 50 38 31

Fix 1 VBRT User brightness setting 0:min, 63: max 26 29 35 31

Fix 2 VCOL User color setting 0:min, 63: max 35 31 31 31

Fix 3 VSHP User sharpness setting 0:min, 63: max 31 33 31 31

Fix 4 VVM 0: OFF, 1: Low, 2: High, 3: N/A 2 1 0 0

Fix 5 VTRI 0: Cool, 1: Neutral, 2: Warm, 3: N/A 0 1 2 1

Fix 6 VGMA 0: OFF, 1: Low, 2: Mid, 3: Max 2 1 0 0

Fix 7 VNRM 0: 3D, 1: 2D 0 0 0 0

Fix 8 VYDC

Fix 9 VVEN Vertical; Enhancement 4 3 3 0

Fix 10 VHK0 Horizontal Peaking 0:On, 1:Off 0 0 0 1

Fix 11 VDBK

Fix 12 VYPL Y-Peaking Limit 1 0 0 0

Fix/

No. Name

Var

Fix 0 FUNN Function (0 / 7-6) for NTSC 3

Fix 1 FUNP Function (0 / 7-6) for PALM, PALN 3

Fix 2 DRNG DRANG (0 / 2) 0

Fix 3 YCSM Y/C Sep Mode (0 / 1-0) 0

Fix 4 CNRK CNRK (1 / 7-6) 1

Fix 5 CNRL CNR Lim (1 / 5-4) 1

Fix 6 CLPF C-LPF(1 / 3) 1

Fix 7 SLPF SelC-LPF(1 / 2) 0

Fix 8 MODE Mode1 (1 / 1) 0

Fix 9 YPG Y - Peaking Gain (2 / 7-6) 3

Fix 10 PDSC Pds. Clip (2 / 3) 0

Fix 11 YLPF Y-LPF(2 / 2) 1

Fix 12 VENL V-Emph N.L (3 / 4-2) 4

Fix 13 VEC V - Emph Core (3 / 1-0) 3

DC Transmission Ratio 0,1: 100%, 2:

92%, 3: 85

User Dynablack 0: OFF, 1: Low, 2: High,

3: N/A

DescriptionNo. Name

Description

VIVID STANDARD MOVIE PRO

Init Init Init Init

Data Data Data Data

3211

2110

Common

Init

Data

— 21 —

Page 22

SERVICE DATA LISTS

KV-34FV310/38FV310

Service

Group

3D_COMB

Fix/

No. Name

Var

Fix 0 COUT COUTS(00 / 2-3) 3

Fix 1 YAPS YAPS(00 / 0-1) 1

Fix 2 NSDS NSDS(01 / 4-5) 0

Fix 3 MSS MSS(01 / 2-3) 0

Fix 4 KILS KILS (01 / 1-0) 1

Fix 5 DYC DYCOS ( 02 / 7-6) 2

Fix 6 EXAD EXADINS(02 / 5) 0

Fix 7 EXCS EXCSS(02 / 1- 0) 1

Fix 8 CPP CPP(03 / 6) 0

Fix 9 HDP HDP(03 / 3-5) 6

Fix 10 CDL CDL(03 / 0-2) 6

Fix 11 DYCO DYCOR(04 / 4-7) 2

Fix 12 DYGA DYGAIN(04 / 0-3) 10

Fix 13 DCCO DCCOR(05 / 4-7) 2

Fix 14 DCGA DCGAIN(05 / 0-3) 9

Fix 15 YNRL YNRLIM(06 / 4-5) 1

Fix 16 CNRL CNRLIM(06 / 0-1) 1

Fix 17 ID1O ID1ON(07 / 7) 0

Fix 18 ID1W ID1W0A1(07 / 6) 0

Fix 19 ID1N ID1W0A2(07 / 5) 0

Fix 20 WSC WSC(08 / 6-7) 1

Fix 21 VTRH VTRH(08 / 4-5) 1

Fix 22 VTRR VTRR(08 / 2-3) 1

Fix 23 LDSR LDSR(08 / 0-1) 2

Fix 24 WSS WSS(09/7) 0

Fix 25 ID1E ID1ECON ( 09/6) 1

Fix 26 TT TT ( 09 / 4 -5) 0

Fix 27 FELC FELCHK ( 09/3) 1

Fix 28 TH TH ( 09 / 1 -2) 0

Fix 29 VAPG VAPGAIN(0A / 5-7) 3

Fix 30 VAPI VAPINV(0A / 0-4) 25

Fix 31 YPFT YPFT(0B / 4-5) 3

Fix 32 YPFG YPFG(0B / 0-3) 9

Fix 33 V1PS V1PS(0C / 6-7) 3

Fix 34 VEGS VEGS(0C / 4-5) 2

Fix 35 CC3N CC3N(0C / 3) 0

Fix 36 C0HS C0HS(0C / 2) 0

Fix 37 SEL2 SELD2FH(0C / 0) 1

Fix 38 SEL1 SELD1FL(0D / 5) 1

Fix 39 YHCO YHCOR(10 / 6-7) 0

Fix 40 YHCG YHCGAIN(10 / 5) 1

Fix 41 OVST +OVST(10 / 3) 0

Fix 42 CSHD CSHDT(10 / 2) 0

Fix 43 KCTT KCTT(10 / 0-1) 0

Fix 44 SHT SHT(11 / 7-6 ) 0

Fix 45 VCT VCT(11/ 5) 0

Fix 46 CGAT CLKGAT ( 11 / 4) 0

Fix 47 CG2D CLK2D ( 11 / 3) 1

Fix 48 CGGT CLKGGT ( 11 / 2) 0

Fix 49 CGEB CLKGEB ( 11 / 1) 0

Fix 50 CGT CLKGT ( 11 / 0) 0

Fix 51 HPLL HPLLFS(12 / 7) 1

Fix 52 BPLL BPLLFS (12 / 6) 0

Fix 53 FSCF FSCFG(12 /5) 0

Fix 54 PLLF PLLFG(12 / 4) 1

Description

Common

Data

Init

— 22 —

Page 23

SERVICE DATA LISTS

KV-34FV310/38FV310

Service

Group

3D_COMB

Service

Group

PIP

Fix/

No. Name Description

Var

Fix 55 KILR KILR(12 / 0-3) 3

Fix 56 HSSL HSSL(13 / 4-7) 12

Fix 57 VSSL VSSL(13 / 0-3) 8

Fix 58 BGPS BGPS(14 / 4-7) 4

Fix 59 BGPW BGPW(14 / 0-3) 10

Fix 60 ADCL ADCLKS(15 / 6-7) 3

Fix 61 NSDW NSDSW(15 / 4) 1

Fix 62 HIZE HIZEN ( 16 / 4) 0

Fix 63 HCNT HCNTFSYN ( 17 / 6) 0

Fix/

No. Name Description

Var

Fix 0 PFRN VCXO oscillation 0

Fix 1 PRVS HD/VD input synchronous mode selection 1

Fix 2 PCON PIP sub contrast control 97

Fix 3 PUCO PIP U level control 5

Fix 4 PVCO PIP V level control 17

Fix 5 PHUE PIP sub hue control 12

Fix 6 PKIL Color killer 0

Fix 7 PSEP C-sync sep input selection 1

Fix 8 PDCN Sub pic sync sep. Threshold setting 3

Fix 9 PBGS bgp position setting 15

Fix 10 PDL0 Y/C delay adjust (for video) 11

Fix 11 PDL1 Y/C delay adjust (for yuv) 13

Fix 12 PBRT Y brightness control 25

Fix 13 PVP1 V pedestal level for YUV 0

Fix 14 PUP1 U pedestal level for YUV 0

Fix 15 PVP2 V pedestal level for main w/ burst 0

Fix 16 PUP2 U pedestal level for main w/ burst 0

Fix 17 PVP3 V pedestal level for main w/o burst 0

Fix 18 PUP3 U pedestal level for main w/o burst 0

Fix 19 PACS 0D, 0Eh setting mode 1

Fix 20 PSYS Color system =

Fix 21 PSDL Sync delay control 0

Fix 22 PCCL YUV color level 11

Fix 23 PCGA Croma gain 1

Fix 24 PAAF Auto AFC 1

Fix 25 PSU2 For test 0

Fix 26 PCVF Internal 1H comb filter 0

Fix 27 PBIT Y clamp time constant 0

Fix 28 PAFC AFC time constant 0

Fix 29 PACC Color decoder amplitude 21

Fix 30 PSDT System automatic judgment =

Fix 31 PBUR VCXO mode selection 0

Fix 32 PEVE Main picture PAL-N 0

Fix 33 PINW Invert sub picture field definition 0

Fix 34 PINR Invert main picture field definition 0

Fix 35 PVMD Vertical display mode when pal-n =

Fix 36 PREF Main picture field fix 0

Fix 37 PARE Automatic 50/60 Hz judgment 0

Fix 38 PBWD BW det. Threshold setting 1

Fix 39 PFRA Freq. Adjustment for free run mode 0

Common

Data

Common

Data

Init

Init

— 23 —

Page 24

SERVICE DATA LISTS

KV-34FV310/38FV310

Service

Group

PIP

Fix/

No. Name Description

Var

Fix 40 PPAL Parameter setting for PAL-M judgment 52

Var 41 PHPO Sub picture h position

Fix 42 PVPO Sub picture v position 22

Fix 43 PHTI Display timing adjust 6

Fix 44 PHAJ Main/Sub switch delay control 2

Fix 45 PBGY Back ground Y level setting 0

Fix 46 PCRO Sub picture read mode 0

Fix 47 PPAR

Fix 48 PHPF Y output HPF 0

Fix 49 PFSC FSC output 0

Fix 50 PVCH 15h,16h,17h, setting mode 0

Fix 51 PVON V-chip decode mode 1

Fix 52 PVLN V-chip data slicer line selection 17

Fix 53 PVSB

Fix 54 PVLV V-chip data slicer slice parameter 130

Fix 55 SUSW Sub-Unlock bit position switch 0

Fix 56 PDL5 YDL by when PALN system 0

Fix 57 PHT5 HT by when PALN system 15

Threshold control for ident judgment of

sub

V-chip data slicer start bit detection

parameter

Common

Init

Data

1

64

Service

Group

AP

Fix/

No. Name

Var

Fix 0 SBAL Sub Balance 4 4

Fix 1 SBAS Sub Bass 2 0

Fix 2 STRE Sub Treble 0 0

Fix 3 SRL Surround level 0 0

Fix 4 BBOH Surround Off - BBE high 6 6

Fix 5 BBOL Surround Off - BBE low 8 10

Fix 6 BBSH Simulated - BBE high 3 3

Fix 7 BBSL Simulated - BBE low 4 4

Fix 8 BBMH da 0 0

Fix 9 BBML Surround - BBE low 0 0

Fix 10 BBGH WOW - BBE high 7 7

Fix 11 BBGL WOW - BBE low 9 12

Fix 12 BBTH Trusurround - BBE high 5 6

Fix 13 BBTL Trusurround - BBE low 9 12

Fix 14 VFIX Audio output fix data 255 255

Fix 15 AGCL AGC Level 2 2

Fix 16 BTAB Bass/Treble curve selection 1 1

Description

27FV 32/36FV

Init Init

Data Data

— 24 —

Page 25

SERVICE DATA LISTS

KV-34FV310/38FV310

Service

Group

CCD

Service

Group

OP

Service

Group

ID Fix 0 ID0 Model variation ID0 SEE ID MAP

Fix/

No. Name

Var

Fix 0 DUM0 Only for testing =

Fix 1 VOSD Only for testing =

Fix/

No. Name Description

Var

Var 0 DISP OSD Display position

Fix 1 RAMW =

Fix 2 ICMP

Fix 3 IPOR 0:Even, 1: Odd, Other: do not change 1

Fix 4 FAWD 1: Forced to auto wide mode, 0:normal 0

Fix 5 HCLW H-Count Lower limit 67

Fix 6 HCHG H-Count Higher limit 254

Fix 7 9VTM Delay for 9V check subsystem 55

Fix 8 ZDET Zero detect relay delay 123

Fix/

No. Name Description

Var

Fix 1 ID1 Model variation ID1 SEE ID MAP

Fix 2 ID2 Model variation ID2 SEE ID MAP

Fix 3 ID3 Model variation ID3 SEE ID MAP

Fix 4 ID4 Model variation ID4 SEE ID MAP

Fix 5 ID5 Model variation ID5 SEE ID MAP

Fix 6 ID6 Model variation ID6 SEE ID MAP

Fix 7 ID7 Model variation ID7 SEE ID MAP

Comparison data to determine Noninterlace signal for OSD

Description

Common

Init

Data

Common

Init

Data

Common

Init

Data

4

4-5. ID MAP TABLE

Model Destination ID-O ID-1 ID-2 ID-3 ID-4 ID-5 ID-6 ID-7

KV-34FV310 BRAZIL 63 191 237 194 46 128 6 81

KV-38FV310 BRAZIL 63 191 237 194 46 128 6 81

— 25 —

Page 26

KV-34FV310/38FV310

4-6. A BOARD ADJUSTMENTS

H. FREQUENCY (FREE RUN) CHECK

1. Input a TV mode (RF) with no signal.

2. Connect a frequency counter to base of Q501

(TP-25 H. DRIVE) on the A Board.

3. Check H. Frequency for 15734 ± 400/-200 Hz.

V. FREQUENCY (FREE RUN) CHECK

1. Select video 1 with no signal input.

2. Set the conditions for a standard setting.

3. Connect the frequency counter to TP-27 (V OUT) or CN501 pin

6

(V DY+) and ground on the A Board .

4. Check that V. Frequency shows 60 ± 4 Hz.

SUBCONTRAST ADJUSTMENT (RDRV)

1. Input a color-bar signal and set the level to 75%.

2. Set in Pro mode.

3. Activate the Service Adjustment Mode.

3

4. Set GON and BON items. Using

values. Leave RON set to “1”.

Display

Mode

service video rdrv

Signal

Type

ntsc

vchp

Category

Item

00000000 00000000

R ON: ON (1)

G ON: OFF (0)

B ON: OFF (0)

5. Select SCON with

1

and 4 .

6. Connect an oscilloscope probe to C Board, CN705 Pin 3 Blue Out.

7. Adjust the value of SCON with

3

1.90 ± 0.01Vpp.

6

and

Item

Data

26

and 6 for

set each to the following

DISPLAY POSITION ADJUSTMENT (DISP)

1. Input a color-bar signal.

2. Set to Service Adjustment Mode.

3. Select DISP with 1 and 4 .

4. Adjust values of DISP with

5. Write to memory by pressing

3

and 6 to adjust characters to the center.

MUTING

then

ENTER

.

6. Check to see if the text is displayed on the screen.

Mode

Category

service micro disp 48

Signal

Type

ntsc

vchp

Display

00000000 00000000

Item

Item

Data

SUB BRIGHT ADJUSTMENT (SBRT)

1. Input a monoscope signal.

2. Activate the Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Select the SBRT item with

5. Adjust the values of SBRT with

1

and 4 .

3

and 6 to obtain a faintly visible

crosshatch.

6. Press

MUTING

then

ENTER

to save into the memory.

SUB HUE, SUB COLOR ADJUSTMENT

(SHUE, SCOL)

[RF], [VIDEO] [VIDEO MODE PRO]

1. Input color-bar signal at 75%.

2. Set screen to Pro Mode.

3. Activate the Service Adjustment Mode.

4. Set (PIC) to 100% and (COL) to 50%.

5. Connect an oscilloscope probe to C Board, CN705 Pin

1

6. Select the SHUE and SCOL item with

and 4 .

7. While showing the SHUE item, adjust the waveform with

the second and third bars show the same level

(V2 = V3 +

0.2Vpp).

8. While showing the SCOL item, adjust the waveform with 3 and 6 until

the fi rst and fourth bars show the same level

(V1 = V4 +

0.2Vpp).

9. For Trinorma models inspect each system NTSC, PAL M & N.

V1

V2 V3

V4

4

Blue Out.

1

and 4 until

8. Reset GON and BON values to “1”.

R ON: ON (1)

G ON: ON (1)

B ON: ON (1)

9. Press

MUTING

then

to save into the memory.

ENTER

10. After adjusting SCON, if still out of xpec, use RDRV resistor as a

fi ne adjustment.

10. Press

— 26 —

MUTING

then

ENTER

to save into the memory.

Page 27

KV-34FV310/38FV310

[YUV] [VIDEO MODE PRO]

1. Input color-bar signal at 75%.

2. Set screen to Pro Mode.

3. Activate the Service Adjustment Mode.

4. Set (PIC) to 100% and (COL) to 50%.

5. Connect an oscilloscope probe to C Board, CN705 Pin

1

6. Select the SHUE and SCOL item with

7. While showing the SHUE item, adjust the waveform with

until the second and third bars show the same level

(V2 = V3 +

8. While showing the SCOL item, adjust the waveform with

until the fi rst and fourth bars show the same level

(V1 = V4 +

9. Press

0.2Vpp).

0.2Vpp).

V2 V3

V1

MUTING

then

V4

ENTER

to save into the memory.

and 4 .

4

Blue Out.

1

and 4

3

and 6

[YUV] [VIDEO MODE VIVID]

V. CENTER ADJUSTMENT (VPOS)

Perform this adjustment after performing H. Frequency

(Free Run) Check.

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the VPOS item with

4. Adjust value of VPOS with

5. Press

MUTING

then

1

and 4 .

3

and 6 for the best vertical center.

ENTER

to save into the memory.

H. CENTER ADJUSTMENT (HPOS)

Perform this adjustment after performing H. Frequency

(Free Run) Check.

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the HPOS item with

4. Adjust the value of HPOS with

5. Press

MUTING

then

1

and 4 .

ENTER

3

and 6 for the best horizontal center.

to save into the memory.

1. Input color-bar signal at 75%.

2. Set screen to Vivid Mode.

3. Activate the Service Adjustment Mode.

4. Set (PIC) to 100% and (COL) to 50%.

5. Connect an oscilloscope probe to C Board, CN705 Pin

1

6. Select the SHUE and SCOL item with

7. While showing the SHUE item, adjust the waveform with

until the second and third bars show the same level

(V2 = V3 +

8. While showing the SCOL item, adjust the waveform with

until the fi rst and fourth bars show the same level

(V1 = V4 +

9. Press

0.2Vpp).

0.2Vpp).

V2 V3

V1

MUTING

then

V4

ENTER

to save into the memory.

and 4 .

4

Blue Out.

1

and 4

3

and 6

V. SIZE ADJUSTMENT (VSIZ)

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the VSIZ item with

4. Adjust value of VPOS with

5. Press

MUTING

then

1

and 4 .

1

and 4 for the best vertical center.

to save into the memory.

ENTER

H. SIZE ADJUSTMENT (HSIZ)

1. Input a monoscope signal.

2. Activate the Service Adjustment Mode.

3. Select HSIZ with

4. Adjust with

5. Press

MUTING

1

and 4 .

3

and 6 for the best horizontal size.

ENTER

then

to save into the memory.

— 27 —

Page 28

KV-34FV310/38FV310

V. LINEARITY (VLIN), V. CORRECTION

(SCOR), PIN AMP (PAMP), AND

HORIZONTAL TRAPEZOID (HTRP)

ADJUSTMENTS

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select VLIN, SCOR, PAMP, and HTRP with

4. Adjust with

5. Press

3

and 6 for the best horizontal size.

MUTING

then

V LINEARITY (VLIN)

V CORRECTION (SCOR)

PIN AMP (PAMP)

HORIZONTAL TRAPEZOID (HTRP)

to save into the memory.

ENTER

1

and 4.

V. ANGLE (VANG), V. BOW (VBOW), UPPER

PIN (UPIN) AND LOW PIN (LPIN)

ADJUSTMENTS

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select VANG, VBOW, UPIN, and LPIN with

4. Adjust with

5. Press

3

and 6 for the best picture.

ENTER

MUTING

then

V ANGLE (VANG)

V BOW (VBOW)

UPPER PIN (UPIN)

LOW PIN (LPIN)

to save into the memory.

1

and 4.

SERVICE ADJUSTMENT MODE MEMORY

ENTER

0

Item

then

Item

Data

7

.

Green

0

Red

ENTER

1. After completing all adjustments, press

Read From Memory

Mode

Signal

Type

Category

service defl vbow

ntsc

vchp

Display

00000000 00000000

— 28 —

Page 29

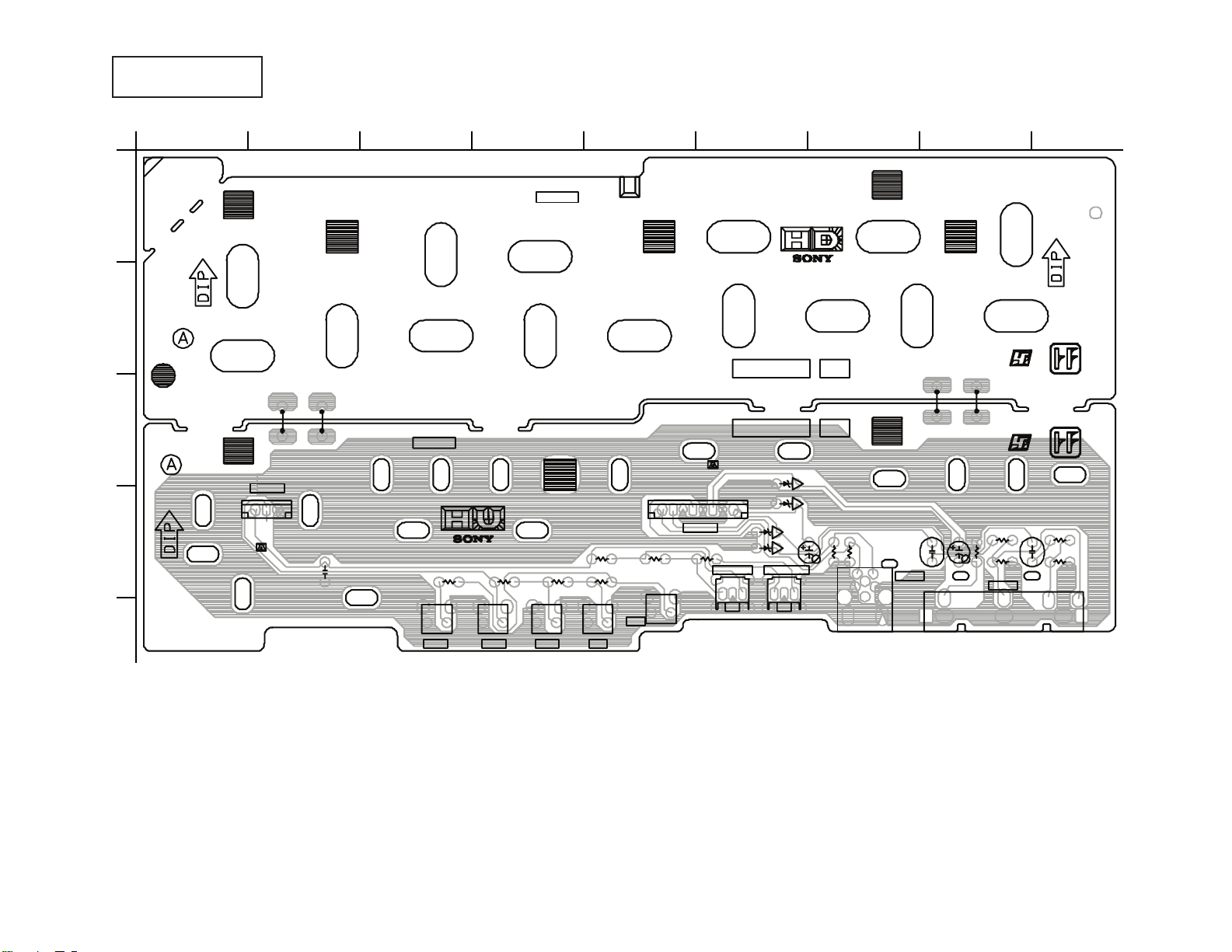

5-1. CIRCUIT BOARDS LOCATION

C Board

V Board

GW Board

A Board

SECTION 5: DIAGRAMS

The components identifi ed by shading and ! symbol are critical for safety. Replace

only with part number specifi ed.

The symbol indicates a fast operating fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

The components identifi ed by X in this basic schematic diagram have

been carefully factory-selected for each set in order to satisfy regulations

regarding X-ray radiation. Should replacement be necessary, replace

only with the value originally used.

When replacing components identifi ed by

adjustments as indicated. If the results do not meet the specifi ed value,

change the component identifi ed by

the specifi ed value is achieved. (Refer to Section 3: Safety Related

Adjustments on Page 16.)

D Board

When replacing the parts listed in the table below, it is important to

perform the related adjustments.

KV-34FV310/38FV310

Y

, make the necessary

X

and repeat the adjustment until

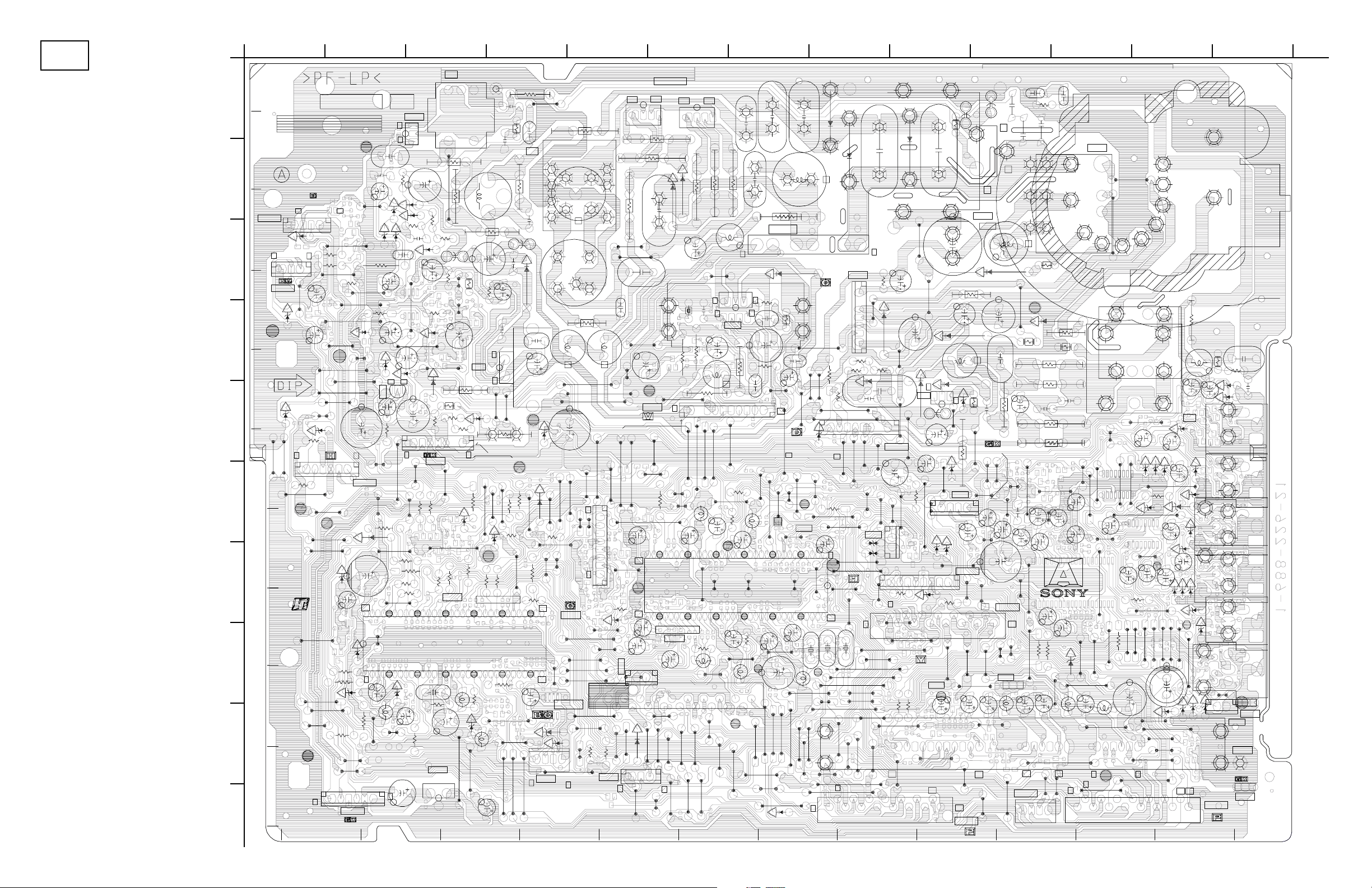

5-2. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM INFORMATION

All capacitors are in µF unless otherwise noted. pF : µµF 50V or less are

not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. kΩ=1000Ω, MΩ=1000kΩ

Indication of resistance, which does not have one for rating electrical

power, is as follows: Pitch : 5mm

Rating electrical power :

1

/

W in resistance, 1/

4

W and 1/

10

W in chip resistance.

8

: nonfl ammable resistor

: fusible resistor

: internal component

: panel designation and adjustment for repair

: earth ground

: earth-chassis

All variable and adjustable resistors have characteristic curve B, unless

otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10MΩ digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production tolerances.

All voltages are in V.

S : Measurement impossibility.

: B+line

: B-line (Actual measured value may be different).

: signal path (RF)

Circled numbers are waveform references.

1

/

W

4

Part Replaced (Y) Adjustment (X)

D BOARD: HV HOLD DOWN

D8022, IC8001, IC8004, IC8005, RV8002

IC8104, R8014, R8015, R8016,

R8017, R8019, R8021, R8046,

R8052, R8072, R8078, R8079,

R8082, R8091, R8095

GW BOARD:

IC601

REFERENCE INFORMATION

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

— 29 —

Page 30

5-3. BLOCK DIAGRAM A BOARD BLOCK DIAGRAM

KV-34FV310/38FV310

Stereo Tu ner

Mono Tuner

I.R.

L.E.D.

From

GK Brd

det-Out

2

Menu

CTRL

5V

Sub

L

2

LR

V

MOUT

2

M306V5ME

S

REAR

V1

2

Det. out

Audio Processor

NJW1134

I2C Bus

Iprot

Mircoprocessor

(For FV only)

BC board

SRT

TA1226N

Yout

Yin

From

GK Brd 9V

From

GK Brd

LR

2

3D comb

MN82832.

135V

S

Y/C

2

2

2

4

Video processor

CXA2154/5AS

YUV

C

PinP Proc.

M65665FP.

Pboard

HOT

FRONT

V2

LR

3

3

2

For FA/FS only

3 RGB

Y/C

2

3L comb

TC90A69.

REAR

V3

CVBS,FSC

LR

2

Vd

2

Hp

Pin

Out

2SC4159

200v

Rect.

V4

Y

UV

YUV SW

NJM2283

RGB Driver

TDA6108

V-Out

AN552 2 (24-27”)

STV9379(32-36”)

E/W

Y

R

L

H-Out

2SD2634(24-27”)

2SD2645(32-36”)

For FA/FS only

V5

UV

Audio SW

NJM2750

3

H.Drive

L

2

Horiz.

R

AUDIO OUT

LR

To

YBrd

YUV

3RGB

DF

VM

To

GK Brd

L,R Audio

DF/QP

DF/QP

VBoard

Vert.

Y25RSA

Y29RSA

Y34RSA

Y38RSA

DY

For FV only

— 30 —

OCP

+13v

Rect.

-13v

Rect.

G2

FBT

HV

Focus

FBT

24”-NX4011

27”-NX4521

32-36”-NX4600

Page 31

GW BOARD BLOCK DIAGRAM

To A Brd

Energy Star

5V

STBY

G board

5VDC

TV-8

DEC

Rect.

L.F.T

Relay

THP

AC Line

Via Hz Board

D.G.C.

2

GW Board

To A BrdTo A Brd

5V

Reg.

Power Mosfet

2SK2876

Power Supply

Reg.

9V

SRT

HV

Rect.

2

14V

B+

Rect.

Low B

Rect.

Audi o

Rect.

To A Brd

135V

12.5V

24V

To

D/TK

Brd

To A Brd

From A Brd

L,R process signals

2

TruSurround

NJM2188

KV-34FV310/38FV310

Audio Amplifier

TFA9844

Stereo

7.5 + 7.5w

10 + 10w

2

2

R

L

Front Spk Audio Amplifier

To

DBrd

D.C. from block

Capacitors

Main Power Supply

To

DBrd

D.C. for HV. P.S.

— 31 —

Page 32

D BOARD BLOCK DIAGRAM

KV-34FV310/38FV310

inductor

Power Mosfet

2SK2876

2

From

ABrd

D.C. for

HV Power Supply

High Voltage Power Supply

H.V.

VR

control

FBT

G2

14V

2

From

GK Brd

D.C. for H V. P.S.

HV

DF

From

ABrd

RHT

Focus

DF/QP

VBoard

Audio Vcc

From

GK Brd

24V

From GK Brd

L,R signals

2

Audio Filter

NJM4558

Audio Amplifier

1

2

TFA9844

Stereo

20w @ 2KHz

— 32 —

L

Sub Woofer Audio Amplifier

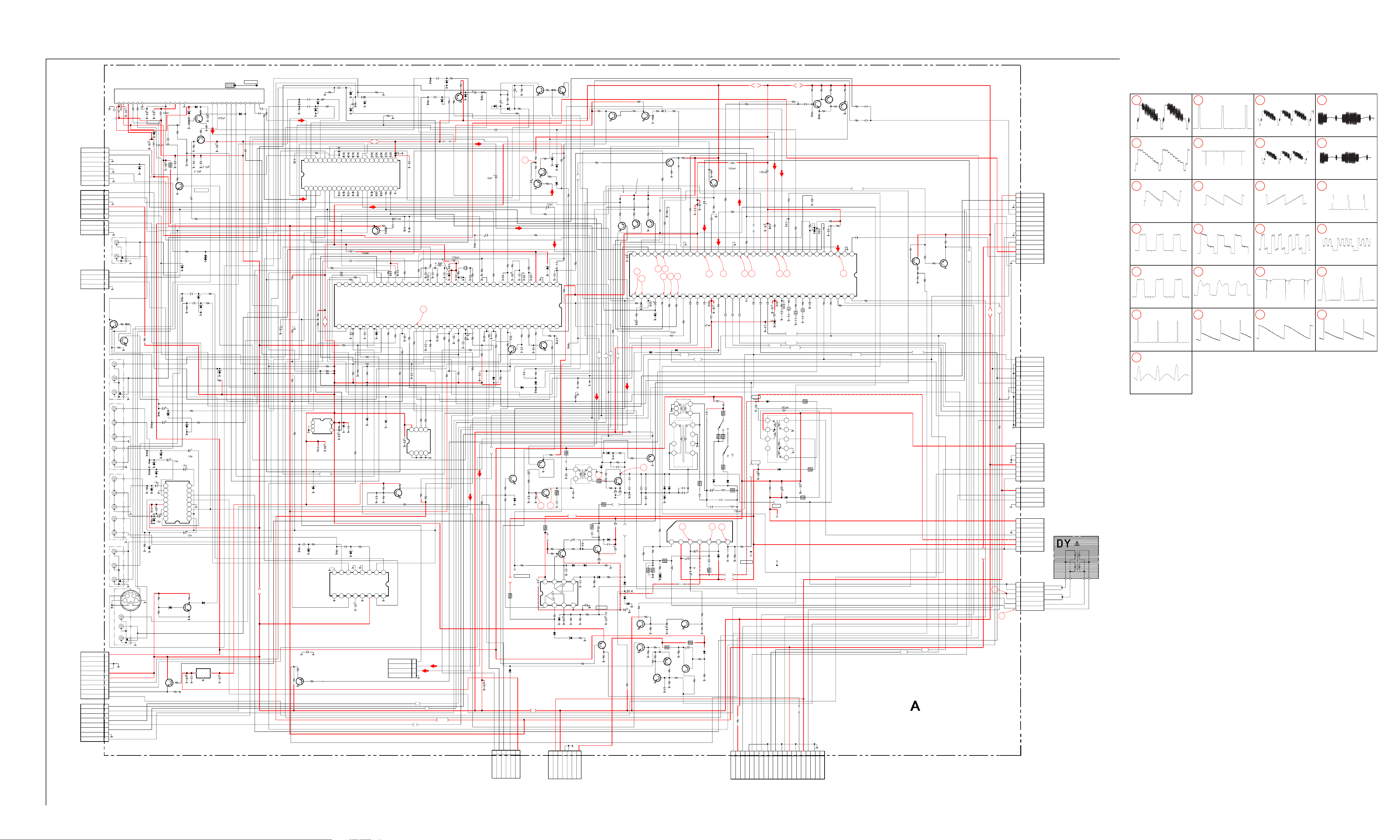

Page 33

5-4. SCHEMATICS AND SUPPORTING INFORMATION

A BOARD SCHEMATIC DIAGRAM

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 |

A

D313

Q404

1/10W

C056

DET OUT

C032

MA111-TX

SW

R098

1k

10

R234

:CHIP

D218

D211

220

R099

TP102

MTZJ-T-77-9.1B

2

T

T

U

U

D

O

O

N

I

T

T

E

E

T

D

D

S

C425

R420

0

VIDEO

100

C103

100

C057

220

:CHIP

D212

R224

220

D005

MTZJ-T-77-10B

R037

4.7k

—

B

—

C

—

D

—

E

—

F

—

G

—

H

—

I

—

J

—

K

TO HW BOARD

TO HU BOARD

TU001

T

C

U

O

F

T

D

I

V

F

N

V

9

A

G

D403

D404

MTZJ-T-77-8.2B

R418

1k

R419

47k

R087

22k

Q002

1/10W

:CHIP

2SD601A

BUFFER

R086

33k

:CHIP

R085

15k

3W

R089

4.7k

1/16W

Q005

2SD601A

AGC

R053

1k :CHIP

R203

100

1/10W

RD9.1EW-T1

MTZJ-T-77-5.1C

R222 R223

C208

100k

0.1

:CHIP

:CHIP

R225

100k

220 :CHIP

D219

MTZJ-T-77-9.1B

C307

C308

C310

IC303

YUV SW

C312

TUNER

R421

6.8k

2CS2412K

D004

C209

0.1

MTZJ-T-77-9.1B

R235

1 2 3 4 5 6 7 8

G

C051

C049

10

RF-AGC

R145

47

R233

470k

1/16W

75

C374

RD10ES-T1B2

47

D317

RD10ES-T1B2

C315

D316

L009

C054

47

RD10ES-T1B2

RD10ES-T1B2

0.1

C373

100

25V

C314

D315

:CHIP

C213

C212

4.7

R232

470k

4.7

D310

D311

A

F

R

L003

2200000p

RD10ES-T1B2

9

10111213141516

C052

4700p

:CHIP

C053

6.3V

F

MTZJ-T-77-9.1B

D309

NJM2283

V

L

A

V

0

V

C

D

3

5

MTZJ--T-77-9.1B

J207

2SD601A-QRS-TX

J205

5P

S

S

S

A

TP100

0

0

0

0

1

1

6.3V

7

8

0

0

1

1

R

R

D009

MTZJ-T-77-30D

C055

100

D312

5V

TP603

2P

Q403

MUTE

R932

75

R953

75

R934

75

:CHIP

R317

RD10ES-T1B2

R316

75

R315

75

9

CN600

4

0

0

9V

L

9V

TP602

C050

2200

TO HU

CN004

TO CN1003

CN003

6P

CN003

CN006

3P

CN1001

8P

FRONT-L

FRONT-R

GND

C2

GND

VIDEO-2

GND

Y2

TMR

LED

MAIN PWR LED

GND

5V STBY

SIRCS

POWER

MENU

KEY

GND

CN007

4P

B-CLK

B-DAT

B-INT

GND

FOR

JIGS

1

2

3

4

5

6

7

8

1

2

3

4

5

6

1

2

3

4

3

2

1

2SD601A-QRS-TX

R416

4.7k

J204

J206

J203

3P

Q402

MUTE

R405 R408

2.2k 2.2k

3P

5P

—

L

—

SW

1342

V

L

R

J201

4P

R411

470

1/10W

MTZJ-T-77-7.5B

R413

10k

R412

D412

1k

D413

Q407

2SD601A

MA111-TX

SW

M

B+

DF-HDRV

N/S

1

NC

2

GND

3

GND

4

9V

5

9V

6

VM

7

8

HP

9

VD+

10

8

7

6

5

G

4

B

R

3

GND

2

I-K

1

2SD601A

C6001

Q500

330

25V

IO

G

C6002

C102

1000p

R583

10k

R584

4.7k

:CHIP

IC6008

NJM2930F05

5V REG

47

25V

—

N

—

O

TO V BOARD

TO C BOARD

CN705

CN901

CN502

10P

H-TRAP

NS-MUTE

CN303

8P

KV-34FV310/38FV310

R208

C203

220

Q315

1/4W

2SB709A

:CHIP

BUFFER

C397

R951

220

470

R210

220

L001

P

C017

2200p

I

H

C

:

p

0

1

1

0

2

2

1

1

C

R

I

_

V

0

C

S

C

C

O

S

U

B

I

T

-

M

O

U

C

T

P

P

I

H

W

C

4

:

/

1

1

0

0

2

0

2

.

0

R131

0

6

6

220

0

3

R

0

C

R065

47k

16V

R396

470k

D308

MTZJ-T-77-9.1B

R950

100

JW901

V

6

1

0

7

4

6

1

0

C

I

_

X

I

N

O

T

M

U

T

E

R064

220

1/4W

R135

MTZJ-T-77-9.1B

L

C029

R050

10k

1

0

p

0

7

X

2

P

I

5

1

0

C

R008

0

P

I

H

C

7

:

3

0

C

p

0

2

2

220

R004

H

C

1M

p

0

7

CHIP

2

9

0

4

0

1

R

0

C

I

0

-

_

G

R

X

N

E

O

D

S

U

E

T

T

O

A

I

O

G

-

-

C

P

M

M

O

M

U

W

U

T

E

T

E

R

E

N

P

I

C133

H

C

220p

:

p

R134

0

2

220

2

R066

1/16W

10k

8

3

0

C

R409

100

R133

47k

C043

220p

:CHIP

R

R359

10k

1/10W

L

R395

75

D217

C426

1

C

N

V

S

S

I

B

I

N

T

W

6

1

/

1

0

2

2

0

7

0

R

1SS133T-77

2200

16V

C210

C368

1011121314151617181920212223242526272829303132

0

_

A

M

U

T

E

P

I

H

C

:

1

0

0

.

0

9

3

0

C

D415

A

D

S

4.7

MTZJ-T-77-9.1B

0.47 10V

W

4

/

1

k

1

6

0

0

R

I

S

I

R

C

S

5

1

4

R

J

R590

100

1/16W

C211

D213

R140

220

1

0

0

.

0

9

0

0

C

0

I

R

H

P

1

O

Y

U

V

S

W

0

R114

220

1/4W

R121

1k

1/4W

R076

47k

2SD601A-QRS-TX

HP PROT

TO-CN601

4.7

R228

100k

O

N

S

O