SONY KV-32FV26, KV-34FV16, KV-34FV16C, KV-34FX260, KV-34FX260C Service Manual

SERVICE MANUAL

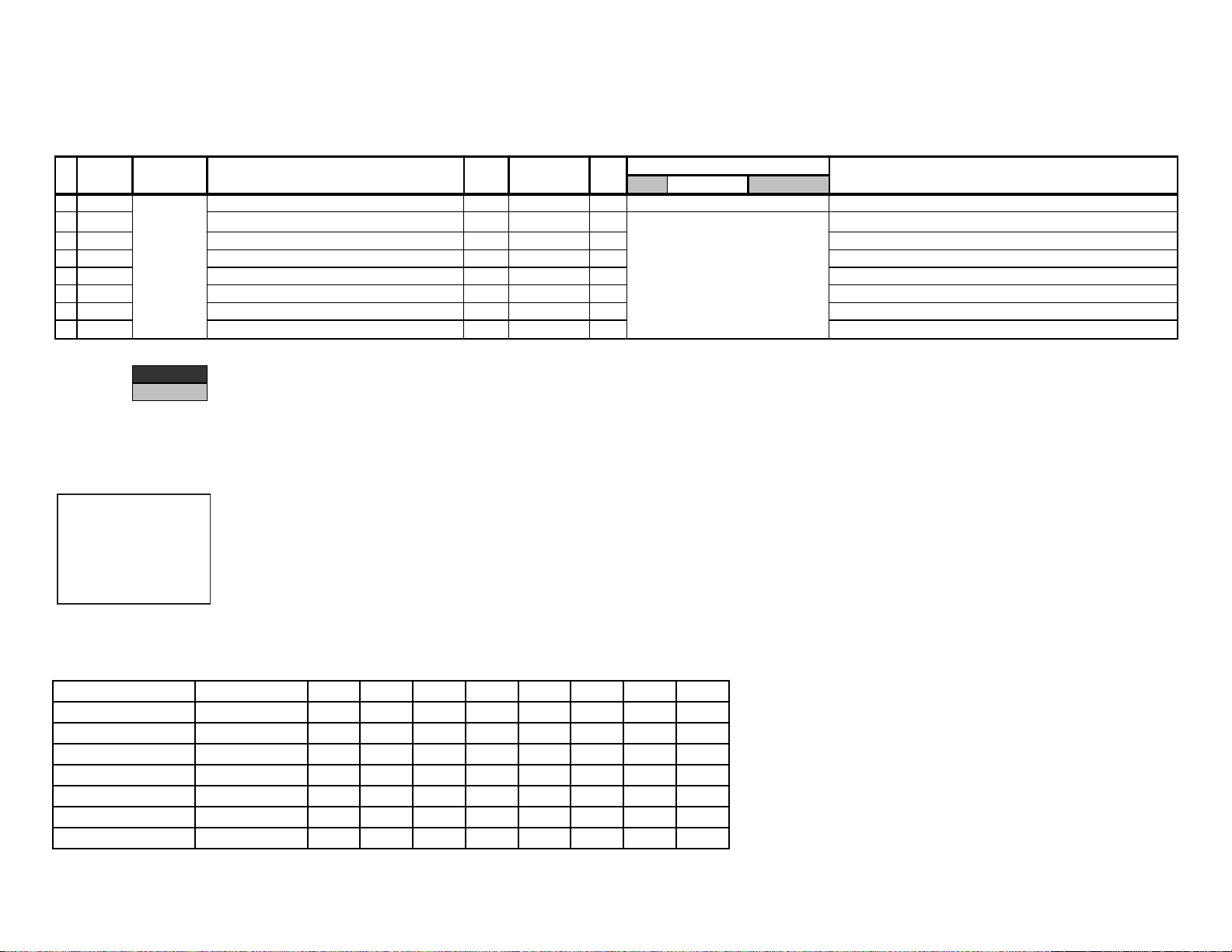

MODEL COMMANDER DEST CHASSIS NO.

AA-2U CHASSIS

KV-32FV16

KV-32FV26

KV-32FV26

KV-34FV16

KV-34FV16C

KV-34FX260

KV-34FX260C

RM-Y171 US SCC-S44E-A

RM-Y170 US SCC-S44F-A

RM-Y170 CN D SCC-S45D-A

RM-Y171 E SCC-S50A-A

RM-Y171 E SCC-S50B-A

RM-Y170 E SCC-S50C-A

RM-Y170 E SCC-S50D-A

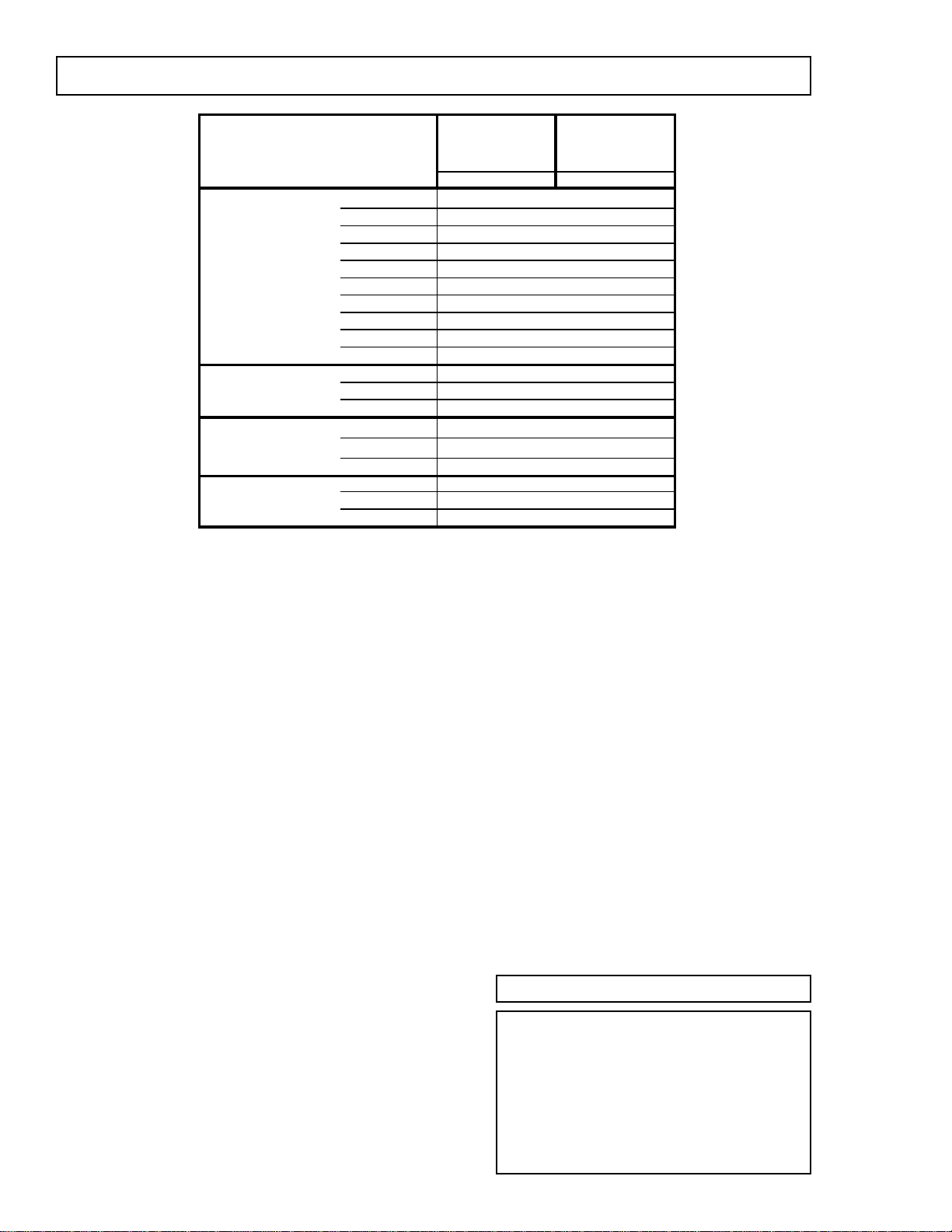

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

KV-32FV16

KV-32FV26

KV-34FV16

KV-34FV16C

KV-34FX260

KV-34FX260C

Power requirements 120V/60Hz 120V-220V / 60Hz, 50Hz

Number of inputs/outputs

Video

1)

S Video

2)

Y,P

, PR

3)

Audio

4)

Audio Out

5)

Monitor Out

S-Link

Control-S (IN/OUT)

Speaker output(W)

Power Consumption(W)

In use(Max)

In standby

Dimensions(W/H/D)

(mm)

(inches)

Mass

(kg)

(lbs)

882 x 687 x 592 mm

34

3/4

x 27 x 23

1/4

176 lbs.

80 kg

3

2

1

4

1

1

3

1

200W

SPECIFICATIONS

B

15Wx2

2W

Television system

American TV standard, NTSC

Channel coverage

VHF: 2-13/ VHF: 14-69/ CATV : 1-125

Picture tube

Flat Trinitron® tube

Visible screen size

32-inch picture measured diagonally

Actual screen size

34-inch measured diagonally

— 2 —

Antenna

75 ohm external terminal for VHF/UHF

Supplied Accessories

RM-Y170 (KV-32FV26/KV -34FX260/34FX260C ONL Y)

RM-Y171 (KV-32FV16/34FV16/34FV16C ONL Y)

Batteries size AA (R6) (2)

Wireless Stereo Headphones MDR-1F0230

(ALL EXCEPT KV -32FV16/34FV16/34FV16C)

Battery for Headphones size AA (R6) (1)

(ALL EXCEPT KV -32FV16/34FV16/34FV16C)

Optional Assessories

AV Cable: VMC-810/820/830 HG

Audio Cable: RKC-515HG

S-LINK Cable: RK-G69HG

Component Video Cable: VMC-10/30 HG

TV Stand: SU-32FD3

Design and specifications are subject to change without notice.

1)

1 Vp-p 75 ohms unbalanced, sync negative

2)

Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3)

Y: 1.0 Vp-p, 75 ohms, sync negative; PB: 0.7 Vp-p, 75 ohms;

PR: Vp-p, 75 ohms

4)

500 mVrms (100% modulation), Impedance: 47 kilohms

5)

More than 408 mVrms at the maximum volume setting (variable)

More than 408 mVrms (fix); Impedance (output): 2 kilohms

( • ) SRS (SOUND RETRIEVAL SYSTEM)

The ( • ) SRS (SOUND RETRIEVAL SYSTEM) is

manufactured by Sony Corporation under license

from SRS Labs, Inc. It is covered by U.S. Patent No.

4,748,669. Other U.S. and foreign patents pending.

The word ‘SRS’ and the SRS symbol ( • ) are

registered trademarks of SRS Labs, Inc.

BBE and BBE symbol are trademarks of BBE Sound,

Inc. and are licensed by BBE Sound, Inc. under U.S.

Patent No. 4,638,258 and 4,482,866.

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

TABLE OF CONTENTS

Section Title Page

Warnings and Cautions...............................................................................................................................................................4

Self-Diagnostic Function ............................................................................................................................................................. 4

Safety Check-Out Instructions ...................................................................................................................................................7

1. DISASSEMBL Y

1-1. Rear Cover Removal....................................................................................................................................................... 8

1-2. Chassis Assembly Removal ........................................................................................................................................... 8

1-3. Service Position .............................................................................................................................................................. 8

1-4. Picture Tube Removal .....................................................................................................................................................9

2. SET -UP ADJUSTMENTS

2-1. Beam Landing ............................................................................................................................................................... 10

2-2. Convergence ................................................................................................................................................................11

2-3. Focus ............................................................................................................................................................................ 13

2-4. Screen (G2) ..................................................................................................................................................................13

2-5. White Balance Adjustments..........................................................................................................................................13

3. SAFETY RELA TED ADJUSTMENTS

3-1. R530, R531 Confirmation Method (HV Hold-Down Confirmation and Readjustments)..........................................14

3-2. B+ Voltage Confirmation and Adjustment .....................................................................................................................14

4. CIRCUIT ADJUSTMENTS

4-1. Setting the Service Adjustment Mode .......................................................................................................................... 15

4-2. Memory Write Confirmation Method..............................................................................................................................15

4-3. Adjust Buttons and Indicators ......................................................................................................................................15

4-4. Adjustment Items...........................................................................................................................................................16

4-5. Feature ID Map ..............................................................................................................................................................21

4-6. Program Palette Settings...............................................................................................................................................22

4-7. A Board Adjustments ....................................................................................................................................................22

5. DIAGRAMS

5-1. Block Diagram ............................................................................................................................................................... 25

5-2. Circuit Board Location ..................................................................................................................................................33

5-3. Printed Wiring Boards and Schematic Diagrams .........................................................................................................33

• A Board .................................................................................................................................................................... 34

• UX (MAIN) Board......................................................................................................................................................41

• UX (PIP) Board .........................................................................................................................................................45

• AK Board ..................................................................................................................................................................49

• HA Board ..................................................................................................................................................................50

• G Board ....................................................................................................................................................................51

• GA Board..................................................................................................................................................................55

• HX Board ..................................................................................................................................................................58

• WA Board ................................................................................................................................................................. 59

• T Board.....................................................................................................................................................................61

• C Board .................................................................................................................................................................... 63

• HB Board ..................................................................................................................................................................64

5-4. Semiconductors ............................................................................................................................................................ 65

6. EXPLODED VIEW

6-1. Chassis .........................................................................................................................................................................66

6-2. Picture Tube ..................................................................................................................................................................67

7. ELECTRICAL P ARTS LIST ...................................................................................................................................................68

— 3 —

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

WARNINGS AND CAUTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD,

OR CARBON PAINTED ON THE CRT, AFTER REMOVING

THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD,

BECAUSE OF LIVE CHASSIS. THE CHASSIS OF THIS

RECEIVER IS DIRECTLY CONNECTED TO THE AC POWER

LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS, AND IN

THE PAR TS LIST ARE CRITICAL FOR SAFE OPERA TION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE

OPERATION ARE IDENTIFIED IN THIS MANUAL. FOLLOW

THESE PROCEDURES WHENEVER CRITICAL

COMPONENTS ARE REPLACED OR IMPROPER OPERA TION

IS SUSPECTED.

A TTENTION!!

APRES AVOIR DECONNECTE LE CAP DE L'ANODE, COURT-CIRCUITER

L'ANODE DU TUBE CATHODIQUE ET CELUI DE L'ANODE DU CAP AU

CHASSIS METALLIQUE DE L'APPAREIL, OU AU COUCHE DE CARBONE

PEINTE SUR LE TUBE CATHODIQUE OU AU BLINDAGE DU TUBE

CATHODIQUE.

ATTENTION!!

AFIN D'EVITER TOUT RESQUE D'ELECTROCUTION PROVENANT D'UN

CHÁSSIS SOUS TENSION, UN TRANSFORMATEUR D'ISOLEMENT DOIT ETRE

UTILISÉ LORS DE TOUT DÉPANNAGE. LE CHÁSSIS DE CE RÉCEPTEUR EST

DIRECTEMENT RACCORDÉ À L'ALIMENTATION SECTEUR.

A TTENTION AUX COMPOSANTS RELA TIFS A LA SECURITE!!

LES COMPOSANTS IDENTIFIES PAR UNE TRAME ET PAR UNE MARQUE

SUR LES SCHEMAS DE PRINCIPE, LES VUES EXPLOSEES ET LES

LISTES DE PIECES SONT D'UNEIMPORTANCE CRITIQUE POUR LA

SECURITE DU FONCTIONNEMENT . NE LES REMPLACER QUE P AR DES

COMPOSANTS SONY DONT LE NUMERO DE PIECE EST INDIQUE DANS

LE PRESENT MANUEL OU DANS DES SUPPLEMENTS PUBLIES P AR SONY .

LES REGLAGES DE CIRCUIT DONT L'IMPORT ANCE EST CRITIQUE POUR

LA SECURITE DU FONCTIONNEMENT SONT IDENTIFIES DANS LE PRESENT

MANUEL. SUIVRE CES PROCEDURES LORS DE CHAQUE REMPLACEMENT

DE COMPOSANTS CRITIQUES, OU LORSQU'UN MAUVAIS

FONTIONNEMENT SUSPECTE.

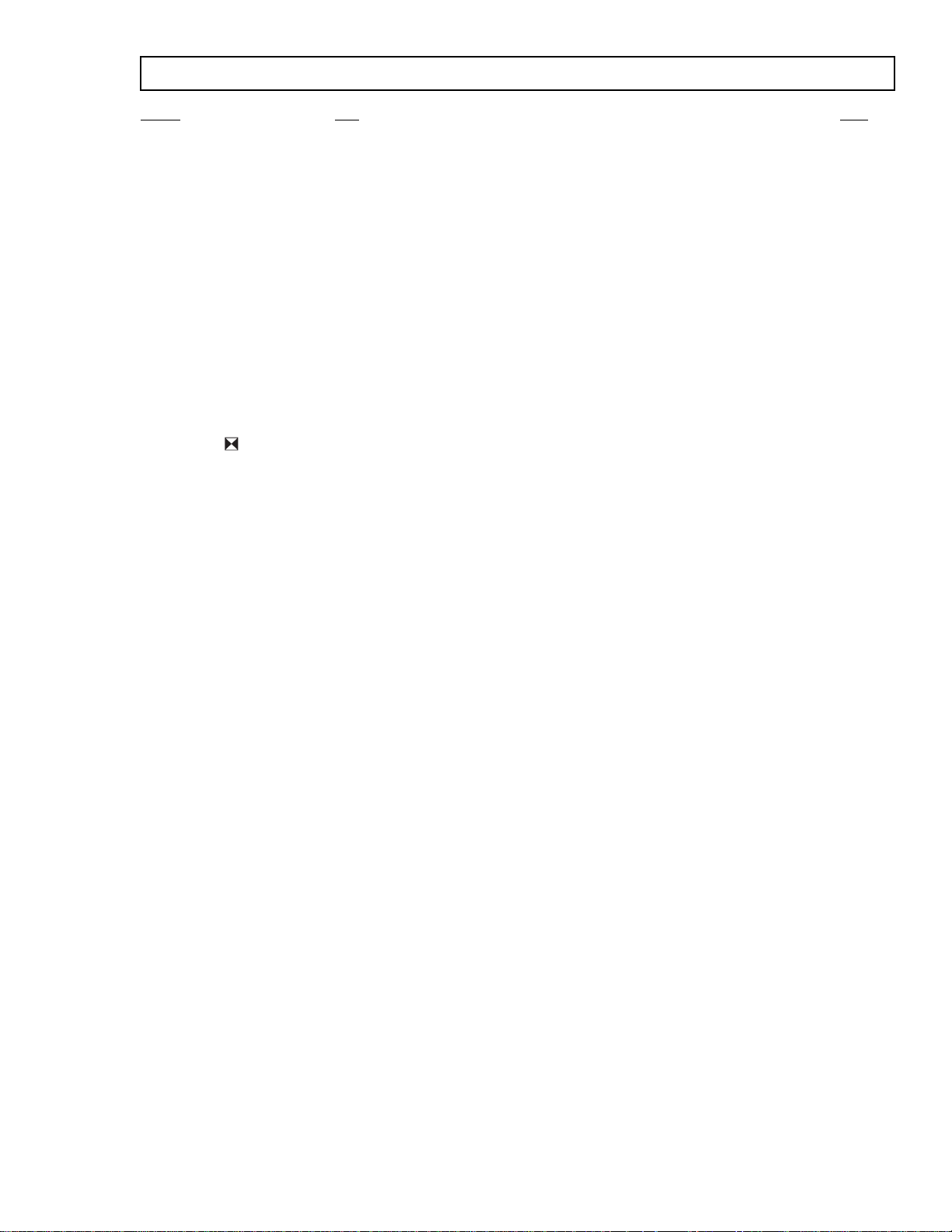

SELF-DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically begin to

flash. The number of times the LED flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER LED

flash indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the

Remote Commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will flash a set number of times to indicate the possible cause of the problem. If there

is more than one error, the LED will identify the first of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic Item

Description

Power does not turn on Does not light

+B overcurrent (OCP)* N/A

+B overvoltage (OVP)* N/A

V-STOP* 4 times 4:0 or 4:1 • +12V is not supplied. (A Board)

IK (AKB) 5 times 5:0 or 5:1 • Video OUT (IC502) is faulty. (A Board)

No. of Times

STANDBY/TIMER

LED Flashes

Self-diagnostic Display/

Diagnostic Result

N/A

N/A

N/A

Probable Cause

Location

• Power cord is not plugged in.

• Fuse is burned out. (F601) (A Board)

• H.OUT (Q502) is shorted. (A Board)

• IC1701 is shorted. (C Board)

• IC643 or T603 is open. (G Board)

• IC6003 or PH6001 is open (GA Board)

• IC502 is faulty. (A Board)

• IC355 is faulty. (A Board)

• Screen (G2) is improperly adjusted.**

Detected Symptoms

• Power does not come on.

• No power is supplied to the TV.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is shorted.

• Power does not come on.

• Has entered standby state after horizontal raster.

• Vertical deflection pulse is stopped.

• Power line is shorted or power supply is stopped.

• No raster is generated.

• CRT cathode current detection reference

pulse output is small.

* If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously.

The symptom that is diagnosed first by the microcontroller is displayed on the screen.

** Refer to Screen (G2) Adjustments in Section 2-4 of this manual.

— 4 —

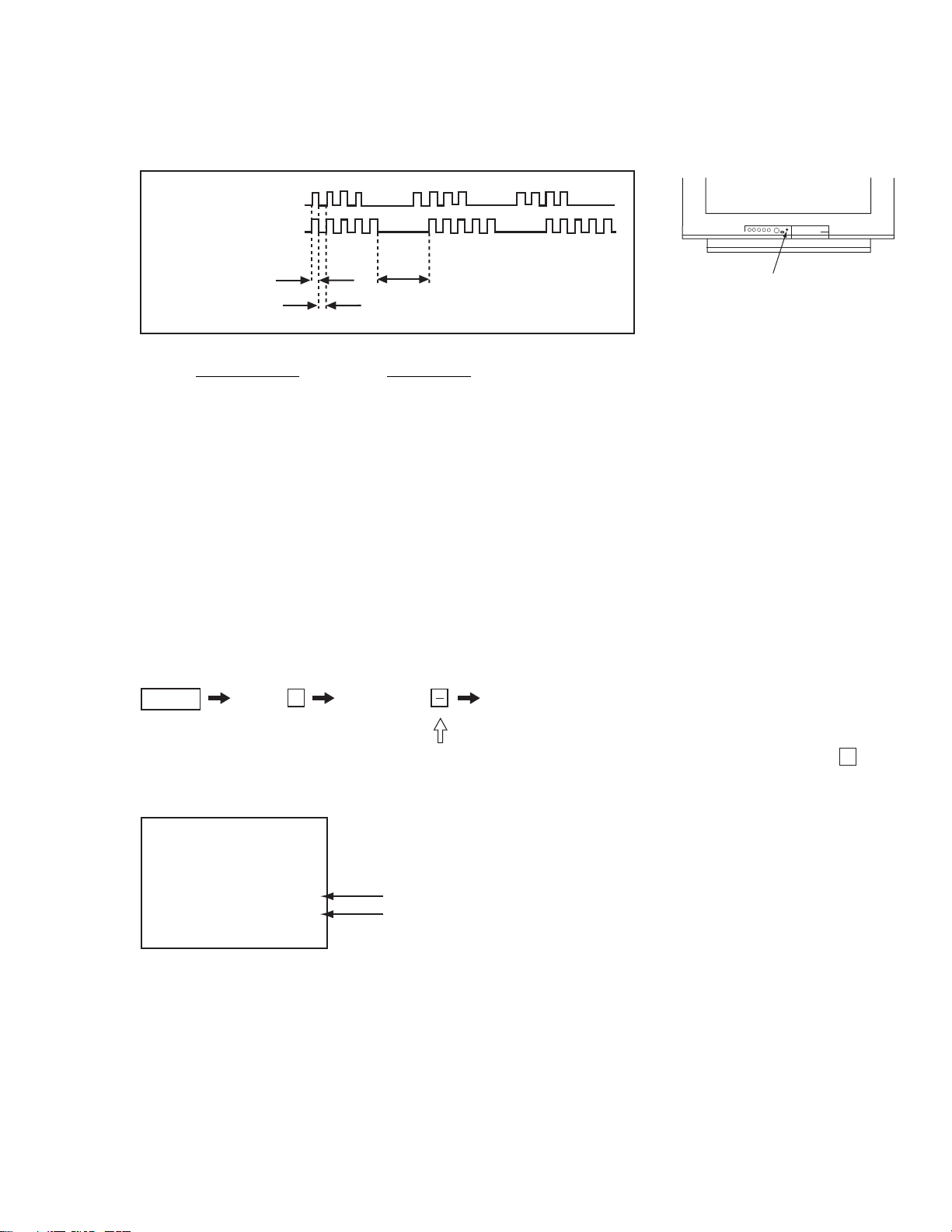

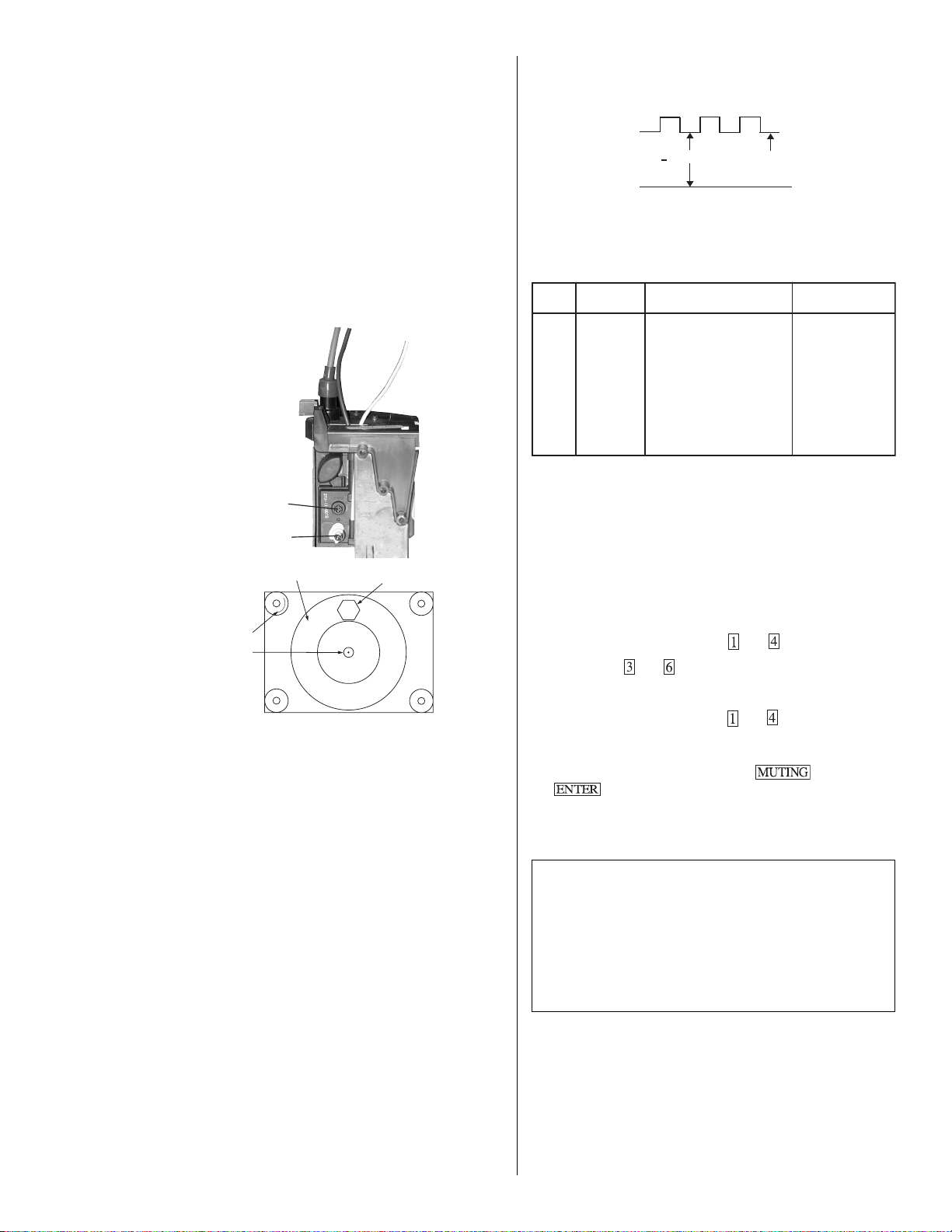

Display of Standby/Timer LED Flash Count

4 times

5 times

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

LED ON 0.3 sec.

LED OFF 0.3 sec.

LED OFF

STANDBY/TIMER LED

3 sec.

Diagnostic Item Flash Count*

V-STOP 4 times

IK (AKB) 5 times

*One flash count is not used for self-diagnostic.

Stopping the Standby/Timer LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER LAMP from flashing.

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible

to bring up past occurrences of failure on the screen for confirmation.

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

Display Channel

5

Sound volume

Power ON

Self-Diagnostic Screen Display

SELF DIAGNOSIS

2: +B OCP N/A

3: +B OVP N/A

4: VSTOP 0

5: AKB 1

101: WDT 24

Note that this differs from entering the service mode (sound volume

Numeral “0” means that no fault was detected.

Numeral “1” means a fault was detected one time only.

— 5 —

+

).

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

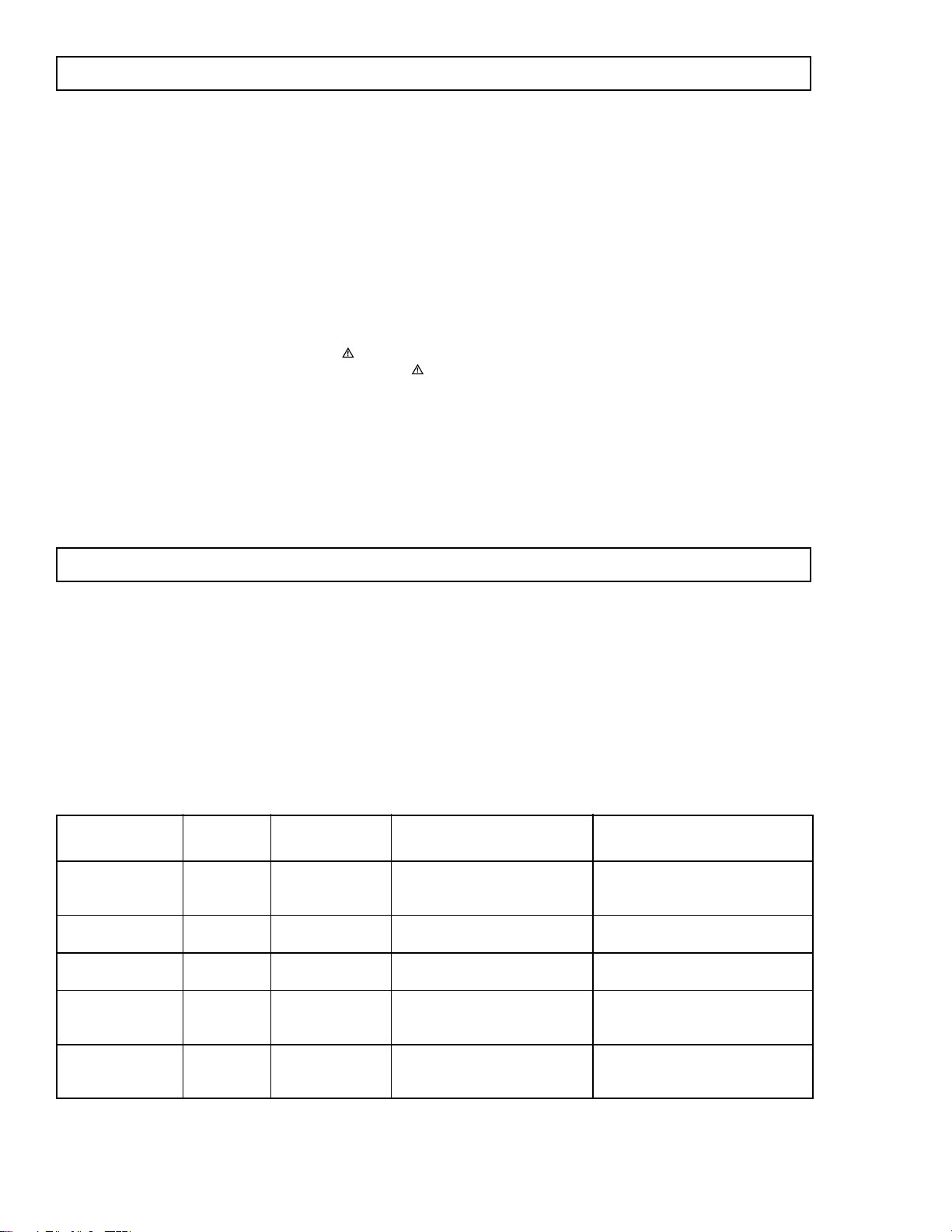

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs.

When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the

repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed,

as shown below:

8

ENTERChannel

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

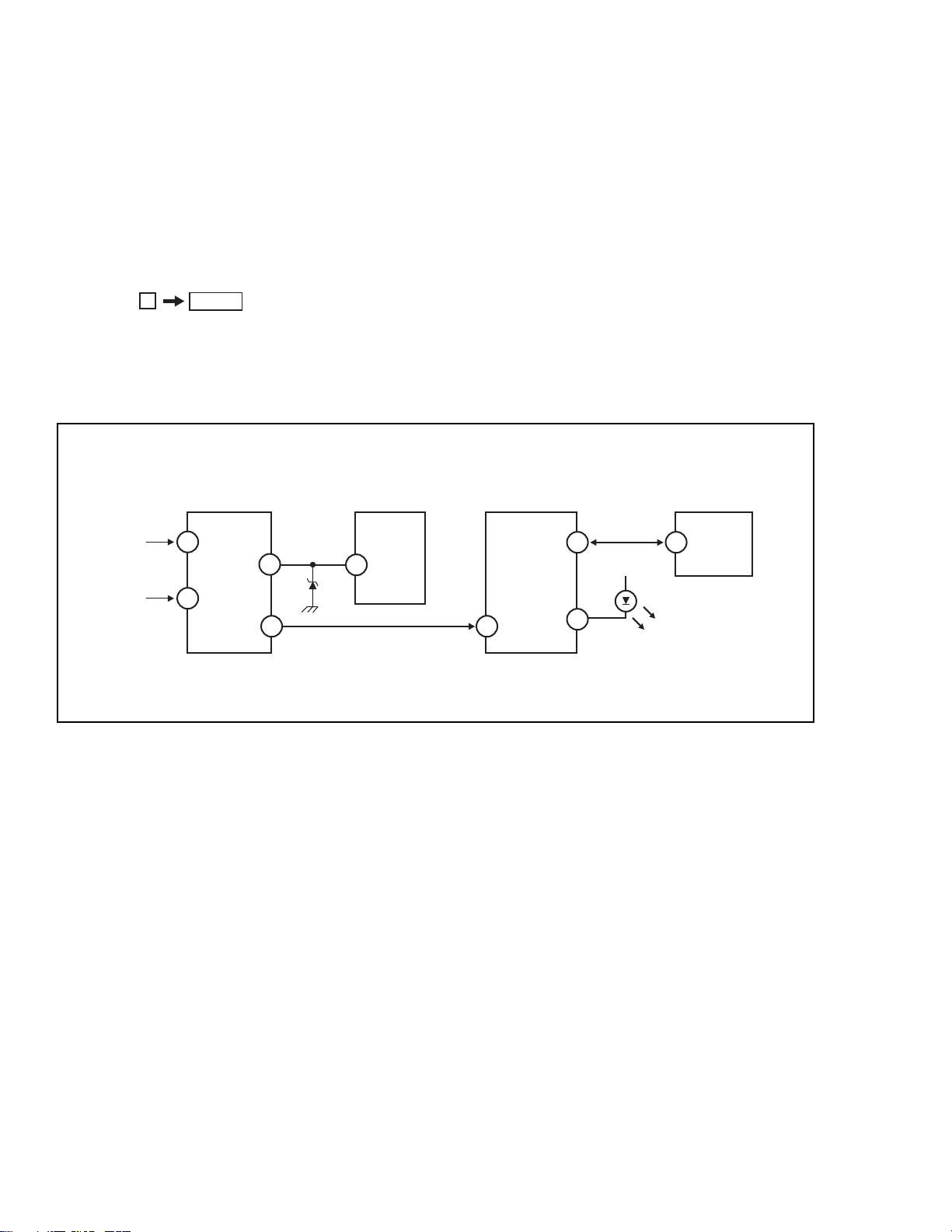

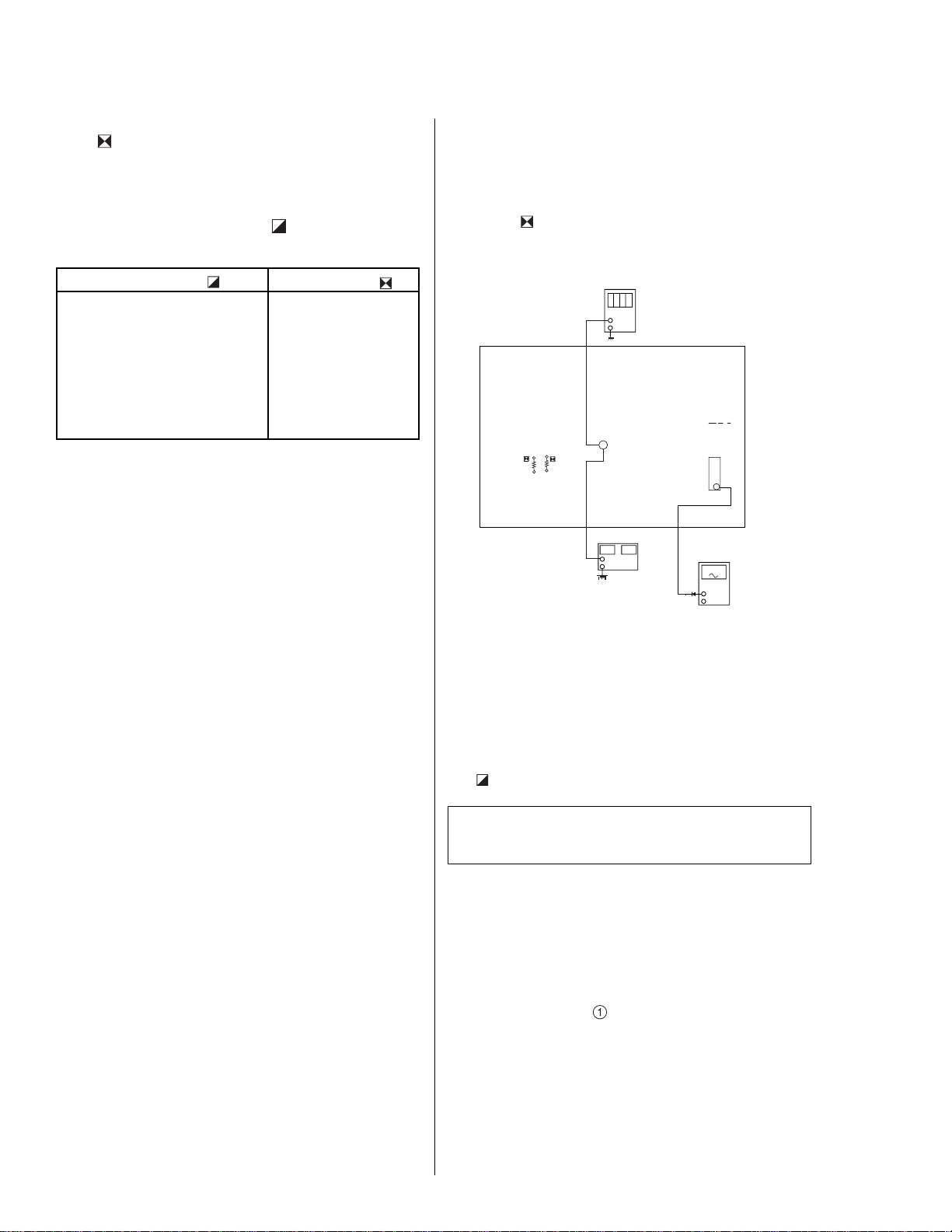

Self-Diagnostic Circuit

FROM

C BOARD

IC1701 PIN1

A BOARD

FROM

IC501

PIN 1

A BOARD

IC355

Y/CHROMA JUNGLE

IK IN

21

V-STOP

HP/PROTECT

18

SDA

A BOARD

IC561

V. OUT

15

35

REF

3

27

A BOARD

IC001

SYSTEM

IO-BDATN

O-TIMELED

IO-SDATN

26

59

DISPLAY

5

A BOARD

IC1002

MEMORY

BDA

+B overcurrent (OCP) Occurs when an overcurrent on the +B (135V) line is detected by pin 18 of IC355 (A Board).

If the voltage of pin 18 of IC355 (A Board) is less than 1V when V.SYNC is more than seven

verticals in a period, the unit will automatically turn off.

+B overvoltage (OVP) Occurs when the feedback circuit from +B opens IC643 or T603 (G Board)/IC6003 or PH6001

(GA Board) or any other associated feedback components.

V-STOP Occurs when an absence of the vertical deflection pulse is detected by pin 15 of IC355 (A

Board). Power supply will shut down when waveform interval exceeds 2 seconds.

IK (AKB) If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will

be detected by IC355 (A Board). TV will stay on, but there will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

NOTE:

Watch Dog Timer Indicates how many times the Watch Dog Timer functions have been activiated. Whenever

micro is reset by the Watch Dog Timer, this number is incremented. Maximum number is 255.

— 6 —

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

SAFETY CHECK-OUT

After correcting the original service problem, perform the

following safety checks before releasing the set to the

customer:

1. Check the area of your repair for unsoldered or

poorly soldered connections. Check the entire board

surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires

are “pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground

straps, and mounting hardware have been replaced.

Be absolutely certain that you have replaced all the

insulators.

4. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous

repair. Point them out to the customer and

recommend their replacement.

5. Look for parts which, though functioning, show

obvious signs of deterioration. Point them out to the

customer and recommend their replacement.

6. Check the line cords for cracks and abrasion.

Recommend the replacement of any such line cord

to the customer.

7. Check the B+ and HV to see if they are specified

values. Make sure your instruments are accurate;

be suspicious of your HV meter if sets always have

low HV.

8. Check the antenna terminals, metal trim, “metallized”

knobs, screws, and all other exposed metal parts for

AC leakage. Check leakage as described below.

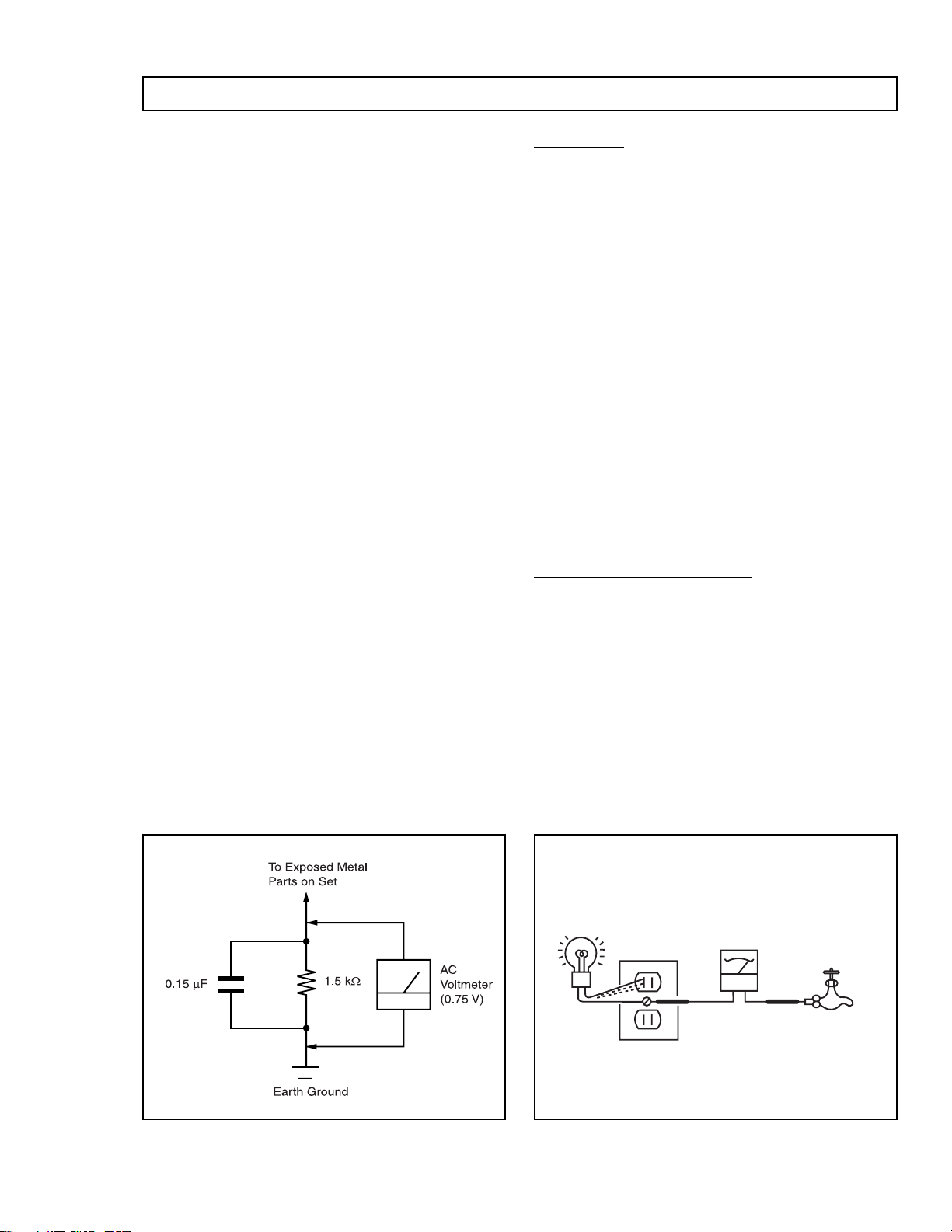

Leakage Test

The AC leakage from any exposed metal part to earth

ground and from all exposed metal parts to any exposed

metal part having a return to chassis, must not exceed 0.5

mA (500 microamperes). Leakage current can be

measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson

229 or RCA WT-540A. Follow the manufacturers'

instructions to use these instructions.

2. A battery-operated AC milliammeter. The Data

Precision 245 digital multimeter is suitable for this

job.

3. Measuring the voltage drop across a resistor by

means of a VOM or battery-operated AC voltmeter.

The “limit” indication is 0.75 V, so analog meters

must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples

of passive VOMs that are suitable. Nearly all batteryoperated digital multimeters that have a 2 VAC

range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the coverplate retaining screw on most AC outlet boxes is also at earth

ground. If the retaining screw is to be used as your earth

ground, verify that it is at ground by measuring the resistance

between it and a cold-water pipe with an ohmmeter. The

reading should be zero ohms. If a cold-water pipe is not

accessible, connect a 60- to 100-watt trouble- light (not a

neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if

the screw is at ground potential (see Figure B).

Figure B. Checking for earth ground.Figure A. Using an AC voltmeter to check AC leakage.

— 7 —

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

SECTION 2

DISASSEMBLY

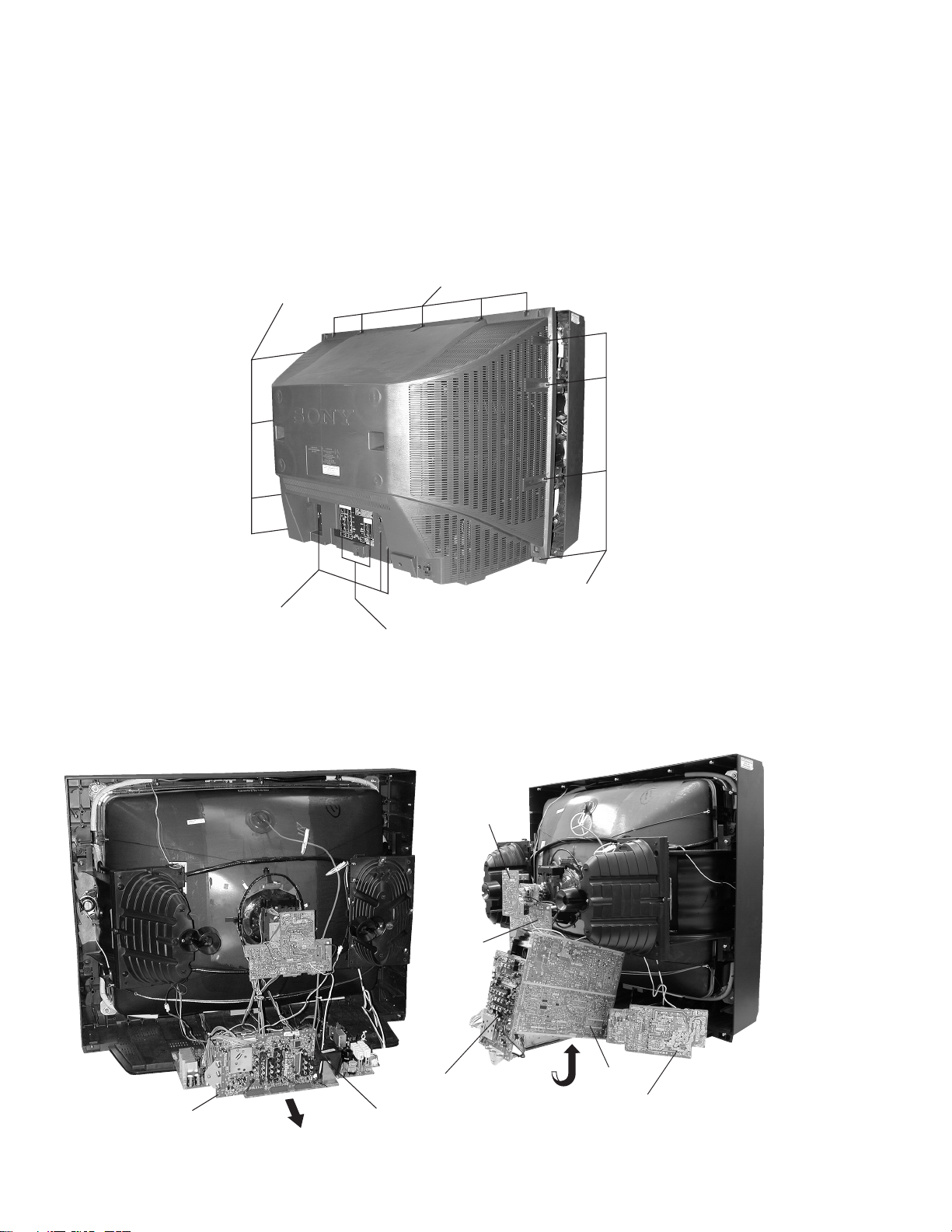

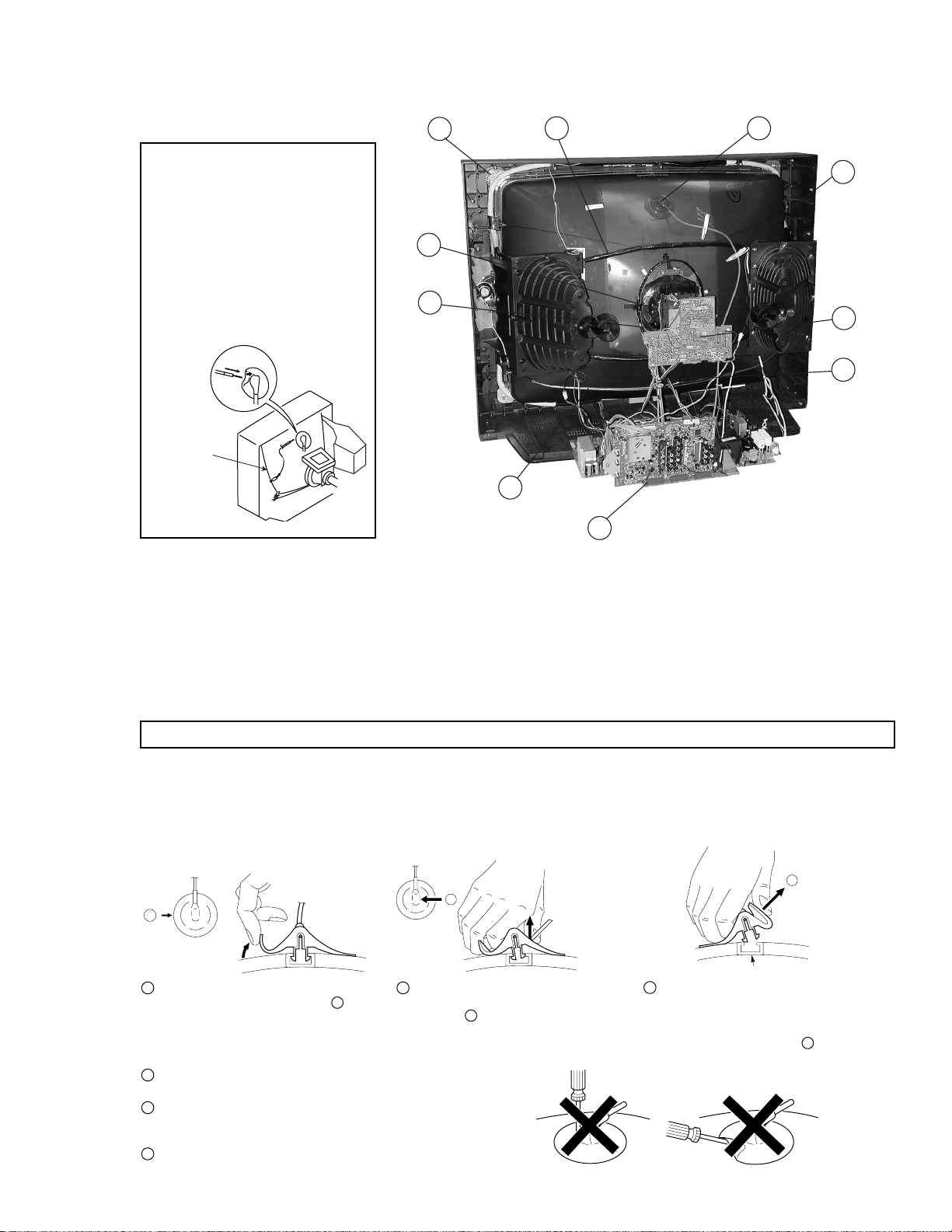

1-1. REAR COVER REMOV AL

4 Screws

(+BVTP 4x16)

3 Screws

(+BVTP 4x16)

5 Screws (+BVTP 4x16)

4 Screws (+BVTP 4x16)

2 Screws (+BVTP 3x12)

1-2. CHASSIS ASSEMBLY REMOVAL

Chassis Assembly

Claw

1-3. SERVICE POSITION

C Board

WA Board

UX Board

A Board

G Board (KV-32FV16/32FV26 ONLY)

GA Board (ALL EXCEPT KV-32FV16/32FV26)

— 8 —

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

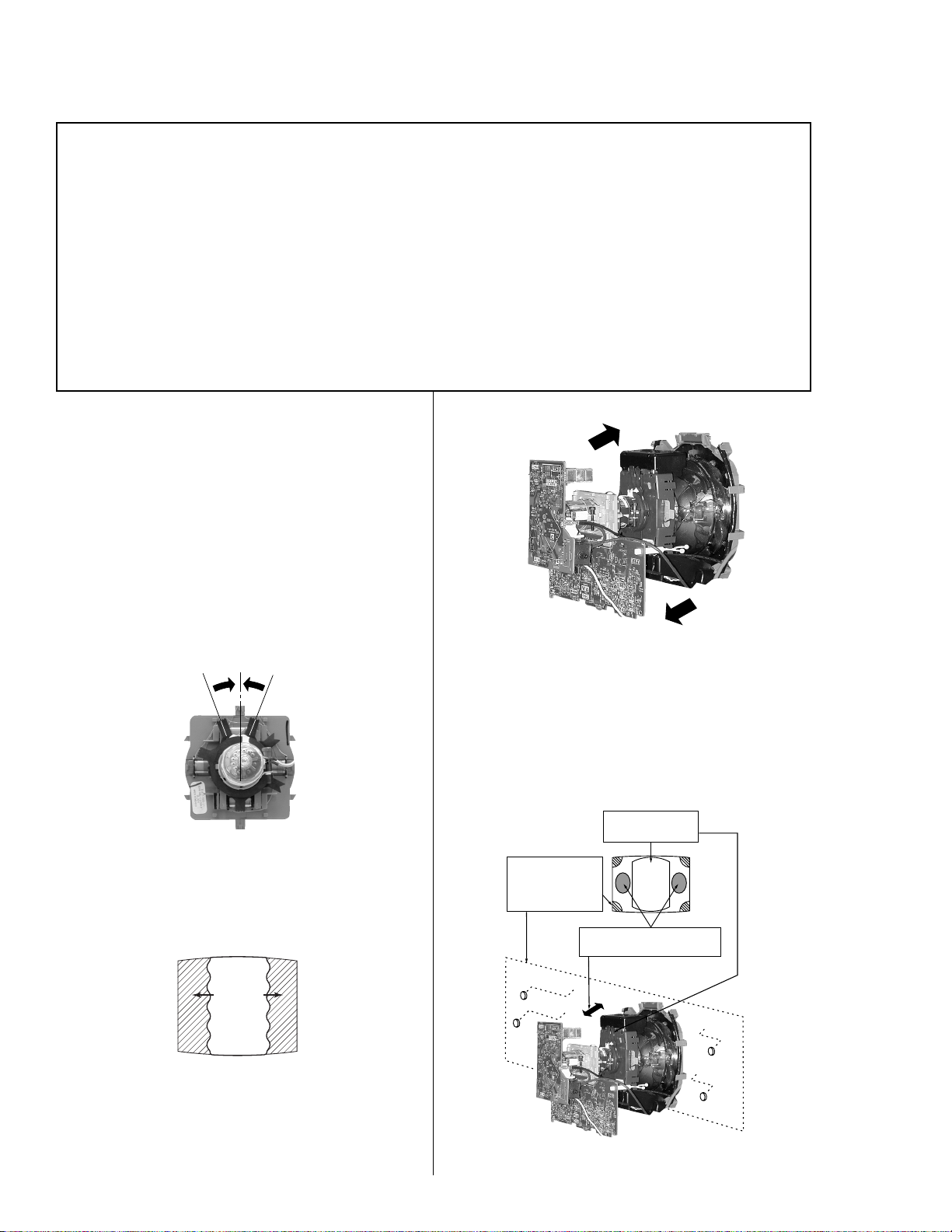

1-4. PICTURE TUBE REMOVAL

10

WARNING:

BEFORE REMOVING

THE ANODE CAP

High voltage remains in the CRT

even after the power is disconnected. To avoid electric shock,

6

discharge CR T before attempting

to remove the anode cap. Short

between anode and CRT coated

5

earth ground strap.

Coated

Earth

Ground

Strap

1. Discharge the anode of the CRT and remove the anode cap.

2. Unplug all interconnecting leads from the deflection yoke, neck

assembly, degaussing coils and CRT grounding strap.

3. Remove the C Board from the CRT.

4. Remove the chassis assembly.

5. Loosen the neck assembly fixing screw and remove.

6. Loosen the deflection yoke fixing screw and remove.

8

1

7

3

2

9

4

7. Place the set with the CRT face down on a cushion and remove

the degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring tension devices.

10. Unscrew the four CRT fixing screws [located on each CRT

corner] and remove the CRT [Take care not to handle the CRT

by the neck].

ANODE CAP REMOVAL

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electrical shock, discharge the CRT before

NOTE: After removing the anode, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield,

attempting to remove the anode cap. Short between anode and coated earth ground strap of CRT.

or carbon painted on the CRT.

REMOVAL PROCEDURES

c

b

a

Anode Button

1

Turn up one side of the rubber cap in

the direction indicated by arrow

2

Use your thumb to pull the rubber

a

.

cap firmly in the direction indicated

by arrow

b

.

3

When one side of the rubber cap

separates from the anode button,

the anode cap can be removed by

turning the rubber cap and pulling

it in the direction of arrow

c

.

HOW TO HANDLE AN ANODE CAP

1

Do not use sharp objects which may cause damage to the

surface of the anode cap.

2

To avoid damaging the anode cap, do not squeeze the rubber

covering too hard. A material fitting called a shatter-hook terminal

is built into the rubber.

3

Do not force turn the foot of the rubber cover. This may cause

the shatter-hook terminal to protrude and damage the rubber.

— 9 —

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

SECTION 2

SET-UP ADJUSTMENTS

The following adjustments should be made when a

complete realignment is required or a new picture tube is

installed.

These adjustments should be performed with rated power

supply voltage unless otherwise noted.

The controls and switch should be set as follows

unless otherwise noted:

PICTURE control ......................................... normal

BRIGHTNESS control..................................normal

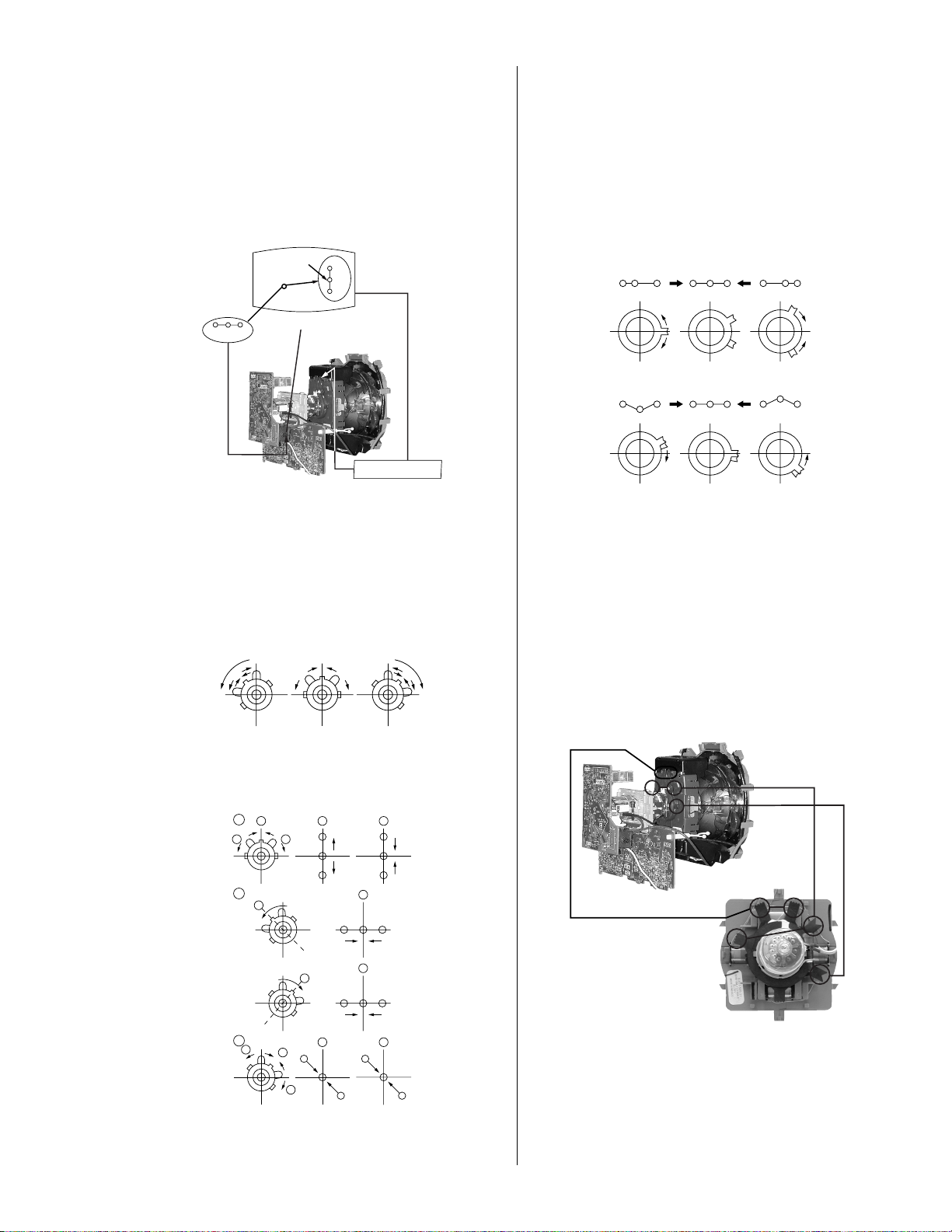

2-1. BEAM LANDING

Preparation:

• Input a white pattern signal.

• Face the picture tube in an East or West direction to reduce

the influence of geomagnetism.

NOTE: Do not use the hand degausser because it magnetizes

the CRT .

1. Input white pattern from pattern generator.

2. Loosen the deflection yoke mounting screw, and set the

purity control to the center as shown below:

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4 . Screen (G2)/White Balance

Note: T est Equipment Required:

1 . Color Bar Pattern Generator

2. Degausser

3 . DC Power Supply

4. Digital Multimeter

5. Oscilloscope

6. CRT Analyzer

6. Switch over the raster signal to red and blue and confirm the

condition.

7. When the position of the deflection yoke is determined,

tighten it with the deflection yoke mounting screw.

8. When landing at the corner is not right, adjust by using the

disk magnets.

3. Input green pattern from pattern generator.

4. Move the deflection yoke backward, and adjust with the

purity control so that green is in the center and red and blue

are even on both sides.

Blue Red

Green

5. Move the deflection yoke forward, and adjust so that the

entire screen becomes green.

— 10 —

Disk magnets

or rotatable disk

magnets correct

these areas (a-d)

b

d

Purity control

corrects this area

ba

cd

Deflection yoke positioning

corrects these areas

a

c

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

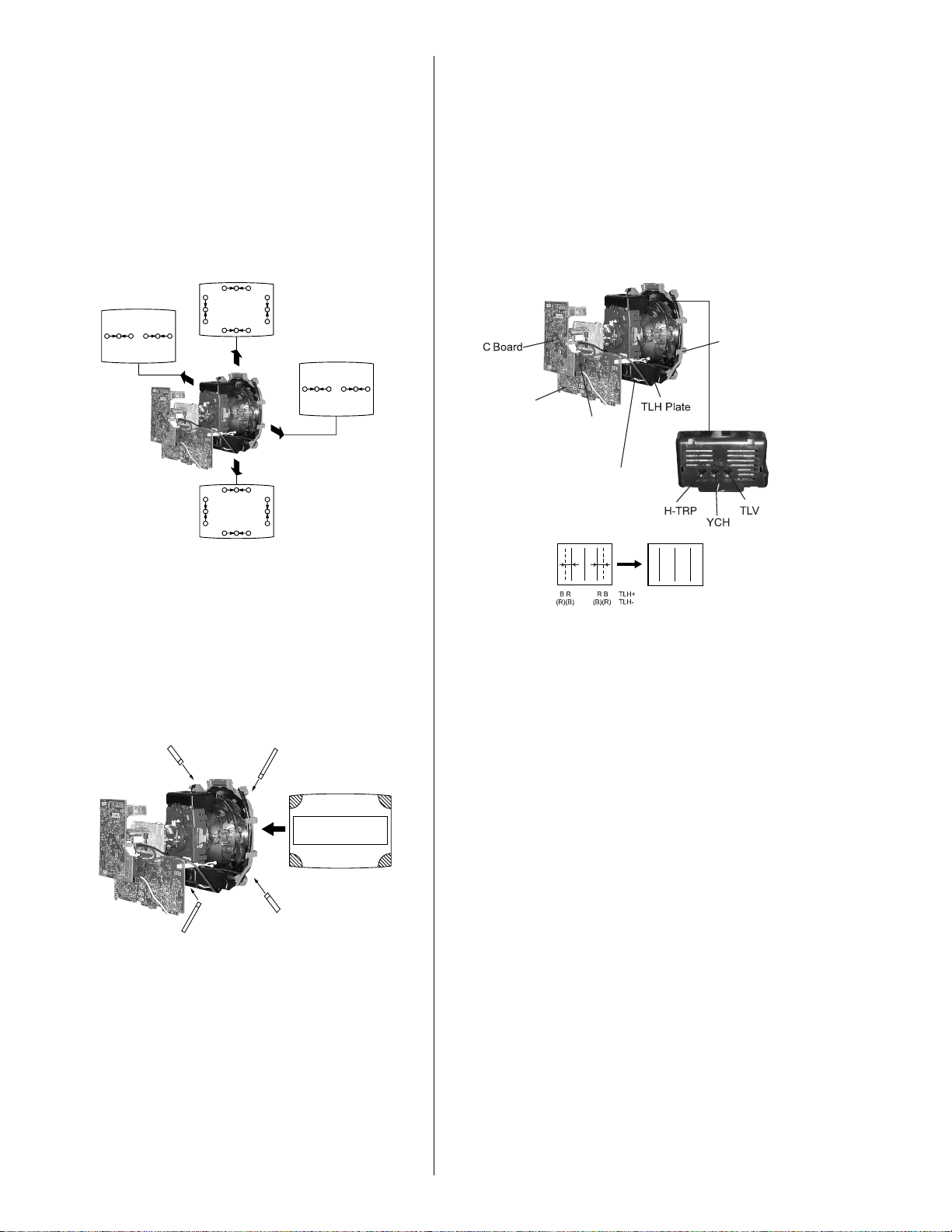

2-2. CONVERGENCE

Preparation:

• Perform FOCUS, V. LIN and V. SIZE adjustments.

• Set BRIGHTNESS control to minimum.

• Input dot pattern.

R G B

Center dot

RV1761 V.STAT

R

G

B

V.STAT magnet

Vertical and Horizontal Static Convergence

1. Adjust V. STAT magnet to conver ge red, green and blue dots

in the center of the screen (Vertical movement).

Tilt the V. STAT magnet and adjust static convergence to

open or close the V. STAT magnet.

Operation of BMC (Hexapole) Magnet

The respective dot positions resulting from moving each magnet

interact, so perform adjustment while tracking.

1 Use the V.STAT tabs to adjust the red, green, and blue dots

so they line up at the center of the screen (move the dots in

a horizontal direction).

RG B

RGB RGB

RGB

RGB

RGB

Y Separation Axis Correction

Magnet Adjustment

1. Input cross-hatch pattern, adjust PICTURE to minimum

and BRIGHTNESS to normal.

2. Adjust the deflection yoke upright so it touches the CRT.

3. Adjust so that the Y separation axis correction magnet on

the neck assembly is symmetrical from top to bottom (open

state).

2. When the V. STAT magnet is moved in the direction of arrow

a and b, red, green, and blue dots move as shown below:

1

a

b

2

a

3

b

a

B

b

G

R

b

a

a

R

G

b

B

b

B

G

R

a

RG B

b

BG R

b

B

G

R

V.S TAT

BMC MAGNET

PURITY

4. Return the deflection yoke to its original position.

— 11 —

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

Dynamic Convergence Adjustment

Before starting, perform Vertical and Horizontal Static Convergence Adjustment.

1. Slightly loosen deflection yoke screw .

2. Remove deflection yoke spacers.

3. Move the deflection yoke for best convergence as

shown below:

BGR

RGB

BGR

R

G

B

B

G

R

RGB

RGB

G

B

R

B

G

R

R

G

B

BGR RGB

TLH Plate Adjustment

• Input crosshatch pattern.

• Adjust PICTURE QUALITY to standard, PICTURE and

BRIGHTNESS to 50%, and OTHER to standard.

• Adjust the Horizontal Convergence of red and blue dots

by tilting the TLH plate on the deflection yoke.

Y Magnet

WA Board

RV1761

V. STAT

XCV

4. T ighten the deflection yoke screw.

5. Install the deflection yoke spacers.

Screen-corner Convergence

1. Affix a permalloy assembly corresponding to the

misconverged areas:

b

a

a-d: screen-corner

misconvergence

cd

c

d

1. Adjust XCV core to balance X axis.

2. Adjust YCH VR to balance Y axis.

3. Adjust vertical red and blue convergence with V.TILT (TLV

VR.)

Perform adjustments while tracking items 1 and 2.

4. Adjust Y MAGNET to correct V.BOW Geometery

Distortion.

ba

5. Adjust H-TRP to correct H.Trapezoid Geometry Distortion.

After adjusting items 4 and 5, confirm overall geometry again.

— 12 —

2-3. FOCUS

pedestal

GND

170Vdc

170 + 2.0 Vdc

NO.

24

25

26

27

28

29

38

Disp.

RDRV

GDRV

BDRV

RCUT

GCUT

BCUT

SBRT

Item

Red Drive

Green Drive

Blue Drive

Red Cut-off

Green Cut-off

Blue Cut-off

Sub Bright

All Models

*

44

38

14:Fix

7

6

6

1. Input monoscope signal.

2. Set user controls to normal.

3. Set video mode to STANDARD.

4. Set the PICTURE to maximum.

5. Adjust at 325 Mark for best center/corner focus balance.

6. Receive an entire white signal. Make sure Magenta Ring is

at an acceptable level.

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

2-5. WHITE BALANCE ADJUSTMENTS

Focus

Screen (G2)

325 MARK

35

35 MARK

CENTER

CIRCLE

325

2-4. SCREEN (G2)

1. Input dot pattern from the pattern generator.

2. Set the user controls to NORMAL.

3. Attach the G2-Jig to the C Board.

5. Adjust RCUT, GCUT, BCUT, and SBRT in service mode

with an oscilloscope so that voltages on the red, green, and

blue cathodes are 170 ± 2.0Vdc.

5. Observe the screen and adjust SCREEN (G2) VR to obtain

the faintly visible background of dot signal.

6. Push the TEST + JUMP (+ Channel) to cut off the signal.

The screen should be bright or dark. Brightness of raster

must be increased when adjusting.

7. Adjust screen VR until the screen is slightly cut off, or

scarcely lights up. A signal cannot be seen when the

brightness of the raster is high.

8. Push the JUMP again to release the cut off.

1. Set program palette to STANDARD and pust RESET.

2. Input an entire white signal.

3. Set to Service Adjustment Mode.

4. Set the PICTURE and BRIGHT to minimum.

5. Adjust with SBRT if necessary.

6. Set RCUT to "14".

7. Select GCUT and BCUT with

8. Adjust with

and for the best white balance.

and .

9. Set the PICTURE and BRIGHT to maximum.

10. Select GDRV and BDRV with and .

11. Adjust with 3 and 6 for the best white balance.

12. Write into the memory by pressing

.

13. Repeat steps 1-12 for GDR4, BDR4, GCU4 and BCU4

using V ideo 4 input.

* Use values from Sub Contrast Adjustments

NOTE:

White balance should be adjusted after Sub Contrast

because RDRV is also used in Sub Contrast Adjustment.

(See page 22).

— 13 —

then

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

SECTION 3

SAFETY RELATED ADJUSTMENTS

3-1. R530, R531 CONFIRMATION METHOD

(HOLD-DOWN CONFIRMATION) AND

READJUSTMENTS

Always perform the following adjustments when replacing the

following components marked with a

diagram:

Part Replaced ( ) Adjustment ( )

R387, R550, R529, R530, R531,

R532, R533, D519, D520, D521,

IC501, C531, C532, T503, IC351,

IC355, D302, Q301, R356, R359,

R361, .............................A Board

IC643, R661 .................. G Board

IC6003,R6008 ............. GA Board

mark on the schematic

HV HOLD-DOWN

R530, R531

Preparation before Confirmation

1. Using a V ariac, apply AC input voltage: 130+2.0/-0.0 VAC.

2. Turn the POWER switch ON.

3. Input a white signal and set the PICTURE and BRIGHT

controls to maximum.

4. Confirm that the voltage of more than 23.0 VDC appears

between TP85 and ground on the A Board.

Hold-Down Readjustment

If the setting indicated in Step 2 of Hold-Down Operation

Confirmation cannot be met, readjustment should be performed

by altering the resistance value of R530, R531 component

marked with

.

digital multimeter

R531

R530

DC Power Supply

+

-

TP85

TP85

+

-

T503

T503

FBT

FBT

11

ammeter

3mA DC range

A

+

-

Hold-Down Operation Confirmation

1. Connect the current meter between Pin 11 of the FBT

(T503) and the PWB land where Pin 11 would normally

attach (See Figure 1 above).

2. Input a dot signal and set PICTURE and BRIGHTNESS

to minimum: IABL = 2175 + 100/ -325 µA.

3. Confirm the voltage of A Board TP91 is 135 ± 1.5 VDC.

4. Connect the digital voltmeter and the DC power supply to

TP85 and ground. (See Figure 1 above).

5. Increase the DC power voltage gradually until the picture

blanks out.

6. Turn DC power source off immediately.

7. Read the digital voltmeter indication

(standard = 27.24 + 0.0/ - 0.1 VDC).

8. Input a white signal and set PICTURE and BRIGHTNESS

to maximum: IABL = 2175 + 100/ -325 µA.

9. Repeat steps 4 to 7.

Figure 1

3-2. B+ VOLTAGE CONFIRMATION AND

ADJUSTMENT

Note: The following adjustments should always be performed

when replacing the following components, which are marked

with on the schematic diagram on the G Board or GA Board.

G BOARD: IC643, R661

GA BOARD: IC6003, R6008

1. Using a V ariac, apply AC input voltage: 130 + 2.0/-0.0 VAC

2. Input a monoscope signal.

3. Set the PICTURE control and the BRIGHT control to

initial reset value.

4. Confirm the voltage of G Board CN641 or GA Board

CN6007 between pin

5. If step 4 is not satisfied, replace the R661 on G Board or

R1008 on GA Board and repeat the above steps.

to ground is less than 136.5 VDC.

— 14 —

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

SECTION 4

CIRCUIT ADJUSTMENTS

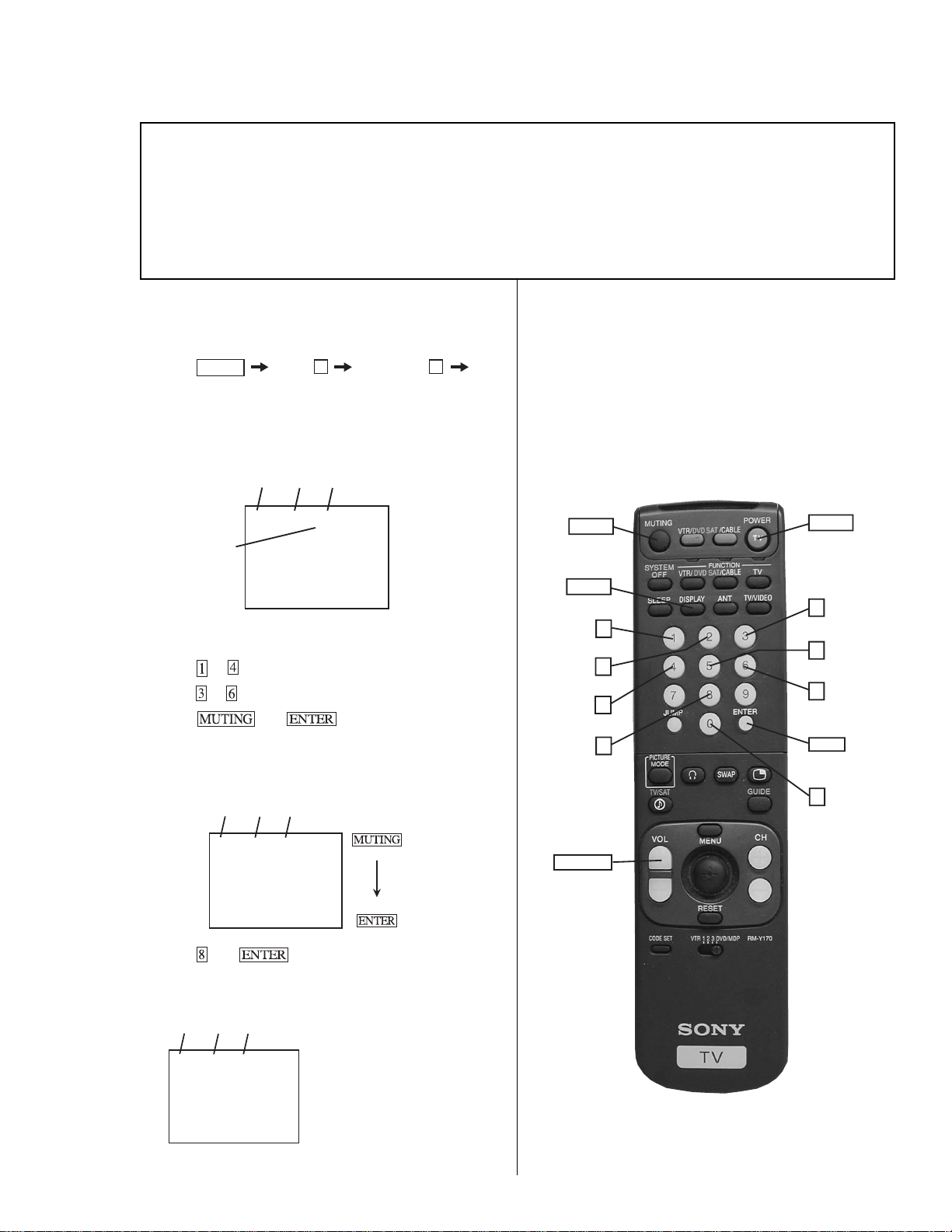

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y170, RM-Y171) to perform the circuit adjustments in this section.

NOTE: Test Equipment Required:

• Pattern generator

• Frequency counter

• Digital multimeter

• Audio oscillator

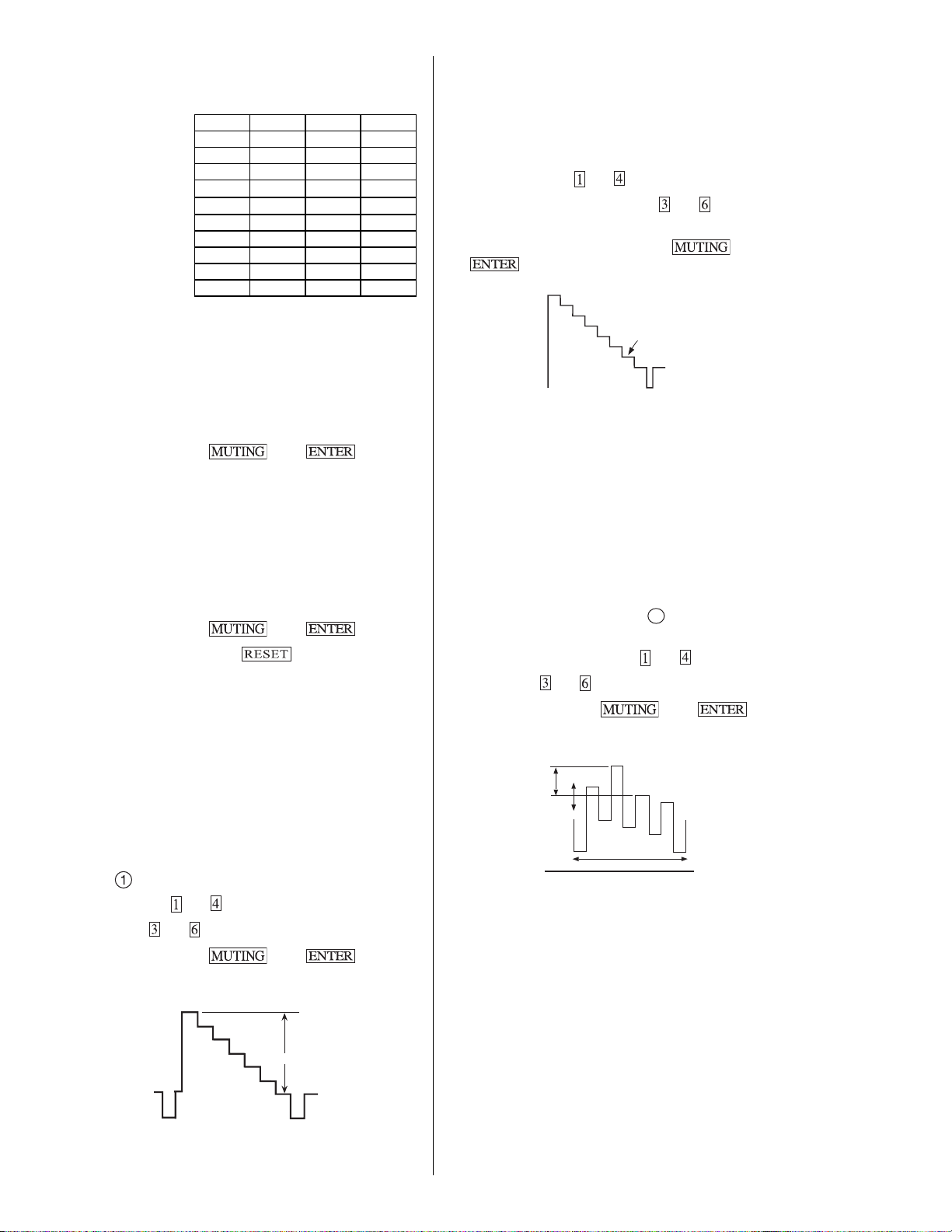

4-1. SETTING THE SERVICE ADJUSTMENT

MODE

1. Standby mode (Power off).

2. Press

Display Channel

5

Sound volume Power

+

on the Remote Commander (Press each button within a

second).

Service Adjustment Mode In

Item

order

0

TV

Item

data

7

SERVICE

Mode

Disp.

(Item)

VP

HSIZ

3. The CRT displays the item being adjusted.

4. Press

5. Press

6. Press

or on the Remote Commander to select the item.

or on the Remote Commander to change the data.

then to write into memory.

Service Adjustment Mode Memory

Item

order

0

TV

Item

data

7

SERVICE

Green

Disp.

(Item)

VP

HSIZ

4-2. MEMORY WRITE CONFIRMATION

METHOD

1. After adjustment, pull out the plug from the AC outlet, then

replace the plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confirm they were adjusted.

4-3. ADJUST BUTTONS AND INDICATORS

MUTING

(Enter into

memory)

DISPLAY

(Service Mode)

Disp. (Item up)

(Device Item Up)

Disp. (Item down)

(Initialize)

VOLUME (+)

(Service mode)

1

2

4

8

POWER

(Service mode)

3

Item (Data up)

5

(Device item

down)

6

Item(Data down)

ENTER

(Enter into

memory)

0

(Remove from

memory)

Red

7. Press then on the Remote Commander to

initialize.

Item

order

0

Item

data

7

WRITE

TV

Carry out step 7 when adjusting

IDs 0 to 7 and when replacing

Disp.

(Item)

VP

HSIZ

and adjusting IC002.

8. DO NOT turn off set until SERVICE appears.

RM-Y170

— 15 —

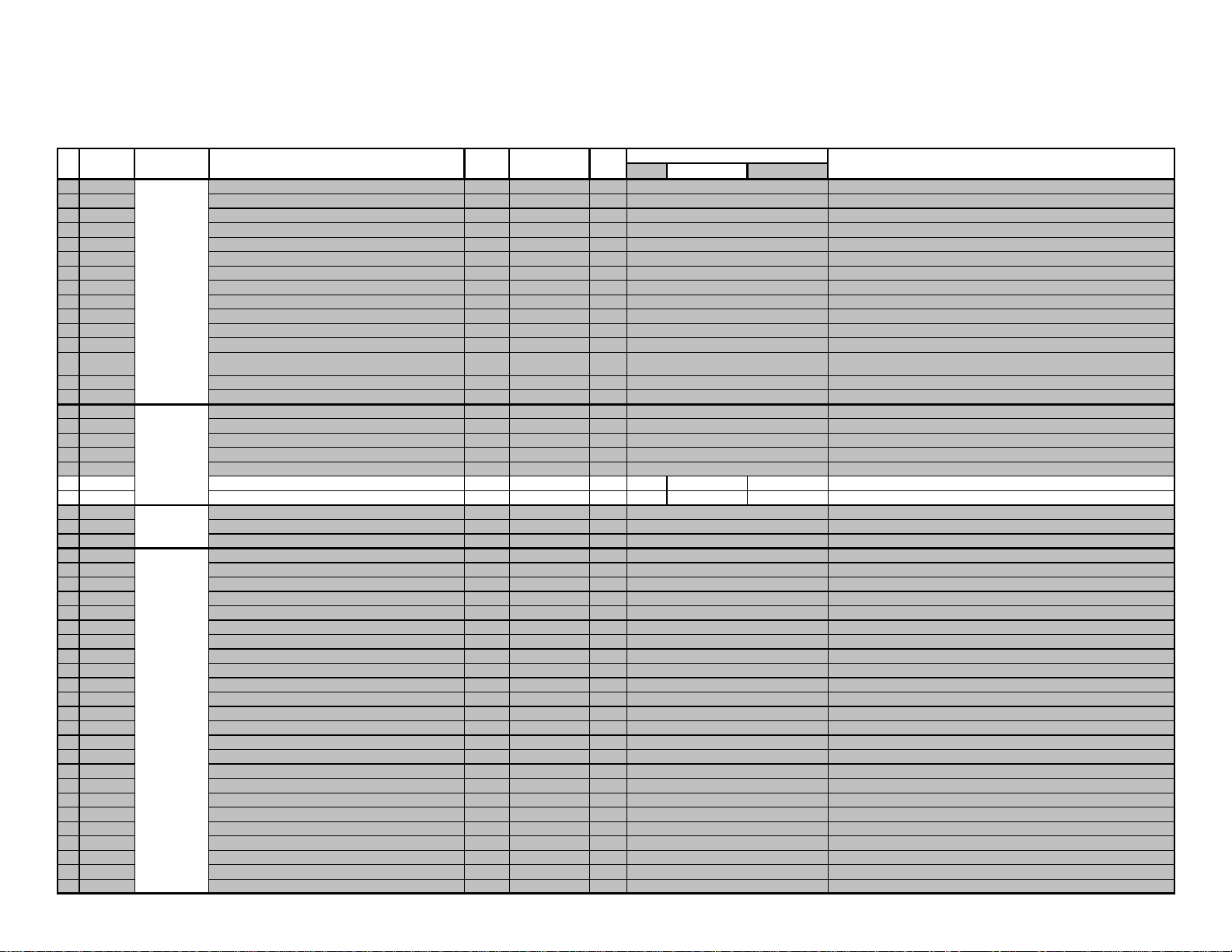

4-4. ADJUSTMENT ITEMS

Register

Name

0

HPOS

1

HSIZ

2

VBOW

3

VANG

4

TRAP

5

PAMP

6

UCPN

7

LCPN

8

VSIZ

9

VPOS

10

VLIN

11

VSCO

12

VZOM

13

EHT

14

ASP

15

ASP1

16

SCRL

17

HBSW

18

LBLK

19

— 16 —

RBLK

20

HDW

21

EWDC

22

LVLN

23

UVLN

24

RDRV

25

GDRV

26

BDRV

27

RCUT

28

GCUT

29

BCUT

30

RDR4

31

GDR4

32

BDR4

33

RCU4

34

GCU4

35

BCU4

36

SBRT

37

RON

38

GON

39

BON

40

AXPL

41

CBPF

42

COFF

43

TSSP

44

TSPF

45

VSSP

46

VSPF

47

YSSP

48

YSPF

VP

CXA2131AS

Description Data Adj/Fix Initial 32" Comments

H-Position 0-63 Adj 7

Range Data

H-Size 0-63 Adj 10

AFC Bow 0-15 Adj 6

AFC Angle 0-15 Adj 5

Trapezium Adjustment 0-15 Adj 6

Pin Compensation 0-63 Adj 32

Upper Corner Pin 0-63 Adj 36

Lower Corner Pin 0-63 Adj 36

V-Size 0-63 Adj 0

V-Position 0-63 Adj 31

V-Linearity 0-15 Adj 7

S-Correction 0-15 Adj 7

16:9 CRT Zoom Mode On/Off 0,1 FIX 0

Vertical Size High Voltage Correction 0-15 FIX 4

Aspect Ration Control 4:3 Mode 0-63 FIX 47

Aspect Ration Control 16:9 Mode 0-63 FIX 47

16:9 Vertical Scroll During Zoom 0-63 FIX 31

H Blanking Switch 0,1 FIX 1

Left Blanking 0-15 FIX 15

Right Blanking 0-15 FIX 0

H Drive Pulse Width 0,1 FIX 1

EW/DC Display 4x3 on 16x9 CRT 0,1 FIX 0

Picture Bottom Lin Adjust 0-15 Adj 0

Picture Top Lin Adjust 0-15 Adj 0

Red Drive 0-63 Adj 31

Green Drive 0-63 Adj 31

Blue Drive 0-63 Adj 31

Red Cutoff 0-15 FIX 7

Green Cutoff 0-15 Adj 7

Blue Cutoff 0-15 Adj 7

Video 4 Red Drive 0-63 Adj 31

Video 4 Green Drive 0-63 Adj 31

Video 4 Blue Drive 0-63 Adj 31

Video 4 Red Cutoff 0-15 FIX 7

Video 4 Green Cutoff 0-15 Adj 7

Video 4 Blue Cutoff 0-15 Adj 7

Sub Brightness 0-31 Adj 15

Red Off 0,1 FIX 1

Green Off 0,1 FIX 1

Blue Off 0,1 FIX 1

Axis PAL 0,1 FIX 0 0 0: Normal Axis, 1: Forced PAL Asix

Chroma BPF On/Off 0,1 FIX 1 1 0: BPF OFF, 1: BPF ON

Color On/Off 0,1 FIX 0 0 0: Chroma OFF, 1: Chroma ON

Sub Sharpness for TV Input 0-15 Fix by model 6

Sharpness fo for TV Input 0,1 FIX 1

Sub Sharpness for Video Input 0-15 Fix by model 7

Sharpness fo for Video Input 0,1 FIX 1

Sub Sharpness for YUV Input 0-15 Fix by model 7

Sharpness fo for YUV Input 0,1 FIX 1

FV16 FV26 FX260

10

18

8

6

7

36

39

39

9

36

6

11

0

4

47

47

31

1

15

0

1

0

0

0

52

44

38

14

7

6

42

33

29

14

7

6

6

1

1

1

6

1

7

1

7

1

0: 2ms delay, 63: 2ms advance

EW DC bias, 0: -0.5V, 31: 0V, 63: +0.5V

0: top/bottom delay 900ns, 7: center, 15: top/bottom advance 900ns

0: top delay/bottom advance 650ns, 7: center,

15: top advance/bottom delay 650ns

0: 1.5ms advance, 15: 1.5ms delay

0: 0.15Vpp, 31: 0.7Vpp, 63: 1.3Vpp

0: -0.4V, 63: +0.4V

0: -0.4V, 63: +0.4V

0: -15%, 31: 0%, 63: +15%

0: -0.1V, 31: 0V, 63: +0.1V

0: 85% top enlarged, 7: 100% top normal, 15: 115% top compressed

0: 0V added to VD, 15: 100mVpp added to VD

0: Zoom Off, 1: Zoom On

(top/bottom cut by 25% when ASPECT=31, RGB blanked in this interval)

0: Picture adjusted 0%, 15: Picture Adjusted -5%

0: 75%(16x9 CRT Full), 31: 100%(4x3 CRT Full), 63: 110%

0: 75%(16x9 CRT Full), 31: 100%(4x3 CRT Full), 63: 110%

0: Scrolled toward top 32H, 63: Scrolled toward bottom 32H

0: OFF, 1: ON

0: +1.2ms, 7: Center, 15: -1.2ms

0: +1.2ms, 7: Center, 15: -1.2ms

0: Normal Mode (25ms), 1: Narrow Pulse Width

0: OFF, 1: ON

0: 100%, 15: 85% Picture top compressed

0: 100%, 15: 85% Picture bottom compressed

0: 1.5Vpp, 63: 3.0Vpp Red Signal Output

0: 1.5Vpp, 63: 3.0Vpp Greem Signal Output

0: 1.5Vpp, 63: 3.0Vpp Blue Signal Output

0: 3.5mA IK, 7: 13mA IK, 15: 22.7mA IK

0: 3.5mA IK, 7: 13mA IK, 15: 22.7mA IK

0: 3.5mA IK, 7: 13mA IK, 15: 22.7mA IK

0: 1.5Vpp, 63: 3.0Vpp Red Signal Output

0: 1.5Vpp, 63: 3.0Vpp Greem Signal Output

0: 1.5Vpp, 63: 3.0Vpp Blue Signal Output

0: 3.5mA IK, 7: 13mA IK, 15: 22.7mA IK

0: 3.5mA IK, 7: 13mA IK, 15: 22.7mA IK

0: 3.5mA IK, 7: 13mA IK, 15: 22.7mA IK

Sub Brightness

0:OFF, 1:ON

0:OFF, 1:ON

0:OFF, 1:ON

0=-12dB, 7=+3.5dB, 15=+9dB

0=2.5MHZ, 1=3.0MHz

0=-12dB, 7=+3.5dB, 15=+9dB

0=2.5MHZ, 1=3.0MHz

0=-12dB, 7=+3.5dB, 15=+9dB

0=2.5MHZ, 1=3.0MHz

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

— 17 —

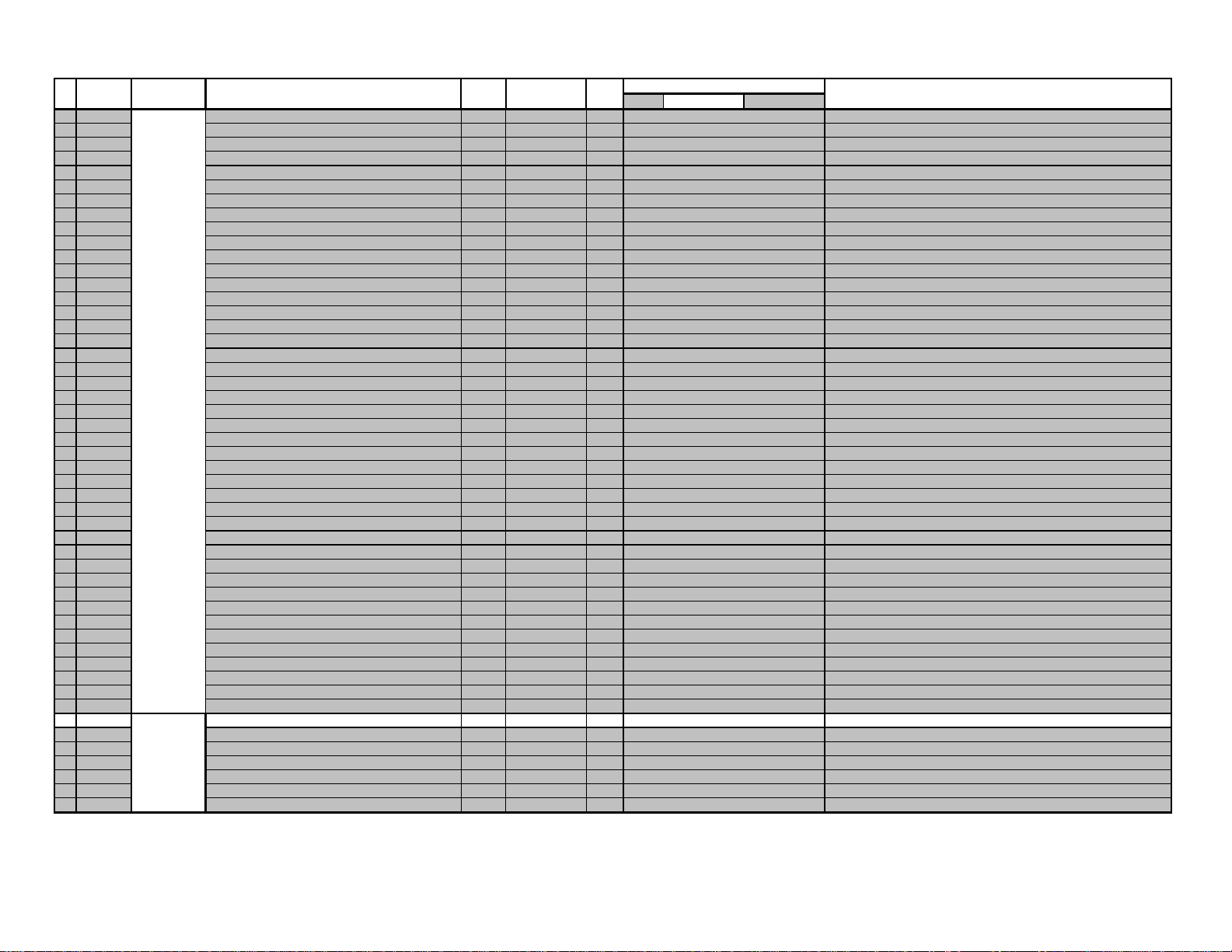

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

0

1

2

3

4

5

6

0

1

2

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Register

Name

AXNT

PREL

DCT

ABLM

FSC

HOSC

VSS

HSS

HMSK

VTMS

AFC

REFP

VBSW

BKOF

AGN2

SREF

BBLP

BBHP

SVOL

SBAL

SBAS

STRE

SPCA

CENA

INPA

COUT

YAPS

NSDS

MSS

EXAD

PECS

EXCS

CPP

HDP

CDL

DYCO

DYGA

DCCO

DCGA

YNRK

YNRI

YNRL

CNRK

CNRI

CNRL

ID1O

ID1W

ID1N

CLK

VP

CXA2131AS

AP

BH3868

SRS

TDA7464

uPD64082

3D COMB

Description Data Adj/Fix Initial 32" Comments

Axis NTSC 0,1 FIX 0

Range Data

Pre/Overshoot Ratio 0,1 FIX 1

DC Transmission Ratio 0,1 FIX 1

ABL Mode 0,1 FIX 1

FSC Output On/Off 0,1 FIX 1 1 0: FSC output OFF, 1: FSC output ON

H VCO Frequency Adjustment 0-15 FIX 7 7 0: Low, 15: High (40 Hz Steps)

Vsync Slice Level 0,1 FIX 0 1 0: 1/3 from sync tip, 1: 1/4 from sync tip

Hsync Slice Level 0,1 FIX 0 1 0: 1/3 from sync tip, 1: 1/4 from sync tip

Macrovision Countermeasure 0,1 FIX 1 1 0: Off, 1: ON

Select Signal VTIM Pin 0-3 FIX 0 0 0: V retrace timing, 1: Hsync signal, 2: Vsync signal, 3: don't use

AFC 0-3 FIX 0 0 0: High Gain, 1: Medium Gain, 2: don’t use, 3: Extremely low gain

REFP 0,1 FIX 0 0 0: R=20H/G=21H/B=22H, 1: R=23H/G=24H/B=25H

VBLK Width Control 0-3 FIX 0 0

ABL Signal Detection Level 0,1 FIX 0 0 0: VTH=3V, 1: VTH=1V

Aging Mode 2 - Black Output Mode 0,1 FIX 0 0 0: Black Output Mode OFF, 1: Black Output Mode ON

Surround Effect 0-15 FIX 7 7 0: Min, 15: Max (8-15 LOOP=1)

BBE Low PAss 0-15 FIX 5

BBE High Pass 0-15 FIX 3

Sub Volume 0-15 FIX 7

Sub Balance 0-15 FIX 7

Sub Bass 0-15 Fix by model 5

Sub Treble 0-15 Fix by model 3

SRS Space Attenuation 0-63 FIX 0

SRS Center Attenuation 0-63 FIX 0

Input Attenuation 0-127 FIX 3

Chroma Signal Gain / BPF 0-3 FIX 3 3 Input/Output gain=1 / BPF ON

Y V-Compensation/Peaking 0-3 FIX 3 3 Correctin enabled for digital/analog inputs

Standard/Non-Standard Processing 0-3 FIX 0 0 Standard adaptive processing

Inter-frame/Inter-line Mode 0-3 FIX 0 0 Adaptive Processing

External ADC Insert 0,1 FIX 0 0 Internal Y-ADC

Pedestal Error Correction 0-3 FIX 0 0 Standard

C sync Input 0-3 FIX 1 1 Use CSI

Y ADC Amplitude/Clamp Method 0-3 FIX 0 0 Y-ADC & C-ADC Vtb=1.25V

H Phase Fine Adjustment 0-7 FIX 3 3 Phase +/- 0msec

C Output Delay Fine Adjustment 0-7 FIX 5 5 Y/C Delay +/- 0msec

Y Moving Coring Level 0-15 FIX 2 2 0: Close to moving pictures, 15: Close to still pictures

Y Moving Coring Gain 0-15 FIX 10 10 0: Close to still Pictures, 15: Close to moving Pictures

C Moving Coring Level 0-15 FIX 2 2 0: Close to moving pictures, 15: Close to still pictures

C Moving Coring Gain 0-15 FIX 9 9 0: Close to still Pictures, 15: Close to moving Pictures

YNR Non-linear Filter Gain 0,1 FIX 1 1 x7/8 large noise reduction and large after image

YNR Non-linear Filter Convergence 0,1 FIX 0 0 6LSB small noise reduction and small after image

YNR Non-linear Filter Limit Level 0-3 FIX 1 1 0: YNR Off , 3: 3LSB large noise reduction

CNR Non-linear Filter Gain 0,1 FIX 1 1 x7/8 large noise reduction and large after image

CNR Non-linear Filter Convergence 0,1 FIX 0 0 6LSB small noise reduction and small after image

CNR Non-linear Filter Limit Level 0-3 FIX 1 1 0: CNR OFF , 3: 3LSB large noise reduction

ID-1 Superimpose Signal 0,1 FIX 0 0 Through, no superimposition

Specifies bit A1 of Word 0 0,1 FIX 0 0 0: 4x3, 1: 16x9

Spedifies bit A2 of Word 0 0,1 FIX 0 0 0: normal, 1:letterbox

CLK8 Pin Output 0,1 FIX 1 1 0: Output 8fsc, 1: Output OFF

FV16 FV26 FX260

0

1

1

1

5

3

7

7

85 5

83 5

0

0

3

0: Japan Axis, 1: US Axis

0: 1:1, 1: 2:1

0:100%, 1:85%

0:Picture ABL, 1:Picture/Brightness ABL

0: 9H from B, 1: 10H from B, 2: 11H from B, 3:12H from B

(When JUMP SW=1)

0: 0.5dB, 15: 10dB

0: 0.5dB, 15: 10dB

0:-0 volume steps, 15:-15 volume steps

0: +Right, 15:+Left

0:-7 steps, 15: +8 steps

0:-7 steps, 15: +8 steps

0: 0dB, 63: -31db (1dB steps)

0: 0dB, 63: -31db (1dB steps)

0: 0dB, 127: -31.5dB (0.5dB steps)

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

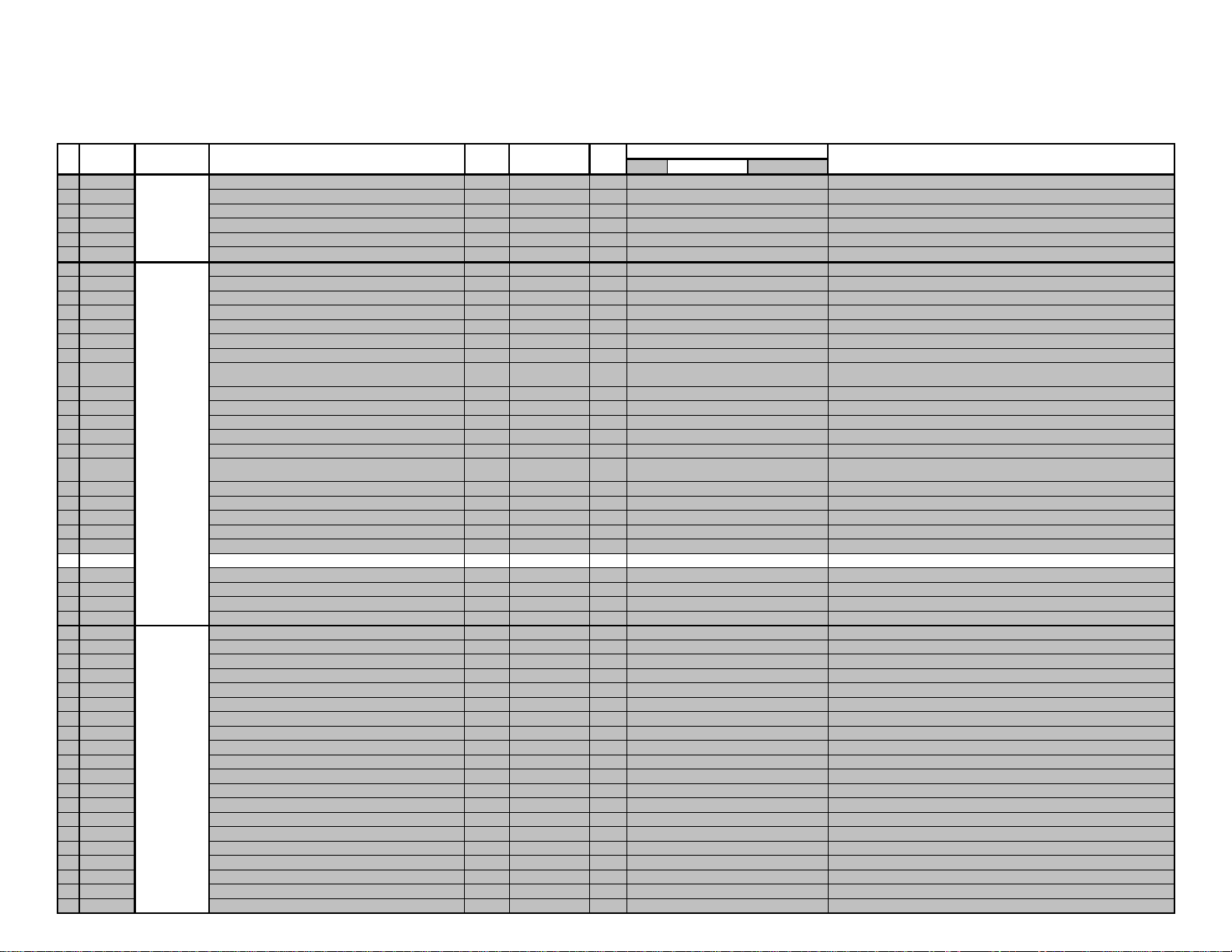

ADJUSTMENT ITEMS (cont.)

Register

Name

24

ST0S

25

WSC

26

VTRH

27

VTRR

28

LDSR

29

PWRE

30

VAPG

31

VAPI

32

TEST

33

YPFT

34

YPFG

35

V1PS

36

VEGS

37

CC3N

38

C0HS

39

CLPH

40

SEL2

41

SEL1

42

YHCO

43

YHCG

44

— 18 —

OVST

45

CSHD

46

KCTT

47

SHT

48

VCT

49

OTT

50

CL2D

51

CGGT

52

CLEB

53

CGT

54

HPLL

55

BPLL

56

FSCF

57

PLLF

58

KILR

59

HSSL

60

VSSL

61

BGPS

62

BGPW

63

ADCL

64

ADPD

65

NSDW

66

CNRF

0

SHPR

1

BLAD

2

SRTS

3

YNR

4

GIRE

5

DAC1

6

DAC2

uPD64082

3D COMB

TA1226N

PIC IMP

Description Data Adj/Fix Initial 32" Comments

Select ST0 Pin Output Signal 0-3 FIX 1 1 External Y-ADC clamp pulse

Range Data

Noise Detection Coring 0-3 FIX 1 1 1LSB coring for noise detection circuit

H-sync Non-Standard Detection Hysteresis 0-3 FIX 1 1 Low hysteresis (2 clock pulses)

H-sync Non-Standard Detection Sensitivity 0-3 FIX 1 1 Medium sensativity (+/- 8 clock pulses)

Frame Sync Non-Std Detection Sensativity 0-3 FIX 2 2 Low sensativity (1.5 clock pulses)

Internal ADC Input Range 0,1 FIX 0 0 Same input range on Y-ADC and C-ADC

Vertical Aperture Compensation Gain 0-7 FIX 4 4 0: Correction OFF, 7: Max Correction

Vertical Aperture Comp Convergence 0-31 FIX 12 12 0: Correction OFF, 31: Max Correction

Test Bit 0,1 FIX 0 0 Normal Mode

Y Peaking Filter Center Frequency 0-3 FIX 3 3 4.22 MHz

Y Peaking Filter Gain 0-15 FIX 7 6 0: -1 gain, 15: 0.875 gain

Horizontal Dot Supression Level 0-3 FIX 2 2 Medium suppression

Vertical Dot Supression Level 0-3 FIX 2 2 Medium supression

Line Comb C Separation Filter 0,1 FIX 0 0 Narrow bandwidth

C Signal Delay Time at NR 0,1 FIX 0 0 1H Delay

Y-ADC Clamp Test Bit 0,1 FIX 0 0 Normal Mode

DC Detection High Freq Sensativity 0,1 FIX 0 0 Low sensativity, Close to still pictures

DY detection Low Freq Sensativity 0,1 FIX 0 0 Low sensativity, Close to still pictures

Y High Freq Coring 0-3 FIX 1 0 Small Amount of coring (+/- 1LSB)

Y High Freq Coring Gain 0,1 FIX 0 0 Gain = 1

Non Standard Detection Test Bit 0,1 FIX 0 0 Normal Mode

H/V counter Test Bit 0,1 FIX 0 0 Normal Mode

H/V counter Test Bit 0-3 FIX 0 0 Normal Mode

Non Standard Detection Test Bits 0,1 FIX 0 0 Normal Mode

H/V counter Test Bit 0,1 FIX 0 0 Normal Mode

H/V counter Test Bit 0,1 FIX 0 0 Normal Mode

Clock Generator Test Bit 0,1 FIX 1 1 Normal Mode

Clock Generator Test Bit 0,1 FIX 0 0 Normal Mode

Clock Generator Test Bit 0,1 FIX 0 0 Normal Mode

Clock Generator Test Bit 0,1 FIX 0 0 Normal Mode

Horizontal PLL Filter 0,1 FIX 1 1 Quick convergence

Burst PLL Filter 0,1 FIX 1 1 Quick convergence

Burst Extraction Gain 0,1 FIX 0 0 High gain

PLL Loop Gain 0,1 FIX 1 1 High gain, quick convergence

Killer Detection Reference 0-15 FIX 3 3 0: Detection off, 15: High detection sensativity

Horizontal Sync Slice Level 0-15 FIX 12 12 0: 4LSB, 15: 19LSB

Vertical Sync Slice Level 0-15 FIX 8 8 0: HSSL + 0LSB, 15: HSSL + 15LSB

Burst Gate Start Position 0-15 FIX 5 5 0: Hsync center + 2ms, 15: Hsync center +5.75ms

Internal Burst Gate Pulse Width 0-15 FIX 10 10 0: 0.5ms, 15: 4.25ms

ADC Clock Delay 0-3 FIX 3 3 0: 0ns, 3: 20.5ns (typical)

ADC Power Down 0,1 FIX 1 1 Stop ADC when not in use

Non Standard Detection Test Bit 0,1 FIX 0 0 Normal Mode

CNR Section Test Bit 0,1 FIX 0 0 Normal Mode

Controls both DL APACON and SRT 0-127 Fix by Model 52 52 0: Minimum, 127: Maximum

Black Area Detect 0-3 FIX 0 0 0: 10IRE, 1: 20IRE, 2: 30IRE, 3: 40IRE

SRT Start Amplitude 0-3 FIX 3 3 0: 7IRE, 1: 10IRE, 2: 14IRE, 3: 28IRE

Controls YNR ON/OFF 0,1 FIX 1 1 YNR ON

Gamma Correction Start Point 0-3 FIX 3 3 0: 70IRE, 1: 80IRE, 2: 90IRE, 3: OFF

1 bit DAC Output 0,1 FIX 0 0 Open

1 bit DAC Output 0,1 FIX 0 0 Open

FV16 FV26 FX260

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

— 19 —

7

8

9

10

11

12

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Register

Name

GCUR

BLKC

TEST

RS

RTC

VMLO

PIPH

PIPV

POFV

POFH

VACQ

HACQ

PVID

VERB

PSEL

SELD

4SLD

PCOR

AGCR

AGCM

AGCV

CLMD

CLMS

LMOF

PYDL

FRMY

FRSL

FRWH

FRWV

PBSW

CKIL

COLO

PSHU

4PSU

CPLL

SCAD

PCON

4PCN

PBRT

4PBR

IPER

4IPR

IPEG

4IPG

IPEB

4IPB

BLKR

BLKB

PVGA

4PVG

Controls Curve of Gamma Correction 0,1 FIX 0 0 0: -2.4dB, -1.6dB

Gain of DL APACON at 8MHz Peak 0-7 FIX 0 0 0: 0dB, 7: +6dB

TA1226N

PIC IMP

Compensation Ratio of SRT and DL APACON 0-7 FIX 4 4 0: Min, 7: Max

PIP

SDA9588X

PiP Block Selection (PIPBG vs PIPBLK) 0,1 FIX 0

Sub Carrier Freq Fine Adjustment 0-31 FIX 5

SDA9588X

PIP-YC

Peak Level V Output YUV Input 0-255 FIX 69

Description Data Adj/Fix Initial 32" Comments

Range Data

Black Conpensation 0,1 FIX 1 1 OFF

Test Bit 0-3 FIX 3 3 Pin 20 Output: 0=RS, 1=SHR, 2=RTC, 3=TEST3

Gain for Menu VM=LOW 0-2 FIX 1 1 0=off, 1=-6dB, 2=-3dB, 3=0dB

PIP H-position 0-127 FIX 34

PIP V-position 0-63 FIX 22

Position Ofset Vertical 0-15 FIX 4

Position Ofset Horizontal 0-31 FIX 17

PiP V-Acquisition Window 0-15 FIX 8

PiP H-Acquisition Window 0-15 FIX 8

PiP Vsync Delay 0-31 FIX 0

Vertical Blanking 0,1 FIX 0

SELDOWN Bit Control 0,1 FIX 1

Select PYS Delay 0-15 FIX 8

Select PYS Delay YUV Input 0-15 FIX 8

Position Correction 0,1 FIX 1

AGC Gain Control Reset 0,1 FIX 1

AGC Mode 0-3 FIX 0

ADC Value 0-15 FIX 11

Clamp Pulse Duration 0-3 FIX 3

Clamp Pulse Start 0-3 FIX 2

Luminance Offset 0-3 FIX 3

Y/C Delay 0-15 FIX 8

Frame Y Level 0-15 Fix by Model 6

Frame Type Select 0,1 FIX 1

Frame Width Horizontal 0-7 FIX 4

Frame Width Vertical 0-3 FIX 1

Color Killer Threshold 0-3 FIX 0

Color Killer Off 0,1 FIX 0

PiP Sub Hue 0-15 FIX 7

PiP Sub Hue YUV Input 0-15 FIX 7

Chroma PLL Off 0,1 FIX 0

PiP Contrast 0-15 FIX 0

PiP Contrast YUV Input 0-15 FIX 0

PiP Brightness 0-15 FIX 0

PiP Brightness YUV Input 0-15 FIX 0

V Pedestal 0-15 FIX 0

V Pedestal YUV Input 0-15 FIX 4

Y Pedestal 0-15 FIX 0

Y Pedestal YUV Input 0-15 FIX 0

U Pedestal 0-15 FIX 1

U Pedestal YUV Input 0-15 FIX 1

Invert V Pedestal 0,1 FIX 1

Invert U Pedestal 0,1 FIX 0

Peak Level V Output 0-255 FIX 84

FV16 FV26 FX260

34

22

4

17

8

8

0

0

1

8

8

1

1

3

9

3

2

3

2

5

1

4

1

1

0

0

7

7

0

6

0

0

0

0

0

0

0

0

1

1

0

1

84

69

0:Right, 127:Left

0:Up, 63:Down

Vertical PiP Offset from Center

Horizontal PiP Offset from Center

0: -8 lines up, 8: Center, 15: +7 pixels down

0: -16 pixels right, 8: Center, 15: +14 pixels left

Step size 3.56ms< 1 step < 6.4ms

0: DAC Blanking during line blanking interval,

1: DAC Blanking during line AND field intervals

0:Open out, 1:TTL out

0: -8 clock cycles, 8: NO delay, 15: +7 clock cycles

0: -8 clock cycles, 8: NO delay, 15: +7 clock cycles

0: OFF, 1: ON (Position correction during varying parent frequency)

0: Normal, 1: Reset (transition of 0-->1 resets AGC)

0: Sync height & ADC Overflow, 1: sync height,

2: ADC overflow, 3: AGC Fixed

0: Input valtage 0.5Vpp, 15: Input Voltage is 1.5Vpp

0: 0.5ms, 1: 0.9ms, 2: 1.2ms, 3: 1.5ms

0: 1.0ms, 1: 1.5ms, 2: 2.0ms, 3: 2.5ms

0: NO OFFSET, 1: +16LSB, 2: -8LSB, 3: -16LSB

0: -8 pixels, 15: +7 pixels

Adjusts 4 MSB of Frame Y Signal

0: Normal frame, 1: 3D frame

0: No frame, 7: 7 pixels

0: No frame, 3: 3 lines

Blocking Type: 0= PIPBG(gray), 1=PIPBLK(black)

0: -30dB, 1: -18dB, 2: -24dB, 3: color always off

0: Color killer active, 1: Color always on

PiP sub hue

PiP sub hue

0: Chroma PLL active, 1: Chroma PLL free running

0: -150 PPM, 7: default, 31: +310 PPM

0: nominal, 15: +30% increase

0: nominal, 15: +30% increase

0: nominal, 15: +20% increase

0: nominal, 15: +20% increase

0: nominal, 15: +15LSB offset

0: nominal, 15: +15LSB offset

0: nominal, 15: +15LSB offset

0: nominal, 15: +15LSB offset

0: nominal, 15: +15LSB offset

0: nominal, 15: +15LSB offset

0: Offset add during blanking, 1: Offset add during active

0: Offset add during blanking, 1: Offset add during active

0: 0.3Vpp, 192: 1.0Vpp, 255: 1.2Vpp

0: 0.3Vpp, 192: 1.0Vpp, 255: 1.2Vpp

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

ADJUSTMENT ITEMS (cont.)

Register

Name

20

PUGA

21

4PUG

22

PYGA

23

4PYG

24

CHRO

25

SATA

26

— 20 —

YPKG

27

4YPK

28

YCOR

29

CLPL

0

RTCO

1

T2CO

2

V2CO

3

4COL

4

T2HU

5

V2HU

6

4SHU

0

XJGL

1

LNJ1

0

DUM1

1

VOSD

0

DISP

1

RAMW

2

ICMP

3

IPOR

4

FAWD

5

TILT

0

VPIC

1

VBRT

2

VCOL

3

VSHP

4

VVM

5

VTRI

6

VGMA

7

VBLK

8

VAPA

9

VSRT

10

VNRM

0

RDOF

1

GDOF

2

BDOF

3

RCOF

4

GCOF

5

BCOF

6

DCOF

CXD2085

M306V5

SDA9588X

PIP-YC

CXA1315

DAC

ID1

CCD

OP

PROGRAM FOR EACH PALETTE MODE

Set Current Program Pallette PICTURE Reset Level 0-63 FIX by Palette 50

Set Current Program Pallette BRIGHTNESS Reset Level 0-63 FIX by Palette 31

Set Current Program Pallette COLOR Reset Level 0-63 FIX by Palette 31

Set Current Program Pallette SHARPNESS Reset Level 0-63 FIX by Palette 31

Set Current Program Pallette VM Reset Level 0-3 FIX by Palette 1

Set Current Program Pallette Color Temp Reset Setting 0-3 FIX by Palette 1

Set Current Program Pallette YC/J GAMMA 0-3 FIX by Palette 2

Set Current Program Pallette Black Stretch 0,1 FIX by Palette 1

PALETTE

PROGRAM

Set Current Program Palette APACON 0,1 FIX by Palette 1

Set Current Program Pallette SRT 0,1 FIX by Palette 0

Set Current Program Pallette NRMD 0,1 FIX by Palette 0

Red Drive offset for WARM 0-63 FIX 0 0 Red Drive MOVIE=RDRV(RDR4)-RDOF

Green Drive offset for WARM 0-63 FIX 4 4 Green Drive MOVIE=GDRV(GDR4)-GDOF

Blue Drive offset for WARM 0-63 FIX 15 15 Blue Drive MOVIE=BDRV(BDR4)-BDOF

Red Cutoff offset for WARM 0-31 FIX 0 0 Red Cutoff MOVIE=RCUT(RCU4)-RCOF

Green Cutoff offset for WARM 0-31 FIX 2 2 GREEN Cutoff MOVIE=GCUT(GCU4-GCOF)

Blue Cutoff offset for WARM 0-31 FIX 7 7 BLUE Cutoff MOVIE=BCUT(BCU4)-BCOF

TEMP OFFSET

WARM COLOR

Dynamic Color setting for WARM 0,1 FIX 0 0 0=OFF, 1=ON

Description Data Adj/Fix Initial 32" Comments

Peak Level U Output 0-255 FIX 52

Range Data

Peak Level U Output YUV Input 0-255 FIX 36

Peak Level Y Output 0-255 Fix by Model 104

Peak Level Y Output YUV Input 0-255 Fix by Model 129

UV Output Polarity 0,1 FIX 0

Color Saturation Adjustment 0-15 FIX 8

Y Peaking Adjustment 0-7 FIX 7

Y Peaking Adjustment YUV Input 0-7 FIX 7

Y Coring Enable 0,1 FIX 1

Clamp Pulse Length 0-3 FIX 0

Rotation Coil 0-63 FIX 31

Sub Color TV Input 0-7 Adj 120

Sub Color Video Input 0-7 Adj 120

Sub Color YUV Input 0-7 Adj 120

Sub Hue TV Input 0-7 Adj 15

Sub Hue Video Input 0-7 Adj 15

Sub Hue YUV Input 0-7 Adj 15

Decoding Result Held For VCR Scanning 0,1 FIX 0

ID-1 Signal Location 0,1 FIX 0

CCD Dummy Register Used to display CC data in Service Mode

VChip OSD Test Register 0,1 FIX 0

OSD Position 0-63 Adj 15

OSD RAM Window 0,1 FIX 0

OSD Non-interlace Threshold 0-15 FIX 4

OSD Non-interlace Even/Odd Display 0-3 Fix 1

Factory AutoWide Mode 0,1 Fix 0

Tilt Correction Spec 0,1 Fix 0

FV16 FV26 FX260

52

36

125

135

0

9

7

7

1

0

31

102

148

145

16

19

16

0

0

0

17

0

4

1

0

2

VIVID STD MOVIE

63 50 38 63

31 31 31 31

38 31 31 38

31 31 31 31

2102

0120

3222

1111

0111

1000

0001

0: 0.3Vpp, 192: 1.0Vpp, 255: 1.2Vpp

0: 0.3Vpp, 192: 1.0Vpp, 255: 1.2Vpp

0: 0.3Vpp, 192: 1.0Vpp, 255: 1.2Vpp

0: 0.3Vpp, 192: 1.0Vpp, 255: 1.2Vpp

0: +U/+V output, 1: -U/-V output

0: No color, 8: nominal saturation, 15: nominal x 1.875

0: No peaking, 7: Strongest Peaking

0: No peaking, 7: Strongest Peaking

0: OFF, 1: ON

0=5ms, 1=3.75ms, 2=2.5ms, 3=1.25ms

Rotation coil adjustment for nominal value

TV Sub Color Adjustment (CXA2039 YUV Models AT DAC)

VIDEO1-3 Sub Color Adjustment (CXA2039 YUV Models at DAC)

YUV Sub Color Adjustment (CXA2039 YUV Models at DAC)

TV Sub HUE Adjustment (CXA2039 YUV Models at DAC)

VIDEO1-3 Sub HUE Adjustment (CXA2039 YUV Models at DAC)

YUV Sub HUE Adjustment (CXA2039 YUV Models at DAC)

Hold data during VCR variable speed playback

Search for ID-1 data +/- one line in VBI

Used to display VChip data in Service Mode

OSD horizontal position

0: 0 fields, 15: 15 fields

0=Even OSD display, 1= Odd OSD display, 2&3=N/A

0= No Autowide in RF mode, 1= Autowide in RF Mode

0= New Tilt Spec for AA2U (less VANG offset), 1= AA2W/AA2H Tilt Spec

SPORTS

0=MIN, 63=MAX

0=MIN, 63=MAX

0=MIN, 63=MAX

0=MIN, 63=MAX

0=OFF, 1=LOW, 2=HIGH, 3=N/A

0=COOL, 1=NEUTRAL, 2=WARM, 3=N/A

0=GAMMA CORRECTION OFF, 3=+12 IRE CORRECTION @ 40 IRE INPUT

0=BLACK STRETCH OFF, 1=BLACK STRETCH ON

0=APACON OFF, 1=APACON ON

0=SRT OFF, 1=SRT ON

0=3D YCS, 1=2D YCS

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

Register

ID-6

Name

0

ID-0

1

ID-1

2

ID-2

3

ID-3

4

ID-4

5

ID-5

6

ID-6

7

ID-7

VALUE = Not Used for AA-2U

VALUE = Fixed Item For AA-2U

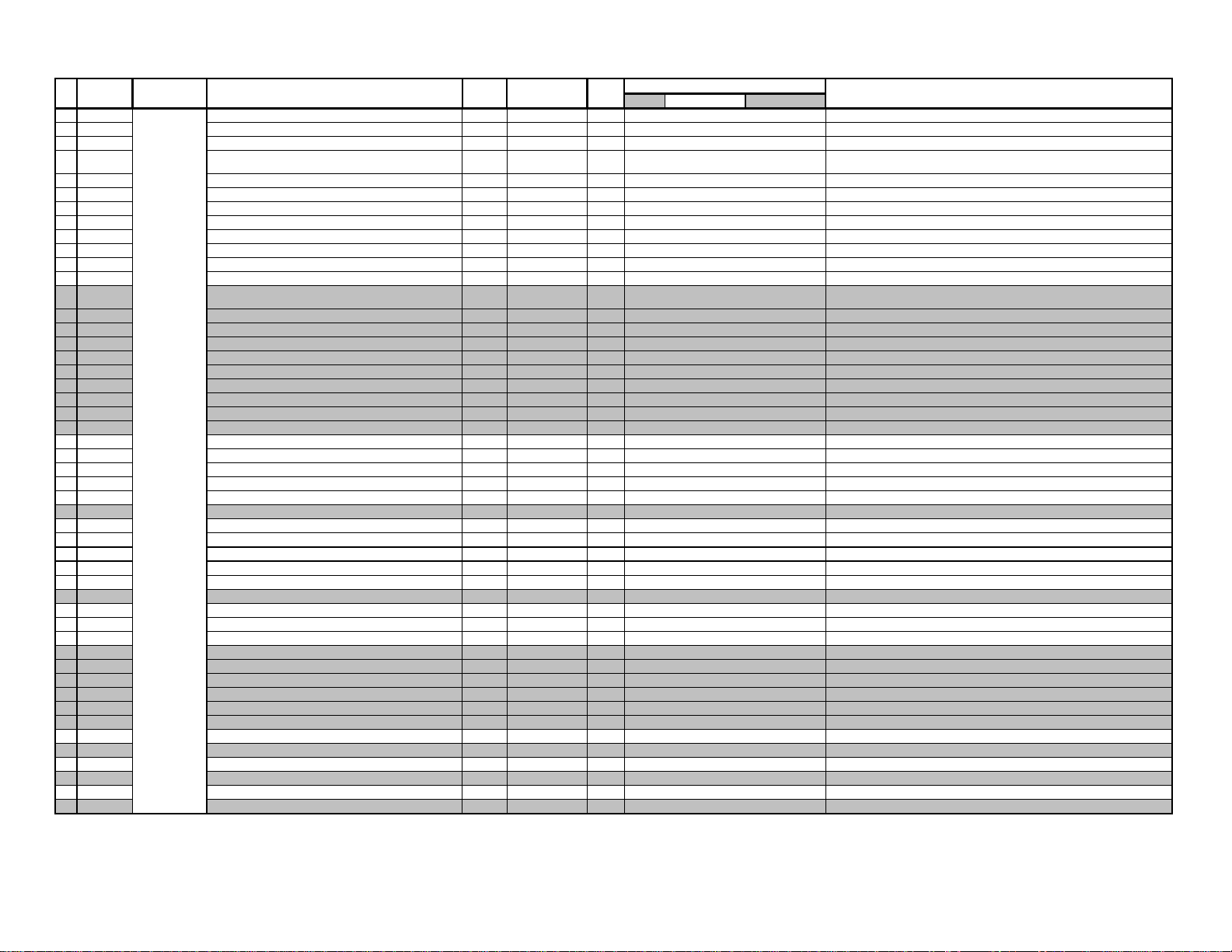

4-5. FEATURE ID MAP

— 21 —

ID

ID7

24

TV

SERVICE

00011000

7

ID

MAP

Description Data Adj/Fix Initial 32" Comments

Range Data

ID-0 (Language/Color Systems) 0-255 Fix by model 89 See ID map

ID-1 (Input/Output Conifguration) 0-255 Fix by model 63 See ID map

ID-2 (Audio) 0-255 Fix by model 239 See ID map

ID-3 (OSD/Timer/V-chip/Ch Fix) 0-255 Fix by model 99 See ID map

ID-4 (CC/Spot Killer/etc) 0-255 Fix by model 139 See ID map

ID-5 (V-series Features/etc) 0-255 Fix by model 181 See ID map

ID-6 (PiP/Ant Sw related) 0-255 Fix by model 6 See ID map

ID-7 (Special Models/etc) 0-255 Fix by model 24 See ID map

FV16 FV26 FX260

refer to NVM ID Chart

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

M306V5ME-1015P

VERSION: 1.0__

NVM:G

Note: Check to be sure NVM is good (NVM: G)

Model Destination ID-0 ID-1 ID-2 ID-3 ID-4 ID-5

KV-32FV16 US 89 63 239 99 139 181 6 17

KV-32FV26 US 89 63 239 99 139 181 6 24

KV-32FV26 CND 89 63 239 83 139 181 6 24

KV-34FV16 E 25 63 239 195 187 181 6 81

KV-34FV16C E 25 63 239 195 187 181 6 81

KV-34FX260 E 25 63 239 195 187 181 6 88

KV-34FX260C E 25 63 239 195 187 181 6 88

ID-7

KV-32FV16/32FV26/34FV16/34FV16C/34FX260/34FX260C

W

GND

U

V

)

)

4-6. PROGRAM PALETTE SETTINGS

Vivid Standard Movie Sports

Picture (VPIC) 63 50 38 63

Brightnness (VBRT) 31 31 31 31

Color (VCOL) 38 31 31 38

Sharpness (VSHP) 31 31 31 31

1

VM

1)

C Temp

Gamma (VGMA) 3222

Blk Comp (VBLK) 1111

V Apa Comp (VAPA) 0111

SRT ON/OFF (VSRT) 1000

NRMD (VNRM) 0001

1

Setting of 3 is invalid for these registers

(VVM) 2102

(VTRI) 0 1 2 0

To Program Program Palette RESET Levels

1. Switch to Program Palette to edit.

2. Enter Service Mode.

3. Set desired values for current Program Palette settings.

4. Write into memory by

then .

5. Repeat steps 1-4 for each palette.

Example

To Set RESET Level of Standard Mode to 60%

1. Switch to STANDARD Palette.

2. Enter Service Mode.

3. Change value of VPIC to 38 (38/63 = 60%).

4. Write into memory by then .

5. Enter Video Menu and press

.

6. Reset level of picture for STANDARD PALETTE ONLY is

now 38 steps.

4-7. A BOARD ADJUSTMENTS

Sub Bright Adjustment (SBRT)

1. Set to Service Adjustment Mode.

2. Input a gray scale pattern signal.

3. Set the PICTURE to minimum, and BRIGHT to normal.

4. Select SBRT with

5. Adjust SUB BRIGHT level with

and .

and so that the stripe

second from the right is faintly visible.

6. Write into the memory by pressing then

.

white

second from the right

black

Sub Hue, Sub Color Adjustment

(T2HU, T2CO, V2HU, V2CO, 4SHU, 4COL)

Note: T2HU and T2CO are for Tuner inputs.

V2HU and V2CO are for all other Video inputs.

4SHU and 4COL are for Video 4 input.

1. Input a 75% color-bar signal.

2. Set to Service Adjustment Mode and set: VIDEO mode =

Standard, PICTURE = 100%, COLOR = 50%, HUE = 50%.

3

3. Connect an oscilloscope to Pin

the A Board.

4. Select T2HU and T2CO with and .

5. Adjust with

and for flat ± 50mV.

6. Write into memory by

7. Repeat steps 1-6 for V2HU & V2C0 and 4SHU & 4COL.

of CN351 Blue Out on

then .

Sub Contrast Adjustment (RDRV, RDR4)

1. Input a 75% color-bar signal.

2. Set to: VIDEO mode = Standard, COLOR = Minimum,

PICTURE = 100%, GON = 0 (OFF), BON = 0 (OFF).

3. Set to Service Adjustment Mode and connect an oscilloscope

to pin

4. Set RDRV with

5. Adjust with

6. Write into memory by

7. Repeat steps 1-6 for RDR4 using Video 4 input.

of CN351 on the A Board.

and .

and for: 1.95 ± 0.05 Vp-p.

then .

White

1.95 ± 0.05 Vp-p

Black

— 22 —

Loading...

Loading...