SONY KV-32XBR400, KV-36XBR400, KV-38DRC1, KV-38DRC1C Service Manual Part3

SECTION 3

SET-UP ADJUSTMENTS

KV-32XBR400/36XBR400/38DRC1/38DRC1C

The following adjustments should be made when

a complete realignment is required or when a new

picture tube is installed.

These adjustments should be performed with rated

power supply voltage unless otherwise noted.

Set the controls as follows unless otherwise noted:

VIDEO MODE: ST ANDARD

PICTURE control: ............... 100%

BRIGHTNESS control: ....... 50%

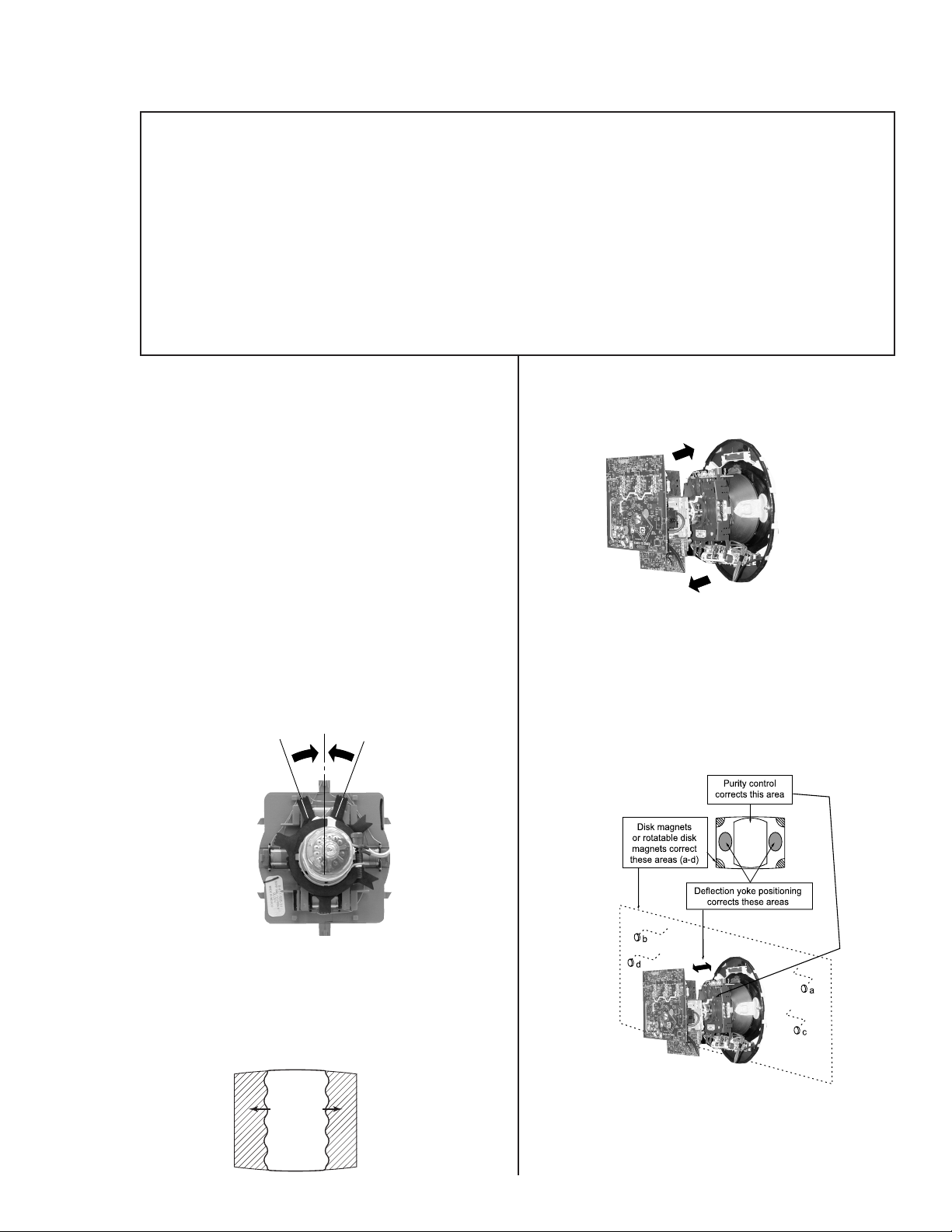

3-1. BEAM LANDING

Before beginning adjustment procedure:

• Input a white pattern signal.

• Face the picture tube in East or West direction to reduce the

influence of geomagnetism.

NOTE: Do not use hand degausser because it magnetizes CRT.

1. Input white pattern from pattern generator. Set the

PICTURE control to maximum and BRIGHTNESS control

to standard.

2. Perform Focus, G2 and White Balance adjustments.

3. Loosen the deflection yoke mounting screw and set the

purity control to the center as shown below.

Purity Control

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Note: T est equipment required:

• Color Bar Pattern Generator

• Degausser

• DC Power Supply

• Digital Multimeter

6. Move the deflection yoke forward and adjust so that the

entire screen becomes green.

7. Switch over the raster signal to red and blue and confirm

the condition.

8. When the position of the deflection yoke is determined,

tighten it with the deflection yoke mounting screw.

9. If landing at the corner is not right, adjust by using the disk

magnets.

4. Input a green pattern from the pattern generator.

5. Move the deflection yoke backwards and adjust the purity

control so that green is in the center and red and blue are

even on both sides.

Blue Red

Green

ﱢﱡ

cd

— 15 —

KV-32XBR400/36XBR400/38DRC1/38DRC1C

3-2. V-PIN and V-CEN ADJUSTMENT

Before beginning adjustment procedure:

• Input a cross hatch pattern signal.

• Face the picture tube in North/South direction and correct

rotation.

1. Set PICTURE control to 100% and BRIGHTNESS control

to 50%.

2. Adjust service mode CXA2150D-1 04 VCEN so that top

pin and bottom pin are symmetrical from top to bottom.

3. Adjust service mode CXA2150D-1 05 VPIN so top and

bottom pin are symmetrical from top to bottom.

4. Lines should be straight from left to right. Check landing for

side effect.

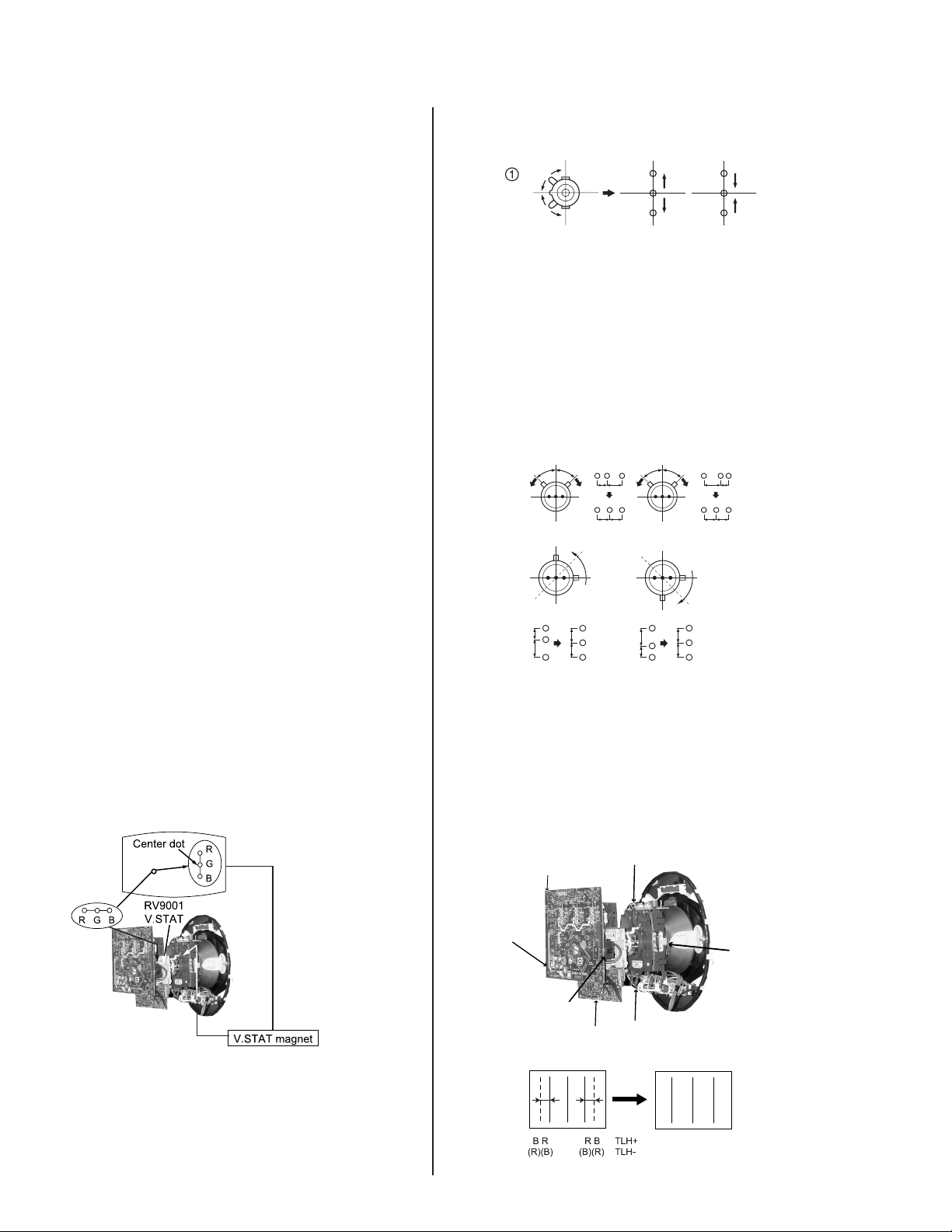

3-3. Con vergence Adjustment

Before starting convergence adjustments:

• Set CONTRAST AND BRIGHTNESS control to 50%.

• Input HD dot pattern.

5. Tilt the V.STAT magnet and adjust static convergence to

open or close the V.STAT magnet.

B

G

R

B

G

R

Operation of BMC (Hexapole) Magnet

The respective dot positions resulting from moving each

magnet interact, so perform the following adjustment while

tracking.

Use the V.STAT tabs to adjust the red, green, and blue dots

so they line up at the center of the screen (move the dots in

a horizontal direction.)

HMC Correction HMC Correction

A<B

GB

R

AB

RGB

A=B

AB

VMC Correction

VMC Correction

A=B

A>B

RGB

GB

R

AB

AB

Vertical and Horizontal Static Convergence

1. Disconnect dynamic convergence before adjusting static

convergence (CN5510), except for minor touch-up.

2. Adjust H.ST AT convergence, RV 9001, to conver ge red,

green and blue dots in the center of the screen.

3. Adjust V.STAT magnet to converge red, green and blue

dots in the center of the screen.

4. If horizontal convergence is not correct, adjust V.STAT

manget and R V9001 on C Board while tracking.

C<D

C=D

R

C

G

D

R

G

B

B

C<D

C=D

R

C

G

D

R

G

B

B

TLH Plate Adjustment

• Input crosshatch pattern.

• Adjust PICTURE QUALITY to standard, PICTURE and

BRIGHTNESS to 50%, and OTHER to standard.

• Adjust unbalanced horizontal convergence of red and blue

dots by adjusting TLH plate on the deflection yoke.

RV9002

C Board

RV9001

V Board

TLV

TLH Plate

XCV

— 16 —

Loading...

Loading...