SONY KV-32XBR400, KV-36XBR400, KV-38DRC1, KV-38DRC1C Service Manual Part4

KV-32XBR400/36XBR400/38DRC1/38DRC1C

3.7 WHITE BALANCE (CRT) AND SUB

BRIGHT ADJUSTMENT

White Balance

1. Input an all white 480I (15.734KHz) signal into the

VIDEO 1 input terminal to perform the white balance

(highlight, cut-off) adjustments. The parameters to adjust are

in the CXA2150P in service mode.

2. Set the following:

Picture: Full Mode

Pro Mode

Color: Center

3. Adjust white balance in the ser vice mode and set the

following data:

2150P-1

No. Name Control Function Avg. Data

05 RDRV R-DRIVE Fix: 41

06 GDRV G-DRIVE Adjust

07 BDRV B-DRIVE Adjust

08 RCUT R-CUT OFF Fix: 41

09 GCUT G-CUT OFF Adjust

10 BCUT B-CUT-OFF Adjust

3-8. RASTER CENTER ADJUSTMENT

1. Input a monoscope signal.

2. Set to NTSC (DRC) mode.

3. Enter service mode and set the following:

CXA2150P-2

No. Name Control Function Avg. Data

06 AGNG AGING1, AGING2 2

CXA2150D-2

No. Name Control Function Avg. Data

00 HBLK Blanking enable 0

02 HSIZ Horiz Size 31

4. Reduce HSIZ to see sides of raster.

5. Adjust H-Center with CXA2150D-2 00.

6. Adjust the best screen position with H-CENT and write data.

7. Restore aging, HSIZ and HBLK to original condition.

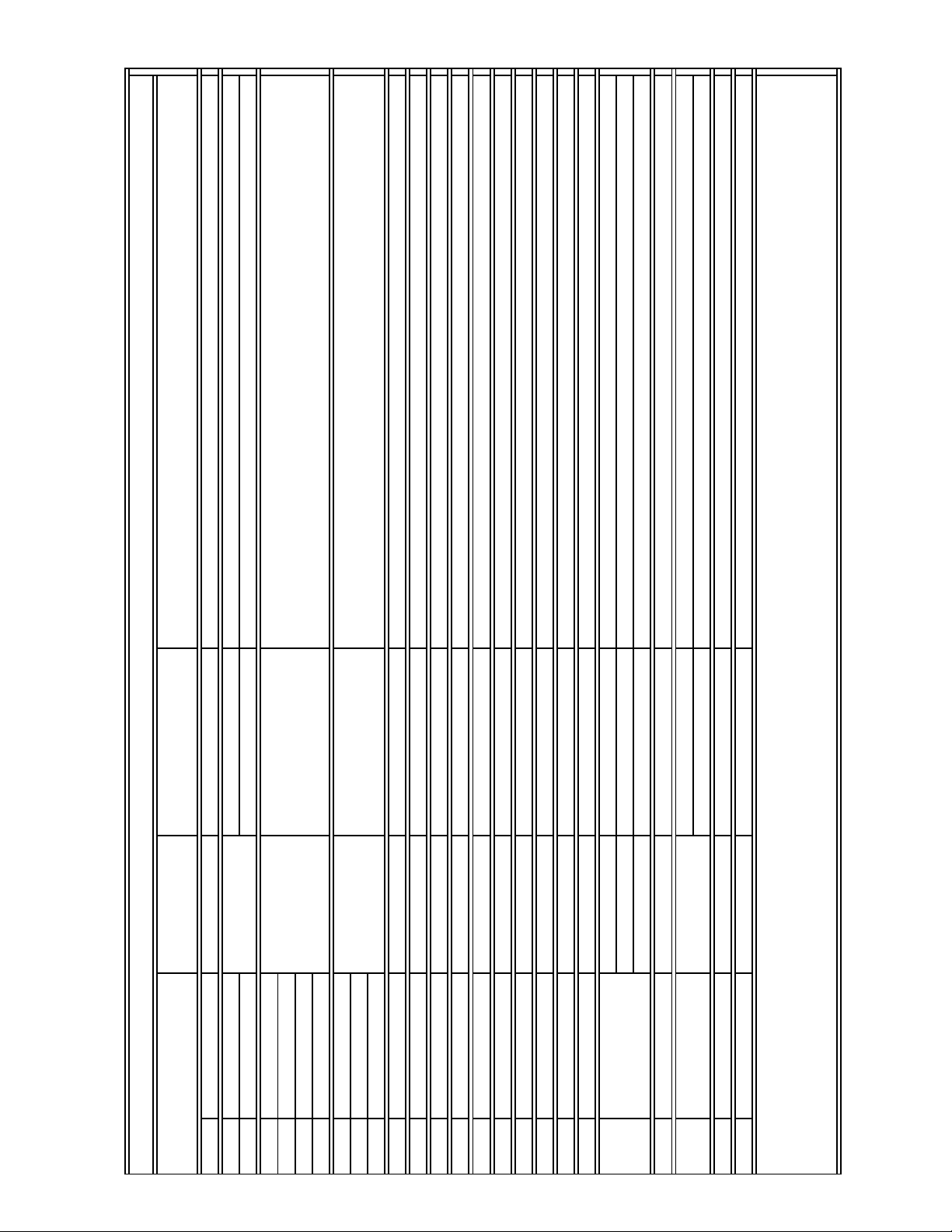

3-9. PICTURE DISTORTION ADJUSTMENTS

CXA2150D-1 and CXA2150D-2

4. Adjust sub-brightness: Input an all black signal (to IRE 7.5%

set up) 480i (15.75KHz) signal into the VIDEO 1 input

terminal and adjust the following parameter of the

CXA2150P-1.

CXA2150P-1

No. Name Control Function Avg. Data

04 SBRT SUB-BRIGHT Adjust

5. Check INITIAL DATA (Important)

2150P-1

No. Name Control Function Avg. Data

00 SBOT SUB-BRT OFFSET 7

12 SBOF SUB-BRT OFFSET 63

6. Repeat steps 3 to 5.

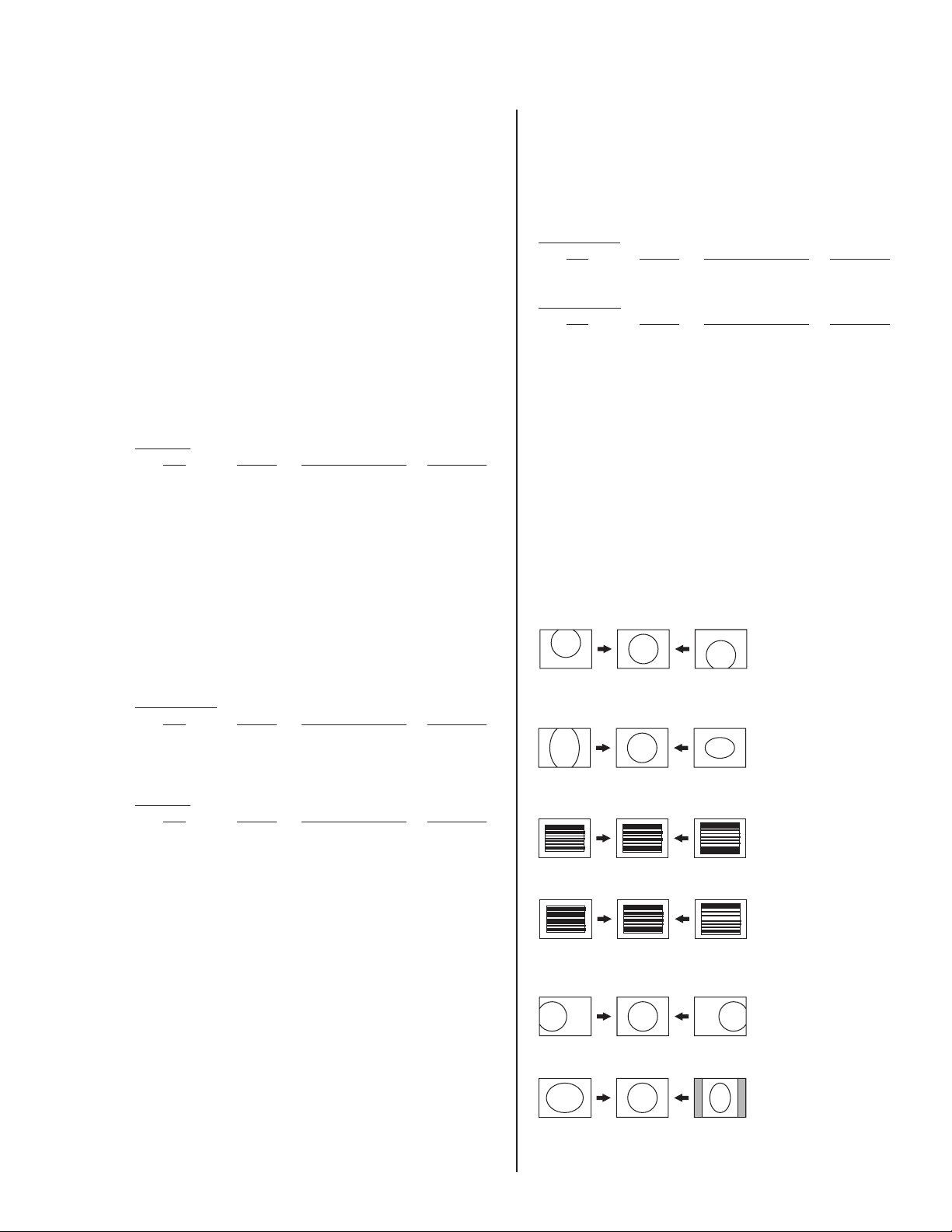

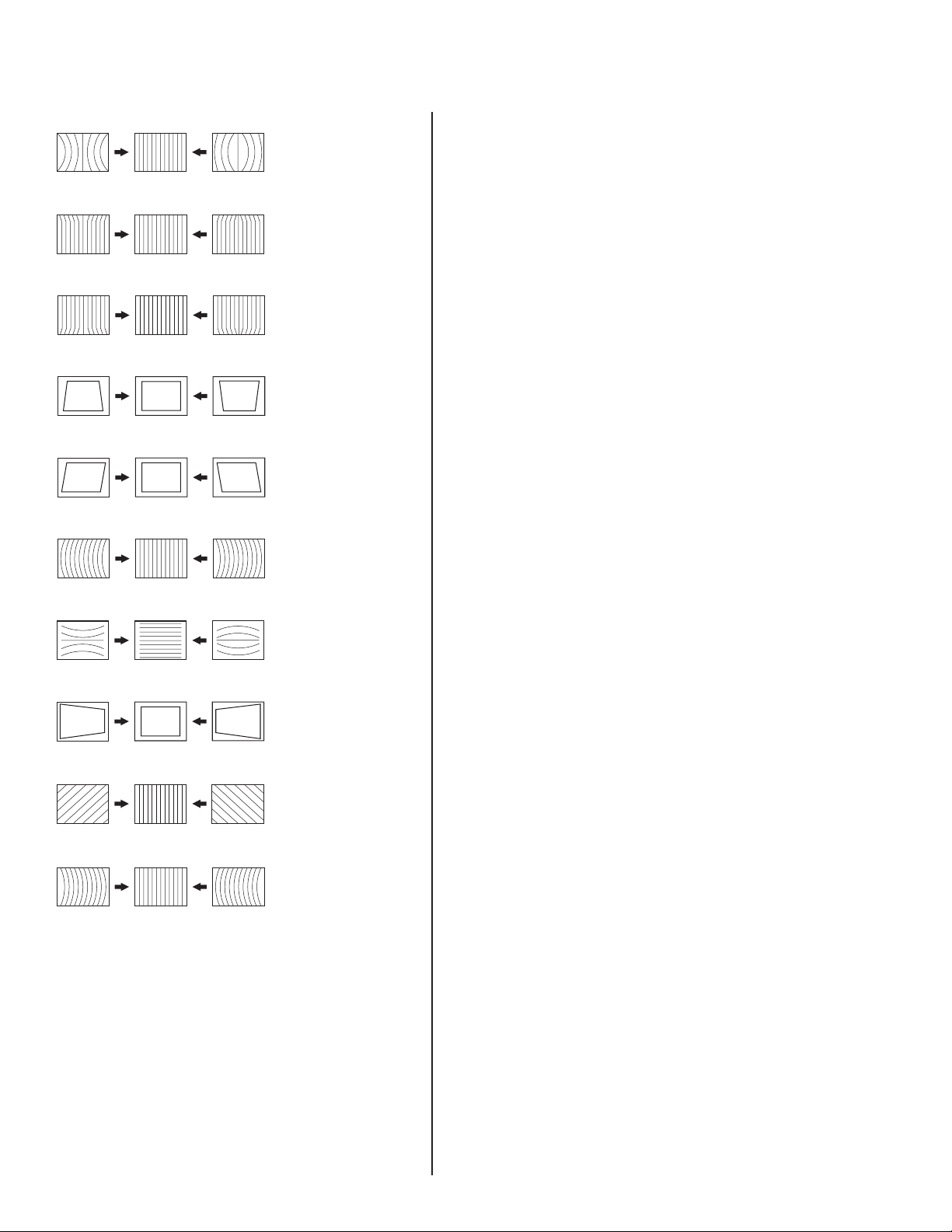

0. VPOS ( V-POSITION)

1. VSIZ (V-SIZE)

2. VLIN (V-LINE)

3. VSCO (VS-COR)

4. HCNT (H-CENTERING)

— 21 —

5. HSIZ (H-SIZE)

KV-32XBR400/36XBR400/38DRC1/38DRC1C

6. PIN (PIN AMP)

7. UCP (UP COR PIN COR)

8. LCP (LOW CO PIN COR)

9. PPHA(PIN PHASE)

10. VANG (AFC-ANGLE)

11. VBOW (AFC-BOW)

12. VPIN (V-PIN)

13. HTPZ (H-TRAPEZOID)

14. LANG (L-ANGLE)

A2150-D1 00 VPOS

A2150-D1 01 VSIZ

0

A2150-D1 02 VLIN

A2150-D1 03 VSCO

A2150-D1 04 VCEN

A2150-D1 05 VPIN

A2150-D1 07 HTPZ

A2150-D2 01 HPOS

A2150-D2 02 HSIZ

A2150-D2 03 SLIN

A2150-D2 05 PIN

A2150-D2 06 UCP

A2150-D2 07 LC P

A2150-D2 13 PPHA

A2150-D2 14 VANG

A2150-D2 15 LANG

A2150-D2 16 VBOW

A2150-D2 17 LBOW

Make sure picture size is within specs. Vertical size is 11.8 sq.

and Horizontal size is 15.8 sq.

4. Write data into memory then set screen to 1080i Mode.

1080i HD mode adjustment

1. Input a 1080i HD cross-hatch signal and an HD monoscope

signal that contains overscan markers.

2. Adjust raster position per section 3-8 only if this procedure

was not performed for full mode.

3. Adjust geometr y similar to Full DRC mode. Ve rtical size is

11.8 sq. and Horizontal size is 15.8 sq if monoscope signal is

available. Otherwise use Vertical size as 91.5% scan,

Horizontal size as 90% scan.

4. Use the following registers to adjust vertical and horizontal

parameters:

A2150-D2 01 HPOS

A2150-D1 05 VPIN

A2150-D1 10 ASPT

A2150-D2 11 SCRL

15. LBOW (L-BOW)

3-10. NTSC (DRC) Full mode adjustment

1. Face picture tube to east or west direction.

2. Complete VPIN and VCEN adjustment first. (A2150-D1 05

VPIN, A2150-D1 04 VCEN)

3. Input a monoscope and a cross-hatch signal. Adjust picture

distortion with the following service parameters to balance

the best condition for these two signals.

If necessary, touch up geometry using the data registers listed

above for Full mode.

5. Write data into memory.

Vertical Compressed Mode Adjustment

1. Input a monoscope and a cross-hatch signal.

2. T ouch up g eometry using the data re gisters listed above f or

Full mode, however no adjustment should be necessary.

Vertical size is 11.8 sq. and Horizontal size is 15.8 sq.

3. Check Full mode for any side effect for any adjustments to

Vertical Compressed mode or 1080i HD mode.

— 22 —

KV-32XBR400/36XBR400/38DRC1/38DRC1C

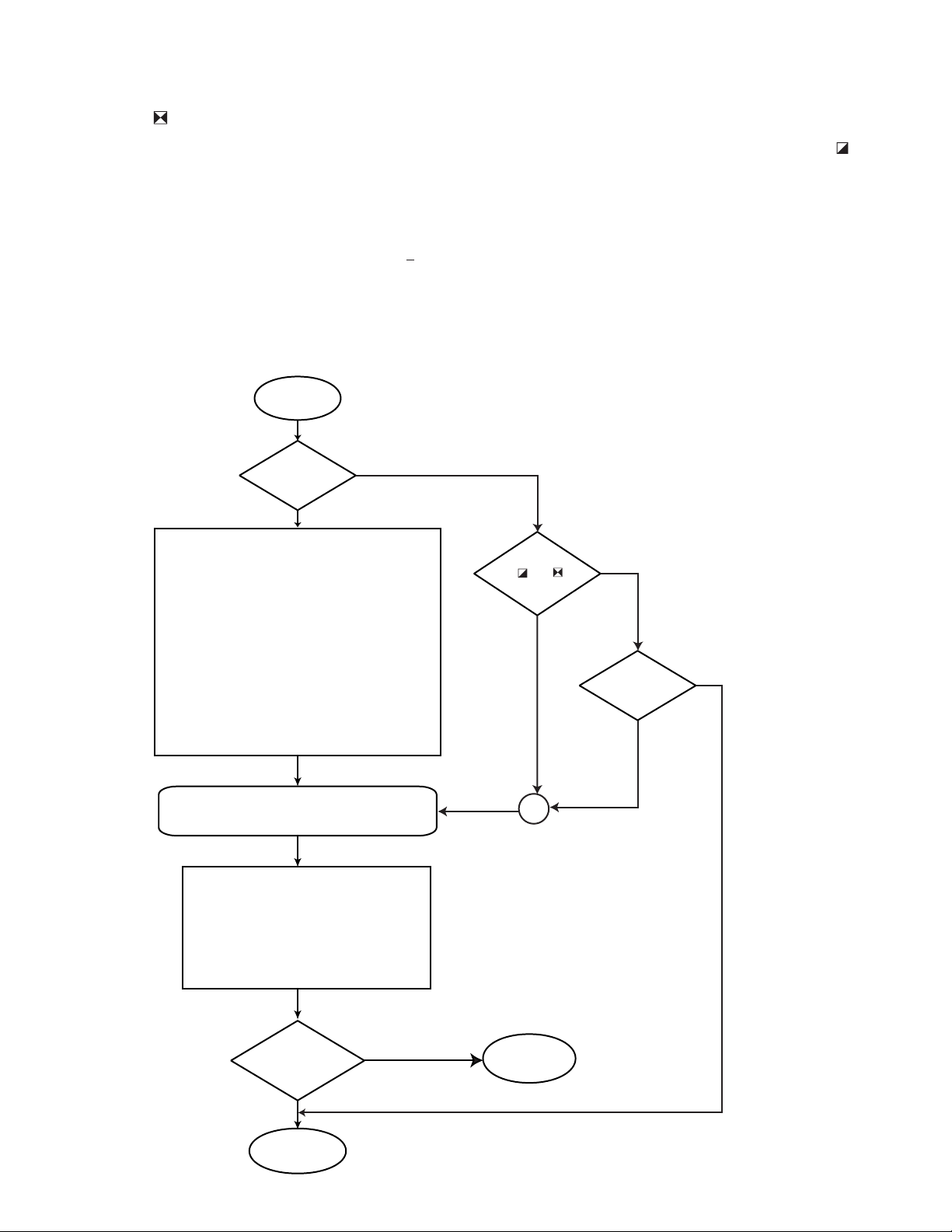

SECTION 4

SAFETY RELATED ADJUSTMENTS

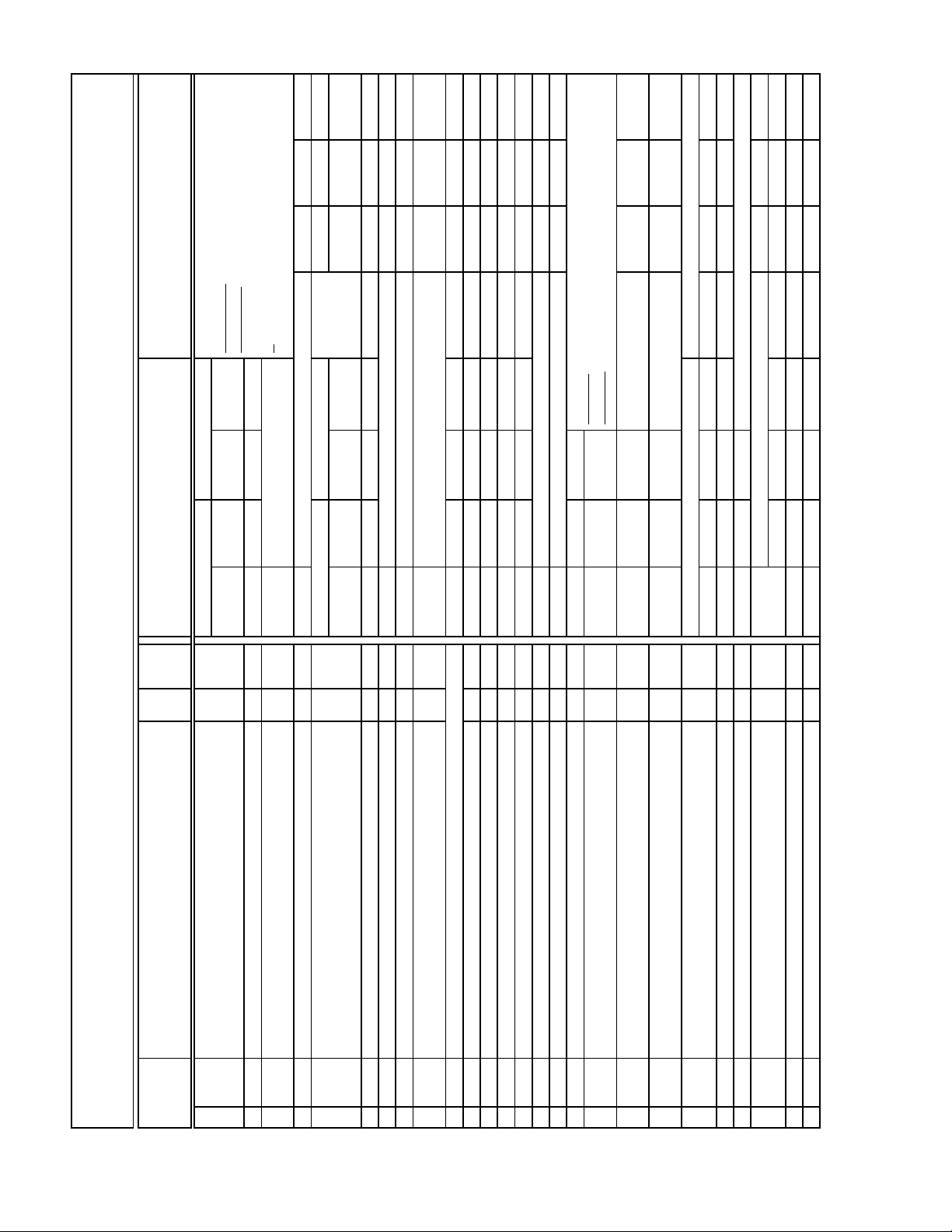

RV8001, RV8002, RV8003 CONFIRMATION METHOD AND HV SERVICE ADJUSTMENTS

The following adjustments should always be performed when replacing the following components which are marked with on the

schematic diagram:

D BOARD: DY, CRT, IC6503, IC8001, IC8003, IC8004, D8004, D8014, R8016, R8021, R8028, R8041, R8042,

R8044, R8072, R8073, R8074, R8077, R8078, R8080, R8081, R8082, R8091, R8095

B+ Max Confirmation:

Standard: 135.3 + 1 VCD

Check Condition: AC input voltage : 120 (± 2) V A C at Board Adjustment Process

HV Service Flowchart

Start

Is RHT Changed?

Yes

Replace RV8001,RV8002 and RV8003 with same value.

HV protect adjust and inspection

1. Turn RV8001and RV8003 fully counter clockwise.

2. Turn set on with black video signal then adjust RV8002

slowly to obtain 35.5kv.

3. Adjust RV8001 clockwise slowly until hold down

protection just activates, turn off set. Turn back

RV8001 about 1/16 turn; then turn set back on.

4. Turn RV8003 (fine adjust) slowly clockwise until hold

down protect just activates. Then turn the set off.

5. Adjust RV8002 clockwise, then turn the set on. Change

video to white field then slowly turn RV8002 counter

clockwise to get 35.0 ±0.2 kv. Confirm set does NOT

TURN OFF at this condition. If yes then repeat from

step 1 again.

6. Finally, set back RV8002 to 31.50kv ± 0.2kv at video

cut off ( black video).

No

130 ( ± 2) VAC at QC

120 ( ± 2 ) VAC at Overall Adjustment (After aging)

*Note: If using stabilized power supply , make sur e the distortion factor is 3% or less.

Setting Mode: Full mode

Signal input : Cross hatch of NTSC at QC

Initial setting : Reset condition at QC

Confirm point : Across C6544 for B+ of [D] board.

Change any

or

marked parts?

Yes

No

Is D board

replaced?

Yes

No

If all adjustment are finished, then seal and secure

RV8001,RV8002 and RV8003 with epoxy to prevent any

possible misadjustment by non- trained technical service.

Confirm +B, Vd and check Hold down on D

board with black video with the following steps:

1. Confirm +B across C6544 to make sure it is

135.3 ± 1 V dc.

2. Confirm Vd at pin 2 CN6506 or at TP-Vd for

4.9 v < Vd < 5.1 V dc.

3. Apply 5.5 +0.5 VDC at pin 2 of CN6544

then confirm set holds down.

Is +B Vd. and

Hold down

confirmed?

Yes

Finish for

hold-down check

No

Start from

the beginning.

— 23 —

KV-32XBR400/36XBR400/38DRC1/38DRC1C

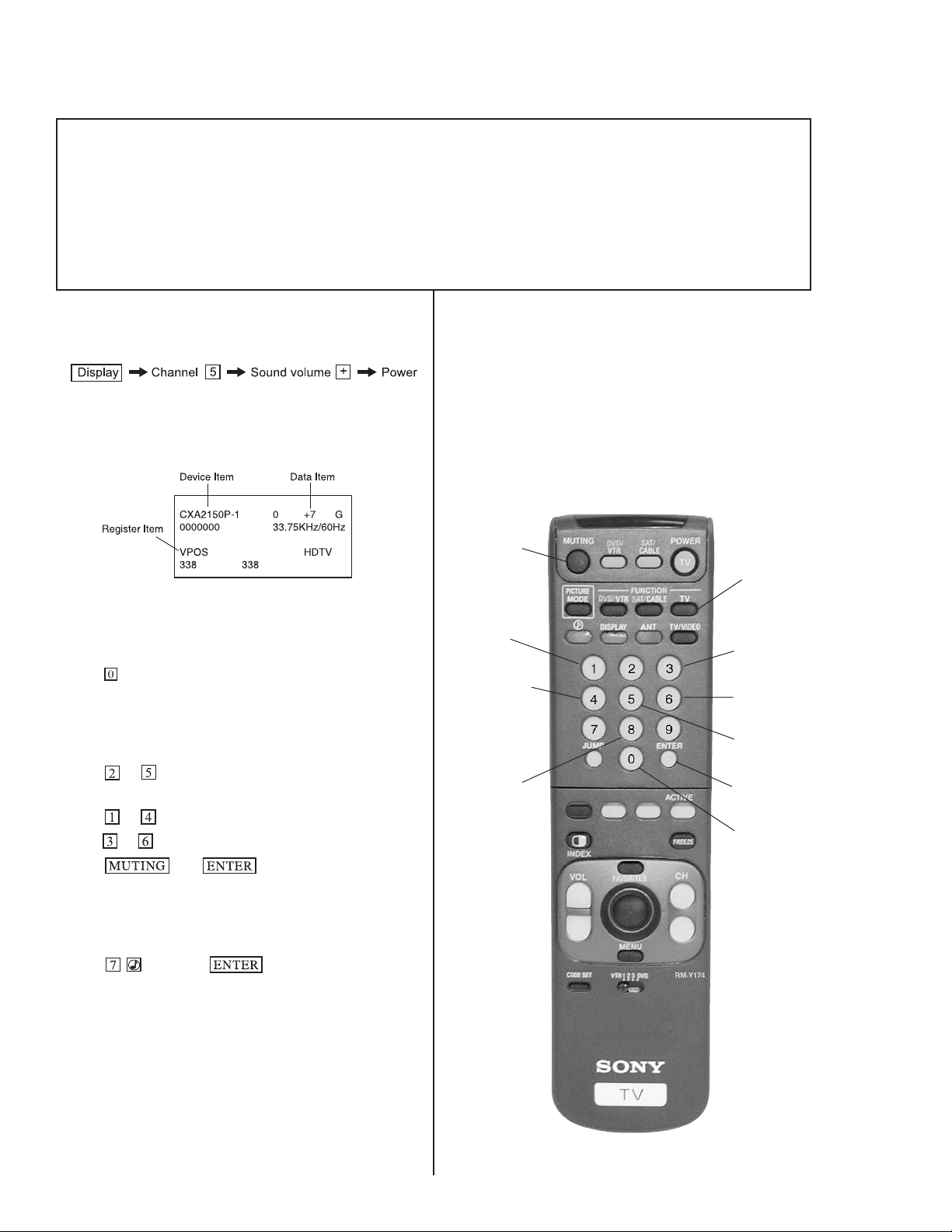

SECTION 5

CIRCUIT ADJUSTMENTS

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y74) to perform the circuit adjustments in this section.

NOTE: Test Equipment Required:

• Pattern generator

• Frequency counter

• Digital multimeter

• Audio oscillator

5-1. SETTING THE SERVICE ADJUSTMENT MODE

1. Standby mode (power off).

2.

on Remote Commander (press each button within a second).

SERVICE ADJUSTMENT MODE VIEW

Reading the Memory

1. Enter into Service Mode

2. Press on the remote commander.

Adjusting the Picture

1. Enter into Service Mode.

5-2. MEMORY WRITE CONFIRMA TION METHOD

1. After adjustment, remove the power plug from the AC

outlet, then plug it in again.

2. Turn the power switch ON and set to service mode.

3. Call the adjusted items again to confirm they were adjusted

.

5-3. ADJUSTMENT BUTTONS AND INDICA TORS

WRITE INTO

MEMORY

SERVICE MODE

ITEM UP

ITEM DOWN

DA TA UP

DAT A DOWN

DEVICE ITEM DOWN

2. Press

device item.

2. Press

3. Press

4. Press

or on the Remote Commander to select the

or on the Remote Commander to select an item.

or on the Remote Commander to change the data.

then to save into the memory.

Resetting the Data

1. Enter into Service Mode.

2. Press then press on the Remote

Commander .

— 24 —

INITIALIZE

WRITE INTO MEMORY

REVIEW MEMORY

RM-Y174

KV-27FS12/27FS16/29FS12/29FS12C

IC3048 (Main) / B-board

y

(

)

(

)

IC3048 (Main) / B-board

IC3602 (Main) / B-board

y

(

)

(

)

y

(

)

(

)

Service Control

Device Slave Address & Microprocessor Version

Slave Address: 9Ah

Slave Address: 86h

Slave Address: 86h

, Slave Address: 60h

Patch A

with ROM correction

Version 1.0

stem Micro

S

Slave Address: 9Ah

CCD&Vchip Micro (Version 2.14), Slave Address: 68h (Main)

, Slave Address: 60h

, Slave Address: 60h

Patch A

Patch A

with ROM correction

with ROM correction

Version 1.0

Version 1.0

stem Micro

stem Micro

S

S

DX1A Service List ------ Contents

5-4. SERVICE DATA LISTS

Service Control

IC2004 / BC-board Slave Address: B8h (Write) & B9h (Read)

IC201 / A-board

IC201 / A-board

Device Reference Number

µPD64082

Device Name

Service Control

CXA2103Q

CXA2150Q

CXA2150Q

Service Control

# 1 3D-COMB

Category Number & Name

# 2-1 CXA2103-1 (Main)

# 2-2 CXA2103-2 (Sub) IC3110 (Sub) / B-board Slave Address: 9Eh

# 3-1 CXA2150P-1

# 3-2 CXA2150P-2

# 3-3 CXA2150P-3

# 3-4 CXA2150P-4

# 4-1 CXA2150D-1

# 4-2 CXA2150D-2

# 5 CXA2151 CXA2151Q IC3001 / B-board Slave Address: 84h

# 6 D-CONV CXA8070P IC5513 / D-board Slave Address: DEh

# 7 CXA2026 CXA2026AS IC5511 / D-board Slave Address: 8Eh

# 4-3 CXA2150D-3

# 8 AP BH3868FS IC7001 / A-board Slave Address: 82h

IC2004 / BC-board Slave Address: B8h (Write) & B9h (Read)

IC3601 (Sub) / B-board CCD&Vchip Micro (Version 2.14), Slave Address: 6Ch (Sub)

µPD64082

CXA2150Q IC201 / A-board Slave Address: 86h

CXA2103Q

M306V2ME-150FP IC701 / A-board

OSD

SNNR

CXP85840A-039Q

M306V2ME-150FP IC701 / A-board

M306V2ME-150FP IC701 / A-board

ID

OP

CCD&VCHIP

# 9 TRUS NJM2180M IC4101 / S-board Controlled through CXA1315M ( IC4103 / S-board, Slave Address: 48h )

# 10 MID1 CXD9509AQ IC3408 / B-board Slave Address: 2Eh { Controlled through MID-X Micro ( IC3090 / B-board / 64h ) }

# 11 MID2 CXD9509AQ IC3408 / B-board Slave Address: 2Eh { Controlled through MID-X Micro ( IC3090 / B-board / 64h ) }

# 12 MID3 CXD9509AQ IC3408 / B-board Slave Address: 2Eh { Controlled through MID-X Micro ( IC3090 / B-board / 64h ) }

# 13 MID5 CXD9509AQ IC3408 / B-board Slave Address: 2Eh { Controlled through MID-X Micro ( IC3090 / B-board / 64h ) }

# 14

# 15

# 17

# 16 ID1 CXD2085M IC3603 / B-board Slave Address: 40h

# 18

# 19

Note:

DX1A System Micro & Software: M306V2ME-150FP (MASK), Software Version 1.0 {with ROM correction (Patch A)}, IC701/A-board (Slave Adress: 60h)

DX1A MID-X Micro & Software: MB94918RPF-G-128-BND (MASK1), Software Version 03/30/00, IC3090/B-board (Slave Address: 64h)

MB94918RPF-G-130-BND (MASK2), Software Version 04/20/00, IC3090/B-board (Slave Address: 64h)

DX1A CCD&Vchip Micro Software: CXP85840A-039Q (MASK), Software Version 2.14, IC3602/B-board (Main/Slave Address: 68h) & IC3601/B-board (Sub/Slave Address: 6Ch)

— 25 —

KV-27FS12/27FS16/29FS12/29FS12C

Comment

: CVideo1~4 inputs

: SVideo1~3 inputs

SVideo (SV)

CVideo (CV)

: Common data

C

: YCbCr-480i/480p/1080i inputs

: CVideo1~4 & SVideo1~3 inputs

Data Initial Setting

Data

Data

DX1A SERVICE LIST (#1): 3D-COMB / µPD64082 (Part 1)

Non-

standard

SVideo

Standard

(32V&36V CRTs)

Range

Type

Non-

standard

UHF/VHF & CVideo

Standard

Non-

standard

Standard

Non-

standard

UHF/VHF & CVideo SVideo

Standard

C 0~3 3

C 0~7 3

Video1~4

Video5&6

UHF/VHF Video1~4 Video5&6

0~3 1 1 1

4 (32V) / 8 (36V) {Initial Data: 8 (36V)}

SNNR Setting (-Offset)

SNNR = 0 SNNR = 1 SNNR = 2 SNNR = 3

VAPG1 Data Based on MENU/VM Setting VAPG2 Data Based on SNNR/Offset-setting

VM = Off VM = Low VM = Mid VM = High SNNR = 0 SNNR = 1 SNNR = 2 SNNR = 3

0~3 1 1 1

0~3 2 2 2

Control Register

Function & Link

Selection for standard/non-satndard signal processing 0~3 0 0 0 0

Operation mode setting 0~3 0 1 3 3

Y-output correction

(V-aperture compensation & Y-peaking filtering)

System clock setting C 0~3 1

YAPS

Register

Device Name: µPD64082 { 3D-Comb Filter / NEC } / IC2004 (BC-board)

Slave Address: B8h (Write Address) / B9h (Read Address)

No & Name

NRMD

0

CLKS

1

2

Selection for inter-frame/inter-line processing C 0~3 0

MSS

NSDS

3

4

Killer processing selection C 0~3 1

C-signal phase with respect to the Y-signal

(Fine adjustment at 70 ns/step)

NRMD Setting-based Control Table for DYCO, DYGA, DCCO, DCGA NRMD = 0 NRMD = 1 NRMD = 2 NRMD = 3

DY detection coring level (Y motion detection coring) 0~15 2 2 2 2

DY detection gain (Y motion detection gain) 0~15 10 10 10 10

DC detection coring level (C motion detection coring) 0~15 5 5 5 5

DC detection gain (C motion detection gain) 0~15 5 5 5 5

Frame recersive YNR nonlinear filter limit level C 0~3 1

Frame recersive CNR nonlinear filter limit level C 0~3 1

CDL

KILS

5

DYCO

DYGA

6

7

8

DCCO

DCGA

9

10

YNRL

CNRL

11

12

— 26 —

V-aperture compensation gain 0~7 0 2 3 4 0 0 0 0

Sensitivity for Hsync non-standard signal detection

(out-of-Hsync intra-field)

Sensitivity for frame non-standard signal detection

Hysteresis for Hsync non-standard signal detection

(out-of-Hsync intra-field)

VTRH

13

(out-of-Hsync inter-frame)

VM&SNNR Setting-based Control Table for VAPG & VAPI

LDSR

VTRR

15

14

V-aperture compensation convergence point 0~31 4 4 4

VAPG= VAPG1 - VAPG2

VAPI

VAPG

17

16

Y peaking filter (BPF) gain 0~15 7 0 1 2 3

Y peaking filter (BPF) center frequency 0~3 0 0 0 0 0

SNNR Setting-based Control Table for YPFT & YHFG

YPFT

YPFG

18

19

Loading...

Loading...