SONY KP-FS57M31, KP-FS57M61, KP-FS57 M90, KP-FS57 M91 Service Manual

SERVICE MANUAL

AG-3X

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KP-FS57M31 RM-997 AUS SCC-XXX-A

KP-FS57M61 RM-997 GE SCC-XXX-A

KP-FS57M90 RM-997 HK SCC-XXX-A

KP-FS57M91 RM-997 ME SCC-XXX-A

MODEL COMMANDER DEST. CHASSIS NO.

VIDEO

A/B

DRC-MF

V CENTER

INDEX

PROG

MENU

HD/DVD

123

456

7809

JUMP

PROG

OPTION RESET

TV

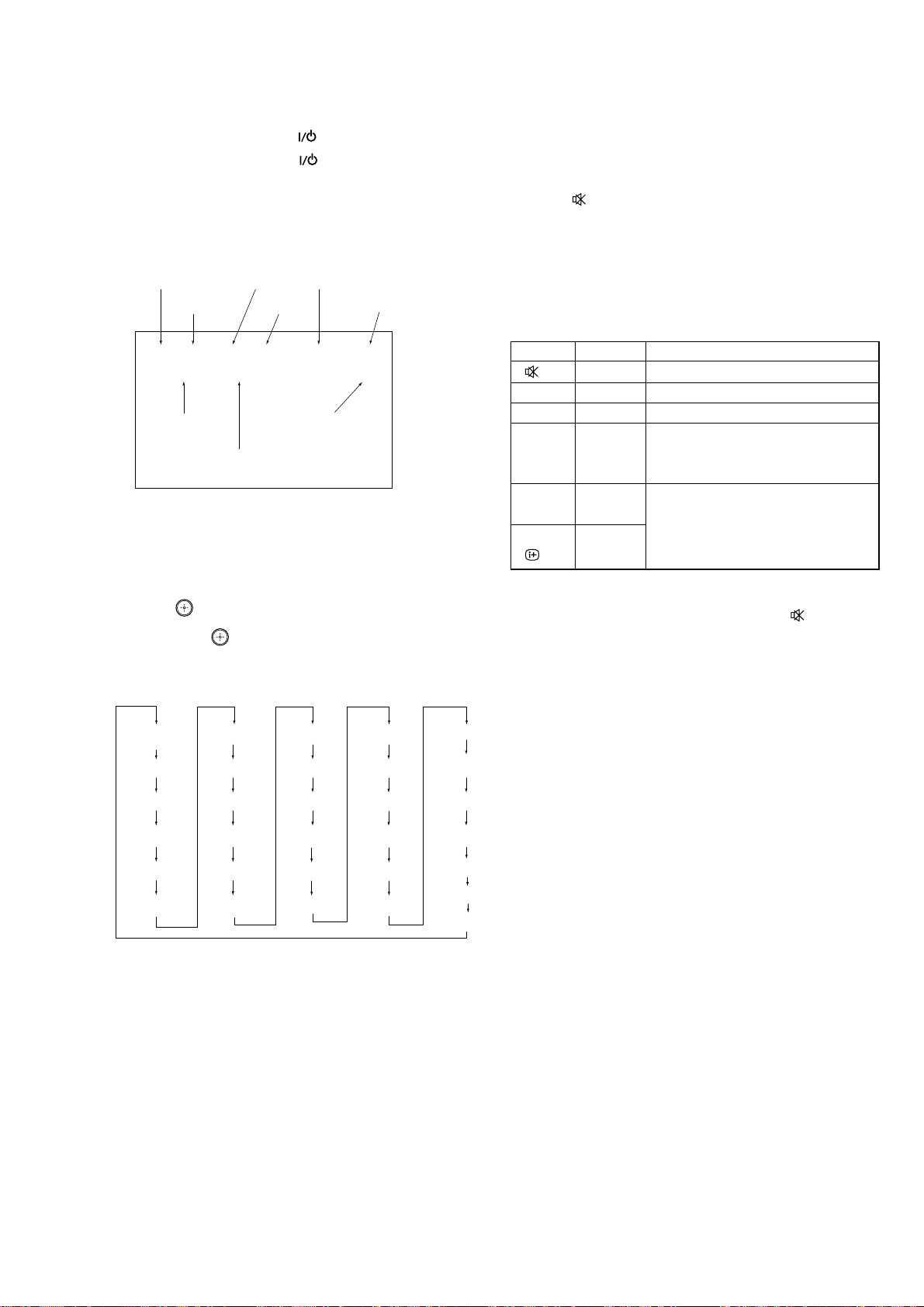

RM-997 KP-FS57M31/M61/M90/M91

PROJECTION TV

Projection system

Picture tube

Projection lenses

Screen size

Television system

Color system

Stereo/Bilingual

system

Channel coverage

B/G

I

D/K

M

8 (Antenna)

Audio output (Speaker)

Number of terminal

(Video)

(Audio)

(S Video)

(Component

Video)

(G/B/R/HD/

VD Video)

(Headphones)

Power requirements

Power consumption (W)

Dimensions (w/h/d, mm)

Mass (kg)

KP-FS57M31/M61/M90/M91

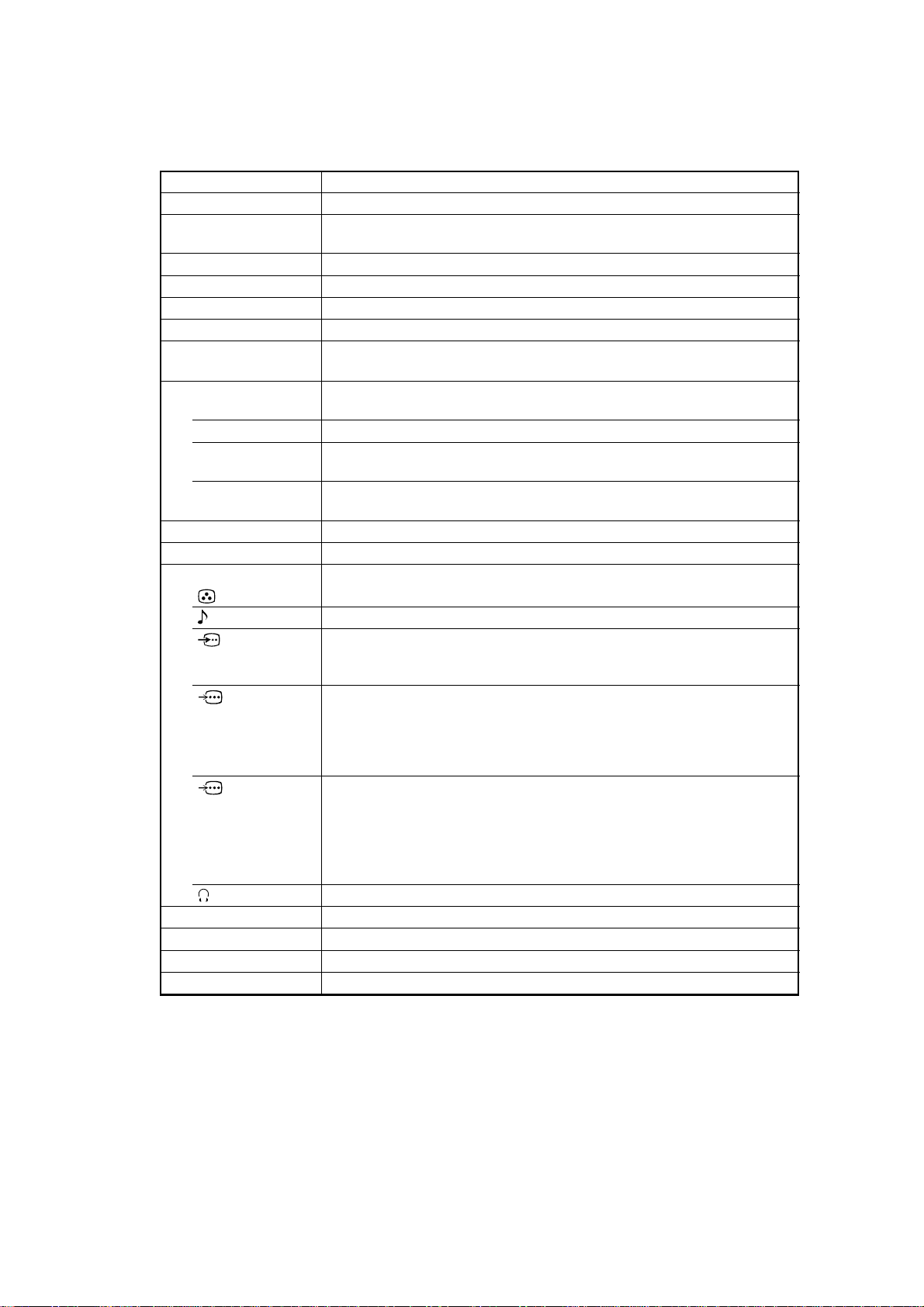

SPECIFICATIONS

KP-FS57M31/M61/M90/M91

3 picture tubes, 3 lenses, horizontal inline system

7 inch high-brightnes monochorome tubes (6.3 raster size), with optical coupling

and liquid cooling system

High performance, large-diameter highbrid lens F1.0

57 inches

B/G, I, D/K, M

PAL, PAL 60, SECAM, NTSC4.43, NTSC3.58

NICAM Stereo/Bilingual B/G, I;

A2 Stereo/Bilingual (German) B/G

VHF : E2 to E12 / UHF : E21 to E69 / CATV : S01 to

S03, S1 to S41

UHF : B21 to B68 / CATV : S01 to S03, S1 to S41

VHF : C1 to C12, R1 to R12 / UHF : C13 to C57, R21

to R60 / CATV : S01 to S03, S1 to S41, Z1 to Z39

VHF : A2 to A13 / UHF : A14 to A79/

CATV : A-8 to A-2, A to W+4, W+6 to W+84

75-ohm external terminal

15W + 15W (10% distortion)

Input: 4 Output: 1 Phono jacks; 1 Vp-p, 75 ohms

Input: 4 Output: 1 Phono jacks; 500 mVrms

Input: 2 Y: 1 Vp-p, 75 ohms,

unbalanced, sync negative

C: 0.286 Vp-p, 75 ohms

Input: 2 Phono jacks

Y: 1 Vp-p, 75 ohms, sync negative

P

B/CB: 0.7 Vp-p, 75 ohms

P

R/CR: 0.7 Vp-p, 75 ohms

Audio: 500 mVrms

Input: 1 Phono jacks

G: 0.7 Vp-p, 75 ohms

B: 0.7 Vp-p, 75 ohms

R: 0.7 Vp-p, 75 ohms

HD: 0.7 Vp-p, 75 ohms

VD: 0.7 Vp-p, 75 ohms

Output: 1 Stereo minijack

110 - 240 V AC, 50/60Hz

260 W

1360 × 1395 × 688

100

RM-997

Design and specifications are subject to change without notice.

CAUTION

SHORT CIRCUIT THE ANODE OF HTE PICTURE TUBE

AND THE ANODE CAP TO THE METAL CHASSIS, CRT

SHIELD, OR CARBON PAINTED ON THE CRT, AFTER

REMOVING THE ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

! ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL TO

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

TABLE OF CONTENTS

1. SELF DIAGNOSIS FUNCTION

1-1. Diagnostic Test Indicators ................................. 5

1-2. Display of STANDBY/TIMER

Light Flash Count............................................... 6

1-3. Stopping the STANDBY/TIMER Flash ............ 6

1-4. Self-Diagnostic Screen Display ......................... 7

1-5. Handling of Self-Diagnostic

Screen Display.................................................... 7

1-6. Self-Diagnostic Circuit ...................................... 8

2. DISASSEMBLY

2-1. Rear Board Removal ......................................... 9

2-2. Main Bracket Block Removal ........................... 9

2-3. Service Position ................................................. 9

2-4. Front Panel Removal ......................................... 10

2-5. H1, H2, and H3 Boards Removal ..................... 10

2-6. Beznet and Mirror Cover Removal ................... 11

2-7. Main Bracket Removal ...................................... 11

2-8. G Board Removal ............................................... 12

2-9. Connector Cover Removal ................................. 12

2-10. J Board Removal ................................................ 13

2-11. A1, E, B4, and V2 Boards Removal .................. 13

2-12. A, AD, and D Boards Removal ......................... 14

2-13. Picture Tube Removal ........................................ 14

2-14. High-Voltage and Cable Installation Removal.. 15

2-15. Mechaseal ........................................................... 15

3. SET-UP ADJUSTMENTS

3-1. Screen Voltage Adjustment

(Rough Alignment) ........................................... 16

3-2. Screen (G2) Adjustment .................................... 16

3-3. Focus Rough Adjustment .................................. 16

2-4. Deflection Yoke Tilt Adjustment ...................... 16

3-5. 2-Pole Magnet Adjustment ................................ 17

3-6. Center Magnet Adjustment ................................ 17

3-7. 4-Pole Magnet Adjustment ................................ 17

3-8. Defocus Adjustment ........................................... 17

3-9. Green, Red, and Blue Focus Adjustment

3-9-1. Green, Red, and Blue Lens Focus

Adjustment .................................................... 17

3-9-2. Green, Red, and Blue Electrical Focus

Adjustment .................................................... 17

3-10. Adjustment with Commander ............................ 18

3-10-1. How to Select Each Mode ............................. 18

- 3-10-2. How to Enter Service Mode .......................... 18

3-10-3. Method of Cancellation

from Service Mode ........................................ 19

3-10-4. How to Adjustments ...................................... 19

3-10-5. How to Write the Data ................................... 19

3-10-6. Memory Write Confirmation Method ........... 16

KP-FS57M31/M61/M90/M91

RM-997

Section Title PageSection Title Page

3-11. Service List ......................................................... 20

3-12. Registration Adjustment

3-12-1. Adjustment Flow ............................................ 47

3-12-2. Setup for Adjustment ..................................... 47

3-12-3. Method of Main Deflection Adjustment ....... 47

3-12-4. Operation Method

for Projector Engine (PJE) Mode .................. 48

3-12-5. Method of Projector Engine Adjustment

(Sub Deflection Adjustment)......................... 49

3-13. Auto Convergence Setting ................................. 52

3-14. Blue Offset Adjustment...................................... 52

3-15. White Balance Adjustment ................................ 52

3-16. Auto Convergence Error Code List ................... 53

4. SAFETY RELATED ADJUSTMENT

4-1. HV Regulation Adjustment ............................... 54

4-2. HV Hold-Down Adjustment ............................. 54

4-3. +B Max Voltage Confirmation ......................... 54

4-4. +B OVP Voltage Confirmation ........................ 54

5. ELECTRICAL ADJUSTMENTS

5-1. Picture Quality Adjustment

5-1-1. Preparation ..................................................... 55

5-1-2. NTSC Video Input ......................................... 56

5-1-3. NTSC RF Input .............................................. 56

5-1-4. PAL Video Input ............................................ 57

5-1-5. PAL RF Input ................................................. 57

5-2. Color Offset ........................................................ 57

6. DIAGRAMS

6-1. Block Diagrams .................................................. 58

6-2. Frame Schematic Diagram................................. 78

6-3. Circuit Boards Location ..................................... 80

6-4. Schematic Diagrams........................................... 82

(1)-(3) Schematic Diagram of A Board .................... 82

(4) Schematic Diagram of A1 Board .................. 88

(5)-(8) Schematic Diagram of AD Board.................. 90

(9)-(15) Schematic Diagram of B4 Board ................... 98

(16) Schematic Diagram of CR,CG and CB Boards

........................................................................ 112

(17)-(19)Schematic Diagram of D Board ................... 114

(20) Schematic Diagram of E Board ..................... 120

(21) Schematic Diagram of G Board .................... 122

(22) Schematic Diagram of H1,H2 and H3 Boards

........................................................................ 124

(23)-(27)Schematic Diagram of J Board .................... 126

(28) Schematic Diagram of SR, V2, and VM Boards

........................................................................ 136

(29) Schematic Diagram of HM Boards ..............

........................................................................ 138

(30)-(31)Schematic Diagram of BM1C Boards ........

........................................................................ 140

– 3 –

Section Title Page

6-5. Printed Wiring Boards ....................................... 144

6-6. Wave Forms ....................................................... 168

6-7. IC Block Diagrams ............................................. 172

6-8. Semiconductors .................................................. 178

7. EXPLODED VIEWS

7-1. Front Panel Block ............................................. 181

7-2. Cabinet Block (KP-FS53) ................................ 182

7-3. Cabinet Block (KP-FS43) ................................. 183

7-4. Bezenet and Mirror Cover Block (KP-FS53) ... 184

8. ELECTRICAL PARTS LIST ............................ 185

KP-FS57M31/M61/M90/M91

RM-997

– 4 –

KP-FS57M31/M61/M90/M91

SECTION 1

SELF DIAGNOSIS FUNCTION

The unit in this manual contain a self-diagnostic function. If any error occurs, the STANDBY/TIMER lamp will automatically

begin to flash.

The number of times the lamp flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER

lamp flash indicators is listed in the instruction manual for the user's knowledge and reference. If an error symptom cannot be

reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past problems

and how often these problems occur.

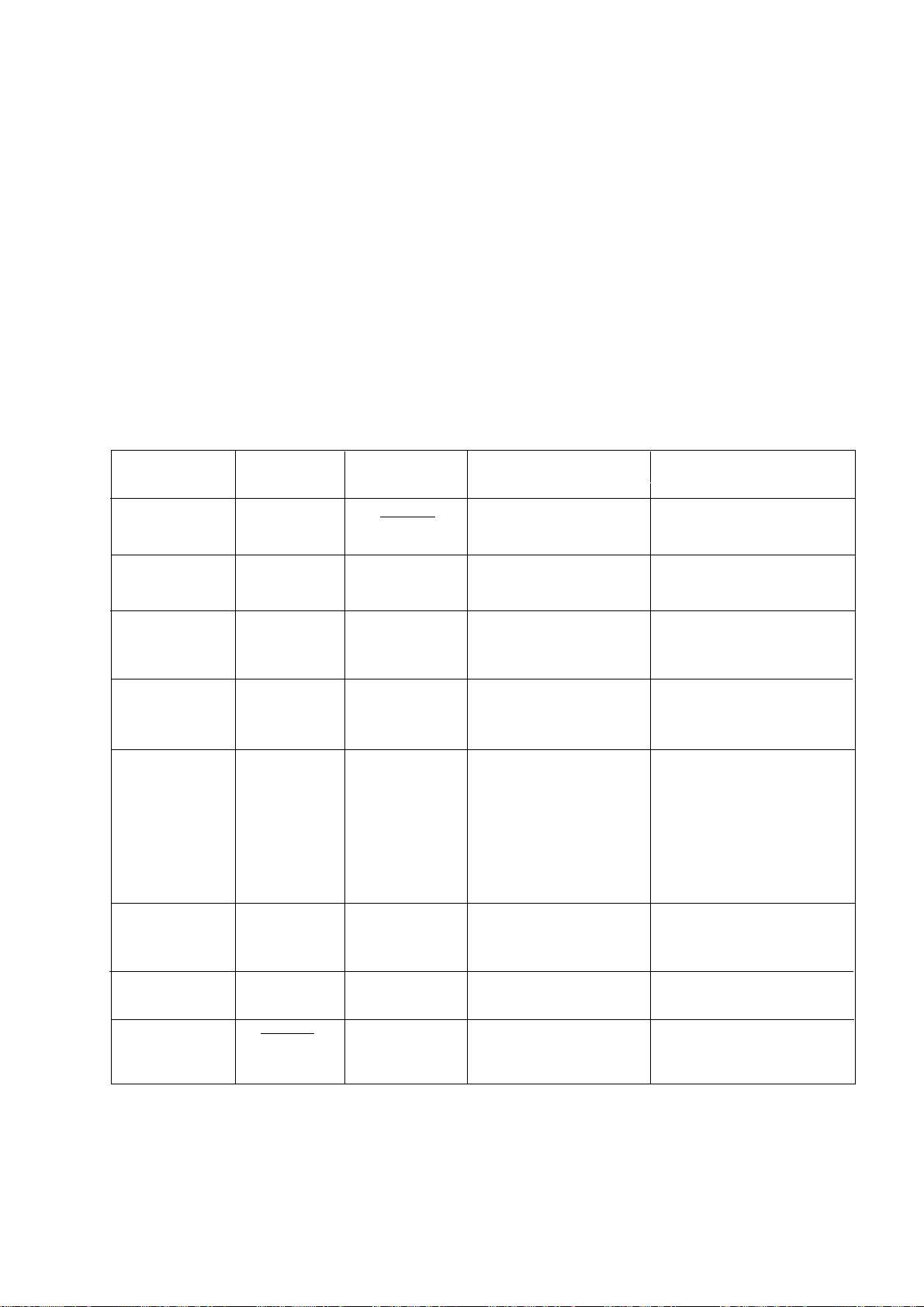

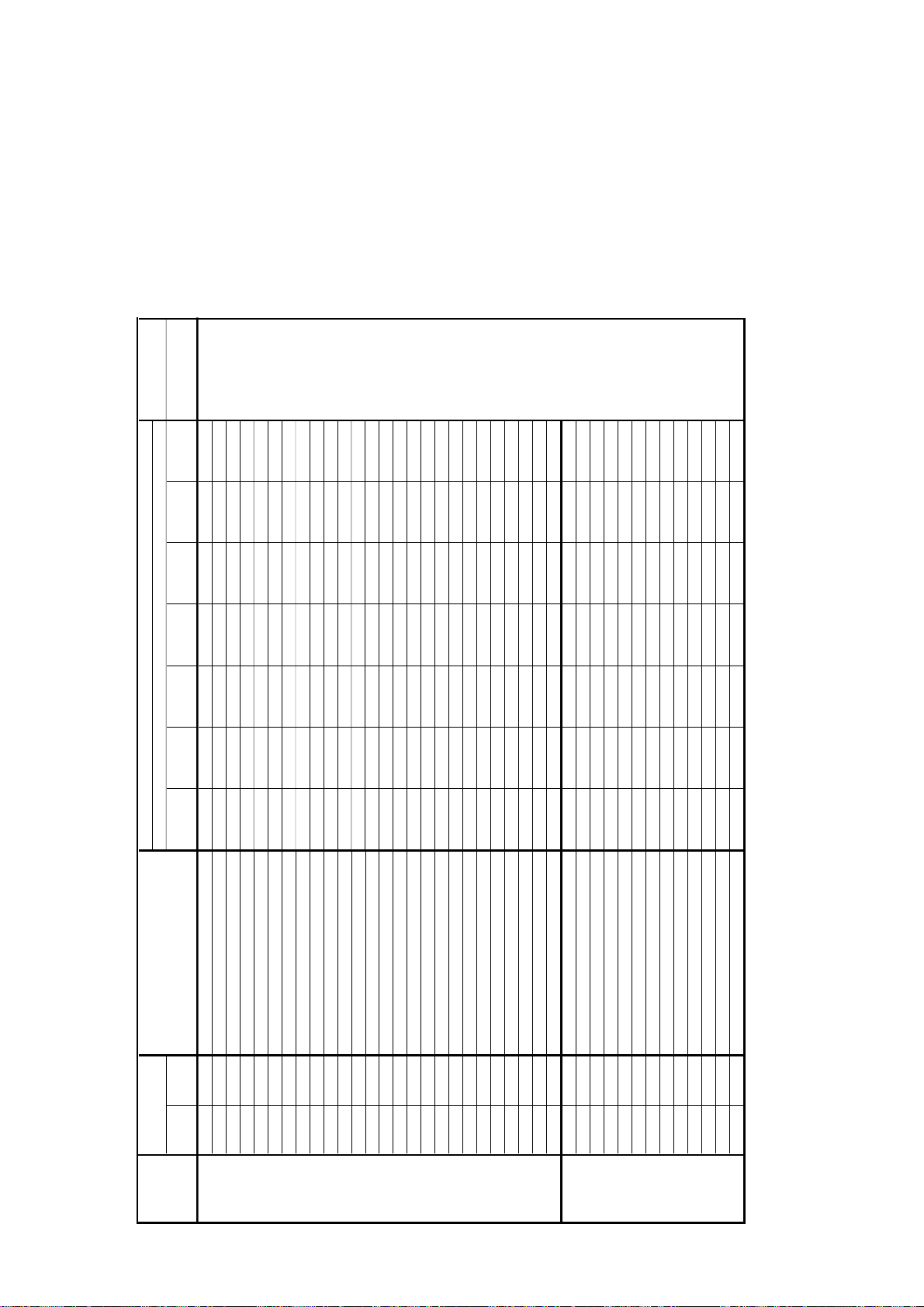

1-1. DIAGNOSTIC TEST INDICATORS

When any error occurs, the STANDBY/TIMER lamp will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

RM-997

Diagnostic

Item

Description

•Power does not

turn on

•+B overcurrent

(OCP)

•+B overvoltage

(OVP)

•Vertical deflection

failure

•White balance

failure

(no PICTURE)

•

Horizontal deflection

failure or +5v down

or High Voltage

failure

No. of times

STANDBY/TIMER

lamp flashes

Does not light

2 times

3 times

4 times

5 times

6 times

Self-diagnostic

display/

Diagnostic result

002:000 or

002:001 ~ 255

003:000 or

003:001 ~ 255

004:000 or

004:001 ~ 255

005:000 or

005:001 ~ 255

006:000 or

006:001 ~ 255

Probable Cause Location

•Power cord is not plugged in.

•Fuse (F6701) is burned out.

(G board)

•H. OUT Q8024 is shorted.

•H. LIN Q8027 is shorted.

(D board)

•HV OUT Q8043 is shorted.

•PH6001 faulty.

•+19V is not supplied.

(G board)

•V. OUT IC8003 faulty.

(D board)

•G2 is improperly adjusted.

(Note 1)

•CRT problem.

•Video OUT IC9101 (CR

board), IC9201 (CG board),

IC9001 (CB board) are faulty.

•IC8306 (J board) and IC4300

(E board) are faulty.

•No connection E board to CR

board.

•IC6502 (G board) faulty.

•HV Circuit failure.

Detected Symptoms

•Power does not come on.

•No power is supplied to the PJ.

•AC power supply is faulty.

•Power does not come on.

•Load on power line is shorted.

•+135V is too high.

•Vertical deflection pulse is

stopped.

•Vertical size is too small.

•Vertical deflection stopped.

•No raster is generated.

•CRT cathode current detection

reference pulse output is small.

•Abnormal High voltage.

•Abnormal H.drive.

•+5v down.

•Audio Protection

•Micro reset

Note 1 : Refer to screen (G2) adjustment in section 3-2 of this manual.

7 times

007:000 or

007:001 ~ 255

101:000 or

101:001 ~ 255

•Power supply fails.

•IC1203,1204 (A board) faulty.

•Discharge CRT

(CR, CG, CB boards)

•Static discharge

•External noise

– 5 –

•There is picture but speaker does

not release sound.

•Power is shut down shortly, after

this return back to normal.

•Detect Micro latch up.

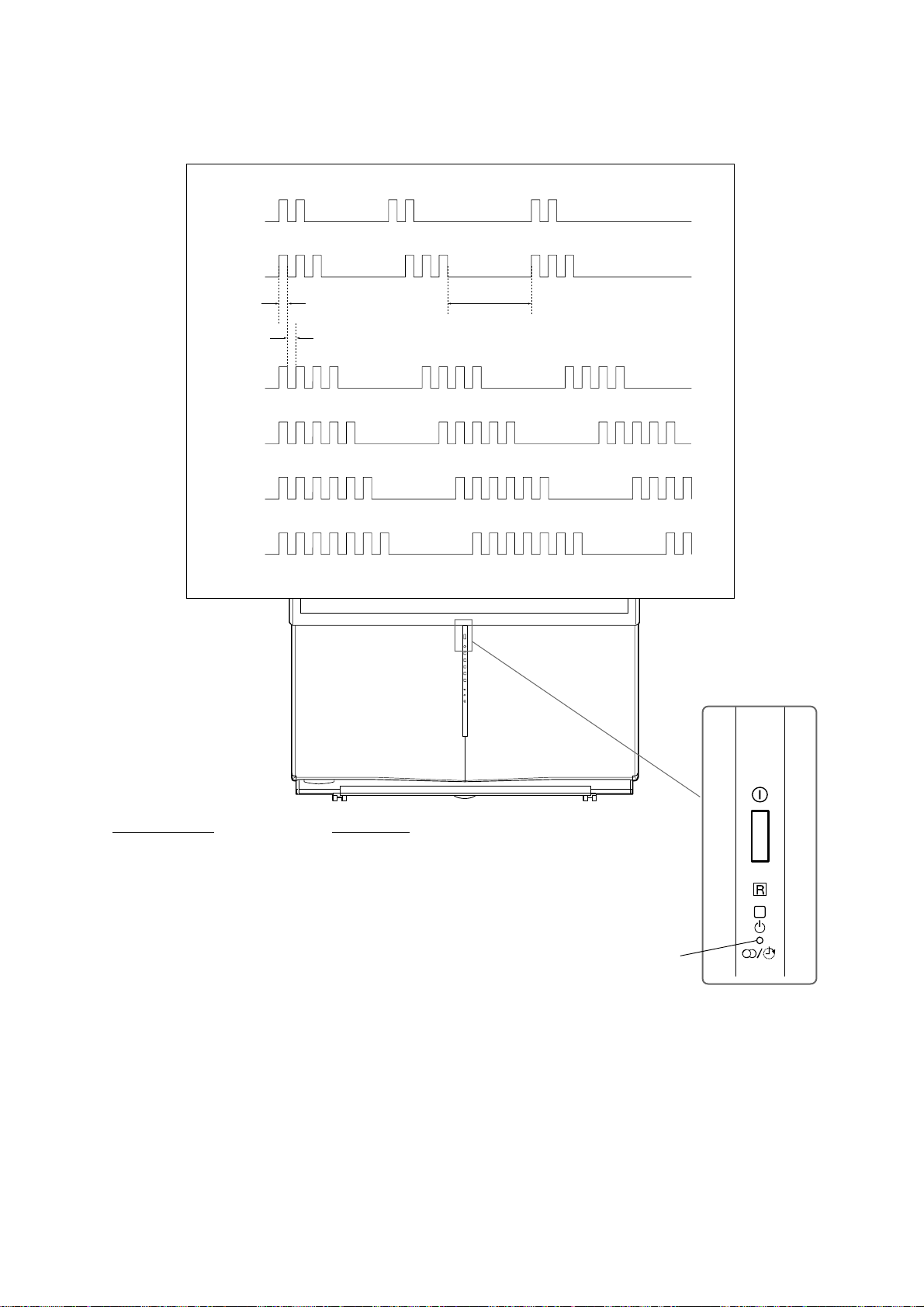

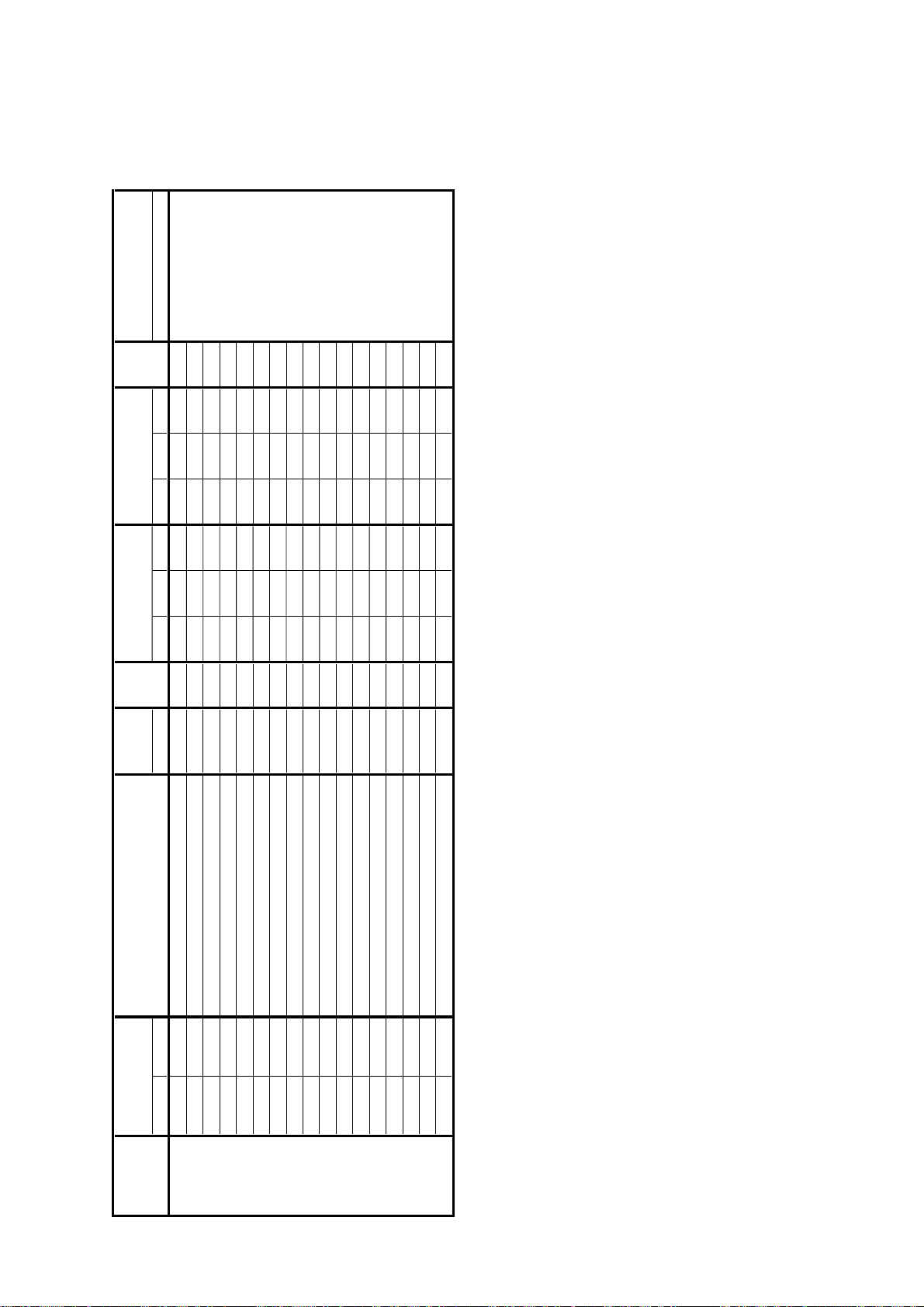

1-2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

2 times

3 times

Lamp ON

0.3 sec.

Lamp OFF

0.3 sec.

4 times

5 times

Lamp OFF

3 sec.

KP-FS57M31/M61/M90/M91

RM-997

6 times

7 times

Diagnostic Item Flash Count *

+B overcurrent 2 times

+B overvoltage 3 times

V deflection stop 4 times

White balance failure 5 times

High voltage protector 6 times

Audio Protection 7 times

* One flash count is not used for self-diagnostic.

STANDBY/TIMER

lamp

1-3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp from

flashing.

– 6 –

KP-FS57M31/M61/M90/M91

1-4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is

possible to bring up past occurrences of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

Self-Diagnosis screen display

1-5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

5

RM-997

(

DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

SELF DIAGNOSTIC

(DIGIT 5) (VOLUME –) (POWER)ON SCREEN

)

002:000

*

* : Note that this differs from entering the service mode (volume +)

Numeral “0” means that no fault has been detected.

003:000

004:000

005:001

006:002

Numeral “1” means a fault has been detected.

Numeral “2” means two faults have been detected.

007:000

101:000

during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

[Clearing the result display]

To clear the result display to “0”, press button on the remote commander sequentially as shown below when the diagnostic

screen is being displayed.

Press “8” button

(It will indicate “CLEAR” on the screen.)

,

(The “CLEAR” display change to red color.)

Press “-” button

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

– 7 –

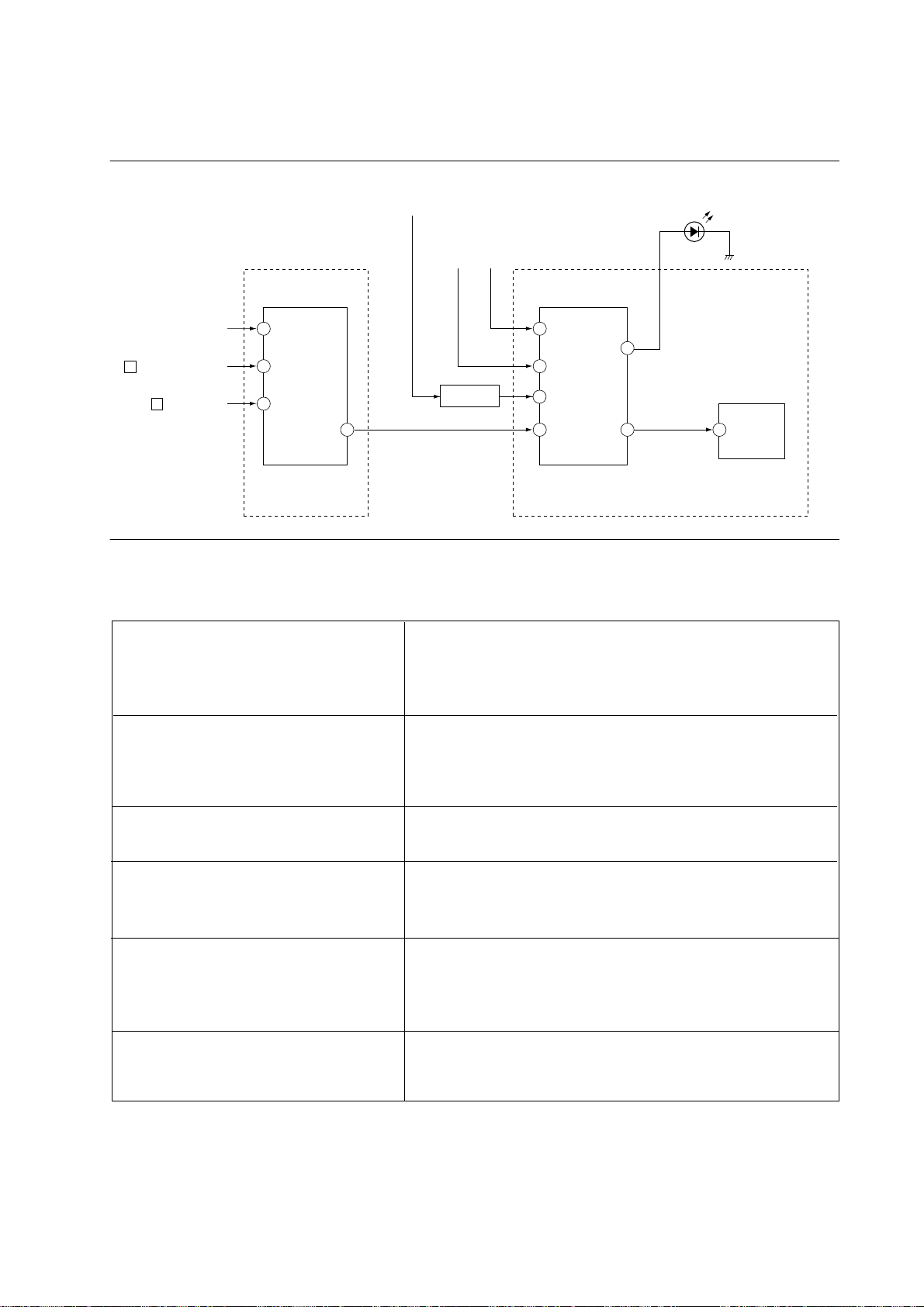

1-6. SELF-DIAGNOSTIC CIRCUIT

IC4300

Y/C JUNGLE

From IC1203,1204

(A board)

From G board

OCP

OVP

KP-FS57M31/M61/M90/M91

RM-997

To H1 board

IC001

SYSTEM

24 IKINFrom CRT (IK)

H

V

(D board)

(D board)

57 XRAYFrom IC8005,8006

56 V PROTFrom Q8001

SDA 52 13 SDA0 SDA1 SDA15 5

Q1209-1211

5 OCP

8 OVP

100

SPPROT

LED1 22

IC003

MEMORY

CXA2170Q CXP961048-003Q

A boardE board

+B overcurrent (OCP) Occurs when an overcurrent on the +B (135 V) line is detected by

Q6504.

Then the voltage to pin 5 of IC001 goes UP. The unit will automatically

turn off.

+B overvoltage (OVP) Occurs when an overvoltage on the +B (135 V) line is detected by

IC6502.

Then the voltage to pin 8 of IC001 goes UP. The unit will automatically

turn off.

Vertical deflection failure Occurs when an absence of the vertical deflection pulse is detected by

Q8001 and D8001. Shut down the power supply.

White balance failure If the RGB levels do not balance or become low level within 5 seconds.

This error will be detected by IC4300.

TV will stay on, but there will be no picture.

High voltage or Horizontal Deflection Protect Occurs when an overvoltage of horizontal pulse is detected by D8038

and IC8006.

If the voltage of pin 1 of IC8006 goes to High, the voltage to pin 57 of

IC4300go to UP. The unit will automatically turn off.

Audio Protector If the Audio out lines become DC.This error will be detected by Q1211,

Q1209 and Q1210.

The unit will automatically turn off.

– 8 –

SECTION 2

DISASSEMBLY

KP-FS57M31/M61/M90/M91

RM-997

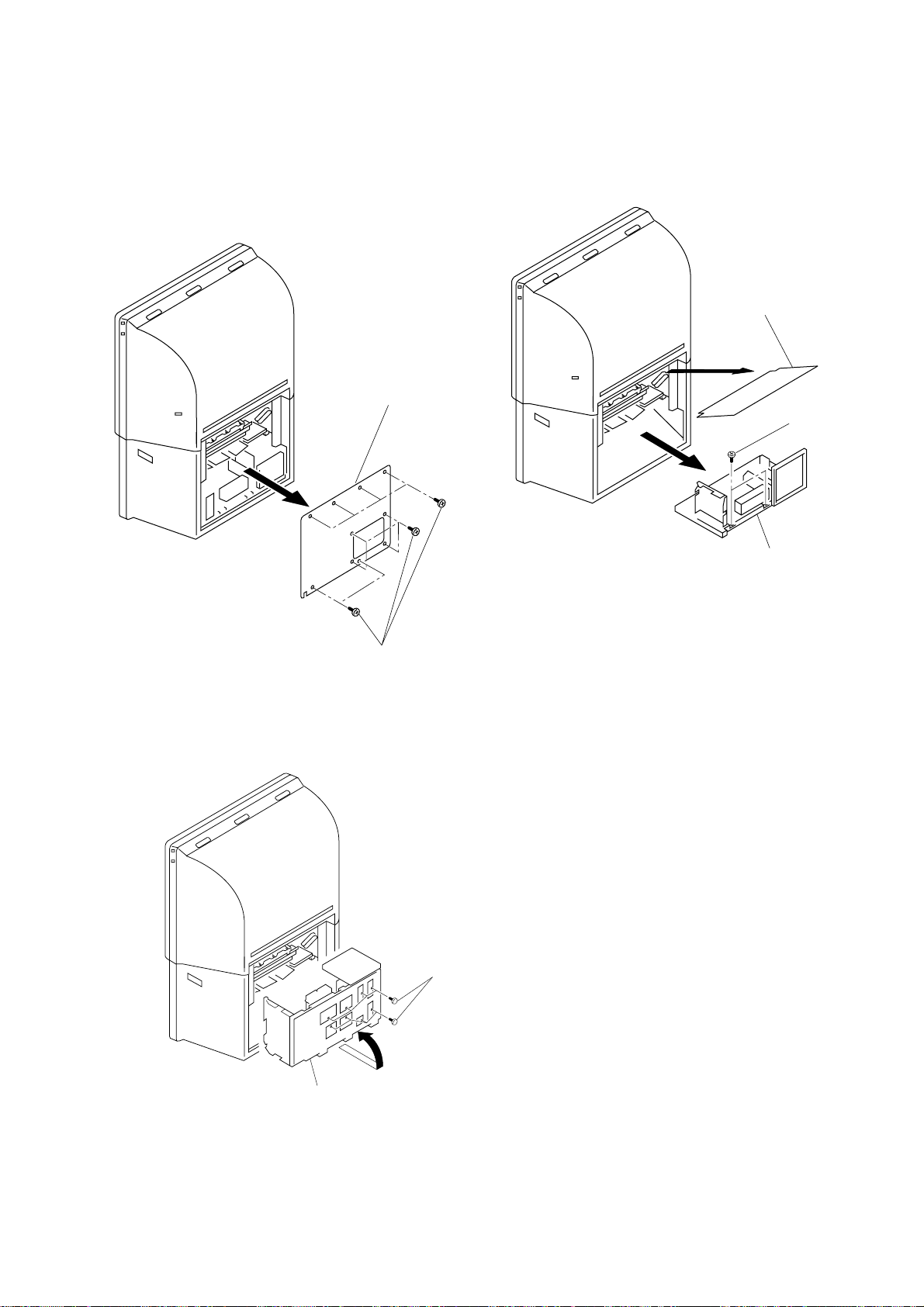

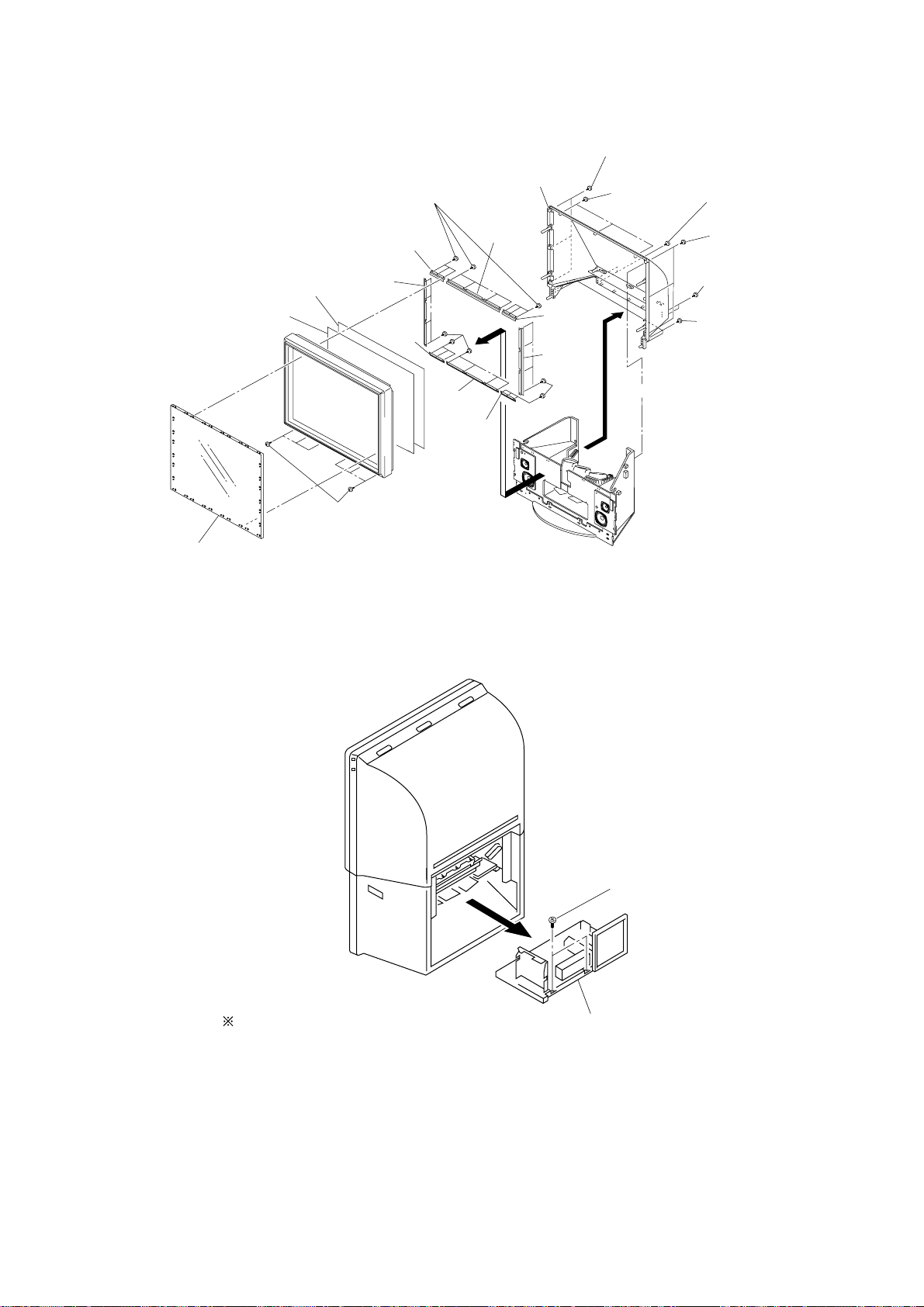

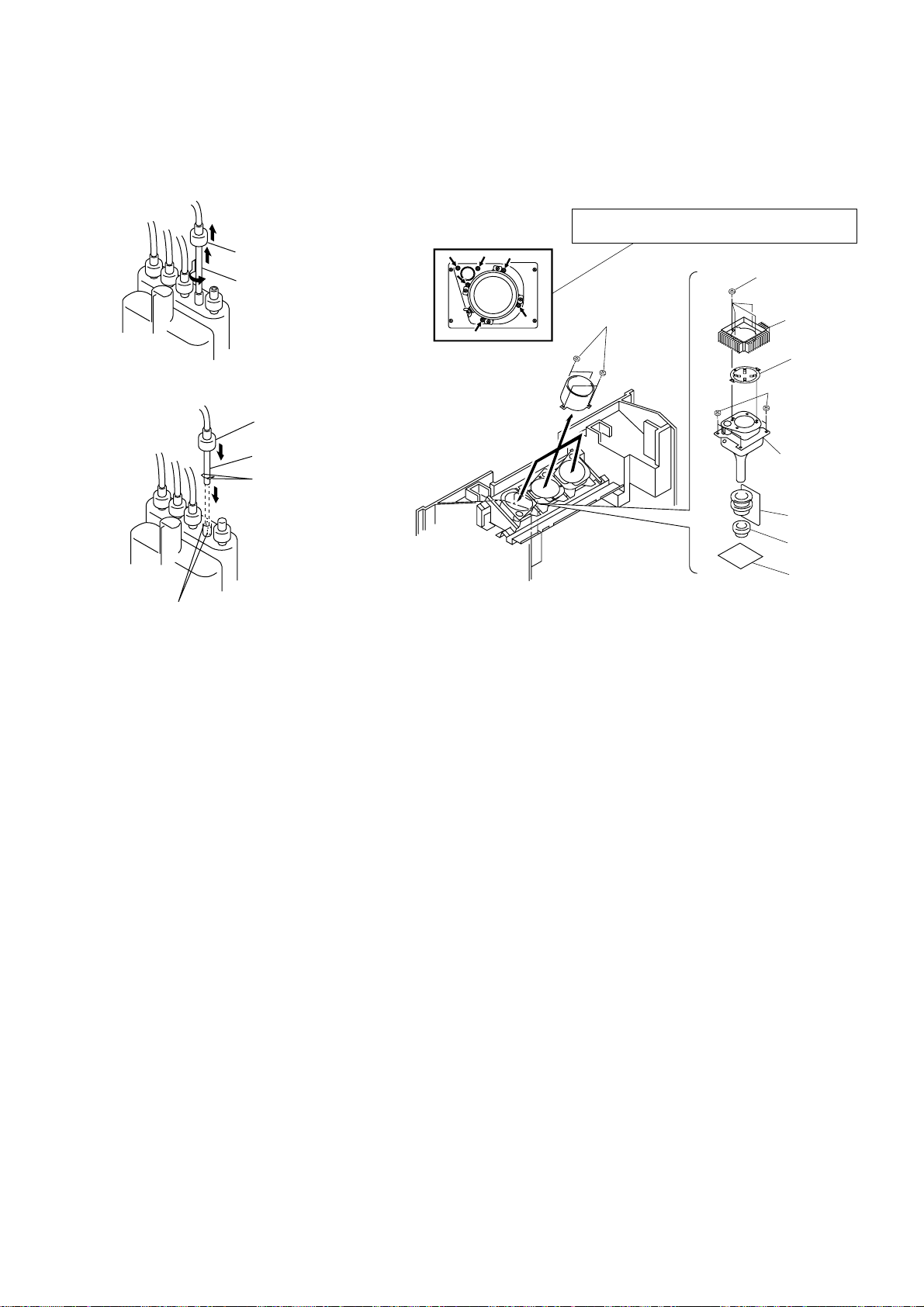

2-1. REAR COVER REMOVAL

2 Rear board

2-2. MAIN BRACKET REMOVAL

1 Optical shield

2 Two screws

(tapping screw

hexagon head)

3 Main bracket section

2-3. SERVICE POSITION

1 Main bracket section

1 Ten screws

(Hexagon head)

2 Eight screws

(BVTP 3X12)

2 COVERS

Cut them off with a plier or the like from

chassis assembly in case of checking

printed circuit boards.

After checking, turn over the covers and

secure them with screws.

(screws 7-685-648-79 -BVTP 3X12)

– 9 –

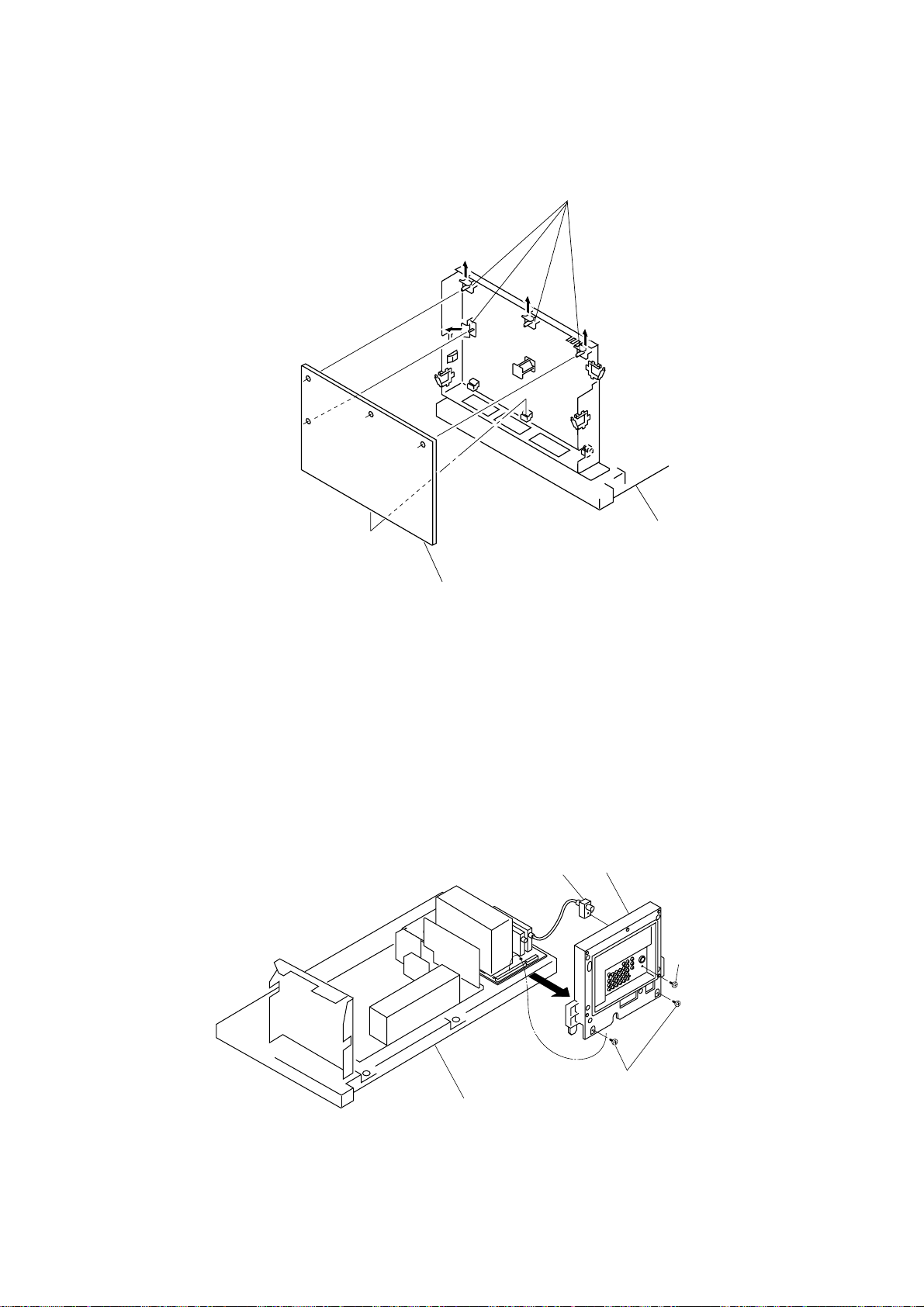

2-4. FRONT PANEL REMOVAL

2 Two screws

(tapping screw

hexagon head)

KP-FS57M31/M61/M90/M91

RM-997

4 Side panel L(57) assy

3 Two screws

(tapping screw

hexagon head)

1 three screws

(BVTP 4x16)

6 Speaker gril (57)

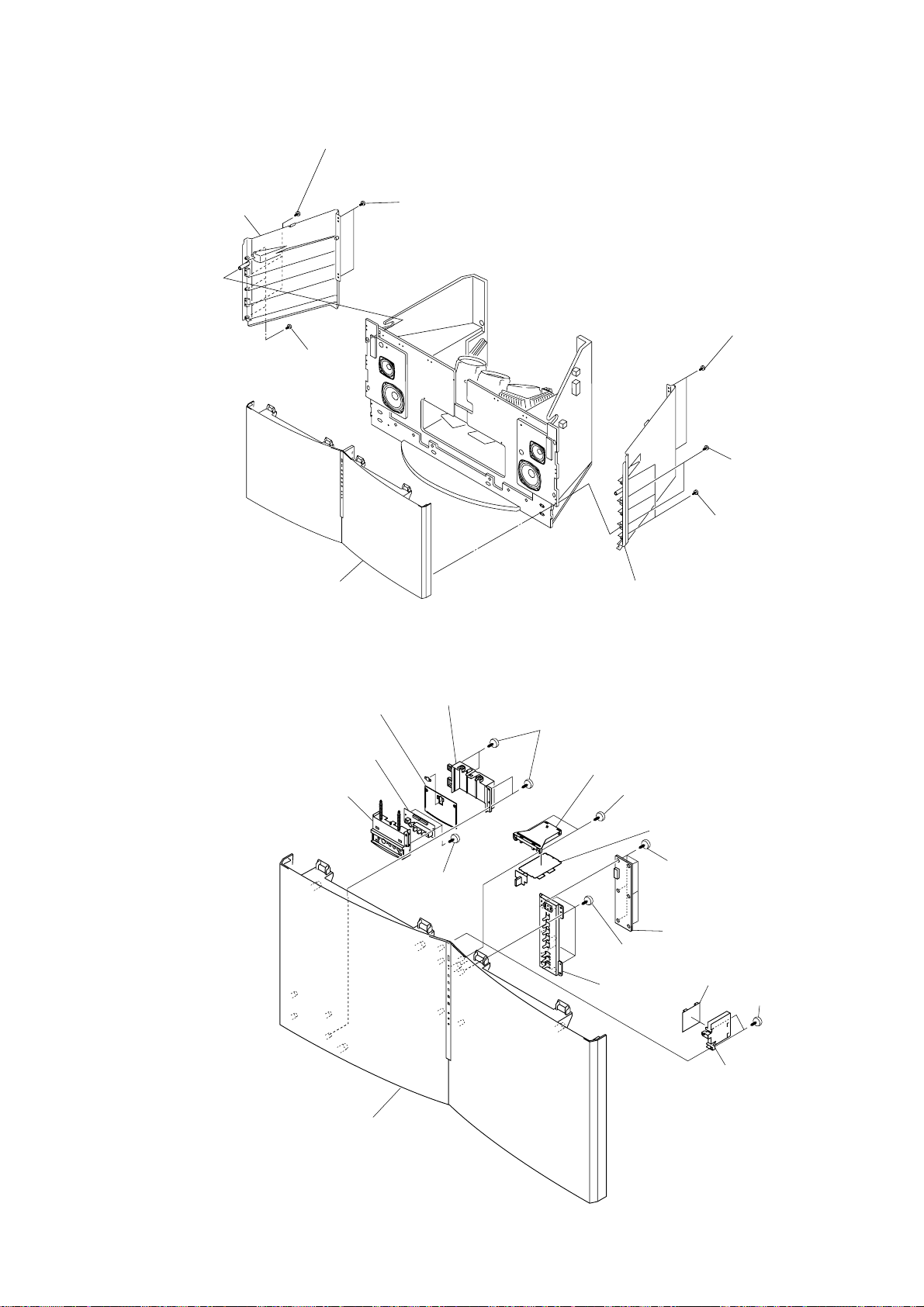

2-5. H1, H2 AND H3 BOARDS REMOVAL

3 Two screws

(tapping screw

hexagon head)

2 Two screws

(tapping screw

hexagon head)

1 three screws

(BVTP 4x16)

5 Side panel R(57) assy

4 Plate input terminal

6 H3 board

3 Cover assy input terminal

Speaker Grill(57) assy

2 Input terminal bracket

5 Two screws

(BVTP 3x12)

1 Four screws

(BVTP 3x12)

8 H1 bracket

qd Control button

7 Two screws

(BVTP 3x12)

9 H1 board

0 Six screws

(BVTP 3x12)

qa H2 board

qs Four screws

(BVTP 3x12)

qh HM board

qf Two screws

(BVTP 3x12)

qg HM bracket

– 10 –

2-6. BEZNET AND MIRROR COVER REMOVAL

7 Ten screws

(BVTP 4X12)

8 Screen

holder

short

6 Screen

qa Diffusion plate (57WF)

qs Diffusion plate (57WL)

holder

8 Screen

holder

short

7 Eleven

holder

short

6 Screen

holder

8 Screen

holder

short

3 Mirror cover

6 Screen

holder

8 Screen

holder

short

6 Screen

holder

7 Seven

holder

short

KP-FS57M31/M61/M90/M91

1 Three screws

(BVTP 4X25)

1 Three screws

(BVTP 4X25)

RM-997

2 Two screws

(Hexagon head)

1 Three screws

(BVTP 4X25)

2 Two screws

(Hexagon head)

2 Four screws

(Hexagon head)

4 Six screws

(Hexagon head)

0 Contrast screen assy

2-7 MAIN BRACKET REMOVAL

1 Two screws

(Tapping screw

hexagon head)

Pay particular attention to the wires

of each printed circuit boards when

puling out the mainbracket.

2 Main bracket section

– 11 –

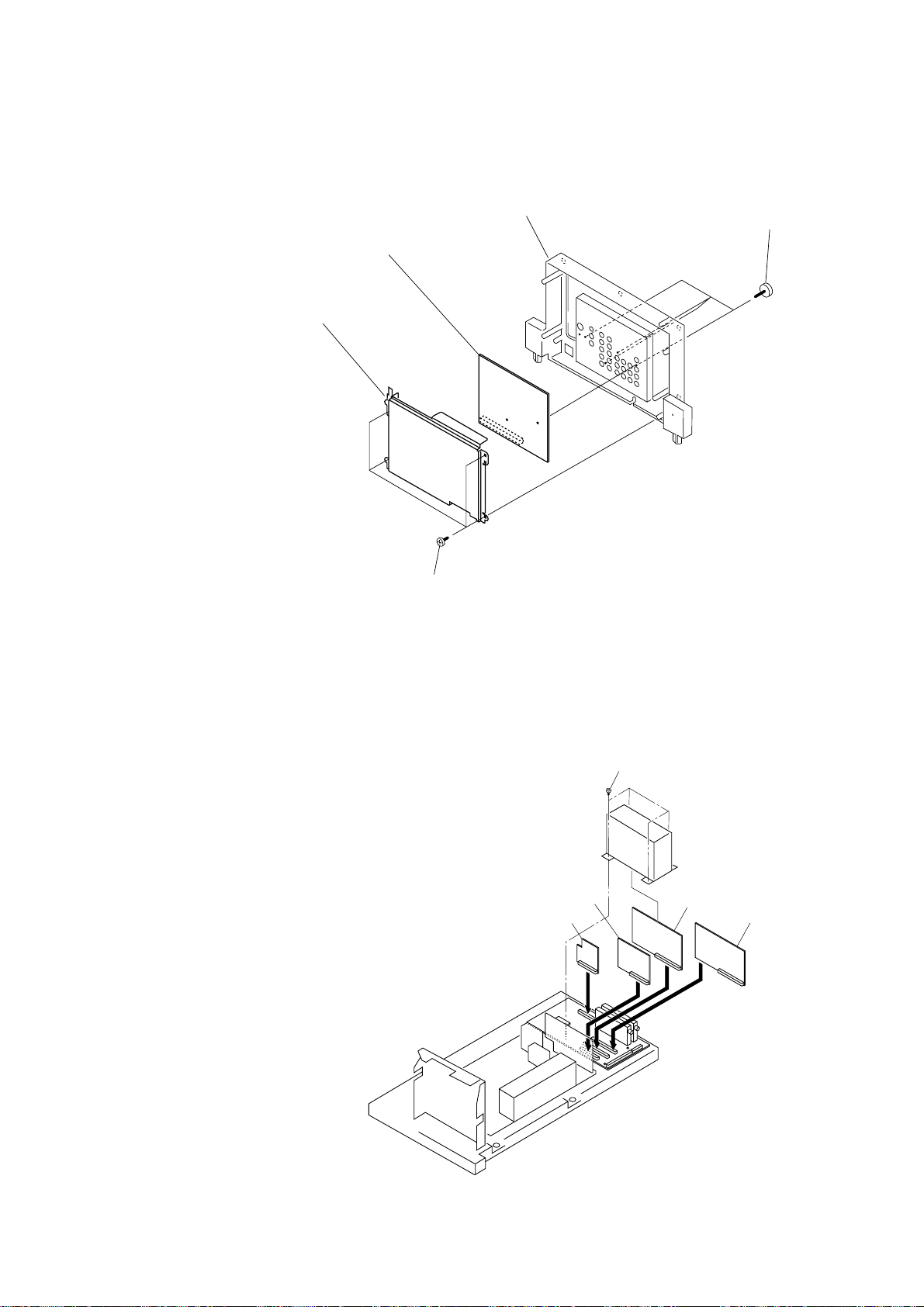

2-8. G BOARD REMOVAL

KP-FS57M31/M61/M90/M91

RM-997

1 Four holder PWB

2-9. CONNECTOR COVER REMOVAL

2 G board

RF Connector

Main bracket section

3 Connector cover section

2 Screw

(PSW 2.6X6)

Main bracket section

– 12 –

1 Tow screws

(BVTP 4X16)

2-10. J BOARD REMOVAL

KP-FS57M31/M61/M90/M91

RM-997

4 J board

2 J board cover

5 Connector cover

1 Four screws

(BVTP 3X12)

3 Four screws

(BVTP X12)

2-11. A1, E, B4, AND V2 BOARDS REMOVAL

2 E board

1 A1 board

3 Four screws

(Hexagon head)

4 B4 board

5 V2 board

– 13 –

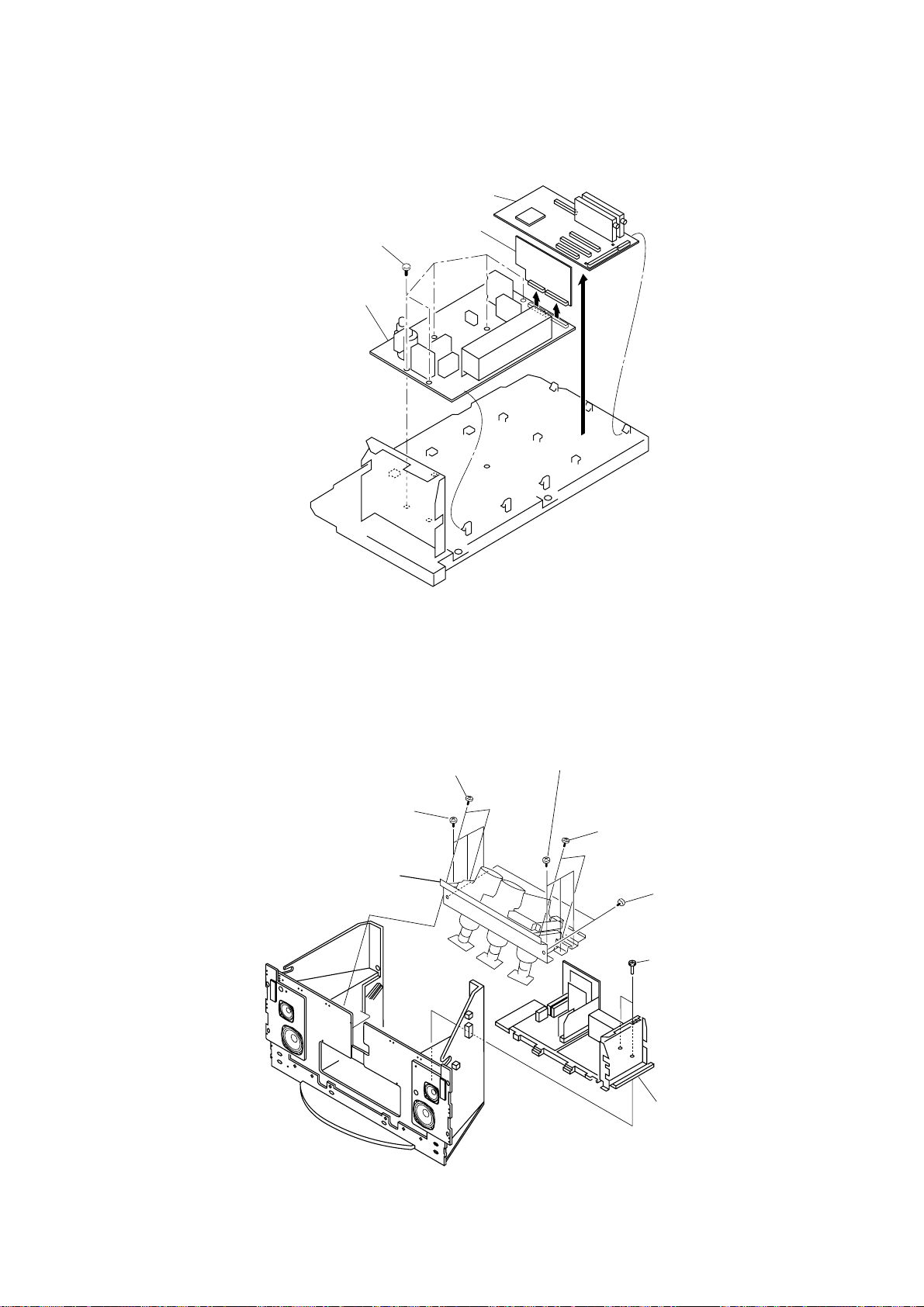

2-12. A, AD AND D BOARDS REMOVAL

KP-FS57M31/M61/M90/M91

RM-997

1 A board

3 Five screws

(BVTP 3X12)

4 D board

2 AD board

2-13. PICTURE TUBE REMOVAL

2 Three screws

(Hexagon head)

(4X20)

4 PICTURE TUBE

BLOCK ASSY

1 Two screws

(BVTP 4X16)

2 Three screws

(Hexagon head)

(4X20)

1 Two screws

(BVTP 4X16)

3 Two screws

(Hexagon head)

(4X20)

5 Two screws

(Hexagon head)

(4X20)

6 Main bracket section

– 14 –

KP-FS57M31/M61/M90/M91

RM-997

2-14 HIGH-VOLTAGE CABLE

INSTALLATION AND REMOVAL

(1) Remover

1 Rubber cap

2 HV cable turn 90°

(2) Installation

2 Rubber cap

1 HV cable

Hook

2-15. MECHASEAL

Removing the arrow-marked screw is strictly inhibited.

If removed, it may cause liquid spill.

1 Four screws

(BVTP 4X16)

7 Two screws

(BVTP 4X16)

8 Heat sink

9 Shade

5 Four screws

(BVTP 4X16)

6 Mechaseal assy

4 Deflection yoke

3 Neck assy

*

Gutter

2 CR board

– 15 –

SECTION 3

SET-UP ADJUSTMENTS

KP-FS57M31/M61/M90/M91

RM-997

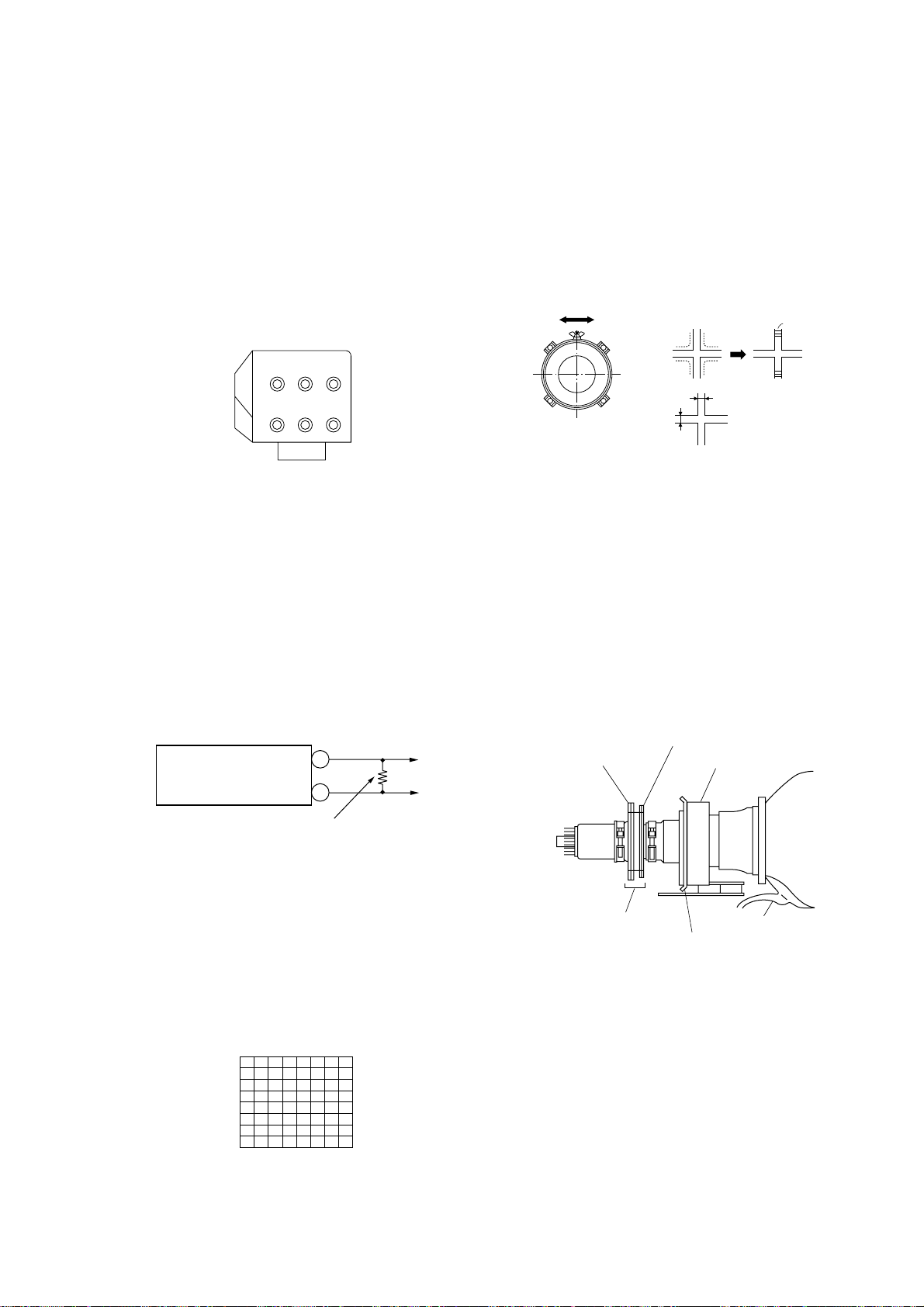

3-1. SCREEN VOLTAGE ADJUSTMENT

(ROUGH ALIGNMENT)

1. Receive the Monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the focus pack all the way to the left and

then gradually turn it to the right until the point where you

can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

Focus Pack

FOCUS

B

BRG

RG

SCREEN

Fig. 3-1

3-2. SCREEN (G2) ADJUSTMENT

(FINE ADJUSTMENT)

1. Turn on the power of the set.

2. Select VIDEO1 mode without signal.

3. Supply DC 175 ± 0.5 V from external power supply to KR,

KG or KB of CR board, CG board and CB board.(Fig.3-2)

3. Adjust red, green and blue screen voltage to until retrace

line disappears with screen VR on the focus pack.

4. Supply DC 172 ± 0.5 V from external power supply to KR,

KG or KB of CR board, CG board and CB board.(Fig.3-3)

5. Confirm if retrance can be seen.

Power

Supply

+

–

5. Rotate the green lens and align to obtain the best lens focus

at the center area.

6. Rotate the green focus VR on the focus pack and align to

obtain the best electrical focus in the center area.

7. Perform the same alignment for red and blue lenses and electric focus.

8. Fix lens screw.

Scanning line visible.

A

Minimize both A and B.

Lens

Fig. 3-4

B

Fig. 3-5

3-4. DEFLECTION YOKE TILT ADJUSTMENT

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color.

3. Loosen the deflection yoke setscrew and align the tilt of the

Deflection yoke so that the bars at the center of the

monoscope pattern are horizontal.

4. After aligning the deflection yoke, fasten it securely to the

funnel-shaped portion of the CRT.

5. The tilt of the deflection yoke for red and blue is aligned the

same as was done for green.

4-pole magnet

2-pole magnet

Deflection yoke

Dummy Resister

3k ohm 20W

Fig. 3-2

3-3. FOCUS ROUGH ADJUSTMENT

1. Loose the lens screw.

2. Set in the service mode.

3. Place the caps on the red and blue lens so that only the green

color is shown.

4. Press “1” or “4” button on the commander and select

“PJE”, press “6” three times on the Commander to display

the test signal (crosshatch) on the screen.

Test signal

Fig. 3-3

– 16 –

Neck Assy

Anode cap

Centering magnet

Make sure deflection yoke is

touching CRT closely.

Fig. 3-6

KP-FS57M31/M61/M90/M91

RM-997

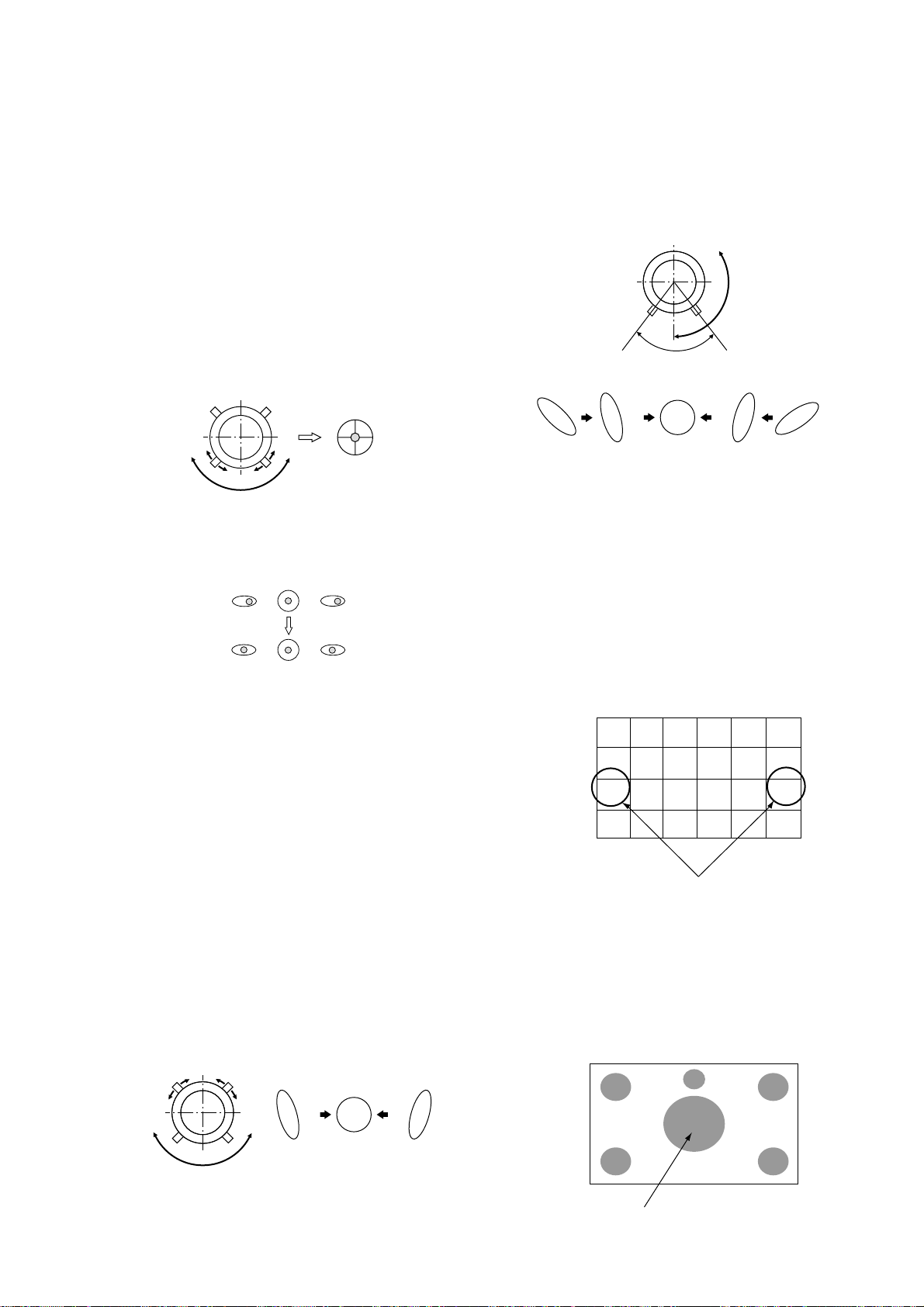

3-5. 2-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Turn the green focus VR on the focus pack to the left and set

to under focus to enlarge the spot.

4. Adjust the 2-Pole Magnet so that the bright spot should be

centered.

(center of the dot doesn't move)

5. Align the green focus VR and set for just (precise) focus.

6. Select Dynamic mode, turn BLUE FOCUS VR on the focus

pack to the left.

7. Confirm that right- end and left-end dot core are in center of

dot.

8. If cores are not in center, adjust blue 2 pole magnet as cores

are in center.

Use the center dot

Fig. 3-7

NG

OK

Left-end dot

(BLUE)

Right-end dot

(BLUE)

Fig. 3-8

3-6. CENTERRING MAGNET ADJUSTMENT

1. Receive the SPCB signal.

2. Cover the both red and blue picture lenses with the lens caps

to show only the color.

3. Adjust the green centering magnet to put the center of the

SPCB signal to the center of the screen.

4. Adjust red centering magnet in the same way.

5. Adjust blue centering magnet in the same way.

3-8. DEFOCUS ADJUSTMENT (BLUE)

1. Receive the Dot signal.

2. Cover the both red and green picture lenses with the lens

caps to show only the color..

3. Turn the blue focus VR on the focus pack to the right to

make the round dot elipical.

4. Set 4 pole magnet tab angle 90°.

5. Rotate 4 pole magnet keeping Tab angle 90° make the spot

shape vertical ellipse.

Rotate

90° Fix

OK

Fig. 3-10

3-9. GREEN, RED AND BLUE FOCUS

ADJUSTMENT

3-9-1. Green, Red and Blue Lens Focus Adjustment

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Rotate the green lens and adjust to obtain the best lens focus

at the center area.

4. Fix lens screw.

5. Repeat above process for red and blue.

6. Rotate the blue lens and adjust to obtain the best lens focus at

the both side area.

7. Fix blue lens screw.

3-7. 4-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Turn the green focus VR on the focus pack to the right and

set to over focus to enlarge the spot.

4. Now align the 4-Pole Magnet so that the enlarged spot becomes a perfect circle.

5. Perform the same alignment for red.

Use the center dot

Fig. 3-9

OKNG NG

Adjust Point of Blue

Fig. 3-11

3-9-2. Green and Red Dot/Hatch Electrical Focus

Adjustment

1. Receive the signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Rotate the green focus VR on the focus pack and adjust to

obtain the best electrical focus in the adjust point.

4. Repeat above process for red and blue.

Adjust Point of Green and Red

Fig. 3-12

– 17 –

KP-FS57M31/M61/M90/M91

Enter the

“Service mode”

5

(DIGIT 5) (VOLUME +)ON SCREEN

DISPLAY

(

)

TV

STANDBY

(

)

RM-997

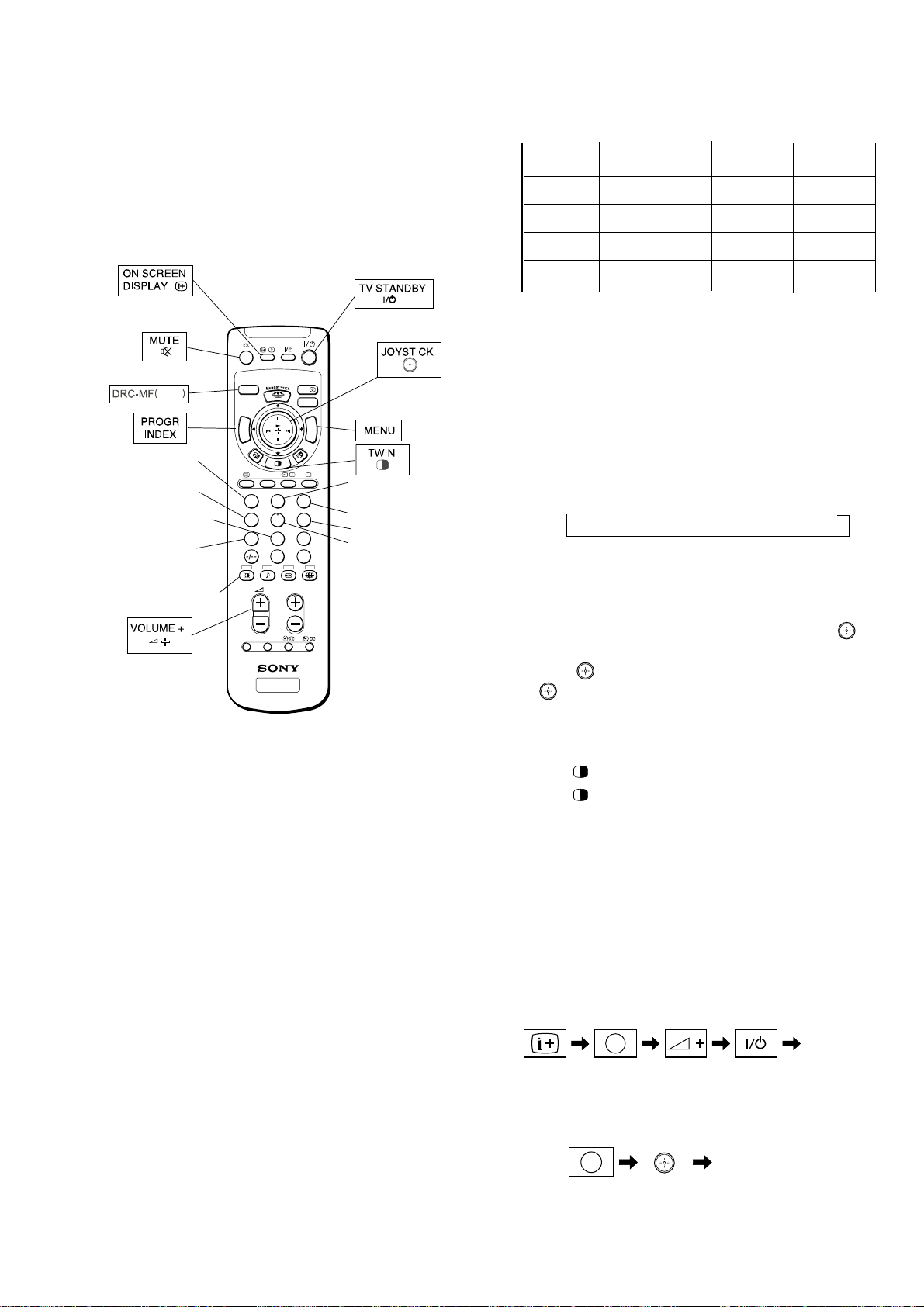

3-10. ADJUSTMENTS WITH COMMANDER

Service adjustment to this model can performed with the supplied

remote commander RM-998

Copy PAL data

to NTSC

VIDEO

Write data to NVM

blue

Adjustment item

up

Adjustment item

down

User control goes

to the standard state

Read data from

NVM

Change

the PICTUER MODE

DRC-MF

INDEX

PROG

HD/DVD

123

456

7809

PROG

OPTION RESET

TV

RM-997

A/B

V CENTER

MENU

JUMP

Up : Category up

Down : Category down

Push : Enter

Copy data to all

mode

Data up

Data down

Initialize data

(Not stored)

3-10-1. How to Select Each Mode

50 Hz 60 Hz WIDE 60 Hz WIDE 50 Hz

(PAL) (NTSC) (NTSC) (PAL)

DRC1250 aa a a

DRC100 aa a a

TWIN aa

INDEX aa

1. Selection of Mode Between 50 Hz and 60 Hz

50 Hz : Enter the PAL signal.

60 Hz : Enter the NTSC signal.

WIDE 60 Hz : Enter the NTSC signal MENU WIDE ON.

WIDE 50 Hz : Enter the PAL signal MENU WIDE ON.

2. Selection of DRC Mode

1) Press “DRC-MF (blue)” button on the commander, repeatedly until displays the mode that you want to select on the

screen.

→ DRC1250 → DRC100 → PROGRESSIV

Note : The DRC-MF mode is not selectable when using the

“PROGRAM INDEX” or “TWIN” mode is turned “ON”.

3. Selection of WIDE mode

1) Press “MENU” button on the commander and move “

or down to enter the “FEATURE” b “WIDE MODE”.

2) Move “

” up or down to select “ON” or “OFF”, and push

“ (ENTER)” button.

3) Press “MENU” button to return to normal screen.

4. Selection of TWIN mode

1) Press “

2) Press “

(TWIN)” button on the commander.

(TWIN)” button again to return to normal screen.

XX

XX

” up

5. Selection of INDEX mode

1) Press “PROGR INDEX” button on the commander.

2) Press “PROGR INDEX” button again to return to normal

screen.

3-10-2. How to Enter Service Mode

1. Turn on the main power switch to place this set in standby

mode. (LED will light in red.)

2. Press the buttons on the commander as follows, and enter service mode.

3. After entering service mode, reset current aadjustment data.

Then turn off the power switch.

8

(DIGIT 8)

4. Turn on the main power switch and enter mode again as step 2

above.

– 18 –

(ENTER)

Enter the

“Reset”

KP-FS57M31/M61/M90/M91

RM-997

3-10-3. Method of Cancellation from Service

Mode

1. Set the standby mode (Press “ (TV STANDBY)” button on

the commander), then press “

(TV

STANDBY)” button again, hereupon it becomes TV mode.

3-10-4. How to Adjustments

1. Set in the service mode, the following screen will appear.

Category Name Item Name Mode

Item No.

GE1 00 VPS 1C SERVICE 50

0 003Q 2.9M 00 00 01B7

Suffix No.

Software

Version

Data

Total Power On time

(Hours)

2. Press “1” or “4” button on the commander to select the adjustment item.

3. Press “3” or “6” button on the commander to change the

adjustment data.

50 : PAL, SECAM

60 : NTSC

3-10-5. How to Write the Data

1. Set in the service mode.

2. Press “1” or “4” button on the commander, select the adjustment item, and press “3” or “6” button to change the

data.

3. Press “

cate “WRITE” on the screen.

4. Press “-” button on the commander to write into memory.

(The “WRITE” display will be changed to red color while

executing, and back to “SERVICE”.)

Commander Function (Except PJE mode)

Button Mode Description

+ - WRITE Writes data to NVM.

7 + - READ Reads data from NVM.

8 + - NORMAL All user control goes to the standard.

5 + - INITIAL Service data initialization. Not

2 + - COPY Do not operate with a remote

+ - WRT5060

(MUTE)” button on the commander and it will indi-

stored.

(Be sure not to use usually)

commander.

(The data vary with among mode.)

4. Move “

” up or down to select the adjustment category.

When move “ ” up (category up), service mode changes in

the order as shown below.

GE1

GE2

GE3

GE4

WHB

SAJ

* : When it moves from PJE to other categrys,

repeat 1 or 4 button and press it.

DCN

LDG

JGL

YCT

SYC

SYN

AP

MSP

LTI

MD1

MD2

MD3

MD4

MD5

MD6

MD7

3NR

3CM

2CM

TXT

WID

PJE*

OSD

OPM

OPB

Note : Before changing to other modes, press “ (MUTE)” +

“-” buttons on the commander to write the data.

(Omission of this operation causes the data to be returned

to the data before adjustment.)

: Confirm the adjustment mode before writing data for data

values because to vary in each adjustment mode.

: The adjustment item that there are no relations in the ad-

justment is not to change data values because all items are

written in each adjustment mode.

3-10-6. Memory Write Confirmation Method

1. After adjustment, turn off the AC main power switch off.

2. Turn the power switch ON and set in service mode.

3. Call the adjustment items again to confirm adjustments were

made.

– 19 –

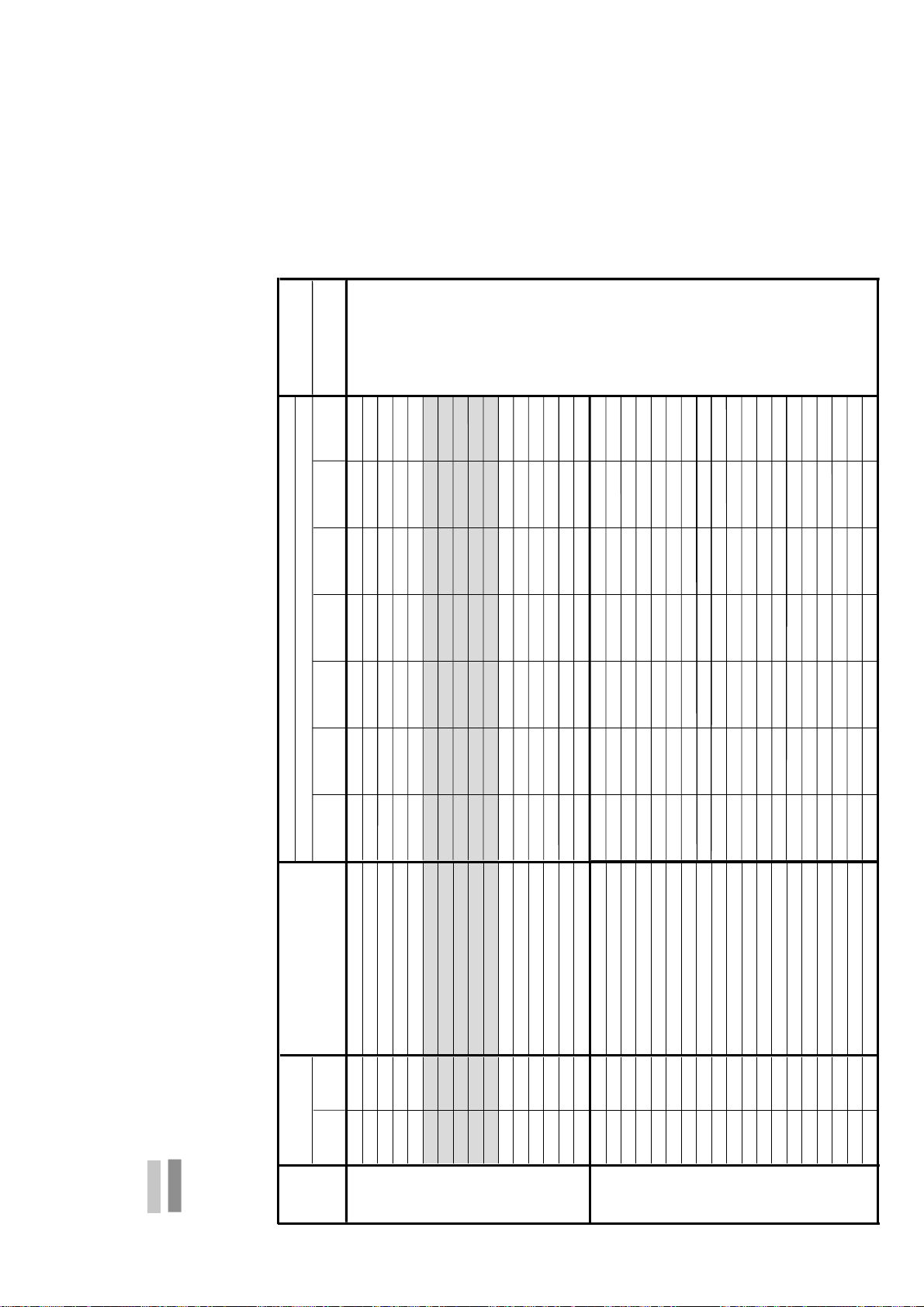

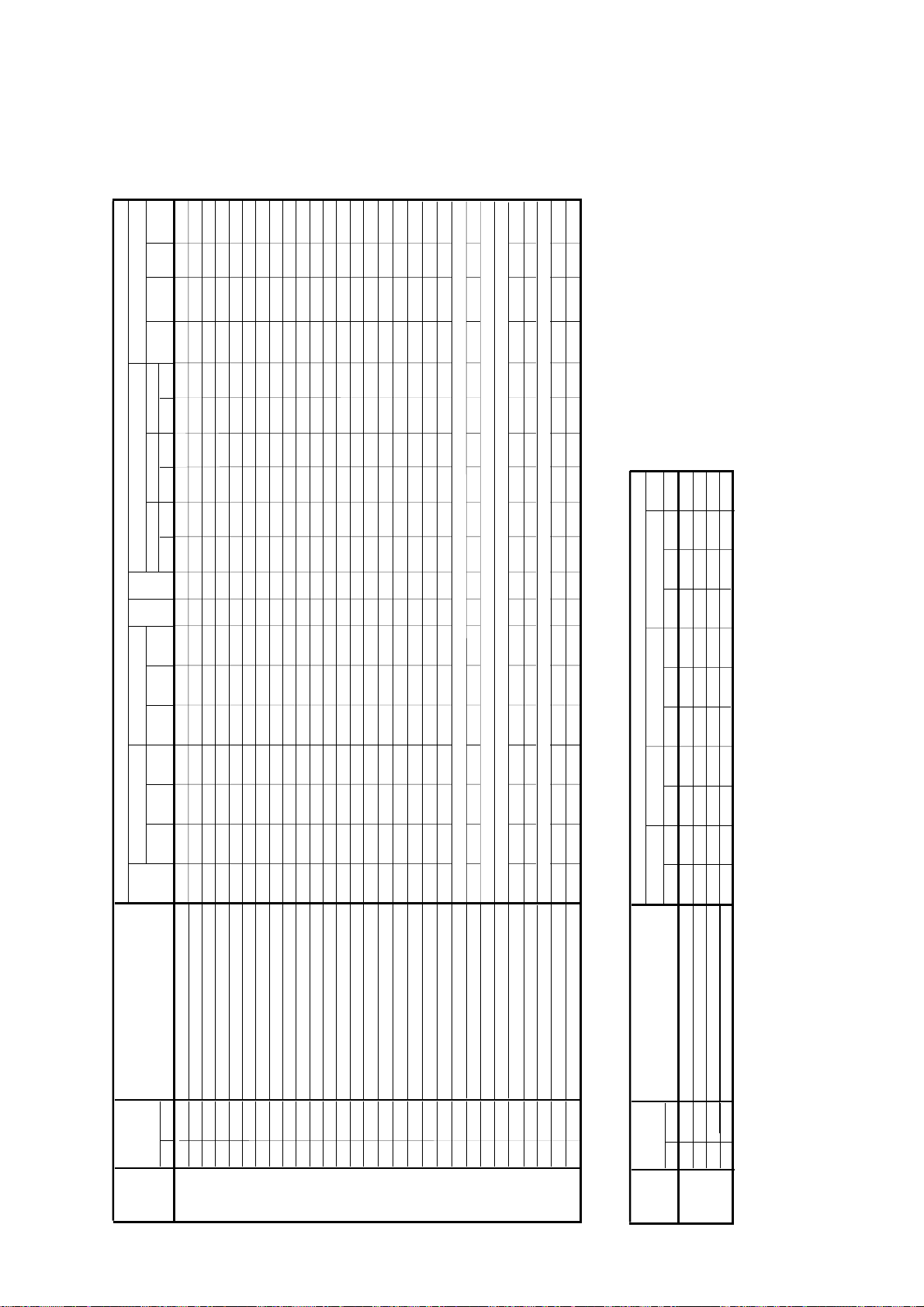

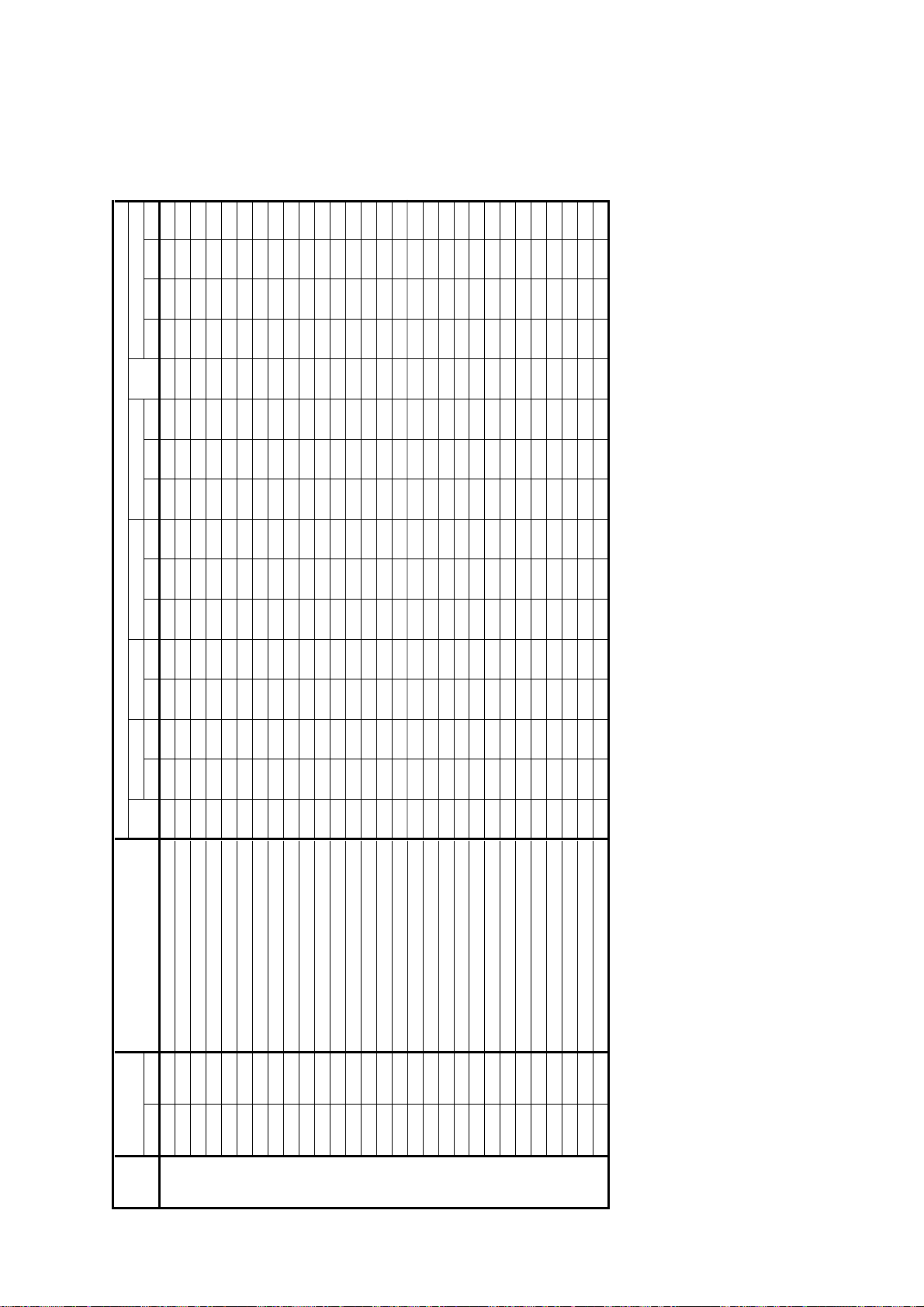

3-11. SERVICE LIST

ely in the memory.

mode.

Device Name

(Slave Address)

HD

DRC100

KP-FS57M31/M61/M90/M91

RM-997

CXA2170AQ(86H)

W/Z

W/Z

DRC1250

Zoom

50 Hz

DRC100

Standard Data

Zoom

DRC1250

Full

DRC100

Full

DRC1250

Function

09 09 09

1F 1F 1F 1F 1F 1F

0F 0F 0F 0F 0F 0F

1F 1F 1F 1F 1F 1F

19 19 19 19 19 19

00 00 00 00 00 00

05 05 05 05 05 05

08 08 08 0A 0A 08

1F

19

00

05

08

0F 0F 0F 0F 0F 0F

00 00 00 00 00 00

00 00 00 00 00 00

00 01 01 01 01 00

01 01 01 01 01 01

07 36 33 1C 19 12

1D 1D 1D 1D 1D 1D

00 00 00 04 04 00

1F

0F

0F

00

00

00

01

0A

1D

00

1F 1F 1F 1F 1F 1F

00 00 00 04 04 00

13 13 13 13 13 13

17 17 17 17 17 17

09 09 09

00

1F

13

17

09

1F 1F 1F 1F 1F 1F

00 00 00 00 00 00

00

1F 1F 1F 1F 1F 1F

01 01 01 01 01 01

07 07 07 07 07 07

00 00 00 00 00 00

00 00 00 00 00 00

1F

1F

01

07

00

00

23 1F 23 1F 23 1F

1F 1F 1F 1F 1F 1F

1F 1F 1F 1F 1F 1F

02 02 02 02 02 02

02 02 02 02 02 02

00 00 00 00 00 00

02

02

00

1F 1F 1F 1F 1F 1F

30 30 30 30 30 30

1F

1F

1F

1F

30

VERTICAL SIZE

V SIZE OFF SET (PJ only)

VERTICAL LINEARITY

VERTICAL S CORRECTION

VERTICAL CENTERING

VERTICAL PIN

VERTICAL MIDDLE PIN

HORIZONTAL TRAPEZOID

VERTICAL POSITION

MIDDLE HORIZONTAL TRAPEZOID

Item

01 VSZ

02 VZO

03 VLN

04 VSC

05 VCN

06 VPN

07 MVP

08 HTZ

No. Name

Those are the standard data values written on the microprocessor. Therefore , the data values of the modes and stored respectiv

Note

• Common : The data value of each mode. Other are set up by each mode.

• : Shaded items are fixed data.

• : Though data value is indicated on the screen, it is not used.

• Standard data listed on the Adjustment Item Table are reference valies, therefore it may be different for each model and each

In case of a device replacement, adjustment by rewriting the data value is necessary for some items.

• Note for Different Data :

GE1 00 VPS

Category

09 MHZ

– 20 –

ASPECT SWITCH

ASPECT RATIO

ZOOM SW

VERTICAL SCROLL

0B ASP

0C VSP

0A ZOM

0D VSR

UPPER VERTICAL LINEARITY

LOWER VERTICAL LINEARITY

HORIZONTAL POSITION

HORIZONTAL CENTERING

0E UVL

0F LVL

01 HPS

GE2 00 HCT

HORIZONTAL SIZE

HORIZONTAL S CORRECTION

HORIZONTAL MIDDLE PIN

HORIZONTAL PIN

PIN

02 HSZ

03 SLN

04 MPN

05

PIN OFF SET (PJ only)

UPPER CORNER PIN

LOWER CORNER PIN

UPPER EXTRA CORNER PIN GAIN

UPPER EXTRA CORNER PIN POSITION

LOWER EXTRA CORNER PIN POSITION

LOWER EXTRA CORNER PIN GAIN

06 PN0

07 UCP

08 LCP

09 UXG

0B UXP

0C LXP

0A LXG

PIN PHASE

AFC ANGLE

LINEARITY ANGLE

AFC BOW

EXTRA CORNER PIN POLARITY

0E PPH

0D XPL

LINEARITY BOW

0F VAG

10 LNA

11 VBW

12 LBW

Device NameItem

(Slave Address)

HD

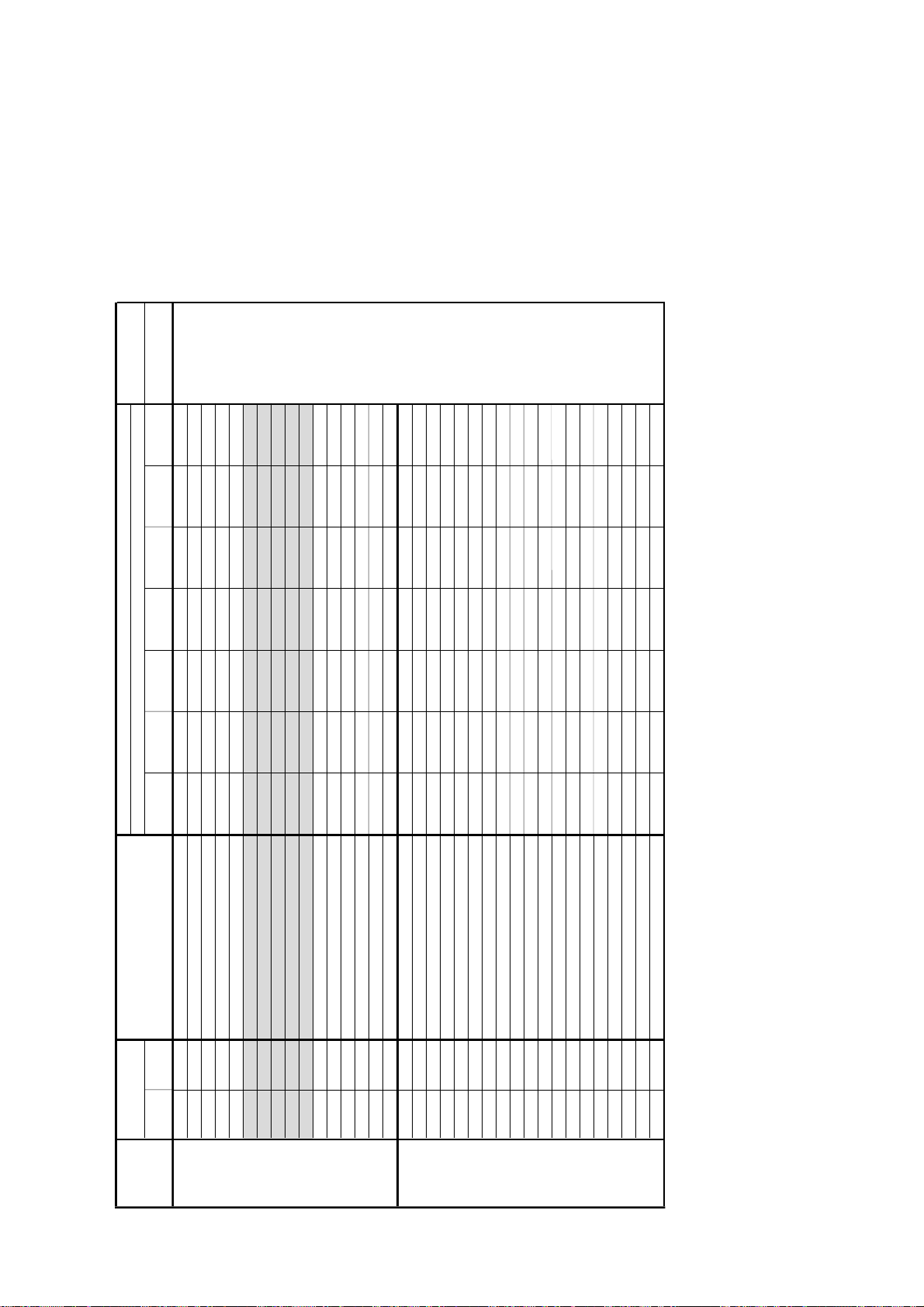

KP-FS57M31/M61/M90/M91

RM-997

CXA2170AQ(86H)

DRC120

ZoomW/Z

ZoomW/Z

DRC1250

Zoom

60 Hz

DRC120

Standard Data

Zoom

DRC1250

Full

DRC1230

Full

DRC1250

1F 1F

1F 1F 1F

1F 1F

No. Name

Category Function

VERTICAL POSITION 19 19 19 19 19 19 19

GE1 00 VPS

HORIZONTAL CENTERING 13 13 13 13 13 13 13

HTZ HORIZONTAL TRAPEZOID 0F 0F 0F 0F 0F 0F 0F

ASP ASPECT SWITCH 01 01 01 01 01 01 000DVSP ASPECT RATIO 05 02 31 2E 18 17 030EVSR VERTICAL SCROLL 1D 1D 1D 1D 1D 1D 1D

MHZ MIDDLE HORIZONTAL TRAPEZOID 00 00 00 00 00 00 000BZOM ZOOM SW 00 00 01 01 01 01 00

01 VSZ VERTICAL SIZE 1F 1F 1F 1F 1F 1F 1F

02 VZO V SIZE OFF SET (PJ only) 00 00 00 00 00 00 00

03 VLN VERTICAL LINEARITY 05 05 05 05 05 05 05

04 VSC VERTICAL S CORRECTION 08 08 08 08 0A 0A 08

05 VCN VERTICAL CENTERING 1F 1F 1F 1F 1F 1F 1F

06 VPN VERTICAL PIN 0F 0F 0F 0F 0F 0F 0F

07 MVP VERTICAL MIDDLE PIN 00 00 00 00 00 00 000809

0A

LVL LOWER VERTICAL LINEARITY 00 00 00 00 00 00 00

UVL UPPER VERTICAL LINEARITY 00 00 00 00 00 00 00

0F

0C

GE2 00 HCT

01 HPS HORIZONTAL POSITION 17 17 17 17 17 17 17

02 HSZ HORIZONTAL SIZE 1F 1F 1F 1F 1F 1F 1F

03 SLN HORIZONTAL S CORRECTION 09 09 09 09 09 09 09

04 MPN HORIZONTAL MIDDLE PIN 00 00 00 00 00 00 00

08 LCP LOWER CORNER PIN 1F 1F 1F 1F 1F 1F 1F

05 PIN HORIZONTAL PIN 01 01 01 01 01 01 01

06 PN0 PIN OFF SET (PJ only) 07 07 07 07 07 07 07

07 UCP UPPER CORNER PIN

09 UXG UPPER EXTRA CORNER PIN GAIN 00 00 00 00 00 00 00

0A LXG LOWER EXTRA CORNER PIN GAIN 00 00 00 00 00 00 00

0E PPH PIN PHASE 1F 23 1F 1F23 1F 23 1F

0B UXP UPPER EXTRA CORNER PIN POSITION 02 02 02 02 02 02 02

0F VAG AFC ANGLE 1F 1F 1F 1F 1F 1F 1F

0C LXP LOWER EXTRA CORNER PIN POSITION 02 02 02 02 02 02 02

0D XPL EXTRA CORNER PIN POLARITY 00 00 00 00 00 00 00

10 LNA LINEARITY ANGLE 1F 1F 1F 1F 1F 1F 1F

11 VBW AFC BOW 1F 1F 1F 1F 1F 1F 1F

12 LBW LINEARITY BOW 30 30 30 30 30 30 30

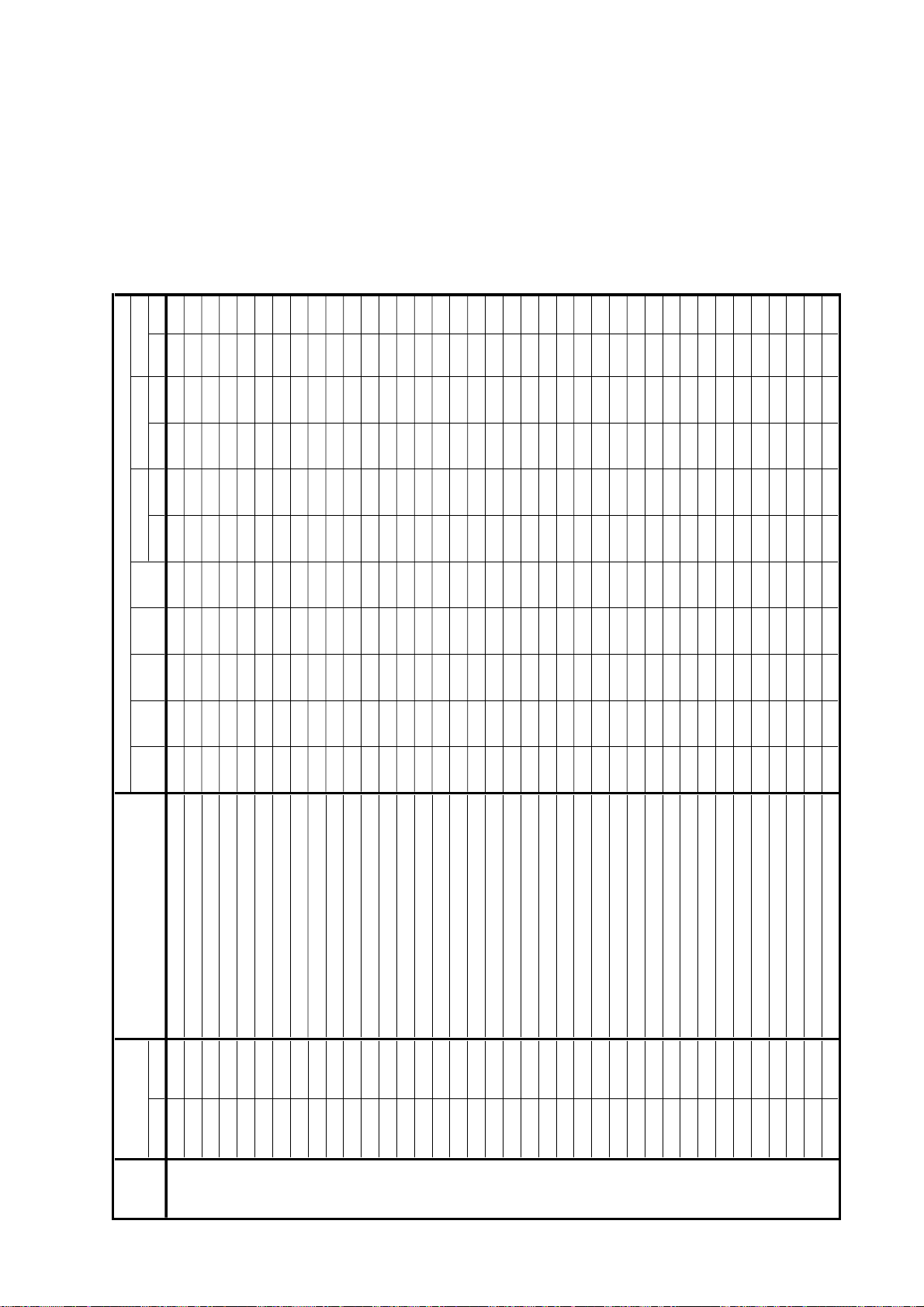

– 21 –

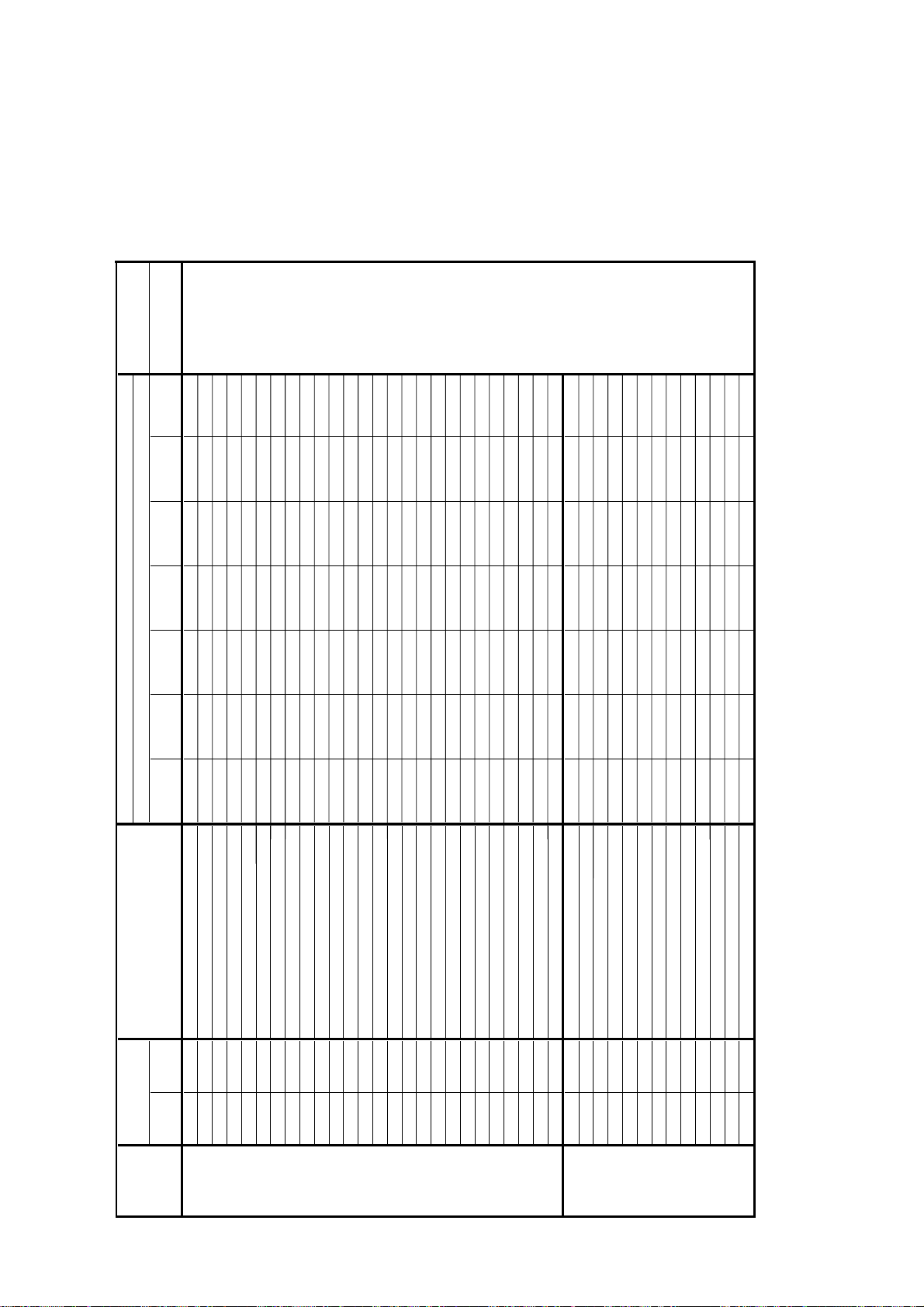

Device Name

(Slave Address)

HD

W/Z

DRC100

KP-FS57M31/M61/M90/M91

RM-997

CXA2170AQ(86H)

W/Z

DRC1250

Zoom

50 Hz

DRC100

Standard Data

Zoom

DRC1250

Full

DRC100

Full

DRC1250

Function

3F 3F 3F 3F 3F 3F

0F 07 O7 O7 07 0F

01 01 01 01 01 01

01

3F

0F 07 07 07 07 0F

01 00 00 00 01 01

00 00 00 00 00 00

00 00 00 00 00 00

00 00 00 00 00 00

00 00 00 00 00 00

00 00 00 00 00 00

03 03 03 03 03 03

00 00 00 00 00 00

01 01 01 01 01 01

00 00 00 00 00 00

00 00 00 00 00 00

09 09 09 09 09 09

00 00 00 00 00 00

00 00 00 00 00 00

50 50 50 50 50 50

19 19 19 19 19 19

00 00 00 00 00 00

00 00 00 00 00 00

00 00 00 00 00 00

00 00 00 00 00 00

17 17 17 17 17 17

00

00

01

00

00

00

00

00

03

00

01

00

00

16

00

00

50

19

17

00

00 00 00 00 00 00

00

00

00

00

1F 1F 1F 1F 1F 1F

11 11 11 11 11 11

07 07 07 07 07 07

14 14 14 14 14 14

3C 3C 3C 3C 3C 3C

07 07 07 07 07 07

00 00 00 00 00 00

1F

11

3C

07

14

07

00

Item

HORIZONTAL BLANKING SWITCH

No. Name

GE3 00 HBL

Category

BOTTOM BLANKING

BLANKING OFF

TOP BLANKING

LEFT BLANKING

RIGHT BLANKING

VERTICAL BLANKING SWITCH

05 BBL

06 BLK

04 TBL

01 LBL

02 RBL

03 VBL

VERTICAL COMPENSATION

07 VCM

HORIZONTAL COMPENSATION

08 HCM

AFC COMPENSATION

PIN COMPENSATION

AFC LOOP GAIN

REFERENCE PULSE JUMP SWITCH

VERTICAL DRIVE JUMP SWITCH

VERTICAL DRIVE START SWITCH

PIN DC LEVEL SHIFT

AKB TIMING

0E RST

0C JMP

0D VSW

0F EWD

10 AKT

09 ACM

0B AFC

0A PCM

PIN COMP POLARITY

FH=15K @ MS MODE

Fh setting @multi-scan

Reciprocal Fh @mult-scan

VERTICAL MULTI-SCAN MODE

FREERUN INTERLACE SETTING

11 PPL

12 M15

13 HFQ

14 HFX

15 VMP

16 ITL

– 22 –

VERTICAL # OF LINE(L)

VERTICAL # OF LINE(H)

AGC SW for PAL

DF SW

DF Phase

DFH

17 VLL

18 VLH

19 AGC

01

GE4 00 DFS

QP Phase

DQP AMPLITUDE

DQP AMPLITUDE VERTICAL MODULATION

DQP AMPLITUDE TILT

02 QPH

03 QAM

04 QAV

05 QAA

DQP DC LEVEL TILT

DQP DC LEVEL

DQP DC LEVEL VERTICAL MODULATION

DQP AMPLITUDE

08 QPP

06 QPC

07 QPV

09 QAM

DQP AMPLITUDE VERTICAL MODULATION

0A QAV

DQP AMPLITUDE TILT

0B QAA

COPY FUNCTION (Full to Vcomp/normal)

0C CPY

Device NameItem

(Slave Address)

HD

CXA2170AQ(86H)

KP-FS57M31/M61/M90/M91

RM-997

14

3C1700

W/Z

DRC120

W/Z

DRC1250

Zoom

60 Hz

DRC120

Standard Data

Zoom

DRC1250

Full

DRC120

Full

DRC1250

14

14

14

14

14

3C1700

3C1700

3C1700

3C1700

3C1700

No. Name

Category Function

HORIZONTAL BLANKING SWITCH 01 01 01 01 01 01 01

GE3 00 HBL

DF SW

DF Phase

DFH

0E RST VERTICAL DRIVE START SWITCH 00 00 00 00 00 00 00

01 LBL LEFT BLANKING 3F 3F 3F 3F 3F 3F 3F

02 RBL RIGHT BLANKING 17 17 17 17 17 17 17

03 VBL VERTICAL BLANKING SWITCH 01 01 01 00 00 00 00

04 TBL TOP BLANKING 00 0A 07 07 07 07 07

05 BBL BOTTOM BLANKING 00 0E 07 07 07 07 07

06 BLK BLANKING OFF 00 00 00 00 00 00 00

07 VCM VERTICAL COMPENSATION 00 00 00 00 00 00 00

0B AFC AFC LOOP GAIN 03 03 03 03 03 03 03

08 HCM HORIZONTAL COMPENSATION 00 00 00 00 00 00 00

09 ACM AFC COMPENSATION 00 00 00 00 00 00 00

0A PCM PIN COMPENSATION 00 00 00 00 00 00 00

0F EWD PIN DC LEVEL SHIFT 00 00 00 00 00 00 00

0C JMP REFERENCE PULSE JUMP SWITCH 00 00 00 00 00 00 00

0D VSW VERTICAL DRIVE JUMP SWITCH 01 01 01 01 01 01 01

10 AKT AKB TIMING 10 09 09 09 09 09 09

11 PPL PIN COMP POLARITY 00 00 00 00 00 00 00

12 M15 FH=15K @ MS MODE 00 00 00 00 00 00 00

13 HFQ Fh setting @multi-scan 50 50 50 50 50 50 50

14 HFX Reciprocal Fh @mult-scan 19 19 19 19 19 19 19

15 VMP VERTICAL MULTI-SCAN MODE 00 00 00 00 00 00 00

16 ITL FREERUN INTERLACE SETTING 00 00 00 00 00 00 00

17 VLL VERTICAL # OF LINE(L) 00 00 00 00 00 00 00

18 VLH VERTICAL # OF LINE(H) 00 00 00 00 00 00 00

19 AGC AGC SW for PAL 00 00 00 00 00 00 00

01

02 QPH QP Phase

03 QAM DQP AMPLITUDE

04 QAV DQP AMPLITUDE VERTICAL MODULATION

05 QAA DQP AMPLITUDE TILT

06 QPC DQP DC LEVEL 11 11 11 11 11 11 11

07 QPV DQP DC LEVEL VERTICAL MODULATION 1F 1F 1F 1F 1F 1F 1F

GE4 00 DFS

0B QAA DQP AMPLITUDE TILT 17

08 QPP DQP DC LEVEL TILT 07 07 07 07 07 07 07

0C CPY COPY FUNCTION (Full to Vcomp/normal) 00

09 QAM DQP AMPLITUDE 14

0A QAV DQP AMPLITUDE VERTICAL MODULATION 3C

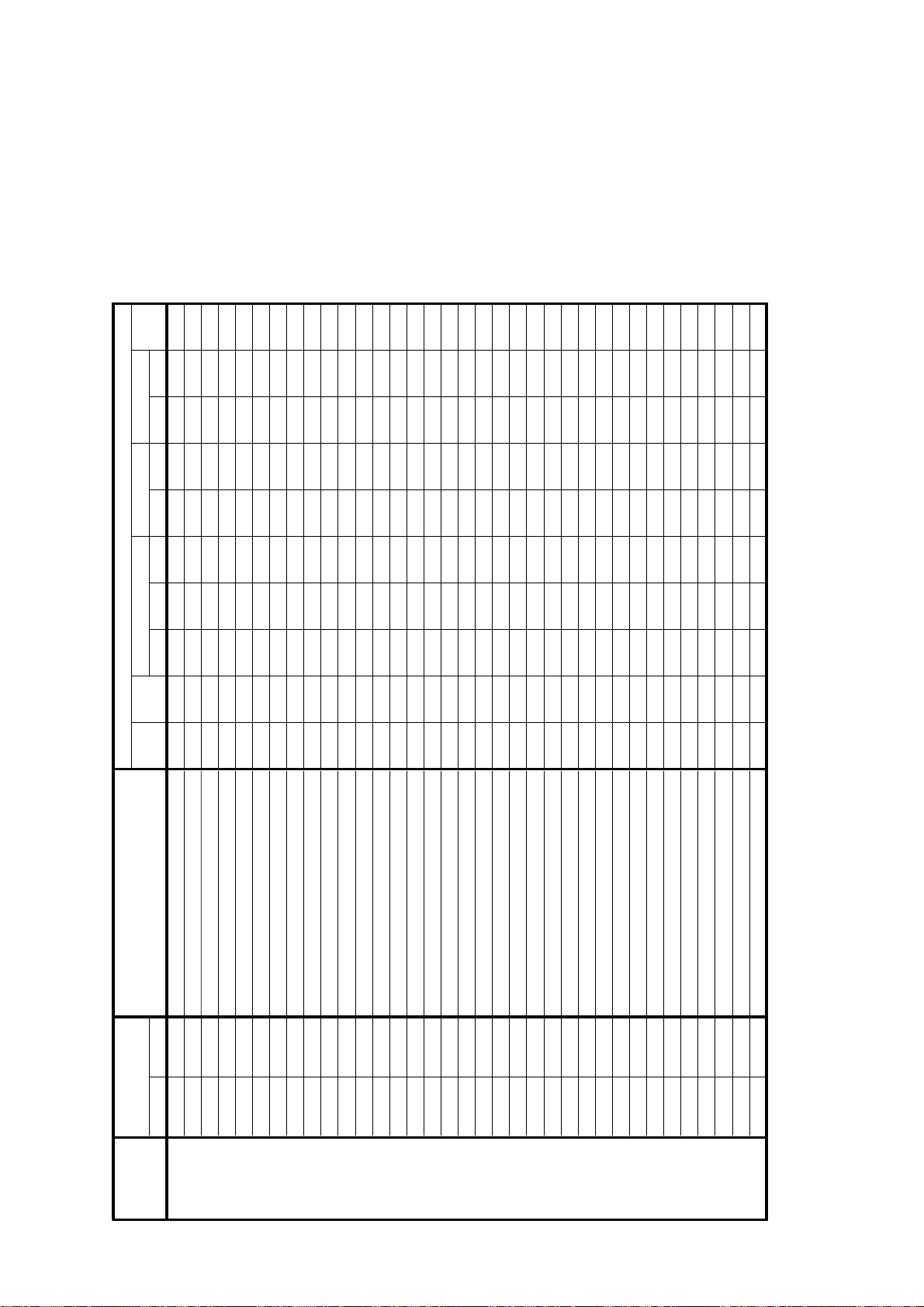

– 23 –

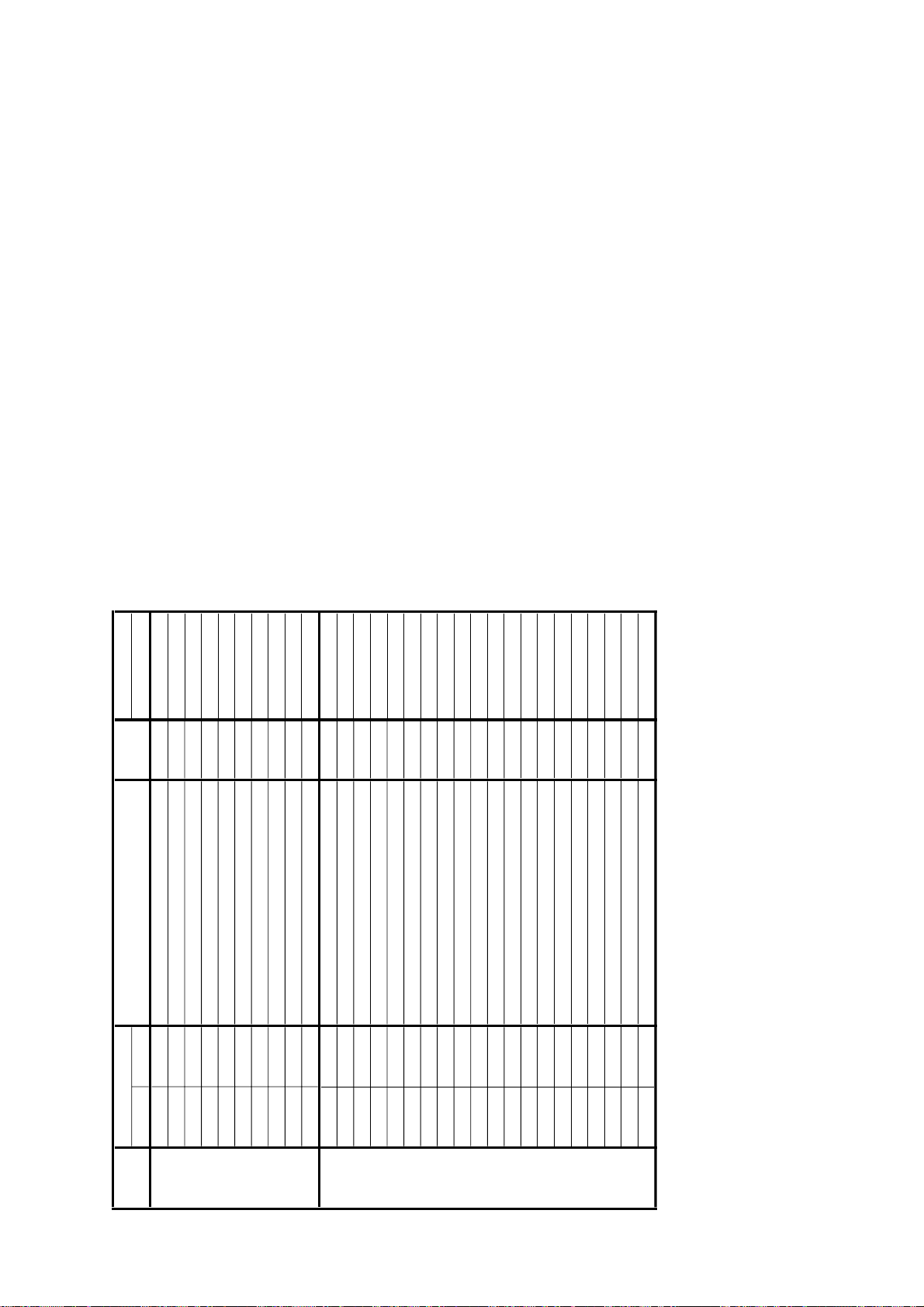

WHB 00 YOS

DC Offset Canceller for Y Signal 07

CXA2170AQ(86H)

01 UOS

DC Offset Canceller for Cb Signal 1F 22 2A 27 21 2A 27 1F

02 VOS

DC Offset Canceller for Cr Signal 1F 25 28 29 25 28 29 1F

03 SBR

Sub Brightness Control 1F

04 RDR

R Drive 1F

05 GDR

G Drive 17

06 BDR

B Drive 1F

07 RCT

R Cutoff 1F

08 GCT

G Cutoff 1B

09 BCT

B Cutoff 1F

0A SBO

Sub Brightness Offset 1F

0B RDO

R Drive Offset 1F

0C GDO

G Drive Offset 1F

0D BDO

B Drive Offset 1F

0E RCO

R Cutoff Offset 1F

0F GCO

G Cutoff Offset 1F

10 BCO

B Cutoff Offset 1F

Device Name

(Slave Address)

MS

RGB

*YUV, RGB : Component Signal

SD-I : 480i, 576i

SD-P : 480P, 576P

HD : 720P, 1080i (50/60 Hz)

KP-FS57M31/M61/M90/M91

RM-997

YUV

Others

NVM

Address

Function

Common SD-I SD-P HD SD-I SD-P HD

No. Name

Item

Category

– 24 –

3F 32 25

No. Name

SAJ

14 CLO

Color Offset

07 07 07 07

16

HUO

Hue Offset

07 07 07 09

17 SHO

Sharpness Offset

0F 0F 0F 0F

1A BRO

Brightness Offset

60

Function

0C 08 03

07 07 07

0F 0F 0B

SD - P HDSD - I

YUV

0C 08 03

07 07 07

0F 0F 0F

SD - P HDSD - I

RGB

05

0B

17

MS

0F 06 03

0F 06 03

06

Standard Data

Dynamic Standard Hi-Fine Personal

OthersWD -NTwin / Index

ECO Mode Picture Mode

KP-FS57M31/M61/M90/M91

RM-997

07 07 00 07

07 03 00 03

07 03 00 03

07 03 00 03

06 03 00 03

01 02 00 02

21 1F 1F

2F 2A 22

22 1F 1D

01 01 00 01

1F 1F 1F

00 00 00 00

0C 0C 09 0C

02 02 00 02

Standard Data

EcoOff EcoOn EcoOff EcoOn EcoOff EcoOn

Index

Twin

60

HD/DVDVIDEO HD/DVDVIDEOTV

50

07 07 07 09 09 09

04 04 04 06 06 06

TV

0F 0F 0F 09 09 09

0D 0D 0D 08 08 08

08 0B 0C 0F 08 0B

*1

*1

*1

*1

07 07

VIDEO VIDEOTVTV

50

03

Common

02

00

00

Function

Item

Category

Picture Control

Brightness Control

01 BRT

No. Name

SAJ 00 PIC

Color Control

Hue Control

Sharpness Control

VM Level

02 COL

03 HUE

04 SHP

05 VML

Color Matrix Specification

Color Matrix Specification

Dynamic Color on/off

White Balance Offset Setting

Color Matrix Specification

06 DYC

07 WBS

08 RYR

Gamma Shape Correction

Color Matrix Specification

09 RYB

0A GYR

0B GYB

0C GMS

Gamma Red

Gamma Green

Gamma Blue

0F GMB

0D GMR

0E GMG

DC Transmission Control

Auto Pedestal Level Control

ABL Mode Control

10 DCT

11 APL

12 ABM

Sharpness Offset

Hue Offset

Color Offset

ABL Current detection Vth Control

Color Step Width to the Change of S/N

14 CLO

13 ABT

17 HUO

15 CLW

16 HUO

– 25 –

Hue Offset

Sharpness Step Width to the Change of S/N

Brightness Offset

APED BLACK SIZE INFLECTED SETTING

COLOR ON/OFF SETTING

18 SHW

1A BRO

1B SHO

1C DPL

19 SHW

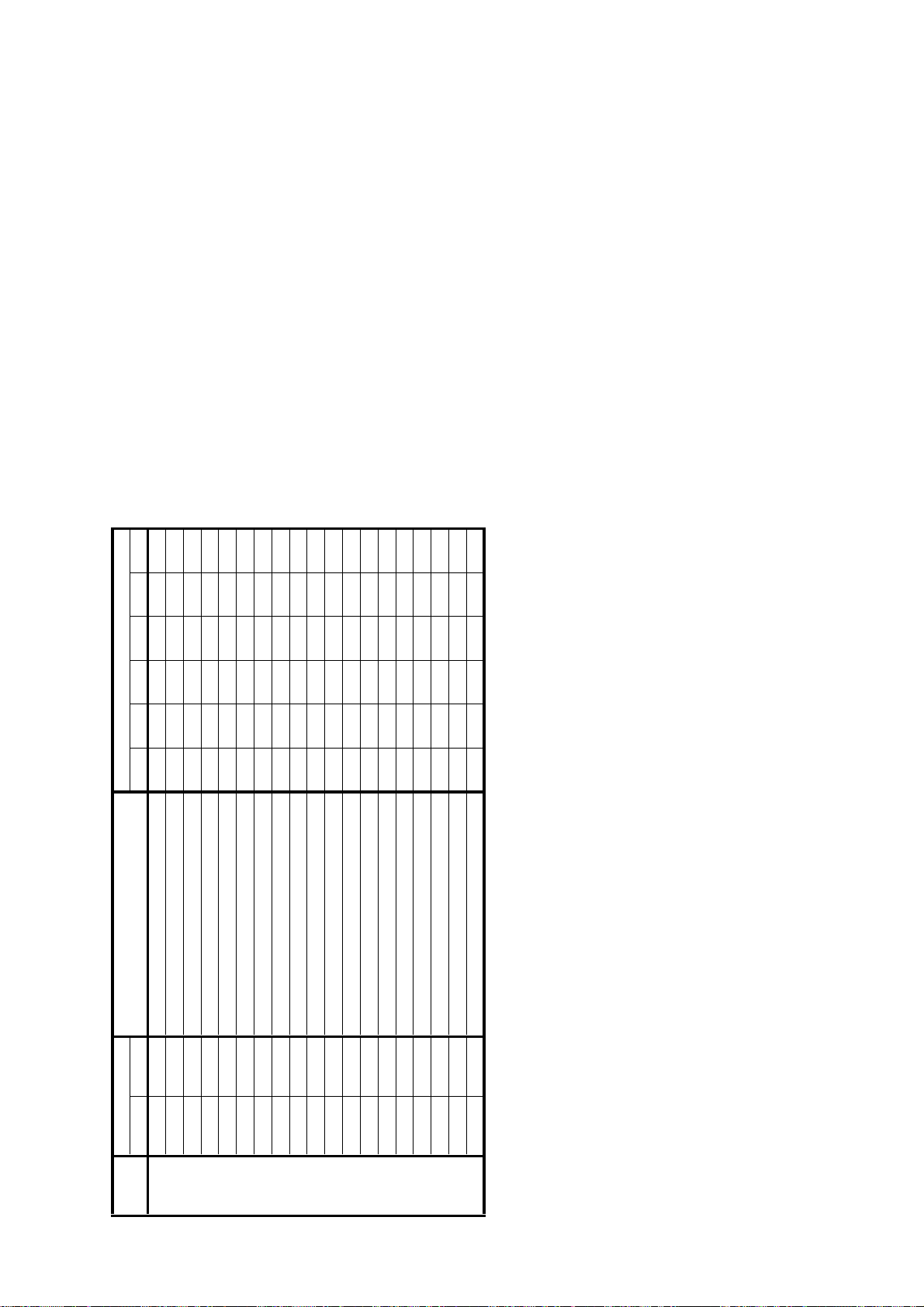

SAJ: Standard Data *1

Item

Category

KP-FS57M31/M61/M90/M91

RM-997

0000000000

Standard Data

Data

Range

Function

DC AMP3

VCA9

Item

01 YBU

No. Name Common

VCA10

DC AMP2

02 YBL

03 RAP

0000000000000000000000

00

VCA5

VCA6

DC AMP1

VCA1

VCA2

DC AMP4

NS Correction

EW Correction

Left Cross Correction

04 RUB

05 RLB

06 LAP

07 LUB

08 LLB

09 CAJ

01 EWC

02 LX

00

0000000000000000000000

Right Cross Correction

H Shift Correction

Environmental SW

Temperature SW

NS SW

EW SW

RX

03

04 HST

05 ENS

06 TES

07 NSS

08 EWS

NS Correction Gain

EW Correction Gain

Environmental Correction Gain

NS Correction by Environment

Temp. Corr. DC of Left side

Temp. Corr. DC of Left side

09 NSG

0A EWG

0B ENG

0C ENS

0D TLD

0E TLU

00

Temp.Corr. Gain of Left Upper

Temp. Corr. Gain of Left Lower

Temp. Corr. Gain of Right Upper

Temp. Corr. Gain of Right Lower

DH Mute

0F TLL

10 TRD

11 TRU

12 TRL

13 DHM

Category

DCN 00 SHS

LDG 00 NSC

– 26 –

MS

RGBYUV

Dynamic Standard Hi-Fine Personal

KP-FS57M31/M61/M90/M91

RM-997

02 02 00 02

01 01 00 01

Standard Data

SD-I SD-P HD SD-I SD-P HD

60 Picture Mode

TV VIDEO TV VIDEO

01

Common

Function 50

07 07 07 07 0A 0B 0B 0A 0B 0B 0B

01 01 01 01 01 02 03 01 02 03 03

00 01 00 01 01 01 03 01 01 03 03

03 03 03 03 03 03 03 03 03 03 03

07

00

00

00

01 01 01 01 01 01 01 00 01 01 01 00

08 07 0A 07 07 07 0F 07 07 0F 0F

00 00 00 00 00 00 00 00 00 00 00

02 02 02 02 02 02 02 02 02 02 02

03 03 03 03 03 03 00 03 03 00 00

01

00

03

00

01 01 01 01 01 01 01 01 01 01 01

00

00

03

03

00

00

0C

Item

01 RGB RGB Output Selection

No. Name

JGL 00 PON RGB and AKB Reference Pulse Output On/Off

Category

02 AGG Aging Mode Selection

03 BBT RGB Bottom Limitter Control

04 LML RGB Amplitude Limitter Control

05 SCO Sub Picture Control

06 LEV RGB Level for RGB0507 SYS Signal Band Selection

0B LTI Luminance Transient Improvement

08 SF0 Shar pness f0 setting

09 SF1 High f0 shar pness gain control

0A PRO Pre/Over-Shoot Ratio Control

0E VDL VM OUT Phase Control

0F VCR VM OUT Coring Level Setting

0C LTM LTI Mode Setting

0D CTI Chrominance Transient Improvement

10 VFO VM OUT F0 Setting

11 VLM VM OUT Limiter Level Setting

12 SPH H Sync Delay Timing Setting

13 CLP CLP Pulse Phase Control

14 CLG CLP Pulse Gate Setting

– 27 –

AUTO REGI LRGB_LEV

15 CLS CLP Pulse Start Phase Setting

16 YOS DC_OFFSET RANGE FOR Y SIGNAL SETTING

17 YLT Y AMPLITUDE LIMITER LEVEL SETTING

18 YCS Y SIGNAL GAIN SETTING

1B HBS RGB OUTPUT H BLANKING WHEN AKBOFF=0

19 PHA PHASE ADJ

1A AKO AKB_OFF

1C ARG

YCT 00 TNT

Tint Adjustment for NTSC

1F 1F

01 PNG

02 PNI

03 SCL

04 SCT

05 SF0

Sharpness Center Frequency Changing

02

06 SEQ

07 SHG Sharpness Gain Control

07 06 05 06

07

08 YOL

09 BSP

0A COL

Cb/Cr Output Level Control

1A

0B DCR

0C BF0

0D BFQ

0E FSW

BPF/TQF Switch

01

0F SDT

10 LPF

11 YDL

12 B01

Cb Offset1 Adjustment (main route)

0A

13 RO1

14 CDF

V Count Down Frequency Switch

00

15 CDM

16 AFC AFC Sensitivity Switch

00 00

17 MVM

Macrovision Mask + AFC Mask

00

18 SRY

SECAM R-Y Black Adjustment

07

19 SBY

SECAM B-Y Black Adjustment

01

1A BEL

SECAM BELL/HPF Switching

02

1B BLF

1C SVI

1D SGP

SECAM Gate Position Adjustment

00

1E SID

SECAM Sensitivity Switch

01

1F SIH

SECAM Inhibition Switch

00

20 STP

Y Black Level Setup for PAL plus

00

21 ASW

AUTO SWITCH

01

22 3NR

3D NR Operation on/off

01

23 BW6

3D NR for 60Hz non-bust signal on/off

01

24 WSH

Sharpness Gain Step for noise reduction

00

25 WCO

Cb/Cr Output Level Step for noise reduction

00

DVDVIDEO

Standard Data

1F1F

00 00

07

KP-FS57M31/M61/M90/M91

RM-997

TV

50TV 60TV 50Video 60Video 50DVD 60DVD

othersS-Input3DComb2DCombCommon

07 07 07 07

07 07 07 07

01

00

1F

03

00

00

00

02

06 05 05 03

01

01

07

00

00

00

Item

No. Name

Category Function

Sub Color Control

PAL/NTSC Gate Width

PAL/NTSC Sensitivity SW

Sub Contrast Control

Sharpness Equalizer Characteristic

Y-output Level Control

Black Stretch Start Point Changing

DC Restoration Ratio Adjustment

BPF/TQF F0 Adjustment

BPF/TQF Q Adjustment

SECAM Double Trap Switch

Y/Cb/Cr LPF Switch

Y-DL Time Adjustment

Cr Offset1 Adjustment

– 28 –

V Count Down Judge Switch

BELL f0 Adjustment

SECAM V-ID Switch

KP-FS57M31/M61/M90/M91

Sharpness Equalizer Characteristic

03

Macrovision Mask + AFC Mask

00

SECAM B-Y Black Adjustment

01

TV

Video

RM-997

00

1F

1F

1F 1F

Standard Data

COLOR MODE

SECAM NTSC PAL 50 60 50 60

S-InputCommon DVD

00

00

07 07 07 07

07 07 07 07

05 03 03 03

1F

00

01

02

1F

00

07

02

01

00

01

01

01

07

01

00

00

07

07

00

00

00

02

01

01

00

00

Function

Item

Category

Tint Adjustment for NTSC

No. Name

SYC 00 TNT

Sharpness Center Frequency Changing

Sub Contrast Control

Sub Color Control

PAL/NTSC Sensitivity SW

PAL/NTSC Gate Width

06 SEQ

05 SF0

04 SCT

03 SCL

02 PNI

01 PNG

Cb/Cr Output Level Control

Y-output Level Control

Sharpness Gain Control

08 YOL

07 SHG

DC Restoration Ratio Adjustment

Black Stretch Start Point Changing

0B DCR

09 BSP

0A COL

Y-DL Time Adjustment

1-H Addition Switch

BPF/TQF Q Adjustment

BPF/TQF F0 Adjustment

0C BF0

0D BFQ

Y/Cb/Cr LPF Switch

BPF/TQF Switch

SECAM Double Trap Switch

LPF

0E FSW

0F SDT

11 YDL

10

12 NCM

– 29 –

Cb Offset1 Adjustment (main route)

16 CDM

15 CDF

14 RO1

13 B01

17 AFC

18 MVM

SECAM R-Y Black Adjustment

19 SRY

BELL f0 Adjustment

SECAM BELL/HPF Switching

1B BEL

1C BLF

1A SBY

AFC Sensitivity Switch

V Count Down Judge Switch

V Count Down Frequency Switch

Cr Offset1 Adjustment

Y Black Level Setup for PAL plus

SECAM V-ID Switch

1D SVI

SECAM Inhibition Switch

SECAM Gate Position Adjustment

SECAM Sensitivity Switch

1E SGP

1F SID

21 STP

20 SIH

SUB AUTO SWITCH

22 ASW

KP-FS57M31/M61/M90/M91

RM-997

00 01 03

Standard Data

Function

03 03 01

00 01

01 00

03 00

01

00

00

00

00

00

07

01

Dummy Frequency Select

Item

Category

01 VFR Dummy Sync Freq0102 SL1 Input Signal Type for IN10003 SL2 Input Signal Type for IN20104 FSY Sync Identification Mode

No. Name Common fh15k otherfh DVD HD RGB

SYN 00 MAT Matrix Conversion

05 VTC V sync Separation Time Constant

06 HWD Output Pulse Width

07 HSL Sync Separation Mode

08 HTC H-Sync Separation Time Constant

09 HSW YG Out signal Output

0B MAC Macrovision010C DUM Out dummy sync or signal sync

0A HMA Hsync within V sync

0E GSL Gain Select

0D CLK Clock Select

0F CBG CB Gain

10 CRG CR Gain0711 YG Y Gain0712 HFR

– 30 –

Loading...

Loading...