Sony KP-FS43M90, KP-FS53M90 Service Manual

SERVICE MANUAL

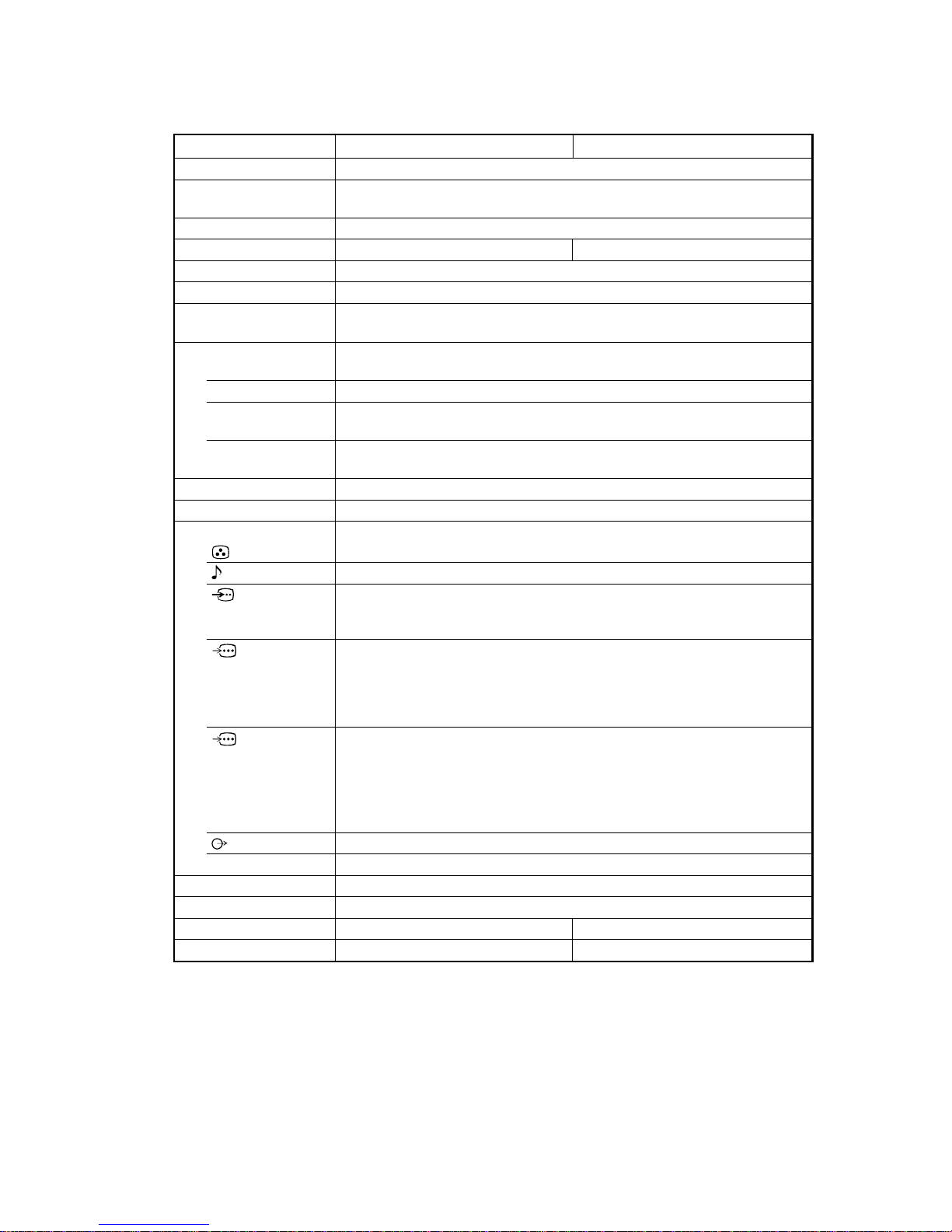

MODEL COMMANDER DEST. CHASSIS NO.

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

AG-3X

PROJECTION TV

KP-FS43M90 RM-998 AUS SCC-P89X-A

KP-FS43M90 RM-998 GE SCC-P89X-A

KP-FS43M90 RM-998 HK SCC-P89X-A

KP-FS43M90 RM-998 ME SCC-P89X-A

RM-998

KP-FS53M90 RM-998 AUS SCC-P89X-A

KP-FS53M90 RM-998 GE SCC-P89X-A

KP-FS53M90 RM-998 HK SCC-P89X-A

KP-FS53M90 RM-998 ME SCC-P89X-A

KP-FS43M90/FS53M90

TV

VIDEO

DRC-MF

HD/DVD

123

456

7809

JUMP

PROG

OPTION RESET

A/B

PROG

INDEX

MENU

T

W

I

N

P

R

O

G

+

T

W

I

N

P

R

O

G

–

– 2 –

KP-FS43M90/FS53M90

RM-998 RM-998

CAUTION

SHORT CIRCUIT THE ANODE OF HTE PICTURE TUBE

AND THE ANODE CAP TO THE METAL CHASSIS, CRT

SHIELD, OR CARBON PAINTED ON THE CRT, AFTER

REMOVING THE ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

! ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL TO

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SPECIFICATIONS

3 picture tubes, 3 lenses, horizontal inline system

7 inch high-brightnes monochorome tubes (6.3 raster size), with optical coupling

and liquid cooling system

High performance, large-diameter highbrid lens F1.0

53 inches 43 inches

B/G, I, D/K, M

PAL, PAL 60, SECAM, NTSC4.43, NTSC3.58

NICAM Stereo/Bilingual B/G, I;

A2 Stereo/Bilingual (German) B/G

VHF : E2 to E12 / UHF : E21 to E69 / CATV : S01 to

S03, S1 to S41

UHF : B21 to B68 / CATV : S01 to S03, S1 to S41

VHF : C1 to C12, R1 to R12 / UHF : C13 to C57, R21

to R60 / CATV : S01 to S03, S1 to S41, Z1 to Z39

VHF : A2 to A13 / UHF : A14 to A79/

CATV : A-8 to A-2, A to W+4, W+6 to W+84

75-ohm external terminal

12W + 12W (7% distortion)

Input: 4 Output: 1 Phono jacks; 1 Vp-p, 75 ohms

Input: 6 Output: 1 Phono jacks; 500 mVrms

Input: 2 Y: 1 Vp-p, 75 ohms,

unbalanced, sync negative

C: 0.286 Vp-p, 75 ohms

Input: 2 Phono jacks

Y: 1 Vp-p, 75 ohms, sync negative

P

B/CB

: 0.7 Vp-p, 75 ohms

P

R/CR

: 0.7 Vp-p, 75 ohms

Audio: 500 mVrms

Input: 1 Phono jacks

G: 0.7 Vp-p, 75 ohms

B: 0.7 Vp-p, 75 ohms

R: 0.7 Vp-p, 75 ohms

HD: 0.7 Vp-p, 75 ohms

VD: 0.7 Vp-p, 75 ohms

Output: 1 Phono jack; 500 mVrms

Output: 1 Stereo minijack

220 V AC, 50/60Hz

260 W

1140 × 1440 × 670 926 × 1255 × 534

85 66

Design and specifications are subject to change without notice.

KP-FS53M90

KP-FS43M90

Projection system

Picture tube

Projection lenses

Screen size

Television system

Color system

Stereo/Bilingual

system

Channel coverage

B/G

I

D/K

M

(Antenna)

Audio output (Speaker)

Number of terminal

(Video)

(Audio)

(S Video)

(Component

Video)

(G/B/R/HD/

VD Video)

(Headphones)

Power requirements

Power consumption (W)

Dimensions (w/h/d, mm)

Mass (kg)

– 3 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

1. SELF DIAGNOSIS FUNCTION

1-1. Diagnostic Test Indicators ................................. 5

1-2. Display of STANDBY/TIMER

Light Flash Count............................................... 6

1-3. Stopping the STANDBY/TIMER Flash ............ 6

1-4. Self-Diagnostic Screen Display ......................... 7

1-5. Handling of Self-Diagnostic

Screen Display.................................................... 7

1-6. Self-Diagnostic Circuit ...................................... 8

2. DISASSEMBLY

2-1. Rear Cover Removal ......................................... 9

2-2. Main Bracket Removal ..................................... 9

2-3. Service Position ................................................. 9

2-4. Front Panel Removal ......................................... 10

2-5. H1, H2 and H3 Boards Removal ...................... 11

2-6. Beznet and Mirror Cover Removal ................... 11

2-7. Main Bracket Removal ...................................... 12

2-8. G Board Removal............................................... 13

2-9. Connector Cover Removal................................. 13

2-10. J Board Removal ................................................ 14

2-11. A1, E, B4 and U2 Boards Removal ................... 14

2-12. A1, AD and B Boards Removal......................... 15

2-13. Picture Tube Removal ........................................ 15

2-14. High-Voltage Cable and Installation Removal.. 16

2-15. Mechaseal ........................................................... 16

3. SET-UP ADJUSTMENTS

3-1. Screen Voltage Adjustment

(Rough Alignment) ........................................... 17

3-2. Screen (G2) Adjustment .................................... 17

3-3. Focus Rough Adjustment .................................. 17

3-4. Deflection Yoke Tilt Adjustment ...................... 17

3-5. 2-Pole Magnet Adjustment ................................ 18

3-6. 4-Pole Magnet Adjustment ................................ 18

3-7. Green, Red and Blue Focus Adjustment

3-7-1. Green, Red and Blue Lens Focus

Adjustment .................................................... 18

3-7-2. Green, Red and Blue Electrical Focus

Adjustment .................................................... 18

4. SAFETY RELATED ADJUSTMENT

4-1. HV Regulation Adjustment ............................... 19

4-2. HV Hold-Down Adjustment ............................. 19

4-3. +B Max Voltage Confiration ............................ 19

4-4. +B OVP Confiration ........................................ 19

TABLE OF CONTENTS

5. ELECTRICAL ADJUSTMENTS

5-1. Adjustments with Commander

5-1-1. How to Select Each Mode ............................. 20

5-1-2. How to Enter Service Mode .......................... 21

5-1-3. Method of Cancellation

from Service Mode ........................................ 21

5-1-4. How to Adjustments ...................................... 21

5-1-5. How to Write the Data ................................... 21

5-1-6. Memory Write Confirmation Method ........... 21

5-2. Service List......................................................... 22

5-3. Picture Quality Adjustment

5-3-1. Preparation ..................................................... 46

5-3-2. NTSC Video Input ......................................... 47

5-3-3. NTSC RF Input .............................................. 47

5-3-4. PAL Video Input ............................................ 48

5-3-5. PAL RF Input ................................................. 48

5-4. Color Offset........................................................ 49

5-5. Registration Adjustment

5-5-1. Setup for Adjustment ..................................... 49

5-5-2. Method of Main Deflection Adjustment ....... 50

5-5-3. Operation Method

for Projector Engine (PJE) Mode .................. 50

5-5-4. Method of Projector Engine Adjustment

(Sub Deflection Adjustment)......................... 52

5-5-5. Deflection Adjustment ................................... 53

5-6. Auto Convergence Setting ................................. 58

5-7. White Balance Adjustment ................................ 58

5-8. Auto Convergence Error Code List ................... 59

Section Title PageSection Title Page

– 4 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

6. DIAGRAMS

6-1. Block Diagrams .................................................. 49

6-2. Frame Schematic Diagram................................. 62

6-3. Circuit Boards Location ..................................... 63

6-4. Schematic Diagrams........................................... 63

6-5. Printed Wiring Boards........................................ 97

6-6. Wave Forms ....................................................... 110

6-7. IC Block Diagrams............................................. 117

6-8. Semiconductors .................................................. 119

7. EXPLODED VIEWS

7-1. Screen and Cover Block (KP-ER43) ................ 122

7-2. Screen and Cover Block (KP-ER53) ................ 123

7-3. Cabinet and Panel Block (KP-ER43) ............... 124

7-4. Cabinet and Panel Block (KP-ER53) ............... 125

7-5. Main Bracket Block ........................................... 126

7-6. Picture Tube Block............................................. 127

8. ELECTRICAL PARTS LIST ............................ 128

Section Title Page

– 5 –

KP-FS43M90/FS53M90

RM-998RM-998

• Power does not come on.

• No power is supplied to the PJ.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is shorted.

• Power does not come on.

• Vertical deflection pulse is

stopped.

• Vertical size is too small.

• Vertical deflection stopped.

• No raster is generated.

• CRT cathode current detection

reference pulse output is small.

• +135 V is too high.

• There is picture but speaker

does not release sound.

• Power is shut down shortly,

after this return back to normal.

• Detect Micro latch up.

SECTION 1

SELF DIAGNOSIS FUNCTION

The unit in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically begin to

flash.

The number of times the lamp flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER lamp flash

indicators is listed in the instruction manual for the user's knowledge and reference. If an error symptom cannot be reproduced, the

remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

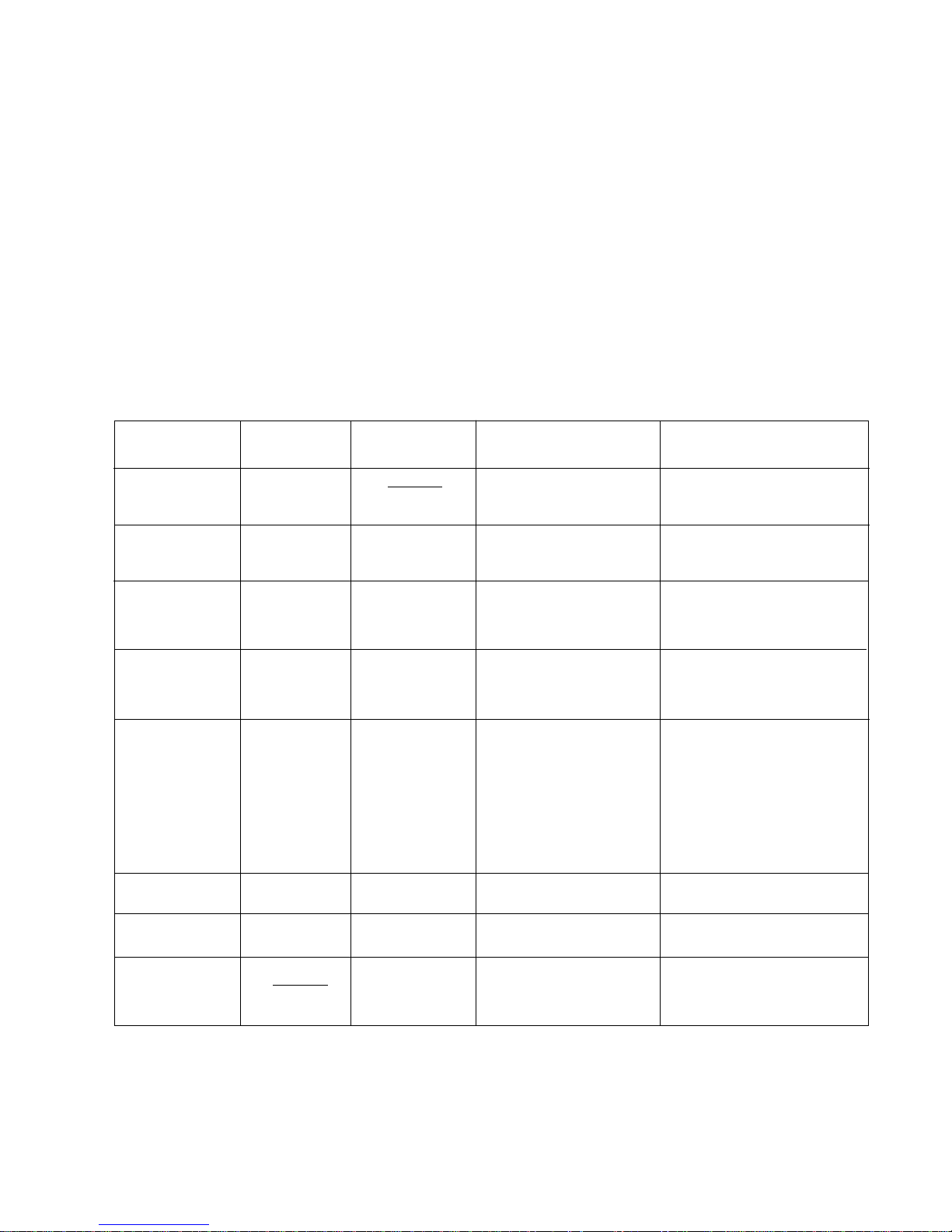

1-1. DIAGNOSTIC TEST INDICATORS

When an errors occurs, the STANDBY/TIMER lamp will flash a set number of times to indicate the possible cause of the problem. If

there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

002:000 or

002:001 ~ 255

003:000 or

003:001 ~ 255

004:000 or

004:001 ~ 255

005:000 or

005:001 ~ 255

006:000 or

006:001 ~ 255

007:000 or

007:001 ~ 255

101:000 or

101:001 ~ 255

No. of times

STANDBY/TIMER

lamp flashes

Detected Symptoms

Diagnostic

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP)

• +B overvoltage

(OVP)

• Vertical deflection

failure

• White balance

failure

(no PICTURE)

• High Voltage

failure

• Audio Protection

• Micro reset

Self-diagnostic

display/

Diagnostic result

Probable Cause Location

Does not light

2 times

3 times

4 times

5 times

6 times

7 times

• Power cord is not plugged in.

• Fuse (F6701) is burned out.

(G board)

• H. OUT Q8024 is shorted.

• H. LIN Q8027 is shorted.

(D board)

• HV OUT Q8043 is shorted.

• PH6001 faulty.

• +19V is not supplied.

(G board)

• V. OUT IC8003 faulty.

(D board)

• G2 is improperly adjusted.

(Note 1)

• CRT problem.

• Video OUT IC9101 (CR

board), IC9201 (CG board),

IC9001 (CB board) are faulty.

• IC8306 (J board) and IC4300

(E board) are faulty.

• No connection E board to CR

board.

• IC6502 (G board) faulty.

• Power supply fails.

• IC1203,1204 (A board) faulty.

•Discharge CRT

(CR, CG, CB boards)

• Static discharge

• External noise

Note 1 : Refer to screen (G2) adjustment in section 4-2 of this manual.

– 6 –

KP-FS43M90/FS53M90

RM-998RM-998

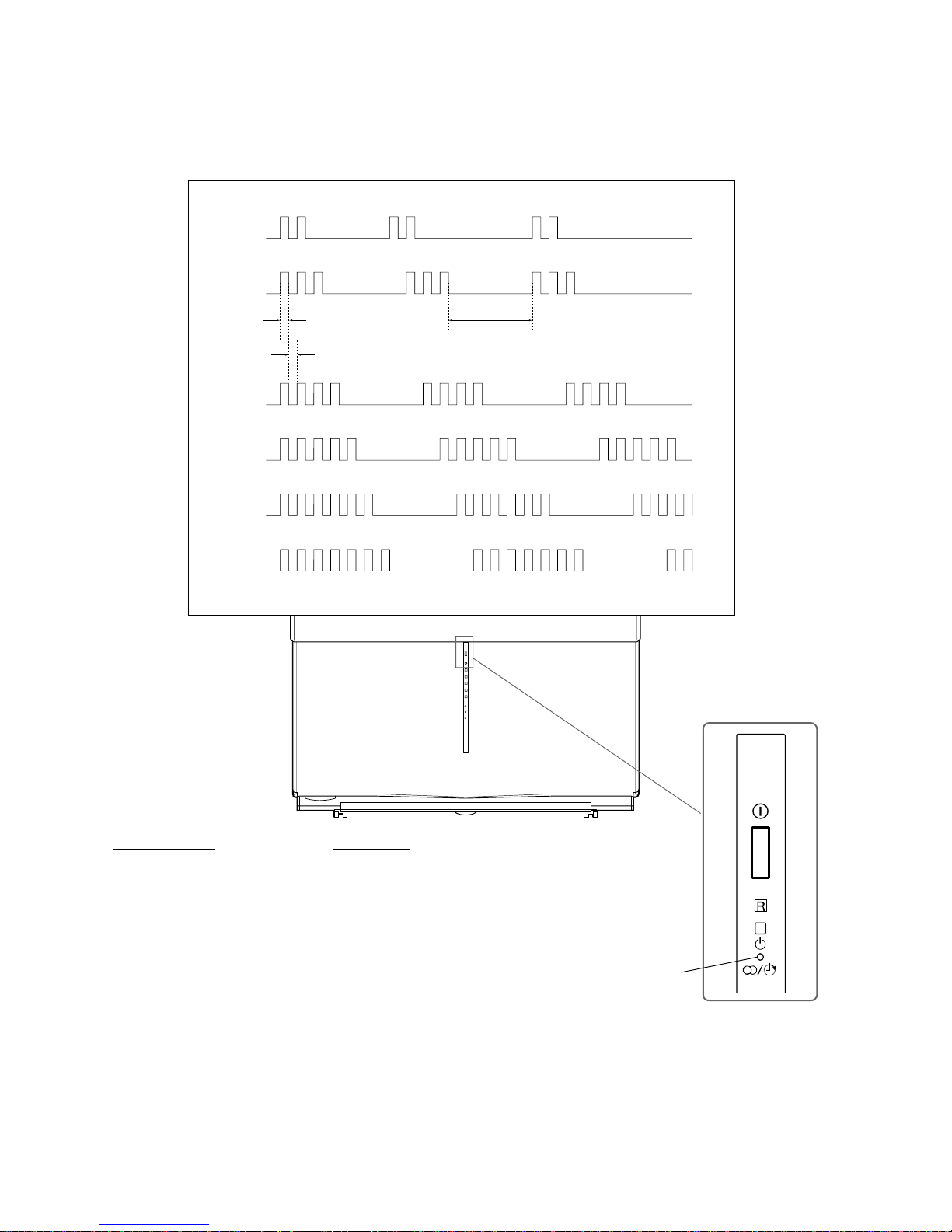

1-2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

1-3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp from

flashing.

Diagnostic Item Flash Count *

+B overcurrent 2 times

+B overvoltage 3 times

V deflection stop 4 times

White balance failure 5 times

High voltage protector 6 times

Audio Protection 7 times

* One flash count is not used for self-diagnostic.

STANDBY/TIMER

lamp

Lamp ON

0.3 sec.

Lamp OFF

0.3 sec.

Lamp OFF

3 sec.

2 times

3 times

5 times

6 times

4 times

7 times

– 7 –

KP-FS43M90/FS53M90

RM-998RM-998

1-4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible

to bring up past occurrences of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

5

(DIGIT 5) (VOLUME –) (POWER)ON SCREEN

DISPLAY

(

)

*

* : Note that this differs from entering the service mode (volume +)

Self-Diagnosis screen display

SELF DIAGNOSTIC

002:000

003:000

004:000

005:001

006:002

007:000

101:000

Numeral “0” means that no fault has been detected.

Numeral “1” means a fault has been detected.

Numeral “2” means two faults have been detected.

1-5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of

the repairs.

[Clearing the result display]

To clear the result display to “0”, press button on the remote commander sequentially as shown below when the diagnostic screen is

being displayed.

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

Press “8” button

(It will indicate “CLEAR” on the screen.)

Press “-” button

(The “CLEAR” display change to red color.)

,

– 8 –

KP-FS43M90/FS53M90

RM-998RM-998

1-6. SELF-DIAGNOSTIC CIRCUIT

+B overcurrent (OCP) Occurs when an overcurrent on the +B (135 V) line is detected by Q6504.

If Q6504 go to ON, the voltage to pin 3 of IC001 go to UP. The unit will

automatically turn off.

+B overvoltage (OVP) Occurs when an overvoltage on the +B (135 V) line is detected by IC6502.

If IC6502 go to ON, then voltage to pin 6 of IC001 go to UP. The unit will

automatically turn off.

Vertical deflection failure Occurs when an absence of the vertical deflection pulse is detected by

Q8001 and D8001. Shut down the power supply.

White balance failure If the RGB levels do not balance or become low level within 5 seconds. This

error will be detected by IC4300.

TV will stay on, but there will be no picture.

High voltage protector of Horizontal Deflection Occurs when an overvoltage of horizontal pulse is detected by D8038 and

IC8006.

If the voltage of pin 1 of IC8006 goes to High, the voltage to pin 20 of

IC4300go to UP. The unit will automatically turn off.

Audio Protector If the Audio out lines become DC.This error will be detected by Q1211,

Q1209 and Q1210.

The unit will automatically turn off.

IC4300

Y/C JUNGLE

CXA2170Q CXP961048-003Q

24 IKINFrom CRT (IK)

From G board

From IC1203,1204

(A board)

To H1 board

57 XRAYFrom IC8005,8006

(D board)

56 V PROTFrom Q8001

(D board)

IC001

SYSTEM

IC003

MEMORY

5 OCP

OCP

8 OVP

OVP

LED1 22

SPPROT

100

H

V

SDA 52 13 SDA0 SDA1 SDA15 5

A boardE board

Q1209-1211

– 9 –

KP-FS43M90/FS53M90

RM-998 RM-998

SECTION 2

DISASSEMBLY

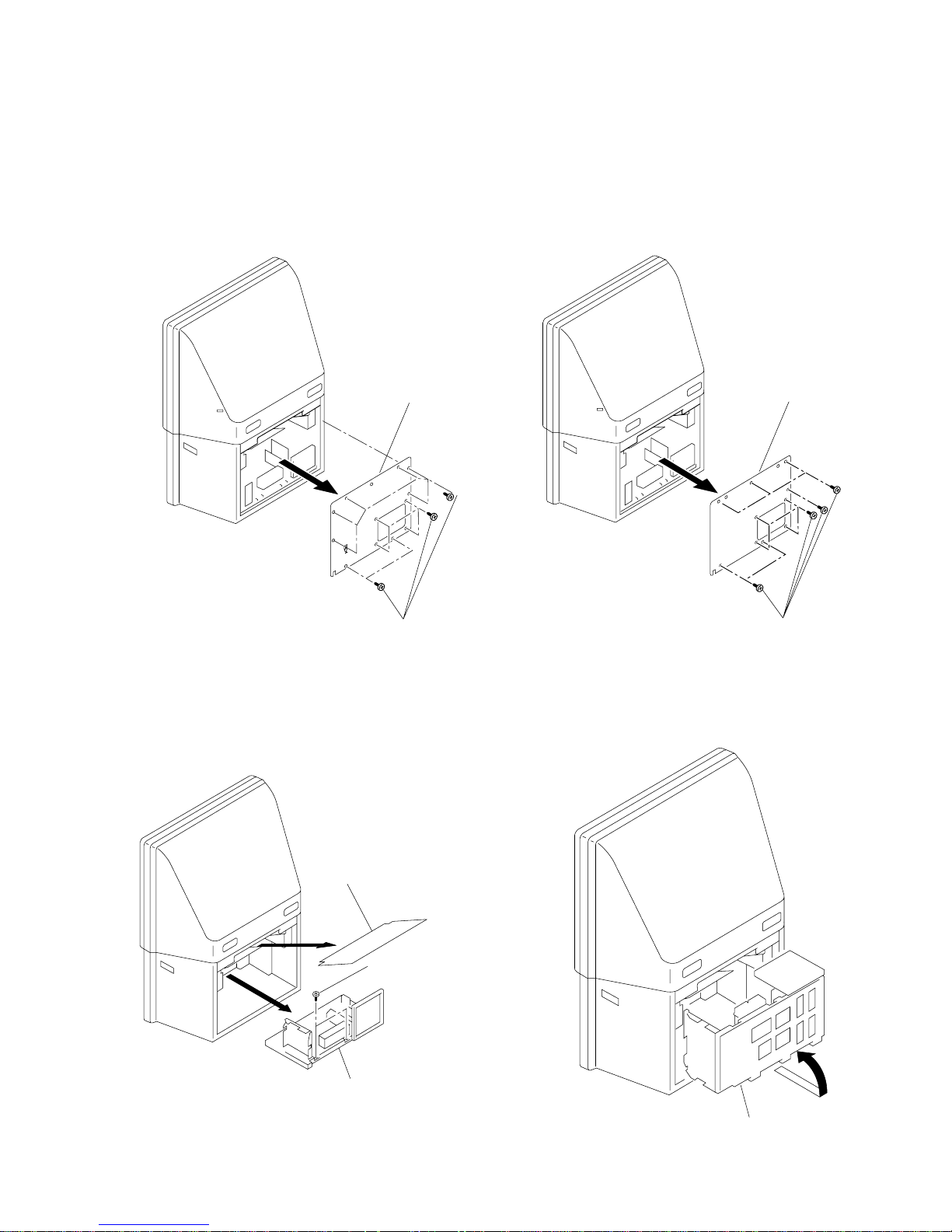

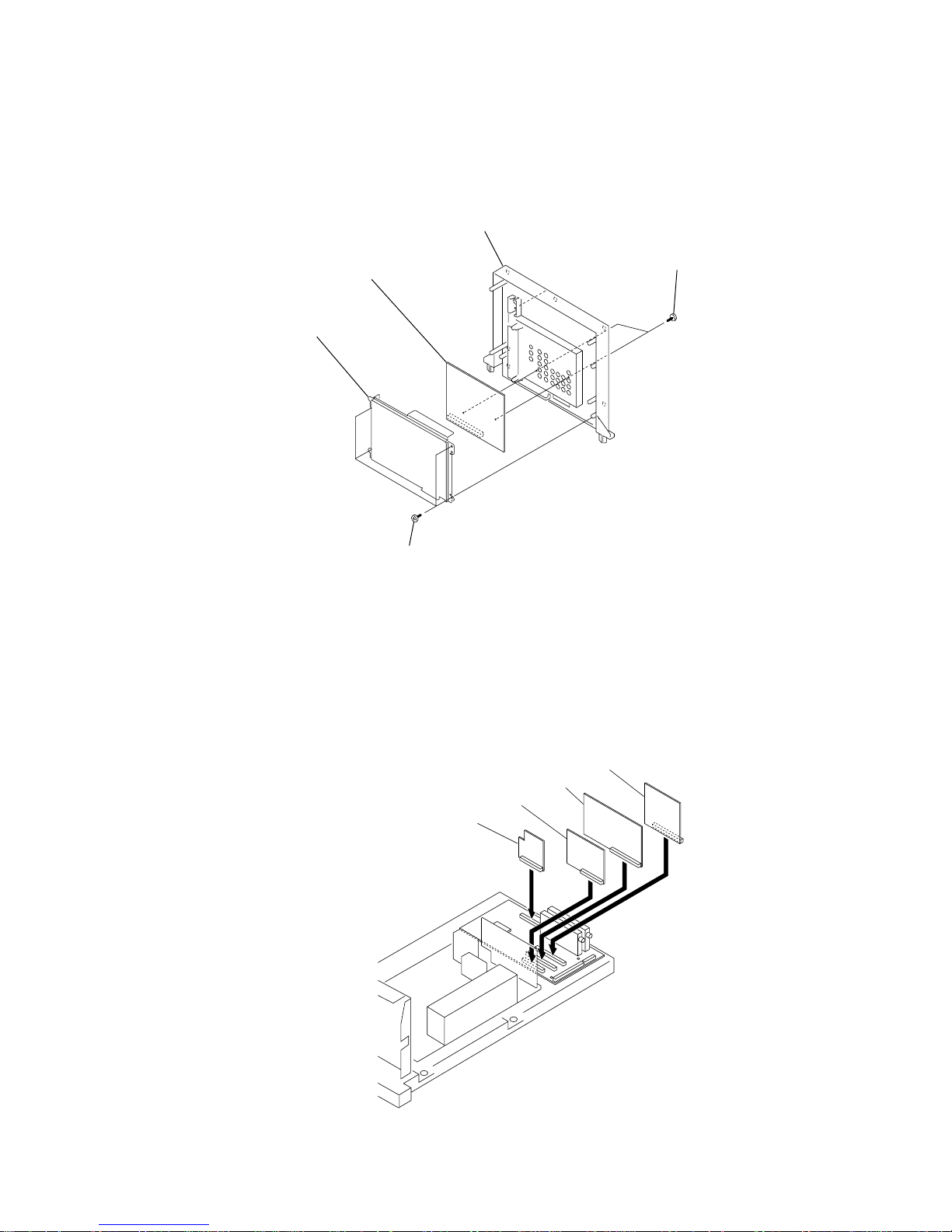

2-1. REAR COVER REMOVAL

(1) KP-FS43 (2) KP-FS53

2-2. MAIN BRACKET REMOVAL

1 Twelve screws

(BVTP 4X16)

2 Rear board

1 Ten screws

(Hexagon head)

2 Rear board

3 Main bracket section

1 Optical shield

2 Two screws

(tapping screw

hexagon head)

2-3. SERVICE POSITION

1 Main bracket section

– 10 –

KP-FS43M90/FS53M90

RM-998 RM-998

2-4. FRONT PANEL REMOVAL

(1) KP-FS43

(2) KP-FS53

1 Three screws

(BVTP 4x16)

1 Three screws

(BVTP 4x16)

3 Two screws

(BVTP 4x16)

3 Two screws

(tapping screw

hexagon head)

2 Three screws

(tapping screw

hexagon head)

2 Three screws

(tapping screw

hexagon head)

4 Side panel (43L) assy

5 Side panel (43R) assy

6 Front panel (43) assy

1 Three screws

(BVTP 4x16)

1 three screws

(BVTP 4x16)

3 Two screws

(tapping screw

hexagon head)

3 Two screws

(tapping screw

hexagon head)

2 Three screws

(tapping screw

hexagon head)

2 Three screws

(tapping screw

hexagon head)

4 Side panel (53L) assy

6 Front panel (53) assy

5 Side pane (53R) assy

– 11 –

KP-FS43M90/FS53M90

RM-998 RM-998

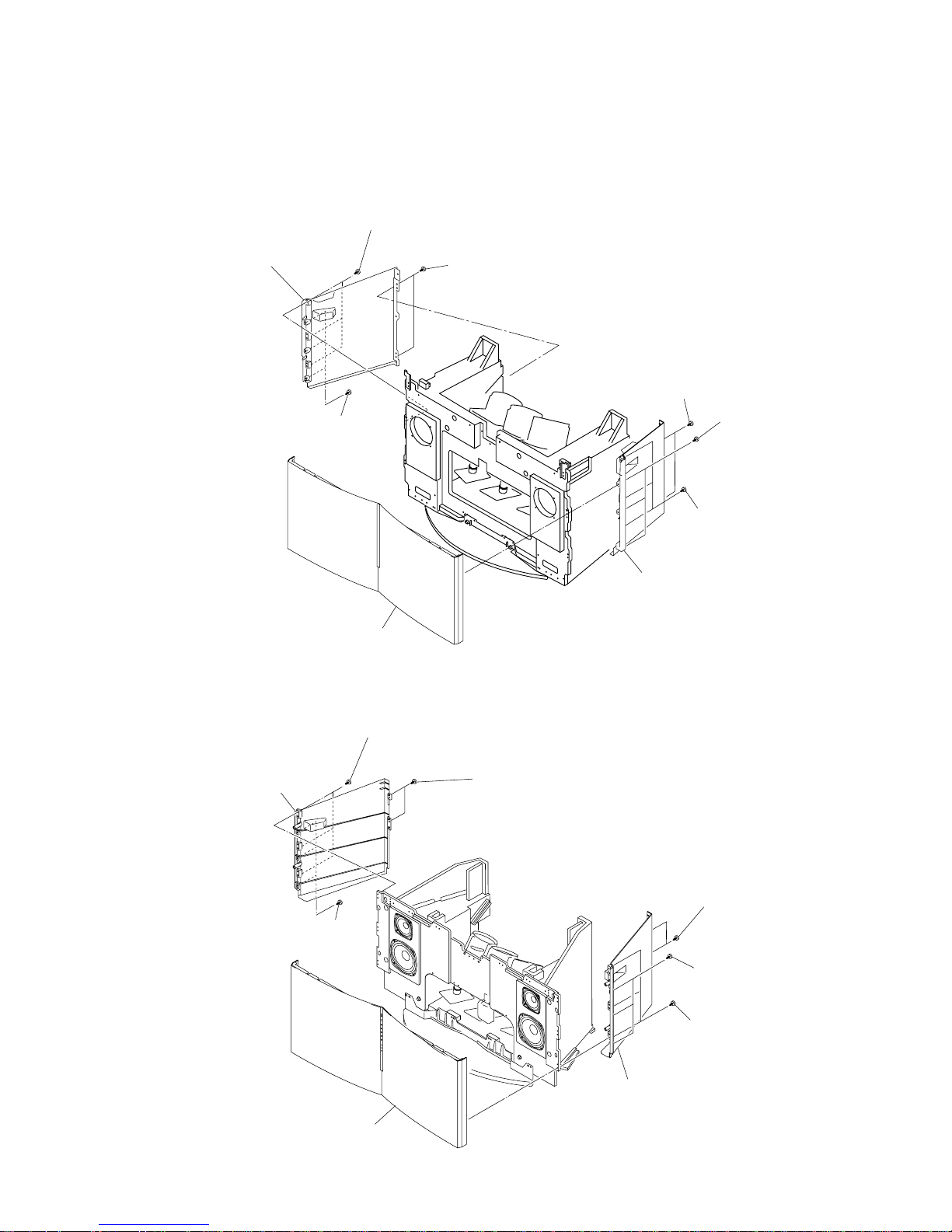

2-5. H1, H2 AND H3 BOARDS REMOVAL

2-6. BEZNET AND MIRROR COVER REMOVAL

1 Four screws

(BVTP 3x12)

6 Two screws

(BVTP 3x12)

4 Input terninal cover

2 Input terninal bracket

5 H3 board

3 Input terninal plate

9 Six screws

(BVTP 3x12)

0 H2 board

qa Four screws

(BVTP 3x12)

qs Control button

Front panel assy

7 H1 bracket

8 H1 board

2 Four screws

(BVTP 4X16)

2 Six screws

(BVTP 4X16)

1 Four screws

(Hexagon head)

2 Four screws

(BVTP 4X16)

0 Beznet assy

8 Screen

holder (V)

7 Screen holder (V)

6 Screen

holder (H)

9 Screen

holder (H)

qs Diffusion plate (F)

qd Diffusion plate (L)

qa Contrast screen

4 Four screws

(BVTP 4X12)

3 Mirror cover

5 Four screws (BVTP 3X12)

5 Four screws

(BVTP 3X12)

5 Ten screws (BVTP 3X12)

(1) KP-FS43

– 12 –

KP-FS43M90/FS53M90

RM-998 RM-998

2-7 MAIN BRACKET REMOVAL

(2) KP-FS53

2-6. BEZNET AND MIRROR COVER REMOVAL

2 Six screws

(BVTP 4X16)

1 Four screws

(Hexagon head)

2 Six screws

(BVTP 4X16)

2 Six screws

(BVTP 4X16 )

5 Four screws

(BVTP 3X12)

5 Four screws

(BVTP 3X12)

0 Beznet assy

8 Screen

holder (V)

7 Screen holder (V)

6 Screen

holder (H)

9 Screen

holder (H)

qs Diffusion plate (F)

qd Diffusion plate (L)

qa Contrast screen

4 Six screws

(Hexagon head)

3 Mirror cover

5 Six screws

(BVTP 3X12)

5 Ten (BVTP 3X12)

5 Four screws (BVTP 3X12)

2 Main bracket section

1 Two screws

(Tapping screw

hexagon head)

Pay particular attention to the wires

of each printed circuit boards when

puling out the mainbracket.

– 13 –

KP-FS43M90/FS53M90

RM-998 RM-998

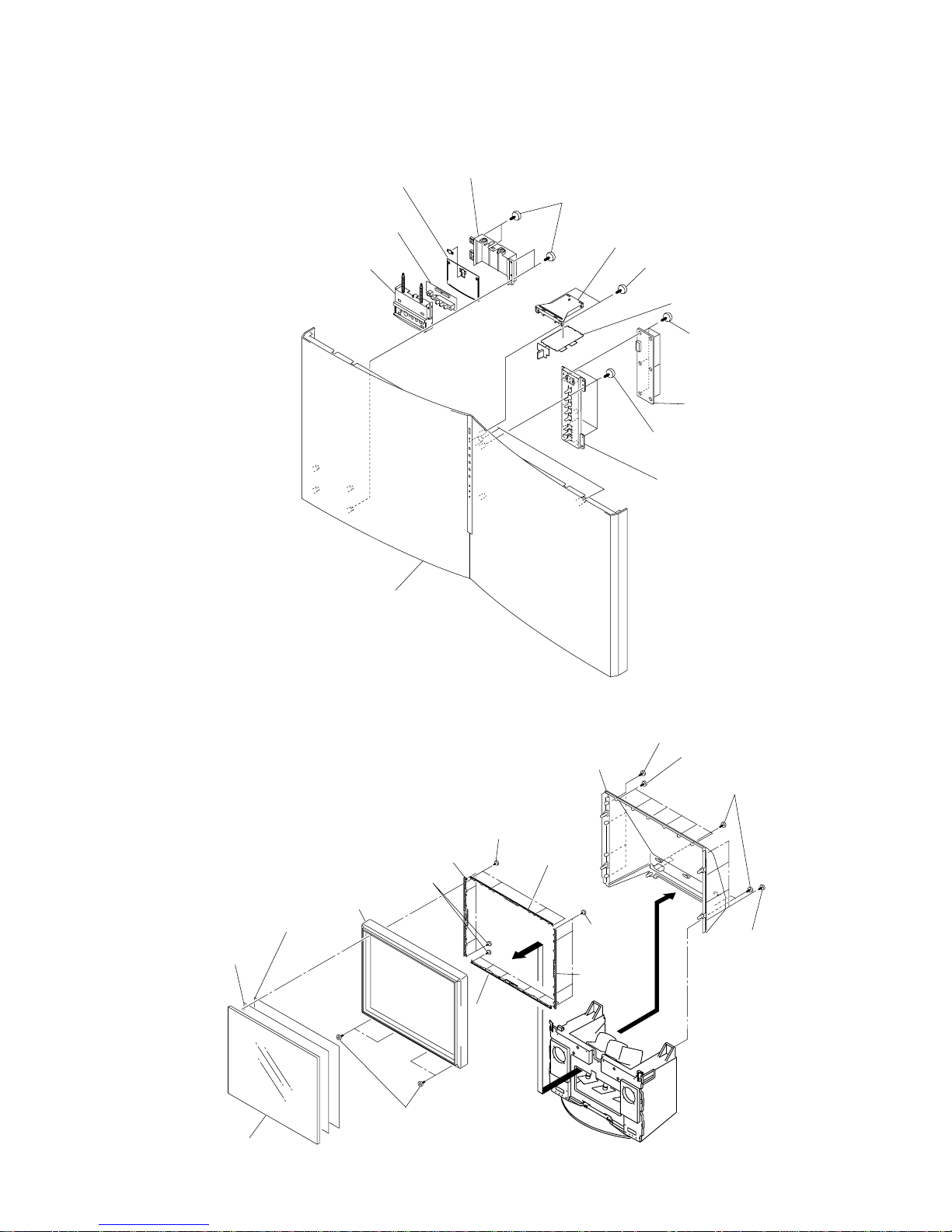

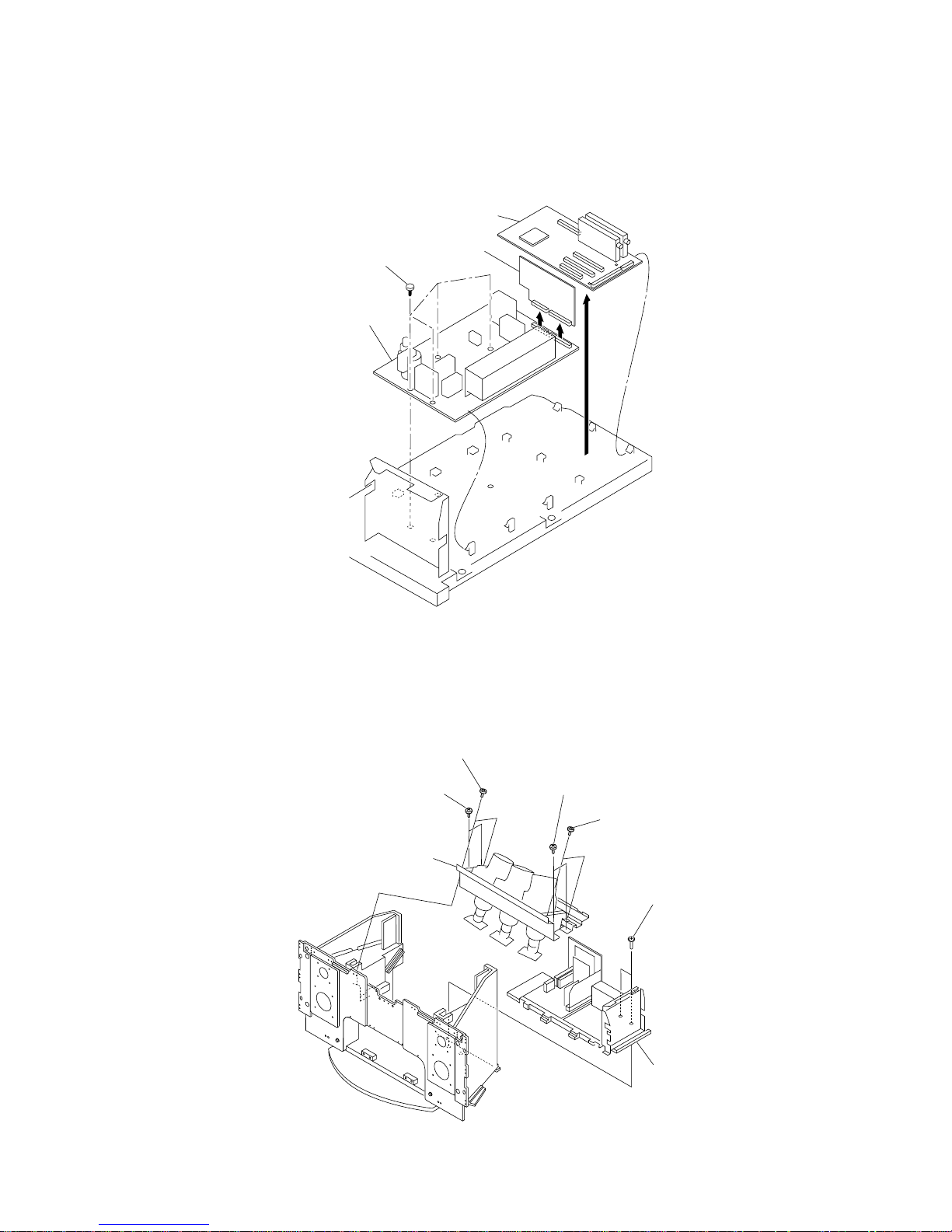

2-8. G BOARD REMOVAL

2-9. CONNECTOR COVER REMOVAL

3 Connector cover section

Main bracket section

1 Tow screws

(BVTP 4X16)

2 Screw

(PSW 2.6X6)

RF Connector

1 Three holder PWB

Main bracket section

2 G board

– 14 –

KP-FS43M90/FS53M90

RM-998 RM-998

2-10. J BOARD REMOVAL

2-11. A1, E, B4 AND U2 B0ARDS REMOVAL

3 Tow screws

(BVTP 2.6X12)

1 Four screws

(BVTP 3X12)

5 Connector cover

4 J board

2 J board cover

1 A1 board

2 E board

3 B4 board

4 U2 board

– 15 –

KP-FS43M90/FS53M90

RM-998 RM-998

2-12. A, AD AND B BOARDS REMOVAL

2-13. PICTURE TUBE REMOVAL

1 A board

4 B board

3 Four screws

(BVTP 3X12)

2 AD board

5 Main bracket section

3 Picture tube block assy

2 Two screws

(Hexagon head)

4X20)

2 Two screws

(Hexagon head)

4X20)

4 Two screws

(Taping screw

hexagon head)

1 Two screws

(BVTP 4X16)

1 Two screws

(BVTP 4X16)

– 16 –

KP-FS43M90/FS53M90

RM-998 RM-998

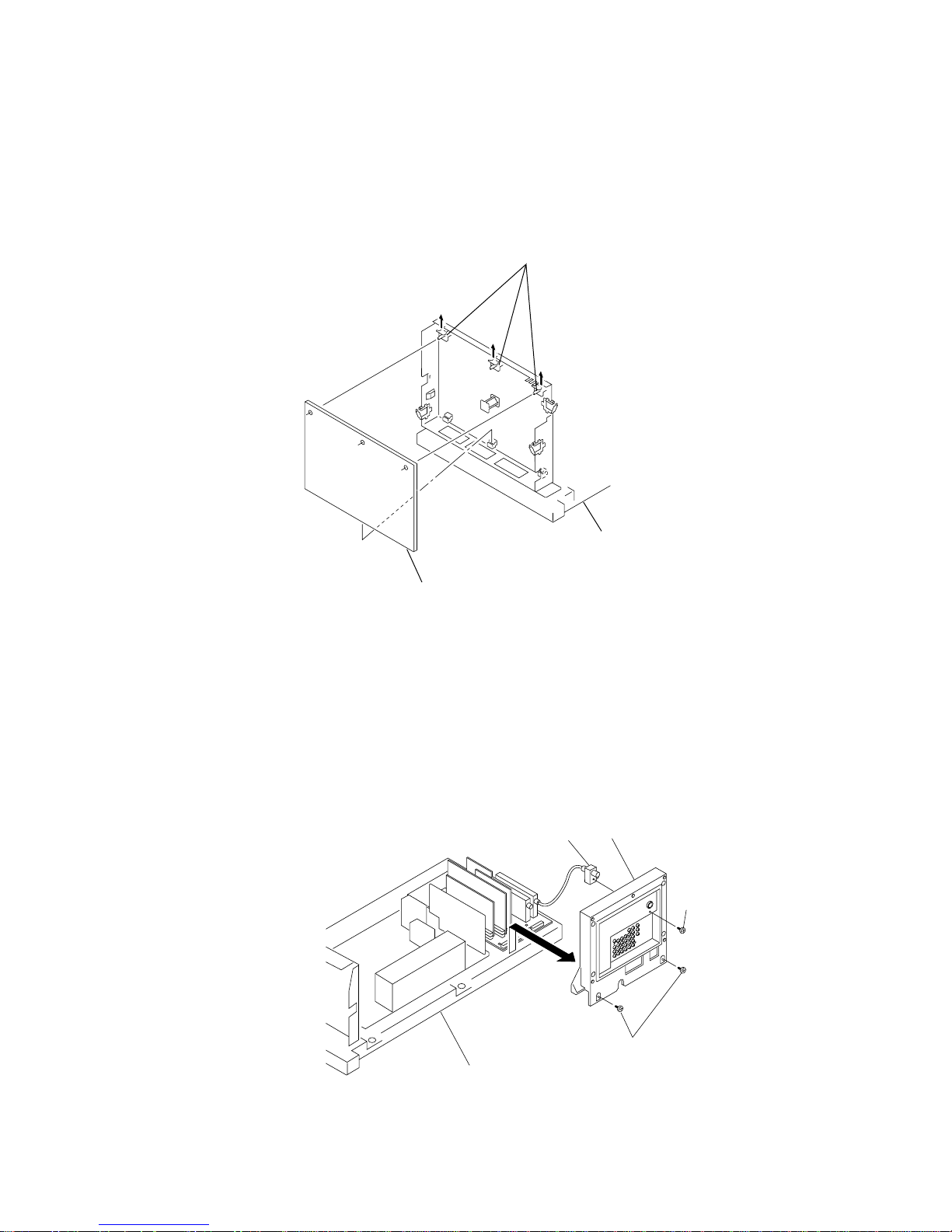

2-14 HIGH-VOLTAGE CABLE

INSTALLATION AND REMOVAL

2-15. MECHASEAL

1 Four screws

(BVTP 4X16)

5 Four screws

(BVTP 4X16)

Removing the arrow-marked screw is strictly inhibited.

If removed, it may cause liquid spill.

2 CR board

3 Neck assy

4 Deflection yoke

6 Mechaseal assy (R)

7 Extension spring

(2) Installation

(1) Remover

1 Rubber cap

2 HV cable turn 90°

2 Rubber cap

1 HV cable

Hook

Gutter

– 17 –

KP-FS43M90, FS53M90

RM-998

RM-998

SECTION 3

SET-UP ADJUSTMENTS

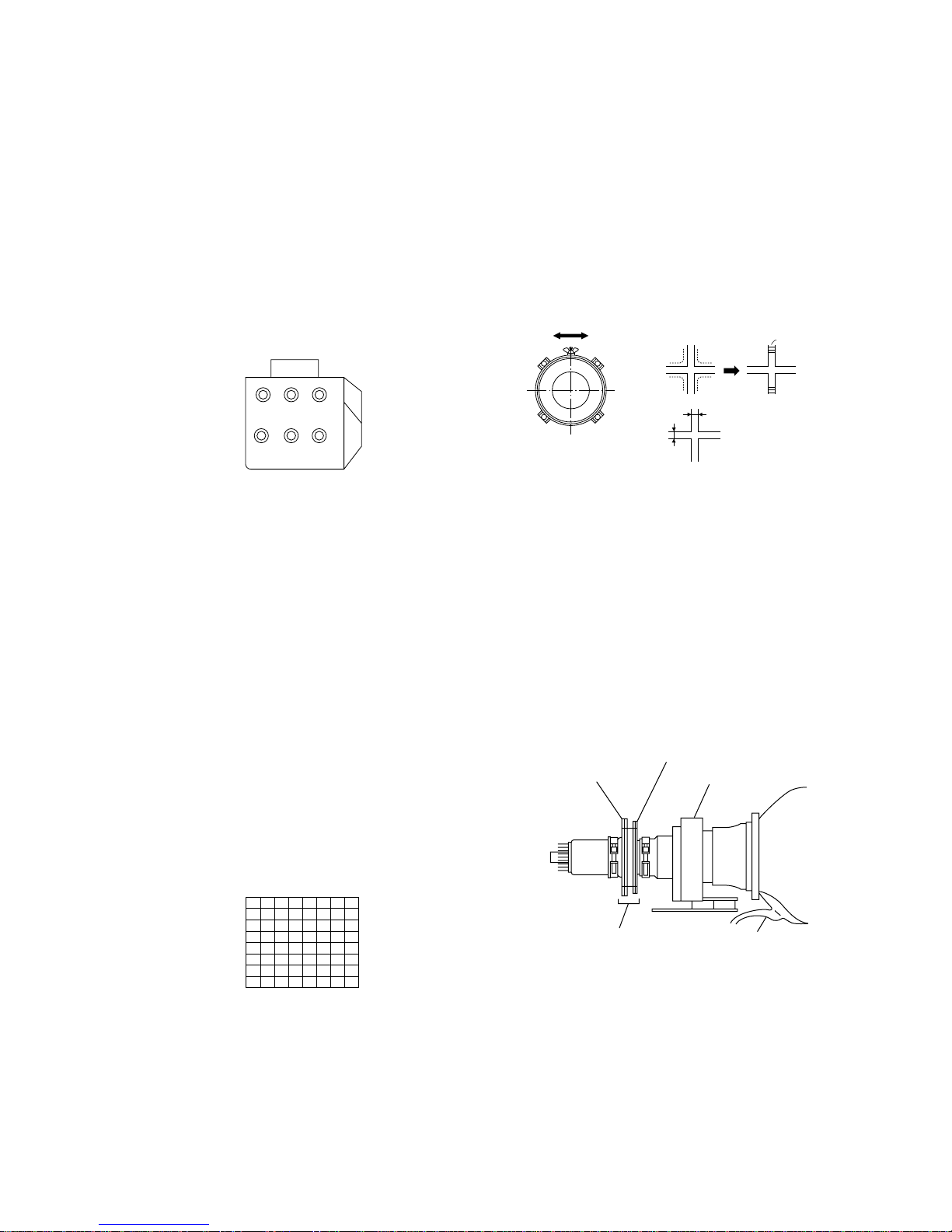

3-1. SCREEN VOLTAGE ADJUSTMENT

(ROUGH ALIGNMENT)

1. Receive the Monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the focus pack all the way to the left and

then gradually turn it to the right until the point where you

can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

Fig. 3-1

3-2. SCREEN (G2) ADJUSTMENT

1. Turn on the power of the set.

2. Select VIDEO1 mode without signals.

3. Supply DC 175 ±0.5 V from external power supply to

TP7103 (KR), TP7203 (KG) or TP7303 (KB) of CR board,

CG board and CB board.

3. Adjust red, green and blue screen voltage to until retrace

line disappears with screen VR on the focus pack.

3-4. DEFLECTION YOKE TILT ADJUSTMENT

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color.

3. Loosen the deflection yoke setscrew and align the tilt of the

Deflection yoke so that the bars at the center of the

monoscope pattern are horizontal.

4. After aligning the deflection yoke, fasten it securely to the

funnel-shaped portion (neck) of the CRT.

5. The tilt of the deflection yoke for red and blue is aligned the

same as was done for green.

Fig. 3-5

Neck Assy

Make sure deflection yoke is

touching CRT closely.

2-pole magnet

4-pole magnet

Deflection yoke

Anode cap

RG

SCREEN

B

RG

FOCUS

Focus Pack

B

Fig. 3-4

Lens

Fig. 3-3

Fig. 3-2

Test signal

Minimize both A and B.

A

B

Scanning line visible.

3-3. FOCUS ROUGH ADJUSTMENT

1. Loose the lens screw.

2. Set in the service mode. (Refer to SECTION 5.)

3. Place the caps on the red and blue lens so that only the green

color is shown.

4. Press “1” or “4” button on the commander and select

“PJE”, press “6” three times on the Commander to display

the test signal (crosshatch) on the screen.

5. Rotate the green lens and align to obtain the best lens focus

at the center area.

6. Rotate the green focus VR on the focus pack and align to

obtain the best electrical focus in the top right corner.

7. Perform the same alignment for red and blue lenses and electric focus.

8. Fix lens screw.

– 18 –

KP-FS43M90, FS53M90

RM-998

RM-998

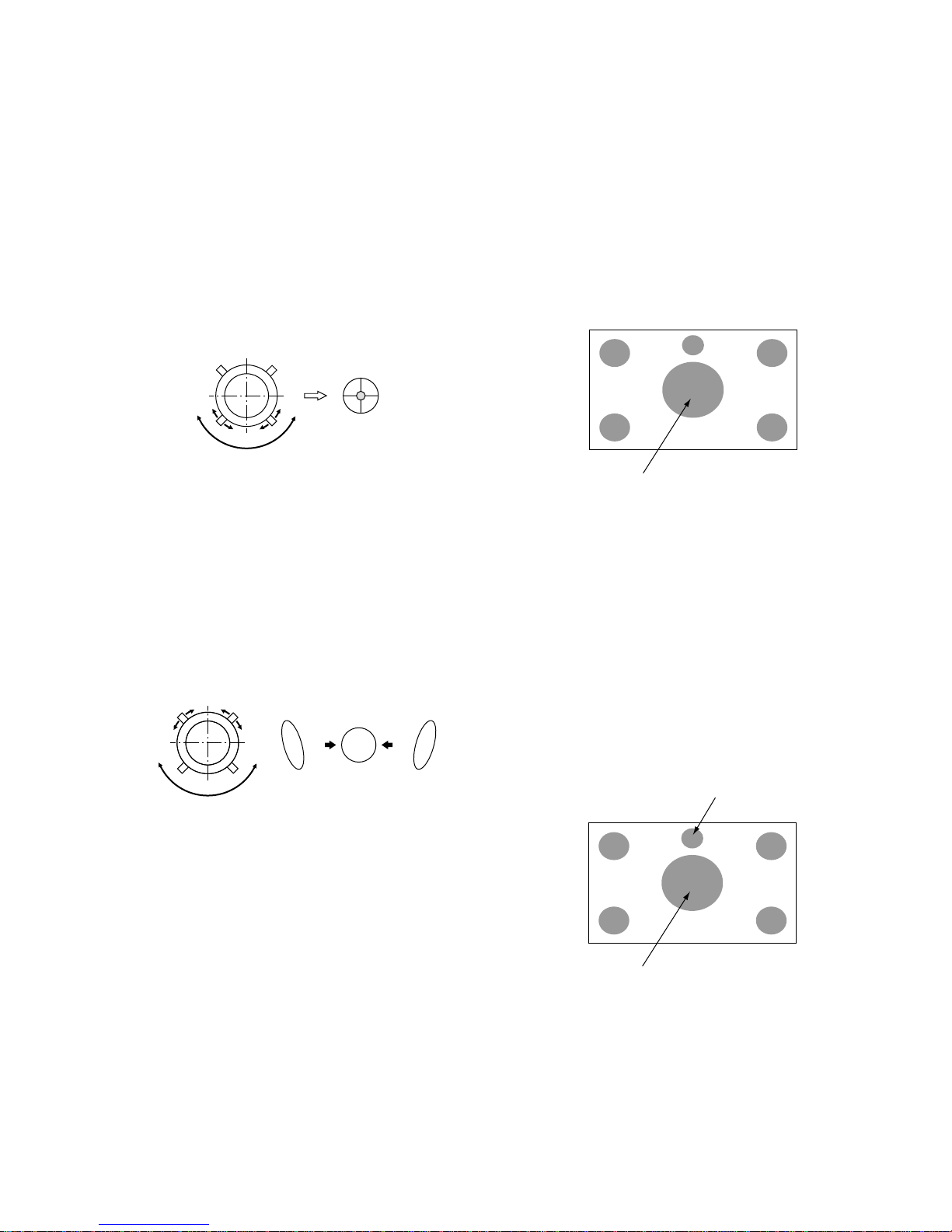

3-5. 2-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Turn the green focus VR on the focus pack to the right and

set to over focus to enlarge the spot.

4. Now align the 2-Pole Magnet so that the enlarged spot is in

the center of the just focus spot.

(center of the dot doesn't move)

5. Align the green focus VR and set for just (precise) focus.

6. Perform the same alignment for red and blue.

Fig. 3-6

3-6. 4-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Turn the green focus VR on the focus pack to the left and set

to under focus to enlarge the spot.

4. Now align the 4-Pole Magnet so that the enlarged spot becomes a perfect circle.

5. Perform the same alignment for red and blue.

Fig. 3-7

3-7. GREEN, RED AND BLUE FOCUS

ADJUSTMENT

3-7-1. Green, Red and Blue Lens Focus Adjustment

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Rotate the green lens and adjust to obtain the best lens focus

at the center area.

4. Fix lens screw.

5. Repeat above process for red and blue.

3-7-2. Green, Red and Blue Electrical Focus

Adjustment

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Rotate the green focus VR on the focus pack and adjust to

obtain the best electrical focus in the adjust point.

4. Repeat above process for red and blue.

5. Repeat adjustment items 3-3. FOCUS ROUGH ADJUSTMENT, 3-5. 2-POLE MAGNET ADJUSTMENT, 3-6. 4POLE MAGNET ADJUSTMENT and 3-7. GREEN, RED

AND BLUE FOCUS ADJUSTMENT, and adjust to obtain

the best focus.

Fig. 3-8

Adjust Point

Use the center dot

Use the center dot

OKNG NG

Adjust Point of Green and Red

Adjust Point of Blue

Fig. 3-9

Loading...

Loading...