Sony KP-ER43M31, KP-ER43M61, KP-ER43M90, KP-ER43M91, KP-ER53M31 Service manual

...

SERVICE MANUAL

RG-3A

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KP-ER43M31 RM-961 AUS SCC-P87A-A

KP-ER43M61 RM-961 GE SCC-P85A-A

KP-ER43M90 RM-961 HK SCC-P84A-A

KP-ER43M91 RM-961 ME SCC-P86A-A

MODEL COMMANDER DEST. CHASSIS NO.

KP-ER53M31 RM-961 AUS SCC-P87B-A

KP-ER53M61 RM-961 GE SCC-P85B-A

KP-ER53M90 RM-961 HK SCC-P84B-A

KP-ER53M91 RM-961 ME SCC-P86B-A

RM-961

KP-ER43M31/ER43M61

/ER43M90/ER43M91

KP-ER53M31/ER53M61

/ER53M90/ER53M91

PROJECTION TV

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

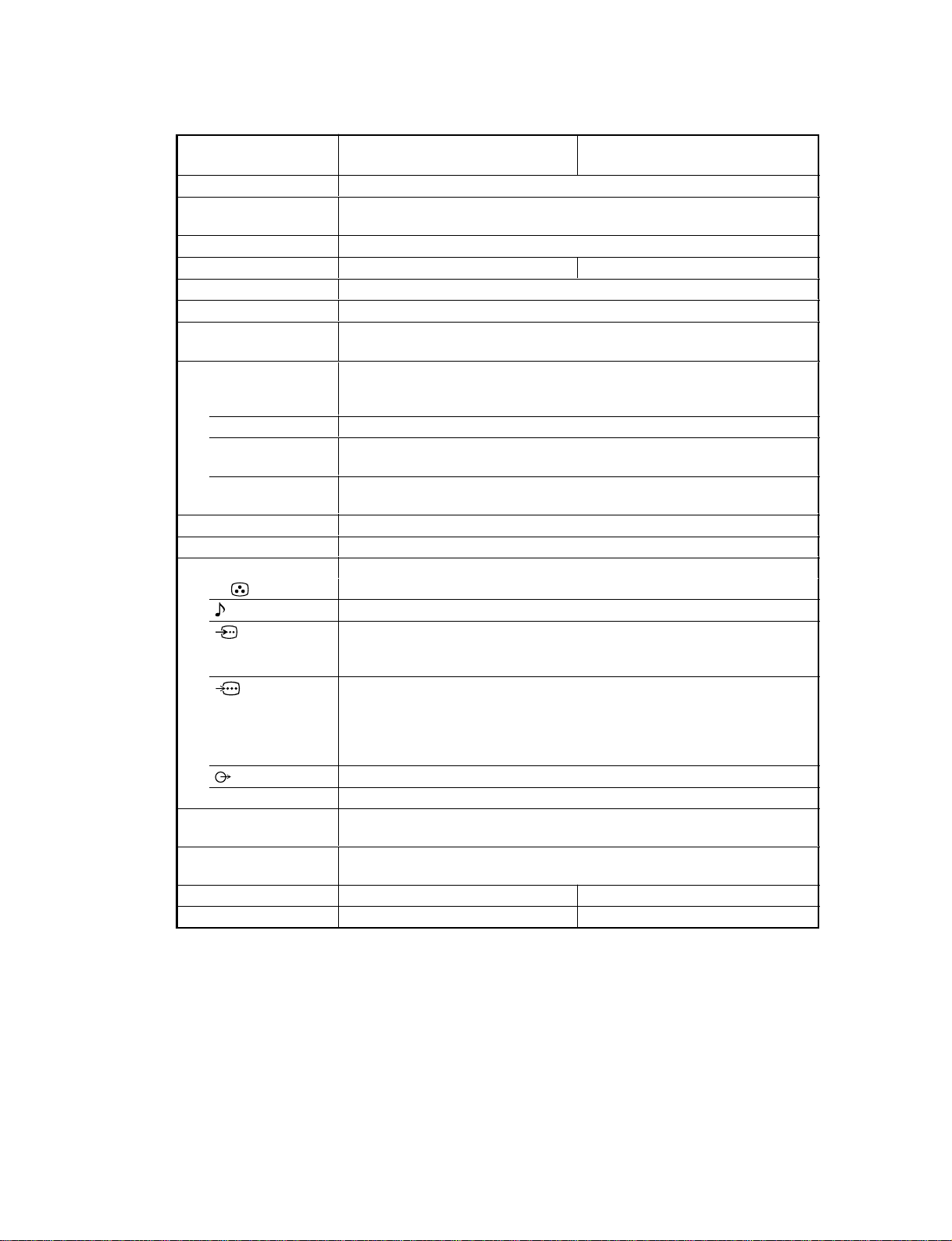

SPECIFICATIONS

Projection system

Picture tube

Projection lenses

Screen size

Television system

Color system

Stereo/Bilingual

system

Channel coverage

B/G

I

D/K

M

8(Antenna)

Audio output (Speaker)

Number of terminal

(Video)

(Audio)

(S Video)

(Component

Video)

i (Headphones)

Power requirements

Power consumption (W)

Dimensions (w/h/d, mm)

Mass (kg)

KP-ER53M90/KP-ER53M91

KP-ER53M61/KP-ER53M31

3 picture tubes, 3 lenses, horizontal inline system

7 inch high-brightnes monochorome tubes (6.3 raster size), with optical coupling

and liquidcooling system

High performance, large-diameter highbrid lens F1.0

53 inches 43 inches

B/G, I, D/K, M

PAL, PAL 60, SECAM, NTSC4.43, NTSC3.58

NICAM Stereo/Bilingual B/G, I;

A2 Stereo/Bilingual (German) B/G

VHF : E2 to E12 / UHF : E21 to E69 / CATV : S01 to

S03, S1 to S41

UHF : B21 to B68 / CATV : S01 to S03, S1 to S41

VHF : C1 to C12, R1 to R12 / UHF : C13 to C57, R21

to R60 / CATV : S01 to S03, S1 to S41, Z1 to Z39

VHF : A2 to A13 / UHF : A14 to A79/

CATV : A-8 to A-2, A to W+4, W+6 to W+84

75-ohm external terminal

15W + 15W (10% distortion)

Input: 4 Output: 1 Phono jacks; 1 Vp-p, 75 ohms

Input: 4 Output: 1 Phono jacks; 500 mVrms

Input: 2 Y: 1 Vp-p, 75 ohms,

unbalanced, sync negative

C: 0.286 Vp-p, 75 ohms

Input: 1 Phono jacks

Y: 1 Vp-p, 75 ohms, sync negative

C

B

/B-Y: 0.7 Vp-p, 75 ohms

C

R

/R-Y: 0.7 Vp-p, 75 ohms

Audio: 500 mVrms

Output: 1 Phono jack; 500 mVrms

Output: 1 Stereo minijack

110 V – 240 V (KP-ER53M91/KP-ER43M91/KP-ER53M61/KP-ER43M61)

220 V – 240 V (KP-ER53M90/KP-ER43M90/KP-ER53M31/KP-ER43M31)

270 W (KP-ER53M91/KP-ER43M91/KP-ER53M61/KP-ER43M61)

255 W (KP-ER53M90/KP-ER43M90/KP-ER53M31/KP-ER43M31)

1180 × 1427 × 623 966 × 1074 × 505

79 60

KP-ER43M90/KP-ER43M91

KP-ER43M61/KP-ER43M31

Design and specifications are subject to change without notice.

CAUTION

SHORT CIRCUIT THE ANODE OF HTE PICTURE TUBE

AND THE ANODE CAP TO THE METAL CHASSIS, CRT

SHIELD, OR CARBON PAINTED ON THE CRT, AFTER

REMOVING THE ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

! ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL TO

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

TABLE OF CONTENTS

1. SELF DIAGNOSIS FUNCTION

1-1. Diagnostic Test Indicators ................................. 5

1-2. Display of STANDBY/TIMER

Light Flash Count............................................... 6

1-3. Stopping the STANDBY/TIMER Flash ............ 6

1-4. Self-Diagnostic Screen Display ......................... 7

1-5. Handling of Self-Diagnostic

Screen Display.................................................... 7

1-6. Self-Diagnostic Circuit ...................................... 8

2. DISASSEMBLY

2-1. Rear Board Removal ......................................... 9

2-2. Main Bracket Block Removal ........................... 9

2-3. Service Position ................................................. 10

2-4. H1, H2 Boards and Resistor (Focus Pack)

Removal ............................................................. 10

2-5. Main Bracket Removal ..................................... 11

2-6. Chissis Block Removal ..................................... 11

2-7. Terminal Board Removal ................................... 12

2-8. BD, DS and D Boards Removal ........................ 12

2-9. G and G1 Board Removal .................................. 13

2-10. J1, B3, E and M1 Boards Removal .................... 13

2-11. A1 Board Removal ............................................. 14

2-12. High-Voltage Cable Installation and Removal.. 14

2-13. Mechaseal ........................................................... 14

3. SET-UP ADJUSTMENTS

3-1. Screen Voltage Adjustment

(Rough Alignment) ........................................... 15

3-2. Screen (G2) Adjustment .................................... 15

3-3. Focus Rough Adjustment .................................. 15

2-4. Deflection Yoke Tilt Adjustment ...................... 15

3-5. 2-Pole Magnet Adjustment ................................ 16

3-6. 4-Pole Magnet Adjustment ................................ 16

3-7. Green, Red and Blue Focus Adjustment

3-7-1. Green, Red and Blue Lens Focus

Adjustment .................................................... 16

3-7-2. Green, Red and Blue Electrical Focus

Adjustment .................................................... 16

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

Section Title PageSection Title Page

5. ELECTRICAL ADJUSTMENTS

5-1. Adjustments with Commander

5-1-1. How to Select Each Mode ............................. 18

5-1-2. How to Enter Service Mode .......................... 19

5-1-3. Method of Cancellation

from Service Mode ........................................ 19

5-1-4. How to Adjustments ...................................... 19

5-1-5. How to Write the Data ................................... 19

5-1-6. Memory Write Confirmation Method ........... 19

5-2. Service List ......................................................... 20

5-3. Picture Quality Adjustment

5-3-1. Preparation ..................................................... 34

5-3-2. NTSC Video Input ......................................... 34

5-3-3. NTSC RF Input .............................................. 35

5-3-4. PAL Video Input ............................................ 35

5-3-5. PAL RF Input ................................................. 36

5-4. Color Offset (53, 61 inch model only)

5-4-1. 50 Hz (PAL) TV Mode .................................. 36

5-4-2. 50 Hz (PAL) Video Mode ............................. 36

5-4-3. 60 Hz (NTSC) TV Mode ............................... 36

5-4-4. 60 Hz (NTSC) Video Mode........................... 36

5-5. Registration Adjustment

5-5-1. Setup for Adjustment ..................................... 37

5-5-2. Method of Main Deflection Adjustment ....... 37

5-5-3. Operation Method

for Projector Engine (PJE) Mode .................. 38

5-5-4. Method of Projector Engine Adjustment

(Sub Deflection Adjustment)......................... 39

5-5-5. Deflection Adjustment ................................... 41

5-6. Auto Convergence Setting ................................. 47

5-7. White Balance Adjustment ................................ 47

5-8. Auto Convergence Error Code List ................... 48

4. SAFETY RELATED ADJUSTMENT

4-1. HV Hold-Down Adjustment ............................. 17

– 3 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

Section Title Page

6. DIAGRAMS

6-1. Block Diagrams .................................................. 49

6-2. Frame Schematic Diagram ................................. 62

6-3. Circuit Boards Location ..................................... 63

6-4. Schematic Diagrams........................................... 63

6-5. Printed Wiring Boards........................................ 97

6-6. Wave Forms ....................................................... 110

6-7. IC Block Diagrams ............................................. 117

6-8. Semiconductors .................................................. 119

7. EXPLODED VIEWS

7-1. Screen and Cover Block (KP-ER43) ................ 122

7-2. Screen and Cover Block (KP-ER53) ................ 123

7-3. Cabinet and Panel Block (KP-ER43) ............... 124

7-4. Cabinet and Panel Block (KP-ER53) ............... 125

7-5. Main Bracket Block ........................................... 126

7-6. Picture Tube Block............................................. 127

RM-961

8. ELECTRICAL PARTS LIST ............................ 128

– 4 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

SECTION 1

SELF DIAGNOSIS FUNCTION

The unit in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically begin to

flash.

The number of times the lamp flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER lamp flash

indicators is listed in the instruction manual for the user's knowledge and reference. If an error symptom cannot be reproduced, the

remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

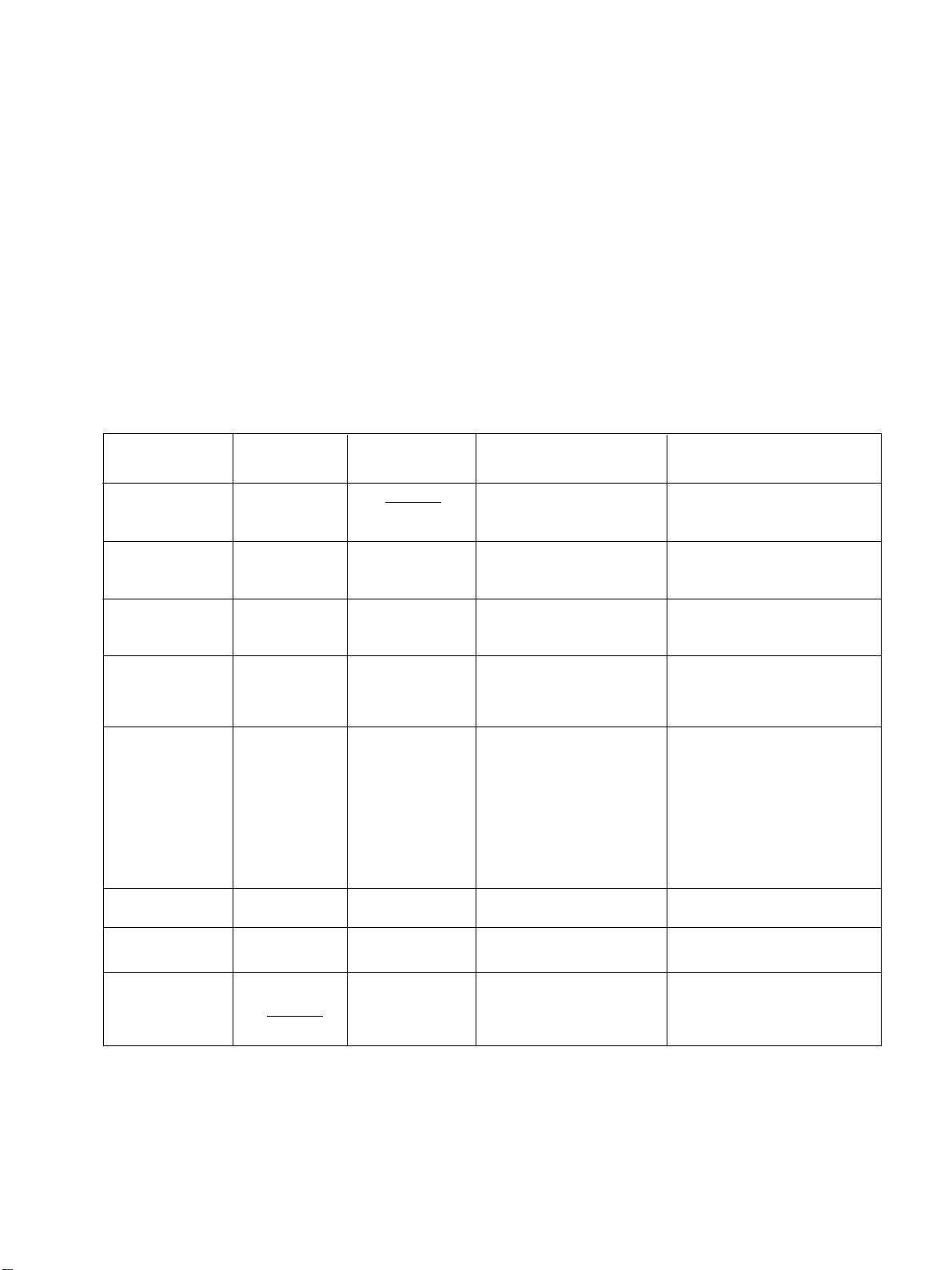

1-1. DIAGNOSTIC TEST INDICATORS

When an errors occurs, the STANDBY/TIMER lamp will flash a set number of times to indicate the possible cause of the problem. If

there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic

Item

Description

No. of times

STANDBY/TIMER

lamp flashes

Self-diagnostic

display/

Diagnostic result

Probable Cause Location

Detected Symptoms

RM-961

•Power does not

turn on

•+B overcurrent

(OCP)

•+B overvoltage

(OVP)

•Vertical deflection

failure

•White balance

failure

(no PICTURE)

•High Voltage

failure

•Audio Protection

Does not light

2 times

3 times

4 times

5 times

6 times

7 times

002:000 or

002:001 ~ 255

003:000 or

003:001 ~ 255

004:000 or

004:001 ~ 255

005:000 or

005:001 ~ 255

006:000 or

006:001 ~ 255

007:000 or

007:001 ~ 255

•Power cord is not plugged in.

•Fuse (F6001) is burned out.

(G, G1 board)

•H. OUT Q5104 is shorted.

•H. LIN Q5105 is shorted.

(D board)

•IC6002 faulty.

•10.5 V is not supplied.

(G, G1 board)

•V. OUT IC5302 faulty.

•R5340 open

•R5341 open

(D board)

•G2 is improperly adjusted.

(Note 1)

•CRT problem.

•Video OUT IC7101 (CR

board), IC7201 (CG board),

IC7301 (CB board) are faulty.

•IC8306 (J1 board) and

IC4301 (E board) are faulty.

•No connection E board to CR

board.

•IC6301 (G, G1 bard) faulty.

•Power supply fails.

•IC1101 (A1 board) faulty.

•Power does not come on.

•No power is supplied to the PJ.

•AC power supply is faulty.

•Power does not come on.

•Load on power line is shorted.

•Power does not come on.

•Vertical deflection pulse is

stopped.

•Vertical size is too small.

•Vertical deflection stopped.

•No raster is generated.

•CRT cathode current detection

reference pulse output is small.

•+135 V is too high.

•There is picture but speaker

does not release sound.

•Micro reset

Note 1 : Refer to screen (G2) adjustment in section 4-2 of this manual.

101:000 or

101:001 ~ 255

•Discharge CRT

(CR, CG, CB boards)

•Static discharge

•External noise

– 5 –

•Power is shut down shortly,

after this return back to normal.

•Detect Micro latch up.

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

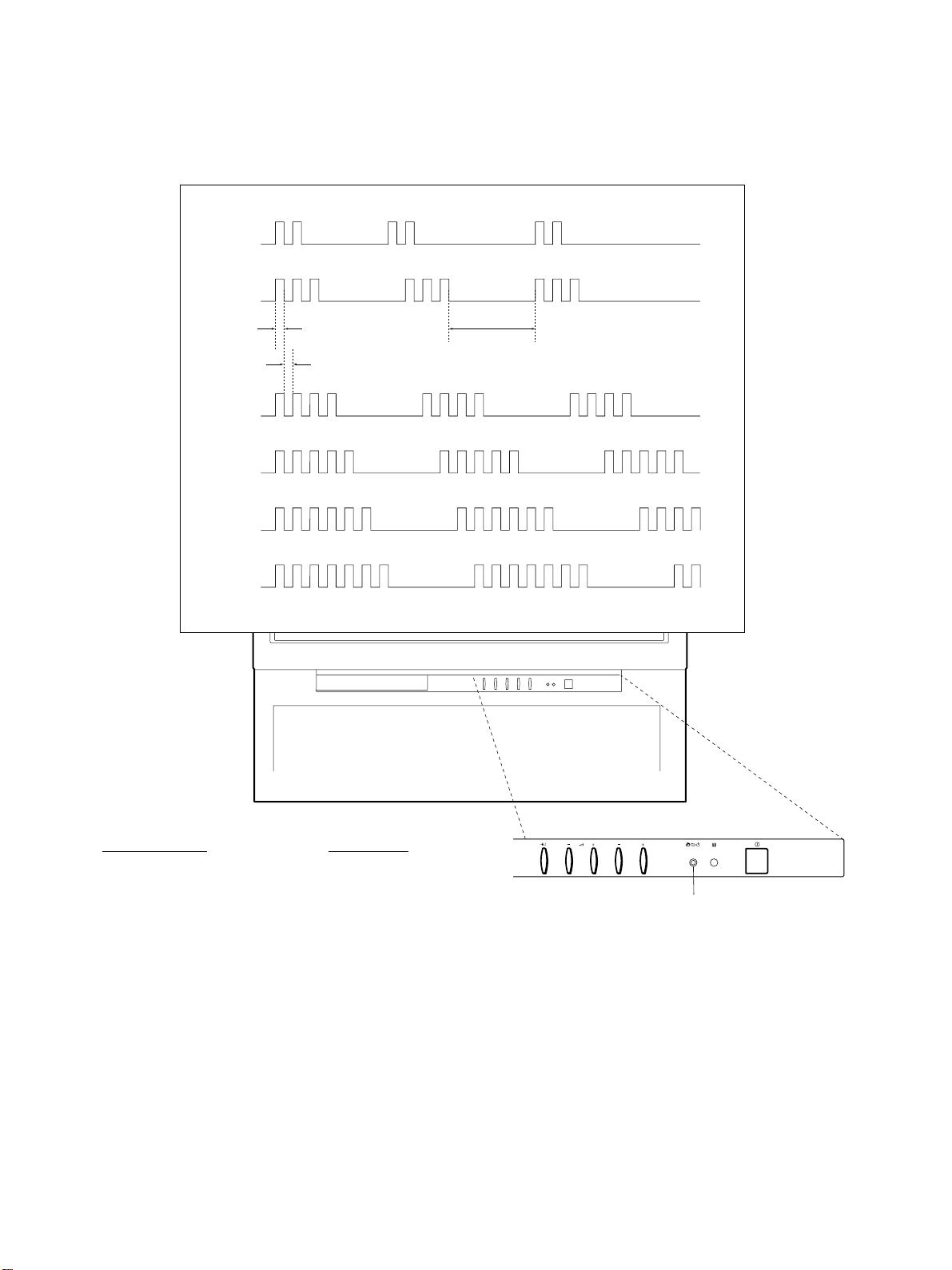

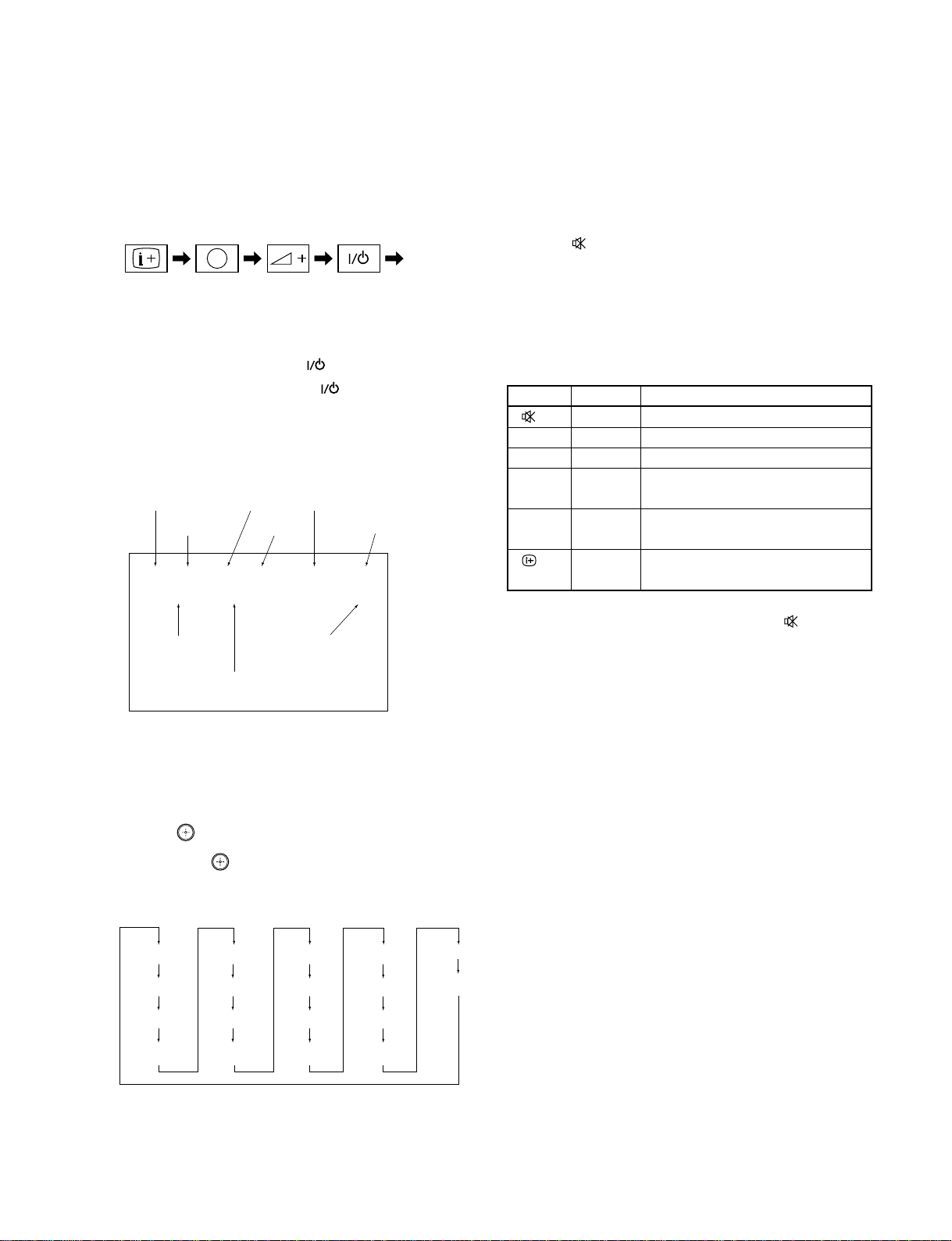

1-2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

2 times

3 times

Lamp ON

0.3 sec.

Lamp OFF

0.3 sec.

4 times

5 times

Lamp OFF

3 sec.

RM-961

6 times

7 times

Diagnostic Item Flash Count *

+B overcurrent 2 times

+B overvoltage 3 times

V deflection stop 4 times

White balance failure 5 times

High voltage protector 6 times

Audio Protection 7 times

PROGR

STANDBY/TIMER

lamp

* One flash count is not used for self-diagnostic.

1-3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp from

flashing.

– 6 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

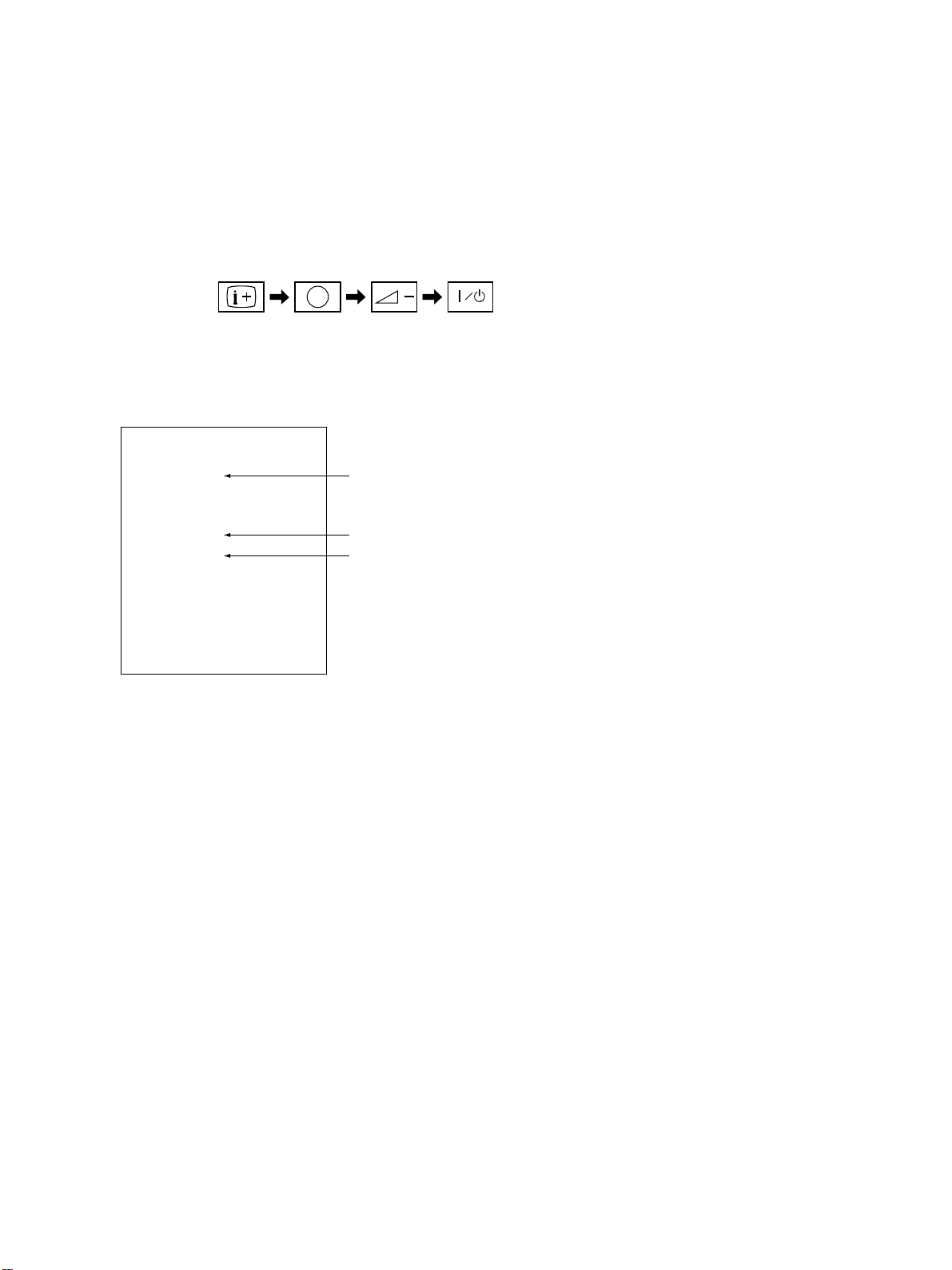

1-4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible

to bring up past occurrences of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

5

RM-961

(

DISPLAY

(DIGIT 5) (VOLUME –) (POWER)ON SCREEN

)

*

* : Note that this differs from entering the service mode (volume +)

Self-Diagnosis screen display

SELF DIAGNOSTIC

002:000

Numeral “0” means that no fault has been detected.

003:000

004:000

005:001

006:002

Numeral “1” means a fault has been detected.

Numeral “2” means two faults have been detected.

007:000

101:000

1-5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of

the repairs.

[Clearing the result display]

To clear the result display to “0”, press button on the remote commander sequentially as shown below when the diagnostic screen is

being displayed.

Press “8” button

(It will indicate “CLEAR” on the screen.)

,

(The “CLEAR” display change to red color.)

Press “-” button

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

– 7 –

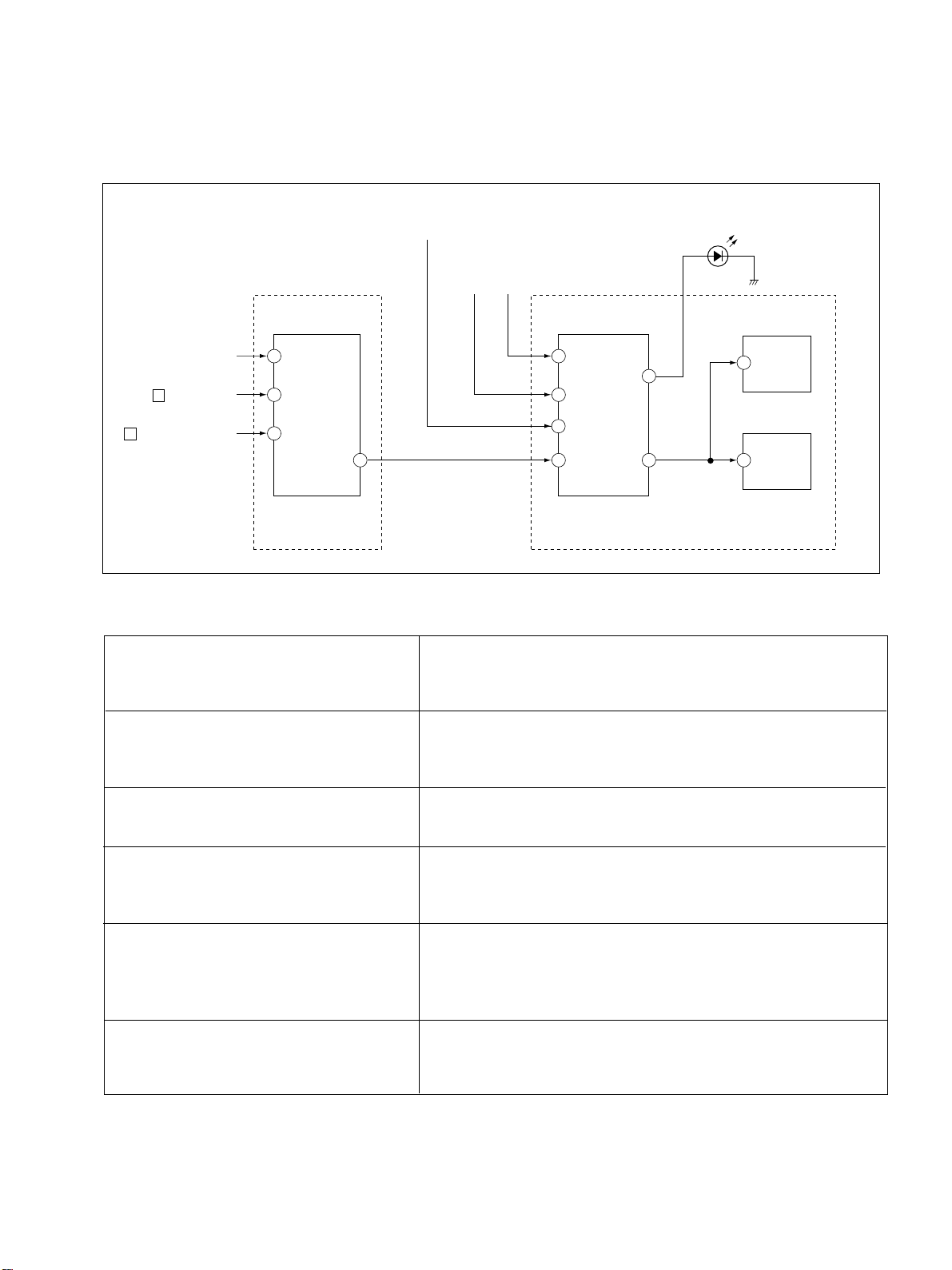

1-6. SELF-DIAGNOSTIC CIRCUIT

IC4301

Y/C JUNGLE

From Q1203

(A1 board)

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

From G,G1 board

OCP

OVP

IC002

SYSTEM

To H1 board

IC004

MEMORY

RM-961

25 IKINFrom CRT (IK)

H

(D board)

V

(D board)

20 XRAYFrom IC5201

16 V PROTFrom D5303/D5704

SDA 61 48 SDA0 SDA1 SDA47 5

3 OCP

6 OVP

APROT

57

LED1 54

SDA5

IC006

MEMORY

CXA2100Q CXP750096

M1 boardE board

+B overcurrent (OCP) Occurs when an overcurrent on the +B (135 V) line is detected by Q6303.

If Q6303 go to ON, the voltage to pin 3 of IC002 go to UP. The unit will

automatically turn off.

+B overvoltage (OVP) Occurs when an overvoltage on the +B (135 V) line is detected by D6318.

If D6318 go to ON, then voltage to pin 6 of IC002 go to UP. The unit will

automatically turn off.

Vertical deflection failure Occurs when an absence of the vertical deflection pulse is detected by

Q5302, Q5303, and D5303. Shut down the power supply.

White balance failure If the RGB levels do not balance or become low level within 5 seconds. This

error will be detected by IC4301.

TV will stay on, but there will be no picture.

High voltage protector of Horizontal Deflection Occurs when an overvoltage of horizontal pulse is detected by D5115 and

IC5201.

If the voltage of pin 1 of IC5201 goes to High, the voltage to pin 20 of IC4301

go to UP. The unit will automatically turn off.

Audio Protector If the Audio out lines become DC.This error will be detected by Q1202,

Q1204 and Q1203.

The unit will automatically turn off.

– 8 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

SECTION 2

DISASSEMBLY

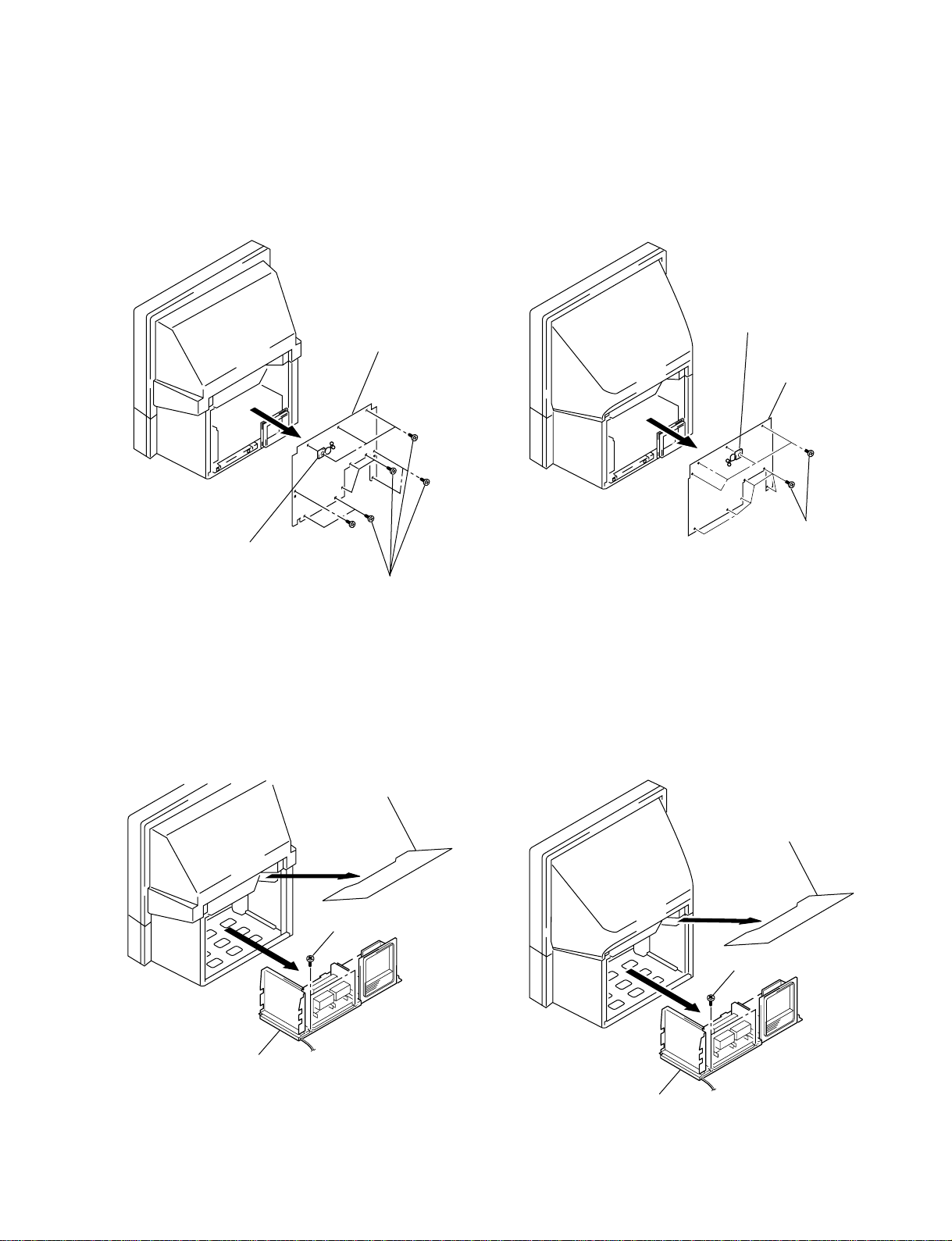

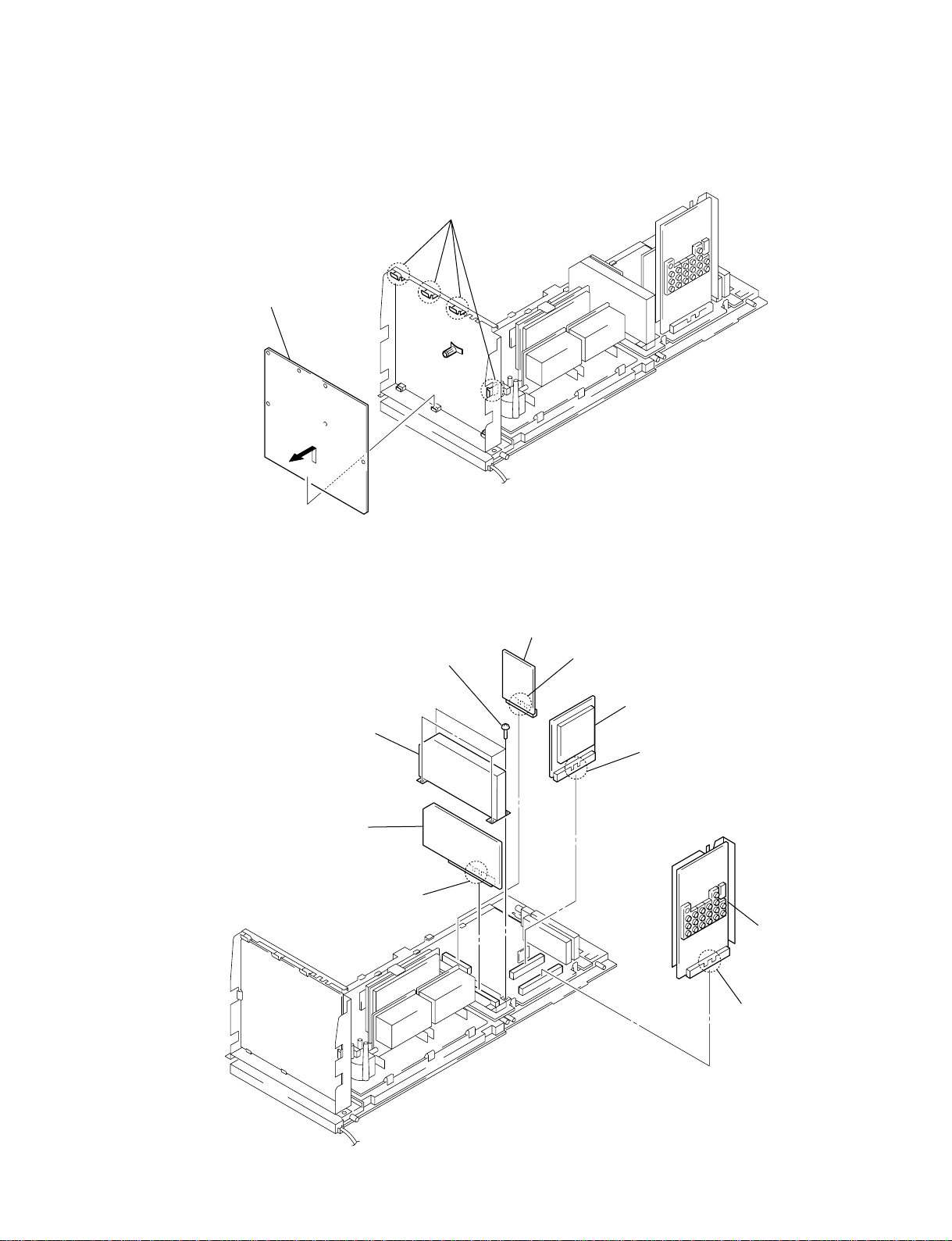

2-1. REAR BOARD REMOVAL

(1) KP-ER43 (2) KP-ER53

2 Rear board

RM-961

3 Purse lock

2 Rear board

3 Purse lock

1 Thirteen screws

(BVTP4 X16)

2-2. MAIN BRACKET BLOCK REMOVAL

(1) KP-ER43 (2) KP-ER53

1 Light shield block

2 Two screws

(Hexagon head)

1 Thirteen screws

(BVTP4 X16)

1 Light shield block

2 Two screws

(Hexagon head)

3 Main bracket block

3 Main bracket block

– 9 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

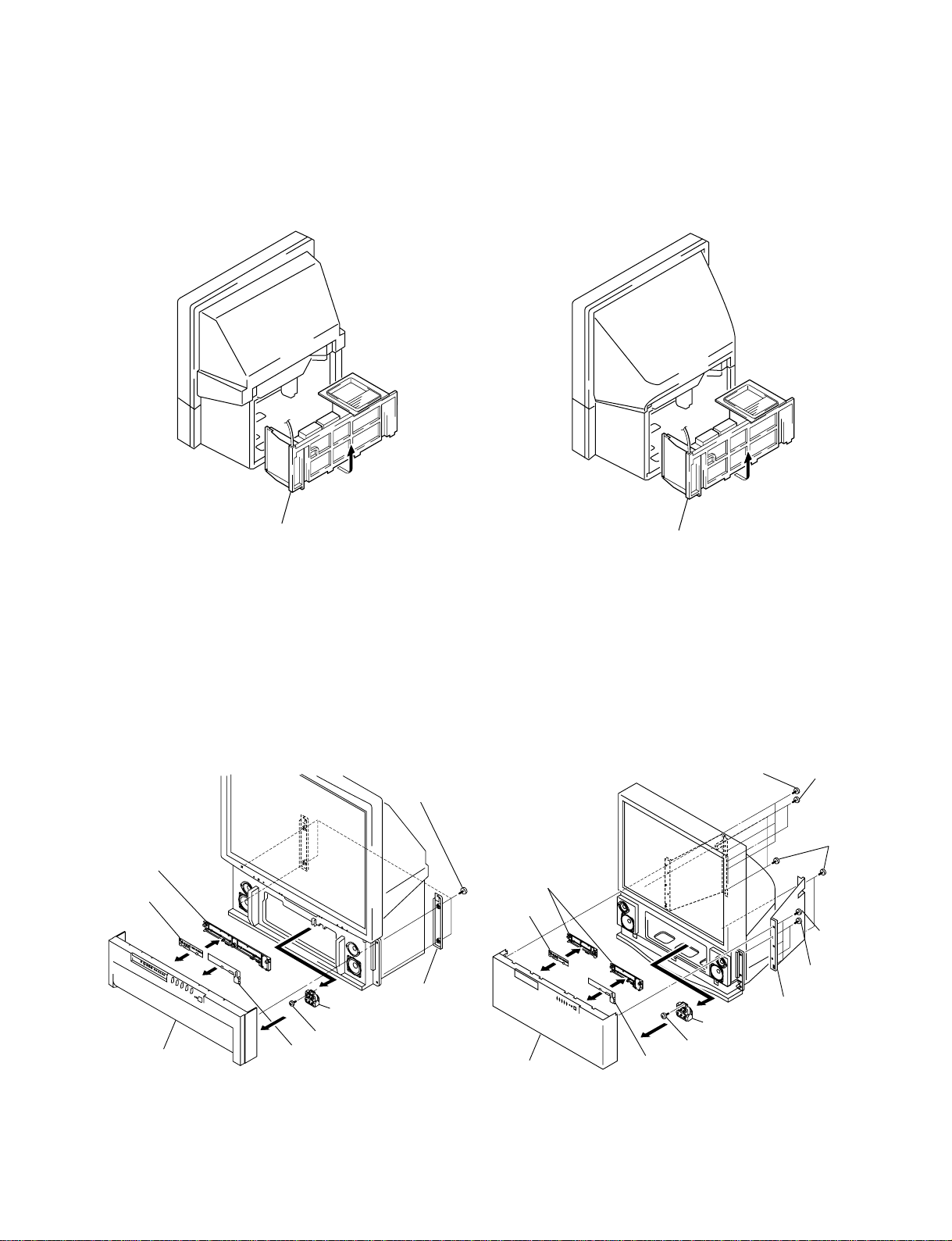

2-3. SERVICE POSITION

(1) KP-ER43 (2) KP-ER53

RM-961

Main bracket block Main bracket block

2-4. H1, H2 BOARDS AND RESISTOR (FOCUS PACK) REMOVAL

(1) KP-ER43 (2) KP-ER53

1 Four screws

(Hexagon head)

4Bracket (H)

6Bracket (H)

5H2 board

3 Speaker grille

2 Grille cover

8Resistor

(Focus pack)

7Screw (BVTP4 X16)

6H1 board

7H2 board

5 Speaker grille

8H1 board

1 Three screws

(BVTP4 X16)

q;Resister

(Focus pack)

9Screw (BVTP4 X16)

2 Two screws

(Hexagon head)

3 Four screws

(Hexagon head)

1 Three screws

(BVTP4 X16)

2 Two screws

(Hexagon head)

4 Grille cover

– 10 –

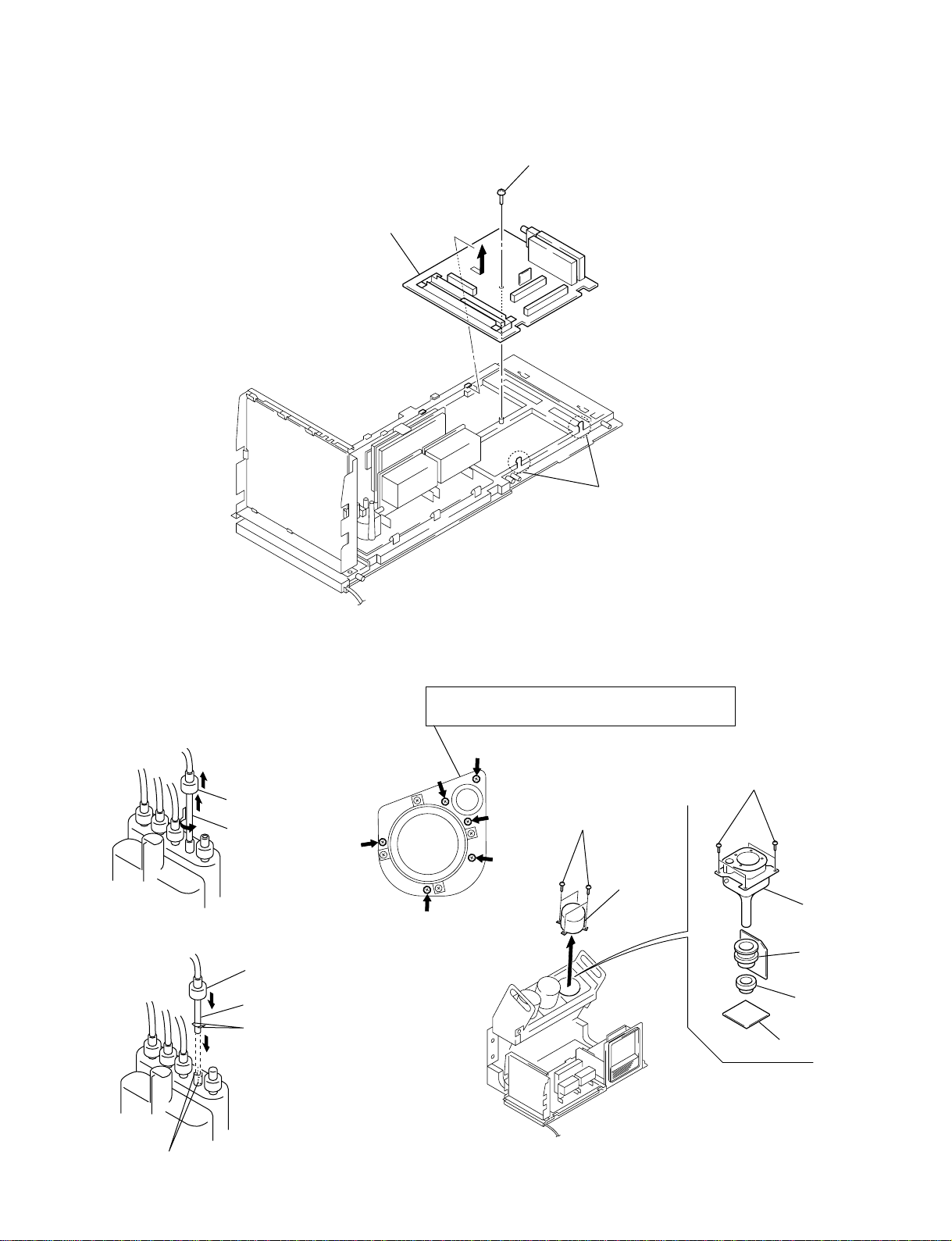

2-5. MAIN BRACKET REMOVAL

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

1 Two screws

(Hexagon head)

3 Set the main bracket.

Pay particular attention to the wires of each printed circuit boards when puling out the main bracket.

2-6. CHASSIS BLOCK REMOVAL

2 Pull the main braket, and remove each connectors on main bracket.

1 Four screws

(Hexagon head)

1 Two screws

(Hexagon head)

Pull out the chassis block by gripping the handles as shown in the diagram.

At this time, pay particular attention to the components removed in (1).

2 Pull out the chassis block.

– 11 –

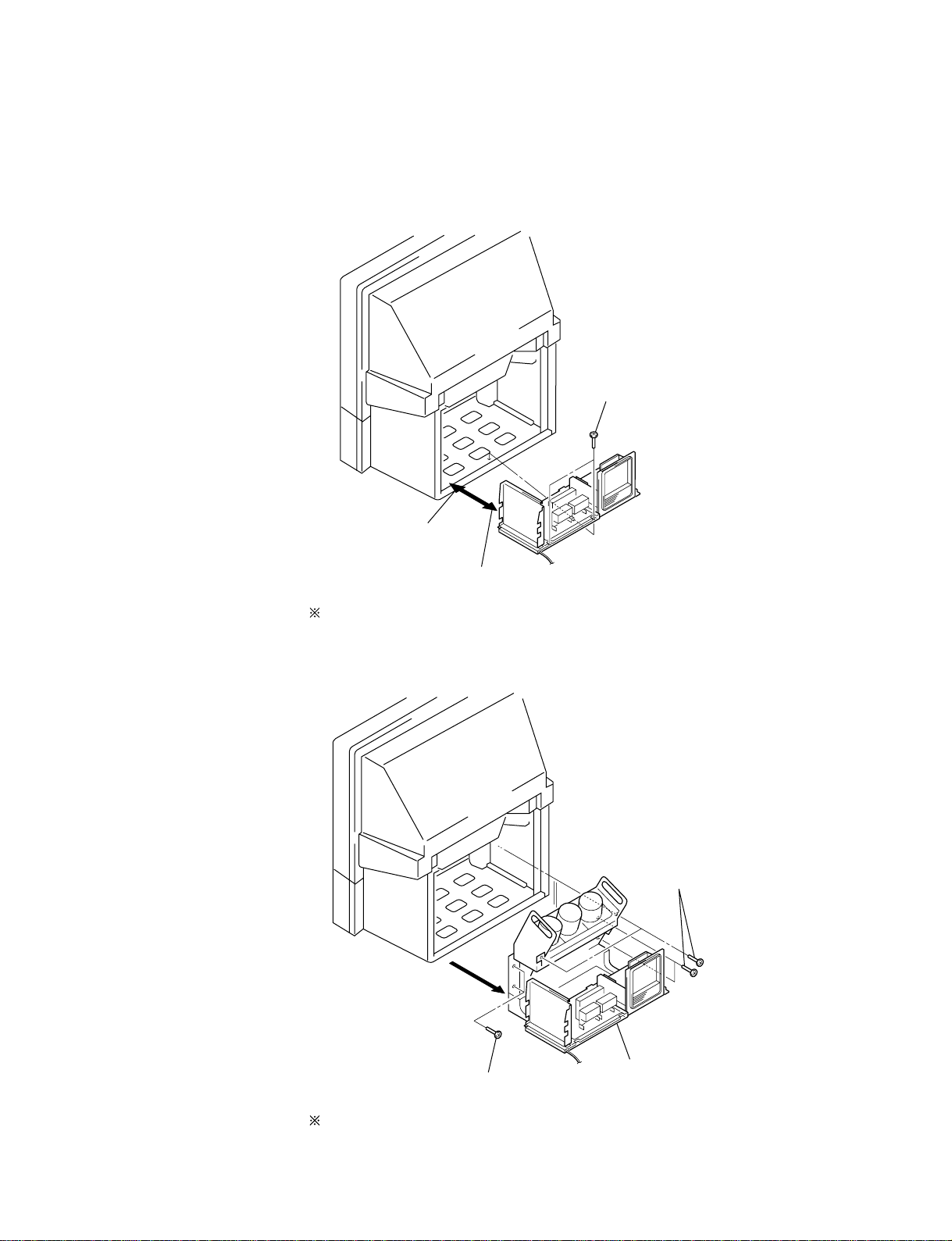

2-7. TERMINAL BOARD REMOVAL

3 RF cable

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

4 Terminal board

1 Five screws

( + BVTP 3 X 12)

2-8. BD, DS AND D BOARDS REMOVAL

1 Screw

( +BVTP 3X12)

5 DS board

8 D board

6 Screw

( +BVTP 3X12)

2 Two screws

( + BVTP 4 X 16)

2 BD holder

3 claw

4 BD board

6 Screw

( +BVTP 3X12)

– 12 –

7 Three claws

2-9. G AND G1 BOARD REMOVAL

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

2 G board

(KP-ER43M30/ER43M91,

KP-ER53M30/ER53M91)

G1 board

(KP-ER43M61/ER43M90,

KP-ER53M61/ER53M90)

1 Four claws

2-10. J1, B3, E AND M1 BOARDS REMOVAL

7 Four serews

( + BVTP 3 X 12)

6 E board

5 claw

8 Shield case

0 B3 board

4 M1 board

3 claw

9 claw

2 J1 board

1 claw

– 13 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

2-11. A1 BOARD REMOVAL

1 Screw

( +BVTP3 X12)

3 A1 board

2 Two claws

2-12. HIGH-VOLTAGE CABLE

INSTALLATION AND REMOVAL

(1) Remover

1 Rubber cap

2 HV cable turn 90°

(2) Installation

2 Rubber cap

1 HV cable

Hook

2-13. MECHASEAL

Removing the arrow-marked screw is strictly inhibited.

If removed, it may cause liquid spill.

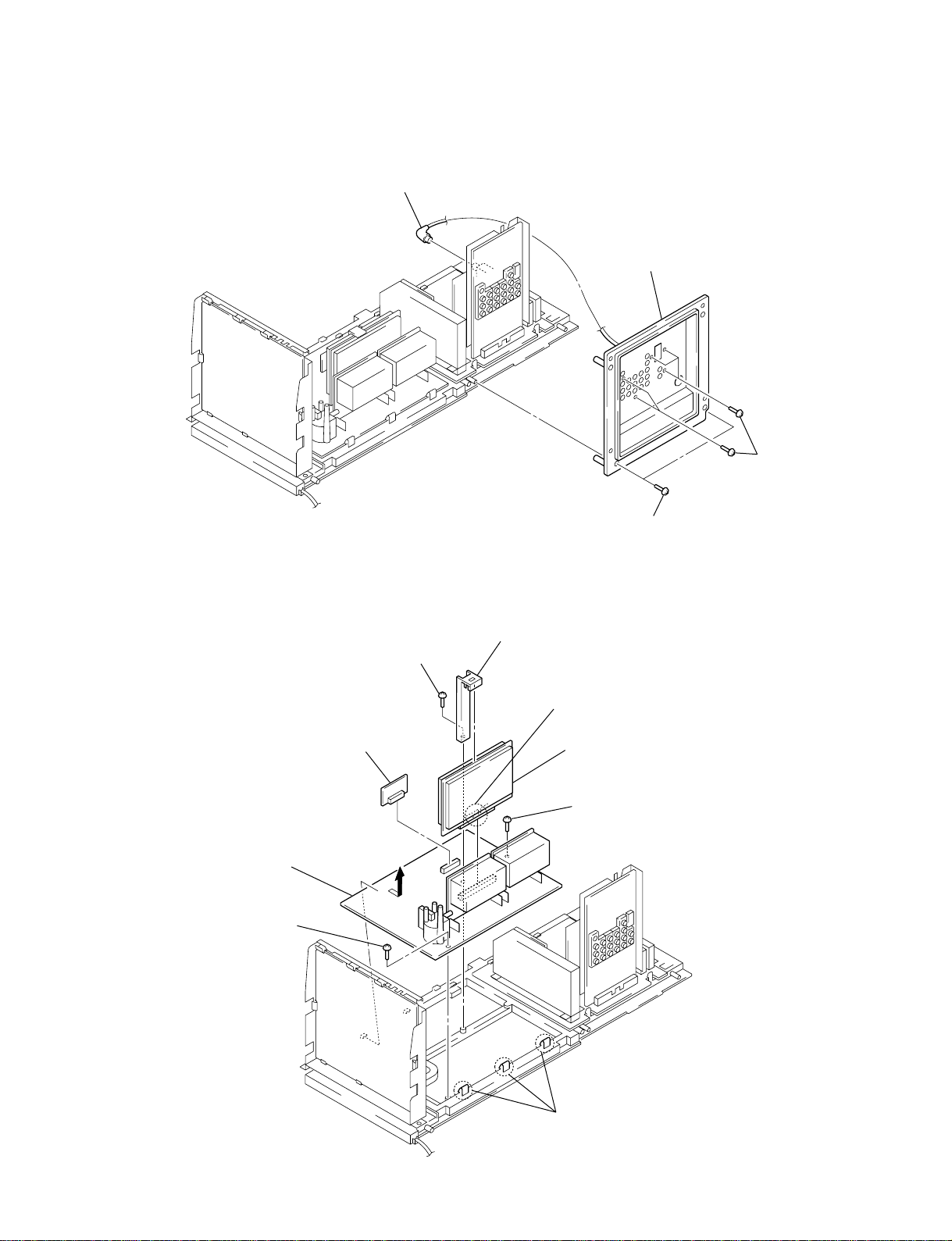

6 Four screws

( +BVTP4 X16)

1 Four screws

( +BVTP4 X16)

2 Lens

7 Picture tube

5 Deflection yoke

4 Neck assembly

3 CR board

Gutter

– 14 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

Scanning line visible.

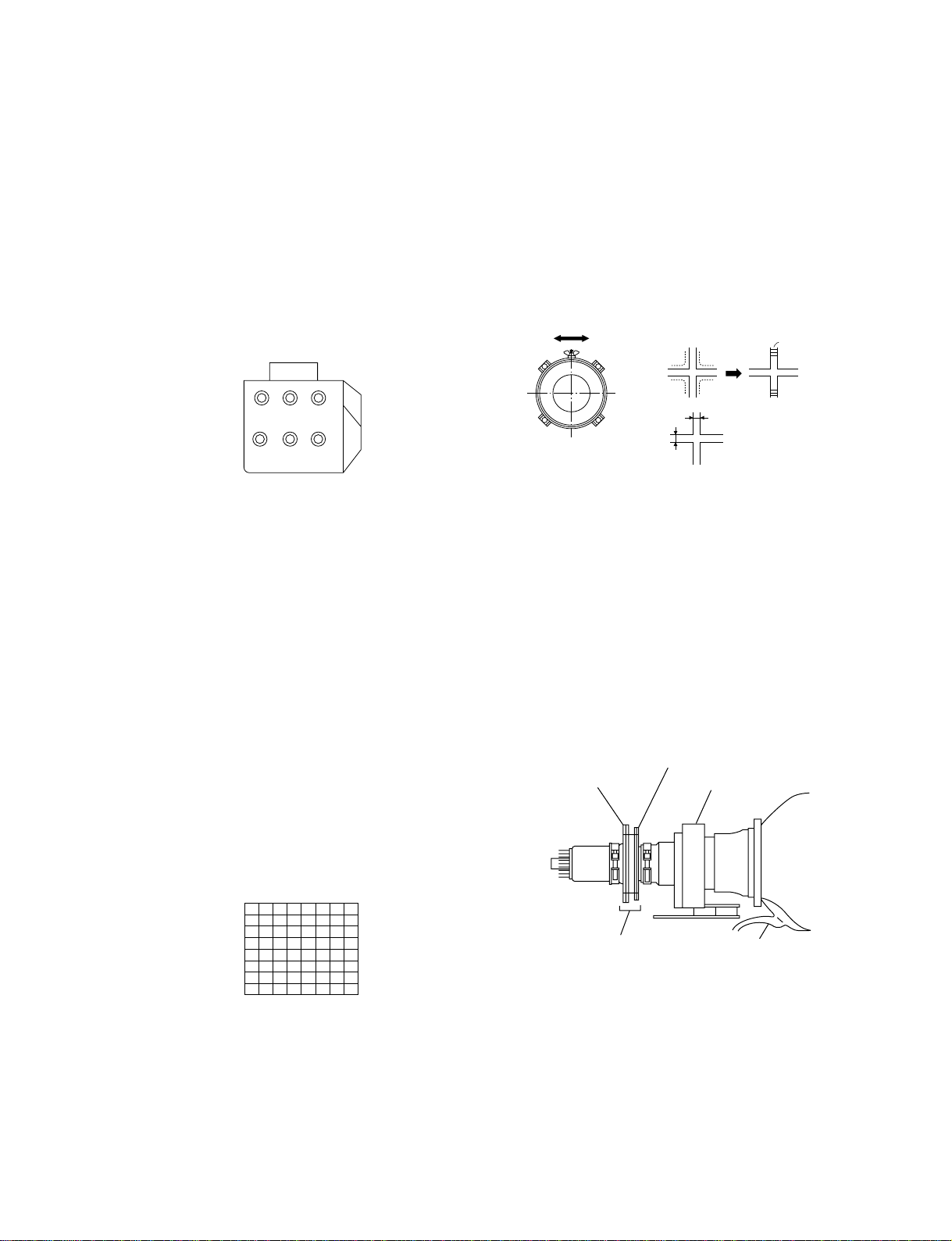

SECTION 3

SET-UP ADJUSTMENTS

RM-961

3-1. SCREEN VOLTAGE ADJUSTMENT

(ROUGH ALIGNMENT)

1. Receive the Monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the focus pack all the way to the left and

then gradually turn it to the right until the point where you

can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

RG

RG

B

SCREEN

B

FOCUS

Focus Pack

Fig. 3-1

3-2. SCREEN (G2) ADJUSTMENT

1. Turn on the power of the set.

2. Select VIDEO1 mode without signals.

3. Supply DC 175 ±0.5 V from external power supply to

TP7103 (KR), TP7203 (KG) or TP7303 (KB) of CR board,

CG board and CB board.

3. Adjust red, green and blue screen voltage to until retrace

line disappears with screen VR on the focus pack.

3-3. FOCUS ROUGH ADJUSTMENT

1. Loose the lens screw.

2. Set in the service mode. (Refer to SECTION 5.)

3. Place the caps on the red and blue lens so that only the green

color is shown.

4. Press “1 ” or “4” button on the commander and select

“PJE”, press “6” three times on the Commander to display

the test signal (crosshatch) on the screen.

5. Rotate the green lens and align to obtain the best lens focus

at the center area.

6. Rotate the green focus VR on the focus pack and align to

obtain the best electrical focus in the top right corner.

7. Perform the same alignment for red and blue lenses and electric focus.

8. Fix lens screw.

A

Minimize both A and B.

Lens

Fig. 3-3

B

Fig. 3-4

3-4. DEFLECTION YOKE TILT ADJUSTMENT

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color.

3. Loosen the deflection yoke setscrew and align the tilt of the

Deflection yoke so that the bars at the center of the

monoscope pattern are horizontal.

4. After aligning the deflection yoke, fasten it securely to the

funnel-shaped portion (neck) of the CRT.

5. The tilt of the deflection yoke for red and blue is aligned the

same as was done for green.

4-pole magnet

2-pole magnet

Deflection yoke

Test signal

Fig. 3-2

– 15 –

Neck Assy

Anode cap

Make sure deflection yoke is

touching CRT closely.

Fig. 3-5

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

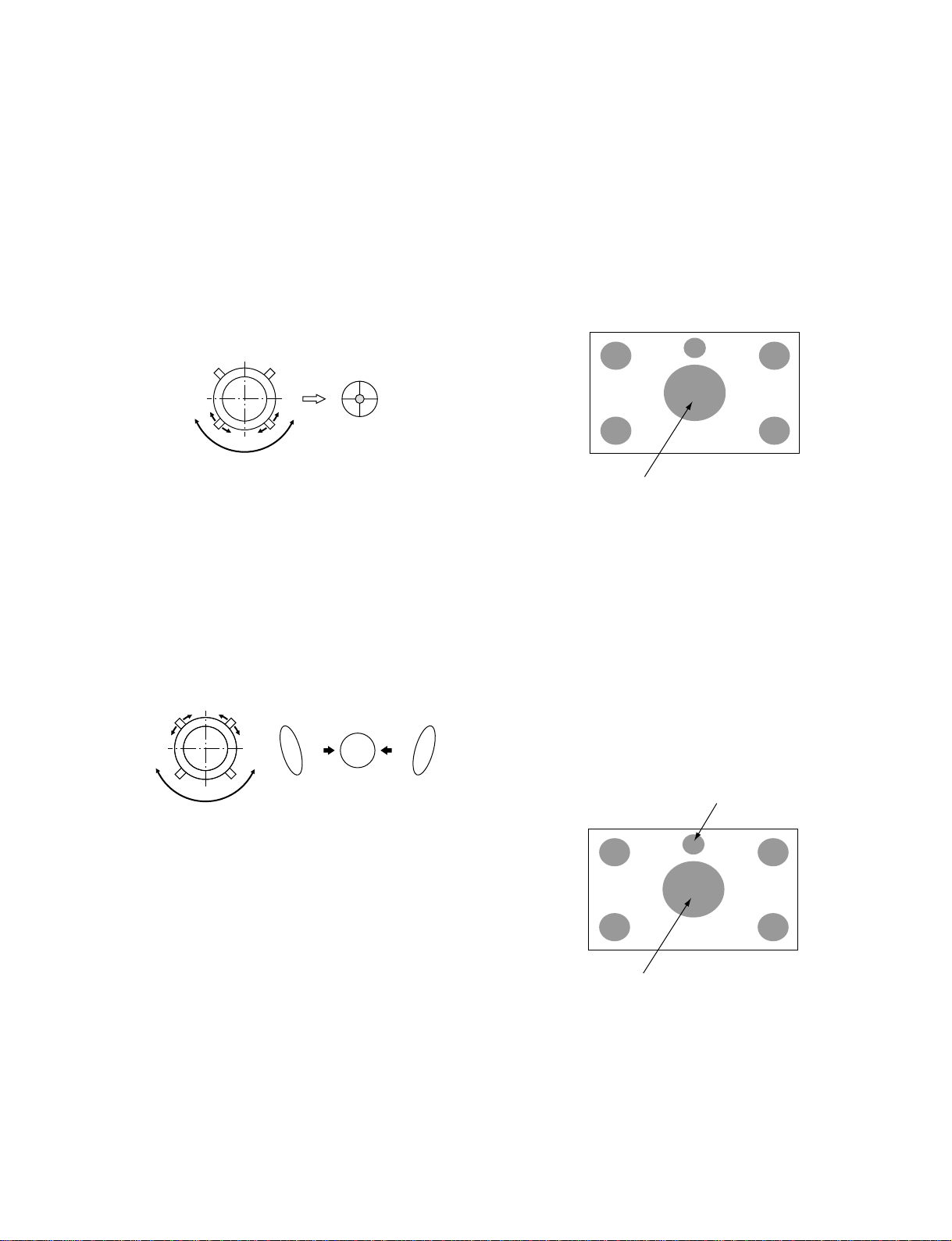

RM-961

3-5. 2-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Turn the green focus VR on the focus pack to the right and

set to over focus to enlarge the spot.

4. Now align the 2-Pole Magnet so that the enlarged spot is in

the center of the just focus spot.

(center of the dot doesn't move)

5. Align the green focus VR and set for just (precise) focus.

6. Perform the same alignment for red and blue.

Use the center dot

Fig. 3-6

3-6. 4-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Turn the green focus VR on the focus pack to the left and set

to under focus to enlarge the spot.

4. Now align the 4-Pole Magnet so that the enlarged spot becomes a perfect circle.

5. Perform the same alignment for red and blue.

Use the center dot

OKNG NG

3-7. GREEN, RED AND BLUE FOCUS

ADJUSTMENT

3-7-1. Green, Red and Blue Lens Focus Adjustment

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Rotate the green lens and adjust to obtain the best lens focus

at the center area.

4. Fix lens screw.

5. Repeat above process for red and blue.

Adjust Point

Fig. 3-8

3-7-2. Green, Red and Blue Electrical Focus

Adjustment

1. Receive the Monoscope signal.

2. Place the caps on the red and blue lens so that only the green

color is shown.

3. Rotate the green focus VR on the focus pack and adjust to

obtain the best electrical focus in the adjust point.

4. Repeat above process for red and blue.

5. Repeat adjustment items 3-3. FOCUS ROUGH ADJUSTMENT, 3-5. 2-POLE MAGNET ADJUSTMENT, 3-6. 4POLE MAGNET ADJUSTMENT and 3-7. GREEN, RED

AND BLUE FOCUS ADJUSTMENT, and adjust to obtain

the best focus.

Fig. 3-7

Adjust Point of Blue

Adjust Point of Green and Red

Fig. 3-9

– 16 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

CN5003

R9901

SECTION 4

SAFETY RELATED ADJUSTMENT

RM-961

When replacing the following components marked with ] on

the schematic diagram, always check hold-down voltage and

if necessary re-adjust.

Part Replaced ([)

R9901

Part Replaced (])

D Board C5117, C5123, C5127, C5143, D5115,

D5204, Q5104, R5136, R5138, R5140,

R9901, T5102, T5104, T5103 (FBT)

G Board C6024, C6032, D6020

4-1. HV HOLD-DOWN ADJUSTMENT

1. Connect HV static voltmeter to HV Block.

2. Mount a resistor (R9901 : 43 k , 1/4 W, METAL

FILM) at CN5003.

3. Remove CN5002 and connect External Power Supply to

CN5002 1 pin (+135 V) and 2 pin (GND).

4. Turn on the set.

Power

Supply

+

–

Fig. 4-1

Remove the cap off

from the unused

terminal and connect a

HV static voltmeter

there.

1

CN5002

2

D BOARD

CN5002

– CONDUCTOR SIDE –

CN5003

Fig. 4-3

Fig. 4-4

5. Receive the Dot signal and set PICTURE/BRIGHTNESS

to minimum.

6. Slowly up the supply voltage from 0 V to 135 V until

hold-down circuit works (picture disappear).

7. Read the HV static voltmeter of peak HV voltage.

Spec : 33.7 ~ 35.3 kV

8. If Hold-down voltage is less than 33.7 kV then replace

R9901 of 43 k with that of 39 k , and check if the

voltage is within the spec.

9. If hold-down voltage is over than 35.3 kV then replace

R9901 of 43 k with that of 47 k , and check if the voltage is within the spec.

Fig. 4-2

– 17 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

SECTION 5

ELECTRICAL ADJUSTMENTS

RM-961

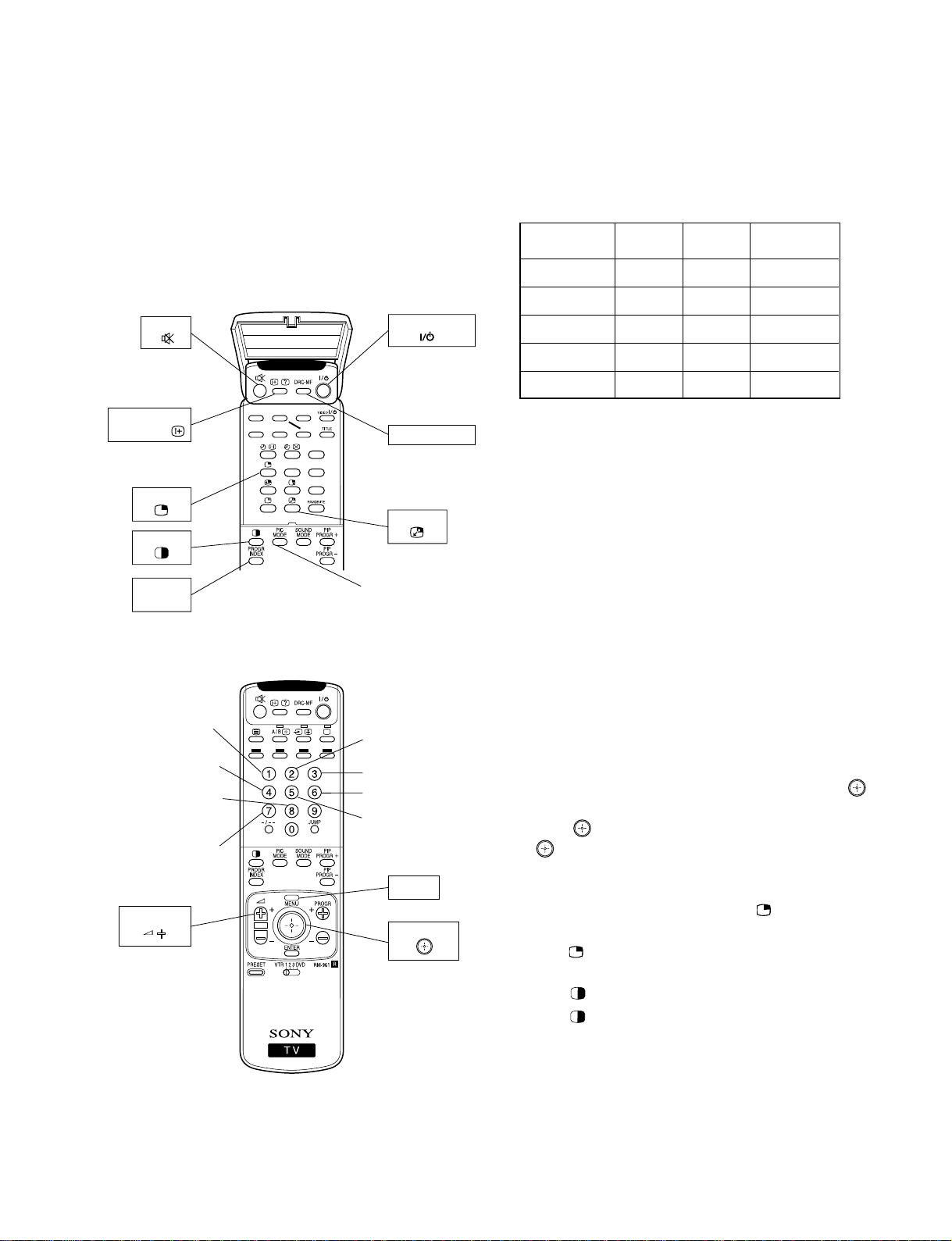

5-1. ADJUSTMENTS WITH COMMANDER

Service adjustment to this model can performed with the supplied remote commander RM-961

(open the cover)

MUTE

Write data to NVM

ON SCREEN

DISPLAY

Copy PAL data

to NTSC

PIP

TWIN

PROGR

INDEX

Adjustment item

up

Adjustment item

down

User control goes

to the standard state

Read data from

NVM

VOLUME +

.>N

xX

z

TV STANDBY

DRC-MF (blue)

SWAP

Change

the PICTUER MODE

Copy data to all

mode

Data up

Data down

Initialize data

(Not stored)

MENU

JOYSTICK

Up : Category up

Down : Category down

Push : Enter

RM-961

5-1-1.How to Select Each Mode

The adjustment requires the following modes:

50 Hz 60 Hz WIDE 60 Hz

(PAL) (NTSC) (NTSC)

DRC1250 aaa

DRC100 aa

X

PIP aaa

TWIN aa

INDEX aa

X

X

1. Selection of Mode Between 50 Hz and 60 Hz

50 Hz : Enter the PAL signal.

60 Hz : Enter the NTSC signal.

WIDE 60 Hz : Enter the NTSC signal with video input

2. Selection of DRC Mode

1) Press “DRC-MF (blue)” button on the commander, repeatedly until displays the mode that you want to select on the

screen.

Note : The DRC-MF mode is not selectable when using the

“PROGRAM INDEX” or “FAVORITE CH” feature, or

when the “GAME MODE”, “PIP”, or “TWIN” mode is

turned “ON”.

3. Selection of WIDE mode

The WIDE mode is selected only when the DRC1250 of NTSC

signal with video input mode is active.

1) Enter the NTSC signal with video input.

2) Press “DRC-MF (blue)” button on the commander to select

“DRC1250”.

3) Press “MENU” button on the commander and move “

up or down to enter the “FEATURE” b “WIDE MODE”.

4) Move “

” up or down to select “ON” or “OFF”, and push

“ (ENTER)” button.

5) Press “MENU” button to return to normal screen.

4. Selection of PIP mode

1) Open the remote control cover, press “ (PIP)” button on

the commander.

2) Press “

(PIP)” button again to return to normal screen.

5. Selection of TWIN mode

1) Press “ (TWIN)” button on the commander.

2) Press “

(TWIN)” button again to return to normal screen.

6. Selection of INDEX mode

1) Press “PROGR INDEX” button on the commander.

2) Press “PROGR INDEX” button again to return to normal

screen.

”

– 18 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

5-1-2. How to Enter Service Mode

1. Turn on the main power switch to place this set in standby

mode. (LED will light in red.)

2. Press the buttons on the commander as follows, and enter

service mode.

Enter the

“Service mode”

)

(

DISPLAY

5

(DIGIT 5) (VOLUME +)ON SCREEN

)

TV

(

STANDBY

5-1-3. Method of Cancellation from Service Mode

1. Set the standby mode (Press “ (TV STANDBY)” button

on the commander), then press “

(TV STANDBY)” but-

ton again, hereupon it becomes TV mode.

5-1-4. How to Adjustments

1. Set in the service mode, the following screen will appear.

Category Name Item Name Mode

Item No.

GEO 00 VSZ 2B SERVICE 50

0 025Q 1.4M 00 FF 0001

Data

50 : PAL, SECAM

60 : NTSC

5-1-5.How to Write the Data

1. Set in the service mode.

2. Press “1” or “4” button on the commander, select the adjustment item, and press “3” or “6” button to change the

data.

3. Press “ (MUTE)” button on the commander and it will

indicate “WRITE” on the screen.

4. Press “-” button on the commander to write into memory.

(The “WRITE” display will be changed to red color while

executing, and back to “SERVICE”.)

Commander Function (Except PJE mode)

Button Mode Description

+ - WRITE Writes data to NVM.

7 + - READ Reads data from NVM.

8 + - NORMAL All user control goes to the standard.

5 + - INITIAL Service data initialization. Not stored.

(Be sure not to use usually)

2 + - COPY Copies and writes data of DRC1250

(50Hz) mode to all other modes.

+ - WRT5060 Copies data of 50 Hz (PAL) mode to

60 Hz (NTSC) mode.

Suffix No.

Software

Version

Total Power On time

(Hours)

2. Press “1” or “4” button on the commander to select the

adjustment item.

3. Press “3” or “6” button on the commander to change the

adjustment data.

4. Move “

When move “

” up or down to select the adjustment category.

” up (category up), service mode changes in

the order as shown below.

GEO

DAC

WHB

SAJ

JGL

YCT

SYC

AP

MSP

LTI

MID

3CM

2CM

DSP

TXT

PJE*

OPM

OPB

Note : Before changing to other modes, press “ (MUTE)” +

“-” buttons on the commander to write the data.

(Omission of this operation causes the data to be returned

to the data before adjustment.)

: Confirm the adjustment mode before writing data for data

values because to vary in each adjustment mode.

: The adjustment item that there are no relations in the ad-

justment is not to change data values because all items are

written in each adjustment mode.

5-1-6.Memory Write Confirmation Method

1. After adjustment, pull put the plug from AC outlet, and then

plug into AC outlet again.

2. Turn the power switch ON and set in service mode.

3. Call the adjustment items again to confirm adjustments were

made.

* : When it moves from PJE to other categrys,

repeat 1 or 4 button and press it.

– 19 –

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

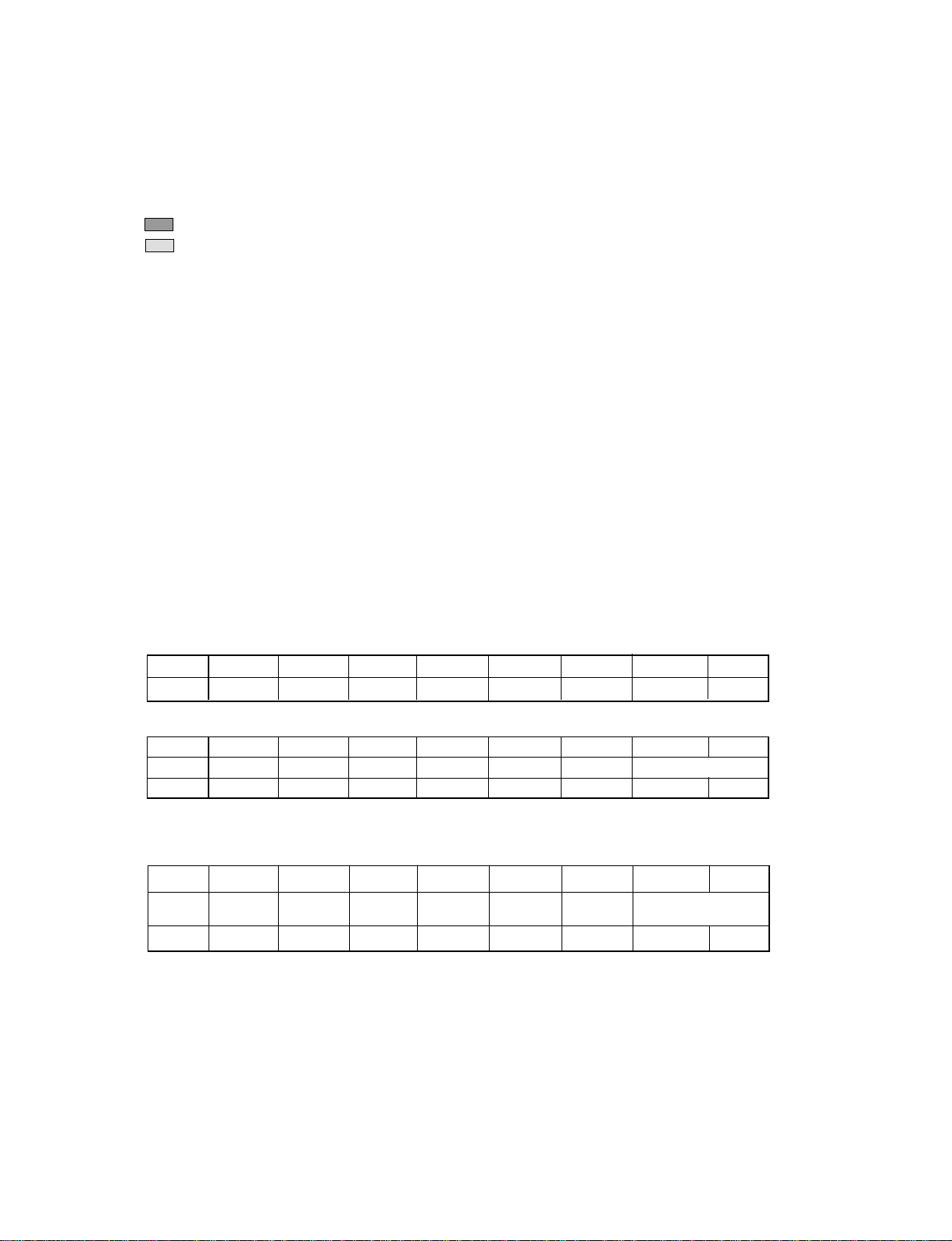

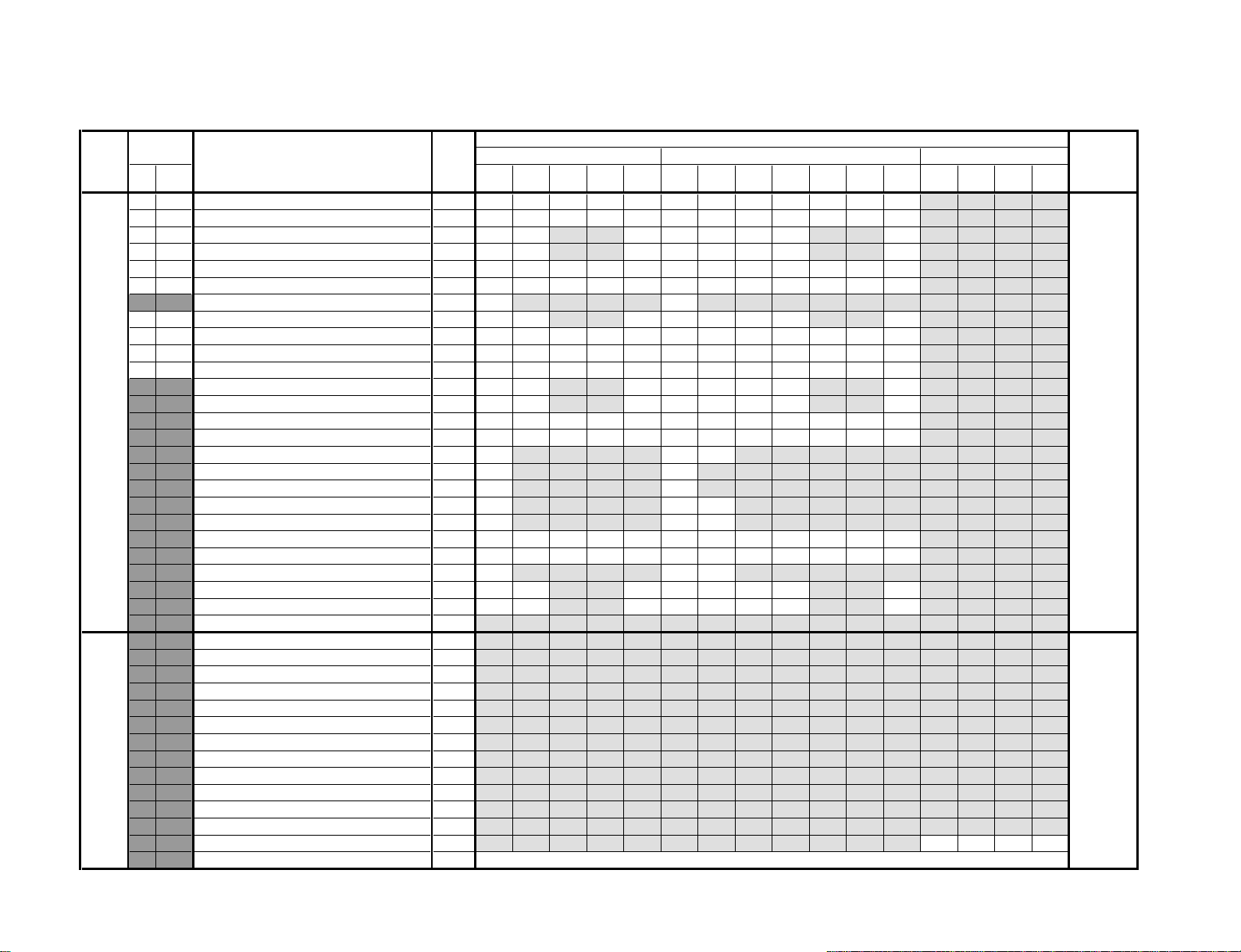

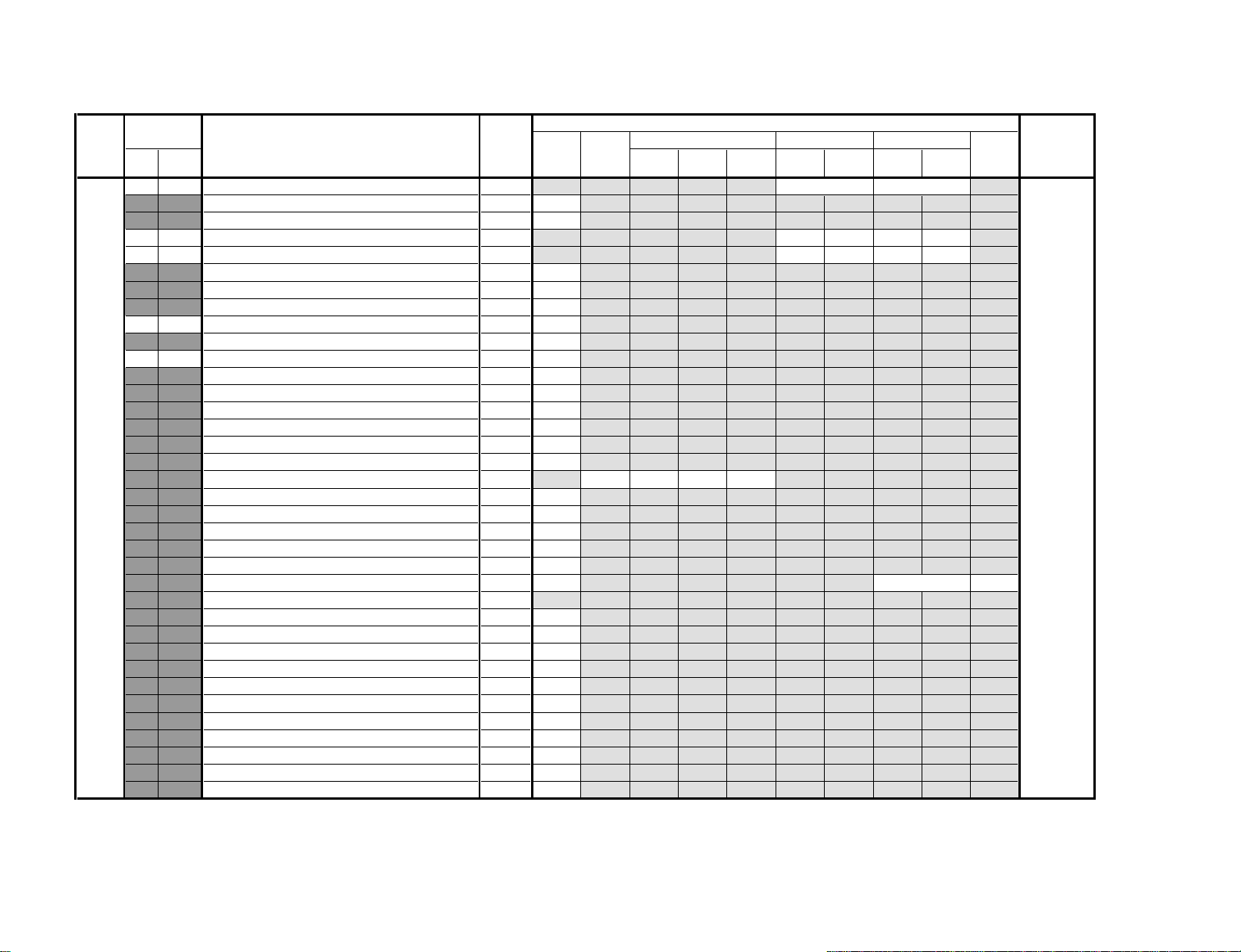

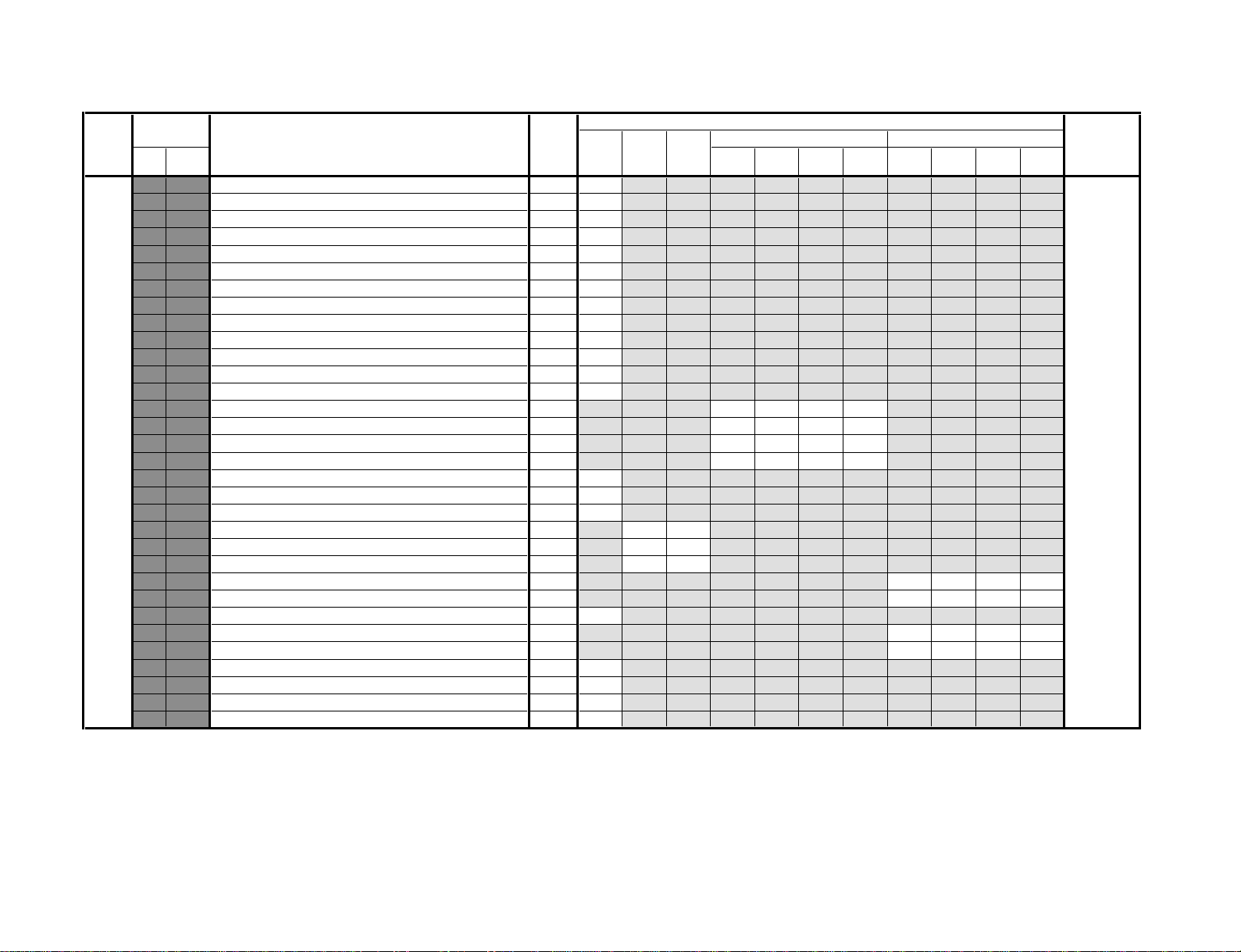

5-2. SERVICE LIST

Note

• Common : The data value of each mode commonness. Others are set up by each mode.

• : Shaded items are fixed data.

• : Though data value is indicated on the screen, it is not used.

• Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and for each

mode.

• Note for Different Data :

Those are the standard data values written on the microprocessor. Therefore, the data values of the modes and stored respectively

in the memory.

In case of a device replacement, adjustment by rewriting the data value is necessary for some items.

OPTION NOTE

Category : OPM

Item : COM Comb Operation Selection 00 = automatic operation (depends on color system status)

01 = no comb operation

02 = forced 2D-comb operation

03 = forced 3D-comb operation

RM-961

Item : TSY TV System Selection for Auto TV System 00 = B/G, 01 = I, 10 = D/K, 11 = M

Item : SSO Speed CH Search Selection 00 = normal, 01 = 4 times, 10 = 6 times, 11 = 8 times

Item : TRP MPEG/JPEG Noise Reduction

Bit bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

Input ––TV Video 1 Video 2 Video 3 Video 4 DVD

Category : OPB

OP1 bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

Item TOP NICAM HDEV (reserved) – DVD Input AV Input

Data 11100111

AV Input 00 = no AV Input 01 = 1 AV Input

10 = 3 AV Input 11 = 4 AV Input

OP2 bit7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

Item C-Text

Data 00010011

C-Text Text Decoder Selection 0 = original, 1 = chinese

Korean Stereo* Korean Stereo 0 = disabled, 1 = enabled

Video NTSC 3.58* Video Color System 0 = Multi System, 1 = Single System

A-TVsys Auto TV System in Auto Program 0 = disabled, 1 = enabled

US ST* USA Stereo 0 = disabled, 1 = enabled

SSV Model SSV-production Model 0 = original, 1 = disable PIP/TWIN/Digital

OSD Language 00 = English only, 01 = English & Chinese,

* : APPLICABLE FOR NTSC MODELS ONLY

Korean Korean

Stereo Mode Mode

10 = English & Arabic/Korean* 11 = English, Chinese & Arabic/Korean*

A-TVsys US ST

SSV

OSD Language

– 20 –

V : WIDE (V-Compressed) mode

DRC

1250 V

Standerd Data

PIP

PIP V

00

INDEX TWIN

DRC

100

ECOONECO

OFF

ECO

ON V

ECO

OFF V

Device NameFunction

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

Category

GEO 00 VSZ V SIZE 00 ~ 3F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F CXA2100AQ

– 21 –

DAC 00 HCT H CENTER 00 ~ FF MB88141

Item

No. Name

01 VPS V POSITION 00 ~ 3F 23 23 1F 1F 23 1F 1F 1F 1F 1F 1F 1F

02 VLN V LINEARITY 00 ~ 0F 07 07 07 07 07 07 07 07

03 SCO S CORRECTION 00 ~ 0F 07 07 07 07 07 07 07 07

04 HSZ H SIZE 00 ~ 3F 33 33 33 33 33 33 33 33 33 33 33 33

05 HPS H POSITION 00 ~ 3F 37 37 37 37 37 37 37 37 37 37 37 37

06 DVH H POSITION OFFSET FOR DVD 00 ~ 0F 09 07

07 PAP PIN AMP 00 ~ 3F 22 22 22 22 22 22 22 22

08 UPN UPPER CORNER PIN 00 ~ 3F 22 22 22 22 22 22 22 22 22 22 22 22

09 LPN LOWER CORNER PIN 00 ~ 3F 22 22 22 22 22 22 22 22 22 22 22 22

0A TRZ TRAPEZIUM 00 ~ 0F 06 06 06 06 06 06 06 06 06 06 06 06

0B AGL AFC ANGLE 00 ~ 0F 07 07 07 07 07 07 07 07

0C BOW AFC BOW 00 ~ 0F 07 07 07 07 07 07 07 07

0D LBL LEFT H BLANKING 00 ~ 3F 34 34 34 34 34 34 34 34 34 34 34 34

0E RBL RIGHT H BLANKING 00 ~ 3F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F 1F

0F MPN MIDDLE PIN DISTORTION COMPENSATION 00 ~ 03 00 00 00

10 UVL UPPER V LINEARITY 00 ~ 0F 00 00

11 LVL LOWER V LINEARITY 00 ~ 0F 00 00

12 HCP HORIZONTAL HIGH VOLTAGE COMPENSATION 00 ~ 03 01 01 01

13 VCP VERTICAL HIGH VOLTAGE COMPENSATION 00 ~ 03 00 00 00

14 VAS V ASPECT 00 ~ 3F 2F 2F 2F 2F 2F 2F 2C 2F 2C 2F 2F 2F

15 VSC V SCROLL 00 ~ 3F 1F 1F 1F 1F 1F 22 22 22 22 22 22 22

16 USC UNDER-SCAN MODE ON/OFF 00, 01 00 00 01

17 VBW V BLANKING WIDTH CONTROL 00 ~ 03 00 00 00 00 03 00 03 00

18 AT1 AKB REFERENCE TIMING 00 ~ 03 00 00 00 00 00 00 00 00

19 CPY COPY THE GEO DATA TO ALL 50/60Hz NVM AREA 00, 01

01 HLN H LINEARITY 00 ~ 3F

02 MDP MIDDLE PIN 00 ~ 3F

03 CCP LOWER CORNER PIN 00 ~ 3F

04 HTR HORIZONTAL TRAPEZIUM 00 ~ 3F

05 DF DF ON/OFF SWITCH 00, 01

06 DPH DF PHASE 00 ~ 3F

07 QPH QP PHASE 00 ~ 3F

08 QAC QP AMPLITUDE 00 ~ 3F

09 QDC QP DC LEVEL 00 ~ 3F

0A QDV QP V MODULATION 00 ~ 3F

0B QAV QP AMPLITUDE MODULATION 00 ~ 3F

0C ABC ABL D/A CONTROL 00 ~ FF 00 00 7E 7E

0D CPY COPY THE DAC DATA TO ALL 50/60Hz NVM AREA 00, 01

Data

Range

DRC

1250

50Hz (PAL) 60Hz (NTSC) ECO Mode

DRC

PIP INDEX TWIN

100

DRC

1250

Category Device NameFunction

WHB 00 CBO DC OFFSET CANCELLER FOR CB1 00 ~ 0F 0A CXA2100AQ

Item

No. Name Common

01 CRO DC OFFSET CANCELLER FOR CR1 00 ~ 0F 0A

02 SBR SUB BRIGHTNESS CONTROL 00 ~ 3F 25

03 RDR R DRIVE 00 ~ 3F 29

04 GDR G DRIVE 00 ~ 3F 29

05 BDR B DRIVE 00 ~ 3F 29

06 RCT R CUTOFF 00 ~ 3F 29

07 GCT G CUTOFF 00 ~ 3F 1A

08 BCT B CUTOFF 00 ~ 3F 29

09 SBO SUB BRIGHTNESS OFFSET 00 ~ 3F 1F

0A RDO R DRIVE OFFSET 00 ~ 3F 1F

0B GDO G DRIVE OFFSET 00 ~ 3F 1F

0C BDO B DRIVE OFFSET 00 ~ 3F 1F

0D RCO R CUTOFF OFFSET 00 ~ 3F 1F

0E GCO G CUTOFF OFFSET 00 ~ 3F 1F

0F BCO B CUTOFF OFFSET 00 ~ 3F 1F

– 22 –

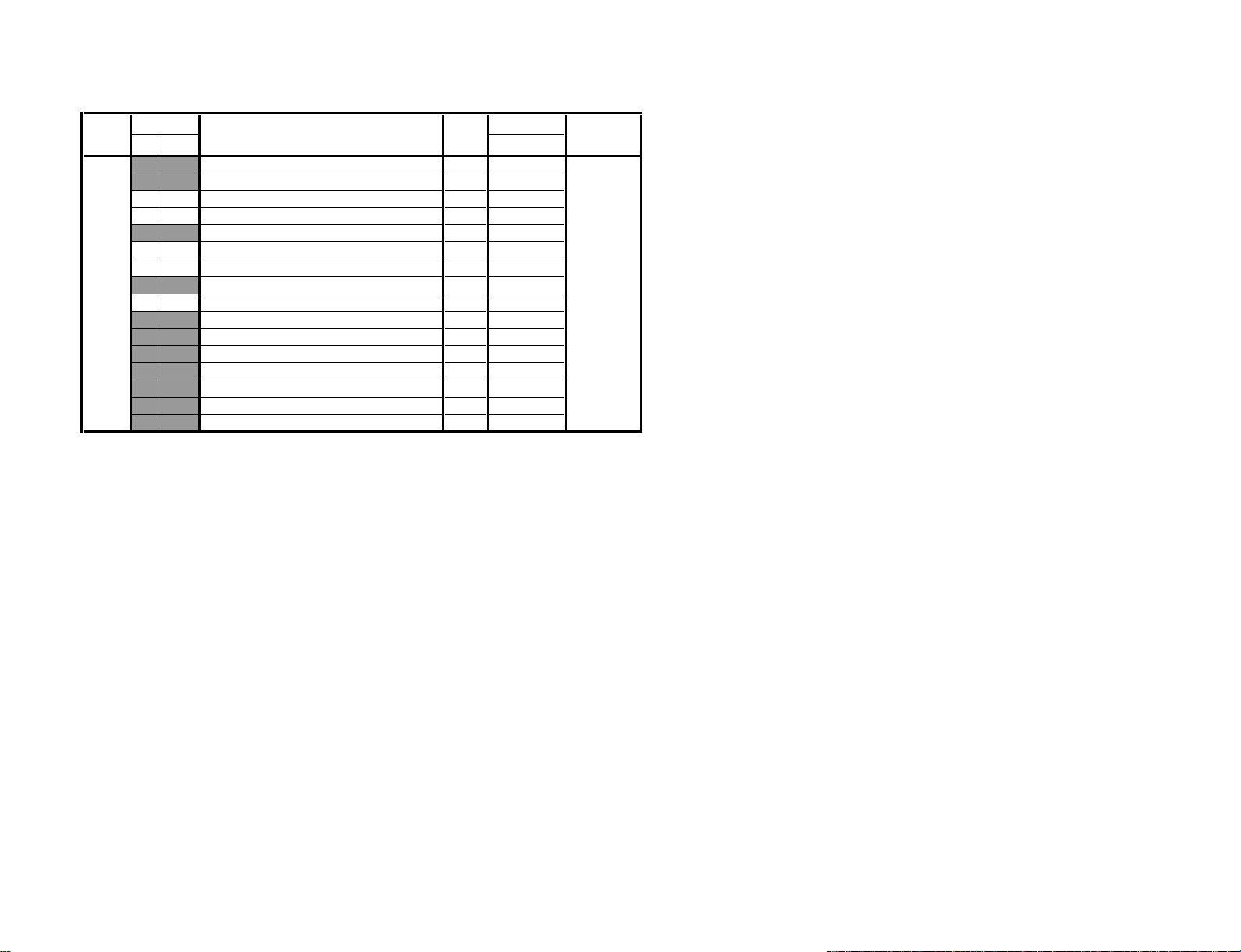

Data

Range

Standerd Data

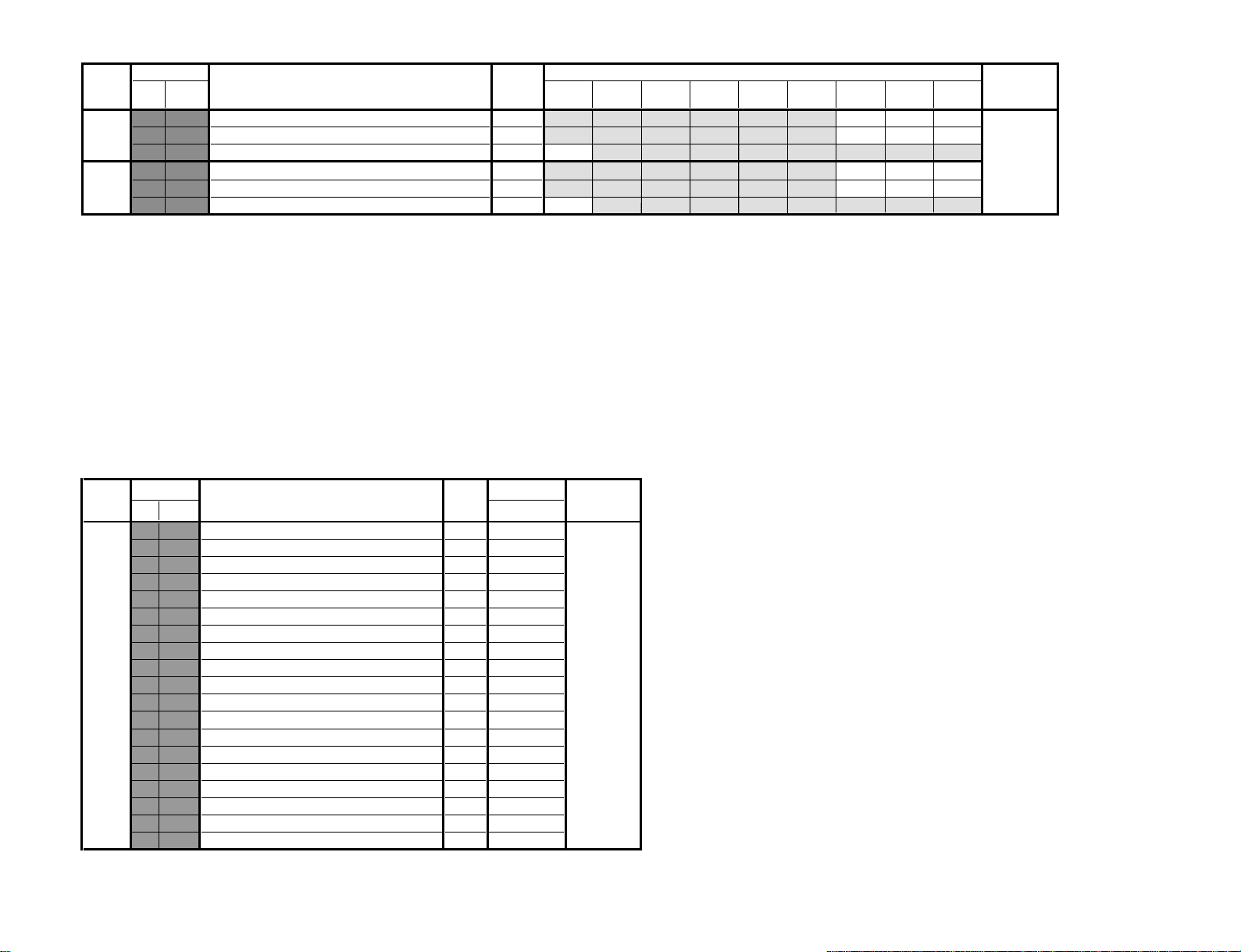

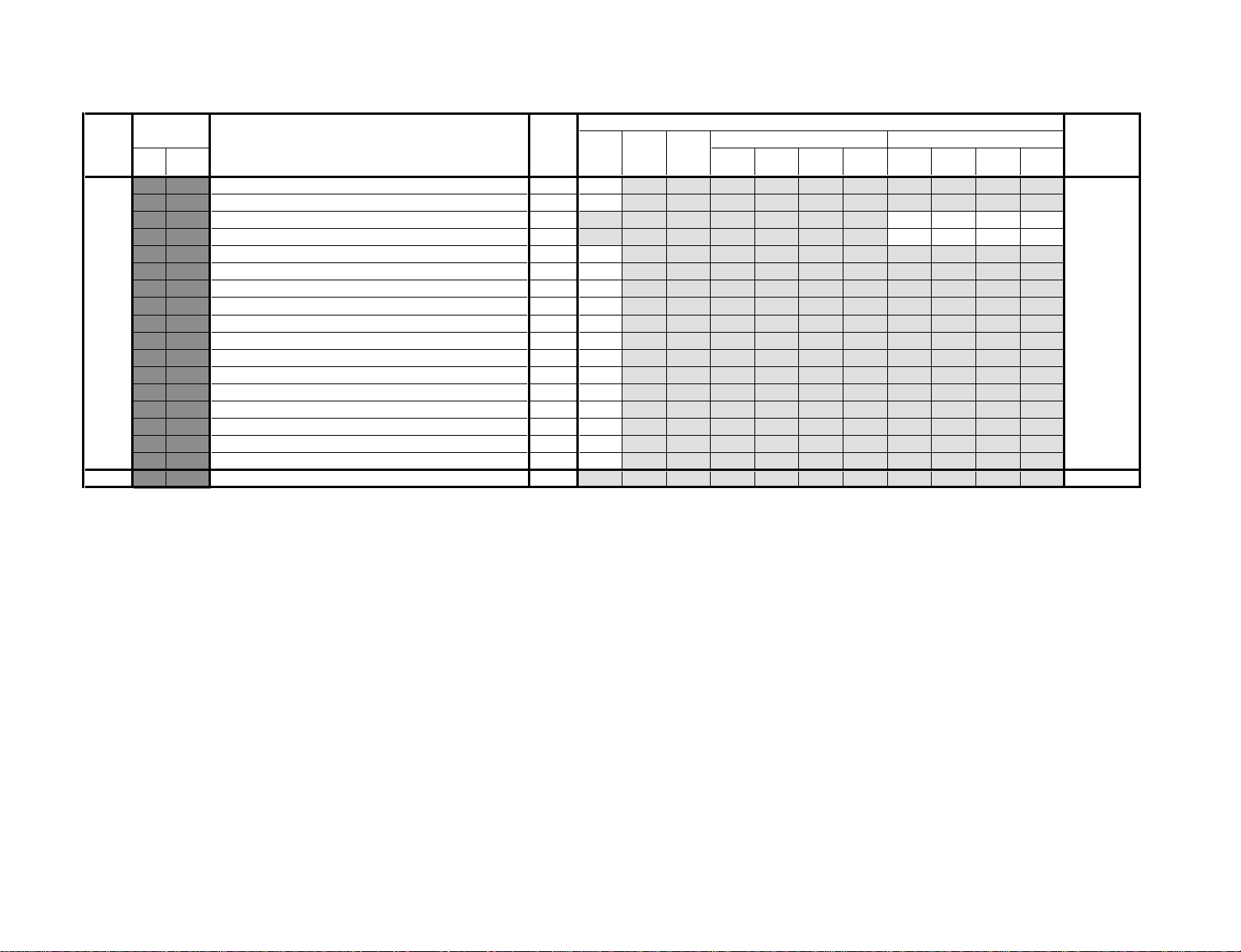

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

V : WIDE (V-Compressed) mode

Twin IndexCommon

Standerd Data

ECOONECO

OFF

ECO

ON V

ECO

OFF V

Device Name

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

Category

SAJ 00 PIC PICTURE CONTROL 00 ~ 3F 3F 2C 1C CXA2100AQ

– 23 –

JGL 00 PON

Item

No. Name TV Video DVD TV Video DVD Dynamic Standard Hi-Fine Personal

01 BRT BRIGHTNESS CONTROL 00 ~ 3F 21 1F 1B

02 COL COLOR CONTROL 00 ~ 3F 27 23 1F

03 HUE HUE CONTROL 00 ~ 3F 1F 1F 1F

04 SHP SHARPNESS CONTROL 00 ~ 3F 22 1F 1D

05 VML VM LEVEL 00 ~ 03 03 03 02 03

06 DYC DYNAMIC COLOR ON/OFF 00, 01 01 01 00 01

07 CTM COLOR TEMPERATURE FOR DYNAMIC COLOR 00, 01 00 00 00 00

08 CAX COLOR MATRIX SPECIFICATION 00 ~ 03

09 GMA GAMMA CORRECTION 00 ~ 03 03 03 03 03

0A DCT DC TRANSMISSION CONTROL 00 ~ 03 01 00 00 00

0B DPL AUTO PEDESTAL LEVEL CONTROL 00 ~ 03 02 01 00 01

0C ABM ABL MODE CONTROL 00 ~ 03 01 00 00 00

0D ABT ABL CURRENT DETECTION Vth CONTROL 00 ~ 03 02 00 02 00

0E CLO COLOR OFFSET 00 ~ 0F 07 07 0C 0C

0F CLW COLOR STEP WIDTH TO THE CHANGE OF S/N 00 ~ 07 01

10 HUO HUE OFFSET 00 ~ 0F 08 08 09 09

11 SHO SHARPNESS OFFSET 00 ~ 1F 0F 0F 0F 0C 0F 0F

12 SHW

13 PIO PICTURE OFFSET FOR TWIN/INDEX 00 ~ 07 07 07

14 BRO BRIGHTNESS OFFSET 00 ~ 0F 07 07 07 07

01 RGB RGB OUTPUT SELECTION 00 ~ 07 07

02 AGG AGING MODE SELECTION 00 ~ 03 00

03 DPS Y/C DELAY LINE PASS MODE SWITCH 00, 01 00

04 BBT RGB BOTTOM LIMITTER CONTROL 00 ~ 03 03

05 LML RGB AMPLITUDE LIMITTER CONTROL 00 ~ 03 00

06 PAB DC LEVEL FOR PEAK ABL 00 ~ 0F 0F

07 SCO SUB PICTURE CONTROL 00 ~ 0F 07

08 LV2 RGB LEVEL FOR RGB2 00 ~ 0F 06

09 SF0 SHARPNESS CIRCUIT F0 00, 01 01 01 01 01 01 01

0A PRO PRE/OVER-SHOOT RATIO CONTROL 00 ~ 03 00 03 03 03 03 03

0B LTI LUMINANCE TRANSIENT IMPROVEMENT 00 ~ 03 02 02 00 02

0C CTI CHROMINANCE TRANSIENT IMPROVEMENT 00 ~ 03 01 01 00 01

SHARPNESS STEP WIDTH TO

THE CHANGE OF S/N

RGB AND AKB REFERENCE PULSE

OUTPUT ON/OFF

Function

Data

Range

00 ~ 07 01

00, 01 01 CXA2100AQ

50Hz (PAL) 60Hz (NTSC) ECO ModePicture Mode

02 00

RM-961

Category

YCT 00 TNT TINT ADJUSTMENT FOR NTSC 00 ~ 3F CXA2123Q

– 24 –

Item

No. Name

01 PNG PAL/NTSC GATE WIDTH 00, 01 01

02 PNI PAL/NTSC SENSITIVITY SW 00, 01 00

03 SCL SUB COLOR CONTROL 00 ~ 0F 07 07 07 07

04 SCT SUB CONTRAST CONTROL 00 ~ 0F 08 07 08 07

05 SF0 SHARPNESS CENTER FREQUENCY CHANGING 00 ~ 03 02

06 SEQ SHARPNESS EQUALIZER CHARACTERISTIC 00 ~ 03 03

07 SHG SHARPNESS GAIN CONTROL 00 ~ 0F 05 06 05 06 05 05

08 YOL Y-OUTPUT LEVEL CONTROL 00 ~ 3F 1F

09 BSP BLACK STRETCH START POINT CHANGING 00 ~ 03 00

0A COL CB/CR OUTPUT LEVEL CONTROL 00 ~ 3F 1A

0B DCR DC RESTORATION RATIO ADJUSTMENT 00 ~ 03 00

0C BF0 BPF/TQF F0 ADJUSTMENT 00 ~ 03 01

0D BFQ BPF/TQF Q ADJUSTMENT 00 ~ 03 02

0E FSW BPF/TQF SWITCH 00, 01 01

0F SDT SECAM DOUBLE TRAP SWITCH 00, 01 01

10 LPF Y/CB/CR LPF SWITCH 00, 01 01

11 YDL Y-DL TIME ADJUSTMENT 00 ~ 0F 06 05 05 03

12 CMT CB/CR OUTPUT MUTE SWITCH 00, 01 00

13 BO1 CB OFFSET ADJUSTMENT (MAIN ROUTE) 00 ~ 0F 07

14 RO1 CR OFFSET ADJUSTMENT 00 ~ 0F 07

15 CDF V COUNT DOWN FREQUENCY SWITCH 00 ~ 07 00

16 CDM V COUNT DOWN JUDGE SWITCH 00 ~ 03 00

17 AFC AFC SENSITIVITY SWITCH 00 ~ 03

18 MVM MACROVISION MASK + AFC MASK 00, 01 00

19 SRY SECAM R-Y BLACK ADJUSTMENT 00 ~ 0F 07

1A SBY SECAM B-Y BLACK ADJUSTMENT 00 ~ 0F 01

1B BEL SECAM BELL/HPF SWITCHING 00 ~ 03 02

1C BLF BELL F0 ADJUSTMENT 00, 01 00

1D SVI SECAM V-ID SWITCH 00, 01 00

1E SGP SECAM GATE POSITION ADJUSTMENT 00 ~ 03 00

1F SID SECAM SENSITIVITY SWITCH 00, 01 01

20 SIH SECAM INHIBITION SWITCH 00, 01 00

21 STP Y BLACK LEVEL SETUP FOR PAL PLUS 00, 01 00

22 HVC H-VCO TEMPERATURE CHARACTER CANCELLING 00 ~ 03 02

23 3NR 3D NR OPERATION ON/OFF 00, 01 01

24 BW6 3D NR FOR 60Hz NON-BURST SIGNAL ON/OFF 00, 01 01

25 WSH SHARPNESS GAIN STEP FOR NOISE REDUCTION 00 ~ 03 00

26 WCO CB/CR OUTPUT LEVEL STEP FOR NOISE REDUCTION 00 ~ 03 00

Data

Range

Common 2D Comb 3D Comb S-Input others

Standerd Data

50Hz

(PAL)

TV Video DVD

60Hz

(NTSC)

24 1F

50Hz

(PAL)

60Hz

(NTSC)

00 00

50Hz

(PAL)

(NTSC)

Device NameFunction

60Hz

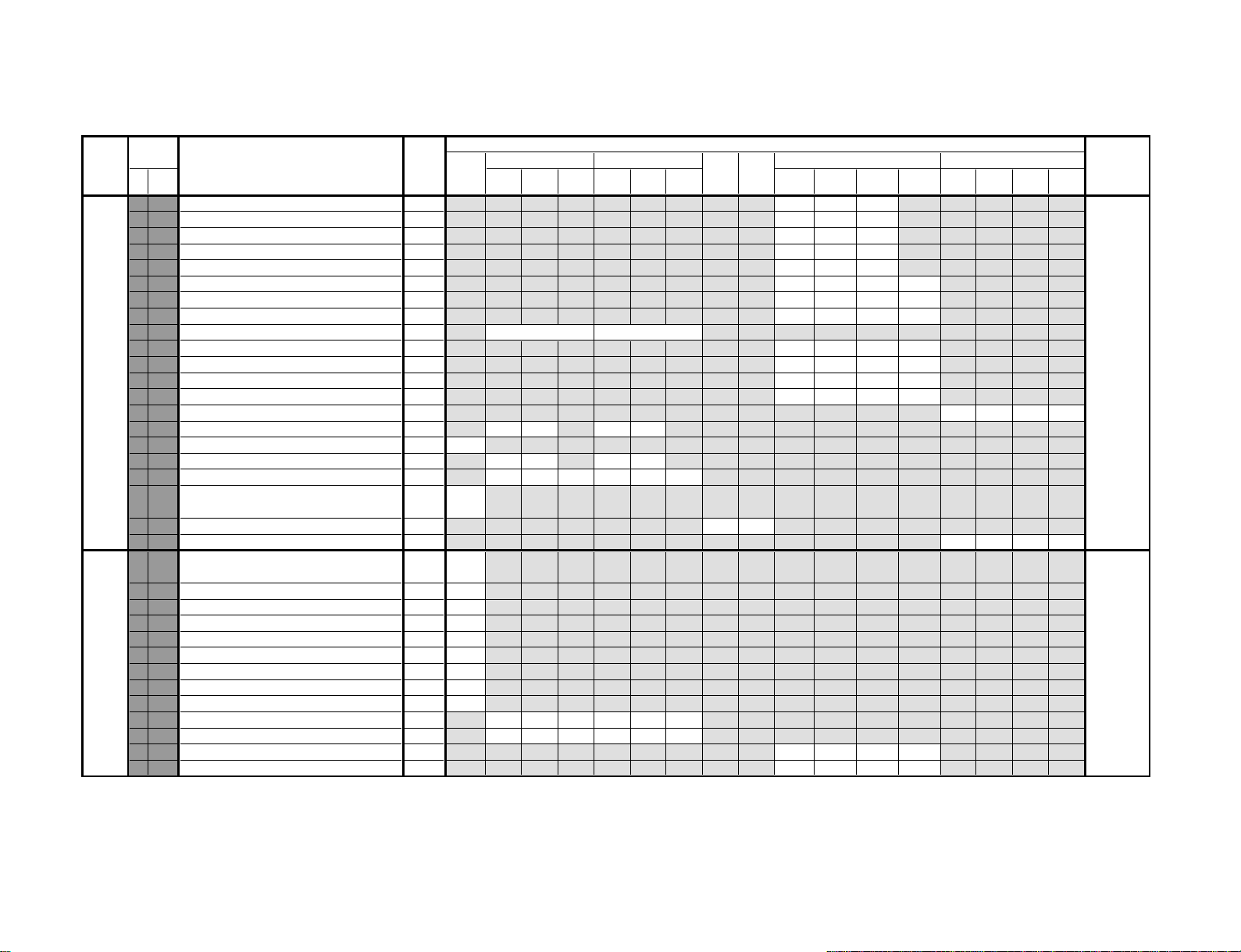

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

Category

SYC 00 TNT TINT ADJUSTMENT FOR NTSC 00 ~ 3F CXA2123Q

– 25 –

Item

No. Name SECAM NTSC PAL

01 PNG PAL/NTSC GATE WIDTH 00, 01 01

02 PNI PAL/NTSC SENSITIVITY SW 00, 01 00

03 SCL SUB COLOR CONTROL 00 ~ 0F 06 06 07 07

04 SCT SUB CONTRAST CONTROL 00 ~ 0F 08 07 08 07

05 SF0 SHARPNESS CENTER FREQUENCY CHANGING 00 ~ 03 02

06 SEQ SHARPNESS EQUALIZER CHARACTERISTIC 00 ~ 03 03

07 SHG SHARPNESS GAIN CONTROL 00 ~ 0F 07

08 YOL Y-OUTPUT LEVEL CONTROL 00 ~ 3F 1F

09 BSP BLACK STRETCH START POINT CHANGING 00 ~ 03 00

0A COL CB/CR OUTPUT LEVEL CONTROL 00 ~ 3F 1A

0B DCR DC RESTORATION RATIO ADJUSTMENT 00 ~ 03 00

0C BF0 BPF/TQF F0 ADJUSTMENT 00 ~ 03 01

0D BFQ BPF/TQF Q ADJUSTMENT 00 ~ 03 02

0E FSW BPF/TQF SWITCH 00, 01 01

0F SDT SECAM DOUBLE TRAP SWITCH 00, 01 01

10 LPF Y/CB/CR LPF SWITCH 00, 01 01

11 YDL Y-DL TIME ADJUSTMENT 00 ~ 0F 05 03 02 03

12 NCM 1-H ADDITION SWITCH 00, 01 01

13 CMT CB/CR OUTPUT MUTE SWITCH 00, 01 00

14 BO1 CB OFFSET ADJUSTMENT (MAIN ROUTE) 00 ~ 0F 07

15 RO1 CR OFFSET ADJUSTMENT 00 ~ 0F 07

16 CDF V COUNT DOWN FREQUENCY SWITCH 00 ~ 07 00

17 CDM V COUNT DOWN JUDGE SWITCH 00 ~ 03 00 00

18 AFC AFC SENSITIVITY SWITCH 00 ~ 03

19 MVM MACROVISION MASK + AFC MASK 00, 01 00

1A SRY SECAM R-Y BLACK ADJUSTMENT 00 ~ 0F 07

1B SBY SECAM B-Y BLACK ADJUSTMENT 00 ~ 0F 01

1C BEL SECAM BELL/HPF SWITCHING 00 ~ 03 02

1D BLF BELL F0 ADJUSTMENT 00, 01 00

1E SVI SECAM V-ID SWITCH 00, 01 00

1F SGP SECAM GATE POSITION ADJUSTMENT 00 ~ 03 00

20 SID SECAM SENSITIVITY SWITCH 00, 01 01

21 SIH SECAM INHIBITION SWITCH 00, 01 00

22 STP Y BLACK LEVEL SETUP FOR PAL PLUS 00, 01 00

23 HVC H-VCO TEMPERATURE CHARACTER CANCELLING 00 ~ 03 02

Data

Range

Common

S-Input

Col Mode

Standerd Data

50Hz

(PAL)

TV Video

60Hz

(NTSC)

21 20

50Hz

(PAL)

00

60Hz

(NTSC)

DVD

Device NameFunction

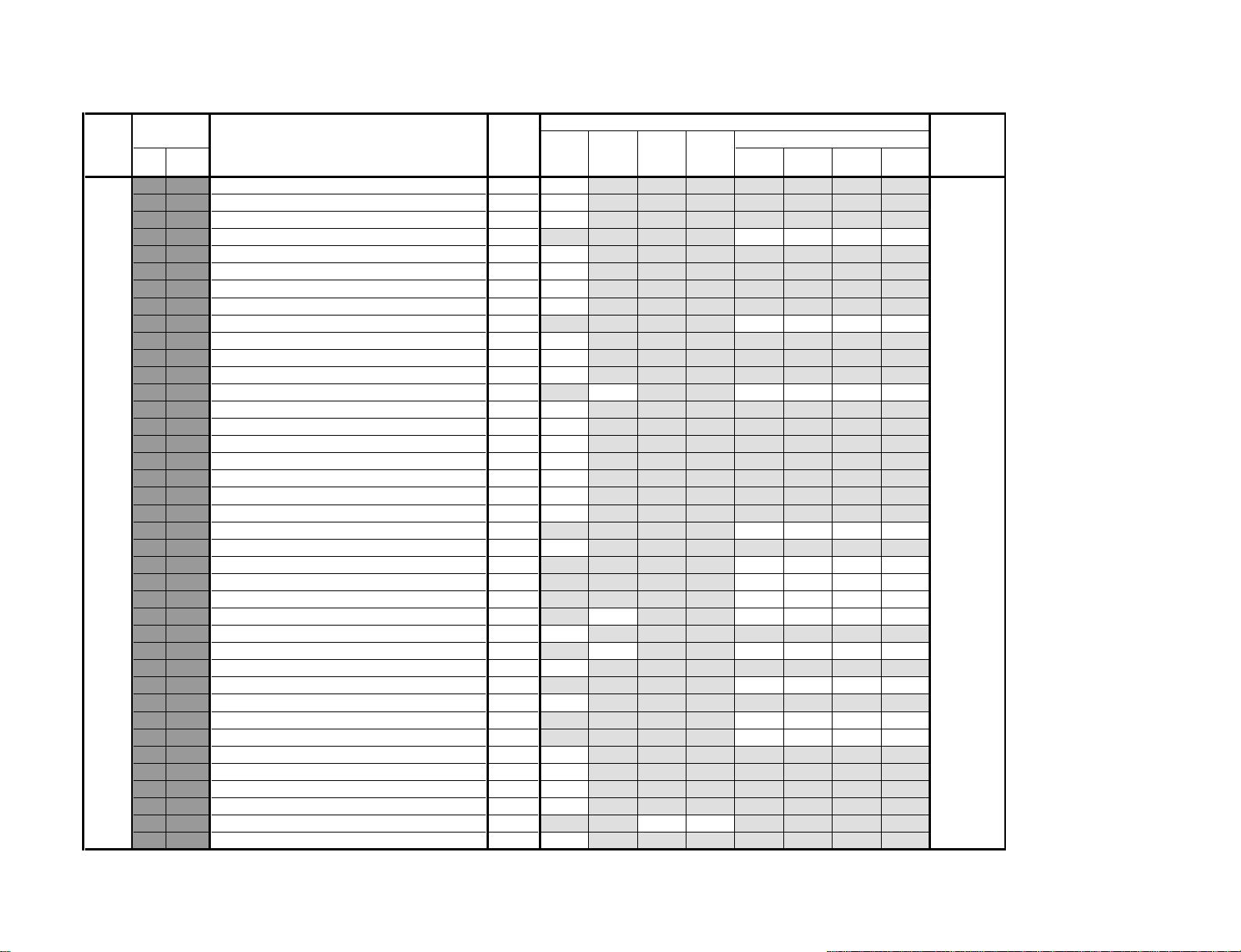

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

Category

43" 00 BAS BASS CONTROL 00 ~ 0F 0B 0A 07 TDA7315

53" 00 BAS BASS CONTROL 00 ~ 0F 09 07 05

Item

No. Name Common Sur VDD Sur VDP Sur TRS Sur SIM Sur OFF Dynamic Drama Soft

01 TRE TREBLE CONTROL 00 ~ 0F 0A 09 07

02 LDN LOUDNESS ON/OFF 00, 01 01

01 TRE TREBLE CONTROL 00 ~ 0F 0B 09 06

02 LDN LOUDNESS ON/OFF 00, 01 01

Sur : Surround mode

VDD : Virtual Dolby Digital

VDP : Virtual Dolby Prologic

TRS : Tru Surround

SIM : Simulated

– 26 –

Category Device NameFunction

MSP 00 WST W/G STEREO THRESHOLD 00 ~ FF 15 MSP3415D

Item

No. Name Common

01 WBT W/G BILINGUAL THRESHOLD 00 ~ FF EA

02 WLL W/G MONAURAL THRESHOLD 00 ~ FF 05

03 WAC W/G AGREEMENT COUNT 00 ~ 0F 01

04 WDL W/G SEARCH DELAY 00 ~ FF 30

05 NDL NICAM SEARCH DELAY 00 ~ FF 20

06 SDL STEREO STATUS READ DELAY 00 ~ FF 10

07 AGC AGC SWITCH AUTO/CONSTANT 00, 01 01

08 REL AGC GAIN AT CONSTANT MODE 00 ~ 3F 28

09 CRM CARRIER MUTING ON/OFF 00, 01 00

0A ACO AUDIO CLOCK OUT ON/OFF 00, 01 01

0B FP FM PRESCALE FOR NON-M SYSTEM 00 ~ 7F 1B

0C FPM FM PRESCALE FOR M SYSTEM 00 ~ 7F 32

0D FH FM PRESCALE FOR HDEV 00 ~ 7F 2D

0E FHM FM PRESCALE FOR HDEV AND M 00 ~ 7F 65

0F WGP W/G PRESCALE 00 ~ 7F 2A

10 NIP NICAM PRESCALE 00 ~ 7F 6D

11 ERR AUTO FM SWITCH THRESHOLD 00 ~ FF 50

12 VOL LOUD SPEAKER GAIN 0700h to 07FFh 00 ~ FF 6D

Data

Range

Data

Range

Standerd Data

Standerd Data

Device NameFunction

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

Category

LTI 00 LDH HISTOGRAM SEGMENT SELECTION 00, 01 01 TDA9178

– 27 –

Item

No. Name Dynamic Standard Hi-Fine Personal

01 CFS CONTOUR FILTER SELECTION 00, 01 01

02 WLB LETTERBOX WINDOW SWITCH 00, 01 00

03 VDC VIDEO DEPENDENT CORING 00, 01 01 01 01 01

04 DEM DEMONSTRATION MODE 00, 01 00

05 CDP LUMINANCE DELAY 00 ~ 07 04

06 OSP OVERRULE SMART PEAKING 00, 01 00

07 WPO WHITE POINT STRETCH OFF 00, 01 00

08 DSK SKIN TONE SWITCH 00, 01 00 00 00 00

09 ASK SKIN TONE ANGLE SELECTION 00, 01 00

0A WSK SKIN TONE WIDTH SELECTION 00, 01 00

0B SSK SKIN TONE SIZE SELECTION 00, 01 00

0C DGR GREEN ENHANCEMENT SWITCH 00, 01 00

0D DGT THRESHOLD OF GREEN ENHANCEMENT SWITCH 00 ~ 07 07

0E GGR GREEN ENHANCEMENT GAIN 00, 01 00

0F WGR GREEN ENHANCEMENT WIDTH 00, 01 00

10 SGR GREEN ENHANCEMENT SIZE 00, 01 00

11 DBL BLUE STRETCH SWITCH 00, 01 00

12 GBL BLUE STRETCH GAIN SELECTION 00, 01 00

13 SBL BLUE STRETCH SIZE SELECTION 00, 01 00

14 CDS COLOR DEPENDENT SHARPNESS 00, 01 01 01 01 01

15 CST THRESHOLD OF COLOR DEPENDENT SHARPNESS 00 ~ 07 07

16 CTI COLOR TRANSIENT IMPROVEMENT 00, 01 00 00 00 00

17 BON BLACK OFFSET COMPENSATION 00, 01 00 00 00 00

18 BTD ADAPTIVE BLACK STRETCH 00 ~ 3F 00 00 00 00

19 NLD NON-LINEARITY AMPLIFIER 00 ~ 3F 00 13 13 05 13

1A NLW STEP WIDTH OF NON-LINEARITY AMPLIFIER 00 ~ 07 07

1B VGD VARIABLE GAMMA 00 ~ 3F 1F 15 15 1A 15

1C VGW STEP WIDTH OF VARIABLE GAMMA 00 ~ 07 00

1D PKD PEAKING AMPLITUDE 00 ~ 3F 32 32 1D 32

1E PKW STEP WIDTH OF PEAKING AMPLITUDE 00 ~ 0F 08

1F SPD STEEPNESS CORRECTION 00 ~ 3F 00 00 00 00

20 CRD CORING LEVEL 00 ~ 3F 14 0D 05 14

21 CRW STEP WIDTH OF CORING LEVEL 00 ~ 0F 09

22 CRO CORING LEVEL OFFSET FOR VIDEO MODE 00 ~ 0F 05

23 LWD LINE WIDTH CORRECTION 00 ~ 3F 1F

24 SNM S/N MODE UNDER UNRELIABLE S/N CONDITION 00 ~ 07 00

25 SNC S/N RATIO AVERAGE COUNTER 00 ~ 0F 03 03

26 FMC FEATURE MODE MATCHING COUNTER 00 ~ 0F 02

Data

Range

Common

Twin

TV

Standerd Data

Video

Picture Mode

*

01 00 01

Device NameFunction

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

Mark Data Value GE/HK/ME model: 01

*

AUS model: 00

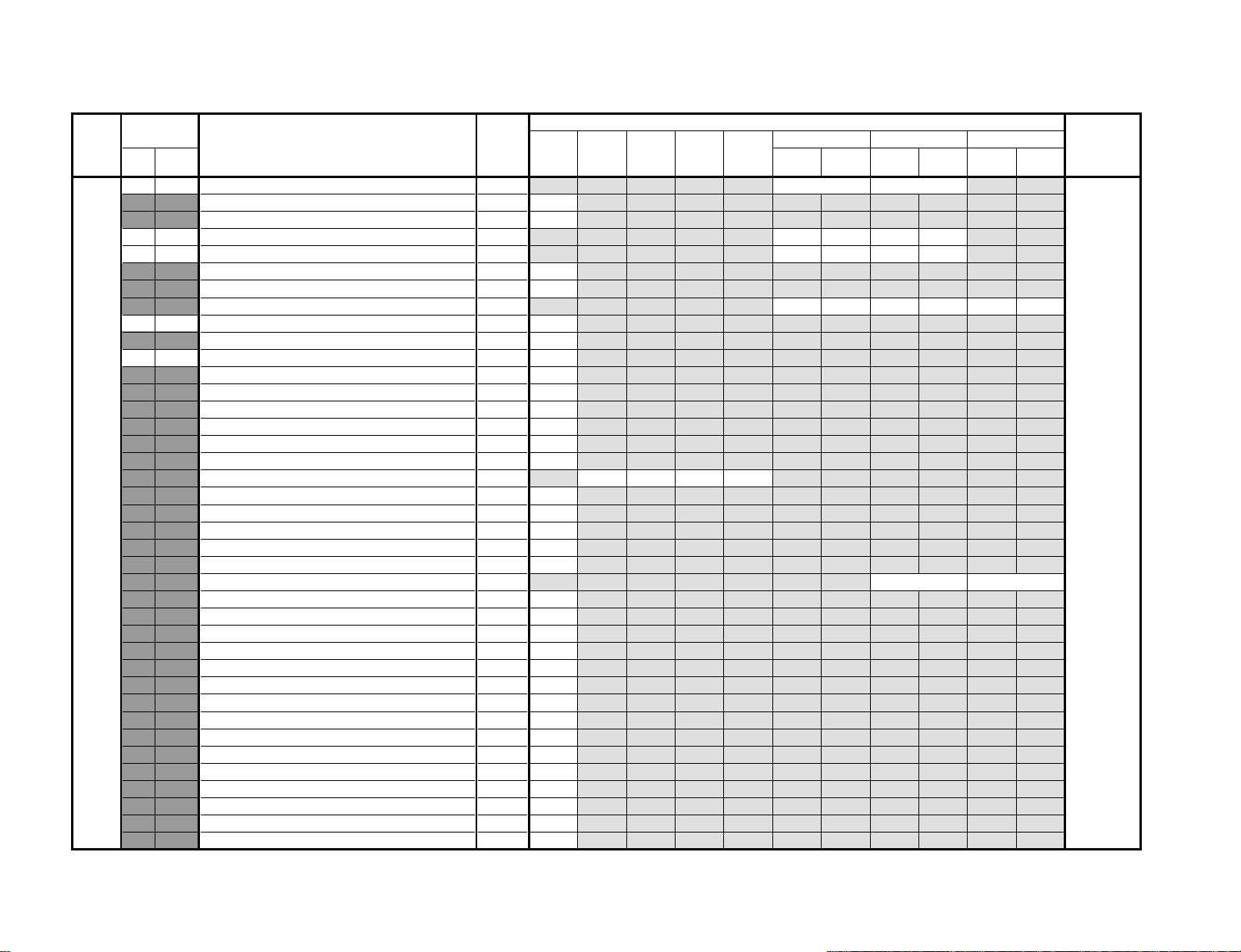

RM-961

Category

MID 00 HPH HORIZONTAL ACTIVE DISPLAY AREA PHASE 00 ~ FF 3E 3E 7B 78 3E 49 49 6F 6C 49 MB94918

– 28 –

Item

No. Name DRC1250 PIP TWIN INDEX DRC100 DRC1250 PIP TWIN INDEX DRC100

01 VPH VERTICAL ACTIVE DISPLAY AREA PHASE 00 ~ 3F 15 15 20 1A 0C 25 25 2E 2D 13

02 HSZ HORIZONTAL ACTIVE DISPLAY AREA SIZE 00 ~ FF 7F 7F 7F 7F 7F 7F 7F 7F 7F 7F

03 VSZ VERTICAL ACTIVE DISPLAY AREA SIZE 00 ~ FF 7F 7F 7F 7F 7F 7F 7F 7F 7F 7F

04 HPW DISPLAY H-SYNC PULSE WIDTH 00 ~ 3F 3F 3F 3F 3F 3F 3F 3F 3F 3F 3F

05 VPW DISPLAY V-SYNC PULSE WIDTH 00 ~ 07 03 03 03 03 03 03 03 03 03 03

06 YDL DISPLAY OUTPUT Y/C DELAY CORRECTION 00 ~ 3F 00 00 00 00 00 00 00 00 00 00

07 MHP MAIN PICTURE HORIZONTAL POSITION (SINGLE & PIP) 00 ~ FF 7F 7F 7F 7F 7F 7F

08 MVP MAIN PICTURE VERTICAL POSITION (SINGLE & PIP) 00 ~ FF 7F 7F 7F 7F 7F 7F

09 MHS MAIN PICTURE HORIZONTAL SIZE (SINGLE & PIP) 00 ~ FF 7F 7F 7F 7F 7F 7F

0A MVS MAIN PICTURE VERTICAL SIZE (SINGLE & PIP) 00 ~ FF 7F 7F 7F 7F 7F 7F

0B PHP PIP SUB PICTURE HORIZONTAL POSITION 00 ~ FF 6B 53

0C PVP PIP SUB PICTURE VERTICAL POSITION 00 ~ FF 5E 57

0D PHS PIP SUB PICTURE HORIZONTAL SIZE 00 ~ FF 7F 7F

0E PVS PIP SUB PICTURE VERTICAL SIZE 00 ~ FF 7F 7F

0F PHO PIP SUB PICTURE HORIZONTAL POSITION OFFSET 00 ~ FF 76 68

10 PVO PIP SUB PICTURE VERTICAL POSITION OFFSET 00 ~ FF 6E 6B

11 TMP TWIN MAIN PICTURE HORIZONTAL POSITION 00 ~ 03 01

12 TSP TWIN SUB PICTURE HORIZONTAL POSITION 00 ~ FF 00

13 TVP TWIN MAIN & SUB PICTURE VERTICAL POSITION 00 ~ FF

14 THS TWIN MAIN & SUB PICTURE HORIZONTAL SIZE 00 ~ FF

15 TVS TWIN MAIN & SUB PICTURE VERTICAL SIZE 00 ~ FF

16 THO TWIN MAIN & SUB PICTURE HORIZONTAL POSITION OFFSET 00 ~ FF

17 TVO TWIN MAIN & SUB PICTURE VERTICAL POSITION OFFSET 00 ~ FF

18 XHS INDEX SUB PICTURE HORIZONTAL SIZE 00 ~ FF

19 XVS INDEX SUB PICTURE VERTICAL SIZE 00 ~ FF

1A XHG INDEX HORIZONTAL GAP WIDTH BETWEEN PICTURES 00 ~ FF

1B XVG INDEX VERTICAL GAP WIDTH BETWEEN PICTURES 00 ~ FF

1C XHP INDEX 1st SUB PICTURE HORIZONTAL POSITION 00 ~ FF

1D XVP INDEX 1st SUB PICTURE VERTICAL POSITION 00 ~ FF

1E DHP DRC HORIZONTAL ACTIVE AREA POSITION 00 ~ FF 7F 7F

1F DHS DRC HORIZONTAL ACTIVE AREA PIXEL SIZE 00 ~ FF 7F 7F

20 DVP DRC VERTICAL ACTIVE ARE LINE POSITION 00 ~ 3F 1A 1A

21 DVS DRC VERTICAL ACTIVE AREA LINE SIZE 00 ~ FF 7F 7F

22 VHP VDO HORIZONTAL ACTIVE AREA POSITION 00 ~ FF

23 VHS VDO HORIZONTAL ACTIVE AREA PIXEL SIZE 00 ~ FF

24 VEP VDO VERTICAL ACTIVE AREA EVEN POSITION 00 ~ 3F

25 VVS VDO VERTICAL ACTIVE AREA LINE SIZE 00 ~ FF

26 VOP VDO VERTICAL ACTIVE AREA ODD POSITION 00 ~ 03

27 CLT VDO CLAMP PULSE OUTPUT TIMING 00 ~ FF

28 CLW VDO CLAMP PULSE WIDTH 00 ~ 07

29 VYD VDO ANALOG INPUT Y/C DELAY CORRECTION 00 ~ 3F

2A VCR VDO CHROMA SIGNAL ORDER 00, 01

2B VDI VDO DIGITAL ANGLE INPUT SELECTION 00 ~ 03

Data

Range

50 Hz (PAL) 60 Hz (NTSC)

7F 7F

7F 7F

1A 3F

7F 7F

7F

7F

1E

7F

00

7F

04

00

01

01

Standerd Data

Device NameFunction

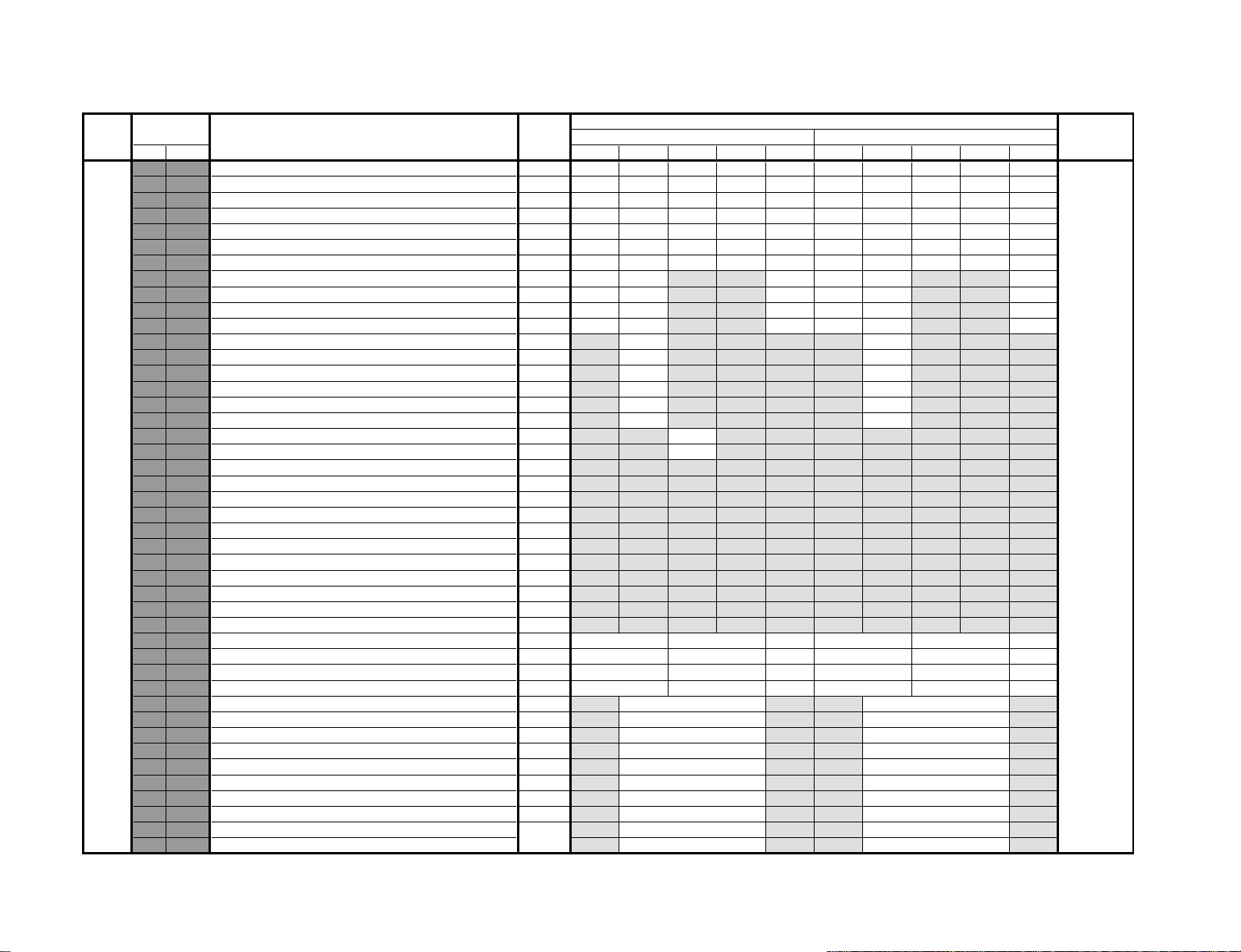

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

7F

7F

1A

7F

7F

7F

39

7F

7F

7F

1B

7F

00

7F

04

00

01

01

RM-961

Category

3CM 00 FRZ EXTERNAL MEMORY TEST BIT 00, 01 00 µPD64082

– 29 –

Item

No. Name

01 NRM NOISE REDUCTION OPERATION MODE 00 ~ 03 00

02 YCO Y/C SINGLE OUTPUT SELECTION 00 ~ 0F 0D

03 SYC SYSTEM CLOCK SELECTION 00 ~ 03 01

04 STD STANDARD/NON-STANDARD OPERATION SELECTION 00 ~ 03 00

05 MSS INTER-FRAME/INTER-LINE OPERATION SELECTION 00 ~ 03 00

06 KIL KILLER/NON-KILLER OPERATION SELECTION 00 ~ 03 03

07 EAD EXTERNAL Y-ADC SWITCH 00, 01 00

08 ECS EXTERNAL C-SYNC INPUT SELECTION 00 ~ 03 01

09 CPP ADC INPUT LEVEL & CLUMP PULSE WIDTH SELECTION 00 ~ 03 02

0A PWR ADC INPUT WIDTH SWITCH 00, 01 00

0B HDP HORIZONTAL PHASE ADJUSTMENT 00 ~ 07 05

0C CDL C-SIGNAL DELAY ADJUSTMENT 00 ~ 07 04

0D DYC DY DETECTION CORING LEVEL ADJUSTMENT 00 ~ 0F 02 02 02 04

0E DYG DY DETECTION GAIN ADJUSTMENT 00 ~ 0F 0A 0A 0A 0A

0F DCC DC DETECTION CORING LEVEL ADJUSTMENT 00 ~ 0F 05 03 03 05

10 DCG DC DETECTION GAIN ADJUSTMENT 00 ~ 0F 05 0A 0A 05

11 YNR YNR NON-LINEAR FILTER SETUP 00 ~ 0F 01

12 CNR CNR NON-LINEAR FILTER SETUP 00 ~ 0F 01

13 WSC NOISE DETECTION CORING ADJUSTMENT 00 ~ 03 01

14 VTH HYSTERESIS SELECTION FOR H-SYNC NON-STANDARD 00 ~ 03 01 01

15 VTR SENSITIVITY SELECTION FOR H-SYNC NON-STANDARD 00 ~ 03 01 01

16 LDR SENSITIVITY SELECTION FOR FRAME-SYNC NON-STANDARD 00 ~ 03 02 01

17 VAP GAIN ADJUSTMENT FOR VERTICAL SHAPE CORRECTION 00 ~ 07 03 02 00 02

18 VAI VANISHING ADJUSTMENT FOR VERTICAL SHAPE CORRECTION 00 ~ 1F 0C 06 00 06

19 TST TEST BIT 00, 01 00

1A YPF CENTER FREQUENCY SELECTION FOR Y-PEAKING BPF 00 ~ 03 03 03 03 03

1B YPG GAIN ADJUSTMENT FOR Y-PEAKING BPF 00 ~ 0F 08 08 08 08

1C VSE LINE COMB FILTER SETUP 00 ~ 0F 0A

1D CCN C-SIGNAL SPLIT FILTER SWITCH 00, 01 00

1E COS C-SIGNAL DELAY SWITCH AT NOISE REDUCTION 00, 01 00

1F SDC DC DETECTION SENSITIVITY SWITCH 00, 01 00

Function

Data

Range

Common TV Video

NR

Mode 0NRMode 1NRMode 2NRMode 3

Standerd Data

Picture ModeNR Mode

Dynamic Standard Hi-Fine Parsonal

Device Name

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

Category

3CM 20 SDY DY DETECTION LOWER-LEVEL SENSITIVITY SWITCH 00, 01 01

– 30 –

2CM 00 APA 2D COMB APACON ON/OFF 00, 01 CXA2069Q

Item

No. Name

21 D2G D2 GAIN SELECTION 00 ~ 07 04

22 YHC Y-SIGNAL HIGHER-LEVEL CORING SELECTION 00 ~ 03 00 00 00 00

23 YHG Y-SIGNAL HIGHER-LEVEL GAIN SWITCH 00, 01 00 00 00 00

24 SHT NON-STANDARD DETECTION & H/V COUNTER TEST BITS 00 ~ 0F 00

25 CLK CLOCK TEST BITS 00 ~ 0F 08

26 PLL PLL FILTER SETUP 00 ~ 0F 0D

27 KRF KILLER DETECTION REFERENCE ADJUSTMENT 00 ~ 0F 03

28 HSL H-SYNC SLICE LEVEL ADJUSTMENT 00 ~ 0F 0C

29 VSL V-SYNC SLICE LEVEL ADJUSTMENT 00 ~ 0F 08

2A BPS INTERNAL BURST GATE START POSITION ADJUSTMENT 00 ~ 0F 04

2B BPW INTERNAL BURST GATE WIDTH ADJUSTMENT 00 ~ 0F 0A

2C ADC ADC CLOCK DELAY SELECTION 00 ~ 03 03

2D APD ADC POWER-DOWN SWITCH 00, 01 01

2E NSD NON-STANDARD DETECTION TEST BIT 00, 01 01

2F SPD MEMORY POWER-DOWN SWITCH 00 ~ 03 02

30 CNT CNR TEST BIT 00, 01 00

Function

Data

Range

Common TV Video

NR

Mode 0NRMode 1NRMode 2NRMode 3

Standerd Data

Picture ModeNR Mode

Dynamic Standard Hi-Fine Parsonal

Device Name

µPD64082

KP-ER43M31/M61/M90/M91, ER53M31/M61/M90/M91

RM-961

Loading...

Loading...