Sony KDL-40R455 Schematic

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

Self Diagnosis

Supported model

SERVICE MANUAL

ELECTRICAL SERVICE INTERNAL DISTRIBUTION ONLY

MODEL COMMANDER DESTINATION

KDL-24R400A RM-YD092 Mexico / Latin America

KDL-24R405A RM-YD093 Chile / Peru / Venezuela

KDL-24R407A RM-YD093 Colombia

KDL-32R400A RM-YD093 US / Canada

KDL-32R400A RM-YD092 Mexico / Latin America

KDL-32R405A RM-YD093 Chile / Peru / Venezuela

KDL-32R407A RM-YD093 Colombia

KDL-32R421A RM-YD092 Mexico

KDL-32R425A RM-YD093 Chile / Peru / Venezuela

RB1FK

Segments: BA

CHASSIS

KDL-40R450A RM-YD092 US / Canada

KDL-40R450A RM-YD092 Mexico / Latin America

KDL-40R471A RM-YD092 Mexico

KDL-40R457A RM-YD093 Colombia

KDL-40R455A RM-YD093 Chile / Peru / Venezuela

KDL-40R475A RM-YD093 Chile / Peru

KDL-46R450A RM-YD092 Mexico / Latin America

KDL-46R450A RM-YD092 Canada

KDL-46R455A RM-YD093 Chile / Peru / Venezuela

KDL-46R457A RM-YD093 Colombia

KDL-46R471A RM-YD092 Mexico

LEVEL

CONFIDENTIAL

3

ORIGINAL MANUAL ISSUE DATE: 11/2013

REVISION DATE SUBJECT

11/15/2013 Original Manual Release Date

9-883-556-51

LCD DIGITAL COLOR TV

Chassis: RB1FK, BA

TABLE OF CONTENTS

SECTION TITLE PAGE

SECTION 1: DIAGRAMS ................................................................................................................................................................................................... 3

1-1. Printed Circuit Boards and Schematic Diagrams Information .................................................................................................................... 3

1-2. Connector Diagrams ........................................................................................................................................................................................ 4

1-3. Main Board (A Board) ...................................................................................................................................................................................... 5

A Board Component Side ................................................................................................................................................................................5

A Board Conductor Side ..................................................................................................................................................................................6

A Board Schematic

1-4. Electrical Parts List / Main Board (A) .......................................................................................................................................................... 27

..........................................................................................................................................................................................7

SECTION 2: POWER SUPPLY BOARD (G BOARD)

G Board Component Side .............................................................................................................................................................................28

G Board Schematic

SECTION 3: IR BOARD (H BOARD)

H Board Component Side ..............................................................................................................................................................................30

H Board Conductor Side ...............................................................................................................................................................................30

H Board Schematic

APPENDIX A: ENCRYPTION KEY COMPONENTS

........................................................................................................................................................................................ 29

..............................................................................................................................................................................30

..........................................................................................................................................................................................31

..................................................................................................................................................... 28

..................................................................................................................................................... A-1

Chassis: RB1FK, BA 2

Chassis: RB1FK, BA

CAUTIONS AND WARNINGS

CAUTION

. To reduce the risk of electric shock, do not

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, in case of live chassis.

!

SAFETY-RELATED COMPONENT WARNING!!

shading and

NOTE: Do not modify the original design without obtaining written permission from the manufacturer or you will void the

original parts and labor warranty.

!

mark on the schematic diagrams and the parts list. It is essential that these critical parts be replaced only

ATTENTION!!

ainsi.

ALERTE!!

lors de tout dépannage.

!

ATTENTION AUX COMPOSANTS

RELATIFS A LA SECURITE!!

!

sur les schemas de principe, les vues explosees et

les listes de pieces sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des

composants Sony dont le numero de piece est indique dans le present manuel ou dans des supplements publies par

present manuel. Suivre ces procedures lors de chaque remplacement de composants critiques, ou lorsqu’un mauvais

fonctionnement suspecte.

Chassis: RB1FK, BA 3

Chassis: RB1FK, BA

When installing the LCD panel on a wall, the LCD panel must be secured using the 4 mounting holes on the rear

, or volatile solvent, such as

TV screen . If liquid drips into the bottom of the screen it may

SETTING UP AND CARRYING THE TV

• Disconnect all cables when carrying the TV.

• Carry the TV with the adequate number of people; larger size TVs require two or more people.

• Correct hand placement while carrying the TV is very important for safety and to avoid damage.

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

cover.

To avoid damaging the LCD panel:

1. Do not press on the panel or frame edge to avoid the risk of electric shock.

2. Do not scratch or press on the panel with any sharp objects.

3. Do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

4. Do not expose the LCD panel to direct sunlight.

5. Avoid contact with water. It may cause a short circuit within the module.

6. Disconnect the AC power when replacing the backlight (CCFL) or inverter circuit.

(High voltage occurs at the inverter circuit at 650Vrms.)

7. Always clean the LCD panel with a soft cloth material.

8. Use care when handling the wires or connectors of

the inverter circuit. Damaging the wires may cause a

short.

9. Protect the panel from ESD to avoid damaging the

electronic circuit (C-MOS).

10. During the repair,

more than 1 hour

cloth.

DO NOT leave the Power On for

while the TV is face down on a

CLEANING THE LCD PANEL

CAUTION: When cleaning the TV, be sure to unplug the power cord to avoid any chance of electric shock.

Clean the cabinet of the TV with a dry soft cloth.

Wipe the LCD screen gently with a soft cloth.

Stubborn stains may be removed with a cloth slightly moistened with a solution of mild soap and warm water.

If using a chemically pretreated cloth, please follow the instruction provided on the package.

Never use strong solvents such as a thinner, alcohol or benzine for cleaning.

Periodic vacuuming of the ventilation openings is recommended to ensure proper ventilation.

Do Not use paper towels, any type of abrasive pad, rags, rubber or vinyl materials to clean the screen. Using

these materials could easily scratch the screen which may result in permanent damage.

Do Not use any cleaning product containing alkaline/acid cleaner, scouring powder

alcohol, ammonia, benzine, thinner or insecticide. Using any of these harsh cleaners may result in permanent

damage to the screen.

Do Not spray water or detergent directly onto the

cause a failure.

Chassis: RB1FK, BA 4

SAFETY CHECK-OUT

Trouble Light

Chassis: RB1FK, BA

After correcting the original service problem, perform the

following safety checks before releasing the set to the

customer:

1. Check the area of your repair for unsoldered or

poorly soldered connections. Check the entire

board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no

wires are “pinched” or touching high-wattage

resistors.

3. Check that all control knobs, shields, covers,

ground straps, and mounting hardware have been

replaced. Be absolutely certain that you have

replaced all the insulators.

4. Look for unauthorized replacement parts,

particularly transistors, that were installed during

a previous repair. Point them out to the customer

and recommend their replacement.

5. Look for parts which, though functioning, show

obvious signs of deterioration. Point them out to

the customer and recommend their replacement.

6. Check the line cords for cracks and abrasion.

Recommend the replacement of any such line

cord to the customer.

7. Check the antenna terminals, metal trim,

“metallized” knobs, screws, and all other exposed

metal parts for AC leakage. Check leakage as

described in “Leakage Test”.

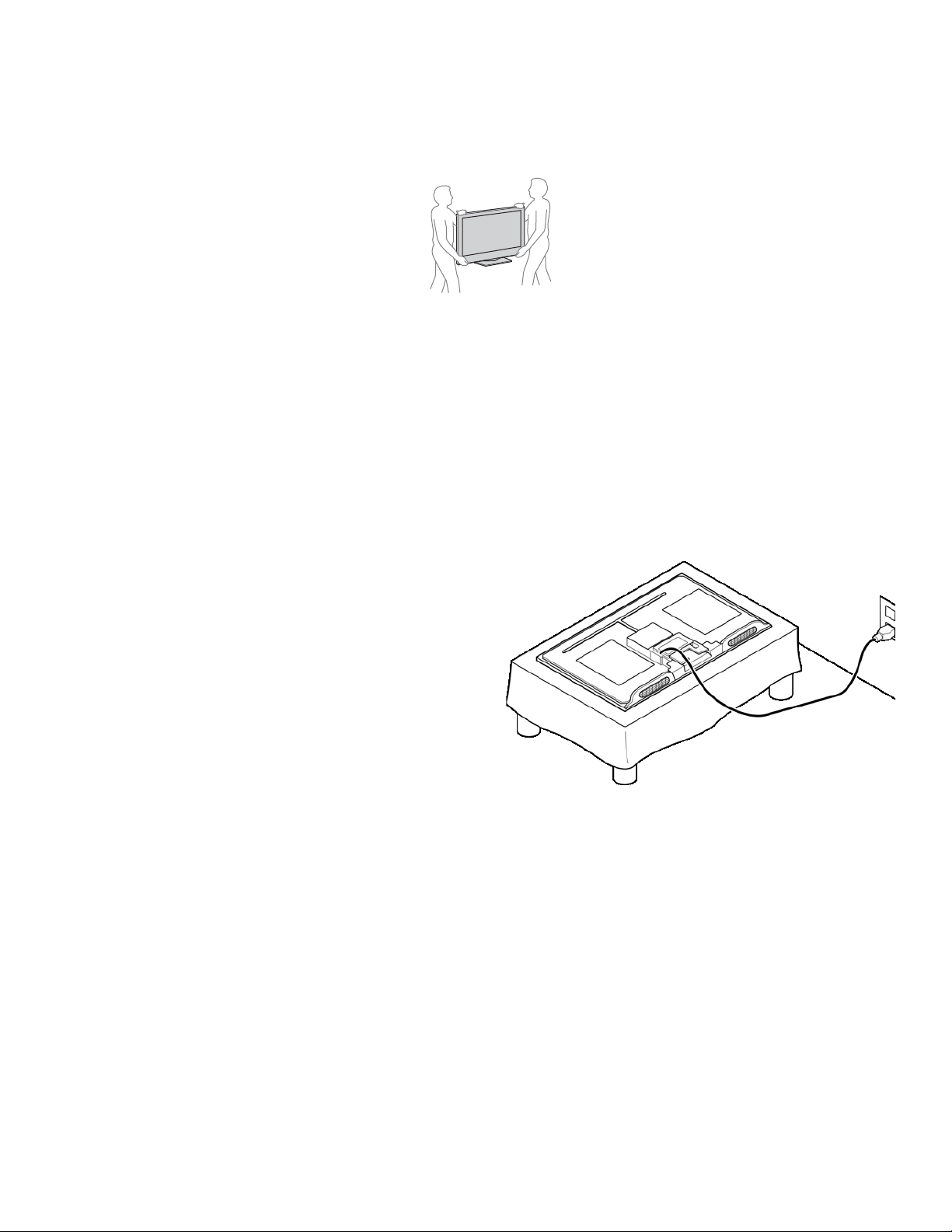

LEAKAGE TEST

The AC leakage from any exposed metal part to earth

ground and from all exposed metal parts to any exposed

metal part having a return to chassis, must not exceed

0.5 mA (500 microamperes). Leakage current can be

measured by any one of three methods.

1. A commercial leakage tester. Follow the

manufacturers’ instructions provided with the

tester.

2. A battery-operated AC milliammeter.

3. Measuring the voltage drop across a resistor

by means of a VOM or battery-operated AC

voltmeter. The “limit” indication is 0.75 V, so

analog meters must have an accurate low

voltage scale. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable.

(see Figure A)

To Exposed Metal

Parts on Set

AC

0.15 µF

Voltmeter

(0.75V)

Chassis: RB1FK, BA 5

Earth Ground

Figure A. Use an AC voltmeter to check AC leakage.

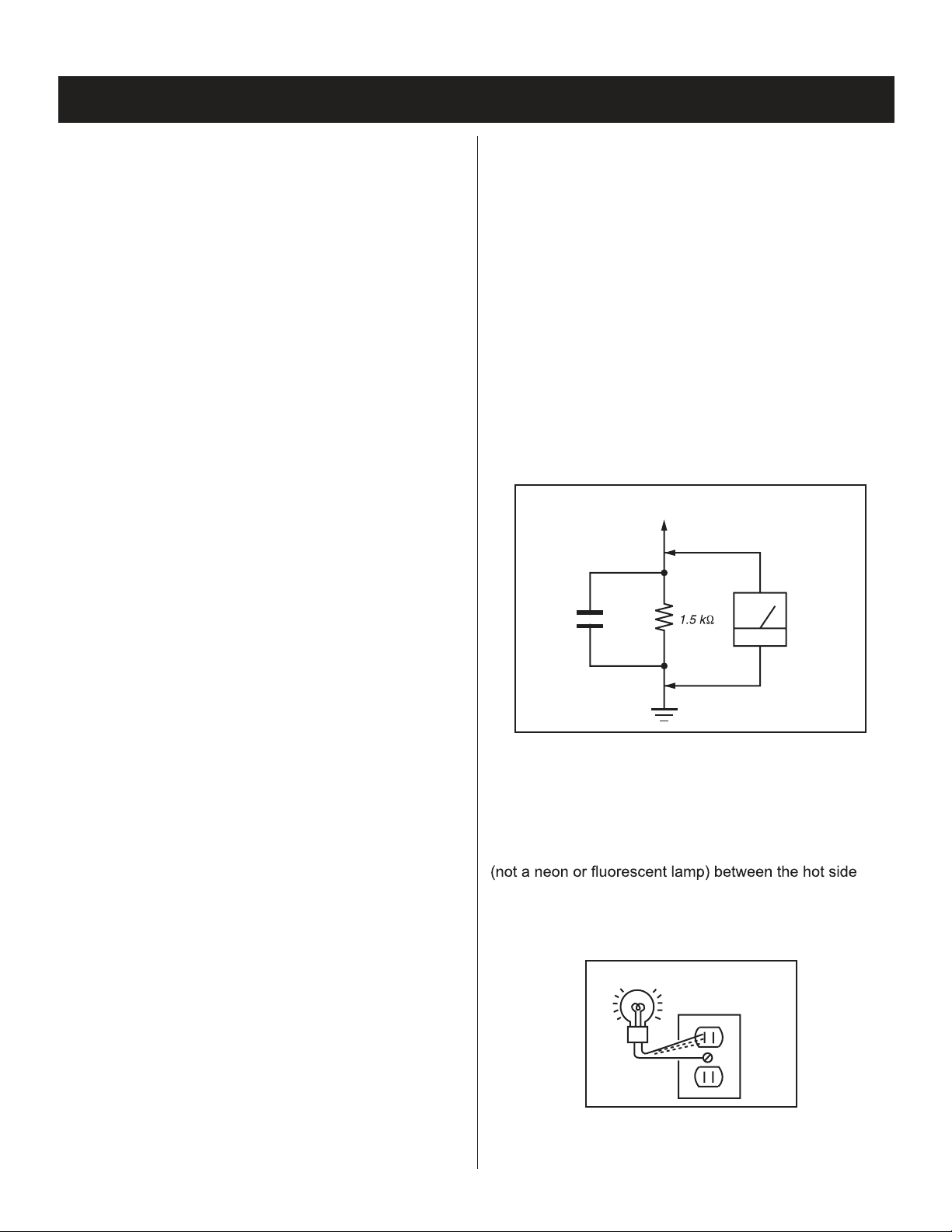

HOW TO FIND A GOOD EARTH GROUND

The cover-plate retaining screw on most AC outlet boxes

is at earth ground. Verify the AC outlet box retaining screw

ground by connecting a 60W to 100W incandescent

of the receptacle and the retaining screw. Try both slots,

if necessary, to locate the hot side on the line; the lamp

should light at normal brilliance if the screw is at ground

potential. (see Figure B)

AC Outlet Box

Figure B. Checking for earth ground.

Chassis: RB1FK, BA

Th

e circuit boards used in these models have been processed using

Due

This

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

example

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints.

Lead Free Solder is available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046- m7 m3. g0 K52.0

02-500-046- m7 m4. g0 K05.0

12-500-046- m7 m5. g0 K05.0

22-500-046- m7 m6. g0 K52.0

32-500-046- m7 m8. g0 K00.1

42-500-046- m7 m0. g1 K00.1

52-500-046- m7 m2. g1 K00.1

62-500-046- m7 m6. g1 K00.1

to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees celsius.

requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

Chassis: RB1FK, BA 6

Chassis: RB1FK, BA

Terminal name of semiconductors in silk screen

SECTION 1: DIAGRAMS

1-1. PRINTED CIRCUIT BOARDS AND SCHEMATIC DIAGRAMS INFORMATION

REFERENCE INFORMATION

All capacitors are in µF unless otherwise noted. pF : µµF 50WV or

less are not indicated except for electrolytics and tantalums.

$OOHOHFWURO\WLFVDUHLQ9XQOHVVRWKHUZLVHVSHFL¿HG

All resistors are in ohms. k:=1000:, M:=1000k

:

Indication of resistance, which does not have one for rating

electrical power, is as follows: Pitch : 5mm

Rating electrical power :

1

/4 W in resistance, 1/

W and 1/

10

W in chip resistance.

16

1

/4 W

QRQÀDPPDEOHUHVLVWRU

IXVLEOHUHVLVWRU

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

: internal component

: panel designation and adjustment for repair

: earth ground

printed circuit ( )

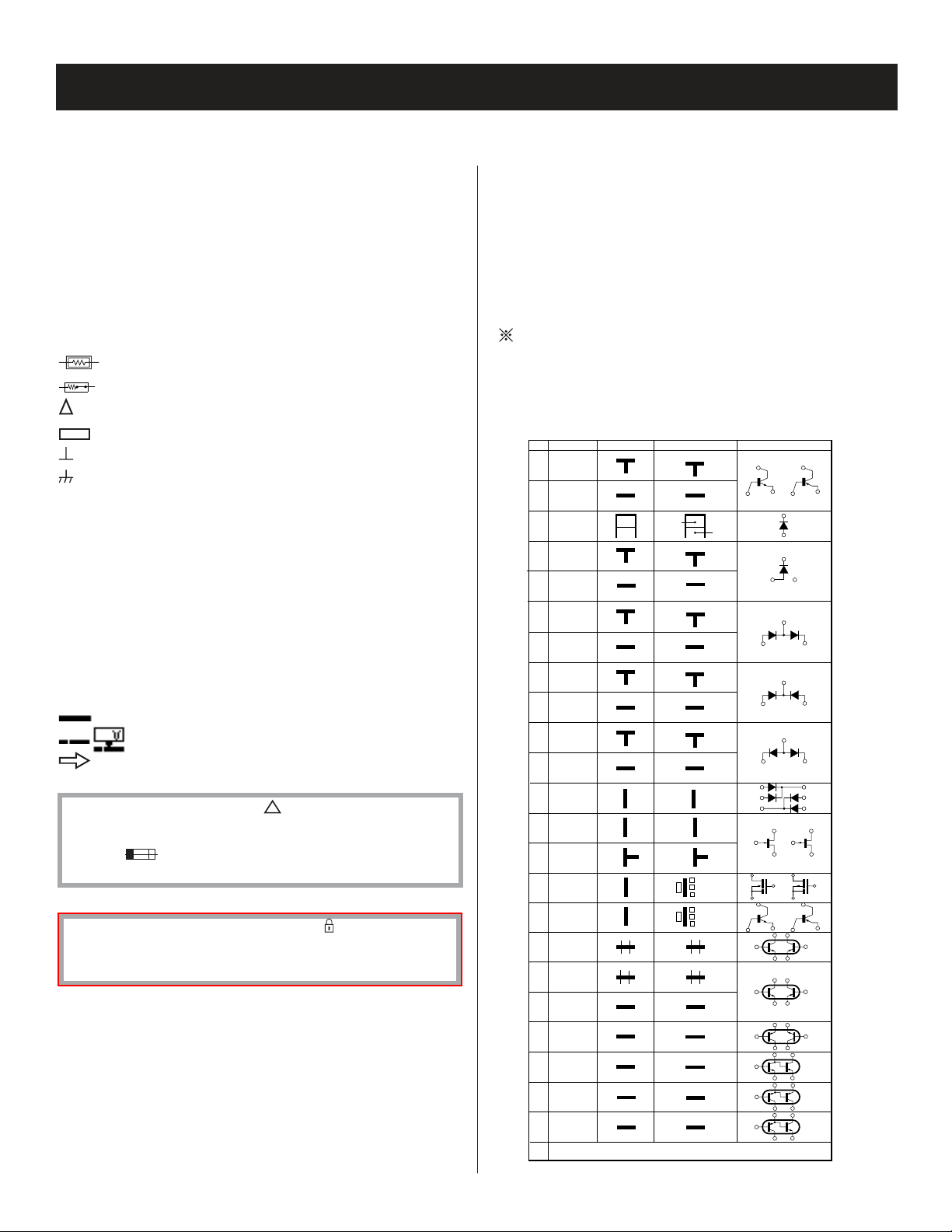

Device Printed symbol Terminal name

Transistor

1

*

: earth-chassis

Transistor

2

All variable and adjustable resistors have characteristic curve B, unless

3

Diode

Cathode

otherwise noted.

4

5HDGLQJVDUHWDNHQZLWKDFRORUEDUVLJQDOLQSXW

Readings are taken with a 10M: digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Diode

Diode

5

Diode

6

9ROWDJHYDULDWLRQVPD\EHQRWHGGXHWRQRUPDOSURGXFWLRQ

Diode

tolerances.

All voltages are in V.

60HDVXUHPHQWLPSRVVLELOLW\

: B+line.

%OLQH$FWXDOPHDVXUHGYDOXHPD\EHGLIIHUHQW

: signal path. (RF)

&LUFOHGQXPEHUVDUHZDYHIRUPUHIHUHQFHV

7KHFRPSRQHQWVLGHQWL¿HGE\ VKDGLQJDQG!V\PERODUHFULWLFDO IRUVDIHW\5HSODFH

RQO\ZLWKSDUWQXPEHUVSHFL¿HG

7KHV\PERO

LQGLFDWHVDIDVWEORZIXVH DQGLV GLVSOD\HGRQWKHFRPSRQHQW

VLGHRIWKHERDUG5HSODFHRQO\ZLWKIXVHRIWKHVDPHUDWLQJDVPDUNHG

127(7KHFRPSRQHQWVLGHQWL¿HG E\DUHGRXWOLQHDQGD PDUNFRQWDLQFRQ¿GHQWLDO

LQIRUPDWLRQ6SHFL¿FLQVWUXFWLRQVPXVWEHDGKHUHGWRZKHQHYHUWKHVHFRPSRQHQWV

are repaired and/or replaced.

6HH$SSHQGL[$(QFU\SWLRQ.H\&RPSRQHQWVLQWKHEDFNRIWKLVPDQXDO

Chassis: RB1FK, BA 7

7

8

Diode

Diode

9

Diode

10

Diode

11

Diode

12

Transistor

13

(FET)

Transistor

14

(FET)

Transistor

15

(FET)

Transistor

16

Transistor

17

Transistor

18

Transistor

19

Transistor

20

Transistor

21

Transistor

22

Transistor

23

Discrete semiconductor

–

(Chip semiconductors that are not actually used are included.)

Anode

Anode

Anode

Anode Cathode

Anode

Anode Anode

Cathode

Cathode

Anode

Anode

Cathode

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

Collector

Base

Collector

Base

Cathode

Cathode

Common

Common

Common

Common

Common

Common

Drain

Drain

C2

C1

E1

E2

C2

B1

E2

C2

Emitter

Emitter

(NC)

(NC)

Cathode

Anode

Cathode

Cathode

Cathode

Anode

Anode

Source

Gate

Source

Gate

Source

Drain

Gate

Emitter

Collector

Base

B1 E1

B2 C1E2

B2 E2

B1 C2

B2 E2C1

B1 C2E1

B2 E2C1

B1 C2E1

B1 E1

C1(B2)

(B2)

E1

E2

C2C1

(B2)

E1

B1

C1

Anode

Circuit

D

G

D

S

B1

B1

B1

B1

B1

B1

D

G

S

S

D

G

S

C2

C1

B2

E1

E2

C2

C1

B2

E1

E2

E2B2E1

C1

C2

C2C1(B2)

E2

E2

E2E1(B2)

C1

C2

C2E1(B2)

C1

C2

Ver.1.6

G

Chassis: RB1FK, BA 8

Chassis: RB1FK, BA

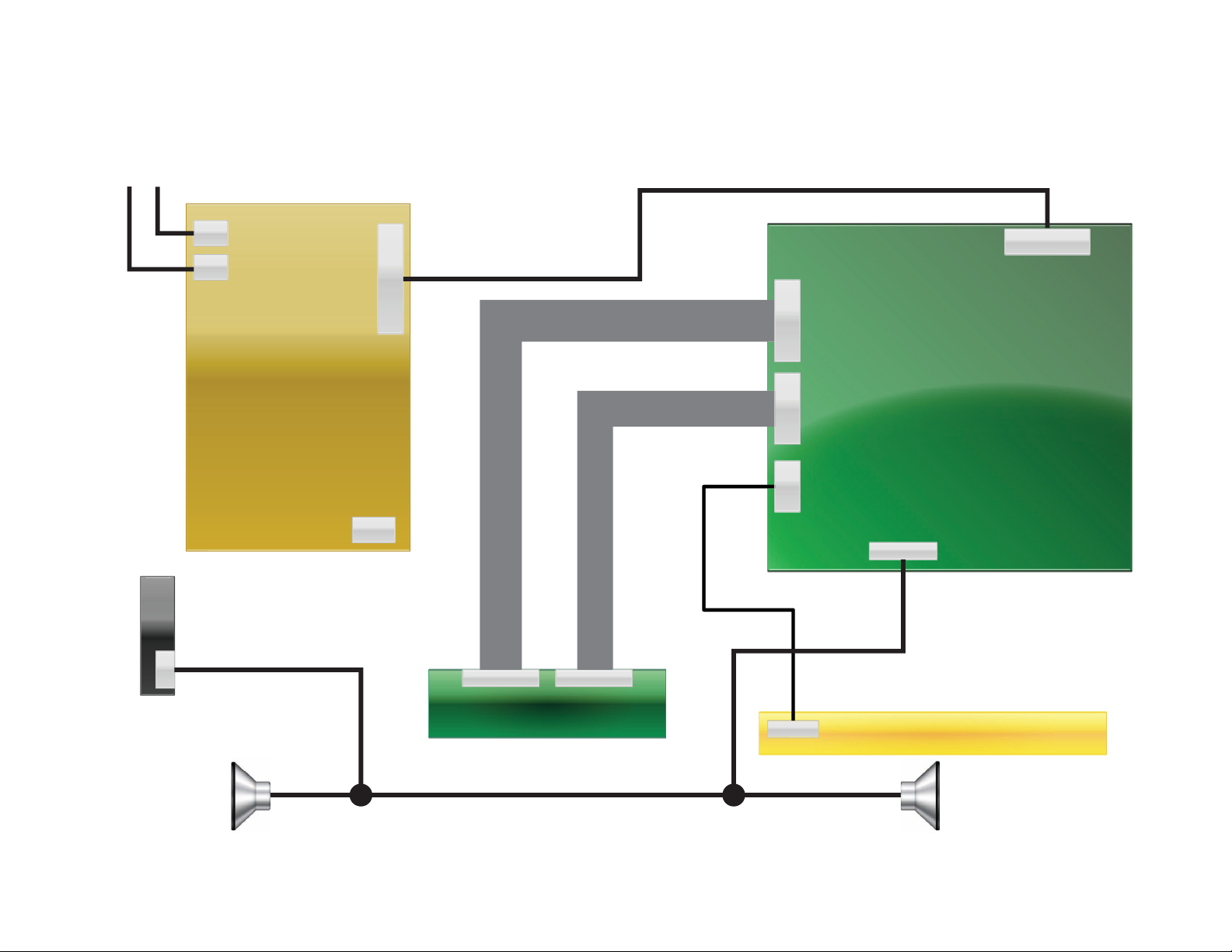

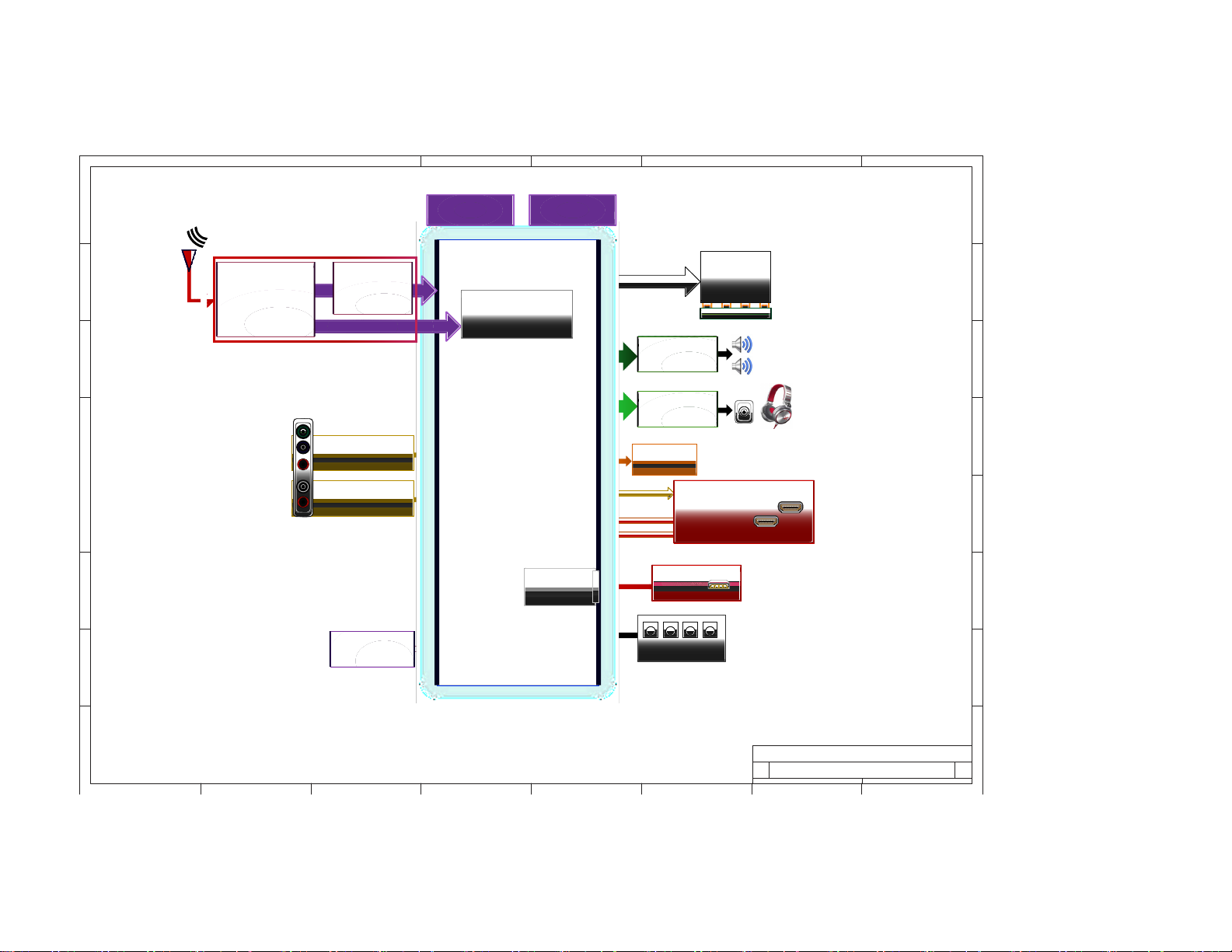

1-2. CONNECTOR DIAGRAMS

TCON Board

CN4001

CN201

CN4002

CN4003

AC

Main Board

IR Board

Power Board

Keypad Board

LCD Panel

CN8001

A

A

—

B

—

C

Chassis: RB1FK, BA

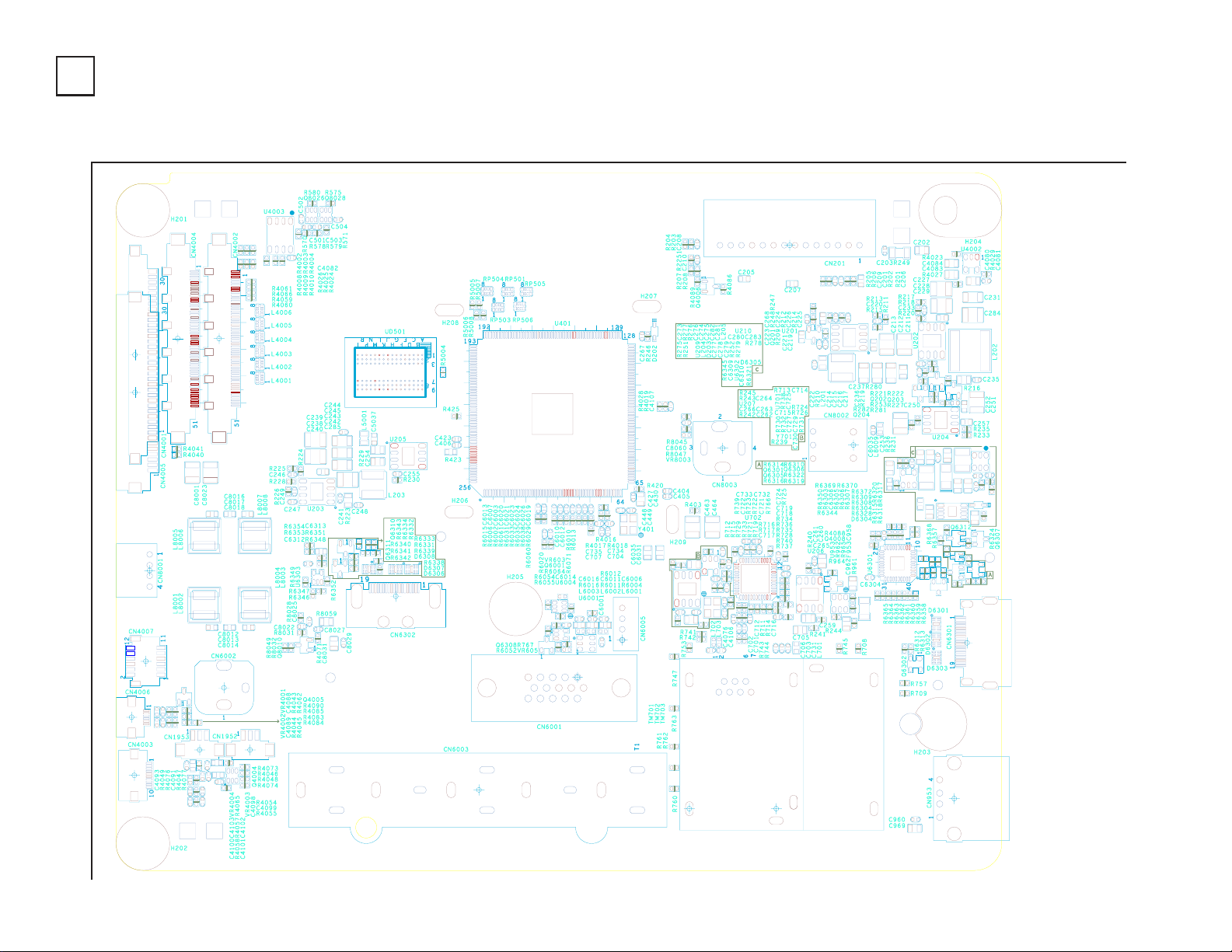

1-3. MAIN BOARD (A BOARD)

[SYSTEM POWER/YPBPR/AV/SPDIF/USB/HDMI/DDR/FLASH/PREAMP/AUDIO AMP/LVDS/DEMOD/TUNER/ETHERNET]

A BOARD COMPONENT SIDE

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

—

D

—

E

—

F

—

Chassis: RB1FK, BA 9

Chassis: RB1FK, BA

A

A

—

B

—

C

—

[SYSTEM POWER/YPBPR/AV/SPDIF/USB/HDMI/DDR/FLASH/PREAMP/AUDIO AMP/LVDS/DEMOD/TUNER/ETHERNET]

A BOARD CONDUCTOR SIDE

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

D

—

E

—

F

—

Chassis: RB1FK, BA 10

Chassis RB1FK, BA 11

Chassis RB1FK, BA

A BOARD SCHEMATIC

A BOARD SCHEMATIC DIAGRAM (1 OF 20)

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C

C

D

D

E E

F F

G G

H H

Title

veRrebmuN tnemucoDeziS

teehS:etaD

of

FY13 BA_MT5389

A

Block Diagram

A3

2 21Thursday, December 20, 2012

Title

veRrebmuN tnemucoDeziS

teehS:etaD

of

FY13 BA_MT5389

A

Block Diagram

A3

2 21Thursday, December 20, 2012

Title

veRrebmuN tnemucoDeziS

teehS:etaD

of

FY13 BA_MT5389

A

Block Diagram

A3

2 21Thursday, December 20, 2012

DDR3x1

(1GB)

MT5367/5389

Ypbpr/CVBS

Ypbpr-R/L/CVBS-R/L

IR LED Keypad

USB(Side)

HDMI1/MHL (Side)

SPDIF

HP Driver

Amplifier

Speaker

:

R

L

Headphone/Line out

LVDS

12S

IF

TS

IF

LCM Panel

HDMI2(ARC)

86%

NAND Flash

64 MB

S-Tuner

RE227TN(PAD)

RA227TN(NA/MX)

RB221TN(COL/CHI)

DEMO

CXD2817ER(PAD)

CXD2837ER(COL)

CXD2838ER(CHI)

Demodulador

PAL/SECAM/ATSC

Chassis RB1FK, BA 12

Chassis RB1FK, BA

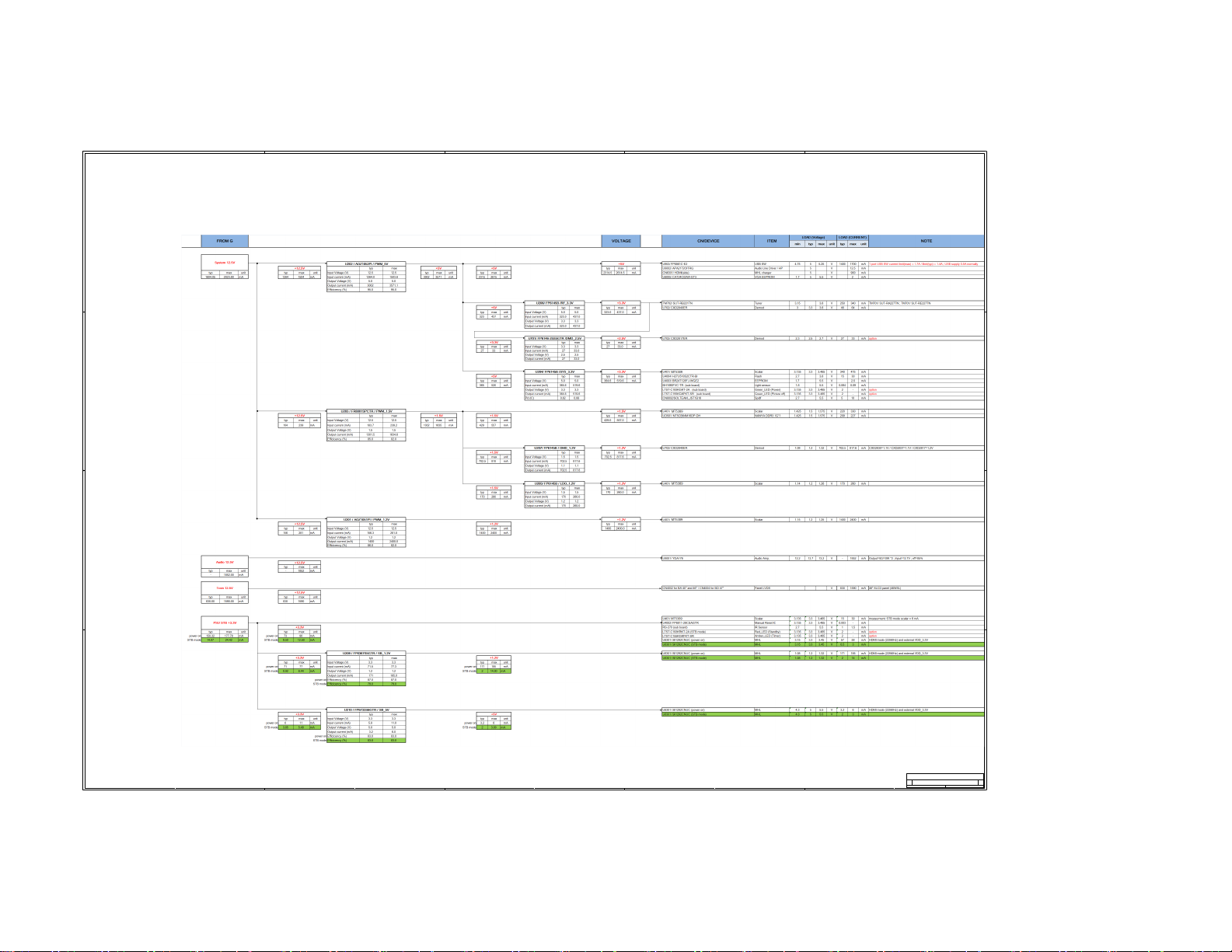

A BOARD SCHEMATIC DIAGRAM (2 OF 20)

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A

A

Title

veRrebmuN tnemucoDeziS

teeh

S

:et

aD

of

FY13 BA_MT5389

A

Power Structure

A0

3 21Thursday, February 28, 2013

Title

veRrebmuN tnemucoDeziS

teeh

S

:et

aD

of

FY13 BA_MT5389

A

Power Structure

A0

3 21Thursday, February 28, 2013

Title

veRrebmuN tnemucoDeziS

teeh

S

:et

aD

of

FY13 BA_MT5389

A

Power Structure

A0

3 21Thursday, February 28, 2013

Loading...

Loading...