SONY KDL-32L4000, KDL-37L4000 Service Manual

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDL-32L4000

KDL-32L4000

KDL-37L4000

KDL-37L4000

RM-YD026 CHILE

RM-YD026 LATIN NORTH

RM-YD026 CHILE

RM-YD026 LATIN NORTH

MA2

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 8/2008

REVISION DATE SUBJECT

8/2008 No revisions or updates are applicable at this time.

LCD DIGITAL COLOR TELEVISION

9-883-796-01

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDL-32L4000

KDL-32L4000

KDL-37L4000

KDL-37L4000

RM-YD026 CHILE

RM-YD026 LATIN NORTH

RM-YD026 CHILE

RM-YD026 LATIN NORTH

MA2

CHASSIS

9-883-796-01

KDL-37L4000 RM-YD026

LCD DIGITAL COLOR TELEVISION

KDL-32L4000/37L4000

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 6

Safety-Related Component Warning .............................................. 7

Safety Check-Out ........................................................................... 9

Self-Diagnostic Function ............................................................... 10

SECTION 1: DISASSEMBLY ............................................................... 12

1-1. Rear Cover Removal ............................................................ 12

1-2. Switch Unit Removal (Contains H1 Board) .......................... 12

1-3. Side Jack Bracket, BM4 Board Removal ............................. 13

1-4. Power Unit (G1D/G2D Board) Removal ............................... 13

1-5. Table-Top Stand Removal .................................................... 14

1-6. Structural Frames and Vesa Bracket Removal .................... 15

1-7. Speakers, Under Bar, HM6 Board and

Light Guide Removal ........................................................... 16

1-8. LCD Panel RemovaL ........................................................... 17

1-8-1. Cleaning the LCD Panel .......................................... 17

Wire Dressing ............................................................................... 19

KDL-32L4000 Only ............................................................... 19

KDL-37L4000 Only ............................................................... 28

SECTION 2: SERVICE ADJUSTMENTS ............................................. 38

2-1. Resetting the TV to the Factory Defaults ............................. 38

SECTION 3: DIAGRAMS ..................................................................... 39

3-1. Circuit Boards Location ........................................................ 39

3-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 39

3-3. Block Diagram ...................................................................... 41

3-4. Schematics and Supporting Information .............................. 42

BM4 Board Schematic Diagram (1 of 10) ............................ 42

BM4 Board Schematic Diagram (2 of 10) ............................ 43

BM4 Board Schematic Diagram (3 of 10) ............................ 44

BM4 Board Schematic Diagram (4 of 10) ............................ 45

BM4 Board Schematic Diagram (5 of 10) ............................ 46

BM4 Board Schematic Diagram (6 of 10) ............................ 47

BM4 Board Schematic Diagram (7 of 10) ............................ 48

BM4 Board Schematic Diagram (8 of 10) ............................ 49

BM4 Board Schematic Diagram (9 of 10) ............................ 50

BM4 Board Schematic Diagram (10 of 10) .......................... 51

G1D Board Schematic Diagram

(KDL-32L4000 Only) ................................................ 53

G2D Board Schematic Diagram (1 of 2)

(KDL-37L4000 Only) ................................................ 56

G2D Board Schematic Diagram (2 of 2)

(KDL-37L4000 Only) ................................................ 57

HM6 Board Schematic Diagram .......................................... 60

3-5. Semiconductors ................................................................... 62

SECTION 4: EXPLODED VIEWS ........................................................ 63

4-1. Rear Cover Assembly and Table-Top Stand Assembly ....... 63

4-2. Chassis ................................................................................ 64

4-3. Connectors ........................................................................... 65

4-4. Bezel Assembly, LCD Panel and Speakers ......................... 66

4-5. Screw Legend ...................................................................... 67

SECTION 5: ELECTRICAL PARTS LIST ............................................ 68

APPENDIX A: ENCRYPTION KEY COMPONENTS ..........................A-1

APPENDIX B: TILED SCHEMATIC NOTE ..........................................B-1

KDL-32L4000/37L4000

3

SPECIFICATIONS

KDL-32L4000/37L4000

Power Requirements

Power Consumption (W)

In Use (Max)

In Standby

120 V, 60 Hz

220 V, 50/60 Hz (Chile)

155W (KDL-32L4000 Only)

190W (KDL-37L4000 Only)

Less than 1W

VIDEO (IN) 1/2:

S Video (4-Pin Mini DIN) (VIDEO 1 Only)

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

Video

1.0 Vp-p, 75 ohms unbalanced, sync negative

Audio

500 mVrms (100% modulation)

Impedance: 47 kilohms

COMPONENT IN 1/2:

YP

(Component Video)

BPR

Y:1.0 Vp-p, 75 ohms unbalanced, sync negative

PB:0.7 Vp-p, 75 ohms

PR:0.7 Vp-p, 75 ohms

Signal format: 480i, 480p, 720p, 1080i

AUDIO

500 mVrms (100% modulation)

Impedance: 47 kilohms

HDMI IN 1/2:

HDMI: Video: 480i, 480p, 720p, 1080i

Audio: Two channel linear PCM 32, 44.1 and

48 kHz, 16, 20 and 24 bits

AUDIO: 500 mVrms (100% modulation)

Impedance: 47 kilohms

DIGITAL AUDIO OUT (COAXIAL):

PCM 2.0 Coaxial Signal

AUDIO OUT:

500 mVrms (100% modulation)

More than 500 mVrms (Fixed)

PC IN:

D-sub 15-pin, analog RGB

0.7 Vp-p, 75 ohms, positive

PC AUDIO INPUT:

Stereo mini

500 mVrms, 47 kilohms

HEADPHONES:

Stereo mini

Impedance: > 16 ohms

Trademark Information

Macintosh is a trademark licensed to Apple,

Inc., registered in the U.S.A. and other countries.

Manufactured under license from Dolby

Laboratories. “Dolby” and the double-D symbol

are trademarks of Dolby Laboratories.

HDMI, the HDMI logo and High-Definition

Multimedia Interface are trademarks or

registered trademarks of HDMI Licensing, LLC.

Blu-ray is a trademark.

“BRAVIA” and , , BRAVIA

Theatre Sync and DMPORT are trademarks or

registered marks of Sony Corporation.

“PLAYSTATION” is a registered trademark

and “PS3” is a trademark of Sony Computer

Entertainment Inc.

KDL-32L4000/37L4000

Design and specifi cations are subject to change without notice.

4

p

)

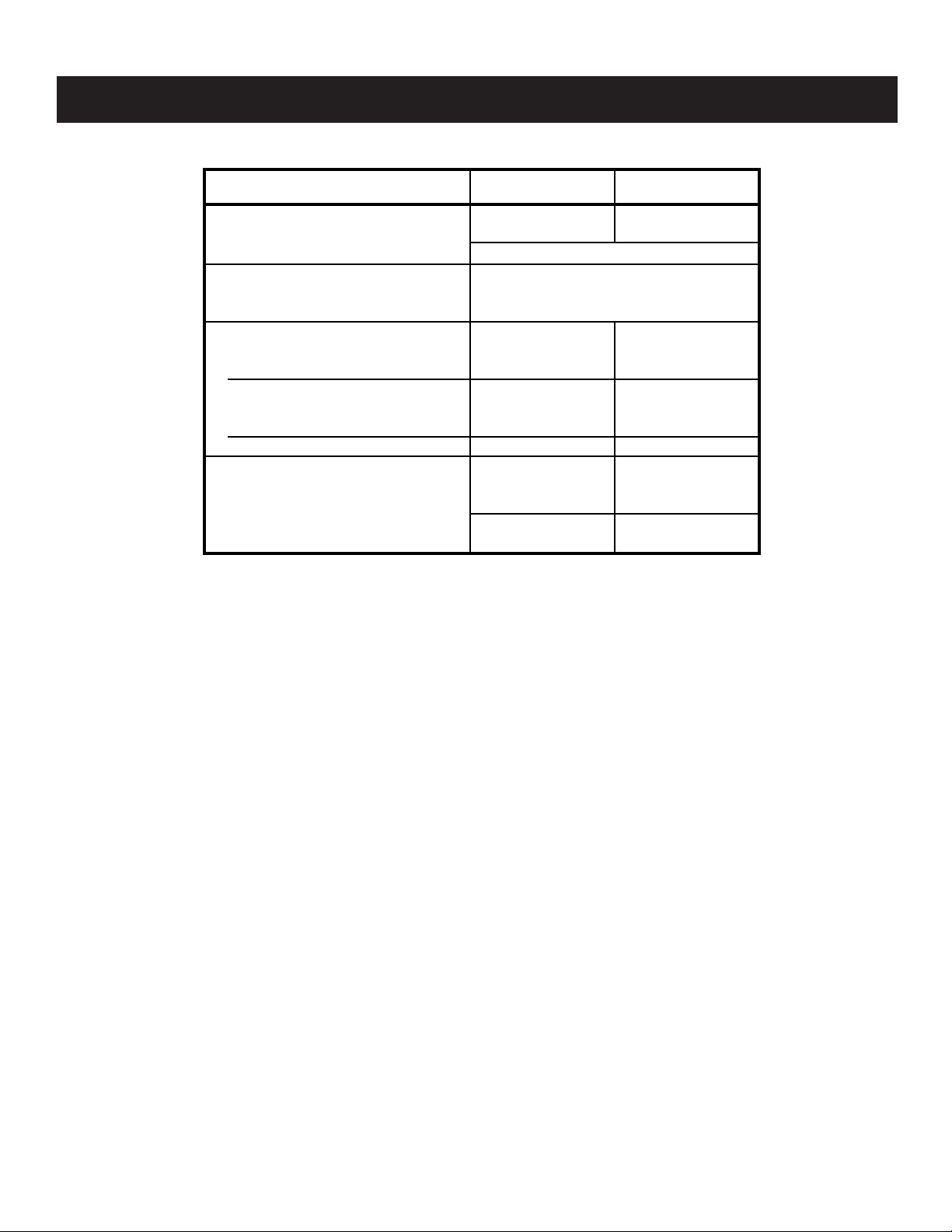

SPECIFICATIONS (CONTINUED)

KDL-32L4000 KDL-37L4000

Power Consumption

in use

in standby

Speaker Output (W)

S

eaker/Full Range(2

mm

Dimensions (W x H x D)

with stand

mm

Dimensions (W x H x D)

without stand

mm

wall-mount hole pattern (mm) 200 x 200 300 x 300

Mass

with stand

kg

without stand

kg

155W 190W

Less than 1W

10W + 10W

146 x 35 mm

807 x 584 x 242 mm 933 x 649 x 276 mm

807 x 547 x 100 mm 933 x 614 x 110 mm

14.5 kg 19.5 kg

12 kg 16.5 kg

All measurements are approximations.

KDL-32L4000/37L4000

Television System

NTSC American TV Standard

ATSC (8VSB Terrestrial) ATSC compliant 8VSB

QAM on cable ANSI/SCTE 07 2000

Channel Coverage

Analog Digital

Terrestrial 2-69 2-69

Cable 1-125 1-135

Antenna

75-ohm external terminal for VHF/UHF

Panel System

LCD (Liquid Crystal Display) Panel

Display Resolution (horizontal x vertical):

1,366 dots x 768 lines

Screen Size (measured diagonally)

approx. 31.5 inches, 80 cm (KDL-32L4000 Only)

approx. 37 inches, 94cm (KDL-37L4000 Only)

Supplied Accessories

Remote Commander RM-YD026

Two Size AA (R6) Batteries

Instruction Manual

Quick Setup Guide

Warranty Card

Safety Instructions

Cable Holder (1 attached to TV)

Optional Accessories

Connecting Cables

Headphones Plug Adapter

Wall-Mount Bracket

SU-WL500

TV Stand

SU-FL71M

KDL-32L4000/37L4000

5

KDL-32L4000/37L4000

WARNINGS AND CAUTIONS

CAUTION

These servicing instructions are for use by qualifi ed service personnel only. To reduce the risk of electric shock, do not

perform any servicing other than that contained in the operating instructions unless you are qualifi ed to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis.

The chassis of this receiver is directly connected to the ac power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are

critical for safe operation. Replace these components with Sony parts whose part numbers appear as shown in this

manual or in supplements published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in

this manual. Follow these procedures whenever critical components are replaced or improper operation is suspected.

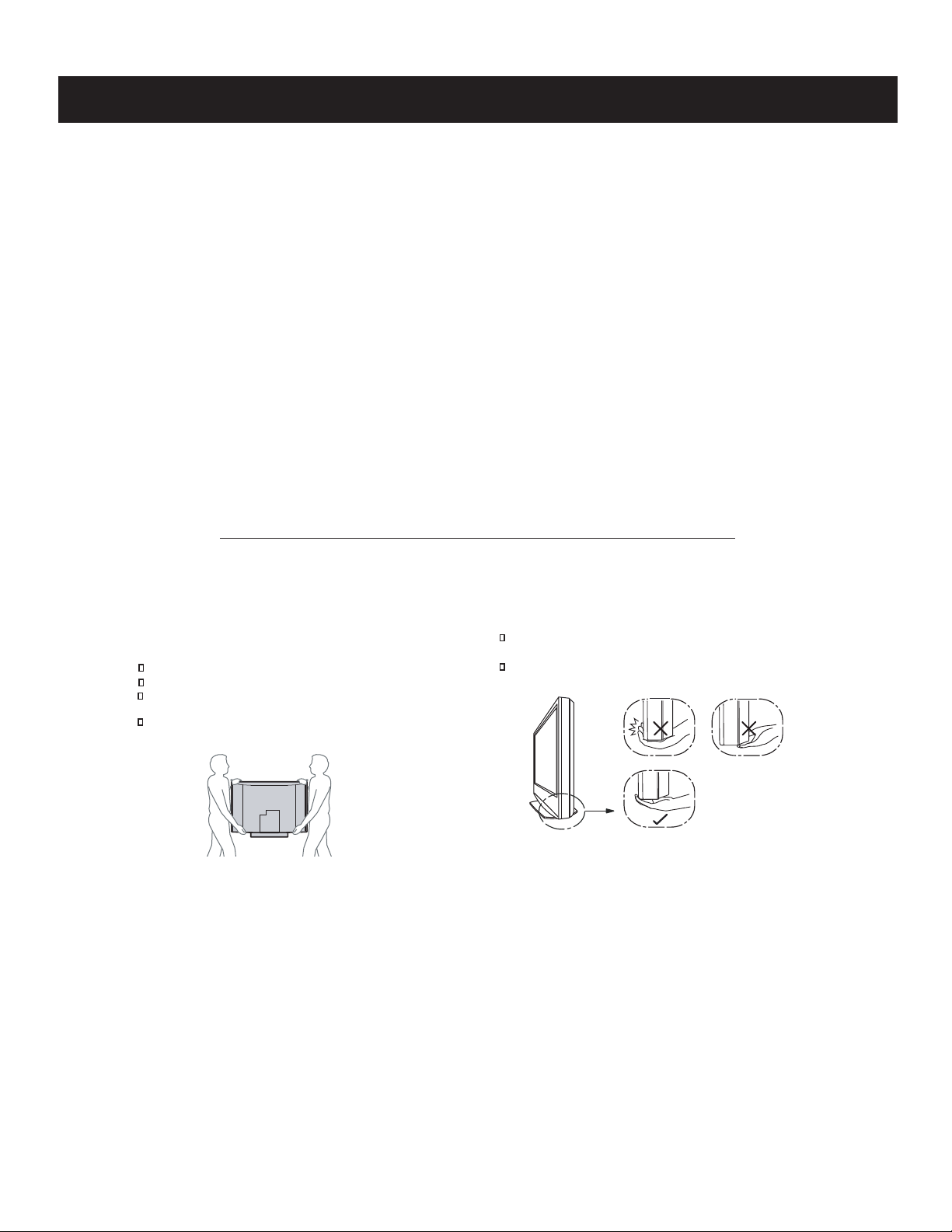

CARRYING THE TV

To avoid dropping the TV and causing serious injury, be sure to follow

these guidelines:

Before carrying the TV, disconnect all cables.

Carrying the large size TV requires two or more people.

When carrying, do not subject the TV to shocks or vibration, or

excessive force.

When you carry the TV, place your hand as illustrated and hold it

securely. Do not put stress on the LCD panel.

When lifting or moving the TV, hold it firmly from the bottom. Place

your palm directly under the panel.

Place your palm directly underneath, but do not squeeze the

panel’s speaker grill area.

KDL-32L4000/37L4000

6

SAFETY-RELATED COMPONENT WARNING

KDL-32L4000/37L4000

There are critical components used in LCD color TVs that are important for safety. These components are identifi ed with shading and

mark on the schematic diagrams and the electrical parts list. It is essential that these critical parts be replaced only with the part number

specifi ed in the electrical parts list to prevent electric shock, fi re, or other hazard.

NOTE: Do not modify the original design without obtaining written permission from the manufacturer or you will void the original parts and

labor guarantee.

!

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

When installing the LCD panel on a wall, the LCD panel must be secured using the 4 mounting holes on the rear cover.

To avoid damaging the LCD panel:

do not press on the panel or frame edge to avoid the risk of electric shock.

do not scratch or press on the panel with any sharp objects.

do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

do not expose the LCD panel to direct sunlight.

avoid contact with water. It may cause a short circuit within the module.

disconnect the AC adapter when replacing the backlight (CCFL) or inverter circuit.

(High voltage occurs at the inverter circuit at 650Vrms.)

always clean the LCD panel with a soft cloth material.

use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

LEAKAGE CURRENT HOT CHECK CIRCUIT

KDL-32L4000/37L4000

7

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

KDL-32L4000/37L4000

example 1

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints.

Lead Free Solder is available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade.

This requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to

http://www.sony-training.com

KDL-32L4000/37L4000

8

SAFETY CHECK-OUT

KDL-32L4000/37L4000

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

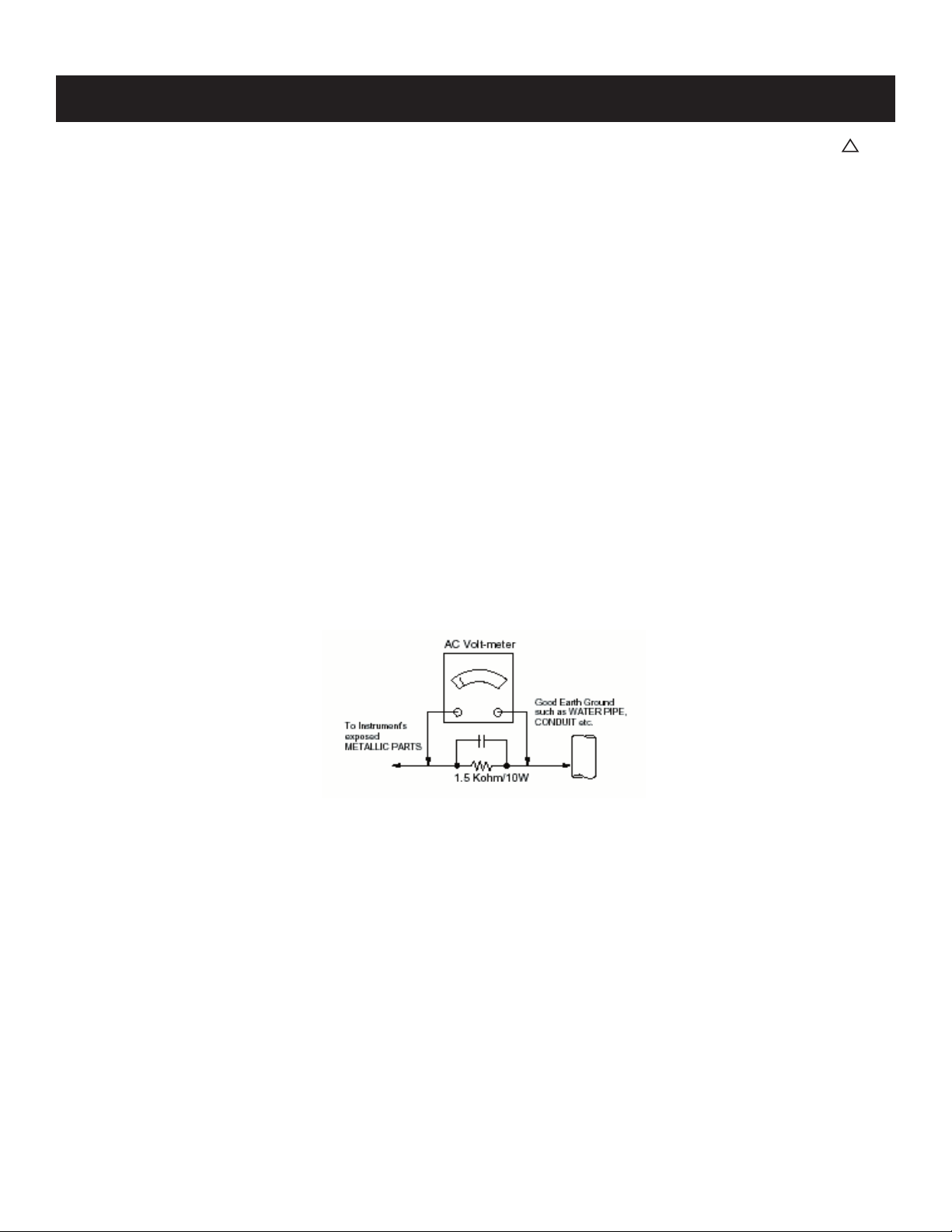

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

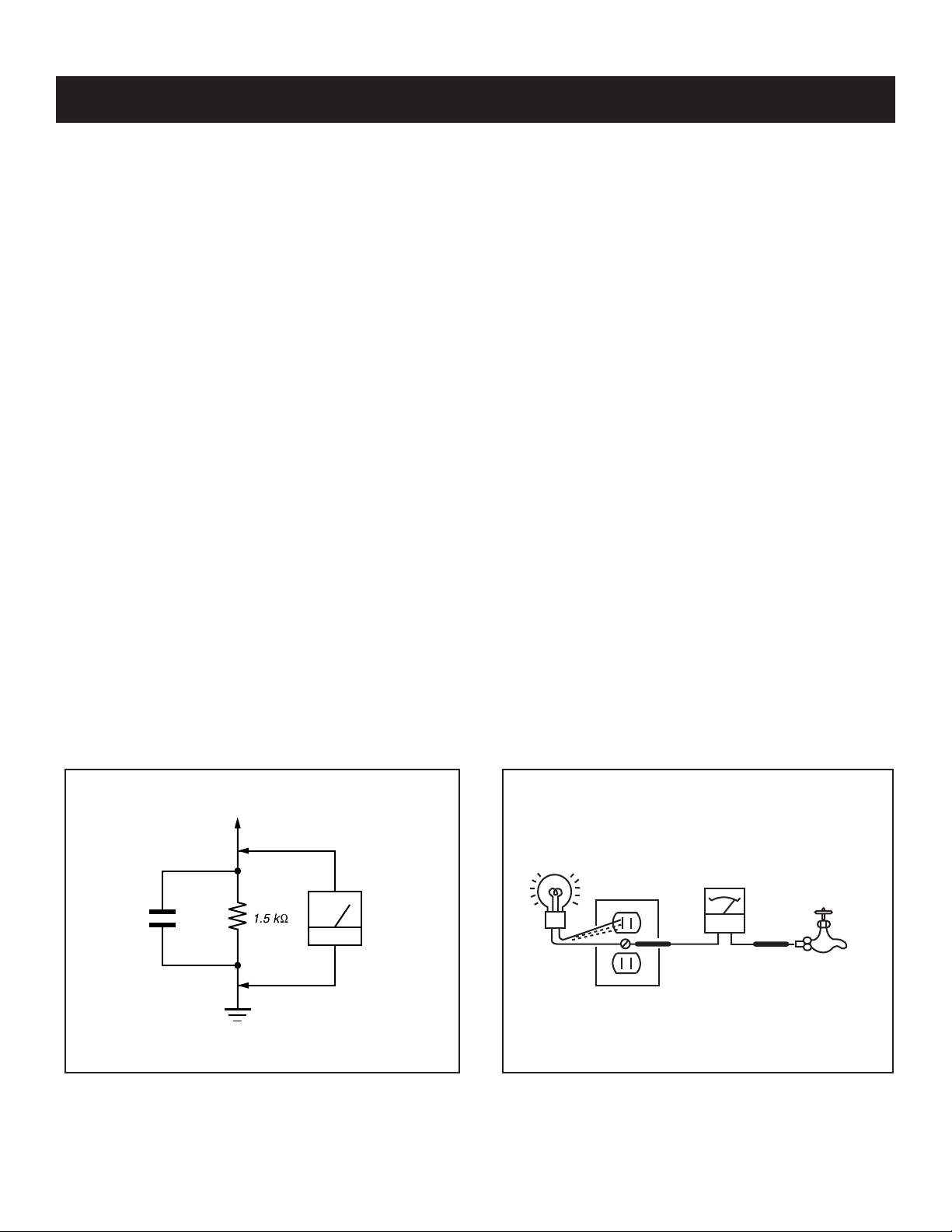

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

Leakage Test

0.15 F

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

To Exposed Metal

Parts on Set

Earth Ground

AC

Voltmeter

(0.75V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

KDL-32L4000/37L4000

9

KDL-32L4000/37L4000

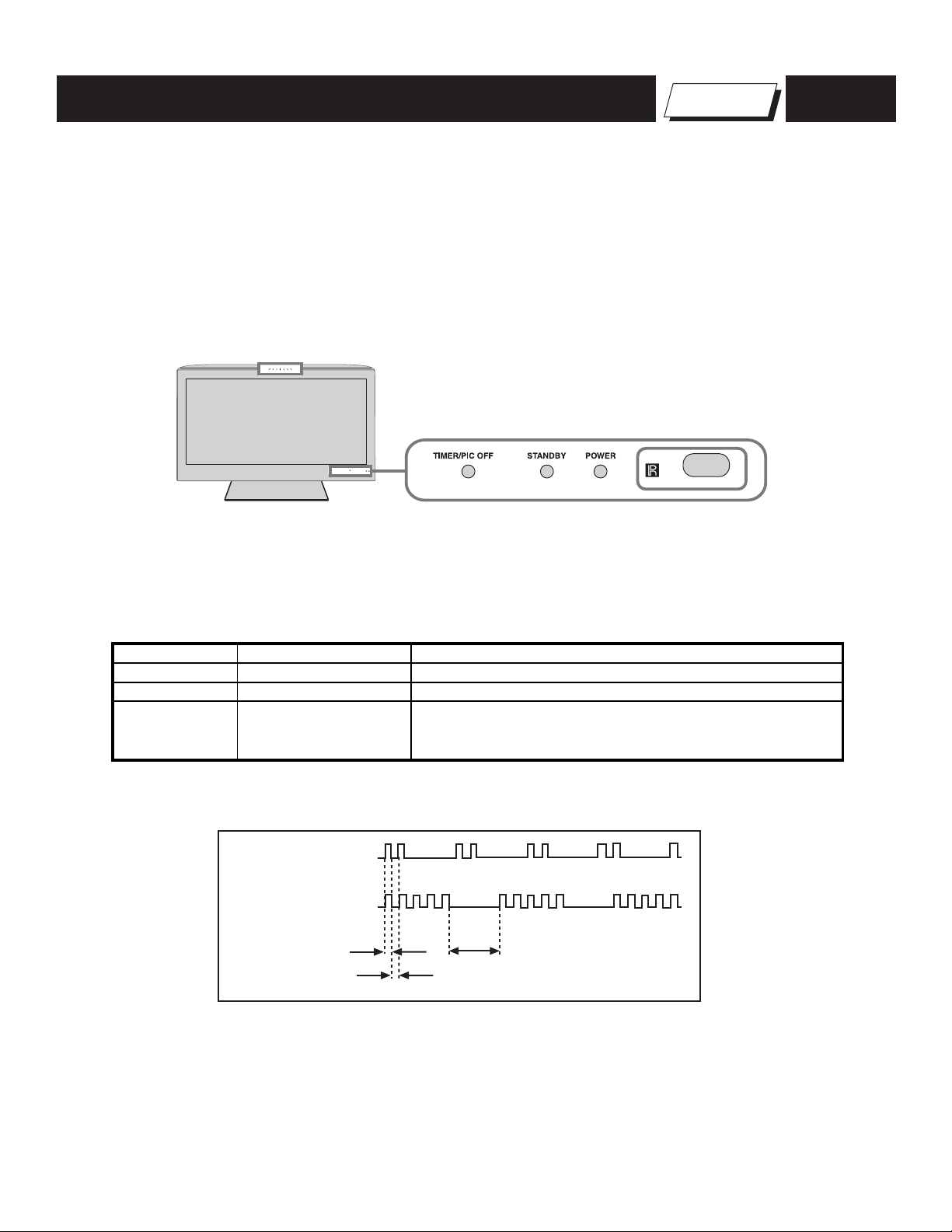

SELF-DIAGNOSTIC FUNCTION

IThe units in this manual contain a self-diagnostic function. If an error occurs, the TIMER/PIC OFF LED indicator will automatically begin to fl ash. The

number of times the LED fl ashes translates to a probable source of the problem. A defi nition of the TIMER/PIC OFF LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

1. Diagnostic Test Indicators

When an error occurs, the TIMER/PIC OFF LED indicator will fl ash a set number of times to indicate the possible cause of the problem. If there is more

than one error, the indicator will identify the fi rst of the problem areas.

Control Buttons

Self Diagnosis

Supported model

Description of LED Indictors

LED LED Type Description

POWER LED Green LED

STANDBY LED Red LED

TIMER/PIC OFF

LED

Display of TIMER/PIC OFF LED Flash Count

Amber/Green/Red LED

2 times

5 times

LED ON 0.3 sec.

LED OFF 0.3 sec.

* Light is green when the TV set is on

* Light is red when the TV set is in PC standby mode.

* Light is amber when the timer is set.

* Light is green when the Backlight feature is activated.

* Blinks red when indicating the TV may need servicing

LED OFF

3 sec.

KDL-32L4000/37L4000

10

KDL-32L4000/37L4000

r

Viewing the Diagnostic List

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a second of each other:

DISPLAY

The Self Check list displays. This is the SAME as accessing Service Adjustments.

Results for all of the following diagnostic items are displayed at the bottom of the screen. No error has occurred if the screen displays a “0”.

Channel 5 Volume +

TV POWER

.

Resets all settings

to the Factory Defaults

Stored Data

from ADC calibration

(from factory)

Diagnostic

List

QR0.5-C510

Model Information: 32L4000 8000001

Factory Default

Power On Time: 00001H

SMPTE

ADC Auto Calibration

Cr Y Cb

Gain

424

ColorBar100

1608 424

ITU 709

Offset

Gain

1020

420

128

1592

1020

422

ITU 601

Offset

Gain

1020

456

128

1840

1020

460

VGA

Offset

16 8

16

2:MAIN POWER 0 6:BL 0

3:DC ALERT1 0 7:TEMP 1

4:DC ALERT2 0 8:Audio 0

5:DC ALERT3 0

Software Version

Model Information & Serial Numbe

Power Time

Indicates an error was detected

Indicates no error was detected

Clearing the Diagnostic List

CAUTION: T

settings. Before performing this reset, contact the customer to determine what adjustments they have made.

1. Using the remote commander, select Factory Default button.

2. T

3. To start Auto Program, select Yes.

NOTE: Allow 30+ minutes for Auto Program to complete.

4. Using the customers information, reset their adjustments.

KDL-32L4000/37L4000

o remove the error indicator number you have to reset the settings back to the Factory Defaults. This action over-writes all customer

o reset the Diagnostic List, select Yes.

11

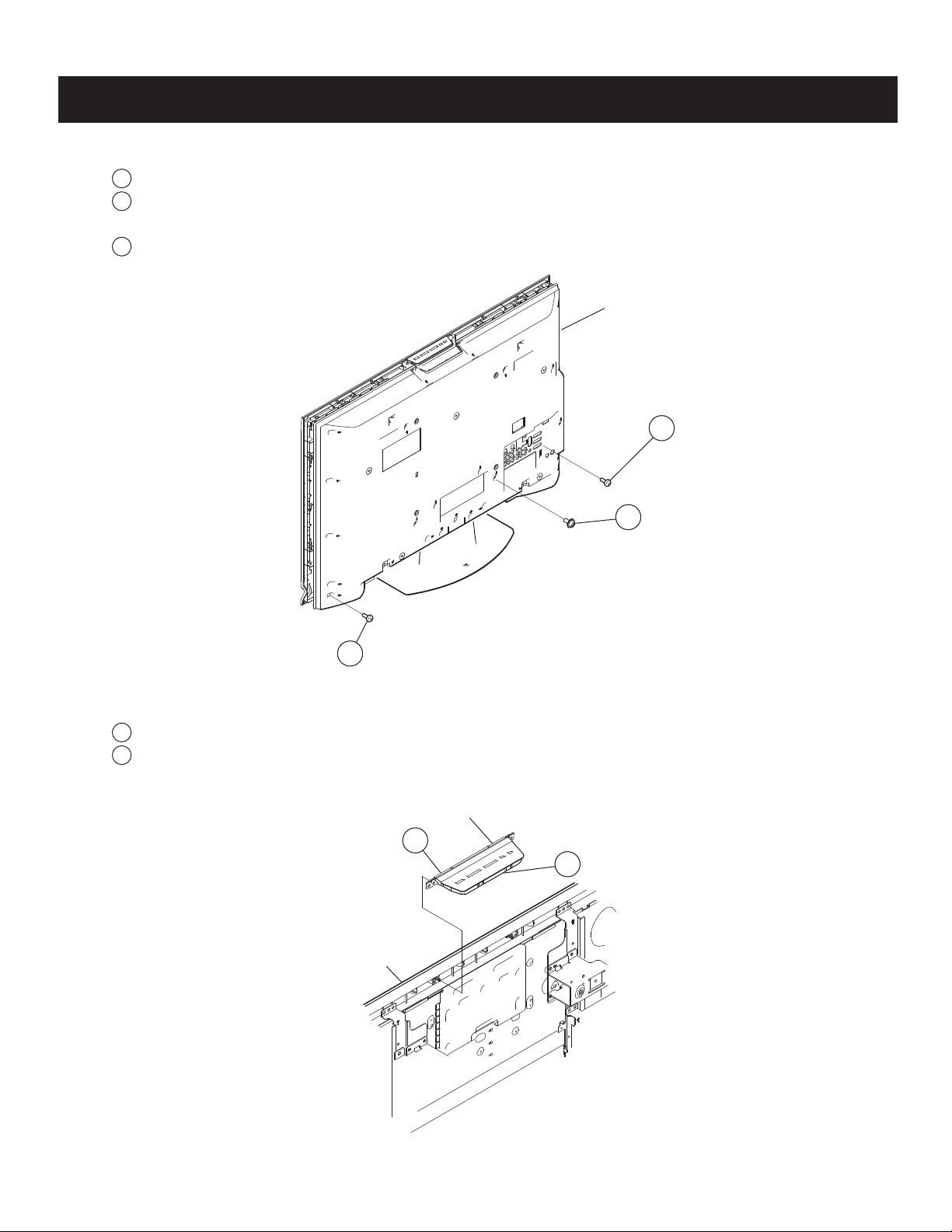

1-1. REAR COVER REMOVAL

Remove 2 screws from Terminal Position

1

Remove 1 screw (KDL-32L4000 ONLY)

2

Remove 6 screws (KDL-37L4000 ONLY)

Remove 17 screws (KDL-32L4000 ONLY)

3

Remove 20 screws (KDL-37L4000 ONLY)

KDL-32L4000/37L4000

SECTION 1: DISASSEMBLY

Rear Cover

1

3

1-2. SWITCH UNIT REMOVAL (CONTAINS H1 BOARD)

Remove from Bezel

1

Disconnect 1 connector

2

Switch Unit

(Contains H1 Board)

1

Bezel

2

2

KDL-32L4000/37L4000

12

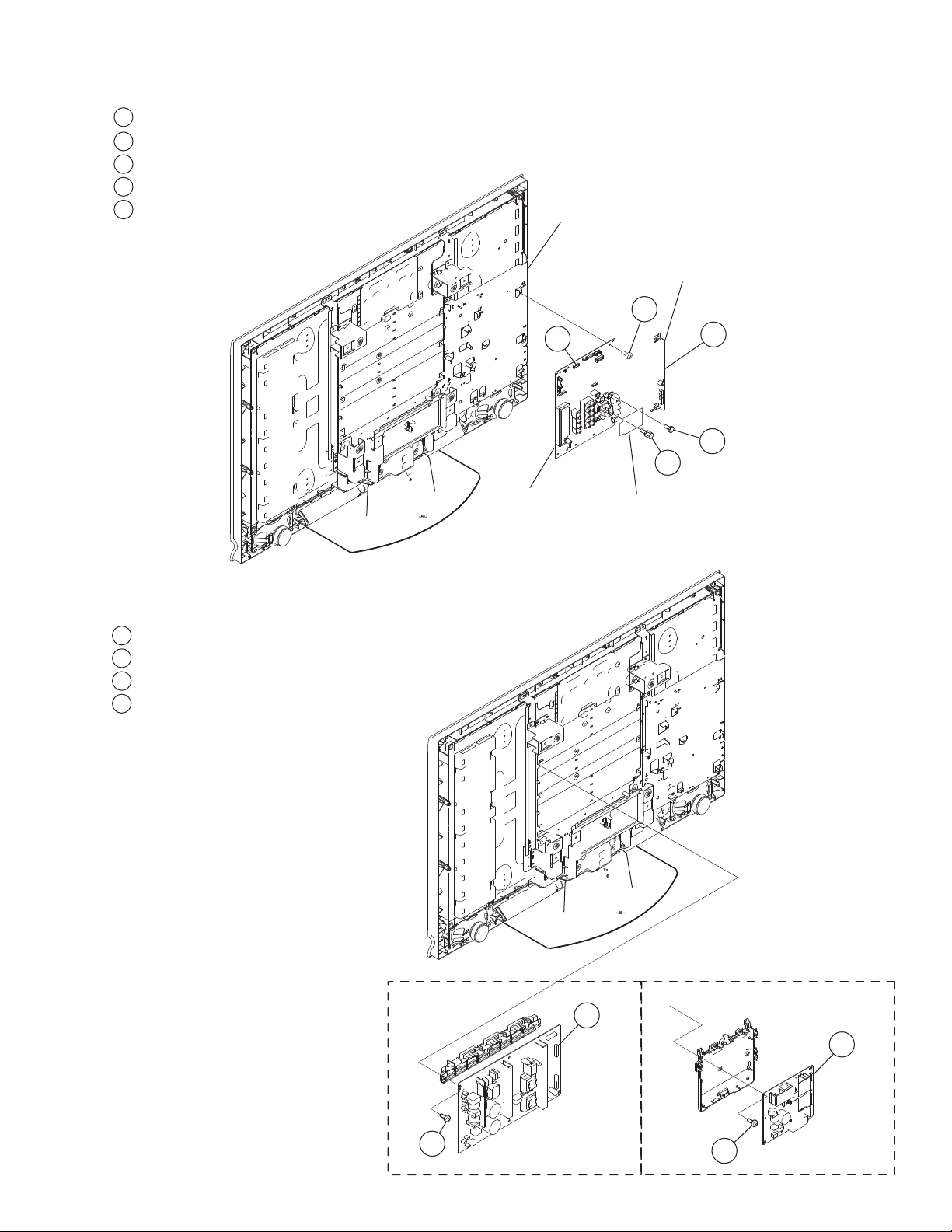

1-3. SIDE JACK BRACKET, BM4 BOARD REMOVAL

1

Release hook and slide out Side Jack Bracket from BM4 Board

Disconnect 5 connectors

2

Remove 7 screws

3

Remove 2 screws

4

Remove 2 HEX screws

5

Main Bracket

2

KDL-32L4000/37L4000

Side Jack Bracket

3

1

4

5

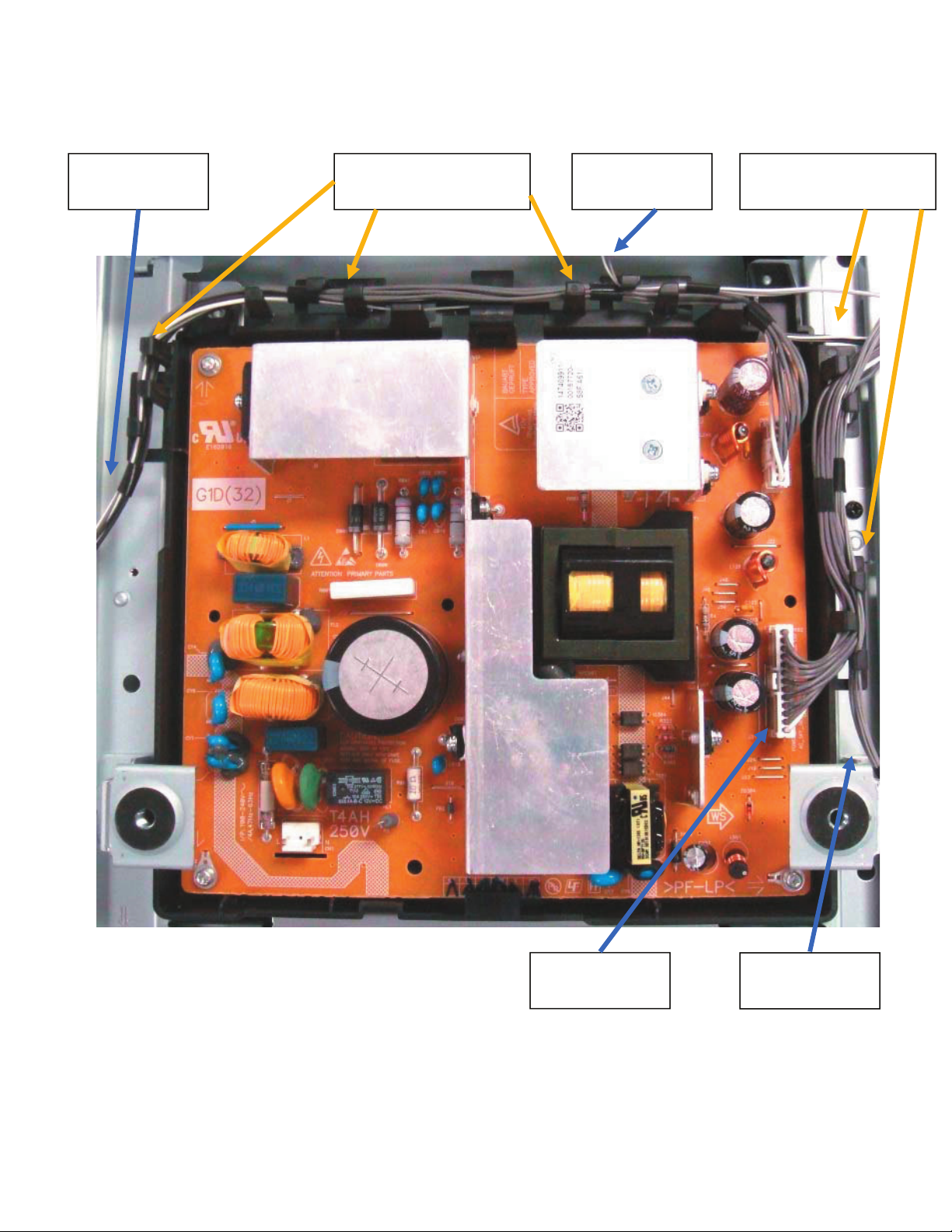

1-4. POWER UNIT (G1D/G2D BOARD) REMOVAL

Disconnect 4 connectors (KDL-32L4000 ONLY)

1

Remove 3 screws (KDL-32L4000 ONLY)

2

Remove 6 screws (KDL-37L4000 ONLY)

3

Disconnect 3 connectors (KDL-37L4000 ONLY)

4

BM4 Board

Terminal Bracket

KDL-32L4000/37L4000

3

1

4

2

KDL-32L4000KDL-37L4000

13

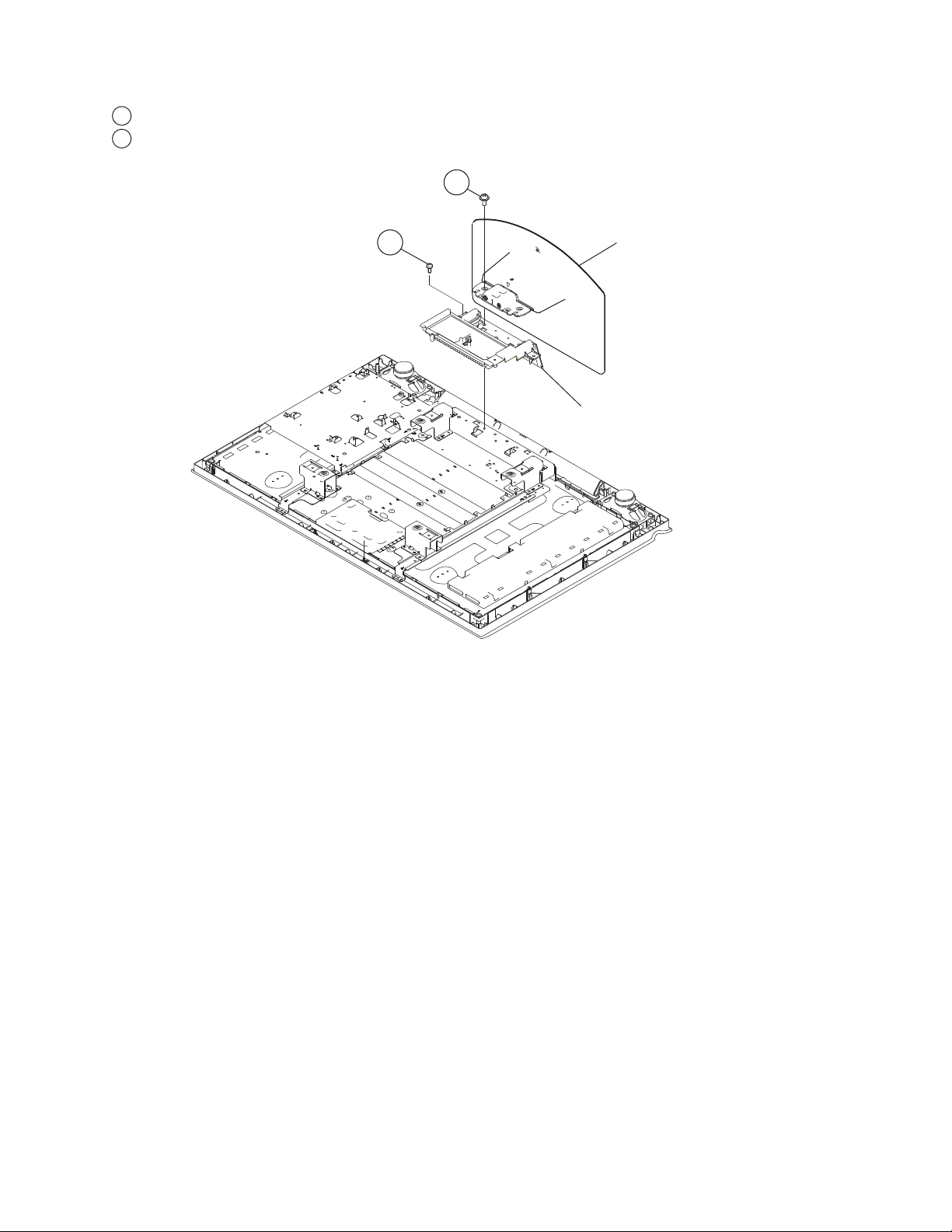

1-5. TABLE-TOP STAND REMOVAL

Remove 3 screws

1

Remove 1 screw (KDL-37L4000 ONLY)

2

KDL-32L4000/37L4000

1

2

Table-Top Stand Assembly

Under Cover

KDL-32L4000/37L4000

14

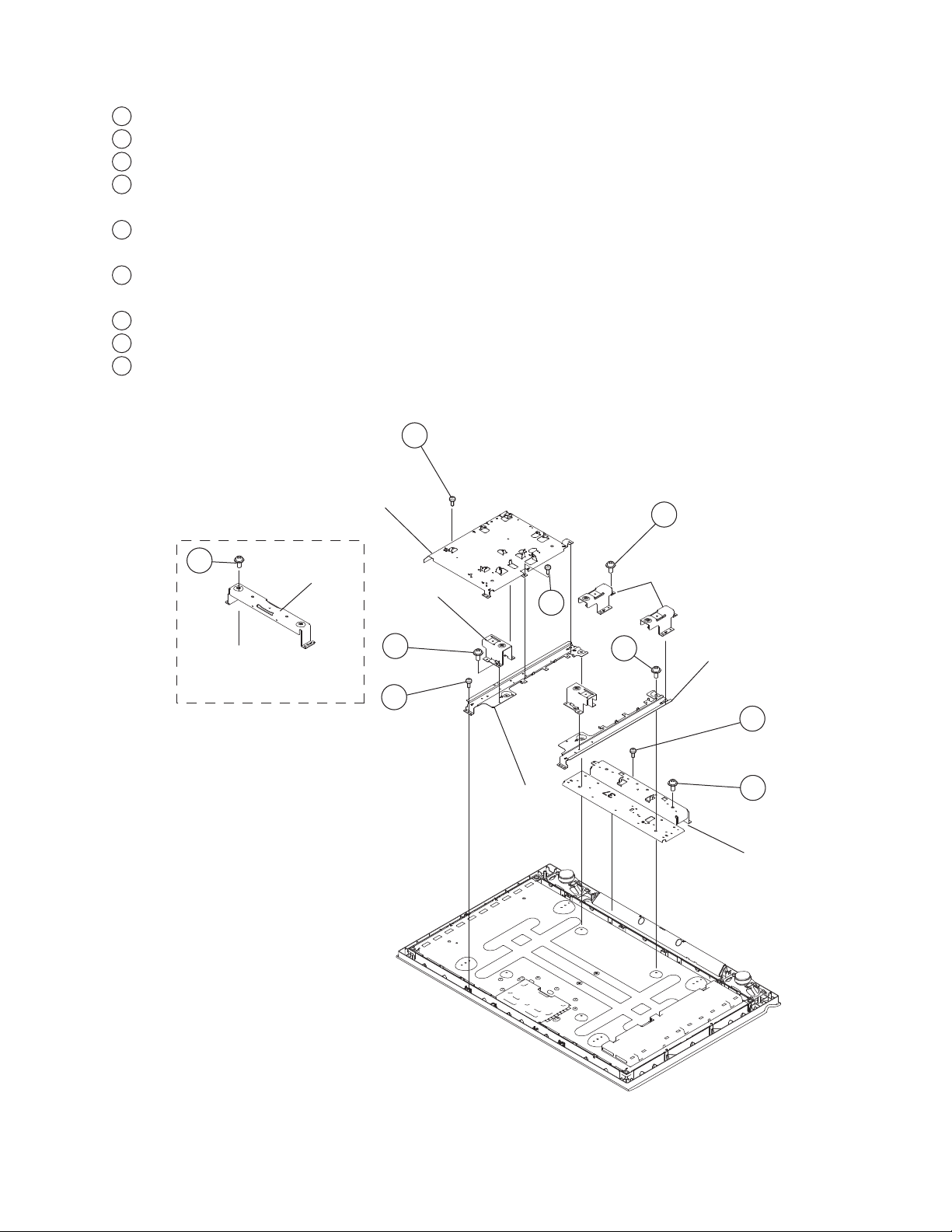

1-6. STRUCTURAL FRAMES AND VESA BRACKET REMOVAL

Remove 4 screws from Top Vesa Brackets (KDL-37L4000 ONLY)

1

Remove 2 screws from Top Vesa Bracket (KDL-32L4000 ONLY)

2

Remove 1 screw

3

Remove 4 screws (KDL-32L4000 ONLY)

4

Remove 3 screws (KDL-37L4000 ONLY)

Remove 2 screws from Bottom Vesa Bracket (KDL-32L4000 ONLY)

5

Remove 6 screws from Bottom Vesa Bracket (KDL-37L4000 ONLY)

Remove 5 screws from Spine Frames (KDL-32L4000 ONLY)

6

Remove 6 screws from Spine Frames (KDL-37L4000 ONLY)

Remove 2 screws from Bottom Bracket

7

Remove 4 screws from Bottom Bracket (KDL-32L4000 ONLY)

8

Remove 2 screws from Top of Spine Frames (KDL-32L4000 ONLY)

9

3

KDL-32L4000/37L4000

Main Bracket

5

2

Vesa (Top)

KDL-32L4000

Vesa (Top)

4

1

9

Spine (L)

Vesa (Bottom)

6

Spine (R)

7

8

Bottom Bracket

KDL-32L4000/37L4000

15

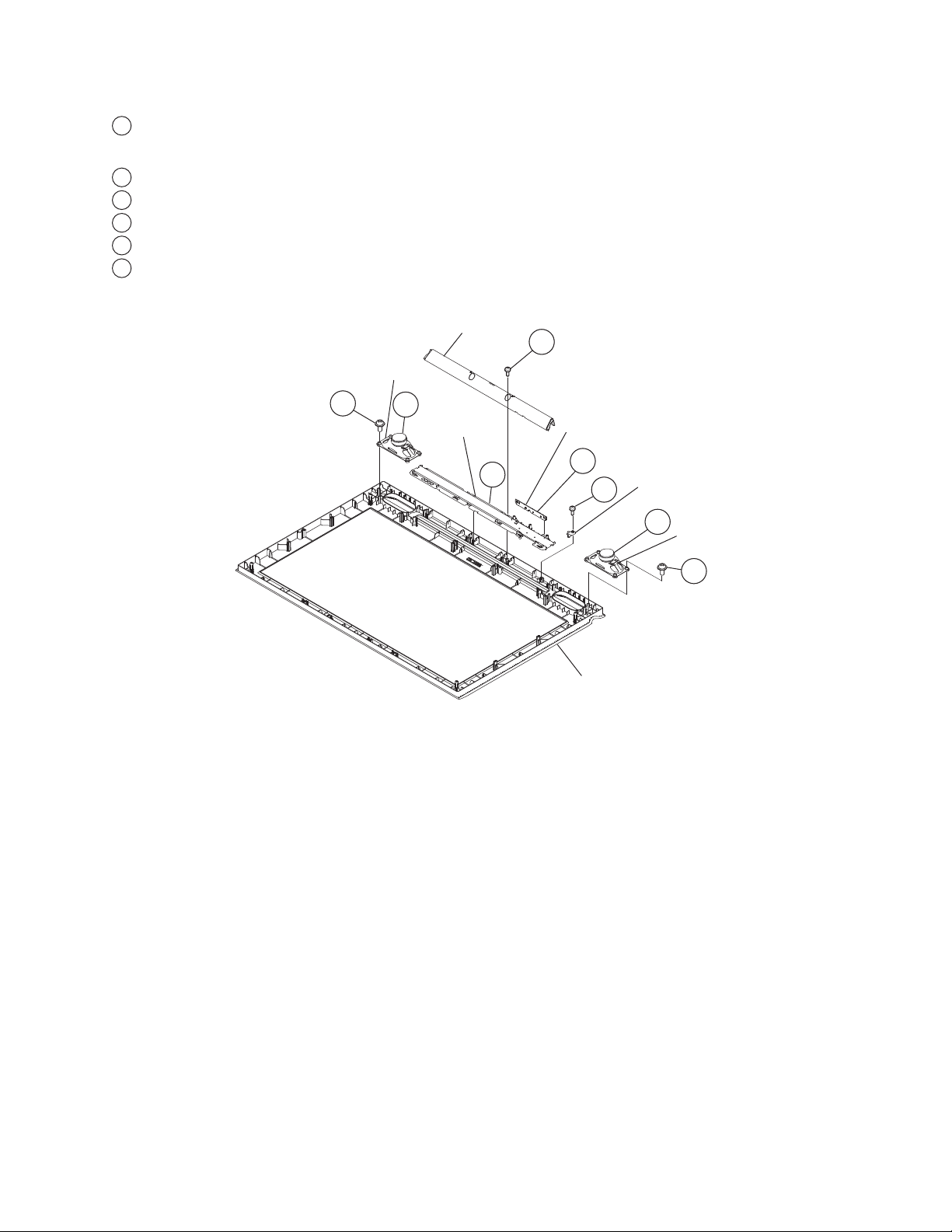

1-7. SPEAKERS, UNDER BAR, HM6 BOARD AND LIGHT GUIDE REMOVAL

r

1

Remove 1 screw from Under Bar (KDL-32L4000 ONLY)

Remove 2 screws from Under Bar (KDL-37L4000 ONLY)

Disconnect connector and slide out HM6 Board from Clear Panel

2

Release hooks and remove from Bezel

3

Remove 1 screw

4

Remove 4 screws from Speakers

5

Slide out Speakers from Bezel

6

Under Bar

1

Speaker

KDL-32L4000/37L4000

5

6

Clear Panel

HM6 Board

3

2

Bezel

4

Light Guide

6

Speake

5

KDL-32L4000/37L4000

16

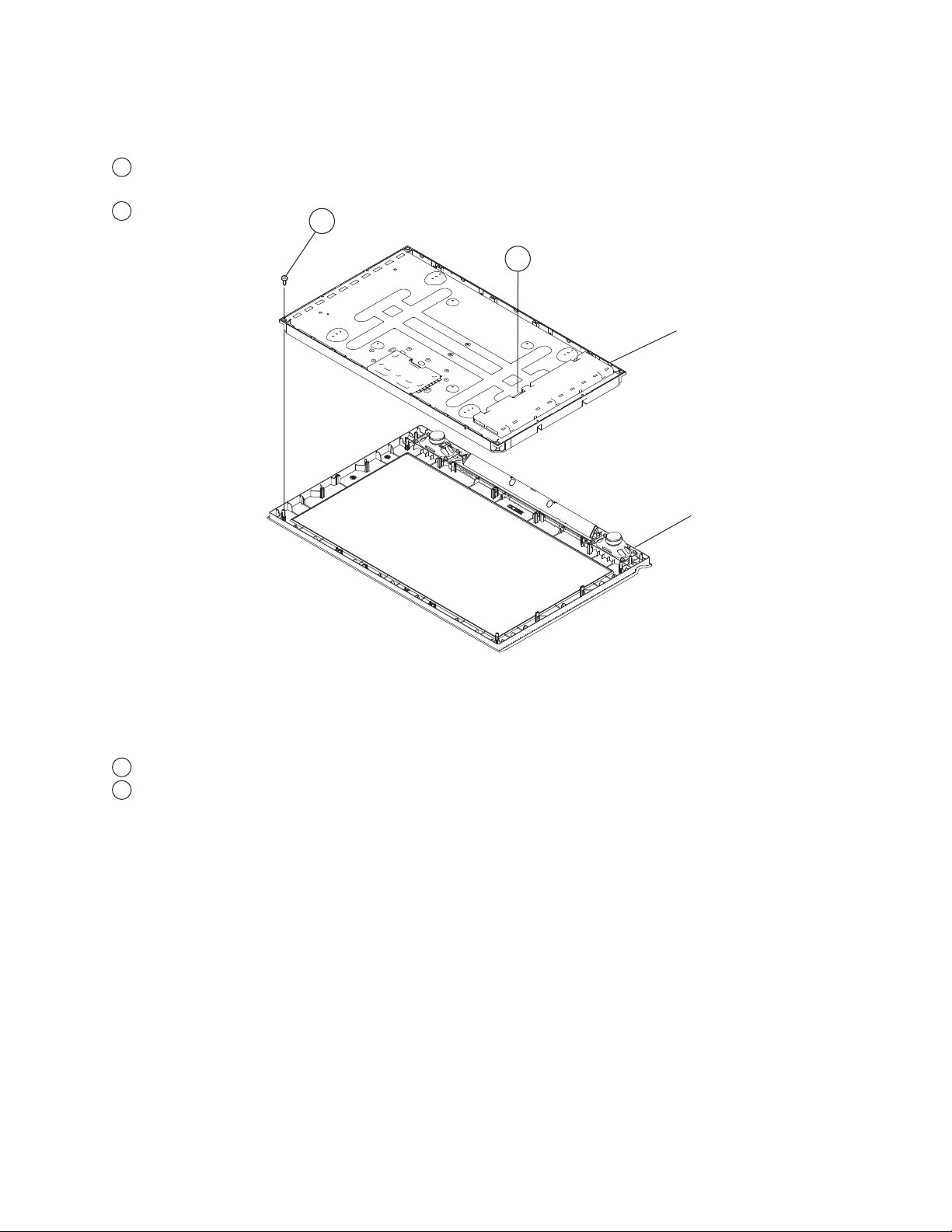

1-8. LCD PANEL REMOVAL

NOTE: The LVDS cable can only be installed one way. There is colored tape on the cable to determine which side

is attached to the TCON and which side is attached to the BM4 Board

Remove 2 screws (KDL-32L4000 ONLY)

1

Remove 5 screws (KDL-37L4000 ONLY)

Disconnect 1 connector

2

KDL-32L4000/37L4000

1

2

LCD Panel

Bezel

1-8-1. CLEANING THE LCD PANEL

CAUTION: When cleaning the TV, be sure to unplug the power cord to avoid any chance of electric shock.

1

Clean the cabinet of the TV with a dry soft cloth.

2

Wipe the LCD screen gently with a soft cloth.

Stubborn stains may be removed with a cloth slightly moistened with a solution of mild soap and

warm water.

If using a chemically pretreated cloth, please follow the instruction provided on the package.

Never use strong solvents such as a thinner, alcohol or benzine for cleaning.

Periodic vacuuming of the ventilation openings is recommended to ensure to proper ventilation.

KDL-32L4000/37L4000

17

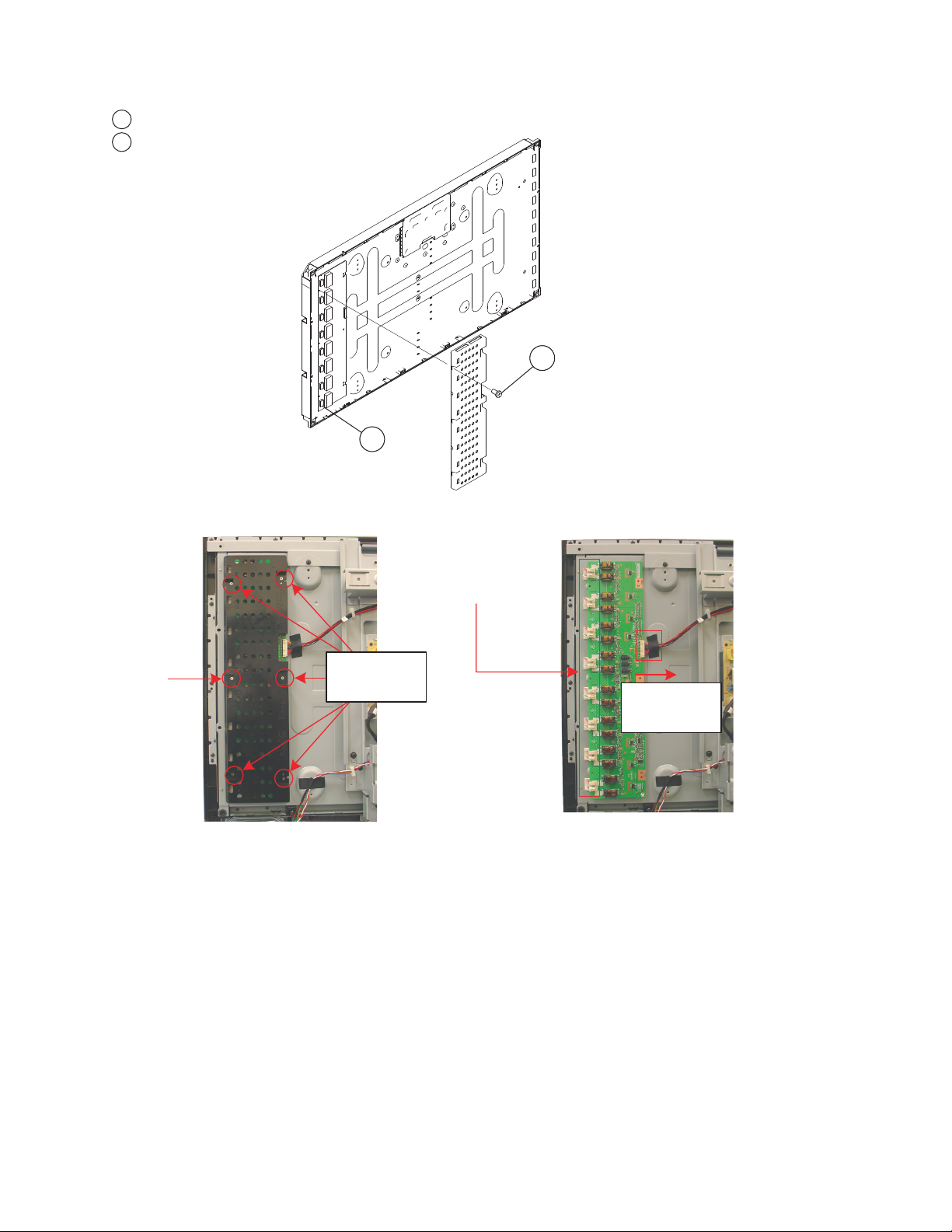

1-9. INVERTER BOARD REMOVAL

Remove 6 screws from cover

1

Disconnect 6 connectors from board

2

KDL-32L4000/37L4000

1

2

SHIELD REMOVAL

Balancer Board Connectors

REMOVE SCREWS

SECURING

SHIELD

CAUTION!

Disconnect the

REMOVE

CONNECTOR AND

PULL BOARD TO

THE RIGHT

KDL-32L4000/37L4000

18

�MA2L Wire Dressing 32L [Rev: 1.0]

MA2 CHASSIS

“L” Series

WIRE DRESSING and EMI

32L4000

32L4000C

MB609391 (2 / 10)

WIRE DRESSING

�MA2L Wire Dressing 32L [Rev: 1.0]

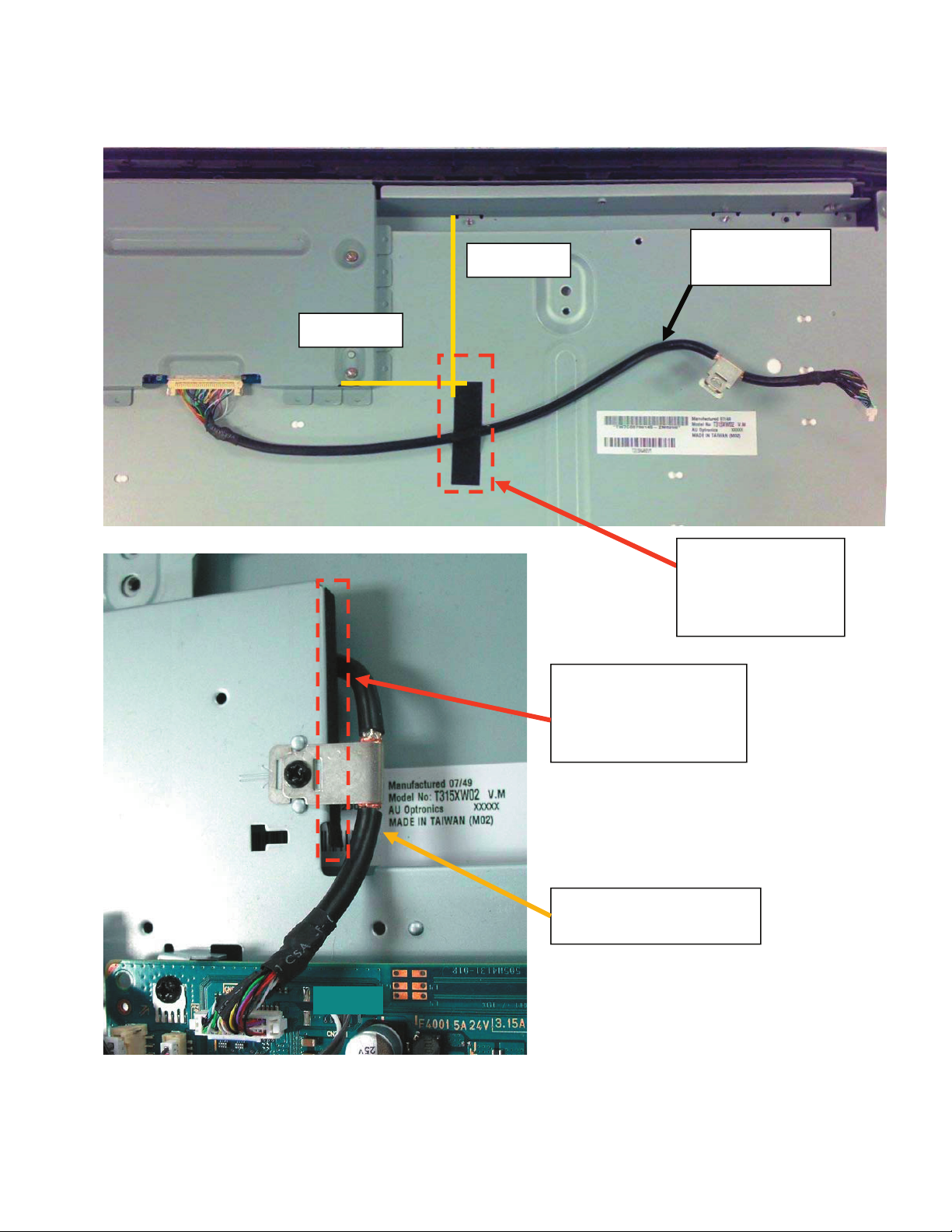

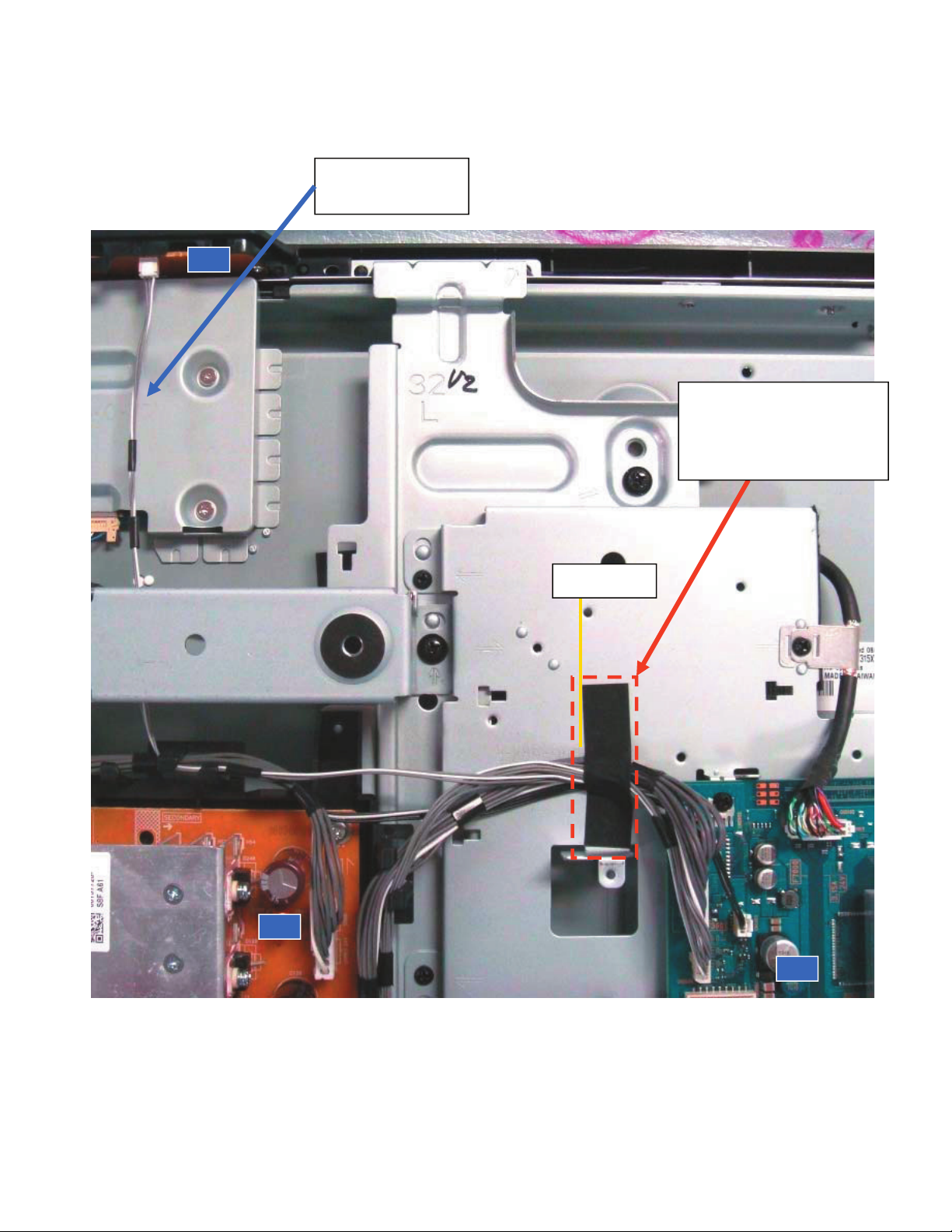

LVDS Cable:

LVDS Cable:

1-835-169-11

Reference

Reference

Dress LVDS cable to

have this route.

Fix LVDS cable to

Panel using:

Himelon Tape

2-688-011-01

Cover Sharp Edge on

Main Bracket using:

Himelon Tape

2-688-011-01

MB609391 (3 / 10)MB609391 (3 / 10)

�MA2L Wire Dressing 32L [Rev: 1.0]

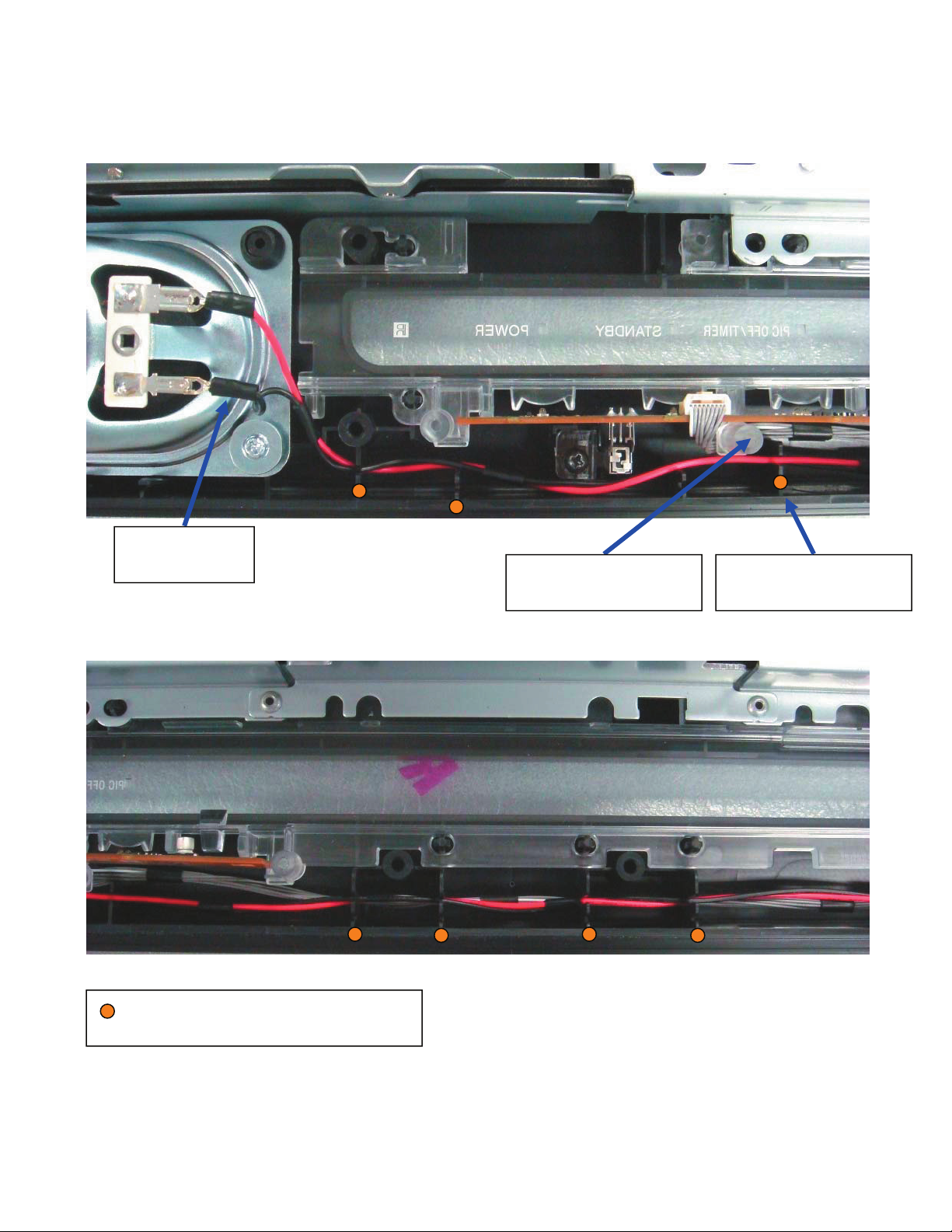

HM6 and speakers cables:

Only Spkr cable

through this holder rib.

HM6 cable under this

transparent boss.

Spkr cable

1-910-048-12

Route cables by inserting it through

these 7 Holder Ribs on Bezel.

MB609391 (4 / 10)MB609391 (4 / 10)MB609391 (4 / 10)

�MA2L Wire Dressing 32L [Rev: 1.0]

Fix HM6 + Spkrs

cables to panel using

Himelon Tape

2-688-011-01

Reference

Route cables by inserting it through

these 3 Holder Ribs on Bezel.

MB609391 (5 / 10)MB609391 (5 / 10)MB609391 (5 / 10)MB609391 (5 / 10)

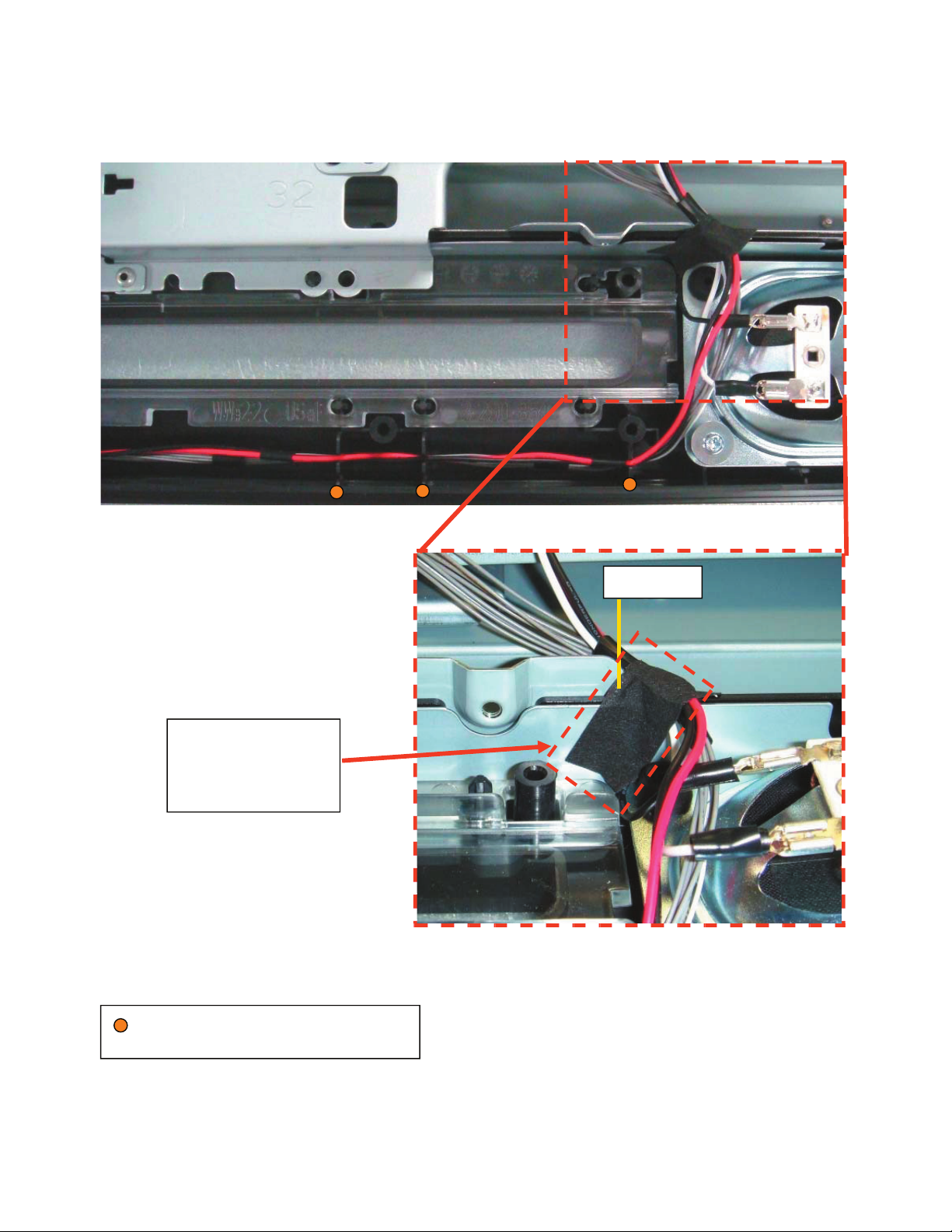

�MA2L Wire Dressing 32L [Rev: 1.0]

Inverter cable:

Use clamps on bracket

to route harness

Reference

Cover Sharp Edge on

Spine Frame using:

Himelon Tape

2-688-011-01

Inverter cable

1-910-044-78

MB609391 (6 / 10)MB609391 (6 / 10)MB609391 (6 / 10)MB609391 (6 / 10)MB609391 (6 / 10)

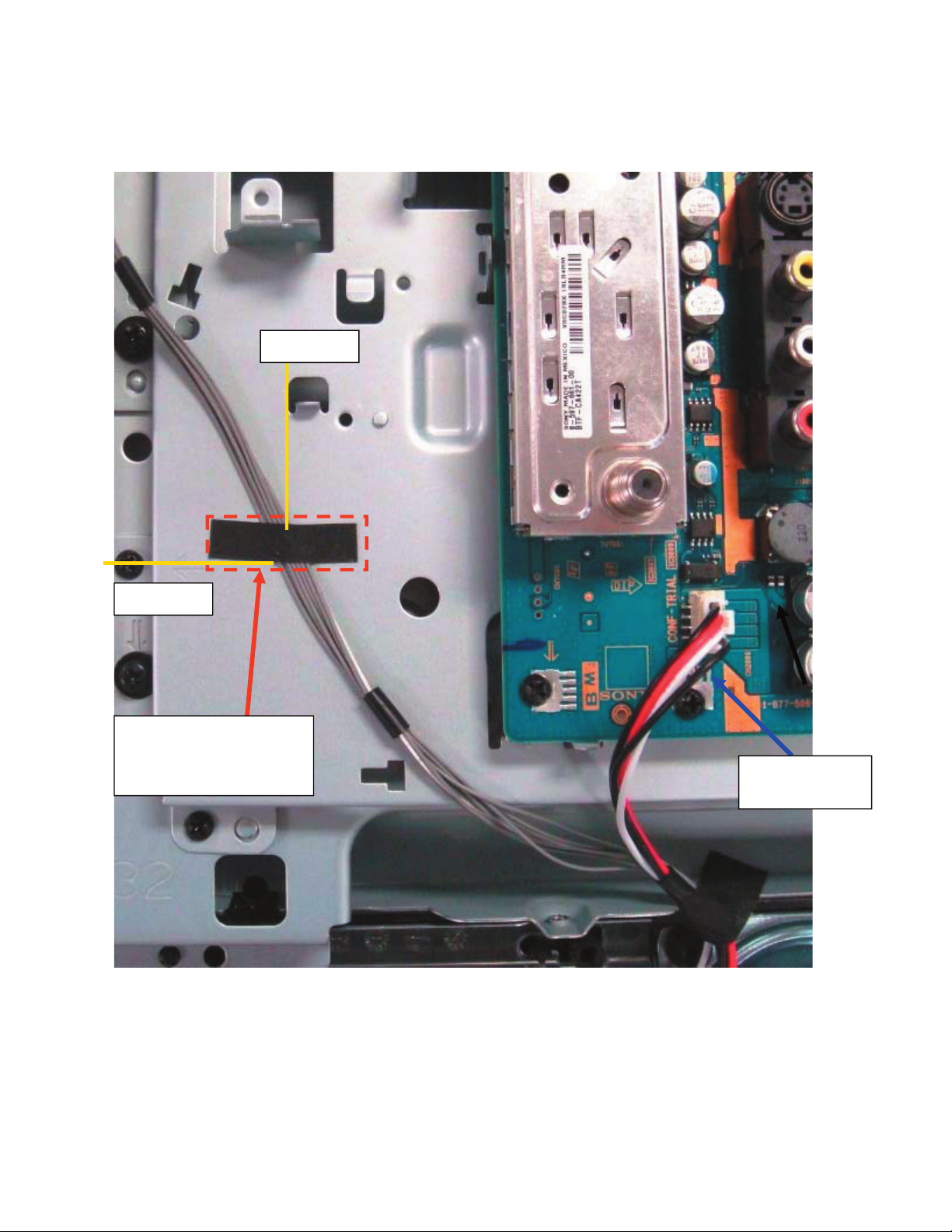

�MA2L Wire Dressing 32L [Rev: 1.0]

G1 Dressing:

Use clamps on bracket

to route cables

StandBy cable

1-910-044-86

HM6/H1 cable

1-910-048-11

Inverter cable

1-910-044-78

Use clamps on bracket

to route cables

HM6/H1 cable

1-910-048-11

MB609391 (7 / 10)MB609391 (7 / 10)MB609391 (7 / 10)MB609391 (7 / 10)MB609391 (7 / 10)MB609391 (7 / 10)

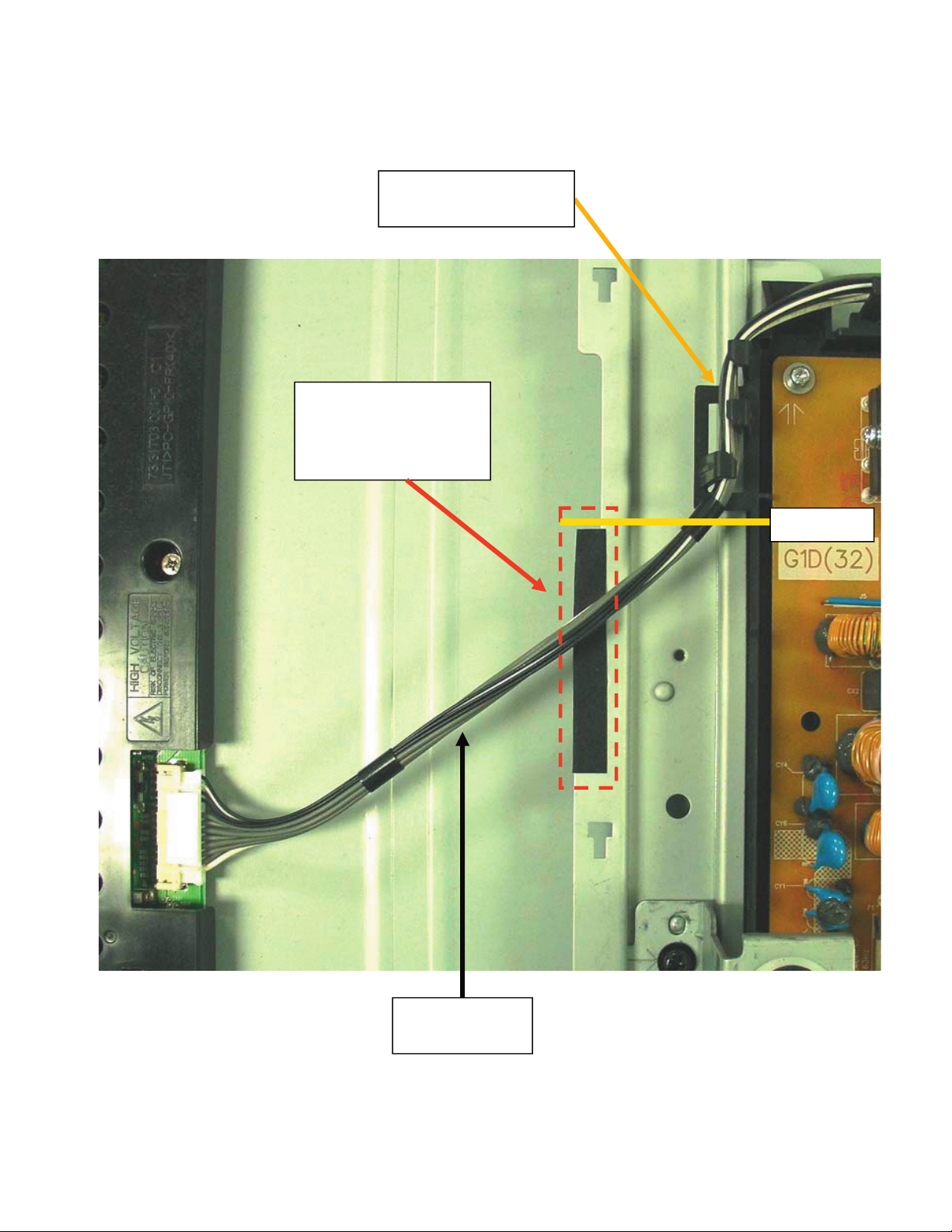

�MA2L Wire Dressing 32L [Rev: 1.0]

H1 cable:

H1

HM6/H1 cable:

1-910-048-11

Reference

Fix HM6/H1 + Standby

+ BL cables to Main

Bracket using:

Himelon 2-688-011-01

G1

BM

MB609391 (8 / 10)MB609391 (8 / 10)MB609391 (8 / 10)MB609391 (8 / 10)MB609391 (8 / 10)MB609391 (8 / 10)MB609391 (8 / 10)

�MA2L Wire Dressing 32L [Rev: 1.0]

Reference

Reference

Fix HM6 cables to Main

Bracket using:

Himelon 2-688-062-01

Spkr cable:

1-910-048-12

MB609391 (9 / 10)MB609391 (9 / 10)MB609391 (9 / 10)MB609391 (9 / 10)MB609391 (9 / 10)MB609391 (9 / 10)MB609391 (9 / 10)MB609391 (9 / 10)

Loading...

Loading...