Sony kdl 32l4000, kdl 37l4000 schematic

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDL-32L4000

KDL-32L4000

KDL-37L4000

KDL-37L4000

RM-YD025 US

RM-YD025 CANADA

RM-YD025 US

RM-YD025 CANADA

CZ1

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 3/2008

:UPDATED ITEM

☛

REVISION DATE SUBJECT

3/2008 No revisions or updates are applicable at this time.

5/2008 Corrected steps to access service mode. Replaced page 30.

Revised information regarding “Resetting to Factory Defaults...” Replaced page 31.

Replaced Frame Diagrams to include Board labels. Replaced pages 36 & 37.

8/2008 Reissue entire manual due to multiple updates.

8/2008 Updated reference to LCD Panels service manual. Replaced pages 63 & 64.

LCD DIGITAL COLOR TELEVISION

9-883-774-04

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDL-32L4000

KDL-32L4000

KDL-37L4000

KDL-37L4000

RM-YD025 US

RM-YD025 CANADA

RM-YD025 US

RM-YD025 CANADA

CZ1

CHASSIS

9-883-774-04

KDL-37L4000 RM-YD025

LCD DIGITAL COLOR TELEVISION

KDL-32L4000/37L4000

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 6

Safety-Related Component Warning .............................................. 8

Safety Check-Out ......................................................................... 10

Self-Diagnostic Function ................................................................11

SECTION 1: DISASSEMBLY ............................................................... 12

1-1. Rear Cover Removal ............................................................ 12

1-2. H1 Board Removal ............................................................... 12

1-3. A Board and G Board Removal ............................................ 13

1-4. Table-Top Stand Assembly and Under Cover Removal ....... 13

1-5. AC Inlet and Bracket Removal ............................................. 14

1-6 Under Bar, H2 Board (IR), H3 Board (LED) Removal .......... 14

1-7. Loudspeakers Removal ....................................................... 14

1-8. Structural Frames and Brackets Removal

(KDL-32L4000 Only) ............................................................ 15

1-9. Structural Frames and Brackets Removal

(KDL-37L4000 Only) ............................................................ 16

1-10. LCD Panel Removal ............................................................. 17

1-11. Balancer (MT Inverter) Board Removal

(KDL-32L4000 Only) ............................................................ 18

1-12. Balancer (MT Inverter) Board Removal

(KDL-37L4000 Only) ............................................................ 19

Wire Dressing ............................................................................... 20

KDL-32L4000 Only ............................................................... 20

KDL-37L4000 Only ............................................................... 25

SECTION 2: SERVICE ADJUSTMENTS ............................................. 30

2-1. Accessing Service (Factory) Mode ...................................... 30

2-2. Reviewing Service (Factory) Mode ...................................... 31

2-3. Resetting to Factory Defaults after Board Replacement ...... 31

2-4. Viewing Model Information ................................................... 32

SECTION 3: DIAGRAMS ..................................................................... 33

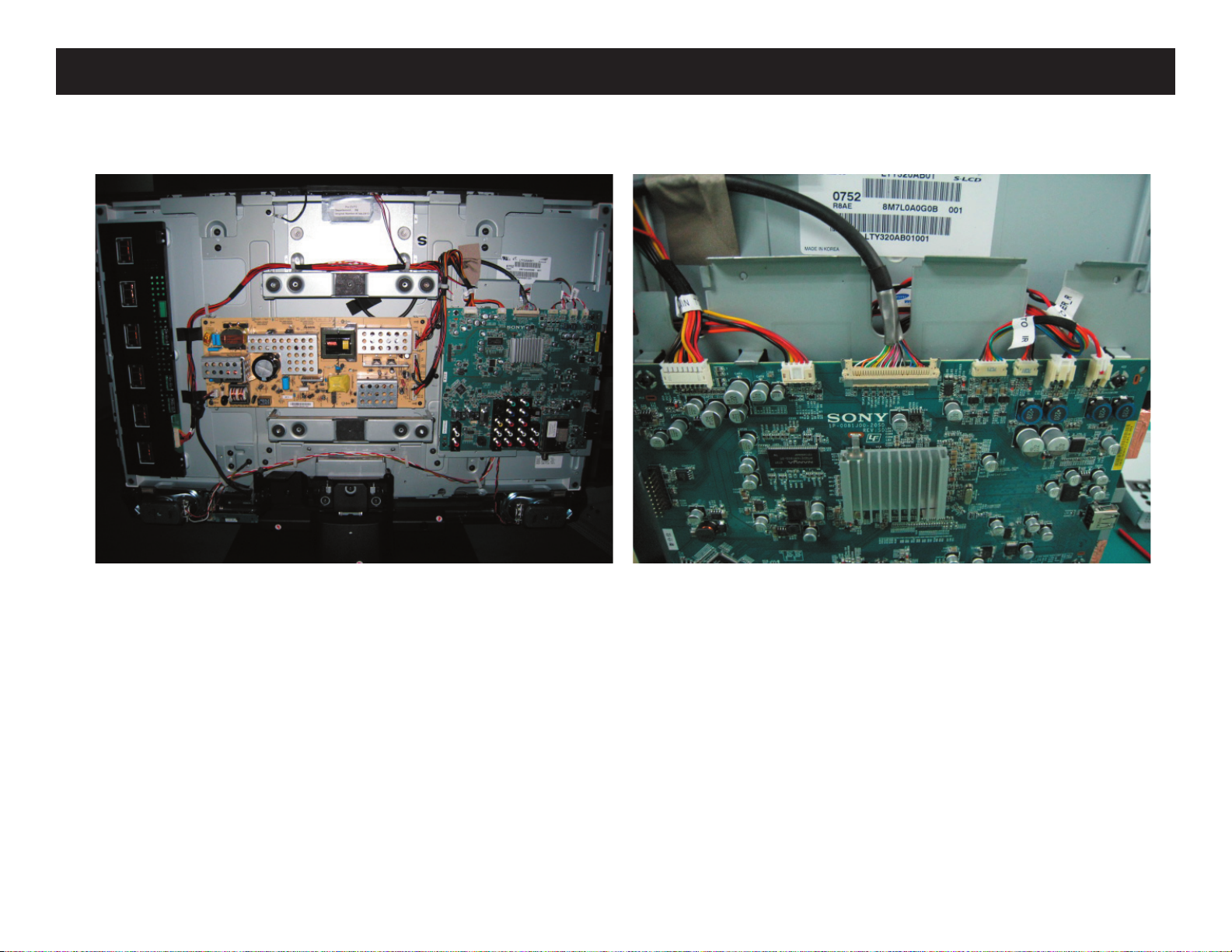

3-1. Circuit Boards Location ........................................................ 33

3-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 33

3-3. Block Diagram ...................................................................... 35

3-4. Frame Diagrams .................................................................. 36

3-4.1. KDL-32L4000 Only .................................................. 36

3-4.2. KDL-37L4000 Only .................................................. 37

3-5. Schematics and Supporting Information .............................. 38

A Board Schematic Diagram (1 of 16) .................................. 38

A Board Schematic Diagram (2 of 16) .................................. 39

A Board Schematic Diagram (3 of 16) .................................. 40

A Board Schematic Diagram (4 of 16) .................................. 41

A Board Schematic Diagram (5 of 16) .................................. 42

A Board Schematic Diagram (6 of 16) .................................. 43

A Board Schematic Diagram (7 of 16) .................................. 44

A Board Schematic Diagram (8 of 16) .................................. 45

A Board Schematic Diagram (9 of 16) .................................. 46

A Board Schematic Diagram (10 of 16) ................................ 47

A Board Schematic Diagram (11 of 16) ................................ 48

A Board Schematic Diagram (12 of 16) ................................ 49

A Board Schematic Diagram (13 of 16) ................................ 50

A Board Schematic Diagram (14 of 16) ................................ 51

A Board Schematic Diagram (15 of 16) ................................ 52

A Board Schematic Diagram (16 of 16) ................................ 53

G Board Schematic Diagram (1 of 2) ................................... 55

G Board Schematic Diagram (2 of 2) ................................... 56

H1 Board Schematic Diagram .............................................. 59

H2 Board Schematic Diagram .............................................. 60

H3 Board Schematic Diagram .............................................. 61

KDL-32L4000/37L4000

SECTION 4: EXPLODED VIEWS ........................................................ 62

4-1. Rear Cover Assembly and Table-Top Stand Assembly ....... 62

4-2. Chassis ................................................................................ 63

4-3. Bezel Assembly and LCD Panel .......................................... 64

APPENDIX A: ENCRYPTION KEY COMPONENTS ..........................A-1

3

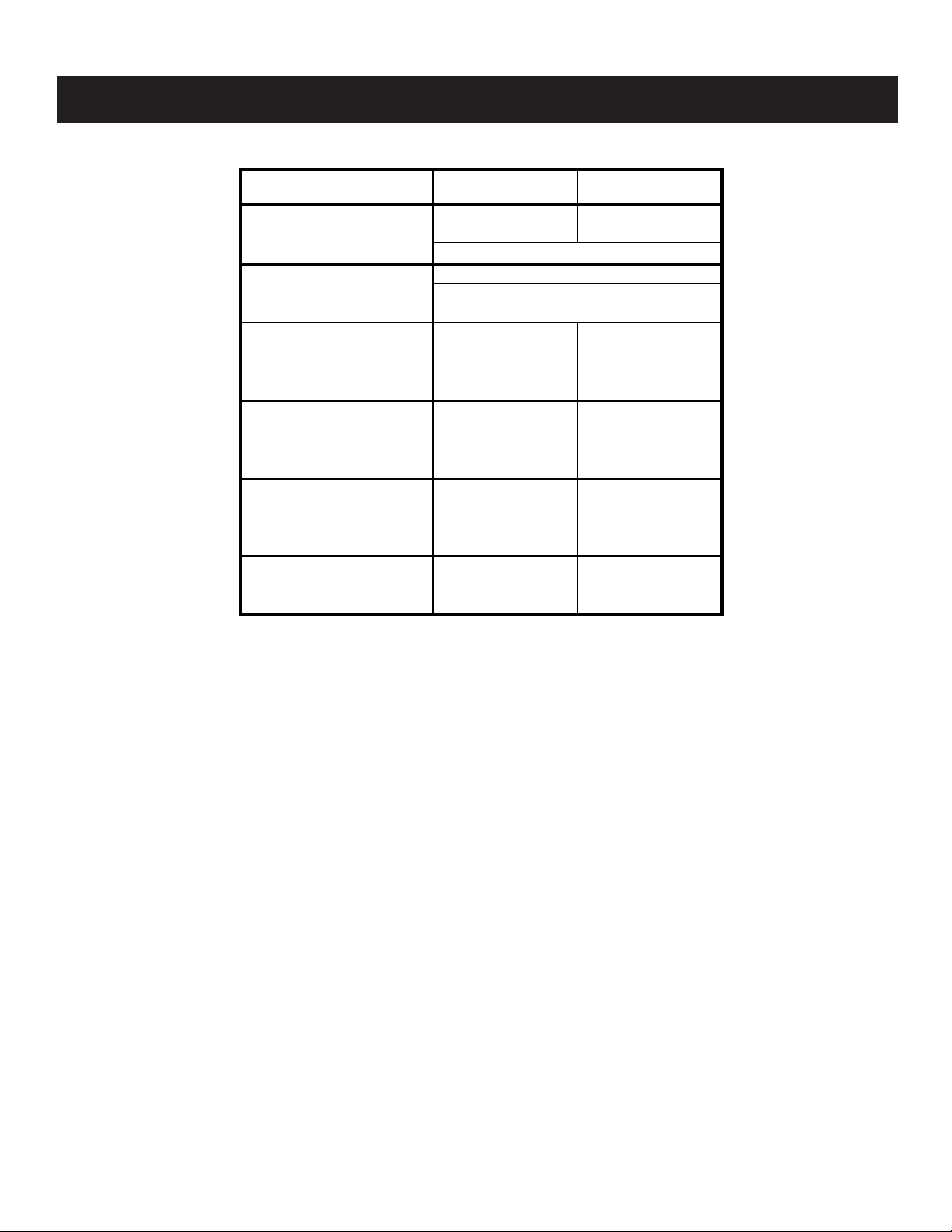

SPECIFICATIONS

KDL-32L4000/37L4000

Power Requirements

120V - 240V AC, 50/60Hz

Video (IN) 1/2

S Video (4-Pin Mini DIN)

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

Video

1.0 Vp-p, 75 ohms unbalanced, sync negative

Audio

500 mVrms (100% modulation)

Impedance: 47 kilohms

COMPONENT IN 1/2

YP

Y:1.0 Vp-p, 75 ohms unbalanced, sync negative

PB:0.7 Vp-p, 75 ohms

PR:0.7 Vp-p, 75 ohms

Signal format: 480i, 480p, 720p, 1080i

AUDIO

500 mVrms (100% modulation)

Impedance: 47 kilohms

HDMI IN 1/2:

HDMI: Video:480i, 480p, 720p, 1080i, 1080p

Audio: Two channel linear PCM 32, 44.1 and

48 kHz, 16, 20 and 24 bits

AUDIO: (HDMI IN 1 only) 500 mVrms (100% modulation)

Impedance: 47 kilohms

AUDIO OUT:

500 mVrms (100% modulation)

DIGITAL SUDIO OUT (OPTICAL):

Optical Digital Audio Output (PCM/Dolby Digital)

PC IN:

Analog RGB (D-sub 14-pin)

0.7 Vp-p, 75 ohms, positive

AUDIO (Stereo mini jack):

500 mVrms (100% modulation)

Impedance: 47 kilohms

(Component Video)

BPR

Television System

NTSC American TV Standard

ATSC (8VSB Terrestrial) ATSC compliant 8VSB

QAM on cable ANSI/SCTE 07 2000

Channel Coverage

Analog Digital

Terrestrial 2-69 2-69

Cable 1-135 1-135

Antenna

75-ohm external terminal for VHF/UHF

Panel System

LCD (Liquid Crystal Display) Panel

Display Resolution (horizontal x vertical):

1,366 dots x 768 lines

Screen Size (measured diagonally)

approx. 32 inches (KDL-32L4000 Only)

approx. 37 inches (KDL-37L4000 Only)

Supplied Accessories

Remote Commander RM-YD025

Two Size AA (R6) Batteries

AC Power Cord

Table-Top Stand

Screws (3)

Cable Band

Operating Instructions

Quick Setup Guide

Warranty Card

Online Registration Card

Open-source Software Flyer

Optional Accessories

Connecting Cables

Support Belt Kit

Wall-Mount Bracket

SU-WL500

TV Stand

SU-FL300M

Trademark Information

HDMI, the HDMI logo and High-Definition Multimedia Interface are

trademarks or registered trademarks of HDMI Licensing LLC.

Manufactured under license from Dolby Laboratories. “Dolby” and the

double-D symbol are trademarks of Dolby Laboratories.

Blu-ray Disc is a trademark.

KDL-32L4000/37L4000

Design and specifi cations are subject to change without notice.

4

SPECIFICATIONS (CONTINUED)

Power Consumption

in use

in standby

Speaker Output (W)

mm

Dimensions (W x H x D)

with stand

mm

Dimensions (W x H x D)

without stand

mm

Mass

with stand

without stand

KDL-32L4000 KDL-37L4000

165W 190W

Less than 1W

10W + 10W

50 x 115 mm

3/4

in

2 x 4

in

807 x 585 x 242 mm 933 x 653 x 276 mm

7/8

1/8

in

31

x 23

x 9

5/8

in 36

3/4

x 25

3/4

x 10

807 x 548 x 101 mm 933 x 616 x 112 mm

7/8

in

kg

x 21

5/8

x 4 in 36

31

16 kg 21.2 kg

3/4

x 24

3/8

x 4

lbs 35 lbs 5 oz 46 lbs 12 oz

kg

13.8 kg 18.2 kg

lbs 30 lbs 7oz 40 lbs 2 oz

All measurements are approximations.

1/2

7/8

KDL-32L4000/37L4000

in

in

KDL-32L4000/37L4000

5

KDL-32L4000/37L4000

WARNINGS AND CAUTIONS

CAUTION

These servicing instructions are for use by qualifi ed service personnel only. To reduce the risk of electric shock, do not

perform any servicing other than that contained in the operating instructions unless you are qualifi ed to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis.

The chassis of this receiver is directly connected to the ac power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are

critical for safe operation. Replace these components with Sony parts whose part numbers appear as shown in this

manual or in supplements published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in

this manual. Follow these procedures whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Ces instructions de service sont à l’usage du personnel de service qualifi é seulement. Pour prévenir le risque de choc

électrique, ne pas faire l’entretien autre que celui contenu dans le Mode d’emploi à moins que vous soyez qualifi é

faire ainsi.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre

utilisé lors de tout dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et

les listes de pieces sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des

composants Sony dont le numero de piece est indique dans le present manuel ou dans des supplements publies par

Sony. Les reglages de circuit dont l’importance est critique pour la securite du fonctionnement sont identifi es dans le

present manuel. Suivre ces procedures lors de chaque remplacement de composants critiques, ou lorsqu’un mauvais

fonctionnement suspecte.

KDL-32L4000/37L4000

6

WARNINGS AND CAUTIONS (CONTINUED)

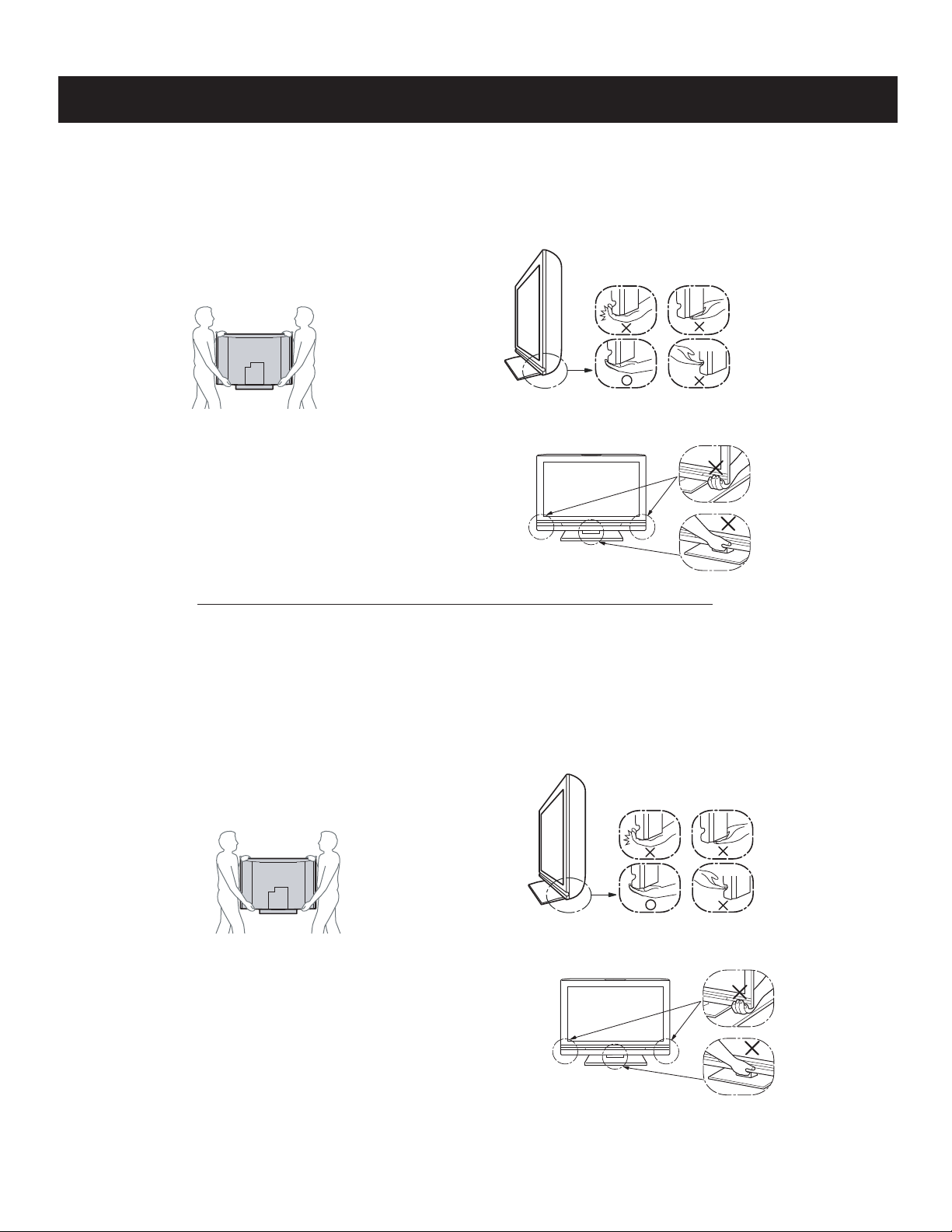

CARRYING THE TV

KDL-32L4000/37L4000

To avoid dropping the TV and causing serious injury, be sure to follow

these guidelines:

s Before carrying the TV, disconnect all cables.

s Carrying the large size TV requires two or more people.

s When carrying, do not subject the TV to shocks or vibration, or

excessive force.

s When you carry the TV, place your hand as illustrated and hold it

securely. Do not put stress on the LCD panel.

s When lifting or moving the TV, hold it firmly from the bottom. Place

your palm directly under the panel.

s Place your palm directly underneath, but do not squeeze the

panel’s speaker grill area.

s When carrying the TV, to avoid pinching your hands or fingers do not

put your hands between the TV and stand, or hold the bottom corner of

the TV.

POUR TRANSPORTER LE TÉLÉVISEUR

Assurez-vous de suivre ces consignes pour éviter de laisser tomber le

téléviseur et de provoquer des blessures graves :

s Avant de transporter le téléviseur, débranchez tous les câbles.

s Le transport du téléviseur doit être effectué par au moins deux

personnes.

s Lorsque vous transportez le téléviseur, ne le soumettez pas à des

chocs ou vibrations, ni à une force excessive.

s Lorsque vous le transportez, placez vos mains tel que cela est illustré

et tenez solidement l’appareil. N’appliquez pas de pression sur

l’écran ACL.

s Lorsque vous levez ou déplacez le téléviseur, assurez-vous de tenir

solidement de la base. Placez la paume des mains directement sous

le panneau.

s Positionnez votre paume directement sous l’appareil et veillez à

ne pas exercer de pression contre la grille des haut-parleurs

du panneau.

s Quand porter la TV, pour éviter de pincer vos mains ou doigts ne

mettent pas vos mains entre la TV et le stand, ou tenez le coin

inférieur de la TV.

KDL-32L4000/37L4000

7

SAFETY-RELATED COMPONENT WARNING

KDL-32L4000/37L4000

There are critical components used in LCD color TVs that are important for safety. These components are identifi ed with shading and

mark on the schematic diagrams and the electrical parts list. It is essential that these critical parts be replaced only with the part number

specifi ed in the electrical parts list to prevent electric shock, fi re, or other hazard.

NOTE: Do not modify the original design without obtaining written permission from the manufacturer or you will void the original parts and

labor guarantee.

!

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

When installing the LCD panel on a wall, the LCD panel must be secured using the 4 mounting holes on the rear cover.

To avoid damaging the LCD panel:

do not press on the panel or frame edge to avoid the risk of electric shock.

do not scratch or press on the panel with any sharp objects.

do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

do not expose the LCD panel to direct sunlight.

avoid contact with water. It may cause a short circuit within the module.

disconnect the AC adapter when replacing the backlight (CCFL) or inverter circuit.

(High voltage occurs at the inverter circuit at 650Vrms.)

always clean the LCD panel with a soft cloth material.

use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

LEAKAGE CURRENT HOT CHECK CIRCUIT

KDL-32L4000/37L4000

8

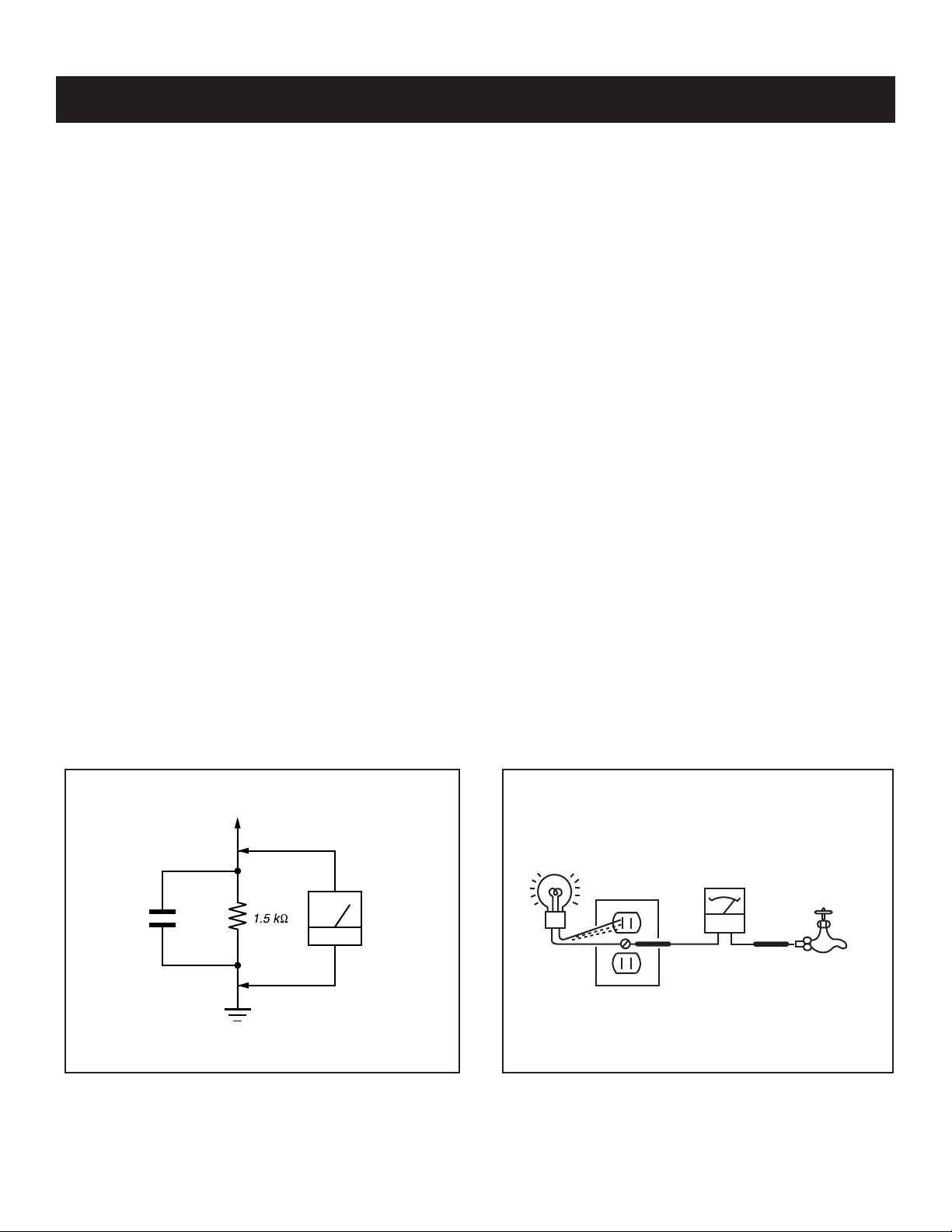

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

KDL-32L4000/37L4000

example 1

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints.

Lead Free Solder is available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade.

This requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to

http://www.sony-training.com

KDL-32L4000/37L4000

9

SAFETY CHECK-OUT

KDL-32L4000/37L4000

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

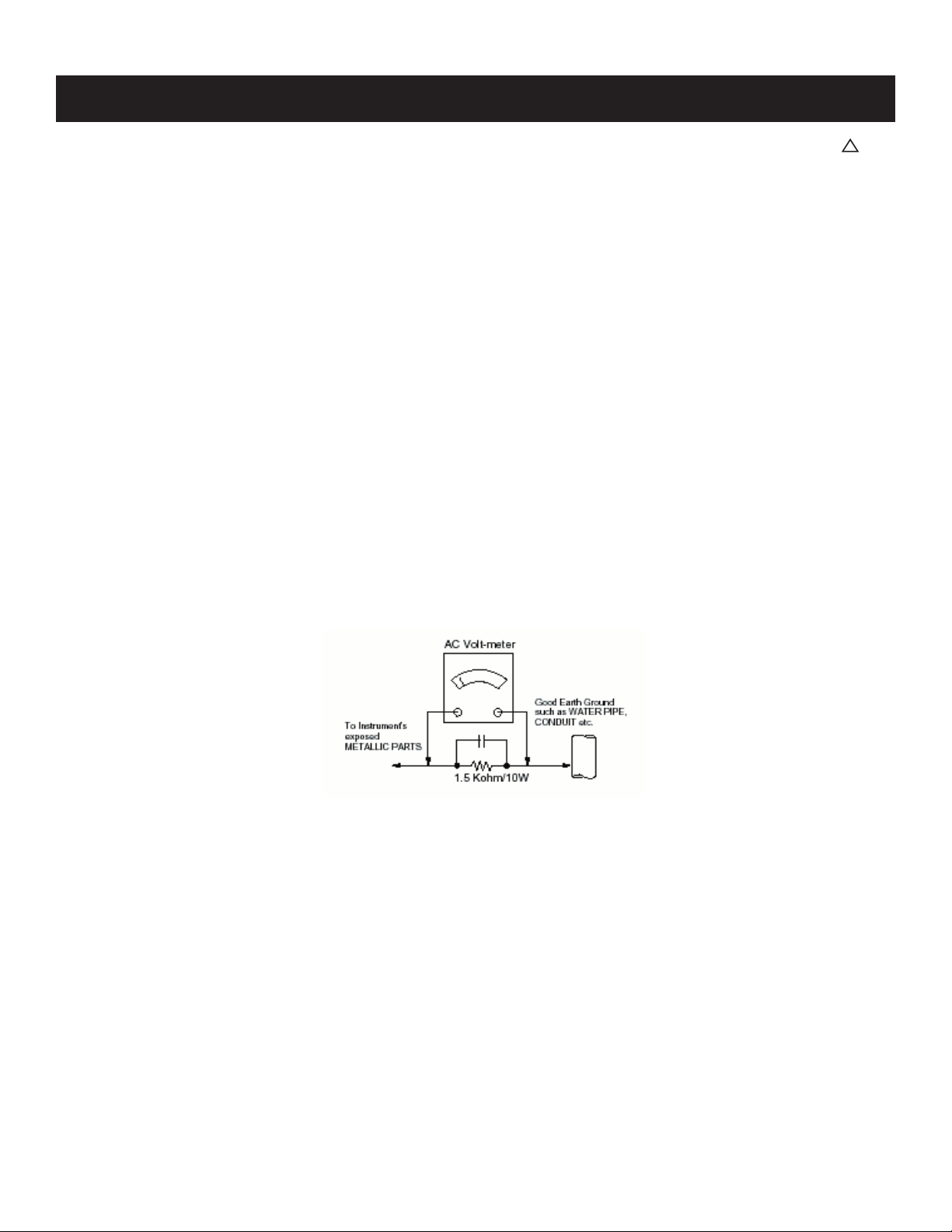

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

Leakage Test

0.15 μF

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

To Exposed Metal

Parts on Set

Earth Ground

AC

Voltmeter

(0.75V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

KDL-32L4000/37L4000

10

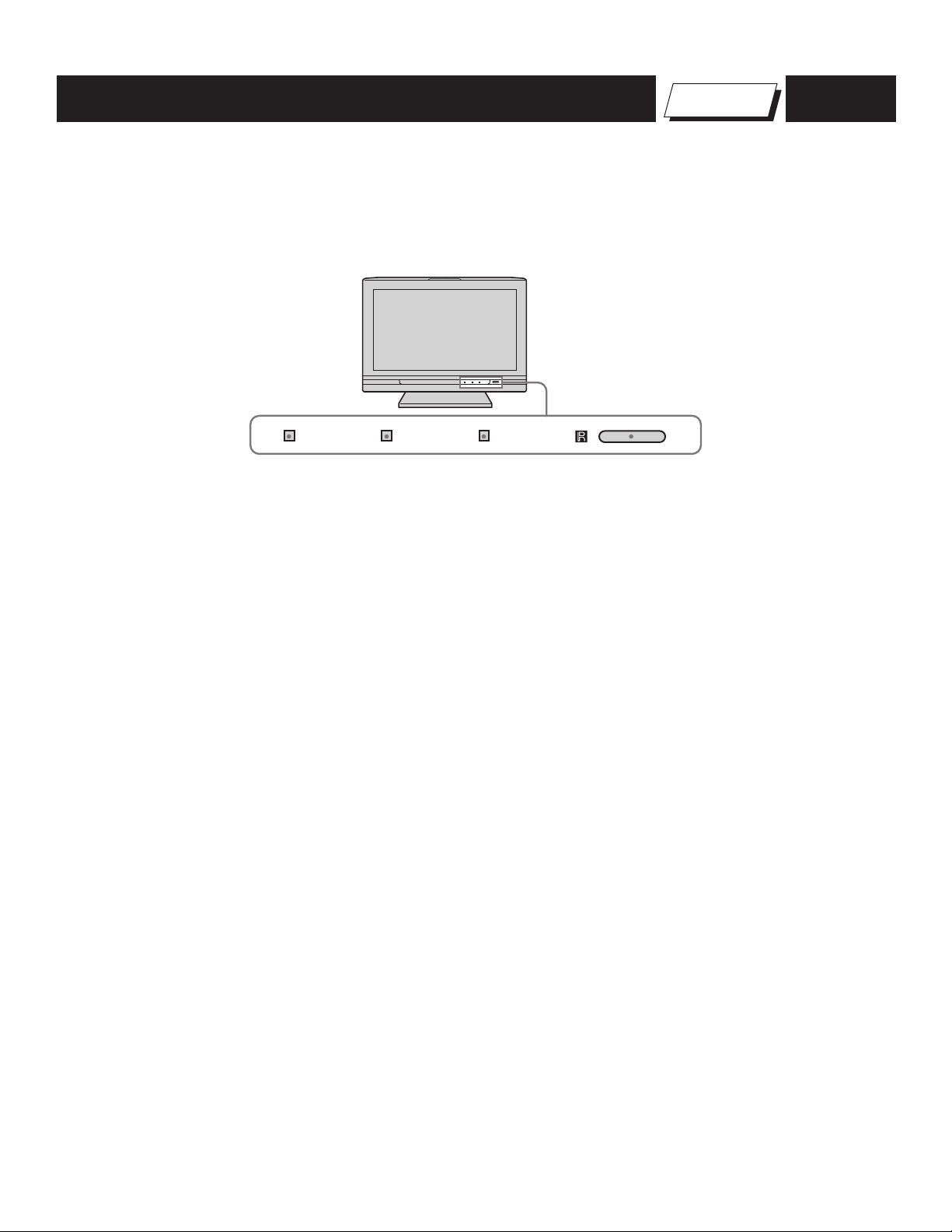

KDL-32L4000/37L4000

SELF-DIAGNOSTIC FUNCTION

IMPORTANT:

The units in this manual DO NOT contain a self-diagnostic function. If an error occurs, the TV will not stay on. It is our recommendation that if a repair

is required for these sets, the technician should bring both the A Board and the G Board to the customer location.

Control Buttons

TIMER STANDBY POWER

Description of LED Indictors

The units in this manual DO NOT contain a self-diagnostic function.

Self Diagnosis

Supported model

KDL-32L4000/37L4000

11

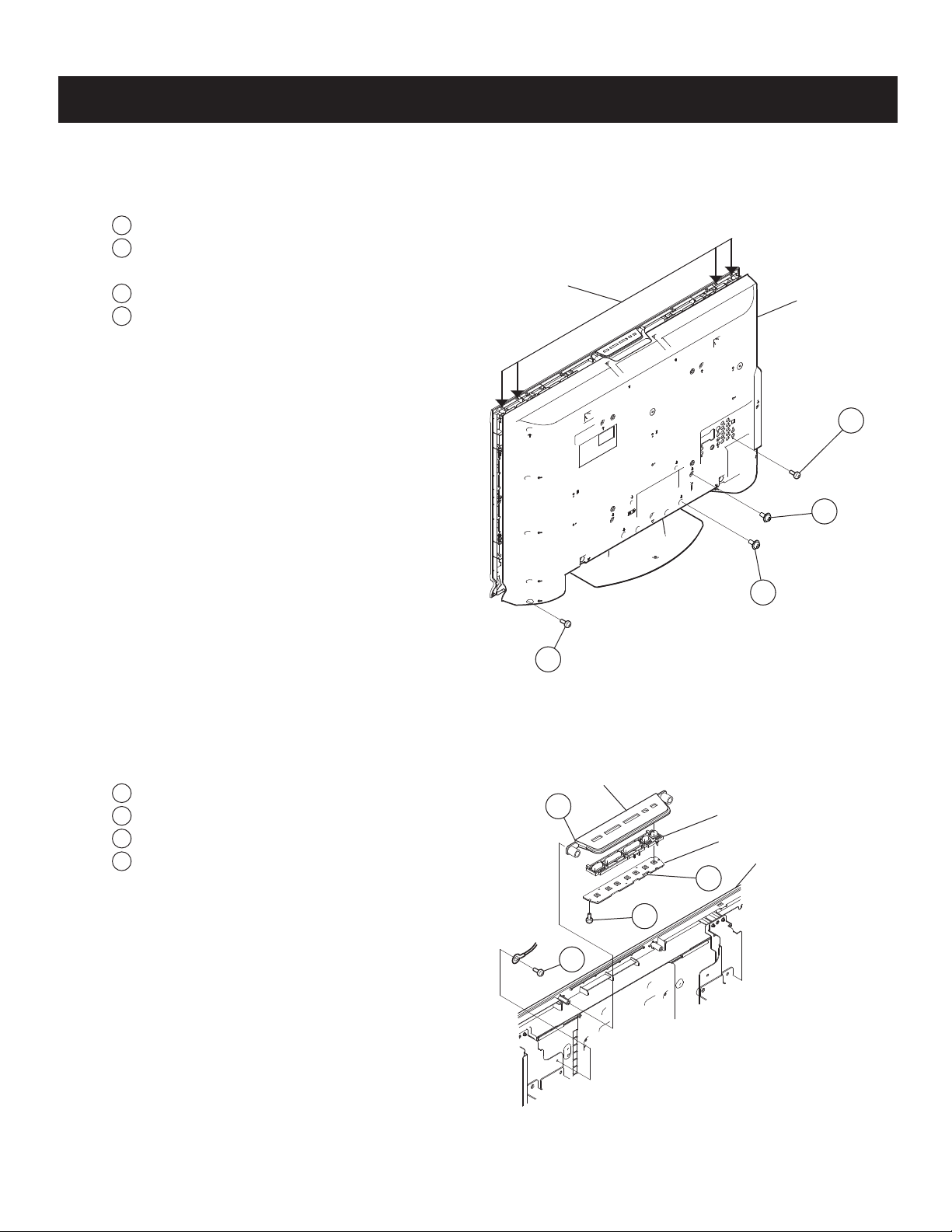

1-1. REAR COVER REMOVAL

NOTE: The Rear Cover of both models is attached to the Bezel Assembly with 4 small tabs.

Use caution when removing the Rear Cover not to damage these tabs.

1

Remove 6 screws from terminals, +BVTP 3X12 TYPE2 IT-3

2

Remove 3 screws, +PSW M4X8 (KDL-32L4000 ONLY)

Remove 4 screws, +PSW M5X8 (KDL-37L4000 ONLY)

3

Remove 2 screws, +PSW M5X12 (KDL-37L4000 ONLY)

4

Remove 17 screws +BVTP2 4X16(KDL-32L4000 ONLY),

18 screws +BVTP2 4X16 (KDL-37L4000 ONLY)

KDL-32L4000/37L4000

SECTION 1: DISASSEMBLY

Tab Inserts

Rear Cover

1

1-2. H1 BOARD REMOVAL

1

Remove from bezel

2

Disconnect 1 connector

3

Remove 5 screws, +B 2X6 TYPE 2

4

Remove 1 screw, +PSW M3X5 and release Earth Connector

(KDL-32L4000 ONLY)

Remove 1 screw, +BVST 3X8 and release Earth Connector

(KDL-37L4000 ONLY)

4

1

4

2

3

Button Bracket

Button

H1 Board

Bezel

2

3

KDL-32L4000/37L4000

12

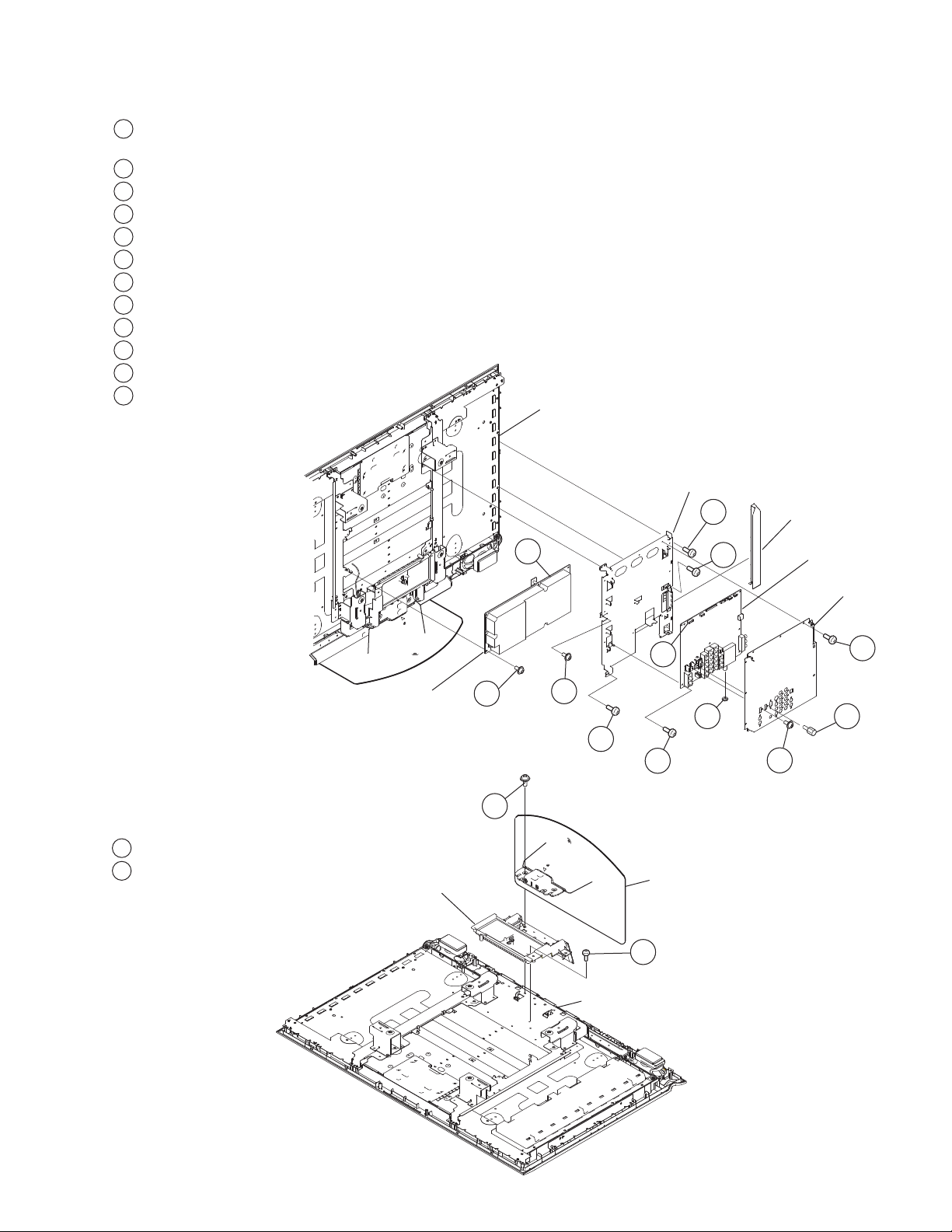

1-3. A BOARD AND G BOARD REMOVAL

1

Remove 4 screws +BVST 3X8 (KDL-32L4000 ONLY),

12 screws +BVST 3X8 (KDL-37L4000 ONLY),

2

Remove 2 screws, 4/40 UNC (HEX)

3

Remove 2 screws, +PSW M3X5

4

Remove Hexagon Nut from tuner

5

Remove 6 screws, +BVST 3X8

6

Disconnect 7 connectors

7

Remove 3 screws from Main Bracket, +BVST 3X8 (KDL-37L4000 ONLY)

8

Remove 2 screws from Main Bracket, +PSW M3X5 (KDL-32L4000 ONLY)

9

Remove 1 screw, +BVTP2 4X16

10

Remove 2 screws from Main Bracket, +BVST 3X8 (KDL-32L4000 ONLY)

11

Disconnect 4 connectors

12

Remove 4 screws, +BVST 3X8

KDL-32L4000/37L4000

Bezel

Main Bracket

1-4. TABLE-TOP STAND ASSEMBLY AND

☛

UNDER COVER REMOVAL

1

Remove3 screws, +PSW M5X16

2

Remove 1 screw, +BVTP2 4X16

Under Cover

G Board

12

10

11

6

8

7

5

1

Table-Top Stand Assembly

2

9

4

Side Bracket

A Boar d

Main Shield

1

2

3

KDL-32L4000/37L4000

Bottom Bracket

13

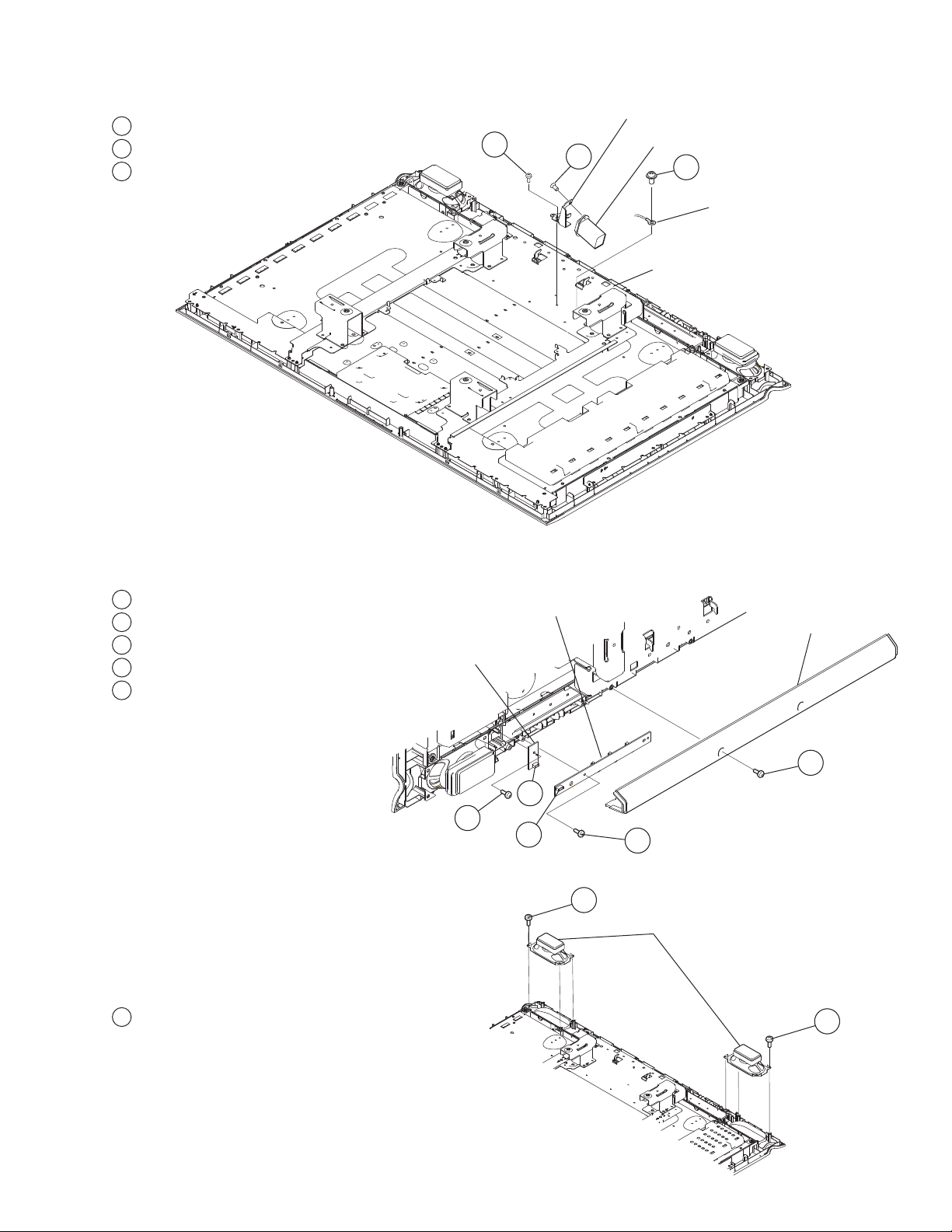

1-5. AC INLET AND BRACKET REMOVAL

1

Remove 1 screw, +PSW M4X6

2

Remove 2 screws, KTT 3X10 (S TYPE)

3

Remove 1 screw, +BVST 3X8

KDL-32L4000/37L4000

AC Bracket

3

2

AC Inlet

1

Earth Terminal

Bottom Bracket

1-6 UNDER BAR, H2 BOARD (IR), H3 BOARD (LED) REMOVAL

1

Remove 2 screws, +BVTP2 4X16

2

Remove 2 screws, +BVTP 3X8 TYPE2 IT-3

3

Disconnect 1 connector

4

Disconnect 1 connector

5

Remove 1 screws, +BVTP 3X8 TYPE2 IT-3

H2 Board (IR)

5

H3 Board (LED)

4

3

1

1-7. LOUDSPEAKERS REMOVAL

Under Bar

1

2

Speakers

1

Remove 3 screws from each loudspeaker, +BVTP2 4X16

KDL-32L4000/37L4000

1

14

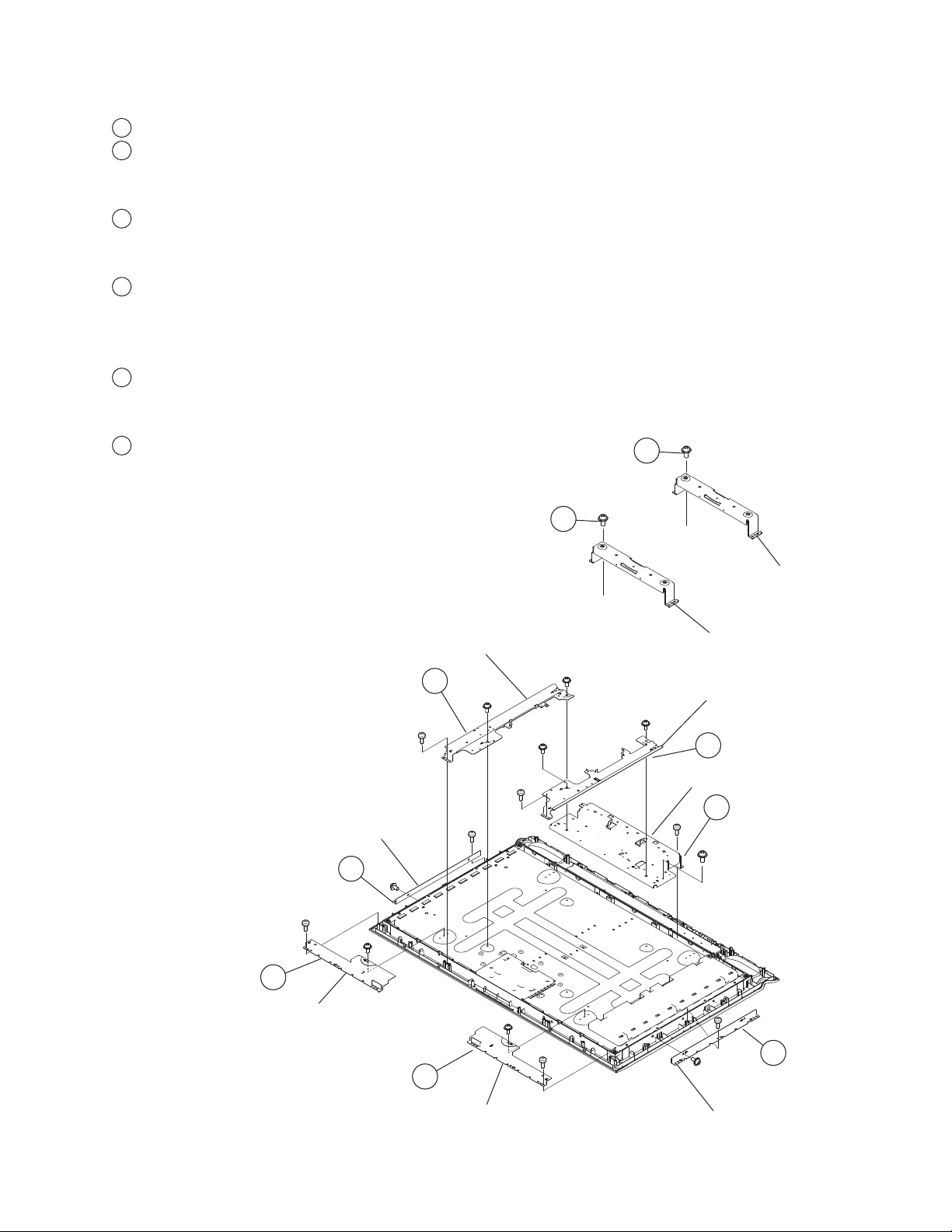

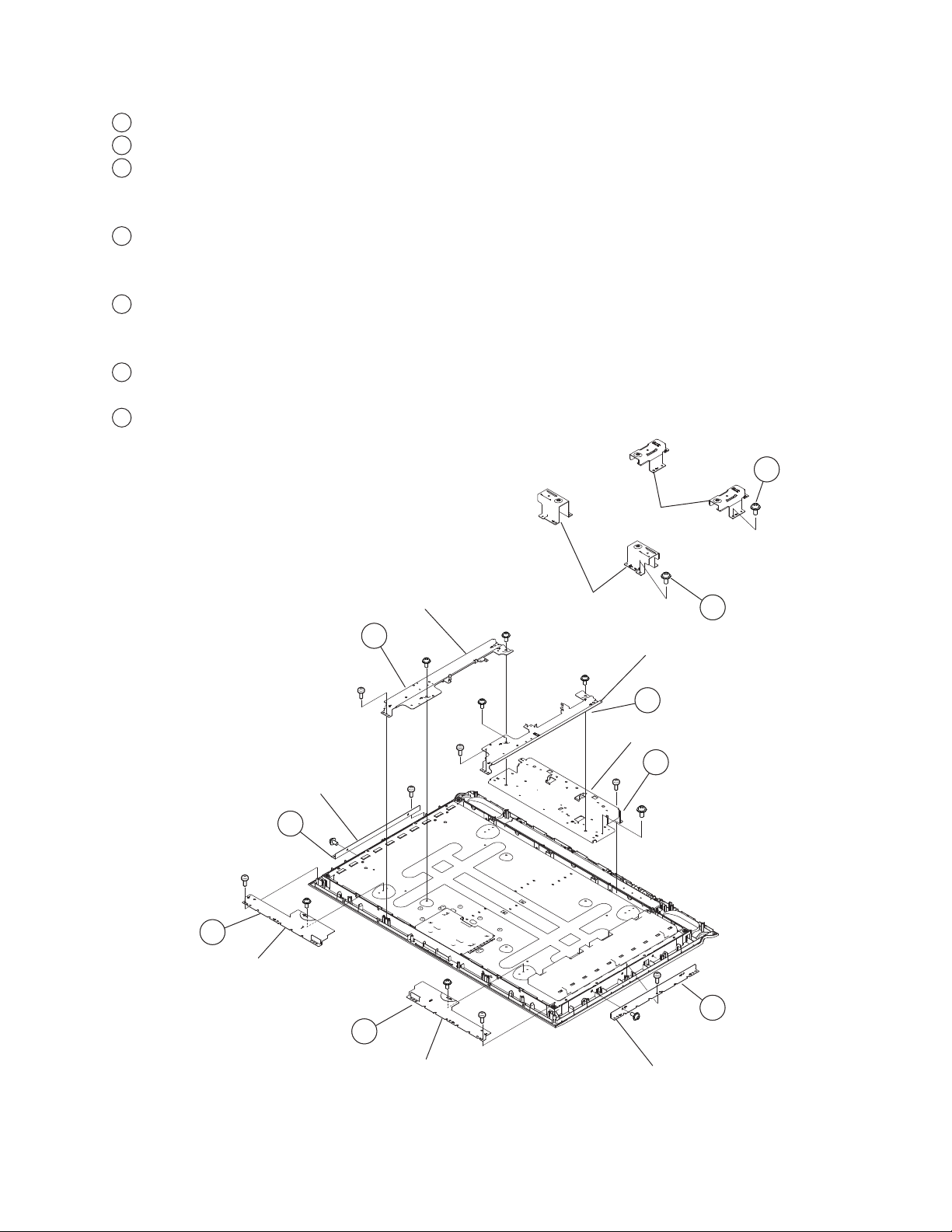

1-8. STRUCTURAL FRAMES AND BRACKETS REMOVAL (KDL-32L4000 ONLY)

1

Remove 4 screws from both Top Vesa Bracket and Bottom Vesa Bracket, +PSW M4X8

2

Top Frame (L) and Top Frame (R) Removal

Remove 2 screws from Bezel and each Top Frames, +BVTP2 4X16

Remove 1 screw from Panel and each Top Frames, +PSW M4X6

3

Side Bracket (L) Removal

Remove 2 screws from Bezel and Side Bracket (L), +BVTP2 4X16

Remove 2 screws from Panel and Side Bracket (L), +PSW M4X8

4

Main Frame (L) and Main Frame (R) Removal

Remove 1 screw from Bezel and each Main Frames, +BVTP2 4X16

Remove 1 screw from Panel and each 32-Main Frames, +PSW M4X6

Remove 2 screws from Bottom Frame and each 32-Main Frames, +PSW M4X8

5

Bottom Frame Removal

Remove 1 screw from Bezel and Bottom Frame, +BVTP2 4X16

Remove 4 screws from Panel and Bottom Frame, +PSW M4X6

6

Side Bracket (R) Removal

Remove 3 screws from Bezel and Side Bracket (R), +BVTP2 4X16

Remove 2 screws from Panel and Side Bracket (R), +PSW M4X8

1

1

KDL-32L4000/37L4000

Side Bracket (L)

2

Top Frame (L)

Vesa (Bottom)

Main Frame (L)

4

Bottom Frame

3

Vesa (Top)

Main Frame (R)

4

5

KDL-32L4000/37L4000

2

Top Frame (R)

6

Side Bracket (R)

15

1-9. STRUCTURAL FRAMES AND BRACKETS REMOVAL (KDL-37L4000 ONLY)

1

Remove 4 screws from Top Vesa Brackets, +PSW M4X8

2

Remove 6 screws from Bottom Vesa Brackets, +PSW M4X8

3

Top Frame (L) and Top Frame (R) Removal

Remove 2 screws from Bezel and each Top Frames, +BVTP2 4X16

Remove 1 screw from Panel and each Top Frames, +PSW M4X8

4

Side Bracket (L) Removal

Remove 2 screws from Bezel and Side Bracket (L), +BVTP2 4X16

Remove 2 screws from Panel and Side Bracket (L), +PSW M4X8

5

Main Frame (L) and Main Frame (R) Removal

Remove 1 screw from Bezel and each Main Frames, +BVTP2 4X16

Remove 3 screws from each 37-Main Frames, +PSW 5X8

6

Bottom Frame Removal

Remove 4 screws from Bezel and Bottom Frame, +BVTP2 4X16

7

Side Bracket (R) Removal

Remove 2 screws from Bezel and Side Bracket (R), +BVTP2 4X16

Remove 2 screws from Panel and Side Bracket (R), +PSW M4X8

KDL-32L4000/37L4000

2

Side Bracket (L)

3

Top Frame (L)

Vesa (Bottom)

Main Frame (L)

5

4

Vesa (Top)

Main Frame (R)

Bottom Frame

1

5

6

KDL-32L4000/37L4000

3

Top Frame (R)

9

Side Bracket (R)

16

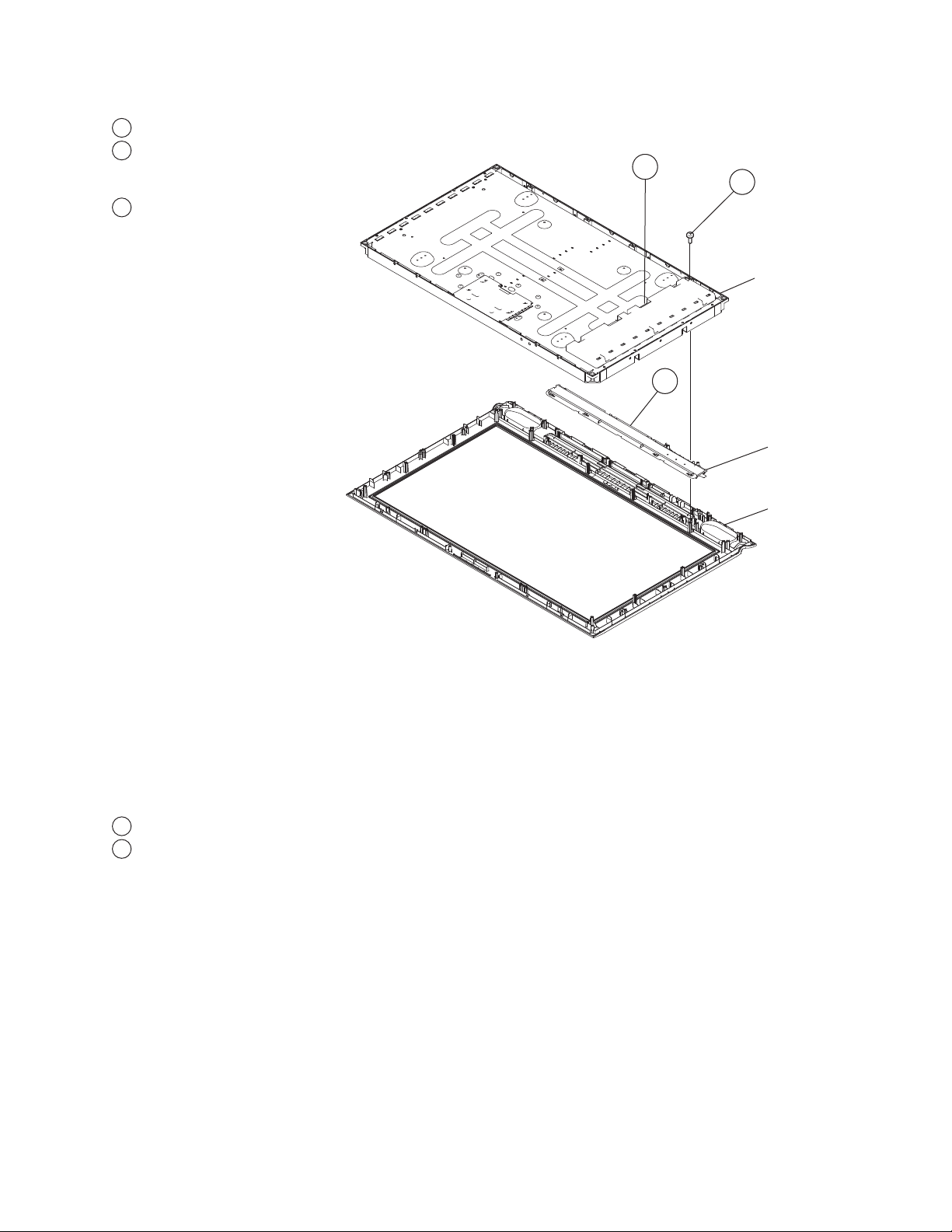

1-10. LCD PANEL REMOVAL

1

Disconnect 1 connector.

2

Remove ,

2 screws +BVTP2 4X16 (KDL-32L4000 ONLY),

3 screws +BVTP2 4X16 (KDL-37L4000 ONLY)

3

Release hooks and slide out from Bezel.

KDL-32L4000/37L4000

1

2

LCD Panel

3

Clear Panel

1-10-1. CLEANING THE LCD PANEL

☛

CAUTION: When cleaning the TV, be sure to unplug the power cord to avoid any chance of electric shock.

1

Clean the cabinet of the TV with a dry soft cloth.

2

Wipe the LCD screen gently with a soft cloth.

Stubborn stains may be removed with a cloth slightly moistened with a solution of mild soap and warm water.

If using a chemically pretreated cloth, please follow the instruction provided on the package.

Never use strong solvents such as a thinner, alcohol or benzine for cleaning.

Periodic vacuuming of the ventilation openings is recommended to ensure to proper ventilation.

Bezel Assembly

KDL-32L4000/37L4000

17

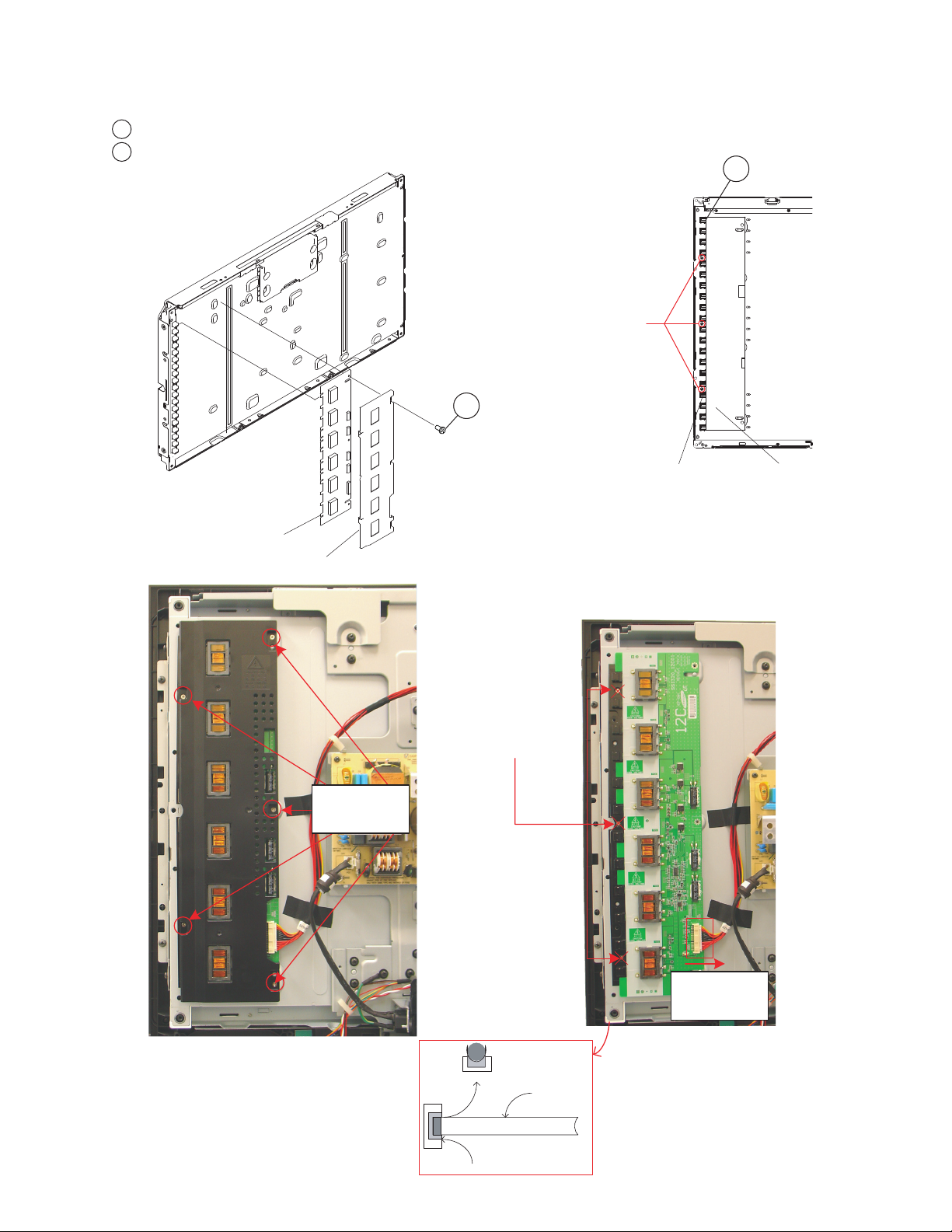

1-11. BALANCER (MT INVERTER) BOARD REMOVAL (KDL-32L4000 ONLY)

1

Remove 5 screws from Board Cover.

2

Pull out the Board from Lamp socket

DO NOT

REMOVE

BACKLIGHT

SCREWS

1

KDL-32L4000/37L4000

2

Balancer Board

Inverter Cover

REMOVE SCREWS

SECURING

SHIELD

WARNING

NEVER REMOVE THE

SCREWS SECUR ING THE

PLASTIC STRIP HOLDING

THE LAMP SOCKETS

DAMAGE TO TH E

BACKLIGHT TUBES W ILL

!

.

OCCUR!

Plastic Strip

holding

Lamp Socket

Inverter Board

KDL-32L4000/37L4000

SHIELD REMOVAL

END VIEW

SOCKET

BACKLIGHT

REMOVE

CONNECTOR AND

PULL BOARD TO

THE RI GHT

INVERTER BOARD REMOVAL

Only remove the screws securing the inverter

cover which may be metal or plastic. The

remaining plastic strip contains sockets for the

fluorescent backlights and should never be

loosened. The backlights will pop out of the

sockets and/or break the backlight requiring a

LCD panel replacement. The example shown

is a 32” model but applies to all models.

18

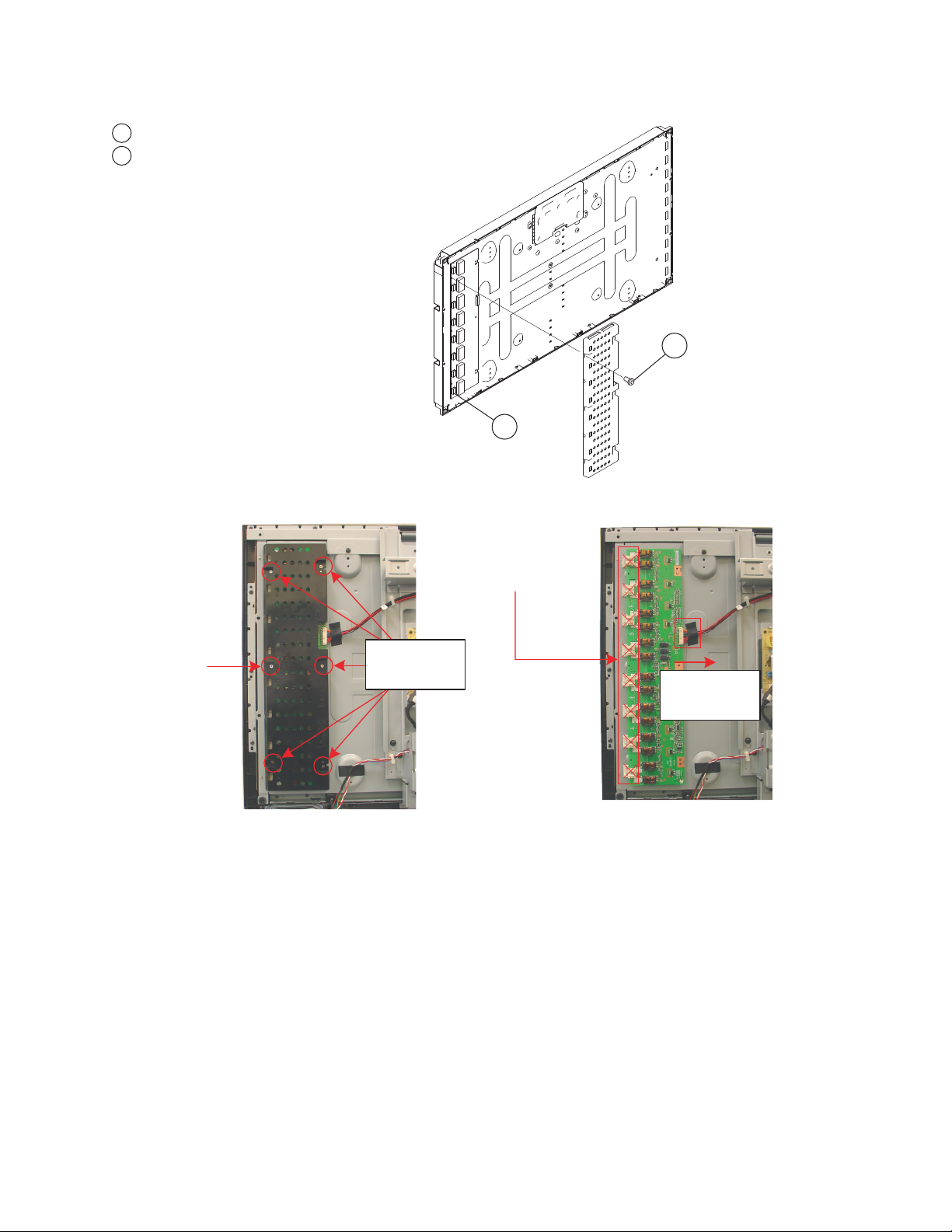

1-12. BALANCER (MT INVERTER) BOARD REMOVAL (KDL-37L4000 ONLY)

1

Remove 6 screws from Board Cover

2

Disconnect 8 balancer connectors

1

2

KDL-32L4000/37L4000

SHIELD REMOVAL

Balancer Board Connectors

REMOVE SCREWS

SECURING

SHIELD

CAUTION!

Disconnect the 8

REMOVE

CONNECTOR AND

PULL BOARD TO

THE RIGHT

KDL-32L4000/37L4000

19

KDL-32L4000 ONLY

KDL-32L4000/37L4000

WIRE DRESSING

OVERALL

VIEW

KDL-32L4000/37L4000

20

Loading...

Loading...