Page 1

HISTORY

Model Name :

SERVICE MANUAL

Click on Page Number to display detail of changes.

Date Part Number Description of Revisions

Original Manual.

KDL-32/40/46D3000

Version

1.09-927-543-01 2007.04

Page 2

WAX3

RM-ED009

SERVICE MANUAL

MODEL

KDL-32D3000

KDL-40D3000

KDL-46D3000

COMMANDER DEST

RM-ED009 AEP

RM-ED009 AEP

RM-ED009 AEP

WAX3

MODEL

KDL-32D3000

KDL-40D3000

KDL-46D3000

COMMANDER DEST

CHASSIS

RM-ED009 UK

RM-ED009 UK

RM-ED009 UK

KDL-32D3000 / KDL-40D3000 / KDL-46D3000

FLAT PANEL COLOR TV

- 1 -

RM-ED009

Page 3

WAX3

RM-ED009

TABLE OF CONTENTS

Section Title Pag e Section Title Pa ge

1. GENERAL ................................................................... 3

Caution ................................................................ 3

Specifications ...................................................... 5

UK Plug Warning ............................................... 6

Connectors .......................................................... 6

Self Diagnosis ..................................................... 8

2. DISASSEMBLY

2-1. Rear Cover Removal ........................................... 9

2-2. Stand Removal .................................................... 9

2-3. Bottom Frame Removal ...................................... 10

2-4. AC Inlet Removal ............................................... 10

2-5. Loudspeaker Removal ........................................ 11

2-6. Heatsink Removal ............................................... 11

2-7. BE1 Board Removal ........................................... 12

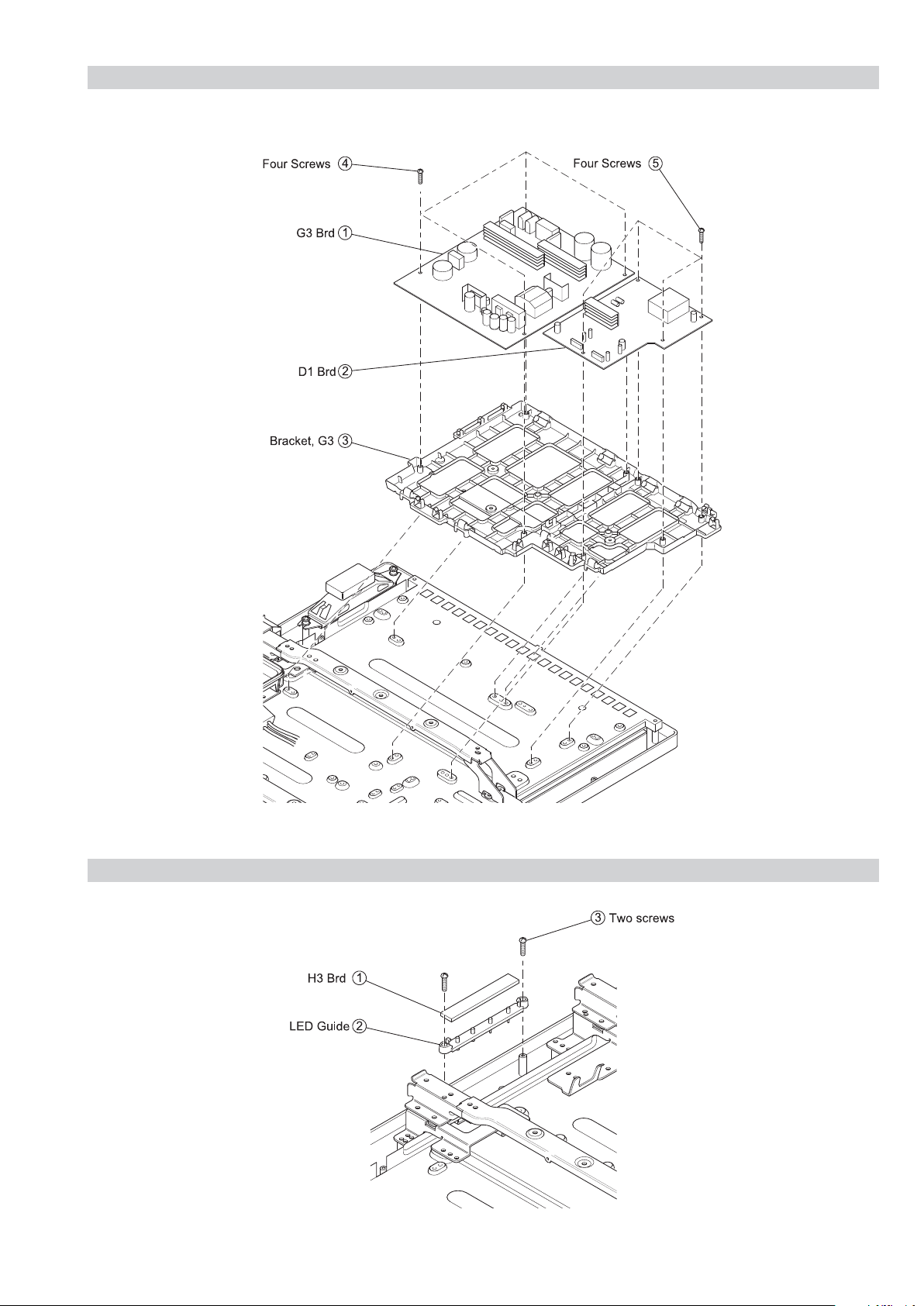

2-8. D1 and G3 Board Removal ................................ 13

2-9. H3 Board Removal ............................................. 13

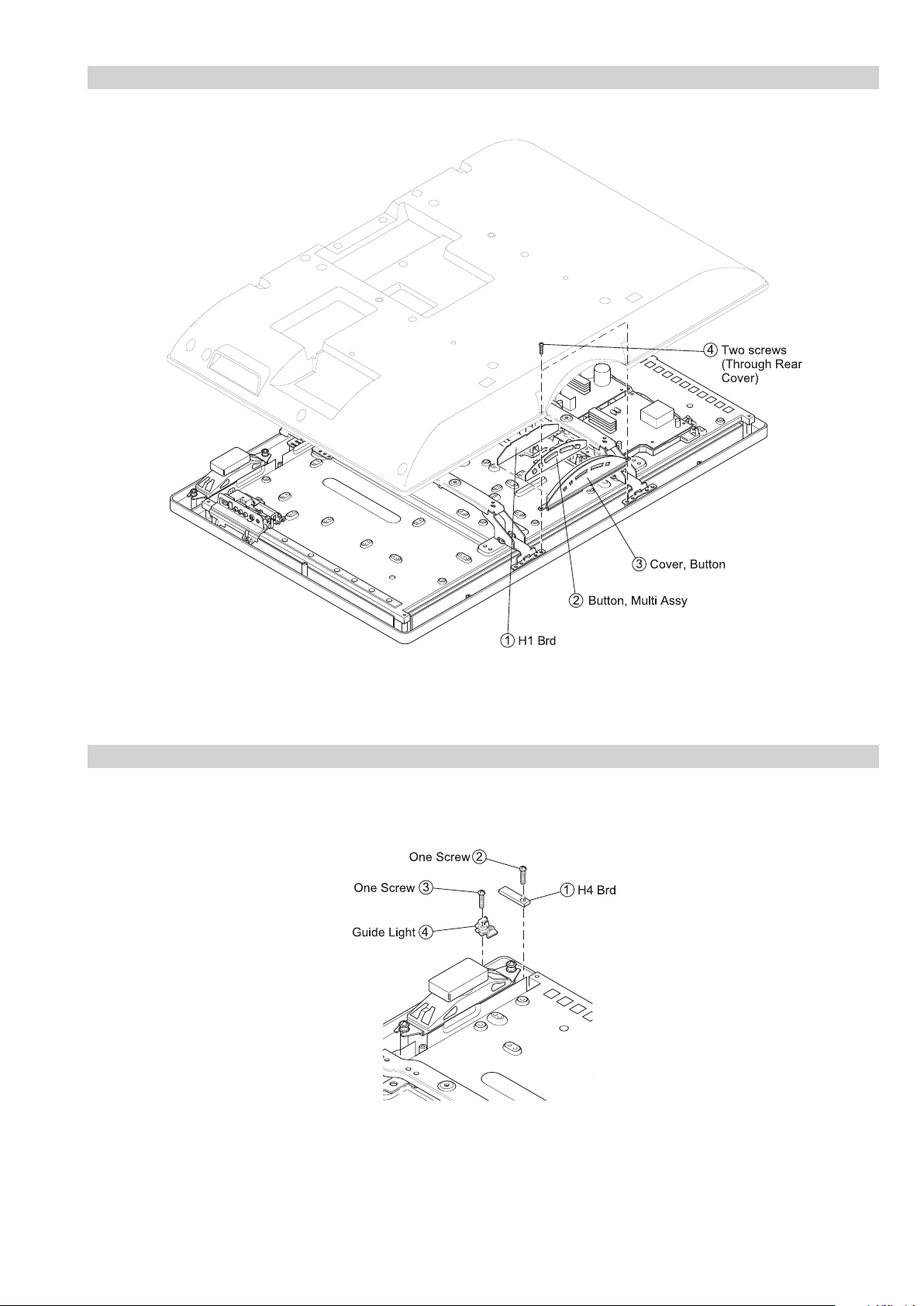

2-10. H1 Board Removal ............................................. 14

2-11. H4 Board Removal ............................................. 14

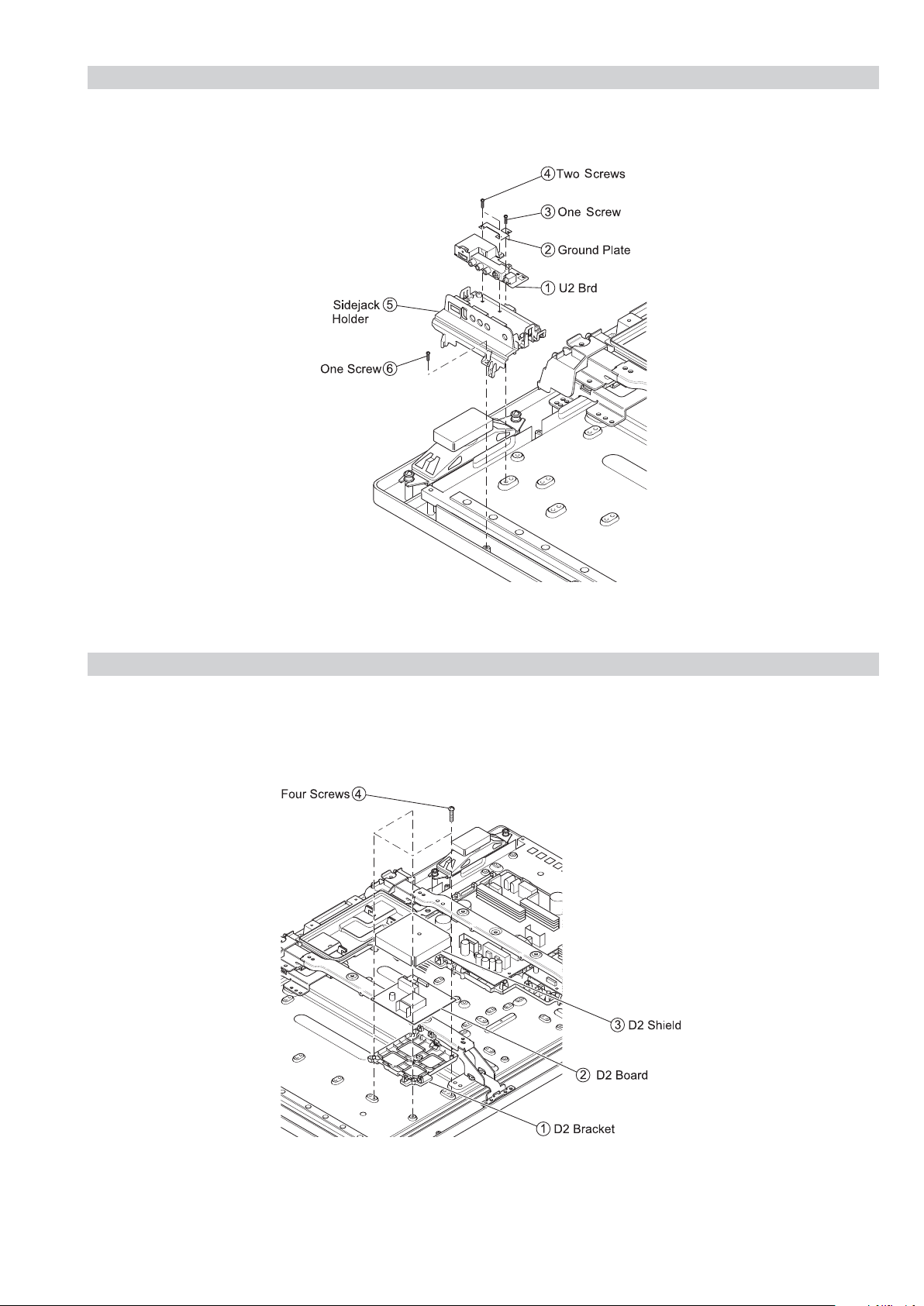

2-12. U2 Board Removal ............................................. 15

2-13. D2 Board Removal ............................................. 15

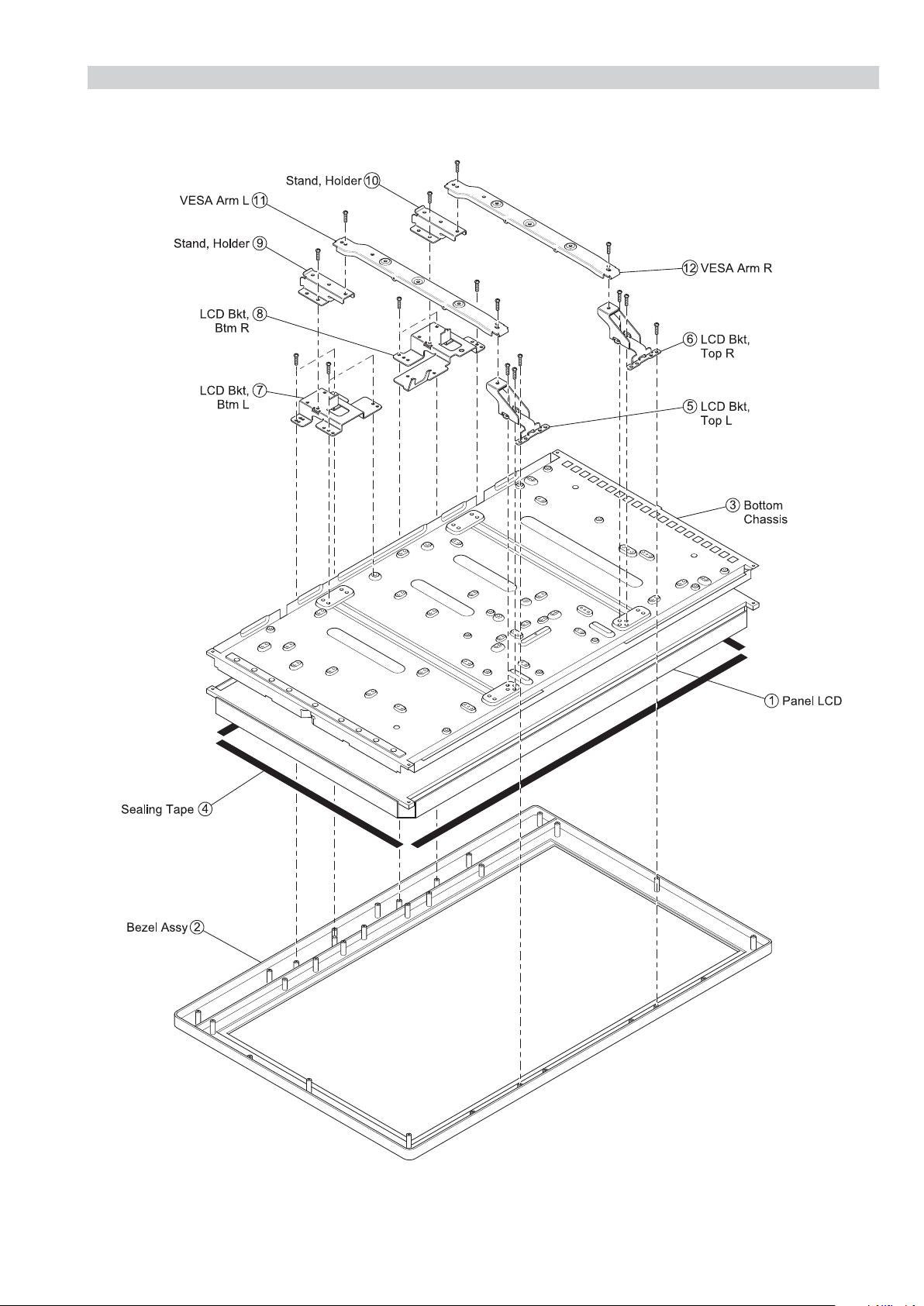

2-14. Vesa Arm and LCD Panel Removal ................... 16

3. SET-UP ADJUSTMENTS

3-1. How to enter Service Mode ............................... 17

3-2. Signal Level Adjustment .................................... 17

3-2-1. Set up of AD calibration1 adjustment for

terrestrial analog ............................................... 17

3-2-2. Y signal calibration1 adjustment for

terrestrial analog ............................................... 17

3-2-3. C signal calibration1 adjustment for

terrestrial analog ............................................... 17

3-2-4. Set up of AD calibration1 adjustment for

video ................................................................ 18

3-2-5. Y signal calibration1 adjustment for PAL

video ................................................................ 18

3-2-6. C signal calibration1 adjustment for PAL

video ................................................................ 18

3-2-7. Set up of Y signal adjustment for video .......... 18

3-2-8. Y signal calibration1 adjustment for SECAM

video ................................................................ 18

3-2-9. C signal calibration1 adjustment for SECAM

video ................................................................ 19

3-3. Gamma Adjustment ........................................... 19

3-3-1. Preparation before Gamma Adjustment .......... 19

3-3-2. Set up mode for Gamma Adjustment .............. 19

3-3-3. Set up Trident Internal SG and Brightness

measurement .................................................... 19

3-4. White Balance Adjustment ................................. 20

3-4-1. Set up mode for White Balance Adjustment ... 20

3-4-2. White Balance of colour temperature “Cool” .. 20

3-4-3. White Balance of colour temperature “Neutral” 21

3-4-4. White Balance of colour temperature “Warm1” 22

3-4-5. White Balance of colour temperature “Warm2” 23

3-5. Panel Replacement ............................................. 23

3-6. Board Replacement ............................................ 23

3-7. TT Modes .......................................................... 23

4. DIAGRAMS

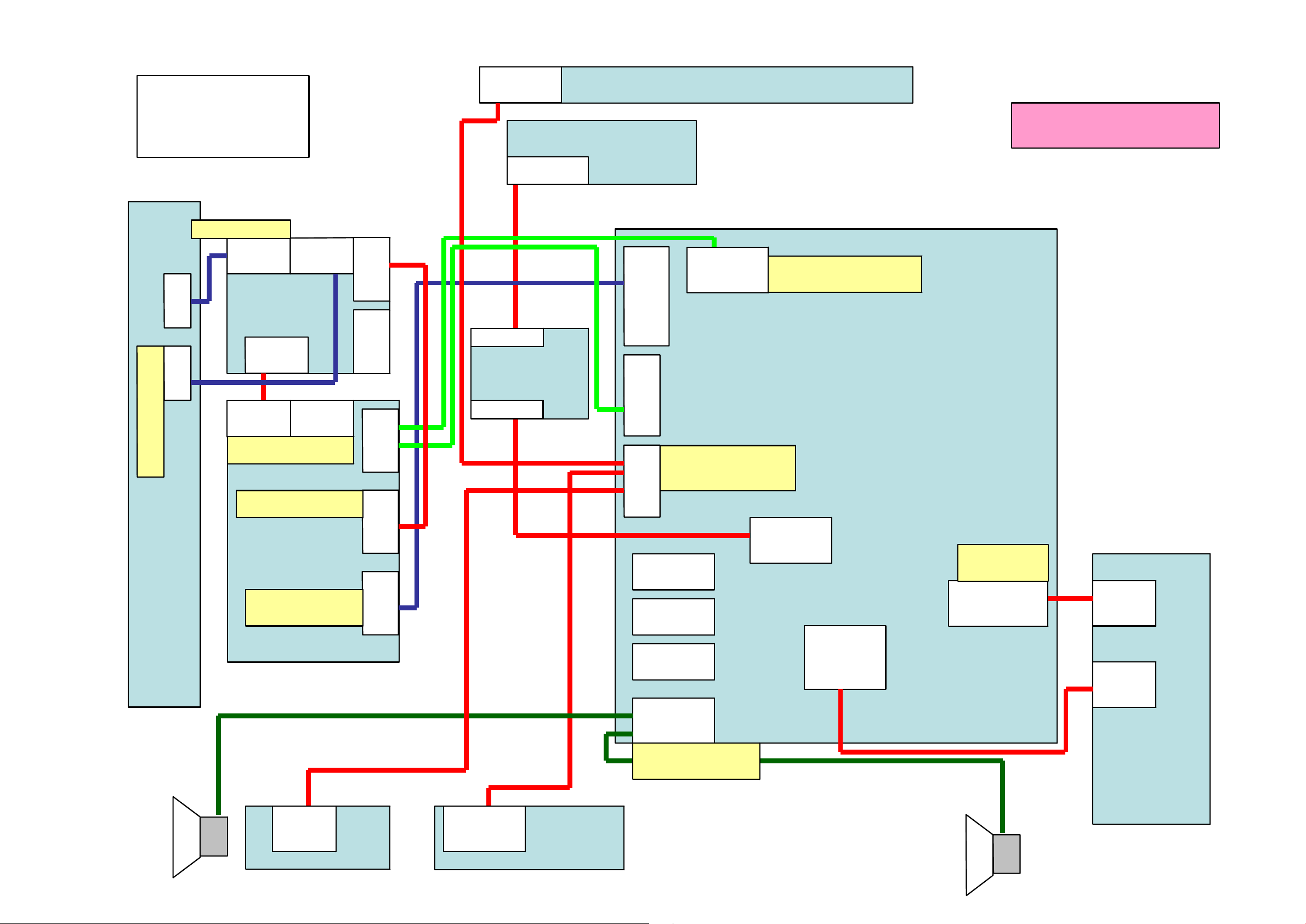

4-1. Block Diagrams(1) ............................................. 24

Block Diagrams(2) ............................................. 25

Block Diagrams(3) ............................................. 26

4-2. Circuit Board Location ........................................ 27

4-3. Schematic Diagrams and Printed Wiring

Boards ................................................................. 27

BE1 Board Schematic Diagram .......................... 28

BE1 Printed Wiring Board .................................. 72

BH Board Schematic Diagram ............................ 74

BH Printed Wiring Board ................................... 88

U2 Board Schematic Diagram ............................ 89

U2 Printed Wiring Board .................................... 94

D1 Board Schematic Diagram

(KDL-40D30XX, KDL-46D30XX) .................. 95

D1 Printed Wiring Board

(KDL-40D30XX, KDL-46D30XX) .................. 99

D2 Board Schematic Diagram

(KDL-46D30XX Only) ..................................... 101

D2 Printed Wiring Board

(KDL-46D30XX Only) ..................................... 102

G3 Board Schematic Diagram

(KDL-40D30XX, KDL-46D30XX) .................. 103

G3 Printed Wiring Board

(KDL-40D30XX, KDL-46D30XX) .................. 107

H1 Board Schematic Diagram ............................ 109

H1 Printed Wiring Board .................................... 110

H3 Board Schematic Diagram ............................ 111

H3 Printed Wiring Board .................................... 110

H4 Board Schematic Diagram ............................ 109

H4 Printed Wiring Board .................................. 110

5. EXPLODED VIEWS

5-1. Chassis................................................................ 112

5-2. Rear Cover, Stand & Bezel ................................. 113

5-3. Vesa Arm, Power Unit & Power Cords............. 114

6. ELECTRICAL PARTS LIST .................................. 115

WARNING !!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE WORK TO AVOID POSSIBLE SHOCK HAZARD

DUE TO LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS

DIRECTLY CONNECTED TO THE POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ON

- 2 -

Page 4

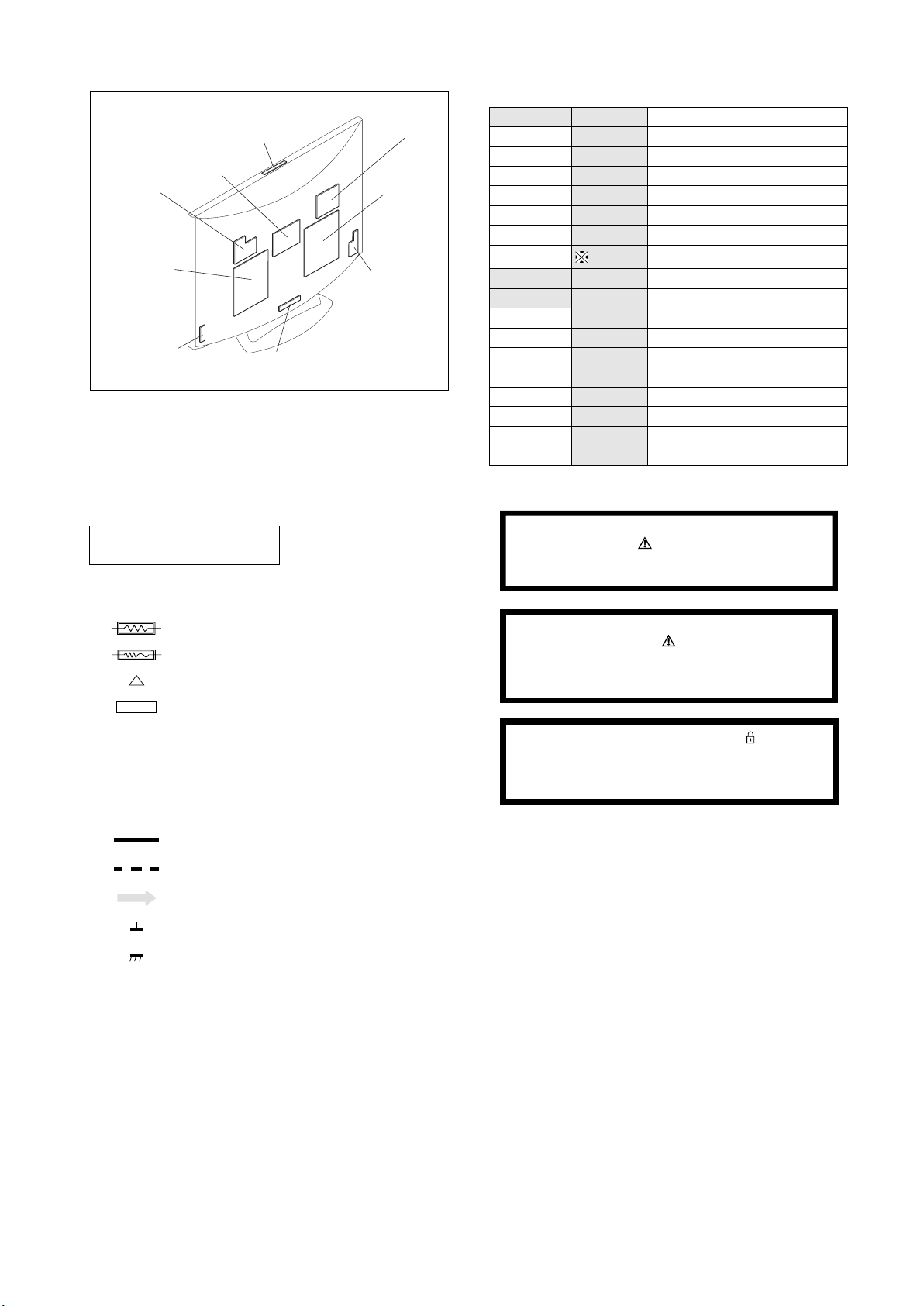

SECTION 1 GENERAL

CAUTION

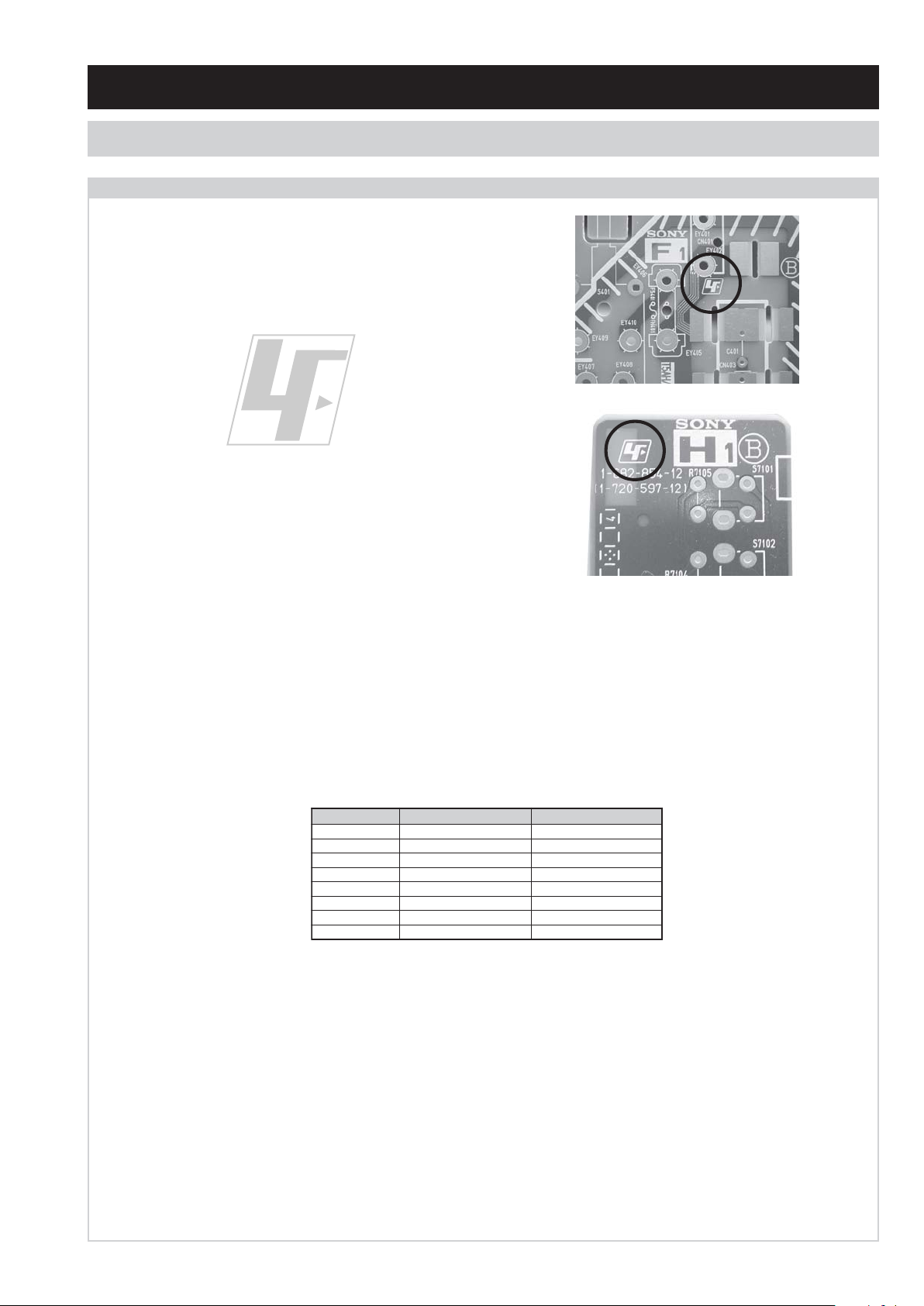

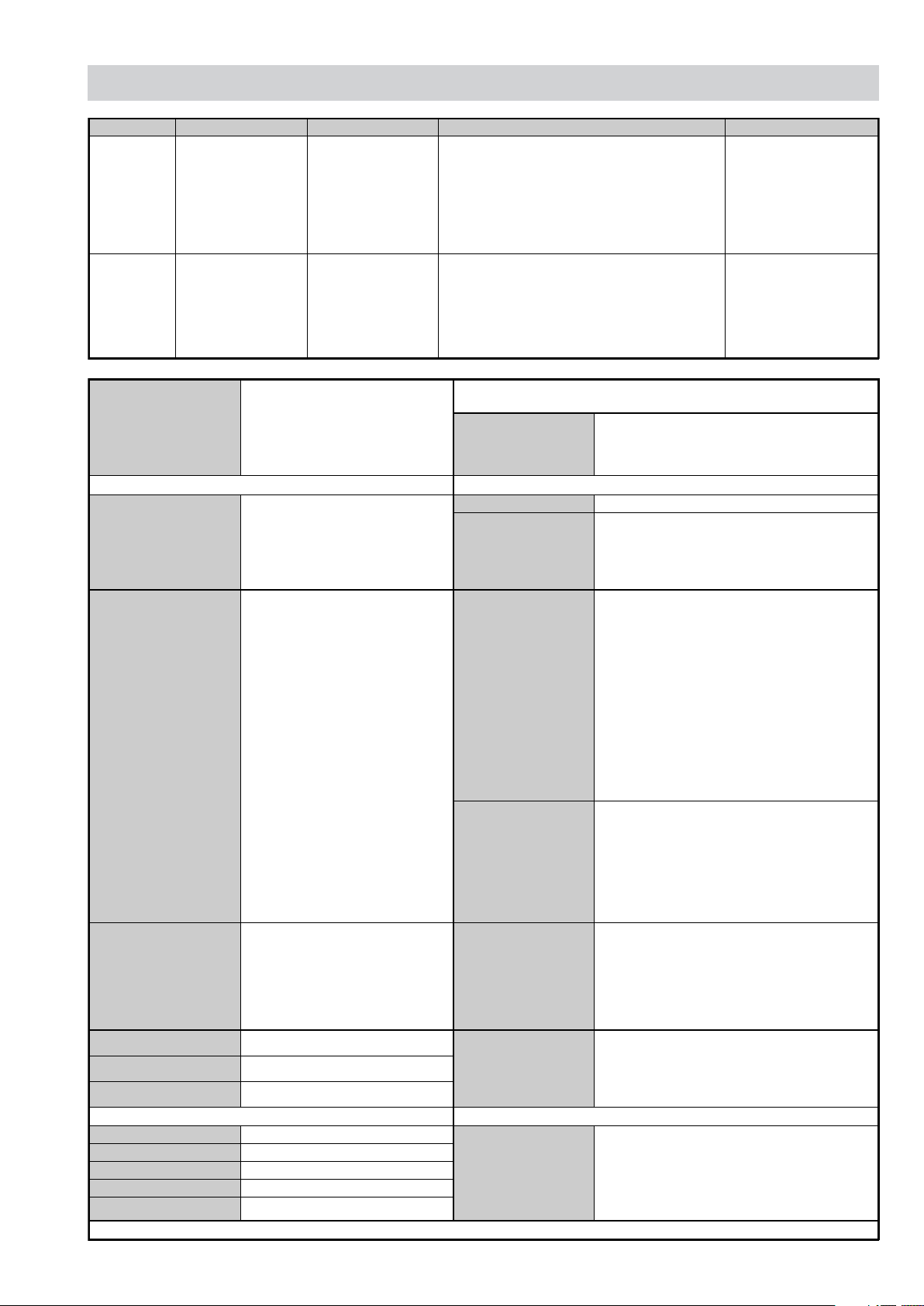

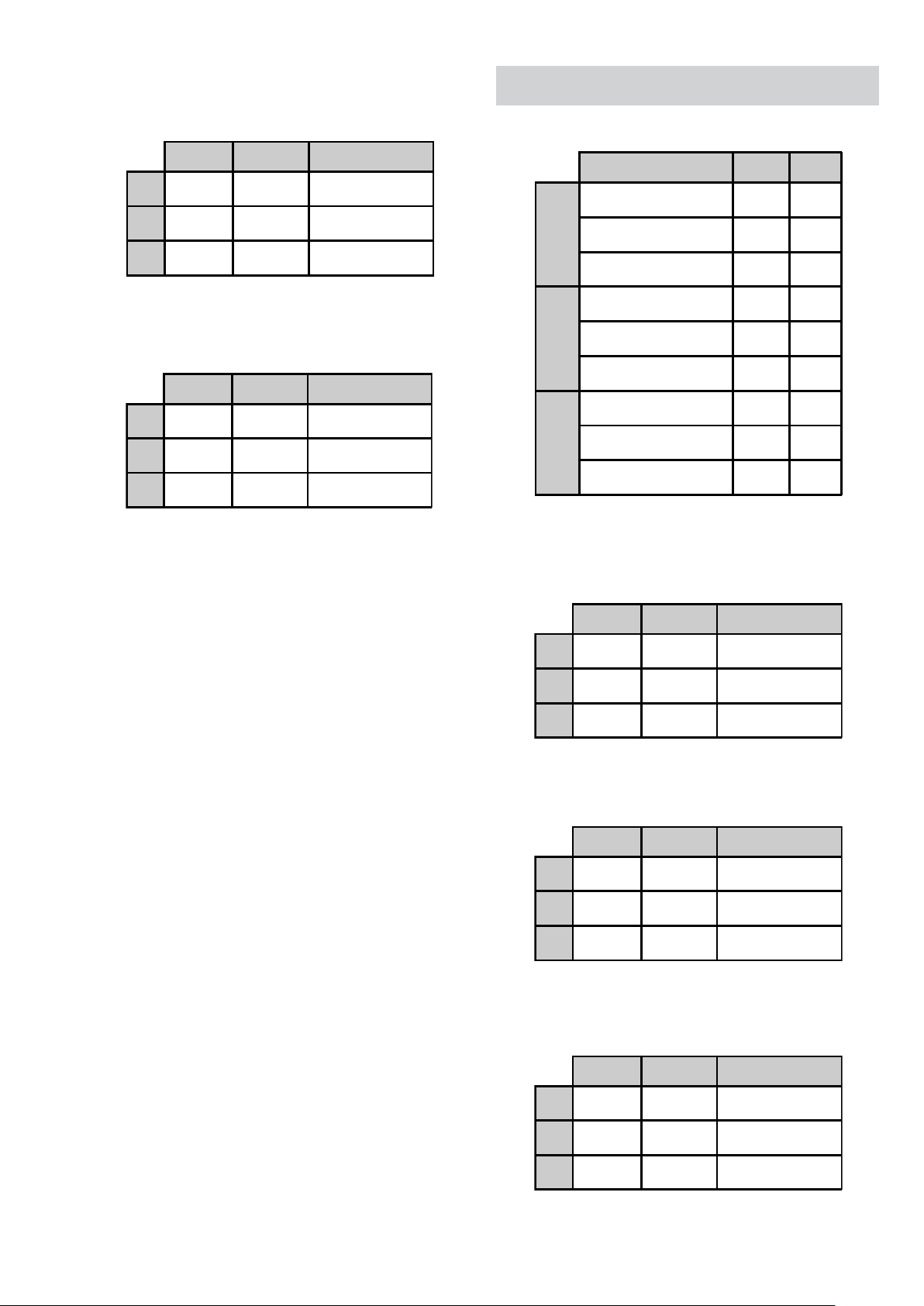

Lead Free Soldered Boards

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation e.g. F1, H1 etc [ see examples ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

WAX3

RM-ED009

example 1

example 2

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints. Lead Free Solder is

available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade. This requires

soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to http://www.sony-training.com

- 3 -

Page 5

CAUTION

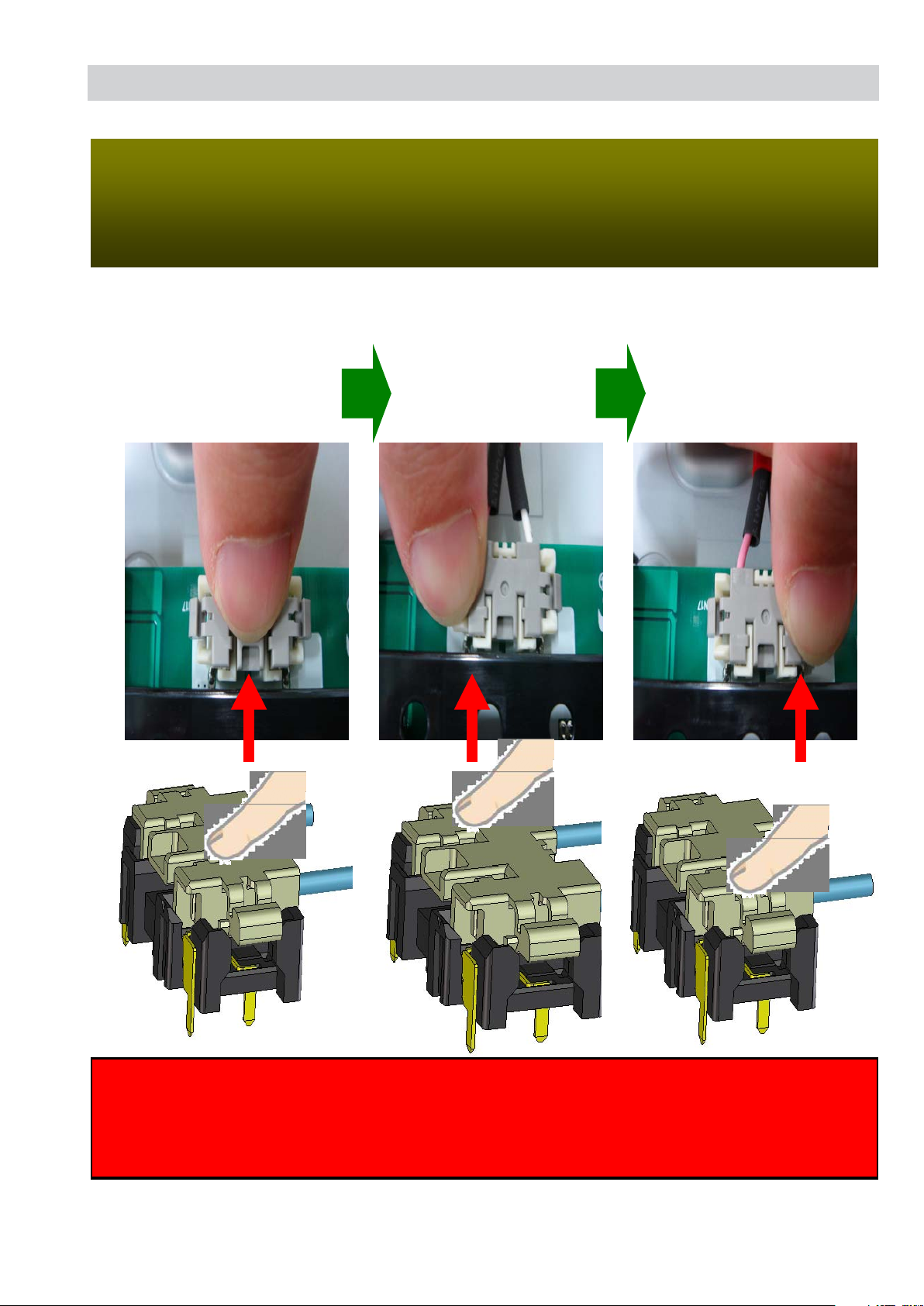

HIROSE MDF CONNECTOR

INSERTION

1. TO INSERT THE CONNECTOR

WAX3

RM-ED009

(1) Press the

middle part of

the connector to

confirm it locks.

(2) Press the

right side to

confirm it is

locked.

(3) Press the left

side to confirm it

is locked.

CAUTION :The connector might not be properly locked when only

pressed in the middle.

Be sure to press both sides to confirm it is properly

locked.

- 4 -

Page 6

SPECIFICATIONS

WAX3

RM-ED009

ITEM MODEL Television System Stereo System Channel Coverage Color System

Analogue:

E

U

Projected Picture Size

Input/Output Terminals [REAR] General Specifications

1: 21-pin Euro connector

(CENELEC standard)

B/G/H, D/K, I, L

Digital:

DVB -T/DVB-C

Analogue:

I

Digital:

DVB -T/DVB-C

LCD(Liquid Crystal Display) Panel

Approx 80.0cm (KDL-32D30XX)

Approx 101.5cm (KDL-40D30XX)

Approx 116.8cm (KDL-46D30XX).

Inputs for Audio and Video signals.

Inputs for RGB.

Outputs of TV Video and Audio

signals.

GERMAN/NICAM

Stereo

NICAM Stereo

Analogue: VHF : E2-E12

UHF : E21-E69

CATV : S1-S20

HYPER : S21-S41

D/K: R1-R12, R21-R69

L: F2-F10, B-Q, F21-F69

I: UHF B21-B69

Digital: VHF/UHF

Analogue: I: UHF B21-B69

Digital: VHF/UHF

Sound Output

Right and Left speaker

Sub-woofer

Power Requirements 220 - 240V

Power Consumption/

Standby

2 x 10W (RMS)

Approx 149W/0.3W (KDL-32D30XX)

Approx 169W/0.3W (KDL-40D30XX)

Approx 199W/0.3W (KDL-46D30XX)

Analogue:

PAL, SE C A M

NTSC 3.58/4.43

(VIDEO ONLY)

Digital:

MPEG-2 MP@ML

Analogue:

PAL, SE C A M

NTSC 3.58/4.43

(VIDEO ONLY)

Digital:

MPEG-2 MP@ML

Approx 790x581x214mm

(KDL-32D30XX with stand)

Approx 790x530x100mm

(KDL-32D30XX without stand)

Approx 981x696x265mm

Dimensions

2: 21-pin Euro connector

(CENELEC standard)

Phono Jacks

HDMI Inputs HDMI Connectors

PC Input 15 Pin D Sub Connector

CAM Conditional Access Module

Input/Output Terminals [SIDE] Remote control system : Infrared control

Headphone jack Stereo mini jack

Audio input Phono jacks

Video input Phono jack

S Video input 4 pin mini DIN

HDMI Input HDMI Connector

Inputs for Audio and Video signals.

Inputs for RGB.

Outputs of Video and Audio signals

(Selectable). SmartLink interface.

Output Connectors variable for

Audio Signals.

Design and specifications are subject to change without notice.

Weight

Supplied Accessories

Other Features

Power requirements

(KDL-40D30XX with stand)

Approx 981x643x110mm

(KDL-40D30XX without stand)

Approx 1114x782x306mm

(KDL-46D30XX with stand)

Approx 1114x730x115mm

(KDL-46D30XX without stand)

Approx 17.5kg (KDL-32D30XX with stand)

Approx 15.0kg (KDL-32D30XX without stand)

Approx 25.5kg (KDL-40D30XX with stand)

Approx 21.5kg (KDL-40D30XX without stand)

Approx 32.5kg (KDL-46D30XX with stand)

Approx 28.0kg (KDL-46D30XX without stand)

RM-ED009 Remote Commander (1)

IEC designated R06 battery (2)

Mains lead (Type BF) (1)

Coaxial cable (1)

Support belt (1) and screws (2)

Wide viewing angle LCD Panel, Intergrated

digital TV Tuner, Live colour creation, BBE digtal,

Trusurround XT, 3 HDMI inputs, PC input.

3V dc

2 batteries IEC designation

R06 (size AA)

- 5 -

Page 7

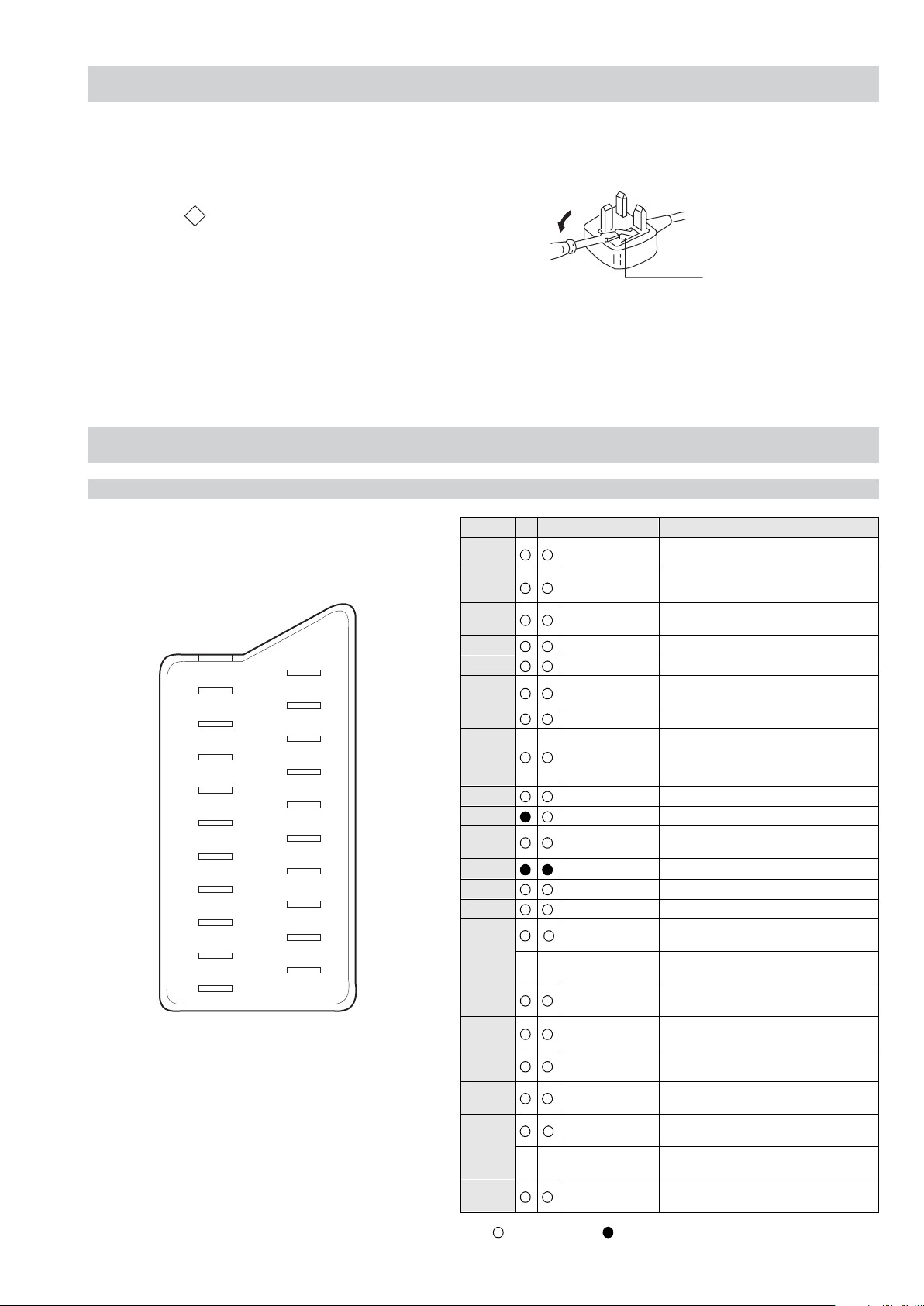

How to replace the fuse.

Open the fuse compartment with

a screwdriver blade and replace

the fuse.

FUSE

UK PLUG WARNING

WARNING (UK Models only)

The flexible mains lead is supplied connected to a B.S. 1363 fused

plug having a fuse of 13 AMP rating. Should the fuse need to be

replaced, use a 13AMP FUSE approved by ASTA to BS 1362, ie one

that carries the

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NOT SUITABLE FOR THE OUTLET SOCKETS IN YOUR HOME, IT SHOULD

BE CUT OFF AND AN APPROPRIATE PLUG FITTED. THE PLUG

SEVERED FROM THE MAINS LEAD MUST BE DESTROYED AS A

PLUG WITH BARED WIRES IS DANGEROUS IF ENGAGED IN A

LIVE SOCKET.

When an alternative type of plug is used, it should be fitted with a

13 AMP FUSE, otherwise the circuit should be protected by a

13AMP FUSE at the distribution board.

ASA

T

mark.

CONNECTORS

WAX3

RM-ED009

21 Pin Connector (SCART)

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Pin No 1 2 Signal Signal level

1 Audio output B

2

3

4 Ground (audio)

5 Ground (blue)

6 Audio input A

7 Blue input 0.7 +/- 3dB, 75 ohms positive

8 Function select

9 Ground (green)

10 AVlink

11 Green Green signal : 0.7 +/- 3dB, 75 ohms,

12 Open

13 Ground (red)

14 Ground (blanking)

15

_ (S signal Chroma

16 Blanking input

17 Ground (video

18 Ground (video

19 Video output 1V +/- 3dB, 75ohms, positive sync 0.3V

20

21 Common ground

(right)

Audio input B

(right)

Audio output A

(left)

(left)

(AV control)

_ _ Red input 0.7 +/- 3dB, 75 ohms, positive

-

-

input)

(Ys signal)

output)

input)

Video input 1V +/- 3dB, 75ohms, positive sync 0.3V

Video input

--

Y (S signal)

(plug, shield)

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

High state (9.5-12V) : Part mode

Low state (0-2V) : TV mode

Input impedence : More than 10K ohms

Input capacitance : Less than 2nF

positive

0.3 +/- 3dB, 75 ohms, positive

High state (1-3V) Low state (0-0.4V)

Input impedence : 75 ohms

(-3+10dB)

(-3+10dB)

1V +/- 3dB, 75ohms, positive sync 0.3V

(-3+10dB)

Connected Not Connected (open) * at 20Hz - 20kHz

- 6 -

Page 8

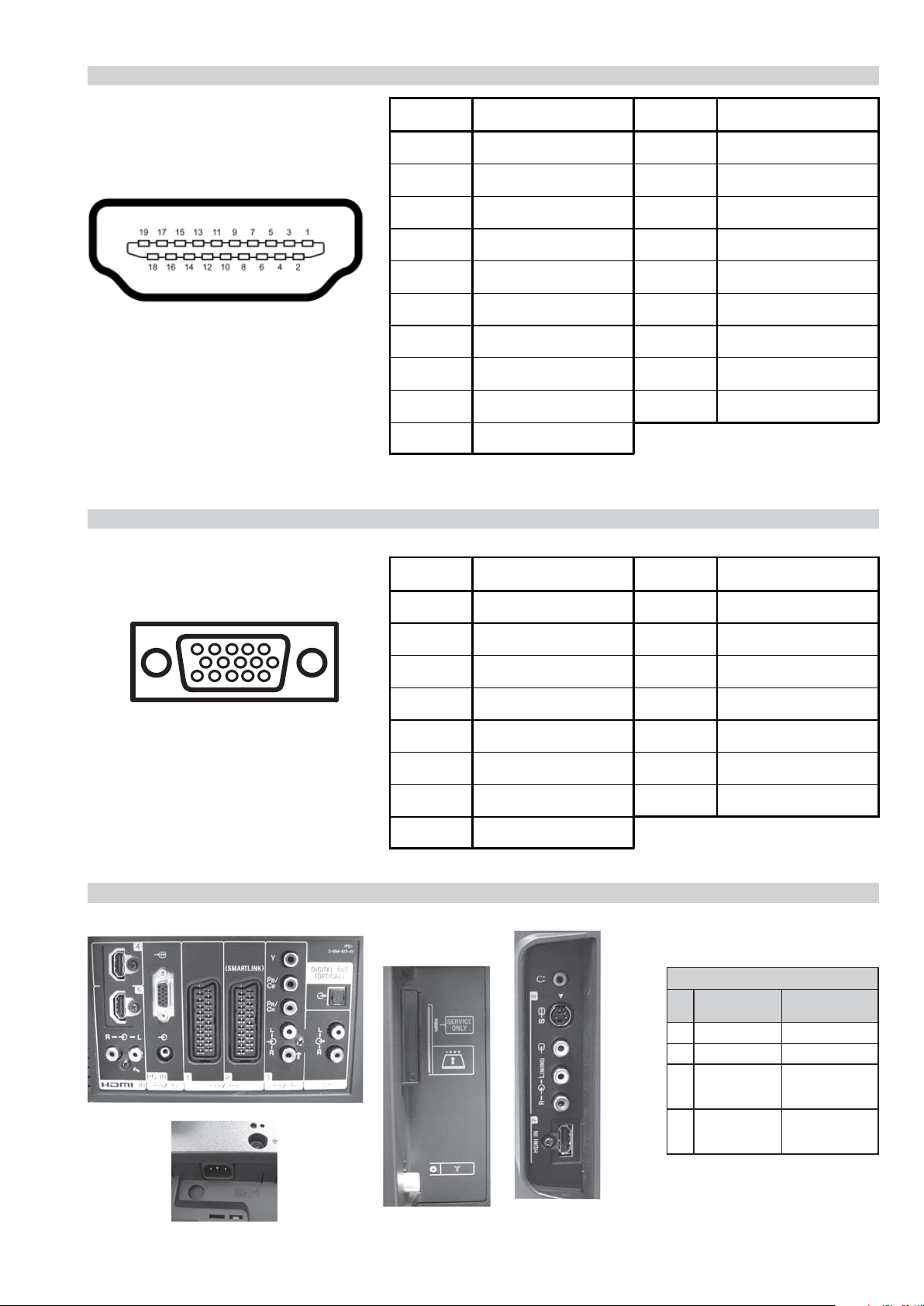

HDMI Connector

1

WAX3

RM-ED009

Pin No Signal Assignment Pin No Signal Assignment

1 TMDS Data2+ 11 TMDS Clock Shield

2 TMDS Data2 Shield 12 TMDS Clock-

3 TMDS Data2- 13 CEC

4 TMDS Data1+ 14 Reserved (N.C. on device)

5 TMDS Data1 Shield 15 SCL

6 TMDS Data1- 16 SDA

7 TMDS Data0+ 17 DDC/CEC Ground

8 TMDS Data0 Shield 18 +5V Power

9 TMDS Data0- 19 Hot Plug Detect

10 TMDS Clock+

15 Pin D Sub Connector (PC)

Pin No Signal Assignment Pin No Signal Assignment

1 Red Out 9 +5V DC

2 Green Out 10 Sync Return (Ground)

3 Blue Out 11 Monitor ID0 in Display

4 Unused 12 DCC Serial Data

5 Ground 13 Horizontal Sync

6 Red Return 14 Vertical Sync

7 Green Return (Ground) 15 DCC Serial Clock

8 Blue Return (Ground)

Rear Connection Panel Side Connection Panel

noitarugifnocniptekcosoediVS

S-Video

socket

niP

oN

1dnuorG-

2dnuorG-

3tupni)langisS(Y,mho57Bd3-/+V1

4tupni)langisS(CBd3-/+V3.0

langiS leveLlangiS

V3.0.cnySevitisop

Bd01+3-

ev

itisop,mho57

.cnyS

- 7 -

Page 9

WAX3

RM-ED009

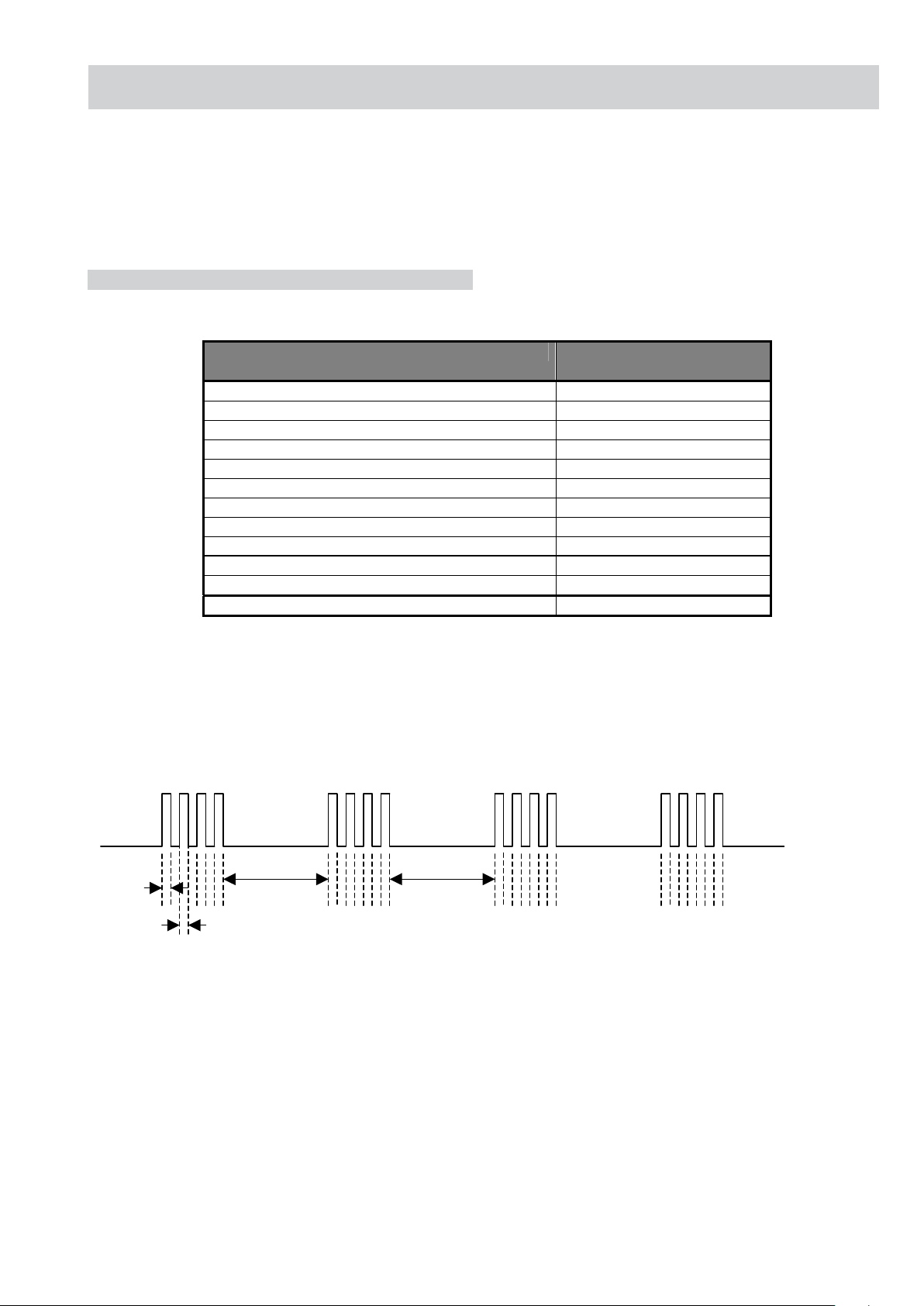

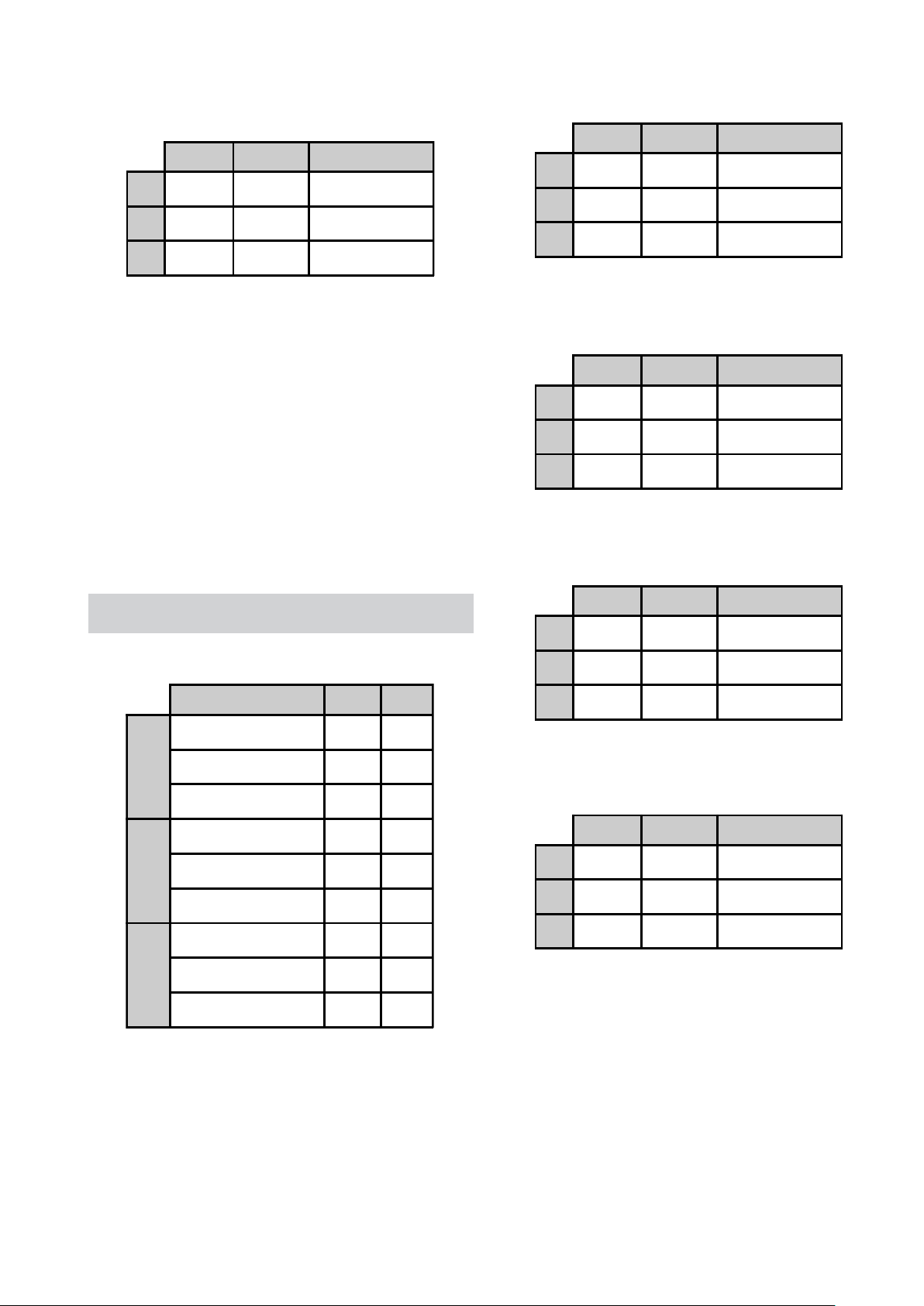

WAX3 SELF DIAGNOSTIC SOFTWARE

The identification of errors within the WAX3 chassis is triggered in one of two ways :- 1: Busy or 2: Device failure to respond to IIC. In the

event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with a continuous

flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant

device number will be displayed through the LED (Series of flashes which must be counted).

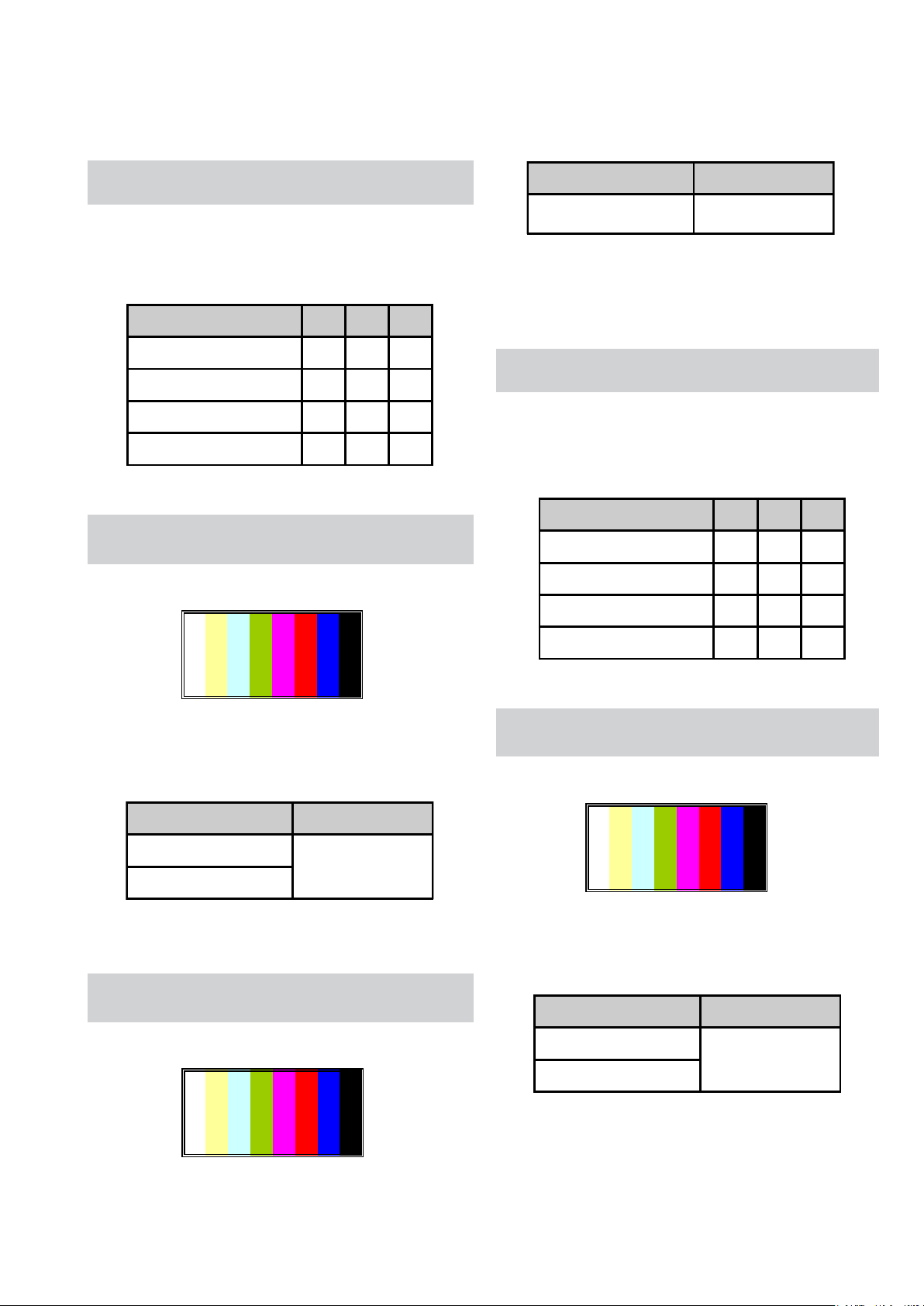

LED Error Code

Monitoring Items Number of Standby LED

(Red) Blinking

Main power supply voltage error 2

DC_ALERT1 3

DC_ALERT2 4

DC_ALERT3 5

Backlight error 6

Internal temperature error 7 *2

Audio error 8

Fan error (HFR model only) 9

Digital FE error 10

Trident error 11

HFR error *1 12

Balancer error 13

Note *1: It is judged as HFR Error when Safety Shutdown is activated due to either of FRC ACK error,

1.5V error, 2.5V/3.3V error, or Panel 12V error.

Note *2: The number of LED-blinking times for Internal temperature error is also used for BH-board

temperature error: these two errors are distinguished from whether TV Shutdown is involved

or not.

2.0 2.0

0.3

0.3

The figure above illustrates the LED display of DC_ALERT2.

Blinking is repeated in cycles of 0.3sec for the specified times, and, after the 2sec light-off

period, the blinking is again repeated for the same times. Note that the 2sec light-off period is

fixed regardless of contents of error.

- 8 -

Page 10

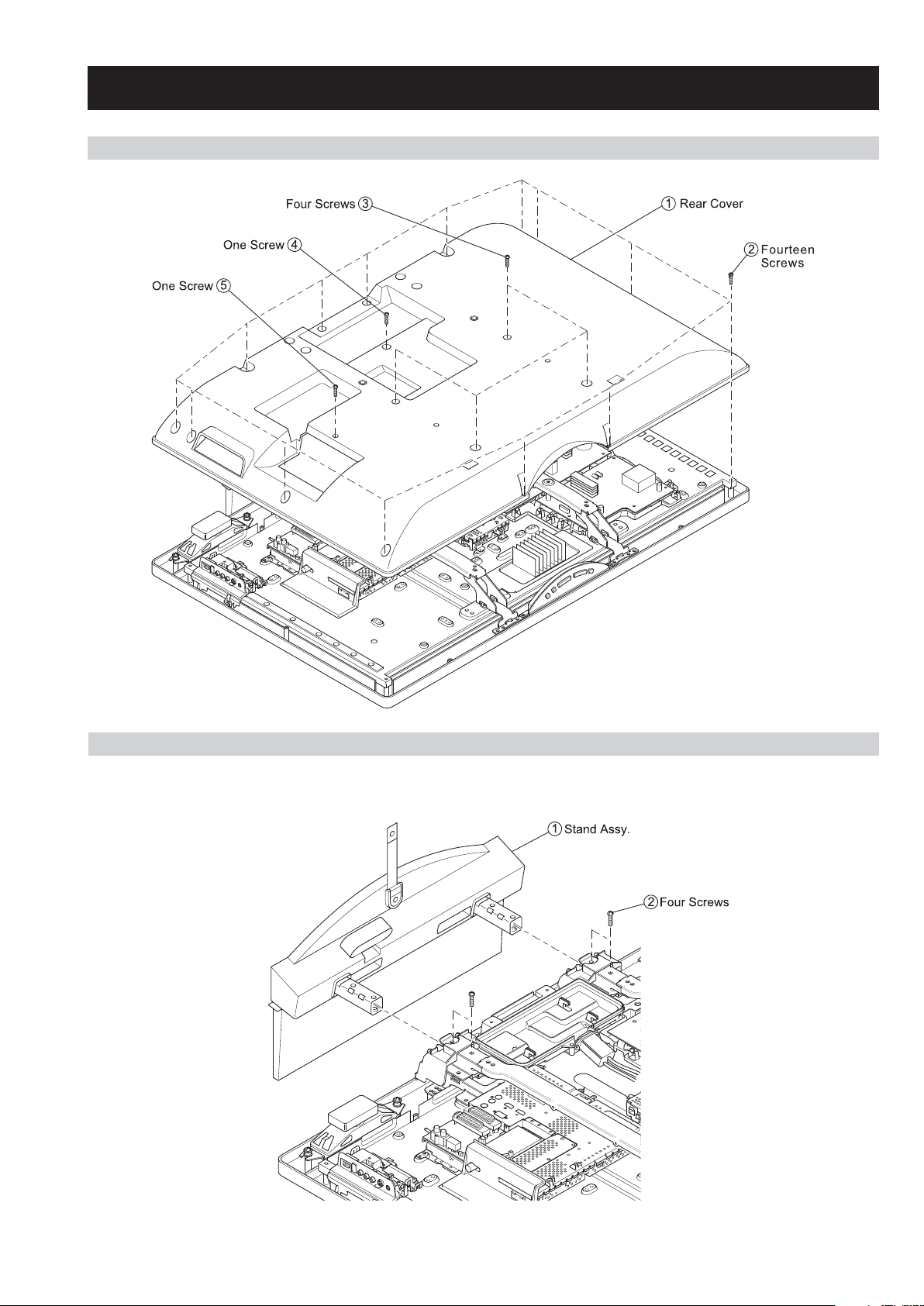

2-1. REAR COVER REMOVAL

WAX3

RM-ED009

SECTION 2 DISASSEMBLY

2-2. STAND REMOVAL

– 9 –

Page 11

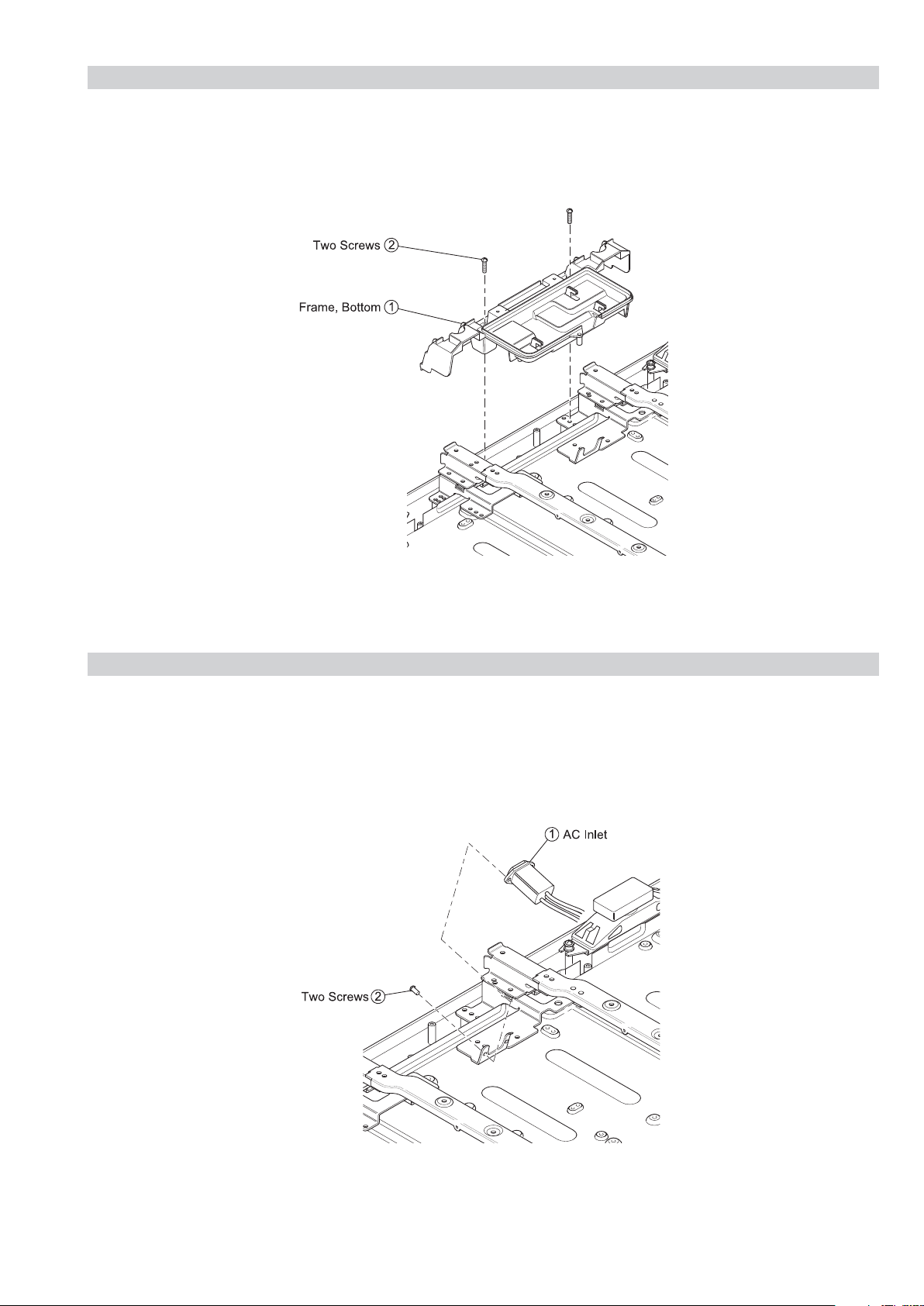

2-3. BOTTOM FRAME REMOVAL

WAX3

RM-ED009

2-4. AC INLET REMOVAL

– 10 –

Page 12

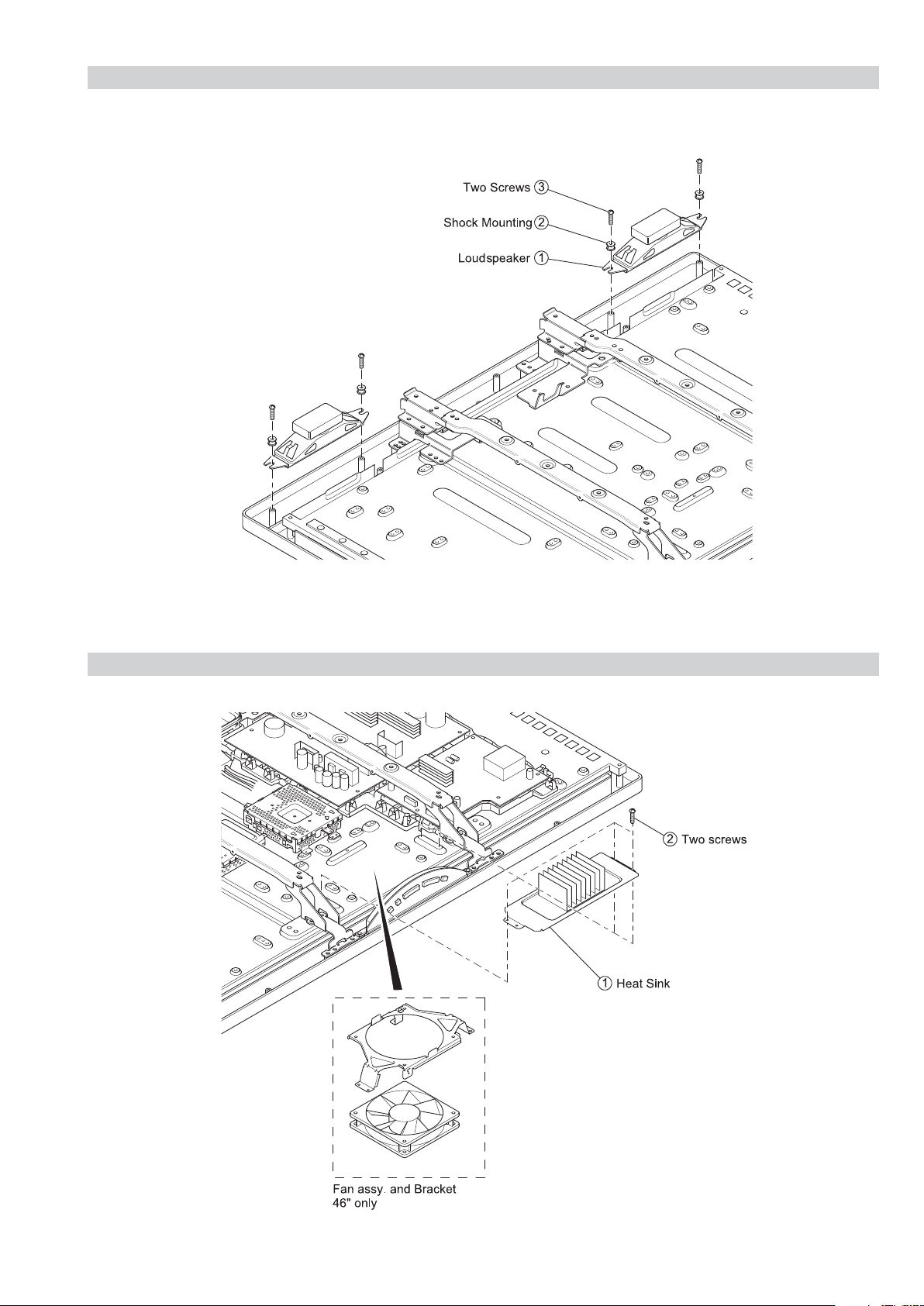

2-5. LOUDSPEAKER REMOVAL

WAX3

RM-ED009

2-6. HEATSINK REMOVAL

– 11 –

Page 13

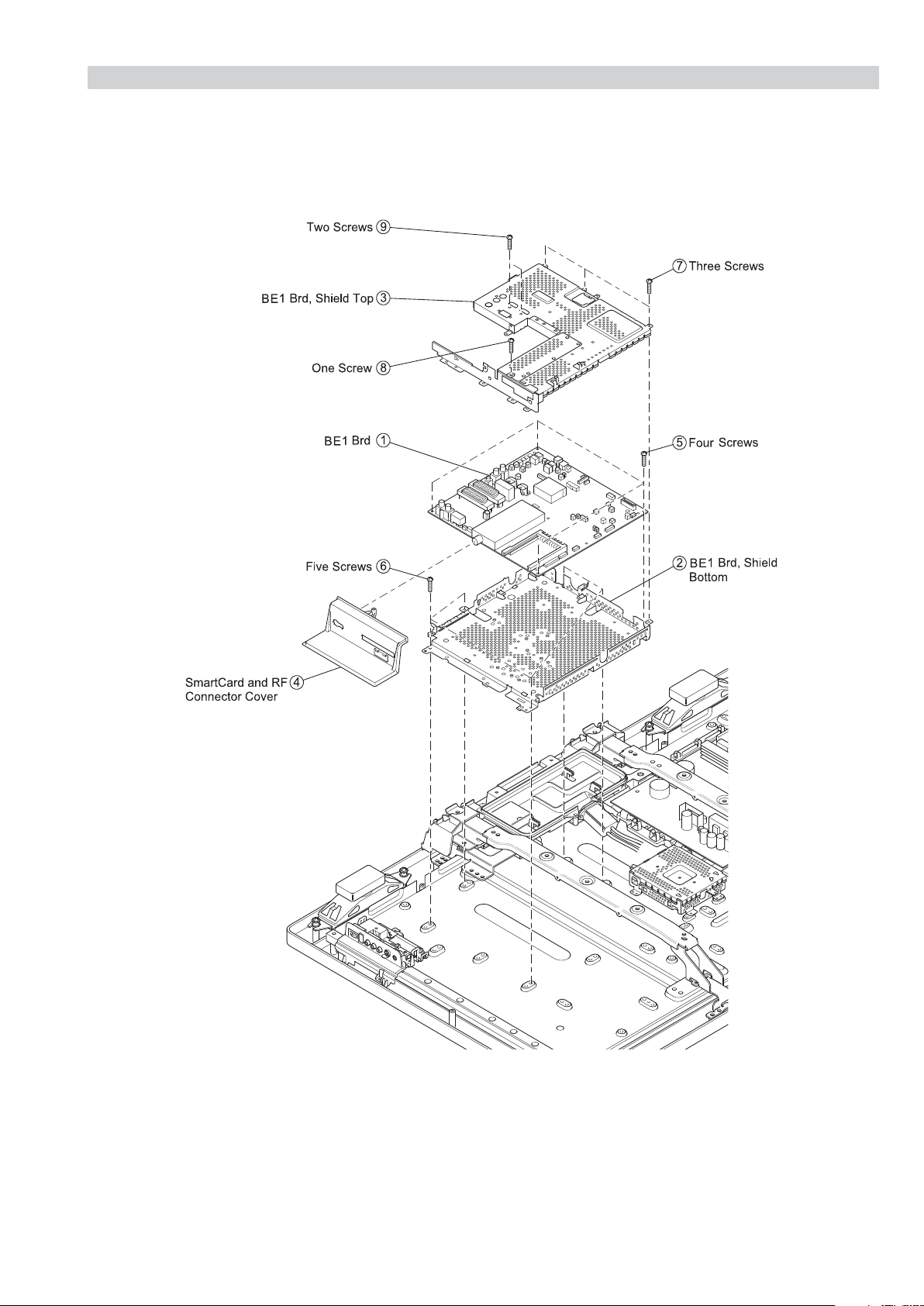

2-7. BE1 BOARD REMOVAL

WAX3

RM-ED009

– 12 –

Page 14

2-8. D1 and G3 BOARD REMOVAL

(KDL-40/46D30XX)

(KDL-40/46D30XX)

WAX3

RM-ED009

2-9. H3 BOARD REMOVAL

– 13 –

Page 15

2-10. H1 BOARD REMOVAL

WAX3

RM-ED009

2-11. H4 BOARD REMOVAL

– 14 –

Page 16

2-12. U2 BOARD REMOVAL

WAX3

RM-ED009

2-13. D2 BOARD REMOVAL

(KDL-46D30XX)

– 15 –

Page 17

2-14. VESA ARM and LCD PANEL REMOVAL

WAX3

RM-ED009

– 16 –

Page 18

SECTION 3 SET-UP ADJUSTMENTS

㧜

㧞㧟㧠㧡㧢㧣

WAX3

RM-ED009

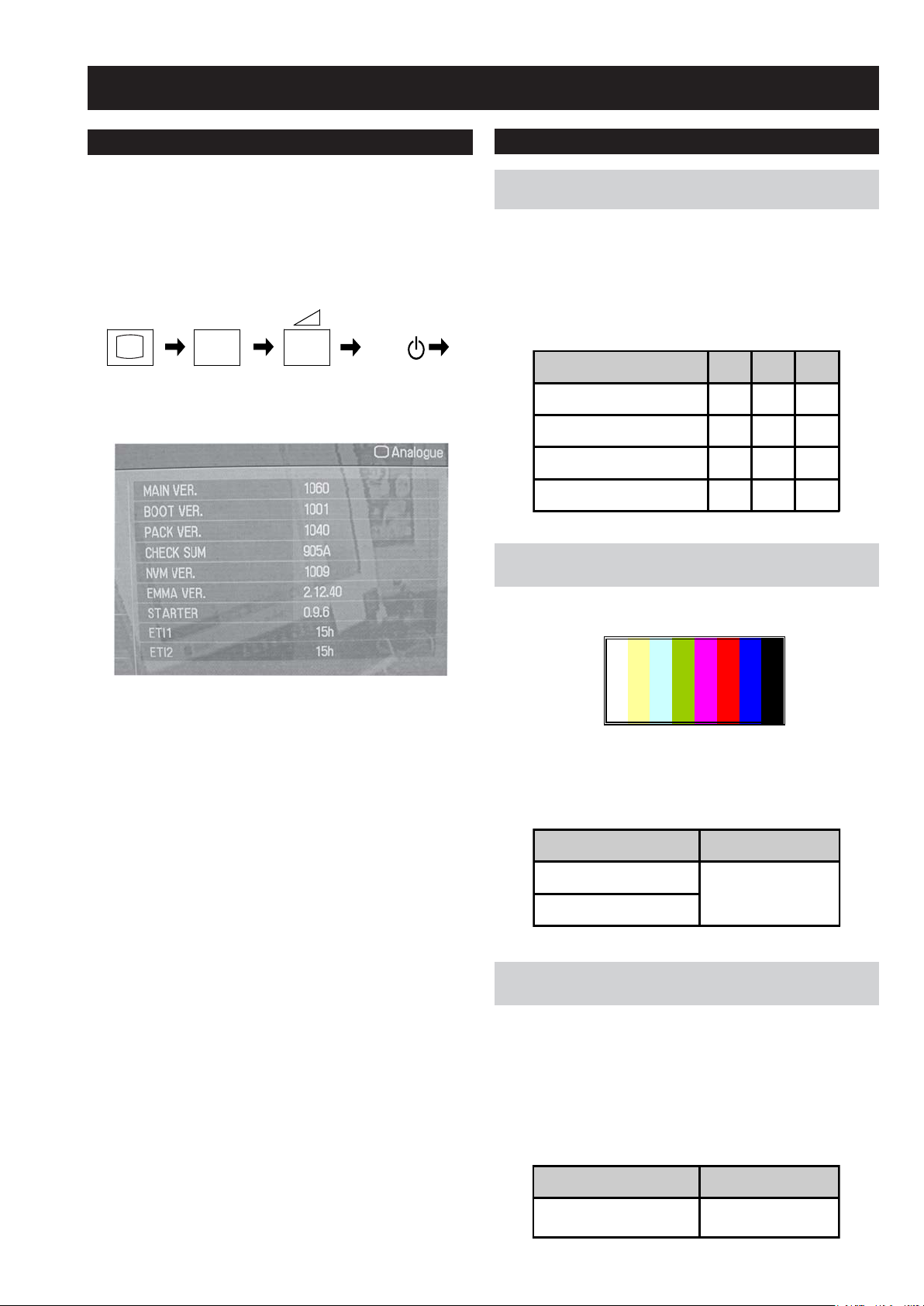

3-1. How to enter Service Mode

Service adjustments to this model can be performed using the

supplied remote Commander RM-ED009.

1. Turn on the power to the TV set and enter into the stand-by

mode.

2. Press the following sequence of buttons on the Remote

Commander.

i+

(ON SCREEN (DIGIT 5) (VOLUME +) (TV)

DISPLAY)

3. The following menu will then appear on the screen.

5

+

TV

I/

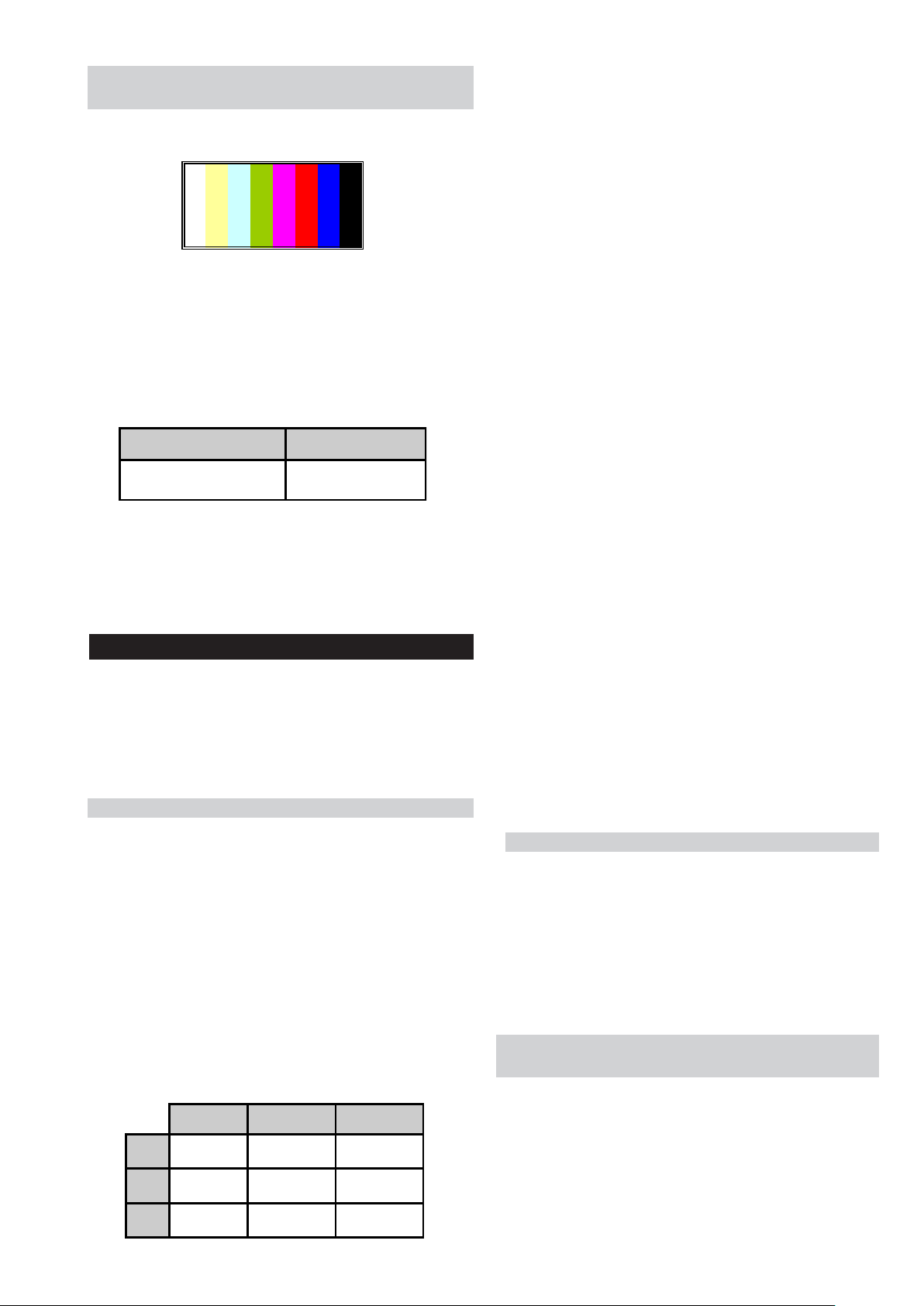

3-2. Signal Level Adjustment

Set up of AD calibration1 adjustment for

3-2-1.

terrestrial analog.

The following adjustments are done via ECS.

1. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

2. Set: SREG_NR = 3 (High), HREG_P4_CVD2_85[2:0] = 0 and

ADJ_COLOR_PAL = 3.

3. Set the following registration items.

Screen Size 32" 40" 46"

SREG_TARGET_Y_RF 160 160 160

SREG_TCD3_CONT_PAL_RF 128 128 128

SREG_TCD3_SAT_PAL_RF 128 128 128

SREG_TCD3_HUE_PAL_RF 128 128 128

3-2-2.

Y signal calibration1 adjustment for

terrestrial analog.

4. Move to the relevant command using the up or down arrow

buttons on the remote commander.

5. Press the right arrow button to enter into the required menu item.

6. Press the ‘Menu’ button on the remote commander to quit the

Service Mode when all adjustments have been completed.

Note :

• After carrying out the service adjustments, to prevent the

customer accessing the ‘Service Menu’ switch the TV set OFF

and then ON.

1. Input PAL colour bar 75%Y, 75%C via terrestrial input.

2. Send ECS_ADJUST_TCD3_CONT_RF command.

3. Read the value of S-REG_APL_LUMA via ECS. Confirming that

the value is within spec of the table below.

AD-ADJUST RF SPEC SPEC

Reference register name

SREG_TARGET_Y_RF±2

S-REG_APL_LUMA

3-2-3.

C signal calibration1 adjustment for

terrestrial analog.

1. Send ECS_ADJUST_TCD3_HUE_RF command.

2. Read S-REG_AVE_VAL_B_AREA0 via ECS.

(READ_AREA = 0).

3. Read S-REG_AVE_VAL_B_AREA6 via ECS.

(READ_AREA = 6).

4. Confirm that 8 bits of MSB of item number 2) and 3) are within

spec of the table below.

- 17 -

Reference Item Spec.

S-REG_AVE_VAL_B_AREA*

difference

±2

Page 19

㧜

㧞㧟

㧠㧡㧢㧣

㧜

㧞㧟

㧠㧡㧢㧣

5. Read S-REG_TCD3_SATURATION via ECS.

㧜

㧞㧟㧠㧡㧢㧣

6. Restore the original value. S-REG_NR = 4 (Auto).

7. Send ECS command ADJUST_LEVEL_SETTING_CLR.

3-2-4.

Set up of AD calibration1 adjustment for

video.

1. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

2. Set SREG_NR = 1 (Low), HREG_P4_CVD2_85[2:0] = 0 and

SREG_ADJ_COLOR_PAL = 3.

3. Set the following registration items.

Screen Size 32" 40" 46"

WAX3

RM-ED009

4. Read S-REG_AVE_VAL_B_AREA6 via ECS

(READ_AREA = 6).

5. Confirm that 8 bits of MSB of item number 3) and 4) are within

spec of the table below.

Reference Item Spec.

S-REG_AVE_VAL_B_AREA*

difference

6. Read S-REG_TCD3_SATURATION via ECS.

7. Restore original value. SREG_NR = 2 (Mid).

8. Send ECS command ADJUST_LEVEL_SETTING_CLR.

±2

SREG_TARGET_Y_V 160 160 160

SREG_TCD3_CONT_PAL_V 128 128 128

SREG_TCD3_SAT_PAL_V 128 128 128

SREG_TCD3_HUE_PAL_V 128 128 128

3-2-5.

Y signal calibration1 adjustment for

PAL video.

1. Input PAL colour bar 75%Y, 75%C via AV1 input.

㧠㧡㧢㧣

2. Send ECS_ADJUST_TCD3_CONT_V command.

3. Read the value of S-REG:APL_LUMA via ECS. Confirming that

the value is within spec of the table below.

3-2-7.

Set up of Y signal adjustment for

video.

1. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

2. Set SREG_NR = 1 (Low), HREG_P4_CVD2_85[2:0] = 0 and

SREG_ADJ_COLOR_PAL = 2.

3. Set the following registration items.

Screen Size 32" 40" 46"

SREG_TARGET_Y_V 160 160 160

SREG_TCD3_CONT_SCM_V 128 128 128

SREG_TCD3_SAT_SCM_V 128 128 128

SREG_TCD3_HUE_SCM_V 128 128 128

3-2-8.

Y signal calibration1 adjustment for

SECAM video.

1. Input SECAM colour bar 75%Y, 75%C via AV1 input.

AD-Adjust Video Spec. Spec.

Reference register name

SREG_TARGET_Y_V±2

S-REG_APL_LUMA

4. Read the value of S-REG:TCDS_contrast via ECS.

3-2-6.

C signal calibration1 adjustment for

PAL video.

1. Input PAL colour bar 75%Y, 75%C via AV1 input.

2. Send ECS_ADJUST_TCD3_HUE_V command.

3. Read S-REG_AVE_VAL_B_AREA0 via ECS

(READ_AREA = 0).

㧠㧡㧢㧣

2. Send ECS_ADJUST_TCD3_CONT_V command.

3. Read the value of S-REG:APL_LUMA via ECS. Confirming that

the value is within spec of the table below.

AD-Adjust Video Spec. Spec.

Reference register name

SREG_TARGET_Y_V±2

S-REG_APL_LUMA

4. Read the value of S-REG:TCDS_contrast via ECS.

- 18 -

Page 20

㧜

㧞㧟㧠㧡㧢㧣

3-2-9. C signal calibration1 adjustment for

SECAM video.

1. Input SECAM colour bar 75%Y, 75%C via AV1 input.

2. Send ECS_ADJUST_TCD3_HUE_V command.

3. Read S-REG_AVE_VAL_B_AREA0 via ECS

(READ_AREA = 0).

4. Read S-REG_AVE_VAL_B_AREA6 via ECS

(READ_AREA = 6).

5. Confirm that 8 bits of MSB of item number 3) and 4) are within

spec of the table below.

Reference Item Spec.

S-REG_AVE_VAL_B_AREA*

difference

6. Read S-REG_TCD3_SATURATION via ECS.

7. Restore original value. SREG_NR = 2 (Mid).

8. Send ECS command ADJUST_LEVEL_SETTING_CLR.

±2

WAX3

RM-ED009

· [Case A] if y => 0.298, check that the brightness is equal to or

greater than Spec A.

Set and save WB register A as follows :-

WB_GAM_G01 = 124

WB_GAM_G02 = 120

WB_GAM_G03 = 116

WB_GAM_G04 = 118

WB_GAM_G05 = 112

WB_GAM_G06 = 109

WB_GAM_G07 = 108

· [Case B] if 0.293 =< Y < 0.298, check that the brightness is

equal to or greater than Spec B.

Set and save WB register B as follows :-

WB_GAM_G01 = 126

WB_GAM_G02 = 124

WB_GAM_G03 = 122

WB_GAM_G04 = 123

WB_GAM_G05 = 120

WB_GAM_G06 = 119

WB_GAM_G07 = 118

· [Case C] if y < 0.293, check that the brightness is equal to or

greater than Spec C.

Set and save WB register C as follows :-

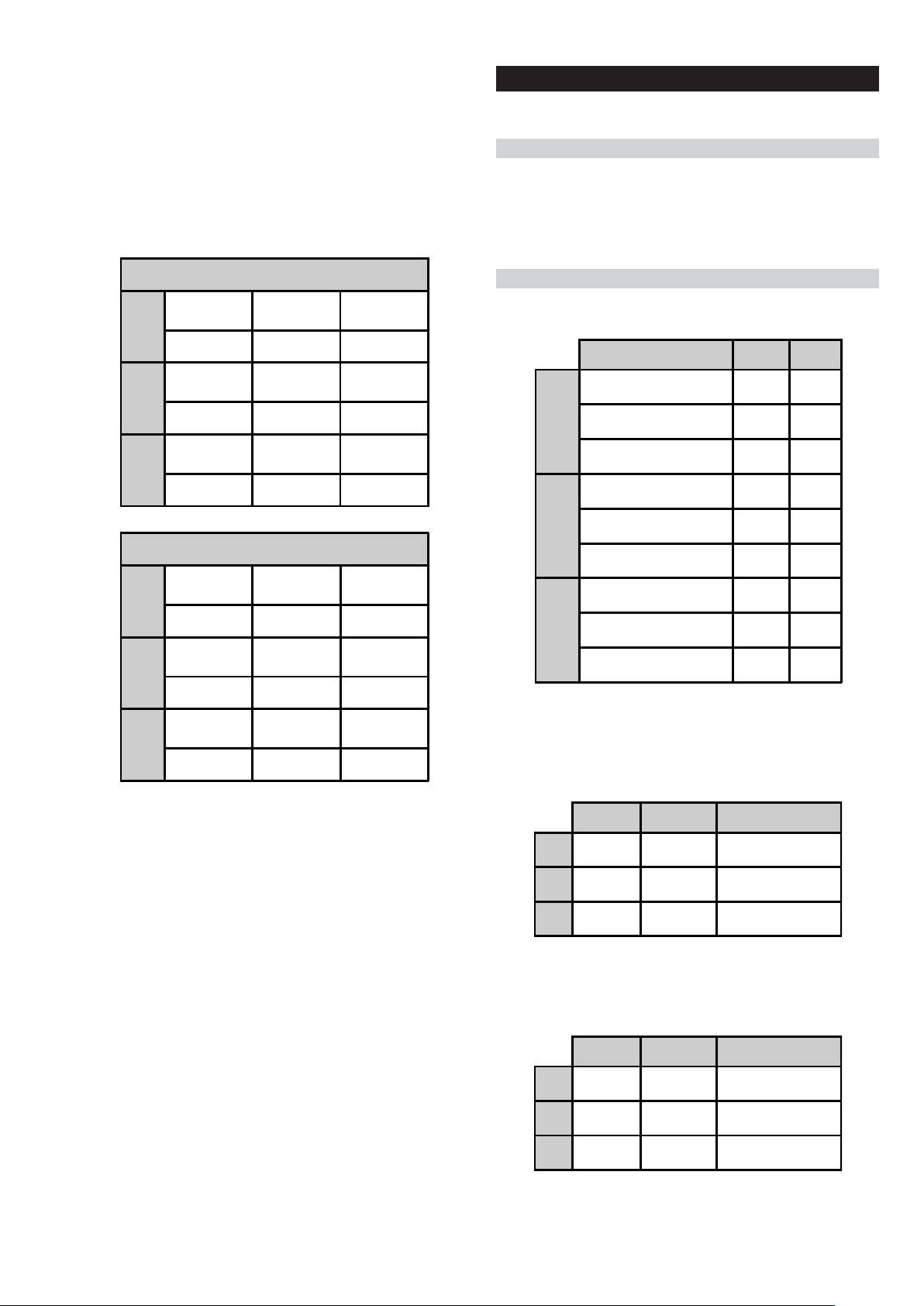

3-3. Gamma Adjustment

The following adjustments are done via ECS.

Note: Before Gamma adjustment can begin the set needs 20

minutes aging with an ambient temperature between 22 to

28 degrees centigrade.

3-3-1. Preparation before Gamma Adjustment

1. Set SREG_BL_MANU = 1.

2. Set SREG_MUTE_DISPLAY = 0.

3. Set SREG_BL_GAIN = 255.

4. Send ECS command OSD_OFF.

5. Send ECS command CSC_BYPASS_INIT_SET.

6. Wait for successful retrieval.

7. Set SREG_BRIGHT = 100(max).

8. Set SREG_ECO_MODE = 0(Standard).

9. Set SREG_TEST_G_LEVEL = 255.

10. Set SREG_GAMMA_EN = 0(OFF).

11. Measure ‘maximum brightness’ and ‘panel peak white color’ and

record x, y and Y data.

12. Confirm this data with the following table.

Spec A Spec B Spec C

440cd/m^2 425cd/m^2 410cd/m^2

32"

40" 440cd/m^2 425cd/m^2 410cd/m^2

440cd/m^2 425cd/m^2 410cd/m^2

46"

WB_GAM_G01 = 128

WB_GAM_G02 = 128

WB_GAM_G03 = 128

WB_GAM_G04 = 128

WB_GAM_G05 = 128

WB_GAM_G06 = 128

WB_GAM_G07 = 128

· If the brightness is lower than the spec consider the panel as no

good.

3-3-2. Set up mode for Gamma Adjustment

1. Set SREG_BRIGHT = 50.

2. Set SREG_GAMMA_EN = 1 (On).

3. Set SREG_COL_MTRX_IDX_OFF = 4.

4. Set SREG_COL_MTRX_IDX_L = 4.

5. Set SREG_COL_MTRX_IDX_M = 4.

6. Set SREG_COL_MTRX_IDX_H = 4.

7. Set SREG_G_GAM_IDX_OFST = 15.

3-3-3. Set up Trident Internal SG and Brightness

measurement

1. Set up SREG_TEST_G_LEVEL = 204.

2. Measure brightness A.

3. Set up SREG_TEST_G_LEVEL = 102.

4. Measure brightness B.

5. Set up SREG_MEASURE_GAM_01 = (brightness B/brightness

A)*10000.

6. Send Gamma_Tbl_Search_1 command.

7. Set up SREG_TEST_G_LEVEL = 153.

- 19 -

Page 21

8. Measure brightness C.

9. Set up SREG_MEASURE_GAM_02 = (brightness C/brightness

A)*10000.

10. Send Gamma_Tbl_Search_2 command.

11. Wait for calculation in UCOM.

12. Calculate register SREG_G_GAM_IDX_OFST using the formula

and tables below.

SREG_G_GAM_IDX_OFST = A - C - D

WAX3

RM-ED009

3-4. White Balance Adjustment

The following adjustments are done via ECS.

3-4-1. Set up mode for White Balance Adjustment

1. Set up SREG_COL_MTRX_IDX_OFF = 3.

2. Set up SREG_COL_MTRX_IDX_L = 3.

3. Set up SREG_COL_MTRX_IDX_M = 3.

4. Set up SREG_COL_MTRX_IDX_H = 3.

32"

40"

46"

32"

40"

46"

Offset Value C

temp75_temp-

=<7280

210

temp75_temp-

=<7000

210

temp75_temp-

=<8256

210

Y>=550cd/m^2

210

Y>=535cd/m^2

210

Y>=550cd/m^2

210

7280<temp75_temp=<9250

7000<temp75_temp=<9300

8256<temp75_temp=<9920

Offset Value D

550cd/m^2>Y-

>=530cd/m^2

535cd/m^2>Y-

>=510cd/m^2

550cd/m^2>Y-

>=520cd/m^2

9250<temp75-

_temp

9300<temp75-

_temp

9920<temp75-

_temp

530cd/m^2>Y

510cd/m^2>Y

520cd/m^2>Y

3-4-2. White Balance of Colour Temperature “Cool”

1. Refer to the table below and apply offset.

temp75_temp U V

temp75_temp<9856 -0.0015 0.002

9856<=temp75_temp<10500 -0.001 0.001

32"

10500<=temp75_temp 0 0

temp75_temp<9250 -0.0007 0.002

9250<=temp75_temp<10240 -0.0004 0.0004

40"

10240<=temp75_temp 0 0

temp75_temp<9665 -0.0007 0.0018

9665<=temp75_temp<10240 -0.0002 0.0007

46"

10240<=temp75_temp 0 0

2. Set up SREG_COLOR_TEMP = 0 (Cool).

3. Set up SREG_TEST_G_LEVEL = 204 (80 IRE).

4. Adjust SREG_WB_GAM_R(B)05 chroma values so that they are

within tolerance in the table below.

13. Set SREG_G_GAM_IDX_OFST.

U V Tol er an ce

0.1918 0.4287 0.0008->0.0014

32"

0.1916 0.4290 0.0008->0.0014

40"

0.1909 0.4295 0.0008->0.0014

46"

5. Set up SREG_TEST_G_LEVEL = 128 (50 IRE).

6. Adjust SREG_WB_GAM_R(B)04 chroma values so that they are

within tolerance in the table below.

U V Tol er an ce

0.1915 0.4287 0.0014->0.00196

32"

0.1921 0.4295 0.0014->0.00196

40"

0.1912 0.4285 0.0014->0.00196

46"

- 20 -

Page 22

7. Set up SREG_TEST_G_LEVEL = 76 (30 IRE).

8. Adjust SREG_WB_GAM_R(B)03 chroma values so that they are

within tolerance in the table below.

U V Tole ran ce

0.1915 0.4279 0.0014->0.00196->0.0028

32"

0.1919 0.4293 0.0014->0.00196->0.0028

40"

0.1908 0.4278 0.0014->0.00196->0.0028

46"

3-4-3. White Balance of Colour Temperature

“Neutral”

1. Refer to the table below and apply offset.

temp75_temp U V

temp75_temp<9856 -0.002 0.001

9856<=temp75_temp<10500 -0.001 0.0005

32"

10500<=temp75_temp 0 0

WAX3

RM-ED009

9. Set up SREG_TEST_G_LEVEL = 51 (20 IRE).

10. Adjust SREG_WB_GAM_R(B)02 chroma values so that they are

within tolerance in the table below.

U V Tol er an ce

0.1918 0.4276 0.0014->0.00196->0.0028

32"

0.1927 0.4298 0.0014->0.00196->0.0028

40"

0.1905 0.4267 0.0014->0.00196->0.0028

46"

11. The value of SREG_WB_GAM_R(B)01 is determined by the

following conditions.

a). If WB_GAM_R(B)02 < WB_GAM_R(B)03

· SREG_WB_GAM_R(B)01 = SREG_WB_GAM_R(B)02 +

{WB_GAM_R(B)02 - WB_GAM_R(B)03}

b). If SREG_WB_GAM_R(B)02 >=

SREG_WB_GAM_R(B)03

· SREG_WB_GAM_R(B)01 = SREG_WB_GAM_R(B)02

12. The value of SREG_WB_GAM_R(B)06~07 is determined

by the following conditions.

a). If SREG_WB_GAM_B05 > 154 and SREG_WB_GAM_

R05 > 128

temp75_temp<9250 -0.0008 0.0004

40"

9250<=temp75_temp<10240 -0.0005 0.0001

10240<=temp75_temp 0 0

temp75_temp<9665 -0.0008 0.0011

46"

9665<=temp75_temp<10240 -0.0003 0.0006

10240<=temp75_temp 0 0

2. Set up SREG_COLOR_TEMP = 1 (Neutral).

3. Set up SREG_TEST_G_LEVEL = 204 (80 IRE).

4. Adjust SREG_WB_R(B)05_OFST chroma values so that they

are within tolerance in the table below.

U V Tol er an ce

0.1956 0.4432 0.0008->0.0014

32"

40" 0.1931 0.4426 0.0008->0.0014

0.1929 0.4430 0.0008->0.0014

46"

5. Set up SREG_TEST_G_LEVEL = 128 (50 IRE).

6. Adjust SREG_WB_GAM_R(B)04_OFST chroma values so that

they are within tolerance in the table below.

U V Tol er an ce

· SREG_WB_GAM_R(B)06 = SREG_WB_GAM_R(B)05 -

{SREG_WB_GAM_R(B)05 - SREG_WB_GAM_R(B)04}

/ 2

· SREG_WB_GAM_R(B)07 = 128

b). If SREG_WB_GAM_R05 =< 128

· SREG_WB_GAM_B06 = SREG_WB_GAM_B05- {SREG_

GAM_B05 - WB_GAM_B04} / 2

· SREG_WB_GAM_B07 = 128

· SREG_WB_GAM_R06 = SREG_WB_GAM_R07 =

SREG_WB_GAM_R05

c). If SREG_WB_GAM_B05 =< 154

· SREG_WB_GAM_R(B)06 = SREG_WB_GAM_R(B)07 =

SREG_WB_GAM_R(B)05

13. Send WB_SAVE command.

0.1943 0.4430 0.0014->0.00196

32"

0.1933 0.4432 0.0014->0.00196

40"

0.1927 0.4428 0.0014->0.00196

46"

7. Set up SREG_TEST_G_LEVEL = 76 (30 IRE).

8. Adjust SREG_WB_GAM_R(B)03_OFST chroma values so that

they are within tolerance in the table below.

U V Tol er an ce

0.1947 0.4441 0.0014->0.00196->0.0028

32"

0.1936 0.4441 0.0014->0.00196->0.0028

40"

0.1927 0.4431 0.0014->0.00196->0.0028

46"

- 21 -

Page 23

9. Set up SREG_TEST_G_LEVEL = 51 (20 IRE).

10. Adjust SREG_WB_GAM_R(B)02_OFST chroma values so that

they are within tolerance in the table below.

U V Tol er an ce

0.1934 0.4435 0.0014->0.00196->0.0028

32"

40" 0.1918 0.4458 0.0014->0.00196->0.0028

0.1919 0.4413 0.0014->0.00196->0.0028

46"

WAX3

RM-ED009

4. Adjust SREG_WB_R(B)05_OFST chroma values so that they

are within tolerance in the table below.

U V Toleran ce

0.1973 0.4510 0.0008->0.0014

32"

40" 0.1952 0.4509 0.0008->0.0014

0.1954 0.4514 0.0008->0.0014

46"

11. Set the value of SREG_WB_GAM_R(B)01_OFST as follows

· SREG_WB_R(B)01_OFST = SREG_WB_R(B)_02_OFST

+ {SREG_WB_R(B)02_OFST-SREG_WB_R(B)03_OFST}

12. Set the value of SREG_WB_R06~07_OFST as follows

· SREG_WB_R(B)07_OFST = SREG_WB_R(B)05_OFST +

{SREG_WB_R(B)05_OFST - SREG_WB_R(B)04_OFST}

· SREG_WB_R(B)06_OFST = SREG_WB_R(B)05_OFST +

{SREG_WB_R(B)05_OFST - SREG_WB_R(B)04_OFST}/2

13. Send COLOR_SAVE command.

3-4-4. White Balance of Colour Temperature

“Warm 1”

1. Refer to the table below and apply offset.

temp75_temp U V

temp75_temp<9856 -0.002 0.0005

9856<=temp75_temp<10500 -0.0012 0.0005

32"

10500<=temp75_temp 0 0

5. Set up SREG_TEST_G_LEVEL = 128 (50 IRE).

6. Adjust SREG_WB_GAM_R(B)04_OFST chroma values so that

they are within tolerance in the table below.

U V Tole ran ce

0.1972 0.4503 0.0014->0.00196

32"

40"

46"

0.1961 0.4522 0.0014->0.00196

0.1957 0.4506 0.0014->0.00196

7. Set up SREG_TEST_G_LEVEL = 76 (30 IRE).

8. Adjust SREG_WB_GAM_R(B)03_OFST chroma values so that

they are within tolerance in the table below.

U V Toleran ce

0.1965 0.4522 0.0014->0.00196->0.0028

32"

40" 0.1969 0.4527 0.0014->0.00196->0.0028

0.1956 0.4509 0.0014->0.00196->0.0028

46"

9. Set up SREG_TEST_G_LEVEL = 51 (20 IRE).

10. Adjust SREG_WB_GAM_R(B)02_OFST chroma values so that

they are within tolerance in the table below.

temp75_temp<9250 -0.0011 0

40"

9250<=temp75_temp<10240 -0.0006 0

10240<=temp75_temp 0 0

temp75_temp<9665 -0.001 0.0008

46"

9665<=temp75_temp<10240 -0.0003 0.0004

10240<=temp75_temp 0 0

2. Set up SREG_COLOR_TEMP = 2 (Warm 1).

3. Set up SREG_TEST_G_LEVEL = 204 (80 IRE).

U V Tole ran ce

0.1948 0.4527 0.0014->0.00196->0.0028

32"

0.1970 0.4528 0.0014->0.00196->0.0028

40"

0.1944 0.4489 0.0014->0.00196->0.0028

46"

11. Set the value of SREG_WB_GAM_R(B)01_OFST as follows

· SREG_WB_R(B)01_OFST = SREG_WB_R(B)_02_OFST

+ {SREG_WB_R(B)02_OFST-SREG_WB_R(B)03_OFST}

12. Set the value of SREG_WB_R06~07_OFST as follows

· SREG_WB_R(B)07_OFST = SREG_WB_R(B)05_OFST +

{SREG_WB_R(B)05_OFST - SREG_WB_R(B)04_OFST}

· SREG_WB_R(B)06_OFST = SREG_WB_R(B)05_OFST +

{SREG_WB_R(B)05_OFST - SREG_WB_R(B)04_OFST} / 2

13. Send COLOR_SAVE command.

- 22 -

Page 24

3-4-5. White Balance of Colour Temperature

“Warm 2”

1. Refer to the table below and apply offset.

temp75_temp U V

temp75_temp<9856 -0.0025 0

9856<=temp75_temp<10500 -0.0015 0

32"

10500<=temp75_temp 0 0

WAX3

RM-ED009

9. Set up SREG_TEST_G_LEVEL = 51 (20 IRE).

10. Adjust SREG_WB_GAM_R(B)02_OFST chroma values so that

they are within tolerance in the table below.

U V Toleran ce

0.2012 0.4722 0.0014->0.00196->0.0028

32"

40" 0.2056 0.4650 0.0014->0.00196->0.0028

0.2029 0.4628 0.0014->0.00196->0.0028

46"

temp75_temp<9250 -0.0017 -0.0005

40"

9250<=temp75_temp<10240 -0.0009 -0.0002

10240<=temp75_temp 0 0

temp75_temp<9665 -0.0015 0.0003

46"

9665<=temp75_temp<10240 -0.0004 0.0003

10240<=temp75_temp 0 0

2. Set up SREG_COLOR_TEMP = 3 (Warm 2).

3. Set up SREG_TEST_G_LEVEL = 204 (80 IRE).

4. Adjust SREG_WB_R(B)05_OFST chroma values so that they

are within tolerance in the table below.

U V Tol er an ce

0.2032 0.4667 0.0008->0.0014

32"

0.2055 0.4633 0.0008->0.0014

40"

0.2034 0.4633 0.0008->0.0014

46"

5. Set up SREG_TEST_G_LEVEL = 128 (50 IRE).

6. Adjust SREG_WB_GAM_R(B)04_OFST chroma values so that

they are within tolerance in the table below.

U V Tol er an ce

0.2033 0.4674 0.0014->0.00196

32"

11. Set the value of SREG_WB_GAM_R(B)01_OFST as follows

· SREG_WB_R(B)01_OFST = SREG_WB_R(B)_02_OFST

+ {SREG_WB_R(B)02_OFST-SREG_WB_R(B)03_OFST}

12. Set the value of SREG_WB_R06~07_OFST as follows

· SREG_WB_R(B)07_OFST = SREG_WB_R(B)05_OFST +

{SREG_WB_R(B)05_OFST - SREG_WB_R(B)04_OFST}

· SREG_WB_R(B)06_OFST = SREG_WB_R(B)05_OFST +

{SREG_WB_R(B)05_OFST - SREG_WB_R(B)04_OFST} / 2

13. Send COLOR_SAVE command.

3-5. Panel Replacement

When replacing the panel please reset the gamma and white balance

before performing W/B (See page 20, 3-4) for new panel.

3-6. Board Replacement

When replacing the ‘BE1’ board please readjust the AD (See page 17,

3-2) and readjust the W/B (See page 20, 3-4).

Note :

In the event of a ‘BE1’ board being re-used in service, please

ensure that the Serial number is cleared in the NVM.

0.2060 0.4661 0.0014->0.00196

40"

0.2049 0.4651 0.0014->0.00196

46"

7. Set up SREG_TEST_G_LEVEL = 76 (30 IRE).

8. Adjust SREG_WB_GAM_R(B)03_OFST chroma values so that

they are within tolerance in the table below.

U V Tol er an ce

0.2027 0.4681 0.0014->0.00196->0.0028

32"

0.2067 0.4647 0.0014->0.00196->0.0028

40"

0.2030 0.4636 0.0014->0.00196->0.0028

46"

- 23 -

3-7. TT Modes

Digital BER Display

81

TS CI Path Through

84

Disable software Download

91

TS CI Path Through With ReadSolomon Off

92

LNA Setting On/Off (Toggle)

93

Page 25

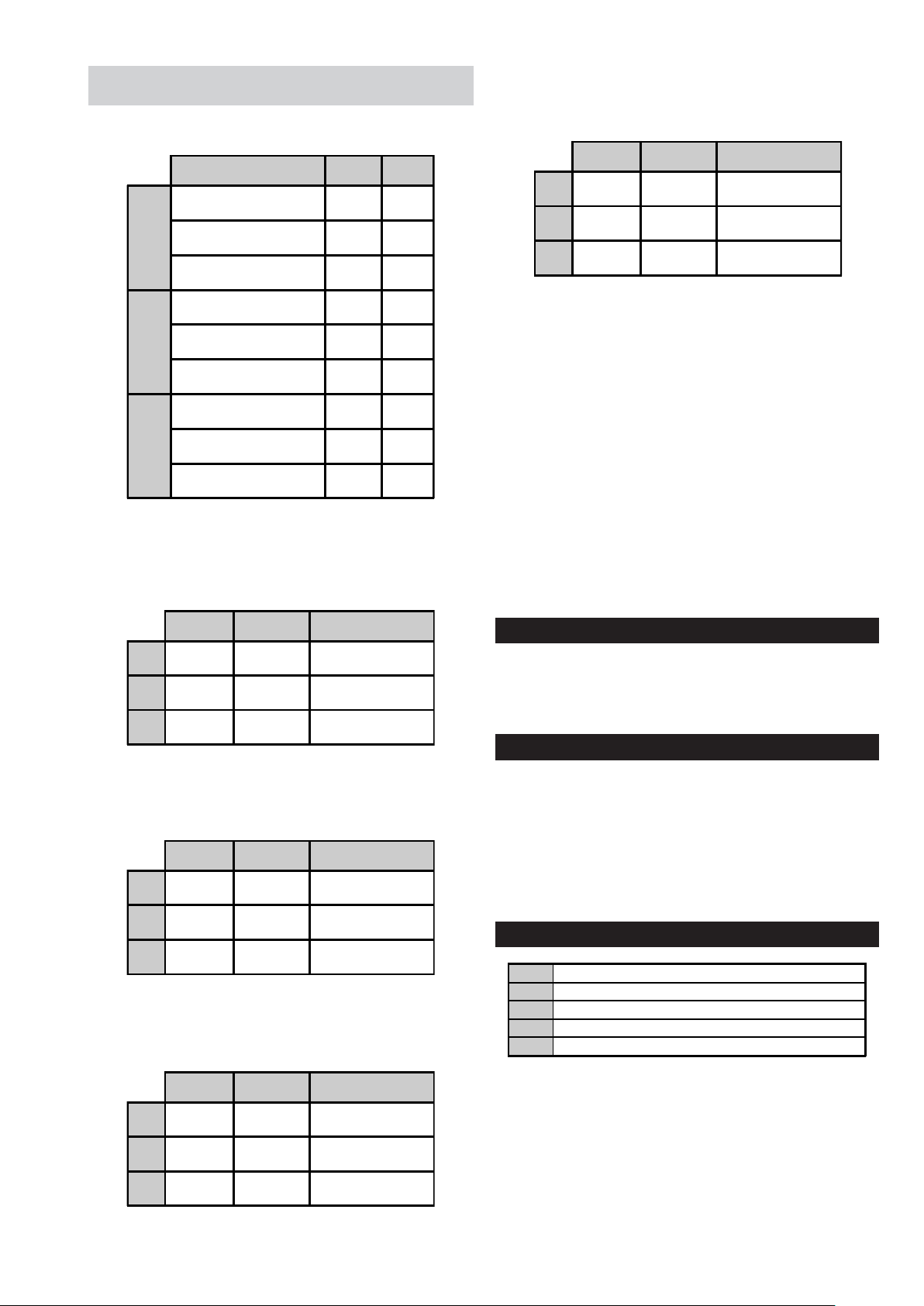

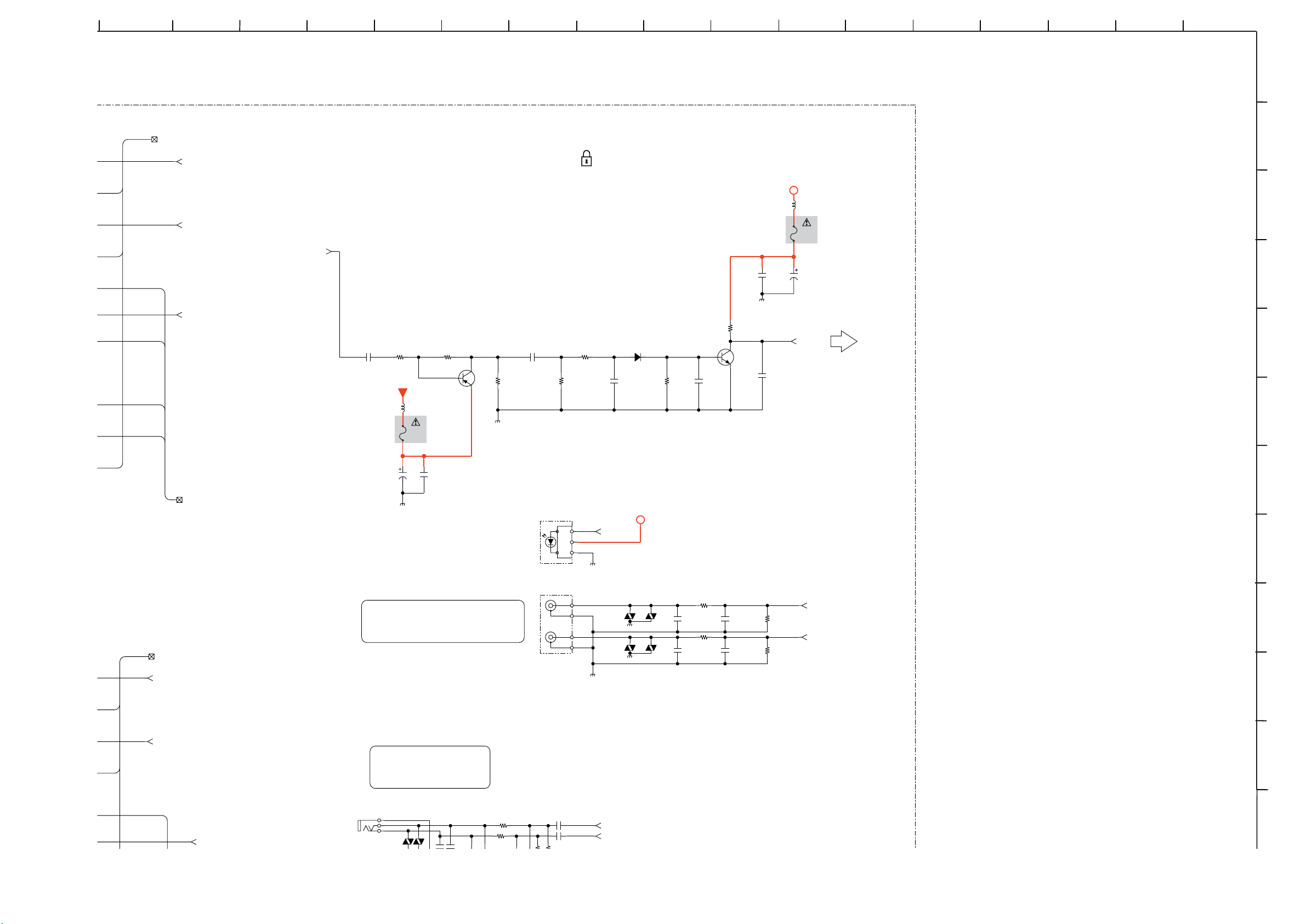

4-1. BLOCK DIAGRAMS (1)

WAX3

RM-ED009

WAX3D

AEP 32

(14P)

1-910-BJ-G1-INV

1-910-LUG-LUG

1P

1-910-BJ-G1

CN6201

(13P)

CN6202

(12P)

CN101

(3P)

Panel T-CON

LVDS 51P

LVDS 51P

BH

LVDS 40P

(6P)

CN8101

(12P)

CN4001

(5P)

CN4003

H1

(3P)

CN4002

(6P)

Conf-Trial

FAN

1-910-BH-FAN

INV

G1H

ޓޓޓޓޓ

1-910-BJ-H1H3H4

(20P)

CN3008

CN3003

chipdebuger

CN3004

ECS

CN3009

forHOTEL

CN2000

SP(4P)

1-910-BJ-SP

BE1

CN4500

LVDS 40P

HDMI(21P)

CN5504

1-910-BJ-U2

CN1400

(㧞㧜P)

CN201

(㧞㧜P)

(21P)

CN251

U2

CN401

(3P)

H4

CN301

(9P)

ޓޓH3

- 24 -

Page 26

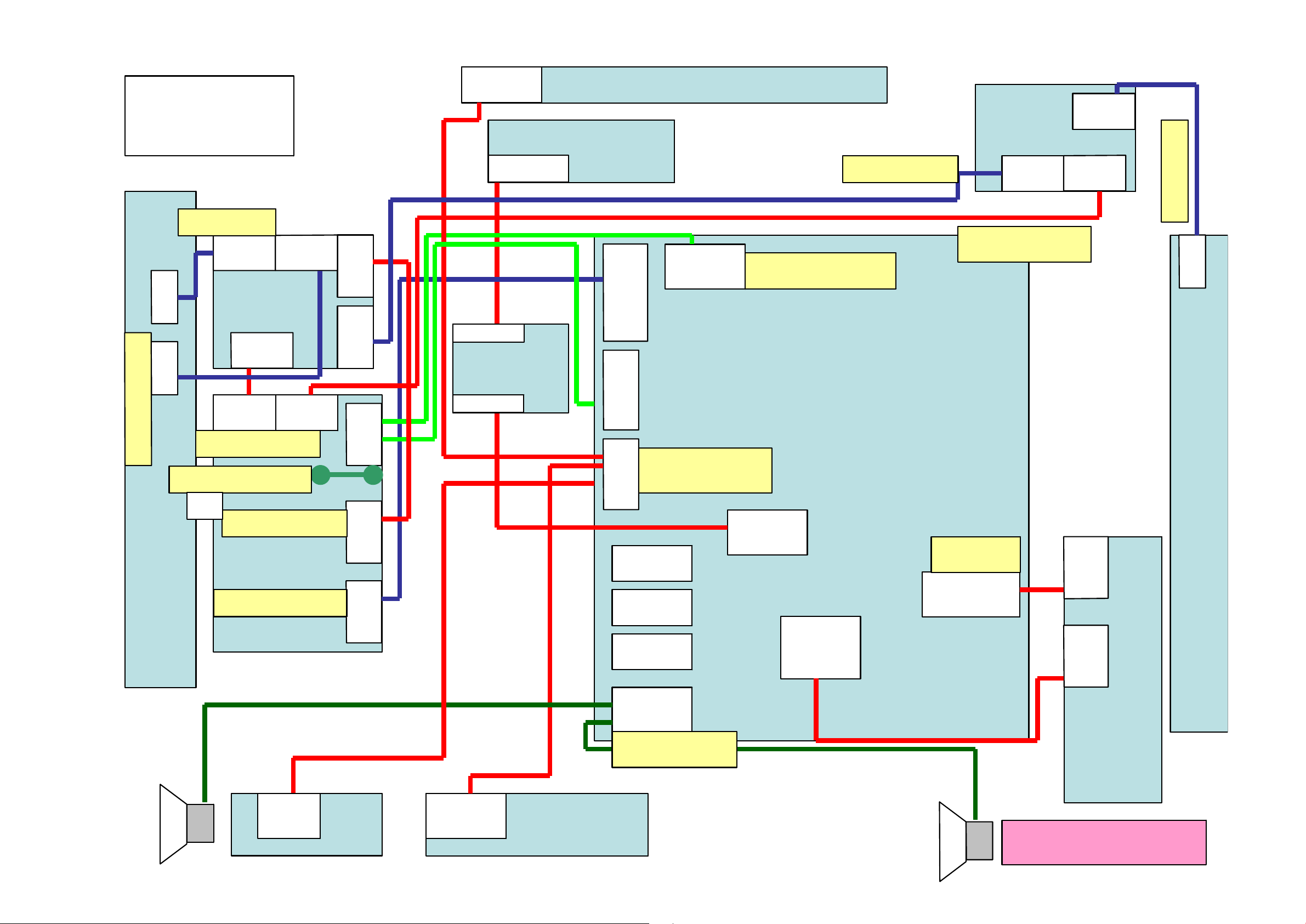

4-1. BLOCK DIAGRAMS (2)

WAX3D

CN101

(3P)

WAX3

RM-ED009

H1

AEP 40

1-910-Z-G2

CN6700

(2P)

(2P)

(5P)

D1_40”HFR

CN6600

CN6501

(2P)

(2P)

CN6701

(7P)

CN6502

(2P)

(8P)

CN6705

(13P)

CN6704

ޓPanel T-CON

LVDS 51P

CN4001

LVDS 51P

BH

LVDS 40P

CN4003

(12P)

(5P)

CN4002

(6P)

Conf-Trial

1-910-BJ-G3(11Pin)

1-910-Z-D1(7Pin)

Invertor

1-910-G2-D1(3Pin)

1-910-G3-D1(8Pin)

G㧟

1-910-BJ-G3

(11P)

CN6203

ޓ(8P)

CN6204

(12P)

CN6202

1-910-BJ-H1H3H4

(20P)

CN3008

CN3003

chipdebuger

CN3004

ECS

CN3009

forHOTEL

CN2000

SP(4P)

1-910-BJ-SP

BE1

CN4500

LVDS 40P

CN5504

HDMI

(21P)

1-910-BJ-U2

CN1400

(㧞㧜P)

CN201

(㧞㧜P)

CN251

(21P)

U2

CN401

(3P)

H4

CN301

(9P)

ޓޓޓH3

- 25 -

Page 27

4-1. BLOCK DIAGRAMS (3)

㧰㧞

WAX3D

AEP 46

1-910-Z-D1

CN101

(3P)

H1

ޓPanel T-CON

LVDS 51P

1-910-D1-D2

CN6950

(13P)

WAX3

RM-ED009

CN6951

(2P)

CN6900

(2P)

1-910-Z-D2

(2P)

(5P)

1-910-Z-D1(7Pin)

1-910-G3-D1(3Pin)

1-910-LUG-FASTEN

1P

Invertor

CN6700

(2P)

CN6701

(7P)

㧰㧝

CN6600

(2P)

CN6501

(2P)

1-910-G3-D1(8Pin)

CN6502

(2P)

G3

1-910-BJ-G3(11Pin)

(8P)

CN6705

(13P)

CN6704

(11P)

CN6203

(8P)

CN6204

(12P)

CN6202

LVDS 51P

BH

LVDS 40P

CN4002

(6P)

(12P)

CN4001

(5P)

CN4003

1-910-BJ-H1H3H4

(20P)

CN3008

CN3003

chipdebuger

CN3004

ECS

CN3009

forHOTEL

1-910-BJ-G3(12Pin)

BE1

CN4500

LVDS 40p

CN5504

HDMI

(21Pin)

1-910-G3-D2

1-910-BJ-U2

CN1400

(㧞㧜P)

CN201

(㧞㧜P)

(21P)

CN251

(2P)

Invertor

CN401

(3P)

H4

CN301

(9P)

H3

CN2000

SP(4P)

1-910-BJ-SP

- 26 -

U2

Conf-Trial

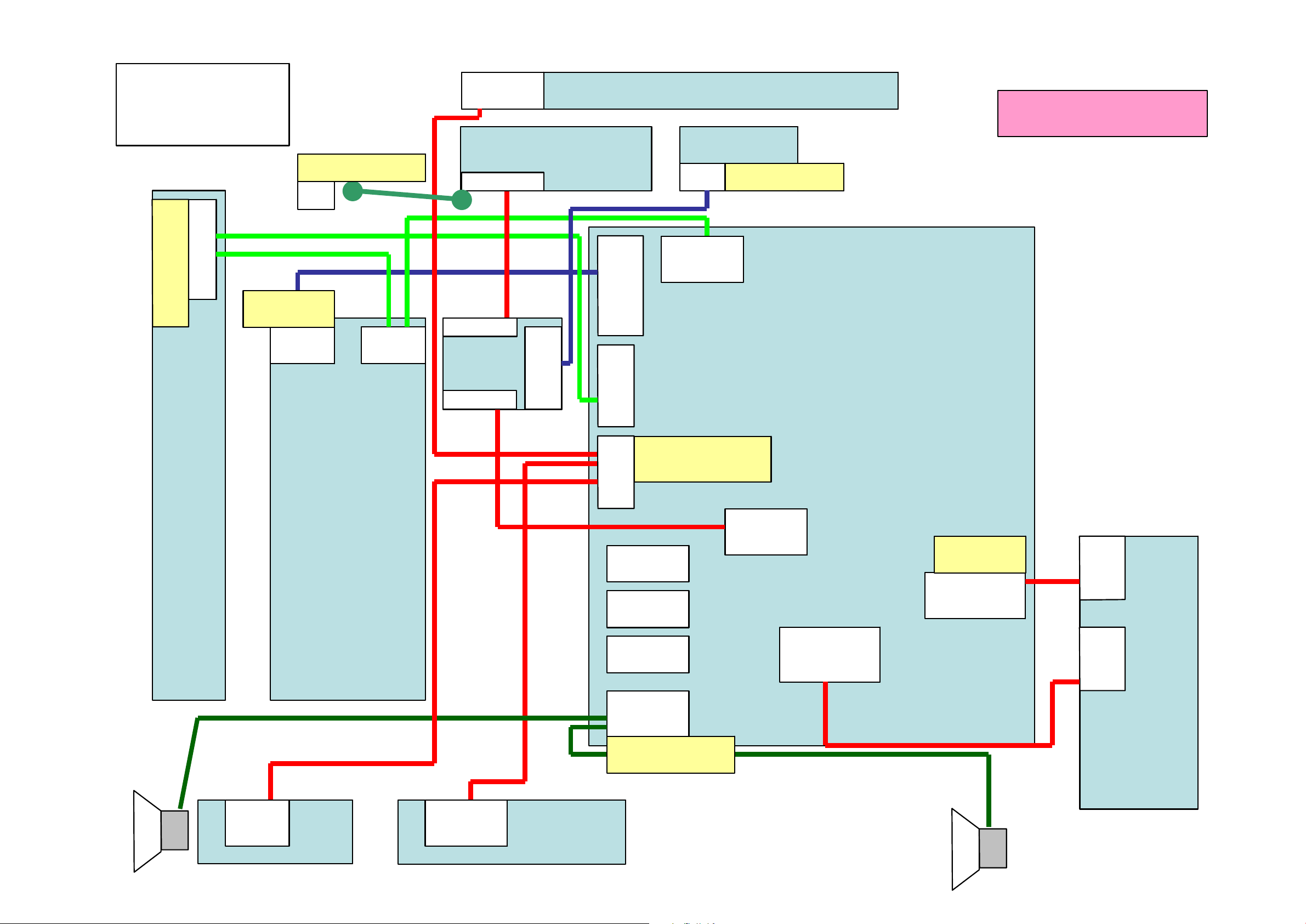

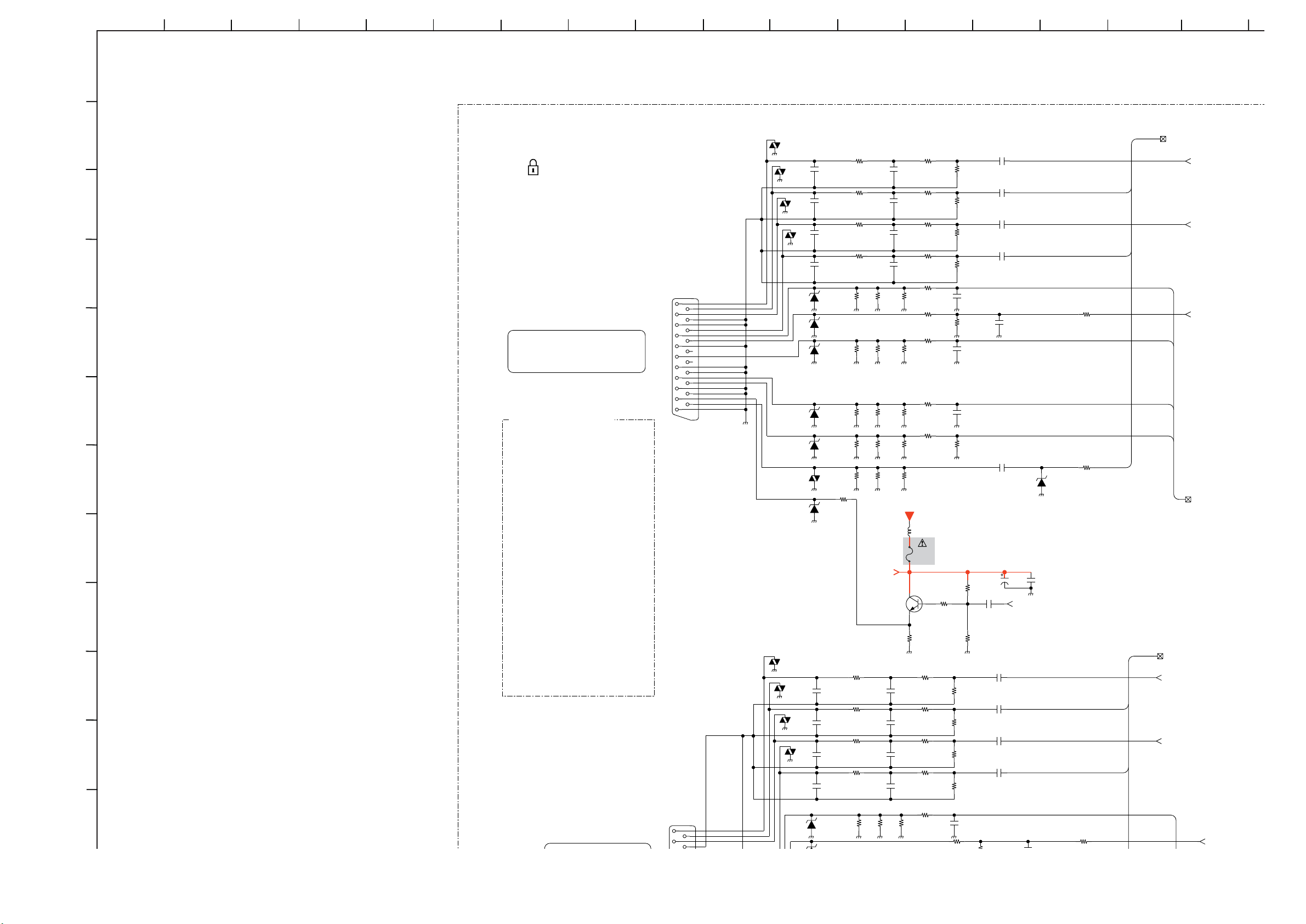

Page 28

4-2. CIRCUIT BOARD LOCATION

5-2. CIRCUIT BOARD LOCATION

WAX3

RM-ED009

Reference Information

H1

D2 (KDL-46D30XX)

C

BH

D1 (KDL-40/46D30XX)

C

BE1

N

VM

CVM Board

H

G1H (KDL-32D30XX)

G3 (KDL-40/46D30XX)

D1

4-3. SCHEMATIC DIAGRAMS AND

5-3. SCHEMATIC DIAGRAMS AND

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

Note :

• All capacitors are in µF unless otherwise noted.

• pF : µµF 50WV or less are not indicated except for

electrolytic types.

• Indication of resistance, which does not have one for

rating electrical power, is as follows.

Pitch : 5mm

Electrical power rating : 1/4W

• Chip resistors are 1/10W

• All resistors are in ohms.

k = 1000 ohms, M = 1000,000 ohms

• : nonflammable resistor.

• : fusible resistor.

• : internal component.

• : panel designation or adjustment for repair.

• All variable and adjustable resistors have

characteristic curve B, unless otherwise noted.

• All voltages are in Volts.

• Readings are taken with a 10Mohm digital mutimeter.

• Readings are taken with a color bar input signal.

• Voltage variations may be noted due to normal production

tolerences.

•: B + bus.

A

H4

A Board

S1 Board

U2

D2

A

H3

D

J

A1

A2

RESISTOR RN

RC

FPRD

FUSE

RS

RB

RW

COIL LF-8L

CAPACITOR TA

PS

PP

PT

MPS

MPP

ALB

ALT

ALR

Note :

The components identified by shading

and marked are critical for safety.

Replace only with the part numbers

specified in the parts list.

Note :

Les composants identifiés par une trame et

par une marque sont d'une importance

critique pour la sécurité. Ne les remplacer

que par des pièces de numéro spécifié.

specified.

Note :

The components identified by mark

confidential information.

Strictly follow the instructions whenever the

components are repaired and/or replaced.

: METAL FILM

: SOLID

: NON FLAMMABLE CARBON

: NON FLAMMABLE FUSIBLE

: NON FLAMMABLE METAL OXIDE

: NON FLAMMABLE CEMENT

: NON FLAMMABLE WIREWOUND

: ADJUSTMENT RESISTOR

: MICRO INDUCTOR

: TANTALUM

: STYROL

: POLYPROPYLENE

: MYLAR

: METALIZED POLYESTER

: METALIZED POLYPROPYLENE

: BIPOLAR

: HIGH TEMPERATURE

: HIGH RIPPLE

contain

• : B - bus.

• : RF signal path.

• : earth - ground.

• : earth - chassis.

Note: Schematic diagrams are for reference only. Please refer to the electrical parts list for

the correct value and part number of components.

- 27 -

Page 29

ABCD EF G H JIKLMN

N

_

O

P

Q

1

BE1.WAX3

10

11

12

2

VD1201

GND

BE1

1A/14

GND

3

4

21P

J1200

1

2

3

4

5

6

7

5

Scart1

REF.1200~1299

6

SCART 21PinAssign

Pin

8

9

10

11

12

13

14

15

16

17

18

19

20

21

GND

No.: Function

----------------------- 1 : Audio OUT R

7

2 : Audio IN R

3 : Audio OUT L

4 : Audio GND

5 : Video GND(BLUE)

6 : Audio IN L

PDZ5.6B-115

7 : Video IN BLUE

8

8 : MODE

9 : Video GND(GREEN)

10 : AVLINK

11 : Video IN GREEN

12 : N.C.

13 : Video GND(RED)

9

14 : GND(FB)

15 : Video IN RED

16 : FB

17 : Video GND(OUT VIDEO)

18 : Video GND(IN VIDEO)

19 : Video OUT CV

20 : Video IN CV

21 : GND

21P

J1300

1

3

2

GND

VD1301

GND

VD1202

VD1203

GND

GND

D1210

VD1302

VD1303

GND

GND

VD1204

VD1304

C1200

470p

50V

C1203

XX

C1206

470p

50V

C1209

XX

D1204

PDZ10B-115

GND

D1205

PDZ13B-115

GND

D1206

PDZ10B-115

GND

D1207

PDZ10B-115

GND

PDZ5.6B-115

GND

VD1205

GND

GND

C1300

470p

50V

C1303

C1306

470p

50V

C1309

D1304

PDZ10B-115

GND

R1200

330

1/16W

R1203

1k

1/16W

R1206

330

1/16W

R1209

1k

1/16W

R1212

R1213

220

220

1/10W

1/10W

RN-CP

RN-CP

0.5%

0.5%

GND GND GND

R1219

R1220

220

220

1/10W

1/10W

RN-CP

RN-CP

0.5%

0.5%

R1223

R1224

220

220

1/10W

1/10W

RN-CP

RN-CP

0.5%

0.5%

GND GND GND

R1227

R1228

220

220

1/10W

D1208

XX

XX

R1237

75

1/10W

RN-CP

1608

1/10W

RN-CP

RN-CP

0.5%

GND GND

R1232

R1233

220

1/10W

1/10W

RN-CP

RN-CP

0.5%

GNDGND

SC_OUT_VCC

Q1200

2SC3052EF-T1-LEF

R1300

330

1/16W

R1303

1k

1/16W

R1306

330

1/16W

R1309

1k

1/16W

R1312

220

1/10W

RN-CP

0.5%

GND GND

0.5%

220

0.5%

R1313

220

1/10W

RN-CP

0.5%

R1238

1k

1/16W

C1201

0.022

25V

1608

C1204

0.001

50V

C1207

0.022

25V

1608

C1210

0.001

50V

GND

GND

GND

GND

GND

BE_+5V

GND

C1301

0.022

25V

1608

C1304

0.001

50V

C1307

0.022

25V

1608

C1310

0.001

50V

R1314

1/10W

RN-CP

0.5%

GND

R1214

220

1/10W

RN-CP

0.5%

R1221

220

1/10W

RN-CP

0.5%

R1225

220

1/10W

RN-CP

0.5%

R1229

220

1/10W

RN-CP

0.5%

R1234

220

1/10W

RN-CP

0.5%

L1200

220

R1201

1/16W

R1204

R1207

1/16W

R1210

R1216

1/16W

RN-CP

0.5%

10uH

10%

PS1200

0.5A

50V

R1301

220

1/16W

R1304

CHIP

R1307

220

1/16W

R1310

220

0

220

0

33k

0

0

R1315

1/16W

R1215

1/16W

R1222

1/16W

R1226

1/16W

100

100

100

100

R1230

470

1/16W

R1239

1/16W

GND

R1202

C1202

470k

1/16W

R1205

470k

1/16W

R1208

470k

1/16W

R1211

470k

1/16W

C1212

R1217

22k

1/16W

RN-CP

0.5%

C1214

GNDGND GND

C1215

XX

R1231

680

1/16W

GND

0.5%

RN-CP

1/16W

10k

R1240

100

0.5%

RN-CP

1/16W

10k

R1241

GND

R1302

470k

1/16W

R1305

470k

1/16W

R1308

470k

1/16W

R1311

470k

1/16W

C1312

XX

R1316

2.2

10V

X7R

2012

A_SC1_IN_AU_L

R1218

100

1/16W

R1235

100

1/16W

A_SC2_IN_AU_R

A_SC2_IN_AU_L

R1318

A_SC1_IN_AU_R

A_SC1_IN_CV

C1205

2.2

10V

X7R

2012

C1208

2.2

10V

X7R

2012

C1211

2.2

10V

X7R

2012

XX

C1213

0.1

25V

1608

C1217

47

16V

C1219

4.7

6.3V

X6S

2012

R1317

C1216

0.01

25V

10%

1608

C1302

2.2

10V

X7R

2012

C1305

2.2

10V

X7R

2012

C1308

2.2

10V

X7R

2012

C1311

2.2

10V

X7R

2012

GNDGND

GND

C1218

1005

GND

A_SC1_OUT_CV

C1313

D1209

PDZ10B-115

0.01

25V

XX

A_SC1_IN_AU_L,A_SC1_IN_AU_R,A_SC1_I

A_SC1_OUT_AU_R

A_SC1_OUT_AU_L

SC1_B

A_SC1_IN_MODE

SC1_G

SC1_R

SC1_FBSC1_FB

SC1_B,SC1_FB,SC1_G,SC1_R

A_SC2_IN_AU_L,A_SC2_IN_AU_R,A_SC2_IN

A_SC2_OUT_AU_R

A_SC2_OUT_AU_L

SC2_B

A_SC2_IN_MODE

~ BE1 Board Schematic Diagram [ Micro Processor, Video/Audio Processor, Audio Amplifier, AV Switch, Tuner, Rear Input Terminal ] Page 1A/14 ~

- 28 -

Page 30

QRST UVWXY AA

C

N

Z

BE1.WAX3

DDCCBBP

EE

FF

1

1_IN_AU_R

_IN_AU_L

A_SC1_IN_AU_L,A_SC1_IN_AU_R,A_SC1_IN_CV

A_SC1_OUT_AU_R

A_SC1_OUT_AU_L

SC1_B

A_SC1_IN_MODE

SC1_G

SC1_R

SC1_FBSC1_FB

TV_DET_V

REF.1900~1999

SyncSep

R1901

1M

R1900

C1900

0.022

25V

B

4.7k

1/16W

BE_+5V

Q1900

ISA1235AC1TP-1EF

L1900

10uH

F1901

0.5A

50V

GND

R1902

2.2k

1/16W

M_HSYNC AEP NotUSE

C1903

4700p

50V

B

R1903

2.7k

1/16W

RN-CP

0.5%

BE1

R1904

3.9k

1/16W

RN-CP

0.5%

RB501V-40TE-17

C1904

2200p

50V

B

D1900

1B/14

Q1901

2SC3052EF-T1-LEF

R1905

1/16W

C1905

1M

0.22

16V

B

R1906

3.3k

1/16W

C1906

0.1

16V

GND

C1908

4.7

6.3V

B

2012

FE_+3V3

22uH

L1901

F1900

0.5A

50V

C1907

6.3V

TV_V_DET1/16W

2

3

47

TV_micro

4

5

6

1_IN_CV

SC1_B,SC1_FB,SC1_G,SC1_R

Audio Output

A_SC2_IN_AU_L,A_SC2_IN_AU_R,A_SC2_IN_CV

A_SC2_OUT_AU_R

REF.1700~1799

GND

C1901

47

6.3V

C1902

0.1

16V

J1700

3P

BLK

J1701

GND

1

VIN

2

VCC

3

L

1

2

R

3

4

ƒ[ qV [hfmc

@›¯ –¢•

A_SPDIF_OUT

GND

VD1700

XX

VD1701

XX

GND

D3.3V

GND

GND

VD1702

VD1703

C1702

0.001

50V

X7R

C1703

0.001

50V

X7R

R1702

2.2k

1/16W

R1703

2.2k

1/16W

C1700

XX

C1701

XX

R1700

220k

1/16W

R1701

220k

1/16W

7

8

A_AUOUT_AU_L

9

A_AUOUT_AU_R

10

IN_AU_R

A_SC2_OUT_AU_L

11

_AU_L

PC_LR IN

C1714

SC2_B

A_SC2_IN_MODE

J1710

C1711

XX

R1710

1M

R1712

2.2k

1/16W

R1713

2.2k

R1714

XX

1

25V

2012

C1715

1

PC_IN_L

PC_IN_R

12

~ BE1 Board Schematic Diagram [ Micro Processor, Video/Audio Processor, Audio Amplifier, AV Switch, Tuner, Rear Input Terminal ] Page 1B/14 ~

- 29 -

Page 31

11

C

R

12

13

14

15

16

Scart2

REF.1300~1399

21P

J1300

1

3

5

7

9

11

13

15

17

19

21

VD1303

GND

VD1304

GND

PDZ10B-115

D1307

D1308

D1310

GND

GND

PDZ10B-115

GND

GND

GND

GND

VD1305

GND

GND

2

4

6

8

10

12

14

16

18

20

PDZ10B-115

PDZ5.6B-115

GND

PDZ5.6B-115

1/16W

XX

R1306

C1306

330

470p

1/16W

50V

R1309

1k

C1309

1/16W

XX

D1304

D1305

PDZ13B-115

GND GND

D1306

D1350

PDZ5.6B-115

GND GND GND

GND GND

SC_OUT_VCC

Q1300

2SC3052EF-T1-LEF

R1337

75

1/10W

R1338

RN-CP

1k

1/16W

1608

R1312

220

1/10W

RN-CP

0.5%

R1319

220

1/10W

RN-CP

0.5%

R1323

220

1/10W

RN-CP

0.5%

R1327

220

1/10W

RN-CP

0.5%

R1332

220

1/10W

RN-CP

0.5%

GND

R1313

1/10W

RN-CP

0.5%

R1320

1/10W

RN-CP

0.5%

R1324

1/10W

RN-CP

0.5%

R1328

1/10W

RN-CP

0.5%

GNDGND

R1333

1/10W

RN-CP

0.5%

R1303

1k

C1303

R1304

C1304

0

0.001

CHIP

50V

R1307

C1307

220

0.022

1/16W

25V

1608

R1310

C1310

0

0.001

50V

R1314

GND

GND

GND

GND

GND

R1339

100

1/16W

220

1/10W

RN-CP

0.5%

R1321

220

1/10W

RN-CP

0.5%

R1325

220

1/10W

RN-CP

0.5%

R1329

220

1/10W

RN-CP

0.5%

R1334

220

1/10W

RN-CP

0.5%

RN-CP

1/16W

R1340

RN-CP

1/16W

R1341

0.5%

10k

0.5%

10k

R1350

100

1/16W

R1330

1/16W

GND

R1315

100

1/16W

R1322

100

1/16W

R1326

100

1/16W

470

GND

C1318

4.7

6.3V

X6S

2012

R1316

33k

1/16W

RN-CP

0.5%

GNDGNDGND

R1351

GND

C1315

R1331

1/16W

GND

220

220

220

220

220

R1305

470k

1/16W

R1308

470k

1/16W

R1311

470k

1/16W

C1312

XX

R1317

1/16W

RN-CP

GND GND

C1314

XX

XX

XX

680

C1305

2.2

10V

X7R

2012

C1308

2.2

10V

X7R

2012

C1311

2.2

10V

X7R

2012

22k

0.5%

SC2_IN_AVLINK

C1316

0.01

25V

10%

1608

A_SC2_OUT_CV

C1313

0.1

25V

1608

D1309

PDZ10B-115

GND

A_SC2_IN_AU_R

A_SC2_IN_AU_L

R1318

100

1/16W

A_SC2_IN_CV

R1335

100

1/16W

A_SC2_OUT_AU_L

SC2_B

A_SC2_IN_MODE

SC2_G

SC2_R

SC2_FBSC2_FB

SC2_B,SC2_FB,SC2_G,S

17

18

19

20

21

1

2

3

ComponentInput

4

5

6

REF.1100~1199

7

VD1103

8

9

10

J1100

GND

BE1

1C/14 MICRO PROCESSOR, VIDEO/AUDIO PROCESSOR, AUDIO AMPLIFIER, AV SWITCH, TUNER, REAR INPUT

COMPONENTS MARKED AS XX REFER TO PARTS LIST, WILL ONLY BE LISTED IF FITTED

BE1.WAX3

VD1104

GND

GND

C1103

XX

C1101

XX

R1115

1M

1/16W

R1117

1M

1/16W

R1110

220

1/10W

RN-CP

0.5%

1608

R1111

220

1/10W

RN-CP

0.5%

1608

R1112

220

1/10W

RN-CP

0.5%

1608

R1106

220

1/10W

RN-CP

0.5%

1608

R1114

2.2k

1/16W

R1116

2.2k

1/16W

R1107

220

1/10W

RN-CP

0.5%

1608

C1126

0.001

50V

X7R

C1127

0.001

50V

X7R

R1108

220

1/10W

RN-CP

0.5%

1608

R1120

XX

R1121

XX

R1102

220

1/10W

RN-CP

0.5%

1608

R1103

220

1/10W

RN-CP

0.5%

1608

C1100

2.2

10V

X7R

2012

C1102

2.2

10V

X7R

2012

R1104

220

1/10W

RN-CP

0.5%

1608

VD1100

XX

GND

VD1106 VD1107VD1105

VD1102

XX

GND

GND

VD1101

XX

A_D1_IN_AU_L,A_D1_IN_AU_R

A_D1_IN_AU_L

A_D1_IN_AU_R

C1124

XX

R1113

22

1/16W

C1125

XX

C1122

XX

R1109

22

1/16W

C1123

XX

22

ABCDEF GH JIKLMN

O

~ BE1 Board Schematic Diagram [ Micro Processor, Video/Audio Processor, Audio Amplifier, AV Switch, Tuner, Rear Input Terminal ] Page 1C/14 ~

- 30 -

P

Q

Page 32

IN_AU_R

_AU_L

A_SC2_OUT_AU_L

SC2_B

SC2_G

SC2_R

A_SC2_IN_MODE

PC_LR IN

J1710

VD1710

VD1711

GND

C1710

XX

C1711

XX

R1710

1M

1/16W

R1711

1M

1/16W

R1712

2.2k

1/16W

R1713

2.2k

1/16W

C1712

1000p

50V

B

1608

R1714

XX

C1713

1000p

50V

B

1608

R1715

XX

GND

C1714

1

25V

2012

C1715

1

25V

2012

PC_IN_L

PC_IN_R

11

12

13

SC2_FBSC2_FB

_IN_CV

SC2_B,SC2_FB,SC2_G,SC2_R

R1105

22

1/16W

C1124

XX

R1113

22

1/16W

C1125

XX

C1122

XX

R1109

22

1/16W

C1123

XX

C1120

XX

REF.1400~1499

WITCH, TUNER, REAR INPUT TERMINAL

AUDIO IN

CP1_IN_CB,CP1_IN_CR,CP1_IN_Y

CP1_IN_CR

CP1_IN_CB

CP1_IN_Y

C1121

XX

J1720

L

R

GND

V2_IN_AU_L

AU_IN_GND

V2_IN_AU_R

V2_IN_SSW

AU_IN_GND

V2_IN_C

HP_OUT_AU_L

V2_IN_S2SW

HP_IN_GND

HP_OUT_AU_R

V2_IN_Y

HP_DET

V2_IN_V

CN1400

20P

D3.3V

GND

GND

GND

GND

D5V

GND

VD1720

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

VD1721

GND

R1401

0

1608

R1414

GND

R1408

XX

0

C1403

0.001

R1407

XX

C1720

XX

C1721

XX

D3.3V

50V

X7R

1005

REG5V

GND

GND

GND

C1405

C1401

XX

R1402

XX

0

R1403

0

R1404

0

R1405

0

R1406

0

R1722

2.2k

1/16W

R1720

1M

1/16W

R1723

1/16W

R1721

1M

1/16W

GND_HP

C1409

2.2k

XX

GND

GND

C1406

XX

C1407

GND

C1408

GND

C1722

0.001

50V

X7R

C1723

0.001

JL1402

JL1403

XX

JL1404

XX

JL1405

JL1406

50V

X7R

A_V2_IN_AU_L

A_V2_IN_AU_R

R1724

C1724

1

25V

2012

C1725

XX

1

25V

2012

R1725

XX

GND

A_V2_IN_AU_L,A_V2_IN_AU_R

R1430

GND

GND

GND

XX

R1433XXR1434

R1436

XX

A_HP_OUT_AU_L

A_HP_OUT_AU_R

HP_DET

TO AUDIO

DVI_IN_L

DVI_IN_R

A_V2_IN_C,A_V2_IN_S2SW,A_V2_IN_SSW,A_V2_IN_V,A_V2_IN_Y

VideoInput6

R1409

GND

GND

GND

R1431

XX

GND

XX

GND

R1437

XX

GND

R1432

XX

R1435

XX

R1438

XX

0

R1410

0

R1411

0

R1412

0

R1413

0

GND

JL1409

JL1410

JL1411

JL1412

JL1413

C1404

XX

BE1

A_V2_IN_SSW

A_V2_IN_C

A_V2_IN_S2SW

A_V2_IN_Y

A_V2_IN_V

1D/14

14

15

16

17

18

19

20

21

BE1.WAX3

22

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

~ BE1 Board Schematic Diagram [ Micro Processor, Video/Audio Processor, Audio Amplifier, AV Switch, Tuner, Rear Input Terminal ] Page 1D/14 ~

- 31 -

Page 33

ABCD EF G H JIKLMN

S

N

1

1

2

1

2

5

7

/

BE1.WAX3

O

P

Q

10

11

12

1

2

3

BE1

4

5

ATT_SW_LINE

ATT_SW_HP

6

7

8

HDMI_I2S

9

A_SPDIF_OUT

SPDIF_OUT

CN2001

1

GND

2

XX

TAS digital 3.3V

GND

D3.3V

FB2016

0uH

F2002

0.5A

50V

D3.3V

R2269

10k

1/16W

R2268

100

1/16W

R2270

100

1/16W

R2271

10k

1/16W

F2001

1.6A

32V

C2181

XX

GND

2A/14

R2042

47

1/16W

R2155

C2014

X7R

C2016

X6S

HDMI_SDO

HDMI_WS

HDMI_SCK

HDMI_MCLK

FB2015

0uH

6.3V

100

C2013

R2023

0

CHIP

GND

R2154

0

0

50V0.001

6.3V4.7

2012

RB2007

10k

R2156

0

RB2012

10k

XX

L2005

C2015

XX

C2022

0.001

C2019

4.7

25V

X7R

C2017

3216

0.001

50V

X7R

C2018

XX

12345678

DVSS1

100

47

47

47

XX

R2079

GND

9 1011121314151617181920212223

24 25

/VREG_EN

STEST

LS_LRCKOUT

LS_SCLKOUT

GPIO4

GPIO3

MCLKOUT

LRCLKOUT

SCLKOUT

SDOUT1

SDOUT2/SPDIF_OUT

DVDD2

VR_DIG1

DVSS2

SPDIF_IN

SDIN1A

LRCLKINA

SCLKINA

MCLKINA

SDIN3

SDIN2

SDIN1

LRCLKIN

SCLKIN

10k

RB2010

10k

RB2006

R2044

R2033

R2207

R2035

50V

X7R

C2029

9p

50V

CH

10k

C2025

4.7

6.3V

X6S

2012

100

DVDD1

MCLKIN

262728

C2024

XX

RB2003

2

95

XTAL_IN

AVSS_ESD

I2C_SCL2

I2C_SDA1

RB2004

6.8k

6.8k

R2056

0.1C2033

94

AVDD_HP

I2C_SCL1

R2057

10k

C2030

9p

50V

CH

A_HP_OUT_R

10kR2063

93

HPOUTR

CS

R2062XX

R206410k

R2065XX

RB2011

10kR2070

92

AVSS_HP

GPIO1

C2039

0.001

50V

X7R

A_HP_OUT_L

90

91

HPOUTL

AVDD_HP

CXD9890Q

IC2002

GPIO2

/MUTE

R2020

10k

100

RB2008

R2068XX

100 R2073

R2072XX

54

VCC

C2041

4.7

25V

X7R

3216

89

AVDD_DAC

/RESET

R20741k

C2042

0.001

24.576MHz

X2001

1

0

R2049

R2050

1M

96

97

98

99

VR_ANA

XTAL_OUT

AVDD_OSC

I2C_SDA2

DVSS3

DVDD3

303132333435363738394041424344

29

100

C2027

0.001

50V

X7R

XX

RB2002

88

AVSS_DAC

DVSS4

C2044

XX

OUTY

R2075 4 7

86

87

DACOUT2L

DACOUT2R

DVSS5

DVDD4

C2045

0.001

50V

X7R

C2180

0.1

10V

X7R

1005

32FU(TE85R)

R2076 4 7

C2014

R2077 10k

84

85

DACOUT1R

VR_DIG2

X6SC2051

20126.3V4.7

R2208

R2080 4 7

R2078 10k

83

DACOUT1L

LINEOUT1R

LINEIN1L

AVSS_ESD

33k

33k

R2209

R2082 4 7

80

81

82

AVSS_LO

LINEOUT2R

LINEOUT1L

LINEIN2L

LINEIN1R

AVDD_LI

4546474849

C2054

C2055

4.7

0.001

25V

50V

X7R

X7R

3216

Q2029

RT1N141M-TP-1

R2245

100

1/16W

CHIP

L2009

10uH

TAS analogue 3.3V

C2059

C2058

4.7

0.001

25V

50V

X7R

X7R

3216

76

77

78

79

AVDD_REF

LINEOUT3L

LINEOUT3R

LINEOUT2L

V1P5_REF

BG_REF

BIAS_REF

AVSS_ADC/REF

AVDD_ADC

LINEIN10R

LINEIN10L

AVSS_LI

LINEIN9R

LINEIN9L

AVDD_LI

LINEIN8R

LINEIN8L

AVSS_LI

LINEIN7R

LINEIN7L

AVDD_LI

LINEIN6R

LINEIN6L

AVSS_LI

LINEIN5R

LINEIN5L

AVDD_LI

LINEIN4R

LINEIN4L

LINEIN3L

LINEIN2R

LINEIN3R

AVSS_LI

50

R209133k

R208533k

R209233k

R208733k

D3.3V

R2249

1k

1/16W

C2183

XX

L2010

10uH

C2060

100

6.3V

C2064

10V1

1608

C2065

10V1

1608

24kR2095

XXC2066

C2068

50V0.001

X7R

C2067

25V4.7

3216

X7R

R2096 4 7

R2097 4 7

6869707172737475

R2098 4 7

R2099 4 7

C2061

25V0.1

1608

B

X7R 2012

C2062

1608

B

C2063

1608

B

C2163

25V0.1

25V0.1

X7R 2012

10V2.2

X7R 2012

X7R 2012

GND

R2100

10k

R2101

10k

R2102 33k

R2103 33k

R2104 33k

R2105 33k

R2106 33k

R2107 33k

535455565758596061626364656667

R2108 33k

5152

R2109 33k

HDMI_MUTE

C2162

C2164

C2165

10V2.2

10V2.2

10V2.2

A_HP_OUT_R

A_HP_OUT_L

A_SP_OUT_R

A_SP_OUT_L

A_LINE_OUT_R

A_LINE_OUT_L

A_REC/SC2_OUT_R

A_REC/SC2_OUT_L

C2052

C2053

2.2

10V

X7R

2012

DIGITAL_AU_R

DIGITAL_AU_L

TV_R

TV_L

DVI_IN_R

DVI_IN_L

PC_IN_R

PC_IN_L

A_SC1_IN_AU_R

A_SC1_IN_AU_L

A_SC2_IN_AU_R

A_SC2_IN_AU_L

A_V2_IN_AU_R

A_V2_IN_AU_L

A_D1_IN_AU_R

A_D1_IN_AU_L

2.2

10V

X7R

2012

A_SP_OUT_R

A_SP_OUT_L

ATT_SW

25V

4.7

C2074

25V

4.7

C2075

L2015

10uH

R2117

4.7k

1/16W

CHIP

5%

R2118

4.7k

1/16W

CHIP

5%

1/16W

22k

R2121

1/16W

22k

R2122

R2123

Q2023

RT1N141M-TP-1

C2169

1000p

50V

B

1608

C2078

16V2.2

C 2012

XX

C2178

4.7

25V

C2179

4.7

25V

Q2024

RT1P441M-TP-1

R2234

100k

1/16W

RN-CP

0.5%

C2177

1

25V

2012

C2168

1000p

50V

B

1608

R2129

1/16W

R2236

1/16W

RN-CP

0.5%

R2237

3.3k

1/16W

RN-CP

0.5%

22k

3.3k

R2235

33k

1/16W

RN-CP

0.5%

C2086

0.001

50V

X7R

16V

47

C2085

DTC614TUT106

AUDIO_12V

0.5%

RN-CP

1/16W

15k

R2143

4321

V-

B+ IN

0.5%

RN-CP

1/16W

15k

R2145

R2133

22k

1/16W

R2238

1k

1/16W

RN-CP

0.5%

Q2025

Q2026

DTC614TUT106

HDMI_MUTE

PQ200WNA1ZPH

VIN

VC

12345

C2095

1

25V

2012

R2210

C2094

6.8k

100p

50V

1/16W

RN-CP

CH

0.5%

1608

A OUT

A- IN

A+ IN

NJM4558V-TE2

IC2006

B- IN

V+

B OUT

8765

C2096

100p

50V

CH

1608

R2211

6.8k

1/16W

RN-CP

0.5%

SP_MUTE

R2239

R2246

1k

3.3k

1/16W

1/16W

RN-CP

CHIP

0.5%

5%

RT1N141M-TP-1

IC2005

VOUT

Q2030

VADJ

GND

R2229

1/16W

RN-CP

R2228

1/16W

RN-CP

0.5%

R2227

1/16W

RN-CP

C2097

0.1

25V

1608

Q2006

RT1N141M-TP-1

1k

0.5%

6.8k

2.2k

0.5%

R2277

100k

1/16W

C2

4

2

X

R

1

1

R

4

1/

R

1/

H

~ BE1 Board Schematic Diagram [ Micro Processor, Video/Audio Processor, Audio Amplifier, AV Switch, Tuner, Rear Input Terminal ] Page 2A/14 ~

- 32 -

Page 34

QRST UVWXY AA

-

Z

DDCCBBP

EE

FF

BE1.WAX3

1

AUDIO_12V

12345

C2095

1

25V

2012

R2210

6.8k

0.5%

1/16W

RN-CP

RN-CP

1/16W

0.5%

15k

R2143

4321

V-

A+ IN

NJM4558V-TE2

IC2006

B- IN

B+ IN

%

CP

6W

k

145

R2211

6.8k

1/16W

2133

RN-CP

22k

/16W

0.5%

SP_MUTE

R2239

R2238

1k

1k

1/16W

1/16W

RN-CP

RN-CP

0.5%

0.5%

025

TUT106

2026

14TUT106

HDMI_MUTE

IC2005

PQ200WNA1ZPH

VIN

VC

VOUT

C2094

100p

50V

CH

1608

A OUT

A- IN

V+

B OUT

8765

C2096

100p

50V

CH

1608

R2246

3.3k

1/16W

CHIP

5%

Q2030

RT1N141M-TP-1

VADJ

GND

1/16W

RN-CP

R2228

1/16W

RN-CP

1/16W

RN-CP

C2097

0.1

25V

1608

Q2006

RT1N141M-TP-1

R2229

1k

0.5%

6.8k

0.5%

R2227

2.2k

0.5%

R2277

100k

1/16W

C2190

C2191

4.7

4.7

25V

25V

X7R

X7R

C2101

0.001

50V

X7R

R2279

100k

1/16W

R2148

R2149

47k

22k

1/16W

1/16W

R2150

22k

1/16W

R2147

1k

1/16W

5

Q2010

HN1B01FU-TE85R

SP_SD

C2102

0.001

50V

X7R

4

6

AU_HP12V

C2103

4.7

25V

C2106

4.7

25V

1

2

3

R2163

47k

1/16W

Q2009

RT1N141M-TP-1

C2105

C2104

4.7

25V

4.7

25V

R2151

1/16W

AU_13V

AUDIO_13V

12

40

P40

ROUTN

LOUTN

P21

39

ROUTN

LOUTN

C2118

0.001

50V

X7R

P39

38

P22

C2120

0.22

25V

B

2012

C2119

B

P38

BSRN

BSLN

P23

L2016

22uH

25V0.22

2012

P37

37

GND

PVCCR

PVCCR

PGNDR

PGNDR

VCLAMPR

VCLAMPL

PGNDL

PGNDL

PVCCL

PVCCL

GND

24

P24

C2121

0.001

50V

X7R

GND

GND

GND

C2123

470

25V

D2014

MA8091-M-TX

TO DETECT

R2198

6.8k

Q2013

RT3AMMM

C2153

XX

C2154

XX

1/16W

C2145

1

R2177

25V

100k

1/16W

2012

C2146

1

R2178

25V

100k

1/16W

FB2006

0uH

FB2007

0uH

FB2008

0uH

FB2009

0uH

2012

GND

C2147

XX

C2148

XX

4

1

23

L2022

22uH

4

1

23

L2023

C2124

100

35V

C2125

P36

P35

P34

P33

P32

P31

P30

2930313233343536

P29

P28

P27

P26

25262728

P25

0.1

25V

B

1608

C2126

1

25V

2012

C2127

1

25V

2012

C2129

0.1

25V

B

1608

C2128

22uH

C2132

0.22

25V

B

2012

100

35V

4

1