Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDF-46E2000

KDF-46E2010

KDF-50E2000

KDF-50E2010

KDF-55E2000

KDF-55E2010

RM-YD010 US/CND

RM-YD010 MEXICO

RM-YD010 US/CND

RM-YD010 MEXICO

RM-YD010 US/CND

RM-YD010 MEXICO

LA-4

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 5/2006

REVISION DATE SUBJECT

5/2006 No revisions or updates are applicable at this time.

6/2006 Replaced Pages 70, 72, & 73 to include Power supply note.

:UPDATED ITEM

☛

LCD PROJECTION TELEVISION

9-883-709-02

Page 2

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDF-46E2000

KDF-46E2010

KDF-50E2000

KDF-50E2010

KDF-55E2000

KDF-55E2010

RM-YD010 US/CND

RM-YD010 MEXICO

RM-YD010 US/CND

RM-YD010 MEXICO

RM-YD010 US/CND

RM-YD010 MEXICO

LA-4

CHASSIS

9-883-709-02

KDF-50E2010 RM-YD010

LCD PROJECTION TELEVISION

Page 3

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 6

Safety Check-Out ........................................................................... 7

Self-Diagnostic Function ................................................................. 8

SECTION 1: DISASSEMBLY ............................................................... 14

1-1. Overview .............................................................................. 14

1-2. Rear Cover Removal ............................................................ 15

1-3. Chassis Removal and Service Position ............................... 16

1-4. G Board Removal ................................................................. 16

1-5. B Block Assembly, A Block Assembly, Antenna,

U Board and K Board Removal ............................................ 17

1-6. Lamp Block Assembly and Optical Block Removal .............. 18

1-6-1. Lamp Connector and T2 Board Removal ................ 19

1-6-2. Lamp Driver Fan Removal ....................................... 20

1-7. HC Board Removal .............................................................. 21

1-8. HA Board and HB Board Removal ....................................... 21

1-9. Screen Frame Assebmly and Speaker Removal ................ 22

1-10. Mirror Assembly and Mirror Cover Assembly Removal ........ 23

Wire Dressing ....................................................................... 24

Caution Points ...................................................................... 42

SECTION 2: CIRCUIT ADJUSTMENTS .............................................. 49

2-1. Using the Remote Commander for Electrical Adjustments .. 49

2-2. Accessing Service Adjustment Mode ................................... 49

2-3. Viewing the Service Menus .................................................. 49

2-4. Using the Remote Commander to Change Service Data .... 50

2-4-1. Exiting Service Mode ............................................... 51

2-5. Verifying Service Data Changes .......................................... 51

2-6. Resetting Wega (User) Menu to Factory Defaults ............... 51

2-7. H/V Center Confi rmation and Adjustments .......................... 52

2-8. IRIS Adjustments .................................................................. 52

SECTION 3: DIAGRAMS ..................................................................... 53

3-1. Circuit Boards Location ........................................................ 53

3-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 53

3-3. Signal Flow Block Diagram .................................................. 55

3-4. Schematics and Supporting Information .............................. 56

A Board Schematic Diagram ................................................ 56

B Board Schematic Diagram (1 of 11) .................................. 58

B Board Schematic Diagram (2 of 11) .................................. 59

B Board Schematic Diagram (3 of 11) .................................. 60

B Board Schematic Diagram (4 of 11) .................................. 61

B Board Schematic Diagram (5 of 11) .................................. 62

B Board Schematic Diagram (6 of 11) .................................. 63

B Board Schematic Diagram (7 of 11) .................................. 64

B Board Schematic Diagram (8 of 11) .................................. 65

B Board Schematic Diagram (9 of 11) .................................. 66

B Board Schematic Diagram (10 of 11) ................................ 67

B Board Schematic Diagram (11 of 11) ................................ 68

G Board Schematic Diagram (1 of 2) ................................... 70

G Board Schematic Diagram (2 of 2) ................................... 71

HA Board Schematic Diagram ............................................. 74

HB Board Schematic Diagram ............................................. 76

HC Board Schematic Diagram ............................................. 78

K Board Schematic Diagram ................................................ 80

S2 Board Schematic Diagram .............................................. 83

T1 Board Schematic Diagram .............................................. 86

T2 Board Schematic Diagram .............................................. 86

U Board Schematic Diagram ................................................ 91

3-5. Semiconductors ................................................................... 93

SECTION 4: EXPLODED VIEWS ........................................................ 94

4-1. Covers .................................................................................. 94

4-2. Chassis ................................................................................ 95

4-3. Optics Unit Block Assembly and Lamp Assembly ................ 96

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

SECTION 5: ELECTRICAL PARTS LIST ............................................ 97

APPENDIX A: REPLACING THE LAMP ............................................A-1

3

Page 4

SPECIFICATIONS

p

)

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Power Requirements

Power Consumption (W)

In Use (Max)

In Standby

Inputs/Outputs

120V AC, 60Hz

200W

Less than 0.8W

HDMI IN

2 Video - 1080i, 720p, 480p, 480i

1 Audio - Two channel linear PCM 32, 44.1 and 48 kHz,

16, 20, and 24 bit

Video (IN)

3 total (1 on side panel)

1Vp-p, 75ohms unbalanced, sync negative

S Video (IN)

1 total

Y: 1Vp-p, 75ohms unbalanced, sync negative

C: 0.286Vp-p (Burst signal), 75ohms

Audio (IN)

5 total (1 on side panel)

500 mVrms (100% modulation)

Impedance:47 kilo ohms

KDF-46E2000

KDF-46E2010

Component Video Input

3 (Y, P

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

P

PR: 0.7 Vp-p, 75 ohms

Audio (VAR/FIX) Out

1 total

500 mVrms at the maximum volume setting

(Variable)

500 mVrms (Fixed)

Impedance (Output):2 kilo ohm

RF Input

2 total

Digital Audio Optical Output (PCM/Dolby Digital)

1 total

Optical Rectangular

) (1 on Side Panel)

B/CB

:

0.7 Vp-p, 75 ohms;

B

KDF-50E2000

KDF-50E2010

KDF-55E2000

KDF-55E2010

S

eaker Output(W

Dimensions (W x H x D)

mm 1096 x 766 x 382 mm 1184 x 827 x 408 mm 1301 x 907 x 442 mm

in

43

1/4

x 30

1/4

x 15

1/8

in 46

Mass

kg 27 kg 29.3 kg 34 kg

lbs 59 lbs 5 oz 64 lbs 7 oz 75 lbs

Trademark Information

As an ENERGY STAR® Partner, Sony

Corporation has determined that this product

meets the ENERGY STAR

®

guidelines for

energy efficiency.

ENERGY STAR

TruSurround XT, SRS and the ( )

®

is a U.S. registered mark.

®

symbol are

trademarks of SRS Labs, Inc. TruSurround XT

technology is incorporated under license from SRS Labs, Inc.

This TV is manufactured under license from Dolby

Laboratories. “Dolby” and the double-D symbol are

trademarks of Dolby Laboratories.

KDF-46E2000/50E2000/55E2000 KDF-46E2010/50E2010/55E2010

WEGA, Grand WEGA, WEGA GATE, Steady Sound,

Digital Reality Creation and CineMotion

are registered trademarks of Sony Corporation.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

12W (L), 12W (R)

5/8

BBE and BBE Symbol are trademarks of BBE Sound,

Inc. and are licensed by BBE Sound, Inc. under U.S.

Patent No. 4,638,258 and 4,482,866.

(HDMI

Definition Multimedia Interface are trademarks or

registered trademarks of HDMI Licensing LLC.

Macintosh is a trademark licensed to Apple Computer, Inc.,

registered in the U.S.A and other countries.

“BRAVIA” and are trademarks of Sony Corporation.

x 32

5/8

x 16

1/8

in 51

1/4

x 35

3/4

x 17

1/2

in

This TV incorporates High-

™

) technology. HDMI, the HDMI logo and High-

Definition Multimedia Interface

Design and specifi cations are subject to change without notice.

4

Page 5

Television system

American TV standard, NTSC

ATSC Compliant 8VSB, ATSC (8VSB terrestrial)

ANSI/SCTE 07 2000, QAM on cable

Channel coverage

Terrestrial 2-69/ Cable TV: 2-125 (analog)

Terrestrial 2-69/ Cable TV: 2-135 (digital)

Screen Size (measured diagonally)

46 inches (KDF-46E2000/46E2010 Only)

50 inches (KDF-50E2000/50E2010 Only)

55 inches (KDF-55E2000/55E2010 Only)

Antenna

75-ohm external antenna terminal for VHF/UHF

Projection System

3 LCD Panels, 1 lens projection system

LCD Panel

0.73 inch TFT LCD panel

(1,280 x 720 pixels)

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Projection Lens

High Performance, large diameter hybrid lens F2.4

Lamp

100W, XL-2400 Ultra High Pressure Lamp

Supplied Accessories

Remote Commander RM-YD010

Two Size AA (R6) Batteries

Operating Instructions

Quick Setup Guide

Warranty Card

Product Registration Card

Optional Accessories

HDMI Cable

HDMI-to-DVI Cable

Component Video Cable

S VIDEO Cable

A/V Cable

Audio Cable

TV Stand:

SU-RG12S (KDF-46E2000/46E2010 Only)

SU-RG12L (KDF-50E2000/50E2010/55E2000/55E2010 Only)

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

5

Page 6

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

WARNINGS AND CAUTIONS

CAUTION

These servicing instructions are for use by qualifi ed service personnel only. To reduce the risk of electric shock, do not perform any

servicing other than that contained in the operating instructions unless you are qualifi ed to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe

operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Ces instructions de service sont à l’usage du personnel de service qualifi é seulement. Pour prévenir le risque de choc électrique, ne

pas faire l’entretien autre que celui contenu dans le Mode d’emploi à moins que vous soyez qualifi é faire ainsi.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces

sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont le numero

de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont l’importance

est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de chaque

remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

6

Page 7

SAFETY CHECK-OUT

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

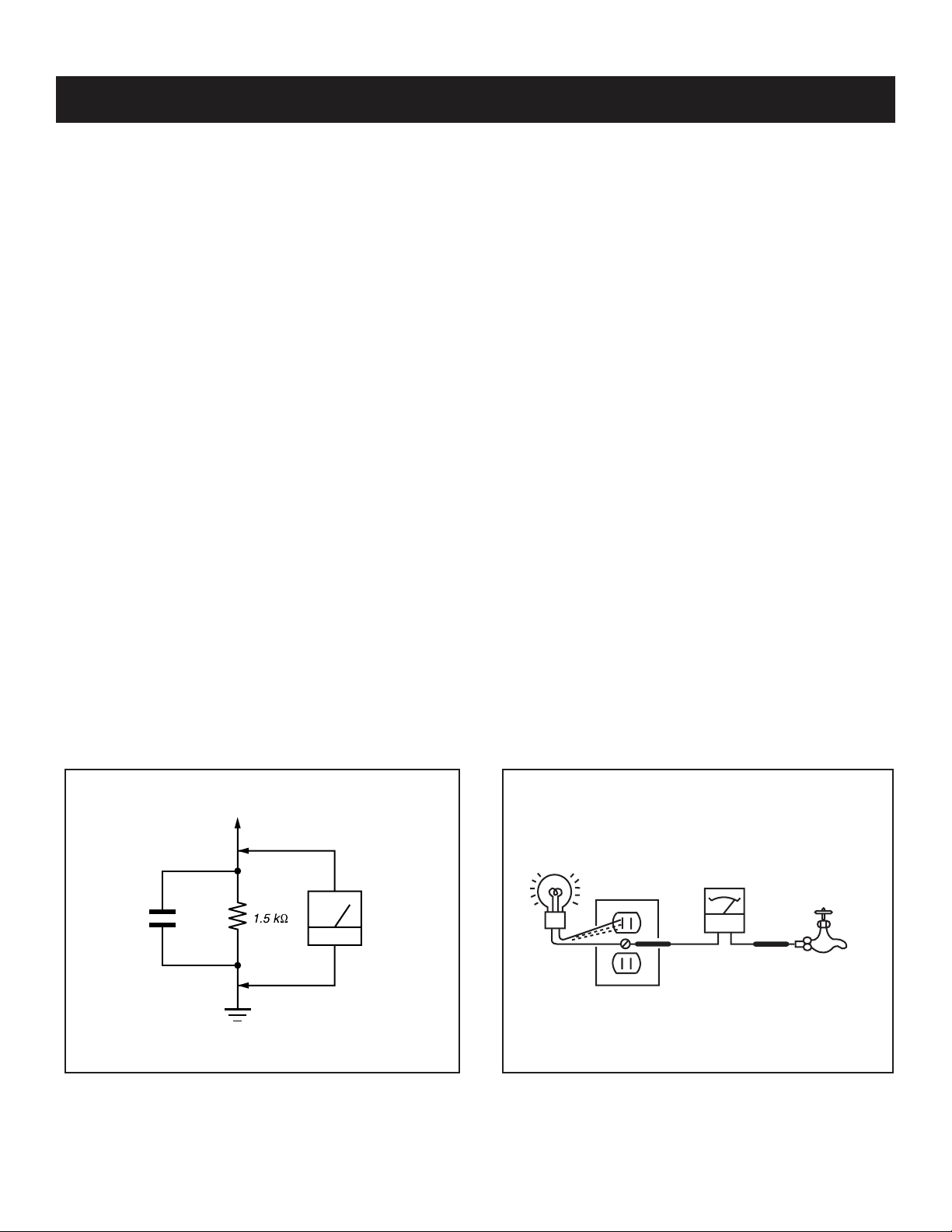

Leakage Test

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

To Exposed Metal

Parts on Set

AC

0.15 µF

Earth Ground

Voltmeter

(0.75V)

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

7

Page 8

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

SELF-DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the POWER/STANDBY will automatically begin to fl ash. The number of

times the LED fl ashes translates to a probable source of the problem. A defi nition of the POWER/STANDBY fl ash indicators is listed in the instruction

manual for the user’s knowledge and reference. If an error symptom is diffi cult to reproduced use the Remote Commander to display the record that is

stored at the internal NVM to specify the cause of the failure.

Diagnostic Test Indicators

When an error occurs, the POWER/STANDBY will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the POWER/STANDBY will identify the fi rst of the problem areas. If the errors occur simultaneously, the one that corresponds to the fewest

fl ashes is identifi ed fi rst.

Results for all of the following diagnostic items are displayed on screen. (No error has occurred if the screen displays a “0”.)

Diagnosis Item

Temp error

Lamp cover /

Lamp position error

Fan error

Number of times

POWER/STANDBY

indicator blinks

2 times

3 times

4 times

Probable Cause/

Location

- Set temperture is high.

- Temp sensor connector

is not attached securely.

(CN110 on HB board,

CN160 on S2 board)

- Lamp cover is not

securely attached (T1 Bd)

-Lamp is not inserted

properly (T2 Bd)

- Fan 1-4 power is not

supplied. (B board)

-F

an connector is not

securely attached ..

-Fan caught wires or

harnesses.

- No Picture/No sound

- No Picture/No sound

- No Picture/No sound

Self Diagnosis

Detected symptoms

Supported model

Lamp driver error

LowB LVP

Thermal Fuse Open

LowB OVP

Lamp Error LAMP-LED flashes

5 times

6 times

8 times

-Lampdriverisfaulty.

- Check 10.5V audio IC

(B Board)

-B -10.5V is over voltage.

(B board)

- Lamp is burnt out.

- No Picture/No sound

- Relay click on/off

- No Picture/No sound

- No Picture/No sound

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

8

Page 9

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

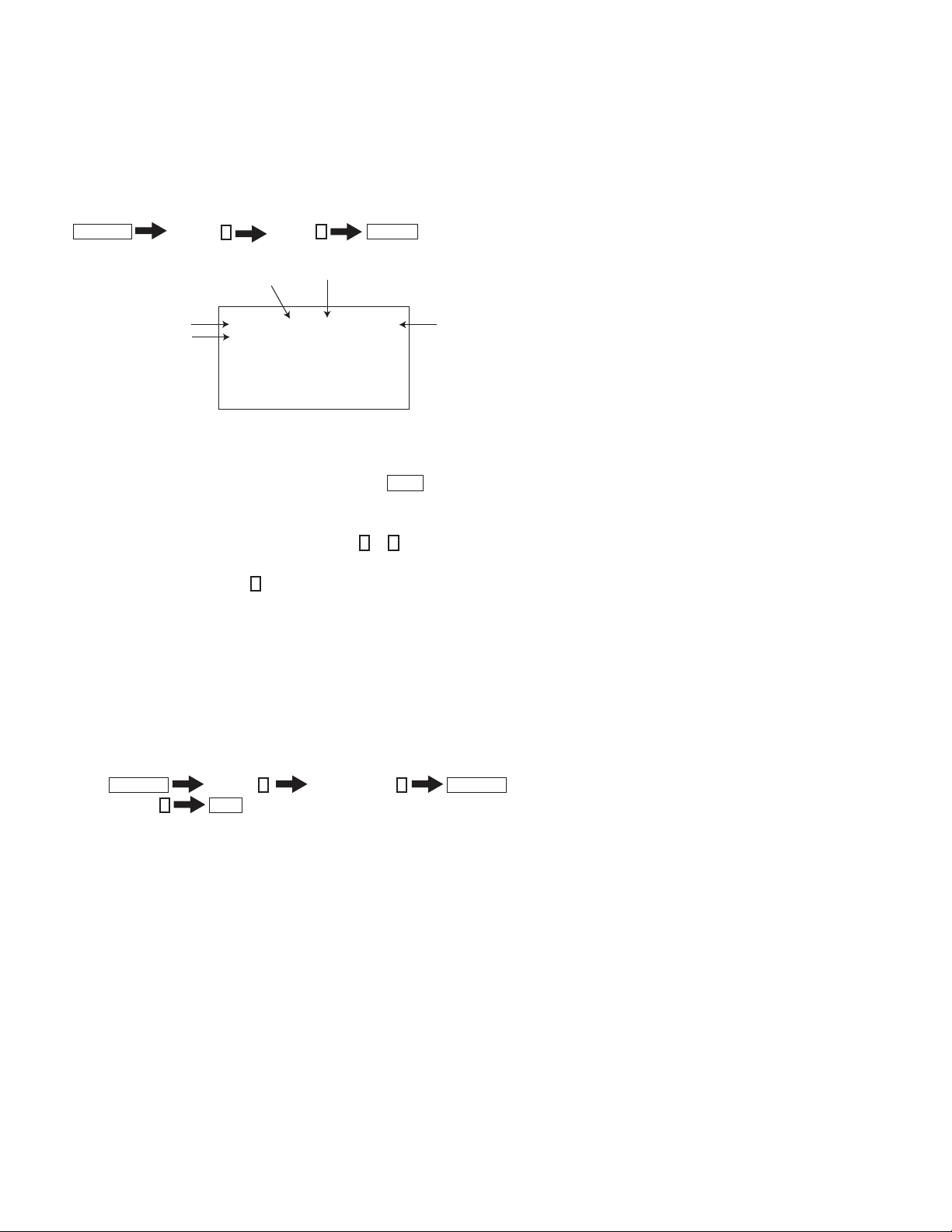

DISPLAY OF POWER/STANDBY OR LAMP LED FLASH COUNT

POWER/STANDBY

TIMER LAMP

PUSH OPEN

- One flash is not us ed for self- diagnosis.

Example

Diagnosis

Number of times LED Flash

Lamp cove r 3 times

Fan 4 times

LED ON : 0.3 se c

LED OFF : 0.3sec

Indicators

POWER

LED OFF

Screen

3.0 sec

LED OFF

3.0 sec

RELEASING THE POWER/STANDBY LED FLASH

Unplug the power cord from the outlet to temporarily stop the POWER/STANDBY lamp from fl ashing.

Self-Diagnostic Screen Display

For failures that are diffi cult to reproduce, or accompany occasional power off and/or picture mute, the Self-Diagnostic screen display is useful to

specify the cause.

VIEWING THE SELF-DIAGNOSTIC SCREEN

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a second of each other:

DISPLAY

Channel

5

Volume -

NOTE: This differs from the method of accessing service mode which is Volume

Sample Self-Diagnostic Screen Display

SELF CHECK

1 : LAMP_ERR 0

2 : Lamp Temp Over 0

3:

LAMP_ COVER

FAN_ERR 1

4:

5 : LAMP_DRIVER

0

0

6 : LowB-ERROR 0

8 : D_OVP 0

POWER

+

"1" is displayed when an error is detected one or more times

"0" is displayed when no error has been detected

WDT101 : 0

Name: KDF-50E2000

Serial: XXXXXXX

NOTE: To refresh the Self Check menu when all the items are not displayed, press

JUMP

3. Proceed to Viewing the Self-Diagnostic Errors.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

on the Remote Commander.

9

Page 10

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

VIEWING THE SELF-DIAGNOSTIC ERRORS

The TV MICRO service menu contains a Log category that stores the errors. To view the fi rst error detected, display the SHUTDOWN_LOG1

Adjustment Item of the STATUS category. If other errors are detected, they are stored in the SHUTDOWN_LOG2 Adjustment Item of the STATUS

category.

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a second of each other:

DISPLAY

Channel 5 Volume +

Item Number

POWER

Data Value

.

Category

Adjustment

Item

VERSION 0 0 SERVICE

VERS Wide Zoom Video 1

F/A: 00000000 00000000

CBA: 00000000 00000000

WSL: 480I

Service

Menu

3. Do one of the following:

a. If the TV MICRO Service Menu is displayed, proceed to the next step.

b. If the TV Micro Service Menu is not displayed, press

JUMP

on the Remote Commander until the TV MICRO service menu is displayed.

4. Do one of the following:

a. If the STATUS Category is displayed, proceed to the next step.

b. If the STATUS Category is not displayed, press 2 or 5 on the Remote Comman until the STATUS Category is displayed.

5. The SHUTDOWN_LOG1 Adjustment Item is the fi rst item of the STATUS Category and contains the fi rst error the set detected.

6. To view additional errors, press 1 until the SHUTDOWN_LOG2 Adjustment Item is displayed

7. After repairing the errors, proceed to Clearling the Self-Diagnostic Screen.

CLEARING THE SELF-DIAGNOSTIC SCREEN

The self-diagnostic results displayed on the screen are not cleared automatically, therefore you should always check the self-diagnostic screen during

repairs. When you have completed the repairs, clear the self-diagnostic screen to reset the results to “0”.

Note: The self-diagnostic function will not be able to detect any subsequent faults after completion of the repairs unless the Self-Diagnostic

result display is cleared to reset the results to “0”.

1. If the Self-Diagnostic screen is already displayed, proceed to step 3. If not, Power off (Set to Standby mode).

2. Press

3. Press Channel 8

DISPLAY

Channel

ENT

5

Sound Volume -

The status in the upper right corner changes to “WRITE”. When the operation is complete, the status returns to “SERVICE” and the Self-Diagnostic

screen is reset.

4. To exit the Self-Diagnostic screen, turn the power off.

POWER

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

10

Page 11

SELF-DIAGNOSTIC FUNCTION OPERATION

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

11

Page 12

SELF-DIAGNOSTIC BLOCK DIAGRAM

G BOAR D B BOARD

CN6800

FAN 1

FAN 2

FAN 3

3

CN6805

3

CN6801

2

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

IC3002

TV Micro-computer

FAN 4

S2 BOARD

IC160

TEMP

SENSOR

HB BOARD

IC110

TEMP

SENSOR

T2 BOARD

SW

CN6802

2

CN6804

9

3

8

1

CN6904

I2C

I2C

2

CN3002

2

137

I_FAN_PROT

I2C

I2C

LB-ERROR

D_OVP

129

126

10.5V

T1 BOARD

10

1

CN6904

SW

LAMP DRIVER

HV-DET

11

3

CN6803

1

7

12

10

6

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

CN3002

12

10

6

150

151

152

I_LAMP_COVER

I_LAMP_PROT

I_HV_DET

12

Page 13

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

READING LAMP AND PANEL TIME

The TV_Micro menu of the Service Menu displays the current lamp and

panel time of a set. The Lamp Hours and Panel Hours are shown in

hexadecimal format.

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a

second of each other:

DISPLAY

One of the three Service Menu displays. (For more information

regarding the Service Menus, see

2-2. Accessing Service Adjustment Mode.)

3. To read the Lamp time, press 4 to display the TIME category and the

LMPH item.

Channel 5 Volume +

VERSION 00 SERVICE

VERS Wide Zoom Video 1

WSL: 480I

POWER

The screen displays:

TIME 0 0 SERVICE

LMPH

LMPH: 01H LMPL: A0H

Wide Zoom TV

.

RESETTING THE LAMP TIME

When replacing the lamp, use the following to reset the lamp time.

1. If the Self-Diagnostic screen is already displayed, proceed to step 4.

If not, Power off (Set to Standby mode).

2. Press

3. To access the Lamp reset, press 5 until the TIME category displays.

4. Press 1 until the RSET item displays.

5. To reset the Lamp time, press 3 to change the data value to 1.

6. Press

DISPLAY

POWER

MUTING

Channel

TIME 0 0 SERVICE

RSET

TIME 0 1 SERVICE

RSET

TIME 0 1 WRITE

RSET

Wide Zoom TV

Wide Zoom TV

ENT

Wide Zoom TV

5

Sound Volume -

to write the change into memory.

Total hours 256 Total hours 160

Total LAMP TIME is 416 hours

4. To read the Panel time, press 4 to display the PHLH item.

The screen displays:

TIME 0 0 SERVICE

PNLH

PNLH: 01H PNLL: A0H

Wide Zoom TV

Total hours 256 Total hours 160

Total PANEL TIME is 416 hours

5. Do one of the following:

a. If you have replaced the lamp, proceed to step 4 of “Resetting the

Lamp Time”.

b. If you have not replaced the lamp, turn off the set by pressing

POWER

6. To verify the Lamp has been reset press 5 until the TIME category

displays, and then press 1 until the LMPH item displays.

NOTE: You cannot reset the Panel time with the Service menu.

EXITING SERVICE MODE

After completing the changes, exit service mode by turning off the set

using the Remote Commander or the power switch.

NOTE: After exiting service mode wait 2 minutes before restarting

the set to allow the fans to shut down properly.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

13

Page 14

1-1. OVERVIEW

TOOLS NEEDED

Long Phillips Screwdriver

Needle Nose Pliers

Small Flathead Screwdriver or Jewelers Screwdriver

The connectors in the MIX5 chassis have been redesigned to ensure they are securely fasten to the boards. Please review the

illustrations below.

Use caution not to rock the Type 2 or Type 3 connectors when removing or reinstalling to avoid breaking the solder leads off the

Printed Circuit Boards.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

SECTION 1: DISASSEMBLY

TYPE 1

LIFT ONE SIDE AT A TIME

BY PUSHING TAB IN WITH

SMALL SCREWDRIVER

TYPE 2

SQUEEZE DOWN ON

TAB TO RELEASE

TYPE 3

SQUEEZE LOCKING TAB

TOWARDS CONNECTOR

BEFORE PULLING FREE

CAUTION! IF THE TYPE 2 FEMALE

CONNECTOR HAS A SLOT (AS SHOWN)

MAKE SURE THE LOCK TAB SEATS INSIDE

THIS SLOT.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

14

Page 15

1-2. REAR COVER REMOVAL

1

Pull down the claw to release the Lamp Door

2

Remove the Lamp Door

3

Remove 13 screws (+BVTP2 4X16)

to remove the Rear Cover

1

Lamp door

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

3

When reassembling the rear cover, be sure to securely lock

the lamp door to avoid a lamp cover failure warning.

2

Lamp door

Lamp door

Turn the handle until it is in

the CLOSE position

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

15

Page 16

1-3. CHASSIS REMOVAL AND SERVICE POSITION

1

Remove 2 screws to release the Left Stay

2

Disconnect CN8400 from U Board

3

Disconnect CN2500 from K Board

4

Release wires from purse locks

5

Gently pull chassis out towards the right of the TV to access

connectors on B Block Assembly.

6

Disconnect CN308 and CN3750 on B Block Assembly

7

Release connectors from Wire Holders

8

Remove 4 screws to release the G Board

9

Remove 6 screws to detach Metal Shield from G Board

2

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

4

1

3

9

8

7

5

6

1-4. G BOARD REMOVAL

Using the picture above as a reference, disconnect CN6018,

CN6801, CN6804, CN6803, CN6800, CN6805, CN6900,

CN6901, CN6009, CN6002, CN6904, and CN6010.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

16

Page 17

1-5. B BLOCK ASSEMBLY, A BLOCK ASSEMBLY, ANTENNA,

U BOARD AND K BOARD REMOVAL

1

1

Remove 6 screws and 2 hexagon washers

Terminal Bracket from the U Board.

On the U Board, disconnect CN8400 then using a fl at

head screw driver gently release the CN3006 connector

from the B Board to remove the U Board.

2

Disconnect the coaxial cable to release the antenna

switch. Remove 3 screws then gently lift the A Block

Assembly up to disconnect CN1002 from the B Block

Assembly.

3

Using caution remove the LVDS cable from the B Board,

then remove 1 screw (connecting the B Block Assy & K

Board to the Main Bracket) and lift up on the tab of the

Main Bracket to release the B Block Assembly.

4

Using tweezers gently pinch the fan dampers to release

the fan.

5

On the K Board, disconnect CN2502 then remove 1

screw to release the K Board. Gently pull the K Board out

of the Main Bracket.

to

release the

U Board

B Block Assembly

5

K Board

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

2

A Block Assembly

LVDS Connection

3

4

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

17

Page 18

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

1-6. LAMP BLOCK ASSEMBLY AND OPTICAL BLOCK REMOVAL

Note: Remove the Lamp door and Lamp before removing the Lamp Block Assembly

(See “Replacing the Lamp” in the Appendix section of this service manual.)

1

Remove 2 screws to release the Right Stay.

2

Disconnect CN150 T1 Board

3

Disconnect CN155 T2 Board

4

Disconnect the Termal Fuse connector.

5

Disconnect CN160 S2 Board

6

Remove 2 screws then pull out the fan cover.

7

Turn the fan cover over to remove the T1 Board and S2

Board.

8

Using caution remove the LVDS cable and 2 screws.

9

Remove 2 screws to release the Lamp Block Assembly and

the Optical Block assembly from the cabinet.

0

Gently pull the Lamp Block Assembly and the Optical Block

Assembly out of the cabinet.

11

Turn the assemblies around 180 degrees and release the

high voltage lead from the purse lock.

2

1

6

3

4

5

T1Board

7

9

S2 Board

8

0

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

11

18

Page 19

1-6-1. LAMP CONNECTOR AND T2 BOARD REMOVAL

1

Pull retaining clip outward to release and drop the high

voltage connector and the T2 Bracket.

2

Separate the HV Connector from the bracket

3

Remove 1 screw to release the T2 Board.

1

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

2

1

3

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

19

Page 20

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

20

Lamp duct cover

Note position of wires

Note: Watch for

fan grommets

NOTE:

Reinsert the

fan grommets

when replacing

the fan

2

3

4

5

6

1

1

From the inside of the assembly, release the 3 claws

securing the fan duct, then remove the fan duct by grasping

as shown.

Remove 1 screw.

Release 3 clips to detach cover.

Remove Fan.

Release wire from wire holders.

Remove 2 screws.

2

3

4

5

6

Page 21

1-7. HC BOARD REMOVAL

1

Remove 2 screws to detach the H2 Bracket.

2

Disconnect connector.

3

Remove 2 screws.

4

Lift out to remove HC Board.

3

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

1

4

1-8. HA BOARD AND HB BOARD REMOVAL

1

Remove 2 screws from inside the front panel.

2

Using a screwdriver, gently push through the hole to

release the speaker grill.

3

Firmly pull on the speaker grill to detach from the cabinet.

4

Disconnect CN7000 and remove 2 screws to release the

HA Board

5

Disconnect CN7020 and remove 2 screws to release the

HB Board

2

1

HA Board

4

HB Board

5

3

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

21

Page 22

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

1-9. SCREEN FRAME ASSEBMLY AND SPEAKER REMOVAL

CAUTION: When removing the Screen Frame Assembly be sure to clean the Mirror and Diffusion Plate(s) to remove any dust particles.

1

Release the wire harness from the purse locks.

2

Disconnect the CN2500 from the K Board.

3

Remove 15 screws to detach the Mirror Cover Assembly

from the Screen Frame Assembly.

4

Remove 4 screws to detach the Screen Frame Assembly

from the front bezel.

5

Gently pull the Screen Frame Assembly forward.

6

Remove 20 screws from the screen frame to release the

disfussion plates. Be sure to keep the retaining brackets.

7

To remove the speakers, remove 2 screws and release the

speaker wires.

1

2

5

3

4

6

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

7

7

22

Page 23

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

1-10. MIRROR ASSEMBLY AND MIRROR COVER ASSEMBLY REMOVAL

CAUTION: When removing the Mirror Cover Assembly be sure to clean the Mirror and Diffusion Plate(s) to remove any dust particles.

1

Remove 4 screws to release the 2 top mirror brackets.

2

Remove 3 screws to release the mirror holders (46” & 50”

models only)

3

Using caution gently lift the mirror up and out of the mirror

cover. (Slide the mirror up and to one side on the 55” model

to release it from the mirror holders.)

4

Remove 4 screws to detach the front of the Mirror Cover

Assembly from the cabinet.

5

Remove 2 screws from back of the cover and then lift the

Mirror Cover Assembly off of the cabinet.

3

1

2

4

5

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

23

Page 24

WIRE DRESSING

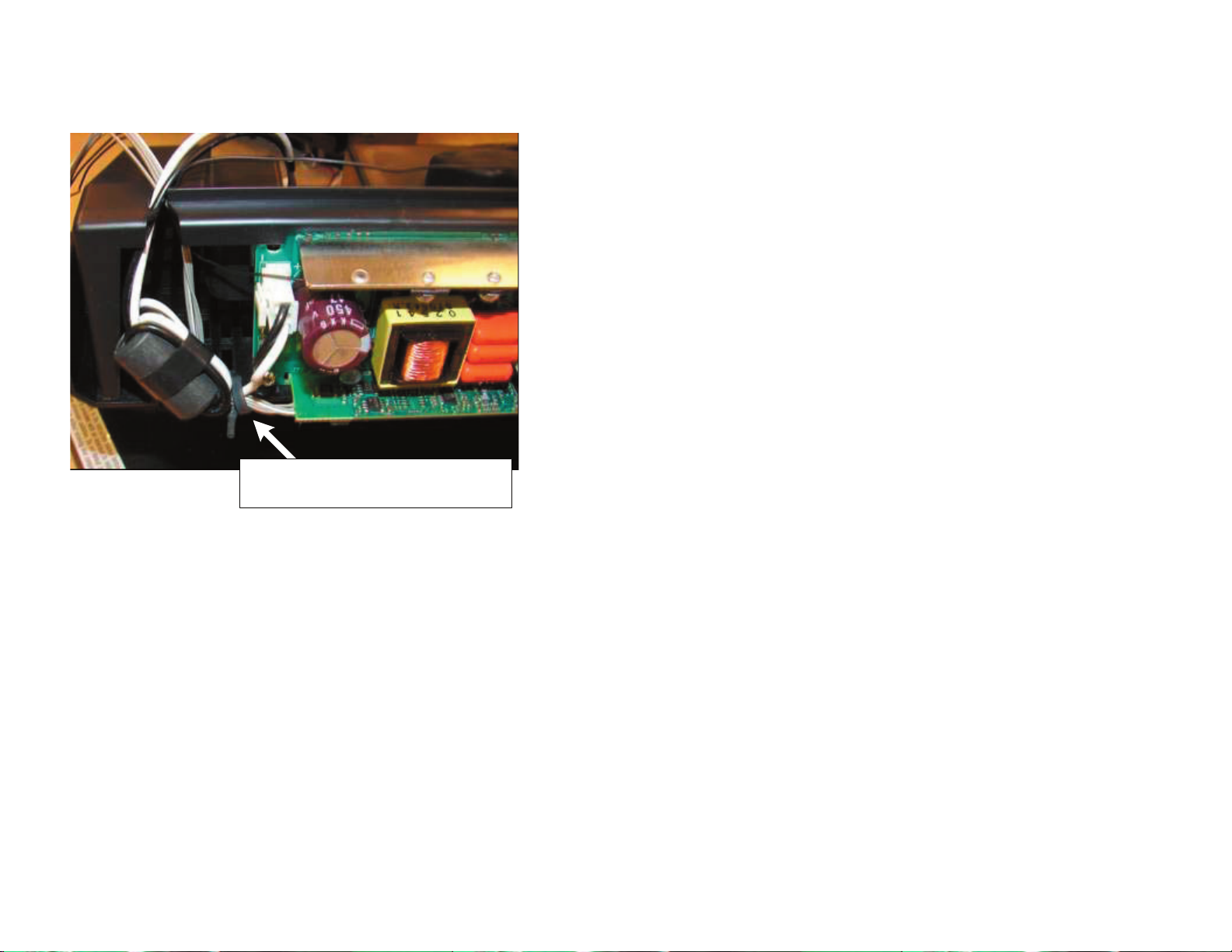

BALLAST WIRE DRESSING

“Top” Lead

Dress Lamp Driver Leads as shown

below to wire holders.

Dress "Bottom" Lamp Driver Lead as

shown to wire holder on Duct Block Assy

“Bottom”

Lead

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

After Installing Duct Block assy to

Optical Block Dress “TOP” Lamp Lead

to Purse Lock on [C] Shield

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

1-910-024-31 Connector Assy should be

dressed around Heat Sink and around Duct

Block Cover as shown above.

24

Page 25

BALLAST WIRE DRESSING (CONTINUED)

1-910-024-31 Connector Assy should be

dressed around Heat Sink and around Duct

Block Cover as shown above.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

25

Page 26

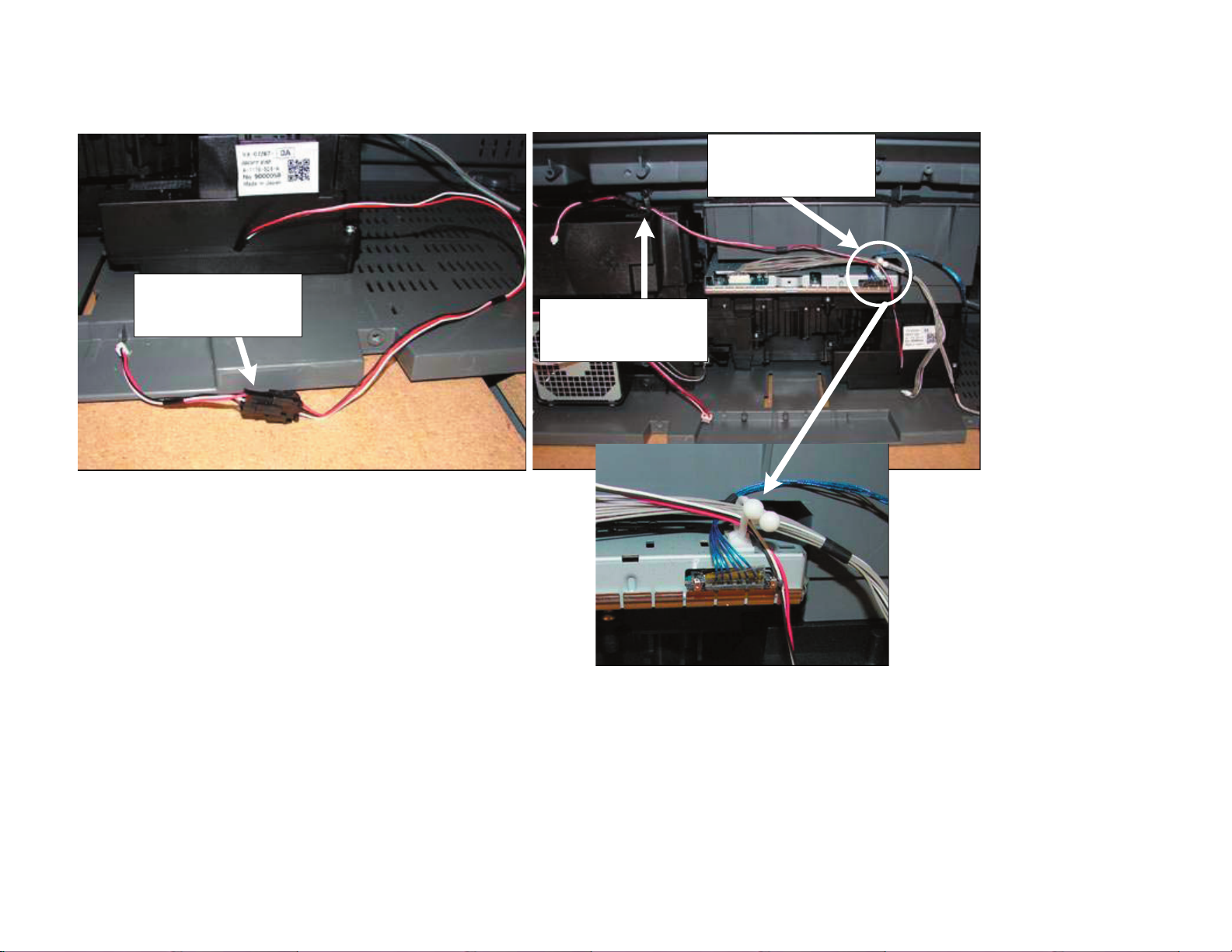

BOTTOM BLOCK WIRE DRESSING

Before installing chassis

Dress CN3004[B],

CN8400[U], and CN3008[B]

to purse lock on bottom

block as shown.

Loop Video 2 Connector

before installing into Purse

Lock as shown to avoid

Connector assy from

Touching [K] Board Heat

Sink.

ONLY FOR 46" and 50"

models

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Install Ferrite Clamp

154383011 to the following

Connector Assys

1. Speaker Conn Assy

2. HA/HB Conn Assy

3. HC Conn Assy

26

Page 27

C BLOCK WIRE DRESSING

Install Conn Assy

1-910-024-21 to "FAN1"

Optical Block Fan.

Route Optical Block Fan

to Wire Holder to avoid

being “Pinched” when [G]

Shield is installed

Dress 15P CN9000 [C]

LVDS Connector and Fan

Connector to Purse Lock

on [C] Shield

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

27

Page 28

CHASSIS WIRE DRESSING

Dress [B] Block Fan and [K] Board Connector Assy to Purse

Lock on [B] Block as shown above.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

DUCT BLOCK ASSEMBLY WIRE DRESSING

Dress the following

Connector Assys to

Purse Lock on Duct Block

Assy :

1. CN150 [T1]

2. X1 (Ballast)

3. X2 (Ballast)

Note:

Duct Block Fan is not

installed to Purse Lock

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Dress the following

Connector Assys to Wire

Holder on Bottom Block:

1. 1-910-024-29

2. X1 (Ballast)

3. X2 (Ballast)

4. Duct Block Assy Fan

5. Optical Block Fan

Route Lamp Fan

“inside” of 1-910-024-29

and Inside of X2 (Ballast

Power)

28

Page 29

G BOARD WIRE DRESSING

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

1

G-Board Wire Pin Holders Instructions. There are (3)

wire pin Holders on the [G] board. See below to see

which wires are dressed to each wire pin holder

2

1. LVDS and 8P CN6009[G]

2. LVDS, 8P CN6009, and 7P CN3004[B]

3. LVDS and 7P CN3004[B]

Ensure wires are dressed to the side of the G Board

as shown.

3

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Install Purse Lock

404928101 PURSE LOCK (DIA.11)

Purse lock should hold the following:

32P Conn Assy [G] to [B]

3P Conn Assy [G] to [K]

3P Conn Assy [G] to ANT SWT

3P Conn Assy [G] to B-Blk FAN

After installing Purse Lock ensure “open” end is

facing towards the front of the set.

29

Page 30

OPTICAL BLOCK ASSEMBLY WIRE DRESSING

ROUTE IRS CONNECTOR AS SHOWN

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

APPLY HIMELONE TAPE TO SECURE IRIS CONNECTOR AS SHOWN ABOVE.

APPLY TAPE SO THAT THE CONNECTOR ASSEMBLY WILL NOT BE IN SHADED AREA ABOVE.

APPLY HIMELONE TAPE AS SHOWN ABOVE

AND DRESS IRIS CONNECTOR ASSY

TO WIRE HOLDER AS SHOWN BELOW

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

IF CONNECTOR ASSEMBLY IS IN THE SHADED

ARER IT WILL GET PINCHED BETWEEN THE

OPTICAL BLOCK ASSEMBLY AND THE BOTTOM

BLOCK ASSEMBLY WHEN INSTALLED.

30

Page 31

OPTICAL BLOCK ASSEMBLY LIGHTNING GROUND POSITION

1-910-016-90

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

x Secure Ring Terminal of 1-910-016-90 to G-Block as shown above.

x Install Faston Terminal to Antenna Switch.

Note: Orientation of ring terminal should be towards the top of the set.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

31

Page 32

SPEAKER GRILL WIRE DRESSING

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

For 55”, MUST use 2 screws

on each side (total 4 screws)

to secure Speaker Grill to

Screen Frame.

For 50” and 46” use

only 1 screws each

side (total 2 screws)

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

32

Page 33

SPEAKER GRILL WIRE DRESSING (CONTINUED)

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

See above for Connector Assy Routing of CN110 [HB]

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

See above for Connector Assy Routing of CN100 [HA]

33

Page 34

SPEAKER GRILL WIRE DRESSING (CONTINUED)

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Dress HA/HB Connector Assy to Wire holder as shown above.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

When routing HA/HB Connector Assy through Wire Holder

“RED” tape should be approximately in the position shown

above.

34

Page 35

SPEAKER GRILL WIRE DRESSING (CONTINUED)

-

h

s

t

C

3

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

NO Sound

Cushion on 55”

and 46” Speaker

Grill

1

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

2

1) Use Holder (M3), Wire 2

screw to wire dress as s

2) Wire must enter from the

Holder 2-599-956-01 as

3) Must pull wire to the righ

from wire assy (around

and Cable Holder area)

594-860-01 and 3x12

own

bottom of Cable

shown

t to minimize sound vib

ontrol Tray Bracket

35

Page 36

SPEAKER GRILL ASSEMBLY CUSHIONS

Add 2-638-237-02 Cushion, Sound (SF) to 55” Speaker Grill 2-671-852-

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Align Sound

(SF)

Cushion to

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

the lines as

shown

36

Page 37

SPEAKER WIRE DRESSING

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Dress Positive Tab of Speaker wire around speaker bracket

and then Himelon Tape should be installed to secure the wire

as shown.

Wire Should be pulled so that there is no excess wire.

THIS IS VERY IMPORTANT TO AVOID NOISE DUE TO

SPEAKER VIBRATION

a

Tape should wrap around bracket as shown to the right and

securely hold the speaker wire so that it does not move once

the tape is applied.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

37

Page 38

SPEAKER WIRE DRESSING (CONTINUED)

3 4

12

Speaker Bracket must be secured following the above Screw

Order.

On “Left” Speaker Secure Speaker

wire as shown below using

265206401 TAPE, HIMELON (20X40)

Note:

PCN MB607734 Shows different Tape position

please disregard that location and use above

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

38

Page 39

RIGHT SPEAKER WIRE DRESSING

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

39

Page 40

LEFT SPEAKER WIRE DRESSING

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

40

Page 41

LEFT SPEAKER WIRE DRESSING (CONTINUED)

All these applies for 55”, 46”

For 50”, this starts from MP set #1 (no

need to re-work PP and PVT sets)

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

41

Page 42

CAUTION POINTS

BOTTOM BLOCK ASSEMBLY HIMELON TAPE LOCATION

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Apply tape on B-Shield to keep

LVDS Connector Assy and 7P

CN3004 Connector on [B] from

being "pinched" when Chassis

is installed into Bottom Block

Connector Assy should be

pulled tight against fan Duct in

order to avoid vibration of wire

against bracket.

Himelon Tape should secure

the (2) connectors coming

from the Ballast, the Fan

connector assy and 3P

Connector Assy from T1

ONLY FOR 50" MODELS

Himelon Tape should secure

Duct Block Assy fan

Connector as shown

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

42

Page 43

BOTTOM BLOCK WIRE DRESSING CAUTION POINTS

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Before installing chassis Dress CN3004[B],

CN8400[U], and CN3008[B] to purse lock on

bottom block as shown.

Loop Video 2 Connector before installing

into Purse Locak as shown to avoid

Connector assy from Touching [K] Board

Heat Sink.

ONLY FOR 46" and 50" models

After dressing Speaker Wire, HA/HB Connector Assy

and HC Connector assy to Bottom Block.

REMOVE as much excess slack in wires and dress to

Purse Lock.

Ensure no excess wire is hanging loose in

this area.

THIS IS VERY IMPORTANT TO AVOID

NOISE DUE TO SPEAKER VIBRATION

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

43

Page 44

CHASSIS WIRE DRESSING CAUTION POINTS

-Install Angled Purse

Lock to C Shield as

shown to the right.

-Dress 15P connector

Assy, LVDS Connector

Assy and Optical Block

Fan Connector Assy to

Purse Lock as shown.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

435591211

PURSE LOCK (DIA. 11)

265206401

TAPE, HIMELON (20X40)

-Apply Himelon to [K]

Board Power Connector

Assy and tape to B

–Shield as shown.

-Tape must be placed in

this position to avoid

connector from being

pinched by [U] bracket

when installed.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

44

Page 45

DAMPER AND GASKET CAUTION POINTS

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

When Pulling the damper through

the fan be careful not to use

excessive force which may break the

damper in this area

269304701

GASKET(5 X 10 X 30)

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

45

Page 46

G BOARD WIRE DRESSING CAUTION POINTS

1

2

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

G-Board Wire Pin Holders

Instructions. There are (3)

wire pin Holders on the [G]

board. See below to see which

wires are dressed to each wire

pin holder

1. LVDS and 8P CN6009[G]

2. LVDS, 8P CN6009, and

7P CN3004[B]

When Dressing 1-910-024-29

and Duct Block Fan to wire

Holder ensure the wires are

not positioned above

capacitors on [G].

This is to avoid the connector

wires from touching the rear

cover.

3

3. LVDS and 7P CN3004[B]

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Install Purse Lock

404928101 PURSE LOCK (DIA.11)

Purselock should hold the

following:

32P Conn Assy [G] to [B]

3P Conn Assy [G] to [K]

3P Conn Assy [G] to ANT SWT

3P Conn Assy [G] to B-Blk FAN

46

Page 47

RIGHT SPEAKER WIRE DRESSING CAUTION POINTS

Dress Positive Tab of Speaker

wire around speaker bracket

and then Himelon Tape should

be installed to secure the wire

as shown.

Wire Should be pulled so that

there is no excess wire.

THIS IS VERY IMPORTANT TO

AVOID NOISE DUE TO

SPEAKER VIBRATION

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

Tape should wrap around

bracket as shown to the right

and securely hold the speaker

wire so that it does not move

once the tape is applied.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

47

Page 48

LEFT SPEAKER WIRE DRESSING CAUTION POINTS

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

265206401 TAPE,

HIMELON (20X40)

Pull wire in direction of arrow to

take out slack

Apply Himelon tape to speaker

wire as shown to the left.

Speaker wire must be placed

inside Grooved slot in speaker

and then secured with Himelon

Tape.

Before applying tape ensure as

much slack is taken out of the

wire by pulling it towards the

negative terminal.

Wire Holder is installed on

speaker bracket as shown.

Remove as much slack out of

wire before dressing it to the

wire holder.

ONLY FOR 50" MODELS

After dressing to wire holder

dress wire through speaker

bracket as shown to the left.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

48

Page 49

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

SECTION 2: CIRCUIT ADJUSTMENTS

2-1. USING THE REMOTE COMMANDER

FOR ELECTRICAL ADJUSTMENTS

To adjust various set features, use the Remote Commander to put the

set into service mode to display the service menus and categories.

Equipment Needed:

Pattern Generator (with component outputs)

Oscilloscope

Digital multimeter

2-2. ACCESSING SERVICE ADJUSTMENT

MODE

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a

second of each other:

DISPLAY

Channel 5 Volume +

SLEEP

DVR/VCR

FUNCTION

POWER TV POWER

SAT/CABLE

TV

TV/VIDEO

BD/DVD

POWER

POWER

.

2-3. VIEWING THE SERVICE MENUS

Use the Remote Commander to view the 3 service menus options.

1. To display the Service Menu that contains the Category you want to

adjust, press

(For a complete list of the service Categories refer to Service Menus)

JUMP

on the Remote Commander.

TV

VERSION 00 SERVICE

VERS Wide Zoom Video 1

WSL: 480I

Press JUMP

Q Box

QM 0 0 SERVICE

INFO DTV

Press JUMP

Sample TV Service Menu

Displays

JUMP

Service Menus

VOLUME (+)

JUMP ANT FREEZE

SURROUND

VISUAL SEARCH

MUTING

MODE

SOUND

PICTURE

E

D

I

U

G

R

NRUTE

MENU

REPLAY ADVANCE NEXTPREV

PLAY

PAUSE

VOL

REC REC PAUSE REC STOP

BD/DVD

TOP MENU MENU F1 F2

CH

ENT

D

I

WIDE

PSY

AL

O

T

STOP

DISPLAY

S

LO

TV

RM-YD010

The fi rst service menu (TV) displays.

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

49

Page 50

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

2-4. USING THE REMOTE COMMANDER TO

CHANGE SERVICE DATA

Use the buttons on the Remote Commander to access the service menu

items and adjust the data values.

Data Value

WSL: 480I

Service

Menu

Category

Adjustment

Item

Item Number

VERSION 0 0 SERVICE

VERS Wide Zoom Video 1

F/A: 00000000 00000000

CBA: 00000000 00000000

1. Access Service Adjustment Mode and select the Service Menu that

contains the Category with the Adjustment Item you want to change.

2. To change the Category, press 2 or 5 on the Remote Commander.

Note: Pressing 2 or 5 only changes the categories within the

Service Menu displayed. To change a Category on one of the other

Service Menus, press the

JUMP

button until the correct Service

Menu is displayed.

3. To change the Adjustment Item, press 1 or 4 on the Remote

Commander.

4. To change the Data Value, press 3 or 6 on the Remote

Commander.

Note: To go back to the last saved Data Value, press 0 then

ENT

on the Remote Commander to read the memory.

5. To save the changes, press

MUTING

then

ENT

to write into

memory.

6. To exit service mode, turn the power off by pressing

POWER

.

Wait 2 minutes before restarting the set to allow the fans to

completely shut down or the Service Menu will appear on the screen.

Display

Next Item

Display

Next Category

Displays

Service Menus

1

2

Display

4

Previous Item

JUMP

MUTING

Writes data

into memory

SLEEP

TV/VIDEO

BD/DVD

JUMP ANT FREEZE

SURROUND

R

VISUAL SEARCH

MUTING

TOP MENU MENU F1 F2

POWER TV POWER

SAT/CABLE

DVR/VCR

FUNCTION

MODE

SOUND

PICTURE

E

D

I

U

G

NRUTE

MENU

REPLAY ADVANCE NEXTPREV

PLAY

PAUSE

VOL

CH

REC REC PAUSE REC STOP

BD/DVD

TV

ENT

D

I

PSY

WIDE

AL

O

T

STOP

TV

Increase

3

Data Value

6

Decrease

Data Value

Display

5

Previous

Category

ENT

S

LO

0

Reads data

from last

saved NVM

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

RM-YD010

50

Page 51

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

X

SERVICE MENUS

(CATEGORIES ONLY)

TV MICRO TV MICRO (cont.) Q BO

VERSION IRIS_DBC

ID IRIS_ADJ

NVM_SEL IRIS_UFOFS

MODEL IRIS_WBOFS

OSD IRIS_SCSB

CCD IRIS_FIXED

CCT DSP_STEP

OPTIONS DSP_SURR

CXA2229Q DSP_MIXR

USER_NR

LPF_1 DSP_BT

SNNR DSP_BBE

SNSS DSP_DRC

CCPM_1 DSP_BQ

CCPM_2 FAN_CTRL

CCPM_3 TEMP_SRV

CCPM_4 TEMP_BRTO

CCPM_5 PAWN_3DG

CCPM_6 PAWN_SYS

CCPM_7 PAWN_CAP

CCPM_8 PAWN_MUT

CCPM_9 PAWN_PIC

CCPM_10 PAWN_BLK

CCPM_11 PAWN_WBO

CCPM_12 PAWN_TSP

HELIOS_1

HELIOS_2

HELIOS_3

HELIOS_4

HELIOS_5

SCREEN IMG_SHIFT

DCP_INT HDMI

DCP_OSD

DCP_BLK

DCP_ADJ1

DCP_ADJ2

DCP_USER

DCP_AVP

A7001R

A7001G

A7001B

A7007R

A7007G

A7007B

A7007RGB

DSP_AGC

PAWN_CUR

PAWN_TIM

PAWN_HPF

IRIS_APL

TIME

QM

QT

2-4-1. EXITING SERVICE MODE

After completing the changes, exit service mode by turning off the set

using the Remote Commander or the power switch.

NOTE: After exiting service mode wait 2 minutes before restarting

the set to allow the fans to shut down properly.

2-5. VERIFYING SERVICE DATA CHANGES

1. After completing all adjustments turn the set off with the Remote

Commander and WAIT for the fans to turn off before proceeding to

the next step.

Note: It may take up to two minutes for the fans to stop.

Caution: To avoid over heating the lamp, do not unplug the set

until the fans have stopped.

2. After the fans have stopped, unplug the set from the AC outlet, then

plug the set back in the AC outlet.

3. To verify the changes repeat steps 1 through 3 of 2-4. Using the

Remote Commander to Change Service Data.

4. To exit service mode, turn the power off by pressing

Wait 2 minutes before restarting the set to allow the fans to

completely shut down or the Service Menu will appear on the screen.

NOTE: After exiting service mode wait 2 minutes before restarting

the set to allow the fans to shut down properly.

POWER

.

2-6. RESETTING WEGA (USER) MENU TO

FACTORY DEFAULTS

Use the following instructions to restore the User Controls and

Channel Memory settings to the preset factory conditions.

1. Turn the TV on by press

2. While holding down the

POWER button on the Front Panel of the set.

The set restarts and displays the initial setup screen. This may take

several minutes.

POWER

on the Remote Commander.

on the Remote Commander, press the

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

51

Page 52

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

2-7. H/V CENTER CONFIRMATION AND

ADJUSTMENTS

Use the following instructions to adjust the pictures horizontal and

vertical center after replacing either of the following:

Optical Block Assembly

Mirror Cover

1. Set the signal to RF Monoscope, check the H/V center in “Full”

picture mode.

2. If the center is shifted, adjust the Horizontal and/or Vertical settings.

a. Access Service Adjustment Mode.

b. Press 2 until the HELIOS_3 category displays.

c. To adjust the Horizontal setting, press 1 until the DHPS (22) item

displays.

d. Press 3 to increase the data value, or 6 to decrease the data

value.

e. To adjust the Vertical setting, press 1 to display the DVPS (23)

item.

f. Press 3 to increase the data value, or 6 to decrease the data

value.

g. To save the changes, press

memory.

h. To exit service mode, turn the power off by pressing

Wait 2 minutes before restarting the set to allow the fans to

completely shut down or the Service Menu will appear on the

screen.

MUTING

then

ENT

to write into

POWER

.

2-8. IRIS ADJUSTMENTS

Use the following instructions to adjust the IRIS after replacing

either of the following:

Optical Block Assembly

B Block Assembly

1. Access Service Adjustment Mode.

2. Press

3. Press

4. Press

5. Wait approximately 5 seconds until the data value is reset to 0.

6. To exit service mode, turn the power off by pressing

Wait 2 minutes before restarting the set to allow the fans to

2

until the IRIS_ADJ category displays.

1

until the AUTO (7) item displays.

3

to change the data value to 1.

POWER

completely shut down or the Service Menu will appear on the screen.

.

K

DHPS 22 (for H center)

DVPS 23 (for V center)

DVPS

DHPS

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

52

Page 53

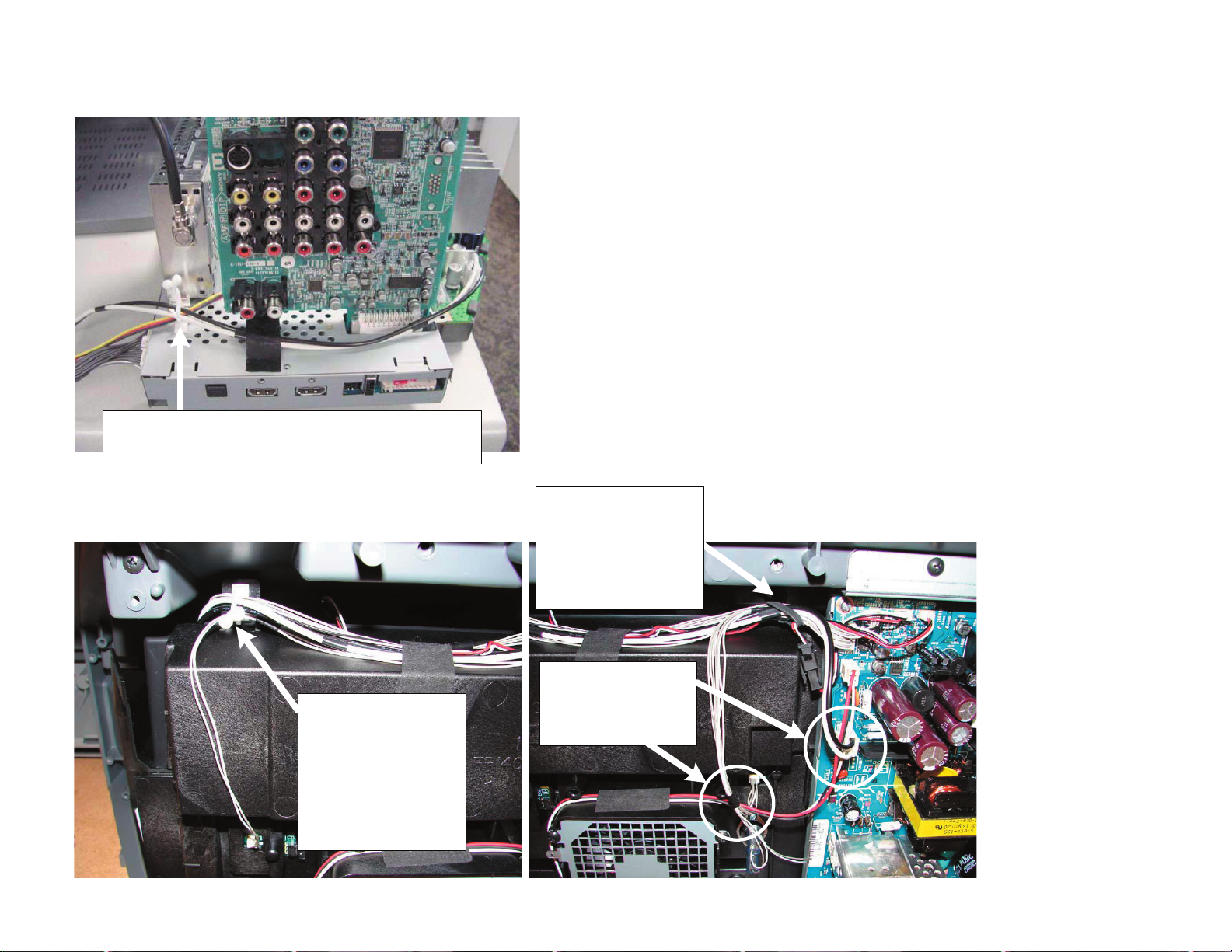

3-1. CIRCUIT BOARDS LOCATION

The C Board is part of the

Optics Unit Block Assembly

and cannot be ordered separately

HB

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

SECTION 3: DIAGRAMS

A

C

HA

T2

HC

K

Powe r

Supply

Block

T1

S2

3-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS INFORMATION

All capacitors are in µF unless otherwise noted. pF : µµF 50WV or

less are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. kΩ=1000Ω, MΩ=1000kΩ

Indication of resistance, which does not have one for rating

electrical power, is as follows: Pitch : 5mm

Rating electrical power :

1

/

W in resistance, 1/

4

W and 1/

10

W in chip resistance.

16

: nonfl ammable resistor

: fusible resistor

: internal component

: panel designation and adjustment for repair

: earth ground

: earth-chassis

All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10MΩ digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production

tolerances.

1

/

W

4

U

B

G

All voltages are in V.

S : Measurement impossibility.

: B+line.

: B-line. (Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

!

The components identifi ed by shading and

only with part number specifi ed.

The symbol indicates a fast operating fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

Les composants identifi es per un trame et une marque

securite. Ne les remplacer que par une piece portant le numero specifi e.

Le symbole indique une fusible a action rapide. Doit etre remplace par une

fusible de meme yaleur, comme maque.

symbol are critical for safety. Replace

!

sont critiques pour la

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

53

Page 54

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

(

)

REFERENCE INFORMATION

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

Terminal name of semiconductors in silk screen

printed circuit ( )

Device Printed symbol Terminal name

Transistor

1

Transistor

2

3

Diode

4

Diode

Diode

5

Diode

6

Diode

7

8

Diode

Diode

9

Diode

0

qa

Diode

Diode

qs

Transistor

qd

(FET)

Transistor

qf

(FET)

Transistor

qg

(FET)

Transistor

qh

Transistor

qj

Transistor

qk

Transistor

ql

Transistor

w;

Transistor

wa

Transistor

ws

Transistor

wd

Discrete semiconductot

–

Chip semiconductors that are not actually used are included.

*

Collector

Base

Collector

Base

Cathode

Cathode

Anode

Cathode

Anode

Common

Anode

Common

Anode Cathode

Common

Anode

Common

Anode Anode

Common

Cathode

Common

Cathode

Anode

Anode

Cathode

Drain

Drain

B1 E1

C2

B2 C1

E2

B2 E2

C1

B1 C2

E1

B2 E2

C1

B1 C2

E1

B2 E2

C1

B1 C2

E1

E2

B1 E1

C2

(B2)

E1

B1

C1

(B2)

E1

E2

C2

Emitter

Emitter

Anode

(NC)

(NC)

Cathode

Anode

Cathode

Cathode

Cathode

Anode

Anode

Source

Gate

Source

Gate

Source

Drain

Gate

Emitter

Collector

Base

C1(B2)

E2

C2

B1

C1

Circuit

D

G

D

S

B1

B1

B1

B1

B1

B1

D

G

S

S

D

G

C1

E1

C1

E1

E1

C1

E2

C1

C1

G

S

C2

B2

E2

C2

B2

E2

E2

B2

C2

C2C1(B2)

E2

E2E1(B2)

C2

C2E1(B2)

C2

Ver.1.5

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

54

Page 55

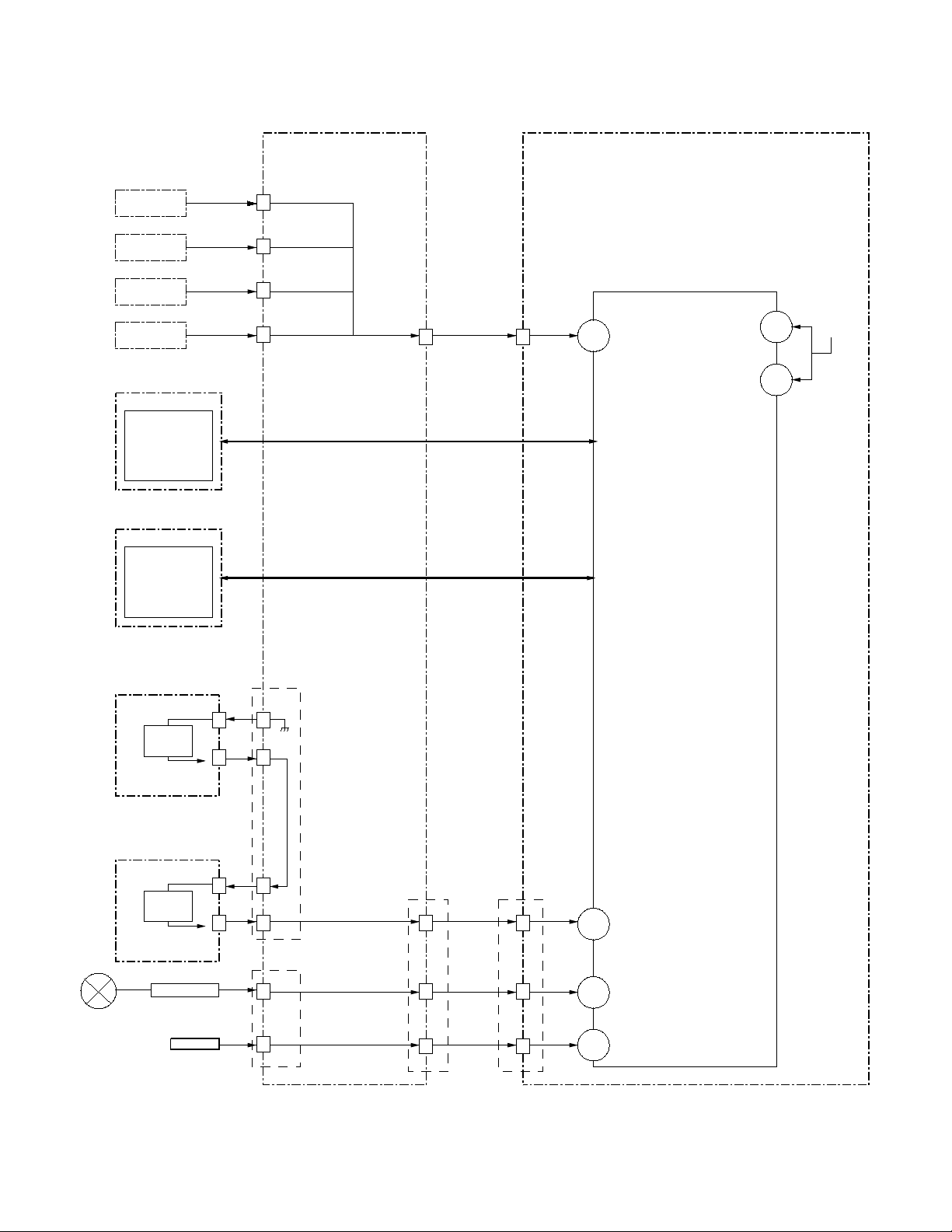

3-3. SIGNAL FLOW BLOCK DIAGRAM

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

FY06 LA4 GW Signal Flow

S2

TMP75

256Mb*2

Opt Audio

AIR

CABLE

ANT SW

(LAMP)

HB

TMP75

(FAN)

A

Bus I/F

Tuner

Demod.

NTSC/BTSC

NAND

Flash

128Mb

Serial

Flash

1Mb

Bus SW

IF

Audio

DAC

DDR

DDR

256Mb*2

ATi XILLEON

NVM

x240H

64k

EDID

2k

I2S

656

8bit+sync

LPF

SM5302

HDMI Rx

SiI9023

YPbPr/RGB

CCPXA

CXD3814

SDRAM

64Mb

HDMI2HDMI1

EDID

2k

MUX 24bit RGB

13bit

Helios

CXD3808

SDRAM

64Mb

UART-TV

Digital Video

Analog Video

HDMI

Micro

DeMUX

FLIPFLOP

DCP

CXD9690

APL

TV Micro

Saiph

Graphics

B

LVDS

Tx

NVM

128k

Digital Audio

Analog Audio

C

LVDS

Rx

NVM

32k

NVM

256k

PAWN

CXD9809

Digital Video

Memory

Control

RLCD

A7001

G LCD

A7001

BLCD

A7001

I2C-E1

Bus Level Shift

3.3V 5V

HC

COMP2

VIDEO2

S/VIDEO1

VIDEO3

COMP1

COMP3

AUDIO4

For DVI

Audio OUT

U

Video SW

Audio SW

CXA2229R

CXA2188

Audio SW

CD4052

UART-JIG

111

BUS Connector

Audio

ADC

I2C-TV1

I2C-E1

Audio DSP

CXD9835

Bus Level Shift

5V 3.3V

Bus Level Shift

5V 3.3V

Audio

DAC

I2C-TV0

I2C-E0

I2C-ADSP0

CXA1875

Linear AMP

TA8258

K

G

IRIS

FAN

SPEAKER

(L: 12W)

SPEAKER

(R: 12W)

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

55

Page 56

3-4. SCHEMATICS AND SUPPORTING INFORMATION

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

A BOARD SCHEMATIC DIAGRAM

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 |

A

—

B

—

C

—

D

—

E

CN1002

22P

BLK

—

F

—

G

—

H

—

D_SDA

D_SCL

AGC_MUTE

GND

GND

D_IF1

GND

D_IF2

MODE

GND

GND

IF_AGC

GND

AFT_OUT

ST_ID

DET_OUT

F_MONO

10.5V

SAP_ID

5.1V

NTSC_R

NTCS_L

TOBBOARD

CN7802

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

I

—

J

—

Due to the complexity of this board, performing component level fi eld repairs is not recommended. If service is required, complete block assembly replacement is the preferred repair method.

R1006

CHIP

FB1007

0uH

FB1008

0uH

FB1009

0uH

R1013

2.2k

1/10W

RN-CP

R1011

22k

1/10W

RN-CP

5%

R1012

22k

1/10W

RN-CP

5%

R1014

2.2k

1/10W

RN-CP

5%

0

C1036

33p

50V

CH

1608

C1037

33p

50V

CH

1608

C1038

33p

50V

CH

1608

C1039

15p

50V

CH

1608

R1003

0

CHIP

C1042

1p

50V

CK

1608

R1004

0

CHIP

C1043

15p

50V

CH

1608

R1005

0

CHIP

5%

FB1000

0uH

C1041

50V

1608

C1040

15p

50V

CH

1608

1p

CK

C1044

15p

50V

CH

1608

R1009

1k

1/10W

RN-CP

5%

R1007

1k

1/10W

RN-CP

5%

R1008

1k

1/10W

RN-CP

5%

R1010

1k

1/10W

RN-CP

5%

C1000

100

10V

C1001

4.7

10V

3216

B

C1002

0.1

16V

1608

5V

B

5V

R1034

10k

Q1001

2SC3052EF-T1-LEF

AGC-MUTE

R1033

15k

1/10W

C1021

1000

6.3V

RN-CP

5%

C1030

1000p

50V

1608

C1027

1000p

50V

1608

C1032

2.2

10V

B

2012

FB1006

0uH

FB1005

0uH

B

B

C1022

0.01

25V

B

1608

R1031

0

CHIP

C1020

0.01

25V

1608

B

R1040

100

1/10W

RN-CP

5%

1608

R1030

100k

1/10W

RN-CP

0.5%

9V

C1023

0.1

25V

1608

L1005

10uH

F

C1019

47

16V

R1032

R1047

10k

1/10W

RN-CP

5%

5V

R1041

100

1/10W

RN-CP

5%

C1045

1000p

50V

B

1608

L1007

10uH

FB1003

0uH

FB1002

0uH

FB1004

0uH

Q1002

2SA1235TP-1EF

INVERTER

C1028

470

10V

C1025

FB1001

R1043

1/10W

RN-CP

4.7

50V

0uH

1k

5%

5V

L1006

10uH

R1042

1k

1/10W

RN-CP

5%

Q1003

2SC3052EF-T1-LEF

BUFFER

C1029

0.01

25V

1608

C1026

0.022

50V

1608

R1044

1k

1/10W

RN-CP

5%

B

F

100

1/10W

RN-CP

5%

32V

L1004

9V

10uH

VIDEO

C1015

100

16V

C1016

4.7

16V

3216

C1017

R1025

0.1

R1039

CHIP

25V

1608

0

B

F

1k

1/10W

RN-CP

5%

Q1000

2SA1235TP-1EF

VIDEO-BUFF

R1038

100

1/10W

RN-CP

5%

C1018

16V

1608

0.1

B

2SC3052EF-T1-LEF

R1046

0

CHIP

1608

Q1004

BUFFER

R1045

470

1/10W

RN-CP

5%

1/10W

RN-CP

5%

C1035

1000p

50V

1608

B

ADR

TU SDA

TU SCL

AGC IN

A5V

IF OUT

A32V

C1048

33p

50V

CH

1608

IF_AGC

1608

16V

0.1

C1024

B

D_IF1

D_IF2

AGND

A5V_VIF

AFT_OUT

DET_OUT

AGND

ST_ID

SAP_ID

MODE

F_MONO

A9V_MPX

R_OUT

L_OUT

TU1000

K

—

L

—

M

—

N

—

O

—

L1000

0uH

C1003

0.1

16V

B

1608

C1004

47

16V

R1015

22k

1/10W

RN-CP

5%

R

L

TK11819MTL

IC1000

DC-DC CONV.

L1001

22uH

C1005

16V

L1002

C1006

47

0.022

50V

1608

1.2mH

F

C1007

0.022

50V

F

1608

123

R1016

1k

1/10W

RN-CP

5%

456

C1008

4.7

50V

R1017

100k

1/10W

RN-CP

5%

L1003

22uH

C1009

0.1

50V

2012

R1018

32V

1k

1/10W

RN-CP

5%

C1010

4.7

F

50V

ABoard

R1019

0

CHIP

5V

C1012

C1011

0.1

4.7

16V

16V

B

B

1608

3216

R1021

100

1/10W

RN-CP

5%

MIC5235YM5TR

IC1001

LDO REGULATOR

321

54

R1022

470k

1/10W

RN-CP

0.5%

R1023

68k

1/10W

RN-CP

0.5%

R1024

6.8k

1/10W

RN-CP

0.5%

C1013

4.7

16V

3216

D1000

UDZSTE-1710B

C1014

0.1

16V

1608

B

B

9V

TUNER

P

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

9-883-709-01<LA4>A

56

Page 57

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

A

[TUNER]

COMPONENT SIDE

1

A

B

C

D

C1035

R1034

FB1006

R1029

R1027

E

F

C1031

C1034

1

FB1005

R1028

R1026

C1040

C1036

C1037

FB1007

FB1008

L1008

C1032

C1033

R1033

R1032

FB1009

R1047

21

22

CN1002

C1039

234567

1-869-670-11

(172753811)

C1029

C1030

C1048

Q1001

L1007

C1045

R1013

R1009

C1038

C1041

R1003

C1044

C1042

R1004

C1043

C1000

L1009

C1025

C1028

FB1000

C1001

R1005C1047

127

C1026

R1006

C1002

C1027

A-1168-

L1000

C1046

R1008R1012

21

R1011

R1014

C1004

R1007

R1010

C1022

C1024

L1006

C1021

C1003

R1031

361-A

C1023

R1030

Q1000

R1039

R1025

C1018

R1038

R1044

R1045

R1040

FB1001

R1046

Q1004

R1043

R1041

R1042

FB1002

FB1003

Q1002

FB1004

Q1003

C1020

C1019

L1005

26

L1004

C1011

C1012

L1001

TU1000

L1002

C1007

C1017

C1016

R1019

R1015

R1021

R1016

C1015

R1020

R1018

R1037

R1036

R1035

D1001

R1024

C1006

R1022

IC1001

R1023

C1005

IC1000

R1017

D1000

C1013

C1014

C1010

C1009

L1003

C1008

61

CN1000

GND

TU-BR

GND

TU-BL

GND

TU-BV

A

[TUNER]

CONDUCTOR SIDE

1

A

B

C

D

E

F

234567

1-869-670-11

(172753811)

JL1019

JL1018

EP GW GN

JL1015

26

JL1014

JL1007

JL1013

JL1012

JL1010

JL1011

12

JL1009

1

2

1

2

JL1008

NTSC-L

5.1V

NTSC-R

SAP-ID

DET-OUT

10.5V

ST-ID

F-MONO

JL1006

JL1016

IF-AGC

AFT-OUT

GND

GND

JL1017

7

GND

D-IF2

MODE

GND

JL1004

CN1002

GND

D-IF1

AGC-MUTE

GND

D-I2C-SCL

21

D-I2C-SDA

22

JL1005

JL1002

JL1003

JL1000

1

JL1001

2122

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

57

Page 58

KDF-46E2000/46E2010/50E2000/50E2010/55E2000/55E2010

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 |

A

—

B

—

C

—

D

—

E

—

F

—