Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDF-46E3000

KDF-50E3000

RM-YD016 US/CND

RM-YD016 US/CND

LA-5

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 6/2007

: UPDATED ITEM

☛

REVISION DATE SUBJECT

6/2007 No revisions or updates are applicable at this time.

8/2007 Updated Disassembly Section 1-6. Replaced Page 14.

LCD PROJECTION TELEVISION

9-883-754-02

Page 2

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDF-46E3000

KDF-50E3000

RM-YD016 US/CND

RM-YD016 US/CND

LA-5

CHASSIS

9-883-754-02

KDF-50E3000 RM-YD016

LCD PROJECTION TELEVISION

Page 3

KDF-46E3000/50E3000

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 6

Safety Check-Out ........................................................................... 7

Self-Diagnostic Function ................................................................. 8

SECTION 1: DISASSEMBLY ............................................................... 10

1-1. Overview .............................................................................. 10

1-2. Lamp Removal ......................................................................11

1-3. Power Supply (Ballast Unit) Removal .................................. 12

1-4. HAE Board Removal ............................................................ 13

1-5. HCE Board Removal ............................................................ 13

1-6. Ornamental Cover, Screen Frame,

and Light Guide Removal ..................................................... 14

1-7. Diffusion Plates and Screen Frame Removal ...................... 15

1-7-1. Diffusion Plates (Screens) Tape Method ................. 15

1-8. Separator, Speaker, and HBE Board Removal .................... 16

1-9. Lamp Duct Removal ............................................................. 17

1-10. Optical Unit Block Removal .................................................. 18

1-11. Chassis Removal ................................................................. 19

1-12. Mirror Replacement .............................................................. 20

Wire Dressing ....................................................................... 21

SECTION 2: CIRCUIT ADJUSTMENTS .............................................. 32

2-1. Using the Remote Commander for Electrical Adjustments .. 32

2-2. Accessing Service Adjustment Mode ................................... 32

2-3. Viewing the Service Menus .................................................. 32

2-4. Using the Remote Commander to View Service Data ......... 33

2-4-1. Changing Service Data ............................................ 33

2-4-2. Exiting Service Mode ............................................... 33

2-5. Updating the Model Information when

Replacing the BE Board ....................................................... 33

2-5-1. Verifying Model Information ..................................... 34

2-6. Adjusting the Horizontal and vertical Settings ...................... 34

2-7. Resetting the Lamp .............................................................. 34

2-8. Verifying Service Data Changes .......................................... 34

2-9. Resetting to Factory Defaults ............................................... 35

SECTION 3: DIAGRAMS ..................................................................... 36

3-1. Circuit Boards Location ........................................................ 36

3-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 36

3-3. Block Diagrams .................................................................... 38

Signal Flow Block Diagram .................................................. 38

Connection Diagram ............................................................ 39

3-4. Schematics and Supporting Information .............................. 40

BE Board Schematic Diagram (1 of 12) ............................... 40

BE Board Schematic Diagram (2 of 12) ............................... 41

BE Board Schematic Diagram (3 of 12) ............................... 42

BE Board Schematic Diagram (4 of 12) ............................... 43

BE Board Schematic Diagram (5 of 12) ............................... 44

BE Board Schematic Diagram (6 of 12) ............................... 45

BE Board Schematic Diagram (7 of 12) ............................... 46

BE Board Schematic Diagram (8 of 12) ............................... 47

BE Board Schematic Diagram (9 of 12) ............................... 48

BE Board Schematic Diagram (10 of 12) ............................. 49

BE Board Schematic Diagram (11 of 12) ............................. 50

BE Board Schematic Diagram (12 of 12) ............................. 51

G Board Schematic Diagram (1 of 2) ................................... 53

G Board Schematic Diagram (2 of 2) ................................... 54

HAE Board Schematic Diagram ........................................... 57

HBE Board Schematic Diagram ........................................... 59

HCE Board Schematic Diagram ........................................... 62

SE Board Schematic Diagram ............................................. 64

TE Board Schematic Diagram .............................................. 67

U Board Schematic Diagram ................................................ 70

3-5. Semiconductors ................................................................... 73

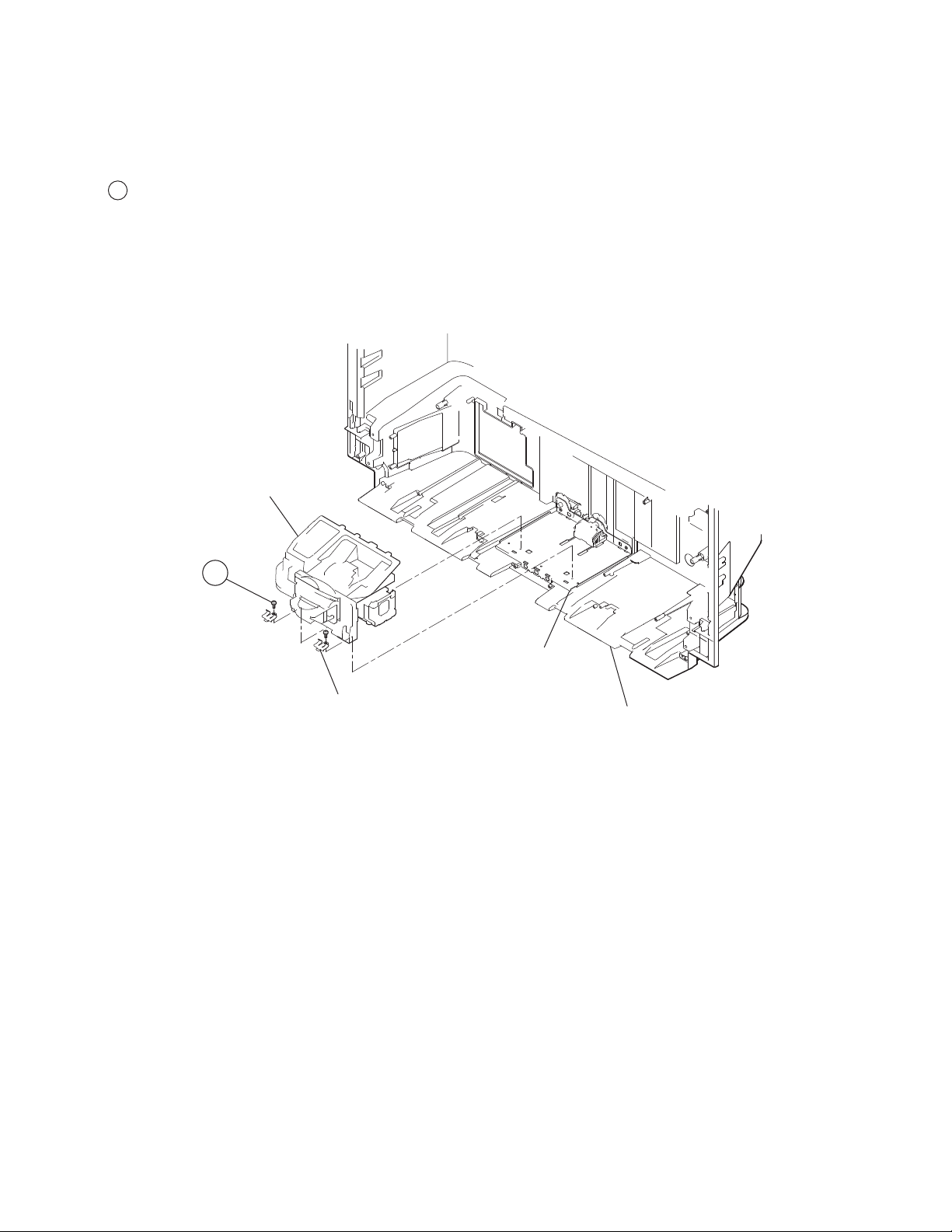

SECTION 4: EXPLODED VIEWS ........................................................ 74

4-1. Screen Frame and Mirror Assemblies .................................. 74

4-2. Chassis and Optical Block Assembly ................................... 75

4-3. Connectors ........................................................................... 76

SECTION 5: ELECTRICAL PARTS LIST ............................................ 77

KDF-46E3000/50E3000

APPENDIX A: ENCRYPTION KEY COMPONENTS ..........................A-1

APPENDIX B: REPLACING THE LAMP ............................................B-1

3

Page 4

SPECIFICATIONS

p

)

b

a

KDF-46E3000/50E3000

Power Requirements

Power Consumption (W)

In Use (Max)

In Standby

Inputs/Outputs

120V, 60Hz

200W

Less than 0.8W

HDMI IN 1/2

Video - 480i, 480p, 720p, 1080i, 1080p, PC timing

Audio - Two channel linear PCM 32, 44.1 and 48 kHz,

16, 20, and 24 bit

Audio - (HDMI IN 2 only) 500 mVrms

(100% modulation) Impedance:47 kilo ohms

Video (IN) 1/2/3

Video

1 total Y: 1.0 Vp-p, 75ohms unbalanced,

sync negative

S Video (IN)

1 total (4-pin mini DIN)

Y: 1Vp-p, 75ohms unbalanced, sync negative

C: 0.286Vp-p (Burst signal), 75ohms

Audio (IN)

500 mVrms (100% modulation)

Impedance:47 kilo ohms

Component In 1/2/3

) (Component Video)

(Y, P

B/CB

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

:

0.7 Vp-p, 75 ohms;

P

B

PR: 0.7 Vp-p, 75 ohms

Signal format: 480i, 480p, 720p, 1080i

Audio (IN)

500 mVrms (100% modulation)

Impedance:47 kilo ohms

Audio Out

500 mVrms (100% modulation) Up to 2 Vrms at the

maximum volume setting (Varies with input level)

Digital Audio Optical Output (PCM/Dolby Digital)

Optical Rectangular

eaker Output(W

S

Speaker Dimension

Dimensions (W x H x D)

Mass

Trademark Information

As an ENERGY STAR® Partner, Sony

Corporation has determined that this product

meets the ENERGY STAR

®

guidelines for

energy efficiency.

ENERGY STAR

®

is a U.S. registered mark.

Blu-ray Disc is a trademark.

“BRAVIA” and , BRAVIA ENGINE EX, “XMB”

and “XrossMediaBar”, S-Force, BRAVIA Theatre Sync, , DM

BRAVIA Internet Video Link Ready and “PS3” are trademarks

or registered marks of Sony Corporation and/or

Sony Computer Entertainment Inc.

KDF-46E3000/50E3000

KDF-46E3000 KDF-50E3000

12W + 12W

mm

in

65 x 130 mm

2

9/16

x 5

1/8

in

mm 1099 x 795 x 301 mm 1187 x 847 x 320 mm

in

43

5/16

x 31

5/16

x 11

7/8

in 46

3/4

x 33

3/8

x 12

5/8

kg 27 kg 30 kg

lbs 59.9 lbs 66.3 lbs

All measurements are approximations

This TV is manufactured under license from Dol

Laboratories. “Dolby” and the double-D symbol

trademarks of Dolby Laboratories.

This TV incorporates High-

™

(HDMI

) technology. HDMI, the HDMI logo and HighDefinition Multimedia Interface are trademarks or

registered trademarks of HDMI Licensing LLC.

x

,

Macintosh is a trademark licensed to Apple Computer, Inc.,

registered in the U.S.A and other countries.

Definition Multimedia Interface

Design and specifi cations are subject to change without notice.

in

4

Page 5

Television system

American TV standard, NTSC

ATSC Compliant 8VSB, ATSC (8VSB terrestrial)

ANSI/SCTE 07 2000, QAM on cable

Channel coverage

Terrestrial 2-69/ Cable TV: 1-125 (analog)

Terrestrial 2-69/ Cable TV: 1-135 (digital)

Screen Size (measured diagonally)

KDF-46E300 - approximately 46 inches

KDF-50E300 - approximately 50 inches

Antenna

75-ohm external antenna terminal for VHF/UHF

Projection System

3 LCD Panels, 1 lens projection system

LCD Panel System

LCD (Liquid Crystal Display) Panel

KDF-46E3000/50E3000

LCD Panel

0.73 inch TFT LCD panel (1,280 x 720 pixels)

Projection Lens

High Performance, large diameter hybrid lens F2.4

Lamp

100W, XL-2500 Ultra High Pressure Lamp

Supplied Accessories

Remote Commander RM-YD016

Two Size AA (R6) Batteries

Operating Instructions

Quick Setup Guide

Warranty Card

Online Registration Card

Optional Accessories

Connecting Cables

Lamp

XL-2500 Ultra High Pressure Lamp

TV Stand

SU-RG13M (for both models)

KDF-46E3000/50E3000

5

Page 6

KDF-46E3000/50E3000

WARNINGS AND CAUTIONS

CAUTION

These servicing instructions are for use by qualifi ed service personnel only. To reduce the risk of electric shock, do not perform any servicing other

than that contained in the operating instructions unless you are qualifi ed to do so.

CARRYING THE TV

Carrying the TV requires at least two people. Do not hold

by the pedestal or the front panel of the TV. Doing so may

cause these parts to break off.

When moving the TV, place one hand in the hole on the

lower portion of the TV while grasping the top with the other

hand, as shown in the illustration below.

Do not grasp the

pedestal or the front

panel of the TV.

If you have connected cables and cords, be sure to

unplug them before moving the TV.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of this receiver is

directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace

these components with Sony parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that

are critical for safe operation are identifi ed in this manual. Follow these procedures whenever critical components are replaced or improper operation is

suspected.

ATTENTION!!

Ces instructions de service sont à l’usage du personnel de service qualifi é seulement. Pour prévenir le risque de choc électrique, ne pas faire

l’entretien autre que celui contenu dans le Mode d’emploi à moins que vous soyez qualifi é faire ainsi.

TRANSPORTER LE TÉLÉVISEUR

Le transport du téléviseur doit être effectué par au

moins deux personnes. Ne tenez pas le téléviseur

par son socle ni par le panneau avant. Ces pièces

risqueraient de se détacher.

Lorsque vous déplacez le téléviseur, placez une

main dans l’orifice de la partie inférieure du

téléviseur tout en tenant la partie supérieure de

l’autre main, comme illustré ci-dessous.

Ne tenez pas le

téléviseur pa r son soc le

ni par le panneau avant.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout dépannage. Le

chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

Si vous avez branché les câbles et les cordons

d’alimentation, veillez à les débrancher avant de

déplacer le téléviseur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces sont d’une

importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont le numero de piece est indique dans le

present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont l’importance est critique pour la securite du fonctionnement

sont identifi es dans le present manuel. Suivre ces procedures lors de chaque remplacement de composants critiques, ou lorsqu’un mauvais

fonctionnement suspecte.

KDF-46E3000/50E3000

6

Page 7

SAFETY CHECK-OUT

KDF-46E3000/50E3000

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

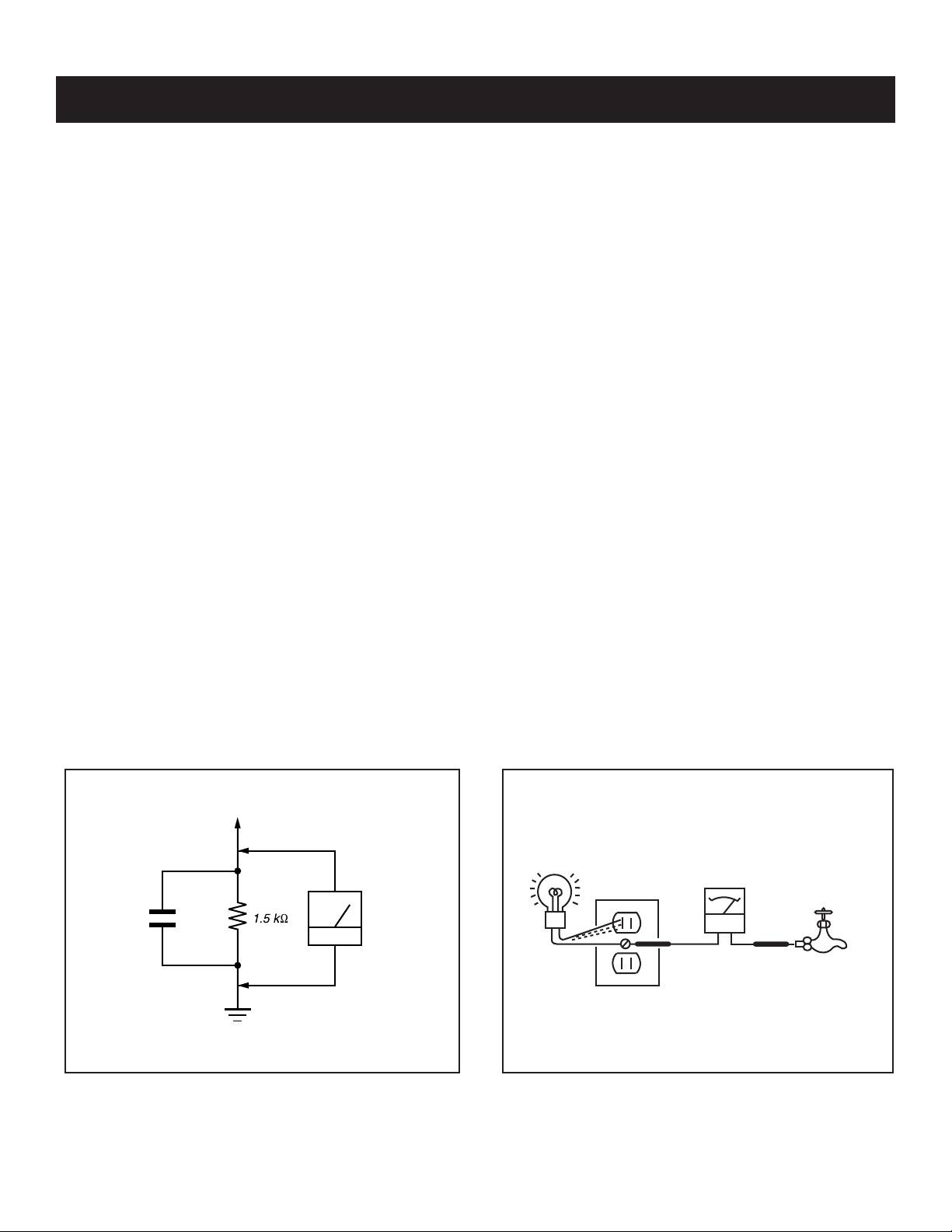

Leakage Test

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

To Exposed Metal

Parts on Set

0.15 μF

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

KDF-46E3000/50E3000

Earth Ground

AC

Voltmeter

(0.75V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

7

Page 8

KDF-46E3000/50E3000

SELF-DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the POWER/STANDBY will automatically begin to fl ash. The number of

times the LED fl ashes translates to a probable source of the problem. A defi nition of the POWER/STANDBY fl ash indicators is listed in the instruction

manual for the user’s knowledge and reference. If an error symptom is diffi cult to reproduced use the Remote Commander to display the record that is

stored at the internal NVM to specify the cause of the failure.

Diagnostic Test Indicators

When an error occurs, the POWER/STANDBY will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the POWER/STANDBY will identify the fi rst of the problem areas. If the errors occur simultaneously, the one that corresponds to the fewest

fl ashes is identifi ed fi rst.

Results for all of the following diagnostic items are displayed on screen. (No error has occurred if the screen displays a “0”.)

Self Diagnosis

Supported model

Number of times

LED indicator

flashes Diagnosis Item Probable Cause

Lamp not seated properly

1 Lamp Error

(Note: The lamp LED will flash red when

this error occurs, not the Power LED)

2 OVP 10.5V is high on B Board

3 LowB Error 10.5V is low on B Board

4 Not Used in this model

5 HV Detect Ballast is not working

6 Lamp Cover/ Lamp Position The Lamp cover is not closed securely.

7 Temp Error High Temperature or sensor connection

8 Audio Error DC error on U Board

9 Fan Error Fan is not working properly

DISPLAY OF POWER/STANDBY OR LAMP LED FLASH COUNT

Screen

TIMER LAMP POWER

Flashes red for Lamp error

TIMER LAMP POWER

Flashes red for all except Lamp error

- 4 Flash is not used for self-diagnosis

-Example

Diagnosis

LowB Error

Number of times LED Flashes

LED OFF

3.0sec

3 times

Lamp Cover 6 times

KDF-46E3000/50E3000

LED ON : 0.3sec

LED OFF : 0.3sec

LED OFF

3.0sec

8

Page 9

KDF-46E3000/50E3000

RELEASING THE POWER/STANDBY LED FLASH

Unplug the power cord from the outlet to temporarily stop the POWER/STANDBY lamp from fl ashing.

Self-Diagnostic Screen Display

For failures that are diffi cult to reproduce, or accompany occasional power off and/or picture mute, the Self-Diagnostic screen display is useful to

specify the cause.

VIEWING THE SELF-DIAGNOSTIC SCREEN

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a second of each other:

DISPLAY

NOTE: This differs from the method of accessing service mode which is Volume

Sample Self-Diagnostic Screen Display

Channel

1 : LAMP_ERR 0

2 : OVP 0

3 : LowB-ERROR 0

5:

6:

7 : TEMP-ERROR

8 : AUDIO-ERROR 0

9 : FAN-ERROR 0

5

Volume -

SELF CHECK

HV DETECT

LAMP_COVER 1

0

0

POWER

+

"1" is displayed when an error is detected one or more times

"0" is displayed when no error has been detected

Name: KDF-37H1000

Serial: XXXXXXXXXX

NOTE: To refresh the Self Check menu when all the items are not displayed, press

3. Proceed to Viewing the Self-Diagnostic Errors.

JUMP

on the Remote Commander.

CLEARING THE SELF-DIAGNOSTIC SCREEN

The self-diagnostic results displayed on the screen are not cleared automatically, therefore you should always check the self-diagnostic screen during

repairs. When you have completed the repairs, clear the self-diagnostic screen to reset the results to “0”.

Note: The self-diagnostic function will not be able to detect any subsequent faults after completion of the repairs unless the Self-Diagnostic

result display is cleared to reset the results to “0”.

1. If the Self-Diagnostic screen is already displayed, proceed to step 3. If not, Power off (Set to Standby mode).

2. Press

3. Press Channel 8

The status resets to 0.

4. To exit the Self-Diagnostic screen, turn the power off.

DISPLAY

Channel

0

5

Volume -

POWER

KDF-46E3000/50E3000

9

Page 10

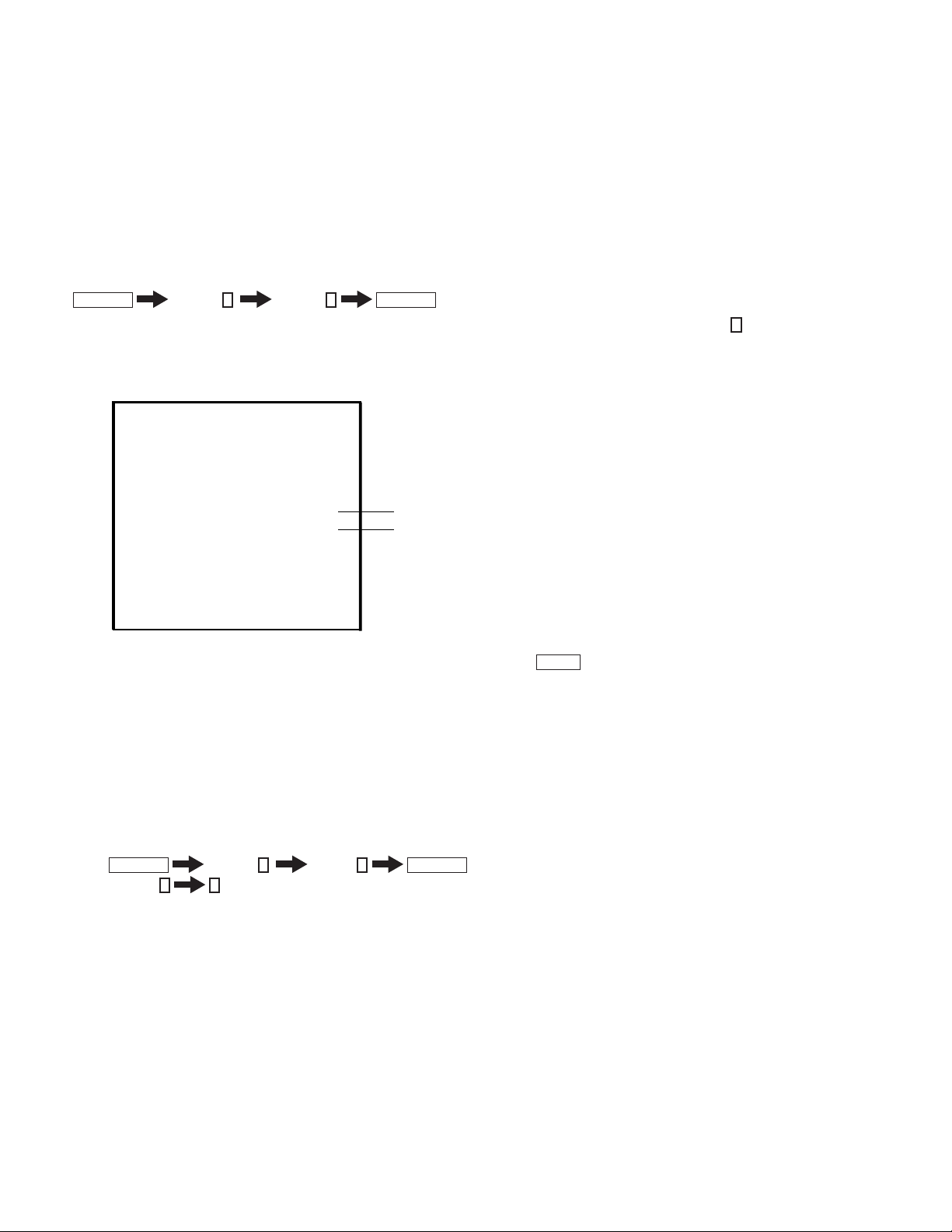

1-1. OVERVIEW

TOOLS NEEDED

Long Phillips Screwdriver

Needle Nose Pliers

Small Flathead Screwdriver or Jewelers Screwdriver

The connectors in this chassis have been redesigned to ensure they are securely fasten to the boards. Please review the illustrations below.

Use caution not to rock the Type 2 or Type 3 connectors when removing or reinstalling to avoid breaking the solder leads off the

Printed Circuit Boards.

KDF-46E3000/50E3000

SECTION 1: DISASSEMBLY

TYPE 1

LIFT ONE SIDE AT A TIME

BY PUSHING TAB IN WITH

SMALL SCREWDRIVER

TYPE 2

SQUEEZE DOWN ON

TAB TO RELEASE

TYPE 3

SQUEEZE LOCKING TAB

TOWARDS CONNECTO R

BEFORE PULLING FREE

CAUTION! IF THE TYPE 2 FEMALE

CONNECTOR HAS A SLOT (AS SHOWN)

MAKE SURE THE LOCK TAB SEATS INSIDE

THIS SLOT.

KDF-46E3000/50E3000

10

Page 11

1-2. LAMP REMOVAL

For detailed instructions, refer to “Replacing the Lamp” in the Appendix section of this manual

1

Remove the Lamp Door and the Lamp Cover.

2

Disconnect the Lamp Block Assembly by pulling

it out of the Power Supply.

KDF-46E3000/50E3000

Lamp Door

Lamp Block Assembly

XL-2500

2

Lamp Cover

1

KDF-46E3000/50E3000

11

Page 12

KDF-46E3000/50E3000

1-3. POWER SUPPLY (BALLAST UNIT) REMOVAL

1

Remove 1 screw (+BVTP2 4x16) from the Power Supply (Ballast Unit Lead Cover)

2

Slide out the Ballast Bracket.

3

Release the connector wire from the Bracket

4

Rotate the Bracket.

5

Disconnect 2 connectors

6

Remove 1 screw (+BVTP 3x12 TYPE2 IT-3) from the Power Supply (Ballast Unit)

Ballast Bracket (E)

Ballast Lead Cover

3

1

Power Supply

(Ballast Unit)

2

4

5

6

KDF-46E3000/50E3000

12

Page 13

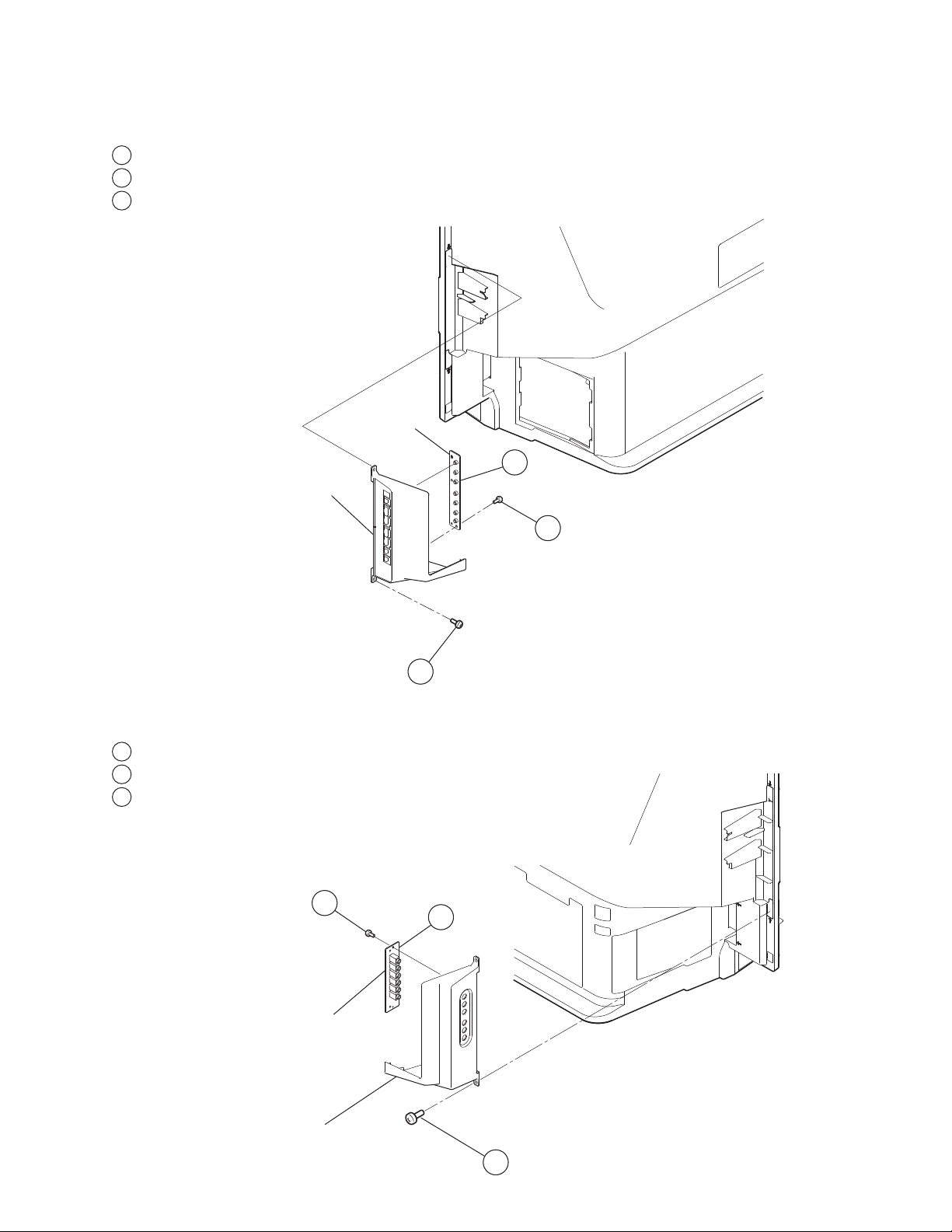

1-4. HAE BOARD REMOVAL

1

Remove 2 screws for 46” model, 3 screws for 50” model, +BVTP2 4x16

2

Disconnect a connector from HAE board

3

Remove 2 screws for HAE board removal, +BVTP 3x12 TYPE2

Side Control Bracket

KDF-46E3000/50E3000

HAE Board

2

1-5. HCE BOARD REMOVAL

1

Remove 2 screws for 46” model, 3 screws for 50” model, +BVTP2 4x16

2

Disconnect a connector from HCE board

3

Remove 2 screws for HCE board removal, +BVTP 3x12 TYPE2

3

1

3

2

Side Terminal Bracket

KDF-46E3000/50E3000

HCE Board

1

13

Page 14

1-6. ORNAMENTAL COVER, SCREEN FRAME, AND LIGHT GUIDE REMOVAL

☛

All of the components of this model can be reached by removing the Screen Frame Assembly from the Rear Cover.

Remove the Side Control Bracket and the Side Terminal Bracket before proceeding. (See 1-4. HAE Board Removal and

1-5. HCE Board Removal.

Caution:

When removing the Rear Cover or the Screen Frame

to remove any dust particles.

1

Remove 20 screws from the Rear Cabinet to release the Screen Frame, +BVTP2 4x16

2

Slide Ornamental Cover to right and pop off from Screen Frame.

3

Remove 3 screws from Screen Frame, +BVTP2 4x16

A

The Light Guide is not included with the Ornamental Cover. When replacing the Ornamental Cover remove 1 screw from

Light Guide, +BVTP 3x12 TYPE2 IT-.

Assembly

, be sure to clean the mirror and Diffusion Plate(s)

KDF-46E3000/50E3000

Rear Cabinet

Screen Frame

3

2

A

Light Guide

1

Ornamental Cover

1

Screen Frame

KDF-46E3000/50E3000

Rear Cabinet

14

Page 15

1-7. DIFFUSION PLATES AND SCREEN FRAME REMOVAL

Caution:

When replacing the Diffusion Plates be sure to remove any dust particles.

1

Remove 5 screws(Top Holder), 6 screws(Bottom Holder) and 3 screws from each side holders, total 17 screws, +BVTP2 4x16

Screen Frame

KDF-46E3000/50E3000

1

Diffusion Plates

1-7-1. DIFFUSION PLATES (SCREENS) TAPE METHOD

Note:

The following diaglam illustrate the taping method when replacing the diffusion Plates.

For Part Numbers refer to the Explode view section of this manual.

Black Acetate Tape

Diffusion Plate

(Lenticular - Front side)

Screen Holder

Diffusion Plate

(Frensnel - Rear side)

KDF-46E3000/50E3000

15

Page 16

1-8. SEPARATOR, SPEAKER, AND HBE BOARD REMOVAL

1

Remove 9 screws from Separator, +BVTP2 4x16

2

Release connector wires from hook

3

Disconnect joint connectors from HB board

4

Disconnect joint connectors from Speakers

5

Lift tabs and slide out Separator unit.

6

Remove 4 screws from speakers, +BWTP2 4x16

7

Remove 2 screws for HB board removal, +BVTP 3x12 TYPE2 IT-3

KDF-46E3000/50E3000

Rear Cabinet

1

3

4

Separator

2

7

HBE Board

5

5

Speaker

6

KDF-46E3000/50E3000

16

Page 17

1-9. LAMP DUCT REMOVAL

1

Remove 3 screws, +BVTP 3x10 TYPE2 IT-3, connecting the Lamp Duct to the Rear Cover (from the bottom of the Lamp Duct)

2

Disconnect 4 connector joints (not shown)

3

Remove Duct unit from rear cabinet.

4

Slide out Fuse unit from Lamp Duct, locating it inside of the duct.

5

Remove one screw, +BVTP 3x12 TYPE2 IT-3

6

Remove fan from Lamp Duct and take Fan cushions off from fan

7

Remove one screw, +BVTP 3x12 TYPE2 IT-3

Note: To remove each duct, lift tabs gently and release from hooks.

KDF-46E3000/50E3000

4

Lamp Duct (EA)

2

1

Fuse Holder

SE Board

Fuse Sheet

4

Fuse Plate

2P Connector

(Thermal Fuse)

5

6

Fan Cushion

Fan

7

TE Board

3

Rear Cabinet

KDF-46E3000/50E3000

Lamp Duct (EB)

Lamp Duct (EC)

17

Page 18

1-10. OPTICAL UNIT BLOCK REMOVAL

Caution:

When replacing the Optics Unit Block Assembly be sure to remove any dust particles.

1

Remove 2 screws, +PSW M4x12

Note: The connectors are not included with the optical block assembly.

Optical Unit Block

KDF-46E3000/50E3000

1

Optical Unit

Bracket

Main Plate Holder

Main Plate

KDF-46E3000/50E3000

18

Page 19

1-11. CHASSIS REMOVAL

Caution: When replacing any part of the chassis be sure to remove any dust particles and clean the mirror.

1

Disconnect 9 connectors from G board

2

Disconnect a lead wire connector from B board

3

Disconnect 2 connectors from B board

4

Remove 1 screw, +BVTP 3x12 TYPE2 IT-3, from Fan Bracket

5

Remove 2 screws, +BVTP2 4x16

6

Remove one screw, +BVTP 3x12 TYPE2 IT-3

7

Remove 3 screws, +PSW M3X8

8

Remove 6 screws, +BVTP 3x12 TYPE2 IT-3

9

Disconnect 4 connectors from U board

10

Remove 2 screws, SPECIAL (+PW 4X30)

11

Remove 2 screws, +PSW M3X8

12

Remove 2 screws, +BVTP 3x12 TYPE2 IT-3

13

Remove 1 nut from tuner

1

KDF-46E3000/50E3000

G Board

8

G Bracket

7

2

6

B-Shield

10

9

B Board

11

12

13

Terminal

Bracket

U Board

4

3

5

KDF-46E3000/50E3000

Rear Cabinet

Main Base

19

Page 20

1-12. MIRROR REPLACEMENT

CAUTION

1

Replace mirror by laying fl at and face-up position.

2

Holder screws should be tighten from center to outer screw positions.

KDF-46E3000/50E3000

KDF-46E3000/50E3000

20

Page 21

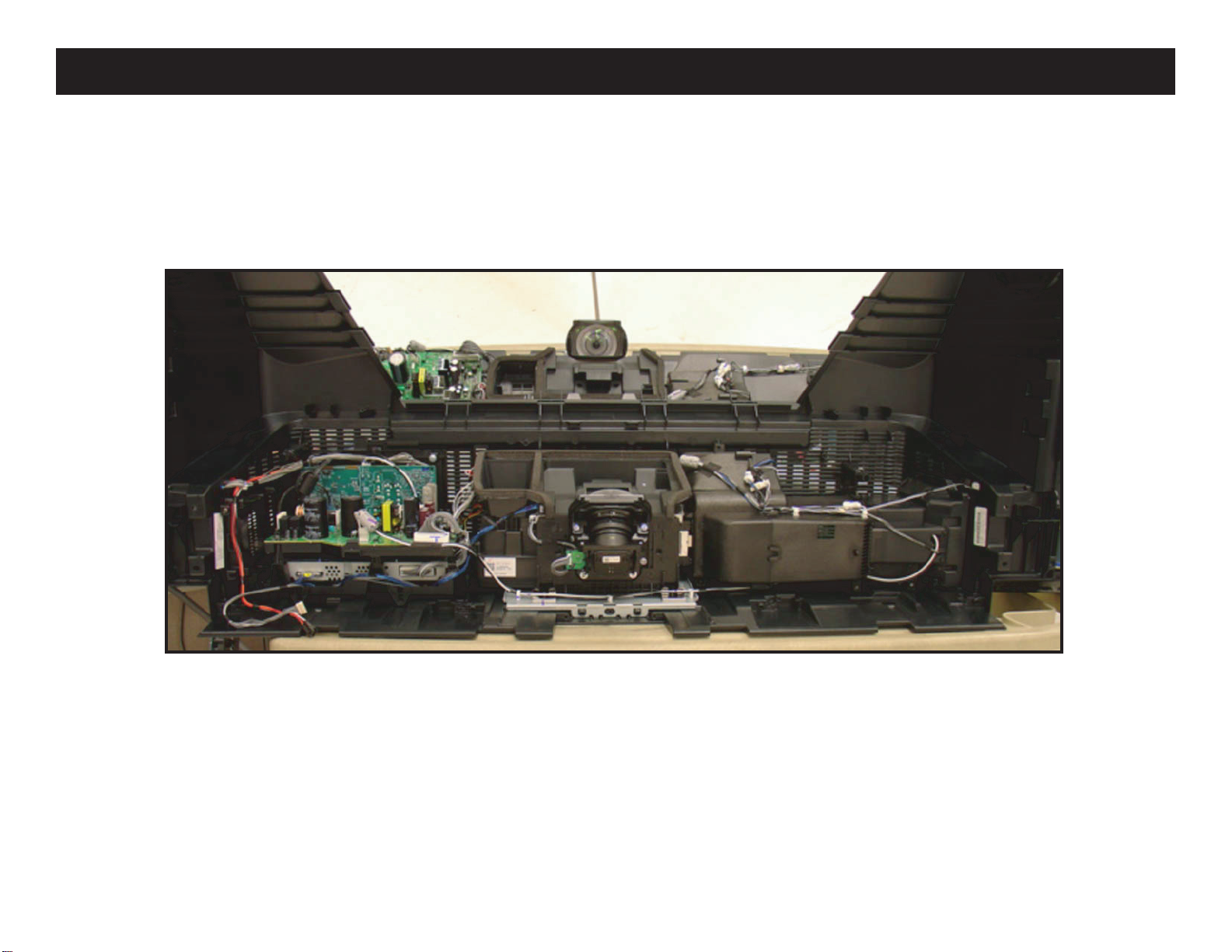

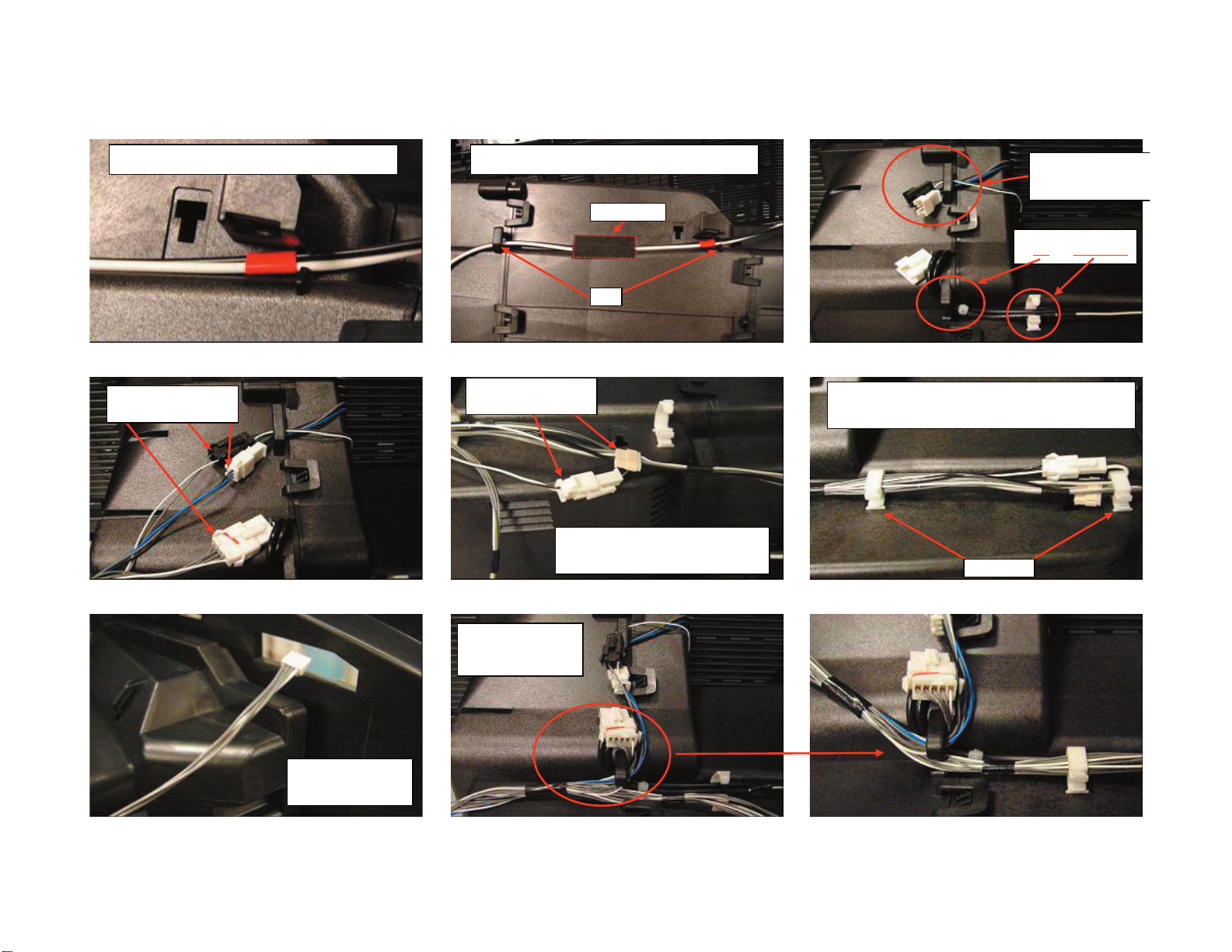

WIRE DRESSING

COMPLETE INTERNAL WIRE DRESSING

KDF-46E3000/50E3000

KDF-46E3000/50E3000

21

Page 22

r

r

A

OVERALL ASSEMBLY

KDF-46E3000/50E3000

fter installing Optical Block route

HARNESS ASSY into clips behind TOP

BRACKET, OPT (E)

Install 8P connector

from [CE] to [BE]

Install 3P Fan Connector

from Optical Block to

HARNESS ASSY

Install 15P connecto

Install 15P connecto

from [CE] to [G]

from [CE] to [G]

Dress 15P Connector

Dress 15P Connector

to wire pin on [G]

to wire pin on [G]

Dress 3P Fan Connector to

clips on TOP BRACKET,

OPT(E) as shown

Install 20P and 9P connector

from Duct Block Assy to [G]

Dress LVDS connector to

on Main Brkt

Install LVDS connector

from [CE] to [BE]

KDF-46E3000/50E3000

clips

22

Page 23

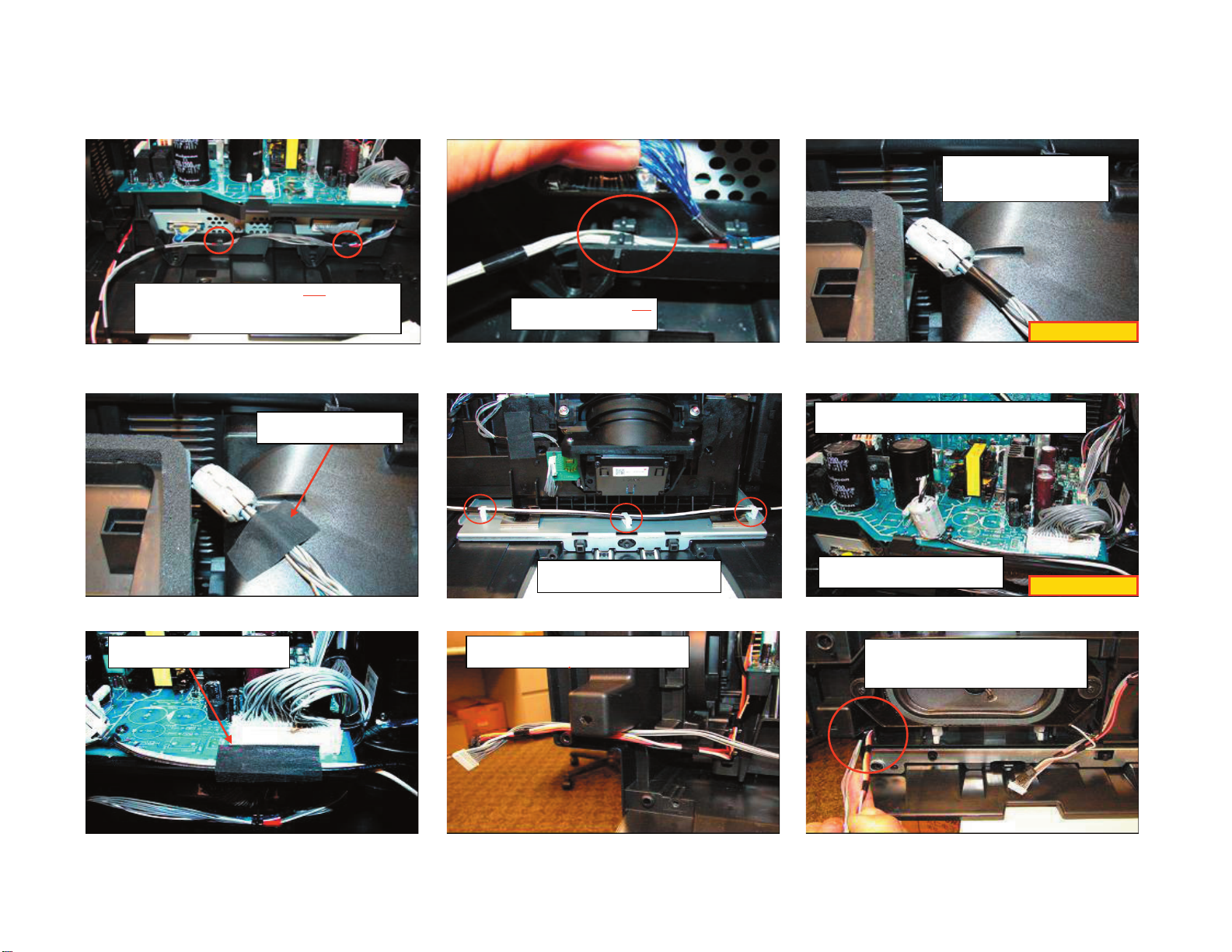

OVERALL ASSEMBLY (CONTINUED)

Dress 8P connector from [BE] to clips on Main Brkt.

RED Tape should line up with clips. This connector

should be on top of LVDS Connector

Dress 8P connector to clip

under LVDS connector

KDF-46E3000/50E3000

Install Ferrite Clamp

(146908911) to HARNESS

ASSY as shown.

CRITICAL FOR EMI

Secure HARNESS ASSY

with 20 X 40 HIMELON tape

Secure Ballast Power with 20 X 40

HIMELON tape as shown

Route Ballast Power as shown and

install to wire holders

Route 4P Speaker and 9P HAE connector

as shown before installing Seperator Blk

Install Ballast Power to [G], install Ferrite Clamp

(146908911) and dress to wire pin on [G] as shown.

Ferrite Clamp must be vertical and

as close to Connector as possible

After installing Separator Blk Assy ensure

4P and 9P Connetor are not pinched

between Rear cover and Separator

CRITICAL FOR EMI

KDF-46E3000/50E3000

23

Page 24

SPEAKER ASSEMBLY

Connect 4P Speaker and 9P HAE

connector as shown .

KDF-46E3000/50E3000

Dress 4P Speaker and 9P HAE connector

to wire holders on Separator Blk Assy

KDF-46E3000/50E3000

24

Page 25

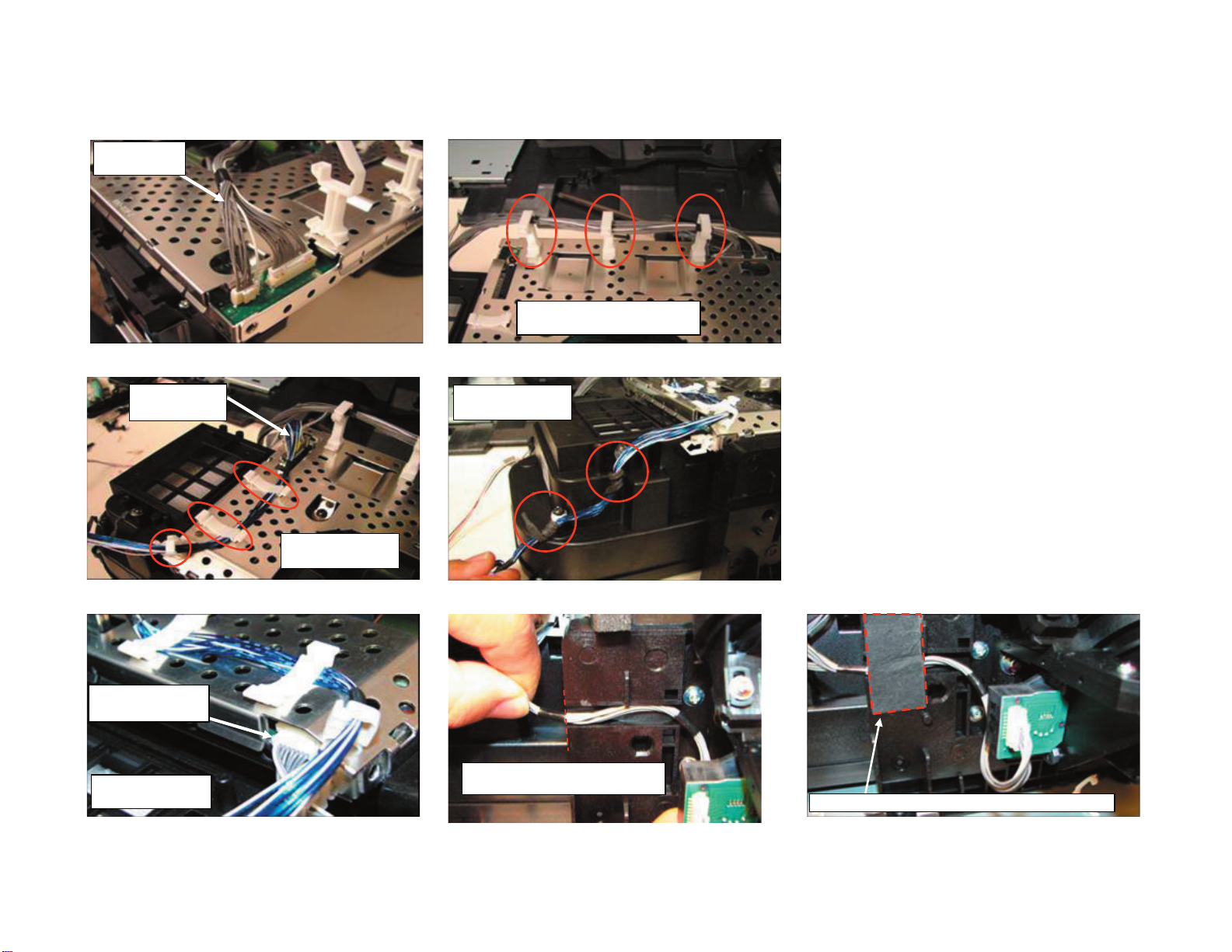

OPTICAL BLOCK ASSEMBLY

191003656

Harness Assy

KDF-46E3000/50E3000

Dress 191003656 to (3) Wire

Holders on CE Block

183411811 LVDS

Connector Assy

191003666

CONN ASSY, 8P 200

8P connector should be

below LVDS

Dress to (2) wire

holders as shown

Dress to (3) Wire

Holders on CE Block

Place wire into channel in Optical Blk.

Line up edge with tape on 8P Connector

Secure 8P Connector with 20 X 40 Himelon Tape 265206401

KDF-46E3000/50E3000

25

Page 26

A

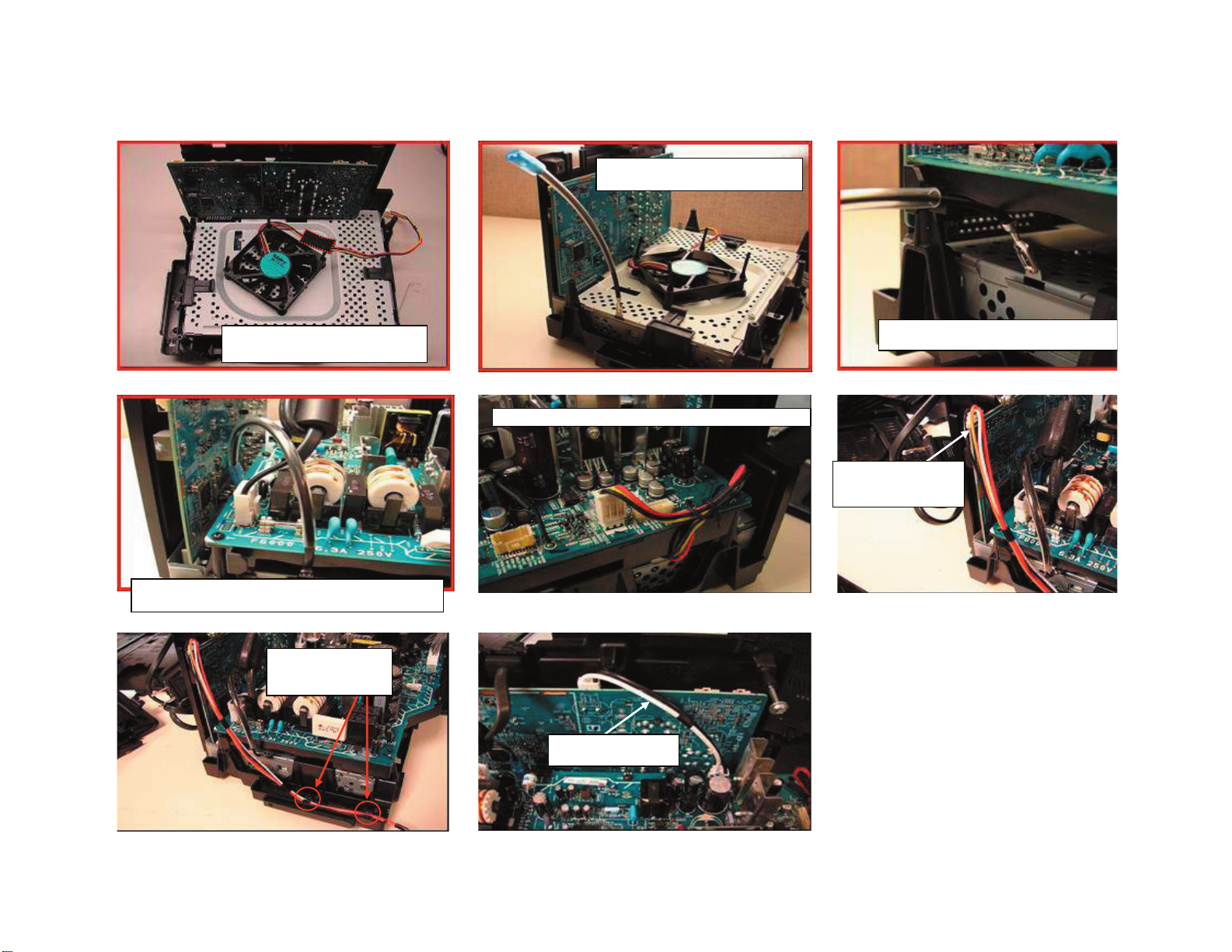

DUCT BLOCK ASSEMBLY

KDF-46E3000/50E3000

191002827

CONNECTOR ASSY 2P

fter installing 7P

Conn assy Secure to

Ballast Bracket with

20 X 40 Himelon

Tape 265206401 as

Shown. This is to

avoid it from hitting

Capacitor on ballast

5P Connector should be

under 2P Connector

191003664

CONN ASSY, 5P SMR 60

191003658

CONN ASSY, 7P 455

[T] Board

191003517

CONN ASSY 3P, SMR

191003659

CONN ASSY, 3P VH1120

Route Duct Blk Fan

toward [T] as shown

Use Caution when installing Duct block that 5P

and 2P Connectors are not pinched

191003658

CONN ASSY, 7P 455

Connector should be

routed outside of post

Secure Both Connectors to hooks on Ballast bracket and

ensure Ferrite core is placed in rib as shown

Rib

Hooks

KDF-46E3000/50E3000

After Installing Ballast Bracket route wires through

openings in Duct Block as shown.

26

Page 27

DUCT BLOCK ASSEMBLY (CONTINUED)

KDF-46E3000/50E3000

Install Ballast Power in Clip on bottom of Duct Block.

Wire should be routed with RED tape in this position

191003657

HARNESS ASSY

Install Ballast Power to Clip and secure with Himelon

Tape 20 X 40. Tape should be centered between clips

Himelon Tape

Clips

191003657

HARNESS ASSY

Connect 9P Ballast Control Connector and

2P Thermal Fuse Connector from

HARNESS ASSY 191003657

Route 3P Fan and 3P

[S] connector to clip on

top of Duct Blk.

Route 2P Thermal fuse

and wire holder.

to clip

Secure Harness Assy, 2P Thermal fuse,4P [HAE], and 9P

Ballast control connector to wire holders as shown.

NOTE: Ensure 9P Connector is routed as shown

Wire Holders

KDF-46E3000/50E3000

Route HARNESS ASSY

191003657 to Clip on

Duct Block.

Route 4P [HAE]

Connector through

Opening in Rear Cover

27

Page 28

A

r

b

CHASSIS ASSEMBLY

KDF-46E3000/50E3000

fter installing Fan Secure wire with 20 X

40 Himelon Tape as shown.

Lighting ground should be behind AC cord. UL Tube should be

located on [G] board side of connection as shown below

WIRE ASSY, FASTON TERMINAL

191003511

191003507

Dress 3P Chassis Fan Connector to WIRE PIN on [G] as shown

Before Installing [G] Board it may be necessa

bend tab slightly in order to properly install [G]

191003667

CONN ASSY, 4P

SPEAKER SMR

Dress 4P Speaker

Connector to (2) Clips

on Main Bracket

191003508

CONN ASSY, 3P VH 130

KDF-46E3000/50E3000

28

Page 29

CHASSIS ASSEMBLY (CONTINUED)

KDF-46E3000/50E3000

191003507

CONN ASSY, 40P

Dress 40P Connector to WIRE PIN on [G]

191003660

CONN ASSY, 9P

ZMR 500

KDF-46E3000/50E3000

29

Page 30

HCE BLOCK ASSEMBLY

KDF-46E3000/50E3000

HARNESS ASSY MUST BE INSTALLED BEFORE

PUTTING INTO HC BRACKET

191003665

HARNESS ASSY

Route HARNESS ASSY THROUGH

OPENING IN THE REAR COVER

Dress to wire holder installed on HCE Board.

Ensure connector is routed so that it does not go

above red line shown above.

Install on [U] board as shown. Connector

should be above 3P Connector

Dress to wire holder

on FAN BRACKET

Dress to Wire Holder on Terminal Bracket.

46" Models must be looped to take up excess slack

50" Models DO NOT need to be looped

KDF-46E3000/50E3000

Correct Routing

of HC wire

30

Page 31

r

SEPARATOR BLOCK ASSEMBLY

KDF-46E3000/50E3000

Dress Speaker Wire to clips on Separator before

installing. Black tape should be inside of clips.

Dress Speaker Wire and 9P [HBE] connector to wire

holders on the FRONT STAY

DO NOT install to wire holder

this should be done later.

Route 9P and Speaker

Wire as shown.

191003661

CONN ASSY, 9P ZHR 860

Route 9P and Speake

Wire as shown.

9P [HBE] should be

under speaker wire

KDF-46E3000/50E3000

31

Page 32

SECTION 2: CIRCUIT ADJUSTMENTS

KDF-46E3000/50E3000

2-1. USING THE REMOTE COMMANDER

FOR ELECTRICAL ADJUSTMENTS

To adjust various set features, use the Remote Commander to put the

set into service mode to display the service menus and categories.

Equipment Needed:

Pattern Generator (with component outputs)

Oscilloscope

Digital multimeter

2-2. ACCESSING SERVICE ADJUSTMENT

MODE

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a

second of each other:

DISPLAY

Channel 5 Volume +

DISPLAY

POWER

5

JUMP

Displays

Service Menus

POWER

.

2-3. VIEWING THE SERVICE MENUS

Use the Remote Commander to view the BE and Digital service menus

options.

1. To display the Service Menu that contains the Category you want to

adjust, press

(For a complete list of the service Categories refer to Service Menus)

SOFTWARE VERSION

VIDEO1 WIDE ZOOM

Press JUMP

PANEL

DIFF 1 60HZ

Press JUMP

0

0

JUMP

TVM:

ATSC:

BE:

NVM:

SWDL

F A:

CBA:

on the Remote Commander.

SERVICE

480I

P1. 000U. - BOOT: 0.005

HO7-01.01 0035

2.710 BOOT:A.103

AO-1.001:OK AC-1.000:OK

0.000

00000000 00000000

00000000 00000000

SERVICE

OPMODE

ONO

VOLUME (+)

RM-YD016

The fi rst service menu (TV) displays.

Onscreen cursor

and select button

WEM VERSION

Main

WM2. 710U00GA

Diff

WM2. 710U00GA

DL 0. 00 Gra 0216

SelfCheck 00 00 00 00

DEM VERSION

PMO. 000 PBO. 000

NVM: PDO. 000

Press JUMP

QM 0 0 SERVICE

INFO DTV

Press JUMP

Boot

Boot

Sample Service Menu

WM1. 103W00AA

WC2. 712U00GAa

KDF-46E3000/50E3000

32

Page 33

KDF-46E3000/50E3000

2-4. USING THE REMOTE COMMANDER TO

1. Access Service Adjustment Mode and select the Service Menu that

VIEW SERVICE DATA

Use the buttons on the Remote Commander to access the service menu

items and adjust the data values.

Adjustment

Item

Data Value

1 SN1 1

SN: 00000000

Service

Menu

Increase

3

Data Value

6

Decrease

Data Value

Display

5

Previous

Category

Read data

9

JUMP

Displays

Service Menus

Category

Display

Next Item

Display

Next Category

2

Display

Previous Item

Saves data

Item

Number

MODEL SERVICE

VIDEO1 WIDE ZOON 480I

NAME: KDF-46E3000

1

4

0

2. To change the Category, press 2 or 5 on the Remote Commander.

Note: Pressing 2 or 5 only changes the categories within the

3. To change the Adjustment Item, press 1 or 4 on the Remote

2-4-1. CHANGING SERVICE DATA

The service data values have been selected to provide the best

possible viewing performance. Although some of the data values

are adjustable, the adjustments are very sensative and changing

them may reduce the picture quality of the set. The following

instructions are provided for informational purposes only.

4. To change the Data Value, press 3 or 6 on the Remote

5. To save the changes, press

2-4-2. EXITING SERVICE MODE

After completing the changes, exit service mode.

6. To exit service mode, turn the power off by pressing

Wait 2 minutes before restarting the set to allow the fans to

2-5. UPDATING THE MODEL INFORMATION

contains the Category with the Adjustment Item you want to change.

Service Menu displayed. To change a Category on one of the other

Service Menus, press the

Menu is displayed.

Commander.

Commander.

completely shut down or the Service Menu will appear on the screen.

JUMP

button until the correct Service

MUTING

then 0 to write into memory.

POWER

.

WHEN REPLACING THE BE BOARD

MUTING

Writes data

into memory

RM-YD016

Use following instructions to update the model specifi c information

after replacing the BE Board.

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a

second of each other:

DISPLAY

3. Press 2 on the Remote Commander until the MODEL category

displays.

4. The fi rst adjustment item to display is SZID. The initial data value of

the SZID adjustment item is set to 0 and displays the Model name as

KDF-37H1000. To change the Model name, press 3 on the Remote

Commander until the correct Model name displays. 3 displays KDF-

46E3000 and 4 displays KDF-50E3000.

5. Press 1 on the Remote Commander until the SN8 adjustment item

displays.

NOTE: The SN1 adjustment item displays fi rst, however, SN8 allows

you to change the fi rst digit of the serial number.

6. The initial data value of the SN8 adjustment is set to 0 and displays

the serial number as 00000000. To change the fi rst digit of the serial

number to the correct number, press 3 on the Remote Commander

until the correct fi rst digit displays.

7. Press 4 on the Remote Commander to display the SN7 adjustment

item.

Channel 5 Volume +

POWER

.

KDF-46E3000/50E3000

33

Page 34

KDF-46E3000/50E3000

t

s

s

/

8. Change the data value of the serial number to the correct serial

number, by pressing 3 on the Remote Commander until SN7

adjustment displays. (SN7 is the second digit of the serial number

range.)

9. Repeat steps 7 and 8 for SN6 through SN1 until the correct serial

number displays.

10. To save the changes, press

After completing the changes, exit service mode.

11. To exit service mode, turn the power off by pressing

MUTING

then 0 to write into memory.

POWER

.

2-5-1. VERIFYING MODEL INFORMATION

Verify the changes to the model information by viewing the

information in the Product Support category of the user Settings

menu options.

1. Turn the TV on by pressing

2. Press

The user menu icons display.

HOME

Menu items.

on the Remote Commander to display the User

Settings

POWER

on the Remote Commander.

Product Support

Clock/Timers

2-6. ADJUSTING THE HORIZONTAL AND

VERTICAL SETTINGS

1. Turn the TV on by pressing

2. Press

The user menu icons display.

3. Press the

4. Press the

HOME

Menu items.

Settings option, and then press the

Screen Settings category, and then press the

on the Remote Commander to display the User

buttons on the Remote Commander to select the

B/b

button on the Remote Commander to select the

V/v

POWER

Screen Setting

5. Press the

Screen Position category, and then press the

6. Press the

Vertical or Horizontal position, and then press the

increase or decrease the position.

button on the Remote Commander to select the

V/v

button on the Remote Commander to select the

V/v

on the Remote Commander.

button.

button.

button.

buttons to

B/b

2-7. RESETTING THE LAMP

Use the following to reset the lamp after replacement.

1. Turn the TV on by pressing

2. Press

The user menu icons display.

3. Press the

4. Press the

HOME

Menu items.

Settings option, and then press the

General Settings category, and then press the

on the Remote Commander to display the User

buttons on the Remote Commander to select the

B/b

button on the Remote Commander to select the

V/v

POWER

on the Remote Commander.

button.

button.

Sound

Screen

Video Options

3. Press the

Settings option, and then press the

4. Press the

Product Support category, and then press the

buttons on the Remote Commander to select the

B/b

button.

button on the Remote Commander to select the

V/v

button.

Product Suppor

5. Press the

Contact Sony option, and then press the

6. Verify the changes you made in Service Mode are correct.

buttons on the Remote Commander to select the

B/b

button.

General Setting

5. Press the

Replacement category, and then press the

6. To select Yes, press the

button on the Remote Commander to select the Lamp

V/v

button.

button and then press the button.

B

2-8. VERIFYING SERVICE DATA CHANGES

1. After completing all adjustments turn the set off with the Remote

Commander and WAIT for the fans to turn off before proceeding to

the next step.

Note: It may take up to two minutes for the fans to stop.

Caution: To avoid over heating the lamp, do not unplug the set

until the fans have stopped.

2. Press the following buttons on the Remote Commander within a

second of each other:

DISPLAY

3. To verify the changes repeat steps 1 through 3 of 2-4. Using the

Remote Commander to View Service Data.

4. To exit service mode, turn the power off by pressing

NOTE: After exiting service mode wait 2 minutes before restarting

the set to allow the fans to shut down properly.

Channel 5 Volume +

POWER

POWER

.

.

KDF-46E3000/50E3000

34

Page 35

2-9. RESETTING TO FACTORY DEFAULTS

Use the following instructions to restore the User Controls and

Channel Memory settings to the preset factory conditions.

KDF-46E3000/50E3000

1. While holding down the

POWER button on the Front Panel of the set.

The set restarts and displays the initial setup screen. This may take

several minutes.

on the Remote Commander, press the

KDF-46E3000/50E3000

35

Page 36

3-1. CIRCUIT BOARDS LOCATION

KDF-46E3000/50E3000

SECTION 3: DIAGRAMS

3-2. PRINTED WIRING BOARDS

B-BLOCK

G

U

OPTICAL UNIT BLOCK

(Includes the C Board)

HCE

SE

TE

HBE

HAE

AND SCHEMATIC DIAGRAMS INFORMATION

All capacitors are in μF unless otherwise noted. pF : μμF 50WV or

less are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. kΩ=1000Ω, MΩ=1000kΩ

Indication of resistance, which does not have one for rating

electrical power, is as follows: Pitch : 5mm

Rating electrical power :

1

/

W in resistance, 1/

4

W and 1/

10

W in chip resistance.

16

1

/

W

4

: nonfl ammable resistor

: fusible resistor

: internal component

: panel designation and adjustment for repair

: earth ground

: earth-chassis

All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10MΩ digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production

tolerances.

All voltages are in V.

S : Measurement impossibility.

: B+line.

: B-line. (Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

The components identifi ed by shading and ! symbol are critical for safety. Replace

only with part number specifi ed.

The symbol indicates a fast operating fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

!

Les composants identifi es per un trame et une marque

securite. Ne les remplacer que par une piece portant le numero specifi e.

Le symbole indique une fusible a action rapide. Doit etre remplace par une

fusible de meme yaleur, comme maque.

NOTE: The components identifi ed by a red outline and a mark contain confi dential

information. Specifi c instructions must be adhered to whenever these components

are repaired and/or replaced.

See Appendix A: Encryption Key Components in the back of this manual.

sont critiques pour la

KDF-46E3000/50E3000

36

Page 37

REFERENCE INFORMATION

(

)

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

KDF-46E3000/50E3000

Terminal name of semiconductors in silk screen

printed circuit ( )

Device Printed symbol Terminal name

Transistor

1

Transistor

2

3

Diode

4

Diode

Diode

5

Diode

6

Diode

7

8

Diode

Diode

9

Diode

0

Diode

qa

Diode

qs

Transistor

qd

(FET)

Transistor

qf

(FET)

Transistor

qg

(FET)

Transistor

qh

Transistor

qj

Transistor

qk

Transistor

ql

Transistor

w;

Transistor

wa

Transistor

ws

Transistor

wd

Discrete semiconductot

–

Chip semiconductors that are not actually used are included.

*

Collector

Base

Collector

Base

Cathode

Cathode

Anode

Cathode

Anode

Common

Anode

Common

Anode Cathode

Common

Anode

Common

Anode Anode

Common

Cathode

Common

Cathode

Anode

Anode

Cathode

Drain

Drain

B1 E1C2

B2 C1

E2

B2 E2C1

B1 C2

E1

B2 E2

C1

B1 C2E1

B2 E2

C1

B1 C2E1

E2

B1 E1

(B2)

E1

B1

(B2)

E1

E2

C2

Emitter

Emitter

Anode

(NC)

(NC)

Cathode

Anode

Cathode

Cathode

Cathode

Anode

Anode

Source

Gate

Source

Gate

Source

Drain

Gate

Emitter

Collector

Base

C1(B2)C2

E2

C2C1

B1

C1

Circuit

D

G

D

S

B1

B1

B1

B1

B1

B1

D

G

S

S

D

G

C1

E1

C1

E1

E1

C1

E2

C1

C1

G

S

C2

B2

E2

C2

B2

E2

E2

B2

C2

C2C1(B2)

E2

E2E1(B2)

C2

C2E1(B2)

C2

Ver.1.5

KDF-46E3000/50E3000

37

Page 38

3-3. BLOCK DIAGRAMS

SIGNAL FLOW BLOCK DIAGRAM

KDF-46E3000/50E3000

+$&%3)'.!,&,/7

"US)&

4UNER

$EMOD

.43#"43#

(#

#/-0

6)$%/

36)$%/

$46)&

)3

30$)&

#69#9#B#R

30)

-B

!4I8),,%/.

.!.$

&LASH

-B

3-!6

X

,0&

$$2

-B

.6KB

BIT$$2A2'"

BITSYNC

5!24!4)*)'

##08!

#8$

2'A

&,)0&,/0

4#6#8&4

'"A

BIT

5!2446!4)

$E-58

BIT

$2#-&6

#8$1

$$2

$$2

-B

-BX

)&03

#8$

7%-ICRO

!2-

.6-

KB

$IGITAL6IDEO

!NALOG6IDEO

5!24467%

BIT2'"X

#-/3

&LASH

-B

46-ICRO

3AIPH

"%

,6$3

4X

$IGITAL!UDIO

)#7%

)#46

!NALOG!UDIO

#%

.!#%,

%PSON

,%

)#.!#%,

$%-ICRO

)#$%

.6-

KB

,INE"US

"US

3W

$IGITAL6IDEO

-EMORY

#ONTROL

2,#$$R

ON&&#

',#$$R

ON&&#

",#$$R

ON&&#

.6-

KB

,-!

0ANEL

6)$%/

#/-0

#/-0

!5$)/

&OR$6)

!UDIO/54

/PT!UDIO

5

6IDEO37

!UDIO37$30

#8!2

4!3

#LASS$ !-0

40!$

3$2!-

-B

30%!+%2

,7

30%!+%2

27

)3

3$2!-

-B

($-)%Q

#8"!2

($-)

($-)

9#B#R BIT&ORP

9#B#R BIT2'"BIT

($-)2X

3I)

"US3W

KBX

($-)

-ICRO

%$)$

)#($-)

)#!$30

5!2446*)'

)#46

"53#ONNECTOR

)2)3

&!.

'

6 6

"US,EVEL3HIFT

3

,-!

,!-0

(#

,-!

&!.

KDF-46E3000/50E3000

38

Page 39

CONNECTION DIAGRAM

KDF-46E3000/50E3000

S

P

HBE

CN110

CN6002

CN3008

CN3006

G

CN6904

CN3002

BE

CN6501

CN6906

CN6802

CN6804

CN6009

CN6019

CN3750

CN3700

CN3009

TO LAMP DRIVER

TO FANS

CN160

CN150

CN100

SE

TE

HAE

CN8150

CN8152

CN8151

CN8300

CE

S

P

TO IRIS

KDF-46E3000/50E3000

HCE

CN180

CN181

Included with optical block

CN2503CN2502

CN2504

U

CN2500

CN2501

CN2000

BtoB

Conventional

LVDS

39

Page 40

3-4. SCHEMATICS AND SUPPORTING INFORMATION

BE BOARD SCHEMATIC DIAGRAM (1 OF 12)

KDF-46E3000/50E3000

A

—

B

—

C

—

D

—

E

—

F

—

G

—

H

—

I

—

J

—

K

—

L

—

M

—

N

—

O

—

P

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 |

TO HBE BOARD

CN110

CN3008

9P

STBY_5V

FAN2/4-VC

R3010

22k

1/16W

RN-CP

0.5%

2

R3009

1/16W

RN-CP

L3000

10uH

47k

0.5%

1

A5V

2

C3002

1608

L3001

10uH

0.1

16V

B

1

R3002

470k

1/16W

CHIP

5%

1

2

12

C3000

C3001

0.1

47

10V

16V

B

1608

1

2

12

C3004

C3003

47

10V

I

VSS

IC3006

XC6203P182PR

1.8V REG.

R3007

47k

1/16W

RN-CP

0.5%

Q3006

2SC3052EF-T1-LEF

S-VBUS

S-UDM

S-UDP

S-UDP

R3019

0

12

CHIP

1005

IC3001

TAR5S33(TE85R)

5

54

3.3V REG.

123

12

STBY1.8V

1

C3006

2

12

0.1

16V

B

1608

O

HDMI-CEC/OUT

FAN-CTRL

FAN-PROT

ADSP-MUTE

LINE-MUTE

LAMP-CTRL

LAMP-COVER

LAMP-PROT

S-UDM

R3020

0

12

CHIP

1005

4

321

12

12

C3007

C3005

0.1

0.01

16V

25V

B

B

1608

1608

47

6.3V

FAN1-VC

FAN3-VC

SP-MUTE

HV-DET

S-VBUS

RT1N141C-TP-1

STBY_3.3V

TIMER_LED

PITMUTE_LED

GND

STBY_3.3V

STBY_3.3V

12

1

C3008

6.3V

2

47

C3011

0.01

1608

2

1

12

L3002

10uH

25V

B

X3000

48MHz

12

C3012

0.01

25V

1608

B

C3009

1608

12

C3014

6.3V

10

L3003

10uH

2

1

RB3006

100

10V0.1

10V0.1C3087

10V0.1

47R3029

R3021

10k

1/16W

CHIP

12

47kR3111

47kR3112

47kR3113

R3115

100

RB3008

100

RB3009

100

0

CHIP

R3108

22

R3012

1/16W

12

C3015

0.1

R3031

47

1/16W

12

12

1/16W

1.5kR3028

1/16W

R3075

10k

1/16W

CHIP

5%

Q3017

RT1N141C-TP-1

12

133

134

135

136

137

138

139

140

141

TP3007

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

12

12

1

C3013

22

10V

2

TP3009

C3089

C3088

16V0.1C3010

12

12

R3003

47k

1/16W

3

CHIP

5%

12

0.1

16V

B

MAIN-H

TIMER-LED

PICMUTE-LED

RB3011

100

I_HDMI_HPD1

I_HDMI-PID2

I_HDMI-PID3

O_HDMI_HPC1

I_HDMI_HPD2

0_HDMI_HPC2

I_HDMI_HPD3

O_HDMI_HPC3

O_HDMI_CEC/OUT

O_IRIS_BL

O_FAN1_VC

O_FAN3_VC

O_FAN_CTRL

I_FAN_PROT

O_ADSP_MUTE

O_SP_MUTE

O_LINE_MUTE

O_LAMP_CTRL

I_LAMP_COVER

I_LAMP_PROT

I_LAMP_HV_DET

I_USB_DET

L1.8V

USB_CLK1

GND

USB_CLK0

3.3V

UDM

UDP

O_D_B0

O_D_B1

O_D_B2

O_D_G0

O_D_G1

O_D_G2

O_D_R0

O_D_R1

O_D_R2

L1.8V

O_YM

O_YS

FH

DOT_CLK_O

DOT_CLK_I

I_OSD_V

I_OSD_H

I_MAIN_H

1234567891011121314151617181920212223242526272829303132333435363738394041424344

12

R3039

100

1/16W

CHIP

5%

STBY_3.3V

12

2

Q3009

2

R3054

1/16W

CHIP

STBY_3.3V

10k

12

5%

Q3016

RT1N141C-TP-1

2

12

LAMP_LED

CHIP

CHIP0

0R3071

12

R3073

LAMP-LED

STBY-LED

HDMI-MICRO-RST

I_HDMI-PID1

O_HDMI_RST

HSYNC3

3.3V

R3044

10k

1/16W

CHIP

5%

RT1N141C-TP-1

R3057

10k

1/16W

CHIP

5%

RT1N141C-TP-1

STBY_LED

CHIP

0

12

R3022

POWER-LED

DL-MODE

O_DL_MODE

GND

Q3102

2

Q3101

2

SIRCS

GND

POWER_LED

123456789

CHIP

CHIP

0

0

12

12

R3023

R3074

WE-WDT

1kR3050

12

1/16W

I_OVP

I_WE_WDT

VGS1

CPO1

12

1608

CH

100V

100p

C3084

12

R3049

3.3k

1/16W

12

R3048

510

1/16W

CHIP

12

C3020

0.22

16V

B

1608

LOW-B

OVP

1/16W1kR3137

1608

16V

0.1

12

3.3V

I_LB_ERROR

VSSP1

A3.3V

1608

CH

100V

100p

C3086

5%

12

C3021

0.1

16V

B

1608

12

UDZS-TE17-12B

12

PICMUTE-LED

C3026

0.1

16V

B

1608

12

1/16W1k

R3104

C3022

GND

L1.8V

VGS2

CPO2

12

R3056

3.3k

1/16W

12

R3055

510

1/16W

CHIP

5%

12

C3027

C3025

0.1

0.22

16V

16V

B

1608

1608

10.5V

D3103

UDZSTE-178.2B

10.5V

D3102

SIRCS

LAMP-LED

TIMER-LED

1/16W

1k

R3058

O_TIMER_LED

O_PICMUTE_LED

VSSP2

A3.3V

1608

CH

100V

100p

C3085

12

B

STBY-LED

1/16W

1k

R3105

1/16W

1k

R3060

O_STBY_LED

O_LAMP_LED

VGS3

CPO3

12

12

R3064

3.3k

1/16W

12

R3063

510

1/16W

CHIP

5%

12

C3030

0.22

16V

B

1608

POWER-LED

1/16W C HIP5%100R3017

1/16W

1k

R3065

O_POWER_LED

VSSP3

12

C3031

0.1

16V

B

1608

UART_TV_JIG_TX

UART_TV_JIG_RX

NOTCH-FIL

1/16W47k

R3086

100

RB3026

O_NOTCH_FIL

UART_TVJIG/SO3

A3.3V

VDDR

C3078

1608

UART_TV_ATI_TX

UART_TV_ATI_RX

1/16W100

R3125

SDA-TV0

10RB3025

O_DM_RST

UART_DM/SI2

UART_DM/SO2

UART_TVJIG/SI3

SAIPH

IC3002

MB91F318RPMC-G-001E1

VREF

VRO

ROUT

VSSR

12

0.1

16V

B

I2C-WE

UART_TV_JIG

UART_TV_ATI

SCL-TV0

I2C_TV0/SDA4

I2C_TVMNVM/SDA3

VDDG

GOUT

10kR3124

I2C_WE/SDA2

I2C_TV0/SCL4

I2C_TVMNVM/SCL3

VSSG

VDDB

BOUT

R3066

1M

1/16W

CHIP

5%

ISA1235AC1TP-1EF

SCL-WE0

SDA-WE0

RT1N141C-TP-1

10kR3123

O_SP_SD

I2C_WE/SCL2

VSSB

I_DATA_SLICER_0

12

Q3001

B-INT-CE

LAMP-CTRL

Q3000

2

SP-SD

100

RB3007

I_HDMI_CEC/IN

I_DATA_SLICER_1

R3110

100

1/16W

CHIP

5%

12

C3032

0.1

16V

B

1608

SCL-DE

SDA-DE

RST-ADSP

AU-PROT

I_AU_PROT

O_ADSP_RST

A3.3V

GND

12

R3068

1/16W

3

1

R3070

15k

1/16W

CHIP

5%

2.2k

CHIP

NMIX

L1.8V

5%

2

12

R3038

100

1/16W

CHIP

5%

INT-ADSP

C3040

18p

50V

12

1

3

31

C3039

0.1

16V

B

1608

100R3121

1/16W

INT_ADSP

INT_HDMI

INT_OSD_V

AVCC

AVRH

AVSS/AVRL

R3091

1.5k

1/16W

CHIP

5%

C3033

0.1

16V

B

1608

12

1005

12

12

CH

50V

82p

C3034

12

R3072

56k

1/16W

CHIP

5%

ATSC-RST

C3041

15p

50V

CH

32.768kHz

1005

X3001

12

1/16W270kR3094

1/16W100R3088

12

L1.8V

SUB_CLK1

I_KEY

I_POWER_KEY

12

R3092

1k

1/16W

12

12

R3090

1k

1/16W

CHIP

5%

12

12

C3038

D3008

1000p

UDZSTE-175.6B

50V

B

1005

1

C3035

100

16V

2

12

3

R3076

4.7k

1/16W

CHIP

5%

1

5%

CHIP

1/16W

10k

R3101

12

ISA1235AC1TP-1EF

2

24

4

12

16V0.1

12

C3042

3.3V

GND

SUB_CLK0

I_TUNER_AFT

TP3008

TP3010

R3082

10k

1/16W

R3096

12

330k

C3064

12

1000p

50V

1005

2

1

L3004

R3081

12

10uH

2.2k

1/16W

CHIP

5%

Q3002

ISA1235AC1TP-1EF

2

POWER-KEY

12

3

2

1

Q3003

ISA1235AC1TP-1EF

R3100

47

R3107

1/16W

10k

CHIP

1/16W

12

5%

CHIP

5%

10k

R3122

8990919293949596979899100101102103104105106107108109110111112113114115116117118119120121122123124125126127128129130131132

I_MAIN_HIN

INT_WAKE

I_MAIN_V_CCD

O_FAN2&4_VC

I_MAIN_H_CCD

I_SIRCS

O_WE_RST

UART_WE/SO1

UART_WE/SI1

UART_PROGJIG/SCK0

UART_PROGJIG/SO0

UART_PROGJIG/SIO

I2C_ADSP/SDA1

I2C-ADSP/SCL1

I2C_HDMI/SDA0

I2C_HDMI/SCL0

I_RESET

IBREAK

TRSTX

L1.8V

MAIN_CLK1

MAIN_CLK0

I_B-INT

I_VOUT_DET

0_LAMP_SEL

O_TUNER_AGC

0_HDMI_SEL

O_TVMNVM_WP

O_POWER_MUTE

C3036

0.01

25V

B

1608

12

12

R3087

47

1/16W

CHIP

5%

3

1

MD3

MD2

MD1

MD0

ICD3

ICD2

ICD1

ICD0

ICS2

ICS1

ICS0

ICLK

GND

3.3V

P25

P24

Q3004

O_AC_RELAY

2

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

C3053

0.1

10V

X7R

1005

R3119

100

12

C3044

R3126

1/16W

A9V

MAIN_Y/CV_SAIPH

R3120

100

100

12

R3117

10k

1/16W

RB3002

8

6

4

2

0.1

100

RB3022

100

RB3021

To Upgrade To Emmulatar

CN3000

8P

12

R3118

10k

1/16W

CHIP

5%

Q3103

2SC3052EF-T1-LEF

100

RB3016

1

3

5

7

47

RB3024

1

3

5

7

47

RB3023

12

R3133

47

1/16W

47

7

5

3

1

RB3012

16V

1608

R3127

100

1/16W

R3131

47

R3130

0

2

4

6

8

R3114

10k

1/16W

2

4

6

8

47

12

C3045

0.1

16V

B

1608

STBY_3.3V2RESET3MD24P255E6SI07SO08SCK0

1234567

1

R3089

100k

1/16W

CHIP

5%

R3139

10k

1/16W

SDA-HDMI0

SCL-HDMI0

RB3003

47

8

6

4

2

R3135

1k

1/16W

CHIP

5%

12

R3128

10k

1/16W

CHIP

5%

SI0

R3136

2.2M

1/16W

CHIP

5%

12

8

SO0

SCK0

HDMI-CEC/IN

O_IFPVSOUT

MAIN-V

WE-RST

SIRCS

D3.3V

7

5

3

1

R3132

47

12

2

10.135MHz

1

12

V-DET

LAMP-SEL

D3.3V

AGC_MUTE_TVM

HDMI-SEL

AC-RELAY

POWER-MUTE

POWER-KEY

KEY

X3002

SI0

SO0

SCK0

HDMI-I2C

R3134

47

1/16W

CHIP

5%

C3047

15p

50V

CH

1005

50V15pC3046

UVCC2XTRST3XRSTIN4XINIT5BREAK6ICD37ICD28ICD19ICD010ICS211ICS112ICS013GND14ICLK

123456789

1

R3143

R3142

10k

12

47

1/16W

1/16W

CHIP

CHIP

12

5%

5%

12

12

C3043

1000p

50V

B

12

12

C3050

0.1

16V

B

1608

12

MC2838-T112-1

1

2

B-INT-CE

RST

4

54

VCC

5

BD4729GTR

R3145

2.2k

1/16W

CHIP

5%

12

R3140

47

1/16W

CHIP

5%

I2C-TV0

(3.3V)

R3106

10k

1/16W

CHIP

5%

SCL-TV0

SDA-TV0

R3141

470

1/16W

CHIP

5%

1608

C3037

0.1

16V

1005

B

D3007

RESET

IC3003

3

12

1011121314

321

R3147

12

2.2k

1/16W

CHIP

5%

B-INT

RT1N141C-TP-1

3

2

1

D3104

MC2836

D3105

MC2836

C3074

2200p

50V

B

1005

R3053

1/16W

R3146

10k

12

1/16W

CHIP

5%

STBY3.3VSTBY3.3V

Q3007

2

RT1N141C-TP-1

SSM6N15FU(TE85R)

IC3004

324

D2G1S1

CN3001

14P

ISA1235AC1TP-1EF

R3008

2.2k

1/16W

CHIP

5%

12

1005

10k

12

CHIP

5%

12

R3153

2.2k

1/16W

CHIP

5%

2

Q3010

D1 G2 S2

8

7

6

5

4

3

2

1

RB3004

10k

C3052

0.1

25V

F

1608

12

3

Q3005

2

1

12

R3013

R3011

1M

10k

1/16W

1/16W

12

CHIP

CHIP

5%

5%

1005

1005

H- COUNT

R3181

10k

1/16W

12

CHIP

5%

R3151

47k

1/16W

CHIP

5%

R3186

10k

12

1/16W

CHIP

12

12

5%

R3185

10k

1/16W

CHIP

ISA1235AC1TP-1EF

5%

MC2838-T112-1

651

R3102

10k

1/16W

CHIP

5%

C3057

47

10V

2

1

1

L3006

10uH

2

12

R3005

C3075

0.022

4.7k

25V

1/16W

12

B

CHIP

1608

1005

D3.3V

3

2

1

Q3011

R3168

1/16W

D3004

3

1

2

23

1

MC2836

D3003

R3103

10k

1/16W

CHIP

5%

5%

1.8k

CHIP

5%

12

TP3002

D3.3V

TUNER_CV_SAIPH

SDA-ADSP

SCL-ADSP

12

R3164

10k

1/16W

CHIP

5%

12

R3170

1.8k

1/16W

CHIP

5%

D3.3V

JL3759

JL3760

SAIPH_TXD

SAIPH_RXD

123456789

0

0

R3043

R3042

12

12

12

RXD

TXD

UART0_TXD

TXD

I2C-ADSP

R3169

10k

1/16W

CHIP

5%

12

1

C3056

23

0.01

25V

B

1005

D3005

MC2836

MC2838-T112-1

C3090

12

LEVEL SHIFT

BE BOARD

ATI-TXD

0

R3041

12

1

2

D3006

0.1

16V

B

1608

ATI-RXD

0

R3014

SDA-DE

UART0_RXD

12

R3173

10k

1/16W

CHIP

5%

3

SDA-DE

12

SCL-DE

D5VEB-INT

0

0

R3027

R3030

12

A5V

SCL-DE

UART_TV_WE_RX

12

L3008

10uH

i 5V_I2C)

I2C-TV1

SDA_TV1

SCL_TV1

10

11

0

0

R3025

R3026

12

12

12

B-INT

JL3017

R3045

1k

1/16W

CHIP

5%

R3080

0

CHIP

R3083

0

CHIP

UART_TV_WE_TX

8765

WP

CLK

$A0

TVM NVM

4321

D3.3V

A5V

JIG_CONNECTOR

CN3007

11P

BRN

0

R3024

Q3012

2SC3052EF-T1-LEF

DAT

IC3005

M24128-BWMN6T(A)

UART_TV_JIG_TX

UART_TV_JIG_RX

UART_TV_WE

10.5V

R3061

4.7k

1/16W

CHIP

5%

STBY_5V

12

UART_TV_JIG

3

2

D3107

MC2838-T112-1

ISA1235AC1TP-1EF

D3108

RB425D-T146

1

Q3008

A5V

R3059

4.7k

1/16W

12

CHIP

5%

2

HDMI-MUTE

C3080

0.01

25V

1005

3

1

2

1

B

C3051

470

16V

3

1

C3079

FL3003

100

0uH

16V

2

12

AC-OFF/HDMI-MUTE

1

2

TO U BOARD

CN2502

CN3006

SPDIF

ATI_I2S

AU-PROT

SP-SD2

ADSP-MUTE2

RST-ADSP

INT-ADSP

SCL-ADSP

MAIN_CR

MAIN_CB/C

MAIN_Y/CV

3

C3083

0.01

25V

B

1005

SDA-TV1

SCL-TV1

1

2

C3062

0.01

25V

B

1005

TUNER_R

TUNER_L

SDA-ADSP

SCL-TV1

SDA-TV1

C3063

0.01

25V

12

B

1005

1

C3082

100

16V

2

12

C3066

100

16V

12

C3095

1000p

50V

R3099

0

CHIP

1005

R3144

0

CHIP

1005

1

2

C3065

1

1

100

16V

2

EMI

3

G

1

EMI

R3040

0

R3037

1/16W

R3032

R3034

R3033

POWER-MUTE

PAWN-MUTE

ADSP-MUTE

SP-MUTE

SP-MUTE2

LINE-MUTE2

LINE-MUTE

SP-SD

SP-SD2

2

FL3004

FL3002

0uH

3

G

1k

5%

0

0

0

I2C-ADSP

I2C-TV1

D3.3V

10.5V

A9V

LAMP-SEL

FAN3-VC

FAN2/4-VC

FAN1-VC

I2C-TV1

AC-RELAY

LAMP-COVER

LAMP-PROT

LAMP-CTRL

HV-DET

FAN-CTRL

1

EMI

3

G

12

R3062

10k

1/16W

CHIP

5%

FAN-PROT

2

DE-BUSY

RESETX

PAWN-MUTE

POWER-KEY

KEY

TUNER_R

TUNER_L

TUNER-CV

SP-MUTE2

MAIN-Y/CB/CR

LINE-MUTE2

MC2838-T112-1

D3113

MC2838-T112-1

D3112

MC2838-T112-1

D3109

2

3

1

D3110

MC2838-T112-1

MC2838-T112-1

D3111

0uH

C3093

0.01

25V

1005

2

B

R3098

CHIP

0

R3069

1k

1/16W

CHIP

5%

Q3018

RT1N141C-TP-1

ATI_SD0

ATI_WS

ATI_SCK

ATI_MCLK

D3.3V

ADSP-MUTE2

SPDIF

1

ATI_SD0

2

ATI_WS

3

ATI_SCK/DIG_AU_R

4

ATI_MCLK/DIG_AU_L

5

GND

6

AU_PROT

7

SP_SD2

8

GND

9

ADSP_MUTE2

10

ADSP_RST

11

ADSP_INT

12

GND

13