Page 1

Page 2

KD-65/85X9500B

3

Page 3

These servicing instructions are for use by qualified service personnel only.

To reduce the risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis.

The chassis of this receiver is directly connected to the ac power line.

Be sure to follow these guidelines to protect your property and avoid causing serious injury.

• Carry the TV with an adequate number of people; larger size TVs require two or more people.

C t h d l t hil i th TV i i t t f f t d t id d• Correct hand placement while carrying the TV is very important for safety and to avoid damages.

Components identified by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace these components with Sony

parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that are critical for safe operation are identified in this manual.

Follow these procedures whenever critical components are replaced or improper operation is suspected.

• Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type.

O t b k b tt h ld t t t t t• Outer case broken battery should not contact to water.

KD-65/85X9500B

4

Page 4

When repairing the LCD panel, be sure you are grounded by using a wrist band.

When repairing the LCD panel on the all the LCD panel m st be sec red sing the 4 mo nting holes on the rear co erWhen repairing the LCD panel on the wall, the LCD panel must be secured using the 4 mounting holes on the rear cover.

1) Do not press on the panel or frame edge to avoid the risk of electric shock.

2) Do not scratch or press on the panel with any sharp objects.

3) Do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause a short circuit within the module.

6) Disconnect the AC power when replacing the backlight (CCFL) or inverter circuit. (High voltage occurs at the inverter circuit at 650Vrms.)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.) g g g y

9) Protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

10) It is recommended not to exceed 1 hour of Power-On nor Burn-in period with LCD panel face down condition, in repair activity.

WARNINGS AND CAUTIONS

KD-65/85X9500B

5

Page 5

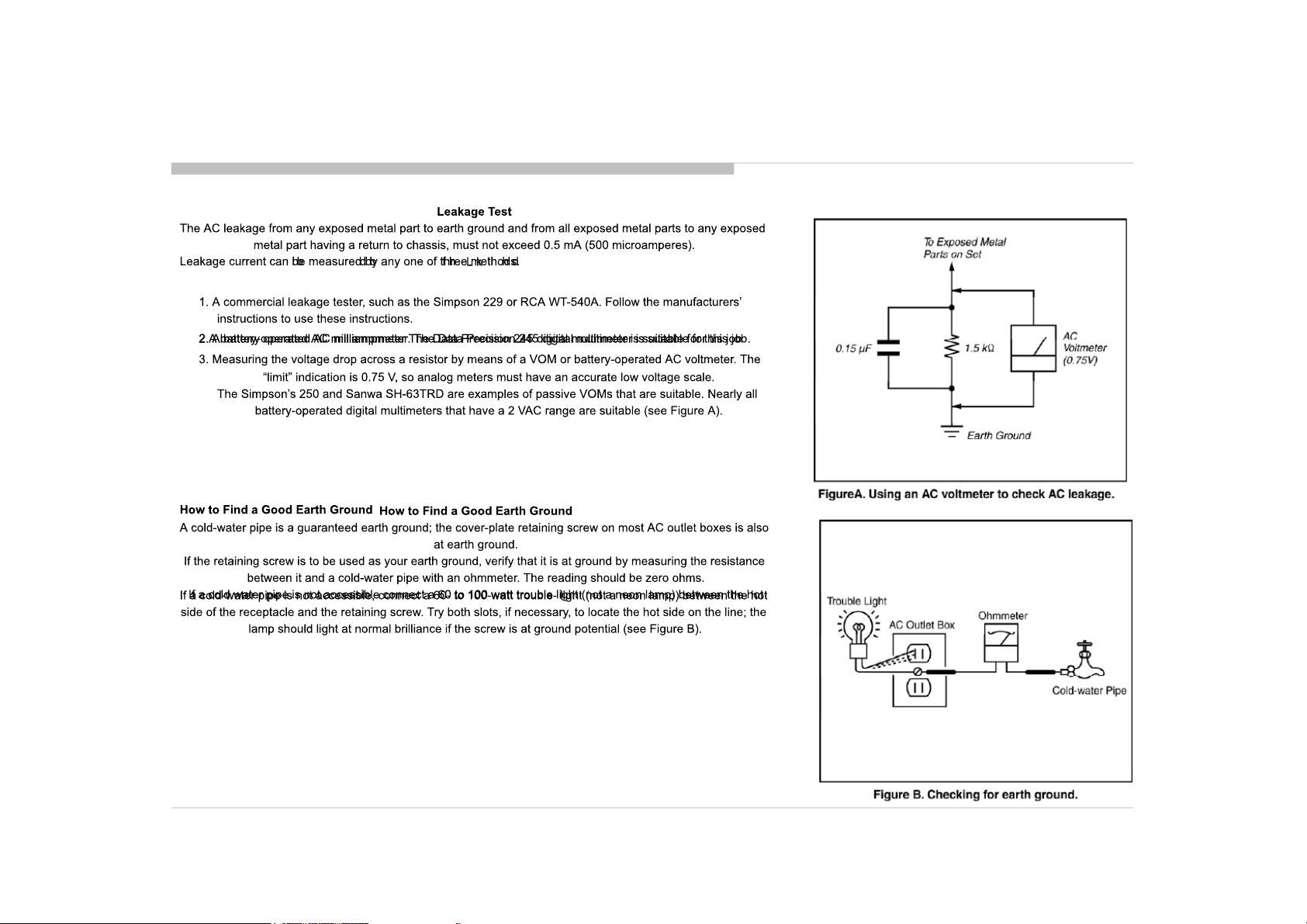

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered connections. Check the entire board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and mounting hardware have been replaced. Be absolutely certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of deterioration. Point them out to the customer and recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend the replacement of any such line cord to the customer.6. Check the line cords for cracks and abrasion. Recommend the replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs, screws, and all other exposed metal parts for AC leakage. Check leakage as described below.

8. For safety reasons, repairing the Power board and/or Inverter board is prohibited.

KD-65/85X9500B

6

Page 6

SAFETY CHECK-OUT

KD-65/85X9500B

7

Page 7

The units in this manual contain a self-diagnostic function. If an error occurs, the Smart Core Red LED will automatically begin to flash.

The number of times the LED flashes translates to a probable source of the problem.

A definition of the Smart Core Red LED flash indicators is listed in the instruction manual for the user’s knowledge and reference.

If an error symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

DIAGNOSTIC TEST INDICATORS

When an error occurs, the Smart Core Red LED will flash a set number of times to indicate the possible cause of the problem.

If there is more than one error, the LED will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen.

If the screen displays a “0”, no error has occurred .

RED LED b linking coun t Detect ion Items

2x

3x

3x

4x

4x

5x

6x

6x

7x

8x

9x <U>Tuner b oard err or [TU_BOARD]

<G/B> Main 12V failure [MAIN_POWE]

* This fa ilure is not saved

* This fa ilure is not saved.

<B> Main 5. 0/3.3/1.8/ 1.0 failure [DC_ALERT]

* 5.0/1. 0V failures a re not sav ed.

<B/S> Audio amp. prote ction / Audio amp. I2C NACK [AU D_ERR]

<B> HDMI equalizer/switch I2C NACK [HDMI_EQ/HDMI_EQ2/HDMI_EQ3] * T here is Temp. se nsor on th e same I2C bu s

<B/U> Tuner or demodu lator I2C NACK [TU_DEMOD]

<B/U> AFE dev ice I2C NACK [AFE_I2C]

<B/U> AFE dev ice SPI NACK [AFE_ SPI] * only f or AEP,CH

<B> V-by-On e lock monito ring between CXD4746 and NT7232 4[SC_OUT_ERR]

<B> CXD4746 I2C NACK and V-by-O ne lock monito ring between CXD4746 and Ayu2[SC_ ERR]

<B> FW in itialization erro r and I2C NACK for NT723 24[FRCD_I2C]

<L/P> LED driver failu re [LD_ERR]

<L/P> LED voltage er ror [VLED]

<B/T>Tcon d evice initializatio n failure de tection [TC ON_ERR]

<B/T>Tcon d evice I2C communic ation erro r detection [TCON_ERR]

<P/T/G/ B> Panel ID EEPROM I2C NACK (Also panel power failure is a suspect) [ P_ID_ERR]

*PCON_ERR and TG_ERR is n ot used.

<G/P/B> Bac klight failure [BACKLIGHT]

<G/T/P/ B> Backlight con verter OVP [ BACKLIGHT]

Over t emperature protection [TEMP_ERR]

<B> Temp. sen sor I2C NACK [TEMP_ERR] * T here is HDMI Eq on the same I2C b us.

Software Er ror (Also t he main boar dʼs memory or CAM module is a s uspect)

<B> CXD4754 device err or and WDT detection [LYON_ERR]

*Even if d etecting CXD474 5 Device er ror, the set does not g o to safety shutdown (o nly when user uses CXD4754 function, th e set reb oots)

Even if d etecting CXD47 45 Device er ror, the se t does not go to safet y shutdown (o nly when user uses CXD4754 function, the set reb oots)

and n ot flash LED, only recor ds error logs.

<G>: Power supply board, <B>: Main board, <T>: Tcon board, <L>: LED driver (LD) board ,

<P>: Panel module , <S>: Speaker , <A>: Power Adapter, <U> Tuner board

KD-65/85X9500B

8

Page 8

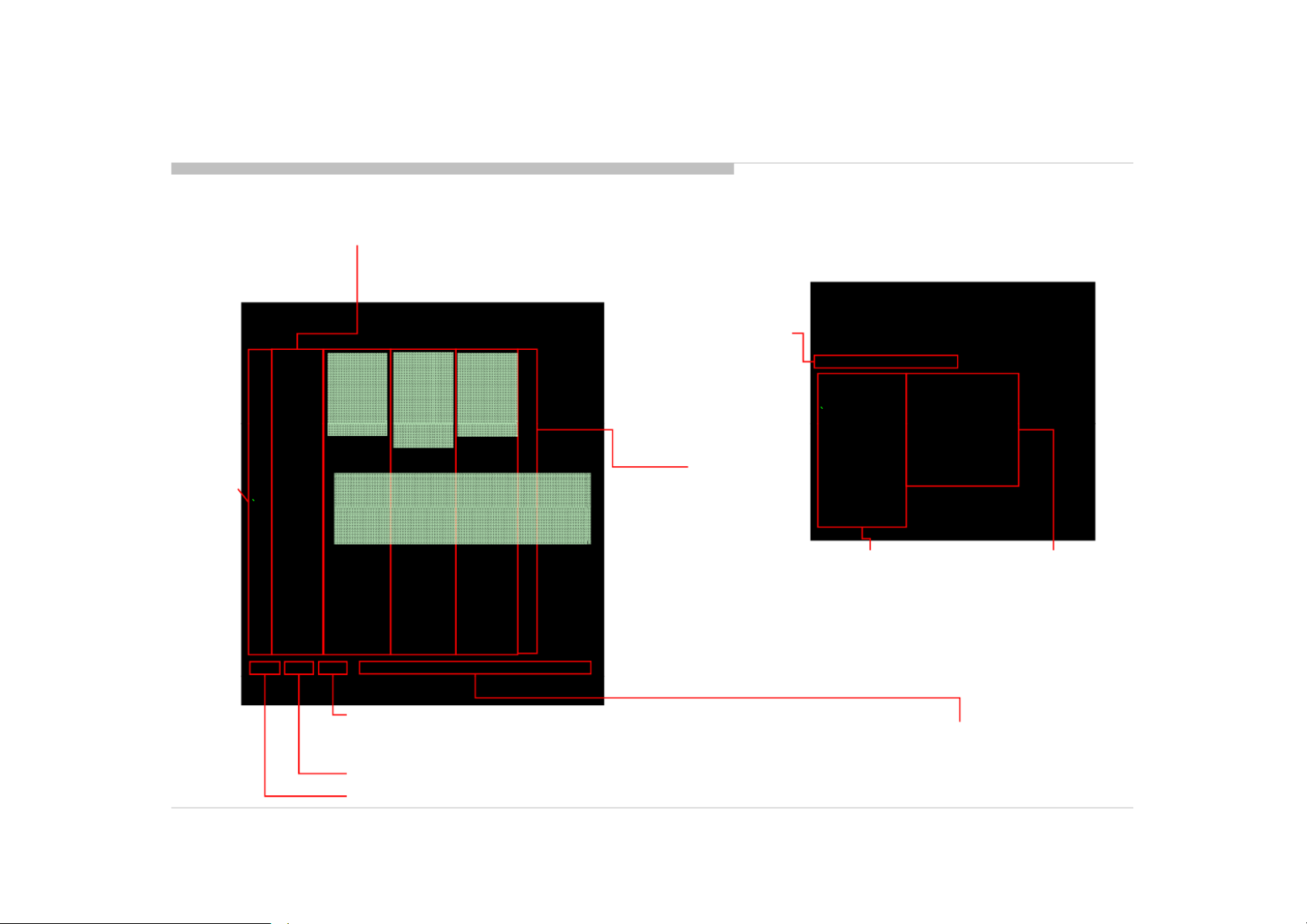

[SELF DIAGNOSTIC SCREEN DISPLAY]

SELF DIAGNOSIS FUNCTION

Smart Core

Red LED

blinking count

g

Error item name

SELF CHECK

002 MAIN_POWE - --- --- ---- - -- --- --- ---- -- ---- --- --- 00

003 AF E_I2C ---- --- --- -- - --- --- ---- - -- --- --- --- - 00

003 DC _ALERT -- ---- --- --- --- --- ---- -- ------- --- -- 0 0

003 AUD_PRO T --- ---- --- -- - --- --- ---- - -- --- --- --- - 00

003 HDMI_EQ ------ ---- -- - --- --- --- -- - ---- --- --- - 00

003 T U_DEMOD ------- --- -- - --- --- --- -- - ---- --- --- - 00

_

003 SC_ OUTERR ---- --- --- -- - --- ---- --- - - ---- --- --- - 00

003 SC_ ERR --- --- ---- -- ------- --- -- - --- --- ---- - 00

003 F RCD_I2C --- --- --- --- --- ---- --- -- - --- --- ---- - 00

003 HDMI_EQ2 ------ --- --- ------ ---- -- ------- --- -- 0 0

003 LYON_ERR ------ --- --- --- --- ---- -- ------- --- -- 0 0

004 VL ED --- --- ---- -- - --- --- --- -- - --- ---- --- - 00

004 L D_ERR 00

005 T CON_ERR --- --- ---- -- - --- --- --- -- - --- ---- --- - 00

005 P_ ID_ERR ------- --- -- - --- ---- --- - -- --- --- ---- 00

005 PCO N_ERR - --- --- --- -- - ---- --- --- - -- --- ---- --- 00

006 BACKL ITE - --- ---- --- - -- --- --- ---- -- ---- --- --- 00

007 T EMP_ERR 1208 23132523 ------ --- --- --- --- ---- -- 0 1

008 VPC WDT ------ ---- -- - --- --- --- -- - --- ---- --- - 00

008 VPC_ WDT --- --- ---- -- ------- --- -- - --- --- ---- - 00

008 MEPS_W DT --- ---- --- -- - --- --- ---- - -- --- --- --- - 00

008 HOST _WDT -- --- ---- --- --- --- --- --- ------- --- -- 0 0

008 ST BY_WDT -- --- --- ---- -- ---- --- --- --- --- ---- -- 0 0

008 AF E_WDT - ---- --- --- - -- --- ---- --- --- --- --- --- 00

009 T U_BOARD ------ --- --- --- ---- --- -- - --- --- ---- - 00

00081 -000671 -00088 0000000 00000000 00570-0 00000000 00000000 132

Error

timestam

p for last

recorded

error

003 AF E SPI

---- --- --- -- - ---- --- --- - -- --- ---- --- 00

003 HDMI_EQ3

---- --- --- -- - ---- --- --- - -- --- ---- --- 00

Format of error timestamps

YYMMDDhhmmss (in UTC)

004 L D ERR

---- --- --- -- - ---- --- --- - -- --- ---- --- 00

Example:

120823132523 -> Aug 23 2012 13:25:23 UTC

* Only when time is set, an error timestamp is saved.

005 T G_ERR

---- --- --- -- - ---- --- --- - -- --- ---- --- 00

007 FAN_ERR

---- --- --- -- - ---- --- --- - -- --- ---- --- 00

*Following error is invalid in RB2.

FAN_ERR

EMIT_ERR

TCON_ERR

Error

timestam

p for

second

last

recorded

recorded

error

Example:

Error

timestam

p for 3rd

last

recorded

error

error

MAC address

of Wi-Fi USB

Error count

Model Name :KDL-RB2T

Serial Numbe r :1000 162

Package Number :PKG0. 410EUA

Device ID :B0:00:0 2:4D:72:88

Wired Ma c

dongle*1.

Wired Mac :D8:D4:3C :A2:EE:9F

Wireles s Mac :34:2 3:87:d4:4 8:a4

USB dongle :N/A

<MAIN> <EXT>

DM0.410 EUA WF :3.5.3.999 9

WF0.3 00W00AA WF:----- ---

DF5.1 37W00AA BT:

YM1 224W 00AA 2 1 14 4 71

YM1.224W 00AA 2.1.14.4 71

M5.503C EFR:03 .01.01.18

(DM0.39 0EUA)

DD0.37 0W00AA

PK0.370 W00AA SCF :50.10

AM0.410W W R OF:---- --- ---- --- ---

MID:2411AB19

PID 0E0420 40

PID:0E0420 40

PNL:YD4S550 LTU010

:D8:D4: 3C:A2:EE:9F

<FS>

Main CPU

information

*1

1

1. When no Wi-Fi USB dongle is connected, NA is displayed.

2. If you insert/disconnect Wi-Fi USB Dongle during Self Diagnosis

Display, press <1> -> <4> on remote commander to refresh Mac

address displayed on “USB dongle”.

- Alternatively, you can re-display Self Diagnosis Display to update the

information.

information.

External module

information

KD-65/85X9500B

Panel operation time by hour

Panel Operation Time is recorded every 30 min, but Total Operation Time is recorded every 1 hr.

Therefore, the panel op. time might become larger than the total op. time.

Boot count

Total operation time by hour

Count of writing to NAND device:

As vfat partition– As ext4 partition

9

Page 9

SELF DIAGNOSIS FUNCTION

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible to bring up past occurrences of failure for

SELF-DIAGNOSTIC SCREEN DISPLAY

confirmation on the screen:

S

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

*

: Note that this differs from entering the service mode (volume +)

*

Since the diagnostic results displayed on the screen are not automatically cleared always check the self diagnostic screen

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen.

After you have completed the repairs, clear the result display to “0”.

Clearing the Self Check Diagnostic List

1. Error history : Press the Channel 8 => Channel 0 .

2. Panel operation time : Press the Channel 7 => Channel 0 .

Exiting the Self-diagnostic screen

To exit the Self Diagnostic screen, turn off the power to the TV by pressing the POWER button on the remote or the POWER button on the TV.

KD-65/85X9500B

10

Page 10

• There are clutch in the yellow frame[ ]. Therefore please be careful in the case of the disassembly or assembly of parts.

KD-65/85X9500B

11

Page 11

1-1-1. STAND

DISASSEMBLY

KD-65/85X9500B

2 Screws (SCREW, +PSW M5X16) P/N: 2-580-608-01

STAND,RIGHT (2L MIA)

P/N: 4-486-550-02

2 Screws (SCREW, +PSW M5X16) P/N: 2-580-608-01

2

STAND,LEFT (2L MIA)

P/N: 4-486-545-02

1

12

Page 12

1-1-2. CAMERA MODULE EXTERNAL TYPED

DISASSEMBLY

1

Screw (SCREW +PSW M4X10) P/N: 4-159-298-01

KD-65/85X9500B

2

CAMERA MODULE

EXTERNAL TYPED

13

Page 13

1-1-3. COVER, TERMINAL SIDE

DISASSEMBLY

2

31

COVER, TERMINAL SIDE

KD-65/85X9500B

14

Page 14

1-1-4. COVER, TERMINAL REAR

1 3

DISASSEMBLY

2

KD-65/85X9500B

COVER, TERMINAL REAR

15

Page 15

1-1-5. LABEL, REAR TERMINAL/LABEL, SIDE TERMINAL

LABEL REAR TERMINALLABEL, REAR TERMINAL

DISASSEMBLY

LABEL, SIDE TERMINAL

KD-65/85X9500B

16

Page 16

DISASSEMBLY

1-1-6. REAR COVER (2L MIA) A

1

16 Screws (SCREW, +PSW M3X6 STEP) P/N: 4-457-815-02

1 Screw (SCREW, +PSW M4X10) P/N: 4-159-298-01

3 Screws (SCREW, +BVTP 4X12 TYPE2 IT-3) P/N: 2-580-639-01

( , )

4 Screws (SCREW, ORNAMENTAL M6X12) P/N: 4-268-126-02

2

3

REAR COVER (2L MIA) A

CATCH, HOOK N

KD-65/85X9500B

17

Page 17

1-1-7. TAPE

DISASSEMBLY

TAPE

TAPETAPE

TAPE

TAPE

KD-65/85X9500B

18

Page 18

1-1-8. WIRE DRESSING

DISASSEMBLY

KD-65/85X9500B

19

Page 19

1-1-9. TAPE

DISASSEMBLY

TAPE

TAPE

KD-65/85X9500B

20

Page 20

1-1-10. TAPE

TAPE

DISASSEMBLY

TAPE

KD-65/85X9500B

21

Page 21

1-1-11. WIRE DRESSING

DISASSEMBLY

KD-65/85X9500B

22

Page 22

1-1-12. WIRE DRESSING

DISASSEMBLY

KD-65/85X9500B

23

Page 23

DISASSEMBLY

1-1-13. AC INLET ASSY

1

2

3

4

AC INLET ASSY

KD-65/85X9500B

Screw (SCREW, +PSW M3X6 W12) P/N: 4-256-393-11

24

Page 24

1-1-14. AC INLET

DISASSEMBLY

1 2

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

BRACKET, AC INLET

AC INLET

KD-65/85X9500B

25

Page 25

1-1-15. USB ASSY

1

DISASSEMBLY

2

33

USB ASSY

KD-65/85X9500B

26

Page 26

1-1-16. USB HOLDER, CABLE WITH CONNECTOR (USB) and BRACKET, TOP (MIA)

DISASSEMBLY

BRACKET, TOP (MIA)

2

CABLE WITH CONNECTOR (USB)

USB HOLDER

31

KD-65/85X9500B

27

Page 27

1-1-17. CONNECTOR ASSY

DISASSEMBLY

KD-65/85X9500B

CONNECTOR ASSY, 3P

P/N: 1-846-714-11

CONNECTOR ASSY 20P

P/N: 1-910-109-27

28

Page 28

1-1-18. SWF-SPEAKER BOX ASSY

1 3

DISASSEMBLY

2

SWF-SPEAKER BOX ASSY

KD-65/85X9500B

29

Page 29

1-1-19. SPEAKER BOX ASSY (L)

DISASSEMBLY

2

1

KD-65/85X9500B

3

SPEAKER BOX ASSY (L)

30

Page 30

1-1-20. SPEAKER BOX ASSY (R)

DISASSEMBLY

2

1

KD-65/85X9500B

3

SPEAKER BOX ASSY (R)

31

Page 31

1-1-21. BRACKET, SC(MIA 2L)

1 3

DISASSEMBLY

2

KD-65/85X9500B

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

BRACKET, SC(MIA 2L)

BRACKET, SC(MIA 2L)

32

Page 32

1-1-22. SMART CORE

DISASSEMBLY

SMART CORE

KD-65/85X9500B

33

Page 33

1-1-23. SWITCH UNIT ASSY

DISASSEMBLY

1

2

S C SSSWITCH UNIT ASSY

KD-65/85X9500B

34

Page 34

1-1-24. HARNESS ASSY (MAIN)

DISASSEMBLY

HARNESS ASSY (MAIN)

P/N: 1-910-109-25

KD-65/85X9500B

35

Page 35

1-1-25. SLIDE, CLAMP

DISASSEMBLY

1

2

SLIDE, CLAMP

KD-65/85X9500B

36

Page 36

1-1-26. SHEET (CORE), C

DISASSEMBLY

SHEET (CORE), CSHEET (CORE), C

KD-65/85X9500B

37

Page 37

1-1-27. TAPE (DK020FR-19) 19X70 SHEET

DISASSEMBLY

KD-65/85X9500B

TAPE (DK020FR-19)

19X70 SHEET

38

Page 38

1-1-28. BRACKET, SWF (2L MIA)

1 3

DISASSEMBLY

2

KD-65/85X9500B

BRACKET, SWF (2L MIA)

6 Screws (SCREW, +PSW M3X6 W12) P/N: 4-256-393-11

39

Page 39

DISASSEMBLY

1-1-29. HOLDER, SIDE SW (MIA)

1 2 4

3

HOLDER, SIDE SW (MIA)

Screw (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-65/85X9500B

40

Page 40

1-1-30. WIRE DRESSING

DISASSEMBLY

KD-65/85X9500B

41

Page 41

1-1-31. CONNECTOR ASSY AND HARNESS ASSY

CONNECTOR ASSY 28P

P/N: 1-910-109-24

DISASSEMBLY

HARNESS ASSY

P/N: 1-910-109-26

KD-65/85X9500B

42

Page 42

1-1-32. BRACKET, STAND (MIA)

DISASSEMBLY

2

31

BRACKET STAND (MIA)

BRACKET, STAND (MIA)

KD-65/85X9500B

Don’t put the bracket on the dowel.

p

4 Screws (SCREW, +PSW M4X10) P/N: 4-159-298-01

43

Page 43

DISASSEMBLY

1-1-33. BRACKET, RL (MIA)

1 4

2

3

BRACKET RL (MIA)

BRACKET, RL (MIA)

KD-65/85X9500B

2 Screws (SCREW, +PSW M4X10) P/N: 4-159-298-01

44

Page 44

1-1-34. BRACKET, VESA (MIA)

1

DISASSEMBLY

2

3

KD-65/85X9500B

4

BRACKET, VESA (MIA)

4 Screws (SCREW, +PSW M4X10) P/N: 4-159-298-01

45

Page 45

1-1-35. FLEXIBLE FLAT CABLE

DISASSEMBLY

FLEXIBLE FLAT CABLE 30P

P/N: 1-910-109-29

FLEXIBLE FLAT CABLE 20P

P/N: 1-910-109-19

KD-65/85X9500B

46

Page 46

1-1-36. TAPE

DISASSEMBLY

TAPE

KD-65/85X9500B

TAPETAPE

47

Page 47

1-1-37. FLEXIBLE FLAT CABLE

DISASSEMBLY

FLEXIBLE FLAT CABLE(41P)

P/N: 1-848-310-11

FLEXIBLE FLAT CABLE 51P (HX65)

P/N: 1-848-311-11

KD-65/85X9500B

48

Page 48

1-1-38. BRACKET, SIDE (MOLD)

DISASSEMBLY

1

2

BRACKET, SIDE (MOLD)

KD-65/85X9500B

49

Page 49

DISASSEMBLY

1-1-39. PLATE, MAIN (MIA) ASSY

1

2

3

4

PLATE, MAIN (MIA) ASSY

KD-65/85X9500B

8 Screws (SCREW +PSW M3X6 W12) P/N: 4-256-393-11

50

Page 50

DISASSEMBLY

1-1-40. K0

1

2

3

K0

KD-65/85X9500B

4 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

51

Page 51

1-1-41. TUS

1 2 3

DISASSEMBLY

TUS

KD-65/85X9500B

4 Screws (SCREW +PSW M3X6 W12)

4 Screws (SCREW +PSW M3X6 W12)

P/N: 4-256-393-11

52

Page 52

DISASSEMBLY

1-1-42. BAXF

1

BAXF

2 3

KD-65/85X9500B

7 Screws (SCREW +PSW M3X6) P/N: 2-990-421-41

53

Page 53

1-1-43. SHEET, THERMAL (BAF)/SHEET, THERMAL (EU TU)/SPACER (G A)

SHEET THERMAL (EU TU)

SHEET, THERMAL (EU TU)

DISASSEMBLY

SHEET, THERMAL (BAF)

KD-65/85X9500B

SPACER (G A)

54

Page 54

1-1-44. GASKET(TU)

DISASSEMBLY

GASKET(TU)

KD-65/85X9500B

55

Page 55

1-1-45. G3

DISASSEMBLY

2

1

5 Screws (SCREW +PSW M3X6 W12) P/N: 4-256-393-11

KD-65/85X9500B

3

G3

56

Page 56

1-1-46. G4B

1

DISASSEMBLY

2

3

5 Screws (SCREW +PSW M3X6 W12) P/N: 4-256-393-11

KD-65/85X9500B

G4B

57

Page 57

1-1-47. SPACER

DISASSEMBLY

KD-65/85X9500B

58

Page 58

1-1-48. SHEET, INSULATION (G34)

DISASSEMBLY

1 21 2

SHEET, INSULATION (G34)

KD-65/85X9500B

59

Page 59

1-1-49. LCD PANEL

DISASSEMBLY

LCD PANELLCD PANEL

KD-65/85X9500B

60

Page 60

1-2-1. LIGHT CASE ASSY

1

DISASSEMBLY

2

LIGHT CASE ASSY

KD-65/85X9500B

61

Page 61

1-2-2. BACK COVER (M)

DISASSEMBLY

2

3

BACK COVER (M)

41

KD-65/85X9500B

Screw (SCREW +BVTP 4X12 TYPE2 IT-3) P/N: 2-580-639-01

62

Page 62

1-2-3. MIC UNIT

1 2

DISASSEMBLY

MIC UNIT

KD-65/85X9500B

63

Page 63

1-2-4. BT MODULE

DISASSEMBLY

1 2

KD-65/85X9500B

BT MODULE

64

Page 64

1-2-5. WIRELESS LAN CARD

1 3

DISASSEMBLY

2

WIRELESS LAN CARD

KD-65/85X9500B

65

Page 65

1-2-6. FRONT COVER (M)

DISASSEMBLY

FRONT COVER (M)

KD-65/85X9500B

66

Page 66

1-2-7. TOP COVER (L)

DISASSEMBLY

1

2

3

TOP COVER (L)

KD-65/85X9500B

67

Page 67

1-2-8. HSC2-M BOARD

DISASSEMBLY

1

2

3

KD-65/85X9500B

HSC2-M BOARD

68

Page 68

1-2-9. BOTTOM CASE (LL) A

DISASSEMBLY

BOTTOM CASE (LL) A

KD-65/85X9500B

69

Page 69

HOW TO ENTERING SERVICE MODE

1) Turn on the main power switch to place this set in standby mode.

2) Press the buttons on the remote commander as follows, and entering service mode.

3) Service mode display.

Note: First of all when you enter Service Mode you can see “Digital” service modeNote: First of all, when you enter Service Mode, you can see Digital service mode.

Whenever you press “OPTIONS” on remote, each service mode is changed.

“Digital” -> “Chassis” -> “VPC”

KD-65/85X9500B

70

Page 70

4) How to use the remote commander.

5) After entering service mode then turn off the power switch5) After entering service mode, then turn off the power switch.

ADJUSTMENT

KD-65/85X9500B

71

Page 71

CHANGE DATA

Note: “Digital” service mode don’t have to Save ( except “002 MODEL”)Note: Digital service mode don t have to Save. ( except 002 MODEL )

1) Change Data of “Digital” service mode. ( except “003 DIG_SRV_MODE” category)

a. Press “2 / 5” on remote to select (up / down) category.

b. Press “1 / 4” on remote to select (up / down) Item.

c. Press “3 / 6” on remote change (up / down) data.

ADJUSTMENT

KD-65/85X9500B

72

Page 72

2) Change Data of “Digital” service mode. ( “003 DIG_SRV_MODE” category)

“003 DIG SRV MODE” i t f “Di it l” i d“003 DIG_SRV_MODE” is one category of “Digital” service mode.

Please note because this operation is special.

a. Press “2 / 5” on remote to select “003 DIG_SRV_MODE”.

b. Press “1 / 4” on remote to select (up / down) Item.

c. Press “0 / 10” on remote to select item.

d. Press number key “1”~”9” directly. “*” stamp move.

e. Press “12 / enter / select” to decide and advance next step. Press “return”, when returning on the

previous page.p p g

ADJUSTMENT

KD-65/85X9500B

73

Page 73

SAVE CHANGING DATA 1 (Only when B* board is replaced)

1) In “Digital” service mode1) In Digital service mode

( “002 MODEL” category)

000 SEGSelect segment information

001 DEST Select destination information

l d l002 MODELNAME Select Model Name

003 SERIAL Can be set Only Once for the new board

005 VAR_TYPE Select variable information

a. Change data for each model.

b. Press “Mute” , “0” on remote sequentially . Red “ WRITE ” is shown. This indicates writing is in process.

c. After a while, red “ WRITE ” disappears. Green Done will be displayed for a while, which means writing process is done.

d. For the items SEG, DEST, MODELNAME and VAR_TYPE,

after changing each item service save (“mute”+”0”) isafter changing each item, service save ( mute + 0 ) is

required. For the item SERIAL, after inputting the serial

number, press key “12” or “Enter” to save the data.

– Please save the items according to the sequence “SEG ->

DEST -> MODELNAME ->VAR_TYPE”

– When Saving the item "SEG", sometimes instead of "Writing",

the word "Pending" will appear. In this case, skip "SEG",

saving "DEST“, "MODELNAME“ and “VAR_TYPE” is OK.

ADJUSTMENT

KD-65/85X9500B

Note : Please refer “RB2G WW Service Update Procedure for

Panel, Board and Software” (manual P/N 9-888-155- ) in TISS for

details

details.

74

Page 74

SAVE CHANGING DATA 2

1) Write data for “Chassis” or “VPC” service mode1) Write data for Chassis or VPC service mode

a. Press “Mute” on remote.

It shows green “ SERVICE ” changes to green “ WRITE ”.

b. Press “0” or “enter” on remote. Green “ WRITE ” changes to red “ WRITE ”. It indicate writing is processing.

c. After a while, red “ WRITE ” changes to green “ SERVICE ”. Writing process is done at this point.

2) TV reboot is necessary for applying data change.

ADJUSTMENT

KD-65/85X9500B

75

Page 75

WHITE BALANCE ADJUSTMENT

Note: Please execute this adjustment if necessaryNote: Please execute this adjustment if necessary.

Change Data of “VPC” service mode. ( “003 WB” category)

a. Press “1” or “4” on remote to select WB adjustment menu.

b. Change data by pressing “3” or “6”. Each range of these items is 0~1023.

c. Press “mute” +”0” on remote to save the data.

“SERVICE” comment is changed to “ WRITE ”, indicating writing process.

d. After a while, “ WRITE ” comment returns to “SERVICE”, which means writing process is done..

ADJUSTMENT

KD-65/85X9500B

76

Page 76

SET TO SHIPPING CONDITION

H t d hi i ditiHow to do shipping condition.

a. Move to “Digital” service mode.

b. Press “8” on remote. It shows green “ SERVICE ” changes to green “ RST- ”.

c. Press “mute” on remote. Added green “ EXE ” after green “ RST- ” .

d. Press “0” on remote. Green “ EXE-RST ” changes to red “ EXE-RST ”. It indicate writing is processing.

e. After a while, red “ EXE-RST ” changes to green “ SERVICE ”.

f. And BLINK Smart Core WHITE LED. Writing process is done at this point.

SONY

<Another way>

You can set to shipping condition w/o entering Service Mode.

-> “Cursor Up” on remote + “Power Key” on TV.

ADJUSTMENT

KD-65/85X9500B

77

Page 77

RED DOT: Most likely defective part

BLUE TRIANGLE: Secondary possible defective part

BLACK TEXT: Board that may correct the symptom

Refere nce

B* Board

TU board

K* Board

G* Board

H* BoardH* Board

Speaker

Camera Module

Mic. Module

Wifi Module

BT Module

LD* Board

LVDS FFC

Tcon

LCD Panel

Problem

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

2 3 4 5 6 7 8 9 10

Power Power LD

Audio

Local

I2C

4K

unique

(Rogue/(Rogue/

Scorpio/

4K FRC

Panel

(Tcon)

Panel

(Backlig

ht) TEMP

Soft-

ware

No

Power

No White

Power LED

& does not

response to

response to

remote (Dead

Set)

- missing or distorted

Stationary

colour lines

d t

or dots Inputs

Video

No video

One of

I t

No video

all Inputs

all Inputs

Remote Ne twork Audio Skype Smart Core

No

Remote

(IR RC)

(IR RC) connect

Wireless

can't tNo Audio

Skype

Can't Work

Can t Work

Smart Core no

LED (Set is still

li )

alive)

Bluetooth

(BT)

Bluetooth /

One Step

Remote

(OSR) 't

(OSR) can't

connect

KD-65/85X9500B

78

Page 78

No Power

TROUBLE SHOOTING

KD-65/85X9500B

Check STBY 3.3V

L9700 or C9707

OK

B* Board

NG

Replace

Between G* Board to

B* Board Harness

B Board Harness

OK

Harness

DC/DC converter check

NG

G* Board

79

Page 79

1) DC/DC converter check

START

TROUBLE SHOOTING

KD-65/85X9500B

Check C9159, 9161

or C9163 Voltage.

Is the voltage 1V?

yes

Check C9158

or C9160 Voltage.

Is the voltage 5V?

Is the voltage 5V?

yes

Check C9120 Voltage.

Is the voltage 3.3V?

yes

Check C9153 Voltage.

Is the voltage 1.5V?

yes

no

Check F9105

Check C9168

is it 1.18V?

no

Check F9106

yes

no

no

no

Check F9104

Check F9102

Check F9102

Check F9102

END

80

Page 80

1) 3 times blinking (DC Alert & Communication Error)

TROUBLE SHOOTING

3-time blinking

Check D+1.0V

at JL9129 on

the B* Board

OK

OK

Check

+3.3V_MAIN_1

at JL9116 on

the B* Board

the B Board

OK

Check

Check

+1.8V_MAIN on

Pin 2 of IC9201

OK

Check

+5.0V_MAIN

at JL9132on

the B* Board

NG

NG

NG

NG

NG

DC_ALERT

F9105,IC9103,

etc (B* Board)

F9102,IC9102,

etc (B* Board)

IC9201,etc

(B* Board)

F9104 / IC9101

,etc (B* Board)

DMD_TU_I2C

or I2CB bus check:

Probe CL2101,

CL2102 / CL2318

CL2102 / CL2318,

CL2101 on

TU* Board

OK

SPIC check

Probe RB8522

OK

I2C_CCP check

R8502 and R8506 /

R8507 and R8508

OK

I2CA bus check:

Probe CL5069,

CL5072

OK

O

TUNER

NG

I2C bus dumping or

Brownie

NG

NG

NG

AYU2

AYU2

SPI

dumping

resistor

or AYU2

I2C_CCP

Pull Up

Pull Up

I2CA b

I2CA bus

dumping

resistor

or AYU2

Or FW of

IC5605 is

broken

broken

I2CD bus check:

Probe CL5423,

CL5428

OK

I2CC bus check:

I2CC bus check:

Probe CL3371,

CL3372

OK

V-by-One check:

Probe CL8064,

CL8066, R6020

HDMI

NG

BackEnd

NG

NG

NG

I2CD bus

Dumping resistor

or Ayu2

or FW of IC3150

is broken

I2CC bus

dumping

dumping

resistor

or AYU2

or Scorpio

/FRC

VBO

dumping

resistor and

capacitor

or AYU2

or Scorpio

/FRC

Check

Speaker

Speaker

Impedance

at

SP

Connector

OK

Check

Audio +12.5V

at pin 18/20

of CN9101

on the B* Board

(except Adapter

model)

OK

Check

+12.5V / +19.5V

at Power Amp

side of F4401

/ F4601 on

the B* Board

OK

IC4901 / IC4601

,etc

(B* Board)

NG

NG

NG

AUDIO

Speaker

G* Board

F4401/F4601,

IC4901/IC4601

,etc

(B* Board)

KD-65/85X9500B

81

Page 81

2) 3 times blinking (Audio Error)

(Audio amp. error

detection.

or Audio amp. I2C o ud o a p C

communication error

detection.)

TROUBLE SHOOTING

KD-65/85X9500B

3-4-2. No Sound Power Off Check

G tGo to

Go to

3-4-3. No Sound Power On Check

82

Page 82

3) 4 times blinking (LED Voltage Error)

TROUBLE SHOOTING

KD-65/85X9500B

83

Page 83

4) 5 times blinking (T-Con Error)

TROUBLE SHOOTING

KD-65/85X9500B

84

Page 84

5) 6 times blinking (Backlight Error)

TROUBLE SHOOTING

KD-65/85X9500B

85

Page 85

6) 7 times blinking (Temperature Error)

7-time blinking

TROUBLE SHOOTING

KD-65/85X9500B

Setting

circumstance is OK?

Temperature,

Ventilation, etc.

Yes

Change B* Board

Change B* Board,

and Aging a few

hours

Symptom

improvement

improvement

B* Board

No

NG

NG

I2CA bus dumping or

Ayu2 / Ayu2L check

Set to another

location, etc.

Panel

I2CA bus check:

HDMI is working?

No

No

Yes

Temp sensor

IC7001

86

Page 86

No Sound

Without LED 3x

[S k ] tti i

[Speakers] setting is

[Audio System] ?

Yes

Yes

Ch th tti t

Change the setting to

[TV Speakers]

No sound only

Analog RF and

Digital RF ?

No

No

Yes

TROUBLE SHOOTING

Tuner relation issue

KD-65/85X9500B

No

AV receiver is

connected

to HDMI in ?

No

Headphone is connected to

HP/Audio Out terminal ?

NNo

→

[Sound]

[Headphone Speaker Link]

setting is [On] ?

No

Go to

3-4-2. No Sound

Power Off Check

Yes

Select [External Inputs]

[BRAVIA Sync Settings]

[BRAVIA Sync Control]

Yes

Disconnect the Headphone

Change [Sound]

[Headphone Speaker Link]

Yes

HP/Audio out terminal or Headphone

→

→[off]

→

to [Off], OK ?

Replace B-PWB

detect GPIO may be broken

No sound only HDMI ?

→

No

Yes

HDMI relation issue

Go to

3-4-1. No Sound Audio

87

Page 87

3-4-1. No Sound Audio

No Sound

TROUBLE SHOOTING

Audio

From 3-4

KD-65/85X9500B

Replace B-K Harness

Yes

OK ?

No

Replace K-PWB

OK ?

(check / diagnose K-PWB itself before replace.

See next page.)

See next page )

No

Replace B-PWB

Yes

OK ?

No

Finish

Yes

Finish

88

Page 88

3-4-2. No Sound Power Off Check

TROUBLE SHOOTING

Power Off Check

From 3-3 or 3-4

(1) K-PWB

PVDD-GND short ?

(See APPENDIX-5)

No

(2) K-PWB

LDO out short ?

(See APPENDIX-5)

No

(3) K-PWB

Fuse broken ?

(See APPENDIX--5)

No

Yes

Yes

Yes

Yes

Replace K-PWB

Power Off Check

From 3-4

Measure the Speaker

impedance by multi meter

impedance by multi-meter

Less than 3

Ω ?

No

Confirm the speaker

harness

Cut or shorted

to the chassis ?

No

Return to 3-3 or 3-4

Yes

Yes

Replace Speaker

Replace Speaker

Replace Speaker Harness

KD-65/85X9500B

89

Page 89

3-4-3. No Sound Power On Check

Power On Check

From 3-3

TROUBLE SHOOTING

(4) 12.5V check

12.5V is supplied to

K-PWB for a moment

before LED 3x blinking ?

No

Replace G-K Harness

OK ?

OK ?

No

Replace G-PWB

OK ?

No

No

Return to 3-3

Yes

Yes

Yes

Measure voltage between PVDD and GND at capacitor C4341,

(4) 12.5V check K1-PWB (HJ)

C4342, C4441 or C4442. (See 3.3)

Voltage rise more than 0V for a moment at power on

→ Yes

Finish

KD-65/85X9500B

90

Page 90

3-4-4. No Sound Audio HP/Audio out

TROUBLE SHOOTING

No Sound Audio

HP/Audio out

KD-65/85X9500B

Headphone Volume

is set to MIN?

No

Replace B-PWB

[Headphone]

Yes

[Sound]

→

[Headphone/Audio out]

is set to ?

[Audio Out]

Increase Headphone VolumeReplace B PWB Increase Headphone Volume

[Subwoofer]

Set [Headphone/Audio Out]

to [Headphone] or [Audio Out]

Replace B-PWB

91

Page 91

No Picture

TROUBLE SHOOTING

KD-65/85X9500B

All blue picture is on?

(Factory SW

is booted )

is booted.)

Yes

B* Board

No

Check the G*- LD*

Harness

NG

OK

the B-Tcon, B-LD*

Symptom

improvement

B-Tcon, B-LD*

Symptom

improvement

Replace

FFC

FFC

Change G* Board

G* Board

NG

Change B* Board

Symptom

improvement

NG

B* BoardHarness

LCD Panel

(T con LD* )

(T-con, LD )

NG

92

Page 92

1) EXT. Analog Video/Component Input

Video 1 Video 2 Component

No Picture No Picture

TROUBLE SHOOTING

No Picture

KD-65/85X9500B

Check if input OSD

is GREY OUT

OK

Check wave between

C3000 and IC9001

OK

OK

Confirm Analog RF

input wor king

OK

Brownie [IC90 01]

Brownie [IC90 01]

Problem

NG

Check J3101

VIDEOA_DET

NG

Detailed check

J3101 sign al path

Detaile d SDIF path

Check b etween

IC9001 a nd IC9000

NG

Check signal

between IC9001 and

IC9000 [R 8652]

Ayu2 [IC900 0]

y [ ]

Change B* board

conne ction,

Proble m

NG

Check J3104

Check if input OSD

is GREY OUT

OK

Check wave between

C3018 and IC9001

OK

OK

NG

Confir m Analo g RF

input wor king

OK

OK

Brownie [IC90 01]

Brownie [IC90 01]

Proble m

Conne ction,

VIDEOB_DET

NG

Detailed check

J3104 sign al path

Detailed SDIF path

Check b etween

IC9001 a nd IC9000

G

NG

Check s ignal

between IC9001 and

IC9000 [R 8652]

Ayu2 [IC900 0]

At C802 5

At C802 5

Problem

NG

OK

Check if input OSD

is GREY OUT

OK

Check wave

Between C3 018/C3019

and IC90 01

OK

OK

Confirm HDMI

input wor king

OK

Confirm other ana log

Input workin g

OK

Brownie [IC90 01]

Proble m

Check J3104

NG

VIDEOB_DET a t

NG

Detailed check

J3104 signal pa th

NG

HDMI EQ [IC5009]

Detaile d TMDS path

check between

IC9001 a nd IC5009

NG

Check s ignal

between IC9001 and

between IC9001 and

IC5009 [R B5008]

Ayu2 [IC900 0]

Conn

C8025 ,

CR DET at

CR_DET at

C8014

Proble m

Proble m

NG

OK

93

Page 93

TROUBLE SHOOTING

Side Key button

malfunction

Change Switch Unit

NG

Harness on Switch Unit

and B* Board properly connected

and B Board properly connected

NG

Change

Switch unit-B* board Harness

NG

Change B* Board

OK

OK

OK

Switch unit issue

Harness connection

issue

issue

Harness issue

Harness issue

KD-65/85X9500B

94

Page 94

TROUBLE SHOOTING

IR do not response to

Remote Commander

Center white LED

lit up when remote is

control is pressed

OK

Harness on H-

board and B* Board

properly connected

NG

Change

Change

H-B* board Harness

NG

Change Smart Core

NG

Change B* Board

NG

Check whether center

white LED blink ,when using

commander near the

sensor windows

OK

OK

OK

OK

Harness connection

H B* board harness

H-B board harness

Smart core issue

i

issue

issue

NG

NG

OK

Remote control battery

could be weak.

Change battery.

KD-65/85X9500B

95

Page 95

TROUBLE SHOOTING

Backlight doesn’t change

when ambient lighting

level changed

Check UI setting for light

Sensor. Make sure it is “on”

Change the UI

setting to “:ON”

NG

NG

Harness on H-board and

B* Board

properly connected

NG

NG

Change

H-B* board Harness

NG

Change Smart Core

NG

Change B* Board

OK

User did not activate light

sensor function

OK

OK

Harness connection

H-B* board harness

OK

Smart Core issue

issue

issue

KD-65/85X9500B

96

Page 96

[Network Set-up]

>[Wired Set-up]

on the TV

TROUBLE SHOOTING

KD-65/85X9500B

Connection Results

Connection Results

Cable Connection

Failed Failed

OK

OK

Check cable B board

IP address setting

IP address setting

Manual

Ethernet Cable

Check IP address

Local router setting

Local Access

Wired Set-up

&NG&

OK

Auto

Check

Local router

DHCP server

Connection Results

Internet Access

Failed

Proxy setting

OK

B board

97

Page 97

Wireless Network

on the TV

TROUBLE SHOOTING

Error Message appear

when the Wireless

Network is selected?

Check harness

connection is OK

between WiFi and Bxx

OK

Change

Wi-Fi module

OK

Wi Fi module

Wi-Fi module Main Harness

No

NG

NG

NG NG

Is the radio field

Strength too weak

Strength too weak Bxx Board

or even No signal?

YesYes

Ch WiFi d l

Change WiFi module

OK

WiFi module

Connect properly

No

NG

OK

Change harness

between Bxx board

and WiFi

Loose harness

and WiFi

Main Harness

oa d

OK

Access Point

Access Point

Change Bxx board

If Wi-Fi malfunction happens,

• Harness between WiFi and Bxx

• Bxx board are suspected.

•

Wi-Fi module

KD-65/85X9500B

98

Page 98

Touch pad Remote doesn’t work

Touch pad Remote doesn t work

Or

One touch remote doesn’t work

Or

3D-glasses (Active) doesn’t work

BT version check

in Service Menu

Ver = --------

Check harness

connection is OK

between BT and Bxx

Ver info.

can be read

NG

Connect properly

Confirm

Touch pad Remote malfunction trouble shooting flow

Or

One touch remote doesn’t work

Or

Or

3D-glasses (Active) malfunction trouble shooting flow

OK

L h

Loose harness

TROUBLE SHOOTING

Service Menu

001 OP

000 VERS

000 VERS

<MAIN> <EXT>

DM0.001JPA WF: 3.0.0.1021

WF0.300W00AA WF: -------DF2.070W00AA FD: 0.003

YM0.619W00AA BT:

M4.922C 2.1.14.470

(DM0.0J00AA)

DD0.320W00AA

BT Version info.

PK0.320W00AA EFR:----------AM0 030JP

AM0.030JP

MID: 04A3B50F

PID: 0F051040

PNL:

DQ3Y400LN0101

Q

OK

Change BT module

OK

OK

BT module

KD-65/85X9500B

NG

NG

Change harness

Between Bxx board

and BT

OK

OK

Main Harness

NG

Change Bxx board

If Bluetooth malfunction happens,

BT module

• Harness between BT module and Bxx

•

a ess bet ee odu e a d

• Bxx board are suspected.

99

Page 99

*(2) BT Active 3D glasses doesn’t work(2) BT Active 3D glasses doesn t work

<2 8V

Ch k 3D Gl

Check 3D-Glasses

<2.8V

Battery voltage is

>2.8V?

Restart TV. Power-off 3D-Glasses

and TRY registration again with 50cm

distance.

Cannot Register

Registered

Registered

Replace to New Battery and try again.

(use CR2025 only.)

Interference from other devices.

TROUBLE SHOOTING

Check if 2.4GHz devices are used or not?

(ex. WiFi, other bluetooth devices, microwave,

cordless phone,....)

Check another 3D-Glasses and re-

register.

OK

3D-Glasses NG.

KD-65/85X9500B

NG

Change to another

environment and try

i t ti i

registration again.

OK

Very strong interference on that spot.

NG

Confirm BT (Bluetooth) malfunction

trouble shooting flow.

g

100

Page 100

TROUBLE SHOOTING

Camera function doesn’t

work well

Self pic?

Far-end pic?

Self pic

Self pic

Check camera direction.

Camera module is set

properly or not.

Far-end pic

Check Video Call

Check self pic by push

“Social Viewing” key.

Update SW

version to latest.

RC OFF/ON

Change Camera module

Change Harness

Change B*Board

Far-end user needs

to prepare Camera

device or unmute

camera function

Camera module issue

Harness issue

Far-end issue

KD-65/85X9500B

101

Loading...

Loading...