Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

ORIGINAL MANUAL ISSUE DATE: 2017/6/27

Version Date Subject

1.0 2017/6/27 First version issue.

GN3FK CHASSIS

Segment: KCL

LCD Digital Color T V

9-888-740-01

Page 2

MODEL LIST

KD-60X690E Black RMT-TX300U UC2/LA1

KD-70X690E Black RMT-TX300U UC2/LA1

KD-60X695E Black RMT-TX300B AR4/LA8

KD-60X697E Black RMT-TX300B CO1

KD-60X6700E Black RMT-TX300E/300P AZ1/ME6/EA4

KD-70X6700E Black RMT-TX300E/300P AZ1/ME6/EA4

MODEL COLOR COMMANDER DEST. MODEL COLOR COMMANDER DEST.

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

2

Page 3

WARNINGS AND CAUTION S

CAUTION

These servicing instructions are for use by qualified service personnel only.

To reduce the ri sk o f ele ct ri c sho c k, d o not perfo r m any se r vici ng other than t hat c o nta ine d i n the op e ra ti ng instr uc tio ns unless you are qualified to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis.

The chassis of this receiver is directly connected to the ac power line.

CARRYING THE TV

Be sure to follow these guidelines to protect your property and avoid causing serious injury.

• Carry the TV with an adequate number of people; larger size TVs require two or more people.

• Correct hand placement while carrying the TV is very important for safety and to avoid damages.

SAFETY-RELATED COMPONENT WARNING!!

Components identified by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace these components with Sony

parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that are critical for safe operation are identified in this manual.

Follow these procedures whenever critical components are replaced or improper operation is suspected.

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

3

Page 4

USE CAUTION WHEN HANDLING THE LCD PANEL

When re pa ir ing the LCD p a nel, b e sure you ar e gr o und ed b y using a wrist b and .

When repa ir ing the LCD p a nel o n the wall, the LCD panel must b e sec ur ed using the 4 mounting ho le s o n the r ea r c o ver .

1) Do not press on the panel or frame edge to avoid the risk of electric shock.

2) Do not scratch or press on the panel with any sharp objects.

3) Do not l eave the module in high t emperatures or in areas of high humidity for an extended perio d of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause a short circuit within the module.

6) Disconnect the AC power when replacing the backlight (CCFL) or inverter circuit. (High voltage occurs at the inverter circuit at 650Vrms.)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

9) Protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

10) It is recommended not to exceed 1 hour of Power-On nor Burn-in period with LCD panel face down conditio n, in repair activity.

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

4

Page 5

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered connections. Check the entire board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and mounting hardware have been replaced. Be absolutely certain that you have replaced all the insulators.

4. Look for unauthorize d replacement parts, particularly transistors, that were installed during a pre vious repair. Point them out to the customer and recommend their replacement.

5. Look for par ts which, though functio ning, show obvi ous s igns o f d et er io r ati o n. P o int them out to the cust o mer a nd re c ommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend the replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs, screws, and all other exposed metal parts for AC leakage. Check leakage as described below.

8. For safety reasons, repairing the Power board and/or Inve rt er board is prohibited.

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

5

Page 6

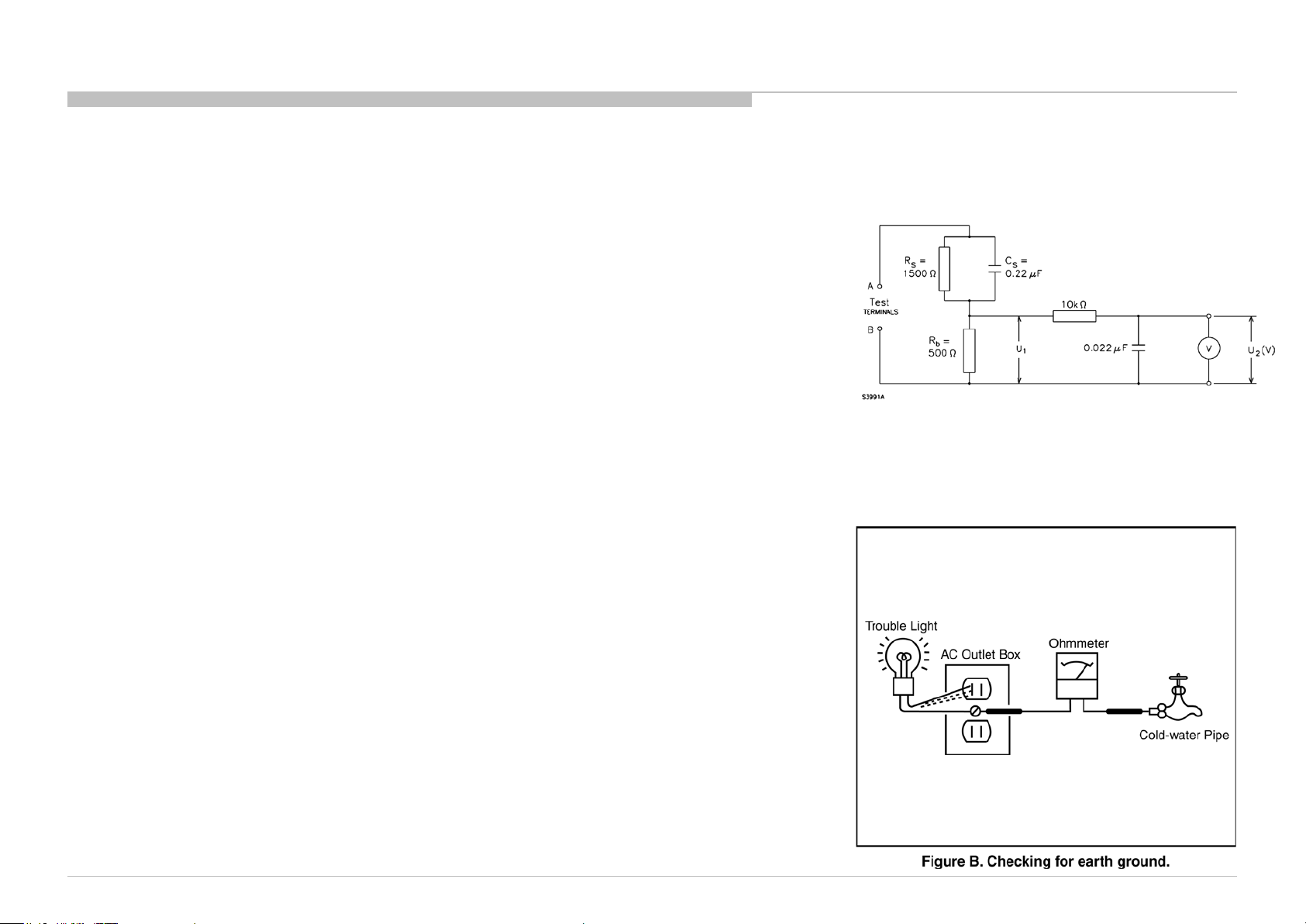

Leakage Test

(To protect electric shock when customer touch the term inal.)

Leakage current can be m easured by V: Voltmeter or oscilloscope (r.m.s. or peak reading)

Stabilized power supply instrument and isolated voltage transformer: Use too much current capacity and

isolated voltage transformer does not need to use stabilized power supply equipment Specification of RMS v olt

meter: Input resistance > 1 M ohm, Input capacitance < 200 pF, Frequency range: 15 Hz – 1MHz (Refer Figure

A). Isolated type volt -m eter (FLUKE 8921A etc *1)

*1 Not use FLUKE 8920A that connected to protective earth by diode

# Leakage current of measurement instrument is less than 10μArms when under test equipment AC plug is

opened # Set up the following condition and turn on the set.

Applied voltage: Nominal input voltage (Description on Nameplate) # Measure the leakage current between

one phase conductor and neutral for terminal A and terminal B.

Read rms value, and then calculate to peak value PEAK VALUE =√2 RMS VALUE

Comply with the following requirement Class II equipment (2-pin plug): for each terminal, the worst value of

measurement must not exceed AC 350uA peak). Note: including AC adaptor, AC adaptor/DC operated unit

combination

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining screw on most AC outlet boxes is also

at earth ground.

If the retaining screw is to be used as your earth ground, verify that it is at ground by measuring the resistance

between it and a cold-water pipe with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt trouble- light (not a neon lamp) between the hot

side of the receptacle and the retaining screw. Try both slots, if necessary, to locate the hot side on the line; the

lamp should light at normal brilliance if the screw is at ground potential (see Figure B).

SAFETY CHECK-OUT

Figure A. Measuring network for Leakage Current

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

6

Page 7

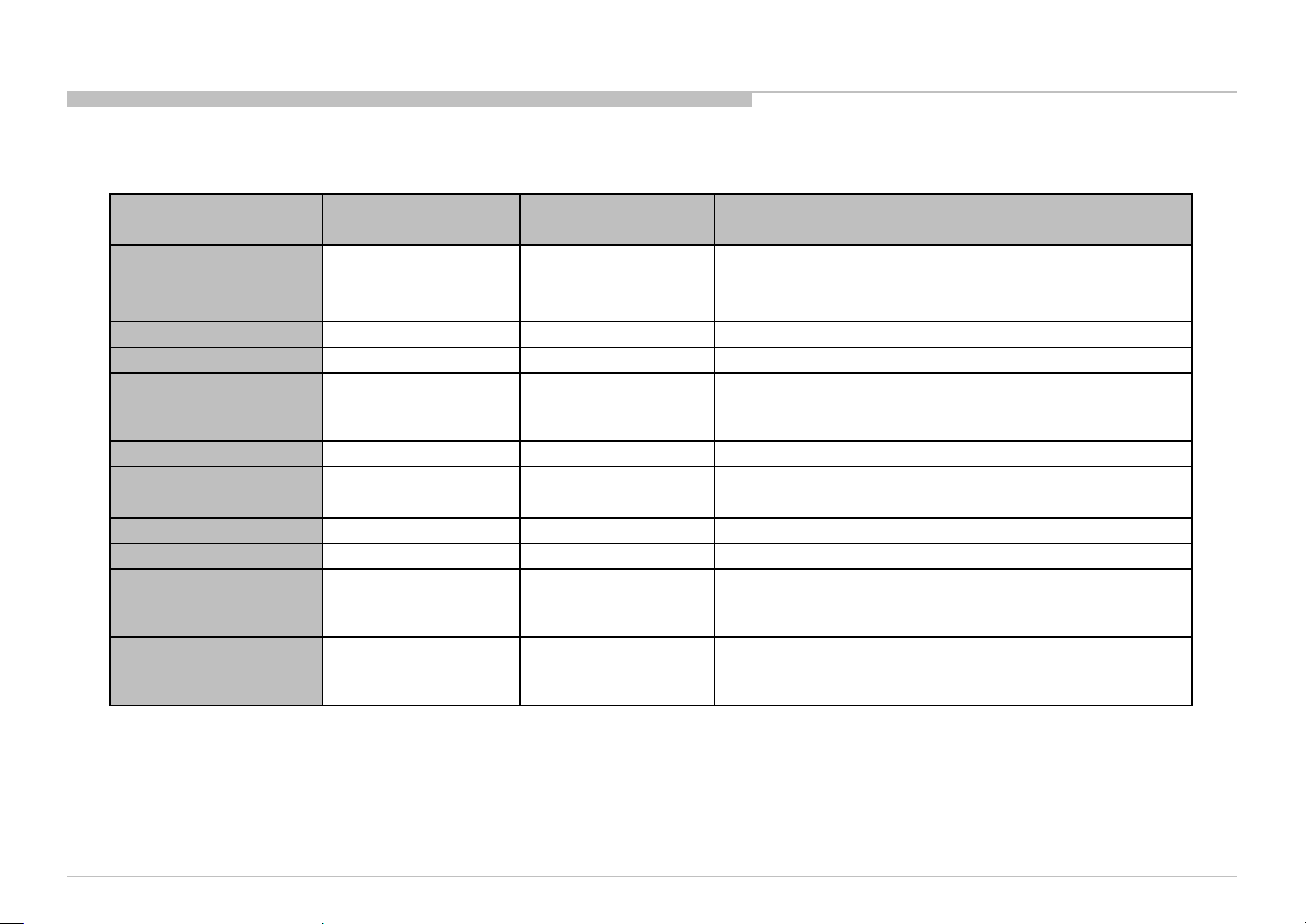

SELF DIAGNOSIS FUNCTION

Error Items

MAIN_POWER

AUD_ERR

AUD_I2C

TU_DEMOD

PANEL_POWER_ERR

PANEL_I2C_ERR

BACKLIGHT

LED_I2C

BE_I2C

PMIC_I2C

Number of LED

flashing

2

3

3

-

4

5

6

6

-

-

Go to Shutdown

Yes

Yes

Yes

No

log)

Yes

Yes

Yes

Yes

No

log)

No

log)

State

(Only record error

(Only record error

(Only record error

Description

Detect and observe main voltage

(1) 19.5V from AC adapter

(2) 12V from power board (TBD)

Detecting/Observing audio AMP error

Audio AMP communication error

Tuner & Demodulator I2C communication

monitoring.

Tuner Detect signal monitoring.

Detect and observe for Panel_12V

Detect Panel I2C Communication access error

Detect and observe backlight error

LED Driver commu nication error

BE device I2C communication error detection.

PMIC communication erro r

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

7

Page 8

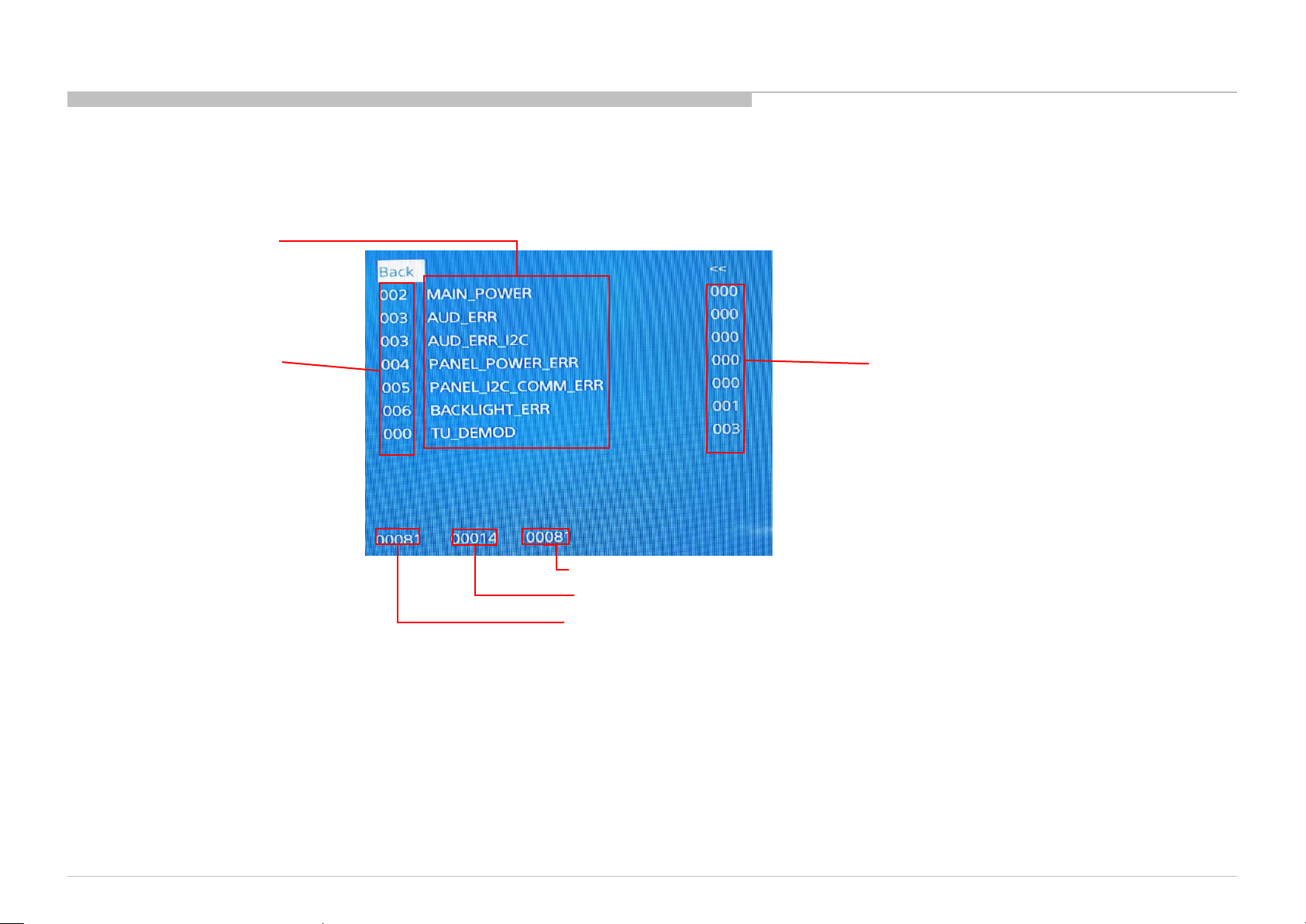

[SELF DIAGNOSTIC SCREEN DISPL AY]

Item name

SELF DIAGNOSIS FUNCTION

STBY LED flash time

Error count

Panel operation time by hour

Boot count

Total operation time by hour

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen.

After you have completed the repairs, clear the result display to “0”.

Clearing the Self Check Diagnostic List

1. Error history and Error count : Press the Channel 8 => Channel 0 .

2. Panel operation time : Press the Channel 7 => Channel 0 .

Exiting the Self-diagnostic screen

To exit the Self Diagnostic screen, turn off the power to the TV by pressing the POWER button on the remote or the POWER button on the TV.

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

8

Page 9

SEC 1. DISASSEMBLY AND PARTS LIST

• Items with no part number and no description are not stocked because they are seldom required for roution service.

• The construction parts of an assembled part are indicated with a collation number in the remark colum.

• Items marked " * " are not stocked since they are seldom required for routine service. Some delay should be anticipated when ordering these items.

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

9

Page 10

1-2. KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

4

7

4

DESCRIPTION

MARK

STAND, NECK

STAND, COVER

STAND, BRACKET L

STAND, BRACKET R

STAND, BRACKET FRONT

DISASSEMBLY AND PARTS LIST

1-2-1. STAND BLOCK

1-2-2. STAND COVER ASSY AND ST AND BASE ASSY AND NE CK

REF.NO. PART No.

1 4-723-281-01

2 4-723-280-01

3 4-723-282-01

4 4-723-283-01

5 4-723-284-01

-723-296-01 SCREW, +PSW M5X12

-682-961-09 SCREW, +PSW M4x8 W8

-729-979-01 SCREW,F,CROSS,T.T-3*6,BLK-ZN.

4

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

1

5

2

3

10

Page 11

1-2. KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

DISASSEMBLY AND PARTS LIST

1-2-3. AC COVER AND R E AR C O VE R

6

7

REF.NO. PART No. DESCRIPTION MARK

6 4-725-317-01 COVER, AC

7 1-912-305-11 AC Cord(USA 2pin) For UC2/LA1/CO1

1-912-304-11 AC Cord(Argentina 2pin) For AR4

8

1-912-303-11 AC Cord(Europe 2pin) For LA8/ME6

1-912-301-11 AC Cord(UK 3pin) For EA4

1-912-302-11 AC Cord(AUS/NZ 2pin) For AZ1

8 4-723-275-01 COVER, REAR (UC2) ForUC2

4-723-277-01 COVER, REAR (LA1/EA4/ME6) ForLA1/EA4/ME6

4-723-276-01 COVER, REAR (LA8/CO1/AR4 ) ForLA8/CO1/AR4

4-723-298-01 COVER, REAR (AZ1) ForAZ1

4-729-978-01 SCREW, +PSW M3X8 W8

4-268-126-02 SCREW,ORNAMENTAL M6X12

7-685-646-79 SCREW, +BVTP 3X8 TYPE2 IT-3

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

11

Page 12

1-2. KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

PART No.

MARK

1

1

1

1

For

1

For LA8

1

For

1

For AR4

1

For

1

For AZ1/ME6/EA4

1

1

1

1

1

1

1

1

1

1

1

1

4

4

4

4

4

For UC2/LA1/

EA4/ME6/AZ1

4

For LA8/CO1/AR4

4

4

4

2

4

4

DISASSEMBLY AND PARTS LIST

1-2-4. OVERALL

30

27

31

28

17

26

22

25

11

13

19

20

16

REF.NO.

9

10

11

9

10

12

-522-035-11 ANTENNA 1 (W)

-522-033-11 ANTENNA 2 (B)

-897-219-11 MOUNTED PWB POWER UNIT

-897-214-11 MOUNTED PWB A

-897-209-11 MOUNTED PWB A

-897-217-11 MOUNTED PWB A

-897-211-11 MOUNTED PWB A

-897-210-11 MOUNTED PWB A

23

12

15

14

29

21

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

-897-208-11 MOUNTED PWB A (AZ1, ME6, EA4)

-897-212-11 MOUNTED PWB H

-897-213-11 MOUNTED PWB KEY

-897-207-11 MOUNTED PWB WF

-910-112-59 CONNECTOR ASSY 15P (MB-PSU)

-910-112-60 CONNECTOR ASSY (MB-SPK 1)

-910-112-61 CONNECTOR ASSY (MB-SPK 2)

-910-112-56 LVDS CABLE 41P (MB-Panel)

-910-112-57 CONNECTOR ASSY 10P (MB-IR)

-910-112-58 CONNECTOR ASSY 6P (MB-key)

-910-112-63 CONNECTOR ASSY (PSU-Panel)

-910-112-62 CONNECTOR ASSY (MB-WIFI)

-859-242-11 SPEAKER 12W

-723-286-01 SHEET, INSULATION

-723-287-01 DECO

-545-671-01 BRACKET, VESA (60)

-723-278-01 BRACKET, BOTTOM

DESCRIPTION

UC2

LA1

CO1

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

24

32

18

29

30

31

32

-723-297-01 BRACKET, SIDE IO

-723-279-01 BRACKET, SIDE IO (LA8/CO1/AR4)

-729-982-01 CUSHION W25*T5

-723-294-01 CLAMP, CABLE

-729-986-01 NWF 145*8*0.35mm

-990-421-41 SCREW(PSW)(M3X6)

-729-978-01 SCREW, +PSW M3X8 W8

-459-864-01 SCREW, +PWTP2 4X10

12

Page 13

1-2. KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

DESCRIPTION

TUNER MODULE SUT

TUNER MODULE SUT

TUNER MODULE SUT

TUNER MODULE SUT

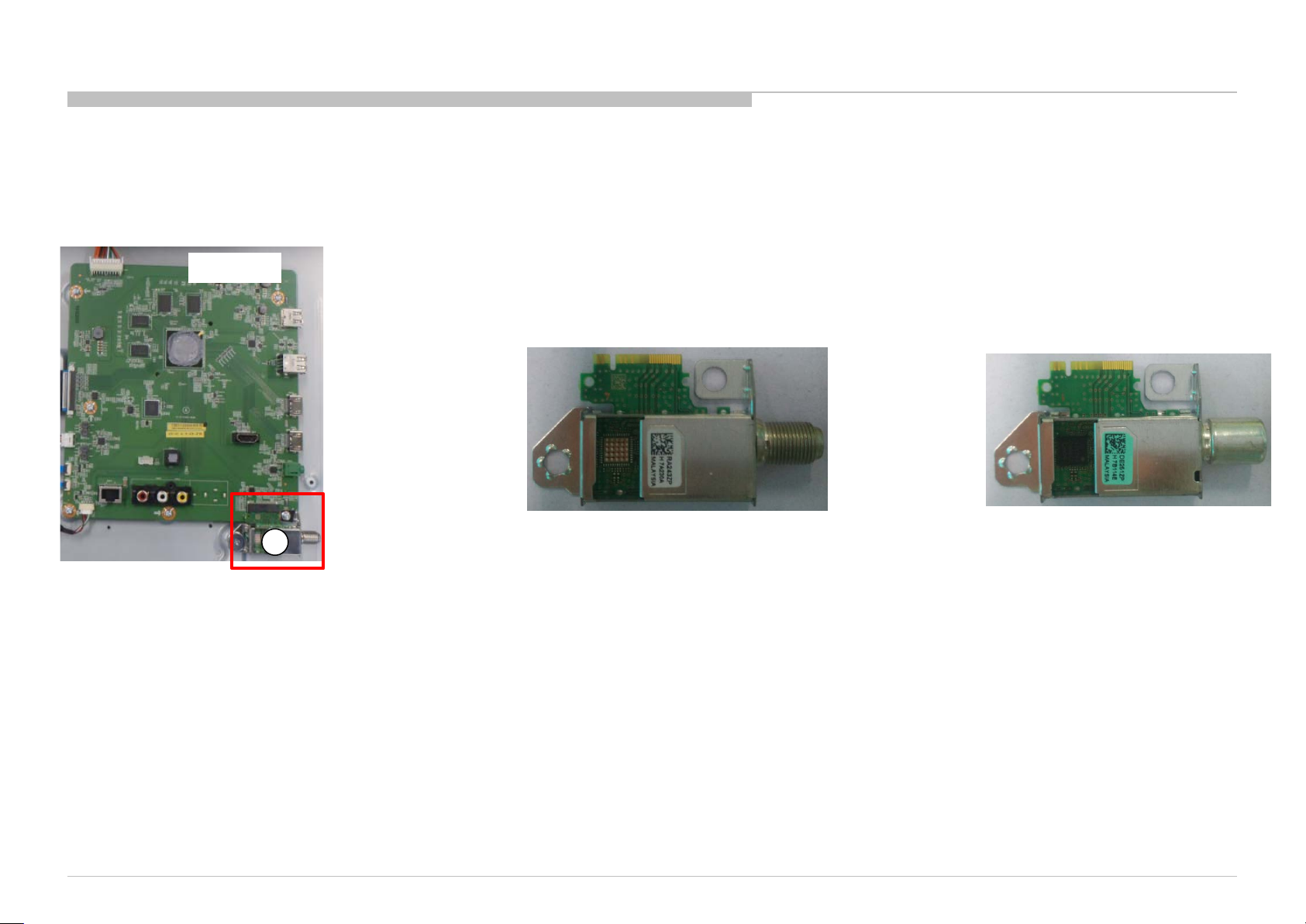

DISASSEMBLY AND PARTS LIST

1-2-5. TUNER MODULE

A BOARD

33

REF.NO. PART No.

33

8-594-302-70

8-594-308-30

8-594-325-00

8-594-328-10

For CO1

MARK

-RA243ZP

-RT243ZP

-DB251ZP

-DE251ZP

For UC2/LA1

For LA8/AR4

For CO1

For AZ1/EA4/ME6

For LA8/AR4

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

For UC2/LA1

For AZ1/EA4/ME6

13

Page 14

1-2. KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

MARK

4

SCREW,A,M2.5,L5

4

SCREW(B)/M2.5*L10

DISASSEMBLY AND PARTS LIST

1-2-6. LCM

1-2-7. LCM (W/O BEZEL)

34

35

REF.NO. PART No. DESCRIPTION

34

35

36

37

1-812-368-11 LCM ASSY (60) (S600DUC-1)

4-724-143-01 BEZEL, FRONT

4-729-983-01 FC BTM BRACKET (60)

4-729-985-01 Double Side Tape

-729-980-01

-729-981-01

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

36

37

14

Page 15

1-2. KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

PART No.

MARK

4

4

4

4

4

4

For UC2

4

For

R4

4

For

3

4

4

4

4

4

DISASSEMBLY AND PARTS LIST

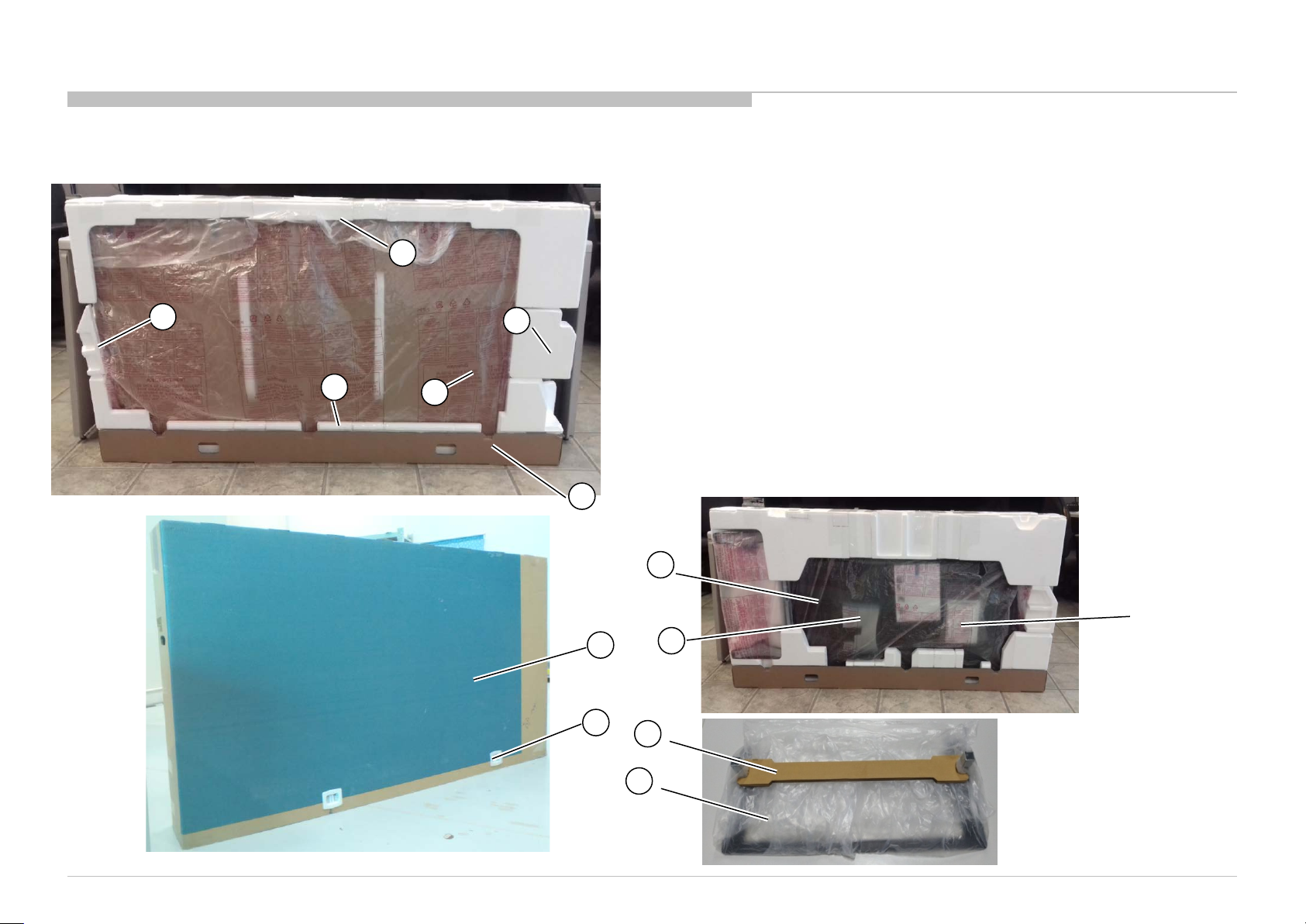

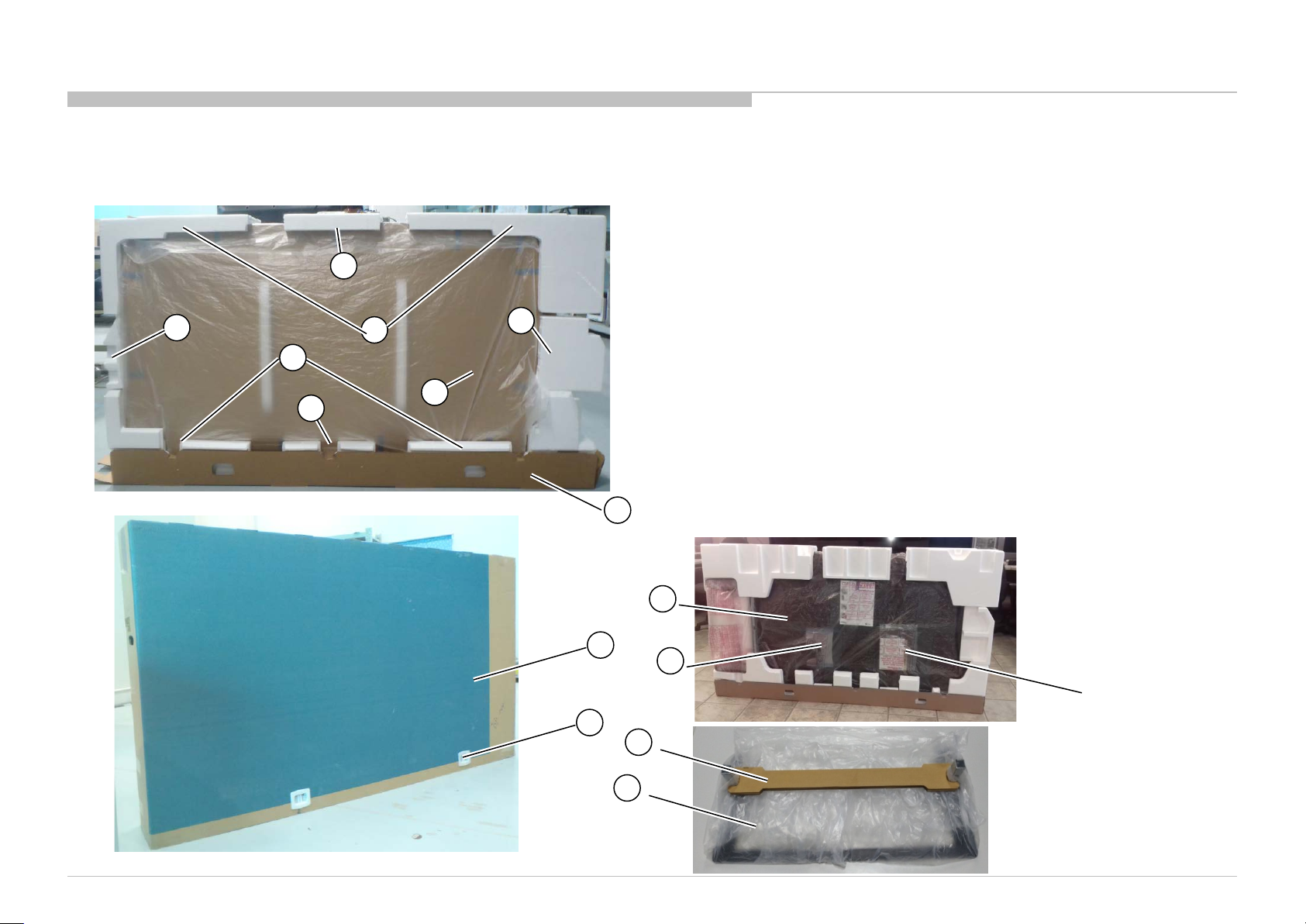

1-2-8. PACKAGE

40

39

38

42

41

49

REF.NO.

38

39

40

41

42

43

44

45

46

47

48

49

47

DESCRIPTION

-723-288-01 CUSHION, UPPER(60)

-723-289-01 CUSHION, LOWER (60)

-723-290-01 CUSHION, SIDE L (60)

-723-291-01 CUSHION, SIDE R (60)

-723-292-01 PLATE, EPE FRONT (60)

-723-547-01 CARTON, INDIVIDUAL (UC2)

-723-549-01

CARTON, INDIVIDUAL

(LA1/LA8/CO1/AR4)

-723-551-01 CARTON, INDIVIDUAL (AZ1/ME6/EA4)

-674-673-22 STOPPER (A)

-723-285-01 BAG, STAND

-723-293-01 CARTON STAND SUPPORT (60MB)

-409-919-33 BAG,PROTECTION PEHD(1720*1050)

-729-987-01

SHEET, PROTECTION PE

(L180xW260xT1.01mm)

-729-990-01 CARTON TRAY (60)

LA1/LA8/CO1/A

AZ1/ME6/EA4

43

44

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

ASSESSORY BAG

48

46

45

15

Page 16

1-2. KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

PART No.

DESCRIPTION

MARK

REMOTE COMMANDER (RMT

For UC2/LA1

REMOTE COMMANDER (RMT

For AR4/CO1/LA8

REMOTE COMMANDER (RMT

For AZ1

REMOTE COMMANDER (RMT

For ME6/EA4

CARBON ZINC DRY BATTERY(R03)

1-2-9. OTHER PART

DISASSEMBLY AND PARTS LIST

1-493-312-11

1-493-313-11

1-493-314-11

1-493-315-11

1-853-643-21

-TX300U)

-TX300B)

-TX300E)-AZ1

-TX300P)-ME6/EA4

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

16

Page 17

1-3. KD-70X690E/KD-70X6700E

PART No.

DESCRIPTION

MARK

4

STAND, NECK

4

STAND, COVER

4

STAND, BRACKET L

4

STAND, BRACKET R

4

STAND, BRACKET FRONT

DISASSEMBLY AND PARTS LIST

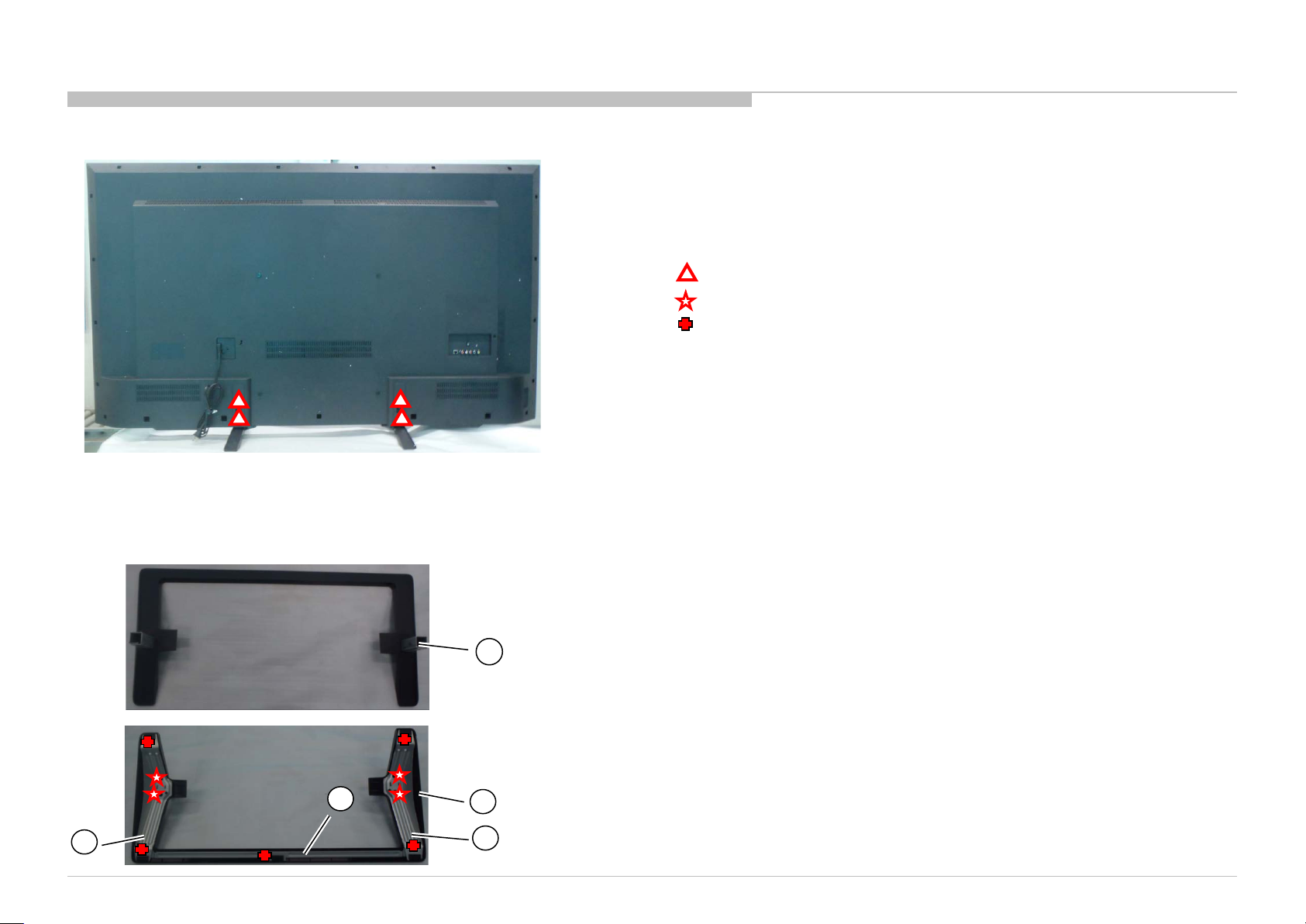

1-3-1. STAND BLOCK

1-3-2. STAND COVER ASSY AND ST AND BASE ASSY AND NE CK

REF.NO.

1

2

3

4

5

-723-281-01

-723-280-01

-723-282-01

-723-283-01

-723-284-01

4-723-296-01 SCREW, +PSW M5X12

7-682-961-09 SCREW, +PSW M4x8 W8

4-729-979-01 SCREW,F,CROSS,T.T-3*6,BLK-ZN.

4

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

1

5

2

3

17

Page 18

1-3. KD-70X690E/KD-70X6700E

PART No.

DESCRIPTION

MARK

4

COVER AC

1

AC Cord(USA 2pin)

For UC2/LA1

1

AC Cord(Europe 2pin)

For ME6

1

AC Cord(UK 3pin)

For EA4

1

AC Cord(AUS/NZ 2pin)

For AZ1

4

COVER, REAR (UC2)

ForUC2

4

COVER, REAR (LA1/EA4/ME6 )

For

4

COVER, REAR (AZ1)

F

DISASSEMBLY AND PARTS LIST

1-3-3. AC COVER AND RE AR COVER

6

7

REF.NO.

6

7

-725-317-01

-912-305-11

-912-303-11

-912-301-11

-912-302-11

8

8

-723-306-01

-723-307-01

-723-308-01

LA1/EA4/ME6

orAZ1

4-729-978-01 SCREW, +PSW M3X8 W8

4-268-126-02 SCREW,ORNAMENTAL M6X12

7-685-646-79 SCREW, +BVTP 3X8 TYPE2 IT-3

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

18

Page 19

1-3. KD-70X690E/KD-70X6700E

PART No.

MARK

1

1

1

1

For

1

For ZA1/EA4/ME6

1

For LA1

1

1

1

1

1

1

1

1

1

1

1

1

4

4

4

4

4

4

4

4

2

4

4

DISASSEMBLY AND PARTS LIST

1-3-4. OVERALL

27

28

30

31

26

11

22

25

20

13

19

17

16

15

9

23

12

21

29

14

10

REF.NO.

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

DESCRIPTION

-522-034-11 ANTENNA 1 (W)

-522-032-11 ANTENNA 2 (B)

-897-216-11 MOUNTED PWB POWER UNIT

-897-215-11 MOUNTED PWB A

-897-206-11 MOUNTED PWB A

-897-218-11 MOUNTED PWB A

-897-212-11 MOUNTED PWB H

-897-213-11 MOUNTED PWB KEY

-897-207-11 MOUNTED PWB WF

-910-112-67 CONNECTOR ASSY 15P (MB-PSU)

-910-112-68 CONNECTOR ASSY (MB-SPK 1)

-910-112-69 CONNECTOR ASSY (MB-SPK 2)

-910-112-64 LVDS CABLE 41P (MB-Panel)

-910-112-65 CONNECTOR ASSY 10P (MB-IR)

-910-112-66 CONNECTOR ASSY 6P (MB-key)

-910-112-71 CONNECTOR ASSY (PSU-Panel)

-910-112-70 CONNECTOR ASSY (MB-WIFI)

-859-242-11 SPEAKER 12W

-723-312-01 SHEET, INSULATION

-723-287-01 DECO

-723-309-01 BRACKET, VESA

-723-310-01 BRACKET, BOTTOM

-723-297-01 BRACKET, SIDE IO

-723-311-01 COVER, BOTTOM

-723-294-01 CLAMP, CABLE

-729-986-01 NWF 145*8*0.35mm

UC2

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

24

32

18

-990-421-41 SCREW(PSW)(M3X6)

-729-978-01 SCREW, +PSW M3X8 W8

-459-864-01 SCREW, +PWTP2 4X10

19

Page 20

1-3. KD-70X690E/KD-70X6700E

PART No.

DESCRIPTION

MARK

8

TUNER MODULE SUT

For

8

TUNER MODULE SUT

For AZ1/EA4/ME6

DISASSEMBLY AND PARTS LIST

1-3-5. TUNER MODULE

A BOARD

33

REF.NO.

33

For UC2/LA1

-594-302-70

-594-328-10

-RA243ZP

-DE251ZP

For AZ1/EA4/ME6

UC2/LA1

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

20

Page 21

1-3. KD-70X690E/KD-70X6700E

MARK

4

SCREW,A,M2.5,L5

4

SCREW(B)/M2.5*L10

DISASSEMBLY AND PARTS LIST

1-3-6. LCM

1-3-7. LCM (W/O BEZEL)

34

35

REF.NO. PART No. DESCRIPTION

34

35

36

1-812-369-11 LCM ASSY (70) (S700DUC-1)

4-724-144-01 BEZEL, FRONT

4-729-984-01 FC BTM BRACKET (70)

-729-980-01

-729-981-01

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

36

21

Page 22

1-3. KD-70X690E/KD-70X6700E

PART No.

4

4

4

4

4

4

4

4

4

4

3

4

4

4

4

4

DISASSEMBLY AND PARTS LIST

1-3-8. PACKAGE

41

39

40

37

38

43

42

50

REF.NO.

37

38

39

40

41

42

43

44

45

46

47

48

49

50

DESCRIPTION MARK

-723-314-01

-723-313-01

CUSHION, UPPER CENTER

CUSHION, UPPER

-723-315-01 CUSHION, LOWER

-723-316-01

-723-317-01

CUSHION, LOWER CENTER

CUSHION, SIDE L

-723-318-01 CUSHION, SIDE R

-723-319-01 PLATE, EPE FRONT (70)

-723-546-01 CARTON, INDIVIDUAL (UC2)

-723-548-01 CARTON, INDIVIDUAL (LA1)

-723-550-01 CARTON, INDIVIDUAL (AZ1/ME6/EA4)

-674-673-22 STOPPER (A)

-723-285-01 BAG, STAND

-723-293-01 CARTON STAND SUPPORT (60MB)

-409-920-33 BAG, PROTECTION PEHD(1950x1200)

-729-987-01

SHEET, PROTECTION PE

(L180xW260xT1.01mm)

-729-991-01 CARTON TRAY (70)

For UC2

ForLA1

For AZ1/EA4/ME6

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

48

44

49

ASSESSORY BAG

45

47

46

22

Page 23

PART No.

MARK

4

4

1-3. KD-70X690E/KD-70X6700E

1-3-8. PACKAGE

50

REF.NO.

50

51

-729-988-01

-729-989-01

50

DESCRIPTION

CUSHION, EPS BAR

(150MMX25MMX11MM)

CUSHION, EPS BLOCK

(120MMX120MMX30MM)

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

51

51

23

Page 24

1-3. KD-70X690E/KD-70X6700E

PART No.

DESCRIPTION

MARK

REMOTE COMMANDER (RMT

For UC2/LA1

REMOTE COMMANDER (RMT

For AZ1

REMOTE COMMANDER (RMT

For ME6/EA4

CARBON ZINC DRY BATTERY(R03)

1-3-9. OTHER PART

DISASSEMBLY AND PARTS LIST

1-493-312-11

1-493-314-11

1-493-315-11

1-853-643-21

-TX300U)

-TX300E)-AZ1

-TX300P)-ME6/EA4

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

24

Page 25

1-4 DISASSEMBLY OF REAR COVER AND SERVICE POSITION

1-4-1. KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

1. LAY DOWN THE SET IN A FLAT TABLE

DISASSEMBLY AND PARTS LIST

Make sure no mess things

under the front s et.

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

25

Page 26

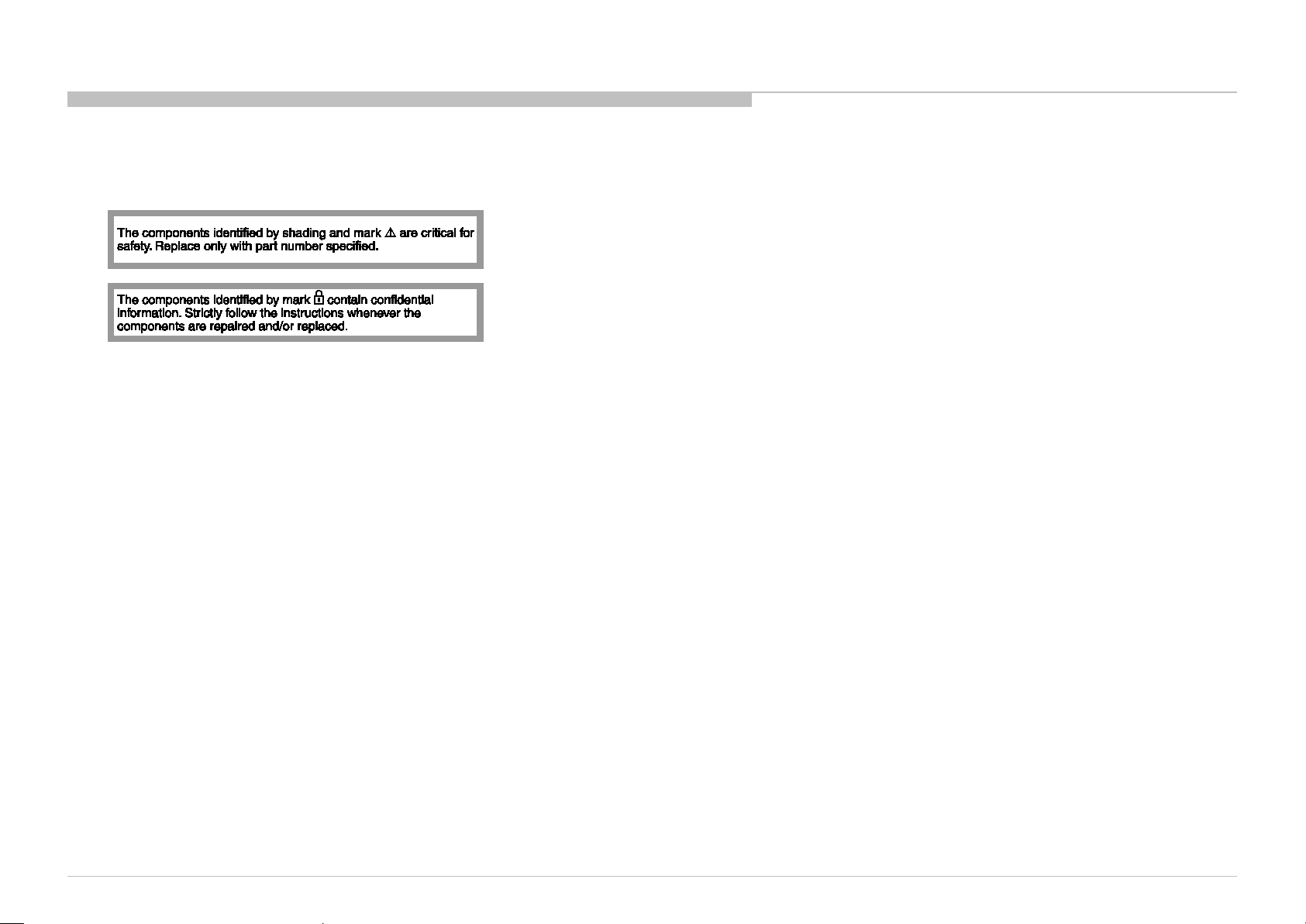

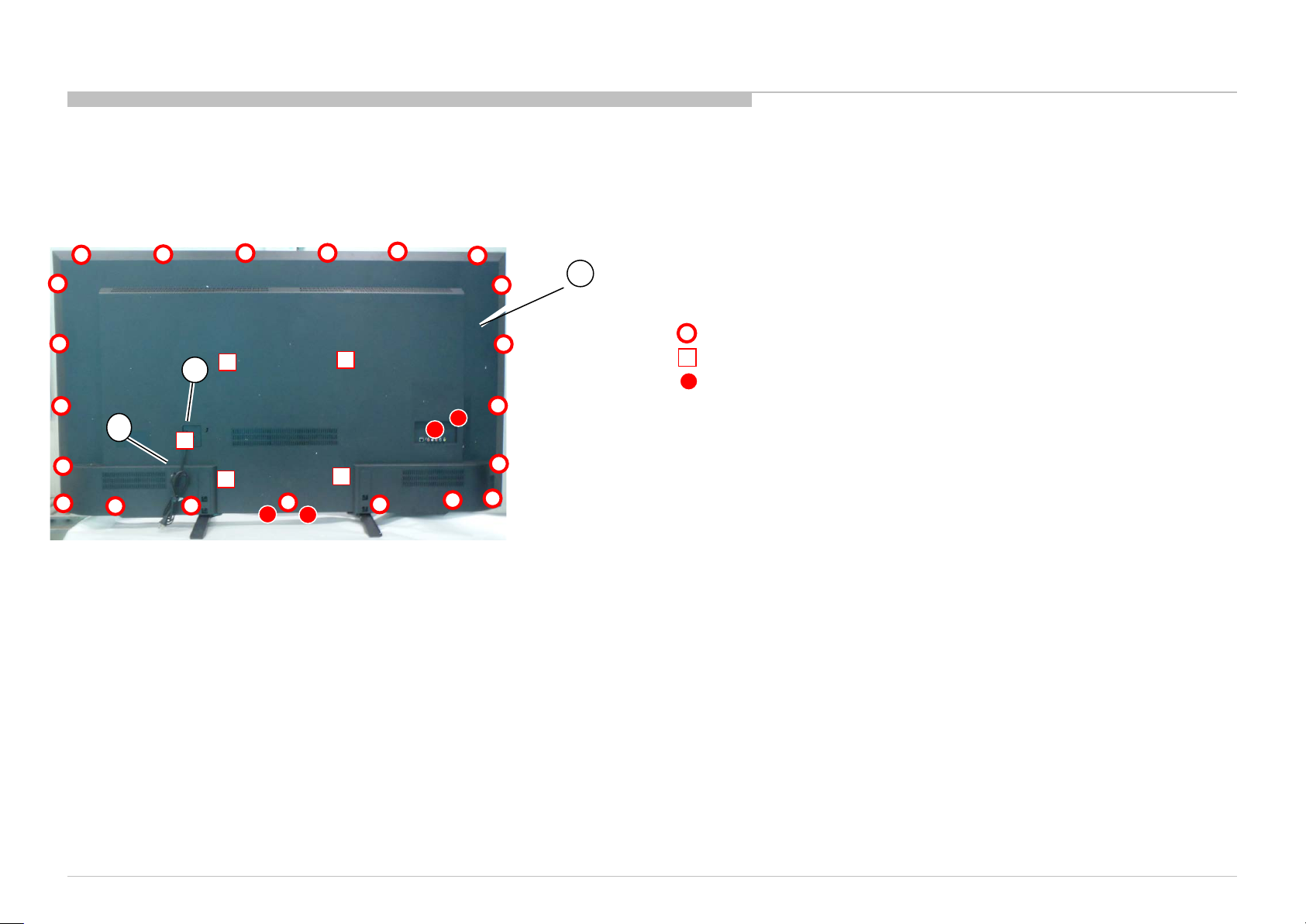

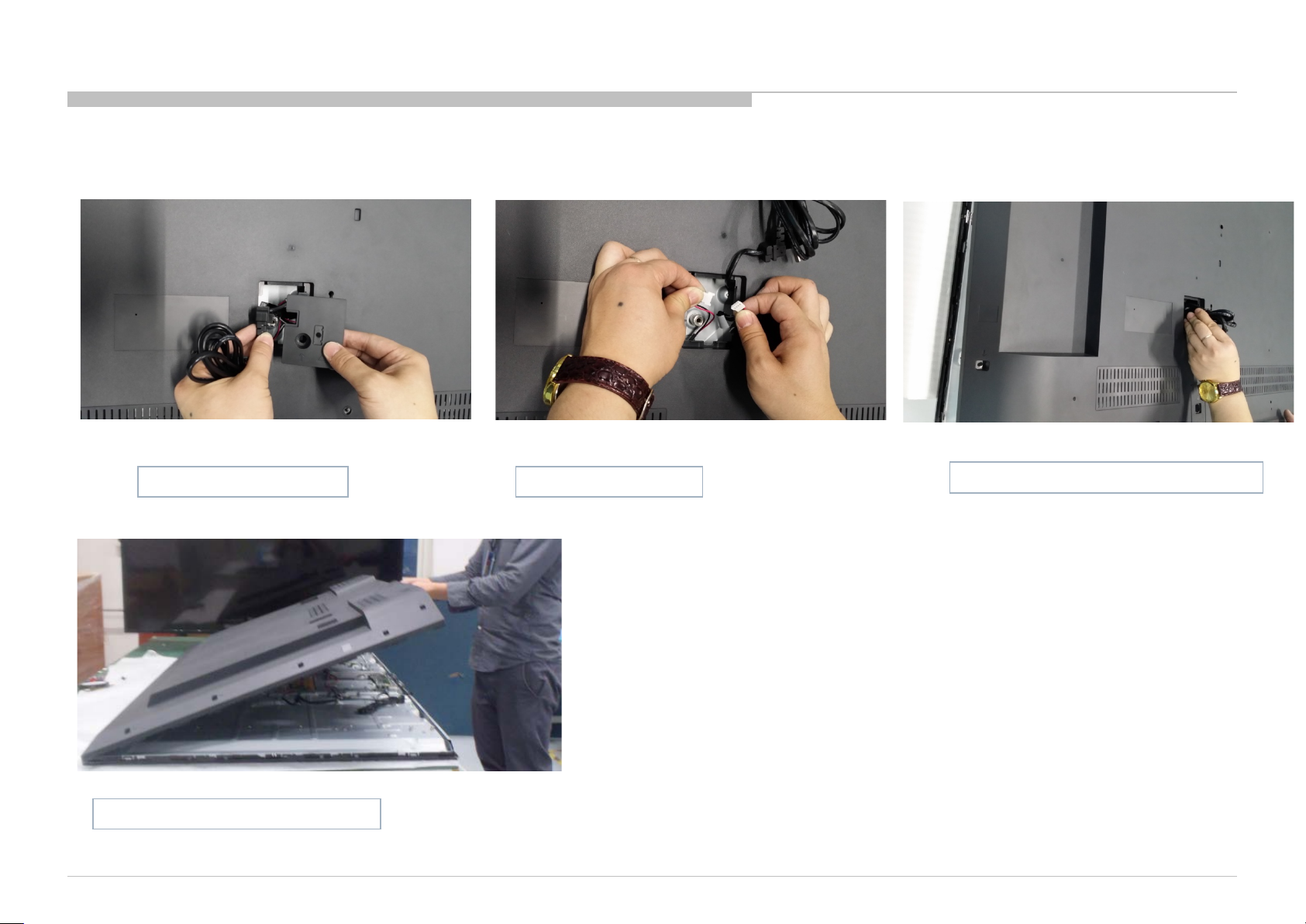

2. UNLOCK SCREWS

DISASSEMBLY AND PARTS LIST

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

SCREW, +PSW M3X8 W8 18PCS

SCREW,ORNAMENTAL M6X12 5PCS

SCREW, +BVTP 3X8 TYPE2 IT-3 4PCS

26

Page 27

3. REMOVE THE REAR COVER

DISASSEMBLY AND PARTS LIST

Take off the AC cover first Take off the SP connector

Lift up the rear cover from the bottom

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

Insert the AC co r d thought t he r ea r c o ver ho le .

27

Page 28

4. SET UP THE SET

DISASSEMBLY AND PARTS LIST

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

28

Page 29

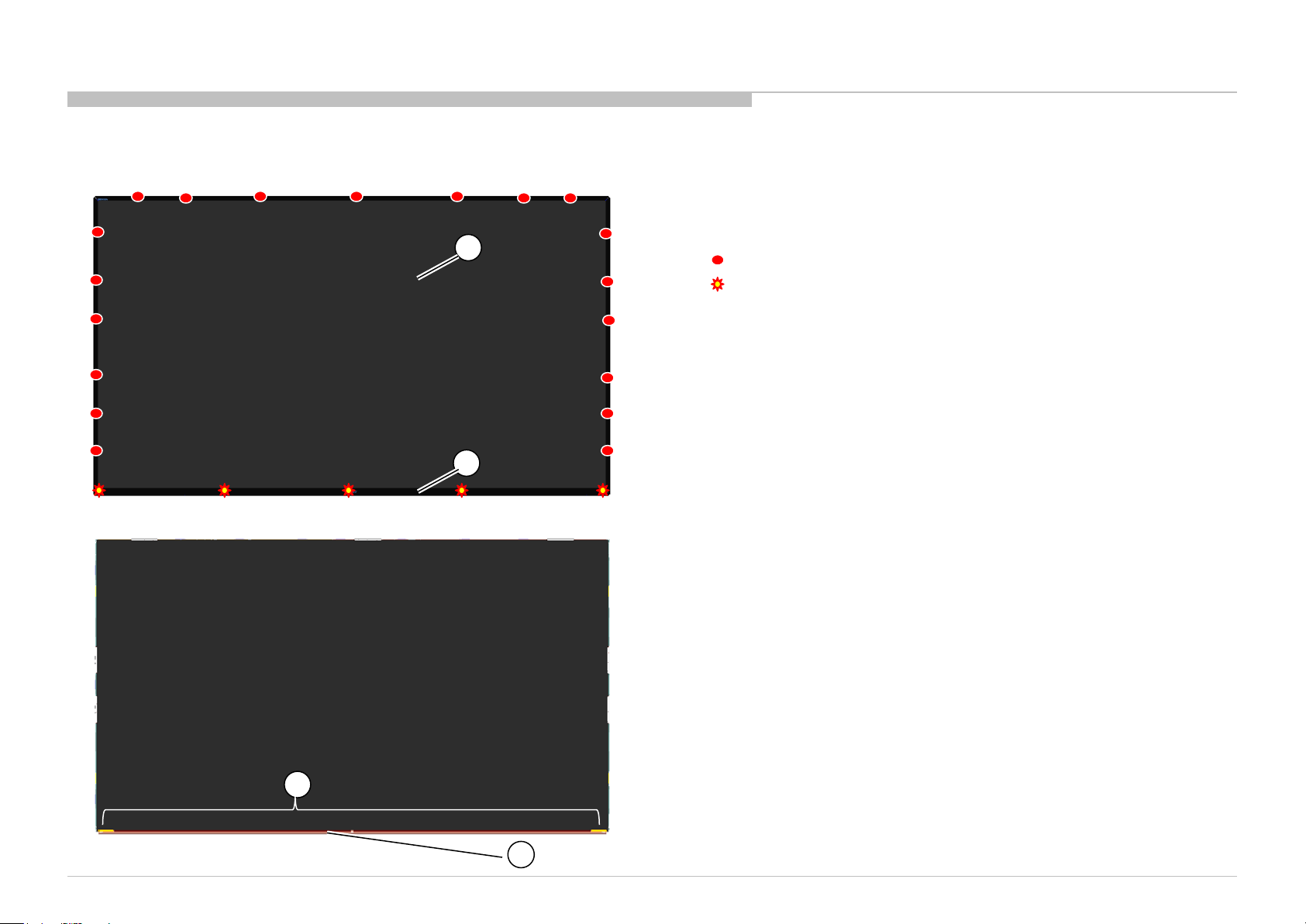

HOOK POSITION

KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

Rear Cover

DISASSEMBLY AND PARTS LIST

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

29

Page 30

HOOK POSITION

KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

DISASSEMBLY AND PARTS LIST

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

30

Page 31

1-4 DISASSEMBLY OF REAR COVER AND SERVICE POSITION

1-4-2. KD-70X690E/KD-70X6700E

1. LAY DOWN THE SET IN A FLAT TABLE

DISASSEMBLY AND PARTS LIST

Make sure no mess things

under the front s et.

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

31

Page 32

2. UNLOCK SCREWS

DISASSEMBLY AND PARTS LIST

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

SCREW, +PSW M3X8 W8 21PCS

SCREW,ORNAMENTAL M6X12 5PCS

SCREW, +BVTP 3X8 TYPE2 IT-3 4PCS

32

Page 33

3. REMOVE THE REAR COVER

DISASSEMBLY AND PARTS LIST

Take off the AC cover first Take off the SP connector

Lift up the rear cover from the bottom

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

Insert the AC co r d thought t he r ea r c o ver ho le .

33

Page 34

4. SET UP THE SET

DISASSEMBLY AND PARTS LIST

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

34

Page 35

HOOK POSITION

KD-70X690E/KD-70X6700E

DISASSEMBLY AND PARTS LIST

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

35

Page 36

HOOK POSITION

KD-70X690E/KD-70X6700E

DISASSEMBLY AND PARTS LIST

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

36

Page 37

1-5 DISASSEMBLY OF LCM AND SERVICE POSITION

1-5-1. KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

1. REMOVE THE STAND

DISASSEMBLY AND PARTS LIST

Make sure no mess things

under the front s et.

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

Lay down the set.

Take off the stand

Unlock stand screws.

SCREW, +PSW M5X12 4PCS

Unlock bottom bracket screws and take off

SCREW, +PSW M3X8 12PCS

37

Page 38

2. REMOVE THE ORNAMENT PANEL.

DISASSEMBLY AND PARTS LIST

Take off the IR board.

Take off the ornament panel.

Peel off bottom Aluminum tape.

20*50mm 6PCS

30*160mm 2PCS

Remark: Aluminum tape can not reu se.

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

38

Page 39

3. TURN THE SET.

DISASSEMBLY AND PARTS LIST

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

Cushion can’t touch t his area, the height

of cushion must more than 35mm..

39

Page 40

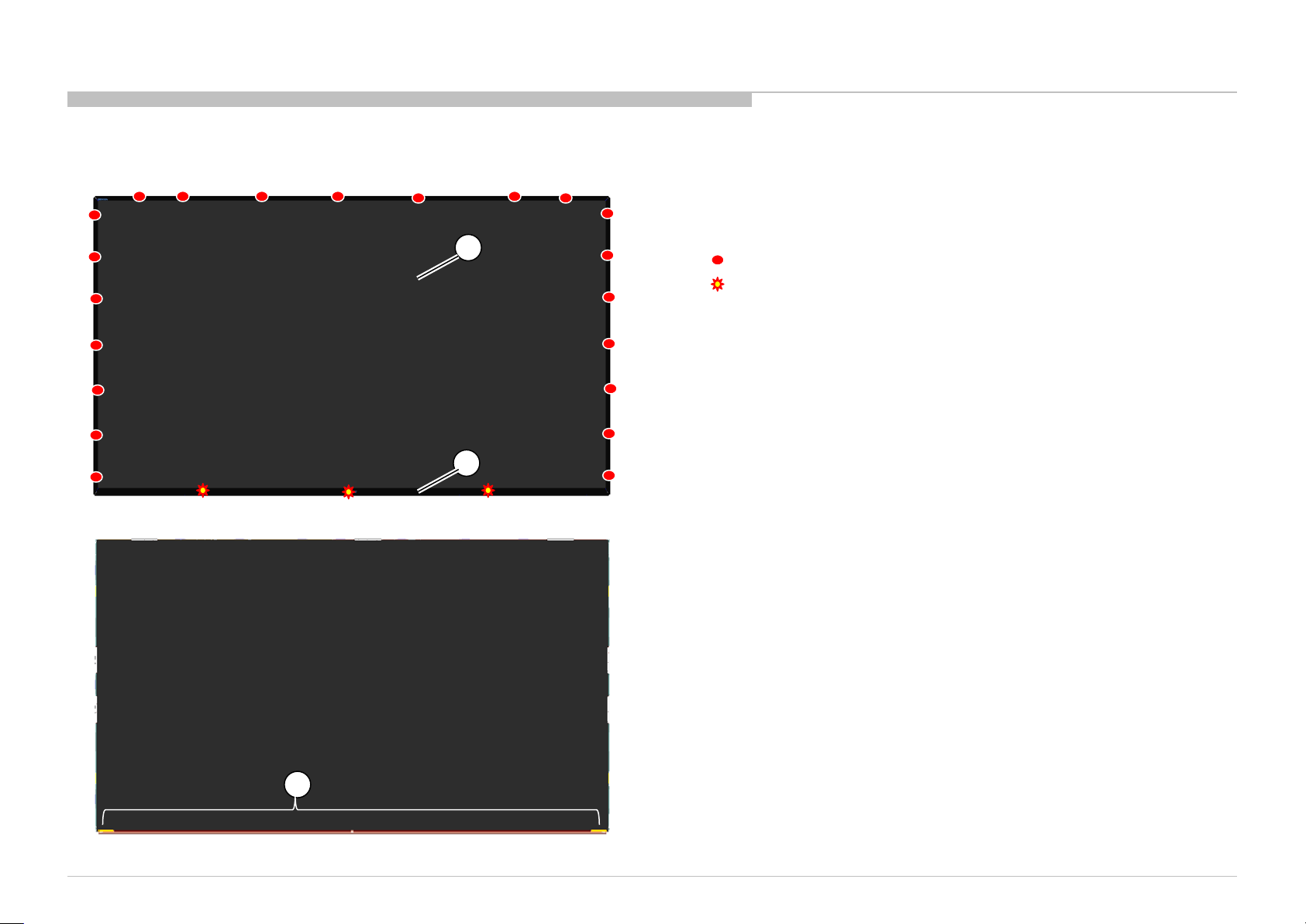

4. UNLOCK THE SCREWS.

19PCS

5PCS

DISASSEMBLY AND PARTS LIST

SCREW SILVER/M2.5 x 6 Ni/C1018

SCREW SILVER/M2.5*L10 Ni/C1018

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

40

Page 41

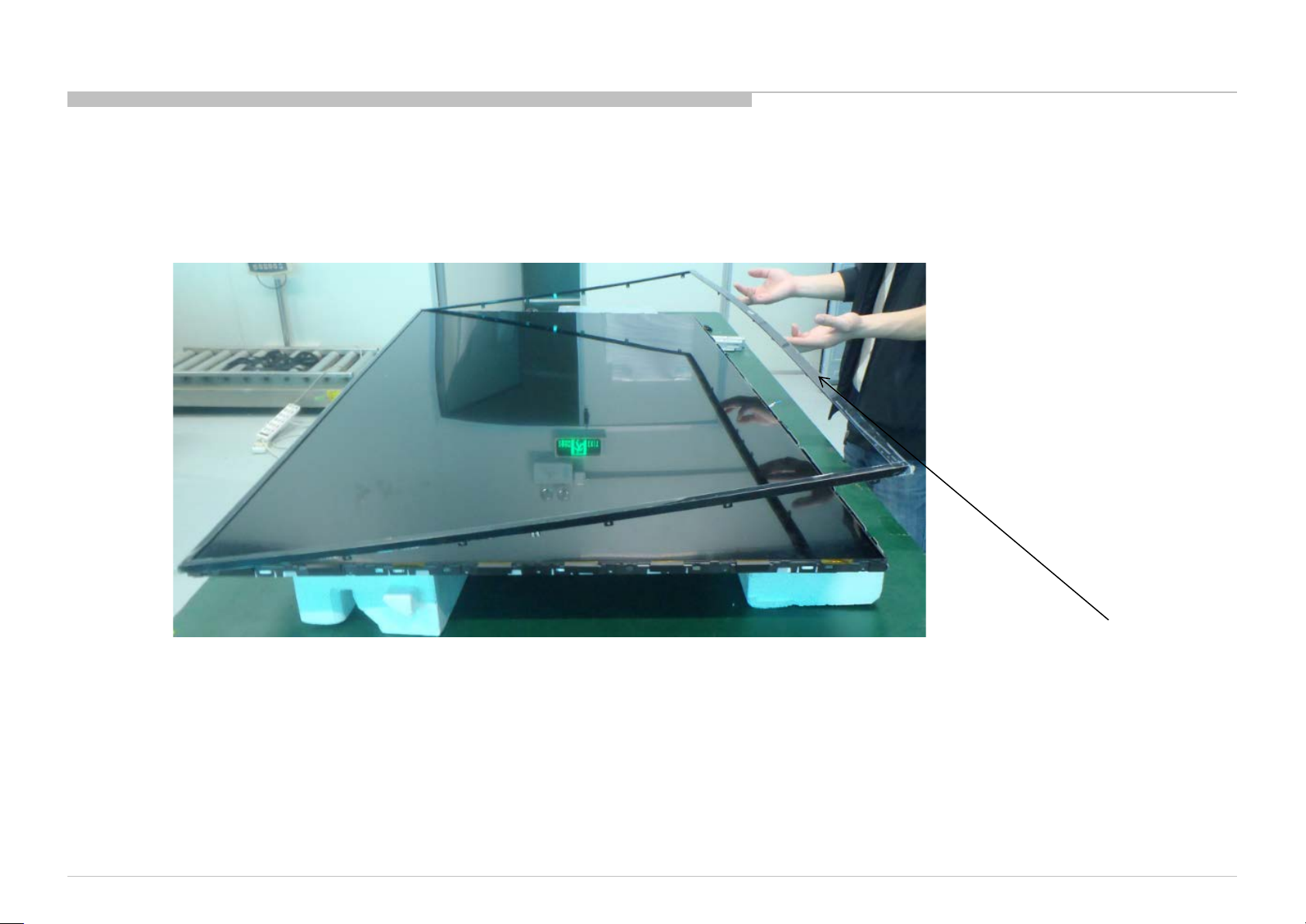

5. REMOVE THE BEZEL

DISASSEMBLY AND PARTS LIST

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

Take off Bezel top side firstly.

41

Page 42

6. REMOVE THE CORE TAPE

SHEET CORE TAPE (E60)

Please replace this photos ,

it too shinny,

DISASSEMBLY AND PARTS LIST

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

3PCS

42

Page 43

7. UNLOCK SCREWS AND TAKE OFF FC BOTTOM BRACKET.

SCREW SILVER/M2.5*L10 Ni/C1018

3PCS

Unlock screws.

DISASSEMBLY AND PARTS LIST

Take off FC bottom bracket.

Remark: F C Bott om Bracket ca n n ot reu se.

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

43

Page 44

TAPE LAYOUT

PART No.

KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

DISASSEMBLY AND PARTS LIST

DESCRIPTION MARK

20*50mm 6PCS

60*15mm 20PCS

30*160mm 2PCS

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

TAPE (3M 1350FB-1)15MMX66M BLK Can not reuse

Aluminum tape.

Aluminum tape.

Can not reuse

Can not reuse

44

Page 45

CUSHION ON REAR COVER

NWF 20*8*0.35mm

NWF

NWF

KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

DISASSEMBLY AND PARTS LIST

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

8 PCS

30*8*0.35mm 2 PCS

60*8*0.35mm 1 PCS

45

Page 46

1-5 DISASSEMBLY OF LCM AND SERVICE POSITION

12PCS

1-5-2. KDKD-70X690E/KD-70X6700E

1. REMOVE THE STAND

DISASSEMBLY AND PARTS LIST

Make sure no mess things

under the front s et.

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

Lay down the set.

Take off the stand

Unlock stand screws.

SCREW, +PSW M5X12 4PCS

Unlock bottom bracket screws and take off

SCREW, +PSW M3X8

46

Page 47

2. REMOVE THE ORNAMENT PANEL.

DISASSEMBLY AND PARTS LIST

Take off the IR board.

Peel off bottom Aluminum tape.

20*50mm 5PCS

30*160mm 2PCS

30*90mm 2PCS

Take off the ornament panel.

Remark: Aluminum tape can not reu se.

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

47

Page 48

3. TURN THE SET.

DISASSEMBLY AND PARTS LIST

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

Cushion can’t touch t his area, the height

of cushion must more than 35mm..

48

Page 49

4. UNLOCK THE SCREWS.

21PCS

3PCS

DISASSEMBLY AND PARTS LIST

SCREW SILVER/M2.5 x 6 Ni/C1018

SCREW SILVER/M2.5*L10 Ni/C1018

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

49

Page 50

5. REMOVE THE BEZEL

DISASSEMBLY AND PARTS LIST

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

Take off Bezel top side firstly.

50

Page 51

6. REMOVE THE CORE TAPE

SHEET CORE TAPE (E60)

Please replace this photos ,

it too shinny,

DISASSEMBLY AND PARTS LIST

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

6PCS

51

Page 52

7. UNLOCK SCREWS AND TAKE OFF FC BOTTOM BRACKET.

SCREW SILVER/M2.5*L10 Ni/C1018

3PCS

Unlock screws.

DISASSEMBLY AND PARTS LIST

Take off FC bottom bracket.

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

52

Page 53

TAPE LAYOUT

PART No.

KD-70X690E/KD-70X6700E

DISASSEMBLY AND PARTS LIST

20*50mm 5PCS

60*15mm 23PCS

30*160mm 2PCS

30*90mm 2PCS

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

TAPE (3M 1350FB-1)15MMX66M BLK Can not reuse

DESCRIPTION MARK

Aluminum tape.

Aluminum tape.

Aluminum tape.

Can not reuse

Can not reuse

Can not reuse

53

Page 54

CUSHION ON REAR COVER

NWF 115*8*0.15mm

NWF

KD-70X690E/KD-70X6700E

DISASSEMBLY AND PARTS LIST

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

4 PCS

60*8*0.35mm 1 PCS

54

Page 55

SEC 2. ADJUSTMENT

HOW TO ENTER SERVICE MODE

TV Under Standby Mode

1) Turn on the main power switch to place this set in standby mode.

2) Press the buttons on the remote commander as below, and enter service mode.

Info(DISPLAY) (Digit key) 5 Volume “+” Power On

3) TV will power on, and then Service menu will display.

TV Power On

1) Turn on the TV.

2) Press the buttons on the remote commander as below,

and enter service mode.

Left Right Mute Enter Mute Volume “+”

3) Service mode display.

When replace Main Board or panel, please confirm " SERIAL NUMBER EDIT " and "Model

Number Setting" in service menu, and set to the correct name according to your info.

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

55

Page 56

STATUS INFORMATION

*Below information is just for example, and may not match the actual info you see on consumer’s TV set.

Press “Return” key or “Home” key on RC to exit the Status Information screen.

ADJUSTMENT

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

56

Page 57

HOW TO ENTER SERVICE MODE (2 ways)

TV Under Standby Mode

1) Turn on the main power switch to set TV in standby mode.

2) Press the buttons on the remote commander as below:

Info (DISPLAY) (Digit key) 5 Volume “+” Power On

3) TV will power on, and then Service menu will display.

TV Power On

1) Turn on the TV.

ADJUSTMENT

2) Press the buttons on the remote commander as below,

NOTICE:

1. Change of SERIAL NUMBER EDIT and Model Number

and enter service mode.

Setting are only possible when the text is displayed in white.

Once you edit and confirm the result, the text color will turn

Left Right Mute Enter Mute Volume “+”

into orange.

3) Service mode display.

Function The flow of control

Service mode off <Return> / <Menu>

Adjustment Item up / down /

Data Value up / down /

2. When replace Main Board or panel, please confirm Serial

Number and Model Number are correct according to the full

set type. If they are different, please adjust to the correct one.

3. Software upgrade guide, please refer to “APPENDIX-2”.

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

57

Page 58

HOW TO APPLY GAMMA/CUC/MURA with service board

Service Mode

1) Purpose: For After Serv ice In The Mark et and Engineer ing Eval uation Purpose.

2) How to get into Service Mode

Push following key s sequentially.

Standby Mode : <DISPLAY>, <5>, <VOL+>, <POWER>

Power ON Mode : <LEFT>,<R IGHT>,<MUTE>,<OK/ENTER>,<MUTE>,<VOL+>

6/27 added

ADJUSTMENT

Service Mode

Status information .>>

Self diagnosis history >>

NO SIGNAL MUTE

TUNING SYSTEM

WIDE BAND TUNING

・・・・

・・・・

・・・・

LVDS SPREAD SPECTRUM (%)

LVDS Drive Strength (mA)

・・・・

・・・・

Panel/PQ >>

BACK <<

WB data transfer <[ 1.T-con To SoC ]>

MURA data transfer <[ 1.T-con To SoC ]>

CUC data transfer <[ 1.T-con To SoC ]>

[Start]

BACK <<

WB Adjustment >>

WB/Mura/CUC data transfer >>

Description :

※1. Select the Value 1 for each WB/MURA/CUC, then enter "Start" to ex ecute data tr ansfer.

2. Waiting 5 seconds.

3. AC Off/On

0. SoC to T-con

1. T-con to SoC

2. No Action

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

58

Page 59

SEC 3. DIAGRAMS AND CHASSIS STRUCT U RE

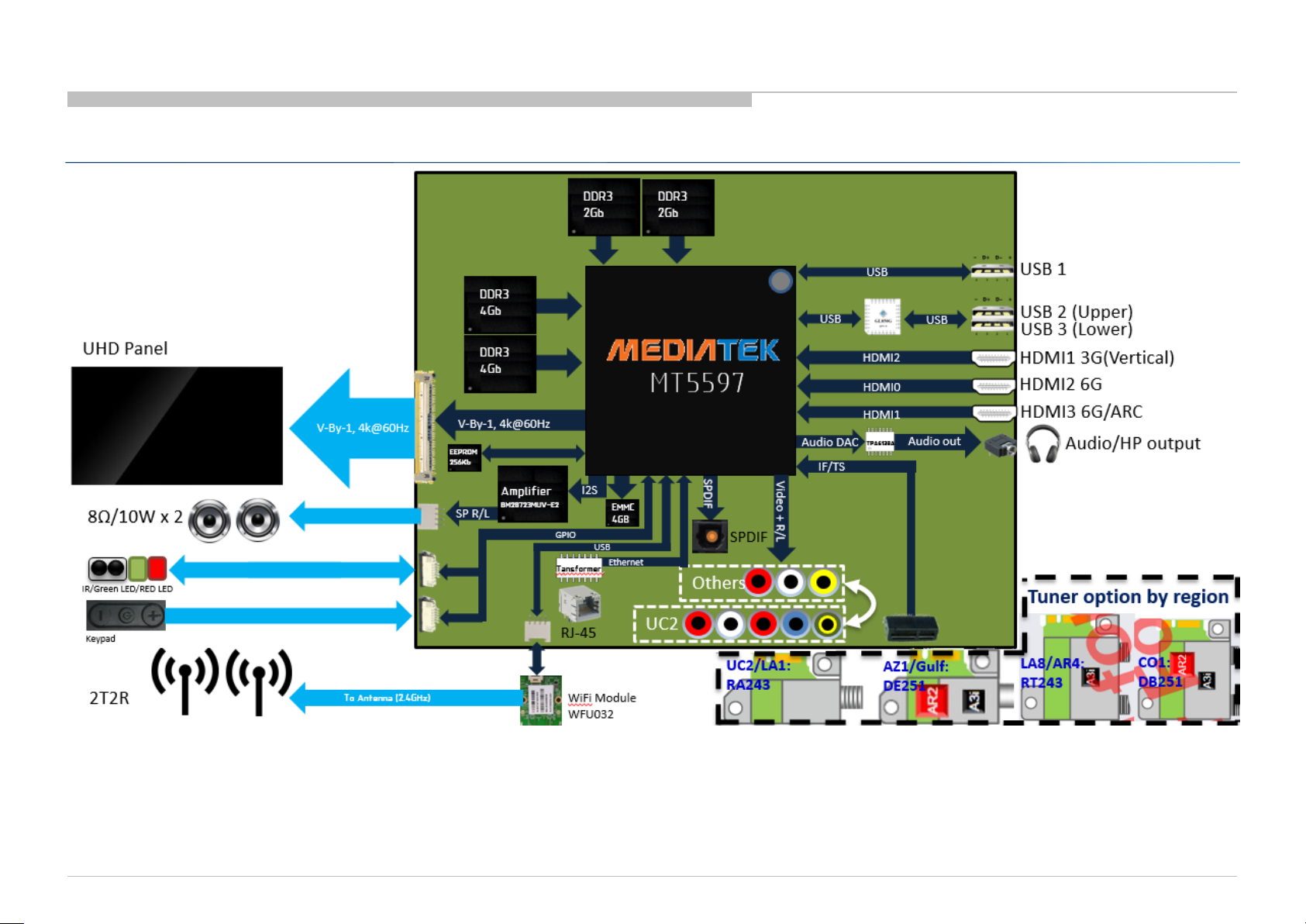

3-1. BLOCK DIAGRAM

VGA(Step up only)

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

59

Page 60

3-2. CONNECTOR DIAGRAM

DIAGRAMS AND C H AS S IS STRUCTURE

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

60

Page 61

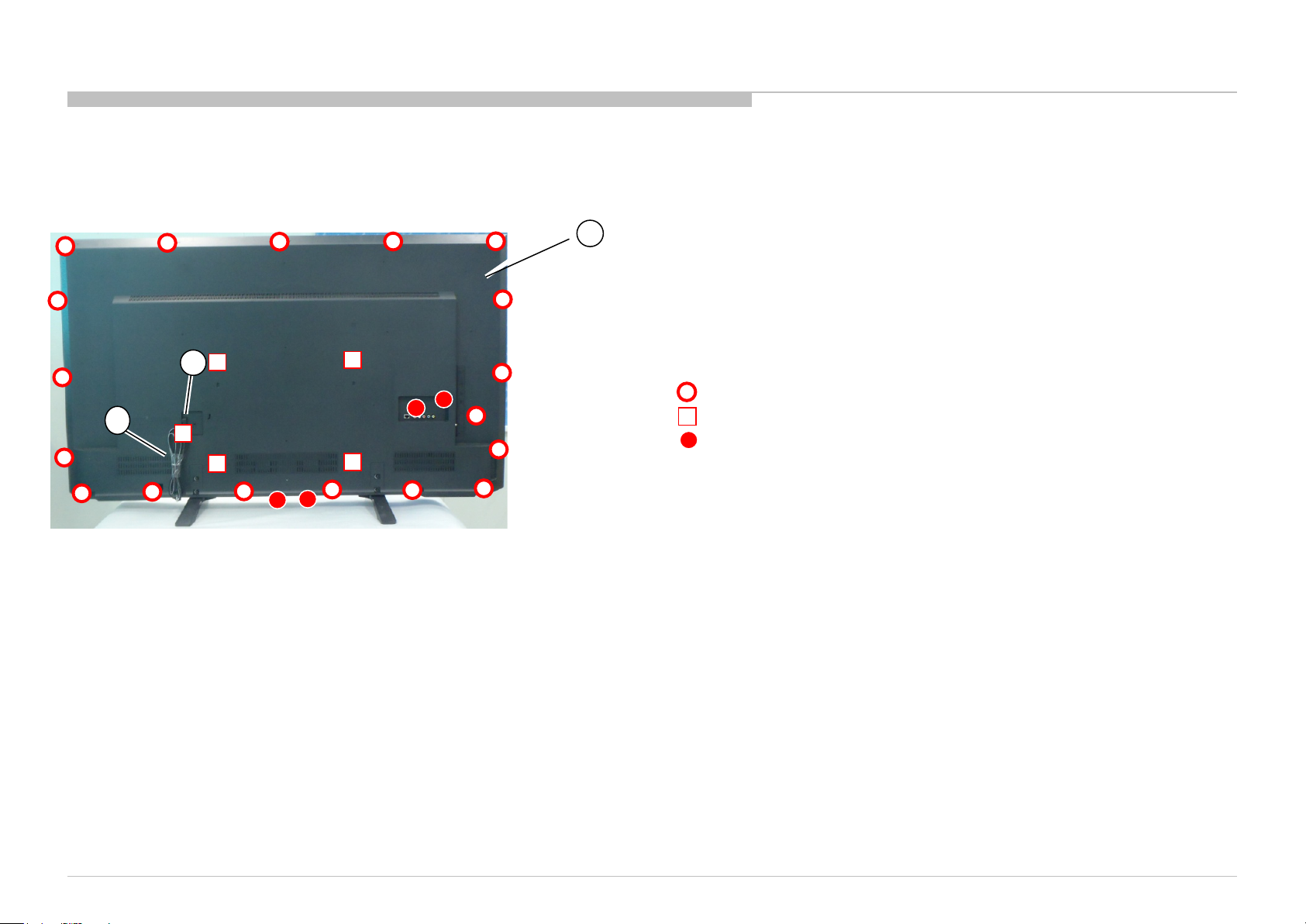

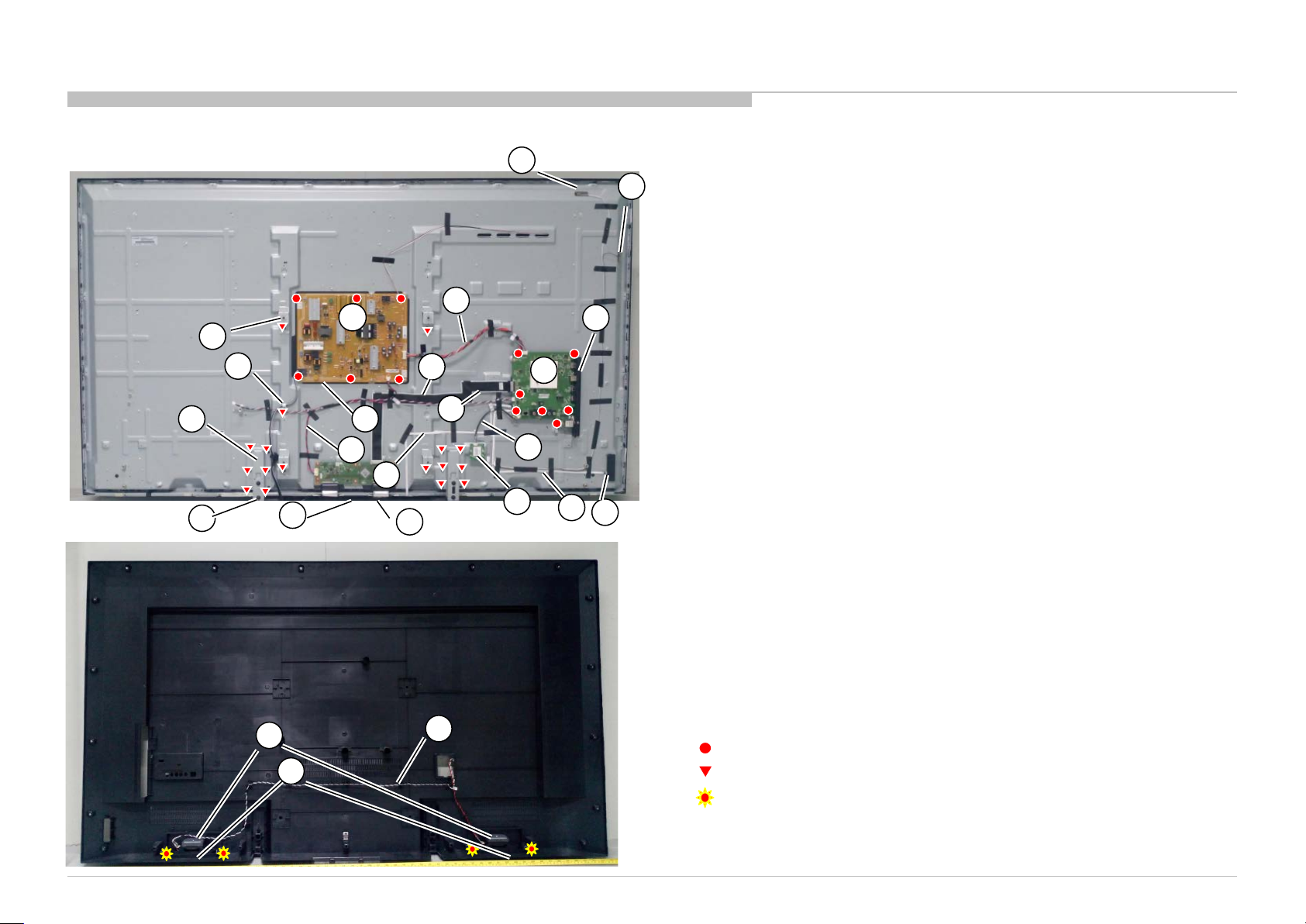

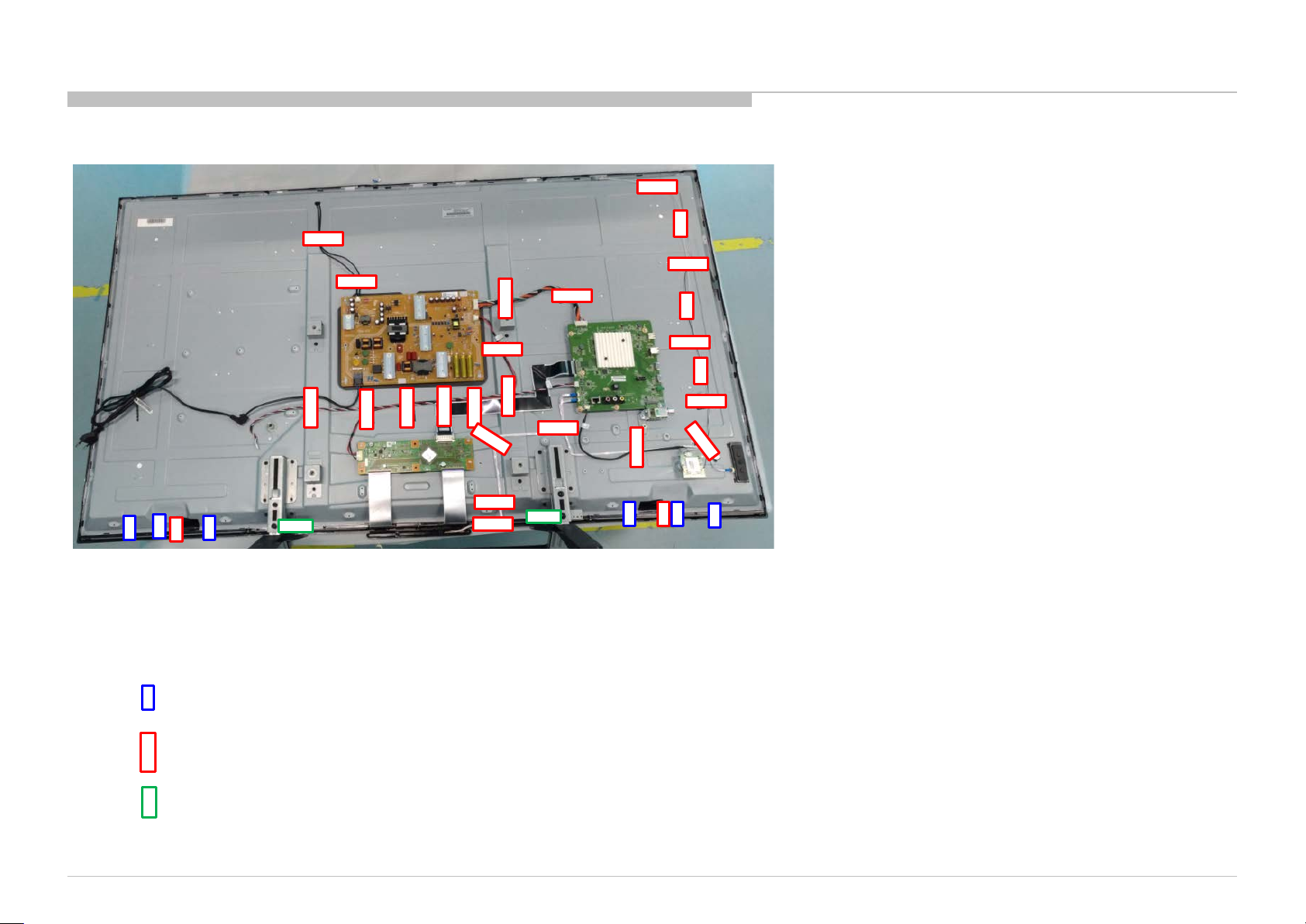

3-3. CIRCUIT BOARDS LOCATION

KD-60X690E/KD-60X695E/KD-60X697E/KD-60X6700E

DIAGRAMS AND C H AS S IS STRUCTURE

KD-60X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E(AZ1/ME6/EA4)

H Board

PSU

A Board

SWITCH UNIT

Board

WIFI

61

Page 62

3-3. CIRCUIT BOARDS LOCATION

KD-70X690E/KD-70X6700E

DIAGRAMS AND C H AS S IS STRUCTURE

A Board

PSU

KD-70X690E(UC2/LA1)/KD-70X6700E(AZ1/ME6/EA4)

H Board

WIFI

SWITCH UNIT

Board

62

Page 63

End

9-888-740-01

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

Sony Corporation

63

Page 64

APPENDIX-1 Trouble Shooting

1-1. NO POWER

No power

Long AC off(> 15 min.)

and then

Power On

NG

Check 5VSB

at 1 pin of TP209

on the Main board

OK

Check PSU_12V at 12 pin

of TP220

on the Main board

OK

Change

Main board

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

NG

NG

Change

PSU

Change

PSU

64

Page 65

1-2. NO PICTURE

No picture

TROUBLE SHOOTING

Press HOME Key.

Menu displayed?

Yes

Change Equipment

Or Player to check

TV display

OK

Signal or Equipment

Problem

No

No display

Check the harne ss

MB to Panel

connection

NG

Fix the harness

connection

Change

Main board

OK

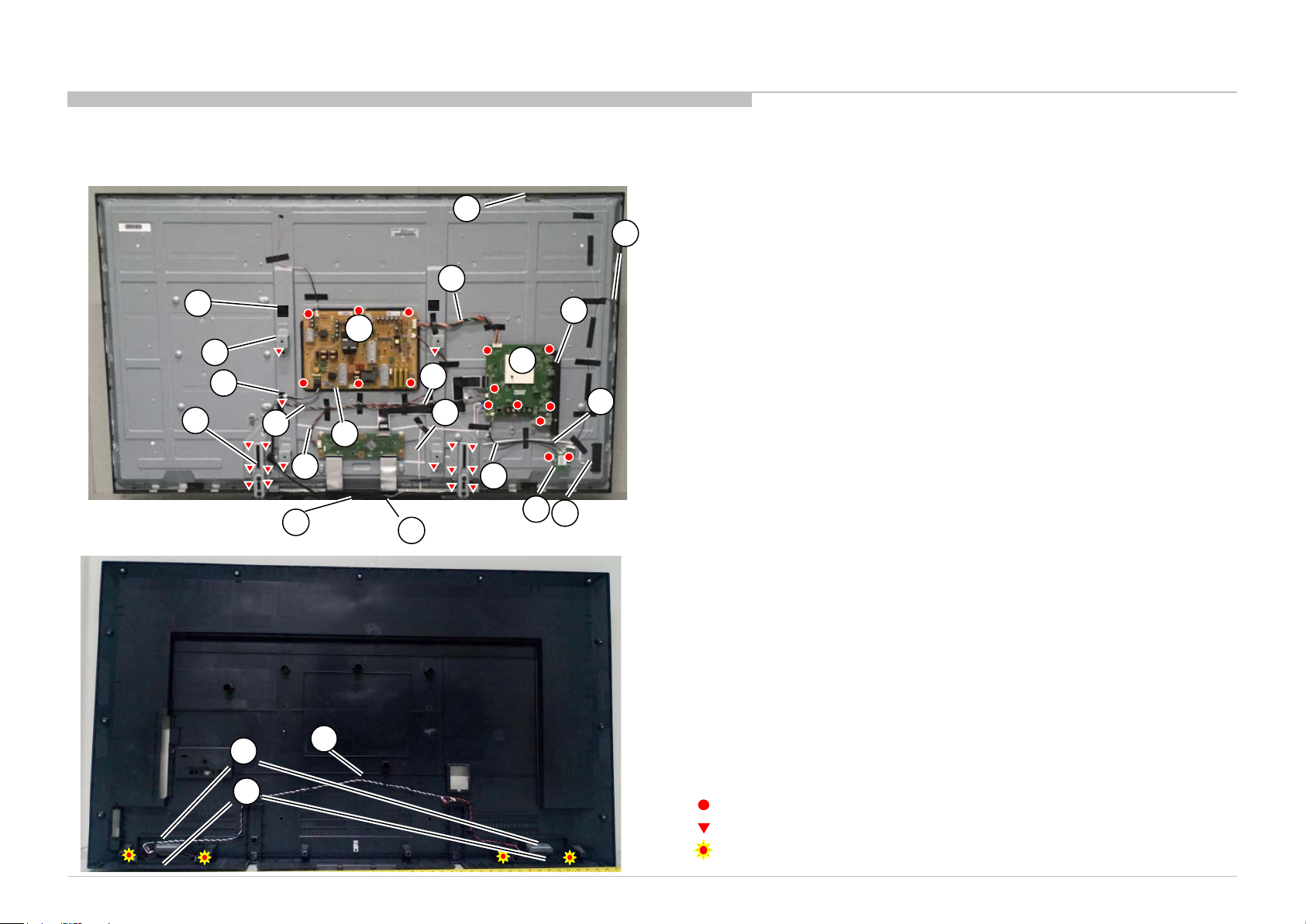

Replace

MB to Panel

Harness

Symptom

OK

improvement

Harness issue

NG

Check the FFC(LVD S)

Fix the FFC(LVDS)

Change PSU

Symptom

OK

improvement

Adaptor issue

MB to Panel

connection

NG

connection

NG

OK

Replace the

FFC(LVDS) Between

MB and Panel

OK

FFC(LVDS) issue

Change

Panel

NG

Main board issue

Change

Main board

OK

NG

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

65

Page 66

1-3. NO SOUND

No Sound

TROUBLE SHOOTING

Check if TV is

set to Mute

No

Check the

“Speakers setting”

“TV Speakers”

Change the speaker

harness

OK

Symptom

improvement

Speaker Harness

issue

Yes

“Audio System”

NG

Change to

Un-mute

Change to

“TV Speaker”

Replace

Main board

NG

Change

Speaker

Symptom

improvement

Main board issue

OK

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

66

Page 67

1-4. TV COMMANDER BUTTONS MALFUNCTION

1) TV button malfunction

Button malfunction

on the TV

TROUBLE SHOOTING

Replace the harness

between Main board

and Key module

Symptom

OK

improvement

Harness issue

NG

Change

Key module

NG

Change

Main board

Symptom

improvement

Key module issue

OK

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

67

Page 68

2) IR remote commander malfunction

TV isn’t controlled

by remote commander

TROUBLE SHOOTING

Green LED li ght

at power indicator

OK

Green LED blinks at power indicator

when using commander

NG

Symptom

Change Main board to

IR board FFC

improvement

OK

IR FFC

issue

NG

Symptom

improvement

Change IR board IR board issue

OK

NG

Change

Main board

near sensor’s windo w

NG

OK

Change

Remote Control

battery

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

68

Page 69

APPENDIX-2 Software data update

SOFTWARE DATA UPDATE

THE CONFIRMATION OF THE SOFTWARE VERSION OF THE TV SET

Entering product information of setting menu.

Press the buttons on the remote commander as below

Note: When changing Main board, Model Name and

Serial Number will not be displayed.

[HOME] - [Settings] – [Preferences] - [Set-up] –[Customer Support]-[Product Information]

or [HOME] - [Settings] – [Preferences] - [Set-up] - [Customer Support]-[Product Information]

SOFTWARE DOWNLOAD

The downloaded software may be compressed(.zip).

If the downloaded software was compressed(.zip), please unzip it.

Store the software package to USB memory. (Applicable USB memory : Format by FAT32, USB2.0 type )

However, please store ONLY ONE PKG file to USB Root folder for software update.

Software PKG file name format: sony_fw_2017_1000_UUUSB.pkg

version model Name

Model Name

1.KD-60X690E/KD-70X690E(UC2/LA1):UUUSB

2. KD-670X6700E/KD-70X6700E(AZ1/EA4/ME6):UUPAB

3. KD-60X695E(LA8):UUCPB

4. KD-60X697E(CO1):UUCOB

5. KD-60X695E(AR4):UUBRB

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

69

Page 70

SOFTWARE UPDATE BY USB MEMORY

1. Prepare USB with update PKG file, Set TV to AC Off.

2. Insert USB device to TV that contains the new version software.

***Be sure only one PKG file is directly located under ROOT folder

of the USB device.

SOFTWARE DATA UPDATE

5. When upgrade complete, TV will turn on and LED will be green.

KD-60X690E/KD-70X690E

Model Name

1.KD-60X690E/KD-70X690E(UC2/LA1):UUUSB

2. KD-670X6700E/KD70X6700E(AZ1/EA4/ME6):UUPAB

3. KD-60X695E(LA8):UUCPB

4. KD-60X697E(CO1):UUCOB

5. KD-60X695E(AR4):UUBRB

3. Press and hold Power Tact Key for 5s while AC ON TV

***Please remember to remove USB after upgrade finish.

6. After software update, you will need to do Initial Setup again, so please

follow the steps to confirm the settings.

7. Remember to check the software version is same as the target version

you want to update.

CONFIRM SOFTWARE VERSION

Remember to check the software version after upgrade.

Product information page will show software version.

[HOME] - [Settings] – [Preferences] - [Set-up] –[Customer Support]-[Product Information]

4. Wait for a while, If valid file is found, LED change UPDATE mode

(Orange is Blink-1sec On / 1sec Off ) few second later. From now, all

key & Remote are not allowed (no response) until update finish.

(*If AC Off/On with USB memory inserted, UPDATE start again.)

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

or [HOME] - [Settings] – [Preferences] - [Set-up] - [Customer Support]-[Product Information]

WARNING:

During the firmware installation process, do not remove the

USB device, or switch off the TV set or remove the power.

70

Page 71

APPENDIX-3 Operation Time, Boot Count, Panel Operation Time

SELF DIAGNOSIS HISTORY DISPLAY >> Operation Time, Boot Count, Panel Operation Time

*Below information is just for example, and may not match the actual info you see on consumer’s TV set.

Press “Return” key or “Home” key on RC to exit the Self Diagnosis screen.

After repair or board exchange, you can reset the Self Diagnosis

history to (0, 0, 0) by here.

Just move the cursor to “Test Reset” and then press Right key ,

the “Off” will change to “On”, then TV will reboot and you will

need to perform Initial Setup.

KD-60X690E/KD-70X690E(UC2/LA1)/KD-60X695E(AR4/LA8)/KD-60X697E(CO1)/KD-60X6700E/KD-70X6700E(AZ1/ME6/EA4)

Panel operation time by hour

Boot count

Total operation time by hour

71

Loading...

Loading...