Page 1

2018/03/1622:32:44(GMT+09:00)

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL (COMMON)

GN4TR CHASSIS

ORIGINAL MANUAL ISSUE D ATE: 03/2018

Version Date Subject

1 03/2018 1st Issue

Segment : CR

OLED TV

9-888-748-01

For SM - Unique , please refer :

9-888-748-Ax ( America )

9-888-748-Cx ( China)

9-888-748-Ex ( Europe )

9-888-748-Px (Asia)

SYSSET

Page 2

2018/03/1622:32:44(GMT+09:00)

SERVICE MANUAL (COMMON)

GN4TR CHASSIS

Segment : CR

OLED TV

SYSSET

Page 3

KD

KD

KD

KD

XBR

XBR

KJ

KJ

2018/03/1622:32:44(GMT+09:00)

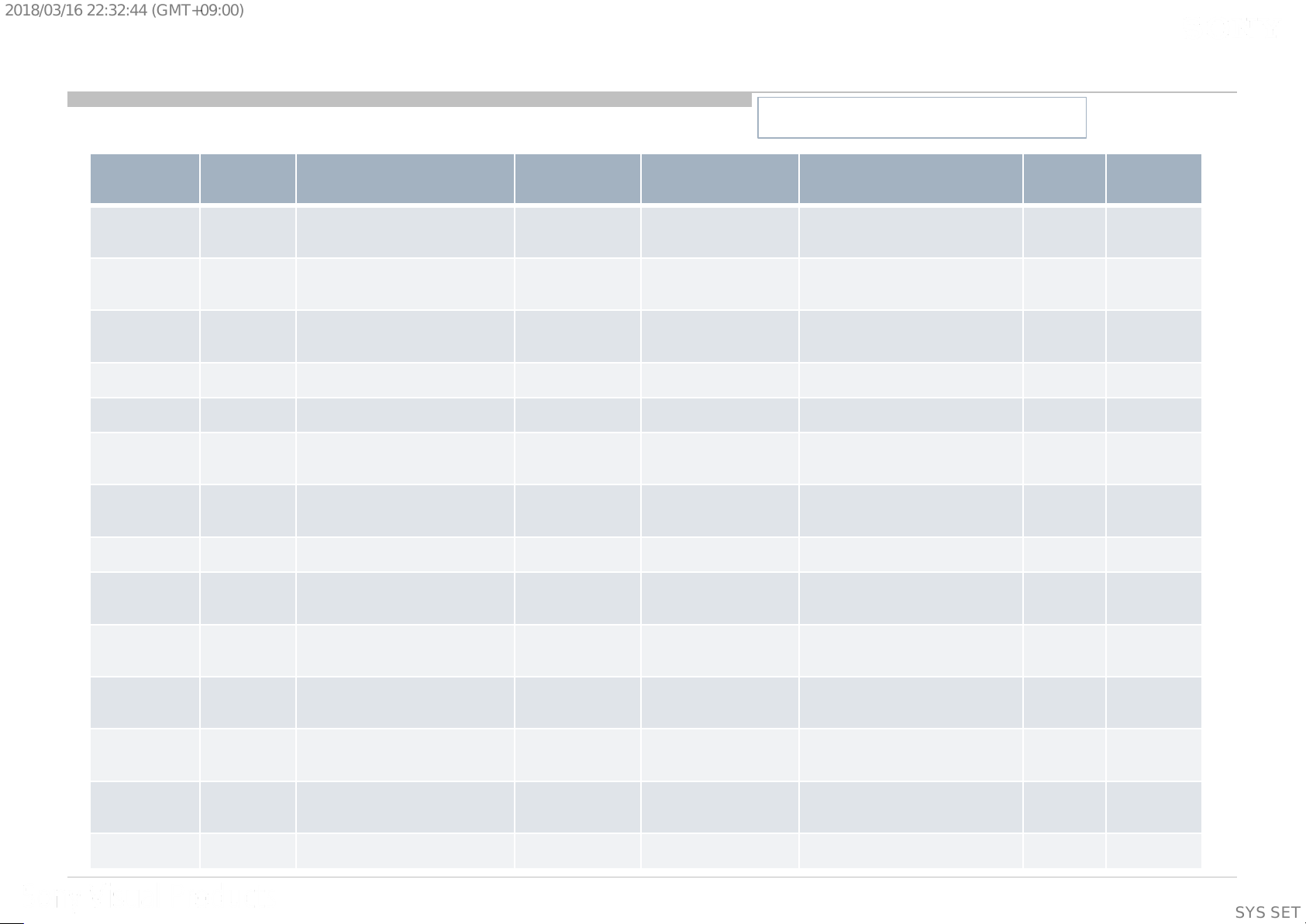

MODEL LIST

THIS SERVICE MANUAL CONTAINS COMMON INFORMATION FOR BELOW REGIONS AND MODELS:

REGION

ASIA AMERICA EUROPE CHINA

MODEL

-55A8F

-55AF8

-55A8F

-55A8F

-65A8F

-65AF8

-65A8F

-65A8F

JAPAN

3

SYSSET

Page 4

Title

Page

SAFETY NOTES

SELF DIAGNOSTIC FUNCTION

TROUBLE SHOOTING

4.

SERVICE ADJUSTMENTS

5.

DIAGRAMS

PANEL and TV SET HANDLING

2018/03/1622:32:44(GMT+09:00)

TABLE OF CONTENTS

Section

1.

2.

3.

6.

5

10

14

69

79

81

Please refer Service Manual – Unique for below information :

-Disassembly and Removal Caution

-Wire Dressing

-Circuit Board Location

-Exploded Views and Parts List

Note: Pictures provided in this Service Manual might have slight difference from the

actual sets.

4

SYSSET

Page 5

2018/03/1622:32:44(GMT+09:00)

1-1. Warnings and Caution

1) CAUTION :These servicing instructions are for use by qualified service

personnel only.

2) To reduce the risk of electric shock, do not perform any servicing other than

that contained in the operating instructions unless you are qualified to do so.

3) WARNING!! : An isolation transformer should be used during any service

to avoid possible shock hazard, because of live chassis. The chassis of this

receiver is directly connected to the ac power line.

SECTION 1

SAFETY NOTES

Whenever a TV Main board is replaced, the correct TV Model and Serial

number must be reinserted into memory.

This is a MANDATORY procedure that each service center must apply.

Please refer to the chapter of ADJUSTMENT in this service manual to

find out how to set the model number and serial number in service mode.

1-2-1. Caution Handling of LCD Panel

The replaceable fuse could be in the neutral of the mains supply. When

replacing the fuse, the mains shall be disconnected for de-energize the phase

conductors.

(*Except AC ADAPTOR, Because it does not carry out replacing an internal

fuse.)

4) CARRYING THE TV : Be sure to follow these guidelines to protect your

property and avoid causing serious injury :

• Carry the TV with an adequate number of people; larger size TVs require

two or more people.

• Correct hand placement while carrying the TV is very important for

safety and to avoid damages.

5) SAFETY-RELATED COMPONENT WARNING!! : Components identified

by shading and ! mark on the exploded views, and in the parts list are critical

for safe operation. Replace these components with Sony parts whose part

numbers appear as shown in this manual or in supplements published by

Sony. Circuit adjustments that are critical for safe operation

this manual. Follow these procedures whenever critical components are

replaced or improper operation is suspected.

6) IMPORTANT REMINDER FOR TV MAINBOARD REPLACEMENT :

It is mandatory for service centers to confirm the TV‘s system information after

each repair carried out with Main board replacement.

are identified in

When repairing the LCD Panel, make sure you are grounded with a wrist

band.

When repairing the LCD Panel on the wall, the panel must be secured

using the 4 mounting holes on the rear cover.

1) Do not press the panel or frame edge to avoid the risk of electric

shock.

2) Do not scratch or press on the panel with any sharp objects.

3) Do not leave the module in high temperature or in areas of high

humidity for an extended period of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause short circuit within the module.

6) Disconnect the AC power when replacing the backlight (CCFL) or

inverter circuit. (High voltage occurs at the inverter circuit at 650Vrms)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the inverter circuit.

Damaging the wires may cause a short circuit.

9) Protect the panel from ESD to avoid damaging the electronic circuit

(C-MOS).

5

SYSSET

Page 6

2018/03/1622:32:44(GMT+09:00)

10) During the repair, DO NOT leave the Power On or Burn-in period for

more than 1 hour while the TV is face down on a cloth. Refer Figure 1 .

Figure 1.

1-2-2. Caution for OLED Panel

1) Handling

When repairing the TV set, be sure you are grounded by using a wrist band.

*Do not press on the panel or frame edge to avoid the risk of electric shock.

*Do not scratch or press on the panel with any sharp objects.

*Do not leave the module in high temperatures or in areas of high humidity

for an extended period of time.

*Do not expose the panel to direct sunlight.

*Avoid contact with water. It may cause a short circuit within the module.

*Disconnect the AC power when replacing.

*Always clean the panel with a soft cloth material.

*Use care when handling the wires or connectors. Damaging the wires may

cause a short.

*Protect the panel from ESD to avoid damaging the electronic circuit.

*Do not recommend power-on in the conditions which laid face down the

panel, in repair activity. Refer Figure 1 .

*When transporting by hand, do not put stress on the panel and the frame

around the screen.

Refer to the panel handling chapter of each Service manual,

or the "Transporting" information of the Reference Guide of each model for

how to hold it.

2) OLED Screen

•Although the OLED screen is made with high-precision technology and

99.99% or more of the pixels are effective, black dots may appear or bright

points of light (white, red, blue, or green) may appear constantly on the

OLED screen. This is a structural property of the OLED screen and is not a

malfunction.

•Do not push or scratch the front filter, or place objects on top of this TV

set. The image may be uneven or the OLED screen may be damaged.

•The screen and cabinet get warm when this TV set is in use. This is not a

malfunction.

3) Precautions to Protect the Screen from Damage

Image retention

OLED TV’s are susceptible to image retention (burn-in) due to the

characteristics of the materials used. Image retention may occur if images

are displayed in the same location on the screen repeatedly or over

extended periods of time. This is not a malfunction of the TV. Avoid

displaying images that may cause image retention.

The following are examples of images that may cause image

retention:

•Content with black bars either on the top and bottom and/or the left and

right sides of the screen. (for example, Letterboxed, 4:3 screen, Standard

definition)

•Static images such as photos.

•Video games that might have static content in some part of the screen.

•On-screen menus, program guides, channel logos etc.

•Static content from applications.

•On-screen tickers, such as those used for news and headlines.

6

SYSSET

Page 7

2018/03/1622:32:44(GMT+09:00)

To reduce the risk of image retention:

•Fill the screen by changing [Wide mode] to eliminate the black bars.

Select [Wide mode] other than [Normal].

•Turn off the OSD (On Screen Display) by pressing the DISPLAY button,

and turn off the menus from connected equipment. For details, refer to

the instruction manuals for the connected equipment.

•Avoid displaying static images with bright colours (including white),

clocks or logos on any portion of the screen.

•Set the picture settings based on the ambient conditions. The Standard

Picture is recommended for home use and when viewing content that

often displays the station logos, etc.

The TV has following features to help reduce/ prevent image retention.

Press the HOME button, then select [Settings] – [Picture & Display] –

[Expert panel settings] – the desired option.

Panel refresh

Panel refresh will automatically run to adjust the uniformity of the TV

screen after it has been in use for long periods of time.

Panel refresh can also be performed manually and should only be used if

image retention is very noticeable or you see the following message:

[Panel refresh did not finish...]

Caution:

•The Panel refresh function may affect the panel. As a reference, perform

the Panel refresh only once a year, do not perform it more than once a

year as it may affect the usable life of the panel.

•Panel refresh takes about one hour to complete.

•A white line may be displayed on the screen during the Panel refresh,

this is not a malfunction of the TV.

•Panel refresh will only work when the room temperature is between 10

ºC and 40 ºC.

Pixel shift

Automatically moves the image on the screen to prevent image retention.

Other feature

The screen brightness is automatically reduced when displaying still

images, clocks, bright colours or logos etc.

IMPORTANT REMINDER FOR OLED PANEL REPLACEMENT

When carrying out OLED panel replacement, it is mandatory of a

service center to confirm and record Panel ON time & Panel

Refresh times.

It is because they are indispensable information in order to clarify

responsibility for image retention after panel replacement.

Please refer to the chapter of SELF DIAGNOSIS FUNCTION in this

service manual to find out how to confirm the Panel ON time &

Panel Refresh times in service mode.

1-3. Caution About the Lithium Battery

1) Danger of explosion if battery is incorrectly replaced. Replace only with

the same or equivalent type.

2) Outer case broken battery should not contact to water.

1-4. Safety Check-Out

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:-

1) Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2) Check the inter board wiring to ensure that no wires are pinched or

contact high-wattage resistors.

3)Check all control knobs, shields, covers, ground straps and mounting

hardware have been replaced. Be absolutely certain you have replaced

all the insulators.

7

SYSSET

Page 8

2018/03/1622:32:44(GMT+09:00)

4) Look for unauthorized replacement parts, particularly transistors that

were installed during a previous repair. Point them out to the customer and

recommend their replacement.

5) Look for parts which, though functioning show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6) Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7) Check the antenna terminals, metal trim, metalized knobs, screws and all

other exposed metal parts for AC leakage. Check leakage test as described

next.

8. For safety reasons, repairing the Power board and/or Inverter board is

prohibited.

1-5.Leakage Test

(To protect electric shock when customer touch the terminal.)

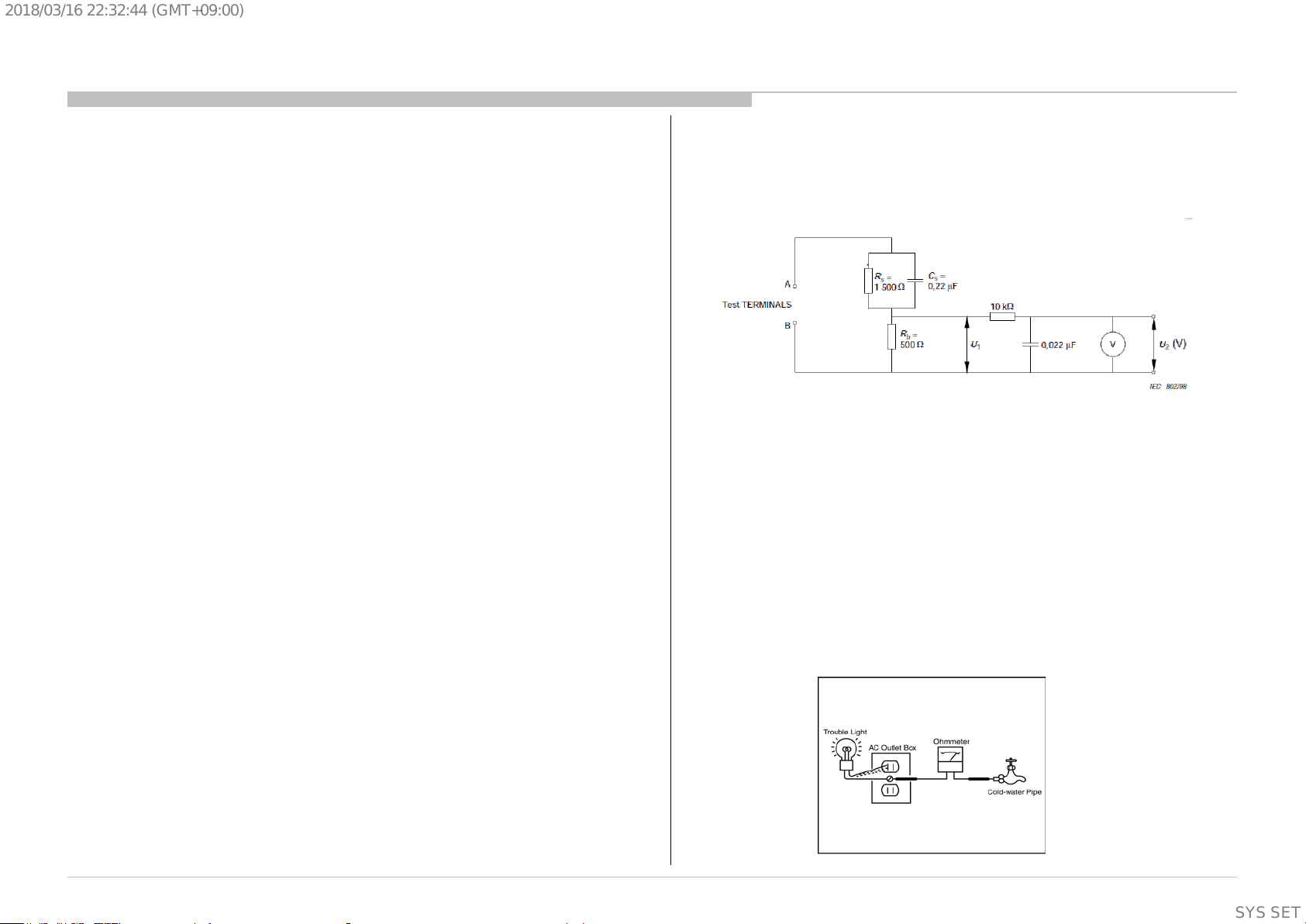

Leakage current can be measured by V: Voltmeter or oscilloscope (r.m.s. or

peak reading)

Stabilized power supply instrument and isolated voltage transformer:

Use too much current capacity and isolated voltage transformer does not

need to use stabilized power supply equipment.

Specification of RMS volt meter: Input resistance > 1 Mohm, Input

capacitance < 200 pF, Frequency range: 15 Hz – 1MHz . Refer Figure 2.

Isolated type volt -m et er (FLUKE 8921A etc *1)

*1 Not use FLUKE 8920A that connected to protective earth by diode

# Leakage current of measurement instrument is less than 10μArms when

under test equipment AC plug is opened

# Set up the following condition and turn on the set. Applied voltage:

Nominal input voltage (Description on Nameplate)

# Measure the leakage current between one phase conductor and neutral

for terminal A and terminal B.

Read rms value, and then calculate to peak value PEAK VALUE =√2 RMS

VALUE

Comply with the following requirement

Class II equipment (2-pin plug): for each terminal, the worst value of

measurement must not exceed AC 350uA peak).

Note: including AC adaptor, AC adaptor/DC operated unit combination

Figure 2 – Measuring network

for Leakage Current

1-6. How to Find a Good Earth Ground

1) A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground.

2) If the retaining screw is to be used as your earth ground, verify that it is

at ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

3) If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure 3).

Figure 3. Checking for earth

ground.

8

SYSSET

Page 9

2018/03/1622:32:44(GMT+09:00)

1-7. Lead Free Information

The circuit boards used in these models have been processed using

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation.

The servicing of these boards requires special precautions. It is

strongly recommended to use Lead Free Solder material in order to

Figure 4: LF Logo

Figure 5: LF logo on circuit board

guarantee optimal quality of new solder joints.

9

SYSSET

Page 10

2018/03/1622:32:44(GMT+09:00)

The units in this manual contain a self-diagnostic function. If an error occurs, the Smar t C ore R ed LE D will automatically begin to flash.

The number of times the LED flashes translates to a probable source of the problem.

A definit ion of the Smart Core Red LED flash indicators is listed in the instruct ion manual for the user’s knowl edge and reference.

If an error symptom cannot be reproduced, the r emote c ommander can be used to review the failure occurrenc e data stored in memory to

reveal past problems and how often these pr oblems occur.

DIAGNOSTIC TEST INDICATORS

When an error occurs , the Smart Core Red LED w il l flash a set number of times to indicate the poss i ble cause of the problem.

If there is more than one error , the LED wil l identify the first of the problem areas .

Result for all of the foll owing diagnostic items are displayed on screen.

If the screen display s a “ 0”, no error has occ urr ed .

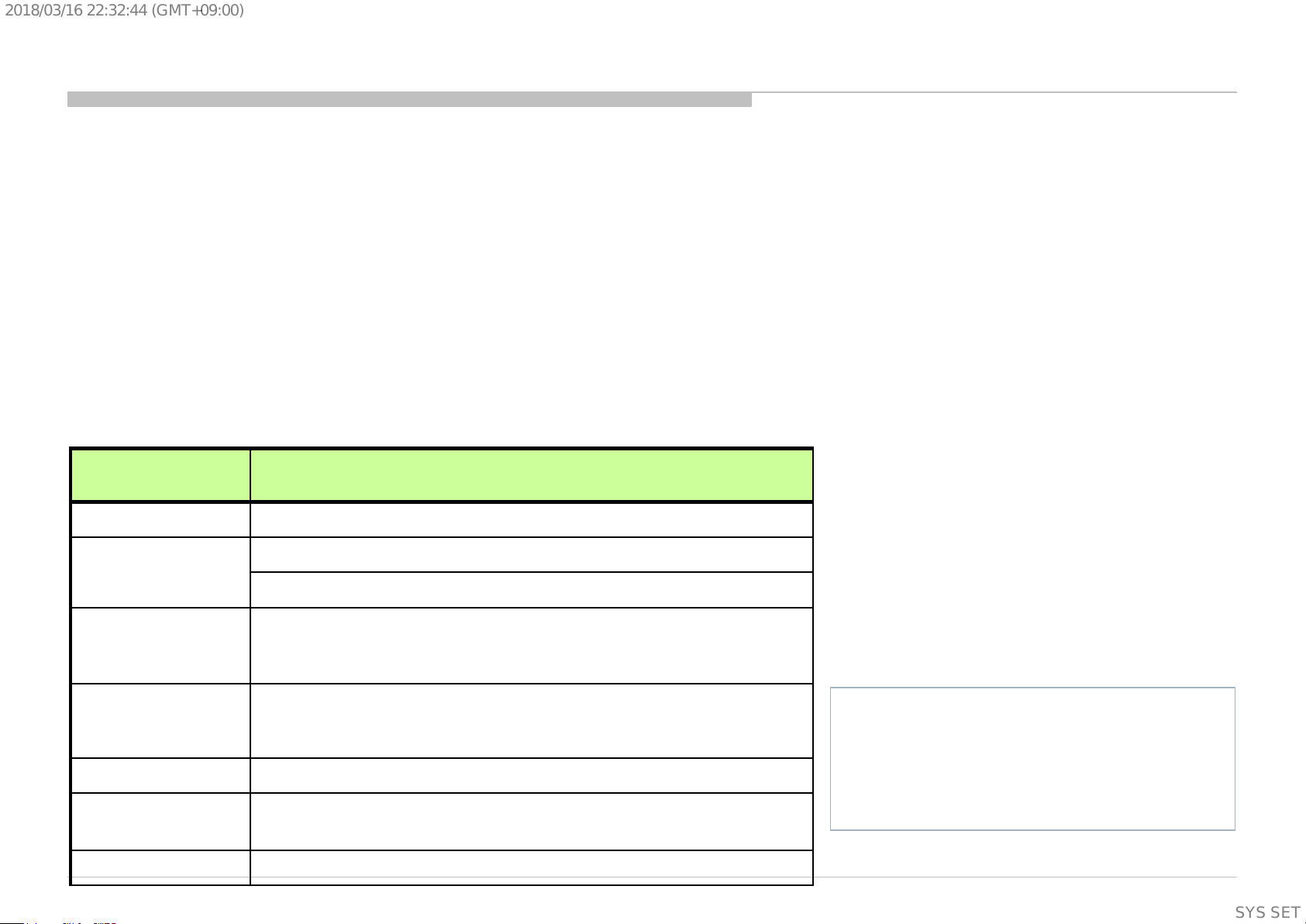

Self Diag. Quick Reference (LED blinking)

SECTION 2

SELF DIAGNOSTIC FUNCTION

Smart Core RED

LED blinking count

2x <B/G> Main 12V over voltage [MAIN_POWER]

3x

4x <T/B>TCON internal error/TCON I2C communication error[LD_ERR]

5x

6x <G/B> G board error[BACKLIGHT]

7x

8x <B> 4KBE Error (4KBE WDT)

Detection Items

<B/G> Main 5.0V failure [DC_ALERT]

<B/S/G> Audio amp. protection [AUD_ERR]

<P/T/G/B> Panel ID EEPROM I2C No ACK

(Also panel power failure is a suspect) [P_ID_ERR]

<T/B>Data corruption in EEPROM[P_ID_ERR]

<B/P> Over temperature protection [TEMP_ERR]

<B> Temp. sensor I2C No ACK [TEMP_ERR]

Blue italic: detect at startup sequence only.

<G>: Power supply board,

<B>: Main board,

<T>: T-con board,

<P>: Panel module,

<S>: Speaker,

<Tu>: Tuner board,

10

SYSSET

Page 11

2018/03/1622:32:44(GMT+09:00)

Self Diag. Quick Reference (Not LED blinking [Record Only])

Error Item

( Not LED blinking

[Record Only])

TU_DEMOD

TCON ERR

AUD_ERR_I2C <B> Audio amp I2C communication failure

Detection Items

<B/Tu> Tuner & Demodulator I2C communication failure

Tuner board set detect signal monitoring

None

*CR is shutdown by I2c communication failure[LD_ERR]

<G>: Power supply board,

<B>: Main board,

<T>: T-con board,

<P>: Panel module,

<S>: Speaker,

<Tu>: Tuner board,

11

SYSSET

Page 12

2018/03/1622:32:44(GMT+09:00)

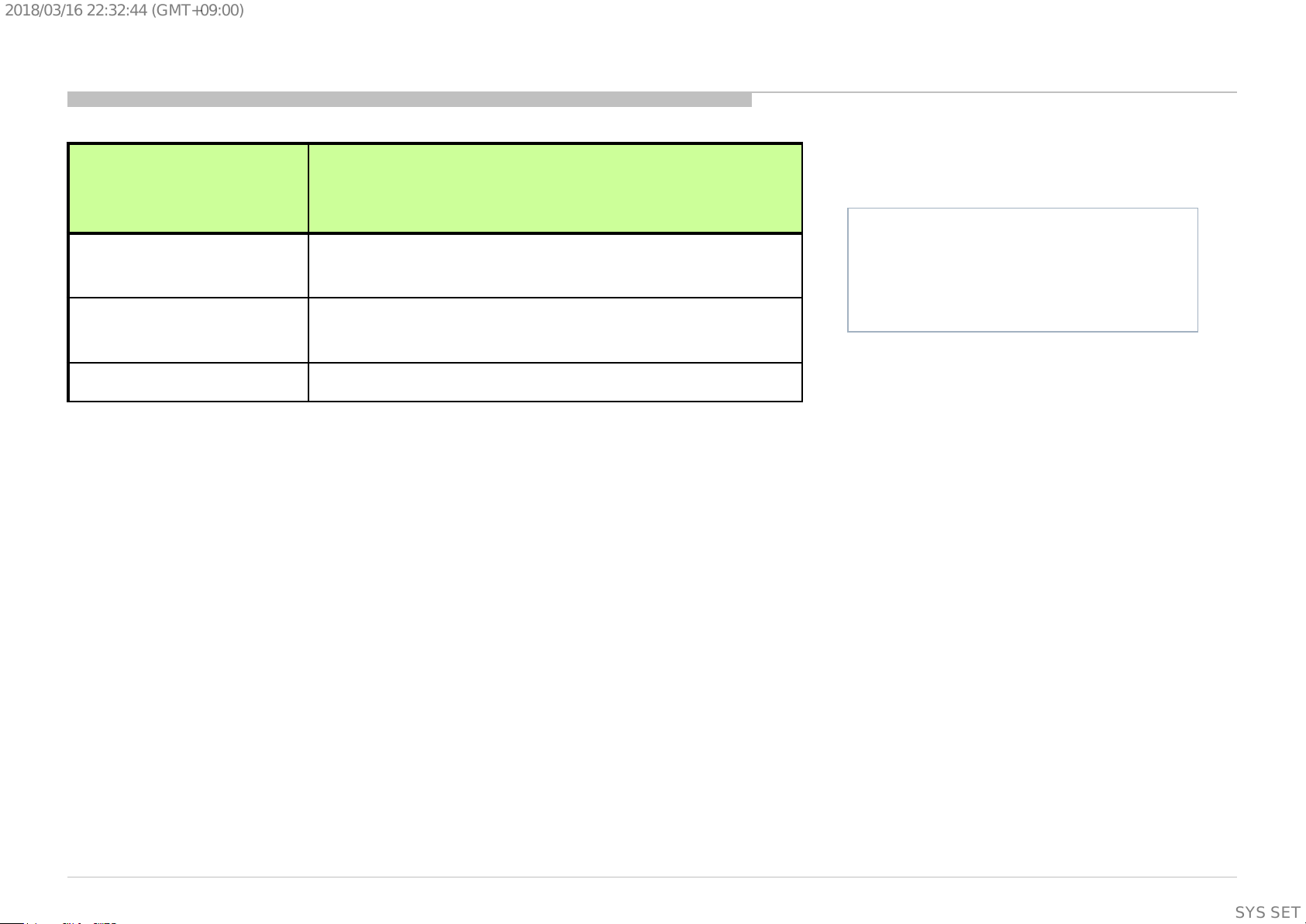

Self Diagnosis Service Menu and Display

Entry (Self Diagno sis D ispl ay)

- Go to the standby by a remote.

- Push the buttons sequentially:

<Display><5><Vol-><Power>

Exit

-If you want to finish service mode app, do AC OFF/ON

→ *Service mode app is disable perfectly

-if you want to move home menu, push <HOME>button

→ *Service mode app do background(not disabl e perfectly )

Format of error timestamps

YYMMDDhhmmss (in UTC)

Example:

120823132523 -> Aug 23 2012 13:25:23 UTC

* Only when time is set, an error timestamp

is saved.

Smart

Core Red

LED

blinking

count

Error Item

Error count

SELF CHECK

Back

<<

002 MAIN POWER 000000000000 000000000000 000000000000 000

003 DC ALERT 000000000000 000000000000 000000000000 000

003 AUD ERR 150101000018 150101000018 150101000018 003

003 AUD ERR I2C 000000000000 000000000000 000000000000 000

003 TU DEMOD 150101000218 150101000223 150101000105 003

004 LD ERR 000000000000 000000000000 000000000000 000

004 BCM ERR 000000000000 000000000000 000000000000 000

005 TCON ERR 150101000504 000000000000 000000000000 001

005 P ID ERR 000000000000 000000000000 000000000000 000

006 BACKLIGHT ERR 000000000000 000000000000 000000000000 000

007 TEMP ERR 150101000200 150101000002 000000000000 002

008 4KBE ERR 000000000000 000000000000 000000000000 000

00005 00414 00002

[Home]Exit

Error

timestamp

for last

recorded

error

Error

timestamp

for second

last

recorded

error

Error

timestamp

for 3rd

last

recorded

error

Panel Operation Time clear

<7> -> <0>

Timestamps and Error Count clear

<8> -> <0>

Total Operation Time and Boot Count clear

<9> -> <0>

Total Operation Time [hr] – Boot Count – Panel Operation Time [hr]

•Panel Operation Time is recorded every 30 min, but Total Operation

Time is recorded every 1 hr.

Therefore, the panel op. time might become larger than the total op. time.

12

SYSSET

Page 13

2018/03/1622:32:44(GMT+09:00)

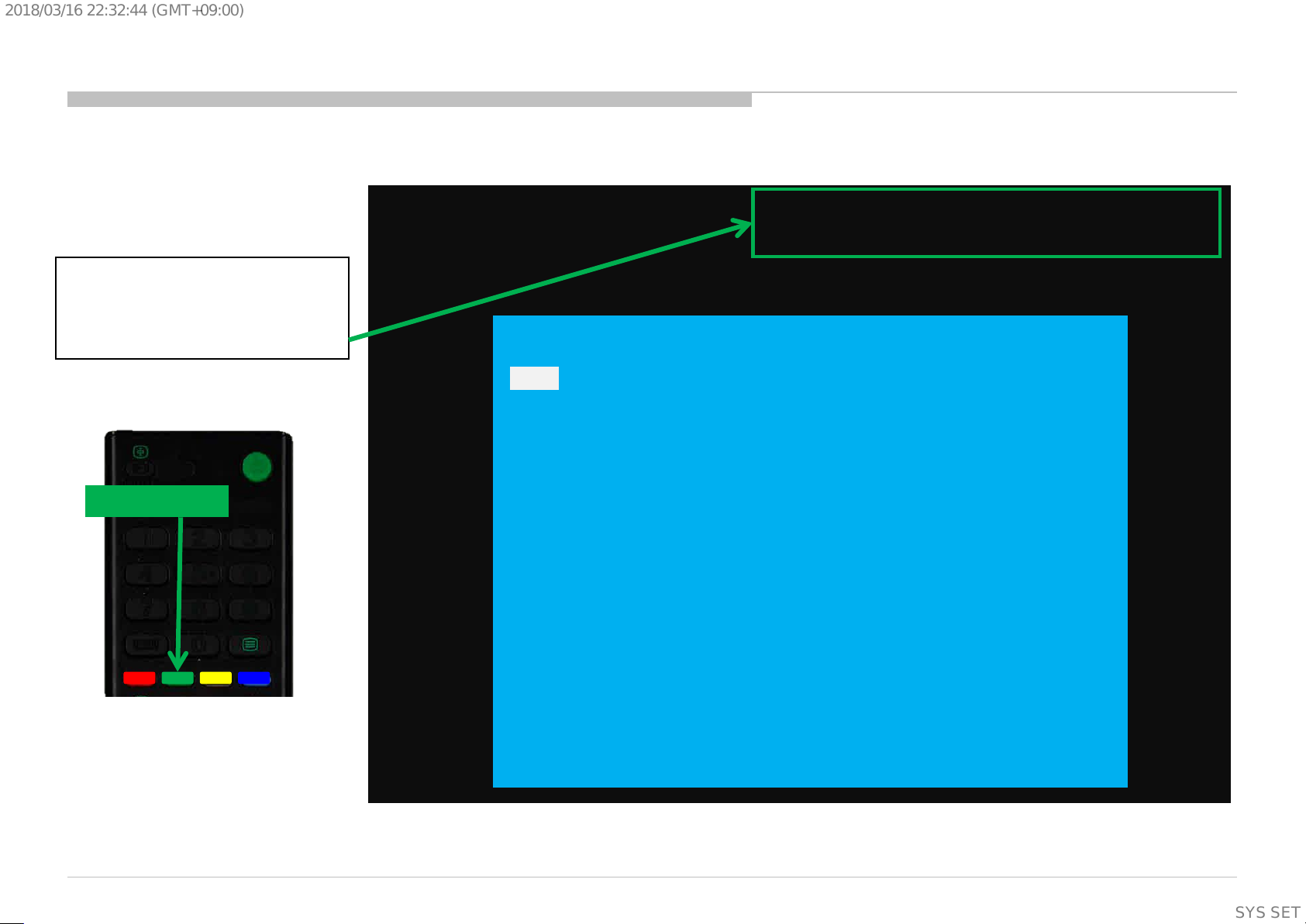

Self Diagnosis Display

How to confirm

- Panel ON time

- Panel Refresh times

Enter Self Diagnosis D ispl ay.

Then Push ‘Green button’ on

remote controller.

Then display upper right corner.

Green button

1

4 5 6

7

2 3

8

9

Panel ON time[hour] /Panel Refresh times[times]

Ex) 100 / 20

SELF CHECK

<<

Back

002 MAIN POWER 000000000000 000000000000 000000000000 000

003 DC ALERT 000000000000 000000000000 000000000000 000

003 AUD ERR 150101000018 150101000018 150101000018 003

003 AUD ERR I2C 000000000000 000000000000 000000000000 000

003 TU DEMOD 150101000218 150101000223 150101000105 003

004 LD ERR 000000000000 000000000000 000000000000 000

004 BCM ERR 000000000000 000000000000 000000000000 000

005 TCON ERR 150101000504 000000000000 000000000000 001

005 P ID ERR 000000000000 000000000000 000000000000 000

006 BACKLIGHT ERR 000000000000 000000000000 000000000000 000

007 TEMP ERR 150101000200 150101000002 000000000000 002

008 4KBE ERR 000000000000 000000000000 000000000000 000

;

00005 00414 00002

[Home]Exit

13

SYSSET

Page 14

Before yo u make the service call…

1. Confirm the symptom from the customer .

2. Select that symptom from the chart.

3. Bring all the boards and c abl es listed for that symptom.

4. Follow the troublesho oti n g charts in the technical guides to isol ate the board.

5.

RED DOT: Most likely defective par t

BLUE TRIANGLE: Secondary possible defectiv e part

BLACK TEXT: Board that may correct the symptom

FRCT

C_I2

R_I2

LED & does not

Stationary

dots

No Remote

(Communication)

2018/03/1622:32:44(GMT+09:00)

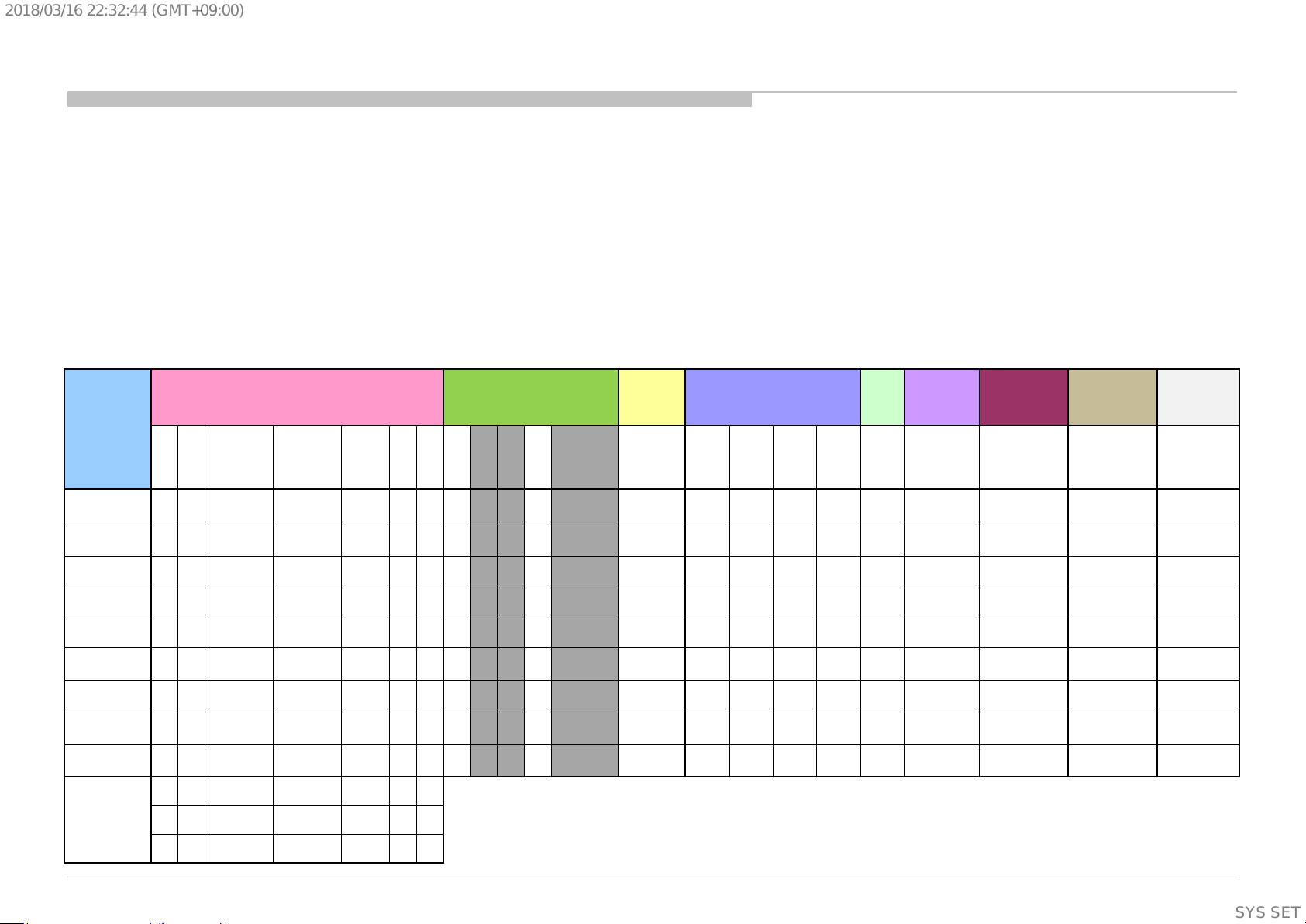

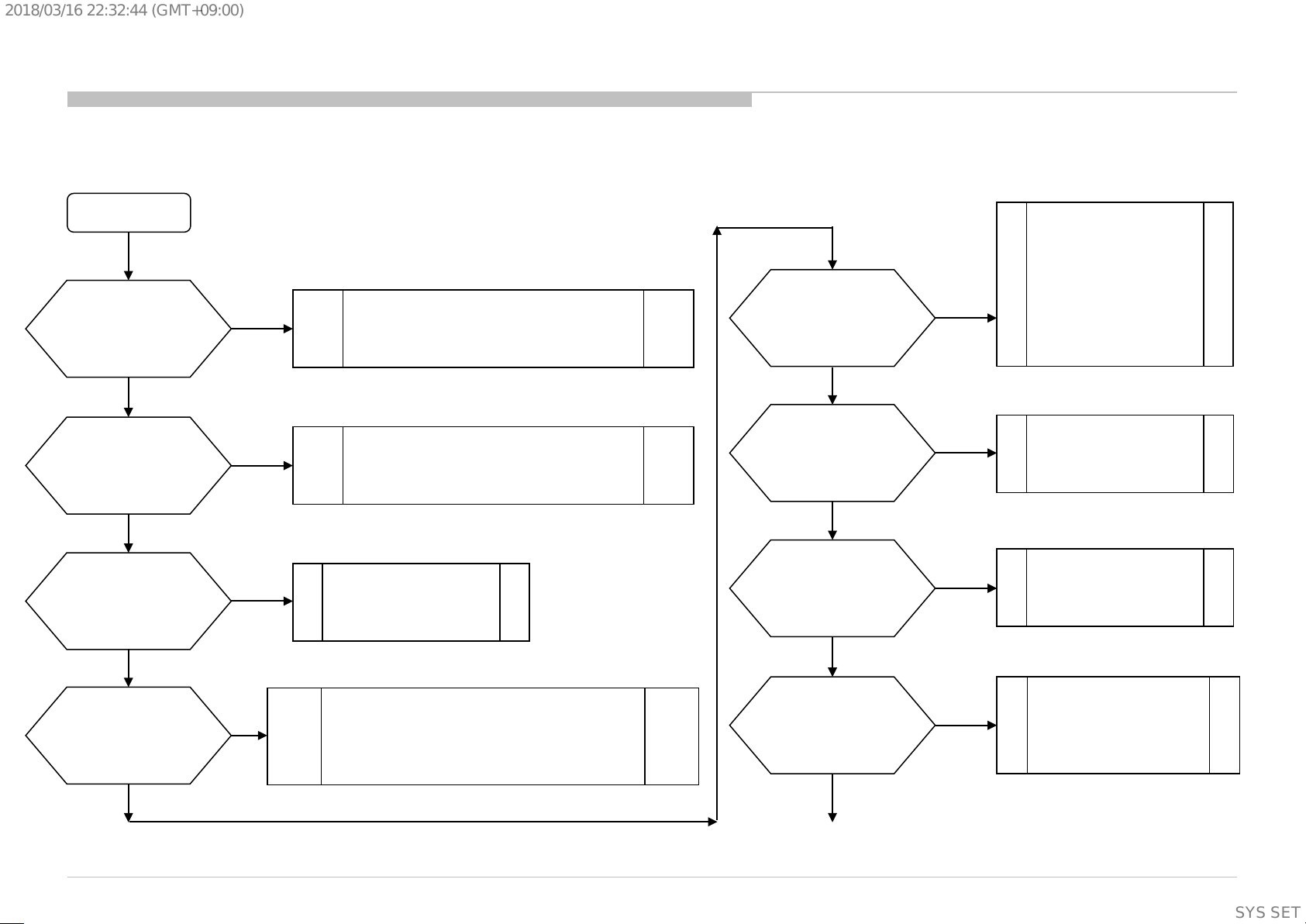

T r i ag e C har t

Chart Colour Code

SECTION 3

TROUBLESHOOTING

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

Reference

2 3 4 5 6 7 8

B* Board

G* Board

H* Board

Actuater

(Panel module)

Speaker

(Sub woofer)

Wifi & BT

Module

V By One FFC

Tcon

(Panel module)

OLED Panel

(Panel module)

Problem

Power Power Tcon

Audio

Panel

Panel

Power

TEMP 4KBE

Symptoms - no shutdown

Error log record only

TU_

TCO

DEM

N_E

OD

RR

AUD

_ER

4KPQ_ERR_

C

I2C

C

Power

No White Power

reponse to

remote (Dead

No

Set)

Video

- missing or distorted

No video

colored

lines or

One of

Inputs

NO RF

input

Remote Network Audio Smart Core Bluetooth (BT)

No video

all Inputs

Wireless

can't connect

No Audio

Smart Core no LED

(Set is still alive)

Bluetooth / Voice

Remote can't

connect

14

SYSSET

Page 15

2018/03/1622:32:44(GMT+09:00)

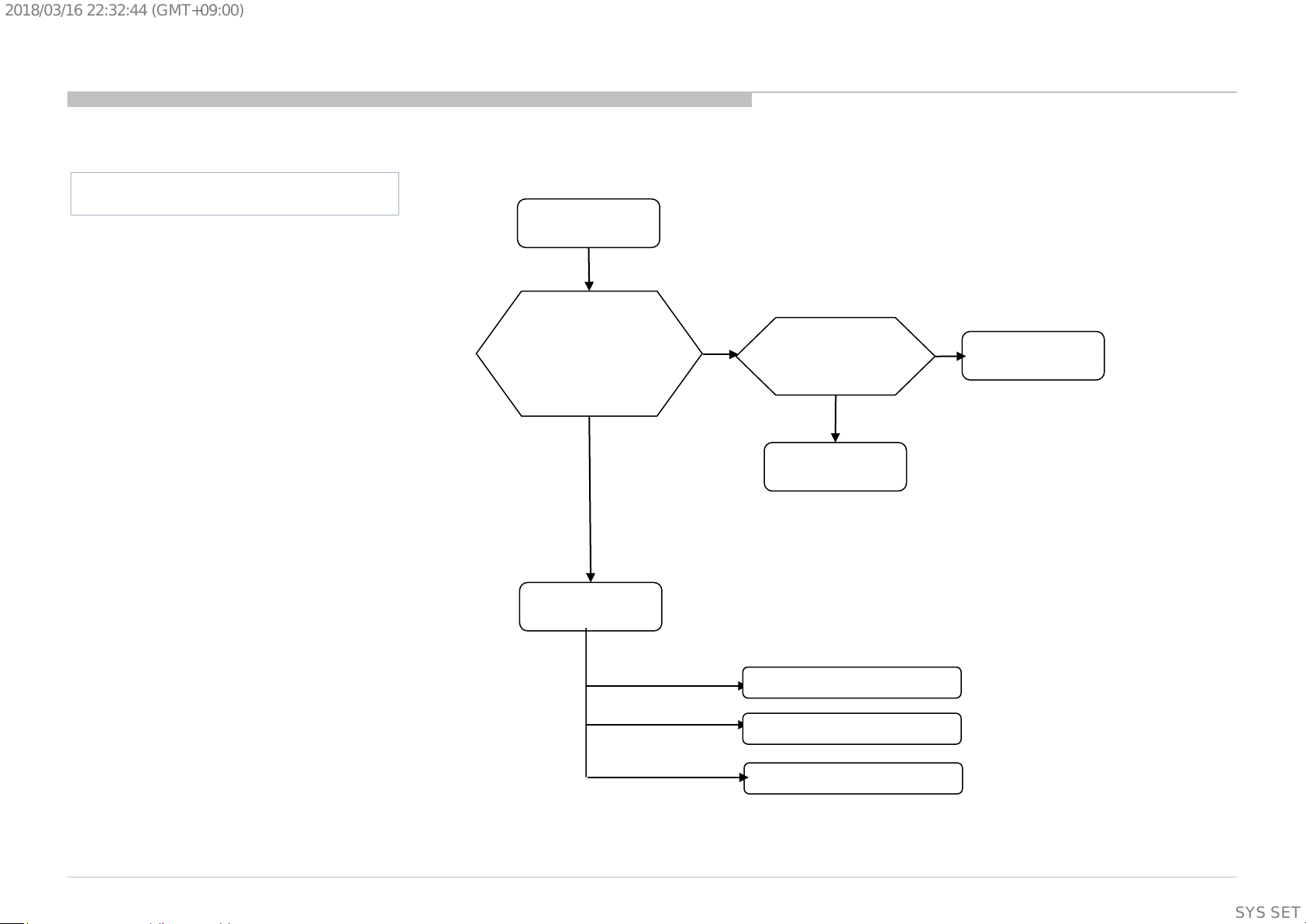

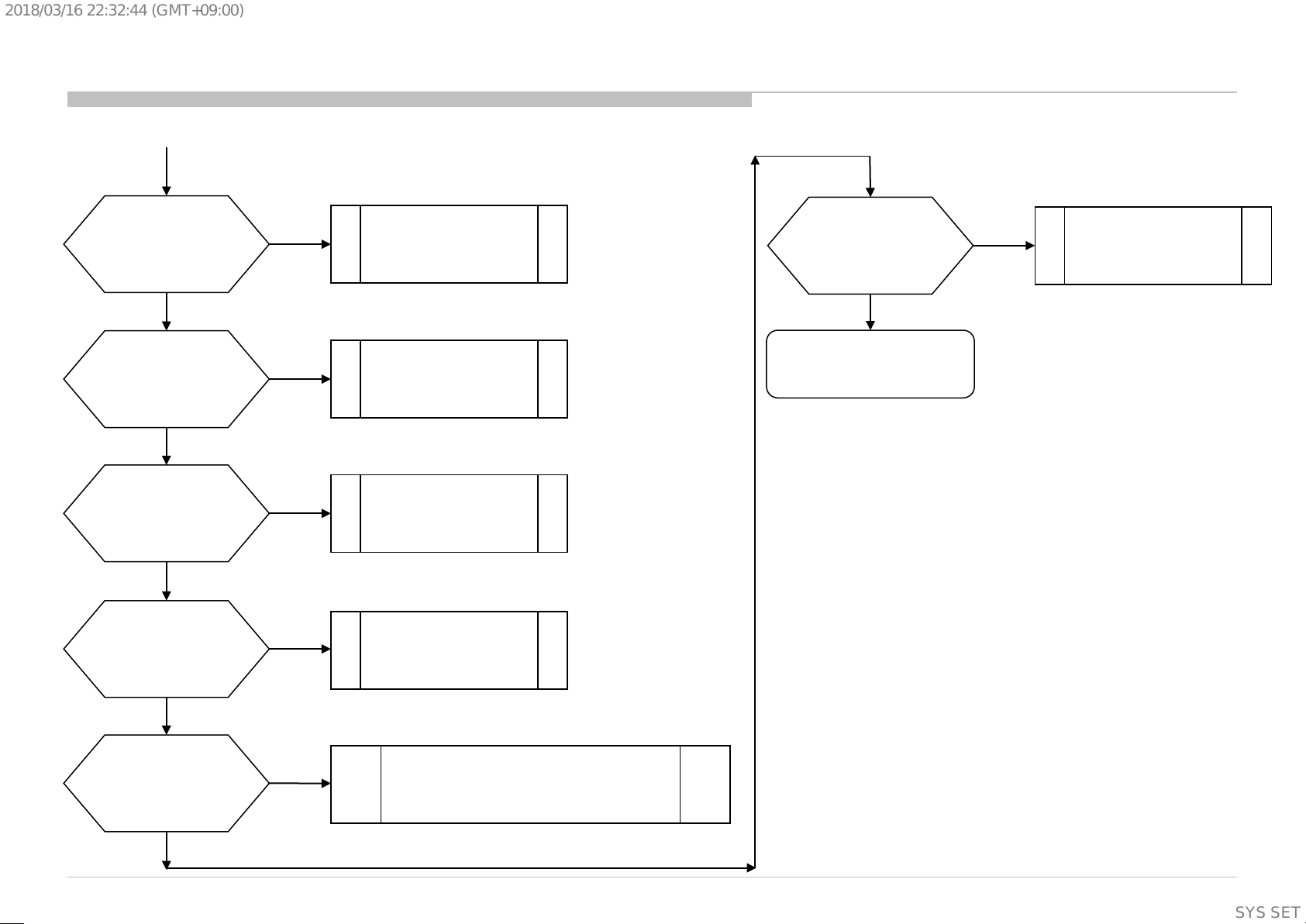

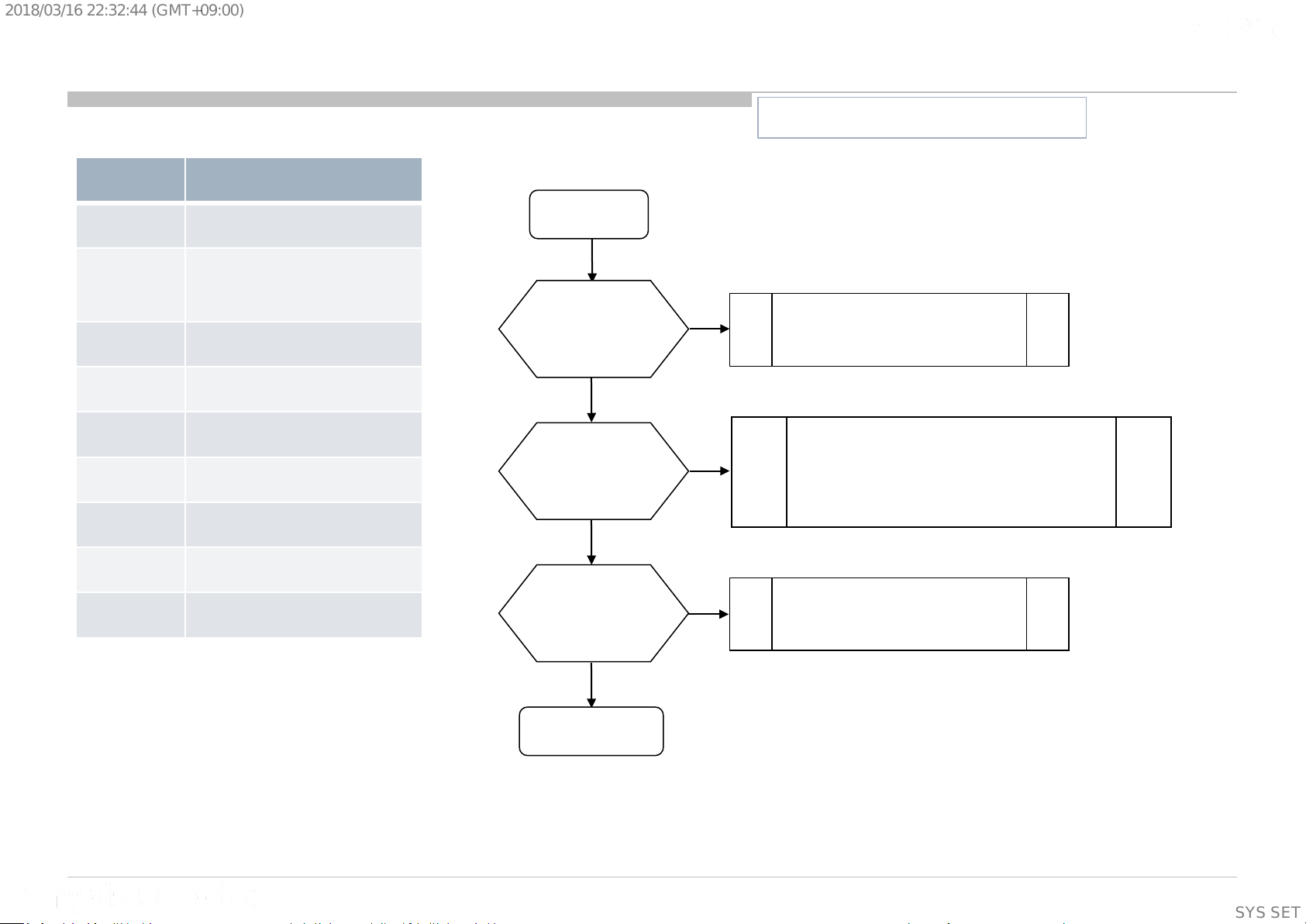

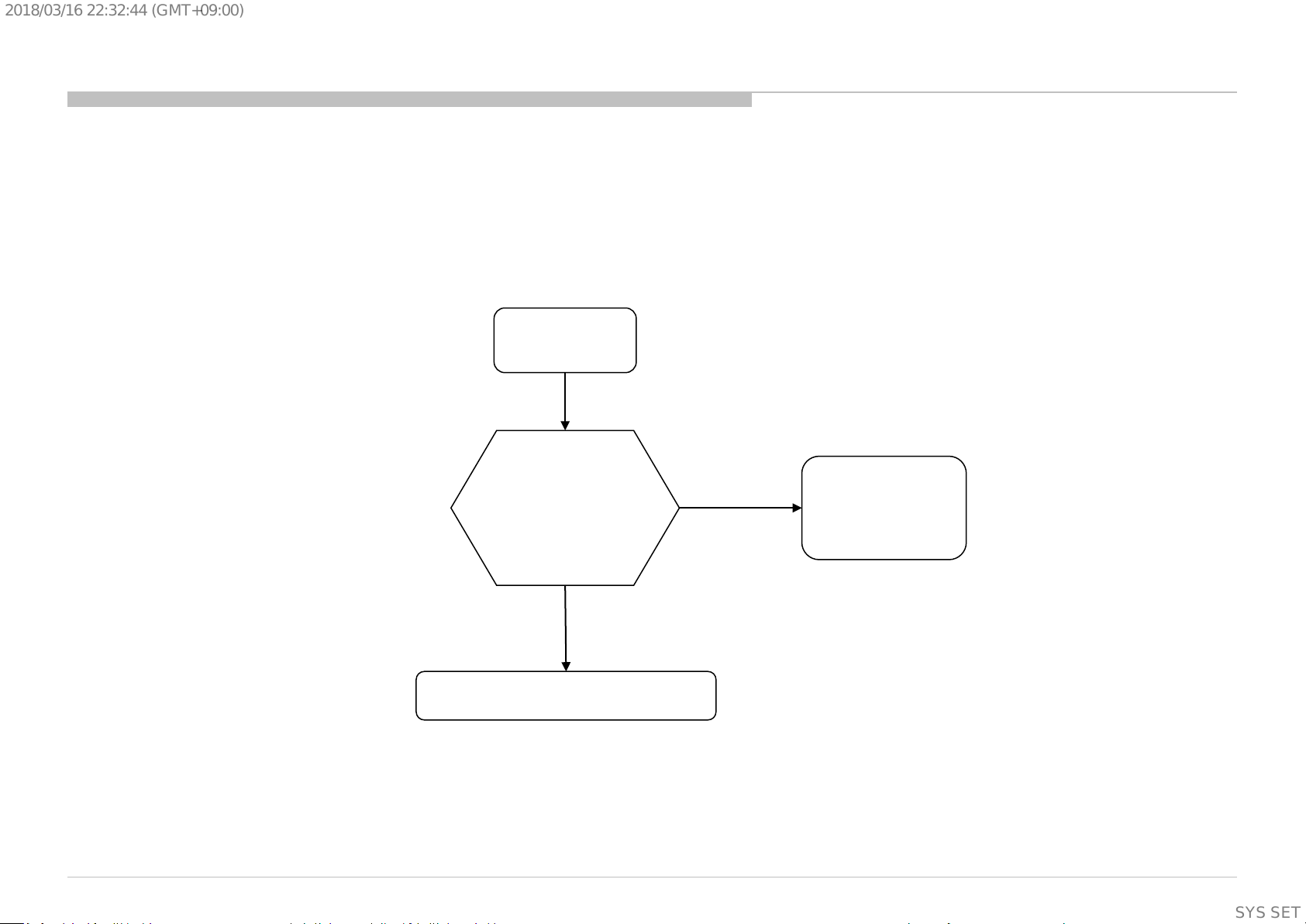

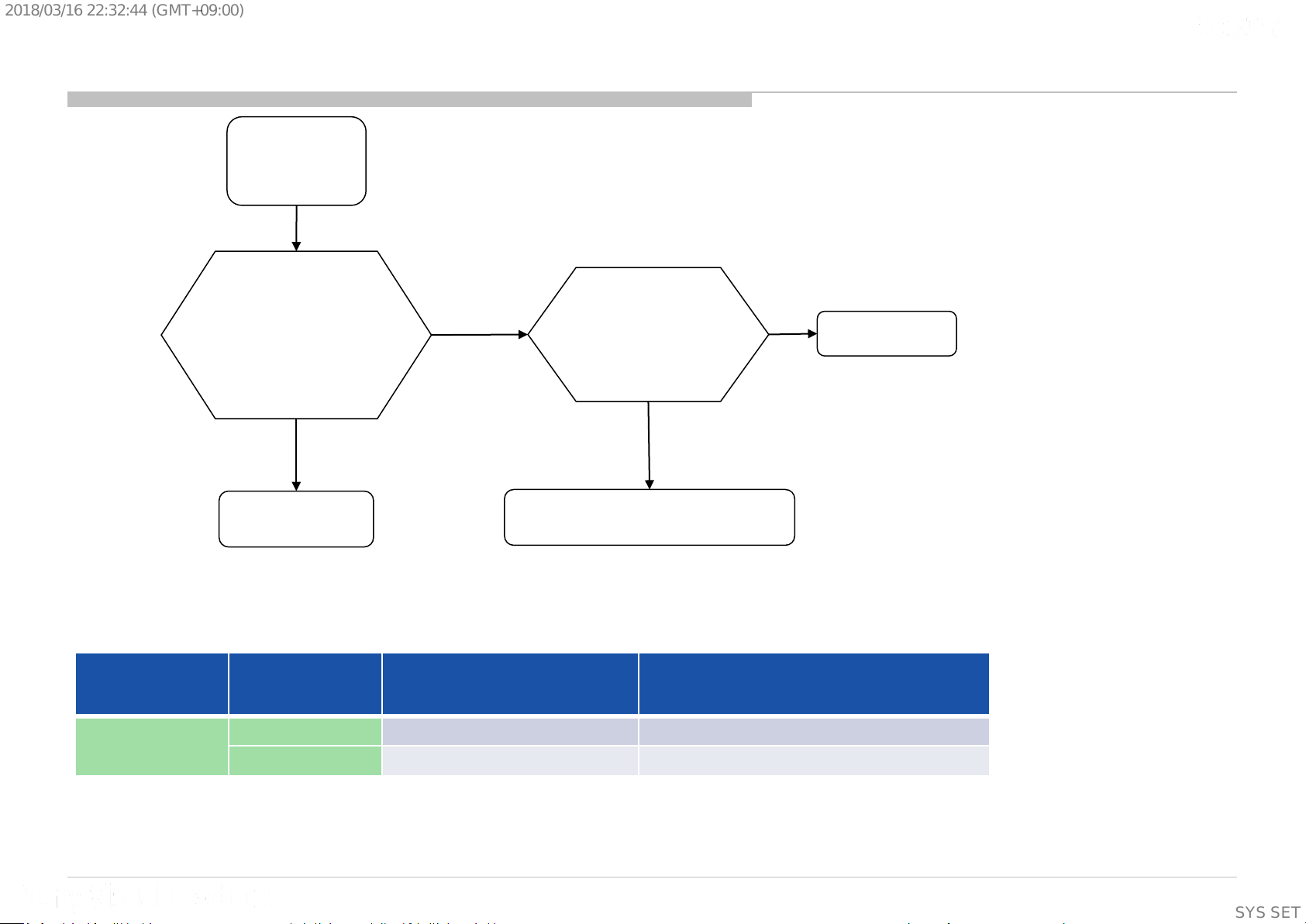

TROUBLESHOOTING Flow

1.0 No Power

BM2A Board Model

No Power

Check STBY 3.3V

C408

near CN400

on BM2A board

OK

BM2A Board

NG

Replace

Between G* Board to

BM2A Board Harness

OK

Harness

u-Com Failure

DDCON/LDO

NG

G* Board

Main Device Failure

15

SYSSET

Page 16

2018/03/1622:32:44(GMT+09:00)

1.2 No Power u-com Failure

+3.3V_STBY

#pin6

Vdd u-com

supply

voltage

#pin9

P-on u-com control signal path summary

BM2A

PGOOD_1

DDC : +1.0V_M2 (IC604)

TCON_P_ON

Delay (IC408)

G-Board

+12V_MAIN

AC_OFF_DET_OUT

from SOC BE (IC4000)

R426

R427/Q410

BL_ON

POWER_ON

R446

GND

R439

#pin7

#pin10

#pin16

12V_MON

ADC port

#pin11

DC_MON

ADC port

#pin12

P_ON_#1

DDCs : +1.8V_TU (IC405), +1.0V_BE (IC4003)

DDCs : +5V_MAIN (IC402), +3.3V_MAIN (IC403),

P-on u-com

IC401

#pin13

P_ON_#2

+1.5V_BE (IC4001), +1.1V_BE (IC4002)

LDOs : +1.05V_M2_A_1 (IC603), +1.05V_M2_A_2

(IC606),

VCC3IO_EMMC (IC607), +1.8V_BE (IC 4004)

DDC : +12V_LNB (Q408/Q409)

#pin18

#pin2

#pin14

#pin3

#pin20

#pin8

P_ON_HL

OPWRSB

ORESETB

DC_OFF_DET

X_SYSTEM_RST

BE_PANEL_PWR_ON_#2

USB VBUS SW (IC3406, IC3407, IC3408)

SOC Muffin 2 (IC1000)

Tuner (TU2802/TU2803)

SOC BE (IC4000)

GND

16

SYSSET

Page 17

2018/03/1622:32:44(GMT+09:00)

1.2 No Power u-com Failure

START

Check VDD

C506 Voltage.

Is the voltage >3.0V?

no

Check +3.3V_STBY Line (C408, CN400 #9pin)

Check 12V_MON

R446 Voltage.

Is the voltage >2.6V?

no

Check +12V_MAIN Line

(from G board).

Check “AC_OFF_DET_OUT”

(from BE SOC IC4000)

Check “AC_DET_IN”

(C407, CN400 #16pin

from G board)

yes

Check TYPE_DET

R428 Voltage.

Is the voltage 2.6±0.2V?

yes

Check OPWRSB

R443 Voltage.

Is the voltage 0V?

yes

Check POWER_ON

R526 or P-on u-com #pin10

Is the voltage >3.0V?

yes

no

no

no

Type Detection Circuit problem.

Check TYPE_DET Line (R521, R522, R523).

SOC

Muffin 2

problem

Try AC Off and On after few minutes.

If #pin10 keep Low, change IC401.

If #pin10 goes High few seconds and downs to Low,

Check +12V_MAIN Line (from G board).

yes

Check DC_OFF_DET

R448 or P-on u-com #pin3

is >3.0V?

yes

Check P_ON_#1

CL418 or P-on u-com #pin12

is >3.0V?

yes

Check PGOOD_1

R440 Voltage.

Is the voltage >3.0V?

Continue next page…

no

Change IC401

no

Change IC401

no

1.3 No POWER - DDCON/LDO

Check 1.0V DDCON (IC604)

17

SYSSET

Page 18

2018/03/1622:32:44(GMT+09:00)

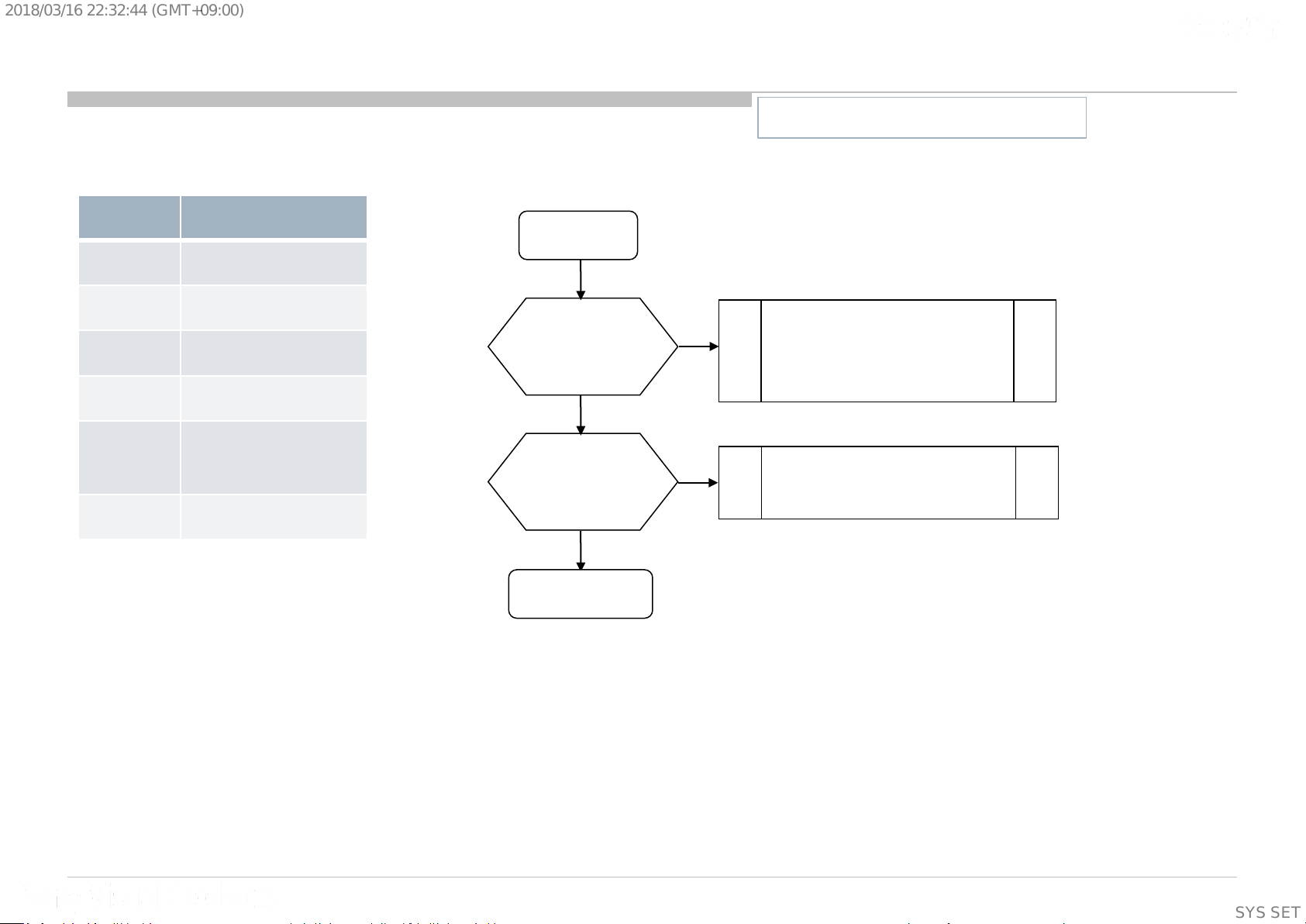

1.2 No Power u-com Failure

Previous page

Check P_ON_#2

CL417 or P-on u-com #pin13

is >3.0V?

yes

Check P_ON_HL

CL414 or P-on u-com #pin18

is >3.0V?

yes

Check ORESETB

CL416 or P-on u-com #pin14

Is the voltage >3.0V?

yes

Check X_SYSTEM_RST

CL412 or P-on u-com #pin20

Is the voltage >3.0V?

no

no

no

no

Change IC401

Change IC401

Change IC401

Change IC401

Check BL_ON

R527 or P-on u-com #pin7

Is the voltage >3.0V?

yes

END

u-com IC401 is working OK

no

Change IC401

yes

Check

BE_PANEL_PWR_ON_#2

R441 or P-on u-com #pin8

Is the voltage >3.0V?

yes

no

Check “X_BE_RST” (from SOC Muffin).

*If X_BE_RST is >3.0, SOC BE(IC4000) problem.

Otherwise, SOC Muffin(IC1000) problem.

18

SYSSET

Page 19

-

2018/03/1622:32:44(GMT+09:00)

1.3 No Power DDCON/LDO

Check item summary

Board IC Ref Voltage supply Output ref. Enable pin Enable source Fuse Vcc ref.

BM2A IC402 +5V_MAIN/+5V_AUDIO C430 R455 P-on u-com IC401 #pin13 F400 C423

BM2A IC403 +3.3V_MAIN/+3.3V_AUDIO C445 R465 P-on u-com IC401 #pin13 F401 C436

BM2A IC405 +1.8V_TU C463 IC405 #PIN5 P-on u-com IC401 #pin12 F403 C461

BM2A IC601 +1.5V_DDR C609 C605 R603 (3.3V or 5V) - C602

BM2A IC602 +1.05V_M2_STBY C611 IC602 #PIN3 C610 (+3.3V _STBY) - C610

BM2A IC603 +1.05V_M2_A_1 C613 IC603 #PIN3 P-on u-com IC401 #pin13 - C612

BM2A IC604 +1.0V_M2 C625 R623 P-on u-com IC401 #pin12 F600 C618

BM2A IC605 +1.05V_M2_ST_ET C631 IC605 #PIN3 M2 IC1000 #AP34 - C630

BM2A Board Model

BM2A IC606 +1.05V_M2_A_2 C633 IC606 #PIN3 P-on u-com IC401 #pin13 - C632

BM2A IC607 VCC3IO_EMMC (1.8V) C635 IC607 #PIN3 P-on u-com IC401 #pin13

BM2A IC4001 +1.5V_BE C4007 IC4001 #PIN5 P-on u-com IC401 #pin13 F4000 C4005

BM2A IC4002 +1.1V_BE C4014 IC4002 #PIN5 P-on u-com IC401 #pin13 F4001 C4012

BM2A IC4003 +1.0V_BE C4027 R4020 P-on u-com IC401 #pin12 F4002 C4020

BM2A IC4004 +1.8V_BE C4001 IC4004 #PIN3 P-on u-com IC401 #pin13 - C4000

(Supplementary

information)

C634

19

SYSSET

Page 20

2018/03/1622:32:44(GMT+09:00)

1.3 No Power DDCON/LDO

DDCON check

Check IC402 Vcc voltage

Is voltage >12V?

Check Vcc voltage

Is voltage >4V?

START

C423

yes

C602

yes

no

no

Check Vcc voltage

C602

Is voltage >3V?

yes

Check

D601

Is diode alive?

yes

no

no

BM2A Board Model

IC Ref Voltage supply

IC601 +1.5V_DDR

Check

D600

Is diode alive?

yes

Change D601

Check +5V_MAIN DDCON (IC402)

no

Change D600

Check +3.3V_STBY.

G* board

Check Enable

IC600 #pin1

Is voltage >2.5V?

yes

Change DDCON

IC601

no

Change IC600

20

(Supplementary

information)

20

SYSSET

Page 21

2018/03/1622:32:44(GMT+09:00)

1.3 No Power DDCON/LDO

DDCONs check

IC Ref Voltage supply

IC402

+5.0V_VBUS/+5V_MAIN

+3.3V_STBY (AC-ADP only)

IC403

/+3.3V_MAIN

Q407 +3.3V_MAIN

IC405 +1.8V_TU

IC601 +1.5V_DDR

IC604 +1.0V_M2

IC4001 +1.5V_BE

START

Check fuse

F4xx / F40xx/F6xx

Is fuse OK?

yes

Check Vcc voltage

C4xx / C40xx/C6xx

Is voltage >12.0V?

yes

BM2A Board Model

Please refer page-19 for Ref number.

no

Change Fuse

no

1) Check POWER_ON P-on u-com #pin10

(Refer 1.2 No Power U-Com Failure)

2) Check G* board

IC4002 +1.1V_BE

IC4003 +1.0V_BE

Check Enable pin

voltage

Is voltage >2.5V?

yes

Change DDCON IC

no

1.2 No Power U-Com Failure

or

Enable source

21

(Supplementary

information)

21

SYSSET

Page 22

2018/03/1622:32:44(GMT+09:00)

1.3 No Power DDCON/LDO

LDOs check

IC Ref Voltage supply

IC602 +1.05V_M2_STBY

IC603 +1.05V_M2_A_1

IC605

+1.05V_M2_ST_ET

IC606 +1.05V_M2_A_2

VCC3IO_EMMC

IC607

(1.8V)

IC4004 +1.8V_BE

START

yes

Check Vcc voltage

C4xxx or C6xx

Is voltage >3V?

yes

Check Enable pin

voltage

Is voltage >3V?

yes

no

no

BM2A Board Model

Please refer page-19 for Ref number.

Check +3.3V_DDC_OUT

DDCON (IC403)

or

+3.3V_STBY (G* board)

1.2 No Power U-Com Failure

or

Enable source

Change LDO IC

22

(Supplementary

information)

22

SYSSET

Page 23

2018/03/1622:32:44(GMT+09:00)

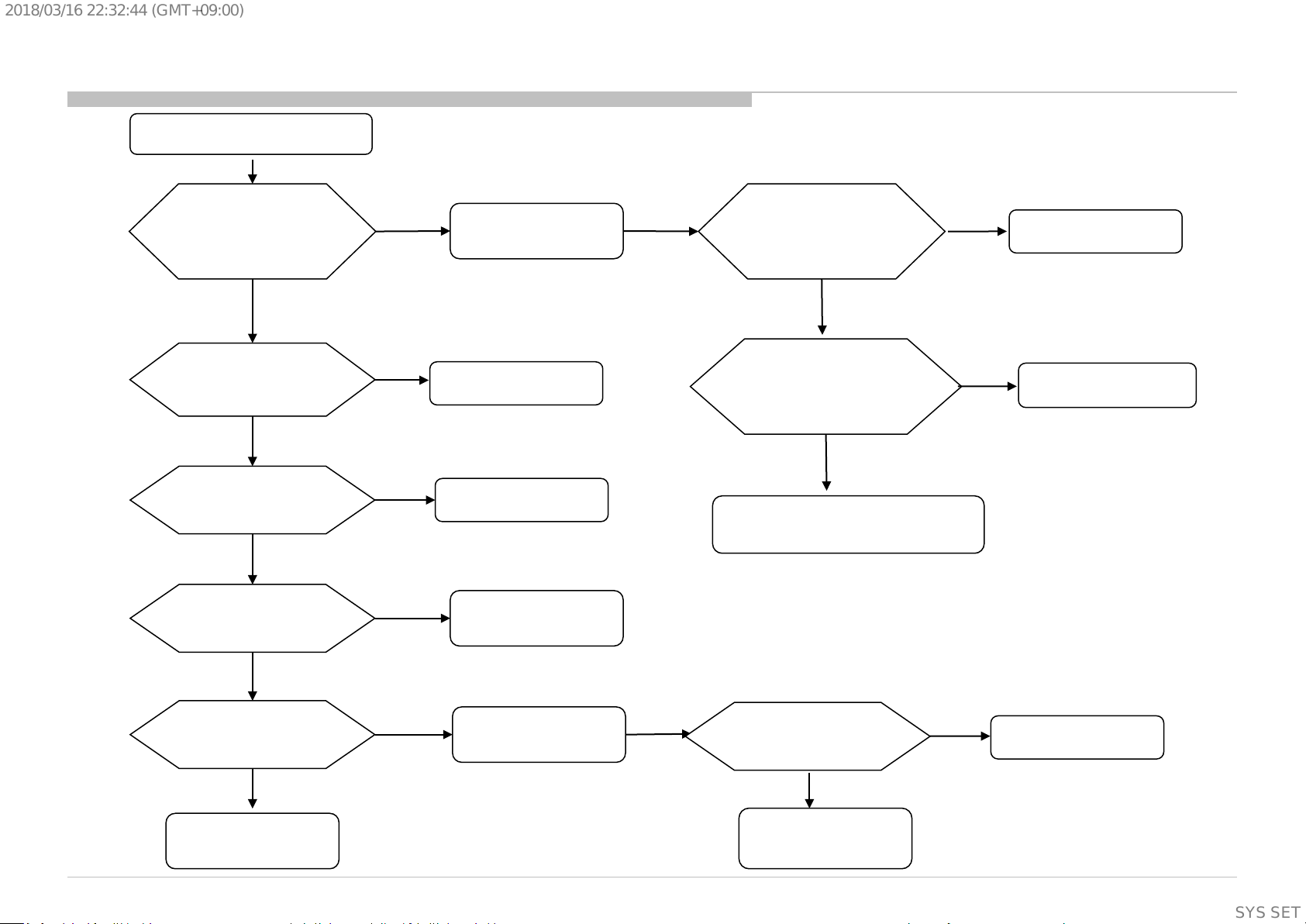

1.4 NO POWER-Muffin2 Failure

Muffin2 Fail Suspected

Muffin2 LOG is

displayed

No

Power uCom and

DDCON/LDO OK?

Yes

Crystal X1000

Is there 24MHz?

Yes

Muffin reset released?

ORESETB=High

Yes

No

No

No

W rite DD R check

bootloader

Follow 1.2&1.3

Replace crystal

Check uCom

Follow 1.2

Is there DDR error?

No

Check Muffin Log

related to eMMC

Is there “CRC error”

No

Store SW log, check SW

behaviors.

Yes

Replace DDR

Yes

Replace eMMC

Yes

eMMC clock present?

No

Replace Muffin

Yes

W rite DD R check

bootloader

Is there DDR error?

No

eMMC

data corruption

Yes

Replace DDR

23

SYSSET

Page 24

2018/03/1622:32:44(GMT+09:00)

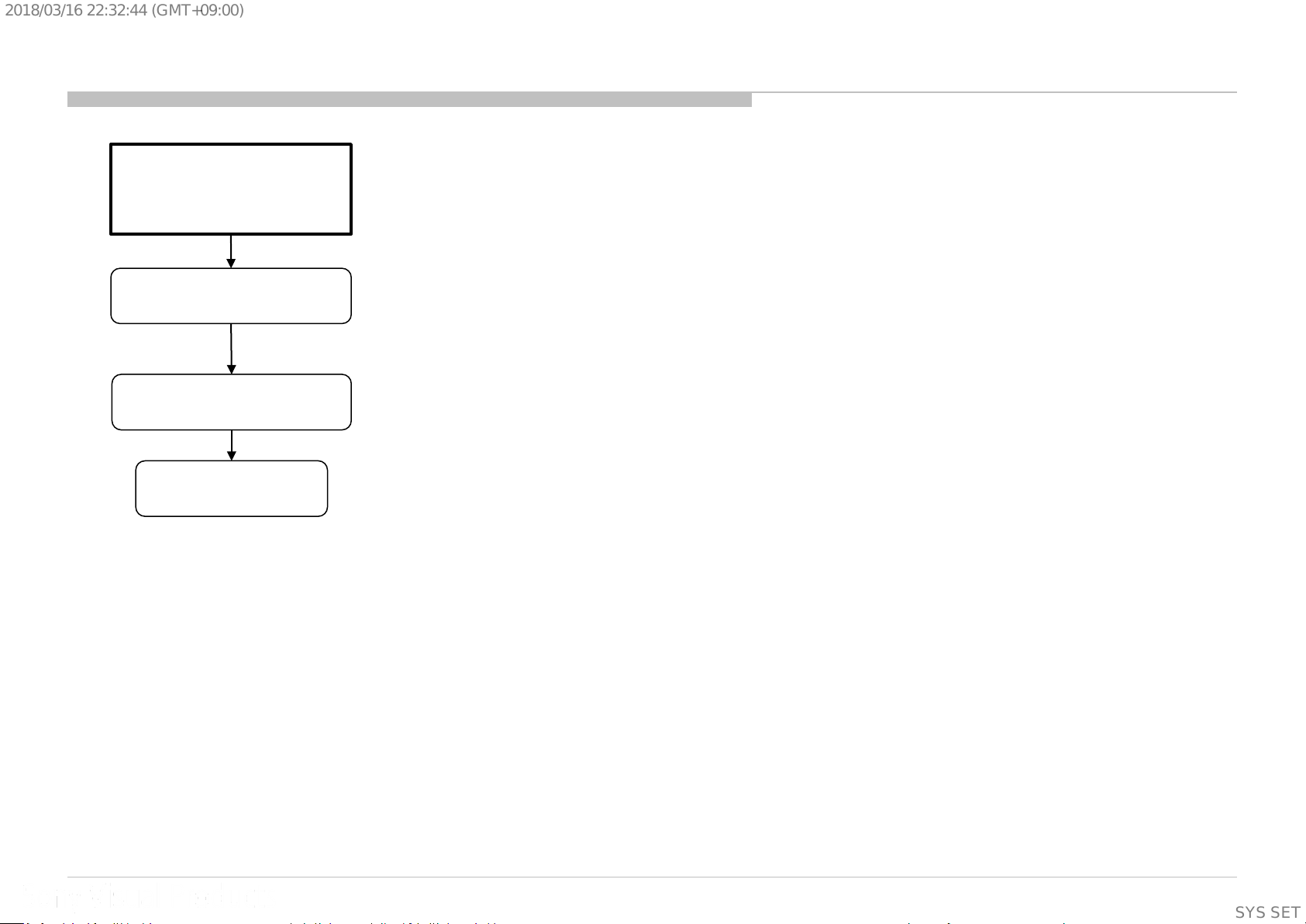

1.5 NO POWER-Muffin2 Replacement

Muffin2

replacement

flow

eMMC erase

Muffin2 replacement

Data on eMMC need

to be erase first before

changing Muffin

If cannot be erased,

erase after replacing

Muffin

SW write

(Supplementary

information)

24

SYSSET

Page 25

2018/03/1622:32:44(GMT+09:00)

2.0 LED Blinking: 2x (Main power Error)

BM2A

2-time blinking

Check “+12V_MAIN”

at pin 1 1/13 of CN400

on BM2A Board,

Vol tage > 13.2V ?

No

BM2A Board

Yes

G* Board

25

SYSSET

Page 26

2018/03/1622:32:44(GMT+09:00)

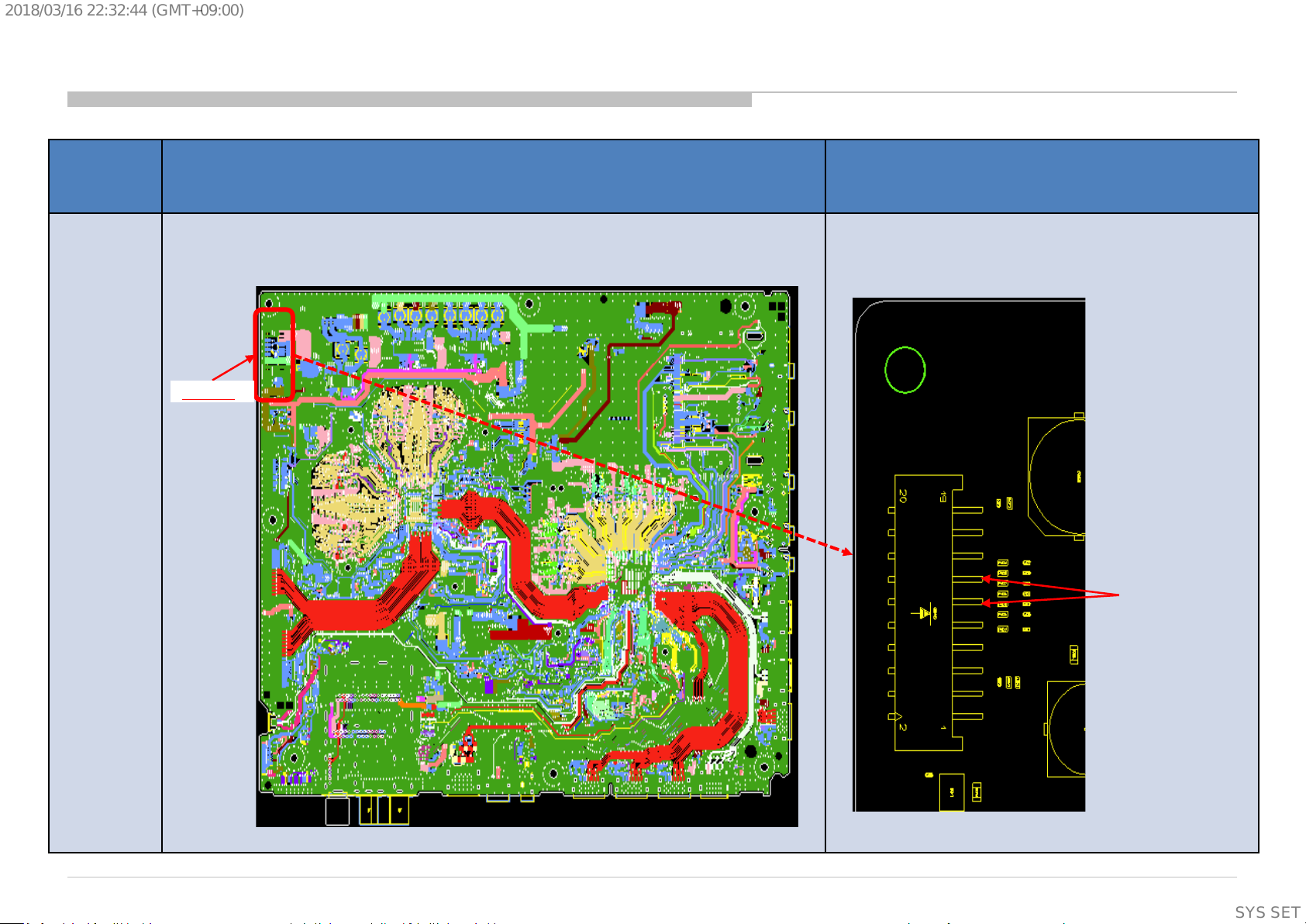

Check point for BM2A

Name Board PWB (A side) Detail

CN400

BM2A

+12V_MAIN

26

SYSSET

Page 27

2018/03/1622:32:44(GMT+09:00)

2.1 LED Blinking: 3x (DC Alert Error)

BM2A

Check “POWER_MAIN”

at pin 17/19 of CN400

Voltage = 18.0~20.0V or

22.5~24.5V ?

3-time blinking

(DC Alert)

on BM2A board,

OK

Check “+5.0V_VBUS”

at C431 on BM2A board

4.959V<Voltage<5.285V?

OK

Retry

NG

G Board

Detail of 3x LED Blinking

Error Item Number of STBY

Trinity DC_ALERT 3 Main board 5V power rail monitoring

AUD_ERR 3 Audio amp error detection

Trinity3 Board: BM2A

LED flashing

NG

BM2A Board

Description

(Supplementary

information)

27

SYSSET

Page 28

2018/03/1622:32:44(GMT+09:00)

Check point for BM2A

Name Board PWB (A side) Detail

CN400

BM2A

+5.0V_VBUS at C431

POWER_MAIN

Pin17/19 of CN400

(Supplementary

information)

28

SYSSET

Page 29

2018/03/1622:32:44(GMT+09:00)

2.2 LED Blinking: 3x (Audio Error)

LED 3x blinking

(Audio Error)

Power Off Check

Go to 3.3

Power On Check

Go to 3.4

Detail of 3x LED Blinking

Replace

G Board

NG

Measure the Speaker

impedance by multi-meter

Less than 3Ω ?

No

Speaker Harness

OK

Yes

G Board

Replace

Speaker

* In case of Actuator, replace Panel module.

Error Item Number of STBY

Trinity DC_ALERT 3 Main board 5V power rail monitoring

AUD_ERR 3 Audio amp error detection

Trinity3 Board: BM2A

LED flashing

Description

(Supplementary

information)

29

SYSSET

Page 30

2018/03/1622:32:44(GMT+09:00)

2.3 LED BLINKING 4x (TCON Internal Error/TCON I2C Communication Error)

BM2A

4-time blinking

(TCON Internal/

TCON I2C Communication)

OK

FFC Cable

Replace FFC Cable

Detail of 4x LED Blinking

Trinity

3

Error

Item

LD_ERR 4 CR TCON internal error

Number of STBY

LED flashing

(B<->TCON)

NG

BM2A Board

(TCON I2C Communication)

4

Low

Check

“LD_ERR_DET” Voltage

at CL4458 on BM2A Board

High

(TCON Internal)

Segment Description

CR TCON I2C communication error

Replace TCON board

OK

TCON Board

NG

Panel

Trinity3 Board: BM2A

(Supplementary

information)

30

SYSSET

Page 31

2018/03/1622:32:44(GMT+09:00)

Check point for BM2A

Name Board PWB (A side) Detail

BM2A

CL4458

(Supplementary

information)

31

SYSSET

Page 32

2018/03/1622:32:44(GMT+09:00)

2.5 LED BLINKING: 5x (Panel ID Read Error)

BM2A

5-times blinking

Check

“+12.5V_TCON”

on T-CON Board

OK

Replace the Harness

Between G Board

and BM2A

NG

Replace

the V-By-One FFC

NG

Symptom

improve

Symptom

improve

Replace

G Board

NG

Harness

V-By-One FFC

OK

G Board

Replace

BM2A Board

Symptom

improvement

BM2A Board

NG

Replace

Panel (T-con)

Symptom

improvement

Panel (T-con)

NG

32

SYSSET

Page 33

2018/03/1622:32:44(GMT+09:00)

2.6 LED BLINKING: 6x

BM2A

6-times blinking

Check Voltage of

“BL_ERR_DET”

at CL4459 on BM2A

Low

High

harness/connection

G board to BM2A

Harness /

Connection OK

Check

Harness /

Connection

broken

Replace G board.

Replace

harness

No

improvement

G board

No

improvement

Replace

BM2A

No

Improvement

Symptom

Improvement

Improvement

Symptom

Improvement

Harness

Symptom

G board

BM2A Board

Replace

Panel

Symptom

Improvement

Panel

(Supplementary

information)

33

SYSSET

Page 34

2018/03/1622:32:44(GMT+09:00)

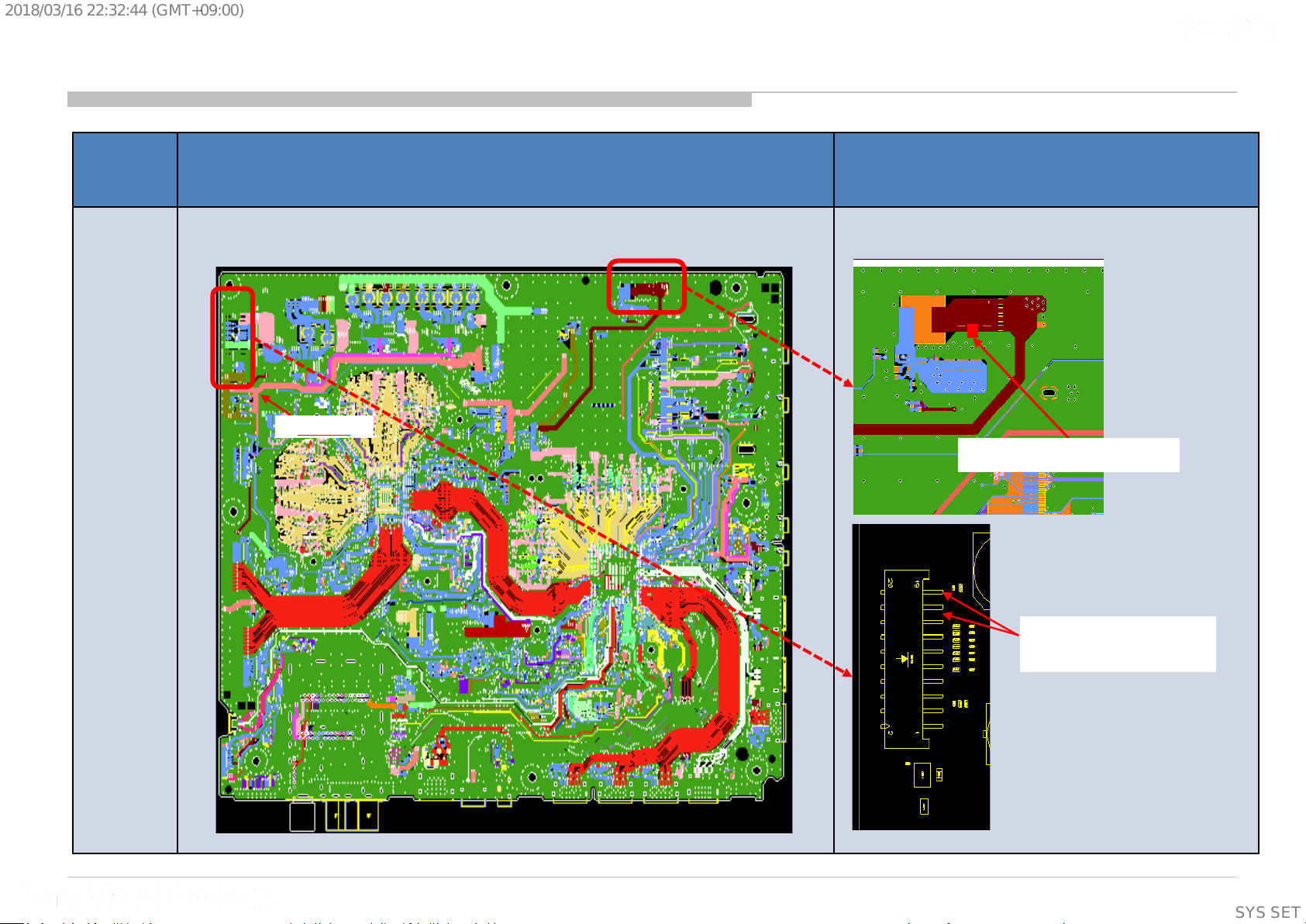

Check point for BM2A

Name Board PWB (A side) Detail

BM2A

CL4459

34

SYSSET

Page 35

2018/03/1622:32:44(GMT+09:00)

2.7 LED BLINKING: 7x (Temperature Error)

BM2A

7-time blinking

Setting

circumstance is OK?

Temperature,

Ventilation, etc.

Yes

No

Set to another

location, etc.

2.8 LED BLINKING: 8x (4KBE Error)

BM2A

8-time blinking

Replace

BM2A Board

Replace BM2A

Board, and Aging a few

hours

Symptom

improvement

BM2A Board

NG

Panel

35

SYSSET

Page 36

2018/03/1622:32:44(GMT+09:00)

3.0 No Sound

No Sound

Without LED 3x

AV receiver is connected

to HDMI in ?

No

[Speakers] setting is

[Audio System] ?

No

Headphone is connected to

HP/Audio Out terminal ?

No

[Sound]→

[Headphone Speaker Link]

setting is [On] ?

Yes

Yes

Yes

Yes

Select [External Inputs]→

[BRAVIA Sync Settings] →

[BRAVIA Sync Control]→[off]

Change the setting to

[TV Speakers]

Disconnect the Headphone

Change [Sound]→

[Headphone Speaker Link]

to [Off], OK ?

No

No sound only

Analog RF and Digital RF ?

No

No sound only HDMI ?

No

Go to

3.1 No Sound Audio

Yes

Yes

Go to

3.7 No Sound Tuner

Go to

3.8 No Sound HDMI

No

Go to

3.3 Power Off Checking

Yes

Replace BM2A board

HP/Audio out termi nal or Headphone

detect GPIO may be broken

36

SYSSET

Page 37

2018/03/1622:32:44(GMT+09:00)

3.1 No Sound Audio

No Sound

Audio

Replace BM2A

OK

Finish

NG

Go to

3.4 No Sound Power On Check

37

SYSSET

Page 38

2018/03/1622:32:44(GMT+09:00)

3.3 No Sound Power Off Check

Power Off Check

From 2.2

(1) BM2A-PWB

Fuse

(F3200,F3201,F3202)

broken?

No

Yes

Power Off Check

From 3.0

Confirm the speaker

harness

Cut or shorted

to the chassis ?

Yes

Replace Speaker

Harness

(2) BM2A-PWB

PVDD-GND(C3288)

short ?

No

(3) BM2A-PWB

LDO out(C3287)

short ?

No

Yes

Yes

Replace BM2A-PWB

NO

Measure the Speaker

impedance by multi-meter

Less than 3Ω ?

NO

Yes

Replace

Speaker

* In case of Actuator, replace Panel module.

(Supplementary

information)

38

SYSSET

Page 39

2018/03/1622:32:44(GMT+09:00)

3.4 No Sound Power On Check

(4) POWER_A U * check

POWER_AU is supplied to

before LED 3x blinking?

Power On Check

From 2.2/3.1

BM2A for a moment

No

*Power AU is same as PVDD

Yes

No

Replace G-PWB

OK ?

No

Return to 2.2

Yes

Finish

39

SYSSET

Page 40

2018/03/1622:32:44(GMT+09:00)

3.5 No Sound Audio HP/Audio out

No Sound Audio

HP/Audio out

Replace BM2A-PWB

40

SYSSET

Page 41

2018/03/1622:32:44(GMT+09:00)

3.7 NO SOUND: @ TUNER

No Sound with normal picture

NO

Only RF tuner input?

YES

Check IC1000 (SOC)

Please refer Audio

troubleshooting

41

SYSSET

Page 42

2018/03/1622:32:44(GMT+09:00)

3.8 NO SOUND: HDMI 1/2/3/4

No Sound

Check the picture

OK

Check the mode

of Source equipment

HDMI

Does this model have

Analog Audio In

(Stereo minijack)?

NO

Check Sound by other TV set

which is same model

NG

NG

Refer to 4.5 HDMI NO PICTURE

DVI

YES

“HDMI/DVI Audio Source”

Auto or HDMI Audio

OK

Does this model have

Analog Audio In

(Stereo minijack)?

setting is?

YES

Connect Stereo minijack cable between Source and the TV, and

Change “HDMI/DVI Audio Source” to Auto or Analog Audio In.

No

Change the mode of Source equipment to HDMI

Analog Audio In

Change “HDMI/DVI Audio Source” to Auto or HDMI Audio In

Refer to 3.0 No Sound Audio

Is Distributor used ?

YES

Connect Source

equipment directly

NO

Check Source equipment

by Reference TV set

(For example, RB2, RB1)

NG

Check the settings of

Source equipment

OK

Change B-Board.

And inform the designer of it

42

SYSSET

Page 43

2018/03/1622:32:44(GMT+09:00)

4.0 No Picture

No Picture

Got Any Normal

Display?

Yes

Check Other

Portion:

Ext. Video Input -

HDMI - No Picture

No

No Picture

Check Smart Core

Behavior

(Blinking)

Yes

4x

5x

6x

No

4x Blinking

5x Blinking

6x Blinking

Replace

the V by One FFC

Harness

Symptom

improvement

V by One FFC

Harness

NG

Replace

the main Board

Symptom

improvement

Main board NG

NG

Panel

(T-CON)

Tuner - No Picture

43

SYSSET

Page 44

2018/03/1622:32:44(GMT+09:00)

4.1: Video Analog Signal Path

Video

(Side Mini Jack)

CVBS3P

VIDEO2_DET

L36:CVBS3P

G16:GPIO66

M2

IC1000

44

SYSSET

Page 45

2018/03/1622:32:44(GMT+09:00)

4.2: No Picture (BM2A)

No Picture

Video

No Picture

NG

Check if input OSD

is GREY OUT

OK if it is highlighted

OK

* Check J2600

Connection,

VIDEO2_DET

At R2612

OK (Vpp: 3.3 V)

** Detailed check all

parts at VIDEO2_DET

signal Path [R2611]

OK (Vpp: 3.3V)

NG (Vpp: 0V)

NG (Vpp: 0V)

Condition Actions to be taken

Muffin [IC1000]

Problem

J2600 Connector

Problem

J2600 Connectivity

Problem

Parts Broken

Refer to IC troubleshooting for

further investigation

Change Connector

Change Part

NG (Vpp: 0 V)

Check wave between

C2609 and IC1000

OK (Vpp: 1 V)

Muffin [IC1000]

Problem

J2600 Connector

Problem

* OK Condition : No solder splash can be seen

NG Condition : Solder splash can be seen

[All voltage measurement using Oscilloscope]

** Detailed check all parts

at CVBS3P signal path

[R2642/R2631/R2607

/C2621/C2609/VD2604]

J2600 Connectivity

Problem

NG

OK

Parts Broken

** OK Condition : No part short-circuited

NG Condition : Part short-circuited

45

SYSSET

Page 46

2018/03/1622:32:44(GMT+09:00)

4.2/4.3: Input Skip function (BM2A)

Input Signal Non-Detect

(Typical)

Video VIDEO2_DET

0V 3.3V

IC1000 G16GPIO66

Video

(Side Mini Jack)

Detect

(Typical)

46

SYSSET

Page 47

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER

RF input no picture / noisy

picture

Check RF source cable

and antenna, OK?

OK

Check Tuner power line:

3.3V at JL2800 = 3.3V?

1.8V at JL2801 = 1.8V?

*1

RESET value at JL2807 = 3.3V? *1

OK

All broadcasting channel

cannot be received?

OK

Refer to next page

NG

NG

Change RF cable and antenna

NG

Please refer DDCON

troubleshooting

Check part mounting condition

for I2C SDA & SCL line. (Refer Note I2C)

OK

NG

Change NG parts

connected to I2C bus

Notes: I2C

I2C line for all tuners except Japan

- Parts for I2C SDA line: R2800, C2803.

- Parts for I2C SCL line : R2801, C2804.

I2C line for Japan

- Parts for I2C SDA line: R2804

- Parts for I2C SCL line : R2805

*1 It does not use 1.8V and RESET in the UC model

47

SYSSET

Page 48

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER

From Previous page

Digital

Analog

Refer Analog Tuning

Terrestrial/Cable

Refer Digital Tuning 1

For TW, NA-ATSC(MX/UC),

and LA-ISDB-T

Satellite

Check Tuner power line

12V at JL2822 = 12V?

OK

For AEP, JP, PA_T2, CH/HK,

and LA-T2(COL)

Refer Digital Tuning 2

NG

12V LNB Voltage

Checking

48

SYSSET

Page 49

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER (BM2A)

BM2A (Top View)

For Tuner Power Lines

1.8V

12V

BM2A Tuner potion(Top View)

For Tuner Power Lines

3.3V

JL2822 = 12V

JL2800 = 3.3V

JL2807 = RESET:3.3V

JL2801 = 1.8V

BM2A Tuner potion(Bottom View)

For Tuner Power Lines

49

SYSSET

Page 50

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER (BM2A)

BM2A (Top View)

For Tuner I2C line

R2801

C2803

C2804

R2800

R2805

R2804

50

SYSSET

Page 51

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER

FOR 12V LNB Voltage Checking : @ AEP and JP

+12V_LNB Voltage Checking

Check fuse F2801

NG

Change the fuse

OK

Check LNB power line

+12V_MAIN at R495 = 12V?

NG

Check +12V_Main at CN400

(JL401/JL411)

NG

Check harness between

B-Board and G-board

OK

NG

OK

Check P_ON_HL signal line

at CL414(R451) = 3.3V?

NG

Please confirm Power

Sequence u-com

Harness broken

OK

MOSFET

Q408/Q409

broken

OK

Please refer G-board

troubleshooting

51

SYSSET

Page 52

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER (BM2A)

BM2A (Top View)

12V LNB V oltage line

R451

CL414

+12V_LNB

F2801

R495

Q409

+12V_MAIN

Q408

52

SYSSET

Page 53

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER

FOR ANALOG TUNING: @ All destination except JP

For LA-ISDB(BR/AR), LA-T2(COL) and TW only

Analog Tuning

For Other destination

Can it preset broadcast?

Confirm ANT or Cable connection

OK

OK

NG

NG

Notes:

- Parts for IFOUT_N line : FB2801, C2807, C2826

- Parts for IFOUT_P line : FB2802, C2808, C2825

- Parts for IFAGC line : R2809,R2838, C2827

: Insert correct signal in correct terminal.

A

A

Check IC1000 (SoC)

Check part mounting condition

for analog control line

“IFOUT_N, IFOUT_P, IFAGC”

NG

Change NG parts

OK

Check IC1000 (SoC) &

Tuner module

53

SYSSET

Page 54

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER

FOR DIGITAL TUNING 1: @ TW, NA-ATSC(MX/UC), and LA-ISDB-T.

For TW/LA-ISDB-T

LA-T2(COL: Cable)

Confirm ANT or Cable connection

Digital Tuning 1

For NA-ATSC(MX/UC)

NG

A

Sound is normal?

No sound

OK

Notes:

- Parts for IFOUT_N line : FB2801, C2807, C2826

- Parts for IFOUT_P line : FB2802, C2808, C2825

- Parts for IFAGC line : R2809,R2838, C2827

A

: Insert correct signal in correct terminal.

Check IC1000 (SoC)

Check part mounting condition

for digital data line

“IFOUT_N, IFOUT_P, IFAGC”

NG

Change NG parts

OK

Check SoC(IC1000) and Tuner module

Check Tuner module

(Supplementary

information)

54

SYSSET

Page 55

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER (BM2A)

BM2A (Top View)

IF & IFAGC line

R2838

C2827

FB2801

FB2802

C2808

C2807

R2809

C2825

C2826

(Supplementary

information)

55

SYSSET

Page 56

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER

FOR DIGITAL TUNIN G 2: @ AEP, JP, PA_ T2, CH /HK , and LA -T2(COL)

Digital Tuning 2

LA-T2(COL)

CH/HK

NG

Confirm ANT or Cable connection Confirm ANT or Satellite connection

OK

Digital cable/ Terrestrial

Cable

Refer to Digital Tuning 1

A A

Terrestrial

OK

Sound is normal?

No sound

NG

Can it preset broadcast?

OK

For AEP/JP For PA_T2 and

OK

Check IC1000 (SoC)

Check part mounting condition

for I2C SDA & SCL line. (Refer Note I2C)

OK

NG

NG

Change NG parts connected to I2C bus

Notes: I2C

I2C line for all tuners except Japan

- Parts for I2C SDA line: R2800, C2803.

- Parts for I2C SCL line : R2801, C2804.

I2C line for Japan

- Parts for I2C SDA line: R2804

- Parts for I2C SCL line : R2805

Check part mounting condition for digital data line

“TU1_TS_DATA0, TU1_TS_CLK,

TU1_TS_VALID, TU1_TS_SYNC”

(Refer Notes)

NG

Change NG parts

OK

Change Tuner module

Check IC1000 (SoC) &

Confirm an insertion state of the

connector

Notes: TS line

-TS line parts for LA-T2/PA-T2/CH/HK :

R2868/R2869/R2870/R2871/RB2802

- TS line parts for AEP/JP :

R2814/R2815/R2816/R2817/RB2802

:Insert correct signal in correct terminal.

A

56

SYSSET

Page 57

2018/03/1622:32:44(GMT+09:00)

4.4 NO PICTURE: @ TUNER (BM2A)

BM2A (Top View)

TS1 line

RB2802

(Under the heatsink)

R2869

R2870

R2871

R2814

R2868

R2815

R2816

R2817

(Supplementary

information)

57

SYSSET

Page 58

2018/03/1622:32:44(GMT+09:00)

4.5 NO PICTURE: HDMI 1

No Picture

Check HDMI cable

OK

Check other

HDMI input

All Inputs NG

Check Picture by other TV set

which is same model

Target board & other

TV set both NG

Is using HDMI splitter ?

NO

Check Source equipment

by Reference TV set

(For example, RB1)

NG

Other TV set

OK

YES

Reference TV Set

OK

Change HDMI cable

Other Input is OK

IC1000 NG

Connect Sourc e

equipment directly

Change B-Board.

And inform the d esigner of i t

+5V line NG

Spec:4.7~5.3V

Replace R3646

Check the below point at

Connector side

・Check +5V line CL3642

・Check HPD line CL3629

・Check DDC lines CL3616/CL3617

・Check TMDS lines

+5V line OK

and HPD line NG

Spec:2.4~5.3V

Replace

R3627,R3634,R3639,

R3643,Q3602

NG

DDC lines NG

IC1000 NG

And inform the desi gner of it

All lines NG

RB3619,RB3620,

Replace

RB3603,R3664,R3665

NG

Replace

CN3603

NG

TMDS lines NG

Replace

RB3611,RB3612

NG

Reference TV set

NG

Check the settings o f

Source equipment,cable

58

SYSSET

Page 59

2018/03/1622:32:44(GMT+09:00)

4.5 NO PICTURE: HDMI 2

No Picture

Check HDMI cable

OK

Check other

HDMI input

All Inputs NG

Check Picture by other TV set

which is same model

Target board & other TV

set both NG

Is using HDMI splitter ?

NO

Check Source equipment

by Reference TV set

(For example, RB1)

NG

Other TV set

OK

YES

Reference TV Set

OK

Change HDMI cable

Other Input is OK

IC1000 NG

Connect Sourc e

equipment directly

Change B-Board.

And inform the d esigner of i t

+5V line NG

Spec:4.7~5.3V

Replace R3647

Check the below point at

Connector side

・Check +5V line CL3643

・Check HPD line CL3624

・Check DDC lines CL3610/CL3611

・Check TMDS lines

+5V line OK

and HPD line NG

Spec:2.4~5.3V

Replace

R3619

NG

DDC lines NG

IC1000 NG

And inform the desi gner of it

All lines NG

RB3613,RB3614,

RB3605,RB3606

Replace

RB3604,R3658,R3659

NG

Replace

CN3600

NG

TMDS lines NG

Replace

NG

Reference TV set

NG

Check the settings o f

Source equipment,cable

59

SYSSET

Page 60

2018/03/1622:32:44(GMT+09:00)

4.5 NO PICTURE: HDMI 3

No Picture

Check HDMI cable

OK

Check other

HDMI input

All Inputs NG

Check Picture by other TV set

which is same model

Target board & other TV

set both NG

Is using HDMI splitter ?

NO

Check Source equipment

by Reference TV set

(For example, RB1)

NG

Other TV set

OK

YES

Reference TV Set

OK

Change HDMI cable

Other Input is OK

IC1000 NG

Connect Sourc e

equipment directly

Change B-Board.

And inform the d esigner of i t

+5V line NG

Spec:4.7~5.3V

Replace R3644

Check the below point at

Connector side

・Check +5V line CL3644

・Check HPD line CL3627

・Check DDC lines CL3612/CL3613

・Check TMDS lines

+5V line OK

and HPD line NG

Spec:2.4~5.3V

Replace

R3627,R3634,R3639,

R3643,Q3602

NG

IC1000 NG

And inform the desi gner of it

DDC lines NG

Replace

RB3601,R3660,R3661

NG

All lines NG

Replace

CN3601

NG

TMDS lines NG

Replace

RB3615,RB3616,

RB3607,RB3608

NG

Reference TV set

NG

Check the settings o f

Source equipment,cable

60

SYSSET

Page 61

2018/03/1622:32:44(GMT+09:00)

4.5 NO PICTURE: HDMI 4

No Picture

Check HDMIcable

OK

Check other

HDMI input

All Inputs NG

Check Picture by other TV set

which is same model

Target board & other TV

set both NG

Is using HDMI splitter ?

NO

Check Source equipment

by Reference TV set

(For example, RB1)

NG

Other TV set

OK

YES

Reference TV Set

OK

Change HDMIcable

Other Input is OK

IC1000 NG

Connect Sourc e

equipment directly

Change B-Board.

And inform the d esigner of i t

+5V line NG

Spec:4.7~5.3V

Replace R3645

Check the below point at

Connector side

・Check +5V line CL3645

・Check HPD line CL3628

・Check DDC lines CL3614/CL3615

・Check TMDS lines

+5V line OK

and HPD line NG

Spec:2.4~5.3V

Replace

R3626,R3633,R3638,

R3642,Q3601

NG

DDC lines NG

IC1000 NG

And inform the desi gner of it

All lines NG

RB3617,RB3618,

RB3609,RB3610

Replace

RB3602,R3662,R3663

NG

Replace

CN3602

NG

TMDS lines NG

Replace

NG

Reference TV set

NG

Check the settings o f

Source equipment,cable

61

SYSSET

Page 62

2018/03/1622:32:44(GMT+09:00)

5.0 Key Switch Buttons Error

Side key buttons error

Check harness

connection between

B-board and switch

module

NG

Change harness

between B-board to

switch module harness

NG

Change switch module

NG

Main device issue

Change B-board

OK

OK

OK

Harness connection issue

B-board to switch module

harness issue

Switch module issue

62

SYSSET

Page 63

2018/03/1622:32:44(GMT+09:00)

5.1 IR Remote Commander Error

IR remote commander

does not respond

Check harness

connection between

B-board and Smart

Core

NG

Change harness

between B-board to

Smart Core harness

NG

Change Smart Core

NG

Change B-board

Main device issue

OK

OK

OK

Harness connection

issue

B-board to Smart Core harness

issue

Smart Core issue

63

SYSSET

Page 64

2018/03/1622:32:44(GMT+09:00)

5.2 Light Sensor Error

Backlight level does not

change when ambient

light changed

Check UI setting and

make sure light sensor

setting is “ON”

Setting is “OFF”

Setting issue

Change setting to “ON”

Setting is “ON”

Check harness

connection between

B-board and Smart

Core

NG

Change harness

between B-board to

Smart Core harness

NG

Change Smart Core

NG

Change B-board

Main device issue

OK

OK

OK

Harness connection

issue

B-board to Smart Core harness

issue

Smart Core issue

64

SYSSET

Page 65

2018/03/1622:32:44(GMT+09:00)

6.0 Network Malfunction: Ethernet (Wired)

[Network Set-up]

>[Wired Set-up]

on the TV

Connection Results

Cable Connection

Failed

Check cable

NG

Ethernet Cable

B Board

Power

+1.05V_M2_ST_ET

OK

OK

OK

B board

Power

Q3401 FET=ON

Connection Results

Local Access

Failed

Wired Set-up

IP address setting

Manual

Check IP address

&

Local router setting

OK

Check Ethernet

Connector pins

Soldering

J3400

OK

Auto

OK

Check

Local router

DHCP server

Check

Pulse Transformer

soldering

T3400,T3401

Connection Results

Internet Access

Failed

Proxy setting

OK

Check CMF

Soldering

L3400

OK

B board

OK

IC1000 issue

Change

B-board

NG

Change IC605

NG

Change Q304

NG NG

Change

Ethernet Connector

NG

Change Pulse Trans

Change CMF

65

SYSSET

Page 66

2018/03/1622:32:44(GMT+09:00)

6.2 Wireless Network malfunction (1/2)

1) Internal Wireless Network malfunction

Wireless Network

on the TV

Error message or no sc an res ul t

appear in the network setting?

Yes

*1

Hardware defect suspected.

Go to the next page

No

Is the Wi-Fi radio

strength too weak

or even No signal?

Yes

Check with another

Wi-Fi/BT module

OK

Wi-Fi/BT module

No

Bxx Board

NG

Access Point

66

SYSSET

Page 67

2018/03/1622:32:44(GMT+09:00)

Wireless Network malfunction (2/2)

*1

From previous page

Check harness

connection is OK

between Wi-Fi/BT

module and Bxx

OK

Check with

another Wi-Fi/BT

module

OK

Wi-Fi/BT module

NG

NG

NG

Connect properly

OK

Loose harness

Change harness

between Bxx board

and Wi-Fi/BT module

OK

Main Harness

NG

Change Bxx board

If Wi-Fi malfunction happens,

• Wi-Fi/BT module

• Harness betw een Wi-Fi/BT and Bxx

• Bxx board

are suspected.

67

SYSSET

Page 68

2018/03/1622:32:44(GMT+09:00)

6.3 Bluetooth malfunction

Voice Remote doesn’t work

Bluetooth Mouse/Keyboard/Controller doesn’t work

Bluetooth Speaker/Headphone/ doesn’t work

Home > Settings >

Bluetooth Settings

NG

else

Or

Or

OK

Can read

Near discoverable

Bluetooth Device

Check BT antenna

Connection is OK

OK

NG

Please refer

Voice Remote manual

Or

Bluetooth Mouse/Keyboard/Controller

Or

Bluetooth Speaker/Headphone operation manual

Check harness

connection is OK between

Wi-Fi/BT module and Bxx

OK

Change

Wi-Fi//BT module

OK

Wi-Fi/BT module

NG

Connect properly

NG

NG

TV Business Division

NG

Connect properly

Change harness

Between Bxx board

and Wi-Fi/BT module

OK

Main Harness

OK

NG

OK

Loose harness

Change Bxx board

Loose BT antenna

connection

68

68

SYSSET

Page 69

2018/03/1622:32:44(GMT+09:00)

When finished the operation of ser vice mode , please AC Plug OFF/ON the TV set

*If you don’t do AC plug OFF/ON, remain the Service Mode App and user can see the Service Mode after RC ON.

4.1 How to Enter Service Mode

From Standby Mode

1. Go to TV standby condition by remote commander.

2. Press “Display or i+ (info)”, “5”, “V olume+ ” then “TV power” on r emote.

3. You can see Serv ic e menu on display.

4

2

1

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

SECTION 4

SERVICE A DJUSTMENT

>>

>>

>>

>>

>>

>>

>>

>> SDB Service Menu

3

Summary of Service Control

Function The flow of control

Service mode on <Display or i+(info)> <5> <Vol. Up> <Power>

Close Service menu <Home>

Service mode off AC plug OFF

Item up / down

Item select left/right

Execute <Enter>

[Home]Exit

<↑> / <↓>

<←> / <→>

69

SYSSET

Page 70

2018/03/1622:32:44(GMT+09:00)

4.2 Software Version

1) In Service Mode, select “Model Information”, press “Enter” or → button to enter Status Information

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

>>

>>

>>

>>

>>

>>

>>

>> SDB Service Menu

[</>] Set [Home]Exit

Model

Status Information

Model Information

Model Number Setting

SERIAL NUMBER EDIT

>>

>>

>>

[</>] Set [Home]Exit

Main Micro

SW Version:

NVM Version:

Boot Version:

PQ Version:

AQ Version:

<ex>

exFRC:

CameraVID:

CameraPIC:

CameraFW:

<4k BE>

MLFW:

MAFW:

ADSP:

NDAT:

PDAT:

BDAT:

BCM:

FDAT:

UDAT:

BDIX:

PKG1.1.0.03.26.1.00.0

0043 CEI

V1.00000000

02000001

AQ2.5030

00.00.00.00

0

0

0

SF0.114

SF2.550

SF0.201

SD2.550

SP2.550

SD2.550

SF------SD0.001

SD0.000

SD2.550

2) Press “Enter” or “BACK” button t o r etur n to Ser vice Mode

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

>>

>>

>>

>>

>>

>>

>>

>> SDB Service Menu

[</>] Set [Home]Exit

70

SYSSET

Page 71

2018/03/1622:32:44(GMT+09:00)

4.3 Serial Number Edit (1)

1) In “Service Mode”, select “Model Information” by

pressing “↑” or “↓” then pressing “Enter” or “→”

button to enter inside.

2) Select “Serial Number Edit” by pressing “↑” or “↓”

button then pressing “→” button

3) Press “↑” or “↓” to input numbers

4) After user input data , press <Enter>

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

Service Mode

>>

>>

>>

>>

>>

>>

>>

>> SDB Service Menu

[</>] Set [Home]Exit

Pop-up dialog appear to confirm input data

correct

Serial Number can be set ONLY ONCE

5) Press “→” or “←” button to select YES

or NO. Select YES if input data is

correct. Select NO if input data is

incorrect. Press <Enter> to save

answer.

Model

Status Information

Model Information

Model Number Setting

Serial Number Edit

Model

Status Information

Model Information

Model Number Setting

Serial Number Edit 9 9 9 9 9 9 9

_ _ _ _ _ _ _

>>

>>

>>

[</>] Set [Home]Exit

>>

>>

>>

Input Data correct?

Yes

No

[</>] Set [Home]Exit

* The font color of Y ES/NO is change to black whe n it is selected.

71

SYSSET

Page 72

2018/03/1622:32:44(GMT+09:00)

4.3 Serial Number Edit (2)

If YES is selected, the input data is saved into EEPROM.

SERIAL NUMBER EDIT is grayed out and the serial

number that has been input is displayed. Operator will

not able to edit anymore.

If NO is selected, the input data is not saved into

EEPROM. The serial number that has been input is

displayed. Operator can still edit the Serial Number.

Model

Status Information

Model Information

Model Number Setting

Serial Number Edit 9999999

>>

>>

>>

[</>] Set [Home]Exit

Model

Status Information

Model Information

Model Number Setting

Serial Number Edit 9 9 9 9 9 9 9

>>

>>

>>

Input Data correct?

Yes

*The font color of Y ES/NO is change to black

when it is selected.

No

[</>] Set [Home]Exit

72

SYSSET

Page 73

2018/03/1622:32:44(GMT+09:00)

4.4 Model Number Setting

1) In “Service Mode”, select “M odel Information” by

pressing “↑” or “↓” then pressing “Enter” or “→”

button to enter inside.

2) Select “Model Number Setting” by pressing “↑” or

“↓” button then pressing “Enter” or “→” button

3) Press “↑” or “↓” arrow key to scroll Product Name

Candidate. (e.g. KD-65XF9005 CEI)

4) Select one Product Name from the list . After that

select “[OK]” and press “Enter” button.

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

>>

>>

>>

>>

>>

>>

>>

>> SDB Service Menu

[</>] Set [Home]Exit

Model

Status Information

Model Information

Model Number Setting

SERIAL NUMBER EDIT

>>

>>

>>

[</>] Set [Home]Exit

[MODEL_NUMBER_SETTING]

_ _ _ _ _ _ _ _ _ _ _ _

OK

73

SYSSET

Page 74

2018/03/1622:32:44(GMT+09:00)

4.5 WB Adjustment (If necessary)

1. In “Panel/PQ” service mode

a. Go to “WB Adjustment” category by “↑” or “↓”.

b. To select “WB Adjustment”, press → button.

c. To change data , press “←” or “→” on remote commander.

a.

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

Tuner

Wi-Fi / BT

SDB Service Menu

Service Mode

>>

>>

>>

>>

>> General Setting

>>

>>

>>

b.

Panel / PQ

Back

WB Adjustment

WB/Mura/CUC data transfer

<<

>>

>>

[</>] Set [Home]Exit

c.

Back

R WB Gain

<<

<[ 0 ]>

<[ 0 ]> G WB Gain

<[ 0 ]> B WB Gain

<[ 0 ]> R WB Offset

<[ 0 ]> G WB Offset

<[ 0 ]> B WB Offset

[</>] Set [Home]Exit

[</>] Set [Home]Exit

74

SYSSET

Page 75

2018/03/1622:32:44(GMT+09:00)

4.6 WB data transfer

1. In “Panel/PQ” service mode

a. Go to “WB/Mura/CUC data transfer” category by “↑” or “↓”.

b. To select “WB/Mura/ CU C dat a tran sf er” , press → button.

c. To change data , press “←” or “→” on remote commander.

Please apply Main board or panel is replaced.

Back

<<

<[ 0.Soc to T-con ]>

<[ 0.Soc to T-con ]>

<[ 0.Soc to T-con ]>

[</>] Set [Home]Exit

Disuse in CR model

2. In “WB/Mura/C U C dat a tr ansf er ”

a. Select “WB/Gamma data transfer” by pressing “↑” or

“↓” on remote commander .

b. To change the items, press “←” or “→” on remote

commander and press “Enter” button.

Selectable items are:

0. SoC to T-con

1. T-con to SoC

2. No action

c. “Mura data transfer” and “ CUC data transfer” are also

displayed on t he menu, but Mura and CUC function

do not work on CR model. Please skip these items by

pressing “↓” on remote commander .

d. Select “[start]” and press “Enter” button to start

transfer.

75

SYSSET

Page 76

2018/03/1622:32:44(GMT+09:00)

4.7 HDD Performance Check (EU only)

1) In “Service Mode”, select

“General Setting” by pressing

“↑” or “↓” then pressing “Enter”

or “→” button to enter inside.

2) Select “HDD Performance

check ” by pressing “↑” or “↓”

then pressing “Enter” or “→”

button to enter inside.

3) A message "Pleas e w ait ..." is

displayed during performance

check processing.

4) Result OK or NG will be

displayed after performance of

HDD is checked

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

SDB Service Menu

HDD Performance Check

Please wait…

>>

>>

>>

>>

>>

>>

>>

>>

[</>] Set [Home]Exit

General Setting

Back

Aging mode

Ship Confirm

HDD Performance Ch

Update CI+ Credent

ECS_Enable

SCART RGB VREF

HDD Performance Check

Result

Back

<<

<[ Off ]>

>>

>>

>> AAA

>>

<[ Off ]>

<[ Auto ]>

[</>] Set [Home]Exit

<[ ]>

<[ NG ]>

<<

[</>] Set [Home]Exit

[</>] Set [Home]Exit

76

SYSSET

Page 77

2018/03/1622:32:44(GMT+09:00)

4.8 HDD Re-Register (EU only)

1) In “Service Mode”, select “General

Setting” by pressing “↑” or “↓” then

pressing “Enter” or “→” button to enter

inside.

2) Select “AAA” by pressing “↑” or “↓” then

pressing “Enter” or “→” button to enter

inside.

3) Result OK or NG will be displayed after

HDD re-registration is succeed/failed

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wi-Fi / BT

SDB Service Menu

>>

>>

>>

>>

>>

>>

>>

>>

[</>] Set [Home]Exit

HDD Re-Register

Result

Back

Back

Aging mode

Ship Confirm

HDD Performance Ch

AAA

Update CI+ Credent

ECS_Enable

SCART RGB VREF

<[ NG ]>

<<

General Setting

<<

<[ Off ]>

>>

>>

>>

>>

<[ Off ]>

<[ Auto ]>

[</>] Set [Home]Exit

[</>] Set [Home]Exit

77

SYSSET

Page 78

2018/03/1622:32:44(GMT+09:00)

USB Update

1:Download USB image and unzip file.

2: copy unzip file to USB memory root folder.

3: USB memory insert TV.

4-a:USB image is newer soft version.

Automatically show message and start update.

Pleas e follow direct ions.

System software update

Copying USB update file. Please wait…

Preparing for system software update. During the system software update, the TV will

automatically restart. Please do not remove the USB device until an update complete

message is dis pl a yed . The update may take up to 15 minutes to complete .

Updating…

*BR/CO/LA only

TV will reboot and enter STBY status.

Press "Power" key of remote comm an d er to turn on T V.

System software update

The system software update is complete .

Some user s ettings may have changed during the update.

Please remove the USB device and select ”OK” to exit

OK

46%

5: finished

4-b:USB image is not newer soft version.

Automatically show message.

Pleas e follow direct ions.

System software update

Your software is up to date

Please remove the USB device and select [OK] to exit

OK

5: finished

Caution:

Do not power off while the update

is in progress.

78

SYSSET

Page 79

2018/03/1622:32:44(GMT+09:00)

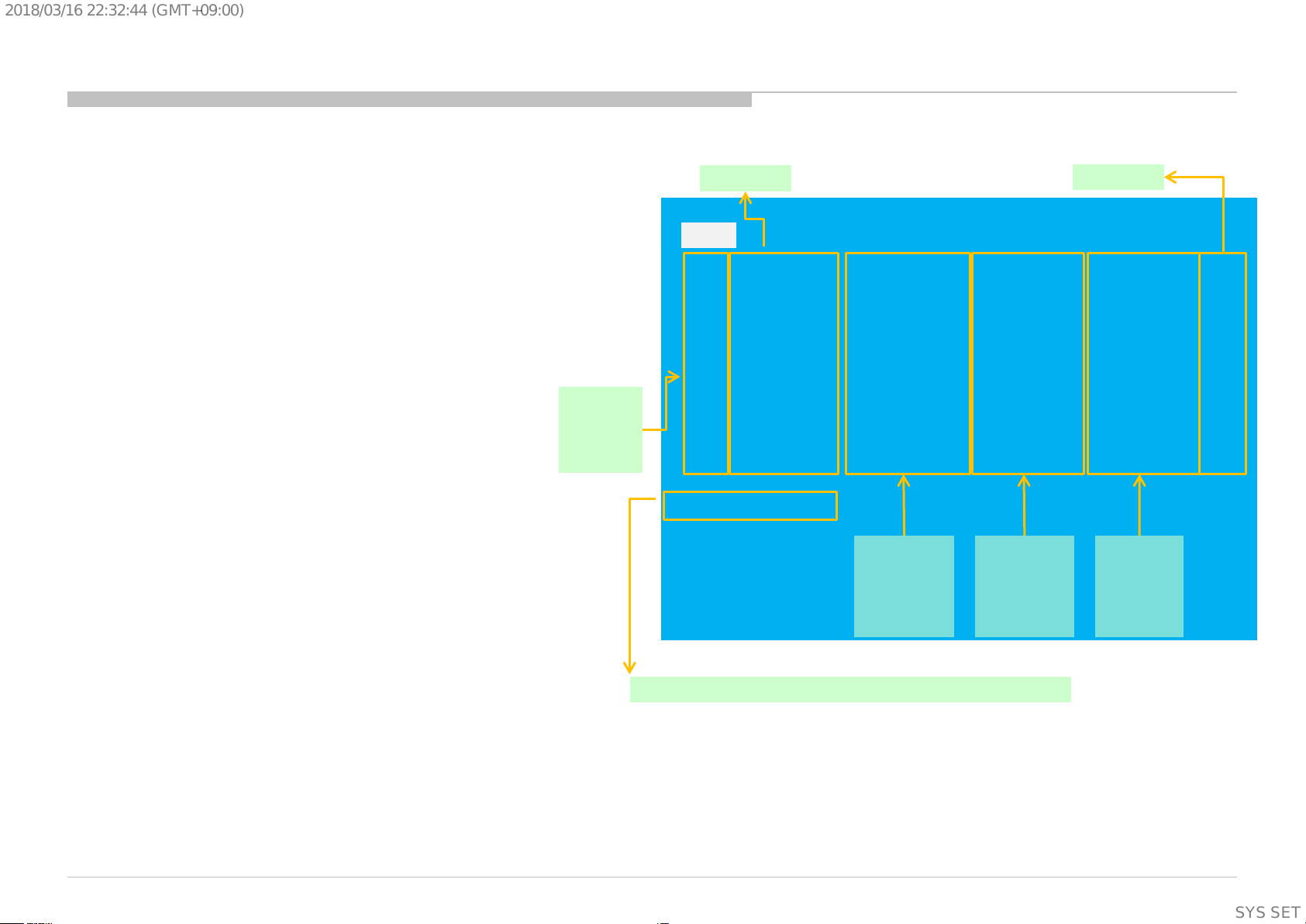

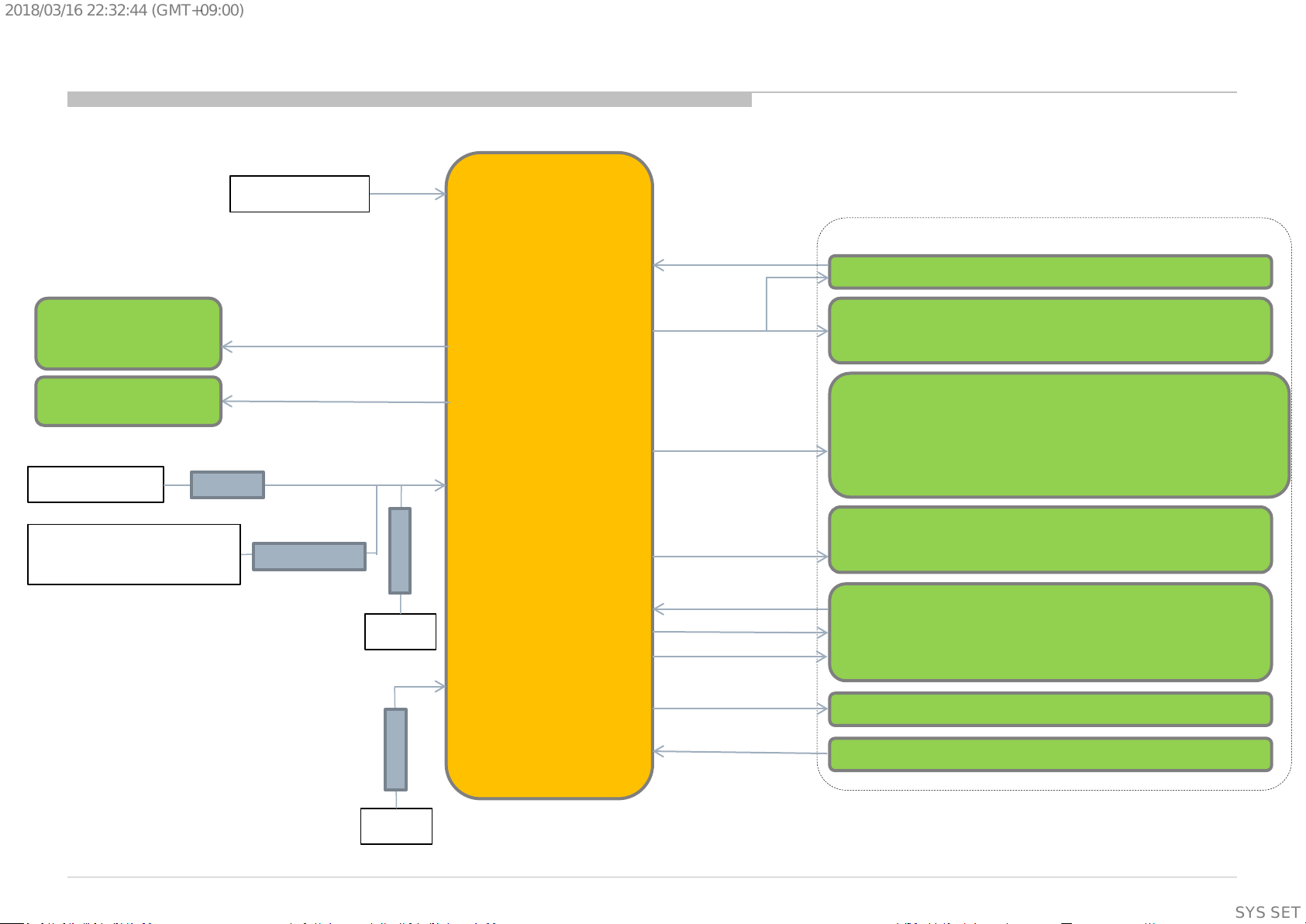

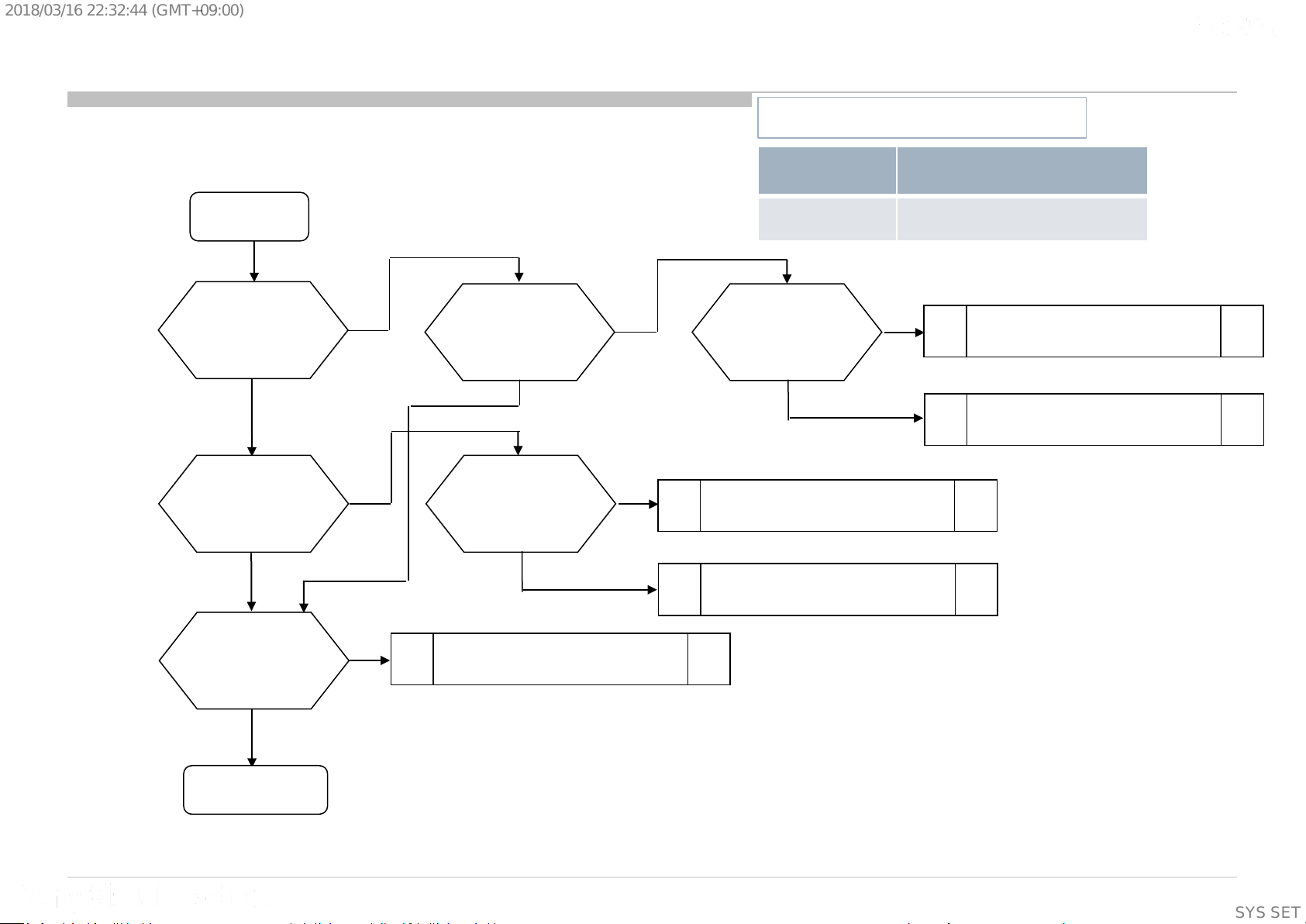

5.1 Block Diagram

* depend on destinations.

SECTION 5

DIAGRAMS

Video signal

Audio signal

Control Bus

RGBW LEDs

Light Sens.

IR Rx

Center Key

L/R Keys

* BCAS/CI

* RF

Composite

HDMI

USB3.0

USB2.0

* IR In

Ethernet

Optical

Out

CEC

S/PDIF

S/PDIF

Main

SoC

(IC1000)

eMMC

16GB

DDR3

4Gib x 5

BM2A board

Power Micro

(STM8S103F2U6)

Temp Sensor

(I2C)

DDCs

Vx1 8-lane (Video)

Vx1 4-lane (Graphics)

UART

I2C

I2S

DDR3

1Gib x 4

4K

BE

(IC4000)

I2C

I2S

Vx1 16-lane

4K/120p

D-Amp.

(TAS5760)

Panel

Tcon

EEPROM

(Panel ID)

Gx board

(PSU)

5-ch (2.1-ch)

Actuator

SP

+ WF

SP

SP

SP

Flash

HP/Line Out

* IR Blaster

* RS232C

IRB Micro

(S3F80P5X9R)

UART

UART

USB HS

WiFi/BT

(J20H088.00)

79

SYSSET

Page 80

CN203 CN5201 CN6

HUS_GND

1 15 #30

GND

1 51 GND

HUS_KEY_AD 2 12 #30

VBTX7P

2 50 RX7_P

HUS_POWER_KEY 3 14 #30

VBTX7N

3 49

RX7_N

1-474-647-11 1-821-900-11

GND

4 48 GND

JAM SZ15-03WLR JAM SZ15-03HGR

VBTX6P

5 47 RX6_P

VBTX6N

6 46 RX6_N

GND

7 45 GND

CN231

VBTX5P

8 44 RX5_P

7 1 WIFI_STBY_3.3V

VBTX5N

9 43 RX5_N

14 2 X_WIFI_BT_RST

GND

10 42 GND

1 3 SC_STBY_3.3V

VBTX4P

11

41

RX4_P

13 4 X_ WIFI_WAKEUP

VBTX4N

12 40 RX4_N

15 5

WIFI_GND

GND

13 39 GND

12 6 X_BT_WAKEUP

VBTX3P

14 38 RX3_P

9 7

WIFI_GND

VBTX3N

15 37 RX3_N

NC

8

3D_LR

GND

16

36 GND

8 9

WIFI_GND

VBTX2P

17 35 RX2_P

NC 10 X_BT_WAKE2

VBTX2N

18 34 RX2_N

4 11

WIFI_GND

GND

19 33

GND

2 12

KEY_AD

VBTX1P

20 32 RX1_P

2 13

5V_MAIN

VBTX1N

21 31 RX1_N

CN001

3 14

POWER_KEY

GND

22 30 GND

STBY3.3V

1 3 #30 1 15

WIFI_GND

VBTX0P

23 29 RX0_P

5V_MAIN 2 13 #30 11 16

SC_OPT_SENSE

VBTX0N

24 28 RX0_N

GND 3 17 #3 0 3 17

SC_GND

GND

25 27 GND

LED_AMBER 4 20 #30 12 18

SC_SIRCS

VBTXLOCKN0

26 26 LO CKN

LED_PWM_W 5 22

#30 10 19

SC_MAIN_3.3V

VBTXHTPDN0

27 25 HT PDN

LEY_STBY_PWM_R 6 28 #30 4 20

SC_LED_AMBER

GND

28 24 GND

LED_STBY_PWM_B 7

26 #30 9 21

SC_GND

GND(AGING_MOD E)

29 23 AGP1

LED_STBY_PWM_G 8 24 #30 5 22