Sony ICX227AK Datasheet

Description

The ICX227AK is an interline CCD solid-state image

sensor suitable for PAL color video cameras.

Compared with the current product ICX207AK, smear

charactristics are improved drastically and power

consumption is reduced. Ye, Cy, Mg, and G

complementary color mosaic filters are used. High

sensitivity and high saturation signal are achieved by

Super HAD CCD technology.

This chip features a field period readout system and

an electronic shutter with variable charge-storage

time.

The package is a 10mm-square 14-pin DIP (Plastic).

Features

• Low smear (–105dB Typ. at F5.6)

• Low power consumption

(–34% compared with ICX207AK)

• High sensitivity

(+2.5dB at F1.2 compared with ICX207AK)

• High saturation signal

• Supply voltage 12V

• Horizontal register: 3.3V drive

• Reset gate: 3.3V drive

• No voltage adjustment

(Reset gate and substrate bias are not adjusted.)

• Low dark current

• Excellent antiblooming characteristics

• Continuous variable-speed shutter

• Recommended range of exit pupil distance: –20 to –100mm

• Ye, Cy, Mg, and G complementary color mosaic filters on chip

Device Structure

• Interline CCD image sensor

• Image size: Diagonal 4.5mm (Type 1/4)

• Number of effective pixels: 500 (H) × 582 (V) approx. 290K pixels

• Total number of pixels: 537 (H) × 597 (V) approx. 320K pixels

• Chip size: 4.34mm (H) × 3.69mm (V)

• Unit cell size: 7.3µm (H) × 4.7µm (V)

• Optical black: Horizontal (H) direction: Front 7 pixels, rear 30 pixels

Vertical (V) direction: Front 14 pixels, rear 1 pixel

• Number of dummy bits: Horizontal 16

Vertical 1 (even fields only)

• Substrate material: Silicon

– 1 –

ICX227AK

E99912-PS

Diagonal 4.5mm (Type 1/4) CCD Image Sensor for PAL Color Video Cameras

Sony reserves the right to change products and specifications without prior notice. This information does not convey any license by

any implication or otherwise under any patents or other right. Application circuits shown, if any, are typical examples illustrating the

operation of the devices. Sony cannot assume responsibility for any problems arising out of the use of these circuits.

Optical black position

(Top View)

14 pin DIP (Plastic)

A

A

A

Pin 1

V

7

30

1

14

Pin 8

H

AAA

AAA

AAA

– 2 –

ICX227AK

5

6

7

9

10

11

13

Note)

Note) : Photo sensor

V

OUT

GND

Vφ

1

Vφ

2

Vφ

3

Vφ

4

V

DD

GND

φSUB

V

L

RG

Hφ

1

Hφ

2

Horizontal Register

2

3

4

NC

12

Cy

Cy

Mg

G

Cy

14

Mg

Ye

Ye

G

Mg

Ye

G

Cy

Cy

Mg

G

Cy

Mg

Ye

Ye

G

Mg

Ye

G

8

1

Vertical Register

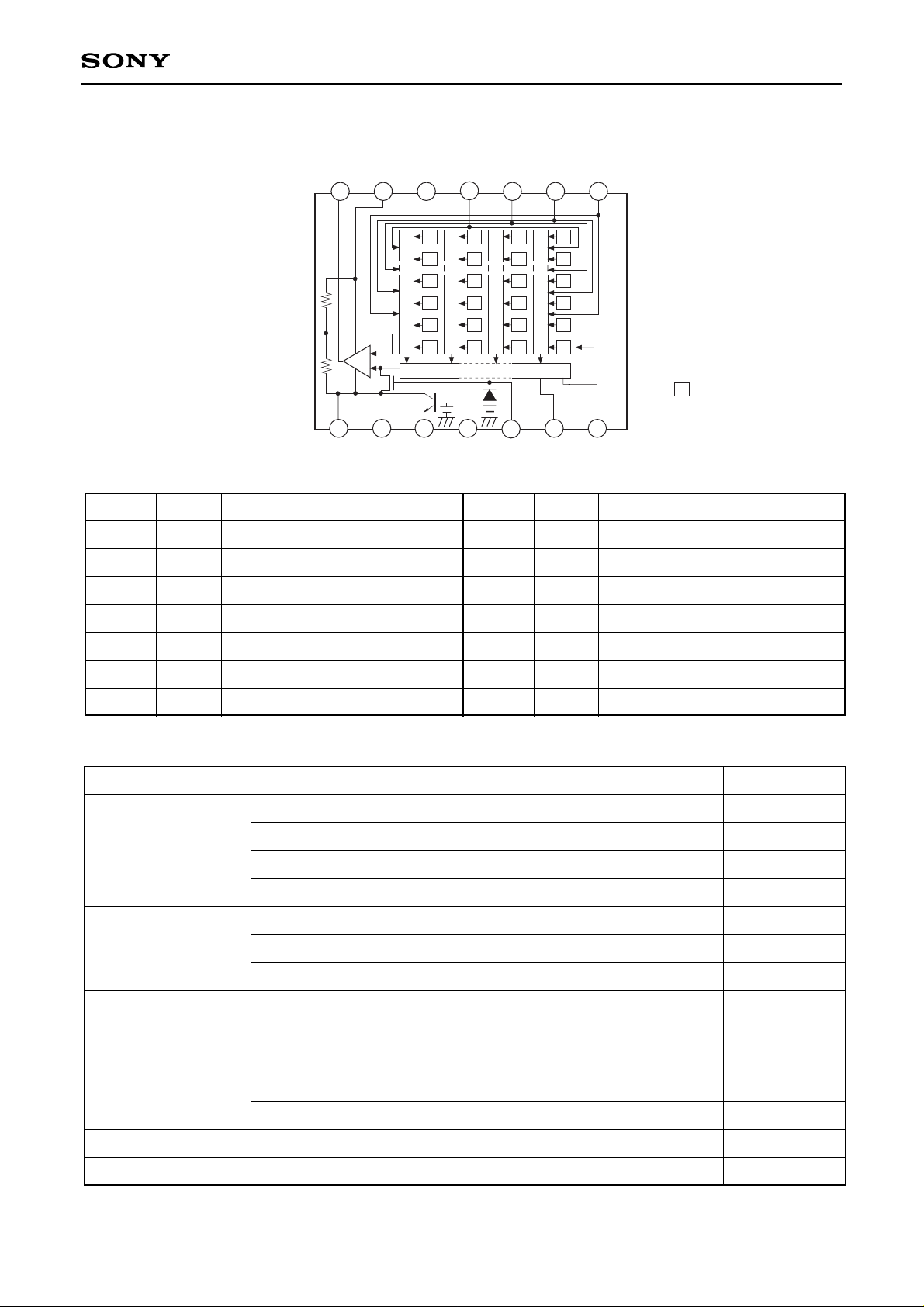

Block Diagram and Pin Configuration

(Top View)

Pin No.

1

2

3

4

5

6

7

Vφ4

Vφ3

Vφ2

Vφ1

NC

GND

VOUT

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

GND

Signal output

8

9

10

11

12

13

14

VDD

GND

φSUB

VL

RG

Hφ1

Hφ2

Supply voltage

GND

Substrate clock

Protective transistor bias

Reset gate clock

Horizontal register transfer clock

Horizontal register transfer clock

Symbol Description Pin No. Description

Pin Description

Absolute Maximum Ratings

∗1

+21V (Max.) when clock width < 10µs, clock duty factor < 0.1%.

Symbol

Against φSUB

Against GND

Against VL

Between input clock

pins

Storage temperature

Operating temperature

–32 to +12

–40 to +15

–40 to +0.3

–32 to +0.3

–0.3 to +17

–7 to +14

–7 to +4.2

–0.3 to +21

–0.3 to +12

to +12

–5 to +5

–12 to +12

–30 to +80

–10 to +60

V

V

V

V

V

V

V

V

V

V

V

V

°C

°C

VDD, VOUT, RG – φSUB

Vφ1, Vφ3 – φSUB

Vφ2, Vφ4, VL – φSUB

Hφ1, Hφ2, GND – φSUB

VDD, VOUT, RG – GND

Vφ1, Vφ2, Vφ3, Vφ4 – GND

Hφ1, Hφ2 – GND

Vφ1, Vφ3 – VL

Vφ2, Vφ4, Hφ1, Hφ2, GND – VL

Voltage difference between vertical clock input pins

Hφ1 – Hφ2

Hφ1, Hφ2 – Vφ4

Item Ratings Unit Remarks

∗1

– 3 –

ICX227AK

Clock Voltage Conditions

Item

Readout clock voltage

VVT

VVH1, VVH2

VVH3, VVH4

VVL1, VVL2,

VVL3, VVL4

VφV

VVH3 – VVH

VVH4 – VVH

VVHH

VVHL

VVLH

VVLL

VφH

VHL

VφRG

VRGLH – VRGLL

VRGL – VRGLm

VφSUB

11.64

–0.05

–0.2

–5.5

4.3

–0.25

–0.25

3.0

–0.05

3.0

16.14

12.0

0

0

–5.0

5.0

3.3

0

3.3

17.0

12.36

0.05

0.05

–4.5

5.55

0.1

0.1

0.3

0.3

0.3

0.3

3.6

0.05

3.6

0.4

0.5

17.86

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

1

2

2

2

2

2

2

2

2

2

2

3

3

4

4

4

5

VVH = (VVH1 + VVH2)/2

VVL = (VVL3 + VVL4)/2

VφV = VVHn – VVLn (n = 1 to 4)

High-level coupling

High-level coupling

Low-level coupling

Low-level coupling

Input through 0.1µF

capacitance

Low-level coupling

Low-level coupling

Horizontal transfer

clock voltage

Reset gate clock

voltage

Substrate clock voltage

Vertical transfer clock

voltage

Symbol Min.

Typ. Max.

Unit

Waveform

diagram

Remarks

Bias Conditions

Item

Supply voltage

Protective transistor bias

Substrate clock

Reset gate clock

VDD

VL

φSUB

φRG

11.64

12.0

∗1

∗2

∗2

12.36 V

Symbol Min. Typ. Max. Unit Remarks

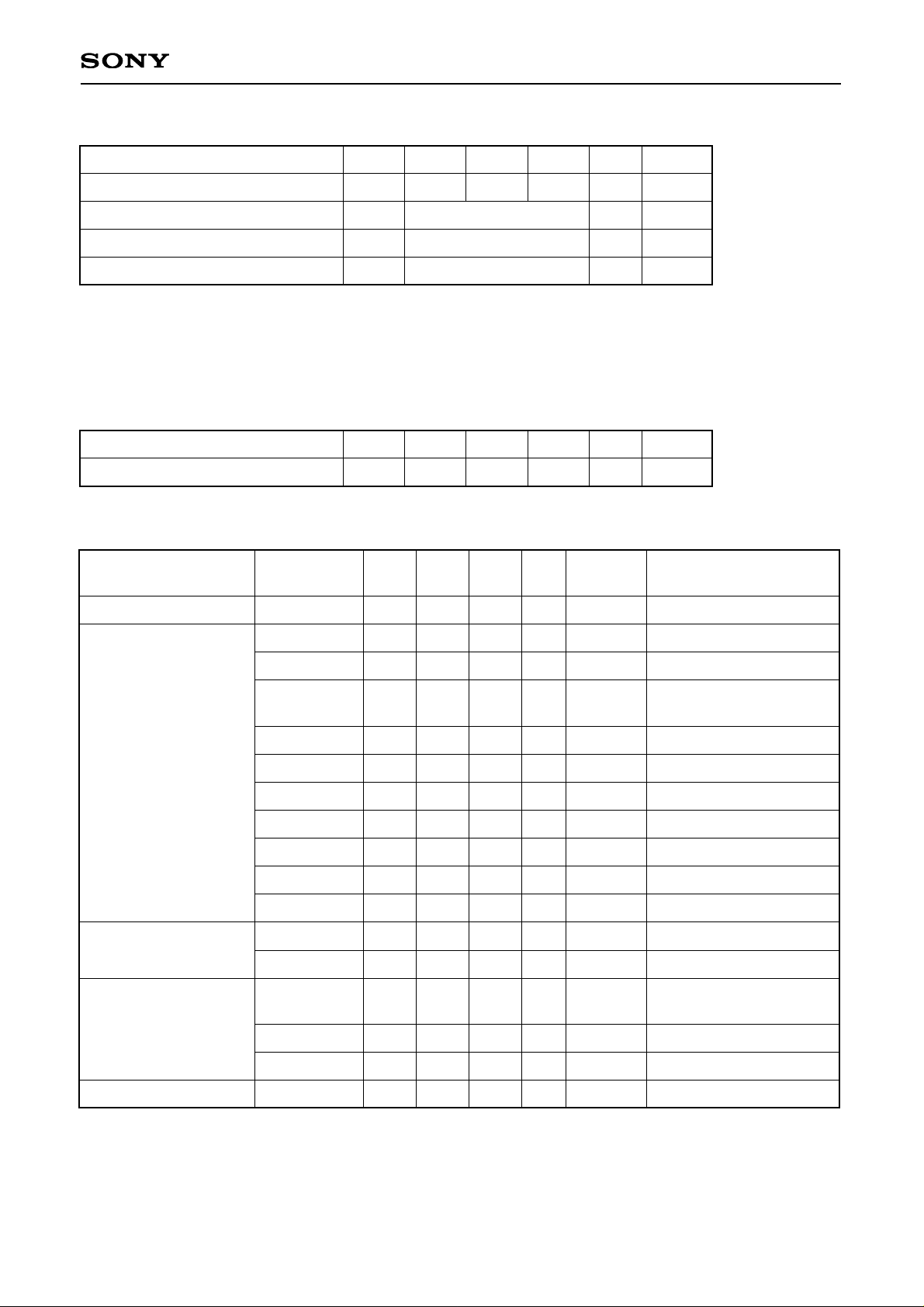

DC Characteristics

Item

Supply current IDD 2.5 5 mA

Symbol Min. Typ. Max. Unit Remarks

∗1

VL setting is the VVL voltage of the vertical transfer clock waveform, or the same power supply as the VL

power supply for the V driver should be used.

∗2

Do not apply a DC bias to the substrate clock and reset gate clock pins, because a DC bias is generated

within the CCD.

– 4 –

ICX227AK

Vφ1

CφV12

Vφ2

Vφ4

Vφ3

CφV34

CφV23CφV41

CφV13

CφV24

CφV1 CφV2

CφV4 CφV3

RGND

R4

R1

R3

R2

Vertical transfer clock equivalent circuit Horizontal transfer clock equivalent circuit

RφRG

RGφ

Cφ

RG

Reset gate clock equivalent circuit

RφH RφH

Hφ2

Hφ1

CφH1

CφHH

CφH2

Item

Capacitance between vertical transfer

clock and GND

CφV1, CφV3

CφV2, CφV4

CφV12, CφV34

CφV23, CφV41

CφV13

CφV24

CφH1, CφH2

CφHH

CφRG

CφSUB

R1, R2, R3, R4

RGND

RφH

RφRG

560

270

180

100

100

100

39

15

5

110

110

15

15

39

pF

pF

pF

pF

pF

pF

pF

pF

pF

pF

Ω

Ω

Ω

Ω

Capacitance between vertical transfer

clocks

Capacitance between horizontal

transfer clock and GND

Capacitance between horizontal

transfer clocks

Capacitance between reset gate clock

and GND

Capacitance between substrate clock

and GND

Vertical transfer clock series resistor

Vertical transfer clock ground resistor

Horizontal transfer clock series resistor

Reset gate clock series resistor

Symbol Min. Typ. Max. Unit Remarks

Clock Equivalent Circuit Constant

– 5 –

ICX227AK

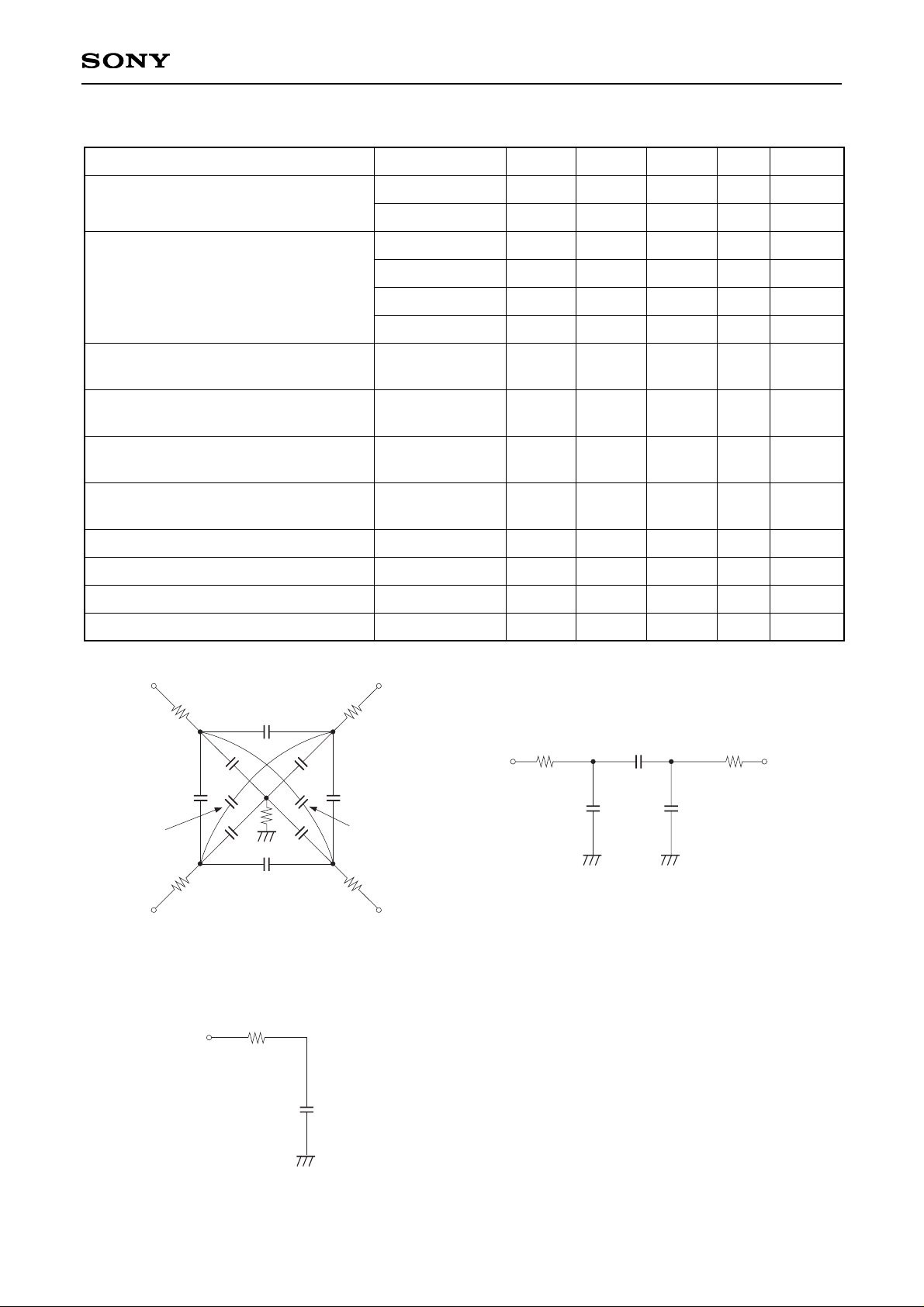

Drive Clock Waveform Conditions

(1) Readout clock waveform

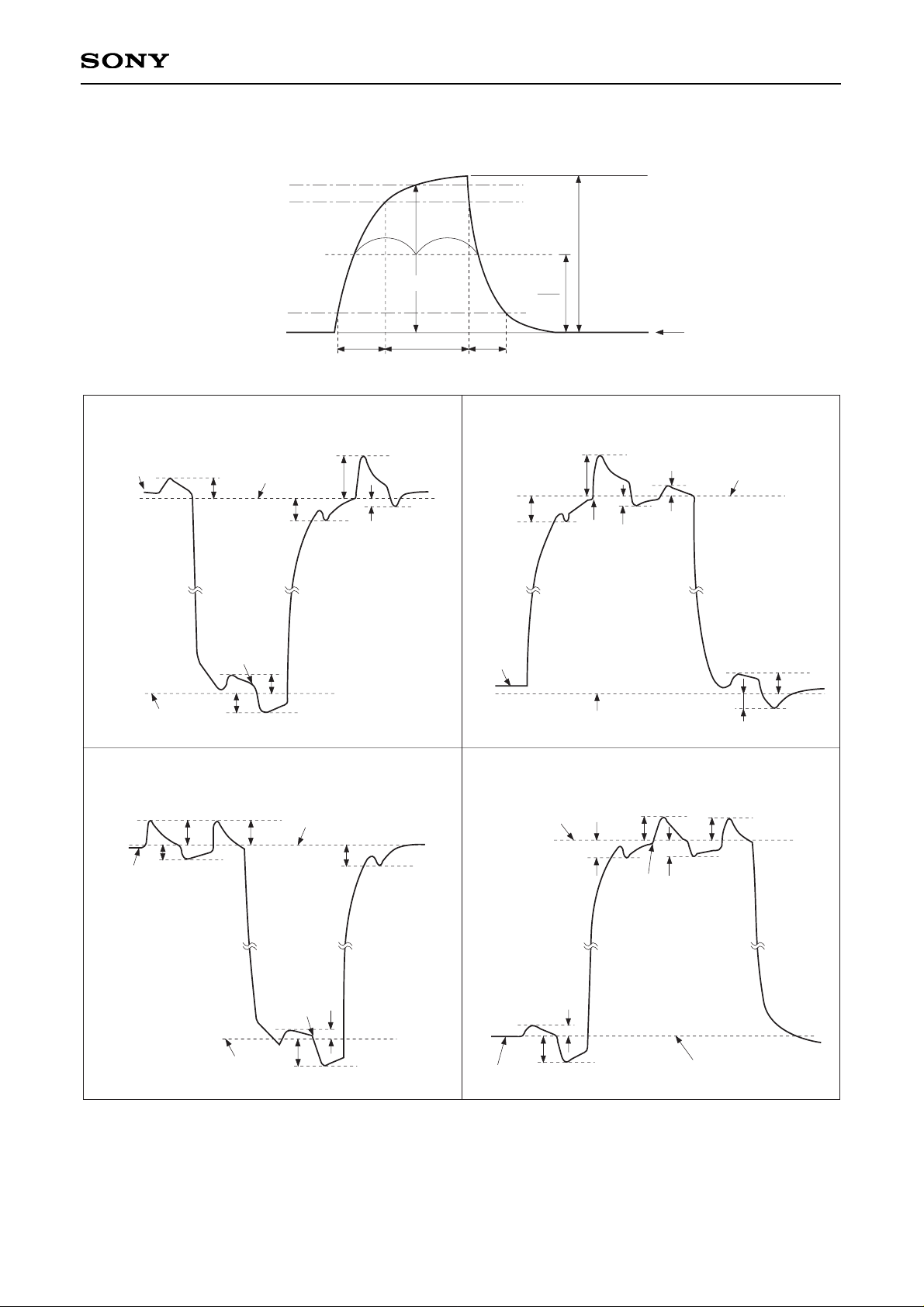

(2) Vertical transfer clock waveform

II II

100%

90%

10%

0%

VVT

tr twh tf

φM

0V

φM

2

Vφ1 Vφ3

Vφ2 Vφ4

VVHH

VVH

VVHL

VVHH

VVHL

VVH1

VVL1

VVLH

VVLL

VVL

VVHH

VVH3

VVHL

VVH

VVHH

VVHL

VVL3

VVL

VVLL

VVLH

VVHH VVHH

VVH

VVHL

VVHL

VVH2

VVLH

VVL2

VVLL

VVL

VVHH VVHH

VVHL

VVH4

VVHL

VVH

VVL

VVLH

VVLL

VVL4

VVH = (VVH1 + VVH2)/2

VVL = (VVL3 + VVL4)/2

VφV = VVHn – VVLn (n = 1 to 4)

– 6 –

ICX227AK

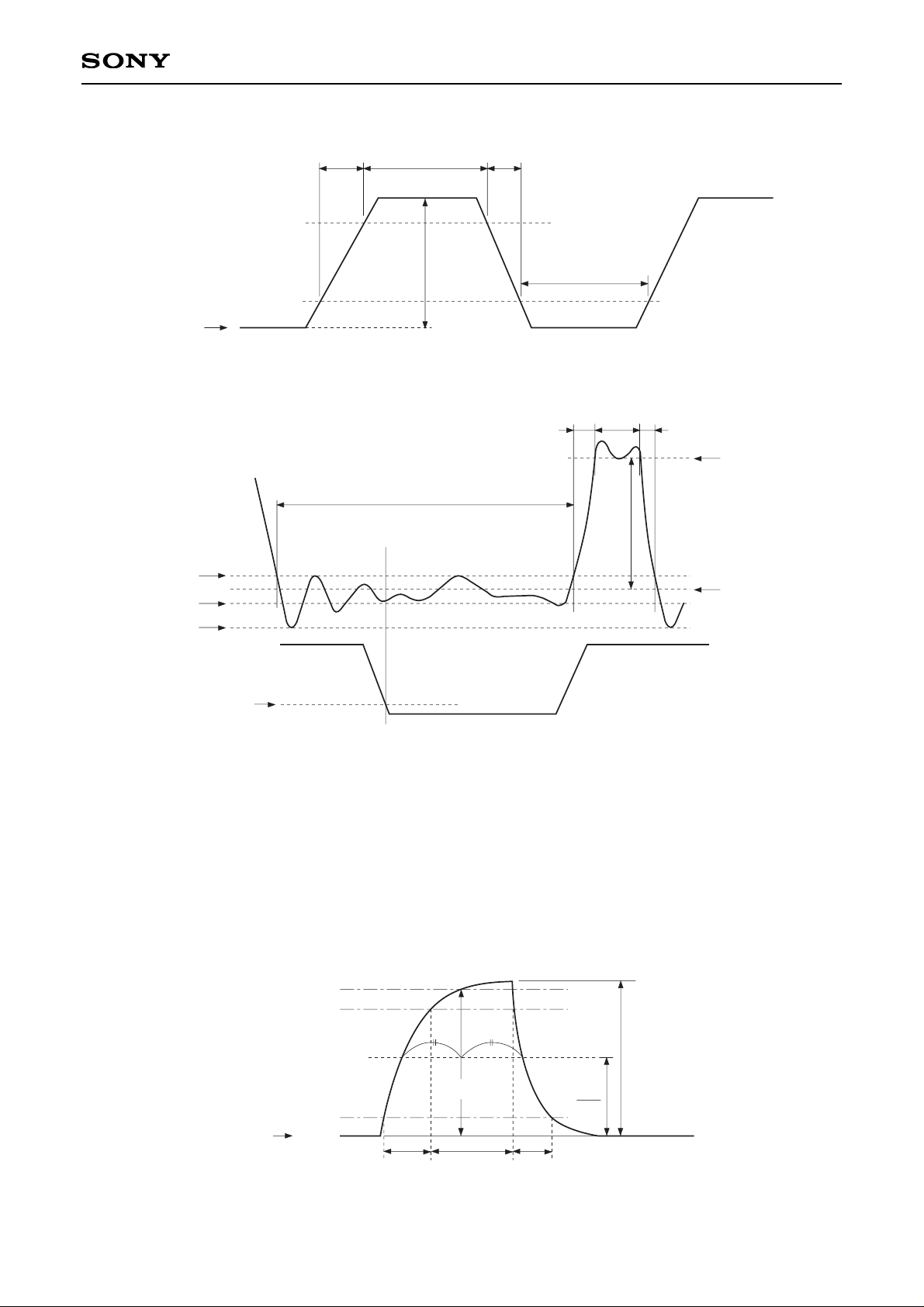

tr twh tf

90%

10%

twl

Vφ

H

VHL

Point A

twl

Vφ

RG

VRGH

VRGL

VRGLH

RG waveform

V

RGLL

Hφ1 waveform

twhtr tf

10%

VRGLm

90%

100%

10%

0%

(A bias generated within the CCD)

V

SUB

tr twh tf

φM

φM

2

VφSUB

(3) Horizontal transfer clock waveform

(4) Reset gate clock waveform

VRGLH is the maximum value and VRGLL is the minimum value of the coupling waveform during the period from

Point A in the above diagram until the rising edge of RG. In addition, VRGL is the average value of VRGLH and

VRGLL.

VRGL = (VRGLH + VRGLL)/2

Assuming VRGH is the minimum value during the interval twh, then:

VφRG = VRGH – VRGL

Negative overshoot level during the falling edge of RG is VRGLm.

(5) Substrate clock waveform

Loading...

Loading...