Sony ICFCD-73 Service manual

ICF-CD73/CD73V

SERVICE MANUAL

Ver. 1.1 2005.02

Photo: ICF-CD73V

SPECIFICATIONS

CD player section

System: Compact disc digital audio system

Laser diode properties: Material: GaAlAs

Wavelength: 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 W

(This output is the value measured at a

distance of about 200 mm from the objective

lens surface on the optical pick-up block with

7 mm aperture.)

Frequency response: 20 — 20 000 Hz

Wow and flutter: Below measurable limit

Radio section

Frequency range: (ICF-CD73)

North America

Band Channel

FM 87.5 — 108 MHz 0.1 MHz

AM 530 — 1 710 kHz 10 kHz

FM 87.5 — 108 MHz 0.05 MHz

AM 531 — 1 710 kHz 9 kHz

Other countries/regions

Band Channel

FM 87.5 — 108 MHz 0.05 MHz

AM 531 — 1 611 kHz 9 kHz

FM 87.5 — 108 MHz 0.1 MHz

AM 530 — 1 610 kHz 10 kHz

Frequency range: (ICF-CD73V)

Band Range Channel

TV 2 — 13 ch 1 channel

WEATHER 1 — 7 ch 1 channel

FM 87.5 — 108 MHz 0.1 MHz

AM 530 — 1 710 kHz 10 kHz

+1

—1.5

step

step

step

dB

US Model

ICF-CD73V

Canadian Model

AEP Model

UK Model

E Model

ICF-CD73

Model Name Using Similar Mechanism ZS-X3CP

CD Mechanism Type KSM-900AAA

Optical Pick-up Name KSS-900A

General

Time display:

North America, UK: 12-hour system

Other countries/regions: 24-hour system

Speaker: 50 mm (2 inches) dia, 6 Ω

Power outputs:

400 mW + 400 mW (at 10% harmonic

distortion)

Power requirements:

6 V DC, 4 R14 (size C) batteries

External power source: DC IN 6 V

Dimensions:

Approx. 151.5 × 248 × 84 mm (w/h/d)

(Approx. 6 × 9

projecting parts and controls

Mass: Approx. 1 350 g (2 lb 16 oz) incl. batteries

Supplied accessories:

Suction cup (1), Strap (1)

AC power adaptor (1)*

* Supplied with European model only

Design and specifications are subject to change

without notice.

7

/8 × 3 3/8 inches) incl.

ICF-CD73

FM/AM CD PORTABLE RADIO

ICF-CD73V

TV/WEATHER/FM/AM

CD PORTABLE RADIO

9-877-131-02 Sony Corporation

2005B05-1 Personal Audio Group

© 2005.02 Published by Sony Engineering Corporation

ICF-CD73/CD73V

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

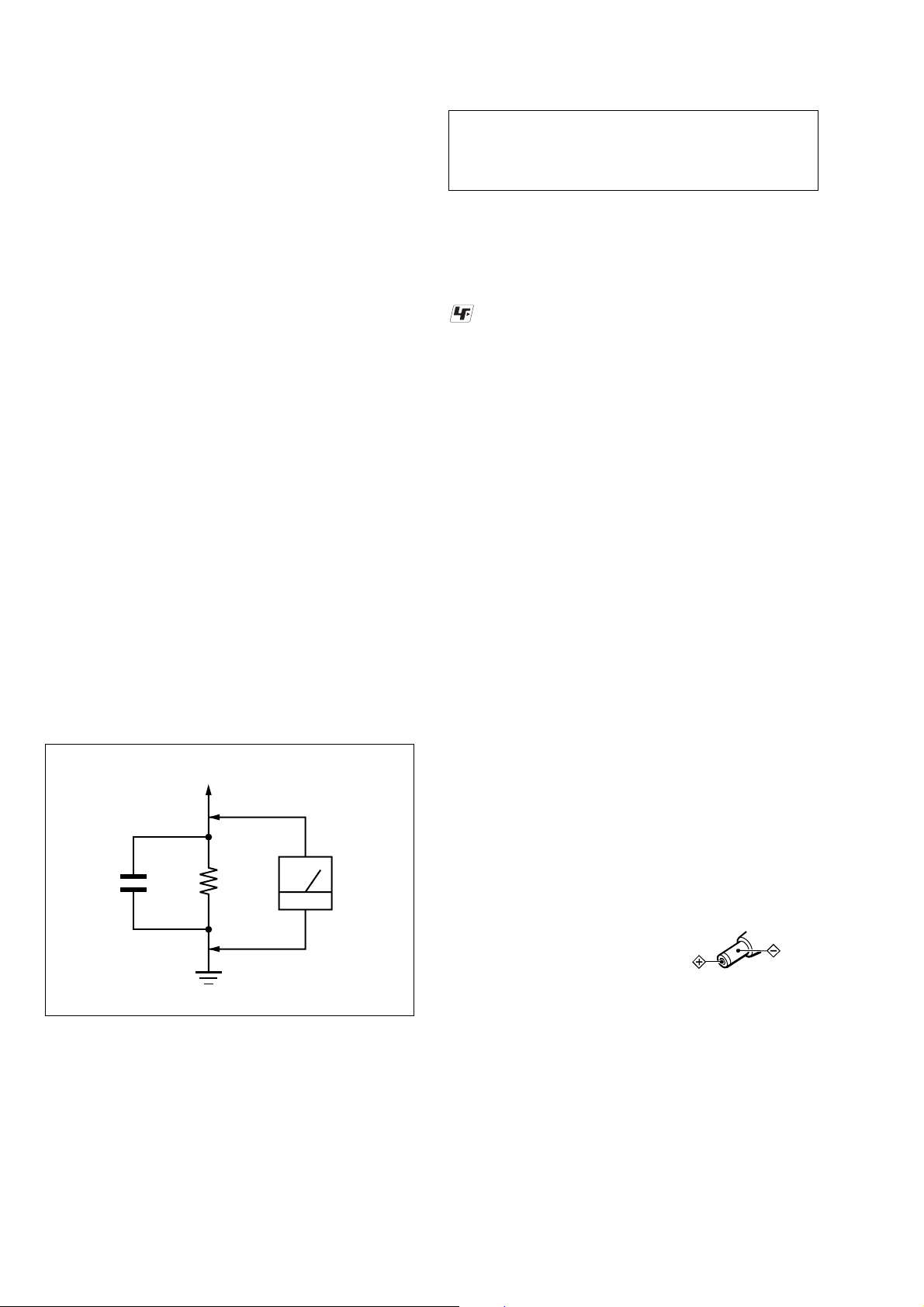

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T rd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

voltmeter

(0.75 V)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

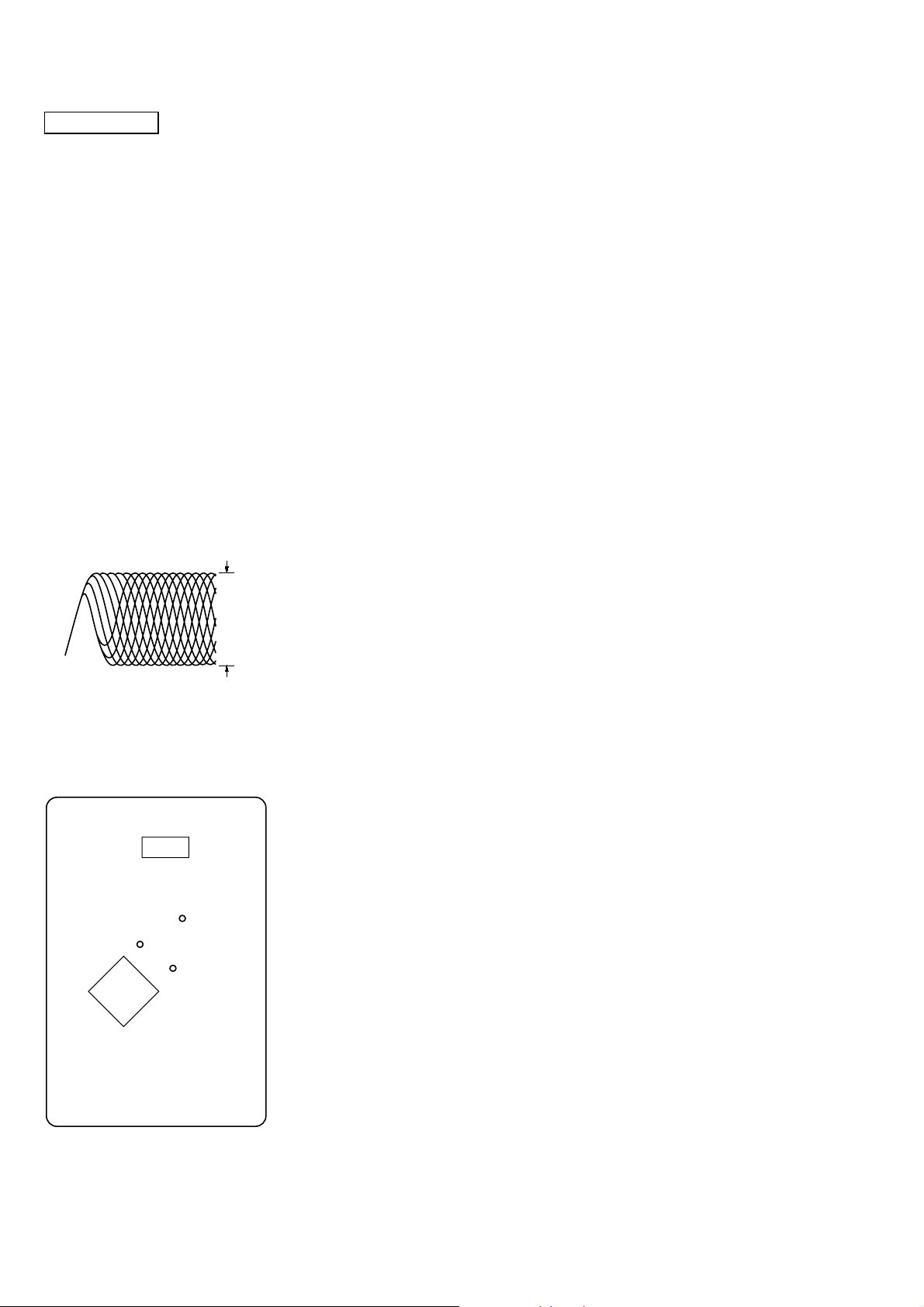

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 ˚C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Using the AC power adaptor

•When operating the unit with an external power source, do not remove the

batteries.

These batteries serve to backup the clock and memory settings. Since the

batteries discharge in this case as well, we recommend changing them about

once a year.

•To pre vent battery leakag e, we recommend removing the batteries when the

unit is connected to a wall outlet.

• Before connecting and disconnecting the external power source plug, be

sure to turn off the radio/CD. Otherwise, “E ” may be displayed. When this

occurs,turn on the radio/CD so that “E ” disappears..

•When the A C power adaptor is not to be used for a long period of time,unplug

it both from the DC IN 6 V jack and from the wall outlet.

•When the cover of the DC IN 6 V jack is open (to use the AC power adaptor), the jack area is not splash-resistant. When the AC power adaptor is not

connected to the DC IN 6 V jack, be sure to close the cover of the DC IN 6

V jack.

• Use the recommended Sony AC poweradaptor * only. The polarity of the

plugs of other manufacturers may be different. Failure to use the recommended AC power adaptor may cause the unit to malfunction.

* Supplied with European model only

If you have any questions or problems concerning your unit,please consult

your nearest Sony dealer.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

Polarity of the plug

About CD-Rs/CD-RWs

This unit is compatible with CD-Rs/CD-RWs but playback capability may v ary

depending on the quality of the disc,the recording device and application software.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

TABLE OF CONTENTS

1. SERVICING NOTES .............................................. 4

2. GENERAL .................................................................. 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 6

3-2. Cabinet (Front) Section ................................................... 6

3-3. Cabinet (Upper) Section ................................................. 7

3-4. Chassis (Main) Section ................................................... 7

3-5. LCD Board ...................................................................... 8

3-6. Mechanism Deck (KSM-900AAA) ................................ 8

3-7. Optical Pick-up (KSS-900A) .......................................... 9

3-8. Speaker (SP101)/(SP201) ............................................... 9

4. TEST MODE .............................................................. 10

5. ELECTRICAL ADJUSTMENTS........................ 13

6. DIAGRAMS

6-1. Block Diagram – CD Section – .................................... 17

6-2. Block Diagram – TUNER Section (ICF-CD73) – ....... 18

6-3. Block Diagram – TUNER Section (ICF-CD73V) – .... 19

6-4. Block Diagram – MAIN Section – ............................... 20

6-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 21

6-6. Printed Wiring Board – CD Section – ......................... 22

6-7. Schematic Diagram – CD Section – ............................. 23

6-8. Printed Wiring Board

– TUNER Section (ICF-CD73) – .................................. 24

6-9. Schematic Diagram

– TUNER Section (ICF-CD73) – .................................. 25

6-10. Printed Wiring Board

– TUNER Section (ICF-CD73V) – ............................... 26

6-11. Schematic Diagram

– TUNER Section (ICF-CD73V) – ............................... 27

6-12. Printed Wiring Boards – MAIN Section – ................... 28

6-13. Schematic Diagram – MAIN Section –........................ 29

6-14. Printed Wiring Boards – POWER Section – ................ 30

6-15. Schematic Diagram – POWER Section – .................... 31

6-16. IC Pin Function Description .......................................... 34

ICF-CD73/CD73V

7. EXPLODED VIEWS

7-1. Overall Section ................................................................ 36

7-2. Cabinet (Front) Section ................................................... 37

7-3. Cabinet (Main) Section ................................................... 38

7-4. Cabinet (Upper) Section ................................................. 39

7-5. Cabinet (Rear) Section-1 ................................................ 40

7-6. Cabinet (Rear) Section-2 ................................................ 41

7-7. Cabinet (Rear) Section-3 ................................................ 42

7-8. Optical Pick-up Section (KSM-900AAA) ..................... 43

8. ELECTRICAL PARTS LIST .............................. 44

3

ICF-CD73/CD73V

Ver. 1.1

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning ON

the S701. (push switch type)

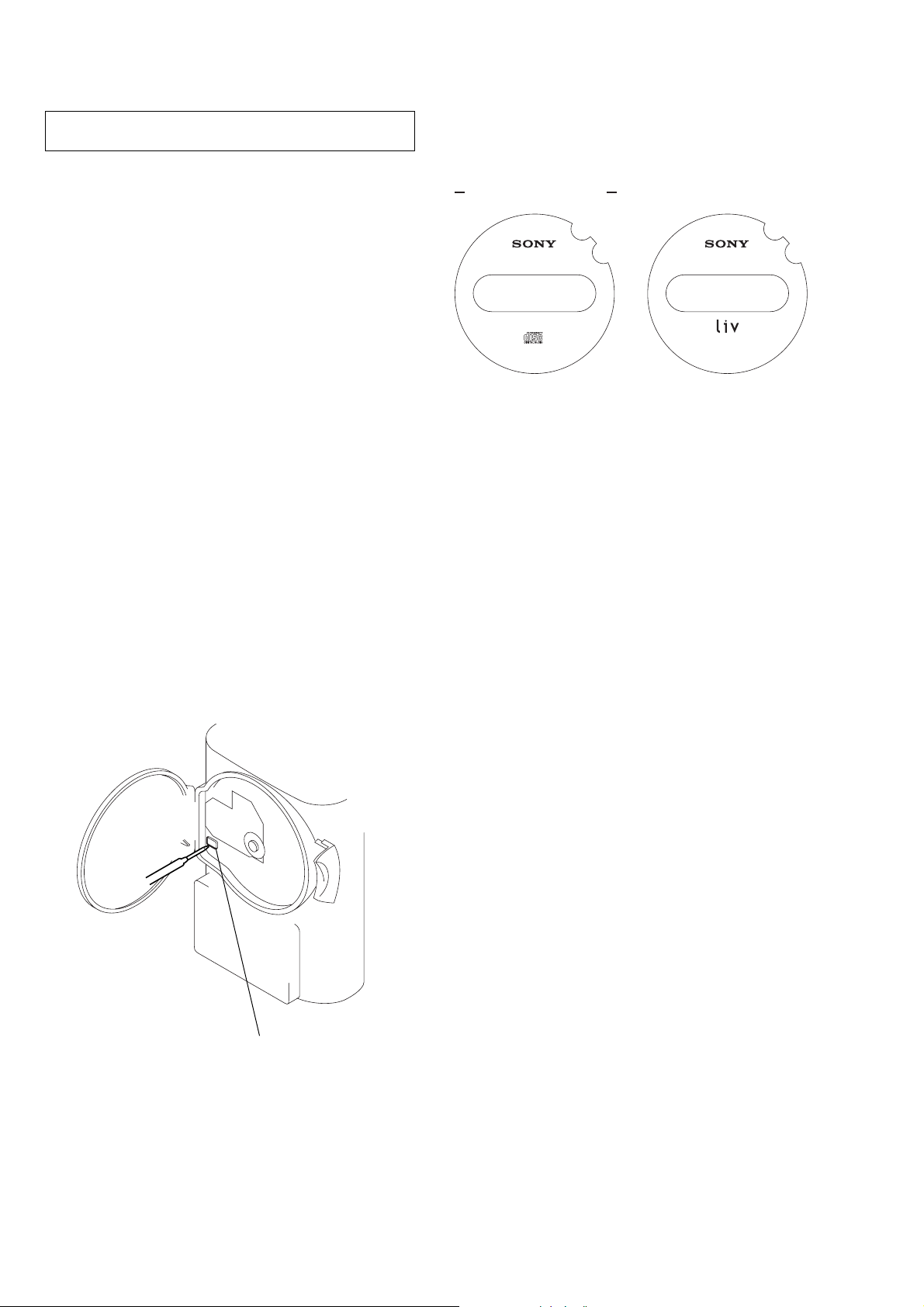

The following checking method for the laser diode is operable.

• Method

Emission of the laser diode is visually checked.

1. Open the lid.

2. Push the S551 as shown in Fig.1.

3. Press the [CD ] button.

4. Check the object lens for confirming normal emission of the

laser diode. If not emitting, there is a trouble in the automatic

power control circuit or the optical pick-up.

In this operation, the object lens will move up and down 2

times along with inward motion for the focus search.

NX

DISCRIMINATION OF ORIGINAL AND LIV MODEL

There are two types of ICF-CD73V.

Refer to following.

WINDOW Front View

ORIGINAL MODEL

LIV MODEL

S551

Fig.1 Method to push the S551

4

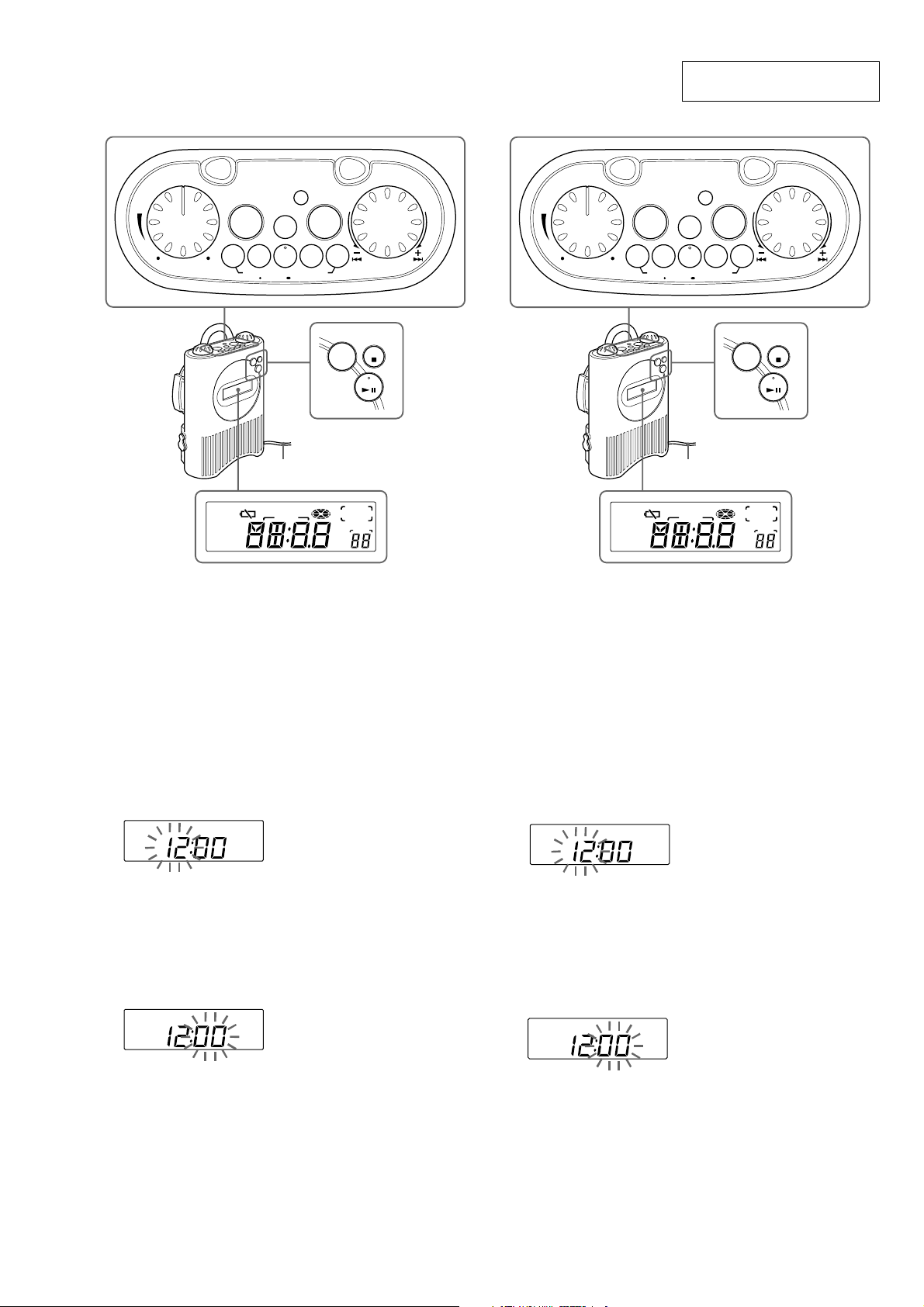

SECTION 2

GENERAL

ICF-CD73 ICF-CD73V

ICF-CD73/CD73V

This section is extracted from

instruction manual.

CLOCK

MODE

AUTO

OFF

M

IN

VOLUME

X

A

M

1

PRESET TUNING/PRESET TIMER

SELECT/ PRESET

TIMER

SET

ON/OFF

5432

RADIO

ON

BAND

TUNE/TIME SET

TIMER SET

OFF

CD

AUTO

OFF

MIN

VOLUME

MAX

1

PRESET TUNING/PRESET TIMER

SELECT/ PRESET

FM wire antenna

AM

AUTO OFF

TIMER

RADIO CD

FM12PM

MHz

kHz

SHUFFLE

ALL

REP1

PRESET

TRACK

RADIO CD

WEATHER

TV

AM

FM12PM

CLOCK

MODE

TIMER

SET

ON/OFF

5432

RADIO

FM wire antenna

AUTO OFF

TIMER

MHz

kHz

ON

BAND

SHUFFLE

REP1

TUNE/TIME SET

TIMER SET

OFF

CD

ALL

PRESET

TRACK

Setting the Clock

The display will flash “AM12:00” when the

batteries are installed or the AC power adaptor is

plugged in for the first time.

1 Press and hold down CLOCK for more

than 2 seconds.

The beep sounds and the hour flashes in the

display.

2 Rotate in either +/– direction the TUNE/

TIME SET/TIMER SET dial until

correct hour appears in the display.

AM

AUTO OFF

TIMER

RADIO CD

WEATHER

TV

FM12PM

Each rotation of the dial changes the digit(s)

by one.

When you hold the dial, the digit(s) change

rapidly.

kHz

MHz

SHUFFLE

REP1

ALL

PRESET

TRACK

3 Press CLOCK .

The beep sounds and the minute starts to

flash. Repeat step 2 to set the minute. After

setting the minute, press CLOCK again. The

two beeps sound and the clock starts from

0 seconds.

AM

AUTO OFF

TIMER

RADIO CD

WEATHER

TV

FM12PM

12-hour system: “AM 12:00” = midnight

24-hour system: “0:00” = midnight

Notes

•You can set the clock also during the radio

reception/CD playback mode.

•To set the current time quickly, rotate and hold

in either +/– direction the TUNE/TIME SET/

TIMER SET dial.

•To set the current time exactly, follow step 2

and press CLOCK again with the time signal of

a radio station.

MHz

kHz

SHUFFLE

ALL

REP1

PRESET

TRACK

the

Setting the Clock

The display will flash “AM12:00” when the

batteries are installed or the AC power adaptor

is plugged in for the first time.

1

Hold down CLOCK for more than

2 seconds.

The beep sounds and the hour flashes in the

display.

2

Rotate in either +/– direction the TUNE/

TIME SET/TIMER SET dial until the

correct hour appears in the display.

SHUFFLE

ALL

REP1

PRESET

TRACK

MHz

kHz

SHUFFLE

ALL

REP1

PRESET

TRACK

MHz

kHz

“PM 12:00” = noon

AM

AUT O O FF

TIMER

RADIO CD

WEATHER

TV

FM12PM

Each rotation of the dial changes the digit(s)

by one.

When you hold the dial, the digit(s) change

rapidly.

3

Press CLOCK .

The beep sounds and the minute starts to

flash. Repeat step 2 to set the minute. After

setting the minute, press CLOCK again. The

two beeps sound and the clock starts from

0 seconds.

AM

AUTO OFF

TIMER

RADIO CD

WEATHER

TV

FM12PM

12-hour system: “AM 12:00” = midnight

Notes

•You can set the clock also during the radio

reception/CD playback mode.

•To set the current time quickly, rotate and hold

in either +/– direction the TUNE/TIME SET/

TIMER SET dial.

•To set the current time exactly, follow step 2

and press CLOCK again with the time signal of

a radio station.

5

ICF-CD73/CD73V

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. CABINET (FRONT) SECTION

(Page 6)

SECTION 3

DISASSEMBLY

3-3. CABINET (UPPER) SECTION

(Page 7)

3-4. CHASSIS (MAIN) SECTION

(Page 7)

3-5. LCD BOARD

(Page 8)

Note: Follow the disassembly procedure in the numerical order given.

3-6. MECHANISM DECK

(KSM-900AAA)

(Page 8)

3-7. OPTICAL PICK-UP

(KSS-900A)

(Page 9)

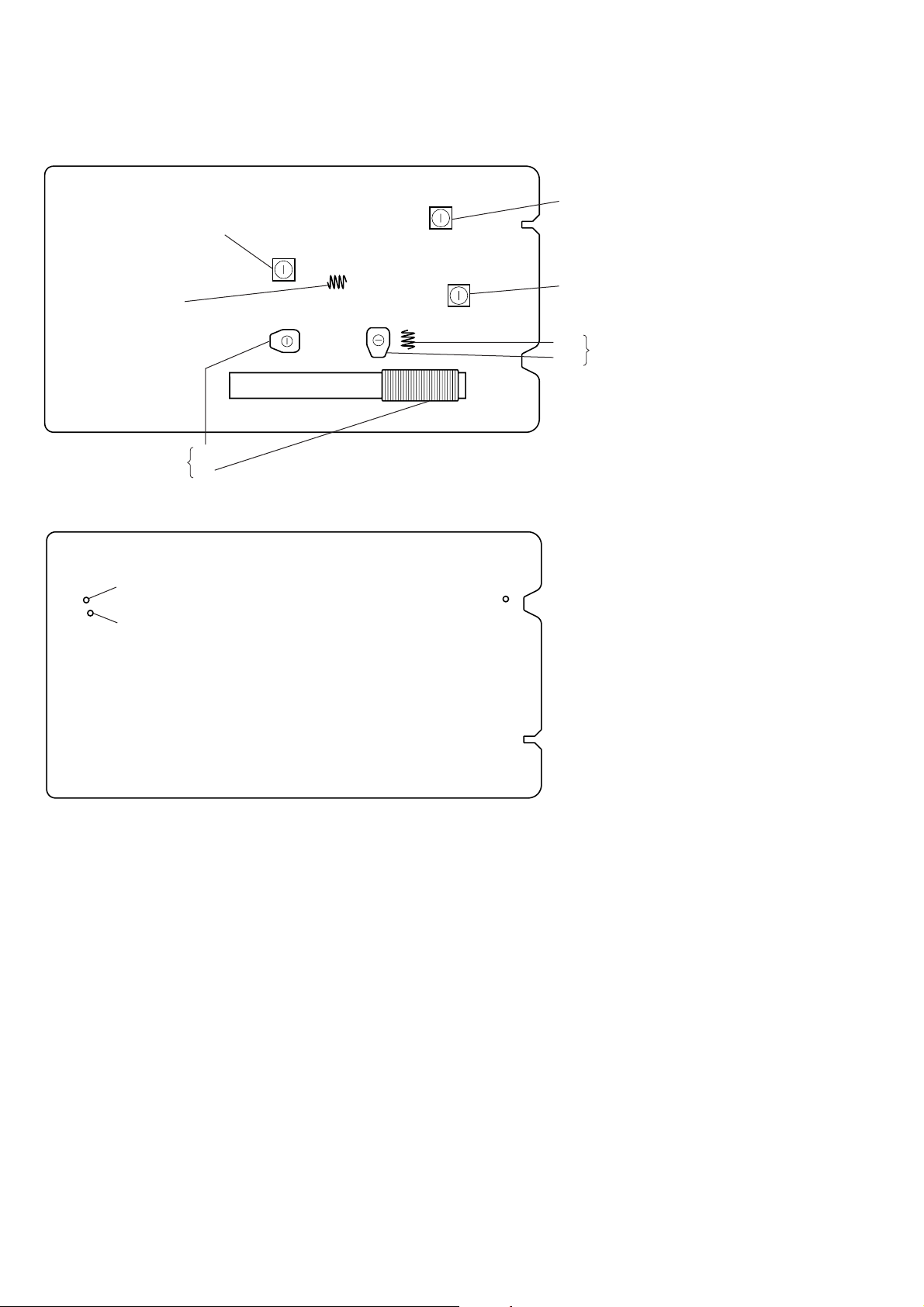

3-2. CABINET (FRONT) SECTION

5

two screws

(2.6

×

7

flat cable (CNP704)

10)

3-8. SPEAKER (SP101)/(SP201)

(Page 9)

8

connector

(CNP302)

6

qa

cabinet (front) section

9

screw (2.6 × 8)

0

SW board block

two screws

4

(2.6

3

×

10)

five screws

(2.6

×

10)

1

Open the buckle

(battery case lid).

2

Open the

battery case lid.

6

3-3. CABINET (UPPER) SECTION

)

4

two claws

3

two screws

(2.6

ICF-CD73/CD73V

2

connector

×

8)

(CNP602)

5

cabinet (upper) section

1

connector

(CNP601

3-4. CHASSIS (MAIN) SECTION

2

connector

(CNP303)

8

Remove the solder

of FM lead wire antenna

(ANT1).

5

two screws

(2.6

1

×

8)

9

chassis (main) section

flat cable

(CNP702)

6

two screws

(2.6

×

8)

3

two screws

(2.6

4

CD board

×

8)

7

cabinet (front) section

7

ICF-CD73/CD73V

)

3-5. LCD BOARD

1

two flat cables

(CNP401, 402)

4

LCD board

2

connector

(CNP1: CD73)/

(CNP2: CD73V

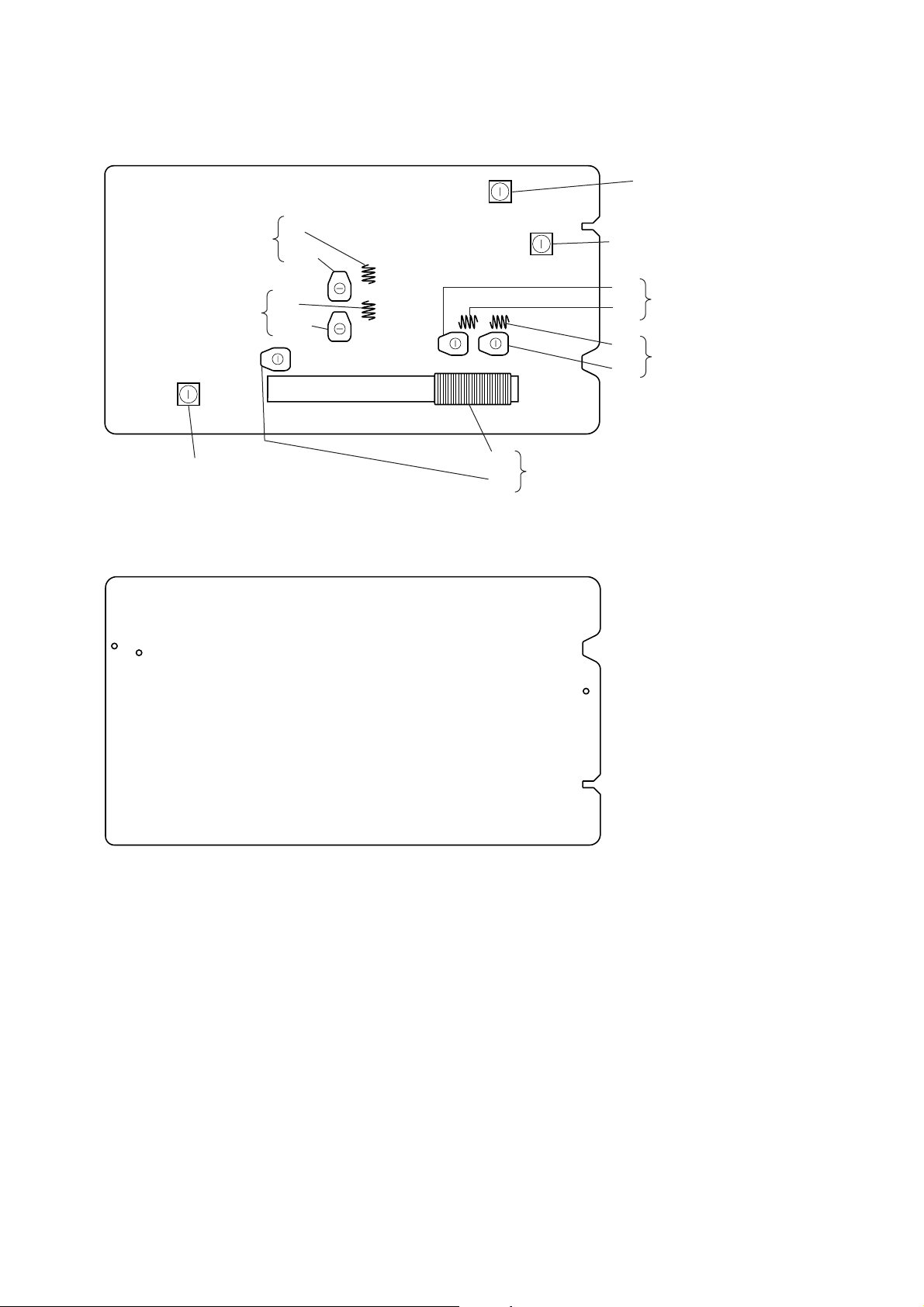

3-6. MECHANISM DECK

(KSM-900AAA)

2

connector

(CNP706)

3

3

screw

(2.6 × 8)

4

relay board

two screws

(2.6

×

8)

1

flexible board

(CNP705)

7

rubber

(vibration)

5

three tapping

screws

8

rubber

(vibration)

0

6

chassis CD block

9

rubber (vibration)

mechanism deck

(KSM900AAA)

8

3-7. OPTICAL PICK-UP

p

s

(KSS-900A)

1

screw

×

8)

(2

2

holder (780C)

7

sled screw assy (780E)

5

rack spring (780C)

6

ICF-CD73/CD73V

4

screw

(B1.7

×

4)

8

optical pick-u

(KSS-900A)

3

gear (B) (780C)

3-8. SPEAKER (SP101)/(SP201)

1

connector

(CNP304)

5

two speakers

(SP101, SP201)

2

screw (2.6 × 8)

3

bracket (SP)

4

spacer (slit)

ditch

2

screw (2.6 × 8)

3

bracket (SP)

Note: When installing the speaker lead wire,

lead the speaker lead wire along ditche

and bosses of the cabinet (front).

ditch

cabinet (front)

boss

boss

ditch

9

ICF-CD73/CD73V

SECTION 4

TEST MODE

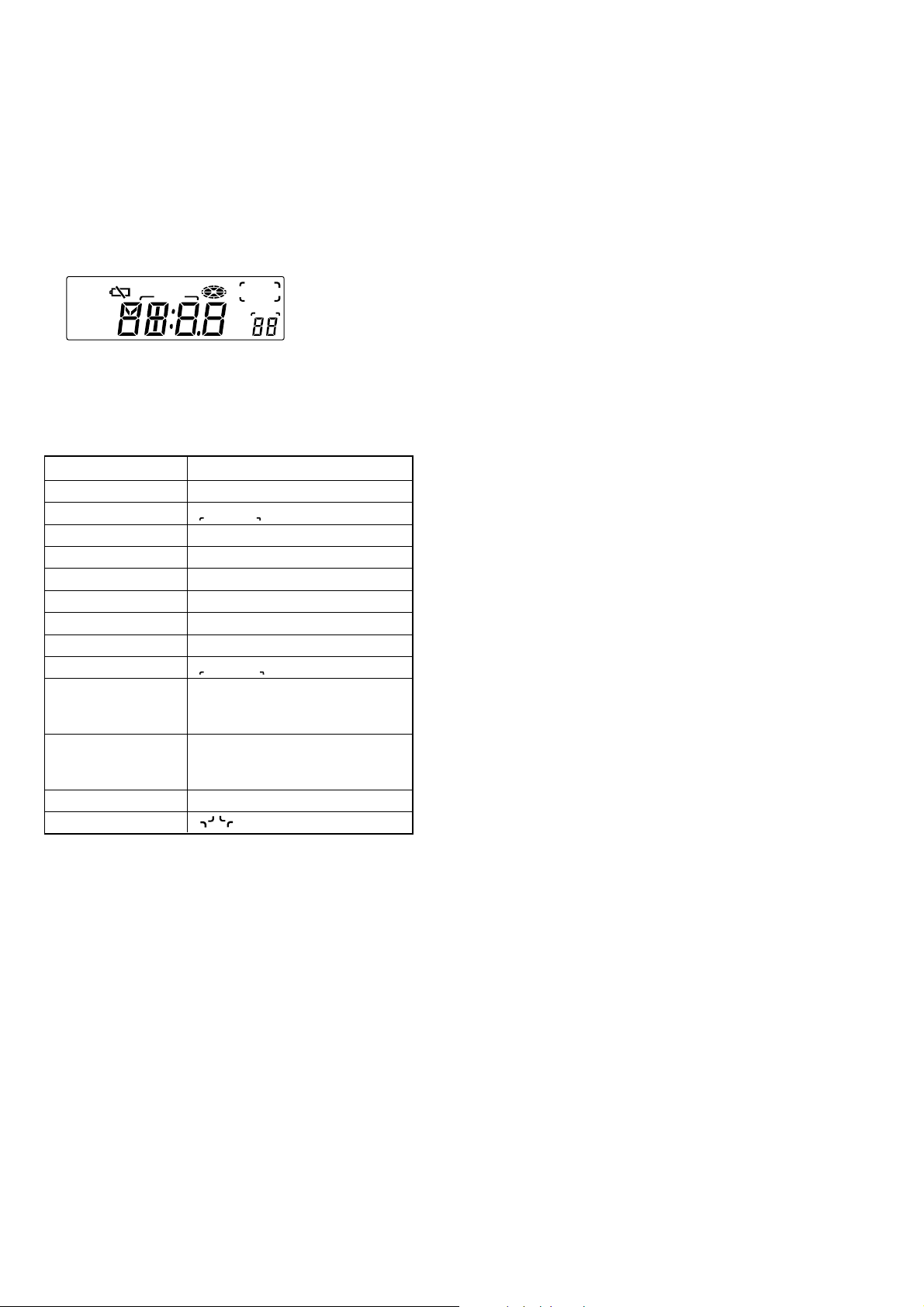

LCD AND KEY TEST MODE

Procedure:

1. Turn the power on while pressing simultaneously three buttons of [RADIO ON BAND], [CLOCK], and [1].

2. The microcomputer version will be displayed on the LCD.

3. Press the [AUTO OFF] button. (The LCD display will become

as follows)

LCD display

MHz

kHz

SHUFFLE

REP1

ALL

PRESET

TRACK

RADIO CD

WEATHER

TV

AM

FM12PM

AUTO OFF

TIMER

4. BEEP (A) will be output and the display corresponding to a

button is turned off, if a button on the set is pressed. Also,

BEEP (A) is output when the button is released.

Button Corresponding Table

Button Segment

CLOCK AM, PM, : (colon),

TIMER SET ON/OFF TIMER , AUTO OFF

1 1b, 1c

2 2a, 2b, 2d, 2e, 2g

3 3a, 3b, 3c, 3d, 3g

4 4b, 4c, 4f, 4g

5 5a, 5c, 5d, 5f, 5g

TUNE – . 6a, 6b, 6c, 6d, 6e, 6f, 6g

TUNE + > TRACK , PRESET

RADIO ON BAND RADIO, WEATHER, TV, FM,

1(FM), 2(FM), TV, .(point), MHz,

kHz

OFF x BatteryLow , 1a, 1d, 1e, 1f, 1g, 1h, 1i,

2c, 2f, 2h, 2i, 3e, 3f, 4a, 4d, 4e, 5b,

5e

CD NX CD, Pz1, Pz2, Pz3, Pz4

MODE , SHUFFLE, REP, 1, ALL

5. After all buttons on the set were pressed, press the [AUTO

OFF] button, and BEEP (B) will be output and the test mode

will be terminated.

6. If there is even one button that was not accepted, the set will

not be r eleased from test mode even though the [AUTO OFF]

button is pressed.

7. The set will return to normal state when the LCD AND KEY

TEST MODE is terminated.

10

ICF-CD73/CD73V

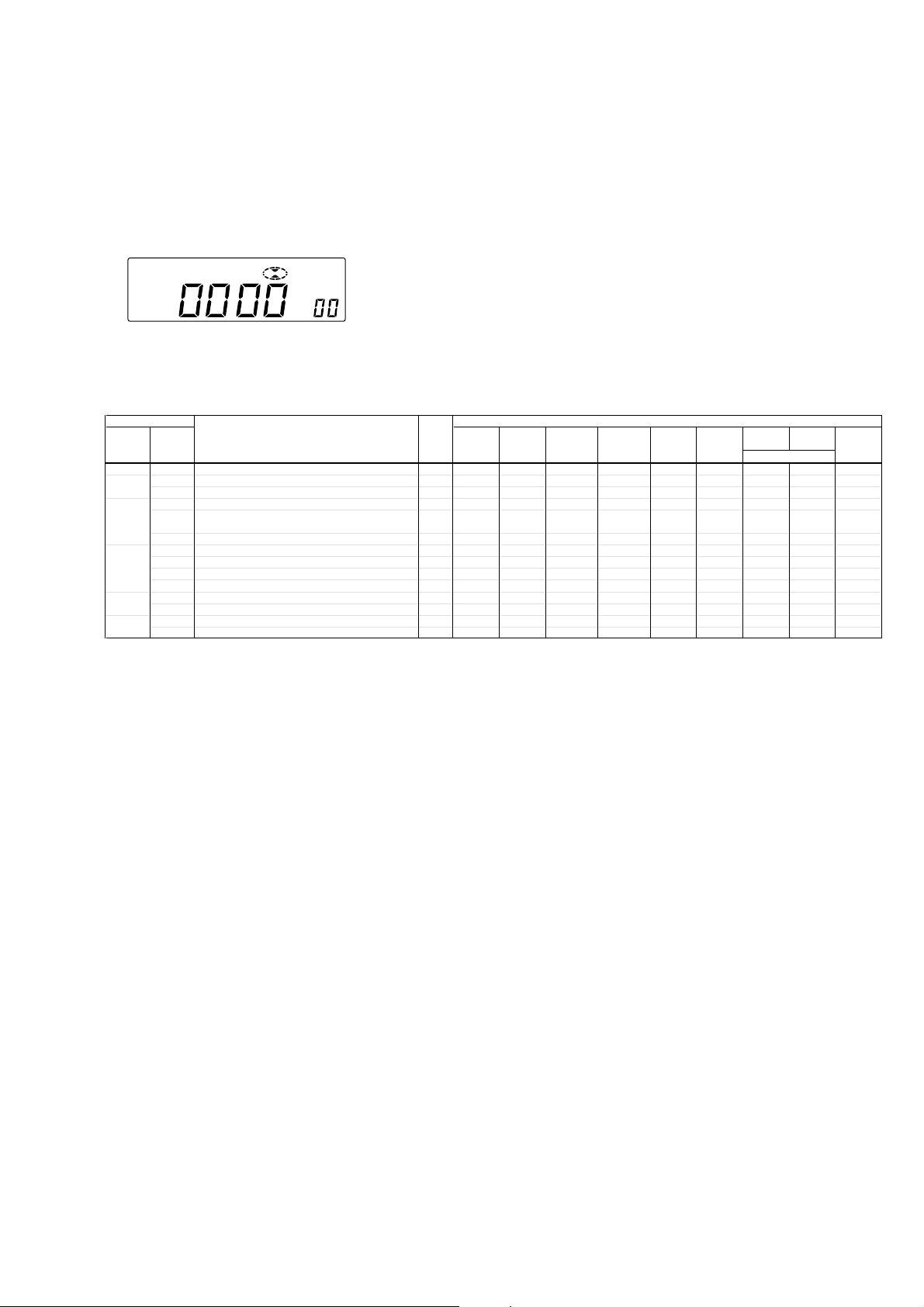

CD TEST MODE

Procedure:

1. Connect 47 kΩ and 100 kΩ resistors in parallel to the end of S501 on the LCD board, and short another end of resistors to the GND,

and the CD TEST MODE will be activated.

2. Insert a CD disc.

3. Turn the power on. Press the [CD ] button.

LCD display

4. The following shows the state transition table for each button operation in respective sub modes of CD TEST MODE.

State Transition T able

If each button is pressed in respective sub modes, the mode will transit to the sub modes listed in table.

MODE Explanation LCD Button

MAIN SUB

INT State when TEST MODE is activated.

STOP STOP0 State when a button is pressed once from initial state.

STOP0 Automatically adjusted value is held.

FOCUS FOCUS0 AUTO FOCUS transfer mode

FOCUS FOCUS SERVO ON state.(CLV-S, TRK/SLED, SERVO OFF)

It will be referred to as LPC ON if FOCUS carries out on.

F.LPC OFF LPC OFF in FOCUS state.

ALL ALSV State where all servo systems are turned on.

SERVO ALPC OFF State where all servo systems are turned on.(LPC:OFF)

TGUP State with TRK GAIN UP in all servo systems are turned on.(LPC:ON)

AUTO Mode in which automatic adjustment is made at once.

SLED SLDF SLED is fed outward in STOP state.

SLDR SLED is fed inward in STOP state.

F.SLED FCSF SLED is fed outward in FOCUS state.

FCSR SLED is fed inward in FOCUS state.

Mode transits to sub modes listed in table, if a button is pressed in respective sub modes.

CD

NX

OFF CD –+ RADIO ON AUTO OFF –+ Processing

NX

x

00 STOP0 FOCUS0

01 FOCUS0 STOP STOP EF Normal SLDF SLDR

02 STOP0 FOCUS0 Normal SLDF SLDR

03 STOP FOCUS

04 STOP F.LPC EF AUTO FCSF FCSR

05 STOP ALSV FOCUS FOCUS FOCUS0 FCSF FCSR

07 STOP ALPC OFF FOCUS FOCUS EF AUTO FCSF FCSR

08 STOP TGUP FOCUS FOCUS FCSF FCSR

09 STOP ALSV FOCUS FOCUS FCSF FCSR

b

cSTOPSTOPSTOPSTOP SLDF

dSTOPSTOPSTOPSTOP SLDR

E FOCUS FOCUS FOCUS FOCUS FCSF

F FOCUS FOCUS FOCUS FOCUS FCSR

OFF

>

.

BAND end

>

.

Long pressed

5. Turn the power off to release the CD TEST MODE.

11

ICF-CD73/CD73V

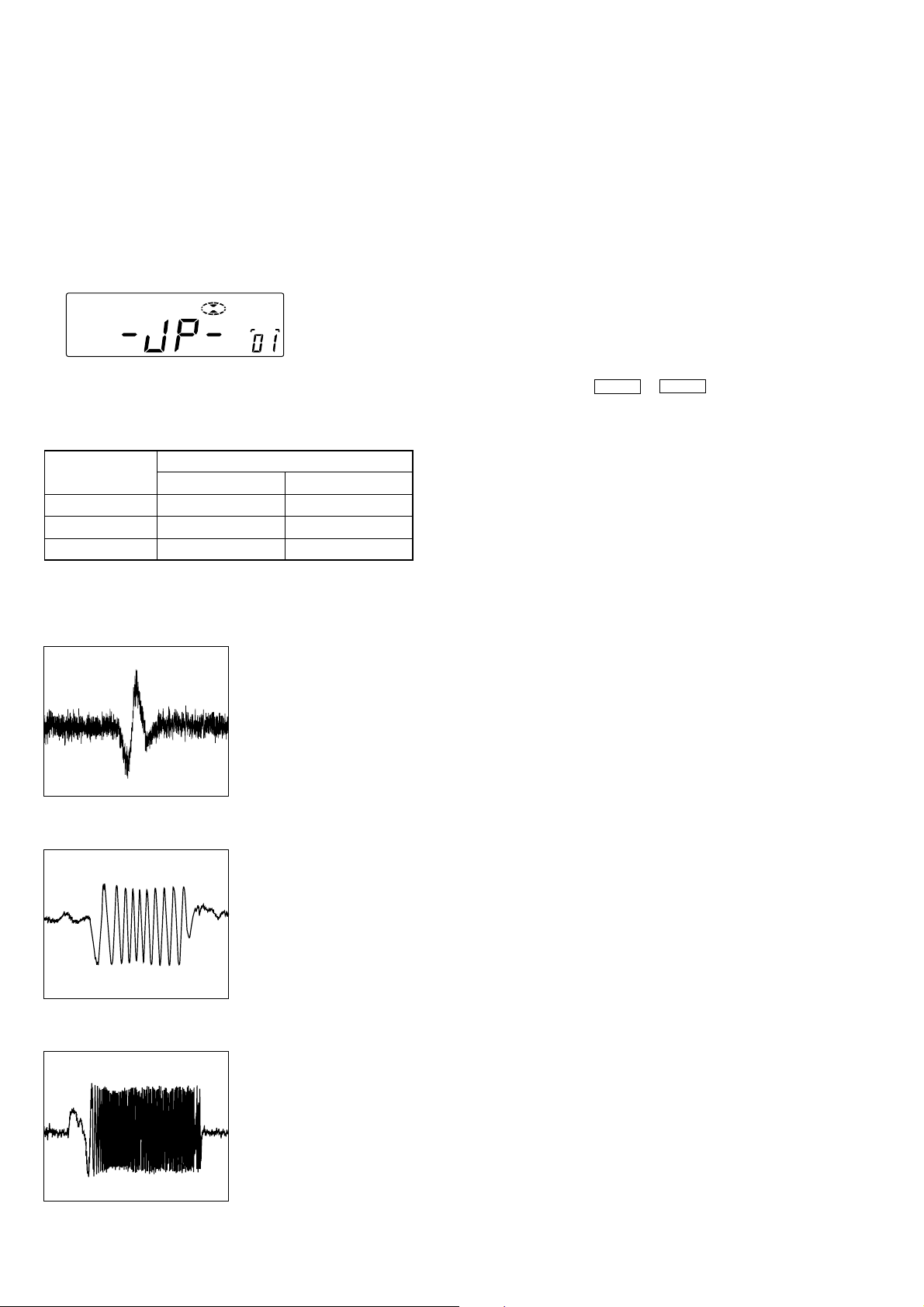

CD-JUMP TEST MODE

Procedure:

1. Connect the oscilloscope to TP (TE) and TP (VC) on the CD board.

Connecting Location: CD board (See page 16)

2. Connect 47 kΩ and 100 kΩ resistors in parallel to the end of S501 on the LCD board, and further connect 100 kΩ and 220 kΩ resistors

respectively and short them to the GND, and the CD-JUMP TEST MODE will be activated.

3. Insert a CD disc.

4. Turn the power on. Press the [CD ] button.

LCD display

5 . If the [MODE] button is pressed, you can jump in fast feed or fast reverse direction with the + > or – . button by the jump

amount set in Table 1.

Table 1

LCD

+ > – .

REP ALL TRACK + 1 TRACK - 1

SHUFFLE TRACK + 10 TRACK - 10

SHUFFLE, REP TRACK + 100 TRACK - 100

NX

CD

TRACK

Button

Waveform of TP (TE) and TP (VC) output in each mode is as follows.

REP ALL mode

500 µs/div

SHUFFLE mode

1 ms/div

SHUFFLE REP mode

10 ms/div

6. Turn the power off to release the CD-JUMP TEST MODE.

12

r

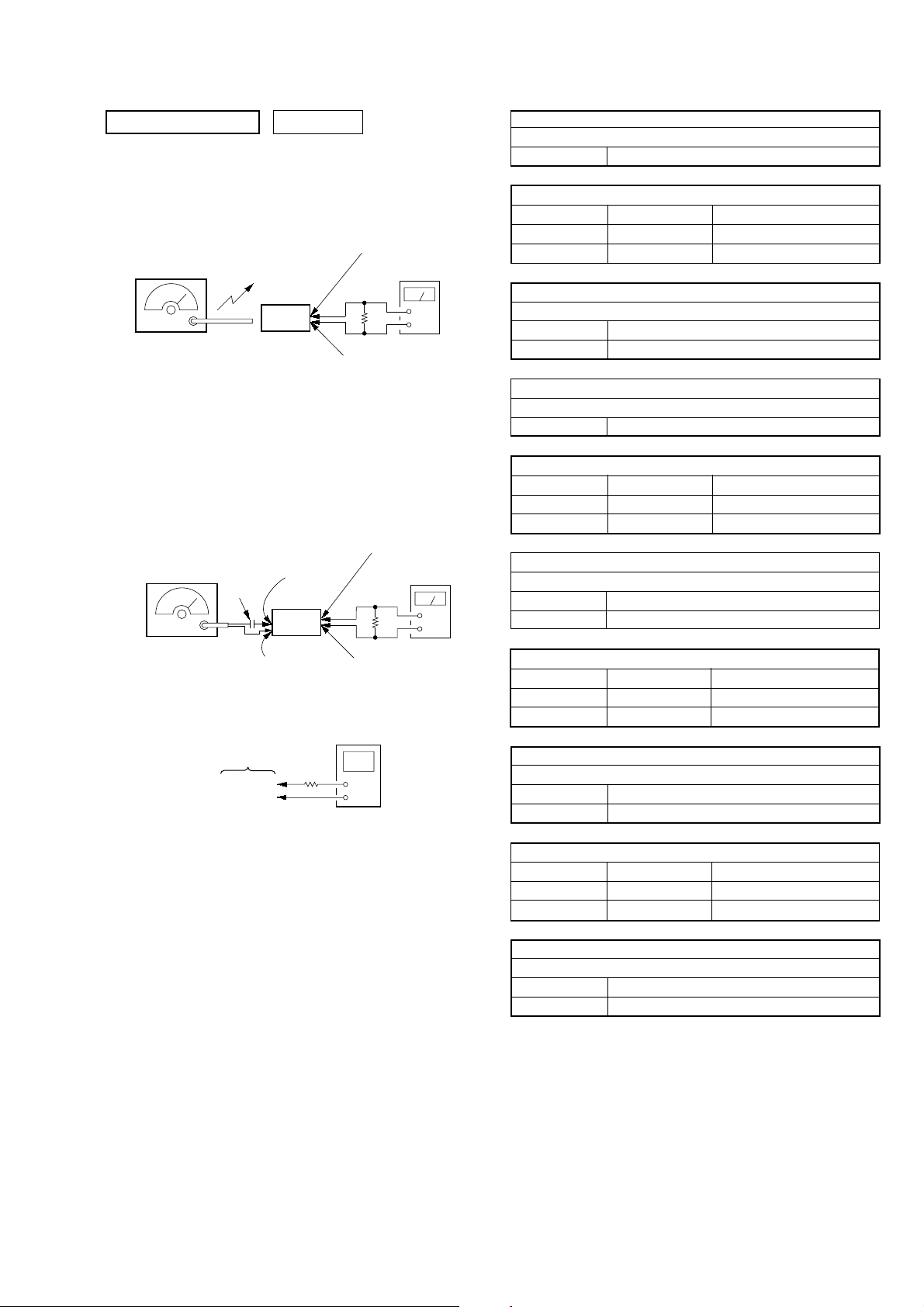

SECTION 5

ELECTRICAL ADJUSTMENTS

ICF-CD73/CD73V

TUNER SECTION 0 dB=1 µV

[AM]

Setting:

Function: RADIO

Band: AM

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

Output level:

as low as possible

[FM/TV/WEATHER]

Setting:

Function: RADIO

Band: FM (ICF-CD73)

FM/TV/WEATHER (ICF-CD73V)

FM RF signal

generator

75 kHz frequency

deviation by 1 kHz

signal

Output level:

as low as possible

Put the lead-wire

antenna close to

the set.

0.01 µF

TUNER board

TP (GND)

TUNER board

TP (VT)

TP (GND)

set

TUNER board

TP (ANT)

set

digital voltmete

100 kΩ

JACK board

CNP304 pin 1

level meter

3.2 Ω

+

–

JACK board

CNP304 pin 2

JACK board

CNP304 pin 1

level meter

3.2 Ω

JACK board

CNP304 pin 2

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter

T1 450 kHz

( ): ICF-CD73V

AM VCO VOLT A GE ADJUSTMENT

Adjustment Part Frequency Display Reading on Digital Voltmeter

L4 (L6) 530 kHz (531 kHz) 1.0 ± 0.05 V (1.0 ± 0.1 V)

Confirmation 1,710 kHz 5.3 ± 0.7 V

( ): ICF-CD73V

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L3 (L5) 620 kHz (580 kHz)

CT3 (CT5) 1,400 kHz (1,490 kHz)

FM IF ADJUSTMENT

Adjust for a minimum reading on level meter

T2 10.7 MHz

FM VCO VOLTAGE ADJUSTMENT (ICF-CD73)

Adjustment Part Frequency Display Reading on Digital Voltmeter

L2 108 MHz 3.0 ± 0.2 V

Confirmation 87.5 MHz 1.3 ± 0.3 V

FM TRACKING ADJUSTMENT (ICF-CD73)

Adjust for a maximum reading on level meter

+

–

L1 87.5 MHz

CT1 108 MHz

FM/TV (2 – 6 CH) VCO VOLTAGE ADJUSTMENT (ICF-CD73V)

Adjustment Part Frequency Display Reading on Digital Voltmeter

L4 TV 2 ch 1.0 ± 0.15 V

CT3 108 MHz 4.0 ± 0.15 V

FM/TV (2 – 6 CH) TRACKING ADJUSTMENT (ICF-CD73V)

Adjust for a maximum reading on level meter

L2 TV 2 ch

Confirmation 108 MHz

•Repeat the procedures in each adjustment several times, and the

tracking adjustments should be finally done by the trimmer capacitors.

• Remove FM/TV/WEATHER antenna in FM/TV/WEATHER

adjustment.

TV (7 – 13 CH)/WEATHER (1 – 7 CH) VCO VOLTAGE ADJUSTMENT (ICF-CD73V)

Adjustment Part Frequency Display Reading on Digital Voltmeter

L3 WEATHER 2 ch 1.0 ± 0.15 V

CT4 TV 13 ch 4.1 ± 0.15 V

TV (7 – 13 CH)/WEATHER (1 – 7 CH) TRACKING ADJUSTMENT (ICF-CD73V)

Adjust for a maximum reading on level meter

L1 WEATHER 2 ch

CT2 TV 13 ch

Adjustment and Connecting Location:TUNER board (ICF-

CD73)

(See page 14)

TUNER board (ICFCD73V)

(See page 15)

13

ICF-CD73/CD73V

Adjustment and Connecting Location:

– TUNER BOARD (Component Side) (ICF-CD73) –

AM VCO Voltage Adjustment

FM VCO Voltage Adjustment

AM T rac king Adjustment

L4

L2

CT3

L3

– TUNER BOARD (Conductor Side) (ICF-CD73) –

TP

(VT)

TP

(GND)

TP

(ANT)

T2 FM IF Adjustment

T1 AM IF Adjustment

L1

FM T rac king Adjustment

CT1

14

Adjustment and Connecting Location:

– TUNER BOARD (Component Side) (ICF-CD73V) –

TV (7 – 13 CH)/

WEATHER (1 – 7 CH)

VCO Voltage Adjustment

TV TV (2 – 6 CH)

VCO Voltage Adjustment

L3

CT4

L4

CT3

T2

IF Adjustment

T1

IF Adjustment

TV (7 – 13 CH)/

CT2

WEATHER (1 – 7 CH)

L1

Tracking Adjustment

L2

FM/TV (2 – 6 CH)

CT1

Tracking Adjustment

ICF-CD73/CD73V

AM VCO Voltage Adjustment

L6

– TUNER BOARD (Conductor Side) (ICF-CD73V) –

TP

)

(GND

TP

(VT)

L5

AM Tracking Adjustment

CT5

TP

(

ANT

)

15

ICF-CD73/CD73V

CD SECTION

Perform all CD section check in the test mode.

FOCUS BIAS CHECK

Procedure:

1. Connect the oscilloscope to TP (RF) and TP (VC) on the CD

board.

2. Set the CD test mode. (Refer to CD TEST MODE (See page

11))

3. Insert the test disc (YEDS-18). (Part No. 3-702-101-01) (CD)

4. Press the [CD ] button. (LPC ON)

5. Confirm that the oscilloscope waveform is as shown in the

figure below. (eye pattern)

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

6. Press the [CD ] button. (LPC OFF)

7. Perform confirmation in the same manner as step 5.

8. Press the [OFF ] button.

9. Change the test disc (TCD-W082L). (Part No. J-2502-063-2)

(CD-RW)

10. Perform confirmation in the same manner as step 4 to 7.

NX

NX

x

• RF signal reference waveform (eye pattern)

VOLT/DIV: 0.2 V (with the 10: 1 probe in use.)

TIME/DIV: 500 ns

CD:

1.1 ± 0.2 Vp-p (LPC ON)

1.1 ± 0.3 Vp-p (LPC OFF)

CD-RW:

1.0 ± 0.2 Vp-p (LPC ON)

0.9 ± 0.3 Vp-p (LPC OFF)

When observing the eye pattern, set the oscilloscope

for AC range and raise vertical sensitivity.

Connecting Location:

– CD BOARD (Conductor Side) –

IC702

TP

(VC)

TP

(TE)

16

TP

(RF)

IC701

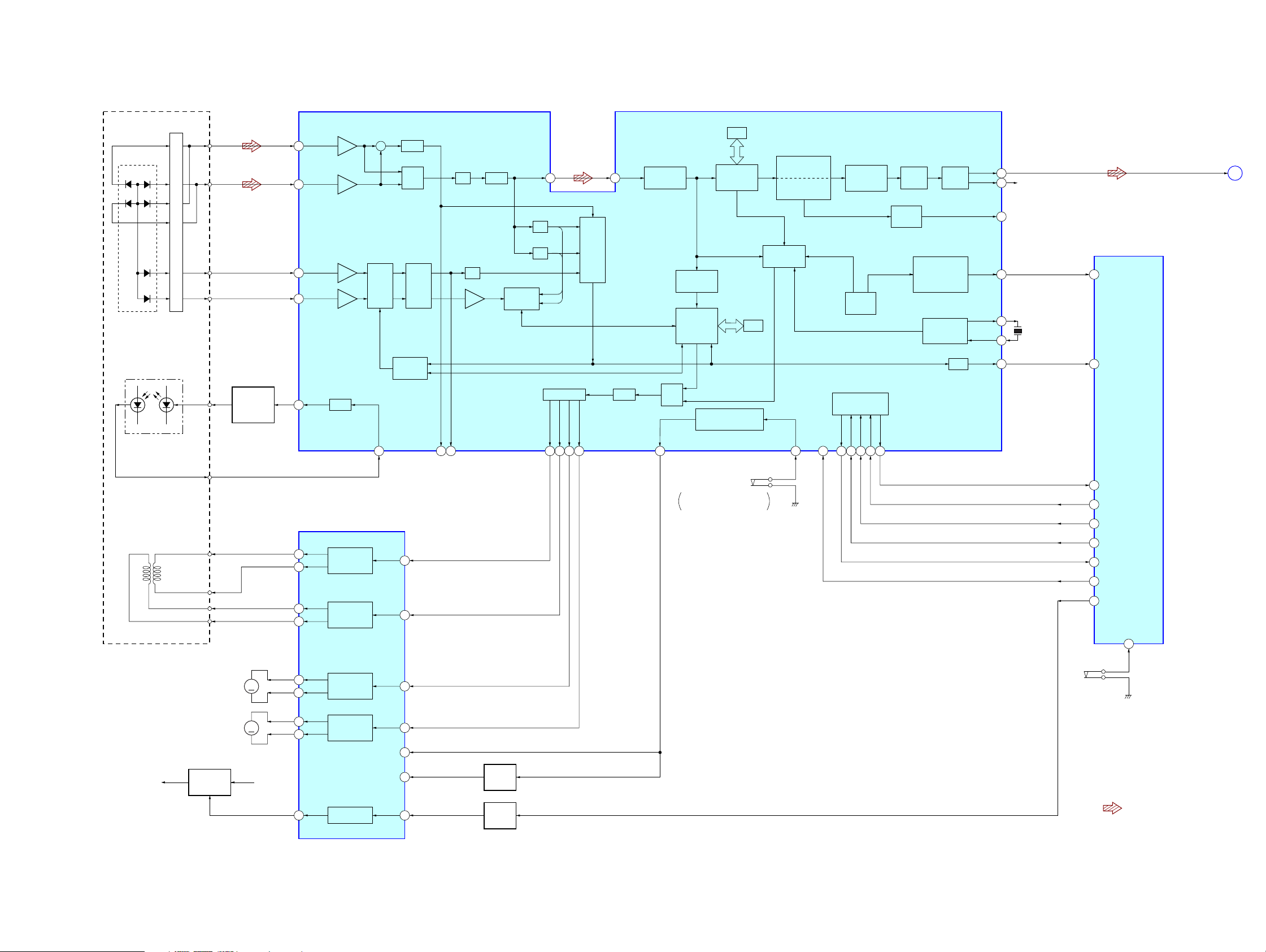

SECTION 6

6-1. BLOCK DIAGRAM – CD Section –

FIN2 (PD1)

8

FIN1 (PD2)

7

DETECTOR

A

B

PD1

D

C

PD2

I-V AMP

DIAGRAMS

+

RF AMP, FOCUS/TRACKING SERVO,

DIGITAL SIGNAL PROCESSOR, CLV SERVO,

DIGITAL FILTER, D/A CONVERTER

LPF

MIX

IC701

EQ

AGC

ICF-CD73/CD73V

RAM

RF

4

PH

3

EFMIN

SLISE LEVEL

CONTROL

ERROR

CORRECTION

AUDIO CD

INTERPOLATION

MUTE

ATTENUATION

DEEMPHASIS

8FS

DIGITAL

FILTER

AUDIO

OUT

1 BIT

DAC

LPF

LCHO

RCHO

DOUT

42

R-CH

45

39

CD LCH

A

(Page 20)

F

E

OPTICAL PICK-UP

BLOCK

(KSM-900AAA)

LASER DIODE

LD

PD

2-AXIS

DEVICE

(FOCUS)

LO LD

LO PD

TRK +

TRK –

(TRACKING)

FCS +

FCS –

S/H

A/D

D/A

CONT4

25

PROCESSOR

SW

RUPTURE

DETECT

SERVO

ON :

GENERAL PURPOSE

PORTS

S701

(LIMIT)

When the optical pick-up

is inner position

BH

F

E

AUTOMATIC

POWER

CONTROL

Q701

TIN2 (F)

10

TIN1 (E)

9

LDD

80

19

20

17

18

APC

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE,

POWER CONTROL

IC702

TRK+

TRACKING

TRK–

COIL DRIVE

FCS+

FOCUS

FCS–

COIL DRIVE

TBAL

LDS

79

TRK IN

FCS IN

AUDIO

ADJUST

9

10

LPF

13FE15

SW

TRACK

JUMP

TE

TDO21FDO23SLDO22SPDO

20

RAM

CLV, CAV

CONTROL

CONT166RES

72

PLL

VCEC

COMMAND

INTERFACE

WRQ61CE62CL63DI64DO

65

FRAME SYNC

DETECT,

PROTECT, INSERT,

EFM DECODE

CLOCK

GENERATOR

DRF

FSEQ

XOUT

DRF

XIN

31

48

49

67

X701

16.9344MHz

39 FSEQ

57 DRF

SYSTEM

CONTROLLER

IC401

(1/2)

53 CD DATA IN

54 CD DATA

55 CD CLK

56 CD CE

50 WRQ

58 XRST

59 CD ON

CD OPEN

61

M701

M

(SLED)

M702

(SPINDLE)

CD +3.3V PVCC

+3.3V

REGULATOR

Q705

M

SL+

22

SL–

23

SP+

25

SP–

24

SLED

MOTOR DRIVE

SPINDLE

MOTOR DRIVE

SL IN

SP IN

8

7

4MUTE34

5MUTE1

MUTING

SWITCH

Q702

S551

(CD LID OPEN/CLOSE)

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

REGB

31

REGULATOR

DC IN

30

CD ON

SWITCH

Q703, 704

: CD PLAY

1717

Loading...

Loading...