Sony ICD-55 Service Manual

ICD-55

SERVICE MANUAL

Ver 1.1 1999. 01

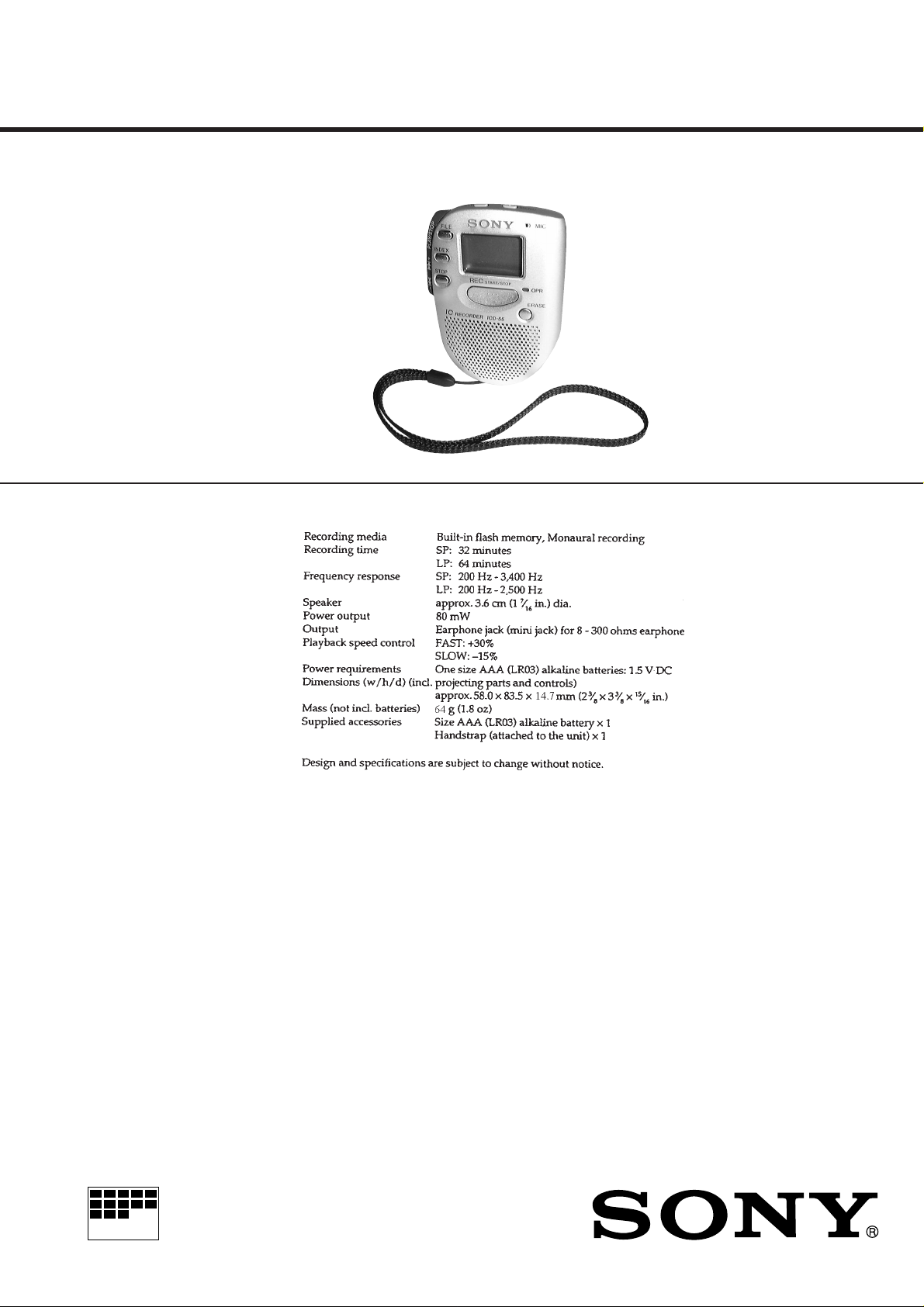

SPECIFICATIONS

US Model

Canadian Model

AEP Model

E Model

Tourist Model

MICROFILM

IC RECORDER

SECTION 1

SERVICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 2

2. GENERAL ................................................................... 3

3. DISASSEMBLY ......................................................... 4

4. DIAGRAMS

4-1. Block Diagram ................................................................ 7

4-2. Printed Wiring Board ...................................................... 9

4-3. Schematic Diagram ......................................................... 11

4-4. IC Pin Function Description ........................................... 17

5. EXPLODED VIEW................................................... 19

6. ELECTRICAL PARTS LIST ............................... 20

CAUTION ON REPLACING FLASH MEMORY

The BAD-BLOCK check* must be executed, when the flash

memory in this set was replaced.

The set will not operation normally, unless this check is finished.

* The BAD-BLOCK check detects an area (bad-block) in the flash

memory where data validity cannot be guaranteed, and saves this

information in the TOC-AREA so that a bad-block is not used.

BAD-BLOCK check Procedure:

1. Apply 1.5V from re gulated po wer supply to the battery terminals.

2. Once the po wer is supplied, the check starts and then proceeds

for approx. 20 seconds. (Be sure to keep applying the power

during the check)

3. When the check completes, the result is shown as bellows.

OK:Only the LCD back light LED (D503) turns on.

NG:Red LED blinks or turns on or green LED turns on in the

OPR LED (D504).

4. In case of OK, press the

Note:

• In case of NG, check system control IC (IC701), flash memory IC and

the peripheral circuit. (Particularly , check carefully the soldering of the

flash memory)

• After finishing the BAD-BLOCK check, assemble the set, load the dry

battery, and confirm if the set operates normally.

[STOP] button.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board. (within 3 times)

• Be careful not to apply force on the conductor when soldering

or unsoldering.

– 2 –

SECTION 2

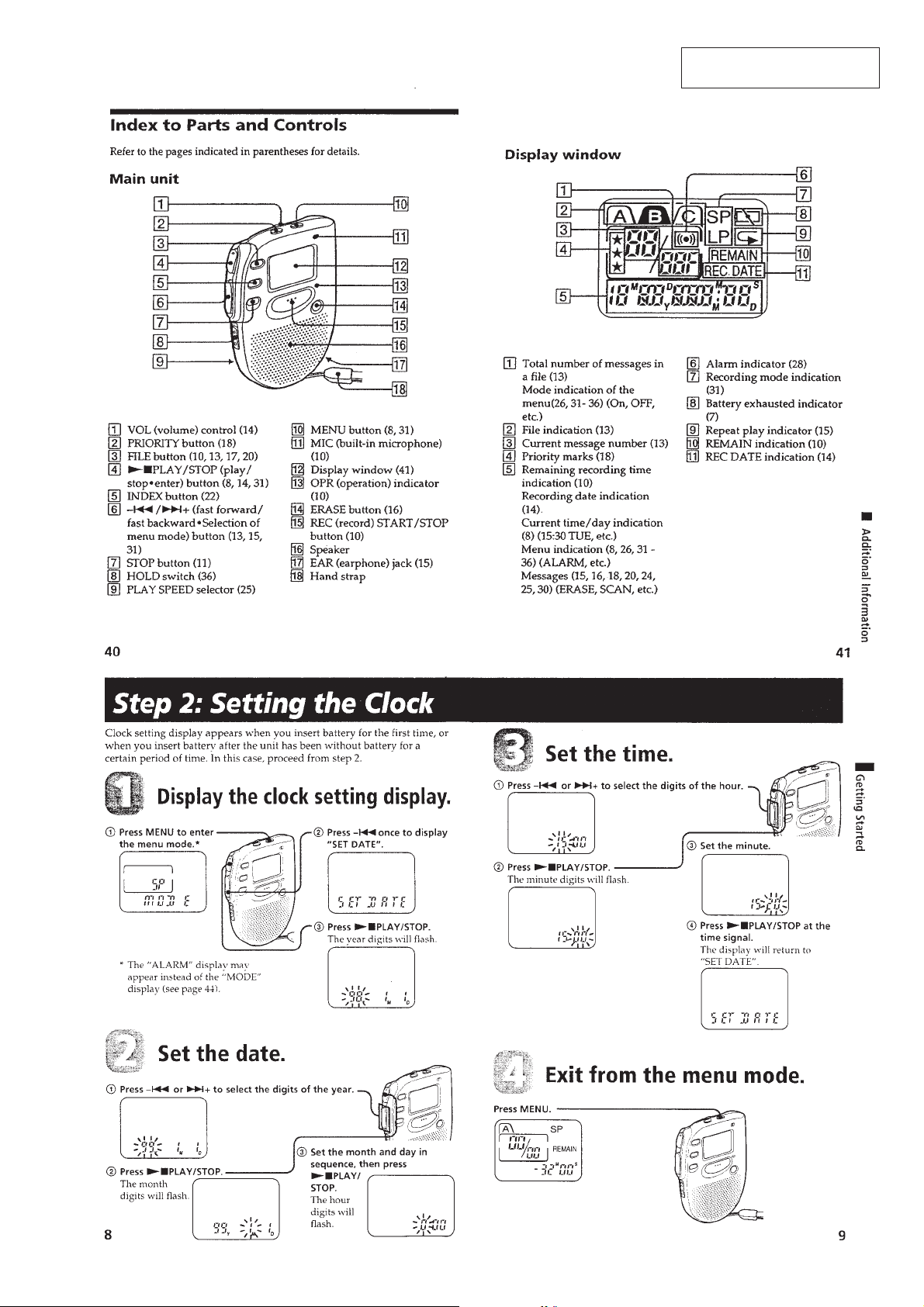

GENERAL

This section is extracted from

instruction manual.

– 3 –

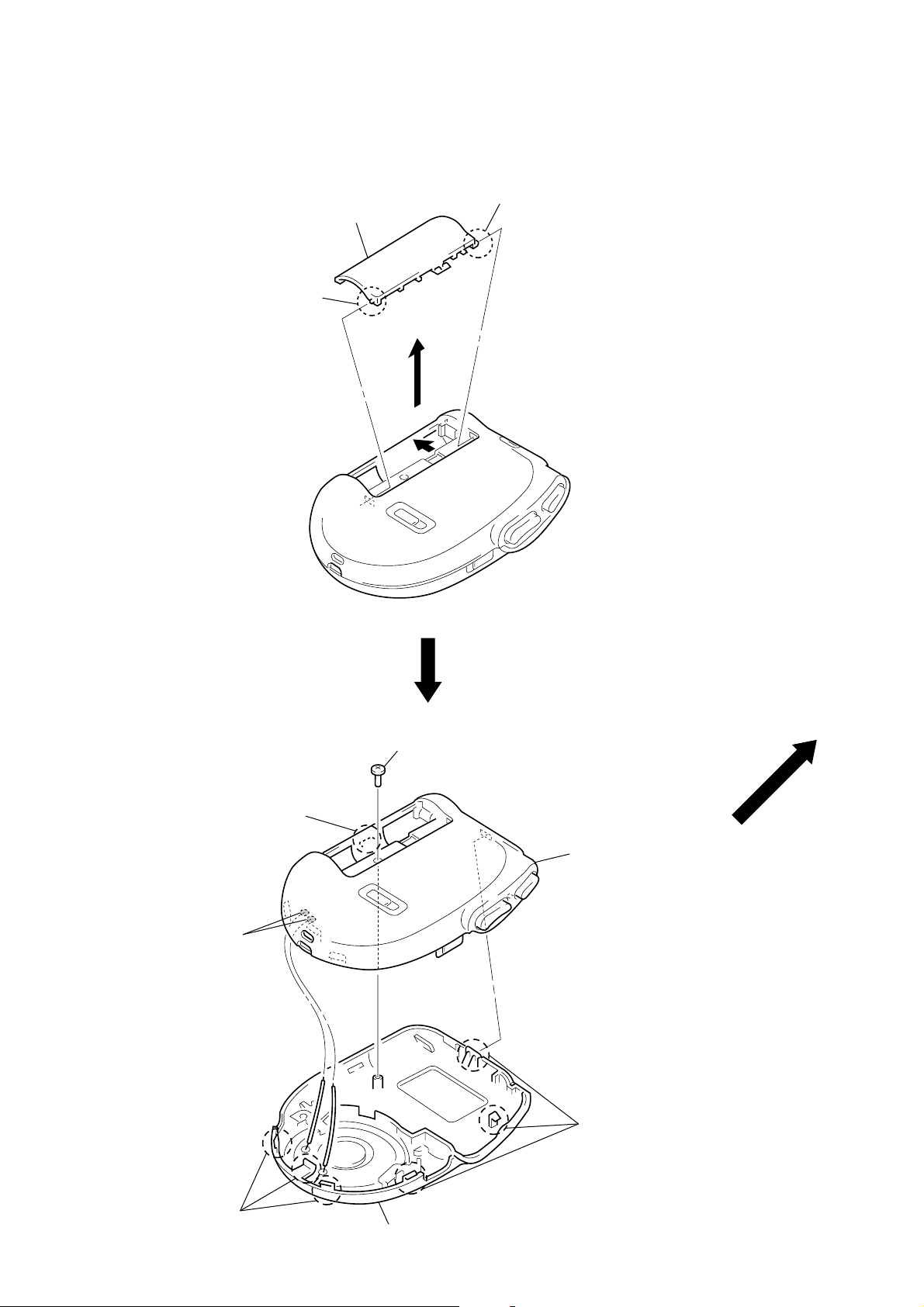

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

LID, BATTERY CASE

3

lid, battery case

2

boss

1

2

boss

CASE (FRONT)/(REAR) SECTION

2

claw

3

Remove the two solders

speaker lead (SP101).

1

screw (1.7 × 4.5)

5

case (rear) section

2

three claws

2

three claws

4

case (front) section

– 4 –

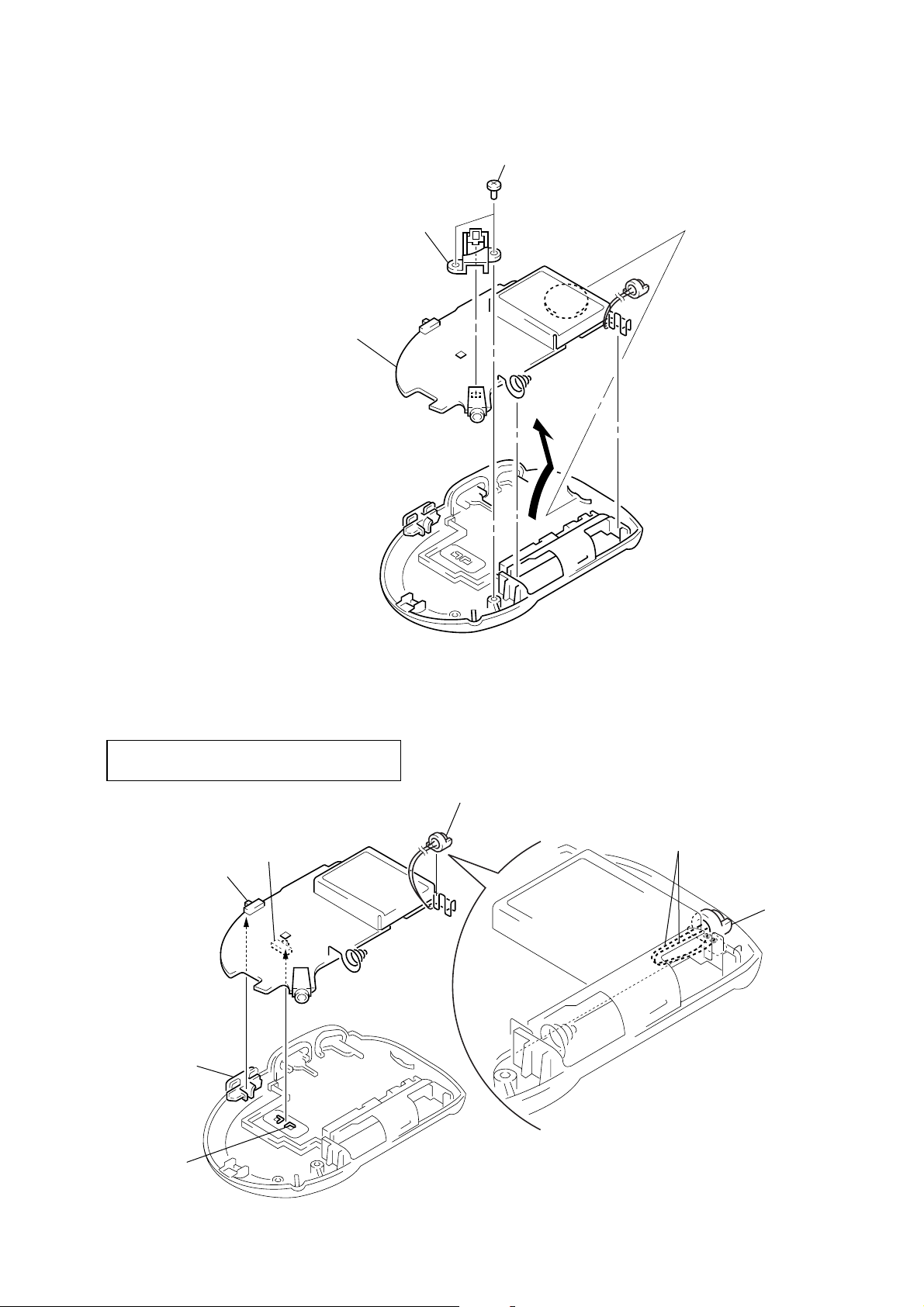

MAIN BOARD

r

3

Remove the MAIN board to

direction of the arrow.

2

bracket

(jack)

1

two screws

(M1.7

×

4)

INSTALLATION “MAIN BOARD”, “MICROPHONE, ELECTRIC CONDENSER” (MIC101)

On installation MAIN board adjust the S711, S712

and knob (HOLD, MODE).

S712

S711

knob (HOLD)

knob (MODE)

microphone, electric condenser

(MIC101)

two leads

Install two leads the electric condenser microphone

(MIC101) in the figure.

microphone,

electric condense

(MIC101)

– 5 –

Loading...

Loading...