Sony HCD-ZX70DVD Service Manual

HCD-ZX70DVD

SERVICE MANUAL

SUPPLEMENT-1

File this supplement with the service manual.

Subject: 1. Correction

2. Servicing Note

3. Service Mode

4. T est Mode

5. Electrical Adjustments

6. Block Diagrams

7. IC Block Diagrams

8. IC Pin Function Description

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Chinese Model

TABLE OF CONTENTS

1. CORRECTION

1-1. Schematic Diagrams ....................................................... 2

1-2. Electrical Parts List ......................................................... 3

2. SERVICING NOTE .................................................. 4

3. SERVICE MODE...................................................... 5

4. TEST MODE.............................................................. 7

5. ELECTRICAL ADJUSTMENTS

DECK Section ................................................................. 17

VIDEO Section ............................................................... 20

6. BLOCK DIAGRAMS

6-1. Block Diagram – SERVO Section – .............................. 21

6-2. Block Diagram

– SIGNAL PROCESS/VIDEO Section –....................... 22

6-3. Block Diagram

– DVD/CD AUDIO, DVD/CD PLL Section – .............. 23

6-4. Block Diagram – DVD/CD MAIN Section –................ 24

6-5. Block Diagram – TUNER/TAPE DECK Section – ...... 25

6-6. Block Diagram – MAIN Section (1/2) – ....................... 26

6-7. Block Diagram – MAIN Section (2/2) – ....................... 27

6-8. Block Diagram – DISPLAY Section – .......................... 28

6-9. Block Diagram – POWER SUPPLY Section – ............. 29

7. IC BLOCK DIAGRAMS........................................ 30

8. IC PIN FUNCTION DESCRIPTION................ 30

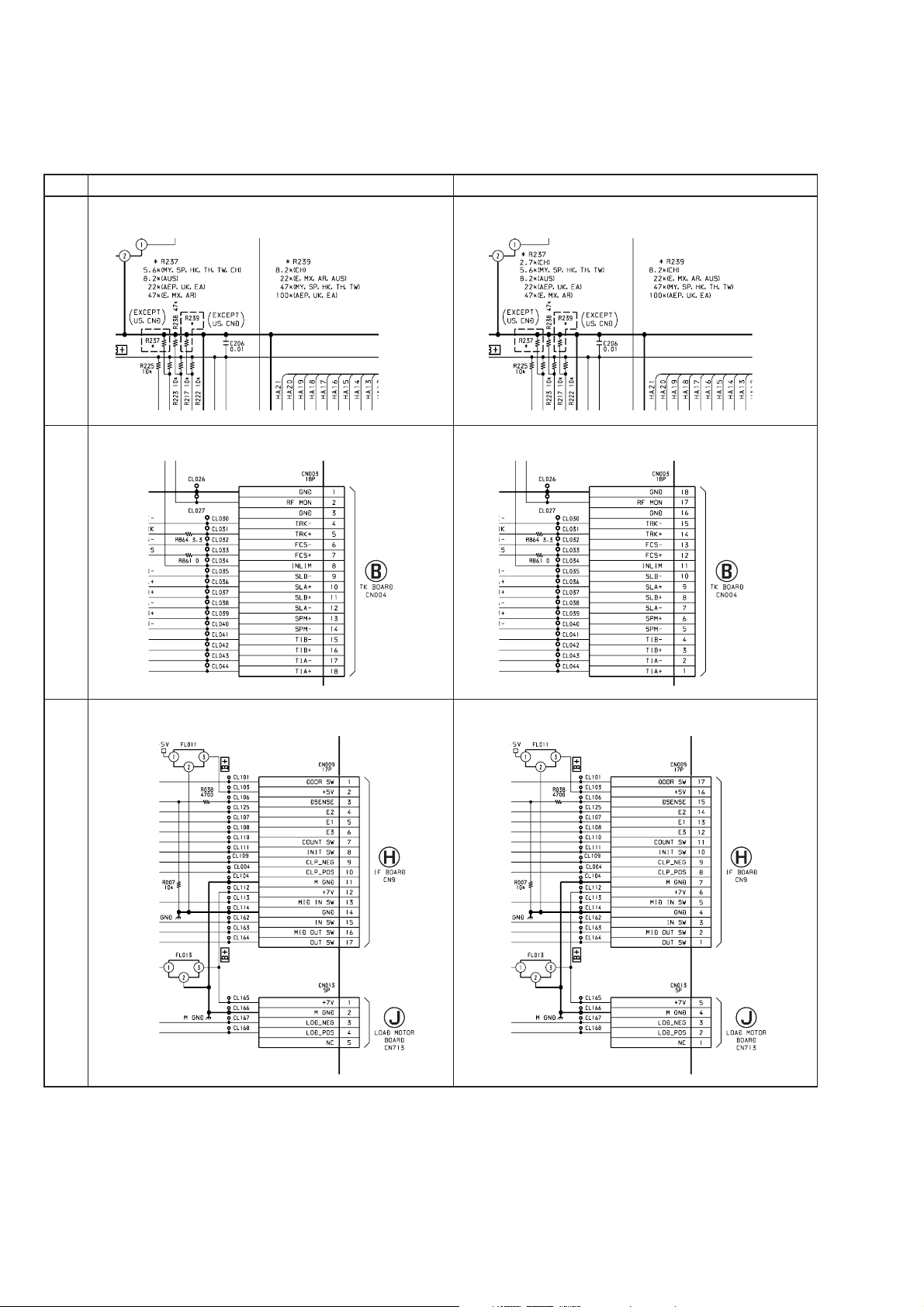

1. CORRECTION

1-1. SCHEMATIC DIAGRAMS

! : Indicates corrected portion.

Page INCORRECT CORRECT

– MB Board (1/10) – Location : B-7

28

– MB Board (8/10) – Location : G-18

35

– MB Board (1/10) – Location : B-7

^

– MB Board (8/10) – Location : G-18

^

(Page 25) (Page 25)

– MB Board (10/10) – Location : I-14

37

• Abbreviation

AR : Ar gentine model

AUS : Australian model

CH : Chinese model

CND: Canadian model

EA : Saudi Arabia model

HK : Hong Kong model

MX : Mexican model

MY : Malaysia model

SP : Singapore model

TH : Thai model

TW : Taiwan model

– MB Board (10/10) – Location : I-14

^

(Page 39) (Page 39)

^

(Page 41)

(Page 41)

2

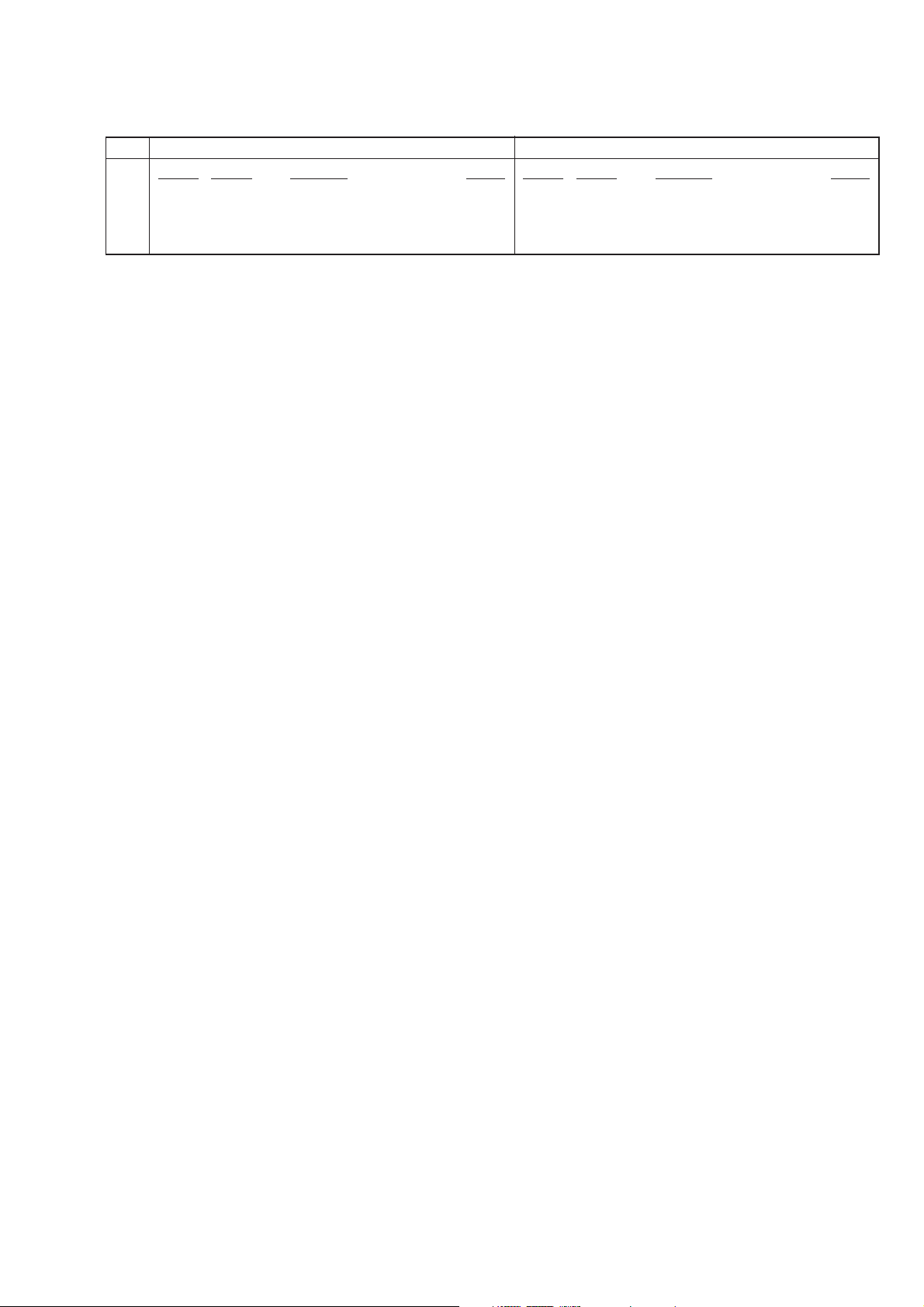

1-2. ELECTRICAL PARTS LIST

Page INCORRECT CORRECT

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

R237 1-216-216-00 RES-CHIP 5.6K 5% 1/8W

88

• Abbreviation

CH : Chinese model

HK : Hong Kong model

MY : Malaysia model

SP : Singapore model

TH : Thai model

TW : Taiwan model

(MY, SP, HK, TH, TW, CH)

R237 1-216-208-00 RES-CHIP 2.7K 5% 1/8W

R237 1-216-216-00 RES-CHIP 5.6K 5% 1/8W

(CH)

(MY, SP, HK, TH, TW)

3

2. SERVICING NOTE

CDM SHIP MODE

In sending the set back to the customers, place the set in the CDM

SHIP MODE through the procedure given below.

If the dummy disc is not inserted in the set returned from the

customers, ask customers for sending it or add new dummy disc

(Part No.: 4-228- 906-01 DISC, DUMMY).

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the Z 1 button to open the disc tray 1, and put the dummy

disc.

3. Press the I/1 button, and the disc tray will close and chucking

the disc automatically.

4. Unplug the power cord when the demo display or clock display

appears on the fluorescent display tube.

Note: Peel off the protection sheets on both sides, if present on the dummy

disc.

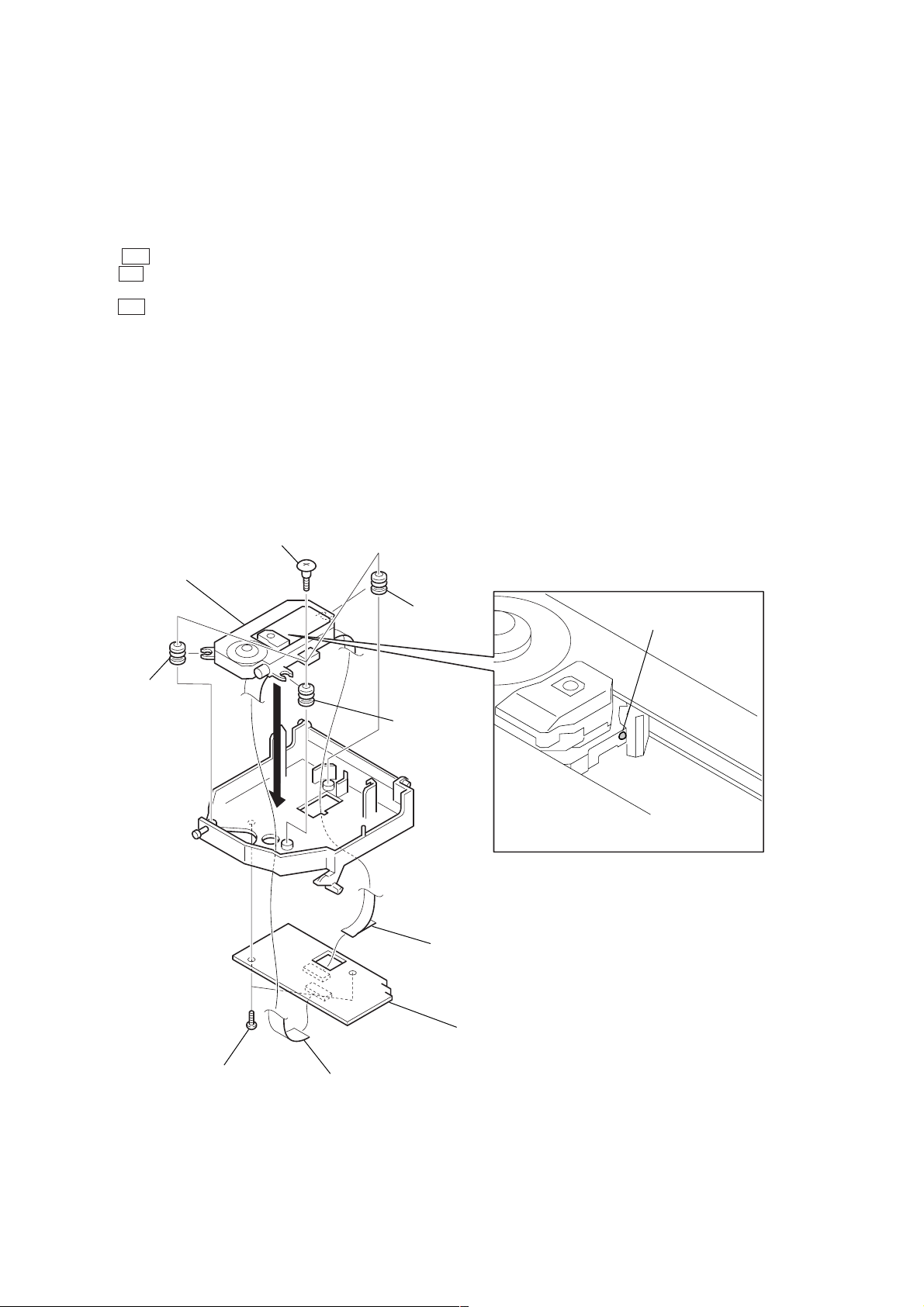

NOTES ON INSTALLING OPTICAL PICK-UP

Note: Follow the assembly procedure in the numerical order given.

3

three step screws

optical pick-up

(KHM-220AAA)

1

insulator

2

1

1

insulator

insulator

Note: Installing optical pick-up,

remove the solder for short.

6

wire (flat type) (21 core) (CN002)

4

TK board

8

Remove the solder.

5

two screws

(BVTP 2.6)

7

wire (flat type) (13 core) (CN001)

4

3. SERVICE MODE

[MC Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press three buttons x , DISPLAY , and DISC 5 simultaneously.

2. The fluorescent indicator tube displays “COLD RESET” and

the set is reset.

Note: To initialize DVD, refer to “Initializing set up data” in the “4. TEST

MODE 4-7. EMERGENCY HISTORY” (see page 15).

[MC Hot Reset]

• This mode resets the set with the preset data kept stored in the

memory. The hot reset mode functions same as if the power

cord is plugged in and out.

Procedure:

1. Press three buttons x , DISPLAY , and DISC 1 simultaneously .

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

[CD Service Mode]

• This mode can run the CD sled motor freely . Use this mode, for

instance, when cleaning the optical pick-up.

Procedure:

1. Enter the test mode. (Refer to “4. TEST MODE” on page 7)

2. Press the [2] key of remote commander to enter the “Drive

Manual Operation”.

3. Press the [2] key of remote commander to enter the “Servo

Control”. (Refer to “2. Servo Control” on page 14)

4. Press the t (outward) or T (inward) key of remote

commander to move the sled motor.

5. To release this mode, press the ?/1 button to turn the power

OFF.

Note: • Always move the pickup to most inside track when exiting from

this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively , otherwise the gear can be

chipped.

• Remote commander: RM-SD170 (Part No.: 1-418-911-11)

[VACS ON/OFF Mode]

• This mode is used to switch ON and OFF the VACS (Variable

Attenuation Control System).

Procedure:

1. Press ?/1 button to turn the set ON.

2. Press the PUSH ENTER and x buttons simultaneously. The

message “VACS OFF” or “VACS ON” appears.

[Change-over of AM Tuner Step between 9 kHz and

10 kHz] (Except AEP, UK and Saudi Arabia models)

• A step of AM channels can be changed over between 9 kHz and

10 kHz.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND

button to select the BAND “AM”.

3. Press ?/1 button to turn the set OFF.

4. Press MODE SELECT and ?/1 buttons simultaneously, and

the display of fluorescent indicator tube changes to “AM 9 k

STEP” or “AM 10 k STEP”, and thus the channel step is

changed over.

[GC Test Mode]

• This mode is used to check the software version, FL tube, LED,

keyboard and VACS.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Press three buttons x , DISPLAY , and DISC 2 simultaneously.

3. LEDs and fluorescent indicator tube are all turned on.

4. When you want to enter the software version display mode,

press DISC 1 . The model number and destination are displayed.

5. Each time DISC 1 is pressed, the display changes starting

from Z-DVD version, MC version, GC version, VC version,

DVD version, ST version, TC version, TA version, TM version

and BR version in this order, and returns to the model number

and destination display.

6. When DISC 3 is pressed while the version numbers are being

displayed except model number and destination, year, month

and day of the software creation appear. When DISC 3 is

pressed again, the display returns to the software version display .

When DISC 1 is pressed while year, month and day of the

software creation are being displayed, the year, month and day

of creation of the software versions are displayed in the same

order of version display.

7. Press DISC 2 button, and the key check mode is activated.

8. In the key check mode, the fluorescent indicator tube displays

“K 0 Vo 0 Stick N”. Each time a button is pressed, “K 0”

value increases. Ho we v er , once a button is pressed, it is no longer

taken into account.

“Vo 0” value increases like 1, 2, 3 ... if rotating VOLUME

knob in “+” direction, or it decreases like 0, 9, 8 ... if rotating in

“–” direction.

Moving the stick changes the “STICK N” display.

When moved up : “STICK R”

When moved down : “STICK r ”

When moved to the left : “STICK T”

When moved to the right : “STICK t”

9. Also when DISC 3 is pressed after lighting of all LEDs and FL

tubes, value of VACS a ppears.

10. To exit from this mode, press three buttons in the same manner

as step 1, or disconnect the power cord.

5

[MC Test Mode]

• This mode is used to check operations of the respectiv e sections

of Amplifier, Tuner, CD and Tape.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Press the three buttons of x , DISPLAY and DISC 3

simultaneously.

3. A message “TEST MODE” appears on the FL display tube.

4. When the joy stick is pushed up, GEQ increases to its

maximum and a message “GEQ MAX” appears.

5. When the joy stick is pushed down, GEQ decreases to its

minimum and a message “GEQ MIN” appears.

6. When the joy stick is pushed left or right, GEQ is set to flat

and a message “GEQ FLAT” appears.

7. When the VOLUME control knob is turned clockwise even

slightly, the sound volume increases to its maximum and a

message “VOLUME MAX” appears for two seconds, then the

display returns to the original display.

8. When the V OLUME control knob is turned counter-clockwise

even slightly, the sound volume decreases to its minimum and

a message “VOLUME MIN” appears for two seconds, then

the display returns to the original display.

9. In the test mode, the default-preset channel is called even when

the TUNER is selected and an attempt is made to call the preset

channel that has been stored in memory, by operating the .

and > buttons. (It means that the memory is cleared.)

10. When a tape is inserted in Deck B and recording is started, the

input source function selects VIDEO automatically.

11. When x button is pressed to stop recording, the Deck B is

selected and tape is rewound using the m button, tape is

rewound, tape is stops at around the record-starting position

and playback of the recorded portion of the tape is started. If

P A USE is inserted even once during recor ding, tape is rewound

to the position around the P AUSE position and is played back.

12. When the HI-DUB Button is press during playback of Deck

B, either normal speed or high speed can be selected by this

button.

13. Select the desired loop as follows. Press the MODE SELECT

button and press the PUSH ENTER button in the “Set Up

Mode”. Push the joy stick to right or left and press the PUSH

ENTER button in the “Direction Set Up”. Push the joy stick

to right or left and press PUSH ENTER at “Cycle”. Insert a

test tape AMS-110A or AMS-RO to Deck A.

14. Press the CD SYNCHRO button to enter the AMS test mode.

15. After a tape is rewound first, the FF AMS is checked, and the

mechanism is shut off after detecting the AMS signal twice.

16. Then the REW AMS is checked and the mechanism is shut of f

after detecting the AMS signal twice.

17. When the check is complete, a message of either OK or NG

appears.

18. When you want to exit this mode, press the ?/1 button twice.

The cold reset is enforced at the same time.

6

4. TEST MODE

4-1. GENERAL DESCRIPTION

The T est Mode allows you to make diagnosis and adjustment easily using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

4-2. STARTING TEST MODE

Press the ?/1 button to turn the set ON, and set the function to

DVD. Press the Z 1 button to insert the DVD disc, and wait for

TOC reading is finish. Next, while pushing the x button and the

[DISPLAY] and [DISC 4] button on the main unit at the same time,

turn the regulator to the right to start Test Mode and display the

menu shown below on the TV screen. At the bottom of the menu

screen, the model name and revision number are displayed.

To execute each function, select the desired menu and press its

number on the remote commander. To exit from Test Mode, press

the ?/1 button.

Note: In the Test Mode, use the remote commander (RM-SD170)

(Part No.: 1-418-911-11).

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Version Information

6. Video Level Adjustment

Exit: Power Key

_

Model : HCX-984_xxxx

Revision : 1.xxx

### Syscon Diagnosis ###

Diag All Check

No. 2 Version

2-3. ROM Check Sum

Check Sum = 2005

Press NEXT Key to Continue

Press PREV Key to Repeat

_

For the ROM Check, the check sum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press [NEXT] key to go to the next item,

or [PREV] ke y to repeat the same check again. To quit the diagnosis and return to the Check Menu screen, press the x or

[ENTER] key. If an error occurred, the diagnosis is suspended

and the error code is displayed as shown below.

### Syscon Diagnosis ###

3-3. EEPROM Check

Error 03: EEPROM Write/Reed N

Address : 00000001

Write Data : 2492

Read Data : 2490

Press NEXT Key to Continue

Press PREV Key to Repeat

_

4-3. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander.

On the Test Mode Menu screen, press [10/0] key on the remote

commander, and the following Check Menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. Peripheral

4. Servo

5. Supply

6. AV Decoder

7. Video

8. Audio

_

0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Men u.

1. All

All items continuous check

This menu checks all diagnostic items continuously . Normally , all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment through a visual check to the result, the following screen is

displayed for the key entry.

Press the x key to quit the diagnosis, or [PREV] key to repeat

the same item where an error occurred, or [NEXT] key to continue

the check from the item next to faulty item.

Selecting 2 and subsequent items calls the submenu screen of each

item.

For example, if “5. Supply” is selected, the following submenu

will be displayed.

### Syscon Diagnosis ###

Check Menu

No. 5 Supply

0. Quit

1. All

2. ARP Register Check

3. ARP to RAM Data Bus

4. ARP to RAM Address Bus

5. ARP RAM Check

_

0. Quit

Quit the submenu and return to the Check Menu.

1. All

All submenu items continuous check

This menu checks 2 and subsequent items successively . At the item

where visual check is required for judgment or an error occurred,

the checking is suspended and the message is output for key entry .

Normally, all items are checked successi vely one after another automatically unless an error is found.

7

Selecting 2 and subsequent items executes respective menus and

outputs the results.

For the contents of each submenu, see “Check Items List”.

General Description of Checking Method

2. Version

(2-2) Revision

ROM revision number is displayed.

Error: Not detected.

The revision number defined in the source file of ROM

(IC206) is displayed with four digits.

(2-3) ROM Check Sum

Check sum is calculated.

Error: Not detected.

The 8-bit data are added at addresses 0x000F0000 ~

0x002EFFFF of ROM (IC206) and the result is displayed

with 4-digit hexadecimal number . Error is not detected.

Compare the result with the specified value.

(2-4) Model Type

Model code is displayed.

Error: Not detected.

The model code read from EEPROM (IC201) is displayed

with 2-digit hexadecimal number.

Model Model No.

US and Canadian models 20

E, Mexican and Argentine models 22

AEP, UK and Saudi Arabia models 23

Australian model 24

Malaysia, Singapore, Hong Kong,

Thai and Taiwan models

Chinese model 26

(2-5) Region

Region code is displayed.

Error: Not detected.

The region code determined from the model code is displayed.

25

4. Servo

(4-2) Servo DSP Check

Data write → read, and accord check

Error 12: Read data discord

Data 0x9249, 0x2942, 0x4294 are written to the address

0x602 of RAM in the Servo DSP (IC701), then read and

checked.

(4-3) DSP Driver Test

Test signal data → DSP Driver

Error: Not detected.

Caution: Do not conduct this test with a mechanical deck

connected.

The maximum voltage is applied to the Servo Driver IC

(IC801, IC802). If mechanical deck is connected, the motor and optics could be damaged. Disconnect mechanical

deck following the output message, then enter specified 4or 5-digit number from the remote commander, and press

the [ENTER]. The test is conducted only when the input

data accord. Check the output level, then press the [NEXT]

to finish the test.

This test is skipped if “All” is selected.

Supplement: How to disconnect mechanical deck

Disconnect flat cables connected to the CN002 and CN003

of MB board. Also, disconnect harness from the CN013 of

MB board.

5. Supply

Caution: Do not conduct this check with a mechanical deck con-

nected.

An access is made to the stream supply and servo control IC (IC303) and external RAM (IC304) using check

data. If mechanical deck is connected, the motor and

optics could be damaged. This check is also executed

by the “All” menu item.

Supplement: How to disconnect mechanical deck

Disconnect flat cables connected to the CN002 and

CN003 of MB board. Also, disconnect harness from

the CN013 of MB board.

3. Peripheral

(3-2) Gate Array Check

Data write → read, and accord check

Error 02: Gate array write/read discord

Data 0x00~0xFF are written to the address 0xF of gate array

(IC601), then read and checked if they accord.

(3-3) EEPROM Check

Data write → read, and accord check

Error 03: EEPROM write/read discord

Data 0x9249, 0x2942, 0x4294 are written to addresses

0x00~0xFF of EEPROM (IC201), then read and checked.

Before writing, the data are saved, then after checking, they

are written to restore the contents of EEPROM.

8

(5-2) ARP Register Check

Data write → read, and accord check

Error 08: ARP register write, and read data discord

Data 0x00 to 0xFF are written to the TMAX register (address 0xC6) in ARP (IC303), then they are r ead and checked.

(5-3) ARP to RAM Data Bus

Data write → read, and accord check

Error 09: ARP ←→ RAM data bus error

Data 0x0001 to 0x8000 where one bit each is set to 1 are

written to the address 0 of RAM (IC304) connected to the

ARP (IC303) through the bus, then they are read and

checked. In case of discord, written bit pattern and read

data are displayed. If data where multiple bits are 1 are

read, the bits concerned may touch each other. Further, if

data where certain bit is always 1 or 0 regardless of written

data, the line could be disconnected or shorted.

(5-4) ARP to RAM Address Bus

Data write → other address read discord check

Error 10: ARP → RAM address bus error

Caution: Address and data display in case of an error is

different from the display of other diagnosis (de-

scribed later).

Before starting the test, all addresses of RAM (IC304) are

cleared to 0x0000.

First, 0xA55A is written to the address 0x00000, and the

address data are read and checked from addresses 0x00001

to 0x80000 while shifting 1 bit each. Next, the data at that

address is cleared, and it is written to the address 0x00001,

and read and checked in the same manner. This check is

repeated up to the address 0x80000 while shifting the address data by 1 bit each.

If data other than 0 is read at the addresses except written

address, an error is given because all addresses were already cleared to 0. In this check, the error display pattern is

different from that of other diagnosis; read data, written

address, and read address are displayed in this order. Ho wever , the message uses same template, and accordingly exchange Address and Data when reading. T he following display, for example,

6. AV Decoder

(6-2) 1930 RAM

Data write → read, and accord check

Error 13: AVD RAM read data discord

The program code data stored in ROM (IC206) are copied

to all areas of RAM (IC402, IC403) connected to the AVD

(IC401) through the bus, then they are read and checked if

they accord. Further, the same test is conducted once again

with the data where all bits are inverted between 1 and 0. If

discord is detected, faulty address, written data, and read

data are displayed following the error code 13, and the test

is suspended.

(6-3) 1930 SP

ROM → AVD RAM → Video OUT

Error: Not detected.

The data including sub picture streams in ROM (IC206)

are transferred to the RAM (IC402, IC403) in AVD (IC401),

and output as video signals from the AVD (IC401).

They are output from all video terminals (Composite, Y/C).

7. Video

### Syscon Diagnosis ###

5-4. ARP to RAM Address Bus

Error 10: ARP - RAM Address B

Address : 0000A55A

Write Data : 00000000

Read Data : 00080000

Press NEXT Key to Continue

Press PREV Key to Repeat

_

shows the data 0xA55A was read from address 0x00080000

though it was written to the address 0x00000000. This implies that these addresses are in the form of shadow. Also,

if the read data is not 0xA55A, another error will be present.

(5-5) ARP RAM Check

Data write → read, and accord check

Error 11: ARP RAM read data discord

The program code data stored in ROM are copied to all

areas of RAM (IC304) connected to the ARP (IC303)

through the bus, then they are read and checked if they accord. If the detail check was selected initially, the data are

written to all areas and read, then the same test is conducted

once again with the data where all bits are inverted between

1 and 0. If discord is detected, faulty address, written data,

and read data are displayed following the error code 11,

and the test is suspended.

(7-2) Color Bar

AVD color bar command write → Video OUT

Error: Not detected.

The command is transferred to the AVD, and the color bar

signals are output from video terminals.

They are output from all video terminals (Composite, Y/C).

8. Audio

(8-2) ARP → 1930

Error 14: ARP → 1930 video NG

15: ARP → 1930 audio NG

9

Check Items List

2) Version

(2-2) Revision

(2-3) ROM Check Sum

(2-4) Model Type

(2-5) Region

3) Peripheral

(3-2) Gate Array Check

(3-3) EEPROM Check

4) Servo

(4-2) Servo DSP Check

(4-3) DSP Driver Test

5) Supply

(5-2) ARP Register Check

(5-3) ARP to RAM Data Bus

(5-4) ARP to RAM Address Bus

(5-5) ARP RAM Check

6) AV Decoder

(6-2) 1930 RAM

(6-3) 1930 SP

7) Video

(7-2) Color Bar

Error Codes List

00: Error not detected

01: RAM write/read data discord

02: Gate array NG

03: EEPROM NG

08: ARP register read data discord

09: ARP ←→ RAM data bus error

10: ARP ←→ RAM address bus error

11: ARP RAM read data discord

12: Servo DSP NG

13: 1930 SDRAM NG

14: ARP → 1930 video NG

15: ARP → 1930 audio NG

16: 1910 UCODE download NG

17: System call error (function not supported)

18: System call error (parameter error)

19: System call error (illegal ID number)

20: System call error (time out)

90: Error occurred

91: User verification NG

92: Diagnosis cancelled

8) Audio

(8-2) ARP → 1930

(8-3) Test Tone

10

4-4. DRIVE AUTO ADJUSTMENT

1. DVD-SL (single layer)

On the T est Mode Menu screen, press [1] k e y on the remote commander, and the Adjustment Menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

4. SACD

Exit: RETURN

Normally, [10/0] is selected to adjust DVD (single layer), CD,

DVD (dual layer), and SACD in this order. But, individual items

can be adjusted for the case where adjustment is suspended due to

an error. In this mode, the adjustment can be made easily through

the operation following the message displayed on the screen.

The disc used for adjustment must be the one specified for adjustment. However, for SACD disc, use the player with initial data if

the disc is not available.

0. ALL

Select [10/0] and press [ENTER] key, and the servo set data in

EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD disc,

3. DVD-DL disc, and 4. SACD disc are adjusted in this order.

Each time one disc was adjusted, it is ejected. Replace it with the

specified disc following the message. Though the message to confirm whether discs other than SACD disc are adjusted is not displayed, you can finish the adjustment if pressing the x button.

During adjustment of each disc, the measurement for disc type

judgment is made. As automatic adjustment does not judge the

disc type unlike conventional models, tak e care not to insert wrong

type discs. Also, do not give a shock during adjustment.

Select [1], insert DVD single layer disc, and press [ENTER] key,

and the adjustment will be made through the following steps, then

adjusted values will be written to the EEPROM.

DVD Single Layer Disc Adjustment Steps

1. SLED TILT Reset

2. Disc Check Memory SL

3. Wait 300 msec

4. Set Disc Type SL

5. LD ON

6. Spdl Start

7. Wait 1 sec

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. CLVA ON

11. Wait 500 msec

12. Tracking ON

13. Wait 1 sec

14. Sled ON

15. Check CLV Lock

16. Auto LFO Adjust

17. Auto Focus Offset Adjust

18. Auto Tilt Position Adjust

19. Auto Focus Gain Adjust

20. Auto Focus Offset Adjust

21. EQ Boost Adjust

22. Auto LFO Adjust

23. Auto Track Gain Adjust

Search Check

24. 32Tj Fwd

25. 32Tj Rev

26. 500Tj Fwd

27. 500Tj Rev

28. All Servo Stop

29. Eep Copy Loop Filter Offset

11

2. CD

3. DVD-DL (dual layer)

Select [2], insert CD disc, and press [ENTER] ke y , and the adjustment will be made through the following steps, then adjusted values will be written to the EEPROM.

CD Adjustment Steps

1. Sled Tilt Rest

2. Disc Check Memory CD

3. Wait 500 msec

4. Set Disc Type CD

5. LD ON

6. Spdl Start

7. Wait 500 msec

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. CLVA ON

11. Wait 500 msec

12. Tracking ON

13. (TC Display Start)

14. Wait 1 sec

15. Jitter Display Start

16. Sled ON

17. Check CLV ON

18. Auto LFO Adjust

19. Auto Focus Offset Adjust

20. Auto Focus Gain Adjust

21. Auto Focus Offset Adjust

22. Eq Boost Adjust

23. Auto LFO Adjust

24. Auto Track Gain Adjust

Search Check

25. 32Tj Fwd

26. 32Tj Rev

27. 500Tj Fwd

28. 500Tj Rev

Select [3], insert DVD dual layer disc, and press [ENTER] key,

and the adjustment will be made through the following steps, then

adjusted values will be written to the EEPROM.

DVD Dual Layer Disc Adjustment Steps

1. Sled Tilt Reset

2. Disc Check Memory DL

3. Wait 500 msec

4. Set Disc Type DL

5. LD ON

6. Spdl Start

7. Wait 1 sec, Layer 1 Adjust

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. Clva ON

11. Wait 500 msec

12. Tracking ON

13. Wait 500 msec

14. Sled ON

15. Check CLV Lock

16. Auto Loop Filter Offset Auto Focus Adjust

17. Auto Focus Gain Adjust

18. Auto Focus Offset Adjust

19. Eq Boost Adjust

20. Auto Loop Filter Offset

21. Auto Track Gain Adjust

Search Check

22. 32Tj Fwd

23. 32Tj Rev

24. 500Tj Fwd

25. 500Tj Rev

Layer 0 Adjust

26. Fj (L1 -> L0)

27. Auto Track Offset Adjust L0

29. All Servo Stop

28. Clva ON

29. Wait 500 msec

30. Tracking ON

31. Wait 500 msec

32. Sled ON

33. Check CLV Lock

34. Auto Focus Filter Offset

35. Auto Focus Adjust

36. Auto Focus Gain Adjust

37. Auto Focus Offset Adjust

38. Eq Boost Adjust

39. Auto Loop Filter Offset

40. Auto Track Gain Adjust

Search Check

41. 32Tj Fwd

42. 32Tj Rev

43. 500Tj fwd

44. 500Tj Rev

Layer Jump Check

45. Lj (L0 -> L1)

46. Lj (L1 -> L0)

47. All Servo Stop

12

Loading...

Loading...