Sony HCD RG121 Service Manual

HCD-RG121

D

C

M

T

5

D

C

S

L

F

W

S

D

t.

SERVICE MANUAL

Ver 1.0 2004.04

• HCD-RG121 is the tuner, deck, CD and

amplifier section in MHC-RG121.

CD

Section

Tape deck

Section

AEP Model

UK Model

E Model

Australian Model

Model Name Using Similar Mechanism New

CD Mechanism Type CDM74-K6BD80

Optical Pick-up Name KSM-213DCP/Z-NP

Model Name Using Similar Mechanism New

Tape Transport Mechanism Type CWM43FF-05

SPECIFICATIONS

Amplifier section

AUDIO POWER SPECIFICATIONS

IN power output (rated): 50 + 50 watts ( 6 oh ms at

ontinuous RMS power output (reference):

usic power output (reference):

he following measured at AC 120, 127, 220 , 240 V

0/60 Hz

IN power output (rated): 50 + 50 watts (6 ohms at

ontinuous RMS power output (reference):

CD player section

ystem Compact disc and digital

aser Semiconductor laser

requency response 2 Hz – 20 kHz (±0.5 dB)

avelength 780 – 790 nm

ignal-to-noise ratio More than 90 dB

ynamic range More than 90 dB

1kHz, DIN)

65 + 65 watts ( 6 oh ms at

1kHz, 10% THD)

130 + 130 watts (6 ohms at

1kHz, 10% THD)

1kHz, DIN)

60 + 60 watts (6 ohms at

1kHz, 10% THD)

audio system

(λ=780 nm)

Emission duration:

continuous

Tape deck section

Recording system 4-track 2-channel, stereo

Frequency response 50 – 13,000 Hz (±3 dB),

Tuner section

FM stereo, FM/AM super he te rodyne tuner

FM tuner section

Tuning range

North American model: 87.5 – 108.0 MHz

Russian model: 65.0 – 74.0 MHz

Other models: 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

using Sony TYPE I

cassettes

(100-kHz step)

(There is no stereo effec

10-kHz step)

87.5 – 108.0 MHz

(50-kHz step)

(50-kHz step)

– Continued on next page –

MINI HI-FI COMPONENT SYSTEM

9-877-658-01

2004D1679-1

© 2004.04

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

HCD-RG121

P

E

O

D

ls

A

M

E

O

D

w

T

P

E

e

O

A

A

l

I

AM tuner section

uning range

an-American models: 530 – 1,710 kHz

uropean, Russian and Saudi Arabian models:

ther models: 530 – 1,710 kHz

ntenna AM loop antenna

ntenna terminals External antenna termina

ntermediate frequency 450 kHz

General

ower requirements

uropean and Russian models:

ther models: 110 watts

imensions (w/h/d) incl. projecting parts and contro

mplifier/Tuner/Tape/CD section:

ass

uropean and Russian models:

ther models:

esign and specifications are subject to change

ithout notice.

(with the tuning interv al

set at 10 kHz)

531 – 1,710 kHz

(with the tuning interv al

set at 9 kHz)

531 – 1,602 kHz (with th

tuning interval set at

9kHz)

(with the tuning interv al

set at 10 kHz)

531 – 1,602 kHz

(with the tuning interv al

set at 9 kHz)

110 watts

0.25 watts (at the Pow er

Saving Mode)

Approx. 280 × 327 ×

425 mm

Approx. 8.5 kg

Approx. 8.5 kg

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

2

The release method of a CD disc tray LOCK function

There is a disc lock function for the disc theft prevention for a

demonstration at a shop front in this machine.

Procedue:

1. Press the ?/1 button to turn the set on.

2. Press two buttons of x and Z (EJECT) simultaneously for

five seconds.

3. The message “LOCKED” is displayed and the tray is locked.

(Even if exiting from this mode, the tray is still locked.)

4. Press two buttons of x and Z (EJECT) simultaneously for

five seconds again.

5. The message “UNLOCKED” is displayed and the tray is

unlocked.

6. To exit from this mode, press the ?/1 button to turn the set

off.

HCD-RG121

TABLE OF CONTENTS

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flow) than

ordinary solder so use caution not to let solder bridges occur

such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

1. SERVICE POSITION ............................................... 4

2. GENERAL ................................................................... 6

3. DISASSEMBLY

3-1. Cover (Top) ........................................................... 9

3-2. CD Door ................................................................ 9

3-3. Front Panel Section ............................................... 10

3-4. CD Mechanism Deck (CDM74-K6BD80)............ 10

3-5. Tape Mechanism Deck, GAME JACK Board ....... 11

3-6. PANEL Board........................................................ 11

3-7. Back Panel Section, SUB-TRANS Board............. 12

3-8. Power Transformer................................................ 12

3-9. MAIN Board ......................................................... 13

3-10. AMP Board ........................................................... 13

3-11. BD80A Board ........................................................ 14

3-12. CONNECT Board ................................................. 14

3-13. DRIVER Board, SW Board .................................. 15

3-14. Optical PICK-UP (KSM-213DCP/Z-NP) ............. 15

3-15. SENSOR Board ..................................................... 16

3-16. MOTOR (TB) Board ............................................. 16

3-17. MOTOR (LD) Board ............................................. 17

4. TEST MODE ............................................................... 18

5. DIAGRAMS

5-1. Block Diagram – PANEL Section –...................... 22

5-2. Block Diagrams – MAIN Section – ...................... 23

5-3. Block Diagrams – BD/DRIVER Section – ........... 24

5-4. Printed Wiring Board – BD80A Section – ............ 25

5-5. Schematic Diagram – BD80A Section –............... 26

5-6. Printed Wiring Board

– CD MECHANISM Section – ............................. 27

5-7. Schematic Diagram

– CD MECHANISM Section – ............................. 28

5-8. Printed Wiring Board – MAIN Section – .............. 29

5-9. Schematic Diagram – MAIN Section (1/2) –........ 30

5-10. Schematic Diagram – MAIN Section (2/2) – ........ 31

5-11. Printed Wiring Board

– PANEL COMB Section –................................... 32

5-12. Schematic Diagram

– PANEL COMB Section –................................... 33

5-13. Printed Wiring Board – PANEL Section – ............ 34

5-14. Schematic – PANEL Section (1/2) –..................... 35

5-15. Schematic – PANEL Section (2/2) –..................... 36

5-16. Printed Wiring Board – TRANS Section – ........... 37

5-17. Printed Wiring Board – AMP Section – ................ 38

5-18. Schematic Diagram – AMP POWER Section –.... 39

5-19. IC Pin Function Description .................................. 42

6. EXPLODED VIEWS

6-1. MAIN Section ....................................................... 48

6-2. Front Panel Section ............................................... 49

6-3. MAIN Board Section ............................................ 50

6-4. CD Mechanism Deck Section-1

(CDM74-K6BD80) ............................................... 51

6-5. CD Mechanism Deck Section-2

(CDM74-K6BD80) ............................................... 52

7. ELECTRICAL PARTS LIST .................................. 53

3

HCD-RG121

d

SERVICE POSITION

• SERVICE POSITION-1 (AMP BOARD)

To inspect the AMP board, turn both of the front panel and the

CD mechanism deck so that the left side of the product faces

down.

CD mechanism deck

SECTION 1

front panel

AMP boar

4

• SERVICE POSITION-2 (BD80A BOARD)

k

Remove the CD mechanism deck and place it on top of the

pedestal as shown.

Inspect the BD80A bard in this set up.

HCD-RG121

BD80A board

CD mechanism dec

5

HCD-RG121

A

A

C

C

D

D

D

D

D

D

D

E

E

E

G

G

G

G

G

I

M

M

O

Illustrati

List of button locations and reference pages

SECTION 2

GENERAL

This section is extracted

from instruction manual.

How to use this page

Use this page to find the lo cation of buttons and other

parts of the system that are mentioned in the text.

TAPE A/B ed (18, 19, 20, 24)

Name of button/part Reference page

on number

r

RR

Main unit

ALPHABETICAL ORDER

A – O P – Z

LBUM +1) qh (12, 14, 19)

LBUM –1) wg (12, 14, 19)

D eg (9, 11, 14, 19, 20)

D SYNC wj (19)

eck A wk (18)

eck B qj (18, 19, 20, 24)

ISC 1 – 3 q; (12, 14, 35)

ISC SKIP/EX-CHANGE qs

(11, 12, 14, 19)

isc tray 9 (11)

ISPLAY 2 (17, 27, 28)

isplay window 5

FFECT ON/OFF 8 (22)

NTER qa (14, 15, 22)

Q BAND 7 (22)

AME es (20, 23, 30)

AME INPUT AUDIO L/R jacks

wd (20, 29)

AME INPUT VIDEO jack wf

(29)

AME MIXING wh (23)

ROOVE 8 (21)

LLUMINATION

IC jack3) ws (24)

IC LEVEL3) wa (24)

peration Dial

(– EQ +/l L) 6 (12,

14, 19, 22)

2)

3 (28)

P FILE qd (22)

PHONES jack ql

PLAY MODE wl (12, 14, 18, 19,

20, 35)

Power illuminator

PRESET EQ qd (22)

REC PAUSE/START wj (19, 20,

23, 24)

Remote sensor 4

SURROUND 8 (23)

TAPE A/B ed (18, 19, 20, 24)

TUNER/BAND ef (15, 16, 20)

TUNING MODE wl (15, 16, 35)

TUNING + qh (15, 16)

TUNING – wg (15, 16)

VIDEO/MD

VOLUME control w; (21)

WIRELESS

2)

qk (28)

3)

ea (20, 30)

4)

ea (32)

12345 6 78 9

eg

ef

ed

es

j

ALBUM

S

s

TUNING TUNING

ea

e;

wl

wk

wj

BUTTON DESCRIPTIONS

?/1 (power) 1 (8, 16, 27, 30, 33,

35)

X (pause) wg (12, 19)

Z (eject) qf (11)

PUSH Z (deck B) (eject) qg (18)

x (stop) wg (12, 19, 24, 35)

M (fast forward) qh (12, 19)

H or hH

19)

m (rewind) wg (12, 19)

Z PUSH (deck A) (eject) e; (18)

1)

MHC-GX750/GX450/RG555/

RG551S/RG444S/RG441/

RG333/RG222/RG221/RX550

only

2)

MHC-GX750/GX450/RG555/

RG551S/RG444S/RG441/

RG333/RX550 only

3)

MHC-RG555 only

4)

MHC-GX750 only

3)

(play) qh (12, 18,

q;

qa

J

ALBUM

H

h

qs

qd

qf

qg

qh

qj

qk

6

wh

ql

wd

wfwg

w;

waws

Remote control

A

A

C

C

C

C

D

D

E

E

)

/

0

U

t

HCD-RG121

ALPHABETICAL ORDER

A – E

LBUM –* qd (12, 14)

LBUM +* qa (12, 14)

D qk (11, 14)

LEAR qg (14)

LOCK/TIMER SELECT 2

(26, 27)

LOCK/TIMER SET 3 (10, 25,

26)

ISC SKIP q; (12, 14)

ISPLAY wa (17, 27, 28)

NTER 9 (10, 14, 15, 25, 26)

Q qf (22)

ws

wa

w;

ql

qk

qj

qh

qg

qf

qd

F – Z

FM MODE 4 (17)

FUNCTION 6 (11, 14, 15, 16)

PLAY MODE w; (12, 14, 18)

REPEAT 4 (13)

SLEEP ws (25)

TAPE qj

TUNER BAND 5 (15, 16)

TUNER MEMORY ql (15)

TUNING MODE w; (15, 16)

VOLUME +/– qs (21, 25)

1

2

3

4

5

6

7

8

9

q;

qa

BUTTON DESCRIPTIONS

?/1 (power) 1 (8, 26)

m/M (rewind/fast forward)

7 (12, 19)

–/+ (tuning) qh (15)

./> (go back/go forward

qh (10, 12, 19)

N (play) 8 (12, 18)

X (pause) 8 (12, 19)

x (stop) 8 (12, 19)

*MHC-GX750/GX450/RG555

RG551S/RG444S/RG441/

RG333/RG222/RG221/RX55

only

Setting the clock

se buttons on the remote for the operation.

1

2

3

4

5

6

Press ?/1 to turn on the system.

Press CLOCK/TIMER SET.

Press . or > repeatedly to set the

hour.

Press ENTER.

Press . or > repeatedly to set the

minute.

Press ENTER.

The clock start s working.

qs

To adjust the clock

1

Press CLOCK/TIMER SET.

2

Press . or > repeatedly to select

“CLOCK SET”, then press ENTER.

3

Do the same procedures as step 3 to 6

above.

Notes

The clock settings are canceled when you disconnec

the power cord or if a power failure occurs.

7

HCD-RG121

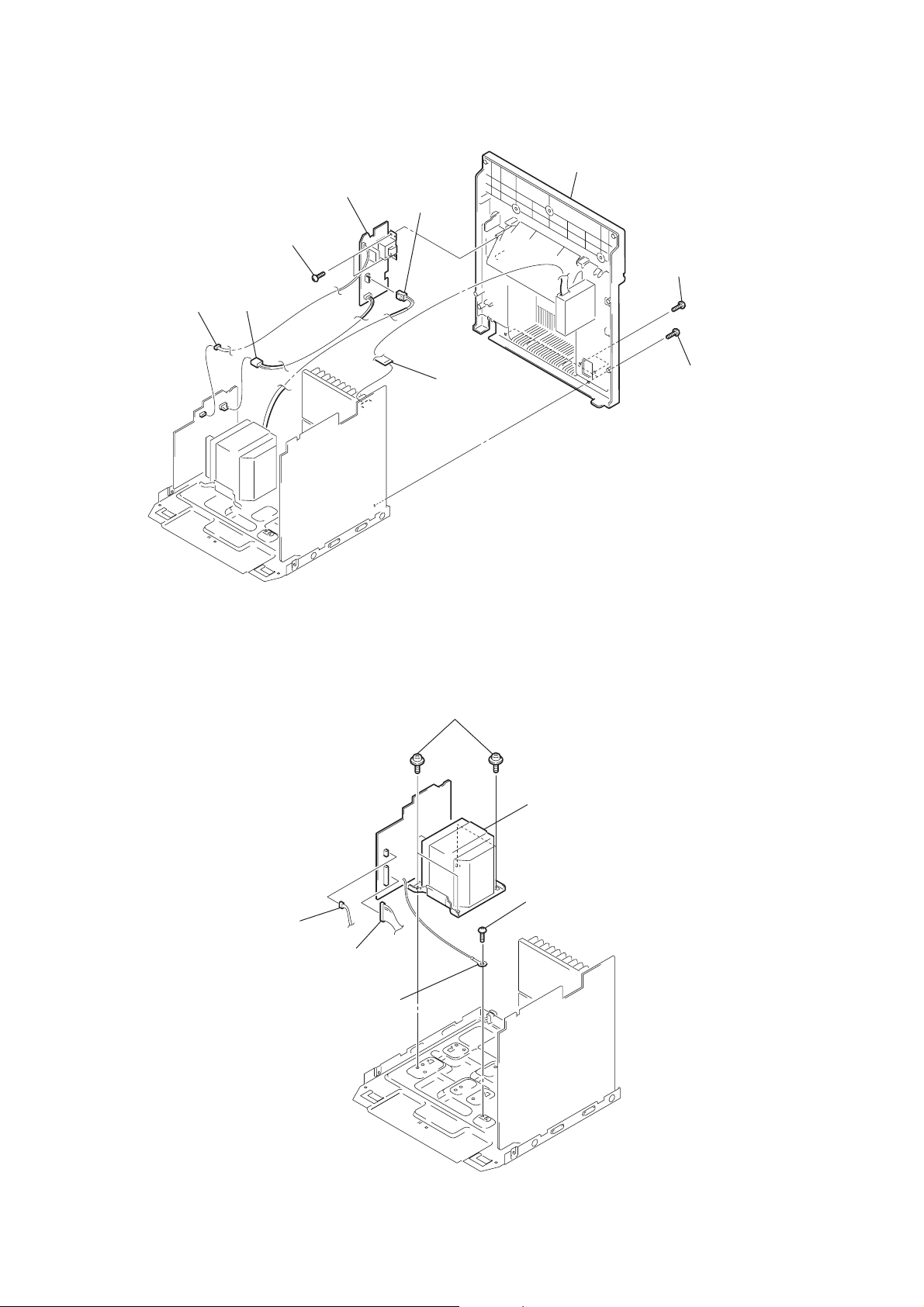

Note: Disassemble the unit in the order as shown below.

SET

3-1.COVER (TOP)

(Page 9)

3-2.CD DOOR

(Page 9)

SECTION 3

DISASSEMBLY

3-3.FRONT PANEL SECTION

(Page 10)

3-4.CD MECHANISM DECK

(CDM74-K6BD80)

(Page 10)

3-11.BD80A BOARD

(Page 14)

3-7.BACK PANEL SECTION,

SUB-TRANS BOARD

(Page 12)

3-8.POWER TRANSFORMER

(Page 12)

3-5.TAPE MECHANISM DECK,

GAME JACK BOARD

(Page 11)

3-12.CONNECT BOARD

(Page 14)

3-13.DRIVER BOARD,

SW BOARD

(Page 15)

3-9.MAIN BOARD

(Page 13)

3-6.PANEL BOARD

(Page 11)

3-14.OPTICAL PICK-UP

(KSM-213DCP/Z-NP)

(Page 15)

3-15.SENSOR BOARD

(Page 16)

3-16.MOTOR (TB) BOARD

(Page 16)

3-17.MOTOR (LD) BOARD

(Page 17)

3-10.AMP BOARD

(Page 13)

8

HCD-RG121

3-1. COVER (TOP)

6

two screws (Case 3 TP2)

9

(+BVTP 3

7

screw (case 3 TP2)

cover

screw

(Side-L)

× 10

)

cover

qf

8

screw

(+BVTP 3

(top)

qs

× 10

q;

qa

two

screws (+BVTP 3

qs

)

qd

5

cover

×

10)

(Side-R)

3

(+BVTP 3

1

two screws

(case 3 TP2)

screw

× 10

)

3-2. CD DOOR

CD mechanism deck (CDM74B)

1

Turn the pulley to the direction of arrow.

pulley

Front panel side

2

Pull-out the disc tray.

3

two claws

4

CD door

4

(+BVTP 3

2

screw (Case 3 TP2)

screw

× 10

)

9

HCD-RG121

)

3-3. FRONT PANEL SECTION

0

connector 3p (CN314C)

8

wire (flat type) 7 core (CN253)

6

connector 2p (CN805)

3

screw (+BVTP 3

×

10)

4

screw (+BVTP 3

× 8

)

2

qs

connector 8p (CN103)

qa

connector 3p (CN112)

screw (+BVTP 3

×

10)

5

screw (+BVTP 3

× 8

)

qd

front panel section

3-4. CD MECHANISM DECK (CDM74-K6BD80)

4

CD mechanism deck (CDM74-K6BD80)

9

connector 5p (CN309)

7

wire (flat type) 31 core (CN302)

1

three screws (+BVTP 3

× 8

)

1

three

screws (+BVTP 3

×

10

10

3

connector 9p (CN254)

2

connector 12p (CN701)

3-5. TAPE MECHANISM DECK, GAME JACK BOARD

)

1

wire (flat type) 13 core (CN602)

3

TRANSRATION board

2

(+BVTP 2.6

HCD-RG121

six

screws

×

8)

3-6. PANEL BOARD

2

seven

claws

6

GAME JACK board

5

two

screws

(+BVTP 2.6

4

connector 6p (CN604)

×

8)

4

tape mechanism deck

5

PANEL board

3

wire (flat type) 13 core (CN602)

1

ten

screws

(+BVTP 2.6

×

8

11

HCD-RG121

)

r

3-7. BACK PANEL SECTION, SUB-TRANS BOARD

7

connector

2p (CN901)

2

connector

2p (CN906)

8

SUB-TRANS board

6

two

screws

(+BVTT 3

1

connector

2p (CN904)

× 10

)

3

wire (flat type)

15 core (CN101)

9

back panel section

5

(+BVTT 3

two

screws

4

(+BVTP 3

×

two

10)

screws

×

10

3-8. POWER TRANSFORMER

1

connector

3p (CN905)

2

connector

10p (CN907)

4

earth wire

5

four

screws

(+ITC 4

× 8

)

6

power transforme

3

screw

(+BVIT 3

×

8R)

12

3-9. MAIN BOARD

d

)

1

connector

10p (CN907)

4

MAIN

Main board

HCD-RG121

boar

3-10. AMP BOARD

4

(transistor)

3

two

screws

(+BVIT 3

two

screws

× 8R

6

)

AMP

2

screw

(+BVTP 3

board

×

14)

3

connector

13p (CN441)

2

two

screws

(+BVTP 3

× 8

)

1

two

screws

(+BVTT 3

5

heat sink

× 8

13

HCD-RG121

)

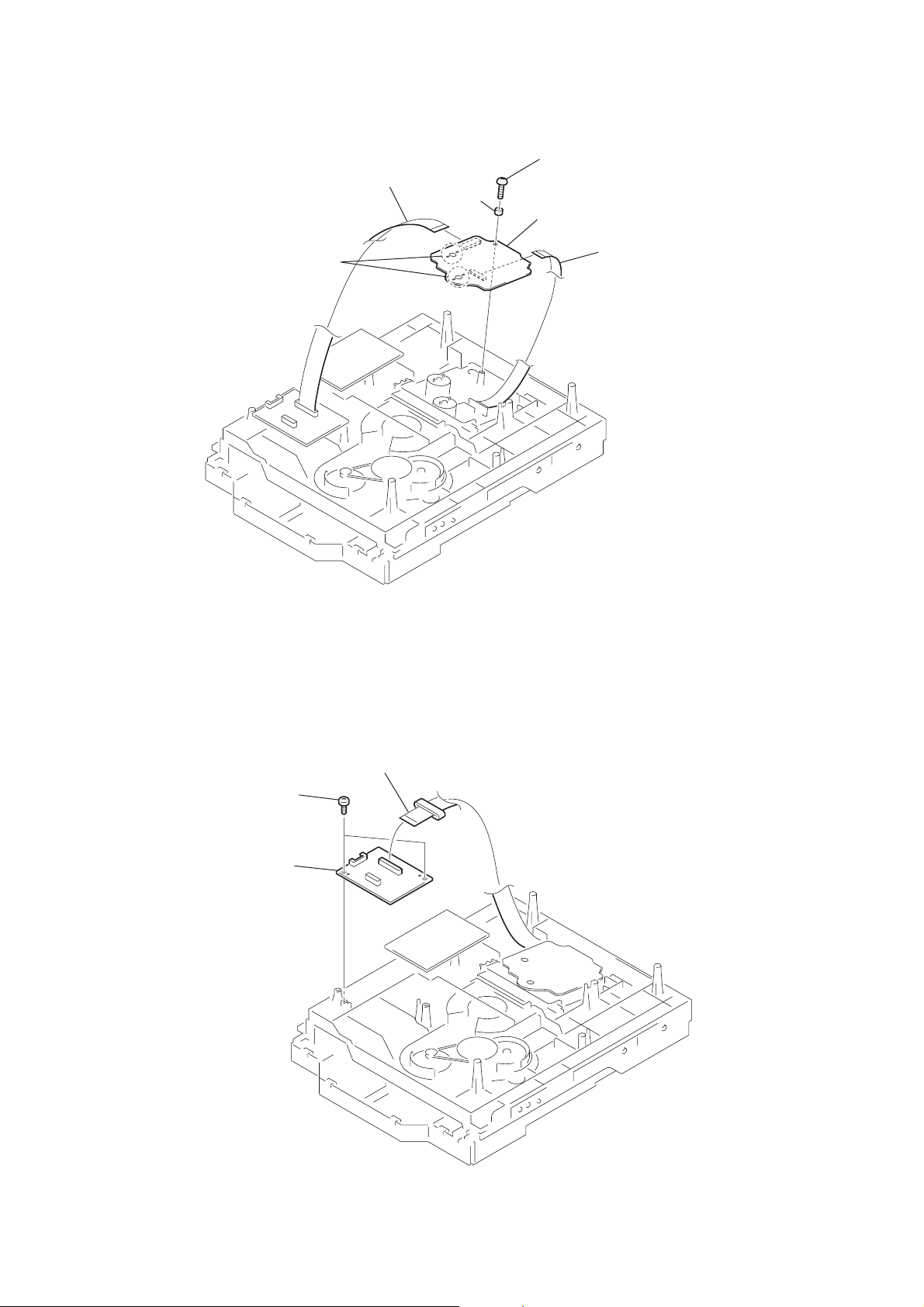

3-11. BD80A BOARD

4

Remove soldering from the four points.

1

wire (flat type) 17 core (CN201)

speacer

3

screw

(+BVTP 2.6

5

BD80A

board

× 8

)

2

wire (flat type) 16 core (CN101

3-12. CONNECT BOARD

2

two

(+BVTP 2.6

3

CONNECT

screws

board

1

wire (flat type) 17 core (CN201)

× 8

)

14

3-13. DRIVER BOARD, SW BOARD

1

two

(+BTTP (M2.6))

4

DRIVER

2

wire (flat type) 5p (CN702)

screws

board

3

connector

4p (CN703)

5

screw

(+BTTP (M2.6))

6

SW board

HCD-RG121

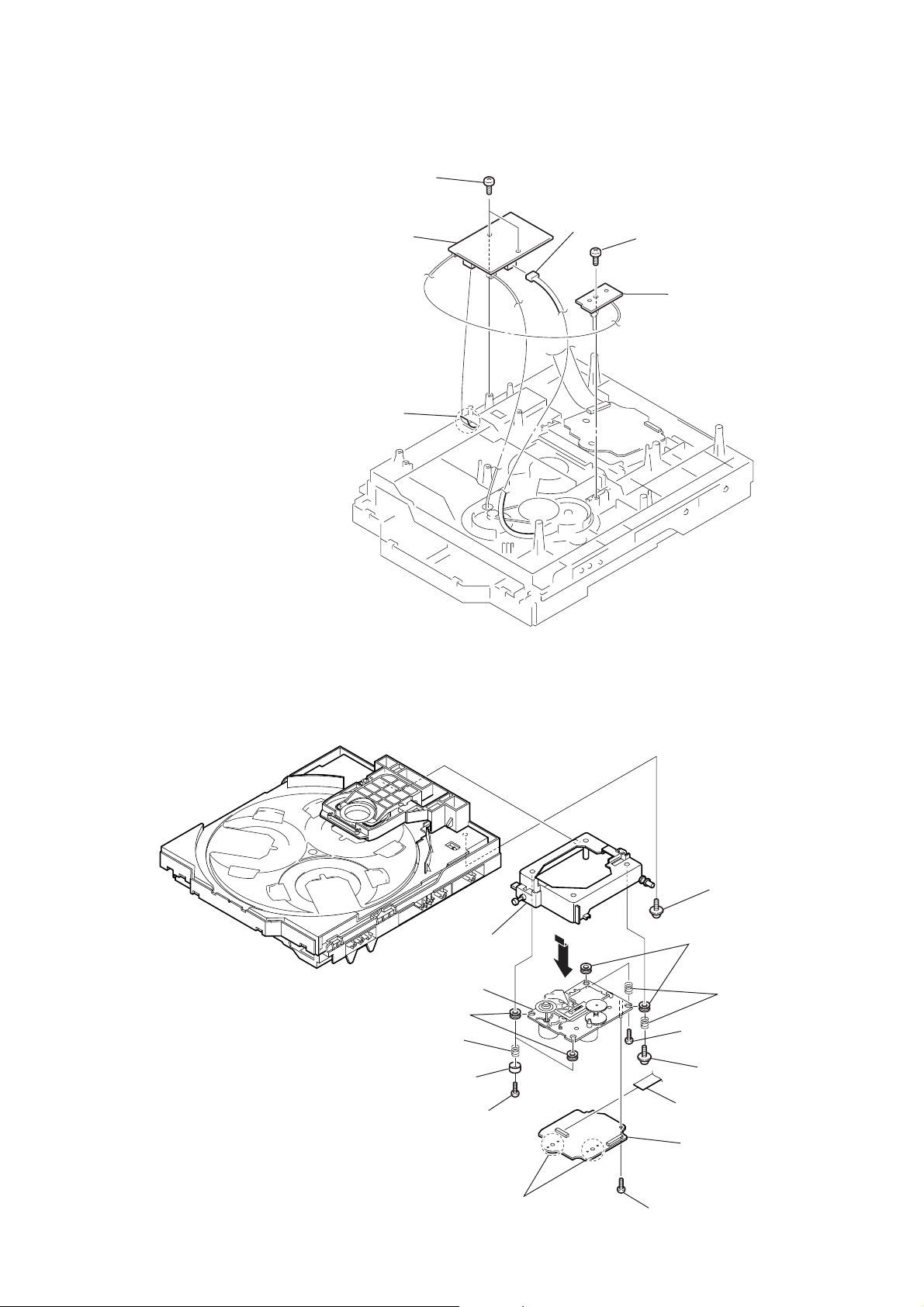

3-14. OPTICAL PICK-UP (KSM-213DCP/Z-NP)

2

h

qh

optical pick-up

(KSM-213DCP/Z-NP)

0

two

insulators

9

two

coil springs

(insulator)

8

t

wo stoppers (BU)

7

t

(BVTT M2.6)

older (213) ASSY

wo screws

qa

1

floating

(+PTPWH M2.6)

6

two

insulators

5

two

(insulator)

3

screw

(BVTT M2.6)

4

floating

(+PTPWH M2.6)

qf

CN101 (flat type)

qg

B

D80A board

screw

coil springs

screw

qd

Remove the four solderings of motor.

qs

s

crew (+BVTP 2.6x 8)

15

HCD-RG121

3-15. SENSOR BOARD

2

t

ray

1

floating

(+PTPWH M2.6)

6

floating

(+PTPWH M2.6)

7

g

screw

8

(+BTTP (M2.6))

screw

ear (geneva)

s

crew

0

SENSOR board

9

connector

CN731)

(

3

b

elt (table)

4

foating

(+PTPWH M2.6)

5

screw

p

ulley (table)

3-16. MOTOR (TB) BOARD

2

stopper

4

1

stopper

5

t

able motor assy (M741)

wire (flat type) 5 core (CN742)

3

7

MOTOR (TB) board

6

Remove the two solderings of motor.

16

5

two

screws

(+BTTP (M2.6))

3-17. MOTOR (LD) BOARD

4

Remove the two solderings of motor.

5

l

oading motor assy (M751)

2

two

screws

(+BTTP (M2.6))

3

MOTOR (LD) board

HCD-RG121

1

b

elt (loading)

17

HCD-RG121

SECTION 4

TEST MODE

[Change-over of AM Tuner Step between 9 kHz and

10 kHz]

•A step of AM channels can be changed ov er between 9 kHz and

10 kHz.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND

button to select the BAND “AM”.

3. Press ?/1 button to turn the set OFF.

4. Press TUNER/BAND and ?/1 buttons simultaneously, and

the display of fluorescent indicator tube changes to “AM 9 k

STEP” or “ AM 10 k STEP”, and thus the channel step is changed

over.

[Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press three buttons x , PLAY MODE/TUNING MODE ,

and DISC1 simultaneously.

2. The fluorescent indicator tube displays “COLD RESET” and

the set is reset.

[Aging Mode]

This mode can be used for operation check of CD section and tape

deck section.

• If an error occurred:

The aging operation stops and is displayed status.

• If no error occurs:

The aging operation continues repeatedly.

1. Operating method of Aging Mode

Turn on the main power and select “CD” of the function.

1) Set three discs in tray. Select ALL DISCS, and REPEAT OFF.

2) Load the tapes recording use into both decks.

3) Press three buttons x , PLAY MODE/TUNING MODE ,

and EX-CHANGE simultaneously.

4) Aging operations of CD and tape are started at the same time.

5) To exit the aging mode, perform [Cold Reset].

2. Aging mode in CD section

1) Operation during aging mode

• In the agining mode ,the progr am is excuted in the following

sequence.

(1) The disc tray opens and closes.

(2) The disc tray turns to select a disc 3.

(3) The pick-up accesses to the first track, and plays 3 seconds.

(4) The pick-up accesses to the last track, and plays 3 seconds.

(5) The disc tray opens and closes.

(6) The disc tray turns to select a disc 1.

(7) The same operation starts like step (3).

(8) After a disc 1 aging operation, a disc 2 is selected.

(9) When an aging operation of a disc 3 is completed, the display

“AGING

∗∗∗∗” value increases.

(10) If no error occurs, the aging operation continues repeatedly.

2) Error display

Disc error

Display Error

E00D01022 Focus error (No disc)

E00D02022 Sub Q error (Focus is good)

E00D02023 TOC reading error

E00D02014 Access error (Unable within regular time)

Mechanism error

Display Error

E00M__E_0 Error during opening tray

E00M__C_2 EX-CHANGE disc error

E00M__D_0 Error during closing tray

E00M__F_3 EX-OPEN error

E00M__D_5 EX-CLOSE error

E00M__C_2 Chuck-up error

E00M__C_3 Unchucking error

3. Aging mode in Tape Deck section

1) Operation during aging mode

• In the agining mode, the program is excuted in the following

sequence.

Step

1

Rewind the TAPE A

2

Rewind the TAPE B

3

Play the TAPE A (1 minute)

4

Stop the TAPE A (1 second)

5

Play the TAPE A (3 minutes)

6

Rewind(AMS) the TAPE A

7

F.F.(AMS) the TAPE A

8

Play the TAPE B (1 minute)

9

Stop the TAPE B (1 second)

10

Record the TAPE B (3 minutes)

11

Rewind(AMS) the TAPE B

12

F.F.(AMS) the TAPE B

Operation

Display

TAPE AAG-1

TAPE BAG-2

TAPE AAG-2

TAPE AAG-3

TAPE AAG-4

TAPE AAG-5

TAPE AAG-6

TAPE BAG-2

TAPE BAG-3

TAPE BAG-4

TAPE BAG-5

TAPE BAG-6

2) Error display

• If error occurred, the display remains like “TAPE BAG-2”.

4. Exiting from the aging mode

• Be sure to perform Cold Reset to exit from the aging mode.

18

HCD-RG121

[PANEL Test Mode]

• All fluorecent segments and LEDs are tested.

•Keyboard check.

Procedure:

1. Press ?/1 button to turn the set ON.

2. To enter the test mode, press the three buttons x ,

PLAY MODE/TUNING MODE and ENTER simultaneously.

3. All segments and LEDs (without STANDBY LED) are turned

on.

4. Press X and ENTER buttons simultaneously, and the key

check mode is activated.

5. The message “KEY 0 0 0” is displayed.

Each time a button is pressed, the key code number is displayed.

6. Press X and ENTER buttons simultaneously, and the key

count mode is activated.

7. The message “KEYCNT 0” is displayed.

Each time a button is pressed, “KEYCNT 0” value increased.

However, once a button is pressed, it is no longer taken into

account.

8. Press X and ENTER buttons simultaneously, and the head

phone detect mode is activated.

9. The message “H_P OFF” is displayed when a headphone jack

is not inserted.

“H_P ON ” is displayed when a headphone jack is inserted.

10. Press X and ENTER buttons simultaneously , and the volume

control detect mode is activated.

11. The message “VOLUME FLAT” is displayed.

“VOLUME UP” is displayed if rotating MASTER VOLUME

knob clockwise, or “VOLUME DO WN” is displayed if rotating

counterclockwise.

12. To exit from the GC test mode after the head phone detect mode ,

press X and ENTER buttons simultaneously.

[Version and Destination Display Mode]

•The version or destination is displayed.

Procedure:

1. Press ?/1 button to turn the set ON.

2. To enter the test mode, press the three buttons x ,

PLAY MODE/TUNING MODE and DISC2 simultaneously.

3. The destination is displayed.

4. Press DISPLAY buttons simultaneously.

5. The version is displayed.

6. To exit from this mode, press ?/1 button to turn the set OFF.

[CD Service Mode]

•This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the pick-up.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. To enter the test mode, press three buttons x ,

PLAY MODE/TUNING MODE , and Z simultaneously.

4. The CD service mode is selected.

5. With the CD in stop status, press M button to mo ve the pick-

up to outside track, or press m button to inside track.

6. To exit from this mode, perform as follows:

1) Move the pick-up to the most inside track.

2) Press ?/1 button to turn the set OFF.

Note: • Always move the pick-up to most inside track when exiting from

this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can be

chipped.

[MC Test Mode]

•This mode is used to test the function of the equalizer.

Procedure:

1. Press ?/1 button to turn the set ON.

2. To enter the test mode, press the three buttons x ,

PLAY MODE/TUNING MODE and DISC 3 simultaneously.

3. Press the EQ+ button.

The function of the equalizer is set to “MIN”.

4. Press the EQ– button.

The function of the equalizer is set to “MAX”.

5. Press the PRESET EQ button.

The function of the equalizer is set to “EQ FLAT”.

6. MASTER VOLUME up and down.

“VOLUME MIN”, “VOLUME 16”, “VOLUME MAX” is

displayed.

7. Press GROOVE button.

The message “VACS OFF” on “VACS ON” is dislayed.

8. To exit from this mode, press ?/1 button to turn the set OFF.

[CD Ship Mode (LOCK) ]

•This mode moves the pick-up to the position durable to vibra-

tion. Use this mode when returning the set to the customer after

repair.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press ?/1 button to turn the set OFF.

4. Press CD button and ?/1 button simultaneously.

5. The “STANDBY” display blinks instantaneously, and the CD

ship mode is set.

[CD Ship (LOCK) & COLD RESET MODE]

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press ?/1 button to turn the set OFF.

4. Press three buttons x , CD and DISPLAY simultaneously.

5. The “STANDBY” display blinks instantaneously and CD ship

mode is set.

6. The fluorescent indicator tube displays “COLD RESET” and

the set is reset.

[Disc Tray Lock]

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press two buttons of x and Z simultaneously for fi ve seconds.

3. The message “LOCKED” is displayed and the tray is locked.

(Even if exiting from this mode, the tray is still locked.)

4. Press two buttons of x and Z simultaneously for f ive seconds

again.

5. The message “UNLOCKED” is displayed and the tray is

unlocked.

6. To exit from this mode, press the ?/1 button to turn the set

OFF.

19

HCD-RG121

[CD Repeat 5 Times Limit Release Mode]

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press three buttons x , CD and ENTER simultaneously.

4. The message “LIMIT OFF” is displayed.

5. Press ?/1 button the set OFF.

[AMP TEST MODE]

Procedure:

1. Press ?/1 button to turn the set ON.

2. To enter the test mode, press the three buttons x ,

PLAY MODE/TUNING MODE and ENTER simultaneously.

3. Press the DISPLAY button.

The message “V0 0 0” “ 000” is displayed.

4. Press the GROOVE button.

The message “DBFB ON” “DBFB OFF” is displayed.

5. Press the SURROUND button.

The message “SURROUND ON” “SURROUND OFF” is

displayed.

6. Press the EQ BAND button.

The message “LOW” “MID” “HIGH” is displayed.

7. Press ?/1 button to turn the set OFF.

20

Loading...

Loading...