Sony HBD-E670W, HBD-E970W Service Manual

HBD-E670W/E970W

SERVICE MANUAL

Ver. 1.2 2011.01

Photo: HBD-E970W

• HBD-E670W is the amplifi er, video, BD/DVD/Super Audio

CD/CD system, USB, LAN and tuner section in BDV-E670W.

• HBD-E970W is the amplifi er, video, BD/DVD/Super Audio

CD/CD system, USB, LAN and tuner section in BDV-E970W.

• This product incorporates copyright protection technology

that is protected by U.S. patents and other intellectual property

rights.

Use of this copyright protection technology must be authorized

by Macrovision, and is intended for home and other limited

viewing uses only unless otherwise authorized by Macrovision.

Reverse engineering or disassembly is prohibited.

• This system incorporates with Dolby* Digital and Dolby Pro

Logic (II) adaptive matrix surround decoder and the DTS**

Digital Surround System.

* Manufactured under license from Dolby Laboratories.

Dolby, Pro Logic, and the double-D symbol are trademarks of Dolby Laboratories.

** Manufactured under license under U.S. Patent #’s:

5,451,942; 5,956,674; 5,974,380; 5,978,762; 6,226,616;

6,487,535; 7,212,872; 7,333,929; 7,392,195; 7,272,567 &

other U.S. and worldwide patents issued & pending.

DTS is a registered trademark and the DTS logos, Sym-

bol, DTS-HD and DTS-HD Master Audio are trademarks

of DTS, Inc. © 1996-2008 DTS, Inc. All Rights Reserved.

• This system incorporates High-Defi nition Multimedia Interface

(HDMITM) technology.

HDMI, the HDMI logo and High-Defi nition Multimedia

Interface are trademarks or registered trademarks of HDMI

Licensing LLC.

• Java and all Java-based trademarks and logos are trademarks

or registered trademarks of Sun Microsystems, Inc.

• “BD-LIVE” and “BONUSVIEW” are trademarks of Blu-ray

Disc Association.

• “Blu-ray Disc” is a trademark.

• “Blu-ray Disc,” “DVD+RW,” “DVD-RW,” “DVD+R,”

“DVDR,” “DVD VIDEO,” and “CD” logos are trademarks.

• “BRAVIA” is a trademark of Sony Corporation.

• “AVCHD” and the “AVCHD” logo are trademarks of Matsushita Electric Industrial Co., Ltd. and Sony Corporation.

• “S-AIR” and its logo are trademarks of Sony Corporation.

• , “XMB,” and “xross media bar” are trademarks of Sony

Corporation and Sony Computer Entertainment Inc.

• “PLAYSTATION” is a trademark of Sony Computer Entertainment Inc.

• DivX®, DivX Certifi ed® and associated logos are registered

trademarks of DivX, Inc. and are used under license.

• Music and video recognition technology and related data are

provided by Gracenote®.

Gracenote is the industry standard in music recognition

technology and related content delivery. For more information,

please visit www.gracenote.com.

CD, DVD, Blu-ray Disc, and music and video-related data

from Gracenote, Inc., copyright © 2000-present Gracenote.

Gracenote Software, copyright © 2000-present Gracenote. One

or more patents owned by Gracenote apply to this product and

service. See the Gracenote website for a nonexhaustive list of

applicable Gracenote patents. Gracenote, CDDB, MusicID,

MediaVOCS, the Gracenote logo and logotype, and the

“Powered by Gracenote” logo are either registered trademarks

or trademarks of Gracenote in the United States and/or other

countries.

Amplifier Section (Except Chinese model)

POWER OUTPUT (rated)

Front L + Front R: 108 W + 108 W (at 3 ohms,

POWER OUTPUT (reference)

Front L/Front R/Center: 167 W (pe r channel at 3

Subwoofer: 165 W (at 3 ohms, 80 Hz)

Inputs (Analog)

AUDIO (AUDIO IN) Sensitivity: 450/250 mV

Inputs (Digital)

SAT/CABLE (COAXIAL), TV (OPTICAL)

Amplifier Section (Chinese model)

POWER OUTPUT (reference)

Front L/Front R/Center: 100 W (pe r channel at 3

Subwoofer: 100 W (at 3 ohms, 80 Hz)

Inputs (Analog)

AUDIO (AUDIO IN) Sensitivity: 450/250 mV

I

nputs (Digital)

SAT/CABLE (COAXIAL), TV (OPTICAL)

Video Section

Outputs VIDEO: 1 Vp-p 75 ohms

BD/DVD/Super Audio CD/CD System

Signal format system PAL/NTSC

AEP Model

Australian Model

Chinese Model

Saudi Arabia Model

Singapore Model

Taiwan Model

HBD-E970W

UK Model

HBD-E670W

Model Name Using Similar Mechanism BDP-S370

Mechanism Type

BPX-5

Optical Pick-up Block Name KEM-460AAA

SPECIFICATIONS

USB Section

1 kHz, 1% THD)

ohms, 1 kHz)

Supported formats: LPCM

2CH (up to 48 kHz), Dolby

Digital, DTS

ohms, 1 kHz)

Supported formats: LPCM

2CH (up to 48 kHz), Dolby

Digital, DTS

COMPONENT:

Y: 1 Vp-p 75 ohms

PB/CB, PR/CR: 0.7 Vp-p

75 ohms

HDMI OUT: Type A (19

pin)

(USB) port: Type A (For connecting

Maximum current: 500 mA

LAN Section

LAN (100) terminal 100BASE-TX Terminal

Tuner Section

System PLL quartz-locked digital

FM tuner section

Tuning range 87.5 MHz - 108.0 MHz

Antenna (aerial) FM wire antenna (aerial)

Antenna (aerial) terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

General

Power requirements

Taiwan models: 120 V AC, 50/60 Hz

Other models: 220 V - 240 V AC,

Power consu

Dimensions (approx.) 430 mm × 85 mm × 335

Mass (approx.) 4.7 kg

Design and specifications are subject to change

without notice.

mption On: 130 W

USB memory, memory

card reader, digital still

camera, and digital video

camera)

synthesizer

(50 kHz step)

50/60 Hz

Standby: 0.3 W (at the

Power Saving mode)

mm (w/h/d) incl.

projecting parts

430 mm × 85 mm × 365

mm (w/h/d) (incl. wireless

transceiver)

BLU-RAY DISC/DVD RECEIVER

9-889-834-03

2011A05-1

2011.01

©

Sony Corporation

Published by Sony Techno Create Corporation

HBD-E670W/E970W

Ver. 1.1

This appliance is classified as a

CLASS 1 LASER product. This

This appliance is classified as a

CLASS 3R LASER product.

Visible and invisible laser radiation

is emitted when the laser protective

housing is opened, so be sure to

avoid direct eye exposure.

This marking is located on the laser

protective housing inside the

enclosure.

marking is located on the rear

exterior.

㚐嬢⡫⫾下ᶞ DMBTT!4S!

MBTFS ḋ␥Ɂ㼤₭ὁ㈈仍ㆷ

㕚Ṿ⌵⅞⍓夥⏰ᵱ⍓夥

㼤₭廴⭨濇♄㫈Ⅻ≣䙘㌉䃋

⭨䚠䚿Ɂ

㫈㝫⼻ằ㚞⡗䗨㼤₭

ὁ㈈仍ᵮɁ

㚐嬢⡫⫾下ᶞ DMBTT!2!

MBTFS ḋ␥Ɂ㫈㝫⼻ằ倰

恌⡺埌曆Ɂ

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

TABLE OF CONTENTS

HBD-E670W/E970W

Ver. 1.1

1. SERVICING NOTES .............................................. 4

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 11

2-2. Case ................................................................................. 11

2-3. MB-134 Board ................................................................ 12

2-4. Bracket (MB) Block ........................................................ 13

2-5. Fuse (F901), POWER Board .......................................... 13

2-6. Front Panel Block ........................................................... 14

2-7. BD Drive (BPX-5) .......................................................... 14

2-8. INCLUDE Board ............................................................ 15

2-9. Back Panel Block ............................................................ 15

2-10. MAIN Board ................................................................... 16

2-11. AUDIO Board ................................................................. 16

2-12. Optical Pick-up Block (KEM-460AAA),

Wire (Flat Type) .............................................................. 17

3. TEST MODE ............................................................ 18

4. ELECTRICAL CHECK .......................................... 27

5. DIAGRAMS

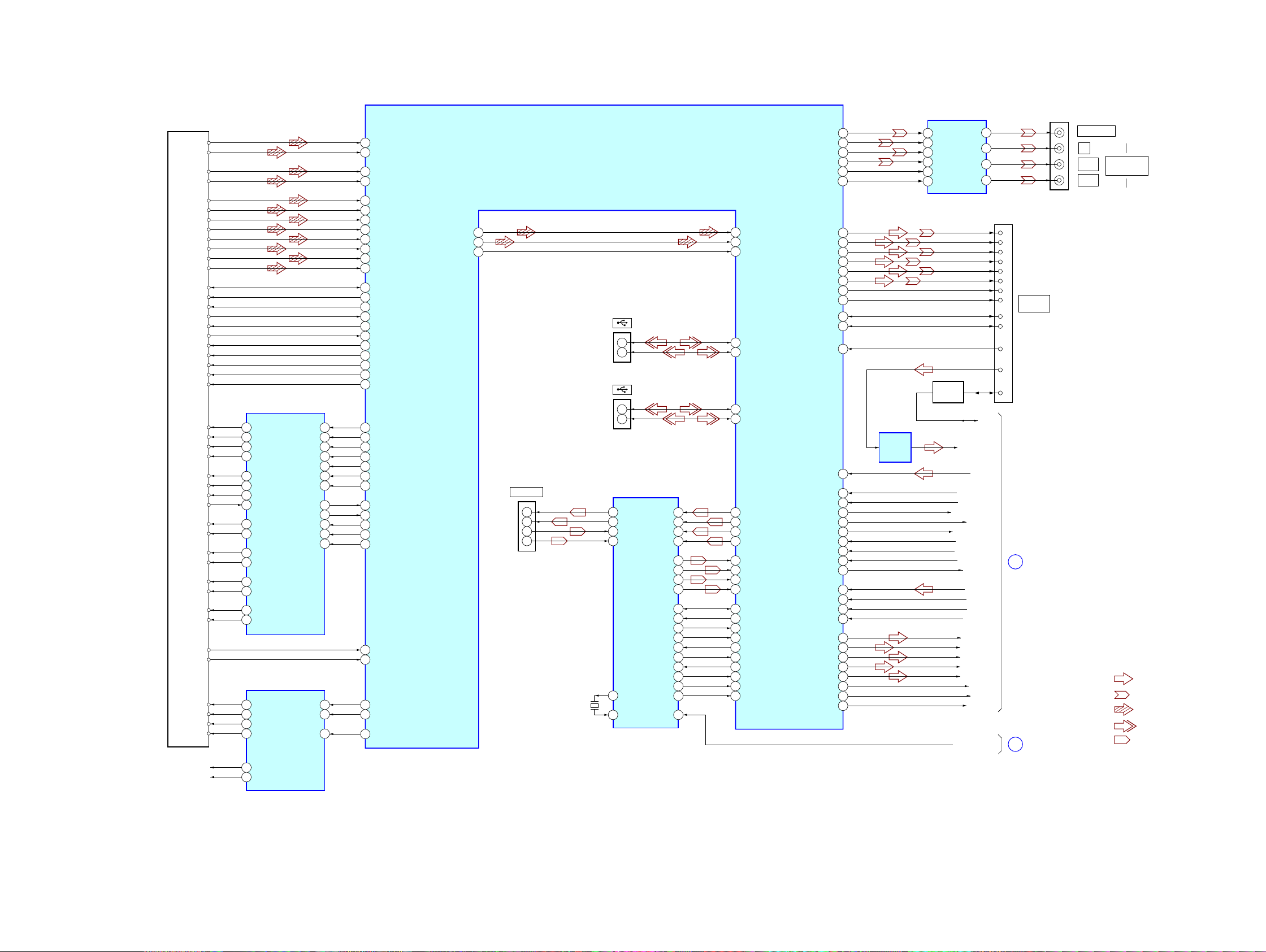

5-1. Block Diagram - SERVO Section - ................................ 28

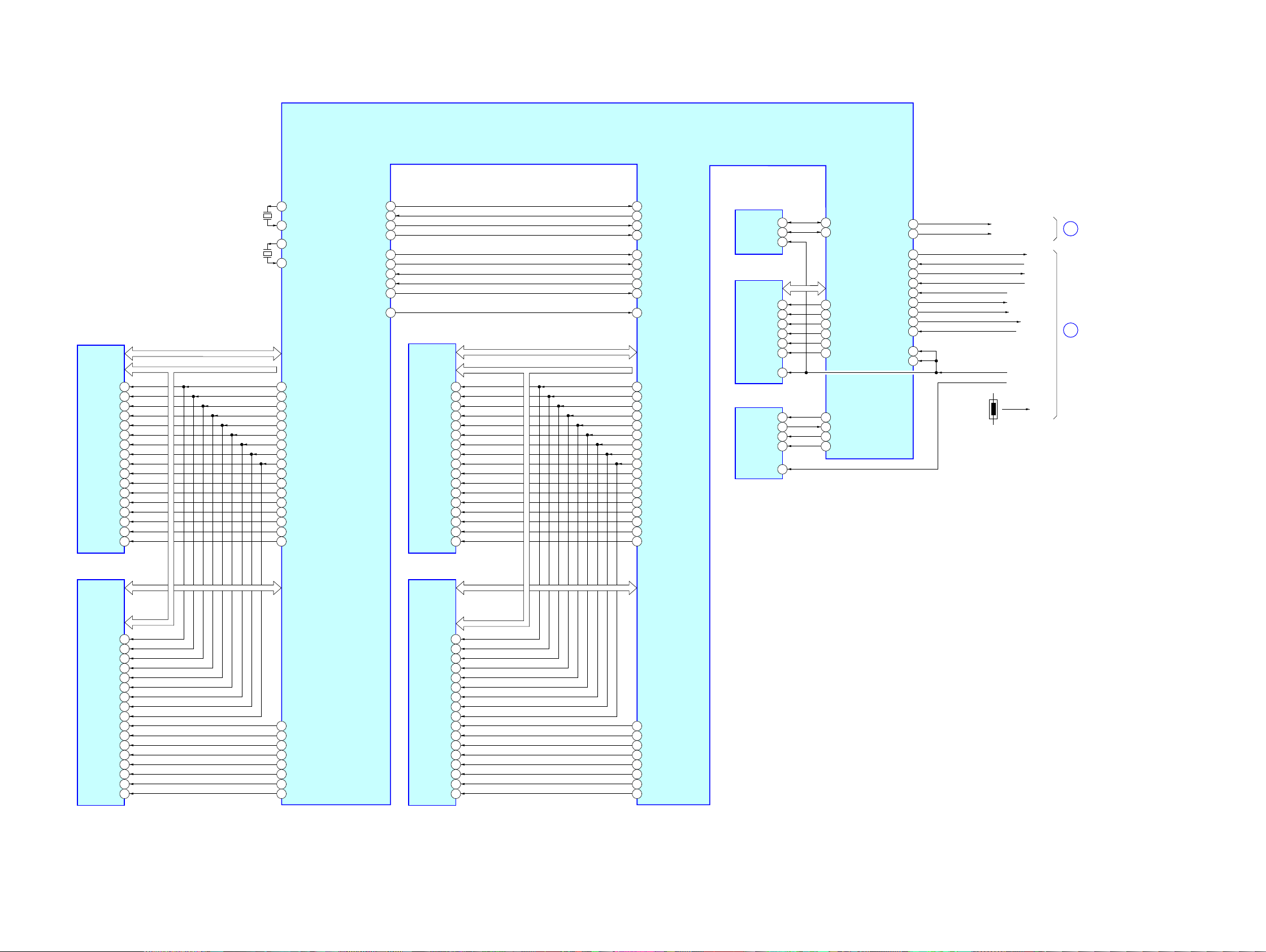

5-2. Block Diagram - MEMORY Section - ............................ 29

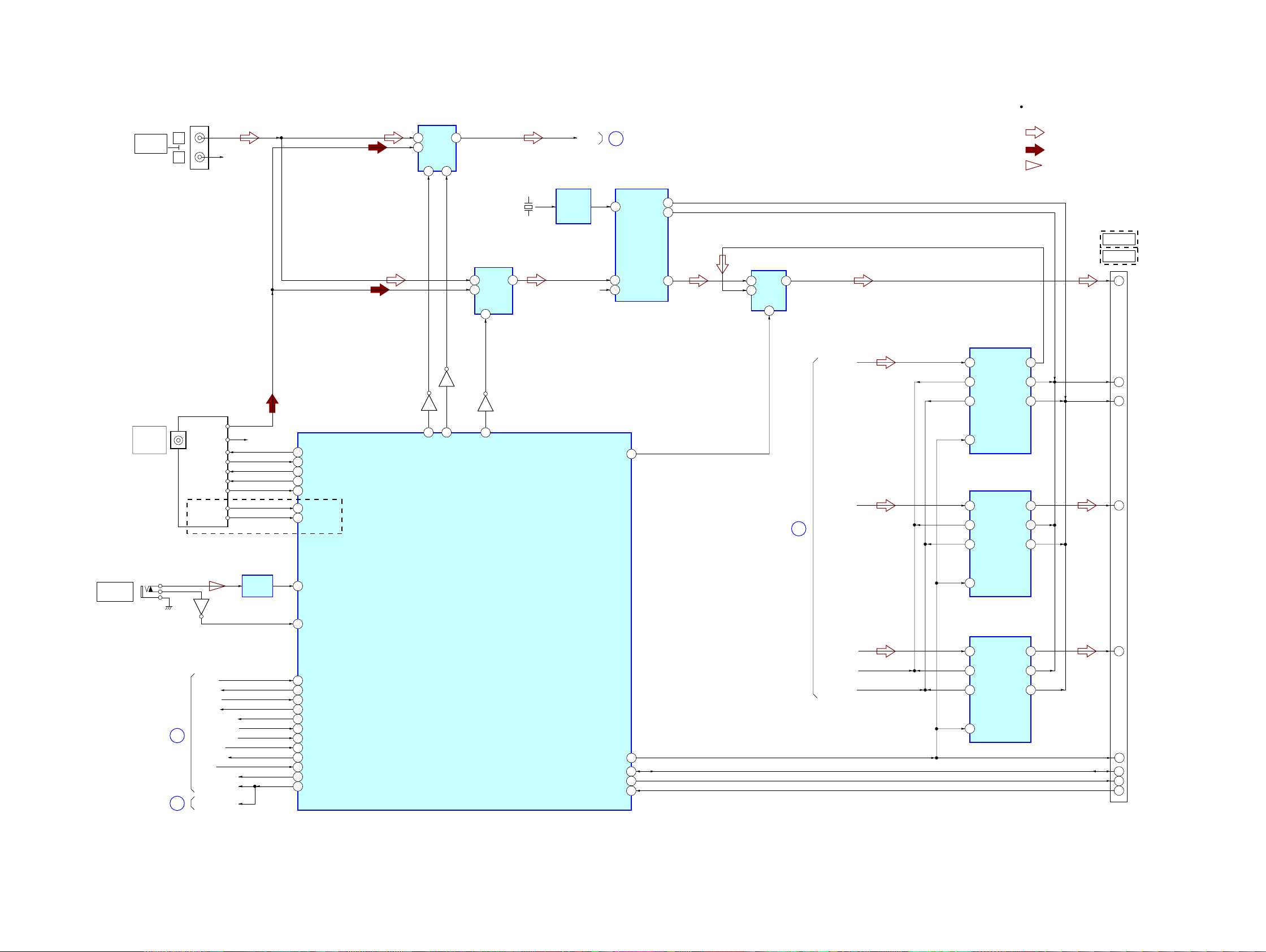

5-3. Block Diagram - TUNER, S-AIR Section - .................... 30

5-4. Block Diagram - AUDIO Section - ................................. 31

5-5. Block Diagram - REGULATOR Section - ...................... 32

5-6. Block Diagram

- PANEL, POWER SUPPLY Section - ........................... 33

5-7. Schematic Diagram - MB-134 Board (1/13) - ................ 35

5-8. Schematic Diagram - MB-134 Board (2/13) - ................ 36

5-9. Schematic Diagram - MB-134 Board (3/13) - ................ 37

5-10. Schematic Diagram - MB-134 Board (4/13) - ................ 38

5-11. Schematic Diagram - MB-134 Board (5/13) - ................ 39

5-12. Schematic Diagram - MB-134 Board (6/13) - ................ 40

5-13. Schematic Diagram - MB-134 Board (7/13) - ................ 41

5-14. Schematic Diagram - MB-134 Board (8/13) - ................ 42

5-15. Schematic Diagram - MB-134 Board (9/13) - ................ 43

5-16. Schematic Diagram - MB-134 Board (10/13) - .............. 44

5-17. Schematic Diagram - MB-134 Board (11/13) - .............. 45

5-18. Schematic Diagram - MB-134 Board (12/13) - .............. 46

5-19. Schematic Diagram - MB-134 Board (13/13) - .............. 47

5-20. Printed Wiring Board

- MB-134 Board (Component Side) - ............................. 48

5-21. Printed Wiring Board

- MB-134 Board (Conductor Side) - ............................... 49

5-22. Printed Wiring Board - AUDIO Board - ......................... 50

5-23. Schematic Diagram - AUDIO Board - ............................ 51

5-24. Printed Wiring Board

- MAIN Board (Component Side) - ................................ 52

5-25. Printed Wiring Board

- MAIN Board (Conductor Side) - .................................. 53

5-26. Schematic Diagram - MAIN Board (1/5) - ..................... 54

5-27. Schematic Diagram - MAIN Board (2/5) - ..................... 55

5-28. Schematic Diagram - MAIN Board (3/5) - ..................... 56

5-29. Schematic Diagram - MAIN Board (4/5) - ..................... 57

5-30. Schematic Diagram - MAIN Board (5/5) - ..................... 58

5-31. Printed Wiring Boards - KEY Section - .......................... 59

5-32. Schematic Diagram - KEY Section - .............................. 59

5-33. Printed Wiring Board - REG Board - .............................. 60

5-34. Schematic Diagram - REG Board - ................................ 61

5-35. Printed Wiring Board - INCLUDE Board - .................... 62

5-36. Schematic Diagram - INCLUDE Board - ....................... 63

5-37. Printed Wiring Board - FL Board - ................................. 64

5-38. Schematic Diagram - FL Board - .................................... 65

5-39. Printed Wiring Board - POWER Board - ........................ 66

5-40. Schematic Diagram - POWER Board - .......................... 67

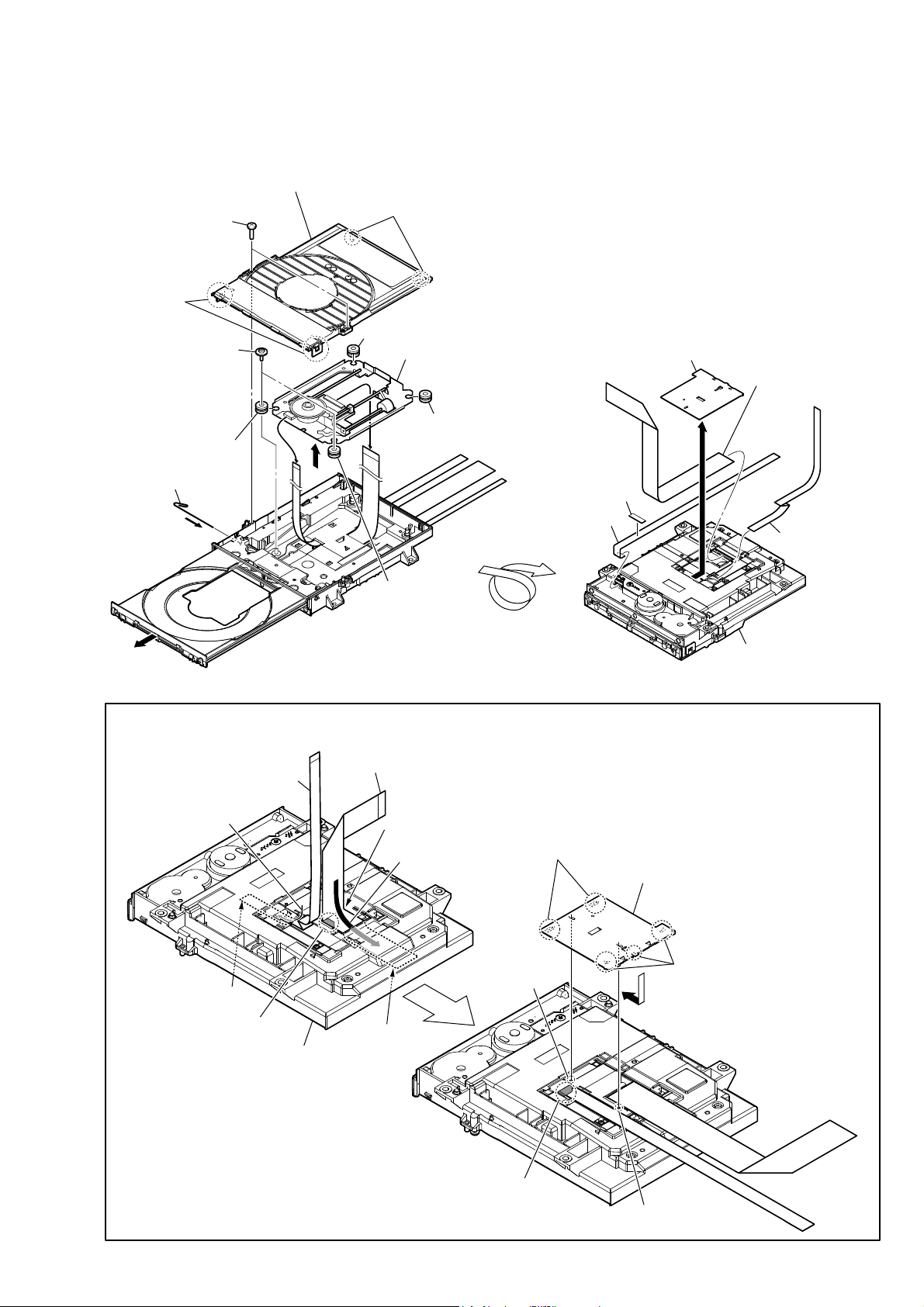

6. EXPLODED VIEWS

6-1. Case, Front Panel Section ............................................... 92

6-2. MB-134 Board Section ................................................... 93

6-3. Back Panel Section ......................................................... 94

6-4. MAIN Board Section ...................................................... 95

6-5. BD Drive Section (BPX-5) ............................................. 96

7. ELECTRICAL PARTS LIST .............................. 97

3

HBD-E670W/E970W

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the Optical Pick-up Block may suffer electrostatic break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

RELEASING THE DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure:

1. Press the [

2. Press the [FUNCTION] button to select “BD/DVD”.

3. Press the [x] and [Z] buttons simultaneously and hold down

unit “DEMO OFF” displayed on the fluorescent indicator tube

(around 5 seconds).

Note: When “DEMO ON” is displayed, the disc tray lock is not released

by turning power on/off with the [

ABOUT THE LENS CLEANING

Do not do the lens cleaning with the cotton bud etc. It causes the

trouble.

] button to turn on the system.

?/1

?/1

] button.

NOTE THE IC101, IC104, IC105, IC204, IC205, IC307,

IC311, IC501 AND IC502 ON THE MB-134 BOARD

REPLACING

IC101, IC104, IC105, IC204, IC205, IC307, IC311, IC501 and

IC502 on the MB-134 board cannot exchange with single. When

these parts are damaged, exchange the entire mounted board.

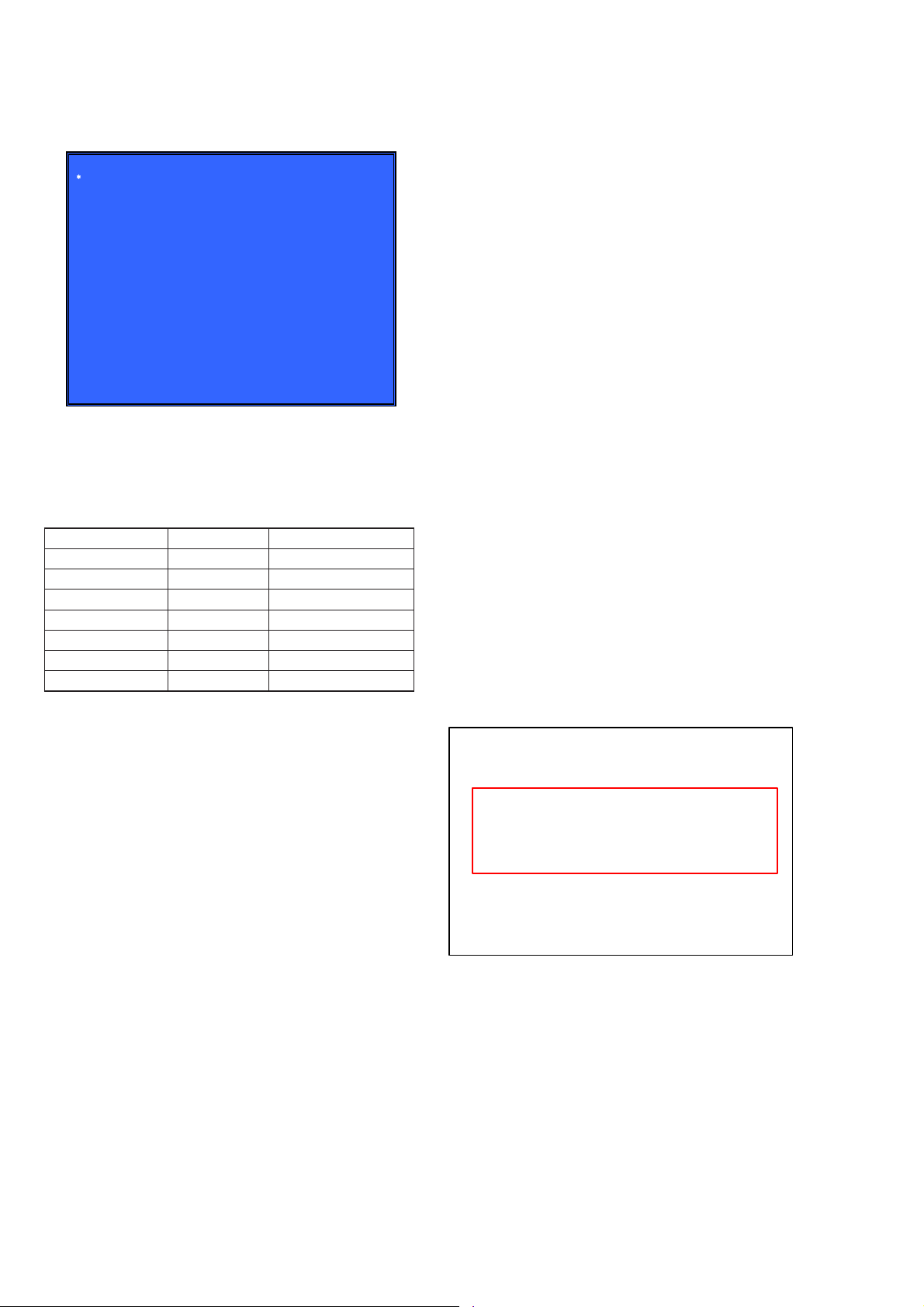

TEST DISC

Part No. Description Layer

J-6090-199-A BLX-104 Single Layer

J-6090-200-A BLX-204 Dual Layer

J-2501-307-A CD (HLX-A1)

J-2501-305-A HLX-513 Single Layer (NTSC)

J-2501-306-A HLX-514 Dual Layer (NTSC)

J-6090-077-A HLX-506 Single Layer (PAL)

J-6090-078-A HLX-507 Dual Layer (PAL)

Note: Refer to the service manual of BDP-BX1/S350 (Part No. 9-883-

989-1[]) (page 1-3 to 1-14E) for the use of BLX-104/204.

Operation and Display:

1. BLX-104

Procedure:

1. Select 23.976Hz/1080p.

2. Play “4.Motion picture”.

3. Check whether player can play back or not.

4. Check each outputs.

Video:

Composite/S Video/component/HDMI.

Audio:

Speaker out.

* When 1080/24p monitor is nothing, 1080i (59.94Hz or 50Hz)

can use instead of 1080/24p.

However this is temporary correspondence.

2. BLX-204

Procedure:

1. Select 1080i (59.94Hz or 50Hz).

2. Play “4.Motion picture”.

3. Check whether player can play back or not (Check the picture

and sound output).

3. CD (HLX-A1)

Procedure:

Check whether player can play back or not (Check the sound output).

4. HLX-513/514 (NTSC), HLX-506/507 (PAL)

Procedure:

1. After displayed Main Menu, select “1.Video Signal”.

2. Play “1.Color bar 100%” (Check the picture and sound output).

3. Return to Menu.

4. Play “Demonstration 4:3” or “Demonstration 16:9” (Check the

picture and sound output).

4

NOTE OF REPLACING THE CASE

“3D logo mark” is added from the midway production to the case.

Please exchange cases after confi rming the presence of “3D logo mark”.

HBD-E670W/E970W

Ver. 1.1

Former: There is no 3D logo mark.

New: There is 3D logo mark.

NOTE OF REPLACING THE OPTICAL PICK-UP BLOCK

(KEM-460AAA) OR MB-134 BOARD

Optical pick-up block (KEM-460AAA) for BD requires precise

read out functions and secure contents protection system for more

than past DVD/CD.

Therefore, in the case repaired as follows, the writing work of the

OP data is necessary.

• When the optical pick-up block (KEM-460AAA) is replaced

(The MB-134 board doesn’t replace).

• When both the optical pick-up block (KEM-460AAA) and

MB-134 board are replaced.

• When the MB-134 board is replaced (The optical pick-up block

(KEM-460AAA) doesn’t replace) (In this case, do the work

of “3. Optical pick-up block (KEM-460AAA) replacement”

other than the replacement of new optical pick-up block).

Note: The servo adjustment is done while writing the OP data. The manual

adjustment is unnecessary.

LD ON TIME history doesn’t carry over.

Do not touch any optical block parts, turn table and during replac-

ing. BD laser diode is very sensitive.

1. Preparation

1-1. ESD Countermeasure

It is necessary to confi rm the state of static electricity in the work

space before the repair is started.

The static electricity resistance of the BD laser is weaker than that

of the DVD/CD laser.

Do work space and worker’s ESD countermeasures to prevent destruction by ESD.

1-3. Barcode decoder (BDBUDEC)

Part No. : J-6090-212-A

Jig name : BDBUDec.exe

Release : 2009.02.19

Version : 1.0.0.0

Software contents :

• BDBUDec.exe : Barcode decoder software

• SavePath.ini : Decoded fi le destination setting fi le (Ini-

tial destination is “C:\BuData.txt”)

• TasmanBars.dll : Decode dll

• Uninst.exe : Uninstall the “BDBUDec.exe” from PC

Install procedure:

1. Unzip the barcode decoder fi les to any PC folder.

2. Check the taken barcode photo click & drop onto “BDBUDec.

exe”.

When the barcode decoder is used for the fi rst time, the pass-

word is necessary. It is unnecessary since the second times.

Note 1: The password will be supplied to only service headquarters, and

service center name/q’ty/all of software registered information

should be maintained by service headquarters.

Note 2: Do not change the decoded fi le name “BuData.txt”.

3. When “.NET frame work requirements” is displayed, down-

load following applications from Microsoft download site.

• Microsoft .NET Framework Version 2.0 Redistributable Pack-

age (x86)

http://www.microsoft.com/downloads/details.aspx?displaylan

g=en&FamilyID=0856eacb-4362-4b0d-8edd-aab15c5e04f5

1-2. Jig

• Digital camera (Recommend with macro mode)

• USB memory

• PC

• Barcode decoder (Refer to “1-3. Barcode decoder

(BDBUDEC)”)

• Microsoft .NET Framework 2.0 Service Pack 1 (x86)

http://www.microsoft.com/downloads/details.aspx?displaylan

g=en&FamilyID=79bc3b77-e02c-4ad3-aacf-a7633f706ba5

5

HBD-E670W/E970W

2. Pass-fail judgment of the optical pick-up block (KEM-460AAA)

Perform pass-fail judgment to judge whether the repair of the optical pick-up block (KEM-460AAA) is necessary.

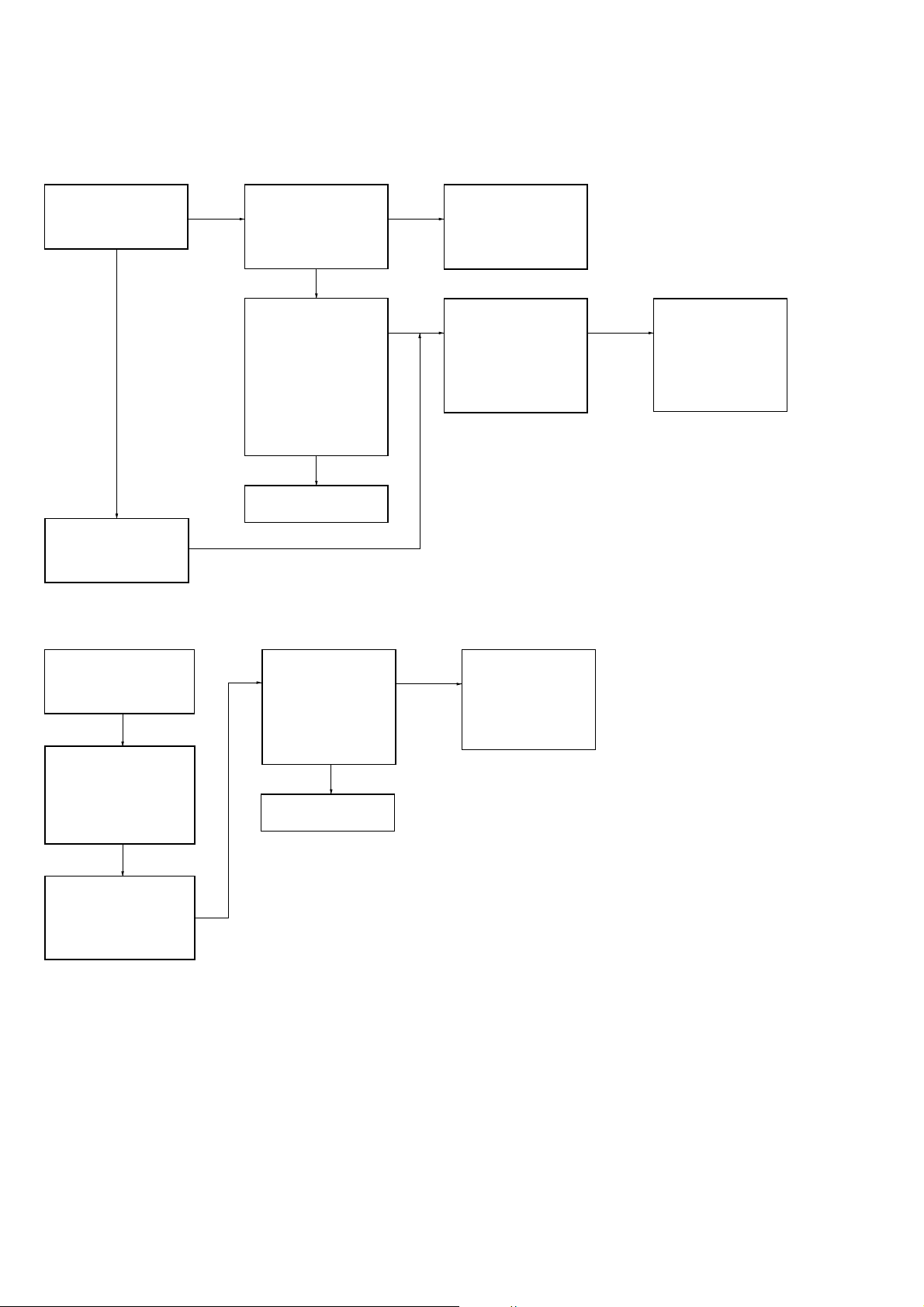

2-1. Flow of drive section check

Confirm whether

BD (BLX-104) can be

reproduced

YES

Confirm whether

DVD (HLX-513)/

CD (HLX-A1) can be

reproduced

Note: Refer to “2-12. OPTICAL PICK-UP BLOCK (KEM-460AAA), WIRE (FLAT TYPE)” (page 17) about how to remove the FFC HOLDER (REAR).

NO

NO

Confirm whether the

drive voltage is the

following values

CN301 pin 2 : 12 V

CN301 pin 6 : 5 V

YES

Confirm OP FFC cable

(Part No. 1-837-494-11)

and SPDL FFC cable

(Part No. 1-837-495-11),

and replace it when it

has been damaged

Then, confirm whether

this set operates

normally

YES

OK

NO

NO NO

Confirm PS301 to

PS304 on the MB-134

board, and replace it

when it has been

damaged

Confirm whether the

optical pick-up block

IOP is normal in the

service mode

(Refer to “2-2. Flow

of optical pick-up block

IOP check”)

Repalece the

optical pick-up block

(KEM-460AAA)

(Refer to “3. Optical

pick-up block

(KEM-460AAA)

replacement”)

2-2. Flow of optical pick-up block IOP check

Turn the power on,

and change function

to “BD/DVD”

Press the buttons on

the remote commander

in order of [RETURN],

[0], [2], [1] [SUBTITLE],

and enter the service

mode

Confirm whether

value is the

specification value

Specification value:

BD : 6 mA

DVD/CD: 9 mA

YES

OK

NO

Repalece the

optical pick-up block

(Refer to “3. Optical

pick-up block

(KEM-460AA)

replacement”)

Press the buttons on

the remote commander

in order of [8], [7], [3],

[ENTER], and the

dIOP value is displayed

6

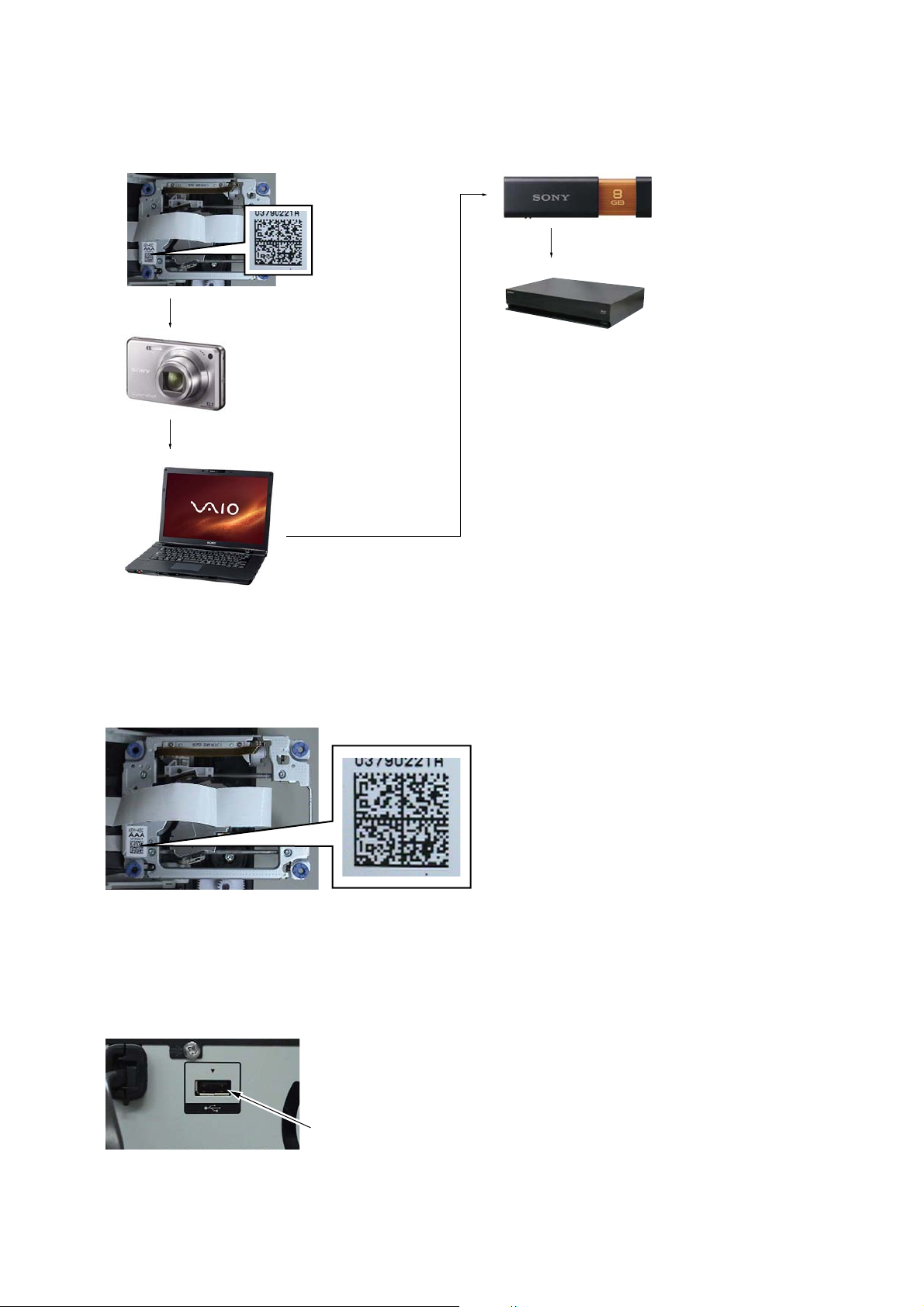

3. Optical pick-up block (KEM-460AAA) replacement Flow of replacement:

Note: The photo in fl ow is an image.

Barcode label on new

optical pick-up block

(KEM-460AAA)

bottom side

Take photo (JPEG)

by digital camera

Change photo into

the text data with

the barcode decoder

HBD-E670W/E970W

Save the text data

to USB memory

(memory capacity

need not be 8GB)

Connect USB memory

with rear USB connector

on this set, and read the

text data by the service mode

Procedure:

1. Remove the INSULATOR (4 pieces) and broken optical pickup block (KEM-460AAA) from LOADING ASSY.

2. Take photo of the barcode on new optical pick-up block (KEM460AAA) bottom side by digital camera.

3. Assemble the INSULATOR (4 pieces) to new optical pick-up

block (KEM-460AAA), fi x (Torque value: 2 kgf) it to LOAD-

ING ASSY with screw, and assemble this set.

4. Drag & drop the taken photo by step 2 to “BDBUDec.exe”,

and make the text data (File name: BuData.txt).

5. Save the text data to USB memory.

6. Connect USB memory with rear USB connector on this set,

and turn the power on.

7. Press the [FUNCTION] button to select “BD/DVD”.

8. Press the buttons on the remote commander in order of

[RETURN], [0], [2], [1], [SUBTITLE], and enter the service

mode.

9. Press the buttons on the remote commander in order of [8], [1],

[ENTER], and execute “[1] Drive OP data Write”.

10. Turn the power off after writing the OP data.

11. Turn the power on, and enter the service mode again.

12. Press the buttons on the remote commander in order of [8], [7],

[3], [ENTER], and the dIOP value is displayed.

13. Confi rm value is the following specifi cation value, and turn the

power off.

Specifi cation value:

BD : 6 mA

DVD/CD : 9 mA

14. Turn the power on, confi rm playback performance of the BD

(BLX-104)/DVD (HLX-513)/CD (HLX-A1).

15. Completely assemble this set, and complete the repair.

Rear USB connector

7

HBD-E670W/E970W

–

–

Ver. 1.1

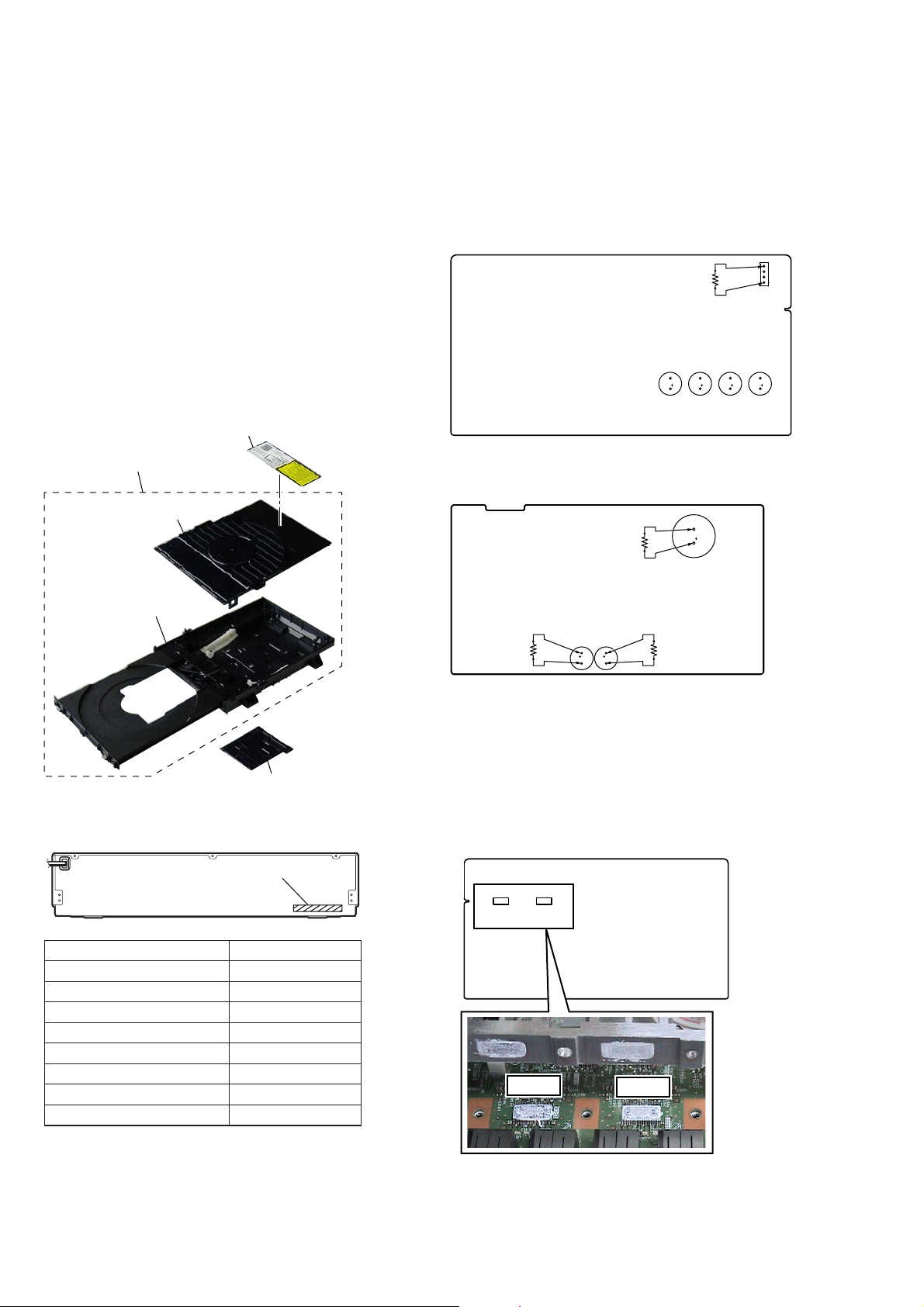

NOTE THE BD DRIVE (BPX-5) PARTS REPLACING

The mechanism blocks except optical pick-up block of BD drive

(BPX-5) are chiefl y composed of the following parts.

• CHUCK HOLDER ASSY

• LOADING ASSY

• HOLDER, FFC (REAR)

These parts are produced by two venders, it is not compatible.

Therefore, CHUCK HOLDER ASSY and LOADING ASSY are

supplied by one pair as repair parts. Please exchange both CHUCK

HOLDER ASSY and LOADING ASSY at the same time.

HOLDER FFC (REAR) need not be exchanged at the same time.

Note: The laser caution label is not pasted to LOADING FOR SERVICE

(Part No. A-1750-926-A). Please peel off an original laser caution

label, and paste it to LOADING FOR SERVICE when you use

LOADING FOR SERVICE.

LASER CAUTION LABEL

LOADING FOR SERVICE

CHUCK HOLDER ASSY

CAPACITOR ELECTRICAL DISCHARGE PROCESSING

When checking the board, the electrical discharge is necessary for

the electric shock prevention.

Connect the resistors referring to the fi gure below.

• MAIN board (C3115, C3125, C3215, C3315)

Both ends of CN3001.

MAIN Board (Conductor Side) –

800 :/2 W

C3215

C3315

C3125

4

1

CN3001

C3115

• POWER board (C903, C932, C933)

Both ends of respective capacitors.

POWER Board (Conductor Side) –

800 :/2 W

C903

LOADING ASSY

MODEL IDENTIFICATION

– Rear Chassis –

E970W: AEP model

E970W: Singapore model

E670W: UK model

E970W: Russian model

E970W: Saudi Arabia model

E970W: Chinese model

E970W: Australian model

E970W: Taiwan model

HOLDER, FFC (REAR)

Part No.

Model Part No.

4-161-684-7[]

4-161-684-8[]

4-161-686-4[]

4-161-687-0[]

4-161-687-1[]

4-161-687-2[]

4-161-687-3[]

4-161-687-4[]

C933

800 :/2 W

C932

800 :/2 W

NOTE OF REPLACING THE IC3100 AND IC3200

ON THE MAIN BOARD AND THE COMPLETE MAIN

BOARD

When IC3100 and IC3200 on the MAIN board and the complete

MAIN board are replaced, it is necessary to spread the compound

(THERMAL COMPOUND (G747)) (Part No. J-2501-221-A ) between parts and heat sink.

Spread the compound referring to the fi gure below.

– MAIN Board (Component Side) –

IC3200IC3100

IC3100

IC3200

8

HBD-E670W/E970W

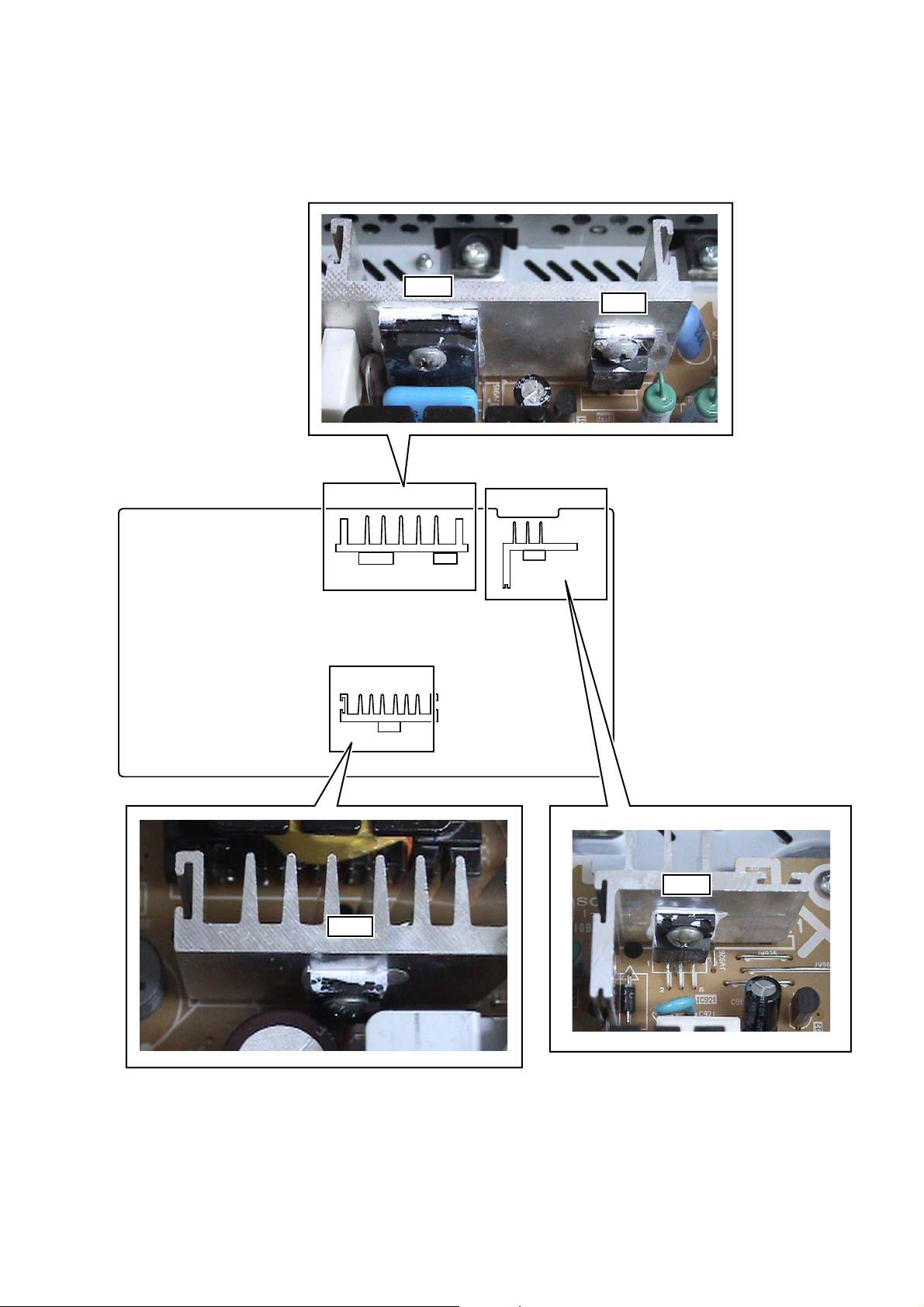

NOTE OF REPLACING THE D913, D931, IC901 AND IC921 ON THE POWER BOARD AND THE COMPLETE

POWER BOARD

When D913, D931, IC901 and IC921 on the POWER board and the complete POWER board are replaced, it is necessary to spread the

compound (THERMAL COMPOUND (G747)) (Part No. J-2501-221-A) between parts and heat sink.

Spread the compound referring to the fi gure below.

IC901

D913

– POWER Board

(Component Side) –

HS901

D931

IC901

HS931

D931

D913

HS921

IC921

IC921

9

HBD-E670W/E970W

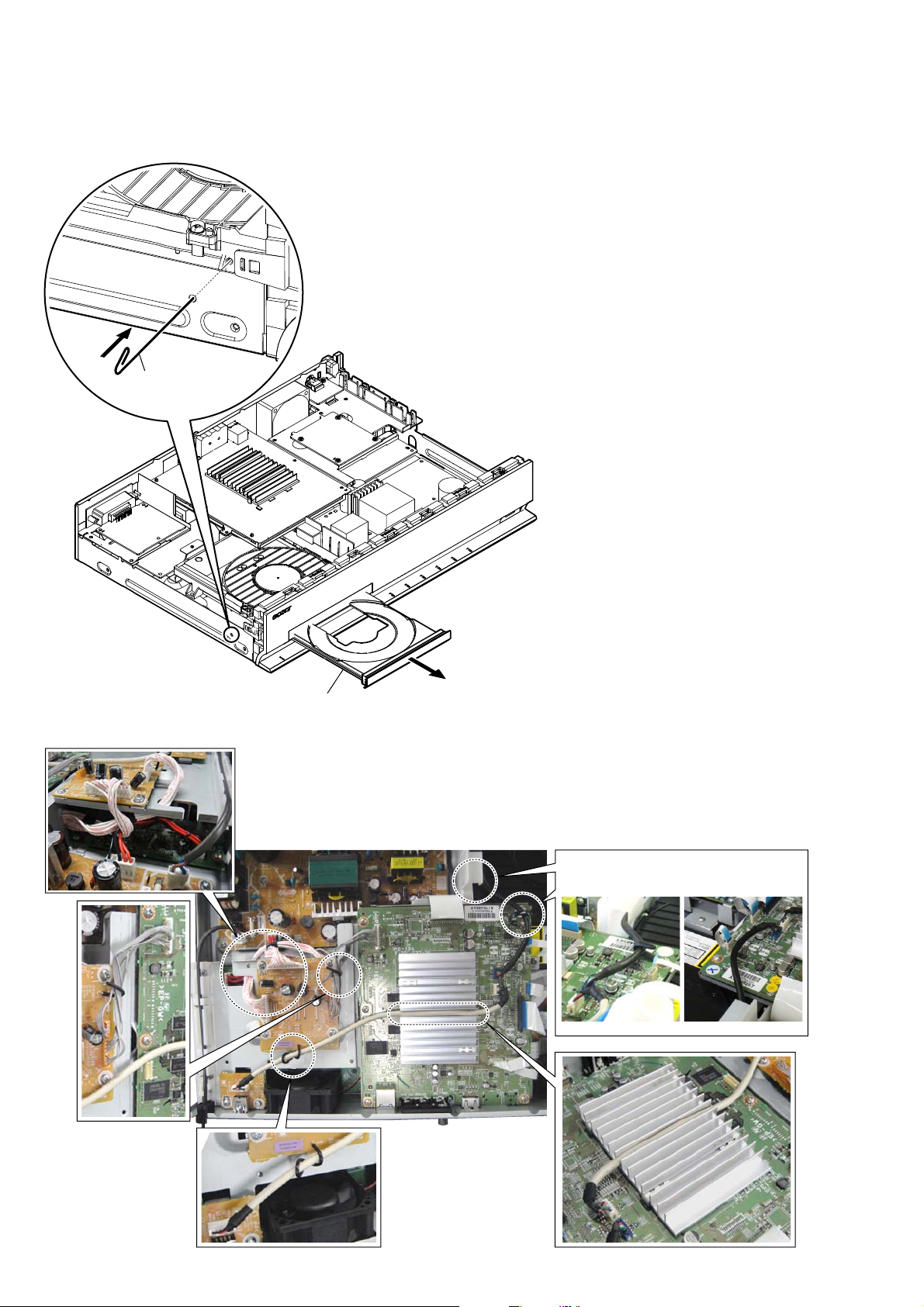

HOW TO OPEN THE TRAY WHEN POWER SWITCH TURN OFF

Note 1: After the case is removed, this work is done.

Note 2: Please prepare the thin wire (clip etc.).

1 Remove the case.

(Illustration of disassembly is omitted.)

2

clip etc.

PROCESSING OF HARNESS (USB)

tray

3

– Top view –

Note: There is a set that does not use clamp

installed in MB-134 board either.

10

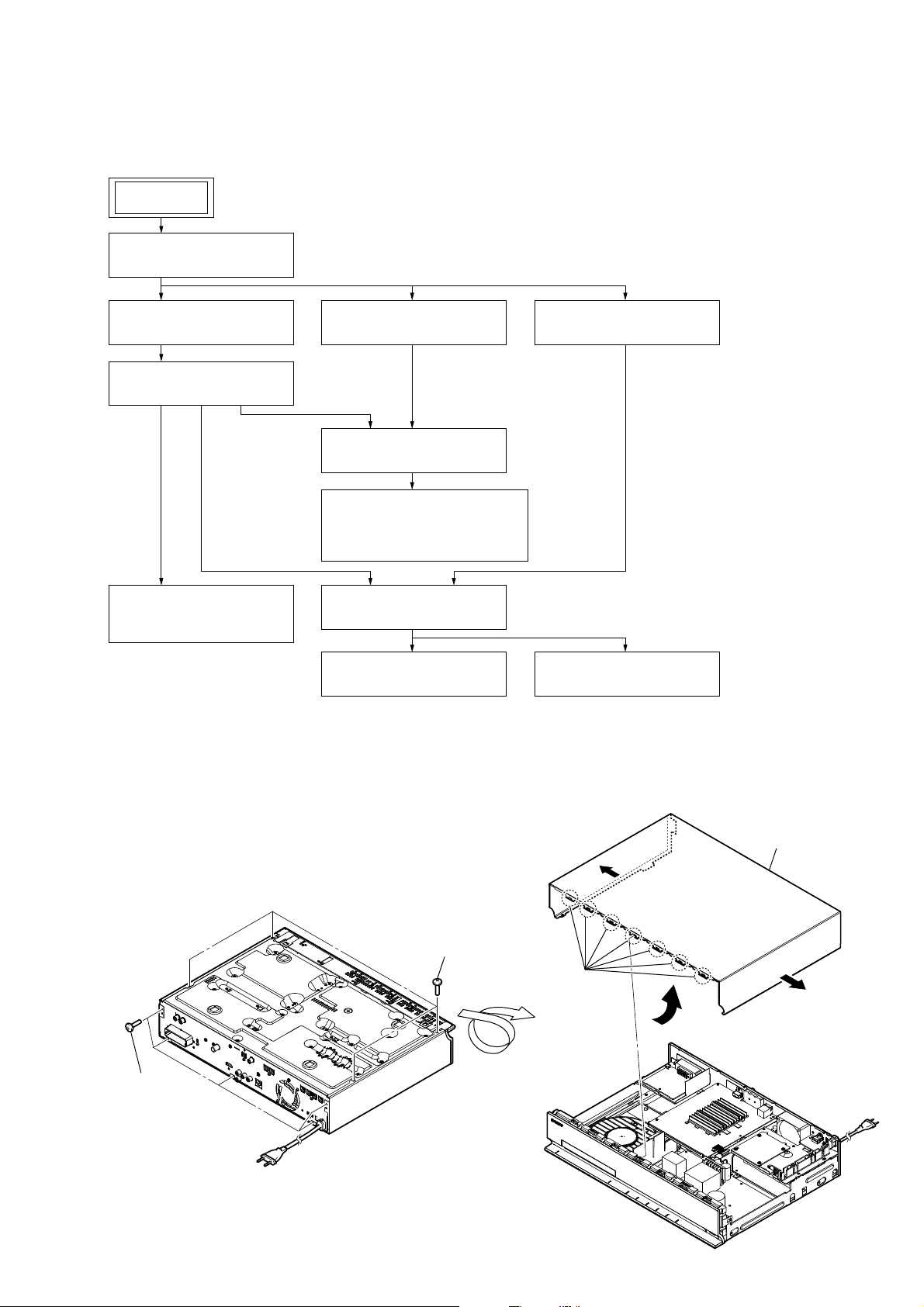

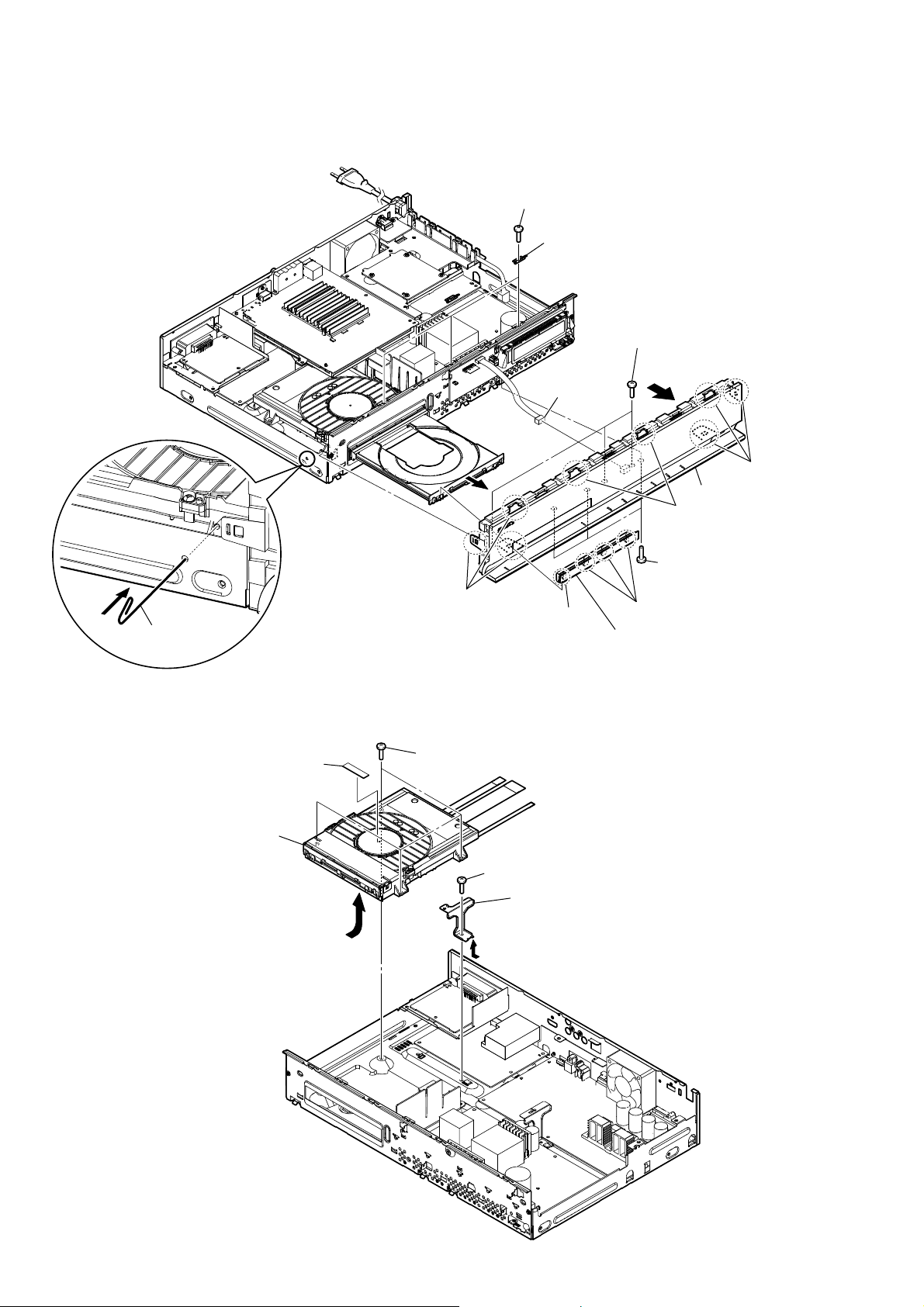

DISASSEMBLY

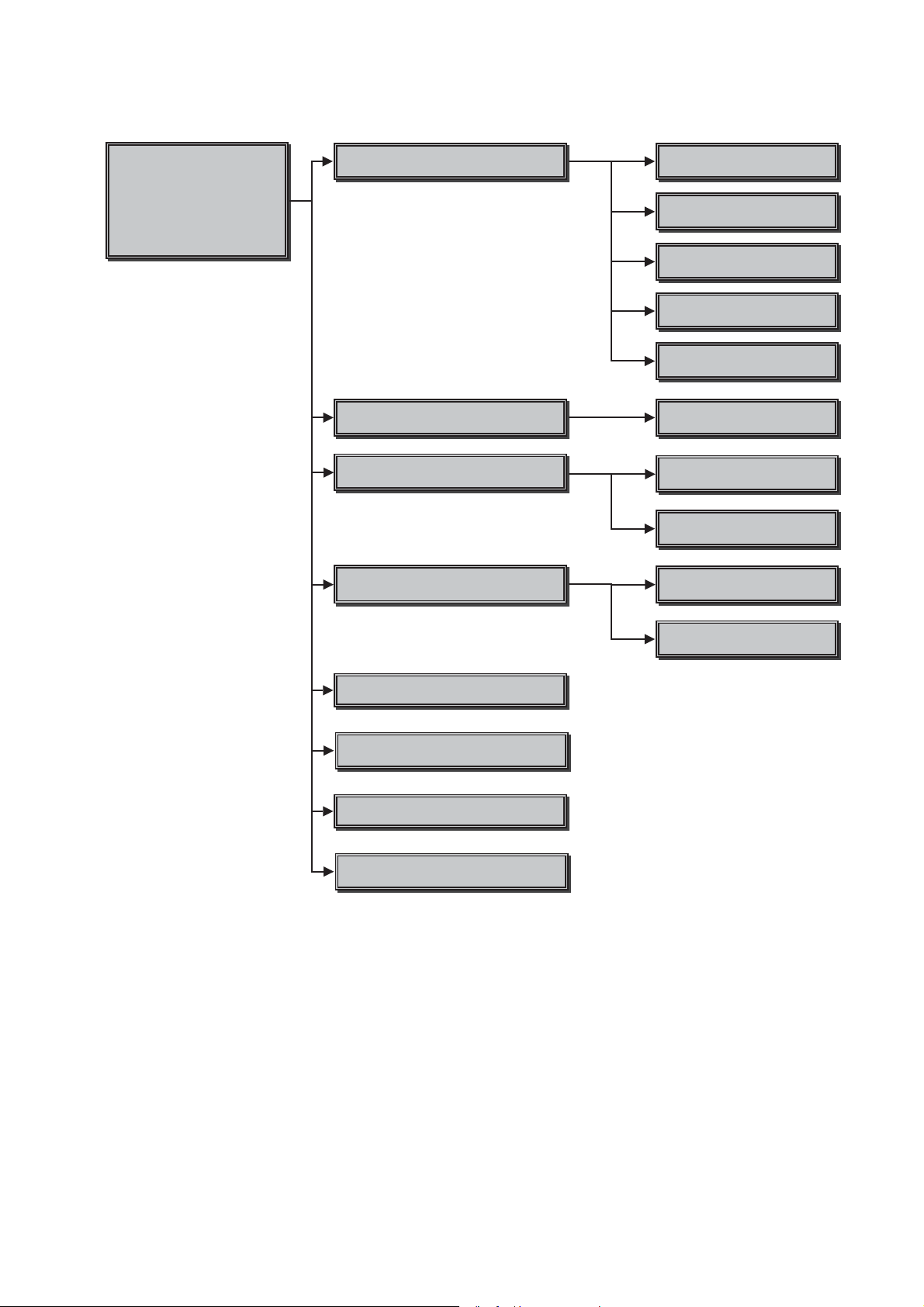

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

2-2. CASE

(Page 11)

SECTION 2

HBD-E670W/E970W

Ver. 1.1

2-3. MB-134 BOARD

(Page 12)

2-4. BRACKET (MB) BLOCK

(Page 13)

2-5. FUSE (F901),

POWER BOARD

(Page 13)

Note: Follow the disassembly procedure in the numerical order given.

2-6. FRONT PANEL BLOCK

(Page 14)

2-7. BD DRIVE (BPX-5)

(Page 14)

2-12. OPTICAL PICK-UP BLOCK

(KEM-460AAA),

WIRE (FLAT TYPE)

(Page 17)

2-9. BACK PANEL BLOCK

(Page 15)

2-10. MAIN BOARD

(Page 16)

2-8. INCLUDE BOARD

(Page 15)

2-11. AUDIO BOARD

(Page 16)

2-2. CASE

Note: When replacing the case, refer to “NOTE OF REPLACING THE CASE” on page 5.

1 four screws

(BV3)

5 seven hooks

2 five screws

(BV/RING)

– Bottom view –

6 case

3

3

4

11

HBD-E670W/E970W

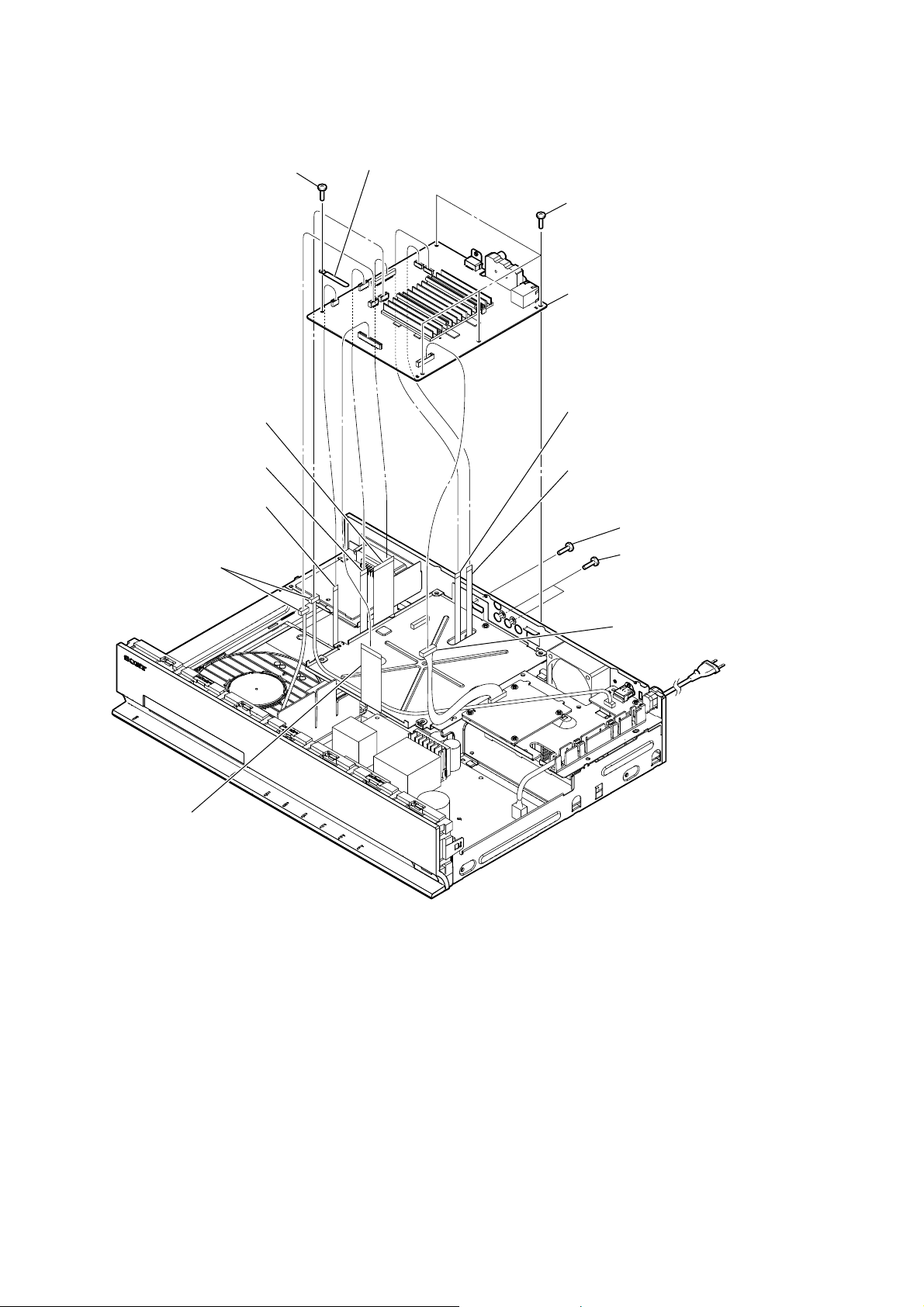

2-3. MB-134 BOARD

9 screw (BV3)

6 wire (flat type) (45 core)

(CN1401)

7 wire (flat type) (9 core)

(CN2460)

8 wire (flat type) (5 core)

(CN2470)

2 two connectors

(CN601, CN602)

q; clamp

Note:

There is a set not used either.

9 four screws (BV3)

qd MB-134 board

4 wire (flat type) (18 core)

(CN902)

5 wire (flat type) (16 core)

(CN901)

qa screw (B3 u 5)

qs two screws (BV3)

3 wire (flat type) (27 core)

(CN1505)

1 connector (CN303)

12

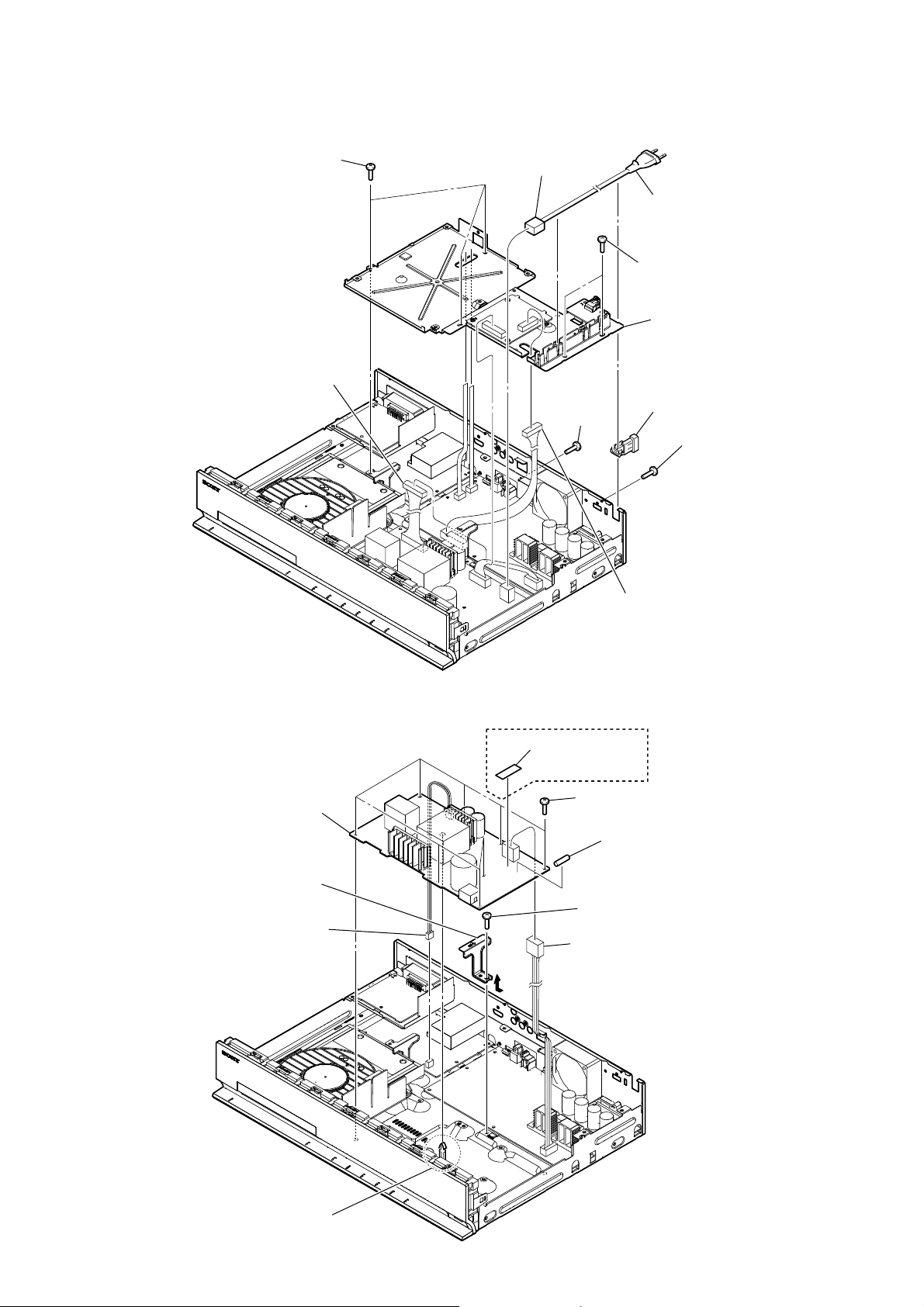

2-4. BRACKET (MB) BLOCK

HBD-E670W/E970W

8 three screws (BV3)

5 connector (CN400)

1 power cord connector

(CN901)

7 screw

(BV3)

3 power cord

8 two screws (BV3)

9 bracket (MB) block

2 cord bush (2104)

6 screw (P3 u 6)

4 connector (CN403)

2-5. FUSE (F901), POWER BOARD

0 POWER board

4 bracket R (MB foot)

6 connector

(CN17)

9 label fuse (T.H)

(EXCEPT Taiwan)

7 eight screws

(BV3)

1 glass fuse (DIA. 5) (8A/125V)

(F901) (Taiwan)

fuse (H.B.C.) (T5AH/250V)

(F901) (except Taiwan)

2 screw (BV3)

5 connector

(CN904)

3

8 Remove the POWER board from

PC board holder.

13

HBD-E670W/E970W

2-6. FRONT PANEL BLOCK

Note: Please prepare the thin wire (clip etc.).

2

5 three screws

(BV3)

6 three ground plates (front)

7 three screws

(BV3)

q; connector

(CN700)

9

8 three claws

qa front panel block

8 two claws

1

clip etc.

2-7. BD DRIVE (BPX-5)

7 BD drive (BPX-5)

6 sound sheet

5

8 three claws

4 four screws (BV3)

1 screw (BV3)

2

3 claw

4 loading panel assy

(10EZ)

3 bracket L (MB foot)

7 three screws

(BV3)

3 three claws

14

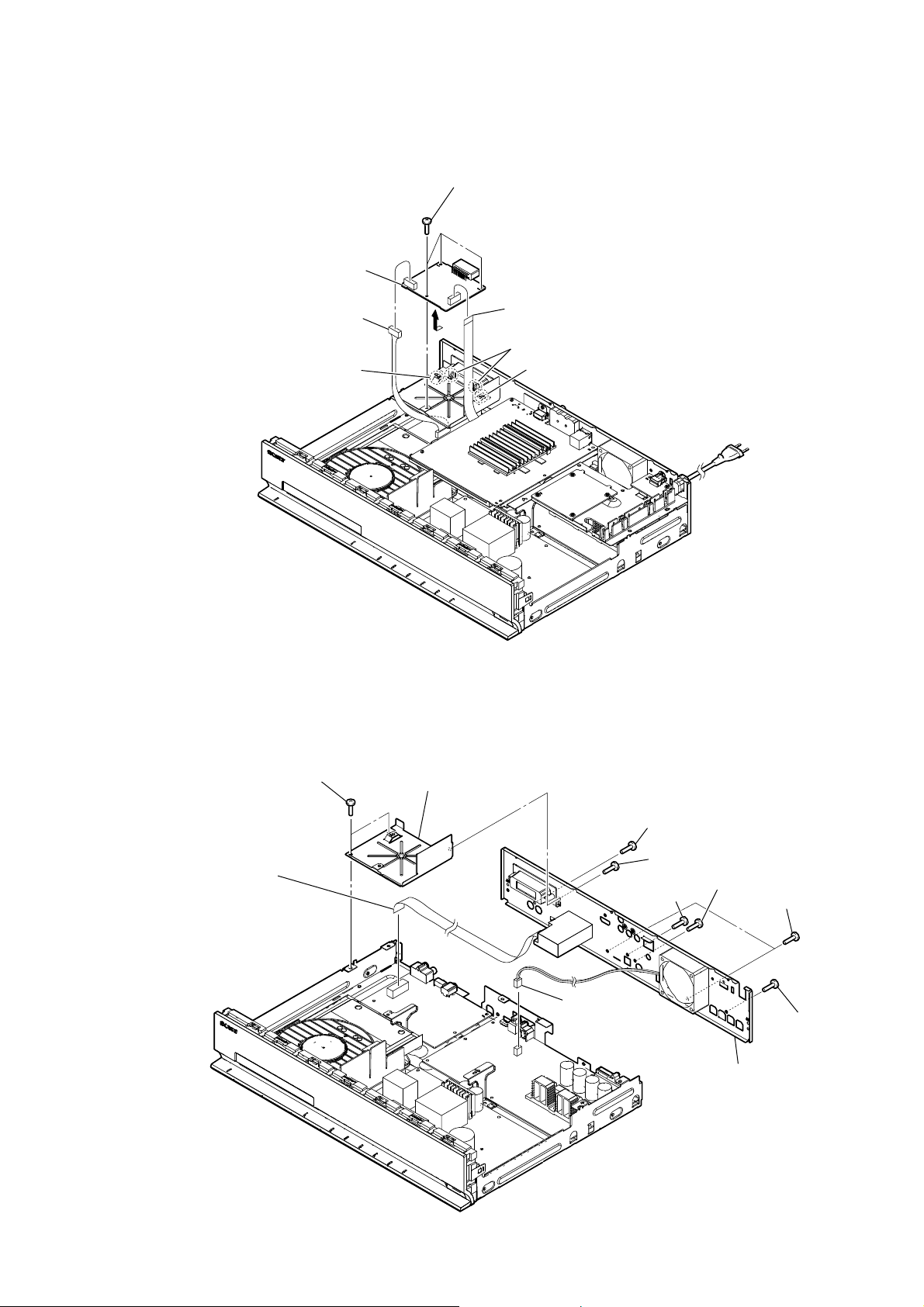

2-8. INCLUDE BOARD

5 INCLUDE board

HBD-E670W/E970W

Ver. 1.1

3 three screws

(BV3)

1 connector (CN204)

2-9. BACK PANEL BLOCK

guide rib

4

2 wire (flat type) (15 core)

(CN200)

two claws

guide rib

2 two screws

(BV3)

4 wire (flat type) (9 core)

(CN10) (AUS, CH, EA, SP, TW)

wire (flat type) (11 core)

(CN11) (AEP, RU, UK)

• Abbreviation

AUS : Australian model

CH : Chinese model

EA : Saudi Arabia model

RU : Russian model

SP : Singapore model

TW : Taiwan model

3 bracket (S-AIR TAKE)

7 screw

(BV3)

5 fan connector

(CN3000)

7 screw (BV3)

1 screw (BV3)

6 screw (BV3)

7 two screws (BV3)

7 screw (BV3)

8 back panel block

15

HBD-E670W/E970W

Ver. 1.1

2-10. MAIN BOARD

9 wire (flat type) (18 core)

(CN701)

7 wire (flat type) (17 core)

(CN503) (AUS, CH, EA, SP, TW)

wire (flat type) (19 core)

(CN501) (AEP, RU, UK)

qd seven screws

(BV3)

5 wire (flat type) (27 core)

(CN505)

6 wire (flat type) (15 core)

(CN508)

1 screw

(BV3)

8 wire (flat type) (15 core)

(CN702)

q; wire (flat type) (16 core)

(CN703)

4 connector

2

(CN904)

3 bracket R

(MB foot)

qa three screws

(BV3)

qs heat sink

(S-master DDV)

qd two screws

(BV3)

qf MAIN board

2-11. AUDIO BOARD

6 three screws (BV3)

1 screw (BV3)

3 bracket L

(MB foot)

2

• Abbreviation

AUS : Australian model

CH : Chinese model

EA : Saudi Arabia model

RU : Russian model

SP : Singapore model

TW : Taiwan model

7 AUDIO board

4 connector

(CN17)

5 wire (flat type) (17 core)

(CN14) (AUS, CH, EA, SP, TW)

wire (flat type) (19 core)

(CN16) (AEP, RU, UK)

16

• Abbreviation

AUS : Australian model

CH : Chinese model

EA : Saudi Arabia model

RU : Russian model

SP : Singapore model

TW : Taiwan model

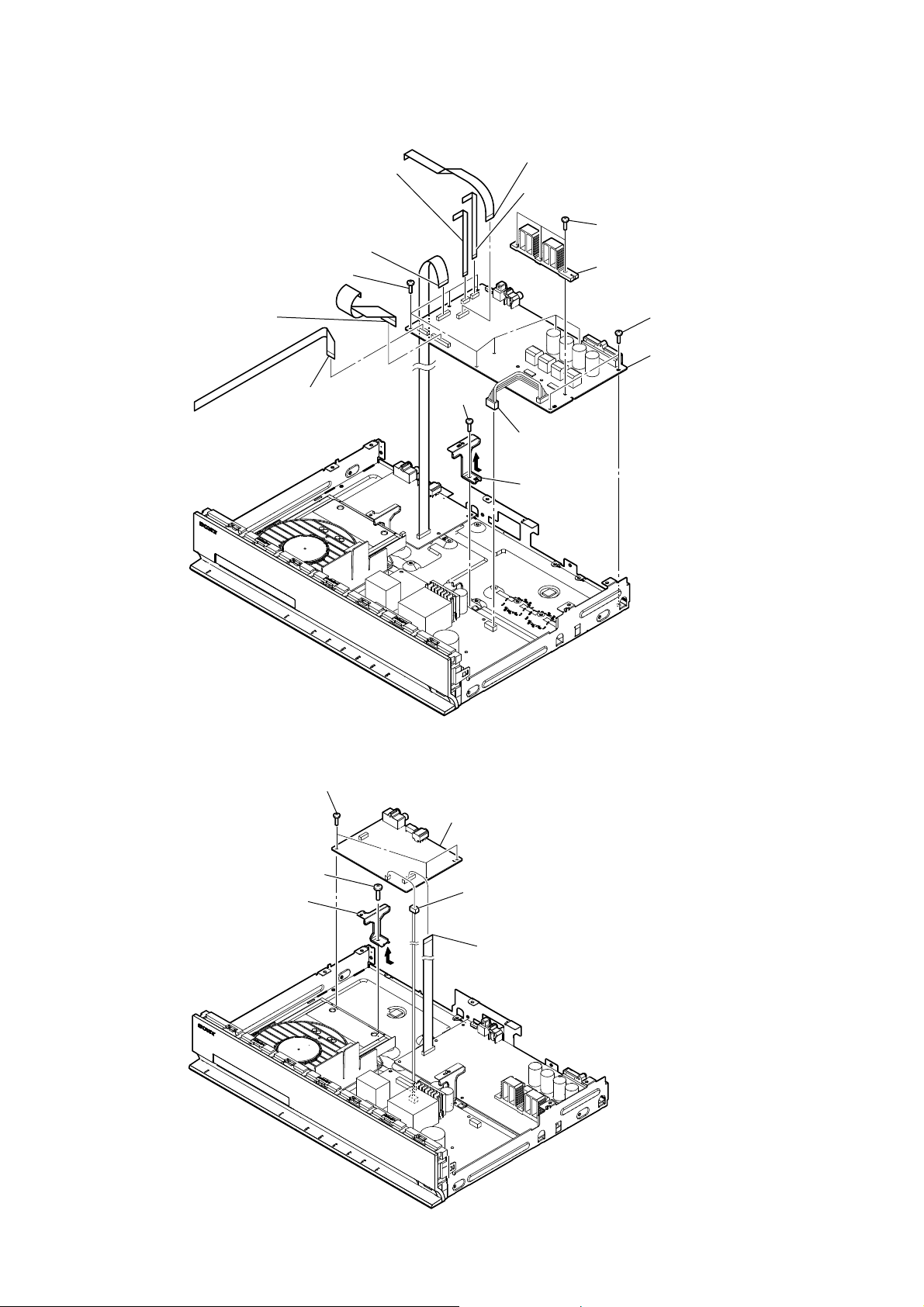

2-12. OPTICAL PICK-UP BLOCK (KEM-460AAA), WIRE (FLAT TYPE)

Note: Please prepare the thin wire (clip etc.).

4 chuck holder assy (D)

1 two screws

(BVTP 2.6)

2 two claws

7 two float screws (S)

qa insulator

5 Insert the thin

wire (clip etc.).

8

0

3 two claws

qa insulator

qs optical pick-up block

(KEM-460AAA)

qa insulator

9

qh ffc holder (rear)

qd non-halogene tape

qf wire (flat type) (5 core)

HBD-E670W/E970W

qk wire (flat type)

(45 core)

qg

qj wire (flat type)

(9 core)

qa insulator

6

,QVWDOODWLRQRIZLUHIODWW\SHFRUHDQGZLUHIODWW\SHFRUH

This illustration sees the loading assy (D) from bottom side.

Note:

3 wire (flat type) (9 core)

4 Through the hole.

terminal face

Under the guide.

loading assy (D)

1 wire (flat type) (45 core)

Fold

2 Through the hole.

terminal face

boss

loading assy (D)

– Bottom view –

7 two claws

5 ffc holder (rear)

7 three claws

6

Under the guide.

(Fold area)

boss

17

HBD-E670W/E970W

SECTION 3

TEST MODE

COLD RESET

The cold reset clears data except BD/DVD data stored in the RAM

to initial conditions. Execute this mode when returning the set to

the customers.

Procedure:

1. Press the [

2. Press the [x] and [VOLUME –] buttons simultaneously and

hold down (around 5 seconds).

3. The message “COLD RESET” appears on fl uorescent indica-

tor tube, then becomes standby states.

DEMO MODE

This mode let you lock the disc tray. When this mode is activated,

the disc will not eject when the [

“LOCKED” will be displayed on the fluorescent indicator tube.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to select the “BD/DVD”.

3. Press the [x] and [Z] buttons simultaneously and hold down

until “DEMO ON” or “DEMO OFF” displayed on the fluorescent indicator tube (around 5 seconds).

S-AIR ID SETTING DISPLAY

Procedure:

1. Press the [

2. Press the [FUNCTION] and [VOLUME +] buttons simultaneously and hold down (around 5 seconds).

3. S-AIR ID setting is displayed on the fl uorescent indicator tube.

] button to turn the power on.

?/1

] button is pressed. The message

Z

] button to turn the power on.

?/1

] button to turn the power on.

?/1

AMP TEST

Procedure:

1. Press the [

2. Press button in order of the [RETURN] → [0] → [1] → [1]

→ [SUBTITLE] on the remote commander (Make the interval

when each button is pressed within two seconds).

3. The message “MEASURE” appears on the fluorescent indicator tube and enter the AMP test mode.

4. Press the [BLUE] button on the remote commander, the state

of D.C.A.C. microphone is displayed on the fl uorescent indica-

tor tube.

*** @@ $$$

*** : Either of “IN”/“NON” is displayed by the state of

@@ : Either of “OK”/“NG” is displayed by the state of

$$$ : Microphone input audio data A/D value (0 – 255).

5. Press the [MUTING] button on the remote commander, “VOL

N” (The change in the volume is usual)/“VOL MSM” (The

change in the volume is a switch of MIN/1/20/MAX) can be

switched.

6. Press the [SUBTITLE] button on the remote commander, the

message “VACS ON” or “VACS OFF” appears on the fl uores-

cent indicator tube and thus the VACS on/off are changed.

7. To release from this mode, press the [

] button to turn the power on.

?/1

detection of the microphone.

digital audio data input.

?/1

] button.

PANEL TEST

Procedure:

1. Press the [

2. Press button in order of the [RETURN] → [0] → [0] → [1]

→ [SUBTITLE] on the remote commander (Make the interval

when each button is pressed within two seconds).

3. All segments in fl uorescent indicator tube are lighted up. And

half segments in fl uorescent indicator tube are lighted up, oth-

ers half segments in fl uorescent indicator tube are lighted up,

then all segments in fl uorescent indicator tube are lighted up.

This operation is repeated.

4. When all segments in fl uorescent indicator tube are lighted up

in the state of step 3, press the [VOLUME +] button on the

remote commander and model information is displayed on the

fl uorescent indicator tube.

Each time the [VOLUME +] button on the remote commander

is pressed, the display changes from destination information,

STR version, SYS version, UI version, BDLIB version, ST

version, TA version, DSP version, TM version, CEC version,

SAIR version, PF version in this order, and returns to the model information display.

Each time the [VOLUME –] button on the remote commander

is pressed, the version and date are switched.

5. In the state of step 3, press the [FUNCTION] button on the

remote commander and “K 0” is displayed on the fluorescent

indicator tube.

“K 0” value increases whenever a button on the set is pressed.

However, once a button has been pressed, it is no longed taken

into account.

All buttons on the set are pressed, “OK” and “K 7” are alter-

nately displayed on the fluorescent indicator tube.

6. To release from this mode, press the [

] button to turn the power on.

?/1

?/1

] button.

BD SERVICE MODE

Note: The operation in this mode must use a remote commander.

Setting method of the BD service mode:

1. Press the [

2. Press button in order of the [RETURN] → [0] → [2] → [1] →

[SUBTITLE] on the remote commander. (Make the interval

when each button is pressed within two seconds)

3. Enter the BD service mode.

1. Main Functions

• ErrorLog display

Display the error log. Displayed contents can also be saved in

an USB memory device.

• Diag

Performs unit test of devices installed on the board.

• Factory Initialize

Restores the set to its factory settings.

• Network

Checks the wired network connection.

• Version Up (version update)

Not used.

• System Information

Displays the system information of the set.

Displays information such as the software version, drive infor-

mation, etc.

• EMC Test Mode

Not used.

• Drive

Write drive OP data and check drive.

] button to turn the power on.

?/1

18

2. Menu Tree

HBD-E670W/E970W

Service Mode Menu

Service Mode Menu

[1] Diag

[1] Diag

[2] Log

[2] Log

[3] Factory Initialize

[3] Factory Initialize

[4] Network

[4] Network

[5] Version Up

[5] Version Up

[6] System Information

[6] System Information

[7] EMC Test Mode

[8] Drive

Diag

Diag Test

Log

Displays Error Log

Factory Initialize

5estores set to factory settings

Network

Network diagnosis for wired

Device Test

US%D$CIFcon test

Video Test

Video output test

$udio Test

$udio output test

$udio Input Test

$udio Input Test

:ireless L$N Test

Not used

Error Log

Displays error log

Start Initialize

Initialize default setting for %Dplayer

Start Initialize for TV

Not used

Ifconfig

View network status

Version Up

Not used

System Information

Displays system information

EMC Test Mode

Not used

Drive

Write drive OP data and check drive

Ping

Confirm network connection

19

HBD-E670W/E970W

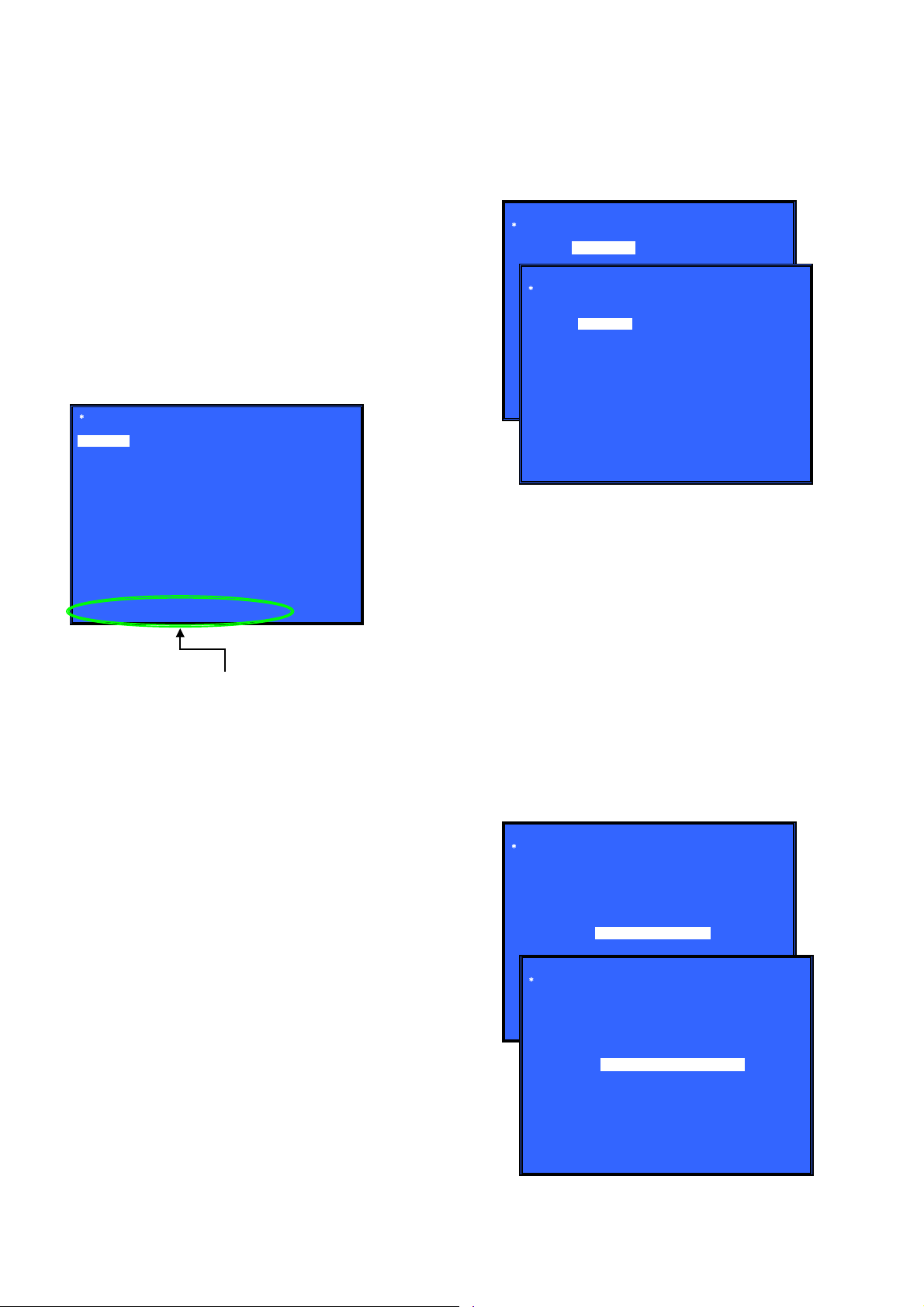

3. Service Mode Menu (Top Menu)

This is the top menu of service mode.

Each function is accessed from this screen.

Operation:

[1] Moves to Diag screen

[2] Moves to Log screen

[3] Moves to Factory Initialize screen

[4] Moves to Network screen

[5] Moves to Version Up (DISC version update) screen (Not

used)

[6] Moves to System Information screen

[7] Moves to EMC test mode screen (Not used)

[8] Moves to Drive screen

[

]/[m] Moves the cursor

M

3] Moves to the screen of the item selected with the cursor

[

* Cursor is not displayed when the menu is fi rst displayed.

Service Mode Menu

[1] Diag

[1] Diag

[2] Log

[3] Factory Initialize

[4] Network

[5] Version Up

[6] System Information

[7] EMC Test Mode

[8] Drive

• Device Test: List of devices

USB Host (*1)

*1) USB media check (front and rear). Only one time.

* For details concerning device test, see the Diag reference.

Diag

Device Test

Category: Device Test

USB Host

Device:

Rear USB Media check ... OK

Front USB Media check ... OK

Checking...

(Screen 1)

(Screen 2)

Category:

Diag

HELP: [RIGHT] [UP] [ENT] [RET]

5. Diag (Video/Audio Test)

This screen performs video and audio tests.

HELP : [DOWN] [ENT] [(NUM)]

HELP (currently available keys, etc.) is displayed

4. Diag (Device Test)

This screen is used to test devices mounted on the board.

Screen 1: Selects the test category

Operation:

[<]/[,] Selects the category

[m]/[3] Moves to the selected category

Screen 2: Device test

Selects the device to test after selecting Device Test in screen 1.

Operation:

[<]/[,] Selects the device to test

[3] Executes the test

[M] Returns to selection of test category

• List of test categories

Device Test

Video Test

Audio Test

Audio Input Test

Wireless LAN Test (not used)

Screen 1: When video test category is selected

Operation:

[3] Shows/hides the color bar

[M]/[RETURN] Returns to the selection of test category

Screen 2: When audio test category is selected

Operation:

[3] Plays back/stops the tone sound

[M]/[RETURN] Returns to the selection of test category

• Video test:

Outputs a color bar (composite & component & HDMI).

• Audio test:

TONE sound output (speaker (8 ch) & HDMI (2 ch)).

Diag

Category: Video Test

[ENT] Show Color Bar

Diag

Category: Audio Test

(Screen 1)

HELP: [UP][ENT][RET]

[ENT] Generate TONE Sound

20

(Screen 2)

HELP: [UP] [ENT] [RET]

HBD-E670W/E970W

6. Diag (Audio Input Test)

This screen performs audio input test.

Screen 1: Selects the test category

Operation:

[<]/[,] Selects the category

[m]/[3] Moves to the selected category

Screen 2: Select Audio Input Test

Operation:

[M]/[m] Select test

[3] Start/stop input sound

[RETURN] Returns to the selection of test category

• Digital Input

Input : SPDIF (optical, 48 kHz, 2 ch only).

Sound output : Speaker (2 ch).

• Analog Input

Input : Line In (2 ch).

Sound output : Speaker (2 ch).

Diag

Category: Audio Input Test

Diag

Category: Audio Input Test

Device: Digital Input

Analog Input

[ENT] Start Input Sound

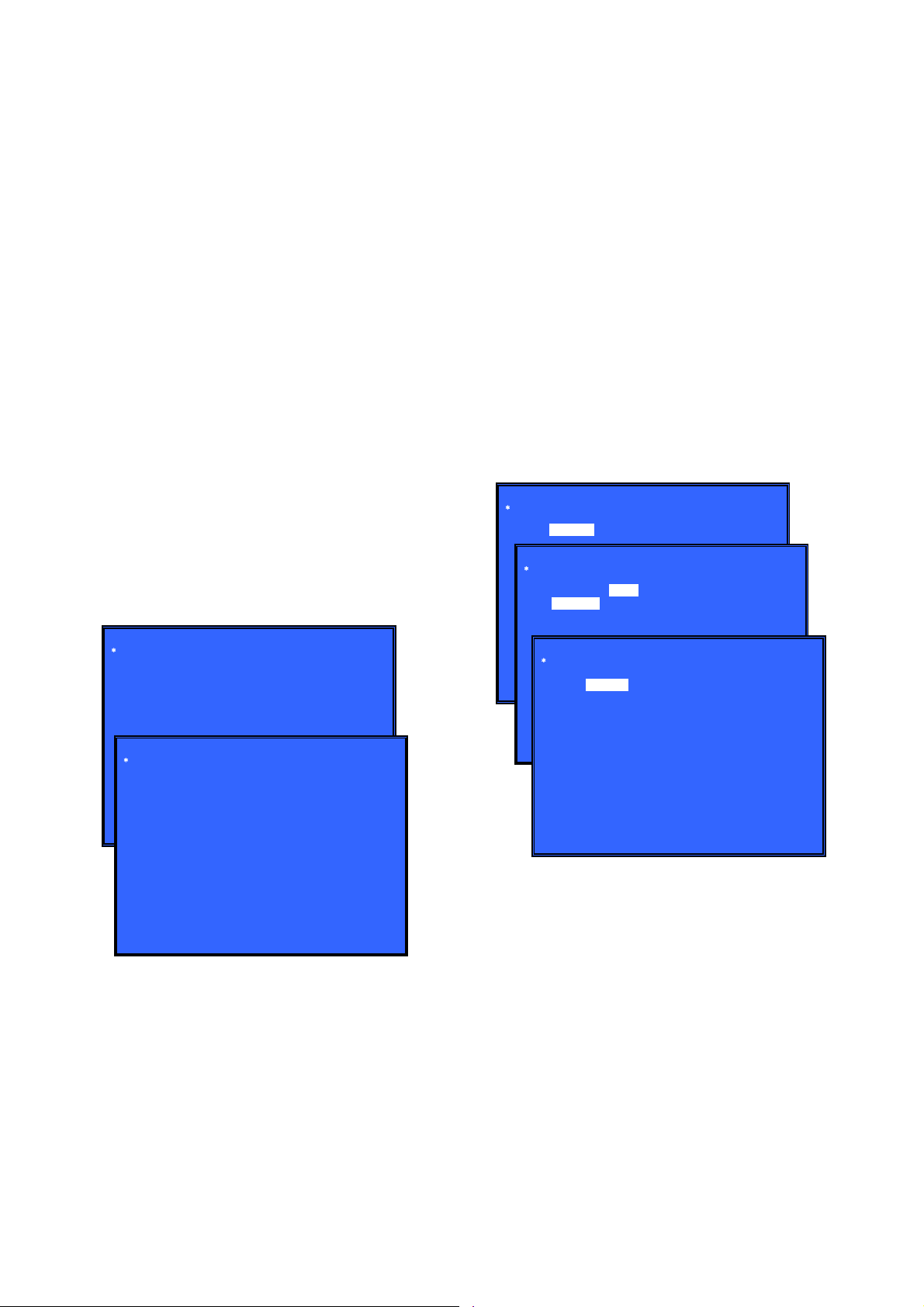

8. Log: Error Log (Output of each Log)

This screen displays the contents of each log.

Note: Do not refer to the displayed date.

Screen 1: Selects log

Operation:

[1]/[3] Moves to the Error Log output screen

[RETURN] Returns to the top menu of the service mode

Screen 2: Displays the Error Log

Operation:

[

] Returns to the previous page

<

[,] Moves to the next page

[RETURN] Returns to the screen (screen 1) that selects the log

type

[RED] Writes the log contents to an USB memory device

• Viewing the log display

Error Log:

001 08/01/01 00: 53: 19: [ErrCode: 080400000000]

[Number (starting from old log) ] [date] [time] [error code]

About copying log to USB memory device:

Press the [RED] button in each log display screen with the USB

memory device inserted into the set

Note: Please do not press the [RED] button immediately after USB mem-

ory is inserted.

Please do not pull out USB memory immediately after the [RED]

button was pressed.

Error Log:

When “getErrLogFile.trm fi le” exists in the USB memory de-

vice, errlog.log fi le is output.

(Screen 1)

HELP: [UP][ENT][RET]

(Screen 2)

HELP: [UP] [ENT] [RET]

7. Diag (Wireless LAN Test)

This screen performs wireless LAN test.

Note: Not used for the servicing.

(Screen 1)

(Screen 2)

Select Log

[1] Error Log

Error Log

001 08/01/01 00: 53: 19: [ErrCode: 080400000000]

002 08/01/01 00: 53: 45: [ErrCode: 080400252100]

003 08/01/01 00: 54: 00: [ErrCode: 080400005555]

HELP : [DOWN][ENT][(NUM)]

:

:

21

HBD-E670W/E970W

Ver. 1.2

9. Factory Initialize (Factory Settings)

Return all of the player setting to their factory defaults.

Operation:

Screen 1

Press the [1] button in this screen when restoring the set to its factory settings.

All saved titles will also be deleted.

[1] Start Factory Initialize

[2] Start Factory Initialize for TV (Not used)

[M]/[m] Moves the cursor

[3] Activate the selected cursor

[RETURN] Returns to the top menu of the service mode

Screen 2

It is a screen of the end of initialization.

[RETURN] Returns to the top menu of the service mode

To complete factory initialize, execute “Reset to Factory Default

Settings” from the OSD menu, next execute COLD RESET.

Please disconnect AC power cord, and connect AC again. Press the

[

] button to turn power on, and press the [HOME] button, Se-

?/1

lect “Setup” → “Resetting” → “Reset to Factory Default Settings”

→ “All settings” → “Start” from the OSD menu, and press the [3]

button. Then press the [

] button to turn the power on, and press

?/1

the [x] and [VOLUME –] buttons on the set simultaneously and

hold down (around 5 seconds) to execute COLD RESET.

Remove the AC power cord and insert the AC power cord again.

* Operations in other service menus can also be performed.

10. Network (Network Test Diagnosis Screen: Ifconfi g)

Network menu for the wired ethernet.

Screen 1: Ifconfi g Test

Operation:

[3] Activate Ifconfi g (Display network setting)

[,] Select ping test

[RETURN] Returns to the top menu of the service mode

Screen 2: Ping Test

Operation:

[<] Select Ifconfi g test

[RETURN] Returns to the top menu of the service mode

(The details of a Ping test are “11. Network (Network Test Diagnosis Screen: Ping)”)

Screen 3: Ifconfi g Test Active

Display Ifconfi g command results.

Operation:

[3] Ifconfi g retry

[,] Select Ping Test

[RETURN] Returns to the top menu of the service mode

Network

Test: Ifconfig Ping

Network

Test: Ifconfig Ping

Ping To:

[START]

(Screen 1)

(Screen 2)

Factory Initialize

[1] Start Initialize

[2] Start Initialize for TV

[RET] Return to Top Menu

Factory Initialize

Reboot to complete.

[RET] Return to Top Menu

HELP: [RET]

(Screen 1)

(Screen 2)

Network

HELP : [DOWN][ENT][(NUM)]

(Screen 3)

Test: Ifconfig Ping

IP 192. 168. 11. 2 MAC 00-16-01-85-21-A3

HELP : [DOWN][ENT][(NUM)]

HELP : [ENT]: Re/Exe [RIGHT]

22

HBD-E670W/E970W

11. Network (Network Test Diagnosis Screen: Ping)

Ping test for the wired ethernet.

Screen 1: Ping Test

Operation:

[<] Select Ifconfi g test

[m] Ping execution preparation

[RETURN] Returns to the top menu of the service mode

Screen 2: The IP address of the Ping point is set up

(IP address input mode)

When “Ping to :>” is reversed, the [3] button is pressed and IP is

inputted.

Operation:

[3] Finish to input

[RETURN] Finish to input

[<] Finish to input and Select Ifconfi g Test

[0] to [9] Input Character sting ‘0-9’

[TIME] Input Character sting ‘.’

[CLEAR] Backspace

Screen 3: Ping Test Active

When [START] is reversed, the [3] button is pressed and execute

ping.

Operation:

[3] Activate ping test

[M] The IP address of the ping point is set up

[RETURN] Returns to the top menu of the service mode

Network

Ifconfig

(Screen 1)

(Screen 2)

Test:

(Screen 3)

Ping To :

Network

Test: Ifconfig

Ping

[START]

Ping to :> 192. 168. 200. 13

Network

Test: Ifconfig

PING 192. 168. 200. 13 OK!

HELP: [ENT] : Start [UP] [LEFT]

Ping

[ENT] : Release

[RET] : Release

Ping

Ping to : 192. 168. 200. 13

[START]

12. System Information (System Information Display)

This screen displays system information.

Screen 2: Drive Information Menu

Operation:

[<] Basic Information displayed (go to screen 1)

[RETURN] Returns to the top menu of the service mode

When delta IOP is measured, it becomes impossible to use the Version Up function.

Contents List:

Model

Destination

Sequence Number

MAC

IP

IFCON IFCON V ersion

Bootloader Bootloader Version

Host Main Host Main Version

Host Sub Host Sub Version

Middleware Middleware V ersion

ADSP ADSP Version

IF Model

IF Dest

Drive Firm Revision

CD DIOP Delta IOP

DVD DIOP Delta IOP

BD DIOP Delta IOP

CD LD TIME LD Time

DVD LD TIME LD Time

BD LD TIME LD Time

(Screen 1)

System Information

Model :

Destination :

Sequence Number :

MAC :

IP :

IF-con Block0 Version : Block1 Version :

Bootloader Version :

Host Main Version :

Host Sub Version :

Middleware Version :

ADSP Version :

IF_MODEL :

IF_DEST :

HELP: [RET] [RIGHT]

(Screen 2)

System Information

Drive Firm Revision :

CD DIOP :

DVD DIOP :

BD DIOP :

CD LD TIME :

DVD LD TIME :

BD LD TIME :

Screen 1: Basic Information

Operation:

[,] Drive information (delta IOP of a drive is measured)

displayed (go to screen 2)

[RETURN] Returns to the top menu of the service mode

HELP: [RET] [LEFT]

23

HBD-E670W/E970W

13. Drive

This menu is used to operate the drive using drive-related diagnostic and tools.

Screen 1: Selecting items under *Service Menu

(Screen 1)

Service Menu

[1] Diag

[2] Log

[3] Factory Initialize

[4] Network

[5] Version Up

[6] System Information

[7] EMC Test Mode

[8] Drive

Screen 2: Selecting items under *Drive

(Screen 2)

Drive

[1]Drive OP data Write

[2]Servo Parameter Check Menu

[3]Servo Signal Check Menu

[4]S -Curve Check Menu

[5]Readability Check Menu

[6]OP Position Check Menu

[7]OP Check Menu

[8]Load Eject Aging

[9]Spindle Control Check Menu

[10]FA Test Mode

Screen 3: *Drive OP data Write

Purpose: Write OP data into fl ash IC

[M]/[m] Move the cursor up and down

[3] Start the selected cursor item

[RETURN] Returns to the top menu of the service mode

(Screen 3)

Drive OP data Write

Insert USB StorageDevice ...

Remove DISC and Close tray.

[1]Disc: Eject

[ENT] Start

Screen 4: *Servo Parameter Check Menu (Not Used)

(Screen 4)

Servo Parameter Check Menu

[1] Disc: Eject

[2] Show Parameters

Operation:

[M]/[m] Move the cursor up and down

[3] Open the selected cursor item

[RETURN] Returns to the top menu of the service mode

• Test item list

[1] Drive OP data Write

[2] Servo Parameter Check Menu

[3] Servo Signal Check Menu

[4] S-Curve Check Menu

[5] Readability Check Menu

[6] OP Position Check Menu

[7] OP Check Menu

[8] Load Eject Aging

[9] Spindle Control Check Menu

[10] FA Test Mode

Not used for the servicing.

Press the [RETURN] button if having entered this mode.

Screen 5: *Servo Signal Check Menu (Not Used)

(Screen 5)

Servo Signal Check Menu

[1] Disc: Eject

[2] Servo Signal Monitor out: OFF

[3] RTADJ: OFF

[4] FocusBias: 0000

[5] SA -Act.move: FWD 00 step

[6] Pl Level: 0000

[7] RF Level: 0000

[8] TRV Level: 0000

[9] Current FB: 0000 SA: 0000

Not used for the servicing.

Press the [RETURN] button if having entered this mode.

24

HBD-E670W/E970W

Screen 6: *S-Curve Check Menu (Not Used)

(Screen 6)

S - Curve Check Menu

[1] Disc: Eject

[2] Media Type: BD - ROM SL

[3] Layer: L0

[4] SLD move to Home

[5] SLD move: FWD 00 step

[6] FCS Search start

Not used for the servicing.

Press the [RETURN] button if having entered this mode.

Screen 7: *Readability Check Menu (Not Used)

(Screen 7)

Readability Check Menu

[1] Disc: Eject

[2] Address: 00000000

[3] Length: 0000

[4] Execute

Jitter P: 0000

Jitter PR: 0000

Jitter DC: 0000

SER: 0000 0000

Screen 9: *OP Check Menu

Purpose: Verify OP related such as delta IOP and LD time

[M]/[m] Move the cursor up and down

[3] Start the selected cursor item

[RETURN] Returns to the top menu of the service mode

(Screen 9)

OP Check Menu

Remove DISC and Close tray

[1] Disc Eject

[2] OP Serial: xxxxxxxxxxxxxx

[3] dIOP

BD: x[xx]

DVD: x[xx]

CD: x[xx]

TEMP: xx.x deg

[4] LD ON Time

BD: xxxxh xxm

DVD: xxxxh xxm

CD: xxxxh xxm

Screen 10: *Load Eject Aging (Not Used)

(Screen 10)

Load Eject Aging

[1] Disc: Eject

[2] Repeat set: 00000

[3] Mecha type: Tray mecha

[4] Aging type: Normal

[5] Start

Not used for the servicing.

Press the [RETURN] button if having entered this mode.

Screen 8: *OP Position Check Menu (Not Used)

(Screen 8)

OP Position Check Menu

[1] Disc: Eject

[2] OP Position Check

Not used for the servicing.

Press the [RETURN] button if having entered this mode.

Not used for the servicing.

Press the [RETURN] button if having entered this mode.

Screen 11: *Spindle Control Check Menu (Not Used)

(Screen 11)

Spindle Control Check Menu

[1] Disc : Eject

[2] rpm: 0000 rpm

[3] Spindle: OFF

Not used for the servicing.

Press the [RETURN] button if having entered this mode.

25

HBD-E670W/E970W

Screen 12: *FA Mode Test (Not Used)

(Screen 12)

FA Mode Test

[1] Enter Repeat FA mode

Repeat number: 0000

[2] Save FE log to USB

Not used for the servicing.

Press the [RETURN] button if having entered this mode.

CONFIRMATION ITEM

1. Playback Operation Confi rmation

1-1. Test Disc

Part No. Description Layer

J-6090-199-A BLX-104 Single Layer

J-6090-200-A BLX-204 Dual Layer

J-2501-307-A CD (HLX-A1)

J-2501-305-A HLX-513 Single Layer (NTSC)

J-2501-306-A HLX-514 Dual Layer (NTSC)

J-6090-077-A HLX-506 Single Layer (PAL)

J-6090-078-A HLX-507 Dual Layer (PAL)

Note: Refer to the service manual of BDP-BX1/S350 (Part No. 9-883-

989-1[]) (page 1-3 to 1-14E) for the use of BLX-104/204.

Operation and Display:

1. BLX-104

Procedure:

1. Select 23.976Hz/1080p.

2. Play “4.Motion picture”.

3. Check whether player can play back or not.

4. Check each outputs.

Video:

Composite/S Video/component/HDMI.

Audio:

Speaker out.

* When 1080/24p monitor is nothing, 1080i (59.94Hz or 50Hz)

can use instead of 1080/24p.

However this is temporary correspondence.

* When the output of HDMI is 1080p, the signal of Composite/S

Video/Component are not output.

It is necessary to lower the output of HDMI to 1080i or less.

3. CD (HLX-A1)

Procedure:

Check whether player can play back or not.

(Check the sound output)

4. HLX-513/514 (NTSC), HLX-506/507 (PAL)

Procedure:

1. After displayed Main Menu, select “1.Video Signal”.

2. Play “1.Color bar 100%”.

(Check the picture and sound output)

3. Return to Menu.

4. Play “Demonstration 4:3” or “Demonstration 16:9”.

(Check the picture and sound output)

1-2. Playback operation confi rmation

Confi rm operation in each signal/output mode of test disc (BLX-

104/204) according to the content of the repair.

Note: “AV Sync.” doesn’t operate.

2. Networking Confi rmation

Confi rm it according to the following procedure when you confi rm

the connection of the network.

Note: Do not execute “Network Connection Diagnostics” of “Network

Settings” of the home menu with only the router connected.

Procedure:

1. Connect the router with the set with LAN cable.

2. Turn on the power of the set and the router.

3. Press the [HOME] button on the remote commander, and the

home menu is displayed.

4. Select “Setup” → “Network Settings” → “Internet Settings”,

and press the [3] button on the remote commander.

5. Select “View Networks Status” and press the [3] button on the

remote commander.

6. Confi rm IP address are displayed in “IP Address”, “Subnet

Mask” and “Default Gateway”.

Physical Connection: XXXX

Internet Access: XXXX

IP Address Setting: XXXX

IP Address: XXX.XXX.XXX.XXX

Subnet Mask: XXX.XXX.XXX.XXX

Default Gateway: XXX.XXX.XXX.XXX

DNS Settings: XXXX

Primary DNS: XXX.XXX.XXX.XXX

Secondary DNS: XXX.XXX.XXX.XXX

MAC Address: XXX.XXX.XXX.XXX

2. BLX-204

Procedure:

1. Select 1080i (59.94Hz or 50Hz).

2. Play “4.Motion picture”.

3. Check whether player can play back or not.

(Check the picture and sound output)

26

SECTION 4

ELECTRICAL CHECK

FM TUNER LEVEL CHECK

signal

generator

set

Procedure:

1. Turn on the set.

2. Input the following signal from Signal Generator to FM antenna

input directly.

Carrier frequency : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Use 75 ohm coaxial cable to connect signal generator and the set.

You cannot use video cable for checking.

Use signal generator whose output impedance is 75 ohm.

3. Set to FM tuner function and tune A, B and C signals.

4. Confi rm “TUNED” is lit on the display for A, B and C signals.

HBD-E670W/E970W

When the selected station signal is received in good condition,

“TUNED” is displayed.

HBD-E670W/E970W

2727

HBD-E670W/E970W

SECTION 5

DIAGRAMS

5-1. BLOCK DIAGRAM - SERVO Section -

%''5,9(

%3;

%'B5)

6',2

6&/.

6(1B/''

&20021

/2$'

/2$'

)'

)5

)'

)5

75$<,1

75$<287

6$B%

6$B%

6$B$

6$B$

)(9

)(9

02725'5,9(5

,&

%

%

$

$

W

V

8

75

7'

6/('B3

52

6/('B153

6/('B3

55

6/('B1

56

8

V

W

0&20

/2$'B332

/2$'B1

33

75.B329

75.B1

30

)&6B327

)&6B1

28

7/7B3

7/7B1

25

02725'5,9(55(*8/$725

673

16

673

17

673

18

673

19

5(*39

5(*3[9

22

96/('

96/('

963,1

9/2$'

975.

9)&6

97/7

;)*

021,725 12

;087(

;087(

*&

,&

673B,1

673B,1

67(3B(1$

16

17

18

19

20

21

22

11

13

15

8

9

7

)(B5),3<%'B5)

)(B5),1<

)(B5),3'9'B5)

W1

)(B5),1'9'B5)

W3

)(B,1$3%

)(B,1%1$

)(B,1&5'

)(B,1'7&

)(B,1(V6*

)(B,1)8H

)(B,1*5(

)(B,1+7)

)(B&)5(4

$'

)(B262(1

$(

)(B&02'

$)

)(B)3'2'9'77(67B9

)(B+$9&-9&B3'

)(B$8;07+(502

)(B9'$&/6$B,1,7

)(B*,2-02'(B$

)(B*,2-02'(B%

)(B*,2*02'(B&

)(B*,2*/'(1

)(B)02

$)

)(B)02

$(

)(B'02

$)

)(B75$<3:0

$(

)(B752

$+

)(B)22

$'

)(B7/2

$0

)(B)**

)(B/,0,7

$*

)(B*,2

$'

)(B*,2

$*

)(B*$,16:

$'

)(B75$<,1

$-

)(B75$<287

$.

)(B)02

$)

)(B)02

$*

)(B*$,16:

$(

)(B03;287

)(B03;287

)(B*,2

9,'(2$03

,&

70'6'$7$

70'6'$7$±

70'6'$7$

70'6'$7$±

70'6'$7$

70'6'$7$±

70'6&/2&.

70'6&/2&.±

6&/

6'$

+3'

&(&

&(&

$5&B63',)

'$7$B,

',5B(5525

&6,B'$7$,1

&6,B'$7$287

&6,B&/.

&6,B;&6B',5

',5B;67$7(

',5B&6)/$*

',5B$8',2

63B'$7$

63B0&.

63B%&.

63B/5&.

$26'$7$

$26'$7$

$26'$7$

$26'$7$

$26'$7$

$20&.

$2%&.

$2/5&.

159RXW

103<RXW

113ERXW

133URXW

7

9

6

1

3

10

12

15

16

19

13

$

(Page 31)

'$&287

'

'$&287

&

'$&287

%''(&2'(5

,&

$0

$/

$/

$.

&

'

'

(

$

%

&

$

%

)

&

$

(

%

'

&

+

)

16B5),3.

16B5),1+

16B&.,1)

86%B'3

86%B'0

86%B'3

86%B'0

(77;'

(77;'

(75;'

(75;'

(75;'

(75;'

(70',2

(70'&

(75;&/.

(75;(5

(77;(1

/

.

(

&1

3

2

&1

3

2

&1

(7+(51(7

&211(&725

/$1

6 7;128

5

2

1

X1201

25MHz

(7+(51(7,17(5)$&(

,&

7;3

29

5;1

31

5;3

32

;7$/13

&/.,1

7;' 23 (77;'

7;'

7;' 26 (77;'

7;' 27

5;' 18

5;' 17

5;' 16

5;' 15

0',2

0'& 2

7;&/.

5;B&/.

7;B(5

5;B(5 21

7;B(1 6

5;B'9

Q567

22 (77;&/.

20

1 (77;(5

36 (7&2/

&2/

3 (7&56

&56

19 (75;'9

5

%

'$&287

$

*

9,1'

+

9,1'

'

&+B3

%

&+B0

&

&+B3

$

&+B0

'

&+B3

%

&+B0

&

&/.B3

$

&/.B0

)

+'0,6&.

+'0,6'

(

*

+73/*

:$9(

6+$3(5

,&

0&,1

)

,5

%

9,1'

(

9,1'

'

9,1'

$

9,1'

)

9,1'

(

9,1'

$

9,1'

*

9,1' ',5B;567

%

63'$7$

*

630&/.

&

63%&.

$

63/5&.

%

$26'$7$

&

$26'$7$

*

$26'$7$

H22

$26'$7$

)

$26'$7$

(

$20&/.

'

$2%&.

%

$2/5&.

(

1

9LQ

7

3<LQ

3ELQ

5

3ULQ

3

6'+'

0XWH

8

5(6(59('$5&

%8))(5

4

&1

+'0,

$5&287

-

9,'(2287

<

3%&%

35&5

&20321(17

9,'(2287

6,*1$/3$7+

$8',2

9,'(2

',6&3/$<

86%

6<6&21B567

%

/$1

(Page 30)

HBD-E670W/E970W

2828

5-2. BLOCK DIAGRAM - MEMORY Section -

NS_XTALI

A25

NS_XTALO

C25

XTAL25MO

BA9

XTAL25MI

BB8

A_RDQ0 - A_RDQ15

A_RA0 - A_RA13

A_RBA0

BB28

A_RBA1

AU27

A_RBA2

AT28

A_RWEB

BC29

A_RCSB

AV24

A_RCASB

AU23

A_RRASB

BB24

A_RODT

AW23

A_RCKE

BA29

A_RCLK0

BC21

A_RCLK0B

BA21

A_RDQM1

AV18

A_RDQS1

BC17

A_RDQS1B

BA17

A_RDQM0

AT18

A_RDQS0

AY16

A_RDQS0B

BB16

SD-RAM

IC104

DQ0 - DQ15

A0 - A12, NC

BA0

BA1

BA2

/WE

/CS

/CAS

/RAS

ODT

CKE

CK

/CK

UDM

UDQS

/UDQS

LDM

LDQS

/LDQS

A_RA0 - A_RA13

L2

L3

L1

K3

L8

L7

K7

K9

K2

J8

K8

B3

B7

A8

F3

F7

E8

X401

27MHz

X802

25MHz

FE_SFDO

FE_SFDI

FE_SFCLK

FE_SFCS#

STXP_1

STXN_1

SRXP_1

SRXN_1

VCLK25MI

MRESET_

E1

F2

C1

K6

BC3

BA3

BC1

BB2

AJ9

C35

SD-RAM

IC204

DQ0 - DQ15

A0 - A12, NC

BA0

BA1

BA2

/WE

/CS

/CAS

/RAS

ODT

CKE

CK

/CK

UDM

UDQS

/UDQS

LDM

LDQS

/LDQS

B_RA0 - B_RA13

L2

L3

L1

K3

L8

L7

K7

K9

K2

J8

K8

B3

B7

A8

F3

F7

E8

BD DECODER

IC101 (2/2)

FESFDO

A1

FESFDI

C3

FESFCK

D4

FESFCS

B2

FE_SRXP

AR1

FE_SRXN

AR3

FE_STXP

AN1

FE_STXN

AP2

FE_XTAL25MI

AJ3

FE_RSTI

M6

B_RDQ0 - B_RDQ15

B_RA0 - B_RA13

B_RBA0

AD40

B_RBA1

AD36

B_RBA2

AC39

B_RWEB

AC43

B_RCSB

AD42

B_RCASB

AH40

B_RRASB

AJ41

B_RODT

AG41

B_RCKE

AC41

B_RCLK0

AL43

B_RCLK0B

AL41

B_RDQM1

AM36

B_RDQS1

AR43

B_RDQS1B

AR41

B_RDQM0

AP38

B_RDQS0

AT40

B_RDQS0B

AT42

EEPROM

IC1101

I2C_SDA

I2C_SCL

RESET

NAND FLASH

IC501

IO1 - IO8

XWE

XRE

XCE

RY/XBY

ALE

CLE

XWP

SERIAL FLASH

IC502

D

Q

C

S

HOLD

HBD-E670W/E970W

SDA

13

12

4

18

8

9

7

17

16

19

5

2

6

1

7

AV14

SCL

AT12

NFD0 - NFD7

NFWEN

G43

NFREN

M36

NFCEN

M38

NFRBN

P38

NFALE

L37

NFCLE

K38

SFDO

F42

SFDI

H40

SFCK

G41

SFCS

J39

VIND5

GPIO3

LCDRD

VDATA

VCLK

GPIO2

GPIO1

GPIO0

GPIO6

OPWRSB

FE_EJECT#

RESET_

CORE_RESETB

F14

B18

G33

B34

A35

C19

A17

C17

AV12

F34

AH4

E35

AP4

TH1501

USB_VBUS_PCONT1

USB_VBUS_PCONT2

IF_SDI

IF_SDO

IF_SCK

XIF_CS

IF_START_BIT

SYSCON_REQ

UPG_STATUS

OPWRSB

FE_EJECT

SYSCON_RST

CPU_PRERST

TEMP

C

(Page 32)

D

(Page 30)

SD-RAM

IC105

DQ0 - DQ15

A0 - A12, NC

BA0

BA1

BA2

/WE

/CS

/CAS

/RAS

ODT

CKE

CK

/CK

UDM

UDQS

/UDQS

LDM

LDQS

/LDQS

SD-RAM

IC205

A_RDQ16 - A_RDQ31

A_RA0 A_RA13

L2

L3

L1

K3

L8

L7

K7

K9

K2

J8

K8

B3

B7

A8

F3

F7

E8

BA39

BC39

AU35

BC35

BA35

AV34

BA33

BC33

A_RCLK1

A_RCLK1B

A_RDQM3

A_RDQS3

A_RDQS3B

A_RDQM2

A_RDQS2

A_RDQS2B

DQ0 - DQ15

A0 - A12, NC

BA0

BA1

BA2

/WE

/CS

/CAS

/RAS

ODT

CKE

CK

/CK

UDM

UDQS

/UDQS

LDM

LDQS

/LDQS

B_RA0 - B_RA13

L2

L3

L1

K3

L8

L7

K7

K9

K2

J8

K8

B3

B7

A8

F3

F7

E8

B_RDQ16 - B_RDQ31

B_RCLK1

N41

B_RCLK1B

N43

B_RDQM3

V36

B_RDQS3

U43

B_RDQS3B

U41

B_RDQM2

V38

B_RDQS2

W41

B_RDQS2B

W43

HBD-E670W/E970W

2929

HBD-E670W/E970W

Ver. 1.1

5-3. BLOCK DIAGRAM - TUNER, S-AIR Section -

$8',2

$8',2,1

$17(11$

)0:

&2$;,$/

J11

/

5

78

781(5)0

781('

5'6B'$7$

5'6B&/.

$(35XVVLDQ8.

5&+

/&+

5&+ 5&+

',

'2

&/

&(

67B',

67B'2

67B&/.

67B&(

781('

5'6B'$7$

5'6B&/.

$8',26(/(&7

5 Y1

Y0

1

$

10

Q13

,&

$6(/B

B

9

$6(/B

3Y

Q13

Q14

;

0+]

$8',26(/(&7

,&

5 Y1

Y

1 Y0

$

10

$6(/B

5FKLVRPLWWHGGXHWRVDPHDV/FK

6,*1$/3$7+

$8/

(

(Page 31)

$8',2

781(5

0,&

&/2&.

%8))(5

,&

3

13

14

5&+

6$,5B$'&B6(/

6&.,

&219(57(5

9,1/

9,15

34

$'

,&

/5&.

%&.

'287

&1

15

13

(;&(37$(38.

$(38.

6',1B$QG

%&.

/5&.

6',1B%6XUU

(=:57

'$7$6(/(&7

,&

B

9

Y

1

$

6(/

5

F

(Page 31)

6$,5B'

6$,5B'

6$03/(5$7(&219(57(5

,&

6'72

6'7,

9

2%,&.

,%,&.

,/5&.2/5&.

3'1

3

6$03/(5$7(&219(57(5

,&

6'72

6'7,

9

2%,&.

,%,&.

,/5&.2/5&.

(=:57$

J10

$&$/0,&

(&0$&

'

(Page 29)

B

(Page 28)

Q10

,)B6',

,)B6'2

,)B6&.

;,)B&6

,)B67$57B%,7

6<6&21B5(4

83*B67$786

23:56%

)(B(-(&7

7(03

&38B35(567

6<6&21B567

6<6&21B567

0,&$03

,&

$FDOB/Y

0,&B'(7

%'B6'2

%'B6%,

49

%'B6&/.

%'B&6

%'B,)B67$57

%'B,)B5(4

83*B67$786

23:56%

)(B(-(&7

91

%'B7(03

&38B35(567

35

%'B5(6(7

6<67(0&21752//(5

,&

6$,5B65&B567

6$,5B6'$

6$,5B6&/

6$,5B*3,2

3'1

3

6$03/(5$7(&219(57(5

,&

6$,5B'

6$,5B%&.

6$,5B/5&.

30

33

9

,%,&.

,/5&.2/5&.

3'1

3

2%,&.

6'72

6'7,

6',1B&6XUUEDFN

19

5(6(7

,&B6'$

14

,&B6&/

11

,17

HBD-E670W/E970W

3030

Loading...

Loading...