Sony ECMDM-5-P Service manual

ECM-DM5P

SERVICE MANUAL

Ver 1.0 2002. 02

SPECIFICATIONS

General

Type Electret condenser microphone

Plug Gold plated miniplug

Power source Plug in power

Dimensions Approx. 10 × 45 mm (dia./h) ( 13 /32 × 113 /16 in.) incl. projecting parts

Mass Approx. 15 g (l oz)

Supplied accessories Wind screen (1)

Performance

Frequency response 100 – 15,000 Hz

Directivity Unidirectional (mono)

Sensitivity Open circuit output voltage *1 : – 34.0 ± 3.5 dB

Maximum sound pressure level *2

Operating temperature range

*1 0 dB = 1 V/Pa, 1,000 Hz (1 Pa = 10 µbar = 94 dB

*2 1 % wave distortion is present at 1,000 Hz.

(0 dB

SPL

and controls

Carrying case (1)

More than 110 dBSPL

0°C – 40°C (32°F – 104°F)

= 2 × 10 –5 Pa)

SPL

E Model

)

9-873-533-01

2002B0200-1

© 2002.02

Design and specifications are subject to change without notice.

ELECTRET CONDENSER MICROPHONE

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

ECM-DM5P

SECTION 1

SERVICING NOTES

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

z

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the

lead-free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed

with the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to

be applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set

to about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to

flow) than ordinary solder so use caution not to let solder

bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder

may also be added to ordinary solder.

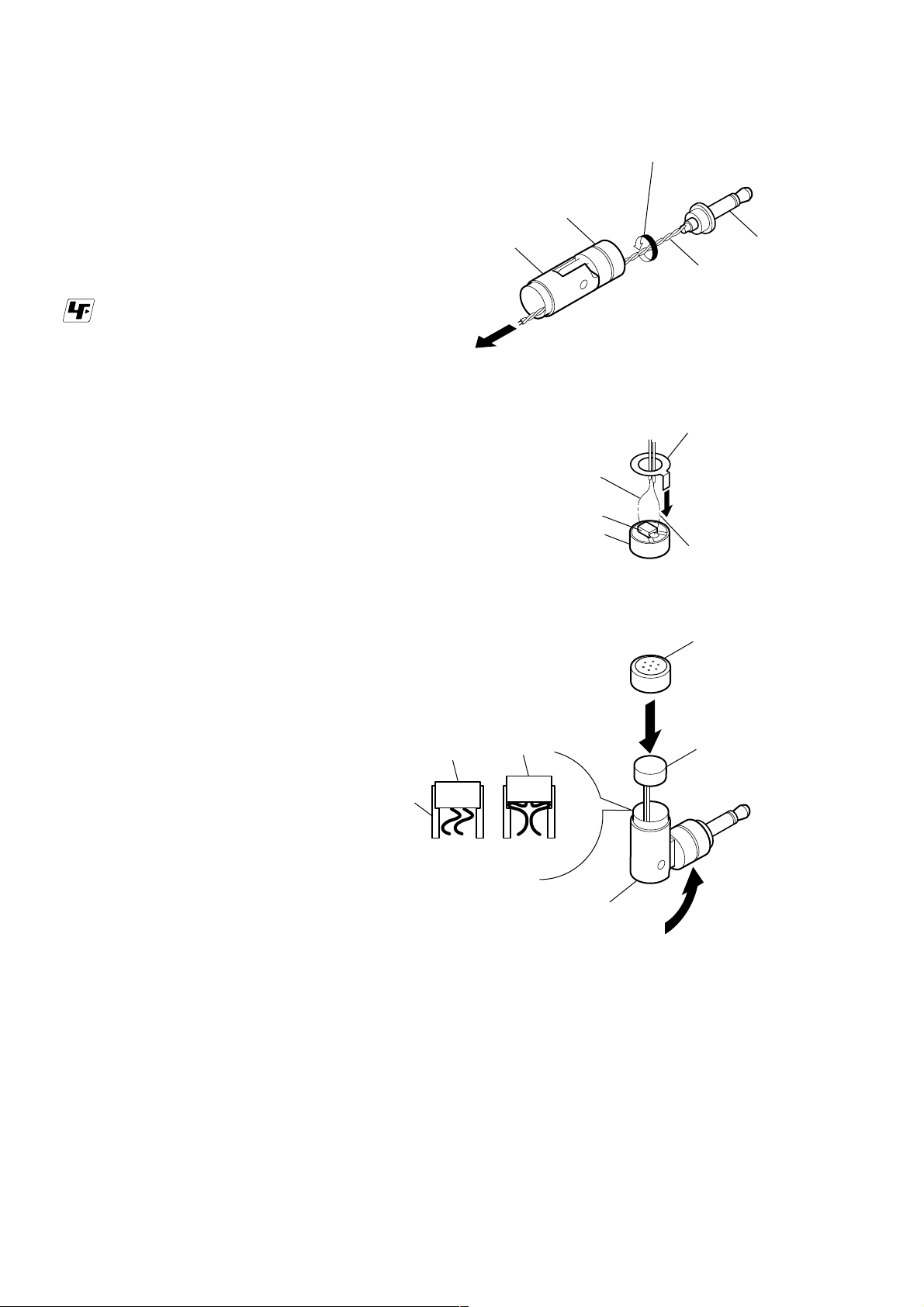

MIC1 INSTALLATION

Arm (rear)

Arm (front)

2

Insert the lead wire then return twist.

Note:

When remove solder front P1,

change the lead wire

(A32) for new one.

4

Soldering white lead wire.

C1

MIC1

1

Twist the lead wire show in

arrow direction.

P1

Lead wire (A32)

5

Screen.

3

Soldering gray

lead wire

to "V" shape

patarn side.

OK

MIC1

Arm (front)

7

Insert the MIC1.

Paying attention as

lead wire isn't niped in.

NG

MIC1

Case, microphone

8

MIC1

Arm (front)

6

2

Loading...

Loading...