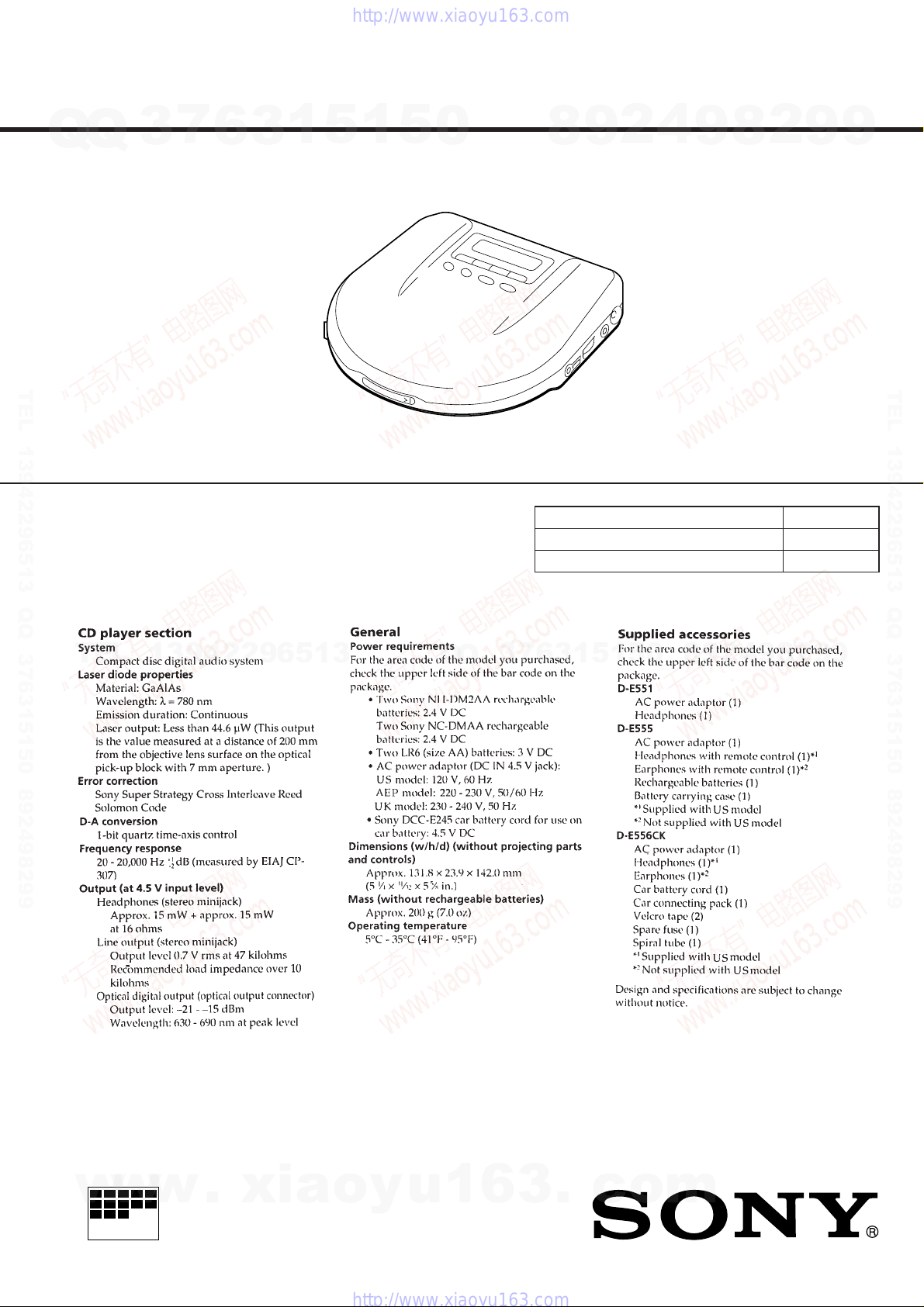

Sony D-E551, D-E555, D-E556CK, D-E771, E776CK Service Manual

...

D-E551/E555/E556CK

Q

Q

3

7

6

3

1

5

1

5

0

SERVICE MANUAL

Ver 1.0 1999. 02

TEL 13942296513 QQ 376315150 892498299

4

2

9

8

Model Name Using Similar Mechanism D-E700/E705

CD Mechanism Type CDM-2911EBA

Optical Pick-Up Name DAX-11E

9

2

8

US Model

D-E551/E555/E556CK

AEP Model

UK Model

D-E555/E556CK

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

SPECIFICATIONS

6

7

3

Q

Q

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

MICROFILM

w

.

xia

COMPACT DISC COMPACT PLAYER

o

y

u

1

6

3

.

c

o

m

TABLE OF CONTENTS

7

Q

Q

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY ......................................................... 7

4. SERVICE MODE...................................................... 8

5. ELECTRICAL ADJUSTMENTS......................... 9

6. DIAGRAMS

6-1. Block Diagram – MAIN Section – ................................. 13

6-2. Block Diagram – POWER SUPPLY Section – .............. 17

6-3. IC Pin Function Description ........................................... 19

TEL 13942296513 QQ 376315150 892498299

6-4. Printed Wiring Board ...................................................... 22

6-5. Schematic Diagram ......................................................... 25

7. EXPLODED VIEWS ................................................ 34

8. ELECTRICAL PARTS LIST ............................... 37

3

6

3

1

5

1

5

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

0

the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board. (within 3 times)

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

2

9

9

w

w

w

.

xia

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

o

y

u

– 2 –

OPERATION. REPLACE THESE COMPONENTS WITH

1

6

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

3

.

c

o

m

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

Q

TEL 13942296513 QQ 376315150 892498299

BLOCK OR BASE UNIT

Q

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

Befor Replacing the Optical Pick-Up Block

Please be sure to check thoroughly the parameters as par the “Optical Pick-Up Block Checking Procedures” (Part No.: 9-960-027-

11) issued separately before replacing the optical pick-up block.

Note and specifications required to check are given below.

• FOK output: IC501 !™ pin

When checking FOK, remove the lead wire to disc motor.

• S curve P-to-P value: 0.6 to 1.8 Vp-p IC501 #¡ pin

When checking S curve P-to-P value, remove the lead wire to

disc motor.

• RF signal P-to-P value: 0.8 to 1.2 Vp-p

• Traverse signal P-to-P value: 1.2 Vp-p

• The repairing grating holder is impossible.

3

7

6

3

1

5

1

5

0

Precautions for Checking Emission of Laser Diode

Laser light of the equipment is focused by the object lens in the

optical pick-up so that the light focuses on the reflection surface

of the disc. Therefore, be sure to keep your eyes more then 30 cm

apart from the object lens when you check the emission of laser

diode.

Laser Diode Checking Methods

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper panel is closed while turning

ON the S801. (push switch type)

The following two checking methods for the laser diode are operable.

• Method (In the service mode or normal operation):

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. Push the S801 as shown in Fig. 1.

3. Press the ^ key.

4. Check the object lens for confirming normal emission of the

laser diode. If not emitting, there is a trouble in the automatic

power control circuit or the optical pick-up.

During normal operation, the laser diode is turned ON about

2.5 seconds for focus searching.

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

9

8

0

5

1

5

1

3

S801

Fig. 1 Method to push the S801

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

– 3 –

.

c

o

m

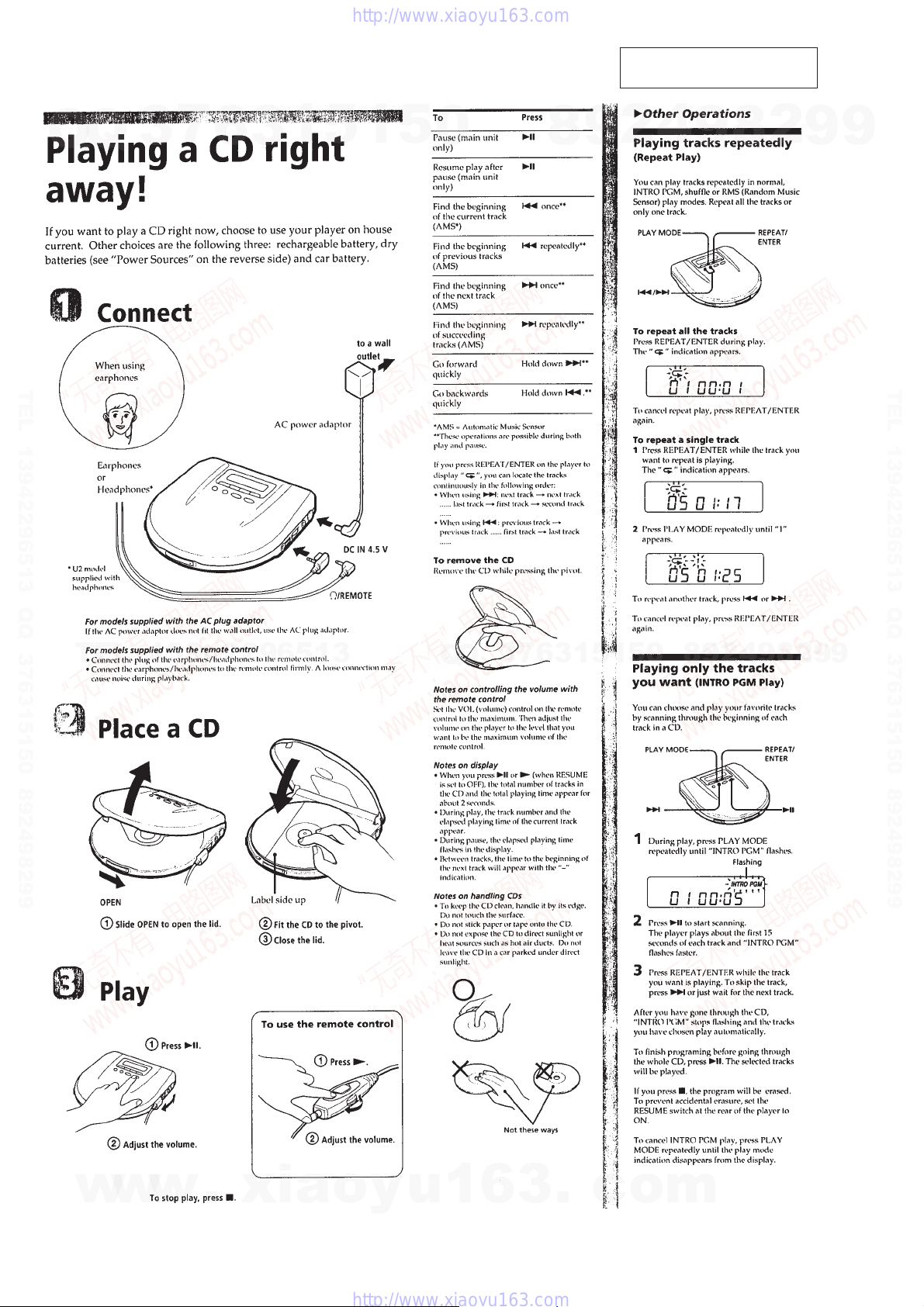

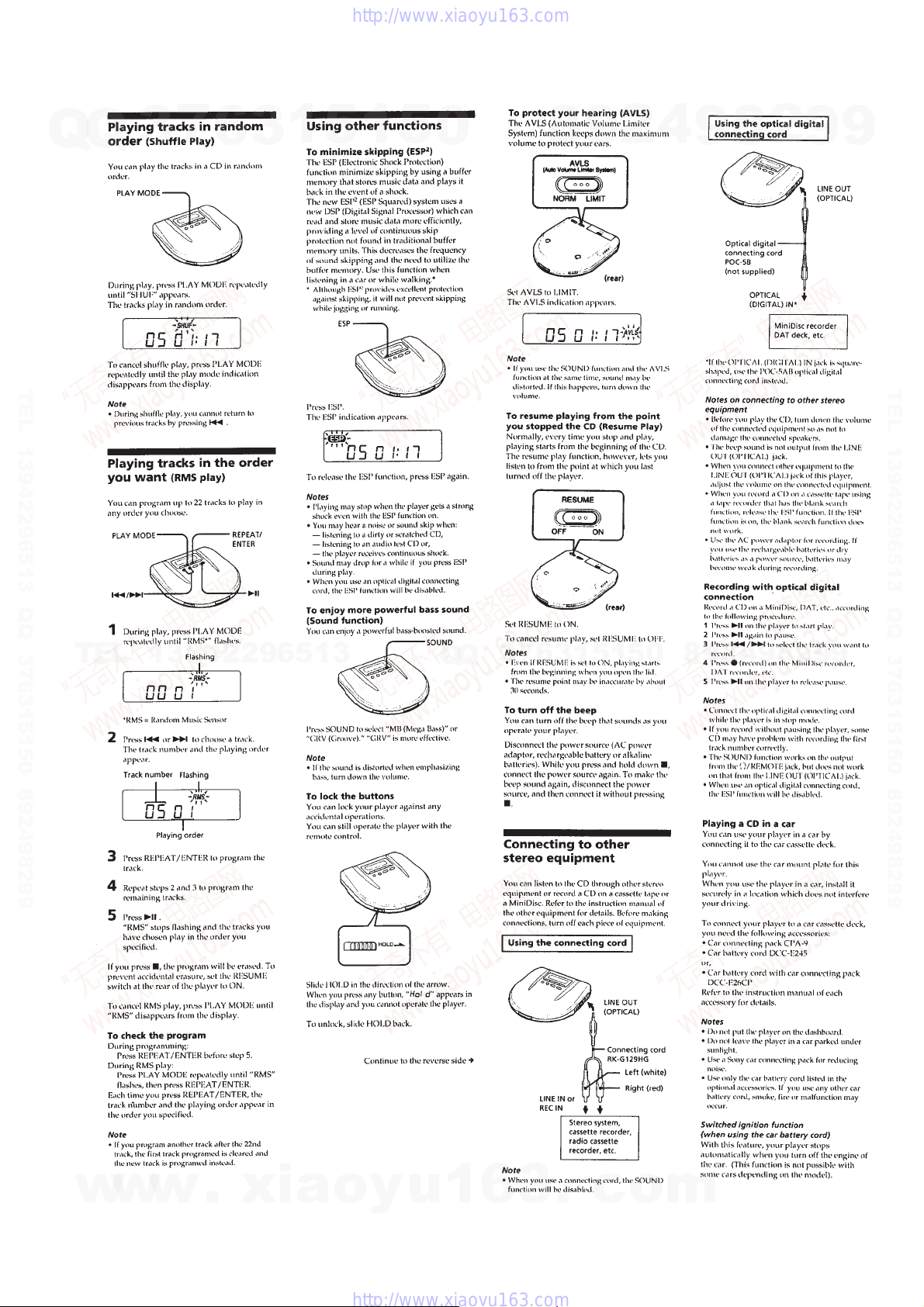

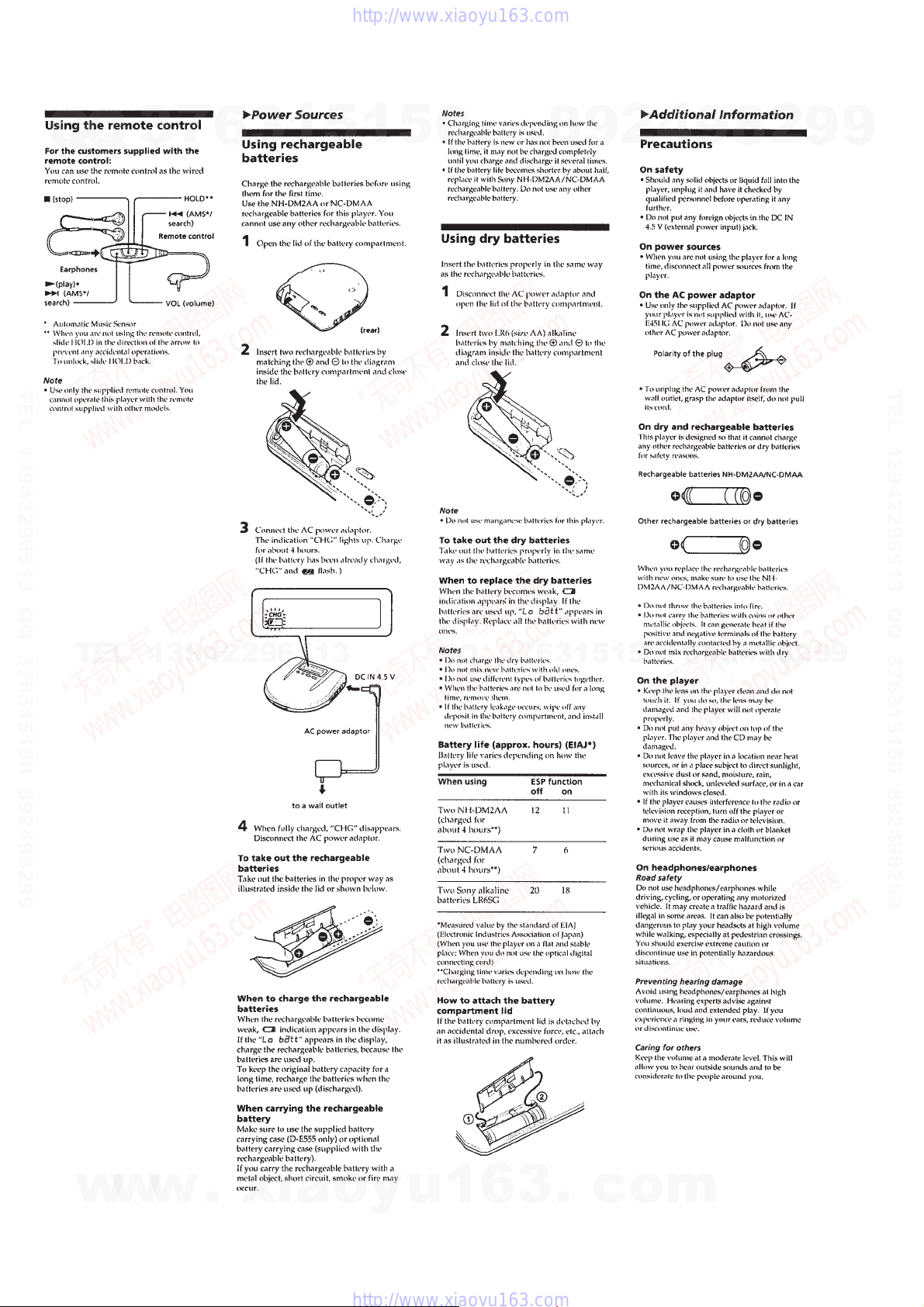

SECTION 2

GENERAL

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

This section is extracted from

instruction manual.

4

9

2

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

– 4 –

.

c

o

m

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

– 5 –

.

c

o

m

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

– 6 –

.

c

o

m

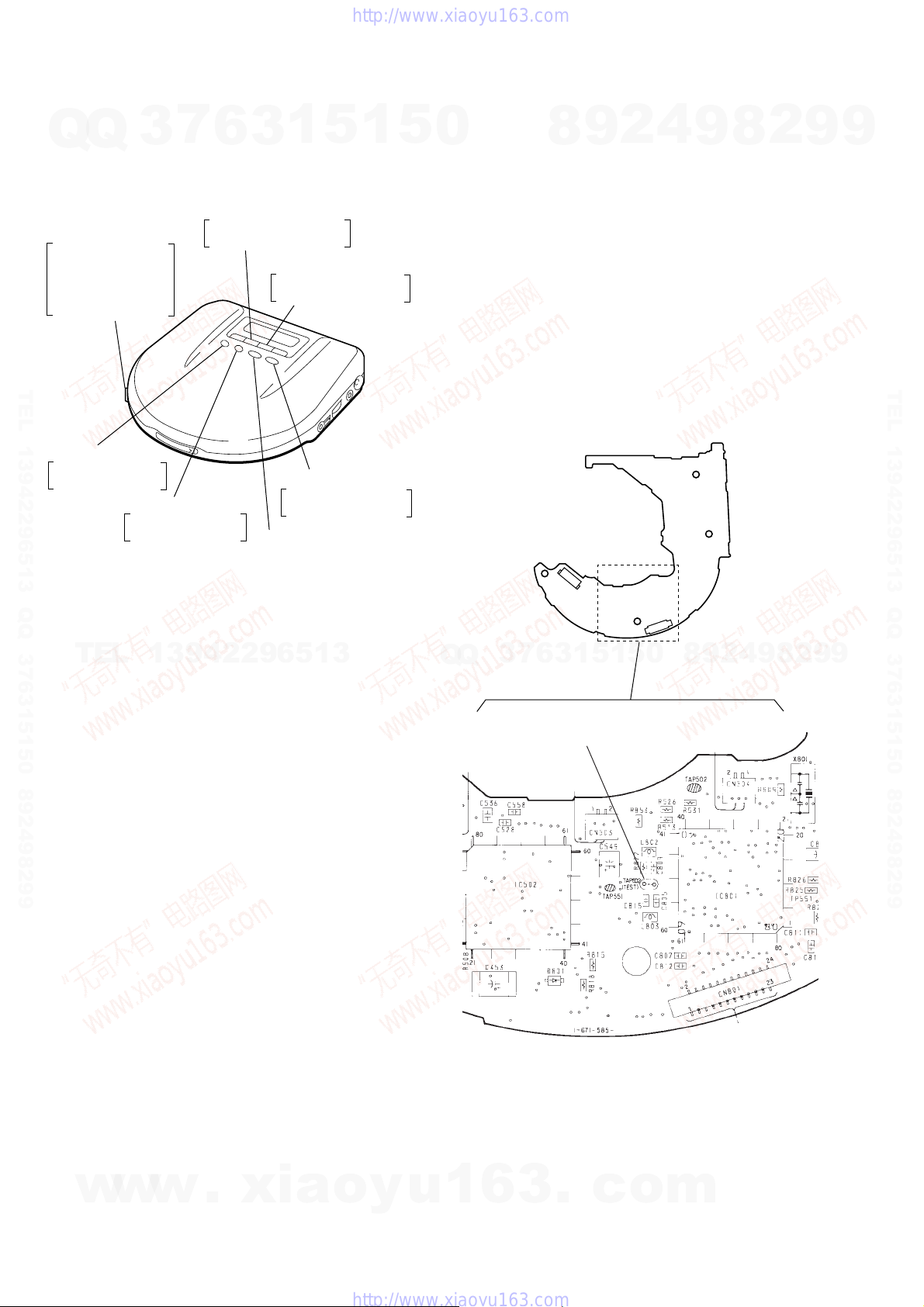

Q

Note: Follow the disassembly procedure in the numerical order given.

7

Q

3

CABINET (LOWER)

5

6

cabinet (lower)

3

1

5

1

five screws

(2

1

×

8)

5

SECTION 3

DISASSEMBLY

0

8

4

9

two claws

2

4

8

9

2

Open the battery case lid.

2

9

9

TEL 13942296513 QQ 376315150 892498299

4

two claws

INSTALLATION MAIN BOARD

On installation MAIN board adjust the

TEL

13942296513

S301, 803, 804, and knob (H-R, A VLS).

S804

Q

Q

3

7

3

two claws

4

2

9

8

0

5

1

5

1

3

6

Note:Take care not to allow the rechargeable

battery detection plate to ride on the mold

of the bottom plate.

S301

S803

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

knob (H-R)

w

.

xia

o

y

u

1

6

3

– 7 –

.

c

knob (AVLS)

o

m

]

SECTION 4

SERVICE MODE

Service Mode (Service program)

The equipment is provided with a service program built in the

Q

Q

microcomputer, like conventional models.

Service program operation methods are described in the following.

HOLD

c

Be sure to turn OFF

the HOLD switch

(If ON, all the LCD

indication and

LED are light up)

TEL 13942296513 QQ 376315150 892498299

=

(FR)

The optical pick-up

is moved inwardly

+

7

3

(FF)

The optical pick-up

is moved outwardly

6

PLAY MODE

Tracking servo and sled

servo are turned ON

1

5

3

REPEAT/ENTER

Tracking gain-up mode

while pressing

^

(PLAY/PAUSE)

Focus is tuned ON to

effect draw-in mode

p

(STOP)

[All servos are turned OFF

1

5

4. By pressing the ^ k ey , focus is turned ON from focus searching while entering CLV-S. (draw-in mode)

0

Without disc, focus searching is repeated continuously.

5. By pressing the PLAY MODE key, tracking servo, sled servo

and CLV-A (servo in PLAY) are turned ON.

6. When step 4 and 5 are performed, playing begins. No muting

is ON in the service mode.

7. By pressing the p key, all servos (focus, tracking and sled)

are turned OFF . Ho we ver, the disc motor revolv es for a while

by inertia.

• Step 3 (Resetting of service mode)

1. Be sure to disconnect the external power supply and remove

the solder bridge at the TEST terminals connected before in

setting.

2. The set thus becomes available for normal operation.

– MAIN BOARD (Side A) –

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

Descriptions in [ ] indicate major operations in the service

mode. For more informatrion, see Step 2.

Fig. 1 Layout of each key

TEL

• Step 1 (Service mode setting methods)

1. Turn OFF the HOLD switch with external power supply disconnected. (power is not applied to the set)

2. Solder across the TEST terminals (TAP802). (pin %¢, IC801

(ESPSL/TEST) is grounded)

3. Connect an external power supply.

Thus, the set is switched to the service mode.

• Step 2 (Operation in the service mode)

1. Once the service mode is ef fected, the LCD displays 5 indications each of which is repeatedly displayed.

However , the following operations can be acti vated e ven if LCD

indication is effected.

2. By pressing the + or = ke y, the optical pick-up is movable inwardly or outwardly . Howev er, if this is acti vated, tracking servo and sled servo are turned OFF, so it can be turned

ON by pressing the PLAY MODE key if required.

3. By pressing the REPEAT/ENTER key, the tracking gain-up

mode becomes active.

13942296513

Q

Q

3

7

6

1

3

TAP802

(TEST)

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

– 8 –

Fig. 2 Location of Test terminal

.

c

o

m

Loading...

Loading...