Page 1

DVP-F5/FX1

RMT-D114A

SERVICE MANUAL

Photo: DVP-FX1

Manufactured under license from Dolby Laboratories

Licensing Corporation.

“DOLBY” and the double-D symbol ; are

trademarks of Dolby Laboratories Licensing

Corporation.

US Model

Canadian Model

AEP Model

UK Model

Chinese Model

DVP-FX1/F5

Hong Kong Model

DVP-FX1

Australian Model

DVP-F5

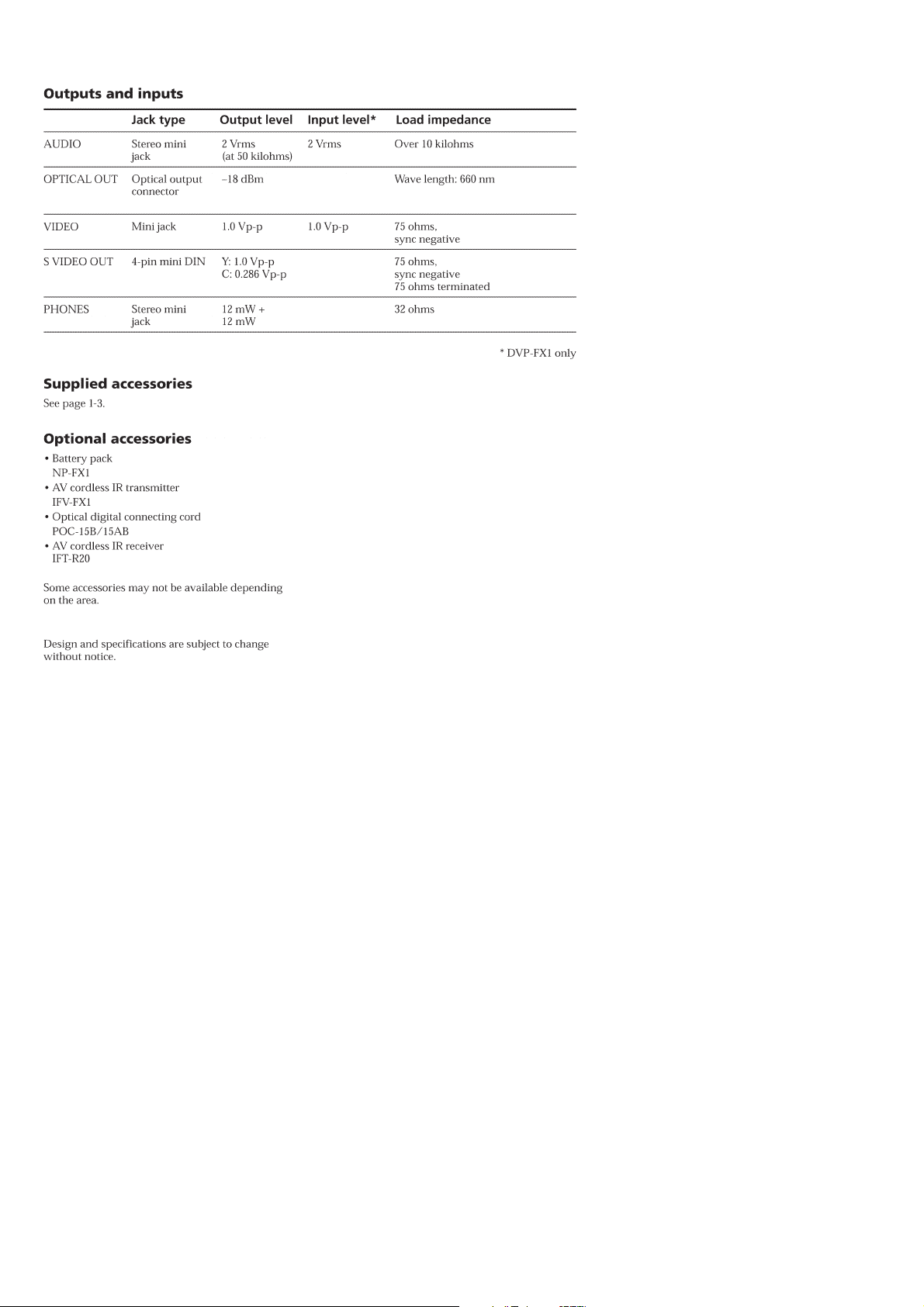

SPECIFICATIONS

PORTABLE CD/DVD PLAYER

Page 2

— 2 —

Page 3

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES

SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT.

NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES

SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL

OU DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 3 —

Page 4

TABLE OF CONTENTS

1. GENERAL

About this manual ··························································· 1-1

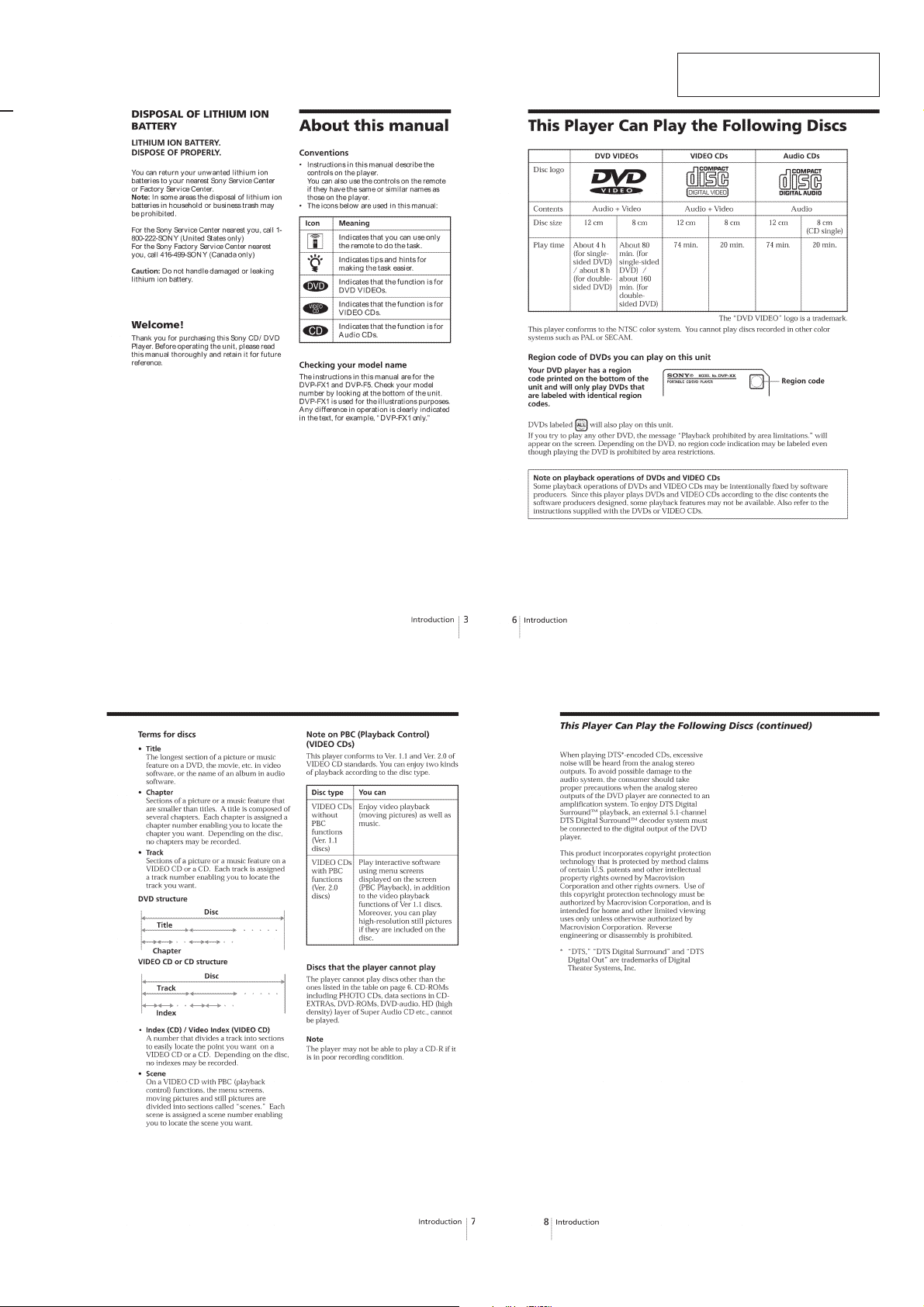

This Player Can Play the Following Discs ······················1-1

Precautions ······································································ 1-2

Notes about the Discs ······················································1-2

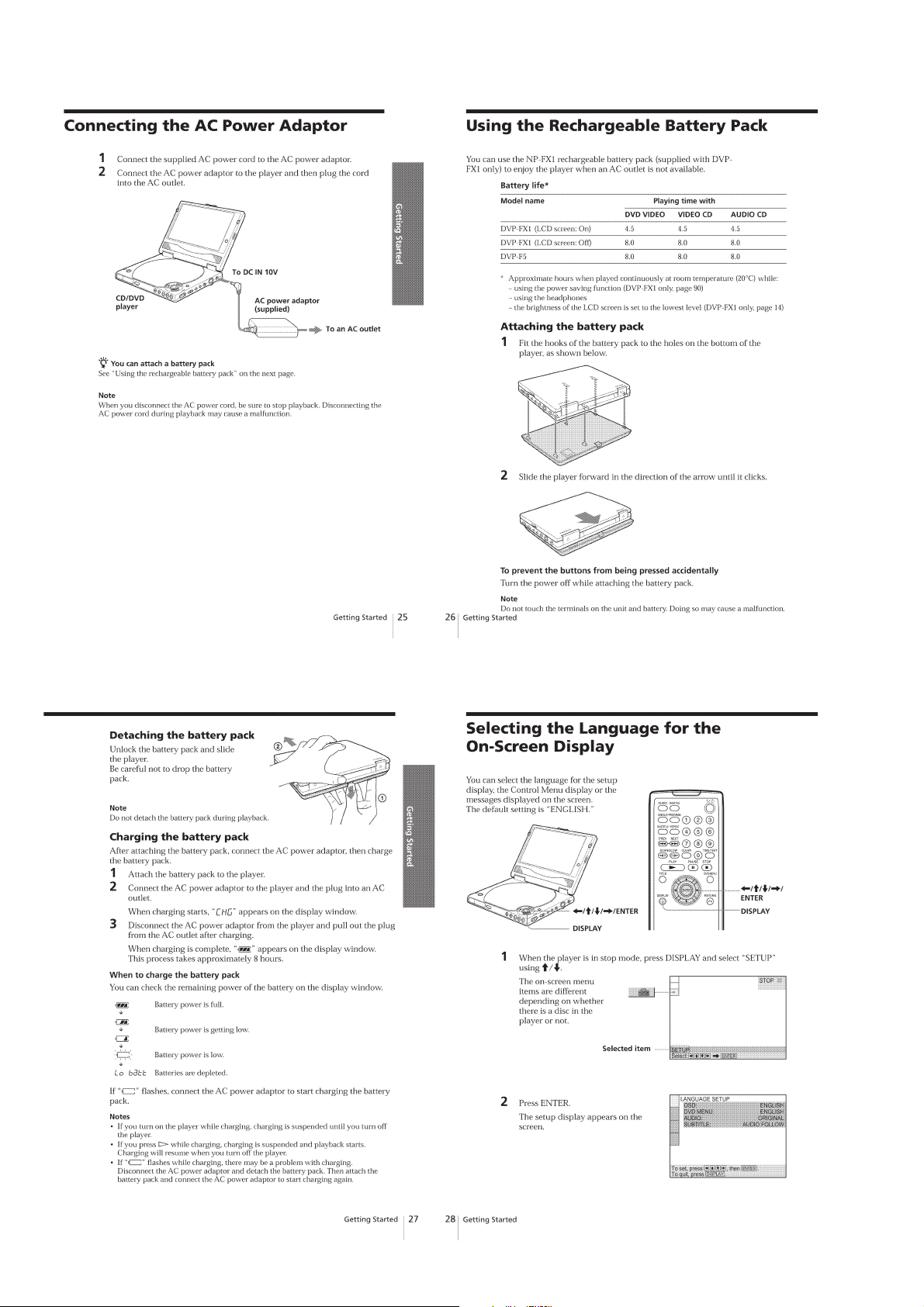

Getting Started

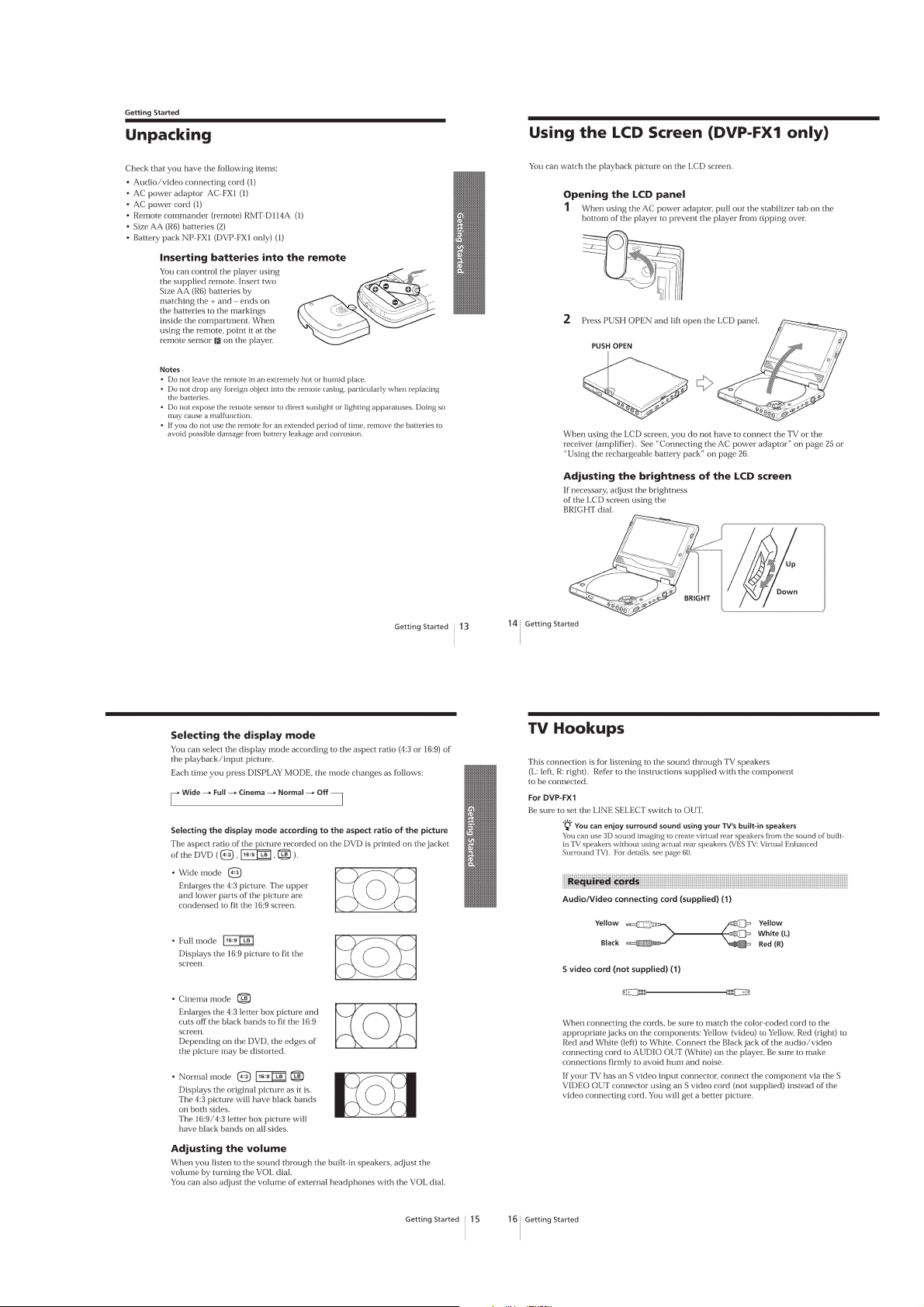

Unpacking ······································································· 1-3

Using the LCD Screen (DVP-FX1 only)·························1-3

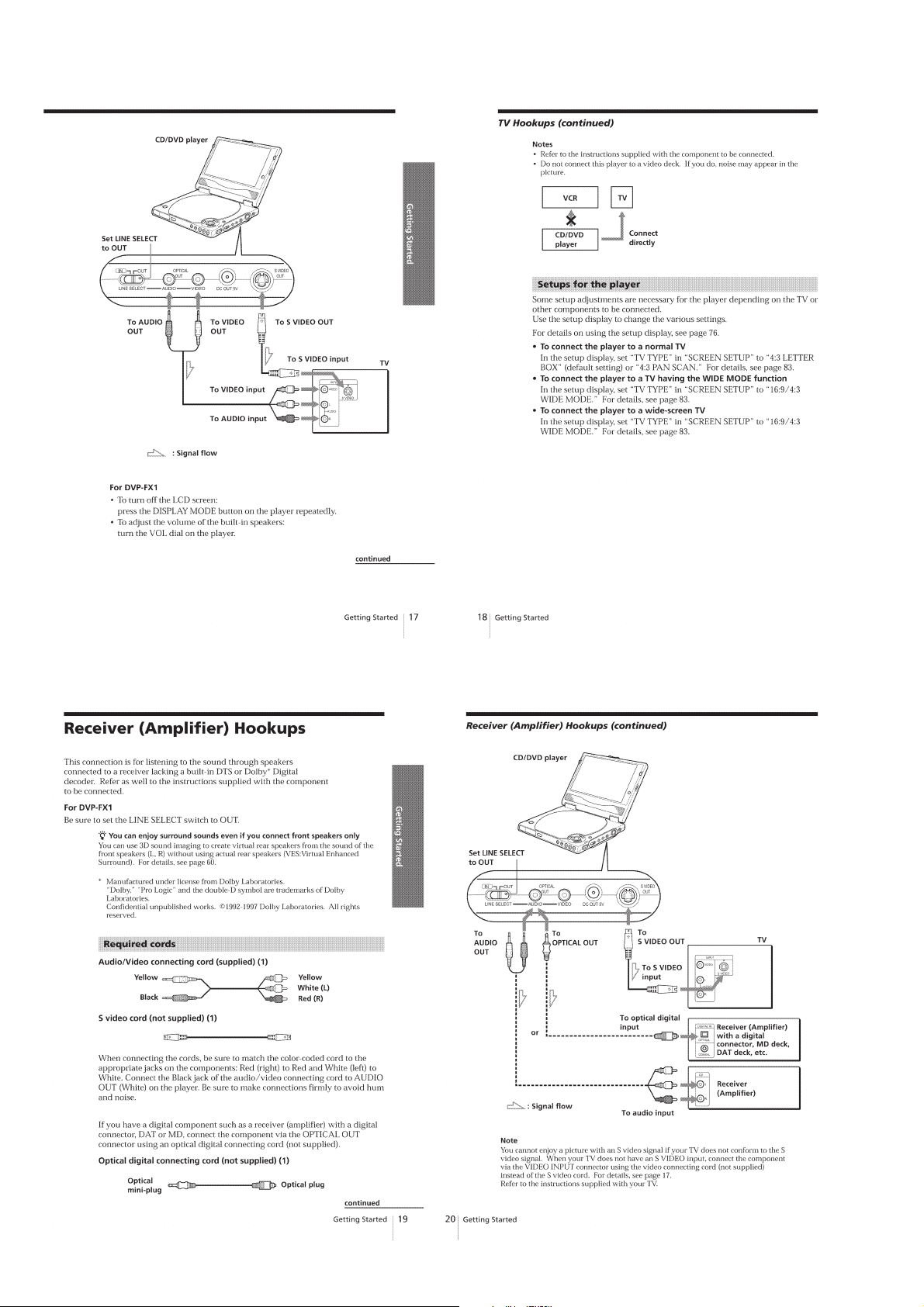

TV Hookups ···································································· 1-3

Receiver (Amplifier) Hookups ········································1-4

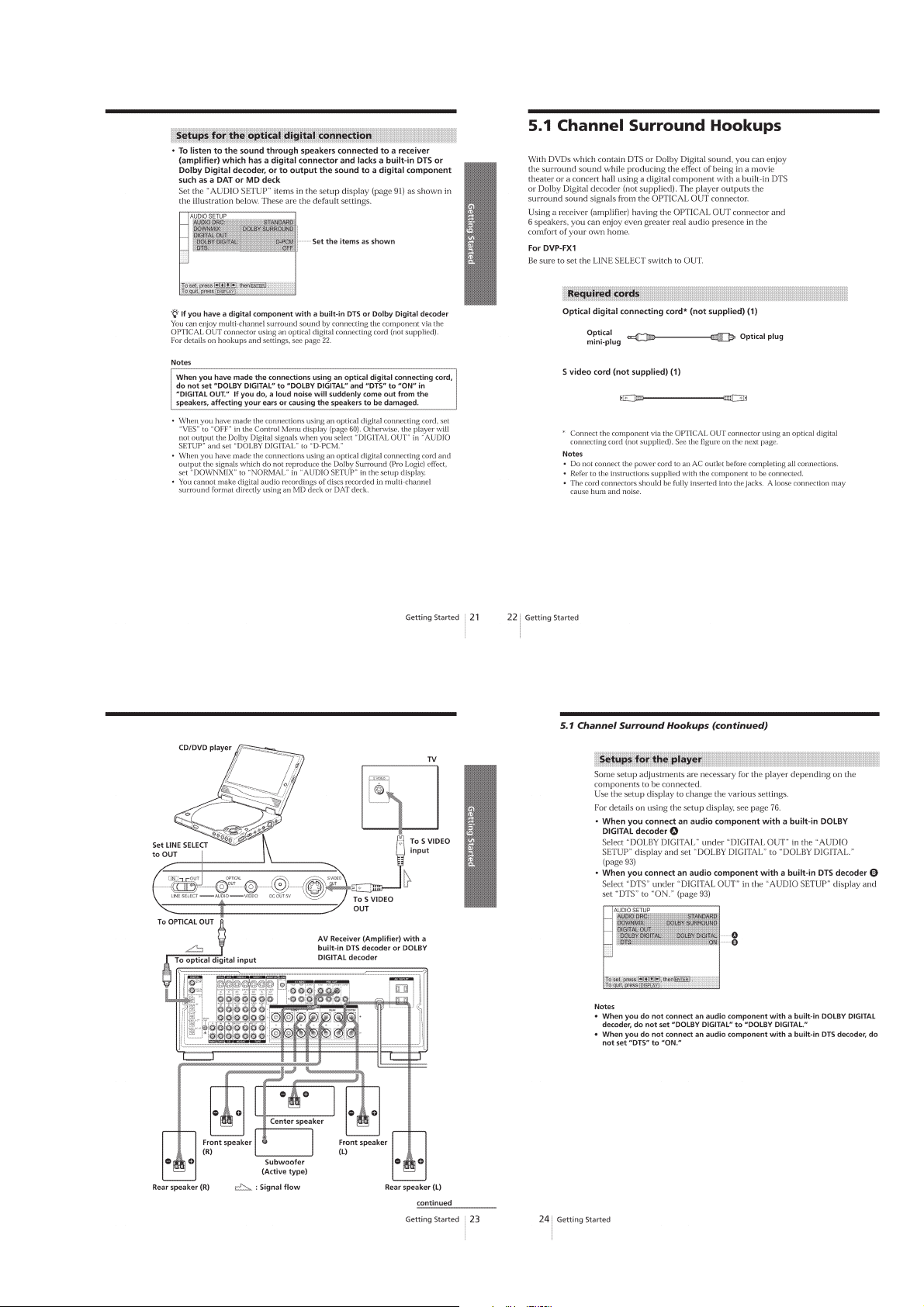

5.1 Channel Surround Hookups ······································ 1-5

Connecting the AC Power Adapoter································ 1-6

Using the Rechargeable Battery Pack ····························· 1-6

Selecting the Language for the On-Screen Display ········ 1-6

Plaing discs

Playing discs ···································································· 1-7

Searching for a Particular Point on a Disc ······················ 1-8

Resuming Playback from the Point Where You

Stopped the Disc (Resume Play) ································1-8

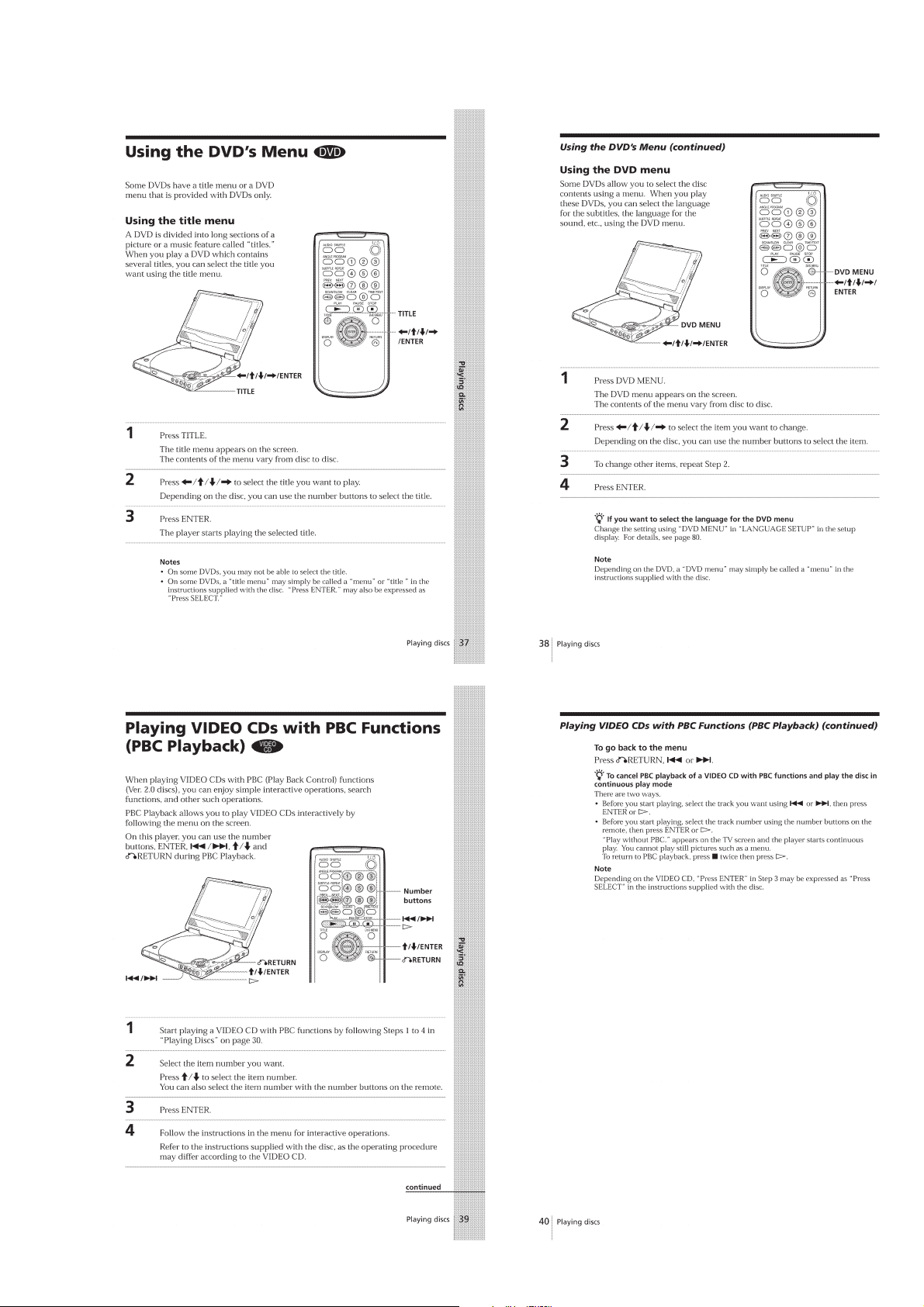

Using the DVD’s Menu ··················································· 1-9

Playing VIDEO CDs with PBC Functions

(PBC Playback) ·························································· 1-9

Using the Display Window ············································1-10

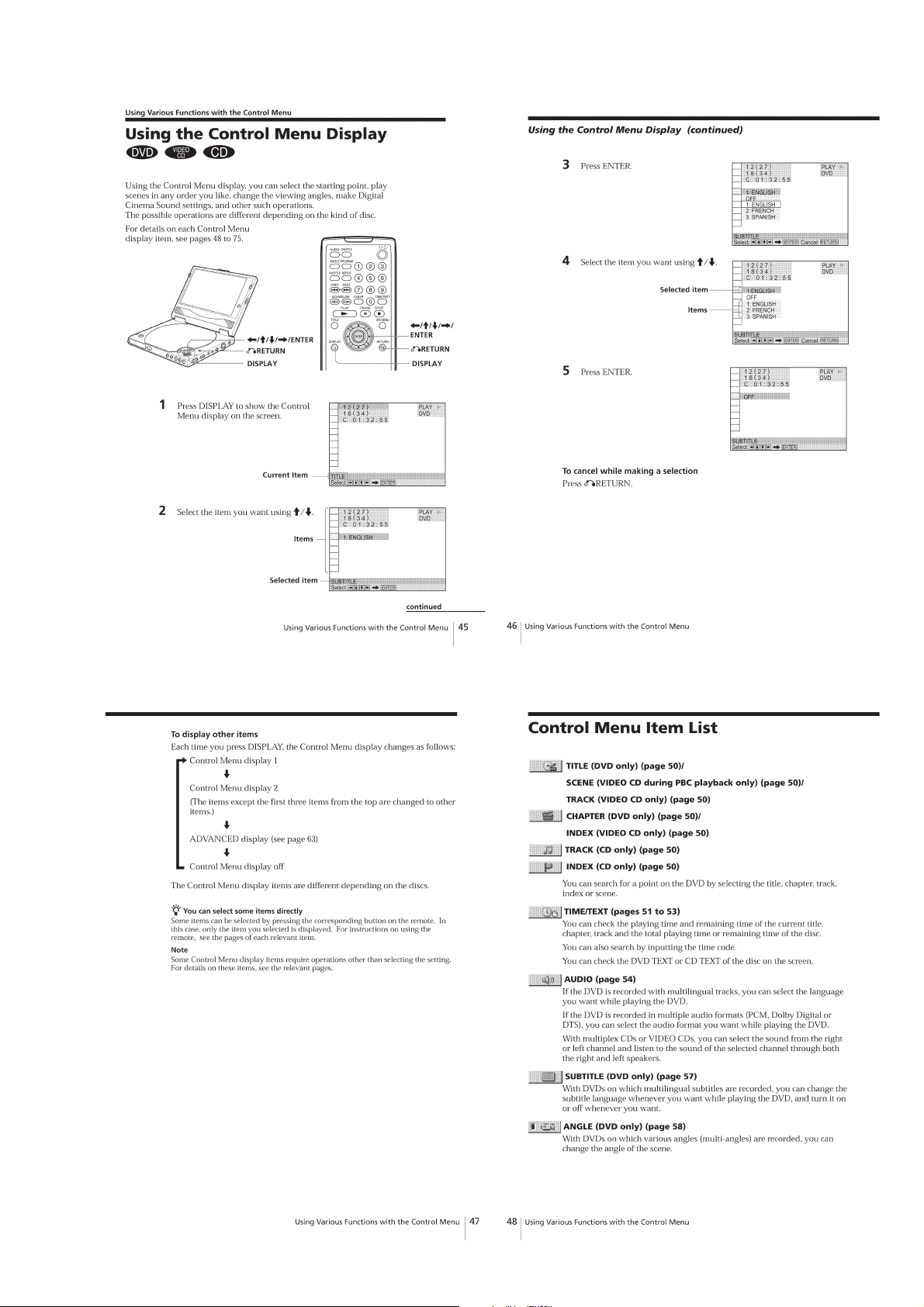

Using Varioius Functions with the Control Menu

Using the Control Menu Display··································· 1-11

Control Menu Item List ·················································1-11

Searching for a Title/Chapter/Track/Index/Scene ········· 1-12

Cheking the Playing Time and Remaining Time ··········· 1-12

Selecting a Starting Point Using the Time Code ···········1-12

Viewing the Disc Information ······································· 1-13

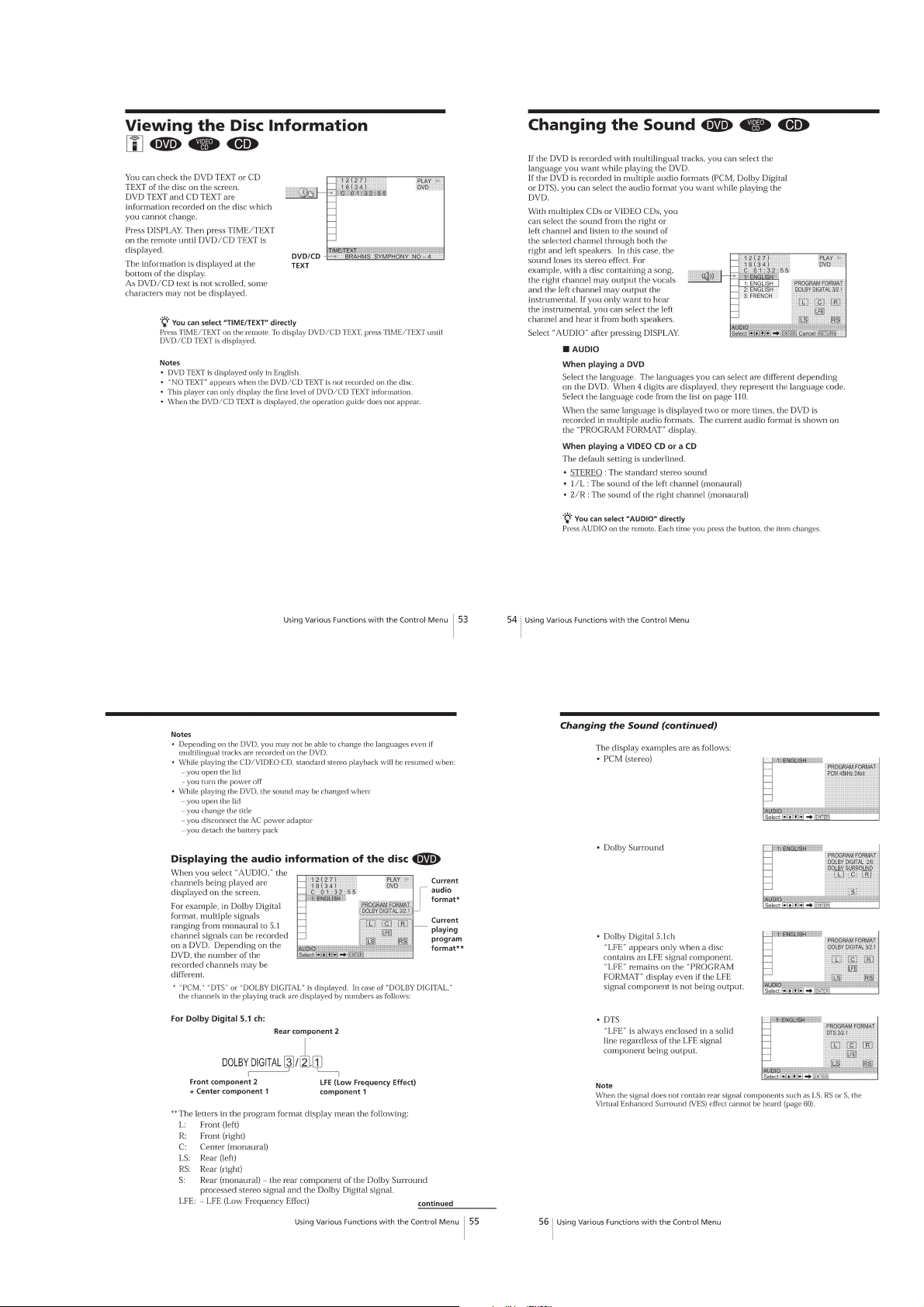

Cheking the Sound ························································ 1-13

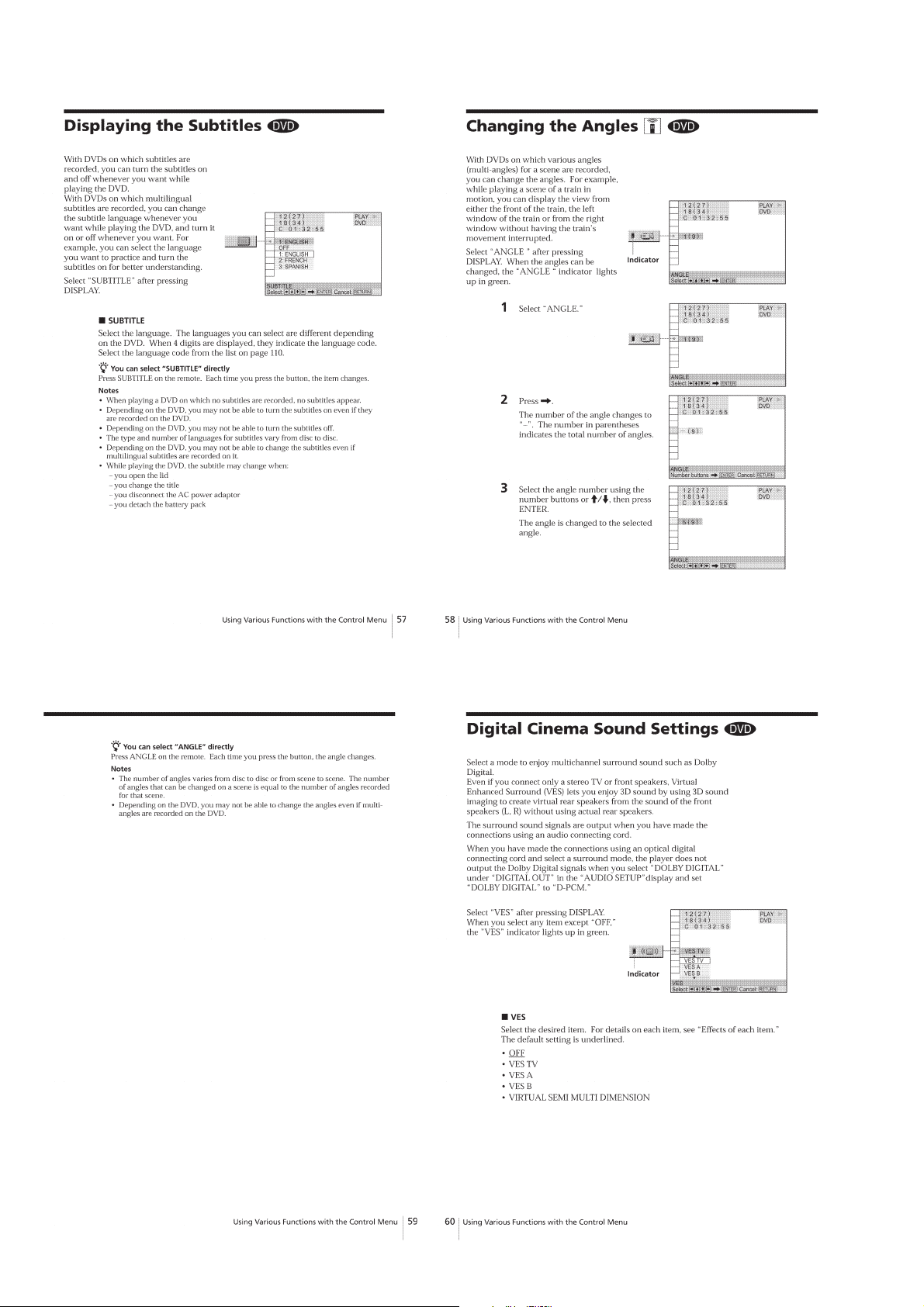

Displaying the Subtitles················································· 1-14

Changing the Angles ····················································· 1-14

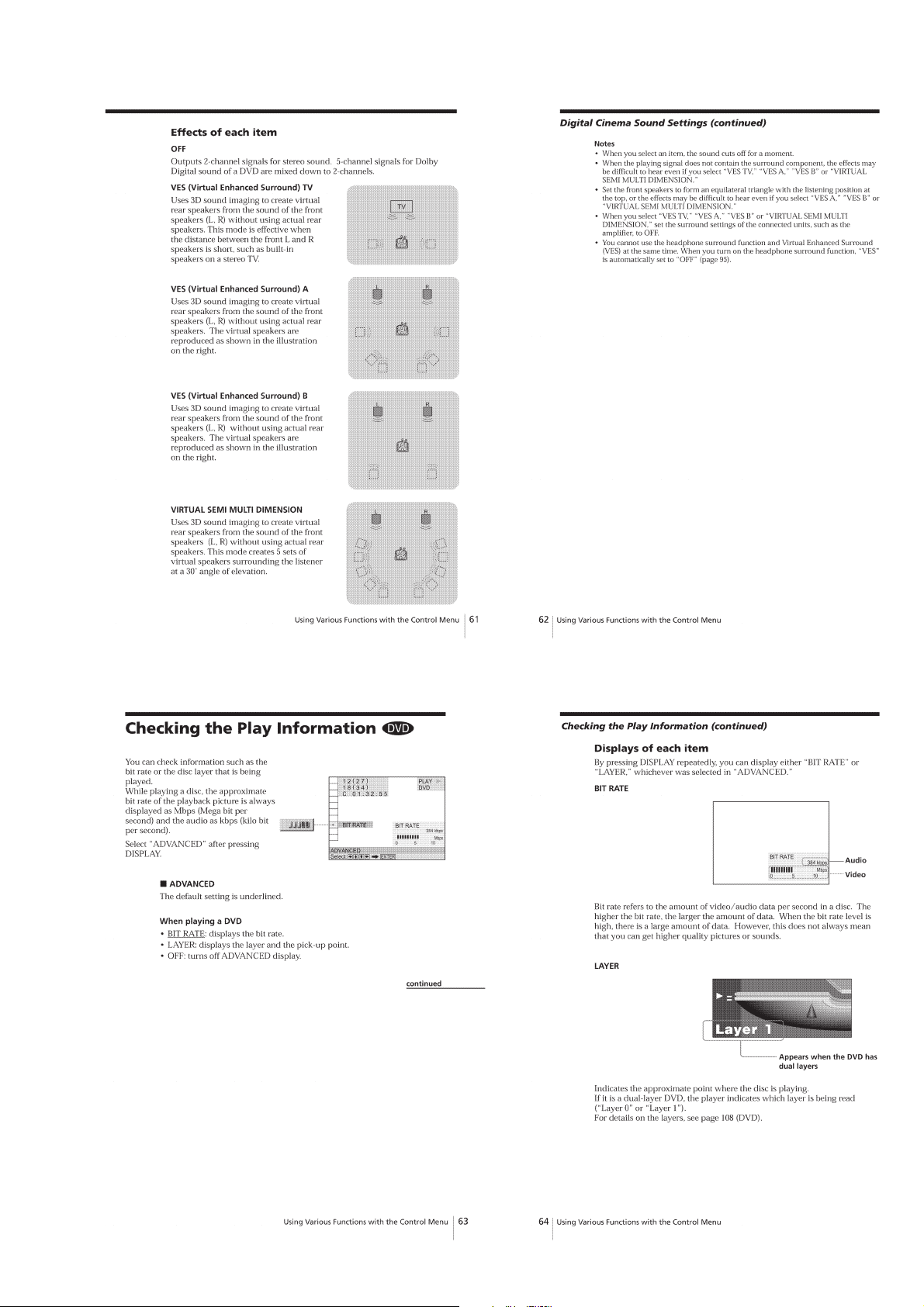

Digital Cinema Sound Settings ····································· 1-14

Checking the Play Information ······································ 1-15

Locking Discs (Custom Parental Control) ···················· 1-16

Creating Your Own Program (Program Play) ················1-16

Plaing in Random Order (Shuffle Play) ························ 1-17

Plaing Repeatedly (Repeat Play) ···································1-18

Repeating a Specific Portion (A-B Repeat) ·················· 1-18

Settings and Adjustments

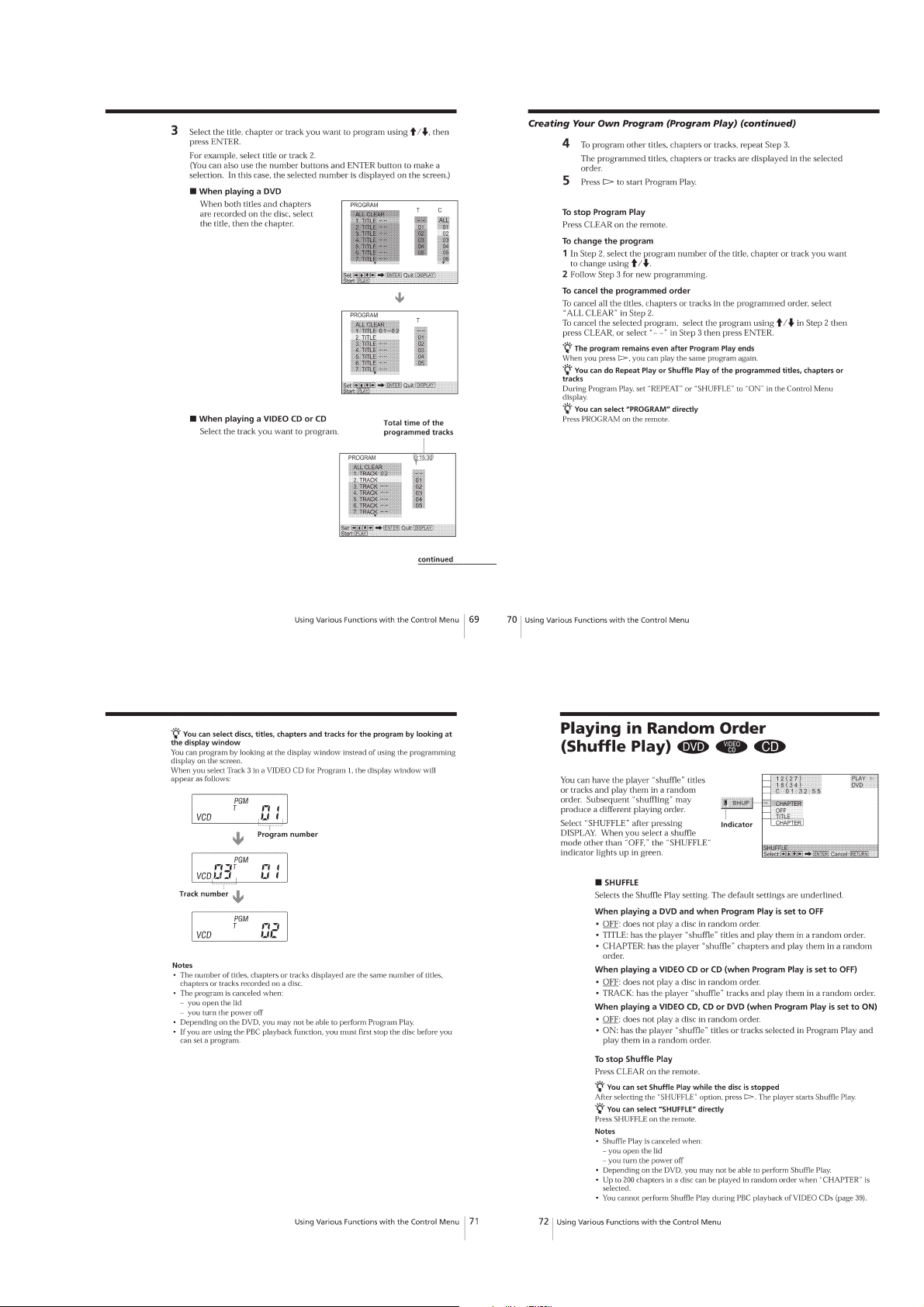

Using the Setup Display ················································1-18

Setup Display Item List ·················································1-19

Setting the Display Language or Sound Track

(LANGUAGE SETUP) ············································ 1-19

Settings for the Display (SCREEN SETUP) ·················1-20

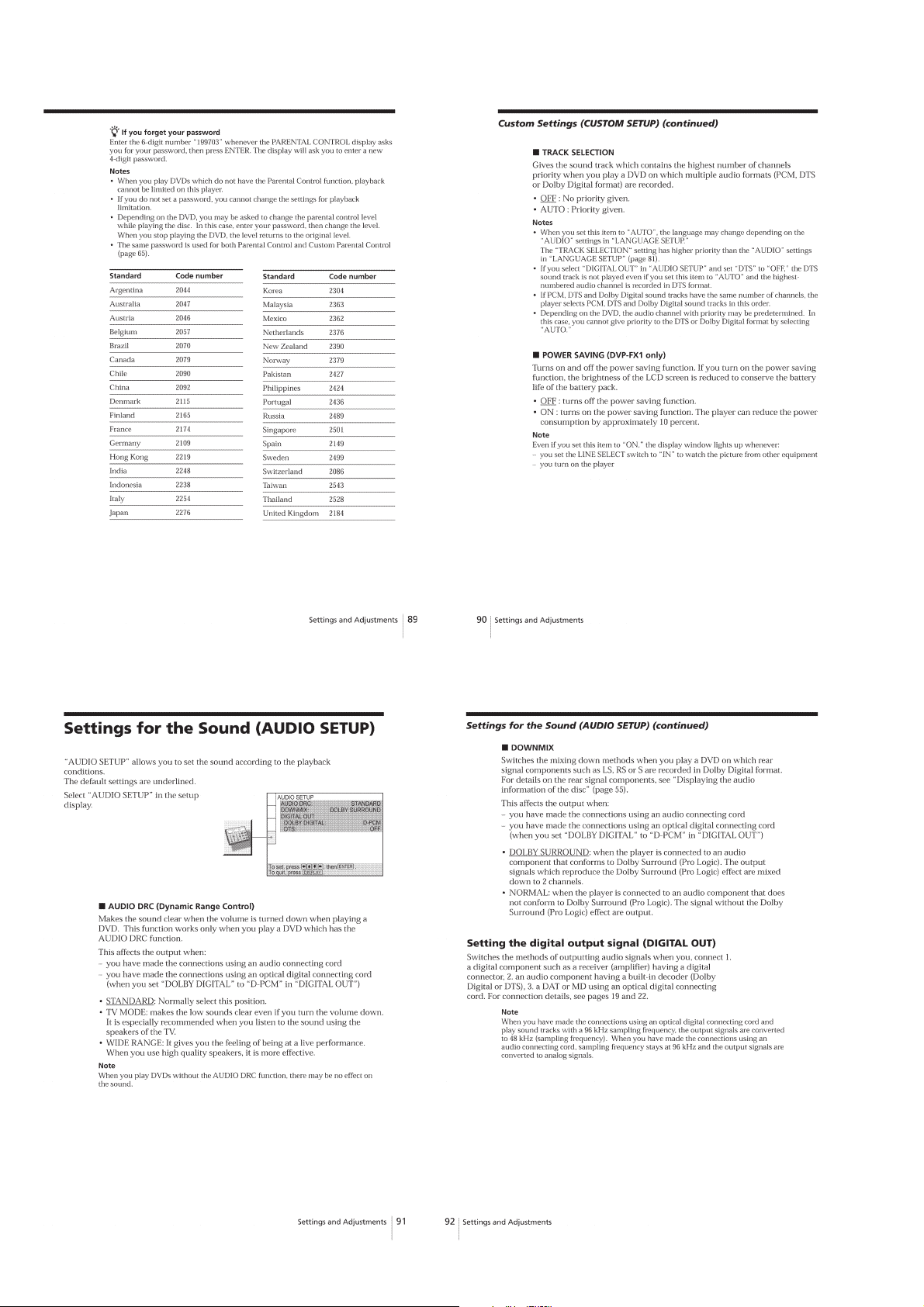

Custom Settings (CUSTOM SETUP) ··························· 1-21

Settings for the Sound (AUDIO SETUP)······················ 1-22

Preventing the Buttons from being Pressed

Accidentally······························································ 1-23

Additional Operations

Listening with Headphones ···········································1-23

Watching the Picture without Connecting Cables

–LASER LINK ························································· 1-23

Watching the Picture of Other Equipment on the

LCD Screen (DVP-FX1 only) ··································1-24

Additional Information

Troubleshooting····························································· 1-24

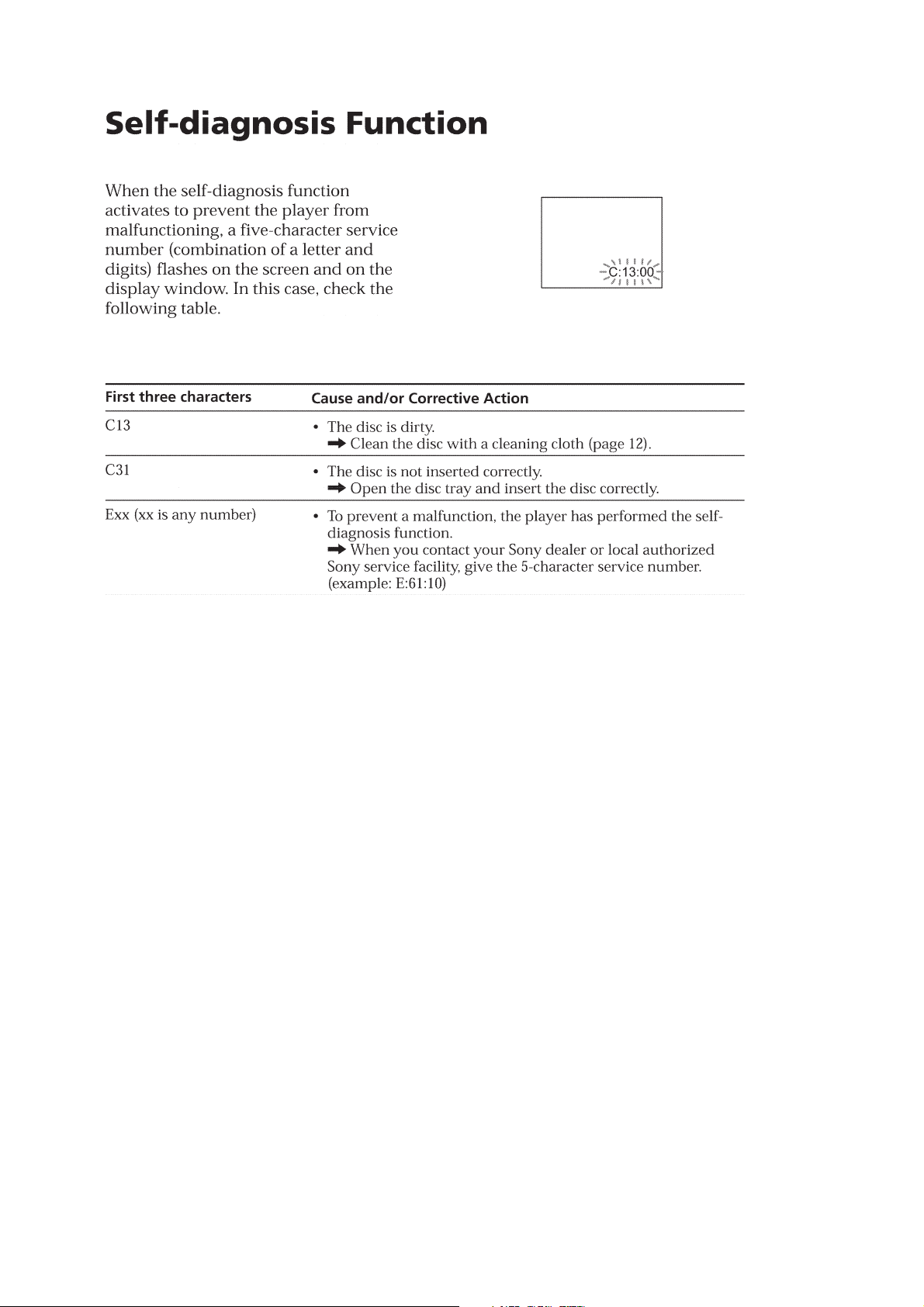

Self-diagnosis Function ·················································1-26

Language Code List······················································· 1-26

Index to Parts and Controls ··········································· 1-26

2. DISASSEMBLY

2-1. Cabinet Assy-1 ································································ 2-1

2-2. Cabinet Assy-2 ································································ 2-1

2-3. Cabinet Assy-3 ································································ 2-1

2-4. CD, LID ··········································································· 2-2

2-5. MB-90 Board, LC-68 Board, MD Comple ····················· 2-2

2-6. Display Panel (FX1) ························································2-3

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2) ··························· 3-1

3-2. OVERALL BLOCK DIAGRAM (2/2) ··························· 3-3

3-3. VIDEO OUT BLOCK DIAGRAM ································· 3-5

3-4. RF BLOCK DIAGRAM (1/2) ········································· 3-7

3-5. RF BLOCK DIAGRAM (2/2) ········································· 3-9

3-6. AUDIO BLOCK DIAGRAM ········································3-11

3-7. LCD BLOCK DIAGRAM ············································ 3-13

3-8. POWER BLOCK DIAGRAM (1/2) ······························3-15

3-9. POWER BLOCK DIAGRAM (2/2) ······························3-17

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAMS ····························· 4-1

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS ············································ 4-4

• LC-68 (LCD) PRINTED WIRING BOARD ··············· 4-5

• LC-68 (LCD) SCHEMATIC DIAGRAM ···················· 4-6

• MB-90 (RF, VIDEO, AUDIO, SERVO,

SYSTEM CONTROL)

PRINTED WIRING BOARD ························· 4-7

• MB-90 (1/12)(DC-DC CONVERTER)

SCHEMATIC DIAGRAM ····························4-11

• MB-90 (2/12)(D/D CONV, BATT, CHG)

SCHEMATIC DIAGRAM ····························4-13

• MB-90 (3/12)(SIGNAL PROCESSOR)

SCHEMATIC DIAGRAM ····························4-15

• MB-90 (4/12)(SERVO (1))

SCHEMATIC DIAGRAM ····························4-17

• MB-90 (5/12)(SERVO, DSP)

SCHEMATIC DIAGRAM ····························4-19

• MB-90 (6/12)(ARP, DRAM)

SCHEMATIC DIAGRAM ····························4-21

• MB-90 (7/12)(AV DECODER)

SCHEMATIC DIAGRAM ····························4-23

• MB-90 (8/12)(16M SDRAM)

SCHEMATIC DIAGRAM ····························4-25

• MB-90 (9/12)(SYSTEM CONTROL)

SCHEMATIC DIAGRAM ····························4-27

• MB-90 (10/12)(IF CONTROLLER)

SCHEMATIC DIAGRAM ····························4-29

• MB-90 (11/12)(AUDIO IN/OUT)

SCHEMATIC DIAGRAM ····························4-31

• MB-90 (12/12)(VIDEO IN/OUT SELECT)

SCHEMATIC DIAGRAM ····························4-33

• MB-90 WAVEFORMS ··············································4-35

• TP-61 (1/3)(DC-DC CONVERTER)

SCHEMATIC DIAGRAM ····························4-39

• TP-61 (2/3)(RGB DECODER)

SCHEMATIC DIAGRAM ····························4-41

• TP-61 (3/3)(TIMING GENERATOR)

SCHEMATIC DIAGRAM ····························4-43

• TP-61 (TIMING GEN, RGB DECODER)

PRINTED WIRING BOARD ······················· 4-45

• TP-61 WAVEFORMS ·············································· 4-47

5. IC PIN FUNCTION

5-1. SYSTEM CONTROL (MB-90 BOARD IC002:

MB91107PFV-G-BEN) ··················································· 5-1

5-2. IF CONTROL (MB-90 BOARD IC701:

M37513MB-055GP) ·······················································5-3

— 4 —

Page 5

6. TEST MODE

6-1. GENERAL DESCRIPTION ··········································· 6-1

6-2. STARTING TEST MODE ··············································· 6-1

6-3. SYSCON DIAGNOSIS ··················································· 6-1

6-4. DRIVE AUTO ADJUSTMENT ······································ 6-5

6-5. DRIVE MANUAL OPERATION ···································6-7

6-6. EVR ADJUSTMENT ······················································ 6-9

6-7. EMERGENCY HISTORY ············································ 6-11

6-8. VERSION INFORMATION ········································· 6-12

6-9. VIDEO LEVEL ADJUSTMENT ·································· 6-12

6-10. SELF-DIAGNOSIS OF IF CONTROLLER ················· 6-12

7. ELECTRICAL ADJUSTMENT

7-1. POWER SUPPLY BLOCK (TP-61 BOARD)·················7-1

7-2. SYSTEM CONTROL ADJUSTMENT

(TP-61 BOARD) ····························································· 7-2

7-3. VIDEO SYSTEM ADJUSTMENT ································· 7-2

7-4. ARRANGEMENT DIAGRAM FOR ADJUSTMENT

PA RTS ············································································· 7-4

8. REPAIR PARTS LIST

8-1. EXPLODED VIEWS ······················································ 8-1

8-2. ELECTRICAL PARTS LIST ·········································· 8-7

— 5 —

Page 6

SERVICE NOTES

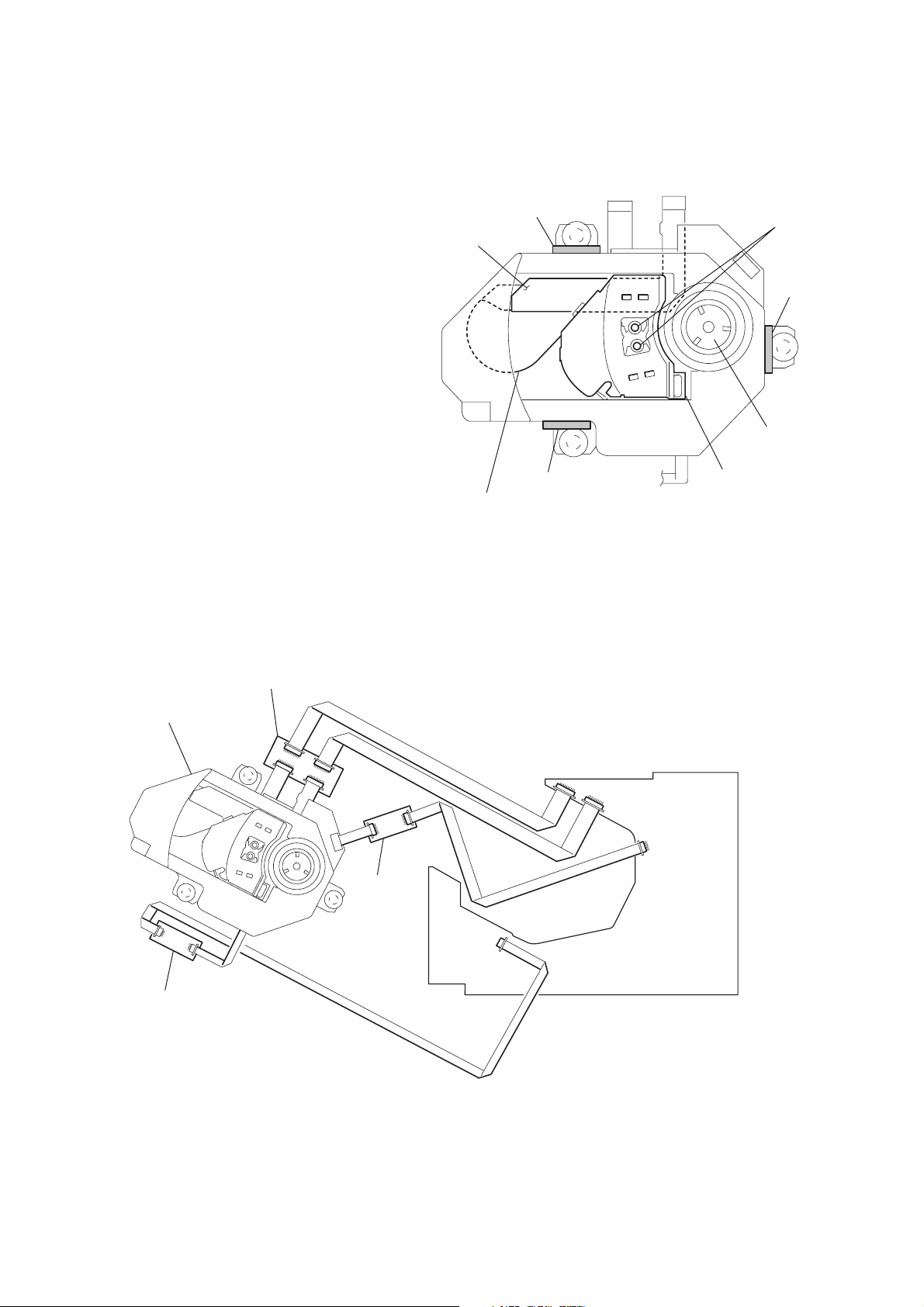

1. REPLACING OPTICAL PICK-UP

1-1. Handling

1) A red laser diode for DVD requires more attention to static

electricity than general infrared laser diodes for CD.

Because its durability to static electricity is far weaker than

that of infrared laser diodes, always use an earth band when

handling the optical pick-up block as service parts.

Double-sided

adhesive tape

Hold position

From

spindle motor

From optical

block pick-up

Objective lens

2) The optical pick-up of the DVP-F5/FX1 cannot be replaced as

a single part. It is supplied as the MD COMPLE (DVDMFX1).

Note: When the MD COMPLE is going to be replaced, be very

careful not to damage the flexible board to peel off the

flexible board because the flexible board is attached

underneath the cabinet by the double-sided adhesive tape.

3) When handling the MD COMPLE (DVDM-FX1), be careful

not to touch the portions specified in the illustration of the MD

COMPLE with hand. Be sure to hold the hatched portions

described as “HOLD” in the illustration.

1-2. Connection of the DM flexible extension

board (J-6090-101-A) for service

For any attempt is going to be made to inspect, check and adjust

the MB-90 board, connect the DM flexible extension board as

shown below.

OP-CN

MD COMPLE

( DVDM-FX1)

16-pin flexible board (114mm)

Hold position

Flexible board

From

sled motor

Hold

position

Turntable

(spindle motor)

Lens actuator

covers

SLED-CN

18-pin flexible

board

(114mm)

SPDL-CN

7-pin flexible board (194mm)

CN802 (16 pin)

CN801 (18 pin)

CN804 (10 pin)

10-pin flexible board

(114mm)

CN803

(7 pin)

MB-90 board

— 6 —

Page 7

SELF DIAGNOSIS

— 7 —

Page 8

MEM

O

— 8 —

Page 9

SECTION 1

GENERAL

DVP-F5/FX1

This section is extracted from

instruction manual.

1-1

Page 10

1-2

Page 11

1-3

Page 12

1-4

Page 13

1-5

Page 14

1-6

Page 15

1-7

Page 16

1-8

Page 17

1-9

Page 18

1-10

Page 19

1-11

Page 20

1-12

Page 21

1-13

Page 22

1-14

Page 23

1-15

Page 24

1-16

Page 25

1-17

Page 26

1-18

Page 27

1-19

Page 28

1-20

Page 29

1-21

Page 30

1-22

Page 31

1-23

Page 32

1-24

Page 33

1-25

Page 34

1-26

Page 35

1-27

Page 36

1-28E

Page 37

SECTION 2

e

)

DISASSEMBLY

NOTE: Follow the disassembly procedure in the numerical order given.

2-1. CABINET ASSY-1

2 Screws (M1.7 × 4)

Cabinet Assy

3

DVP-F5/FX1

2 Screws (M1.7 × 4)

Robber foot rotary tabl

(FX1 only)

1

2-2. CABINET ASSY-2 (FX1)

Fulcrum cover (R)

Fulcrum cover (L

1 Screws (M1.7 × 4)

2-3. CABINET ASSY-3 (FX1)

1

2

2-1

Page 38

2-4. CD, LID

)

3 Compression spring

CD, LID

Plate(CD LID) Assy

3

ful crum

1 Screw (M1.7 x 3)

2 Tension spring

(open)

2 Open blacket

1 Screw (M1.7 x 3)

4 Lock lever

2-5. MB-90 BOARD, LC-68 BOARD, MD COMPLE

2

MD Comple (DVDM-FX1)

1

1

SRS selection knob

1

MB-90 Comple

I/O selection knob (FX1 only

LC-68 Comple

Cursor button

Hold knob

2-2

Page 39

2-6. DISPLAY PANEL (FX1)

LCD cover

2

Inverter

qa

PWB flexible

3 Screws

Speaker

Link chassis assy

9 Screws (M1.7 x 2)

TP-61 comple

6

0

7

5 Screw

4

8 Screws

Open button (LCD)

qs

Display panel

3 Screws

Speaker

3 Screws

1 Screws

(M1.7 x 4)

LCD cushions

4

3 Screws

1 Screw

(M1.7 x 4)

LCD cushion

LCD cabinet

2-3

1 Screws

(M1.7 x 4)

LCD cushion

Lock claws

LCD cushion

Page 40

MEM

O

2-4E

Page 41

BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2)

SECTION 3

DVP-F5/FX1

OPTICAL DEVICE

DVD

PDIC/LD

MODULE

CD

LD/PD

COUPLER

MODULE

DVD

TRK/FCS

COIL

CD

TRK/FCS

COIL

MD BLOCK

M901

SPINDLE

MOTOR

M

M

M902

SLED

MOTOR

LIMIT

A

B

C

D

LD

PD

RF

CD-E

CD-AL

CD-F

PD1

PD2

CP-PD

CD-LD

TRK–

TRK+

FCS–

FCS+

CDF+

CDF–

CDT–

CDT+

SPON

PHDA

SLD–

SLD+

EC

HFGI

LIMSW

MB-90 BOARD

SIGO

XLDON

IC801

RF

IC805

FOCUS

/TRACKING

COIL

DRIVE

IC813

IC808

SLED MOTOR

DRIVE

IC811

SPINDL

MOTOR DRIVE

MIRR

TZC

PI

FE

TE

DFT

SCLK

SDATA

SDEN

IN1

IN3

IN2

IN4

SRDR

SFDR

(SEE PAGE 4-13,15,17,19,21,23,25,27,29,33)

Q812

SW

DOOR SW1

DOOR SW2

GI03

TO S713

TO S714

IC952

IC802

BUFF

IC812

ERROR

AMP

SSCK

SSDATA

SSCS

SPON3

FCD–

FCD+

TRD–

TRD+

TGIN

PWM0

PWM1

PWM2

FGIN

PG REF

SDSP

CLKIN

2

8

HRD

HWR

RS

RFIN1,2

MDP0

MDS0

LOCK

HA0,1

HD8-15

IC602

ARP2

SDI0-7

CDDATA

CDDOUT

MA0-9

MD00-15

CDBCK

CDLRCK

SDEF

XSAK

XSRQ

XSHD

XDCK

XWAT

8 HD8-15

8 HA0-7

XRD

XWR

ARPRST

XCS

XINT

WE

OE

RAS

UCAS

LCAS

BCK

LRCK

SPDIF1

IC603

MEMORY

ARINT

XARPCS

ARPRST

LRCK0

CD1N1I

CD1N2I

IREQ0

ISTARTI

HWATTOB

HD0-15 16

WRHRDXRST

BCK0

IERRI

IVALI

ICLKI

RSTB

ACH12

27M

512FS1

IC005

ACH34

ACH56

VIDEOV

VIDEOY

VIDEOC

ADDT0-15

ADADT0-11

DOHL

DOMU

SDCS0B

SDCS1B

TRST

DM-ACK0,1

DM-REQ0,1

HIRREQ0

HAD22,23

SCLKIN

CLKIN

CRPCLKI

ACLK

22 HA0-21

TO

IC301

IC302

PLL

WE

CAS

RAS

CLK

CKE

3

6

512FS2

33M

27M

44.1/48K

CS

CS

X002

27MHz

IC351

VIDEO AMP

IC653

IC654

16M SDRAM

(IC653)

(IC654)

DACK0,1

DREQ0,1

XAVINT

XAVDCS2,3

IC003

RESET

D0

7

IC652

A/V DEC.

HA0-21

HD0-15

DVP-F5

IC353

C SW

CONTROL

S701-704

FUNCTION

S705-708

FUNCTION

VMUTE-TFT

V-IOCNT

VIDEOSW

XFRRST

KEY

KEY

V

Y

J351

VIDEO OUT

VIDEO IN/OUT

J352

S VIDEO OUT

DVP-FX1

IC352

VIDEO SW

KEY1

(DVP-F5)

(DVP-FX1)

S351

LINE SELECT

IN/OUT

C

KEY2

KEY3

IC701

IF-COM

IC354

C SW

S709

FUNCTION

KEY

IR

(1/2)

VIDEO OUT

IC702

REMOTE CONTROL

RECEIVER

C OUT

V-IOCNT

ACH12

ACH34

ACH56

BCK

LRCK

SPDIF1

XRST

ON PAGE

3-3

IC703

XRESET

HA0-21

HD0-15

HD0-15

HA1-20

ECS

EBSY

WC

R/B

RESET

IC001

CS

EEPROM

WE

OE

IC004

FLASH

MEMORY

16M

CE

XRDMCS

48/44.1K

XFRRST

DACK0,1

DREQ0,1

XAVINT

XAVDCS2,3

WIDE

EWC

SIN1

SOUT1

SCLK11

DO

DI

SK

SI0

SO0

SC0

XIFCS

TEMP

TH701

XIFBSY

HIN

HCS

SDSPINT

XSDSPCS

IC002

(1/2)

SYSTEM CONTROL

16

3-1

3-2

Page 42

DVP-F5/FX1

3-2. OVERALL BLOCK DIAGRAM (2/2)

ON PAGE

3-2

LC-68 BOARD

(SEE PAGE 4-6)

ND1001

VIDEO OUT

C OUT

V-IOCNT

ACH12

ACH34

ACH56

BCK

LRCK

SPDIF1

XRST

512FS

TO

IC005

D1006

D1012

MB-90 BOARD

(SEE PAGE 4-29,31)

COM0-3

SEG0-16

SDI0

SDI1

SDI2

BCKI

LRCKI

MCLK

MCLK

SO

SCK

XCS

IC301

AUDIO DSP

SI

SD00

TO

Q812

S713

S714

S711

S712

S715

S716

S710

FUNCTION SW

R

L

R

L

DOORSW2

DOORSW1

DVP-F5

IC305

LINE AMP

X701

4MHz

DOORSW1

DOORSW2

TFTOPEN

SRSSW

DVP-FX1

XOUT

LCDPCON

PLAY

POWER

HOLD

IC309

ANALOG

SW

XIN

DVP-FX1

INVERTER

MODULE

DVP-FX1

R

G

B

TFT

PANEL

MODULE

RSCNT

IC701

SPMUTE

IF-COM

INV-H-L

INVPCON

ASPECTSW

(2/2)

XPAL

AMUTE

HPJACK

IN

OUT

TP-61 BOARD (DVP-FX1)

Q1202

ACC FILTER

NT/PAL

SW

VCO OUT

PAL

VCO IN

C IN

TO

IC002

IC1201

LCD VIDEO

PROCESS

EVER CS

X1201

3.58MHz

NTSC

Q1205

NT/PAL

SW

X1202

4.43MHz

VIDEO IN

SYNC SEP

(SEE PAGE 4-37,39,41)

R OUT

G OUT

B OUT

SYNC OUT

SYNC IN

FRP

COMMON FRP

A01-012

CS/LD

EA0,EA1,ECL

SI1

DO

SC1

CLK

DI

SO1

NT/PAL

SYNCI

FRPV

IC1202

LCD

VIDEO

CONT.

(EVR)

HSY

FRT

IC1301

LCD

CONTROL

SPOI

HR

PS

CTR

SPIO

CLD

CLS

SPS

VR

MODE1

MODE2

IC308

D1303

TETMODE1-3

IC1302

OPE AMP

RV1302

FREE RUN

H OSC

PDV

OSCI

OSCO

BUFFER

J302

OPTICAL

OUT

R

L

Q101,201

MUTE

DVP-F5

AUDIO

OUT

AUDIO

IN/OUT

DVP-FX1

VES-CS

LRCK

SCLK

MCLK

M1(SDA/CDIN)

M2(SCL/CCLK)

MO(AD0/CS)

RST

SI1

SC1

SO1

SI1

SC1

SO1

2CH-CS

AURST

IC002

SYSTEM CONTROL

IC302

AUDIO DAC

(2/2)

AOUTA–

AOUTB–

AMUTEC

SW1,2

IN1A

IN2A

MAMUTE

IC303

BUFFER

AMP

Q103,203

MUTE

OUT1

OUT2

EVERCS

RV301

VOL

TO

IC202

LIN

RIN

IC304

SRS AMP

MODE

ROUT

LOUT

3-3

SHTDWN

RLIN

LLIN

IN1

IN2

IC307

SP AMP

IC310

HP AMP

Q102,202

MUTE

ROUT+

ROUT–

LOUT+

LOUT–

OUT1

OUT2

J301

PHONES

SP

L

SP

R

DVP-FX1

3-4

Page 43

3-3. VIDEO OUT BLOCK DIAGRAM

DVP-F5/FX1

MB-90 BOARD

TO

A/D DEC.,

SYSTEM CONTROL

BLOCK

(SEE PAGE 3-9)

(PREV)

(NEXT)

(PAUSE)

(STOP)

ND1001

LC-68 BOARD

(SEE PAGE 4-6)

16

1

COM0

COM3

SEG0

SEG16

S704

S703

S702

S701

21

1

4

5

D1006

D1012

VIDEOV

VIDEOY

VIDEOC

WIDE

Q354

MUTE

(SEE PAGE 4-29)

DISPLAY

RETURN

DVDMENU

TITLE

CN1001

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

25

27

VIDEO AMP

4

INB

2

INA

7

INC

1

MUTE

S708

S707

S706

S705

COM0

COM1

COM2

COM3

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

LED

LED

IC351

OUTB1

OUTB2

OUTA1

OUTA2

OUTC1

OUTC2

Q355

SW

CN701

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

25

27

J351 (VIDEO OUT)

V

13

12

Y

15

14

C

10

9

RIGHT

DOWN

LEFT

UP

ENTER

Q702

1.2Vp-p

H

IC702

IC701 ej (X OUT)

LED6V

LED

DRIVE

DVP-F5

S709

REMOTE CONTROL

RECEIVER

OUT

COM0-3

SEG0-6

250 nsec

X701

4MHz

Q701

SW

3.3V

3.6Vp-p

J351

VIDEO OUT DVP-F5

VIDEO IN/OUT

Y C

S S

G G

ENTER

2

KEY3

3

KEY2

KEY1

4

11

3

95

92

88

72

37

36

70

8

IR

COM0

COM3

SEG0

SEG16

XOUT

XIN

LCDPCON

PON-CNK

67 5 12 57 60

J352

S VIDEO

OUT

MUTE

DVP-FX1

J352 C (S-C OUT)

TH701

TEMP

S351

1.8Vp-p

H

LINE SELECT

IN/OUT

IC701

IF-COM

J352 Y (S-Y OUT)

VIDEOSW

(2/2)

V-IOCNT

H

Q353

SW

2.0Vp-p

Q352

SW

INV-H-L

INVPCON

VMUTE-TFT

ASPECTSW

TFTPCON

SRSCNT

AMUTE

SPMUTE

HPJACK

TFTMODE3

TFTMODE2

TFTMODE1

DOORSW1

DOORSW2

XFRRST

XIFBUSY

SCLKI1

MAINPCON

DVDPCON

XRESET

POWER

TFTOPEN

SRSSW

XPAL

ECL

EA0

EA1

XIFCS

SIN1

SOUT1

PLAY

HOLD

V

Y

55

65

14

66

56

68

69

10

25

26

27

28

29

31

30

22

40

61

17

23

SO0

20

SI0

19

SC0

18

PCONT

63

59

33

45

41

39

13

43

3

1

2

V-IOCNT

DVP-FX1

IC352

VIDEO SW

4

TFTOPEN

7

Q356

BUFF

IC703

1 2

OUT VDD

DOORSW1

DOORSW2

(PLAY)

POWER

S715

Q351

BUFF

XFRRST

XIFBSY

XIFCS

SO0

SIO

SC0

EVRCS

DOORSW1

DOORSW2

RESET

S713

S714

S711

S712

EVER 3V

DVP-FX1

C SW

IC353

CONTROL

5

6

7

IC354

5 6

2

7

3

1

2

C SW

3

1

(SEE PAGE 3-12)

TO

A/V DEC,

5 4

SYSTEM CONTROL

BLOCK

(SEE PAGE 3-10)

TO

A/V DEC,

SYSTEM CONTROL

5

BLOCK

TO

A/V DEC,

SYSTEM CONTROL

BLOCK

(SEE PAGE 3-11)

(SEE PAGE 3-10)

EVER 3V

S716

HP SURROUND

ON

OFF

6

TO

AUDIO

BLOCK

S710

HOLD

UNREG

FL701

V-IOCNT

SRSCNT

AMUTE

SPMUTE

HPJACK

SC1

SI1

SO1

+B

+B

+B

P-UNREG

P-UNREG

INV-H-L

INVPCON

ASPECTSW

TFTPCCON

VIDEO OUT

C OUT

SP-RCH+

SP-RCH–

SP-LCH+

SP-LCH–

CS/LD

TFTMODE3

TFTMODE2

TFTMODE1

XPAL

XFRRST

XIFBUSY

XIFCS

SO0

SC0

PCONT

DVDPCON

IFRST

3.3VIN

CLK

ECL

EA0

EA1

SI0

CN703

7

8

9

10

11

4

5

6

12

15

17

TO

18

TP-61 BOARD

CN1101

19

20

LCD VIDEO

/CONTROL

21

BLOCK

(SEE PAGE 3-13)

26

27

DO

28

DI

29

22

23

24

25

30

31

32

CN702

1

2

3

4

5

DOWNLOAD

6

8

10

11

12

3-5 3-6

LCD

LC-68

Page 44

DVP-F5/FX1

3-4. RF BLOCK DIAGRAM (1/2)

OPTICAL

DEVICE

OPT

CN801 4 (RF)

MONITOR

680mVp-p

LD

PD

VCC

RF

DVD-VC

TRK–

TRK+

FCS–

FCS+

CD-VC

CDF+

CDF–

CDT–

CDT+

CD-E

CD-AL

CD-F

PD2

PD1

CD-PD

CD-LD

MB-90 BOARD

CN951

CDRF

6

PI

5

TE

4

FE

3

RE

1

CN801

B

5

A

4

D

3

C

1

FL801 Q801

Q804

LD

SWITCH

LDV

SWITCH

SW

Q802

CD-LD

DRIVE

MPWR

15

18

13

10

11

12

10

16

15

14

13

12

11

4

5

9

3

1

2

5

7

CN802

FL802 Q803

L803

(SEE PAGE 4-15,17,19,21)

B

13

A

14

D

11

C

12

6

B2

5

A2

D2

8

C2

7

DVDLD

22

DVDPD

21

A5V

1

DVDRFP

26

VC

C801 rs (FE)

19

CE1

CEIN

18

CDTE

17

16

E

15

F

PD2

4

3

PD1

23

CDPD

A5V

CDLD

24

IC801

RF

IC801 tj (SIGO)

IC801 ra (TE)

SCLK

SDATA

SDEN

1.4Vp-p

CDRFDC

CDRF

SIGO

VC1

150mVp-p

XLDON

MIRR

TZC

MIN

XFDCHG

DFT

HOLD2

HOLD1

PI

FE

TE

1.0Vp-p

IC805

SW

FOCUS/TRACKING

COIL DRIVE

32

OUT1R

31

OUT1F

30

OUT2R

OUT1F

29

27

OUT3F

26

OUT3R

OUT4F

25

OUT4R

24

OPOUT

13

11

OP–

DOORSW1

DOORSW2

IN1

IN2

IN3

IN4

VREF

XMUTE34

MUTE2

BRAKE1

22

20

17

18

16

19

21

23

IC802

46

47

48

64

63

57

27

11

8

3

6

A5V

13

SSCK

12

10

SSDATA

9

1

SSCS

2

4

SPON3

5

Q812

FCS–

FCS+

TRK–

TRK+

CDF+

CDF–

CDT+

CDT–

DOOR1,2

IC952

Q805

XLDON

25

SW

29

29

36

42

41

35

SSDFCT

32

37

45

49

Q811

SW

PI

FE

TE

52

GIO3

MIRR

27

TZC

26

ADC2

21

ADC1

22

ADC0

23

41

GIO11

39

DFCT1

SDSP

GIO1

PDM3

PDM2

PDM1

PDM0

VRTA

VRBA

54

1

3

5

7

9

13

IC812

7

1

1 2

3.3V

3

2

1

7

ERROR

AMP

CONT

IC810

IC803

2V REG

6

5

2

3

4

1

3

2

5

6

FCD–

FCD+

TRD–

TRD+

FCD–

FCD+

TRD–

TRD+

IC951

VRT/VRB

OUT

D805

MA0-9

IC603 IC602

MEMORY ARP

A0

21

24

27

32

A9

I/O0

I/O15

RAS

UCAS

LCAS

2

5

7

10

MD00-15

41

44

46

49

17

WE

OE

33

18

34

35

HD8-HD13

HD14

HD15

HA0-HA3

HA4-HA7

154

157

159

152

164

167

169

172

148

152

151

150

17

19

52

49

58

63

68

70

71

73

76

79

82

61

60

MD00

MD15

XMWR

XOE

XRAS

XCAS

RFIN1

RFIN2

MDPO

MDSO

LOCK

D0

D7

A0

A7

XRD

MA0

MA9

SD0

SD7

DATA

DOUT

BCLK

LRCK

SDEF

XSAK

XSRQ

XSHD

XDCK

XWAT

SCKI

MCKI

XRST

XCS

XINTXWR

136

139

MA0-9

141

144

146

147

97

98

100

105

107

110

108

109

96

95

94

93

91

86

D601

123

121

87

84

83

SDI0-SDI7

CDDATA

CDDOUT

CDBCK

CDLRCK

SDEF

XSAK

XSRQ

XSHD

XDCK

XAVWT

XWAITCSP

33MARP

ARPRST

XARPCS

XARINT

16

MD BLOCK

M901

SPINDLE

MOTOR

M902

SLED

MOTOR

MPWR

GIO2

53

3.3Vp-p

SSDATA

SPON3

TCK

4.5 S

SSCK

SSCS

SPDR

SFDR

3.3Vp-p

GIO8

45

GIO7

45

48

GIO5

55

GIO0

PWM0

73

PWM1

72

28

PGREF

32

FGIN

29

TGIN

71

PWM2

3.3V

CN803

PHCD

1

PHDA

2

M

SLD–

SLD–

SLD+

SLD+

4

5

6

7

1

3

M

CN804

LIMSW

10

HFG1

8

ECR

7

4

IC808

SLED MOTOR

DRIVE

IC813

14

7

OUT 1B

OUT 1A

IN1B

IN1A

OEB

SRDR

3

SFDR

2

4

Q808

SW

IC952 es (FG IN)

IC811

4

1

2

3

SPINDLE

MOTOR DRIVE

M5V

4

1

3

5.8 msec

IC952 wl (PG IN)

EC

SPON

VM

VM

ADC7

ADC6

ADC5

ADC4

ADC3

HD0

HD7

HA0

HA1

HRD

HWR

HCS

HINT

FGREE

CLKIN

16

17

18

19

20

90

HD8-HD12

86

HD13

84

HD14

83

HD15

82

81

80

79

78

77

76

RS

68

31

95

XDRVMUTE

X3VRST

HD8-HD15

DOORSW1,2

HA0-HA7

RD

WRH

XSDSPCS

SDSPINT

XRST

27MSDP

3-7 3-8

Page 45

3-5. RF BLOCK DIAGRAM (2/2)

DVP-F5/FX1

MB-90 BOARD

TO

AUDIO

2

BLOCK

(SEE PAGE 3-11)

SDIO-SDI7

CDDATA

CDDOUT

CDBCK

CDLRCK

SDEF

XSAK

XSRQ

XSHD

SDCK

XAVWT

XWAITCSP

33MARP

ARPRST

XARPCS

XARINT

(SEE PAGE 4-23,27)

ACH12

ACH34

ACH56

BCK

LRCK

SPDIF1

512FS2CH/VES

XRST

HD0-HD15

245

246

244

242

241

240

230

229

226

225

222

220

217

238

237

236

233

218

212

214

213

216

22

29

28

16

14

8

6

5

255

249

ACH12

ACH34

ACH56

BCK0

LRCK0

D0

DTI1

DTI7

CDIN1I

CDIN2I

CDBCKI

CDLRKI

IERRI

IVALI

IREQ0

ISTARTI

ICLKI

HWATTOB

HCSB

HRWB

RSTB

HD0

HD15

IC652

A/V DEC.

COMPOUT

YOUT

COUT

SDDQ0

SDDQ15

SDCSOB

SDDQMO

SDWEOB

SDCASOB

SDRASOB

SDAD0

SDAD11

SDDQM1

SDCLK0

SDCKE0

SDCSIB

HAD0

HAD21

DM-REQ0

DM-ACK0

DM-REQ1

DM-ACK1

HIREQ0

HAD22

HAD23

TRST

SCLKIN

CLKIN

CRPCLKI

ACLK

WIDE

174

180

178

74

97

114

102

106

101

105

127

112

98

110

108

109

30

61

17

18

20

21

25

56

60

126

69

70

232

248

VIDEOV

VIDEOY

VIDEOC

ADDT0-T15

DOHL

WE

CAS

RAS

ADDT0-T15

DOMU

CLK

CKE

HA0-HA21

DREQ1

DACK1

DREQ0

DACK0

XAVINT

XAVDCS3

XAVDCS2

27MAVD

33MAVD

512FSAVD

TO

VIDEO OUT,IF-COM

1

BLOCK

(SEE PAGE 3-5)

IC653

DO0

2

12

39

49

DO15

18

CS

DOHL

14

WE

15

16

CAS

17

RAS

ADAD0-D11

IC654

2

DO0

12

39

DO15

49

DOHL

14

WE

15

16

CAS

17

RAS

18

CS

16M SDRAM

3.3V

19

A0

24

27

32

A11

36

DOMU

35

CLK

CKE

34

16M SDRAM

19

A0

24

27

32

A11

36

DOMU

35

CLK

CKE

34

IC003

RESET

OUT

ADAD0-D11

ADAD0-D11

4

HA0-HA21

HD0-HD15

XWAITCSP

XARINT

XSDSPCS

SYSTEM CONTROL

WIDE

63

HA0

102

109

111

118

120

1

5

HA21

HD0

85

100

HD15

79

XWAIT

22

ARPRST

69

XARPCS

26

ARINT

82

RD

83

WRH

18

CS6

32

SDSPINT

16

XRST

DREQ1

46

DACK1

47

DREQ0

43

DACK0

44

25

XAVINT

68

XAVDCS3

67

XAVDCS2

74

XFRRST

23

DRVMUTE

61

48/44.1K

IC002

XRDMCS

SO2

SI2

SC0

SO0

SI0

EWC

ECS

EBSY

IFCS

IFBSY

EVRCS

SI1

SO1

SC1

AURST

2CH-CS

VES-CS

MAMUTE

IC004

16M FLASH MEMORY

29

DQ0

HD0-HD15

WRH

65

41

40

36

35

33

36

38

45

DQ15

11

RD

WE

28

OE

26

CE

A16

25

A0

HA1-HA20

16

9

1

48

CN001

TXD

RXD

TO

DIAG

JIG

1

2

IC001

48

49

28

45

29

50

53

XI

54

XO

8

3

1

X001

12.5MHz

WE

CE

R/B

6

DO

5

DI

4

SK

SIO

SO0

SC0

XIFCS

XIFBSY

EVRCS

XFRRST

DOORSW1

DOORSW2

5

TO

VIDEO OUT

IF-COM

BLOCK

(SEE PAGE 3-6)

4

37

38

39

51

59

60

62

SI1

SO1

SC1

AURTS

2CH-CS

6CH/VES-CS

MAMUTE

TO VIDEO OUT,

IF-COM BLOCK,

AUDIO BLOCK

(SEE PAGE 3-11)

TO

3

AUDIO

BLOCK

(SEE PAGE 3-11)

XDRVMUTE

X3VRST

HD8-HD15

DOORSW1,2

HA0-HA7

RD

WRH

XSDSPCS

SDSPINT

XRST

27MSDP

44.1/48K

27M

33M

512FS2

27M

512FS1

IC005 qs (33M)

XTALOUT

IC005

PLL

30 nsec

XTALIN

4.5Vp-p

9

8

IC005 qg,qh (512 FS 1,2)

IC005 9 (XTAL OUT)

X002

27MHz

44.3 nsec

37 nsec

5.0Vp-p

HD0-HD15

27MAVD

33MAVD

512FSAVD

IC005 3,wf (27M)

37 nsec

23

24

12

15

3

16

4.8Vp-p

3-9 3-10

2.4Vp-p

Page 46

DVP-F5/FX1

3-6. AUDIO BLOCK DIAGRAM

MB-90 BOARD

(SEE PAGE 4-19)

SPDIF1

TO

A/V DEC.

SYSTEM CONTROL

BLOCK

2

(SEE PAGE 3-9)

TO

A/V DEC.

SYSTEM CONTROL

BLOCK

4

(SEE PAGE 3-11)

TO

A/V DEC.

SYSTEM CONTROL

BLOCK

3

(SEE PAGE 3-10)

ACH12

ACH34

ACH56

XRST

512FS2CH/VES

LRCK

BCK

SI1

SC1

SO1

6CH/VES-CS

2CH-CS

AURST

MAMUTE

IC301 5 (LRCKI)

20.8 µsec

3.5Vp-p

IC301 3 (MCLK)

40.8 nsec

5.0Vp-p

AUDIO DSP

6

SDI0

7

SDI1

SDI2

8

XRST

48

3

MCLK

LRCKI

5

9

BCKI

17

SO

14

SCK

13

SI

11

XCS

3

SDATA

6

MCLK

LRCK

5

4

SCLK

M2(SCL/CCLK)

8

9

M1(SDA/CDIN)

M0(ADO/CS)

10

1

RST

AMUTEC

20

IC301

IC302

AUDIO DAC

SD00

37

AOUTA–

AOUTA+

AOUTB+

AOUTB–

IC301 9 (BCKI)

19

18

15

14

V5V

325 nsec

IC311

–5V SUPPLY

V+

5

4 2

SD

3.5Vp-p

OUT

DVP-F5

V5V

INC–

9

10

INC+

12

IND+

13

IND–

8

OUTC

5

INB+

OUTD

14

3

INA+

BUFFER AMP

3

IN1A+I/P

2

SW1

16

SW2

15 13

IN2A+I/P

L303

IC305

LINE AMP

IC303

DVP-F5

INB–

OUTB

OUTA

INA–

–VCC

OUT1

IN1A-I/P

IN1B-I/P

IN1B+I/P

OUT2

IN2A-I/P

IN2B-I/P

IN2B+I/P

GND

SWR

IC308

BUFFER

1 4

V5V

IC309

ANALOG SW

6

7

1

2

11

DVP-F5

5

COM2

14

IN4

15

VCC

9

NO3

8

–VCC

1

NO1

13

NO4

6

IN2

7

IN3

COM1

NO2

COM3

COM4

2

4

10

12

IN OUT

2

Q101,201

MUTE

DVP-FX1

Q302

AUDIO

+B SW

RV301

VOL

5

4

6

7

14

12

11

9

10

Q103,

203

NUTE

IC304

SRS AMP

RIN

LIN

ROUT

10

7

LOUT

4 10

MODE

16

1

SP5V

Q301

SW

Q314,315

VCC SW

Q317

SW

2

6

1

4

Q316

INV.

IC310

HP AMP

IN1

VCC

PISW

IN2

MT/S

OUT1

OUT2

9

7

Q318,319

MUTE

SW

Q306

AUDIO OUT

JACK DET

MUTE

Q304

VCC

SW

D304

Q102,

202

Q312

HP JACK

DET

2.3V

J302

VIN

6

7

VCC

DGND

8

J301

PHONES

OPTICAL

OUT

AUDIO

OUT

V5V IR5V

DVP-FX1

D311

Q310,311

SHTDWN

SW

Q313

SW

23

5

22

IC307

SP AMP

RLIN

LLIN

SHITDWN

Q303

SW

ROUT+

ROUT–

LOUT+

LOUT–

V-IOCNT

21

16

4

9

SP-RCH+

SP-RCH–

SP-LCH+

SP-LCH–

SRSCNT

SPMUTE

AMUTE

HPJACK

6

TO

VIDEO OUT,

IF-COM

BLOCK

(SEE PAGE 3-6)

Q305

INV.

Q320

INV.

D303

D308

D301

Q307

SW

Q321,322

MUTE

SW

Q309

INV.

MUTE SW

Q306

16

3-11 3-12

Page 47

3-7. LCD BLOCK DIAGRAM

TP-61 BOARD

(SEE PAGE 4-37,39,41)

TO

MB-90 BOARD

CN703

VIDEO OUT,

IF-COM BLOCK

(SEE PAGE 3-6)

INVERTER

MODULE

SPEAKER

R

L

CN1101

CN1102

CN1103

CN1104

7

8

9

10

11

12

15

17

26

27

28

29

30

31

32

22

23

24

25

18

19

20

21

4

5

6

8

6

5

7

4

3

2

1

1

2

2

1

UNREG +B

P-UNREG

TFTPCON

Y IN

C IN

CLK

CS

D0

D1

ECL

EA0

EA1

TFTMODE3

TFTMODE2

TFTMODE1

XPAL

AUDIO-R+

AUDIO-R–

AUDIO-L+

AUDIO-L–

INV-H-L

INV-PCON

ASPECTSW

ASPECTSW

INVPCON

INV-H-L

5.15V

VIN(UNREG)

AUDIO-R+

AUDIO-R–

AUDIO-L–

AUDIO-L+

IC1201 5 (CIN)

H

5V

UNREG +B

FL1102

(DVP-FX1)

POWER BLOCK

IC1201 3 (VIDEO IN)

900mVp-p

Q1204

R-Y/B-Y

Q1202

NT/PAL

Q1206

INV.

Q1205

NT/PAL

VCO SW

X1201

3.58MHz

NTSC

OUT

SW

H

EA1

EA0

ECL

DI

DO

CS

500mVp-p

PAL MODEL

X1202

4.43MHz

PAL

Q1213

INV.

+13V

+7.5V

+5.0V

–5.0V

–17V

LCD VIDEO PROCESS

3

VIDEO IN

36

SYNC SEP

5

C IN

13

CHROMA OUT

9

R-Y

10

B-Y

11

ACC FILTER

IC1201 qh (VCO OUT)

16

VCO OUT

14

VCO IN

LCD VIDEO CONT. (D/A CONV.)

EA1

22

EA0

21

ECL

16

DI

20

DO

17

CLK

19

18

CS/LD

IC1201 wa (G OUT)

IC1201 ql (R OUT)

IC1201

SYNC OUT

COMMON FRP

BURST OUT

500mVp-p

279 nsec

GAMMA2

GAMMA0

SUB BRIGHTR

SUB BRIGHTB

AGC OUT

COMMON AMP ADJ

CONTRAST

RGB AMPLITUDE ADJ

COMMON OUT

IC1202

A01(RGB AMP)

A02(BRIGHT)

A03(CONTRAST)

A04(COM AMP)

A05(COLOR)

A08(SUB B)

A09(SUB R)

A010(∂0)

A011(∂2)

A012(PICTURE)

A06(TINT/BCL)

A07(COMMO DC)

2H

2H

R OUT

G OUT

B OUT

SYNC IN

FRP

SW

TINT

PICTURE

COLOR

BRIGHT

4.2Vp-p

4.2Vp-p

DVP-F5/FX1

IC1201 wf (B OUT)

4.2Vp-p

2H

5.0V

L1304

L1303

VSHL1

VSHL2

VSHA2

VSHA1

5.0Vp-p

2H

MODE1

MODE2

–17V

D1305

13V

SPOI

CTR

SPOI

CLD

COM

VGL

CLS

SPS

VSS

VCC

VGH

CN1301

1

2

3

4

R

6

G

7

B

8

10

HR

11

PS

12

13

14

TFT PANEL

MODULE

15

17

18

25

26

VR

27

28

29

21

24

32

5.0V

IC1302

4

D1302

1

3

4

2

IC1301 4 (HSY)

IC1301 6 (FRPI)

IC1304

4.8Vp-p

H

4

IC1301 7 (SYNCI)

IC1301

TIMING GENERATOR

7

SYNCI

4

HSY

8

FRPV

6

FRT

10

VCS

5.0Vp-p

H

IC1301 8 (FRPV)

SPOI

28

HR

33

PS

35

CTR

36

SPIO

37

CLD

47

IC1305

ONE SHOT

2

MULTI BIV

R

19

G

21

B

24

35

34

IC1201 eg (SYNC OUT)

H

IC1303

215

4.8Vp-p

33

32

39

PAL MODEL

7

A06

13

A012

48

A011

26

A010

27

A09

31

A08

30

47

A05

6

A04

37

A03

2

A02

29

A01

28

38

Q1212

SW

Q1203

L1201

SW

IC1201 ek

(COMMON OUT)

A01

1

A02

2

A03

3

A04

4

A05

5

A08

8

A09

9

A010

10

A011

11

A012

12

A06

6

Q1207-1211

COMMON OUT

5.0V

AMP

1.7Vp-p

2H

2H

5.0Vp-p

RV1301

PICTURE

FRAME

TFT MODE3

TFT MODE2

TFT MODE1

IC1301 rf (OSCI)

50 nsec

70

BLKI

71

BLKO

11

NT/PAL

16

MDS

20

MDW

21

MDN

43

OSCO

44

OSCI

20MHz OSC

2.0Vp-p

Q1301

–17V

MOD1

MOD2

RV1302

CLS

SPS

VR

PDP

57

58

59

60

32

38

D1303

7

16

3-13

3-14

Page 48

DVP-F5/FX1

3-8. POWER BLOCK DIAGRAM (1/2)

J501

DC IN 10V

J401

DC OUT 5V

BT501

MB-90 BOARD

LF501 F501 D502

Q501

F502

S

Q515

BATT TYPE

SW

DC IN

DET

(SEE PAGE 4-11)

IC501

3.3V REG

3

2

IN OUT

IC502

CHG CONT.

5

1

Q503

SW

FL402

TFTPCON

UNREG

L411

Q509

STBY 3V

SW

Q508

IN OUT

2

3

IC504

5V REG

Q516

SWITCH

4

3

F401

D506

RV501

CHG

D501

D407

IR 5V

3W

Q510

CHG CONT.

Q413

DC OUT SW

DC OUT

JACK SW

Q409

Q517

CHG CONT

Q504

LB CHG

SW

LB CHG

SW

Q518

CHG CONT

S501

D504

Q505

F402

8

28

42

51

63

31

27

30

29

OVP 5.6

DTC3

VREF

CTL1

CTL2

IC401

POWER CONTROL

VCC

IC401 th (OUT 1-3)

IC401 t; (OUT 1-2)

3.0 µsec

IC401 rh (OUT 1-1)

3.0 µsec

IC401 yf (OUT 1-5)

3.0 µsec

IC401 4 (OUT 1-6)

3.0 µsec

3.0 µsec

0.7Vp-p

0.8Vp-p

1.2Vp-p

1.5Vp-p

1.1Vp-p

OUT1-4

IN(C)4

–IN(E)4

FB4

OUT1-3

IN(C)3

–IN(E)3

FB3

OUT1-2

IN(C)2

–IN(E)2

FB2

OUT1-1

IN(C)1

–IN(E)1

FB1

OUT1-5

IN(C)5

–IN(E)5

FB5

OUT1-6

IN(C)6

–IN(E)6

FB6

IC401 tj (OUT 1-4)

3.0 µsec

57

18

19

20

56

34

33

32

50

37

36

35

46

40

39

38

64

14

16

17

4

9

11

12

0.7Vp-p

Q401

UNREG SW

Q402

UNREG SW

Q403

UNREG SW

Q404

UNREG SW

Q405

UNREG SW

Q406

UNREG SW

Q410

D1.8V SW

Q411

A 5V SW

Q412

3.3V SW

IC402

1

IN OUT

Q414

SW

Q415

SW

Q416

SW

V 5V REG

4

STBY 3V

EVER 3V

IR5V

D1.8V

M5V

A5V

A5V

3.3V

SP5V

V5V

LC-68 BOARD

(SEE PAGE 4-6)

9

BATTYPE

32

XDCIN

7

VCCMNT

64

CHGCNT

IC701

IF - COM

(1/2)

1

DCOUTMNT

44

DCOUTJACK

58

IRPCON

21

LBCHG

42

BATTSW

5

89

CHGMNT

VCC

Q702

LED

90

63

VREF

59

DVDPCONT

MAINPCONT

LCDPCON

TFTPCON

XRESET

70

66

33

IC703

1

OUT VDD

RESET

2

Q701

LCD

PCON

DRIVE

LED

CN701

16

3-15 3-16

CN1001

25

25

27

27

D1006

D1012

Page 49

3-9. POWER BLOCK DIAGRAM (2/2)

DVP-F5/FX1

DVP-FX1

MB-90 BOARD

TFTPCON

UNREG

IC702

REMOTE

CONTROL

RECEIVER

IR5V

D1.8V

M5V

A5V

3.3V

SP5V

V5V

FL651

IC805

Q807

SW

IC808

SLED MOTOR DRIVE

FL654

5

OUT

1

HVCC V REF

36

VM1

8

17

VM2

(SEE PAGE 4-13,15,17,19,21,23,25,27,29,31,33)

A/V DEC

IC652

169

VREFI

RV651

VADJ

FL655

FOCUS/TRACKING

COIL DRIVE

16

FL652

IC810

1

2

SW

4

IC651

3.3V REG

AMP

–5V REG

IC813

–5V

IC311

CN804

0.5V

9

VCC

7

3

2

8

9

4

CN801

VCC

CN802

VCC

CN001

+3.3V

7

VM

BLOCK

OPTICAL

PICK UP

BLOCK

DIAG JIG

J302

OPTICAL

OUT

MD

IC653

16M SDRAM 16M SDRAM

IC654

IC801

RF

IC802

AND GATE

L804

FL601

IC811

L301

LINE AMP

IC305 IC303 IC304 IC309

L351

VIDEO AMP

IC351 IC353 IC354 IC352

L801

L802

5

1

SPINDLE

MOTOR

DRIVE

OUT

IC812

ERROR

AMP

4

IC601

3.3V REG

BUFFER

AMP

C SW

CONT

IC951

VRV,VRB

IC310

HP AMP

FL951

SRS AMP

C SW

DVP-FX1

DVP-FX1

FL701

IC302

AUDIO

DAC

SP AMP

IC307

ANALOG

SW

VIDEO

SW

Q304

SW

1

P-UNREG

P-UNREG

TFTPCON

IC803

2V REG

OUT

CN703

+B

+B

+B

–INV

+INV

IC602

FL953

ARP3

IC1101

+9VREG

SWITCHING CONT.

2

5

3

1

Q1102

D1102

SWITCHING

CN1101

11

10

9

8

7

12

INVERTER

MODULE

2

3

11

10

9

8

7

12

1

2

3

4

7

F1101

L1106

L1102

CN1102

VIN(UNREG)

VIN(WNREG)

VIN(UNREG)

VIN(UNREG)

5.15V

1

4

LCD

VIDEO

T1101

8

7

2

3

6

5

D1104

D1105

D1106

D1107

LCD VIDEO

CONTROL

D1103

Q1105,D1110

+7.5V REG

Q1104,D1199

–5V REG

–17V REG

RV1101

L1104

L1103

L1105

L1102

L1101

L1303

L1304

7.5V

–5V

VGH

32

PANEL

MODULE

VSS

21

VSHA1

4

VSHA2

3

VSHL2

2

VSHL1

1

IC1202

IC1201

FL001

FL602

FL603

16M DRAM

MEMORY

IC603

FL002

IC001

RESET

OUT

IC003

XFRRST

IC002

SYSCON

4

TIMING

74

GENERATOR

OPE AMP

IC1302

IC1301

ONE SHOT

MULTI BIV

INV. AND

IC1305 IC1303 IC1304

SDSP

IC952

AUDIO

DISP

IC301

16M FLASH

IC004

FL003

TP-61 BOARD

(SEE PAGE 4-37,39,41)

IC308

BUFFER

PLL

IC005

3-17

3-18

Page 50

MEM

O

3-20E

Page 51

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM

1

26

SECTION 4

DVP-F5/FX1

5

8

9

10 12 13

11

1473

154

A

ND1001

B

LIQUID CRYSTAL

C

LC-68 BOARD

27 LED

25 LED

23 NC

21 SEG16

19 SEG14

17 SEG12

15 SEG10

13 SEG8

11 SEG6

9 SEG4

7 SEG2

5 SEG0

3 COM2

1 COM0

28PCN1001

28GND

26GND

24NC

22NC

20SEG15

18SEG13

16SEG11

14SEG9

12SEG7

10SEG5

8SEG3

6SEG1

4COM3

2COM1

B TO B

1 GND

FPC

FPC

FFC

FPC

BT501

LITHIUM

BATTERY

CHARGER

2B

3A

4RF

5 DVD_VC

6D

7C

8 VCC

9 TRK-

10 TRK+

11 FCS-

12 FCS+

13 VCC

14 N.C.

15 LD

16 LD_GND

17 VR

18 PD

1 PD2

2 PD1

3 CD_E

4 CD_VR

5 CD_PD

6 GND

7 CD_LD

8 N.C.

9 VCC

10 CD_VC

11 CD_F

12 CD_AL

13 CDT+

14 CDT-

15 CDF-

16 CDF+

1 PHCO

2 PHDA

3 DGND

4 SLD-

5 SLD-

6 SLD+

7 SLD+

1 SPON

2VM

3VM

4EC

5 PGND

6 PGND

7 ECR

8 HFG1

9 D5V

10 LIMSW

S

D

DVD

PDIC

E

F

DVD

LD MODULE

DVD

TRACKING/FOCUS

COIL

OPTICAL

PICK-UP

UNIT

CD

LD/PD

COUPLER

MODULE

TRACKING/

FOCUS

COIL

G

H

1PHCO

2PHDA

I

MD

J

K

L

UNIT

M902

SLED

MOTOR

PHOTO

SENSOR

M901

SPINDLE

MOTOR

MODULE

LIMIT SW

16

3DGND

4SLD-

5SLD-

6SLD+

7SLD+

M

M

18PCN801

16PCN802

7PCN803

10PCN804

1 COM0

3 COM2

5 SEG0

7 SEG2

9 SEG4

11 SEG6

13 SEG8

15 SEG10

17 SEG12

19 SEG14

21 SEG16

23 (NC)

25 LED

27 LED

YC

GG

28PCN701

S701-S708,S711,S712

(STOP), (PAUSE), (NEXT), (PREV)

TITLE,DVD,MENU,RETURN,DISPLAY, (PLAY)

POWER

S713,S714

(DOOR SW 1/2)

S715

(TFT OPEN) DVP-FX1 MODEL

MB-90 BOARD

1/12 DD BLOCK

2/12 CHG BLOCK

3/12 RF BLOCK

4/12 SERVO BLOCK

5/12 SERVO BLOCK

6/12 ARP BLOCK

7/12 AV BLOCK

8/12 DEC BLOCK

9/12 SYSCON BLOCK

10/12 IF-COM BLOCK

11/12 AU BLOCK

12/12 VIDEO BLOCK

S351

LINE SELECT

IN/OUT

J351

VIDEO OUT DVP-F5 MODEL

VIDEO IN/OUT DVP-FX1 MODEL

S VIDEO OUT

AUDIO IN/OUT

OPTICAL OUT

AUDIO OUT

OPTICAL OUT

J301

PHONES

J401

DC OUT 5V

DC IN 10V

DVP-FX1 MODEL

J352

J302

DVP-FX1 MODEL

DVP-F5 MODEL

J501

ENTER

LEFT

2COM1

4COM3

6SEG1

8SEG3

10SEG5

12SEG7

14SEG9

16SEG11

18SEG13

20SEG15

22(NC)

24(NC)

26GND

28GND

S709

S716

HP SURROUND

ON-OFF

S710

HOLD

32PCN703

12PCN702

UP

10P

CN952

RIGHTLEFT

CN001

4P

10P_UNREG

11P_UNREG

12TFTPCON

13P_GND

14P_GND

15VIDEO_OUT

16VGND

17C_OUT

18SP_RCH+

19SP_RCH-

20SP_LCH+

21SP_LCH-

22TFTMODE3

23TFTMODE2

24TFTMODE1

25XPAL

26CLK

27CS/LD

28D0

29DI

30ECL

31EA0

32EA1

10DVDPCON

11IFRST

123.3VIN

10EMU1

1+BGND

2+BGND

3+BGND

4INV_H_L

5INVPCON

6ASPECTSW

7+B

8+B

9+B

1XFRRST

2XIFBUSY

3XIFCS

4SOO

5SIO

6SCO

7GND

8PCONT

9GND

1TMS

2TAST

3TDI

43.3V

5TD0

6D_GND

7TCK

8D_GND

9EMU0

1TXD

2RXD

3GND

4+3.3V

DOWNLOAD

SDSP(JIG)

DIAG(JIG)

1 +BGND

2 +BGND

3 +BGND

4 INV_H_L

5 INVPCON

6 ASPECTSW

7 UNREG+B

8 UNREG+B

9 UNREG+B

10 P_UNREG

11 P_UNREG

12 TFTPCON

13 P_GND

14 P_GND

15 YIN

FPC

16 V_GND

17 CIN

18 AUDIO_R+

19 AUDIO_R-

20 AUDIO_L+

21 AUDIO_L-

22 TFTMODE3

23 TFTMODE2

24 TFTMODE1

25 XPAL

26 CLK

27 CS

28 D0

29 DI

30 ECL

31 EA0

32 EA1

32PCN1101

TP-61 BOARD

1/3 DC/DC CONVERTER

2/3 RGB DECODER

3/3 TG BLOCK

CN1102

CN1301

CN1103

CN1104

12P

1VIN(UNREG)

2VIN(UNREG)

3VIN(UNREG)

4VIN(UNREG)

5INV_H_L

FFC

6INVPCON

75.15V

8ASPECTSW

9GND

10GND

11GND

12GND

32P

1VSHL1

2VSHL2

3VSHA2

4VSHA1

5GND

6R

7G

8B

9GND

10SPOI

11HR

12PS

13CTR

14SPIO

15CLD

16GND

17COM

18VGL

19OPEN

20OPEN

21VSS

22OPEN

23OPEN

24VCC

25CLS

26SPS

27VR

28MODE1

29MODE2

30OPEN

31OPEN

32VGH

2P

1AUDIO_R+

2AUDIO_R-

2P

1AUDIO_L+

2AUDIO_L-

1 VIN(UNREG)

2 VIN(UNREG)

3 VIN(UNREG)

4 VIN(UNREG)

5 INV_H_L

6 INVPCON

7 5.15V

8 ASPECTSW

9 GND

10 GND

11 GND

12 GND

TFT PANEL MODULE

SP902

SPEAKER

SP901

SPEAKER

DVP-FX1 MODEL

INVERTER MODULE

(BACK-LIGHT)

4-1

4-2

FRAME SCHEMATIC DIAGRAM

Page 52

DVP-F5/FX1

4-2. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR WIRING BOARDS AND SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

(For printed wiring boards)

• b: Pattern from the side which enables seeing.

• Through hole is omitted.

• Circled numbers refer to waveforms.

• There are few cases that the part printed on diagram

• Chip parts.

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µµF.

• Chip resistors are 1/10W unless otherwise noted.

• Caution when replacing chip parts.

• Some chip part will be indicated as follows.

(The other layers' patterns are not indicated.)

isn’t mounted in this model.

Transistor Diode

C

5

BE

64

2

13

5

46

2

31

45

2

31

12

4

53

3

21321321

50V or less are not indicated except for electrolytics and

tantalums.

kΩ=1000Ω, MΩ=1000kΩ.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum capacitor, Be-

cause it is damaged by the heat.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX indicate

that they are not used.

In such cases, the unused circuits may be indicated.

• Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

• Signal name

XEDIT → EDIT PB/XREC → PB/REC

• 2 : non flammable resistor

• 1 : fusible resistor

• C : panel designation

• A : B+ Line

• B : B– Line

• C : adjustment for repair.

• Circled numbers refer to waveforms.

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

4-4

Page 53

DVP-F5/FX1

LC-68 (LCD) PRINTED WIRING BOARD

For schematic diagram

1

LC-68 BOARD

DISPLAY

A

XX MARK:NO MOUNT

B

C

D

ND1001

LIQUID CRYSTAL

COM 0

COM 1

COM 2

COM 3

SEG 0

SEG 1

SEG 2

SEG 3

SEG 4

SEG 5

SEG 6

SEG 7

SEG 8

SEG 9

SEG 10

SEG 11

SEG 12

SEG 13

SEG 14

SEG 15

SEG 16

3265

COM0

123456789101112131415161718192021

COM1

COM2

COM3

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

COM0

COM2

SEG0

SEG2

SEG4

SEG6

SEG8

SEG10

SEG12

SEG14

SEG16

1

3

5

7

9

11

13

15

17

19

21

23

25

27

R1001

XX

R1003

150

COM 0

COM 2

SEG 0

SEG 2

SEG 4

SEG 6

SEG 8

SEG 10

SEG 12

SEG 14

SEG 16

NC

LED

LED

4

28PCN1001

TO MB-90 BOARD(10/12) CN701

(SEE PAGE 4-29)

D1012

FA1113F-732-TR

(BACK-LIGHT)

R1008

0

COM 1

COM 3

SEG 1

SEG 3

SEG 5

SEG 7

SEG 9

SEG 11

SEG 13

SEG 15

GND

GND

R1006

2

4

6

8

10

12

14

16

18

20

NC

22

NC

24

26

28

XX

COM1

COM3

SEG1

SEG3

SEG5

SEG7

SEG9

SEG11

SEG13

SEG15

D1006

FA1113F-732-TR

(BACK-LIGHT)

E

16

4-5 4-6

LCD

LC-68

Page 54

DVP-F5/FX1

MB-90 (RF, VIDEO, AUDIO, SERGVO, SYSTEM CONTROL) PRINTED WIRING BOARD

– Ref. No. MB-90 Board; 000 Series –

BM-90 BOARD (SIDE A)

CN001 K-8

CN701 J-16

CN702 J-15

CN703 A-5

CN801 B-9

CN802 A-11

CN803 H-14

CN804 D-7

CN951 A-5

CN952 F-5

D101 F-16

D201 F-16

D301 H-3

D303 H-3

D313 H-4

D402 C-5

D502 A-4

D504 B-4

D601 F-5

D651 H-6

D652 J-7

D801 C-8

D802 A-11

D804 I-13

D805 I-9

D806 C-8

D807 A-9

D808 B-9

D809 B-9

IC003 K-11

IC004 J-11

IC005 G-5

IC304 H-15

IC310 I-16

IC311 J-4

IC353 J-6

IC354 J-5

IC602 D-6

IC651 H-5

IC652 I-8

IC653 G-6

IC654 H-7

IC655 J-9

IC702 K-14

IC703 I-15

IC803 A-7

IC804 B-8

IC806 H-14

IC809 I-14

IC810 H-9

IC813 I-14

Q103 H-16

Q203 H-16

Q301 H-3

Q302 H-4

Q305 H-4

Q307 H-3

Q308 H-4

Q309 I-3

Q321 H-16

Q322 H-16

Q351 I-3

Q356 J-5

Q401 E-4

Q402 C-5

Q403 C-4

Q404 D-5

Q407 E-4

Q408 D-5

Q410 F-4

Q411 C-4

Q412 C-5

Q414 F-4

Q415 C-4

Q416 C-5

Q515 A-3

Q801 B-8

Q803 A-10

Q804 A-10

Q805 A-9

Q806 B-8

Q808 I-13

Q811 A-9

Q812 B-9

For printed wiring boards

• Refer to page 4-XX for parts location.

• This board is six-layer print board. However, the pat-

terns of layers two to five have not been included in

the diagram.

• Chip parts

RF, VIDEO, AUDIO, SERVO, SYSTEM CONTROL

MB-90

4-7 4-8

Transistor Diode

C

BE

12

4

53

3

21

3

21

There are few cases that the part printed on this

diagram isn’t mounted in this model.

Page 55

DVP-F5/FX1

BM-90 BOARD (SIDE B)

D102 G-34

D202 G-33

D304 F-33

D305 F-33

D306 F-33

D307 F-21

D308 K-30

D309 J-30

D311 J-30

D312 I-21

D351 C-33

D352 F-34

D353 C-33

D405 G-33

D407 E-33

D501 B-32

D503 A-33

D505 A-31

D506 C-31

D507 A-31

D508 A-33

D653 J-28

D803 G-30

IC001 J-28

IC002 I-26

IC301 I-31

IC302 I-32

IC303 J-32

IC305 H-33

IC307 J-31

IC308 G-33

IC309 H-34

IC351 J-33

IC352 I-33

IC401 B-30

IC402 E-32

IC501 A-33

IC502 A-32

IC504 A-33

IC601 C-30

IC603 D-32

IC701 I-22

IC801 B-28

IC802 C-29

IC805 H-29

IC807 D-30

IC808 I-24

IC811 E-30

IC812 I-27

IC812 I-28

IC951 G-30

IC952 F-31

Q101 H-34

Q102 H-21

Q201 H-33

Q202 G-21

Q303 K-30

Q304 G-33

Q306 F-33

Q310 J-30

Q311 J-30

Q312 H-21

Q313 H-21

Q314 I-21

Q315 I-21

Q316 I-21

Q317 I-21

Q318 H-21

Q319 H-21

Q320 K-32

Q352 J-33

Q353 J-33

Q354 K-33

Q355 J-33

Q405 G-32

Q406 F-33

Q409 E-33

Q413 E-33

Q417 B-30

Q501 A-33

Q502 B-32

Q503 A-32

Q504 C-33

Q505 C-32

Q508 A-33

Q509 A-33

Q510 C-32

Q516 A-31

Q517 C-32

Q518 C-33

Q701 J-21

Q702 J-21

Q802 A-27

Q807 G-30

Q809 E-30

Q810 F-30

4-9 4-10

RF, VIDEO, AUDIO, SERVO, SYSTEM CONTROL

MB-90

Page 56

DVP-F5/FX1

For Schematic Diagram

• Refer to page 4-7 for printed wiring board.

• Refer to page 4-35 for waveforms.

1

MB-90 BOARD(1/12)

DC-DC CONVERTER(DD BLOCK)

XX MARK:NO MOUNT

A

NO MARK:DVD PB MODE

STBY3V

UNREG

B

55

TO(2/12)

C

D

E

F

G

H

I

J

The components identified by

K

16

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

26 18

5

8

9 17

10 12 13

11

1473

16

B+

R454

0

0.1u

0.1u

B

B

L401

15uH

R455

C442

0.1u

R456

R451

L404

15uH

R457

R458

R452

C434

47u

20V

R430

0

R434

33k

±

0.5%

R435

3300

±

0.5%

R436

15k

±

0.5%

0

0R450

±

±

B

0

0

C437

47u

20V

0

0

0

R443

33k

±

0.5%

R444

3300

±

0.5%

R445

15k

±

0.5%

C451

XX

DTC144EUA-T106

DC OUT SW

R449

0

R431

2200

±

0.5%

R432

1500

C440

±

0.5%

0.1u

B

R433

15k

±

0.5%

JL402

L408

47uH

C447

2200p

B

C453

10u

10V

TA

R437

R461

22k

10k

0.5%

R438

C448

1500

XX

0.5%

R439

10k

±

0.5%

R440

1.5k

±

0.5%

R441

510

C443

±

0.5%

0.1u

B

R442

1.5k

±

0.5%

JL405

C450

XX

C456

0.1u

B

R469

0

Q413

XP162A12A6PR

6.2

R463

6.2

10k

Q409

Q401

L411

47uH

JL403

R402

XX

GND

B+

F402

1A

R410

22k

R411

22k

R412

XX

R408

0.1u

2200

R478

XX

C401

0.1u

B

C402

4.7u

16V

R407

2200

R403

68k

C403

100p

R404

XX

C404

0.022u

B

C405

0.022u

Q417

XX

R489

XX

B

C407

0.1u

B

R405

330k

R401

47k

C406

0.1u

B+

0.8

FB5

17181920212223242526272829303132

1.6

IN(C)4

1.5

IN(E)4

R479

XX

0.8

C408

0.01u B

R406

33k

B

R409

2200

C409

0.047u

B

FB4

0.8

RT

1.2

CT

0

CSCP

GND1

GND2

2.0

CS

1.5

VREF

9.7

VCC

3.0

CLT2

3.2

CLT1

1.3

DTC3

0.9

FB3

R480

XX

C459

0.1u

B

C410

B

1.5 1.5 5.2 1.50.9 1.5 9.36.2 9.8 8.49.9 9.5 9.5 8.810.2

JL401

R414

IN(C)5

-IN(E)5

+IN(E)5

-IN(E)3

IN(C)3

FB2

33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

1.81.5 1.51.0 1.7 0.9 1.5 2.0 9.3 9.7 2.4 9.9 9.58.5 9.79.2

R481

XX

2200

R413

C411

0.1u

B

R415

2200

XX

SCP

-IN(E)2

C460

0.1u

B

B

C412

0.1u

FB6

-IN(E)6

+IN(E)6

IC401

DC-DC CONVERTER

MB3825APFV-G-BND-ER

IN(C)2

FB1

-IN(E)1

R482

XX

2200

R416

C413

0.01u

B

C415

R419

R417

10p

10k

0

C416

4700p

B

VB6

OVP5,6

VB1

CB1-6

VCC(O)1,3

OUT2-1

10k

R418

IN(C)6

IC401

IN(C)1

10p

C414

R420

C418

10p

10k

VB5

CB2-6

OUT1-6

65

CB1-1

CB2-1

OUT1-1

C417

4700p

B

R421

10k

B+

C419

4700p

B

12345678910111213141516

CB1-5

CB2-5

9.6

OUT1-5

VCC(O)4,4,6

GND(O)4,5,6

OUT2-4

CB1-4

CB2-4

OUT1-4

4

OUT1-3

3

CB2-3

CB1-3

GND(O)1,2,3

VCC(O)2

OUT1-2

21

CB2-2

VB2

CB1-2

C420

10p

C425

10p

9.7

9.5

VB4

R422

10k

3.4

C421

4700p

10.2

B

8.7

9.6

9.4

C422

4700p

8.4

B

9.9

C424

10p

9.3

VB3

R423

9.7

10k

9.3

8.2

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64