Page 1

DVP-F11

RMT-D109E/D109O

SERVICE MANUAL

SPECIFICATIONS

CD/DVD player

Laser Semiconductor laser

Signal format system PAL/(NTSC)

Audio characteristics

Frequency response DVD (PCM 96 kHz): 2 Hz to 44 kHz

(±1 dB)*

DVD (PCM 48 kHz): 2 Hz to 22 kHz

(±0.5 dB)

CD: 2 Hz to 20 kHz (±0.5 dB)

Signal-to-noise ratio More than 110 dB (LINE OUT (AUDIO

1, 2) connectors only)

Harmonic distortion Less than 0.0025%

Dynamic range More than 100 dB (DVD)

More than 97 dB (CD)

Wow and flutter Less than detected value

(±0.001% W PEAK)

Outputs and inputs

Jack Output Load impedance

type level

LINE OUT Phono 2 Vrms Over 10 kilohms

(AUDIO1, 2) jacks (at 50 kilohms)

OPTICAL Optical –18 dBm Wave length: 660 nm

output

connector

COAXIAL Phono 0.5 Vp-p 75 ohms terminated

jack

LINE OUT Phono 1.0 Vp-p 75 ohms,

(VIDEO1, 2) jacks sync negative

LINE OUT 4-pin Y: 1.0 Vp-p 75 ohms,

(S-VIDEO1, 2) mini DIN sync negative

C: 0.3 Vp-p 75 ohms terminated

(PAL)

0.286 Vp-p

(NTSC)

LINE OUT Phono 2 Vrms Over 10 kilohms

(WOOFER OUT) jacks

PHONES Phone 12 mW 32 ohms

jack

AEP Model

UK Model

E Model

Hong K ong Model

Singapore Model

Australian Model

Chinese Model

General

Power requirements DC 10.5 V

Power consumption 13 W

Dimensions (approx.) 215 × 60 × 314 mm (w/h/d)

incl. projecting parts

Mass (approx.) 2.1 kg

Operating temperature 5°C to 35°C

Operating humidity 25% to 80%

AC power adaptor

Power requirements 220 to 240 V AC, 50/60 Hz

Power consumption 19 W

Output voltage DC 10.5 V, 1.3 A in operating mode

Dimensions (approx.) 125 × 39 × 62 mm (w/h/d)

excl. projecting parts

Mass (approx.) 235 g

Operating temperature 5°C to 35°C

Storage temperature –20°C to +60°C

Supplied accessories

• Audio/Video connecting cord (1)

• S video cord (1)

• AC power adaptor AC-F11 (1)

• AC power cord (1)

• Remote commander (remote) RMT-D109O (1)

(Except Hong Kong, Singapore and Chinese)

Remote commander (remote) RMT-D109E (1)

(Hong Kong, Singapore and Chinese)

• Size AA (R6) batteries (2)

• Stand (1)

• EURO AV adaptor (1)

(Except Hong Kong, Singapore, Australian and Chinese)

* The signals from LINE OUT (AUDIO1, 2) connectors are measured.

When you play the PCM sound tracks with 96 kHz sampling frequency,

the output signals from the OPTICAL and COAXIAL connectors are

converted to 48 kHz (sampling frequency).

Design and specifications are subject to change without notice.

MICROFILM

CD/DVD PLAYER

Page 2

WARNING!!

WHEN SERVICING, DO NO T APPR O A CH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION,

BE SURE TO OBSERVE FROM A DISTANCE OF

MORE THAN 25 cm FROM THE SURFACE OF THE

OBJECTIVE LENS ON THE OPTICAL PICK-UP BLOCK.

CAUTION:

The use of optical instrument with this product will increase eye

hazard.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

CLASS 3B LASER

LUOKAN 3B LASER

LASERKLASS 3B

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

4. Look for parts which, though functioning, show ob vious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

– 2 –

Page 3

TABLE OF CONTENTS

Section Title Page Section Title Page

Service Note ............................................................................ 4

1. GENERAL

This Player Can Play the Following Discs .................... 1-1

Getting Started .............................................................. 1-2

Playing Discs ................................................................. 1-4

Using Var ious Functions with the Control Menu ........... 1-6

Settings and Adjustments ............................................. 1-10

Index to Parts and Controls .......................................... 1-14

2. DISASSEMBLY

2-1. Case (Upper) Removal ................................................. 2-1

2-2. Chassis (Upper) Removal ............................................. 2-1

2-3. AU-222 Board Removal ................................................ 2-1

2-4. Case (Lower) Removal.................................................. 2-1

2-5. Rear Panel, MB-85 Board Removal.............................. 2-2

2-6. DC-DC Converter Unit Removal ................................... 2-2

2-7. Front Panel Section Removal........................................ 2-2

2-8. MD Block Ass’y Removal .............................................. 2-2

2-9. TK-55 Board, Optical Pick-up Removal ........................ 2-3

2-10. Chassis (Top) Block Ass’y, Chucking Arm Ass’y

Removal......................................................................... 2-3

2-11. Cam Slider, Chassis (Front) Block Ass’y Removal....... 2-3

2-12. Roller Arm Block Ass’y, LD Motor Ass’y Removal........ 2-3

2-13. Internal Views................................................................ 2-4

2-14. Circuit Boards Location................................................. 2-5

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram................................................... 3-1

3-2. RF/Servo Block Diagram............................................... 3-3

3-3. Signal Process/Video Block Diagram ........................... 3-5

3-4. System Control Block Diagram ..................................... 3-7

3-5. Audio (1) Block Diagram ............................................... 3-9

3-6. Audio (2) Block Diagram ............................................... 3-11

3-7. Interface Control Block Diagram ................................... 3-13

3-8. Power Block Diagram.................................................... 3-15

4. PRINTED WIRING BOARDS AND SCHEMATIC

DIAGRAMS

HP-122 Printed Wiring Board

and Schematic Diagram................................................ 4-55

MPD0102 Printed Wiring Board

and Schematic Diagram................................................ 4-57

5. IC PIN FUNCTION DESCRIPTION

5-1. System Control Pin Function

(MB-85 Board IC202) .................................................... 5-1

6. TEST MODE

6-1. General Description ...................................................... 6-1

6-2. Starting Test Mode ........................................................ 6-1

6-3. Syscon Diagnosis.......................................................... 6-1

6-4. Drive Auto Adjustment .................................................. 6-5

6-5. Drive Manual Operation ................................................ 6-7

6-6. Mecha Aging ................................................................. 6-9

6-7. Emergency History ........................................................ 6-9

6-8. Version Information ....................................................... 6-10

6-9. Video Level Adjustment ................................................ 6-10

6-10. If Con Self Diagnostic Function .................................... 6-11

7. ELECTRICAL ADJUSTMENTS

7-1. Power Supply Adjustment ............................................. 7-1

1. MPD0102 BOARD......................................................... 7-1

7-2. Adjustment of Video System......................................... 7-2

1. Video Level Adjustment (MB-85 BOARD) .................... 7-2

2. S-terminal Output Check (MB-85 BOARD) .................. 7-2

3. Checking S Video Output S-C (MB-85 BOARD) .......... 7-2

7-3. Adjustment Related Parts Arrangement ....................... 7-4

8. REPAIR PARTS LIST

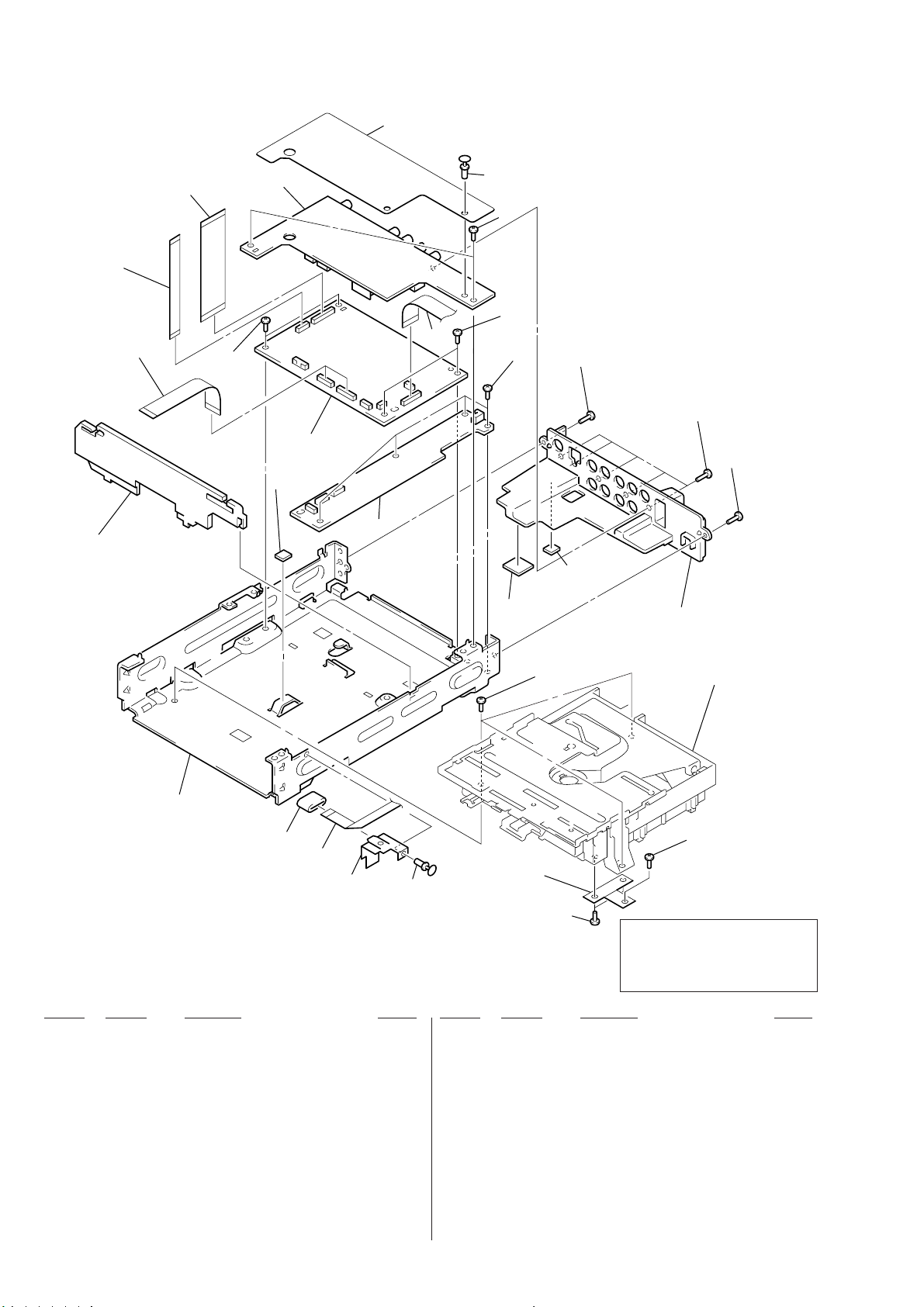

8-1. Exploded Views ............................................................. 8-1

8-1-1. Case and Front Panel Assemblies ........................... 8-1

8-1-2. Chassis Assembly .................................................... 8-2

8-1-3. Mechanism Deck Assembly-1.................................. 8-3

8-1-4. Mechanism Deck Assembly-2.................................. 8-4

8-2. Electrical Parts List ....................................................... 8-5

4-1. Frame Schematic Diagram ............................................ 4-3

Frame (1) Schematic Diagram...................................... 4-3

Frame (2) Schematic Diagram...................................... 4-5

4-2. Printed Wiring Boards and Schematic Diagrams ......... 4-7

TK-55 Printed Wiring Board .......................................... 4-7

TK-55 Schematic Diagram ............................................ 4-11

SW-332 Printed Wiring Board

and Schematic Diagram................................................ 4-13

MB-85 Printed Wiring Board ......................................... 4-15

MB-85 (AV DECODER) Schematic Diagram................ 4-19

MB-85 (SDRAM) Schematic Diagram .......................... 4-21

MB-85 (SERVO DSP) Schematic Diagram................... 4-23

MB-85 (DRIVE) Schematic Diagram ............................ 4-25

MB-85 (ARP) Schematic Diagram ................................ 4-27

MB-85 (SYSTEM CONTROL) Schematic Diagram...... 4-29

MB-85 (HGA) Schematic Diagram................................ 4-31

MB-85 (CLOCK GENERATOR/AUDIO DSP)

Schematic Diagram ....................................................... 4-33

MB-85 (DAC) Schematic Diagram ................................ 4-35

MB-85 (BIAS) Schematic Diagram ............................... 4-37

AU-222 Printed Wiring Board........................................ 4-39

AU-222 (AUDIO) Schematic Diagram ........................... 4-43

AU-222 (VIDEO BUFFER) Schematic Diagram ........... 4-45

FL-111 Printed Wiring Board ........................................ 4-47

FL-111 Schematic Diagram .......................................... 4-49

FR-166 Printed Wiring Board........................................ 4-51

FR-166 Schematic Diagram.......................................... 4-53

– 3 –

Page 4

SERVICE NOTE

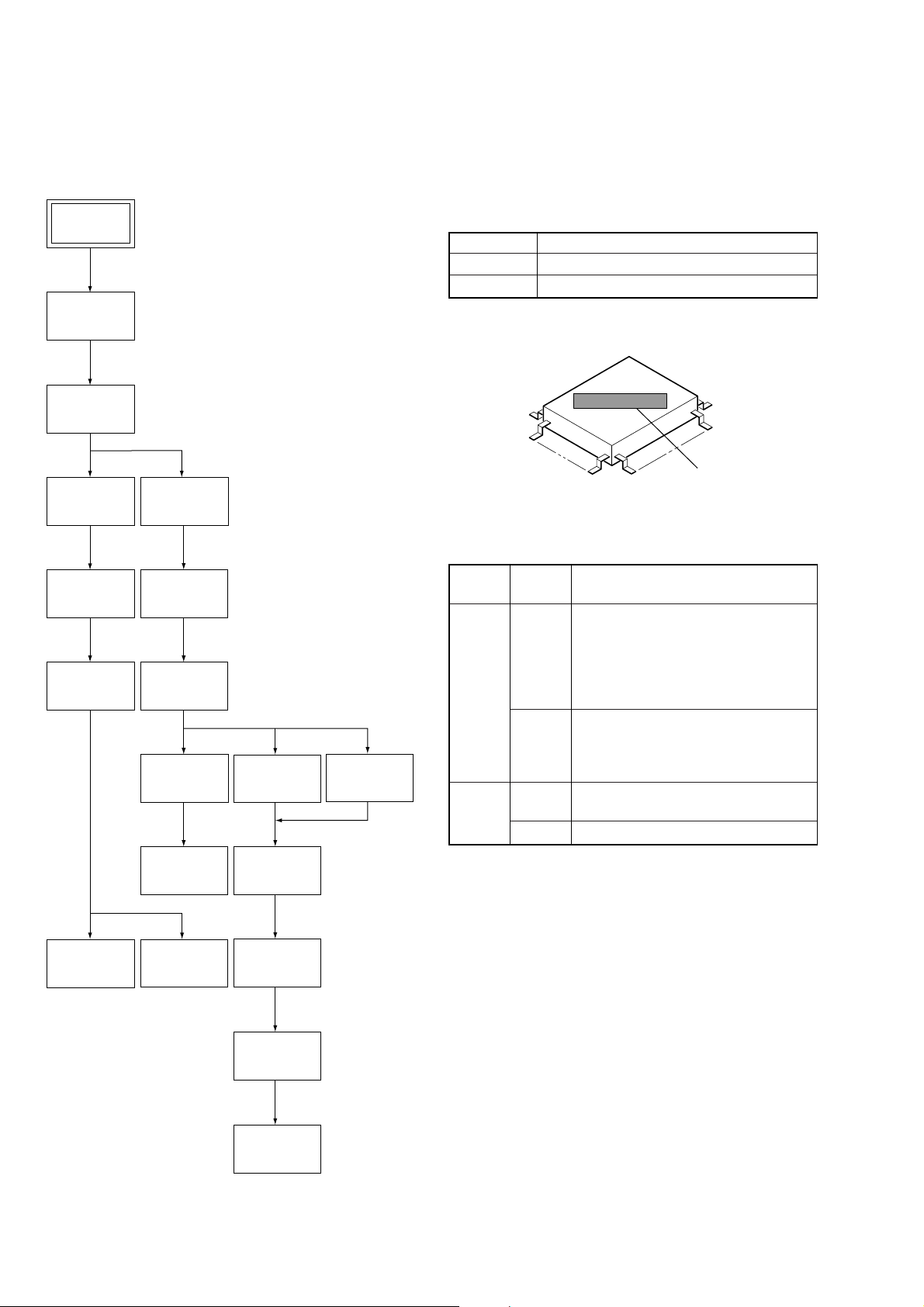

1. DISASSEMBLY

• This set can be disassembled in the order shown below.

Note on Replacing IC601 (IF CON) (FL-111 Board)

Set

Case (Upper)

(Page 2-1)

Chassis(Upper)

(Page 2-1)

AU-222 Board

(Page 2-1)

Case (Lower)

(Page 2-1)

Rear Panel

(Page 2-2)

Case (Lower)

(Page 2-1)

Front Panel

Section

(Page 2-2)

MD Block

Ass’y

(Page 2-2)

TK-55 Board

(Page 2-3)

Optical

Pick-up

(Page 2-3)

Chassis (Top)

Block Ass’y

(Page 2-3)

Cam Slider

(Page 2-3)

Chucking

Arm Ass’y

(Page 2-3)

There are two types of IC601 (IF CON).

Version Type (Par t No.)

Ver. 1.00 M38B57MCH-E227FP (8-759-599-87)

Ver. 1.01 M38B57MCH-D233FP (8-759-658-36)

• Version checking method

Type

When replacing the IC601, always check the version of old part

and new part. If different, follo w the “description of replacement”

given below.

Old part New part

(Ver.) (Ver.)

Description of replacement

Replace as it is. (However, for the CED

Model (serial No. 800001-800100), also

1.00

1.00

replace the resistor R659 47 k (1-216089-00) with 1.5 k (1-216-053-00), and

further remove the resistors R653, 654,

661, 662, 663, 664.)

Replace as it is. (However, for the CED

1.01

Model (serial No. 800001-800100), also

remove the resistors R653, 654, 661,

662, 663, 664.)

Also, replace resistor R659 47 k (1-216089-00) with 1.5 k (1-216-053-00).

1.01

1.00

1.01 Replace as it is.

MB-85 Board

(Page 2-2)

DC-DC CON-

VERTER UNIT

(Page 2-2)

Chassis (Front)

Ass’y

(Page 2-3)

Roller Arm

Block Ass’y

(Page 2-3)

LD Motor

Ass’y

(Page 2-3)

– 4 –

Page 5

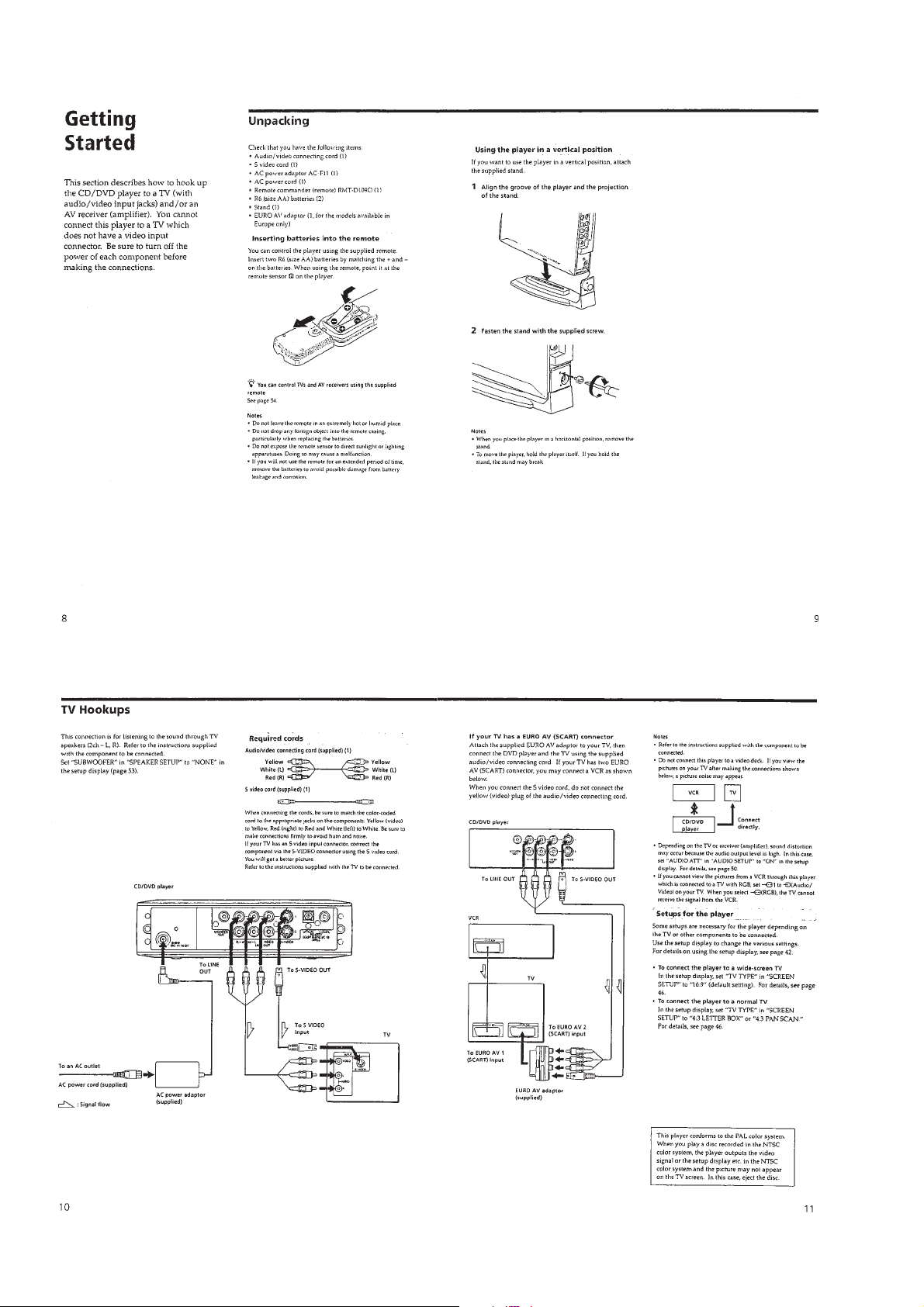

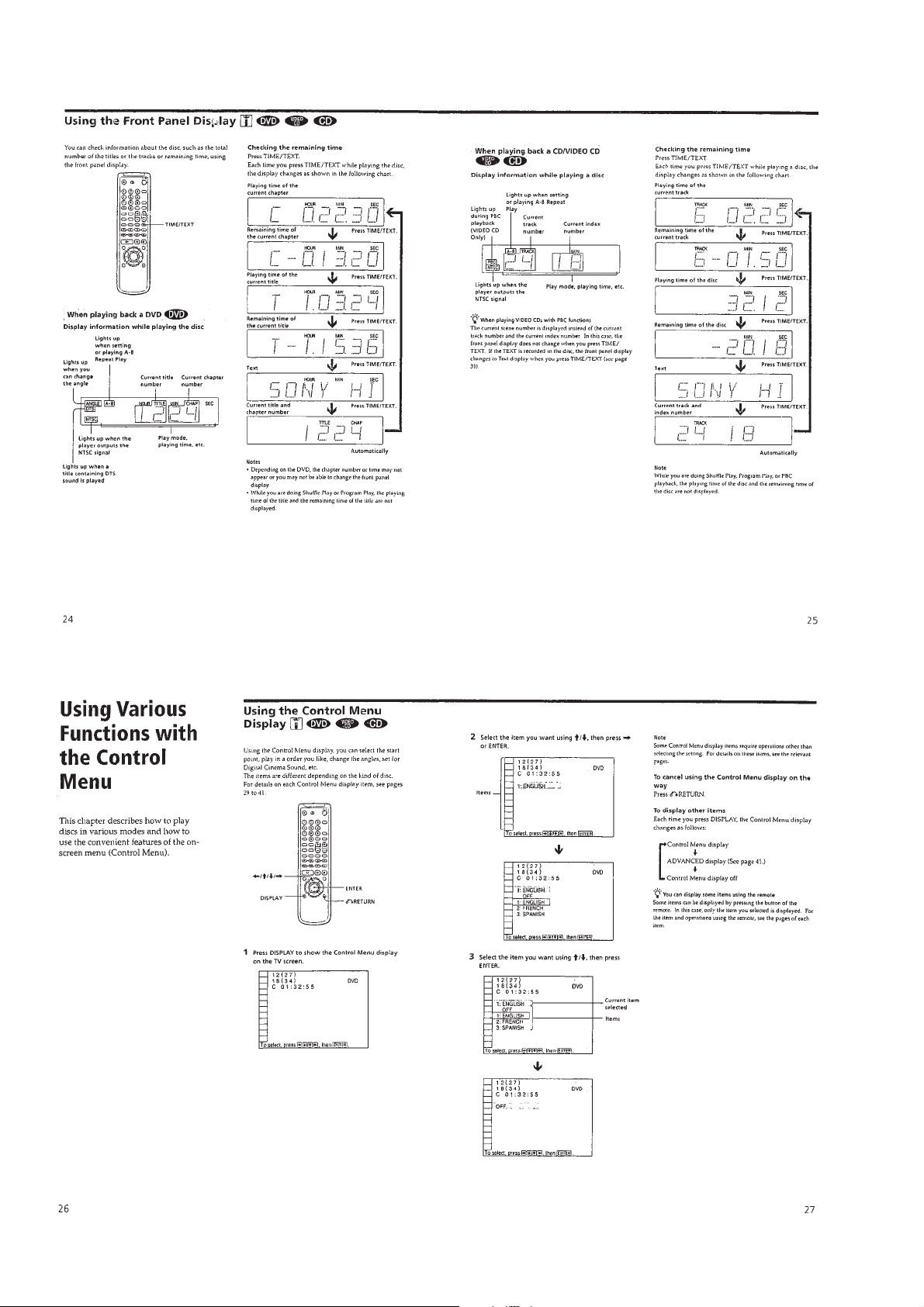

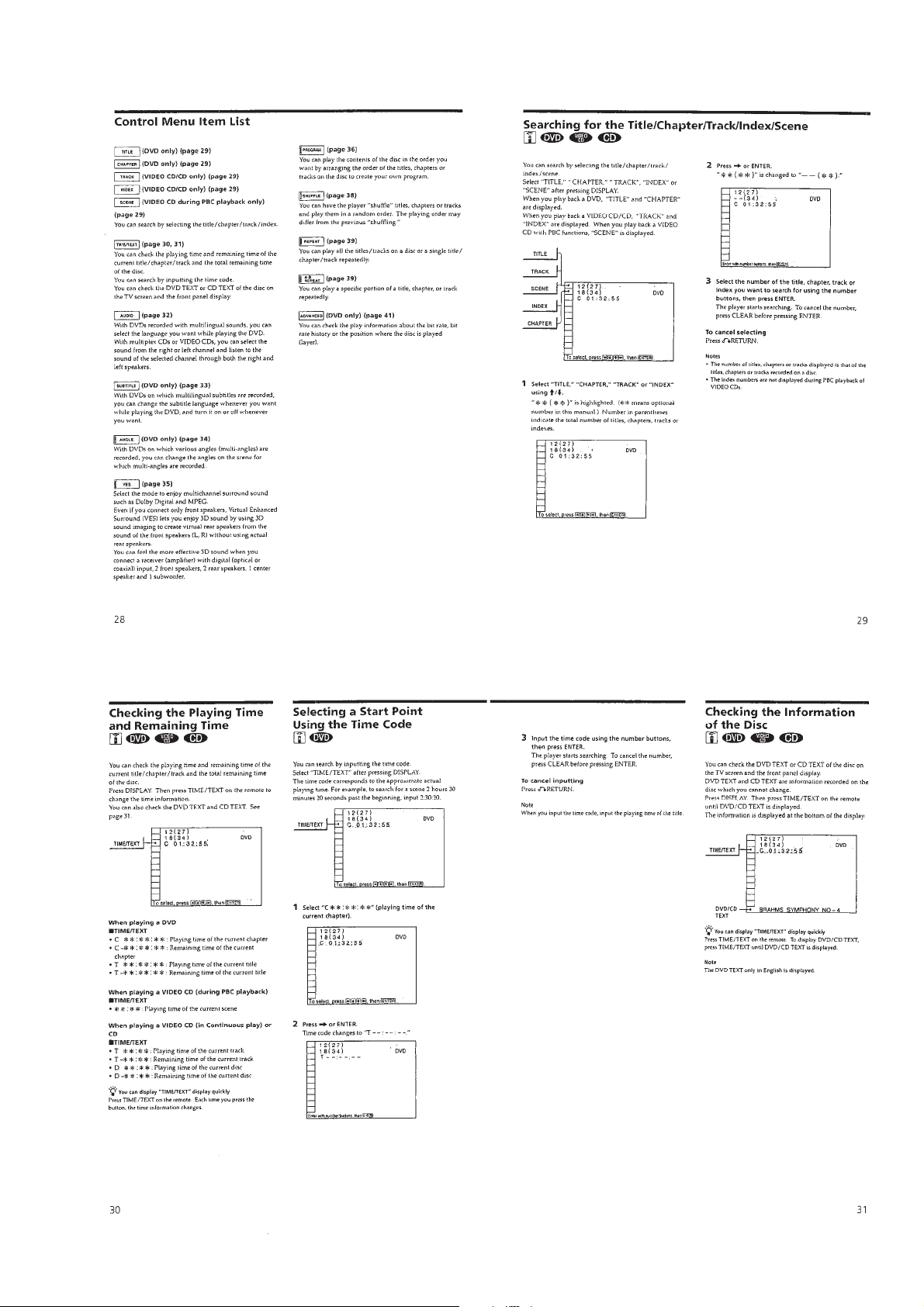

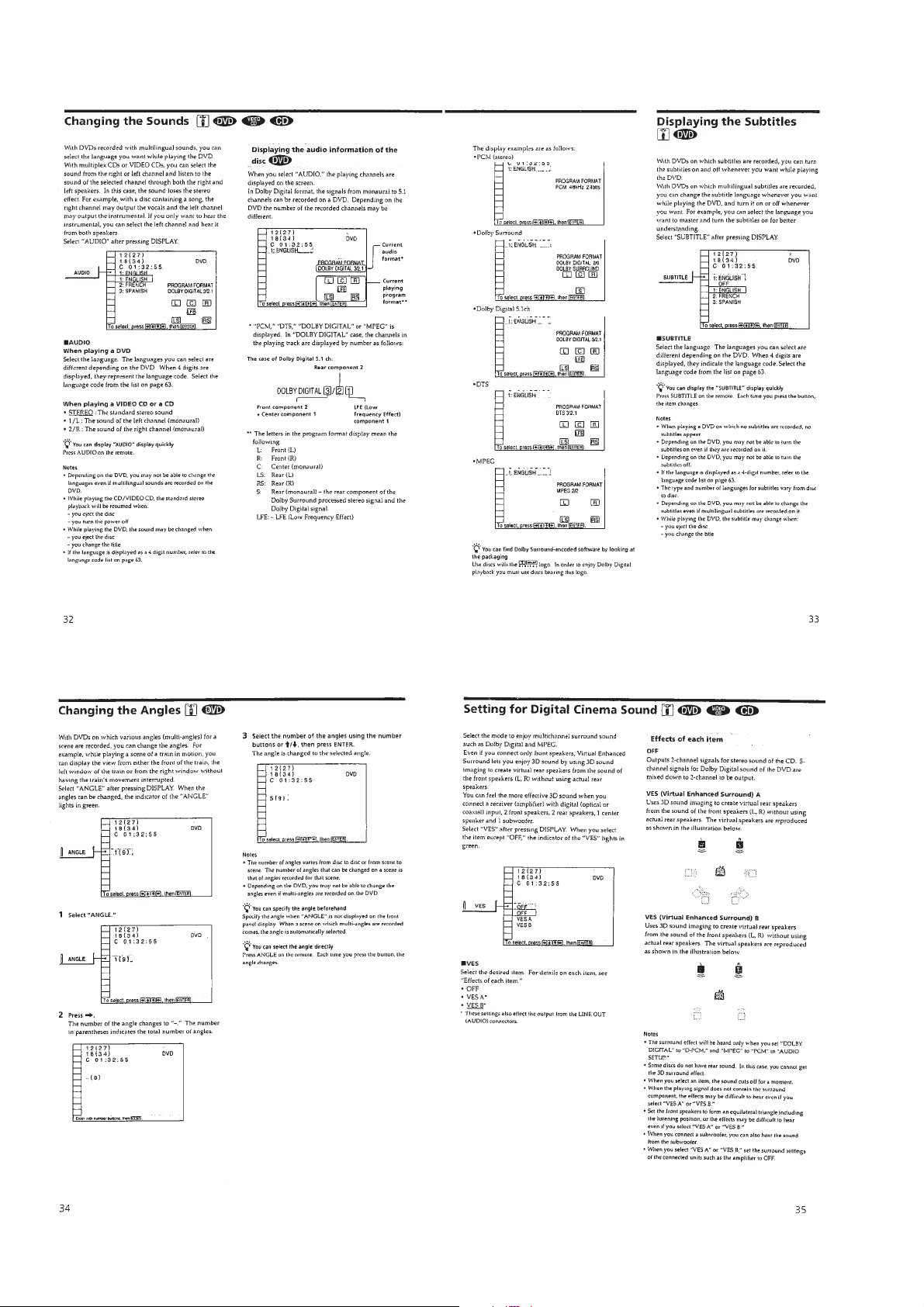

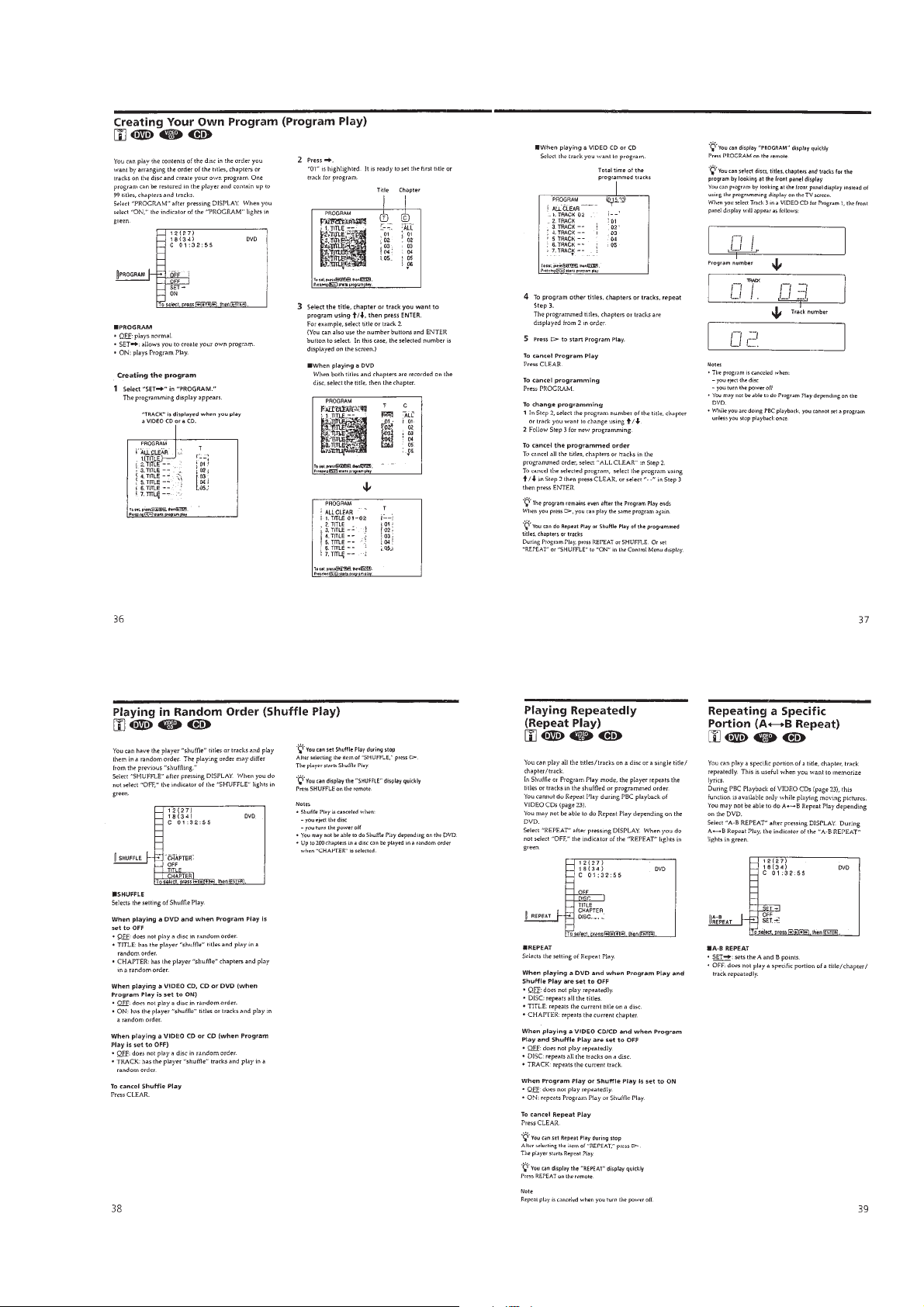

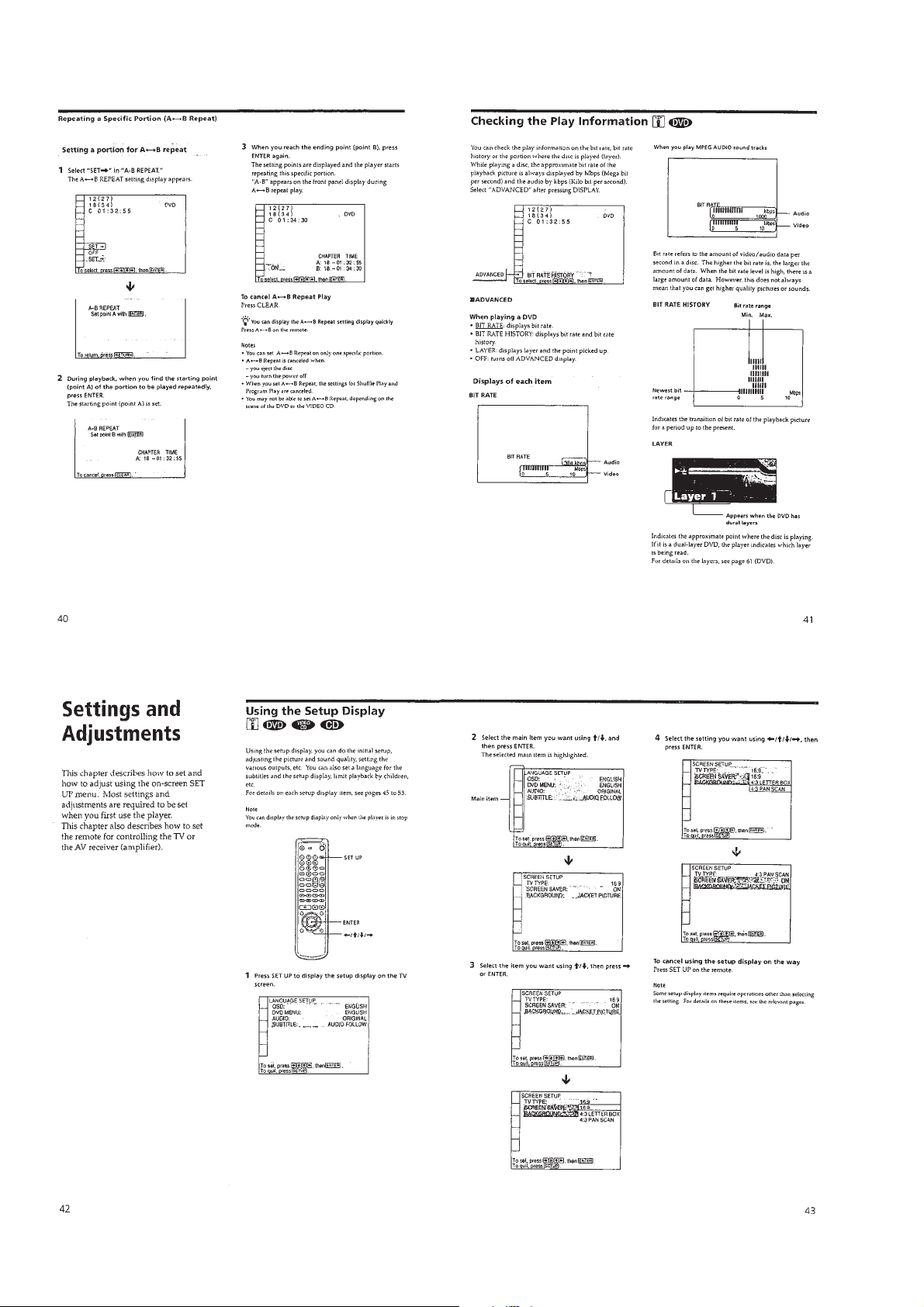

SECTION 1

GENERAL

DVP-F11

This section is extracted from instruction manual (3-867-780-11).

1-1

Page 6

1-2

Page 7

1-3

Page 8

1-4

Page 9

1-5

Page 10

1-6

Page 11

1-7

Page 12

1-8

Page 13

1-9

Page 14

1-10

Page 15

1-11

Page 16

1-12

Page 17

1-13

Page 18

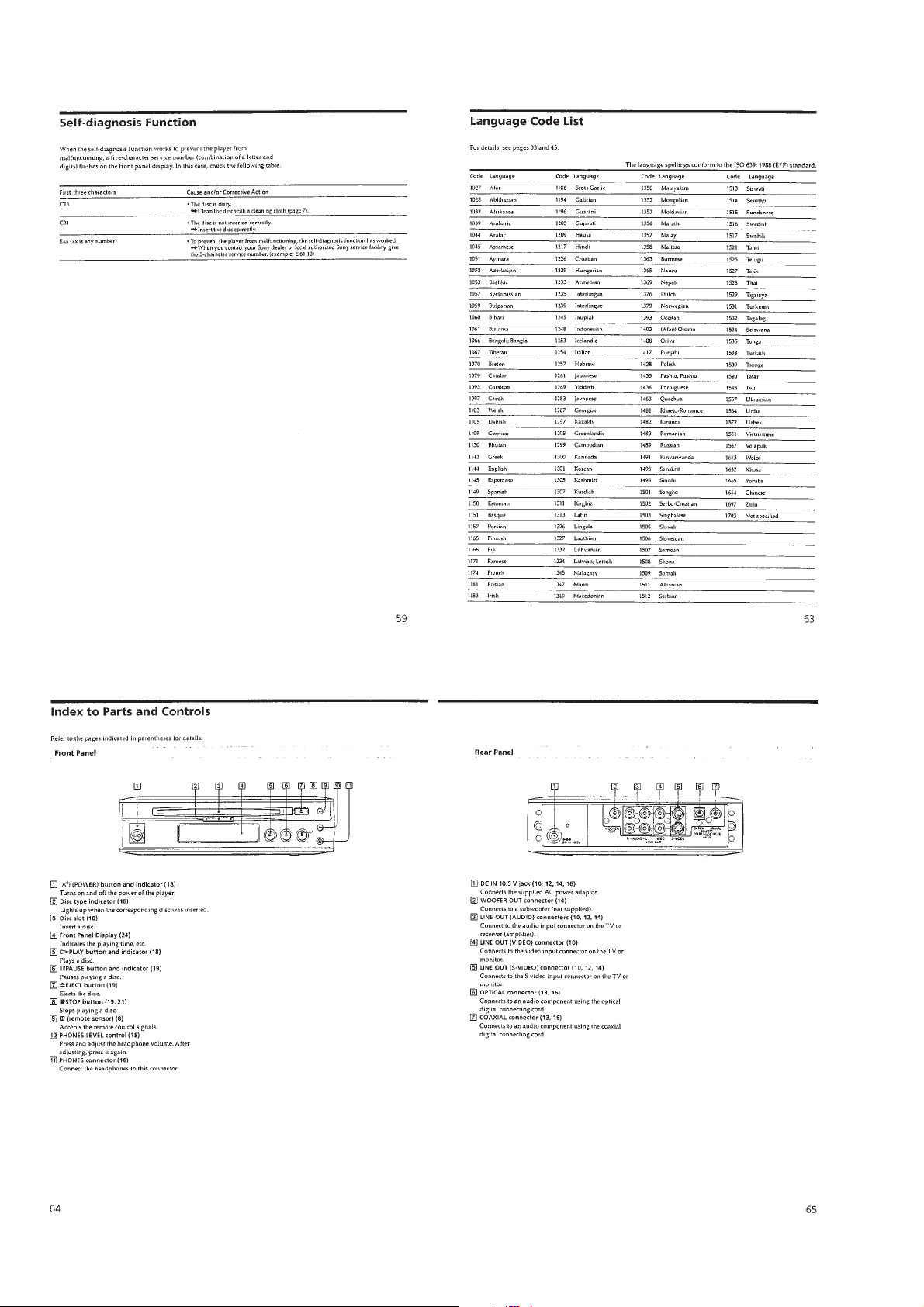

1-14

Page 19

1-15 E

1-15

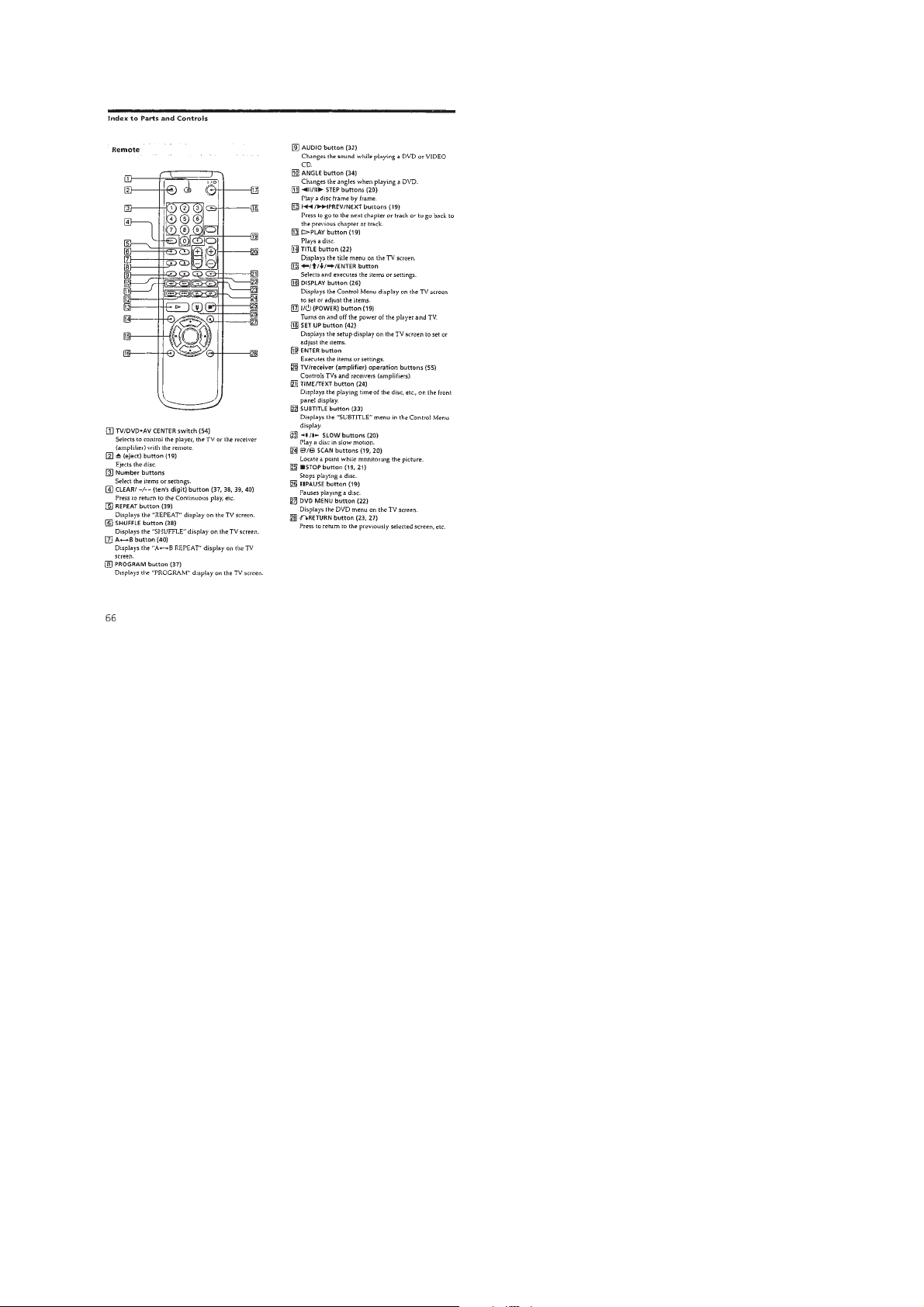

Page 20

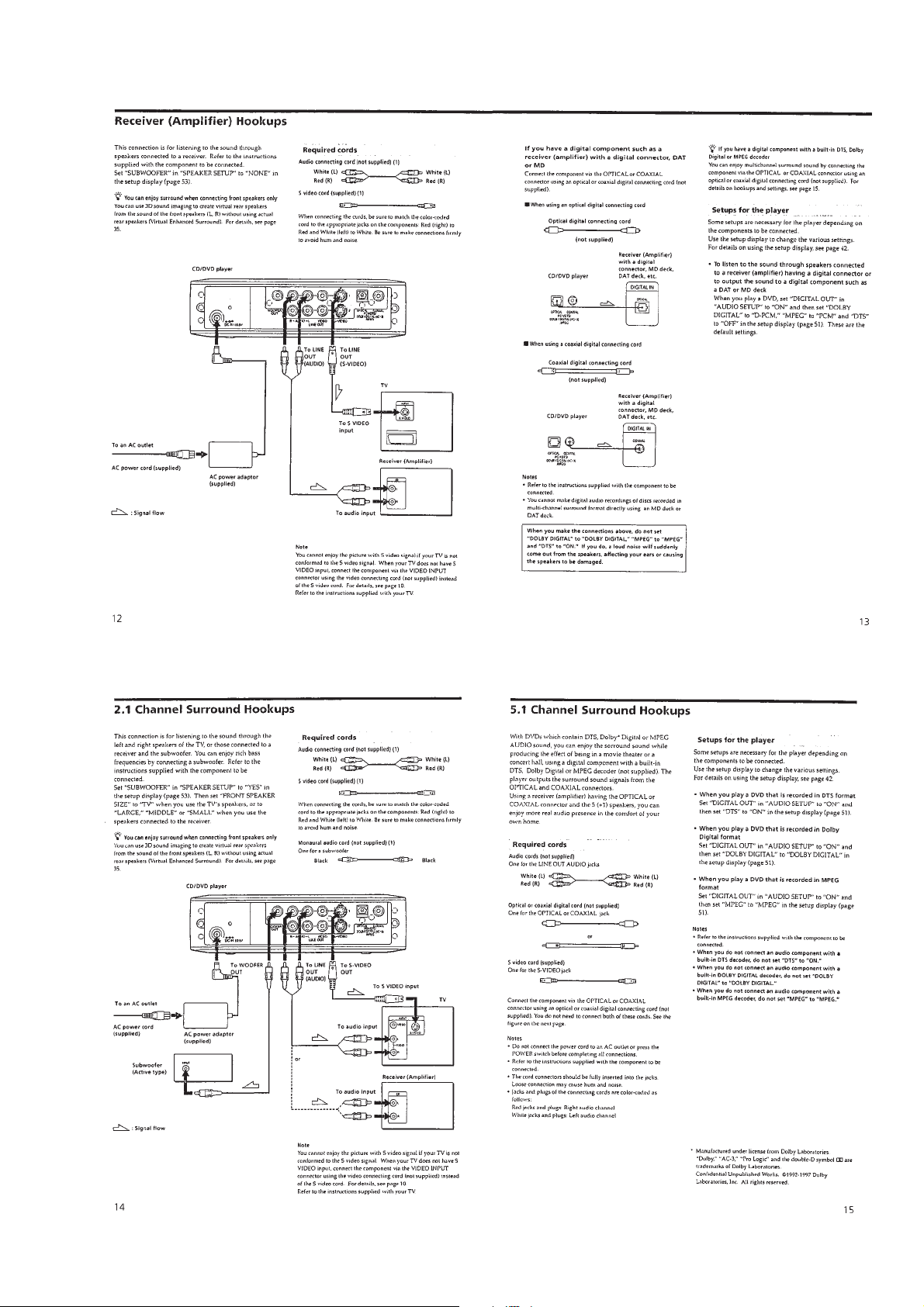

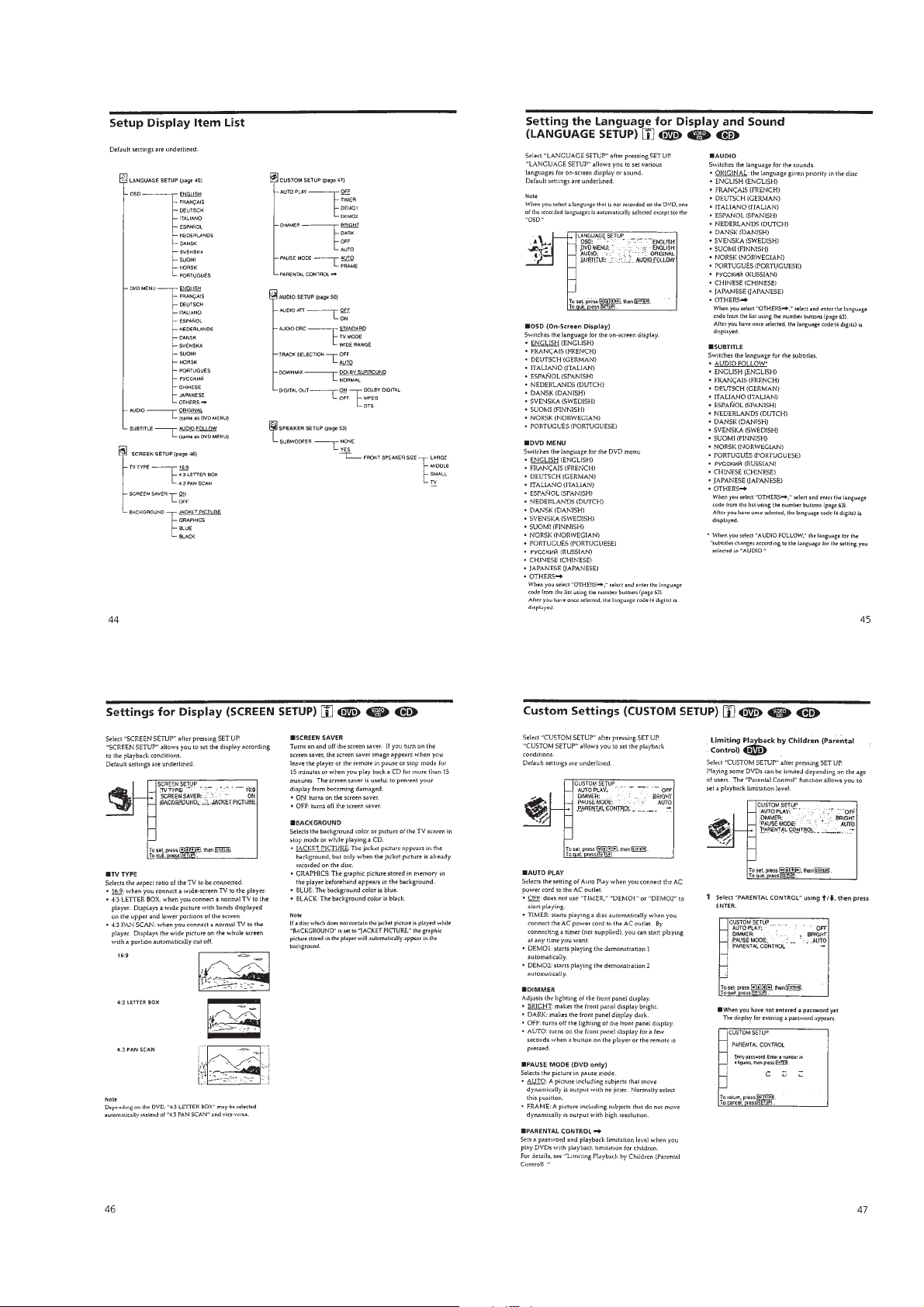

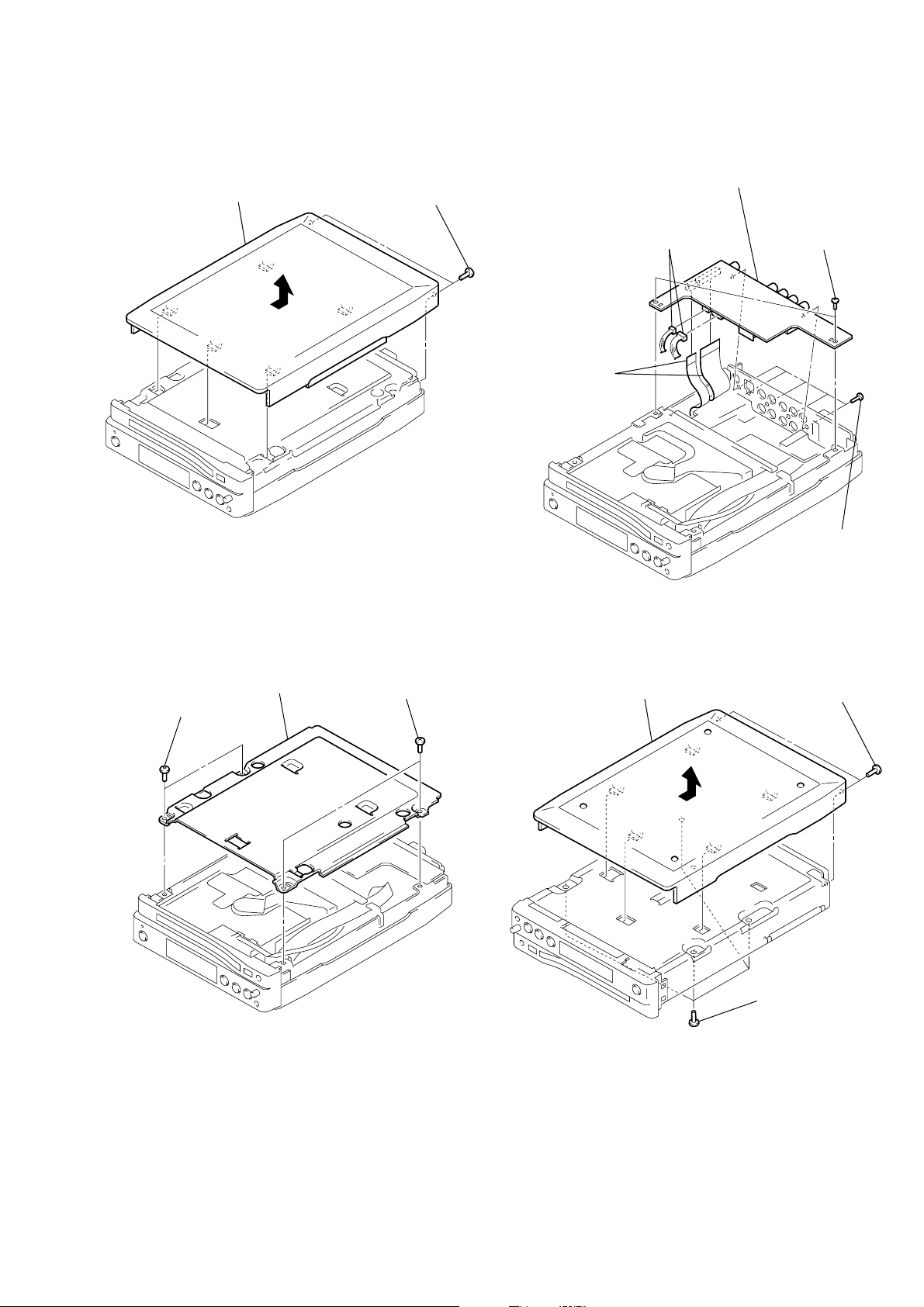

SECTION 2

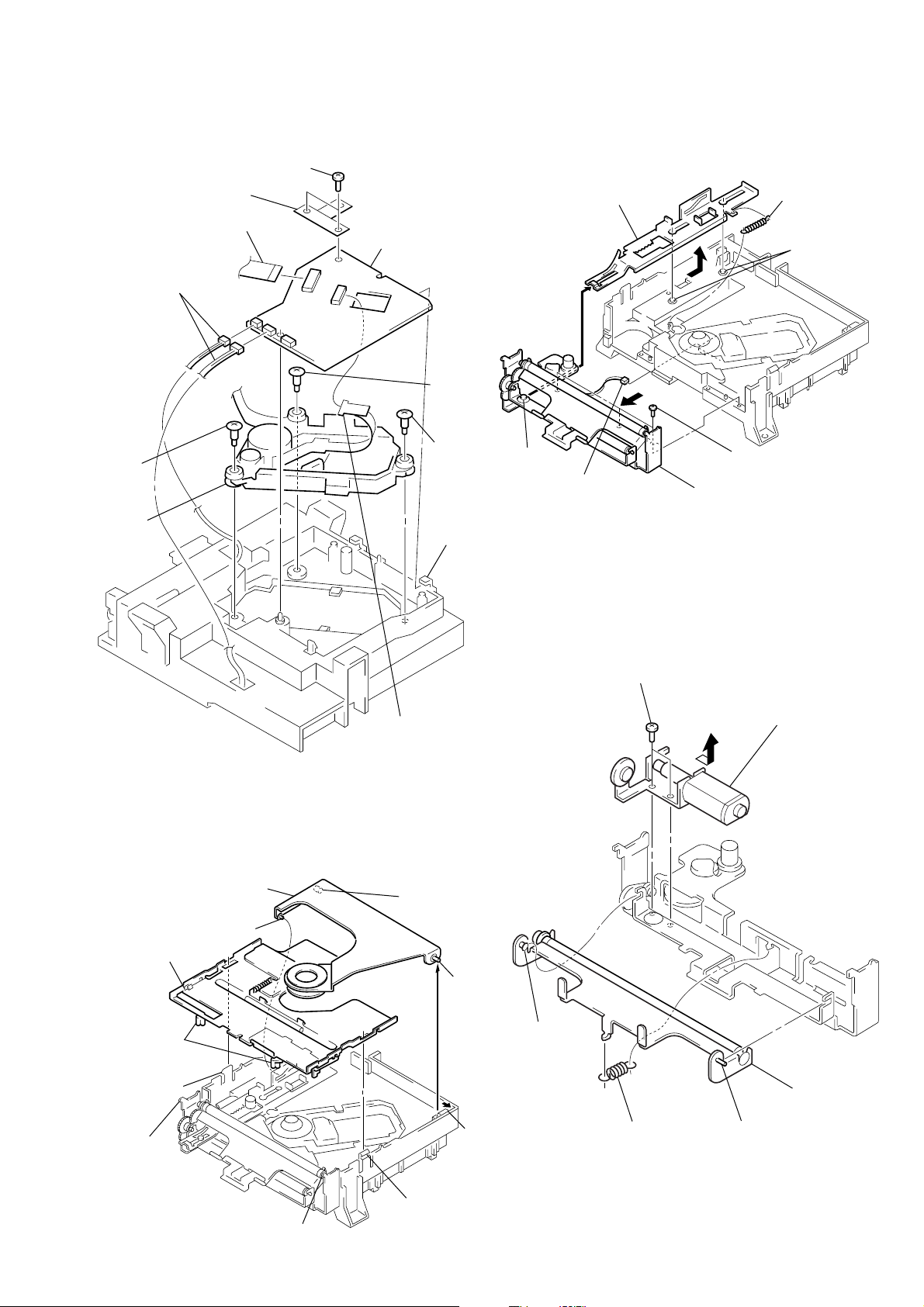

1 Two screws

(B3)

2 Four screws

(B3)

3 Remove the case (lower)

in the direction of the arrow.

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

2-1. CASE (UPPER) REMOVAL 2-3. AU-222 BOARD REMOVAL

DVP-F11

2 Remove the case (upper)

in the direction of the arrow.

1 Two screws

(B3)

5 Two flat cables

(CN301, 302)

4 AU-222 board

1 Two connectors

(CN303, 306)

3 Two screws

(B3) (ring)

2 Five screws

(B3)

2-2. CHASSIS (UPPER) REMOVAL 2-4. CASE (LOWER) REMOVAL

2 Two screws

(B3)

1 Two screws

(B3)

3 Chassis (upper)

2-1

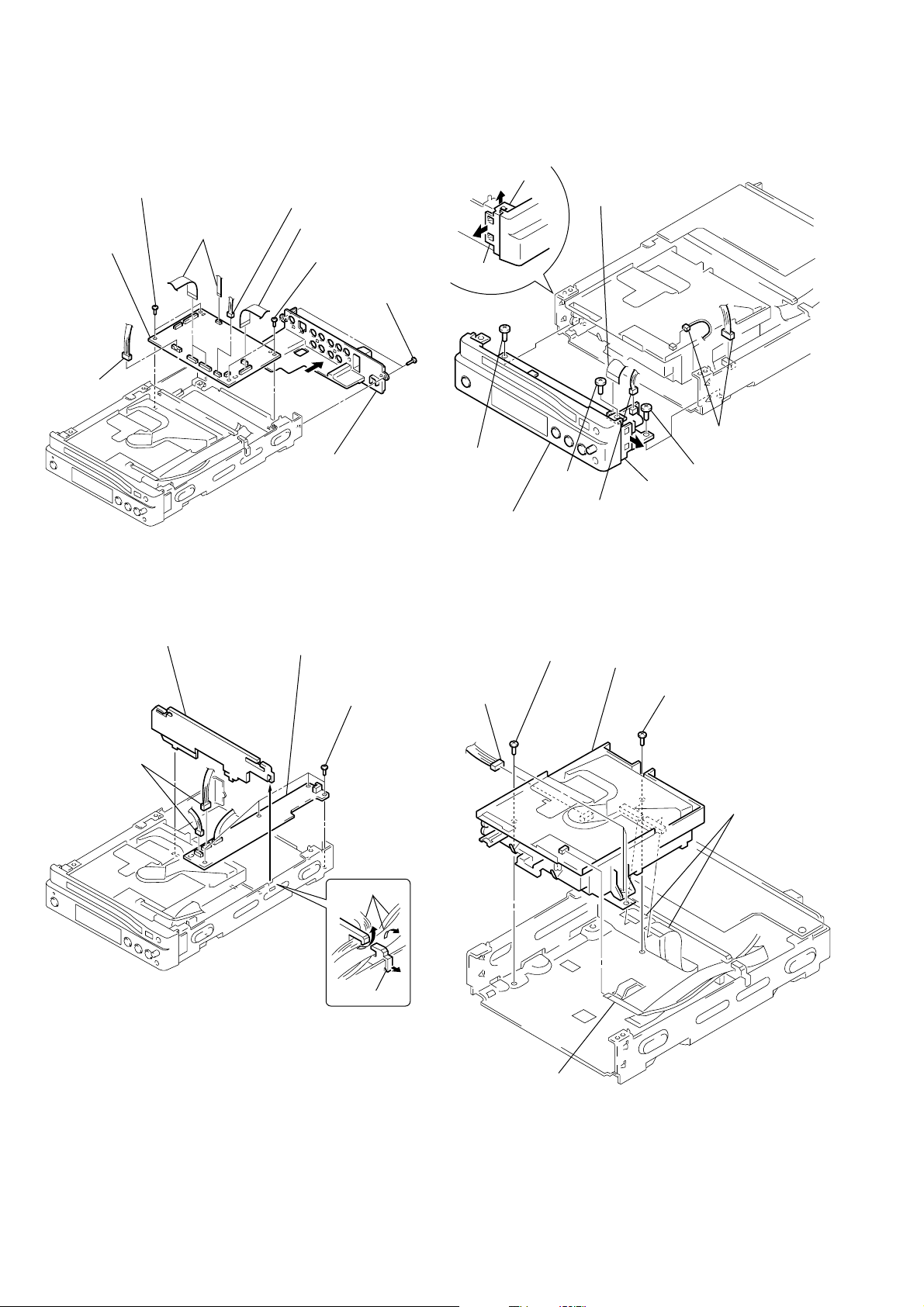

Page 21

2-5. REAR PANEL, MB-85 BOARD

(

)

REMOVAL

2-7. FRONT PANEL SECTION REMOVAL

8 Two screws

(B3) (ring)

9 MB-85 board

3 Connector

(CN001)

4 Three flat cables

(CN002, 003, 009)

5 Connector

(CN011)

6 Flat cable

(CN006)

7 Two screws

2 Rear panel

(B3) (ring)

1 Two screws

(B3)

8 Claw

6 Screw

9 Boss

(B3) (ring) 5 Screw

0 Front panel section

1 Flat cable

4 Screw

(B3)

(CN602)

7 Claw

2 Connector

CN501

3 Two connectors

(B3) (ring)

(CN102, 203)

2-6. DC-DC CONVERTER UNIT REMOVAL 2-8. MD BLOCK ASS’Y REMOVAL

3 Heat insulating plate

4 Two connectors

(CN201, 203)

6 DC-DC converter unit

5 Four screws

(B3) (ring)

1 Harness

2 Claw

6 Connector

(CN005)

2 Three screws

(B3)

1 Flat cable

(CN101)

4 MD block ass’y

3 Screw

(B3)

5 Two flat cables

(CN003, 004)

2-2

Page 22

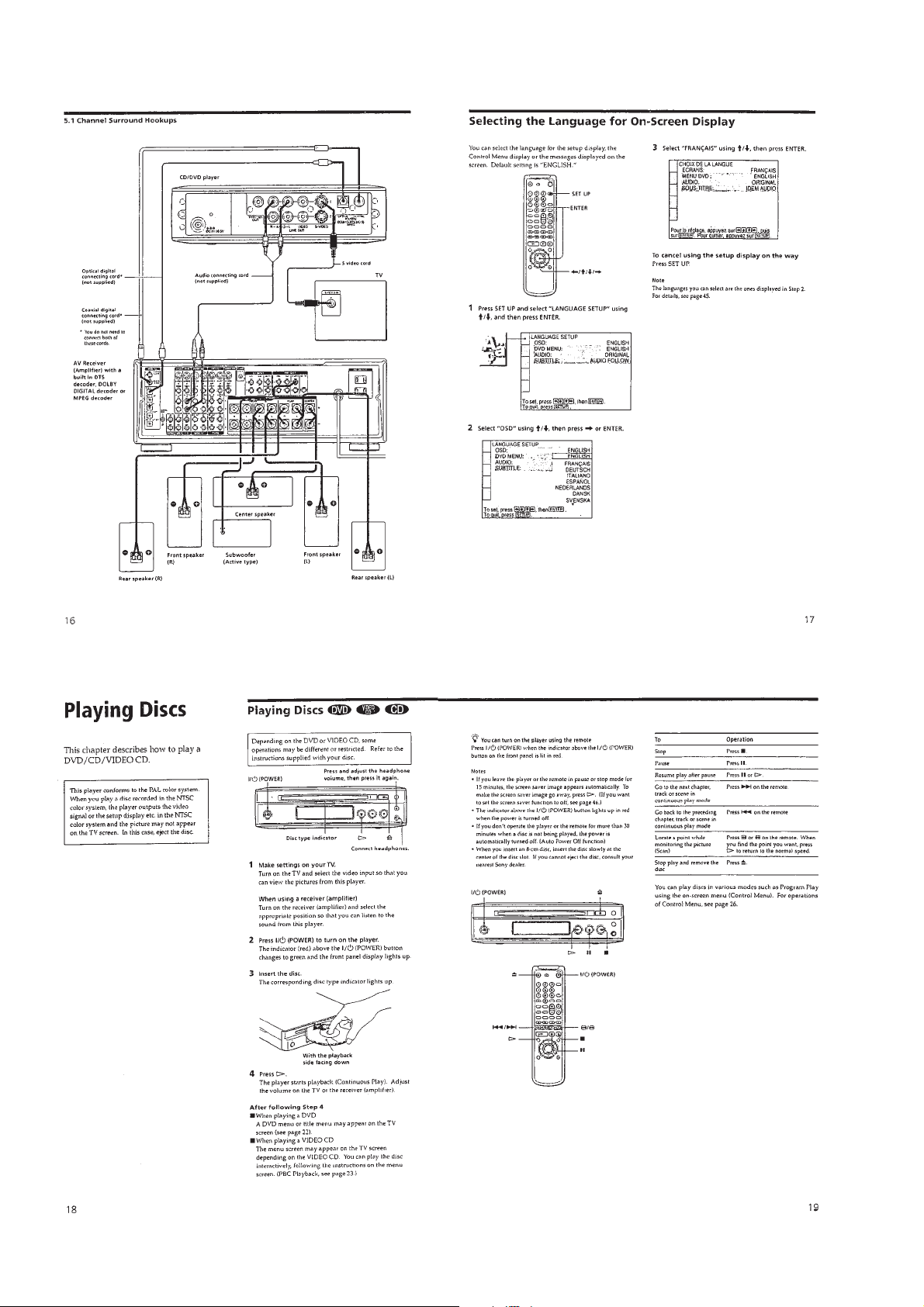

2-9. TK-55 BOARD, OPTICAL PICK-UP

5 Connector

(CN006)

3 Shaft

2 Two shafts

1 Tension spring

(cam slider)

4 Remove the cam slider in the

direction of the arrow A.

6 Three screws

(P2.6 × 6)

7 Chassis (front) block ass’y

A

REMOVAL

1 Two screws

(B3)

2 Ground plate (MD)

2-11. CAM SLIDER, CHASSIS (FRONT)

BLOCK ASS’Y REMOVAL

3 Flexible board

5 Two connectors

(CN006, 007)

q; Screw

qa Optical

pick-up

(CN002)

7 TK-55

board

9 Screw

8 Screw

6 Claw

2-12. ROLLER ARM BLOCK ASS’Y,

LD MOTOR ASS’Y REMOVAL

5 Two screws

(M1.7)

2-10. CHASSIS (TOP) BLOCK ASS’Y,

CHUCKING ARM ASS’Y REMOVAL

qa Chucking arm ass’y

6 Chassis (top)

block ass’y

5 Open the

centering lever.

2 Claw

4 Claw

q; Shaft

4 Flexible board

(CN001)

9 Shaft

8 Shaft

7 Claw

3 Shaft

1 Tension spring

(roller)

6 LD motor ass’y

4 Roller arm

block ass’y

2 Shaft

3 Claw

1 Claw

2-3

Page 23

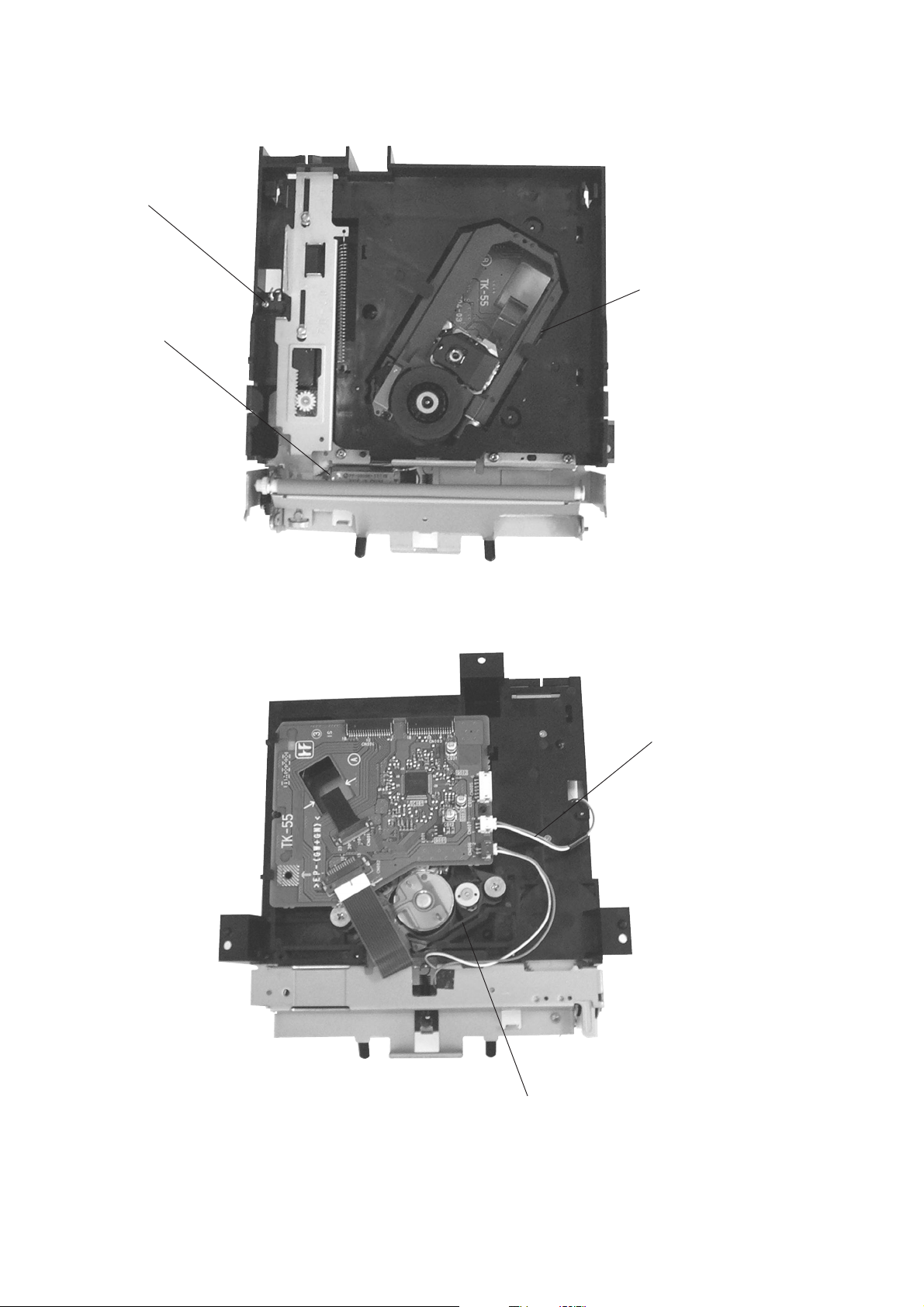

2-13. INTERNAL VIEWS

Switch (chuck sensor)

1-570-771-21

LD motor ass’y

(loading)

A-6062-252-A

Optical pick-up

(KHM-220AAA/J1RP)

8-820-081-09

Optical pick-up

(KHM-220AAA/J1RP)

8-820-081-09

Harness (ST-117)

1-960-020-11

2-4

Page 24

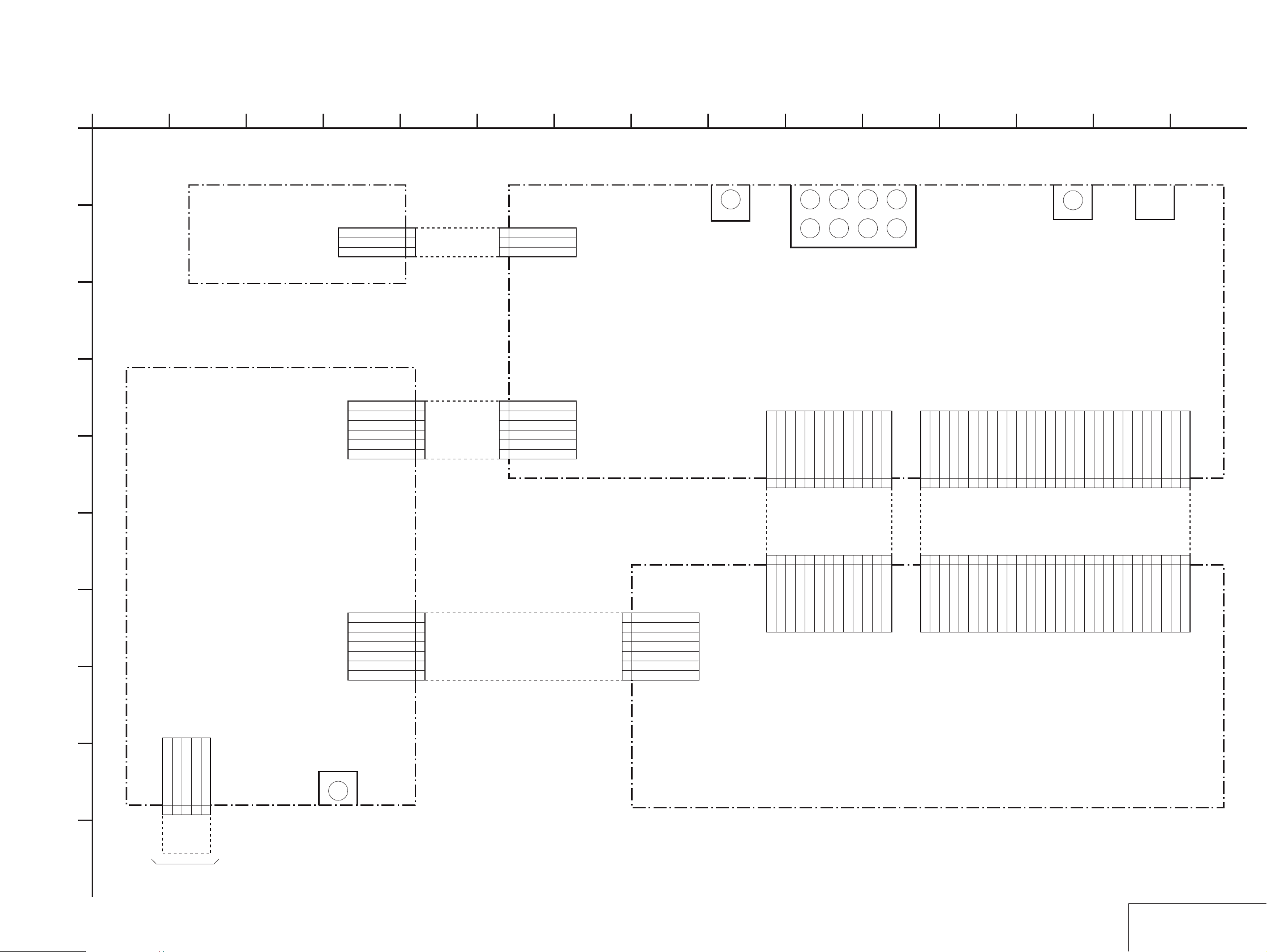

2-14. CIRCUIT BOARDS LOCATION

MB-85

(SIGNAL PROCESS/SERVO)

TK-55

(RF/SERVO)

FR-166

(IR/FUNCTION SWITCH)

SW-332

(CHUCK SENSOR)

AU-222

(AUDIO)

DC-DC Converter Unit

(SWITCHING REGULATOR)

FL-111

(IF CON)

HP-122

(HEAD PHONE)

2-5 E

2-5

Page 25

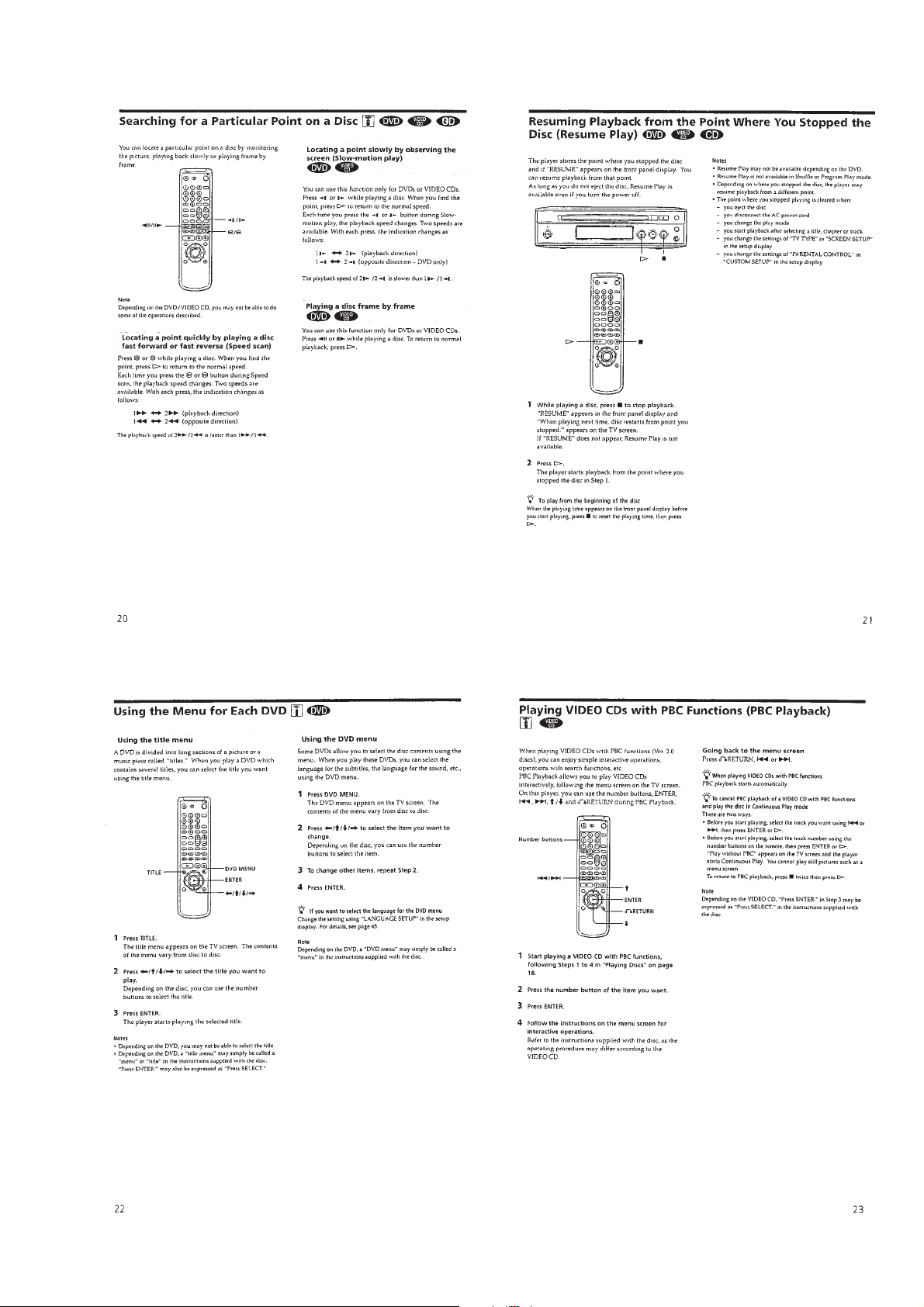

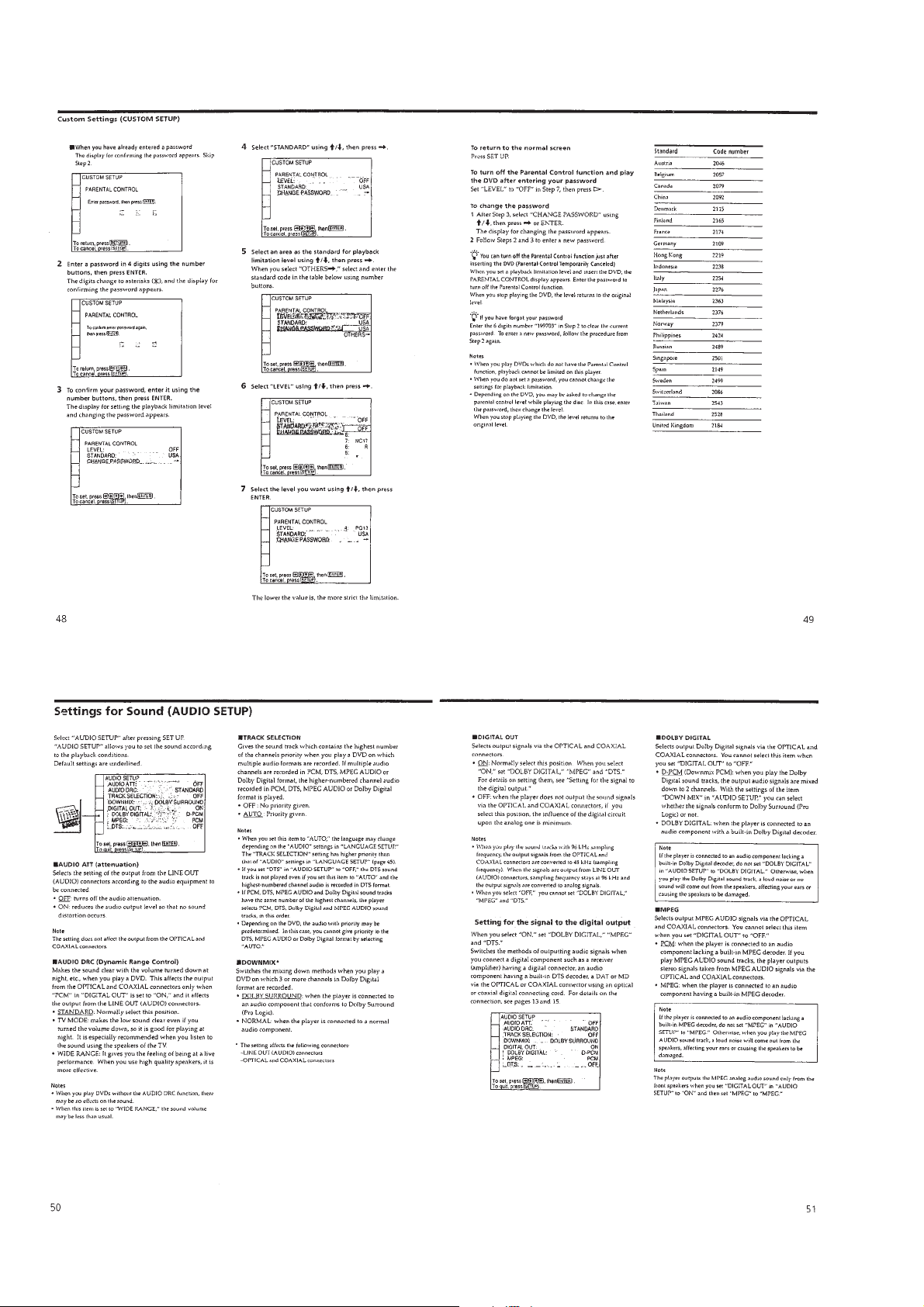

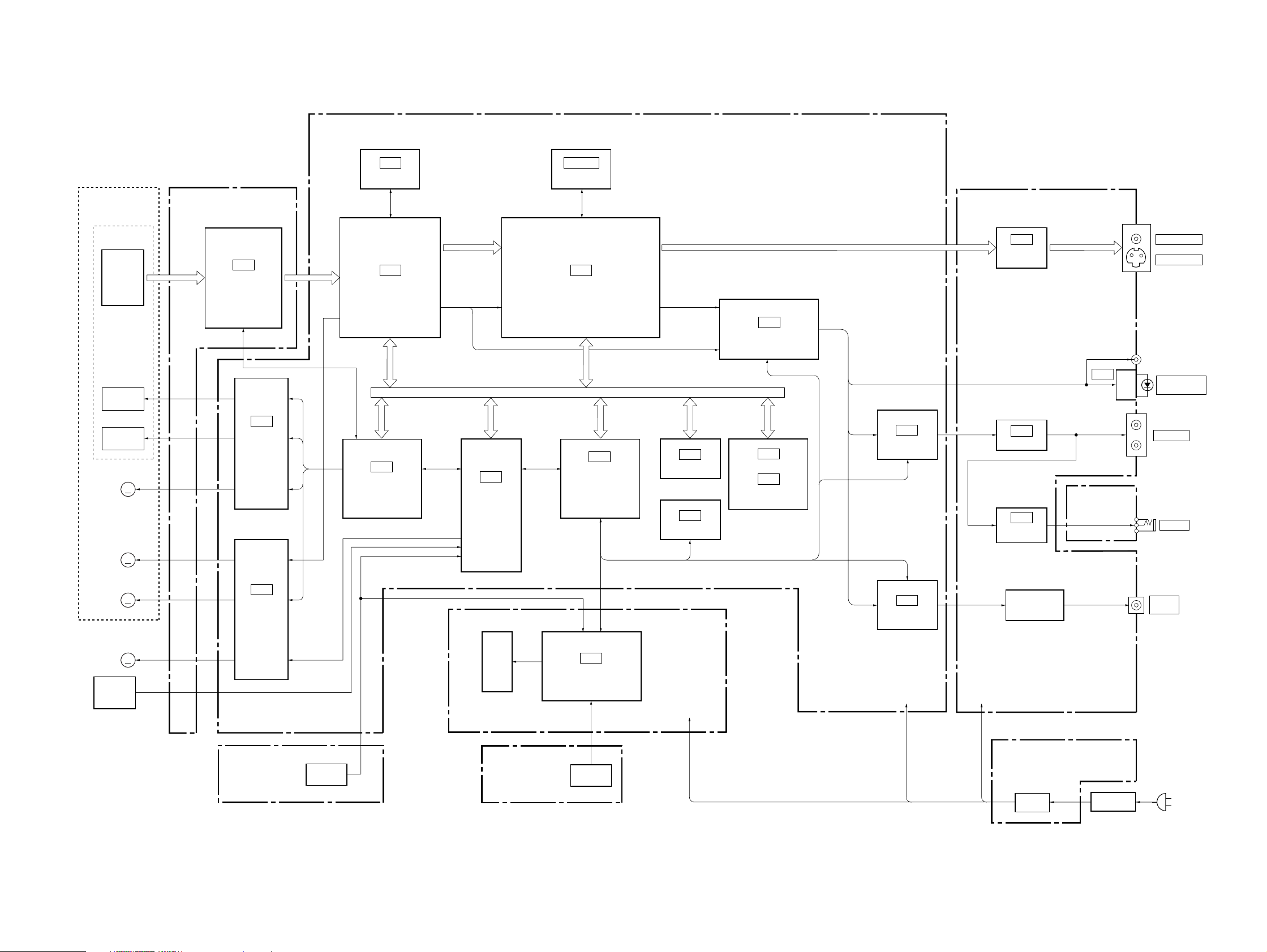

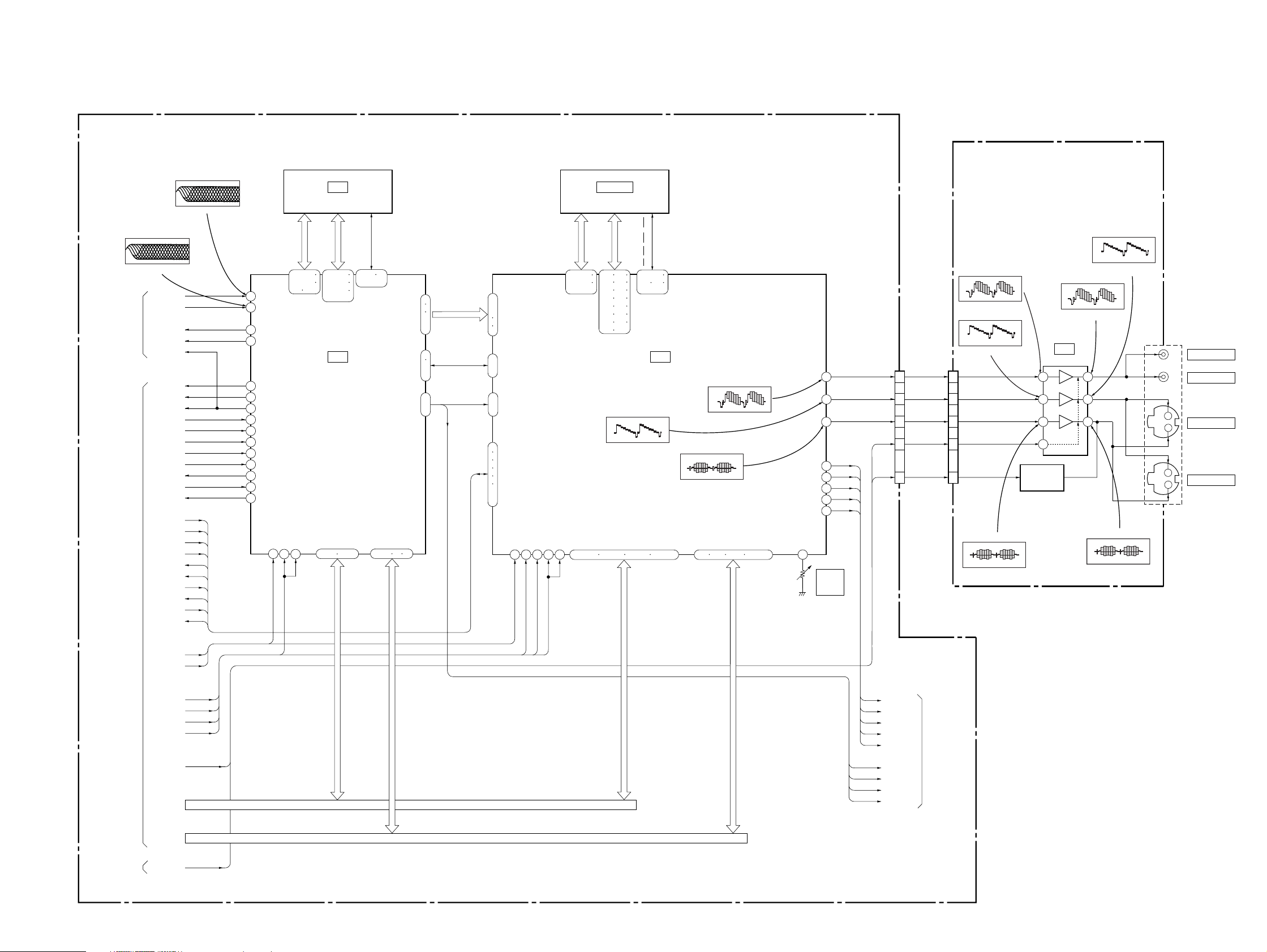

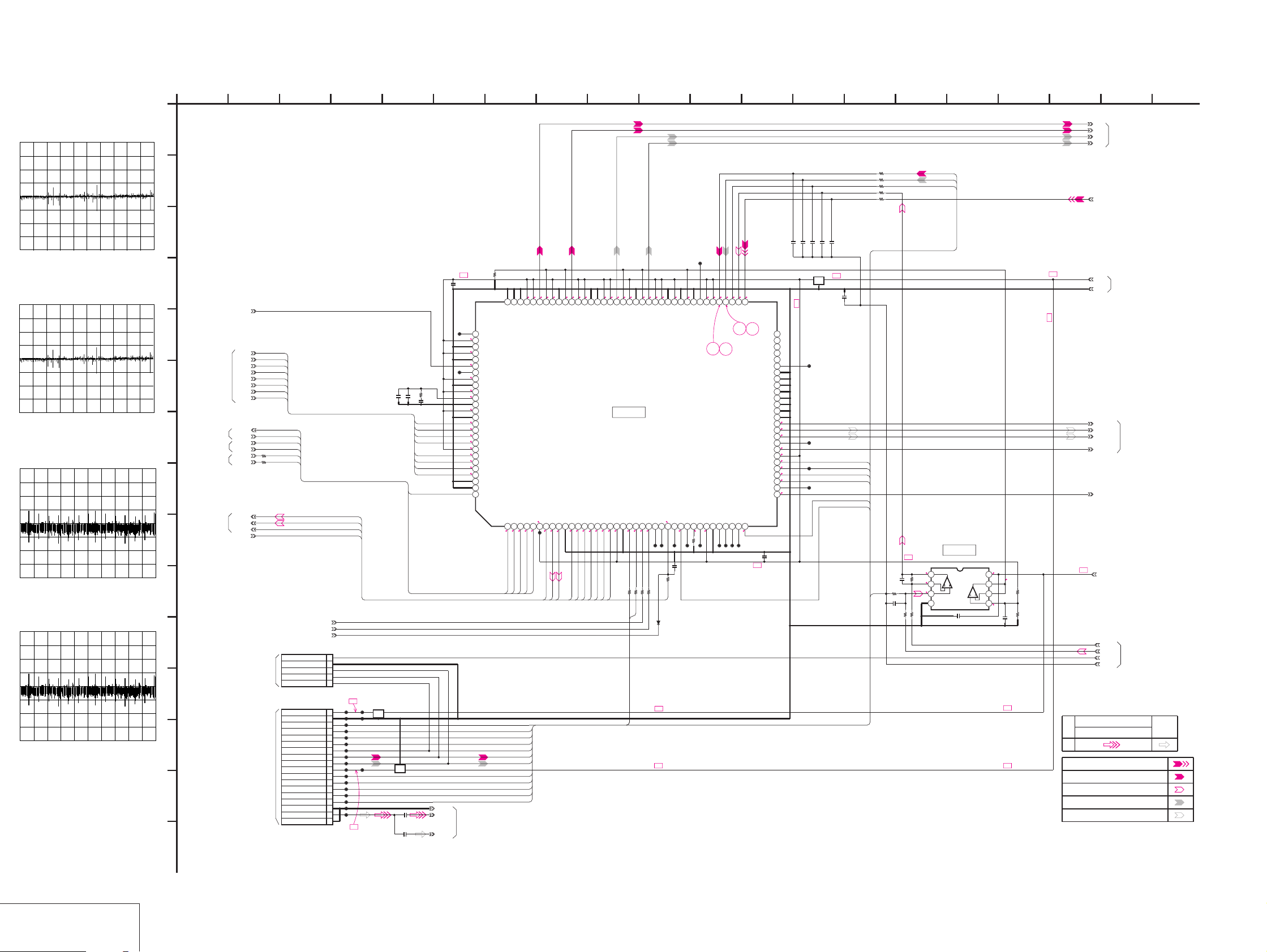

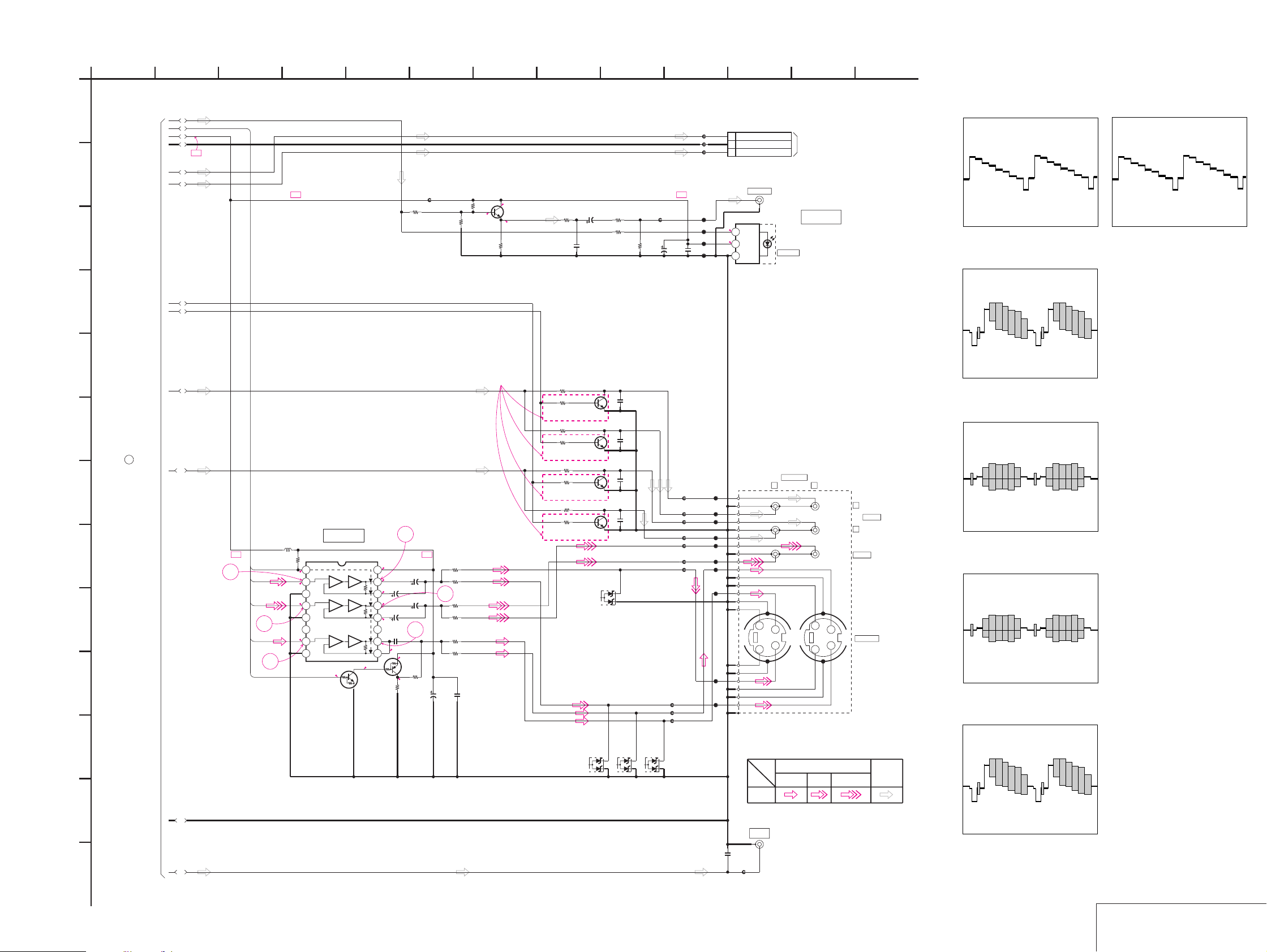

3-1. OVERALL BLOCK DIAGRAM

SECTION 3

BLOCK DIAGRAMS

MB-85 BOARD

(SEE PAGE 4-19 to 37)

DVP-F11

BASE UNIT

KHM-220AAA

OPTICAL DEVICE

DVD/CD

FOCUS

TRACKING

TILT

MOTOR

SPINDLE

MOTOR

PDIC

COIL

COIL

IC304

16M DRAM

TK-55 BOARD

(SEE PAGE 4-11)

SD 0-7

RF

IC001

DVD/CD RF AMP

DIGITAL SERVO

IC801

FOCUS COIL/

TRACKING COIL/

TILT MOTOR

DRIVE

M

DVD RF,

CD RF

IC303

ARP2

IC701

SERVO DSP

CDDOUT, CDDATA,

CDBCK, CDLRCK

IC601

HGA

M

IC402, 403

16M SDRAM

IC401

AV DECODER

IC202

SYSTEM CONTROL

Parallel BUS

Serial BUS

ACH12,

ACH34, ACH56,

BCK, LRCK

IC204

1M SRAM

IC201

4K EEP ROM

IC501

AUDIO DSP

IC205

:EXCEPT CED, UK, Chinese

IC206

:CED, UK, Chinese

16M FLASH

VIDEO V,

VIDEO Y,

VIDEO C

SPDIF

IC902

AUDIO 2CH DAC

AU-222 BOARD

(SEE PAGE 4-43, 45)

AUDIO LT,

AUDIO RT

HEADPHONE

IC308

VIDEO

BUFFER

IC303

LPF

IC307

AMP

IC309

HP-122 BOARD

(SEE PAGE 4-55)

VIDEO 1, 2

S VIDEO 1, 2

PCM/DTS/

DOLBY DIGITAL

AUDIO 1, 2

PHONES

SLED

MOTOR

M001

LOADING

MOTOR

CHUCK

SENSOR

S001

M

M

05

IC802

SPINDLE/SLED/

LOADING

MOTOR DRIVE

SW-332 BOARD

(SEE PAGE 4-14)

SWITCH

ND601

FL-111 BOARD

(SEE PAGE 4-49)

FR-166 BOARD

(SEE PAGE 4-53)

IC601

IF CON

SWITCH

SW–10V

EVER5V

IC907

WOOFER DAC

SW+3.3V

SW+5V

SW+10V

MIX, LPF

SW+5V

SW+10V

SW–10V

EVER5V

DC-DC CONVERTER UNIT (MPD0102)

(SEE PAGE 4-57)

SW REG

AC ADAPTOR

WOOFER

OUT

3-1 3-2

Page 26

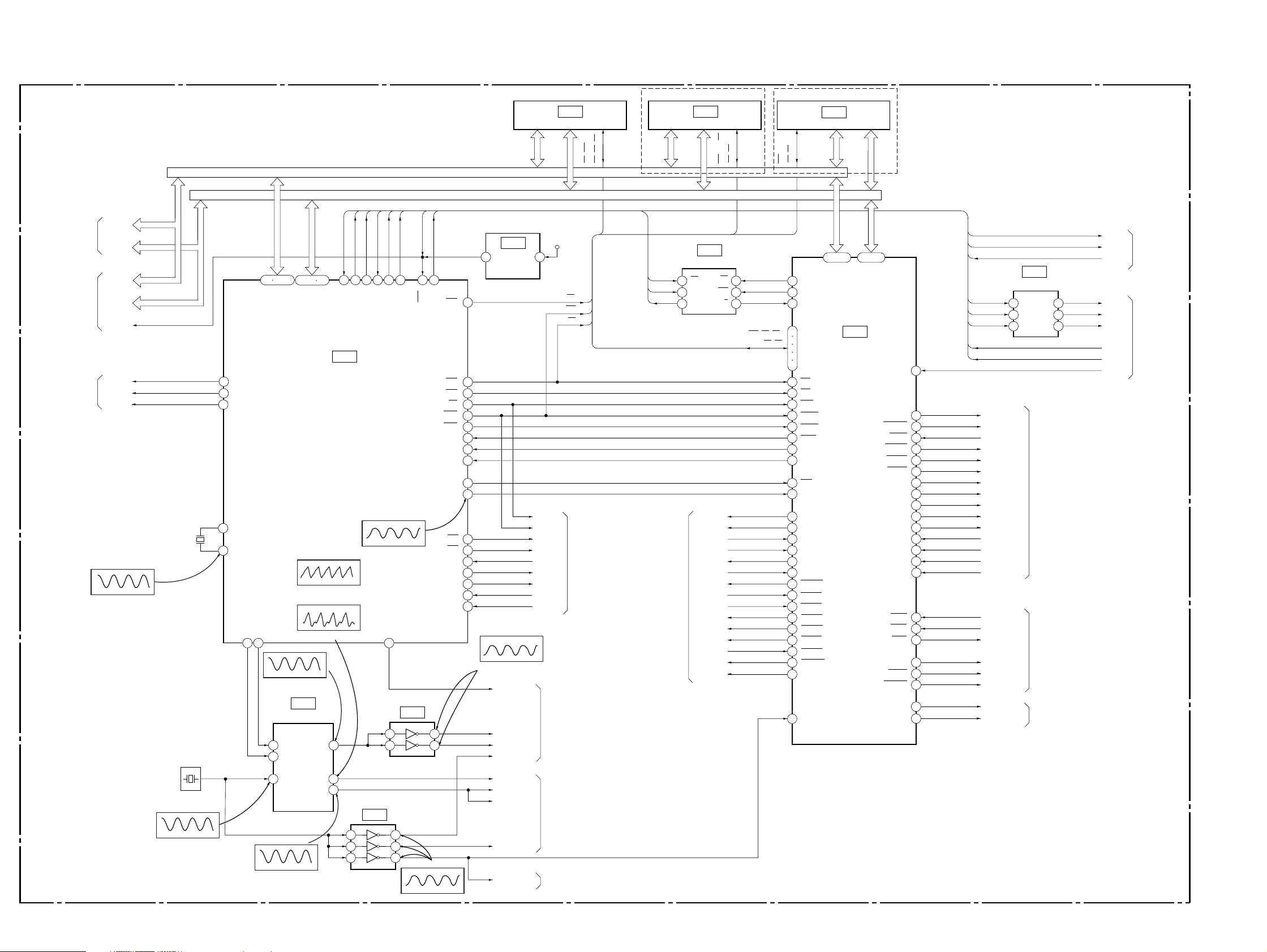

DVP-F11

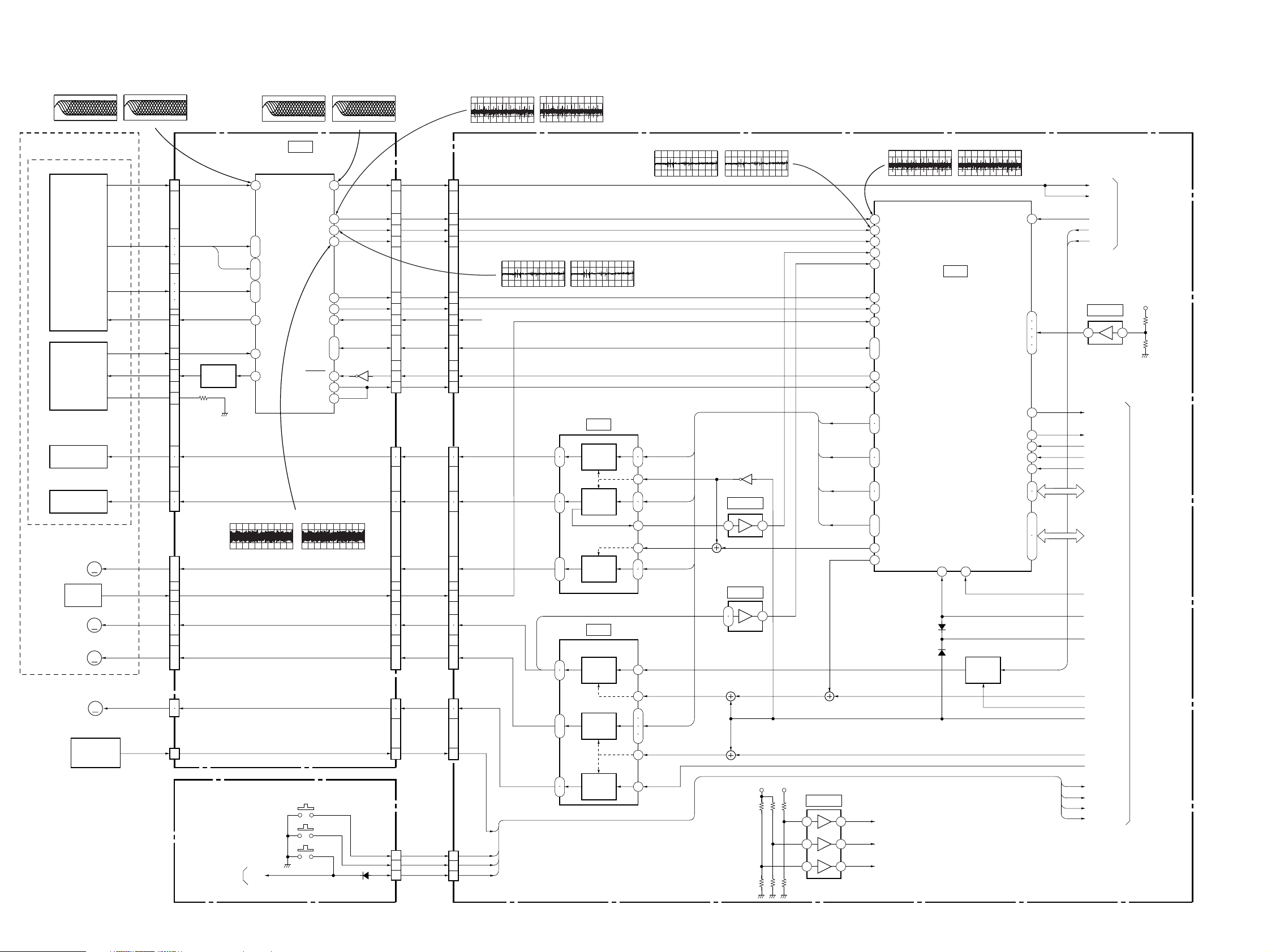

3-2. RF/SERVO BLOCK DIAGRAM

200mV/DIV 100ns/DIV

BASE UNIT

KHM-220AAA

OPTICAL DEVICE

MOTOR

SPINDLE

MOTOR

LOADING

IC0011(DVD play)

536mVp-p

DVD/CD

PDIC

DVD/CD

LD MODULE

COIL

TRACKING

COIL

TILT

M

INLIMIT

SENSOR

M

SLED

M

MOTOR

M001

M

MOTOR

S001

CHUCK

SENSOR

IC0011(CD play)

500mV/DIV 500ns/DIV

880mVp-p

RF

7

9

A-D

10

16

17

8

E-H

11

15

18

VC

13

PD

4

LD

2

VR

5

FCSFOCUS

19

20

TRK

21

22

10

TIA, TIB

ı

13

INLIM

2

8

SPM

9

4

SLA, SLB

ı

7

LDM

1

2

OCSW2

1

05

TK-55 BOARD

CN001

CN002

CN006

CN007

SW-332 BOARD (1/2)

(SEE PAGE 4-14)

Q001

LD DRIVE

(SEE PAGE 4-11)

IC001wl(DVD play)

200mV/DIV 500ms/DIV

(CHUCK SENSOR)

INTERFACE

CONTROL

(SEE PAGE 3-13)

IC001tf(DVD play)

500mV/DIV 100ns/DIV

1.5Vp-p

IC001

DVD/CD RF AMP

DIGITAL SERVO

RF IP

1 54

9

ı

A-D

12

5

ı

A2-D2

8

13

E-H

ı

16

VC

17

19

PD

20

592mVp-p

S101-103

S101

LD

FDCHG

HOLD2

200mV/DIV 20ms/DIV

IC001tf(CD play)

500mV/DIV 500ns/DIV

SIGO

40

FE

39

TE

29

PI

26

MIRR

32

TZC

33

VCI

SCLK

43

SWD

ı

SRD

46

SDEN

27

42

31

DFT

IC001wl(CD play)

448mVp-p

S103

S102

S101

1.5Vp-p

Q002

CN004

CN005

CN101

17

9

8

7

3

5

6

SSCK, SSWD,

11

ı

14

15

4

6

7

4

5

15

ı

18

8

13

14

9

ı

12

1

2

6

4

3

2

RF+

FE

TE

PI

MIRR

TZC

2VC

SSRD, SSCS

SSDFCT

SSDFCTI

FCS

TRK

TIA, TIB

INLIM

SPM

SLA, SLB

LDM

OCSW2

OCSW1

CKSW2

CKSW1

IC001r;(DVD play)

100mV/DIV 50ms/DIV

180mVp-p

MB-85 BOARD (1/6)

(SEE PAGE 4-23, 25)

CN002CN003

2

10

11

12

500mV/DIV 50ms/DIV

16

14

13

15

12

13

14

15

11

10

5

ı

8

4

1

ı

4

5

6

7

ı

1

2

6

1

3

2

3

CN003

CN011

OCSW2

CN009

OCSW1

CKSW2

CKSW1

2VC

IC001r;(CD play)

500mV/DIV 50ms/DIV

IC001el(DVD play)

1.3Vp-p

860mVp-p

IC001el(CD play)

500mV/DIV 200ms/DIV

1.7Vp-p

IC801

FOCUS

13

14

11

12

15

18

15

16

11

14

17

18

COIL

DRIVE

TRACKING

COIL

DRIVE

ı

ı

TILT

MOTOR

DRIVE

IC802

SPINDLE

MOTOR

DRIVE

SLED

MOTOR

DRIVE

LOADING

MOTOR

DRIVE

IC701yl(DVD play)

500mV/DIV 50ms/DIV

2

3

9

5

6

7

20

TLTA, TLTB

23

26

26

20

2

SLDA, SLDB,

3

STVC

5

6

9

23

1.4Vp-p

FCD

TRD

IC701yl(CD play)

500mV/DIV 200ms/DIV

1.7Vp-p

Q801

IC702 (1/2)

3 1

IC803 (1/2)

12

13

+3.3V

14

+5V

IC803 (2/2)

5 7

10

3 1

FCD

TRD

TLTA,TLTB

SLDA, SLDB,

STVC

TILT MUTE

FGMODE

8

IC701yk(CD play)

500mV/DIV 50ms/DIV

68

ADC1

69

ADC0

67

ADC2

66

ADC3

65

ADC4

21

TRIN

20

TRREF

23

FGIN

41

GIO 5-8

ı

44

38

GIO 11

28

DFCTI

80

DAB 2, 3

85

92

DAB 0, 1

97

48

GIO 1, 2

49

7

PWM 0-2

ı

9

46

GIO 4

50

GIO 0

2.5VC

2VC

1.6VC

860mVp-p

IC701yk(DVD play)

100mV/DIV 5ms/DIV

IC701

SERVO DSP

RS

26 108

180mVp-p

X2/CLKIN

Q802, 803

GAIN

CONTROL

FG REF

VRBA,

VRB 0-3

GIO 10

HINT

HRD

HWR

HCS

EA 0, 1

HD 0-7

DVD RF

CD RF

SIGNAL PROCESS,

22

74

81

84

93

96

39

128

1

2

3

4

5

117

ı

120

122

ı

125

LOCK

MDS0

MDP0

IC702 (2/2)

7 5

FCSON

XSDPIT

XSDPRD

XSDPWR

XSDPCS

HA0, 1

HD8-15

N27MSDP

XSDPRST

X3VRST

SPDLSTOP

SPGAIN

XDRV MUTE

LDMM/DMM

LDMP/DMP

OCSW1

OCSW2

CKSW1

CKSW2

VIDEO

(SEE PAGE 3-5)

+3.3V

SYSTEM

CONTROL

(SEE PAGE 3-7, 8)

3-3 3-4

Page 27

3-3. SIGNAL PROCESS/VIDEO BLOCK DIAGRAM

MB-85 BOARD (2/6)

(SEE PAGE 4-19, 21, 27, 35)

IC303qj(DVD play)

500mV/DIV 200ns/DIV

RF, SERVO

(SEE PAGE 3-4)

SYSTEM

CONTROL

(SEE PAGE 3-7, 8)

IC303ql(CD play)

1.6Vp-p

DVD RF

CD RF

MDS0

MDP0

LOCK

DFCT

NORF

LOCK

FWON

MD2

MUTE

XARPWR

XARPRD

XARPIT

XARPCS

XARPWT

XCS2

XCS3

XRD

XWRH

XAVDIT

XAVDWT

DACK0

DREQ0

DACK1

DREQ1

500mV/DIV 100ns/DIV

1.6Vp-p

136-139

141-144

RFIN1

RFIN2

MDS0

MDP0

DFCT

NORF

LOCK

FWON

MD2

MUTE

XWR

XRD

XINT

XCS

XWAT

XRST

87

121

XARPRST

33MARP

146 147

MCKI

123

17

19

49

52

55

56

58

59

113

111

60

61

83

84

86

MA 0-9

SCKI

IC304

16M DRAM

MD 00-15

154-157

159-162

164-167

169-172

IC303

ARP2

A 0-7

73-76 79-82

XRAS, XOE

XMWR, XCAS,

148

150-152

63-68 70 71

SD 0-7

D 0-7

97

SD 0-7

98

100

ı

105

SDCK, SDEF,

91

XSHD, XSAK, XSRQ

93

ı

96

CDDOUT, CDDATA,

107

CDBCK, CDLRCK

ı

110

DVP-F11

AU-222 BOARD (1/2)

(SEE PAGE 4-43, 45)

IC402, 403

16M SDRAM

IC308qg

DDT 0-15

DAD 0-11

105-108

110-113

CRPCLKI

160 163

27M30

33M30

115-118

SCLKIN

CLKI

168-170 172-178 180-187 189-192 2-5 7-10 12-15 205-208

38

ı

43

DT 0-7 I

45

46

47

ı

51

29

ı

32

166

167

193

194

196

198

ı

202

RSTIN

ACLKI

103 19 36

256FS30

XAVDRST

134 135

137 138

140 141

143 144

146 147

149 150

152 153

155 156

CLK, CKE,

DQML, DQMU,

120-123

125 127

129-132

AV DECODER

IC401ya

1.1Vp-p(H)

HAD 0-21 I

CS, WE, CAS, RAS

IC401

IC401ys

816mVp-p(H)

IC401yg

1.2Vp-p(H)

HD 0-15

COMP OUT

Y OUT

C OUT

ACH12O

ACH34O

ACH56O

LRCKO

BCKO

VREFI

70

65

61

62

21

22

23

25

26

RV401

VIDEO

LEVEL

ADJ

CN005

IC3084

1.2Vp-p(H)

IC3082

1.1Vp-p(H)

VIDEO V

1

VIDEO Y

3

VIDEO C

5

V MUTE

8

VS

6

CN301

28

26

24

21

23

IC3087

860mVp-p(H)

VIDEO BUFFER

4 13

2

7 10

1

Q323, 324

DC ON/OFF

IC308

IC308qd

2.4Vp-p(H)

15

2.0Vp-p(H)

IC3080

1.8Vp-p(H)

J302

Y

C

Y

C

VIDEO OUT1

VIDEO OUT2

S VIDEO OUT1

S VIDEO OUT2

INTERFACE

CONTROL

(SEE PAGE 3-14)

05

XARPRST

XAVDRST

33MARP

256FS30

33M30

27M30

VS

HA 0-21

HD 0-15

V MUTE

CDDOUT, CDDATA, CDBCK, CDLRCK

ACH12

ACH34

ACH56

LRCK

HA 0-7

HD 8-15

HA 0-21

HD 0-15

BCK

CDDOUT

CDDATA

CDBCK

CDLRCK

AUDIO 1

(SEE PAGE 3-9)

3-5 3-6

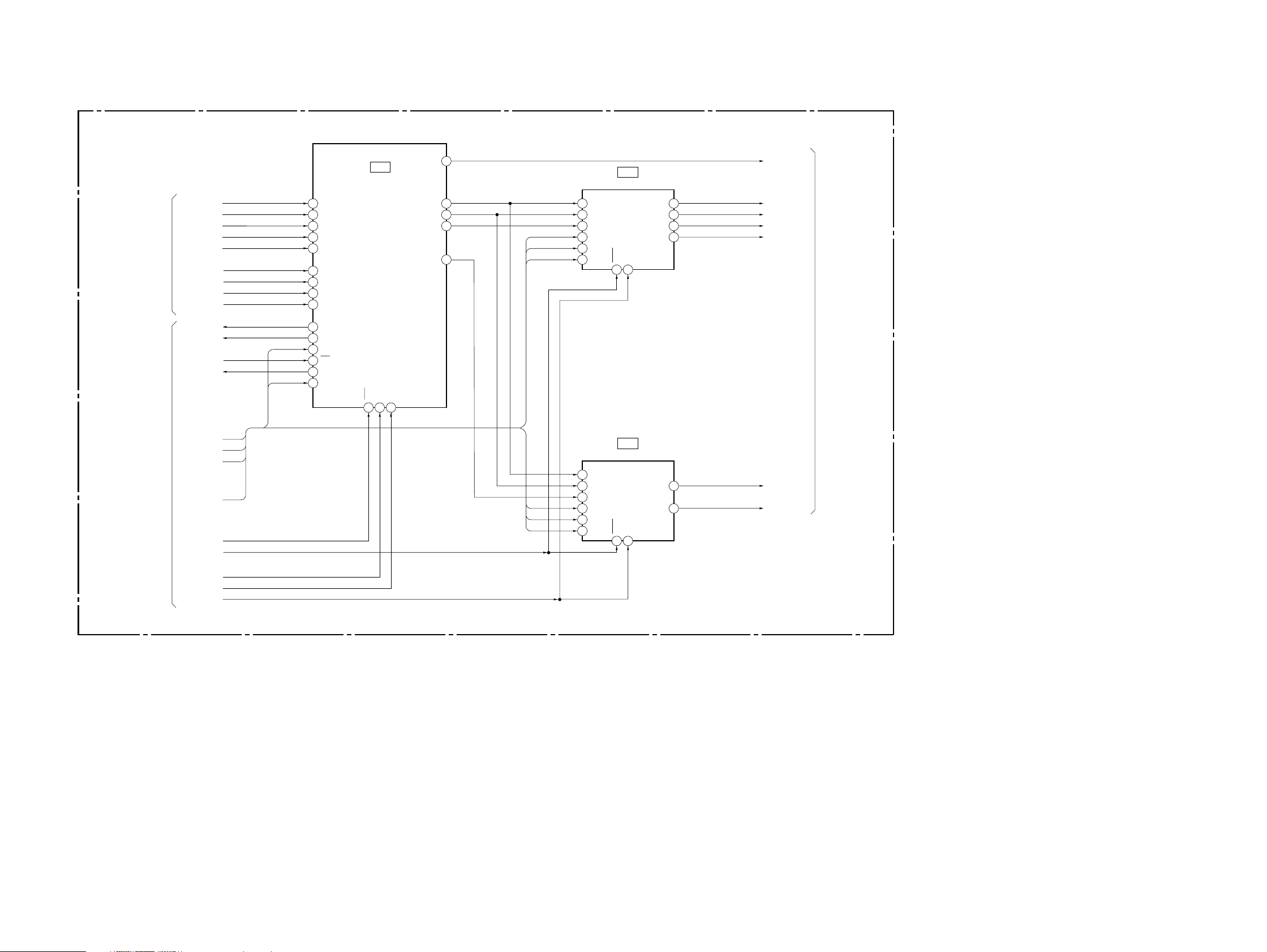

Page 28

DVP-F11

3-4. SYSTEM CONTROL BLOCK DIAGRAM

MB-85 BOARD (3/6)

(SEE PAGE 4-29, 31, 33)

SIGNAL PROCESS,

VIDEO

(SEE PAGE 3-5)

RF, SERVO

(SEE PAGE 3-4)

AUDIO 2

(SEE PAGE 3-11)

05

HA 0-21

HD 0-15

HA 0, 1

HD 8-15

X3VRST

GAIN2

VFC1

VFC2

IC202os

2.4Vp-p(12.5MHz)

X201

12.5MHz

X001

27MHz

IC0016

4.2Vp-p(27.0MHz)

HA 0-21

42 44-64

3

PB7

1

PB5

96

PB0

91

X1

92

X0

P66

PB4

66 100 98

CKSEL

DVD/CD

DVD:5.8Vp-p(36.5MHz)

CD:5.1Vp-p(33.8MHz)

19

1

6

4.6Vp-p(33.8MHz)

A 01-15

IC001qj

MD

ML

XT1

IC001qs

HD 0-15

25-39 41

D 16-31

SYSTEM CONTROL

IC001qf(DVD play)

4.2Vp-p(25.3MHz)

IC001qf(CDplay)

4.7Vp-p(22.5MHz)

IC001

PLL

SCKO3

17

14

SCKO2

12

SCKO1

SI0

SO0

SO0

3

6

1

SI1

SC0

SO1

SI1

SC0

SO1

IC2025

4Vp-p(25.3MHz)

PB2

1

3 5

IC004

5

2

7

SC1

SC1

IC003

IC0042,5,7

4.2Vp-p(26.9MHz)

SIO

76 77 78 79 80 89 14 97

IC202

CS0L

XFRRST

RST

7

PB1

WR0

WR1

INT1

INT3

DACK1

DACK0

DREQ1

DREQ0

CS0

CS1

CS4

RD

RDY

PF7

CLK

CS2

CS3

INT0

IC207

POWER ON

4 5

RESET

11

10

7

22

23

24

19

94

88

83

5

9

8

95

84

85

86

87

IC0035,7

DVD:6.2Vp-p(37.0MHz)

CD:5Vp-p(33.6MHz)

XDACS0

384FSDA

384FS01

27M01

256FS30

33MARP

33M30

27M30

N27MSDP

IC204

1M SRAM

HA 1-16

+3.3V

XRD

XWRH

XCS2

XCS3

XAVDIT

DACK1

DACK0

DREQ1

DREQ0

AUDIO 1

(SEE PAGE 3-9)

HD 0-15

CE

WE

CS

SIGNAL PROCESS,

VIDEO

(SEE PAGE 3-5)

RF, SERVO

(SEE PAGE 3-4)

CS, WE,

OE, UB, LB

SIGNAL PROCESS,

VIDEO

(SEE PAGE 3-5)

SIGNAL PROCESS,

VIDEO

(SEE PAGE 3-5)

EXCEPT CED, UK, Chinese

IC205

16M FLASH

HA 1-20

SC0

SO0

SI0

HD 0-15

IC201

4K EEPROM

4 3

SK

5 8

DI

DO

6 1

MUTE

NORF

DFCT

FWON

LOCK

XARPRST

XARPIT

XARPWT

XARPWR

XARPRD

XARPCS

XAVDWT

XAVDRST

N27MHGA

MD2

VS

WE, RY/BY,

CS

WC

R/B

OE, CE

WE, UB, LB,

RY/BY, OE

CED, UK, Chinese

WE,

OE, CE

23

XECS

24

XEWC

25

XEBSY

4

112

113

124

125

141

CS1

142

CS4

145

HRD

144

HWRH

143

HWRL

157

WAIT

156

HINT1

155

HINT3

3

RST

135

CPUCK

98

MUTE

99

MD2

102

NORF

103

DFCT

104

FWON

105

LOCK

106

ARPRST

107

ARPINT

108

ARPWT

109

ARPWR

110

ARPRD

111

ARPCS

72

AVDWT

71

AVDRST

53

VS

59

MCK

IC206

16M FLASH

HA 1-20

HA 0-5, 17-19

HA 0-5, 17-19

IC601

HGA

HD 0-15

HD 8-15

126-133146-154

HD 0-7

LDMM/DMM

XIFINT

FCSON

SDPRST

SDPIT

SDPWR

SDPRD

SDPCS

SPDLSTOP

SPGAIN

XDRVMUTE

LDMP/DMP

OCSW1

OCSW2

CKSW1

01IT0

01IT1

01CS

XDACS3

01RST

DACRST

EXPO0

MA MUTE

SC1

SO1

SI1

IC203

BUFFER

CS0L

12

SC0

SO0

SI0

XFRRST

22

54

114

115

116

117

118

57

94

93

92

91

64

63

88

83

29

30

28

97

31

26

55

49

4 6

1 3

FCSON

XSDPRST

XSDPIT

XSDPWR

XSDPRD

XSDPCS

SPDLSTOP

SPGAIN

XDRVMUTE

LDMP/DMP

LDMM/DMM

OCSW1

OCSW2

CKSW1

CKSW2CKSW2

X01INT0

X01INT1

X01CS

XDACS3

X01RST

XDACRST

SWSEL

MA MUTE

4A

4Y

2A

2Y

1A

1Y

RF, SERVO

(SEE PAGE 3-4)

AUDIO 1

(SEE PAGE 3-9)

AUDIO 2

(SEE PAGE 3-11)

11

SC1

SO1

SI1

XVIFCS

IFSC0

IFSO0

IFSI0

XFRRST

XIFINT

AUDIO 1

(SEE PAGE 3-9)

INTERFACE

CONTROL

(SEE PAGE 3-14)

3-7 3-8

Page 29

3-5. AUDIO (1) BLOCK DIAGRAM

MB-85 BOARD (4/6)

(SEE PAGE 4-33, 35)

DVP-F11

SIGNAL PROCESS,

VIDEO

(SEE PAGE 3-6)

SYSTEM CONTROL

(SEE PAGE 3-7, 8)

BCK

LRCK

ACH12

ACH34

ACH56

CDDOUT

CDDATA

CDBCK

CDLRCK

X01INT0

X01INT1

X01CS

SI1

SO1

SC1

XDACS0

XDACS3

X01RST

XDACRST

SO1

SC1

CS0

CS3

SO1

SC1

IC501

AUDIO DSP

47 9

BCKI

49 10

LRCKI

52 11

CH12I

51

CH34I

50

CH56I

25

CDDOBYP

26

CDSOBYP

27

CDBKCKI

28

CDLRCKI

55

CPU INT0

56

CPU INT1

61

SI

62

CS

63

SO

66

SCK

CLK

ACKI

RST

33 7 68

DO

BCKO

LRCKO

CH78O

CH56O

16

3

1

SO1

SC1

12

CS0

SO1

SC1

CS3

2

26

27

28

3

1

2

26

27

28

AUDIO 2CH DAC

BCLKIN

LRCIN

D IN

MD

MC

ML

WOOFER DAC

BCLKIN

LRCIN

D IN

MD

MC

ML

IC902

RSTB

522

IC907

RSTB

522

XTI

XTI

V OUT L

V OUT R

ZERO

ZEROR

V OUT R

ZEROR

16

13

21

17

13

17

SPDIF

AUDIOLT

AUDIORT

ZFLT

ZFRT

AUDIOLFE

ZFLFE

AUDIO 2

(SEE PAGE 3-11)

384FS01

27M01

384FSDA

05

3-9 3-10

Page 30

DVP-F11

3-6. AUDIO (2) BLOCK DIAGRAM

MB-85 BOARD (5/6)

(SEE PAGE 4-35)

INTERFACE

CONTROL

(SEE PAGE 3-14)

SYSTEM CONTROL

(SEE PAGE 3-7, 8)

AUDIO 1

(SEE PAGE 3-10)

A MUTE

MA MUTE

VFC2

VFC1

GAIN2

SWSEL

SPDIF

AUDIOLT

AUDIORT

ZFLT

ZFRT

CN005

CN007

IC309

1

D IN

CN306

J301

J302

COAXIAL

PCM/DTS/

DOLBY DIGITAL

OPTICAL

L

AUDIO OUT1

R

L

AUDIO OUT2

R

HP-122 BOARD

(SEE PAGE 4-55)

HPL

1

HPR

3

CN501

1

3

RV501

PHONES LEVEL

J501

PHONES

AU-222 BOARD (2/2)

(SEE PAGE 4-43, 45)

EXCEPT

Hong Kong, Singapore, Australian

IC303

LPF +6dB

3 1

5

Q311, 314

GAIN

7

CONTROL

IC305

MIX, LPF

3 1

6

Q317, 318

MUTE

IC307

HEADPHONE AMP

3

5

9

B

10

A

IC306

VARIABLE FC

CONTROL

1

Y0

2

Y2

Y3

4

7

14

18

16

19

10

20

22

11

1

13

CN301

CN302

Q306

Q304

Q303, 307

LEVEL SHIFT

Q326

Q327

SPDIF

15

AUDIOLT

11

AUDIORT

13

ZFLT

10

ZFRT

19

A MUTE

9

MA MUTE

7

VFC2

18

VFC1

28

GAIN2

1

Q325

BUFFER

Chinese,

Q330-333

FNAC

MUTE

1

7

Q321, 322

MUTE

3

Y

SWSEL

11

AUDIOLFE

AUDIOLFE

ZFLFE

05

9

ZFLFE

12

3

IC304

BUFFER, LPF+16dB

3 1

5

2

Q305

Q301, 302

MUTE CONTROL

5

7

Q319

LFE

MUTE

7

6

5

IC310

SELECTOR

J303

1

Q320

WOOFER

MUTE

WOOFER

OUT

3-11 3-12

Page 31

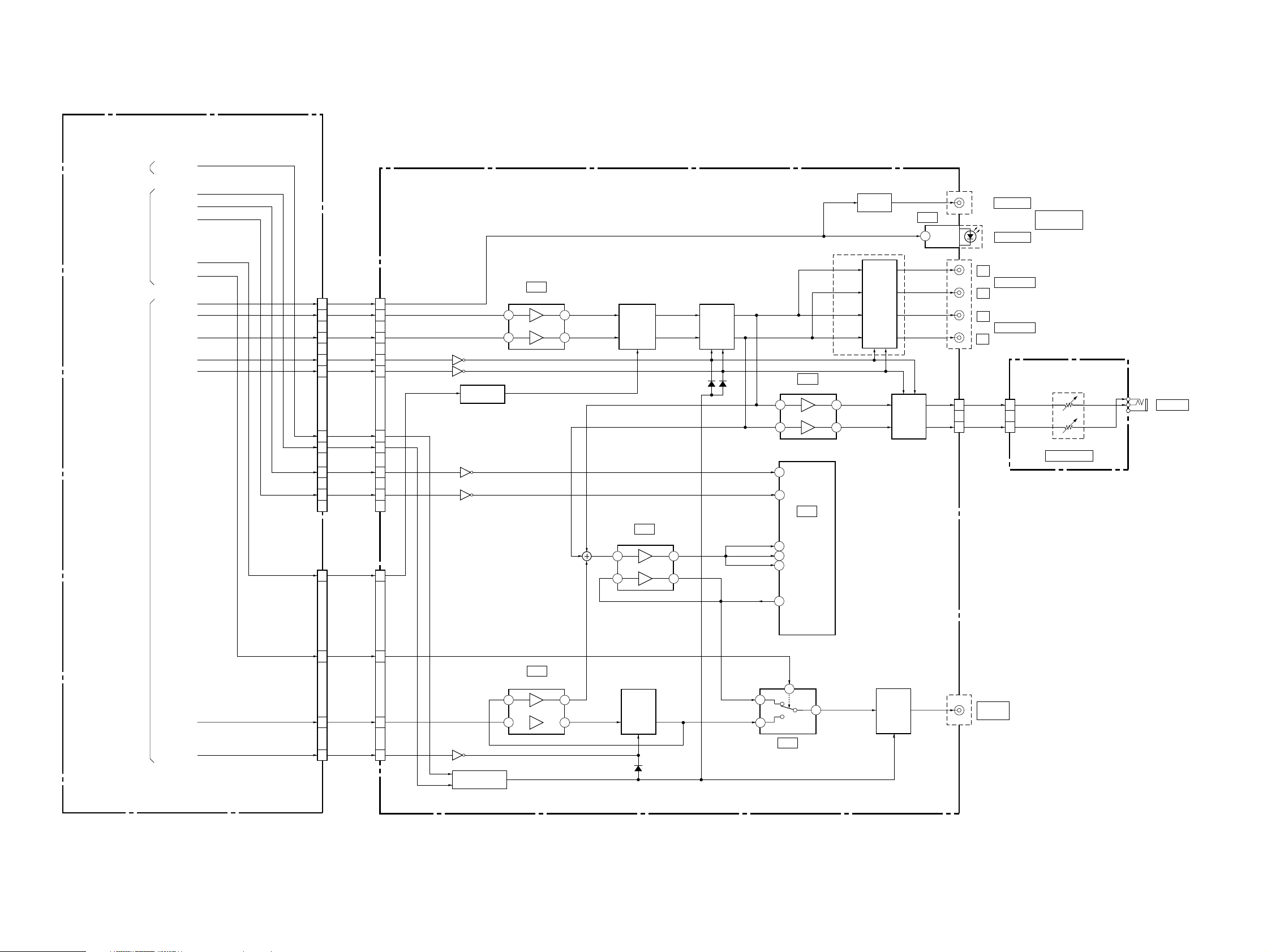

3-7. INTERFACE CONTROL BLOCK DIAGRAM

DVP-F11

FR-166 BOARD

(SEE PAGE 4-53)

D702

DVD

D701

(ON/STANDBY)

D703

VIDEO CD

D704

CD

IC701

REMOTE

COMMANDER

RECEIVER

OUT

1

CN701

FL-111 BOARD

(SEE PAGE 4-49)

CN603

IR

9

8

7

5

4

3

2

1

10

LPOW

LSTBY

LDVD

LVCD

LCD

LPAUSE

LPLAY

BT

9

8

7

IC602

POWER-ON RESET

4

V OUT

5

4

3

2

1

10

9

31

32

10

27

26

25

29

30

6

IR

L POWER

L STBY

RESET <N>

L DVD

L VCD

L CD

L PAUSE

L PLAY

AN0

IC601

IF CON

SCLK1

SOUT1

SIN1

SBUSY1

SRDY1

P CHECK<N>

FRRST <N>

V MUTE

A MUTE <N>

X IN

X OUT

70

71

72

76

78

77

8

11

12

14

15

X601

4MHz

IC601qf

3.9Vp-p(4MHz)

CN602

SC0

10

SI0

12

SO0

11

XIFCS

13

XIFBUSY

14

+3.3V

115

XFRRST

15

V MUTE

8

A MUTE

7

MB-85 BOARD (6/6)

(SEE PAGE 4-29)

CN006

6

4

5

3

2

1

8

9

+5V

+3.3V

IFSC0

IFSI0

IFSO0

XVIFCS

XIFINT

XFRRST

V MUTE

A MUTE

SYSTEM CONTROL

(SEE PAGE 3-8)

SIGNAL PROCESS, VIDEO

(SEE PAGE 3-5)

AUDIO 2

(SEE PAGE 3-11)

S702S701 S703 S704 S705

41

DIG1-8

D705

05

D706

SW-332 BOARD (2/2)

(SEE PAGE 4-14)

RF, SERVO

(SEE PAGE 3-3)

S101

CN102

2

CN604

FLD0

64

S101

2

ı

48

33

ı

SEG1-18

40

49

ı

58

13

ı

20

4

ı

11

22

ı

29

31

32

ND601

VACUUM

FLUORECENT

DISPLAY

3-13 3-14

Page 32

DVP-F11

3-8. POWER BLOCK DIAGRAM

AC ADAPTOR

(AC-F11)

FL-111 BOARD

(SEE PAGE 4-49)

IC601

DC-DC CONVERTER UNIT (MPD0102)

(SEE PAGE 4-57)

J201

ND601

IC602

LINE FILTER

Q201, 221

SWITCH

L202

T201

F1

F2

VEE

EVER5V

PCONT

FR-166 BOARD

(SEE PAGE 4-53)

IC281

EVER+5V REG

Q291, 293

B+ SWITCH

IC251

SW+5V REG

Q292, 294

POWER

CONTROL

IC701

Q604, 605

DC-DC

CONVERTER

CN701

T601

11

CN603

11

EVER5V

CN202

CN201

CN203

B601

1

4

2

6

1

2

5

6

7

2

4

1

4

2

1

EVER5V

SW+10V

SW+5V

SW–10V

SW+10V

SW+5V

SW+3.3V

EVER5V

SW–10V

PCONT

SW–10V

EVER5V

PCONT

SW+5V

SW+3.3V

SW+10V

SW+10V

SW–10V

SW+5V

EVER5V

MB-85 BOARD

(SEE PAGE 4-19 to 37)

CN001

+5V

5

+3.3V

6

7

V3.3V

1

2

CN006

15

+3.3V

AU-222 BOARD

(SEE PAGE 4-43, 45)

CN303

4

+7.5V/–7.5V

6

2

EVER5V

1

IC404

+3.3 REG

IC904

A+5V REG

IC801

IC802

IC301

IC308

IC309

A+5V

REG

IC401

+7.5V

–7.5V

IC902

IC907

IC303

IC304

IC305

IC307

IC306

IC310

IC302

+3.3 REG

IC203

IC702

IC803

+3.3 REG

IC005

IC303

IC001

IC003

IC004

CN002

IC201

IC202

IC204

IC207

IC304

IC402

IC403

IC501

IC601

IC701

IC205

EXCEPT CED, UK,

Chinese

IC206

CED, UK, Chinese

TK-55 BOARD

(SEE PAGE 4-11)

CN003

+5V

+3.3V

1

18

910

IC001

CN001

14

VCC (5V)

OPTICAL

DEVICE

CN602

+3.3V

05

1

3-15 3-16 E

Page 33

SECTION 4

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

DVP-F11

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

For printed wiring boards:

• X : indicates a lead wire mounted on the component

side.

• x : indicates a lead wire mounted on the printed side.

• a : Through hole.

• b : Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) t he parts face are indicated.

For schematic Diagram:

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum capacitor,

because it is damaged by the heat.

• All resistors are in ohms, 1/

unless otherwise specified.

kΩ : 1000 Ω, M Ω : 1000 kΩ.

• All capacitors are in µF unless otherwise noted. pF : µµF

50V or less are not indicated except for electrolytics and

tantalums.

• All variable and adjustable resistors have characteristic curve

B, unless otherwise noted.

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

• f : internal component.

• C : adjustment for repair.

• U : B+ Line.

• V : B– Line.

• Circled numbers refer to waveforms.

• Voltages are dc between measurement point.

• Readings are taken with a color-bar signals on DVD reference disc and when playing CD reference disc.

• Readings are taken with a digital multimeter (DC 10 MΩ).

• Voltage var iations may be noted due to normal production

tolerances.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

4

W (Chip resistors : 1/

10

W)

When indicating parts by reference

number, please include the board

name.

• Abbreviation

AUS : Australian model

CN : Chinese model

HK : Hong Kong model

SP : Singapore model

4-1

Page 34

DVP-F11

4-1. FRAME SCHEMATIC DIAGRAM

FRAME (1) SCHEMATIC DIAGRAM

1

A

B

C

D

E

F

G

H

2345 678910111213141516171819

BASE UNIT

KHM-220AAA/J1N

SLED

MOTOR

SPINDLE

MOTOR

TILT

MOTOR

M001

LOADING

MOTOR

OPTICAL

DEVICE

INLIMIT

SENSOR

M

M

M

S001

CHUCK

SENSOR

M

23P

1N.C.

2LD

3GND

4PD

5VR

6VLD

7RF

8F

9C

10D

11H

12GND

13VC(2.5V)

14VCC(5V)

15G

16A

17B

18E

19FCS+

20FCS-

21TRK+

22TRK-

23N.C.

13P

1LED

2INLIM

3GND

4SLB-(4)

5SLA+(2)

6SLB+(3)

7SLA-(1)

8SPM+

9SPM-

10TIB-(4)

11TIB+(3)

12TIA-(1)

13TIA+(2)

2P

1OCSW2

2GND

2P

1LDM+

2LDM-

FPC

FPC

ST-117

MT-122

CN001 23P

1 N.C.

2LD

3 GND

4PD

5VR

6 VLD

7RF

8F

9C

10 D

11 H

12 GND

13 VC(2.5V)

14 VCC(5V)

15 G

16 A

17 B

18 E

19 FCS+

20 FCS-

21 TRK+

22 TRK-

23 N.C.

1 LED

2 INLIM

3 GND

4 SLB-(4)

5 SLA+(2)

6 SLB+(3)

7 SLA-(1)

8 SPM+

9 SPM-

10 TIB-(4)

11 TIB+(3)

12 TIA-(1)

13 TIA+(2)

CN007

1 OCSW2

2 GND

CN006

1 LDM+

2 LDM-

18P

CN003

18GND

17RF+

16RF-

15SSDFCT

14SSCS

13SSRD

12SSWD

11SSCK

FFC

103.3V

FMT-27

9FE

8TE

PI

7

62VC

TZC

5

SSDFCTI

4

3MIRR

2GND

15V

18P

CN004

18TIA+

17TIA-

CN005

RF MON

16TIB+

15TIB-

14SPM-

13SPM+

12SLA-

11SLB+

10SLA+

6P

FFC

FMT-27

9SLB-

8INLIM

7FCS+

6FCS-

5TRK+

4TRK-

3GND

2

1GND

6OCSW2

5GND

4OCSW1

MT-111

3CKSW1

2LDM+

1LDM-

TK-55 BOARD

13PCN002

2P

2P

1 GND

2 RF+

3 RF-

4 SSDFCT

5 SSCS

6 SSRD

7 SSWD

8 SSCK

9 3.3V

10 FE

11 TE

PI

12

13 2VC

TZC

14

SSDFCTI

15

16 MIRR

17 GND

18 5V

1 TIA+

2 TIA-

3 TIB+

4 TIB-

5 SPM-

6 SPM+

7 SLA-

8 SLB+

9 SLA+

10 SLB-

11 INLIM

12 FCS+

13 FCS-

14 TRK+

15 TRK-

16 GND

RF MON

17

18 GND

6 OCSW2

5 GND

4 OCSW1

3 CKSW1

2 LDM+

1 LDM-

18PCN002

CN010

6P

1TXD

2RXD

3DIAG_ON

TO DIAG JIG

4GND

(CHECK)

18PCN003

5N.C.

6+5V

MB-85 BOARD(1/2)

5PCN012

1RF

2GND

TO RF JIG

3FE

(CHECK)

4TE

5PI

CN101

CN009

4P

4GND

3CKSW1

FMS-12

2CKSW2

1OCSW1

6PCN011

15PCN006

1 XIFRST

2 XIFBUSY

3 XIFCS

4SI0

5 SO0

6 SC0

7 GND

8 VMUTE

9 AMUTE

10 SLINK

11 A1IN

12 A1OUT

13 GND

14 MICCONT

15 +3.3V

1 GND

2 CKSW1

3 CKSW2

4 OCSW1

4P

FMF-38

I

CN701

12P

LPLAY 1

LPAUSE 2

LCD 3

LVCD 4

LDVD 5

J

K

05

FR-166 BOARD

GND 6

LSTBY 7

LPOW 8

IR 9

BT 10

EVER5V 11

12GND

DC-DC

CONVERTER UNIT

CN203

(SEE PAGE 4-5)

B to B

PF-124

CN603

1 LPLAY

2 LPAUSE

3 LCD

4 LVCD

5 LDVD

6 GND

7 LSTBY

8 LPOW

9IR

10 BT

11 EVER5V

12 GND

B601

1 PCONT

2 EVER5V

3 GND

4 SW-10V

5 GND

12P

FL-111 BOARD

5P

15P

CN602

15XIFRST

14XIFBUSY

13XIFCS

9GND

8VMUTE

7AMUTE

6SLINK

5A1IN

4A1OUT

3GND

2MICCONT

12SI0

11SO0

10SC0

1+3.3V

CN604

2P

1GND

FS-133

2S101

1 GND

2 S101

CN102

SW-332 BOARD

2P

L

FRAME (1/2)

4-3 4-4

Page 35

FRAME (2) SCHEMATIC DIAGRAM

DVP-F11

1

2734 65

8 9 10 1514131211

A

HP-122 BOARD

3PCN501

B

HPL 1

GND 2

HPR 3

AH-114

1 HPL

2 GND

3 HPR

CN306

3P

J303

WOOFER OUT

S2

S1

V2

V1

J302

AV JACK

L2

R2

L1

R1

J301

COAX

IC309

OPT

C

AU-222 BOARD

CN202

D

6P

6SW-10V

5GND

4SW+10V

PA-127

3GND

2SW+5V

1EVER5V

6SW-10V

5 GND

4 SW+10V

3 GND

2 SW+5V

1 EVER5V

6PCN303

13PCN302

28PCN301

E

13 GAIN2

12 ZFLS

11 AUDIOLS

9 AUDIORS

10 ALSRSGND

FMA-17

F

G

DC-DC CONVERTER UNIT

(MPD0102)

CN201

1

3

4

13PCN007

ZFLS 2

GAIN2

AUDIOLS

AUDIORS 5

7P

7SW+3.3V

6SW+3.3V

5SW+5V

4GND

3GND

2SW+10V

1SW+10V

PM-104

CN001

7P

SW+3.3V

7

SW+3.3V

6

SW+5V

5

GND

4

GND

3

SW+10V

2

SW+10V

1

ALSRSGND

8 ZFC

FFC

ZFC 6

7 AUDIOC

AUDIOC 7

5 AUDIOLFE

6 ACLFEGND

AUDIOLFE 9

ACLFEGND 8

1 ZFRS

2 ZFLFE

3 SWSEL

4 GND

12ZFLFE

13ZFRS

GND 10

SWSEL 11

28P

CN005

28 VIDEOV

1VIDEOV

27 VVGND

2VVGND

26 VIDEOY

3VIDEOY

25 VYCGND

4VYCGND

24 VIDEOC

5VIDEOC

21 VMUTE

22 MAMUTE

23 VS

6VS

7MAMUTE

8VMUTE

20 AMUTE

9AMUTE

17 ALTRTGND

18 AUDIOLT

19 ZFLT

10ZFLT

11AUDIOLT

12ALTRTGND

15 GND

16 AUDIORT

FFC

FMA-18

13AUDIORT

14GND

14 SPDIF

15SPDIF

13 SLINK

16SLINK

12 GAIN1

17GAIN1

11 VFC2

18

VFC2

9 ZFL

10 ZFRT

19ZFRT

20ZFL

8 AUDIOL

21AUDIOL

7 ALRGND

22ALRGND

6 AUDIOR

23AUDIOR

5 GND

24GND

4 A1IN

25A1IN

3 A1OUT

26A1OUT

1 VFC1

2 ZFR

27ZFR

28

VFC1

H

MB-85 BOARD

(2/2)

J201

5PCN203

DC IN

I

05

5 GND

4SW-10V

3 GND

2 EVER5V

1 PCONT

PF-124

J

FL-111 BOARD

B601

(SEE PAGE 4-3)

FRAME (2/2)

4-5 4-6

Page 36

DVP-F11

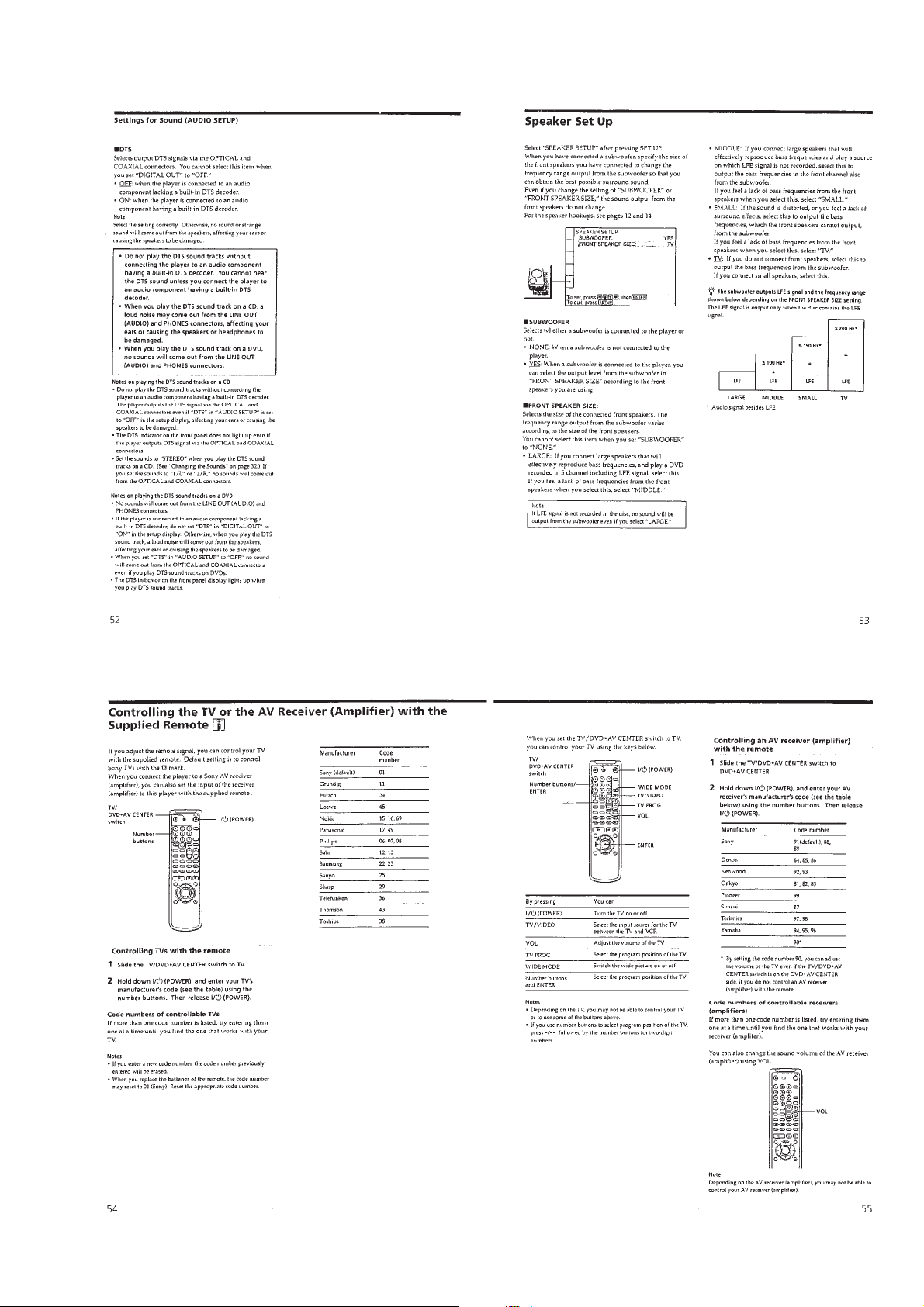

4-2. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

TK-55 (RF/SERVO) PRINTED WIRING BOARD

– Ref. No.: TK-55 board; 2,000 series –

TK-55 BOARD (SIDE A)

CN001 C-2

CN002 C-2

CN003 A-3

CN004 A-2

CN005 B-4

CN006 C-4

CN007 B-4

D003 B-4

IC001 B-3

Q001 C-3

Q002 B-4

There are few cases that the part isn't mounted in this model is printed on this diagram.

EB

C

TK-55

(RF/SERVO)

FR-166

(IR/FUNCTION SWITCH)

SW-332

(CHUCK SENSOR)

FL-111

(IF CON)

B

C

E

MB-85

(SIGNAL PROCESS/SERVO)

AU-222

(AUDIO)

DC-DC Converter Unit

(SWITCHING REGULATOR)

HP-122

(HEAD PHONE)

RF/SERVO

TK-55

4-7 4-8

Page 37

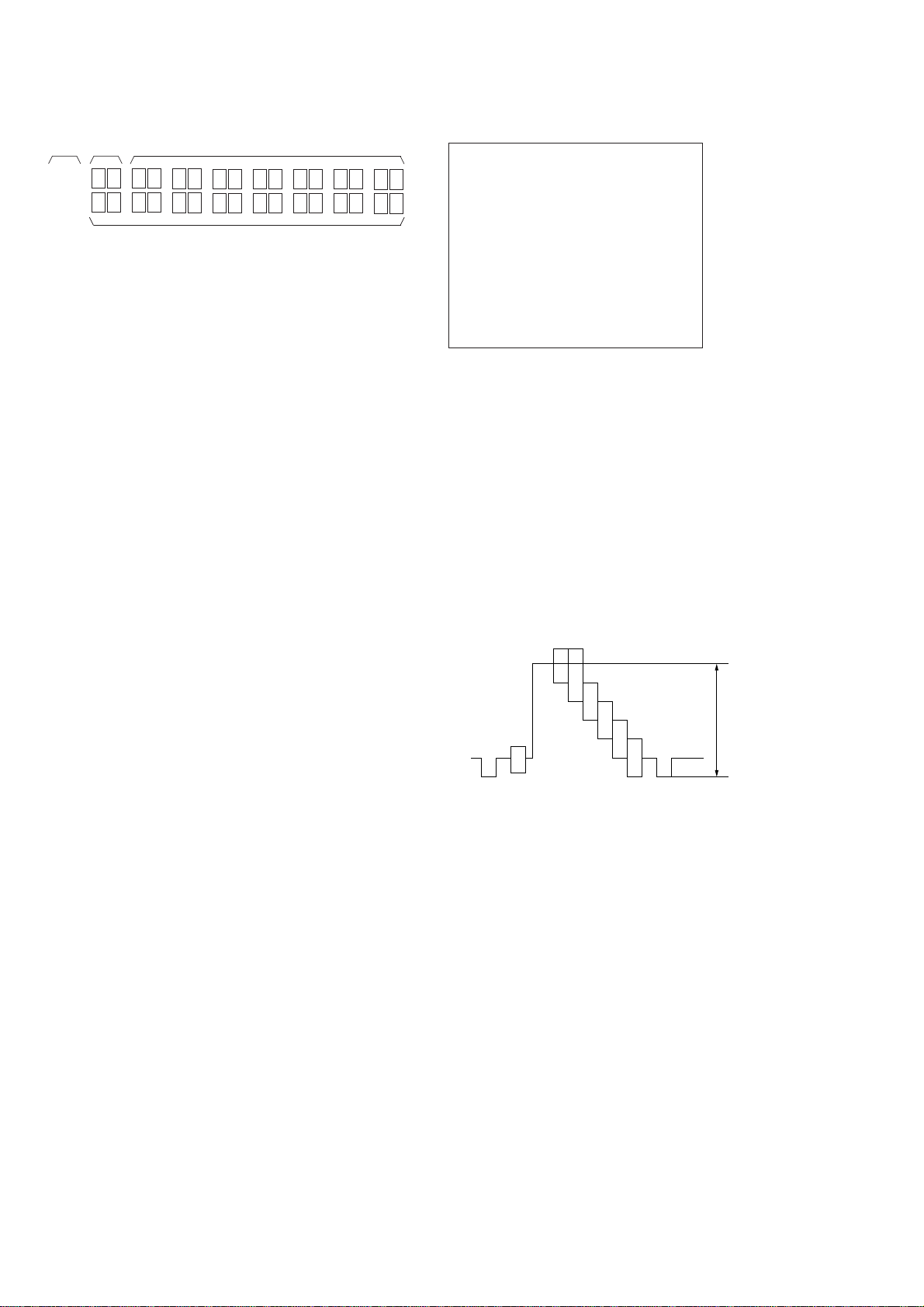

• Wavef orms

1 IC001 1 (DVD play)

200 mV/DIV 100 ns/DIV

DVP-F11

6 IC001 el (CD play)

500 mV/DIV 200 ms/DIV

536 mVp-p

2 IC001 1 (CD play)

500 mV/DIV 500 ns/DIV

880 mVp-p

3 IC001 wl (DVD play)

200 mV/DIV 500 ms/DIV

592 mVp-p

1.7 Vp-p

7 IC001 r; (DVD play)

100 mV/DIV 50 ms/DIV

180 mVp-p

8 IC001 r; (CD play)

500 mV/DIV 50 ms/DIV

860 mVp-p

4 IC001 wl (CD play)

200 mV/DIV 20 ms/DIV

448 mVp-p

5 IC001 el (DVD play)

500 mV/DIV 50 ms/DIV

1.3 Vp-p

9 IC001 tf (DVD play)

500 mV/DIV 100 ns/DIV

1.5 Vp-p

q; IC001 tf (CD play)

500 mV/DIV 500 ns/DIV

1.5 Vp-p

4-9 4-10

RF/SERVO

TK-55

Page 38

DVP-F11

TK-55 (RF/SERVO) SCHEMATIC DIAGRAM • See page 4-7 for printed wiring board and page 4-10 for waveforms.

– Ref. No.: TK-55 board; 2,000 series –

1

A

DVD/CD

LD MODULE

B

DVD/CD

PD IC

C

FOCUS

COIL

D

TRACKING

COIL

OPTICAL

DEVICE

TK-55 BOARD

CN001

23P

N.C. 1

LD 2

GND 3

PD 4

VR 5

VLD 6

RF 7

F8

C9

D10

H11

GND 12

G15

A16

B17

E18

FCS- 20

TRK- 22

N.C. 23

C004

VC(2.5V) 13

VCC(5V) 14

FCS+ 19

TRK+ 21

R002

0.1u

4

LD

100

FCS+

FCS-

TRK+

TRK-

PD

F

H

B

G

E

R003

100

6

C

D

A

B

E

C

D

A

B

F

BASE UNIT

KHM-220AAA/J1N

E

F

G

H

G

PD

H

INLIMIT

SENSOR

SLED

M

MOTOR

I

SPINDLE

M

MOTOR

TILT

M

MOTOR

J

S001

CHUCK

M001

LOADING

MOTOR

SENSOR

M

K

CN002

R001

13P

330

1LED

2INLIM

INLIM

3GND

SLB-

4SLB-(4)

SLA+

5SLA+(2)

SLB+

6SLB+(3)

SLA-

7SLA-(1)

SPM+

8SPM+

SPM-

9SPM-

TIB-

10TIB-(4)

TIB+

11TIB+(3)

TIA-

12TIA-(1)

TIA+

13TIA+(2)

C001

0.1u

C002

0.1u

CN007

2P

1OCSW2

2GND

CN006

2P

1LDM+

2LDM-

LD

L

D003

1SS355TE-17

R004

22k

7

C005

B

2200p

C007

2200p

B

C008

2200p

B

C009

2200p

B

R005

33

Q001

2SB1132-T100-QR

LD DRIVE

CN003

18P

CN004

18P

CN005

6P

6 OCSW2

5 GND

4 OCSW1

3 CKSW1

2 LDM+

1 LDM-

C044

0.1u

C045

0.1u

18123

5V1

GND2

MIRR3

SSDFCTI4

TZC5

2VC6

PI7

TE8

FE9

3.3V10

SSCK11

SSWD12

SSRD13

SSCS14

SSDFCT15

RF-16

RF+17

GND18

GND1

RF MON2

GND3

TRK-4

TRK+5

FCS-6

FCS+7

INLIM8

SLB-9

SLA+10

SLB+11

SLA-12

SPM+13

SPM-14

TIB-15

TIB+16

TIA-17

TIA+18

NO MARK:DVD/CD PLAY

SIGNAL PATH

CL052

CL053

CL054

CL055

CL056

CL057

CL058

CL059

CL060

CL061

CL062

CL063

CL064

CL065

CL066

CL067

0.047u

13

MIRR

SSDFCTI

TZC

PI

SSDFCT

R014

0

SSCS

SSRD

SSWD

SSCK

C035

0.1u

B

R017

4700

10kR015

R018

10k

10kR016

C036

C037

B

560p

C038

0.1u

C039

0.1u

FE

TE

C040

6800p

B

B

B

SSDFCTI

TZC

SSDFCT

17142 161185 159

TE

FE

SSCK

SSWD

SSRD

SSCS

TRK-

TRK+

FCS-

FCS+

INLIM

SLB-

SLA+

SLB+

SLA-

SPM+

SPM-

TIB-

TIB+

TIA-

TIA+

10

C029

0.1u

B

R022

150

C010

0.1u

B

R023

820

B

B

5600p

5600p

C019

C017

12

CL004

3.4

1

22p

22p

22p

22p

C015

C013

C014

C011

R006

33

2.8

R007

47k

2.2

L001

2.8

47uH

C006

10u

16V

CL005

C018

CL006

560p

CL007

CL008

CL009

CL010

CL011

CL012

CL013

CL014

CL015

CL016

CL017

CL018

CL019

C012

10u

16V

R008

10

C016

0.01u

B

RFIP

3.4

2

RFIN

3.4

3

CP

3.4

4

CN

2.5

5

A2

2.5

6

B2

2.5

7

C2

2.5

8

D2

2.6

9

D

2.6

C

10

2.6

B

11

2.6

A

12

2.6

E

13

2.6

F

14

2.6

G

15

2.6

H

16

CL021

R026

0

B

B

0.01u

B

1200p

0.001u

12k

C028

R009

C024

C026

CL030

CL032

CL034

CL036

CL038

CL040

CL042

CL044

4.9

2.9

2.930.6

2.5

2.9

52

53

54

55RX56

57

58

59

VPA

ENV

BYP

SSOUT

CLM

VNA

SIGO

CL020

64

B

0.1u BC022

0.1u

C021

CL022

CL024

CL026

CL028

3.7

3.7

3.4

3.4

60

61

62

63

AIP

AIN

ATOP

ATON

910

IC001

SSI33P3722

IC001

DVD/CD RF AMP,

DIGITAL SERVO

34

VC

VPB18PD19LD20VNB21MP22MB23MLPF24LDON25MIRR26FDCHG27MIN28PI29TPH30DFT31TZC

17

2.5

4.9

0.2

2.2

0.1

2.5

2.504.9

2.5

CL023

CL025

CL027

CL029

CL031

CL033

CL035

CL037

CL039

CL041

CL045

CL043

150p

B

B

C027

C023

C025

0.047u

0.047u

C020

0.1u

B

B

0.1u

C030

R025

220

C041

2200p

B

PI

MIRR

0.1u

C033

CL046

3.4

3.4

51

DIP

DIN

78

56

2.3

CL047

CL048

50

3

CL049

B

0.1u

C032

R010

C031

10u

16V

B

B

0.1u

C034

CL050

2.3

2.2

49

FNP

FNN

0

48

HOLD1

0

47

SIGDET

0

46

SDEN

1.6

45

SRD

3.3

44

SWD

3.3

43

SCLK

0

42

HOLD2

2.7

41

BYP2

1.9

40

FE

2

39

TE

1.8

38

TEI2

1.9

37

TEI

1.8

36

TEO

2.5

35

TZIN

3.3

34

VP3

1.9

33

VCI

32

0

0.4

CL051

R029

2.2M

10k

4.9

Q002

UN5211-TX

INVERTER

R012

0

0

PB

SPINDLE SERVO(SPEED AND PHASE)

TRACKING SERVO DVD/CD CDV

SLED SERVO DVD/CD

FOCUS SERVO

(SEE PAGE 4-23)

(SEE PAGE 4-25)

(SEE PAGE 4-26)

VIDEO SIGNAL

Y/CHROMA

19

MB-85 BOARD

CN002

MB-85 BOARD

CN003

MB-85 BOARD

CN011

AUDIO

SIGNAL

20

SKEW SERVO DVD/CD

05

RF/SERVO

TK-55

Note:The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

4-11 4-12

Page 39

SW-332 (CHUCK SENSOR) PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

S101

S102

S103

JL101

JL102

JL103

JL104

1SS355TE-17

D101

CL105

2P

CN102

1GND

2S101

CN101

4P

GND 1

CKSW1 2

CKSW2 3

OCSW1 4

1

A

B

C

43

05

SW-332 BOARD

25

MB-85 BOARD

CN009

(SEE PAGE 4-32)

CN604

FL-111 BOARD

(SEE PAGE 4-49)

S101-103

(CHUCK SENSOR)

– Ref. No.: SW-332 board; 2,000 series –

There are few cases that the part isn't mounted in this model is printed on this diagram.

DVP-F11

FR-166

(IR/FUNCTION SWITCH)

MB-85

(SIGNAL PROCESS/SERVO)

TK-55

(RF/SERVO)

AU-222

(AUDIO)

FL-111

(IF CON)

HP-122

(HEAD PHONE)

DC-DC Converter Unit

(SWITCHING REGULATOR)

SW-332

(CHUCK SENSOR)

CHUCK SENSOR

4-13 4-14

SW-332

Page 40

DVP-F11

C

E

B

E

B

C

K

KK

AA

A

KK

A

K

A

C

EB

A

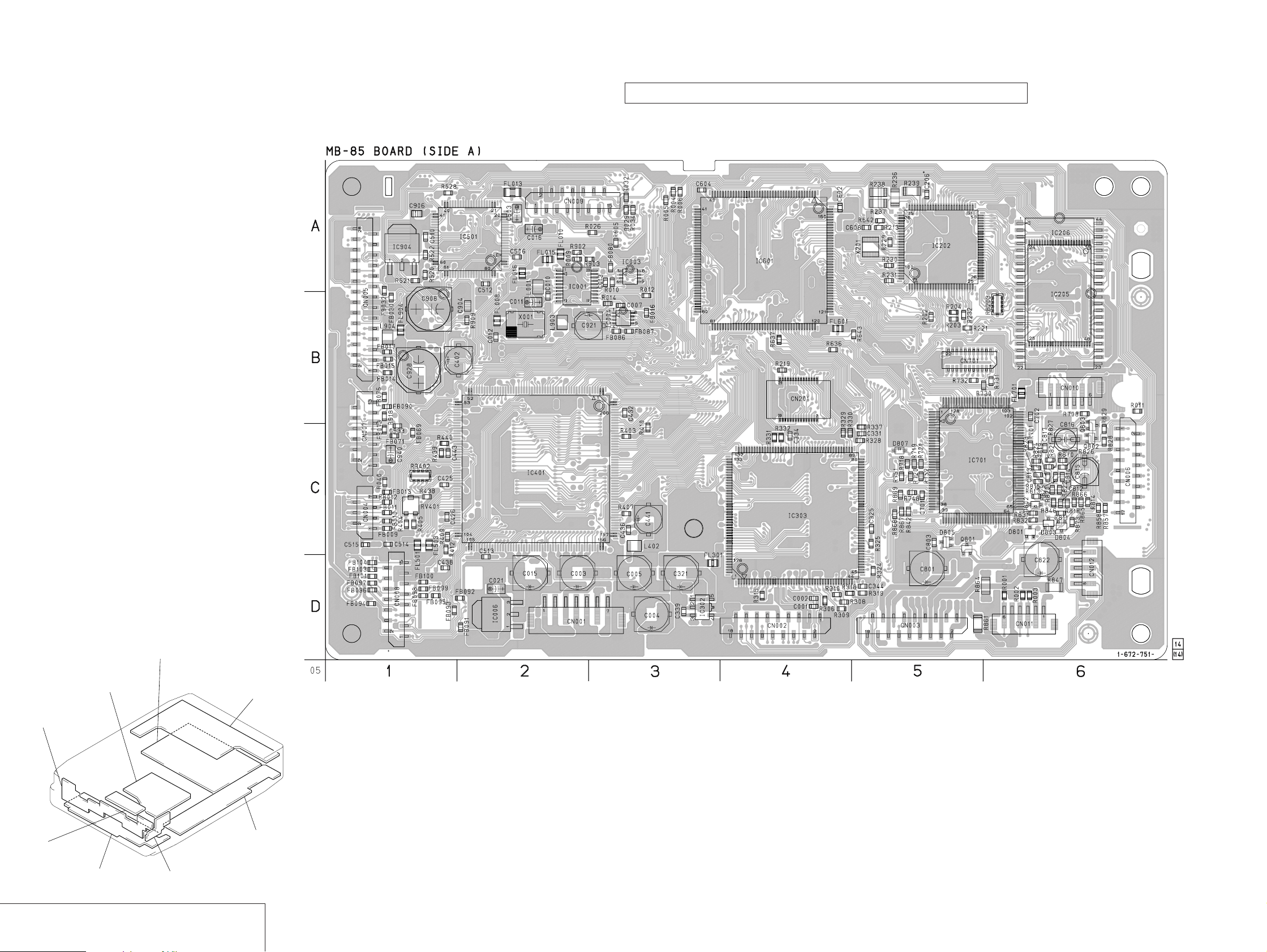

MB-85 (SIGNAL PROCESS/SERVO) PRINTED WIRING BOARD

– Ref. No.: MB-85 board; 1,000 series –

MB-85 BOARD (SIDE A)

CN001 D-2

CN002 D-4

CN003 D-5

CN005 B-1

CN006 C-7

CN007 C-1

CN009 A-2

CN010 B-6

CN011 D-6

CN012 D-6

D801 C-6

D802 C-6

D803 C-6

D804 C-6

D805 C-5

D807 C-5

IC001 A-2

IC003 A-3

IC004 B-3

IC202 A-5

IC205 B-6

IC206 B-6

IC302 D-3

IC303 C-4

IC401 C-2

IC501 A-2

IC601 A-4

IC701 C-5

IC904 A-1

Q801 C-5

Q802 C-6

Q803 C-6

There are few cases that the part isn't mounted in this model is printed on this diagram.

MB-85

(SIGNAL PROCESS/SERVO)

TK-55

(RF/SERVO)

FR-166

(IR/FUNCTION SWITCH)

SW-332

(CHUCK SENSOR)

FL-111

(IF CON)

HP-122

(HEAD PHONE)

DC-DC Converter Unit

(SWITCHING REGULATOR)

SIGNAL PROCESS/SERVO

MB-85

AU-222

(AUDIO)

4-15 4-16

Page 41

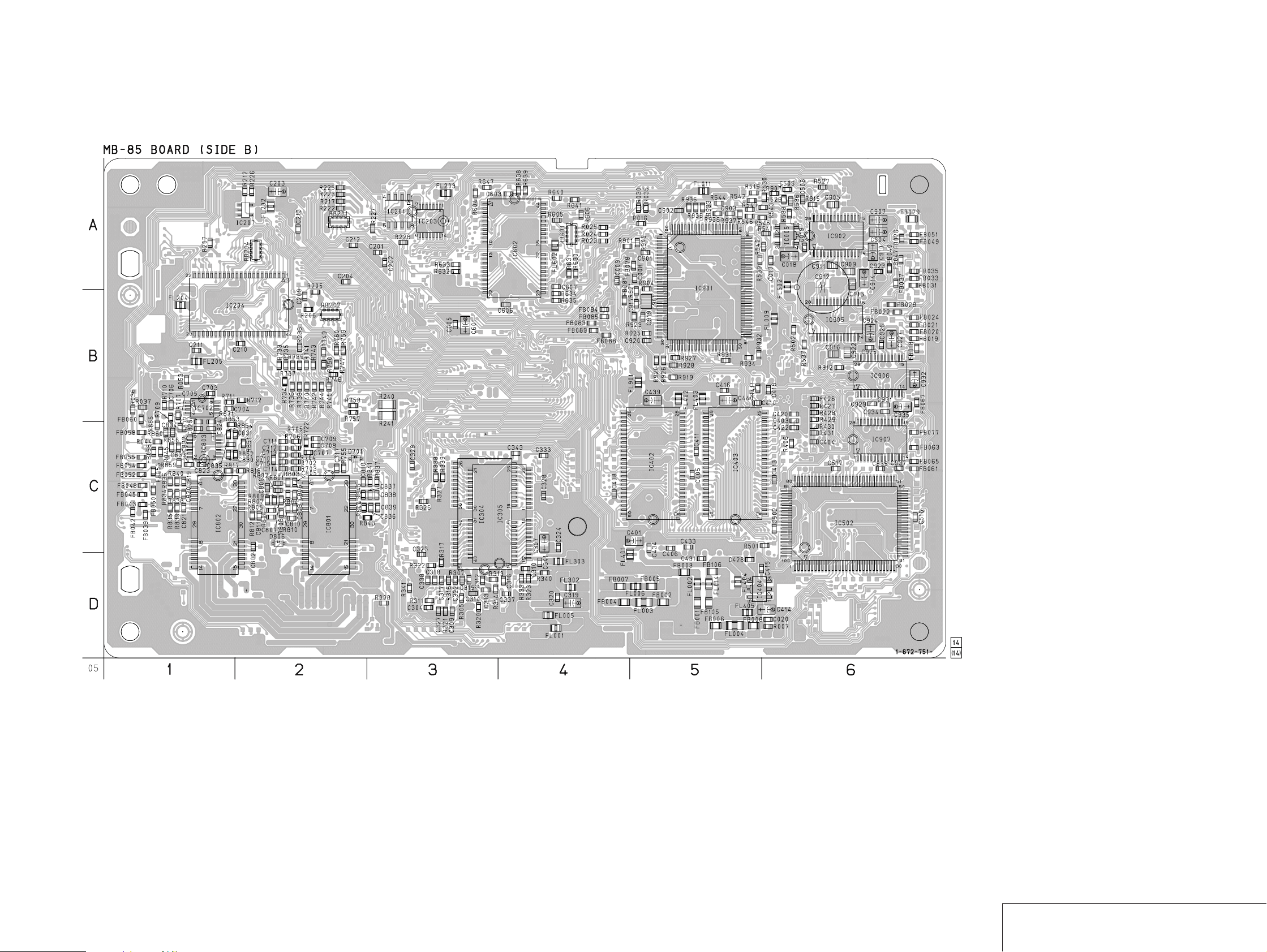

MB-85 BOARD (SIDE B)

15

2

34

D701 C-2

D806 C-2

IC005 A-6

IC201 A-3

IC203 A-3

IC204 B-2

IC207 A-2

IC304 C-3

IC402 C-5

IC403 C-5

IC404 D-5

IC702 B-1

IC801 C-2

IC802 C-1

IC803 C-1

IC902 A-6

IC907 C-6

DVP-F11

4-17 4-18

SIGNAL PROCESS/SERVO

MB-85

Page 42

DVP-F11

MB-85 (AV DECODER) SCHEMATIC DIAGRAM • See page 4-15 for printed wiring board.

– Ref. No.: MB-85 board; 1,000 series –

1

5432

MB-85 BOARD(1/10)

A

B

MB-85 BOARD(6/10)

MB-85 BOARD(6/10)

MB-85 BOARD(7/10)

MB-85 BOARD(6/10)

C

MB-85 BOARD

(6/10)

D

E

256FS30

MB-85 BOARD

F

(8/10)

ACH12

ACH34

(5/10)

(8/10)

(5/10)

(5/10)

33M30

SDCK

SDEF

XSHD

XSAK

XSRQ

ACH56

LRCK

BCK

CDDOUT

CDDATA

CDBCK

CDLRCK

SD0

SD1

SD2

SD3

SD4

SD5

SD6

SD7

MB-85 BOARD

(8/10)

G

MB-85 BOARD

H

MB-85 BOARD

MB-85 BOARD

I

MB-85 BOARD

J

MB-85 BOARD

(10/10)

K

V3.3V

+3.3V

L

VIDEOY

GND

(9/10)

MB-85 BOARD

(10/10)

MB-85 BOARD

(8/10)

VYC

VIDEOC

GND

VV

VIDEOV

+5V

GND

MB-85 BOARD

M

N

XCS2

XCS3

XRD

XWRH

XAVDIT

XAVDWT

DACK0

DREQ0

DACK1

DREQ1

HD0

HD1

HD2

HD3

HD4

HD5

HD6

HD7

HD8

HD9

HD10

HD11

HD12

HD13

HD14

HD15

05

HD0

HD1

HD2

HD3

HD4

HD5

HD6

HD7

HD8

HD9

HD10

HD11

HD12

HD13

HD14

HD15

CL403

CL404

CL405

CL406

CL407

CL408

CL409

SD0

SD1

SD2

SD3

SD4

SD5

SD6

SD7

B+

B+

B+

FL404

FL401

C401

10u

10V

FL405

C414

10u

10V

HD11

HD10

HD9

HD8

HD7

HD6

HD5

HD4

HD3

HD2

HD1

HD0

C416

0.01u

B

R411

10k

C418

0.01u

SD0

B

SD1

SD2

SD3

SD4

SD5

SD6

SD7

C402

100u

4V

CL410

CL411

CL412

CL413

CL414

CL415

B+

3.3

4.9

45

123

CL416

CL417

1.3

C415

0.01u

4.9

B

CL476

CL401

B+

B+

R426

IC404

NJM2370U33-TE2

IC404

+3.3V REG

R410

CL475

B+

1k

B+

1

GND

1.1

2

HD11/PD3

1.1

3

HD10/PD2

0.9

4

HD9/PD1

1.5

5

HD8/PD0

3.3

6

VDD

1.5

7

HD7

1.9

8

HD6

1.3

9

HD5

1.6

10

HD4

11

GND

1.3

12

HD3

0.8

13

HD2

0.8

14

HD1

1.1

15

HD0

3.3

16

VDD

17

N.C.

18

GND

1.1

19

ACLKI

20

GND

1.3

21

ACH120

0.1

22

ACH340

0.1

23

ACH560

3.3

24

VDD

1.6

25

LRCKO

1.6

26

BCKO

1.6

27

DO

28

GND

1.6

29

CDIN2I

0

30

CDIN1I

1.6

31

CDBCKI

1.6

32

CDLRKI

0

33

CDEMPI

34

N.C.

35

GND

1.5

36

CRPCLKI

3.3

37

VDD

0.9~2.2

38

DT0I

0.9~2.2

39

DT1I

0.9~2.2

40

DT2I

0.9~2.2

41

DT3I

0.9~2.2

42

DT4I

0.9~2.2

43

DT5I

44

GND

0.9~2.2

45

DT6I

0.9~2.2

46

DT7I

1.6

47

ICLKI

3.3

48

IERRIN

3.3

49

ISTARTIN

0

50

IVALIN

2.8

51

IREQON

52

PWMO

B+

B+

R428

R427

220

220

220

C432

0.01u

B

HD12

HD13

HD14

HD15

197

198

199

200

201

202

203

204

205

206

207

208

1.1

3.3

53

R429

220

3.3

1.5

1.2

0.9

HD12/PD4

VDD

0.6

3.3

3.3

3.3

3.3

3.3

VDD

GND

HD15/PD7

HD14/PD6

HD13/PD5

R/B-Y OUT54AGND55AVDD56B/R-Y OUT57G/Y OUT58AGND59AVDD60Y_OUT61C_OUT62AGND63AVDD64COMP_OUT65VGO66VBD67AGND68AVDD69VREFI70IREFI71FLDO72HSYNCON73GND74PDI775PDI676PDI577PDI478VDD79PDI380PDI281PDI182PDI083VDD84GND85PDO086PDO187PDO288PDO389GND90PDO491PDO592PDO693PDO794VDD95GND96N.C.97NR_SDOUT98NR_SENO99FLDI

3.3

1.7

0.6

C420

0.01u

B

R430

R431

220

220

DMRQ0ON

3.3

DMACK0IN

0.6

DMRQION

1

1.7

DMACK1IN

HWAITON

2

3.3

C422

0.01u

B

MB-85 BOARD(2/10)

(SEE PAGE 4-21)

MB-85 BOARD(6/10)

1817161514

1

131211109876

XIFAVRST

1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

HA3

HA2

HA1

HA0

R403

10k

191

192

193

194

195

196

3.3

GND

HIRQON

3.3

3.3

HCPUMDI

HRW/HWIN

HCS/HRDIN

HAD0I

2.001.6

HAD1I

HA4

186

187

188

189

190

1.5

2.4

3.3

1.8

1.5

VDD

HAD4I

HAD3I

HAD2I

3

0.6

2.1

1.1

3.3

0.4

0.4

1.6

3.0

1.8

B

C443

0.01u

3300

R405

1k

RV401

C403

C404

0.1u

0.1u

R404

B

B

RV401

VIDEO

LEVEL

ADJ

PDI7

0

1200

R406

HAD5I

HA5

185

0.8

1.1

HAD6I

PDI6

HA6

184

1.2

0.8

HAD7I

IC401

AV DECODER

1.1

1.6

PDI5

HA8

HA7

182

183

1.4

HAD8I

IC401

CXD1930BQ

3.3

PDI4

HAD9I

HA9

HA11

HA10

HA12

177

178

179

180

181

3.3

1.3

1.6

3.3

GND

HAD12I

HAD11I

HAD10I

1.0

0.4

1.1

0.9

3.3

C425

PDI3

PDI2

PDI1

PDI0

HAD13I

0.01u

RB402

HA17

HA16

HA15

HA14

HA13

172

173

174

175

176

0.6

1.6

3.3

3.3

0.6

HAD17I

HAD16I

HAD15I

HAD14I

0.9

1.1

0.4

1.0

B

10k

PDO0

PDO1

PDO2

PDO3

HAD18I

HA21

HA20

HA19

HA18

C434

0.01u

B

166

167

168

169

170

171

3.3

3.3

3.302.8

0.8

VDD

HAD22I

HAD21I

HAD20I

HAD19I

1.6

1.1

1.1

1.8

3.3

C426

0.01u

PDO4

PDO5

PDO6

PDO7

B

L402

10uH

R407

HAD23I

C436

0.01u

B

C441

100u

10k

165

3.3

TESTIN

4V

157

158

159

160

161

162

163

164

1.6

GND

0

SCLKIN

3.3

1.6

3.3

3.3

VDD

VDD

3.3

100

CL418

GND

CLKI

AVDD

AGND

HSYNCIN

SHTDWNIN

RSTIN

VDD

3.3

3.3

3.3

101

102

103

104

R409

0

CL419

C438

0.01u

B

B+

1.9

SDDQ0

156

2.2

SDDQ15

155

GND

154

2.0

SDDQ1

153

2.0

SDDQ14

152

3.3

VDD

151

1.5

SDDQ2

150

2.1

SDDQ13

149

GND

148

2.0

SDDQ3

147

2.1

SDDQ12

146

3.3

VDD

145

2.1

SDDQ4

144

2.0

SDDQ11

143

GND

142

2.1

SDDQ5

141

1.5

SDDQ10

140

3.3

VDD

139

2.0

SDDQ6

138

2.1

SDDQ9

137

GND

136

2.2

SDDQ7

135

1.9

SDDQ8

134

3.3

VDD

133

0.1

SDDQM0O

132

0.1

SDDQM1O

131

3.0

SDWEON

130

2.7

SDCASON

129

GND

128

SDCLKO

127

GND

126

1.6

DCLKI

125

3.3

VDD

124

2.5

SDRASON

123

3.2

SDCKEO

122

2.7

SDCS0ON

121

3.0

SDCS1ON

120

GND

119

1.4

SDAD11O

118

0.1

SDAD9O

117

0.1

SDAD10O

116

0.1

SDAD8O

115

3.3

VDD

114

0.1

SDAD0O

113

1.7

SDAD7O

112

0.6

SDAD1O

111

2.2

SDAD6O

110

GND

109

1.2

SDAD2O

108

1.7

SDAD5O

107

1.4

SDAD3O

106

1.5

SDAD4O

105

NO MARK:DVD/CD PLAY

SIGNAL PATH

VIDEO SIGNAL

CL420

CL421

CL422

CL423

C433

0.01u

B

CL424

CL425

CL426

CL427

C431

0.01u

B

CL428

CL429

CL430

CL431

CL432

CL433

CL434

CL435

CL436

CL437

CL438

CL439

CL440

C428

0.01u

B

CL441

CL442

CL443

CL444

CL445

CL446

CL447

CL448

CL449

CL450

CL451

CL452

CL453

CL454

CL455

CL456

YCHROMA Y/CHROMA

DDT15

DDT14

DDT13

DDT12

DDT11

DDT10

DDT0

DDT1

DDT2

DDT3

DDT4

DDT5

DDT6

DDT9

DDT7

DDT8

AUDIO

SIGNAL

DAD11

DAD9

DAD10

DAD8

DAD0

DAD7

DAD1

DAD6

DAD2

DAD5

DAD3

DAD4

PB

AV DECODER

MB-85 (1/10)

4-19 4-20

Page 43

MB-85 (SDRAM) SCHEMATIC DIAGRAM • See page 4-15 for printed wiring board.

– Ref. No.: MB-85 board; 1,000 series –

1

5432

MB-85 BOARD(2/10)

A

B

C

D

E

1

MB-85 BOARD(1/10)

(SEE PAGE 4-20)

F

G

H

I

J

K

L

1

2

IC402

3

4

C405

0.01u

B

C406

0.01u

C410

0.01u

C411

0.01u

CL477

B

CL478

B

B

DDT0

DDT1

DDT2

DDT3

DDT4

DDT5

DDT6

DDT7

DAD11

DAD10

DAD0

DAD1

DAD2

DAD3

5

6

7

8

DAD11

DAD10

DAD0

DAD1

DAD2

DAD3

DDT0

DDT1

DDT2

DDT3

DDT4

DDT5

DDT6

DDT7

9

10

11

12

13