SONY DSLR-A100 Service Manual

DSLR-A100

SERVICE MANUAL

Ver 1.2 2006.07

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Revised-1

Link

Link

SPECIFICATIONS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Korea Model

Japanese Model

Tourist Model

PRINTED WIRING BOARDS

SERVICE NOTE

DISASSEMBLY

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

FRAME SCHEMATIC DIAGRAM

SCHEMATIC DIAGRAMS

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

DIGITAL SINGLE LENS REFLEX CAMERA

REPAIR PARTS LIST

DSLR-A100_L2

Sony EMCS Co.

2006G0500-1

© 2006.7

Published by Kohda TEC9-852-130-32

SPECIFICATIONS

Camera

[System]

Camera Type Digital Single Lens Reflex

Lens All of Sony Lens

[CCD]

Total pixel number of camera

Effective pixel number of camera

Image sensor 23.6 × 15.8mm (APS-C format)

[Super SteadyShot]

System CCD-Shift mechanism

Super SteadyShot Compensation capability

[Anti-Dust]

System Charge protection coating on

[Viewfinder]

Type Fixed eye-level system with

Focusing Screen Spherical Acute Matte

Field of View 0.95

Magnification 0.83 × with 50 mm lens at

Eye Relief Approximately 20mm from the

Dioptor Adjustment

[Auto Focus System]

System TTL phase-detection system,

Sensitivity Range

Camera with built-in flash and

interchangeable lenses

Approx. 10 800 000 pixels

Approx. 10 200 000 pixels

Interlace scan Primary Color

Approximately 2 EV to 3.5 EV

decrease in shutter speed

(varies according to shooting

conditions and lens used)

Low-Pass Filter and CCD-Shift

mechanism

roof mirror type pentaprism

infinity, –1 m

eyepiece, 16mm from the

eyepiece frame at –1 diopter

(–1m

–2.5 to +1.0 m

CCD line sensors (9 points, 8

lines with center cross-hair

sensor)

0 EV to 18 EV (at ISO 100

equivalent)

–1

–1

)

–1

[Exposure]

Metering Cell 40-segment honeycomb-pattern

Metering Range +1 EV to +20 EV (+4 EV to

SPC

+20 EV with Spot metering),

(at ISO 100 with F1.4 lens)

[Shutter]

Type Electronically-controlled,

Speed range 1/4000 second to 30 seconds,

Flash Sync Speed

vertical-traverse, focal-plane

type

bulb

1/160 second (with Super

SteadyShot off),

1/125 second (with Super

SteadyShot on)

[Built-In-Flash]

Flash G.No. GN 12 (in meters at ISO 100)

Recycling Time Approx. 3 seconds

[Recording media]

CompactFlash card(TypeI,II),

Microdrive, “Memory Stick

Duo” (with Memory Stick Duo

Adaptor for CF Slot)

[LCD monitor]

LCD panel 6.2 cm (2.5type) TFT drive

Total number of dots

230 000 (960×240) dots

[Power, general]

Used battery pack

Rechargeable battery pack

NP-FM55H

[Others]

PictBridge Compatible

Exif Print Compatible

PRINT Image Matching III

Dimensions 133.1 × 94.7 × 71.3 mm

Mass Approx.545 g (1 lb 3.2 oz)

Compatible

(5 1/4 × 33/4 × 27/8 inches)

(W/H/D, excluding protrusions)

(without batteries, recording

medium and body accessories)

Operating temperature

Exif Exif Ver. 2.21

USB communication

0 to +40°C (+32 to +104°F)

(When using the Microdrive:

+5 to +40°C (41 to +104°F))

Hi-Speed USB (USB 2.0

compliant)

BC-VM10 Battery charger

Input rating 100 V to 240 V AC, 50/60 Hz

Output rating 8.4 V DC, 750 mA

Operating temperature range

Storage temperature range

Maximum dimensions

Mass Approx. 90 g (3.2 oz)

0 to +40°C (32 to +104°F)

-20 to +60°C (-4 to +140°F)

Approx. 70 × 25 × 95 mm

(2 7/8 × 1× 3 3/4 inches) (W/H/

D)

Rechargeable battery pack NP-FM55H

Used battery Lithium-ion battery

Maximum voltage

Nominal voltage DC 7.2 V

Capacity 11.5 Wh (1 600 mAh)

Maximum dimensions

Mass Approx. 78 g (2.8 oz)

Design and specifications are subject to change

without notice.

DC 8.4 V

Approx. 38.2 × 20.5 × 55.6 mm

(1 9/16 × 13/16 × 2 1/4 inches)

(W/H/D)

DSLR-A100_L2

— 2 —

TABLE OF CONTENTS

Section Title Page

1. SERVICE NOTE

1-1. Chemicals ········································································ 1-1

1-2. Exterior Parts ···································································1-1

1-3. Unleaded Solder ······························································ 1-1

1-4. Safety Check-out ····························································· 1-1

1-5. Note for Replacing Fuse on the AM-001 Board·············· 1-2

1-6. Demagnetization Method ················································ 1-2

2. DISASSEMBLY

2-1. Disassembly ····································································· 2-2

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/4) ··········································· 3-1

3-2. Overall Block Diagram (2/4) ··········································· 3-2

3-3. Overall Block Diagram (3/4) ··········································· 3-3

3-4. Overall Block Diagram (4/4) ··········································· 3-4

3-5. Power Block Diagram (1/3)·············································3-5

3-6. Power Block Diagram (2/3)·············································3-6

3-7. Power Block Diagram (3/3)·············································3-7

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram ·············································· 4-1

4-2. Schematic Diagrams ························································4-3

4-3. Printed Wiring Boards ··················································· 4-23

5. REPAIR PARTS LIST

5-1. Exploded Views ·······························································5-2

DSLR-A100_L2

— 3 —

1. SERVICE NOTE

1-1. CHEMICALS

Some chemicals used for servicing are highly volatile.

Their evaporation caused by improper management affects your health and environment, and wastes resources.

Manage the chemicals carefully as follows.

• Store chemicals sealed in a specific place to prevent from exposure to high temperature or direct sunlight.

•Avoid dividing chemicals into excessive numbers of small containers to reduce natural evaporation.

•Keep containers sealed to avoid natural evaporation when chemicals are not in use.

•Avoid using chemicals as much as possible. When using chemicals, divide only required amount to a small plate from the container and

use up it.

1-2. EXTERIOR PARTS

Be careful to the following points for plastic parts used in this unit.

• Use a piece of cleaning paper or cleaning cloth for cleaning plastic parts. Avoid using chemicals.

Even if you have to use chemicals to clean heavy dirt, don’t use paint thinner, ketone, nor alcohol.

• Insert the specific screws vertically to the part when installing a plastic part.

Be careful not to tighten screws too much.

1-3. UNLEADED SOLDER

This unit uses unleaded solder.

Boards requiring use of unleaded solder are printed with the lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

Be careful to the following points to solder or unsolder.

• Set the soldering iron tip temperature to 350 °C approximately.

If cannot control temperature, solder/unsolder at high temperature for a short time.

Caution: The printed pattern (copper foil) may peel away if the heated tip is applied for too long, so be careful!

Unleaded solder is more viscous (sticky, less prone to flow) than ordinary solder so use caution not to let solder bridges occur

such as on IC pins, etc.

• Be sure to control soldering iron tips used for unleaded solder and those for leaded solder so they are managed separately. Mixing

unleaded solder and leaded solder will cause detachment phenomenon.

1-4. SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs of deterioration. Point them out to the customer and recommend their

replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 °C during repairing.

• Do not touch the soldering iron on the same conductor of the circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or unsoldering.

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

DSLR-A100_L2

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

1-1

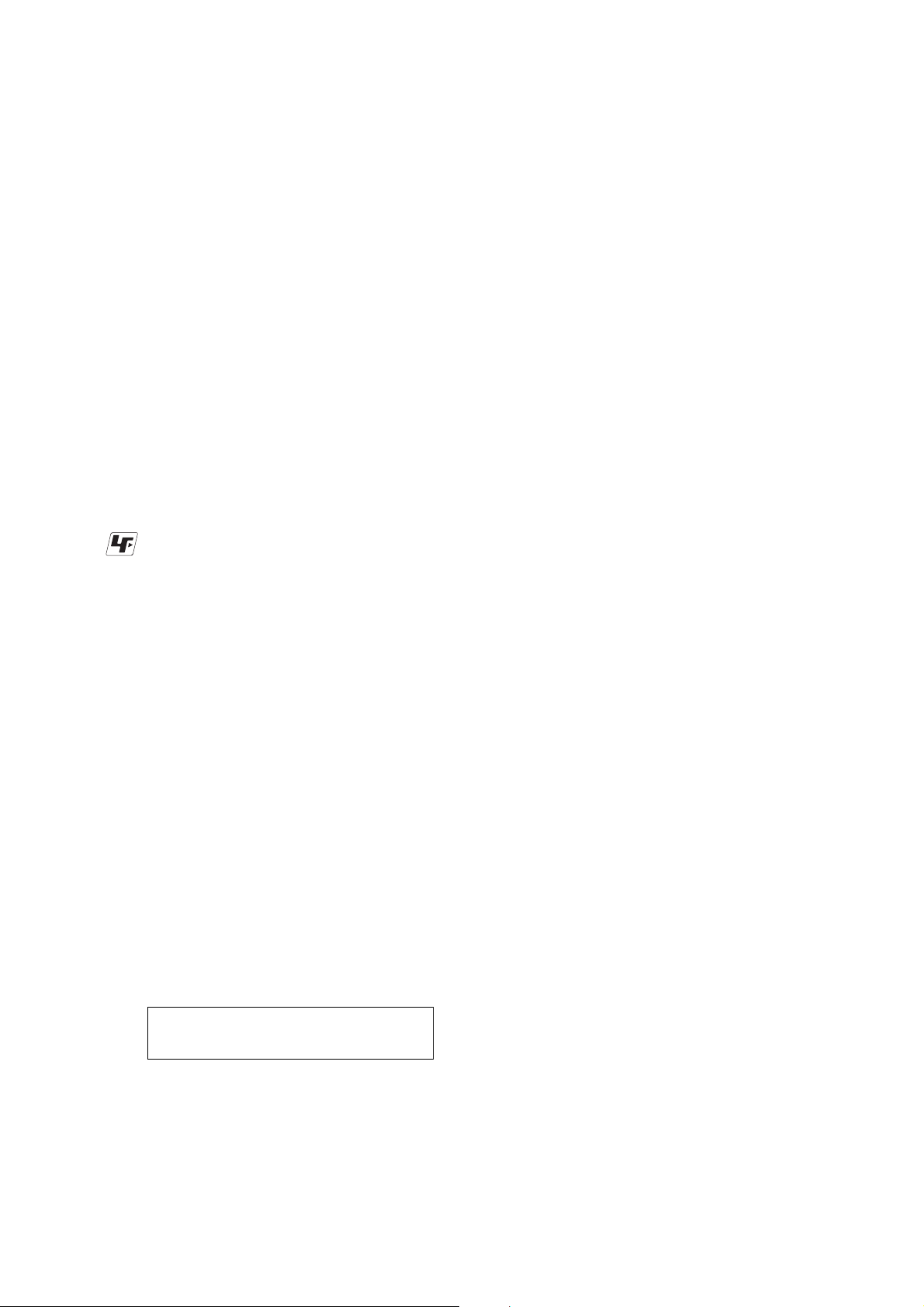

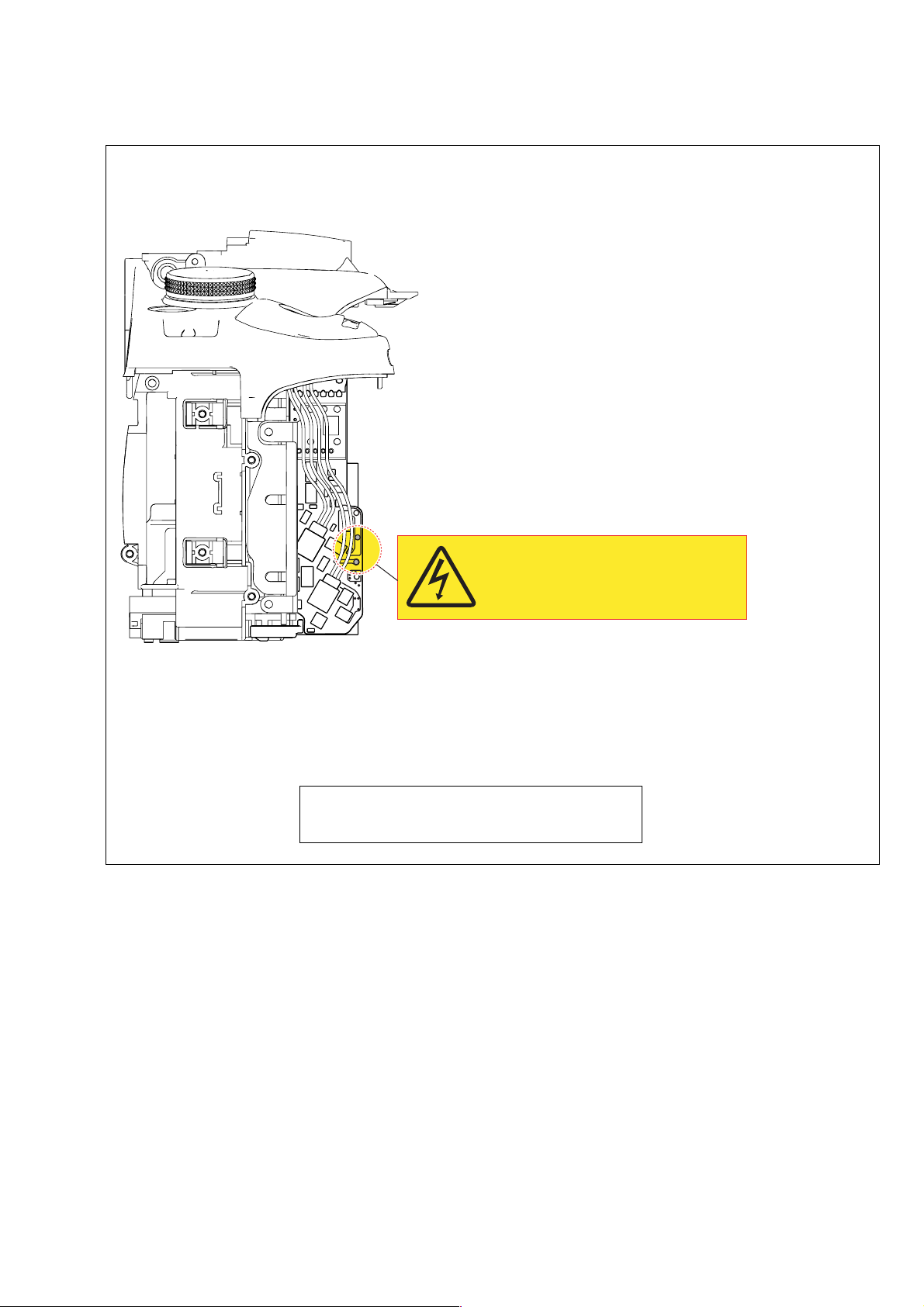

1-5. NOTE FOR REPLACING FUSE ON THE AM-001 BOARD

The caution label for fuse replacing on the AM-001 board is put under the DD-268 board. When replacing the fuse, remove the DD-268 board

and refer to this label.

1-6. DEMAGNETIZATION METHOD

It is easy to receive the influence of the outside magnetism because the slant sensor switch (S624) has the magnet in the inside.

Horizontal and vertical cannot be detected when the influence of magnetism is received, and the display of the LCD panel doesn't change.

Therefore, it is necessary to degauss the screw in the vicinity of the switch.

S624

– AM-001 Board: Side B –

Note it because the user magnetizes set occasionally.

Refer to next page for the demagnetization method.

DSLR-A100_L2

1-2

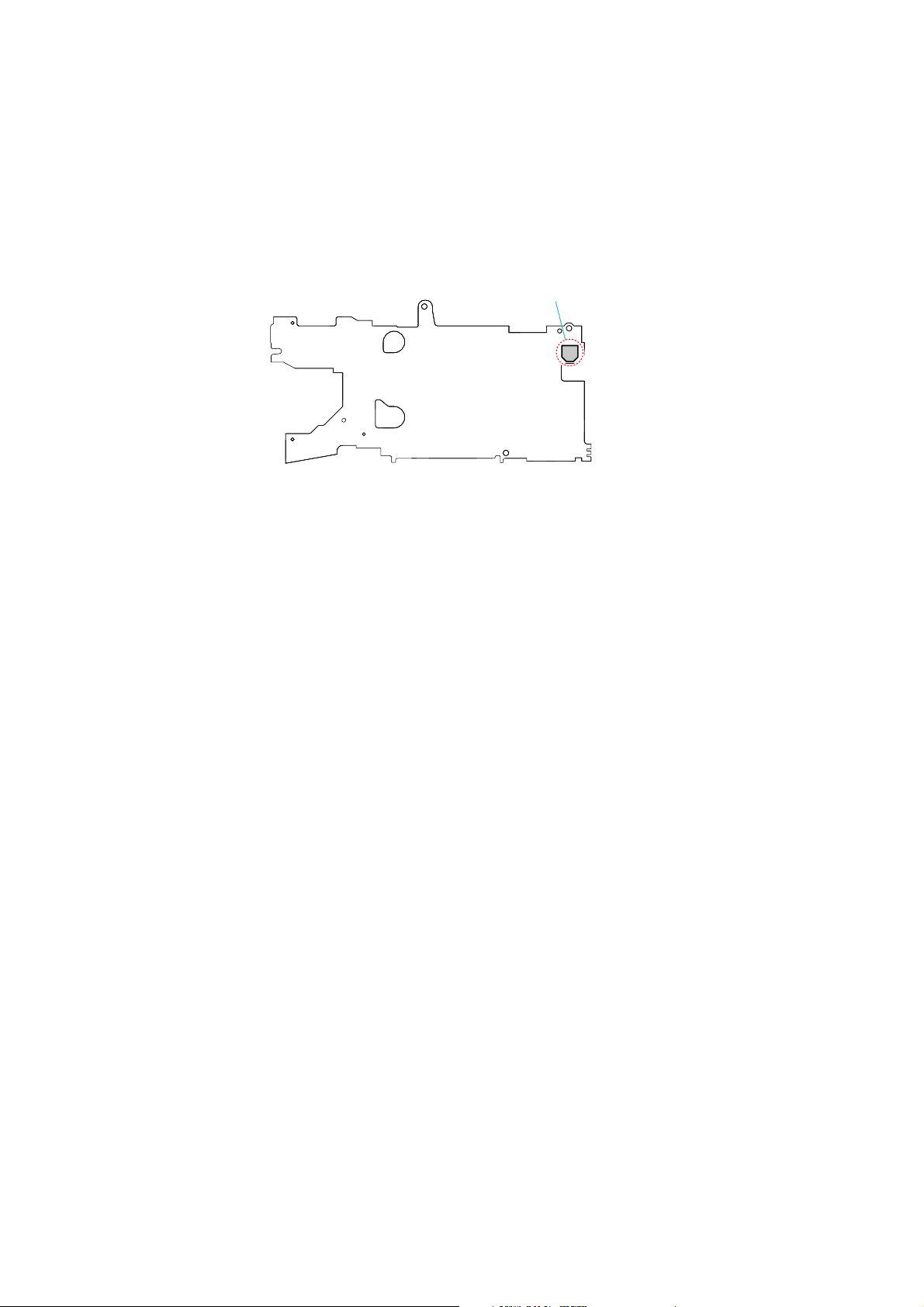

Tools to be prepared:

Push a magnet to the right side of MENU button to

demagnetize.

In the state shown below, operate the demagnetizer for 5 seconds,

and with the demagnetizer operated, detach it in the arrow direction.

At this time, hold the magnet in same position, and remove it after

the demagnetizer was detached.

MENU Button

Magnet

Demagnetizer

Push a magnet to the side of Display button (side surface

of the camera) to demagnetize.

In the state shown below, operate the demagnetizer for 5 seconds,

and with the demagnetizer operated, detach it in the arrow direction.

At this time, hold the magnet in same position, and remove it after

the demagnetizer was detached.

Display Button

Magnet

Demagnetizer

Push a magnet over the Playback button to demagnetize. In the state shown below, operate the demagnetizer for 5 seconds,

and with the demagnetizer operated, detach it in the arrow direction.

At this time, hold the magnet in same position, and remove it after

the demagnetizer was detached.

Magnet

Playback Button

Demagnetizer

Magnet (cover with a tape, etc. for damage prevention)

Demagnetizer

STEP 1:

STEP 2:

STEP 3:

• SLANT SENSOR SWITCH OPERATION INSPECTION

Using the camera already demagnetized, perform the posture switching by five sets, one set comprising “normal posture → Grip up →

Grip down”, to confirm that the LCD display changes over correctly.

DSLR-A100_L2

1-3E

2. DISASSEMBLY

DISCHARGING OF THE MAIN CAPACITOR UNIT

Before disassembly, be sure to discharge the main capacitor unit in the following manner.

Short-circuit the capacitor using the discharger

or a resistor of about 200-300Ω/3W.

After discharge, check the voltage.

SUBSIDIARY MATERIALS

G: Grease B: Bond

G-15 (J-6082-619-A) B-20 (Adhesive (LOCTITE 460)) (Note)

G-85 (J-6082-626-A) B-50 (J-6082-615-A)

G-115 (J-6082-627-A) B-60 (J-6082-616-A)

Note: Use adhesive (LOCTITE 460) or an equivalent article.

Don’t use what becomes white after drying like a quickdrying glue.

DSLR-A100_L2

2-1

HELP

HELP

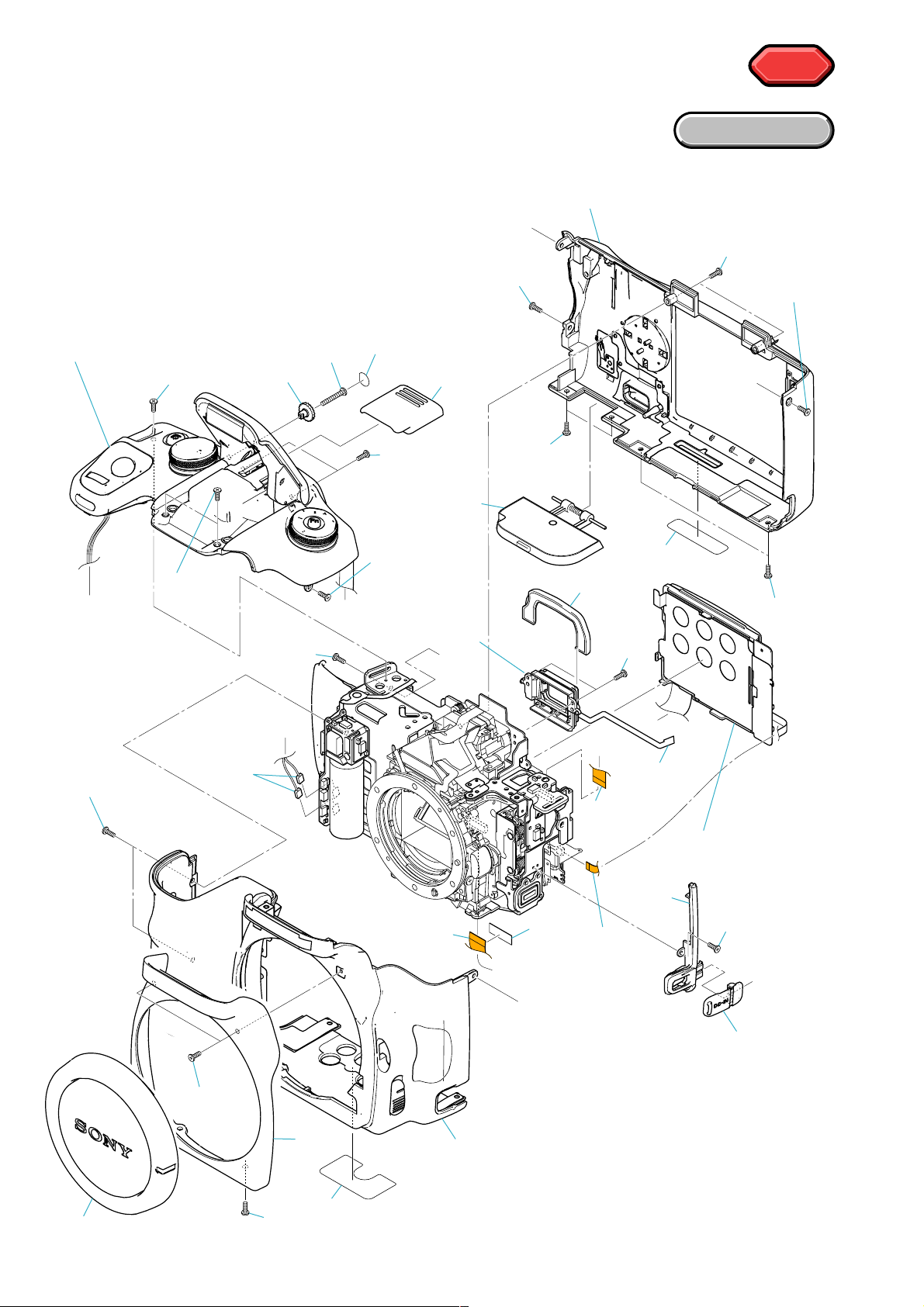

2-1. DISASSEMBLY

2-1-1. OVERALL SECTION

Follow the disassembly in the numerical order given.

1 LCD Holder Unit (1-1 to 1-22)

2 Top Cover Unit (2-1 to 2-11)

3 Eye Piece Frame Unit (3-1 to 3-2)

2 Top Cover Unit

2-10

1-11

1-10

1-9

2-11

2-9

1-3

1-19

(Fig. 1-1)

EXPLODED VIEW

1-18

D

1-17

1-16

1-14

E

1-13

1-4

A

2-1

2-2

2-8

(Fig. 1-3)

1-15

A

B

3 Eye Piece

Frame Unit

1-22

(Fig. 1-2)

D

C

1-21

(Fig. 1-2)

E

1-2

3-2

B

2-7

(Fig. 1-2)

1-20

(Fig. 1-2)

C

3-1

(Fig. 1-4)

1 LCD Holder

(Fig. 1-6, 1-7)

Unit

2-5

2-4

1-12

1-1

DSLR-A100_L2

1-6

1-7

1-8

1-5

(Fig. 1-5)

2-6

2-3

2-2

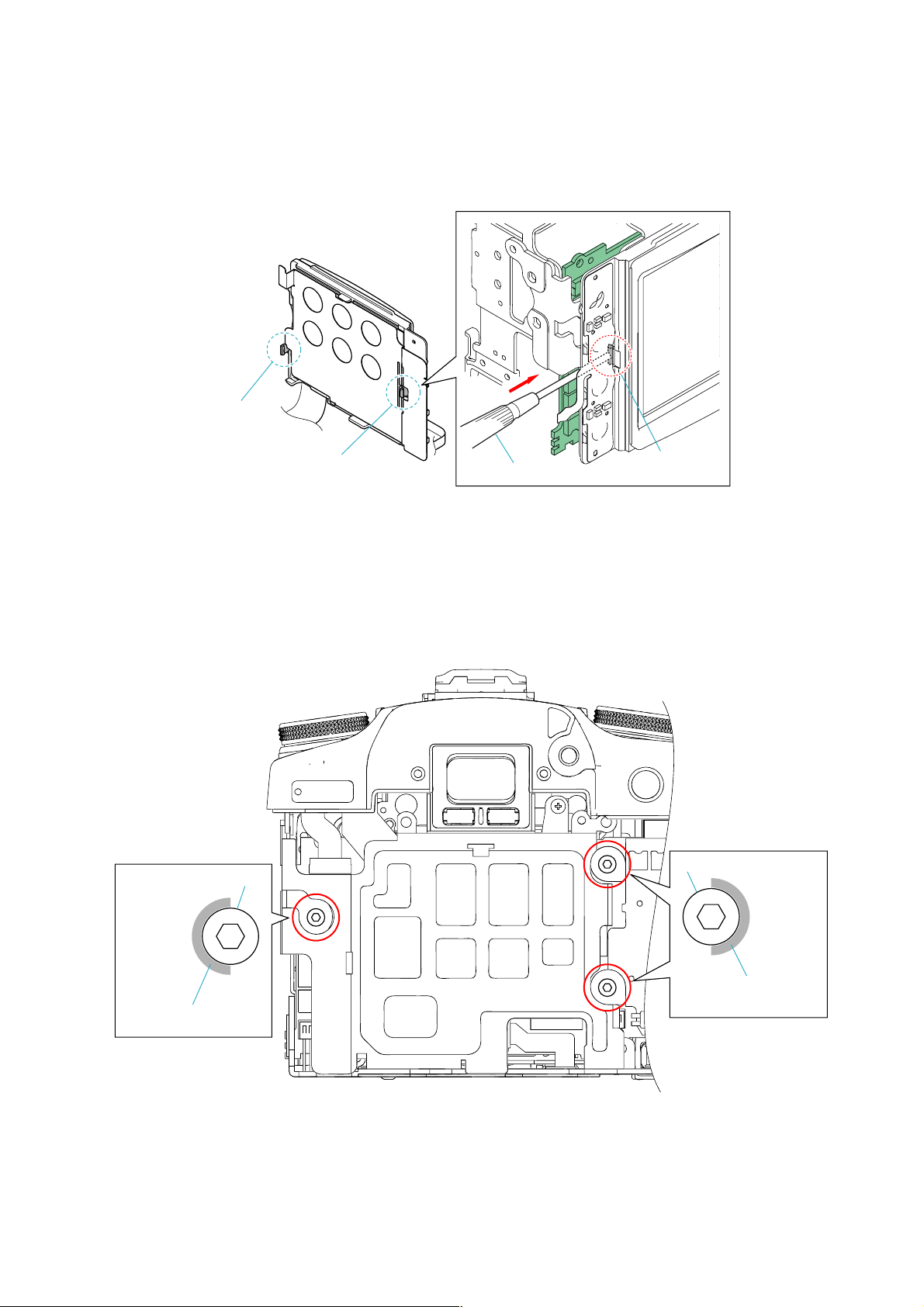

Red Connector

Wires arrangement

Yellow Connector

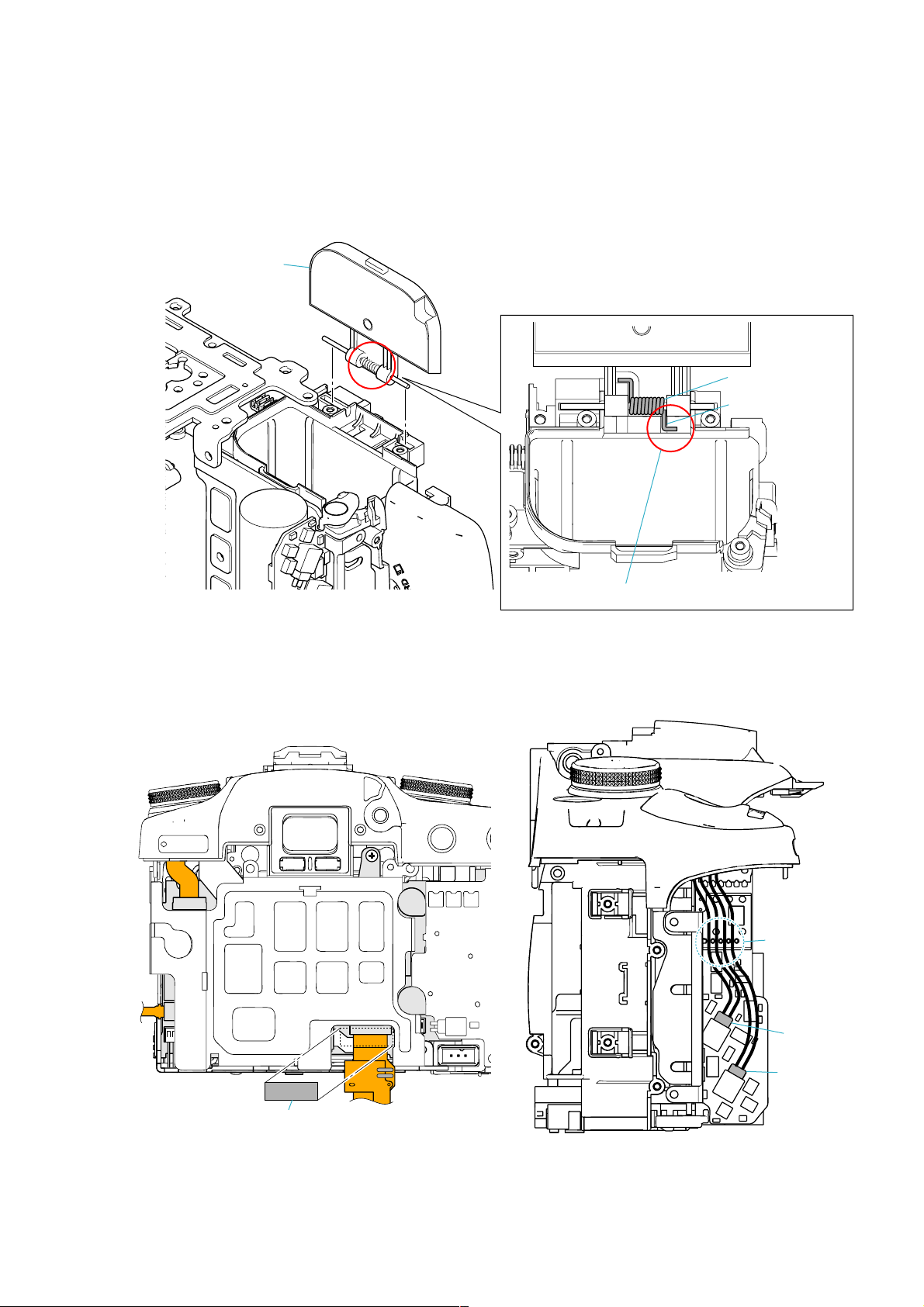

Fig. 1-2

FPC Sticking Tape

Fig. 1-3

Battery Cover Unit

Fig. 1-1

Battery Cover Spring

Install it while charging with the hook of the spring.

Slot

DSLR-A100_L2

2-3

Solder 4 points

Don’t tear.

Fig. 1-4

DSLR-A100_L2

S Adjustment Screw

(Yaw adjust)

B: B-50

Fig. 1-5

2-4

S Adjustment Screw

(Pitch adjust)

Claw

CCD AO Adjustment Screw

Claw

This claw does not see

from the outside.

Claw

Screwdriver

Fig. 1-6

CCD AO Adjustment Screw

DSLR-A100_L2

B: B-50

B: B-50

Fig. 1-7

2-5

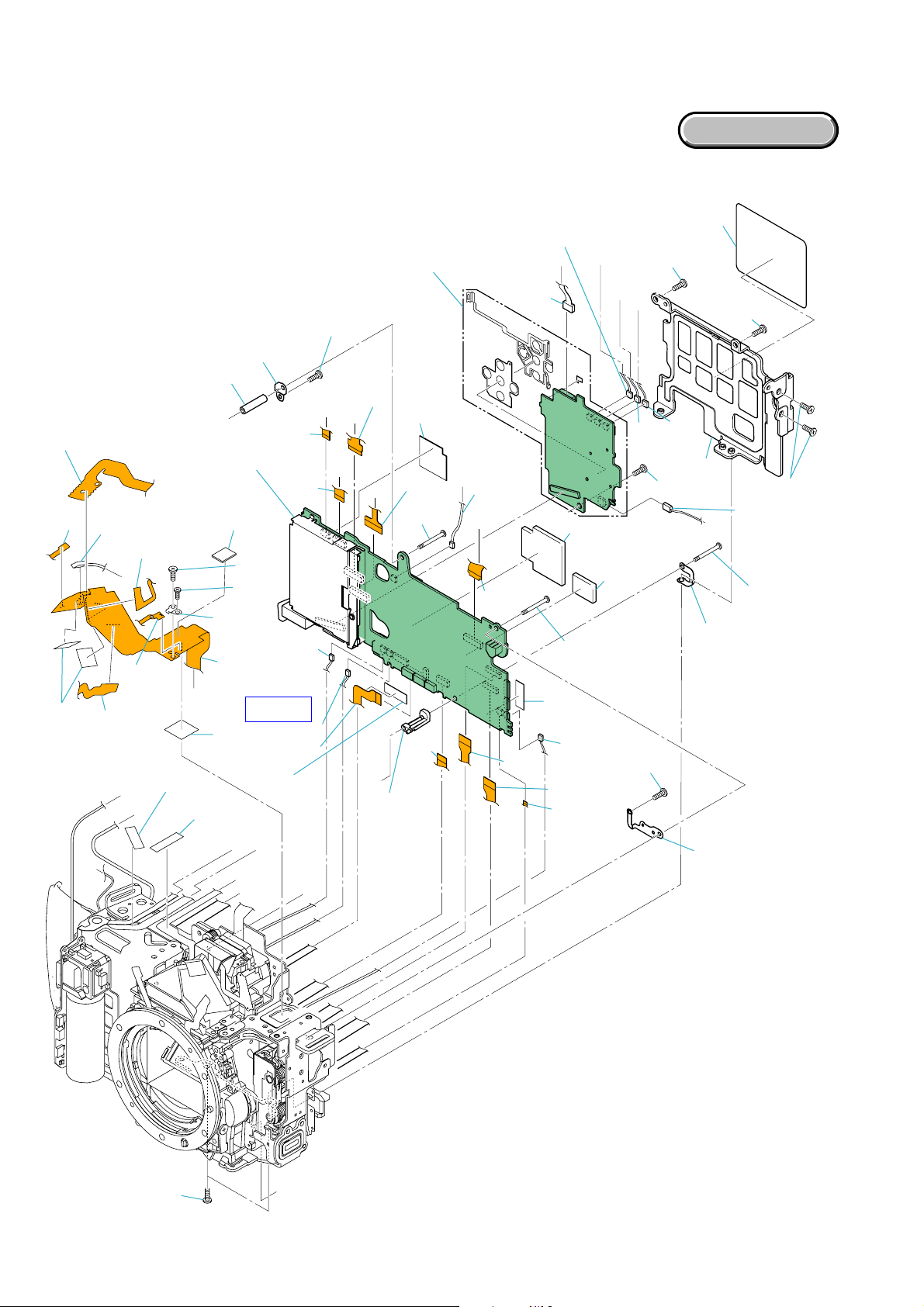

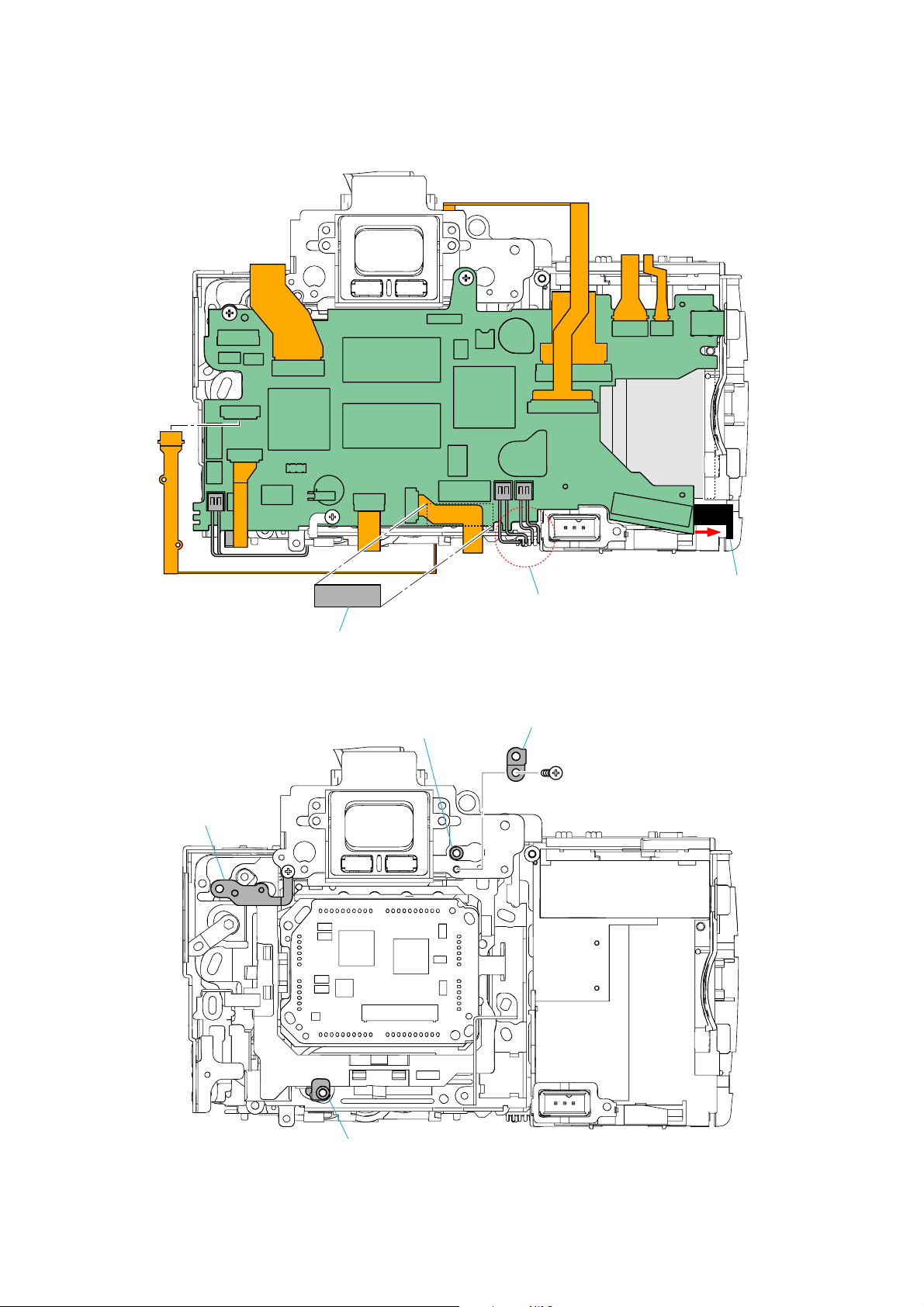

2-1-2. HALF SET BODY-1

Follow the disassembly in the numerical order given.

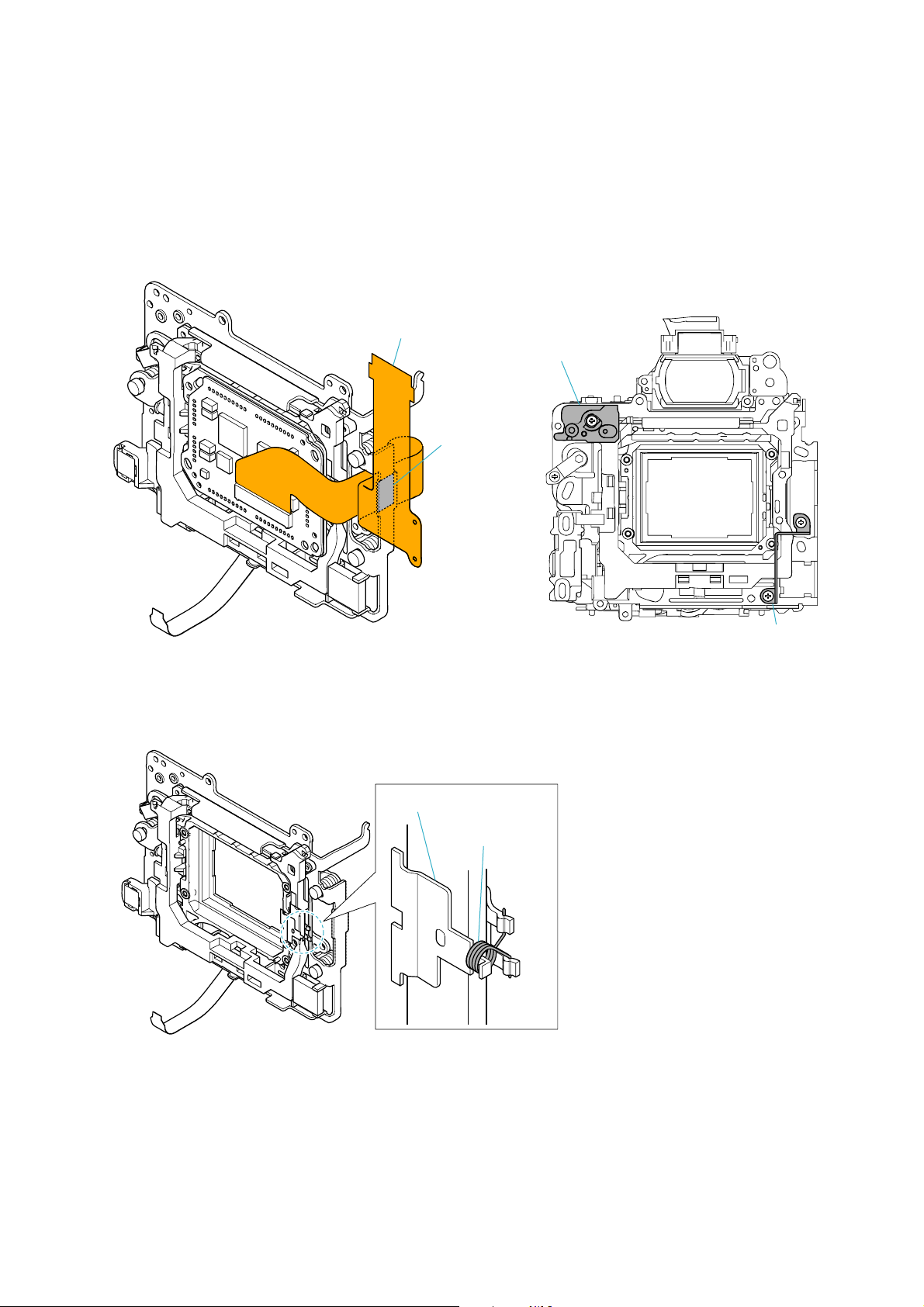

1 FP-528 Flexible Board (1-1 to 1-22)

2 Power Unit (2-1 to 2-8)

3 AM-001 Board (3-1 to 3-25)

2 Power Unit

2-7 (Fig. 2-2)

I

H

EXPLODED VIEW

1-1

1-6

1-14

1-13

1-22

(Fig. 2-2)

K

1-18

(Fig. 2-4)

1-11

J

1-10

1-12

2-2

(Fig. 2-2)

I

H

3-24

3-25

(Fig. 2-9)

(Fig. 2-9)

L

3-5

3 AM-001 Board

(Fig. 2-8)

1-2 (Fig. 2-2)

1-16

1-15

1-17

(Fig. 2-2)

3-6

3-7

1 FP-528

F

(Fig. 2-1)

HELP

1-21

(Fig. 2-2)

3-1

(Fig. 2-2)

A

D

C

3-8

3-10

3-9

(Fig. 2-8)

B

L

3-23

3-4

(Fig. 2-7)

A

C

B

3-2

(Fig. 2-3)

3-3

D

3-19

AM-001

3-11

G

3-22

(Fig. 2-9)

E

2-6

F

1-20

2-1

3-12

1-8 (Fig. 2-3)

1-9

(Fig. 2-3)

3-18

2-3

(Fig. 2-5)

3-15

3-13

3-14

J

E

1-19

(Fig. 2-4)

3-20

2-5

2-8

1-5

1-7

2-4

K

(Fig. 2-5)

3-17

(Fig. 2-6)

3-21

(Fig. 2-9)

1-3

3-16

DSLR-A100_L2

1-4

G

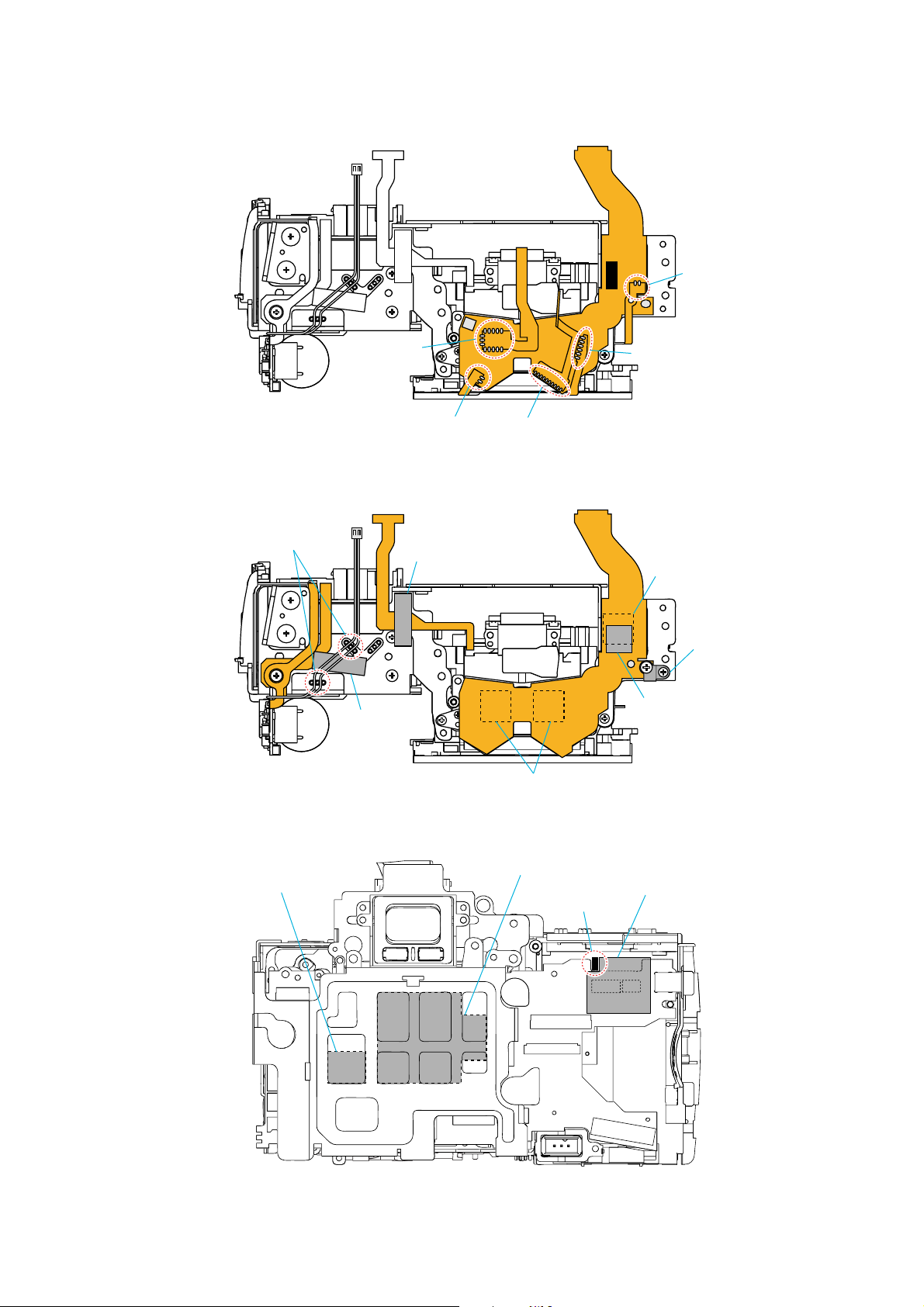

2-6

Solder 2 points

Wires arrangement

Solder 13 points

Solder 2 points

FPC Sticking Tape

FPC Sticking Tape

Solder 6 points

Solder 10 points

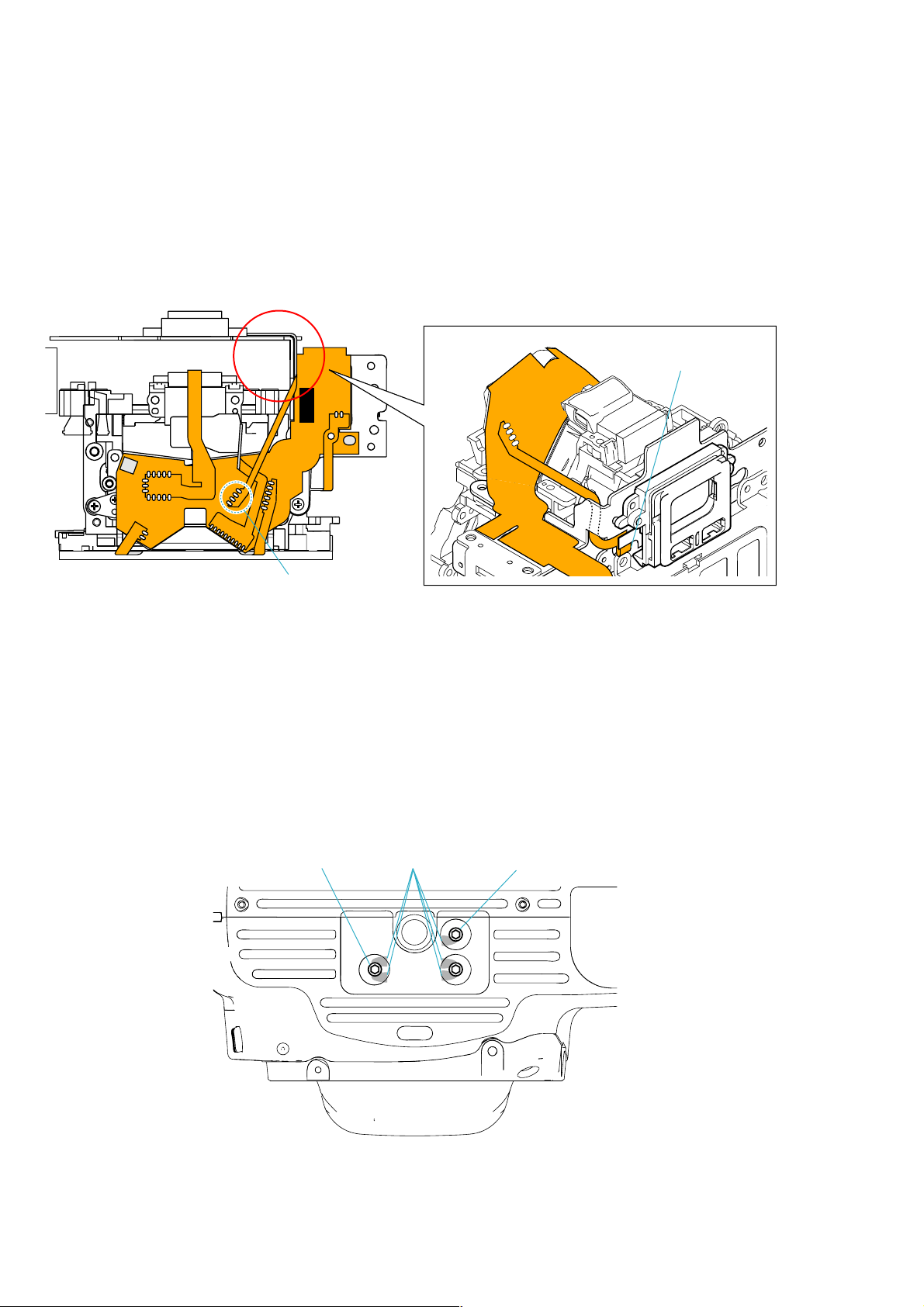

Fig. 2-1

Top Cover Flexible Fixed Tpe

I/O Flexible Lug Plate

FN Plate Support Tpe

Top Cover Flexible Fixed Tpe

DSLR-A100_L2

Heat Transmission Sheet 1 (S)

Fig. 2-2

Heat Transmission Sheet 2 (L)

FPC Connect Eleprevention Sheet

Boss

Fig. 2-3

2-7

Wires arrangement

Main Chassis

Red

Black

Fig. 2-4

AM-001 Board

Main PC Board Lug Plate

Fig. 2-6

Flexible Board arrangement

Don't tear.

FPC Sticking Tape

Wires arrangement

DSLR-A100_L2

Fig. 2-5

Fig. 2-7

2-8

FPC Sticking Tape

AM-001 Board Eject Lever Condition

Wires arrangement

Fig. 2-8

CCD Chassis Lug (2)

PC Board Holding Shaft

Main PC Board Lug Plate

CCD Chassis Lug (1)

DSLR-A100_L2

Fig. 2-9

2-9

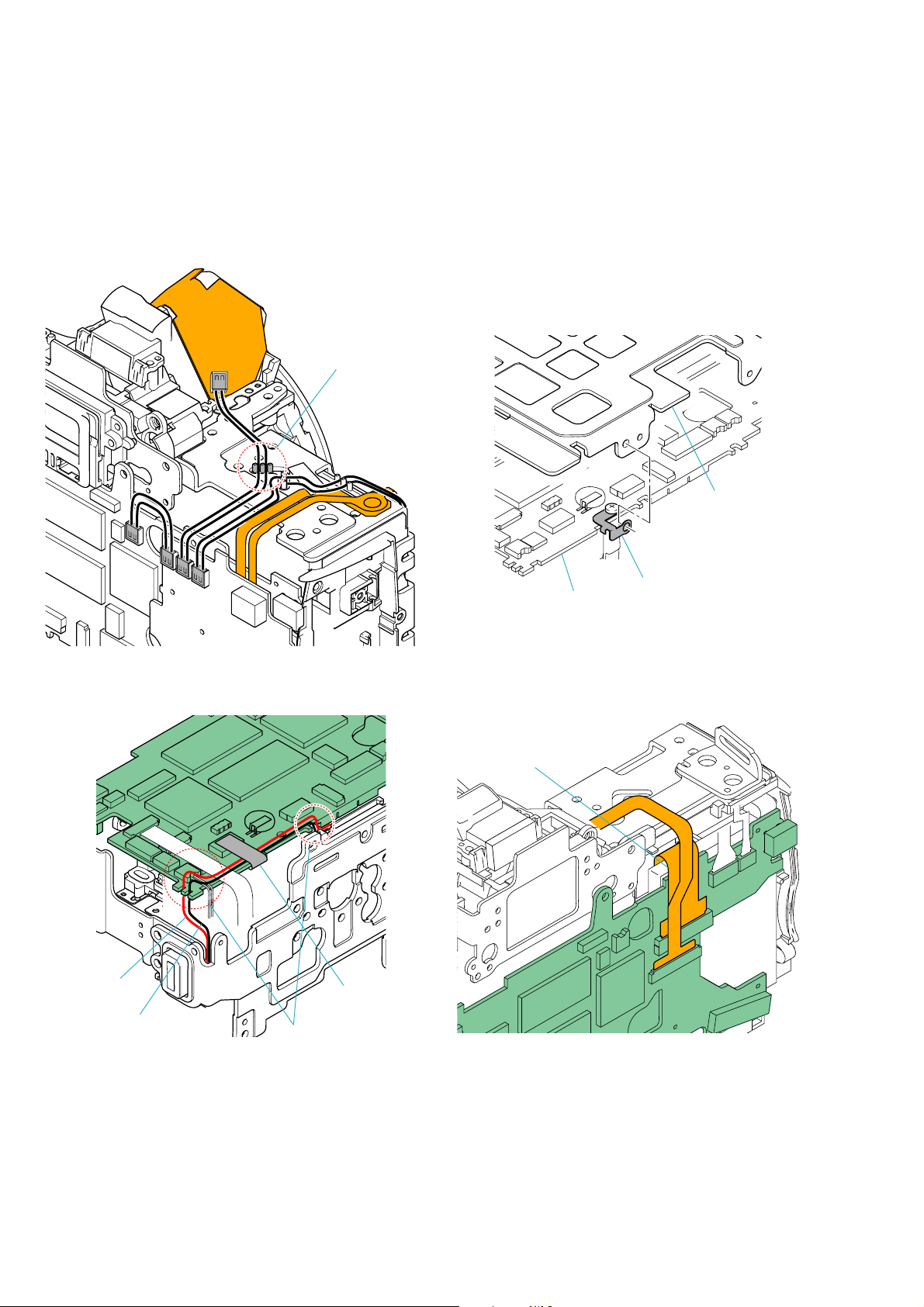

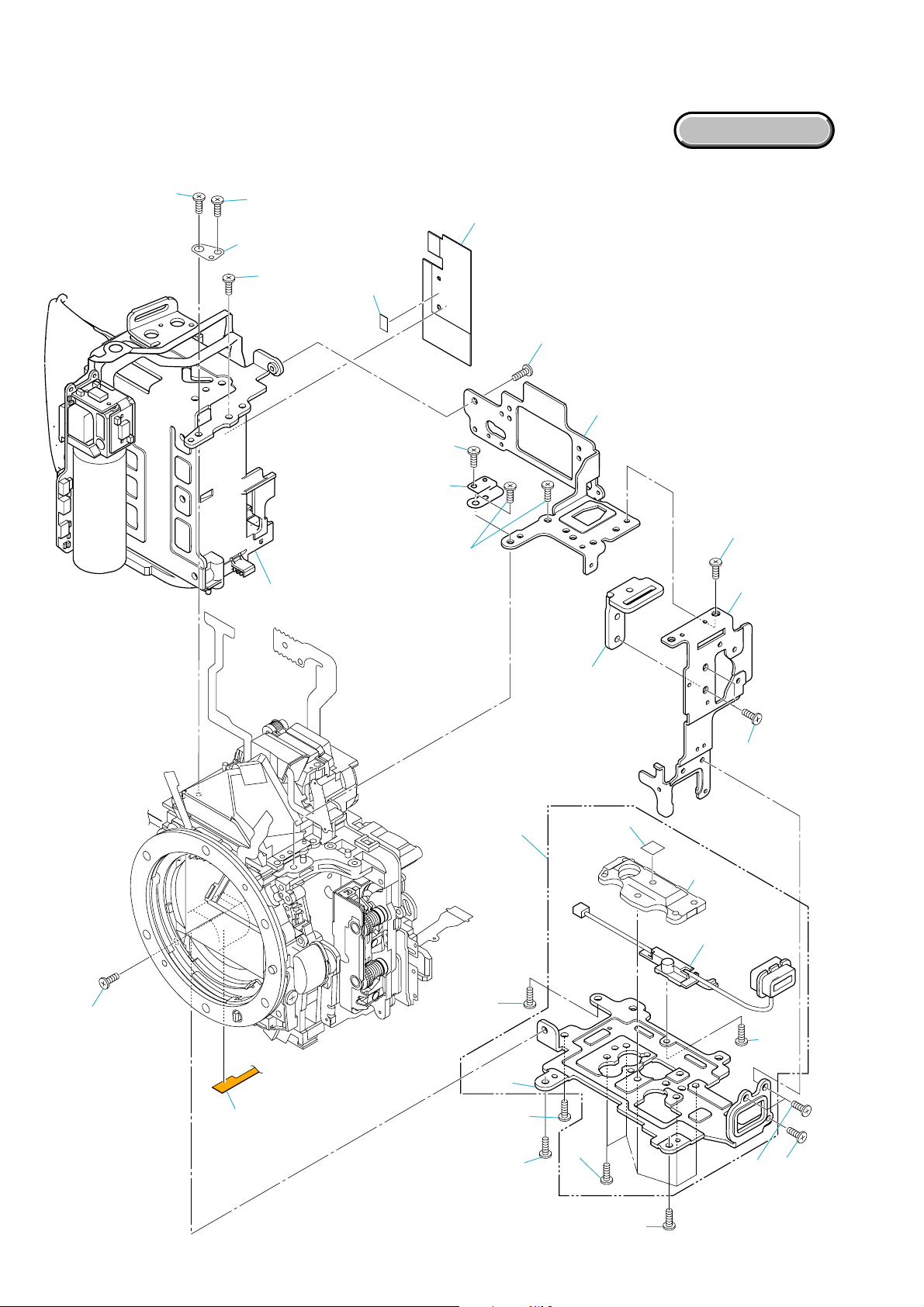

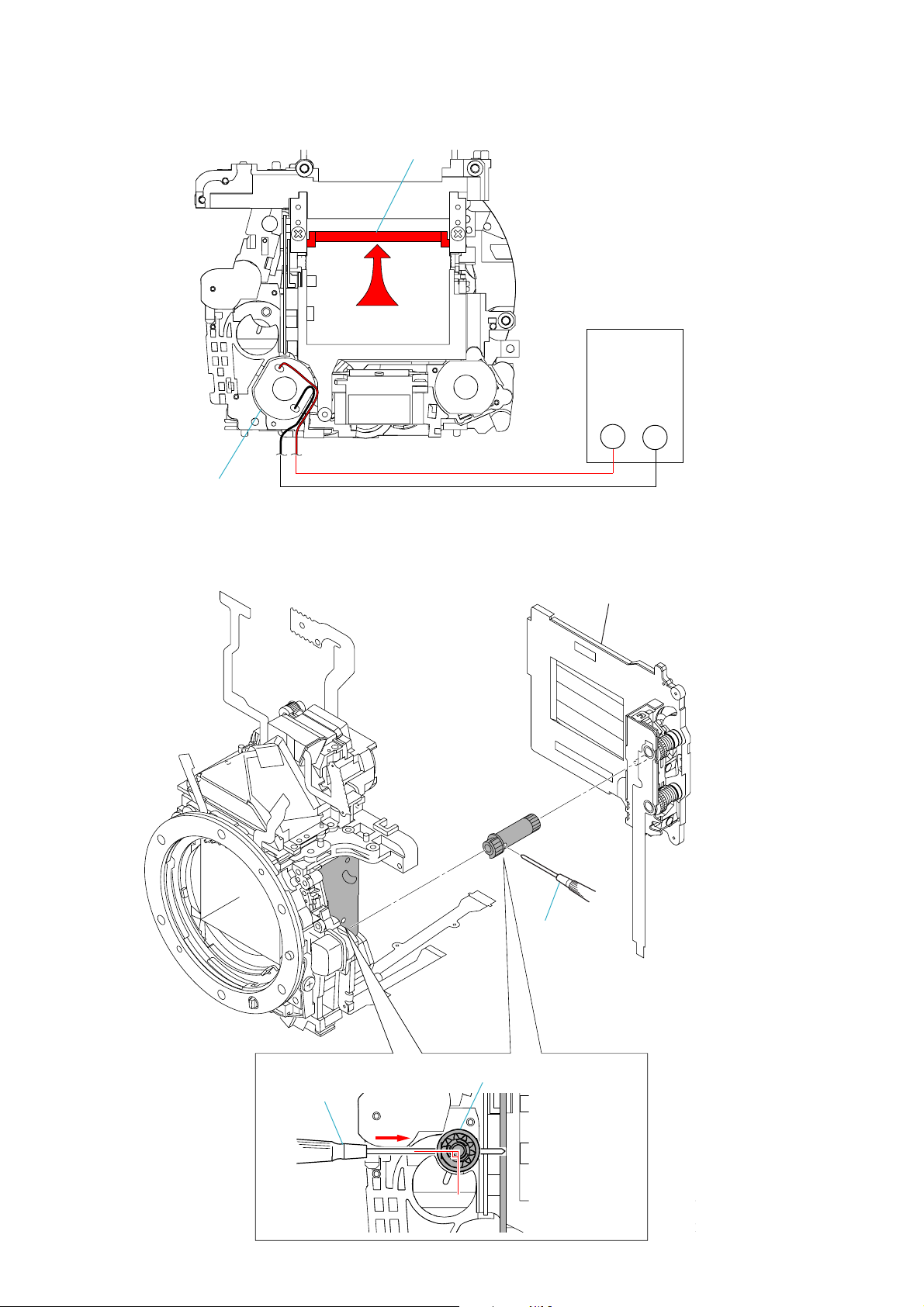

2-1-3. HALF SET BODY-2

Follow the disassembly in the numerical order given.

1 Tripod Unit (1-1 to 1-15)

2 Battery Chamber Unit (2-1 to 2-14)

2-12

2-13

2-14 (Fig. 3-3)

EXPLODED VIEW

1-1 (Fig. 3-1)

2-11

1-2

2-8

2-9 (Fig. 3-3)

2-7

2 Battery Chamber Unit

(Fig. 3-2)

2-6

2-10

2-2

2-3

2-5

1-3

2-1 (Fig. 3-2)

1 Tripod Unit

1-9

1-10

1-8

1-6

1-14

1-11

1-15

1-13

2-4

1-4

1-12

1-5

DSLR-A100_L2

1-7

2-10

Boss

CCD Flexible Retainer Sheet

Fig. 3-1 Fig. 3-2

Solder 3 points

Wires

arrangement

DSLR-A100_L2

Penta Protection Lug Plate (1) Penta Protection Lug Plate (2)

Fig. 3-3

2-11

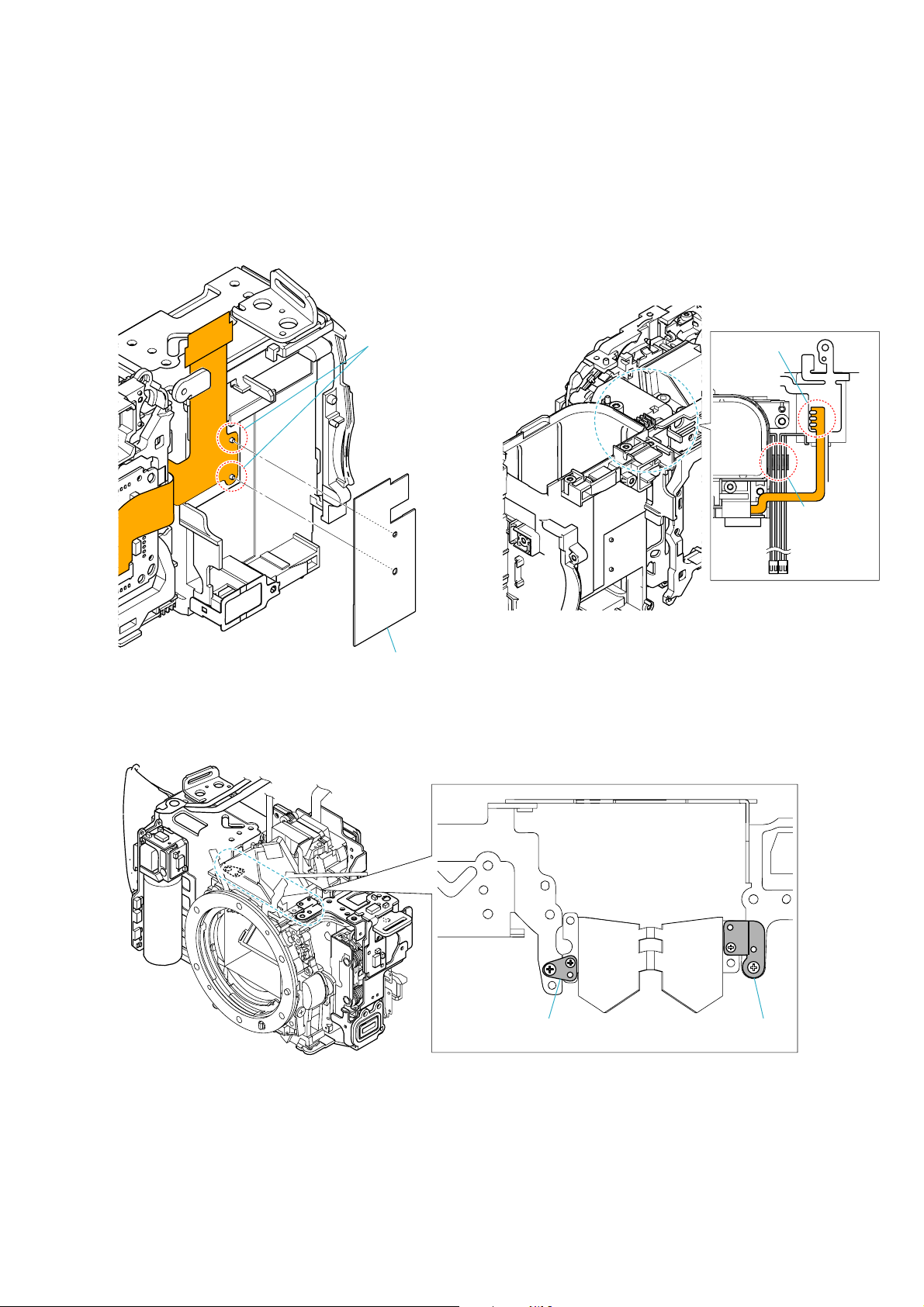

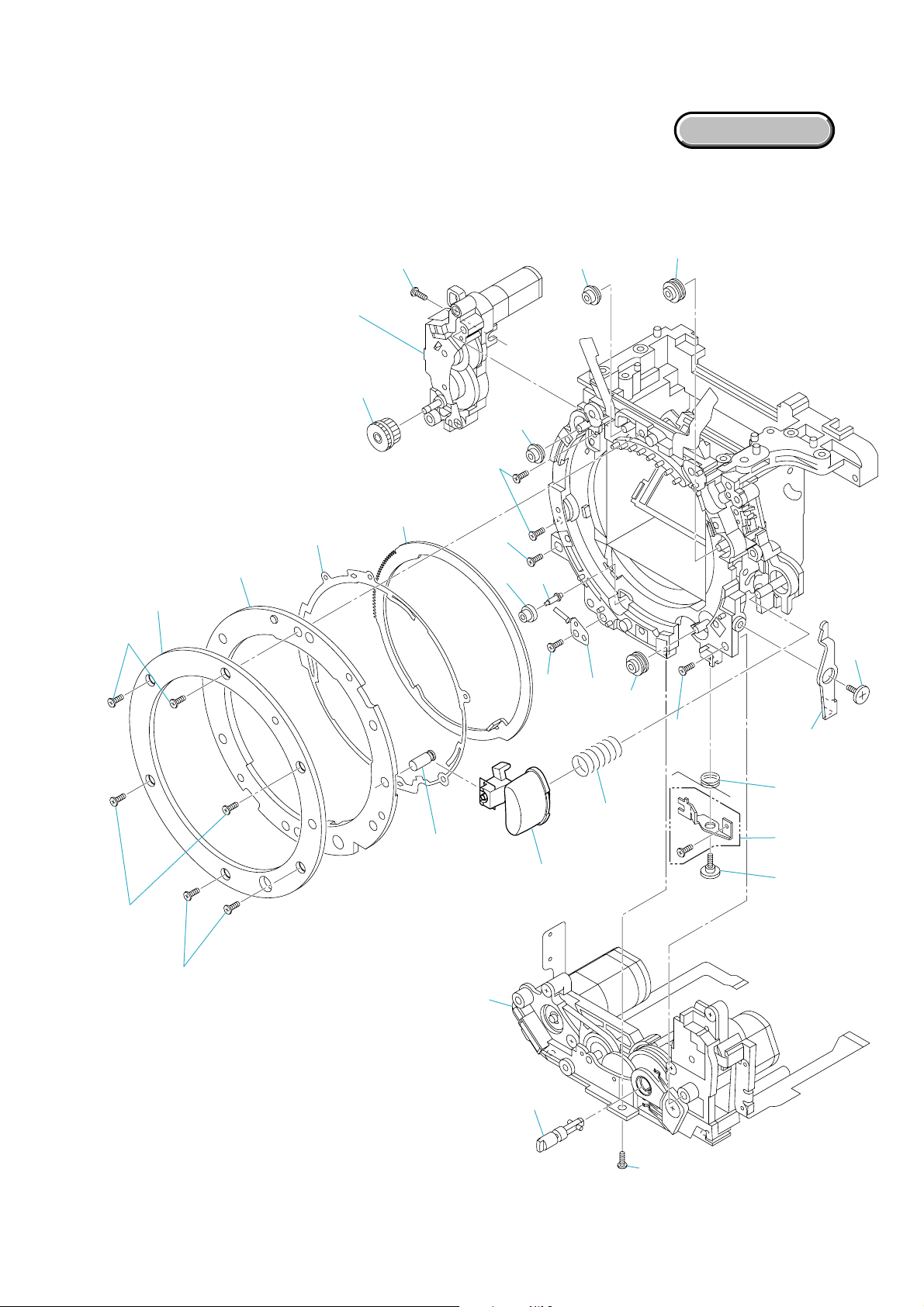

2-1-4. HALF SET BODY-3

Follow the disassembly in the numerical order given.

1 CCD Unit (1-1 to 1-8)

2 Slider Unit (2-1 to 2-27)

3 Shutter Unit (3-1 to 3-3)

2-10

(See page 2-15)

1 CCD Unit

(Fig. 4-1)

EXPLODED VIEW

HELP

1-2

1-3

2-3 (Fig. 4-3)

2-22

2-23

A

B

2-9

2-21

B

2-1

2-2

2-20

A

1-1 (Fig. 4-2)

1-8

2-27

2-8

2-7

C

2-24

2-25

2-6

2-26

1-7

2-13

2-15

2-14

2-16

2 Slider Unit

3-3

2-17

2-18

2-19

1-6

C

1-5

2-11

2-12

2-4

2-5 (Fig. 4-3)

1-4

DSLR-A100_L2

3 Shutter Unit

(See page 2-14)

3-2

3-1

(See page 2-14)

2-12

Fig. 4-1

CCD Connecting Mount

PC Board Holding Table (A)

Adhesive Tape

Slider Stop Plate

Fig. 4-3

Fig. 4-2

Ball Retainer

Slider Tension (SP-C)

DSLR-A100_L2

2-13

2-1-5. SHUTTER UNIT INSTALLATION

1. Supply the power (2V, 1A) to the charge motor to rotate it forward so as to move up the mirror completely.

Mirror

DC Power Supply

(2V, 1A)

Charge Motor

Fig. 5-1

2. Insert a screwdriver into a hole in the shutter charge gear, and hold it at 90 degree as shown in Fig. 4-5, and then install the Shutter Unit.

Screwdriver

Shutter Unit

DSLR-A100_L2

Shutter Charge Gera

Screwdriver

Fig. 5-2

2-14

2-1-6. CCD INCLINATION ADJUSTMENT/REPAIR

Check

1. Use a copy stand, or place a mirror on the wall and adjust the accuracy so that the camera is opposed to its mirror image.

2. Use the AE master lens for inspection.

3. Obtain the tilt angle with the Photoshop, and perform as follows according to the angle:

For the angle above +/–1.0 degree, be sure to repair.

For the angle above +/–0.5 degree and less than +/–1.0 degree, repair according to the user's required level.

For the angle below +/–0.5 degree, re-check and it is within the specification.

Adjustment

1. Remove the eccentric pin stopper. (Fig. 6-1)

2. Check, and adjust the hexagonal eccentric pin. (Fig. 6-2)

*The eccentric pin can be rotated 60 degree (CCD tilt 0.42 degree) in clockwise and counterclockwise directions respectiv ely from

the neutral position.

Adjustment exceeding 60 degree is impossible. (Eccentric pin stopper cannot be installed)

If an image tilts toward the lower right, rotate the eccentric pin 60 degree clockwise.

If an image tilts toward the lower left, rotate the eccentric pin 60 degree counterclockwise.

Eccentric Pin

Eccentric Pin Stopper

Eccentric Pin

Fig. 6-1

Repair (if the adjusting method failed)

1. Disassemble until the CCD Set can be removed.

2. Cut at two bosses for positional reference and directional reference of the CCD holder and the radiation plate. (Fig. 6-3)

3. Attach an insulation sheet to the terminal of CCD Set. (Prevention of short-circuit with CCD holder)

4. Assemble the CCD Set by shifting it by the amount of play

If an image tilts toward the lower right, shift clockwise the CCD Set by the amount of play.

If an image tilts toward the lower left, shift counterclockwise the CCD Set by the amount of play.

The double-sided adhesive tape on the LPF, if shifted by the amount of play, can be corrected in a range of about +/–0.7 degree

maximum.

In this case, however, prepare the service part "Slider Unit: A-1196-100-A" and modify it as described in step 2 above to make it

as a jig, and then shift the LPF on the jig (for prevention of damage to the Steadyshot Set of user's camera).

5. Assemble up to the exterior.

6. Check the tilt following the checking method.

*If not within +/–0.5 degree, replace the "Slider Unit: A-1196-100-A" and recheck.

7. After the repair completed, perform "CCD Aori and Center Adjustment" and "Steadyshot Sensitivity Adjustment".

Two bosses

(neutral Position)

Fig. 6-2

DSLR-A100_L2

Fig. 6-3

2-15

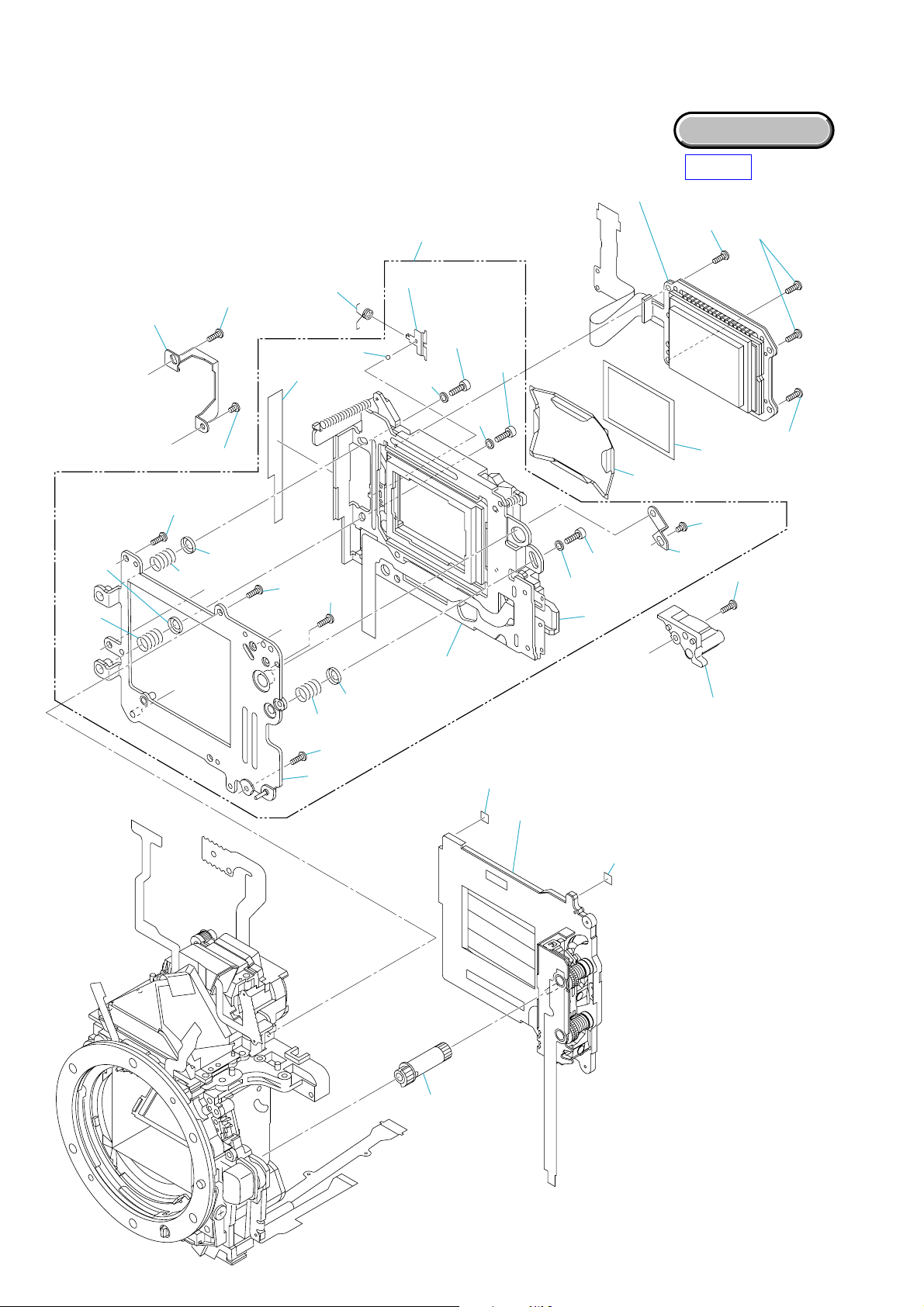

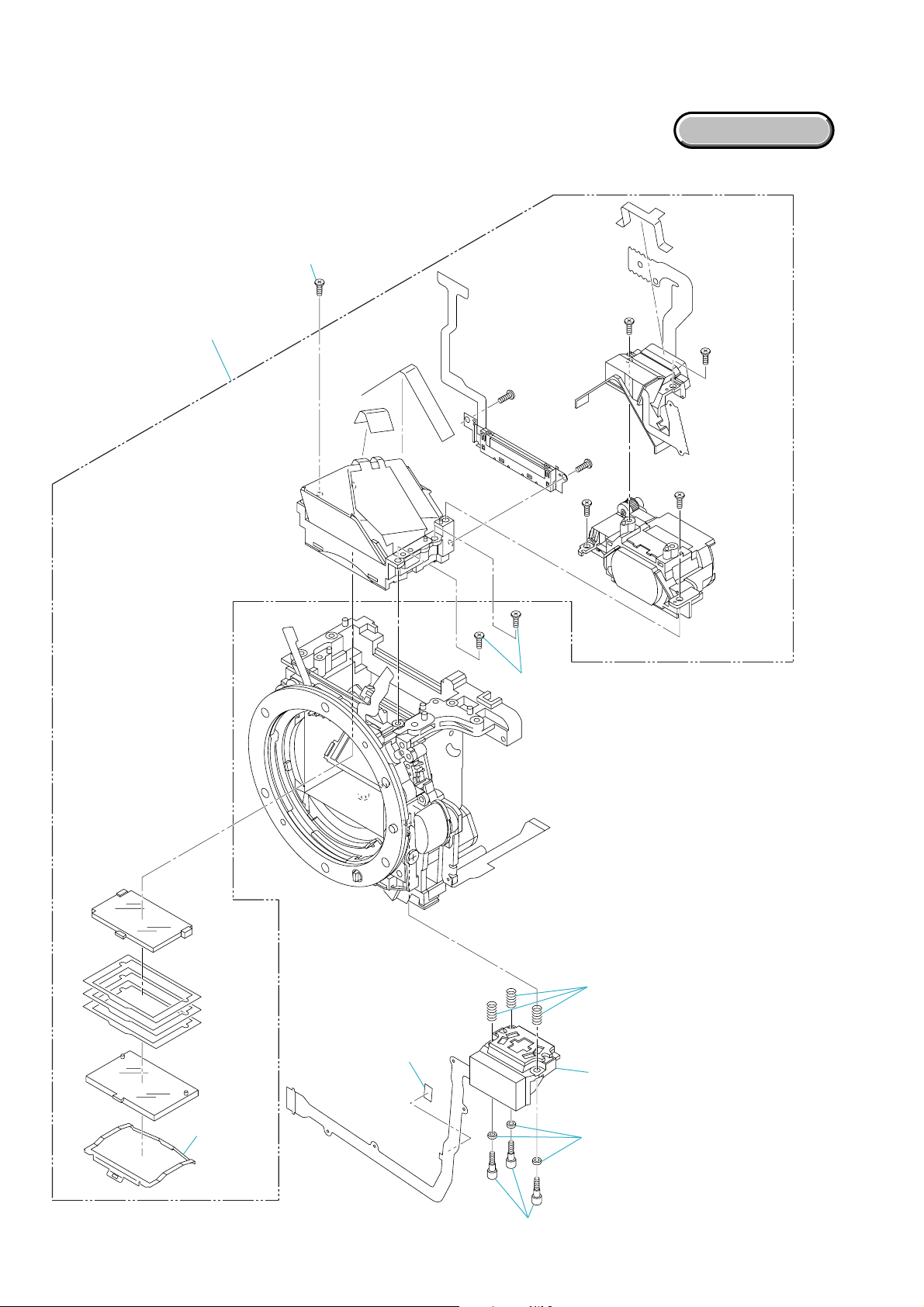

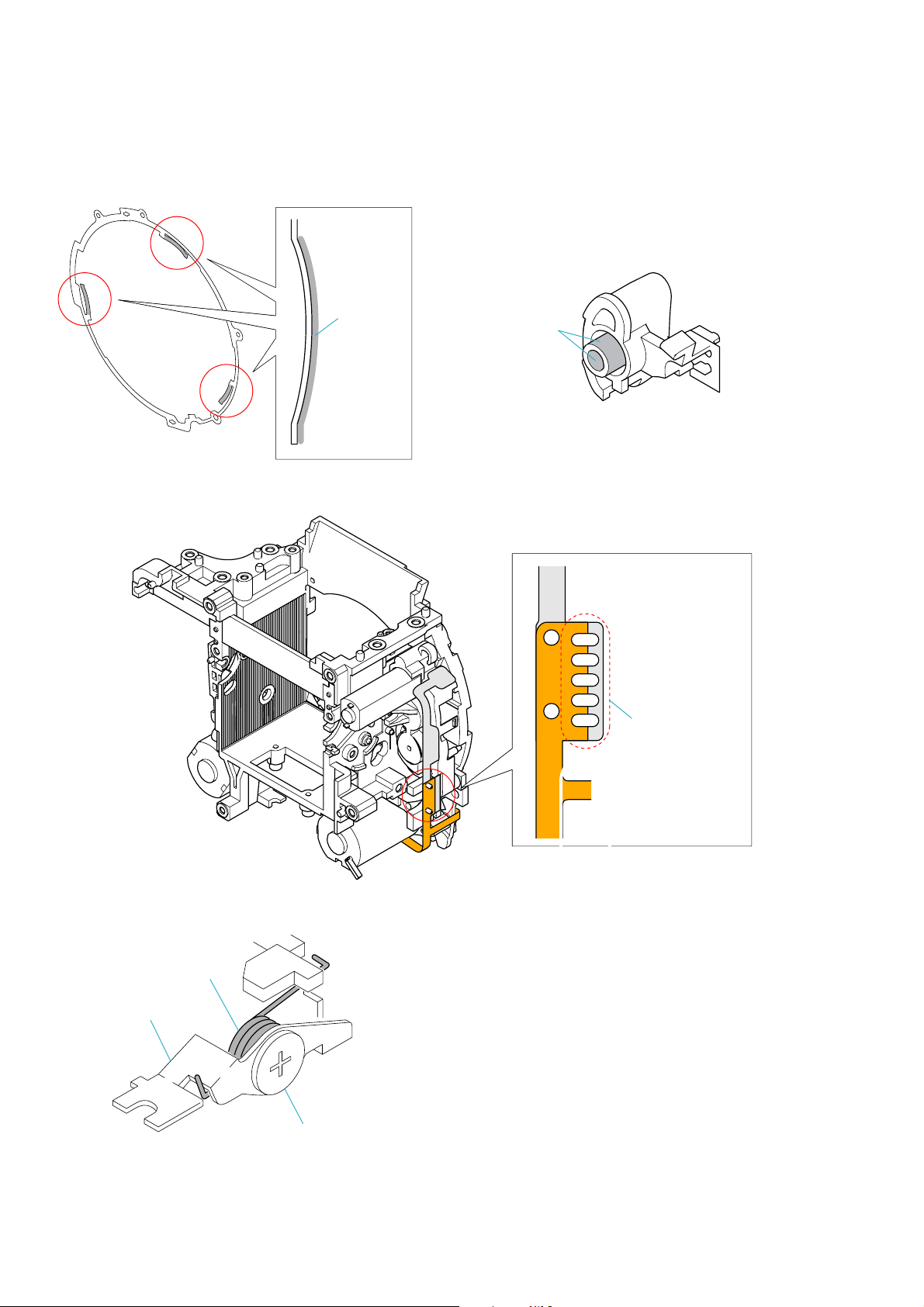

2-1-7. MIRROR BOX UNIT-1

Follow the disassembly in the numerical order given.

1 Penta Unit (1-1 to 1-2)

2 AF Module Unit (2-1 to 2-4)

1-1

1 Penta Unit

EXPLODED VIEW

(Fig. 7-2)

1-2

2-4

2-1 (Fig. 7-1)

2 AF Module Unit

(See page 2-18)

2-3

DSLR-A100_L2

2-2

2-16

AF Module Flexible FixedTape

Fig. 7-1

Claw

Claw

Boss

Claw

Boss

DSLR-A100_L2

Fig. 7-2

2-17

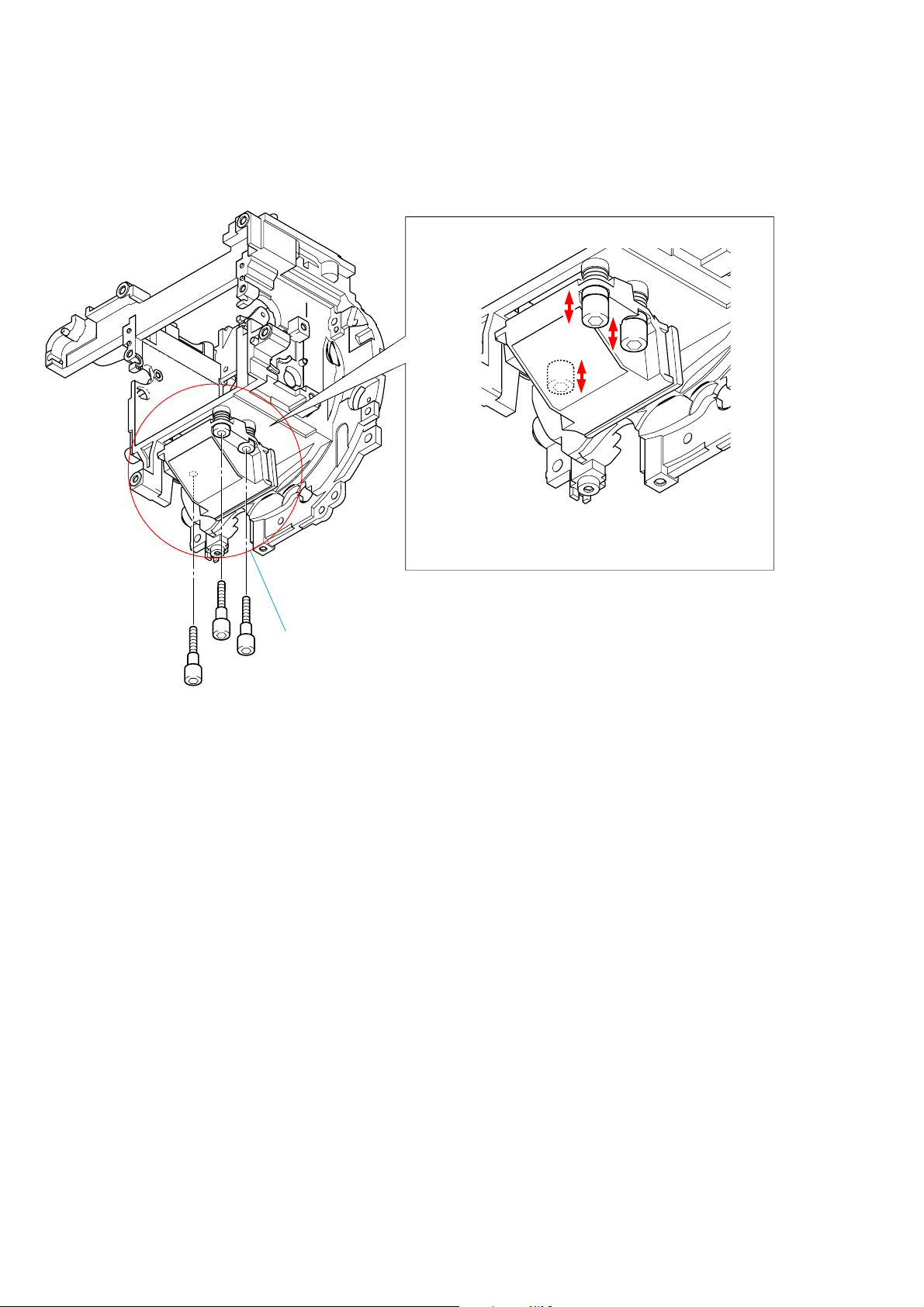

2-1-8. AF MODULE UNIT INSTALLATION

For the AF Module Unit, adjust the height by adjusting the extent

of tightening of three hexagon socket head screws.

Tighten the screws evenly when installing the AF Module Unit.

The AF Module Unit is fixed with three hexagon

socket head screws, washers, and springs.

Fig. 8-1

DSLR-A100_L2

2-18

2-1-9. MIRROR BOX UNIT-2

Follow the disassembly in the numerical order given.

1 Iris Ring (1-1 to 1-16)

2 Aperture Unit (2-1 to 2-3)

3 AF Charge Unit (3-1 to 3-10)

EXPLODED VIEW

1-1

1-4

2 Aperture Unit

(Fig. 9-3)

(See page 2-21 to 2-22)

2-3

1 Iris Ring

1-6 (Fig. 9-1)

1-5

2-1

(See page 2-21)

1-13

2-2

3-9

1-11

1-12

3-6

1-14

3-7

1-15

3-4

1-16

1-2

1-3

1-8

3 AF Charge Unit

(See page 2-23)

1-9 (Fig. 9-2)

1-7

1-10

3-8

3-10

3-5

3-3 (Fig. 9-4)

3-2 (Fig. 9-4)

3-1 (Fig. 9-4)

DSLR-A100_L2

2-19

G: G-15

G: G-115

Fig. 9-1 Fig. 9-2

Solder 5 points

Coupler Lever Tention (SP)

Coupler Lever

DSLR-A100_L2

Fig. 9-3

Coupler Lever Shaft

Fig. 9-4

2-20

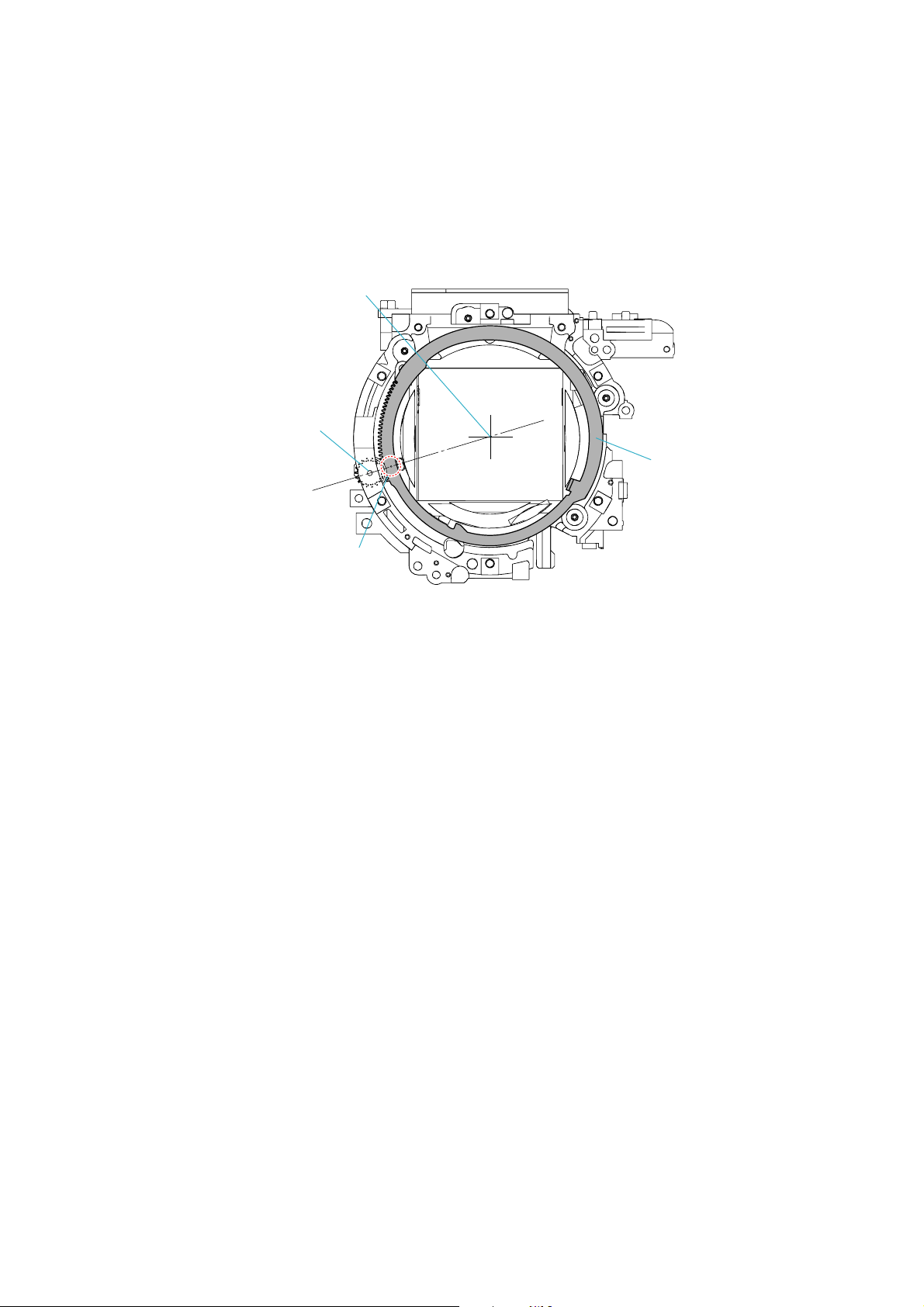

2-1-10. IRIS RING REMOVAL/INSTALLATION

Removal

Rotate the iris ring clockwise, and remove it at the stop position (iris-in end). (Fig. 10-1)

At this time, do not rotate the iris joint gear of the Aperture Unit.

Installation

1. With the Aperture Unit set in the charge position (see "2-1-12. Aperture Unit Charge Position Setting" ), install it on the front frame set.

*The Aperture Unit has been set in the charge position, if it is not removed.

However, the iris ring must be in the removed state (where the iris joint gear is not rotated).

2. Install the iris ring with it's a punch mark aligned with a line that connects the iris joint gear shaft and the optical axis center. (Fig. 10-1)

Optical Axis Center

Iris Joint Gear Shaft

Iris Ring

Punch Mark

Fig. 10-1

2-1-11. APERTURE UNIT INSTALLATION

*The Aperture Unit is supplied by being set in the charge position (initial position), but if this position is disordered when the Aperture Unit is

removed, or if the charge position is to be set again, perform as follows.

*Refer to “2-1-12. Aperture Unit Charge Position Setting” for the confirm method at the charge position.

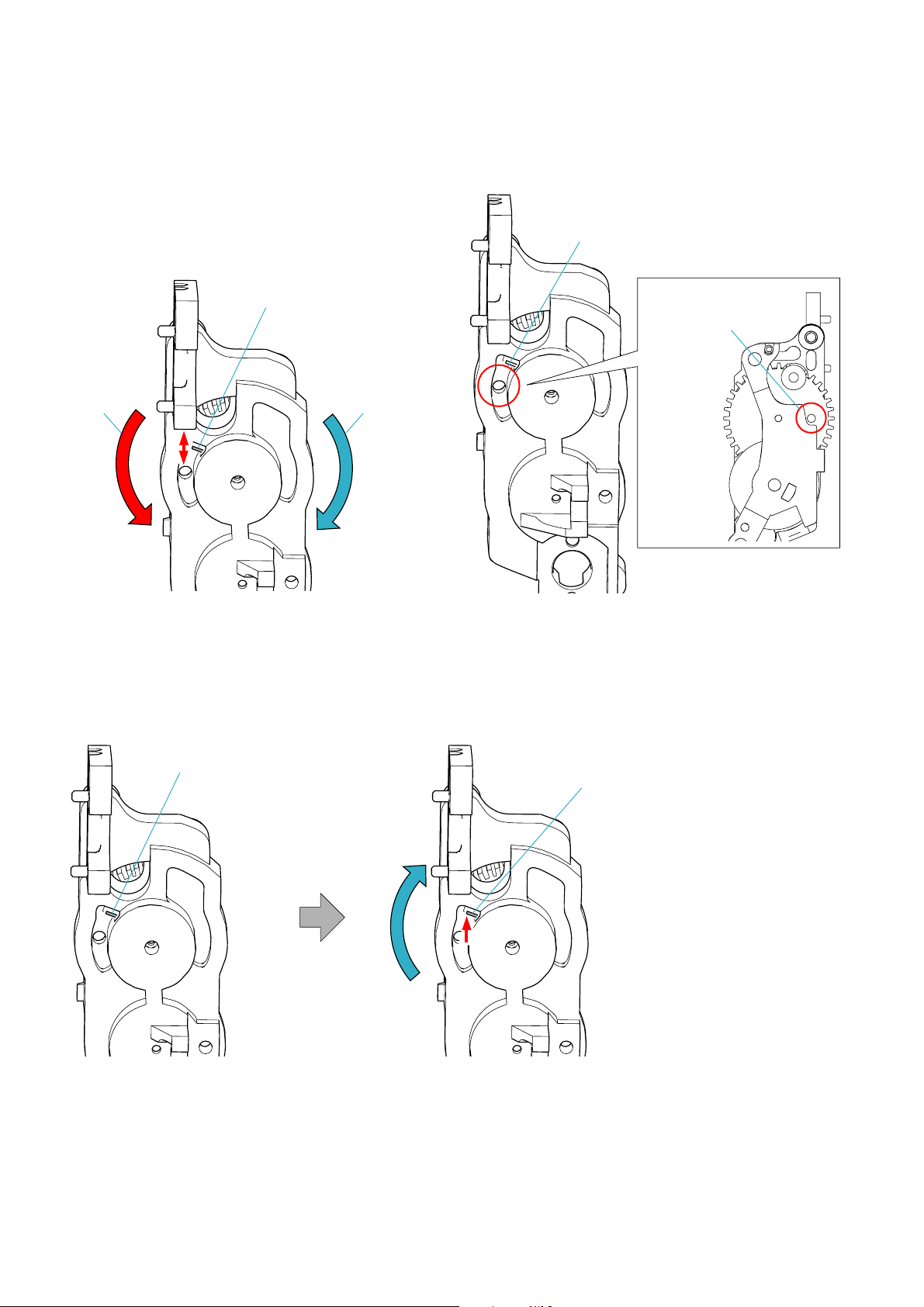

2-1-12. APERTURE UNIT CHARGE POSITION SETTING

1. Check that the Aperture Unit is in a free state.

2. After confirming that the Aperture Unit is in a free state, rotate the gear by 3 turns.

3. After rotating the gear by 3 turns, set the Aperture Unit where the holes in the gear and the Aperture Unit coincide. This position is the charge

position.

*Refer to “2-1-13. Aperture Unit Free Position Setting” for the setting and the confirm method at the free position.

DSLR-A100_L2

2-21

2-1-13. APERTURE UNIT FREE POSITION SETTING

1. Set the Aperture Unit to a free position once, if the gear was rotated accidentally and the charge position is disordered, or if the charge position

was shifted during disassembly. (Fig. 13-1, 13-2, 13-3)

In a free state, a hole in the gear almost

coincides with a hole in the Aperture Unit.

In a free state, the edge of this spring

will move up and down about 1 mm if

the gear is moved a little.

As viewed from gear

(Hole in the gear)

Gear rotating

direction to set

the charge position

Fig. 13-1

First, check the spring edge position.

Gear rotating

direction to make

the unit free

Fig. 13-2

If the edge of spring is located downward,

rotate the gear in the arrow direction to

search a free position.

* In a free position, the edge of spring is

located upward.

DSLR-A100_L2

Note: The spring is deformed and cannot

be used if the gear is rotated too

much from a free state.

Fig. 13-3

2-22

2-1-14. AF CHARGE UNIT INSTALLATION

1. The lever must be in a free state when the AF Charge Unit is installed. (Fig. 14-1)

Check the lever of the AF Charge Unit for position.

If it protrudes outside, rotate the gear in the arrow direction.

Gear

When the lever becomes a free state, it will

retract as shown.

* In this state, install the AF Charge Unit.

Fig. 14-1

DSLR-A100_L2

2-23

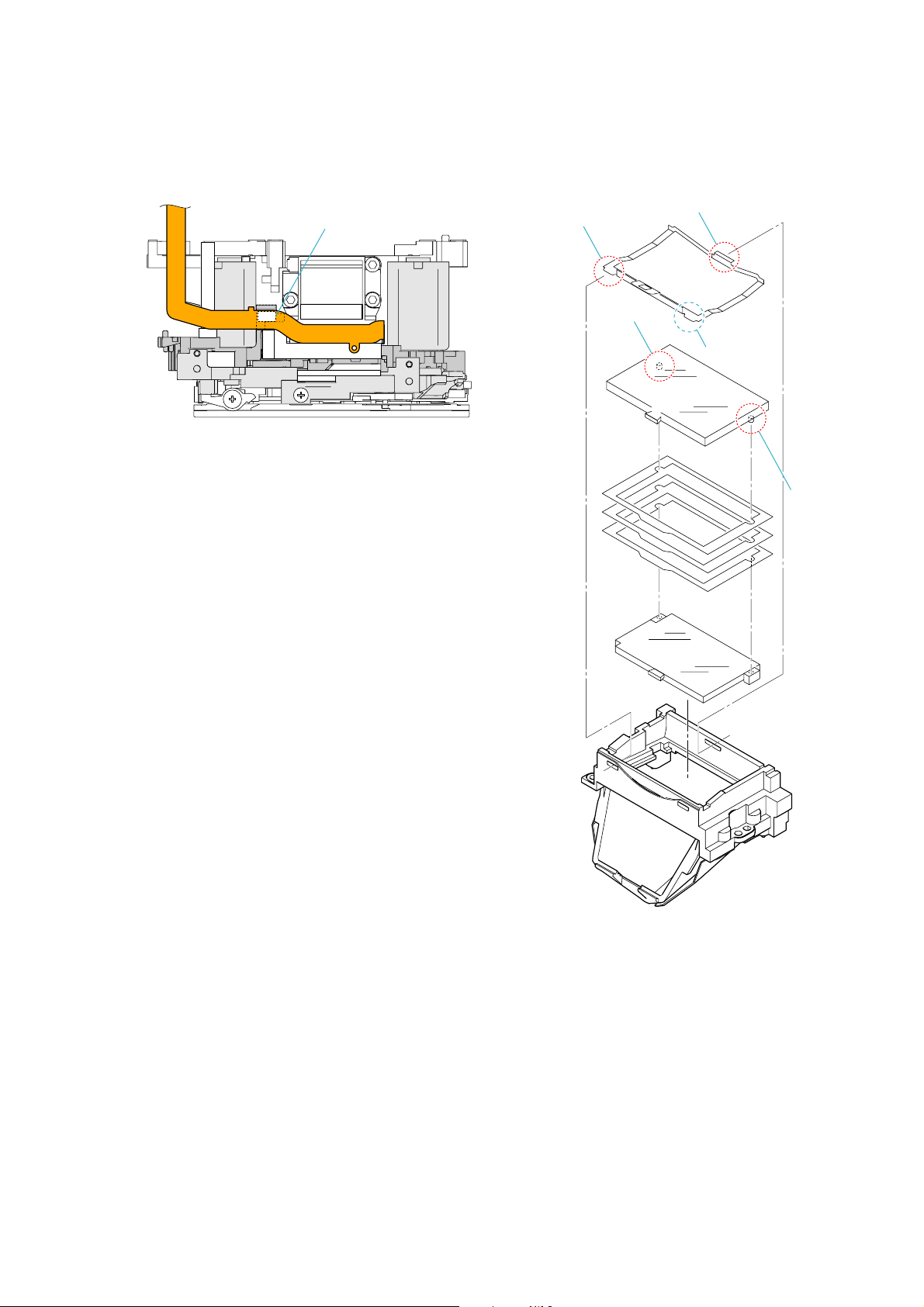

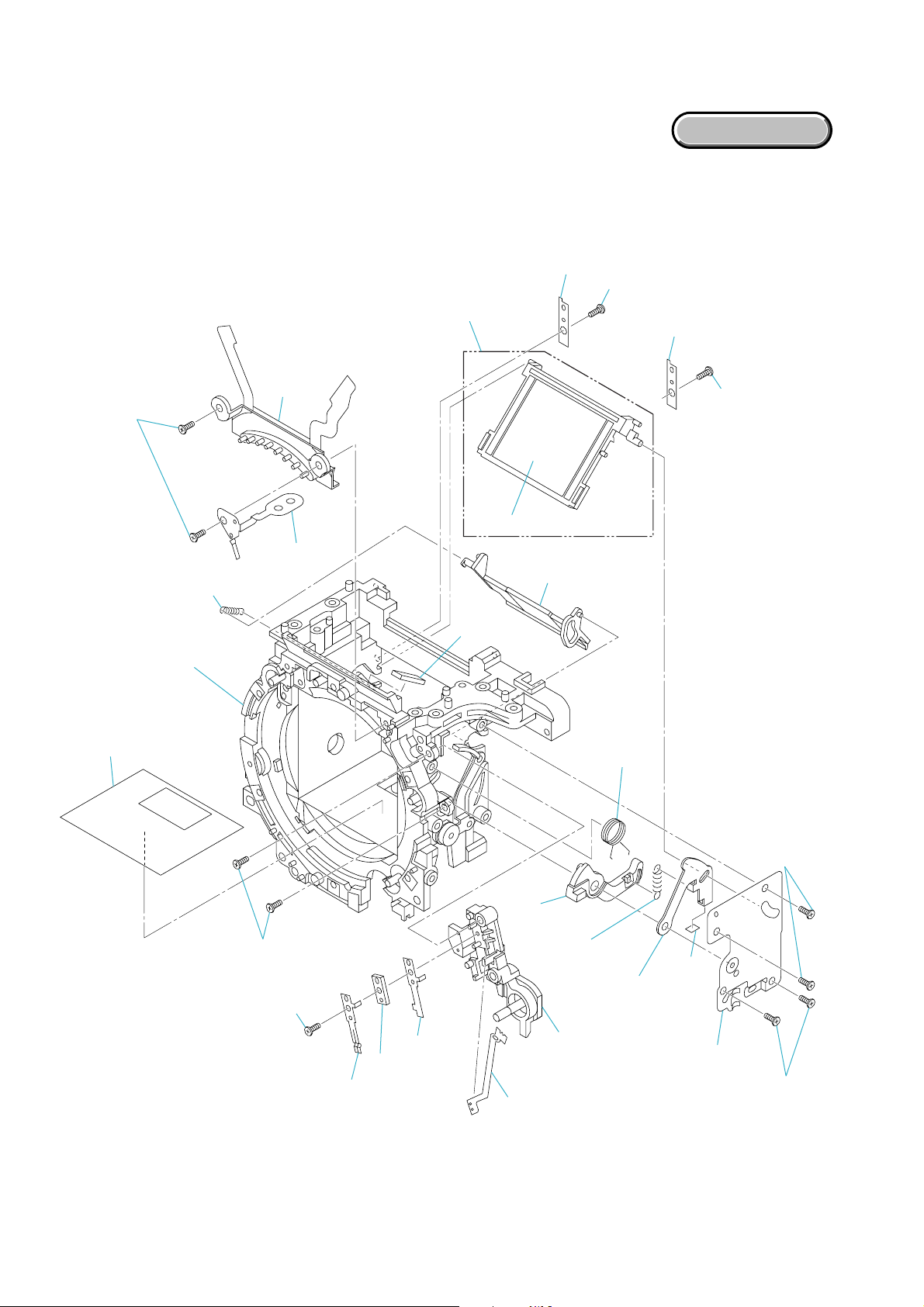

2-1-15. MIRROR BOX UNIT-3

Follow the disassembly in the numerical order given.

1 Main Mirror Holder Unit (1-1 to 1-23)

2 Front Frame Unit (2-1 to 2-3)

1 Main Mirror Holder Unit

(Fig. 15-5)

EXPLODED VIEW

1-23

1-22

1-21

1-8

1-11

(Fig. 15-2)

2 Front Frame Unit

2-3

1-10

1-9

1-20

(Fig. 15-4)

2-1 (Fig. 15-5)

2-2

(Fig. 15-6)

1-19

(Fig. 15-3)

DSLR-A100_L2

1-1

1-4

1-5

1-6

1-7

2-24

1-18

(Fig. 15-3)

1-17

(Fig. 15-3)

1-2

1-3

(Fig. 15-1)

1-12

1-15

1-16

(Fig. 15-3)

1-14

1-13

Loading...

Loading...