Page 1

DSLR-A100

SERVICE MANUAL

Ver 1.0 2006.06

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Link

Link

SERVICE NOTE

PRINTED WIRING BOARDS

LEVEL 3

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Korea Model

Japanese Model

Tourist Model

REPAIR PARTS LIST

SCHEMATIC DIAGRAMS

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety .

Replace only with part number specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

DIGITAL SINGLE LENS REFLEX CAMERA

DSLR-A100_L3

Sony EMCS Co.

2006F0500-1

© 2006.6

Published by Kohda TEC9-852-130-11

Page 2

TABLE OF CONTENTS

Section Title Page

1. SERVICE NOTE

1-1. Chemicals ········································································1-1

1-2. Exterior Parts ···································································1-1

1-3. Unleaded Solder ······························································1-1

1-4. Safety Check-out ·····························································1-1

1-5. Note for Replacing Fuse on the AM-001 Board·············· 1-2

1-6. Demagnetization Method ················································1-2

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-2. Schematic Diagrams························································ 4-8

4-3. Printed Wiring Boards ···················································4-26

4-4. Mounted Parts Location ················································4-29

5. REPAIR PARTS LIST

5-2. Electrical Parts List ·······················································5-24

DSLR-A100_L3

— 2 —

Page 3

1. SERVICE NOTE

1-1. CHEMICALS

Some chemicals used for servicing are highly volatile.

Their evaporation caused by improper management affects your health and environment, and wastes resources.

Manage the chemicals carefully as follows.

• Store chemicals sealed in a specific place to prevent from exposure to high temperature or direct sunlight.

•Avoid dividing chemicals into excessive numbers of small containers to reduce natural evaporation.

•Keep containers sealed to avoid natural evaporation when chemicals are not in use.

•Avoid using chemicals as much as possible. When using chemicals, divide only required amount to a small plate from the container and

use up it.

1-2. EXTERIOR PARTS

Be careful to the following points for plastic parts used in this unit.

• Use a piece of cleaning paper or cleaning cloth for cleaning plastic parts. Avoid using chemicals.

Even if you have to use chemicals to clean heavy dirt, don’t use paint thinner, ketone, nor alcohol.

• Insert the specific screws vertically to the part when installing a plastic part.

Be careful not to tighten screws too much.

1-3. UNLEADED SOLDER

This unit uses unleaded solder.

Boards requiring use of unleaded solder are printed with the lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

Be careful to the following points to solder or unsolder.

• Set the soldering iron tip temperature to 350 °C approximately.

If cannot control temperature, solder/unsolder at high temperature for a short time.

Caution: The printed pattern (copper foil) may peel away if the heated tip is applied for too long, so be careful!

Unleaded solder is more viscous (sticky , less prone to flow) than or dinary solder so use caution not to let solder bridges occur

such as on IC pins, etc.

• Be sure to control soldering iron tips used for unleaded solder and those for leaded solder so they are managed separately. Mixing

unleaded solder and leaded solder will cause detachment phenomenon.

1-4. SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. P oint them out to the

customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs of deterioration. Point them out to the customer and recommend their

replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 °C during repairing.

• Do not touch the soldering iron on the same conductor of the circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or unsoldering.

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

DSLR-A100_L3

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

1-1

Page 4

1-5. NOTE FOR REPLACING FUSE ON THE AM-001 BOARD

The caution label for fuse replacing on the AM-001 board is put under the DD-268 boar d. When replacing the fuse, remov e the DD-268 board

and refer to this label.

1-6. DEMAGNETIZATION METHOD

It is easy to receive the influence of the outside magnetism because the slant sensor switch (S624) has the magnet in the inside.

Horizontal and vertical cannot be detected when the influence of magnetism is received, and the display of the LCD panel doesn't change.

Therefore, it is necessary to degauss the screw in the vicinity of the switch.

S624

– AM-001 Board: Side B –

Note it because the user magnetizes set occasionally.

Refer to next page for the demagnetization method.

DSLR-A100_L3

1-2

Page 5

Tools to be prepared:

Push a magnet to the right side of MENU button to

demagnetize.

In the state shown below, operate the demagnetizer for 5 seconds,

and with the demagnetizer operated, detach it in the arrow direction.

At this time, hold the magnet in same position, and remove it after

the demagnetizer was detached.

MENU Button

Magnet

Demagnetizer

Push a magnet to the side of Display button (side surface

of the camera) to demagnetize.

In the state shown below, operate the demagnetizer for 5 seconds,

and with the demagnetizer operated, detach it in the arrow direction.

At this time, hold the magnet in same position, and remove it after

the demagnetizer was detached.

Display Button

Magnet

Demagnetizer

Push a magnet over the Playback button to demagnetize. In the state shown below, operate the demagnetizer for 5 seconds,

and with the demagnetizer operated, detach it in the arrow direction.

At this time, hold the magnet in same position, and remove it after

the demagnetizer was detached.

Magnet

Playback Button

Demagnetizer

Magnet (cover with a tape, etc. for damage prevention)

Demagnetizer

STEP 1:

STEP 2:

STEP 3:

• SLANT SENSOR SWITCH OPERATION INSPECTION

Using the camera already demagnetized, perform the posture switching by five sets, one set comprising “normal posture → Grip up →

Grip down”, to confirm that the LCD display changes over correctly.

DSLR-A100_L3

1-3E

Page 6

Link

Link

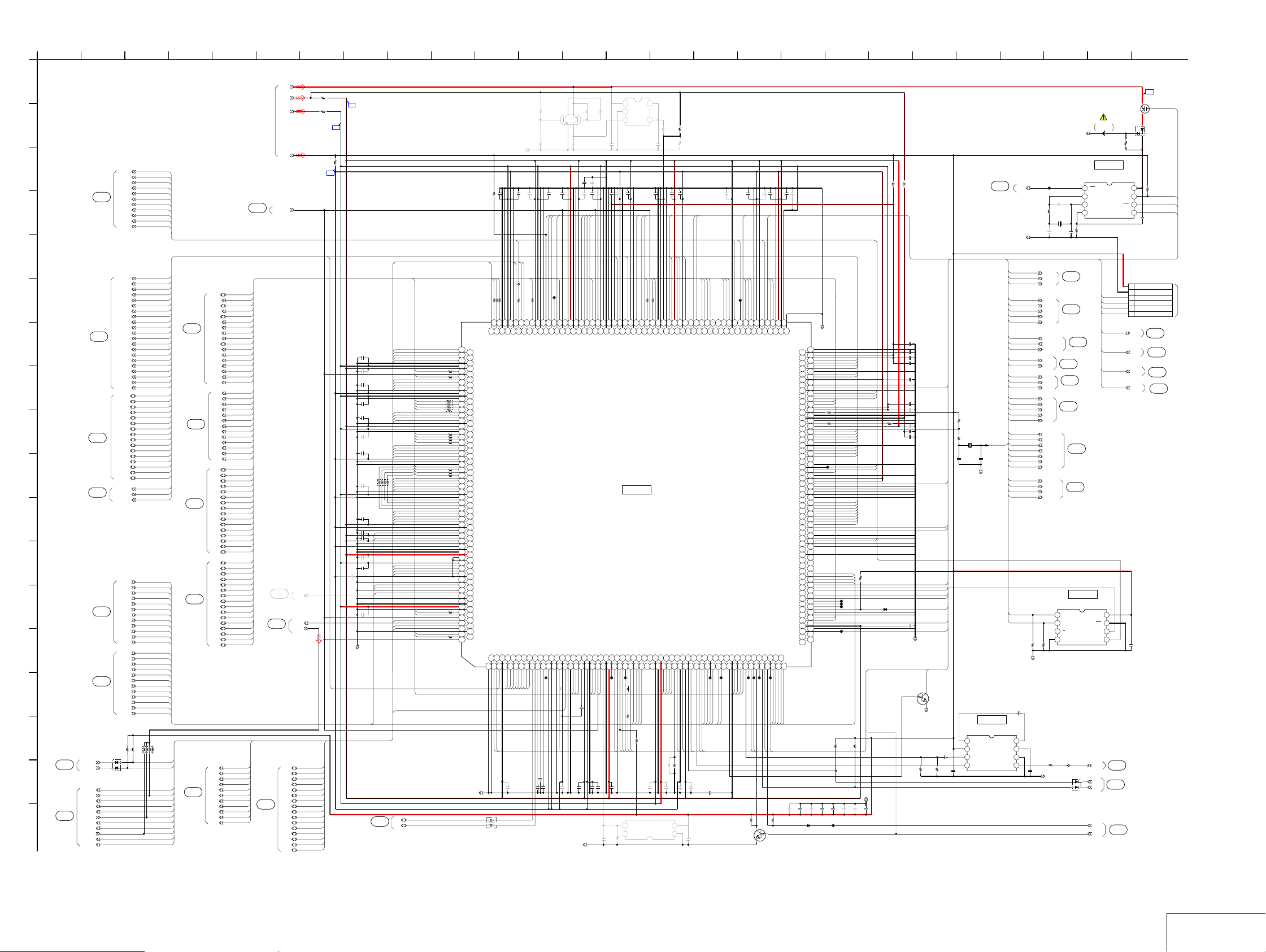

4-2. SCHEMATIC DIAGRAMS

AM-001 BOARD (1/5) (CAMERA DSP)

AM-001 BOARD (2/5)

(FLASH MEMORY, SDRAM)

AM-001 BOARD (3/5) (MAIN/SUB CPU)

COMMON NOTE FOR SCHEMATIC DIAGRAMS

AM-001 BOARD (4/5) (ANTI-SHAKE)

AM-001 BOARD (5/5) (CONNECTOR)

DSLR-A100_L3

Page 7

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

µF. 50 V or less are not indicated except f or electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Precautions for Replacement of Imager

• If the imager has been replaced, carry out all the adjustments

for the camera section.

• As the imager may be damaged by static electricity from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with

dusts nor exposed to strong light.

When indicating parts by reference number, please

include the board name.

Kinds of capacitor

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

•Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors ha ve characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B: B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: not use circuit

External dimensions (mm)

Case size

The components identified by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par une pièce portant le numéro

spécifie.

DSLR-A100_L3

4-3

Page 8

• Refer to page 4-3 for mark 0.

1

AM-001 BOARD (1/5)

A

CAMERA DSP

XX MARK:NO MOUNT

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

@114

(3/5)

(5/5)

Q

@111

(5/5)

R

05

2 18165 17

LCDD0

LCDD1

LCDD2

LCDD3

LCDD4

@101

LCDD5

(5/5)

LCDD6

LCDD7

LCDCLK

LCDVDX

LCDHDX

MSYSA1

MSYSA2

MSYSA3

MSYSA4

MSYSA5

MSYSA6

MSYSA7

MSYSA8

MSYSA9

MSYSA10

MSYSA11

@102

MSYSA12

(2/5)

MSYSA13

MSYSA14

MSYSA15

MSYSA16

MSYSA17

MSYSA18

MSYSA19

MSYSA20

MSYSA21

MSYSD0

MSYSD1

MSYSD2

MSYSD3

MSYSD4

MSYSD5

MSYSD6

MSYSD7

@103

MSYSD8

(2/5)

MSYSD9

MSYSD10

MSYSD11

MSYSD12

MSYSD13

MSYSD14

MSYSD15

MSYSLWRX

@104

MSYSRDX

(2/5)

MSYSCSX

CCDA1

CCDA3

CCDA5

CCDA7

CCDA9

CCDA11

@105

CCDB1

(5/5)

CCDB3

CCDB5

CCDB7

CCDB9

CCDB11

CCDA0

CCDA2

CCDA4

CCDA6

CCDA8

CCDA10

@106

CCDB0

(5/5)

CCDB2

CCDB4

CCDB6

CCDB8

CCDB10

100k

R101

1

4

FFCD1X

FIOWRX

FFCD2X

FREGX

FWAITX

FRESET

FCE1X

FCE2X

FVS1X

FIORDX

FWEX

23

D110

RB48SKTK

FRDY

FOEX

6

VDD1

DV1

DV2

(5/5)

DV3

LCDD0

LCDD1

LCDD2

LCDD3

LCDD4

LCDD5

LCDD6

LCDD7

LCDCLK

LCDVDX

LCDHDX

MSYSA1

MSYSA2

MSYSA3

MSYSA4

MSYSA5

MSYSA6

MSYSA7

MSYSA8

MSYSA9

MSYSA10

MSYSA11

MSYSA12

MSYSA13

MSYSA14

MSYSA15

MSYSA16

MSYSA17

MSYSA18

MSYSA19

MSYSA20

MSYSA21

MSYSD0

MSYSD1

MSYSD2

MSYSD3

MSYSD4

MSYSD5

MSYSD6

MSYSD7

MSYSD8

MSYSD9

MSYSD10

MSYSD11

MSYSD12

MSYSD13

MSYSD14

MSYSD15

MSYSLWRX

MSYSRDX

MSYSCSX

CCDA1

CCDA3

CCDA5

CCDA7

CCDA9

CCDA11

CCDB1

CCDB3

CCDB5

CCDB7

CCDB9

CCDB11

CCDA0

CCDA2

CCDA4

CCDA6

CCDA8

CCDA10

CCDB0

CCDB2

CCDB4

CCDB6

CCDB8

CCDB10

8

100k

RB101

100k

1234567

R102

FCD1X

FCD2X

FREGX

FWAITX

FRESET

FCE1X

FCE2X

FVS1X

FIORDX

FIOWRX

FRDY

FWEX

FOEX

@107

(2/5)

@108

@109

(2/5)

@110

(2/5)

@112

(5/5)

MDQS0

MDQM0

MDQS1

MDQM1

MDQS2

MDQM2

MCKE

MCLK

MCLKX

MDQS3

MDQM3

MWEX

MCASX

MRASX

MCSX

MBA0

MBA1

MA0

MA1

MA2

MA3

MA4

MA5

MA6

(2/5)

MA7

MA8

MA9

MA10

MA11

MA12

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

MD8

MD9

MD10

MD11

MD12

MD13

MD14

MD15

MD16

MD17

MD18

MD19

MD20

MD21

MD22

MD23

MD24

MD25

MD26

MD27

MD28

MD29

MD30

MD31

FA0

FA1

FA2

FA3

FA4

FA5

FA6

FA7

FA8

FA9

FA10

@115

VREF_DDR

(2/5)

MDQS0

MDQM0

MDQS1

MDQM1

MDQS2

MDQM2

MCKE

MCLK

MCLKX

MDQS3

MDQM3

MWEX

MCASX

MRASX

MCSX

MBA0

MBA1

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

MA12

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

MD8

MD9

MD10

MD11

MD12

MD13

MD14

MD15

MD16

MD17

MD18

MD19

MD20

MD21

MD22

@117

MD23

(5/5)

MD24

MD25

MD26

MD27

@116

MD28

(5/5)

MD29

MD30

MD31

FA0

FA1

FA2

FA3

FA4

FA5

FA6

FA7

FA8

FA9

FA10

@113

(5/5)

FD0

FD1

FD2

FD3

FD4

FD5

FD6

FD7

FD8

FD9

FD10

FD11

FD12

FD13

FD14

FD15

7 26

R212

0

DV1

R215

0

DV2

R216

0

DV3

C103

0.1u

C104

XX

C105

0.1u

C106

0.1u

C107

0.1u

C108

XX

C109

0.1u

RB103

27

C110

XX

C101

XX

C111

0.1u

C112

0.1u

C113

0.1u

C114

XX

C115

0.1u

C102

XX

PBLK

C116

CV3C

CV3FB

FD0

FD1

FD2

FD3

FD4

FD5

FD6

FD7

FD8

FD9

FD10

FD11

FD12

FD13

FD14

FD15

XX

DGND

@131

9

FD8

FD5

FD9

FD4

FD2

FD10

FD12

FD7

FD15

FD14

FA1

FD13

FD11

FA3

FA5

FA4

FA0

FA7

MCASX

MCSX

MRASX

MWEX

FA6

1234567

FA10

FA8

FA2

8

FWAITX

FCE1X

FCD1X

FA9

FOEX

FRESET

CCDA6

CCDB10

FIOWRX

FRDY

FWEX

FIORDX

CCDA0

CCDA2

CCDB8

FREGX

FCD2X

FCE2X

DM

DP

(5/5)

10

0.1u

C117

R131

100k

FD6

MA9

MA10

MA11

27

R13427R13227R133

M26

M24

N1

M25

FD6

MA9

MA11

N3

N8

N18

N23

N25

P1

P3

P8

P18

P23

P25

R1

R3

R8

R18

R23

R25

T1

T3

T8

T18

T23

T25

U1

U3

U8

U18

U23

U25

V1

V3

V8

V10

V12

V14

V16

V18

V23

V25

W1

W3

W8

W10

W12

W14

W16

W18

W23

W25

Y1

Y3

Y23

Y25

DGND

FD8

FD5

FD9

FD4

FD2

GND_DDR

VDD_DDR_IF_IO

VDD_INT

MA6

VREF_IO

MA7

FD10

FD12

FD7

FD15

GND_INT

VDD_IO

VDD_DDR_IF_IO

GND_DDR

MA8

MA5

MA4

MA3

FD14

FA1

FD13

FD11

GND_IO

VDD_INT

VDD_DDR_IF_IO

GND_DDR

MA2

MA1

MA0

MCLKX

FA3

FA5

FA4

FA0

FA7

VDD_IO

GND_INT

GND_DDR

MCKE

MBA1

MBA0

MCLK

FA6

FA10

FA8

FA2

FWAITX

GND_INT

VDD_DDR_IF_IO

GND_DDR

MRASX

MWEX

MDRAMCSX

MCASX

FCE1X

FCD1X

FA9

FOEX

FRESET

VDD_INT

VDD_IO

GND_IO

CCDA6

VDD_INT

CCDB10

VDD_INT

GND_INT

VDD_IO

GND_DDR

GND_DDR

VDD_INT

BCONF1

SLEEP

VDD_DDR_IF_IO

FIOWRX

FRDY

FWEX

FIORDX

GND_IO

TADCK

GND_INT

CCDA0

CCDA2

GND_IO

CCDB8

CCDC0

GND_IO

CCDD2

GND_IO

VDD_DDR_IF_IO

GND_INT

MDQM1

MDQS1

MDQS1X

FREGX

FVDDEN

FCD2X

FCE2X

GND_DDR

MD14

MDQM0

MDQS0X

3

1

MA10

MSYSXACK1

GND_IO

MSYSRDX

GND_IO

MSYSXCS1X

A2

A4

A3

A5

A1

MSYSRDX

LV5C

BL1C

4

2

LF101

N2

N4

N9

R108

R109 27

R114

R115

R116

R117

R118

R119

R120

N19

N24

27

N26

P2

P4

P9

P19

1

2

4

3

P24

6

5

7

8

P26

RB102

R2

27

R4

R9

R19

27

27

R24

27

22

R26

T2

T4

T9

T19

27

T24

27

22

T26

U2

U4

U9

U19

U24

U26

V2

V4

V9

V11

V13

V15

V17

V19

V24

V26

W2

W4

W9

W11

W13

W15

W17

W19

R125

W24

10

W26

Y2

Y4

Y24

R126

10

Y26

MA6

MA7

MA8

MA5

MA4

MA3

MA2

MA1

MA0

MCLKX

MCKE

MBA1

MBA0

MCLK

MDQM1

MDQS1

MD14

MDQM0

M23

GND_INT

VDD_INT

A6

M19

GND_DDR

MSYSA22

A7

MSYSA19

DGND

C119

LCDCLK

FD0

51

R140

M4

M9

M8

M18

FD0

VDD_IO

GND_IO

VDD_DDR_IF_IO

MSYSA17

MSYSA9

MSYSA19

MSYSA11

A8

A10

A9

A11

MSYSA2

MSYSA9

MSYSA11

MSYSA17

C118

XX

0.1u

FD3

FB112

M3

VCKPX

MSYSA2

A12

MSYSD13

FD1

M2

FD3

MSYSD13

A13

MSYSD8

M1

FD1

MSYSD8

A14

MSYSD4

L26

MA14

MSYSD4

A15

C120

MSYSD0

R253

R254

MA12

27

R146

L25

MA15

MSYSD0

A16

XX

XX

128

XX

L24

L23

MA12

VDD_INT

UDM

UDP

A18

A17

C121

L9

L19

L18

GND_INT

GND_DDR

VDD_DDR_IF_IO

PLL2FLT

PLL3FLT

PLL1FLT

A20

A21

A19

C122

0.0018u

0.0018u

13

Q104

XX

0.1u

C124

BRSO

BRSCK

URXD0

TP160

L4

L3

L8

LSCK1

VCK2B

URXD0

LSOUT1

EJTRST

EJTCK

RSTOUTX

A24

A22

A23

TP152

C123

0.0018u

R255

46

2

5

3

1

R257

XX

10u

C127

0.1u

C126

XX

C129

BRSI

UTXD0

ANSCK

RTCSIO

ANSOUT

MDQS2

L2

K4

K9

K2

K19

K24

K26

L1

K8

K3

K18

K23

K25

MA13

LSIN1

LSIN0

UTXD0

MDQS2

GND_IO

LSOUT0

MDQS2X

VDD_INT

GND_INT

GND_DDR

VDD_DDR_IF_IO

GND_DDR

MD15

VCOMPA

VDDDAC2

EJTDO

FVS2X

FVS1X

MD12

MDQS0

VDD_INT

GND_INT

GND_INT

AA4

A26

AB2

AA2 VDDDAC1

AA26

AA24

A25

AA3

AB1

AA1

AB3

AA23

AA25

XX

R247

MD12

MD15

MDQS0

FVS1X

0.1u

C128

VBUS

XX

0.1u

C130

C125

DGND

XX

C134

MDQS3

K1

LSCK0

VSSDAC1

AB4

MD4

C132

J26

MDQS3

MD4

AB23

C135

0.1u

MD11

0.1u

XX

C131

J25

MDQS3X

MD11

AB24

XX

J24

GND_DDR

VREF_IO

AB25

MD13

R256

XX

C183

XX

J17

J19

J18

J23

GND_IO

PLL3VDDD

USBVSSA1

VDD_DDR_IF_IO

VVREF

VDD_INT

MD13

VSSDAC2

AC2

AB26

AC3

AC1

10u

C133

R244

XX

C136

0.1u

J15

J16

USBVDDA2

GND_IO_W

GP12

GP8

AC4

AC5

TP167

DSI

0.1u

C137

C138

MSYSD5

XX

J14

MSYSD5

GND_INT

AC6

URXD1

J13

VDDWID

GP14

AC7

TP161

CSMAINX

1411

1

2

3

C139

MSYSA5

J11

J12

MSYSA0

GND_INT

IC101

CAMERA DSP

THD

ACLK

AC8

AC9

100

R220

TGCLK

TGHDX

3

4

IN

GND

EN4FB

IC113

XX

0.1u

AV16C

J9

J8

J10

MSYSA5

VDD_INT

GND_IO_W

IC101

MA07169

TSG1

THS2CK

CCDA5

AC12

AC10

AC11

FB109

CCDA8

CCDA5

ADRESC

VOUT

NC

DGND

R208

100

(3/5)

(3/5)

IC112

HD SELECT

IC112

D109

25

VDD1

Q103

3LP02M

B+ SWITCH

BT101

LITHIUM

BATTERY

R209

560

IC110

REAL TIME

CLOCK

IC110

S-35190A-T8T1G

1

INT

2

3

4

(3/5)

(5/5)

3

4

VDD

XOUT

SIO

XIN

SCK

VSS

CS

CN113

1 DV3

2 DGND

UTXD1

3 TxD1

URXD1

4RxD1

UTXD0

5 TxD0

URXD0

6RxD0

ADV1C

ADV1C

SLLKX

SLLKX

DRESCX

DRESCX

CFLED

CFLED

8

Vcc

7

STB

6

SEL

5

Y

VSAG

S2X

S1X

AVJX

VBUS

@134

@129

@130

(5/5)

(3/5)

(5/5)

(3/5)

(5/5)

LEAKC

2

D108

1

RB715W-TL

3

8

R210

10k

RTCSIO

7

RTCSCK

6

CSRTC

5

C174

0.1u

6P

NC

(3/5)

@126

(3/5)

@127

(5/5)

(2/5)

@128

(3/5)

(5/5)

@132

C182

0.1u

15

5

OUT

R258

R259

0

XX

R260

C184

XX

C185

0.1u

ANRSTX

ADV235C

MDQM3

10

R150

J2

J4

H26

J1

J3

SDD7

SDD6

SDCLK

SDCMD

MDQM3

CCDA8

CCDB3

CCDD0

CCDB1

CCDC10

AC14

AC16

AC17

AC15

AC13

CCDB1

CCDB3

R130

100k

XX

C140

IC108

H25

VREF_IO

CCDD4

AC18

MD16

MDQM2

10

R151

H24

MDQM2

CCDD6

AC19

XX

H17

H19

H18

H23

MD16

TMODE2

USBVDDD1

PLL12VSSD

GND_INT

MD3

VDD_DDR_IF_IO

VDD_DDR_IF_IO

AC20

AC22

AC23

AC21

MD3

R152

VIN

VSS

H16

USBVSSA2

MD6

AC24

MD6

XX

XX

XX

E4

VDD_INT

GP9

AE6

TP156

E3

SCEX

ARSYNC

AE7

C150

LCDD4

RSTSUB

E2

VG0

TCPCK

AE8

RTCSCK

C151

MD27

E1

D26

VDCK

MD27

TSG2

TALP2

AE10

AE9

TP162

TGVDX

0.1u

MD28

D25

D24

MD28

GND_INT

VDD_DDR_IF_IO

VDD_DDR_IF_IO

CCDA7

CCDA1

AE12

AE11

CCDA1

CCDA7

CCDB0

R162

100k

D23

D21

D22

VDD_IO

VDD_INT

PLL3VSSA

PLL12VDDA

USBVDDA1

USBVDDA3

MSYSD2

MSYSD7

MSYSD12

MSYSD14

GND_IO_W

MSYSA8

MSYSA16

VDDWID

MSYSUWRX

GND_INT

MSYSXREQ0

TMODE1

PLL3VDDA

USBVSSD1

PLL12VDDD

MSYSD3

MSYSD9

MSYSD15

MSYSA4

MSYSA7

GND_INT

MSYSA13

MSYSA15

MSYSA20

MSYSLWRX

MSYSXWRX

MSYSXRDX

GND_INT

GND_INT

TMODE0

PLL3VSSD

PLL12VSSA

USBVSSA3

USBVSSA4

MSYSD6

MSYSD11

MSYSA1

MSYSA6

MSYSA10

MSYSA12

MSYSA18

MSYSA21

MSYSCSX

MSYSXCS0X

MSYSXACK0

MSYSXREQ1

GND_IO_W

GND_INT

GND_DDR

GND_DDR

GND_DDR

ADPCMDQ

GND_DDR

VDD_INT

GND_DDR

CCDB4

CCDB0

CCDB9

AE14

AE13

AE15

CCDB4

CCDB9

C173

C152

GND_IO

BCONF0

RESETX

CCDA10

GND_IO

CCDD10

CCDD11

CCDC11

XX

0.1u

D20

TMODE3

UREXT

EJTMS

UTEST

CCDD8

CCDD7

CCDD5

CCDD3

CCDD1

CCDC8

CCDC5

CCDC1

CCDB6

CCDB2

CCDA4

TALP4

CCDC9

CCDC6

CCDC3

VDVD

MD29

MD31

VCP0

MD30

EJTDI

VCP1

TSG3

GP15

GP11

GP10

XX

C153

VDD_DDR_IF_IO

VR0

VB0

XO

VR1

TVD

GP7

GP6

GP4

MD1

MD0

0.1u

C175

RB751S-40TE61

DGND

D19

D18

D17

D16

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

C26

C25

C24

C23

C22

C21

C20

C19

C18

C17

C16

C15

C14

C13

C12

C11

C10

C9

C8

C7

C6

C5

C4

C3

C2

C1

B26

B25

B24

B23

B22

B21

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

AF26

AF25

AF24

AF23

AF22

AF21

AF20

AF19

AF18

AF17

AF16

AF15

AF14

AF13

AF12

AF11

AF10

AF9

AF8

AF7

AF6

AF5

AF4

AF3

AF2

AF1

AE26

AE25

AE24

AE23

AE22

AE21

AE20

AE19

AE18

AE17

AE16

XX

C176

D103

MSYSD2

MSYSD7

MSYSD12

MSYSD14

MSYSA8

MSYSA16

LCDVDX

LCDD2

R200

10k

3300

MSYSLWRX

TP158

C179

R177

MSYSD3

MSYSD9

MSYSD15

MSYSA4

MSYSA7

MSYSA13

MSYSA15

MSYSA20

MSYSD6

MSYSD11

MSYSA1

MSYSA6

MSYSA10

MSYSA12

MSYSA18

MSYSA21

MSYSCSX

CCDB6

CCDB2

CCDA10

CCDA4

TP166

TP165

TP164

XX

LCDD6

±0.5%

R165

100k

C180

R218

100

±0.5%

LCDD0

LCDD3

LCDD1

LCDHDX

R196

100k

D106

RB751S-40TE61

DTC143EE-TL

LED DRIVE

VBUS

DGND

XX

0.1u

C181

MD29

MD31

TP168

MD30

MD1

MD0

R164

100k

0.1u

0.1u

C178

C177

CP154

0.1u

0.1u

C142

C143

12MXI

MSYSA3

MSYSD1

MSYSD10

H11

H13

H15

H12

H14

XI

MSYSA3

MSYSD1

VDD_INT

MSYSD10

VDD_IO

MD9

VIREF

MD10

GP1

AD2

AC26

AD1

AC25

AD3

MD9

MD10

DSCK

CSDSCX

±0.5%

3k

R154

XX

C141

2

1

MSYSA14

H10

VDDWID

GP13

AD4

XX

C144

H9

MSYSA14

VDD_INT

AD5

H8

MSYSA23

ATSYNC

AD6

CSRTC

C145

AV8C

H4

SDD2

ADPCMDI

AD7

C146

XX

C147

AV6C

MD17

MD18

MD19

MD20

H2

G4

G24

G26

H3

G3

H1

G23

G25

SDD5

SDD1

SDD3

SDD4

MD20

MD18

MD17

MD19

SDWP

THS4CK

TALP1

TALP3

CCDA3

CCDA11

CCDC2

TSG4

CCDA9

CCDB5

AD8

AD10

AD12

AD14

AD16

AD9

AD11

AD13

AD15

TP153

CCDA3

CCDA9

CCDA11

CCDB5

VDHD2

CSTGX

C148

0.1u

XX

0.1u

C149

XX

VDHD1

LCDD7

LCDD5

MD21

MD23

MD22

MD24

MD25

MD26

TP169

F2

F4

F26

MD22

CCDC4

AD19

TP154

F24

F25

MD24

MD21

CCDC7

CCDD9

AD20

AD21

DTC144EMT2L

VBUS DETECT

F23

VDD_INT

VDD_INT

AD22

E5

E24

E26

F1

F3

E23

E25

VB1

VG1

SDD0

VDHD

MD26

MD23

MD25

VDD_IO

GND_DDR

MD2

MD8

GP0

VIOUT

GP2

MD5

MD7

GP5

GP3

AE2

AE4

AD24

AD26

AE1

AE3

AE5

AD23

AD25

TP155

TP163

MD2

MD5

MD7

MD8

BRCSMAINX

CSDATAX

R163

47k

Q101

G2

G1

SDCD

SDPOEN

CCDB11

CCDB7

AD18

AD17

CCDB7

CCDB11

2120

4.7uH

L101

4.7uH

L102

C155

10u

C156

0.1u

C157

0.1u

C158

0.1u

C159

0.1u

BRFWE

C160

0.1u

C161

XX

C154

XX

C162

0.1u

C163

10u

DRESCX

LV3C

LV8C

ADV1C

CSADX

UTXD1

DSOUT

SLLKX

CSLCDX

C164

XX

CSBRX

DGND

CFLED

Q102

DGND

R197

75

±0.5%

±0.5%

22 243 19

R241

3900

R250

0

X101

12MHz

C170

5p

BH76812FVM-TR

1

C1

2

VCC

C165

1u

3

VIN

4

STBY

R199

C166

75

4.7u

FB108

C172

5p

DGND

IC111

VIDEO AMP

IC111

@133

(3/5)

12MXI

234

CP153

32KHZ

DGND

ANSOUT

TGHDX

CSADX

TGCLK

ANSCK

ANRSTX

CSTGX

TGVDX

BRCSMAINX

BRSI

BRFWE

BRSCK

BRSO

LV5C

CSLCDX

LV3C

BL1C

LV8C

AV16C

AV8C

AV6C

LEAKC

CSDSCX

CSDATAX

DSOUT

DSCK

DSI

CSMAINX

ADRESC

RSTSUB

ADV235C

CSBRX

VDHD1

VDHD2

C167

1u

8

C2

7

-VCC

6

GND

5

VOUT

R204

XX

R203

0

X102

32.768kHz

C171

C169

10p

XX

ANSOUT

@118

TGHDX

(5/5)

CSADX

TGCLK

ANSCK

@119

ANRSTX

(5/5)

CSTGX

TGVDX

BRCSMAINX

@120

BRSI

BRFWE

BRSCK

@121

BRSO

LV5C

@122

CSLCDX

(5/5)

LV3C

BL1C

LV8C

@123

AV16C

(5/5)

AV8C

AV6C

LEAKC

CSDSCX

CSDATAX

@124

DSOUT

DSCK

DSI

CSMAINX

ADRESC

RSTSUB

@125

ADV235C

(3/5)

CSBRX

HD74ALVC2G157USE-E

1

A

2

B

3

Y

4

R251

1M

GND

R252

1M

DGND

R206

75

FB110

±0.5%

C168

1u

DGND

2

1

RB48SKTK

DSLR-A100_L3

4-8

AM-001 (1/5)

Page 9

1 165

4 13

6

10

15

173

1992 1881411712

20

21

AM-001 BOARD (2/5)

A

FLASH MEMORY, SDRAM

XX MARK:NO MOUNT

B

C

D

E

F

G

H

@103

I

J

K

L

M

N

O

P

05

DSLR-A100_L3

DV2

R804

IC201

DDR SDRAM

IC201

EDD5116AFTA-6B-E-TR

1

RB801

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

DV3

(5/5)

MSYSCSX

@104

MSYSRDX

(1/5)

MSYSLWRX

MSYSD8

MSYSD7

MSYSD5

MSYSD2

TP203

IC203

MSYSA14

MSYSA17

E6

TP205

MSYSA5

A16F1CE#

MSYSA18

MA10

MA11

MA12

MSYSD0

MA10

MSYSA1

TP206

E1

E2

A0

DQ0E3DQ2E4DQ5E5DQ7

D6

D5

D4

D3

D2

D1

C6

C5

C4

C3

C2

C1

MDQS0

MDQM0

MDQS1

MDQM1

MDQS2

MDQM2

MCLKX

MDQS3

MDQM3

MCASX

MRASX

MSYSA16

MSYSA12

MSYSA20

MSYSA21

MSYSA6

MSYSA2

MSYSA15

MSYSA11

MSYSA19

MSYSA7

MSYSA3

MCKE

MCLK

MWEX

MCSX

MBA0

MBA1

A15

A11

A19

A20

A5

A1

A14

A10

NC

A18

A6

A2

MSYSA13

MSYSA9

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

@107

MA9

(1/5)

MA0

MA1

MA2

MA3 MA4

MD16

MD17

MD18

MD19

MD20

MD21

MD22

MD23

MA0

MA2

MA3

MSYSD10

MSYSD12

MSYSD14

MSYSD0

MSYSD1

MSYSD2

MSYSD3

MSYSD4

MSYSD5

MSYSD6

MSYSD7

MSYSD8

(1/5)

MSYSD9

MSYSD10

MSYSD11

MSYSD12

MSYSD13

MSYSD14

MSYSD15

MSYSD0

MSYSD1

MSYSD2

MSYSD3

MSYSD4

MSYSD5

MSYSD6

MSYSD7

MSYSD8

MSYSD9

MSYSD10

MSYSD11

MSYSD12

MSYSD13

MSYSD14

MSYSD15

@109

@102

(1/5)

MSYSA1

MSYSA2

MSYSA3

MSYSA4

MSYSA5

MSYSA6

MSYSA7

MSYSA8

MSYSA9

MSYSA10

MSYSA11

MSYSA12

MSYSA13

MSYSA14

MSYSA15

MSYSA16

MSYSA17

MSYSA18

MSYSA19

MSYSA20

MSYSA21

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

MD8

MD9

MD10

MD11

MD12

MD13

MD14

MD15

MSYSA1

MSYSA2

MSYSA3

MSYSA4

MSYSA5

MSYSA6

MSYSA7

MSYSA8

MSYSA9

MSYSD9

MSYSA10

MSYSD11

MSYSA11

MSYSA12

MSYSD13

MSYSA13

MSYSD15

MSYSA14

MSYSA15

MSYSD1

MSYSA16

MSYSA17

MSYSD3

MSYSD4

MSYSA18

MSYSD6

MSYSA19

MSYSA20

MSYSA21

@128

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

@110

MD8

MD9

MD10

MD11

MD12

MD13

MD14

MD15

(1/5)(1/5)

DV3

OE#

G1

TP202

DQ9

G2

DQ11

TP201

DGND

DRESCX

G3

Vcc

G4

DQ13

G5

DQ15/A-1

G6

Vss

H1

DQ1

H2

DQ3

H3

DQ4

H4

DQ6

H5

Vss

H6

MD16

MD17

MD18

MD19

MD20

MD21

@108

MD22

MD23

(1/5)

MD24

MD25

MD26

MD27

MD28

MD29

MD30

MD31

C801

0.1u

(1/5)

(3/5)

MD16

MD17

MD18

MD19

MD20

MD21

MD22

MD23

MD24

MD25

MD26

MD27

MD28

MD29

MD30

MD31

F2

F3

F6

DQ8

DQ10F4DQ12F5DQ14

BYTE#

IC203

FLASH MEMORY

S29AL032D70BFI03-92

A3A2A7A3RY/BY#A4WE#A5A9A6A13B1A4B2A17B3WP#/ACCB4RESET#B5A8B6A12

A1

TP204

MSYSA10

MSYSA8

MSYSA4

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

MA12

56

1

2

3

4

5

6

7

8

RB802

56

1

2

3

4

5

6

7

8

R814

56

RB805

56

1

2

3

4

5

6

7

8

RB806

56

2

1

4

3

6

5

8

7

R823

56

DGND

VDD

C803

0.1u

2

DQ0

3

VDDQ

C804

0.1u

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

C805

0.1u

DQ5

10

DQ6

11

VSSQ

12

DQ7

13

NC

14

VDDQ

15

C806

0.1u

LDQS

16

NC

17

VDD

18

C807

0.1u

NC

19

LDM

20

/WE

21

/CAS

22

/RAS

23

/CS

24

NC

25

BA0

26

BA1

27

A10(AP)

28

A0

29

A1

30

A2

31

A3

32

VDD

33

C808

0.1u

1

VDD

C809

0.1u

2

DQ0

3

VDDQ

C810

0.1u

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

C811

0.1u

DQ5

10

DQ6

11

VSSQ

12

DQ7

13

NC

14

VDDQ

15

C812

0.1u

LDQS

16

NC

17

VDD

18

C813

0.1u

NC

19

LDM

20

/WE

21

/CAS

22

/RAS

23

/CS

24

NC

25

BA0

26

BA1

27

A10(AP)

28

A0

29

A1

30

A2

31

A3

32

VDD

33

C814

0.1u

IC202

DDR SDRAM

IC202

EDD5116AFTA-6B-E-TR

VSS

66

DQ15

65

VSSQ

64

DQ14

63

DQ13

62

VDDQ

61

DQ12

60

DQ11

59

VSSQ

58

DQ10

57

DQ9

56

VDDQ

55

DQ8

54

NC

53

VSSQ

52

UDQS

51

NC

50

VREF

49

VSS

48

UDM

47

/CK

46

R825

CK

45

CKE

44

NC

43

A12

42

A11

41

A9

40

A8

39

A7

38

A6

37

A5

36

A4

35

VSS

34

VSS

66

DQ15

65

VSSQ

64

DQ14

63

DQ13

62

VDDQ

61

DQ12

60

DQ11

59

VSSQ

58

DQ10

57

DQ9

56

VDDQ

55

DQ8

54

NC

53

VSSQ

52

UDQS

51

NC

50

VREF

49

VSS

48

UDM

47

/CK

46

CK

45

CKE

44

NC

43

A12

42

A11

41

A9

40

A8

39

A7

38

A6

37

A5

36

A4

35

VSS

34

4-9

0

RB803

56

MD15

1

2

3

4

5

6

7

8

MD14

MD13

C815

0.1u

C816

0.1u

200

C817

0.1u

C818

0.1u

R826

200

MD12

RB804

56

MD11

1

2

3

4

5

6

7

8

MD10

MD9

MD8

R835

56

0.1u

C819

MA12

MA11

MA9

MA8

MA7

MA6

MA5

R824

0

RB807

56

MD31

7

8

5

6

3

4

1

2

MD30

MD29

MD28

RB808

56

MD27

7

8

5

6

3

4

1

2

MD26

MD25

MD24

R844

56

0.1u

C820

DGND

MA12

MA11

MA9

MA8MA10

MA7

MA6MA1

MA5

MA4

C821XXC823

XX

C822

R845

100k

±0.5%

XX

R847

10

C825

R846

1u

100k

±0.5%

XX

C824

IC205

REFERENCE

VOLTAGE

GENERATOR

IC205

XC221A1100MR

1

VOUT

VSS

2

VDD

3

IN+4IN-

C826

4.7u

DV2

(5/5)

DV3

VREF_DDR

5

DGND

@115

(1/5)

AM-001 (2/5)

Page 10

• Refer to page 4-3 for mark 0.

AM-001 BOARD (3/5)

A

MAIN/SUB CPU

XX MARK:NO MOUNT

B

C

D

VDD1

(5/5)

@137

(5/5)

DETX

TRIG

FULL

FCHG

E

F

COM0

COM1

@153

(5/5)

@126

(1/5)

@141

(5/5)

COM2

COM3

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

ADV1C

IFBL_K

RJU003N03T1

BACKLIGHT

ON/OFF

Q308

G

H

I

J

K

L

M

N

O

VDD1

(5/5)

P

Q

R

S

05

DSLR-A100_L3

TP303

(5/5)

TRIG

FULL

FCHG

COM0

COM1

COM2

COM3

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

D304

RB751S-40TE61

R323

33

PGND

RB301

100k

1

7

3

456

2

8

KEY4X

KEY7X

KEY6X

KEY5X

R317

100k

Q309

HN1L02FU(TE85R)

BATTERY

CHARGE DETECT

MV6

R308

680

123

R371

10k

CP339

RB302

100k

1234567

EXBRRXD

R316

100k

5

EXBRTXD

3 12 25131

RB521S-30-TE61

IC305

4.5V REG

IC305

S-812C45BPI-C4ZTFG

IC312

VOLTAGE

DETECT

IC312

BD4830FVE

R326

R327

0

100k

VCC1C

R369

1k

KEY0X

DV1C

KEY1X

XXR307

KEY2X

KEY3X

S1X

X303

4MHz

S2X

SLLKX

SFLDX

FEN

DGND

C335

XX

SMX

8

EXBRSCK

DGND

D309

RB521S-30-TE61

6

3

2

4

1

R332

100k

D318

RB521S-30-TE61

DGND

@136

48 19

D321

1SS400TE-61

CP303

R328

100k

FLWX

FLWX

(5/5)

KEY4X

D322

EXBRRXD

EXBRTXD

EXBRSCK

BRSO

BRSI

BRSCK

GSW

HPFSWX

R304

1M

C313

R315

100k

KEY4X

DGND

R361

1

VOUT

2

SUB

3NC4

R329

100k

0.1u

CP337

CP338

CP348

SOUT

SIN

TP305

C327

0.1u

BAT_C

D316

RB48SKTK

@138

VIN

560

VDD

GND

@130

(1/5)

(5/5)

2

3

(5/5)

C315

0.1u

4

5

6

VIN

VSS

ON/OFF

VIN3VOUT

NC

2

1

C317

4.7u

R360

VDD1

100k

C319

1u

5

C331

1u

V0

91

V1

92

V2

93

V3

94

EXBRRXD

95

EXBRTXD

96

EXBRSCK

97

BRSO

98

BRSI

99

BRSCK

100

VCC1C

101

DV1C

102

KEY0x

103

KEY1x

104

VCC

105

VSS

106

X1

107

X0

108

KEY2x

109

KEY3x

110

S1x

111

S2x

112

SLLKx

113

SFLDx

114

FLED

115

IFBL

116

GSW

117

HPFSWx

118

SOUT

119

SIN

120

DGND

CSBRX

BRCSMAINX

R393

R370

100k

100k

VBUS

AVJX

DGND

PUPCN3X

1

4

SPVX

SAFMFX

@139

(5/5)

IC317

3.3V REG

IC317

S-812C33BPI-C4NTFG

R398

10

TP314

R392

100k

R391

100k

90

RESET

SCK2BATRxD3BATTxD4USBDETx5PUPCN4x6PUPCN5x7RESCx8SDIAL1x9SDIAL2x10SDCJx11BRPW_P112BRPW_P213X0A14X1A15VCC3B16VSS17VCC318BRPW_Y119BRPW_Y220KEY4x21KEY5x22KEY6x23KEY7x24CSBRx25CSDSPx26SMx27DRESCx28FCHG29FIND30CSLNSx

1

SCK

D306

XX

ASACTVX

R394

100k

Q339

XX

2

F3

F3

PUPCN3X

@146

@125

(1/5)

Q340

DTC144EMT2L

RESET

RESETX

PUPCN3X

PUPCN2X

EXBRMD2

COM3

COM2

COM1

COM0

83

87

COM084COM185COM286COM3

MOD288MOD189MOD0

1k

R362

1kR345

1k

RESET_MX

R346

PUPCN4X

PUPCN5X

SDIAL1X

SDIAL2X

RESETX

C347

0.001u

6

3

5

1

4

BRSI

BRFWE_2

BRCSMAINX

BRSI

BRFWE

BRCSMAINX

@121

@120

(1/5)

F2

BZ

TRX

SFLDX

SDIAL1X

SDIAL2X

F2

BZ

TRX

SFLDX

SDIAL1X

SDIAL2X

@147

(5/5)

(5/5)

C378

22u

DV235C

PUPCN1X

PUPCN0X

79

PUPCN0x80PUPCN1x81PUPCN2x82PUPCN3x

ANTI-SHAKE CONTROLLER,

BRPW_P1

BRPW_P2

C348

0.001u

BRSO

BRSCK

BRSO

BRSCK

(1/5)

(5/5)

S2X

@129

(1/5)

(5/5)

5

6

VIN

ON/OFF

NC2VIN3VOUT

1

CSBRX

ADRESC

RSTSUB

ADV235C

BRFWE

ASACTVX

75

77

78

BRFWE

ASACTVx

IC303

SUB CPU

IC303

MB91F233LPFF-G-91-E1

1M

R302

32KHZ

SDCJX

Q341

XX

EXBRSCK

EXBRMD2

EXBRSCK

EXBRMD2

@155

(5/5)

S1X

S1X

S2X

4

VSS

C304

4.7u

RB751S-40TE61

BRCSMAINX

0.1u

C312

74

VCC76VSS

BRSCMAINx

EXBRTXD

EXBRRXD

EXBRTXD

SMX

PUPCN5X

SMX

@148

(5/5)

D317

32KHZ

PSSW

73

BRPW_Y1

EXBRRXD

PUPCN5X

PSSW

PUPCN4X

MONBA

72

BRPW_Y2

PUPCN4X

BRFWE_2

MONBA

CLIM

71

KEY4X

HPFSWX

1CMG_1

70

CLIM

KEY5X

@133

GSW

HPFSWX

@154

KEY7X

@152

VCC1

(5/5)

VDD2

R319

33

3.3V

R320

XX

ADRESC

R397

1k

CSBRX

CP334 CP335

COM3

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

69

1CMG

DV2356C

CSBRX

CSDSPX

KEY6X

KEY7X

SMX

FCHG

(1/5)

GSW

(4/5)

KEY7X

(5/5)

R364

CLIM

PSSW

MONBA

AD_VMON

AD_GOUT_Y

AD_ICVREFM

CLIM

PSSW

MONBA

AD_VMON

AD_GOUT_Y

AD_ICVREFM

@159

KEY1X

KEY2X

KEY3X

KEY5X

KEY6X

PUPCN2X

KEY5X

KEY6X

KEY3X

KEY2X

KEY1X

PUPCN2X

@151

(5/5)

SEG18

SEG13

FIND

1k

AD_GOUT_P

KEY0X

SEG12

61

CSLNSX

R366

100k

AD_POUT_Y

AD_GOUT_P

KEY0X

SEG1262SEG1363SEG1464SEG1565SEG1666SEG1767SEG1868SEG19

AD_ICVREFM

R338

100k

RESETX

AD_POUT_P

AD_POUT_Y

(4/5)

AD_VMON

AD_GOUT_Y

AD_GOUT_P

AD_POUT_Y

AD_POUT_P

DA_GREF_Y

DA_GREF_P

D305

XX

R365

1k

DA_GREF_Y

AD_POUT_P

DV235C

DV235C

@140

6

ON/OFF

NC2VIN3VOUT

1

C382

10u

1

2

SEG11

SEG10

SEG9

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

VCC3IO

VSS

FULL

BCAN

AVSS

AVRH

AVCC

RW

WAKEx

CFDETx

SMX

DA_GREF_P

DA_GREF_P

DA_GREF_Y

BAT_C

VCC1C

BAT_C

(5/5)

9

R318

100k

4

5

VIN

VSS

C383

4.7u

S624

SLANT

SENSOR

D6B-2L

HORIZONTAL/VERTICAL

5

POSITION DETECT

DGND

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

D303

RB751S-40TE61

CP350

BRPW_Y1

BRPW_Y2

BRPW_Y1

BRPW_Y2

@158

(4/5)

DV1C

DV1C

VCC1C

BRPW_P1

BRPW_P2

BRPW_P2

SDCJX

PUPCN1X

SDCJX

@150

(5/5)

DGND

3

4

0.1uC310

BRPW_P1

PUPCN0X

PUPCN1X

S-812C33BPI-C4NTFG

VAE33REG

SEG11

SEG10

SEG9

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

C309

0.1u

AD_VMON

AD_ICVREFM

AD_GOUT_Y

AD_GOUT_P

AD_POUT_Y

AD_POUT_P

DA_GREF_Y

DA_GREF_P

@128

(1/5)

(2/5)

PUPCN0X

IC318

ADRESC

DRESCX

@163

3.3V REG

(5/5)

10

DGND

SIN

VCC

GND

VP_F

Q307

XX

R313

XX

PGND

R339

100k

CSDSPX

FM2

74

75

FM2

FM1

76

CM2

77

CM1

78

CSDSPx

79

CSLNSx

80

BC1

81

CSLEDx

82

CSBCKx

83

CSLMx

84

CSFLx

85

CSIOx

86

SVH1

87

SVH2

88

TEMP2

89

AFPM

90

AFMPR

91

TEMP

92

LMOUT

93

AVSS

94

VOUT

95

VREF

96

AVCC

97

ADTa

98

RST

99

IST

100

PRADJ2NC3FP24FP15AFP1a6BYTE7CNVSS8XCIN9XCOUT10RESET11XOUT12VSS13XIN14VCC15NMI16CSMAINx17SCAM1x18XONx19AFP220AFP1b21MFP2x22MFP1x23LVPCL24LEDPWM25SCAM2x

1

R336

XX

PRADJ

8

C301

7

NC

0.1u

6

NC

5

F3H

C341

0.1u

F3L

C320

4700p

F2OUT

DGND

F2IN

Q312

EMH11T2R

BUFFER

R311

XX

R312

XX

Q333

XX

IC318

@160

VAE33REG

(5/5)

±0.5%

±0.5%3900

R322

R374

@162

(5/5)

@161

(5/5)

3900

C303

XX

TH101

DGND

BCAN

Q306

EMD12T2R

VOLTAGE

DETECT

4

6

5

1

3

R305

18k

±0.5%

R306

C377

C376

10k

XX

XX

±0.5%

DGND

VDD1

(5/5)

RW

CFDETX

SCK

SOUT

SIN

R375

@165

VOD

(5/5)

Q313,Q314

LEVEL SHIFT

CP333

DGND

CP332

DGND

VDD2

(5/5)

R363

330

LVDD1

LSIN

LSCK

LCSLNSX

LSOUT

D302

RB751S-40TE61

LVPCX

Q311

DTC114EMT2L

LENS ACTIVE

SWITCH

R368

22k

DGND

TEMP2

LMOUT_LPF

FULL

VCC1C

WAKEX

CSEE

F3

F2

LV0C

SLLKX

TEMP2

TEMP2

CSLMX

VOUT

ADT

RST

IST

2

10k

DTD113EK-T-146

C368

XX

R301

R334

470

2SC4081T106Q

Q314

100k

Q313

FM1

CM2

CM1

CSDSPX

CSLNSX

CSLEDX

CSBCKX

CSFLX

CSIOX

AFPM

AFMPR

1

CS

2

SK

3

DI

4

DO

2

R352

22k

2SA1577-T106-Q

R341

5600

SLLKX

DGND

VDD1

IC309

BR93L76RFV-WE2

Q334

VOLTAGE

CONTROL

CP330

EEPROM

C308

0.1u

R337

IC309

6

1

XX

3

4

@127

LCSLNSX

SOUT

5

LVSCX

LSIN

LSCK

LSOUT

(1/5)

(5/5)

15

(5/5)

@145

CSDATAX

WAKEX

TP310

S2X

ADT

CBG

TRIG

BCAN

MOD1

67

68NC69

70

71

72

73

S2x

CBG

TRIG

ADTb

BCAN

WAKEx

CSDATAx

M30620FCPGP-U5C-CX62100

AFP1

FP1

FP2

32KHZ

RESET_MX

R373

100k

123

R314

10k

Q327

DTA114EMT2L

MODE

CONTROL

FLWX

FLSTP

13

ITGSTC

14

SCK2

SCK2

15

SOUT

DIN2

16

CSLEDX

CSDATE

17

LEDC

LEDC

18

VDD1

19

DGND

20

IGBTC

21

ITGST

22

LVSCX

LVSC

23

LCSLNSX

LCSLNS

24

16527

Q301

UM6K1N-TN

SHUTTER DRIVE

TP341

TP342

6

3

5

2

1

4

2CMG

1CMG

R357

R358

10k

10k

R335

1CMG_1

LEDC

C306

0.1u

MOD4

MOD3

MOD2

61

62

63

VSS

MOD464MOD365MOD266MOD1

IC301

MAIN CPU

IC301

0.1u

C307

C379

0.01u

X301

6MHz

SIN

TP354

11

12

DOUT

F2OUT26F2IN27F3L28F3H29LSIN30LSOUT31LVDD132LSCK33LED134LED235LED336LED4

25

F2IN

F2OUT

100k

LV1C

MFPC

AFLED2

STLEDX

RW

TRX

LV0C

CP346

53

54

56

57

58RW59

60

VCC

LEDC

10k

R342

CSMAINX

R330

1M

R331

1M

10

TRIG

WLTRG

F3L

TRX

LV1C55LV0C

MFPC

AFLED2

STLEDx

TP357

AFP2

AFP1

MFPC

C365

0.01u

C361

C360

47p

47p

RW

LV1C

SLLKX

CSLNSX

6RW7

9

LV1C8SLLK

CSLNS

IC304

I/O CONTROLLER

IC304

M50222FP

LSIN

LSOUT

VDD2

F3H

52

LEDPWM

LSCK

D311

UDZSTE-1722B

ASACTVX

51

FACTx

ASACTVx

CSIOX

CSFLX

4

5

CSIO

LED1

C318

0.1u

18

SH1

@167

SH2

(5/5)

SH_COM

D312

UDZSTE-1722B

SCK2

50

VPICx

49

S1x

48

LMODE

47

CSEE

46

AFLED1

DGNDP54

CSDSCx

DSOUT

LEAKC

CCDCP

FWE_M

C366

0.01u

SOUT

3

DIN

CSFL

LED2

AFLED1

45

CE

44

SFLDx

43

AFM1

42

AFM2

41

40

EPM

39

1CMG

38

2CMG

37

36

DSCK

35

DSI

34

33

32

SCK

31

SIN

30

SOUT

29

28

BRFWE

27

BZ

26

R343

2200

DGND

SCK

AFPM

TP353

TP355

1

2

PIM

SCK

PIO4

PIO3

PIO2

PIO1

PII4

PII3

PII2

PII1

LED7

LED6

LED5

AGND

LED3

LED4

IC314

5.5V REG

IC314

XC6201P552PR

SH_COM

SCK2

S1X

LMODE

CSEE

SFLDX

1CMG

2CMG

SCK

SIN

SOUT

BZ

CM1

CM2

LVPCL

XONX

AFMPR

AFMPR

MFP1X

MFP2X

SCAM2X

SCAM1X

SCK

SCK

SIN

SIN

SOUT

SOUT

CSBCKX

CSBCKX

TP365

48

TP364

47

TP363

TP362

46

AFP1

45

AFP2

PII4

44

PII3

43

42

41

LED7

40

LED6

39

LED5

38

37

LED7

LED6

LED5

LED4

LED3

LED2

LED1

@166

@142

CP329

DTB513ZMT2L

B+ SWITCH

@156

@169

(5/5)

Q337

(5/5)

AFP2

AFP1

C372

1u

CSDSCX

(5/5)

(5/5)

@157

(5/5)

@135

(5/5)

FP2

FP1

VOUT2VSS3VIN

1

DSCK

DSI

DSOUT

LEAKC

STLED_K

FM1

FM2

STLEDX

AFLED1

AFLED2

LEDPWM

20146

C324

0.1u

DTC144EMT2L

Q330

C371

PRADJ

VCC1C

CFDETX

EMH10T2R

LED DRIVE

1u

DGND

DGND

TP334

Q335

FEN

TP333

Q338

DTC144EMT2L

SWITCH

2

DTC144EMT2L

0.1u

C322

Q303

20

20

2117

5

R325

1k

VDD1

(5/5)

VPI

@144

TP331

TP332

18

IN119IN2

VCC

GND2PWM3STBY4VM15VM26O17O18PGND19PGND210PGND3

1

TP330

TP329

18

IN119IN2

VCC

GND2PWM3STBY4VM15VM26O17O18PGND19PGND210PGND3

1

C333

2.2u

17

18

19

20

VS

PGND

OUT3P

OUT3N

IN22IN13MD24MD15MD06SGND7VDD8VB9VCONT10VREF

1

6

3

5

4

1

Q330,Q336

B+ SWITCH

PGND

4-10

6

1

3

4

VM317VM4

VM317VM4

R340

3.3

C329

2.2u

PGND

@164

14O215O216

14O215O216

15

OUT216OUT1

R356

1

3

5

7

RB304

22

RB303

1

3

5

7

2

(5/5)

13IB14

PGND

22

2

4

6

8

22

2

4

6

8

DTB513ZMT2L

XN4401-(TX)

CP323

LD307_A

(5/5)

C321

1u

C323

1u

Q336

22 2411

Q305

Q303,Q305

LED DRIVE

CP322

C381

100p

LMOUT_LPF

VP_F

VP

VP_F_301

11

PGND412PGND513PGND6

11

PGND412PGND513PGND6

11VS12

VCC

MOTOR DRIVE,

LB8632V-TLM-E

C330

0.1u

TOKO_K1

TOKO_K2

TOKO_K3

TOKO_K4

TOKO_K5

TOKO_K6

TOKO_K7

TOKO_K8

TOKO_K9

TOKO_A

R347

56k

IC308

APERTURE

LED DRIVE

IC308

DGND

IC307

AF MOTOR

DRIVE

IC307

TB6593FNG

VP_F_302

IC306

CHARGE MOTOR

DRIVE

IC306

TB6593FNG

PGND

2SA1577-T106-Q

TC7S66FU(TE85R)

(1.4A/36V)

(1.4A/36V)

(1.4A/36V)

VP_F_303

Q326

B+ SWITCH

DGND

@170

(5/5)

VPR

IC313

LOW-PASS

FILTER

1

IN

2

OUT

3

GND4GATE

F304

F301

F302

F303

(1.4A/36V)

23

Q304

DTC144EMT2L

INVERTER

R395

100k

IC313

C380

0.1u

DGND

5

VCC

SCK

SOUT

CP311

AFM+

@171

AFM-

CP312

CP313

CM+

@172

CM-

CP314

CP315

FM+

@173

FM-

(5/5)

CP316

CP324

@143

VPR

(5/5)

DGND

CSLMX

C302

XX

LMODE

FIND

FEN

RW

LD307_A

DV235C

MOD3

MOD4

MOD2

MOD1

CP302

ADT

IST

RST

CBG

VOUT

(5/5)

R359

1k

(5/5)

LEAKC

CSDSCX

CSDATAX

DSOUT

DSCK

DSI

CSMAINX

1

C332

0.1u

2

3

IC315

TC7S32FU(TE85R)

C367

XX

R388

100k

IN1

IN2

GND4OUT

CF DETECT

IC315

LMOUT

CSLMX

LMODE

SCK

CP351

FIND

FEN

GRPONX

RW

LD307_A

MOD3

MOD4

MOD2

MOD1

ADT

CCDCP

IST

RST

CBG

VOUT

DGND

VCC1

TP328

R383

R382

100k

100k

TP350TP351TP352

R386

100k

R387

100k

R380

1M

5

VCC

(5/5)

R379

1M

@149

@168

(5/5)

LEAKC

CSDSCX

CSDATAX

DSOUT

DSCK

DSI

CSMAINX

FFCD2X

FFCD1X

2726

(5/5)

@124

(1/5)

VDD1

(5/5)

@114

(1/5)

(5/5)

AM-001 (3/5)

Page 11

1 165

AM-001 BOARD (4/5)

A

ANTI-SHAKE

XX MARK:NO MOUNT

DGND

B

C

AD_POUT_P

AD_POUT_Y

AD_GOUT_P

@159

(3/5)

D

AD_GOUT_Y

AD_ICVREFM

AD_VMON

DA_GREF_P

DA_GREF_Y

DGND

E

F

GSW

@154

(3/5)

PSSW

HPFSWX

MONBA

CLIM

G

BRPW_P1

(3/5)

BRPW_P2

BRPW_Y1

BRPW_Y2

@158

H

I

MV6

(5/5)

DV5

J

K

05

C402

0.47u

C409

TP401

0.01u

C403

TP404

0.01u

C404

TP407

3

TP418

TP410

TP413

TP415

TP416

TP417

0.1u

0.1u

C406

C407

C408

0.47u

0.01u

TP402

TP405

TP411

TP403

R474

TP412

TP406

TP409

TP414

DGND

4 1310

ADVREFH

5V

R412

0

C401

1k

R466

R401

±0.5%

R402

±0.5%1k

R403

±0.5%3300

R404

±0.5%3300

R405

±0.5%1k

R406

±0.5%1k

0

0

22u

DV5

POUTA

POUTB

GVOUTA

GVOUTB

ICVREFM

VMON

DA_GREF_P

DA_GREF_Y

/HPFSW

MONBA

BRPW_P1

BRPW_P2

BRPW_Y1

BRPW_Y2

IC403

5V REG

IC403

TK11150CSCL-G

5

VIN

CONT2GND3NOISEP

1

PSSW

GSW

TP419

C411

5V

10u

4

VOUT

C410

0.1u

PINALP

PINALN

PINAHP

PINAHN

PINBLP

PINBLN

PINBHP

PINBHN

TRC_P

VMON

TP424

C412

6

24k

±0.5%

±0.5%

R425

20k

34

35

PDIFFA

IC401

ANALOG MASTER

UPC5703K9-033-5FH-A

C416

0.001u

POUTB

Q403-Q406

LIMITER

R419

1

±1%

1/4W

Q404

2SA1314C-TE12L

POUTA

C417

0.001u

33

PLPFA

ANTI-SHAKE

IC401

DGND

POUTA

ICVREFM

32

31

ICVREFM

PSSW

GVCCO_COM

2

R429

1k

±0.5%

R415

2400

±0.5%

MONBA

R424

C415

0.01u

0.1u

DGND

40

41

42

43

44

45

46

47

48

49

50

51

52

R407

100k

DGND

VMON

VCCP

PINALP

PINALN

PINAHP

PINAHN

GNDP

PINBLP

PINBLN

PINBHP

PINBHN

GNDP

PSUMGAIN

2

R413

1k

±0.5%

R414

2400

±0.5%

39

MONB/A

FBB2TRBB3TRCB4PDIFFB5PLPFB6POUTB7GNDR8GVCCO9PSSW10GREFA111GINA12GLPF1A13GHPFIA

1

C413

0.01u

Q403

EMT1T2R

1

4

3

6

R416

100

±0.5%

Q401

DTC114EE-TL

INVERTER

36

38

FBA

TRCA37TRBA

±0.5%20k

R422

±0.5%24k

R423

TRC_Y

5

9281411712

PSSW

/HPFSW

ADVREFH

PSPWR

R431

1

6

30

29

ADVREFH

±0.5%

2200

GINA

GREFA1_COM

Q405

EMT1T2R

4

3

R430

100

±0.5%

/HPFSW

5

C418

28

0.015u

VCCR

27

PSW

GSW

GVOUTB

GLPF2B

GREFB2

GHPFOB

GHPFIB

GLPF1B

GINB

GREFB1

GVOUTA

GLPF2A

GREFA2

GHPFOA

R433

1

±1%

1/4W

Q406

2SA1314C-TE12L

C420

4.7u

C414

4.7u

PINALP

TRC_P

PINBHP

PINBHN

PINAHP

PINAHN

TRC_Y

PINBLN

PINBLP

PINALN

XX

±1%

R455

±1%

XX

GREFA1_COM

GINA

GREFB1_COM

GINB

GVCCO_COM

DV5_HALL

R453

1/4W

1/4W

1/4W

R456

1/4W

TP425

1R452

1

GVCCO_COM

TP426

C421

0.1u

DGND

26

25

C422

0.0015u

24

23

22

21

C424

0.015u

20

19

18

17

C423

0.0015u

16

15

14

TP420

MV6

C434

1u

TP423

TP422

TP421

R464

XX

R439

XX

0

XX

R437

C425

R463

XX

R440

XX

C426

R438

XX

0

C419

0.1u

DGND

BRPW_Y1

BRPW_Y2

24

EN2

EN12VM23NC4PGND5OUT46OUT37OUT28OUT19PGND10NC11VM112VG

1

2SA1611T1-M5M6

R441

2200

±0.5%

C427

0.001u

R442

C428

0.1u

R443

C429

0.001u

BRPW_P1

BRPW_P2

Q407

B+ SWITCH

±0.5%2200

±0.5%2200

19

20

IN421IN322IN223IN1

IC402

ANTI-SHAKE

LV8014T-TLM-E

DRIVE

IC402

EXTRA

R460

R459

XX

18

XX

SGND

GVOUTB

DA_GREF_Y

GVOUTA

DA_GREF_P

C430

0.01u

17

C2L

PGND

GSW

GINB

GREFB1_COM

C431

0.01u

14

15

16

C1L

C1H

C2H

DGND

C433

0.1u

13

VCC

C432

0.1u

TP427

TP441

TP428

TP442

TP429

TP443

CP445

TP430

TP444

CP446

TP431

CP447

TP432

CP448

TP434

BR_Y2

BR_Y1

BR_P1

BR_P2

CP449

TP436

CP450

TP438

DGND

15

BR_P1

BR_P2

BR_Y1

BR_Y2

GREFA1_COM

GINA

GREFB1_COM

GINB

GVCCO_COM

BR_P1

BR_P2

BR_Y1

BR_Y2

DV5_HALL

PINALP

TRC_P

PINBHP

PINBHN

PINAHP

PINAHN

TRC_Y

PINBLN

PINBLP

PINALN

VCC1

VDD1

@174

(5/5)

@175

(5/5)

(5/5)

DSLR-A100_L3

4-11

AM-001 (4/5)

Page 12

AM-001 BOARD (5/5)

A

CONNECTOR

XX MARK:NO MOUNT

B

C

D

@163

TEMP2

(3/5)

@118

CSADX CSTGX

(1/5)

CCDA1 CCDA2

CCDA3 CCDA4

CCDA5

CCDA7 CCDA8

CCDA9 CCDA10

CCDA11 CCDB0

@105

CCDB1 CCDB2

(1/5)

CCDB3 CCDB4

CCDB5 CCDB6

CCDB7

CCDB9

CCDB11

E

F

@117

(1/5)

Q002

PBLK

G

H

I

J

K

L

M

N

O

P

Q

05

4 19 22

IS-001 (3/3)

CN001

(Througt the FP-526 flexible board)

(Page 4-7 of Level 2)

DGND

D319

CRS01(TE85R)

D320

CRG01(TE85L)

51PCN104

R309

XX

5

VIN

CONT2GND3NOISEP

1

2DGND

4DGND

6TGCLK

8AN_RSTx

10AN_SCK

12CSTGx

14TGVDx

16CCD_A0

18CCD_A2

20CCD_A4

22CCD_A6

24CCD_A8

26CCD_A10

28CCD_B0

30CCD_B2

32CCD_B4

34CCD_B6

36CCD_B8

38CCD_B10

40DGND

42DGND

44HDRV_6

46AV16

48AV8

50DGND

R292

4700

DGND

AV3

4

IC311

VOUT

3.2V REG

IC311

TK11132CSCL-G

C343

C344

0.1u

1u

IC310

5V REG

IC310

TK11150CSCL-G

VCC1C

DV3

DV5

IC501

5V REG

IC501

XC6213B502NR

LV8

D501

EDZ-TE61-5.6B

DGND

BL1K

BL1A

TGCLK

ANRSTX

@119

ANSCKANSOUT

(1/5)

TGVDXTGHDX

CCDA0

CCDA6

@106

(1/5)

CCDB8

CCDB10

C339

0.1u

EMD3T2R

4

Q501

R091

XX

VOUT

2

TP349

VOD

C508

4.7u

R502

100k

C504

0.1u

R299

15k

C505

1u

IC009

6V REG

IC009

R1173D001B-TR-FA

1

VOUT

2

VOUT

3

ADJ

C326

10u

C325

10u

6

4

1

3

TP507

R295

4700

6

VDD

5

CE

GND

4

VCC1

DGND

5

C507

1u

@121

R296

15k

DGND

R089

51k

±0.5%

C082

R090

10k

10uF

±0.5%

10V

5

VIN

CONT2GND3NOISEP

1

C338

0.1u

VCC2

3

4

VIN

B+ SWITCH

VOUT

CE2VSS

1

C509

0.1u

R506

C506

1u

100k

1 DGND

3 CTHERM

5 DGND

7 DGND

9 AN_SOUT

11 CSADx

13 TGHDx

15 DGND

17 CCD_A1

19 CCD_A3

21 CCD_A5

23 CCD_A7

25 CCD_A9

27 CCD_A11

29 CCD_B1

31 CCD_B3

33 CCD_B5

35 CCD_B7

37 CCD_B9

39 CCD_B11

41 AV3

43 HDRV_6

45 DGND

47 DGND

49 AV8

51 DGND

DGND

XX

R069

R068

XX

XX

1/10W

1/10W

Q003

@165

(3/5)

@145

(3/5)

DGND

XX

VOD

VP_F