Sony DSJ-303 Service manual

D-SJ303

SERVICE MANUAL

Ver. 1.1 2005. 03

SPECIFICATIONS

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength : λ = 780 nm

Emission duration : Continuous

Laser output : Less than 44.6 mW

(This output is the value measured at a distance of 200 mm from

the objective lens surface on the optical pick-up block with 7

mm aperture.)

D-A conversion

1-bit quartz time-axis control

Frequency response

40 - 20 000Hz dB (measured by JEITA CP-307)

Output (at 4.5 V input level)

Headphones (stereo minijack)

Approx. 5 mW + Approx. 5 mW at 16 Ω

Power requirements

For the area code of the model you purchased, check the upper

left side of the bar code on the package.

• Sony NH-WM2AA rechargeable batteries: 2.4 V DC

• Two LR6 (size AA) batteries: 3 V DC

• AC power adaptor (DC IN 4.5 V jack): 120 V, 60 Hz

US Model

Canadian Model

Model Name Using Similar Mechanism D-SJ301

CD Mechanism Type CDM-3125ER

Optical Pick-up Type DAX-25E

Battery life* (approx. hours)

(When you use the CD player on a flat and stable surface.)

Playing time varies depending on how the CD player is used.

When using G-PROTECTION function

12

NH-WM2AA 30 32

(charged for about 5 hours**)

Two Sony alkaline 47 50

batteries LR6(SG)

(produced in Japan)

* Measured value by the standard of JEITA (Japan Electronics and

Information Technology Industries Association).

** Charging time varies depending on how the rechargeable battery is

used.

Operating temperature

5°C - 35°C (41°F - 95°F)

Dimensions (w/h/d) (excluding projecting parts and controls)

Approx. 133.9 x 38.1 x 147.5 mm

(5 3⁄8 x 1 1⁄2 x 5 7⁄8 in.)

Mass (excluding accessories)

Approx. 360 g (12.7 oz.)

Design and specifications are subject to change without notice.

9-879-364-02

2005C02-1

© 2005.03

Accessories

Supplied accessories

Headphones (1)

Hand strap (1)

PORTABLE CD PLAYER

Sony Corporation

Personal Audio Group

Published by Sony Engineering Corporation

D-SJ303

Ver. 1.1

TABLE OF CONTENTS

DANGER

Invisible laser radiation when open and interlock failed or defeated.

Avoid direct exposure to beam.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as a

CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Specifications ............................................................................ 1

1. SERVICING NOTE ................................................... 3

2. GENERAL ................................................................... 3

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 4

3-2. “Lid Upper”, Cabinet (Front) .......................................... 4

3-3. MD Assy, Main Board ..................................................... 4

3-4. “Motor Assy , Turn Table (Spindle) (M901)” ................. 5

3-5. “Motor Assy (Sled) (M902)”,

Optical Pick-Up (DAX-25E) ........................................... 5

4. ELECTRICAL ADJUSTMENT ............................. 6

5. DIAGRAMS

5-1. IC Pin Function Description ............................................ 7

5-2. Block Diagrams ............................................................... 11

5-3. Printed Wiring Boards – Main Section (1/2) –................ 12

5-4. Printed Wiring Boards – Main Section (2/2) –................ 13

5-5. Schematic Diagram – Main Board (1/3) – ...................... 14

5-6. Schematic Diagram – Main Board (2/3) – ...................... 15

5-7. Schematic Diagram – Main Board (3/3) – ...................... 16

6. EXPLODED VIEWS

6-1. Upper Lid Section ........................................................... 18

6-2. Cabinet Section................................................................ 19

6-3. Optical Pick-Up Section (CDM-3125ER) ....................... 20

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE

PA RTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

7. ELECTRICAL PARTS LIST .................................. 21

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES

SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT.

NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES

SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL

OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

2

SECTION 1

SERVICING NOTE

D-SJ303

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe

from more than 30 cm away from the objective lens.

BEFORE REPLACING THE OPTICAL PICK-UP BLOCK

Please be sure to check thoroughly the parameters as par the “Optical

Pick-Up Block Checking Procedures” (Part No.: 9-960-027-11)

issued separately before replacing the optical pick-up block.

Note and specifications required to check are given below.

• FOK output: IC601 yg pin

When checking FOK, remove the lead wire to disc motor.

• RF signal P-to-P value: 0.45 to 0.65 Vp-p

SECTION 2

GENERAL

Laser Diode Checking Methods

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper panel is closed while turning

ON the S801 (push switch type).

The following two checking methods for the laser diode are operable.

Method :

Emission of the laser diode is visually checked.

1. Open the upper lid.

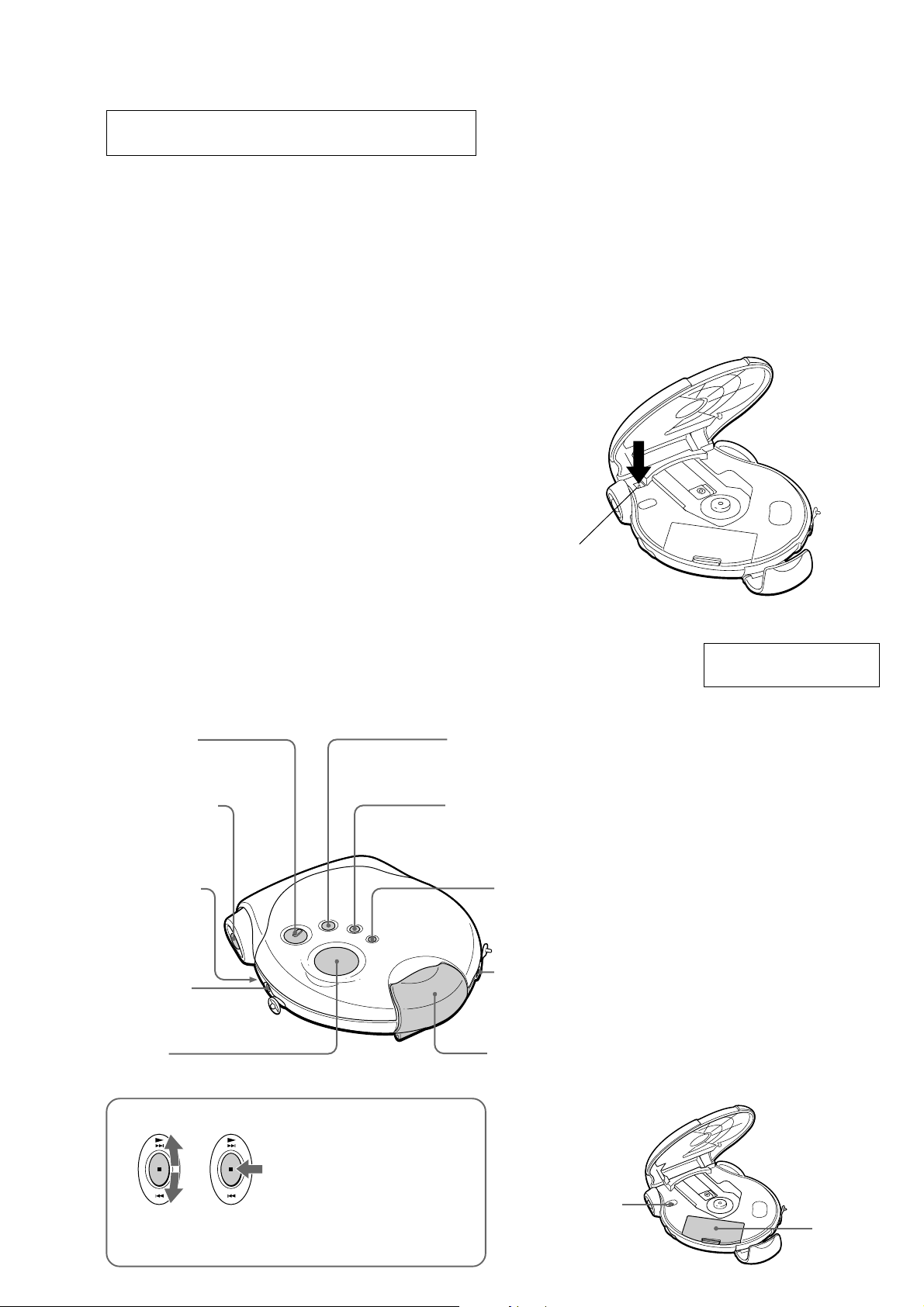

2. Push the S801 as shown in Fig. 1 .

3. Check the object lens for confirming normal emission of the

laser diode. If not emitting, there is a trouble in the automatic

power control circuit or the optical pick-up. During normal

operation, the laser diode is turned ON about 2.5 seconds for

focus searching.

S801

Fig.1 Method to push S801

This section is extracted

from instruction manual.LOCATING THE CONTROLS

CD player (front)

1 HOLD switch

2 3-way control key

3 VOL (volume)

control

4 DC IN 4.5 V

(external power

input) jack

5 Display

3-way control key

N/>: Play/AMS/search

6 PLAY MODE button

7 REPEAT/ENTER button

8 SOUND button

9 i (headphones)

jack

q; Buckle

CD player (inside)

Pushtoward

N/> OR

..

Pressx /CHG.

.: AMS/search

x/CHG: stop/charge

qa G-PROTECTION

switch

qs Battery

compartment

3

D-SJ303

SECTION 3

DISASSEMBLY

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. “LID, UPPER”, CABINET

(FRONT) (Page 4)

Note: Follow the disassembly procedure in the numerical order given.

3-2. “LID, UPPER”, CABINET (FRONT)

4

five screws (B2)

3-3. MD ASSY, MAIN BOARD

(Page 4)

3-4. “MOTOR ASSY, TURN TABLE

(SPINDLE) (M901)’’

(Page 5)

3-5. “MOTOR ASSY (SLED) (M902)’’,

OPTICAL PICK-UP (DAX-25E)

(Page 5)

cabinet (front)

1

open the buckle sub assy

3-3. MD ASSY, MAIN BOARD

5

3

CN502 (white)

2

screw

3

cabinet (lower) sub assy

1

6

flexible cable (24P)

MD assy

2

CN503 (black)

lid, upper

2

screw

• Note ON DURING ASSEMBLY

Align RV301 and Lever (VOL) (B).

4

level (vol) (B)

RV301

4

main board

5

cabinet (lower) sub assy

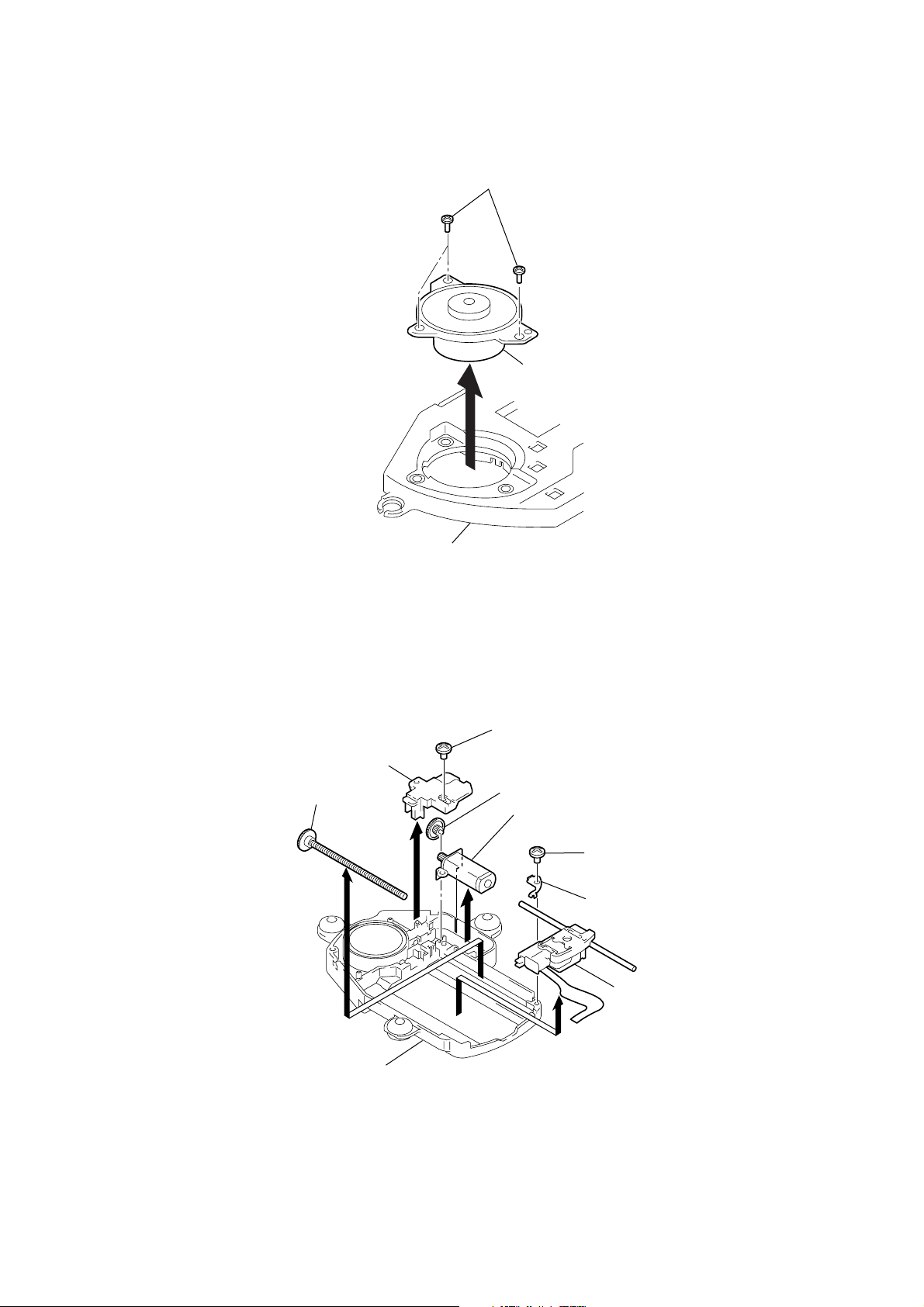

3-4. “MOTOR ASSY, TURN TABLE (SPINDLE) (M901)”

2

motor assy, turn table

(spindle) (M901)

1

three screws (B1.7)

chassis

D-SJ303

3-5. “MOTOR ASSY (SLED) (M902)”, OPTICAL PICK-UP (DAX-25E)

screw (B 1.7)

1

cover, gear

gear (B)

motor assy (sled) (M902)

3

6

screw feed assy

2

5

chassis

4

screw

(P 1.4x3.5)

retainer, shaft

optical pick-up

(DAX-25E)

5

D-SJ303

)

C632

L606

3

4

4

91

120

SECTION 4

ELECTRICAL ADJUSTMENTS

The CD section adjustments are done automatically in this set.

Precautions for Check

1. Perform check in the order given.

2. Use YEDS-18 disc (Part No.: 3-702-101-01) unless otherwise

indicated.

3. Power supply voltage requirement :DC4.5 V in DC IN jack.

(J401)

VOLUME button : Minimum

HOLD switch : OFF

Focus bias Check

Condition:

• Hold the set in horizontal state.

Connection:

oscilloscope

(AC range)

TP630(RF)

[MAIN BOARD] (SIDE B)

D

R6

R4R

IC601

31

R641

607

613

C608

X601

C613

R625

C627

60

R616

90

61

R602

R6

C601

R601

C602

C619

C618

R623

R622

R621

R619

C615

R618

11

2

R620

TAP403

C617

C630

C616

R624

C620

R627

R632

C631

C629

R633

R631

TP630(RF)

R637

R635

Procedure:

1. Connect the oscilloscope to the test point TP630(RF) on the

MAIN board.

2. Set a disc. (YEDS-18)

3. Press the >B button.

4. Check the oscilloscope waveform is as shown below.

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

RF Signal reference Waveform (Eye Pattern)

VOLT/DIV : 100 mV (With the 10 : 1 probe in use

TIME/DIV : 500ns

RF level

0.4 to 0.65 Vp-p

To watch the eye pattern, set the oscilloscope to AC range and

increase the vertical sensitivity of the oscilloscope for easy

watch-ing.

5. Stop revolving of the disc motor by pressing the x button.

6

SECTION 5

DIAGRAMS

5-1. IC PIN FUNCTION DESCRIPTION

• IC601 CXD3029R (SYSTEM CONTROL)

Pin No. Pin name I/O Description

1 XRAM O DRAM low address strobe signal outut

2XWE O DRAM data input enable signal output

3 to 6 D0 to 3 I/O DRAM data bus 0 to 3

7 DCLK O Not used (OPEN)

8 DCKE O Not used (OPEN)

9 XCAS O DRAM column address storobe signal output

10 WFCK O Not used (OPEN)

11 to 13 A7 to 9 O DRAM address 7 to 9

14 DVss – Ground terminal for DRAM interface

15 to 17 A4 to 6 O DRAM addres 4 to 6

18 XRDE I/O Not used (OPEN)

19 VDD0 – Power supply for digital

20 CLOCK I Serial data transfer clock input

21 SDTO I Serial data input

22 SENS O SENS output

23 XLAT I Latch input

24 XSOE I CPU serial data output enable signal input

25 SYSM I Mute input “H” : MUTE

26 WDCK O Word clock output

27 SCOR O SCOR output

28 XRST I Reset terminal

29 PWMI I Spindle moter external control input

30 XQOK I/O Not used (OPEN)

31 XWRE I/O Not used (Fixed at “L”)

32 R4M O System clock output

33 Vss0 – Digital ground terminal

34 SQCK I Not used (Fixed at “H”)

35 SCLK I Not used (Fixed at “H”)

36 SQSO O Not used (OPEN)

37 XEMP O Not used (OPEN)

38 XWIH O Not used (OPEN)

39 SBSO O Not used (OPEN)

40 EXCK I Not used (Fixed at “L”)

41 XTSL I Not used (Fixed at “L”)

42 HVss – Ground terminal for headphones

43 HPL O Not used (OPEN)

44 HPR O Not used (OPEN)

45 HVDD – Power supply terminal for headphones

46 XVDD – Power supply terminal for master clock

47 XTAI I Master clock input (169MHz)

48 XTAO O Master clock output (169MHz)

49 XVss – Ground terminal for master clock

50 AVDD1 – Power supply terminal for DAC block

51 AOUT1 O Audio out (L-CH)

52 VREFL O VREF terminal (L-CH)

53 AVss1 – Ground terminal DAC block

54 AVss2 – Ground terminal DAC block

D-SJ303

7

D-SJ303

Pin No Pin name I/O Description

55 VREFR O VREF terminal(R-CH)

56 AOUT2 O Audio out (R-CH)

57 AVDD2 – Power supply terminal for DAC block

58 TEST1 I Not used (Fixed at “L”)

59 TEST I Not used (Fixed at “L”)

60 Vss1 – Not used (Fixed at “L”)

61 LRMU O OR output of L-CH/R-CH detection flag (AND output) and system flag

62 DOUT O Not used (OPEN)

63 ATSK I/O Not used (OPEN)

64 DFCT I/O Not used (OPEN)

65 FOK I/O Focus OK signal I/O teminal

66 MIRR I/O Not used (OPEN)

67 COUT I/O Not used (OPEN)

68 C2PO O Not used (OPEN)

69 GFS O Not used (OPEN)

70 XUGF O Not used (OPEN)

71 XPCK O Not used (OPEN)

72 VDD1 – Power supply terminal for digital

73 PCO O Charge pump output for master PLL

74 FILI I Filter input for master PLL

75 FILO O Filter output for master PLL

76 CLTV I VC01 contorol voltage input

77 VCTL I VC02 contorol voltage input for wide range EFM PLL

78 VPCO O Charge pump output for wide range EFM PLL

79 AVDD 3 – Ground terminal for analog (servo block)

80 ASYO O EMF fullswing output

81 ASYI I Asymmetric comparate voltage input

82 BIAS I Asymmetric circuit current constrant input

83 AVDD3 – Power supply terminal for analog (servo block)

84 RFAC I EFM signal input

85 AVDD0 – Power supply terminal for analog (servo block)

86 IGEN I Current constant input for OP amplifier

87 AVss0 – Ground terminal for analog (servo block)

88 RFDC I RF signal input

89 CE I E signal input

90 TE I F signal input

91 SE I B signal input

92 FE I A signal input

93 VC I Center voltage input

94 Vss2 – Digital ground terminal

95 FRDR O Focus drive output

96 FFDR O Focus drive output

97 TRDR O Traking drive output

98 TFDR O Traking drive output

99 SRDR O Sled drive output

100 SFDR O Sled drive output

101 SSTP I Most inside disc detection signal input (Fixed at “L”)

102 MDS O Spindle drive output

103 MDP O Servo contorol output for spindle moter

104 C176 O 17644kHz output

8

Loading...

Loading...