Page 1

DSC-W90

SERVICE MANUAL

Ver. 1.0 2007.02

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Internal memory

Internal memory

ON BOARD

ON BOARD

Photo: Silver

Link

Link

SPECIFICATIONS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Korea Model

Argentine Model

Brazilian Model

PRINTED WIRING BOARDS

SERVICE NOTE

DISASSEMBLY

• Precaution on Replacing the SY-169 Board

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

FRAME SCHEMATIC DIAGRAM

SCHEMATIC DIAGRAMS

REPAIR PARTS LIST

DIGITAL STILL CAMERA

DSC-W90_L2

Sony EMCS Co.

2007B0500-1

© 2007.2

Published by Kohda TEC9-852-192-31

Page 2

SPECIFICATIONS

Camera

[System]

Image device:

7.18 mm (1/2.5 type) color CCD,

Primary color filter

Total pixel number of camera:

Approx. 8 286 000 pixels

Effective pixel number of camera:

Approx. 8 083 000 pixels

Lens: Carl Zeiss Vario-Tessar 3× zoom lens f =

5.8 – 17.4 mm (35 – 105 mm when converted

to a 35 mm still camera) F2.8 – 5.2

Exposure control: Automatic exposure, Scene

Selection (7 modes)

White balance: Automatic, Daylight, Cloudy,

Fluorescent 1,2,3, Incandescent, Flash

File format (DCF compliant):

Still images: Exif Ver. 2.21 JPEG compliant,

DPOF compatible

Movies: MPEG1 compliant (Monaural)

Recording media: Internal Memory (approx.

31 MB), “Memory Stick Duo”

Flash:Flash range (ISO sensitivity

(Recommended exposure Index) set to Auto):

approx. 0.2 to 3.3 m (7 7/8 inches to 10 feet

10 inches) (W)/approx. 0.4 to 1.8 m (1 feet

33/4 inches to 5 feet 10 7/8 inches) (T)

[Input and Output connectors]

Multi connector Video output

USB communication: Hi-Speed USB (USB 2.0

compliant)

Audio output (Monaural)

USB communication

[LCD screen]

LCD panel: 6.2 cm (2.5 type) TFT drive

Total number of dots: 115 200 (480 × 240) dots

[Power, general]

Power: Rechargeable battery pack NP-BG1, 3.6 V

AC-LS5K AC Adaptor (not supplied), 4.2 V

Power consumption (during shooting with the

LCD screen on): 1.1W

Operating temperature: 0 to 40°C (32 to 104°F)

Storage temperature: –20 to +60°C (–4 to +140°F)

Dimensions: 91.0 × 58.0 × 22 .9 mm (3 5/8 ×

23/8 × 29/32 inches) (W/H/D, excluding

protrusions)

Approx. 155 g (5.5 oz) (including NP-

Mass:

BG1 battery pack and strap, etc.)

Microphone: Monaural

Speaker: Monaural

Exif Print: Compatible

PRINT Image Matching III: Compatible

PictBridge: Compatible

BC-CSG/BC-CSGB/BC-CSGC

battery charger

Power requirements: AC 100 to 240 V, 50/60 Hz,

2W (BC-CSG/BC-CSGC)/ 2.6 W (BC-

CSGB)

Output voltage: DC 4.2 V, 0.25 A

Operating temperature: 0 to 40°C (32 to 104°F)

Storage temperature: -20 to +60°C (–4 to

+140°F)

Dimensions: Approx. 62 × 24 × 91 mm (2 1/2 ×

31/32 × 35/8 inches) (W/H/D)

Mass: Approx. 75 g (2.7 oz)

Rechargeable battery pack NPBG1

Used battery: Lithium-ion battery

Maximum voltage: DC 4.2 V

Nominal voltage: DC 3.6 V

Capacity: 3.4 Wh (960 mAh)

Design and specifications are subject to change

without notice.

DSC-W90_L2

— 2 —

Page 3

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

CAUTION

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. FLEXIBLE Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

DSC-W90_L2

— 3 —

Page 4

1. SERVICE NOTE

1-1. PRECAUTION ON REPLACING THE SY-169 BOARD

DESTINATION DATA

When you replace to the repairing board, the written destination data of repairing board also might be changed to original setting.

Refer to Service Manual ADJ, and perform “DESTINATION DATA WRITE”.

USB SERIAL No.

The set is shipped with a unique ID (USB Serial No.) written in it.

This ID has not been written in a new board for service, and therefore it must be entered after the board replacement.

Refer to Service Manual ADJ, and perform “USB SERIAL No. INPUT”.

1-2. SELF-DIAGNOSIS FUNCTION

1-2-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the LCD screen what to

do.

Details of the self-diagnosis functions are provided in the Instruction

manual.

LCD screen

Blinks at 3.2 Hz

0 0

Detailed Code

Refer to “1-2-3. Self-diagnosis Code Table”.

Repaired by:

C : Corrected by customer

E : Corrected by service

engineer

3 2C

Block

Indicates the appropriate

step to be taken.

E.g.

13 ....Format the “Memory Stick Duo”.

32 ....Turn on power again.

1-2-2. Self-diagnosis Display

When problems occur while the unit is operating, the LCD screen

shows a 4-digit display consisting of an alphabet and numbers, which

blinks at 3.2 Hz. This 5-character display indicates the “repaired

by:”, “block” in which the problem occurred, and “detailed code”

of the problem.

DSC-W90_L2

1-1

Page 5

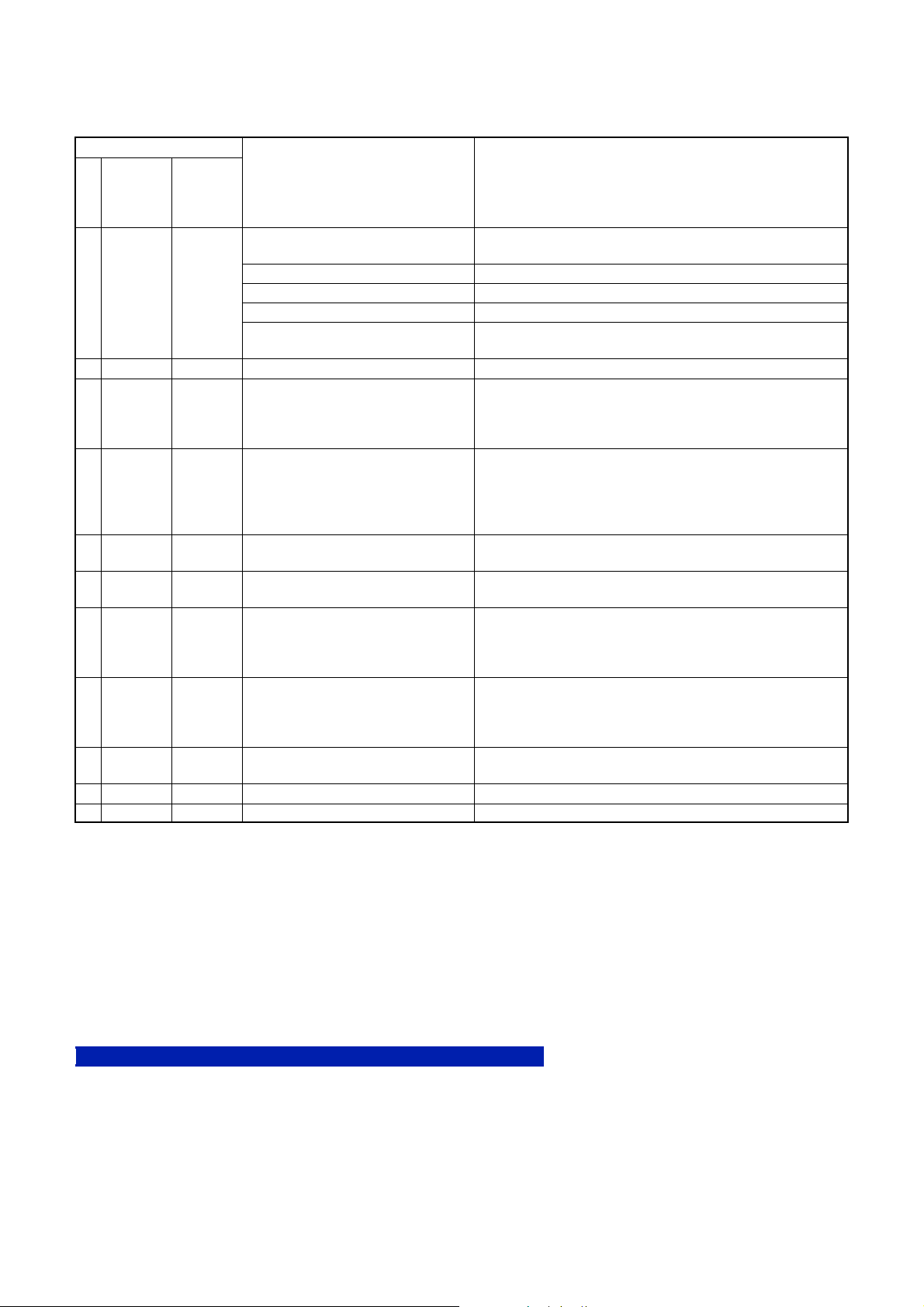

1-2-3. Self-diagnosis Code Table

Self-diagnosis Code

Function

Repaired by:

C

C

Block

13

32

Detailed

Code

01

01

Symptom/State

The internal memory has experienced a

format error.

“Memory Stick Duo” is unformatted.

“Memory Stick Duo” is broken.

“Memory Stick Duo” type error

The camera cannot read or write data

on the “Memory Stick Duo”.

Trouble with hardware

Format the internal memory.

Format the “Memory Stick Duo”.

Insert a new “Memory Stick Duo”.

Insert a supported “Memory Stick Duo”.

Turn the power off and on again, or taking out and inserting the

“Memory Stick Duo” several times.

Turn the power off and on again.

Retry turn the power on by the power switch. If it does not

E

61

00

Difficult to adjust focus

(Cannot initialize focus)

recover, check the focus reset sensor of lens block (pin ws of

CN402 on the SY-169 board). If it is OK, check the focus motor

drive IC (IC401 on the SY-169 board).

Retry turn the power on by the power switch. Check the zoom

reset sensor of lens block (pin ra of CN402 on the SY-169

board) when zooming is performed when the zoom button is

operated. If it is OK, check the zoom motor drive IC (IC401 on

E

61

10

Zoom operations fault

(Cannot initialize zoom lens.)

the SY-169 board).

E

E

62

62

02

10

Abnormality of IC for steadyshot.

Lens initializing failure.

Check or replacement of the IC for steadyshot (IC503 on the SY169 board).

Check or replacement of the IC for steadyshot (IC503 on the SY169 board).

Check the HALL element (PITCH) of optical image stabilizer

E

62

11

Lens overheating (PITCH).

(pin 5, 6 of CN402 on the SY-169 board). If it is OK, check

PITCH angular velocity sensor (SE502 on the SY-169 board)

peripheral circuits.

Check the HALL element (YAW) of optical image stabilizer (pin

E

62

12

Lens overheating (YAW).

ql, w; of CN402 on the SY-169 board). If it is OK, check YAW

angular velocity sensor (SE501 on the SY-169 board) peripheral

circuits.

E

E

E

62

91

92

20

01

00

Abnormality of thermistor.

Abnormality when flash is being charged.

Non-standard battery is used.

Check the OIS temp sensor of optical image stabilizer (pin 4 of

CN402 on the SY-169 board).

Checking of flash unit or replacement of flash unit. (Note)

Use the compatible battery only.

Note: After repair, be sure to perform “1-3. PROCESS AFTER FIXING FLASH ERROR”.

Correction

1-3. PROCESS AFTER FIXING FLASH ERROR

When “FLASH error” (Self-diagnosis Code E : 91 : 01) occurs, to prevent any abnormal situation caused by high v oltage, setting of the flash

is changed automatically to disabling charge and flash setting.

After fixing, this setting needs to be deactivated. Flash error code can be initialized by the operations on the HOME screen.

Method for Initializing the Flash Error Code

Initialize

Initializes the setting to the default setting. Even if you execute this function, the images

stored in the internal memory are retained.

1 Select [Initialize] with v/V/b/B, then press z.

The message “Initialize all settings” appears.

2 Select [OK] with v, then press z.

The settings are reset to the default setting.

To cancel the resetting

Select [Cancel] in step 2, then press z.

•Make sure that the power is not disconnected during resetting.

DSC-W90_L2

1-2

Page 6

1-4. METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

The data can be copied/erased by the operations on the HOME screen. (When erasing the data, execute formatting the internal memory.)

Note 1: When replacing the SY-169 board, erase the data in internal memory of the board before replacement.

Note 2: When replacing the SY-169 board, execute formatting and initialize the internal memory after replacement.

Method for Copying the Data in Internal Memory

Copy

Copies all images in the internal memory to a “Memory Stick Duo”.

1 Insert a “Memory Stick Duo” having 32 MB or larger capacity.

2 Select [Copy] with v/V/b/B on the control button, then press z.

The message “All data in internal memory will be copied” appears.

3 Select [OK] with v, then press z.

Copying starts.

To cancel the copying

Select [Cancel] in step 3, then press z.

•Use a fully charged battery pack. If you attempt to copy image files using a battery pack with little

remaining charge, the battery pack may run out, causing copying to fail or possibly corrupting the data.

•You cannot copy individual images.

•The original images in the internal memory are retained even after copying. To delete the contents of the

internal memory, remove the “Memory Stick Duo” after copying, then execute the [Format] command in

[Internal Memory Tool].

•When you copy the data in the internal memory to the “Memory Stick Duo”, all the data will be copied.

You cannot choose a specific folder on the “Memory Stick Duo” as the destination for the data to be

copied.

•Even if you copy data, a (Print order) mark is not copied

.

Method for Formatting the Internal Memory

This item does not appear when a “Memory Stick Duo” is inserted in the camera.

Format

Formats the internal memory.

•Note that formatting irrevocably erases all data in the internal memory, including even protected images.

1 Select [Format] with v/V/b/B on the control button, then press z.

The message “All data in internal memory will be erased” appears.

2 Select [OK] with v, then press z.

The format is completed.

To cancel the formatting

Select [Cancel] in step 2, then press z.

DSC-W90_L2

1-3

Page 7

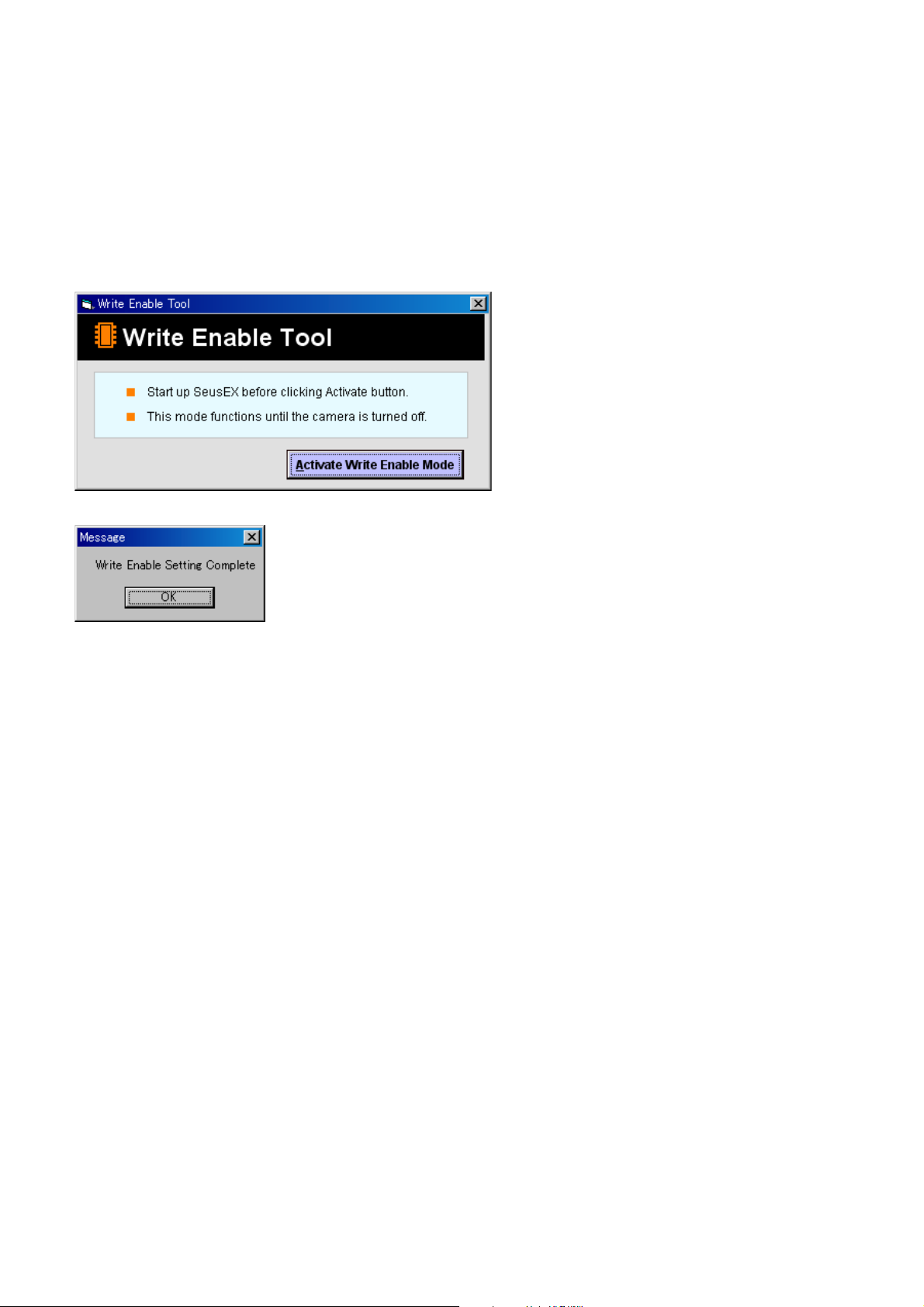

1-5. HOW TO WRITE DATA TO INTERNAL MEMORY

Usually, the camera has been set so as to disable the data writing from the PC to the internal memory of the camera.

This setting must be changed temporarily when the data is to be written to the internal memory such as a case after the board replacement.

To change the setting, use the write enable tool “WriteEnableTool.exe”.

Data writing method

1) Connect the PC to the camera (USB mode: Mass Storage), and switch the driver to the “Sony Seus USB Driver”.

2) Start the Write Enable Tool and the SeusEX.

3) Click the [Activate Write Enable Mode] button of the Write Enable Tool.

4) Upon completion of the setting change, the following message will be displayed.

5) Return the driver to the original one, and connect the PC to the camera (USB mode: Mass Storage).

6) Write the data read out into the PC to the internal memory of the camera.

7) Disconnect the PC from the camera, and turn off the camera.

Note: By turning off the camera, the write enable setting is reset.

DSC-W90_L2

1-4E

Page 8

NOTE FOR REPAIR

2. DISASSEMBLY

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, don’t pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

• Do not apply excessive load to the gilded fle xible board.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

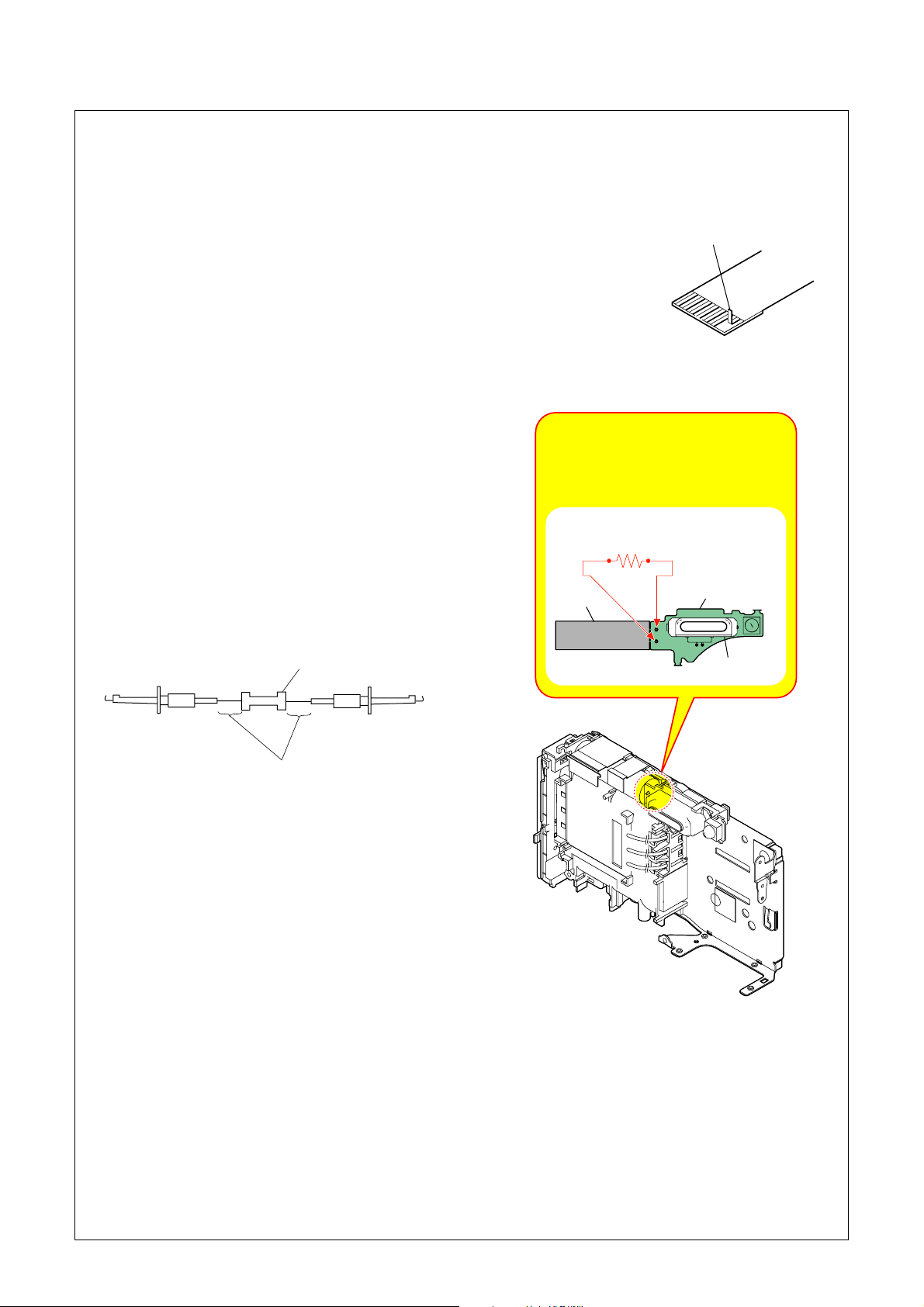

DISCHARGING OF THE ST-160 BOARD’S CHARGING CAPACITOR (C901)

The charging capacitor (C901) of the ST-160 board is charged

up to the maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by

the charged voltage which is kept without discharging when the

main power of the unit is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig, a small clip is attached to each end of

a resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to

prevent electrical shock.

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points

with the short jig about 10 seconds.

R:1 kΩ/1 W

(Part code: 1-215-869-11)

C901

ST-160 Board

1 kΩ/1 W

Wrap insulating tape.

Flash Unit

DSC-W90_L2

2-1

Page 9

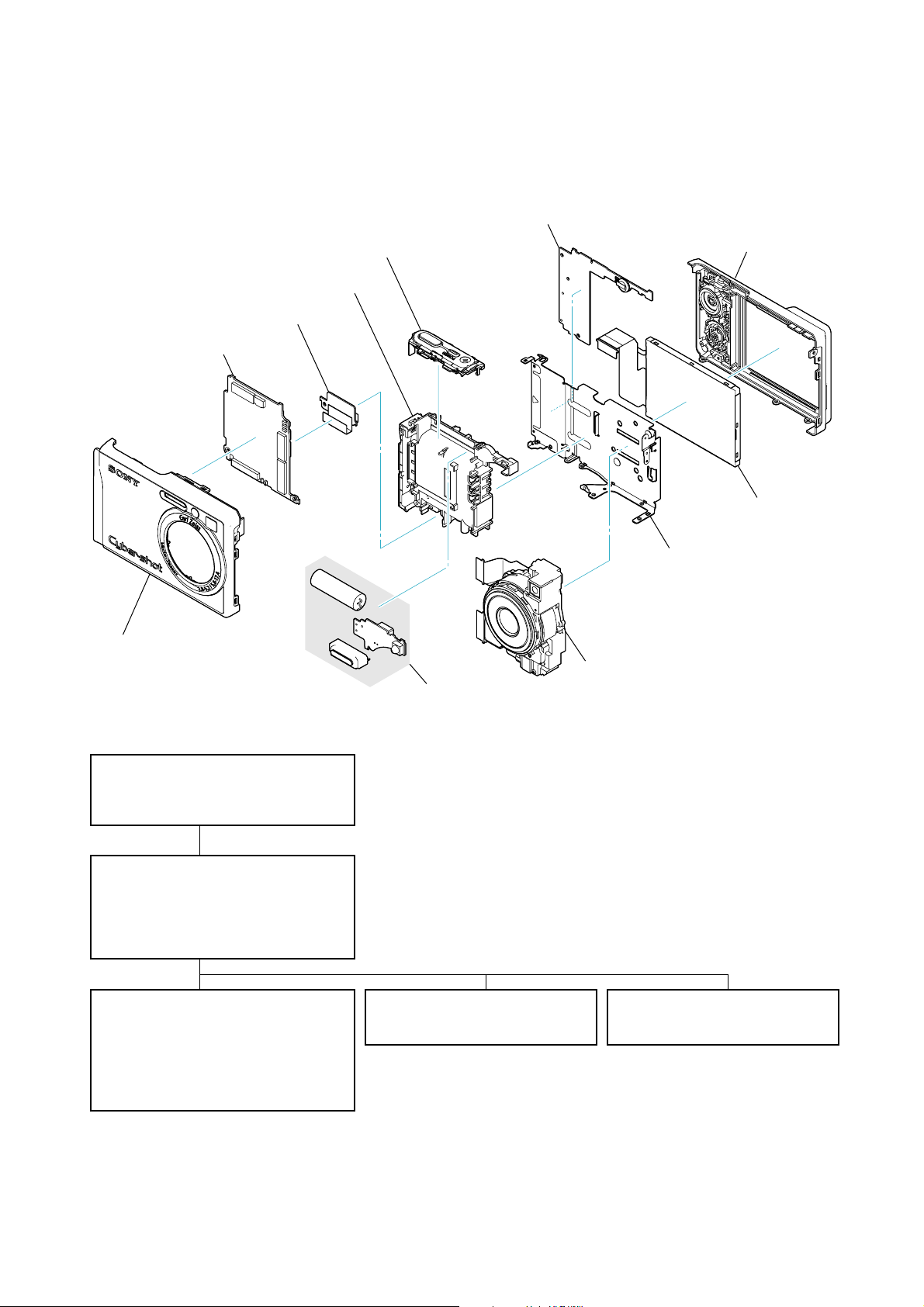

2-1. IDENTIFYING PARTS

Release Block

⋅ RL-071/078 Board

BT Holder

MC-176 Board

SY-169 Board

SW-494 Board

Cabinet (Rear)

LCD Module

Main Frame

Cabinet (Front)

- DISASSEMBLY FLOW -

2-2-1. CABINET SECTION

⋅ Cabinet (Front)

⋅ Cabinet (Rear)

2-2-2. MAIN BOARD SECTION

⋅ Lens Block

⋅ MC-176 Board

⋅ Release Block

⋅ SY-169 Board

2-2-3. LCD/BT HOLDER SECTION

⋅ BT Holder

⋅ Flash Unit

⋅ LCD Module

⋅ Main Frame

⋅ SW-494 Board

Flash Unit

⋅ ST-160 Board

2-3. EXCHANGE METHOD OF

BARRIER BLOCK

Lens Block

⋅ Barrier Block

⋅ Zoom Gear Block

2-4. EXCHANGE METHOD OF

ZOOM GEAR BLOCK

DSC-W90_L2

2-2

Page 10

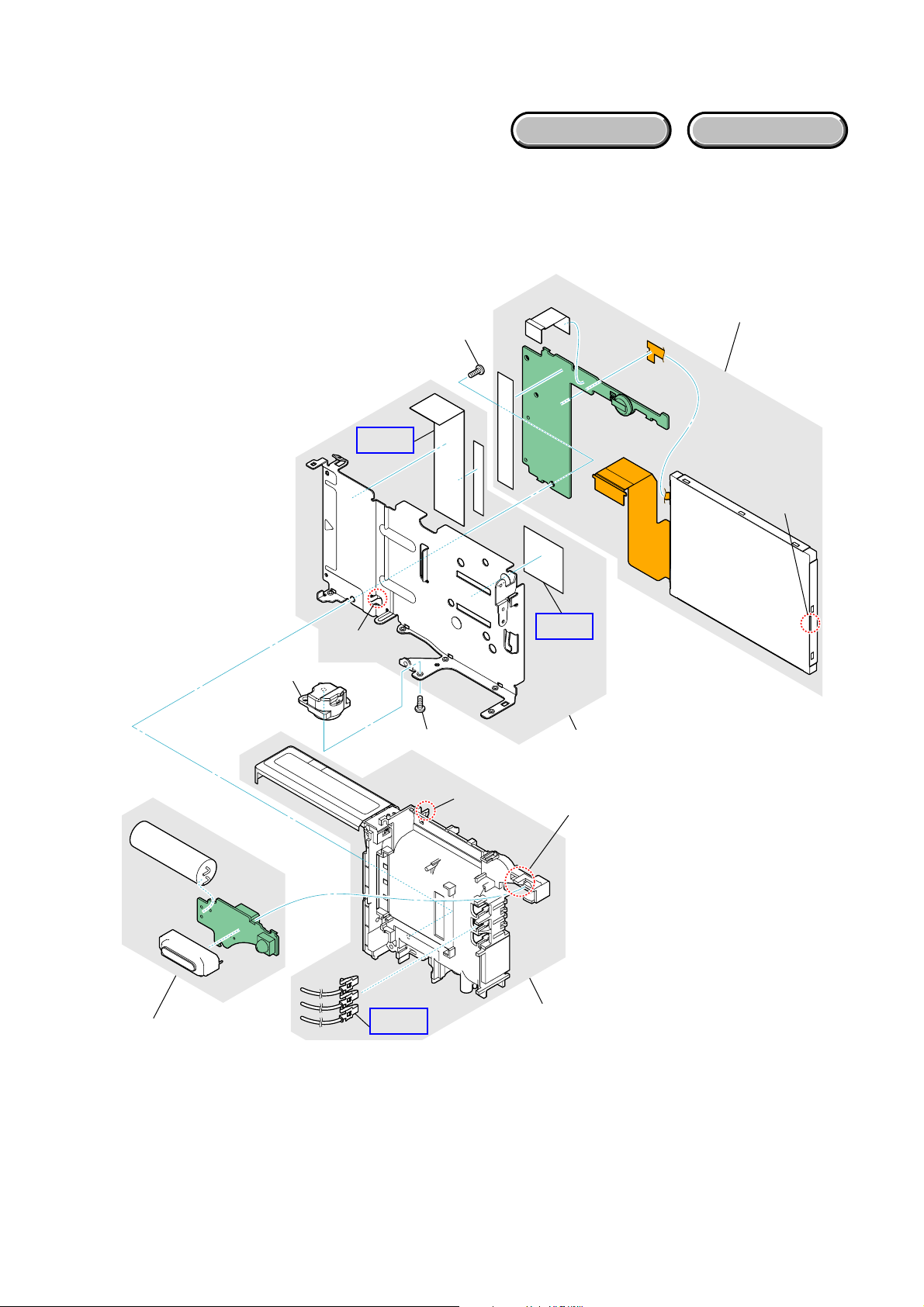

EXPLODED VIEW

HELP

HELP

2-2. DISASSEMBLY

2-2-1. CABINET SECTION

Follow the disassembly in the numerical order given.

1 Cabinet (Front) (1-1 to 1-8)

2 Cabinet (Rear) (2-1 to 2-2)

Note:On installation of the cabinet (rear),

adjust the position of the mode dial

switch and the mode dial.

1-6 (#65)

1-7 (Open)

HARDWARE LIST

2-1 (#65)

HELP

1-5

(#65)

1-8

(Claw)

Main Board Section

(See Page 2-4)

1 Cabinet (Front)

1-4 (#65)

2 Cabinet

(Rear)

2-2 (#65)

1-1 (#65)

1-3

1-2 (Claw)

DSC-W90_L2

2-3

Page 11

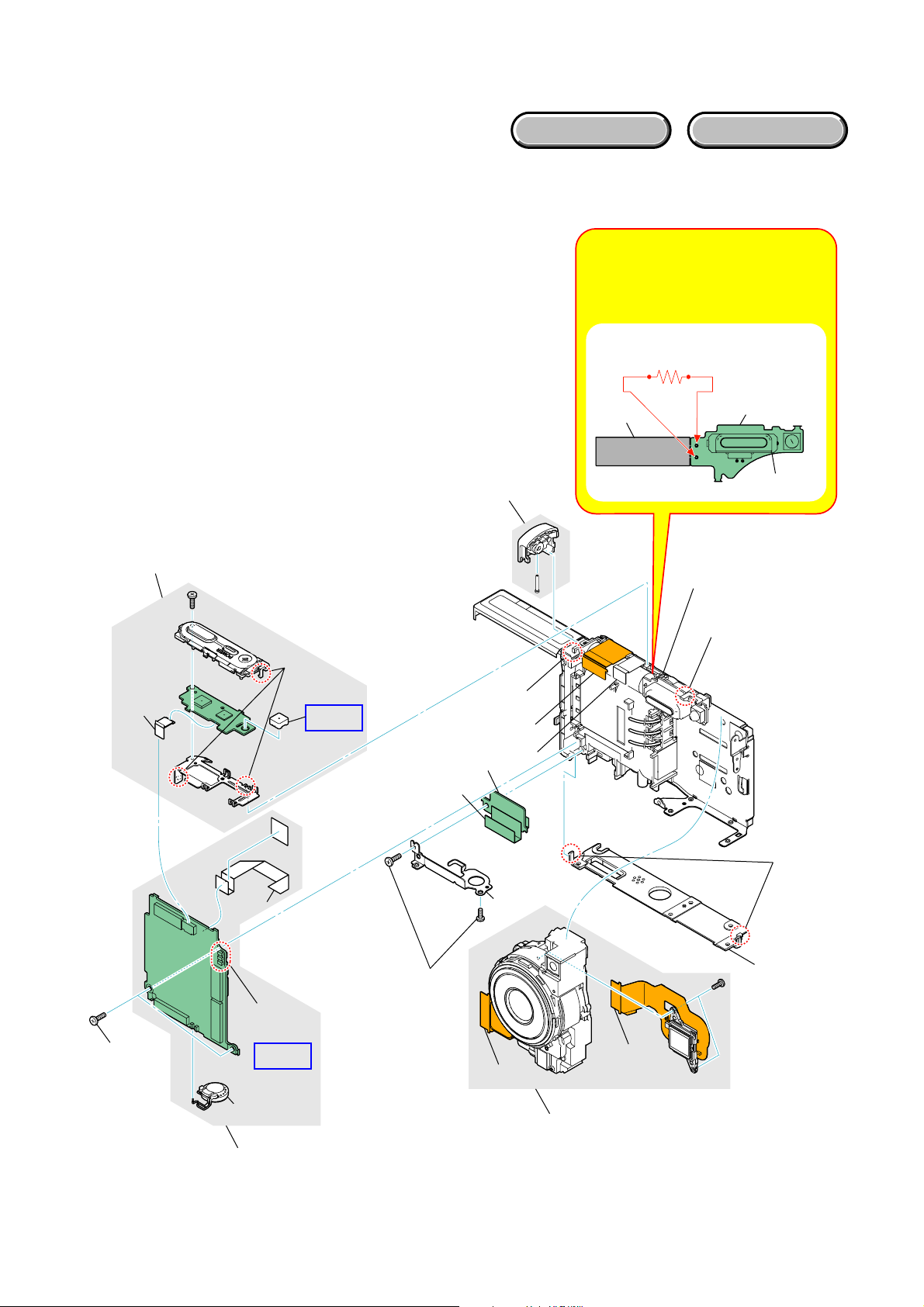

EXPLODED VIEW

2-2-2. MAIN BOARD SECTION

Follow the disassembly in the numerical order given.

1 Release Block (1-1 to 1-3)

2 Lens Block (2-1 to 2-5)

3 SY-169 Board (3-1 to 3-11)

HARDWARE LIST

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points

with the short jig about 10 seconds.

R:1 kΩ/1 W

(Part code: 1-215-869-11)

1 Release Block

1-3

1-2

(Claw)

HELP

3-7 (Claw)

3-11

3-6

1-1

3-1

3-2

C901

ST-160 Board

Flash Unit

LCD/BT Holder

Section

(See Page 2-5)

2-3

(Release the claw

that is the fixation

of the flash unit

once)

3-5

(#3)

DSC-W90_L2

SY-169

3-3

3-4

(Solder)

HELP

3-10

3 SY-169 Board

3-8

(#5)

2-1

(Claw)

3-9

2-2

2-4

2-5

2 Lens Block

(See Page 2-6, 2-8)

2-4

Page 12

EXPLODED VIEW

2-2-3. LCD/BT HOLDER SECTION

Follow the disassembly in the numerical order given.

1 Flash Unit (1-1)

2 LCD Panel/SW-494 Board (2-1 to 2-4)

3 BT Holder (3-1 to 3-3)

HELP

2-1

(#5)

HARDWARE LIST

2 LCD Panel/

SW-494 Board

SW-494

2-4

(Claw)

1 Flash Unit

3-2

2-3

(Claw)

HELP

3-1 (#65)

2-2

(Claw)

HELP

3-3

1-1

(Claw)

3 BT Holder

DSC-W90_L2

2-5

Page 13

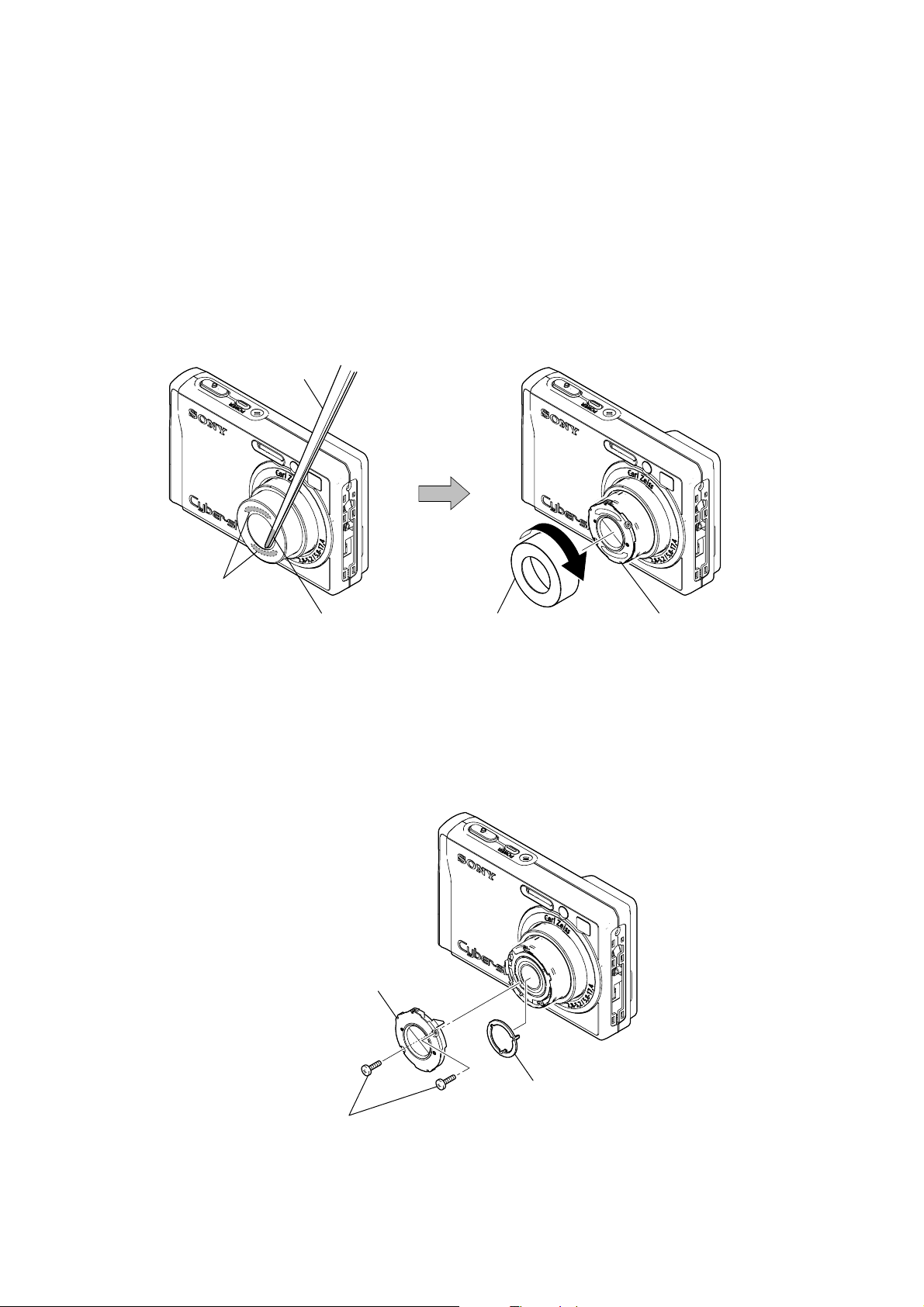

2-3. EXCHANGE METHOD OF BARRIER BLOCK

Note: Do not hold the part of spring.

2-3-1. HOW TO REMOVE THE ORNAMENTAL RING (A)

1 Turn on the power switch.

2 With the ornamental ring (A) extended, remove the battery forcibly.

3 Apply a solvent to the tweezers or a needle, and dissolve the adhesive on

the barrier tapes that secure the ornamental ring (A) to the barrier block.

4 Rotate the ornamental ring (A) clockwise to remove.

Tweezers

Barrier tape

3 Solvent

2-3-2. HOW TO REMOVE THE BARRIER BLOCK

1 Remove two screws.

2 Remove the barrier block and the inner ring.

2 Barrier block

4 Ornamental ring (A)

Barrier block

DSC-W90_L2

2 Inner ring

1 Two screws

2-6

Page 14

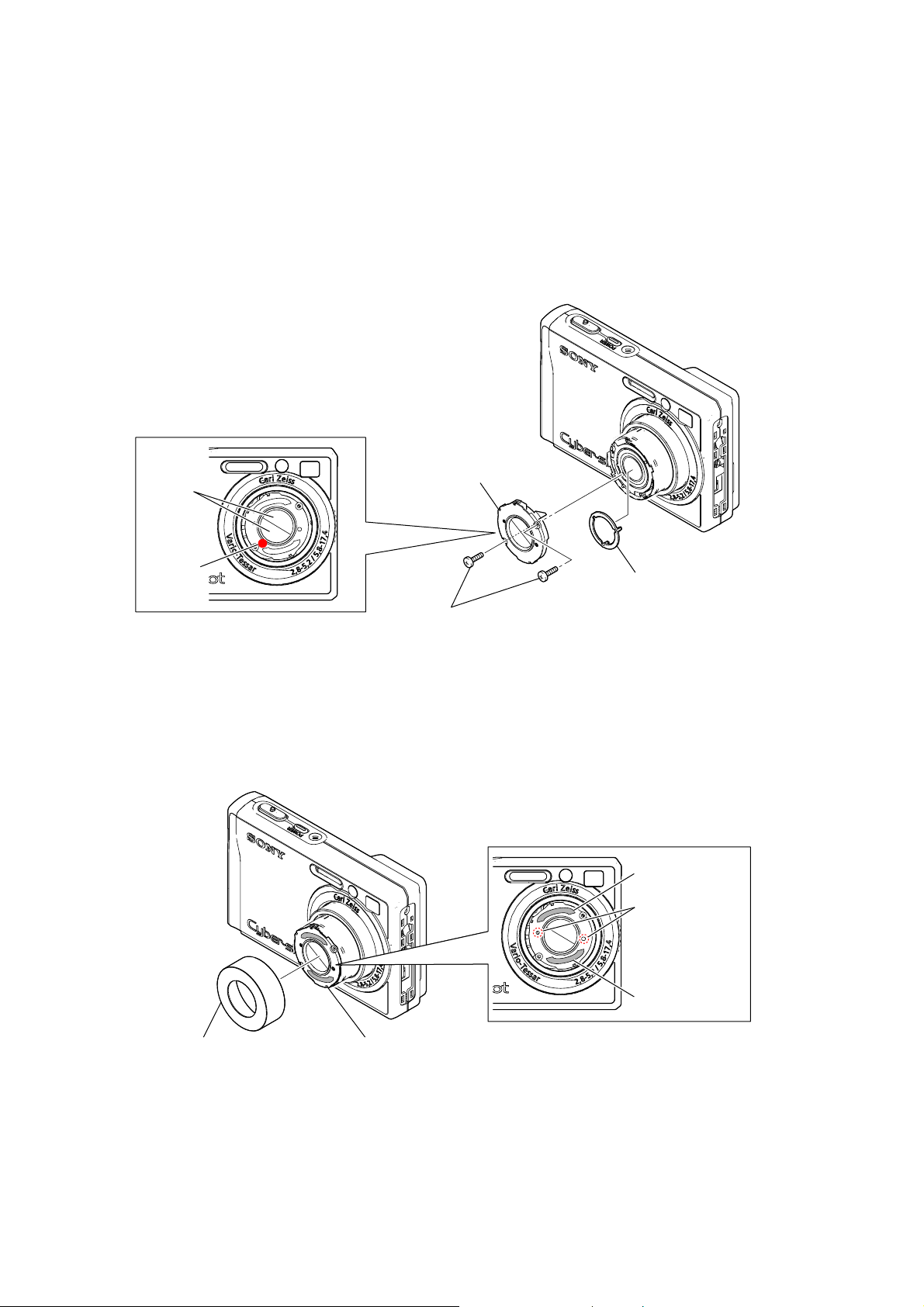

2-3-3. HOW TO INSTALL THE BARRIER BLOCK

1 Install the inner ring and the barrier block.

Note: When installing the barrier block, the CAV No. must be located in the lower left position.

2 Secure the barrier block with two screws.

*Tightening torque = 0.049 ± 0.01N • m (0.5 ± 0.1kgf • cm)

Note: Check that the barrier feather of the barrier block is not opened slightly or half-closed.

Barrier

1 Barrier block

feather

CAV No.

2 Two screws

2-3-4. HOW TO INSTALL THE ORNAMENTAL RING (A)

1 Affix two barrier tapes to the barrier block.

Note: The barrier tape must not cover the boss of the barrier block.

2 Install the ornamental ring (A).

1 Inner ring

1 Barrier tape

Boss

2 Ornamental ring (A)

Note: Turn on and off the power to check the opening and closing of the barrier block with the camera

in horizontal, up and down directions respectively.

Further, check the zoom motion.

Rotate the ornamental ring (A) lightly to check that it is not removed.

Barrier block

DSC-W90_L2

2-7

1 Barrier tape

Page 15

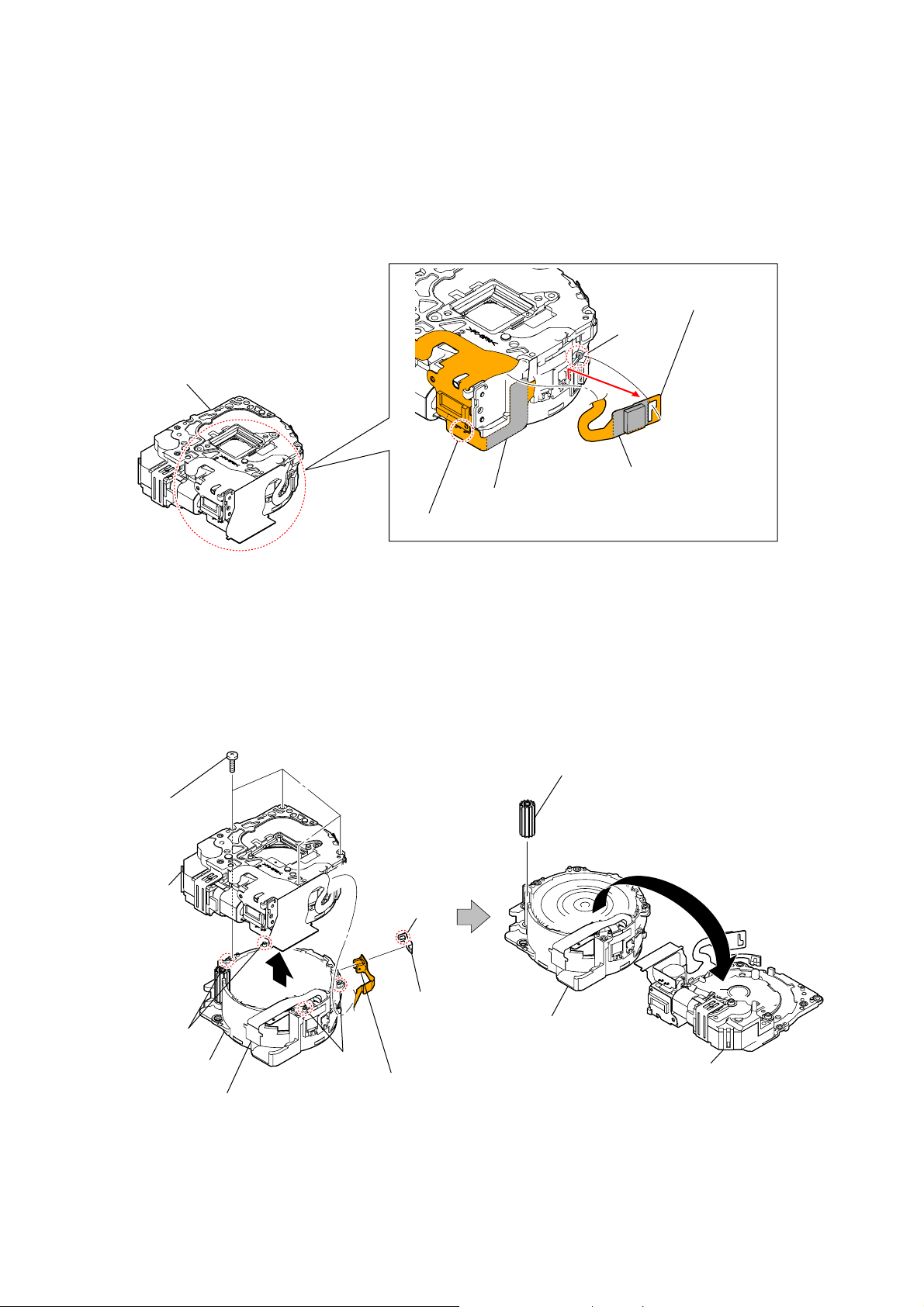

2-4. EXCHANGE METHOD OF ZOOM GEAR BLOCK

Note: Do not hold the part of terminal and the part of spring.

2-4-1. HOW TO REMOVE THE ZOOM GEAR BLOCK

• HOW TO REMOVE THE REAR ASSEMBLY

1 Remove the screw, and then the OVF.

OVF

Screw

2 Remove the shutter flexible board from the connector.

3 Remove the vibration-proof flexible board from the connector.

4 Peel the adhesive sheet that secures the vibration-proof flexible board.

*When peeling the adhesive sheet, turn it over from the opposite side of the hook.

Connector

2 Shutter flexible board

Connector

3 Vibration-proof flexible board

Vibration-proof flexible board

4 Adhesive

sheet

Hook

DSC-W90_L2

2-8

Page 16

5 Peel the adhesive sheet (upper) that secures the main flexible board.

6 Disengage the main flexible board from the hook of the ring assembly, and then slide the main flexible board

to remove.

7 Peel the adhesive sheet (lower) that secures the main flexible board.

*The FOCUS motor must remain soldered.

6 Main flexible board

Hook

Ring assembly

5 Adhesive sheet (upper)

7 Adhesive sheet (lower)

Solder of FOCUS motor

8 Remove four screws that secure the rear assembly.

9 Remove the rear assembly, disengaging the bosses at four places.

*Take care not to get stuck with the vibration-proof flexible board.

q; Unhook the Z leaf spring to remove.

qa Remove the main flexible board from the ring assembly, and remove the rear assembly and the nuruto gear.

qa Nuruto gear

8 Five screws

Rear

assembly

Hook

9

q; Z leaf

Boss

Ring assembly

spring

Boss

Ring assembly

qa Rear assembly

qa Main flexible

Vibration-proof flexible board

board

DSC-W90_L2

2-9

Page 17

• HOW TO REMOVE THE ZOOM GEAR BLOCK

1 Unsolder the zoom motor.

2 Remove the FG leaf spring.

3 Remove the main flexible board from the zoom gear block.

4 Remove the zoom gear block.

Rear assembly

3 Main flexible board

4 Zoom gear block

3 Main flexible board

1 Solder

Hook

2 FG leaf spring

2-4-2. HOW TO INSTALL THE ZOOM GEAR BLOCK

• HOW TO INSTALL THE ZOOM GEAR BLOCK

1 Solder the main flexible board to the zoom gear block.

2 Install the main flexible board to the zoom gear block.

3 Attach the FG leaf spring.

Rear assembly

2 Main flexible board

Zoom gear block

DSC-W90_L2

1 Solder

2 Main flexible board

Hook

3 FG leaf spring

2-10

Page 18

4 Apply the lubricant (SRX-4339) to the nuruto gear, and insert it into the ring assembly.

* Rotate the gear in the ring assembly in the arrow direction until the end of the gear is not engaged

with a concave portion of the ring assembly (because a convex portion of the rear assembly enters

the convex portion).

Ring assembly

Gear

Convex portion

4 Nuruto gear

5 Install the zoom gear block on the rear assembly.

6 Engaging four bosses, install the rear assembly on the ring assembly.

*The vibration-proof flexible board must be engaged with the hook of the rear assembly.

7 Tighten four screws in the order of A to D.

*Tightening torque = 0.049 ± 0.01N • m (0.5 ± 0.1kgf • cm)

8 Check that the projection of the nuruto shaft that protrudes from the rear assembly is within the

specified value given below.

*Specified value: 0.005 – 0.395mm

Hook

Ring assembly

Boss

6 Vibration-proof

flexible board

DSC-W90_L2

Boss

Nuruto shaft

5 Zoom gear block

6 Rear assembly

Nuruto shaft

0.005 – 0.395mm

2-11

8

7 Four screws

B

C

D

A

Page 19

9 Secure and connect the main flexible board.

Ring assembly

Main flexible board

Hook

Main flexible board

Hook

Hook

Z leaf

spring

Adhesive sheet (upper)

Adhesive sheet (lower)

q; Secure and connect the vibration-proof flexible board and the shutter flexible board respectively.

Vibration-proof flexible board

Connector

Shutter flexible board

Connector

Bousin flexible board

Adhesive

sheet

Hook

DSC-W90_L2

2-12

Page 20

qa Install the OVF.

*When installing the OVF, fit a projection of OVF in the groove of the ring assembly.

OVF

Projection

Ring assembly

Groove

Screw

2-4-3. CHECK THE OPERATION

Confirm the operation after installing the lens block in the set.

1 Power ON/OFF

2 Expansion and contraction confirming of lens and opening and shutting confirmation of barrier.

Confirm there are neither dirt nor wounds in the surface of the ornamental ring (A) and lens

if there is no problem in operation.

Wipe off when dirty.

3 Confirm the operation with Wide/Tele.

Note: Do not be of caught etc.

Do not allophone.

DSC-W90_L2

2-13E

Page 21

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

Cabinet (front) assy

SY electrostatic sheet

RL-071/078

board

Harness (Red)

Light interception

sheet

Harness (Black)

Microphone

BT holder

Main frame

1mm

LC flexible sheet

DSC-W90_L2

HELP

Page 22

INSTALLATION METHOD OF BATTERY TERMINAL BOARD

1 Insert the battery terminal board into a slit in the BT holder to install.

*The battery terminal board is attached with the notch for installation.

BT holder

Battery terminal board

2 Fold the notch 3 or 4 times repeatedly to break.

Notch

Battery terminal

board

• HARNESS ARRANGEMENT

DSC-W90_L2

Notch

SY-169 board

Harness (Red)

Harness (White)

Harness (Black)

Notch

Battery terminal board

HELP

Page 23

3. BLOCK DIAGRAMS

Link

Link

OVERALL BLOCK DIAGRAM (1/2) POWER BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (2/2)

POWER BLOCK DIAGRAM (2/2)

DSC-W90_L2

Page 24

3-1. OVERALL BLOCK DIAGRAM (1/2)

3. BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SHUTTER

MOTOR

M

LENS

ZOOM

FG

LENS BLOCK

ZOOM

MOTOR

FOCUS

MOTOR

M

FOCUS

RESET

SENSOR

ZOOM

RESET

SENSOR

OPTICAL IMAGE

STABILIZER

M

(METER)

YAW

MOTOR

PITCH

MOTOR

IRIS

IRIS

MOTOR

M

F_MOTOR_A, F_MOTOR_A(-),

F_MOTOR_B, F_MOTOR_B(-)

LENS TEMP

SENSOR

OIS TEMP

SENSOR

M

HALL

ELEMENT

M

HALL

ELEMENT

CD-694 FLEXIBLE BOARD

IC004

10

17 14

IC003

8.1M CCD

IMAGER

27 - 29

26 39

19 33

3 - 14

16, 15

31, 32

30 12

1 J4

24

ND(±) ND_±

Z_DC_MOTOR(±) ZOOM_A, ZOOM_A-

F_PI_SENS_OUT

XFC_RST_LED

Z_PI_SENS_OUT

XZM_FG_LED

LENS_ID

THERM

THERM

YAW±

YAW_HALL_BIAS±,

YAW_HALL_±

PITCH±

PITCH_HALL_BIAS±,

PITCH_HALL±

CN402

50, 49

38 - 3533 - 30

48 - 45

22

23

41

24, 28

26

44

40

4

15 - 1217 - 20

11 - 82, 3, 5, 6

BUFFER

B10, D10

G6, J8, J9, J7J3, J2, H2, J4

B1, D1

IC503

OPTICAL

IMAGE

STABILIZATION

DRIVE

(3/11)

SY-169 BOARD (1/2)

CN301

CCD_OUT

6

H1 - H3

35 - 37

LH

RG

V1, V2, V3A, V3B, V4,

V5A, V5B, V6 - V10

13 - 24

VST1, VST2

27, 26

VHLD1, VHLD2

11, 10

LV

SUB

29

SUB_CONT

31

FOCUS_A, A, B, B

J5

G5

C9

A7

A3

A5

A6

Q301

SWAOUT

CLK, DATA

D5, D6

SWBOUT

CA_FD

XDD_SYS_RST

A4, B4, B5

CLK_IC_503

XCS_IC_503

XIC_211_IC_503_RST

Q302

13

24, 25

10

D14

P7

P8

G4

C6

IC506

PITCH/YAW

SENSOR

AMP

(3/11)

L5, N4, N3, M2, L2, K4, K3

N5, P4, M4, N2, L3, L1, P5,

IC304

CCD SIGNAL

PROCESS,

P10, P9, P11

GENERATOR

F1, G2, E2, E1,

G1, D4, D3, F4,

J2, H4

H3, H1

LENS DRIVE

IRIS MOTOR

D2, B1

D6, E6, B7, C6

B4, B5

SHUTTER

F4, F3

21

1

K13

J13

TIMING

K14

(1/11)

E4, F3, D1, C2

D7 - D9

D10

IC401

D4

(2/11)

DRIVER

FOCUS

MOTOR

DRIVER

ZOOM

MOTOR

DRIVER

MOTOR

DRIVER

IC_211_0_SO, IC_211_0_SI, XIC_211_0_SCK

D3, F1

D5, A6, B6, C5

A2, C4, B2

G1, E4

SE501

YAW

SENSOR

SE502

PITCH

SENSOR

X201

36MHz

XCS_FE, XIC_211_3_SCK, IC_211_3_SO

FC_DIR_A, FC_DIR_B, FC_EN_A

ZM_DIR_A, ZM_EN_A, ZM_BRK_B

ZM_DC_FG_1A, ZM_DC_FG_1BZ_BOX2_PI_SENS_Col, Z_BOX1_PI_SENS_Col

XDD_SYS_RST

CA_AD00 - CA_AD13

CA_HD

CA_FD

GEN_TG_CLK

IC202

1

CLOCK

(9/11)

FC_SENS

LENS_ID

3

5

2

GENERATOR

XDD_SYS_RST

VSUB_CONT_PRE,

VSUB_CONT_POST

XLENS_DRIVER_PS

IRIS_M_IN, IRIS_M_BRK_2B

MSHUT_DIR, MSHUT_ENSHUTTER_±SHUTTER(±)

XFC_RST_LED

ZM_SENS_1ST

XZM_FG_LED

LENS_TEMP

TZ_HALL_TEMP

OVERALL (2/2)

(PAGE 3-2)

GEAR_ON

GEN_SYS_CLK

1

AF20, AE19, AF19, AE18

AC19, AC18, AE21, AF21, AE20,

AB21, AC21, AB20, AC20, AB19,

AE23

AF22

AF18

IC211

(1/2)

CPU

Y13

(4/11, 5/11)

Y12

V19, D19, C25

R7, AF25

H11

Y18, Y17

W18, AB26, W17

AB23, AA23, AC25

R8, AE25

Y10

M8

AD26

Y11, W11

L8

D9

AE3

AF3

W13

U8

H10

D17, B19, E17, A19,

U19

V8

AF8

AE8

T8

AB13

AF12

AC12

V7

A13 - A15,

E16, A18, D16, A17

B18, D18, B17

XIC_211_2_SCK

IC_211_AUOUT

VIDEO_AMP_ON

IC_211_CVOUT

VOUT_1

VOUT_2

XHD_EN

Y1, AA1 E18, B23

B13 - B15

LCD_CK, LCD_HD, LCD_VD

IC_211_2_SO, XIC_211_2_SCK

IC_211_2_SO,

XCS_AUDIO

IC_211_AUIN

Q242 - Q244

F3, E3

E4

E6

IC603

AUDIO AMP

E5

(7/11)

IC602

4

VIDEO AMP

(7/11)

Q241

BUFFER

USB_DP, USB_DM USB_DP, USB_DM

CLAMP

2

OVERALL (2/2)

(PAGE 3-2)

MSX_BS, MSX_D0 - MSX_D3, MSX_CLK

CN713

LCD_D0 - LCD_D7

XCS_ PANEL

XDD_SYS_RST

3 - 10

11 - 13

36

37

35, 3421, 22

D0 - D7

DCLK, HSYNC, VSYNC

SPENA

RESET Z

SPDA, SPCK

RL-071/078

BOARD (1/2)

CN101

(1/2)

17MIC_SIG

B6

A5, A2

CN707

(1/2)

1

MC-176 BOARD

(1/2)

CN710

AU_LINE_OUT A_OUT_L

D1

53

IC_211_YOUT HD Y3

IC_211_PROUT HD Pr16

(1/2)

24

V_LINE_OUT V_OUT

USB_VBUS USB_VBUS12

XMS_IN

26

28

17

15

19

CN704

6

2 - 5, 7, 8

CN101

(1/2)

5

10, 9

MEMORY

STICK

DUO

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : VIDEO/AUDIO SIGNAL

SP±

LCD901 (1/2)

LCD MODULE

2.5INCH

COLOR

LCD

MIC901

SP901

SPEAKER

16

20

HD Pb14IC_211_PBOUT

24

4

2

10, 12

6

CN102

(1/2)

MULTI

CONNECTOR

DSC-W90_L2

05

3-1

Page 25

3-2. OVERALL BLOCK DIAGRAM (2/2)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

LCD901 (2/2)

LCD MODULE

BACKLIGHT

RL-071/078 BOARD (2/2)

S101

(SHUTTER)

S102

POWER

D101

(POWER)

SW-494 BOARD

S003

N

S001, S002,

S004 - S010

FUNCTION

KEY

S011

MODE

DIAL

D001

AE/AF LOCK/

SELF-TIMER

D002

FLASH CHARGING/

RECORD

BT001

LITHIUM

BATTERY

BL_H

BL_L BL_L

SY-169 BOARD (2/2)

CN101

(2/2)

8

XAE_LOCK_SW

7

XSHUTTER_SW

4

X_PWR_LED

CN001 CN708

XDIRECT_PB XDIRECT_PB8

KEY_AD1, 2 KEY_AD_1, 26, 7

MODE_DIAL1, 2 MODE_DIAL1, 212, 11

4 XAE_LOCK_LED XAE_LOCK_LED

5XSTRB_LED

1 VL_3V

9BL_L

12

8

7

3

4

5

9

8

4

CN707

(2/2)

7, 6

1, 2

XAE_LOCK_SW

XSHUT_SW

XPWR_ONXPWR_ON3

XPWR_LED

XSTRB_LED

VL_3V

2

OVERALL (1/2)

(PAGE 3-1)

Q006

BACKLIGHT

CONTROL

D101

XMS_IN

USB_VBUS

3

2

BL_EN2

XDIRECT_PB

IC102

BACK UP VCC

(8/11)

IC106

RESET

(8/11)

XPWR_ON

X101

32.768kHz

Q101

5

4

1

B8 H8

B7

J5

J4

IC101

FRONT

CONTROL

C6

(8/11)

D8

D7

A9

F9

B9

A1

B4

E2

D1, D2, E1

D102

XPWR_ON

UNREG

ST_UNREG

UNREG

CAM_12V

CAM_-7.5V

TI_5.0V

MAX_5.0V

D_3.0V

A_3.0V

DDR_1.8V

D_1.8V

D_1.2V

XPWR_OFF

XIC_211_RST_REQ

XDD_SYS_RST

XCS_FR

IC_211_0_SO,

IC_211_0_SI,

XIC_211_0_SCK

BL_H

IC001

DC/DC

CONVERTER

(10/11)

G8

W12

AB18

A23

H17, A24, G17

XACV_IN

K8

XACC_IN

G9

IC_211_1_UI, IC_211_1_UO

D26, G19

XCS_IC_201,

XIC_211_1_SCK,

IC_211_1_SO,

IC_211_1_SI

W20, H18, B24, G18

XDD_SYS_RST

Q004,

Q013

BATTERY

B1, B5, C5, D5

AUTHENTICATION

B2

IC201

(9/11)

XPOWER_ON

D002

D003

UART Rx, UART TX

E4

MC-176 BOARD

(2/2)

11 -13

8 - 10

6, 5

+

S

–

CN101

(2/2)

27

18 - 20

24

21 - 23

1

25, 26

TERMINAL

XPOWER_ON

ACV_UNREGACV_UNREG

CHARGE_VCHARGE_V

BT901

BATTERY

XACC_IN

UART Rx,

UART Tx

CN710

(2/2)

4

XACV_DET XACV_DET

XACC_IN

BATT_UNREG

BATT_SIG

7

30

7

19

26

23, 25

17, 21

15, 9

CN102

(2/2)

MULTI

CONNECTOR

FLASH

UNIT

ST-160 BOARD

XE_A(H)

TRIGGER

TRIG_GND

XE_K(L)

Q001

FLASH

DRIVE

+

C901

CHARGING

CAPACITOR

D001

T001

3 2

4

SELF-TIMER/

AF ILLUMINATOR

1

D002

ST_UNREG

15

1, 2

CONTROL,

CHARGE

CONTROL

7

IC001

FLASH

1

OVERALL (1/2)

XDD_SYS_RST

IC_211_0_SO, IC_211_0_SI, XIC_211_0_SCK

(PAGE 3-1)

XAE_LOCK_SW

XSHUT_SW

KEY_AD_1, 2

MODE_DIAL1, 2

XPWR_LED

XAE_LOCK_LED

XSTRB_LED

CN001

10

9

6

4

12

8

9

5

4

XAF_LED

STRB_CHG

XSTRB_FULL

STB_CHG_CNT

STRB_ON

CN701

12

8

9

5

AF LED

CONTROL

Q704

AFLED_CONT

D706

(MS ACCESS)

STRB_CHG

XSTRB_FULL

STB_CHG_CNT

STRB_ON14

N19

R19

AC8, AF6

AB7, AE6

Y9

W9

W8

G15

H8

V2

H9

H15

Y16

IC211

(2/2)

CPU

(4/11, 5/11)

DSC-W90_L2

05

3-2

Page 26

3-3. POWER BLOCK DIAGRAM (1/2)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CN102

MULTI

CONNECTOR

BT901

BATTERY

TERMINAL

+

S

–

ACV_UNREG

23, 25

XACV_DET

19

CHARGE_V

17, 21

XPOWER_ON

7

BATT_UNREG

BATT_SIG

A

POWER (2/2)

(PAGE 3-4)

B

POWER (2/2)

(PAGE 3-4)

C

POWER (2/2)

(PAGE 3-4)

D

POWER (2/2)

(PAGE 3-4)

SY-169 BOARD (1/2)MC-176 BOARD

CN101 CN710

18-20

24

21-23

27

XDD_SYS_RST

XIC_211_RST_REQ

XPWR_OFF

XPWR_ON

XDIRECT_PB

DDC2P9_EN

ACV_UNREG

11-138-10

XACV_DET

7

CHARGE_V BATT_UNREG

XPOWER_ON

4

XPWR_ON

D102

D003

AUTHENTICATION

TXRXE4

XRESET

B2

A9

CS

XSYS_RST

B4

A1

XRESET_REQ

B9

XPOWER_OFF

B8

XPOWER_ON0

XPOWER_ON2

B7

D002

IC201

BATTERY

(9/11)

P144_SOA0

P143_SIA0

P142_XSCKA0

P120_INTP0

IC106

RESET (8/11)

1 4

OUT Vdd

IC101

FRONT CONTROL

(8/11)

Q004, 013

IC_211_1_SI

D5

IC_211_1_SO

C5

XIC_211_1_SCK

B5

XCS_IC_201

B1

BATT_SENS

DDC2P9_AD

DDC1P8_AD

DDC1P2_EN D9

CAMDD_EN B2

DDC2P9_EN E9

BL_EN1 F8

BL_EN2 F9

DDC5PSW_EN F7

VSU_EN J8

DDC1P8_EN E8

DDCPV_EN C9

EVER_PSB J9

SW1P8_EN J1

LDO1P8_EN H2

DISW1P8_EN C2

DISW2P9_EN C1

XRSTX

DDC1P2_RESET

XACV_IN

D_3.0V

H8

H7

J7

D7

C8

F001

F002

E

POWER (2/2)

(PAGE 3-4)

D_3.0V

D_1.8V

BACK_UP_VCC

DDC1P2_EN

CAMDD_EN

DDC2P9_EN

BL_EN1

BL_EN2

DDC5PSW_EN

VSU_EN

DDC1P8_EN

DDCPV_EN

EVER_PSB

SW_1P8_EN

LDO_1P8_EN

DISW1P8_EN

DISW2P9_EN

1.2V_INT

L007

GD28

BATT45

PVSD13

PVBST29

PVLED35

LXSU47

PVAFE9

L002

IC001

DC/DC CONVERTER

(10/11)

LXSD

ONSD

LXBST

SWBST

ONBST

LXINV

PVINV

ONINV

LXLED

SWLED

FBLLED

ONLED

PVSU

ONSU

LXAFE

ONAFE

IC002

SW

9

VBAT

6

LBI

7

1

EN

PVM

LXM

ONM

SU

16

15

31

30

22

21

20

1

4

5

3

33

34

37

36

43

44

46

8

10

5V REG

(10/11)

VOUT

PS 8

Q706

B+ SWITCH

MS_PWR_ON

L009

DDC1P2_EN

L004

CAMDD_EN

L005

DDC2P9_EN

L003

BL_EN1

D011

VSU_EN

L006

DDC1P8_EN

2

EVER_PSB

D007

D010

D006

BL_EN2

DDC5PSW_EN

DDCPV_EN

SW_1P8_EN

LDO_1P8_EN

DISW1P8_EN

DISW2P9_EN

BACKLIGHT

CONTROL

B+ SWITCH

B+ SWITCH

IC003

Vin

B2

Q006

Q003

Q014

1.8V REG

Vcont

A2

(10/11)

Vout

D_3.0V

D_1.8V

Q007

1.8V/3.0V

(8/11)

VOUT

VRO

DISCHARGE

6VBAT3

8

Q010, 012

B+ SWITCH

B1

BACK_UP_VCC

BACK UP VCC

IC102

VCH

2

D101

7

VIN

XRESET

5

4

CS

POWER (2/2)

(PAGE 3-4)

EVER_3.0V

DETECTOR

1

Vout

F

IC007

VOLTAGE

(10/11)

Vsen

4

Vin

3

MS_VCC

ST_UNREG

CAM_-7.5V

L001

9

D_1.2V

CAM_12V

A_3.0V

D_3.0V

BL_H

BL_L

MAX_5.0V

TI_5.0V

D_1.8V

DDR_1.8V

VL_3V

CN704

MEMORY

STICK

DUO

G

POWER (2/2)

(PAGE 3-4)

DSC-W90_L2

05

3-3

Page 27

3-4. POWER BLOCK DIAGRAM (2/2)

SY-169 BOARD (2/2)

A_3.0V

D_1.8V

D_3.0V

MAX_5.0V

ST_UNREG

D_1.2V

CAM_12V

CAM_-7.5V

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

D_1.8V

D_3.0V

A

POWER (1/2)

(PAGE 3-3)

B2

IC501

2.8V REG

(3/11)

Vin

Vcont

A2

B1

Vout

B2 B1

XDD_SYS_RST

XIC_211_IC_503_RST

IC502

1.5V REG

(3/11)

Vin

Vout

XDD_SYS_RST

IC503

OPTICAL

IMAGE

STABILIZATION

DRIVE

(3/11)

RESET_NA7

XDLA6

IC506

PITCH/YAW

SENSOR AMP

(3/11)

SE502

PITCH

SENSOR

SE501

YAW

SENSOR

XDD_SYS_RST

BL_H

BL_L

POWER (1/2)

(PAGE 3-3)

LCD901

LCD MODULE

2.5INCH

COLOR

LCD

BACKLIGHT

D001

AE/AF LOCK/

SELF-TIMER

D002

FLASH CHARGING/

RECORD

FB702

L701

CN713

VDDD

VDD

PVDD

RESET Z

CN708

BL_H

BL_L

VL_3VVL_3V

D_3.0V

XDIRECT_PB

31

32

18

37

SW-494 BOARD

CN001

3

4

12

10

5

10

9

1

BT001

LITHIUM

BATTERY

3

8

S003

BL_H

BL_L

C

RL-071/078 BOARD

CN707

XPWR_ON

3

CN101

3

S102

POWER

G

POWER (1/2)

(PAGE 3-3)

A_3.0V

D_3.0V

BL_H

BL_L

MAX_5.0V

TI_5.0V

D_1.8V

DDR_1.8V

VL_3V

B

POWER (1/2)

(PAGE 3-3)

E

POWER (1/2)

(PAGE 3-3)

F

POWER (1/2)

(PAGE 3-3)

D_1.8V

D_3.0V

TI_5.0V

MAX_5.0V

A_3.0V

B2 B1Vin

IC601

2.8V REG

(7/11)

A_3.0V

D_3.0V

D_1.2V

DDR_1.8V

D_1.8V

XIC_211_RST_REQ

XPWR_OFF

XACV_IN

IC_211_1_SI

IC_211_1_SO

XIC_211_1_SCK

XCS_IC_201

MS_PWR_ON

Vout

R253

L241

FB281

FB282

FB283

GPE_09

H10

XRESET

AB18

W12

XRESET_REQ

GPE_00G8

GPE_05K8

SIO1_RXD

G18

SIO1_TXD

B24

SIO1_SCK

H18

GPS_04

W20

GPE_15

T7

IC211

CPU

(4/11)

(5/11)

(6/11)

AU_AVCC

TPU2_OUT

GPE_03 J8

G15

L211

R601

D601

R723

D_3.0V

D_1.8V

D_1.8V

D_3.0V

TI_5.0V

MAX_5.0V

A_3.0V

AFLED_CONT

CAM_3.5V

D

POWER (1/2)

(PAGE 3-3)

XZM_RST_LED

IC603

AUDIO AMP

(7/11)

IC602

VIDEO AMP

(7/11)

D706

(MS ACCESS)

IC202

CLOCK

GENERATOR

(9/11)

DDC2P9_EN

TI_5.0V

MAX_5.0V

TI_5.0V

D_3.0V

XDD_SYS_RST

D_3.0V

MAX_5.0V

A_3.0V

CAM_12V

CAM_-7.5V

3.5V REG

IC307

(1/11)

Vout B1

Vin

B2

Vcont

A2

2.3V REG

IC306

(1/11)

Vout

B2 B1Vin

Vout

6 4

Vin

IC308

2.8V REG

(1/11)

Q704

FB306

ST_UNREGST_UNREG

TI_5.0V

Q710

AF LED

DRIVE

AF LED

CONTROL

IC305

54

CAM_3.5V

Q305

2.8V/3.5V

DISCHARGE

13V REG

Vin

FB305

FB303

AF_5.0V

XAF_LED

(1/11)

Vout

FB302

TIMING GENERATOR

RESET

D10

D_3.0V

5

CN701 CN001

1, 2

3

11

12

IC304

CCD SIGNAL

PROCESS,

(1/11)

5

ST-160 BOARD

1, 2

3

11

AF ILLUMINATOR

12

B+ SWITCH

D101

(POWER)

D002

SELF-TIMER/

Q304

-7.5V

DISCHARGE

Q401

XZM_RST_LED

L303

L302

R402

R412

R411

R401

L001

IC001

FLASH CONTROL,

CHARGE CONTROL

CAM_12V

CAM_-7.5V

CN402

Z_PI_SENS_Vcc

Z_BOX1_PI_SENS_Vcc

Z_BOX2_PI_SENS_Vcc

F_PI_SENS_Vcc

IC401

LENS DRIVE

(2/11)

T001

D001

CD-694 FLEXIBLE

BOARD

CN301

1

9

42

27

25

21

FLASH

CCD IMAGER

BUFFER

LENS BLOCK

ZOOM

RESET

SENSOR

ZOOM

FG

FOCUS

RESET

SENSOR

UNIT

IC003

8.1M

IC004

05

DSC-W90_L2

3-4E

Page 28

4-1. FRAME SCHEMATIC DIAGRAM

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

12

1

CN001

Note: CN001 is no mount.

(Direct solder)

SW-494

BOARD

BT001

LITHIUM BATTERY

MIC901

MICROPHONE

BLOCK

C901

CHARGING CAPACITOR

FLASH UNIT

1

ST-160 BOARD

11

CN001

122

FLEXIBLE FLAT CABLE

(FFC-093)

Note: CN701 is no mount.

(Direct solder)

2

12

CN701

1

11

(FFC-092)

FLEXIBLE FLAT CABLE

CN708

1

12

110

CN704

MEMORY STICK

CONNECTOR

RL-071/078 BOARD

LCD901

BACKLIGHT

LCD MODULE

2.5INCH

COLOR

LCD

BLK

RED

Note: CN101 is no mount.

CN101

18

(Direct solder)

LEVEL3

FLEXIBLE FLAT CABLE

(FFC-094)

RED

WHT

BLK

BT901

BATTERY

TERMINAL

39

1

39

38

11

LOCK

12

CN713

1

2

(Not supplied)

CN707

8

IC211

1

38

CN301

2

139

51

50

CN402

CD-694 FLEXIBLE BOARD

IC004

(Not supplied)

IC003

(Not supplied)

LENS BLOCK

DSC-W90_L2

LEVEL3

SY-169 BOARD

(SIDE A)

MC-176 BOARD (SIDE A)

26

2

25

CN102

1

27

28

MULTI CONNECTOR

4-1

130

CN710

BLK

RED

SP901

(FFC-095)

FLEXIBLE FLAT CABLE

130

CN101

Note: CN101 is no mount.

(Direct solder)

SPEAKER

MC-176 BOARD (SIDE B)

2

1

LEVEL3

SY-169 BOARD

(SIDE B)

FRAME

Page 29

Link

Link

4-2. SCHEMATIC DIAGRAMS

MC-176 BOARD (MULTI CONNECTOR)

SW-494 BOARD (CONTROL SWITCH)

COMMON NOTE FOR SCHEMATIC DIAGRAMS

ST-160 BOARD (FLASH DRIVE)

RL-071/078 BOARD

(CONTROL SWITCH, MIC)

DSC-W90_L2

Page 30

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

µF. 50 V or less are not indicated except f or electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

External dimensions (mm)

Case size

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

•Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT → EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C : panel designation

• A : B+ Line

• B : B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C : adjustment for repair.

• A : not use circuit

Precautions for Replacement of Imager

• If the imager has been replaced, carry out all the adjustments

for the camera section.

• As the imager may be damaged by static electricity from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with

dusts nor exposed to strong light.

1. Connection

Pattern box

Pattern box PTB-450

J-6082-200-A

or

Small pattern box

PTB-1450

J-6082-557-A

L = 24 cm (PTB-450)

L = 11 cm (PTB-1450)

Pattern box

Color bar chart

L

For PTB-450:

J-6020-250-A

For PTB-1450:

J-6082-559-A

Front of the lens

Camera

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Fig.b (Picture on monitor TV)

Red

Blue

Electronic beam

scanning frame

CRT picture frame

DSC-W90_L2

When indicating parts by reference number, please

include the board name.

The components identified by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par une pièce portant le numéro

spécifie.

4-2

Page 31

Schematic diagrams of the CD-694 flexib le board and SY -169 board are not sho wn.

Pages from 4-3 to 4-14 are not shown.

DSC-W90_L2

Page 32

MC-176 BOARD

MULTI CONNECTOR

A

XX MARK:NO MOUNT

B

D

30

ACV_GND

ACV_GND

29

ACV_GND

UART TX

UART Rx

XACV_DET

REG_GND

HD Pr

REG_GND

HD Pb

REG_GND

USB_GND

USB_DP

USB_DM

USB_GND

A_GND

V_GND

HD Y

REG_GND

XACC_IN

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CN101XX

USB_VBUS

USB_GND

USB_DP

USB_DM

USB_GND

AU_LINE_OUT

A_GND

V_OUT

V_GND

XPOWER_ON

CHARGE_V

CHARGE_V

CHARGE_V

ACV_UNREG

ACV_UNREG

ACV_UNREG

USB_VBUS

AU_LINE_OUT

V_LINE_OUT

Note: CN101 is not mounted. Flexible flat cable (FFC-095) is

soldered to this location instead.

This FFC-095 is not supplied, but this is included in

MC-176 complete board.

3421 8

5

6

7

Note:CN102 (multi connector) is not supplied,

but this is included in MC-176 complete board.

CN102

(MULTI CONNECTOR)

2

4

68

1012

14

16

1820

22

24

26

HD Pb

USB_VBUS

USB_GND

USB_DP

USB_DM

USB_GND

A_OUT_L

A_GND

V_OUT

V_GND

HD Y

XACC_IN

To AV/USB multi cable

ACV_GNDHD Pr

ACV_GND

ACV_GND

XPOWER_ON

UART Tx

UART Rx

CHARGE_V

XACV_DET

CHARGE_V

ACV_UNREG

ACV_UNREG

13

5

79

15

1719

21

23

25

A

B

CC

D

DSC-W90_L2

05

LND102

4-15

STATIC_GND

MC-176

Page 33

• Refer to page 4-2 for mark 0.

1 8

SW-494 BOARD

CONTROL SWITCH

A

XX MARK:NO MOUNT

Note: CN101 is not mounted. Flexible flat cable (FFC-092)

is soldered to this location instead.

CN001XX

1

VL_3V

D_3.0V

BL_L

BL_H

2

3

4

5

6

7

8

9

10

11

12

REG_GND

XAE_LOCK_LED

XSTRB_LED

B

LND001

LND004

KEY_AD1

KEY_AD2

XDIRECT_PB

MODE_DIAL2

MODE_DIAL1

STATIC_GND

STATIC_GND

XX

D003

BT001

(LITHIUM BATTERY)

SML-510MWT86S

5

4

XX

D005

3

2

1

D001

D002

SML-310YTT86

LND002

LND003

XX

D004

342

(AE/AF LOCK/SELF-TIMER)

(FLASH CHARGING/RECORD)

BL_L

BL_H

D001

D002

1

3

5

7

RB001

2200

5

6

7

A

RB003

2200

1

2

4

3

6

5

7

8

R001

2200

2

4

V

(SELF-TIMER)

2

4

1

3

1

3

S004

S005

S001

2

4

6

8

S002

B

(FLASH)

2

4

2

4

1

3

1

3

S006

S007

(DISP)

2

4

2

4

R005

2200

v

1

3

S008

b

(MACRO)

2

4

1

3

S010

z

(SET)

2

1

4

3

B

CC

1

1

3

S009

2

3

4

S011

AUTO

3

AUTO

4

HIGH SENS

5

SOFT SNAP

6

TWILIGHT PORTRAIT

7

TWILIGHT

8

LANDSCAPE

9

LANDSCAPE

10

BEACH

11

SNOW

12

MOVIE

13

PROGRAM AUTO

14

RB002

2200

1

2

4

R006

2200

R007

2200

3

6

5

7

8

Note: S011 (Mode dial) is not supplied,

but this is included in SW-494 complete board.

S003

W

(ZOOM)

T

MENU HOME

D

2

1

4

3

N

E

15

16

1

D

COM

2

COM

17

18

(MODE DIAL)

E

05

DSC-W90_L2

4-16

SW-494

Page 34

• Refer to page 4-2 for mark 0.

ST-160 BOARD

FLASH DRIVE

A

XX MARK:NO MOUNT

B

ST_UNREG

ST_UNREG

TI_5.0V

STRB_ON

STB_CHG_CNT

REG_GND

REG_GND

STRB_CHG

XSTRB_FULL

AF_5.0V

XAF_LED

CN00112P

NC

1

2

3

4

5

6

7

8

9

10

11

12

K1

K2

K3

CL-360S-TD4-X-TL

AF ILLUMINATOR

4

5

6

D002

SELF-TIMER/

3421 8

5

6

7

A

L001

2.2uH

2

1

1

SW

2

SW

3

VCC

4

F_ON

C001

22u

6.3V

C005

A3

3

A2

2

A1

1

XX

10V

220p

50V

C002

C007

D003

1u

R006

4700

RB520S-40TE61

T001

17

HGND

TPS65552RGTR

3

4

13

14

15

16

N.C

N.C

N.C

VBATT

PGND

IC001

PGND

XFULL

CHG

D001

MA2YF8000LS0

12

11

10

9

+

LND015

C901

315V 49uF

CHARGING

CAPACITOR

LND016

R005

LND019

XE_A(H)

C+

C-

XX

C006

10V

R004

1M

C004

0.047u

250V

R002

1M

5

6

7

8

CY25BAJ-8F-T23-G02

Q001

R003

100

1

2

3

4

LND017

TRIGGER

TRIG_GND

LND018

LND020

XE_K(L)

FLASH

UNIT

B

CC

XX

G_IGBT8N.C

I_PEAK

N.C

7

6

5

CL001

D

05

XE-L

XE-H

TRIGGERTRIGGER_GND

D

DSC-W90_L2

4-17

ST-160

Page 35

1

2

3

4

RL-071/078 BOARD

CONTROL SWITCH,MIC

A

XX MARK:NO MOUNT

B

XSHUTTER_SW

XAE_LOCK_SW

Note: CN101 is not mounted. Flexible

flat cable (FFC-094) is soldered

C

to this location instead.

MIC_SIG

MIC_GND

XPWR_ON

X_PWR_LED

D_3.0V

REG_GND

CN101XX

1

2

3

4

5

6

7

8

Note: In this set, either RL-071 or RL-078 board is used.

All mounted parts and schematic diagram are common

to both RL boards.

LND101

MIC_GND

MIC_SIG

LND102

2

1

4

3

S101

5

0.047u

2

3

C001

(SHUTTER)

6

4

1

(POWER)

D101

SML-412MWT86

S102

POWER

MIC901

MICROPHONE

BLOCK

C002

0.047u

A

B

C

LND103

LND104

D

05

STATIC_GND

STATIC_GND

D

DSC-W90_L2

4-18

RL-071/078

Page 36

Signal location of the SY-169 board is not shown.

Pages from 4-19 to 4-20 are not shown.

DSC-W90_L2

Page 37

Link

Link

4-4. PRINTED WIRING BOARDS

MC-176 BOARD

SW-494 BOARD

COMMON NOTE FOR PRINTED WIRING BOARDS

ST-160 BOARD

RL-071/078 BOARD

DSC-W90_L2

Page 38

4-4. PRINTED WIRING BOARDS

21321321

3

345

21

123

654

EB

C

3152

46

123

654

3152

46

123

54

43

12

312

45

534

12

14

23

4625

31

12

4

3

14

23

4-4. PRINTED WIRING BOARDS

4-4. PRINTED WIRING BOARDS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS

• : Uses unleaded solder.

•

: Circuit board

: Flexible board

Pattern from the side which enables seeing.

: pattern of the rear side

(The other layers’ patterns are not indicated)

• Through hole is omitted.

• Circled numbers refer to waveforms.

• There are a few cases that the part printed on diagram

isn’t mounted in this model.

• C : panel designation

• Chip parts.

Transistor Diode

DSC-W90_L2

4-21

Page 39

Printed wiring boards of the CD-694 flexibile board and SY -169 board are not sho wn.

Pages from 4-22 to 4-24 are not shown.

DSC-W90_L2

Page 40

MC-176 (4 layers), SW-494 (2 layers)

CN001

BT001

LND001

112

–+

SW-494 BOARD (SIDE B)

1-871-501-

11

BT001

LITHIUM

BATTERY

Note: CN001 is not mounted. Flexible flat cable (FFC-092)

is soldered to this location instead.

05

12

: Uses unleaded solder.

MC-176 BOARD (SIDE A)

-

MC-176

>EP GW<

226

2728

05

CN102

(MULTI CONNECTOR)

Note: CN102 (multi connector) is not supplied,

but this is included in MC-176 complete board.

125

SW-494 BOARD (SIDE A)

AK

D001

D001

(AE/AF LOCK/SELF-TIMER)

D002

AK

(FLASH CHARGING/RECORD)

D002

A

1-871-499-

MC-176 BOARD (SIDE B)

CN101

11

LND102

05

1-871-499-

Note: CN101 is not mounted. Flexible flat cable (FFC-095) is

soldered to this location instead.

This FFC-095 is not supplied, but this is included in

MC-176 complete board.

W

42

130

(ZOOM)

13

S002

LND003

11

42

28

RB001

17

T

13

S005

Note: S011 (Mode dial) is not

supplied, but this is included

in SW-494 complete board.

LND002

N

42

S003

R007

13

14 13 2 12 11 10

45 6178

39

S011

1716

1815

S011

(MODE DIAL)

17

RB002

MENU

42

S007

13

R005

b

(MACRO)

42

S008

42

S009

13

HOME

05

28

28

RB003

17

13

z

13

5

4

D005

1

3

D003

AK

(SELF TIMER)

LND004

R006

v

(DISP)

S006

(SET)

42

S010

S001

42

V

42

B

(FLASH)

13

13

13

K

D004

1-871-501-

A

S004

R001

42

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

11 12

DSC-W90_L2

4-25

MC-176, SW-494

Page 41

ST-160 (4 layers), RL-071/078 (2 layers)

: Uses unleaded solder.

C901

CHARGING

CAPACITOR

ST-160 BOARD (SIDE A)

XE_K (L) XE_A (H)

C004

R004

LND016

1

D001

+

2

LND015

+

LND020

T001

05

LND018

D003

12

C002

1

1

C007

C005

2

2

43

12

C001

L001

ST-160 BOARD (SIDE B)

ST-160

R003

R002

05

5

4

Q001

8

1

FLASH UNIT

TRIG_GND TRIGGER

LND017

R006

CL001

CN001

14

IC001

17

516

813

11

11

12

12

12 9

C006

B

SELF-TIMER/

AF ILLUMINATOR

RL-071 BOARD (SIDE A)

LND103

65

2

C001

>EP GW<

R005

LND019

-

1-871-500-

05

11

1

(SHUTTER)

S101

S101

3

C002

4

RL-071 BOARD (SIDE B)

46

D002

13

1-871-500-

11

05

Note: In this set, either RL-071 or RL-078 board is used.

All mounted parts and schematic diagram are common to both RL boards.

>EP GW<

LND104

Note: CN101 is not mounted. Flexible flat cable (FFC-094)

is soldered to this location instead.

13

S102

POWER

-502-

1-871

S102

B

D101

KA

42

(POWER)

R

CN101

18

1-871-502-

MIC901

MICROPHONE

BLOCK

B

LND101 LND102

1-871-502-

RL-071

12

12

RL-078 BOARD (SIDE A)

LND103

1-874-109-

C001

05

(SHUTTER)

2

1

S101

65

3

S101

C002

4

RL-078 BOARD (SIDE B)

>EP GW<

LND104

05

A

-1091-874

13

S102

KA

42

(POWER)

S102

POWER

CN101

18

B

D101

RL-078

>EP GW<

R

B

RL-078

1-874-109-

MIC901

MICROPHONE

BLOCK

LND101LND102

1-874-109-

11

11

DSC-W90_L2

4-26E

Note: CN101 is not mounted. Flexible flat cable (FFC-094)

is soldered to this location instead.

ST-160, RL-071/078

Page 42

NOTE

NOTE

5. REPAIR PARTS LIST

NOTE: Characters A to Z of the electrical parts list indicate location of exploded views in which the desired part is shown.

Link

Link

CABINET SECTION

LENS SECTION

EXPLODED VIEWS

EXPLODED VIEWS

ABC

MAIN BOARD SECTION

D

LCD/BT HOLDER SECTION

Link

Link

MC-176 BOARD ST-160 BOARD SW-494 BOARD

RL-071/078 BOARD

ELECTRICAL PARTS LIST

ELECTRICAL PARTS LIST

BCC

B

ACCESSORIES

ACCESSORIES

DSC-W90_L2

Page 43

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

NOTE:

• -XX, -X mean standardized parts, so they may have some differences from

the original one.

• Items marked “*” are not stocked since they are seldom required for routine

service. Some delay should be anticipated when ordering these items.

• The mechanical parts with no reference number in the exploded views are not

supplied.

• Due to standardization, replacements in the parts list may be different from

the parts specified in the diagrams or the components used on the set.

• CAPACITORS:

uF: µF

• COILS

uH: µH

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uP A... , µPA... ,

uPB... , µPB... , µPC... , µPC... ,

uPD..., µPD...

• Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

CH : Chinese model

CND : Canadian model

EE : East European model

HK : Hong Kong model

J: Japanese model

JE : Tourist model

KR : Korea model

NE : North European model

TW : Taiwan model

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

• Color Indication of Appearance Parts

Example:

(SILVER) : Cabinet’s Color

(Silver) : Parts Color

DSC-W90_L2

5-1

Page 44

5. REPAIR PARTS LIST

DISASSEMBLY

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS

5-1-1. CABINET SECTION

#65

2

HARDWARE LIST

4

#65

7

5

6

#65

5

#65

1

#65

#65

Lens/Main Board Section

(See Page 5-3)

3

Ref. No. Part No. Description Ref. No. Part No. Description

1 X-2177-048-1 CABINET (FRONT) ASSY (SILVER)

1 X-2177-049-1 CABINET (FRONT) ASSY (BLACK)

* 2 3-197-910-01 SHEET, SY ELECTROSTATIC

3 3-099-623-01 CABINET, SIDE

4 X-2177-059-1 CABINET (REAR) ASSY (SILVER)

DSC-W90_L2

4 X-2177-060-1 CABINET (REAR) ASSY (BLACK)

5 3-099-626-01 SHEET, LCD WINDOW ADHESIVE

6 3-099-624-01 WINDOW, LCD

7 3-099-625-01 PLATE, MODE

#65 2-635-591-01 SCREW (M1.4), NEW TRUSTAR P2 (Silver)

5-2

Page 45

5-1-2. MAIN BOARD SECTION

DISASSEMBLY

ns: not supplied

#65

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

60

HARDWARE LIST

59

52

#3

57

51

54

ns

(FFC-093)

ns

SY-169

SP901

55

58

ns

56

MIC901

53

(Note 1)

#5

#5

64

Lens Section

(See Page 5-5)

63

61

62

LCD/BT Holder Section

(See Page 5-4)

65

66

#30

68

(including IC003 (CCD imager) and

CD-694 flexible complete board) (Note 2)

Note 1: In this set, either RL-071 or RL-078 board is used.

Ref. No. Part No. Description Ref. No. Part No. Description

51 A-1253-157-A SY-169 BOARD, COMPLETE (SERVICE)

52 3-099-637-01 LABEL, FUSE

* 53 3-099-634-01 SHEET, ST INSULATING

* 54 3-099-636-01 SHEET, RL INSULATING

55 3-099-620-01 RETAINER, RELEASE

56 A-1246-054-A RL-071 BOARD, COMPLETE (Note 1)

56 A-1271-235-A RL-078 BOARD, COMPLETE (Note 1)

57 1-833-618-11 CABLE, FLEXIBLE FLAT (FFC-094)

58 X-2177-054-1 RELEASE ASSY

59 3-099-621-01 CABINET, UPPER

60 3-099-622-01 SHAFT, STRAP

61 A-1246-051-A MC-176 BOARD, COMPLETE

* 62 3-099-639-01 SHEET, MC RADIATION

* 63 3-099-629-01 RETAINER, MULTI

DSC-W90_L2

All mounted parts and schematic diagram are common to both RL boards.

Note 2: Be sure to read “Precuations for Replacement of

Imager” of level 3 on page 4-2.

* 64 3-099-635-01 SHEET, MC INSULATING

65 3-099-632-01 CABINET BOTTOM (SILVER)

65 3-099-632-11 CABINET BOTTOM (BLACK)

66 3-113-705-01 SHEET (PLUS), CD RADIATION

68 A-1253-767-A CCD BLOCK ASSY (including IC003 (CCD

IMAGER) and CD-694 flexible complete board)

(Note 2)

MIC901 1-542-721-11 MICROPHONE BLOCK

SP901 1-826-614-21 LOUD SPEAKER (1.0CM)

#3 2-660-401-01 SCREW (M1.7), NEW TRU-STAR, P2 (Red)

#5 3-080-204-01 SCREW, TAPPING, P2 (Black)

#30 3-086-156-11 SCREW B1.2 (White)

#65 2-635-591-01 SCREW (M1.4), NEW TRUSTAR P2 (Silver)

5-3

Page 46

5-1-3. LCD/BT HOLDER SECTION

DISASSEMBLY

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

HARDWARE LIST

ns: not supplied

105

104

106

#65

103

#5

110

107

111

ns

108

109

BT001

!

: BT001 (BATTERY, LITHIUM

SECONDARY)

Board on the mount position.

(See page 4-25)

LCD901

C901

ns

112

102

101

• Refer to page 5-1 for mark 0.

Ref. No. Part No. Description Ref. No. Part No. Description

101 A-1246-052-A ST-160 BOARD, COMPLETE

0 102 1-480-014-11 FLASH UNIT

* 103 3-113-323-01 LABEL, MS CAUTION

104 3-099-631-01 SCREW, TRIPOD

105 3-099-627-01 FRAME, MAIN

106 3-099-633-01 SHEET, LC FLEXIBLE

* 107 3-100-059-01 SHEET, LC FLEXIBLE ADHESIVE

* 108 3-197-557-01 SHEET, LIGHT INTERCEPTION

109 A-1246-053-A SW-494 BOARD, COMPLETE

* 110 3-100-060-01 SHEET, SW

BT901

(Note)

113

111 1-833-616-11 CABLE, FLEXIBLE FLAT (FFC-092)

* 112 3-198-159-01 SHEET, BT TERMINAL

113 X-2177-056-1 HOLDER ASSY, BT

0 BT001 1-756-710-11 LITHIUM RECHARGEABLE BATTERY

BT901 A-1257-452-A TERMINAL, SERVICE (BT) (Note)

0* C901 1-114-309-11 ELECT 49uF 315V

LCD901 1-802-379-11 LCD MODULE (LQ025A3DD01)

#5 3-080-204-01 SCREW, TAPPING, P2 (Black)

#65 2-635-591-01 SCREW (M1.4), NEW TRUSTAR P2 (Silver)

Note: Ref e r to HELP “Installation method of battery termi-

nal board” when changing the service terminal (BT).

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

CAUTION

DSC-W90_L2

5-4

Page 47

5-1-4. LENS SECTION

ns: not supplied

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

151

155

(Note 2)

ns

ns

HARDWARE LIST

#30

#30

154

(Note 1)

ns

153

152

(Note 1)

Note 1: Be sure to read “Exchange method of barrier b lock”

(Note 1)

#30

on page 2-6.

M901 (Note 2)

157

(Note 2)

ns

156

(Note 2)

Note 2: Be sure to read “Exchange method of zoom gear

block” on page 2-8.

Ref. No. Part No. Description Ref. No. Part No. Description

151 A-1231-924-A LSV-1160A (SERVICE)

152 2-689-851-01 RING (A), ORNAMENTAL (Note 1)

153 2-691-890-01 TAPE, BARRIER (Note 1)

154 A-1205-001-A BARRIER BLOCK ASSY (Note 1)

155 2-689-849-01 SPRING, Z LEAF (Note 2)

156 2-689-850-01 SPRING, FG LEAF (Note 2)

157 2-689-871-01 GEAR, NARUTO (Note 2)

M901 1-479-864-11 GEAR BLOCK, ZOOM (1160) (Note 2)

#30 3-086-156-11 SCREW B1.2 (White)

DSC-W90_L2

5-5

Page 48

Electrical parts list of the CD-694 flexible

board is not shown.

Page 5-6 is not shown.

DSC-W90_L2

Page 49

MC-176 RL-071 RL-078 ST-160 SW-494

5-2. ELECTRICAL PARTS LIST

Ref. No. Part No. Description Ref. No. Part No. Description

A-1246-051-A MC-176 BOARD, COMPLETE

***********************

(Flexible flat cable (FFC-095) and CN102 are not supplied,

but they are included in MC-176 complete board.)

(Not supplied) CABLE, FLEXIBLE FLAT (FFC-095)

< CONNECTOR >

CN102 (Not supplied) CONNECTOR, MULTIPLE (SOCKET)

(MULTI CONNECTOR)

A-1246-054-A RL-071 BOARD, COMPLETE

A-1271-235-A RL-078 BOARD, COMPLETE

**********************

Note: In this set, either RL-071 or RL-078 board is used.

All mounted parts and schematic diagram are common to both RL boards.

IC001 6-707-555-01 IC TPS65552RGTR

* L001 1-400-820-11 INDUCTOR 2.2uH

0*Q001 6-551-452-01 TRANSISTOR CY25BAJ-8F-T23-G02

R002 1-218-989-11 RES-CHIP 1M 5% 1/16W

R003 1-218-941-11 RES-CHIP 100 5% 1/16W

0 R004 1-216-121-11 RES-CHIP 1M 5% 1/10W

R006 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

< IC >

< COIL >