SONY DSC-P52-L3 Service Manual

DSC-P52

SERVICE MANUAL

Ver 1.0 2003. 03

Revision History

Revision History

Link

Link

PRINTED WIRING BOARDS REPAIR PARTS LISTSCHEMATIC DIAGRAMS

PRINTED WIRING BOARDS REPAIR PARTS LISTSCHEMATIC DIAGRAMS

LEVEL 3

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

Korea Model

Chinese Model

Tourist Model

Brazilian Model

• For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (987624841.pdf).

• Reference No. search on printed wiring boards is available.

The information that is not described in this Service Manual is described

in the LEVEL 2 Service Manual.

When repairing, use this manual together with LEVEL 2 Service Manual.

Contents of LEVEL 2 Service Manual

1. SERVICE NOTE

2. DISASSEMBLY

3. BLOCK DIAGRAMS

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

5. REPAIR PARTS LIST

6. ADJUSTMENTS

OVERALL

POWER

ST-82, FP-643 FLEXIBLE, JK-256,

CONTROL SWITCH BLOCK (SW-

392), RL-060, UA-003

EXPLODED VIEWS

ELECTRICAL PARTS LIST

DIGITAL STILL CAMERA

DSC-P52

COVER

COVER

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 2 —

TABLE OF CONTENTS

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

• SY-91 (1/10)(CCD IMAGER, CAMERA A/D CONV.)

SCHEMATIC DIAGRAM ······························4-7

• SY-91 (2/10)(LENS DRIVE)

SCHEMATIC DIAGRAM ······························4-9

• SY-91 (3/10)(CAMERA DSP, VIDEO AMP)

SCHEMATIC DIAGRAM ····························4-11

• SY-91 (4/10)(SH DSP, CLK GEN)

SCHEMATIC DIAGRAM ····························4-13

• SY-91 (5/10)(LCD DRIVE, TIMING GENERATOR)

SCHEMATIC DIAGRAM ····························4-15

• SY-91 (6/10)(FRONT CONTROL)

SCHEMATIC DIAGRAM ····························4-17

• SY-91 (7/10)(AUDIO I/O)

SCHEMATIC DIAGRAM ····························4-19

• SY-91 (8/10)(DC IN)

SCHEMATIC DIAGRAM ····························4-21

• SY-91 (9/10)(DC-DC CONVERTER)

SCHEMATIC DIAGRAM ····························4-23

• SY-91 (10/10)(CONNECTOR)

SCHEMATIC DIAGRAM ····························4-25

4-3. PRINTED WIRING BOARDS

• SY-91 (CCD IMAGER CAMERA A/D CONV.,

LENS DRIVE, CAMERA DSP, VIDEO AMP, SH DSP,

CLK GEN, LCD DRIVE TIMING GENERATOR,

FRONT CONTROL, AUDIO I/O, DC IN, DC-DC

CONVERTER, CONNECTOR)

PRINTED WIRING BOARD ·······················4-39

4-4. WAVEFORMS ······························································4-45

4-5. MOUNTED PARTS LOCATION ································· 4-48

DSC-P52

5. REPAIR PARTS LIST

5-2. ELECTRICAL PARTS LIST ··········································5-7

— 3 —

COVER

COVER

4-2. SCHEMATIC DIAGRAMS

Link

Link

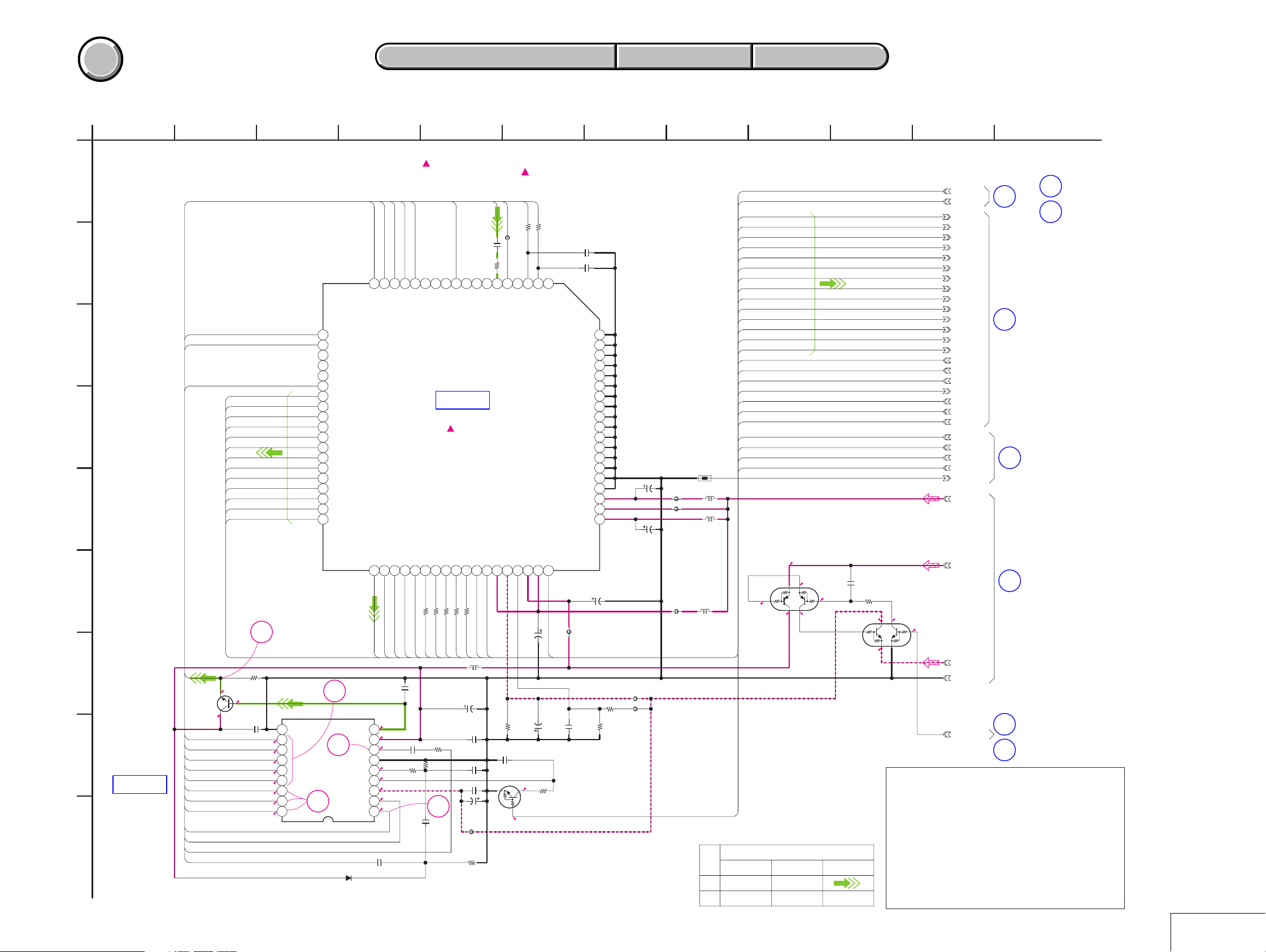

SY-91 BOARD (1/10)

SY-91 BOARD (1/10)

(CCD IMAGER, CAMERA A/D CONV.)

(CCD IMAGER, CAMERA A/D CONV.)

SY-91 BOARD (6/10)

SY-91 BOARD (6/10)

(FRONT CONTROL)

(FRONT CONTROL)

DSC-P52

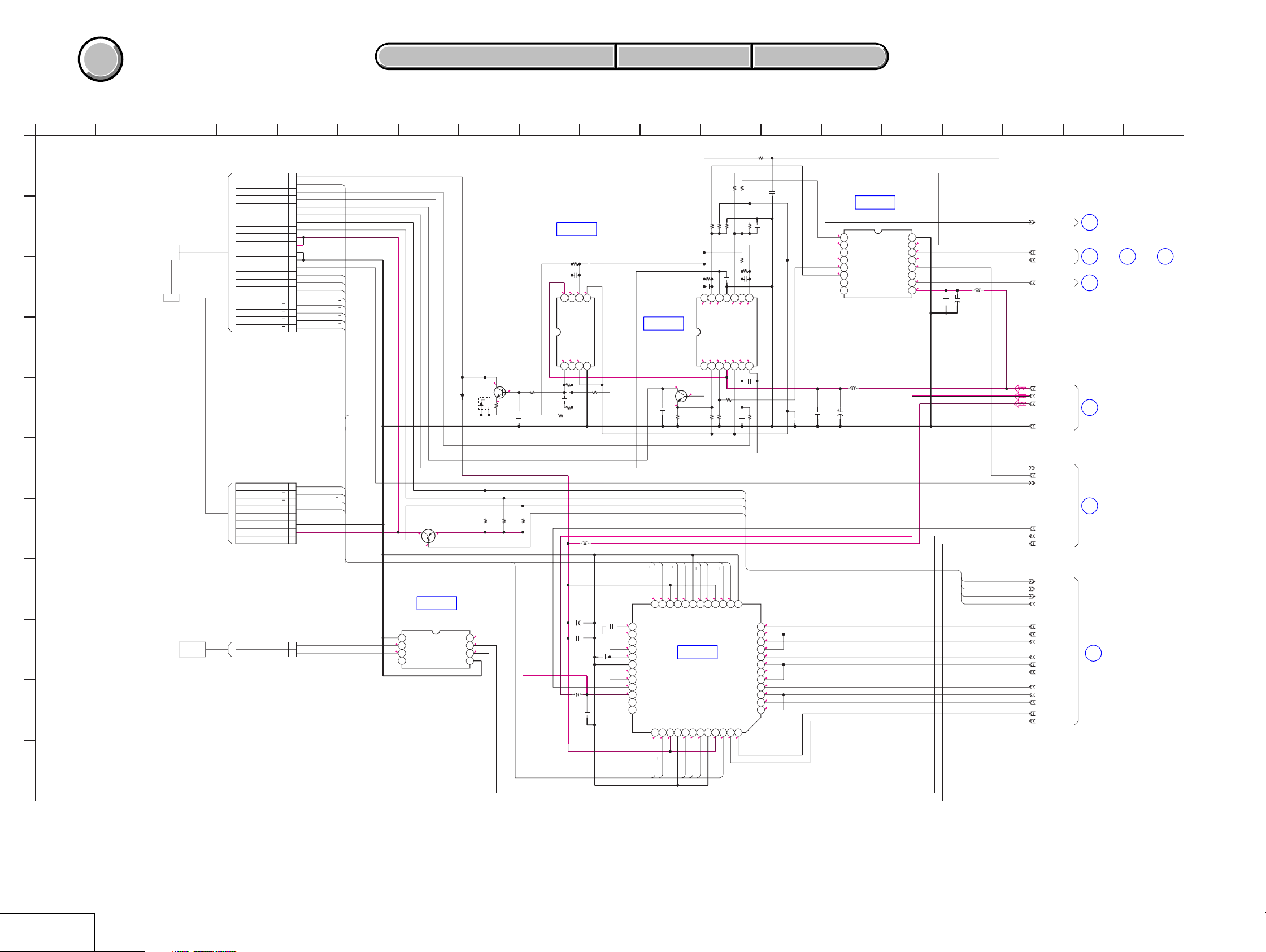

SY-91 BOARD (2/10)

SY-91 BOARD (2/10)

SY-91 BOARD (3/10)

SY-91 BOARD (3/10)

(CAMERA DSP, VIDEO AMP)

(CAMERA DSP, VIDEO AMP)

SY-91 BOARD (4/10)

SY-91 BOARD (4/10)

SY-91 BOARD (5/10)

SY-91 BOARD (5/10)

(LCD DRIVE, TIMING GENERATOR)

(LCD DRIVE, TIMING GENERATOR)

(LENS DRIVE)

(LENS DRIVE)

(SH DSP, CLK GEN)

(SH DSP, CLK GEN)

SY-91 BOARD (7/10)

SY-91 BOARD (7/10)

SY-91 BOARD (8/10)

SY-91 BOARD (8/10)

SY-91 BOARD (9/10)

SY-91 BOARD (9/10)

SY-91 BOARD (10/10)

SY-91 BOARD (10/10)

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

(AUDIO I/O)

(AUDIO I/O)

(DC IN)

(DC IN)

(DC-DC CONVERTER)

(DC-DC CONVERTER)

(CONNECTOR)

(CONNECTOR)

4-2. SCHEMATIC DIAGRAMS

COVER

COVER

4-2. SCHEMATIC DIAGRAMS

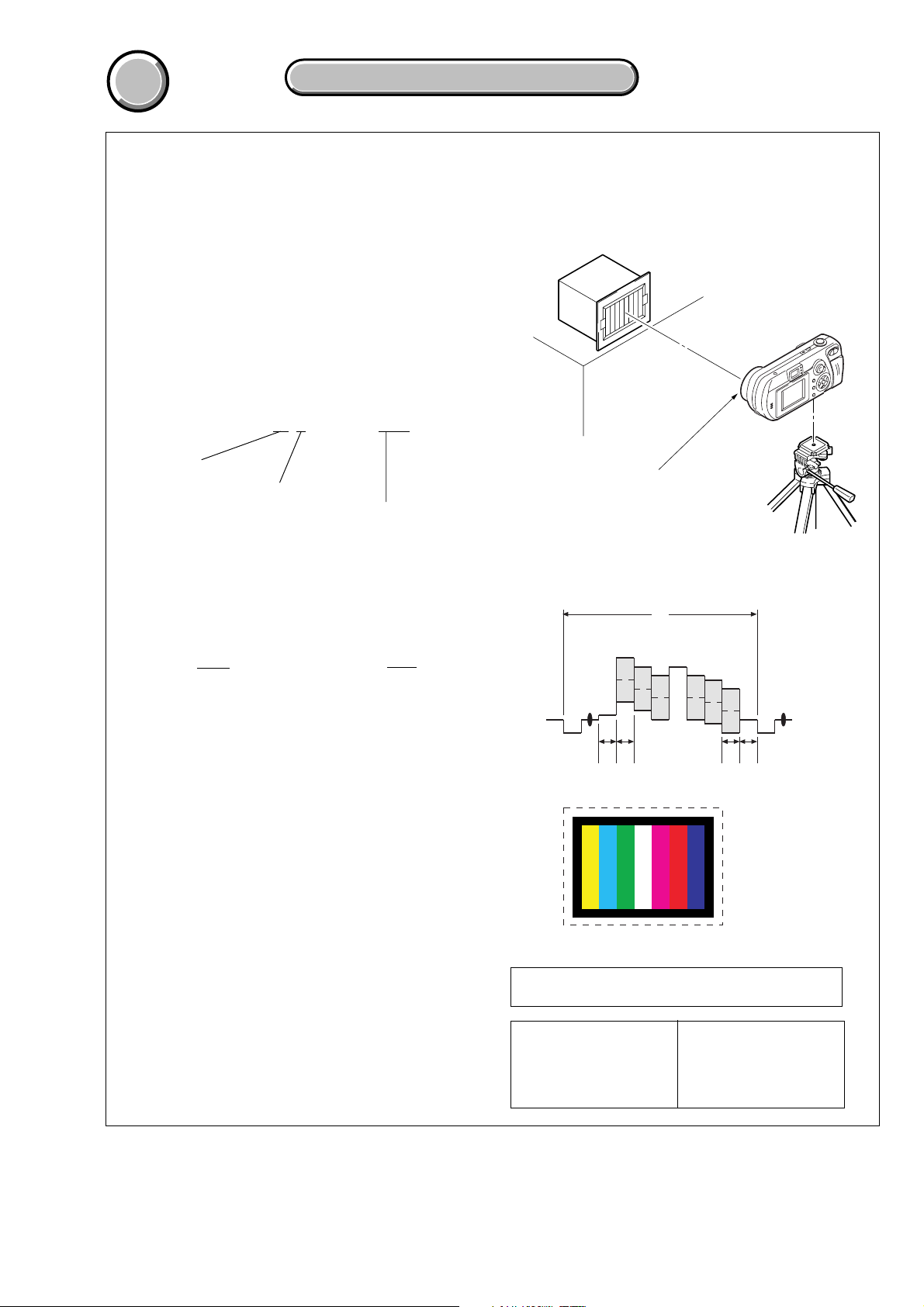

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

DSC-P92

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

Link

µF. 50 V or less are not indicated except for electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

• Parts with * differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT → EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B: B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: VIDEO SIGNAL (ANALOG)

• A: AUDIO SIGNAL (ANALOG)

• A: VIDEO/AUDIO SIGNAL

• A: VIDEO/AUDIO/SERVO SIGNAL

• A: SERVO SIGNAL

• Circled numbers refer to waveforms.

(Measuring conditions voltage and waveform)

• Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference values

and reference waveforms.

(VOM of DC 10 MΩ input impedance is used)

• Voltage values change depending upon input

impedance of VOM used.)

1. Connection

Pattern box

About 36cm

Front of the lens

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Fig.b (Picture on monitor TV)

Red

Blue

When indicating parts by reference number, please

include the board name.

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

4-5

DSC-P52

COVER

COVER

4-2. SCHEMATIC DIAGRAMS

1

2

SY-91 BOARD(1/10)

A

CCD IMAGER,CAMERA A/D CONV.(CCD,CH BLOCK)

XX MARK:NO MOUNT

B

V3A

C

D

E

V3B

VSHT

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

F

G

H

I

Q352

2SC4250(T5LSONY1)

BUFFER

IC351

CCD IMAGER

16

CCD_OUT

V1

V2

V3A

V3B

V4

V5A

V5B

V6

H2

H1

RG

VSHT

R14.9

R358

R10.7

3300

P0

R11.4

P0

C359

P0

0.1u

R-0.5/P0

R-0.5/P0

R-0.5/P0

R-0.5/P0

R-0.5/P0

R-6.1/P0

R-6.1/P0

R-6.1/P0

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

3

V3A

19

V3B

20

NC

21

NC

22

NC

23

VSHT

24

D0

25

D1

26

D2

27

D3

28

D4

29

D5

30

D6

31

D7

32

D8

33

D9

34

D10

35

D11

36

D12

37

4

V1

V6

V5B

V5A

16

17V618

V1

V5B

D1339XFE_CS40XFE_CS41XCAM_SO42XCAM_SCK43CLPOB44CLPDM

38

5

XFE_CS

XTG_CS

CAM_SO

CA_AD13

C361

2

9

GND

8

V1

7

V2

6

V3A

5

V3B

ICX432FQF-13

4

V4

3

V5A

2

V5B

1

1

V6

3

*

IC351

D351

MA2S111-(K8).SO

VOUT

VDD

GND

SUB

CSUB

10p

CH

R11.4

P0

10

R14.9

P0

11

R14.0

P0

RG

12

13

R10.6

P-0.1

14

R10.5

R355

P0

15

R-7.4

P0

16

VL

R2.1

P0

17

H1

R1.2

P0

C355

18

H2

C351

0.22u

B

0.22u

25V

25V

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

5

:Voltage measurement of the CSP IC

and the Transistors with mark,is

not possible.

V4

V5A

V2

CCD_OUT

C903

0.1u

B

R905

150

7NC8NC9NC10V211NC12NC13NC14V415

CCD_OUT

H1

H2

RG

R906

0

0uH

FB901

2H13H24NC5RG6

IC901

CAMERA A/D CONV.

IC901

CSP(CHIP SIZE PACKAGE)IC

(CH-122(3M) BOARD)

CAM_-7.5V

XCAM_SCK

B

C358

0.1u

0

220

R902

CLPOB

220

R901

CLPDM

R356

4

45

1k

R903

1M

XCAM_RESET

CA_HR47CA_VR48TG_CLK49MCK12

46

220

220

R904

R909

XCAM_RESET

CA_HD

L351

R357

0

C354

CA_FD

C352

3.3u

35V

B

TA

C360

C353

22u

16V

B

FB351

0uH

R351

100k

XX

0.1u

TG_CLK

22uH

TA

MCK12

TG3V/HVDD

50

C357

0.1u

C356

2200p

B

51

CAM_15V54TG3V55WEN

52VM53

C907

47u

6.3V

TA

B

R908

100k

10.5

UN9213J-(K8).SO

SWITCH

0

Pin number and index mark

*

of IC351 are shown as

viewed from the bottom.

R907

0

1

NC

TG_WEN

C912

22u

16V

TA

B

Q351

R354

3900

HVDD

DRV3V

FE3V

FB905

C921

XX

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

0uH

C904

C905

SY-91 BOARD SIDE A SY-91 BOARD SIDE B

SY-91 BOARD SIDE A SY-91 BOARD SIDE B

7610

NO MARK:REC/PB MODE

R :REC MODE

P :PB MODE

XX

XX

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

C909

C901

TA

33u

59

6.3V

B

TA

58

57

56

3.3u

35V

B

FB906

0uH

XX

R912

FB910

XX

R911

0

C908

6.3V

FB903

FB904

47u

TA

B

FB902

811

XCAM_SCK

CAM_SO

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

TG_WEN

CA_HD

CA_FD

MCK12

CLPOB

CLPDM

VSUB_CONT

XCAM_RESET

XTG_CS

XFE_CS

TH351

L903

0uH

10uH

0uH

L902

10uH

L901

0uH

10uH

TG_CLK

RN2907FE(TPLR3)

R3.3

P14.9

912

(4/10)

(2/10)

(3/10)

(4/10)

(9/10)

(4/10)

(10/10)

1

(5/10)

1

Q905

SWITCH

5

R15.0

XCAM_SCK

CAM_SO

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

TG_WEN

CA_HD

CA_FD

MCK12

CLPOB

CLPDM

VSUB_CONT

XCAM_RESET

XTG_CS

XFE_CS

TG_CLK

CCD_TEMP

D_3.1V

15.0

C902

R3.3

0.1u

P14.9

4

1

6

3

P0

R3.2

P-7.6

B

R910

R2.4

P14.9

2

82k

R-7.4/P0 R0/P14.7

3

6

5

4

1

-7.4

RN1907FE(TPLR3)

R2.9/P0

2

CAM_15V

Q906

SWITCH

CAM_-7.5V

REG_GND

CAM_DD_ON

1

2

3

4

5

5

Precautions Upon Replaching CCD imager

•

The SY-91 board mounted as a repair part is not equipped

VSUB_CONT

SIGNAL PATH

VIDEO SIGNAL

CHROMA

REC

PB

Y

Y/CHROMA

with a CCD imager.

When replaching this board, remove the CCD imager from the

old one and mount it onto the new one.

•

If the CCD imager has been replaced, carry out all the

adjustments for the camera section.

•

As the CCD imager may be damaged by static electrictiy from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with dusts

nor exposed to strog light.

4-7 4-8

SY-91 (1/10)

DSC-P52

COVER

COVER

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

SY-91 BOARD(2/10)

A

LENS DRIVE(LD BLOCK)

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R :REC MODE

P :PB MODE

B

FP-689

FLEXIBLE

LENS

BLOCK

C

LENS BLOCK is replaced as a block.

So that there PRINTED WIRING BOARD and

SCHEMATIC DIAGRAM are omitted.

OVF

D

E

CN201

DRIVE+

XZM_RST_SENS

XFC_RST_SENS

ZM_SENS_VCC

FC_SENS_VCC

REG_GND

REG_GND

TEMP_OUT

FOCUS_B

ZOOM_B

FOCUS_A

ZOOM_A

FOCUS_B

ZOOM_B

FOCUS_A

ZOOM_A

DRIVE-

HALL-

BIAS+

HALL+

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

810 137

21P

1

SHUTTER+

2

3

4

BIAS-

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

FOCUS_B

ZOOM_B

FOCUS_A

ZOOM_A

FOCUS_B

ZOOM_B

FOCUS_A

ZOOM_A

SHUTTER-

D204

MA111-(K8).S0

D205

1SS401(TE85L)

Q202

2SD2216J-QR(K8).SO

IRIS DRIVE

0.6

0.1

R208

10

0.7

9

IC201

IRIS DRIVE

C211

R213

0.033u

B

100k

C210

3300p

B

0.9

0.9

0.9

3.2

5

6

7

8

VCC

OUT

IN(-)

IN(+)

NJM2904V(TE2)

IC201

OUT2IN(-)3IN(+)4GND

R0.9P00.9

0.9

1

R211

100k

C208

C209

R209

1u

100

6.3V

B

C204

0.22u

B

10V

R214

0.1u

47k

B

R212

10k

R210

4700

SY-91 BOARD SIDE A SY-91 BOARD SIDE B

SY-91 BOARD SIDE A SY-91 BOARD SIDE B

11

IC203

HALL AMP

2SD2216J-QR(K8).SO

IRIS BIAS

C213

0.1u

B

C215

0.001u

Q204

0.6

0.1

R220

330

R230

±0.5%

2700

R226

R224 180k

C216

0.022u

R223

180k

B

12

13

14

0.9

0.9

OUT

P1.5

IN(-)

R0.5

IN(+)

NJM12902V(TE2)

0.7

0.1

0.1

IC203

OUT2IN(-)3IN(+)4VCC5IN(+)6IN(-)7OUT

1

0.7

R225

R227

22k

1200

12

R236

2200

R231

1k

16k

C228

±0.5%

0.1u

B

C220

0.01u

B

R229

R233

180k

100k

R232

22k

R234

B

100k

C217

0.022u

8

9

10

11

OUT

GND

IN(-)

IN(+)

R0.6/P1.7

R0.6/P1.7

R1.0/P2.0

3.2

0.9

0.9

1.3

C219

0.01u

B

R228

12k

R235 10k

C218

XX

C224

0.1u

C223

1u

B

IC204 BH2223FV-E2

R0.1

P0

1

A02

0

2

A03

3

A04

0.9

4

A05

1.0

5

A06

1.7

6

A07

7

A08

8

A09

L205

10uH

C225

10u

6.3V

B

TA P

IC204

D/A CONV.

670215501

1825 15 16

PRELAMP_AF_ON

GND

16

R0.6

P1.8

A01

15

0

DI

14

2.9

CLK

13

0

LD

12

NC

11

R1.2

P2.3

A010

10

3.2

9

VCC

C226

0.1u

B

L206

C227

10uH

10u

6.3V

TA P

CAM_SO

XCAM_SCK

SP_VOL

D_3.1V

D_2.9V

M_5V

REG_GND

(10/10)

9

(1/10)

1

(7/10)

8

(9/10)

6

19144 1763

(4/10)

1

(5/10)

1

F

G

H

DC MOTOR

I

8C-028G

J

K

CN203 8P

OVF_SENS_GND

OVF_SENS_VCC

OVF_SENS_RST

OVF_A

OVF_B

OVF_A

OVF_B

8

7

6

5

NC

4

3

2

1

2PCN202

2LENS_BARIA_CLOSE

1LENS_BARIA_OPEN

OVF_A

OVF_B

OVF_A

OVF_B

R0.7

P0.3

R0.7

P0.3

UN9116J-(K8).SO

R-0.8

P-0.5

2.9

LENS OPEN/CLOSE

IC205

*

8

PGND

7

OUT1

6

OUT2

5

NC

Pin number and index mark

*

of IC205 are shown as

viewed from the bottom.

Q205

SWITCH

IC205

CONTROL

LB1938T-TLM-E

R217

56k

2.9

VCC

1

IN1

2

IN2

3

SGND

4

R207

R216

56k

56k

4.7uHL203

FOCUS_B

FOCUS_B

0.5

0.5

5.0

22

25

26

27

28

29

30

31

32

33

34

35

36

DGND

PS

CP1

CP2

CP3

CP4

VG

VLIM

VREF

VCC

BR6

BR5

23

VM2

OUT4A24OUT4B

OUT5A38OUT5B39VM340PGND2

37

0.4

0.4

5.0

ZOOM_A

ZOOM_A

C202

33u

C207

10V

0.1u

B

TA

5.0

0

0

C205

0.01u

B

L202

10uH

C203

0.1u

B

R2.4

P5.0

R7.4

P4.6

C206

R9.9

0.1u

P4.6

B

R9.9

P4.6

R1.3

P0.3

R1.3

P0.3

R2.9

P0

2.9

B

OVF_B

OVF_B

FOCUS_A

FOCUS_A

0.5

0.5

0.5

0.5

17

19

20

21

OUT3A

OUT3B

PGND1

IC202

FOCUS/ZOOM DRIVE

IC202

BD6752KV-E2

OUT6A42OUT6B43OUT7A44RNF45VM446OUT7B47EN7

41

0.4

0.4

P0.4

R5.0

ZOOM_B

SHUTTER+

ZOOM_B

XZM_RST_SENS1

XFC_RST_SENS

XOVF_RST_SENS

XLENS_RST_LED

OVF_A

5.0

0.4

16

VM1

OUT2A18OUT2B

R0

5.0

P0.5

R2.9

SHUTTER-

14

OVF_A

0.4

P0

XZM_RST_SENS1

XFC_RST_SENS

XOVF_RST_SENS

13

CNF

OUT1A15OUT1B

R0.8

P2.9

IN1

12

0

EN1

11

R2.7

P2.9

IN2

10

0

9

EN2

R2.5

P2.9

8

IN3

0

7

EN3

R2.5

P2.9

6

IN4

0

5

EN4

R0.4

P2.9

4

IN5

0

3

EN5

R2.5

P2.9

2

IN6

0

1

EN6

IN7

48

0

XLENS_RST_LED

HALL_AD

DAC_STB

LENS_TEMP

XCAM_DR_PS

LENSV_OPEN_ON

LENSV_CLOSE_ON

XZM_RST_SENS1

XFC_RST_SENS

XOVF_RST_SENS

XLENS_RST_LED

HR_DIR2A

HR_EN2

HR_DIR2B

HR_DIR0A

HR_EN0

HR_DIR0B

HR_DIR1A

HR_EN1

HR_DIR1B

MSHUT_ON

MSHUT_EN

10

(4/10)

(3/10)

7

16

SY-91 (2/10)

4-9 4-10

DSC-P52

COVER

COVER

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

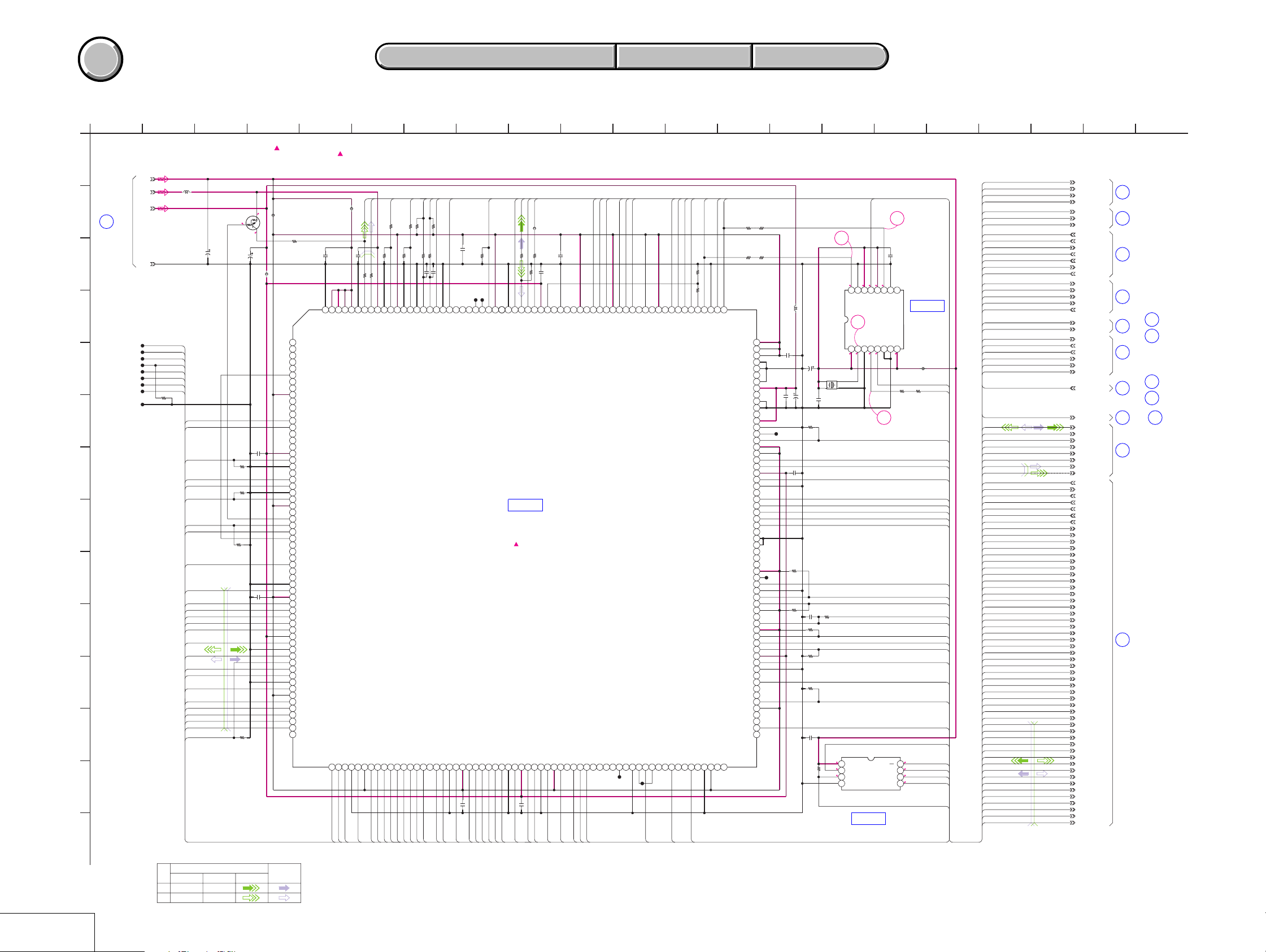

1

A

SY-91 BOARD(3/10)

CAMERA DSP,VIDEO AMP(HMS,VI BLOCK)

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R :REC MODE

P :PB MODE

B

C

D

E

F

G

H

I

J

K

L

M

(4/10)

14 14

N

O

16

14

2

:Voltage measurement of

the CSP IC and

the Transistors with

mark,is not possible.

CA_HD

CA_FD

TG_WEN

CLPOB

CLPDM

CA_AD13

CA_AD12

CA_AD11

CA_AD10

CA_AD09

CA_AD08

(1/10)

2

7

11

12

(5/10)

13

CA_AD07

CA_AD06

CA_AD05

CA_AD04

CA_AD03

CA_AD02

CA_AD01

CA_AD00

MCK12

VSUB_CONT

HR_EN0

HR_DIR0A

HR_DIR0B

MSHUT_ON

MSHUT_EN

XFC_RST_SENS

XLENS_RST_LED

XZM_RST_SENS1

(2/10)

XOVF_RST_SENS

HR_DIR2A

HR_DIR2B

HR_DIR1A

HR_DIR1B

HR_EN2

HR_EN1

MC_A25

MC_A24

MC_A23

MC_A22

MC_A21

MC_A20

MC_A19

MC_A18

MC_A17

MC_A16

MC_A15

MC_A14

MC_A13

MC_A12

MC_A11

MC_A10

MC_A09

MC_A08

MC_A07

MC_A06

MC_A05

MC_A04

MC_A03

(4/10)

(6/10)

(6/10)

(7/10)

MC_A02

MC_A01

MC_XRD

MC_XCS6

MC_XCS4

MC_XWE0

MC_XWE1

IRQIMG

MC_D15

MC_D14

MC_D13

MC_D12

MC_D11

MC_D10

MC_D09

MC_D08

MC_D07

MC_D06

MC_D05

MC_D04

MC_D03

MC_D02

MC_D01

MC_D00

AU_LRCK

PLLBYP

MC_CLK1

VAMP_ON

XRST_SYS

AU_AINL

AU_AOUT

AU_2.9V

XWAIT

SYS_V

SYS_V

TG_WEN

CA_AD13

CA_AD12

CA_AD11

CA_AD10

CA_AD09

CA_AD08

CA_AD07

CA_AD06

CA_AD05

CA_AD04

CA_AD03

CA_AD02

CA_AD01

CA_AD00

VSUB_CONT

HR_EN0

HR_DIR0A

HR_DIR0B

MSHUT_ON

MSHUT_EN

XFC_RST_SENS

XLENS_RST_LED

XZM_RST_SENS1

XOVF_RST_SENS

HR_DIR2A

HR_DIR2B

HR_DIR1A

HR_DIR1B

HR_EN2

HR_EN1

MC_A25

MC_A24

MC_A23

MC_A22

MC_A21

MC_A20

MC_A19

MC_A18

MC_A17

MC_A16

MC_A15

MC_A14

MC_A13

MC_A12

MC_A11

MC_A10

MC_A09

MC_A08

MC_A07

MC_A06

MC_A05

MC_A04

MC_A03

MC_A02

MC_A01

MC_XRD

MC_XCS6

MC_XCS4

MC_XWE0

MC_XWE1

MC_D15

MC_D14

MC_D13

MC_D12

MC_D11

MC_D10

MC_D09

MC_D08

MC_D07

MC_D06

MC_D05

MC_D04

MC_D03

MC_D02

MC_D01

MC_D00

AU_LRCK

MC_CLK1

VAMP_ON

XRST_SYS

AU_AINL

AU_AOUT

AU_2.9V

CA_HD

CA_FD

CLPOB

CLPDM

MCK12

IRQIMG

XWAIT

PLLBYP

SYS_V

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

5 18

CLPOB

CLPDM

CA_HD

CA_FD

CA_AD13

CA_AD12

CA_AD09

CA_AD11

CA_AD10

CA_AD08

CA_AD06

CA_AD07

CA_AD04

CA_AD05

CA_AD03

CA_AD02

CA_AD00

CA_AD01

MC_A23

MC_A25

MC_A22

MC_A24

MC_A19

MC_A21

MC_A18

MC_A20

MC_A15

MC_A14

MC_A17

MC_A11

MC_A16

MC_A13

MC_A08

MC_A07

MC_A12

MC_A05

MC_A10

MC_A04

MC_A09

MC_A03

MC_A02

MC_A06

MC_A01

MC_XRD

MC_XCS6

MC_XCS4

MC_XWE0

MC_XWE1

IRQIMG

XWAIT

MC_D09

MC_D02

MC_D00

MC_D08

MC_D13

MC_D05

MC_D01

MC_D04

MC_D07

MC_D12

MC_D15

6 2110 1612

FB303

0uH

C306

C310

0.1u

B

NC

1

SMCK

JL309

C301

0.1u

2

CAMVDI

3

EXTVALID

4

DGND_0

5

PBLK

6

OPBCLP

7

DUMCLP

8

CCDHD

9

CCDFD

VCC3_0

10

ADIN15

11

ADIN13

12

ADIN12

13

ADIN09

14

ADIN14

15

B0.1u

C302

JL301

JL302

JL303

JL304

JL305

JL306

ADIN11

16

VCC2_0

17

ADIN10

18

ADIN08

19

ADIN06

20

ADIN07

21

ADIN04

22

ADIN05

23

ADIN03

24

ADIN02

25

ADIN00

26

B

ADIN01

27

DGND_1

28

A23

29

A25

30

A22

31

A24

32

A19

33

A21

34

A18

35

A20

36

A15

37

A14

38

A17

39

A11

40

A16

41

VCC3_1

42

A13

43

A08

44

A07

45

A12

46

A05

47

A10

48

A04

49

A09

50

A03

51

A02

52

A06

53

A01

54

RDX

55

VCC2_1

56

CSX

57

CSXRAM

58

WRLX

59

WRHX

60

IRQJPG

61

IRQIMG

62

DGND_2

63

XWAIT

64

D09

65

D02

66

D00

67

D08

68

D13

69

VCC3_2

70

D05

71

D01

72

D04

73

D07

74

D12

75

D15

76

D1178D0379D0680D1481D1082DGND_383XWAITIN84MD[0]85MD[1]86MD[2]87PLLVCC88CLKI89PLLGND90PLLMD[0]91PLLINSEL92DACMD93VCC2_294RSTX95SONYTEST96CLKTG97PLLMD[1]98PLLMD[2]99PLLXMSK

77

MC_D11

MC_D03

MC_D06

MC_D14

MC_D10

C318

0.1u

10u

B

6.3V

289

290

291

292

293

294

295

296

297

298NC299NC300NC301NC302NC303NC304

VSSR

VSSQR

VDDQR

C304

0.01u

B

/cs

VSSL

VDDL

VDDR

VSSQL

VDDQL

L301

10uH

R301

C303

1k

22u

4V

P

MC_CLK1

MST

287SM288

XRST_SYS

AU_2.9V

R313

10k

±0.5%

R314

5600

±0.5%

10k

R315

±0.5%

279

280

281

282

283

284

285

286

XTST

VRPR

VRNR

AVS_2

AVS_3

AOUTR

AVDD_3

DGND_16

VCC3_3

PLL24

PLL12

100

101

102

C307

0.1u

B

C305

B0.1u

MCK12

SY-91 BOARD SIDE A SY-91 BOARD SIDE B

SY-91 BOARD SIDE A SY-91 BOARD SIDE B

1437 22114 17

STRB_ON

MSHUT_ON

VSUB_CONT

C308

0.1u

B

R302

1k

246

247

248

249

250

251

252

253

254

255

SIA

VR_0

AVS_0

AVDD_0

STRBAD

AQ11

AQ03

AQ10

DGND_6

126

127

128

129

C311

0.1u

B

VCC3_13

STROBE1

STROBE2

SUBCNTL

DGND_14

AQ02

VCC2_4

AQ07

AQ08

AQ04

AQ01

130

131

132

133

134

135

278

103

AU_AINL

VCC2_3

13

AU_AOUT

C325

C323

0.1u

0.1u

B

B

B

C326

0.1u

C324

275

276

277

VRBL

VRNL

AOUTL

PLLBYP

XCS00

104

105NC106

PLLBYP

0.1u

B

274

AVDD_2

107

AVDD_1

DGND_4

272

273

VRH

XCS01

108

109

C328

0.1u

B

B

0.1u

C327

269

270

271

AIN

VRL

VR_1

AVS_1

CSP(CHIP SEZE PACAGE)IC

(HM(3M SA)BOARD)

XCS02

XCS03

XRAS

XCAS

110

111

112

268

DGND_15

IC301

CAMERA DSP

IC301

FLGA304

QCLKE

113

114

ACLK

VCC3_4

266NC267

115NC116

265

VCC3_14

QCLK

AU_LRCK

JL307

256

257

258

259

260

261

262

263

264

SOA

SCLK

AUCK

ADCK

XACLK

XPWAD

XPWDA

DGND_5

117

118

VCC2_8

BA01

AQ09

BA00

VCC3_5

AQ12

AQ06

119

AQ05

120

121

122

123

124

125

VCC3_6

C309

0.1u

B

245

SHUTTER

AQ00

136

244

IRISOUT

137

HR_EN2

HR_EN1

HR_EN0

HR_DIR2B

HR_DIR2A

HR_DIR1B

HR_DIR1A

HR_DIR0B

XOVF_RST_SENS

XZM_RST_SENS1

235

236

237

238

239

240

241

242

243

DIR2B

VCC2_7

XWE

DQM03

138

139

DQM02

EN1

EN2

DIR2A

DQM01

140

141

DQM00

DIR0B

DIR1A

DIR1B

SENS1

SENS2

DGND_7

DQ30

DQ31

DQ29

DQ25

145

142

143

144

146

HR_DIR0A

234

DQ28

147

DIR0A

233

VCC3_7

148

XFC_RST_SENS

231

232

EN0

SENS0

DQ27

149

150

DQ23

230

VCC3_12

151

PANEL_V

FB301

0uH

229

VPD

LCDVD

CAMVDO

228

NTVDO

227

FLD

226

HD

225

DGND_13

224

EXTPAL

223

NC

222

VAVS4

221

CO

220

VAVD4

219

VRO2

218

VREF2

217

VAVD3

216

YO

215

VAVS3

214

VAVS2

213

RO

212

VAVD2

211

VRO1

210

VREF1

209

VAVD0

208

GO

207

VAVS0

206

VAVD1

205

BO

204

VAVS1

203

DGND_12

202

PIO00

201

VCC2_6

200

PIO05

199

PIO01

198

PIO06

197

PIO02

196

PIO03

195

PIO09

194

VCC3_11

193

PIO10

192

PIO04

191

PIO12

190

PIO07

189

PIO08

188

PIO13

187

VCC2_5

186

PIO14

185

PI011

184

PIO15

183

DGND_11

182

DQ00

181

DQ02

180

VCC3_10

179

DQ03

178

DQ01

177

DQ06

176

DQ04

175

DQ07

174

DQ05

173

DGND_10

172

DQ09

171

DQ08

170

DQ10

169

VCC3_9

168

DQ12

167

DQ11

166

DGND_9

165

DQ13

164

DQ14

163

DQ16

162

DQ17

161

DQ18

160

VCC3_8

159

DQ15

158

DQ19

157

DQ20

156

DQ21

155

DGND_8

154

DQ24

153

DQ22

DQ26

152

C320

22u

4V

P

FB302

0uH

C312

0.1u

B

R308

560

±0.5%

10k

R306

C315

B

0.1u

R317

100k

C316

0.1u

B

R318

100k

C317

0.1u

B

C604

22u

4V

P

198 15

C321

10u

6.3V

P

C322

10u

6.3V

P

SYS_V

C313

0.1u

B

R305

XX

R303

6800

±0.5%

R307

330

±0.5%

XX

R304

18k

R311

R312

27k

R309

560

±0.5%

R310

560

±0.5%

C314

B0.1u

XLENS_RST_LED

MSHUT_EN

XFC_RST_SENS

XOVF_RST_SENS

XZM_RST_SENS1

TG_WEN

IC601

NJM2574RB1(TE2)

2.9

1

LPF/THR SW

GND

2

1.1

Vsag

3

1.2

V-OUT

4

IC601

VIDEO AMP

C605

100u

4V

R602

68

SIGNAL PATH

VIDEO SIGNAL

CHROMA

REC

PB

209

D_2.9V

D_1.5V

REG_GND

L302

10uH

PANEL_V

C601

1u

B

R316

0

STRB_ON

VAMP_ON

L601

10uH

2.9

8

CL/BI SW

2.9

7

PowerSave

1.6

Video-in

6

2.9

VCC

5

1M

C602

22u

R601

6.3V

TA

A

C603

0.1u

B

Y/CHROMAY SIGNAL

AUDIO

A_2.9V

HDO

PANEL_V

PANEL_R

PANEL_G

PANEL_B

SENCV_OPEN

SENCV_CLOSE

STRB_ON

V_OUT

(9/10)

15

(5/10)

16

(10/10)

17

4-11 4-12

SY-91 (3/10)

DSC-P52

COVER

COVER

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

SY-91 BOARD(4/10)

SH DSP,CLK GEN.(SH,GEN BLOCK)

A

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

D_2.9V

D_3.1V

B

18

C

D_1.5V

(9/10)

REG_GND

D

CL501

CL502

CL503

E

CL504

CL505

CL506

CL507

CL508

CL509

F

G

H

I

J

K

L

M

N

16

10uH

XRST_JTAG

XASEMD0

XASEBREAK

XTRST

TCK

TDI

TDO

TMS

R501 0

SIGNAL PATH

CHROMA

REC

PB

38

L502

Q501

DTA144EMT2L

SWITCH

2.9

0.8

C502

10u

6.3V

P

VAMP_ON

XEPROM_BUSY

DAC_STB

TG_CLK_EN

USB_CLK_EN

XAU_POWER_SAVE

XAU_LINE_MUTE

MS_POWER_ON

AE_LOCK_LED

MC_D15

MC_D14

MC_D13

MC_D12

MC_D11

MC_D10

MC_D09

MC_D08

MC_D07

MC_D06

MC_D05

MC_D04

MC_D03

MC_D02

MC_D01

MC_D00

XAU_SP_MUTE

VIDEO SIGNAL

C501

22u

4V

P

R502

47k

R505

47k

R504

47k

C504

0.1u

B

R503

47k

Y SIGNAL

:Voltage measurement of the CSP IC

and the Transistors with mark,is

not possible.

3.2

FB501

0uH

FB502

0uH

C503

0.1u

B

AUDIO

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

5 13

FB503

0uH

R506

1k

C506

0.1u

B

243

244

245

VCCQ

VCCQ

VSSQ

1

STATUS1/PTE1

2

STATUS0/PTE0

3

XVDATA/PTD0

4

TXENL/PTD1

5

SUSPND/PTD2

6

USB_JACK_IN

7

TO2/PTQ1

8

TO0/PTE2

9

BREQ

TO3/PTQ2

10

TXDMNS/PTD7

11

TXDPLS/PTD6

12

PTM2

13

DPLS/PTD4

14

DMNS/PTD5

15

TEND/PTQ0

16

D31/PTB7

17

VCC

18

D30/PTB6

19

VSS

20

D29/PTB5

21

D28/PTB4

22

D27/PTB3

23

VSSQ

24

D26/PTB2

25

VCCQ

26

D25/PTB1

27

USB_D+PULLUP

28

PTM1

29

D23/PTA7

30

D22/PTA6

31

D21/PTA5

32

D20/PTA4

33

D19/PTA3

34

D18/PTA2

35

D17/PTA1

36

D16/PTA0

37

VSSQ

38

D15

39

VCCQ

40

D14

41

D13

42

D12

43

D11

44

D10

45

VCC

46

D9

47

VSS

48

D8

49

PTM0

50

D7

51

D6

52

VSSQ

53

D5

54

VCCQ

55

D4

56

D3

57

D2

58

D1

59

D0

60

A0/PTK0

61

A163A264A365VSSQ66A467VCCQ68A569A670A771PTN672A873A974TI2A/PTN775A1076A1177TI2B/PTQ778A1279A1380VSSQ81A1482VCCQ83A1584A1685A1786A1887A19/PTK188A20/PTK289VSS90A21/PTK391VCC92A22/PTK493A23/PTK594VSSQ95A24/PTK696VCCQ97A25/PTK798BS99RD

62

MC_A02

MC_A01

6

VG

VCOM_AD

USB_DATA-

USB_DATA+

C507

0.1u

B

27R507

241

242

VCCQ

VCCQ

AVSS_USB

MC_A03

MC_A04

238DM239DP240

MC_A05

237

27

R508

MC_A06

R510

R509

22k

±0.5%

236

AVCC_USB

82k

AN7/PTL7

MC_A07

±

235

0.5%

±

234

AN6/PTL6

MC_A08

XEEPROM_WE

R512

82k

0.5%

R511

±0.5%

AVCC_AD

22k

233

AN5/PTL5

MC_A09

R513

1k

231

232

AN4/PTL4

MC_UPDATE

MC_A10

CCD_TEMP

R514

C508

230

AN3/PTL3

47k

0.1u B

AN2/PTL2

MC_A11

LENS_TEMP

229

AN1/PTL1

1k

R515

228

HALL_AD

R516

AN0/PTL0

MC_A12

47k

C509

227

B

0.1u

MC_A13

AVSS_AD

XFE_CS

C511

0.1u

225

226

TO1/PTE3

B

MC_A14

224

PTM3

C510

0.1u

R517

223

CTS5/SCPT2_6

RTS5/SCPT2_5

B

MC_A15

47k

CL510

222

RXD5/SCPT2_4

MC_A16

CL511

220

221

TXD5/SCPT2_4

MC_A17

XCAM_RESET

219

VCCQ

PTM4

MC_A18

MC_A19

MS_BS

MS_DIO

XMS_ACCESS_LED

0

R519

214

215

216

217

218

VSSQ

CKIO2

MSDIO/PTC1

MSDIR/PTC0

IC501

MC CAM SH DSP

IC501

HJ93D1702LPZ

CSP(CHIP SIZE PACKAGE)IC

C512

0.1u

B

MC_A21

MC_A20

MC_A22

924 7

MS_SCLK

47k

R518

213

MSBS/PTC2

MSSCLK/PTC3

MC_A23

10

MC_A25

VSS

C511

0.1u

B

208

207

TXD3/PTH5

DREQ1/PTC6

MC_XRD

206

100

MC_XWE0

205

SCK3/PTH7

RXD3/PTH6

WE0/DQMLL

WE1/DQMLU

101

MC_XWE1

EEPROM_SCK

204

SCK2/PTH4

WE2/DQMUL

102

FB504

0uH

R520

100

C513

0.1u

B

209

210

211

212

VCC

PTM5

DACK1/PTC7

MC_A24

SY-91 BOARD SIDE A SY-91 BOARD SIDE B

SY-91 BOARD SIDE A SY-91 BOARD SIDE B

11 1514

CAM_SO

XCAM_SCK

EEPROM_SI

EEPROM_SO

202

203

TXD2/PTH2

RXD2/PTH3

WE3/DQMUU/AH

103

104

201

TI3A/PTQ6

105

200

RESERVED4

TXD1/SCPT_4

AUDSYNC/PTG4

RDWR

106

CL512

199

SCK1/SCPT_6

TI3B/PTQ5

107

CAM_DD_ON

198

PTM6

VSSQ

108

CL514

196

197

SCK4/SCPT2_1

CS0

109

110

195

TXD4/SCPT2_0

RXD4/SCPT2_0

PTN5

FCE

111

XTG_CS

193

194

CTS4/SCPT2_3

CS2/PTJ0

112

113

XCAM_DR_PS

192

PTM7

RTS4/SCPT2_2

CS3/PTJ1

CS4/PTJ2

114

MC_XCS4

FR_SO

190

191

RXD0/SCPT_1

CS5A/PTJ3

115

116

12

FR_SI

XEEPROM_CS

TXD0/SCPT_0

CS5B/PTJ4

117

MC_XCS6

R521

47k

188WP189

PTN0

CS6A/PTJ5

118

MC_CLK1

0

R522

187

CS6B/PTJ6

119

17 20 2116 18 19

XAU_SP_MUTE

XAU_LINE_MUTE

AU_HGL_SEL

XAU_POWER_SAVE

XCS_PANEL_TG

XFR_SCK

USB_CLK

R789

R787

0

22

11

R785

R788

22

0

1.4

15

16

L501

184

185

186

CKIO

VSSQ

UCLK/PTH0

SCK0/SCPT_2

MD0

MD1

MD2

RP

EXTAL

XTAL

VSSQ

VCC_PLL2

(RESERVED2)

VSS_PLL2

VSS_PLL1

(RESERVED1)

VCC_PLL1

VSS

AUDCK

IRQ4/PTF4

IRQ3/PTF3

IRQ2/PTF2

IRQ1/PTF1

IRQ0/PTF0

VCC

SCL/PTF6

VSS

SDA/PTF7

TCK

TDI

PTN1

TMS

TRST

PTN2

AUDATA0/PTG0

AUDATA1/PTG1

IRQ7/PTQ4

AUDATA2/PTG2

AUDATA3/PTG3

IRQ6/PTQ3

RDY

TCLK/PTJ7

VSSQ

ASEBRKAK/PTG5

ASEMD0

VCCQ

PTN3

RESETP

RESETM

WAIT

PTN4

NMI

VCC

SCS0/SCPT_3

VSS

BACK

TDO

DACK0/PTC5

DREQ0/PTC4

IRQ5/PTE5

VCCQ

RASU/PTE5

(RESERVED3)

CASU/PTE7

CASL/PTE6

MD3

VCCQ

CKE/PTH1

RASL/PTE4

120

121

122

100uH

183

C514

0.1u

B

182

181

180

179

178

177

176

175

174

173

172

171

170

169

168

167

166

165

164

163

162

161

160

159

158

157

156

155

154

153

152

151

150

149

148

CL515

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

C781

XX

C517

0.1u

B

C518

22u

TA

CL513

C782

4V

P

R525

47k

C515

0.1u

B

R531

47k

C519

0.1u

B

R532

47k

R528

47k

R530

47k

R529

47k

C520

XX

R534

XX

VSS

REF_OUT

SM8720AV-E2

8

IC781

VDD

1

2

2.9

1.4

X781

27MHz

0.1u

B

R533

1k

IC502

*

2.9

VCC

8

0

7

XEPROM_BUSY

2.9

RST

6

GND

5

IC502

10

USB_CLK_EN

C784

0.1u

B

2.902.9

0

9

10

11

12

13

14

VSS

VDD

CLK2_ON

CCD_SEL2

CLK1_OUT

CLK2_OUT

FIN3VSS4CLK3_OUT5CLK3_ON6CCD_SEL17CLK1_ON8VDD

1.3

2.9

2.9

R78122R782

9

AK6417CH-E2

CS

SCK

DI

DO

EEPROM

*

IC781

CLK GEN

FB781

0uH

0

LENSV_CLOSE_ON

XCS_PANEL_TG

LENSV_OPEN_ON

AU_HGL_SEL

XEPROM_BUSY

2.9

XEEPROM_CS

1

2.9

EEPROM_SCK

2

0

EEPROM_SO

3

2.9

4

XEEPROM_WE

Pin number and index mark

of IC502 are shown as

viewed from the bottom.

TG_CLK_EN

MC_HELP

AU_LRCK

XASEBREAK

XASEMD0

XRST_SYS

XRST_JTAG

XMC_NMI

XCS_MC

EEPROM_SI

TG_CLK

IRQIMG

PLLBYP

SYS_V

XTRST

XWAIT

TCK

TDI

TMS

TDO

VCOM_AD

VG

MC_UPDATE

FR_SO

FR_SI

XFR_SCK

XCS_MC

MC_HELP

XMC_NMI

TG_CLK

XTG_CS

XCAM_RESET

XFE_CS

CCD_TEMP

CAM_SO

XCAM_SCK

DAC_STB

HALL_AD

LENS_TEMP

LENSV_OPEN_ON

LENSV_CLOSE_ON

XCAM_DR_PS

XRST_SYS

CAM_DD_ON

MS_DIO

MS_BS

MS_SCLK

MS_POWER_ON

XMS_ACCESS_LED

AE_LOCK_LED

USB_DATA+

USB_DATA-

MC_CLK1

VAMP_ON

IRQIMG

SYS_V

PLLBYP

AU_LRCK

XWAIT

MC_XCS4

MC_XCS6

MC_XWE0

MC_XWE1

MC_XRD

MC_A01

MC_A02

MC_A03

MC_A04

MC_A05

MC_A06

MC_A07

MC_A08

MC_A09

MC_A10

MC_A11

MC_A12

MC_A13

MC_A14

MC_A15

MC_A16

MC_A17

MC_A18

MC_A19

MC_A20

MC_A21

MC_A22

MC_A23

MC_A24

MC_A25

MC_D00

MC_D01

MC_D02

MC_D03

MC_D04

MC_D05

MC_D06

MC_D07

MC_D08

MC_D09

MC_D10

MC_D11

MC_D12

MC_D13

MC_D14

MC_D15

XAU_SP_MUTE

XAU_LINE_MUTE

AU_HGL_SEL

XAU_POWER_SAVE

XCS_PANEL_TG

VCOM_AD

VG

MC_UPDATE

FR_SO

FR_SI

XFR_SCK

XCS_MC

MC_HELP

XMC_NMI

TG_CLK

XTG_CS

XCAM_RESET

XFE_CS

CCD_TEMP

CAM_SO

XCAM_SCK

DAC_STB

HALL_AD

LENS_TEMP

LENSV_OPEN_ON

LENSV_CLOSE_ON

XCAM_DR_PS

XRST_SYS

CAM_DD_ON

MS_DIO

MS_BS

MS_SCLK

MS_POWER_ON

XMS_ACCESS_LED

AE_LOCK_LED

USB_DATA+

USB_DATA-

MC_CLK1

VAMP_ON

IRQIMG

SYS_V

PLLBYP

AU_LRCK

XWAIT

MC_XCS4

MC_XCS6

MC_XWE0

MC_XWE1

MC_XRD

MC_A01

MC_A02

MC_A03

MC_A04

MC_A05

MC_A06

MC_A07

MC_A08

MC_A09

MC_A10

MC_A11

MC_A12

MC_A13

MC_A14

MC_A15

MC_A16

MC_A17

MC_A18

MC_A19

MC_A20

MC_A21

MC_A22

MC_A23

MC_A24

MC_A25

MC_D00

MC_D01

MC_D02

MC_D03

MC_D04

MC_D05

MC_D06

MC_D07

MC_D08

MC_D09

MC_D10

MC_D11

MC_D12

MC_D13

MC_D14

MC_D15

(7/10)

19

(5/10)

20

(6/10)

21

(1/10)

3

(2/10)

1

(1/10)

1

10

14

5

22

11

(2/10)

(3/10)

(1/10)

(10/10)

(3/10)

(5/10)

1

(5/10)

14

(6/10)

14

(10/10)

5

SY-91 (4/10)

4-13 4-14

Loading...

Loading...