Page 1

DSC-P32

SERVICE MANUAL

Ver 1.0 2003. 02

Revision History

Revision History

Link

Link

SPECIFICATIONS

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

K orea Model

Chinese Model

Tourist Model

Japanese Model

PRINTED WIRING BOARDS

PRINTED WIRING BOARDSSPECIFICATIONS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

• For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (987622841.pdf).

• Reference No. search on printed wiring boards is available.

On the SY-84 board

This service manual provides the information that is premised the circuit board replacement service and not intended repair

inside the SY-84 board.

Therefore, schematic diagram, printed wiring board, waveforms, mounted parts location and electrical parts list of the SY-84

board are not shown.

The following pages are not shown.

Schematic diagram .............................Pages 4-7 to 4-26

Printed wiring board............................Pages 4-39 to 4-42

Waveforms ...........................................

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

Mounted parts location .............................

Electrical parts list................................... Pages 5-7 to 5-12

Pages 4-45 to 4-46

REPAIR PARTS LIST

REPAIR PARTS LIST

Page 4-48

DIGITAL STILL CAMERA

Page 2

DSC-P32

COVER

COVER

x Camera

[System]

Image device 6.67 mm (1/2.7 type) color

Total pixels number of camera

Effective pixels number of camera

Lens Single focal lens

Exposure control

White balanceAutomatic, Daylight, Cloudy,

File format (DCF compliant)

Recording media

Flash Recommended distance

[Output connectors]

A/V OUT (MONO) jack (Monaural)

USB jack mini-B

CCD

Primary color filter

Approx. 3 340 000 pixels

Approx. 3 210 000 pixels

f=5.0 mm

(35 mm camera conversion: 33 mm

5

(1

/16 inches))

F2.8

Automatic, Program, Twilight,

Twilight portrait, Landscape, Snow,

Beach

Fluorescent, Incandescent

Still images: Exif Ver. 2.2, JPEG

compliant, GIF (for Clip Motion),

DPOF compatible

Audio with still image: MPEG1

compliant (Monaural)

Movies: MPEG1 compliant

(Monaural)

“Memory Stick”

0.5 to 3.8 m (19

12 feet 5

(when ISO sensitivity is set to Auto)

Minijack

Video: 1 Vp-p, 75 Ω, unbalan ced,

sync negative

Audio: 327 mV (at a 47 kΩload)

Output impedance 2.2 kΩ

19

/32 inches)

3

/4 inches to

SPECIFICATIONS

[LCD screen]

LCD panel used

Total number of dots

[Power, general]

Power AA nickel hydride batteries (2)

Power consumption (when recording)

Operating temperature range

Storage temperature range

Dimensions 101.3 × 57.7 × 32.6 mm

Mass Approx. 217 g (7.7 oz) (two

Microphone Electret condenser microphone

Speaker Dynamic speaker

x BC-CS2A/CS2B Ni-MH battery

charger

Power requirements

Output voltage

Operating temperature range

Dimensions 71 × 30 × 91 mm

Mass Approx. 90 g (3 oz)

4.0 cm (1.6 type) TFT drive

61 600 (280×220) dots

2.4 V

AC-LS5 AC Adaptor

(not supplied), 4.2 V

1.7W

0° to +40°C (32° to +104°F)

–20° to +60°C (– 4 ° to +140°F)

3

(4 × 2

/8 × 1 5/16 inches)

(W/H/D, protruding portions not

included)

batteries, “Memory Stick” and wrist

strap included)

AC 100 to 240V 50/60Hz

3 W

AA : DC 1.4 V 400 mA × 2

AAA : DC 1.4 V 160 mA × 2

0° to +40°C (32° to +104°F)

7

3

/

× 3

16

5

/8 inches) (W/H/

/

× 1

(2

8

D)

x AC-LS5 AC Adaptor (not supplied)

Power requirements

Rated output voltage

Operating temperature range

Storage temperature range

Dimensions 48 × 29 × 81 mm (1

Mass Approx. 180 g (6 oz)

AC 100 to 240 V, 50/60 Hz

11 W 0.16 to 0.09 A

DC 4.2 V, 1.5 A

0° to +40°C (32° to +104°F)

–20° to +60°C (–4° to +140°F)

1

3

/4 inches) (W/H/D, protruding

parts not included)

(adaptor only)

15

/16 × 1 3/16

Accessories

HR6 (size AA) Ni-MH batteries (2)

Battery case

BC-CS2A/CS2B Ni-MH Battery charger (1)

Power cord (mains lead) (1)

USB cable (1)

A/V connecting cable (1)

Wrist strap (1)

“Memory Stick” (16MB) (1)

CD-ROM (USB driver: SPVD-010) (1)

Operating Instructions (1)

Design and specifications are subject to change

without notice.

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

— 2 —

Page 3

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

DSC-P32

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, sho w obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

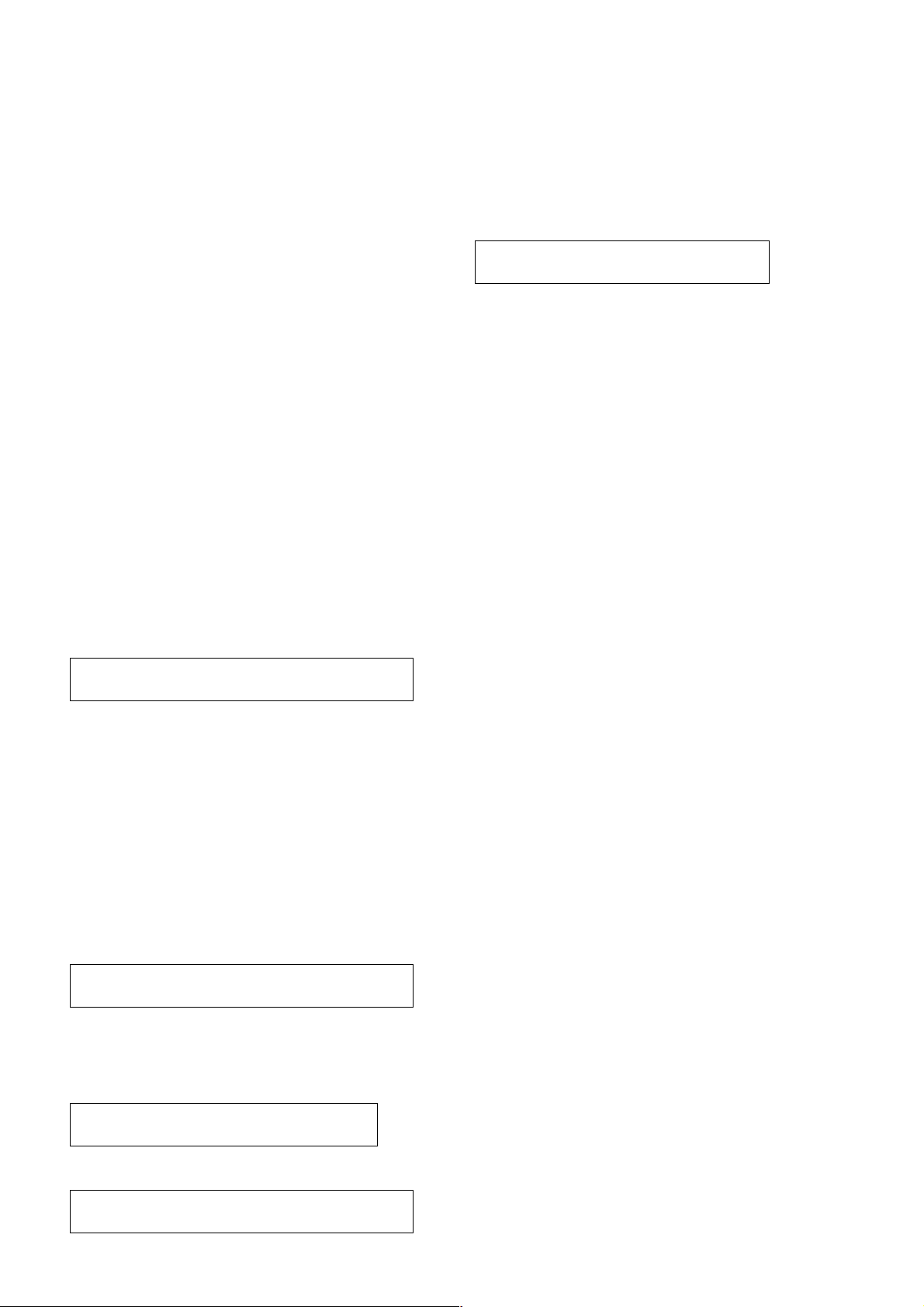

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

Page 4

DSC-P32

TABLE OF CONTENTS

1. SERVICE NOTE ........................................................1-1

2. DISASSEMBLY

2-1. CABINET (REAR) BLOCK ASSEMBLY ·····················2-2

2-2. LCD MODULE, CONTROL SWITCH BLOCK (SW-390),

BLOCK LIGHT GUIDE PLATE ····································2-2

2-3. MAIN BLOCK ASSEMBLY ··········································2-3

2-4. PARTS UNIT (UA-001), DC MOTOR 8C-023G ···········2-4

2-5. MEMORY STICK CONNECTOR,

JK BLOCK (JK-247)·······················································2-4

2-6. CONTROL SWITCH BLOCK (RL-059),

ST-82 BOARD ································································2-5

2-7. LENS FRAME BLOCK ASSEMBLY ···························· 2-5

2-8. SY-84 BOARD ································································2-6

2-9. OPTICAL FINDER (LSV-860A), FP-644 FLEXIBLE

BOARD, LENS (LSV-780A) ··········································2-6

2-10. CIRCUIT BOARDS LOCATION ···································2-8

2-11. FLEXIBLE BOARDS LOCATION ································ 2-9

HELP (List of caution points is shown here)

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM ····································3-1

3-2. CAMERA BLOCK DIAGRAM ·····································3-3

3-3. FRONT/LCD BLOCK DIAGRAM ································3-5

3-4. POWER BLOCK DIAGRAM·········································3-7

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS ······················································5-1

5-1-1.CABINET (FRONT) SECTION ·····································5-3

5-1-2.MAIN BLOCK ASSEMBLY ·········································· 5-4

5-1-3.LENS FRAME BLOCK ASSEMBLY ····························5-5

5-1-4.CABINET (REAR) BLOCK ASSEMBLY ·····················5-6

5-2. ELECTRICAL PARTS LIST ········································5-13

Parts list of the SY-84 board are not shown.

Pages from 5-7 to 5-12 are not shown.

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/2) ······················· 4-1

FRAME SCHEMATIC DIAGRAM (2/2) ·······················4-3

4-2. SCHEMATIC DIAGRAMS

Shematic diagram of the SY-84 board are not shown.

Pages from 4-7 to 4-25 are not shown.

• ST-82 (FLASH DRIVE)/FP-643 FLEXIBLE

SCHEMATIC DIAGRAM ····························4-27

• JK BLOCK (JK-247) (JACK)

SCHEMATIC DIAGRAM ····························4-29

• CONTROL SWITCH BLOCK (SW-390)

(LCD CONTROL SW)

SCHEMATIC DIAGRAM ····························4-31

• RL-059 (POWER/SHUTTER SW)

SCHEMATIC DIAGRAM ····························4-33

• UA-001 (AF LED SW)

SCHEMATIC DIAGRAM ····························4-33

4-3. PRINTED WIRING BOARDS

• ST-82 (FLASH DRIVE)

PRINTED WIRING BOARD ·······················4-37

Printed wiring board of the SY-84 board are not shown.

Pages from 4-39 to 4-42 are not shown.

• JK BLOCK (JK-247) (JACK)

FLEXIBLE BOARD·····································4-43

4-4. WAVEFORMS ······························································4-45

Waveforms of the SY-84 board are not shown.

Pages 4-45 to 4-46 are not shown.

4-5. MOUNTED PARTS LOCATION ································· 4-47

Mounted parts location of the SY-84 board is not shown.

Page 4-48 is not shown.

— 4 —

Page 5

DSC-P32

COVER

COVER

SECTION 1

SERVICE NOTE

• NOTE FOR REPAIR

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the DSC-P32 is simply turned off. Therefore, the remaining

voltage must be discharged as described below.

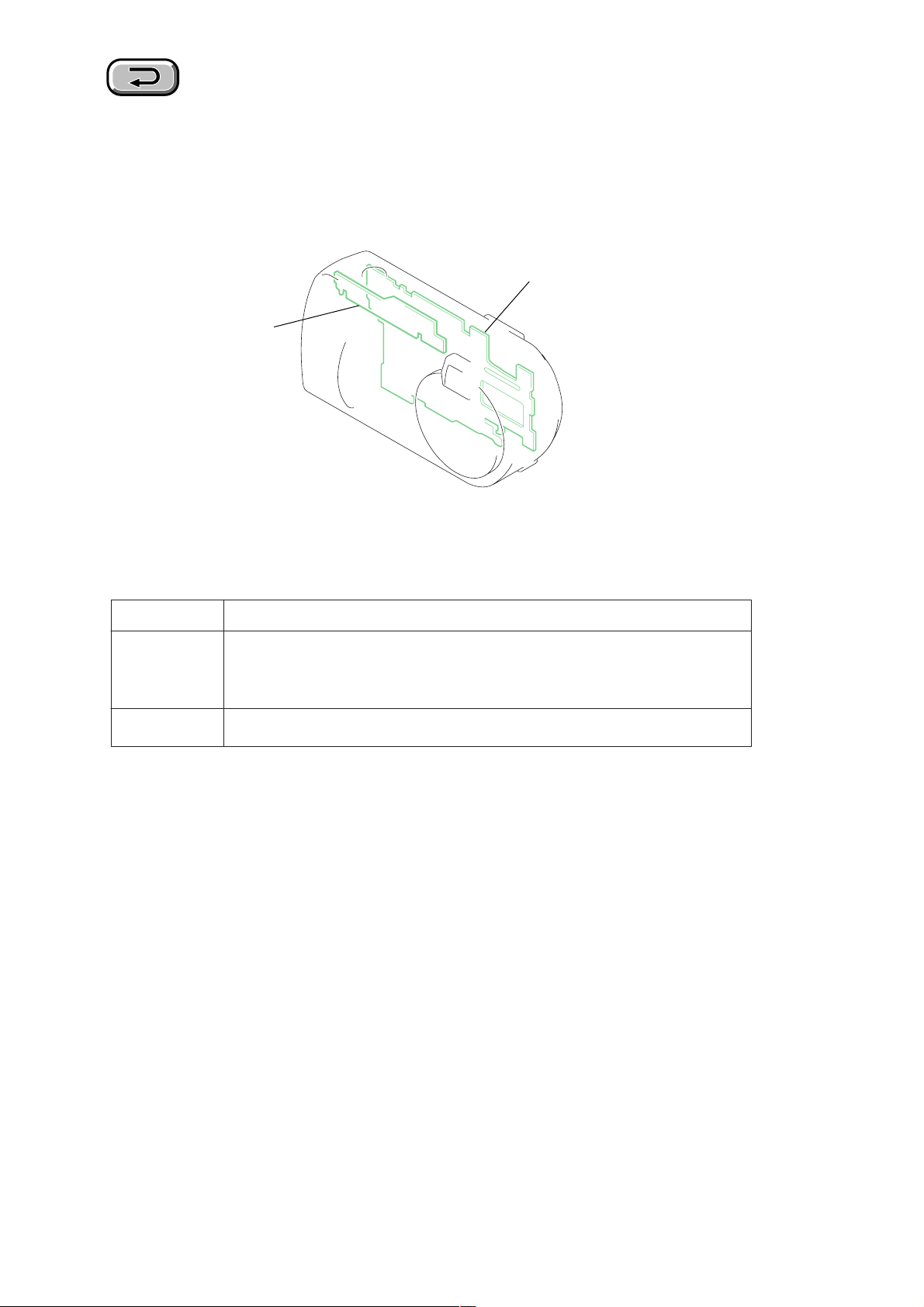

Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11)

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

Discharging the Capacitor

Short circuits between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

1 kΩ/1 W

Wrap insulating tape.

Shorting jig

(1kΩ / 1w)

Capacitor

ST-82 BOARD

1-1

Page 6

DSC-P32

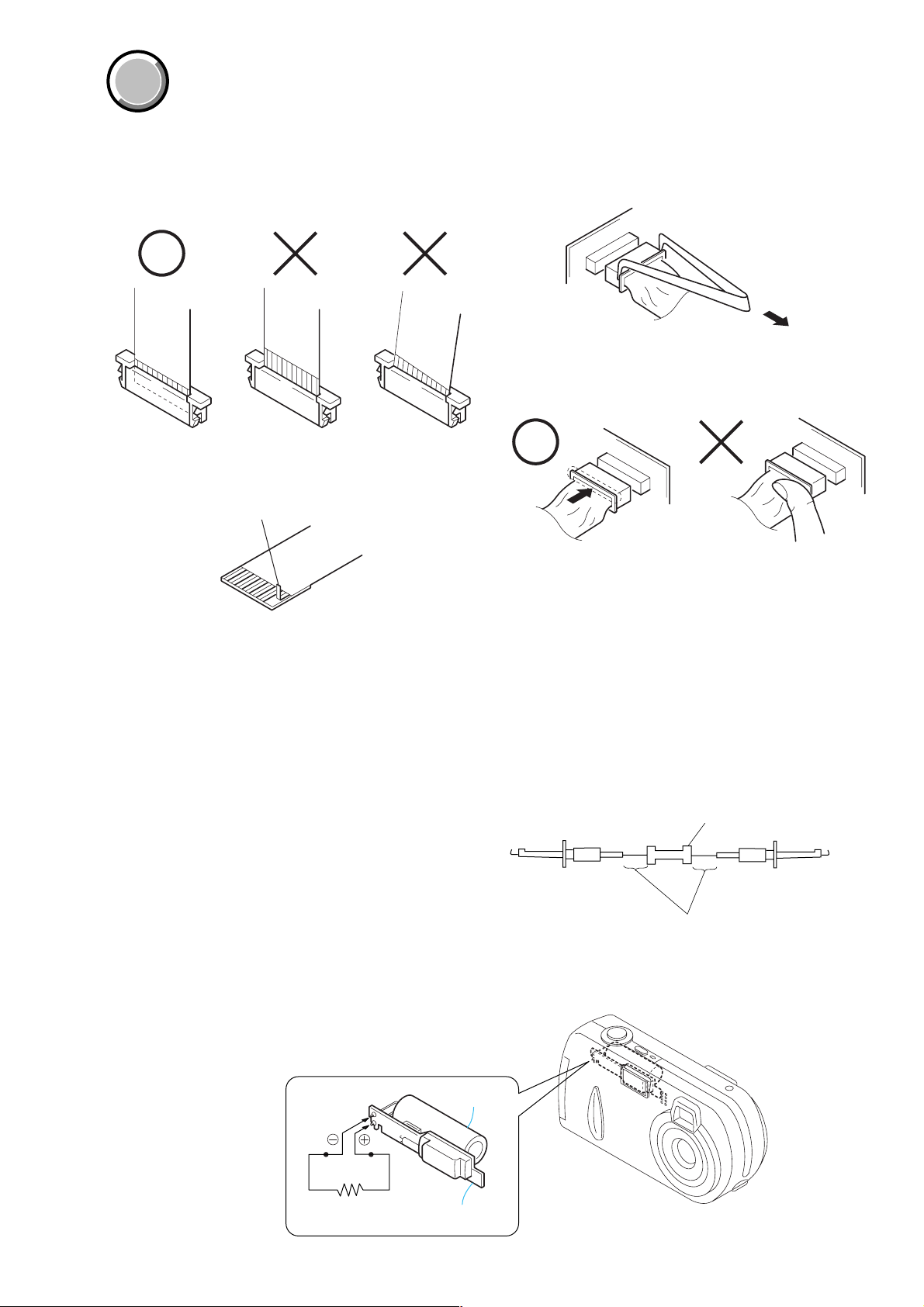

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

• E: ss: ss

The contents which can be handled

by customer, are displayed.

The contents which can be handled

by engineer, are displayed.

Display Code

C:32:01

C:13:01

E:91:01

E:61:00 *1

E61:10 *1

Note : The error code is cleared if the battery is removed, except defective flash unit.

*1: The error display is given in two ways.

Turn off the main power then back on.

Replace the memory stick.

Format the memory stick with the DSC-P32.

Checking of flash unit or replacement of

flash unit.

Checking of lens drive circuit

Countermeasure

Trouble with hardware.

• The type of memory stick that cannot be

used by this machine, is inserted.

• Data is damaged.

• Unformatted memory stick is inserted.

Abnormality when flash is being

charged.

When failed in the focus initialization.

Cause

Caution Display During Error

SYSTEM ERROR

MS ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

1-2E

Page 7

DSC-P32

COVER

COVER

SECTION 2

DISASSEMBLY

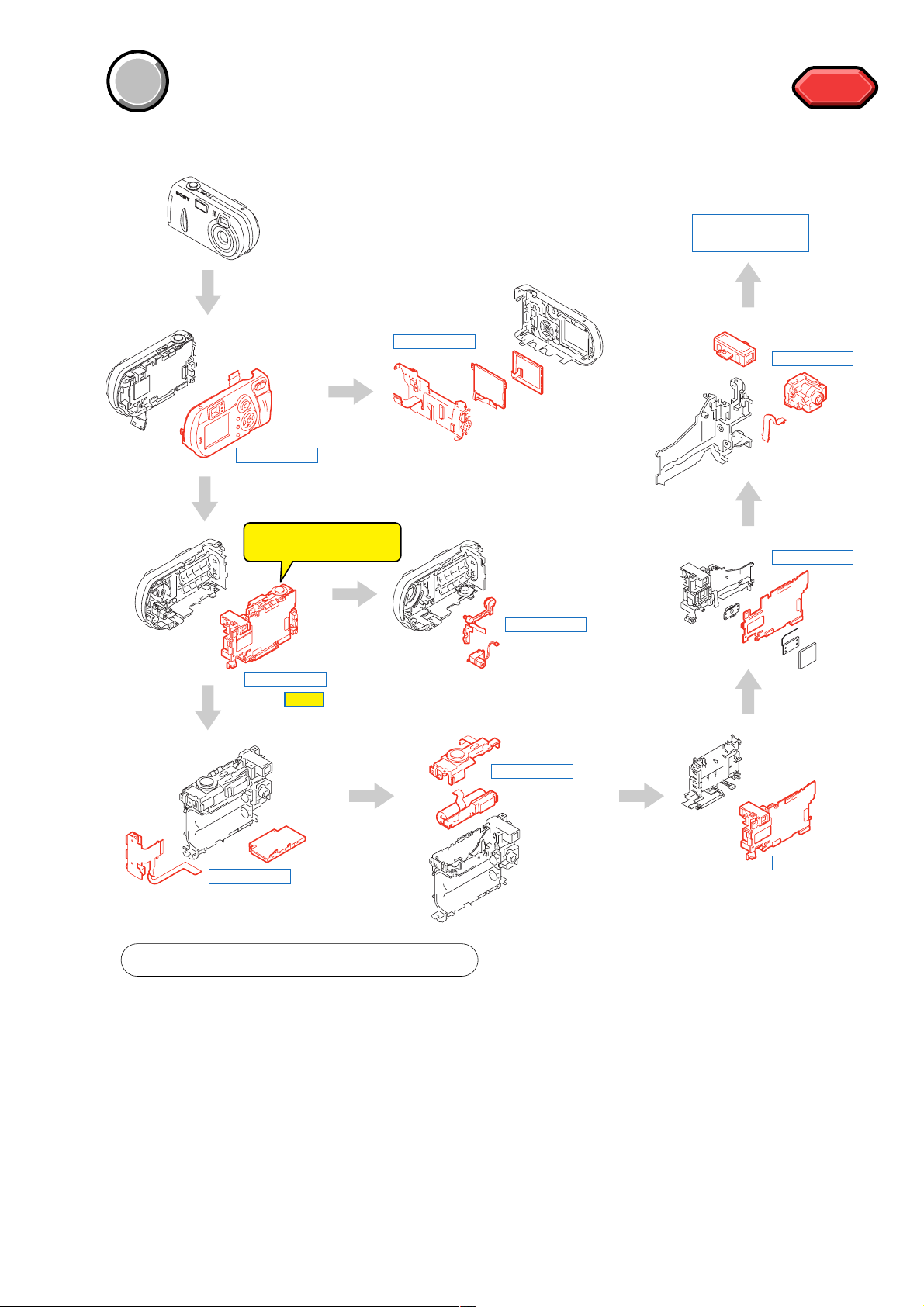

The following flow chart shows the disassembly procedure.

DISASSEMBLY

DISASSEMBLY

SY-84 board

service position

DISASSEMBLY

HELP

HELP

Discharging the Capacitor

DISASSEMBLY

HELP

DISASSEMBLY

PROCEDURE OF REMOVING SY-84 BOARD

1 2-1. CABINET (REAR) BLOCK ASSEMBLY ............................

2 2-2. LCD MODULE, BLOCK LIGHT GUIDE PLATE, ...............

CONTROL SWITCH BLOCK (SW-390)

3 2-3. MAIN BLOCK ASSEMBLY ................................................

4 2-4. PARTS UNIT (UA-001), DC MOTOR 8C-023G ................

5 2-5. MEMORY STICK CONNECTOR, JK BLOCK (JK-247).....

6 2-6. CONTROL SWITCH BLOCK (RL-059), ST-82 BOARD ....

7 2-7. LENS FRAME BLOCK ASSEMBLY ..................................

8 2-8. SY-84 BOARD ...................................................................

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

(page 2-2)

(page 2-2)

(page 2-3)

(page 2-4)

(page 2-4)

(page 2-5)

(page 2-5)

(page 2-6)

2-1

Page 8

DSC-P32

t

NOTE: F ollo w the disassembly procedure in the numerical order given.

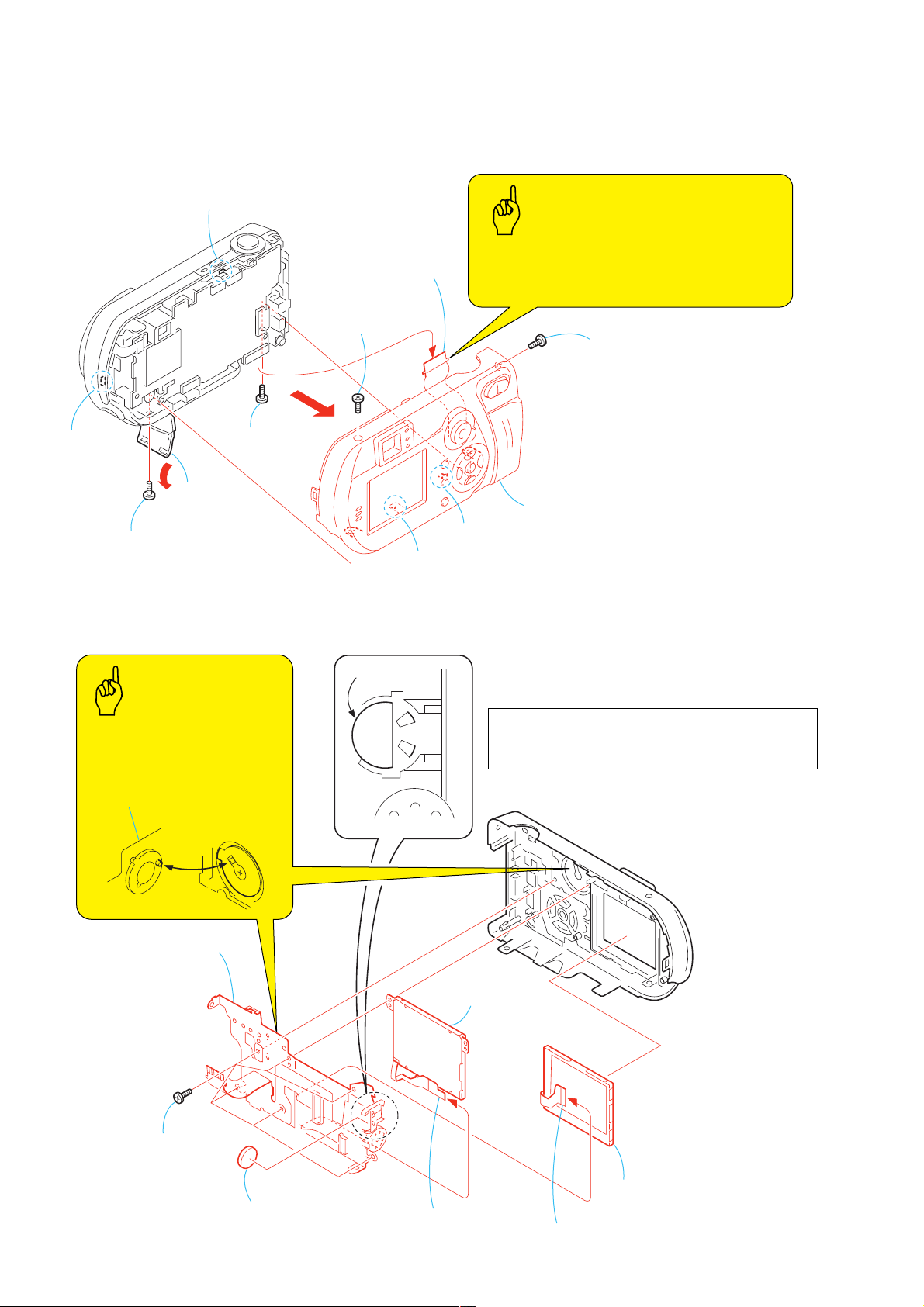

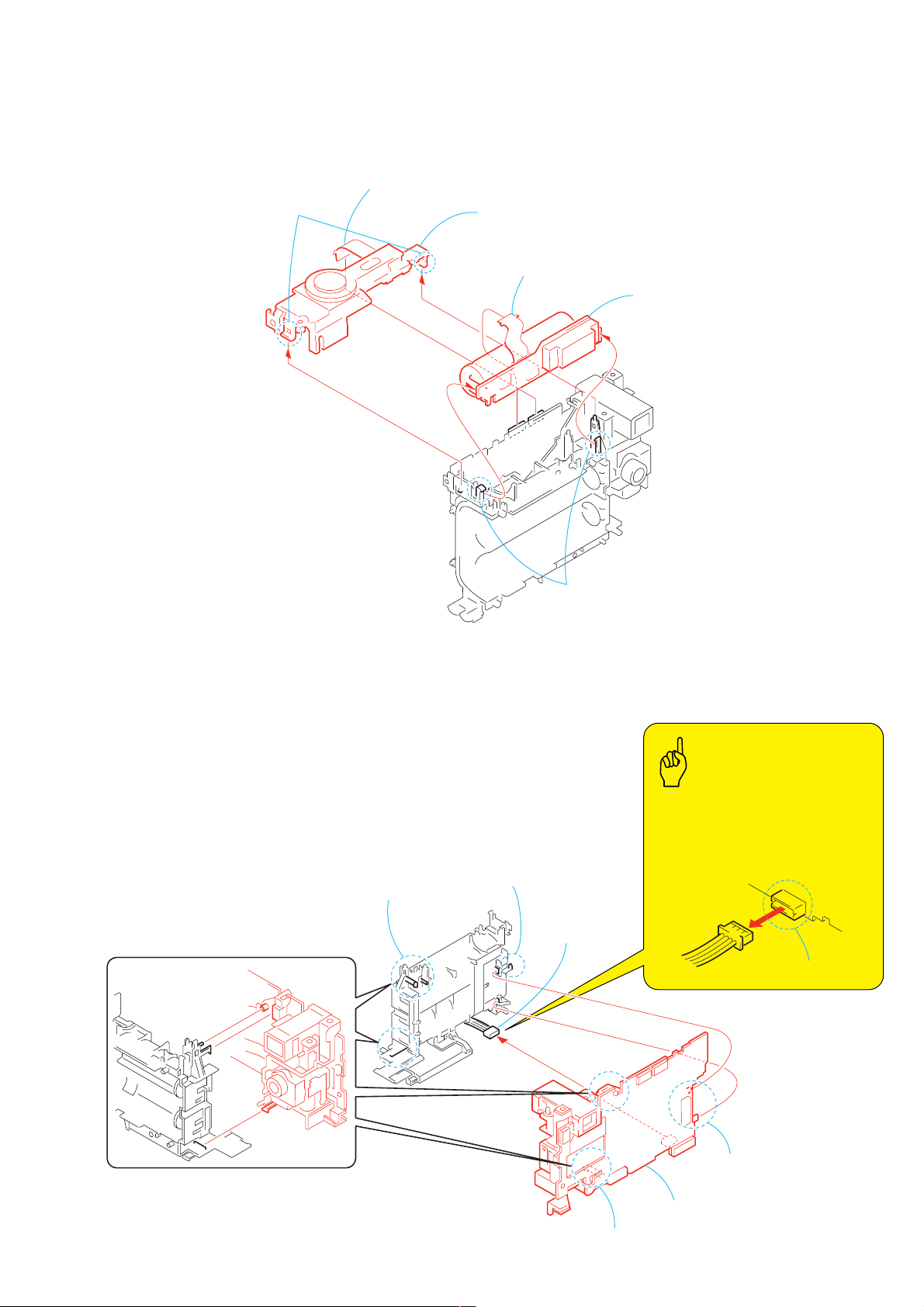

2-1. CABINET (REAR) BLOCK ASSEMBLY

6

Claw

Caution

The flexible board of the Control switch block(SW-390)

may be damaged if you remove the Cabinet (rear) block

assembly forcibly. Be very careful not to damage

the flexible board.

1

Screw (M2 × 4),

lock ace, p2

qa

Cabinet (rear) block assembly

9

Claw

7

Claw

4

Open the

MS lid.

5

Screw (M2 × 4),

lock ace, p2

3

Screw (M2 × 4),

lock ace, p2

q;

Control switch block

(SW-390) (39P)

2

Screw (M2 × 4),

lock ace, p2

8

Claw

2-2. LCD MODULE, CONTROL SWITCH BLOCK (SW-390), BLOCK LIGHT GUIDE PLATE,

LITHIUM BATTERY

Lithium battery

Caution

When installing it,

align the switch position

as shown.

Control switch block (SW-390)

6

Control switch block (SW-390)

1

Six tapping screws

×

(M1.7

4)

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

5

Block light guide plate

7

Lithium battery

4

Block light guide plate

(24P)

2-2

3

LCD module

2

Indicator module liquid crys

(6P)

Page 9

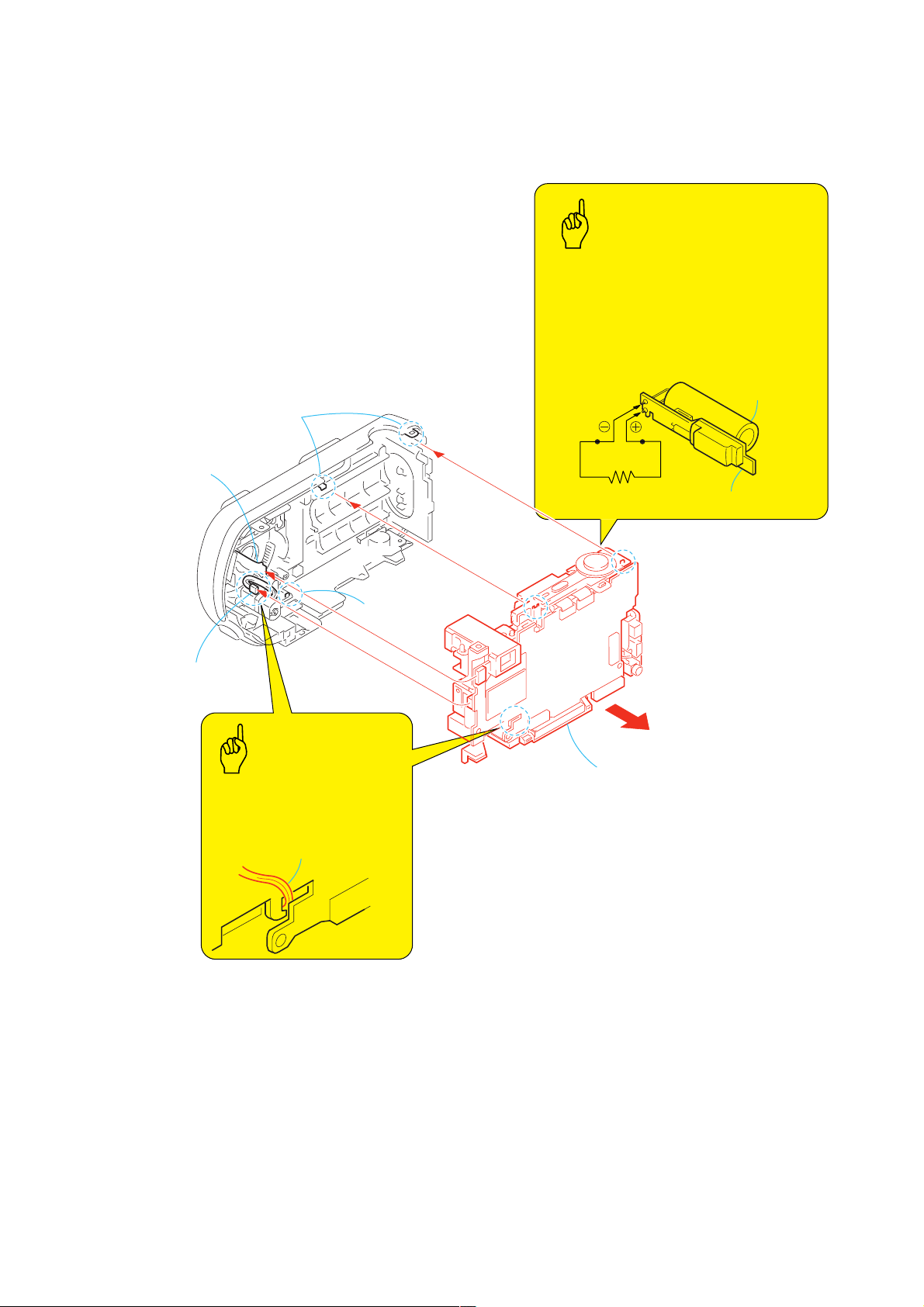

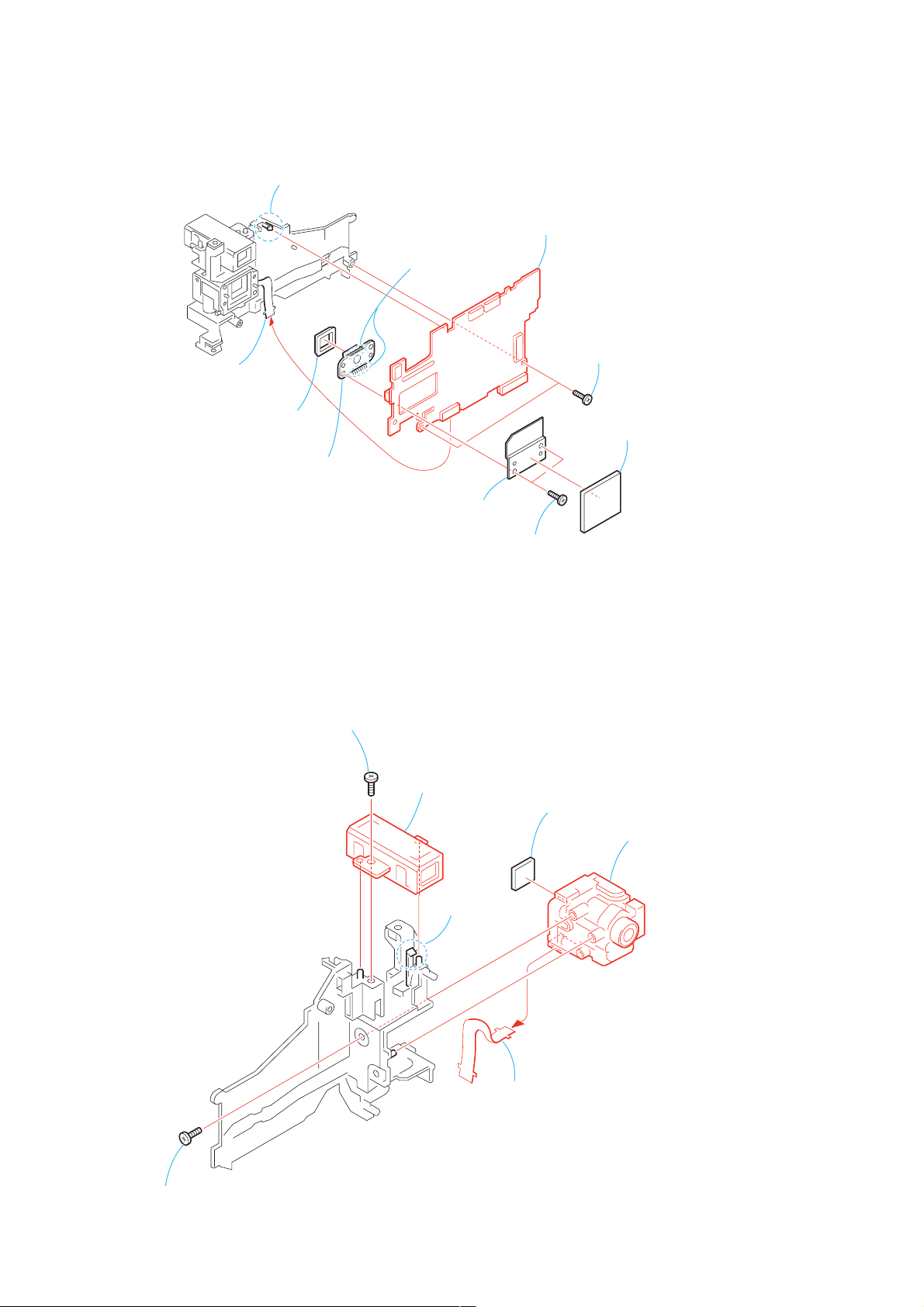

2-3. MAIN BLOCK ASSEMBLY

3

Claws

1

Parts unit (UA-001)

(10P)

Caution

The power supply capacitor of the Flash unit is

charged to the voltage as high as 300 V at a

maximum. The high voltage is not discharged

even after the main power of the machine is

simply turned off and the charged potential still

remains.

Discharge the residual voltage by referring to

Service Note (page 1-1).

Capacitor

Shorting jig

(1kΩ / 1w)

ST-82 BOARD

DSC-P32

2

DC motor 8C-023G

(2P)

4

Claw

Caution

When installing it, pass it through

the cutout of the circuit board.

Dc motor 8C-023G

(2P)

5

Main block assembly

2-3

Page 10

DSC-P32

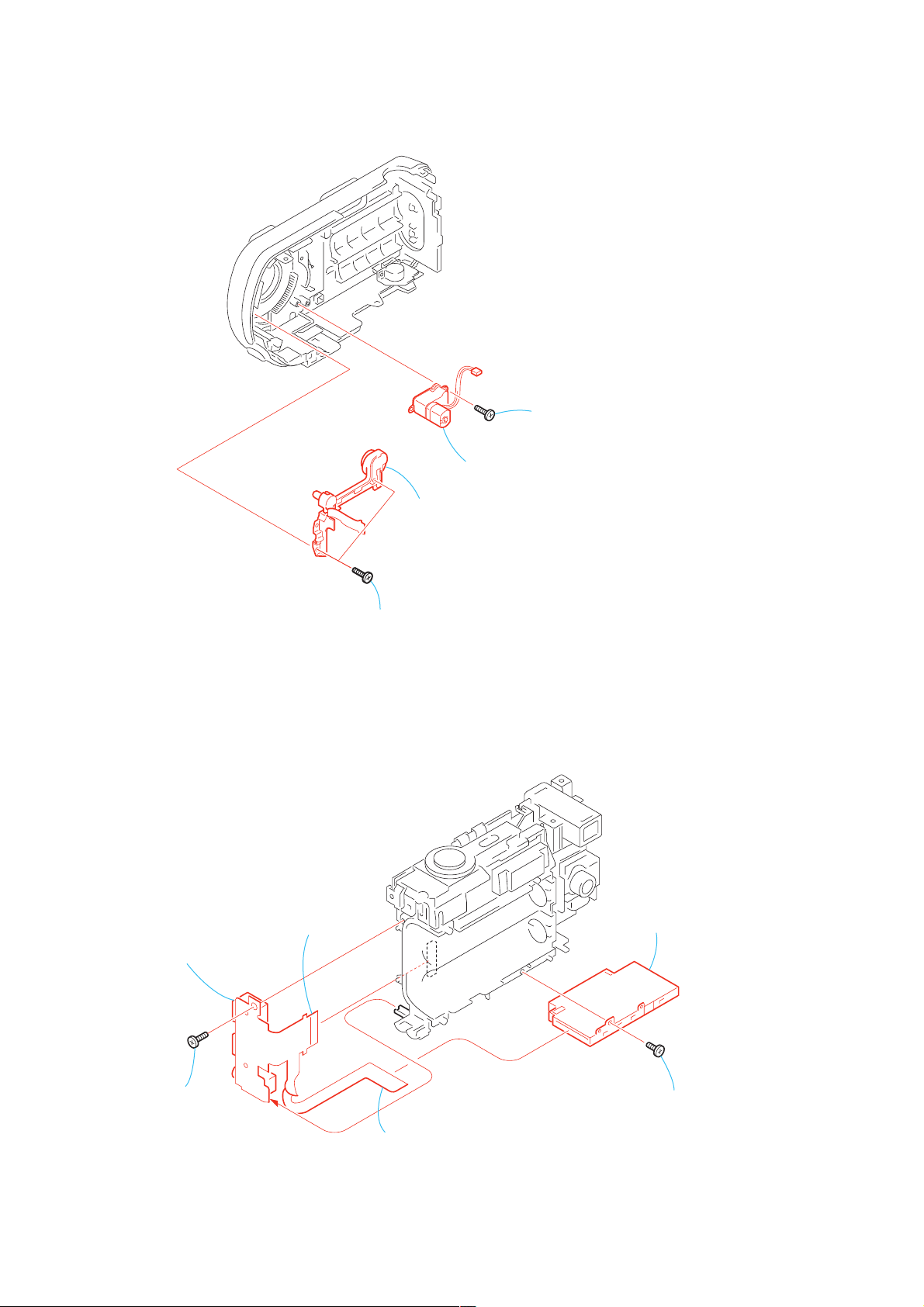

2-4. PARTS UNIT (UA-001), DC MOTOR 8C-023G

3

(1.7

4

DC motor 8C-023G

Tapping screw, p2

×

5)

2

Parts unit (UA-001)

1

Two tapping screws, p2

×

(1.7

5)

2-5. MEMORY STICK CONNECTOR, JK BLOCK (JK-247)

5

JK BLOCK (JK-247)

(39P)

6

JK BLOCK (JK-247)

3

Memory stick connector

4

Tapping screw p2

(1.7

×

5)

2

JK BLOCK (JK-247)

(10P)

2-4

1

T apping screw

×

(1.7

4)

Page 11

2-6. CONTROL SWITCH BLOCK (RL-059), ST-82 BOARD

d

4

T wo claws

Connector

1

Claw

2

Claw

3

Claw

5

Battery holder

(with terminal)

(4P)

6

Lens frame block assembly

Caution

When removing the harness,

be sure to pull the harness up at the

right angle with the board while pressing

down the connector on the circuit board.

2

Control switch block (RL-059)

(10P)

1

T wo claws

3

Control switch block (RL-059)

5

FP-643 flexible board

(12P)

6

ST-82 boar

DSC-P32

2-7. LENS FRAME BLOCK ASSEMBLY

4

T wo claws

2-5

Page 12

DSC-P32

)

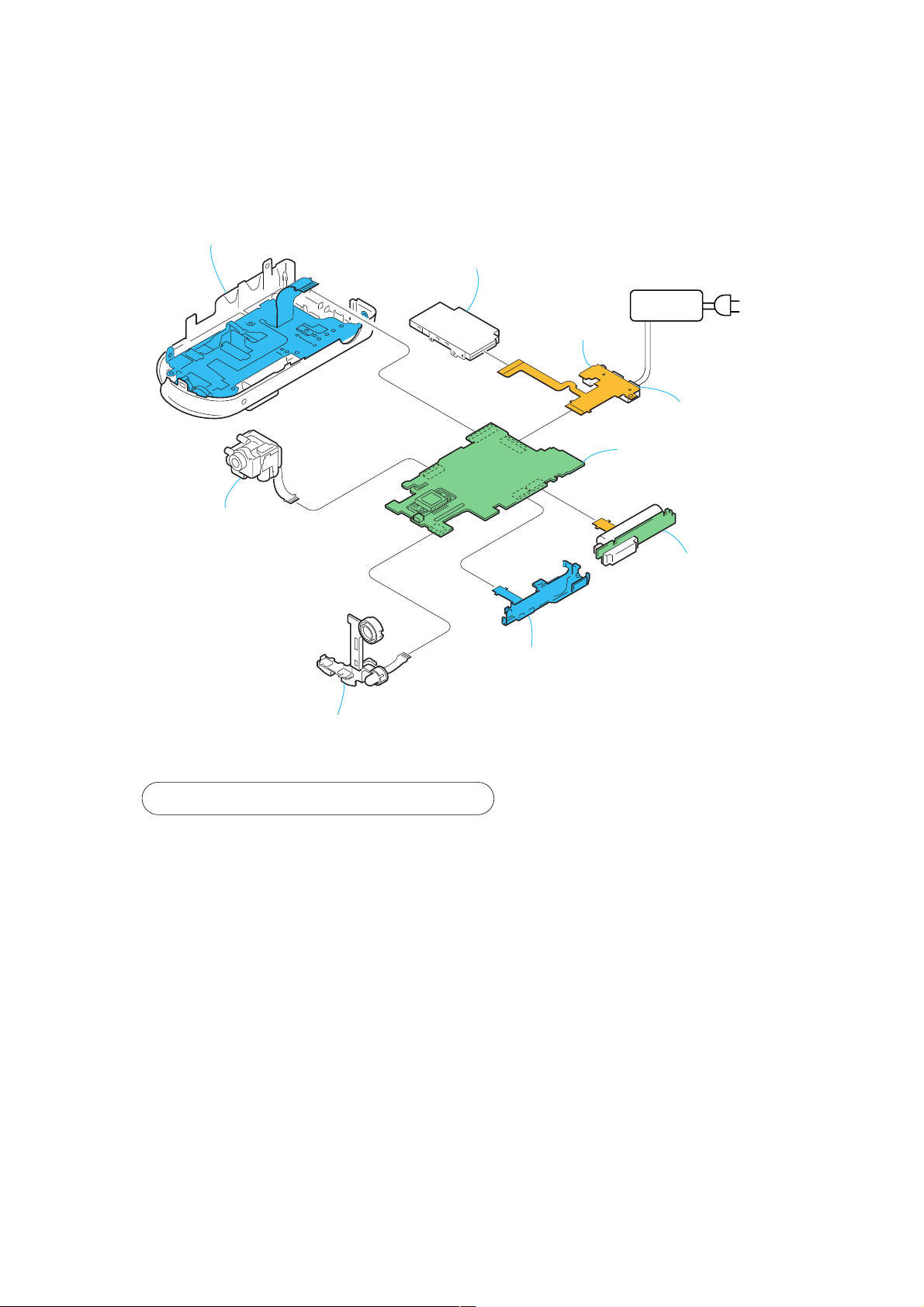

2-8. SY-84 BOARD

6

FP-644 flexible board

(14P)

5

7

CCD seal rubber (MM)

9

CCD block assembly

Claw

8

Remove the solderings.

q;

SY-84 board

4

T wo Tapping screw p2

(1.7

×

5)

1

Sheet, ccd radiation

3

CCD heat sink

2

T wo Tapping screw p2

(1.7 × 5)

2-9. OPTICAL FINDER (LSV-860A), FP-644 FLEXIBLE BOARD, LENS (LSV-780A)

1

Tapping screw p2

×

(1.7

5)

3

Optical finder

(LSV-860A)

2

Claw

5

Optical filter block

7

Lens (LSV-780A

4

Tapping screw p2

×

(1.7

5)

2-6

6

FP-644 flexible board

(14P)

Page 13

[SERVICE POSITION (SY-84 BOARD)]

Cabinet (rear) block assembly

DSC-P32

Memory stick connector

Lens (LSV-780A)

“ Never remove the lens unless removal

is required at the event of checking the

CCD imager and others.’’

Parts unit (UA-001)

CN201

CN706

JK BLOCK

(JK-247)

CN702

CN701

CN704

CN705

Control switch block (RL-059)

AC power

adaptor

DC jack

SY-84 board

ST-82 board

DC IN

PROCEDURE OF REMOVING SY-84 BOARD

1 2-1. CABINET (REAR) BLOCK ASSEMBLY ............................

2 2-2. LCD MODULE, BLOCK LIGHT GUIDE PLATE, ...............

CONTROL SWITCH BLOCK (SW-390)

3 2-3. MAIN BLOCK ASSEMBLY ................................................

4 2-4. PARTS UNIT (UA-001), DC MOTOR 8C-023G ................

5 2-5. MEMORY STICK CONNECTOR, JK BLOCK (JK-247).....

6 2-6. CONTROL SWITCH BLOCK (RL-059), ST-82 BOARD ....

7 2-7. LENS FRAME BLOCK ASSEMBLY ..................................

8 2-8. SY-84 BOARD ...................................................................

(page 2-2)

(page 2-2)

(page 2-3)

(page 2-4)

(page 2-4)

(page 2-5)

(page 2-5)

(page 2-6)

2-7

Page 14

DSC-P32

2-10.CIRCUIT BOARDS LOCATION

ST-82

SY-84

Board Name Function

SY-84 CCD IMAGER, CAMERA A/D CONV, LENS DRIVE, CAMERA DSP,

VIDEO AMP, SH DSP, CLK GEN., FRONT CONTROL, AUDIO I/O,

LCD DRIVE, TIMING GEN., DC IN, DC-DC CONVERTER CONNECTOR.

ST-82 FLASH DRIVE

2-8

Page 15

2-11.FLEXIBLE BOARDS LOCATION

K

The flexible boards contained in the lens device are not shown.

CONTROL SWITCH BLOCK

(SW-390)

DSC-P32

CONTROL SWITCH BLOC

(RL-059)

UA-001

FP-643

JK BLOCK

(JK-247)

FP-644

2-9E

Page 16

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

MAIN BLOCK ASSEMBLY

DSC-P32

27/Feb/2003

DC motor 8C-023G

(2P)

HELP

Page 17

COVER

COVER

Link

Link

DSC-P32

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM

OVERALL BLOCK DIAGRAM

FRONT/LCD BLOCK DIAGRAM

FRONT/LCD BLOCK DIAGRAM

POWER BLOCK DIAGRAMCAMERA BLOCK DIAGRAM

POWER BLOCK DIAGRAMCAMERA BLOCK DIAGRAM

Page 18

DSC-P32

COVER

COVER

3-1. OVERALL BLOCK DIAGRAM

SY-84 BOARD

X781

27MHz

2

4

(1/10)

IC351

CCD

IMAGER

IRIS/HALL

LENS BLOCK

IRIS

IRIS

M

METER

FOCUS

MOTOR

M

H

SHUTTER

M

MOTOR

FOCUS RESET

SENSOR

LENS TEMP

SENSOR

J101

DC IN

FP-644

(FLEXIBLE)

BT901

BATTERY

TERMINAL

JK-247 (1/2)

(FLEXIBLE)

ACV UNREG

BATT/ XEXT

SECTION 3

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CCD OUT

H1,H2

V1,V2,V3A,V3B

V4,V5A,V5B,V6

V SUB

(4/10)

IC781

CLOCK

GEN.

(2/10)

IC201

IRIS

DRIVE

(2/10)

IC203

MOTOR

DRIVER

(2/10)

IC202

CONT

BATT UNREG

EVER 4V

ACV UNREG

ST UNREG

TG CLK

MC CLK1

USB CLK

(1/10)

IC901

CAMERA

MODULE

(CH-122 (3M)

BOARD)

(2/10)

IC205

SHUTTER

DRIVER

(2/10)

IC204

D/A CONV

(9/10)

IC001

DC/DC

CONVERTER

DATA BUS

CLK TG

CCD FD,CCD HD

CAM SO,XCAM SCK

CAM SO,XCAM SCK

SP VOL

UNREG SO,UNREG SCK

SYS DD ON

EVER 3V

BL H

14

D1.5V

D2.9V

A2.9V

PANEL 2.9V

PANEL 13.2V

PANEL -15.3V

D3.1V

A4.9V

PANEL 4.9V

M5V

CAM 15V

CAM-7.5

EVER 3V

(3/10)

IC301

CAMERA

DSP

(HM (3M SA)

BOARD)

PANEL R,G,B

3

PANEL V,HD O

2

YO

A OUT L

A IN

ADDRESS BUS

(4/10)

IC502

EEPROM

SYS V

STRB ON

2

DATA BUS

CONTROL

SIG

(4/10)

IC501

MC CAM

SH DSP

V AMP ON

4

MS DIO,MS SCLK,MS BS

USB DATA+/-

FR SI,FR SO,XFR SCK

CAM SO,XCAM SCK

(3/10)

IC601

VIDEO

AMP

(7/10)

IC151

AUDIO

AMP

(6/10)

IC401

FRONT

CONT

(6/10)

IC402

INITIAL RESET

BACKUP VCC

(5/10)

IC801

LCD

DRIVER

(5/10)

IC802

LCD

TG

SP SP+

MIC IN

KEY AD0,AD1

2

KEY AD3

MODE DIAL

XRST IN

SW-390 (1/2)

(FLEXIBLE)

VR,VG,VB

UA-001

(FLEXIBLE)

S101,102

OPEN/CLOSE

2

JK-247(2/2)

(FLEXIBLE)

AV JACK IN

USB JACK IN

RL-059

(FLEXIBLE)

POWER

(SHUTTER)

SW-390 (2/2)

(FLEXIBLE)

BL H

SENCV

V OUT

AU OUT

XMS IN

S002

S003

FUNCTION

KEY

ZOOM

SWITCH

4 MODE

DIAL

RESET

BT100

LITHIUME

BATTERY

S109

PANEL UNIT

LCD901

COLOR

LCD

MONITOR

ND901

BACK LIGHT

SP901

SPEAKER

MIC901

MIC

A/V OUT

(MONO)

J102

(MS SOCKET)

CN101

TYPE B

USB

ST UNREG

AUDIO SIGNAL

VIDEO SIGNAL

VIDEO/AUDIO SIGNAL

ST UNREG

STB CHARGE

XSTB FULL

STB ON

FP-643

(FLEXIBLE)

ST-82 BOARD

3-1 3-2

CHARGING

CAPACITOR

FLASH

UNIT

Page 19

DSC-P32

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-2. CAMERA BLOCK DIAGRAM

SY-84 BOARD (1/2)

(1/10)

IC351

CCD

IMAGER

V OUT

V1

V2

V3A

V3B

X781

27MHz

CN201

IRIS DRIVE-

1

IRIS DRIVE+

2

IRIS BIAS+

4

IRIS HALL+

6

IRIS HALL-

3

IRIS BIAS-

5

FOCUS A

FOCUS A

FOCUS B

FOCUS B

XFC RST SENS

7

LENS TEMP

CN202

2

1

V5A

V5B

CSUB

V4

V6

H1

H2

2

LENS BLOCK

IRIS

IRIS

METER

M

H

FOCUS

MOTOR

M

FOCUS RESET

SENSOR

LENS TEMP

SENSOR

SHUTTER

M

MOTOR

FP-644

(FLEXIBLE)

IRIS DRIVE-

IRIS DRIVE+

IRIS BIAS+

IRIS HALL+

IRIS HALL-

IRIS BIAS-

FOCUS A

FOCUS A

FOCUS B

FOCUS B

VFC RST SENS

LENS TEMP

LENS BARIA OUT✤A

LENS BARIA OUT✤B

12

14

11

13

10

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

(3/10)

(HM (3M SA) BOARD)

CAMERA DSP

26

21

.

.

27

19

.

.

25

14

.

.

ADIN00

24

18

.

.

ADIN13

22

16

.

.

23

13

.

.

20

12

CLK TG

96

TG WEN

183

CCD HD

8

CCD FD

9

OPB CLP

6

DUM CLP

7

SUB CNTL

250

CLK

88

SHUTTER

246

M SHUT EN

196

DIR 0A

234

DIR 0B

235

EN0

233

SENS0

232

IC301

CS XRAM

STROB E1

SENCV OPEN

SENCV CLOSE

D00

D15

A01

A25

AUCK

WRLX

WRHX

RDX

CSX

LCD HD

RSTX

AOUT L

68

67

.

.

65

72

.

.

81

66

.

.

77

78

.

.

1616 DATA BUS

75

73

.

.

69

71

.

.

80

79

.

.

76

74

54

.

38

.

52

.

37

.

51

.

41

.

49

.

39

.

47

.

35

.

53

.

33

.

45

25

.

36

.

44

.

34

.

50

.

31

.

48

.

29

.

40

.

32

.

46

.

30

43

259

104PLL BYP

64XWAIT

62IRQIMG

59

60

55

58

57

212RO

207GO

204BO

229LCD VD

225

94

227NDVDO

248

SENCV OPEN

201

SENCV CLOSE

190

YO

215

278

AIN

272

ADDRESS BUS

PANEL R

PANEL G

PANEL B

PANEL V

HDO

XRST SYS

SYS V

XRST SYS

STRB ON

10

8

7

6

5

4

3

2

1

17

18

12RG

14SUB

15

Q351

IC781

CLOCK GEN.

FIN

(4/10)

CLK3 OUT

CLK2 OUT

CLK3 ON

CLK2 ON

REF OUT

7

Q203

Q201

Q352

4

11

5

13

16

5

6

(2/10)

IC202(1/4)

HALL

BIAS CONT

(2/10)

IC202(2/4)

HALL

GAIN CONT

13

(2/10)

IC201(1/2)

IRIS DRIVE

1

TG CLK

USB CLK

TG CLK EN

USB CLK EN

MC CLK1

2

3

(2/10)

IC202(3/4)

AMP

12

13

(2/10)

IC201(2/2)

IRIS DRIVE

(2/10)

IC202(4/4)

IRIS CONT

(1/10)

(CH-122(3M) BOARD)

IC901

CAMERA

MODULE

MCK12

CAHR

CLPOB

CLPOM

XFE CS

XTG CS

XCAM RST

IN1

9

IN2

11

EN1

10

EN2

12

WEN

CAVR

25

D0

38

D13

49

55

46

47

43

44

41XCAM SO

42XCAM SCK

39

40

45

CAM SO

XCAM SCK

XFE CS

XTG CS

XCAM RESET

14

CCD OUT

6

V1

18

V2

10

V3A

19

V3B

20

V4

14

V5A

15

V5B

16

V6

17

H1

2

H2

3

RG

5

24

VHST

TG CLK

48

IRIS

B1 FA

23

DRIVER

B2 FB

21

A1 FA

2

A2 FB

4

(2/10)

IC203

FOCUS

MOTOR

DRIVER

(2/10)

(2/10)

IC204

D/A CONV

A07

A06

A05

A02

A01

DI

A10

A03

13IN3

15IN4

EN3

14

EN4

16

2

3

14

13CLK

12LD

10

2

CAM SO

XCAM SCK

DAC STB

SP VOL

PRE LAMP AFON

A3 ZA

5

B3 ZA

19

A4 ZB

7

B4 ZB

17

IC205

SHUTTER

7

DRIVER

6

14

HALL OFFSET

6

HALL GAIN

5

6

7

5

9

8

10

HALL REF

IRIS CONT2

IRIS CONT1

4

1

15

1

2

3

TH351

TEMP

SENSOR

CAM SO

XCAM SCK

DAC STB

16

LCD

BLOCK

(PAGE 3-5)

FRONT

BLOCK

(PAGE 3-5)

FRONT

BLOCK

(PAGE 3-5)

XFE CS

XTG CS

XCAM RESET

USB CLK

TG CLK EN

USB CLK EN

49

60

.

56

47

.

.

45

54

.

52

41

.

.

51

39

62

79

.

64

.

81

.

66

.

83

68

88

.

70

.

90

.

72

.

92

.

73

.

93

.

75

.

95

.

76

.

97

78

146

162

138

165

100

101

99

114

117

140

164

230

187

226

110

220

184

22

23

229

128

168

228

200

199

19

(4/10)

IC501

MC CAM SH DSP

D0

D15

A1

A25

XCS PANEL TG

TCLK

SCL

WAIT

IRQ1

WE0

WE1

RD

CS4

CS6

RESETP

IRQ0

CCD TEMP

XAU LINE MUTE

XAU SP MUTE

CKIO

XFE CS

XTG CS

XCAM RESET

USB CLK

TG CLK EN

USB CLK EN

LENS TEMP

LENS OPEN ON

LENS CLOSE ON

HALL AD

TXD1

SCK1

DAC STB

(4/10)

IC502

EEPROM

RXD2

203

TXD2

202

SCK2

204

CS

189

14BUSY

71WE

TXD0

190

RXD0

191

SCK0

185

SCS0

134

136NMI

74UPDATA

157HELP

137

VG

232

V COM

235

35AE LOCK

MS DIR

216

215MS DIO

213MS SCLK

MS BS

214

28USB D + PULLUP

DP

239

DM

238

13

VAMP ON

29

50

CASU

124

25XAU PWR SAVE STBY

Q701(1/2)

DRIVE

D3.1V

LED

DO

4

DI

3

SCK

2

CS

1

BUSY

7

RST

6

FR SI

FR SO

XFR SCK

XCS MC

XMC NMI

MC UPDATA

MC HELP

XCS PANEL TG

V COM AD

Q501

VG

4

5

D2.9V

(AE LOCK/FLASH)

(MS ACCESS)

FRONT

BLOCK

(PAGE 3-5)

BLOCK

(PAGE 3-5)

D703

D705

7

6

C8

B2

G8

H9

H4

H5

J3

E1

F2

Q704

LED

DRIVE

LCD

FRONT

BLOCK

(PAGE 3-5)

(3/10)

IC601

VIDEO AMP

POWER SAVE

VIDEO IN

(7/10)

IC151

AUDIO AMP

LINE MUTE

SP SAVE

LPF SEL

PB IN

REC OUT

VOL CTL

BEEP

XBEEP MUTE

SELF TIMER LED

6

VOUT

LINE OUT

MUTE DRVR

SP OUT+

MIC IN

MIC SPY

BEEP ON

BEEP

4

B4

A5

A2

D1SP OUT-

B8

B9

XMS IN

USB JACK IN

AV JACK IN

7

(PAGE 3-5)

FRONT

BLOCK

CN701

CN702

(1/3)

CN706

JK-247

(FLEXIBLE)

MS DIO

6

MS SCLK

4

MS BS

9

XMS IN

5

USB JACK IN

19

USB DATA+

22

USB DATA-

21

V OUT

17

AV JACK IN

15

AU OUT

13

SW-390 (1/3)

(FLEXIBLE)

5

4

MIC IN

6

D001

SELF TIMER

AF ILLUMINATOR

3

.

4

UA-001

(FLEXIBLE)

S101

SENCEV OPEN

8

10

S102

SENCEV CLOSE

(MS SOCKET)

CN101

VCC

1

D+

3

D-

2

SP+

SP-

MIC901

MIC

A4.9V

J102

A/V OUT

(MONO)

SP901

SPEAKER

USB

TYPE B

3-3 3-4

XCAM SO

XCAM SCK

8

LCD

BLOCK

(PAGE 3-5)

AUDIO SIGNAL

VIDEO SIGNAL

VIDEO/AUDIO SIGNAL

Page 20

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DSC-P32

3-3. FRONT/LCD BLOCK DIAGRAM

SY- 84 BOARD (2/2)

CAMERA

BLOCK

(PAGE 3-4)

CAMERA

BLOCK

(PAGE 3-4)

CAMERA

BLOCK

(PAGE 3-4)

CAMERA

BLOCK

(PAGE 3-4)

2

4

6

7

SYS V

XRST SYS

FR SI

FR SO

XFR SCK

XCS MC

XMC NMI

MC UPDATA

MC HELP

XMS IN

USB JACK IN

AV JACK IN

SELF TIMER LED

BEEP ON

BEEP

Q401

Q402(1/2)

Q403

MODULATOR

X401

10MHz

X402

32.768kHz

SYS V

32 17

XRST SYS

77

FR SI

23

FR SO

24

XFR SCK

25

XCS MC

26

MC WAKEUP

80

XCS LCD

44

XMC HELP

36

MS IN

6

XUSB JACK IN

9

AV JACK IN

11

SELF TIMER LED

19

BEEP ON

49

MELODY

79

MELODY EN V

74

X1 IN

28

X1 OUT

29

X2 IN

52

X2 OUT

51

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

PANEL R

PANEL G

1

8

XCS PANEL TG

VG

V COM AD

BL ON

BL LEVEL

BL H

BL THL

PANEL B

PANEL V

HDO

RST SYS

XCAM SO

XCAM SCK

(6/10)

IC401

FRONT

CONTROL

PWR LED ON

CHARGE/STB

XPWR ON

XSHTR ON

XAE LOCK

KEY AD0

CAMERA

BLOCK

(PAGE 3-4)

RL-059

(FLEXIBLE)

D002

Q402(2/2)

DRIVE

1

4

5

ON

D2.9V

15XTALLY LED

Q701(2/2)

LED

16

DRIVE

55

56KEY AD1

58KEY AD3

54MODE DIAL

73XRESET

(6/10)

IC402

INITIAL RESET

BACKUP VCC

5RESET

3VBAT

7VIN

CN705

LED

D702

(Self-timer/recording)

D704

(FRASH/CHARGE)

CN702

(2/3)

EVER 4V

(POWER)

10

S002

POWER

5

3

1

S003

(SHUTTER)

SW-390 (2/3)

(FLEXIBLE)

34

33

36

S102 (INDEX)S106

ZOOM

W

35

38

2

LITHIUME

BATTERY

EVER 3.0V

S100,104

S107,110

FUNCTION

KEY

S101,103

S105,108

FUNCTION

KEY

MODE SW

4 MODE

DIAL

S109

RESET

BT100

T

CAMERA

(PAGE 3-4)

CAMERA

BLOCK

(PAGE 3-4)

POWER

BLOCK

(PAGE 3-7)

BLOCK

5

9

SW-390 (3/3)

22

23

24

16

11

12

13

14

15

17

18

19

20

21

30

29

(FLEXIBLE)

CN102

VR

VG

VB

V COM

GRES

GPCK

GSRT

STBYB

RESET

SRT

OE

CLR

MCLK

HCNT

CN101

BL H

BL THL

19

20

21

11

13

10

14

15

16

17

18

6

7

8

9

.

4

3

PANEL UNIT

LCD901

COLOR

LCD

MONITOR

ND901

BACK LIGHT

R IN

48

G IN

47

B IN

46

SI

40

XSCK

39

XCS

41

BIAS

OP IN-

OP IN+

8

9

7

10

FILTER

29

RPD

SO

45

SI

46

XSCK

42

XVD

48

HD

1

XCLR

36

XCS

44

PWM

9

OP OUT

27

OSC

11

OSCI

VCO

26

(5/10)

IC801

LCD

DRIVER

D802

C818

L805

OSCO

(5/10)

IC802

LCD TG

33

37

BGP

32

39SW40

BGP

FRP

BLACK IN

30

FRP

COM FRP

XC SAVE38XP SAVE

29

41

28

COM FRP

45

25

XC SABE

DR PSAVE

COM OUT

EXT DA2

EXT DA1

GSRT

SBTYB

RESET

MCLK

HCNT

VR

VG

VB

SRT

CLR

20

22

24

27

37

35

14GRES

15GPCK

16

17

18

20

OE

21

22

23

24

CN702

(3/3)

AUDIO SIGNAL

XSTB SAVE

STB CHG

XSTB FULL

75

46

34

CAMERA

BLOCK

(PAGE 3-4)

CN704

ST UNREG

10

12

ST UNREG

FP-643

(FLEXIBLE)

XSTB PWR SAVE

3

9

4

STB ON

3

1

STB CHARGE

XSTB FULL

STB ON

10

12

3

9

4

1

CN501

Q501,502

Q503

Q504

TRANS

DRIVE

IC501

FLASH

DRIVER

42

T501

Q505

FLASH

CHARGE DET

D502

Q506

L501

TRIGGER

ST-82

BOARD

XE H

XE L

FLASH

UNIT

3-5 3-6

Page 21

DSC-P32

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-4. POWER BLOCK DIAGRAM

SY- 84 BOARD

CN001

1

BATT UINREG

J101

DC IN

BT901

BATTERY

TERMINAL

JK-247 (1/2)

(FLEXIBLE)

ACV UNREG

ACV GND

BATT/ XEXT

.

2

3

.

4

CN701

Q001

24

29

31

37

30

D002

D003

BATT /XETX

G1

4

G2

5

Q002

Q004,009

SWITCH

Q005

Q006

Q007

D1

S1

S1

D2

S2

S2

1

2

3

8

7

6

CHARGE

SWITCH

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

FAST CHARGE

UNREG SO

UNREG SCK

XCS DD CON

SYS DD ON

EVER 3.0V

F007

F001

F003

F005

BATT UNREG

ST UNREG

ACV UNREG

DC/DC CONVERTER

DATA

45

CLK

46

XCS

44

CONT

57

VCC1

56

RST

47

(9/10)

IC001

OUT1-P

OUT1-N

V-IN1

VCC3

OUT3-P

OUT3-N

V-IN3

VCC4

OUT4-P

OUT4-N

V-IN4

VCC5

OUT5-P

OUT5-N

OUT5-S

V-IN5

OUT6-P

OUT6-N

OUT6-S

V-IN6

OUT9-N

-IN9

-IN (S) 9

OUT10

AMP IN

-IN10

AMP OUT

VCC2

OUT2-N

OUT2-P

OVP2

V-IN2

V+IN2

ON/OFF2

Q021,022

SWITCHING

L001

(8/10)

IC003

BATT

12

DET

D014

D009

D016

D018

36

37

55

42

32

33

54

19

30

31

53

20

38

39

43

52

28

29

18

50

23

80

1

22

4

3

5

41

35

34

58

60

61

48

L005

L003

L002

L001

Q012,018

SWITCHING

Q013,019

SWITCHING

Q016

SWITCHING

Q020,024

SWITCHING

Q017,023

SWITCHING

Q015

SWITCHING

Q011

SWITCHING

Q010

Q003

BACK LIGHT

SWITCHING

D004

D013

L006

L007

L008

D020

L009

L010

Q025

Q026

D012

BL L

BL THH

BL H

BL THL

BL LEVEL

BL ON

Q014,027

SWITCHING

(8/10)

IC004

DC/DC

15

CONV

2

Q028-030

SWITCHING

LCD

9

DRIVER

D001

L011

M5V

BATT UNREG

ST UNREG

ACV UNREG

EVER 4.0V

D1.5V

DD CON SENS

D2.9V

A2.9V

PANEL 2.9V

D3.1V

A4.9V

PANEL 4.9V

PANEL -15.3V

PANEL 13.2V

CAM 15V

CAM -7.5V

BATT /XETX

FAST CHARGE

UNREG SO

UNREG SCK

XCS DD CON

SYS DD ON

L302

L502

L503

L601

L163

L152

(6/10)

IC401

FRONT

CONT

(4/10)

IC781

FB781

CLOCK

GEN.

L203

L205

L204

L202

FB301

FB302

FB303

AU 2.9V

FB501

FB503

FB502

L501

(7/10) (3/10)

IC151

AUDIO

AMP

Q801

L401

STB CHARGE

(3/10)

IC301

CAMERA

DSP

(4/10)

IC501

MC CAM

SH DSP

(4/10)

IC502

EEPROM

IC601

VIDEO

AMP

(2/10)

IC204

CONV.

Q802

D/A

IC205

SHUTTER

(2/10)

DRIVE

XLENS RST LED

(2/10) (2/10)

HALL REF

(2/10)

IC203

MOTOR

DRIVE

CAM DD ON

MS POWER ON

Q905

(1/2)

Q906

(1/2)

Q906

(2/2)

XRESET

BATT IN

IC202

IRIS/HALL

Q202

L901

L902

L903

Q905

(2/2)

(5/10)

IC801

LCD

DRIVER

(5/10)

IC802

LCD

(6/10)

IC402

INTIAL RESET

BACKUP VCC

IC201

IRIS

DRIVE

L804

L801

L802

BACKUP VCC

L803

EVER 3.0V

EVER 3.0V

CONT

TG

FB902

FB904

FB903

FB905

FB906

Q703

Q702

Q702

(1/10)

IC901

CAMERA

MODULE

L351

FB351

STB CHARGE

D701

CN704

A4.9V

CN701

CN201

FC SENS VCC

(1/10)

IC351

CCD

IMAGER

CN706

CN702

LI3V

10

12

9

2

2

1

.

2

2

.

3

8

7

9

26

10

31286

2

FP-643

(FLEXIBLE)

ST UNREG

STB CHARGE

M5V

UA-001

(FLEXIBLE)

D001

(SELF-TIMER /

AF ILLUMINATOR)

MS

PORT

JK-247(2/2)

(FLEXIBLE)

FP-644

(FLEXIBLE)

CN102

VGH

1

VGL

3

VSH

24

VDD

23

4

SW-390

(FLEXIBLE)

CN101

BL L

BL THH

1

LITHIUME

BATTERY

BT100

ST-82 BOARD

CN501

Q501,502

10

12

9

2

LENS ASSY

FOCUS

SENSOR

T501

IC501

IGBT

DRIVER

PANEL UNIT

LCD901

COLOR

LCD

MONITOR

ND901

BACK LIGHT

FLASH

UNIT

3-7 3-8E

Page 22

COVER

COVER

SECTION 4

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/2)

1

2

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

5

610 1612

8 15

9

DSC-P32

1437114 1713

A

FLASH UNIT

ST-82 BOARD

6N.C.

7

REG_GND

POWER

4

5XPWR_ON

N.C.

S002

2N.C.

3XSHTR_ON

1XAE_LOCK_SW

12P

CN501

12P

CN704

1 STRB_ON

1STRB_ON

2 M_5V

2M_5V

3 XSTB_PWRSAVE

3XSTB_PWRSAVE

4 XSTB_FULL

5 REG_GND

6 REG_GND

FP-643

FLEXIBLE

4XSTB_FULL

5REG_GND

6REG_GND

7 REG_GND

8 REG_GND

7REG_GND

8REG_GND

9 STB_CHARGE

10 ST_UNREG

9STB_CHARGE

10ST_UNREG

11 ST_UNREG

12 ST_UNREG

11ST_UNREG

12

ST_UNREG

CN706

10P

PRELAMP_AF_ON

MIC_GND

1AF_LED_4.9V

2AF_LED_4.9V

3PRELAMP_AF_ON

4

(SENCV CLOSE)

5MIC_GND

6MIC_IN

7

8SENCV_OPEN

9REG_GND

UA-001 UNIT

10SENCV_CLOSE

S102

S101

(SENCV OPEN)

S003

(SHUTTER)

B

CONTROL SWITCH

BLOCK(RL-059)

OVF_NZM

C

8

9EVER_3.0V

10PWR_LED

N.C.

D

14PCN201

FOCUS_A-

14

FOCUS_B-

13

FOCUS_A

E

FP-644

FLEXIBLE

F

12

11

10

9

8

7

6

5

4

3

2

1

FOCUS_B

TEMP_OUT

REG_GND

FC_SENS_VCC

XFC_RST_SENS

IRIS_HALL+

IRIS_BIAS-

IRIS_BIAS+

IRIS_HALL-

IRIS_DRIVE+

IRIS_DRIVE-

10P

CN705

LENS BLOCK

G

SY-84 BOARD(1/2)

H

CN202

I

J

16

BT901

BATTERY TERMINAL

(DRY BATTERY)

2P

2 LENS_BARIA_OUT_A

1 LENS_BARIA_OUT_B

CN001

4P

1 BATT_UNREG

2 BATT_UNREG

3 BATT_GND

4 BATT_GND

4-1 4-2

FRAME SCHEMATIC DIAGRAM (1/2)

Page 23

DSC-P32

COVER

COVER

FRAME SCHEMATIC DIAGRAM (2/2)

1

A

B

38

ND901

BACK-LIGHT

LCD901

COLOR LCD

MONITOR

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

5 136

SP901

SPEAKER

924 7

10

11 1514

12

C

VB 21

VR 19

VG 20

VSS 22

VSH 24

VDD 23

24P

D

E

CN101

1 BL_THH

2 N.C.

3 BL_THL

4 BL_H

5 N.C.

6 BL_L

CN102

6P

15

17

OE

SRT 14

CLR 16

HCNT 18

MCLK

2

4

S107

MENU

F

2

4

S104

(DOWN/

SELF TIMER)

10

VBC 12

VCOM 11

RESET

STBYB 13

STBYB 9

1

3

(LEFT/QUICKREVIEW)

1

3

G

H

S109

RESET

I

CONTROL SW BLOCK

16

(SW-390)

7

8

GSAT

GPCK

2

4

S108

(LCD status/

LCD ON-OFF)

2

4

S101

2

4

(SET)

2

4

(RIGHT/

SPOT METER)

4MODE

DIAL

GRES 6

S103

S105

5

VGL 3

N.C.

VSS 2

VDD 4

1

3

1

3

1

3

1

3

/

BT100(LITHIUM BATTERY)

VGH 1

(Image Size

/DELETE)

2

4

(UP/FLASH)

T

ZOOM

W

2

4

S100

S110

1

3

(INDEX)

SP+

SP-

39P

CN702

1

3

S106

2

1

4

3

S102

2

1

4

3

1 REG_GND

2 LI_3V

3 REG_GND

4 SP-

5 SP+

6 REG_GND

7 VGH

8 VSS

9 VGL

10 VDD

11 GRES

12 GPCK

13 GSRT

14 STBYB

15 RESET

16 VCOM

17 SRT

18 OE

19 CLR

20 MCLK

21 HCNT

22 VR

23 VG

24 VB

25 VSS

26 VSH

27 REG_GND

28 BL_THH

29 BL_THL

30 BL_H

31 BL_L

32 REG_GND

33 KEY_AD1

34 KEY_AD0

35 MODE_DIAL

36 KEY_AD3

37 REG_GND

38 XRST_IN

39 REG_GND

(2/2)

CN701

39P

1MS_VSS

2MS_VCC

3MS_VCC

4MS_SCLK

5XMS_IN

6MS_DIO

7N.C.

8N.C.

9MS_BS

10MS_VSS

11MS_VSS

12AV_GND

13AU_OUT

JK BLOCK(JK-247)SY-84 BOARD

14AV_GND

15AV_JACK_IN

16AV_GND

17V_OUT

18AV_GND

19USB_JACK_IN

20USB_GND

21USB_DATA-

22USB_DATA+

23USB_GND

24ACV_UNREG1

25ACV_UNREG1

26ACV_UNREG1

27ACV_UNREG1

28ACV_UNREG1

29ACV_UNREG1

30BATT/XEXT

31ACV_GND

32ACV_GND

33ACV_GND

34ACV_GND

35ACV_GND

36ACV_GND

37ACV_GND

38STATIC_GND

39STATIC_GND

CN101

VCC

1

D-

2

D+

3

4ID

5

GND

10 MS_VSS

9 MS_VCC

8 MS_SCLK

7 N.C.

6 XMS_IN

5 N.C.

4 MS_DIO

3 N.C.

2 MS_BS

1 MS_VSS

J101

DC IN

5P

J102

A/V OUT(MONO)

CN101

(USB)

MEMORY

STICK

CONNECTOR

MEMORY STICK

FRAME SCHEMATIC DIAGRAM (2/2)

4-3 4-4

Page 24

COVER

COVER

Link

Link

DSC-P32

4-2. SCHEMATIC DIAGRAMS

ST-82 BOARD

ST-82 BOARD

FP-643 FLEXIBLE BOARD CONTROL SWITCH BLOCK

FP-643 FLEXIBLE BOARD

JK BLOCK

JK BLOCK

COMMON NOTE FOR SCHEMATIC DIAGRAMS

COMMON NOTE FOR SCHEMATIC DIAGRAMS

(FLASH DRIVE)

(FLASH DRIVE)

(JK-247) (JACK)

(JK-247) (JACK)

CONTROL SWITCH BLOCK

CONTROL SWITCH BLOCK

CONTROL SWITCH BLOCK

UA-001

UA-001

(MIC, AF LED)

(MIC, AF LED)

(SW-390)

(SW-390)

(RL-059)

(RL-059)

Page 25

4-2. SCHEMATIC DIAGRAMS

COVER

COVER

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

DSC-P32

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

Link

µF. 50 V or less are not indicated except f or electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

• Parts with * differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B: B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: VIDEO SIGNAL (ANALOG)

• A: AUDIO SIGNAL (ANALOG)

• A: VIDEO/A UDIO SIGNAL

• A: VIDEO/A UDIO/SER V O SIGNAL

• A: SERVO SIGNAL

• Circled numbers refer to waveforms.

(Measuring conditions voltage and waveform)

• Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference values

and reference wave forms.

(VOM of DC 10 MΩ input impedance is used)

• Voltage values change depending upon input

impedance of VOM used.)

1. Connection

Pattern box

About 26cm

Front of the lens

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Fig.b (Picture on monitor TV)

Red

Blue

When indicating parts by reference number, please

include the board name.

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

4-5

Page 26

COVER

COVER

4-2. SCHEMATIC DIAGRAMS ST-82 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS ST-82 PRINTED WIRING BOARD

DSC-P32

4-2. SCHEMATIC DIAGRAMS

1

A

B

C

D

FP-643

E

TO

SY-84

BOARD

(10/10)

CN704

(PAGE

4-26

of

LEVEL3)

F

16

FLEXIBLE

12ST_UNREG

11ST_UNREG

10ST_UNREG

9STB_CHARGE

8REG_GND

7REG_GND

6REG_GND

5REG_GND

4XSTB_FULL

3XSTB_PWRSAVE

2M_5V

1STRB_ON

For Schematic Diagram

• Refer to page 4-37 for printed wiring board of ST-82 board.

37114 132

5

ST-82 BOARD

FLASH DRIVE(STRB BLOCK)

XX MARK:NO MOUNT

12P

12 ST_UNREG

11 ST_UNREG

10 ST_UNREG

9 STB_CHARGE

8 REG_GND

7 REG_GND

6 REG_GND

5 REG_GND

4 XSTB_FULL

3 XSTB_PWRSAVE

2 M_5V

1 STRB_ON

CN501

12ST_UNREG

11ST_UNREG

10ST_UNREG

9STB_CHARGE

8REG_GND

7REG_GND

6REG_GND

5REG_GND

4XSTB_FULL

3XSTB_PWRSAVE

2M_5V

1STRB_ON

4.1

R502

100k

Q501

DTC144EMT2L

SWITCH

0

R501

4700

T501

9

5

S

2

IC501

FLASH DRIVE

D502

HAU160C030TP

R509

4700

2

0

R5.0/P0

RN1902FE(TPLR3)

FLASH CHARGE

DET

2.80

6

3

1

4

TND721MH5-S-TL-E

123

0

Q505

IC501

5

C506

1u

B

C507

0.1u

B

0

0

45

C508

135u

315V

FLASH

UNIT

LND501

LND502

R510

XE_H

R512

1M

Q506

L501

C509

47000pF

250V

5

4

LND503

TRIGGER

XE_L

CY25AAJ-8-T13

276

SWITCH

6

7

8

1

3

R511

2

0

1M

47

61012

Q502

UPA650TT-E1-A

SWITCH

0

6

4

5

2

1

4.1

3

0

D501

R504

2200

R505

100k

C512

0.1u

B

R503

10k

4.1

C503

C504

10u

10u

B

B

6.3V

6.3V

C510

10u

6.3V

Q503

TRANS DRIVE

0

CPH3209-SONY-TL-E

C511

MA111-(K8).S0

10u

B

B

6.3V

8

NO MARK:REC/PB MODE

R :REC MODE

P :PB MODE

DC-DC CONVERTER

TRANSFORMER

C505

R508

0.22u

82

B

R506

2700

1

3

00

Q504

MCH3405-TL-E

2

R507

10k

SWITCH

0

4

P

1

3

F

Schematic diagram of the SY-84 board are not shown.

Pages from 4-7 to 4-26 are not shown.

4-27 4-28

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

ST-82/FP-643

Page 27

DSC-P32

COVER

COVER

4-2. SCHEMATIC DIAGRAMS JK BLOCK FLEXIBLE BOARD

4-2. SCHEMATIC DIAGRAMS JK BLOCK FLEXIBLE BOARD

A

B

C

D

E

F

1

JK BLOCK(JK-247)

JACK

XX MARK:NO MOUNT

TO

SY-84 BOARD

(10/10)

CN701

(PAGE 4-26

of LEVEL3)

39P

MS_VSS

MS_VCC

MS_VCC

MS_VSS

MS_VSS

AV_GND

AU_OUT

AV_GND

AV_JACK_IN

AV_GND

AV_GND

USB_JACK_IN

USB_GND

USB_DATA-

USB_DATA+

USB_GND

ACV_UNREG1

ACV_UNREG1

ACV_UNREG1

ACV_UNREG1

ACV_UNREG1

ACV_UNREG1

BATT/XEXT

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

STATIC_GND

STATIC_GND

XMS_IN

MS-DIO

N.C.

N.C.

MS_BS

V_OUT

3742

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

CL101

CL102

CL103

CL104

5

MS_VSS

10

MS_VCC

9

8

MS_SCLK

7

N.C.MS_SCLK

6

XMS_IN

5

N.C.

4

MS_DIO

N.C.

3

2

MS_BS

1

MS_VSS

CN101

VCC

1

D-

2

D+

3

4ID

5

GND

10P

6

MEMORY

STICK

CONNECTOR

J102

A/V OUT(MONO)

5P

(USB)

J101

DC IN

LND150

STATIC_GND

8

MEMORY STICK

SIGNAL PATH

VIDEO SIGNAL

CHROMA SIGNAL

REC

PB

AUDIO

Y

Y/CHROMA

16

JK BLOCK (JK-247)

4-29 4-30

Page 28

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

COVER

COVER

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

• CONTROL SWITCH BLOCK (SW-391) is replaced as a block. So that this PRINTED WIRING BOARD is omitted.

1

23 10

4

6597

DSC-P32

8

CONTROL SWITCH BLOACK

(SW-390)

A

LCD,CONTROL SW(SW BLOCK)

XX MARK:NO MOUNT

B

C

D

E

F

TO

SY-84 BOARD(5/10)

CN702

(PAGE 4-16

of LEVEL3)

SIGNAL PATH

39P

1REG_GND

LITHIUM BATTERY

2LI_3V

3REG_GND

4SP-

5SP+

6REG_GND

7VGH

8VSS

9VGL

10VDD

11GRES

12GPCK

13GSRT

14STBYB

15RESET

16VCOM

17SRT

18OE

19CLR

20MCLK

21HCNT

22VR

23VG

24VB

25VSS

26VSH

27REG_GND

28BL_THH

29BL_THL

30BL_H

31BL_L

32REG_GND

33KEY_AD1

34KEY_AD0

35MODE_DIAL

36KEY_AD3

37REG_GND

38XRST_IN

39REG_GND

BT100

R100

SP901

SPEAKER

1200

SET UP

R106

220k

R103

1200

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1 BL_THH

2 N.C.

3 BL_THL

4 BL_H

5 N.C.

6 BL_L

S100

(UP/FLASH)

2

4

VGH

VSS

VGL

VDD

N.C.

GRES

GPCK

GSAT

STBYB

RESET

VCOM

VBC

STBYB

SRT

OE

CLR

MCLK

HCNT

VR

VG

VB

VSS

VDD

VSH

CN101

24PCN102

6P

1500

R107

S103

(SET)

2

1

4

3

1

3

(RIGHT/

SPOT METER)

PANEL UNIT

LCD901

COLOR

LCD

MONITOR

ND901

BACK LIGHT

R110

3300

S105

/

2

1

4

3

S107

MENU

2

1

4

3

2

4

(Image Size

/DELETE)

1

3

S110

G

H

S101

(LEFT/

QUICK

REVIEW)

R108

1500

R104

1200

2

1

2

1

4

4

3

R105

1200

S102

2

1

4

3

W

S104

(DOWN/

SELF TIMER)

ZOOM T

(INDEX)

3

S106

2

4

R109

3300

S108

(LCD status/

LCD ON-OFF)

2

1

4

3

1

3

S109

RESET

REC

PB

AUDIO

SIGNAL

R101

1500

D100-103

MAZS082008SO

R102

3300

STATIC_GND

16

4-31 4-32

SW-390

Page 29

DSC-P32

S102

S101

OPR5052

D001

10PCN001

1

2

3

4

5

6

7

8

9

10

1

A

AF_LED_4.9V

AF_LED_4.9V

PRELAMP_AF_ON

PRELAMP_AF_ON

MIC_IN

MIC_GND

MIC_GND

REG_GND

SENCV_OPEN

SENCV_CLOSE

TO

SY-84 BOARD(10/10)

CN706

23

B

C

4

UA-001 UNIT

XX MARK:NO MOUNT

AF LED,SW

16

(SENCV CLOSE)

(SENCEV OPEN)

MIC901

REC

PB

AUDIO

SIGNAL

SIGNAL PATH

(Self-timer/

AF illuminator)

(PAGE 4-26

of LEVEL3)

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

COVER

COVER

• CONTROL SWITCH BLOCK (RL-059) is replaced as a block. So that this PRINTED WIRING BOARD is omitted. • UA-001 UNIT is replaced as a block. So that this PRINTED WIRING BOARD is omitted.

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

A

B

C

1

CONTROL SWITCH BLOCK(RL-059)

POWER/SHUTTER SWITCH

XX MARK:NO MOUNT

TO

SY-84 BOARD

(10/10)

CN705

(PAGE 4-26

of LEVEL3)

PWR_LED

EVER_3.0V

REG_GND

XPWR_ON

XSHTR_ON

XAE_LOCK_SW

N.C.

N.C.

N.C.

N.C.

10

9

8

7

6

5

4

3

2

1

D004

342

D002

(POWER)

(GREEN)

S003

(SHUTTER)

R002

0

D005

5

D003

STATIC_GND

6

S002

POWER

16

RL-059/UA-001

4-33 4-34

Page 30

COVER

COVER

4-3. PRINTED WIRING BOARDS

Link

Link

COMMON NOTE FOR PRINTED WIRING BOARDS

COMMON NOTE FOR PRINTED WIRING BOARDS

DSC-P32

JK BLOCK (JK-247)ST-82 BOARD

JK BLOCK (JK-247)ST-82 BOARD

MOUNTED PARTS LOCATION

MOUNTED PARTS LOCATION

CIRCUIT BOARDS LOCATION

CIRCUIT BOARDS LOCATION

FLEXIBLE BOARDS LOCATION

FLEXIBLE BOARDS LOCATION

Page 31

4-3. PRINTED WIRING BOARDS

COVER

COVER

4-3. PRINTED WIRING BOARDS

THIS NOTE IS COMMON FOR WIRING BOARDS

(In addition to this, the necessary note is printed in each block)

(For printed wiring boards)

• : Uses unleaded solder.

• : P attern from the side which enables seeing.

(The other layers’ patterns are not indicated)

• Through hole is omitted.

• Circled numbers refer to waveforms.

• There are a few cases that the part printed on diagram

isn’t mounted in this model.

• C: panel designation

BOARD INFORMATION

board name

ST-82

JK BLOCK

SY-84

parts location

(shown on page)

4-47

–

4-48

waveform

(shown on page)

4-45

number of layers

–

–

• Chip parts.

Transistor Diode

C

4

1

8

5

5246

EB

31

21

345

pattern

layers not shown

654

123

12

534

2 to 3

–

2 to 7

43

12

3

43

12

54

45

21321321

123

312

43

12

21

34

CSP IC

–

–

IC151, IC401, IC501, IC001,

IC301, IC901

DSC-P32

31

4625

4

3

12

4-35

Page 32

DSC-P32

COVER

COVER

4-3. PRINTED WIRING BO ARDS

ST-82 (FLASH DRIVE) PRINTED WIRING BOARD

• Refer to page 4-35 for common note for printed wiring board.

ST-82 BOARD(SIDE A)

85

A

R512

Q506

14

C509

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

• : Uses unleaded solder.

L501

MOUNTED PARTS LOCATION

MOUNTED PARTS LOCATION

LND503

1-687-747-

16

123 4

ST-82 BOARD(SIDE B)

LND501

LND502

4

3

C506

R509

112

IC501

R510

1

R511

5

C507

D502

1-687-747-

C510

C511

R502

R503

Q502

R501

C505

3

1

4

2

T501

5

R508

Q503

D501

R504

R506

D

Q504

R505

R507

C512

SG

1

CN501

2

3

Q501

Q505

C503

C504

11 11

11

A

1234

16

Printed wiring board of the SY-84 board are not shown.

Pages from 4-39 to 4-42 are not shown.

4-37 4-38

ST-82

Page 33

DSC-P32

COVER

COVER

JK BLOCK (JK-247) (JACK) FLEXIBLE BOARD

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

JK BLOCK (JK-247)

LND150

J101

DC IN

CN101

(USB)

J102

A/V OUT

(MONO)

LND139

LND138

LND137

LND136

LND135

LND134

LND133

LND132

LND131

LND130

LND129

LND128

LND127

LND126

LND125

LND124

LND123

SOL001

7

CL104

6

15

CL101

CL102

CL103

LND122

LND121

LND120

LND119

LND118

LND117

LND116

LND115

LND114

LND113

LND112

LND111

LND110

LND109

LND108

LND107

LND106

LND105

LND104

LND103

LND102

LND101

JK BLOCK (JK-247)

4-43

LND149

LND148

LND147

1-477-858-

LND145

LND146

LND144

LND143

LND142

LND141

11

LND140

4-44

Page 34

COVER

COVER

4-3. PRINTED WIRING BOARDS

4-3. PRINTED WIRING BOARDS

DSC-P32

4-5. MOUNTED PARTS LOCATION

ST-82 BOARD

* C503 A-3

* C504 A-3

* C505 A-4

* C506 A-2

* C507 A-1

C509 A-1

* C510 A-3

* C511 A-4

* C512 A-3

* CN501 A-2

* D502 A-1

* IC501 A-1

L501 A-1

* Q502 A-3

* Q503 A-3

* Q504 A-3

* Q505 A-2

Q506 A-1

* R501 A-2

* R502 A-3

* R503 A-3

* R504 A-3

* R505 A-3

* R506 A-3

* R508 A-4

* R509 A-2

* R510 A-1

* R511 A-1

R512 A-1

* T501 A-4

no mark : side A

* mark : side B

Mounted parts location of the SY-84 board

is not shown.

Page 4-48 is not shown.

4-47E

ST-82

Page 35

DSC-P32

LENS FRAME BLOCK ASSEMBLY

LENS FRAME BLOCK ASSEMBLY

COVER

COVER

NOTE

NOTE

5. REPAIR PARTS LIST

NOTE: Characters A to Z of the electrical parts list indicate location of exploded views in which the desired part is shown.

Link

Link

CABINET (FRONT) SECTION

CABINET (FRONT) SECTION

Link

Link

EXPLODED VIEWS

EXPLODED VIEWS

AB

MAIN BLOCK ASSEMBLY

MAIN BLOCK ASSEMBLY

ELECTRICAL PARTS LIST

ELECTRICAL PARTS LIST

BA

ST-82 BOARDSY-84 BOARD

ST-82 BOARDSY-84 BOARD

CABINET (REAR) BLOCK ASSEMBLY

CABINET (REAR) BLOCK ASSEMBLY

ACCESSORIES

ACCESSORIES

Page 36

5. REPAIR PARTS LIST

COVER

COVER

NOTE:

• -XX, -X mean standardized parts, so they may have some differences from

the original one.

• Items marked “*” are not stocked since they are seldom required for routine

service. Some delay should be anticipated when ordering these items.

• The mechanical parts with no reference number in the exploded views are not

supplied.

• Due to standardization, replacements in the parts list may be different from

the parts specified in the diagrams or the components used on the set.

• CAPACITORS:

uF: µF

• COILS

uH: µH

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

• Abbreviation

CND : Canadian model

AUS : Australian model

JE : Tourist model

CH : Chinese model

KR : Korea model

HK : Hong Kong model

J : Japanese model

5. REPAIR PARTS LIST

DSC-P32

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

5-1

Page 37

COVER

COVER

5-1. EXPLODED VIEWS

5-1-1. CABINET (FRONT) SECTION

ns : not supplied

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

DSC-P32

A

ns

1

Cabinet (rear) block assembly

(See page 5-6)

1

Main block assembly

(See page 5-4)

A

B

3

4

B

4

5

C

4

C

6

1

2

1

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 3-968-729-71 SCREW (M2), LOCK ACE, P2

2 X-3953-14501 CABINET (FRONT) ASSY

3 3-080-977-01 TRIPOD

4 3-080-204-21 SCREW, TAPPING, P2

5 1-477-808-11 PARTS UNIT (UA-001)

6 1-763-818-21 MOTOR, DC 8C-027G

5-3

Page 38

DSC-P32

COVER

COVER

5-1-2. MAIN BLOCK ASSEMBLY

ns : not supplied

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

57

56

Lens frame block assembly

(See page 5-5)

54

ns

53

J101

J102

55

CN101

A

51

A

ns

58

BT901

52

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 3-078-890-11 SCREW, TAPPING

52 1-815-853-21 MEMORY STICK CONNECTOR

53 1-477-858-11 JK BLOCK (JK-247)

54 3-080-204-21 SCREW, TAPPING, P2

055 A-7078-600-A ST-82 (S) BOARD, COMPLETE

56 1-687-751-11 FP-643 FLEXIBLE BOARD

57 1-477-806-11 CONTROL SWITCH BLOCK (RL-059)

0 58 1-477-803-11 FLASH UNIT

BT901 1-756-346-11 HOLDER, BATTERY(WITH TERMINAL)

CN101 1-794-962-11 CONNECTOR, SQUARE TYPE(USB 5P)

J101 1-817-331-11 DC JACK 5P (DC IN)

J102 1-569-950-31 JACK (SMALL TYPE) (A/V OUT (MONO))

5-4

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

Page 39

5. REPAIR PARTS LIST

COVER

COVER

5. REPAIR PARTS LIST

5-1-3. LENS FRAME BLOCK ASSEMBLY

DSC-P32

104

105

104

103

107

IC351

106

109

104

108

104

102

101

110

Be sure to read “Precautions upon replacing CCD imager”

on page 4-7 when changing the CCD imager.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 8-848-757-01 LSV-780A

102 1-758-917-11 FILTER BLOCK, OPTICAL