Page 1

DSC-P30/P50

System

Image device

6.64 mm (1/2.7 type) color

CCD

Lens

3× zoom lens

f = 6.4 – 19.2 mm (9/32 –

25/32 inches)

(41 – 123 mm (1 5/8 – 4 7/8

inches) when converted into a

35 mm still camera)

F = 3.8 – 3.9

Exposure control

Automatic exposure

White balance

Automatic, Indoor, Outdoor,

Hold

Data system

Movie: MPEG1

Still: JPEG, GIF (in TEXT

mode, Clip Motion), TIFF

Recording medium

“Memory Stick”

Flash

Recommended recording

distance (ISO is set to AUTO):

0.3m to 2.0m

(11 13/16 inches to

6 feet 6 3/4 inches)

Output connector

VIDEO OUT

Minijack

Video: 1 Vp-p, 75Ω

unbalanced, sync negative

USB jack

mini-B

LCD screen

Used LCD panel

1.5 type TFT (Thin Film

Transistor active matrix) drive

Total number of dots

123 200 (560×220) dots

General

Used battery

Two size AA alkaline

batteries: 3 V

NP-FS11: 3.6 V (not supplied)

Power consumption

(during recording)

2.8 W

Operation temperature

0ºC to 40ºC

(32ºF to 104ºF )

Storage temperature

–20ºC to +60ºC

(–4ºF to +140ºF )

Maximum dime nsions

126×61.2×53.7 mm

(5×2 1/2×2 1/8 inches)

(w/h/d)

Mass

Approx. 260 g (9.2 oz)

(including two size AA

batteries, “Memory Stick,”

wrist strap and lens cap etc.)

AC-LS1A AC power

adaptor (not supplied)

Power requirements

100 to 240 V AC, 50/60 Hz

Rated output voltage

DC 4.2 V, 1.5 A in operating

mode

Operation temperature

0ºC to 40ºC (32º F to 104ºF)

Storage temperature

–20ºC to +60ºC

(–4ºF to +140ºF )

Maximum dime nsions

105×36×56 mm

(4 1/4×1 7/16×2 1/4 inches)

(w/h/d) (excluding maximum

protrusions)

Mass

Approx. 180 g (6 oz)

NP-FS11 battery pack

(not supplied)

Used battery

Lithium ion battery

Maximum voltage

DC 4.2 V

Nominal voltage

DC 3.6 V

Capacity

4.1 Wh (1 140 mAh)

Accessories

VIDEO connecting cable (1)

Size AA alkaline batteries (2)

USB cable (1)

Lens cap (1)

Lens cap strap (1)

Wrist strap (1)

“Memory Stick” (4 MB) (1)

CD-RO M (2 )

Operating Instructions (1)

Design and specifications are

subject to change without

notice.

SERVICE MANUAL

Level 1

Ver 1.1 2001. 05

Photo: DSC-P50

SPECIFICATIONS

AEP Model

UK Model

DIGITAL STILL CAMERA

Page 2

Table for differences of function

Model DSC-P30 DSC-P50

CCD Imager 1.3M pixels 2.1M pixels

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

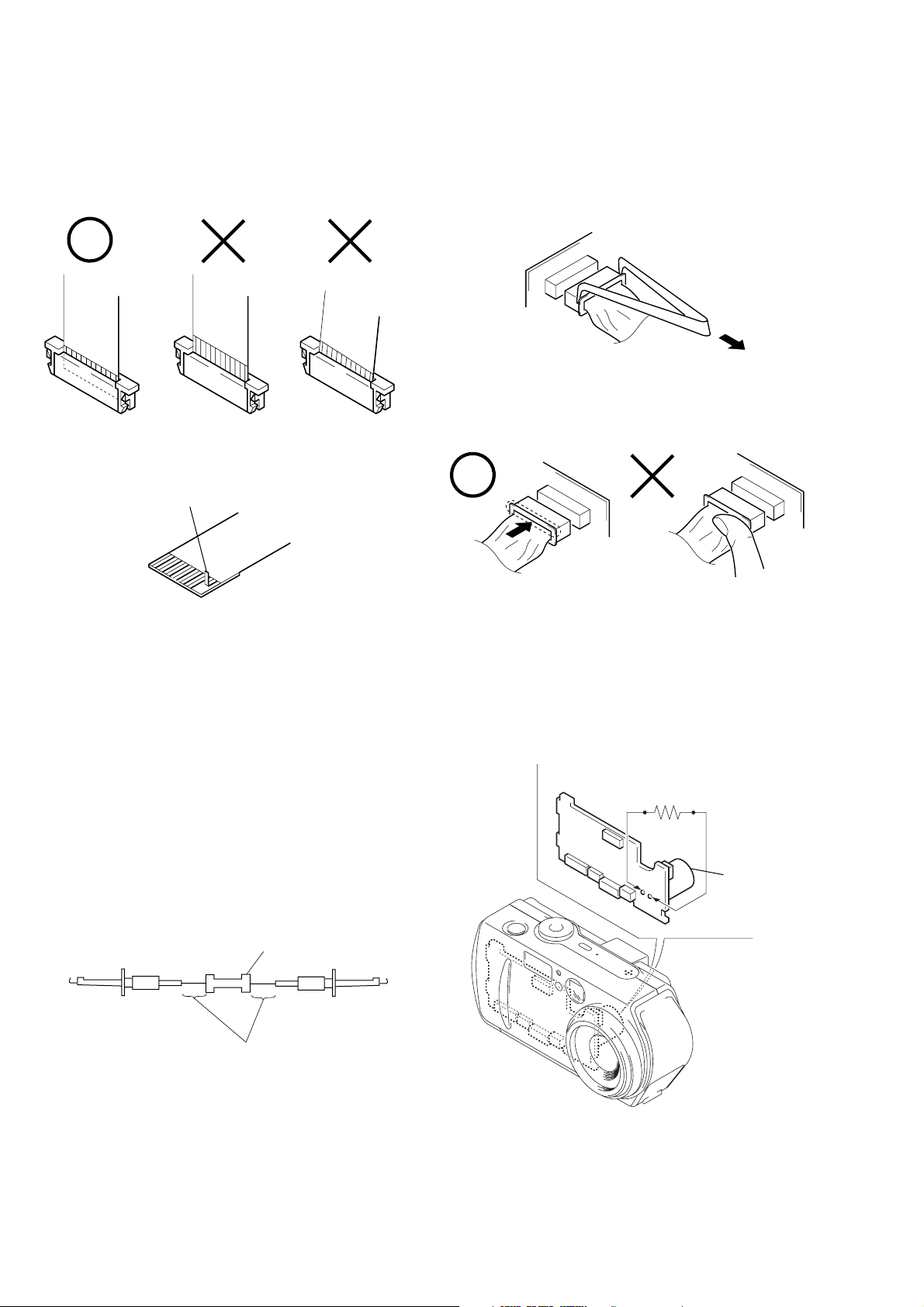

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of

the circuit board (within 3 times).

• Be careful not to apply force on the conductor when sol-

dering or unsoldering.

– 2 –

Page 3

TABLE OF CONTENTS

Section Title Page

SERVICE NOTE................................................................... 4

Self-diagnosis Display................................................... 5

1. MAIN PARTS

1. Ornamental Parts .......................................................... 6

2. DISASSEMBLY

2-1. Cabinet (R) Assembly ................................................... 7

2-2. Cabinet (Front) Block Assembly.................................... 7

2-3. DD-158 Board ............................................................... 8

2-4. Chassis (Main) Assembly.............................................. 8

2-5. Lens Block Assembly .................................................... 8

2-6. Optical Finder ................................................................ 8

2-7. Zoom Lens ..................................................................... 9

2-8. JK-206 Board ................................................................ 9

2-9. DC Jack ......................................................................... 9

2-10. SY-66 Board .................................................................. 9

2-11. LCD Module................................................................... 10

3. REPAIR PARTS LIST

3-1. Exploded Views ............................................................. 11

3-1-1. Cabinet (Front) Block Assembly .............................. 11

3-1-2. Main Chassis Assembly........................................... 12

3-1-3. Lens Block Assembly............................................... 13

3-1-4. Cabinet (Rear) Block Assembly............................... 14

4. GENERAL

Introduction .............................................................................. 16

Identifying the Parts................................................................. 16

Preparing the Power Supply.................................................... 16

Setting the Date and Time....................................................... 18

Inserting the “Memory Stick” ................................................... 18

Basic Operations ..................................................................... 18

Recording Still Images ............................................................ 19

Recording Moving Images....................................................... 20

Playing Back Still Images ........................................................ 21

Playing Back Moving Images .................................................. 21

Viewing Images Using a Personal Computer ......................... 21

Image File Storage Destinations and Image Files.................. 23

Before Performing Advanced Operations ............................... 24

Various Recording ................................................................... 26

Various Playback ..................................................................... 28

Editing ..................................................................................... 29

Additional Information.............................................................. 32

Troubleshooting ....................................................................... 33

Warning and Notice Messages ............................................... 34

Self-diagnosis Display ............................................................. 35

LCD Screen Indicators ............................................................ 35

– 3 –

Page 4

• NOTE FOR REPAIR

SERVICE NOTE

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

When remove a connector, don’t pull at wire of connector.

It is possible that a wire is snapped.

When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

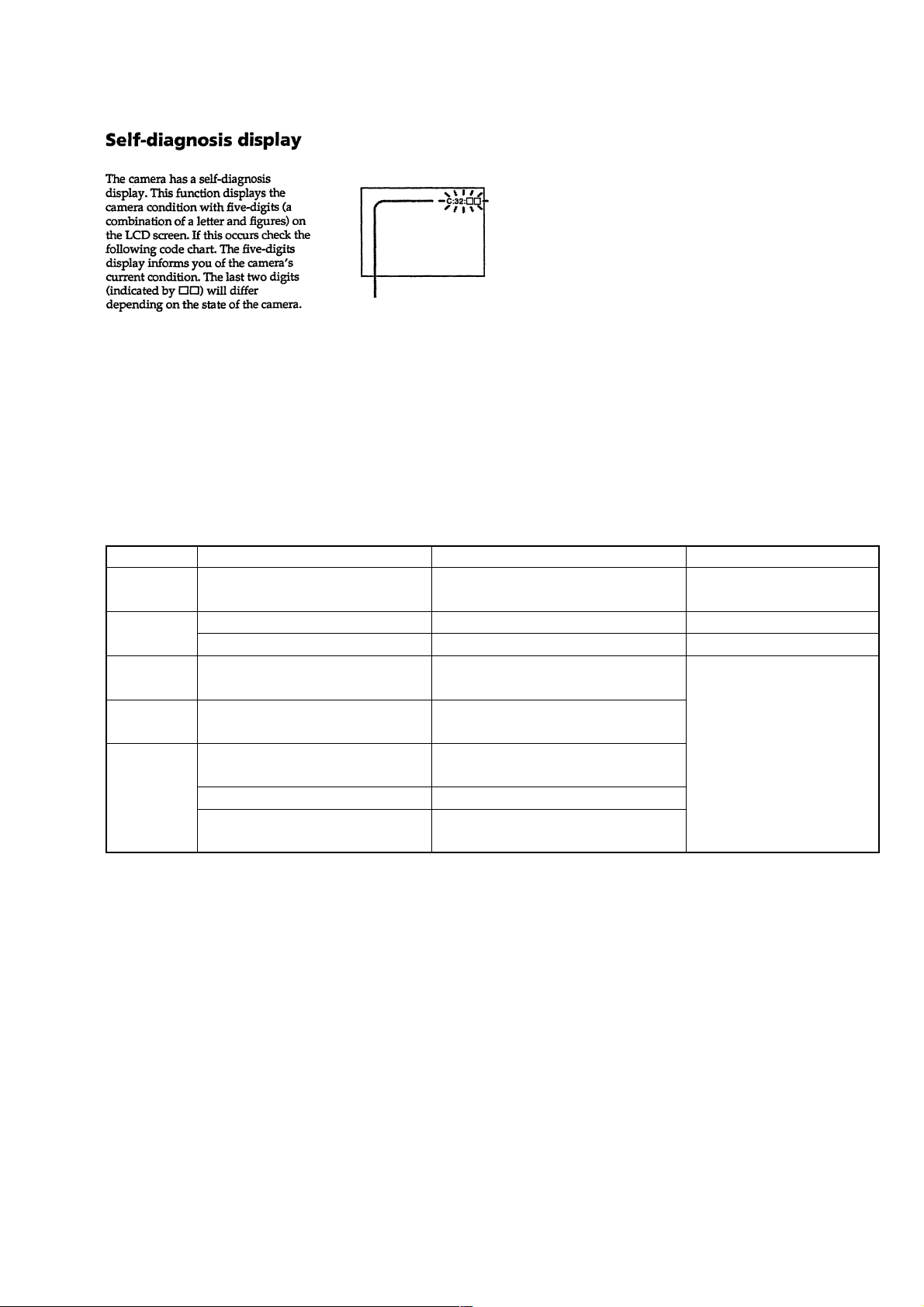

[Discharging of the DD-158 board’s charging capacitor

(C506)]

The charging capacitor (C506) of the DD-158 board is charged up

to the maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

battery is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging w hen the main

power of the unit is simply turned off. Therefore, the remaining

voltage must be discharged as described below.

Preparing the Short Jig

T o preparing the short jig, a small clip is attached to eac h end of a

resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to prevent electrical shock.

1 kΩ/1 W

Wrap insulating tape.

Discharging the Capacitor

Short-circuit between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

R:1 kΩ/1 W

(Part code:

1-215-869-11)

Capacitor

– 4 –

Page 5

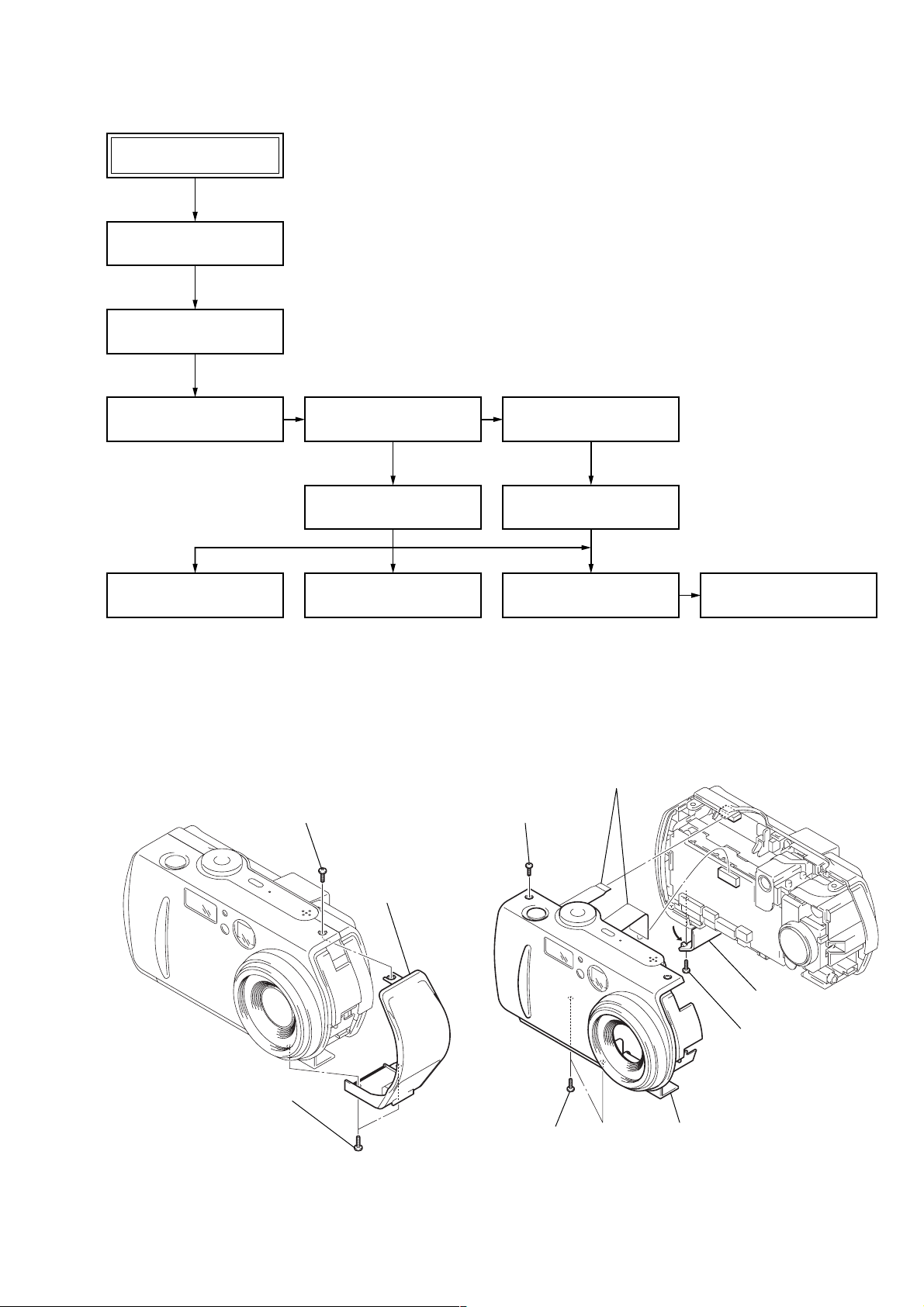

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

You can reverse the camera malfunction yourself. (However , contact your Sony dealer or local

authorized Sony service facility

when you cannot recover from

the camera malfunction.)

• E: ss: ss

Contact your Sony dealer or local authorized Sony service facility.

Display Code

C:32:ss

C:13:ss

E:61:ss

E:91:ss

Countermeasure

Turn the power off and on again.

Format the “Memory stick”.

Insert a new “Memory Stick”.

Checking of lens drive circuit.

Checking of flash unit or replacement

of flash unit.

Use an “InfoLITHIUM” battery pack.

Insert a battery pack correctly. Battery pack is not inserted correctly. E:92:ss

Turn the power off and on again.

Cause

Trouble with hardware.

Unformatted memory stick is inserted.

Memory stick is broken.

When failed in the focus and zoom

initialization.

Abnormality when flash is being

charged.

Battery pack is not “InfoLITHIUM”

compatible.

Battery pack was installed or removed

when using the AC adaptor.

Caution Display During Error

SYSTEM ERROR

FORMAT ERROR

MEMORY STICK ERROR

—

– 5 –

Page 6

DSC-P30/P50

1. MAIN PARTS

Note:

• Items marked “*” are not stocked since they are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• The parts numbers of such as a cabinet are also appeared in this section.

Refer to the parts number mentioned below the name of parts to order.

1. ORNAMENTAL PARTS

Ver 1.1 2001. 05

Cover (DC)

not supplied

Checking supplied accessories.

Lens cap (1)

X-3951-673-1

CD-ROM

(SPVD-004 USB driver) (1)

3-006-677-01

USB cable (1)

1-757-293-11

Lid (CPC) Assembly

X-3951-755-1

Lens cap strap (1)

3-067-797-11

“Memory Stick”

(8 MB) (1)

A/V connecting cable (1)

1-783-738-31

Size AA alkaline batteries (2) Wrist strap (1)

3-068-699-01

Other accessories

3-068-186-11 MANUAL, INSTRUCTION (ENGLISH)

3-068-186-21 MANUAL, INSTRUCTION

(FRENCH, GERMAN) (AEP)

3-068-186-31 MANUAL, INSTRUCTION

(SPANISH, PORTUGUESE) (AEP)

3-068-186-41 MANUAL, INSTRUCTION

(ITALIAN, DUTCH) (AEP)

3-068-186-61 MANUAL, INSTRUCTION

(SWEDISH, RUSSIAN) (AEP)

– 6 –

Page 7

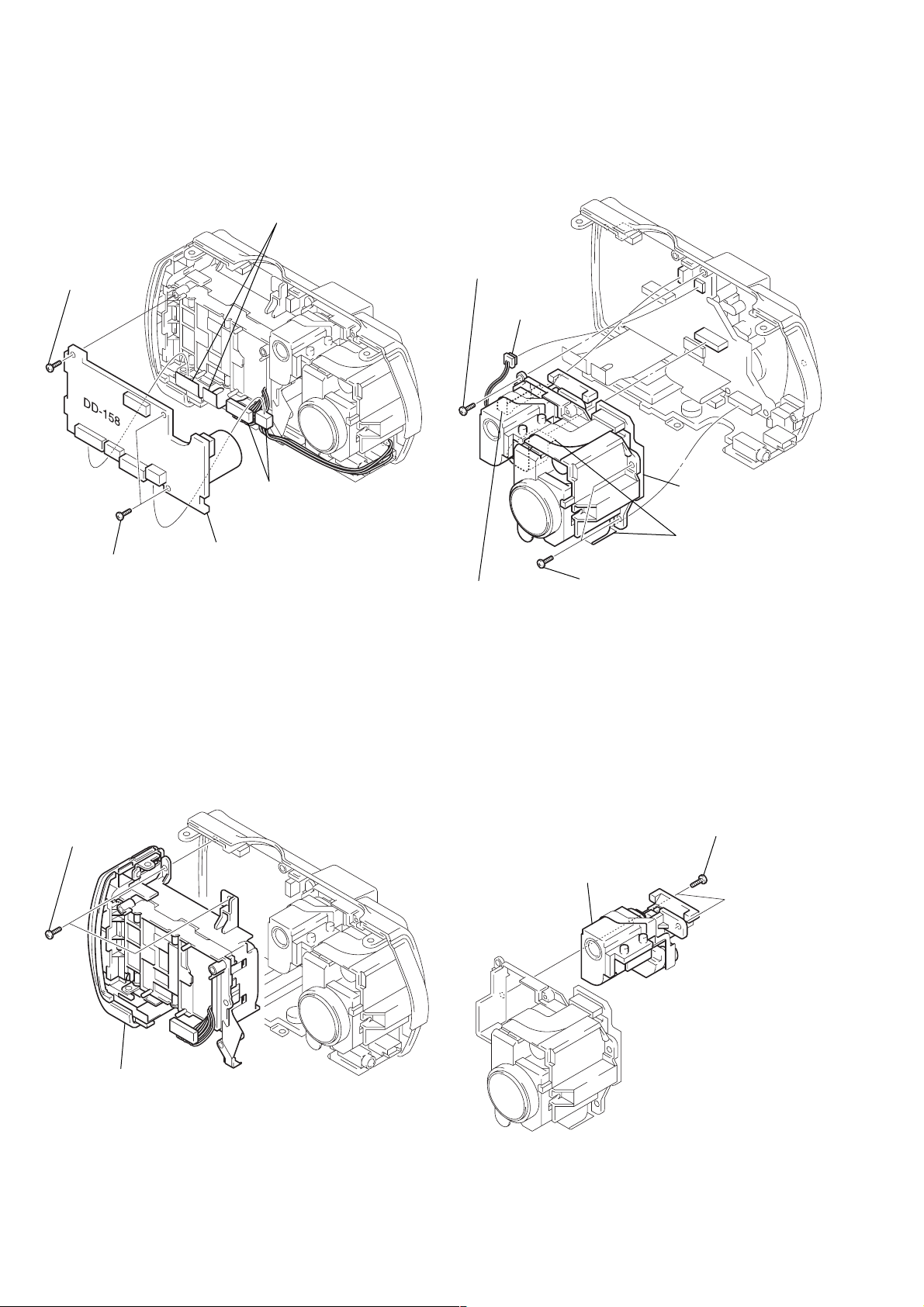

2. DISASSEMBLY

• This set can be disassembled in the order shown below.

DSC-P30/P50

2-1. CABINET (R) ASSEMBLY

(Page 7)

2-2. CABINET (FRONT) BLOCK

ASSEMBLY (Page 7)

DSC-P30/P50

2-3. DD-158 BOARD

(Page 8)

2-6. OPTICAL FINDER

(Page 8)

2-4. CHASSIS (MAIN)

ASSEMBLY (Page 8)

2-5. LENS BLOCK ASSEMBLY

(Page 8)

2-7. ZOOM LENS

(Page 9)

Note: Follow the disassembly procedure in the numerical order given.

2-1. CABINET (R) ASSEMBLY

1 Screw

(M2)

2-8. JK-206 BOARD

(Page 9)

2-9. DC JACK

(Page 9)

2-10. SY-66 BOARD

(Page 9)

2-11. LCD MODULE

(Page 10)

2-2. CABINET (FRONT) BLOCK ASSEMBLY

6 Two flexible boards

(CN501, 708)

3 Screw

(M2)

2 Two screws

(M2)

3 Cabinet (R)

assembly

– 7 –

4 Two screws

(M2)

1 Open the MS lid.

2 Screw

(M2)

5 Cabinet (front)

block assembly

Page 8

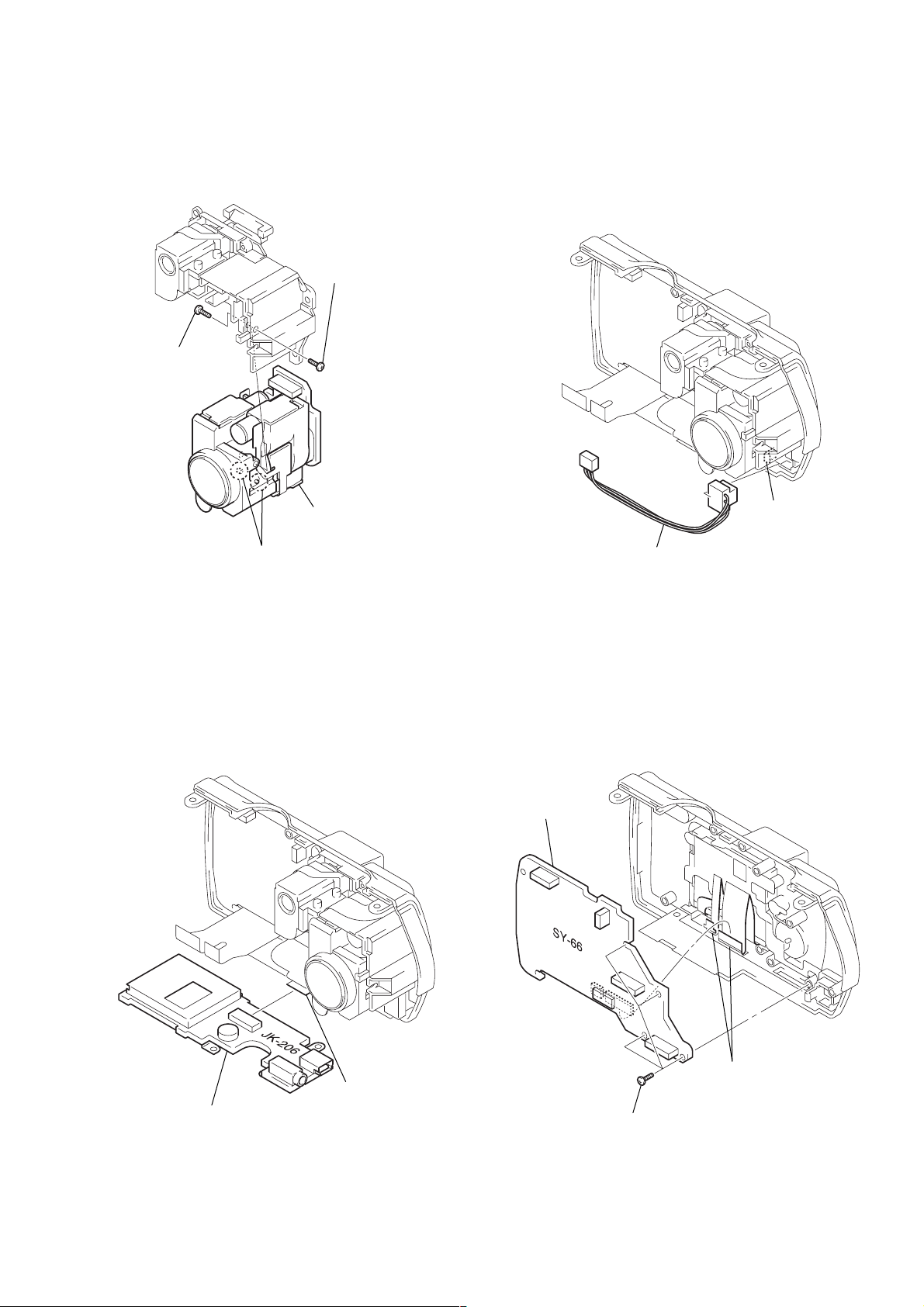

2-3. DD-158 BOARD

2-5. LENS BLOCK ASSEMBLY

1 Two flexible boards

(CN003, 004)

3 Screw

(DIA. 1.7 × 4)

4 Screw

2 Two connectors

(CN001, 002)

5 DD-158 board

(DIA. 1.7 × 4)

4 Screw

(DIA. 1.7 × 4)

6 Connector

(CN702)

1 Flexible board

(CN182)

3 Two screws

(DIA. 1.7 × 4)

2-4. CHASSIS (MAIN) ASSEMBLY 2-6. OPTICAL FINDER

5 Lens block

assembly

2 Two flexible boards

(CN101, 181)

1 Two screws

(DIA. 1.7 × 4)

2 Chassis (main) assembly

1 Two screws

(DIA. 1.7 × 4)

2 Optical finder

– 8 –

Page 9

2-7. ZOOM LENS

2 SY-66 board

3 Two flexible board

(CN805, 806)

1 Four screws

(M1.7 × 5)

2 Screw

(DIA. 1.7 × 4)

2-9. DC JACK

1 Screw

(DIA. 1.7 × 4)

4 Zoom lens

3 Two bosses

2 DC jack

2-8. JK-206 BOARD 2-10. SY-66 BOARD

1 Claw

1 JK-206 board

2 Flexible board

(CN201)

– 9 –

Page 10

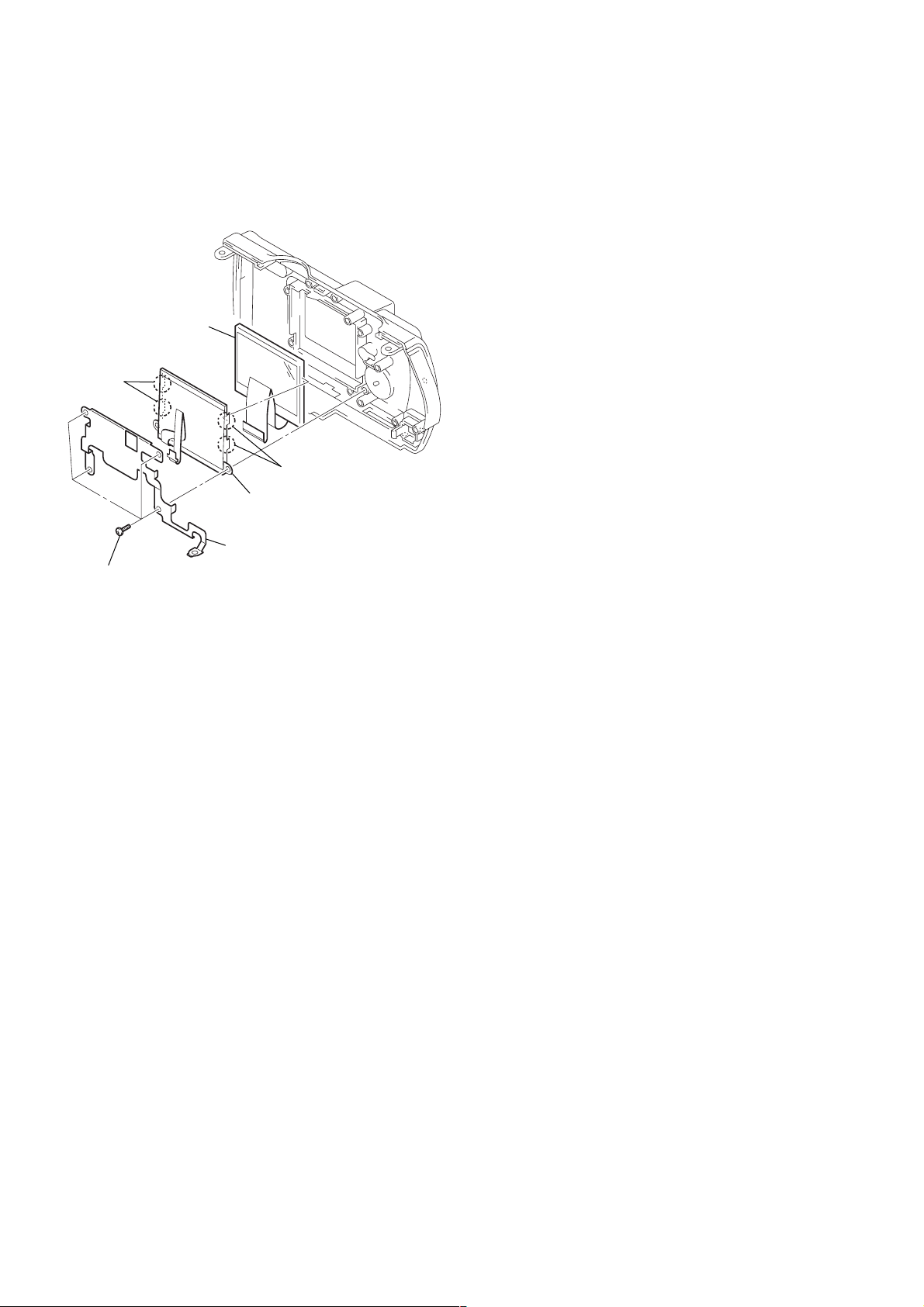

2-11. LCD MODULE

6 LCD module

5 Two claws

1 Four screws

(1.7 × 3)

4 Two claws

3 Light guide plate (1.5) block

2 Ground plate (LCD)

– 10 –

Page 11

3. REPAIR PARTS LIST

3-1. EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they may

have some difference from the original one.

• Items marked “*” are not stocked since they are

seldom required for routine service. Some delay

should be anticipated when ordering these items.

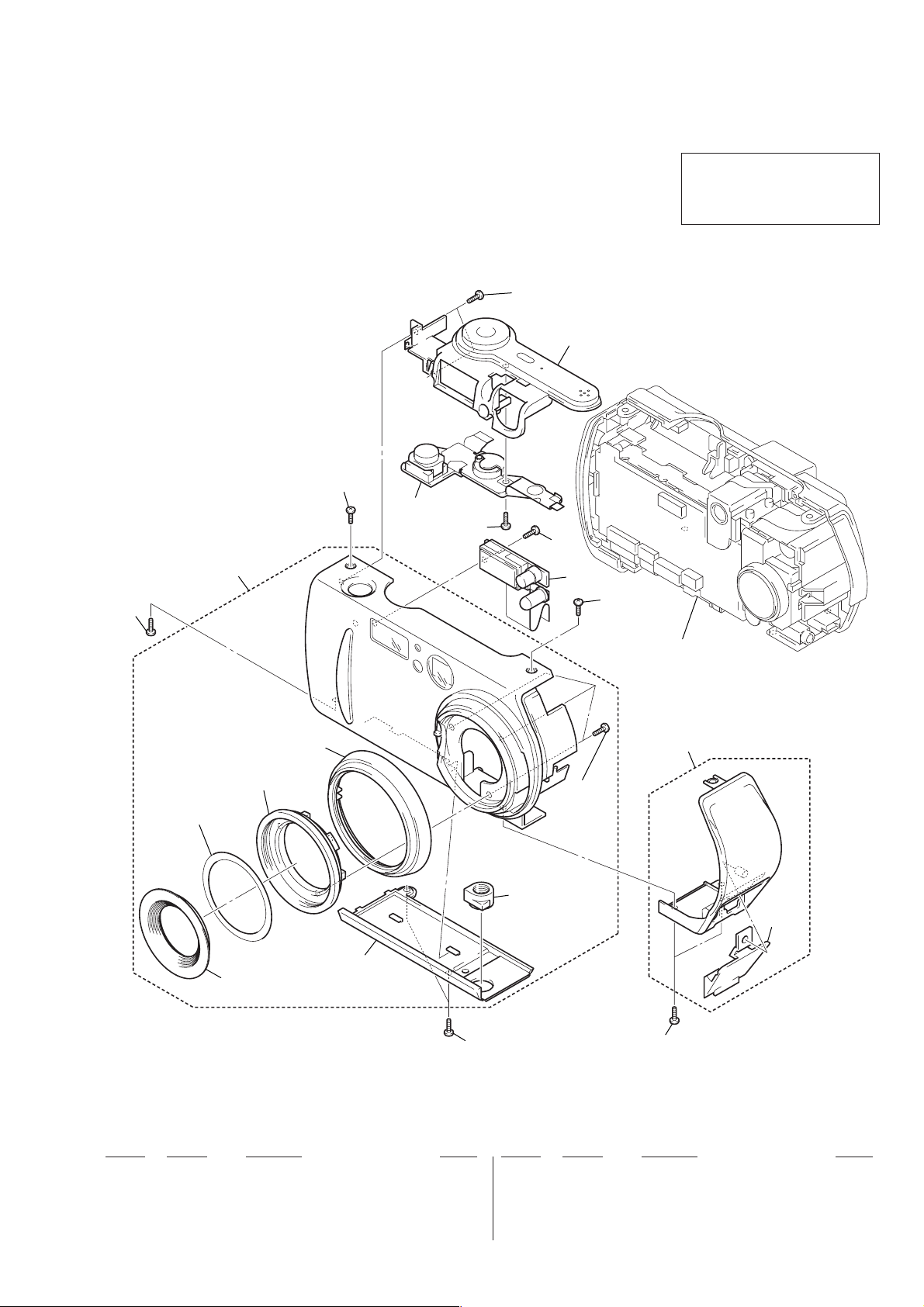

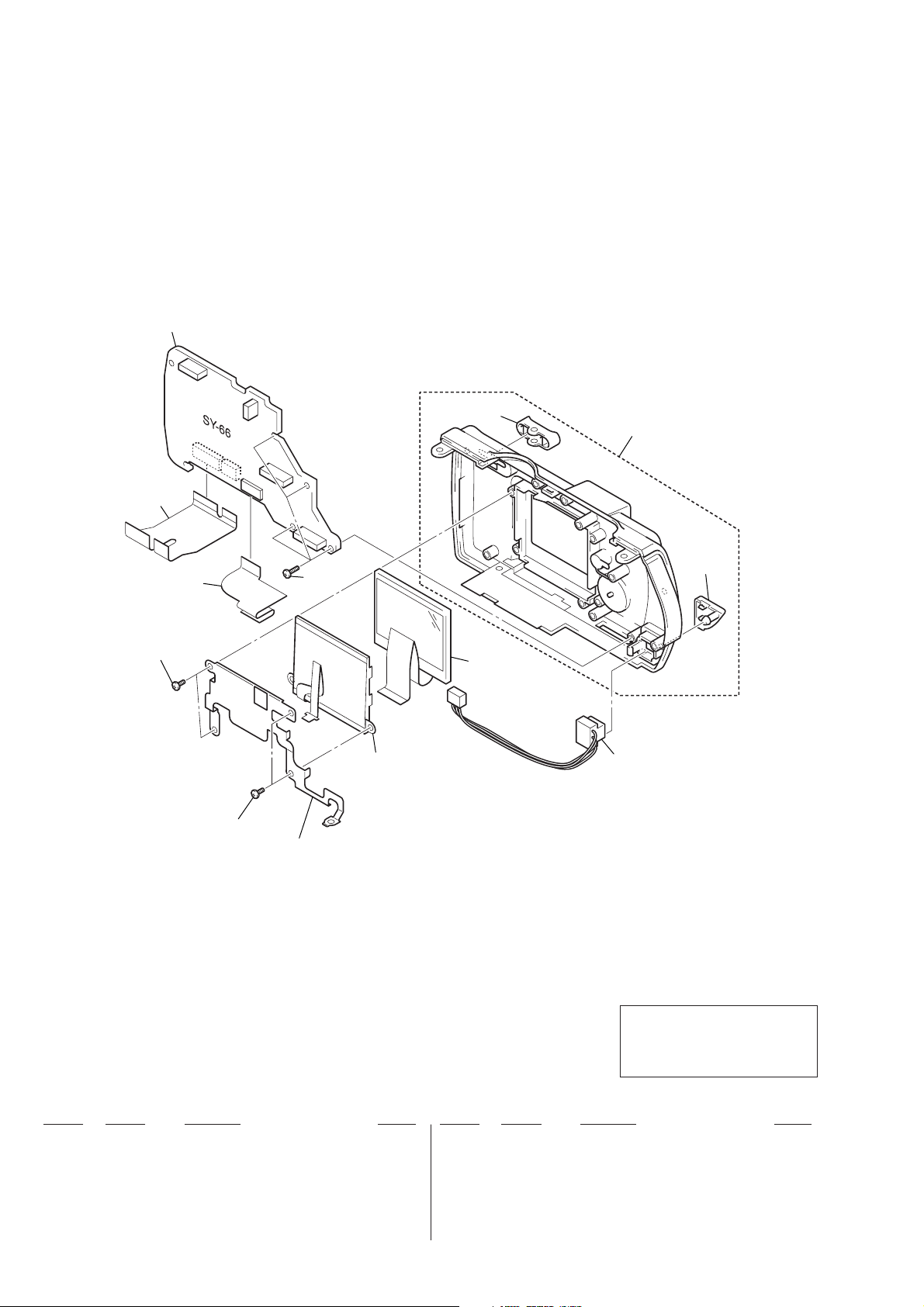

3-1-1. CABINET (FRONT) BLOCK ASSEMBLY

13

1

13

• The mechanical parts with no reference number in

the exploded views are not supplied.

9

DSC-P30/P50

Ver 1.1 2001. 05

The components identified by mark

0 or dotted line with mark 0 are

critical for safety.

Replace only with part number specified.

7

10

7

7

8

13

not supplied

not supplied

not supplied

not supplied

not supplied

13

not supplied

Main chassis assembly

(See page 12.)

11

not

supplied

not

supplied

13

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 X-3951-657-1 CABINET (FRONT) ASSY (P50)

1 X-3951-662-1 CABINET (FRONT) ASSY (P30)

7 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

0 8 not supplied STROBO FLEXIBLE BLOCK ASSY

9 1-476-677-11 SWITCH BLOCK, CONTROL

10 X-3951-661-1 CABINET (UPPER) ASSY

11 X-3951-659-1 COVER (R) ASSY (P50)

11 X-3951-664-1 COVER (R) ASSY (P30)

13 3-968-729-71 SCREW (M2), LOCK ACE, P2

– 11 –

Page 12

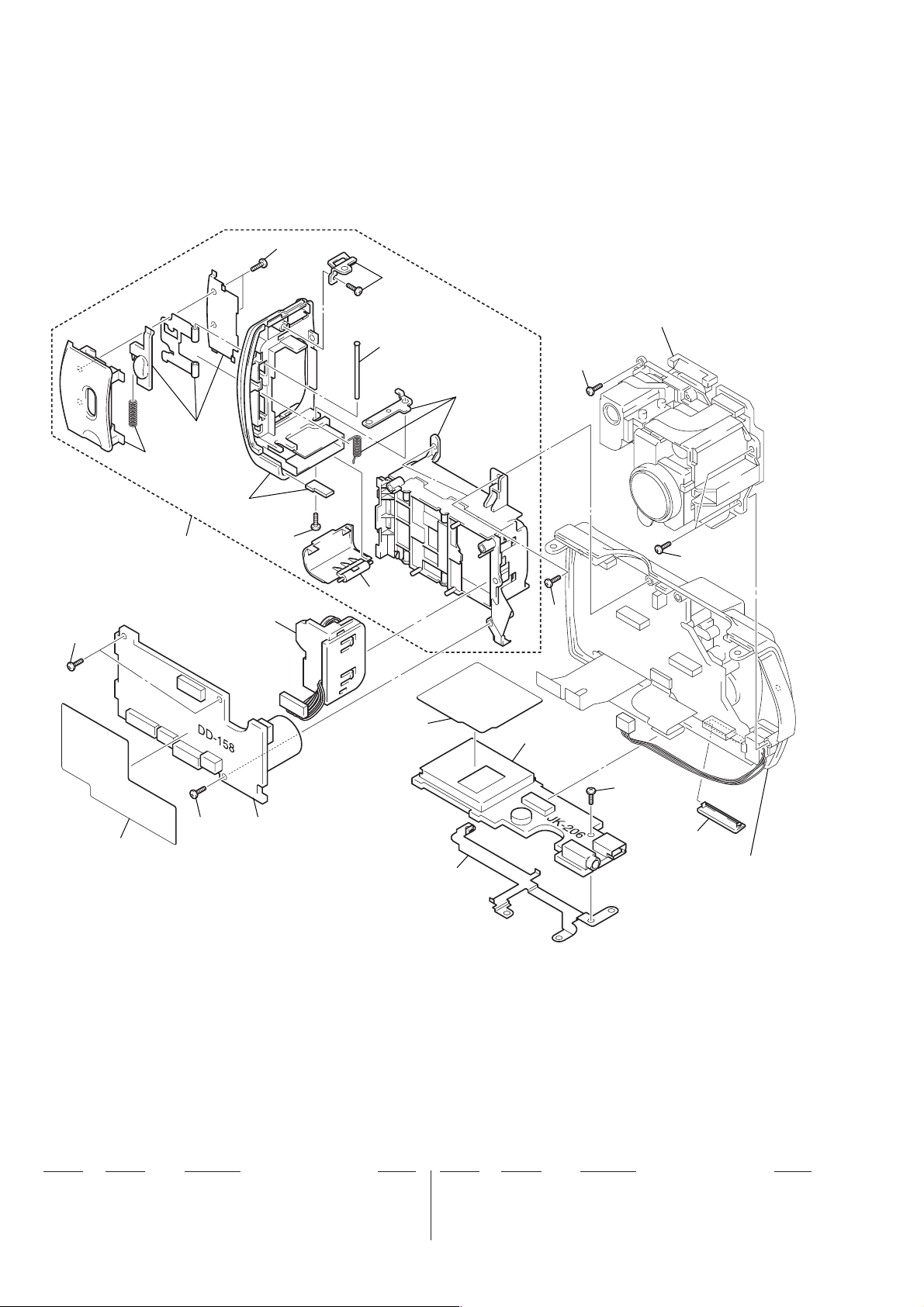

3-1-2. MAIN CHASSIS ASSEMBLY

y

not

supplied

not

supplied

not

supplied

not

supplied

not

53

supplied

not

supplied

not

supplied

Ver 1.1 2001. 05

Lens block assembly

(See page 13.)

52

not

supplied

52

52

not supplied

BT901

5152

not

supplied

not supplied

61

52

60

59

62

Cabinet (rear) block assembl

(See page 14.)

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 not supplied DD-158 BOARD, COMPLETE

52 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

53 X-3951-660-1 CHASSIS (MAIN) ASSY

59 3-968-729-71 SCREW (M2), LOCK ACE, P2

60 not supplied JK-206 BOARD, COMPLETE

61 3-068-555-01 PLATE (JK), GROUND

62 X-3951-755-1 LID (CPC) ASSY

BT901 1-694-812-11 TERMINAL BOARD, BATTERY

– 12 –

Page 13

3-1-3. LENS BLOCK ASSEMBLY

102

101

103

not supplied

BZ701

not supplied

102

110

105

109

102

111

104

106

107

IC401

108

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 not supplied LENS, ZOOM (DE01)

102 3-914-366-01 SCREW (DIA. 1.7X4), PRECISION

103 3-068-554-01 CHASSIS (LENS)

104 1-758-621-11 FINDER, OPTICAL (DE02)

105 1-681-601-11 FP-054 FLEXIBLE BOARD

106 3-318-203-11 SCREW (B1.7X6), TAPPING

107 not supplied CD-319 BOARD, COMPLETE (P50)

107 not supplied CD-319 BOARD, COMPLETE (P30)

108 not supplied CCD SEAL RUBBER

109 not supplied FILTER BLOCK, OPTICAL (P30)

109 not supplied FILTER BLOCK, OPTICAL (P50)

110 1-681-602-11 FP-058 FLEXIBLE BOARD

111 3-069-237-01 SHEET, LENS (FP)

BZ701 1-544-829-11 BUZZER, PIEZOELECTRIC

IC401 not supplied CCD BLOCK ASSY (CCD IMAGER) (P50)

IC401 not supplied CCD BLOCK ASSY (CCD IMAGER) (P30)

– 13 –

Page 14

3-1-4. CABINET (REAR) BLOCK ASSEMBLY

151

152

Ver 1.1 2001. 05

not supplied

154

158

153

158

157

not supplied

D901

not

supplied

LCD901

J001

The components identified by mark

0 or dotted line with mark 0 are

critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 not supplied SY-66 BOARD, COMPLETE (SERVICE) (P50)

151 not supplied SY-66 BOARD, COMPLETE (SERVICE) (P30)

152 1-681-599-11 FP-052 FLEXIBLE BOARD

153 1-681-600-11 FP-053 FLEXIBLE BOARD

154 X-3951-658-1 CABINET (REAR) ASSY (P50)

154 X-3951-633-1 CABINET (REAR) ASSY (P30)

157 3-713-791-11 SCREW (M1.7X5), TAPPING, P2

158 3-318-382-01 SCREW (1.7X3), TAPPING

0 D901 not supplied BLOCK, LIGHT GUIDE PLATE (1.5)

J001 1-815-571-11 JACK, DC

LCD901 not supplied ACX309AK-1

– 14 –

Page 15

DSC-P30/P50

WARNING

To prevent fire or shock hazard, do

not expose the unit to rain or

moisture.

For the Customers in the

U.S.A.

This symbol is intended to

alert the user to the presence

of uninsulated “dangerous

voltage” within the

product’s enclosure that

may be of sufficient

magnitude to constitute a

risk of electric s h ock to

persons.

This symbol is intended to

alert the user to the presence

of important operating and

maintenance (servicing)

instructions in the literature

accompanying the

If you have any questions about this product,

you may call:

appliance.

Sony Customer Information Services Center

1-800-222-SONY (7669)

2

The number below is for the FCC related

matters only.

Declaration of Conformity

Trade Name: SONY

Model No.: DSC-P30

Responsible Party:Sony Electronics Inc.

Address: 680 Kinderkamack

Telephone No.: 201-930-6972

This device complies with Part 15 of the

FCC Rules. Operation is subject to the

following two conditions: (1) This

device may not cause harmful

interference, and (2) this device must

accept any interference received,

including interference that may cause

undesired operation.

Declaration of Conformity

Trade Name: SONY

Model No.: DSC-P50

Responsible Party:Sony Electronics Inc.

Address: 680 Kinderkamack

Telephone No.: 201-930-6972

This device complies with Part 15 of the

FCC Rules. Operation is subject to the

following two conditions: (1) This

device may not cause harmful

interference, and (2) this device must

accept any interference received,

including interference that may cause

undesired operation.

CAUTION

You are cautioned that any changes or

modifications not expressly approved in this

manual could void your authority to operate

this equipment.

Road, Oradell, NJ

07649 USA

Road, Oradell, NJ

07649 USA

4. GENERAL

Note:

This equipment has been tested and found to

comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful

interference in a residential installation. This

equipment generates, uses, and can radiate

radio frequency energy and, if not installed

and used in accordance with the

instructions, may cause harmfu l interference

to radio communications. However, there is

no guarantee that interfere nce will not o ccur

in a particular installation. If this equipment

does cause harmful interference to radio or

television reception, which can be

determined by turning the equipment off and

on, the user is encouraged to try to correct

the interference by one or more of the

following measures:

— Reorient or relocate the receiving

antenna.

— Increase the separa ti on between the

equipment and receiver.

— Connect the equipment into an outlet

on a circuit different from that to which

the receiver is connected.

— Consult the dealer or an experienced

radio/TV technician for help.

The supplied interface cable must be used

with the equipment in order to co mply with

the limits for a digital device pursuant to

Subpart B of Part 15 of FCC Rules.

For the Customers in the

U.S.A.

DISPOSAL OF LITHIUM ION

BATTERY .

LITHIUM ION BATTERY.

DISPOSE OF PROPERLY.

You can return your unwanted lithium ion

batteries to your nearest Sony Service

Center.

Note:

In some areas the disposal o f li thium ion

batteries in household or business trash may

be prohibited.

For the Sony Service Center near est yo u call

1-800-222-SONY (United States only)

This section is extracted from

instruction manual.

Caution:

Do not handle damaged or leaking lithium

ion battery.

For the Customers in

Germany

Directive:EMC Directive 89/336/EEC,

92/31/EEC

This equipment complies with the EMC

regulations when used under the following

circumstances:

•

Residential area

•

Business district

•

Light-industry district

(This equipment complies with the EMC

standard regulations EN55022 Class B.)

Attention for the Customers in

Europe

This product has been tested and found

compliant with the limits sets out on the

EMC Directive for using connection cables

shorter than 3 meters.

Attention

The electromagnetic fields at the s pe cific

frequencies may influence the pictu re a nd

sound of this camera.

“Memory Stick”

N50

3

For the Customers in the

U.S.A. and Canada

THIS CLASS B DIGITAL DEVICE

COMPLIES WITH PART 15 OF THE

FCC RULES AND THE CANADIAN

ICES-003 OPERATION IS SUBJECT

TO THE FOLLOWING TWO

CONDITIONS:

(1) THIS DEVICE MAY NOT CAUSE

HARMFUL INTERFERENCE, AND

(2) THIS DEVICE MUST ACCEPT

ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT

MAY CAUSE UNDESIRED

OPERATION.

Be sure to read the following

before using your camera

Trial recording

Before you record one-time events, you may

want to make a trial recording to make sure

that the camera is working correctly.

No compensation for contents of

the recording

Contents of the recording cannot be

compensated for if recording or playback is

not possible due to a malfunction of your

camera or recording medium, etc.

Notes on image data compatibility

•

This camera conforms with the Design

Rules for Camera File Systems universal

standard establ is hed by the JEITA (Japan

Electric and Information Technology

Industries). You cannot play back on your

camera still images recorded on other

equipment (DCR-TRV890E/TRV900/

TRV900E, DSC-D700, DSC-D770) that

does not conform with this universal

standard. (These models are not sold in

some areas.)

•

Playback of images recorded with your

camera on other equipment and playback

of images recorded or edited with other

equipment on your camera are not

guaranteed.

Precaution on copyright

Television programs, films, video tapes, and

other materials may be copyrighted.

Unauthorized recording of suc h ma terials

may be contrary to the provision of the

copyright laws.

Do not shake or strike the camera

In addition to malfunctions and inability to

record images, this ma y render the

“Memory Stick” unusable or image data

breakdown, damage or loss may occur.

Do not aim the camera at the sun

or other bright light

This may cause irrecoverable damage to

your eyes.

LCD screen, LCD finder (only

models with a finder) and lens

•

The LCD screen and the LCD finder are

manufactured using extremely highprecision technology so over 99.99% of

the pixels are operational for effective use.

However, there may be some tiny black

points and/or bright points (white, red,

blue or green in color) that constantly

appear on the LCD screen and the LCD

finder. These points are normal in the

manufacturing process and do not affect

the recording in any way.

•

Be careful when placing the camera near a

window or outdoors. Exposing the LCD

screen, the finder or the lens to direct

sunlight for long periods may cause

malfunctions.

Notes on batteries

Be careful when removing the b atteries, as

they may be hot after the camera is used for

long periods.

Do not get the camera wet

When taking pictures outdoors in the rain or

under similar conditions, be careful not to

get the camera wet. If moisture

condensation occurs, refer to page 71 and

follow the instructions on how to remove it

before using the camera.

Back up recommendation

To avoid the potential risk of data loss,

always copy (back up) data to a disk.

When the camera is used for long

periods

Note that the camera body may become hot.

4

5

– 15 –

Page 16

Introduction

Checks the image after recording images

Recording still images:

page 19

Playing back still images:

page 28

Deleting images (DELETE):

page 62

Captures images with your computer

You can copy images onto your computer and view and modify images or attach

images to e-mail on your computer using the supplied USB cable and application

software.

Viewing images using a personal computer: pag e 30

Recording still images for e-mail (E-MAIL): page 48

Getting started

Identifying the parts

See the pages in parent hes es for details of operation.

Records a moving picture (MPEG Movie or Clip Motion)

according to your purpose

Recording moving images (MPEG

MOVIE): page 26

Selects the recording mode from various types of recordings

according to your situation

Creating Clip Motion Files: page51

Recording text documents (TEXT): page 49

Recording still images as uncompressed files (TIFF): page50

6

Attaching the str ap

Getting started

A POWER button/lamp (15)

Press and hold down this button

for approximately one second to

turn on the came ra.

B Mode dial (18) (39)

: To record in TWILIGHT

mode

: To record still images

: To playback or edit

images

: T o record moving images

or Clip Motion images

SET UP:To set the setup items

C Shutter button (19) (27)

D Flash (24)

E Photocell window for flash

Do not block while recording with

the flash.

F Self-timer (23) (27)/

AF illuminator (25)

G Lens cap (supplied)

Be sure to remove the lens cap

before recording.

H Finder window

I Beep/shutter sound holes

J Lens

K Jack cover

L USB jack (32) (34)

M VIDEO OUT jack (61)

N Tripod receptacle (bottom

surface)

Use a tripod with a screw length of

less than 5.5 mm (7/32 inch). You

will be unable to firmly secure the

camera to tripods having longer

screws, and may damage the

camera.

O RESET button (75)

8

Preparing the power supply

Installing the supplied batteries or an optional

battery pack

Your camera operates only with the following batteries.

•

Two size AA alkaline batteries (supplied)

•

“InfoLITHIUM” (S series) battery pack (NP-FS11) (not supplied)

•

Two size AA nickel metal hydride batteries (not supplied)

•

Two size AA nickel-cadmium batteries (not supplied)

The “InfoLITHIUM” ba ttery pack is recommen ded for longer operatin g times. Note

that in this Operating Instructions, “batteries” refers to siz e AA al ka lin e batteries.

Batteries

A Finder

Self-timer/recording lamp (red)

AE/AF lock lamp (gr e e n)

/CHG (flash charge/battery

charge) lamp (orange) (24)

B MENU button (40)

C DC IN jack cover (12) (14)

D DC IN jack (12) (14)

E Control button ( 18) ( 39)

F LCD screen

G DISPLAY/LCD ON/OFF button

(21)

H Zoom button (INDEX button

during playback ) ( 2 2 )

I Hook for lens cap/wrist strap

J OPEN switch

K Battery cover

L Access lamp (17)

M “Memory Stick” cover

“InfoLITHIUM” battery p ack (not supplied)

Insert the battery pack with the v mark facing toward the bat tery compartment.

Open the battery cover.

1

Open the cover while sliding the OPEN switch in the direction of the arrow.

9

10

– 16 –

Page 17

Install the batteries.

2

Insert the two size AA batteries with the 3 and # ends facing as illustrated. Be

careful not to insert the batteries facing the wrong way.

Close the battery cover.

3

Pressing the batteries with the cover, close the cover firmly until it clicks into

place.

To remove the batteries

Open the battery cover with the battery cover side facing upward and remove the

batteries. Be careful not to drop the batteries when removing them.

Power save mode

When operating the camera with batteries, set POWER SAVE in the SET UP screen

to ON to extend the battery life. The factory setting is ON (page70).

See page 88 for more info rmation on power save mode.

Auto power-off function

If you do not operate the cam era for about three minutes during recording or

playback, the camera turns off automatically to prevent wearing down the battery. To

use the camera again, pres s the P O WE R b utt on to tu rn on the camera agai n. The auto

power-off function only operates when the camera is operating using a battery pack.

The auto power-off also will not operate when playing back moving images or

playing back a slide show (page 60), or when a connector is plugged into the USB

jack or the DC IN jack.

* What is “InfoLITHIUM”?

“InfoLITHIUM” is a lithium ion battery pack which can exchange information such as battery

consumption with compatible vide o equ ipment. This unit is compatible with the

“InfoLITHIUM” battery pack (S series). “InfoLITHIUM” S series battery packs have the

mark. “InfoLITHIUM” is a trademark of Sony Corporation.

NP-FS11 battery pack (not supplied)

When you record images in an extremely cold location or using the LCD screen, the

operating time becomes short. When using the camera in an ex tremely cold location,

place the battery pack in your pocket or other place to keep it warm , t hen insert the

battery pack into the camera just before recording. When using a pocket heater, take

care not to let the heater di rectly contact the battery.

Charging the battery pack (not supplied)

You cannot charge the battery pack while your camera is turned on. Be sure to turn

Getting started

off your camera.

DC IN jack

cover

AC-LS1A AC power adaptor (not supplied)

Insert the battery pack into your camera.

1

Open the DC IN jack cover and connect the DC connecting cable to

2

the DC IN jack of your camera with the v mark facing up.

Connect the power cord (mains lead) to the AC power adaptor (not

3

supplied) and then to a wall outlet (mains).

The /CHG lamp lights up when charging begins. When the /CHG lamp goes

off, charging is completed.

Battery pack (S series)

(not supplied)

To the wall outlet (mains)

Power cord

(mains lead)

After charging the battery pack

Disconnect the AC power adaptor fr om the DC IN jack on your camera.

Battery remaining indicator

When using an optional “InfoLITHIUM” battery pack, the LCD screen on the

camera shows the rema in in g time for which you can still r ec or d or play back images.

This indication may not be ent i rely accurate depending on th e conditions of use and

the operating environment.

Charging of 10°C to 30°C (50°F to 86°F) circumstances is recommended.

When using size AA alkaline batteries, the remaining time is not shown.

Note

When you turn the LCD screen on and off, it takes about one minute for the correct battery

remaining time to appear.

Battery life and number of images that can be recorded/played back

Still image recording*

SONY alkaline batteries

(supplied)

Battery life

(min.)

Number of

images

NP-FS11 (not supplied)**

Battery life

(min.)

Number of

images

LCD screen ON Approx. 30 Approx. 600 Approx. 90 Approx. 1800

LCD screen OFF Approx. 60 Approx. 1200 Approx. 120 Approx. 2400

Still image playback***

SONY alkaline batteries

(supplied)

Battery life

(min.)

Number of

images

NP-FS11 (not supplied)**

Battery life

(min.)

Number of

images

LCD screen ON Approx. 60 Appr ox. 1200 Approx. 120 App rox. 2400

Approximate battery lif e and number of images that can be recorded/played ba ck

640×480 image size, standard picture quality, no flash, and in NORMAL recording

mode.

Recording at about 3-second intervals with the power save mode off (when continuous

∗

recording, the power save mode does not operate effectively.)

When using a fully charged battery pack at a temperature of 25°C (77°F).

∗∗

Playing back single images in order at about 3-sec ond intervals

∗∗∗

Moving image recording

SONY alkaline batteries

(supplied)

LCD screen

Continuous

recording

Approximate recor ding time in 160×112 imag e size.

When using a fully charged battery pack at a temperature of 25°C (77°F).

∗

Notes

•

The camera may not operate in an extremely cold location when using alkaline batteries.

Even when using an “InfoLITHIUM” battery pack (not supp l ied), the battery life and number

of images will be decreased if you use your camera at low temperatures, use the flash ,

repeatedly turn the power on/off or use the zoom.

•

The numbers of images shown on tables above are as a guide. The numbers may be smaller

depending on conditions.

•

The capacity of the “Memory Stick” is limited. The ab ove figures are a guide when you

continuously record/play back while replaci ng the “M em or y S tic k. ”

•

When LCD BACKLIGHT is set to BRIGHT, th e battery life and number of images will be

decreased.

OFF (min.)

Approx. 60 Approx. 30 Approx. 120 Approx. 90

LCD screen

ON (min.)

NP-FS11 (not supplied)*

LCD screen

OFF (min.)

LCD screen

ON (min.)

11

13

Getting started

12

Charging time

Battery pack Full charge (min.)

NP-FS11 (not supplied) Approx. 180

Approximate time to charge a completely discharged battery pack using the

AC-LS1A AC power adaptor (not supplied) a t a temperature of 25°C (77°F).

Using the AC power adaptor (not supplied)

DC IN jack

cover

To the wall outlet (mains)

Power cord

(mains lead)

AC-LS1A AC power adaptor (not supplied)

Open the DC IN jack cover and connect the DC connecting cable to

1

the DC IN jack of your camera with the v mark facing up.

Connect the power cord (mains lead) to the AC power adaptor (not

2

supplied) and then to a wall outlet (mains).

Using a car battery

Use Sony DC adaptor/charger (not supplied).

Using your camera abroad

For details, see page74.

When using the AC power adaptor

Be sure to use it near the wall outlet. If a malfunction occurs, disconnect the plug

from the wall outlet.

14

– 17 –

Page 18

Setting the date and time

When you first use your camera, set the date and time. If these are not set, the

CLOCK SET screen appear s whenever you turn on your camera.

Control button

Select the item with

, then set with

vVbB

the center z.

Set the mode dial to , , or

1

Press and hold down the POWER button for

2

approximately one second to turn on the

power.

The POWER ON/OFF (CHG) lamp (green) lights

up.

The CLOCK SET screen appears on the LCD

screen.

To change the date and time, set the mode dial to

SET UP (page 69) and perform the procedure from step 3.

Select the desired date display format with

3

on the control button, then press the

v/V

center z.

Select from [Y/M/D] (year/month/da y), [M/D/Y]

(month/day/year) or [D/M/Y] (day/month/year).

Select the year, month, day, hour or minute

4

item you wa nt to se t w it h b/B on the control

button.

The item to be set is indicated with v/V.

ON/OFF(CHG)

CLOCK SET

2001

/:/

1

OK

CLOCK SET

2001

/:/

1

OK

POWER

1

12 00

1

12 00

Y / M / D

M / D / Y

D / M / Y

AM

CANCEL

Y / M / D

M / D / Y

D / M / Y

AM

CANCEL

Set the numeric value with v/V on the

5

control button, then press the center z to

enter it.

Getting started

OK

OK

After entering the number, v/V moves to the next

item.

If you selected [D/M/Y] in step 3, set the time on a

24-hour cycle.

Select [OK] with B on the control button,

6

then press the center z at the desired

moment to begin clock movement.

The date and time are entered.

To cancel the date and time setting

Select [CANCEL] with v/V/b/B on the control button, then press the center z.

Note

If the rechargeable button battery is ever fully discharged (page 72), the CLOCK SET screen will

appear again. When this happens, rese t th e da te and time by starting from step 3 above.

CLOCK SET

2001

OK

CLOCK SET

2001

OK

/:/

/:/

Y / M / D

M / D / Y

D / M / Y

OK

1

12 00

7

AM

CANCEL

Y / M / D

M / D / Y

D / M / Y

OK

4

10 30

7

PM

CANCEL

Inserting the “Memory Stick”

Access lamp

Open the “Memory Stick” cover.

1

Insert the “Memory Stick.”

2

Insert the “Memory Stick” with the B mark facing toward the battery

compartment as illustrated until it clicks.

Close the “Memory Stick” cover.

3

Removing the “Memory Stick”

Open the “Memory Stick” cover, then press the “Memory Stick” once lightly.

Notes

•

Insert the “Memory Stick” firmly until it clicks, otherwise a message such as “MEMORY

STICK ERROR” will be displayed.

•

Never remove the “Memory Stick” or turn off the power while the access lamp is lit up.

•

Y ou can not record or edi t images o n a “Mem ory Stick” if the erasure prevention switch is set to

the LOCK position.

Connector

15

Getting started

16

Basic operations

Recording

B

Basic operations

How to use the mode dial

The mode dial switches the function which is used for recording, playback, or

editing. Set the dial as follows before starting to operate your camera.

: To record still images in TWIL IGHT mode

: To record still images

: To play back or edit images

: To record moving images or Clip Motion images

SET UP: To display the setup items (The SET UP pos ition

changes the settings of infrequently-used

items.)

How to use the control button

When the menu is not displ ayed, the control button is used to pe rform the following

operations.

(v): Recording with flash

(V): Recording with self-timer

7

(b): Checking the last reco rded image

(B): Recording close subjects

When you select above functions with the control button while recording with the

LCD screen turned off, the LCD screen lights for approximatel y 2 seconds and the

selected function icon appears on the screen. The LC D screen also lights

automatically when the MENU button is pressed, but in this case the LCD screen

does not turn off automatically.

Erasure

prevention

switch

The position and shape of the erasure prevention switch may differ depending on the type s of

“Memory Stick” used.

Label space

17

18

– 18 –

Page 19

Recording still images

Still images are recorded in JPEG format.

Before recording still images, press the POWER button to turn on the power and

insert a “Memory Stick.”

POWER

Set the mode dial to or .

1

Press and hold the shutter button halfway down.

2

The image freezes momentarily, but is not yet recorded. While the AE/AF lock

indicator z is flashing, the camera automatically adj us ts the exposure and

focus of the captured imag e. When the camera finishes the automatic

adjustments, the AE/AF lock indicator z stops flashing, then light s up and the

camera is ready for recording.*

If you release the shut ter button, the record ing will be canceled.

AE/AF lock indicator (green) flashes t lights up

BB

B

B

Recording

Press the shutter button fully down.

3

The shutter sounds.

“RECORDING” appears on the LCD screen, and the image will be recorded on

the “Memory Stick.” When “RECORDING” disappears, you can record the

next image.

RCORI

If the flashing AE/AF lock indicator changes to flashing slowly, the subject may be difficult to

∗

focus on (dark, poor contrast) or the subject may be extrem el y cl ose . Re le as e th e shu tte r

button, then focus again.

The number of images you can record on a “Memory Stick”

See pages 46 and 48 to 52.

Notes

•

When recording a bright subject, the LCD screen color may change after AE/AF lock, but this

does not affect the recorded imag e.

•

When you press the shutter button fully down at once in step 2, the camera starts recording

after the automatic adjustment is complete. However, the recording cannot be carried out while

the /CHG lamp (page 21) is flashing. (During this time, the camera is charging the flash.)

Holding the camera correctly

Hold the camera so that yo ur fingers do not block the flash and do not t ouc h the lens

portion when recording images.

19

Recording images with the finder

You can extend the battery time by turning off the LCD screen and recording using

the finder.

Each time you press DISPLAY/LCD ON/OFF, the status of the LCD screen changes

as follows:

See page 85 for a detailed descripti on of th e i ndicated items.

The LCD backlight is turned on.

(All the available indicators are turned on.)

r

The LCD backlight is turned on.

(Warning messages are turned on.)

r

The LCD backlight is turned off.

DISPLAY/LCD ON/OFF

Indicators in the finder

Notes

•

You cannot check the entire recording range with the finder. Recording with the LCD screen is

recommended when it is necessary to correctly unde r sta nd the recording range.

•

Because of the difference of the portion of the finder and lens, use the LCD screen whe n you

record a subject closer than 1 m (3 1/4 feet).

•

When [DEMO] is set to [ON] in the S ET UP sett i ngs, yo u c ann ot tur n off the LCD screen once

the demonstration starts.

•

You cannot turn off the LCD backlight when setting in SET UP and when displaying the menu.

•

You cannot turn off the self-timer indicators and some of the indicators used in advanced

operations.

•

The indicators on the LCD screen are not recorded.

Recording lamp (red)

AE/AF lock lamp (green)

/CHG lamp (orange)

BB

B

B

Recording

20

Recording with the LCD screen

When recording w it h the LCD screen, align the AF frame in the center of the screen

with the subject.

AF frame

Checking the last recorded image (Quick Review)

You can check the last recorded image by clearing the menu from the screen

(page 40) and pressing b (7) on the control b utton. (You can perform this operation

even when the LCD screen is off.)

To return to the norma l recording mode: press lightly on the shutter button or

press b (7) again.

To delete the image: 1. Press MENU. 2. Select [DELETE] with B on the control

button, then press the center z. 3. Select [OK] with v on the control button, then

press the center z.

Using the zoom feature

Zoom button

W side: for wide-angle (subject appears

farther away)

T side: for telephoto (subject appears closer)

If you cannot get a sharp focus on a close subject

Press the zoom W button repeatedly and move closer to the subject until the focus is

sharp.

Minimum focal distance to the subject

W side: About 25cm (9 27/32 inches) or more

T side: About 80 cm (31 1/2 inches) o r m ore

To record even closer subjects, see page 53.

21

22

– 19 –

Page 20

Digital zoom function

VING IMA

GE:

This camera has a digital zoom function.

Digital zoom enlarges the image by digital processing and it starts to function when

zoom exceeds 3×.

Recording images with the flash

The factory setting is auto (no indicator). In this mode, the flash automatically

strobes when the surroundings is dark. To change the flash mode, clear the menu

(page 40), then press the

indicator appears on the LCD screen.

control button v (

) repeatedly so that the flash mode

The T side of the bar shows the

digital zooming zone.

Using digital zoom

•

The maximum zoom magnification is 6×.

•

Digital zooming dete ri or at es the picture quality. When digital zoom is not

necessary, set [DIGITA L ZOOM] to [OFF] in the setup settings (page 69).

Notes

•

Digital zoom does not work for moving images.

•

Use the LCD screen when using digital zoom function. Digitally zoomed images do not appear

in the finder.

•

The AF frame (page85) does not appear on the LCD screen.

Using the self-timer

When you use the self-timer function, the subject is recorded about 10 seconds after

you press the shutte r butt on.

Shutter button

Self-timer lamp

Control button

Clear the menu (page 40), then press the control button V ( ). The (self-timer)

indicator appears on t he LCD scre en, an d about 10 seco nds afte r you pr ess the s hutter

button, the subject is re corded. The self-timer lamp flashes an d t he beep sounds after

you press the shutter button until the shutter is released. To cancel the self-timer

recording, press the control button V ( ) again.

23

BB

B

B

Recording

Control button v ()

Each time you press the control button v ( ), the indicator changes as follows.

(No indicator) t t t (No indicator)

Forced flash: The flash strob es regardless of the surrounding brightness.

No flash: The flash does not strobe.

You can change the brightness of the flash with [ ±] (FLASH LEVEL) in the menu

settings (page 42).

To reduce the red-eye phenomenon

Set [RED EYE REDUCTION] to [ON] in the setup settings, the flash strobes before

recording to reduce the red-eye phenomenon (page 69). When [ON] is selected and

the mode dial is set to or , appears on the LCD screen.

Notes

•

When [ISO] is set to [AUTO] in the menu settings, the recommended shooting distance using

the built-in flash is 0.3 m to 2.0 m (11 13/16 inches to 6 feet 6 3/4 inches). When it is not set to

[AUTO], the flash may be ineffective even if the flash level is changed.

•

Red-eye reduction may not produce the desired effects depending on individual differences, the

distance to the subject, if the subject does not see the pre-strobe, or other conditions.

•

The flash effect is not obtained easily when you use forced flash in a bright locat ion.

•

While charging the flash, the /CHG lamp flashes. After the charging is complete, the lamp

goes out.

•

The flash does not function when recording moving images (excludi ng C lip Motion).

•

When you record images i n a dark place with the camer a set to

becomes slow, so using a tripod is recommended to prevent shaking.

(no flash), the shutter speed

24

Recording images with the AF illuminator

The AF illuminator is fill light to focus on a subject easi ly und er dark conditions. Set

[AF ILLUMINATOR] (page 69) to [ON] in the setup settings, appears on the

LCD screen and the AF illuminator emits light when the shutter button is pressed

halfway. It keeps emitting light until the focus is locked.

AF illuminator

Notes

•

If AF illuminator light does not reach the subject sufficiently or the subj ect ha s no c ontr a st,

focus will not be achieved. (Approximate distance up to 2.0 m (6 feet 6 3/4 inches) is

recommended.)

•

In TWILIGHT mode (page 47), the AF illuminator will emit only when the flash mode is set to

(Forced flash).

•

Focus is achieved as long as AF illuminator light reaches to the subje ct even if its light is

slightly out of the middle position of the subje c t.

•

The AF illuminator is a very bright light. Although it is safe to use, avoid shining it directly into

someone’s eyes at a close distance.

BB

B

B

Recording

Recording moving images

Moving images are reco rded in MPEG format ( page 38).

To recor d moving images, press the POWER button to turn on the power and in sert a

“Memory Stick.”

DISPLAY/LCD ON/OFF

1

2

3

4

5

POWER

Set the mode dial to SET UP.

Select [ ] (CAMERA) with v/V on the

control button, then press B.

Select [MOVING IMAGE] with v/V on the

control button, then press B.

Select [MPEG MOVIE] with v/V on the

control button, then press the center z.

Set the mode dial to .

CAMERA

MOVING IMAGE:

DATE/TIME:

DIGITAL ZOOM:

RED EYE REDUCTION:

AF ILLUMINATOR:

PAGE SELECT

CAMERA

MOMOVING IMA

DATE/TIME:

DIGITAL ZOOM:

RED EYE REDUCTION:

AF ILLUMINATOR:

OK

CAMERA

MOVING IMAGE:

DATE/TIME:

DIGITAL ZOOM:

RED EYE REDUCTION:

AF ILLUMINATOR:

PAGE SELECT

MPEG MOVIE

OFF

OFF

OFF

ON

GE:

MPEG MOVIE

CLIP MOTION

MPEG MOVIE

OFF

OFF

OFF

ON

25

26

– 20 –

Page 21

Press the shutter button fully down.

FILE BACK/NEXT

10:30

PM

2001 7 4100-0028

6/8

640

6

“REC” appears on the LCD screen, and the image is recorded on the “Memory

Stick.”

Sound cannot be recorded with moving images.

Press the shutter button fully down again to stop recording.

7

The recording stops. Or, the recording stops when the “Memory Stick” is full.

For details on the image size, see “Setting the image size (IMAGE SIZE)” on

page 45”.

Using the self-timer

When you use the self-timer function, the subject is recorded about 10 seconds after

you press the shutte r butt on.

Clear the menu (page 40), then press the control button V ( ). The (self-timer)

indicator appears on the LCD screen, and the recording starts about 10 seconds after

you press the shutter button. The self-timer lamp flashes and the beep sounds after

you press the shutter button until the shutter is released. To stop the self-timer

recording, press the control button V ( ) again.

LCD screen indicators during recording

Each time you press DSPL /LCD ON/OFF, the status of t he LCD screen changes as

follows: all indi cators on t indicators off t LCD screen off.

These indicators are not recorded. See page 86 for a detailed description of the

indicators.

Note

If you remove the battery or otherwise turn off the power partway through a recording, the

moving image recorded thus far is not saved. When the battery low mark E appears while

operating the camera with batt er ies, stop the recording at this poi nt be fo re the batteries

completely run out.

BB

B

B

Recording

Playback

B

Playing back still images

DISPLAY/LCD ON/OFF

1

2

Notes

•

•

Each time you press DSPL/LCD ON/OFF, the statu s of the LCD screen changes as

follows: all indicators on t indicators off t LCD screen off.

See page 87 for a detailed description of the indicators.

POWER

Set the mode dial to .

The last recorded image (still or moving) appears on th e LC D screen.

Select the desired still image with the

control button b/B.

: To display the preceding image.

b

: To display the next image.

B

You might not be able to correctly pl ay b ack images reco rded with this camera on other

equipment.

You cannot play back on this camera images larger than the maximum image size that can be

recorded with this camera.

LCD screen indicators during still image playback

Playing back moving images

DISPLAY/LCD ON/OFF

1

2

3

To pause playback

Press the center z on the control button to stop the pl ayback.

To advance or rewind the moving image

Press the control button b/B during playback.

To return to the normal playback, press the center z on the control button.

LCD screen indicators during moving image playback

Each time you press DSPL /LCD ON/OFF, the status of t he LCD screen changes as

follows: all indi cators on t indicators off t LCD screen off.

See page 87 for a detailed descripti on of the indicators.

POWER

,

Set the mode dial to .

The last recorded image (still or moving) appears on the LCD screen.

Select the desired moving image with the

control button b/B.

Moving images are display ed one-size smaller than

still images.

: To display the preceding image.

b

: To display the next image.

B

Select the center z to start the playback.

The moving image is played back.

During playback , B (playback) appears on the LCD

screen.

To advance or rewind, press the control button b/B

during playback .

FILE BACK/NEXTPLAY

STOP REV/CUE

Playback bar

2001 7 4MOV 00001 10:30 PM

6/8

6/8

27

29

28

Viewing images using a personal

computer

You can view data recorded with your camera on a personal computer, modify and

attach it to e-mail using application software. This section describes the method for

viewing images on a personal computer using the supplied USB cable.

There are two ways to make the USB connection, which are the norma l co nnection

BB

B

B

Playback

and the PTP connection (page 70). This is set using [USB CONNECT] in the setup

settings. However, any OS does not conform to [PTP] as of M ar ch, 2001. Here

describes the way using the [NORMAL] setting.

The factory setting of USB mode is [NORMAL].

The mode can be checked and set as follows.

1

Set the mode dial to SET UP.

2

Select [SETUP2] with v/V, then press B.

3

Select [USB CONNECT] with v/V, then press B.

4

Select the connection mode with v/V.

The USB cable is used to connect the camera to a personal computer so that

operations can be performed on image files recorded in a “Memory Stick” from the

personal computer.

In order to use the USB cable, a USB driver must be installed in the personal

computer beforehand.

Be sure to also refer to the operation manuals for your personal computer and the

application soft w a r e .

Notes

•

Data recorded with your camera is stored in the following formats. Make sure that applications

that support these file formats are installed on your per sona l computer.

— Still images (other than TEXT mode, uncompressed mode and Clip Motion): JPEG format

— Moving images: MPEG format

— Uncompressed mode still images: TI FF format

— TEXT mode/Cl ip Motion: GIF format

•

Depending on your application software, the file size may increase when you open a still image

file.

•

When you copy the image to the camera from your comp u ter, which was modified with a

retouching software and was converted to another file format, the “FILE ERROR” message

may appear and you may be unable to open the image.

•

Depending on your application software, only the first frame of the Clip Mot ion file may be

played back.

Communications with your computer (for Windows only)

Communications between your camera and your computer may not recover after recovering

from Suspend or Sleep.

•

When connecting the camera to a computer, use a fully charged “InfoLITHIUM” battery pack

(not supplied) or the AC power adapter (not supplied). Do not use batteries.

30

– 21 –

Page 22

Recommended computer en vironment

Recommended Windows environment

OS: Microsoft Windows 98, Windows 98SE, Windows 2000 Professional, Windows

Millennium Edition

The above OS is required to be instal led at the factory .

Operation is not assured in an environment upgraded to the operating sy ste ms described

above.

CPU: MMX Pentium 200 MHz or faster

The USB connector must be provided as standard.

Recommended Macintosh environment

Macintosh computer with the Mac OS 8.5.1/8.6/9.0/9.1 standard installation

However, note that the update to Mac OS 9.0/9.1 should be used for the following models.

•

iMac with the Mac OS 8.6 factory pre-installed and a slot loading type CD -ROM drive

•

iBook or Power Mac G4 with the Mac OS 8.6 factory pre-inst a lle d

The USB connector must be provided as standard.

QuickTime 3.0 or newer must be installed (to play back moving pictures).

Notes

•

If you connect two or more USB equipment to a single persona l co mputer at the same time,

some equipment may not operate depending on the type of USB eq uipment.

•

Operations are not guaranteed when using a hub.

•

Operations are not guaranteed for all the recommended computer environments menti o n ed

above.

•

Microsoft and Windows are either registered trademarks or trademarks of Microsoft

Corporation in the United States and /or oth er countries.

•

Macintosh and Mac OS, QuickTime are either registered trademarks or trademarks of Apple

Computer, Inc.

•

All other product names mentioned herein may be the tra de ma r ks or register ed trade marks of

their respective companies. Furthermore, “™” and “®” are not mentioned in each case in this

manual

Installing the USB driver

Before connecting your camera to your personal computer, install the USB driver to

the computer. The USB driver is included with the application software in the CDROM which is supplied with your camera.

Be sure to complete installation of the USB driver before connecting the

USB cable. If you connect the USB cable first, you will be unable to

BB

B

B

Playback

install the USB driver properly.

See page 80 for corrective measures if the USB cable was connected before installing

the driver and the driver software could not be ins ta ll ed correctly.

For Windows 98/98SE/Me and Windows 2000 users

Turn on your personal computer and allow Windows to load.

1

Do not connect the USB cable in this step.

Insert the supplied CD-ROM in the CD-ROM drive of your personal

2

computer.

The application software sc r een appears.

Click “USB Driver Installation for Windows 98/98SE/Me and

3

Windows 2000”.

USB driver installation starts.

Follow the on-screen messages to install the USB driver.

4

Your personal computer may restart.

Connect the USB jack (mini-B) on your camera with the USB

5

connector on your personal computer using the supplied USB

cable.

USB cable

to the USB ja ck

(mini-B)

Push the

connector in as

far as it will go.

to the USB connector

Personal computer

Insert a “Memory Stick” into your camera, connect the AC power

6

adaptor and turn on your camera.

“USB MODE” appears on the LCD screen of your camera and the camer a is set

to communication standby mode. Your personal computer recognizes the

camera, and the Windows Add Hardware Wizard starts.

31

Follow the on-screen messages to have the Add Hardware Wizard

7

recognize the hardware.

The Add Hardware Wizard starts twice because two different USB dr ivers are

to be installed. Be sure to allo w the i nstallatio n to complet e without inte rrupting

it.

Notes

•

Do not connect the USB cable bef or e the USB driver installation is completed in step 4.

•

In step 7, make sure that a “Memory Stick” is inserted into your camera before installing the

USB driver. Otherwise, you will be unable to install the USB driver.

For Macintosh users

• When using MacOS9. 1

It is not necessary to install the USB driver. The Macintosh recognizes the camera as

a drive simply by connecting it to the Macintosh with the USB cable.

• When using MacOS8.5.1/8.6/9.0

Follow the procedures below to install the driver.

Turn on your personal computer and allow the Mac OS to load.

1

Insert the supplied CD-ROM in the CD-ROM drive of your personal

2

computer.

Double-click the CD-ROM drive icon to open the window.

3

Double-click the icon of the hard disk containing the OS to open

4

the window.

Move the following two files from the window opened in step 3 to

5

the “System Folder” icon in the window opened in step 4 (drag

and drop) .

•

Sony USB Driver

•

Sony USB Shim

When “Put these items into the Ex te nsions folder?” appears, click

6

“OK.”

Restart your personal computer.

7

32

Viewing images

When viewing moving images on a Windows system, RealPlayer, Windows Media

Player or other moving ima ge playba ck applic ations must be in stalled . When v ie wing

moving images on a Macintosh system, QuickTime3.0 or later must be installed.

Turn on the power of your personal computer and allow Windows

1

or Mac OS to load.

BB

B

B

Playback

Connect the USB jack (mini-B) on the camera with the USB

2

connector on your personal computer using the supplied USB

cable.

to the USB connector

Personal computer

Insert a “Memory Stick” into your camera, and connect the AC

3

power adaptor to your camera and then to a wall outlet (mai ns) .

Turn on the power of your camera.

4

“USB MODE” appears on the LCD screen of th e camera.

USB cable

to the USB ja ck

(mini-B)

Push the

connector in as

far as it will go.

For Windows 98/98SE/Me and Windows 2000 users

Open “ My Computer” on Windows and double click the newly

5

recognized drive. (Example: “Removable Disk (E:)”)

The folders inside the “Memory Stick ” are displayed.

If the drive is not recognized, see “Troubleshooting” on page 75.

33

34

– 22 –

Page 23

Select and double-click the desired image file from the folder.

6

For the detailed folder and file name, see “Image file storage destinations a nd

image files” on page 37.

Desired file type Double-click in this order

Still image “Dcim” foldert“100msdcf” foldertImage file

Moving image* “Mssony” foldert“Moml0001” foldertImage file*

Clip Motion

image

E-mail image

TIFF image

(uncompressed)

Copying a file to the hard disk of your personal computer befor e v iewing it is

∗

recommended. If you play back the file directly from the “Memory Stick”, the image

may break off.

“Dcim” foldert“100msdcf” foldertImage file

“Mssony” folder t“Imcif100” fold ertImage file

For Macintosh users

Follow the procedure 1 – 4 on page 34.

Double click the newly recognized icon on the desktop.

5

The folders inside the “Memory Stick” are displayed.

Select and double-click the desired image file from the folder.

6

Notes on using your personal computer

“Memory Stick”

•

Operation is not guaranteed if you are using a “Memory St ic k” that was formatted with a

personal computer, or if you used a personal computer to format the “Memory Stick” in your

camera through a USB connection.

•

Do not optimize the “Memory Stick” on a Windows machine. This will shorte n the “Memory

Stick” life.

•

Do not compress the data on the “Memory Stick.” Compressed files cannot be played back on

your camera.

For Windows Me and Windows 2000 u sers

The following procedures are recommended when disconnecting the USB cable from

your personal computer or ejecting the “Memory Stick” from the camera while it is

connected to your pers onal computer.

1

Stop the drive by clicking on the “Unplug/Eject” icon in the task tray.

2

When the message appear s confirming the safe removal of the hardware,

BB

B

B

Playback

disconnect the USB cable or eject the “Memory Stick”.

Software

•

Depending on your application software, the file size may increase when you open a still image

file.

•

When you load an image modified using the supplied retouch software from your personal

computer to the camera or when you directly modify the image on the camera, the image

format will differ so the “FILE ERROR” message may appear and you may be unable to ope n

the file.

•

Depending on your application software, only the first frame of the Clip Mot ion file may be

played back.

Communications with your personal computer (for Windows

only)

Communications between your camera and your personal computer may not recover after

recovering from Suspend, Resume, or Sleep.

35

Image file storage destinations and

image files

Image files recorded with y our camera are grouped in fold ers by recording mode.

The meanings of the file names are as follows.

within the range from 0001 to 9999.

For Windows Me users (The drive recognizing the camer a is

“E.”)

Folder containing still im age, TEXT mode image

and Clip Motion image data

Folder containing E-MAIL mo de and TIFF mode

image data

Folder containing movi ng image data

Folder File Meaning

100MSDCF DSC0

CLP0

CLP0

MBL0

MBL0

TXT0

TXT0

.JPG•Still image file recorded normally

ssss

ssss

ssss

ssss

ssss

ssss

ssss

•

.GIF•Clip Motion file recorded in NORMAL

.THM•Index image file of Clip Motion file

.GIF•Clip Motion file recorded in MOBILE

.THM•Index image file of Clip Motion file

.GIF•Still image file recorded in TEXT mode

.THM•Index image file of still image file

stands for any number

ssss

Still image file recorded in

– E-MAIL mode (page 48)

– TIFF mode (page 50)

mode (page51)

recorded in NORMA L m ode

mode (page51)

recorded in MOBILE m ode

(page 49)

recorded in TEXT mode

36

Folder File Meaning

IMCIF100 DSC0

DSC0

MOML0001 MOV0

BB

B

B

Playback

The numerical portions of the following files are the same.

– A small-size image file recorded in E-MAIL mode and its c or r es ponding image file

– A n unc ompressed image file recorded in TIFF mode and its corr es ponding image file

– An image file recorded in TEXT mode and its corresponding index imag e file

– A n image file recorded with Clip Motion and its corres ponding index image file

Tips

The digital still camera saves recorded images as digital data. The format of the

saved data is called as the file format. The formats that can be used with this

camera are as follows:

JPEG format

Most digital still cameras, operating systems of computers, and browser

software adopt this format. This format is able to compress files without

appreciable deterioration. However, if the image is compressed and saved on

repeated occasions, the image will dete riorate. This camera records still images

using the JPEG format for normal recording.

GIF format

Using this format, the image will not deteriorat e ev en if the image is compressed

and saved on repeated occasions. This format limits the number of colors to

256 colors. This camera records still images using the GIF format in Clip

Motion (page51) or TEXT mode (page49).

TIFF format

Stores shooting images without compression, so the image does not deteriorate.

Most of operating systems and applications correspond to this format. This

camera records still images using the TIFF format for the TIFF mode (page 50).

MPEG format

This format is very typical for moving images. This camera records moving

images using the MPEG format.

.JPG•Small-size image file r ecorded in

ssss

ssss

ssss

E-MAIL mode (page 48)

.TIF•Uncompressed image file recorded in

TIFF mode (page 50)

.MPG•Moving image file recorded normally

37

38

– 23 –

Page 24

Advanced operations

Before performing advanced

operations

This section describes the basic control methods that are frequently used for

“Advanced operations.”

How to use the mode dial

The mode dial switches the function which is used for recording, playback, or

editing. Set the dial as follows before starting to operate your camera.

: To record still images in TWILIGHT mode

: To record still images

: To play back or edit images

: To record moving images or Clip Motion

images

SET UP: To display the setup items (The SET UP

position changes the se ttings of infrequentlyused items.)

How to use the control button

When the menu or setup screen is displayed, the control button is used to select the

buttons, images and menu item s displayed on the LCD screen of your camera and

modify the settings. The operation methods that are frequently used for “Advanced

operations” are described below.

Turning on/off the operation buttons (menu) on the LCD screen

Press MENU to display/

clear the menu on the

LCD screen.

0

EV

Menu

0

WB

ISO

You can perform this operation even when the LCD screen is off.

Setting up the items in the setup or menu

Set the mode dial to SET UP so that the

Before performing advanced operations

1

setup screen appears, or press MENU so

that the menu appears.

When the mode dial is set to SET UP or :

2

1

Press v/V/b/B on the control button to select the item you want to set up.

2

Press the center z on the control button to enter the item.

When the mode dial is set to , , or :

Press v/V/b/B on the control button to select the

setting of the item.

The selected setting is turned to yellow, and the

setup is complete.

CAMERA

MOVING IMAGE:

DATE/TIME:

DIGITAL ZOOM:

RED EYE REDUCTION:

AF ILLUMINATOR:

SELECT

MPEG MOVIE

OFF

ON

OFF

ON

00

200

100

O

Menu settings

Menu items that can be modified differ depending on the positions of th e mode dial.

The LCD screen shows only the items you can operate at the mo m ent. Factory

settings are indicated w ith x.

When the mode dial is set to /

Item Setting Description

EV +2.0EV to

9

(FOCUS)

WB

(WHITE

BAL)

(SPOT

METER)

ISO 400

(IMAGE

SIZE)

(P. QUALITY)

–2.0EV

(infinite)

∞

7.0 m

3.0 m

1.0 m

0.5 m

AUTO

x

HOLD

AUTO

x

IN DOOR

OUT DOOR

ON

OFF

x

200

100

AUTO

x

1600×1200

x

(DSC-P50)

1280×960

x

(DSC-P30)

1600 (3:2)

(DSC-P50)

1280(3:2)

(DSC-P30)

1024×768

640×480

FINE Records still images in the fine image quality

x

STANDARD Records still images in the standard image

Adjust the exposure value (page 53).

Sets the distance to the subject (page 52).

Sets the white balance (pag e 54).

Measures the brightness of the spot to be

recorded (page 57).

Selects the ISO film speed. When recording

under dark situations or recording a fast-moving

subject, use a high-number setting. When you

record high-quality images, use a low-number

setting (except when the mode dial i s se t to ).

Selects the image size when recording still

images (page 45).

mode.

quality mode.

39

40

Item Setting Description

MODE

(REC

MODE)

±

(FLASH

LEVEL)

PFX

(P. EFFECT)

Before performing advanced operations

(

SHARPNESS

When the mode dial is set to (MOVING IMAGE is set to

MPEG MOVIE in the setup se ttings.)

Item Setting Description

EV +2.0EV to

9

(FOCUS)

WB

(WHITE

BAL)

(SPOT

METER)