DIGITAL VIDEOCASSETTE RECORDER

DNW-A25WS

DNW-A25WSP

INSTALLATION MANUAL

1st Edition

Serial No. 15001 and Higher: DNW-A25WS

Serial No. 45001 and Higher: DNW-A25WSP

! W ARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Ver letzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

DNW-A25WS/A25WSP

Table of Contents

Manual Structure

Purpose of this manual .............................................................................................. 2

Related manuals......................................................................................................... 2

1. Installation

1-1. Installation Procedure..................................................................................1-1

1-2. Supplied Accessories ..................................................................................1-1

1-3. Operating Conditions ..................................................................................1-1

1-4. Power Supply ..............................................................................................1-2

1-5. Installation Space ........................................................................................1-3

1-6. Connectors/Cables.......................................................................................1-4

1-7. Signal Inputs and Outputs ...........................................................................1-5

1-8. Settings for Internal Switches/Slit Lands.................................................... 1-8

1-8-1. AU-249 Board ............................................................................1-8

1-8-2. RE-150 Board.............................................................................1-9

1-9. Setup Extended Menu ...............................................................................1-10

1-10. Settings for External Editors .....................................................................1-11

1-10-1. Time Code Settings for Recorder.............................................1-11

1-10-2. VTR Constant Settings for External Editors ............................1-11

1-10-3. System Phase Adjustment ........................................................1-11

1-10-4. Setup Menu Setting of ITEM-701............................................1-11

1-11. Removing/Reattaching the Plug-in Boards............................................... 1-12

1-12. How to Take Out the Cassette Whose Tape is Slacked ............................ 1-14

DNW-A25WS/A25WSP

Appendix A Setting Check Sheet

1

Purpose of this manual

Related manuals

Manual Structure

This manual is the installation manual of digital videocassette recorder

DNW-A25WS/A25WSP.

This manual is intended for use by trained system and service engineers, and

provides the information that is required to install (environment, connection information, initial setting, etc.) .

Besides this “installation manual”, the following manuals are available for digital

videocassette recorder DNW-A25WS/A25WSP.

..

. Operation Manual (Supplied with the unit.)

..

This manual is necessary for application and operation (and installation) of the unit.

..

. Maintenance Manual (available on request)

..

Volume-1 : Service Instruction

Volume-2 : Parts List, Diagrams

These manuals describe the maintenace and service information (service overview, adjustments, board layouts, schematic diagrams, detailed parts list, etc.) for

this unit. If these manuals are required, please contact your local Sony Sales

Office/Service Center.

..

. Protocol Manual of Remote (9-pin) Connector (available on request)

..

This manual explains the protocol for controlling the VTR via the RS-422A (9-pin

serial remote). If this manual is required, please contact your local Sony Sales

Office/Service Center.

..

. BKNW-225 Maintenance Manual (Supplied with the BKNW-225)

..

This manual describes the spare parts list and the exploded view for the service

parts of the docking kit BKNW-225, that is used when the two DNWs are coupled.

2

DNW-A25WS/A25WSP

Section 1

Installation

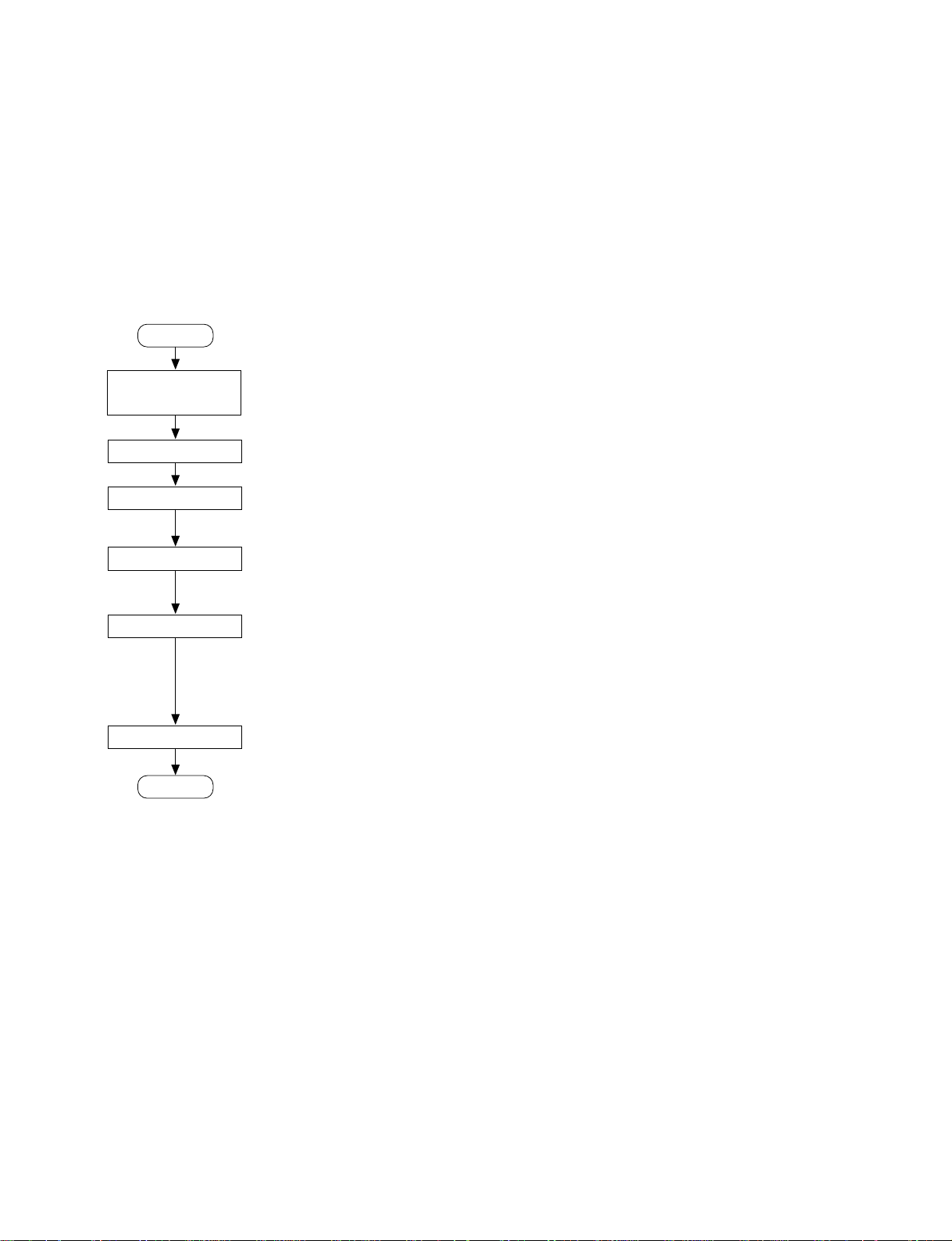

1-1. Installation Procedure

Installation procedure of this unit is shown on the following flowchart.

Refer to each section about detail of each flow.

The operation manual is also reqruired to do *-marked

flow.

Start

Determination of

installation place

Unpacking

Installation

*Connection

1-3. Operating Conditions

1-4. Power Supply

1-5. Installation Space

1-6. Connectors/Cables

1-7. Signal Inputs and Outputs

1-3. Operating Conditions

c

Do not block an air vent. If ventilation is not enough, the

unit may be damaged due to increase the internal temperature of the unit.

. Do not shove the unit into cramped place with poor

ventilation.

. Be sure to make cleaning if a cooling fan is covered with

dust.

. Replace a cooling fan periodically.

. Do not place the unit on a longhaired carpet.

. Do not cover the unit with cloth.

n

Good air circulaiton is essential to prevent internal heat

build-up. Place the unit in location with sufficient air

circulation.

Do not block the ventilation holes of the cabinet and the

front and rear panels.

*Initial setup

*Operation check

End

1-8. Settings for Internal

Switches/Slit Lands

1-9. Setup Extended Menu

1-10. Settings for External Editors

1-2. Supplied Accessories

Cap, BNC ........................................................................ 11

Cap, DC OUT ....................................................................2

Cap, XLR (F)..................................................................... 2

Cap, XLR (M) ................................................................... 5

Cap, DUST ........................................................................ 1

Shoulder belt assembly...................................................... 1

Rear panel cover ................................................................ 1

Operation manual .............................................................. 1

Installation manual ............................................................ 1

Operating temperature: 0dC to 40dC

Operating humidity: 25% to 80% (Condensation not

allowed)

Storage temperature: _20dC to 60dC

Locations to avoid:

. Areas where the unit will be exposed to direct sunlight

of any other strong lights.

. Areas near heat sources.

. Dusty areas or areas subject to vibration.

. Areas with strong magnetic field.

. Areas with much electrical noise.

. Areas with much static electricity.

. Areas that is impossible to find a specified room for

installation.

(Refer to Section “1-5. Installation Space” .)

. Areas windtight.

n

After installation, be sure to use the supplied caps for

protecting unused connectors.

DNW-A25WS/A25WSP

1-1

1-4. Power Supply

1-4. Power Supply

The unit works either on AC current (using the AC adaptor) or battery. When repairing or checking the

unit, however, AC-operation is recommended.

Power Voltage: DC 11 to 17 V

Power Consumption : 65 W

m

. The AC adaptor AC-DN1 cannot be used to derive power.

. The AC adaptor AC-DN2A/DN2B can supply power to two VTRs simultaneously. The AC-DN2 with

serial No.11001 or higher can supply, too. If the above adaptor is used, power on the VTRs and load

cassettes in turn allowing for an inrush current.

. While the unit is battery-operated, the remaining battery capacity is displayed on the sub menu indica-

tor. When the battery is nearly dead, the WARNING indicator on the side of the LCD monitor will

blink. For details, refer to the operation manual supplied with the unit.

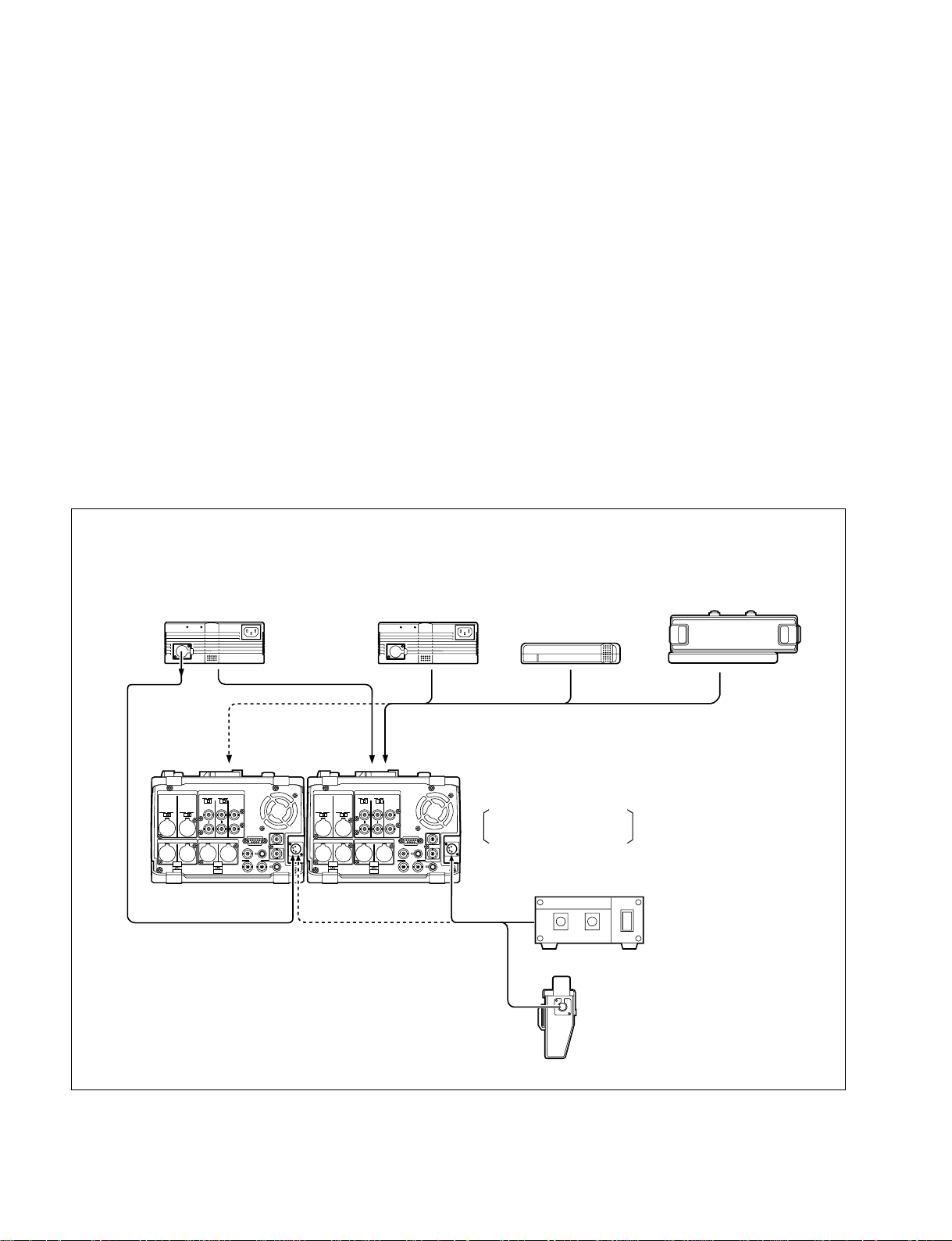

Connection example (when operating two VTRs)

AC adaptor

AC-DN2A/DN2B

DC OUT

(DC cable)

DC IN

AC adaptor

AC-DN2A/DN2B

Battery terminal

Lithium-ion battery

BP-L90A/L60A

DNW-A25WS/A25WSP

Rear View

Ni-cd battery

BP-90A

+

Battery adaptor

DC-L90

AC adaptor

AC-550

1-2

Ni-cd battery

BP-90A

+

Battery adaptor

DC-210

DNW-A25WS/A25WSP

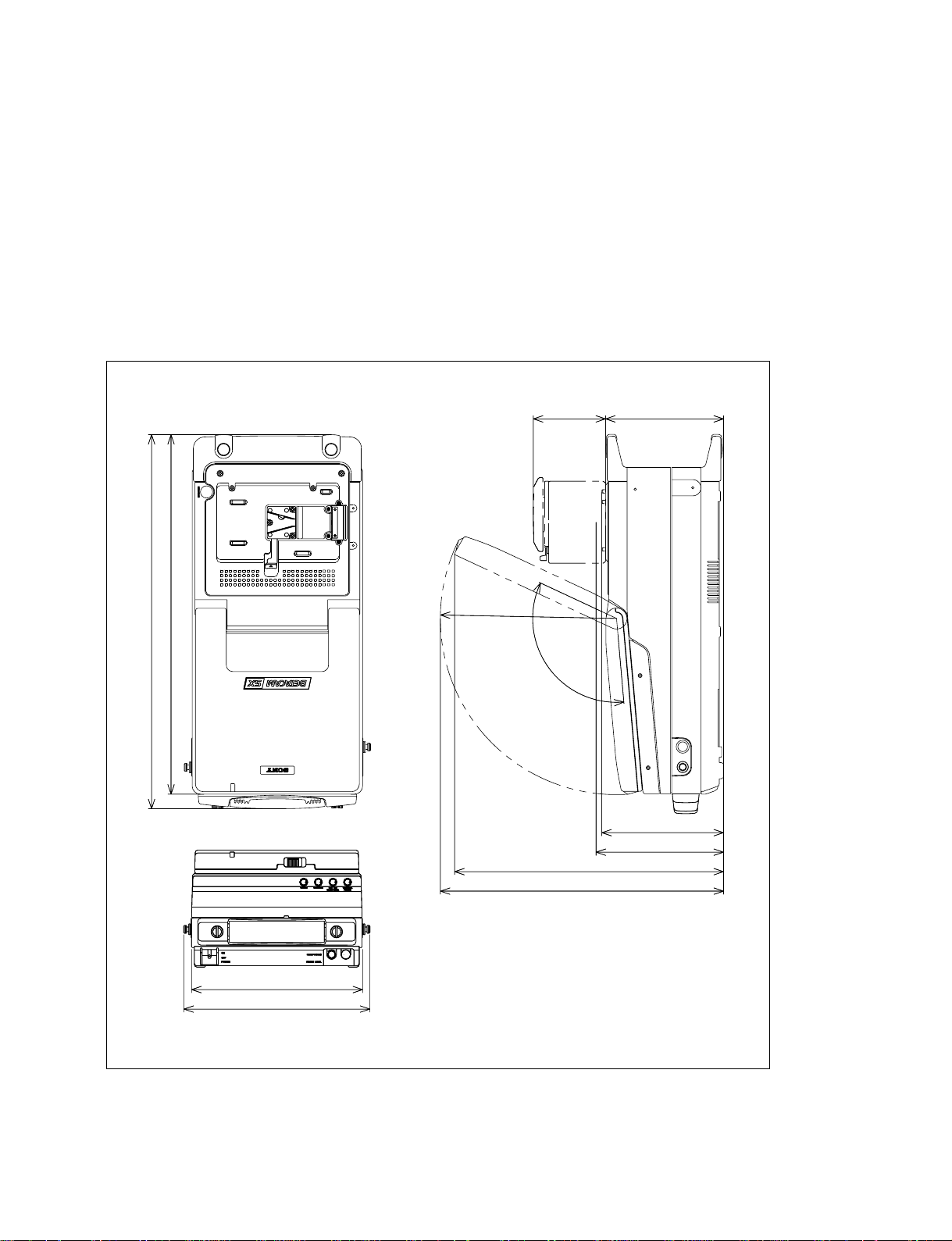

1-5. Installation Space

c

To avoid an injury, do not install the unit on rickety table.

Ventilation and Installation Space for Servicing

. Do not block an exhaust section and an air vent (rear panel).

. In order to make a unit with good ventilation, ensure sufficient clearance around the unit.

. In order to ensure a workspace, more than 20 cm behind the unit is required.

Outside Dimensions

1-5. Installation Space

461

443

R217

120d

89

145

150

157

331

349

DNW-A25WS/A25WSP

210

230

Unit : mm

1-3

1-6. Connectors/Cables

1-6. Connectors/Cables

Connection made with the connector panels during installation or service, should be made with the

connectors or complete cable assemblies specified in the following list, or equivalent parts.

Panel indication Connection connector (Sony P/N) Connection cable (Sony P/N)

VIDEO REF IN Plug, BNC (1-564-742-11) RG-59B/U cable

VIDEO INPUT

VIDEO OUTPUT

TC IN

TC OUT

SDI IN Plug, BNC (1-564-742-11) BNC coaxial cable

SDI OUT (1-791-456-11: supplied with BKNW-225) or

BELDEN 8281 cable (Maximum cable length: 200 m)

AUDIO INPUT XLR 3P, MALE (1-508-084-00) –––––––

AUDIO OUTPUT XLR 3P, FEMALE (1-508-083-00) –––––––

MONITOR OUTPUT

DC IN XLR 4P, FEMALE (1-508-362-00) DC power cord (1-551-577-00:supplied with AC-550/

550CE)

DC OUT Plug 4P MALE (1-566-425-11) –––––––

REMOTE Plug 9P MALE (1-560-651-00) 9P remote control cable

Shell, Junction 9P (1-561-749-00) (1-783-089-12: supplied with BKNW-225) or

RCC-5G(5 m)/10G(10 m)/30G(30 m)

AUX Plug 6P MALE (1-560-078-00) –––––––

HEADPHONES JM-60 stereo phone plug –––––––

(Separately available)

1-4

DNW-A25WS/A25WSP

1-7. Signal Inputs and Outputs

1-7. Signal Inputs and Outputs

+48V

CH-1

AUDIO OUTPUT

1/3

1

ONOFF

+48V

+4dBu_60 0

CH-2

2/4

2 3 4 6 875

75Z

ONOFF

REF.

+4dBu_60 0

IN

MONITOR OUTPUT

R L

9 !/ != ![ !\!]!-

Communications Connectors

VIDEOAUDIO INPUT

ONOFF

OFF

75Z

INPUT OUTPUT

ON

1

2(SUPER)

REMOTE

SDI IN DC OUT

12

TC IN

TC OUTSDI OUT

AUX

DC-IN

< Connector panel >

6 REMOTE D-SUB 9P connector x 1 (RS-422A interface)

Remote control

1-7. Signal Inputs and Outputs

Output Connectors

4 VIDEO OUTPUT 1 BNC x1

Analog composite video 1.0 Vp-p, 75 Z, negative sync

5 VIDEO OUTPUT 2 BNC x1 (Character superimpose enabled)

Analog composite video 1.0 Vp-p, 75 Z, negative sync

9 AUDIO OUTPUT 1/3, 2/4 XLR 3-pin x2

Analog audio 2 channels (CH-1/CH-2 or CH-3/CH-4 selectable by sub menu)

+4 dBm (standard) (600 Z load), low impedance, balanced

!/ MONITOR OUTPUT R/L XLR 3-pin x2

Analog audio channel (AUDIO OUTPUT enabled by selecting sub menu)

+4 dBm (standard) (600 Z load), low impedance, balanced

!= SDI OUT BNC x2

Component digital (270 Mbit/s) SMPTE 259M/ITU-R BT.656

!] TC OUT BNCx1

Time code 1.0 Vp-p ±3 dB (75 Z load), unbalanced

7 DC OUT 4-pin connector x1 (for BVR-3)

DC +12 V (+11 to 17 V), 0.5 A (max)

HEADPHONES JM-60 stereo phone jack

(at the front) Analog audio

up to _20 dBu adjustable (8 Z load), unbalanced

6 REMOTE (9P Female)

Pin No. Signal

1 GND

2 RM TX (_)

3 RM RX (_)

4 GND

5 PRIORITY

6 GND

7 RM TX (+)

8 RM RX (+)

9 GND

!\ DC IN (4P Male)

Pin No. Signal

1 GND

2NC

3NC

4 EXT DC

15

96

(External View)

(External View)

1-6

DNW-A25WS/A25WSP

7 DC OUT (4P Female)

Pin No. Signal

1 UNREG GND

2NC

3NC

4 UNREG +12 V

1 AUDIO INPUT (3P Female)

9 AUDIO OUTPUT (3P Male)

!- MONITOR OUTPUT (3P Male)

Pin No. Signal

1 GND

2X

3Y

1-7. Signal Inputs and Outputs

(External View)

FemaleMale

(External View) (External View)

1-8. Settings for Internal Switches/Slit Lands

1-8. Settings for Internal Switches/Slit Lands

1-8-1. AU-249 Board

A

1

2

SL402

SL401

3

4

5

n

For removing/reattaching the prug-in boards, refer to Section 1-11.

Settings for Audio Input Headroom CH1, CH2 (for slit lands)

Channel Ref.No.(Indication) (20 dB) 18 dB 16 dB

CH1 SL101 (18 dB) Open Short Open

CH2 SL201 (18 dB) Open Short Open

BCDEFGH

SL302

SL301

SL602

SL601

SL502

SL501

ON

1 2 3 4

SL201

SL202

S1

SL101

SL102

AU-249 Board (A Side)

Input headroom ( ) : Factory setting

SL102 (16 dB) Open Open Short

SL202 (16 dB) Open Open Short

AU-249 board

< Top View >

Settings for Audio Output Headroom CH1/CH3, CH2/CH4 (for slit lands)

n

Selections of CH1/CH3 and CH2/CH4 are made using the sub menu.

Output headroom ( ) : Factory setting

Channel Ref.No.(Indication) (20 dB) 18 dB 16 dB

CH1/CH3 SL301 (18 dB) Open Short Open

SL302 (16 dB) Open Open Short

CH2/CH4 SL401 (18 dB) Open Short Open

SL402 (16 dB) Open Open Short

1-8

DNW-A25WS/A25WSP

Settings for Monitor Output Headroom (for slit lands)

Output headroom ( ) : Factory setting

Channel Ref.No.(Indication) (20 dB) 18 dB 16 dB

L SL501 (18 dB) Open Short Open

SL502 (16 dB) Open Open Short

R SL601 (18 dB) Open Short Open

SL602 (16 dB) Open Open Short

Switches

n

Do not change settings of the factory-use switches.

Ref.No. Description Factory setting

S1-1 to S1-4 Factory use OFF

1-8-2. RE-150 Board

A B C D E FG

1

1-8. Settings for Internal Switches/Slit Lands

2

3

4

SL1

RE-150 board

5

RE-150 Board (A Side)

n

For removing/reattaching the boards, refer to the maintenance manual, volume 1.

Slit Land

Ref.No. Description Factory setting

SL1 Selects how the power is derived when the battery and external power supply Open

are used simultaneously

Open: Always derived from the external power supply

Short: Normally derived from the external power supply

When an input voltage is 10.5 V or below, automatically selects the battery

DNW-A25WS/A25WSP

1-9

1-9. Setup Extended Menu

1-9. Setup Extended Menu

The extended menus of the setup menu are usually not accessible. To display them, set the DIP switch

S201 bit-1 on the SY-259A board to ON.

(As for the S201 bit-2, this setting allows the maintenance mode to activate.)

m

. For removing/reattaching the prug-in boards, refer to Section 1-11.

. For details on H-, 9- and B-series items, refer to the operation manual supplied with the unit.

. For details on F-series items, refer to the maintenance manual, volume-1.

Ref.No. Switch name Description Factory setting

S201-1 EXTENDED Turns on and off the indication of extended setup menu OFF

MENU OFF: Not indicated

ON: Indicated

S201-2 MAINTE MODE OFF: Not accessible to the maintenance mode from the OFF

ACEESS control panel

ON: Accessible to the maintenance mode from the

control panel

n

Do not change settings of other than the above switches.

A B C D EF

S201

1

2

S100

3

4

S200

S202

SY-259A Board (A Side)

SY-259A board

< Top View >

1-10

DNW-A25WS/A25WSP

1-10. Settings for External Editors

1-10. Settings for External Editors

1-10-1. Time Code Settings for Recorder

When Editing with an Editor Capable of the 1stedit (BVE-2000)

. Time code operation block on the control panel

INT/EXT switch 8 INT

PRESET/REGEN switch 8 PRESET

F-RUN/R-RUN switch 8 F-RUN

When Editing Directly from VTR to VTR

n

Make sure that the setting of ITEM-610 on the setup menu

is as follows:

. ITEM-610: REGEN CONTROL MODE

8 0: auto edit

. Time code operation block on the control panel

INT/EXT switch 8 INT

PRESET/REGEN switch 8 PRESET

F-RUN/R-RUN switch 8 R-RUN

1-10-3. System Phase Adjustment

An analog composite signal input at the VIDEO REF.IN or

VIDEO INPUT connector of the unit should be within

specifications in SC-H.

In Combination with a Digital Switcher

The system phase adjustment is unnecessary usually.

Refer to the operation manual supplied with the digital

switcher for details.

In Combination with an Analog Switcher

The system phase adjustment for the unit is necessary.

Refer to the operation manual supplied with the analog

switcher for details.

1-10-4. Setup Menu Setting of ITEM-701

When Incorporating the Unit Into an Editing

System

1-10-2. VTR Constant Settings for External

Editors

The following constants are standard for each type and

system listed.

When using an external editor which requires the VTR

constants, use the settings listed. VTR constants must also

be set when switching between the 525 and 625 modes.

Data No.

Operation Mode 1 2 3 4 5 6 7 8

525

mode

625

mode

VTR CONSTANT 1

VTR CONSTANT 2

VTR CONSTANT 1

VTR CONSTANT 2

m

1. Set the data No. 8 of VTR CONSTANT 1 to 0A for

the following editors:

. BVE-900 ROM version 1.08 or lower

. BVE-600 ROM version 1.01 or lower

2. If the unit is controlled by the editor, be sure to set

ITEM-401 on the setup menu as follows:

. ITEM-401: FUNCTION MODE AFTER CUE-UP

B0 4B 00 96 07 07 04 8B

0A 08 FB 00 8D 3D FF 4C

B1 4B 00 7D 07 07 04 8B

0A 07 FB 00 8F 4B FF 4C

Values are represented in hexadecimal

8 0: stop

Set ITEM-701 on the setup menu as follows:

. ITEM-701: SELECTION OF VIDEO/SYNC DELAY

8 1: VIDEO DELAY

To Prevent the Picture Shift in Switching Between

When Editing from VTR to VTR

Be sure to set the data No. of ITEM-701 for a recorder to

“0: SYNC DELAY”.

DNW-A25WS/A25WSP

1-11

1-11. Removing/Reattaching the Plug-in Boards

1-11. Removing/Reattaching the Plug-in

Boards

c

Do not contact a shield spring with bare hands.

The shield spring has sharp edges. Pay careful attention

when servicing.

Removing

n

When removing the AU-249 board, disconnect the harness

from CN1 on the AU-249 board before pulling the board

out.

1. Fully loosen the four screws indicated by arrows on

the battery sub panel.

n

Each screw is held by a stop washer. Do not separate

the washer from the screw when loosening.

2. Disconnect the two harnesses from the CN-1662 board

(CN2 and CN3).

Screw

CN2

Screws

CN-1662 board

CN3

3. Slip off the harnesses (A) and (B) from the SY guard.

Get the harnesses out of the way of removing the

board.

n

At this time, untie the harnesses (A) and (B) separately.

4. Raise the eject levers and pull out the board.

Board lever

SY guard

Shielding spring

Harness (B)

Harness (A)

1-12

Screws

Battery sub panel

Shielding spring

DNW-A25WS/A25WSP

Battery sub panel

Board lever

SY guard

Harness (A)

CN-1662 board

CN3

CN2

Harness (C)

Harness (B)

Harness (A)

Lead pin

CN2

1-11. Removing/Reattaching the Plug-in Boards

Reattaching

1. Raising the eject lever on the right, insert the plug-in

board as far as it will go. (The lever on the left can be

tilted.) Finally push in the board while tilting the lever

as shown in the figure so that the board is connected to

the motherboard connector.

n

If the right lever is tilted when inserting the board, the

lever will strike the edge of the upper frame.

2 Route the harness (B) as shown in the figure, and slip

it into the hole of the SY guard. Then twist the excess

harness several times and push it in.

Shielding spring

Harness (B)

Twist and push in

SY guard

3. Slip the harness (A) into the hole of the SY guard.

Wrapping the harness (A) around the harness (B)

several times, route it to avoid dotted area in the

figure.

4. Connect the harnesses (A) and (C) to the connectors

on the CN-1662 board (CN2 and CN3).

5. Clamp the harness (A) by the lead pin as shown in the

figure.

6. Fasten the four screws (with stopper) of the battery sub

panel to reattach the battery sub panel to the VTR.

n

Make sure that the harnesses are not on the dotted area

before reattaching the battery sub panel. If the harnesses are on the dotted area, the panel and boards will

pinch them.

DNW-A25WS/A25WSP

1-13

1-12. How to Take Out the Cassette Whose Tape is Slacked

1-12. How to Take Out the Cassette Whose Tape is Slacked

1. Open the display panel.

2. To open the control panel, insert a screwdriver into the rectangular hole and unhook as shown in the

figure.

3. Turn the manual eject knob (red) counterclockwise while pushing down it.

4. When the tape is starting to slack, turn the capstan cap counterclockwise to take up the tape to the T

reel.

5. Repeat steps 3 and 4 until the cassette compartment is opened.

m

. Stop turning the manual eject knob just when the cassette compartment is opened.

. If the cassette compartment cannot be closed after taking the tape out by the above procedure, try to

turn the manual eject knob clockwise two or three turns while pushing down.

Driver

Hole

Hook

Control panel

Display panel

Cassette compartment

Turn while

pushing down

Manual eject

knob (red)

Capstan cap

1-14

DNW-A25WS/A25WSP

Appendix A

Setting Check Sheet

It is recommended to make a photocopy of check sheets given in this appendix and write down setup

conditions such as switches’ setting in the check sheets according to application.

If setup conditions are noted, the settings can be returned easily to its original condition after being

changed temporarily (when operating condition changes and so on).

And when the unit is to be checked, maintained or repaired, please attach the filled-in check sheets to the

unit.

If system combinations are frequently changed according to use, it is convenient to prepare check sheets

for every system. Make use of the check sheets to avoid mistakes.

Model name: DNW- Serial No.: _____________________________

. Firmware

SYS1 ROM version: ____________________________

SYS2 ROM version: ____________________________

SV1 ROM version: ____________________________

KY ROM version: ____________________________

A. Setting Check Sheet

. Hours meter

Write down readings of hours meter when checking, servicing or maintaining the unit.

ITEM Date Hours meter

H01: OPERATION HOURS /

H02: DRUM RUNNING HOURS /

H03: TAPE RUNNING HOURS /

H04: THREADING COUNTER /

H12: DRUM RUNNING HOURS(Resettable) /

H13: TAPE RUNNING HOURS(Resettable) /

H14: THREADING COUNTER(Resettable) /

n

The memory card can be used to save and read the setting value of the setup menu.

For details, refer to the maintenance manual, volume 1.

DNW-A25WS/A25WSP

A-1

A. Setting Check Sheet

Connector panel

Switch Factory setting Setting

Analog audio input level CH1/3 +4 dBu [||] _60 [||] 0 [||] +4

CH2/4 +4 dBu [||] _60 [||] 0 [||] +4

48V CH1/3 OFF [||] OFF [||] ON

(at _60 dBu input level setting) CH2/4 OFF [||] OFF [||] ON

Reference video input 75 Z ON [||] ON [||] OFF

Composite video input 75 Z ON [||] ON [||] OFF

Control panel

Switch Factory setting Setting

REC INHI OFF [||] ON [||] OFF

LOCAL/REMOTE LOCAL [||] LOCAL [||] REMOTE

TC GENERATOR INT [||] INT [||] EXT

PRESET [||] PRESET [||] REGEN

F-RUN [||] F-RUN [||] R-RUN

PB /PB/EE PB [||] PB [||] PB/EE

SP TAPE SP PB ONLY [||] SX [||] SP PB ONLY

METER CH-1/2 [||] CH-1/2 [||] CH-3/4

AUDIO INPUT PRESET [||] PRESET [||] VARIABLE

PB AUDIO PRESET [||] PRESET [||] VARIABLE

Internal Slit-lands

Board Name Channel Ref. No. Factory setting Setting

AU-249 Audio input headroom CH-1 SL101 OPEN (20 dB)

SL102 OPEN

CH-2 SL201 OPEN (20 dB)

SL202 OPEN

Audio output headroom CH-1 SL301 OPEN (20 dB)

SL302 OPEN

CH-2 SL401 OPEN (20 dB)

SL402 OPEN

Monitor output headroom L SL501 OPEN (20 dB)

SL502 OPEN

R SL601 OPEN (20 dB)

SL602 OPEN

RE-150 Power select SL1 OPEN (External power only)

A-2

DNW-A25WS/A25WSP

A. Setting Check Sheet

Internal Switches

nNever change setting of factory-use switches.

Board Switch Bit : Name Factory setting Setting

AU-249 S1 1 - 4 : Factory use OFF (OPEN) _

DM-114/ S101 : Y EQ TEST NORMAL POSITION _

DM-114P S301 : C EQ TEST NORMAL POSITION _

S501 : Factory use ON _

S901 1 : RF adjusting switch OFF (OPEN) _

2 : Factory use OFF (OPEN) _

3 : AGC OFF OFF (OPEN) _

4 : Factory use OFF (OPEN) _

S1701 1 : Y MUTE OFF (OPEN)

2 - 3 : Factory use OFF (OPEN) _

4 : C MUTE OFF (OPEN)

5 : COMB OFF (OPEN)

6 - 8 : Factory use OFF (OPEN) _

S1801 1 : D CLP OFF OFF (OPEN)

2 - 4 : Factory use OFF (OPEN) _

PA-218 S500 : CH1 HEAD TUNE Switch Used during adjustment _

S600 : CH2 HEAD TUNE Switch Used during adjustment _

SV-194 S100 1*1: CASSETTE COMPARTMENT LOCK OFF (OPEN) _

2*2: SERVO ERR NOT DET OFF (OPEN) _

3 : Factory use OFF (OPEN) _

4 : AUTO-TRACKING OFF OFF (OPEN) _

5 - 6 : Factory use OFF (OPEN) _

SY-259A S201 1 : EXTENDED MENU OFF (OPEN)

2 : MAINTE MODE ACCESS OFF (OPEN)

3 - 8 : Factory use OFF (OPEN) _

S202 1 - 4 : Factory use OFF (OPEN) _

Never change the settings of S202 for bits 5 to 8 since each is set according to the characteristics of the unit

5, 6 : PLAYER/RECORDER

5: ON (CLOSE) _

6: ON (CLOSE) _

7 : J/UC ON (CLOSE) _

8 : 525/625 DNW-A25WS: OFF (OPEN) _

DNW-A25WSP: ON (CLOSE) _

SY-260 S201 1 - 8 : Factory use OFF (OPEN) _

*1, *2: Never change setting of the switches S101-1 and S101-2.

DNW-A25WS/A25WSP

A-3

A. Setting Check Sheet

Sub menu

The sub menu and the setup menu can store the data for 525 and 625 mode independently. Then fill out

for each mode, selecting mode using the setup menu ITEM-013: 525/625 SYSTEM SELECT.

HOME page

ITEM Factory setting 525 mode setting 625 mode setting

AUDIO SETTING BANK AU-1

TIME CODE READER AUTO

VITC VITCON

VIDEO INPUT SDI

Audio setting page

ITEM Factory setting 525 mode setting 625 mode setting

AU-1 AU- 2 AU- 3 AU-4 AU-1 AU- 2 AU- 3 AU-4

AGC OFF

LIMITER OFF

AUDIO INPUT IN-1 SDI-1

AUDIO INPUT IN-2 SDI-2

AUDIO INPUT IN-3 SDI-3

AUDIO INPUT IN-4 SDI-4

MIX/SWAPCH-1 IN-1

CH-2 IN-2

CH-3 IN-3

CH-4 IN-4

LINE OUT CH-1/2

MONITOR LEVEL FIX

MONITOR CH L CH-1

R CH-2

EMPH OFF

DOLBY OFF

A-4

DNW-A25WS/A25WSP

A. Setting Check Sheet

Video setting page

ITEM Factory setting 525 mode setting 625 mode setting

VIDEO VIN TRIG OFF

CONFI OFF

PREREAD OFF

VIDEO IN 80 PRESET

ZEBRA OFF

OUT REF REF

PROCESS CONTROL PANEL

AUD SG SILNC

VID SG BB

SG OFF

(When the above item is set to Y/C DLY 800 PRESET

PANEL) SYNC PH 80

SC PH 200

WIDE OFF

General setting page

ITEM Factory setting 525 mode setting 625 mode setting

SUPER ALL

CAPSTAN 4F

DF/NDF DF

BACKLGT NORMAL

KEY INH OFF

BAT-END 10.5

BAT-NE 11.0

VFDBRIT LOW

WID/MON AU. MON

DNW-A25WS/A25WSP

A-5

The material contained in this manual consists of

information that is the property of Sony Corporation.

Sony Corporation expressly prohibits the duplication of

any portion of this manual or the use thereof for any

purpose other than the operation or maintenance of the

equipment described in this manual without the express

written permission of Sony Corporation.

Le matériel contenu dans ce manuel consiste en

informations qui sont la propriété de Sony Corporation.

Sony Corporation interdit formellement la copie de

quelque partie que ce soit de ce manuel ou son emploi

pour tout autre but que des opérations ou entretiens de

l’équipement à moins d’une permission écrite de Sony

Corporation.

Das in dieser Anleitung enthaltene Material besteht aus

Informationen, die Eigentum der Sony Corporation sind.

Die Sony Corporation untersagt ausdrücklich die

Vervielfältigung jeglicher Teile dieser Anleitung oder den

Gebrauch derselben für irgendeinen anderen Zweck als

die Bedienung oder Wartung der in dieser Anleitung

beschriebenen Ausrüstung ohne ausdrückliche

schriftliche Erlaubnis der Sony Corporation.

DNW-A25WS/A25WSP

DNW-A25WS (SY)

DNW-A25WSP (SY) E

3-206-875-01

Printed in Japan

Sony Corporation 2002. 2 08

B&P Company ©2002

Loading...

Loading...