Sony DNS-707-F Service manual

D-NS707F

SERVICE MANUAL

Ver 1.0 2004.04

Manufactured under license from Dolby

Laboratories Licensing Corporation.

SPECIFICATIONS

US Model

Canadian Model

Model Name Using Similar Mechanism D-NE10

CD Mechanism Type CDM-3325ERV2

Optical Pick-up Name DAX-25EV

CD player

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wav elength: λ = 770 - 800 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance

of 200 mm from the objective lens surface on the

optical pick-up block with 7 mm aperture.)

D-A conversion

1-bit quartz time-axis control

Frequency response

20 - 20 000 Hz

Output (at 4.5 V input level)

Headphones (stereo minijack)

Approx. 5 mW + Approx. 5 mW at 16 Ω

+1–2

dB (measured by JEITA)

Radio

Frequency range

• 9 kHz step:

TV: 2 - 13 ch

WB (weather band): 1 - 7 ch

FM: 87.5 - 108.0 MHz

AM: 531 - 1 710 kHz

• 10 kHz step:

TV: 2 - 13 ch

WB (weather band): 1 - 7 ch

FM: 87.5 - 108.0 MHz

AM: 530 - 1 710 kHz

Antenna

FM: Headphones/earphones cord antenna

AM: Built-in ferrite bar antenna

General

Power requirements

• LR6 (size AA) batteries: 1.5 V DC 2

• AC power adaptor (DC IN 4.5 V jack):

120 V, 60 Hz

Operating temperature

5°C - 35°C (41°F - 95°F)

Dimensions (w/h/d) (excluding projecting parts

and controls)

Approx. 136 30.5 136 mm (53⁄811⁄453⁄8 in.)

Mass (excluding accessories)

Approx. 276 g (9.8 oz.)

Supplied accessories

•

Headphones

•

CD-ROM (SonicStage)

•

Operating Instructions

•

SonicStage Installation/Operating Guide

Design and specifi cations are subject to change

without notice.

x

x

x

x

x

9-877-798-01

2004D1679-1

© 2004.04

PORTABLE CD PLAYER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

D-NS707F

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

On AC power adaptor

•Use only the AC power adaptor supplied or

recommended in “Accessories (supplied/

optional).” Do not use any other AC power

adaptor. It may cause a malfunction.

Polarity of the plug

TABLE OF CONTENTS

1. SERVICE POSITION .......................................... 3

2. GENERAL ............................................................ 5

3. DISASSEMBLY

3-1. Upper (Lid) Section ......................................................... 6

3-2. Cabinet (Middle) Section ................................................ 7

3-3. MAIN PWB Assy ............................................................ 7

3-4. MAIN Board, CD Mechanism Deck

(CDM-3325ERV2) .......................................................... 8

3-5. Turn Table Motor Assy (M901), Sled Motor Assy (M902),

Optical Pick-up (DAX-25EV) ......................................... 8

4. ELECTRICAL CHECKING ................................ 9

5. DIAGRAMS

5-1. Block Diagram – MAIN Section (1/2) – ......................... 12

Block Diagram – MAIN Section (2/2) – ......................... 13

Block Diagram – TUNER Section – ............................... 14

Block Diagram – POWER Section –............................... 15

5-2. Printed Wiring Board – MAIN Board (Side A) –............ 16

5-3. Printed Wiring Board – MAIN Board (Side B) –............ 17

5-4. Schematic Diagrams – MAIN Board (1/5) –................... 18

5-5. Schematic Diagrams – MAIN Board (2/5) –................... 19

5-6. Schematic Diagrams – MAIN Board (3/5) –................... 20

5-7. Schematic Diagrams – MAIN Board (4/5) –................... 21

5-8. Schematic Diagrams – MAIN Board (5/5) –................... 22

5-9. IC Pin Function Descriptions .......................................... 27

6. EXPLODED VIEWS

6-1. Cabinet Upper.................................................................. 34

6-2. Cabinet Lower ................................................................. 35

6-3. Strap Front ....................................................................... 36

6-4. MAIN PWB Assy ............................................................ 37

6-5. CD Mechanism Deck Section (CDM-3325ERV2).......... 38

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

7. ELECTRICAL PARTS LIST............................... 39

2

SECTION 1

SERVICING NOTE

D-NS707F

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

BEFORE REPLACING THE OPTICAL PICK-UP BLOCK

Please be sure to check thoroughly the parameters as par the “Optical Pick-Up Block Checking Procedures” (Part No.: 9-960-027-11)

issued separately before replacing the optical pick-up block.

Note and specifications required to check are given below.

• FOK output: IC601 yg pin

When checking FOK, remove the lead wire to disc motor.

• RF signal P-to-P value: 0.45 to 0.65 Vp-p

MAIN BOARD (SIDE B)

3160

30

1

120

IC601 FOK output ygpin

61

90

91

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

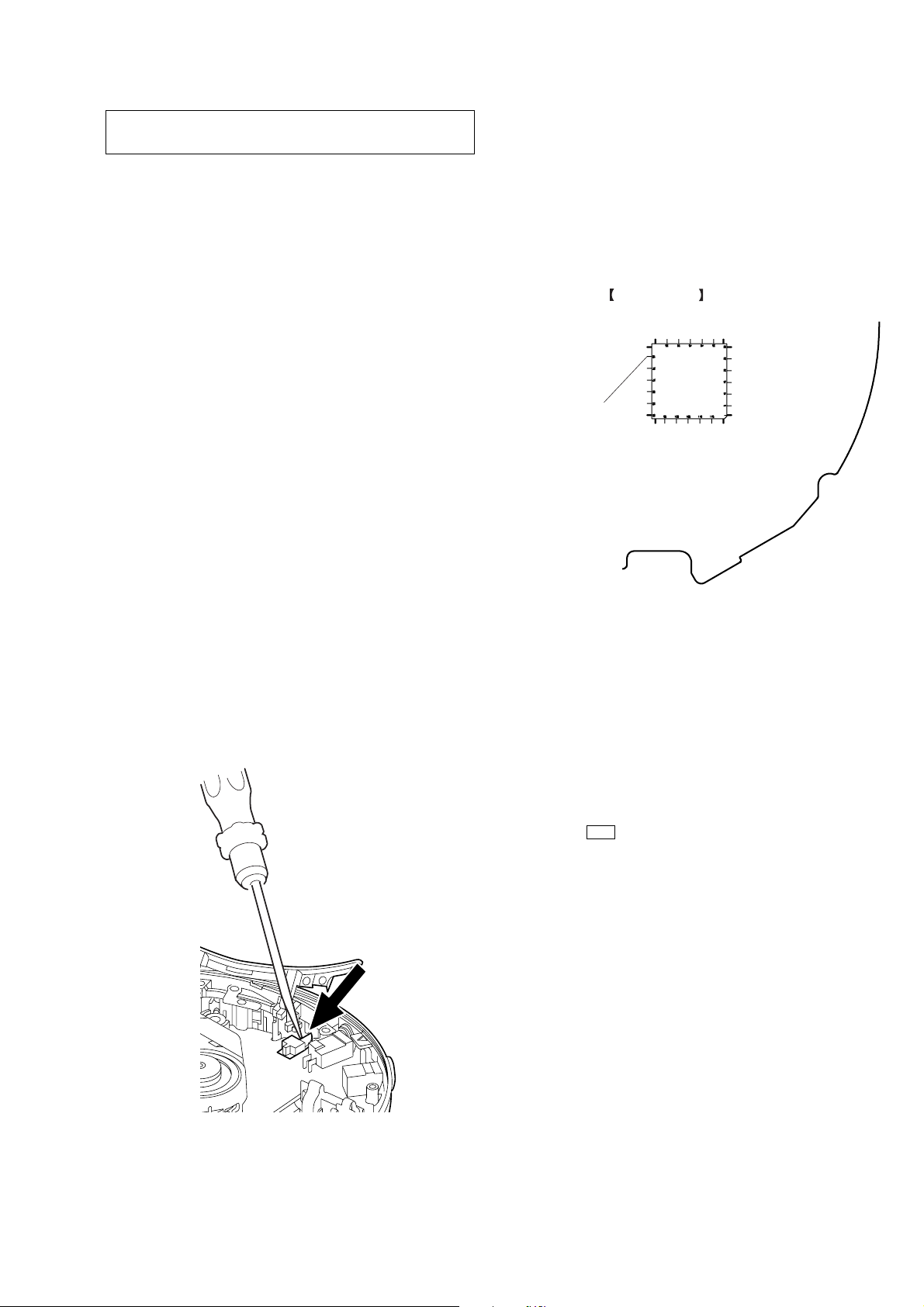

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning ON

the S820.

The following checking method for the laser diode is operable.

• Method:

Emission of the laser diode is visually checked.

1. Remove the upper lid.

2. With a disc not set, turn on the S820 with a screwdriver having

a thin tip as shown in Fig.1.

3. Press the

u

button.

4. Observing the objective lens, check that the laser diode emits

light.

When the laser diode does not emit light, automatic power control circuit or optical pickup is faulty.

In this operation, the objective lens will move up and down 4

times along with inward motion for the focus search.

Fig. 1 Method to push the S820

3

D-NS707F

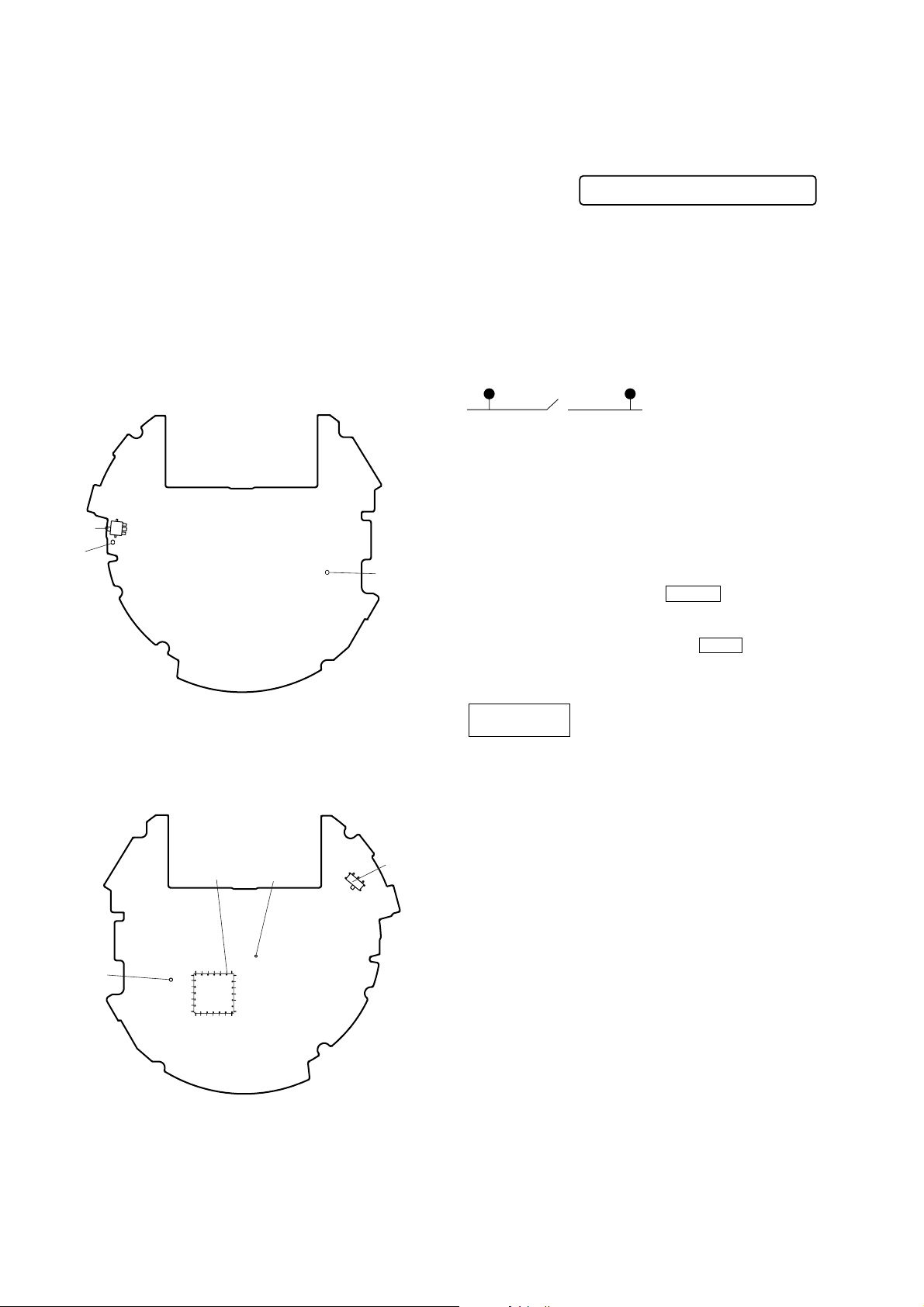

SERVICE MODE

The following confirmation can be performed when the Service

Mode is set.

1. How to set the CD Service Mode.

To set the Service Mode, the following method is available.

1) Confirm the set is not powered on.

2) Confirm the following settings.

OPEN/CLOSE detect switch (S820) ................. OFF

Solder Land (TAP833) ...................................... OPEN

[HOLD] switch (S803)........................................ OFF

3) Short the solder land TAP824 (TEST) on the MAIN board.

4) Turn on the main power.

MAIN BOARD(SIDE A)

S820

TAP833

TAP824

MAIN BOARD(SIDE B)

2. Operation when the Service Mode is set.

When the Service Mode becomes active, following messages are

displayed onthe remote control LCD.

Microcomputer

version display

1) Turn off the power.

2) Open the solder land TAP824 (TEST) on the MAIN board.

Note : The solder should be removed clean.

3. How to set the Tuner Service Mode.

To set the tuner Service Mode, the following method is available.

1) Confirm the set is not powered on.

2) Connect a external switch between TJ80 (Tu Test) and TJ81

(Gnd).

TJ80

(TU Test)

3) Slide the switch to connect TJ80 and TJ81 to be shorted.

4) Short the solder land TAP824 (Test).

5) Turn on the main power.

4. Operation when Tuner Service Mode is set.

When the tuner Service Mode becomes active, following the below

procedure.

1) CD microcomputer version display VS010B .

2) Press play key.

3) Display panel show all segments turn on.

4) Then show DTS microcontroller version: 00008

5) Slide the switch to oposite direction to open the connection of

TJ80(Tu test) and TJ81(Gnd).

6) Tuner mode turned on and display panel show :

FM

87.50 MHz

7) After checking complete, turn of the power.

8) Open solder land TAP824 (Test) and remove the external switch.

Note : The solder should be removed clean.

TJ81

(Gnd)

VS010B:

S803

TP746

IC601yg

TP538

4

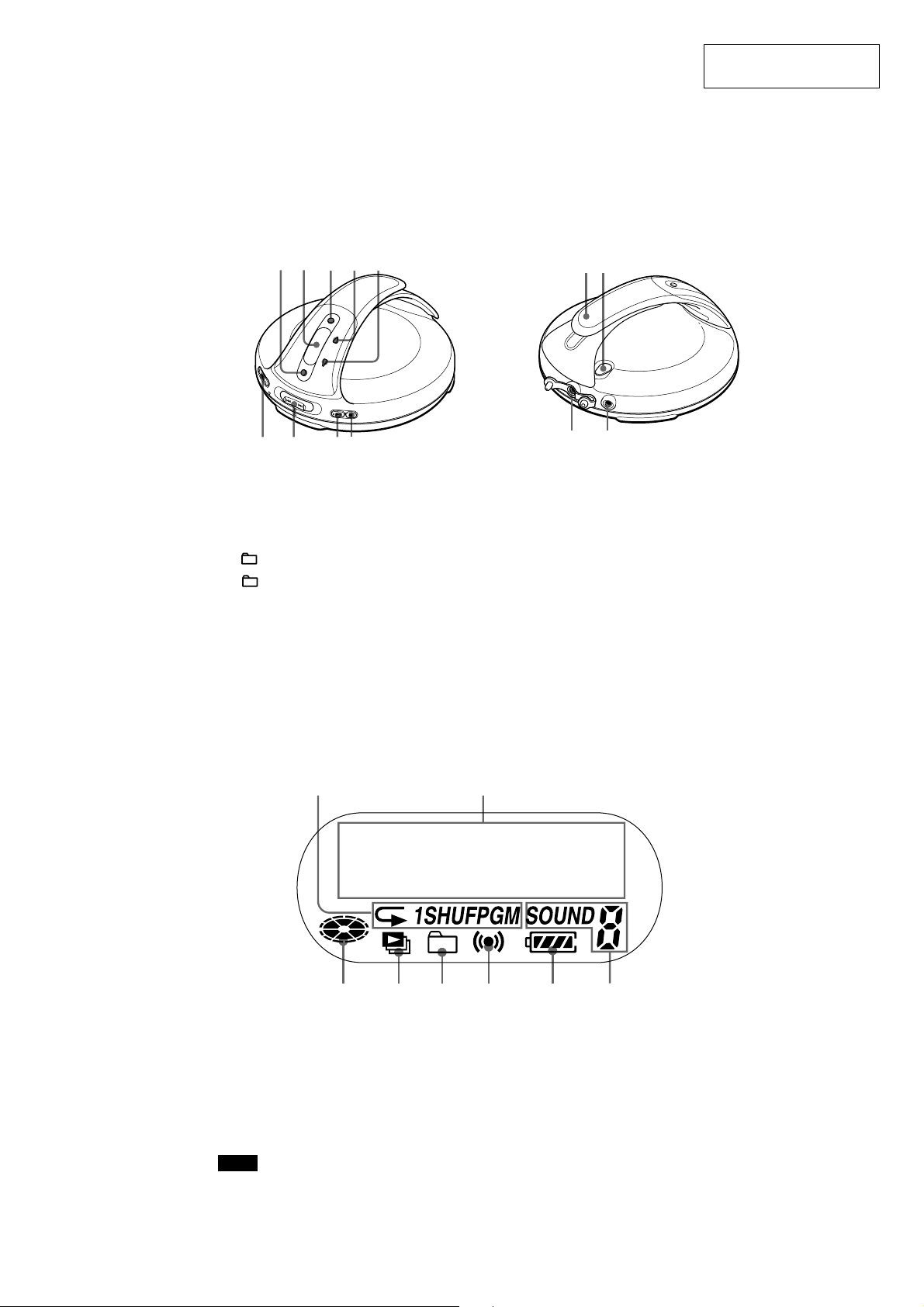

SECTION 2

32145

GENERAL

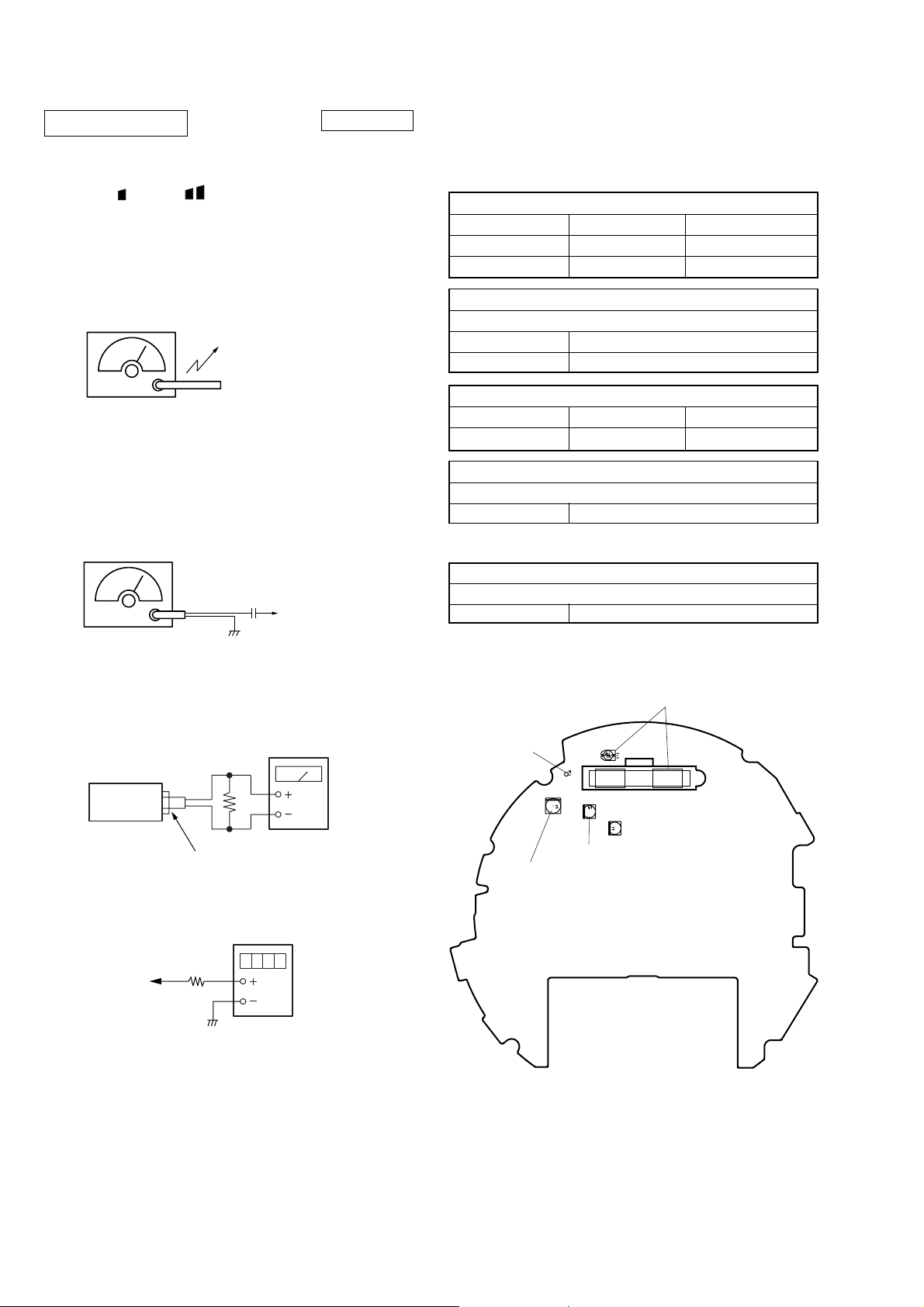

Guide to parts and Controls

0

D-NS707F

This section is extracted

from instruction manual.

qa

RADIO ON/BAND•MEMORY button

1

Display

2

DISPLAY/MENU button

3

4

5

6

VOL (volume) +*/– buttons

.

7

Display

67 89

(group) •TUNE button

(group)

H

•TUNE button

h

/PRESET –, /PRESET + lever

>

H

h

qf qg

qs qd

8

9

0

qa

qs

qd

(play/pause)*/ENTER button

u

(stop)•RADIO OFF button

x

Hand strap

HOLD switch

(headphones) jack

i

DC IN 4.5 V (external power input) jack

* This button has a tactile dot.

qh

Play mode indicator

qf

Character information display

qg

Disc indicator

qh

Play list indicator

qj

Note

Yo u can invert the characters on the display.

qj qk ql w; wa

Group indicator

qk

Timer indicator

ql

w;

Battery indicator

SOUND indicator

wa

5

D-NS707F

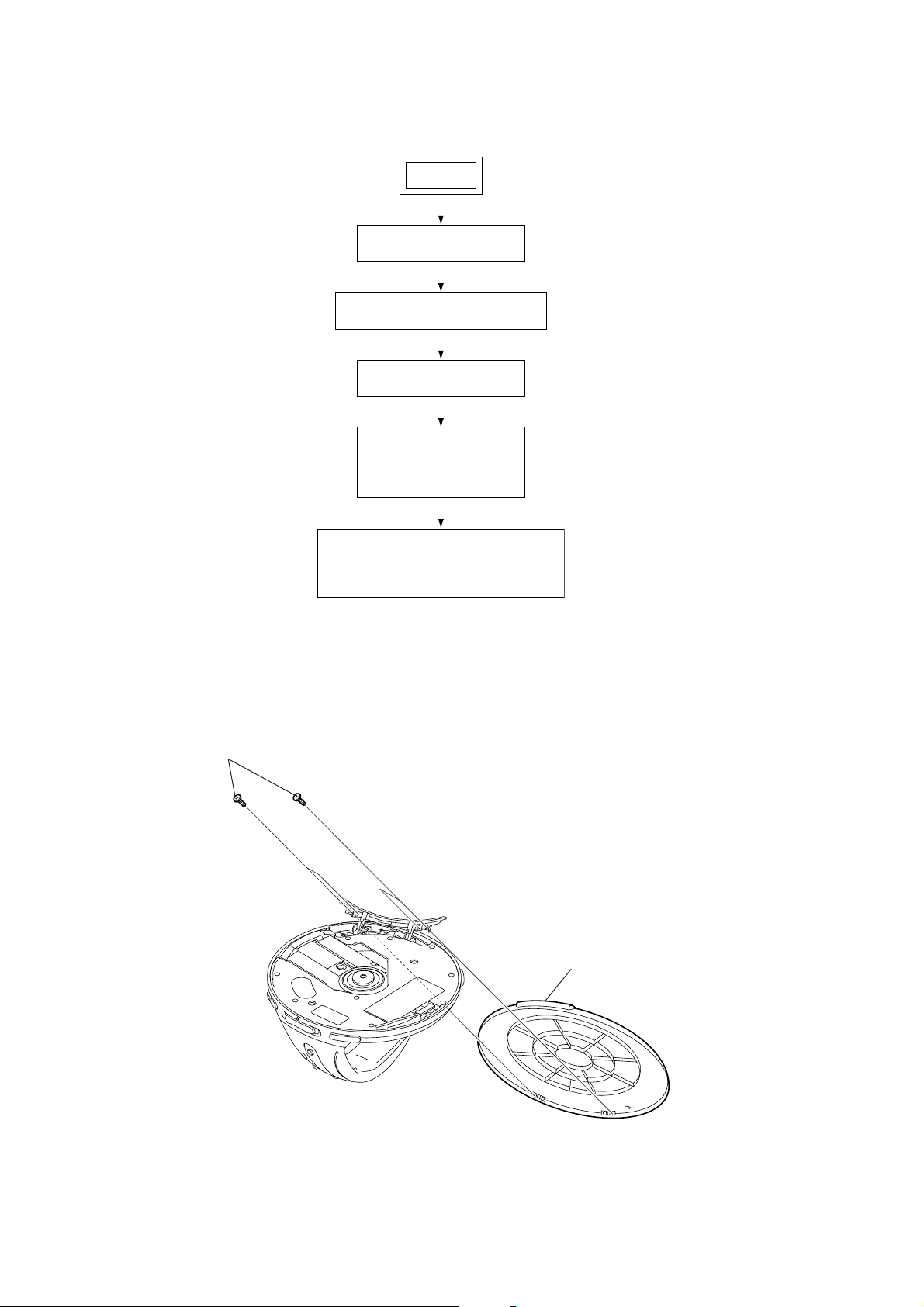

Note: Disassemble the unit in the order as shown below.

SECTION 3

DISASSEMBLY

SET

UPPER (LID) SECTION

CABINET (MIDDLE) SECTION

MAIN PWB ASSY

MAIN BOARD,CD

MECHANISM DECK

(CDM-3325ERV2)

TURN TABLE MOTOR ASSY (M901),

SLED MOTOR ASSY (M902),

OPTICAL PICK-UP (DAX-25EV)

Note: Follow the disassembly procedure in the numerical order given.

3-1. UPPER (LID) SECTION

1

four screws

2

upper lid sub assy

6

s

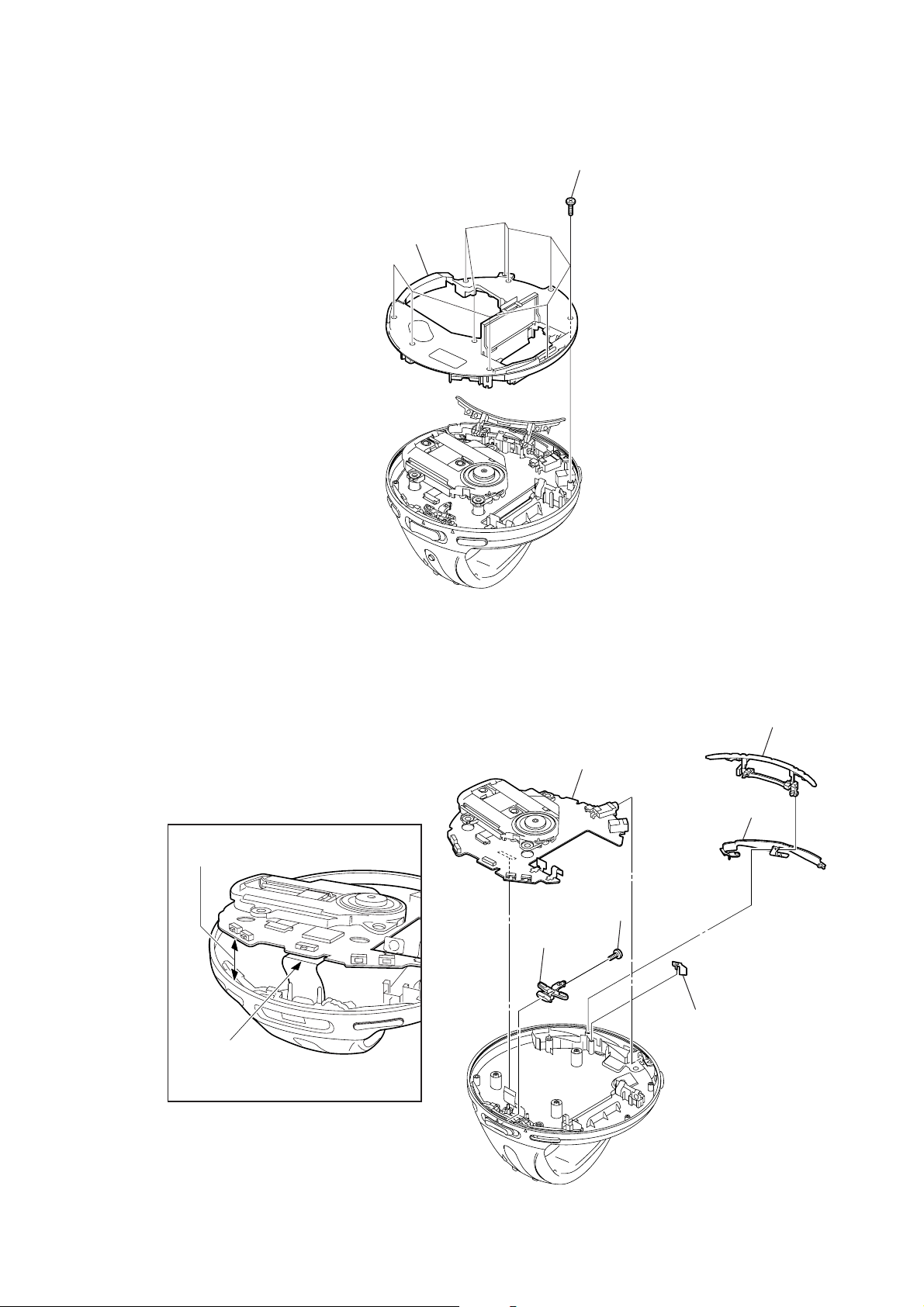

3-2. CABINET (MIDDLE) SECTION

2

cabinet middle

1

ten screw

D-NS707F

3-3. MAIN PWB ASSY

Precaution:PWB can not be lifted up

>5cm from back cabinet.

NG

Prohibit:Can not press FPC during

assembly PWB to back cabinet.

6

main pwb assy

5

jog

actuator

4

screw

2

1

hinge support

3

open spring

hinge sliding

7

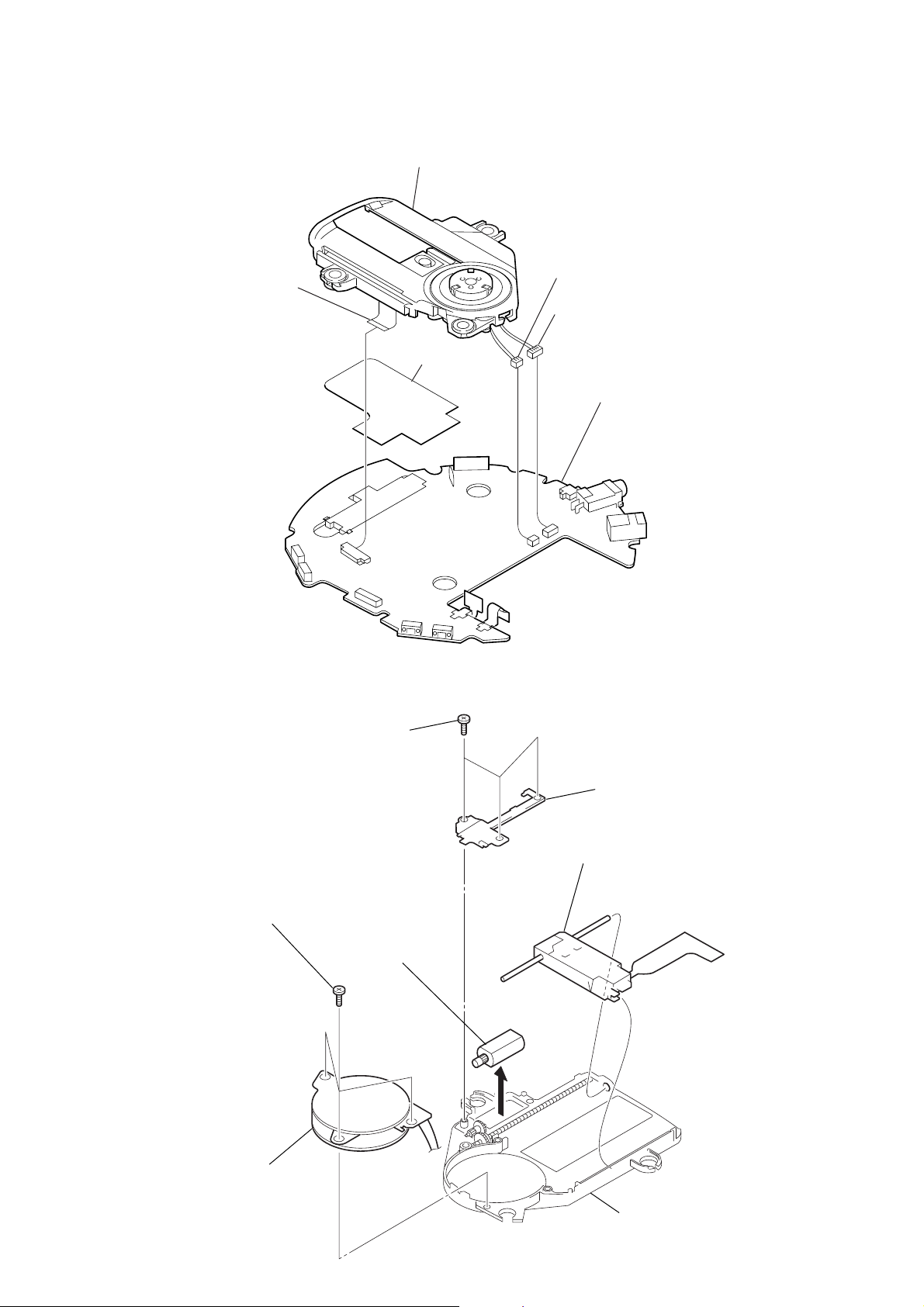

D-NS707F

)

3-4. MAIN BOARD, CD MECHANISM DECK (CDM-3325ERV2)

4

CD mechanism deck

(CDM-3325ERV2)

3

flexible board

(CN601)

5

com cover

sheet

1

connector (2P

(CN401)

2

connector (4P)

(CN402)

main board

3-5. TURN TABLE MOTOR ASSY (M901), SLED MOTOR ASSY (M902), OPTICAL PICK-UP (DAX-25EV)

1

three screws

5

three screws

(B 1.7

×

(B 1.7

4)

×

4)

3

sled motor assy

(M902)

2

gear cover

4

optical pick-up

(DAX-25EV)

6

turn table motor assy

(M901)

chassis

8

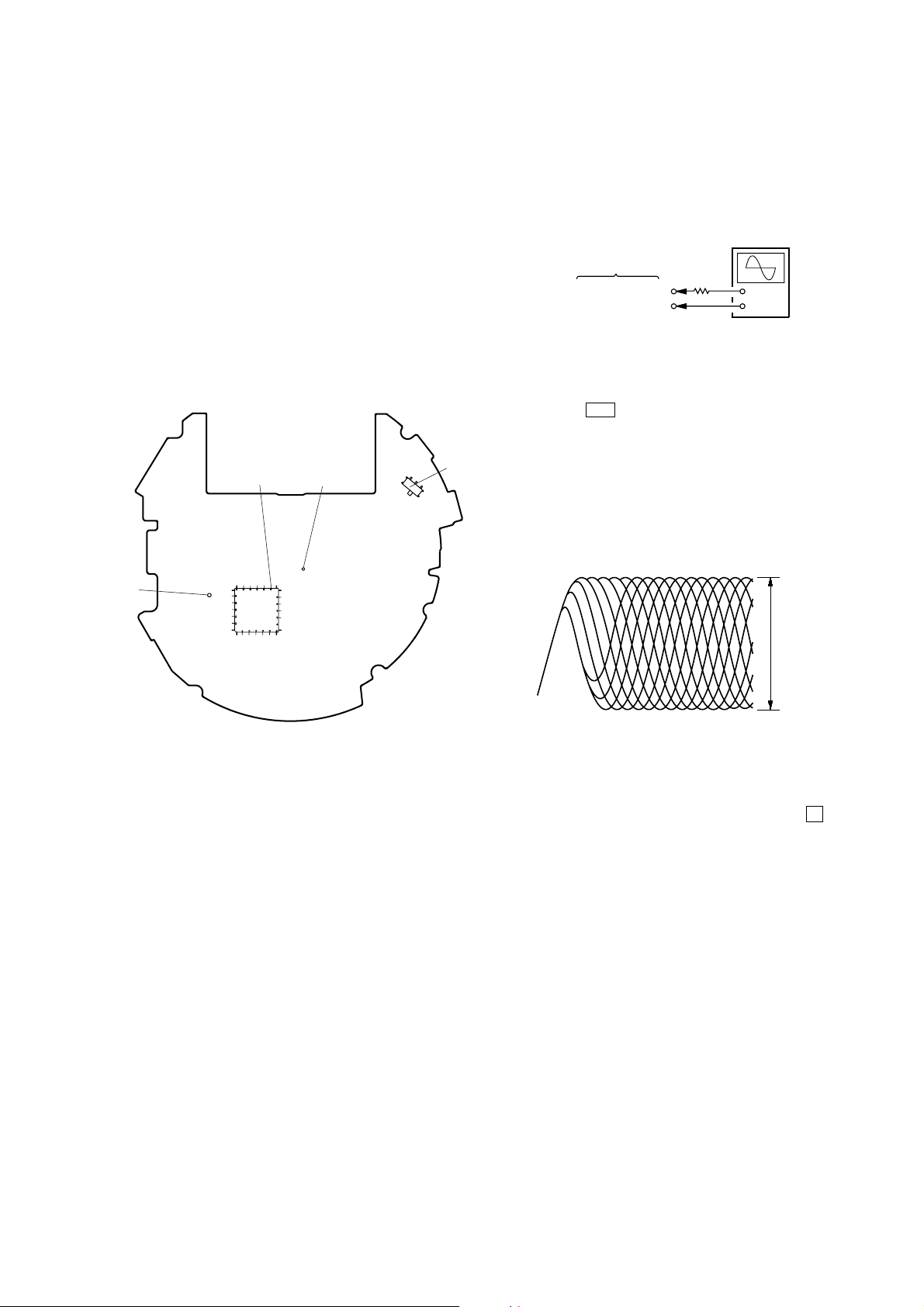

SECTION 4

e

RF level

0.45 to 0.65 Vp-p

ELECTRICAL CHECKING

D-NS707F

The CD section adjustments are done automatically in this set.

In case of operation check, confirm that RF level.

Precautions for Check

1. Perform check in the order given.

2. Use YEDS-18 disc (Part No.: 3-702-101-01) unless otherwise

indicated.

3. Power supply voltage requirement : DC4.5 V in terminals

(J401)

VOLUME button : Minimum

HOLD switch : OFF

Checking Location:

MAIN BOARD(SIDE B)

IC601yg

TP538

S803

RF Level Check

Condition:

• Hold the set in horizontal state.

Connection:

Oscilloscop

(AC range)

MAIN board

Ω

TP746 (RF)

TP538 (AGND)

Procedure:

1. Connect the oscilloscope to the test points TP746 (RF) and

TP538 (AGND) on the MAIN board.

2. Set a disc. (YEDS-18)

3. Press the u button.

4. Check the oscilloscope waveform is as shown below.

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

2 k

+

–

RF Signal reference Waveform (Eye Pattern)

VOLT/DIV : 100 mV (With the 10:1 probe in use)

TIME/DIV : 500 ns

TP746

To watch the eye pattern, set the oscilloscope to AC range and

increase the vertical sensitivity of the oscilloscope for easy

watching.

5. Stop revolving of the disc motor by pressing the x button.

9

D-NS707F

N

TUNER SECTION

• Switch Location and mode setting

VOLUME : MAX

BASS

AVLS : OFF

[AM]

BAND: AM

Signal generator

[FM]

BAND : FM

Signal generator

• Connecting levelmeter

or BASS : OFF

AM RF signal

generator

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

FM RF signal

generator

75kHz(100%) amplitude modulation

by 1kHz signal.

Output level: as low as possible

Put the lead-wire

antenna close to

the set.

0.01µF

FM I

point

0 dB = 1 µV

•Repeat the procedures in each adjustment several times for the

maximum level meter indication.

•The AM tracking adjustments should be finally done by the

trimmer capacitors.

AM FREQUENCY COVERAGE ADJUSTMENT AND CHECK

Adjustment Part Frequency Display

Reading on Digital Voltmeter

L4 530kHz 1.2 ± 0.1V

Confirmation 1710kHz 8.4 ± 0.5V

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on levelmeter

L3 620kHz

CT3 1400kHz

FM FREQUENCY COVERAGE CHECK

Adjustment Part Frequency Display

Reading on Digital Voltmeter

Confirmation 87.5MHz 5.1 ± 0.8V

FM TRACKING ADJUSTMENT

Adjust for a maximum reading levelmeter

L1 98.0MHz

US model only

TV TRACKING ADJUSTMENT

Adjust for a maximum reading on levelmeter

L5 ch10 197.75MHz

Adjustment Location: MAIN board (Side B)

CT3,L3 AM TRACKING adjustment

set

J332 (

i)

• Connecting digital voltmeter

TJ8 (VT)

100k

16 Ω

digital voltmeter

Ω

levelmeter

TJ8(VT)

L4 AM FREQUENCY COVERAGE adjustment

CT3

L3

L1 FM TRACKING adjustment

L5 TV TRACKING adjustment

10

SECTION 5

DIAGRAMS

NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

D-NS707F

Note on Printed Wiring Board

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• :Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF 50 WV

or less are not indicated except for electrolytics and tantalums.

• All resistors are in W and 1/4 W or less unless otherwise

specified.

•%: indicates tolerance.

• C : panel designation.

Note:

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part

number specified.

• A : B+ Line.

•Total current is measured with CD installed.

•Power voltage is dc 4.5 V and fed with regulated dc power supply

from DC IN jack.

•Voltages and waveforms are dc with respect to ground in

playback mode.

no mark : CD PLAY

* : Impossible to measure

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD PLAY

Note:

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

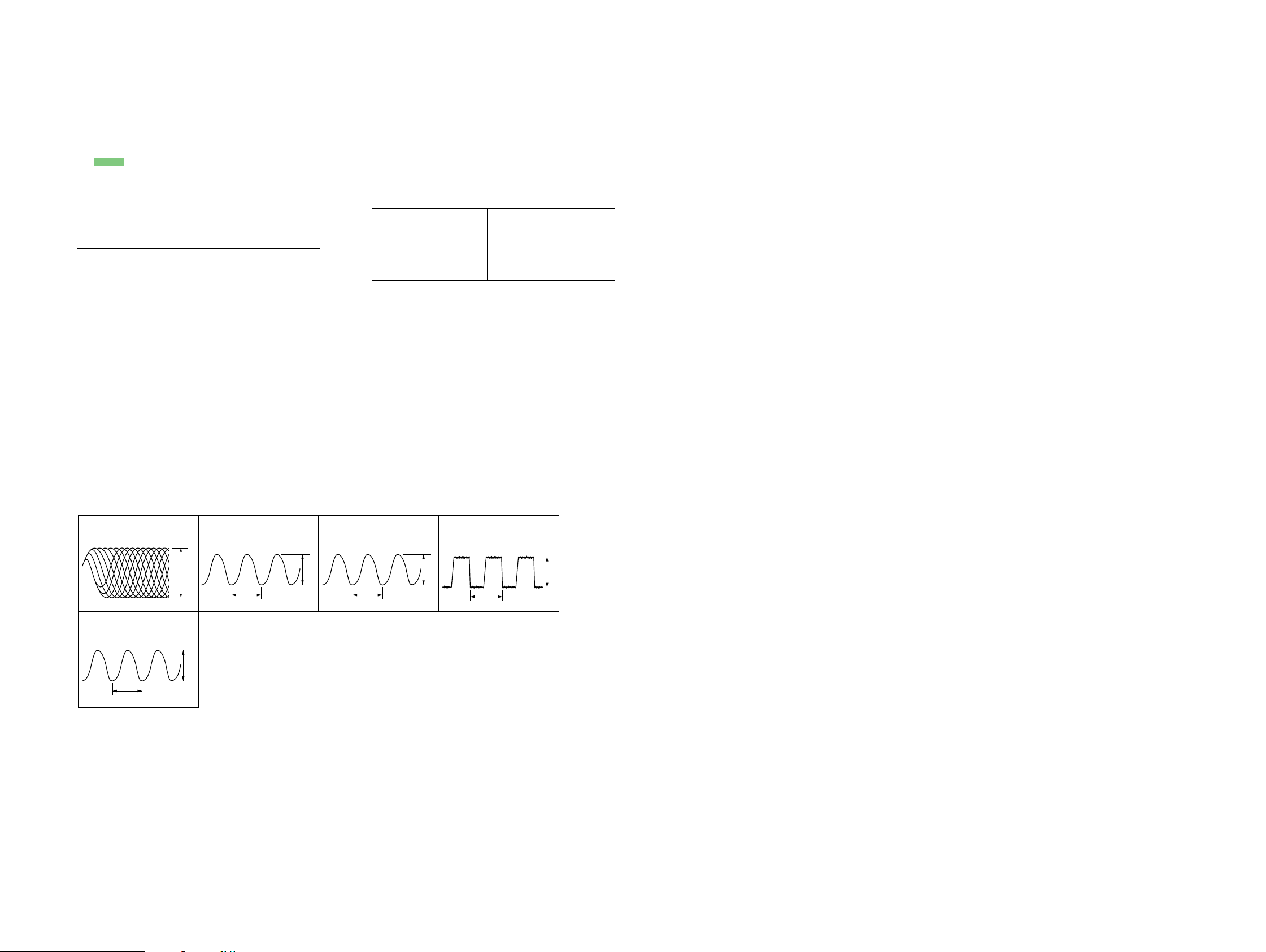

• Waveforms

1

IC601 if RFAC

100mV/DIV, 400ns/DIV

540 mVp-p

5

IC61 ug XIN

500mV/DIV, 10us/DIV

1.4 Vp-p

13.3us

2

IC601 rk XTAO

1V/DIV, 20ns/DIV

3.2 Vp-p

59ns

3

IC801 wk XIN

1V/DIV, 40ns/DIV

3.4 Vp-p

118ns

4

IC403 ef SYNC

1V/DIV, 2us/DIV

5.7us

2.0 Vp-p

1111

D-NS707F

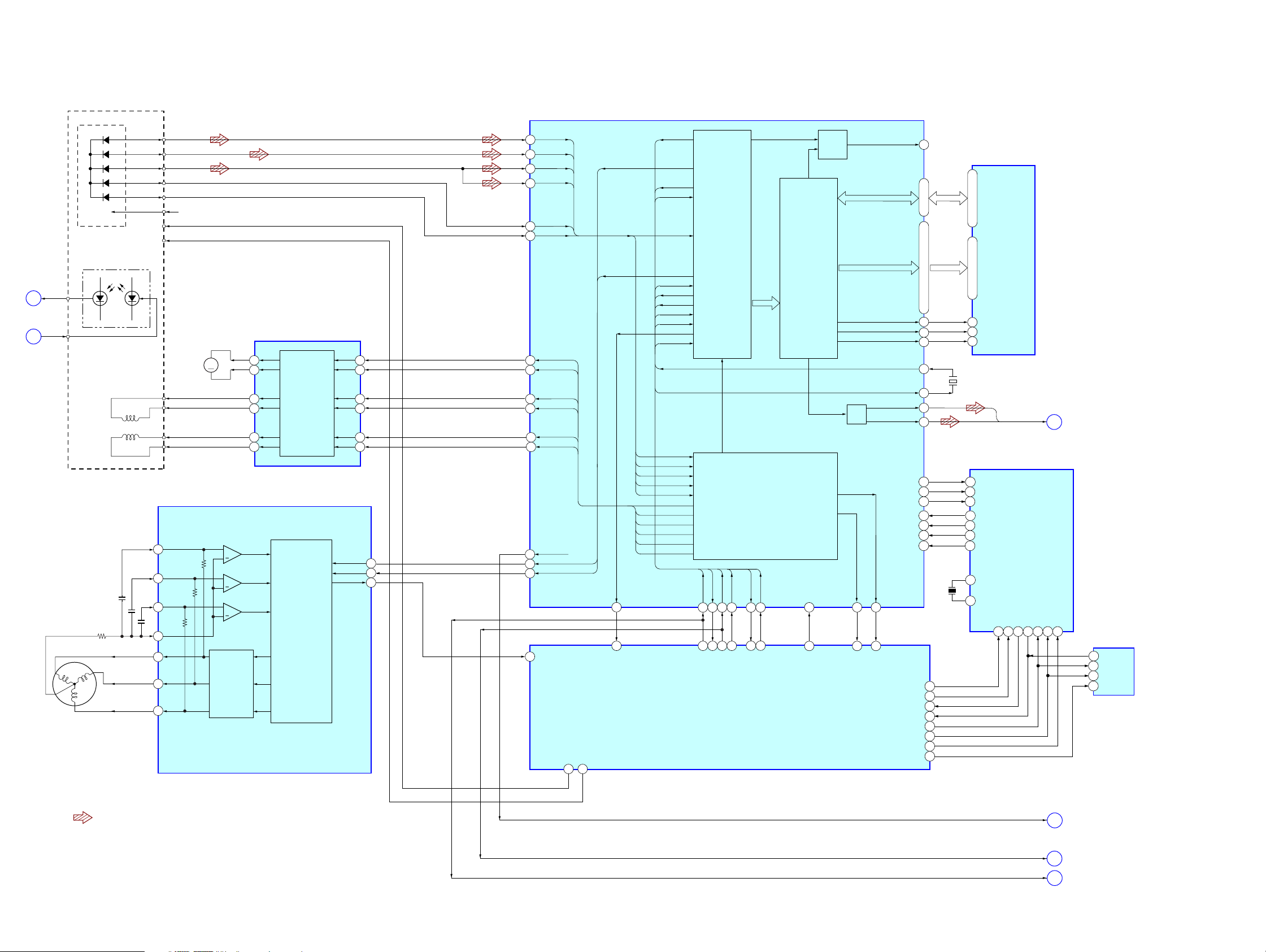

5-1. BLOCK DIAGRAM – MAIN SECTION (1/2) –

DETECTOR

A

(Page 15)

B

(Page 15)

OPTICAL PICK-UP BLOCK

LASER DIODE

PD

LD

(FOCUS)

2-AXIS

DEVICE

(TRACKING)

M902

SPINDLE

MOTOR

V

U

W

A

B

RF

E

F

VCC

DAX-25E

PD

A

B

RF

E

F

VCC3

OPGSW

OPSTB

LD

FOCUS/TRACKING COIL DRIVER

M901

M

SLED

MOTOR

U1

79

V1

78

W1

77

COM

80

U

2

V

4

W

6

+

+

+

MOTOR

DRIVER

FO1

52

RO1

50

FO3

44

RO3

42

FO2

42

RO2

40

IC403 (1/3)

SLED MOTOR DRIVER

CONTROLLER,

H BRIDGE DRIVER

IC403 (2/3)

SPINDLE MOTOR DRIVER

CONTROL

CIRCUIT

FI1

RI1

FI3

RI3

FI2

RI2

APWM

XBRK

IC601

RF AMP,

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR,

D-RAM CONTROLLER

A

92

B

91

RFDC

88

RFAC

84

E

89

F

90

SFDR

56

55

60

59

58

57

73

70

FG

74

100

104

103

102

SRDR

99

FFDR

96

FRDR

95

TFDR

98

TRDR

97

C176

MDP

MDS

SCOR

27

FG_I

10

SCOR_I

HG_XSTB_O

HG_GUP_O

12

13

WFCK

MDS

XTAO

XTAI

RFAC

XSOE

SENS

R4M

XLAT

CLOK

SCOR

SDTO

RFDC

SFDR

SRDR

FFDR

FRDR

TFDR

TRDR

SIGNAL

PROCESSOR

BLOCK

MDP

E

F

B

A

SDTO

SENS

858887838486

MSDTO0_O

IC801 (1/3)

SYSTEM CONTROLLER

CLOK

XLAT

232021

MSCK_O

MSDTI0_I

XLAT0_O

R8M

32

28

SERVO

BLOCK

XSOE

2422

XIN

XSOE_O

MEMORY

CONTROLLER,

BASS BOOST

BLOCK

XRST

28

4

XRST_O

DIGITAL

OUT

FOK

GFS

LPF

GFS

69

53

GFS_I

DOUT

D0-D3

A0-A10

XRAS

XWE

XCAS

XTAI

XTAO

AOUT1

AOUT2

PCMD_O

LRCK_O

BCK_O

PCMD_I

LRCK_I

BCK_I

XRDE

FOK

65

52

FOKI

AT3_MP3_V_O

WAKEUP_K_O

REQ_I

SDIN_I

SDOUT_O

SDCLK_O

SDXLAT_O

EEP_CS_O

62

4, 3, 6, 5

116 – 113, 17 – 15, 13 – 11, 117

1

2

9

47

48

51

56

108

106

110

109

107

111

18

X701

22MHz

60

66

11

20

19

18

17

67

D0 – D3A0 – A10

2, 3, 24, 25

9 – 12, 15 – 19, 21, 8

5

XRAS

4

XWE

23

XCAS

X601

16.9344MHz

4

PCMD

1

LRCK

2

BCK

15

PI0

14

PI2

13

PI3

12

PF4

29

EXTAL

30

XTAL

IC603

D-RAM

AOUTL,

AOUTR

IC701

MP3 DECODER

PF0

NRST

PF3

33

34

37

40

PC1

41

D

(Page 13)

PC0

PC2

38

42

PC3

4

3

2

1

IC803

EEPROM

DO

DI

XSK

XCS

• SIGNAL PATH

: CD PLAY

SYNC

MSCK

MSDTO

E

F

G

(Page 15)

(Page 15)

(Page 15)

1212

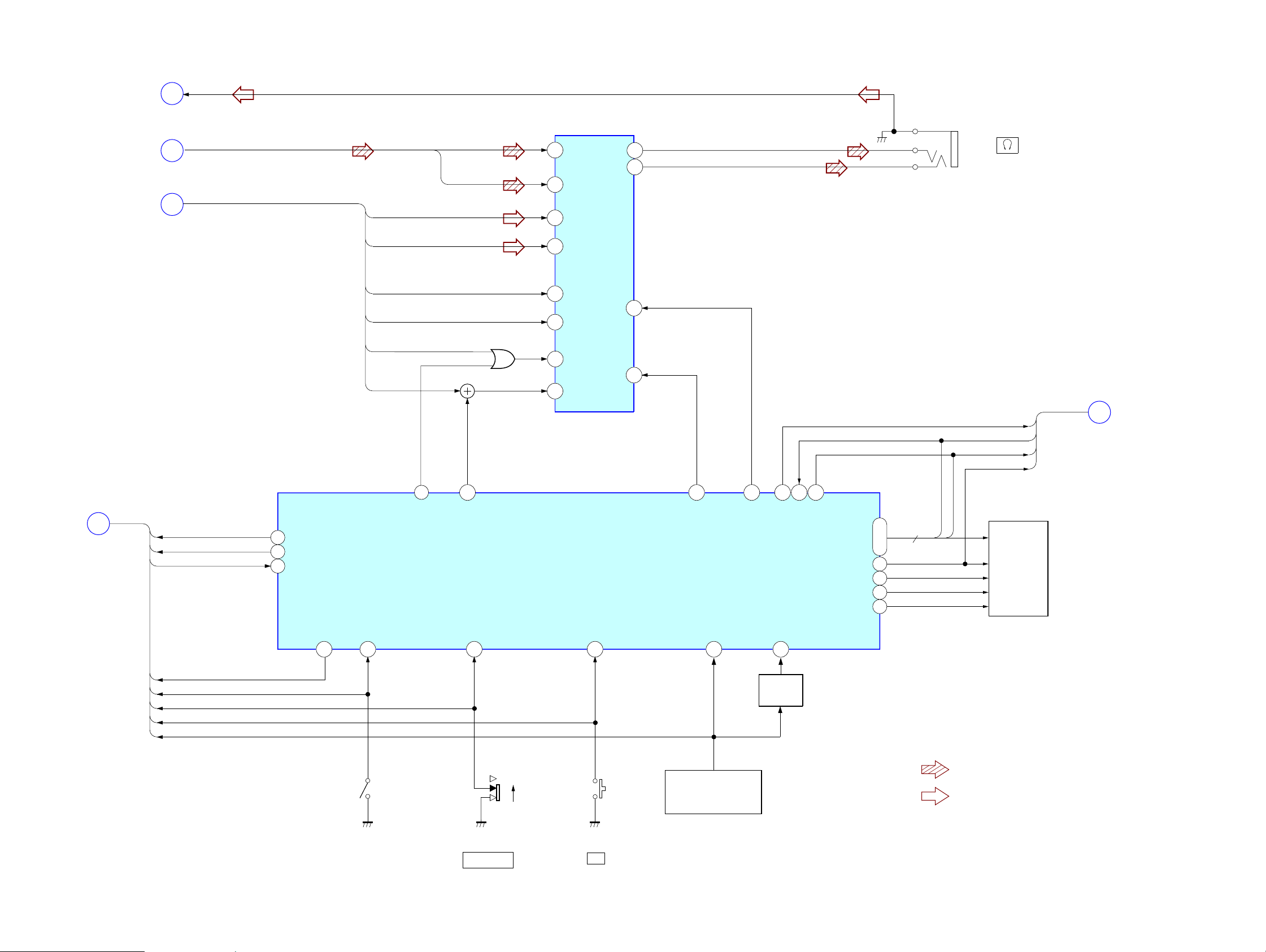

BLOCK DIAGRAM – MAIN SECTION (2/2) –

FMANT

H

(Page 14)

CD L, CD R

D

(Page 12)

CD L

CD R

IC332

HEADPHONE AMP

32

36

CD LIN

CD RIN

LOUT

ROUT

D-NS707F

J332

7

5

K

(Page 14)

I

(Page 14)

CDON

DTS RST

TUON

55 CDON_O

59 DTS_RST_O

68 TUON_I

TU L

TU R

VOL CTRL

BST SW

TU MUTE

TU BEEP

7

AMUTE_O

CD MUTE

6

BEEP_O

D335

33

TU LIN

35

TU RIN

14

VOL CTL

INSW

44

26

BST SW

1

MUTE

PWRSW

BEEP3

IC801 (2/3)

SYSTEM CONTROLLER

31

77

HP_PWRSW

56

AUD_SEL

21

22

DTS_SDTI

DTS_SDTO

23

AD0-7

DTS_SCK

LCD_A0

XRD_O

XWR_O

LCD-XRST_O

44

51

69

71

72

73

DTSSDTO

DTSSDTI

DTSSCK

A0

AD6

|

8

AD7

LCD UNIT

J

(Page 14)

ACK2SCK

LID OPEN

HOLD

ADKEY2

ADKEY1

ACK2SCK

16

(OPEN/CLOSE)

LID-SW_I

37

S820

HOLD_I

40

S810

> HOLD

ON

OFF

97

S801

x

AD-KEY2

S802 - 805

FUNCTION

KEY

1313

AD-KEY1

96

JOGKEY_I

36

Q801

SWITCH

• SIGNAL PATH

: CD PLAY

: FM

D-NS707F

BLOCK DIAGRAM – TUNER SECTION –

(Page 13)

RF/IF AMP, FM/AM DET, FM MPX

FM/TV MIX

TV

OSCFMOSC

1/2

AM

OSC

AM MIX

BPF

REF

REF

REF

TV RF OUT

30

FM RF OUT

29

TV RF IN

1

FM RF IN

2

TV FM OSC

24

AM OSC

25

AM BYPASS

28

AM RF IN

27

VT

Q152

FMANT

H

FL1/FL2

IC1

1/8

1/16

FM MIX

AM MIX

CF2

4 8

CF1

5

10

FM IF IN

AM IF IN

AGC

FM

DET

LEVEL

DET

AM

DET

IF

SW

DET OUT

AF

FM

MPX

MPX IN

L OUT

R OUT

LPF1

12

13

16

15

14

Q1

TU L

TU R

I

(Page 13)

(Page 13)

(Page 15)

FM/AM/TV

PW SW

MODE1

OSC OUT

23

IC61

ACK CD-O

54

ACKCD

73

DST RST

TUNER CONTROLLER

XIN

XOUT

RESET_I

75

74

X61

75kHz

T81

DDCON

3.2V

Q86

OSC

VCPU

Q89

Q84,85

VT

41

TV-L ON_O

65

EQ(DO1)_O

40

NC

AD DC REF

57

45

VCPU

1.4VREF

XTU TEST_I

SUBEY1_2

38

37

TU ON

ADKEY2

CD ON_I

TU ON_O

42

39

ADKEY1

CD ON

BATT_I

KEY_I

44

43

AD I HIDC

AD I BATT

71

HIDC_I

AM IN

TU HOLD_I

51

HOLD

K

L

MODE2

21

22

53

52

BAND CTRL 1_O

BAND CTRL 2_O

EEP CS_O

SCK-I-CDU

SDO-O-CDU

32

48

47

46427

1

2

3

DI

CS

SK

IF REQ

20

Q71

IFREQ_O

SDI-I-CDU

CS_O

A0_O

26

DO

IF COUNT

19

BUFF

6461

60

IFIN_I

+B ON/OFF_O

MONO_O 55

TUBEEP_O

PWM OUT_O 50

BST SW_O 58

TUMUTE_O

49

62

TUBEEP

VOL CTRL

BST SW

TUMUTE

DTS SDTO

DTS SDTI

DTS SCK

• SIGNAL PATH

XCS

A0

J

(Page 13)

: FM

IC62

EEPROM

1414

Loading...

Loading...