Sony Cybershot DCR-SR100,Cybershot DCR-SR90E,Cybershot DCR-SR100E Service Manual

DCR-SR90E/SR100/SR100E

RMT-835

SERVICE MANUAL

Ver. 1.2 2007.04

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Photo: DCR-SR100

Link

Link

SPECIFICATIONS

DISASSEMBLY

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

North European Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Korea Model

Tourist Model

Japanese Model

SCHEMATIC DIAGRAMS

MODEL INFORMATION TABLE

SERVICE NOTE

• Precaution on Replacing the VC-449 Board

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAM

PRINTED WIRING BOARDS

REPAIR PARTS LIST

DIGITAL VIDEO CAMERA RECORDER

DCR-SR90E/SR100/SR100E_L2

9-876-940-31

Sony EMCS Co.

2007D0500-1

© 2007.4

Published by Kohda TEC

These specifications are extracted from instruction

manual of DCR-SR90E/SR100E.

SPECIFICATIONS

ENGLISH JAPANESE

ENGLISH JAPANESE

System

Video compression format

MPEG2/JPEG (Still images)

Hard Disk

30 GB

Audio compression format

Dolby Digital 2/5.1ch

Dolby Digital 5.1 Creator

Video signal

PAL color, CCIR standards

Recording format

Movie

MPEG2-PS

Still image

*1

Exif

Ve r. 2.2

Recording/playback time

HQ:Approx. 440 min

SP:Approx. 650 min

LP: Approx. 1 250 min

Number of recordable movies/still images

Movie: Maximum of 9 999

Still image: Maximum of 9 999

Viewfinder

Electric viewfinder

color

Image device

5.9 mm (1/3 type) CCD (Charge Coupled

Device)

Gross:

Approx. 3 310 000 pixels

Effective (Movie, 4:3):

Approx. 2 050 000 pixels

Effective (Movie, 16:9):

Approx. 2 060 000 pixels

Effective (Still, 4:3):

Approx. 3 050 000 pixels

Effective (Still, 16:9):

Approx. 2 290 000 pixels

Lens

Carl Zeiss Vario-Sonnar T

Filter diameter:30 mm (1 3/16 in.)

Optical:10×, Digital:20×, 120×

F=1.8 - 2.9

Focal length

f=5.1 - 51 mm (7/32 - 2 1/8 in.)

When converted to a 35 mm still camera

For movies:

42.8 - 495 mm (1 11/16 - 19 1/2 in.) (16: 9)

45 - 450 mm (1 13/16 - 17 3/4 in.) (4:3)

For still images:

40.6 - 406 mm (1 5/8 - 16 in.) (16:9 )

37 - 370 mm (1 1/2 - 14 5/8 in.) (4:3)

Color temperature

[AUTO], [ONE PUSH], [INDOOR] (3 200 K),

[OUTDOOR] (5 800 K)

Minimum illumination

5 lx (lux) (F1.8)

0 lx (lux) (in the NightShot function)

*1

“Exif” is a file format for still images, established

by the JEITA (Japan Electronics and Information

Technology Industries Association). Files in this

format can have additional information such as

your camcorder’s setting information at the time

of recording.

*2

In 16:9 mode, the focal length figures are actual

figures resulting from wide angle pixel readout.

•Manufactured under license from Dolby

Laboratories.

Input/Output connectors

DCR-SR90E

Audio/Video output

10-pin connector

Video signal: 1 Vp-p, 75Ω (ohms), unbalanced

Luminance signal: 1 Vp-p, 75Ω (ohms),

unbalanced

Chrominance signal: 0.3Vp-p, 75 Ω (ohms),

unbalanced

Audio signal: 327 mV (at load impedance 47

kΩ (kilohms)), Output impedance with less

than 2.2 kΩ (kilohms)

USB jack

mini-B

REMOTE jack

Stereo mini-minijack (Ø 2.5 mm)

DCR-SR100E

Audio/Video input/output

10 pin connector

Input/Output auto switch

Video signal: 1 Vp-p, 75Ω (ohm s), unbalanced

Luminance signal: 1 Vp-p, 75Ω (ohms),

unbalanced

Chrominance signal: 0.3 Vp-p, 75Ω (ohms),

unbalanced

Audio signal: 327 mV (at load impedance

47 kΩ (kilohms)), Input impedance more than

47 kΩ (kilohms), Output impedance less than

2.2 kΩ (kilohms)

USB jack

mini-B

REMOTE jack

Stereo mini-minijack (Ø 2.5 mm)

LCD screen

Picture

6.9 cm (2.7 type, aspect ratio 16:9)

To tal number of pixels

123 200 (560 × 220)

General

Power requirements

7.2 V (battery pack) 8.4 V (AC Adaptor)

Average power consumption (when using the

*2

battery pack)

During camera recording using LCD

4.1 W

Viewfinder

3.7 W

Operating temperature

0°C to + 40°C (32°F to 104°F)

Storage temperature

-20°C to + 60°C (-4°F to + 140°F)

Dimensions (Approx.)

82 × 69 × 149 mm (3 3/8 × 2 3/4 × 5 7/8 in.)

(w×h×d)

Mass (Approx.)

535 g (1 lb 2 oz) main unit only

615 g (1 lb 5 oz) including the NP-FP60

rechargeable battery pack

Supplied accessories

AC Adaptor (1)

Mains lead (1)

A/V connecting cable (1)

USB cable (1)

Wireless Remote Commander (1)

Rechargeable battery pack

NP-FP60 (1)

CD-ROM “ImageMixer for HDD

Camcorder” (1)

“Camera Operating Guide” (1)

“Computer Application Guide” (1)

See page 5-26.

AC Adap

Power requirements

Current consumption

Power consumption

Output voltage

Operating temperature

Storage temperature

Dimensions (Approx.)

Mass (Approx.)

* See at the label of AC Adaptor for other

tor AC-L200

AC 100 - 240 V, 50/60 Hz

0.35 - 0.18 A

18 W

DC 8.4 V*

0°C to + 40°C (32°F to 104°F)

-20°C to + 60°C (-4°F to + 140°F)

48 × 29 × 81 mm (1 15/16 × 1 3/16 × 3 1/4 in.)

(w×h×d) excluding the projecting parts

170 g (6 oz) excluding the mains lead

specifications.

Rechargeable battery pack

NP-FP60

Maximum outp

DC 8.4 V

Output

DC 7.2 V

Capacity

7.2 wh (1 000 mAh)

Dimensions (Approx.)

31.8 × 33.3 × 45.0 mm

(1 5/16 × 1 5/16 × 1 13/16 in.) (w×h×d)

Mass (Approx.)

80 g (2.9 oz)

Operating temperature

0°C to + 40°C (32°F to 104°F)

Typ e

Li-ion

Design and specifications are subject to change

without notice.

ut voltage

voltage

DCR-SR90E/SR100/SR100E_L2

— 2 —

概略仕様

ENGLISH JAPANESE

ENGLISH JAPANESE

システム

映像圧縮方式

MPEG2/JPEG

ハードディスク

30GB

音声圧縮方式

Dolby Digital2/5.1ch

ドルビーデジタル

記録フォーマット

動画

MPEG2-PS

静止画

Exif Ver.2.2

映像信号

NTSC

再生時間

録画

/

:約

HQ

:約

LP

撮影可能カット数

動画:

静止画:

ファインダー

電子ファインダー:カラー

撮像素子

5.9mm(1/3

総画素数:約

動画有効画素数(

動画有効画素数(

静止画有効画素数(

静止画有効画素数(

レンズ

カールツァイス バリオゾナー

倍(光学)、20倍、

10

フィルター径

値=

F

f(焦点距離):

35mm

動画撮影時

42.8-495

45-450

静止画撮影時

40.6-406mm(16:9

37-370

色温度切り換え

[オート]、[ワンプッシュ]、[屋内](

[屋外](

最低被写体照度

(ルクス)(

11 lx

(ルクス)(

0 lx

*1

(社)電子情報技術産業協会(

された、撮影情報などの付帯情報を追加する

ことができる静止画用のファイルフォーマッ

ト

*2

広角画素読み出しによる実動作値

ドルビーラボラトリーズからの実施権に基づ

•

き製造されています。

(静止画)

*1

カラー、

EIA

分 SP:約

440

分

1 250

枚数

/

個

9 999

枚

9 999

型)

331

30mm

1.8-2.9

5.1-51mm

カメラ換算:

mm(16:9)

mm(4:3)

mm(4:3)

5800K

NightShot

クリエーター搭載

5.1

標準方式

650

固体撮像素子

CCD

万画素

):約

4:3

205

):約

16:9

):約

4:3

):約

16:9

倍(デジタル)

120

*2

)

)

)

F1.8

分

206

305

229

時)

JEITA

万画素

万画素

万画素

万画素

T

)にて制定

3200K

)、

入/出力端子

端子

A/V

ピン特殊コネクター

10

入力

出力自動切り換え

/

USB

映像:

出力

Y

出力

C

音声:

ダンス

Ω以下

k

端子

mini-B

1 Vp-p、75

327mV(47 k

47 k

Ω不平衡

1Vp-p、75

0.286Vp-p、75

Ω不平衡

Ω不平衡

Ω負荷時)、入力インピー

Ω以上、出力インピーダンス

REMOTE

ステレオミニミニジャック(リモート)端子

(

ø2.5mm

)

液晶画面

画面サイズ

6.9cm(2.7

総ドット数

123 200

型アスペクト比

ドット 横

560

×縦

16:9

220

電源部、その他

電源電圧

バッテリー端子入力

端子入力

DC

消費電力(バッテリー使用時)

液晶画面使用時:

ファインダー使用時:

動作温度

℃〜

0

+40

保存温度

℃〜

−

20

+60

外形寸法

82×69×149mm

×高さ×奥行き)

本体質量

付属品

(本体のみ)

約

535g

約

(バッテリーパックを含む)

615g

AC

アダプター

電源コード

AV

接続ケーブル

USB

ケーブル

ワイヤレスリモコン

リチャージャブルバッテリーパック

NP-FP60

(1)

CD-ROM

「ImageMixerforHDD

Camcorder」(1)

取扱説明書

取扱説明書「パソコン編」

保証書

(1)

7.2V

8.4V

4.3W

3.9W

℃

℃

(最大突起部を除く)(幅

(1)

(1)

(1)

(1)

(1)

(1)

(1)

)

2.2

アダプター

AC

電源

AC-L200

AC100〜240V、50/60Hz

消費電力

18W

定格出力

DC8.4V*

動作温度

℃〜

0

保存温度

−

外形寸法

約

(幅×高さ×奥行き)

質量

約

その他の仕様についてはACアダプターのラ

*

ベルをご覧ください。

℃

+40

℃〜

+60

℃

20

48×29×81mm

(本体のみ)

170g

(最大突起部をのぞく)

リチャージャブルバッテリーパック

NP-FP60

最大電圧

DC8.4V

公称電圧

DC7.2V

容量

7.2wh(1 000mAh

最大外形寸法

約

31.8×33.3×45.0mm

(幅×高さ×奥行き)

質量

約

80g

使用温度

℃〜

0

+40

使用電池

Li-ion

)

℃

DCR-SR90E/SR100/SR100E_L2

— 3 —

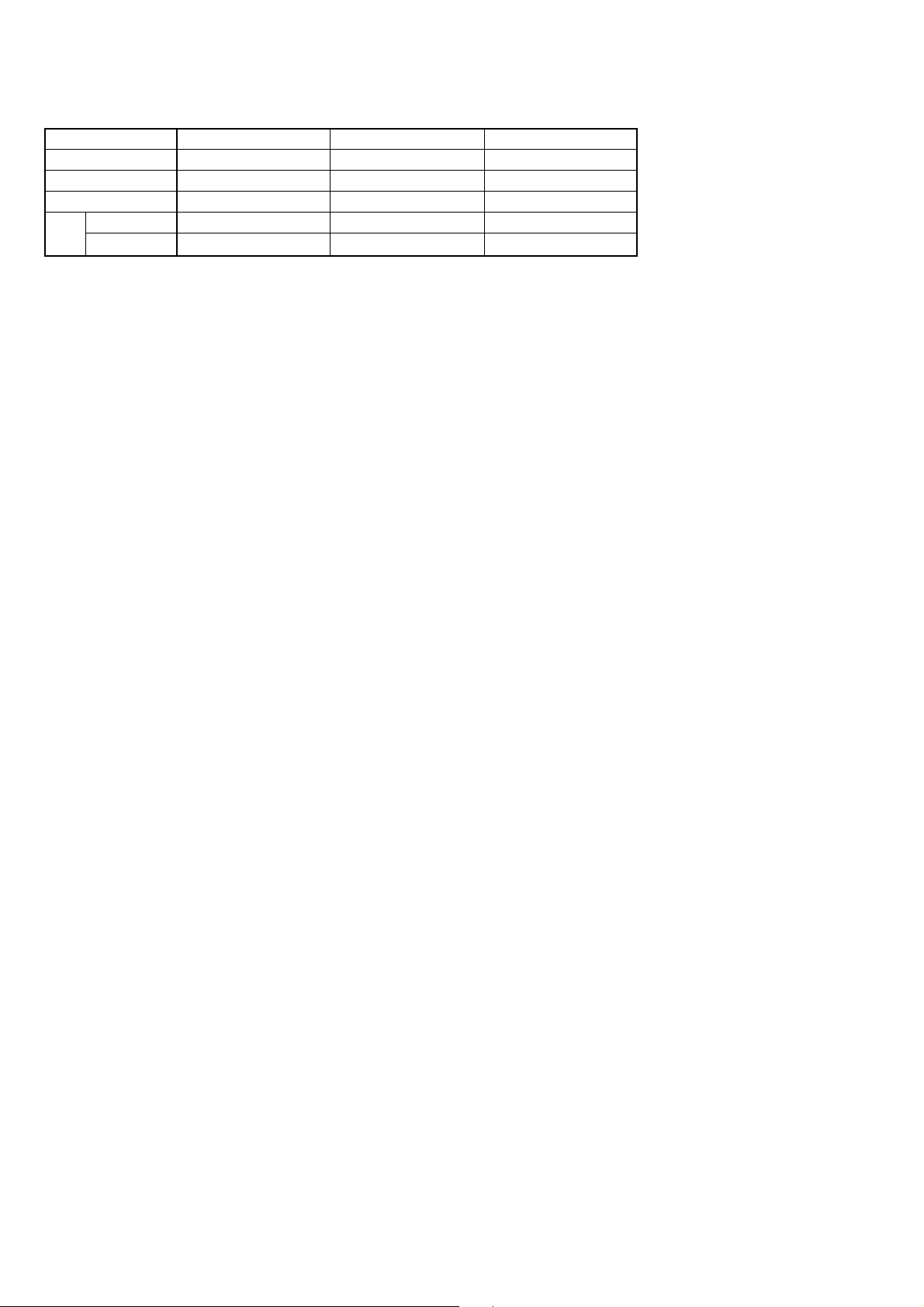

Model information table

Model DCR-SR90E DCR-SR100 DCR-SR100E

Destination AEP, UK US, CND, E, KR, JE, J NE, E, AUS, HK, CH, JE

Color system PAL NTSC PAL

A/V line input × aa

CAM → PC aaa

Data

copy

PC → CAM × aa

•Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

CH : Chinese model

CND : Canadian model

EE : East European model

HK : Hong Kong model

J: Japanese model

JE : Tourist model

KR : Korea model

MX : Mexican model

NE : North European model

DCR-SR90E/SR100/SR100E_L2

— 4 —

ENGLISH JAPANESE

ENGLISH JAPANESE

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DO TTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQ UES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

•Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

DCR-SR90E/SR100/SR100E_L2

— 5 —

ENGLISH JAPANESE

ENGLISH JAPANESE

電池の交換は,正しく行わないと破裂する恐れがあり

注意

ます。電池を交換する場合には必ず同じ型名の電池

又は同等品と交換してください。

サービス,点検時には次のことにご注意下さい。

1. 注意事項をお守りください。

サービスのとき特に注意を要する個所については,

キャビネット,シャーシ,部品などにラベルや捺印で

注意事項を表示しています。これらの注意書き及び取

扱説明書等の注意事項を必ずお守り下さい。

2. 指定部品のご使用を

セットの部品は難燃性や耐電圧など安全上の特性を

持ったものとなっています。従って交換部品は,使用

されていたものと同じ特性の部品を使用して下さい。

特に回路図,部品表に0印で指定されている安全上重要

な部品は必ず指定のものをご使用下さい。

3. 部品の取付けや配線の引きまわしはもとどおりに

安全上,チューブやテープなどの絶縁材料を使用した

り,プリント基板から浮かして取付けた部品がありま

す。また内部配線は引きまわしやクランパによって発

熱部品や高圧部品に接近しないよう配慮されています

ので,これらは必ずもとどおりにして下さい。

4. サービス後は安全点検を

サービスのために取外したネジ,部品,配線がもとど

おりになっているか,またサービスした個所の周辺を

劣化させてしまったところがないかなどを点検し,安

全性が確保されていることを確認して下さい。

5. チップ部品交換時の注意

• 取外した部品は再使用しないで下さい。

• タンタルコンデンサのマイナス側は熱に弱いため交

換時は注意して下さい。

6. フレキシブルプリント基板の取扱いについて

• コテ先温度を270℃前後にして行なって下さい。

• 同一パターンに何度もコテ先を当てないで下さい。

(3回以内)

• パターンに力が加わらないよう注意して下さい。

7. 無鉛半田について

無鉛半田を使用している基板には,無鉛(LeadFree)を

意味するレッドフリーマークがプリントされています。

(注意:基板サイズによっては,無鉛半田を使用して

いてもレッドフリーマークがプリントされて

いないものがあります)

:レッドフリーマーク

無鉛半田には,以下の特性があります。

• 融点が従来の半田よりも約40℃高い。

従来の半田こてをそのまま使用することは可能です

が,少し長めにこてを当てる必要があります。

温度調節機能のついた半田こてを使用する場合,約

350℃に設定して下さい。

注意: 半田こてを長く当てすぎると,基板のパター

ン(銅箔)がはがれてしまうことがあります

ので,注意して下さい。

• 粘性が強い

従来の半田よりも粘性が強いため,IC端子などが半田

ブリッジしないように注意して下さい。

• 従来の半田と混ぜて使用可能

無鉛半田には無鉛半田を追加するのが最適ですが,

従来の半田を追加しても構いません。

DCR-SR90E/SR100/SR100E_L2

— 6 —

TABLE OF CONTENTS

Section Title Page

1. SERVICE NOTE

1-1. Power Supply During Repairs·········································1-1

1-2. Setting The “Forced Power On” Mode····························1-1

1-3. Self-diagnosis Function ···················································1-2

1-4. Process After Fixing Flash Error ·····································1-4

1-5. Precaution on Replacing The VC-449 Board ··················1-4

2. DISASSEMBLY

2-1. Disassembly·····································································2-1

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/5)··········································· 3-1

3-2. Overall Block Diagram (2/5)··········································· 3-2

3-3. Overall Block Diagram (3/5)··········································· 3-3

3-4. Overall Block Diagram (4/5)··········································· 3-4

3-5. Overall Block Diagram (5/5)··········································· 3-5

3-6. Power Block Diagram (1/3)············································· 3-6

3-7. Power Block Diagram (2/3)············································· 3-7

3-8. Power Block Diagram (3/3)············································· 3-8

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram ··············································4-1

4-2. Schematic Diagrams························································4-3

4-3. Printed Wiring Boards ···················································4-33

4-4. Mounted Parts Location ················································4-52

5. REPAIR PARTS LIST

5-1. Exploded V iews·······························································5-2

5-2. Electrical Parts List ······················································· 5-10

DCR-SR90E/SR100/SR100E_L2

— 7 —

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V), the power is shut off so

that the unit cannot operate.

These following method is available to prevent this.

Method:

Use the AC power adaptor (AC-L200).

1-2. SETTING THE “FORCED POWER ON” MODE

It is possible to turn on power by adjustment remote commander (RM-95 or NEW LANC JIG).

Operate the camcorder using the adjustment remote commander.

1-2-1. Setting the “Forced Movie Power ON” Mode

1) Select page: 0, address: 01, and set data:01.

2) Select page: A, address: 10, set data:01 and press the “PAUSE (Write)” button of the adjustment remote commander.

1-2-2. Setting the “Forced Play/Edit Power ON” Mode

1) Select page: 0, address: 01, and set data:01.

2) Select page: A, address: 10, set data:02 and press the “PAUSE (Write)” button of the adjustment remote commander.

1-2-3. Exiting the “Forced Power ON” Mode

1) Select page: 0, address: 01, and set data:01.

2) Select page: A, address: 10, set data:00 and press the “PAUSE (Write)” button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

DCR-SR90E/SR100/SR100E_L2

1-1

1-3. SELF-DIAGNOSIS FUNCTION

ENGLISH JAPANESE

ENGLISH JAPANESE

1-3-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or LCD

screen what to do. This function consists of two display; selfdiagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

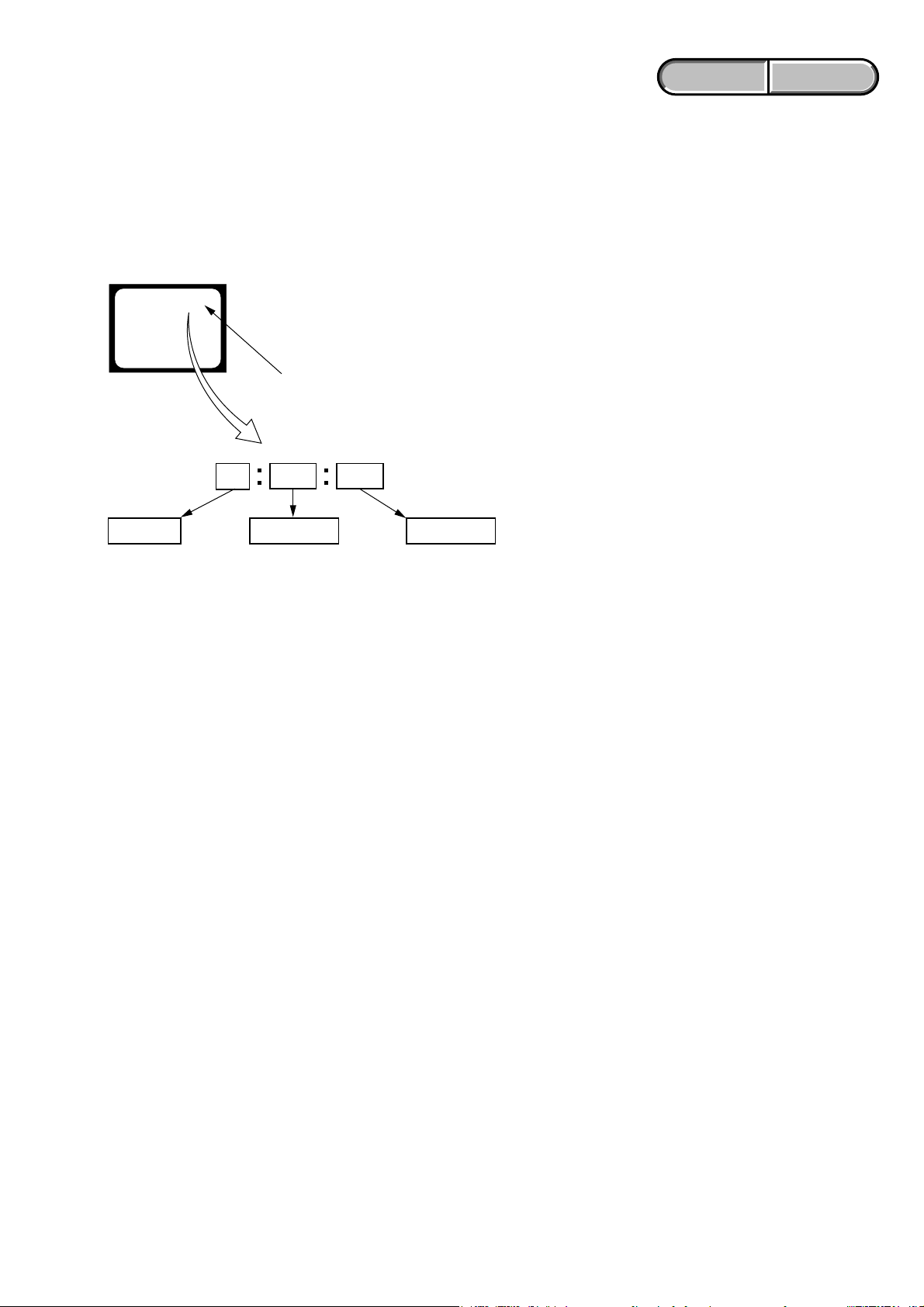

Viewfinder or LCD screen

C : 3 1 : 1 1

Blinks at 3.2Hz

1 1

Refer to “1-3-3. Self-diagnosis Code Table”.

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

3 1C

Block

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn o n power again.

1-3-2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or LCD screen shows a 4-digit display consisting of an

alphabet and numbers, which blinks at 3.2 Hz. This 5-character

display indicates the “repaired by:”, “block” in which the problem

occurred, and “detailed code” of the problem.

Detailed Code

DCR-SR90E/SR100/SR100E_L2

1-2

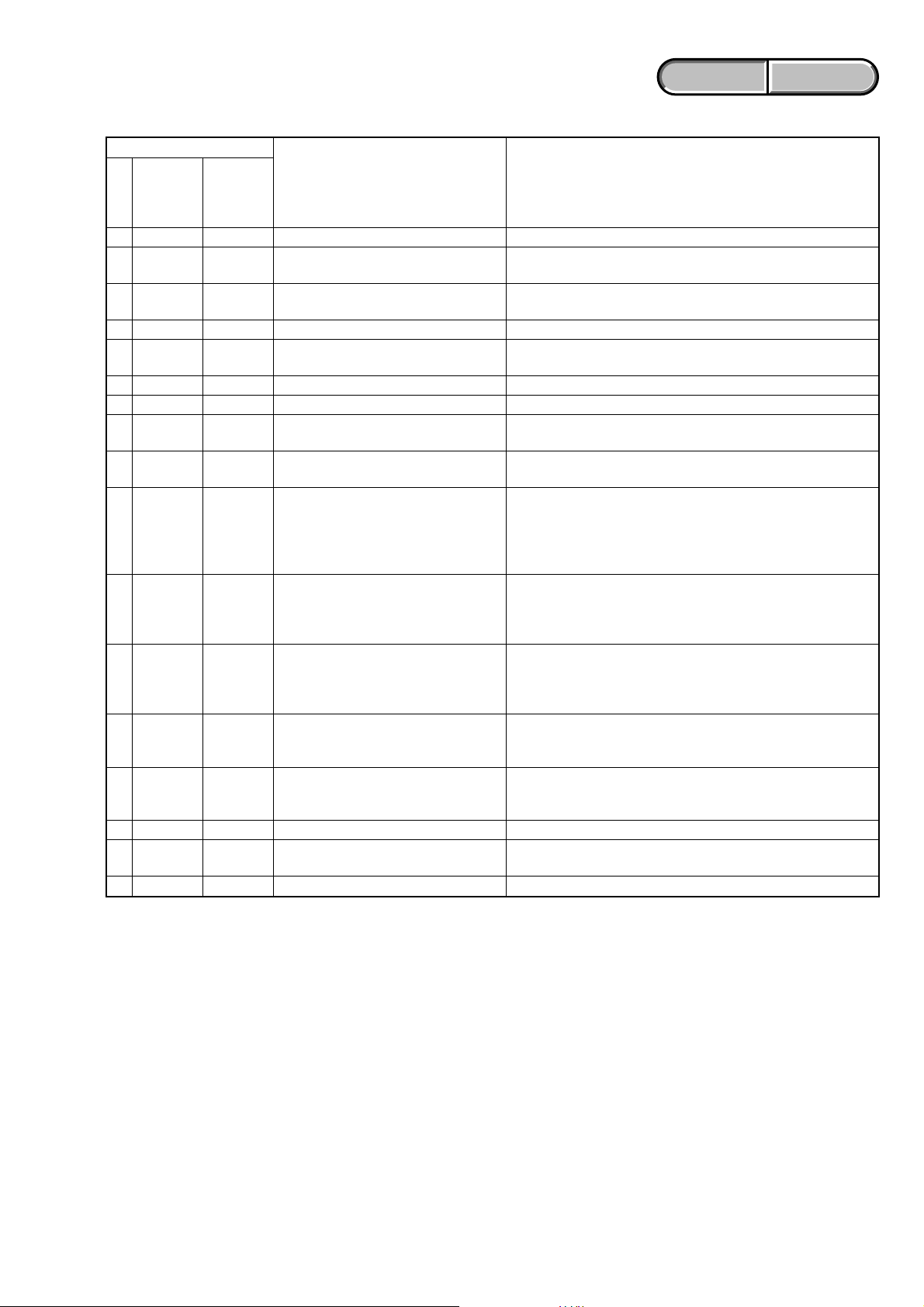

1-3-3. Self-diagnosis Code Table

Self-diagnosis Code

ENGLISH JAPANESE

ENGLISH JAPANESE

Block

Function

Repaired by:

C

04

C

13

C

13

C

21

C

32

E

20

E

31

E

40

E

40

E

61

E

61

E

61

E

62

E

62

E

91

E

94

E

94

Note 1: Refer to “ 12-2. Record of Self-diagnosis check” of “2-5. SERVICE MODE”, ADJ (9-876-940-51).

Note 2: After repair, be sure to perform “1-4. PROCESS AFTER FIXING FLASH ERROR”.

Detailed

Code

00

00

02

00

50

00

00

00

01

00

10

11

00

01

01

00

01

-

Symptom/State

Non-standard battery is used.

Faulty disc is used.

Disc access error

Condensation.

Codec IC dose not return any reply

EEPROM data are rewritten.

Drive fault

Codec IC fault

Audio Codec IC fault

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

The abnormalities in initialization of

the focus lens and the abnormalities in

initialization of the zoom lens occurred

simultaneously.

Handshake correction function does not

work well. (With PITCH angular

velocity sensor output stopped.)

Handshake correction function does not

work well. (With YAW angular velocity

sensor output stopped.)

Abnormality when flash is being charged.

Fault of writing to or erasing the

flashmemory

Fault of writing to or erasing EEPROM

Use the InfoLITHIUM battery.

Remove the power source. Reconnect it again and operate your

camcorder again

Remove the power source. Reconnect it again and operate your

camcorder again

Remove the disc, and insert it again after one hour.

Remove the power source. Reconnect it again and operate your

camcorder again

Make EEPROM data correct value. (Note 1)

Inspect or replacement of the hand disc drive

Inspect or replacement of the codec IC (IC2301on the VC-449

board) peripheral circuits

Inspect or replacement of the Audio Codec IC (IC2301 on the

VC-449 board) peripheral circuits

Inspect the lens block focus MR sensor (pin ql, wa of CN1701

on the VC-449 board) when focusing is performed when the

focus buttons of the touch panel are pressed in the focus manual

mode, and the focus motor drive circuit (IC1701 on the VC-449

board) when the focusing is not performed.

Inspect the lens block zoom MR sensor (pin ws, wf of CN1701

on the VC-449 board) when zooming is performed when the

zoom lever is operated, and the zoom motor drive circuit

(IC1701 on the VC-449 board) when zooming is not performed.

Check whether the flexible board of the lens is broken, and

check whether it is inserted imperfectly. If there is no problem in

the flexible board, inspect the focus/zoom motor drive circuit

(IC1701 on the VC-449 board).

Inspect PITCH angular velocity sensors (SE7104 on the IR-057

board) peripheral circuits.

Inspect YAW angular velocity sensors (SE7103 on the IR-057

board) peripheral circuits.

Checking of flash unit or replacement of flash unit. (Note 2)

Inspect the flash memory (IC2401 on the VC-449 board). (Note 1)

Inspect the EEPROM (IC2602 on the VC-449 board). (Note 1)

Correction

DCR-SR90E/SR100/SR100E_L2

1-3

ENGLISH JAPANESE

ENGLISH JAPANESE

1-4. PROCESS AFTER FIXING FLASH ERROR

When “FLASH error” (Self-diagnosis Code E:91:**) occurs, to prevent an y abnormal situation caused by high v oltage, setting of the flash is

changed automatically to disabling charge and flash setting.

After fixing, this setting needs to be deactivated. Connect the adjustment remote commander and perform the following process.

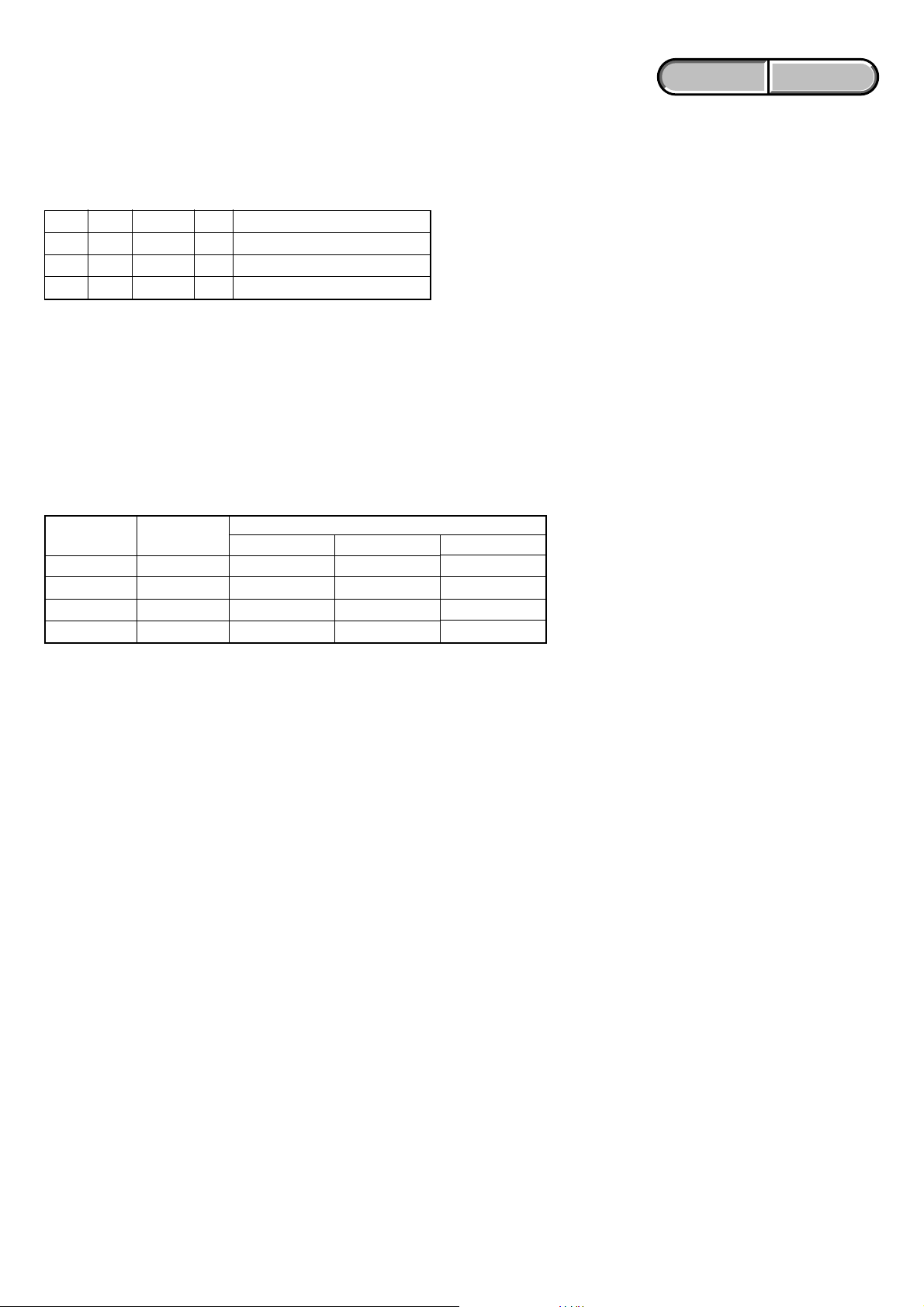

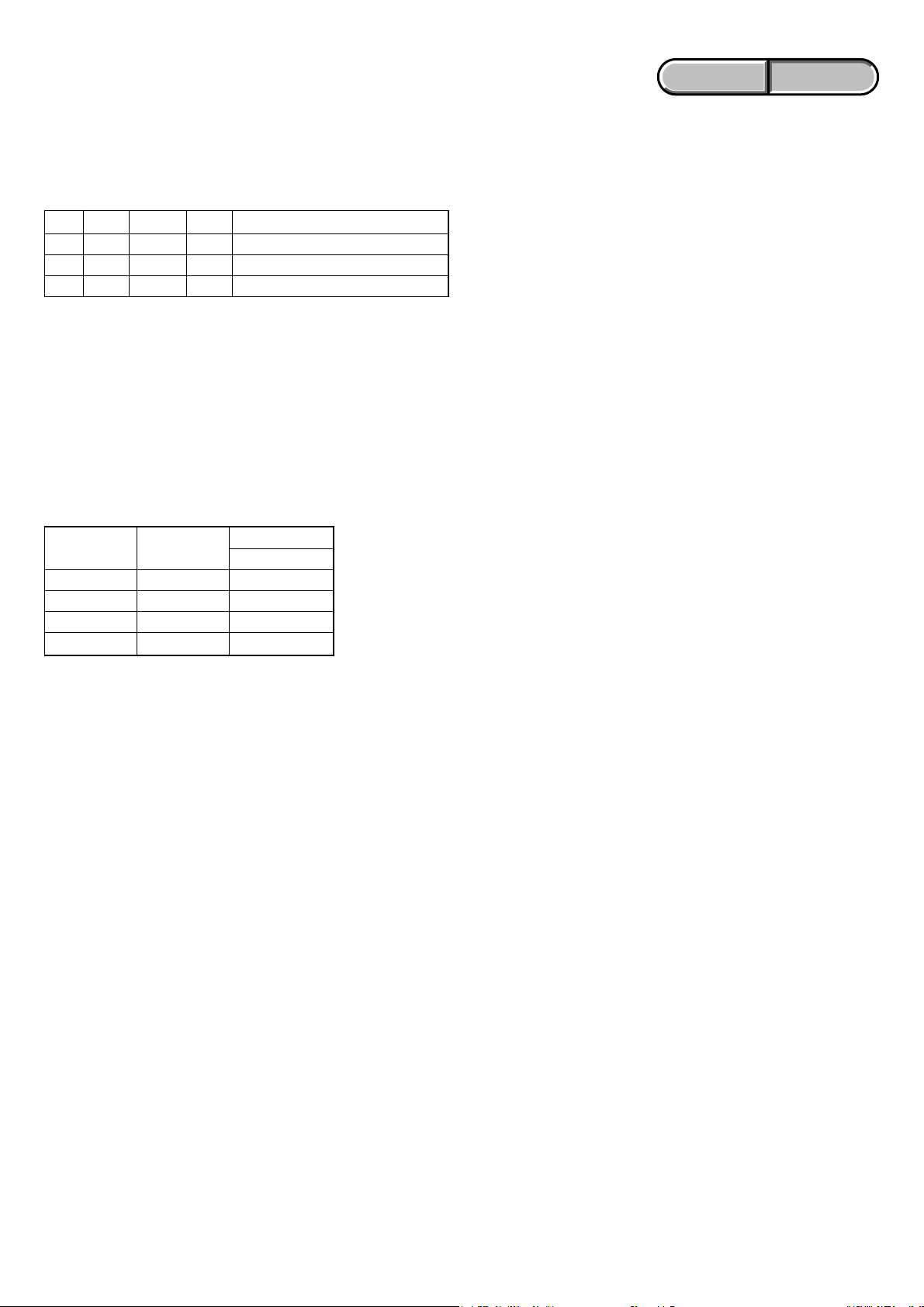

Order Page Address Data Procedure

17 0175

27 00 01 Press PAUSE button.

37 02 Check the data changes to “01”.

1-5. PRECAUTION ON REPLACING THE VC-449 BOARD

Exif Model Data Check

When you replace to the repairing board, the written data of repairing board also might be changed to original setting.

When the data has changed because of board replaceing etc, check the data setting (Exif Model Data) is right. If not, rewrite to the right value.

Exif Model Data

Page

A

A

A

A

Address

B6

B7

B8

B9

DCR-SR100

31

30

30

00

Data

DCR-SR90E

39

30

45

00

DCR-SR100E

31

30

30

45

Writing Method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: A, address: B6 to B9, and set the Exif Model Data.

Note: To write in the non-volatile memory (EEPROM), press the PAUSE (Write) button each time to set the data.

3) Select page: 0, address: 01, and set data: 00.

DCR-SR90E/SR100/SR100E_L2

1-4

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. 修理時の電源供給について

本機では,安定化電源(8.4Vdc)からバッテリ端子に電源を供給した場合,約10秒後にシャットオフし,動作しなくなります。

これを避けるため,下記の方法を用いてください。

方法:

DC入力端子を使用する。(ACアダプタ(AC-L200など)を使用する。)

1-2. 強制電源ONモードの設定

調整リモコン(RM-95またはNEWLANCJIG)を使用して,電源を入れることが出来ます。

カムコーダの操作は調整リモコンで行えます。

1-2-1. 強制Movie電源ONモードの設定

1) ページ:0,アドレス:01にデータ:01をセット。

2) ページ:A,アドレス:10にデータ:01をセットしPAUSE(Write)ボタンを押す。

1-2-2. 強制Play/Edit電源ONモードの設定

1) ページ:0,アドレス:01にデータ:01をセット。

2) ページ:A,アドレス:10にデータ:02をセットしPAUSE(Write)ボタンを押す。

1-2-3. 強制電源ONモードの解除

1) ページ:0,アドレス:01にデータ:01をセット。

2) ページ:A,アドレス:10にデータ:00をセットしPAUSE(Write)ボタンを押す。

3) ページ:0,アドレス:01にデータ:00をセット。

DCR-SR90E/SR100/SR100E_L2

1-5

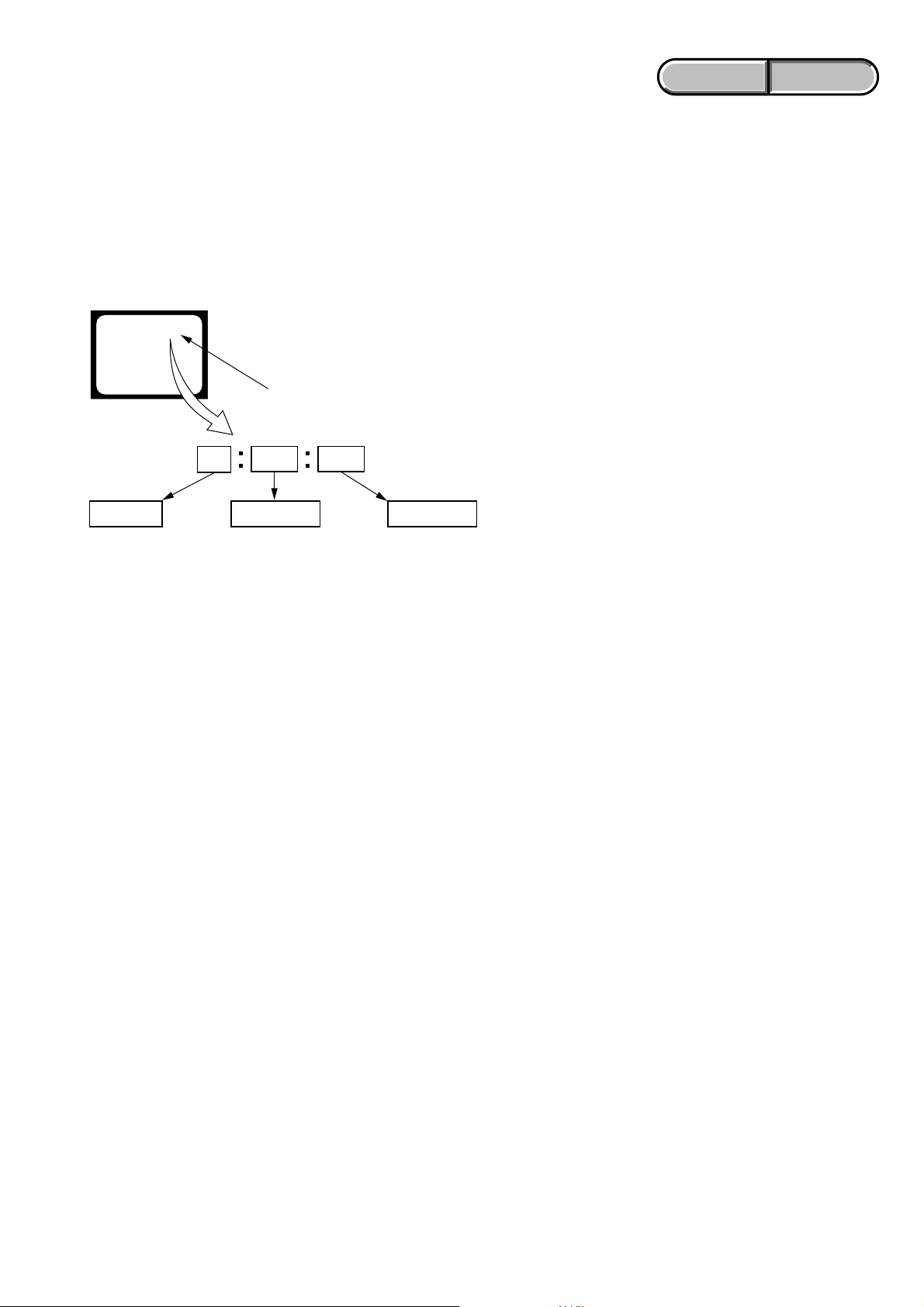

1-3. 自己診断機能

1-3-1.自己診断機能について

本機の動作に不具合が生じたとき,自己診断機能が働き,

ビューファインダまたはLC D 画面に,どう処置したらよい

か判断できる表示を行います。「自己診断表示」と「サービス

モード表示」の2つの表示があります。自己診断機能につい

ては取扱説明書にも掲載されています。

ビューファインダまたはLCD画面

C : 3 1 : 1 1

3.2Hz点滅

ENGLISH JAPANESE

ENGLISH JAPANESE

1-3-2.自己診断表示

本機の動作に不具合が生じたとき,ビューファインダまたは

LCD画面のカウンタ表示部分がアルファベットと数字の4桁

表示になり,3.2Hzで点滅します。この5文字の表示によっ

て対応者分類および不具合の生じたブロックの分類,不具合

の詳細コードを示します。

対応者分類

C :お客さま自身で対応

H:販売店で対応

E :サービスエンジニア

で対応

3 1C

ブロック分類

対応方法の違いにより分類

例 31・・・テープを入れ直す

32・・・電源を入れ直す

1 1

詳細コード

「1-3-3.自己診断コード表」

を参照

DCR-SR90E/SR100/SR100E_L2

1-6

1-3-3.自己診断コード表

自己診断コード

対

応

者

C

C

C

C

C

E

E

E

E

E

E

E

E

E

E

E

E

ブロック

機能

04

13

13

21

32

20

31

40

40

61

61

61

62

62

91

94

94

詳細

コード

00

00

02

00

50

00

00

00

01

00

10

11

00

01

01

00

01

症状/状態

標準以外のバッテリを使用している

ディスク不良

ディスクアクセスエラー

結露している

CodecIC応答せず

EEPROMが書き換えられている

ドライブ不良

CodecIC不良

オーディオCodecIC不良

フォーカスが合いにくい

(フォーカスの初期化ができない)

ズーム動作の異常(ズームレンズの

初期化ができない)

フォーカス,ズーム異常

手振れ補正が効きにくい(PITCH

角速度センサ出力張り付き)

手振れ補正が効きにくい(YAW角

速度センサ出力張り付き)

フラッシュの充電異常

フラッシュメモリの書込み/消去動

作不良

EEPROMの書込み/消去動作不良

ENGLISH JAPANESE

ENGLISH JAPANESE

対応/方法

インフォリチウムバッテリを使用する。

電源を外し,再度入れ直してから操作する。

電源を外し,再度入れ直してから操作する。

ディスクを取り出し,約1時間後にもう一度入れ直す。

電源を外し,再度入れ直してから操作する。

EEPROMのデータを元の値に戻す(注1)

ハードディスクドライブを点検または交換する。

CodecIC(VC-449基板IC2301)周辺回路を点検または

交換する。

オーディオCodecIC(VC-449基板IC2301)周辺回路を

点検または交換する。

タッチパネルでフォーカス操作をしたときにフォーカス動

作をすれば,レンズブロックのフォーカスMRセンサ

(VC-449基板CN1701ql,waピン)を点検する。フォー

カス動作をしなければフォーカスモータ駆動回路(VC449基板IC1701)を点検する。

ズームレバーを操作したときにズーム動作をすれば,レン

ズブロックのズームMRセンサ(VC-449基板CN1701

ws,wfピン)を点検する。ズーム動作をしなければズーム

モータ駆動回路(VC-449基板IC1701)を点検する。

フレキ切れ,半差し等の点検を行う。問題がない場合は

フォーカス/ズームモータ駆動IC(VC-449基板IC1701)

周辺回路を点検する。

PITCH角速度センサ(IR-057基板SE7104)周辺回路を点

検する。

YAW角速度センサ(IR-057基板SE7103)周辺回路を点

検する。

フラッシュユニットの点検または交換をする。(注2)

フラッシュメモリ(VC-449基板IC2401)を点検する。

(注1)

EEPROM(VC-449基板IC2602)を点検する。(注1)

注1: 調整編(9-876-940-51)「2-5.SERVICEMODE」の「12-2.RecordofSelf-diagnosischeck」を参照してください。

注2: 修理後は,必ず「1-4.フラッシュ異常修理後の処置」を行ってください。

DCR-SR90E/SR100/SR100E_L2

1-7

ENGLISH JAPANESE

ENGLISH JAPANESE

1-4. フラッシュ異常修理後の処置

フラッシュエラー(自己診断コードE:91:**)発生時は、高電圧による異常を防止するために自動的にフラッシュ充電・

発光禁止の設定になります。修理後は、この設定を解除する必要があります。調整用リモコンを接続し、下記の処置を行っ

てください。

順序 ページ アドレス データ 作業内容

17 0175

27 00 01 PAUSEボタンを押す

37 02 データが“01”になることを確認

1-5. VC-449基板交換時の注意

Exif機種データ確認

補修用基板と交換する時,補修用基板に書かれているデータは元の設定と違っている場合があります。

基板交換などでデータが変更された場合は,Exif機種データが正しいか確認し,違っている場合は正しい値に書き換えて下

さい。

Exif機種データ

ページ アドレス

AB6 31

AB7 30

AB8 30

AB9 00

データ

DCR-SR100

書き換え方法:

1) ページ:0,アドレス:01にデータ:01をセットする。

2) ページ:A,アドレス:B6〜B9にExif機種データをセットする。

注: 不揮発性メモリ(EEPROM)に書き込むため,データをセットする度にPAUSE(Write)ボタンを押してください。

3) ページ:0,アドレス:01にデータ:00をセットする。

DCR-SR90E/SR100/SR100E_L2

1-8E

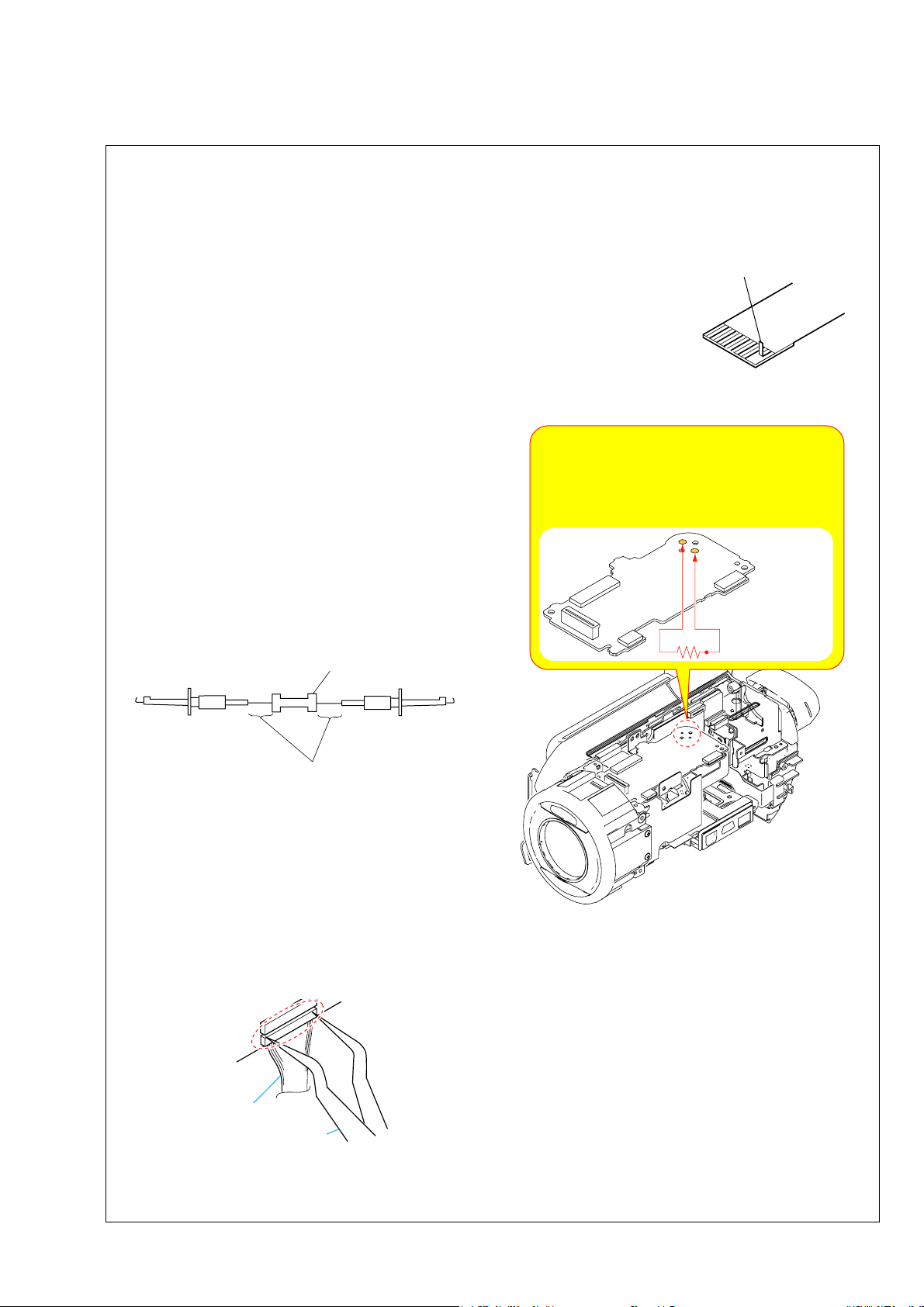

NOTE FOR REPAIR

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points

with the short jig about 10 seconds.

R:1 kΩ/1 W

(Part code:

1-215-869-11)

2. DISASSEMBLY

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, dont’ pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, dont’ press down at wire of connector.

It is possible that a wire is snapped.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

DISCHARGING OF THE MA-444 BOARD’S CHARGING CAPACITOR (C5306)

The charging capacitor (C5306) of the MA-444 board is charged

up to the maximum 330 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by

the charged voltage which is kept without discharging when the

main power of the unit is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig, a small clip is attached to each end of

a resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to

prevent electrical shock.

NOTE FOR DISCONNECTING THE HARNESS (CD-122)

Harness (CD-122)

1 kΩ/1 W

Wrap insulating tape.

When disconnecting the harness (CD-122), do not pull the harness

part but pull off the connector body with tweezers etc.

Tweezers etc.

DCR-SR90E/SR100/SR100E_L2

2-1

HELP

EXPLODED VIEW

HELP

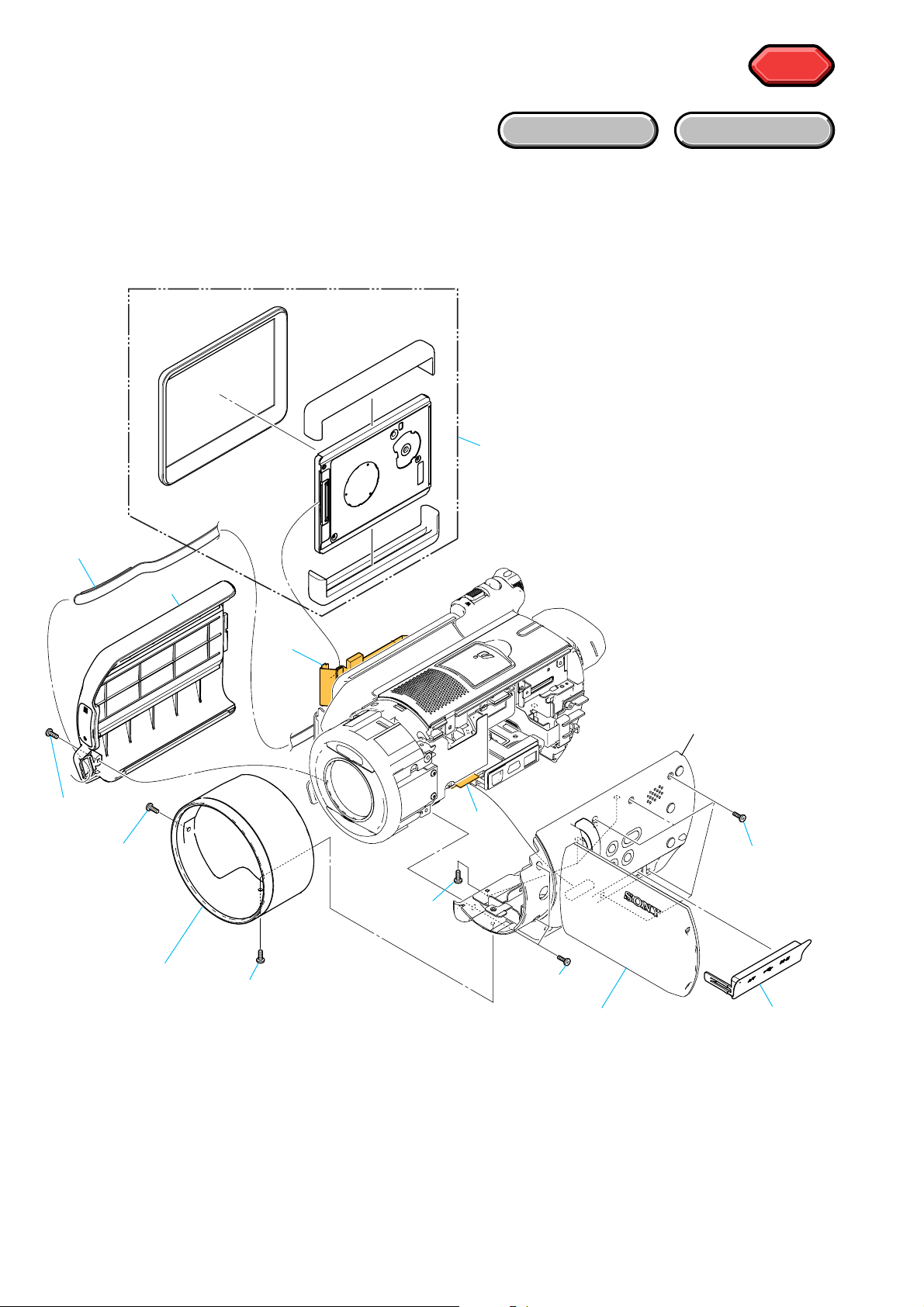

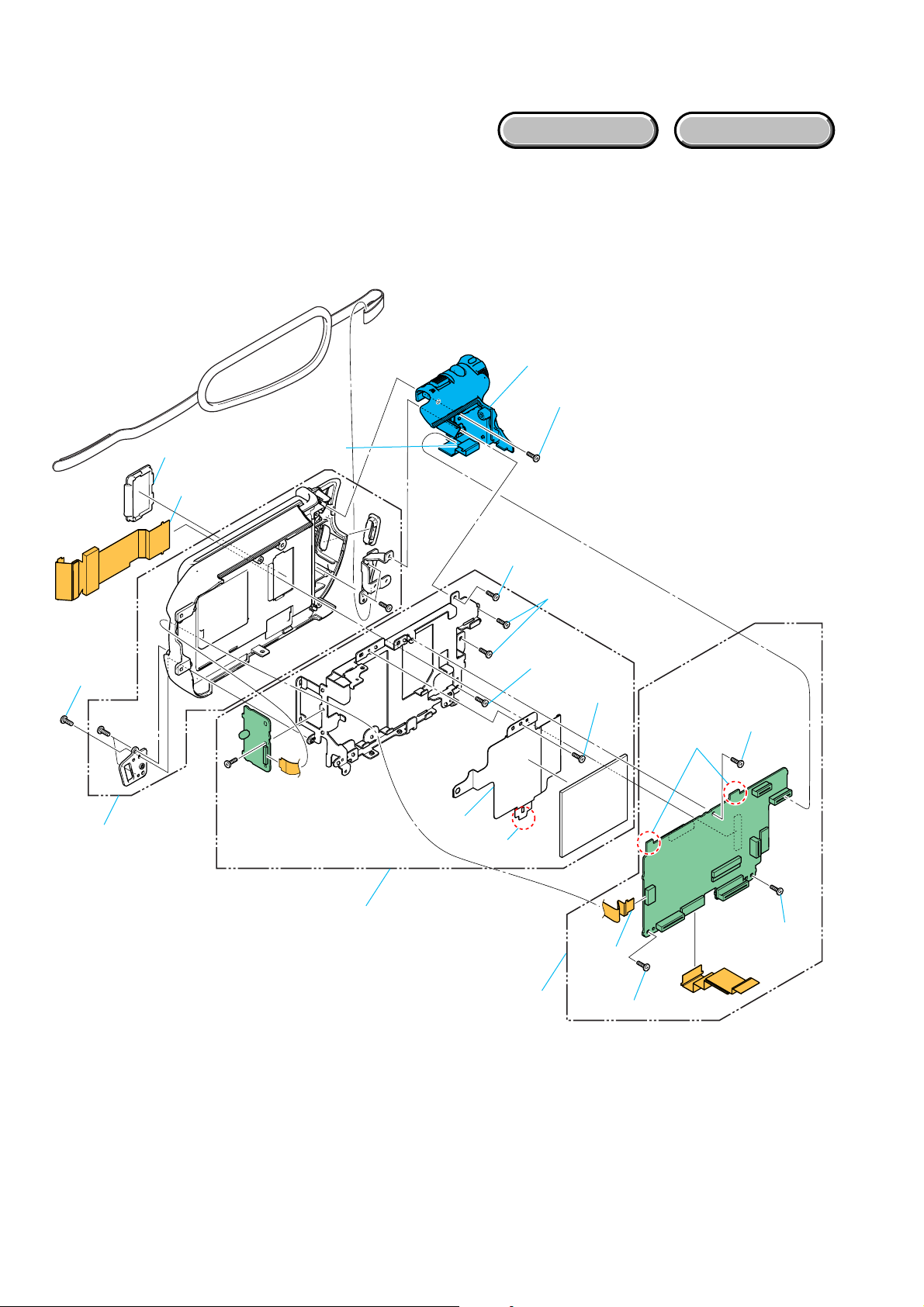

2-1. DISASSEMBLY

2-1-1. OVERALL ASSEMBLY-1

Follow the disassembly in the numerical order given.

1 Lens ring (1-1 to 1-2)

2 HDD (2-1 to 2-4)

3 Cabinet (R) block (3-1 to 3-6)

2-1

HARDWARE LIST

2 HDD

2-2 (#10)

1-1 (#10)

1 Lens ring

2-3

2-4

1-2 (#10)

3-1 (#10)

3-6

3-2 (#10)

3 Cabinet (R) block

3-3

(Open the panel block)

3-5 (#10)

3-4

DCR-SR90E/SR100/SR100E_L2

2-2

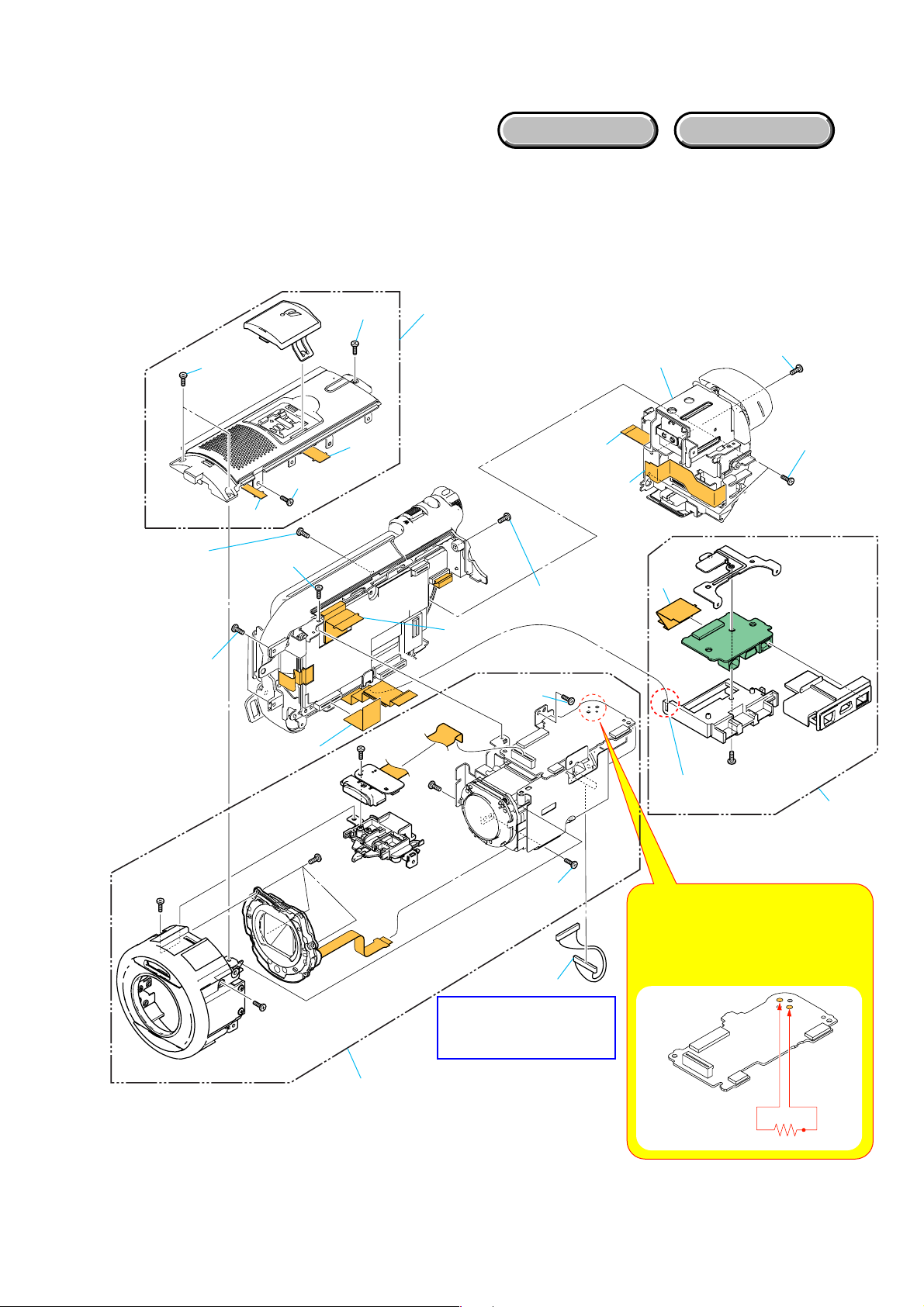

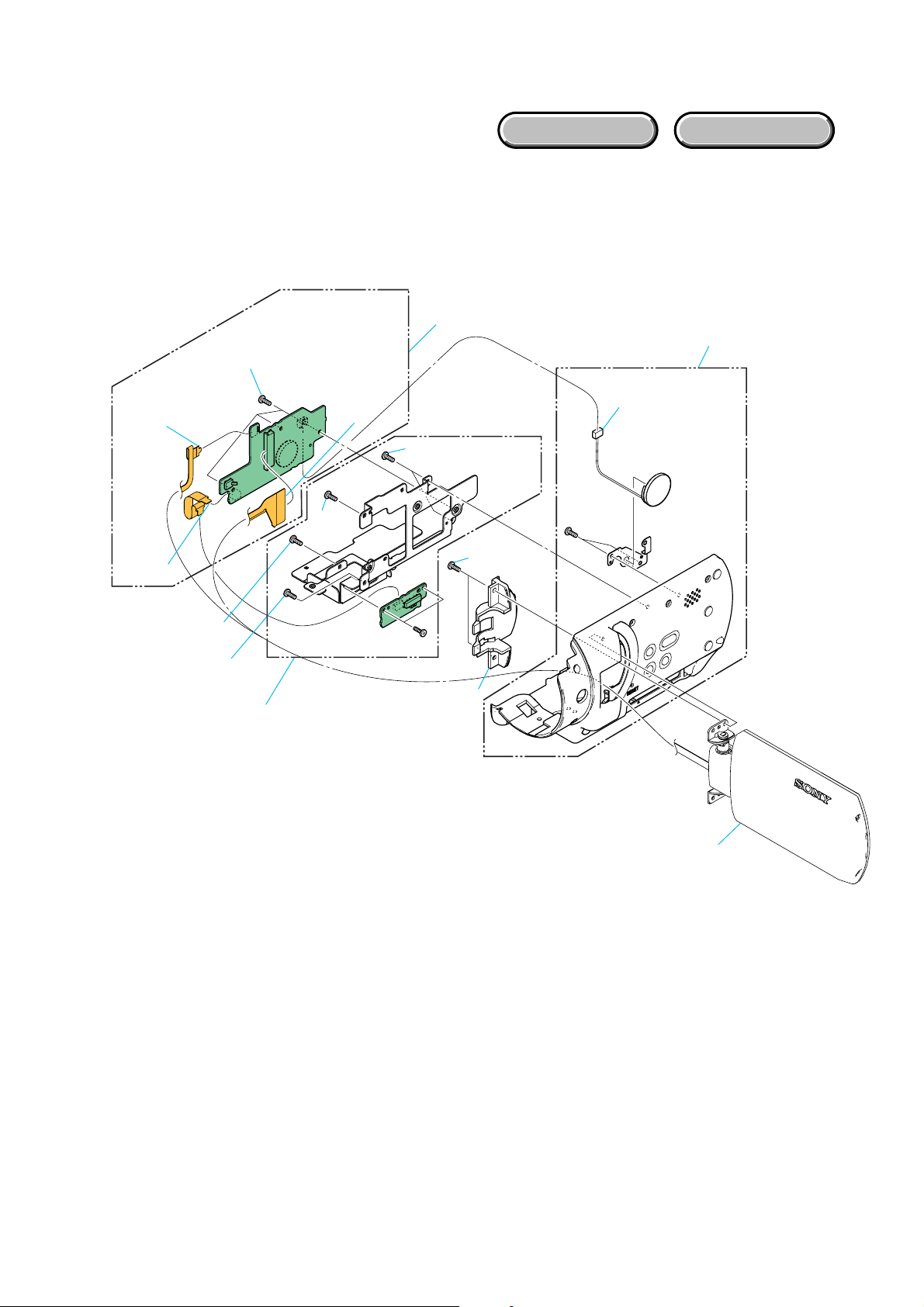

2-1-2. OVERALL ASSEMBLY-2

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Panel (top) block (1-1 to 1-7)

2 EVF/BT panel block (2-1 to 2-7)

3 Lens block (3-1 to 3-7)

HARDWARE LIST

1-6 (#10)

3-6 (#10)

1-4 (#10)

1-2

3-3 (#14)

1-5 (#14)

1-3 (#14)

3-2

1-1

1 Panel (top) block

2 EVF/BT panel block

2-7

2-4

1-7 (#10)

3-7

3-4 (#12)

2-5 (#10)

2-6 (#14)

2-1

JK-310

3 Lens block

2-2 (Claw)

2-3

3-5 (#14)

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points

with the short jig about 10 seconds.

3-1

Refer to page 2-1 Note

for disconnecting the

harness (CD-122) .

R:1 kΩ/1 W

(Part code:

1-215-869-11)

DCR-SR90E/SR100/SR100E_L2

2-3

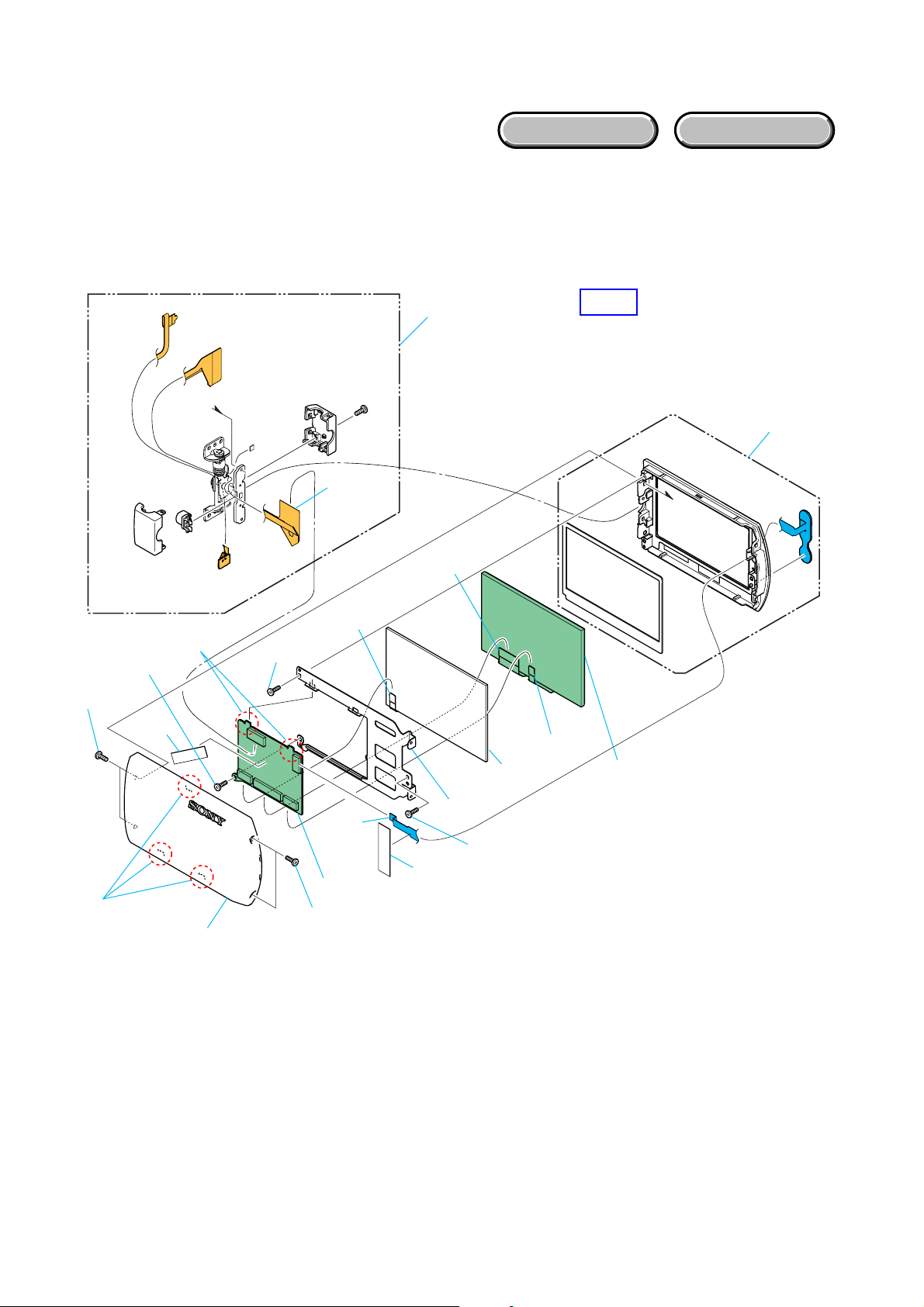

2-1-3. CABINET (L) BLOCK

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 VC-449 board (1-1 to 1-8)

2 Main flame block (2-1 to 2-7)

3 Switch block (3-1 to 3-2)

HARDWARE LIST

3Switch block control

3-1 (#5)

2-7 (#10)

3-2

1-1

1-2

1-3

2-3

2-4 (#5)

2-5 (#5)

2-2 (Claw)

2-6 (#14)

2-1 (#14)

1-8

(Claw)

1-6 (#3)

2 Main flame block

DCR-SR90E/SR100/SR100E_L2

1 VC-449 board

2-4

1-7 (#3)

1-4

1-5 (#3)

2-1-4. CABINET (R) BLOCK

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 CK-162 board (1-1 to 1-5)

2 R flame block (2-1 to 2-4)

3 LCD panel block (3-1 to 3-3)

1-4 (#3)

1-2

CK-162

1-3

1-5

2-2

(#12)

HARDWARE LIST

1 CK-162 board

3-3

1-1

2-1 (#5)

3-1 (#12)

2-4 (#10)

2-3 (#12)

2 R flame block

3-2

3 LCD panel block

DCR-SR90E/SR100/SR100E_L2

2-5

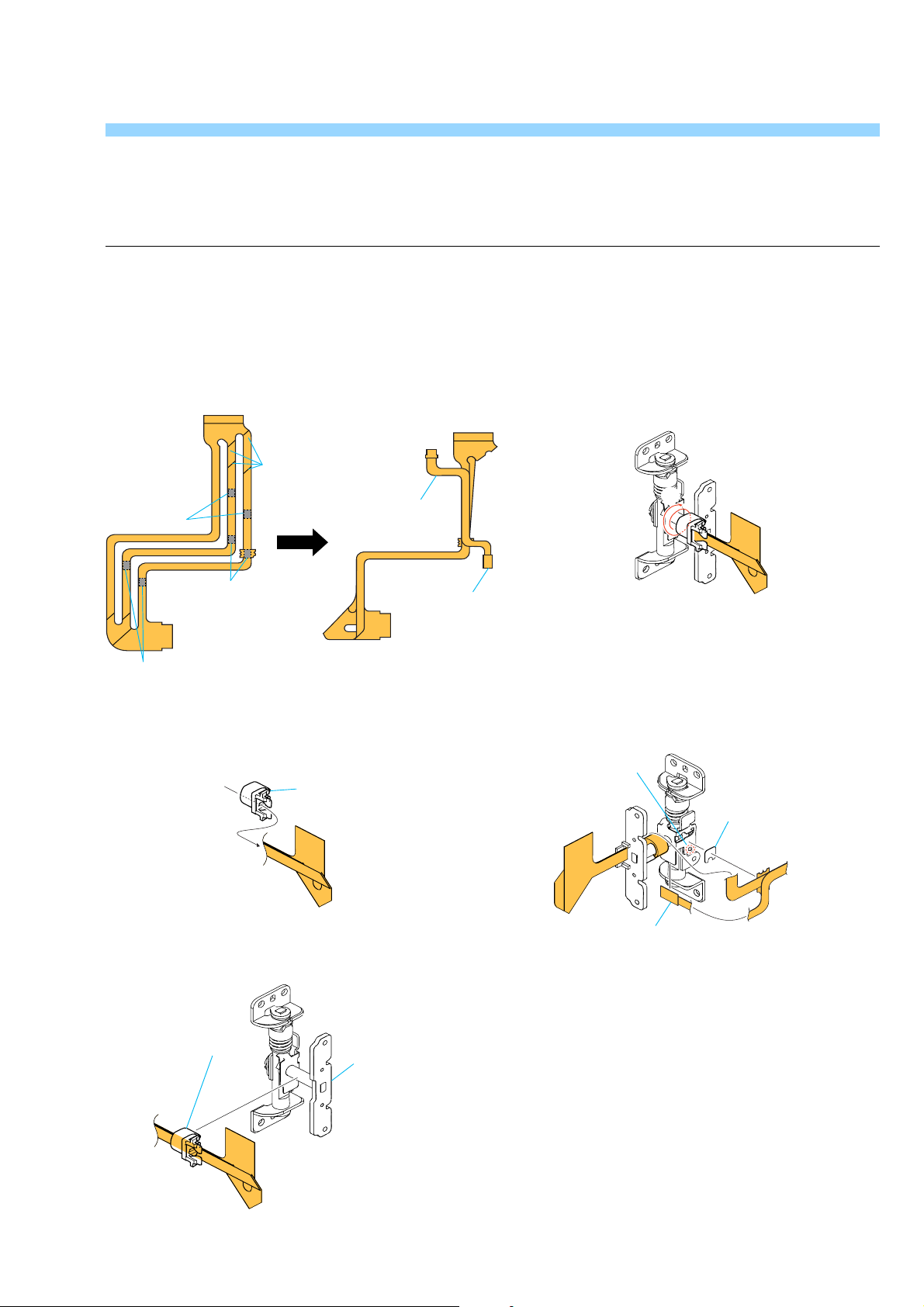

2-1-5. LCD BLOCK

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Hinge block (1-1 to 1-6)

2 PD-250 board (2-1 to 2-7)

3 LCD (3-1 to 3-5)

HARDWARE LIST

2-6 (#5)

1-1 (#10)

2-7 (Claw)

1-5

3-1 (#5)

PD-250

1-6

2-3

1 Hinge block

2-4

3-4

HELP

3-5

2-5

3 LCD

1-3 (Claw)

1-4

DCR-SR90E/SR100/SR100E_L2

2-2

3-3

3-2 (#5)

2-1

2 PD-250 board

1-2 (#10)

2-6E

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

THE METHOD OF ATTACHMENT OF FP-439 FLEXIBLE BOARD

1 Fold dotted line parts of the FP-439 flexible board

as shown in figure.

2 Put the FP-432 flexible board on the FP-439

flexible board.

Fold

FP-432

Adhesive tape

Adhesive tape

Adhesive tape

3 Pass the FP-439 flexible board through

the FPC clamp(H).

FPC clamp(H)

Switch

5 Roll the the FP-439 flexible board 1.5 times,

in the direction of arrow

6 Put the adhesive sheet and FP-439 flexible

board on the hinge assy according to the

position of the boss and insert the switch of

the FP-432 flexible board as shown in figure.

Boss

A.

A

Adhesive tape

4 Install the FPC clamp(H) in the hinge assy.

FPC clamp(H)

DCR-SR90E/SR100/SR100E_L2

Switch

Hinge assy

HELP

Link

Link

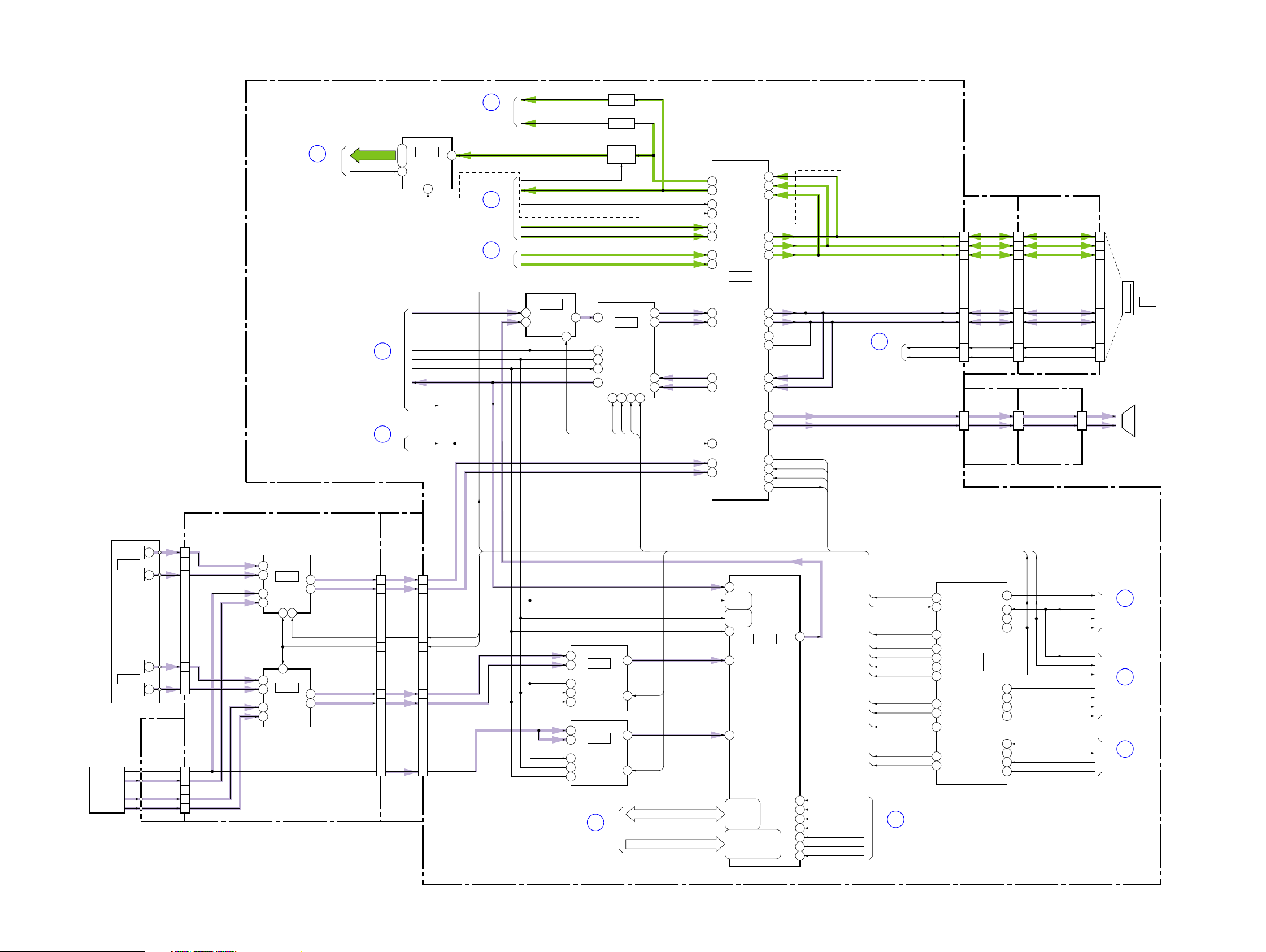

3. BLOCK DIAGRAMS

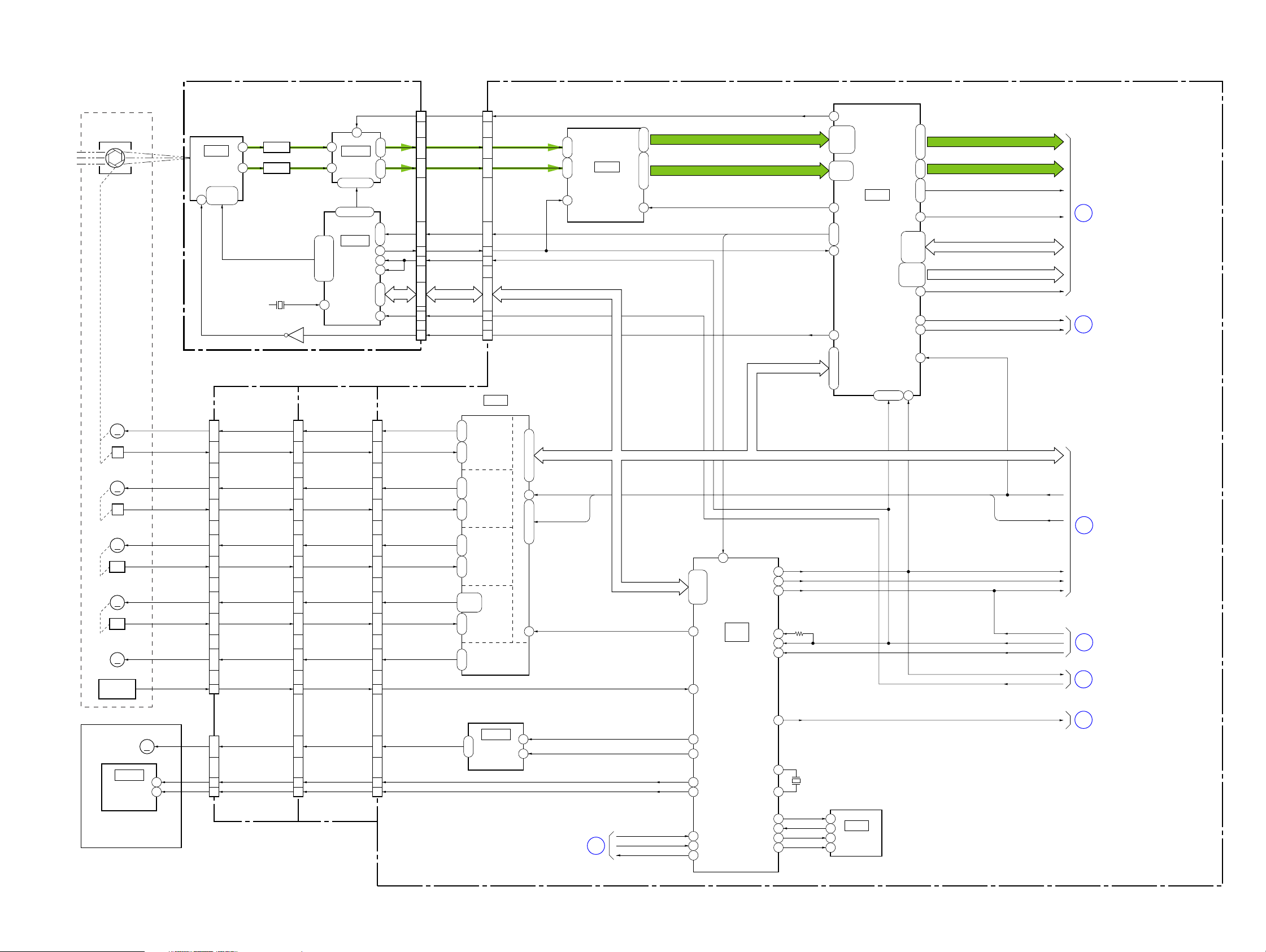

OVERALL BLOCK DIAGRAM (1/5)

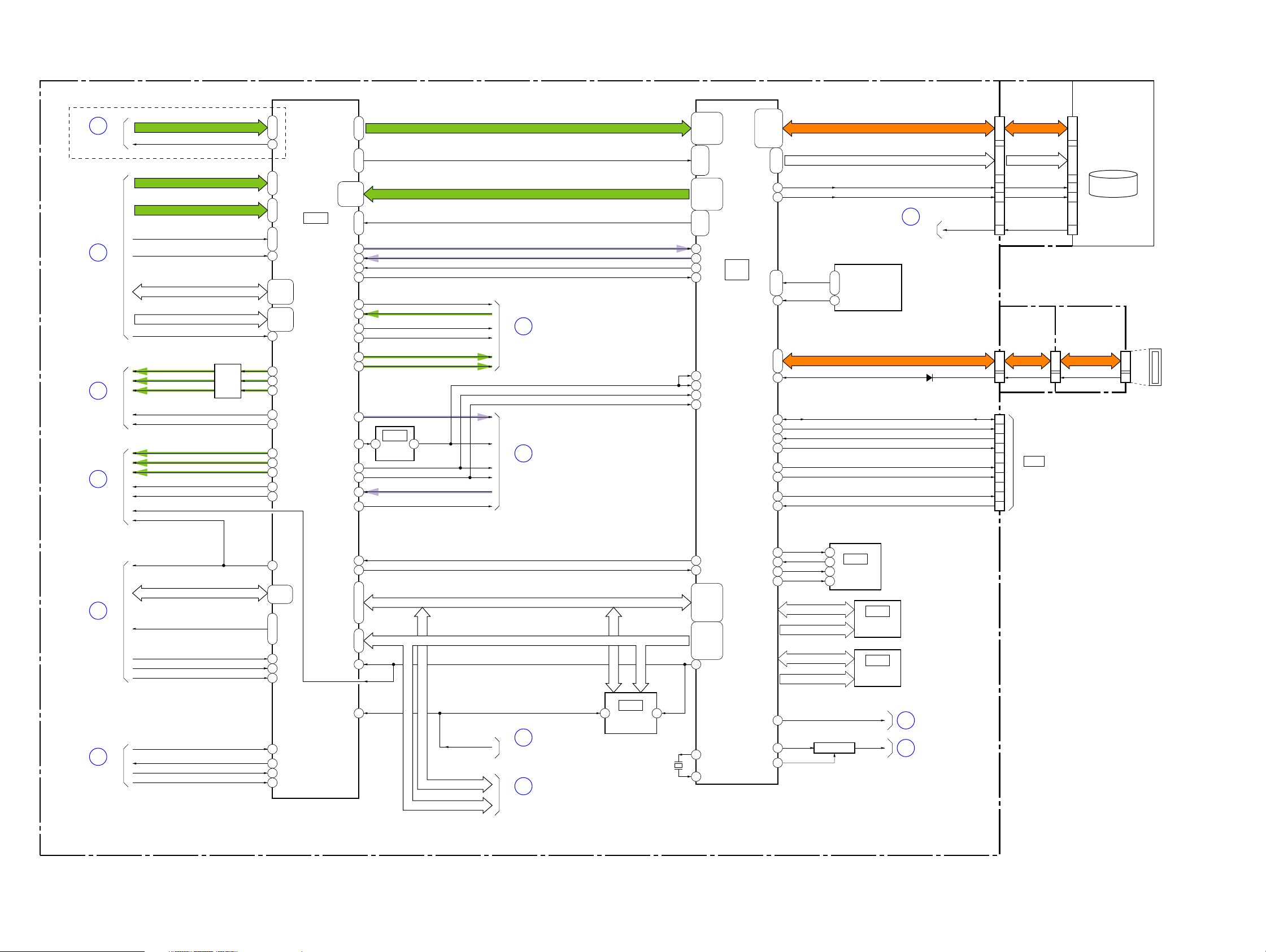

OVERALL BLOCK DIAGRAM (2/5)

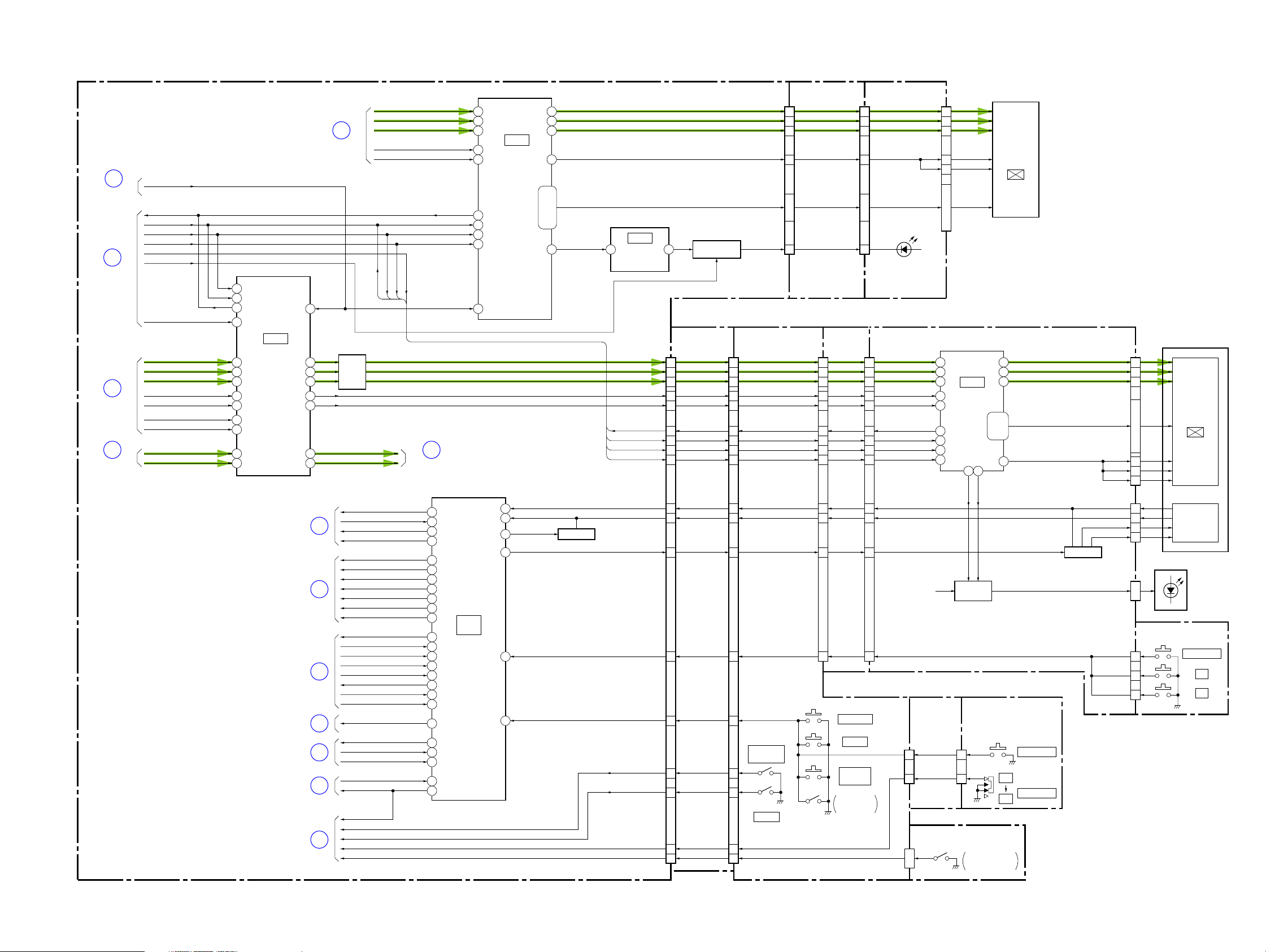

OVERALL BLOCK DIAGRAM (3/5)

OVERALL BLOCK DIAGRAM (4/5)

OVERALL BLOCK DIAGRAM (5/5)

POWER BLOCK DIAGRAM (1/3)

POWER BLOCK DIAGRAM (2/3)

POWER BLOCK DIAGRAM (3/3)

DCR-SR90/SR100/SR100E_L2

3. BLOCK DIAGRAMS

3-1. O VERALL BLOCK DIAGRAM (1/5) ( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

LENS BLOCK

IRIS

(SHUTTER)

IRIS

METER

M

H

ND FILTER

METER

M

H

FOCUS MOTOR

M

MR

ZOOM MOTOR

M

MR

NF MOTOR

M

LENS TEMP

SENSOR

CD-636 BOARD

Q5203

IC5202

CCD IMAGER

3 - 6, 16 - 19,

21 - 24

11

26

14

RG1, RG2,

LH11, LH12,

H1, H3, V1 - V4

67.5MHz: NTSC model

54MHz: PAL model

CLAMP

Q5204

CLAMP

X5201

Q5201

VOUT1

VOUT2

LT-041 BOARD FP-437 FLEXIBLE

CN8003

I_DRIVE+, -

7, 13. 514, 812, 1024 - 2718, 16 29, 2821, 1930 - 33

I_HALL+, -

ND_DRIVE+, -

ND_HALL+, -

FOCUS+, -

F_MR_A, B

ZOOM_A, B,

ZOOM_XA, XB

Z_MR_A, B

NF_DRIVE+, -

TEMP_OUT

23

23

BOARD

7, 13, 514, 812, 1024 - 2718, 16 29, 2821, 1930 - 33

13, 15

17, 25

31, 32

67, 69

71, 72

47

15

10

3, 22, 2, 23

33, 37, 38, 41

TIMING

GENERATOR

4

IC5205

S/H

IC5203

SHP1,2

SHD1, 2

VC-449 BOARD (1/5)

CN5201

18, 19

7, 6

9, 10, 12

53

66

57

2, 5, 1, 3

60

CN1701CN8002

I_DRIVE+, -

33, 3937, 35

I_HALL+, -

ND_DRIVE+, -

26, 3228, 30

ND_HALL+, -

FOCUS+, -

11, 1219, 21

F_MR_A, B

ZOOM_A, B,

ZOOM_XA, XB

16 - 1322, 24

Z_MR_A, B

NF_DRIVE+, -

10 - 76, 1

TEMP_OUT LENS_TEMP_AD

17

23

CCDout1P, 1N

28, 2925, 26

CCDout2P, 2N

TG_HD, VD, FLD

8 - 10

1

15

4, 5, 3, 6

CAM_DD_ON

CLPDM

CHCK

XSYS_RST

CSUB

H1, J1C5, B6

K2, L2

ND FILTER

C10, B11

F3, E3

B1, C4

K6, F1,

L4, G3

E12, E10

L6, L7

CN1501

8

2, 3

6, 5

23 - 21

30

16

CAM_SI, CAM_SO, CAM_SCK, CAM_CS

27, 26, 28, 25

1516

1813

IC1701

(2/15)

IRIS

DRIVE

K11, J11, H12, J12, L12

DRIVE

FOCUS

MOTOR

DRIVE

ZOOM

MOTOR

DRIVE

NF MOTOR

DRIVE

K12

K9, L9, M9, J9

H11

38, 4054, 52

IC1501

A/D

CONVERTER

(1/15)

8

CAM_SI, CAM_SO, CAM_SCK, CAM_CS, CAM_VD

SPCK

EN01,

DIR1A, DIR1B

XIC_1701_RST

17 - 30

1, 2, 61 - 72

14

CAM_SI, CAM_SO,

CAM_SCK, CAM_CS,

CAM_VD

AD1_0 - AD1_13

AD0_0 - AD0_13

AB11, Y11,

AB10, C22, A7

B14

R22

TG_FLD

D13

IC2601

(1/2)

CAMERA

CONTROL

(4/15)

TG_HD, TG_VD, TG_FLD

CAM_SI, CAM_SO,

CAM_SCK, CAM_CS,

CAM_VD

XSYS_RST

CAM_DD_ON

CLPDM

CLPOB

CHCK

CSUB

D14

B13

B8

F2

F4

M22

78

55 - 51,

49 - 45,

42 - 39

56 - 59,

62 - 71

77

92 - 90

137

99

23, 22, 20, 21, 25

SYS_V

IC_2803_CS

LINEOUT_V

XSYS_RST

ZOOM_VR_AD

IC1801

CAMERA SIGNAL

PROCESS

(3/15)

32, 108, 109

XSYS_RST

115

195 - 191,

188 - 185,

182 - 178,

175, 174

161 - 156,

153 - 148,

145, 144

167

101

102

122

24

SYS_V

IFI_Y0 - IFI_Y7

208 - 202, 199

IFI_C0 - IFI_C3

9 - 6

IFI_HD, IFI_VD, IF_OE

11 -13

VCK

MDQ0 - MDQ15

MA0 - MA11, BA0, BA1

MEMCK_OUT

STROBE_ON

EXT_STROBE_ON

CAM_SI, CAM_SO, CAM_SCK, CAM_VD

EN01, DIR1A, DIR1B

SPCK

SYS_V

IC_2803_CS

LINEOUT_V

LINEOUT_V

XSYS_RST

ZOOM_VR_AD

SYS_V

CAM_DD_ON

1

2

3

4

5

OVERALL (2/5)

(PAGE 3-2)

OVERALL (5/5)

(PAGE 3-5)

OVERALL (2/5)

(PAGE 3-2)

OVERALL (5/5)

(PAGE 3-5)

OVERALL (3/5)

(PAGE 3-3)

M9002

LENS COVER

MOTOR

IC001

LENS COVER

OPEN/CLOSE

SENSOR

M

3

2

MOTOR UNIT

(LENS BARRIER)

05

DCR-SR90E/SR100/SR100E_L2

CN8001

LENS_COVER_DRV+,

LENS_COVER_DRV-

8, 1

LENS_COVER_OPEN

4

LENS_COVER_CLOSE

3

A : VIDEO SIGNAL

A : AUDIO SIGNAL

36

37

34, 39

LENS_COVER_DRV+,

LENS_COVER_DRV-

LENS_COVER_OPEN

4

LENS_COVER_CLOSE

3

IC1702

LENS COVER

F3, F2

MOTOR DRIVE

(2/15)

LENS_COVER_DIR_PWM

C6

LENS_COVER_DRV_ON

B6

OVERALL (5/5)

(PAGE 3-5)

X2601

20MHz

EEP_SO

EEP_SI

EEP_SCK

XCS_EEP

XRST_VTR

5

2

32K EEPROM

6

1

IC2602

(4/15)

Y18

AB18

AC18

C1

B5

D5

PITCH_AD

7

YAW_AD

VST_C_RESET

P22

P23

T2

D1

AC14

AB14

AB13

F1

XRST_VTR

6

OVERALL (3/5)

(PAGE 3-3)

3-1

3-2. O VERALL BLOCK DIAGRAM (2/5) ( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-449 BOARD (2/5)

8

OVERALL (4/5)

(PAGE 3-4)

1

OVERALL (1/5)

(PAGE 3-1)

9

OVERALL (3/5)

(PAGE 3-3)

10

OVERALL (3/5)

(PAGE 3-3)

DCR-SR100/SR100E

AD4 - AD13

ADCK27

IFI_Y0 - IFI_Y7

IFI_C0 - IFI_C3

IFI_HD, IFI_VD, IF_OE

VCK

MDQ0 - MDQ15

MA0 - MA11, BA0, BA1

MEMCK_OUT

EVF_R

EVF_G

EVF_B

EVF_HD

EVF_VD

PANEL_R

PANEL_G

PANEL_B

PANEL_XHD

PANEL_XVD

DSCK_CNM

SPCK

Q2801

BUFFER

245

216 - 223224 - 227228 - 230

VIDEO/AUDIO DSP,

241

215 - 210,

208, 207,

205 - 198

185 - 176,

174, 173,

171, 170

196

47

46

52

95

96

40

39

45

92

93

IC2803

LENS CONTROL

(5/15)

264 - 267,

272, 273,

275, 276

301

298

284

304

62

33

66

64

53

60

89

82

83

85

87

91

3 - 10

279 - 282

268 - 270

2 4

DATA_FROM_SFD

IC2802

BUFFER

(5/15)

DATA_TO_SFD

CLPVO

VFE_C_OUT

ACC_CONT

AGC_CONT

IC_2803_Y_OUT

IC_2803_C_OUT

SFD_BCK

SFD_LRCK

SFD_FCK

KASYAON

ED0 - ED7

RCO0_EDHD, RCO1_EDVD,

RCO2_EDFLD, RCO3_FRMREF

RYI0_DE0 - RYI3_DE3, RCI0_DE4 - RCI3_DE7

RYO0_DEHD, RYO1_DEVD,

RYO2_DEFLD

ADATAIN0

ADATAOUT0

HYI_PLL27IN

MPLCK27

12

OVERALL (4/5)

(PAGE 3-4)

SFD_BCK

SFD_LRCK

SFD_FCK

13

OVERALL (4/5)

(PAGE 3-4)

AB15, AE17,

AA14, AB16,

AG17, AH19,

AA15, AG19

AD18,

AD17,

AB19,

AB18

AA18, AE20,

AD20, AG20,

AB17, AG21,

AD19, AE22

AH20,

AE18,

AE19

AA21

AB21

AH23

AB20

CODEC, USB I/F

AC5

AD22

AA20

Y22

IC2301

(1/2)

(6/15)

A13, A14,

B13 - B16,

D13 - D16,

E13 - E16,

G13, G14

D17,

B17,

E17

D18

D20

B28,

D25,

E25

B26

G18

E6

E7

B7

G5

D8

B8

J2

J1

GSENS_X,

GSENS_Y,

GSENS_Z

GSENS_TEMP

A23, A24

VBUS

SE981

3-AXIS

5 - 3

ACCELEROMETER

1

16

OVERALL (5/5)

(PAGE 3-5)

D2302

ATA_D0 - ATA_D15

ATA_A0 - ATA_A2

XATA_DMACK

XATA_RESET

HDD_ACCESS

USB_D+, USB_D-

USB_VBUS

MS_DIO

MS_SCLK

XMS_IN

MS_BS

MS_LED_ON

MS_VCC_ON

TXD4

RXD4

CN1107

CN1109

(1/3)

23

51

13

23

12

15

11

13

16

14

19

18

FP-431 FLEXIBLE

BOARD

DD0 - DD15

DA0 - DA2

17, 19, 16 34 - 49

DMCK-

-RESET

DASP-

FP-434

FLEXIBLE

BOARD (1/3)

18, 20

(FOR CHECK)

23

CN1105

CPC

HARD DISK

(30GB)

33, 31, 34 5 - 20

29

3

37

JK-310 BOARD

(1/3)

CN7201

(1/3)

D+, D-

28, 26

USB_VBUS

DRIVE

3, 2

1

CN7202

(USB)

EEP_TXD3

E11

EEP_RXD3

D10

EEP_SCK3

E10

XCS_EEP3

V2

SDDT0 - SDDT31

SDADR0 - SDADR11

BSDDT0 - BSDDT15

BSDADR0 - BSDADR12

E8

U2

MELODY_ENV

C1

14

15

CNMXCS_IC_2803

JAIRQ

DSCK_CNM

D0_CNM D15_CNM

XSYS_RST

D0_CNM - D15_CNM

A1_CNM - A23_CNM

IC2401

B5

64M FLASH

(7/15)

A1_CNM A23_CNM

B4

X2301

12MHz

SPCK

CAM_SI, CAM_SO,

CAM_SCK, CAM_VD

139

159, 158,

156, 236

3

OVERALL (1/5)

(PAGE 3-1)

11

OVERALL (4/5)

(PAGE 3-4)

05

EN01, DIR1A, DIR1B

SYS_V

IC_2803_CS

LINEOUT_V

MCXCS_IC_2803

BB_SI

BB_SO

XBB_SCK

248, 250, 251 252 - 261

157

154

164

149

152

151

150

144

147

D0_CNM - D15_CNM

137 - 124, 122, 121

A1_CNM - A19_CNM

116 - 98

119

141

XSYS_RST

D0_CNM - D15_CNM

A1_CNM - A20_CNM

OVERALL (5/5)

(PAGE 3-5)

OVERALL (4/5)

(PAGE 3-4)

AD16

P5

AB11 - AB13,

AD10 - AD13,

AE11 - AE13,

AG11 - AG13,

AH11 - AH13

AB9,

AD6 - AD9,

AE5 - AE9,

AG4 - AG10,

AH4 - AH9,

AA22

A21

A22

3

6

64K EEPROM

2

7

Q2301, 2302

MODULATOR

IC2303

(6/15)

IC2403

128M SDRAM

(7/15)

IC2402

256M SDRAM

(7/15)

SHOE_CONT

BEEPMELODY

17

18

OVERALL (5/5)

(PAGE 3-5)

OVERALL (4/5)

(PAGE 3-4)

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : VIDEO/AUDIO SIGNAL

DCR-SR90E/SR100/SR100E_L2

3-2

3-3. O VERALL BLOCK DIAGRAM (3/5) ( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-449 BOARD (3/5)

OVERALL (1/5)

(PAGE 3-1)

OVERALL (4/5)

(PAGE 3-4)

OVERALL (2/5)

(PAGE 3-2)

OVERALL (4/5)

(PAGE 3-4)

05

19

10

20

FP-441 FLEXIBLE

CN1103

PANEL_R

PANEL_G

PANEL_B

PANEL_HD

PANEL_VD

BB_SI

BB_SO

XBB_SCK

XCS_LCD

TP_X

TP_Y

TP_SEL1

BOARD

6

7

8

4

5, 9 - 18

1

CN7301

FP-439

FLEXIBLE

BOARD

1

2

3

19

17

7 7 3

EVF_R

EVF_G

9

OVERALL (2/5)

(PAGE 3-2)

6

XRST_VTR

BB_SI

BB_SO

XBB_SCK

XCS_EVF

XCS_LCD

EVF_BL_ON

XCS_IC_3401

PANEL_R

PANEL_G

PANEL_B

PANEL_XHD

PANEL_XVD

DSCK_CNM

SPCK

IC_2201_Y_OUT_M

IC_2201_C_OUT_M

13

11

10

12

40

38

36

3

4

7

19

42

44

IC3401

ASPECT RATIO

CONVERTER

(8/15)

OVERALL (4/5)

(PAGE 3-4)

OVERALL (4/5)

(PAGE 3-4)

OVERALL (5/5)

(PAGE 3-5)

OVERALL (5/5)

(PAGE 3-5)

OVERALL (5/5)

(PAGE 3-5)

OVERALL (1/5)

(PAGE 3-1)

OVERALL (5/5)

(PAGE 3-5)

5

Q3401

30

28

26

22

23

32

34

BUFFER

IC_3401_Y

IC_3401_C

22

23

25

26

29

5

27

EVF_B

EVF_HD

EVF_VD

BB_SI

BB_SO

HI_SO

HI_SI

XHI_SCK

XCS_IC_2601

ADDO

ADDE

A5.1_SYNC

XCS_A5.1

A5.1_CTRL

A5.1_RESET

XDSP_NMI

HI_TXD0

HI_RXD0

HI_SCK0

HI_CS

OSD_V

XHIDSCON_MAD

XFUPSTAT

XCNM_RESET

IR_ON

SCHARGE_ON

XSCHARGE_FULL

ADAPTER_DETECT

SYS_V

CAM_DD_ON

CAM_DD_ON

XBATT_VIEW

HI_XRESET

PANEL_REVERSE

NIGHTSHOT_SW

XCS_LCD

XBB_SCK

OVERALL (4/5)

XBB_SCK

XCS_EVF

XRST_VTR

EVF_BL_ON

PANEL_R_M

PANEL_G_M

PANEL_B_M

PANEL_XHD_M

PANEL_XVD_M

21

(PAGE 3-4)

G9

H8

H7

V4

AF2

AC4

AD4

AB7

G4

F1

D12

G11

H10

H11

H9

N4

D1

A12

AC2

E4

F4

C2

B2

P4

G7

34

33

32

48

BB_SI

42

BB_SO

45

44

43

IC2301

(2/2)

DS/HI CONTROL

(6/15)

IC5102

EVF DRIVE

(11/15)

1

3

B24

D24

D5

D6

A27

B27

TP_X

TP_Y

TP_SEL_2

TP_SEL_1

20

21

22

26

16, 17, 24, 30

6 - 10, 12, 14,

EXTDA

31

SWITCHING

Q1102

EVF_HCK1, EVF_HCK2,

EVF_PSIG, EVF_REF, EVF_STB

IC5101

EVF BACKLIGHT

1 4

CONTROL

(11/15)

CN1104

(1/2)

PANEL_R

PANEL_G

PANEL_B

PANEL_HD

PANEL_VD

BB_SI

BB_SO

XBB_SCK

XCS_LCD

KEY_AD1 KEY_AD1

KEY_AD3

XBATT_VIEW

HI_XRESET

KEY_AD2

PANEL_REV

30

28

26

18 22 13 13

17 23 14 14

9 31 20 20

6 34 23 23

7 33 22 22

8 32 21 21

TP_X

10

TP_Y

12

TP_SEL1

11

24

33

37

38

1 39

2 38

Q5102

EVF BACKLIGHT

DRIVE

FP-440

FLEXIBLE

BOARD (1/2)

EVF_VR

EVF_VG

EVF_VB

EVF_COM_CS

EVF_HST, EVF_PCG,

EVF_EN, EVF_VCK,

EVF_VST, EVF_BLK,

LED_K

CK-162 BOARD (1/2)

CN7305

(1/2)

10

12

14

30

28

29 18 18

16

7

S7302

DISP/

BATT INFO

3

2

S7301

RESET

6

7

8

4

1

S7306

DVD BURN

S7303

EASY

S7305

WIDE

SELECT

S7304

PANEL

OPEN/CLOSE

VF-176 BOARD

CN5801

HCK1, HCK2,

HST, PCG, EN,

VCK, VST, BLK,

PSIG, REF, STB

5, 9 - 18

D5802

(EVF BACKLIGHT)

PD-250 BOARD

CN7501

PANEL_R

1

PANEL_G

2

PANEL_B

3

PANEL_HD

PANEL_VD

VD_SI

VD_SO

VD_SCK

XCS_LCD

19

17

CN7303

KEY_AD3

KEY_AD4

6

1

CN7302

CN5802

VR

17

VG

18

VB

16

COM

21

CS

19

5 - 7, 9 - 16, 20

37

36

35

IC7501

LCD DRIVE

52

2

6 - 13,

16, 18,

26, 31

20 34

EXTDA

BL_ON

BACKLIGHT

DRIVE

NS-021 BOARD

CN8601

1

6

D_2.8V

FP-442

FLEXIBLE

BOARD

BACK_LIGHT

NIGHT_SHOT

46

49

48

47

Q7513 - 7516

FP-432 FLEXIBLE BOARD

S001

5, 6

PANEL REVERSE

DETECT

LCD9002

COLOR

EVF UNIT

22

23

24

29

ON

OFF

Q7501, 7502

S8601

BACK LIGHT

S8602

NIGHTSHOT

HCK1, HCK2, HST,

PCG, EN, VCK,

VST, PSIG, REF,

XSTBY, DWN, RGT

TP_TOP

TP_BOT

SWITCHING

KEY_AD1

KEY_AD1_2

KEY_AD1_1

A : VIDEO SIGNAL

CN7505

R

4

G

5

B

3

2, 6 - 8, 11 - 14, 19 - 22

COM

24

CS

23

COM

1

CN7503

5

TP_L

2

TP_R

1

4

CN7506

BL_H

5, 6

CONTROL KEY BLOCK

(SB9000)

CN7502

4

5

LCD9001

2.7INCH

WIDE COLOR

LCD UNIT

TOUCH PANEL

D9001

(BACKLIGHT)

S003

START/STOP

S002

T

S001

W

DCR-SR90E/SR100/SR100E_L2

3-3

3-4. O VERALL BLOCK DIAGRAM (4/5) ( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-449 BOARD (4/5)

8

OVERALL (2/5)

(PAGE 3-2)

DCR-SR100/SR100E

AD4 - AD13

ADCK27

13

OVERALL (2/5)

(PAGE 3-2)

18

OVERALL (2/5)

(PAGE 3-2)

IC3801

VIDEO A/D

24 - 15

CONVERTER

14

(9/15)

DATA_FROM_SFD

SFD_BCK

SFD_LRCK

SFD_FCK

KASYAON

BEEP

5

1

LINE_Y_ON

DATA_TO_SFD

20

OVERALL (3/5)

(PAGE 3-3)

AIN

12

OVERALL (2/5)

(PAGE 3-2)

21

OVERALL (3/5)

(PAGE 3-3)

DATA_TO_SFD

DATA_FROM_DSP

IC_2201_ C_OUT_M

IC_2201_ Y_OUT_M

CLPVO

VFE_C_OUT

ACC_CONT

AGC_CONT

IC_2803_Y_OUT

IC_2803_C_OUT

IC_3401_Y

IC_3401_C

IC2203

7

AUDIO

SELECTOR

6

(9/15)

5

DSP_SEL

91

12

10

11

8

Q2202

BUFFER

Q2203

BUFFER

Q3801

BUFFER/

CLAMP

IC2202

AUDIO

A/D, D/A

CONVERTER

(9/15)

14 13 6 7

XPWDA

XPWAD1

DEM0

DEM1

A : VIDEO SIGNAL

A : AUDIO SIGNAL

DCR-SR100/SR100E

IC2201

I/O

(9/15)

12

17

14

88

3

90

57

61

PMUTE_L

58

PMUTE_R

60

55

56

70

74

23

24

XCS_IC_2201_1

25

27

BB_SO

XBB_SCK

SDC_IN

28

OVERALL (5/5)

(PAGE 3-5)

CN1109

S_Y_I/O

S_C_I/O

VIDEO_I/O

AUDIO_L_I/O

AUDIO_R_I/O

LANC_SIG

MULTI_JACK_IN

CN1104

SP+

SP-

(2/3)

(2/2)

FP-434

FLEXIBLE

BOARD (2/3)

14

12

10

2

4

6

7

34

35

FP-440

FLEXIBLE

BOARD (2/2)

JK-310 BOARD (2/3)

CN7201

(2/3)

32

34

36

44

42

40

39

CN7305

(2/2)

6

5

CK-162 BOARD

(2/2)

S_Y

S_C

VIDEO_IN/OUT

AUDIO_L

AUDIO_R

LANC_SIG

JACK_AD

CN7304

SP+

SP-

10

5

9

CN7203

A/V

1

6

2

7

1

2

SP9001

SPEAKER

19

21

20

18

10

7

9

6

VIDEO, AUDIO

PBIN_L

15

PBIN_R

16

3

2

MIC_L

MIC_R

RECOUT_L

RECOUT_R

BEEP

31

30

35

34

65

51

52

MICROPHONE

CN9001

(1/2)

HOT SHOE

UNIT

(L)

FRONT

(R)

(L)

REAR

(R)

FP-436

FLEXIBLE

BOARD

(1/2)

MIC_FL

MIC_FR

MIC_RL

MIC_RR

MA-444 BOARD (1/2)

CN5002

7

3

1

5

CN5003

3

2

6

5

(1/2)

INIT_

MIC_F

INIT_

MIC_B

SHOE_MIC_RL

SHOE_MIC_RR

B8

A1

B7

B2

B8

A1

B7

B2

IC3301

MIC AMP

(1/3)

H3H3G5

IC3351

SUB MIC

AMP

(2/3)

G6

H2

ZOOM_MIC_CONT

SHOE_STEREO

SUB_RECOUT_L

G6

SUB_RECOUT_R

H2

CN5004

MIC_L

MIC_R

(1/2)

FP-435

FLEXIBLE

BOARD

(1/2)

39

37

32 14

33 13

43

41

31 15

CN1102

(1/2)

MIC_L

7

MIC_R

9

ZOOM_MIC

_CONT

SHOE_STEREO

SUB_RECOUT_L

3

SUB_RECOUT_R

5

SHOE_MIC_FLSHOE_MIC_FL

LINE_Y_ON

SFD_FCK

SFD_LRCK

SFD_BCK

3

2

MIC (REAR)

12

CONVERTER

10

11

3

2

WIRELESS

12

CONVERTER

10

11

OVERALL (2/5)

(PAGE 3-2)

IC2903

A/D

(10/15)

IC3551

MIC A/D

(10/15)

15

DATA_TO_SFD

SFD_BCK

SFD_LRCK

SFD_FCK

8 R4

13

8 R9

13

DATA_TO_DSP

XPWAD2

WMIC_DATA

XPWAD3

D0_CNM - D15_CNM

A1_CNM - A20_CNM

U6

R7, U2, U3,

U7, U8, V17

R3, R8, T5,

T9, U15, V9

G17

IC2901

5.1CH AUDIO

DSP

(10/15)

A10, A16, A17,

B11, B13 - B16

C11 - C15, C17,

D11, D13

E16 - E18, F15, F17,

G15, G16, G18, H16, H18,

J17, J18, K16 - K18,

L17, L18, N16, P17, P18

U10

R13

U16

M4

D17

P16

H17

U12

DATA_FROM_DSP

ADDO

ADDE

A5.1_SYNC

XCS_A5.1

A5.1_CTRL

A5.1_RESET

XDSP_NMI

XCS_IC_2201_1

SDC_IN

DSP_SEL

XPWDA

XPWAD1

DEM0

DEM1

ZOOM_MIC_CONT

SHOE_STEREO

LINE_Y_ON

XPWAD2

XPWAD3

23

OVERALL (3/5)

(PAGE 3-3)

U2

U23

B4

L20

Y17

AC10

L23

AB17

W22

W20

B3

A4

IC2601

(2/2)

CAMERA

CONTROL

(4/15)

E23

AC8

AB8

AC7

U1

R4

B20

F20

AB7

Y7

AB6

AC6

BB_SO

XBB_SCK

MCXCS_IC_2803

BB_SI

BB_SO

XBB_SCK

BB_SI

BB_SO

XBB_SCK

XCS_EVF

XCS_LCD

EVF_BL_ON

XCS_IC_3401

HI_SO

HI_SI

XHI_SCK

XCS_IC_2601

11

OVERALL (2/5)

(PAGE 3-2)

19

OVERALL (3/5)

(PAGE 3-3)

22

OVERALL (3/5)

(PAGE 3-3)

DCR-SR90E/SR100/SR100E_L2

05

3-4

Loading...

Loading...